Patents

Literature

322results about How to "Accurately carry-out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

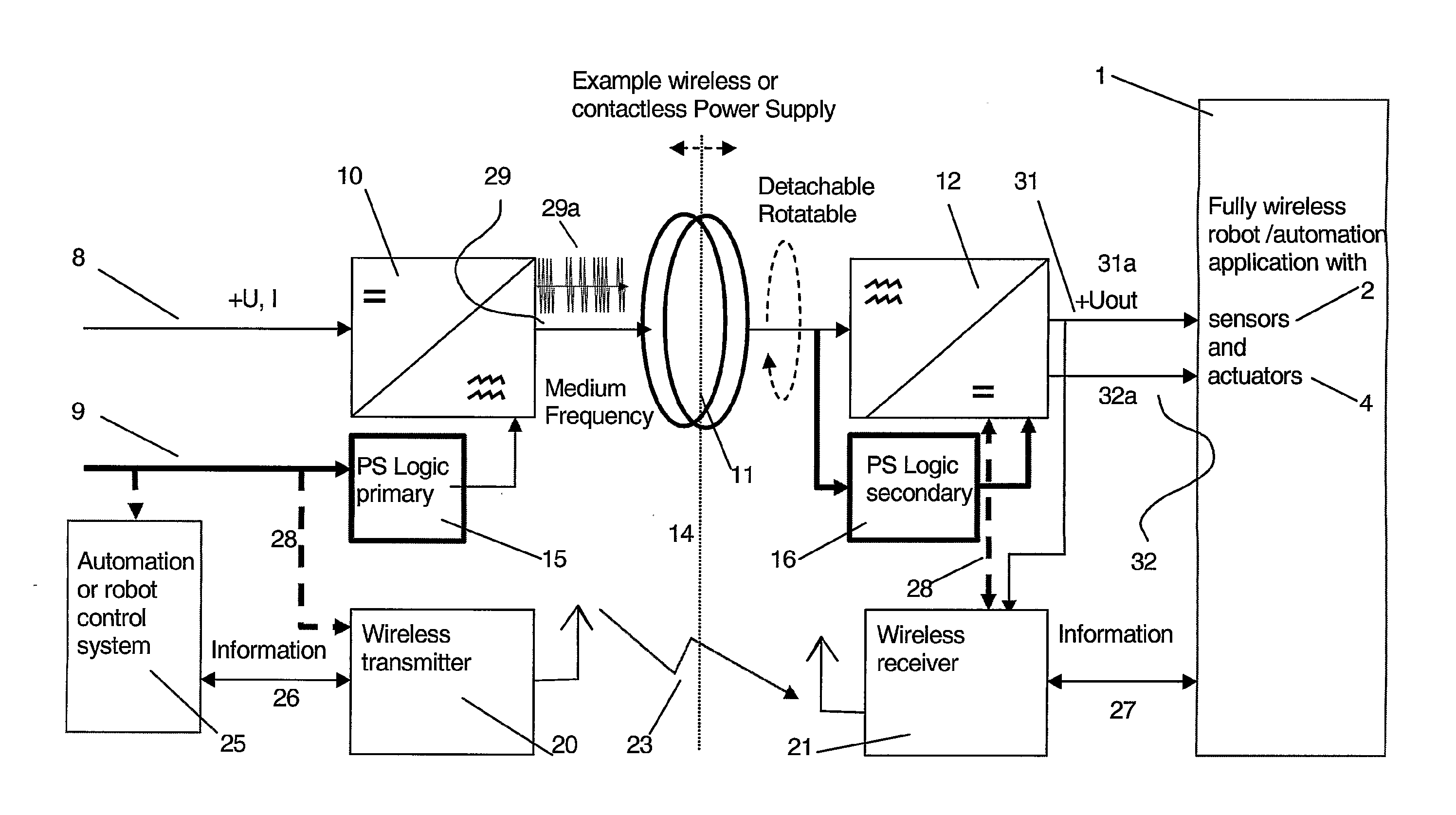

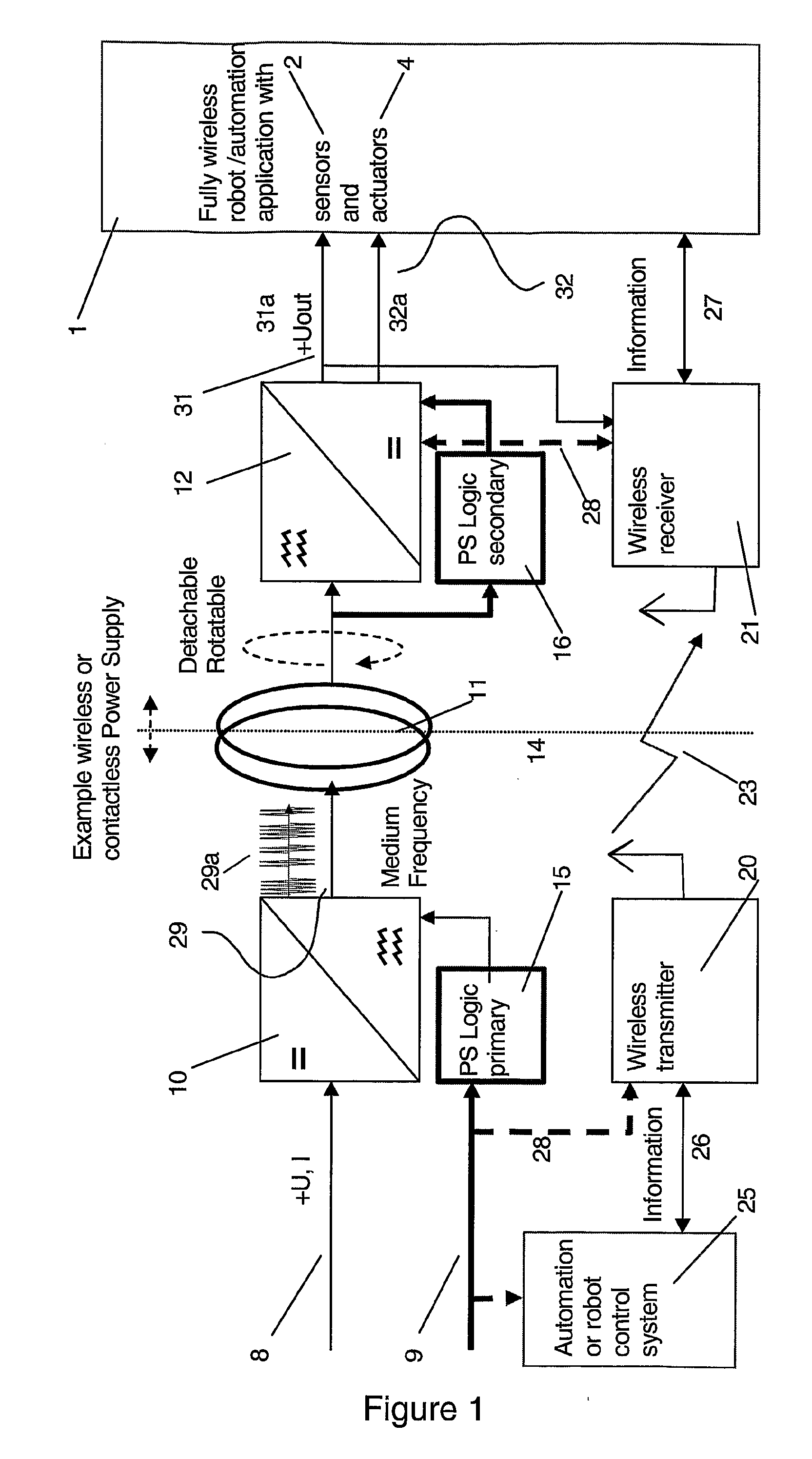

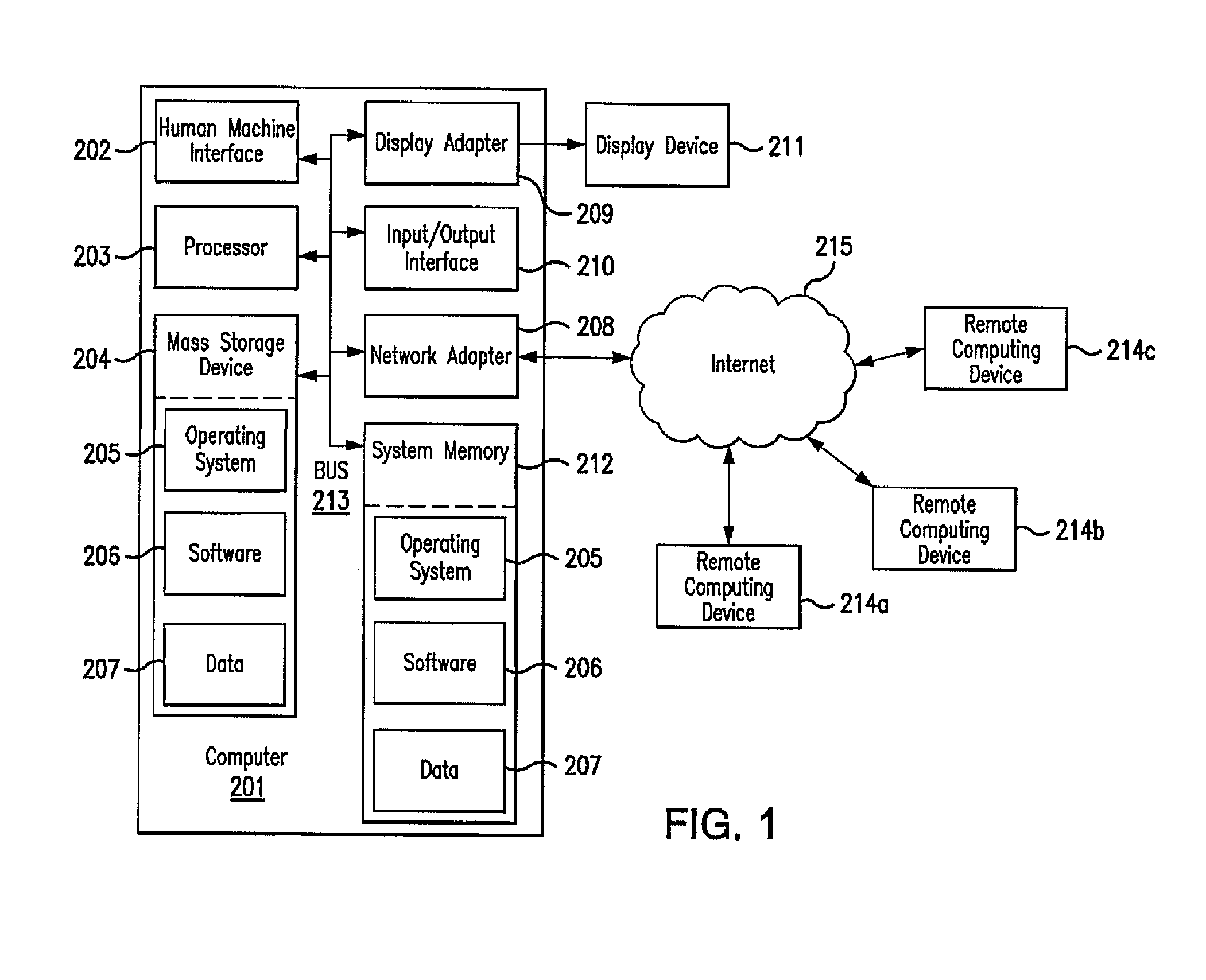

Tool for an Industrial Robot

InactiveUS20070276538A1Speeding up changeReduce downtimeSingle-phase induction motor startersProgramme-controlled manipulatorWireless controlIndustrial robotics

A robot or manipulator including a wireless power supply and a wireless communication device. One or more actuators on the robot tool may be wirelessly powered and wirelessly controlled. The robot tool may have one or more wireless communication members for transmission of data from sensors on the tool. The power supply includes a primary power supply member and secondary power supply member. Tool changes may be carried out automatically by the robot. In other aspects of the invention a method, a control system and a computer program for carrying out the method are described.

Owner:ABB RES LTD

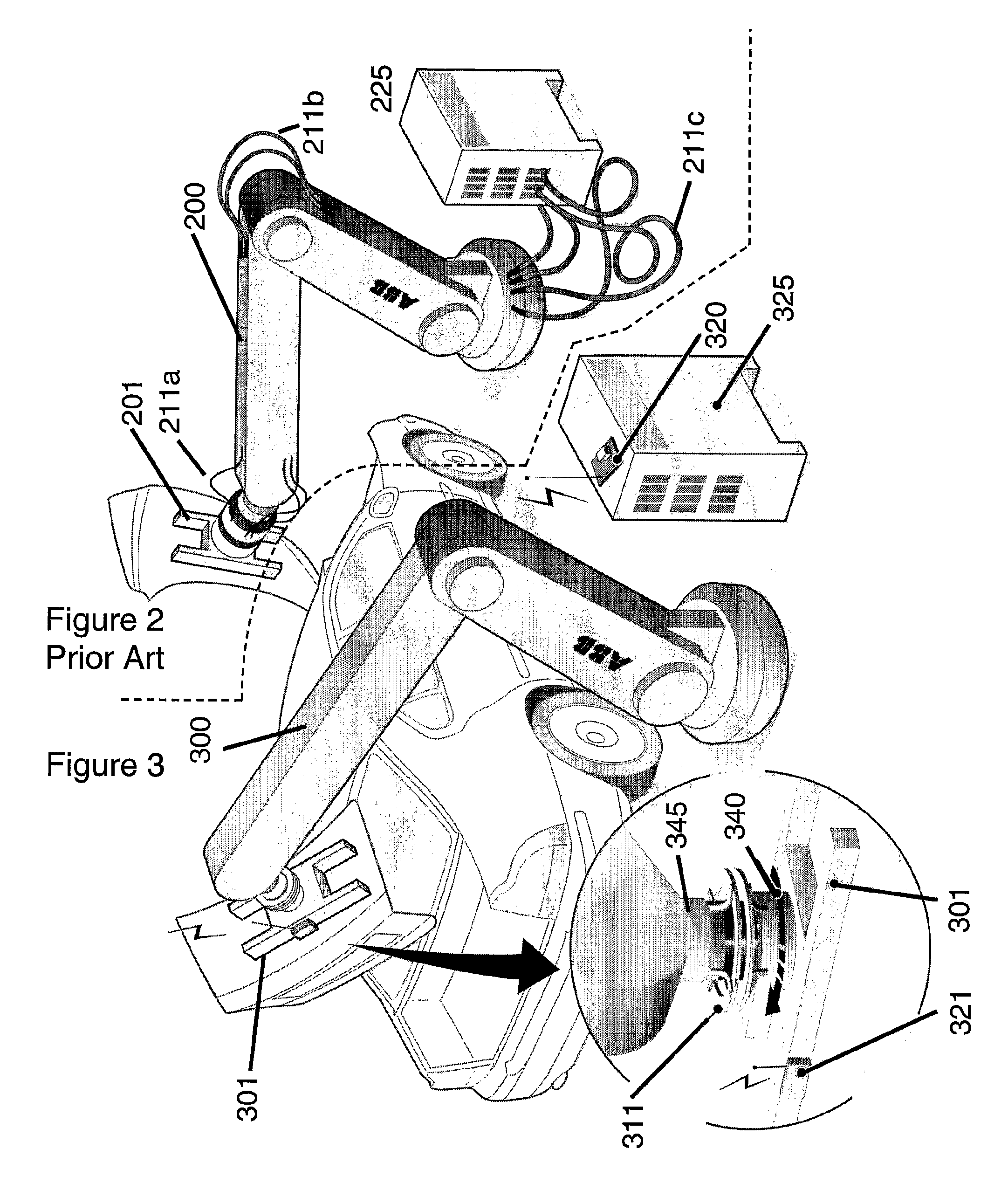

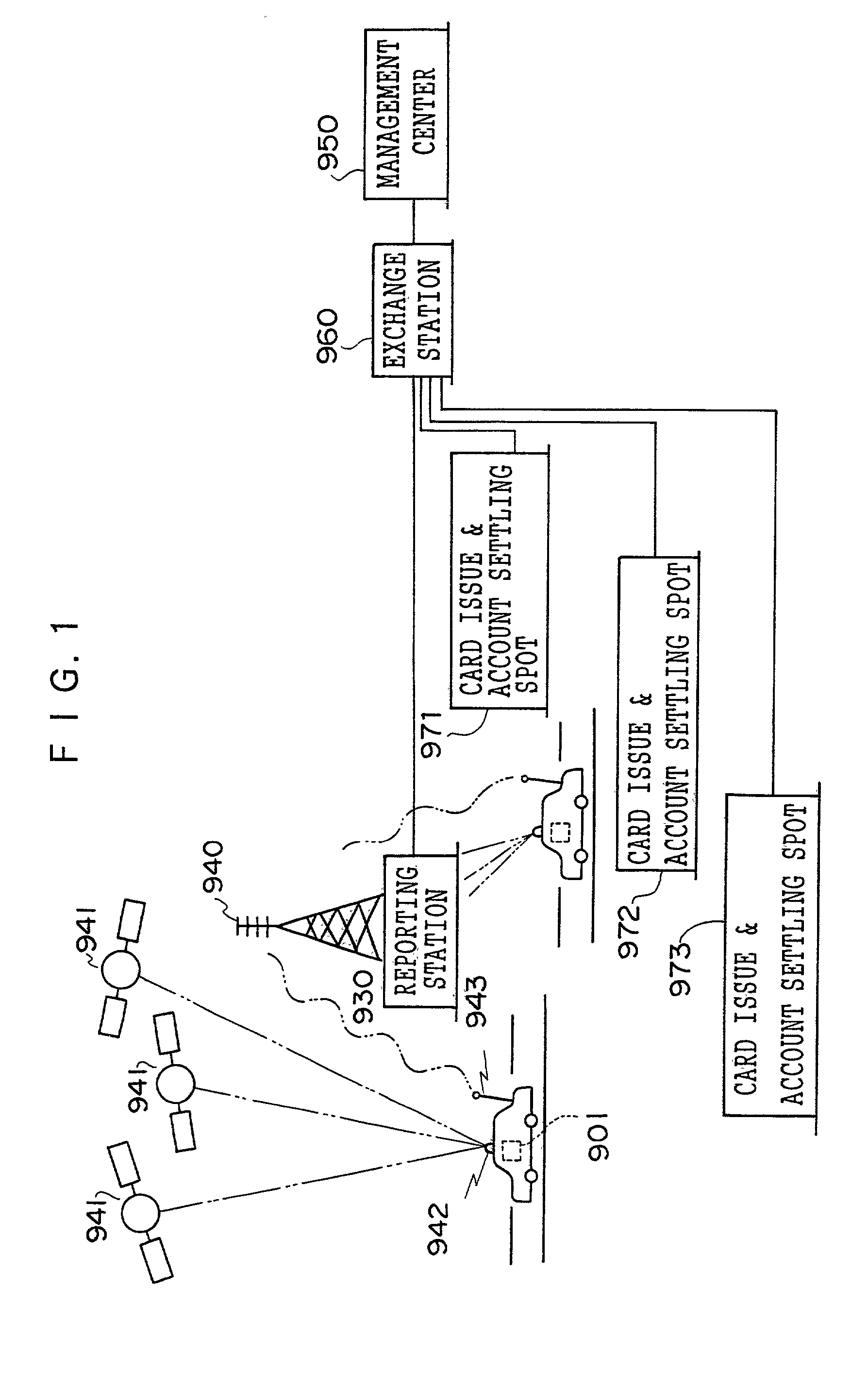

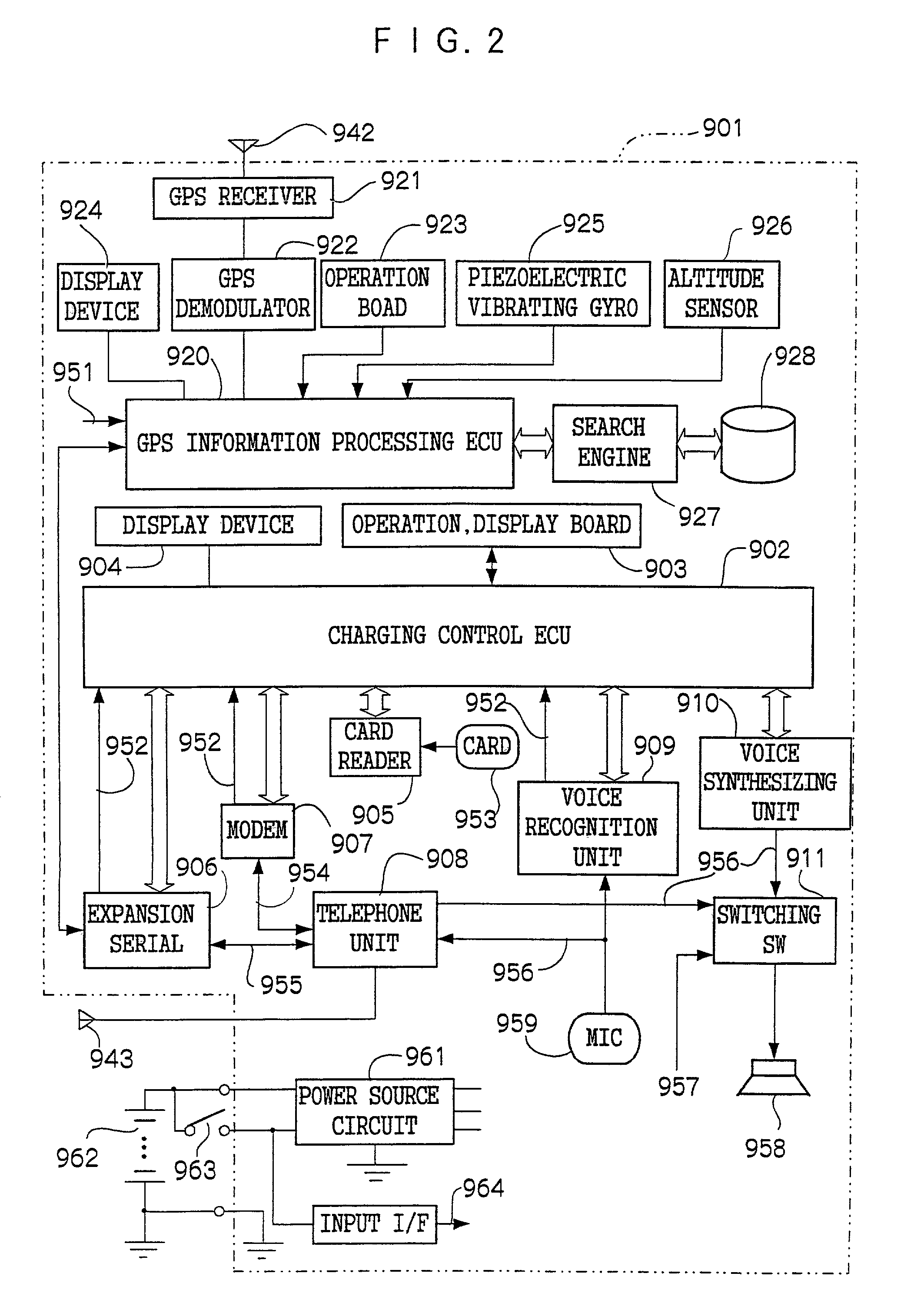

Charging system

InactiveUS20020049630A1Small data amountLow accuracyInstruments for road network navigationTicket-issuing apparatusGeographical featureEngineering

An object of the present invention is to provide a charging system which carries out position confirmation of a moving body at a place where there is a radio wave blocked facility, and which carries out automatic detection of GPS antenna blockage for avoiding charging. In a charging system including a GPS positioning device 921 for recognizing a vehicle position, a vehicle speed pulse measuring device 920 for dead reckoning navigating, a monitor device 920, 927, 928 which generates information expressing a current position by using these, and a charging processing 902 which judges whether or not a recognized current position is within a charge area and which carries out data processing for charging, the monitor 920 includes a simple map database 928 which includes positions of facilities or geographical features at which GPS positioning is impossible, and when GPS positioning is impossible, the facility or geographical feature corresponding to the current position is detected, and that position is made to be a current position.

Owner:TOYOTA JIDOSHA KK +1

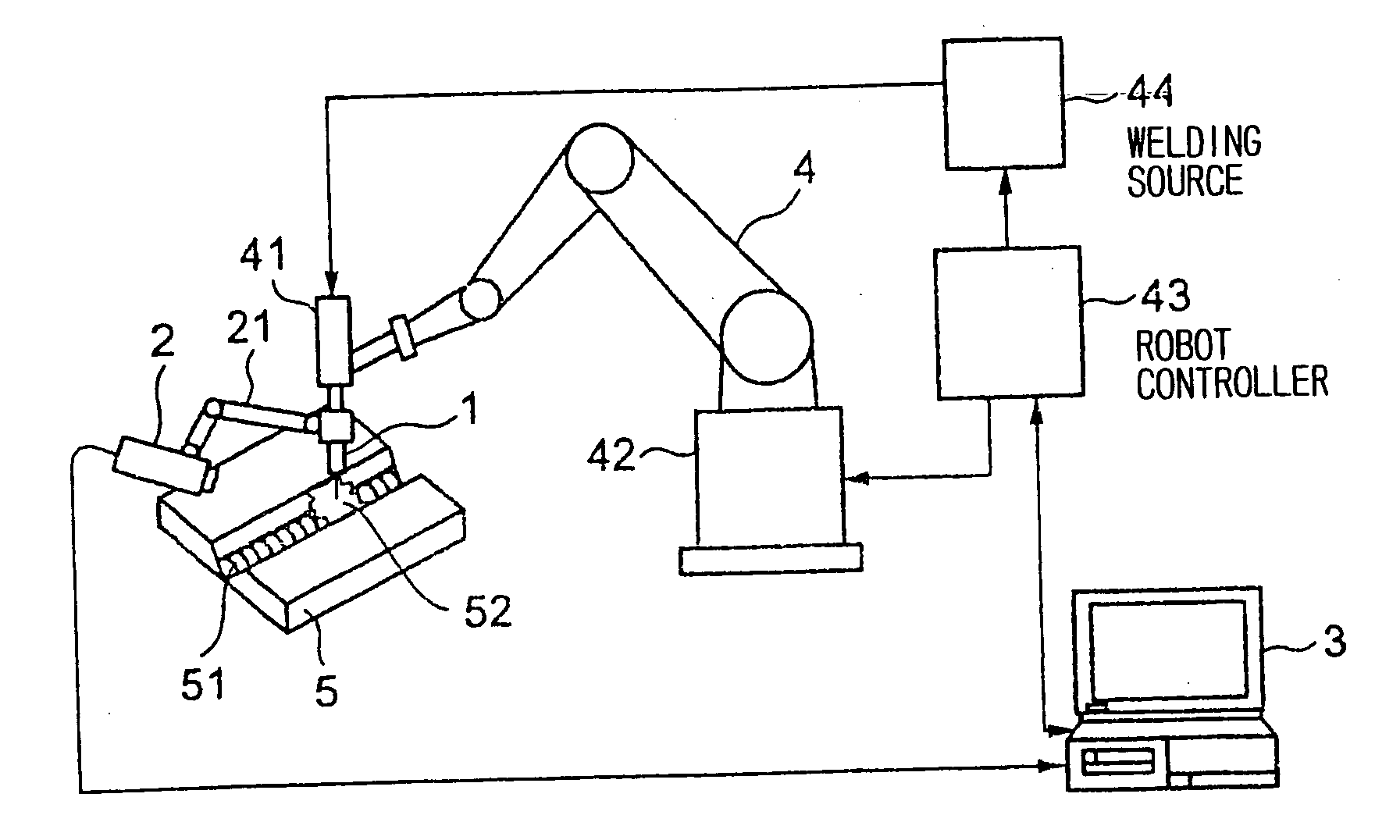

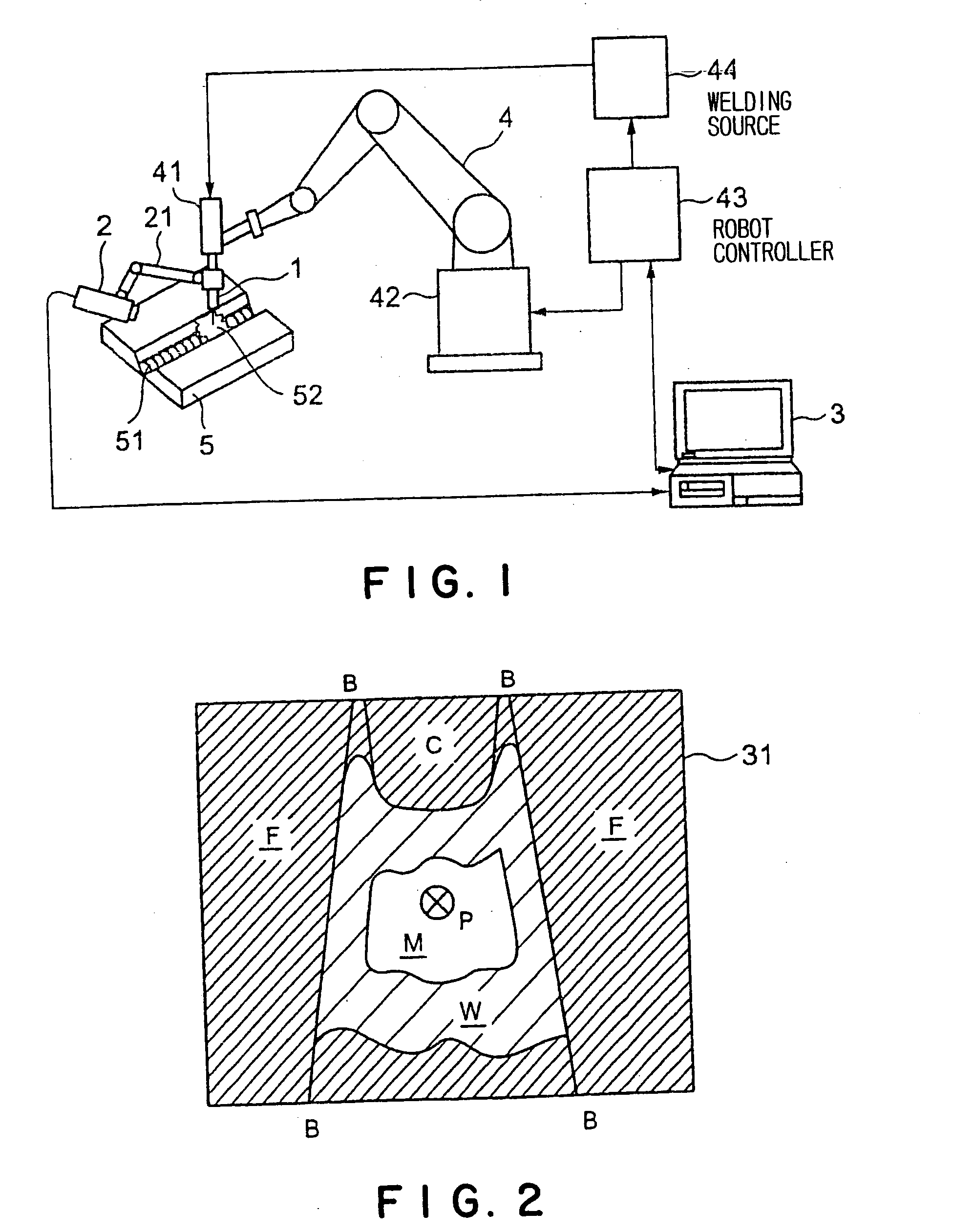

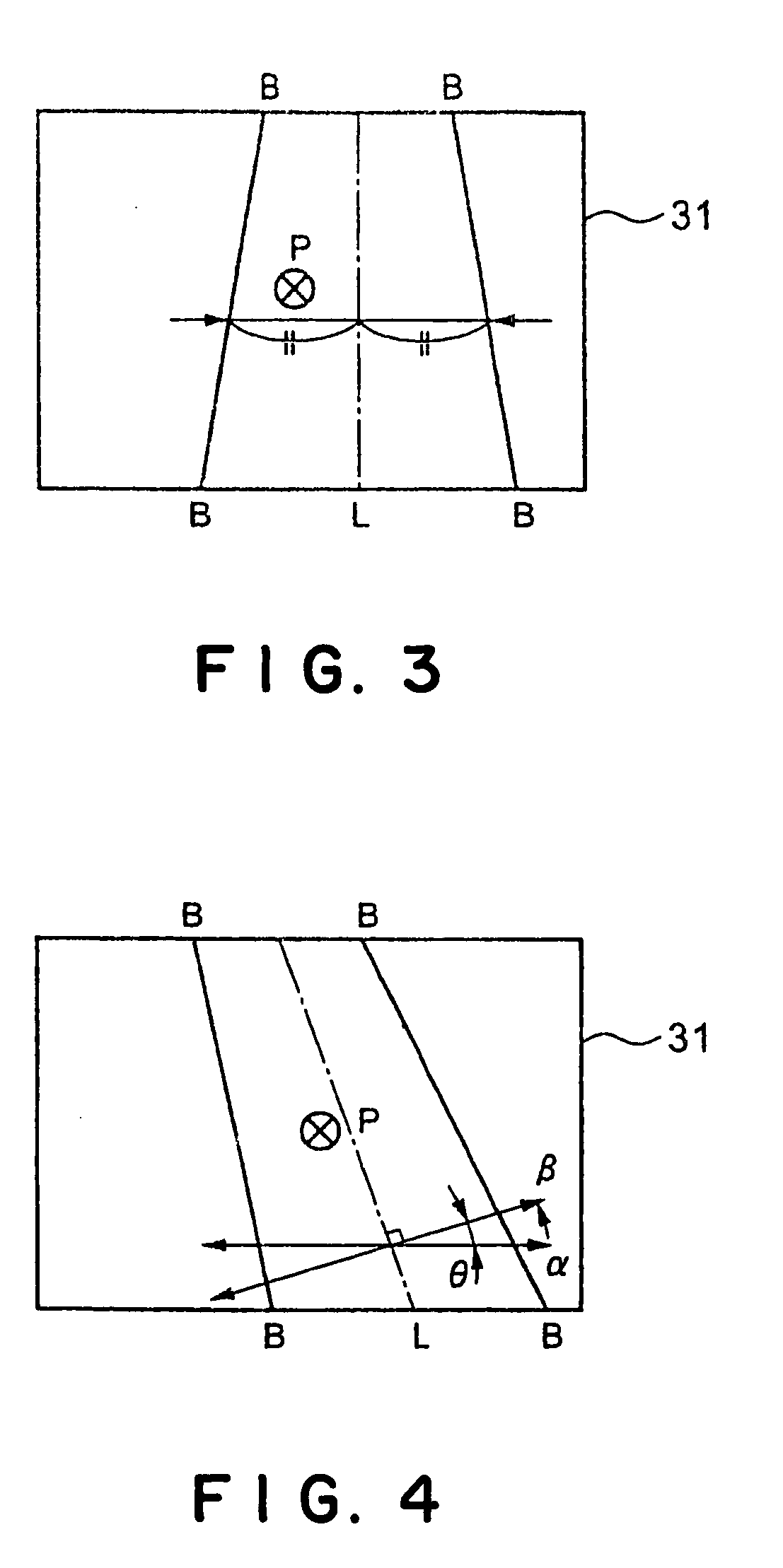

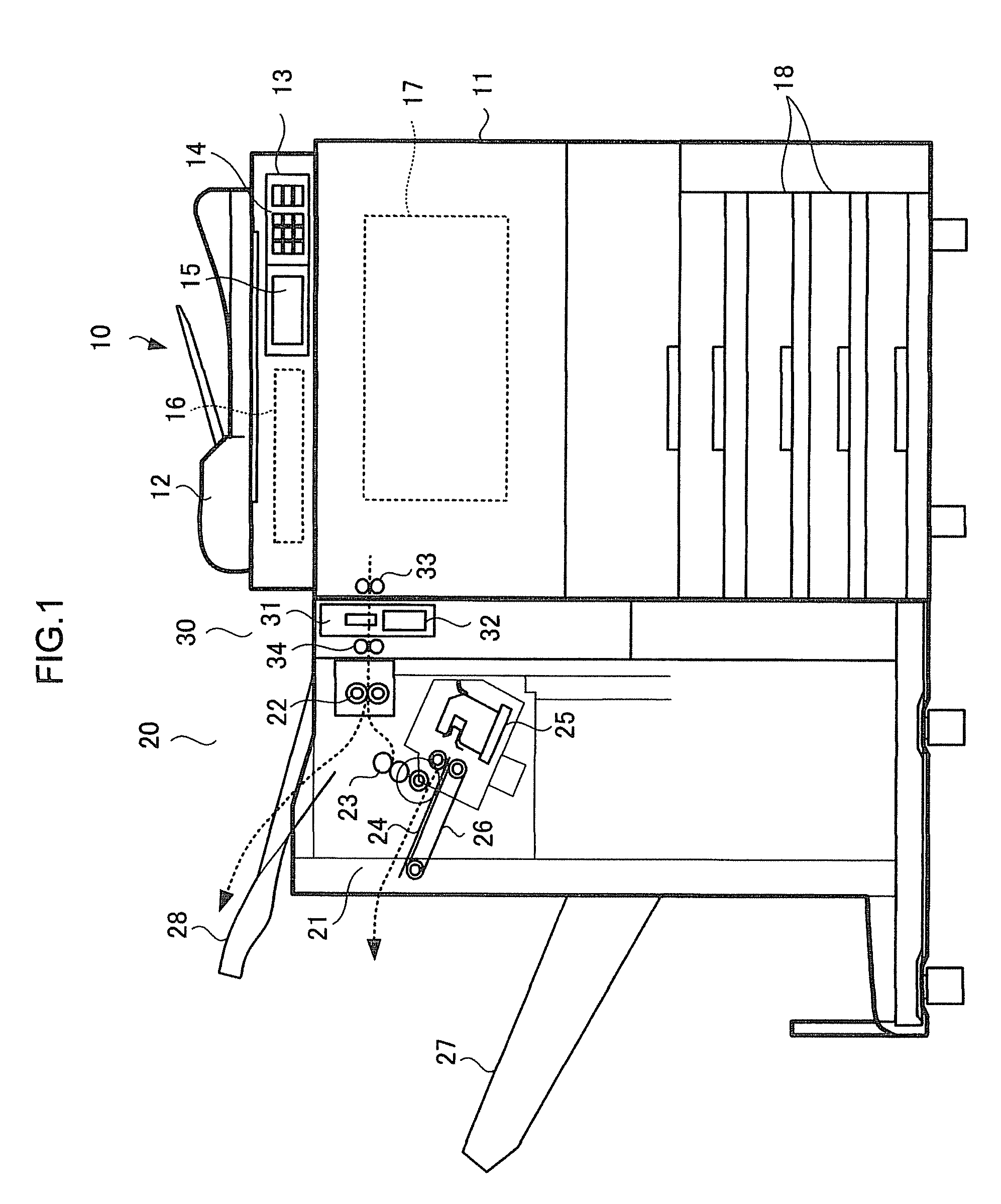

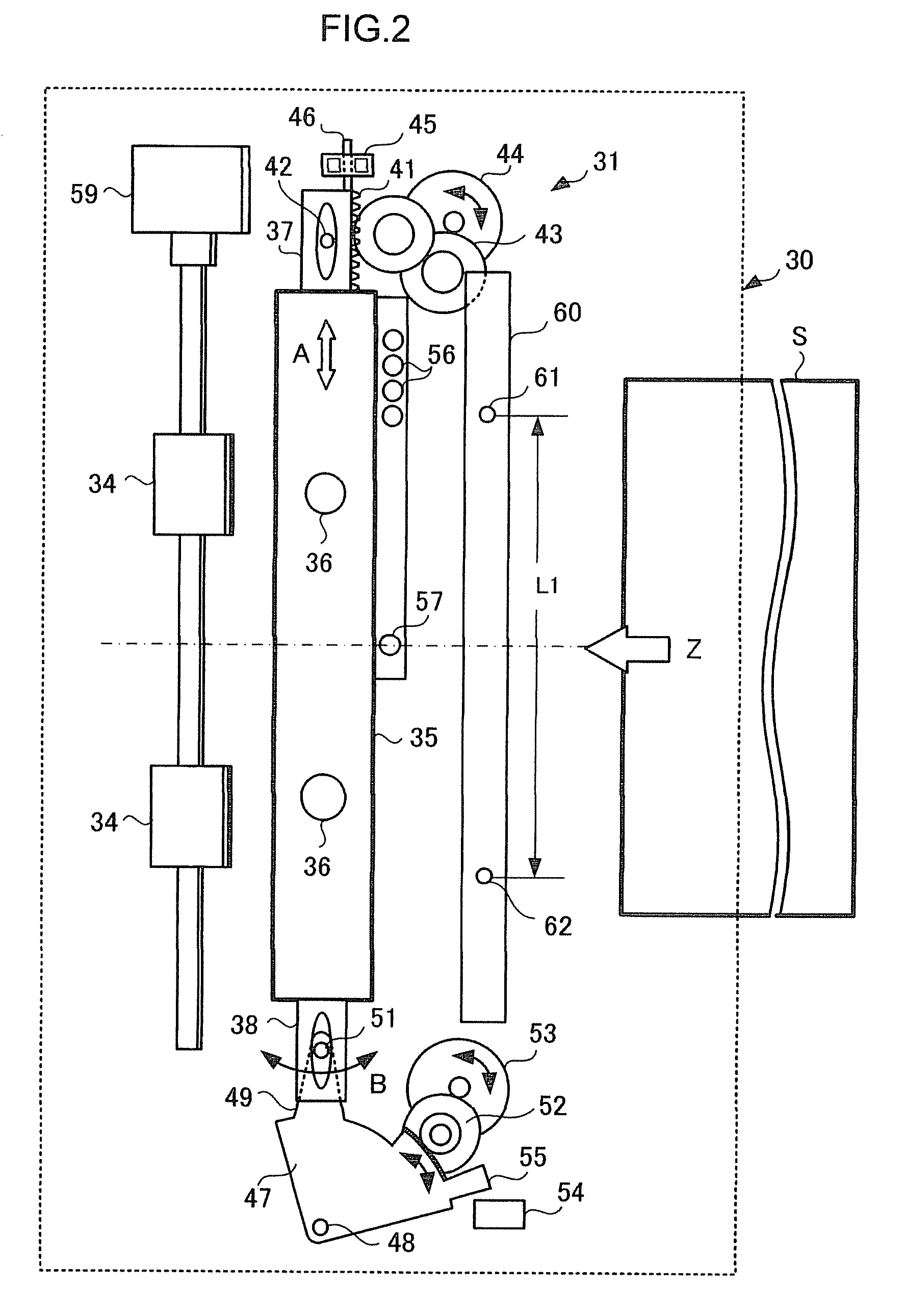

Automatic groove copy welder and welding method

InactiveUS20050103766A1Accurate control operationAccurately carry-outArc welding apparatusEngineeringCcd camera

An automatic groove-tracing welding system is capable of carrying out a welding operation, particularly, a welding operation involving weaving, without requiring monitoring even if conditions of a groove is different from design conditions of the groove. An image processor 3 receives an image signal representing an image of a weld zone 52 including the tip of a welding wire from a camera head 2 provided with a CCD camera, processes the image of the weld zone 52 to determine the position of a groove, calculates the positional relation of the groove with a welding torch 1, and sends a position correction for correcting the position of the welding torch 1 so that the welding path of the tip of the welding torch 1 may coincide with a predetermined middle part in the groove to a robot controller 43 for controlling a welding robot. When the automatic groove-tracing welding system performs a welding operation involving weaving, the image processor 3 receives a weaving phase signal representing phases of weaving from the robot controller 43, calculates the positional relation between the groove and the welding torch on the basis of the phase of weaving, and sends a weaving width correction signal to the robot controller 43.

Owner:KAWASAKI HEAVY IND LTD

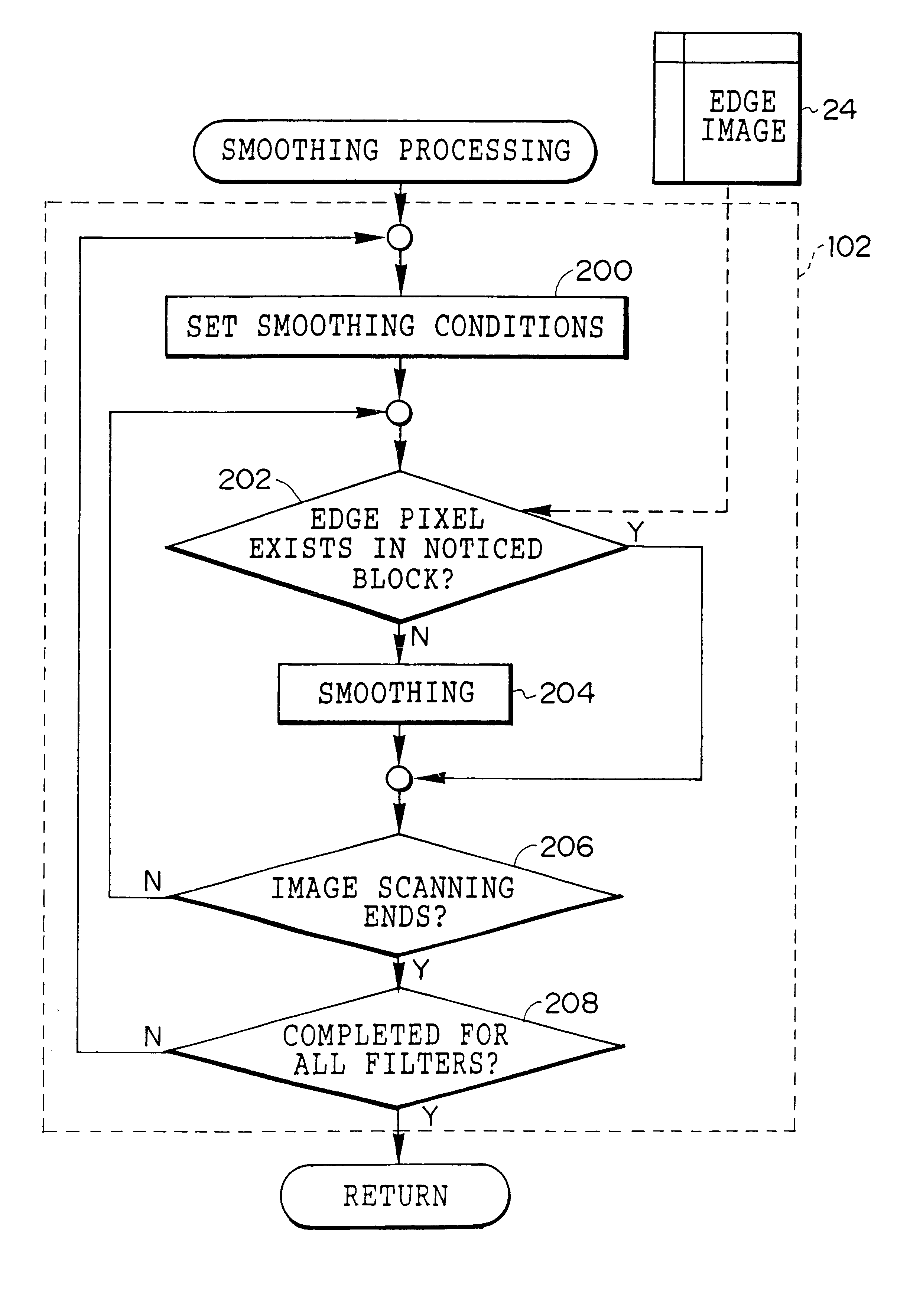

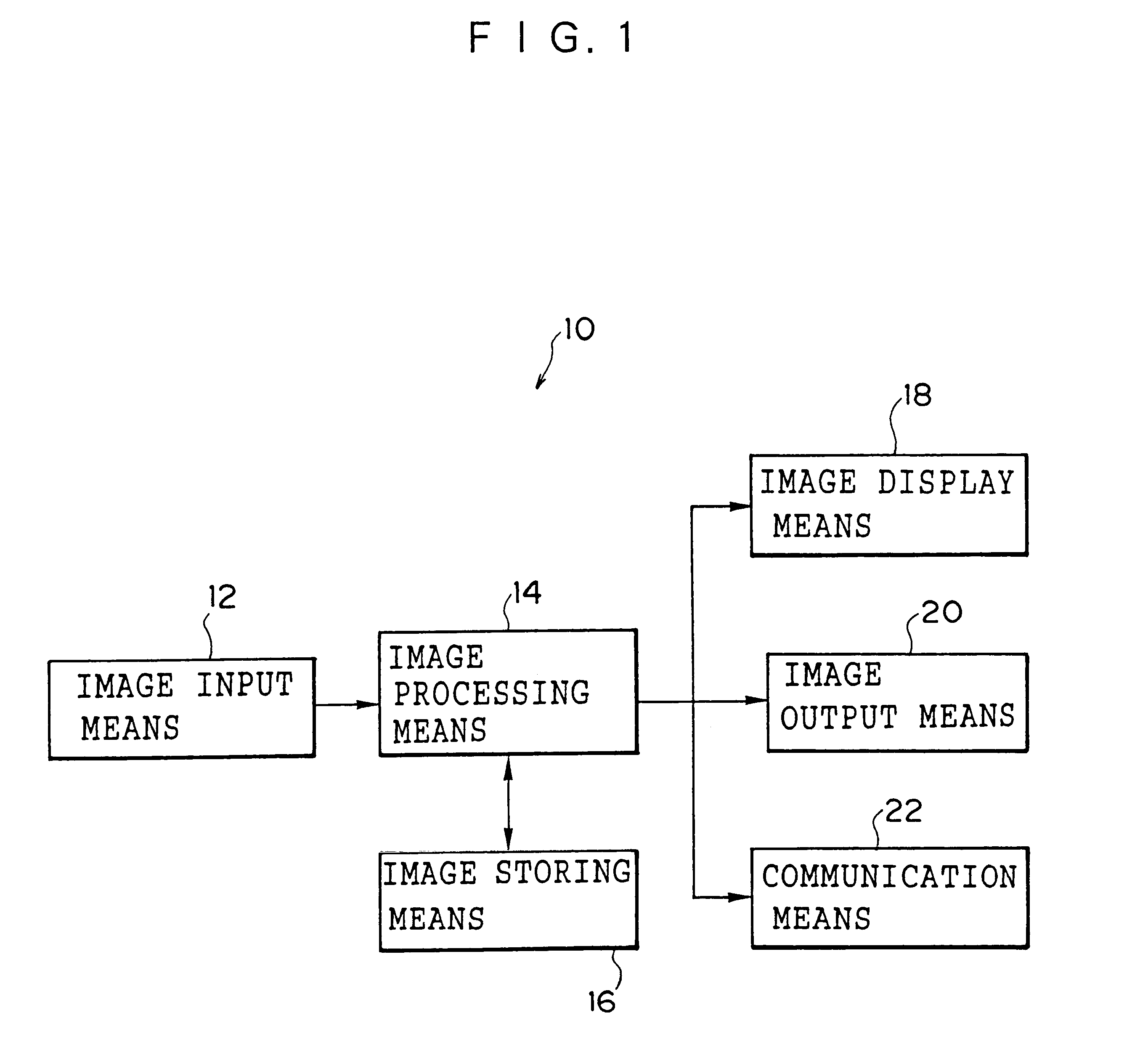

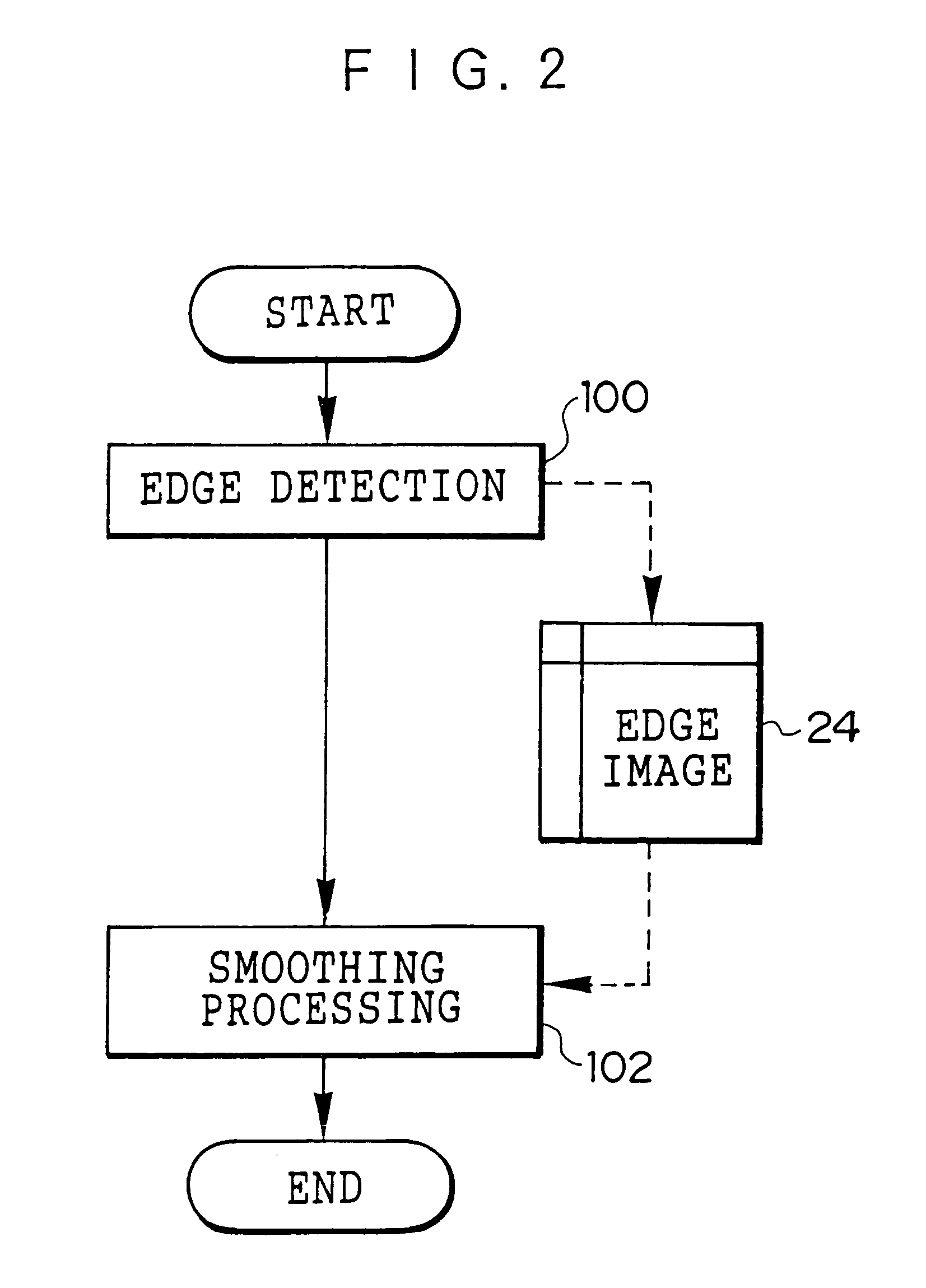

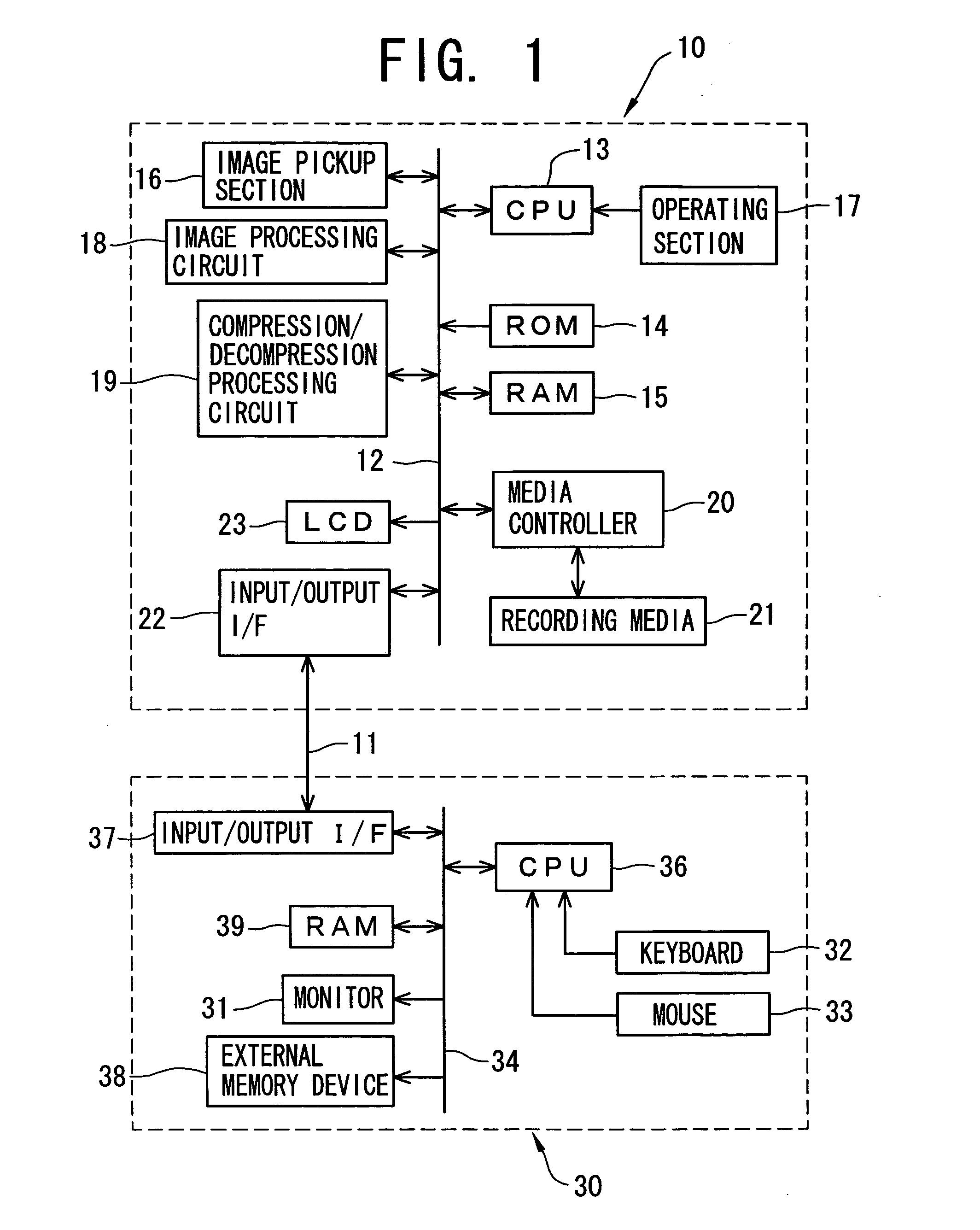

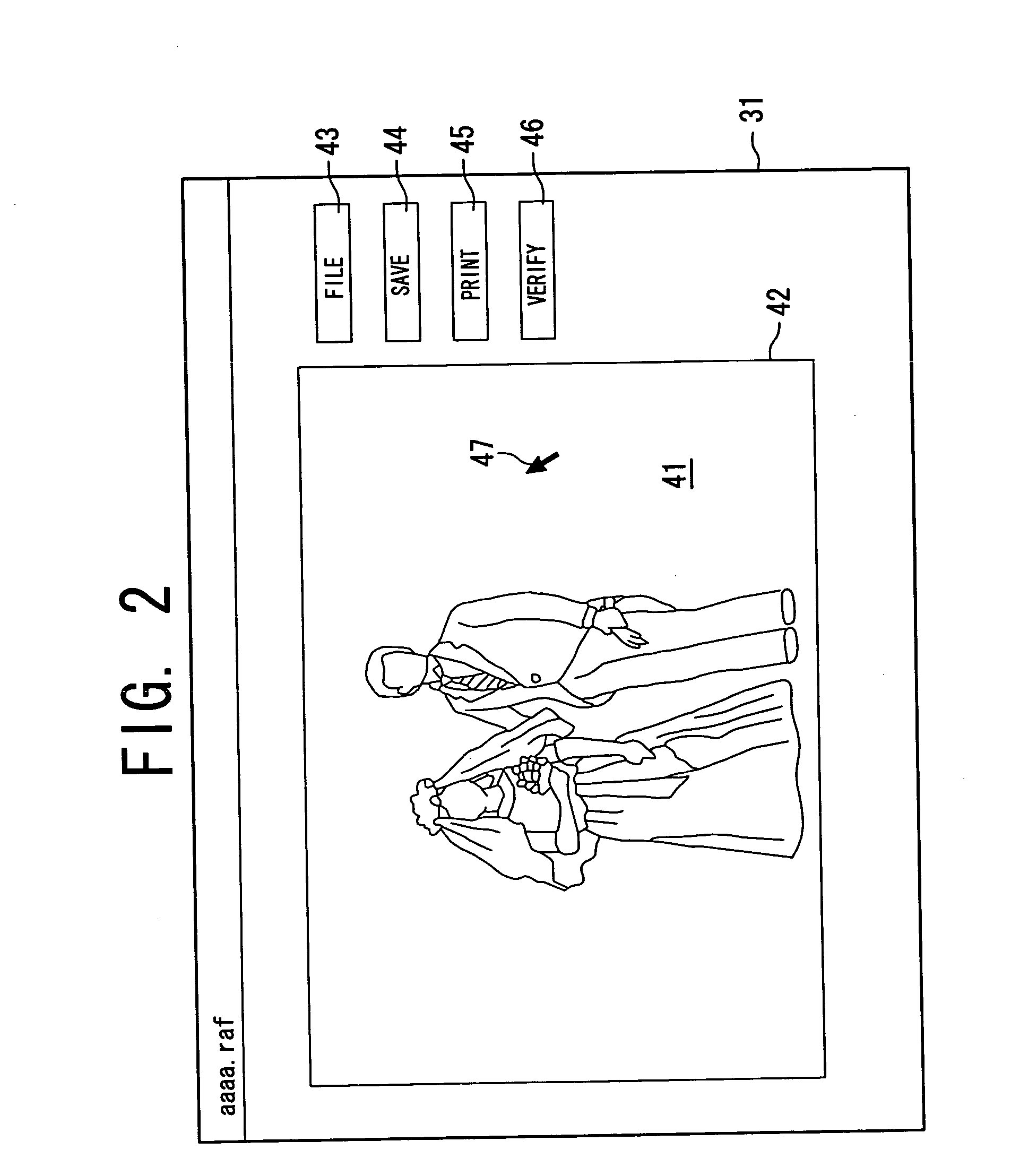

Image processing device and recording medium

InactiveUS6901170B1Low dispersionQuality imageImage enhancementImage analysisImaging processingRecording media

An image processing apparatus and a recording medium which can improve the quality of a color document image. Smoothing conditions which are defined by three parameters of “filter size”, “offset”, and “overlap” are set. An edge image which was generated in an edge detection processing is referred to, and a determination is made as to whether an edge pixel exists in a noticed region. When the edge pixel does not exist in the noticed region, a smoothing processing is carried out. When the edge pixel exists in the noticed region, it is determined inappropriate to effect the smoothing processing, and the process goes to a subsequent processing without effecting the smoothing processing. The processing is carried out until the image scanning ends. When the image scanning ends, the next smoothing conditions are set and the processing which is the same as the one described above is performed.

Owner:FUJIFILM BUSINESS INNOVATION CORP +1

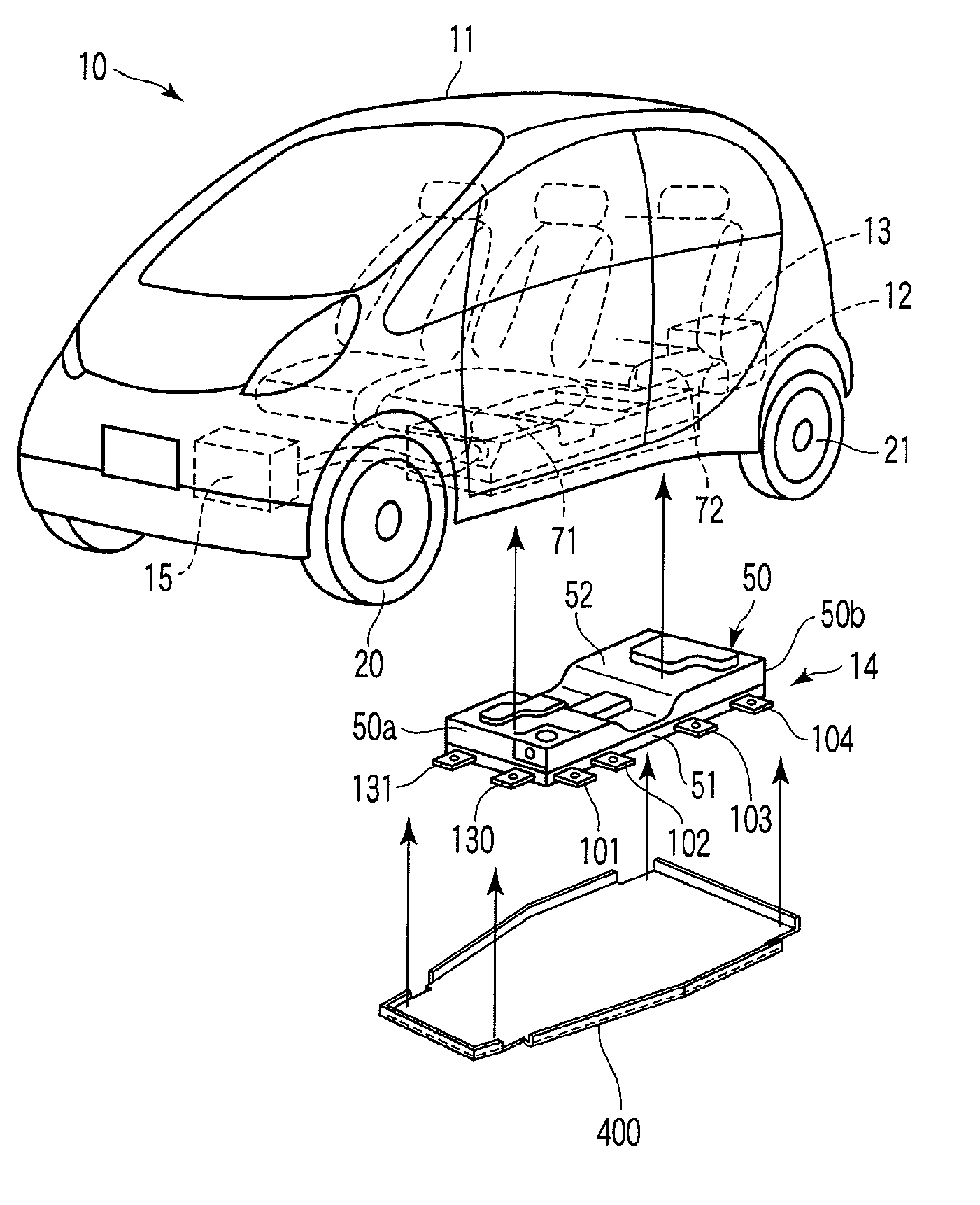

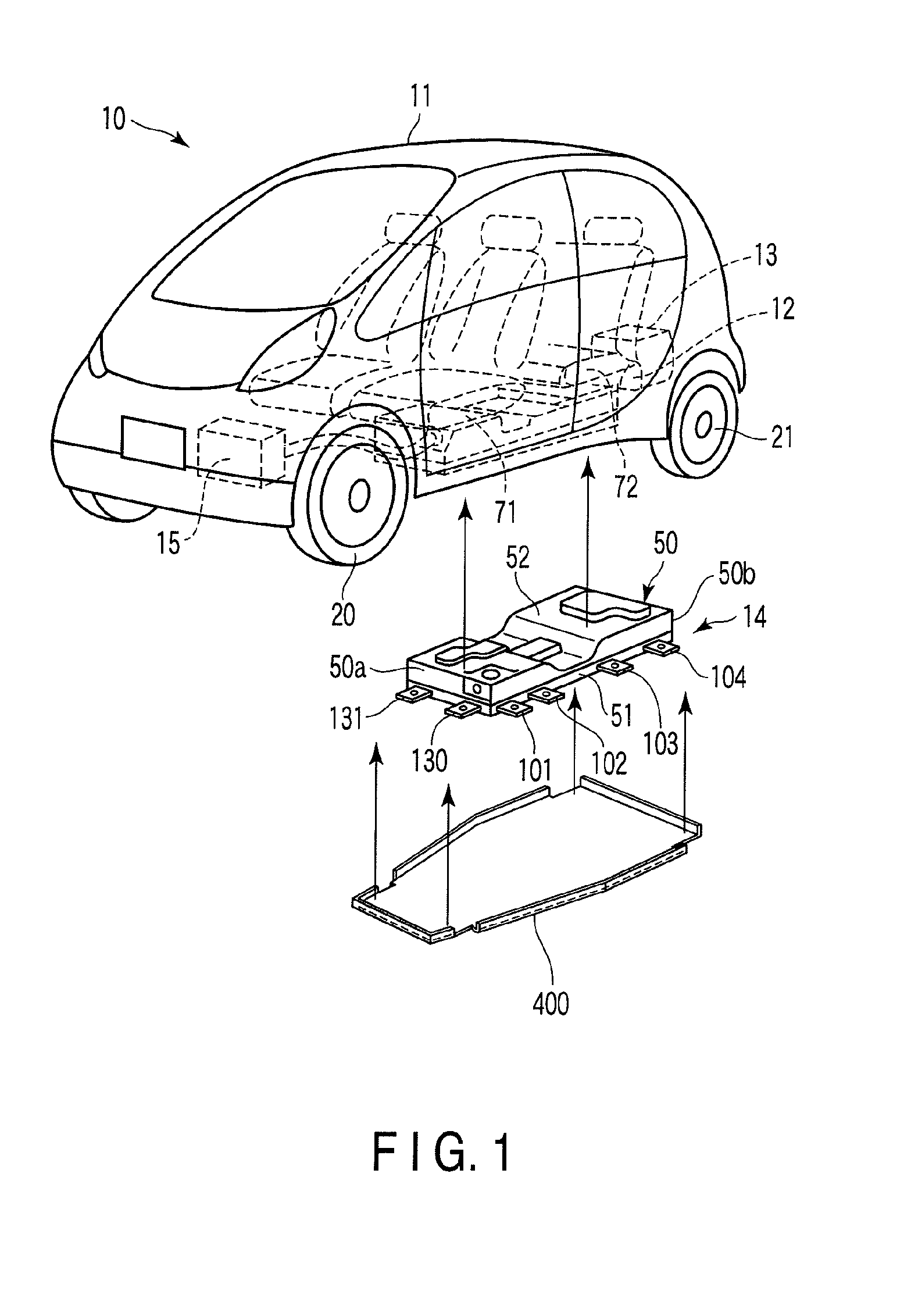

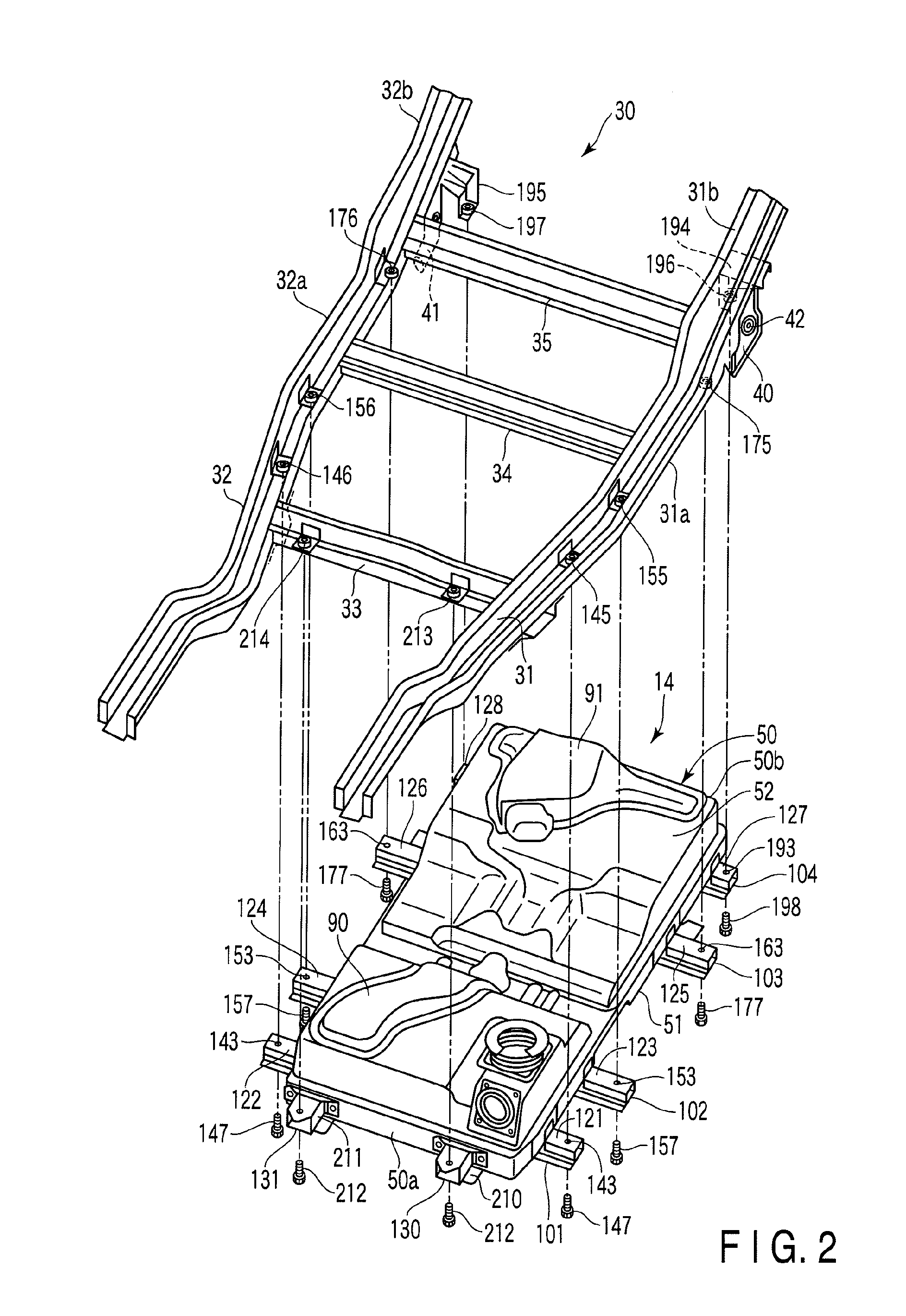

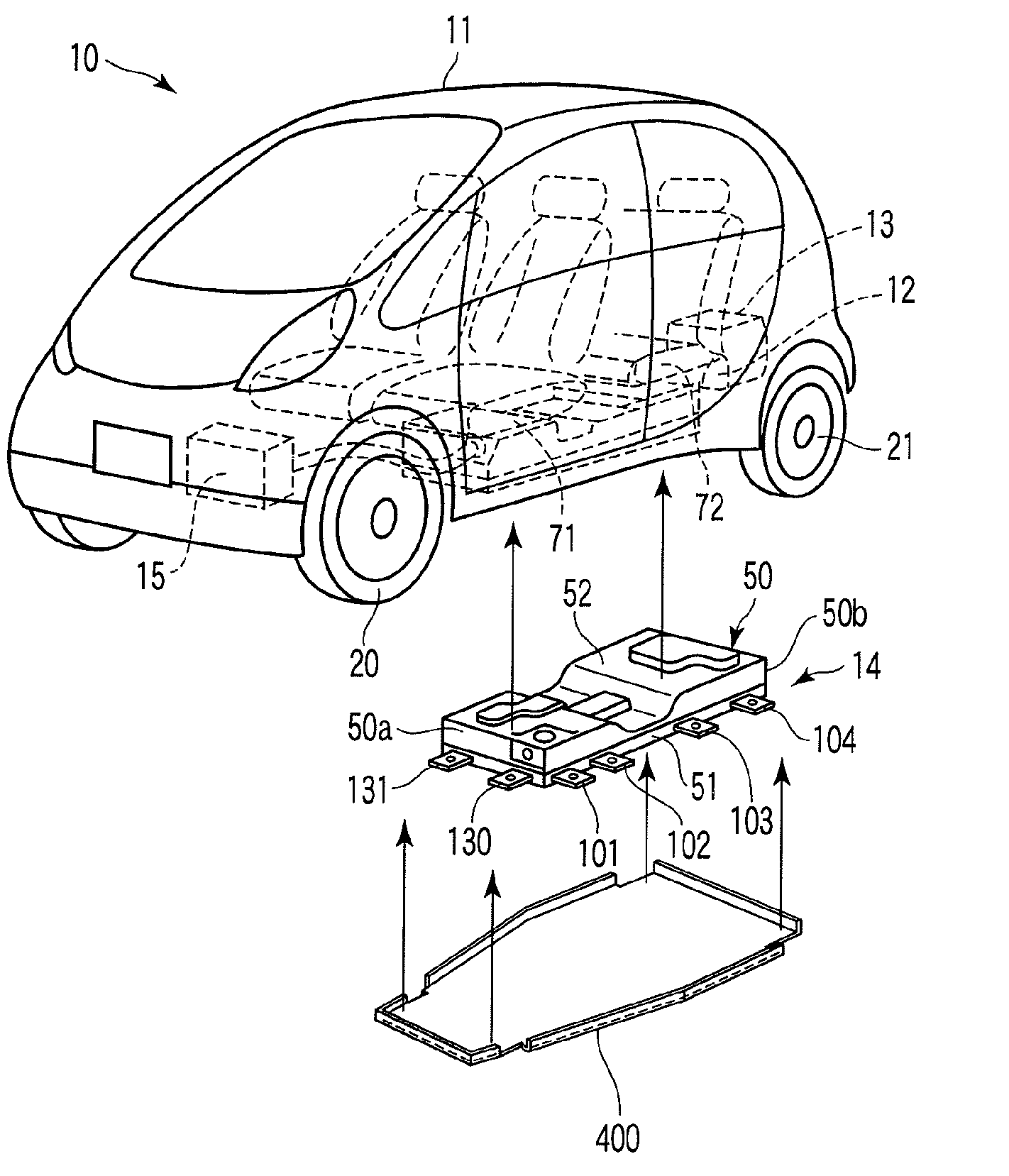

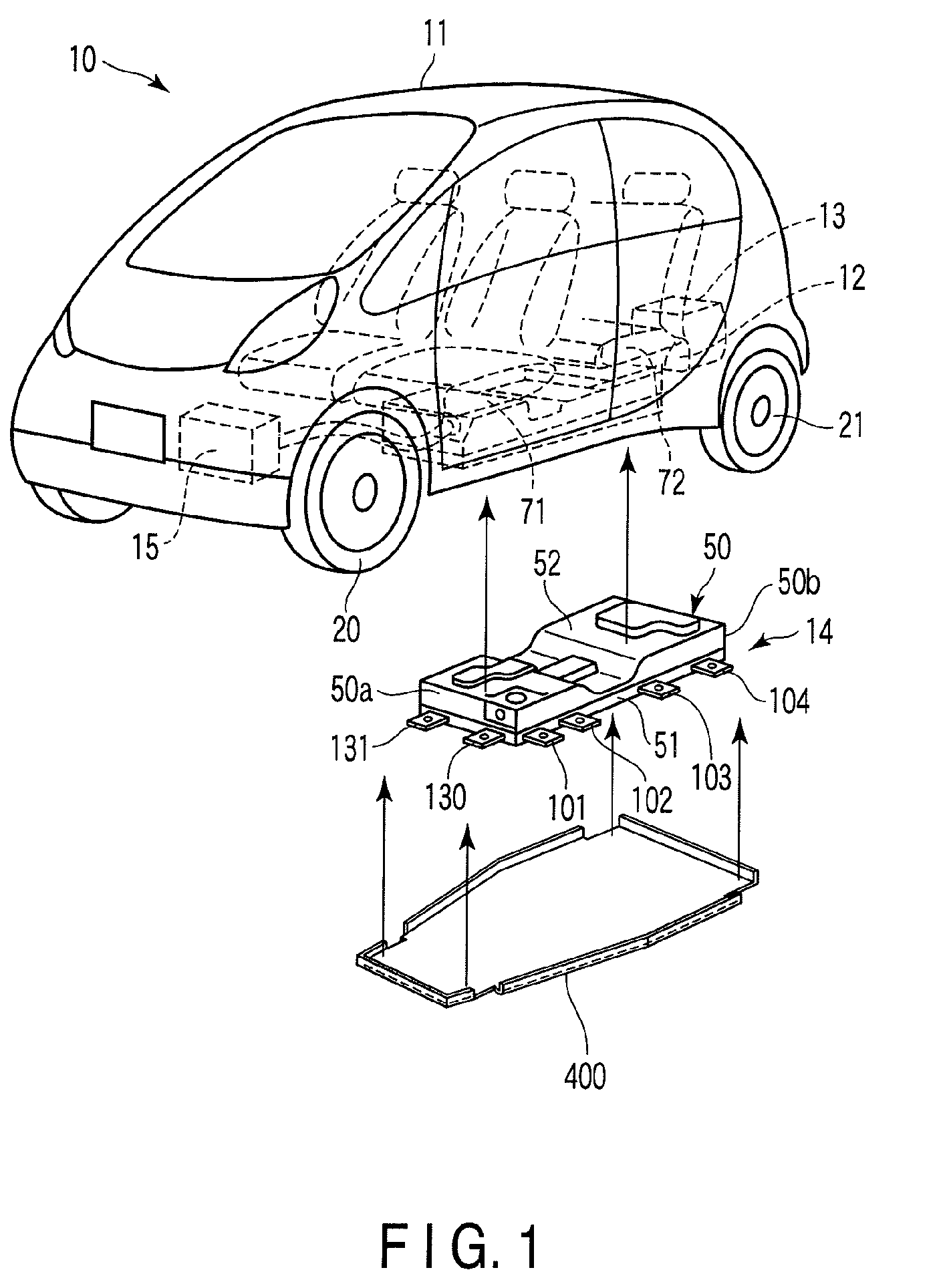

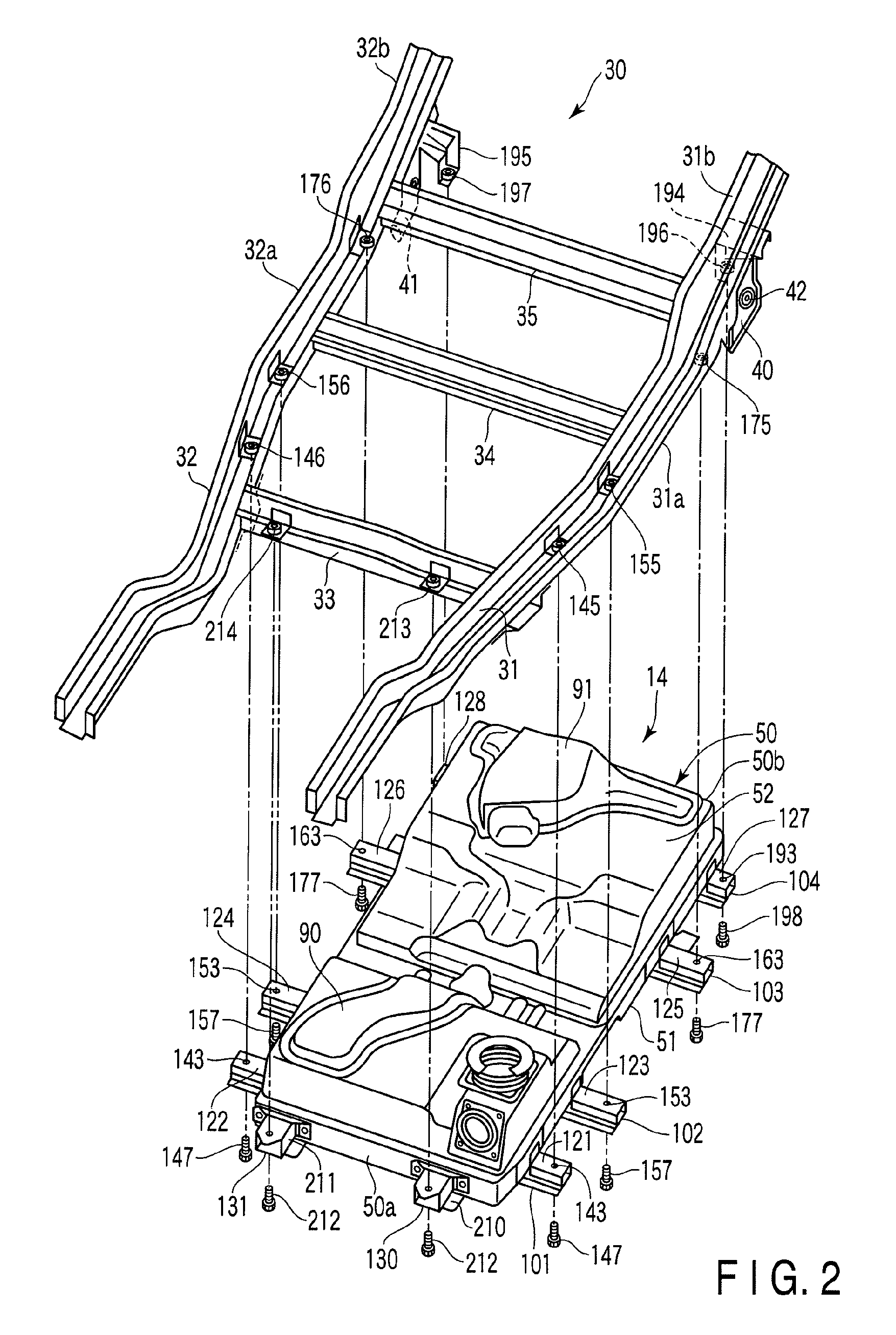

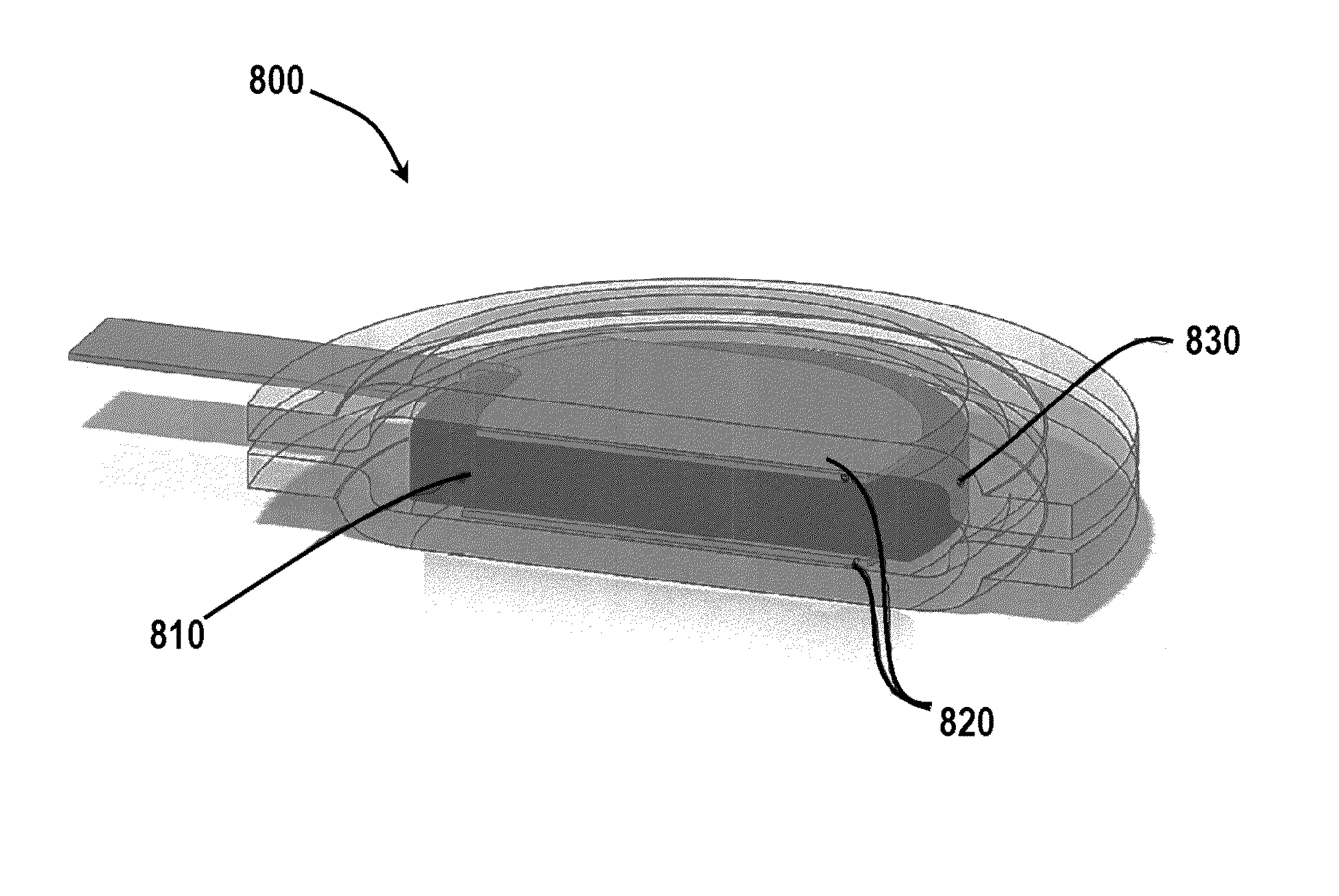

Battery case for electric vehicle

InactiveUS20090236162A1Adversely affectingEasy to set upElectric propulsion mountingPropulsion by batteries/cellsEngineeringElectric vehicle

A battery case for containing therein battery modules includes a tray member, cover member, and seal member. The seal member is applied to a joint part between the tray member and cover member. Insert members made of metal are embedded in the resin of the tray member. Each of the insert members is provided with an embedded bolt a threaded part of which protrudes upward, and embedded nuts. The battery case is provided with first fastening sections and second fastening sections. In the first fastening section, a nut member is screwed onto the embedded bolt from above the cover member. In the second fastening section, a bolt member is screwed into the embedded nut from above the cover members.

Owner:MITSUBISHI MOTORS CORP

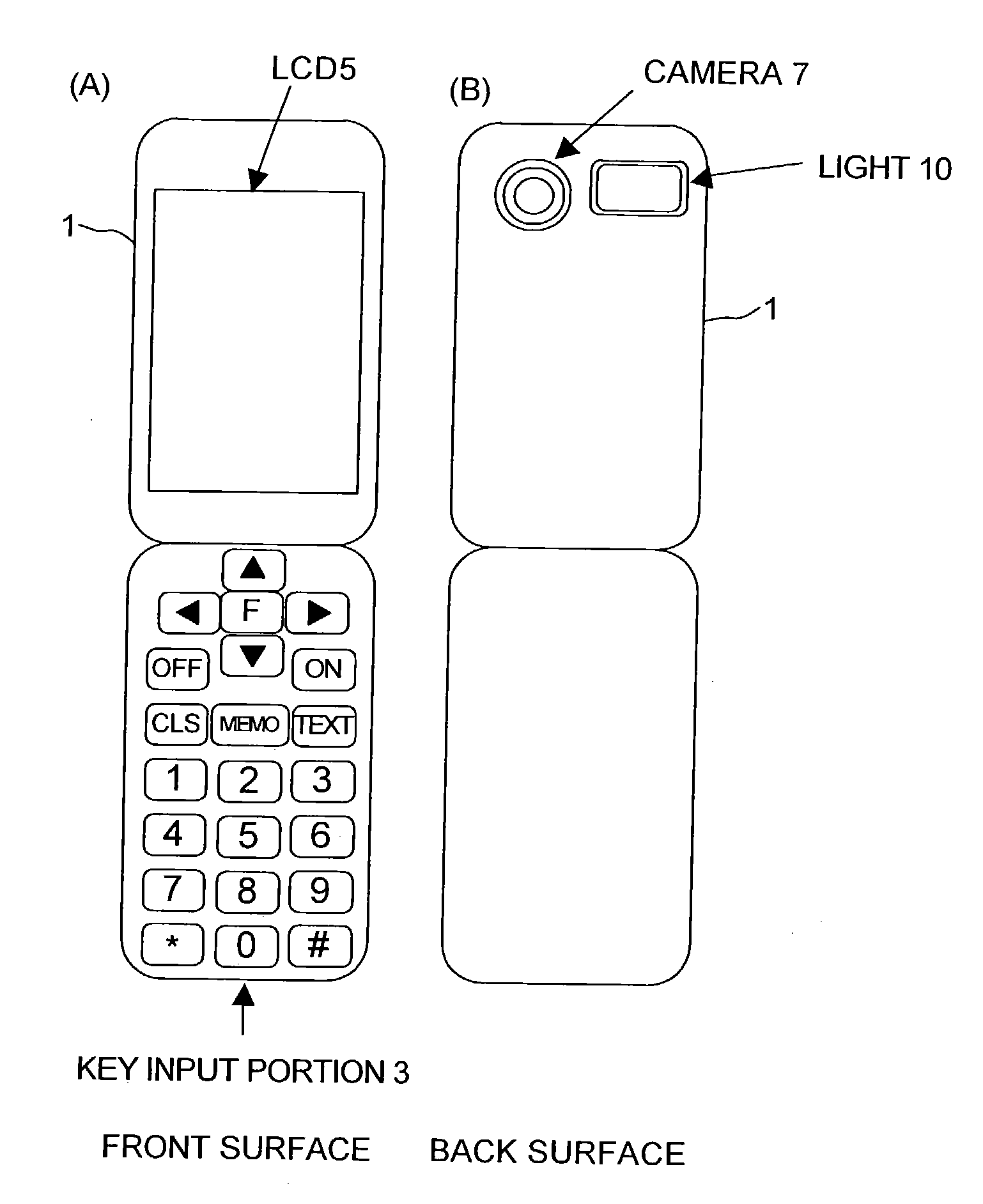

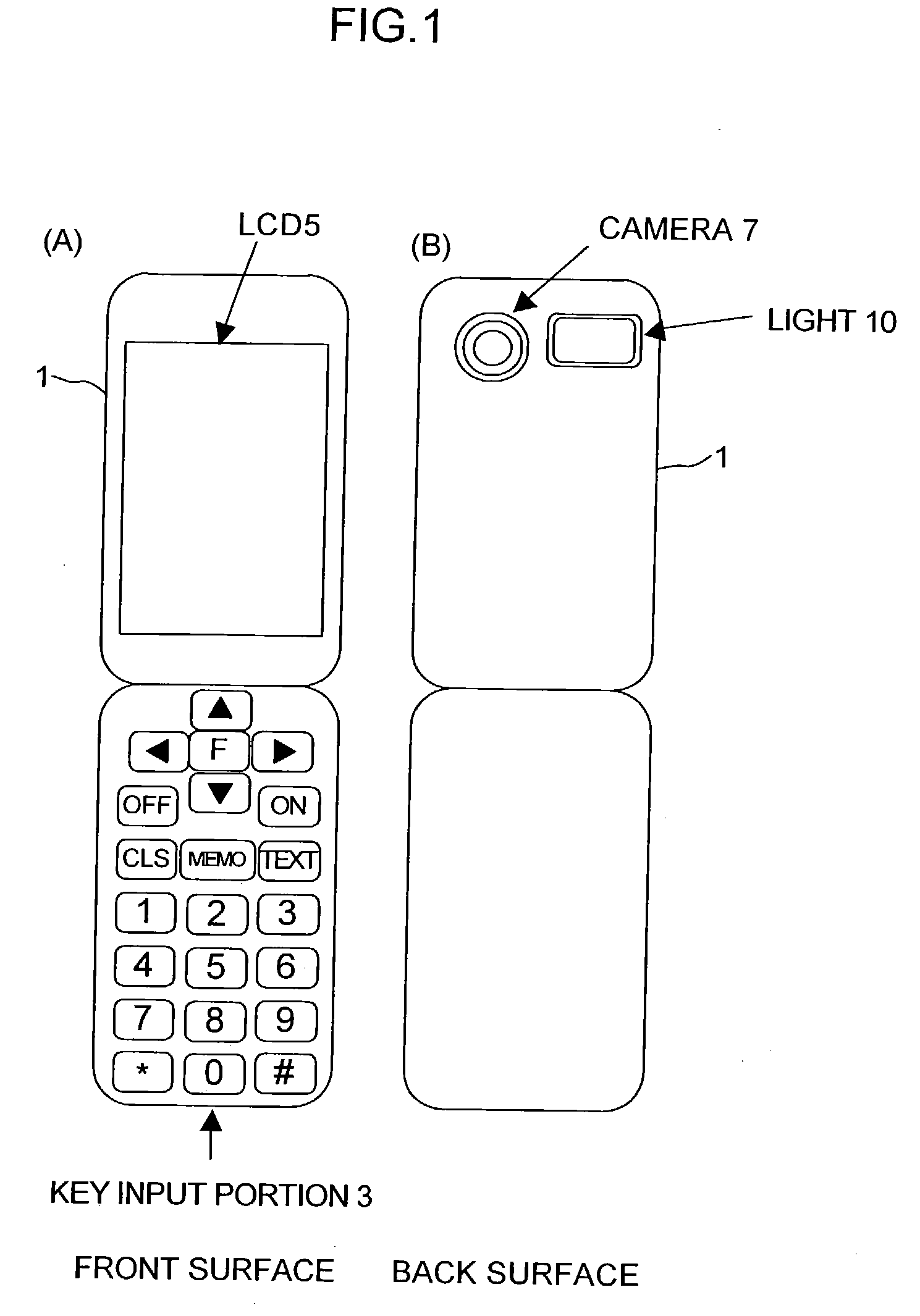

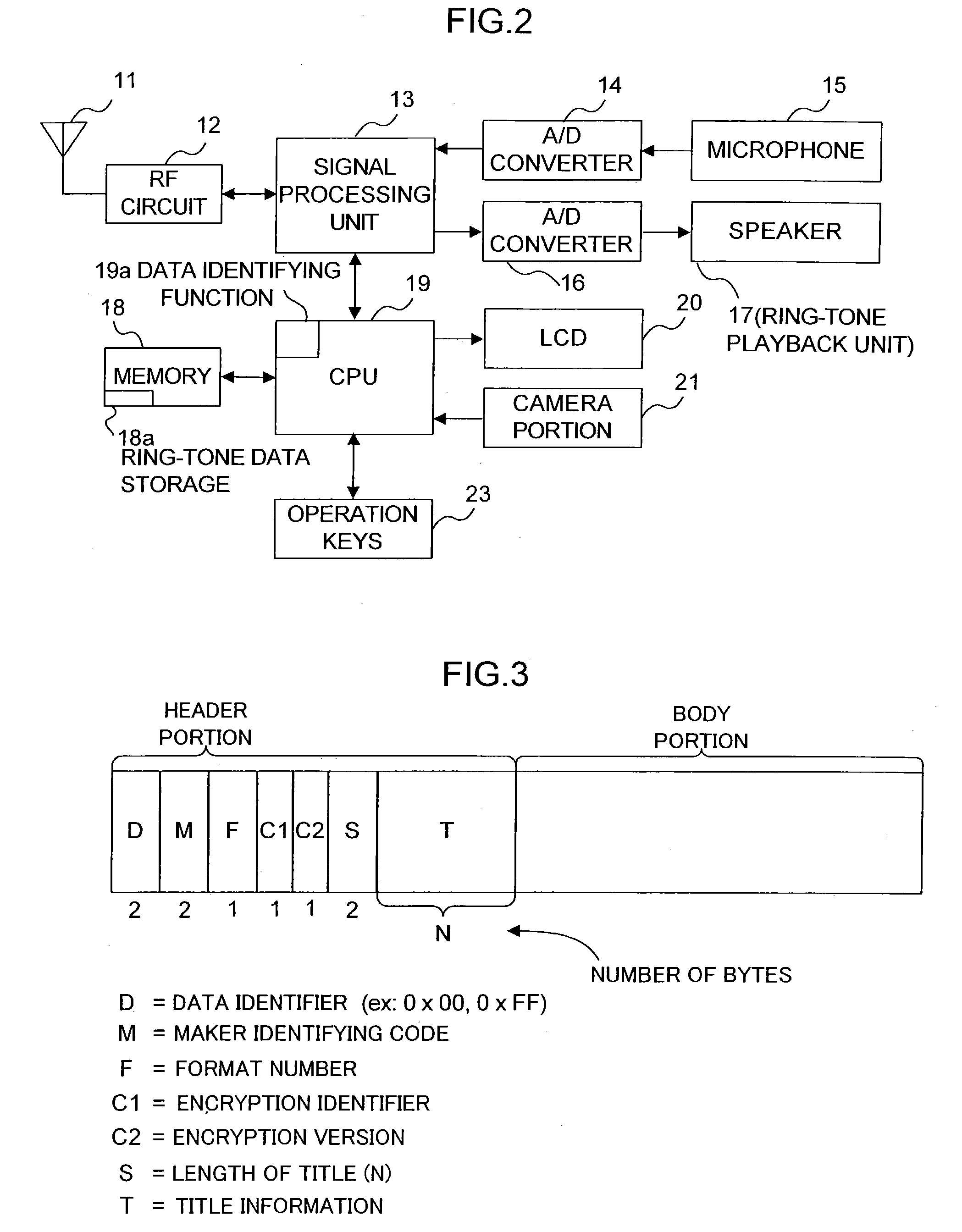

Code structure and code reading terminal

InactiveUS20040014490A1Accurately carry-outElectrophonic musical instrumentsSpeech analysisComputer terminalData type

A code-reading apparatus determines the type of data in recorded code data and carries out appropriate processes depending on the determined type of data. The code-reading apparatus comprises an imaging unit 7 for photographing encoded data. The encoded data comprises a header portion and a body portion, the body portion including encoded ring tone data, the header portion including a data identifier D indicating the type of data in the body portion. The apparatus further comprises a data identifier unit 19a for identifying the type of the encoded data photographed by the imaging unit 7 based on the data identifier D, and control units 13 and 19 for reading the encoded data depending on the identified data type and for reproducing the ring tone data that has been read.

Owner:SHARP KK

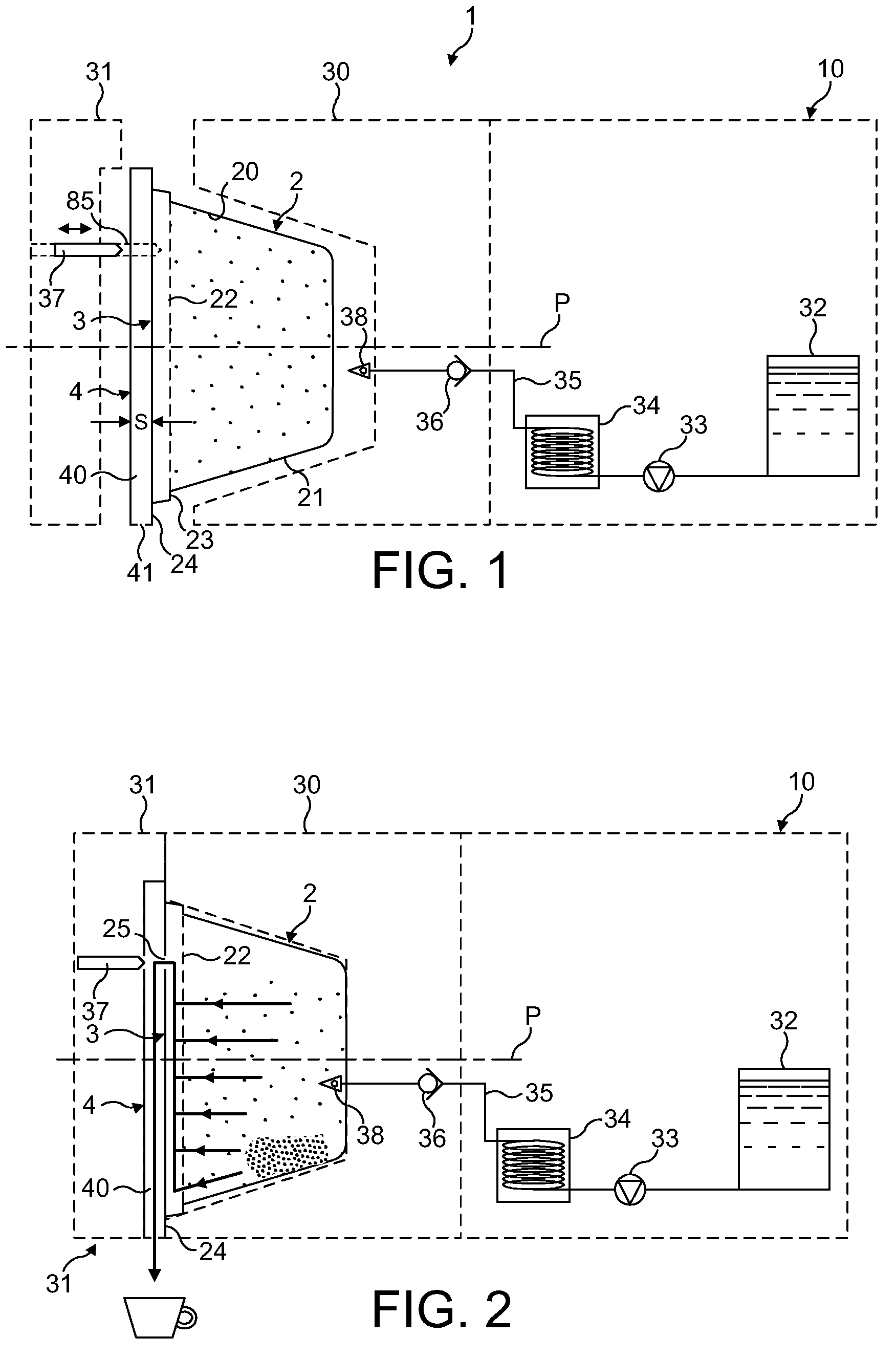

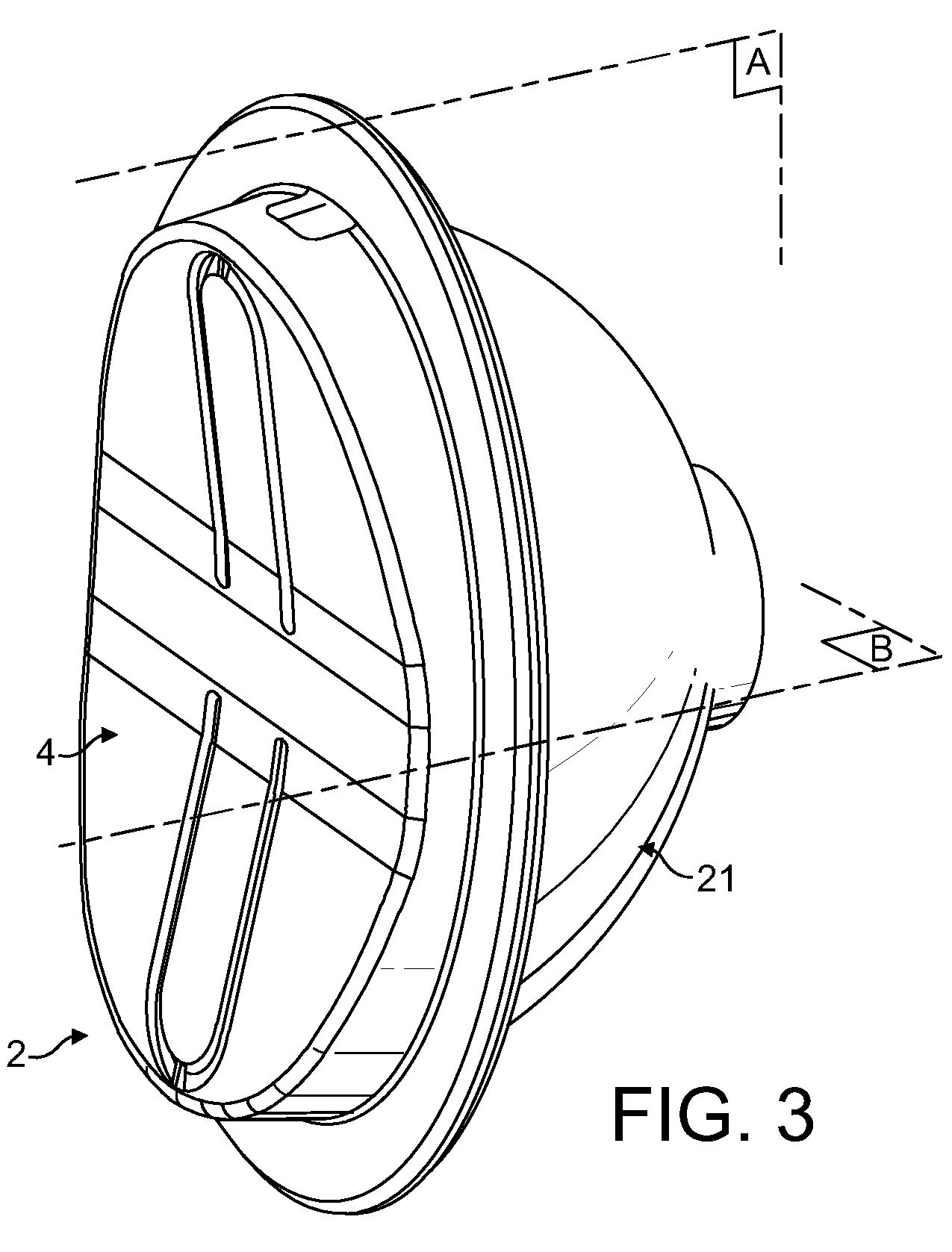

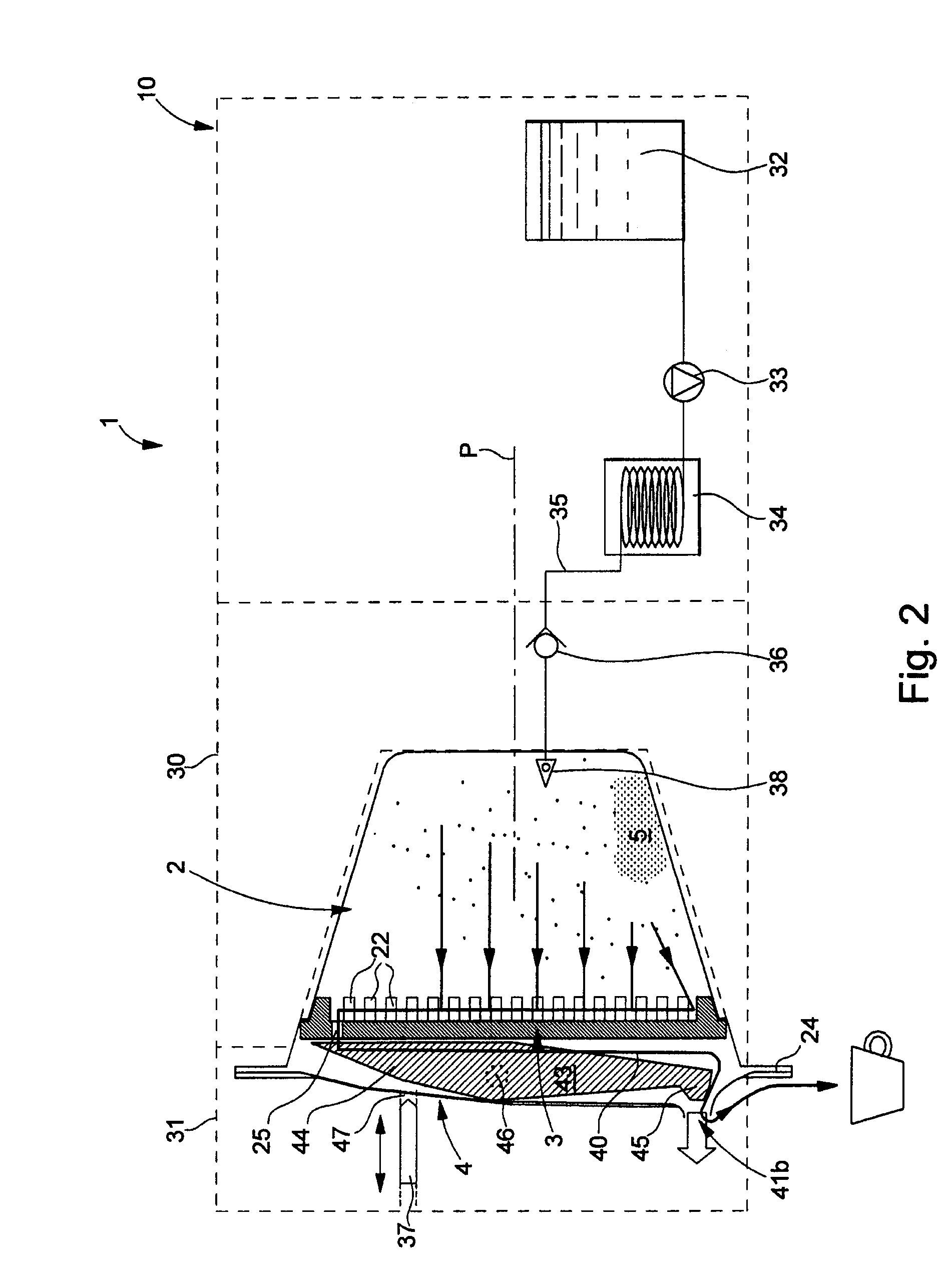

Capsule for the preparation of a beverage

ActiveUS7981451B2Simple capsule constructionEasy to handleBeverage vesselsPackaging foodstuffsAdditive ingredientBiomedical engineering

Capsule for the preparation of a beverage in a beverage machine comprising an enclosure (20) containing one or more beverage ingredients, a filtering wall (22) delimiting at least one filtering side of the enclosure, wherein the capsule further comprises an overflow wall (3B) that is positioned in the path of the brewed liquid after the filtering wall and which comprises at least one overflow aperture or is associated with at least one puncture means (8A, 8B) or, respectively, puncture indication means capable of producing or, respectively, indicating at least one overflow aperture. The capsule of the invention is designed for delivering a brewed liquid at relatively low pressure and is more particularly suited for tea beverages.

Owner:SOC DES PROD NESTLE SA

Battery case for electric vehicle

InactiveUS7997368B2Adversely affectingEasy to set upElectric propulsion mountingCell component detailsElectric-vehicle batteryEngineering

A battery case for containing therein battery modules includes a tray member, cover member, and seal member. The seal member is applied to a joint part between the tray member and cover member. Insert members made of metal are embedded in the resin of the tray member. Each of the insert members is provided with an embedded bolt a threaded part of which protrudes upward, and embedded nuts. The battery case is provided with first fastening sections and second fastening sections. In the first fastening section, a nut member is screwed onto the embedded bolt from above the cover member. In the second fastening section, a bolt member is screwed into the embedded nut from above the cover members.

Owner:MITSUBISHI MOTORS CORP

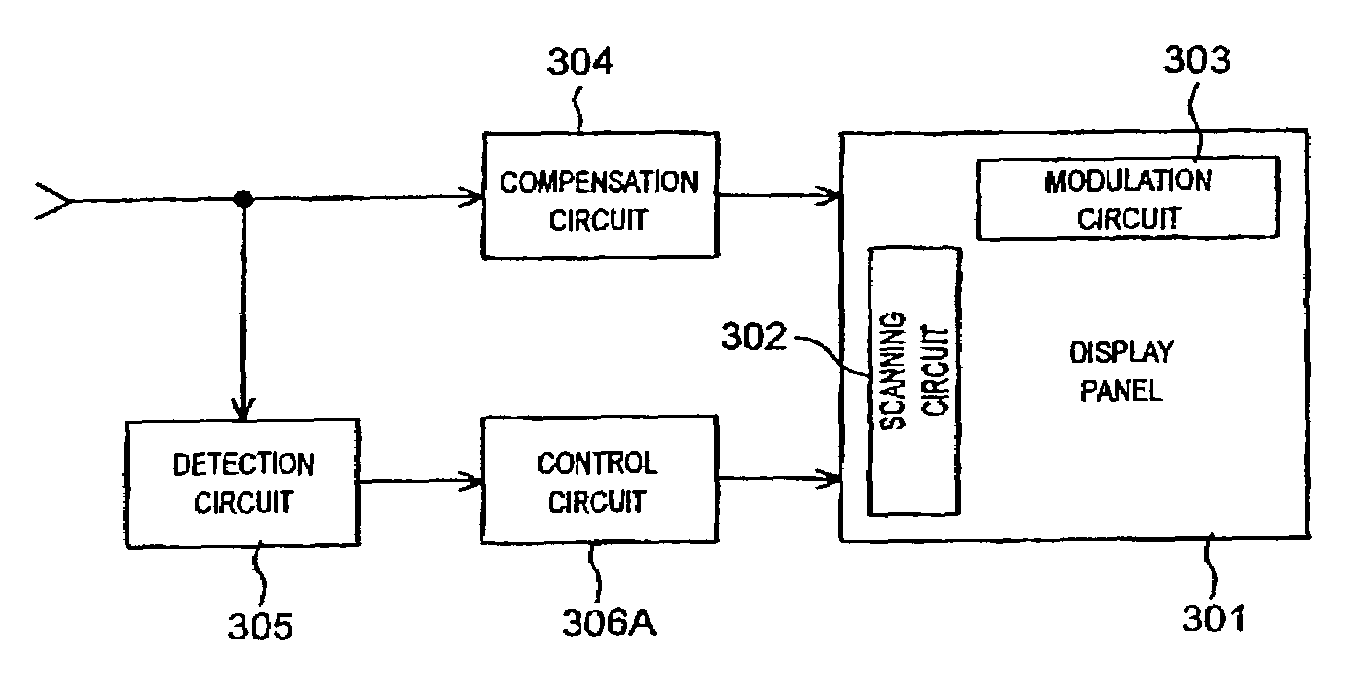

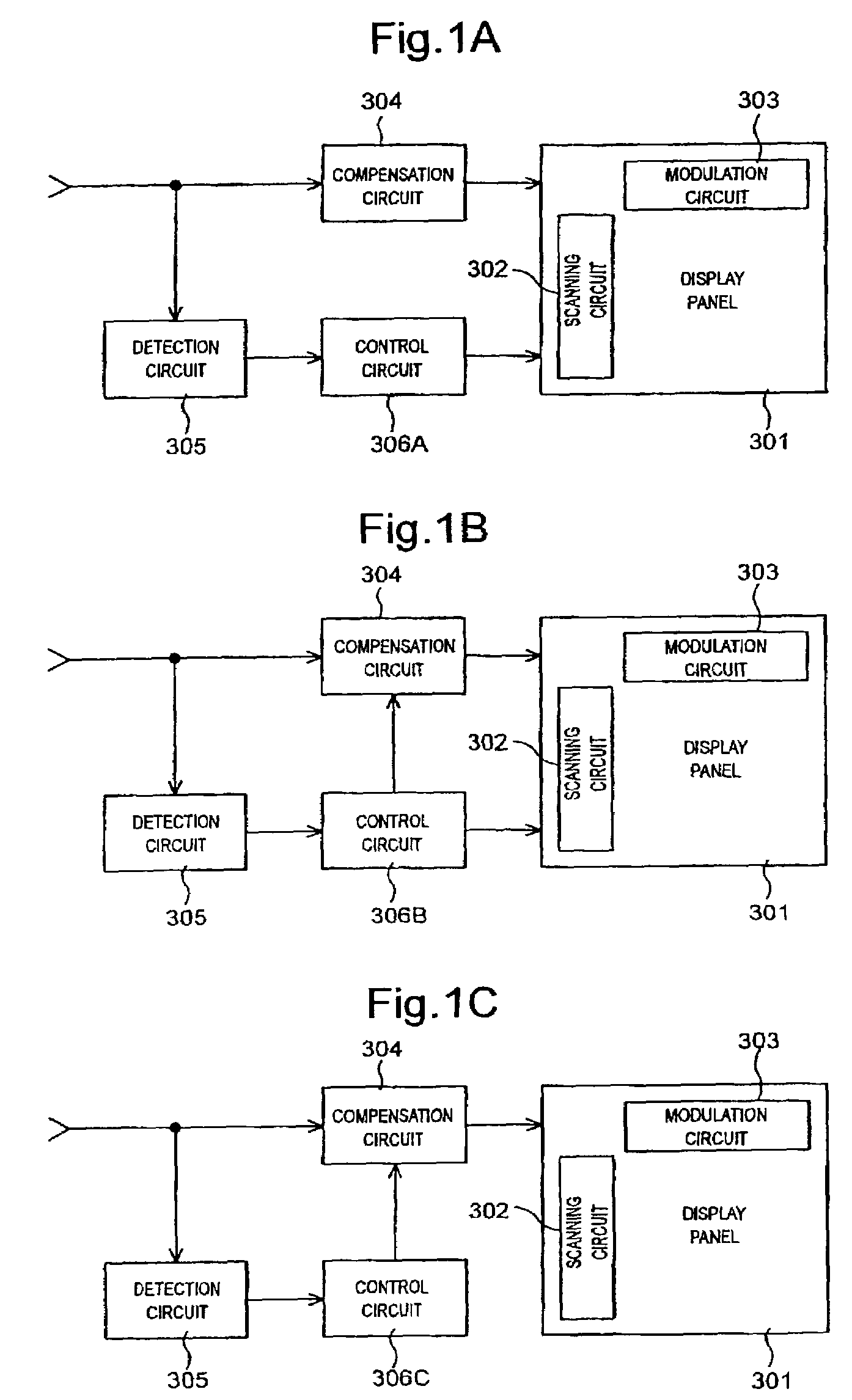

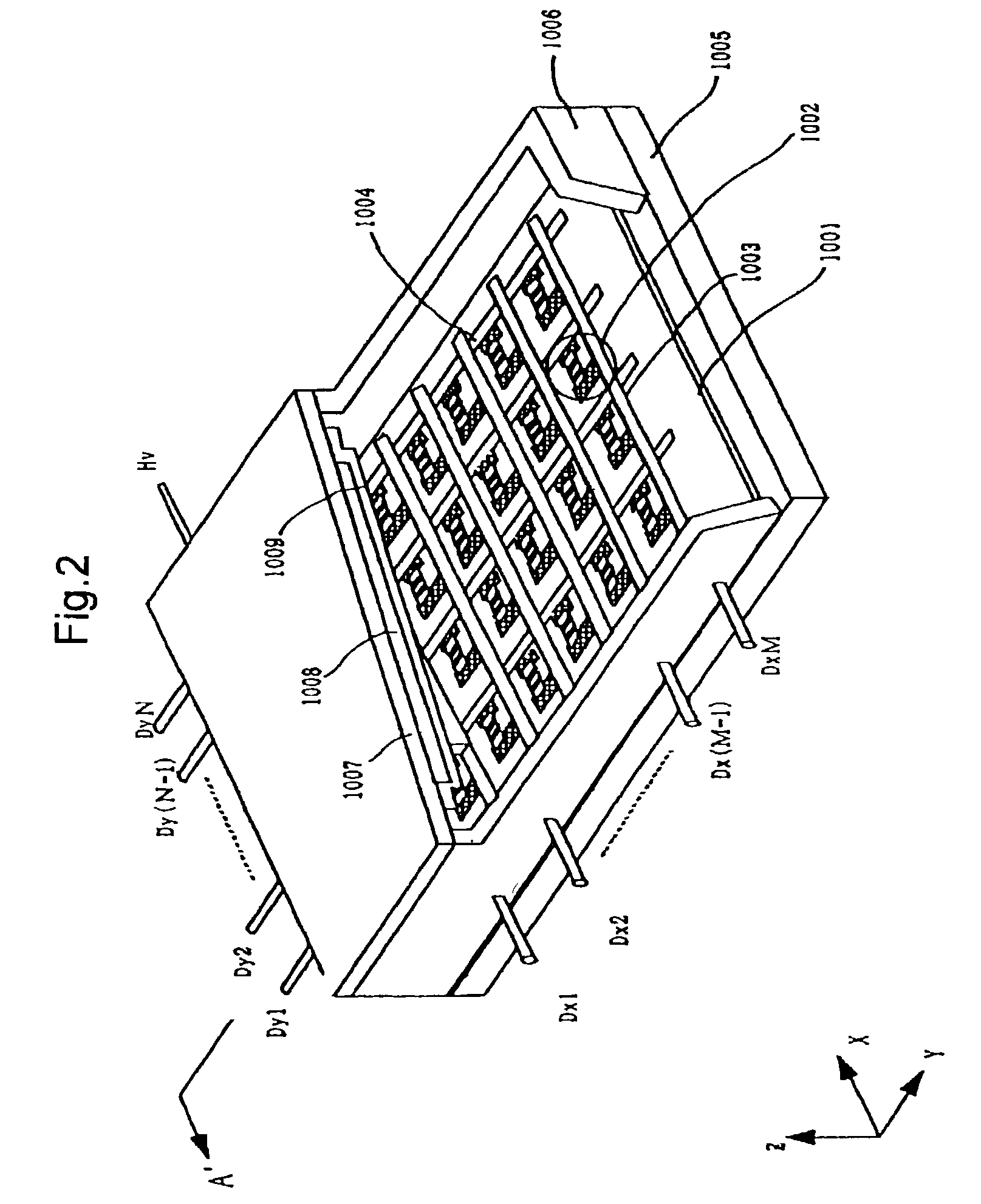

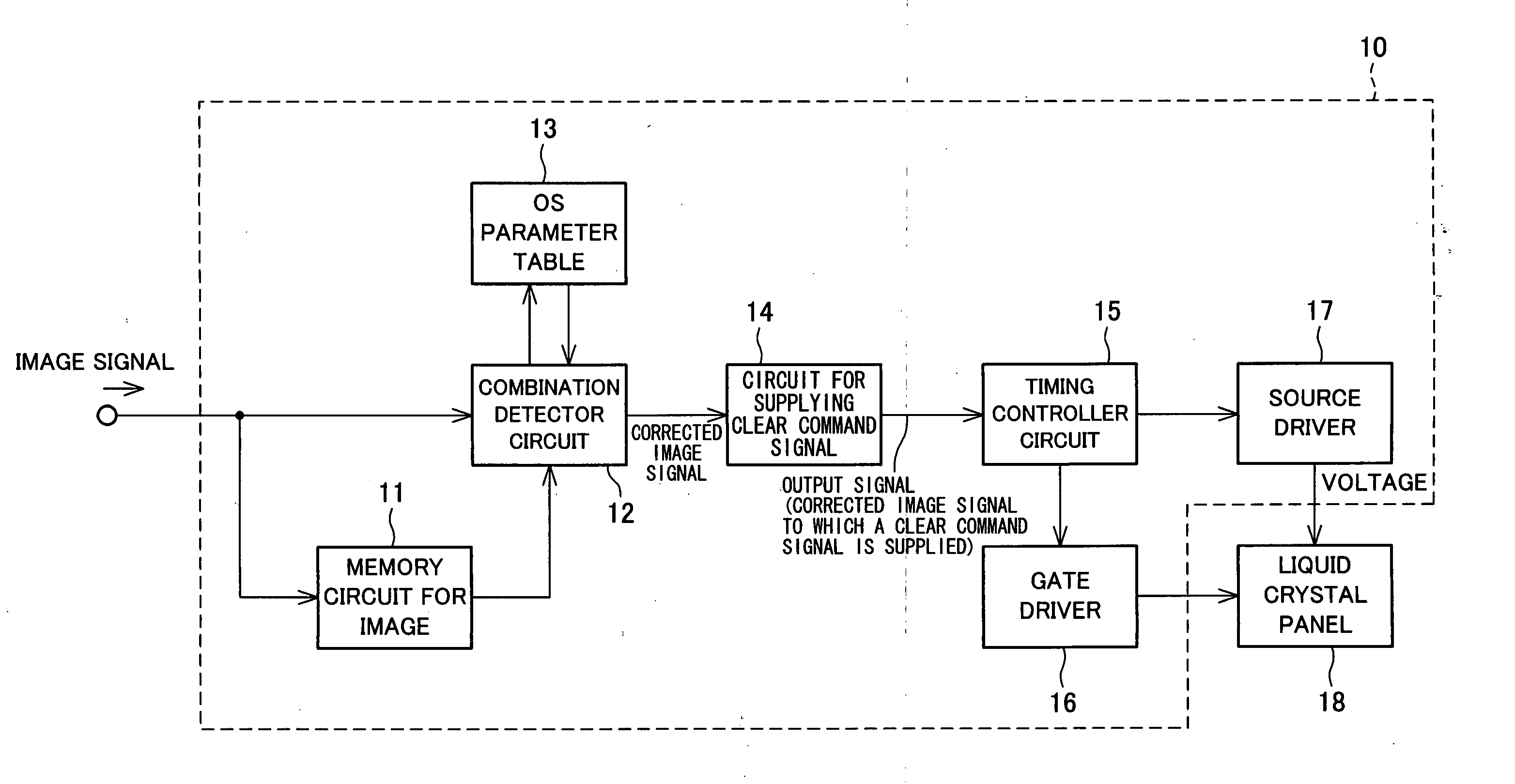

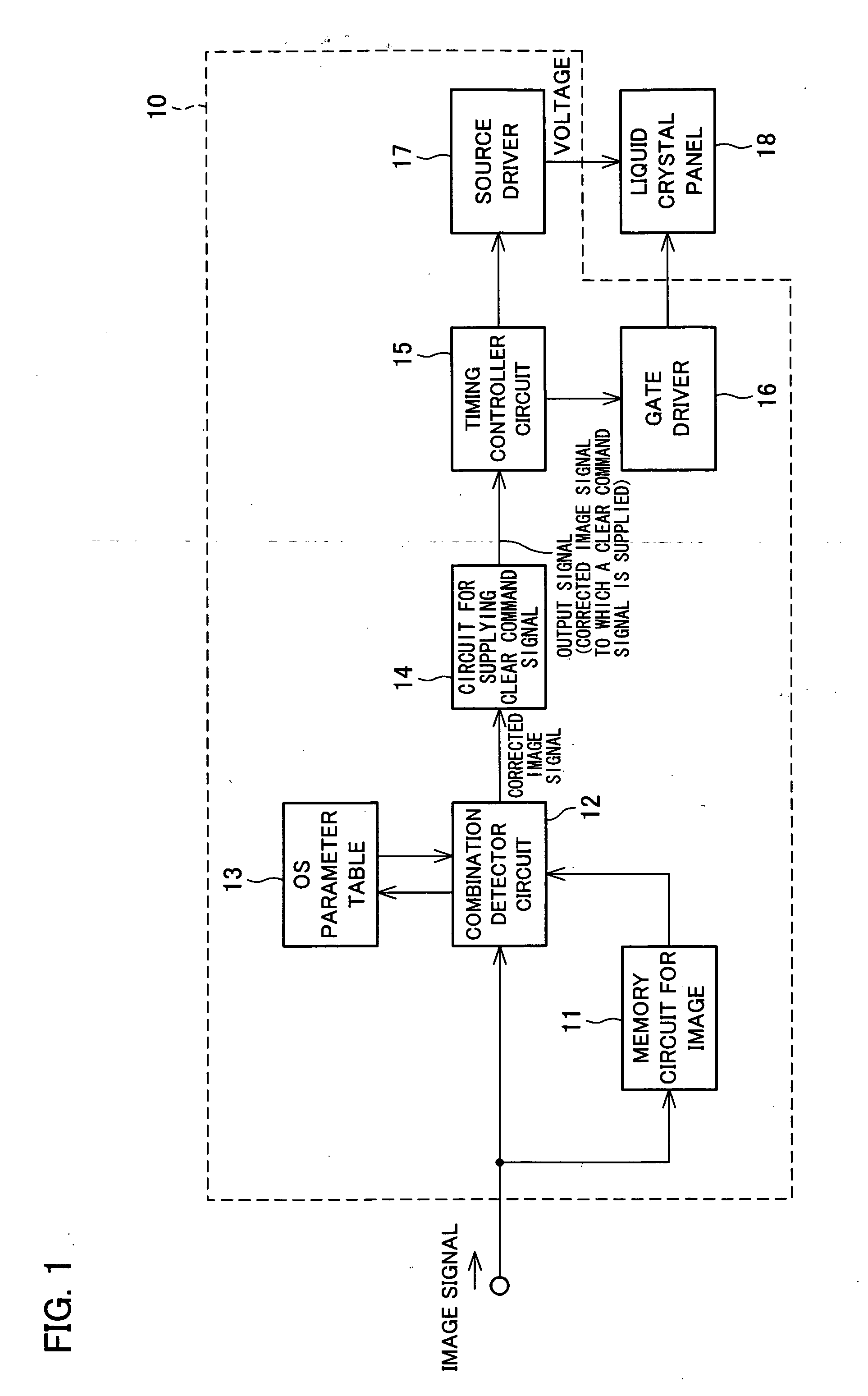

Display apparatus, and image signal processing apparatus and drive control apparatus for the same

InactiveUS7009627B2Accurately carry-outGearingCathode-ray tube indicatorsElectrical resistance and conductanceDisplay device

A display apparatus includes a display panel having display devices arranged in a matrix layout and driven through a plurality of row wirings and column wirings, a scanning unit to scan the row wirings, and a modulation unit to supply a modulation signal to the column wirings. A compensation unit applies compensation processing to compensate for fluctuation of display luminance due to the influence of voltage drop caused by a resistance of the row wiring to the image data, and a luminance control unit controls display luminance of the display panel based upon luminance information of the image data.

Owner:CANON KK

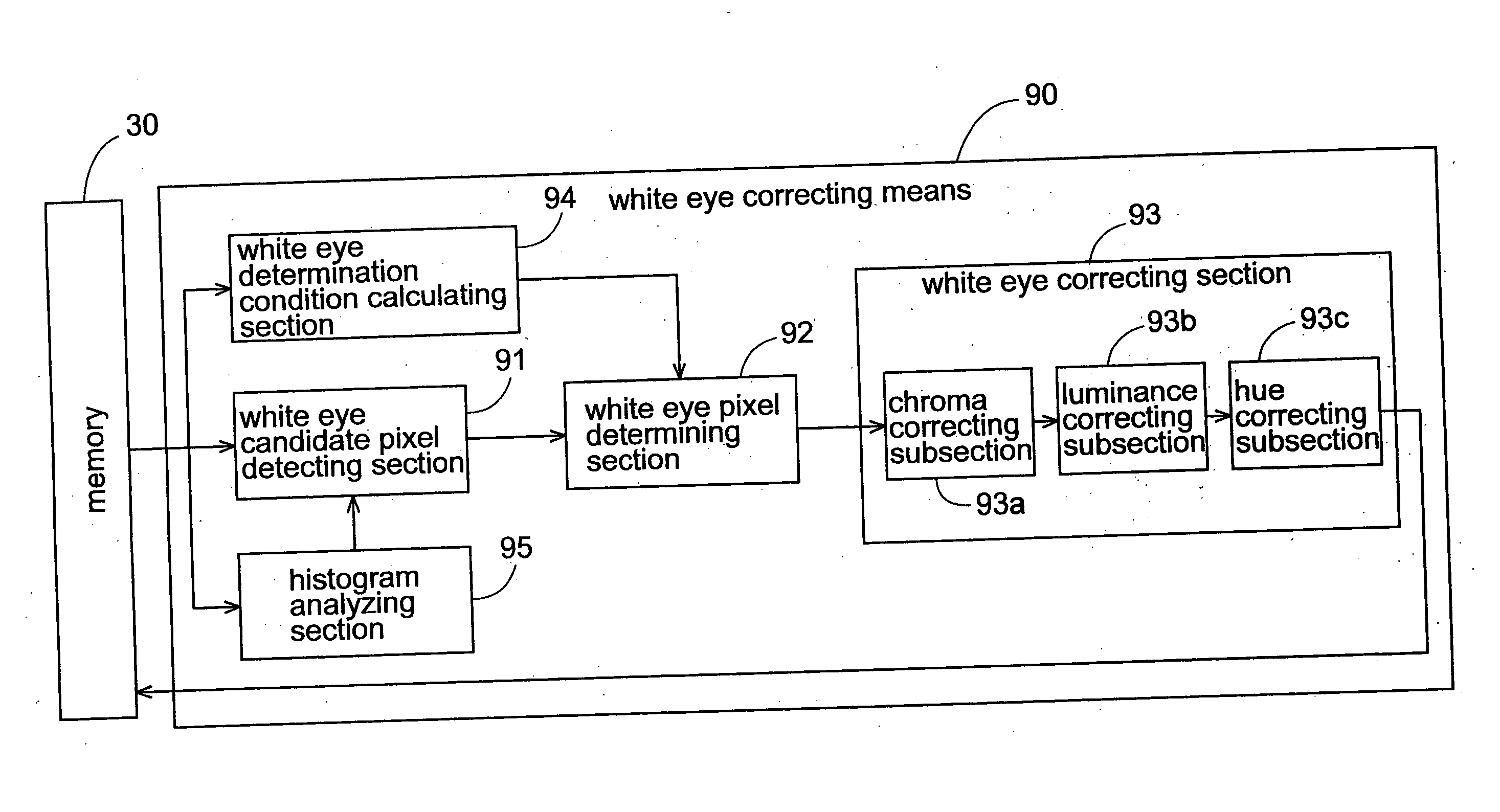

Image processing method and apparatus for white eye correction

InactiveUS20050238230A1Increase brightnessDecrease in luminanceTelevision system detailsImage enhancementImaging processingOphthalmology

A technique for correcting white eye in image data is disclosed. In this technique, a white eye candidate pixel is detected from an eye extracted from the image data based on a predetermined detection condition. The white eye candidate pixel as a white eye pixel based on a predetermined determination condition. Then, white eye correction is effected on the determined white eye pixel by changing its luminance.

Owner:NORITZ CORP

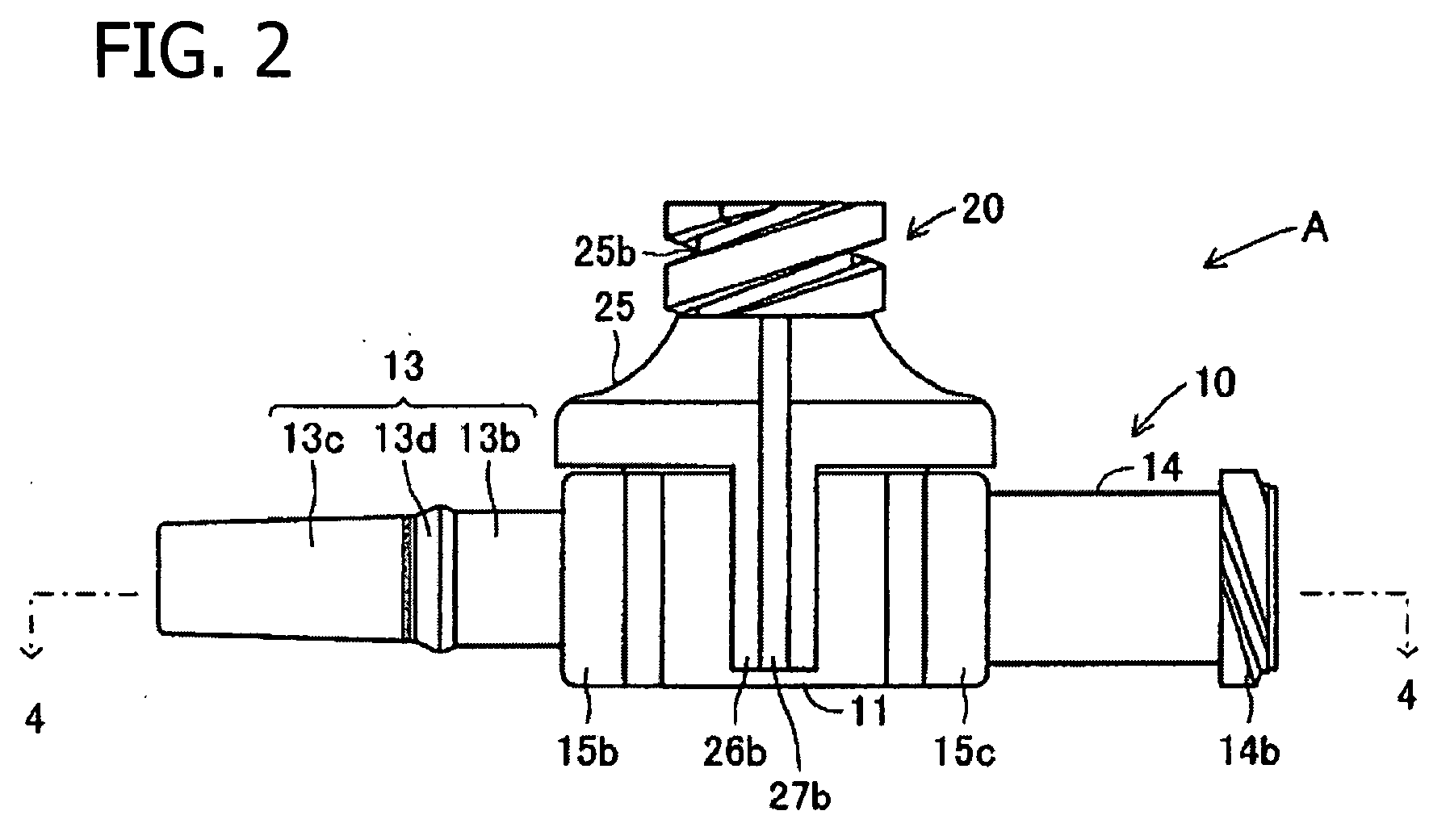

Liquid-mixing infusor

InactiveUS20070255202A1Reliable stopAccurately carry-outMedical devicesHaemostasis valvesEngineeringVALVE PORT

Owner:KPR U S LLC

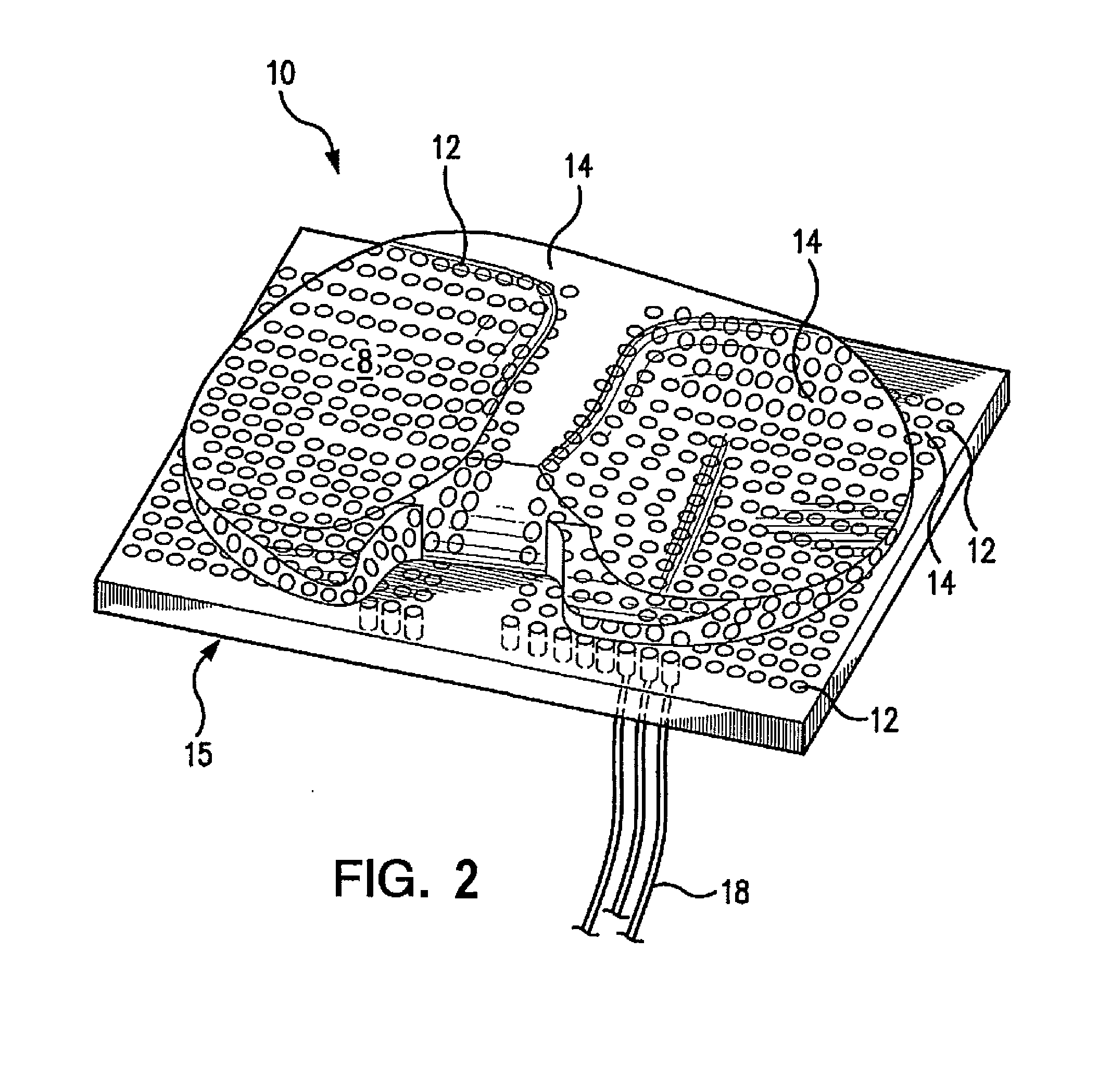

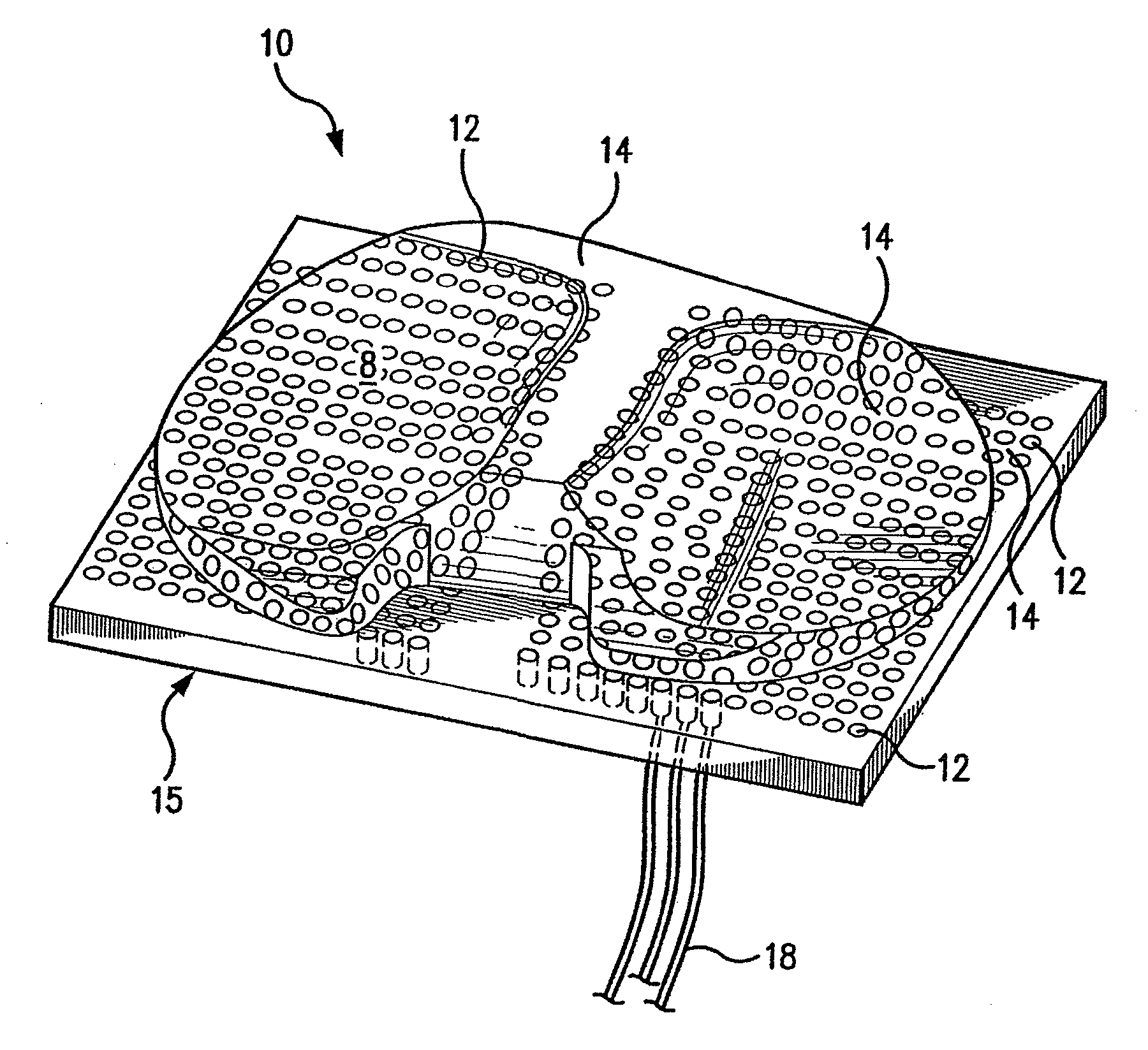

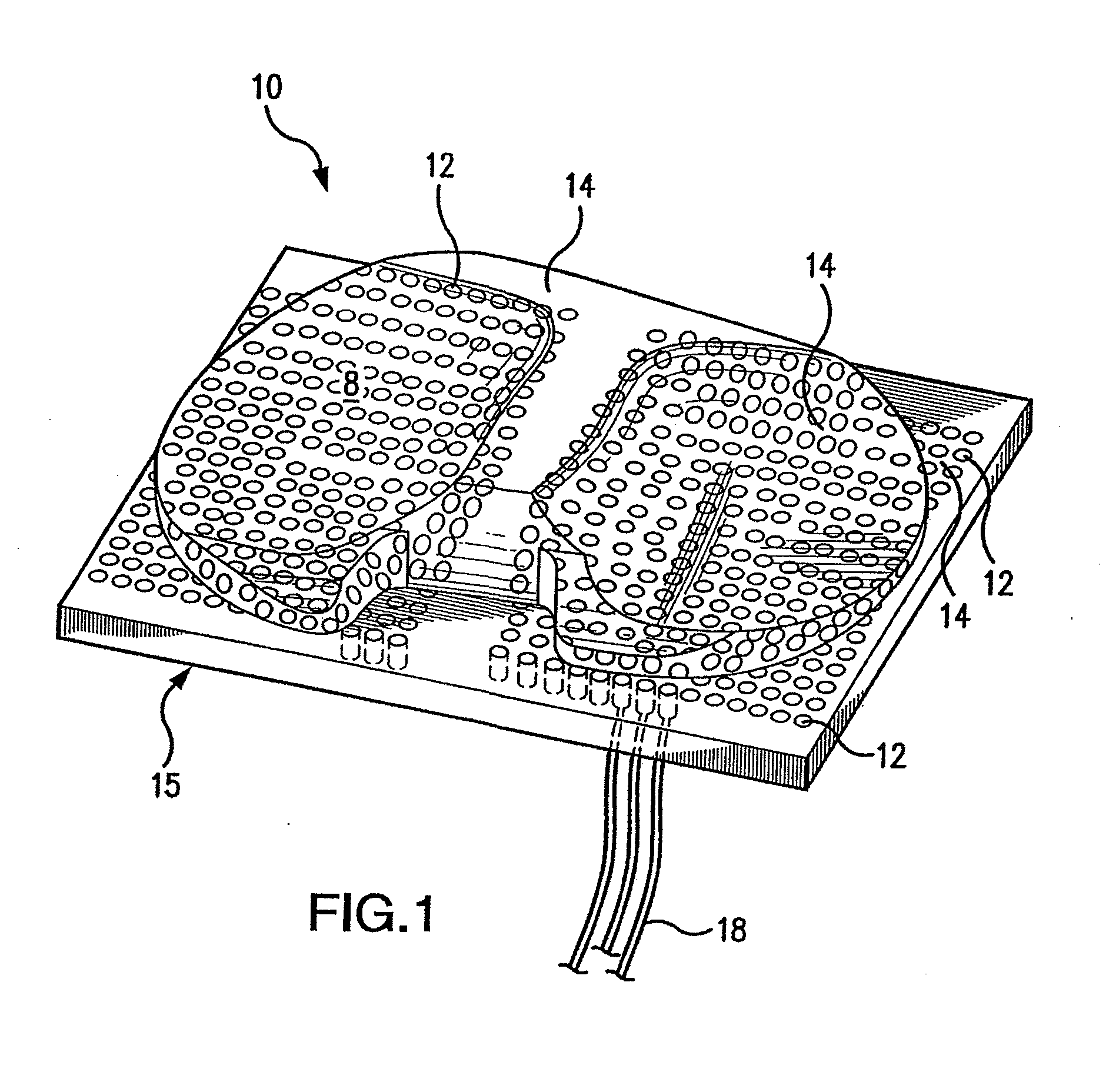

Contact sensors, force/pressure sensors, and methods for making same

InactiveUS20130204157A1Prevent intrusionReduced probability of early failureWeighing apparatus using elastically-deformable membersForce measurementElectrical resistance and conductanceConductive polymer

Disclosed herein are contact sensors having a conductive composite material formed of a polymer and a conductive filler. In one particular aspect, the composite materials can include less than about 10 wt % conductive filler. The composite material of the contact sensors can have physical characteristics essentially identical to the polymer, while being electrically conductive with the electrical resistance proportional to the load on the sensor. Also disclosed herein are novel force / pressure sensors that include conductive polymer elements.

Owner:SENSORTECH CORP

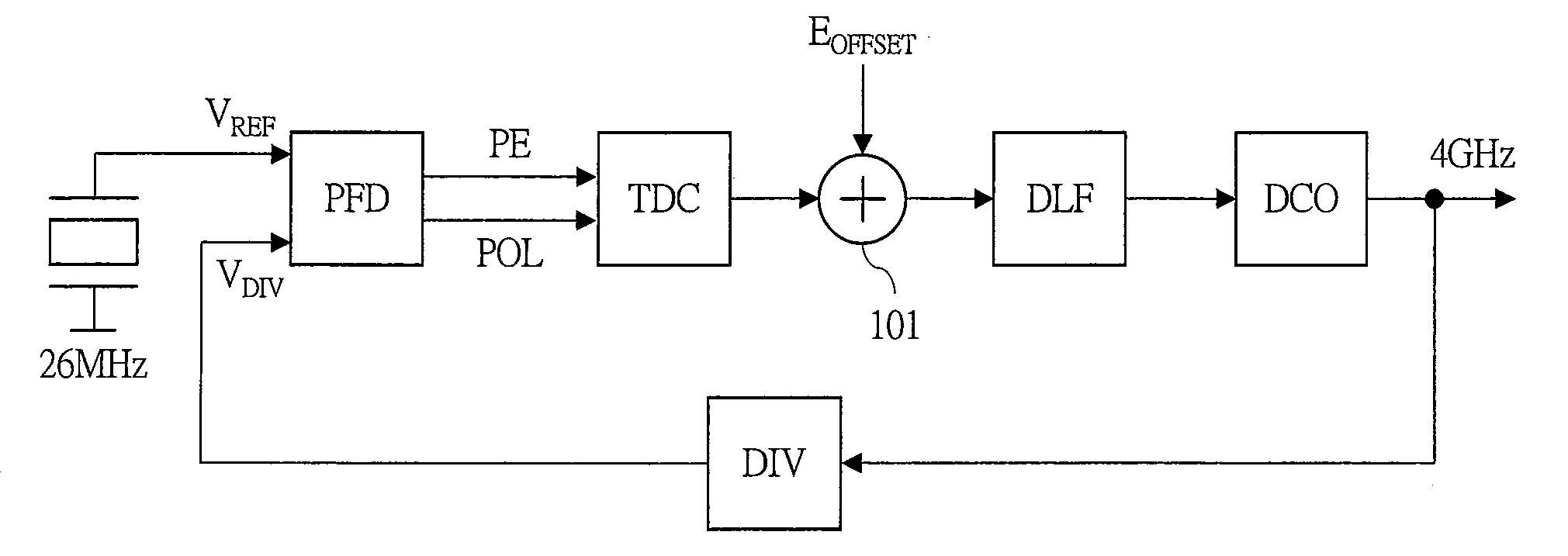

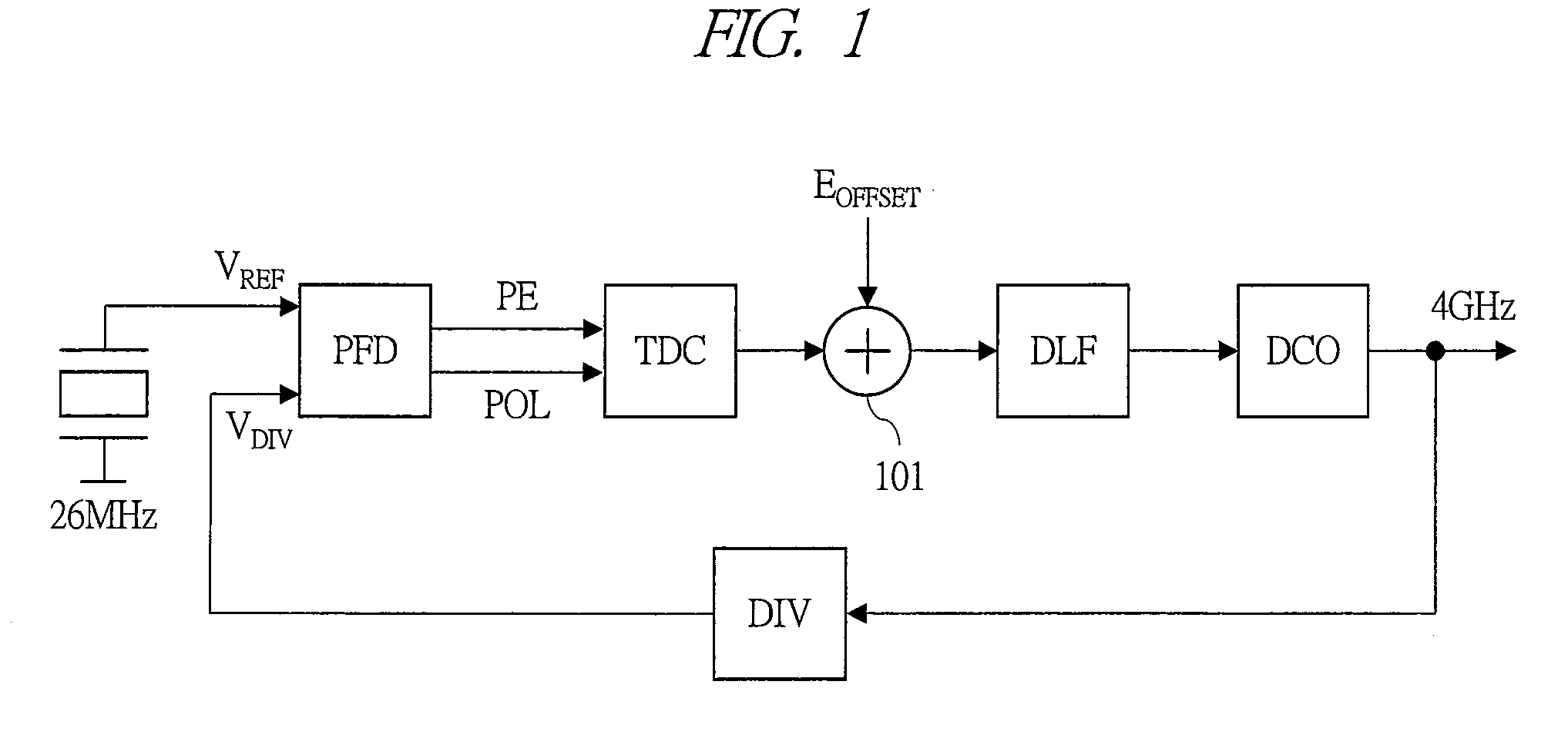

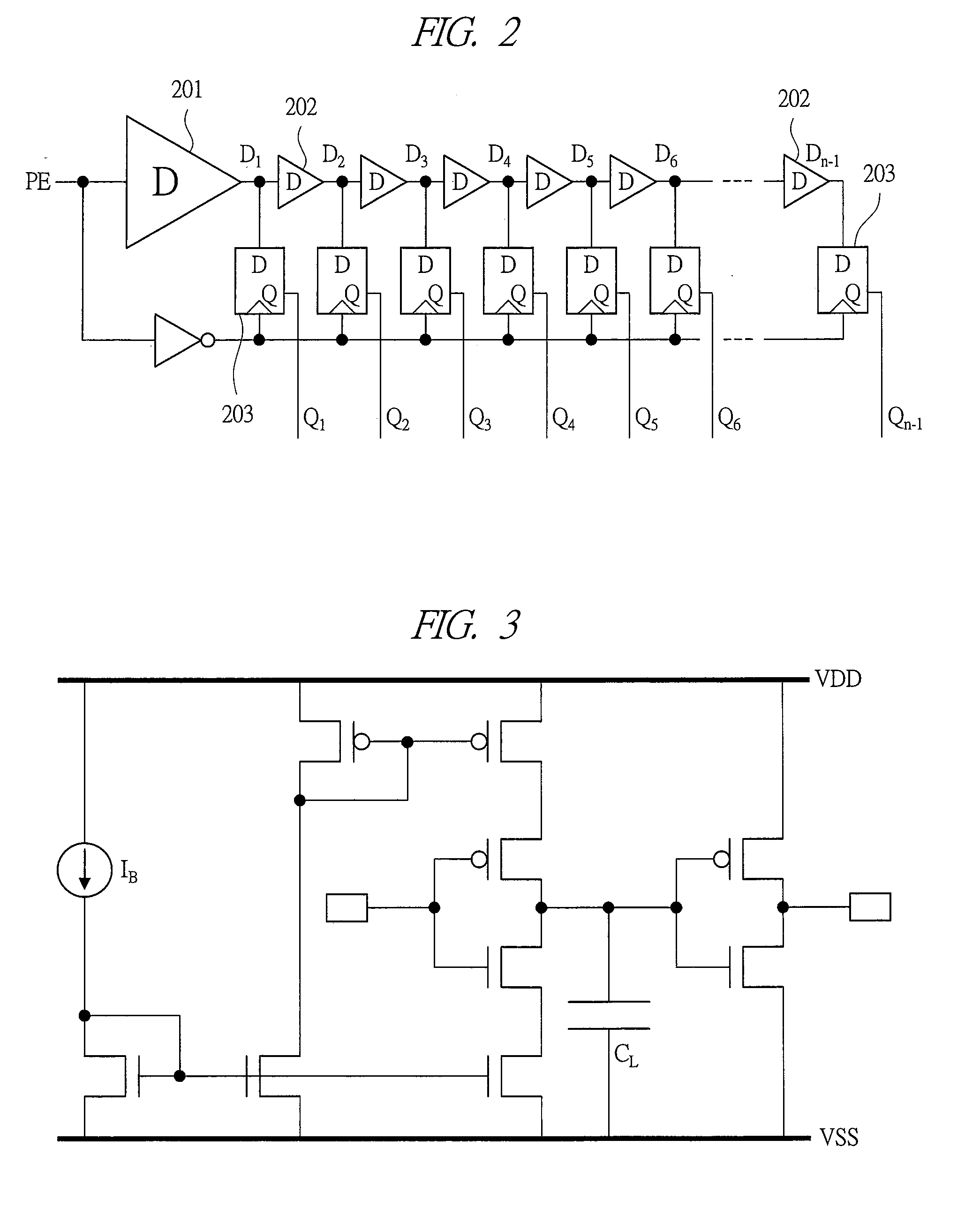

Pll circuit

ActiveUS20090267664A1Improving phase difference detectionEasy to detectPulse automatic controlAngle demodulation by phase difference detectionPhase differenceOutput feedback

In an ADPLL composed of a digital circuit, a technique improving phase difference detection in a vicinity of a phase difference of 0 (zero) is provided. A feedback loop comprises a PFD comparing phases and frequencies of a reference signal and a feedback signal, a TDC converting an output of the PFD into a digital value, a DLF removing a high frequency noise component from an output of the TDC, a DCO controlled based on an output of the DLF and a DIV frequency-dividing an output the DCO and outputting the feedback signal. An offset value is added at any portion of the feedback loop, a phase of the feedback signal is controlled and a value other than 0 is inputted to the TDC even when the ADPLL is locked.

Owner:RENESAS ELECTRONICS CORP

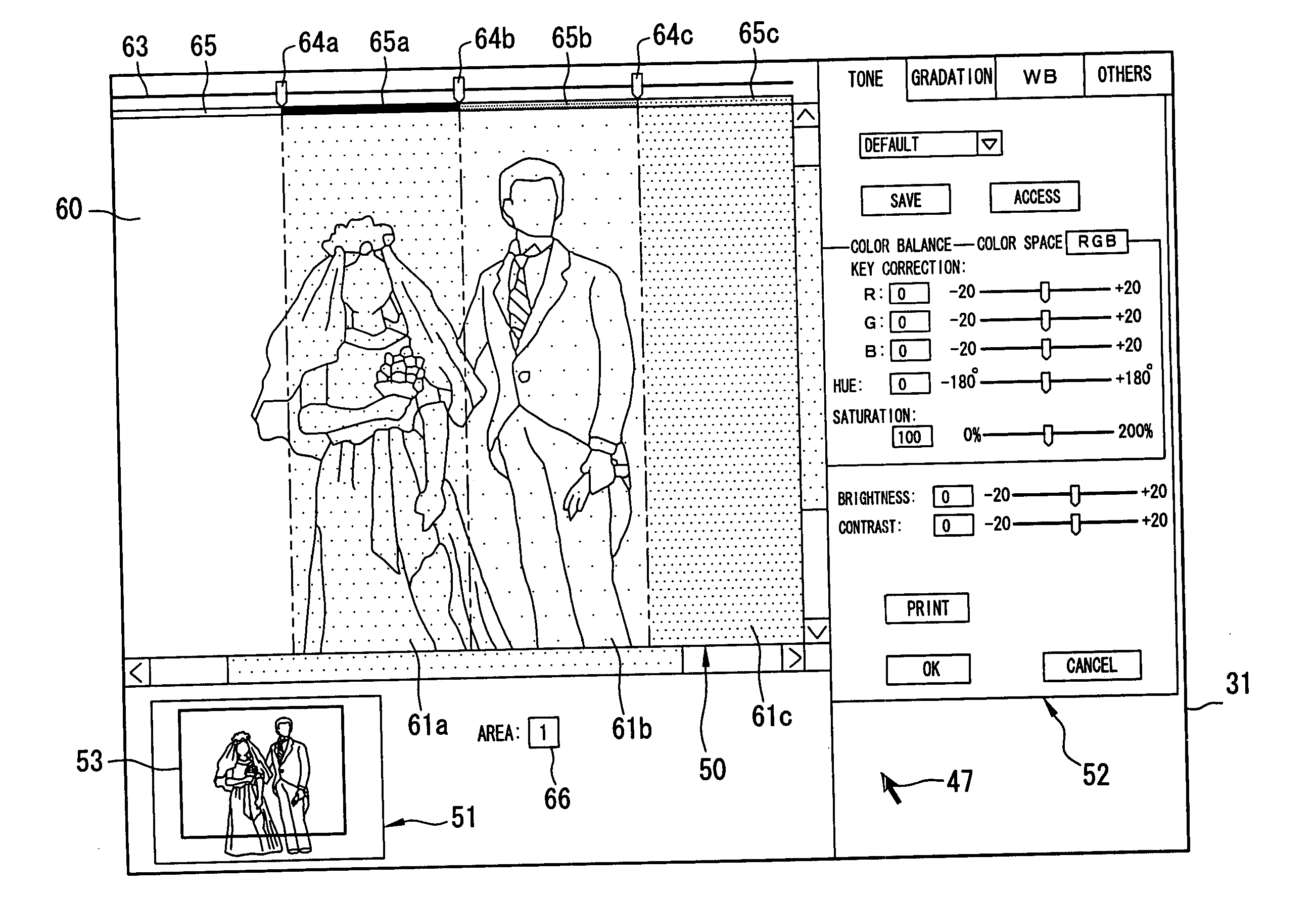

Image correction method, image correction apparatus, and image correction program

InactiveUS20050174590A1Accurately carry-outEfficient executionDigitally marking record carriersVisual presentation using printersZone sizeComputer graphics (images)

A main display section is divided into a plurality of display areas (partial display areas). In each display area, image correction is carried out according to individual correction parameters. A target image for image correction is displayed in an image display area as a single image in a state that each section displayed in each display area has been corrected by using different parameters. In response to moving an indicator, which is displayed on an upper side of the main display section, along a slide bar, a size and a position of each display area is changed. An area size display bar, which shows a display range of each display area, is displayed on the upper side of the main display section. When one display area is selected for inputting the correction parameters, a section of the area size display bar, which corresponds to the selected display area, is highlighted.

Owner:FUJIFILM CORP +1

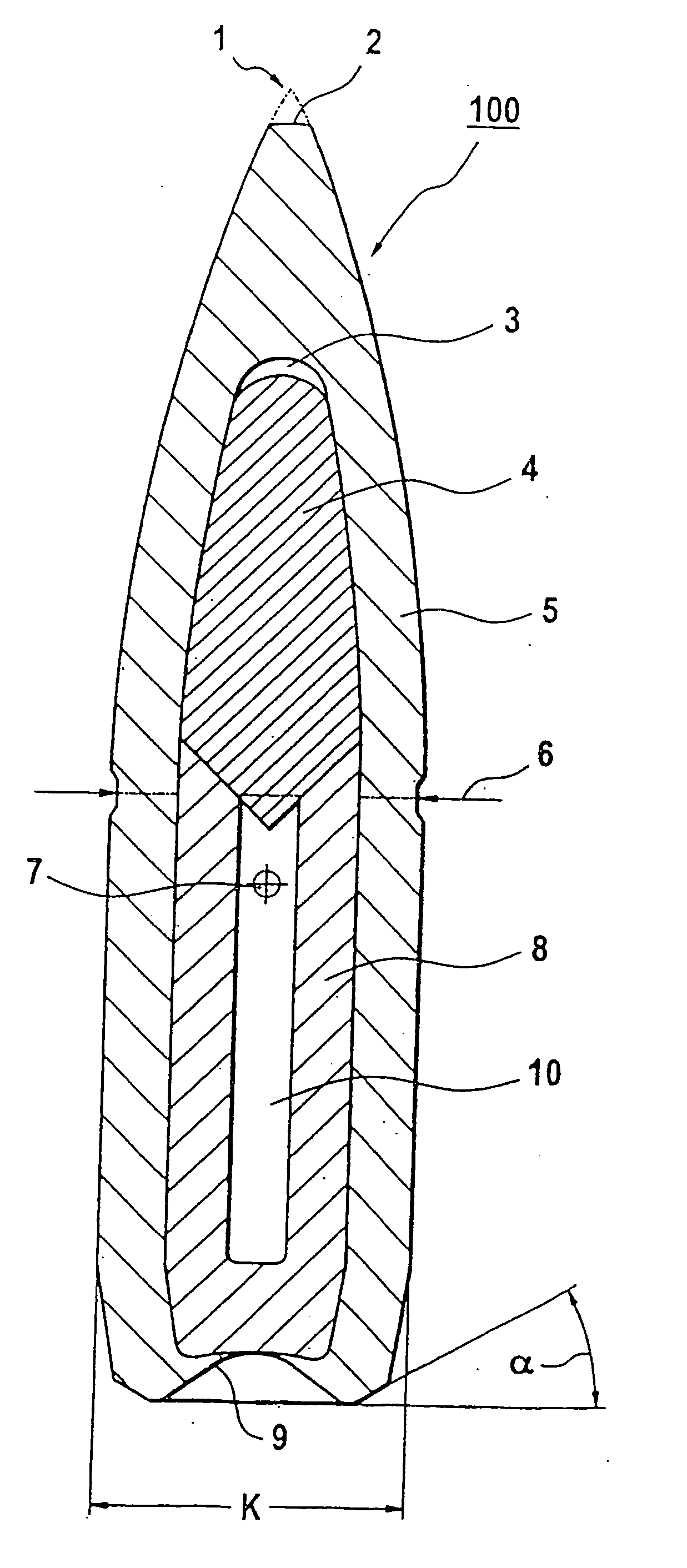

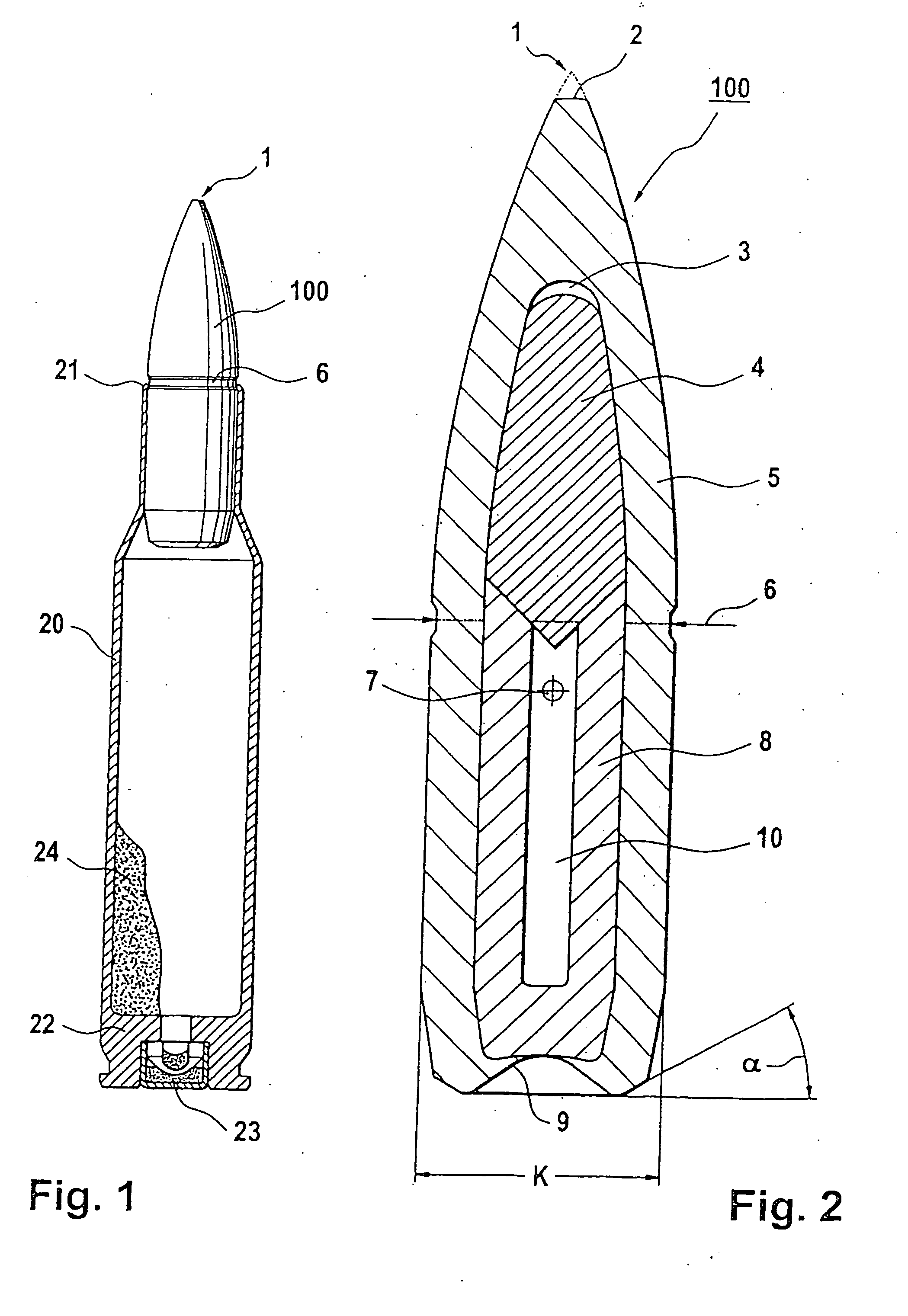

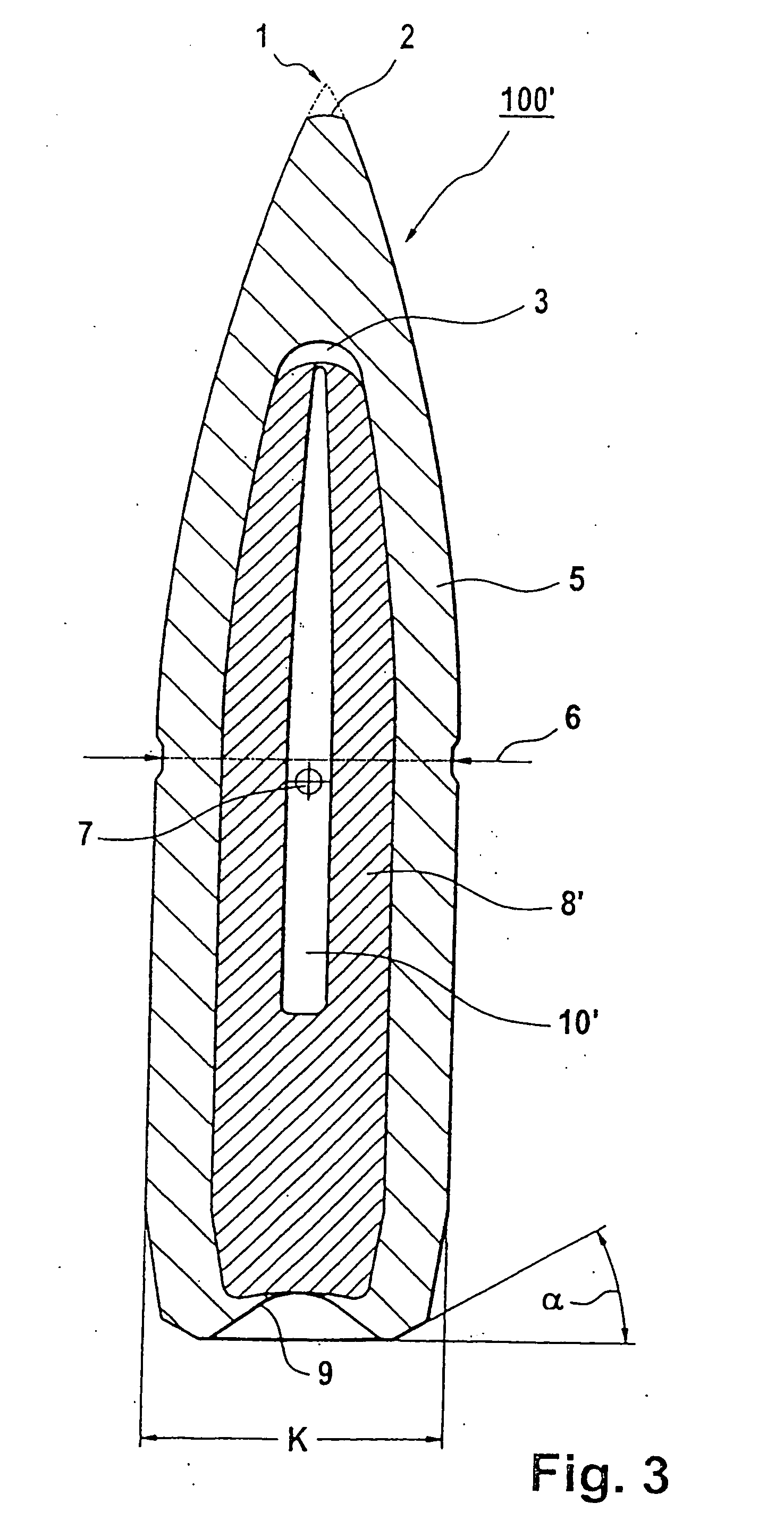

Lead-free projectile

ActiveUS20070204758A1Smooth connectionEasy to assembleAmmunition projectilesProjectilesEngineeringMechanical engineering

A small-bore projectile comprises a ductile outer jacket, a hard core, and a hollow jacket core. Kinetic energy of the projectile is substantially transmitted to the hard core when a target is hit such that said hard core penetrates the target. The outer jacket is supported by the jacket core that is located on the inside and mushrooms up into a deformed state upon impact without fragmenting. The projectile has good flying behavior and great final ballistic performance and can be produced in an entirely lead-free manner.

Owner:RUAG AMMOTEC GMBH

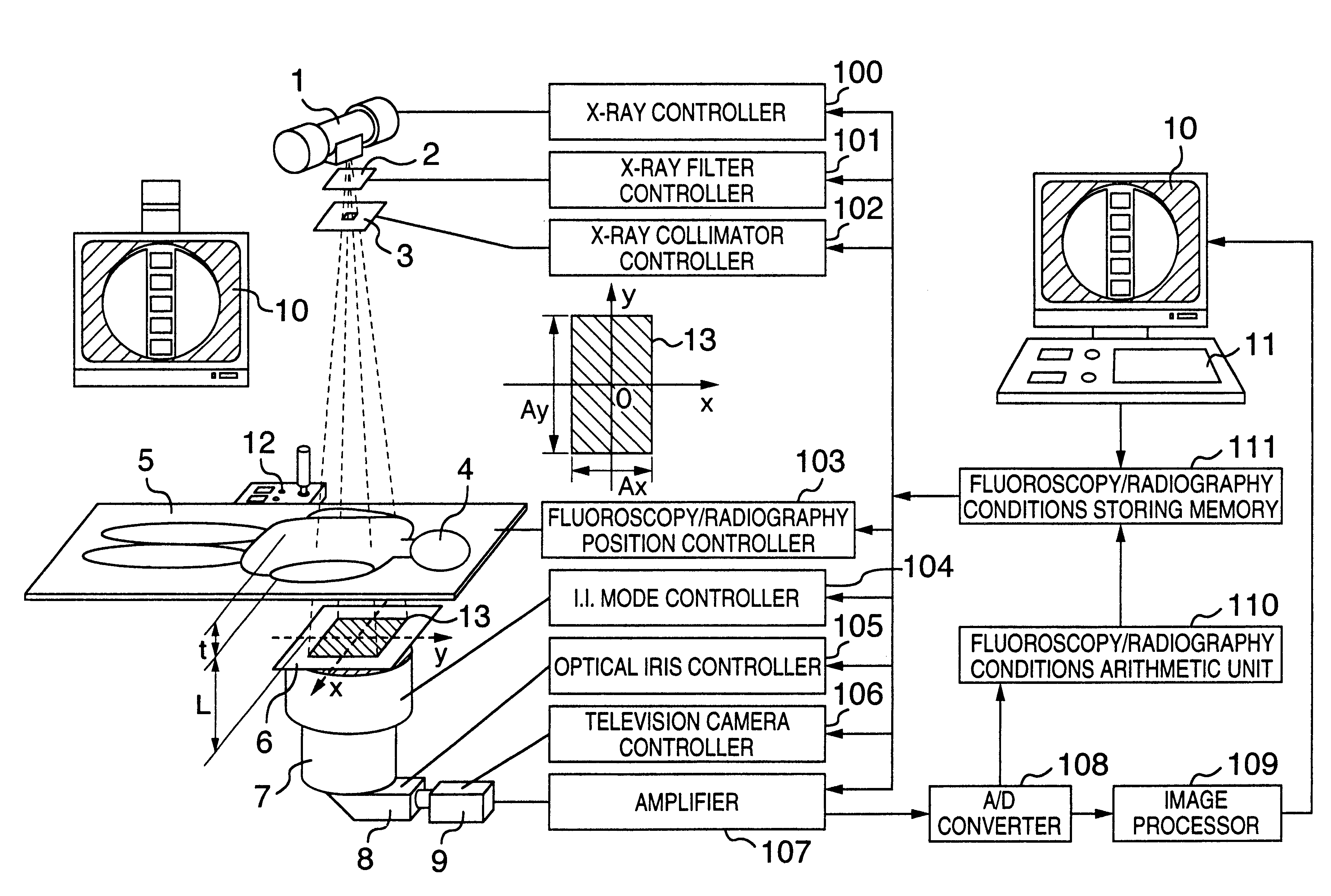

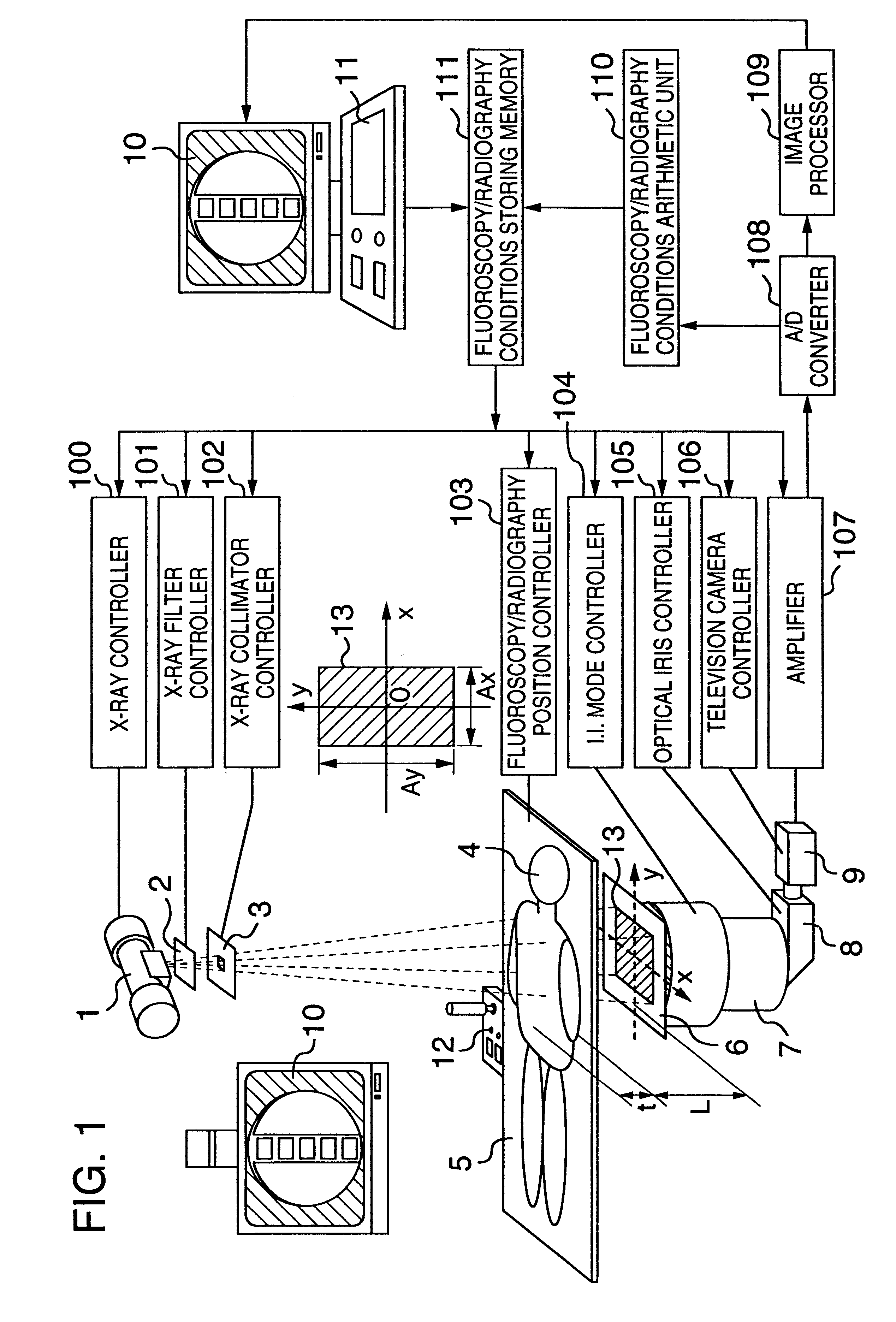

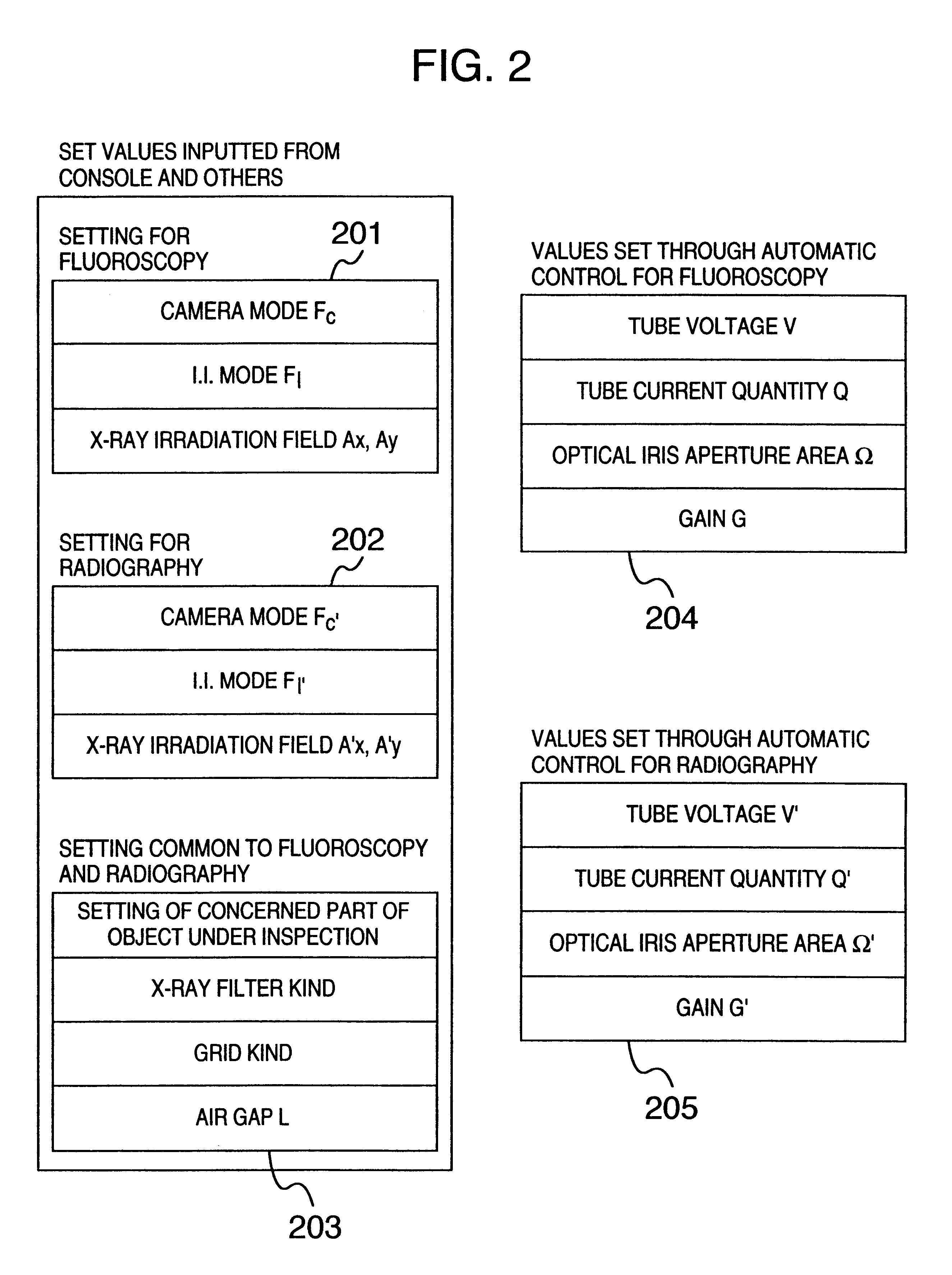

X-ray control method and x-ray apparatus

InactiveUS6377656B1Improve diagnostic capabilitiesAccurately carry-outTomographyDiaphragms for radiation diagnosticsSoft x rayX-ray

An X-ray apparatus in which a mean value of a weighted histogram obtained by multiplying a histogram of numbers of data corresponding to image intensities in a reference image which is an X-ray image picked up in an X-ray fluoroscopy mode and a weighting function whose variable depends on the image intensities is arithmetically determined for controlling an output power of an X-ray tube so that the mean value of the integrated histogram approaches a predetermined value.

Owner:HITACHI MEDICAL CORP

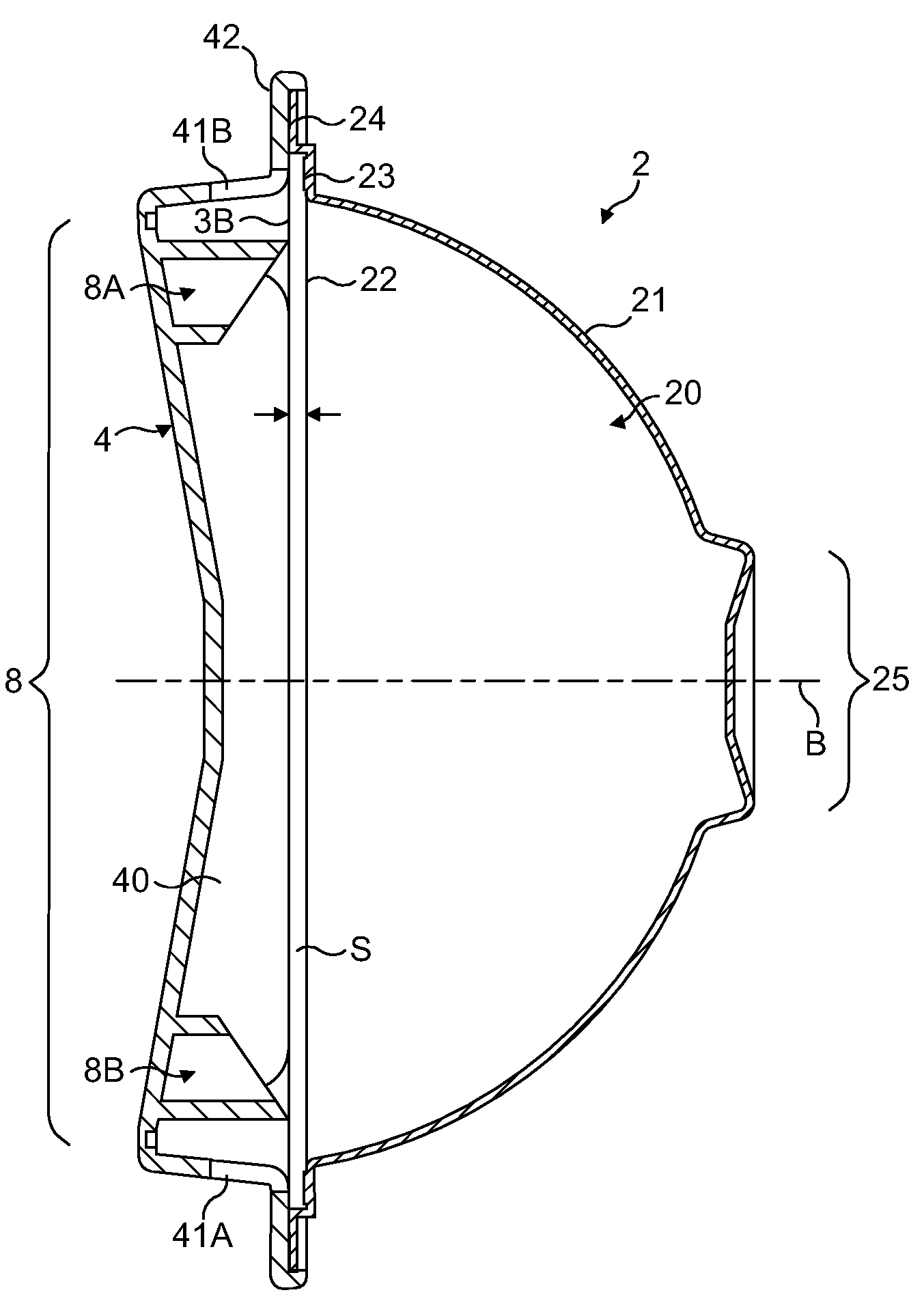

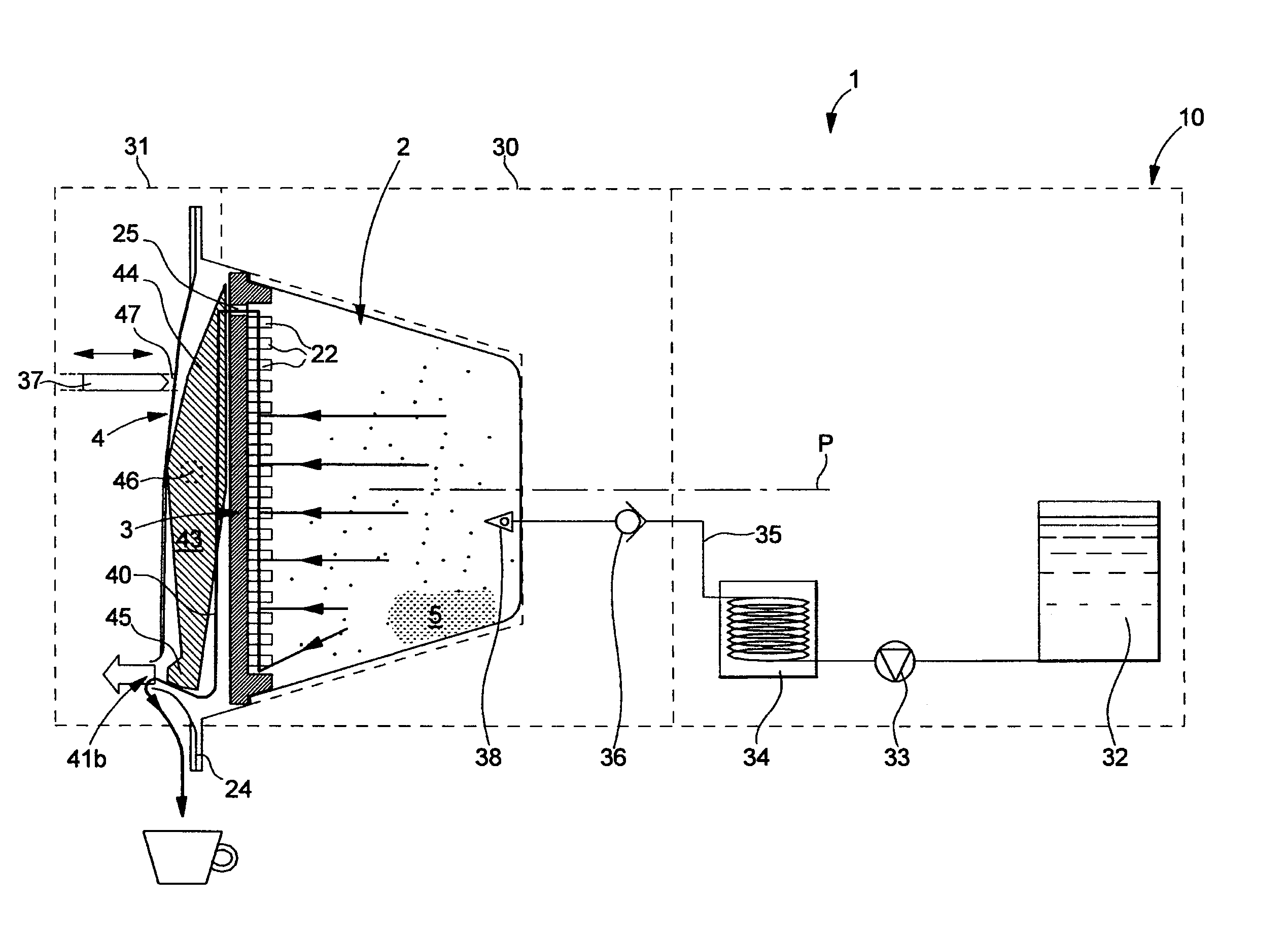

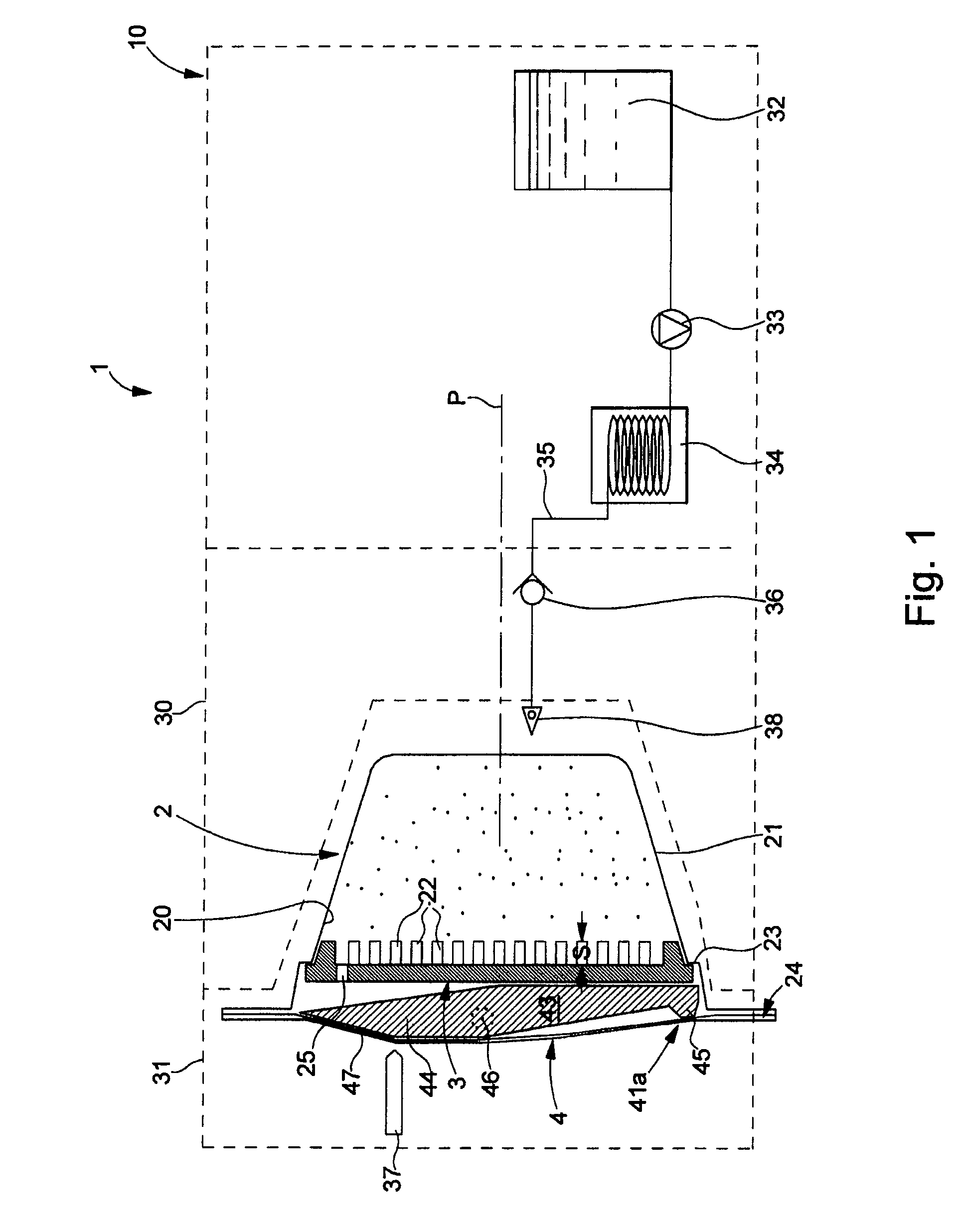

Capsule for the preparation of a beverage

ActiveUS8039029B2Reduce chanceAccurately carry-outTea extractionBeverage vesselsBrewingWaste management

The capsule (2) for brewing food fragments comprises a filtering means (22) delimitating one filtering side of a brewing enclosure (20). It also comprises an overflow wall (3) positioned in the path of brewed liquid after the filtering means. The filtering means (22) are integral with the overflow wall (3).

Owner:SOC DES PROD NESTLE SA

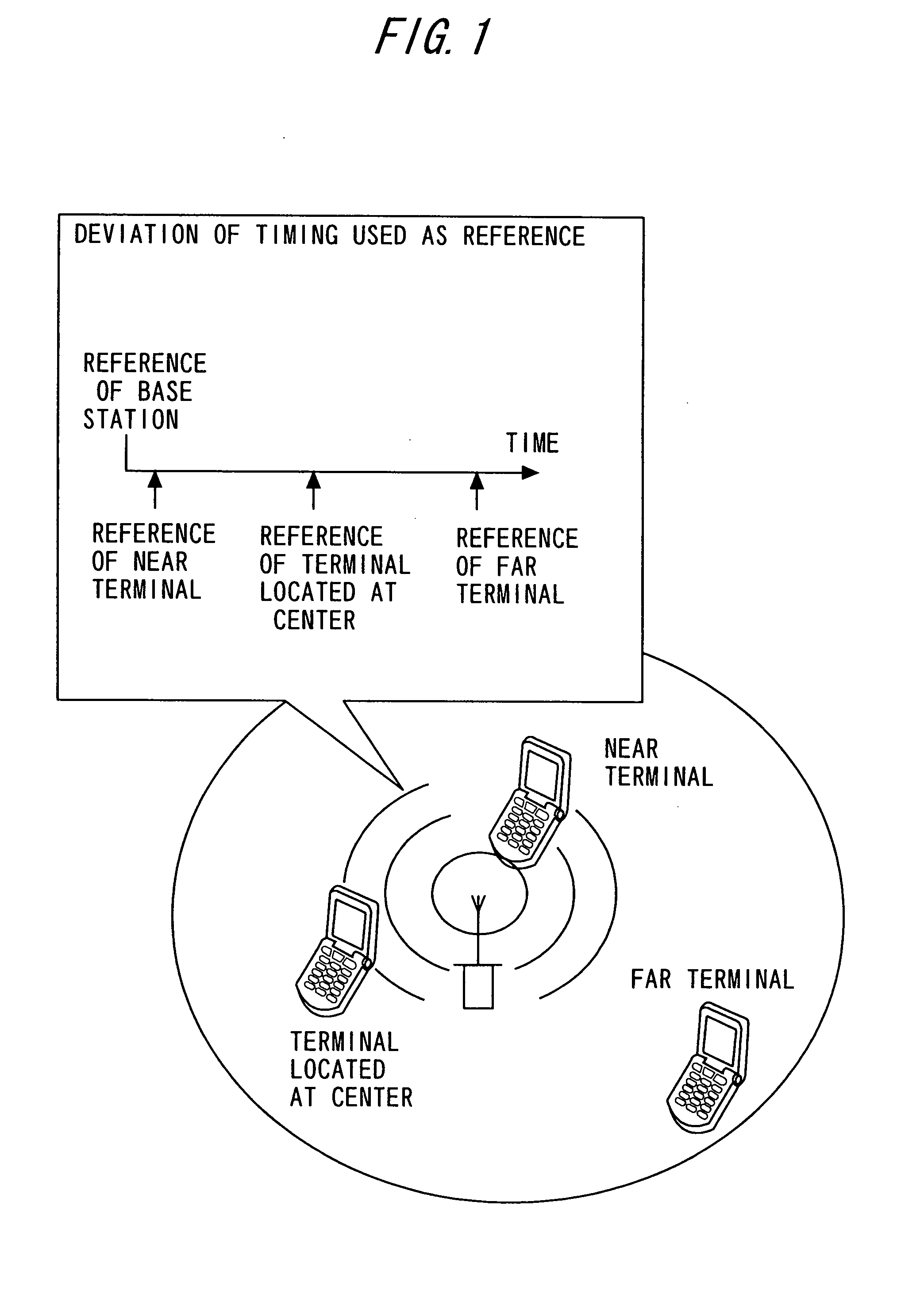

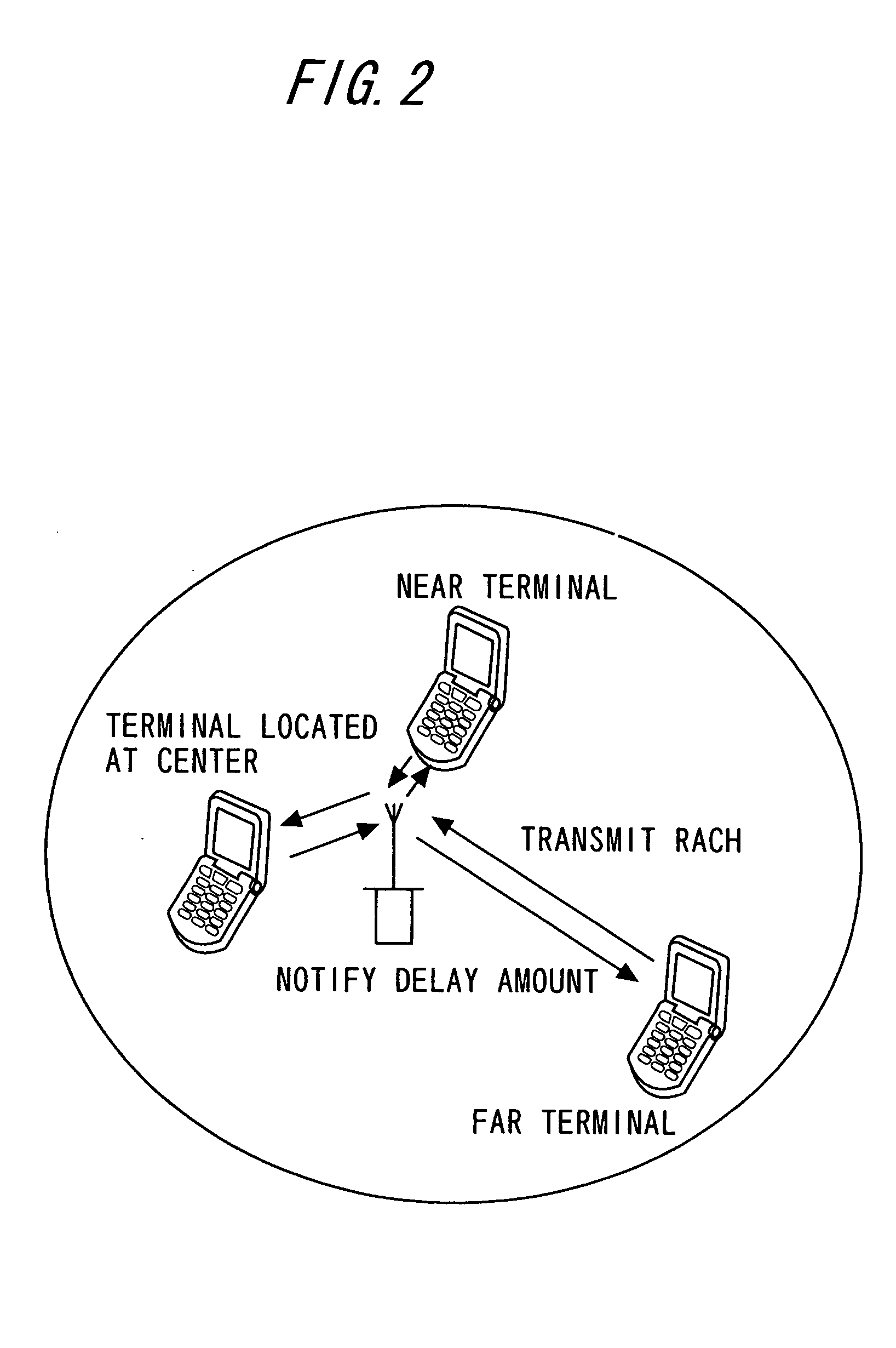

Preamble receiving apparatus

InactiveUS20080062935A1Improve featuresAccurately carry-outModulated-carrier systemsTime-division multiplexPreambleProcessing element

Provided is a preamble receiving apparatus, including: a receiving unit receiving from a transmitting apparatus a frame having a format which contains a preamble section and a margin section subsequent to the preamble section; and a reception processing unit detecting a preamble signal which is transmitted in the preamble section in the transmitting apparatus from the received frame, wherein the reception processing unit includes: a correlation processing unit which defines as a search section a time having a predetermined starting point and which is equal to or shorter than the margin section, and creates a power profile for each of divided sections through a correlating process operation related to a plurality of divided sections obtained by dividing the search section; and a coupled profile creating unit for creating a coupled power profile by coupling the power profile for each of the divided sections to each other.

Owner:FUJITSU LTD

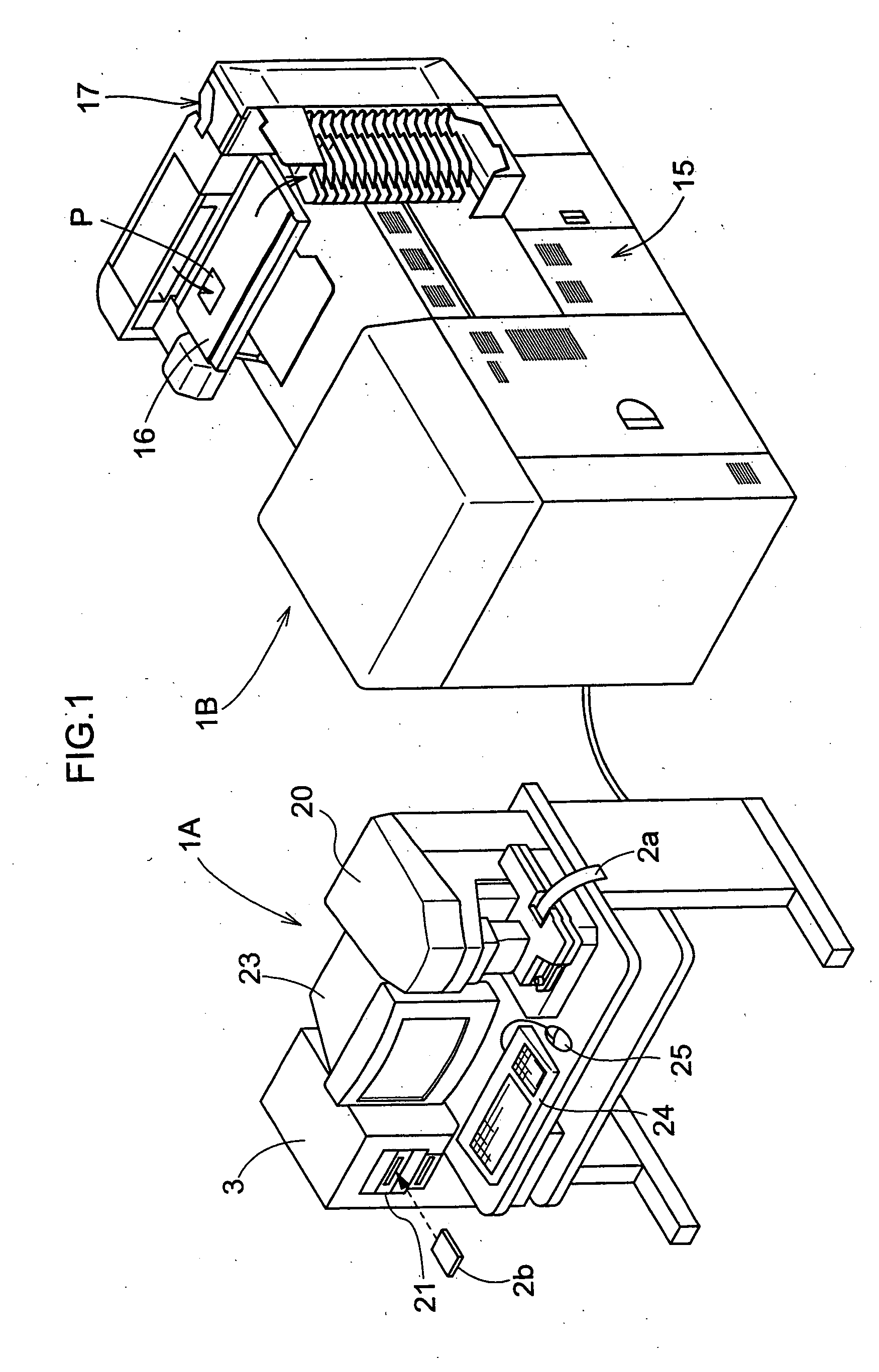

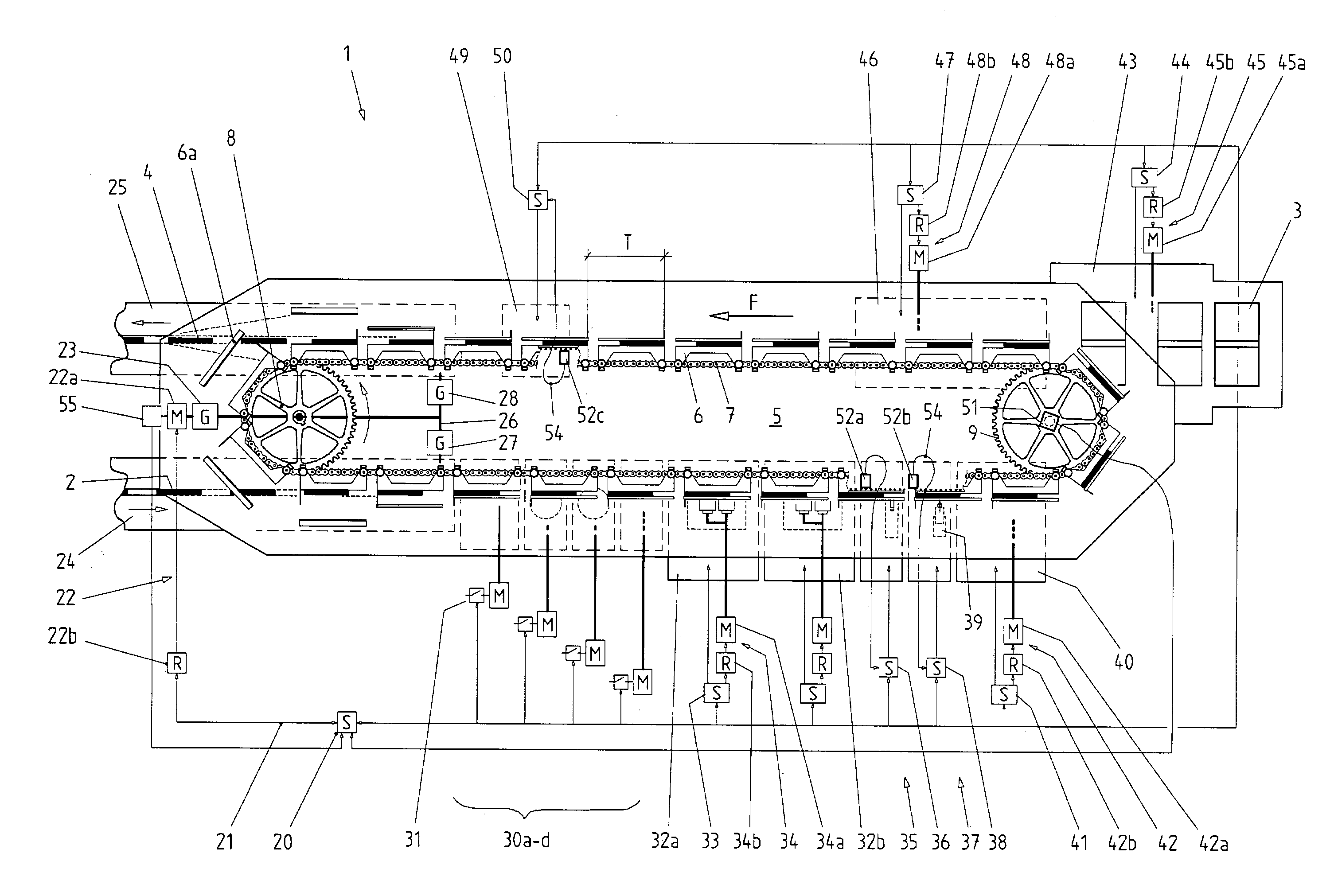

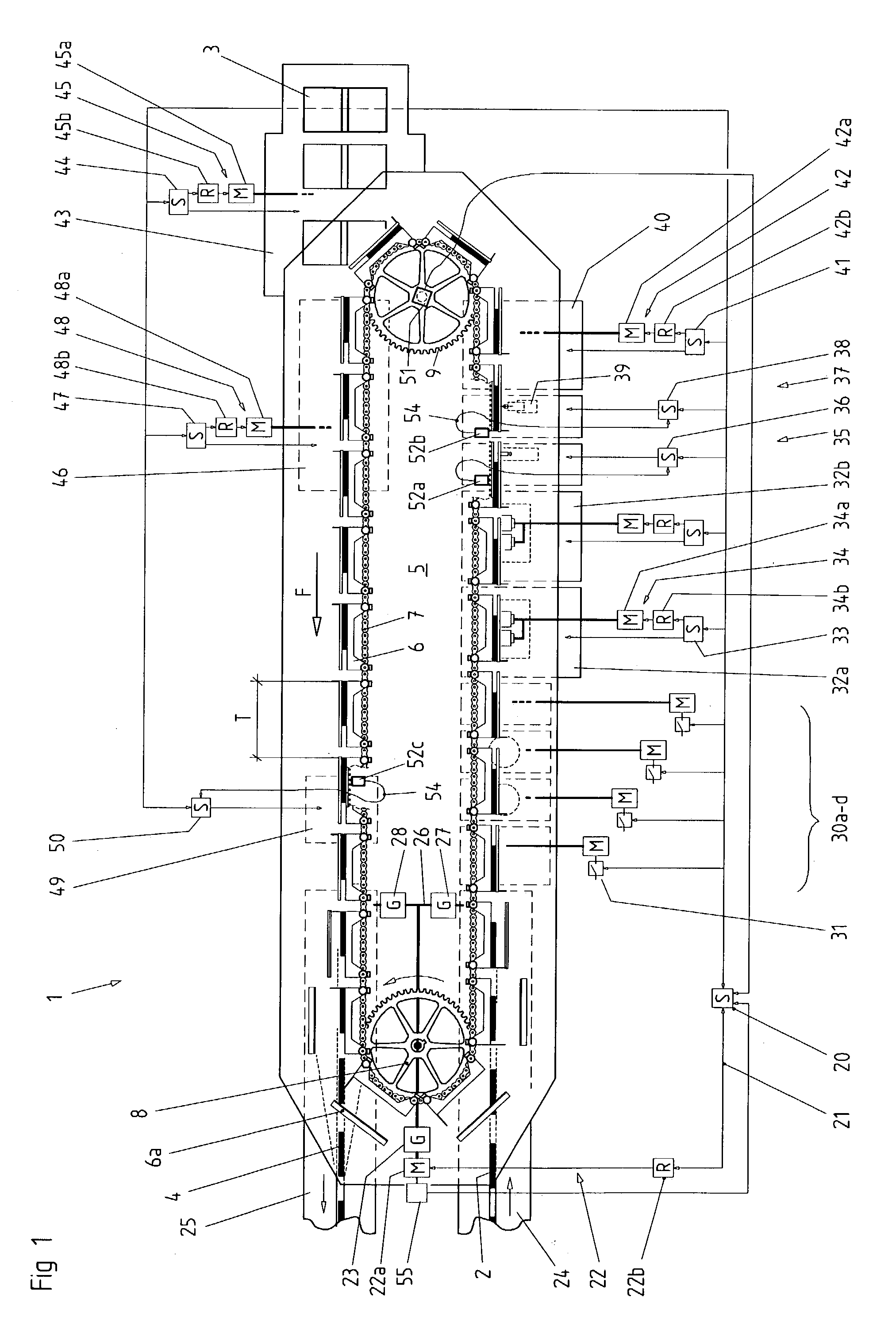

Bookbinding machine

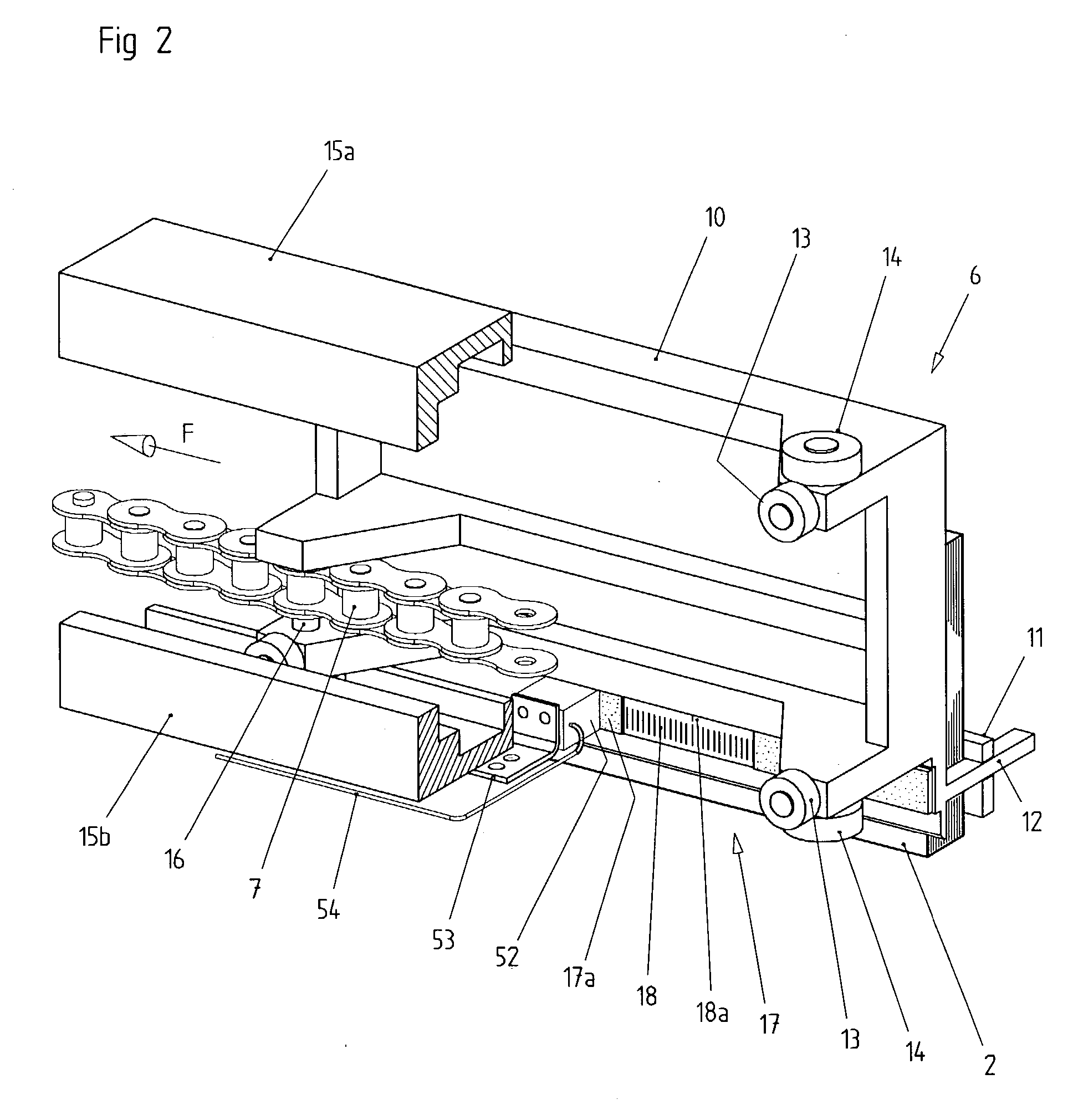

InactiveUS20030215309A1Simplifies replacement and additionEasy to adjustBook making processesArticle feedersEngineeringRoller chain

A bookbinding machine for processing inner books includes a transport system with a multiplicity of inner-book clamps continually movable in a closed continuous track. Each of the inner book clamps is articulated to a circulating roller chain and has a rear-edge stop for aligning the inner books. The bookbinding machine includes workstations that perform positionally accurate operations on the inner books including the application of glue, the application of reinforcement or gauze sections, the application of jackets, binding with wire stitches, the introduction of utilisation features (e.g. punched holes, tear-off perforations, etc.) and the like. The transport system of the inner-book clamps and at least one workstation are driven independently of one another. A measuring system for positional detection of the inner-book clamps or of the inner books is provided in proximity to the independently driven workstation. The measuring system provides inner book or clamp position data used to control the workstation performing positionally accurate operation on the relevant inner book.

Owner:KOLBUS

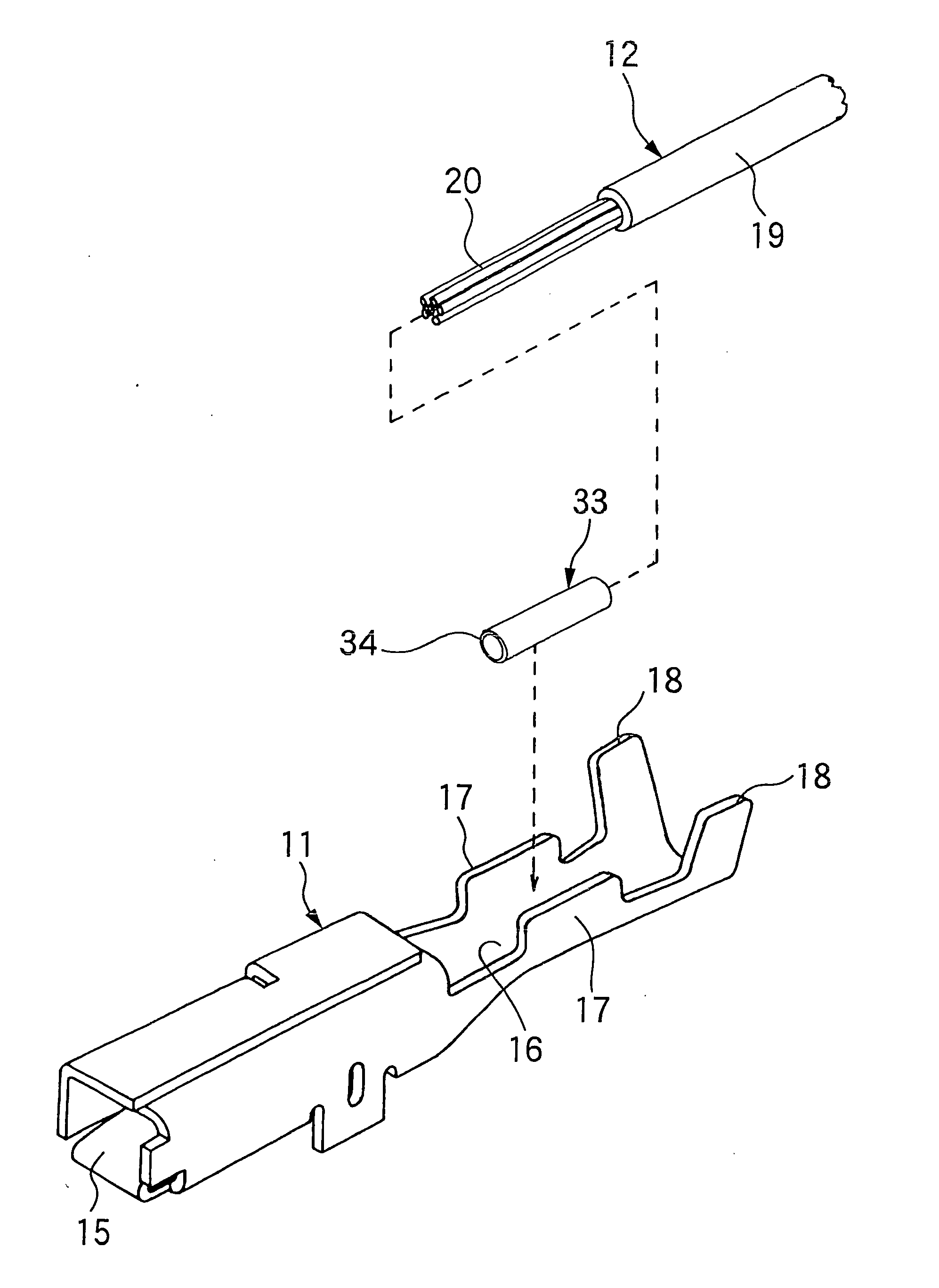

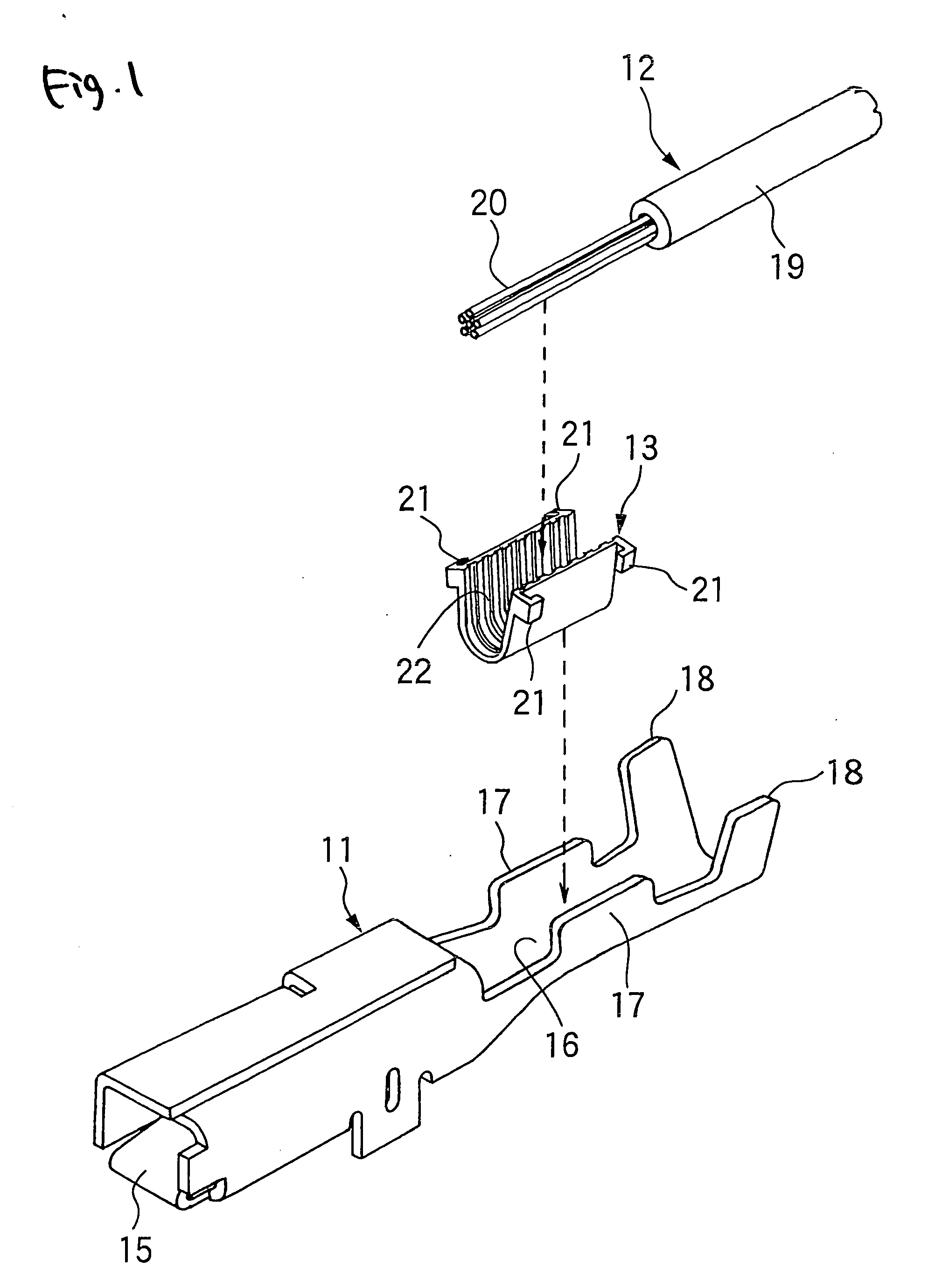

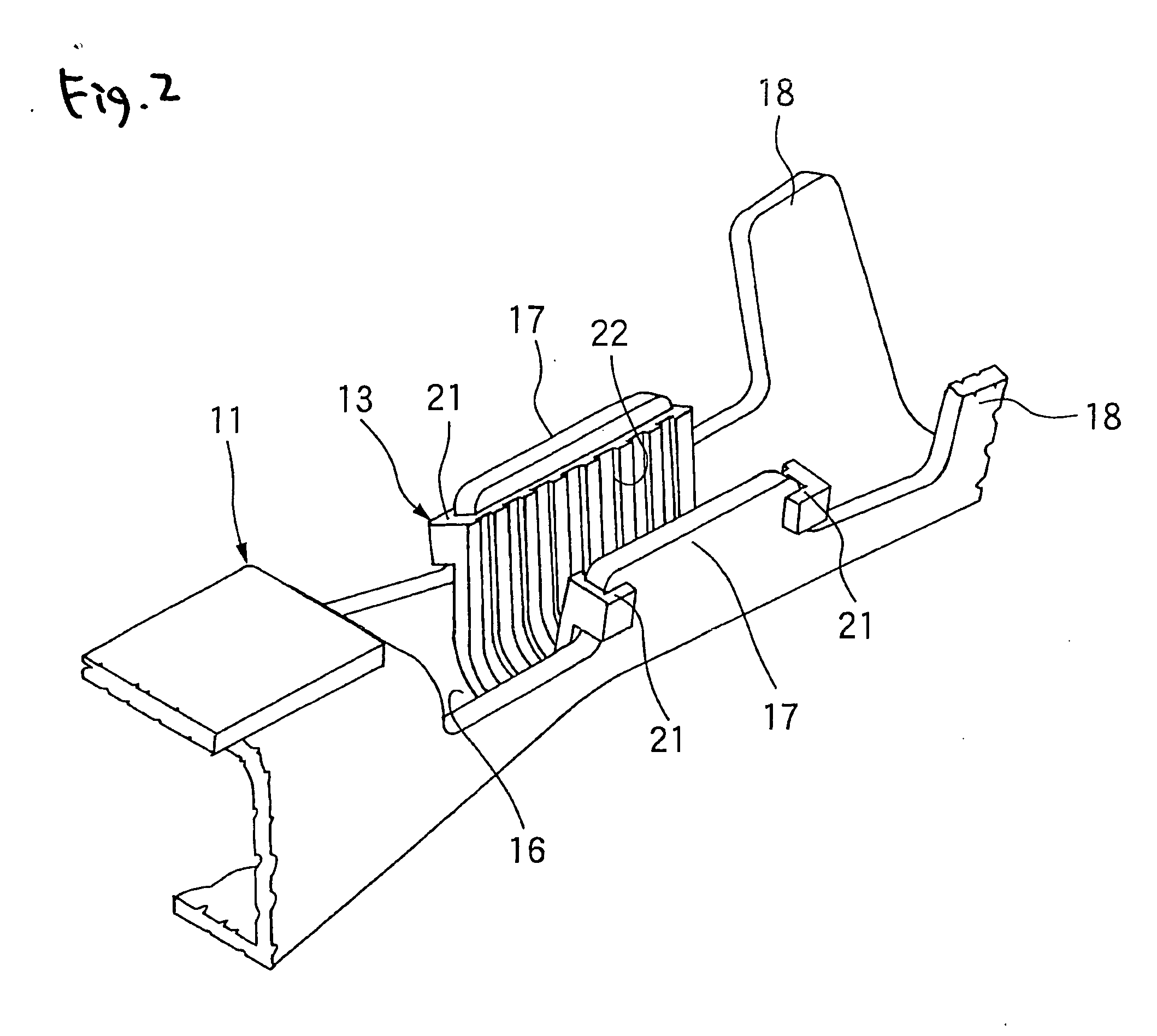

Wire press-clamping method

ActiveUS20050227549A1Reduce resistanceIntuitive effectCoupling contact membersConnections effected by permanent deformationElectrical conductorEngineering

Owner:YAZAKI CORP

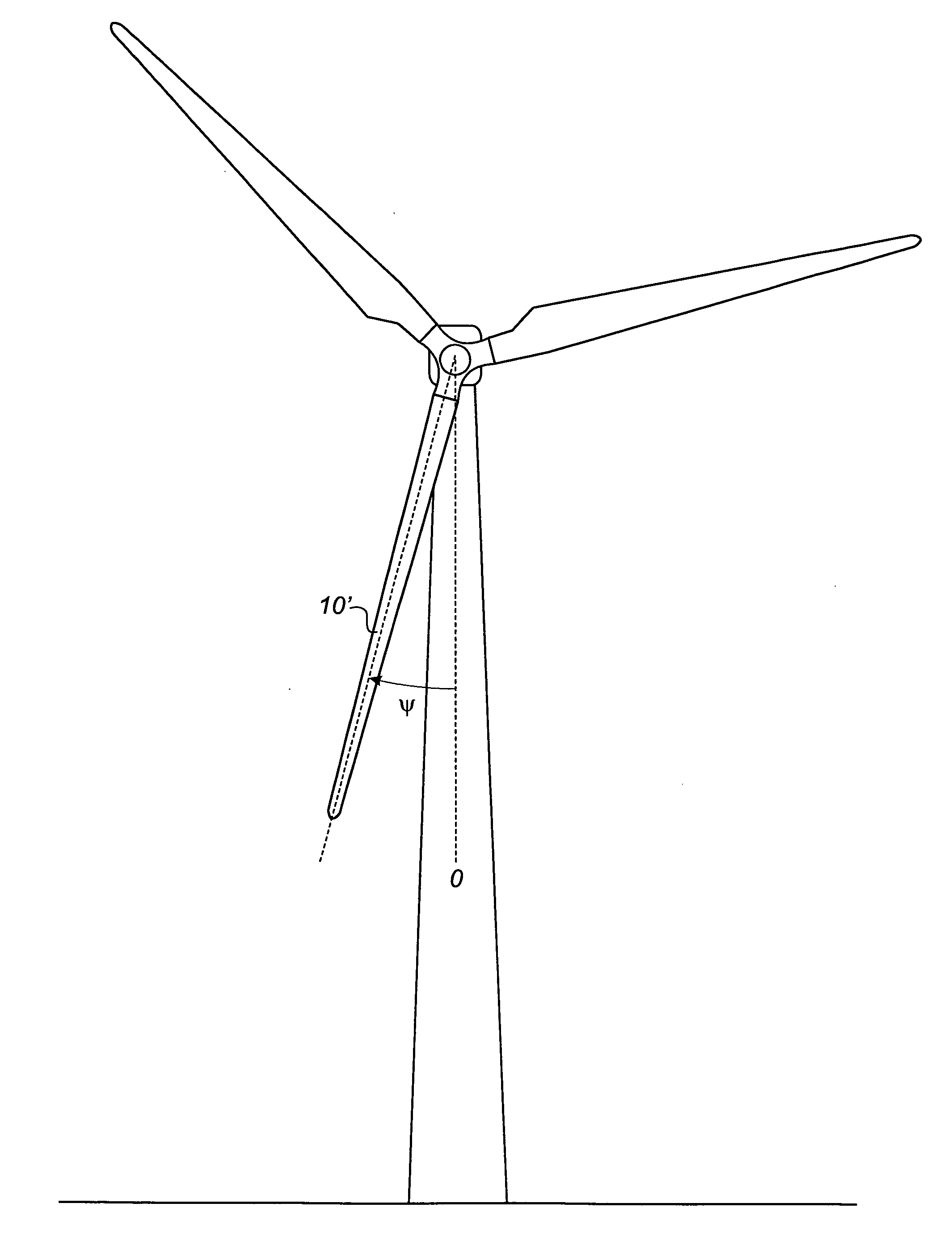

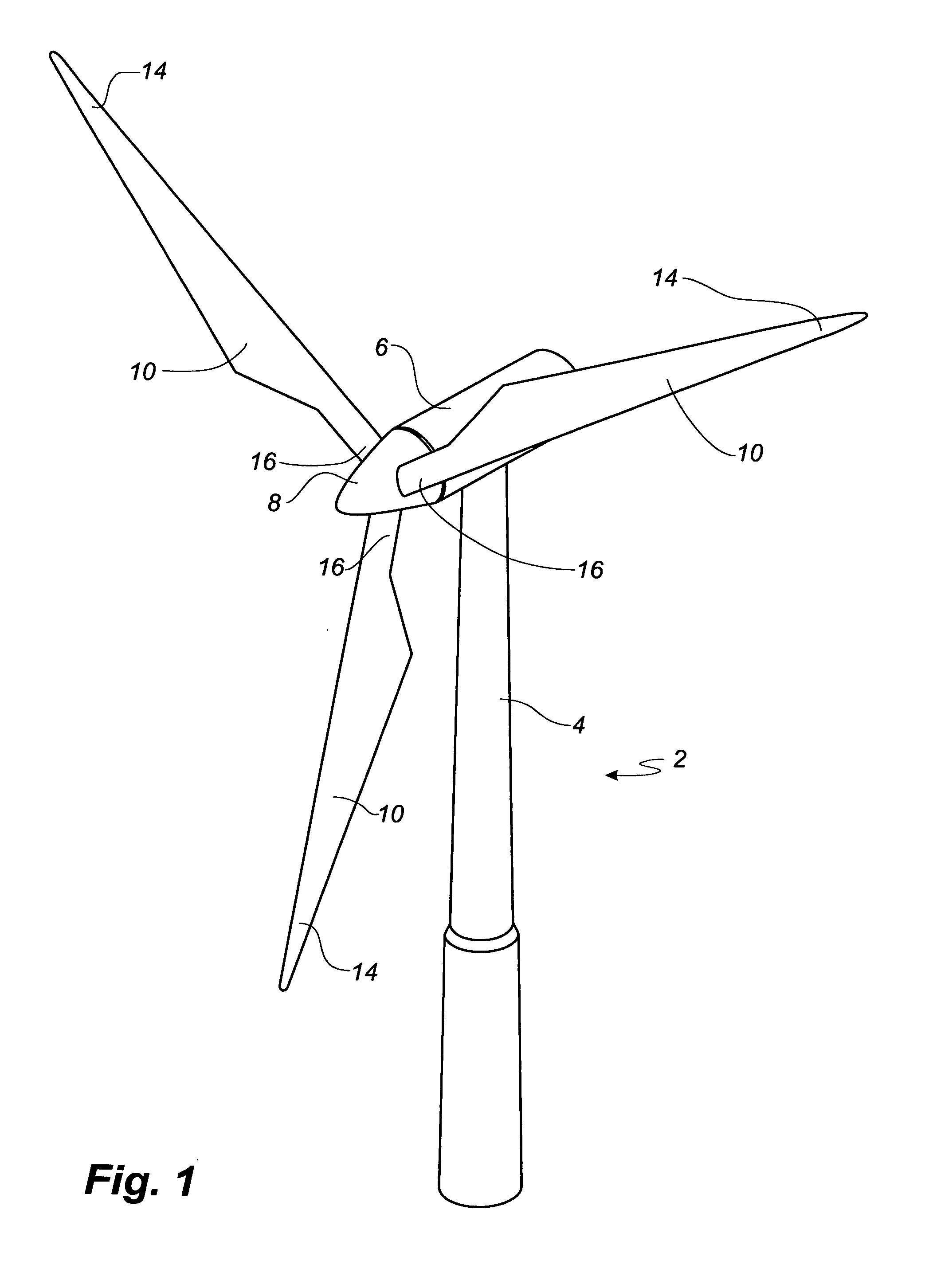

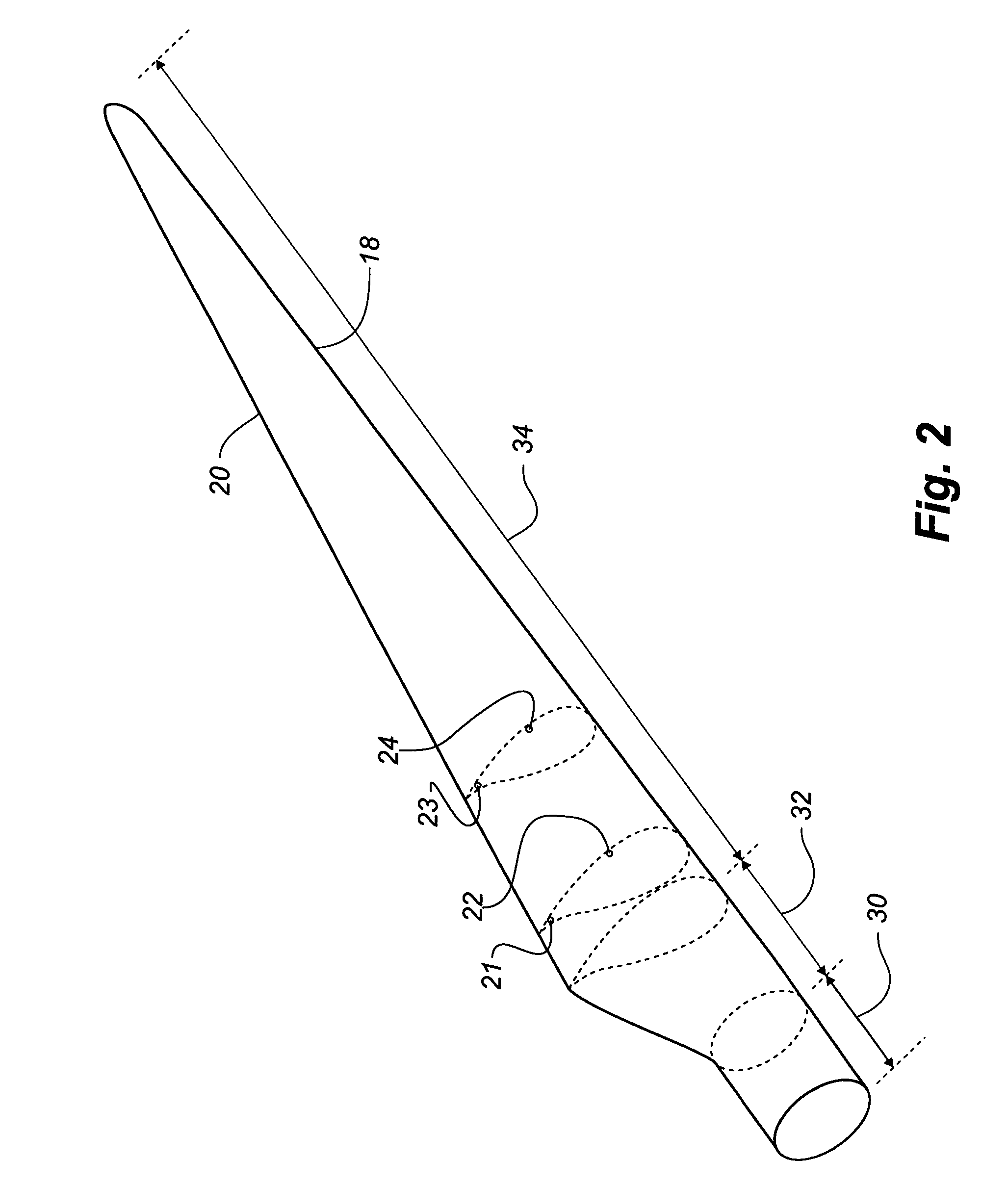

Method of in situ calibrating load sensors of a wind turbine blade

ActiveUS20120292905A1Reliable calibrationReduce needMachines/enginesWind motor combinationsTurbine bladeHorizontal axis

A method of in situ calibrating load sensors of a horizontal axis wind turbine is described. The method comprises the steps of: a) determining a rotor azimuth angle of a first wind turbine blade, b) determining a pitch angle of the first wind turbine blade, c) measuring loads in a first cross-section of the first wind turbine blade using the first load sensors, d) calculating theoretical loads based on at least the rotor azimuth angle and the pitch angle of the blade determined in steps a) and b), e) comparing the loads measured in step c) with the theoretical loads calculated in step d), and f) calibrating the first load sensors based on the comparison of step e), wherein the calibration are based only on measurements carried out, when the generator is cut out.

Owner:LM GLASSFIBER

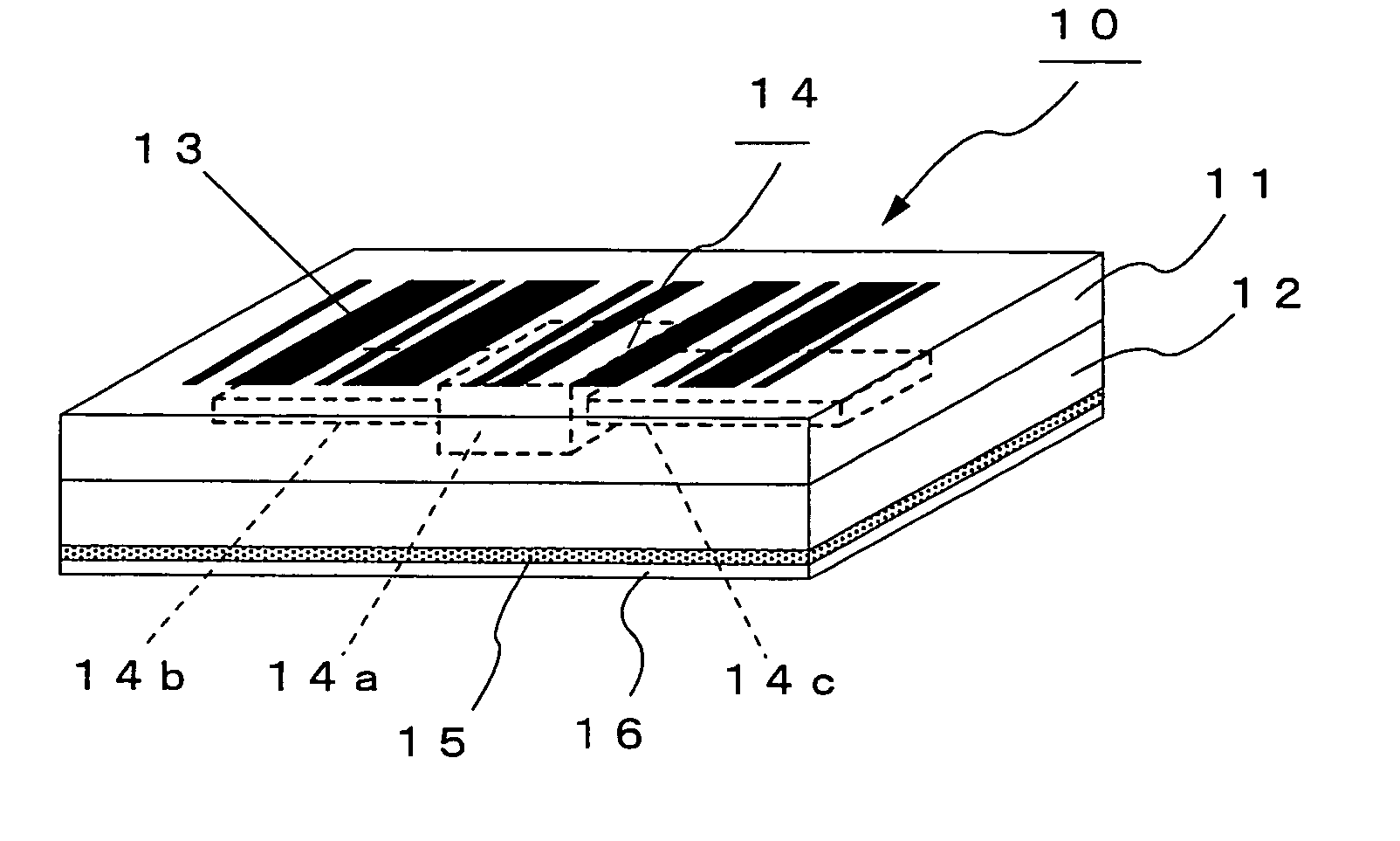

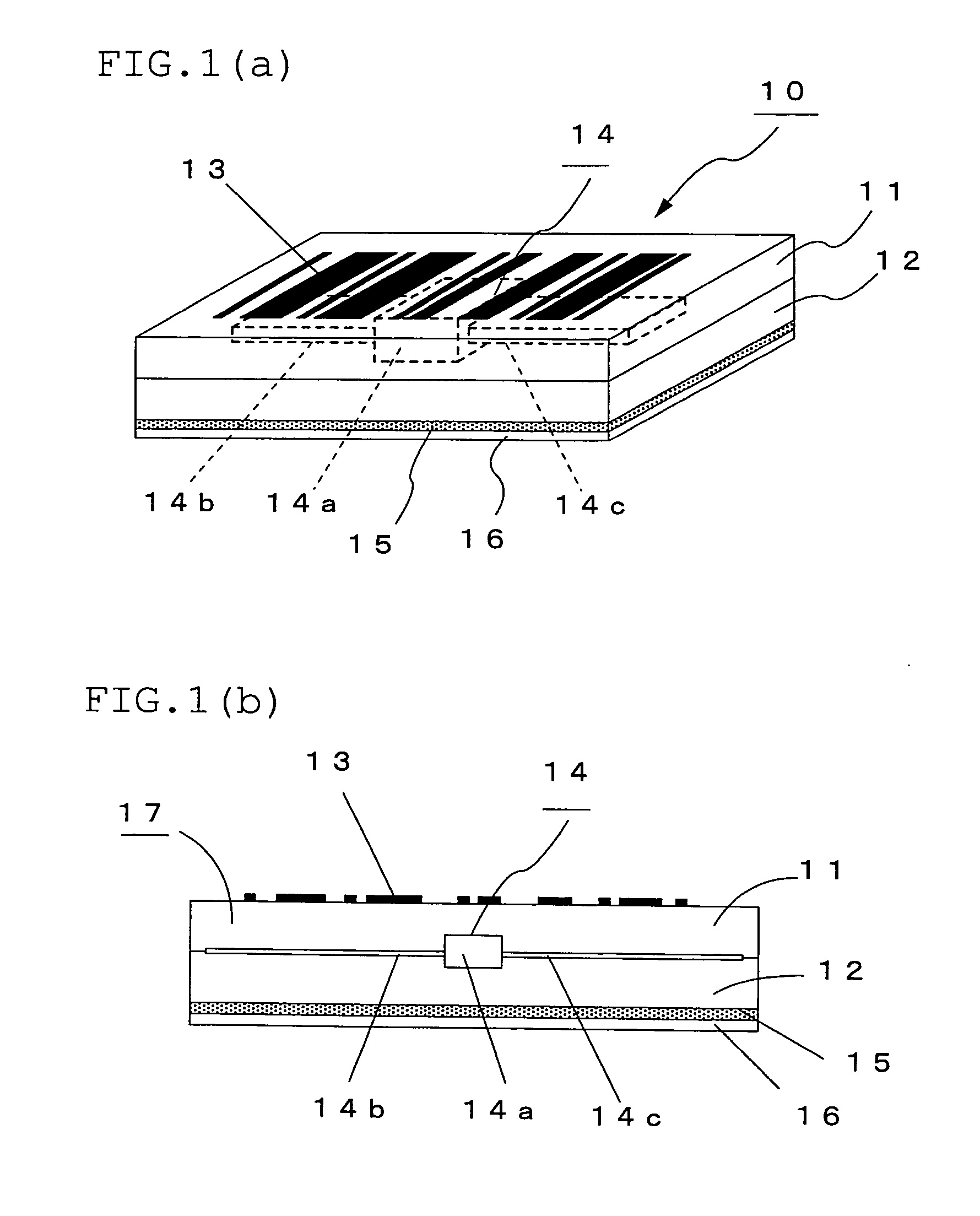

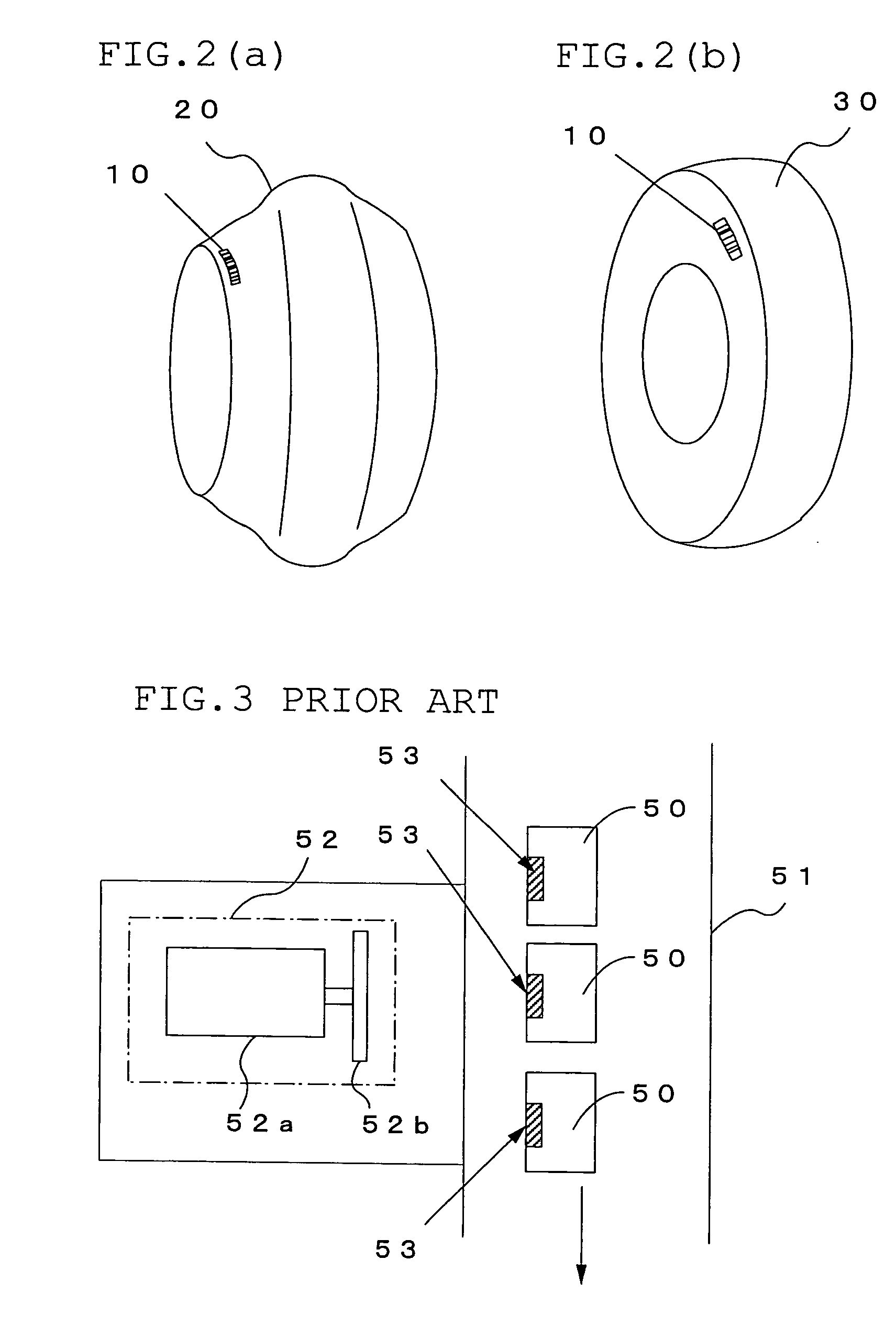

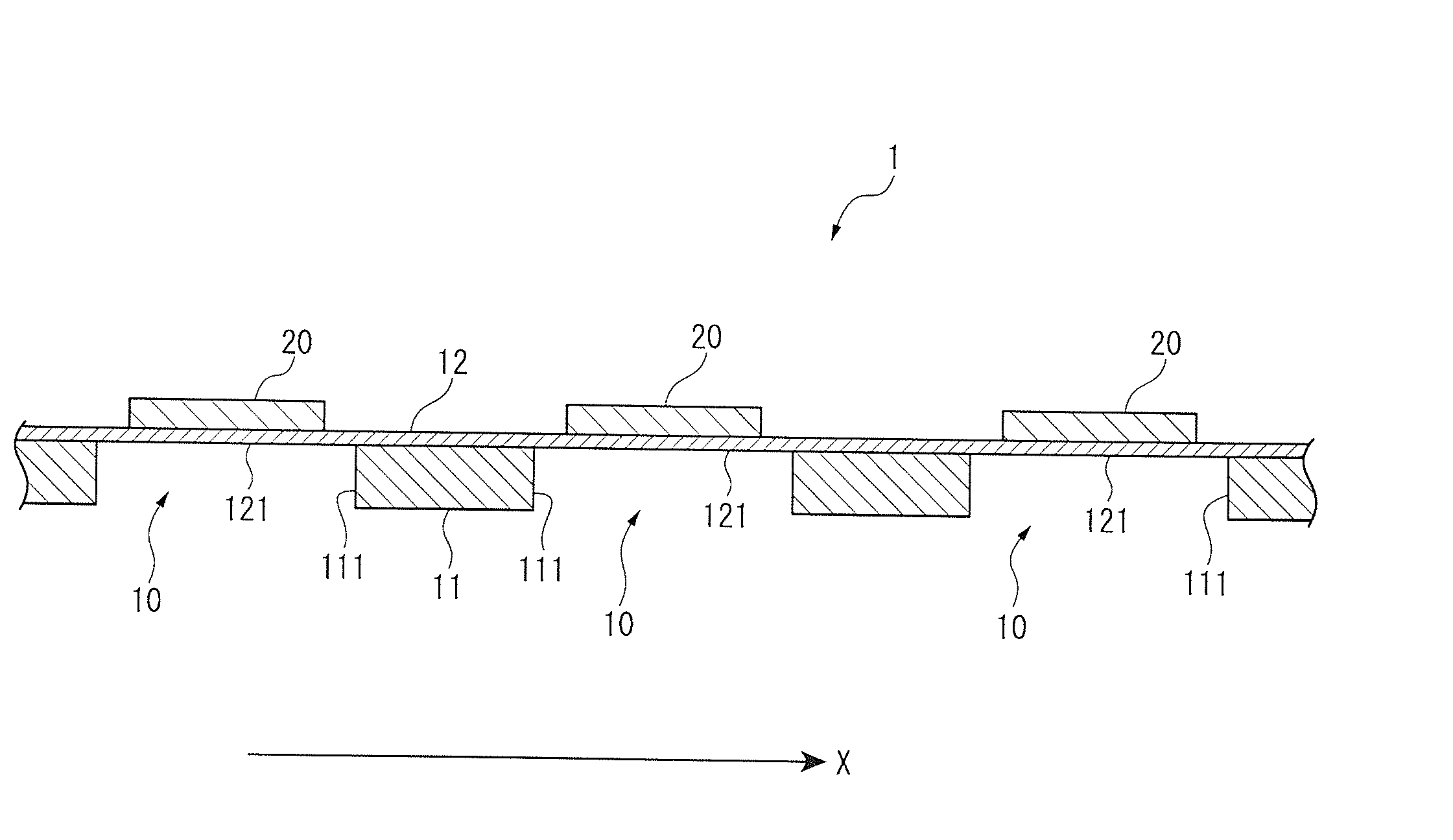

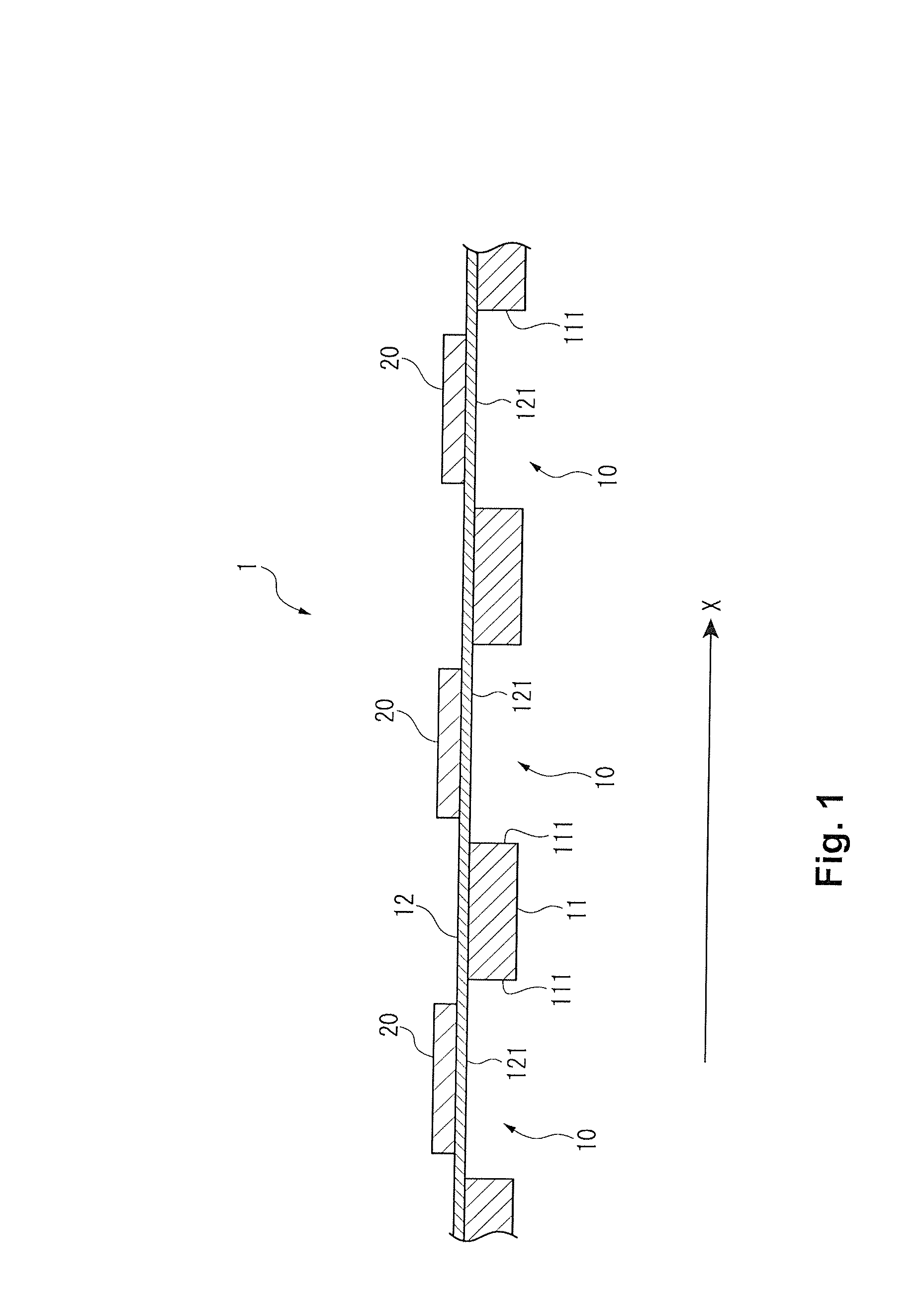

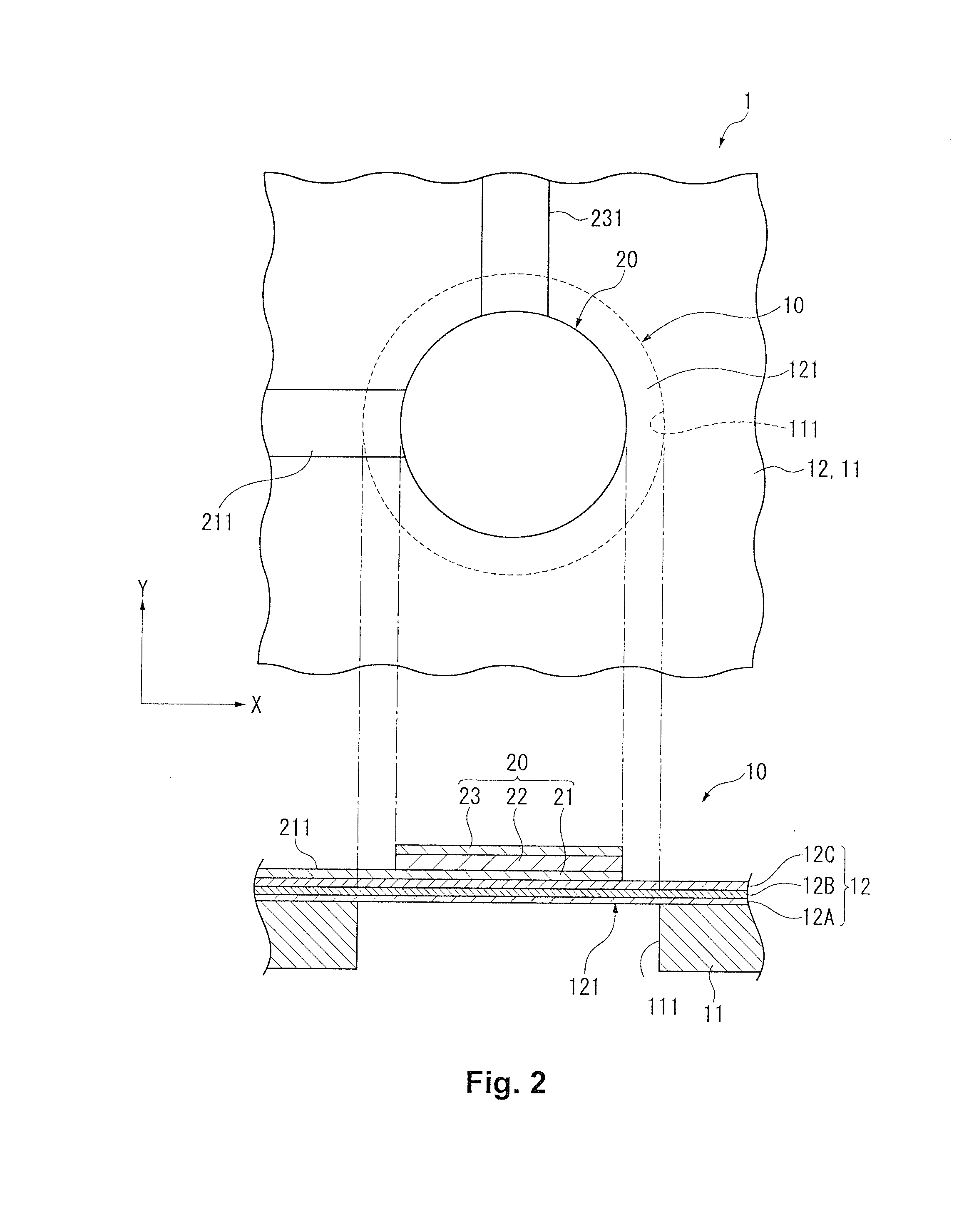

Rfid-incorporating bar code label, tire and management method thereof

InactiveUS20070158436A1Easy to specifyReliable communicationStampsAntenna supports/mountingsBarcodeDipole antenna

An RFID tag-incorporating bar code label having sufficiently high durability even when the label is attached to a tire and capable of reliable communication with a reader. A dipole antenna type RFID tag 14 is interposed and fixed between a first sheet member 11 whose front surface is printed with a bar code 13 and a second sheet member 12 having an adhesive layer formed on the rear surface, thus fabricating an RFID tag-incorporating bar code label 10 having an RFID tag buried in the central portion of a bar code sheet 17. The label 10 is bonded to a tire. Therefore, the position of the RFID tag 14 can be easily specified. Due to the existence of the second sheet member 12, the RFID tag 14 can be spaced apart from a rubber member and a steel product constituting the tire by a predetermined distance.

Owner:BRIDGESTONE CORP

Process for the production of electronic parts

InactiveUS6337288B1High affinityImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingThermoplasticCompound (substance)

A method of supporting a semiconductor substrate according to the present invention can be applied to the step of processing the semiconductor substrate at a high temperature of 350° C. or higher, and there is provided a process for the production of electronic parts, comprising the steps of forming semiconductor circuits on one surface (surface A) of a semiconductor substrate (SEC) having a thickness of at least 0.2 mm, supporting the semiconductor substrate on a supporting substrate (BP) by bonding (AS) of said surface A to the supporting substrate (BP), grinding and polishing the exposed other surface (surface B) of the semiconductor substrate (SEC) by a physical method, a chemical method or a method of combination of these methods, to decrease the thickness of the semiconductor substrate (SEC) to less than 0.2 mm, forming semiconductor circuits in the polished surface, to obtain an electronic-circuits-possessing semiconductor substrate (PSE), and peeling (PS) the electronic-circuits-possessing semiconductor substrate (PSE) off from the supporting substrate (BP), wherein the step of grinding and polishing the surface B or the step of forming electronic parts in the surface B includes the step of processing the surface B at a high temperature of at least 350° C., and the bonding (AS) uses a heat-resistant thermoplastic (RF).

Owner:MITSUBISHI GAS CHEM CO INC

Contact sensors and methods for making same

InactiveUS20120123716A1Reduced probability of early failureAccurately carry-outResistance/reactance/impedenceForce measurementElectrical resistance and conductanceTotal knee replacement surgery

Disclosed herein are novel contact sensors. The contact sensors disclosed herein include a conductive composite material formed of a polymer and a conductive filler. In one particular aspect, the composite materials can include less than about 10 wt % conductive filler. Thus, the composite material of the contact sensors can have physical characteristics essentially identical to the polymer, while being electrically conductive with the electrical resistance proportional to the load on the sensor. The sensors can provide real time dynamic contact information for joint members under conditions expected during use. In one particular aspect, the sensor can be used to properly balance the knee ligaments in a total knee replacement surgery.

Owner:SENCORABLES

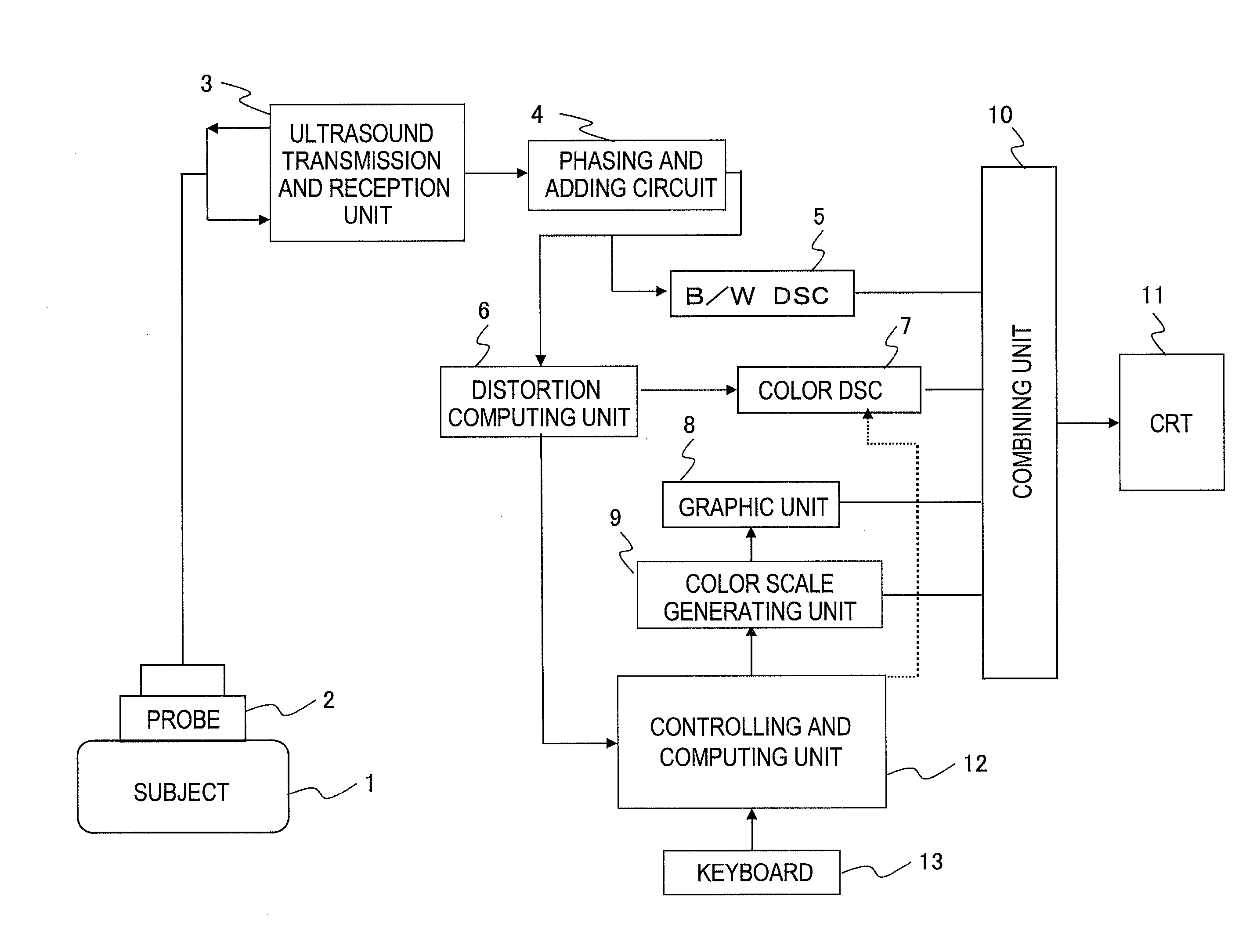

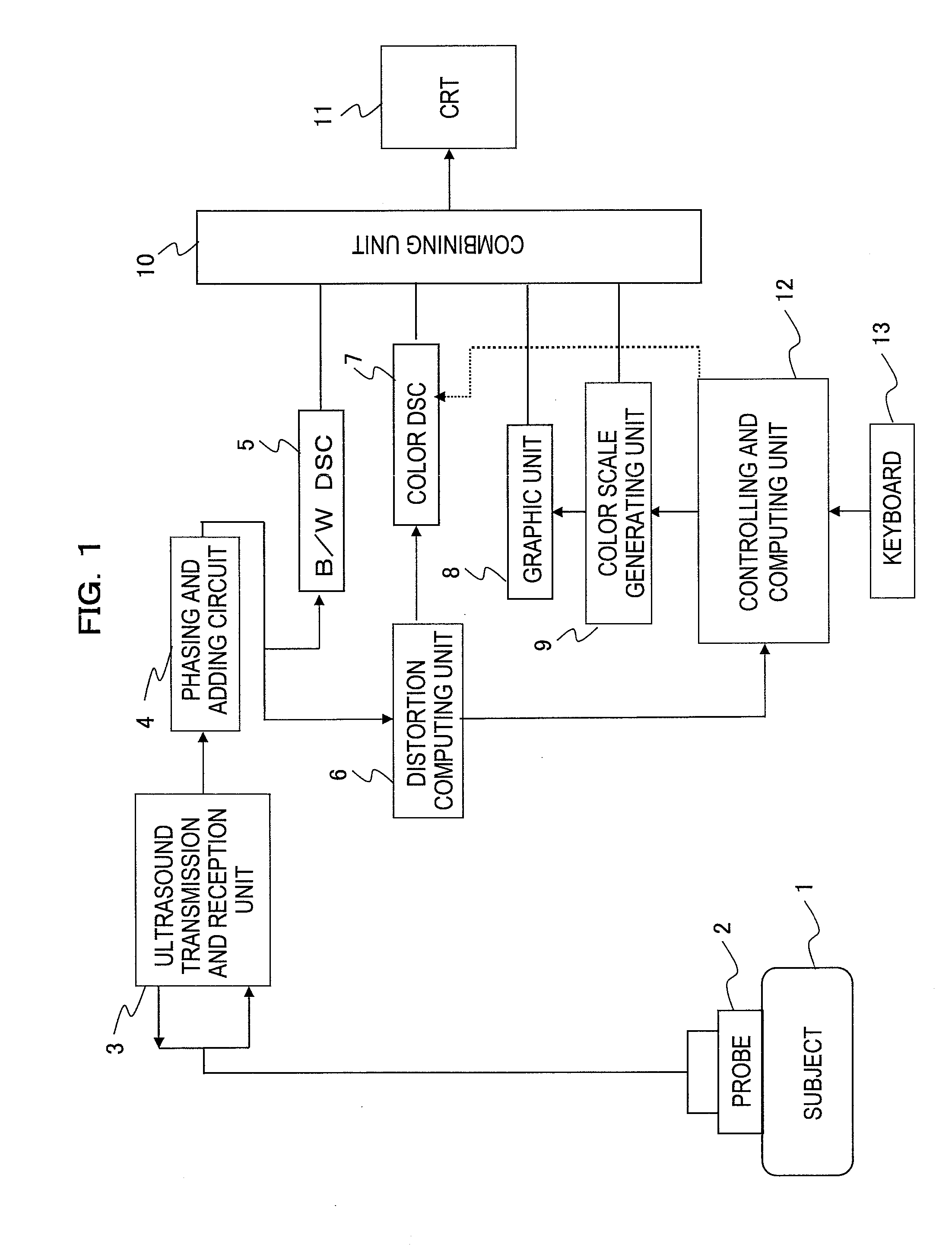

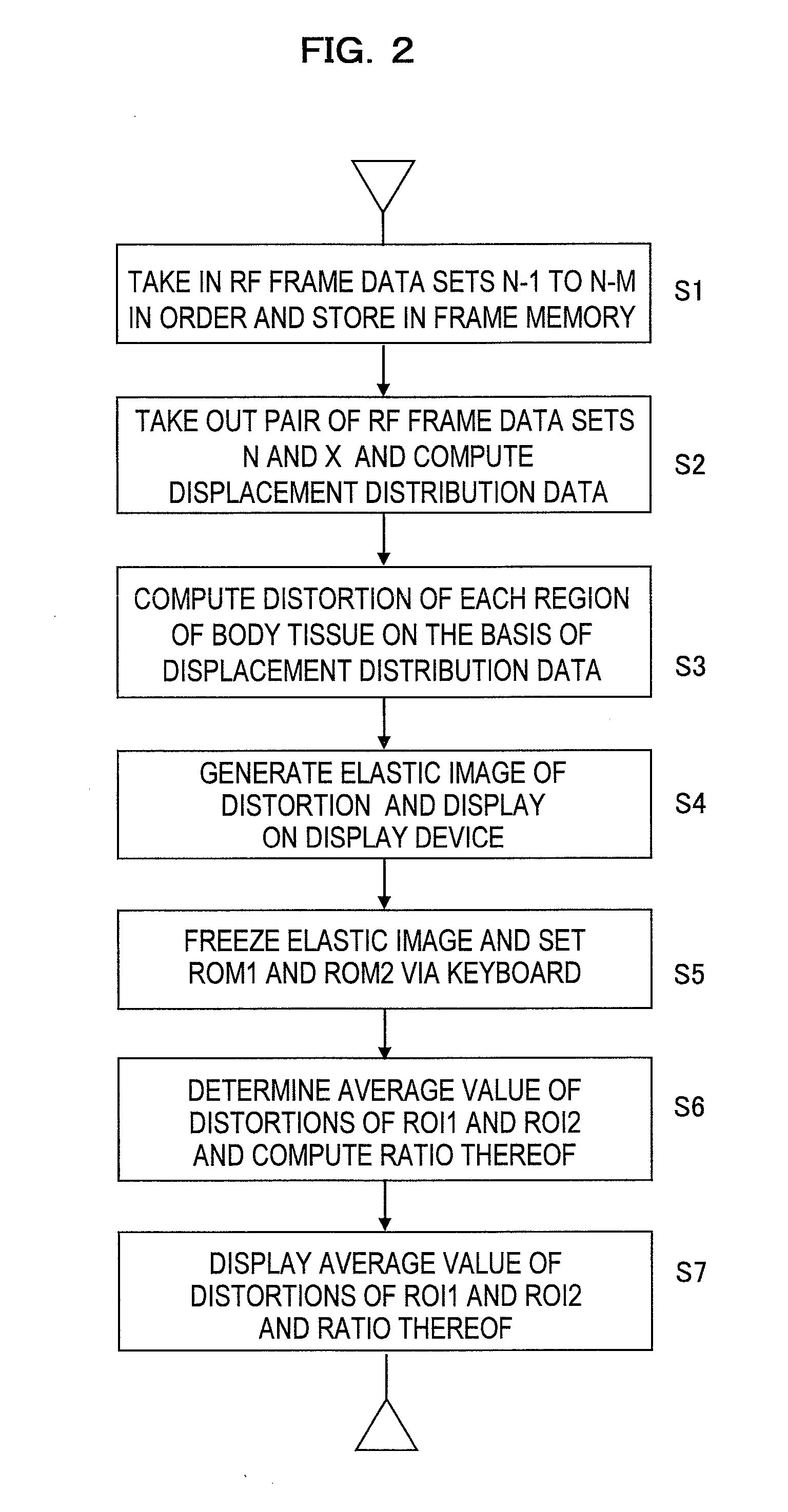

Method of Displaying Elastic Image and Diagnostic Ultrasound System

InactiveUS20080071174A1Easy to identifyAccurate diagnosisWave based measurement systemsHealth-index calculationDiagnostic ultrasoundDisplay device

A method of displaying an elastic image according to the present invention includes the steps of measuring ultrasound cross-section data of a cross-section region of a subject while applying compression to the subject 1 (2, 3, 4), determining distortion of tissue in the cross-section region on the basis of the ultrasound cross-section data, generating an elastic image of the cross-section region on the basis of the distortion, displaying the elastic image on a display device (7), setting a plurality of ROIs on the elastic image displayed on the display device, converting the distortion of each ROI into an index value (12), and displays the index value on the display device (8). In this way, the method enables quantitative evaluation of the hardness of body tissue of a region to be diagnosed.

Owner:HITACHI LTD

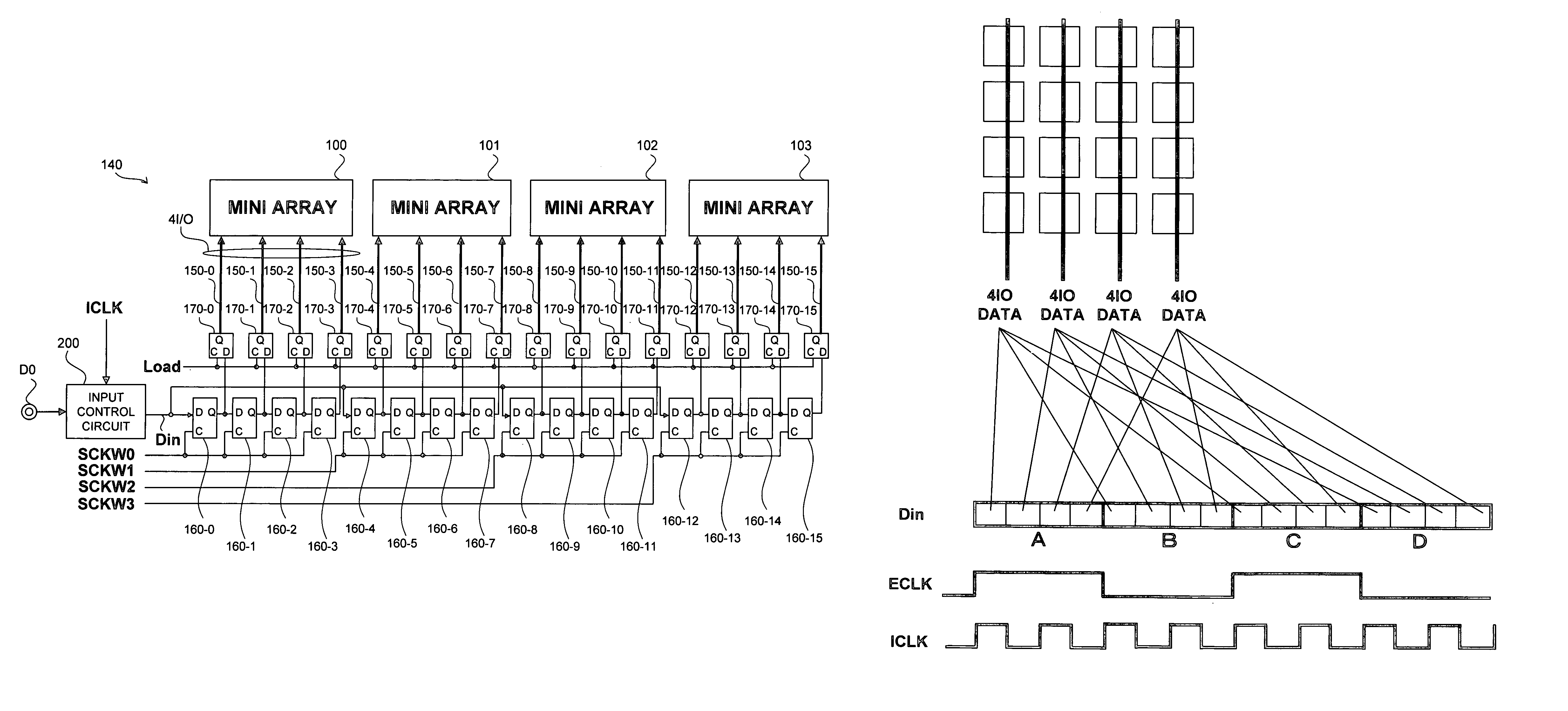

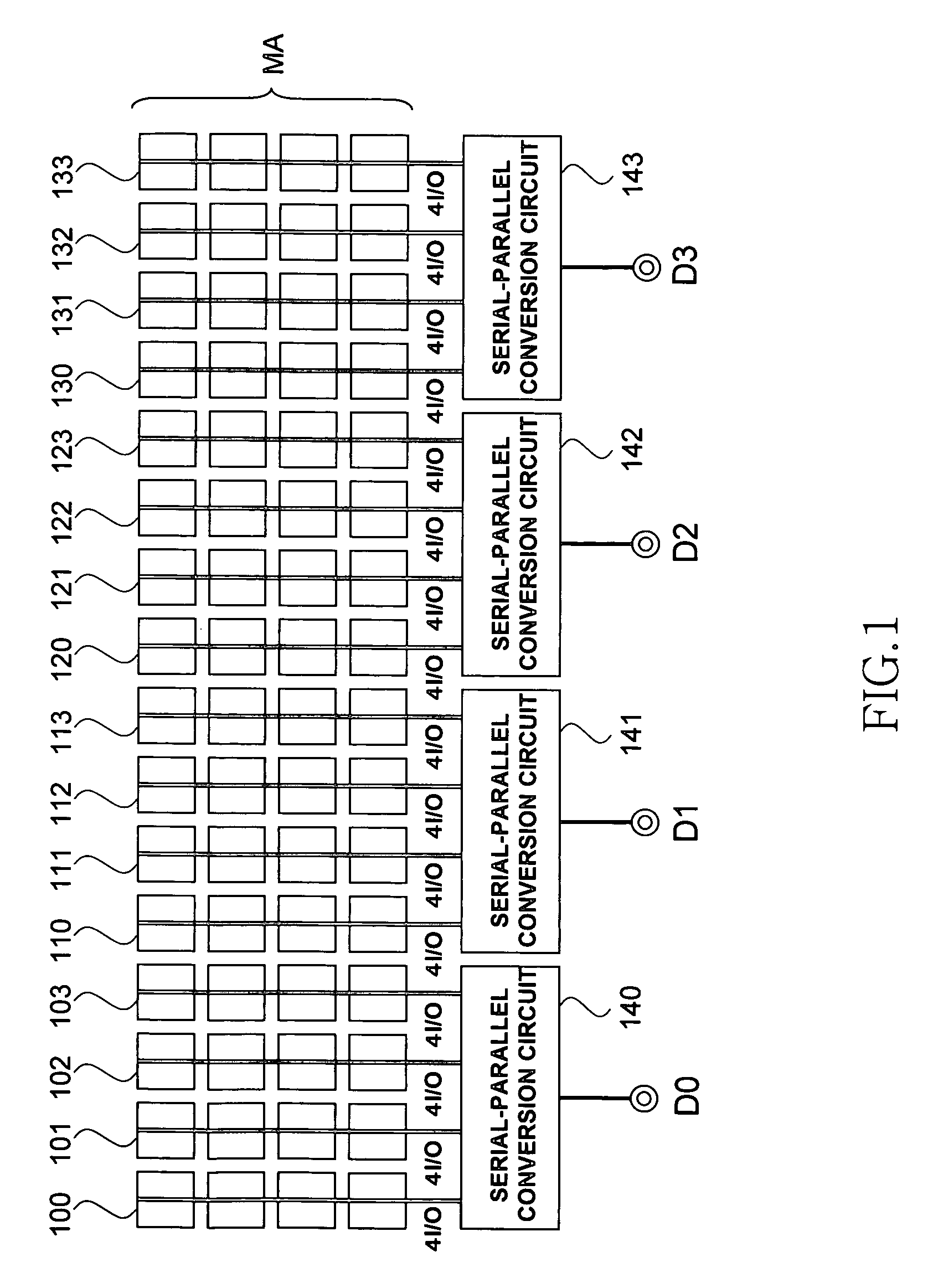

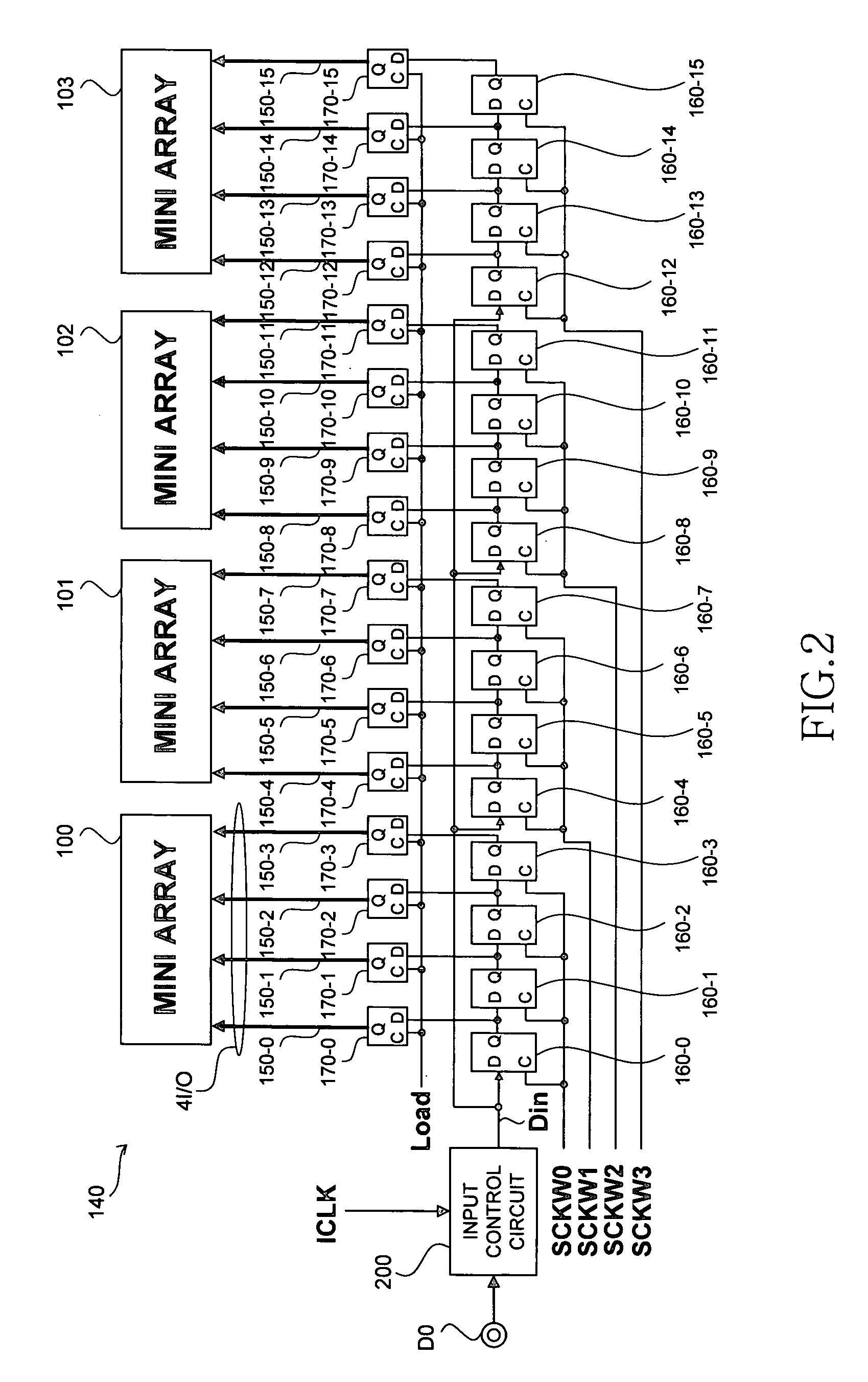

Semiconductor memory device and testing method thereof

InactiveUS7567476B2Accurately carry-outReduce manufacturing costDigital storageComputer scienceSemiconductor

A semiconductor memory device includes mini arrays and a serial-parallel conversion circuit. The serial-parallel conversion circuit simultaneously writes two continuous data into mutually different mini arrays out of plural data that are continuously input synchronously with an internal clock, and continuously outputs two data simultaneously read from different mini arrays, synchronously with the internal clock. In testing the semiconductor memory device according to the present invention, one data is written during a period when an external clock having a cycle of an integer times cycle of the internal clock is fixed to a high level or a low level. With this arrangement, continuous data can be assigned to mutually different mini arrays.

Owner:LONGITUDE SEMICON S A R L

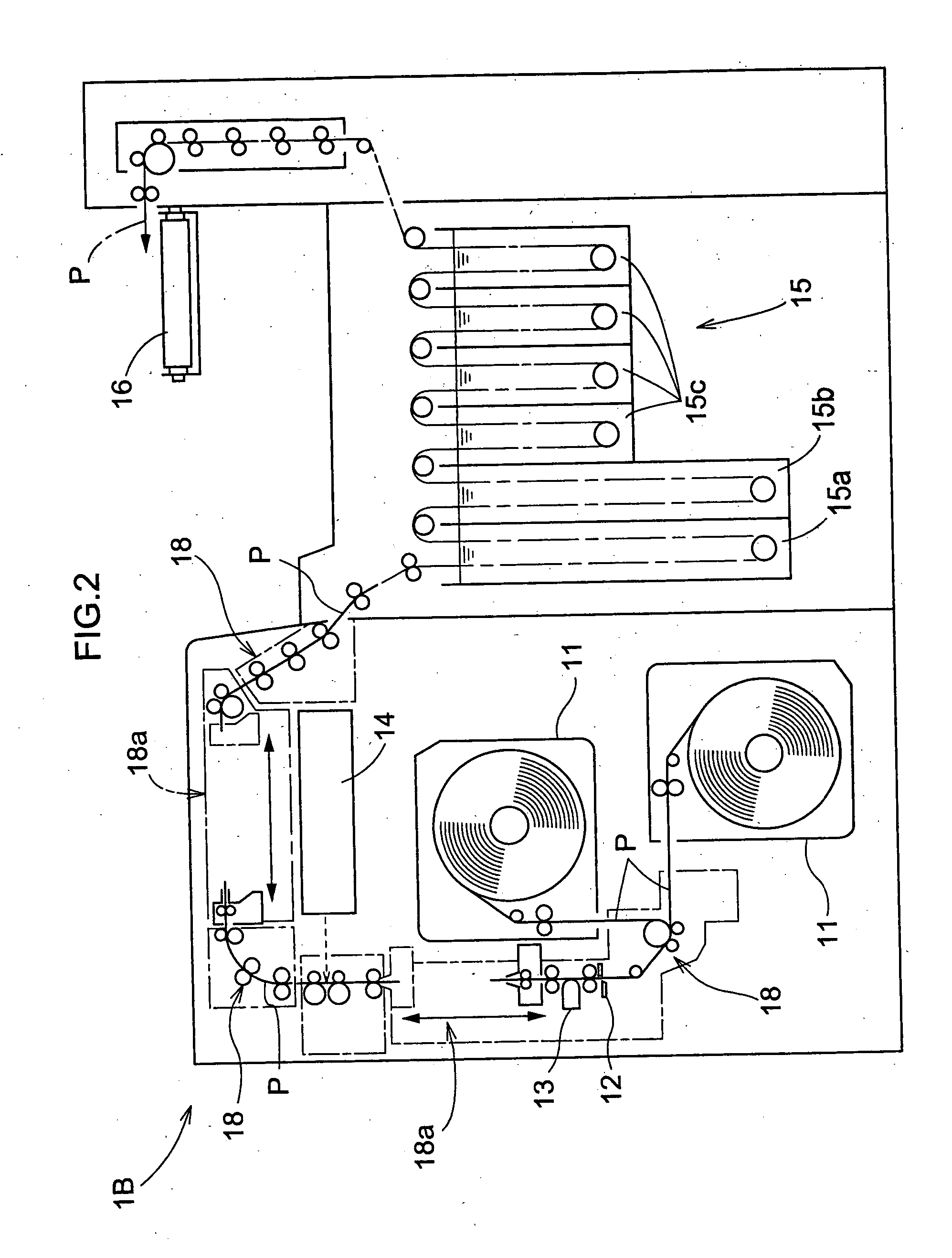

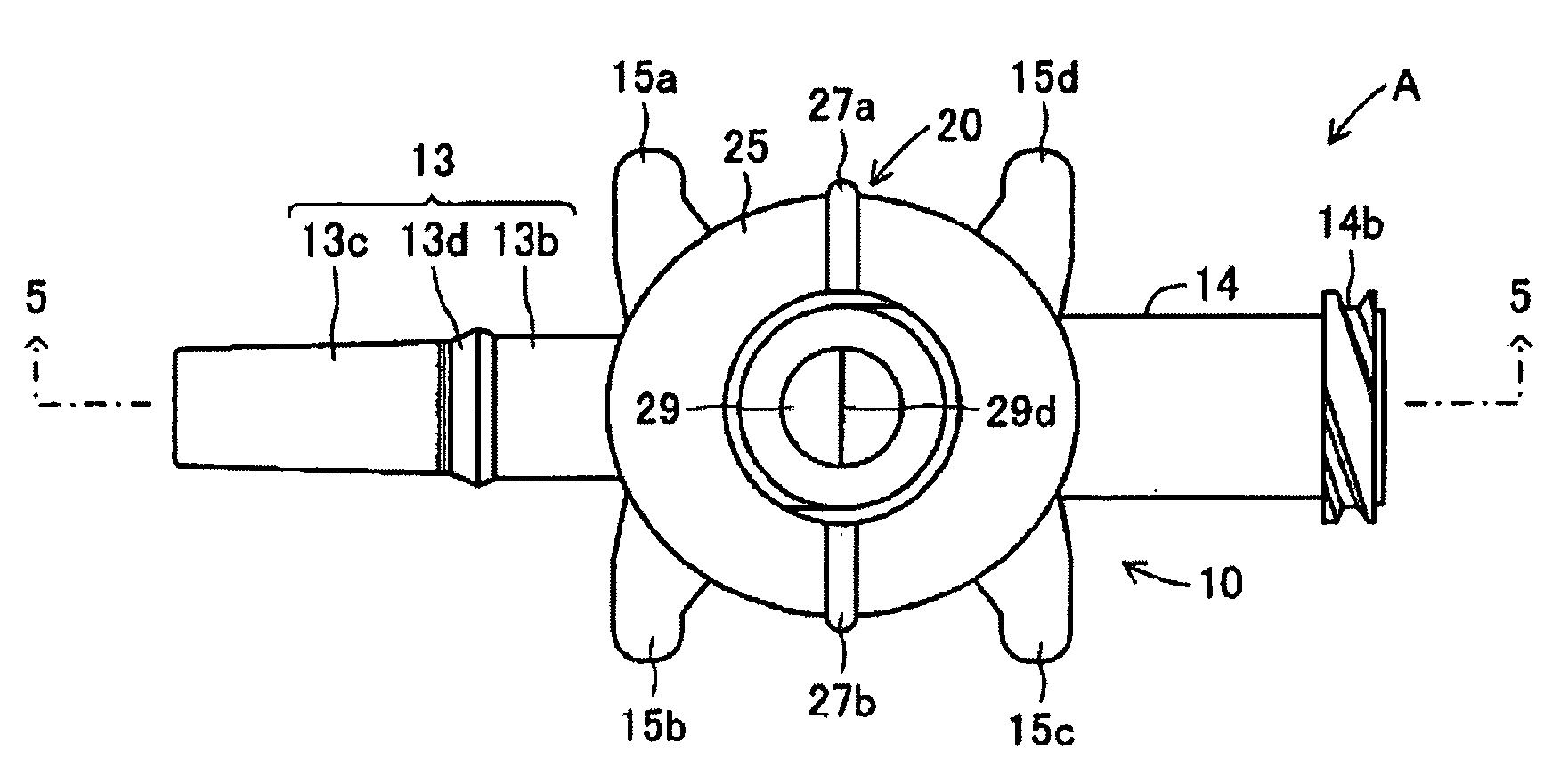

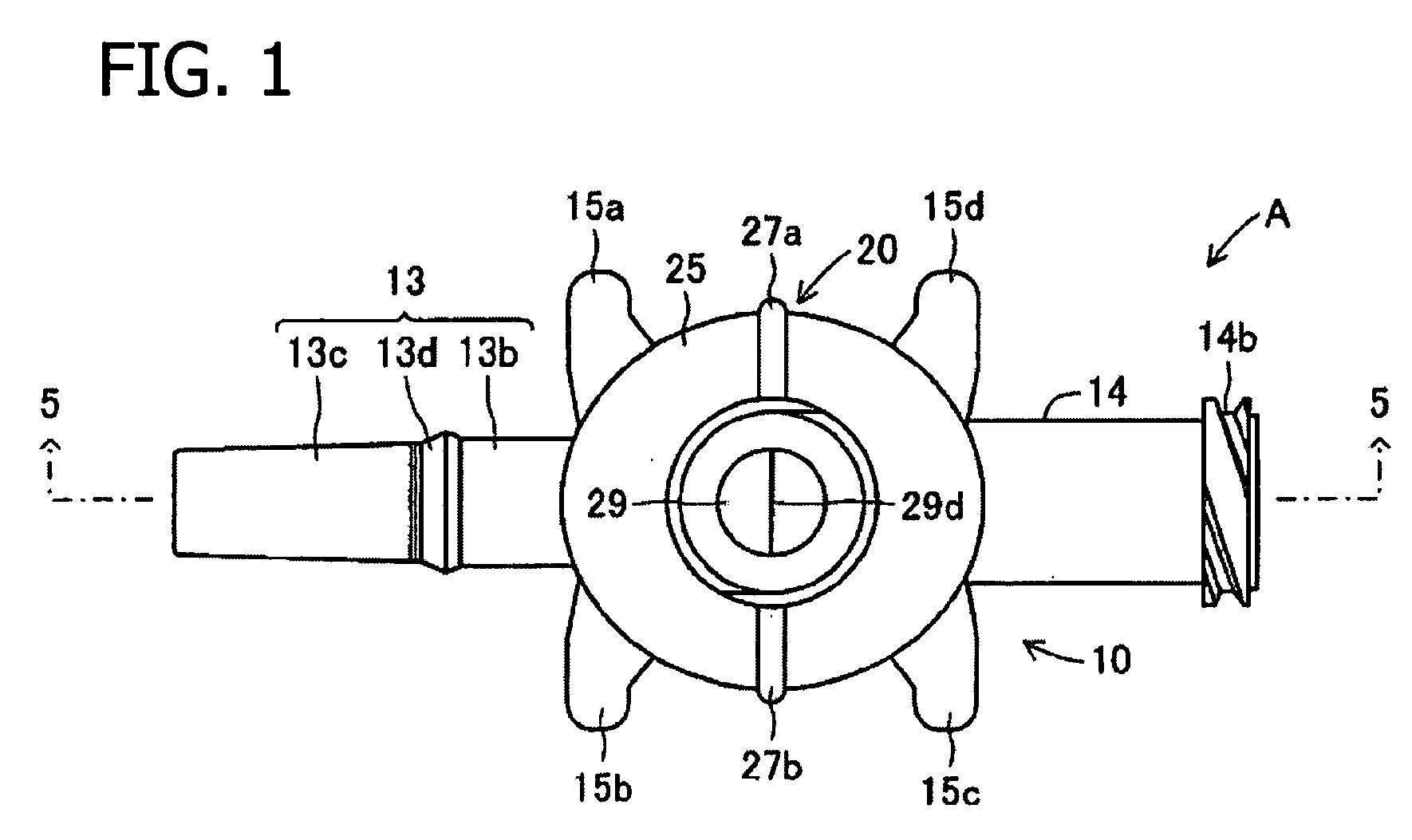

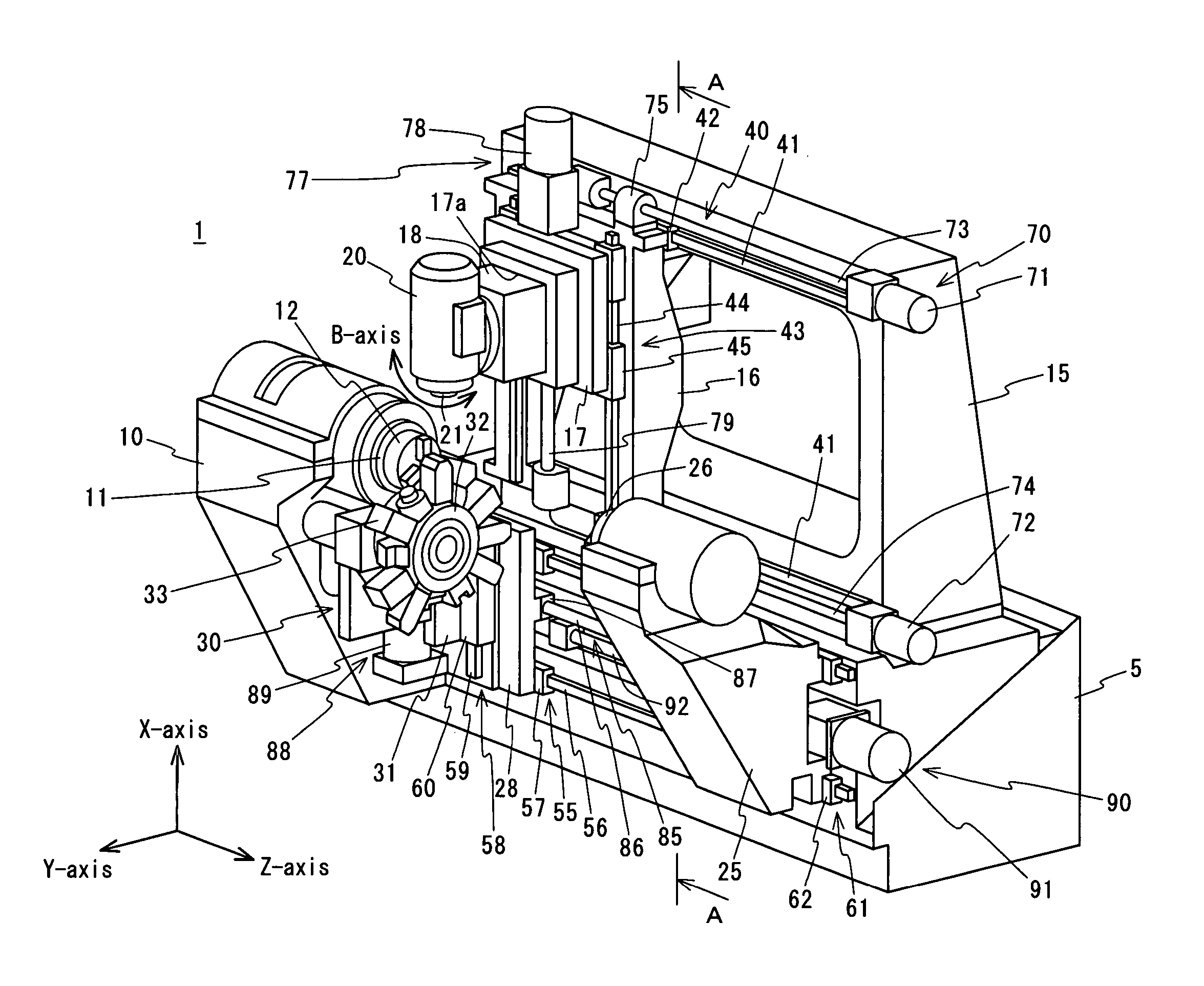

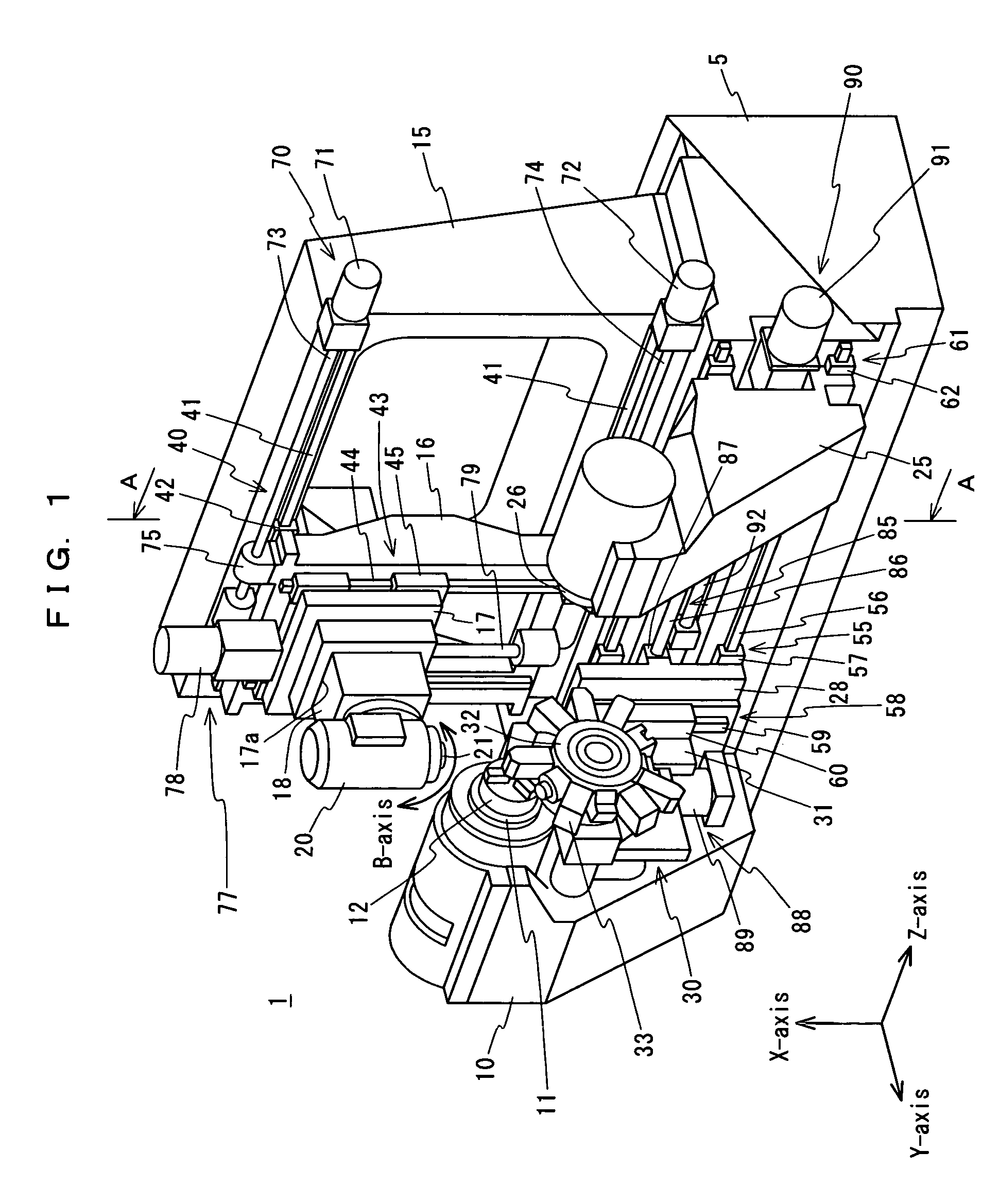

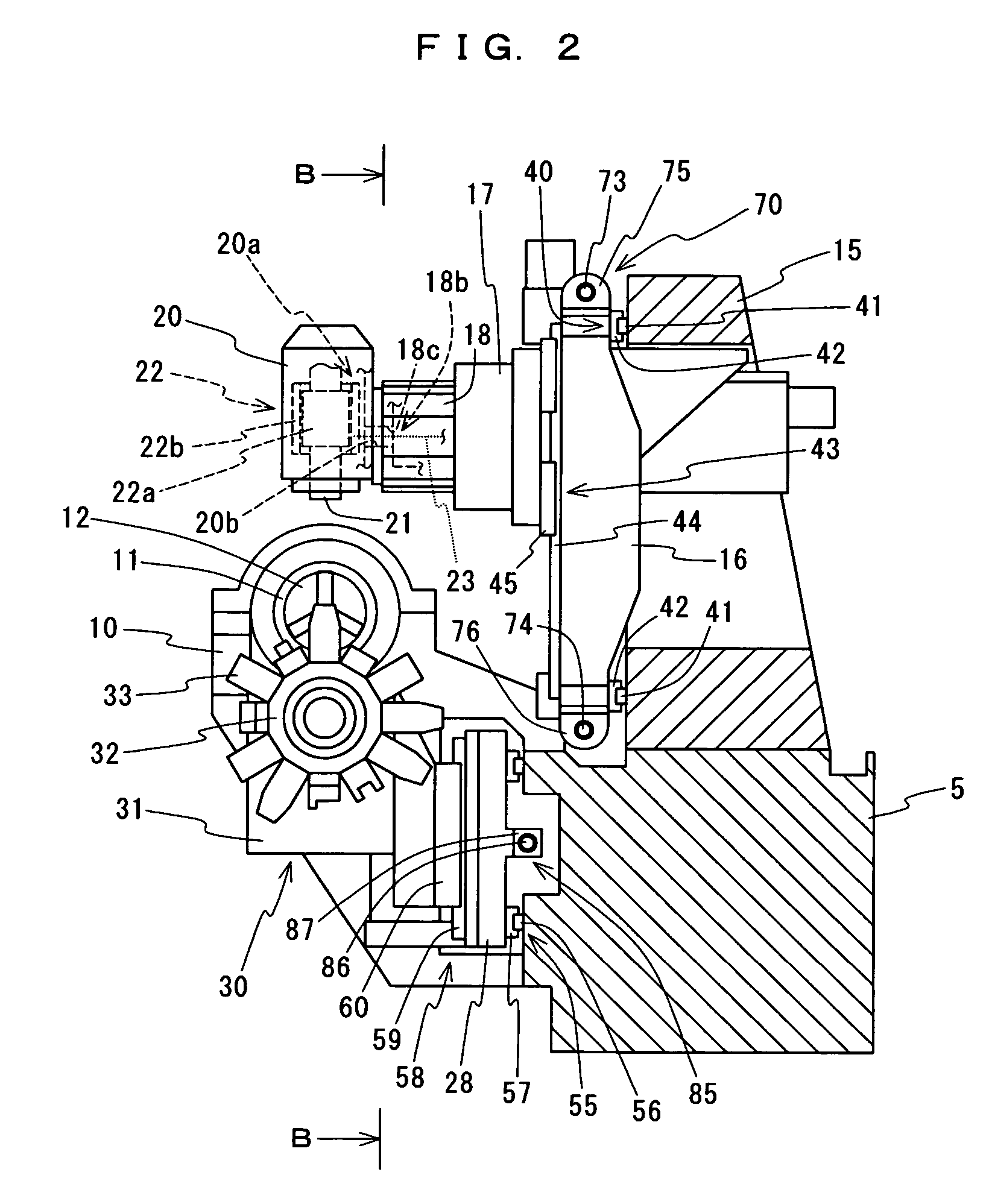

NC lathe

ActiveUS7043805B2Increase feed rateReduce impactAutomatic/semiautomatic turning machinesTurning toolsEngineering

An NC lathe 1 comprises a bed 5, a headstock 10 provided on the bed 5, a main spindle 11 supported on the headstock 10 so as to be rotatable around the axis thereof, a rotation drive device for rotating the main spindle 11, a stationary frame 15 formed in a rectangular frame shape and fixed to the upper face of the bed 5, a movable frame 16 formed in a rectangular frame shape and provided so as to be movable in the Z-axis direction with respect to the stationary frame 15, a saddle 17 provided so as to be movable in the X-axis direction with respect to the movable frame 16, a quill 18 accommodated inside the accommodation hole 17a in the saddle 17 and provided so as to be movable in the Y-axis direction, and a tool rest 20 supported on the quill 18.

Owner:DMG MORI CO LTD

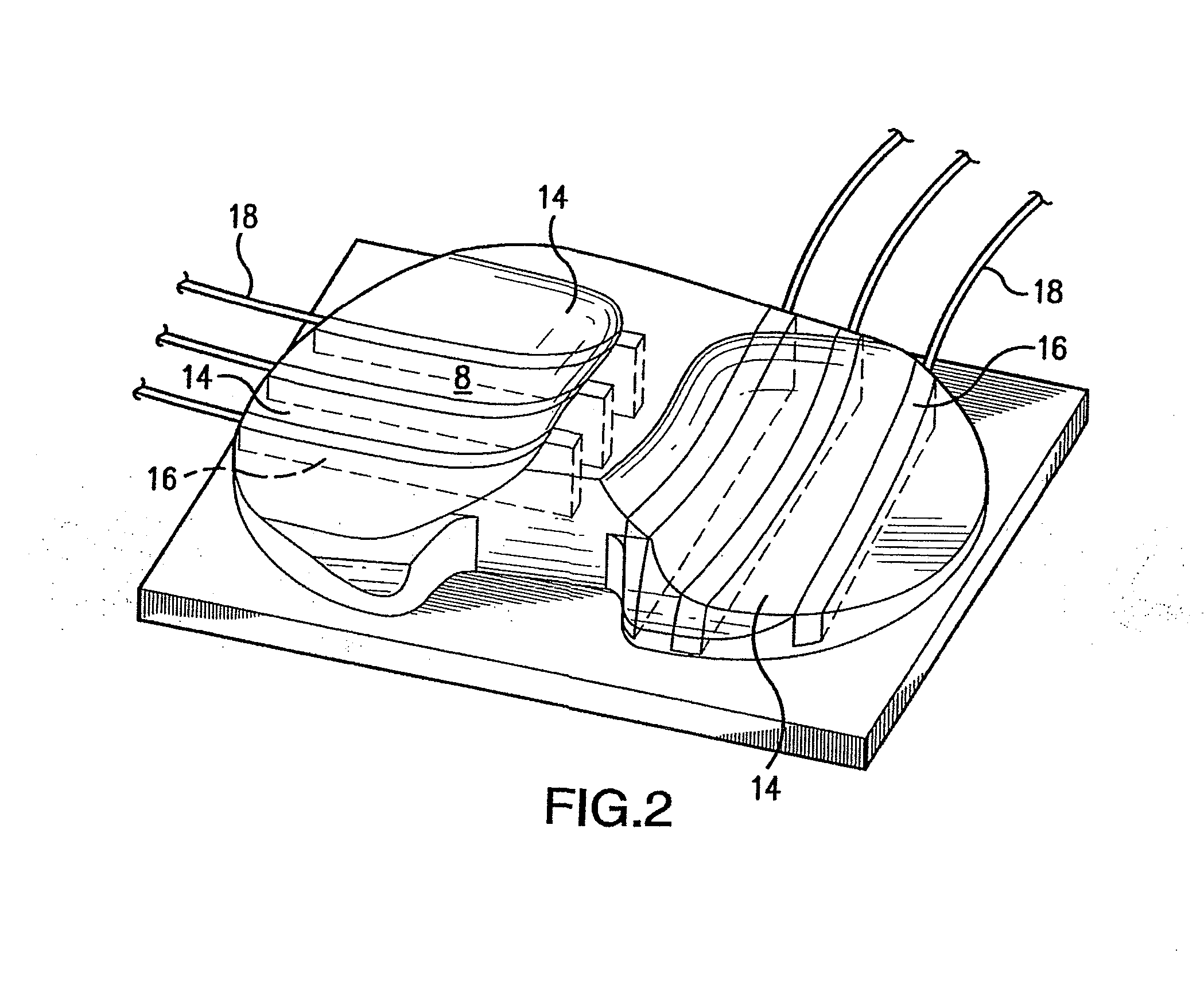

Ultrasonic transducer, biological sensor, and method for manufacturing an ultrasonic transducer

ActiveUS20120306316A1Stable drive characteristicEasily and accurately formedUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostrictive device manufacture/assemblyUltrasonic sensorEngineering

An ultrasonic transducer includes a resin substrate, a support film and a piezoelectric element. The resin substrate has an opening. The support film blocks off the opening in the resin substrate. The piezoelectric element is disposed on the support film in a region that blocks off the opening in plan view from a thickness direction of the support film. The piezoelectric element includes a lamination of a lower electrode, a piezoelectric body, and an upper electrode.

Owner:SEIKO EPSON CORP

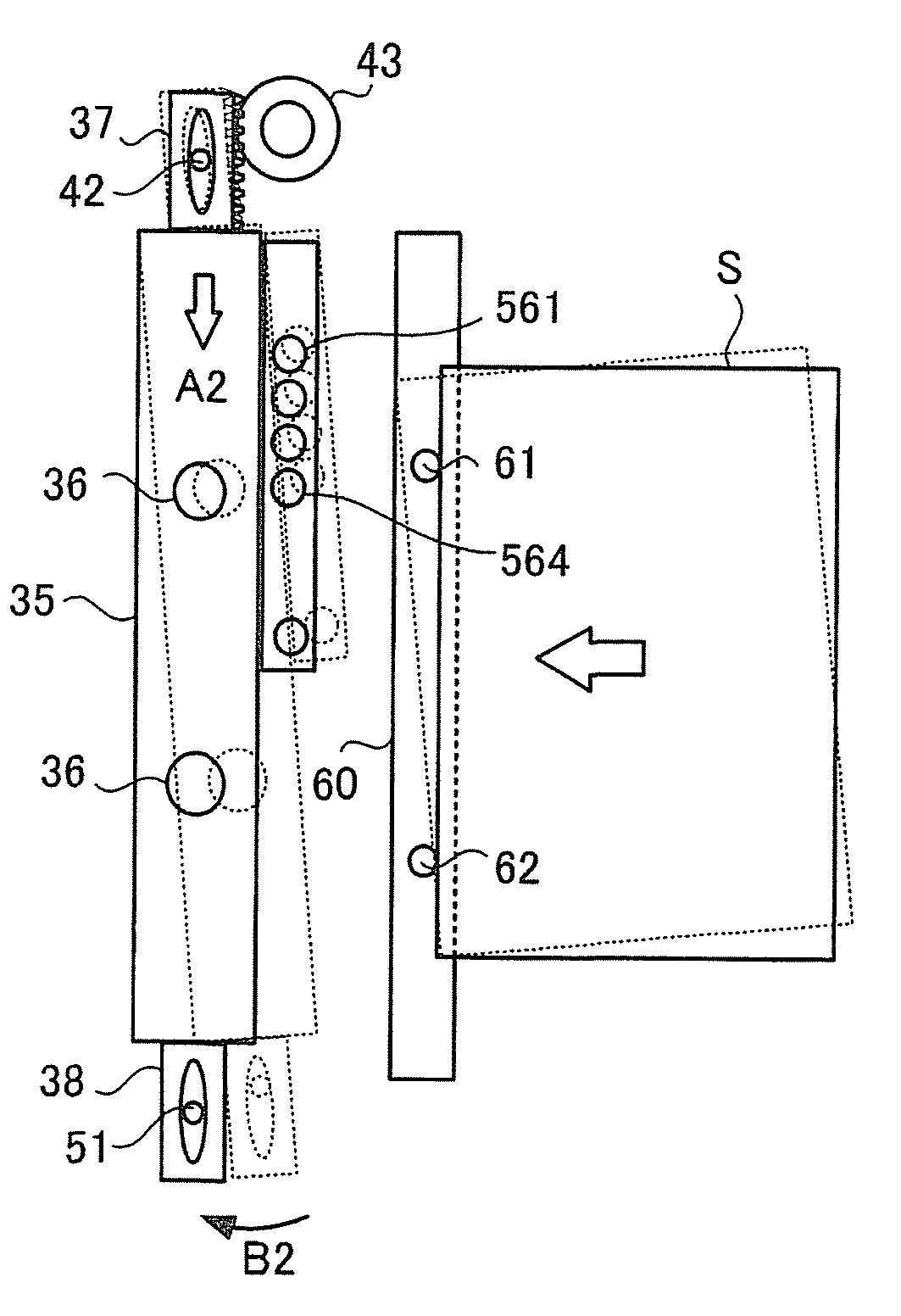

Sheet processing apparatus and sheet processing method

ActiveUS7578498B2Accurately carry-outReduce time skewFunction indicatorsElectrographic process apparatusControl theoryControl unit

A sheet processing apparatus includes a hole punching section arranged downstream from a skew detecting unit and orthogonally to a conveying path of a sheet, and a control unit configured to change the tilt angle of the hole punching section in accordance with each of the quantity of skew at the forward edge and the quantity of skew at the rear edge of the sheet, carry out skew correction at the forward edge within a first correction range w1, and carry out skew correction at the rear edge within a second correction range w2 (where w1>w2≧w1 / 2). The control unit carries out skew correction at the forward edge within the correction range w2, in the case where the detected quantity of skew at the forward edge is a tilt angle exceeding the correction range w2, and then carries out skew correction at the rear edge in accordance with the difference between the quantity of skew at the forward edge after the correction and the quantity of skew at the rear edge.

Owner:KK TOSHIBA +1

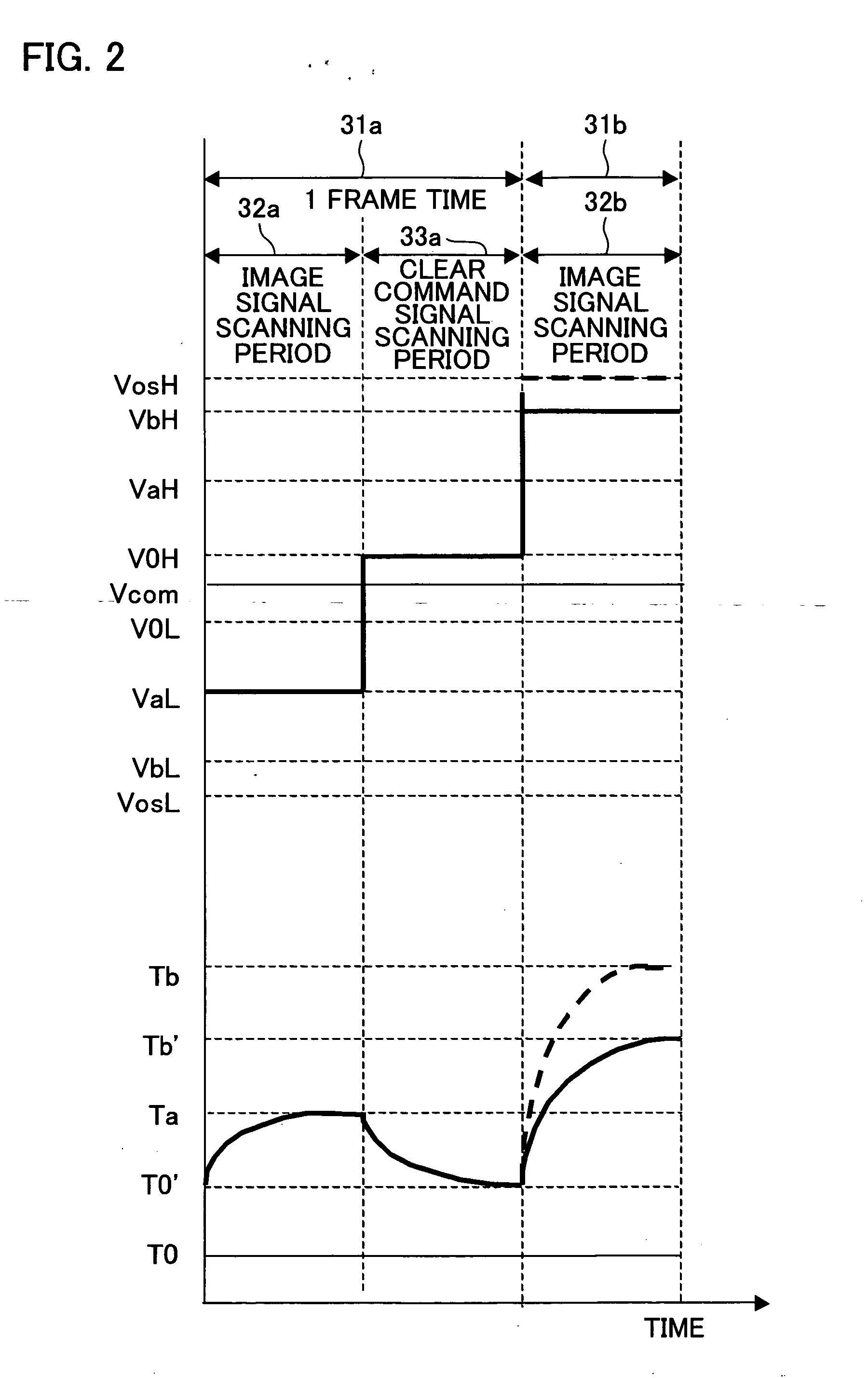

Liquid crystal display device and method for driving liquid crystal display device

ActiveUS20050200619A1Improve image qualityAccurately carry-outCathode-ray tube indicatorsInput/output processes for data processingDetector circuitsLiquid-crystal display

A liquid crystal display device, including (a) a liquid crystal panel for carrying out display by voltage application to pixels, each of which has a liquid crystal layer, and (b) a driving circuit for applying, within one frame time, (i) voltages that respectively correspond with image signals and (ii) a voltage that corresponds with a clear command signal, to the pixels of said liquid crystal panel, is arranged such that said driving circuit includes a combination detector circuit for generating, by looking up an OS parameter table, corrected image signals according to combination of first image signals for a preceding frame time and second image signals for a present frame time, the corrected image signals thus generated causing liquid crystal orientation in the pixels to be transited from initial orientation of the present frame time to orientation indicated by the second image signals. With this arrangement, it is possible to display gray scale levels of the image signals, thereby realizing display of a moving image of high image quality

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com