Patents

Literature

994 results about "Roller chain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

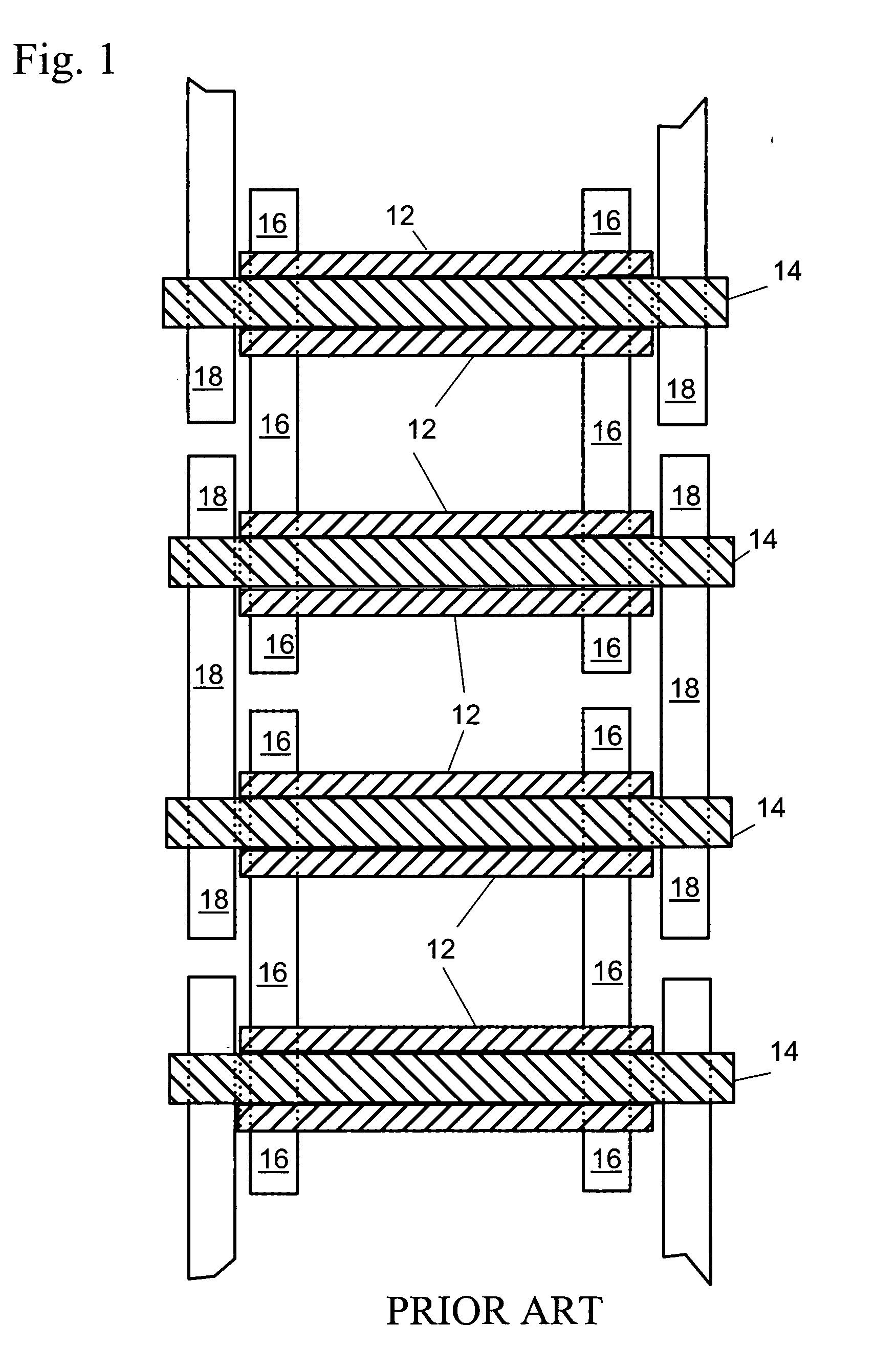

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficient means of power transmission.

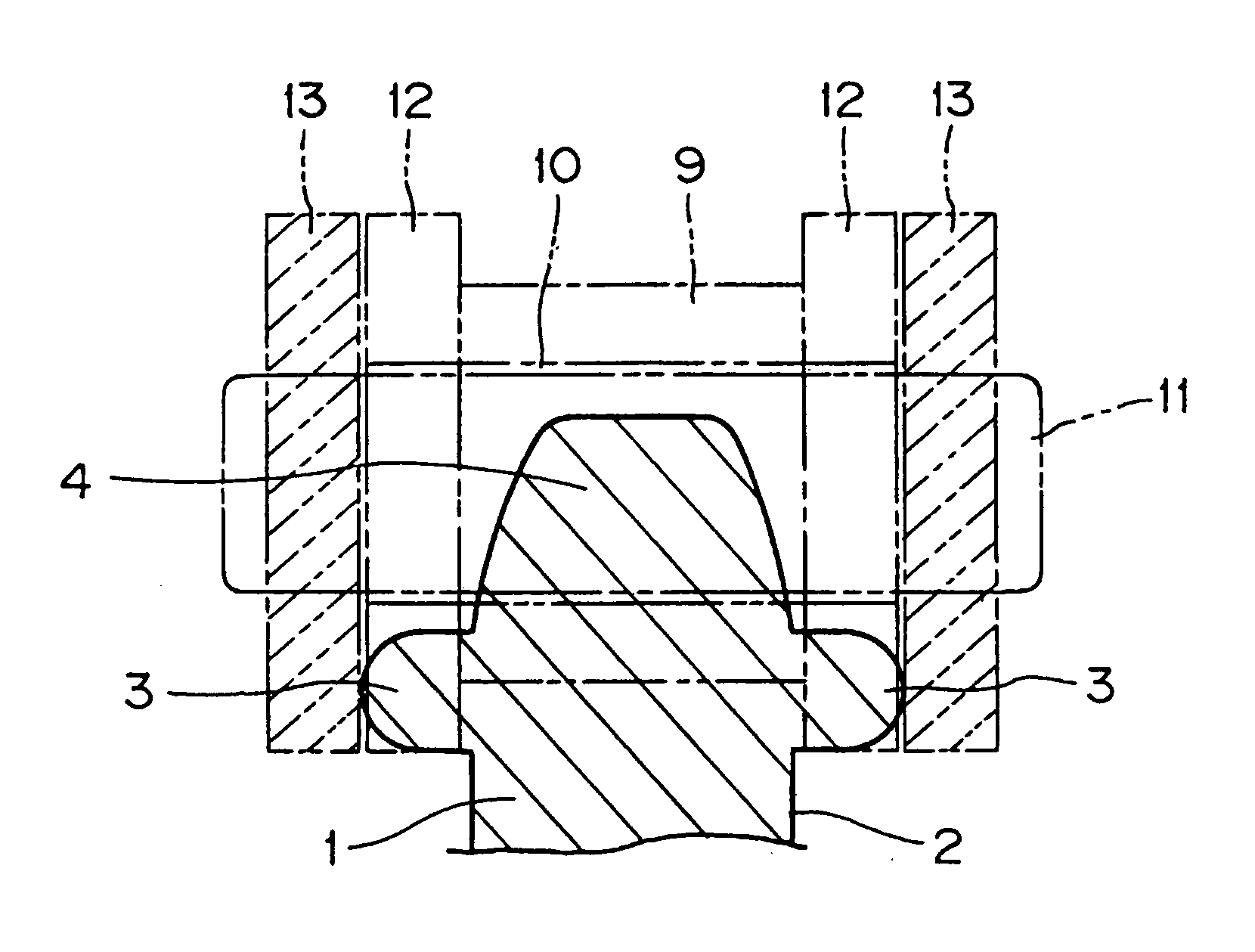

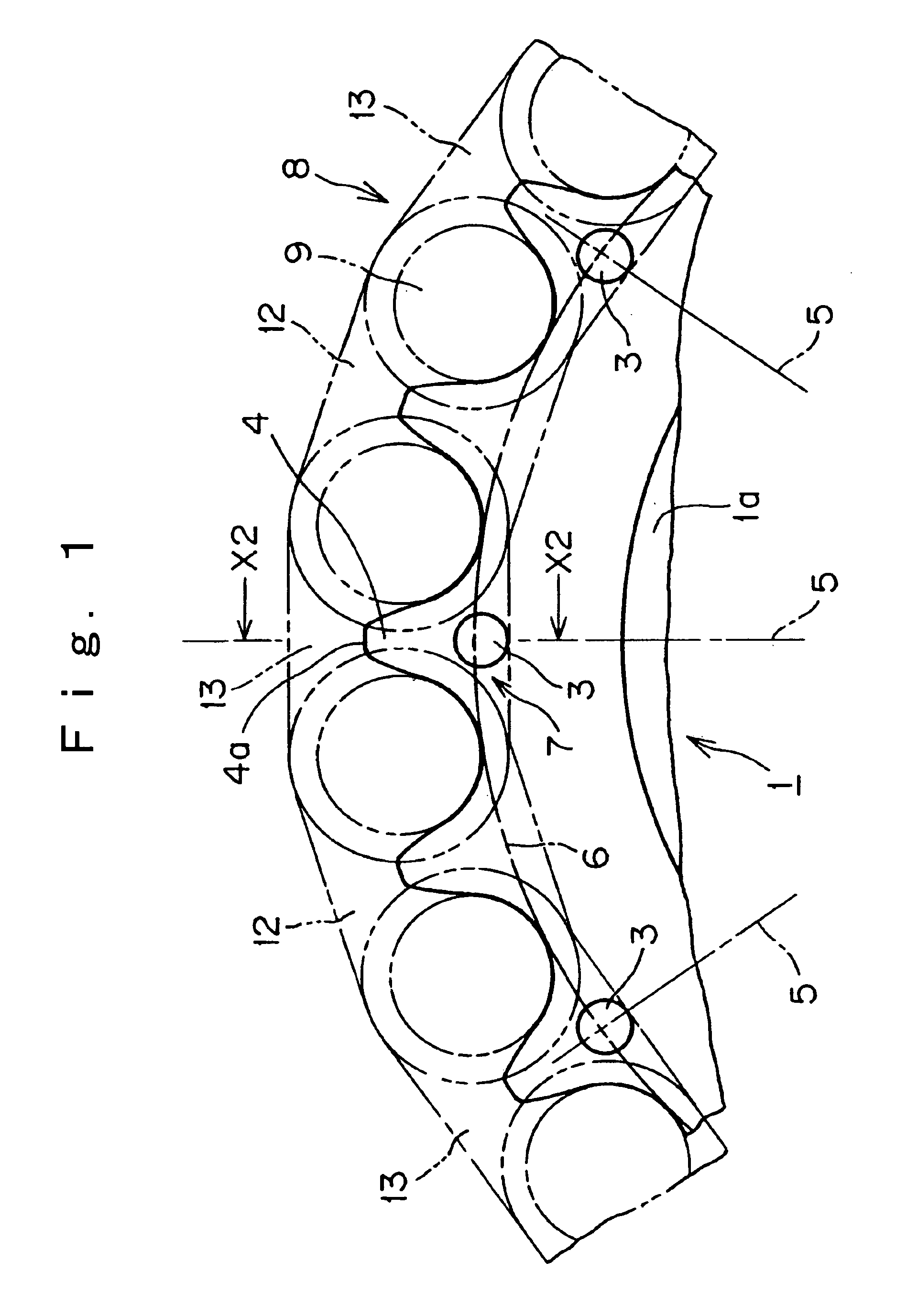

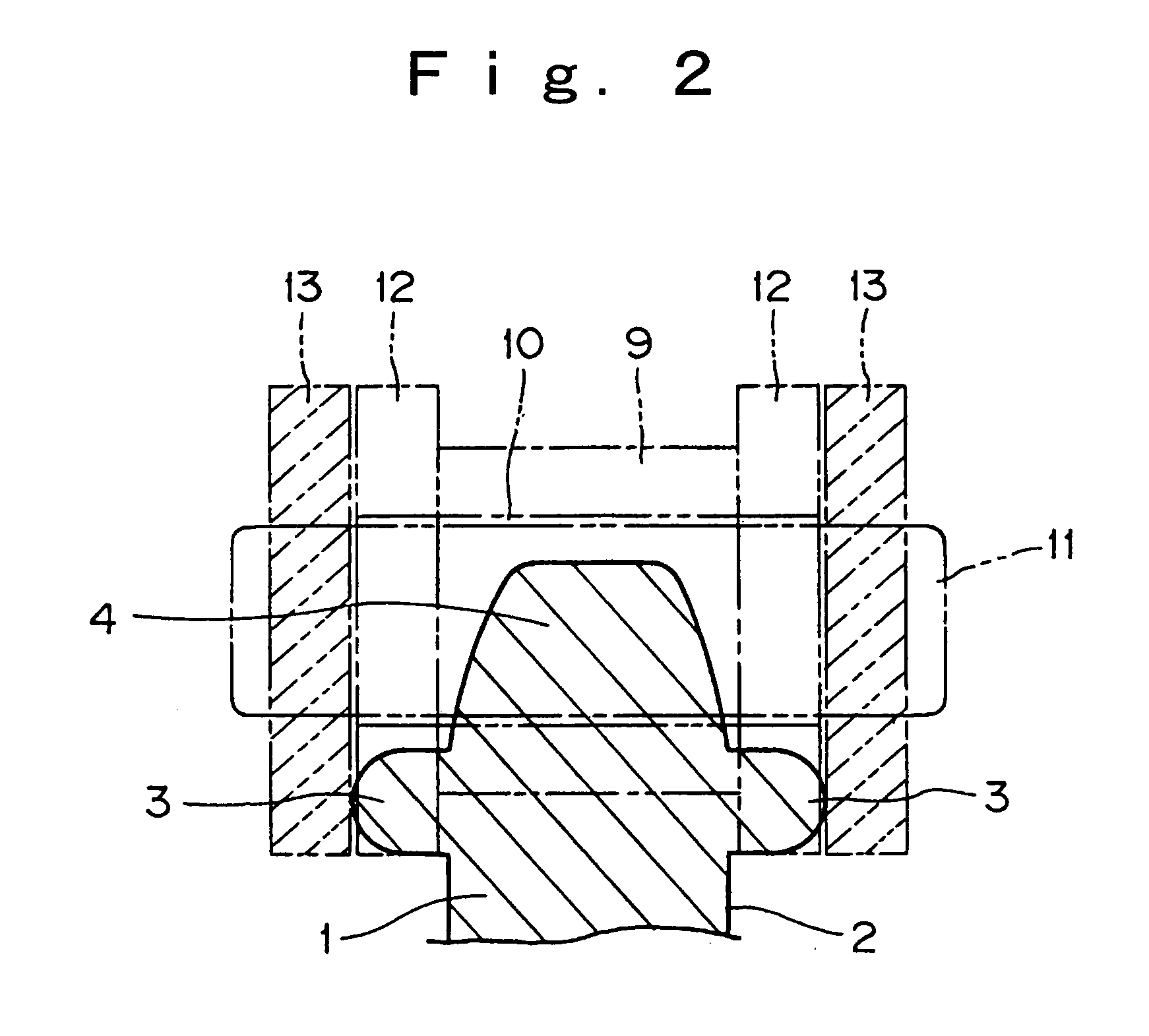

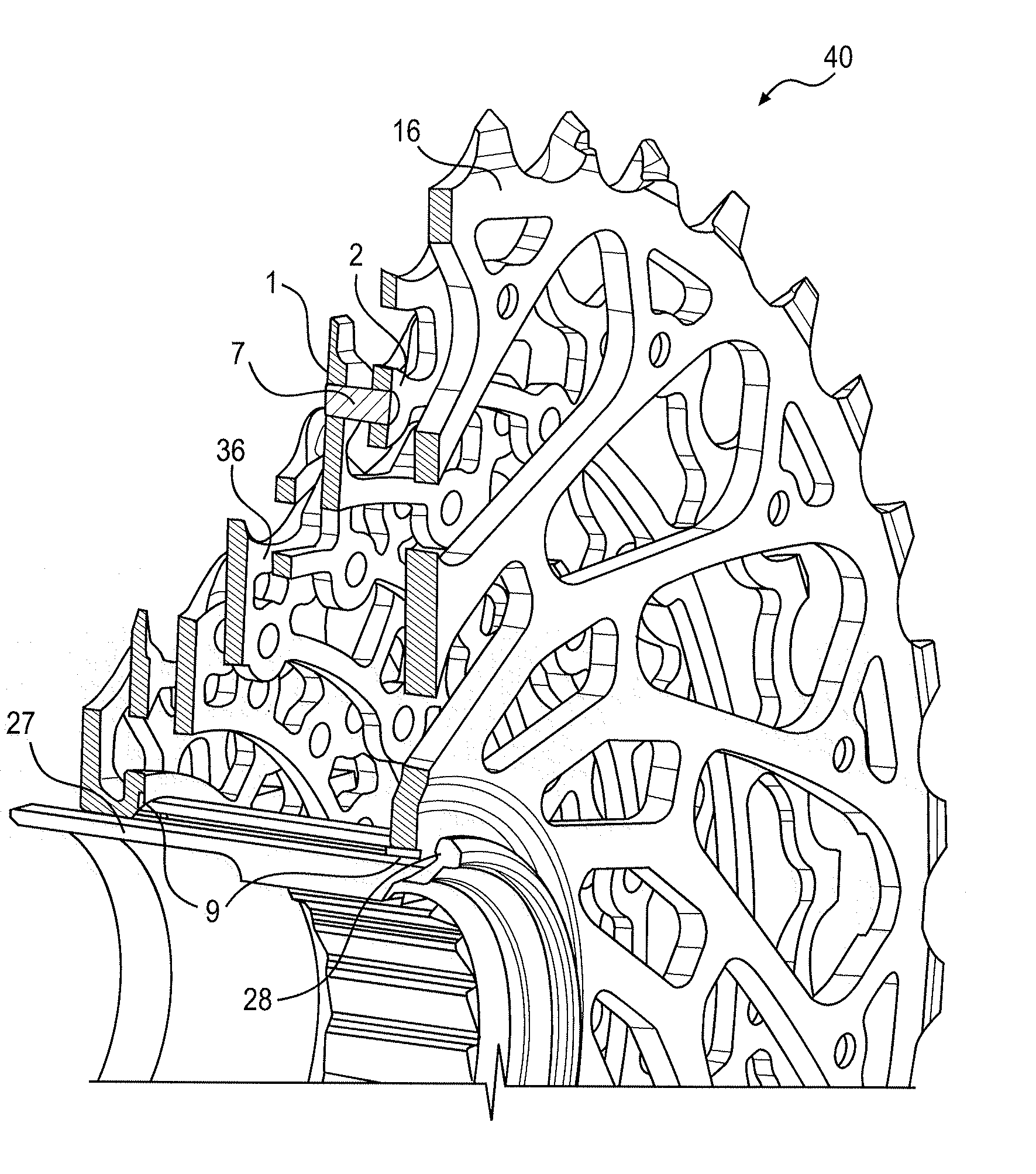

Sintered sprocket with protrusions

InactiveUS20070054768A1Reduce wear elongationPrecise positioningPortable liftingGearing elementsEngineeringRoller chain

A sintered sprocket is formed with protrusions on both sides, arranged along a tooth gap bottom circle and centered on every second tooth. These protrusions engage the outer plates of a roller chain and maintain the chain in centered relationship with the sprocket.

Owner:TSUBAKIMOTO CHAIN CO

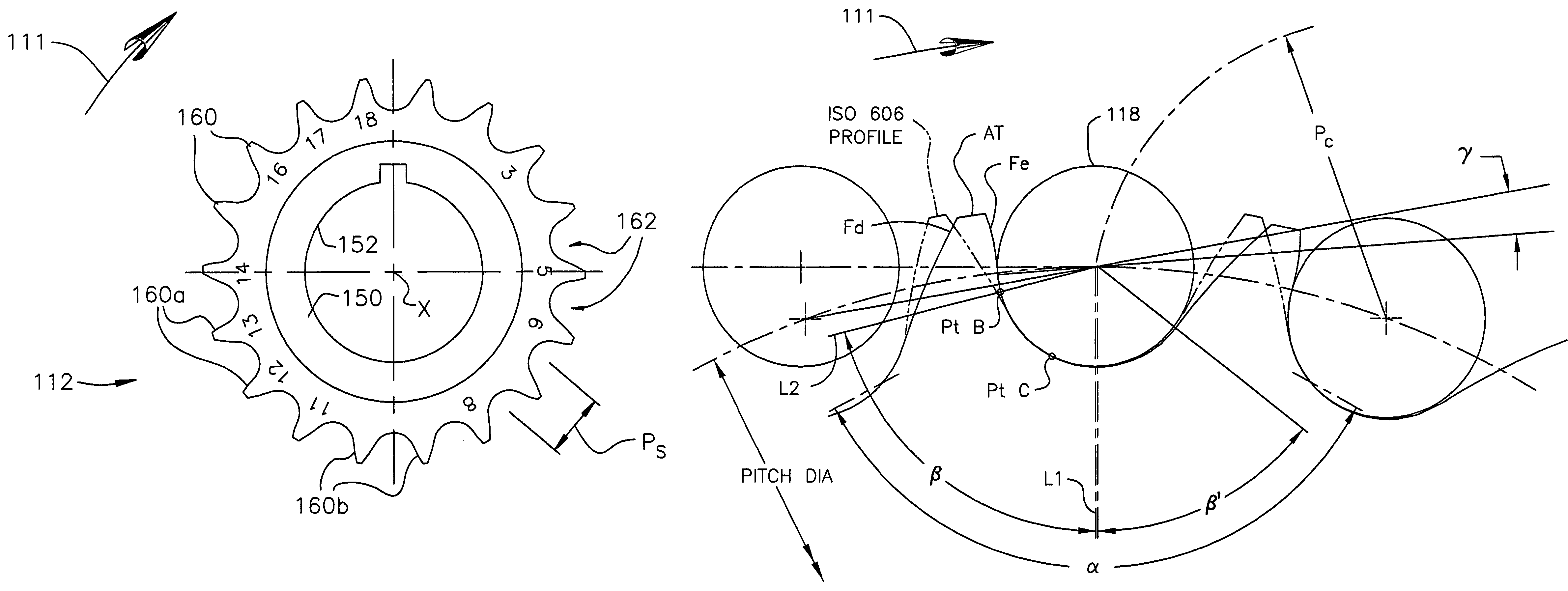

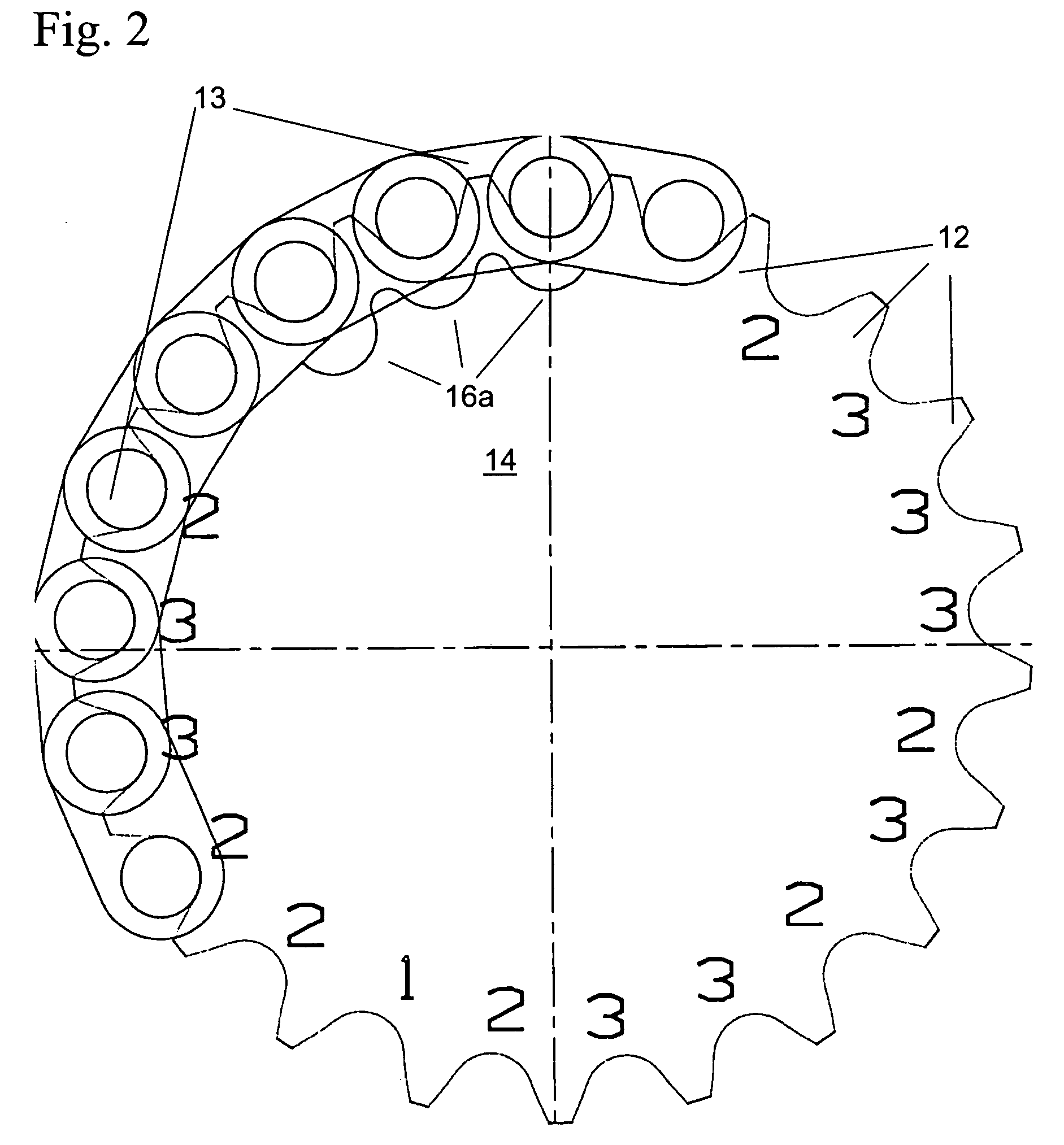

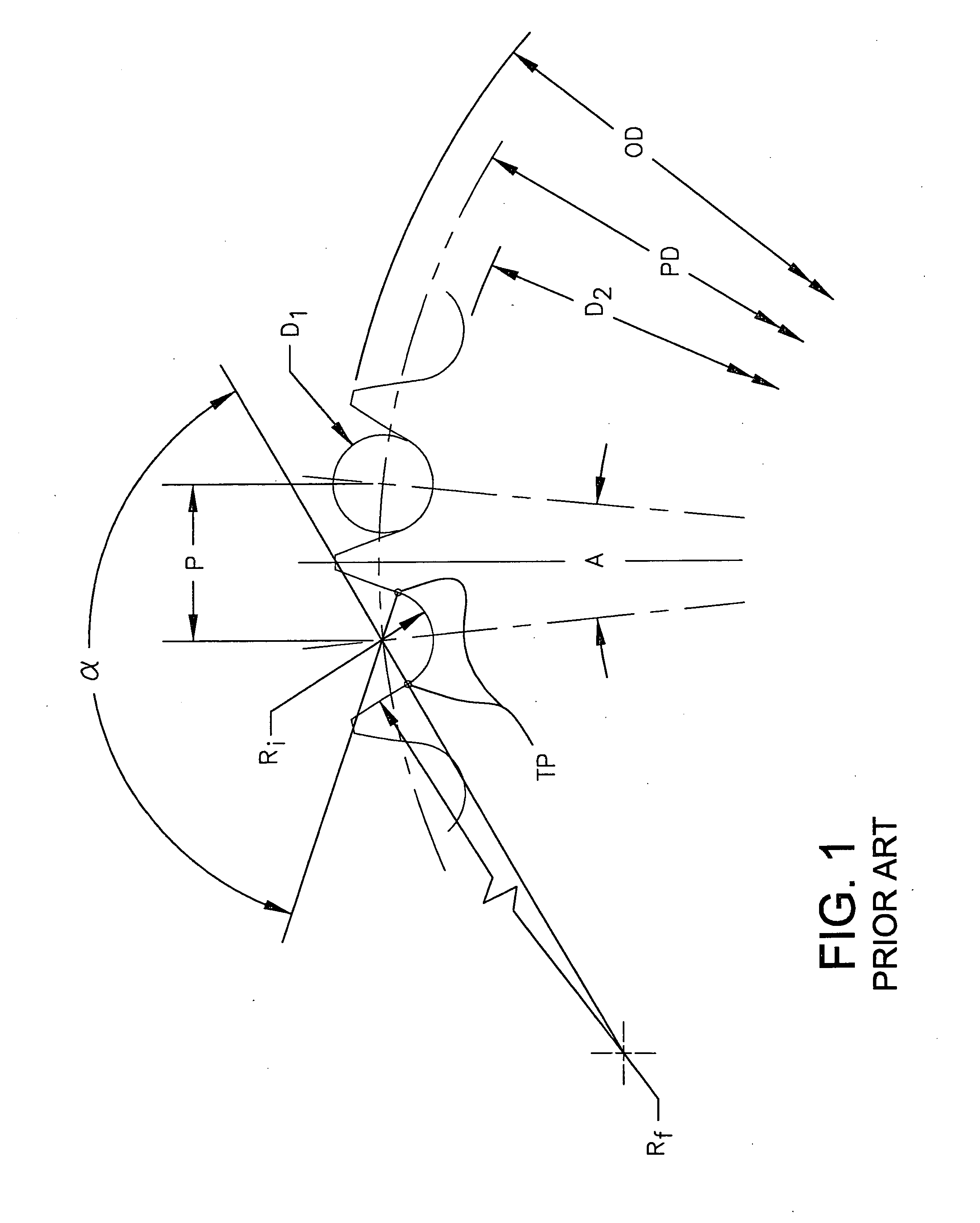

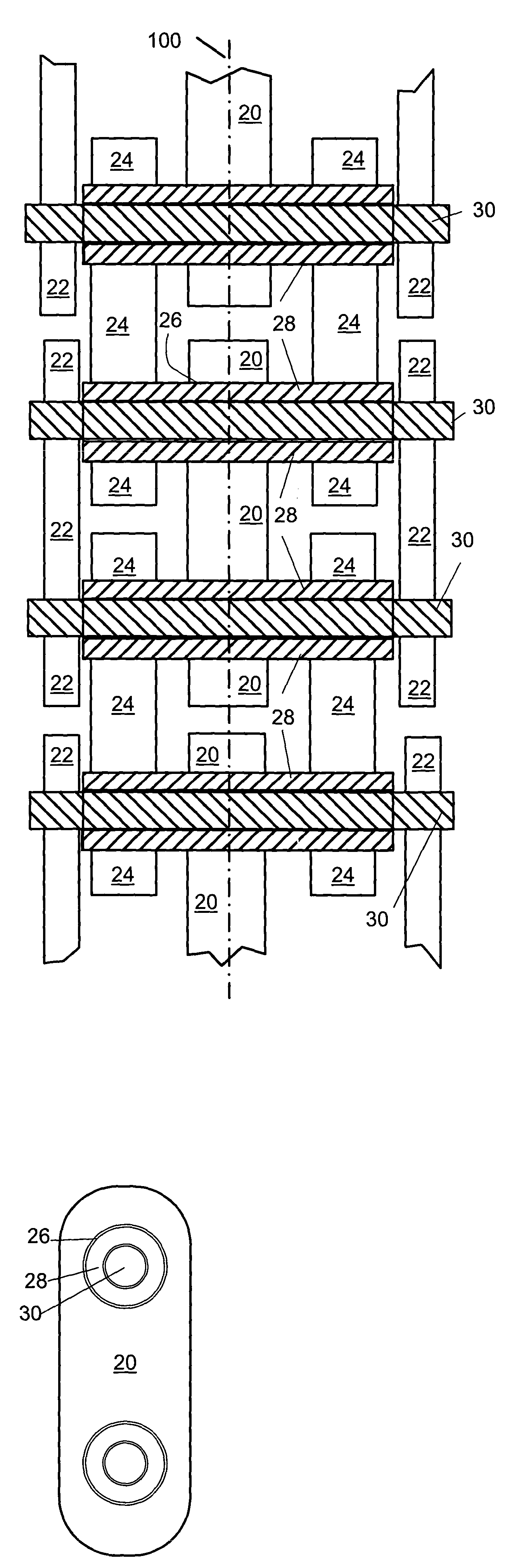

Random engagement roller chain sprocket and timing chain system including same

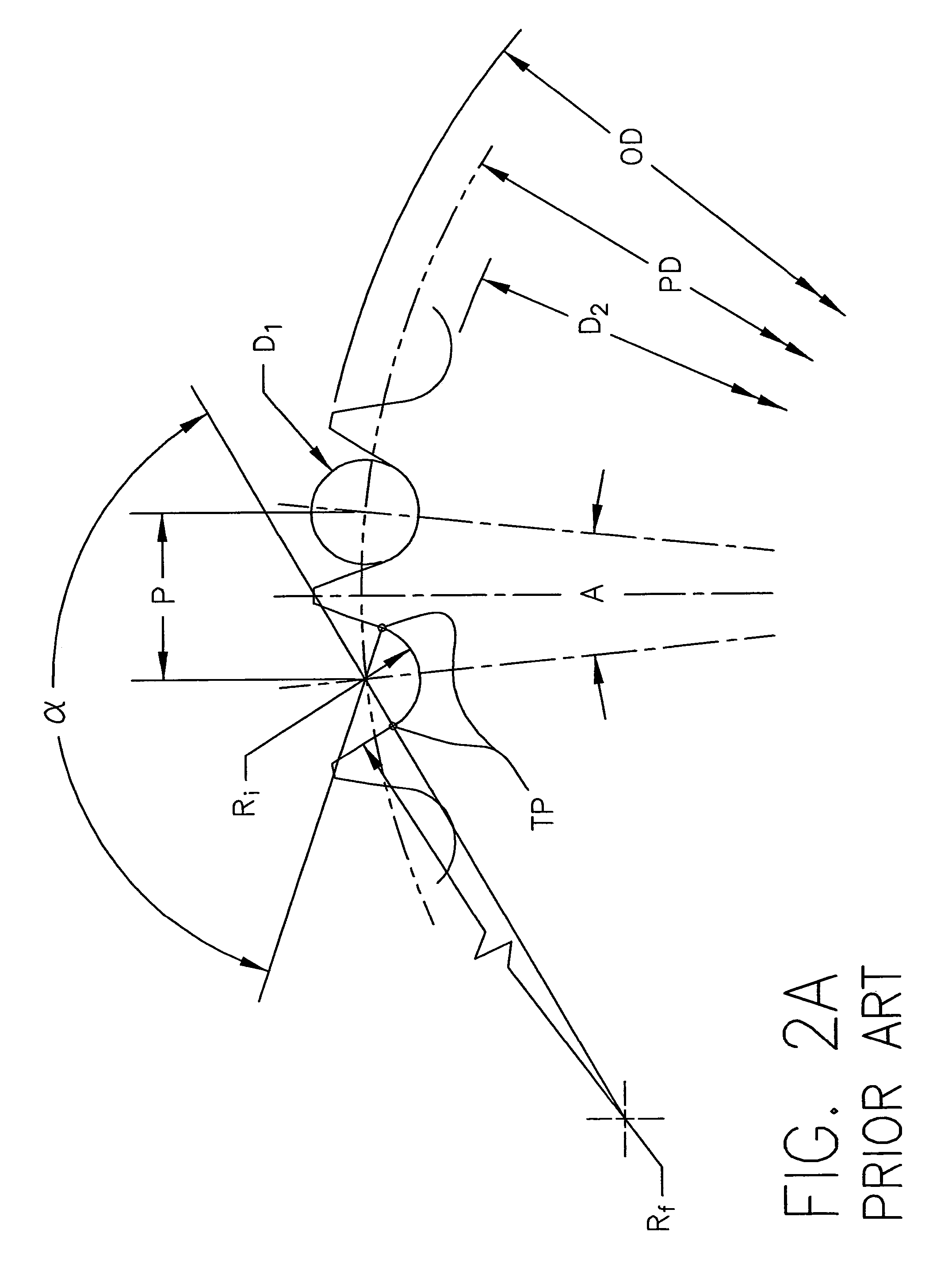

A sprocket and a roller chain drive system including same are disclosed. The sprocket is a random engagement sprocket comprising a first plurality of A-profile teeth formed with a first asymmetric profile and a second plurality of B-profile teeth formed with a second asymmetric profile. The A-profile teeth each define a first pressure angle and the B-profile teeth each define a second pressure angle that is at least 5 degrees greater than said first pressure angle so that a minimum separation Δ is defined. The sprocket is defined with added chordal pitch reduction of 0.2% up to 1% relative to the link pitch of the associated roller chain. The sprocket can be defined with root relief and / or can comprise resilient cushion rings. Initial roller contacts made with the A-profile and B-profile teeth are modulated owing to the pressure angle separation and added chordal pitch reduction.

Owner:HH CLOYES INC

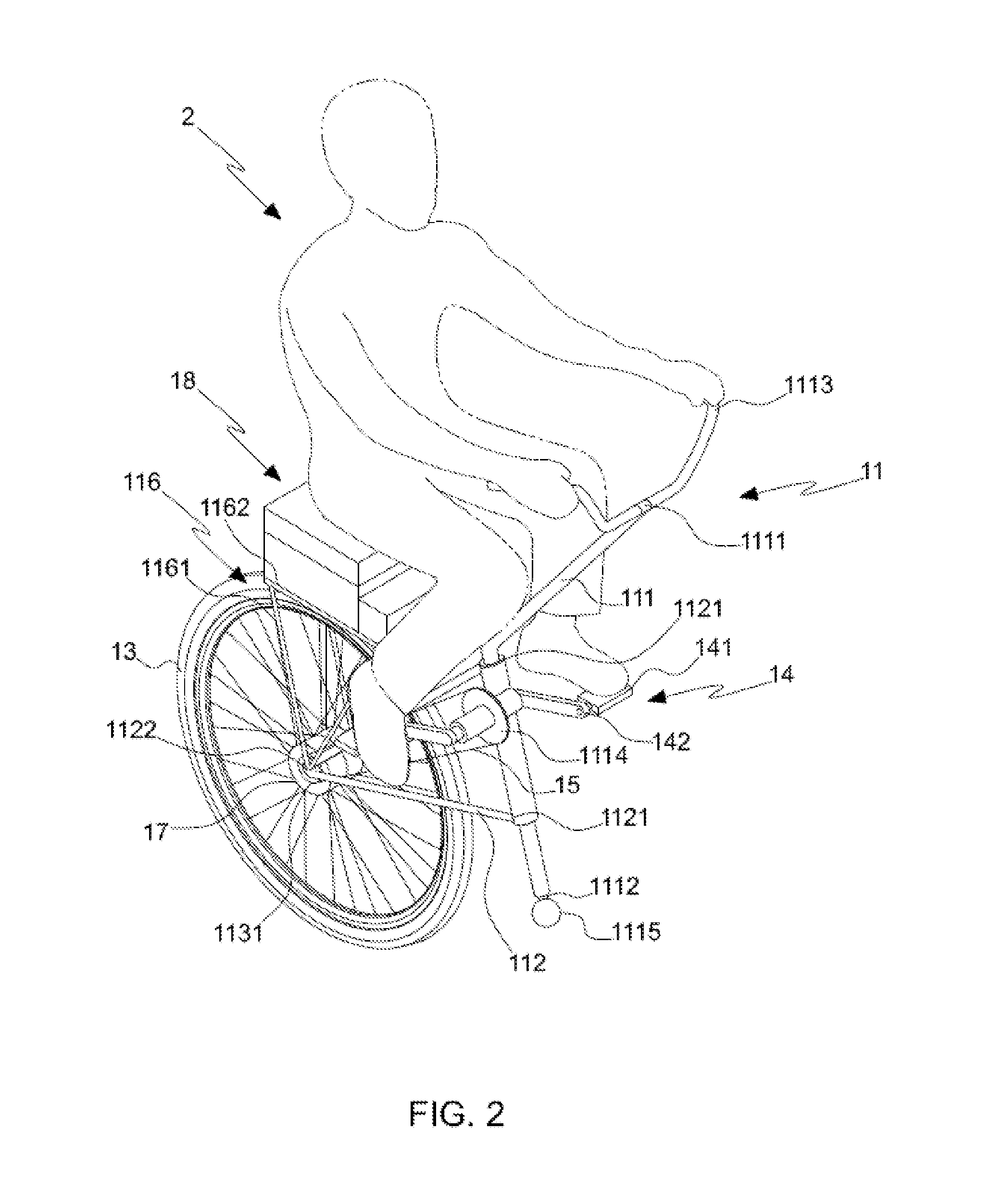

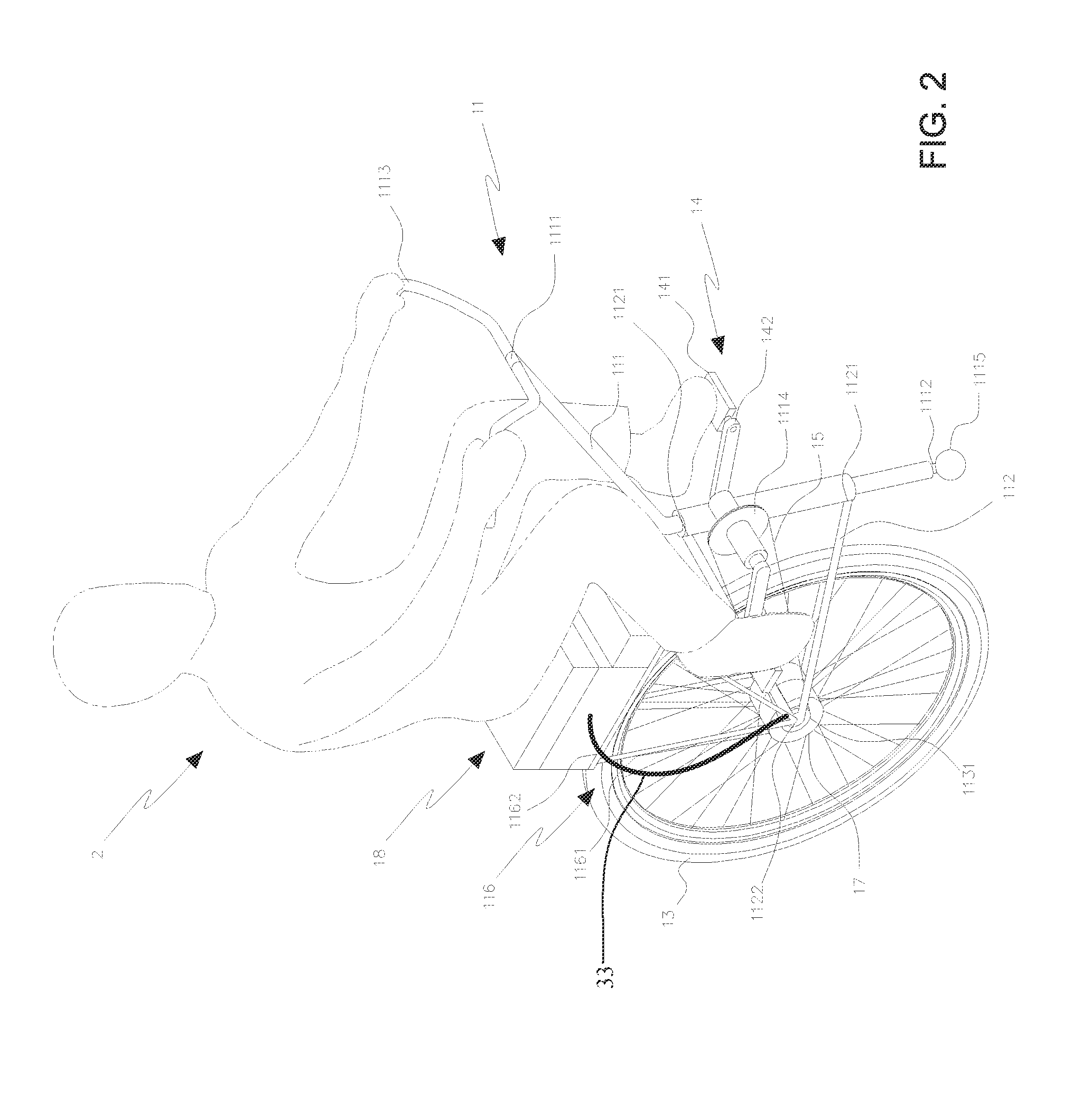

Personal, green-energy, transportation device with single wheel and self-balancing function

InactiveUS20110238247A1Maintain self-balancingUnicyclesDigital data processing detailsBody balanceRoller chain

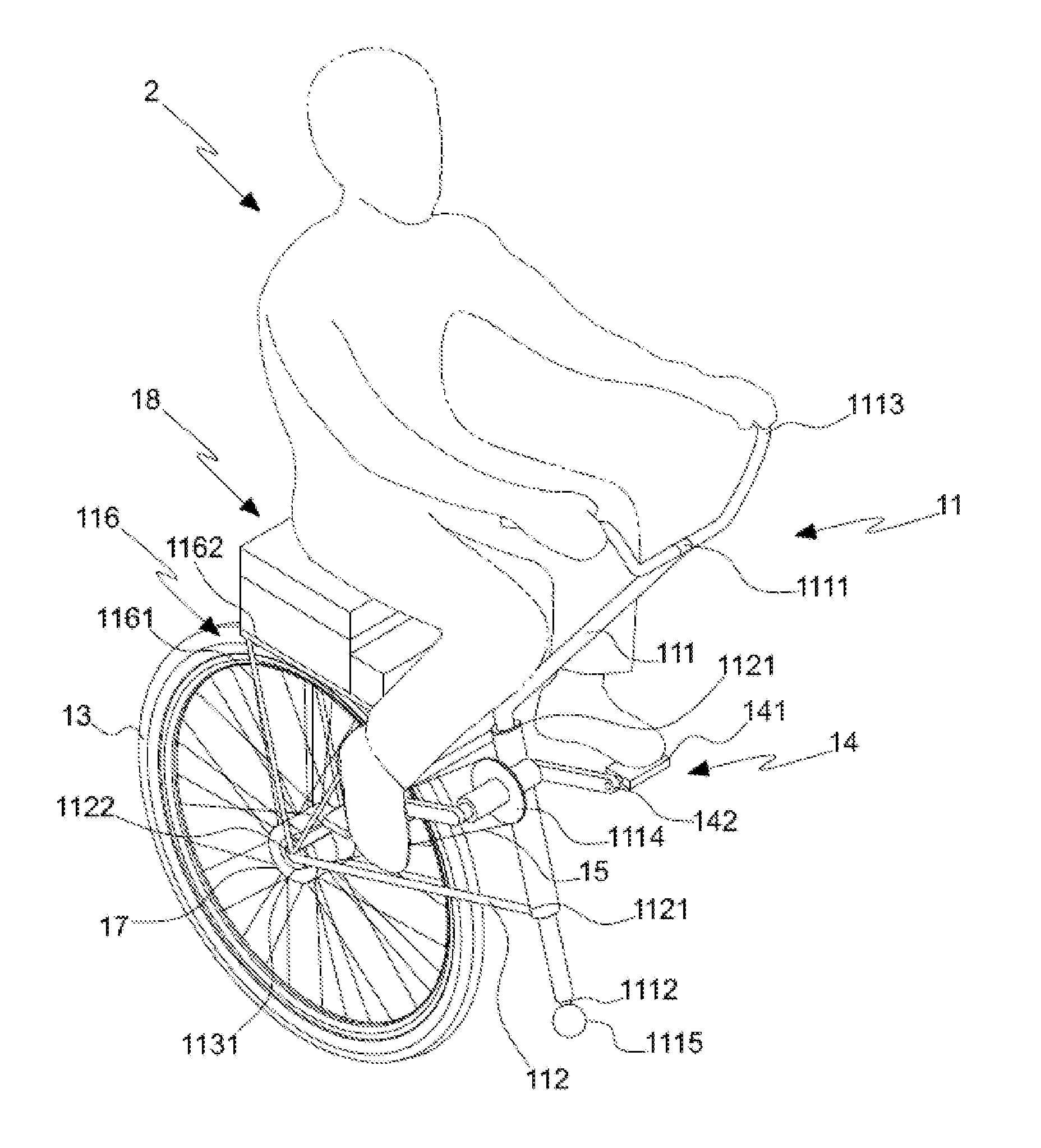

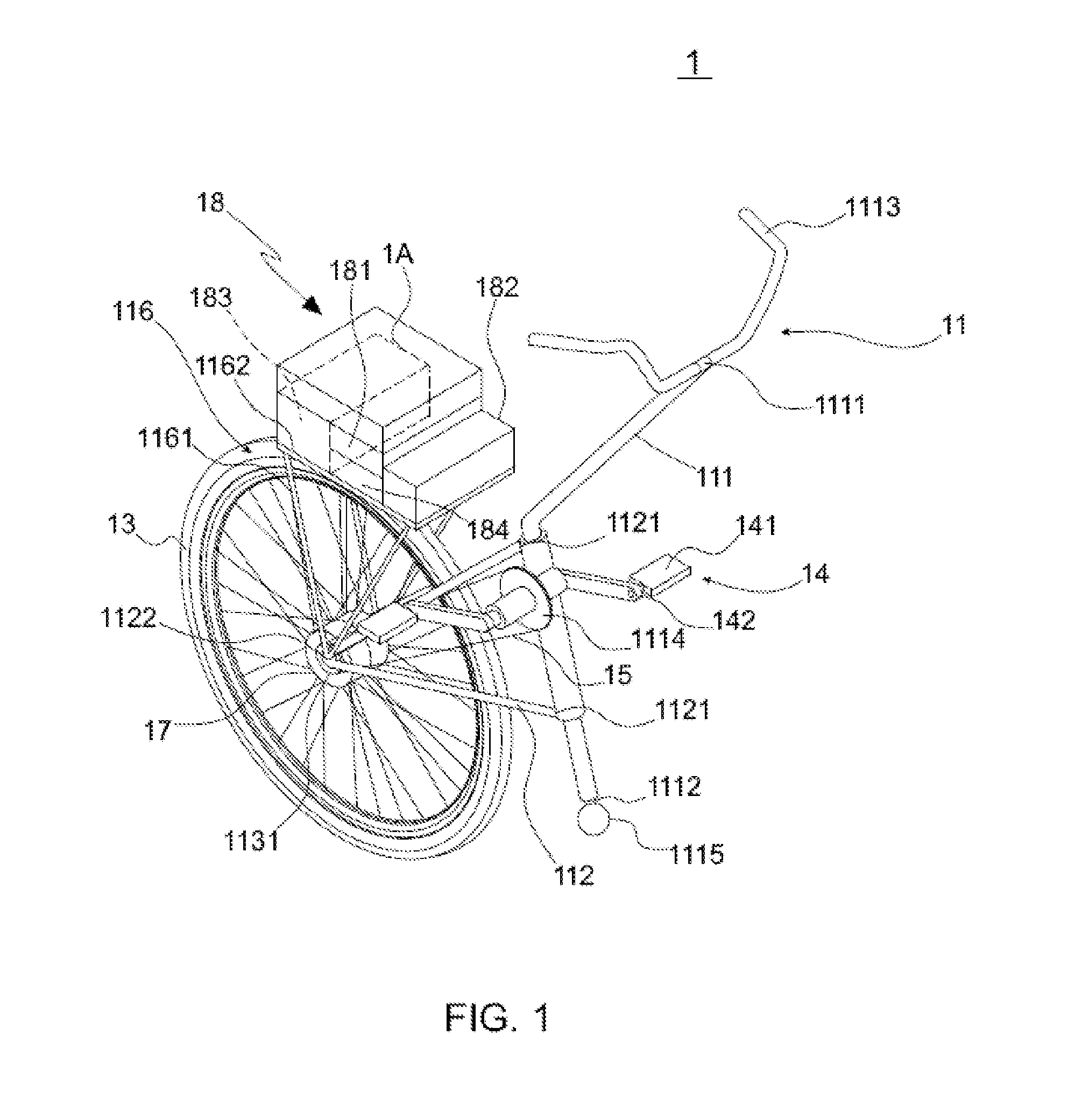

The present invention relates to a personal, green-energy, transportation device with single wheel and self-balancing function. The personal, green-energy, transportation device can be propelled by the manpower and simultaneously execute the self-balancing function thereof. The device comprises: a body, a wheel, a pedal portion, a roller chain, an in-wheel motor, and a sensing-control module, wherein the sensing-control module detects the balancing condition of the body when the personal, green-energy, transportation device is driven, and then the sensing-control module controls the in-wheel motor to output a balancing torque for maintaining the self balance of the body.

Owner:NATIONAL TSING HUA UNIVERSITY

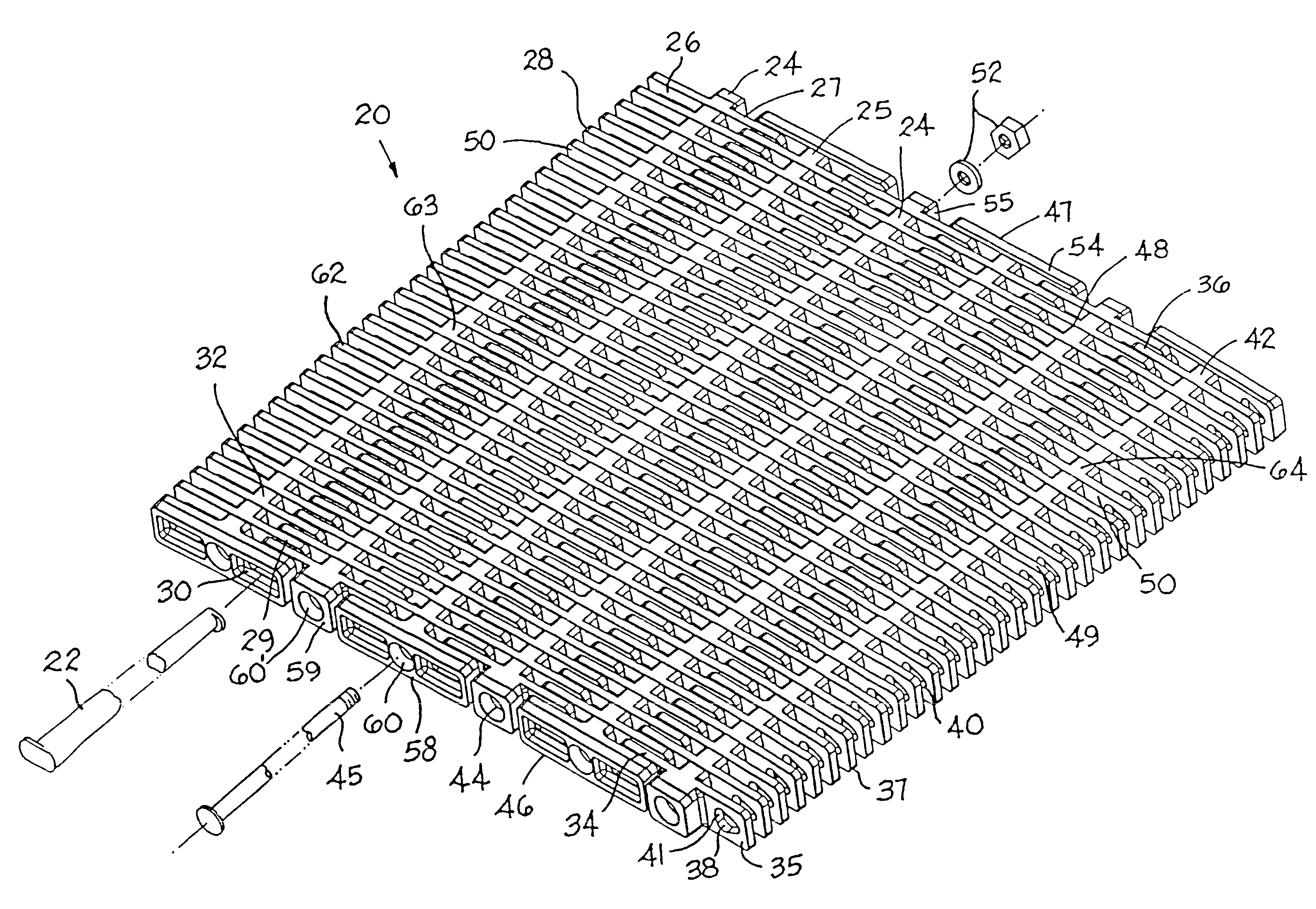

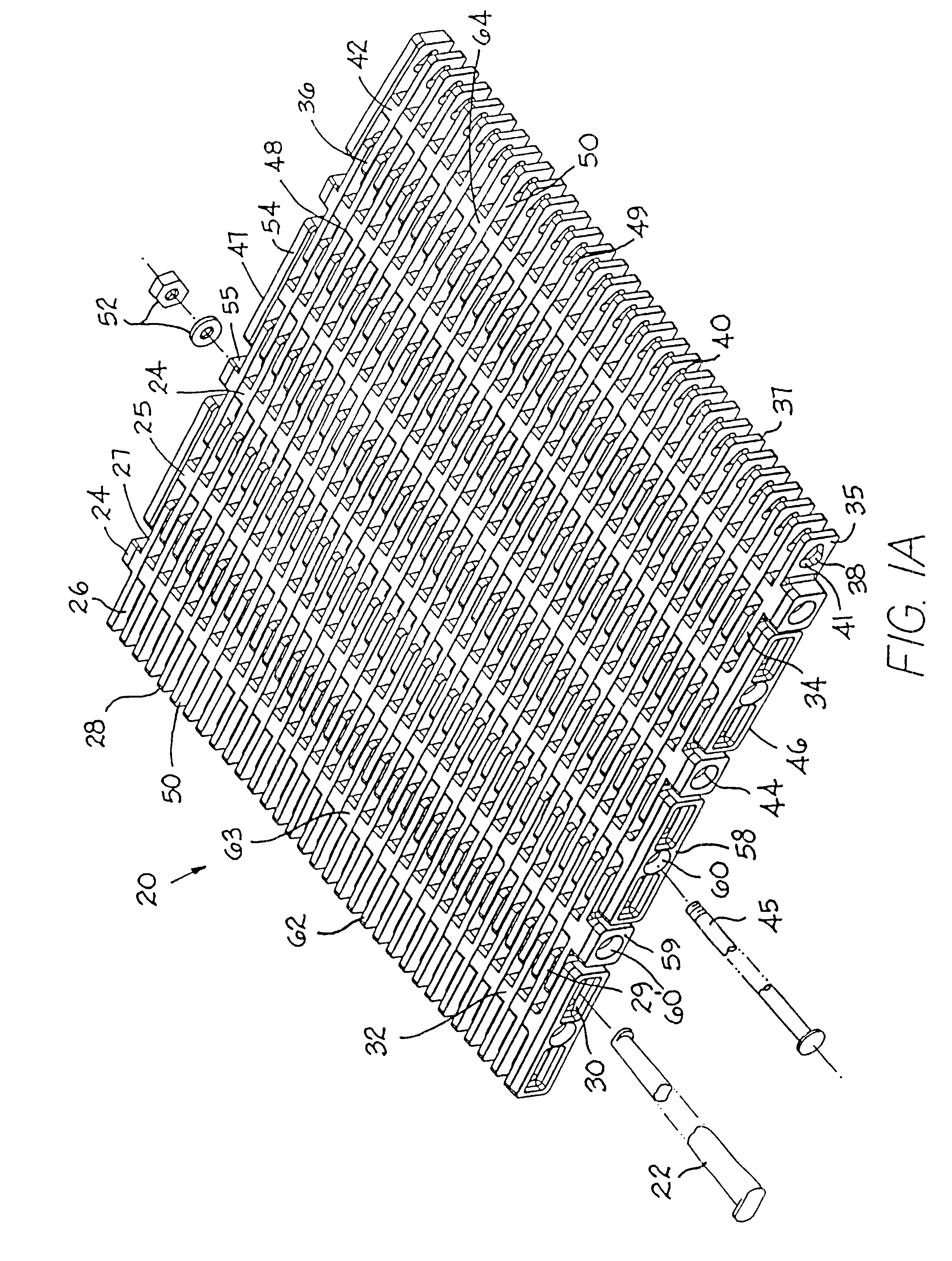

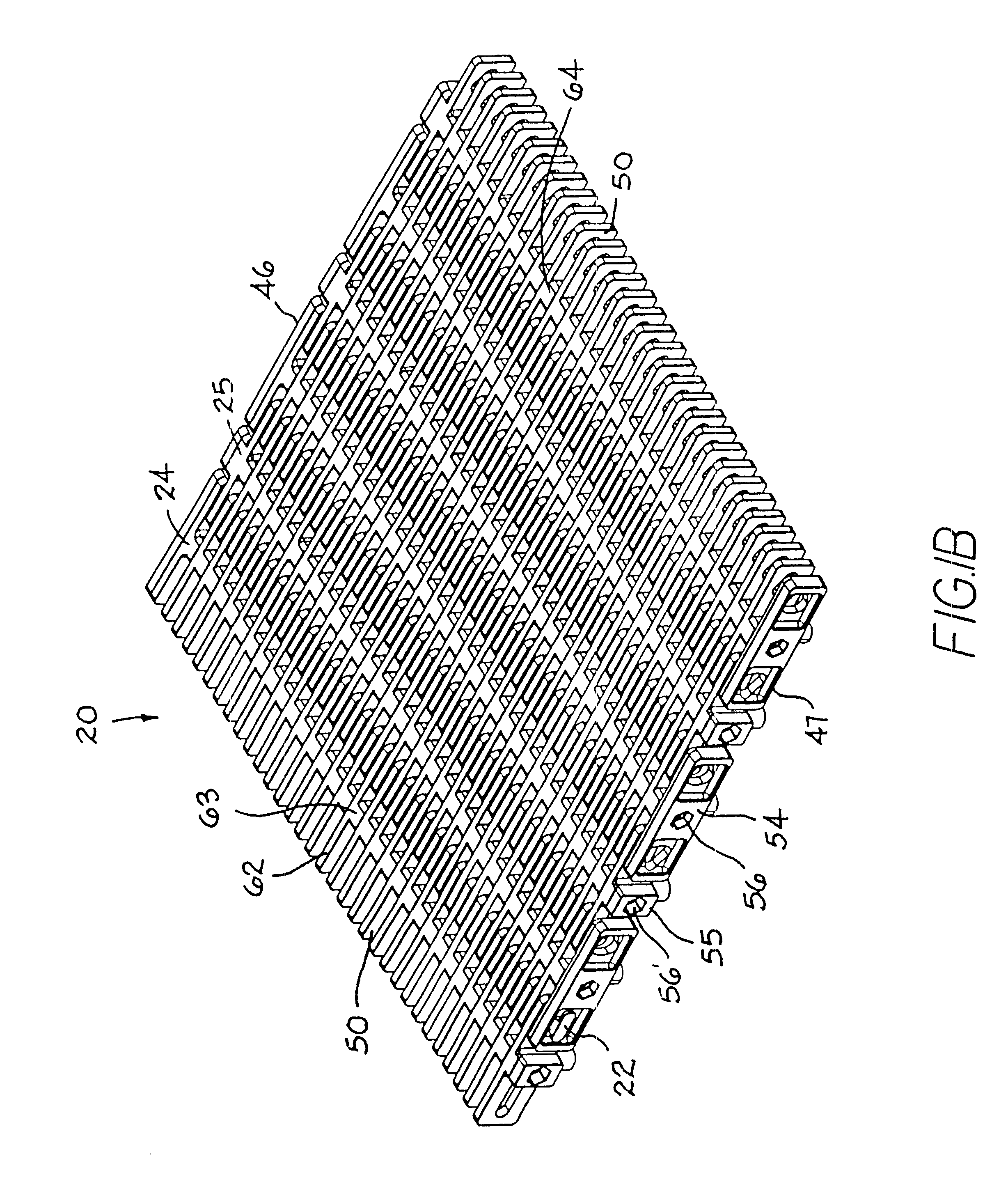

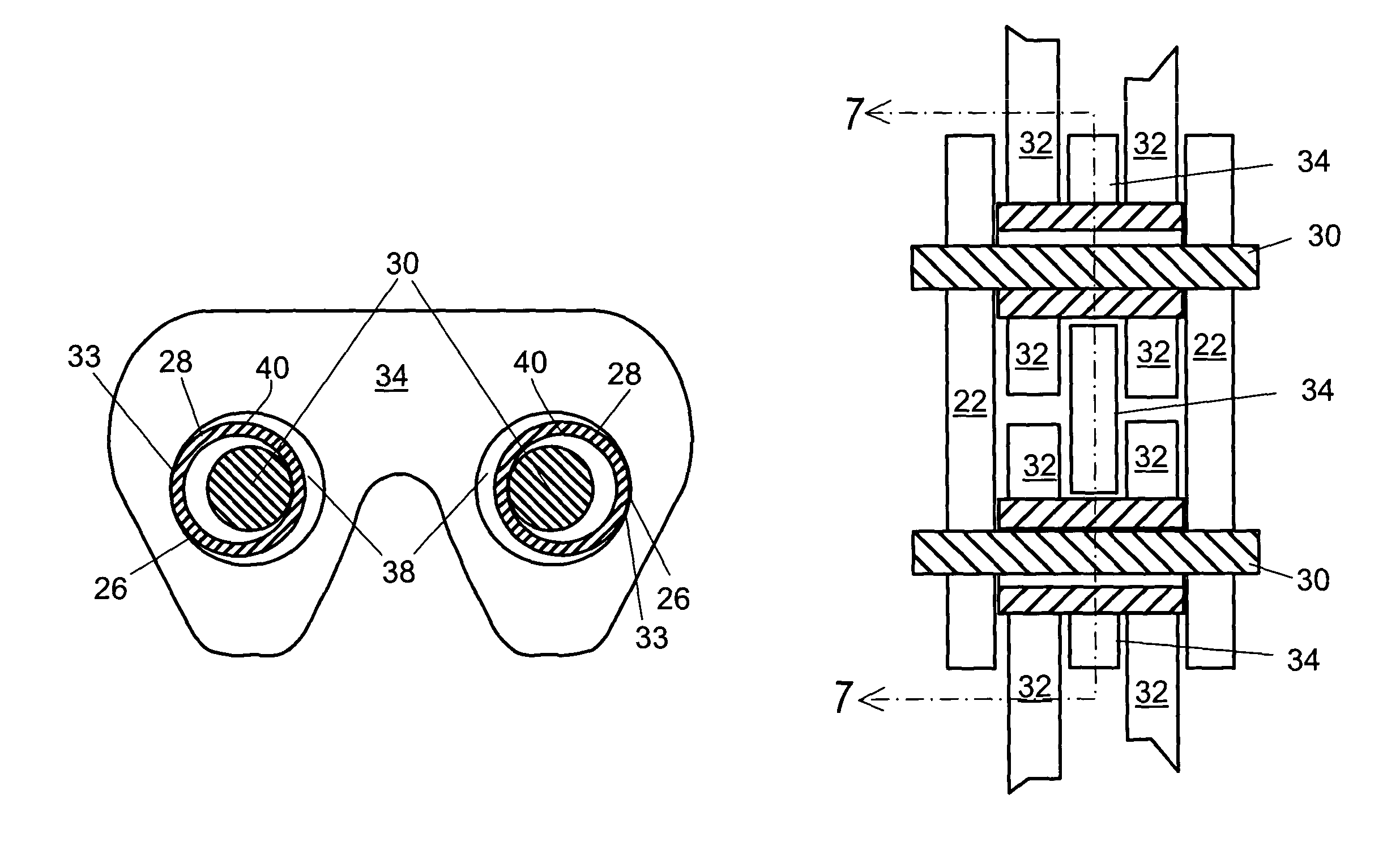

Modular belt with tapered oblong hinge pins

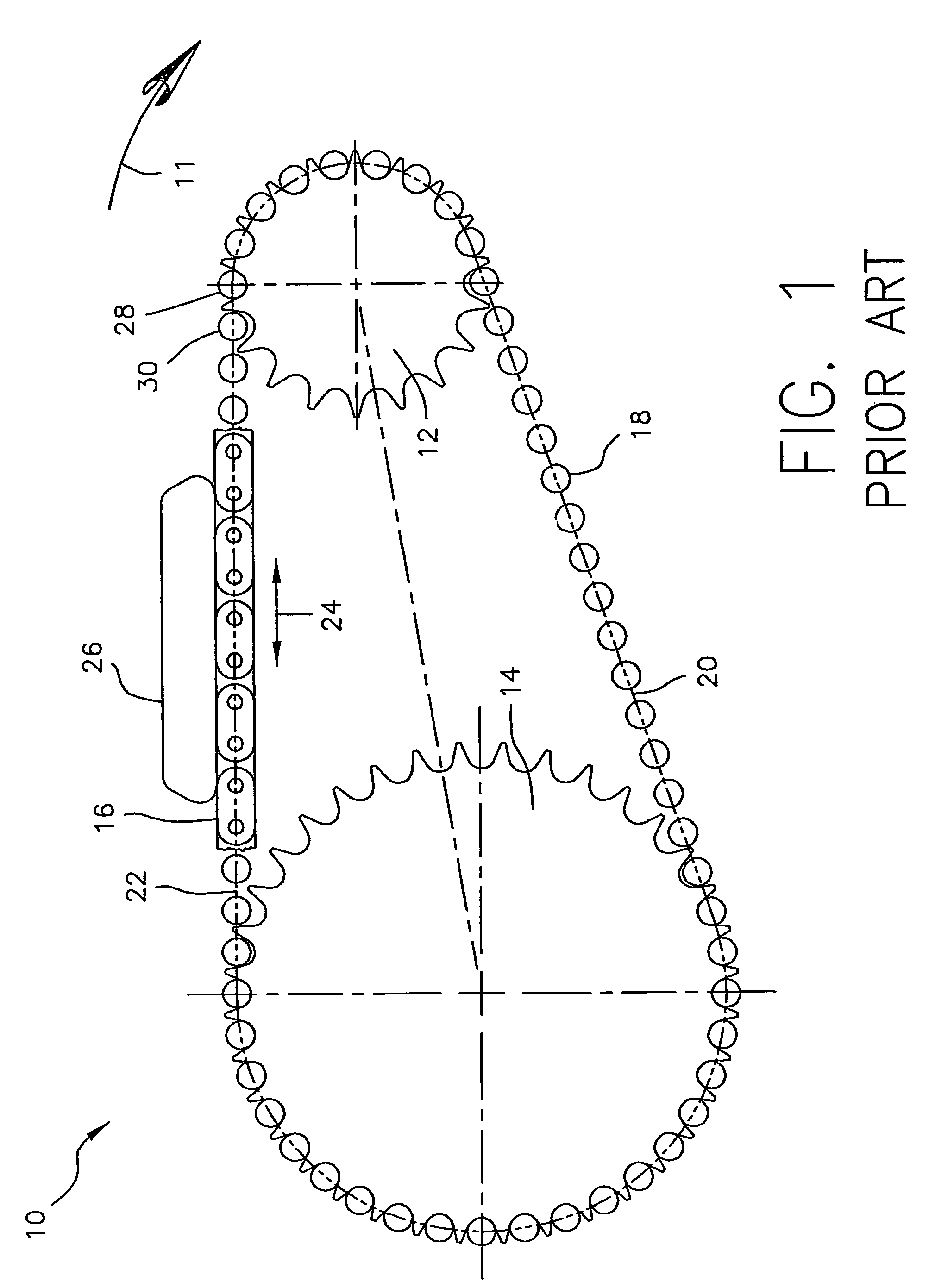

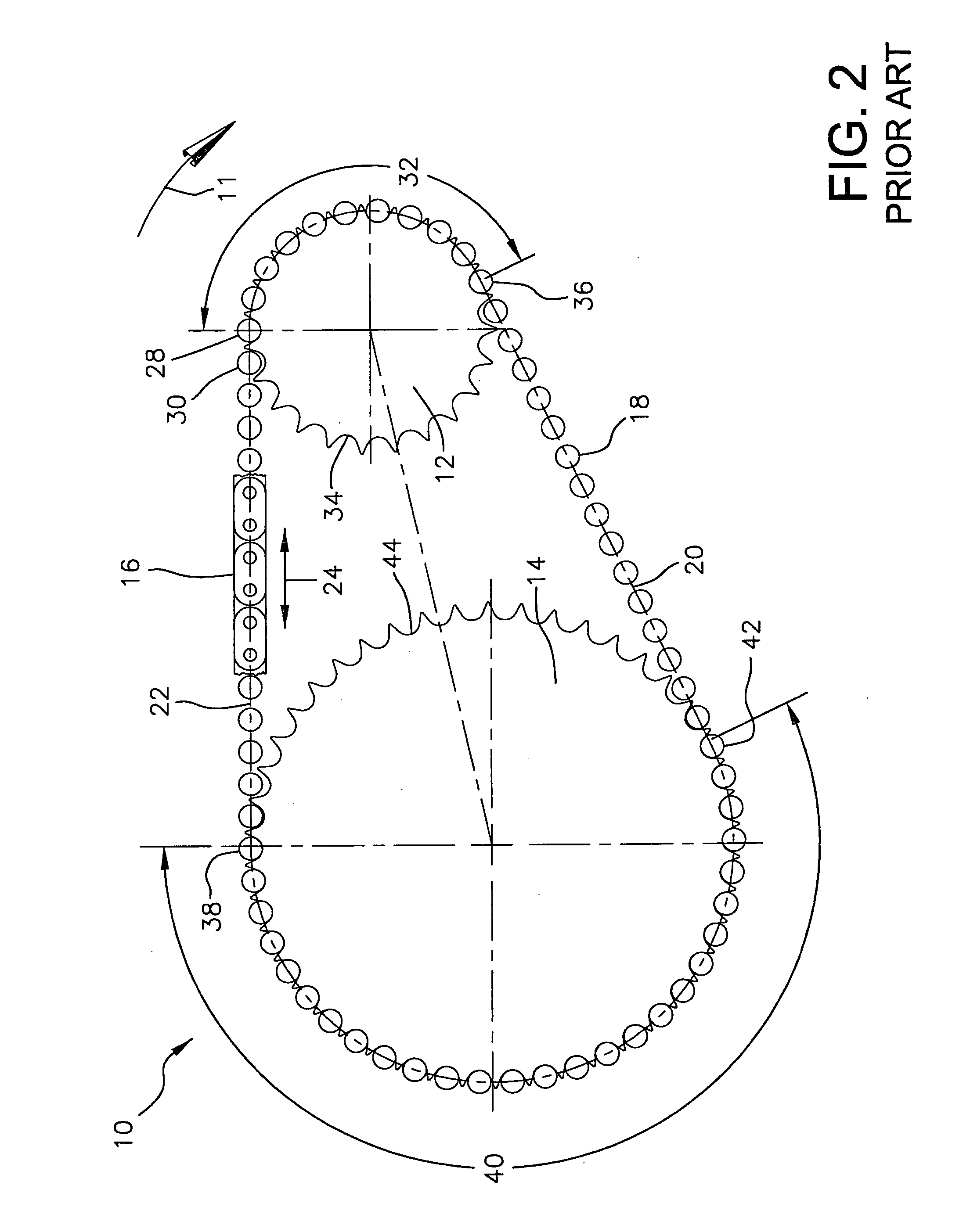

A modular conveyor belt (20) constructed of a series of rows (24, 25) of belt modules hingedly interlined by tapered oblong hinge pins (22) and suitable for following straight or curved conveyor paths. Aligned slots (30) formed in one set of hinge elements between successive rows are elongated in the direction of belt travel to allow the belt to fan out in turns. Fan-shaped apertures (38) formed in interleaved hinge elements of an adjacent row and aligned axially with the slots to admit a hinge pin (22) allow the belt to pivot at the hinge to articulate about a sprocket (181) or idler (186) or to enter and exit an incline. The oblong hinge pin has a first region at a first end (88) with a constant long axis to share the belt load among hinge elements encompassing the first region on straight runs. A second region of the hinge pin at an opposite second end (89) has a tapered oblong cross section, the long axis of which increases with distance from the second end to define a variable pitch and to spread the belt tension among the hinge elements at the outside of a turn encompassing the second region. Each belt row can be constructed of individual links stacked together on a support element (45) and retained by fasteners (52) or of integrally molded modules each comprising a transverse connecting member from which leading and trailing hinge elements extend. Accessory attachments, such as teeth (160) or sideguards (150), can be added to the belt. The belt can be driven by a cog, a roller chain, or other driving means driving lugs (172) extending from the bottom of the belt. The drive surfaces of the lugs can be obliquely arranged for better load sharing.

Owner:HARTNESS INT INC +1

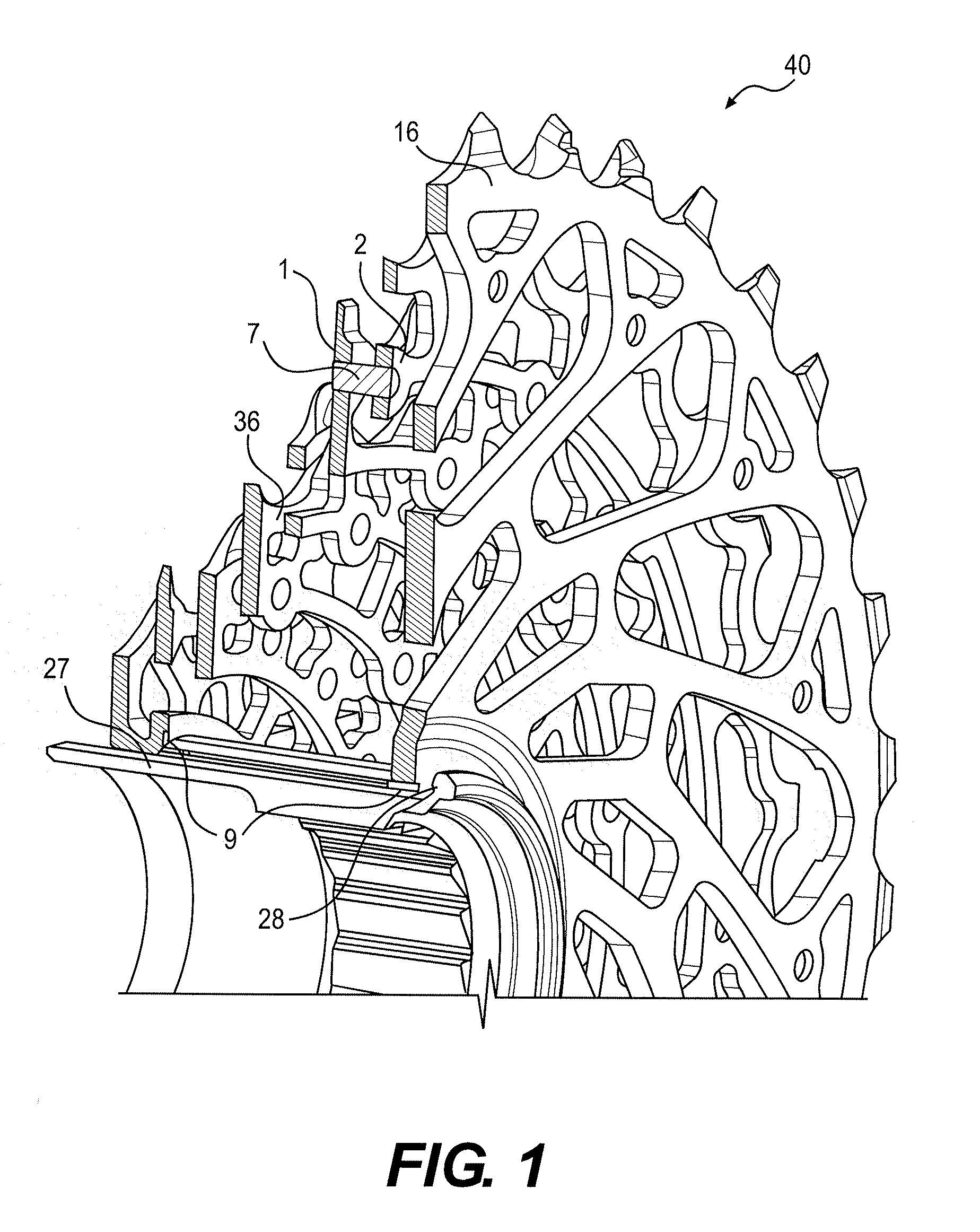

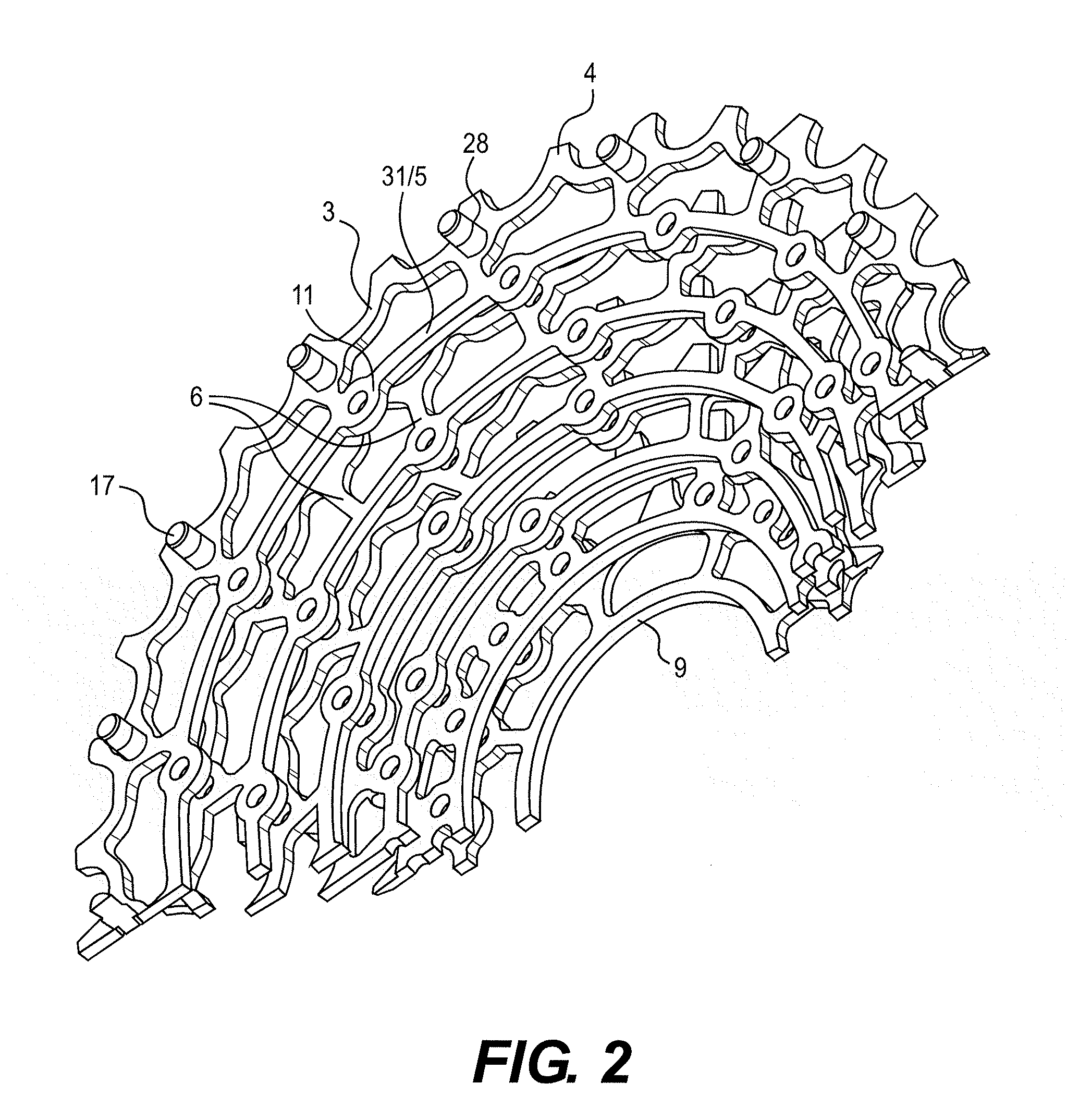

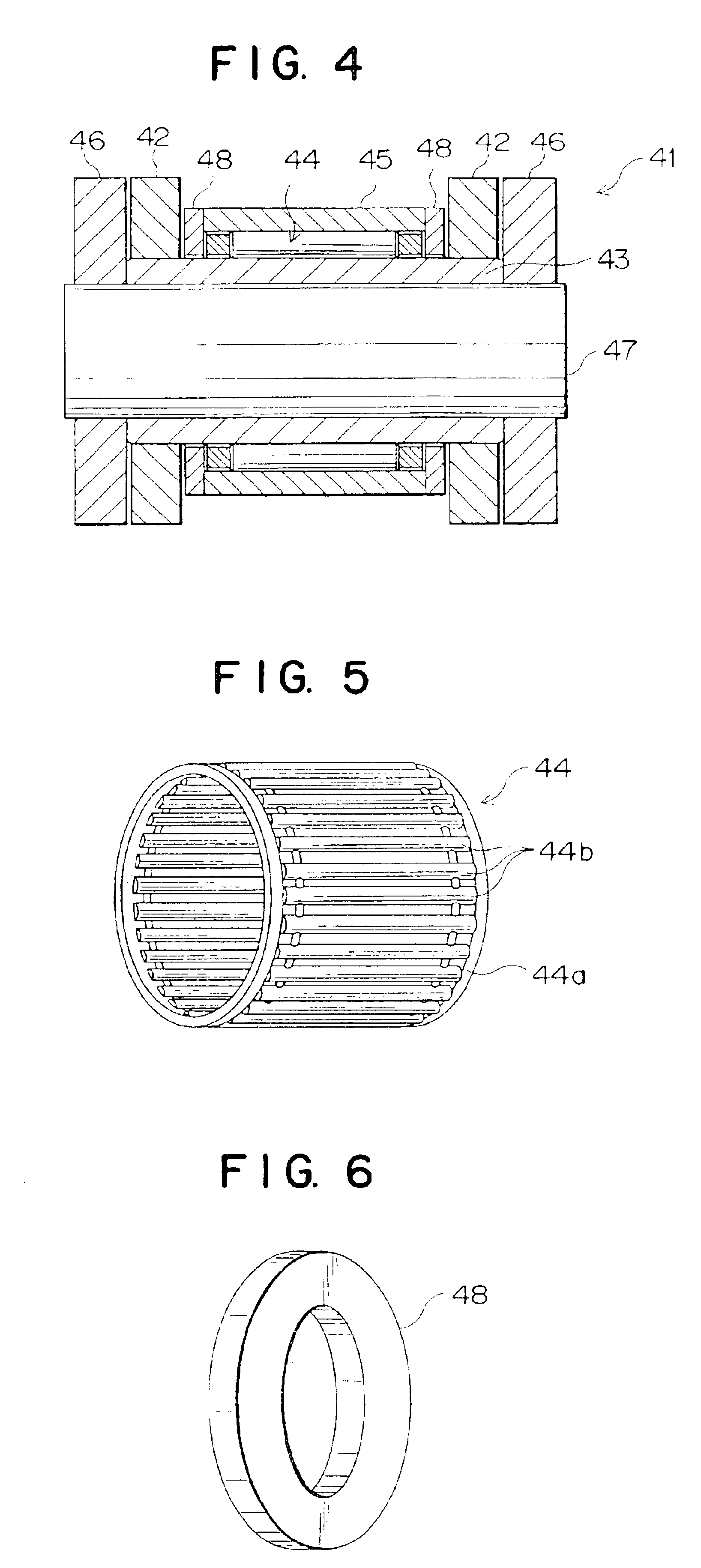

Multiple Sprocket Assembly for a Bicycle

ActiveUS20110105263A1Reduce weightSignificant differenceChain/belt transmissionPortable liftingRoller chainEngineering

A multiple sprocket assembly engageable with a roller chain and mountable to a driver of a rear wheel of a bicycle. The multiple sprocket assembly includes a smaller sprocket and a larger sprocket. Each of the smaller and larger sprockets has a radially outer ring with a plurality of teeth for engaging the roller chain. The radially outer ring has a plurality of radially outer pin mounts including a hole. The radially outer pin mounts are aligned with the teeth. The sprockets have a plurality of radially inner pin mounts connected to the radially outer ring forming a single piece. The radially inner pin mounts includes a hole. The radially inner pin mounts are aligned with the plurality of outer pin mounts disposed on an adjacent smaller sprocket. A plurality of pins connects the smaller sprocket and the larger sprocket to each other. The pins are mounted in the holes in the outer pin mounts on the smaller sprocket and in the holes in the inner, pin mounts of the larger sprocket. A first mounting sprocket is connected to the smaller sprocket by pins and a second mounting sprocket is connected to the larger sprocket by pins. The first and second mounting sprockets are supported on the hub axle at two positions spaced, apart in the axial direction of the hub axle.

Owner:SRAM

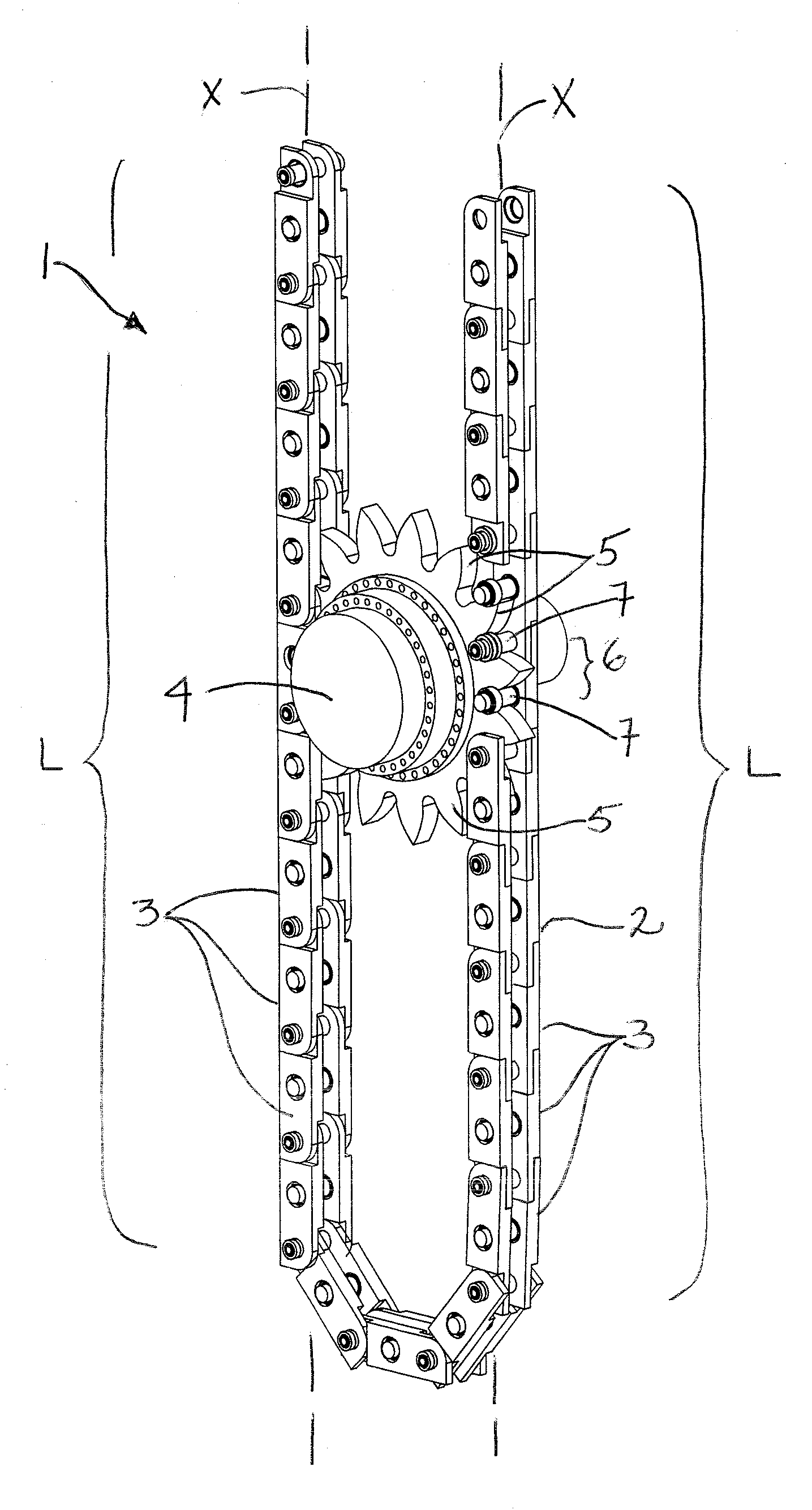

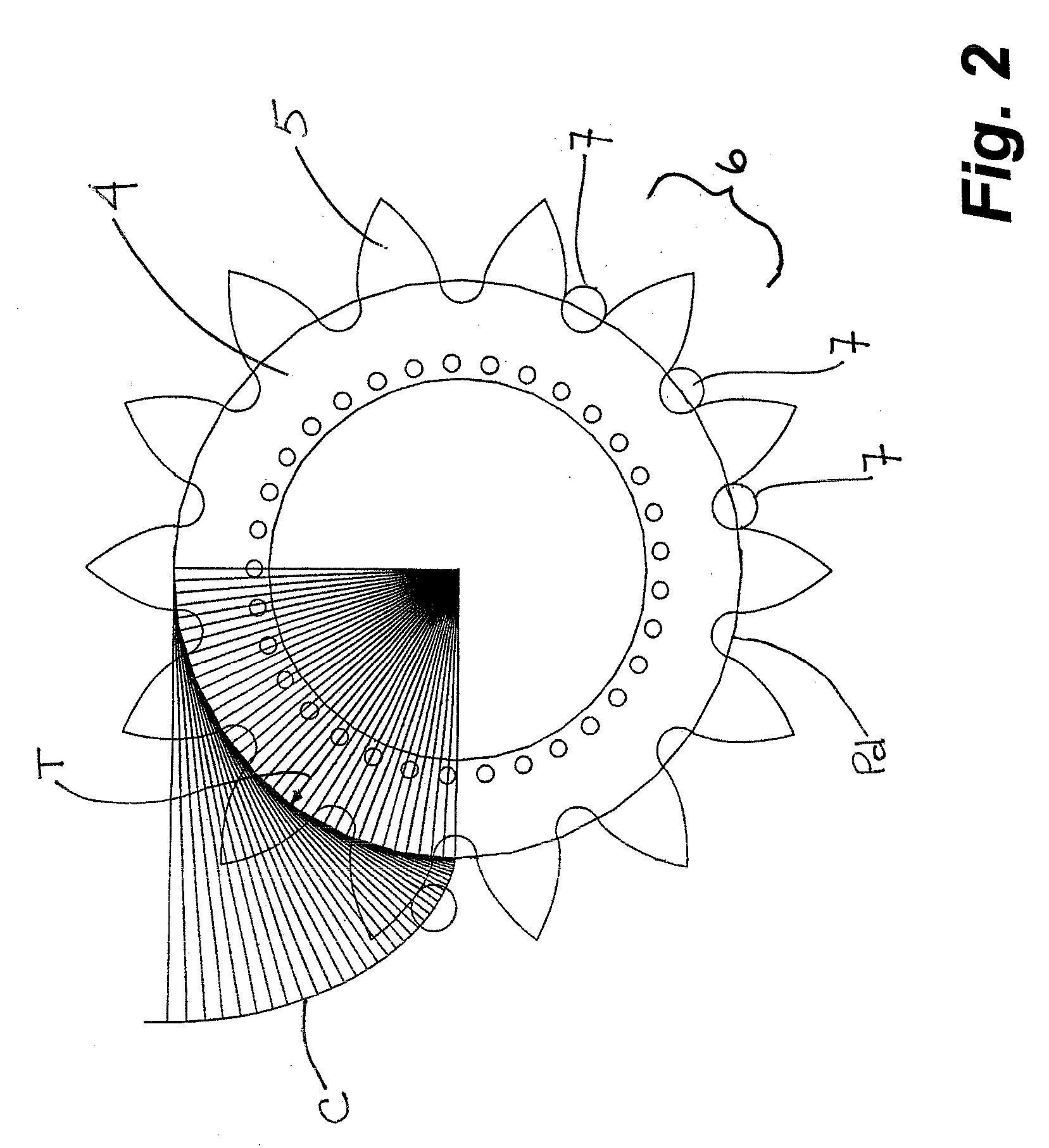

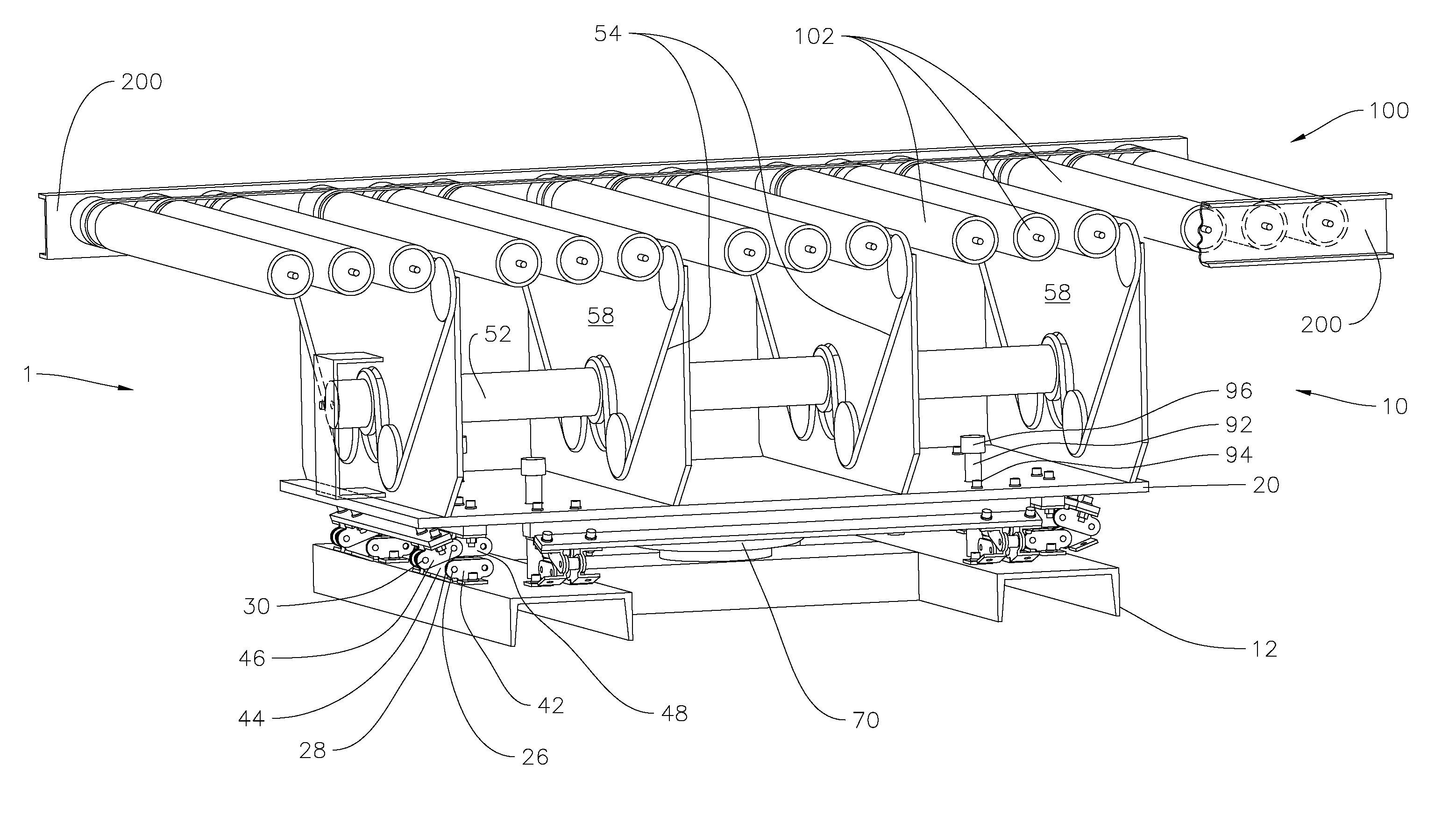

Roller chain and sprocket system

InactiveUS20090008615A1Efficiently translate loadEfficient loadingLifting devicesChain elementsLinear motionRoller chain

A roller chain and sprocket system utilizes an involute profile on the sprocket teeth to engage rollers in the links of a roller chain. The links, when aligned linearly, bear upon one another when pushed to form a substantially rigid column which has an axis. The system results in substantially 100% of the rotational energy imparted to the sprocket being translated into linear motion of the chain along the column axis.

Owner:HIGH ARCTIC ENERGY SERVICES

Personal, green-energy, transportation device with single wheel and self-balancing function

The present invention relates to a personal, green-energy, transportation device with single wheel and self-balancing function, and especially to a self-balancing single-wheel transportation device. The driver can drive the transportation device by manpower, and the transportation device would simultaneously execute a self-balancing function during driving. The transportation device comprises: a body, a wheel, a pedal portion, a roller chain, an in-wheel motor, and a sensing-control module, wherein the sensing-control module is used for detecting the balance condition of the body when the transportation device is driven, and then the sensing-control module controls the in-wheel motor to output a balancing torque for maintaining the self balance of the body.

Owner:NATIONAL TSING HUA UNIVERSITY

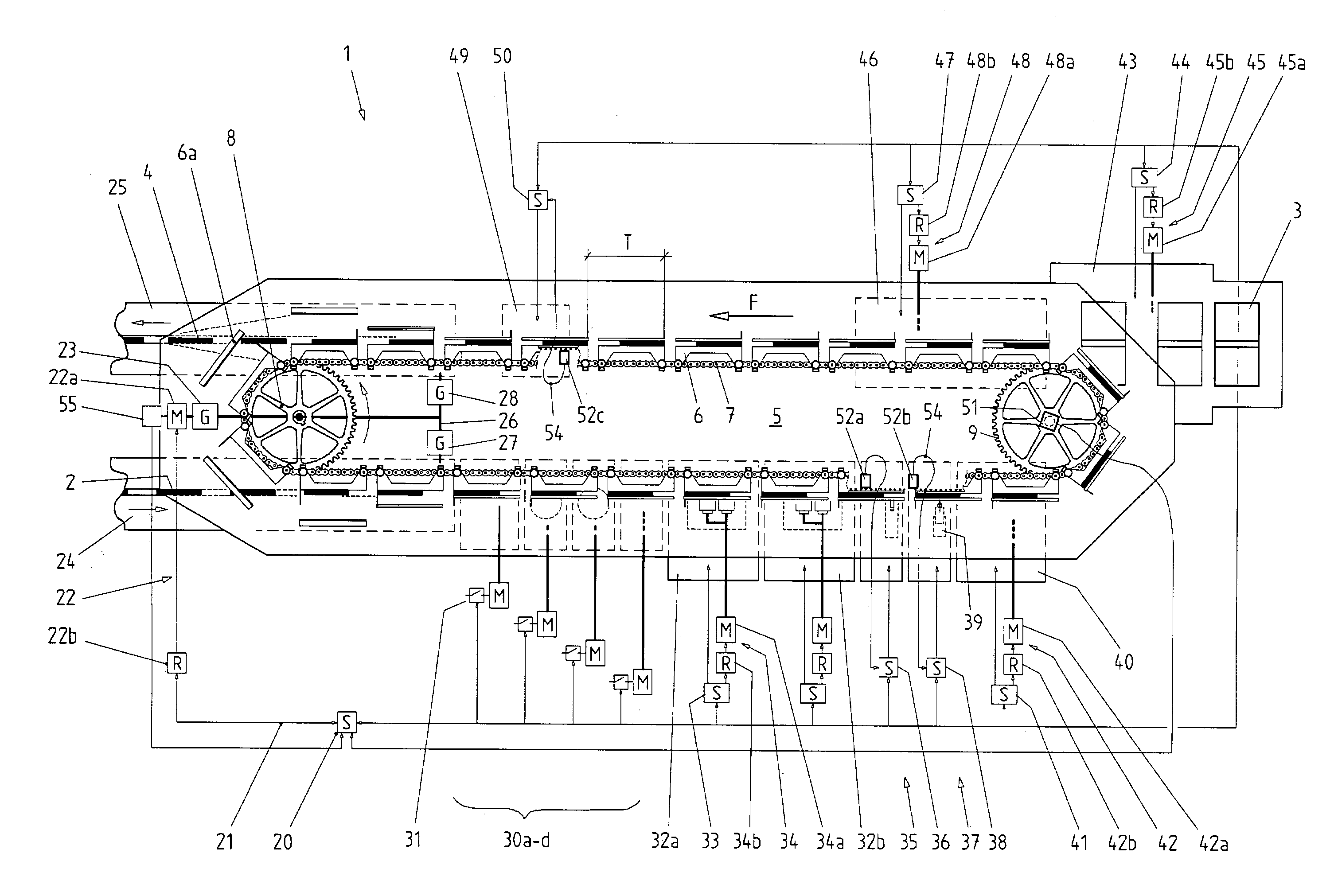

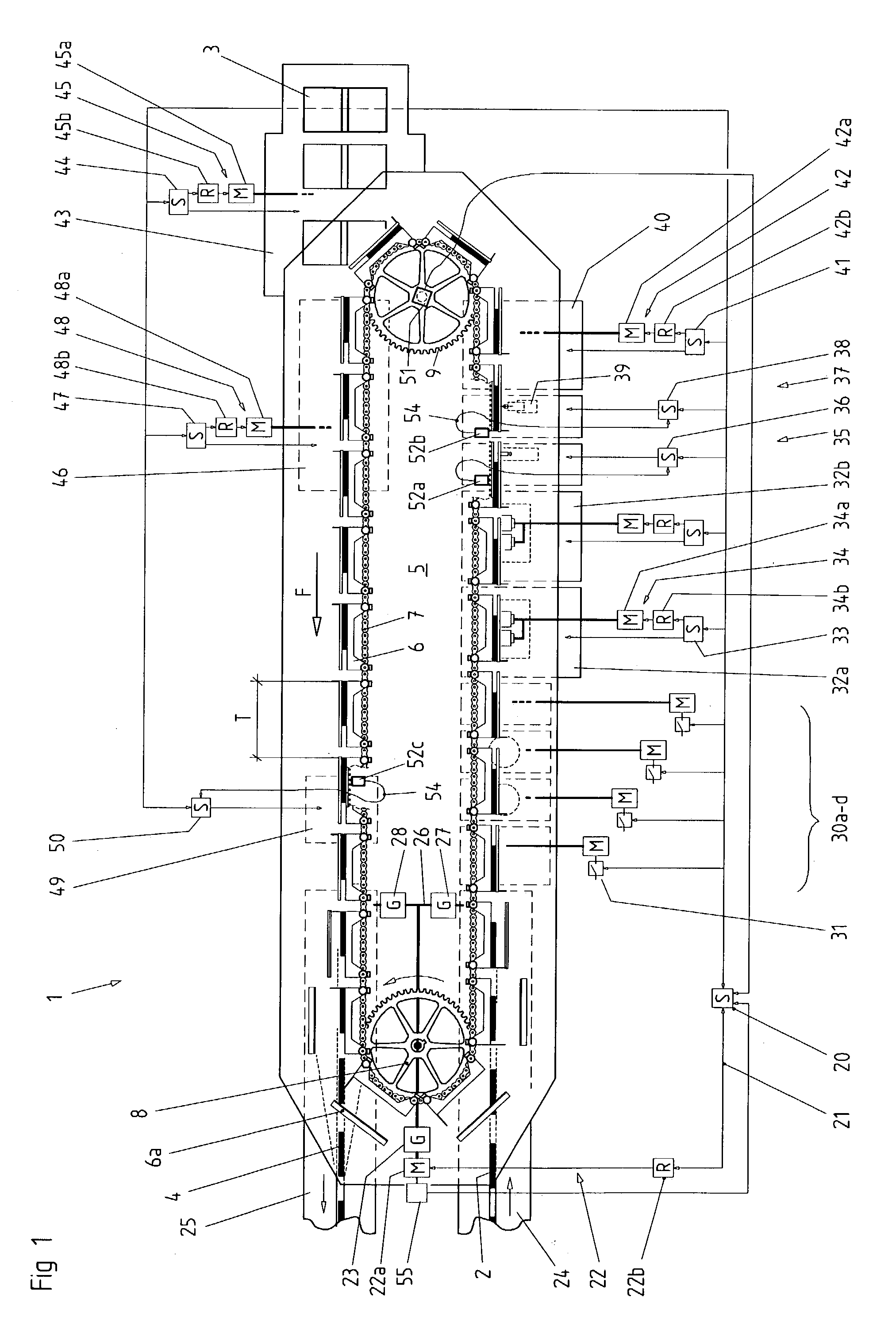

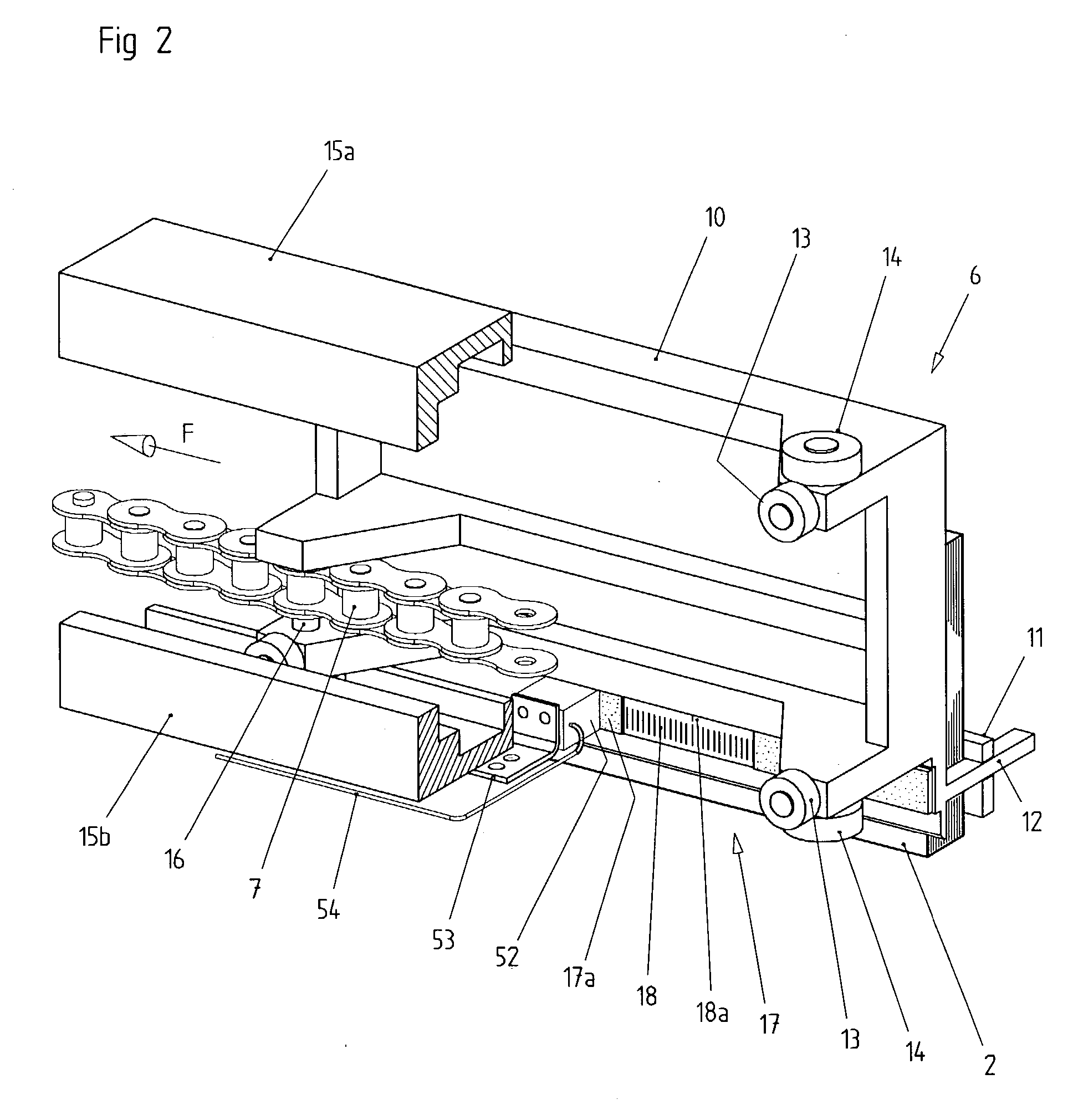

Bookbinding machine

InactiveUS20030215309A1Simplifies replacement and additionEasy to adjustBook making processesArticle feedersEngineeringRoller chain

A bookbinding machine for processing inner books includes a transport system with a multiplicity of inner-book clamps continually movable in a closed continuous track. Each of the inner book clamps is articulated to a circulating roller chain and has a rear-edge stop for aligning the inner books. The bookbinding machine includes workstations that perform positionally accurate operations on the inner books including the application of glue, the application of reinforcement or gauze sections, the application of jackets, binding with wire stitches, the introduction of utilisation features (e.g. punched holes, tear-off perforations, etc.) and the like. The transport system of the inner-book clamps and at least one workstation are driven independently of one another. A measuring system for positional detection of the inner-book clamps or of the inner books is provided in proximity to the independently driven workstation. The measuring system provides inner book or clamp position data used to control the workstation performing positionally accurate operation on the relevant inner book.

Owner:KOLBUS

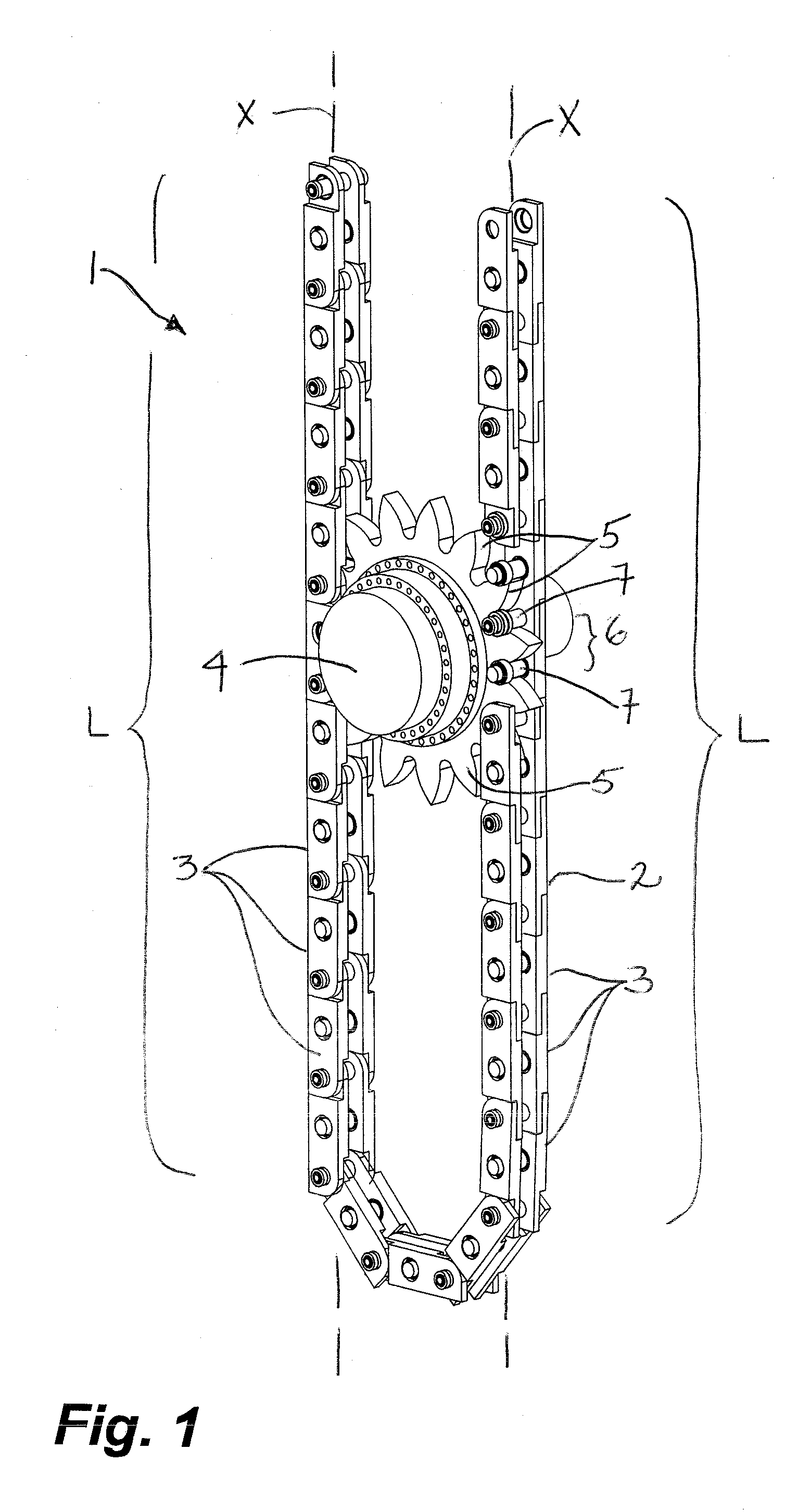

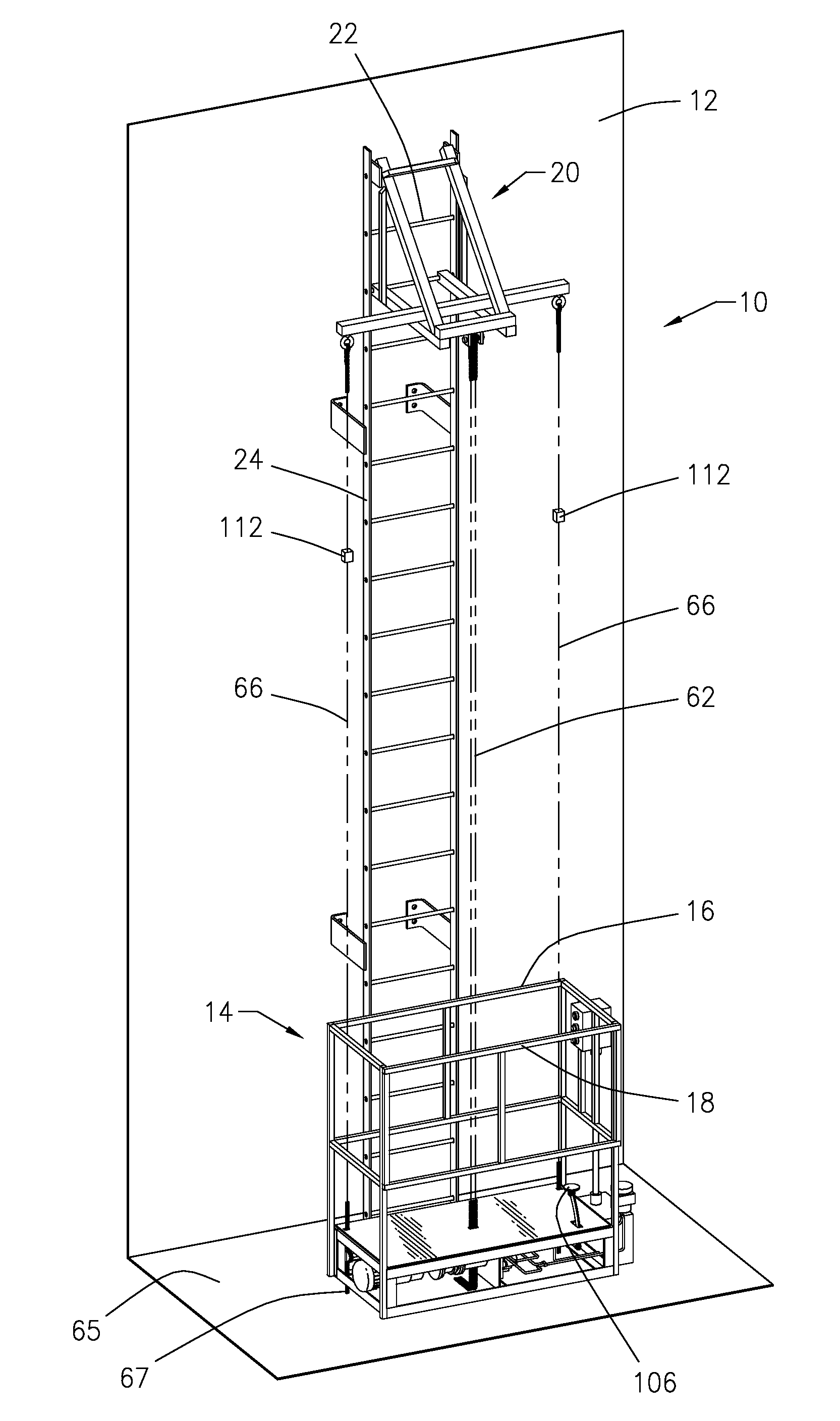

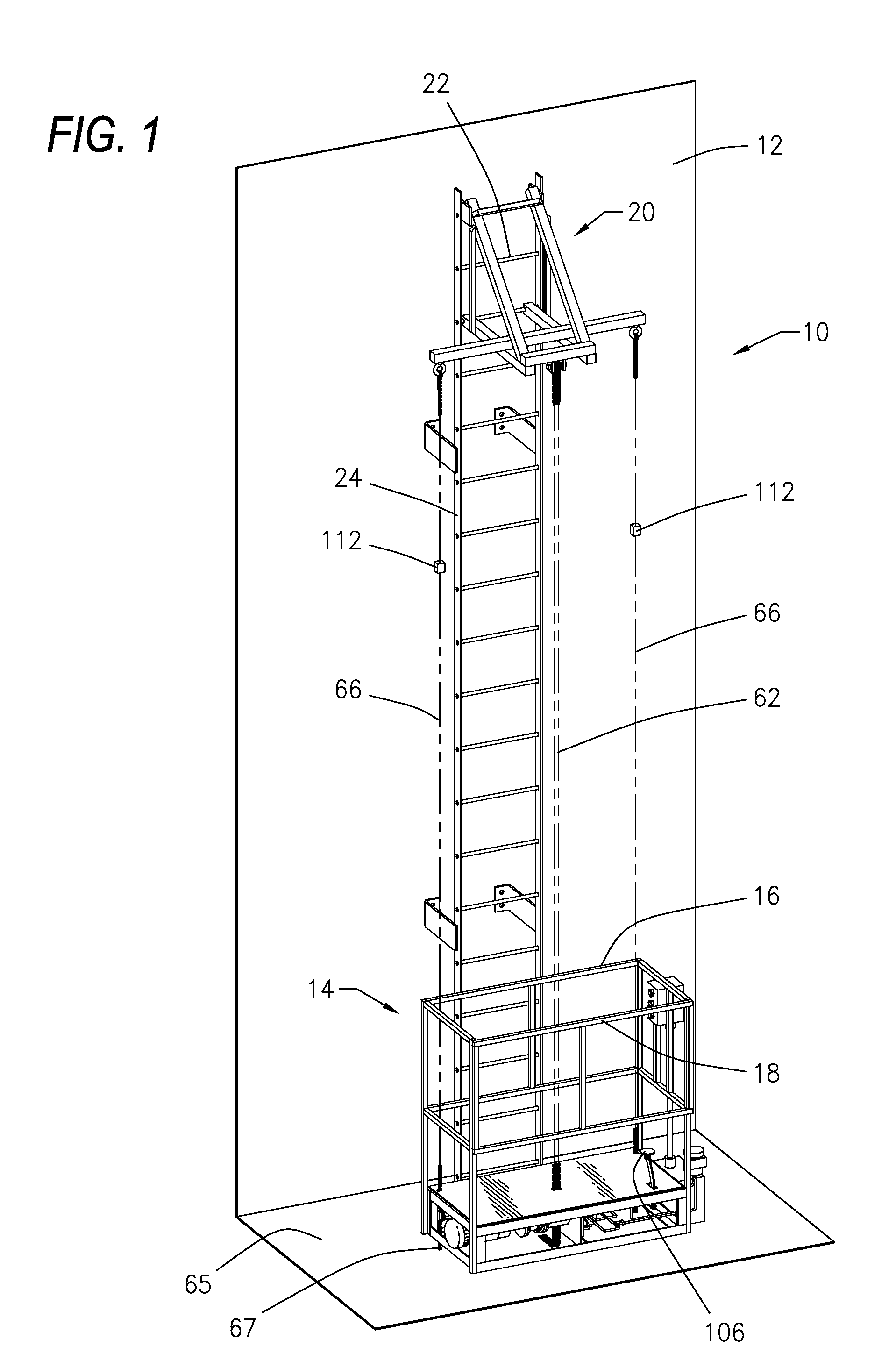

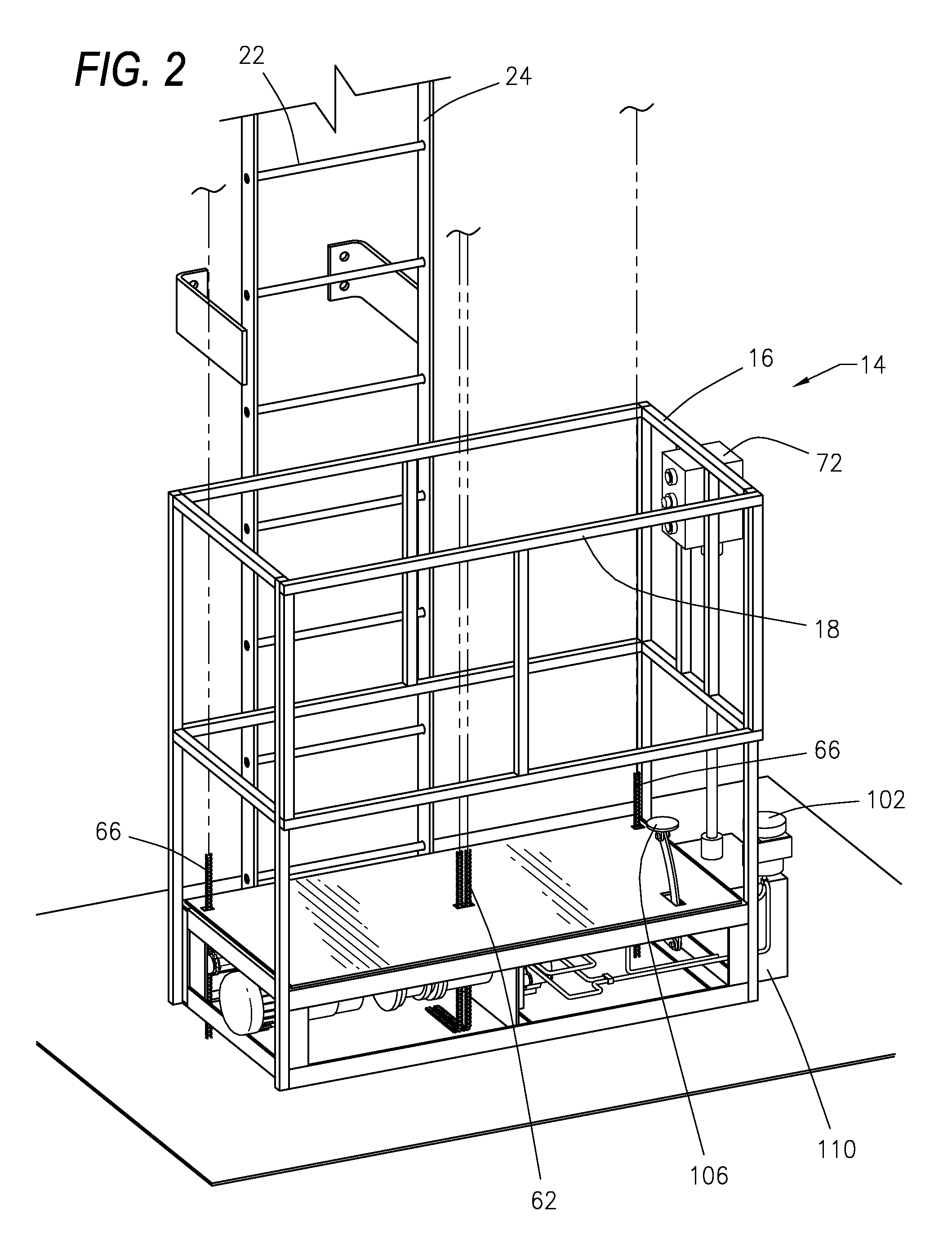

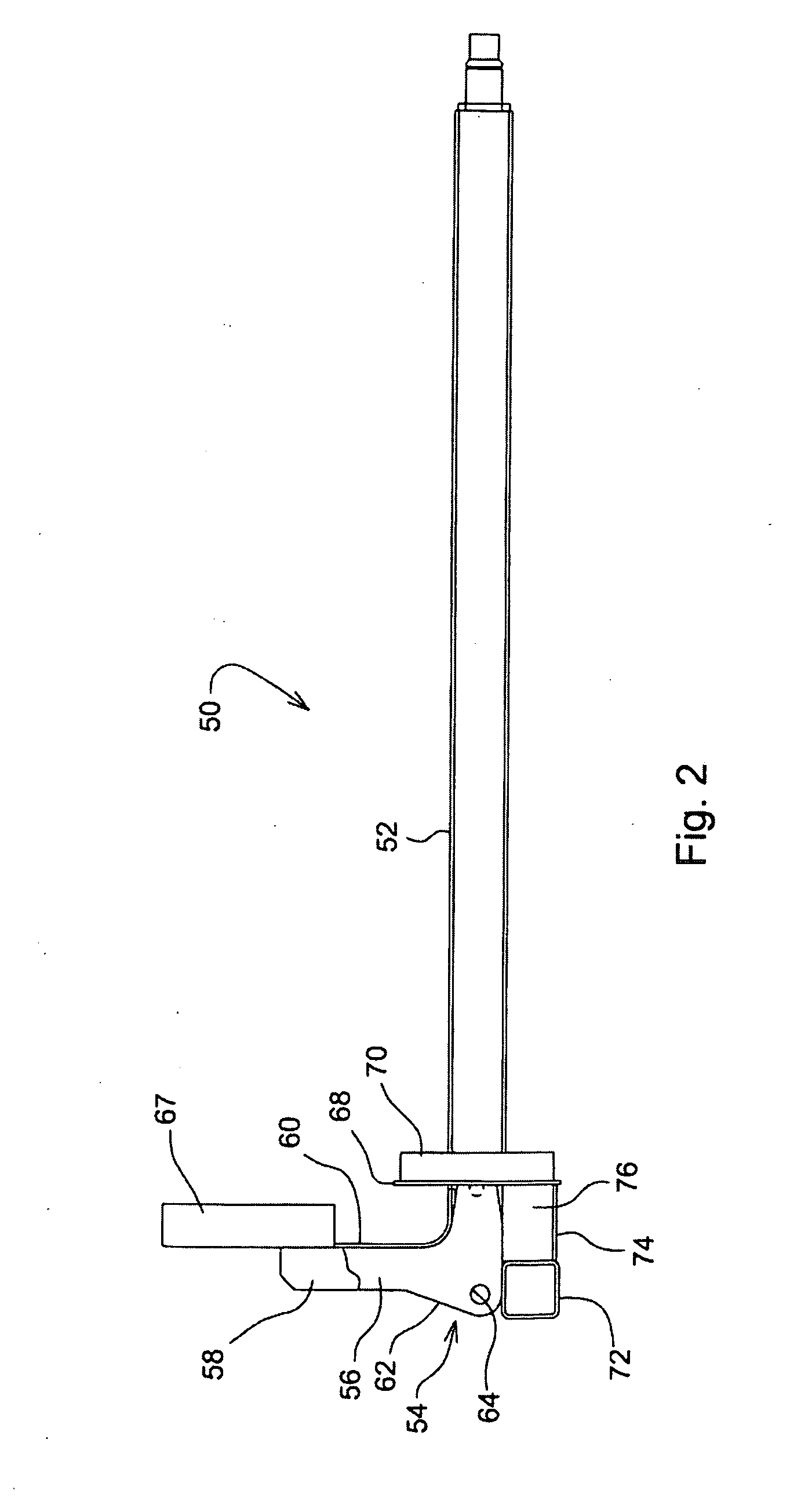

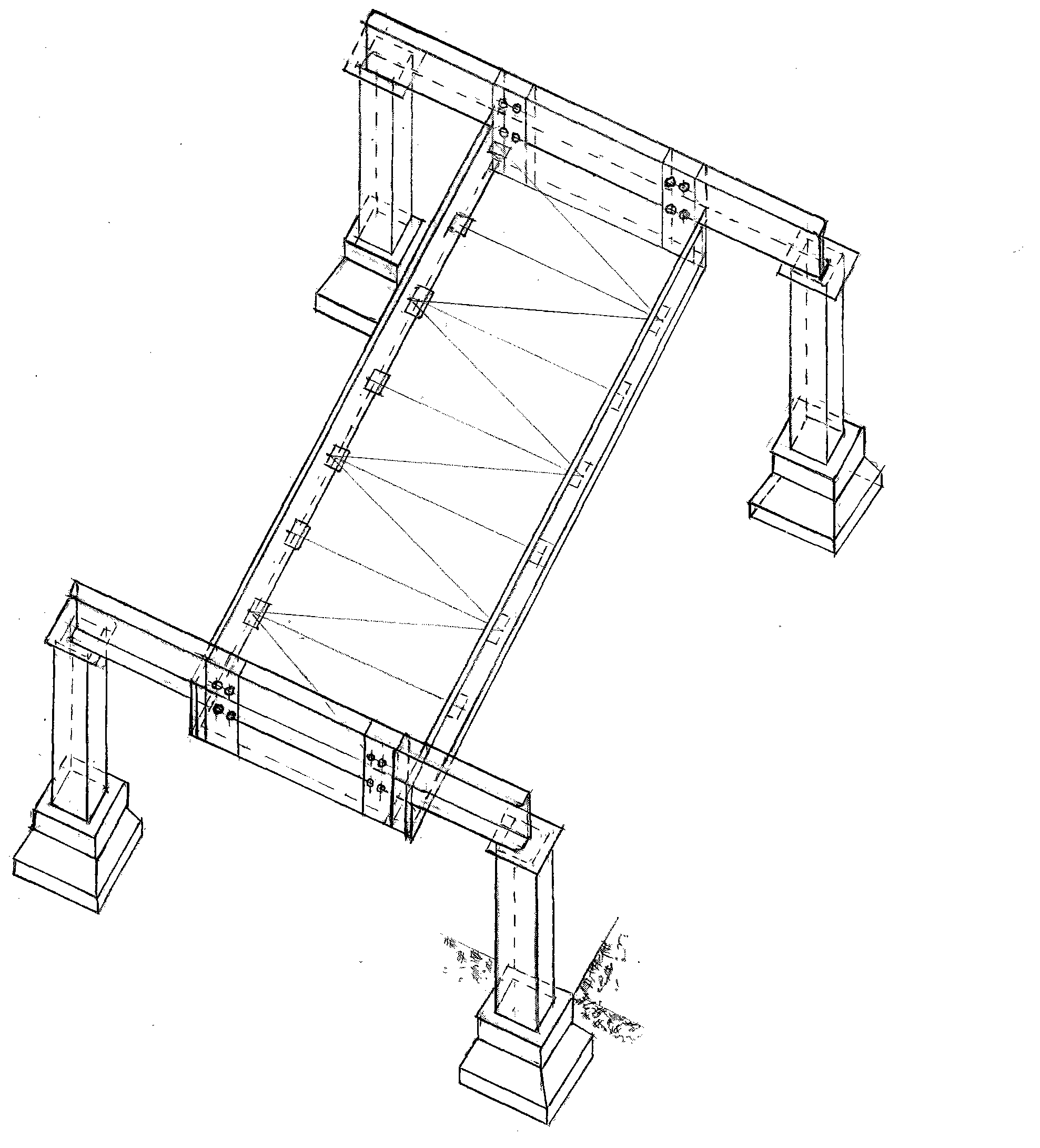

Elevator Climbing System

A portable elevator climbing system removably attachable to a cantilevered overhang on an adjacent structure, whereby an elevator car travels up and down a plurality of roller chains. The roller chains are engaged with sprockets and guide rollers attached to an axle driven by a motor. The orientation and alignment of the sprockets, guide rollers and roller chains provide for a stable elevator car and for a system free of backlash in both directions. The elevator climbing system includes a dampening assembly to control the rate of decent in the event of transmission, motor or other failure. The elevator climbing system may be controlled so that the start and stop of the motor is coordinated with the release and application of a braking assembly. The efficiency of the elevator climbing system may be varied by adjusting the offset between the sprockets and the guide rollers.

Owner:FRLIN SAMUEL H

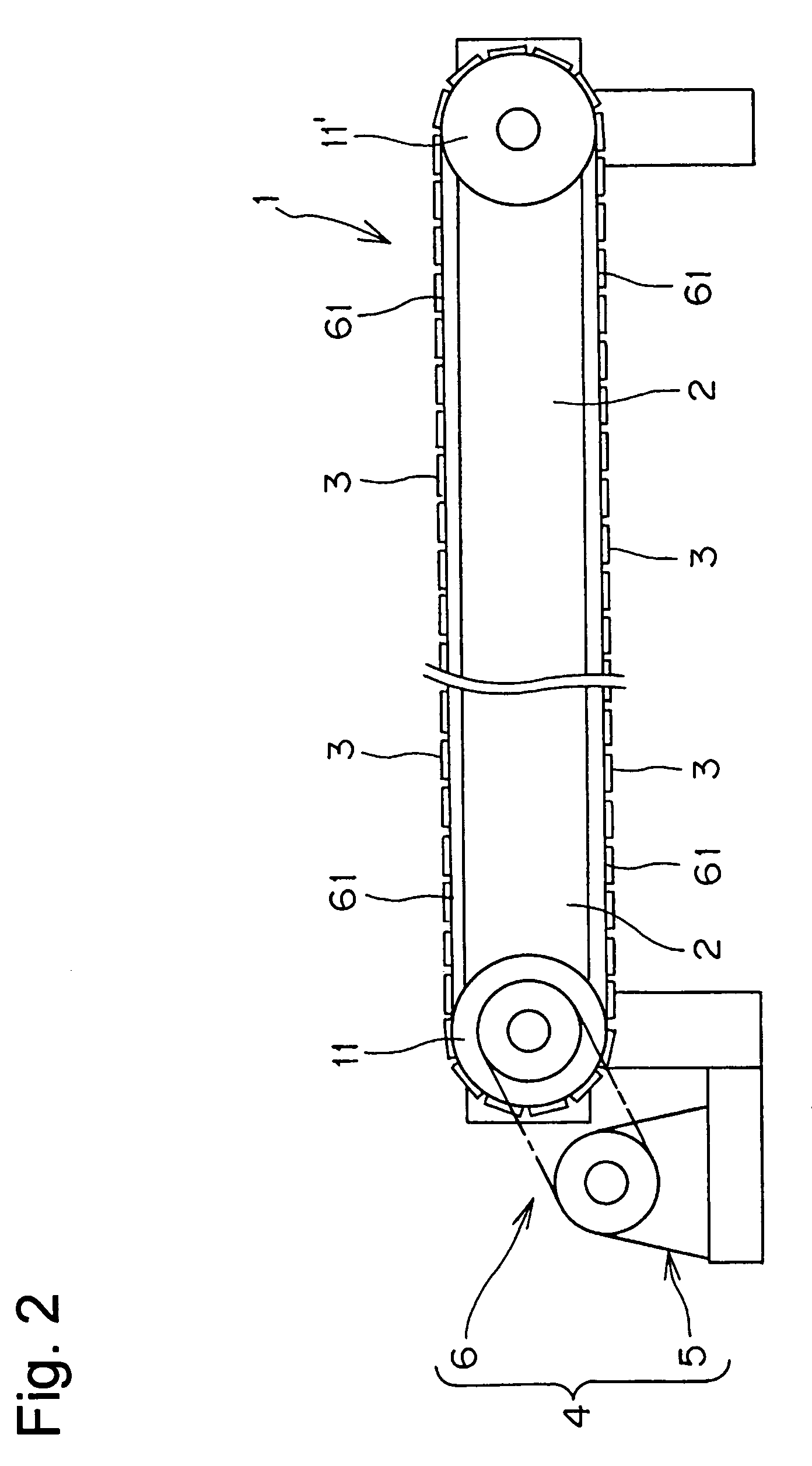

Vertical lift assembly

A vertical lift assembly for raising a plurality of diverting belts between rollers of a roller conveyor, to engage and raise an object from the surface of the conveyor, and to divert it to the side of the conveyor. The vertical lift assembly uses a plurality of hinges to join together a stationary frame, as a base, and a raisable plate on which sets the diverting belt assembly. The hinge is formed from a section of roller chain. A pair of hinges is disposed along each side of the stationary frame and raisable plate. The hinges provide tilt-free lift of the diverting belt assembly.

Owner:TKF CONVEYOR SYST LLC

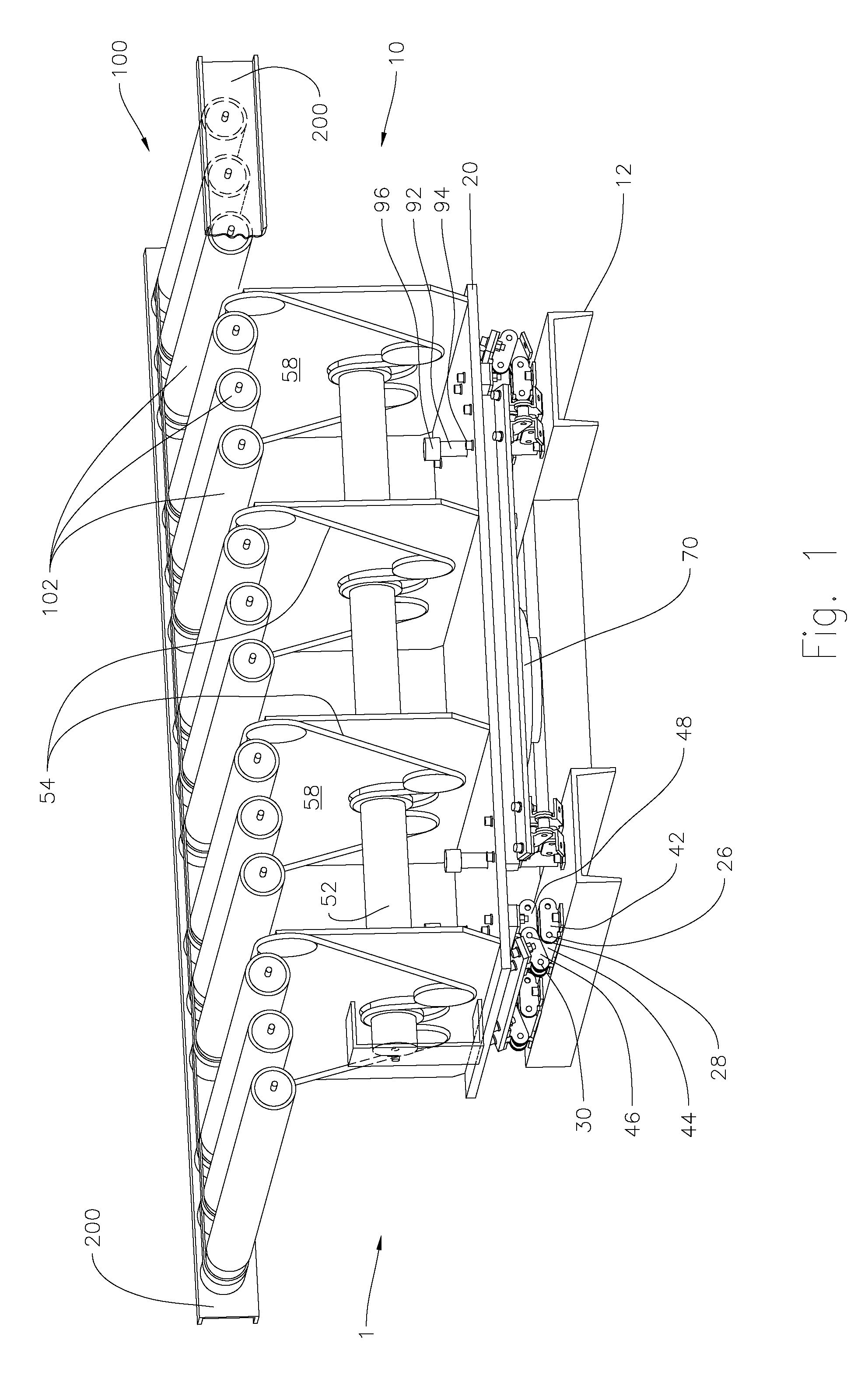

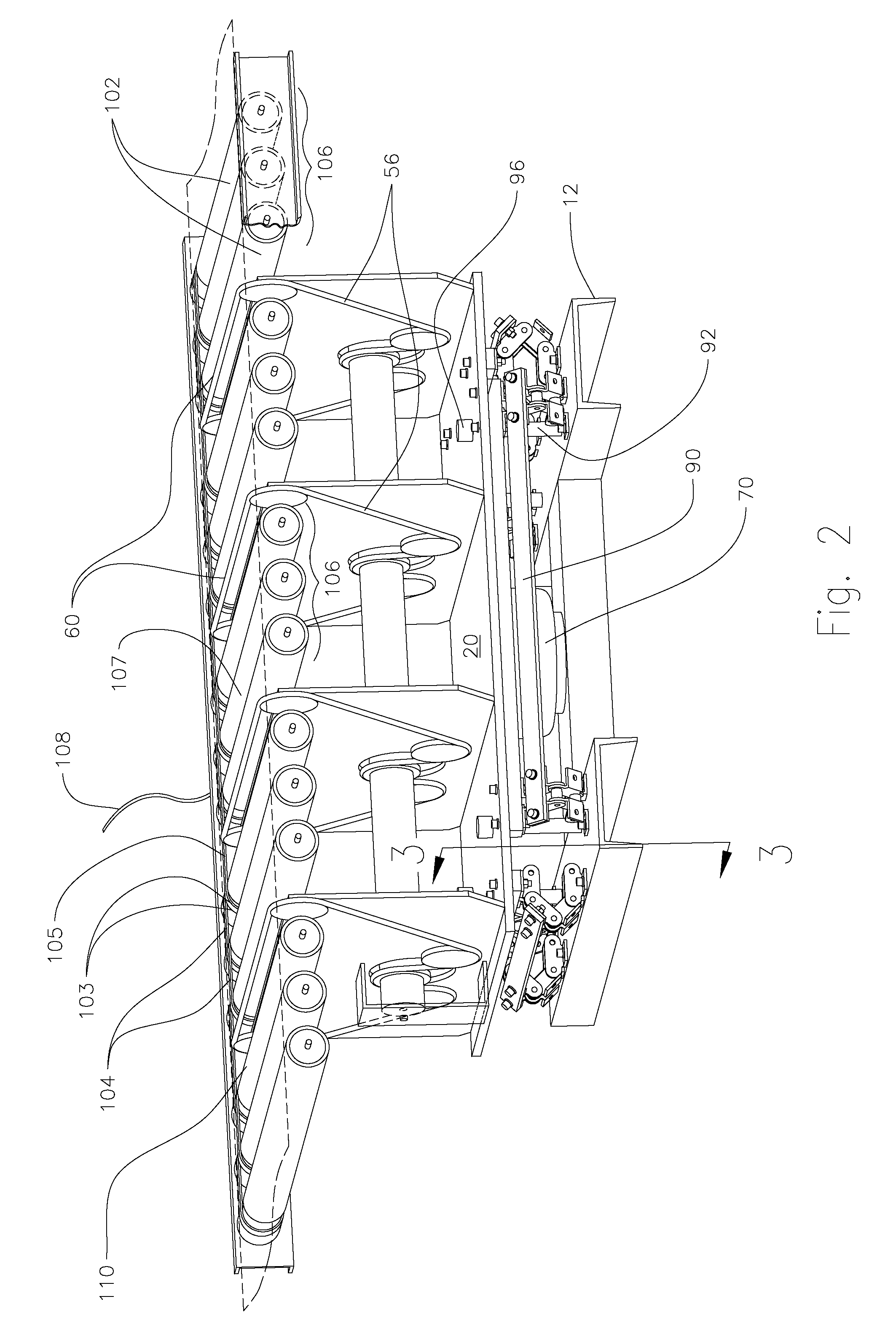

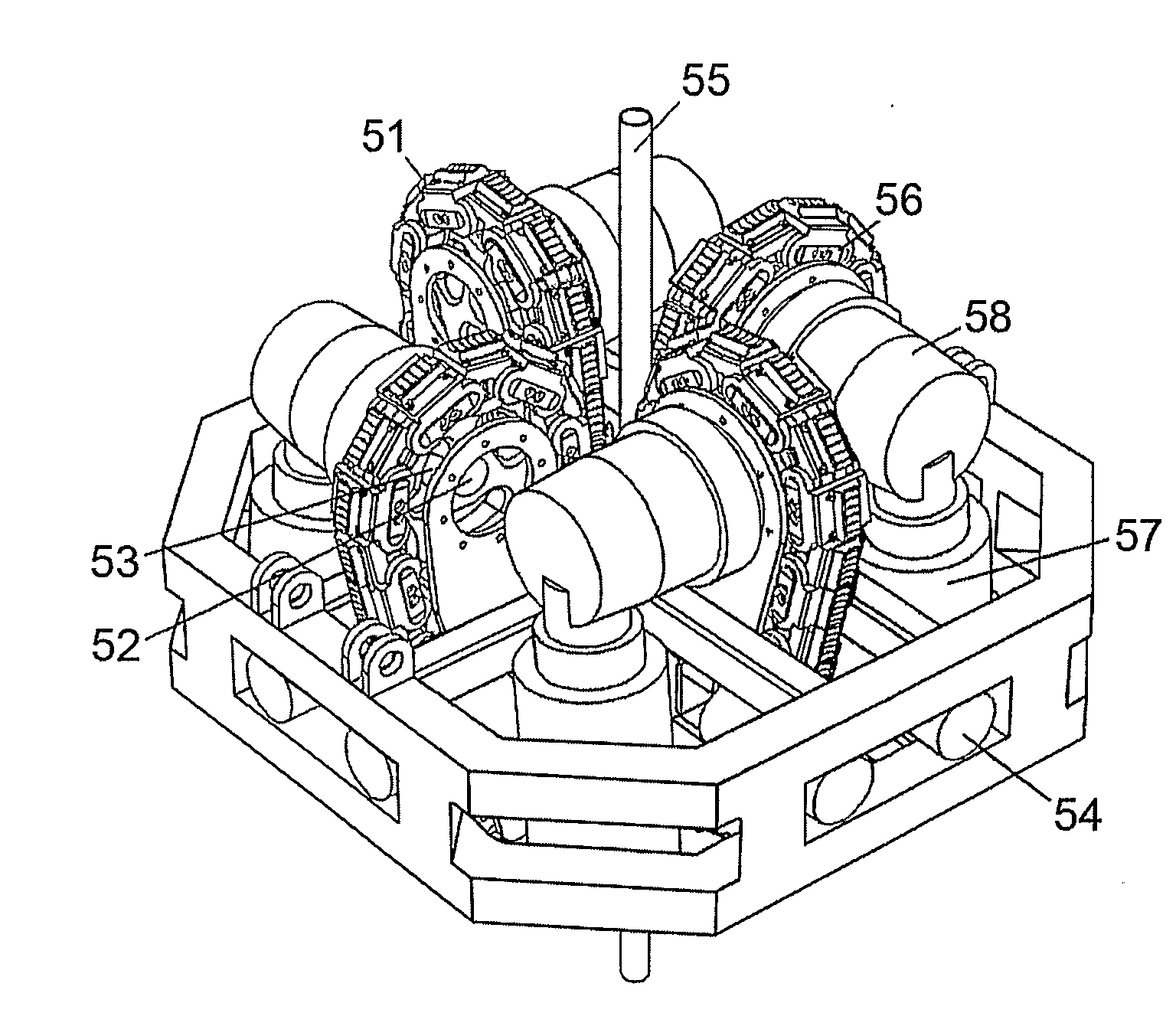

Module Handler Cylindrical Tines Equipped With Retractable Spikes, And Mounting And Drive Arrangements For The Tines

A cylindrical cotton module handling device includes an attachment having a pair of selectively spreadable, powered cylindrical tines adapted for supporting and rotating a module. Each powered tine is constructed from a cylindrical tube supported from a conventional L-shaped fork by a tubular sleeve received on, and dimensioned for fitting closely to, the horizontal leg of the conventional fork. The tubular sleeve is held in place by an L-shaped bracket forming a rearward extension of the sleeve and formed for embracing a region of the convention fork at the junction of its vertical and horizontal legs, with a retaining pin extending through vertical side plates of the bracket at a location just to the rear of the junction. An endless roller chain bearing arrangement is secured in encircling relationship to the tubular sleeve and supports the associated cylindrical tine for rotation. A hydraulic motor drive arrangement is mounted to the sleeve and has a shaft borne chain sprocket meshed with a drive chain carried by a rotating drive plates that are keyed to the cylindrical tube. A hydraulically retractable spike assembly is located inside a forward end section of the cylindrical tube and includes a plurality of spikes mounted for being selectively extended outwardly through holes in the tube for engaging a module wrapping during removal of the wrapping from the module.

Owner:DEERE & CO

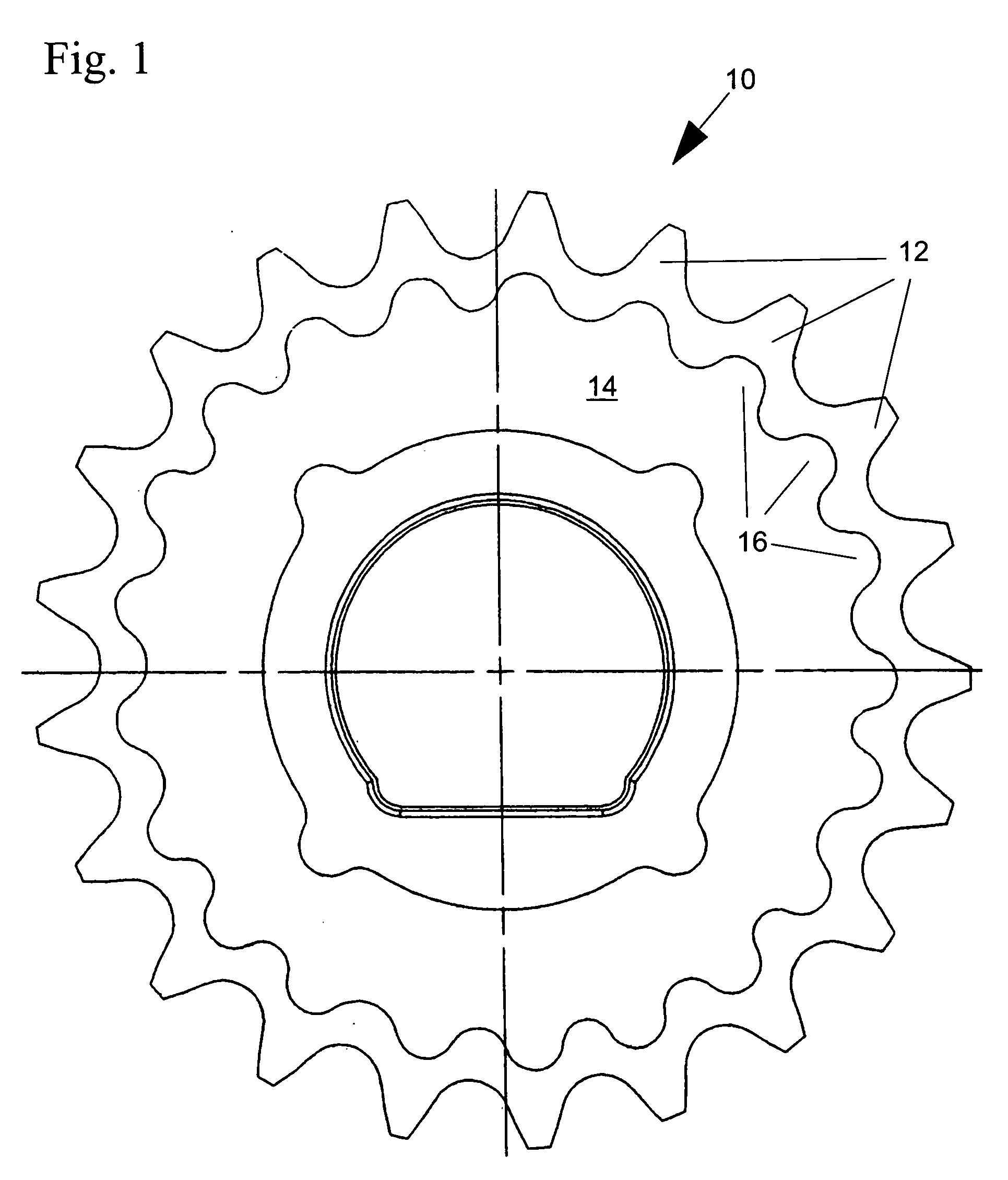

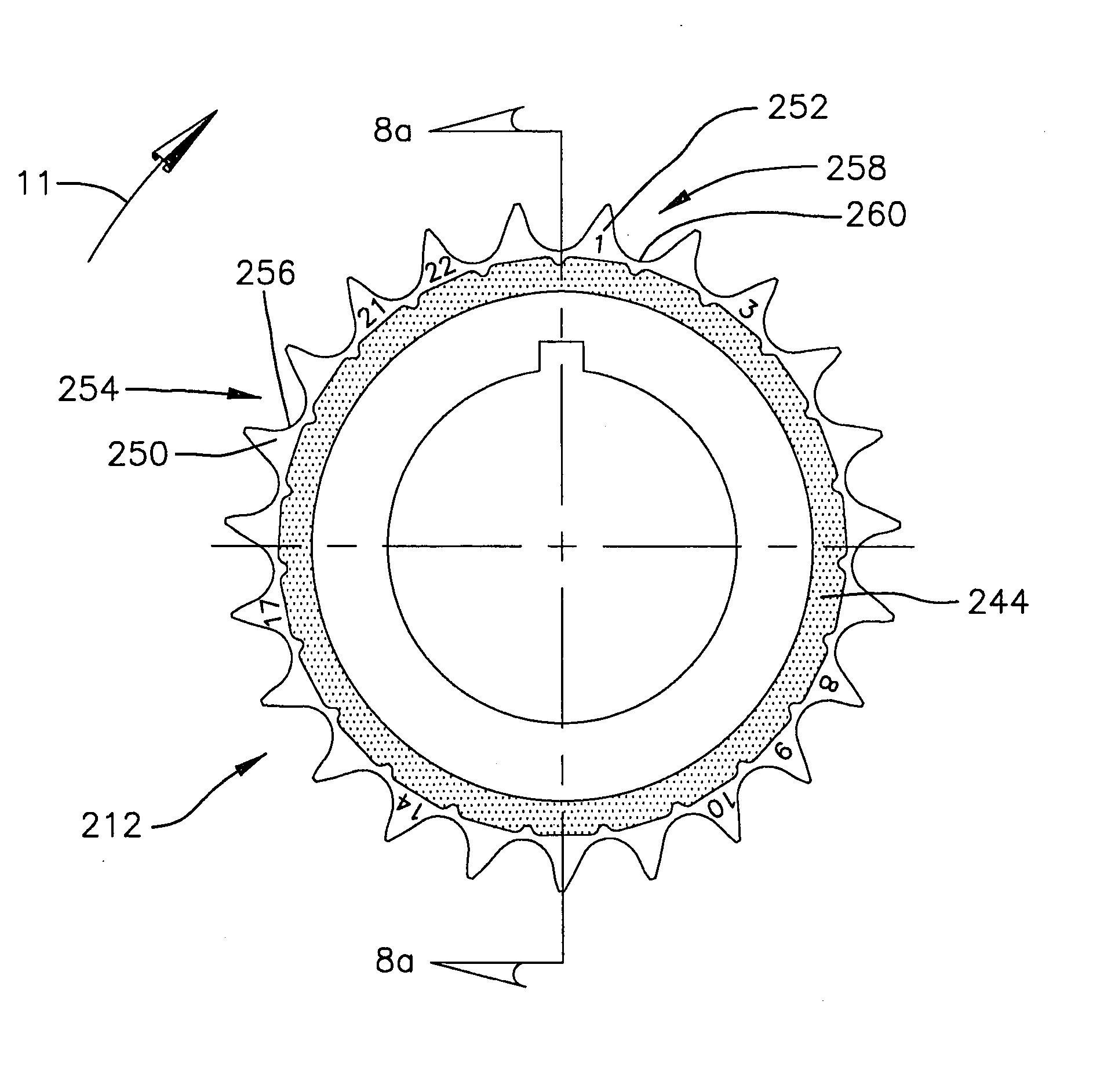

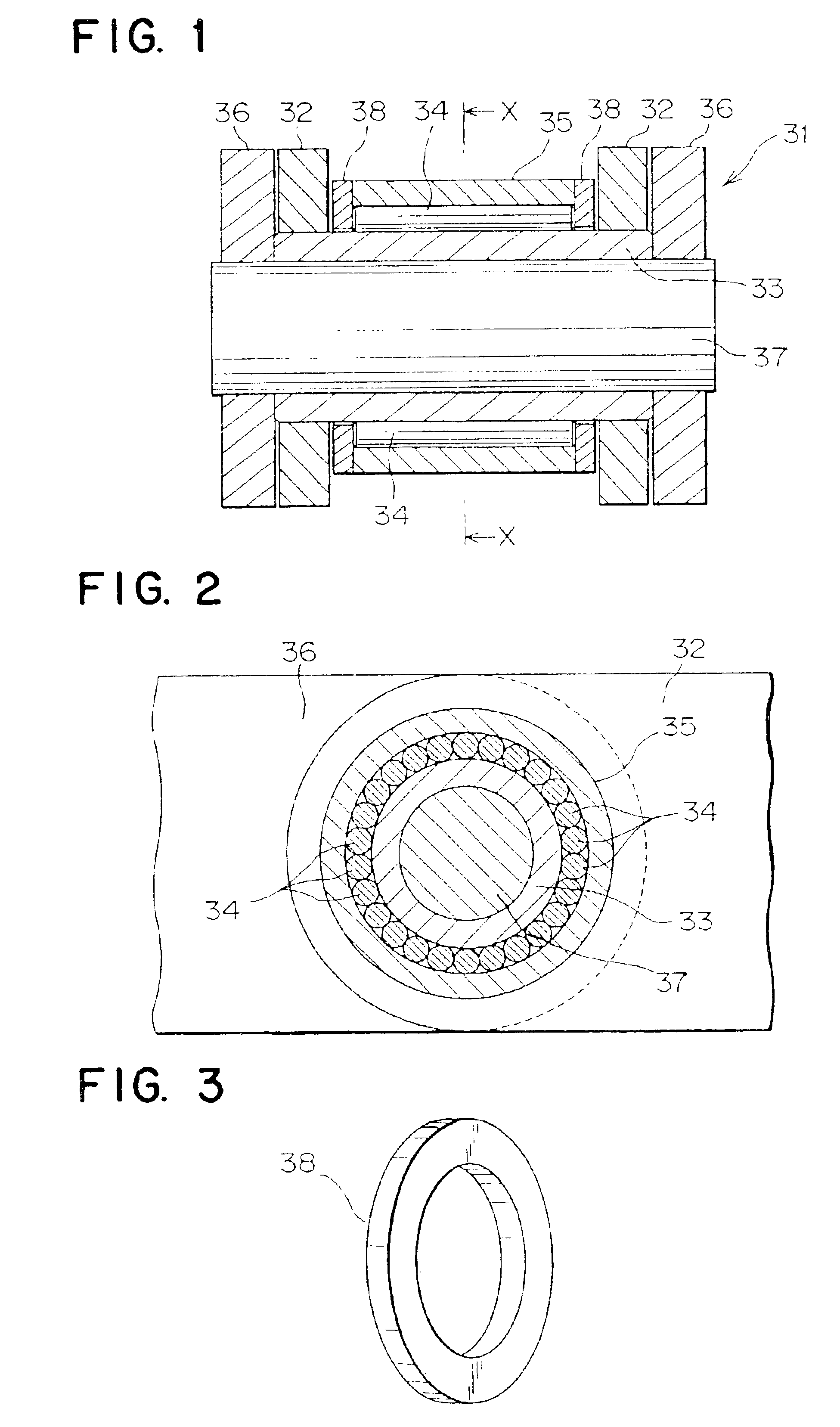

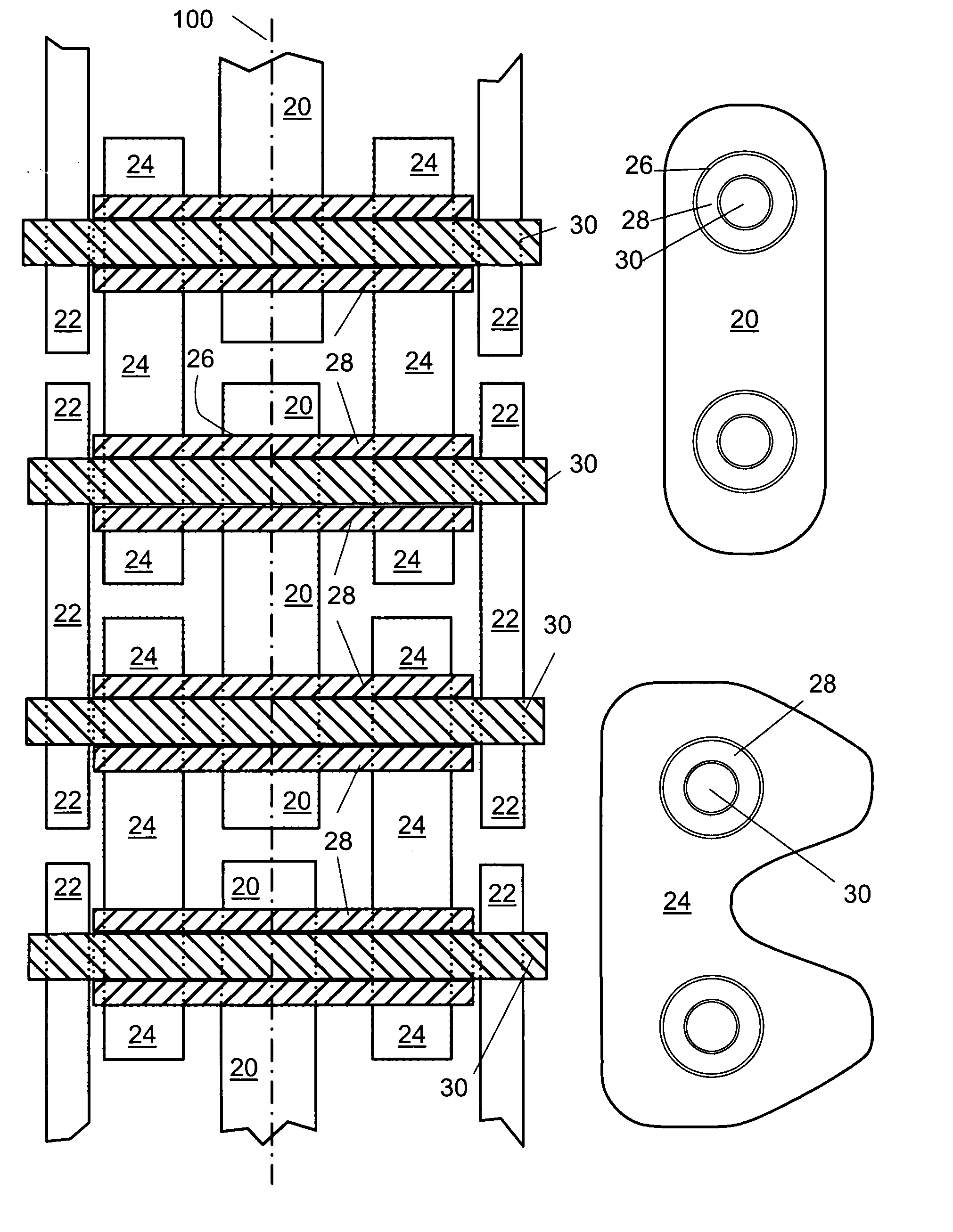

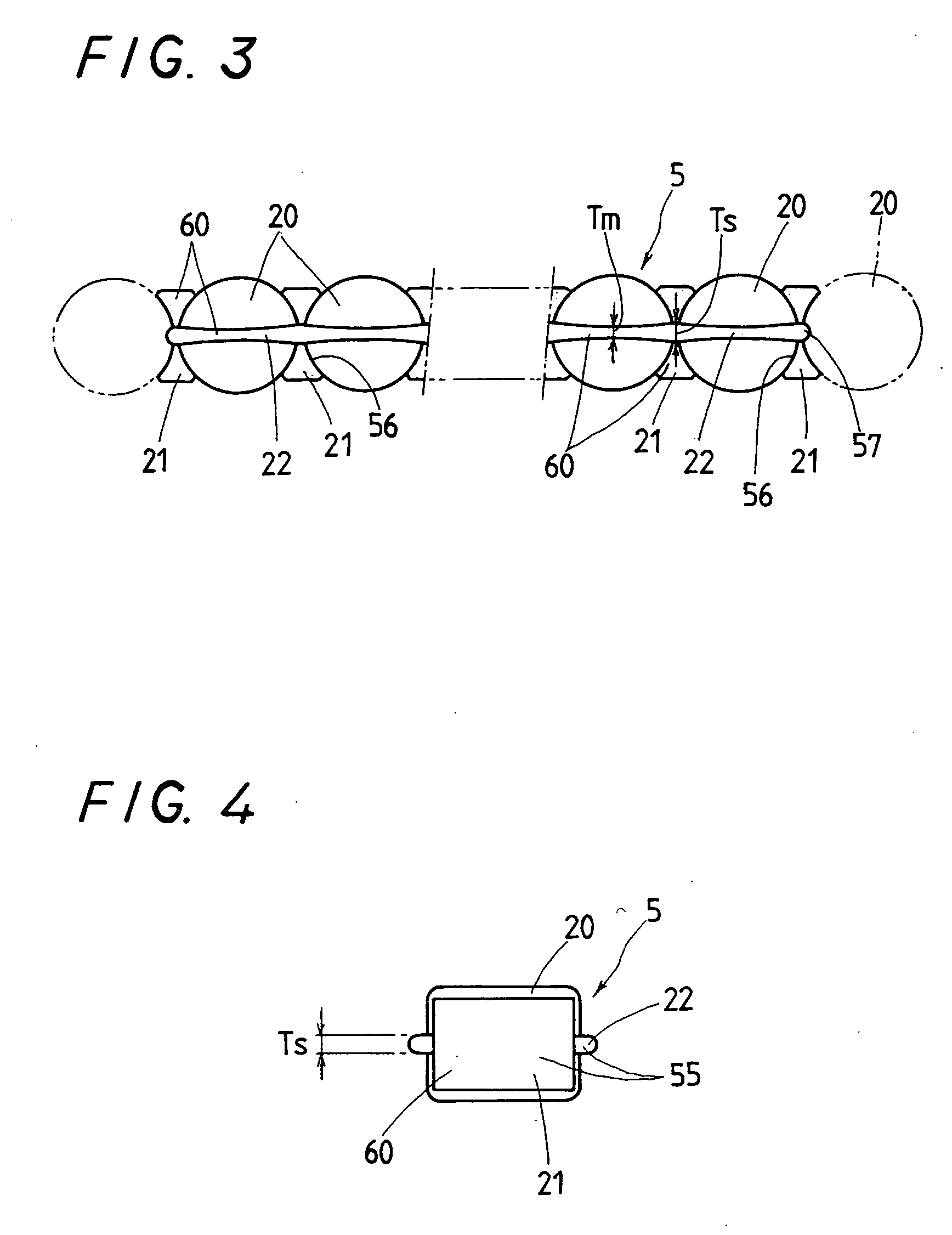

Elastomer cushion ring for a random tooth roller chain sprocket

InactiveUS20060073927A1Minimize negative impactReduce noisePortable liftingGearing elementsElastomerCushioning

A sprocket is provided with a plurality of teeth spaced about its periphery, the sprocket including roots located between pairs of adjacent teeth. The roots have root radii defined as the distance between the center of sprocket and the point along the root closest to the sprocket center in the radial direction. Roots have three distinct radii. a cushioning material for receiving the impact while engaging a chain has a geometry means substantially following the contours of the sprocket teeth geometry.

Owner:BORGWARNER INC

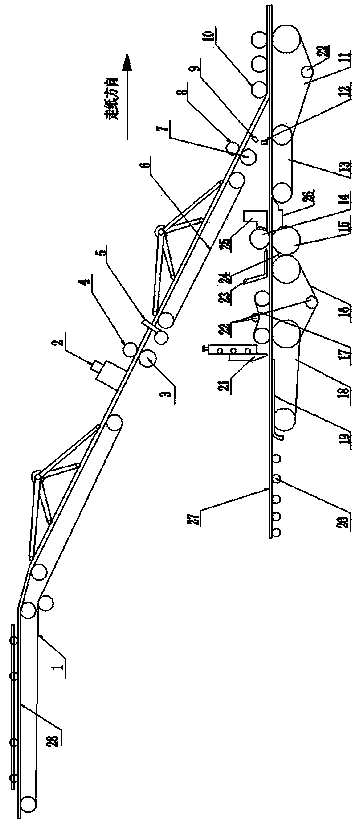

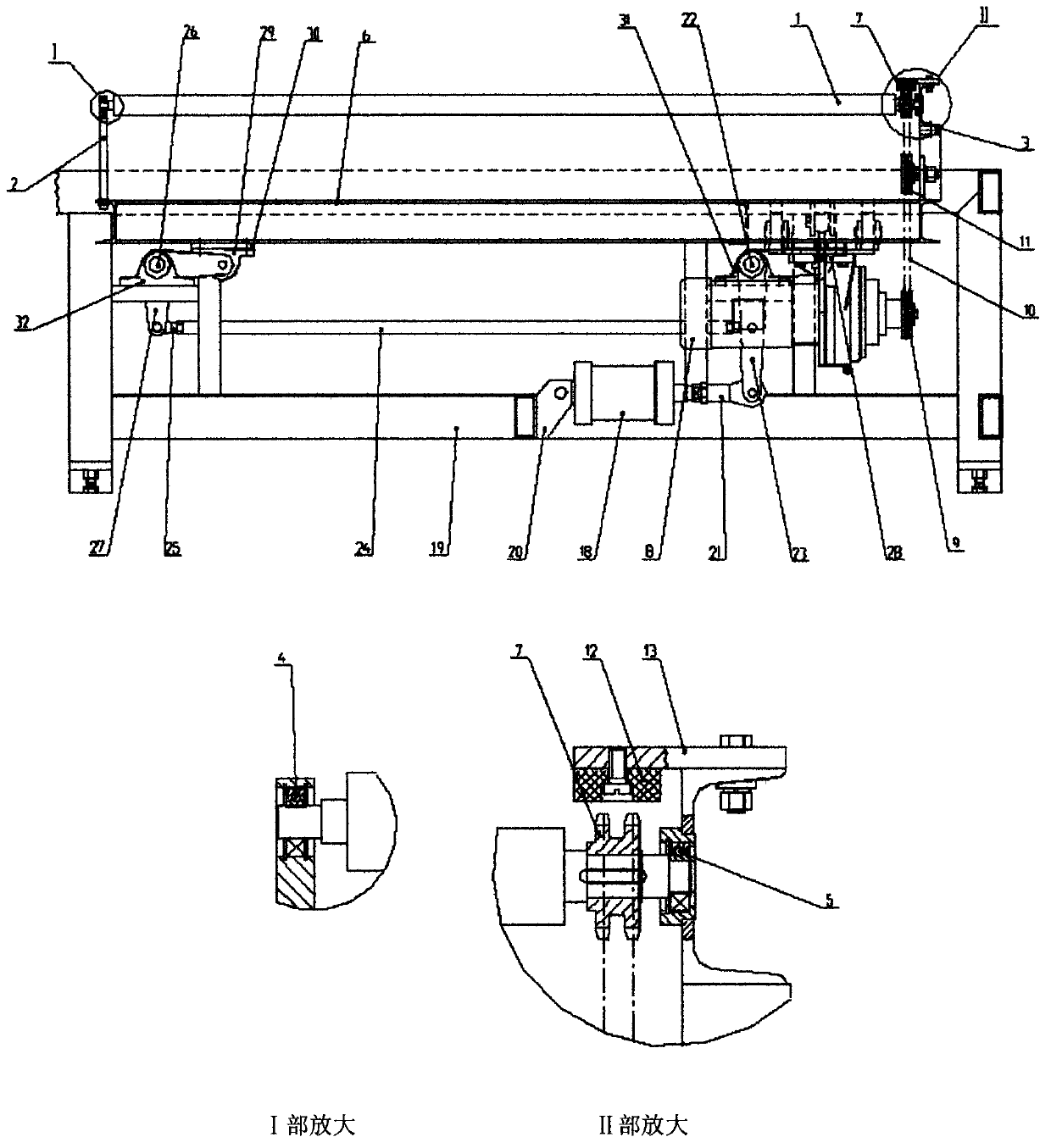

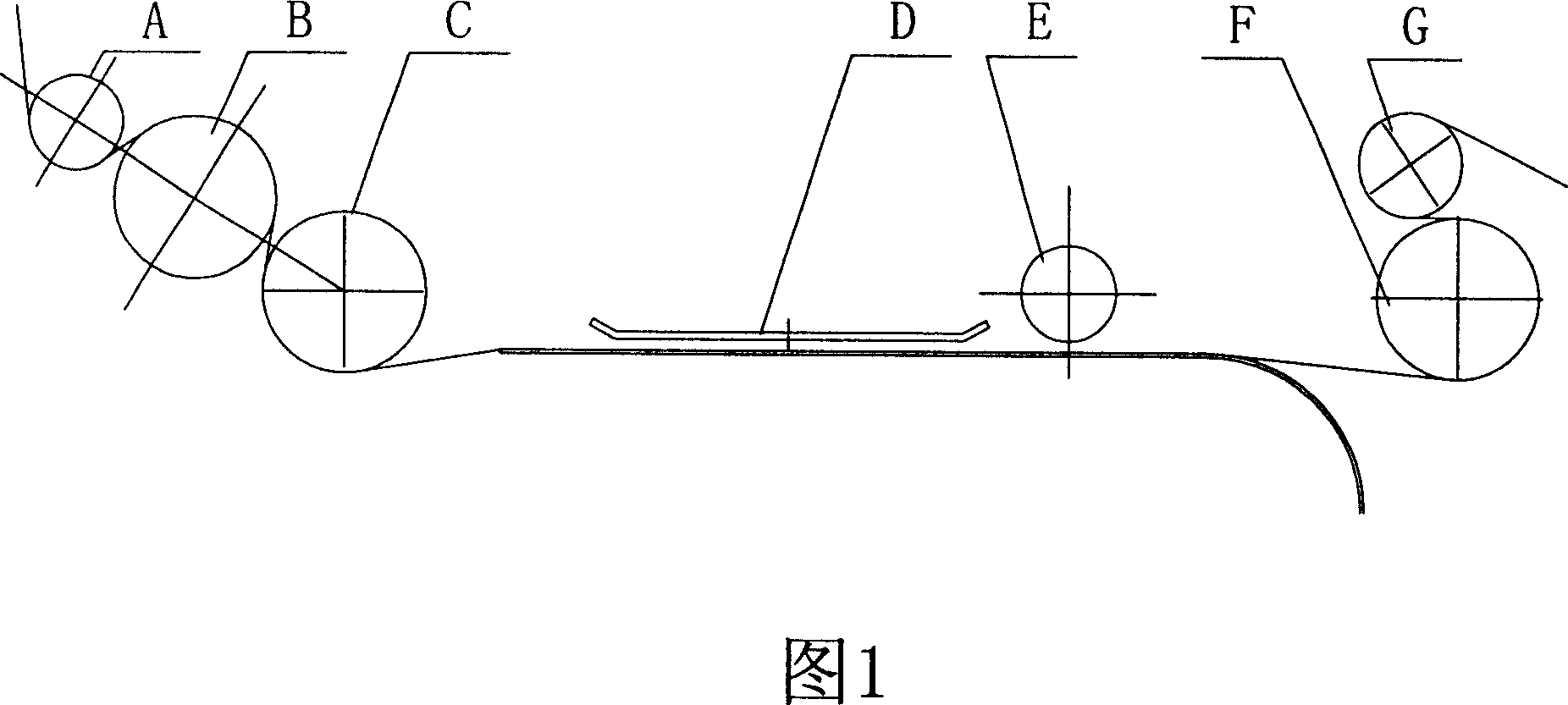

Synchronous body paper and face paper feeding device and control method

ActiveCN104340703ARealize synchronous high-speed paper feedingRealize functionArticle feedersWebs handlingMotor driveLow speed

The invention provides a synchronous body paper and face paper feeding device and a control method. The device is characterized in that a face paper front lay gauge, a face paper pressing wheel, a face paper side lay gauge, a body paper front lay gauge and a body paper lifting plate assembly are configured with cam mechanisms respectively and are driven by the respective cam mechanisms; a face paper motor drives a low-speed face paper feeding belt assembly, a body paper induced draft air distribution valve, a face paper side pull gauge and cam mechanisms thereof through a synchronous toothed belt or a roller chain; a paper injection driving roller, an upper pressing driving roller, a paper feeding driving roller, a high-speed face paper injection wheel and a high-speed face paper conveying belt assembly are driven by a body paper motor at the same speed. The distance between the face paper front lay gauge and a laminating roller is equal to the distance between the body paper front lay gauge and the laminating roller, so that body paper and face paper reach a converging point at the same time, and surface lamination is completed. The functions of synchronously feeding the body paper and the face paper at a high speed and automatically aligning the body paper with the face paper can be realized, the use of the motors is reduced, and the phenomenon that the motors are frequently started is avoided. The working efficiency is improved, and the manufacturing cost is reduced.

Owner:QINGDAO MEIDA INTELLIGENT TECH CO LTD

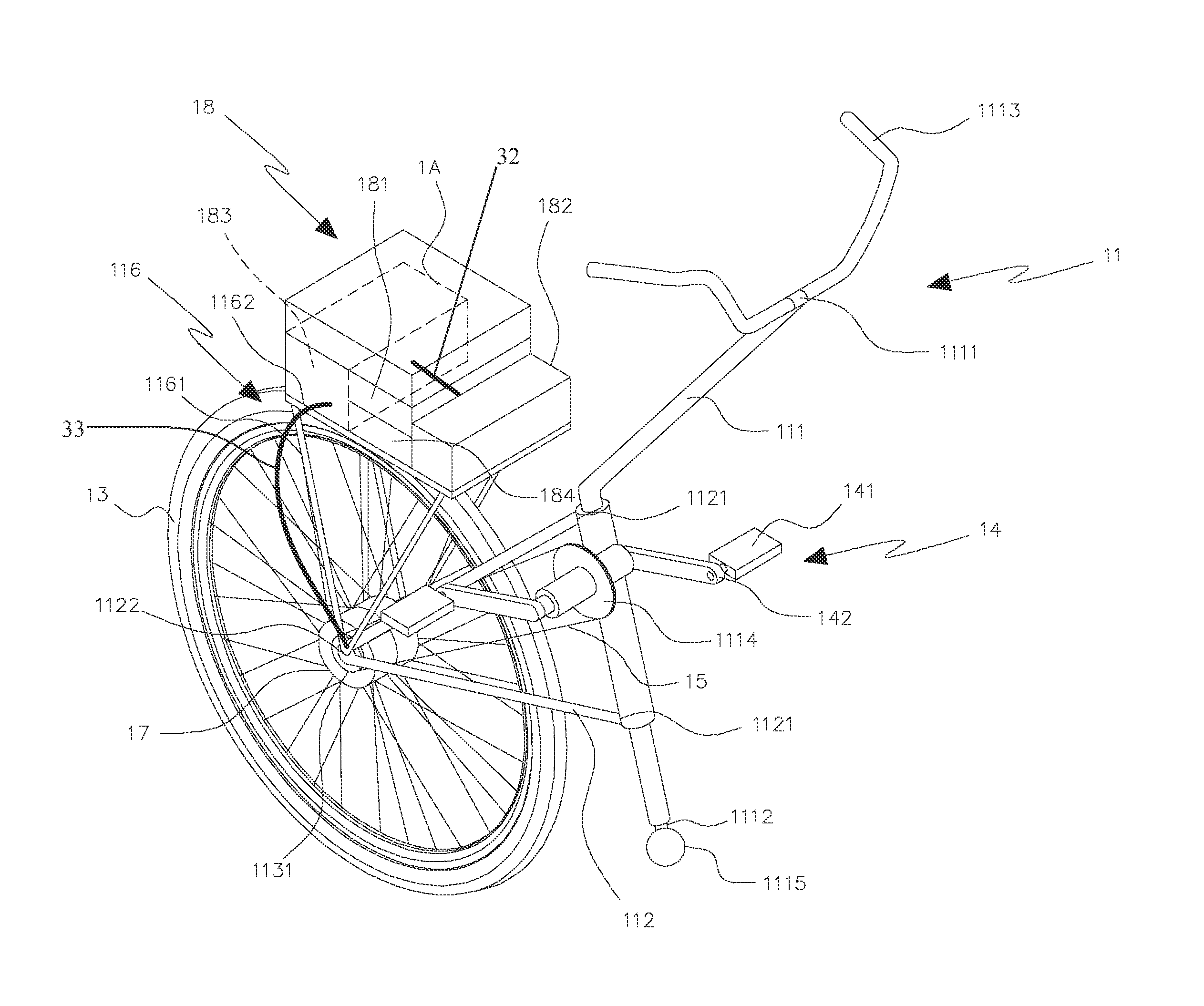

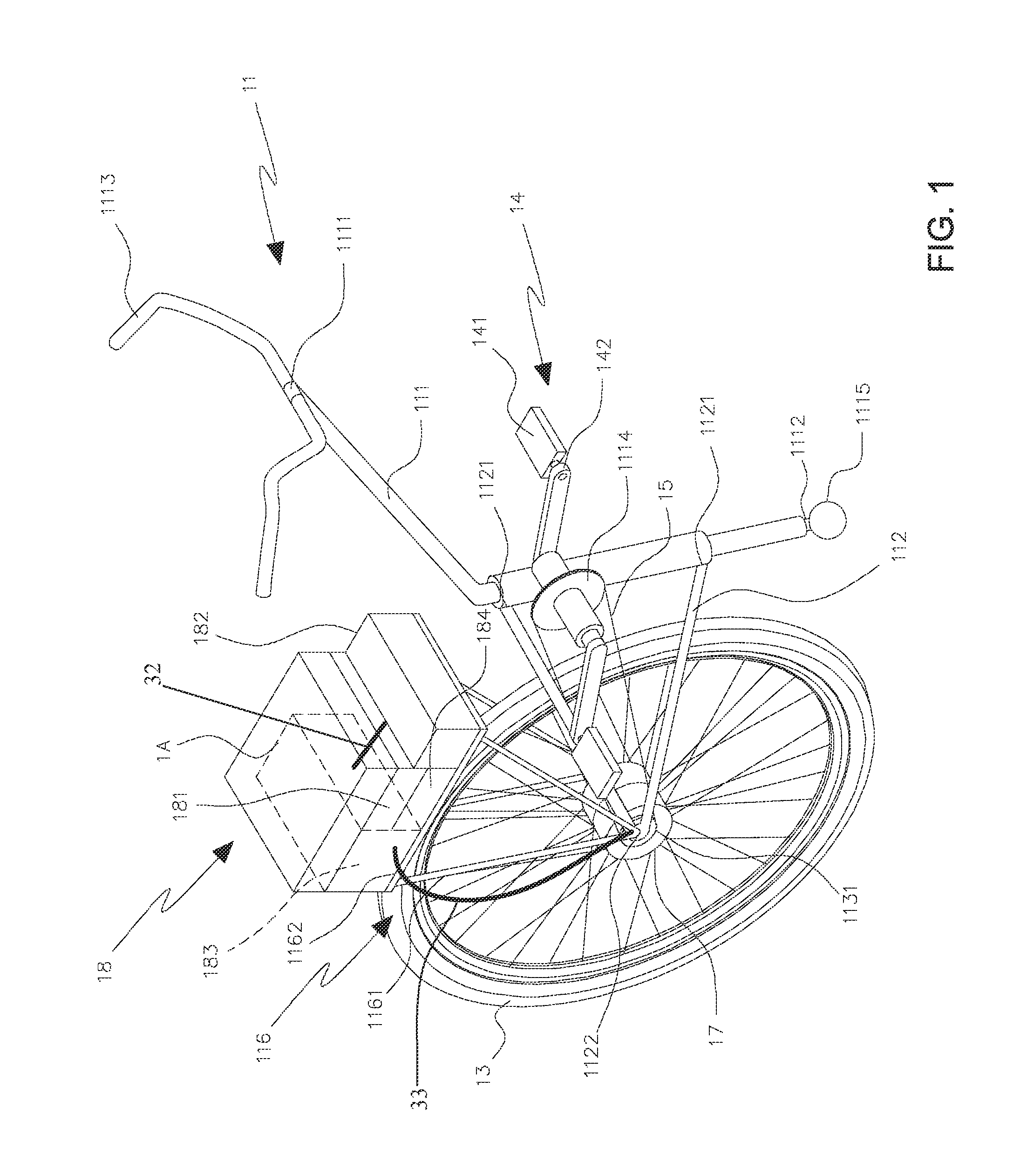

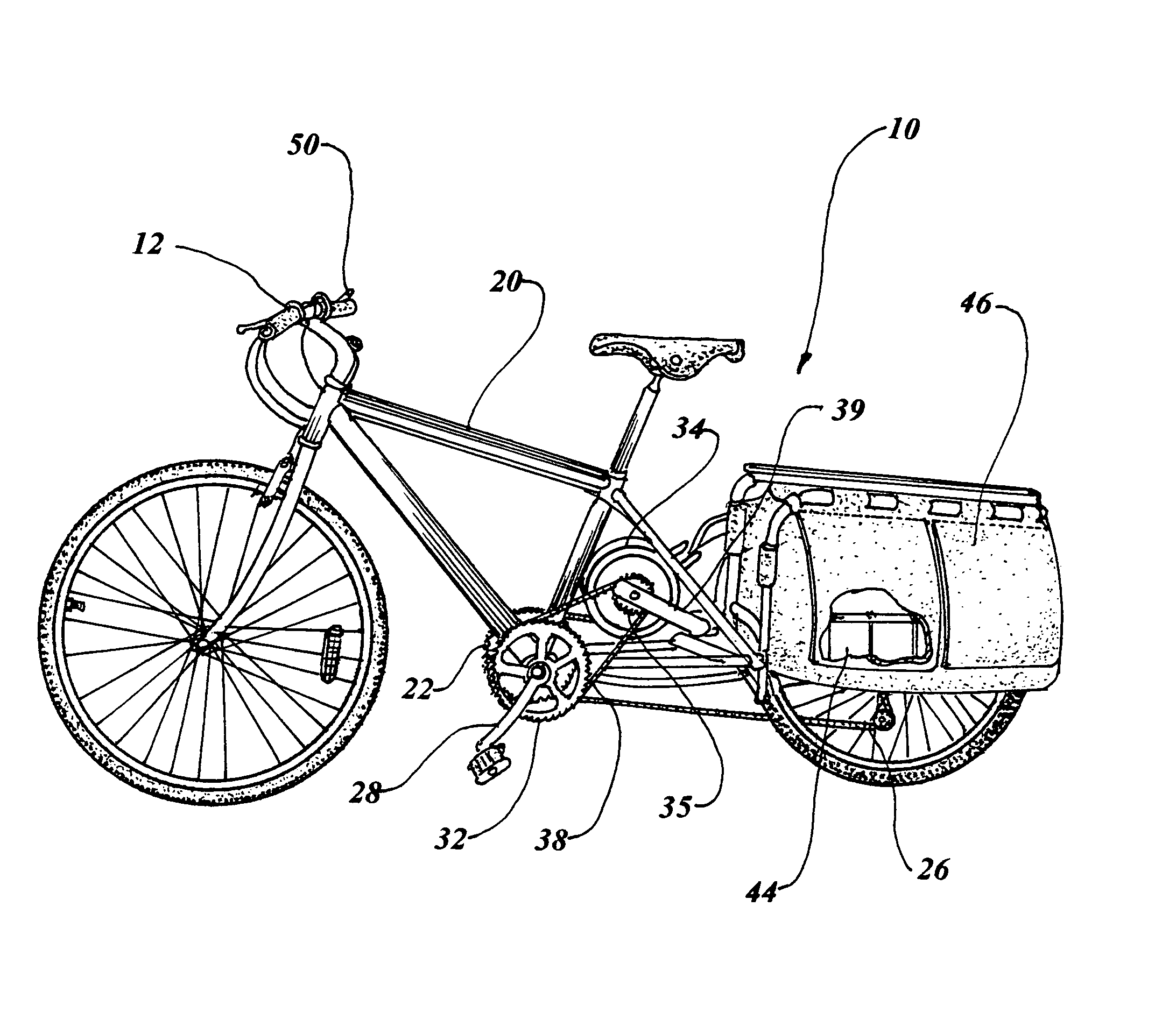

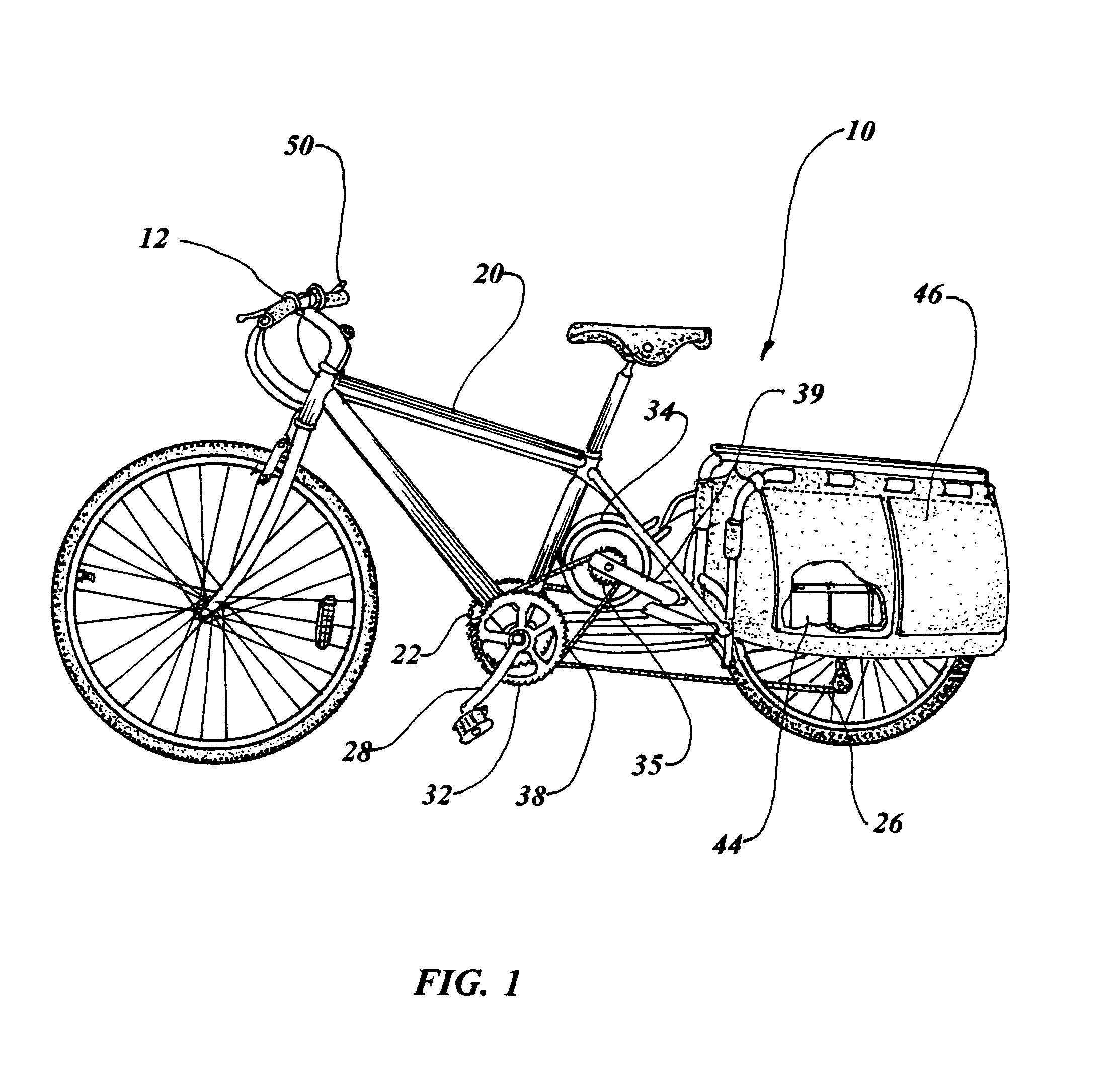

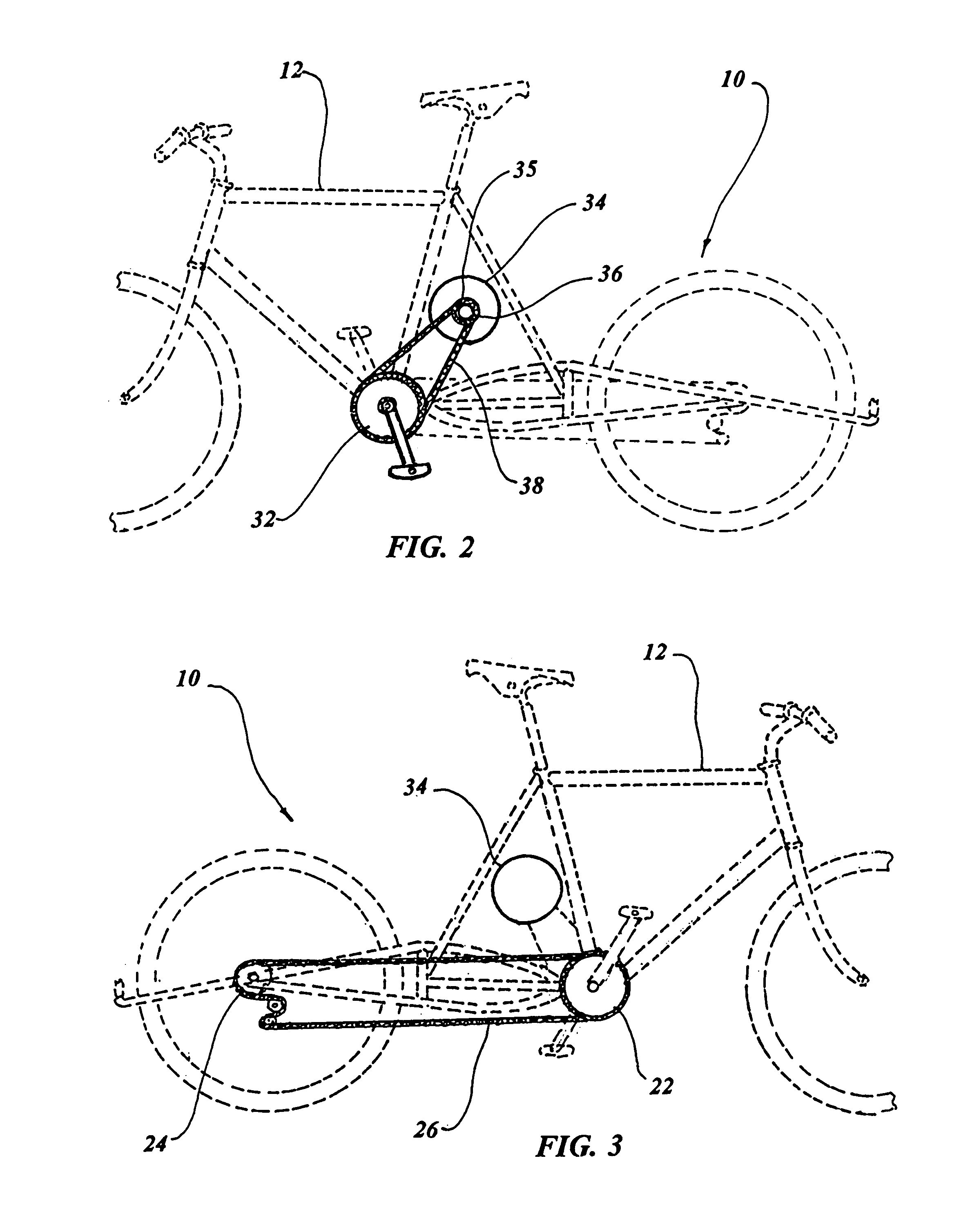

Power assisted bicycle

InactiveUS7261175B1Uncomfortable and wasteful of motor powerEffective maintenanceMotorcyclesRider propulsionElectricityMotor drive

A power assisted bicycle (10) which modifies an existing manually powered bicycle (12) by replacing the left pedal crank arm with a motor-driven sprocket and left pedal assembly (32). An electric motor (34) is attached to the bicycle's frame (20) and has attached a motor drive sprocket (35) and a one-way clutch (36). A motor roller chain ring (38) is connected in concert to the motor drive sprocket (35) and motor driven sprocket (32), such that the electric motor (34), provides a power assist to the manually powered bicycle, with the one-way clutch (36) permitting unassisted pedaling without resistance of the motor when de-energized. An electrical power source (40) interfaces with an electrical control system (42) for supplying electrical energy to operate and control the electric motor.

Owner:FAHRNER TODD

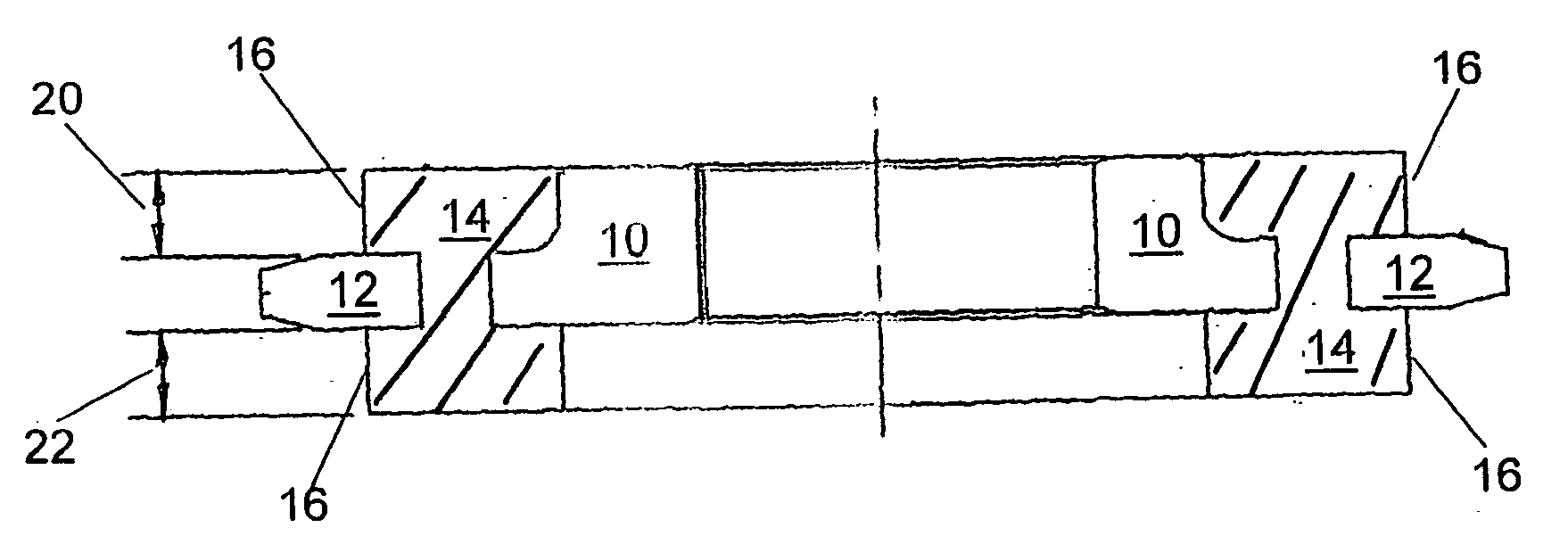

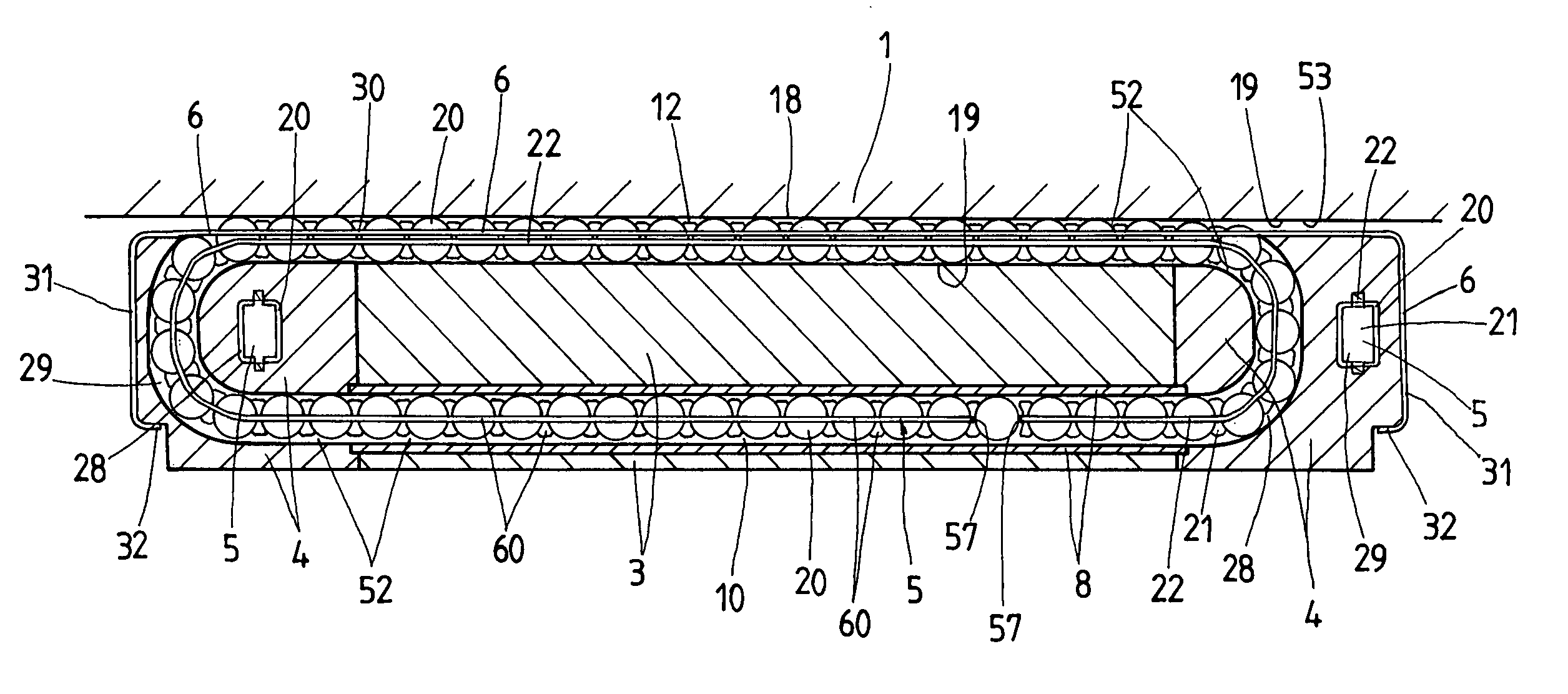

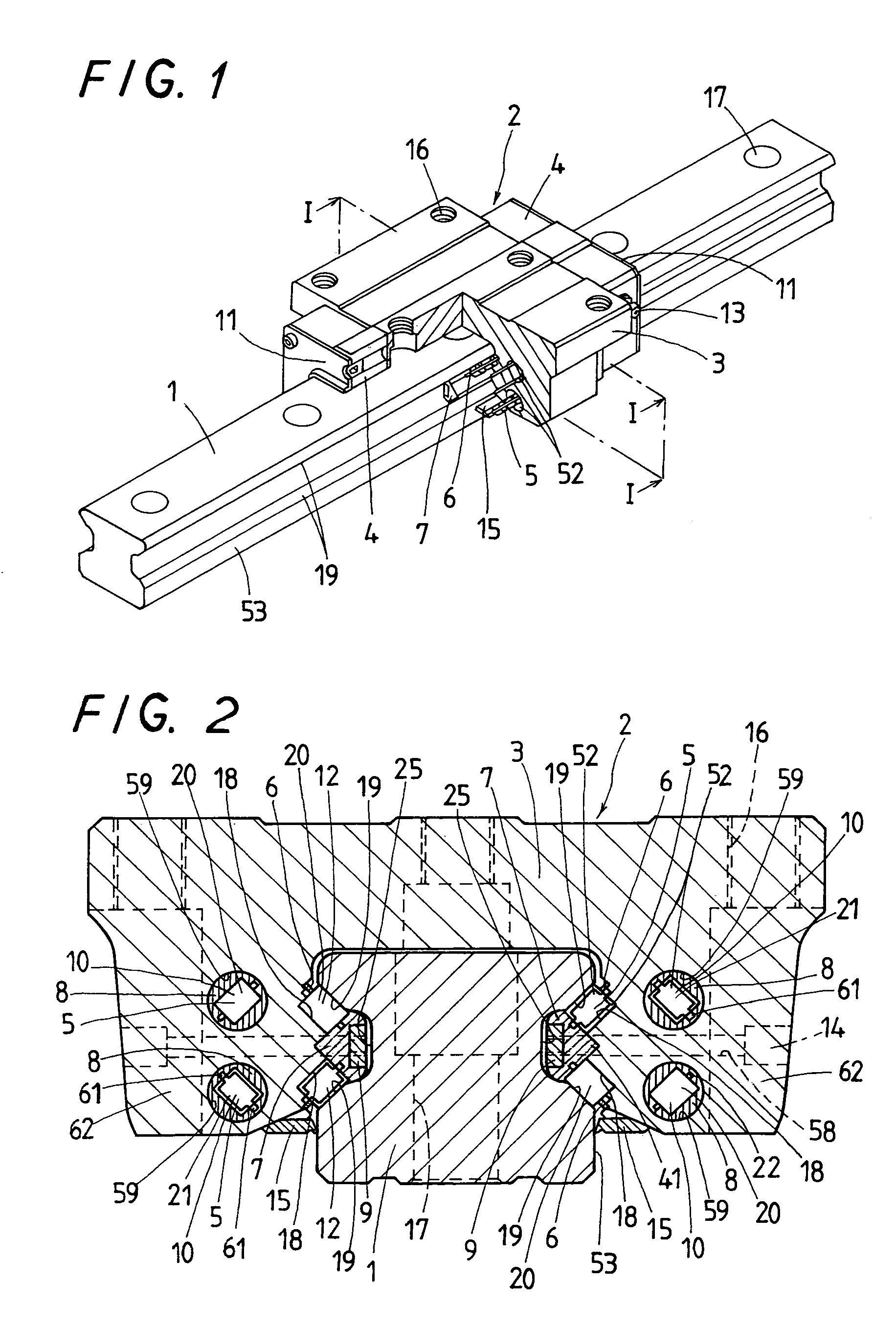

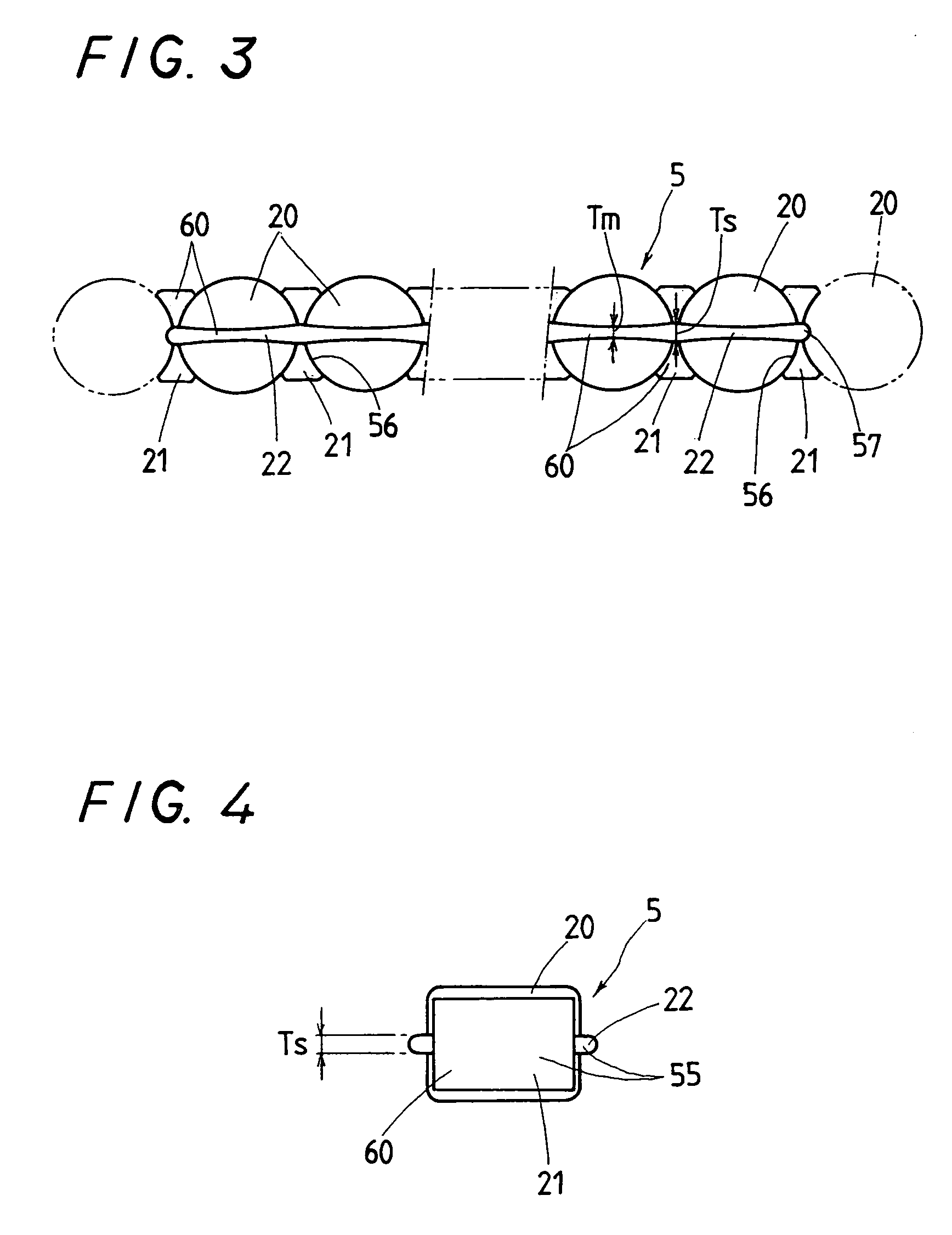

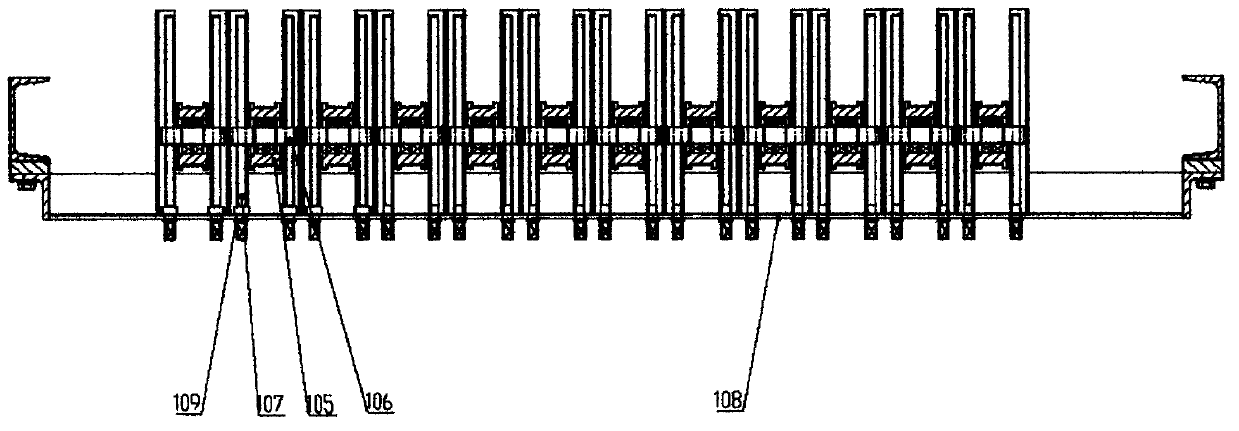

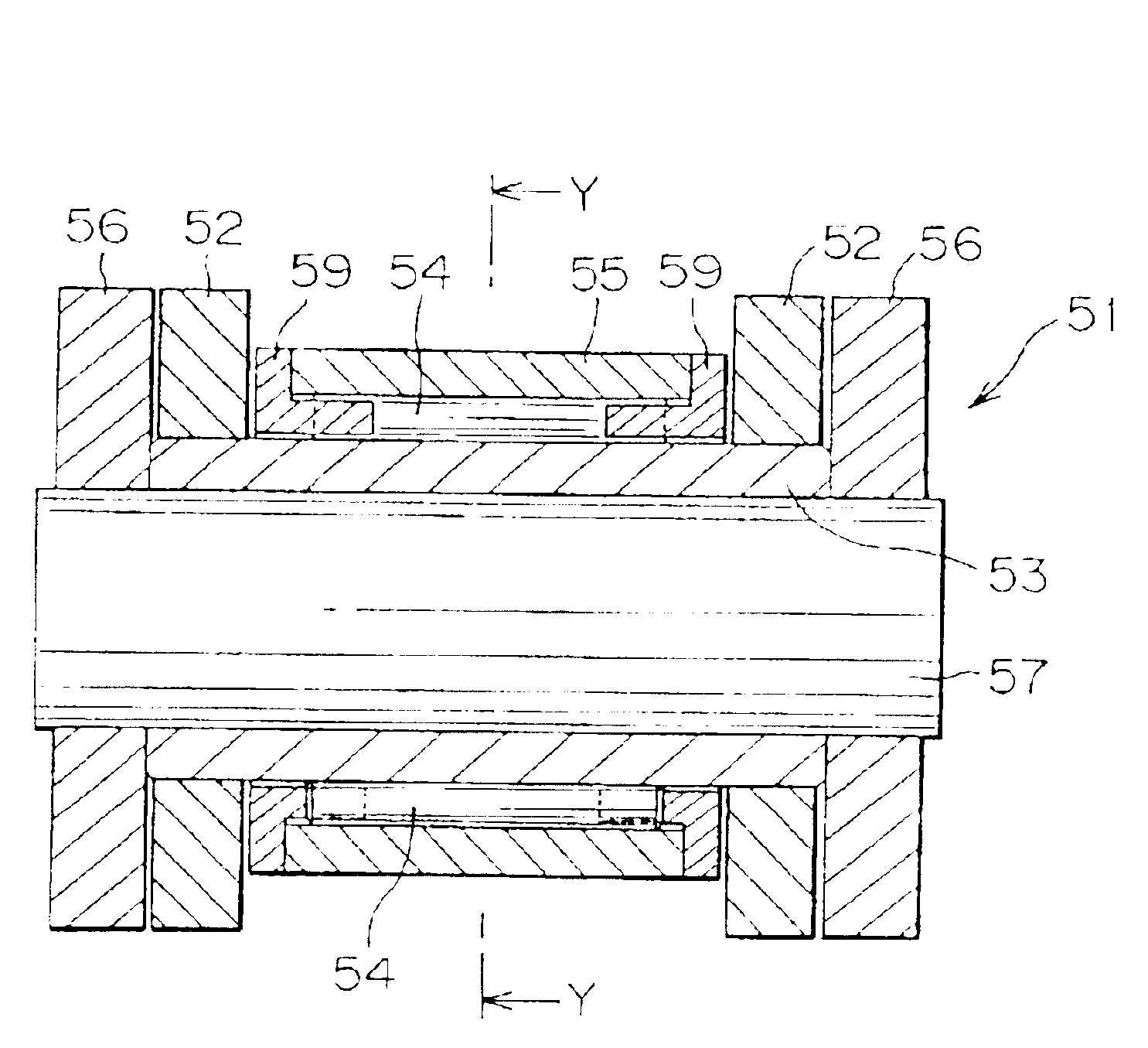

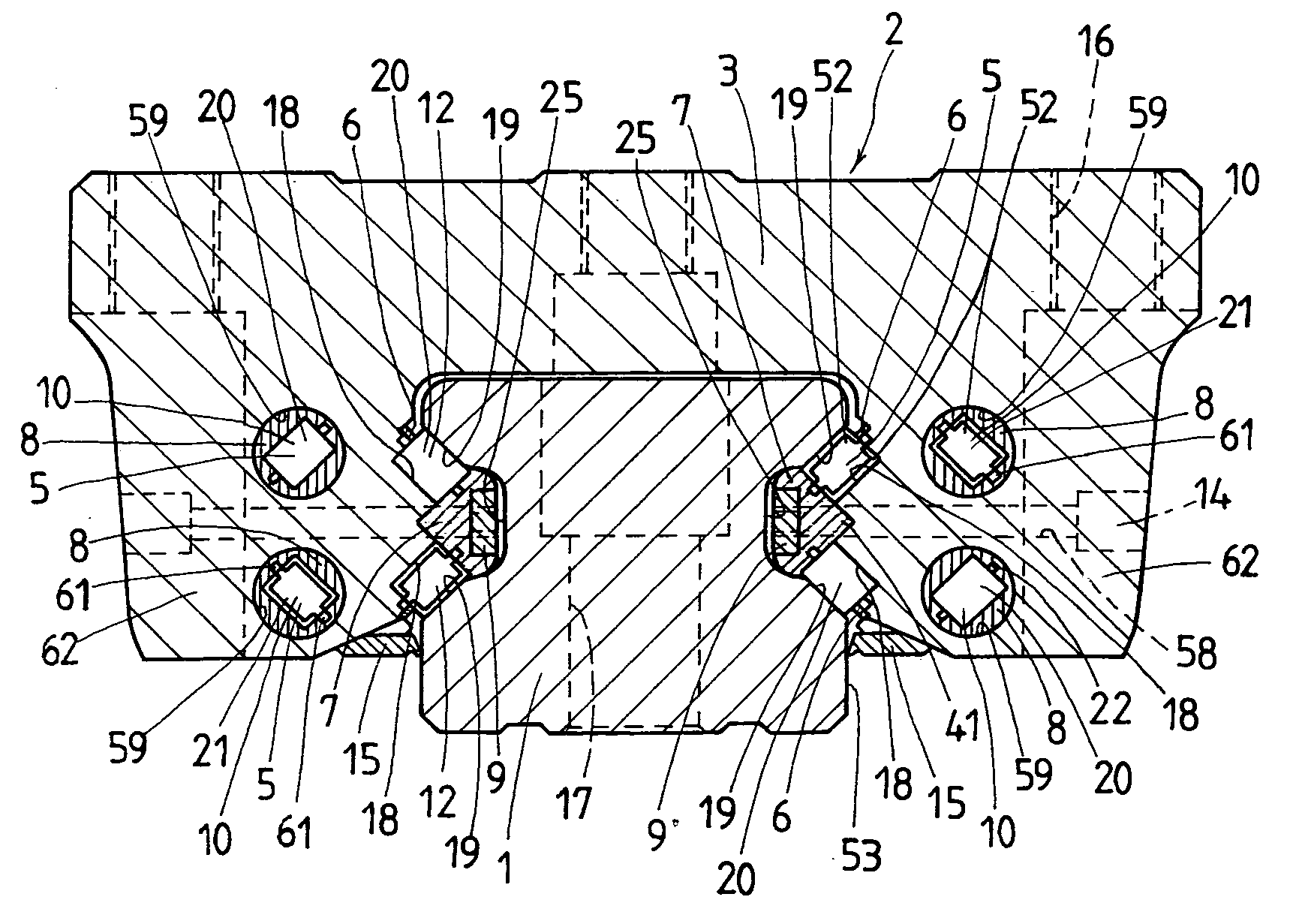

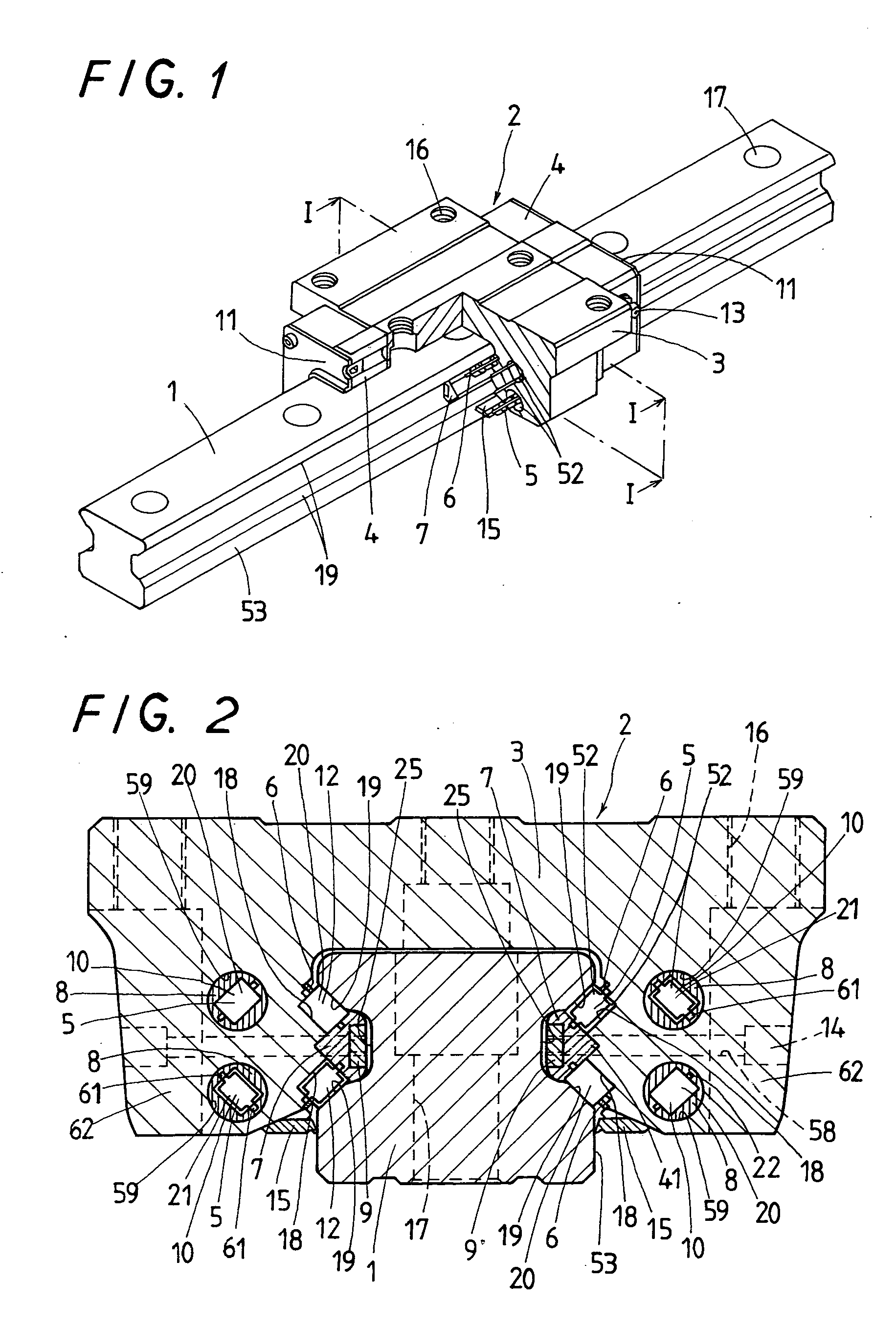

Linear motion guide unit

A linear motion guide unit is disclosed in which there is provided a retainer band making it possible to easily fit a roller chain with rollers traveling through a recirculation circuit into a load way of the recirculation circuit, thereby making sure of smooth recirculation of the roller chain. Cooperation of the retainer band with a retainer plate helps guide links of the roller chain in a load way of the recirculation circuit, keeping the roller chain against running out of the load way thereby ensuring smooth movement of the roller chain throughout the recirculation circuit.

Owner:NIPPON THOMPSON

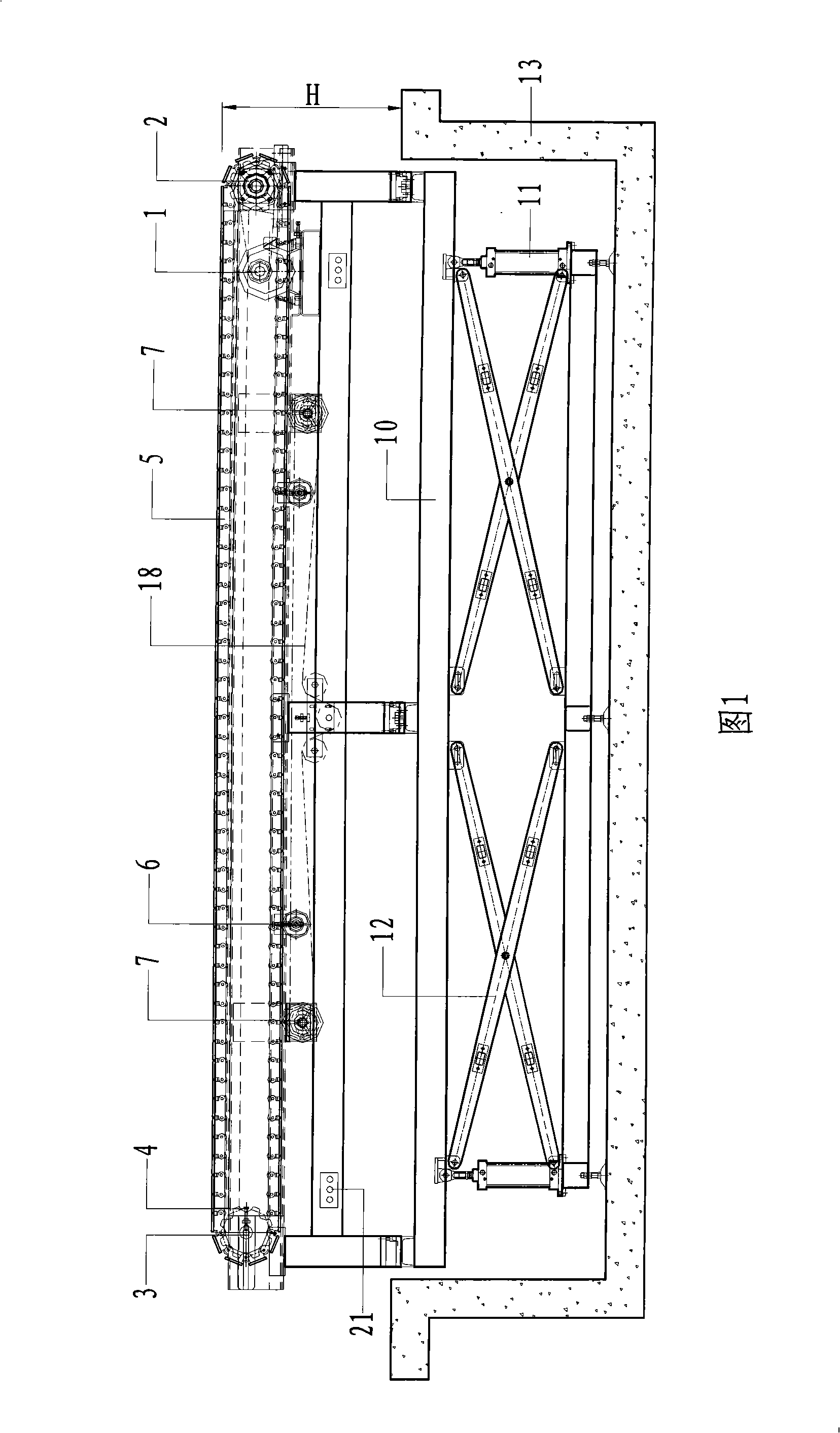

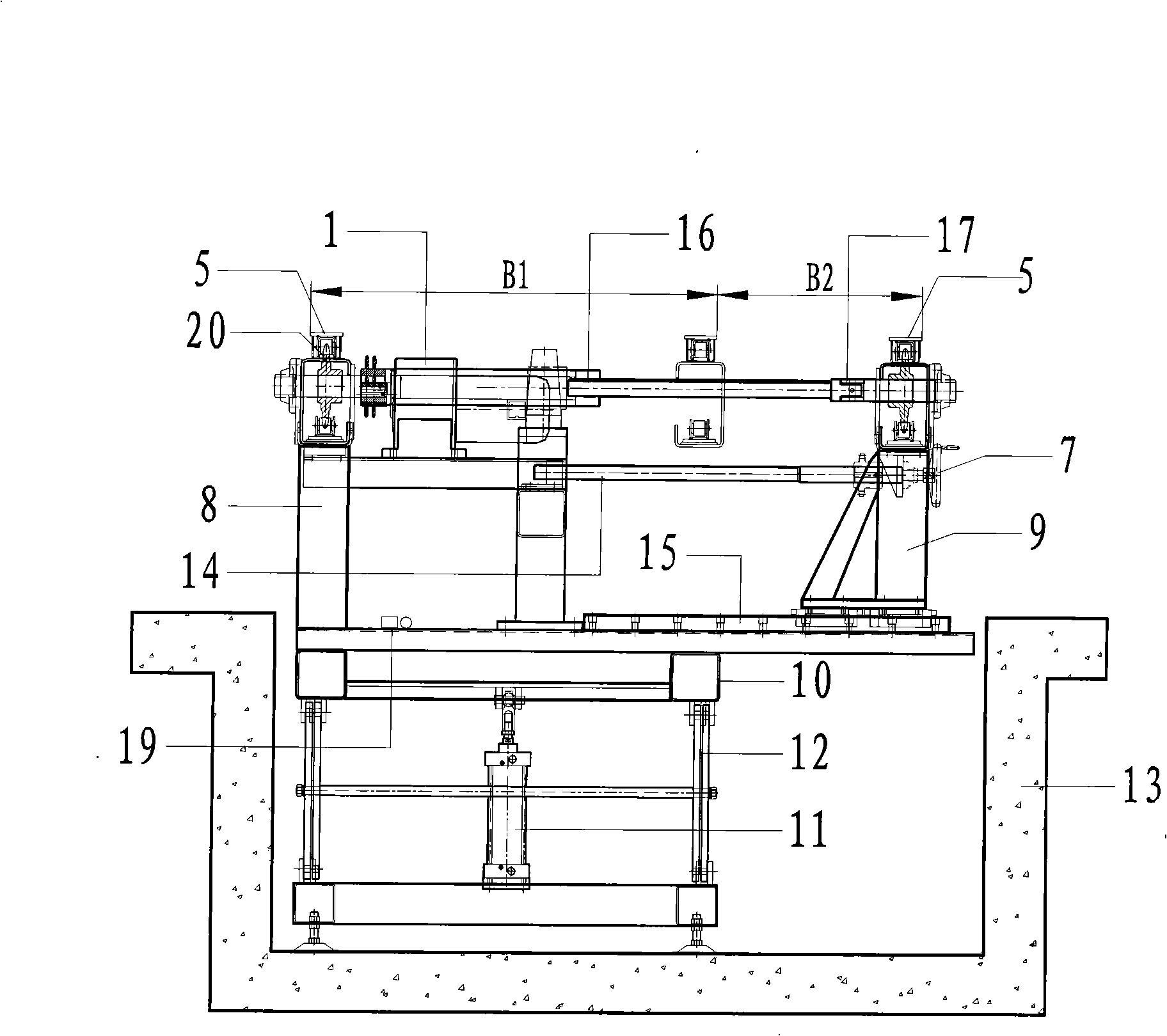

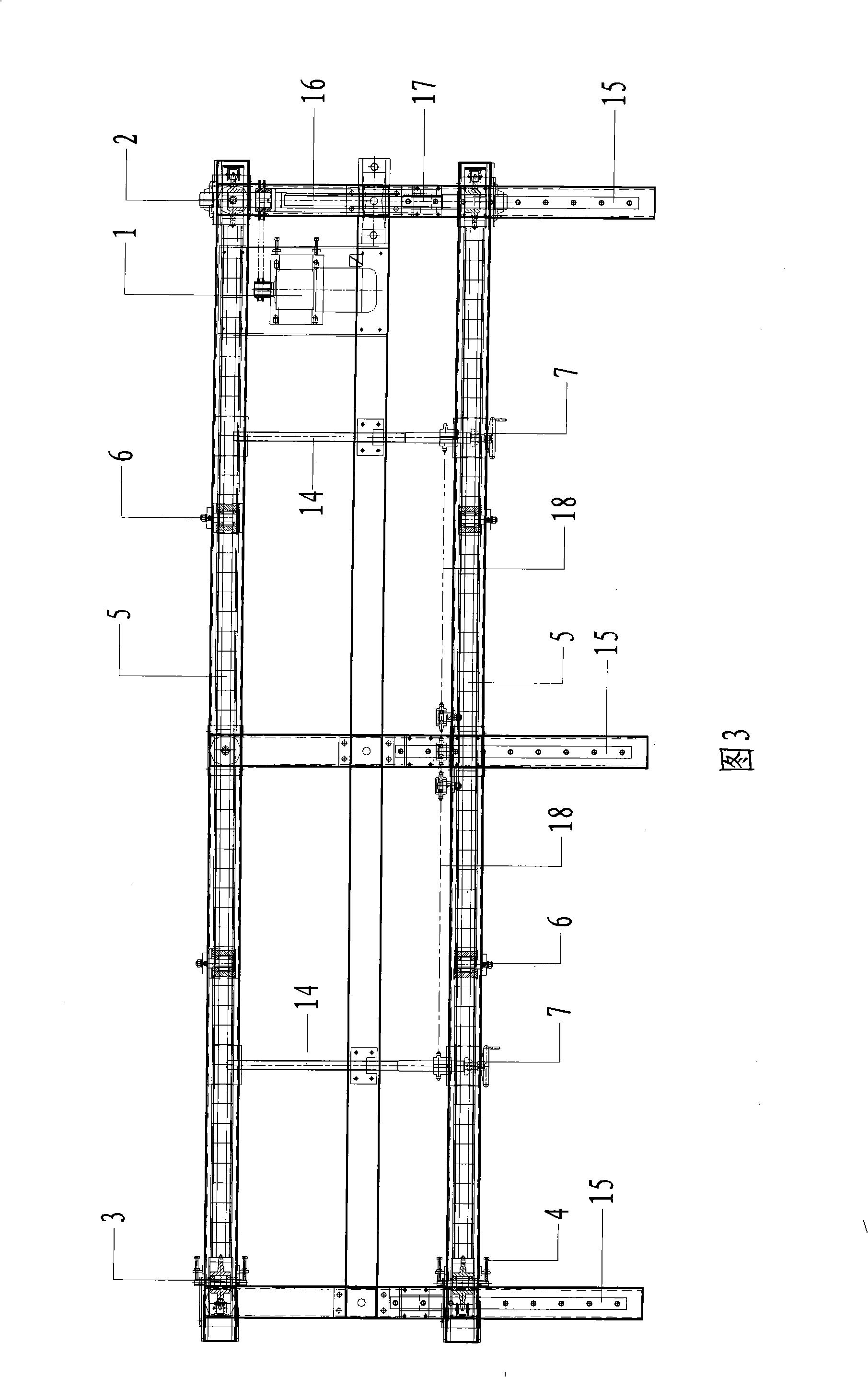

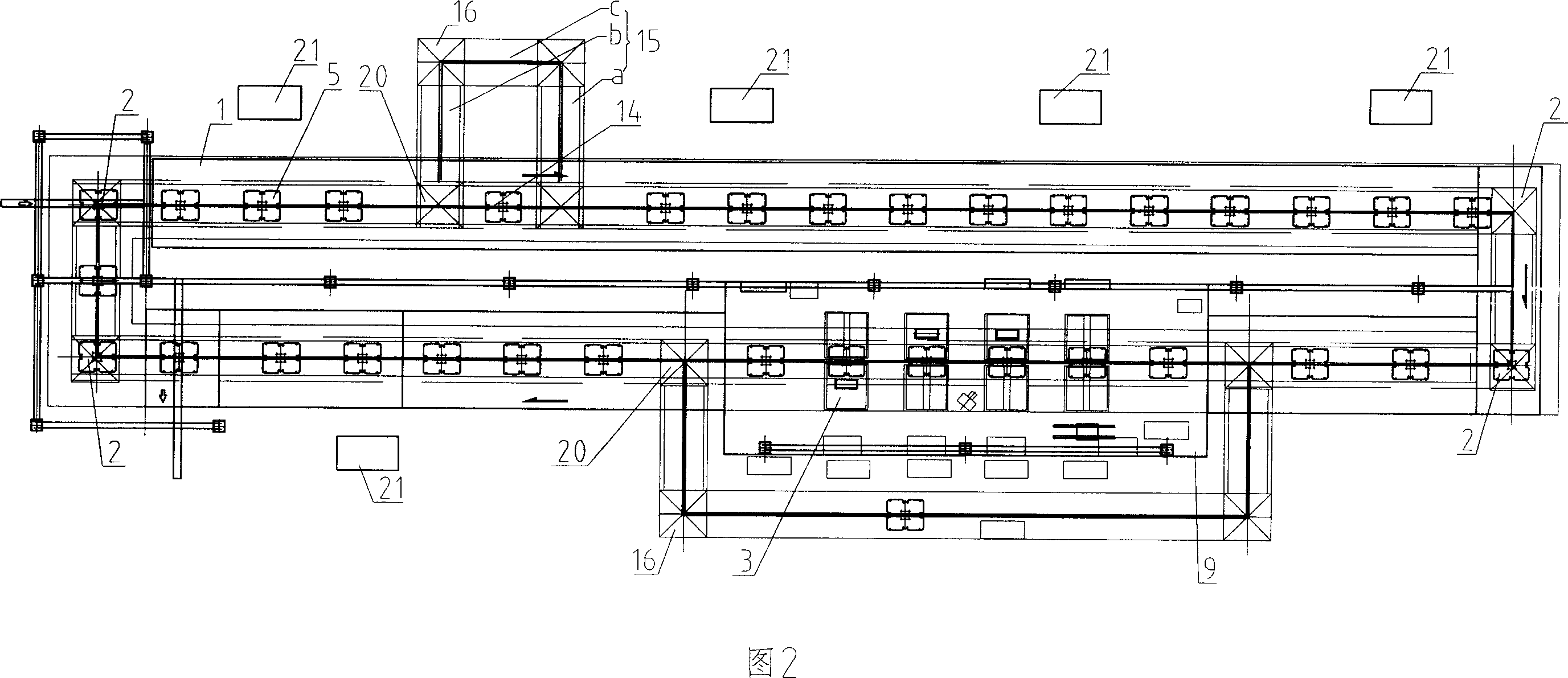

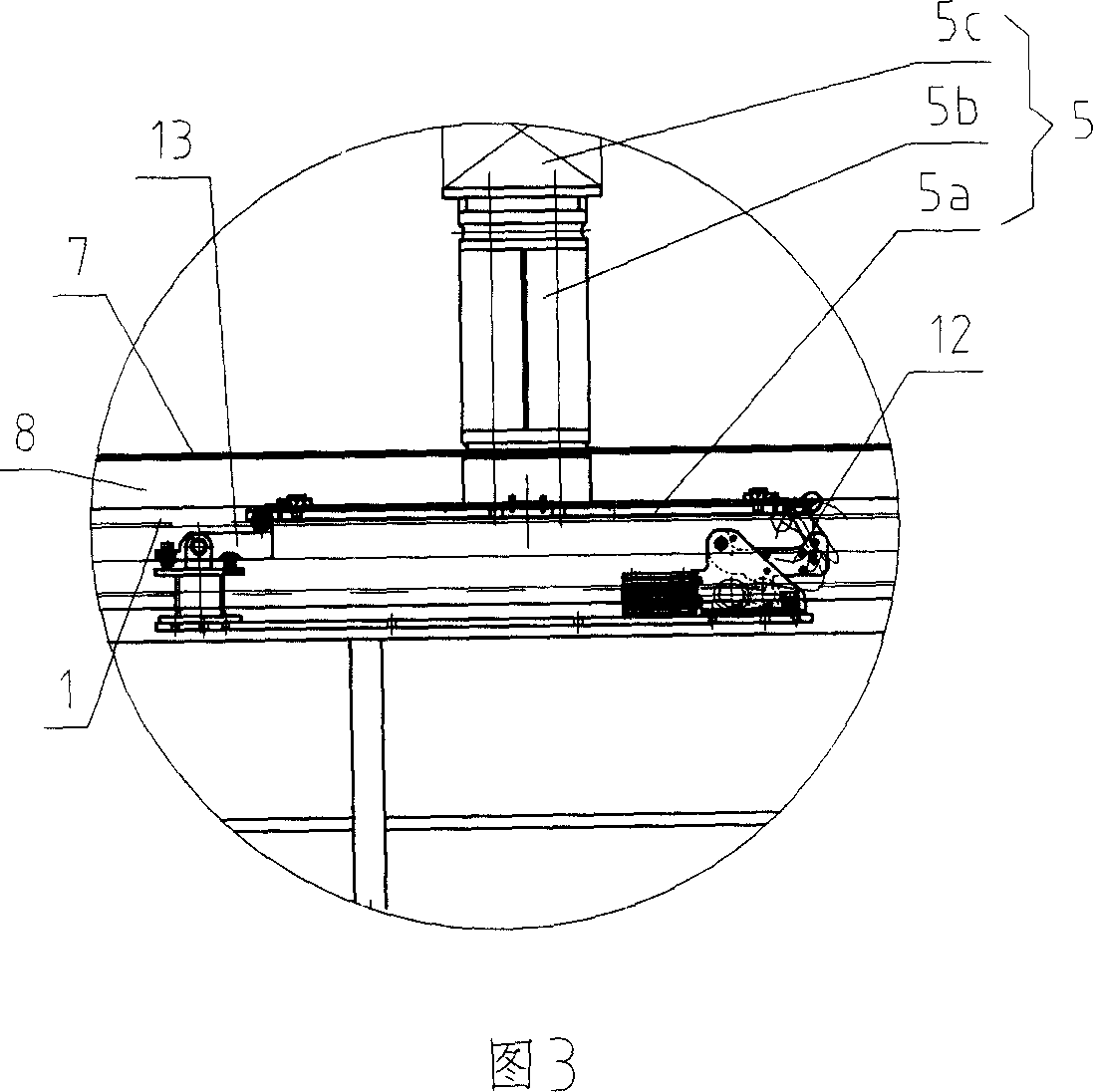

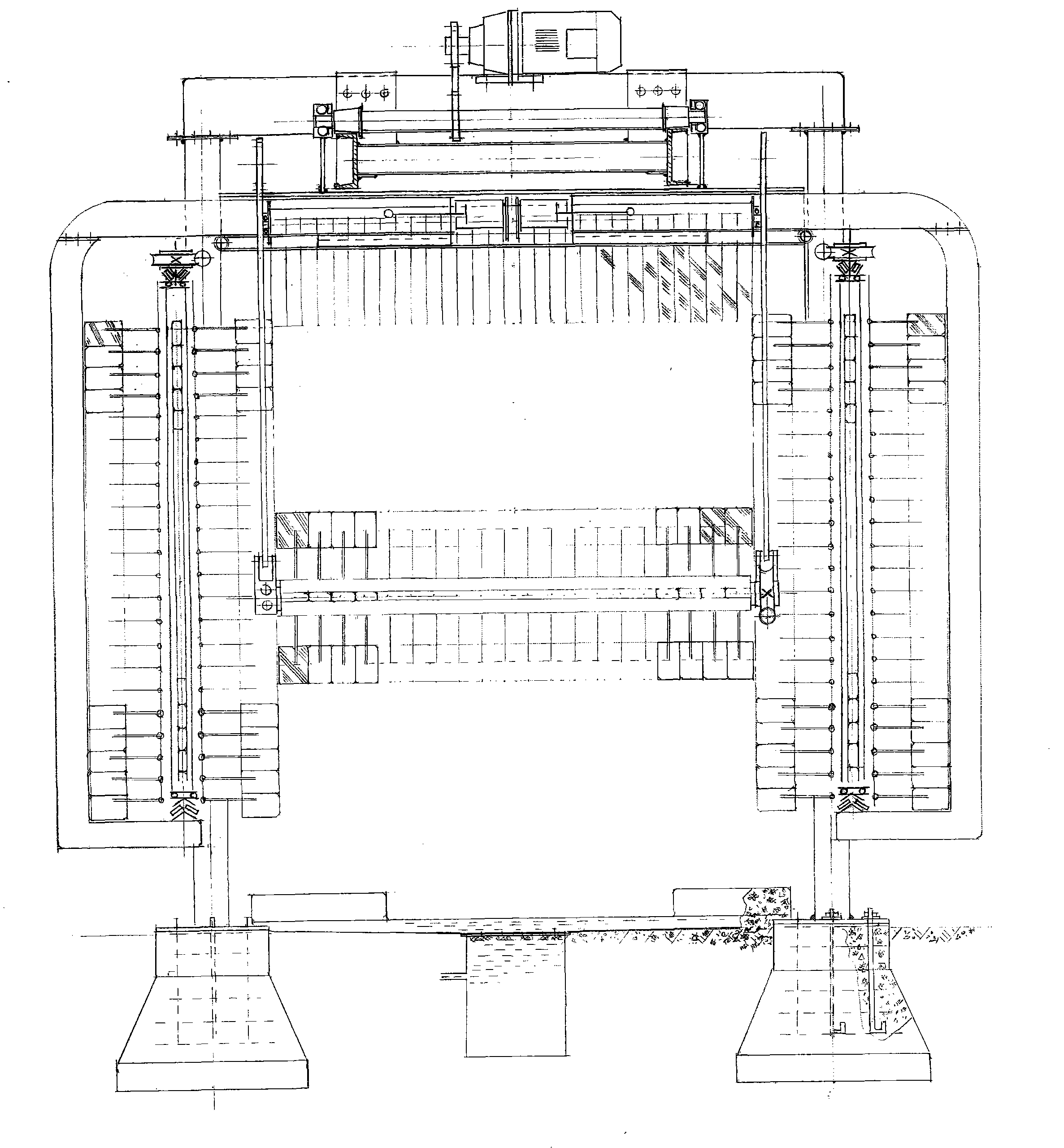

Process for producing unit plate of unit-type curtain wall and operation console thereof

A method for producing unit plate of unit curtain wall and operating desks thereof are disclosed. The production includes six working procedures: 1) the assembly of a metal framework; 2) the installation of inner lining plates and heat insulation cotton; 3) quality inspection for the metal framework; 4) the assembly of panels (including the inspection of glass raster); 5) glue injection; and 6) the mounting and the packaging of exterior decorate lines. The operating desks for the working procedures adopt chain conveyers provided by the invention respectively. Each chain conveyer can work for transmission independently and also can work with the whole work line. The adopted chain conveyer is mainly composed of a drive motor and speed reduction unit (1), a roller chain conveying pedrail (5), and a fixed frame (8) and a movable frame (9) which are parallel to each other. The pedrail type conveyer adopted by the invention has good function for regulating width and height, carries out the quality control for the whole work line, greatly improves the efficiency of the production line for the unit curtain wall, and reduces the labor intensity of the worker.

Owner:ZHONGSHAN SHENGXING

Roller chain sprocket with resilient cushion rings and root relief

InactiveUS20060252592A1Improve fatigue lifeReduce noise levelGearingGear vibration/noise dampingTransverse grooveEngineering

A sprocket includes a hub and a plurality of teeth projecting radially outwardly from the hub. At least one cushion ring is located adjacent the teeth, and the cushion ring defines a plurality of compression pads separated from each other by transverse grooves. Each of the compression pads is defined symmetrically about a circumferential mid-point. When part of a sprocket with symmetric tooth spaces, the cushion ring is being operable identically in first and second opposite rotational directions. In one arrangement, the compression pads each include a planar outer surface having a leading and a trailing end, wherein the leading end and trailing end are located a common radial distance from a center of the hub about which the sprocket rotates. The tooth spaces of the sprocket can be symmetric, asymmetric and the root surface can be relieved. The sprocket can include multiple tooth profiles distributed randomly about the hub.

Owner:HH CLOYES INC

Automatic braiding machine

InactiveCN102774635ARealize the whole stackAdvanced and reasonable structureDischarging arrangementConveyor partsState of artRoller chain

The invention provides a novel automatic braiding machine, aims at improving technical levels of wet green or dry green braiding processes in novel domestic wall material production lines and overcomes defects existing in prior art. The technical scheme includes that the automatic braiding machine is mainly composed of a green feeding carrier roller mechanism, a turning mechanism, a horizontal parting mechanism, a longitudinal parting mechanism and a cover band roller chain conveying mechanism. The automatic braiding machine has scientific and reasonable structures and automatic braiding and automatic parting functions and is capable of automatically finishing braiding, horizontal parting and longitudinal parting in sequence, sequential stacking of green bodies is achieved, gaps among the green bodies are even, green body square matrixes are orderly, the novel automatic braiding machine is stably operated, and the yield is high.

Owner:中节能东方双鸭山建材设备有限公司 +1

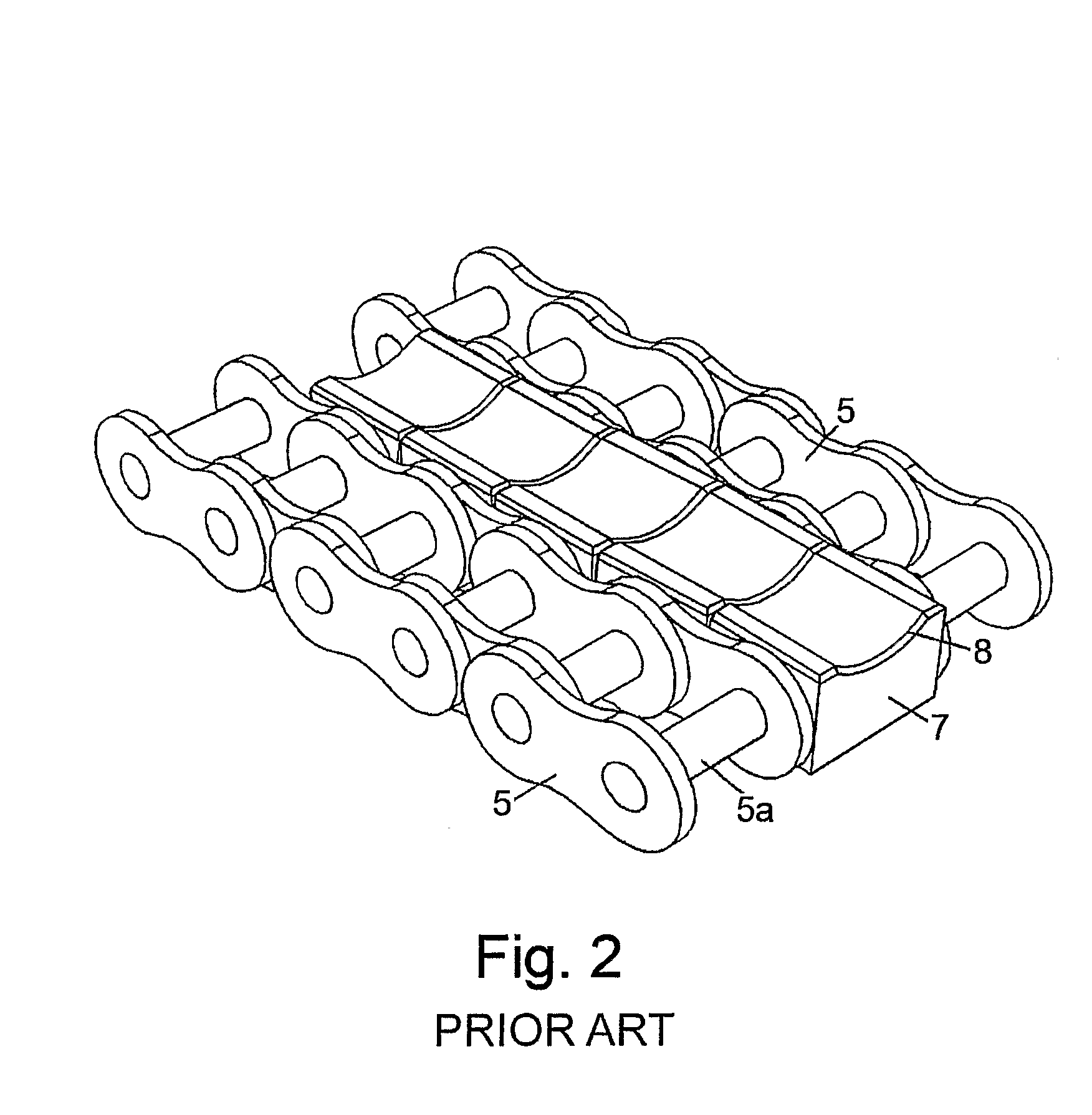

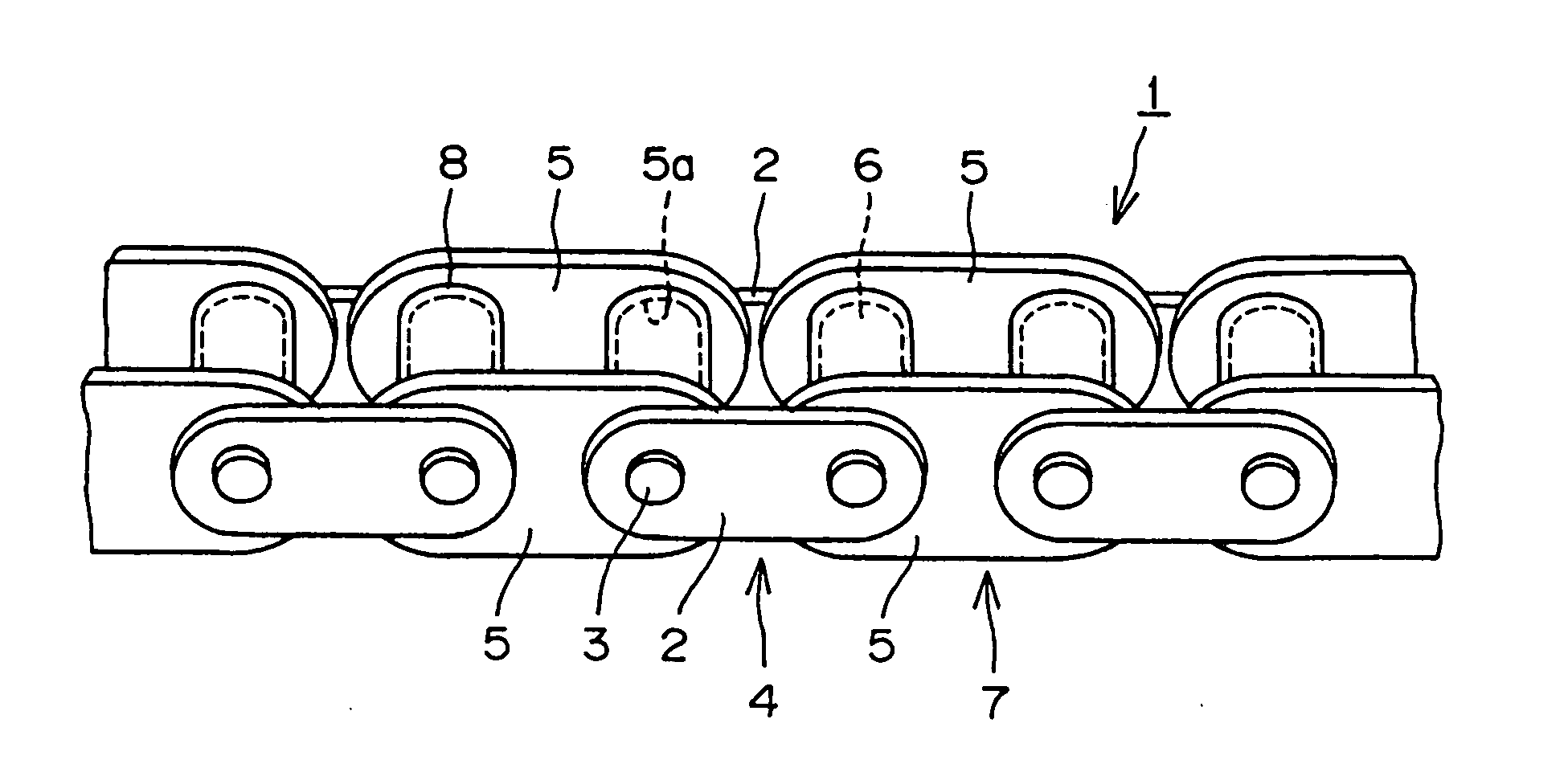

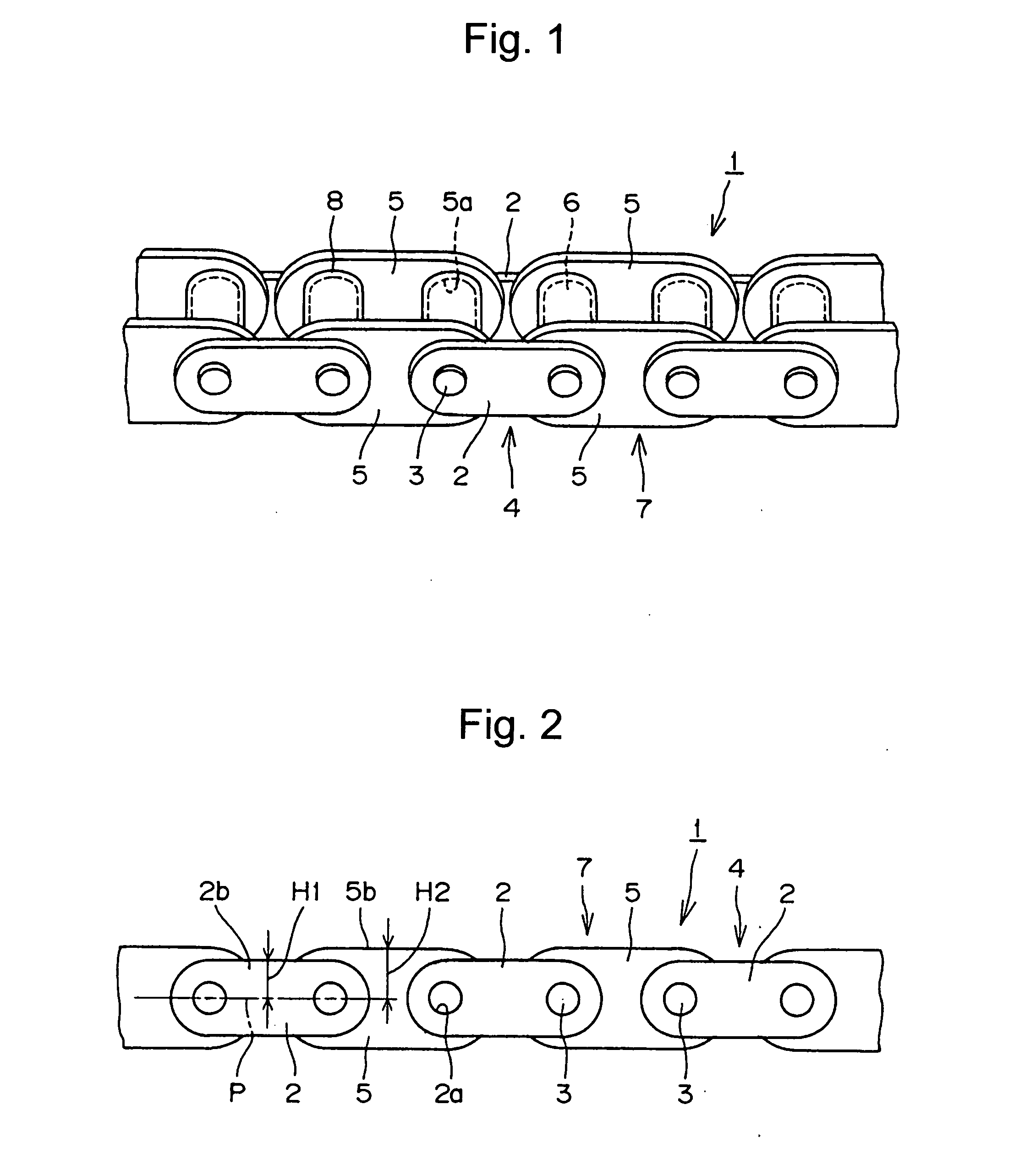

Chain

InactiveUS6855080B2Improve loading effectReduce weightRotary combination bearingsConveyorsProject areaThrust bearing

A roller chain incorporates a plurality of rolling members between a roller and a bushing. A thrust bearing plate is provided between the end surfaces of the roller and inside surfaces of inner link plates. The outer diameter of the roller is smaller than the widths of the inner link plates and the outer link plates and the roller is accomodated in a projected area of the widths of the inner link plates and the outer link plates.

Owner:TSUBAKIMOTO CHAIN CO

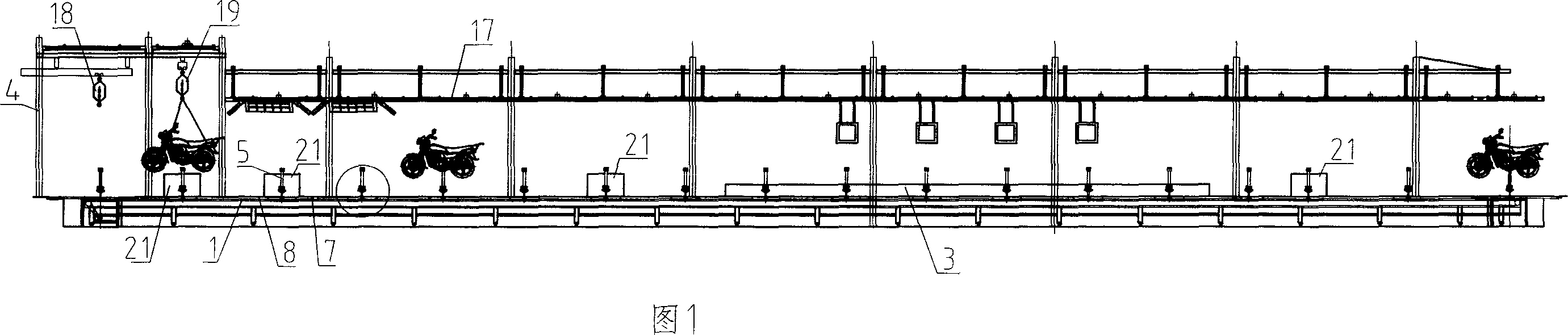

Integrative ground horizontal circular flexible production line for assembling and checking out motorcycle

ActiveCN101003292AFlexible and convenient operationReduce labor intensityVehiclesProduction lineRoller chain

A motorcycle assembling and testing integrated flexible production line circulating horizontally on the ground is composed of an endless master roller-chain conveyer line arranged horizontally underground, the assembling workstations at the side of said master conveyer, the flat base plates of assembling fixture on said roller-chain, performance test position, performance test system, and returning-repairing line.

Owner:ฉงชิ่ง จงเซิน มอเตอร์ไซเคิล อินดัสเทรียล แมนูแฟคเจอร์ โค แอลทีดี

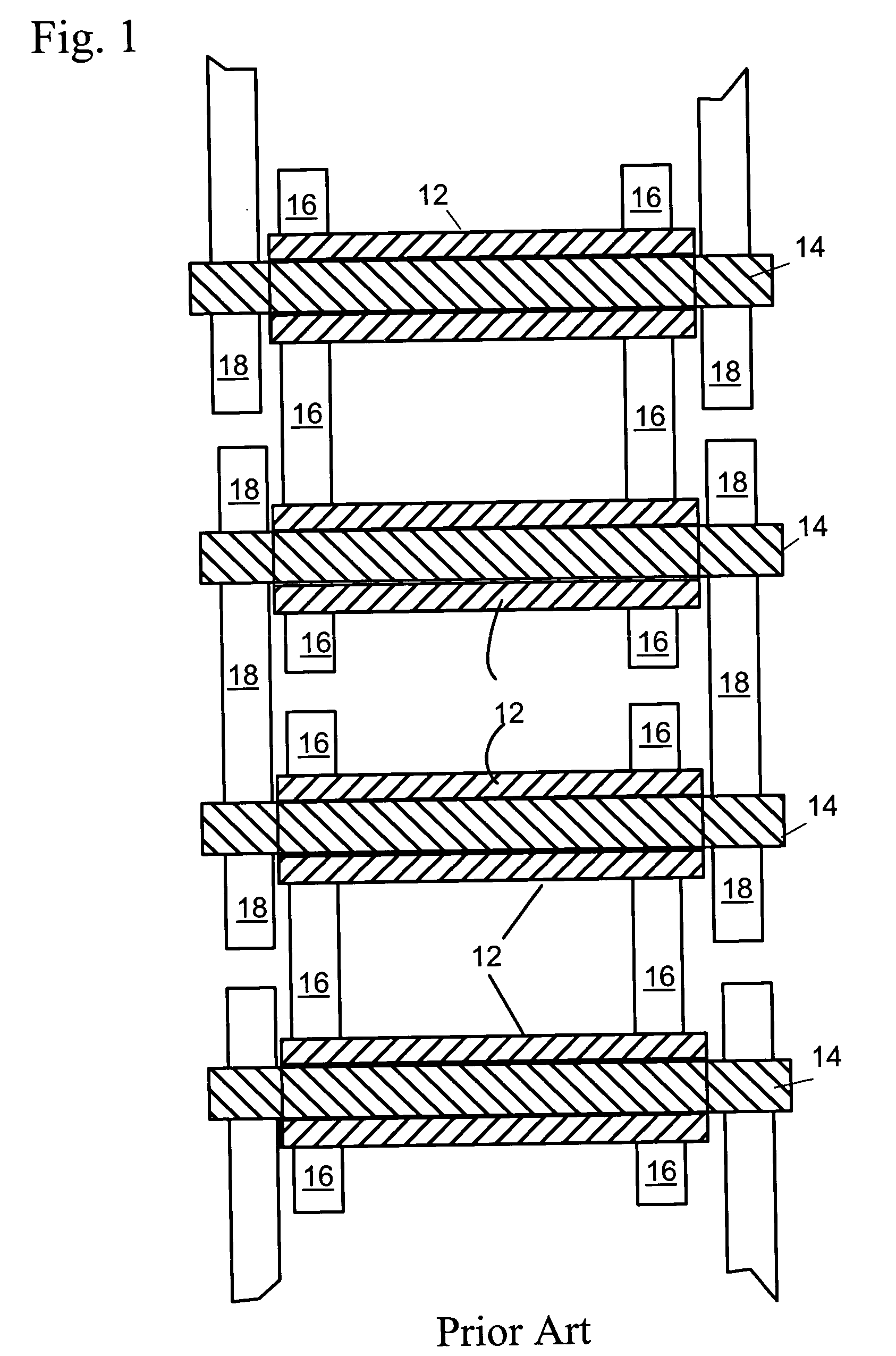

Conveyance system

InactiveUS7442139B2Efficient executionReduce vertical movementConveyorsV-beltsRoller chainEngineering

In a slat conveyor, slats for supporting conveyed articles and personnel extend between two side-by-side, spaced, endless roller chains engaged with driving sprockets at one end of the conveying path and driven sprockets at the other end. At a location radially outward from the pitch circle, the distance between the front surface of the sprocket teeth to the tooth center line is at least as great as the distance from the centerline to the front surface at the pitch circle. The tooth faces merge smoothly with the tooth gap bottom, and the root diameter is smaller than the root diameter according to ISO standards.

Owner:TSUBAKIMOTO CHAIN CO

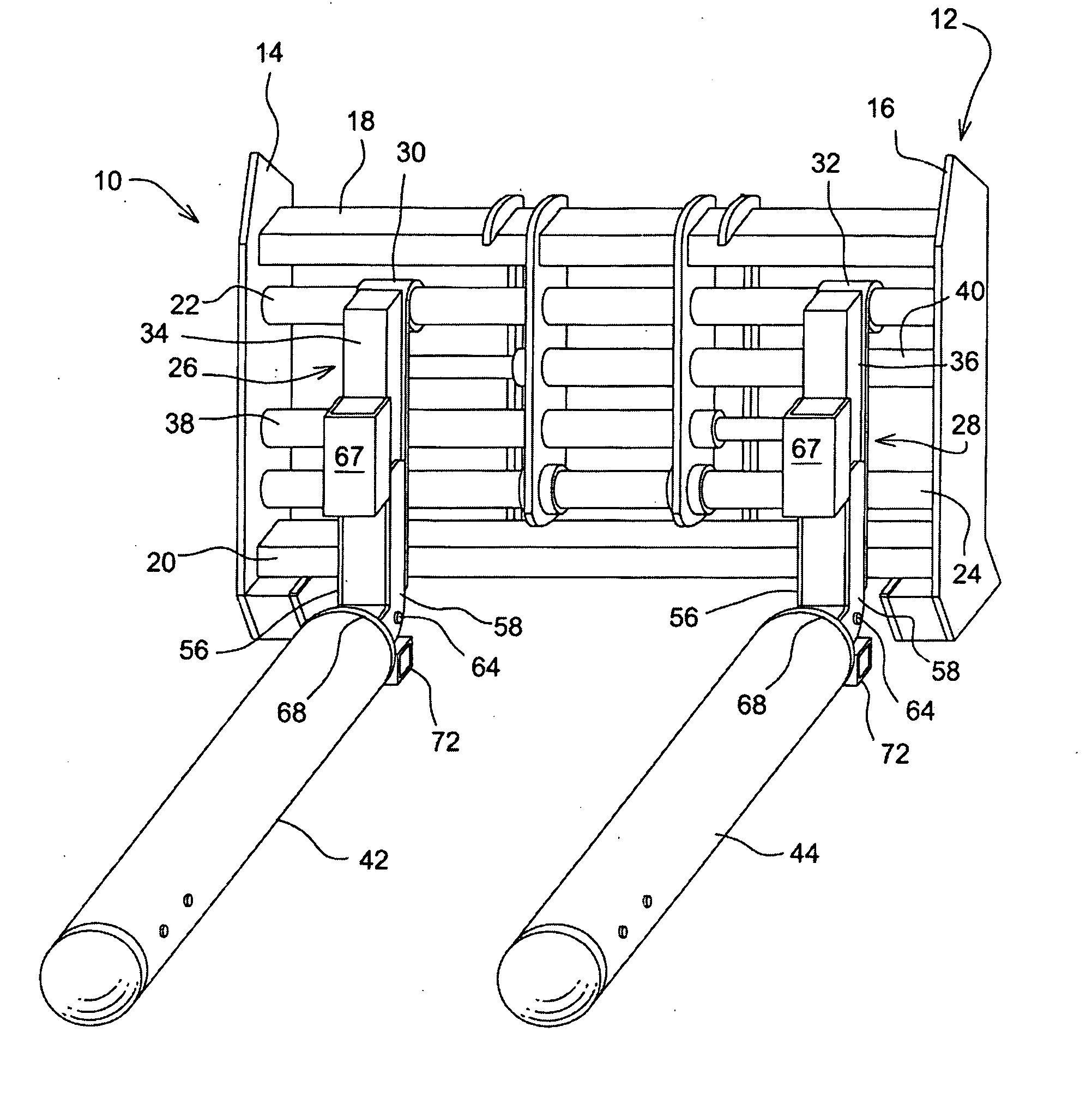

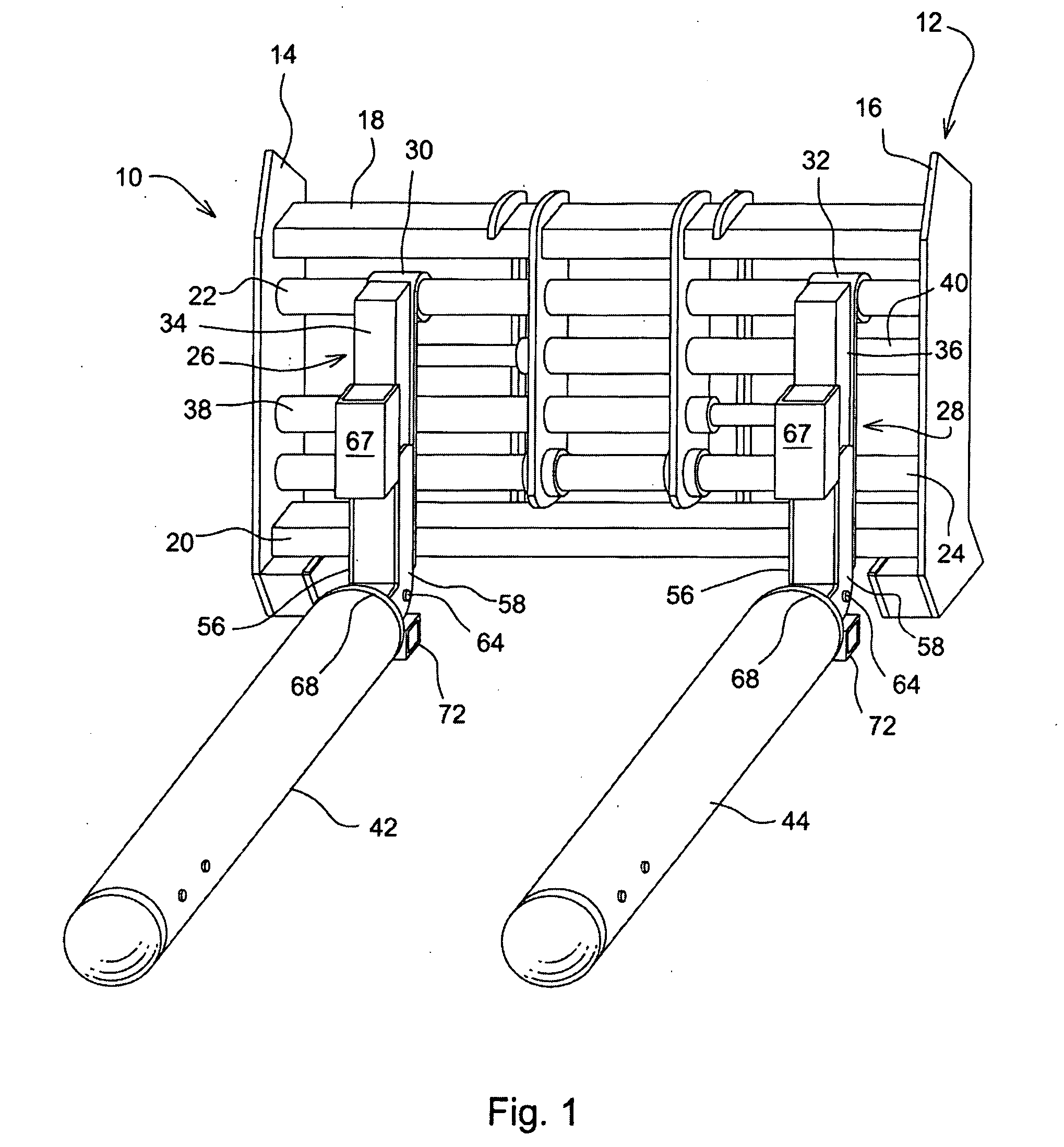

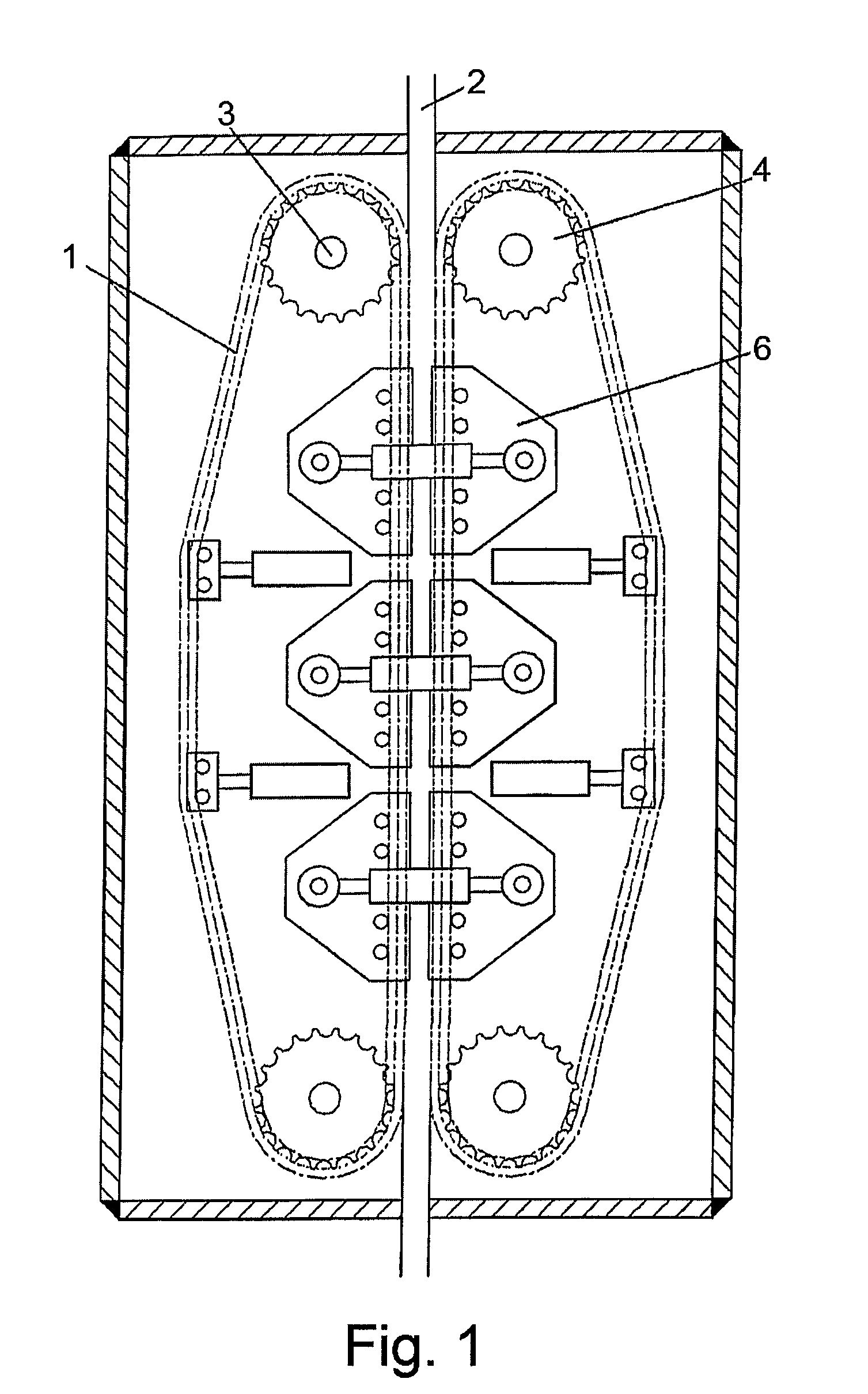

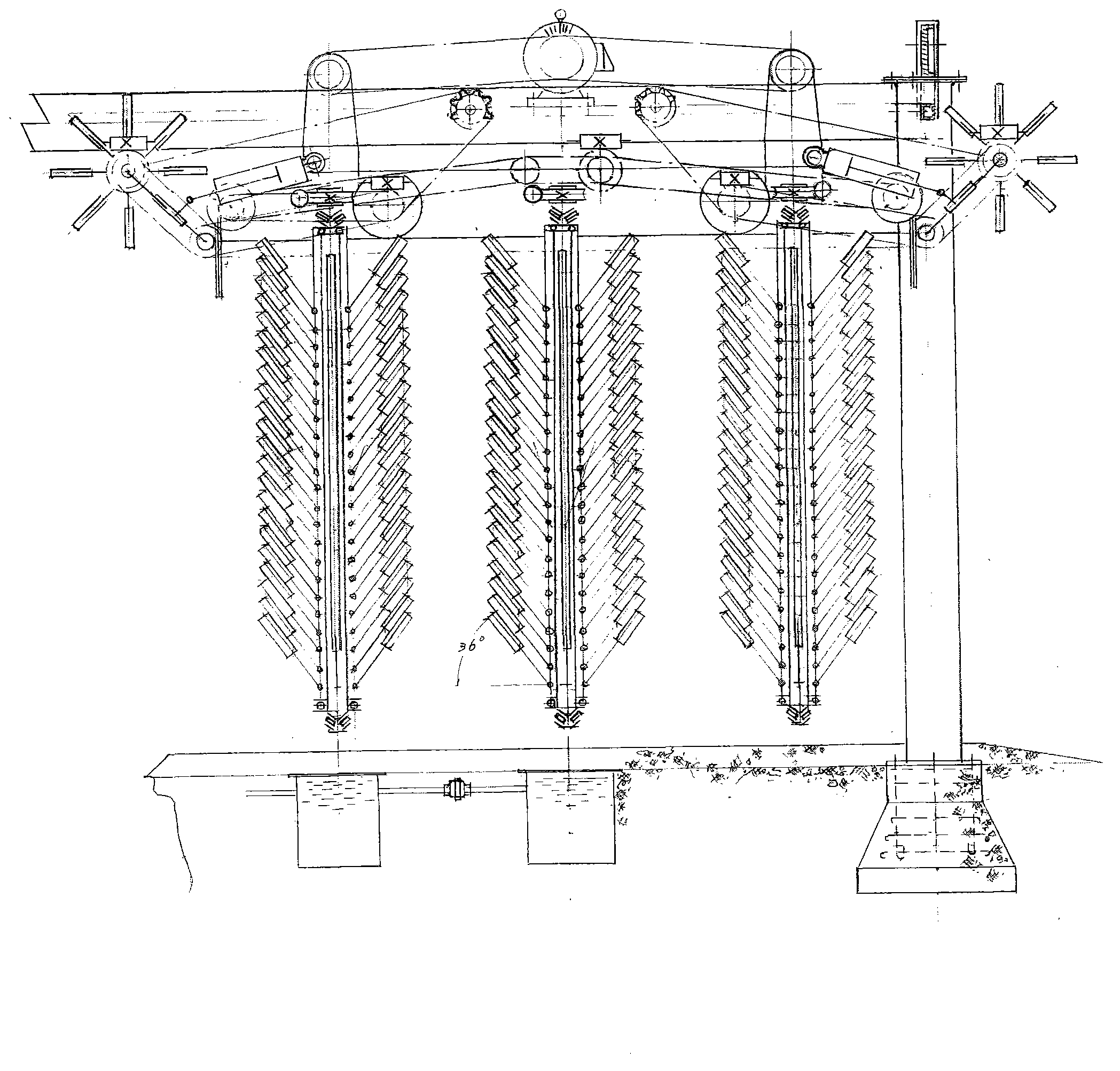

Coiled Tubing Injector Head

ActiveUS20090250205A1To offer comfortReduce distortionDrilling rodsFluid removalCoiled tubingEngineering

An improved coiled tubing injector head, comprising a plurality of powered chain loops (1), each having one practically straight side adjacent to the other chain loop(s) and biased against a tubing (2) running in-between all the loops so as to grip the tubing and allow its transit into and out of a well. The chain loops are assembled from multifunctional links (23, 24) which both transmit drive and also form carriers for replaceable gripper blocks or are the carriers and gripper blocks combined, without need of a roller link chain or chains in addition to the multifunctional links. Three or more chain loops are provided, and the chain loops are driven by electric motors.

Owner:ASEP HLDG

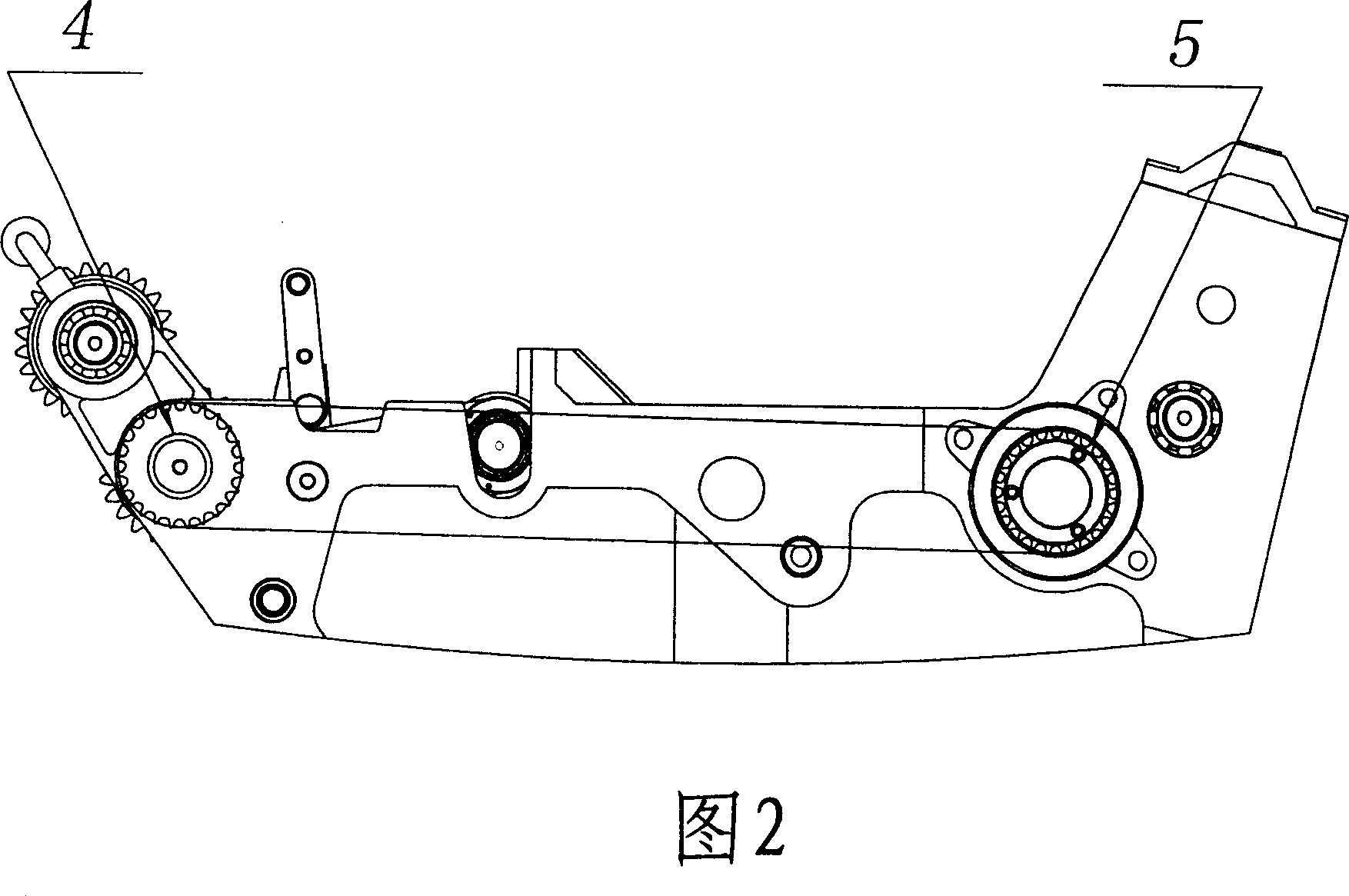

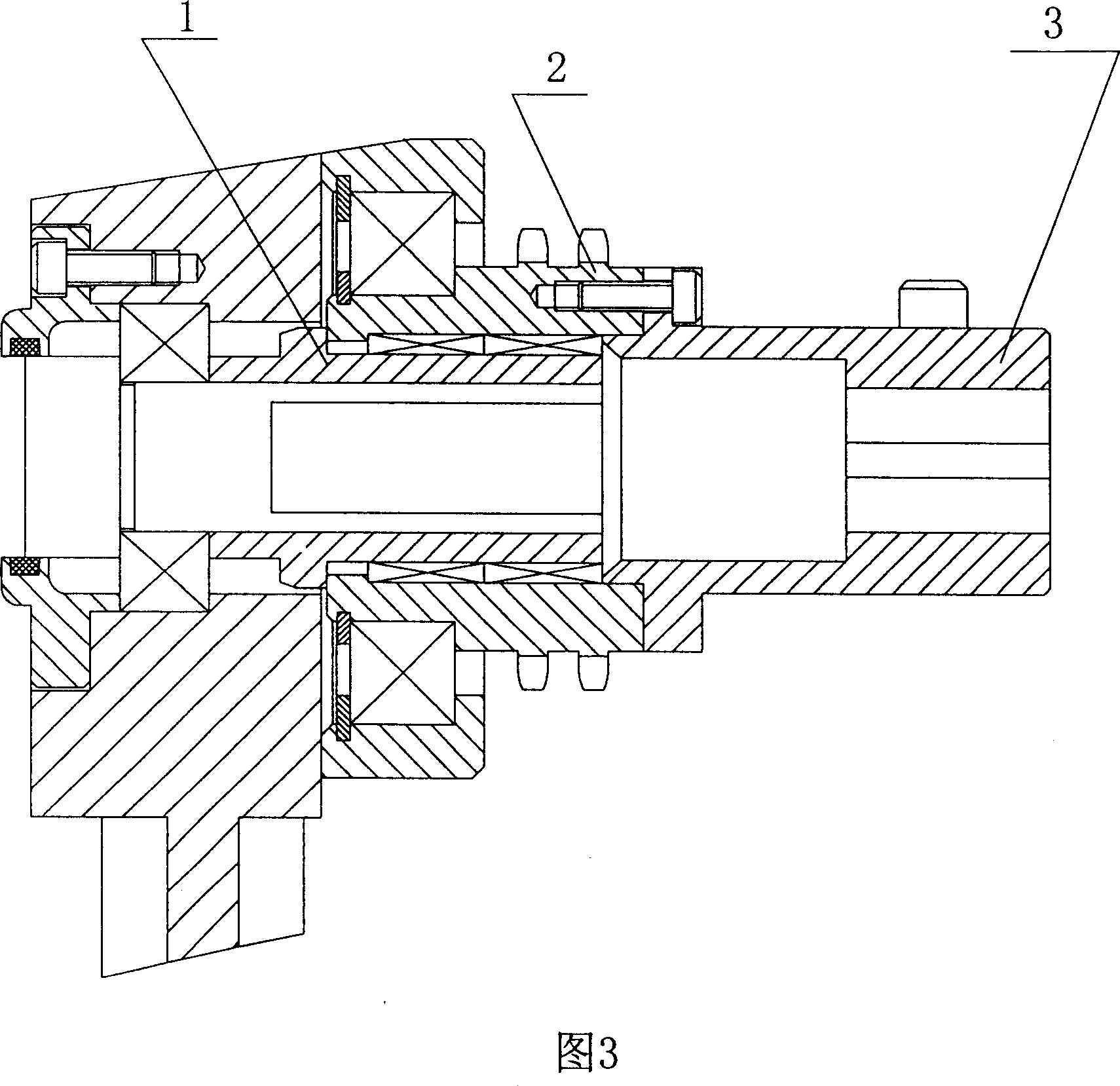

Front and rear roller crosslinked cloth-traction mechanism for quilting machine

InactiveCN1962988ASolve the jumperSolve disconnectionWork-feeding meansMattress sewingElectric machineryRoller chain

The invention discloses a cloth dragging device of quilter which front and rear rollers are interdynamic and in a union. It includes front rollers group, rear rollers group and generator; it is characterized by: it also includes rolling spline connected with and drived by generator, the sub-output ends of rolling spline are equipped with rolling splined hub (3), rear roller chain wheel (2) and the bearing flat hole sleeve (1) one by one, the input ends of the rear and front rollers are equipped with one-way rotating devices (4, 5). The invention solves the problems of pattern aberration, jumper wire and cut line leading by retardation which is the result of the cloth back in the tangential direction and improves the quilting effects.

Owner:李德锵

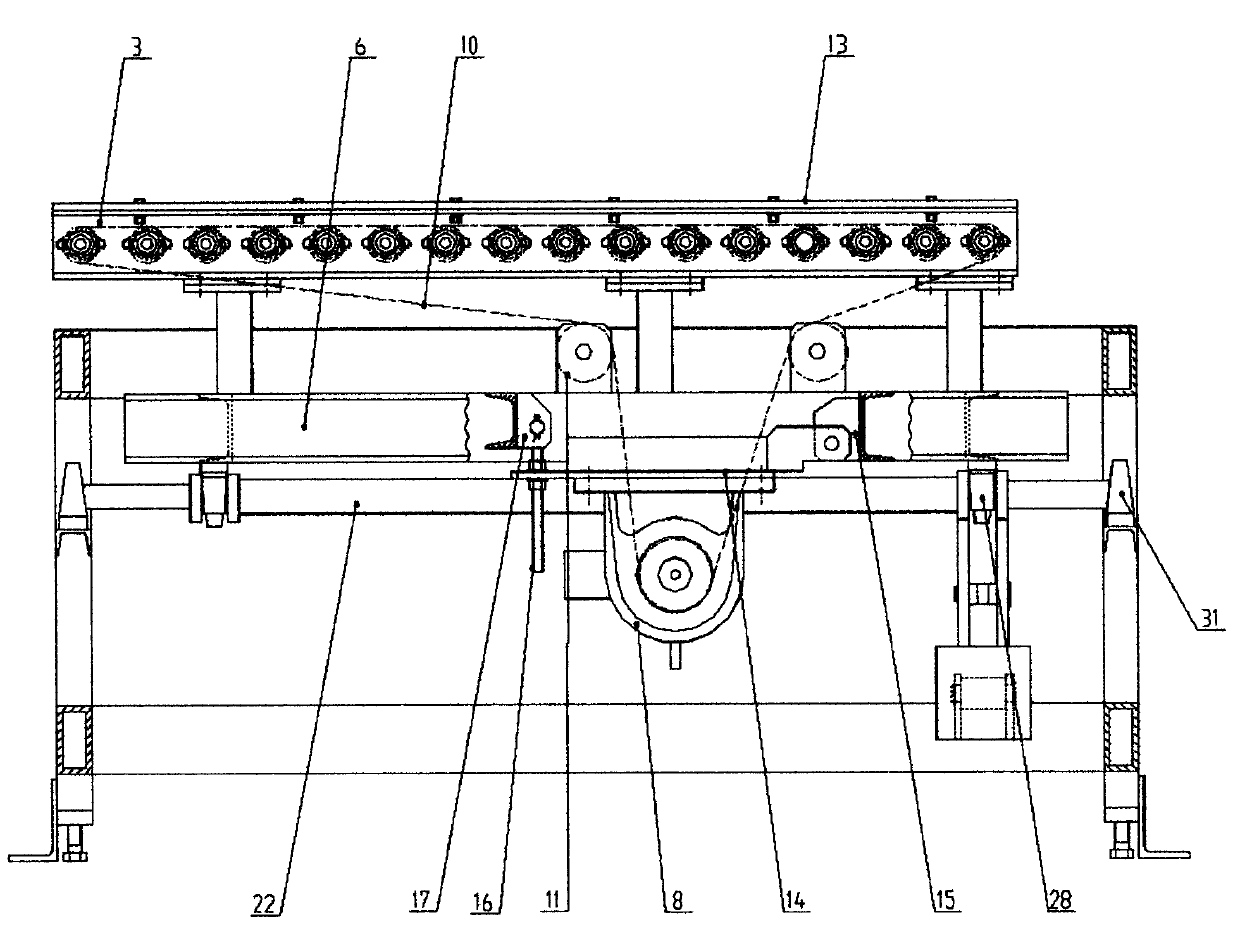

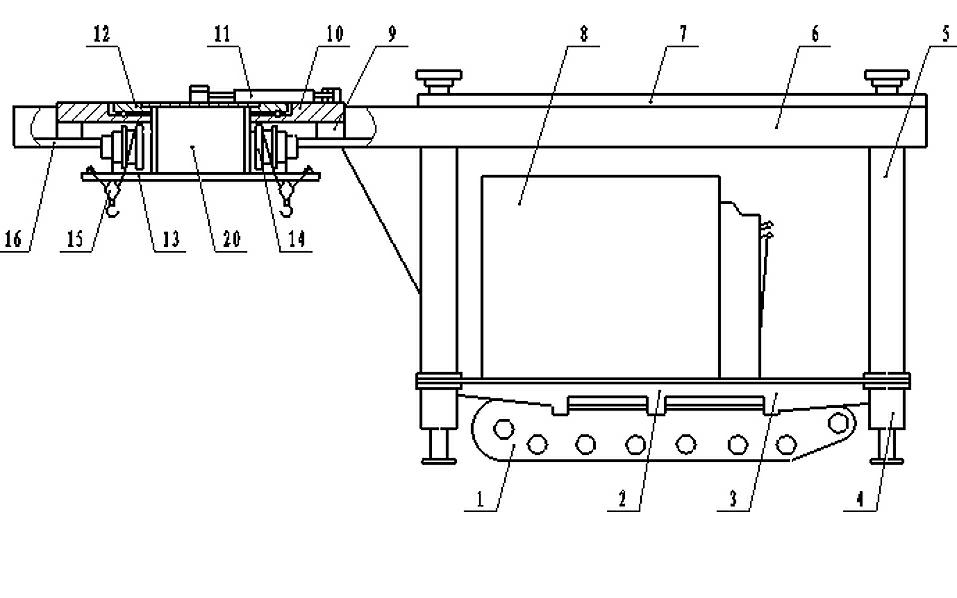

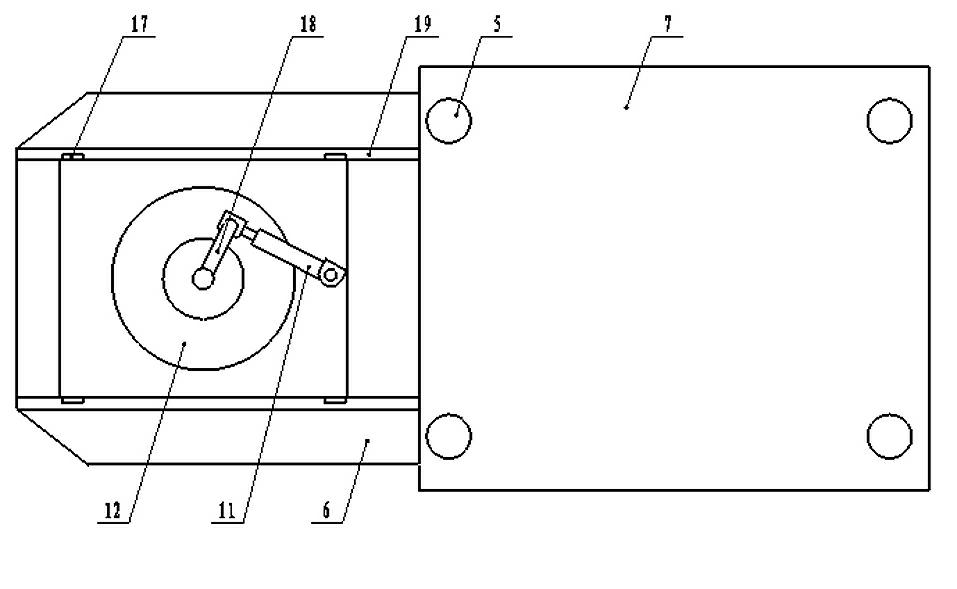

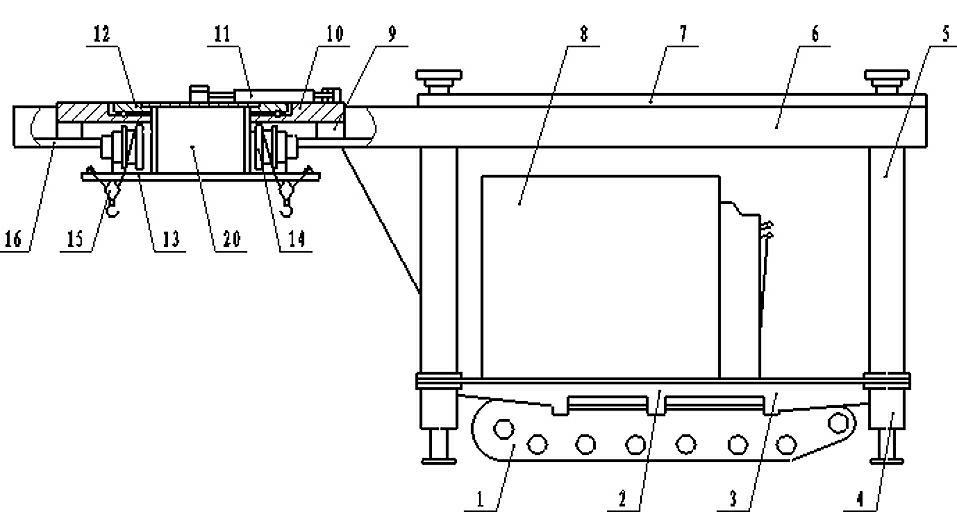

Crawler hydraulic support assembling machine

InactiveCN102134043AAppropriate installation locationTrolley cranesProps/chocksCantilevered beamRoller chain

The invention relates to a crawler hydraulic support assembling machine and belongs to the technical field of underground cranes of coal mines. The technical problem to be solved is to provide a crawler hydraulic support assembling machine which can conveniently lift a hydraulic support and is provided with the hydraulic support. The technical scheme is that: two walking parts are symmetrically arranged on the lower part of a machine frame; two cantilever beams parallel to the walking parts are symmetrically arranged on both sides of the upper part of the machine frame; a rotatable lifting hook part is arranged between the two cantilever beams; in the machine frame, a base is fixed on the walking parts; the four corners of the base are provided with a supporting cylinder respectively; the cylinder body of the supporting cylinder is fixed on the base; a piston rod of the supporting cylinder is vertically upward and is higher than a top cover of the machine frame; a square frame structure is formed by the base, the cylinder body of the supporting cylinder and the top cover of the machine frame; the two cantilever beams are positioned on the two sides at the bottom of the top cover of the machine frame, and each cantilever beam is fixed on the two supporting cylinders; and the running track of the inner side of each cantilever beam is provided with a roller chain. The crawler hydraulic support assembling machine is used for assembling the hydraulic support.

Owner:SHANXI DONGHUA MACHINERY

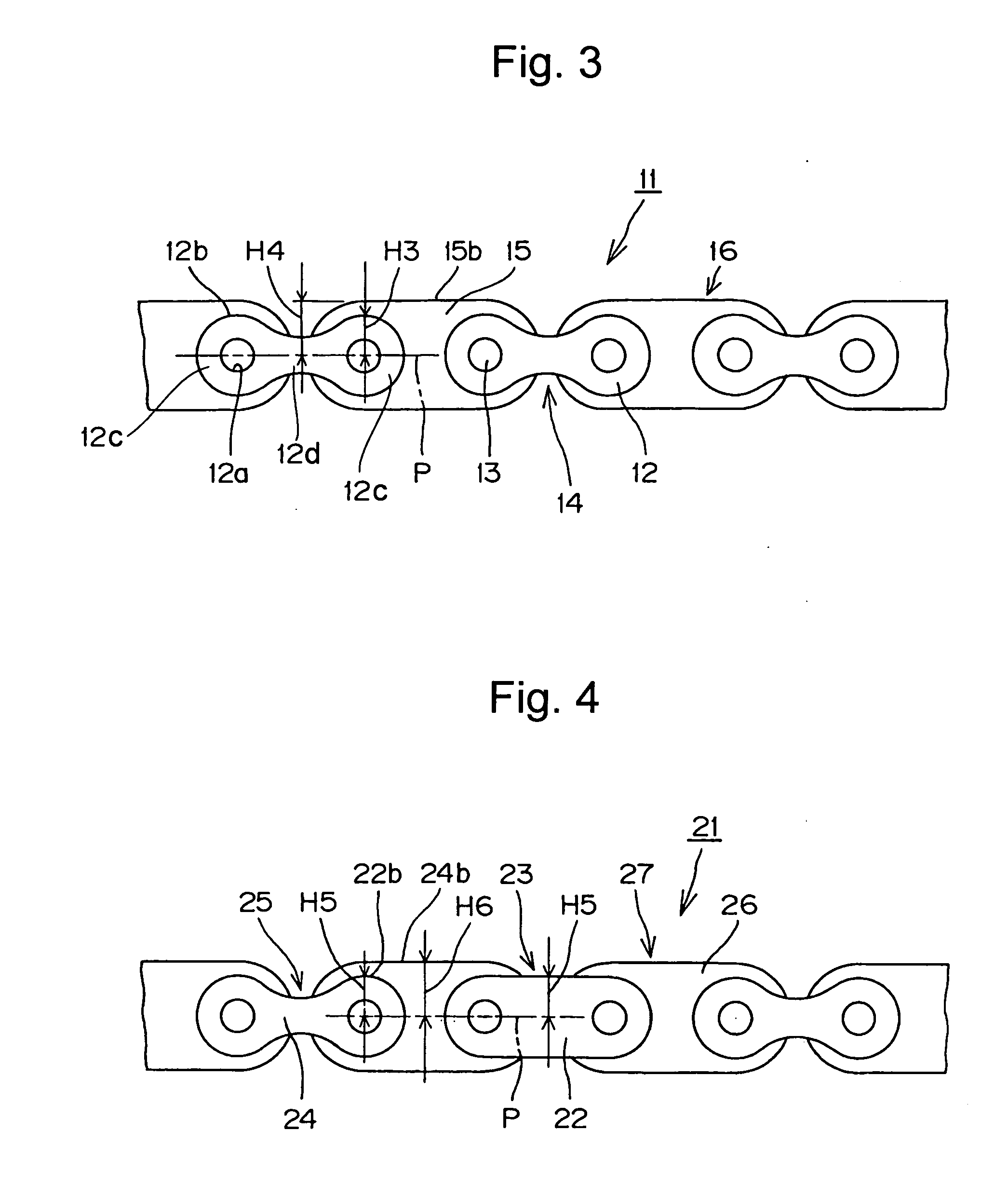

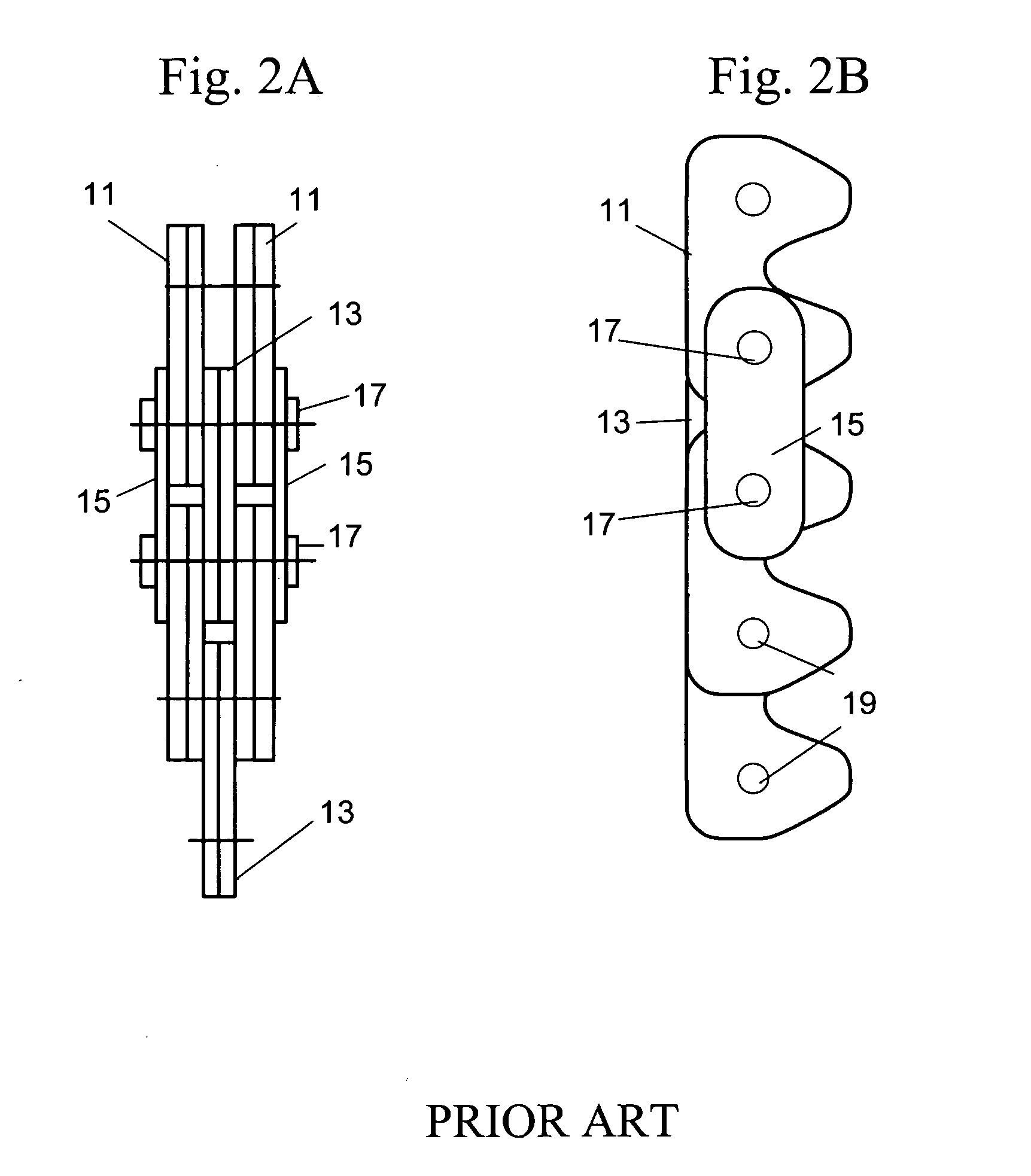

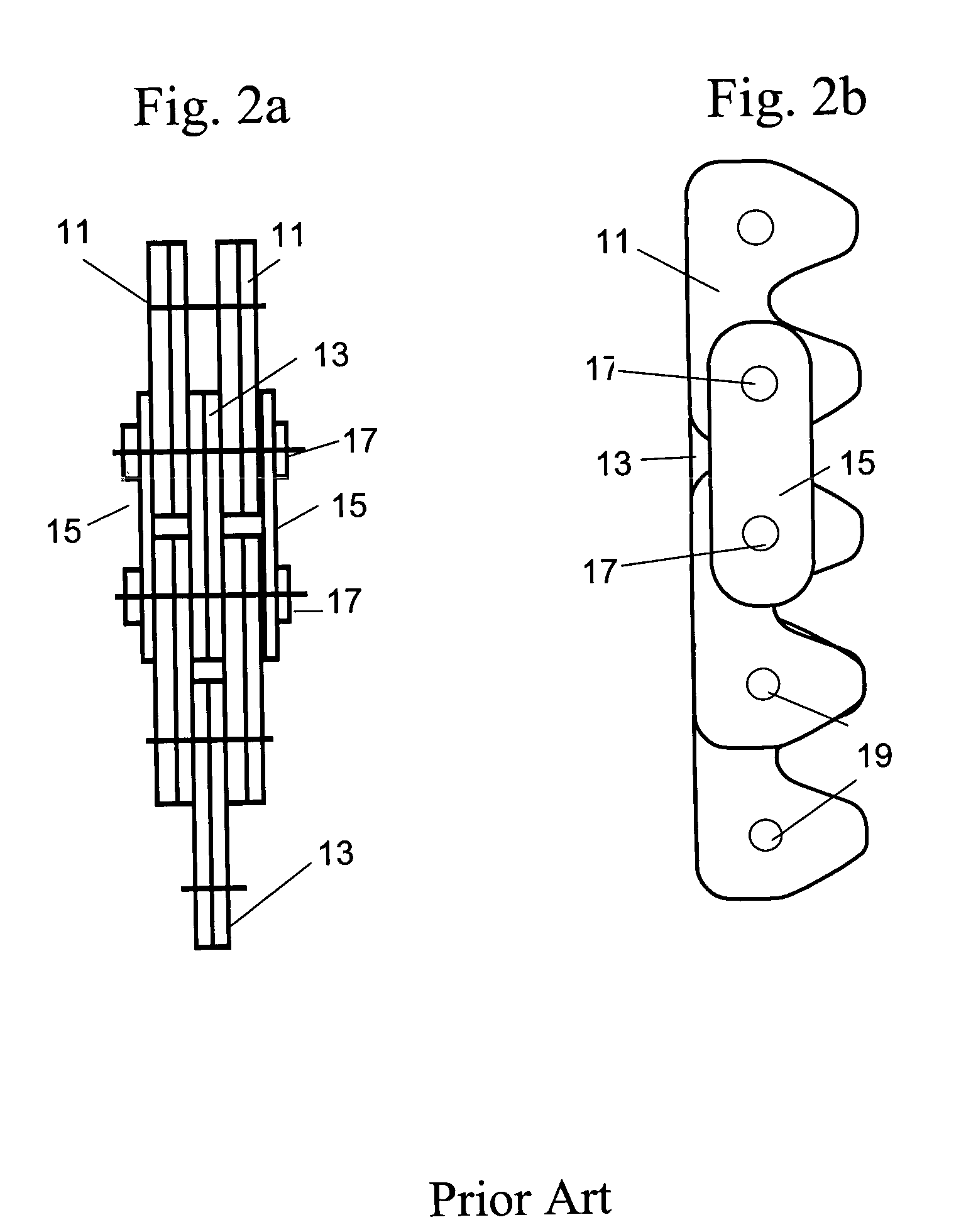

Roller chain

InactiveUS20070082776A1Reduce contact areaReduce frictional resistanceDriving chainsFriction reductionEdge surface

A roller chain, in which when the roller chain comes into contact with guide members, the contact area is reduced, so that frictional resistance is decreased and friction loss generated during transmission of power is reduced. A roller chain is formed such that an outer link assembly comprising a pair of outer link plates and an inner link assembly comprising a pair of inner link plates are alternately connected along the pitch line of the chain to each other by pins. The distance from the pitch line of the roller chain to outermost edge surfaces of the link plates is the backside height. The backside height of the outer link plates is lower than the backside height of the inner link plates. When the roller chain contacts and slides on the guide members, the outer link plate does not come into contact with the guide members so that friction loss can be reduced. In some embodiments, some of the link plates are concave ellipsoidal (gourd-shaped) and others are non-concave ellipsoidal (cucumber-shaped).

Owner:NAGAO KENICHI

Silent chain

Owner:BORGWARNER INC

High-performance silent chain

InactiveUS20050049098A1Increase the carrying areaIncrease widthGearing controlDriving chainsRoller chainWear resistance

A hybrid roller / silent chain of the present invention has the wear resistance of a roller chain combined with the noise performance of a silent chain. This is accomplished with the use of transverse load-bearing elements that allow increased bearing area for the articulating members of the chain by allowing load to be transmitted through both the inside and outside diameter of the element in the same plane. In some embodiments, the transverse load-bearing elements are bushings. In other embodiments, the elements are projections extending from non-guide row inside links.

Owner:BORGWARNER INC

Bridge type hydraulic arch arm mechanical arm bus automatic washing machine

The invention discloses a bridge type hydraulic arch arm mechanical arm bus automatic washing machine. A bridge framework structure is formed by components such as a track, a truss girder, a trimmer and a pile. A hanging type work platform vehicle for surrounding the track face of the truss girder to perform back-and-forth operation is borne on the track face of the truss girder. An aligning auxiliary platform is installed on the top face of the work platform, and the two sides of the aligning auxiliary platform are provided with four sets of single rod-type special TG254 sleeve roller chain transmission structures, and the two sides of the longitudinal center line of the work platform are respectively provided with three hydraulic cylinders controlled by an electromagnetic reversing valve and arch arm mechanical arms connected with an arch shoulder, the position away form the arch shoulder by 127.5cm is provided with a worm speed reducer which drives a rotation brush wheel to perform wiping and cleaning at a lower speed of 29 revolutions per minute, wherein the rotation brush wheel is 260cm in length and contains 88 inflatable milky glass thermal plastic rubber wiping palms. 22 120-degree horseshoe-shaped gap water spraying nozzles are installed on an arch arm and the ground to wash the left side, the right side, the front side, the rear side, the top, the bottom and wheels of a bus in a spraying mode. Each wheel is provided with a wheel protection cover for protection, a far infrared sensing and key type numerical control system and a parallel circuit manual control plate are assembled, a warm air blow-dray device is arranged, and a 220V power supply is used.

Owner:昝士录

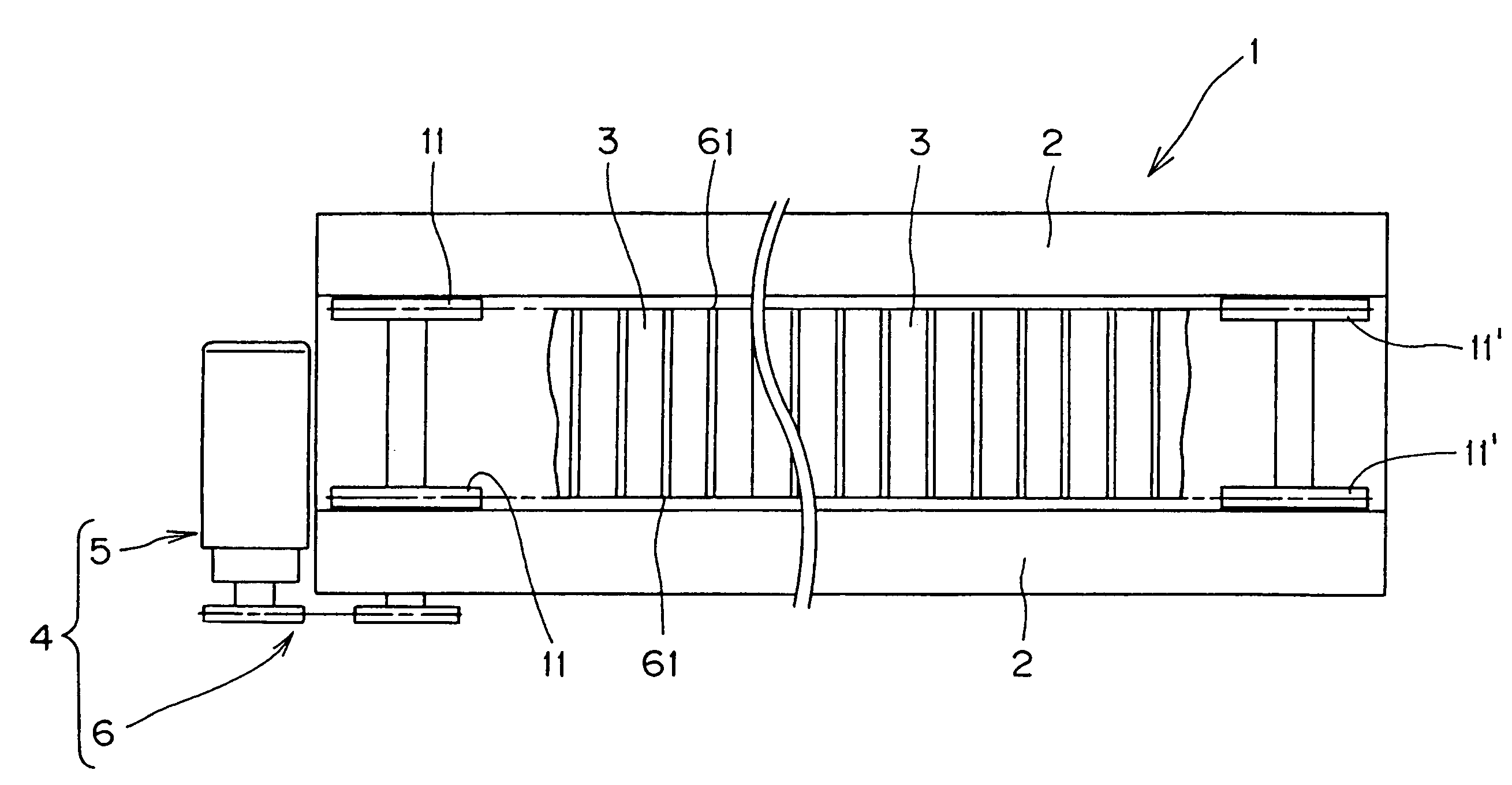

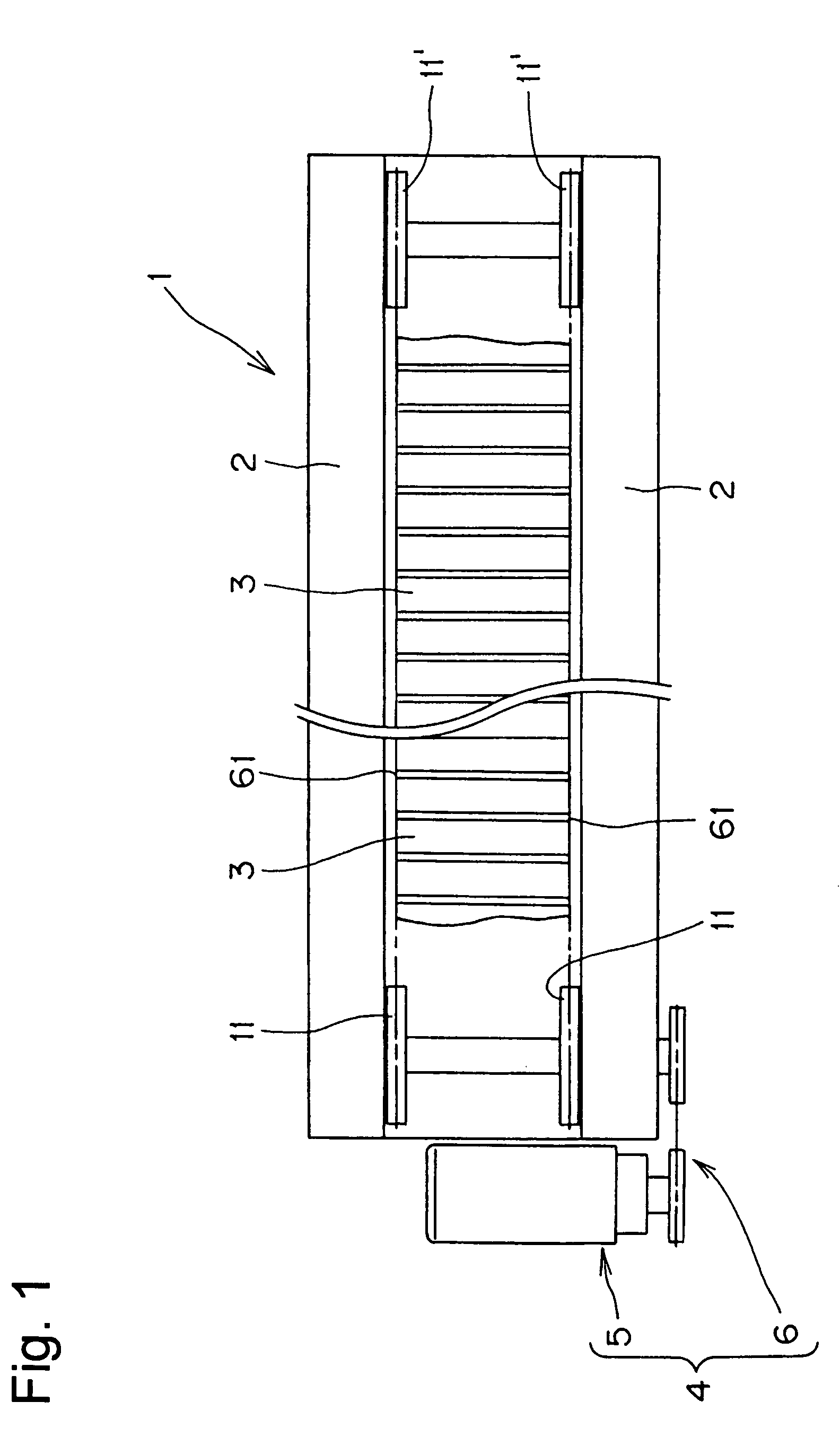

Linear motion guide unit

ActiveUS20050018933A1Good saveEasy to assembleRoller bearingsLinear bearingsLinear motionEngineering

A linear motion guide unit is disclosed in which there is provided a retainer band making it possible to easily fit a roller chain with rollers traveling through a recirculation circuit into a load way of the recirculation circuit, thereby making sure of smooth recirculation of the roller chain. Cooperation of the retainer band with a retainer plate helps guide links of the roller chain in a load way of the recirculation circuit, keeping the roller chain against running out of the load way thereby ensuring smooth movement of the roller chain throughout the recirculation circuit.

Owner:NIPPON THOMPSON

Silent chain

ActiveUS20050049097A1Increase the bearing surfaceImproved silent chain characteristicDriving chainsRoller chainWear resistance

A Hybrid Roller / Silent chain that has the wear resistance of a roller chain combined with the noise performance of a silent chain. This is accomplished with the use of bushings that allow increased bearing area for the articulating members of the chain, specifically by allowing load to be transmitted through both the inside and outside diameter of the bushing in the same plane.

Owner:BORGWARNER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com