Elastomer cushion ring for a random tooth roller chain sprocket

a technology of elastomer cushion rings and random teeth, which is applied in the field of cushion rings, can solve the problems of creating undesirable chain engagement noise and disrupting repetitive chain engagement noise orders, and achieve the effects of reducing noise, reducing chain roller and/or bushing engagement impact force, and increasing roller/bushing fatigue li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

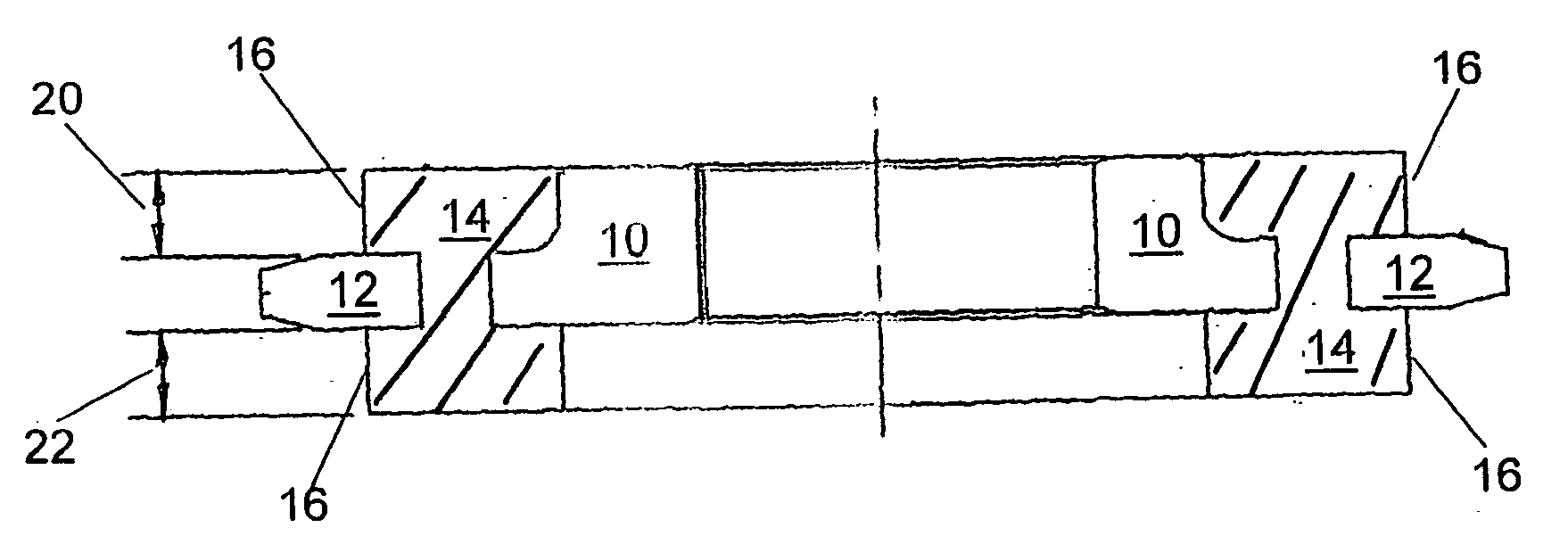

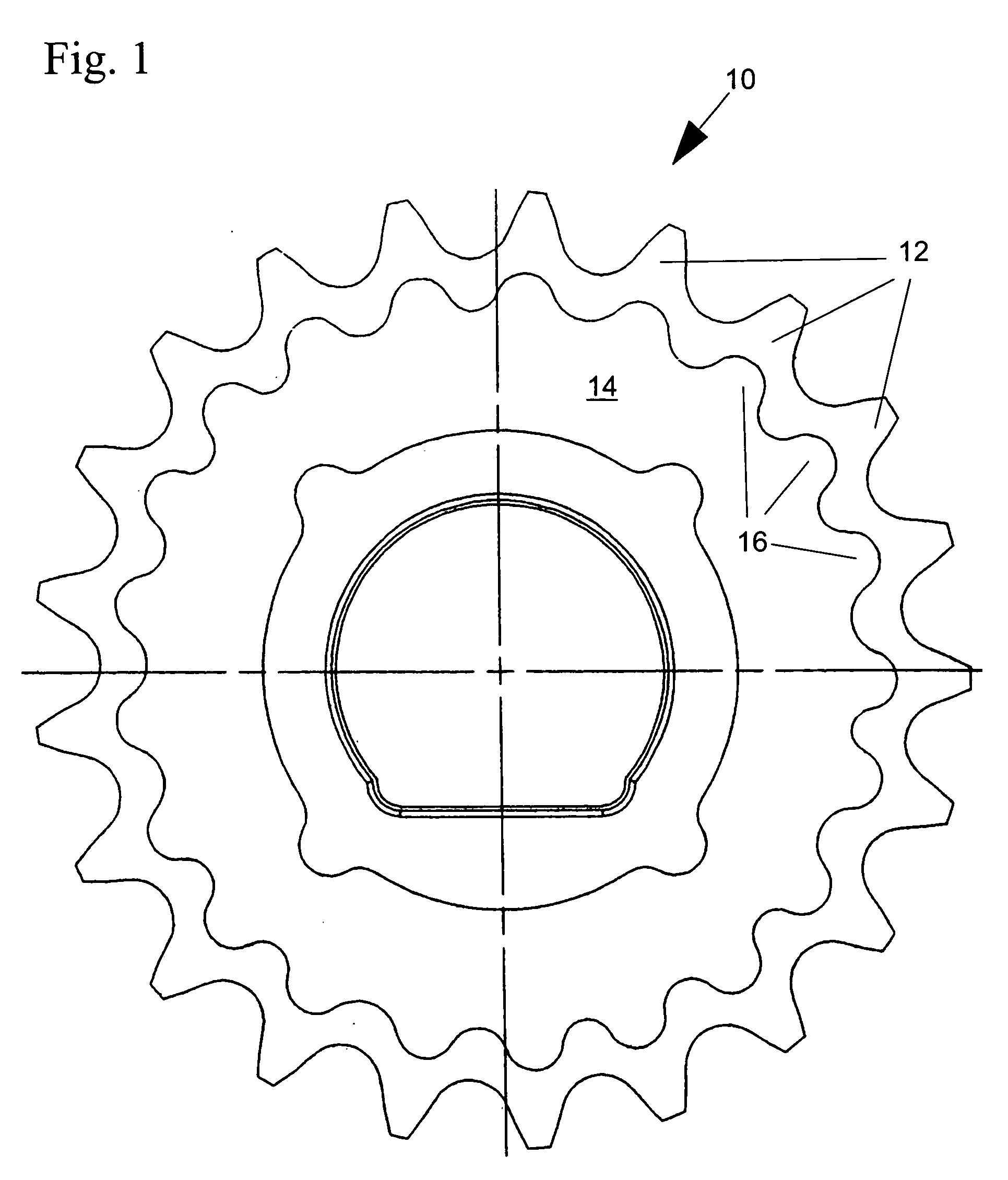

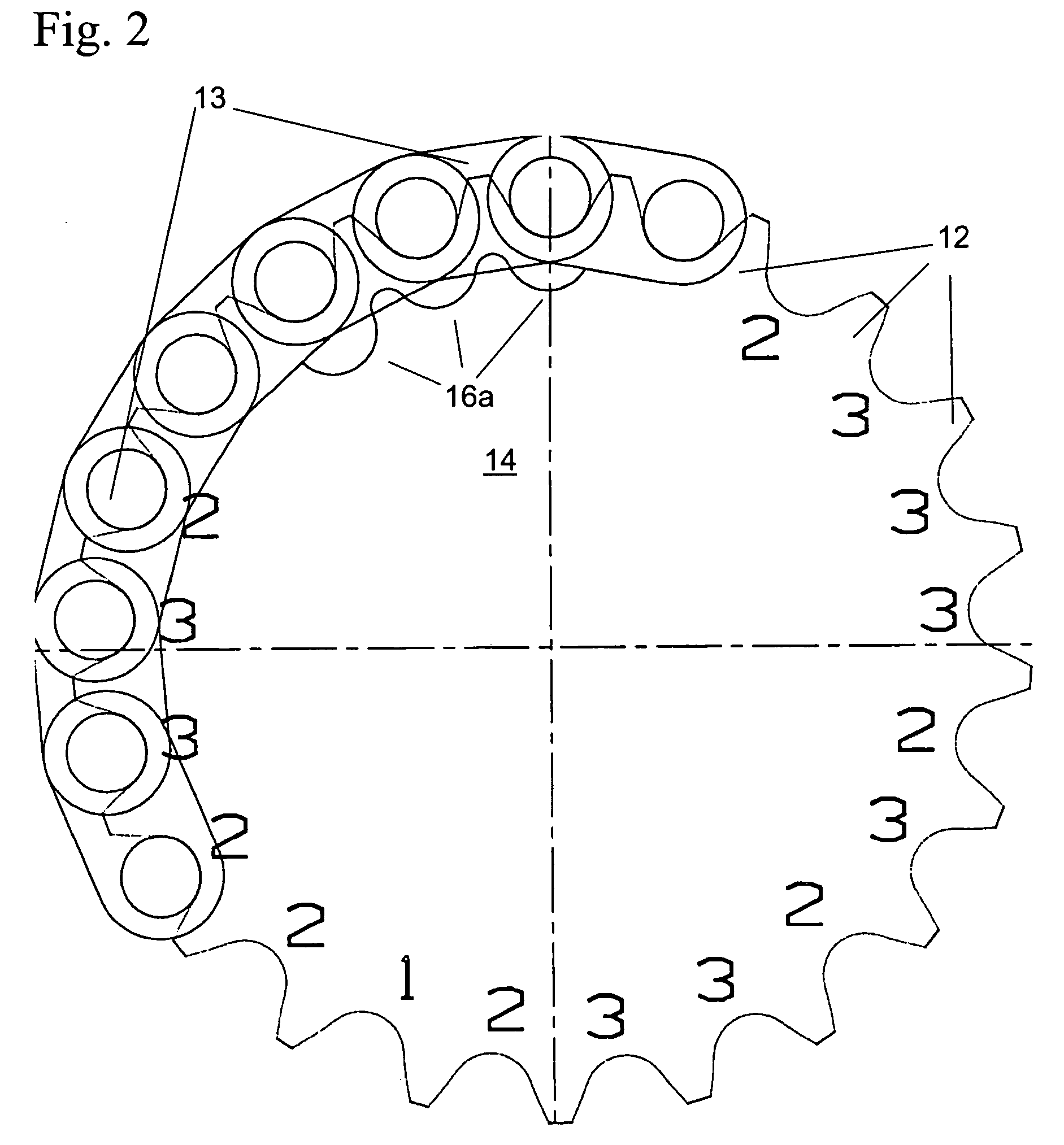

[0024] Referring to FIGS. 1-9, a random tooth chain sprocket 10 having a set of teeth 12 circumferentially distributed upon its circumference is shown. Random tooth chain sprocket 10 may be used in conjunction with a roller chain 13 having random tooth chain sprocket 10 with a plurality of roots with the first root radius and a plurality of roots with the second root radius. The roots having the first root radius are randomly arranged with the roots having the second root radius in a predetermined pattern about the random tooth chain sprocket 10 periphery. By randomly arranged, it is meant that the pattern is staggered between first and second radii, and not a pure alternating pattern between first and second radii. For detailed description of the random tooth sprocket, refer to U.S. Pat. No. 6,155,943, which is hereby incorporated herein by reference. A random sprocket comprises two or more radii for locating the tooth roots. In the preferred embodiment of the present invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com