Patents

Literature

503results about "Fuel cell shape/form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

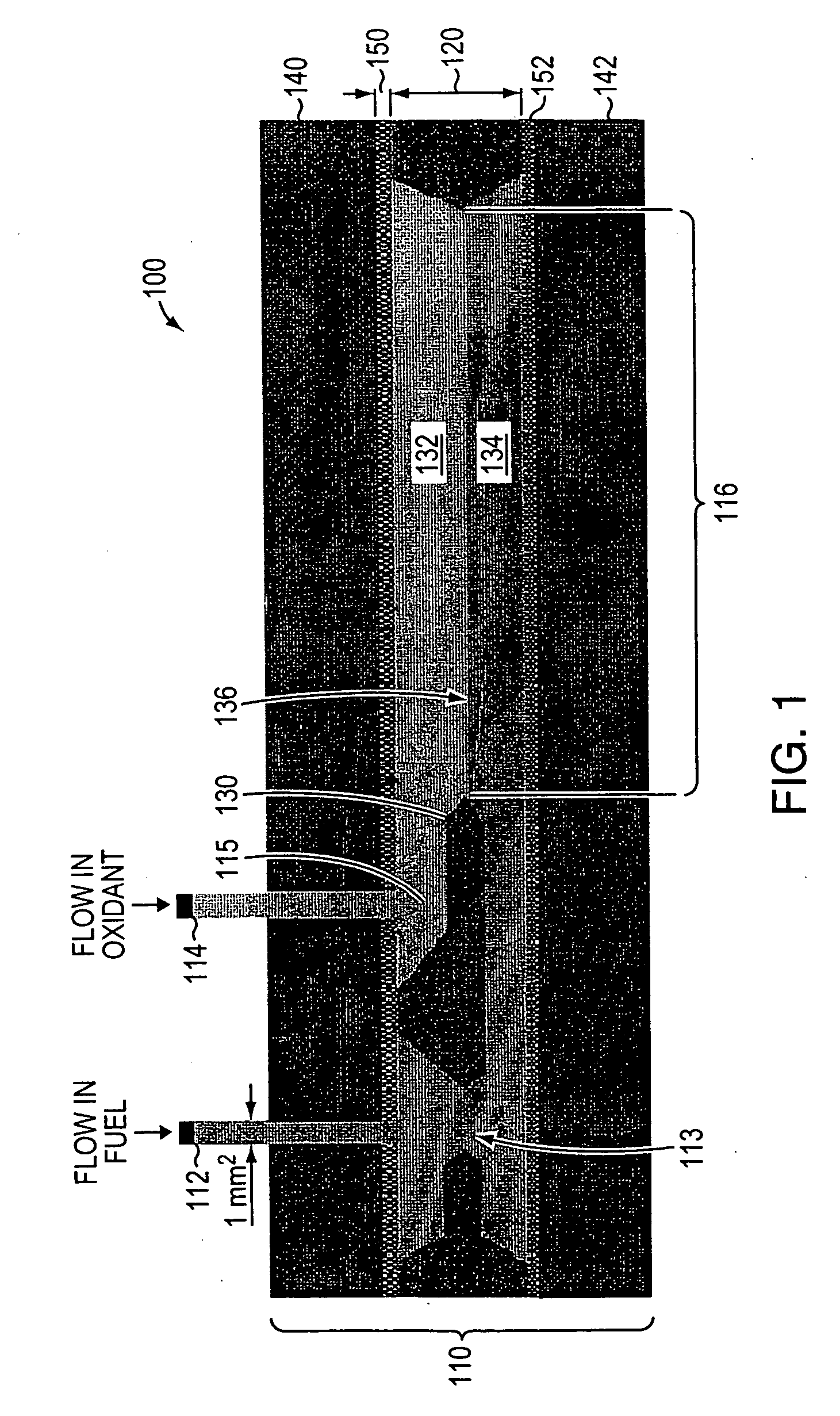

Fuel cell device and system

ActiveUS20090226781A1Additive manufacturing apparatusFuel cell heat exchangeFuel cellsReaction temperature

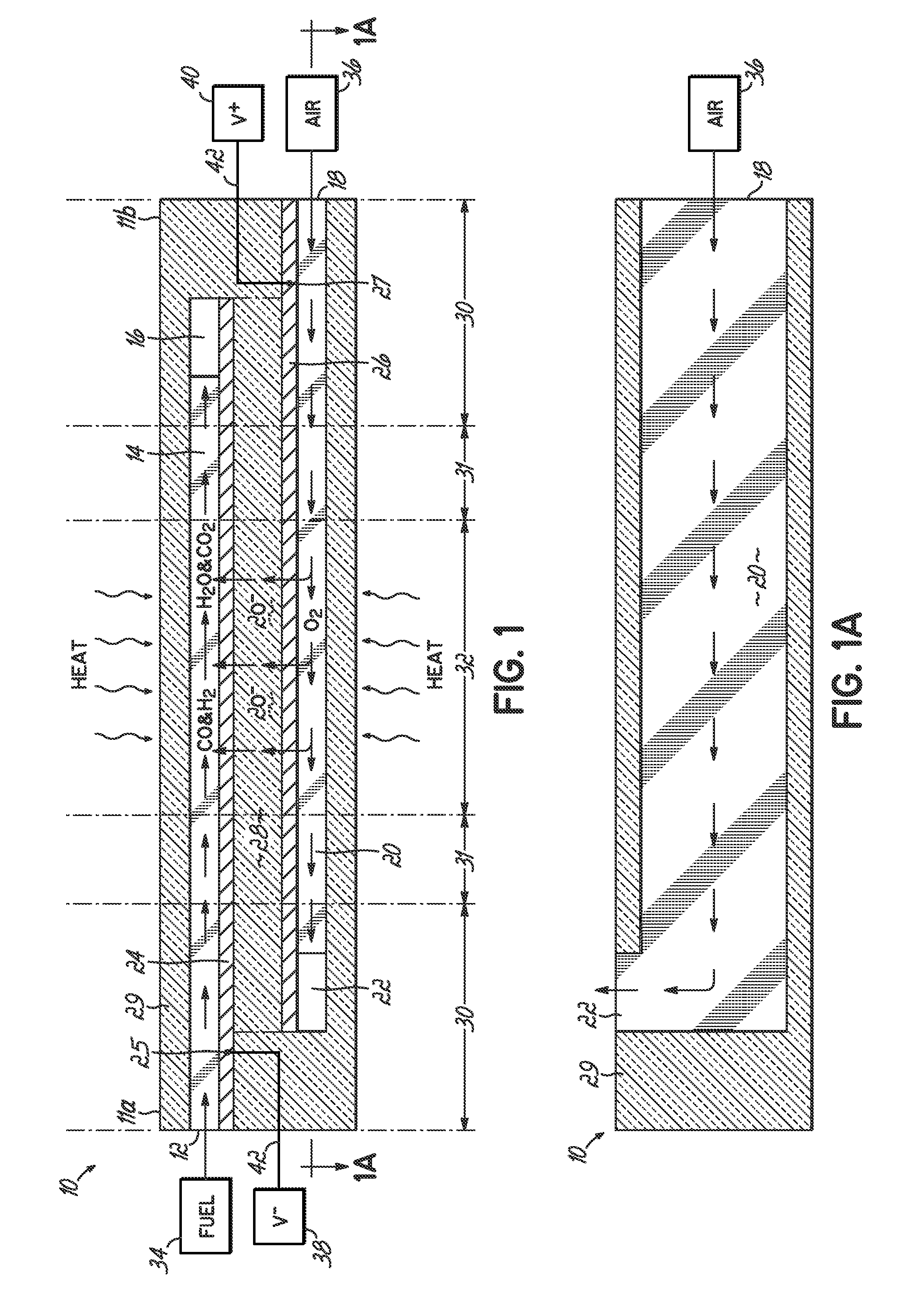

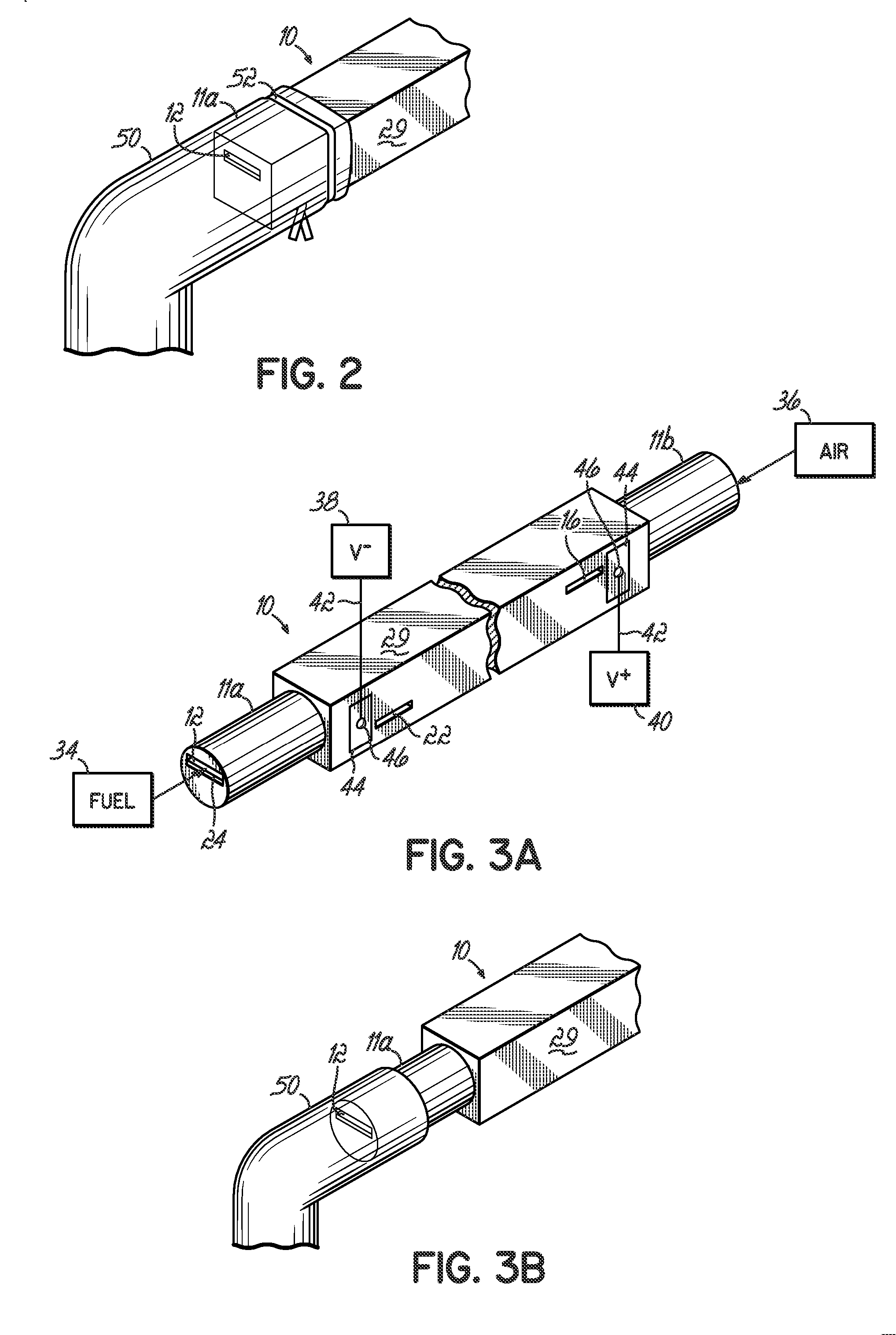

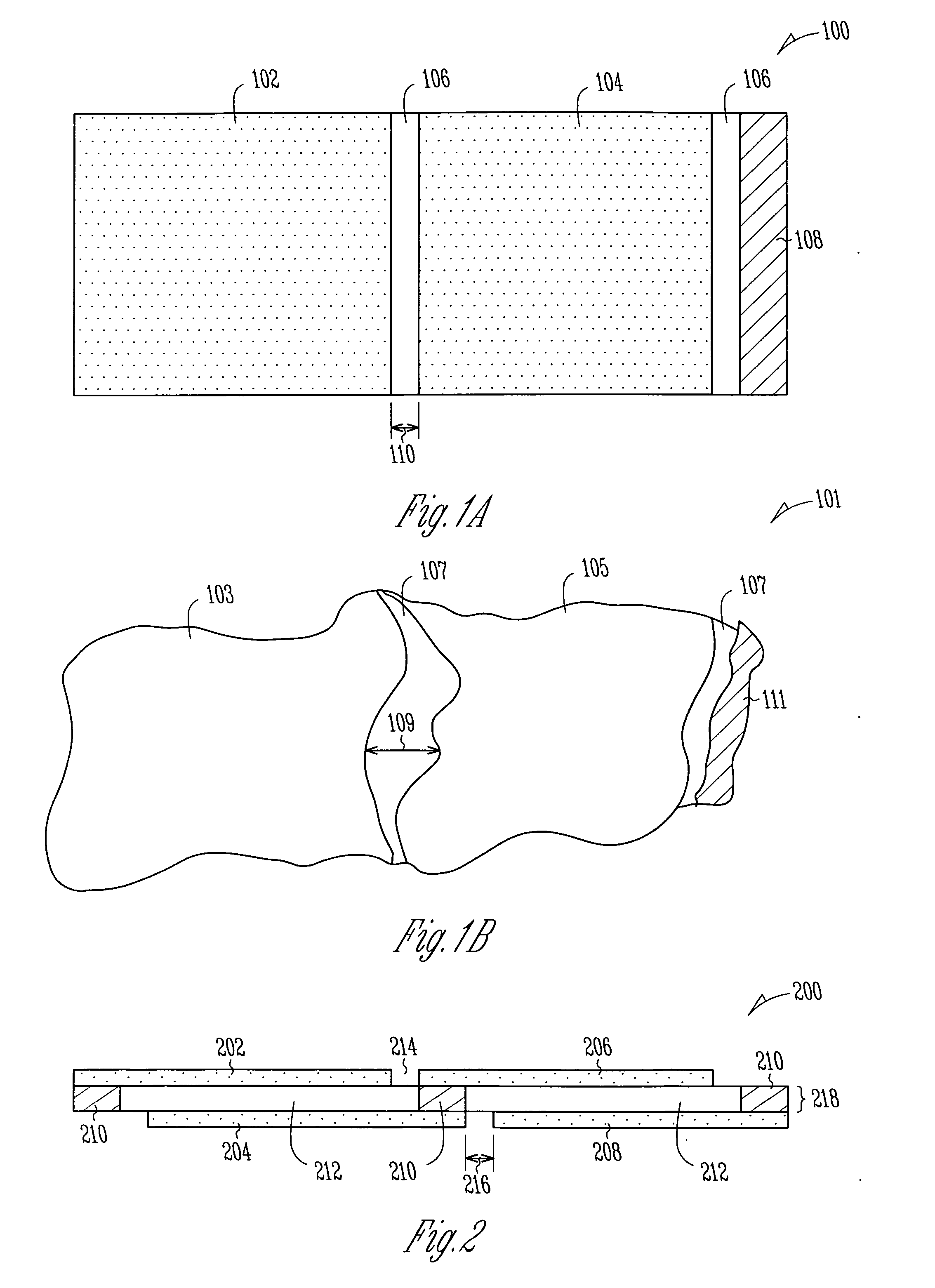

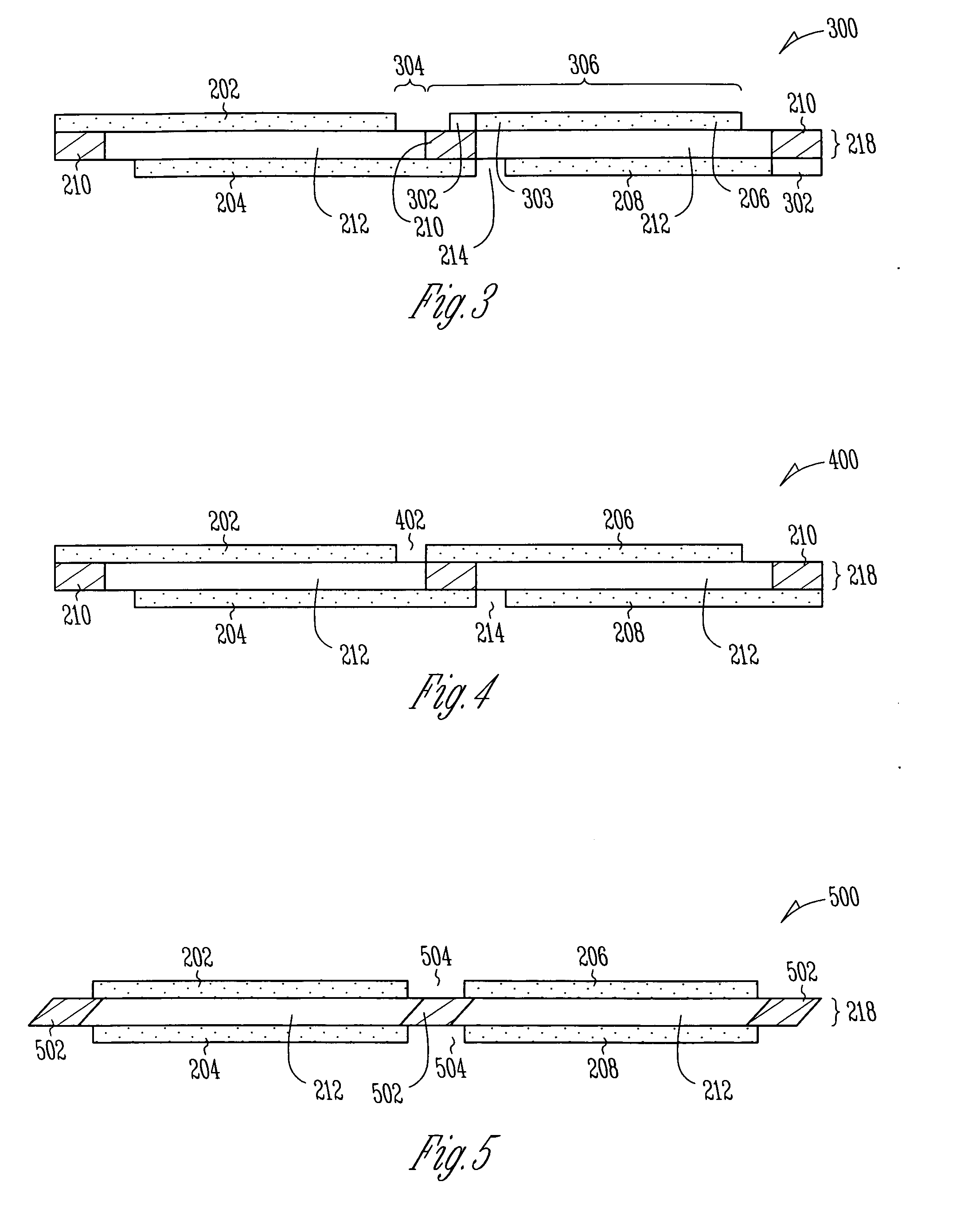

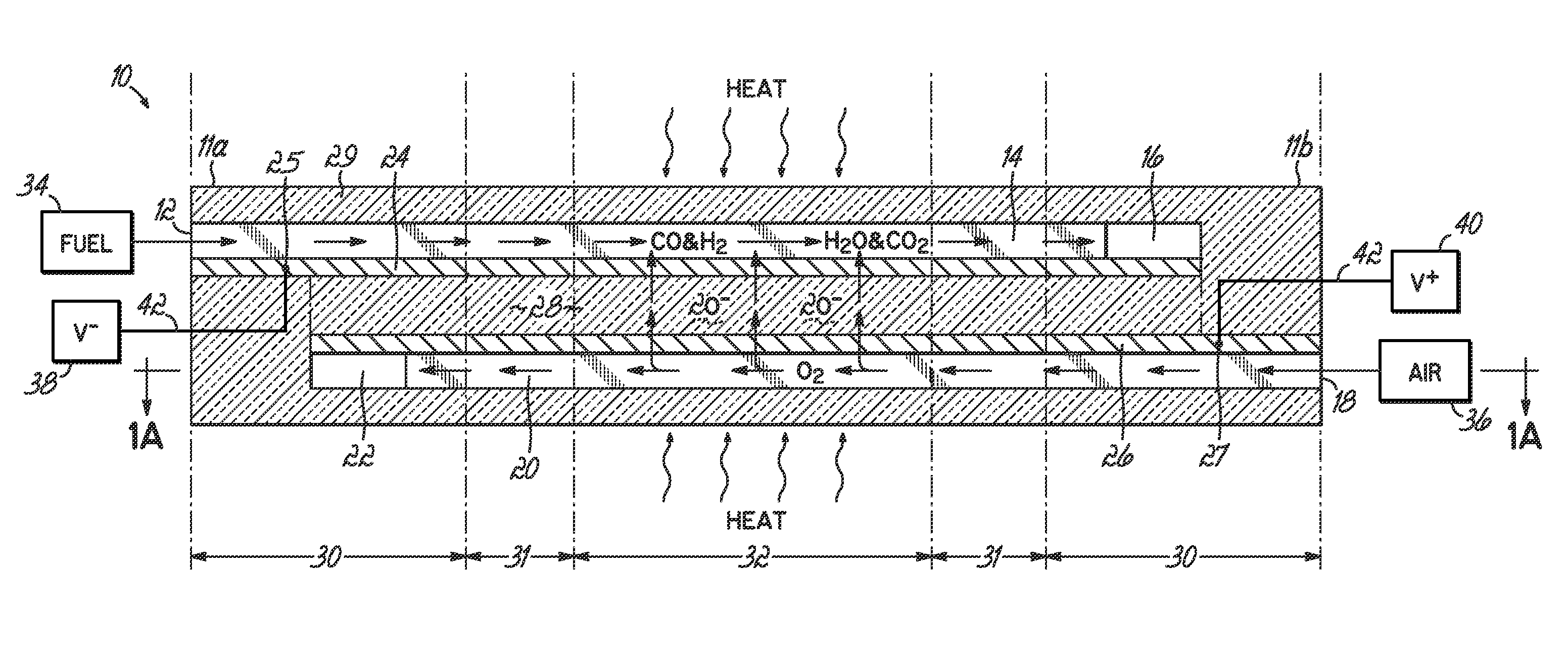

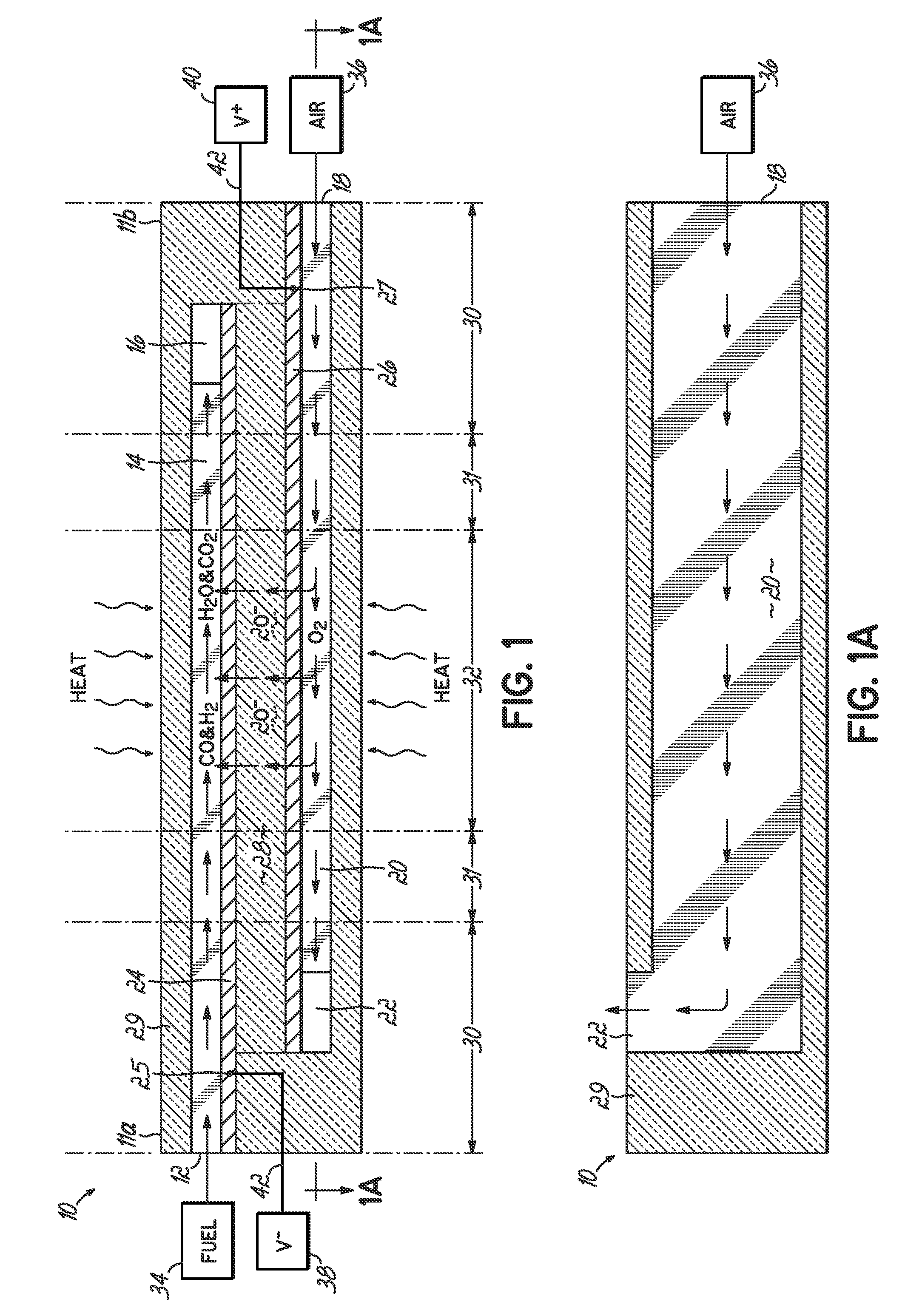

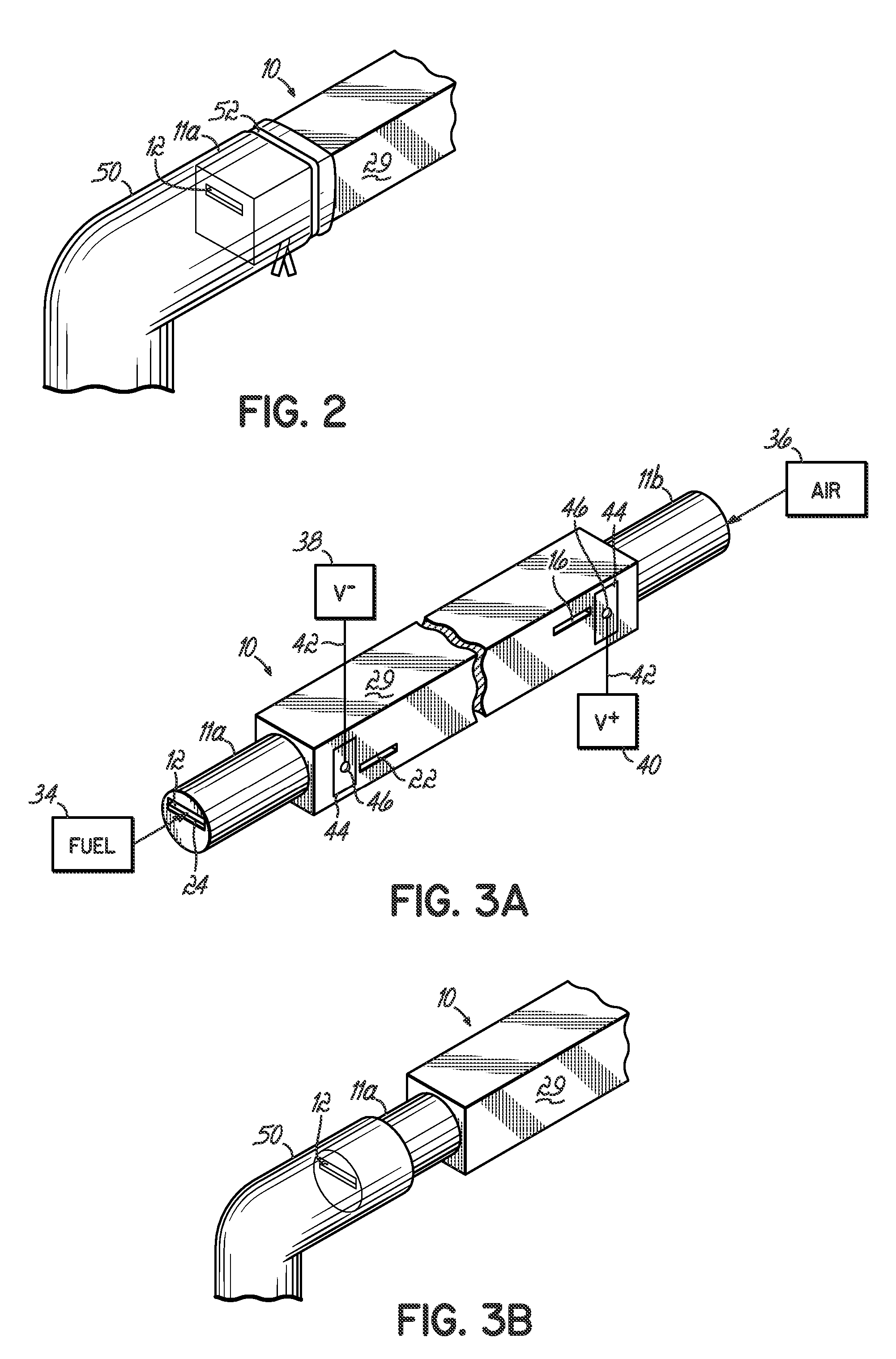

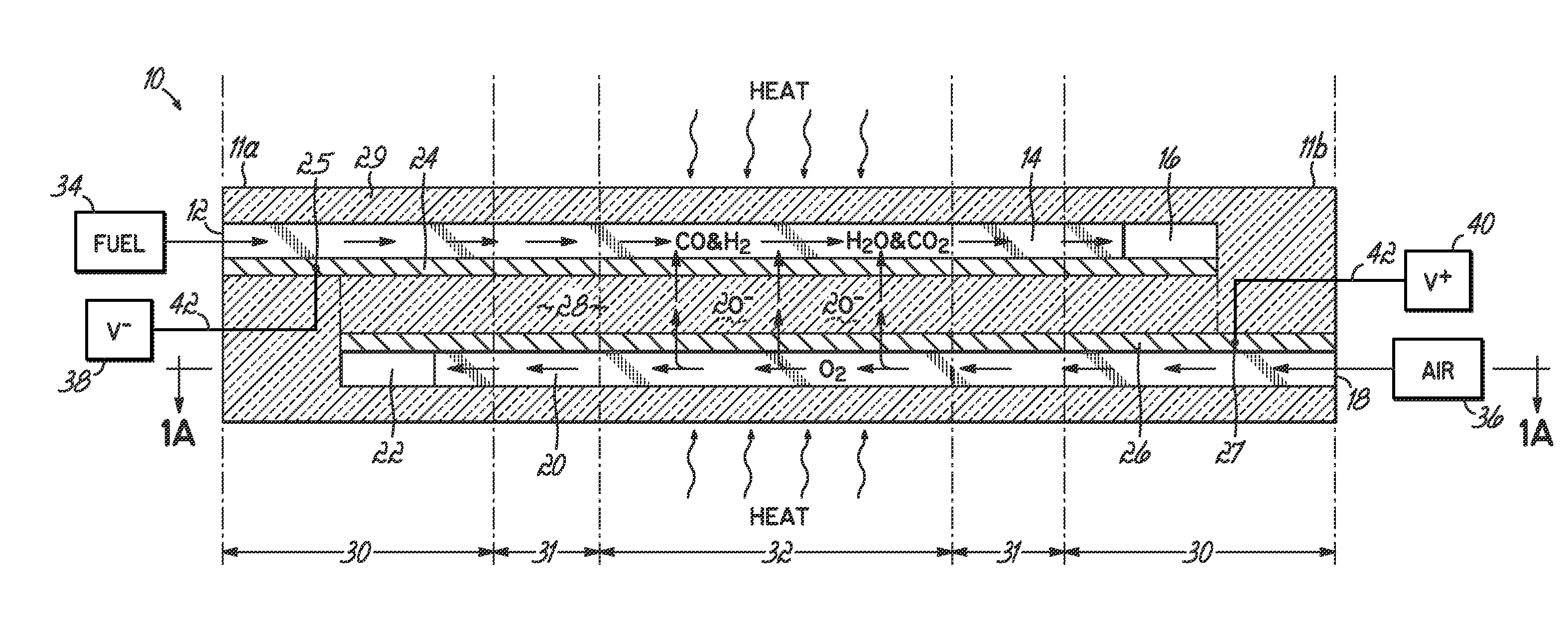

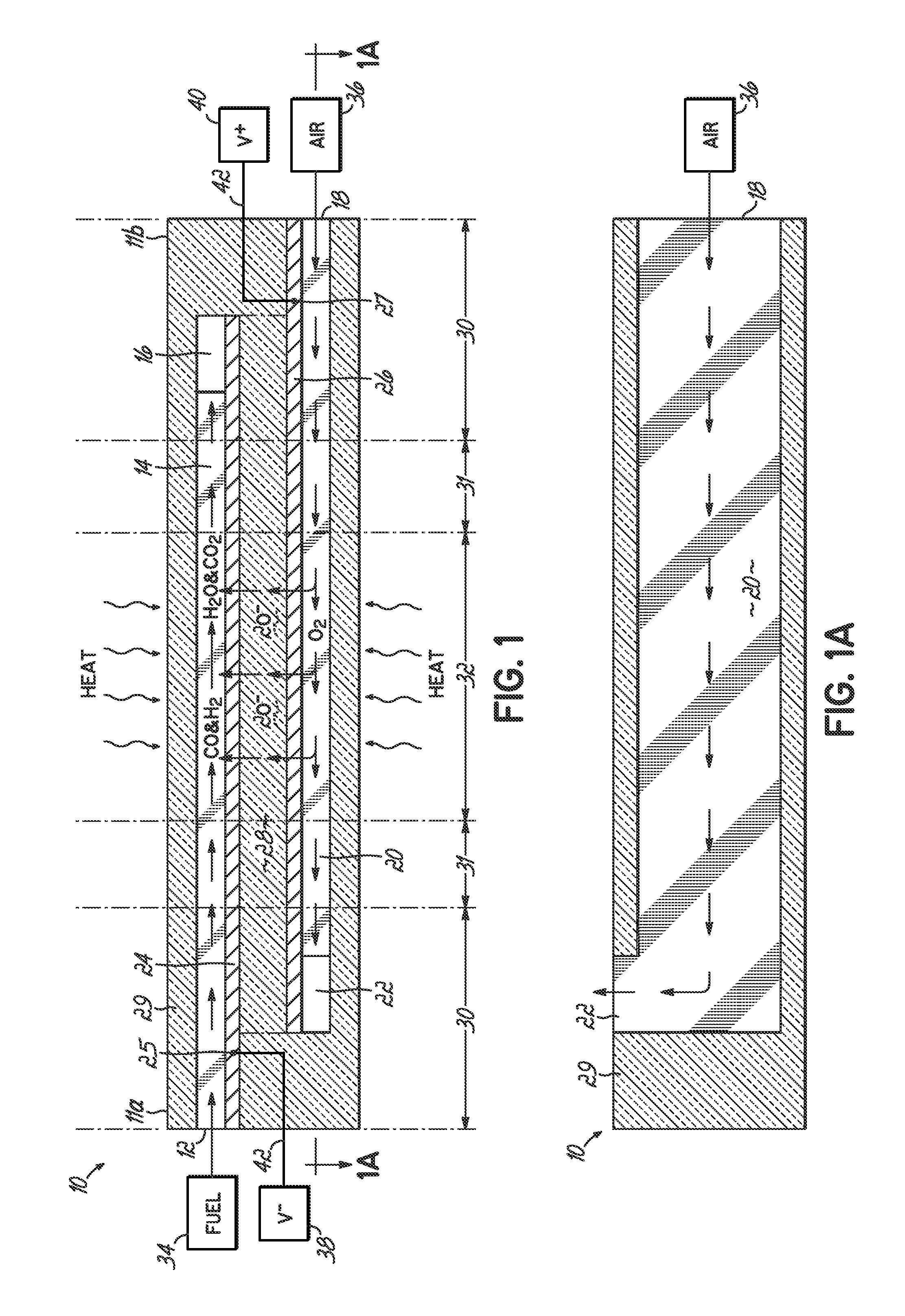

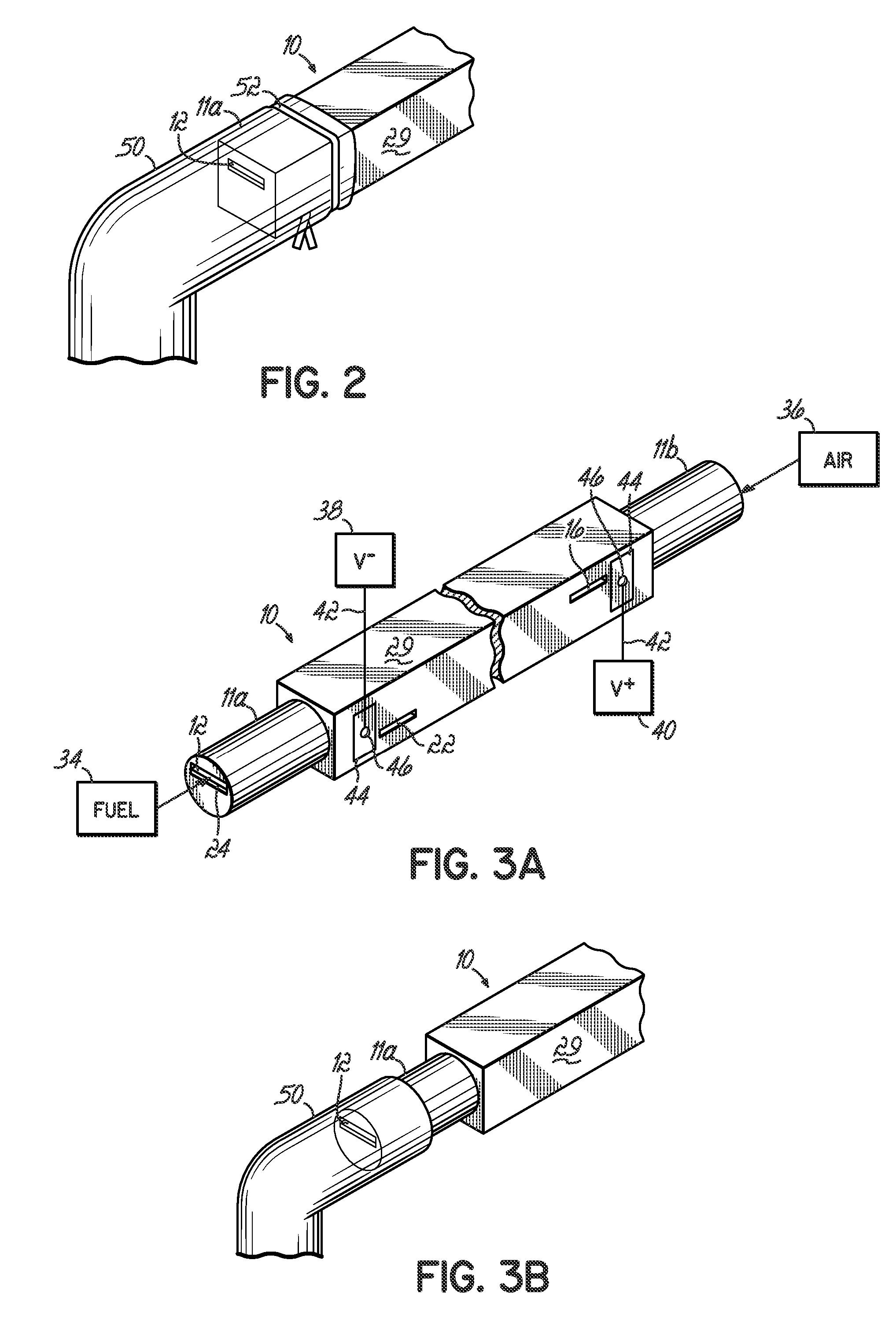

Fuel cell devices and systems are provided. In certain embodiments, the devices include a ceramic support structure having a length, a width, and a thickness. A reaction zone positioned along a portion of the length is configured to be heated to an operating reaction temperature, and has at least one active layer therein comprising an electrolyte separating first and second opposing electrodes, and active first and second gas passages adjacent the respective first and second electrodes. At least one cold zone positioned from the first end along another portion of the length is configured to remain below the operating reaction temperature. An artery flow passage extends from the first end along the length through the cold zone and into the reaction zone and is fluidicly coupled to the active first gas passage, which extends from the artery flow passage toward at least one side. The thickness of the artery flow passage is greater than the thickness of the active first gas passage. In other embodiments, fuel cell devices include an electrolyte having at least a portion thereof comprising a ceramic material sintered from a nano-sized powder. In yet other embodiments, cold zones are provided at each end of the device with the reaction zone therebetween having at least two discrete power sections, each having one or more active layers, the power sections fed by discrete fuel passages to provide a device and system capable of operating at more than one power level.

Owner:DEVOE ALAN +1

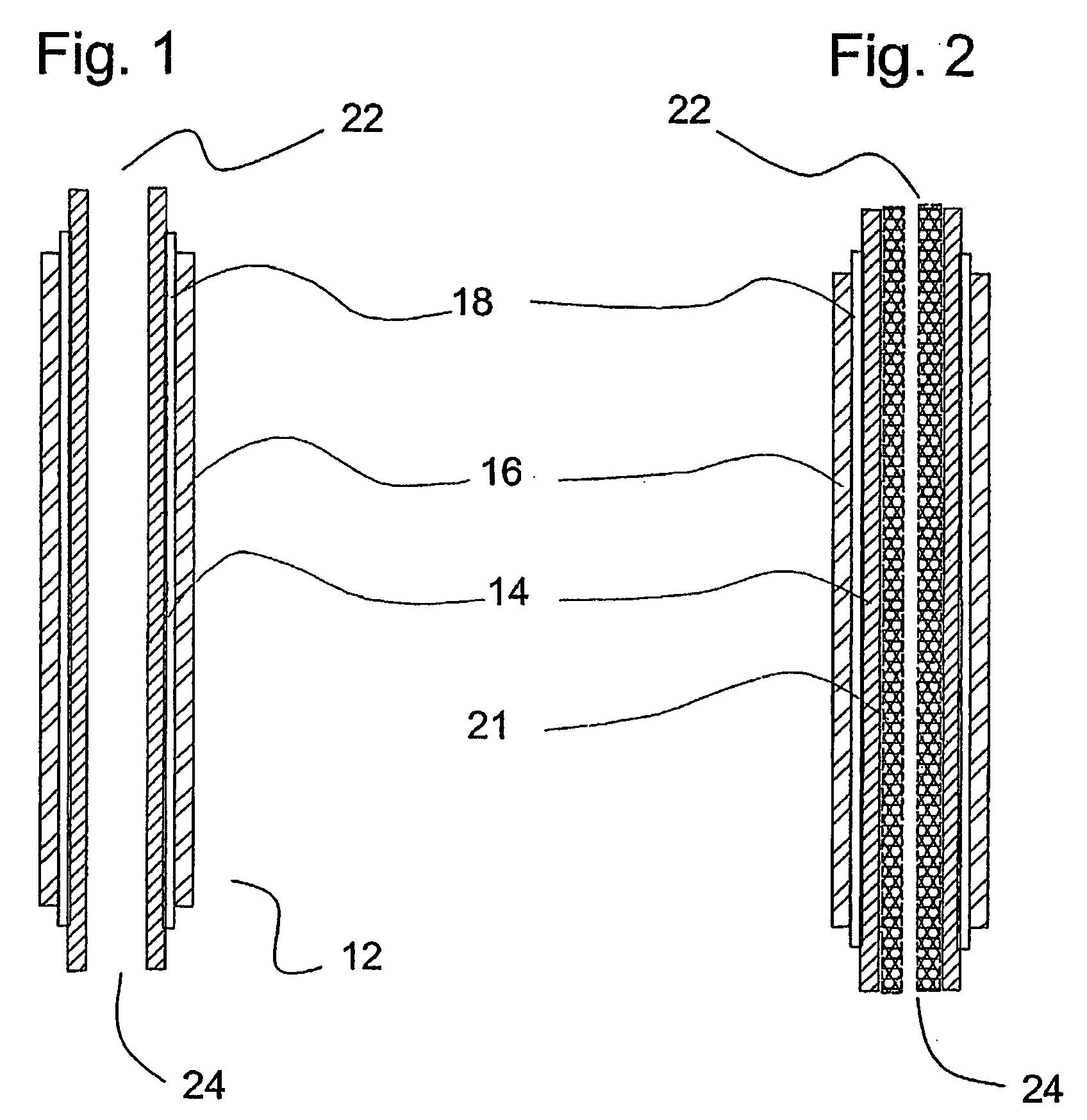

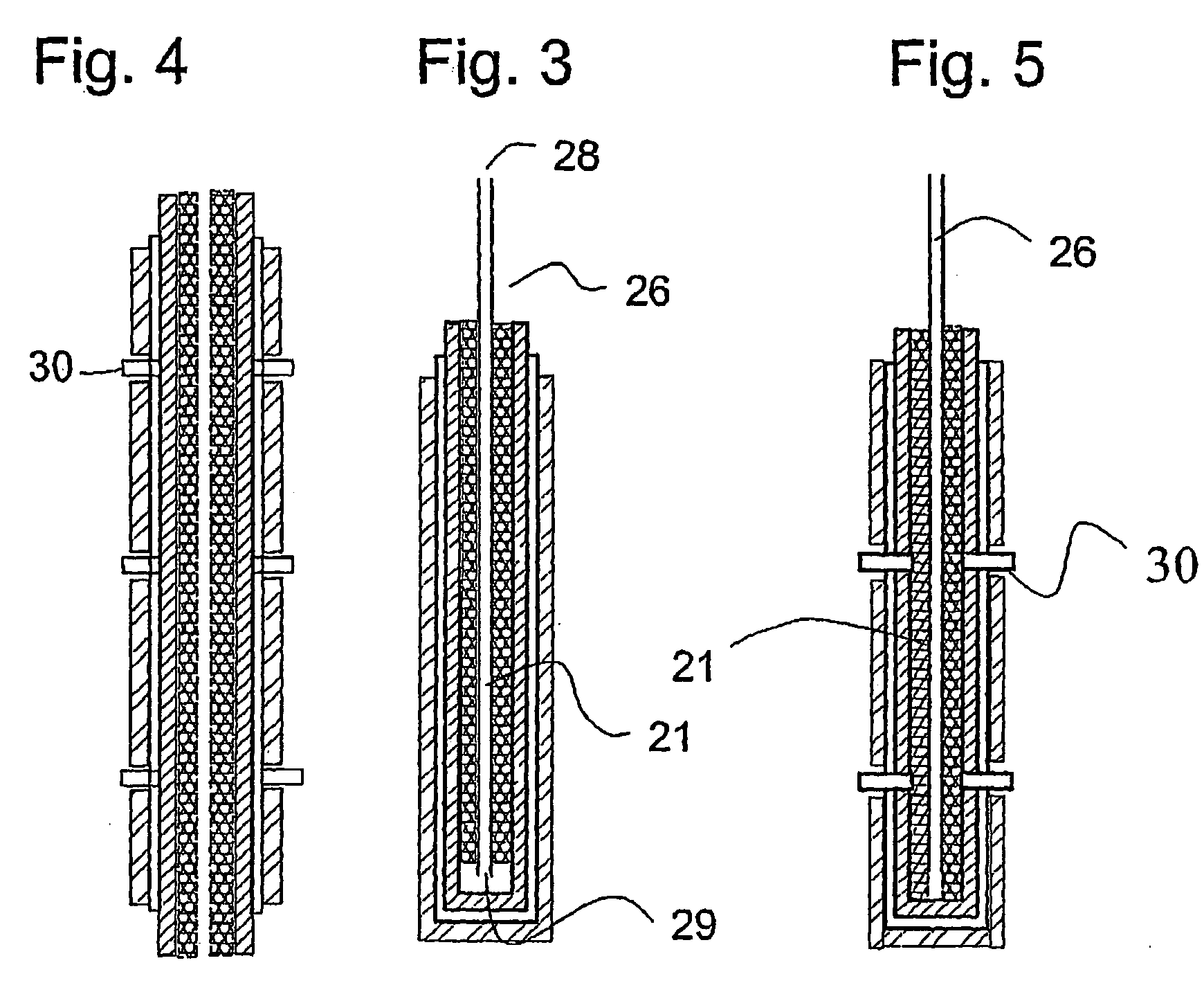

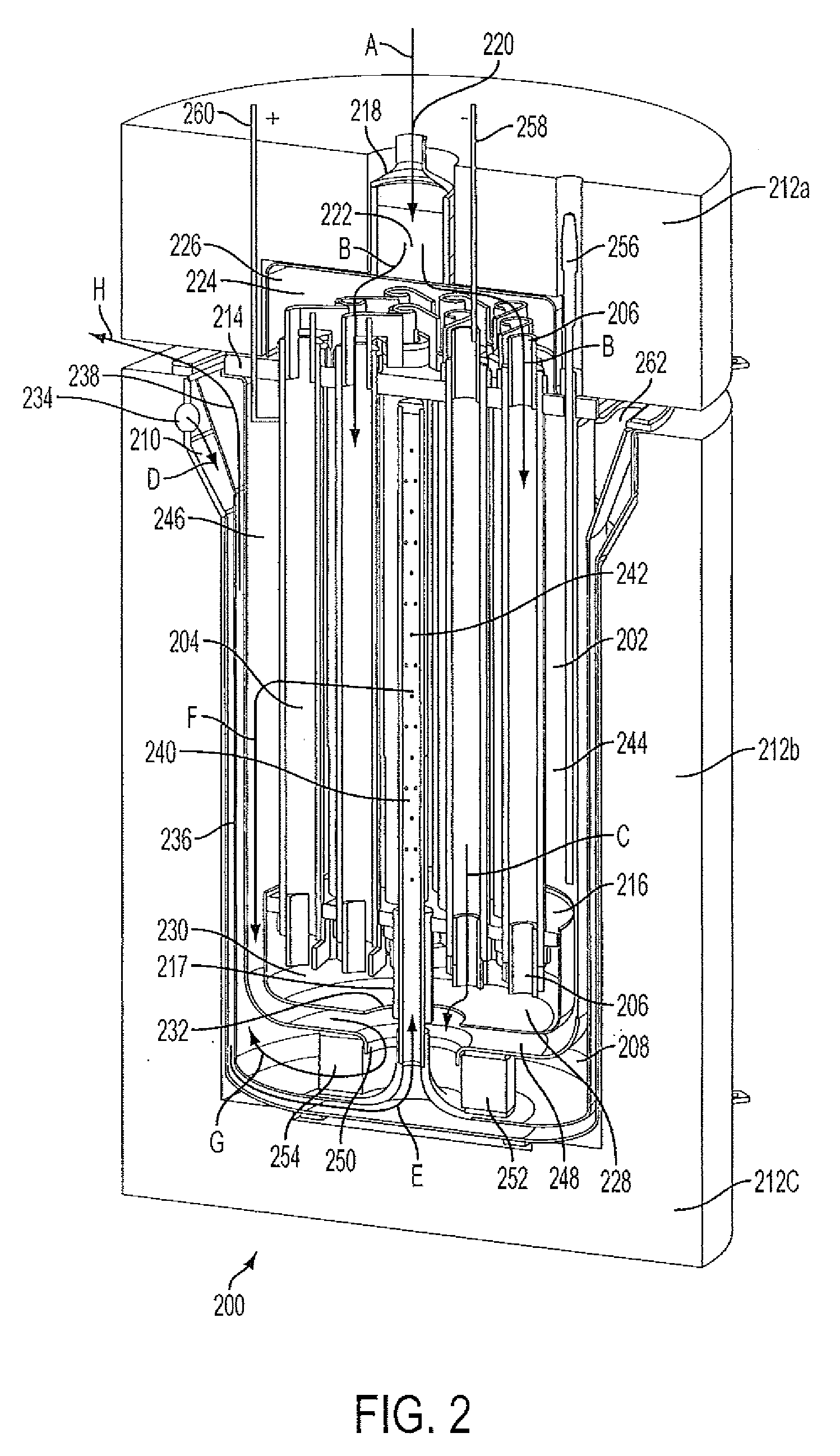

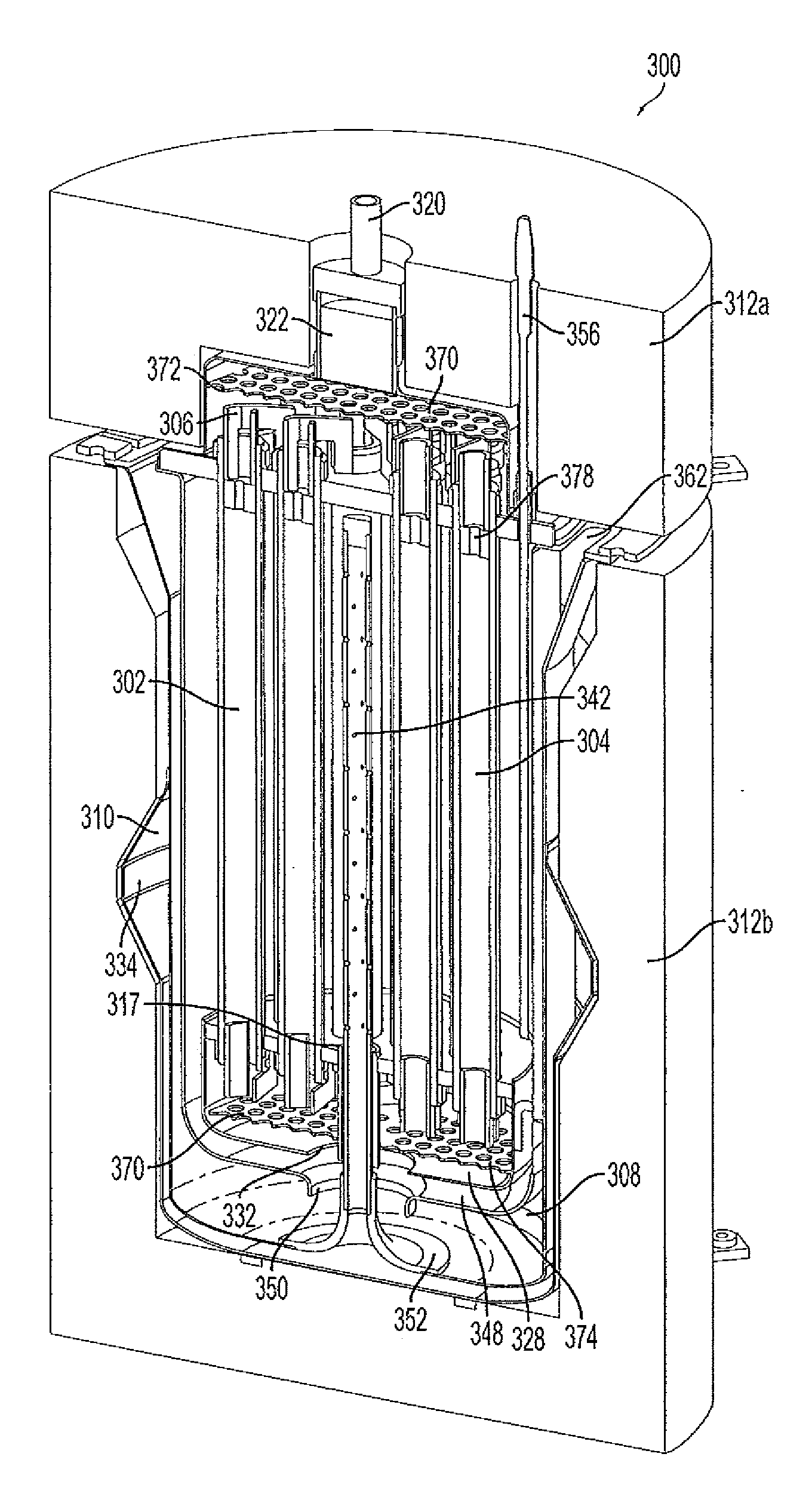

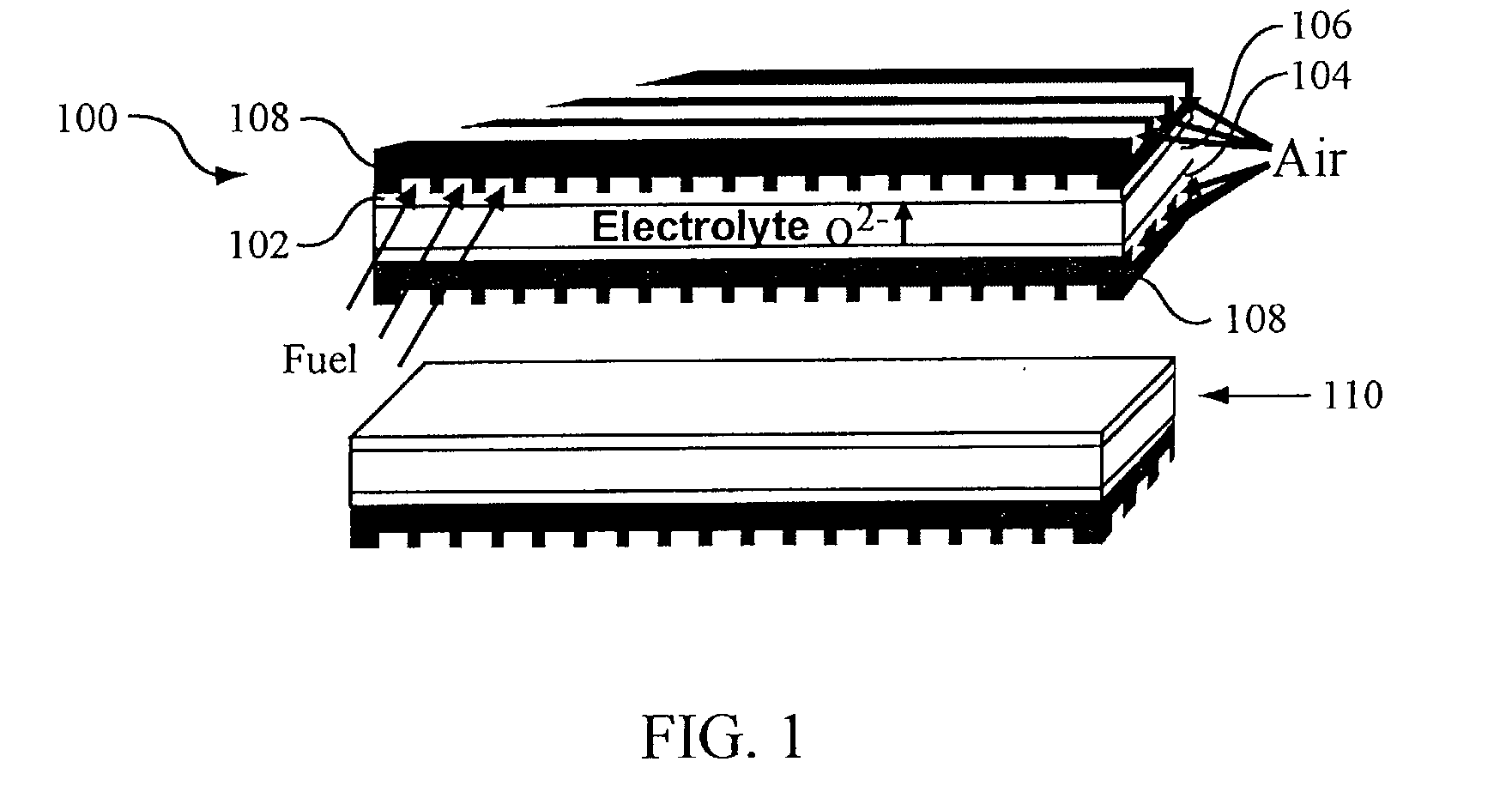

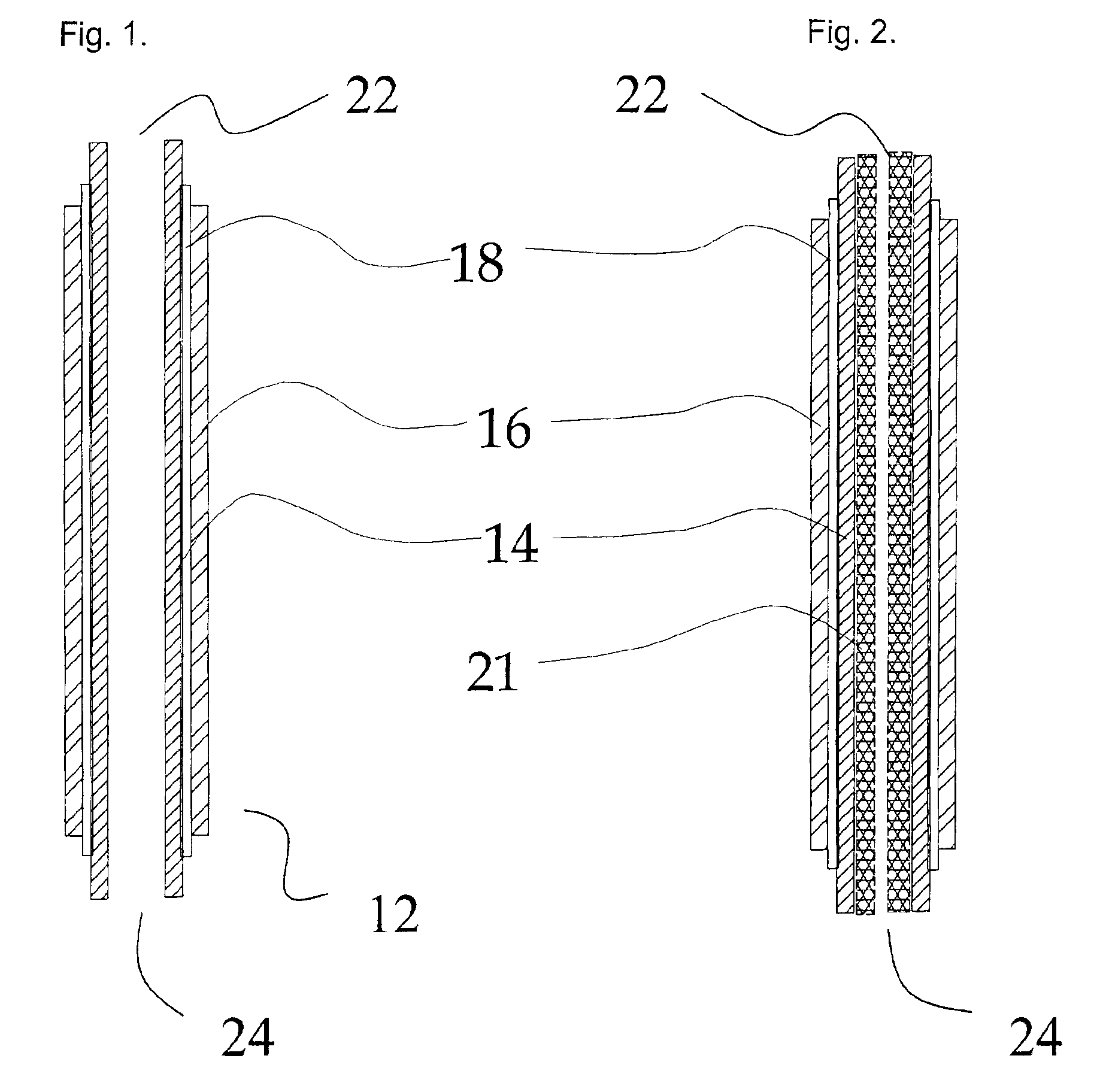

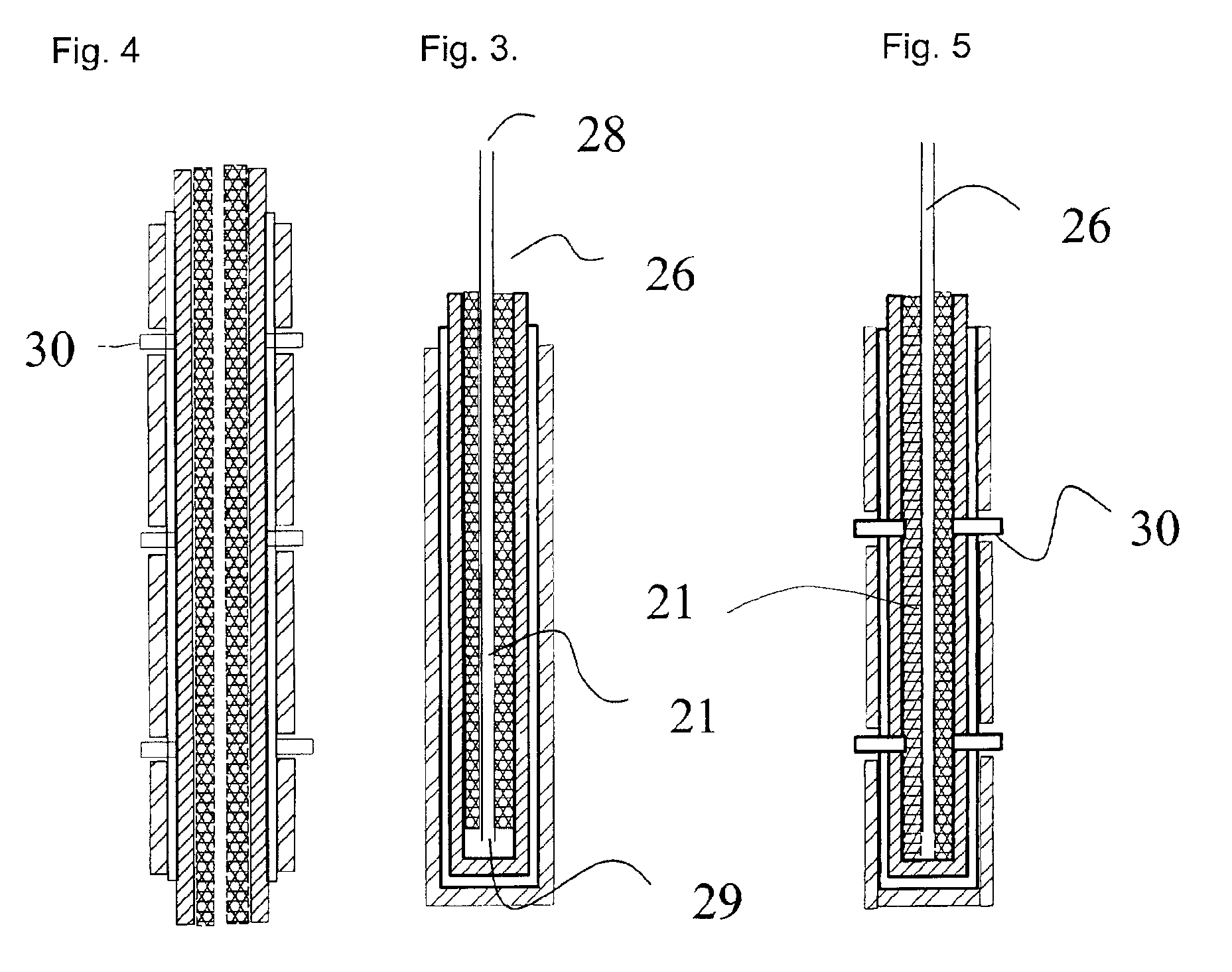

Solid Oxide Fuel Cell Device and System

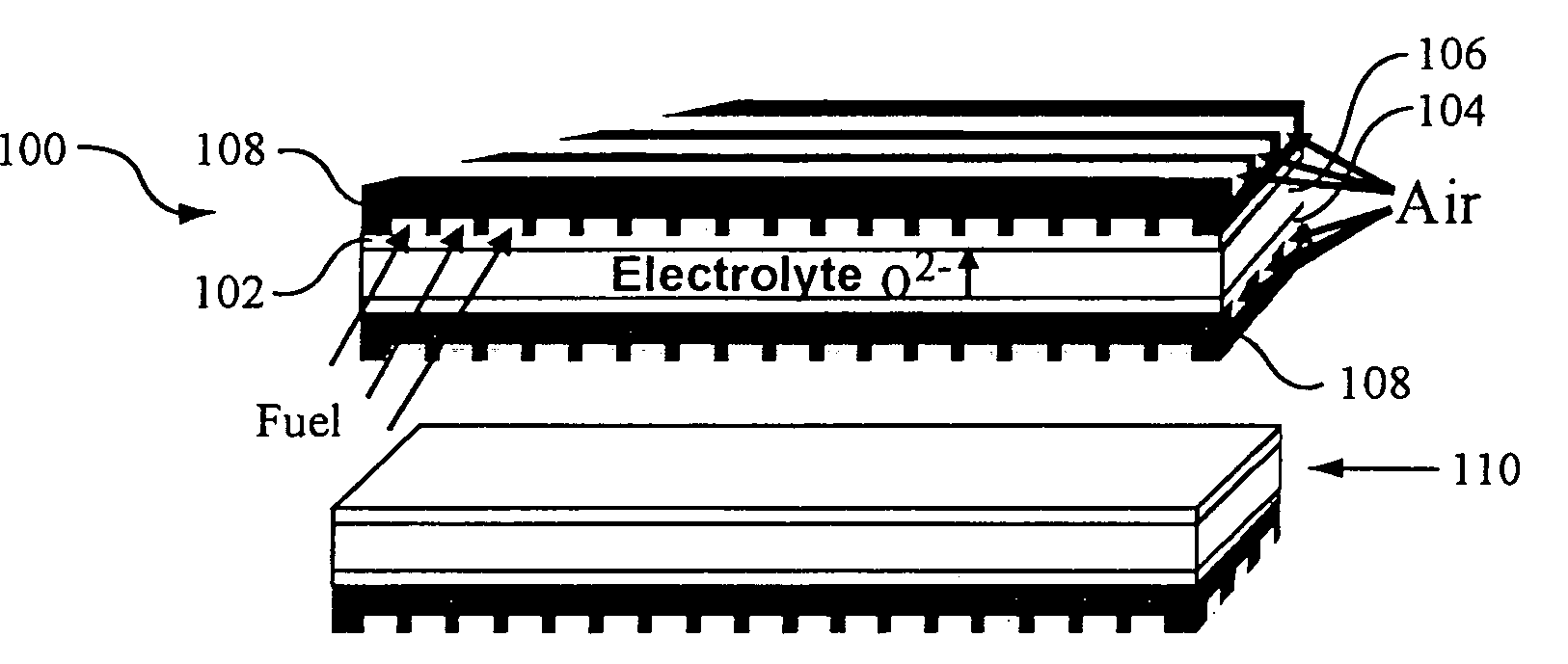

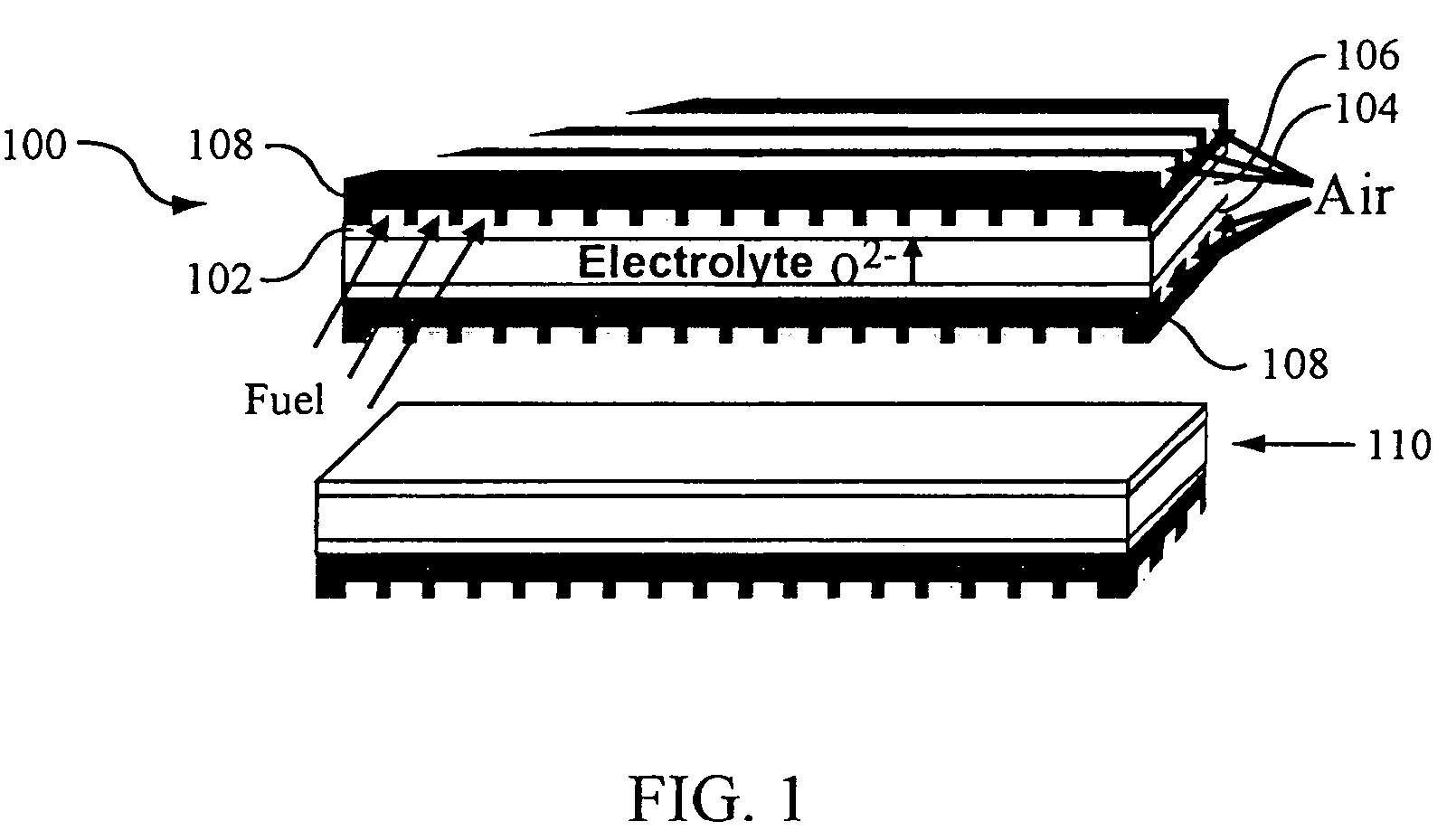

InactiveUS20070105003A1Great dimensionAvoid layeringFuel cell heat exchangeReactant parameters controlFuel cellsHot zone

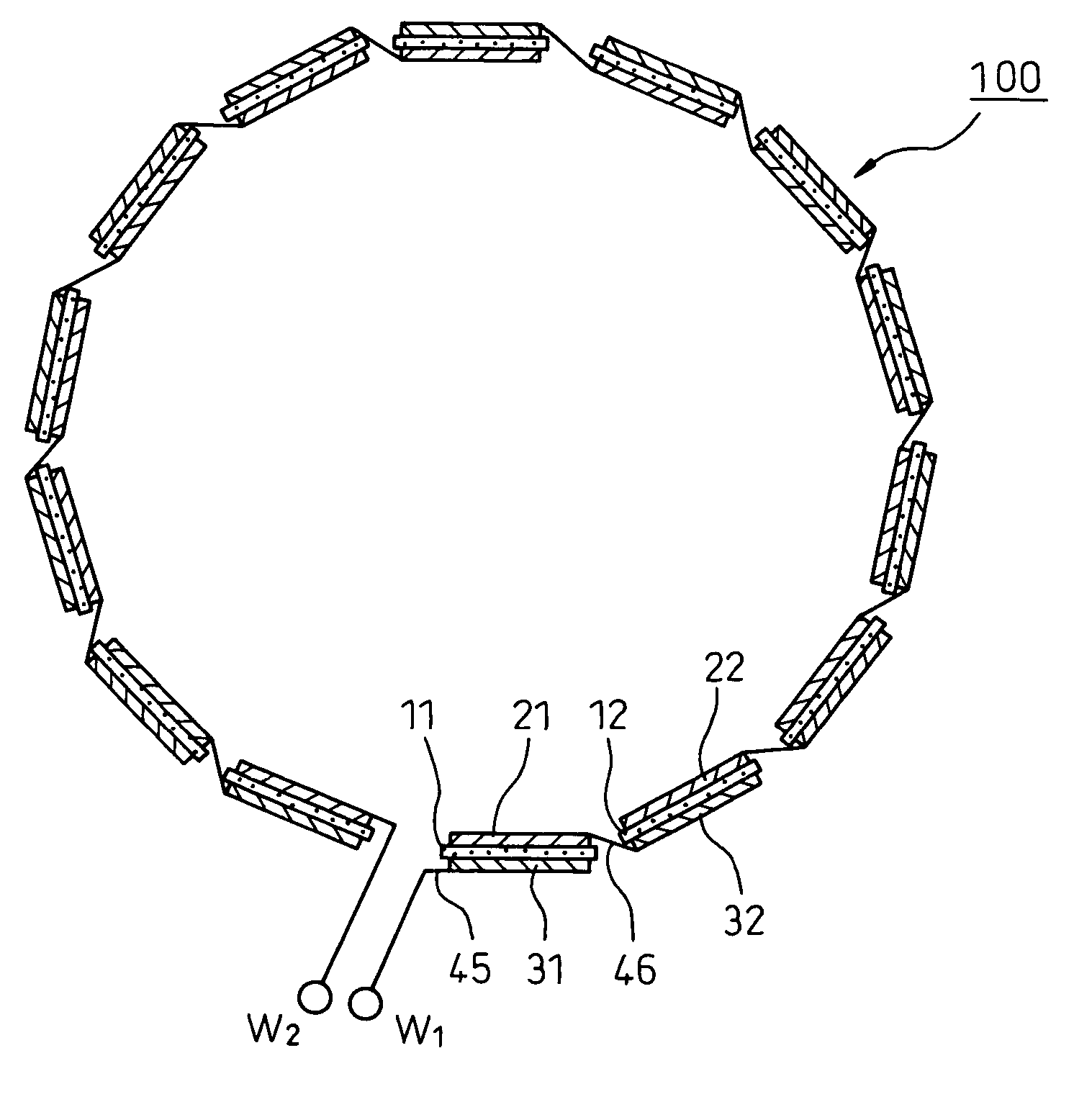

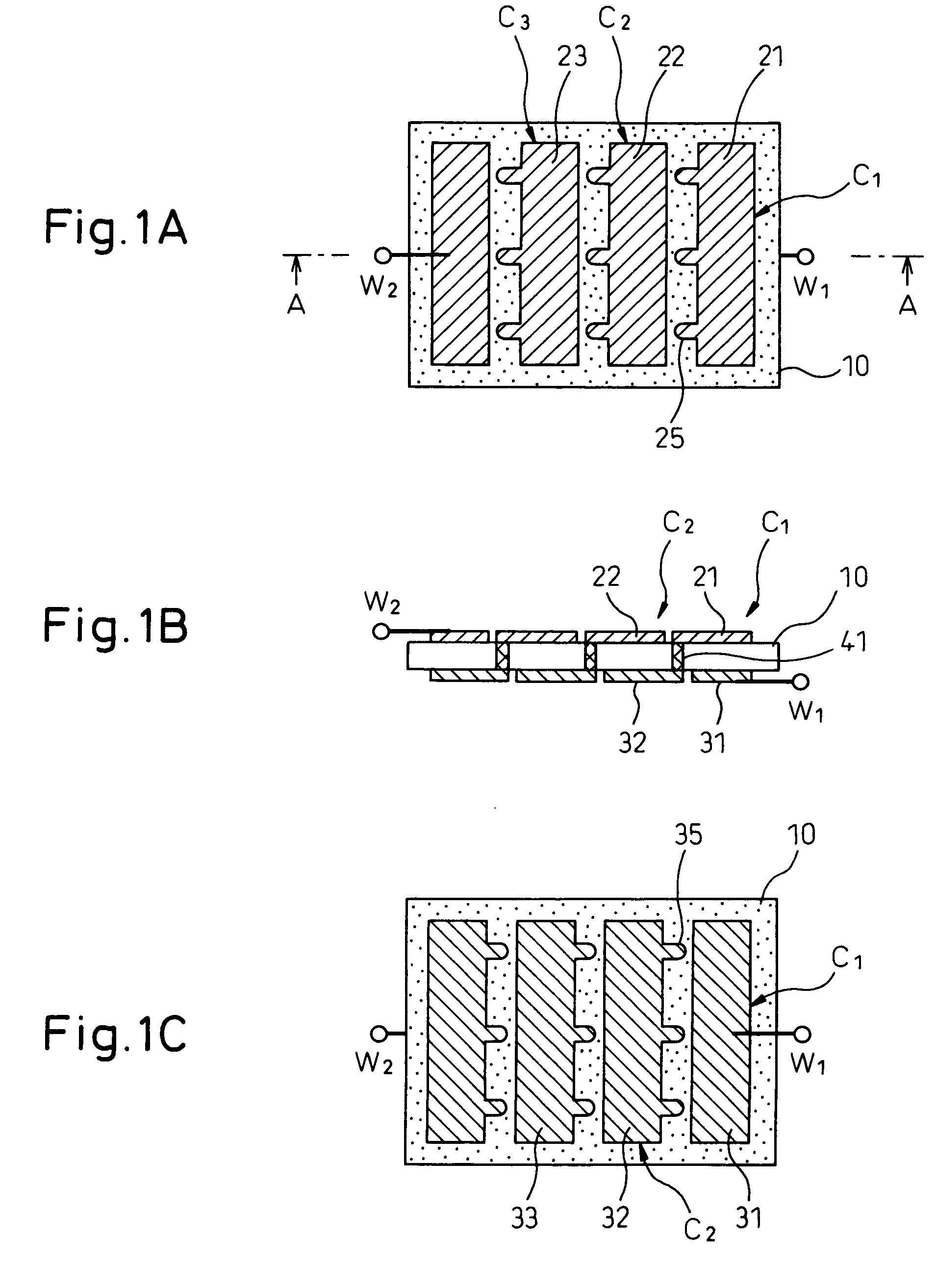

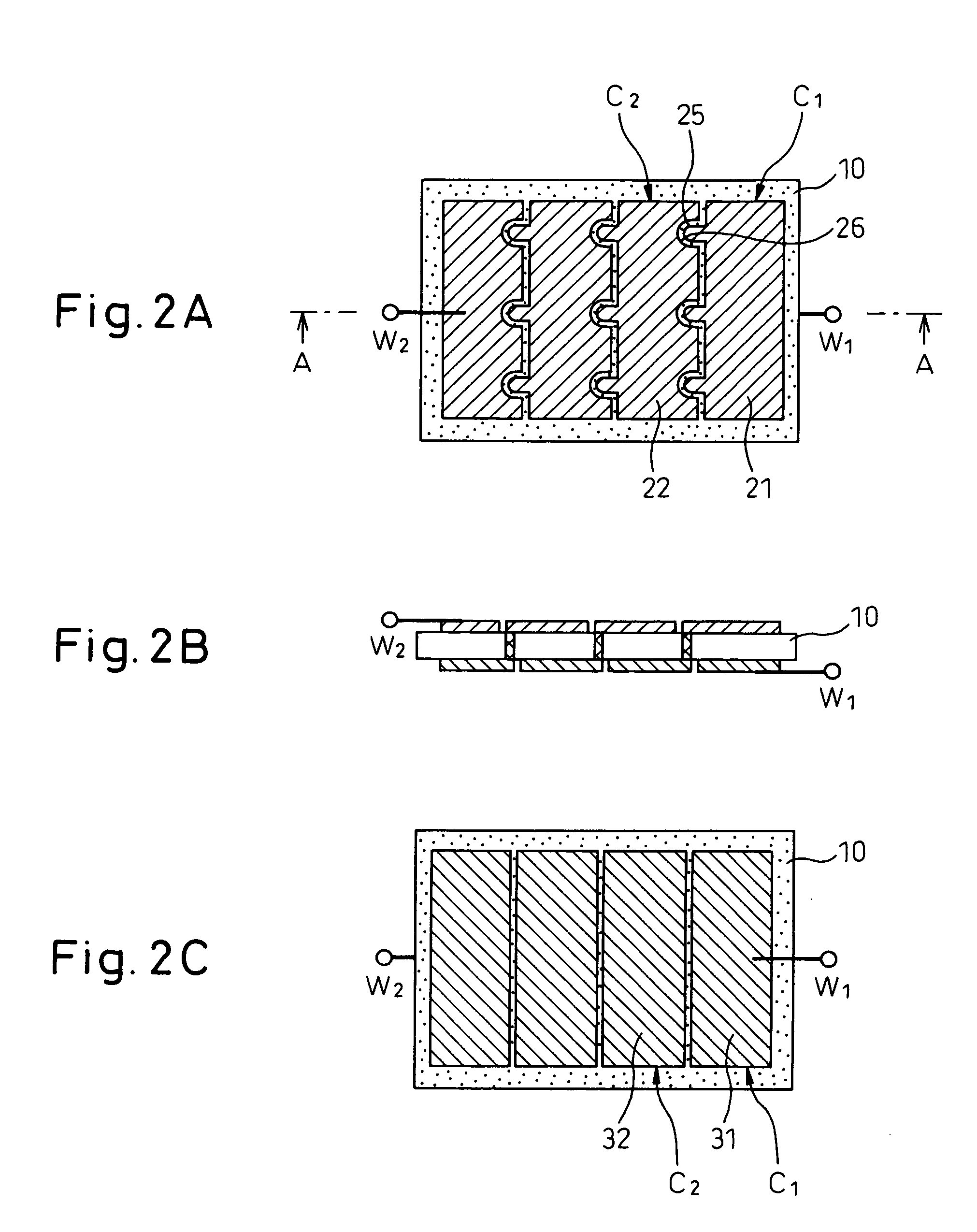

The invention provides a solid oxide fuel cell device and a fuel cell system incorporating a plurality of the fuel devices, each device including an elongate substrate the length of which is the greatest dimension such that the elongate substrate has a coefficient of thermal expansion having only one dominant axis that is coextensive with the length. A reaction zone is provided along a first portion of the length for heating to an operating reaction temperature, and at least one cold zone is provided along a second portion of the length that remains at a low temperature below the operating reaction temperature when the reaction zone is heated. A plurality of fuel passages and oxidizer passages are provided in the elongate substrate extending from the at least one cool zone to the reaction zone, each fuel passage having an associated anode in the reaction zone, and each oxidizer passage having an associated cathode in the reaction zone positioned in opposing relation to a respective one of the associated anodes. An electrolyte is disposed between each of the opposing anodes and cathodes in the reaction zone. The system further includes the devices positioned with their first portions in a hot zone chamber and their cold zones extending outside the hot zone chamber. A heat source is coupled to the hot zone chamber to heat the reaction zones to the operating reaction temperature. A fuel supply is coupled outside the hot zone chamber to the at least one cold zones in fluid communication with the fuel passages for supplying a fuel flow into the fuel passages.

Owner:DEVOE ALAN +1

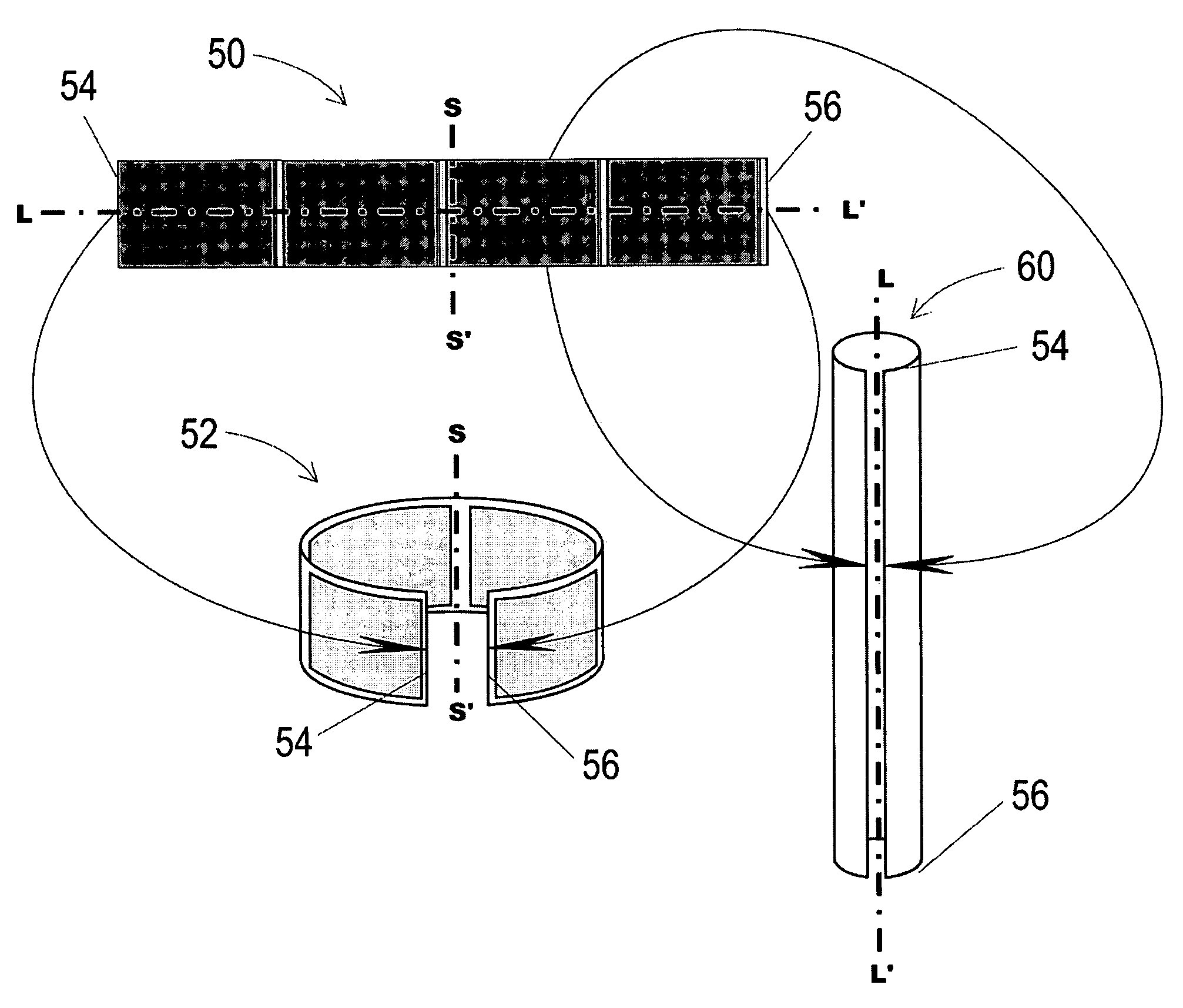

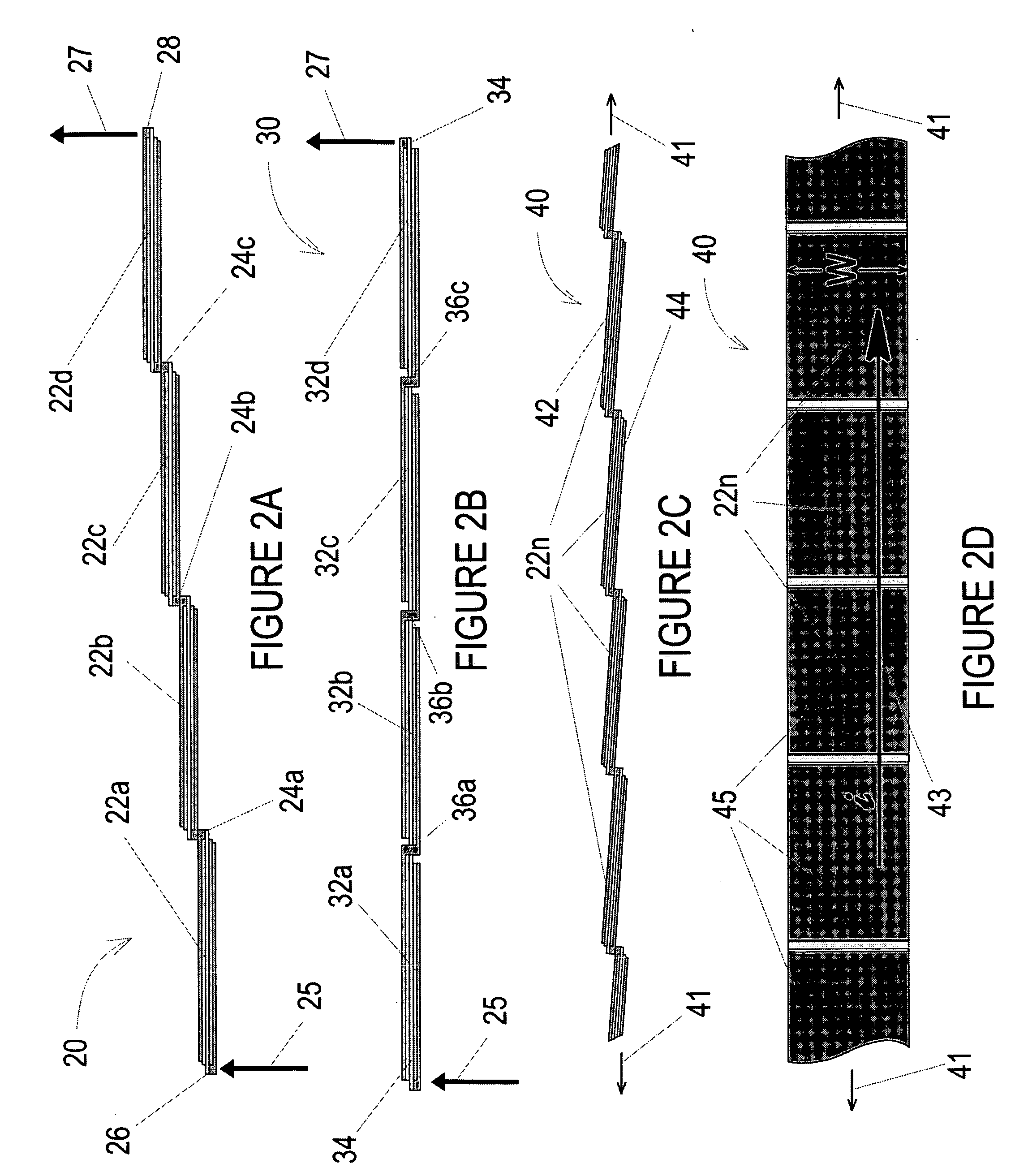

Light-weight, flexible edge collected fuel cells

The invention is a flexible, micro-fabricated fuel cell and fuel cell stack that can be helically wound or bend into cylindrical shapes. The electrolyte is a proton exchange membrane (PEM) upon which can be printed, by ink jet means, the anode and cathode electrodes and the current collectors that convey current to or from the edges of the PEM which has a thickness on the order of 0.001 to 0.010 inch. Pluralities of the series connected fuel cell stacks can be arranged in electrical and physical parallel with one another to provide what are batteries of fuel cell stacks that can be connected by manifolds to sources of fuel and oxidizer. The invention is directed to a thin, light-weight, flexible fuel cell assembly that can be produced in ambient conditions using standard micro-fabrication techniques, such as thick film printing and ink jet deposition. Thick film printing techniques, screen printing or ink jet printing, are used to deposit porous current collectors on either side of the membrane.

Owner:CASE WESTERN RESERVE UNIV

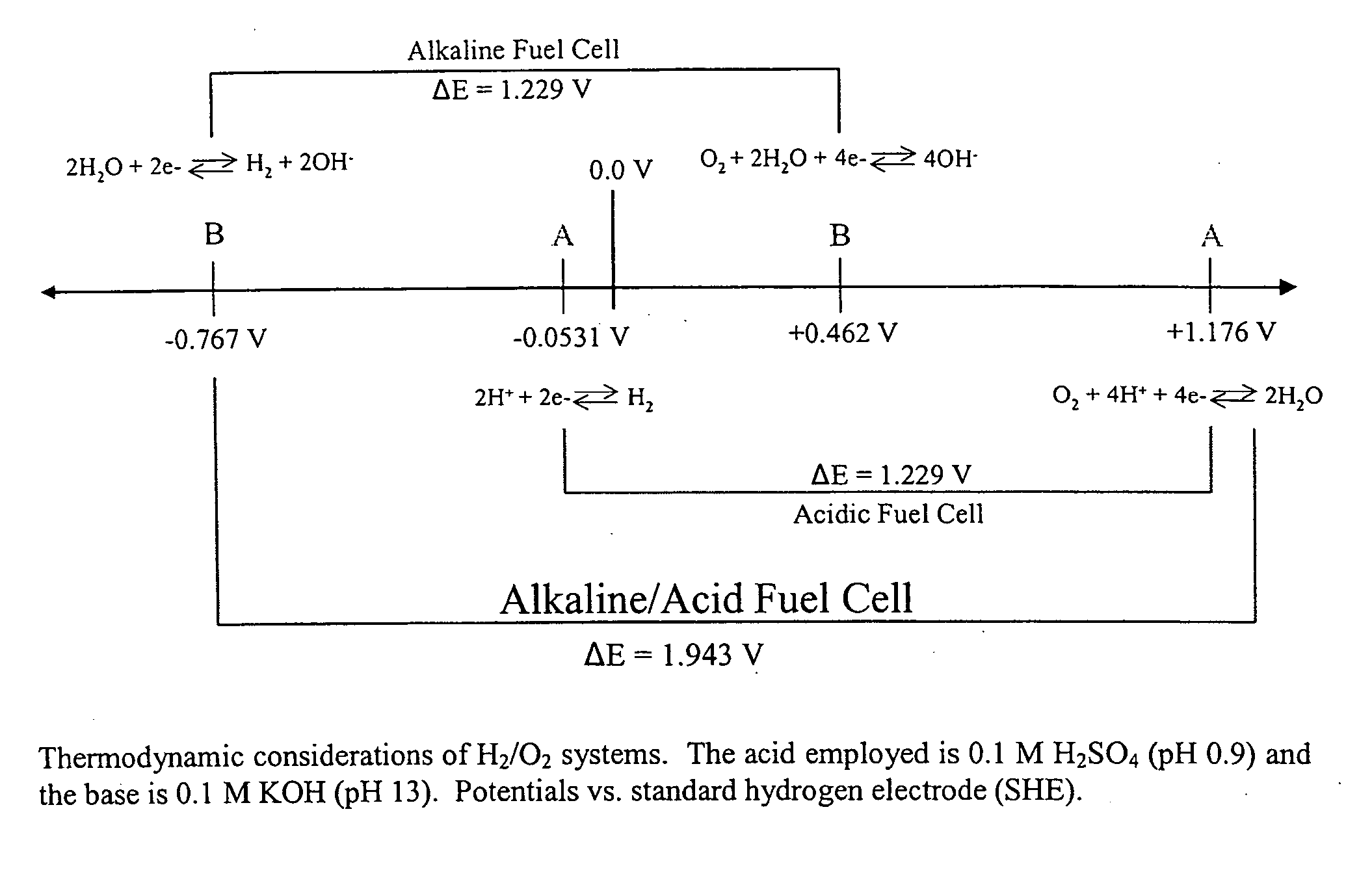

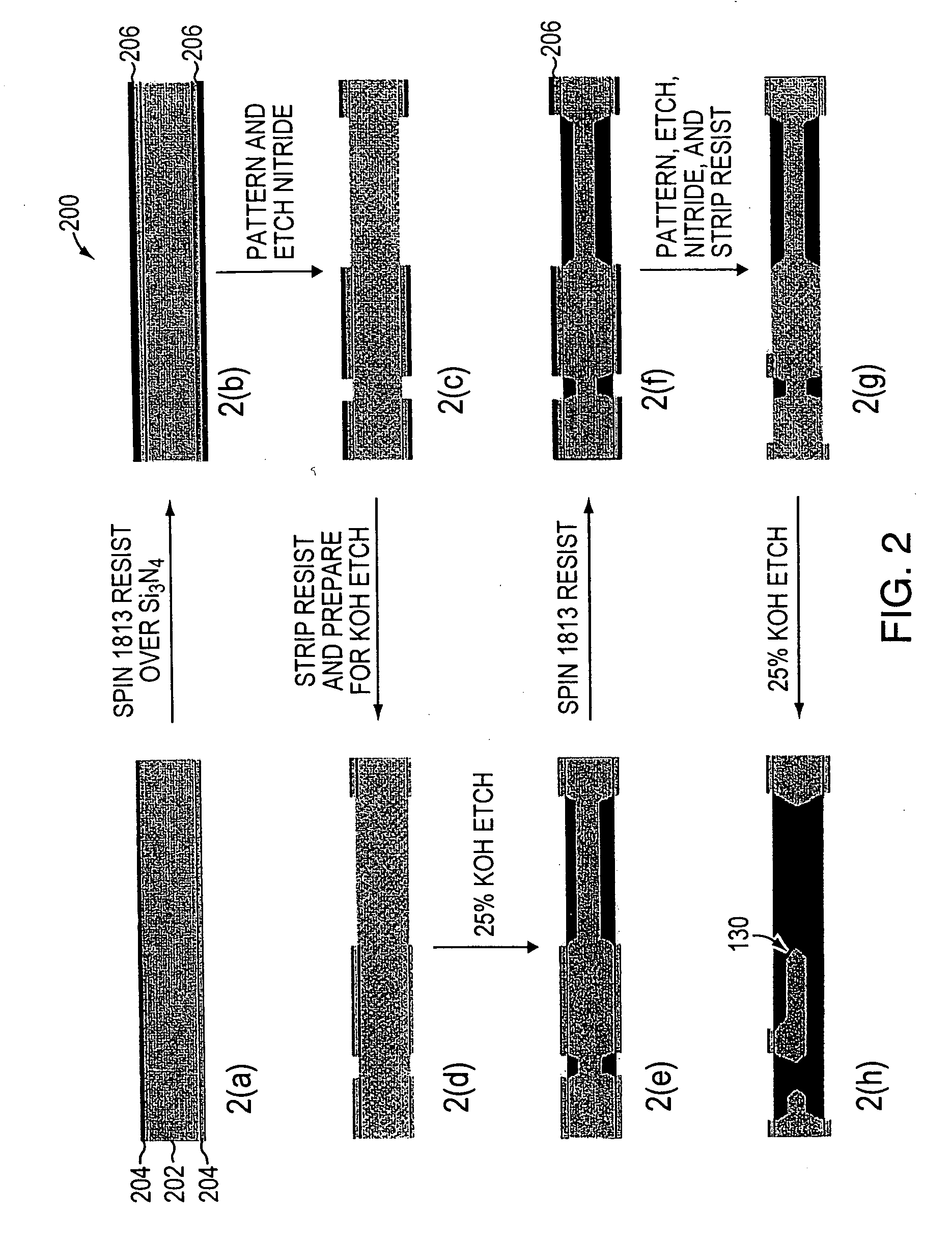

Dual electrolyte membraneless microchannel fuel cells

InactiveUS20060228622A1Maintain structural integrityHigh power deviceElectrolyte holding meansCell electrodesFlow cellEngineering

A microfluidic membraneless flow cell formed with multiple acidic / alkaline electrolyte solutions. The flow cell can be adapted to provide a dual electrolyte H2 / O2 fuel cell that generates thermodynamic potentials of up to 1.943 V or possibly greater. The selected fuel can be hydrogen dissolved in 0.1 M KOH, and the selected oxidant can be oxygen dissolved in 0.1 M H2SO4. Individual fuel cells can be combined to form fuel cell stacks to generate increased power output. Furthermore, microchannels of varying dimensions may be selected, including thickness variations, and different flow rates of acid / base electrolyte solutions can be applied to satisfy predetermined power generation needs. Some (micro-) fuel cell embodiments can be formed with silicon microchannels of fixed length and variable width and height, and can be used with hydrogen or formic acid as a fuel and oxygen as an oxidant, each dissolved in different acid / base electrolyte solutions. Micro-fuel cells are also provided which can be designed to generate different power levels for various applications including portable electronic devices such as wireless communication handsets and cellular telephones.

Owner:CORNELL RES FOUNDATION INC

Solid electrolyte fuel cell configuration

InactiveUS20050249993A1Small sizeLow costFuel cells groupingFuel cell shape/formFuel cellsEngineering

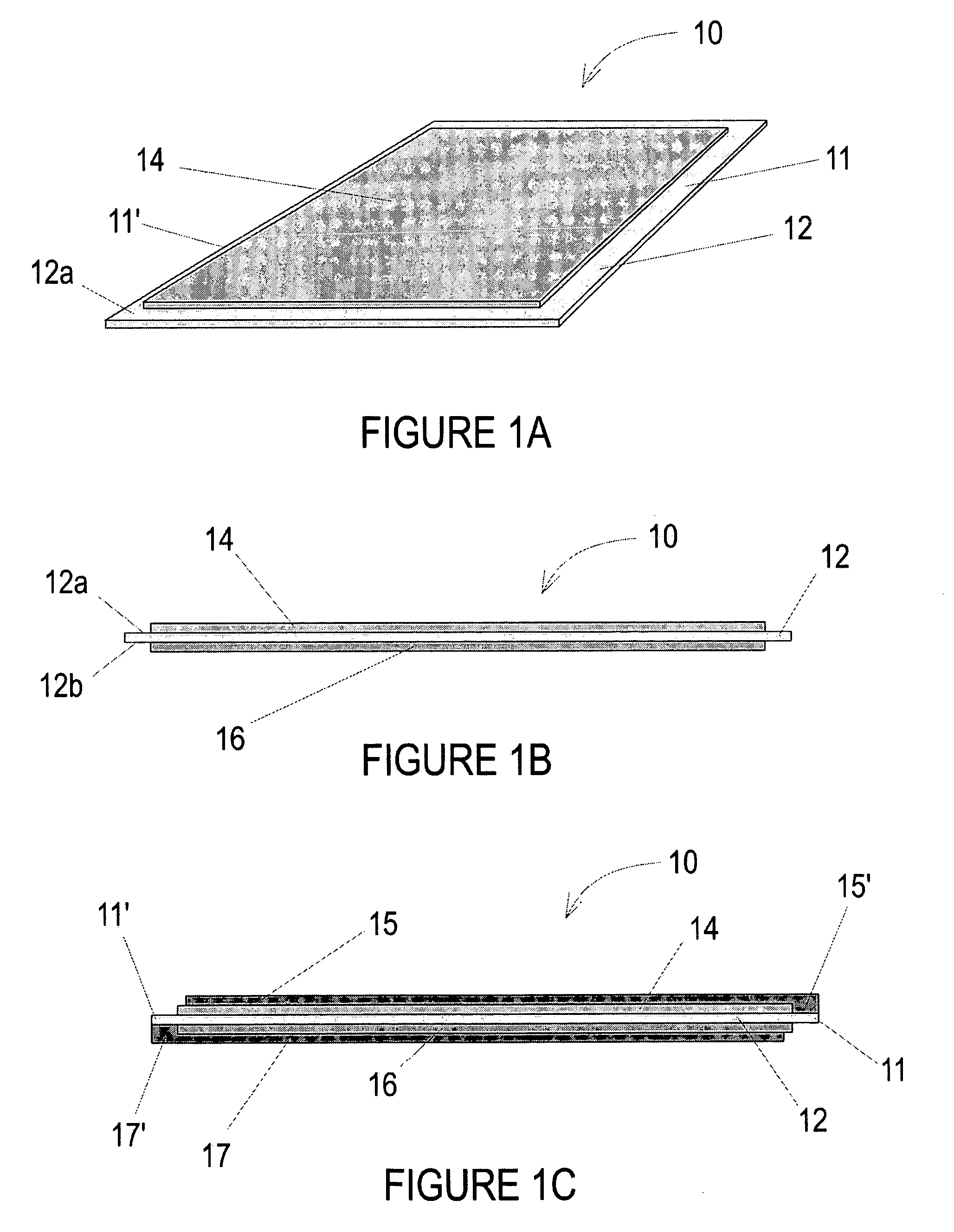

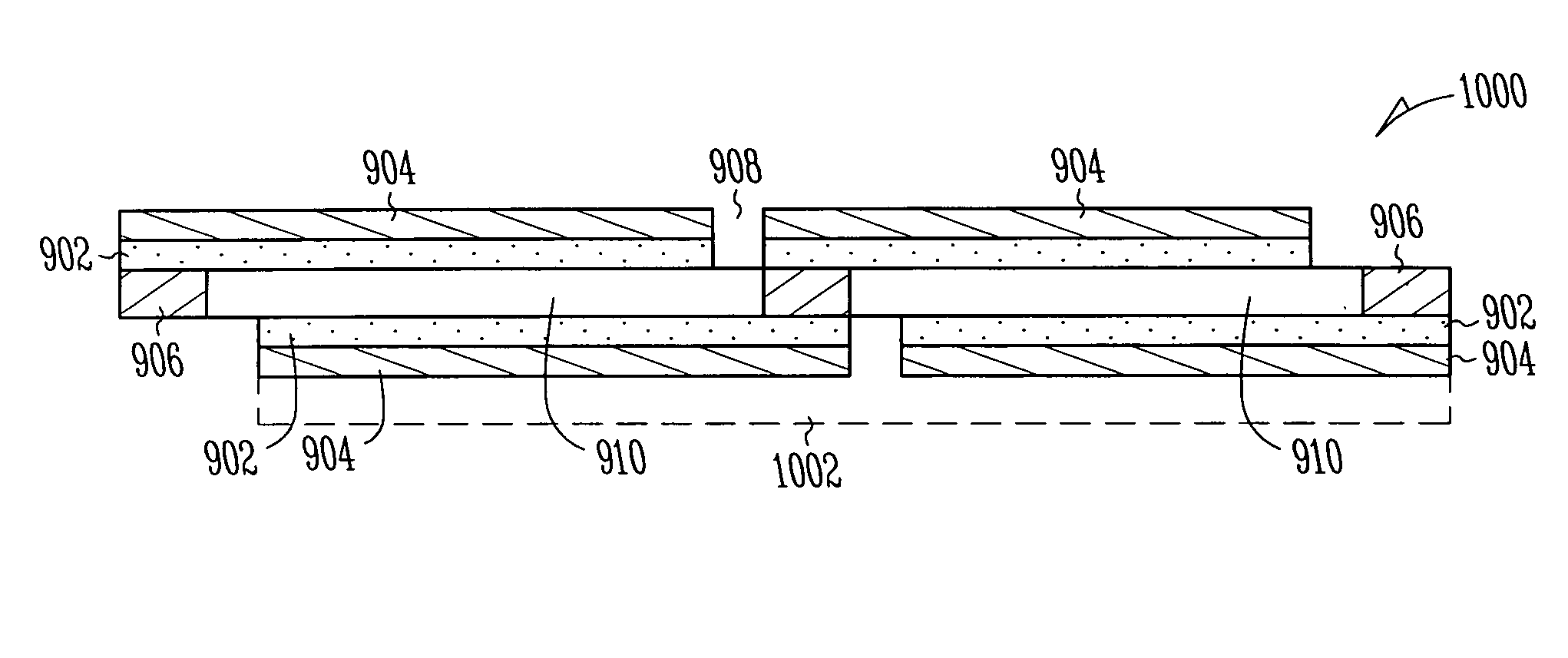

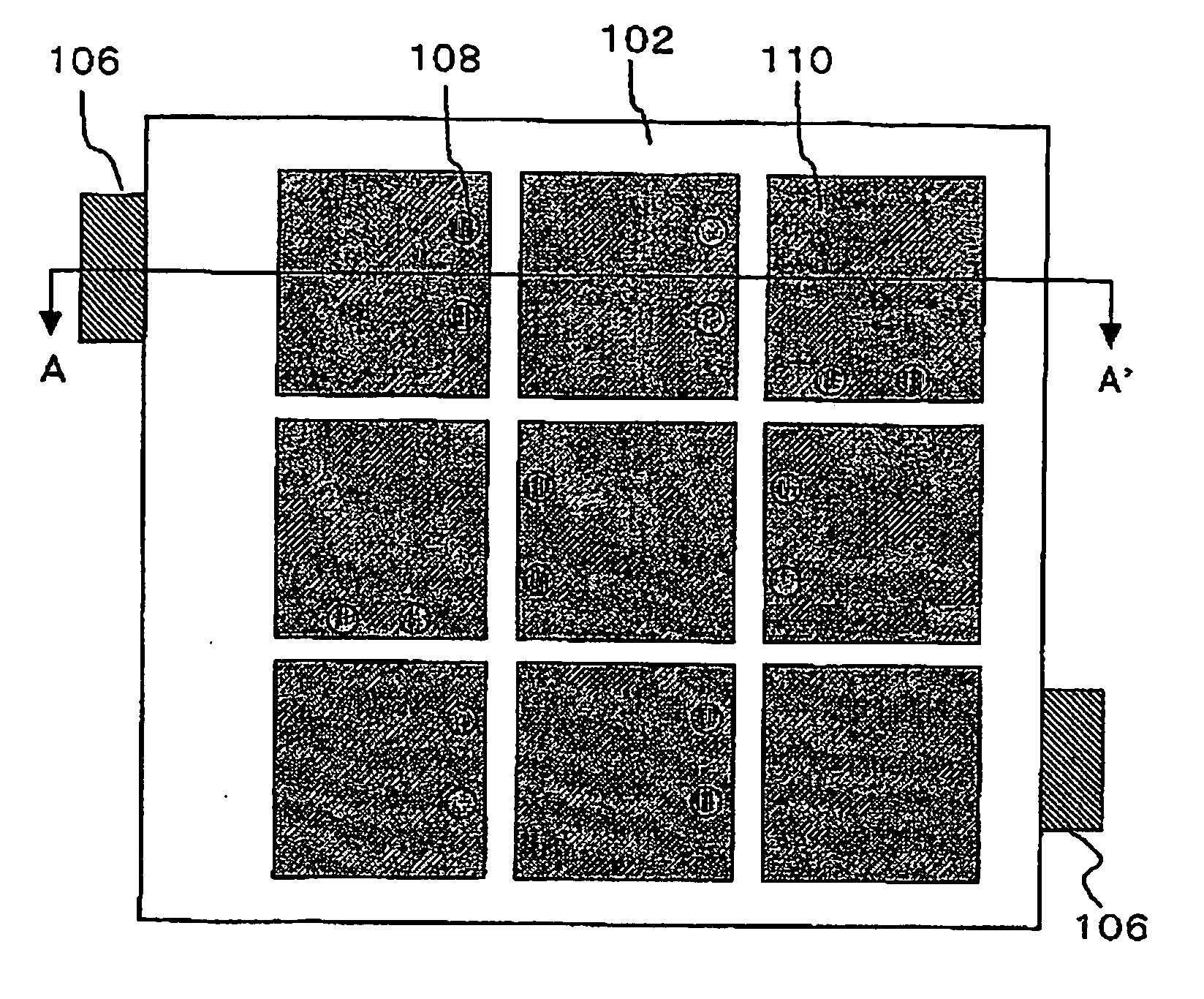

A solid electrolyte fuel cell configuration provided with a single sheet shaped solid electrolyte substrate formed with a plurality of fuel cells and thereby not having a sealed structure, achieving a reduction of the size and a reduction of the cost, and able to improve the durability and improve the power generation efficiency, a single sheet shaped solid electrolyte substrate, in particular a solid electrolyte fuel cell configuration provided with a single sheet shaped solid electrolyte substrate, a plurality of anode layers formed on one side of the solid electrolyte substrate, and a plurality of cathode layers formed on the side opposite to the one side of the solid electrolyte substrate at positions facing the anode layers, the anode layers and cathode layers facing each other across the solid electrolyte substrate forming a plurality of fuel cells, the anode layers and cathode layers being connected in series.

Owner:SHINKO ELECTRIC IND CO LTD

Electrochemical cell assemblies including a region of discontinuity

Embodiments of the invention relate to electrochemical cell assemblies in which a region of discontinuity provides separation and insulation between adjacent cells in an array.

Owner:INTELLIGENT ENERGY LTD

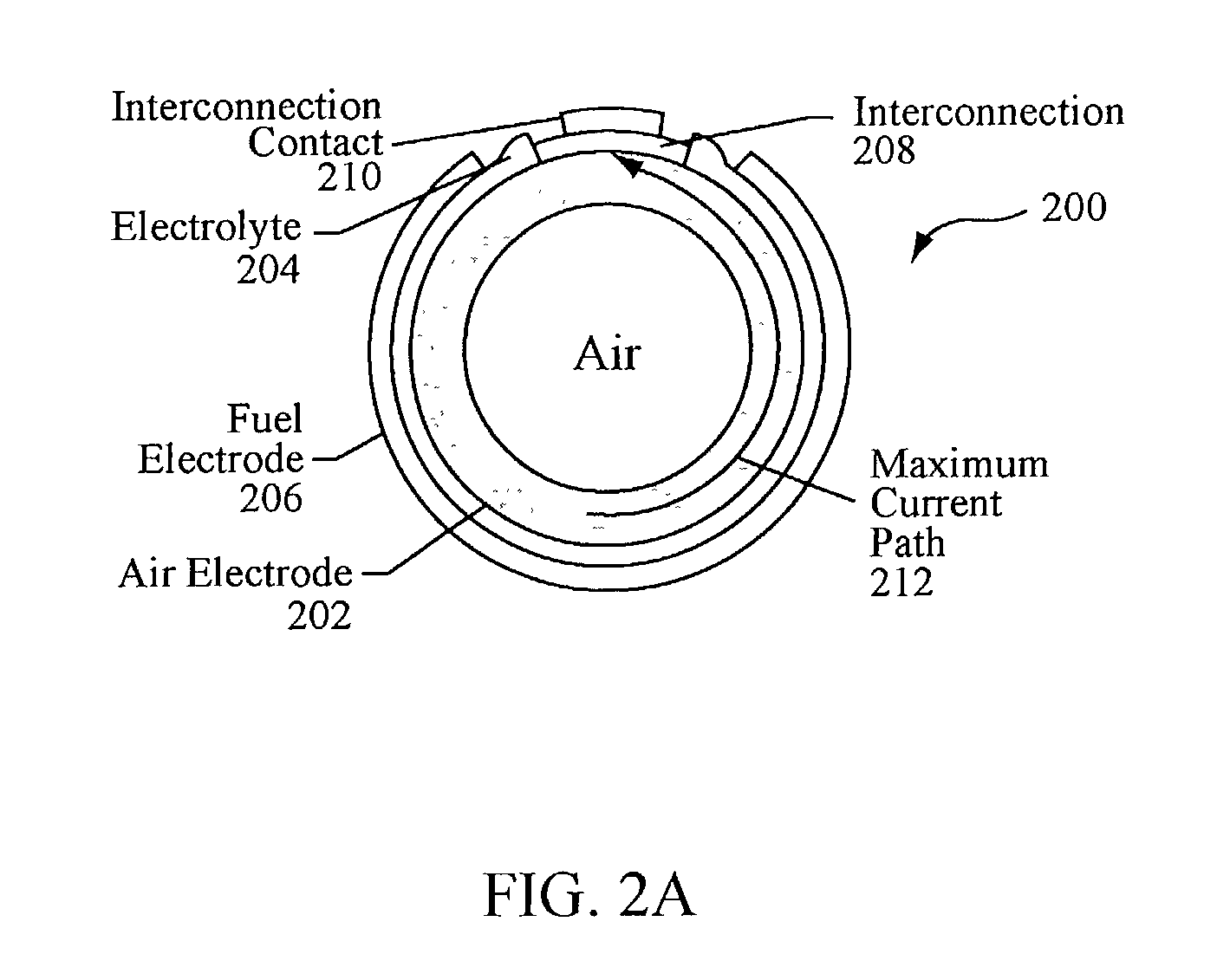

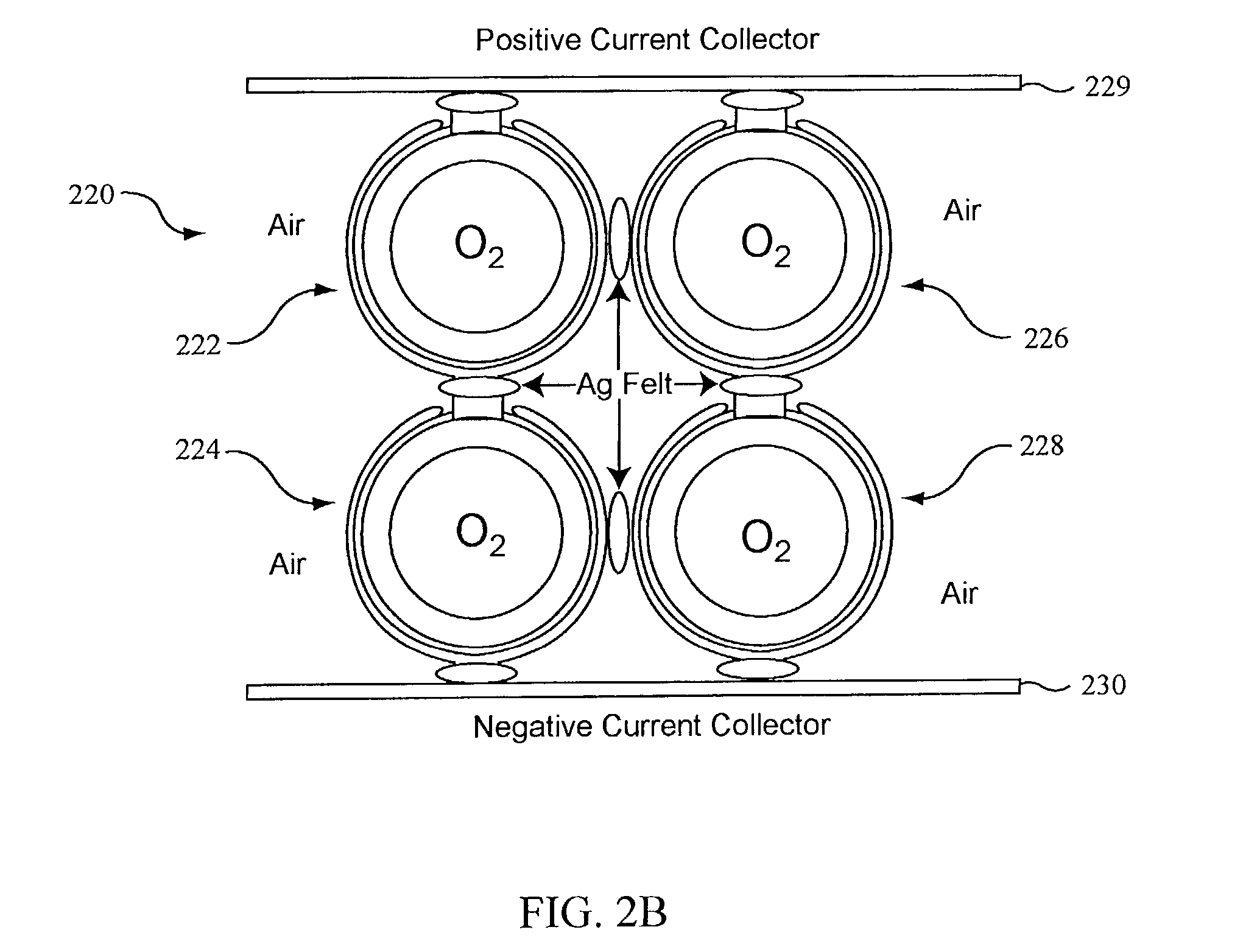

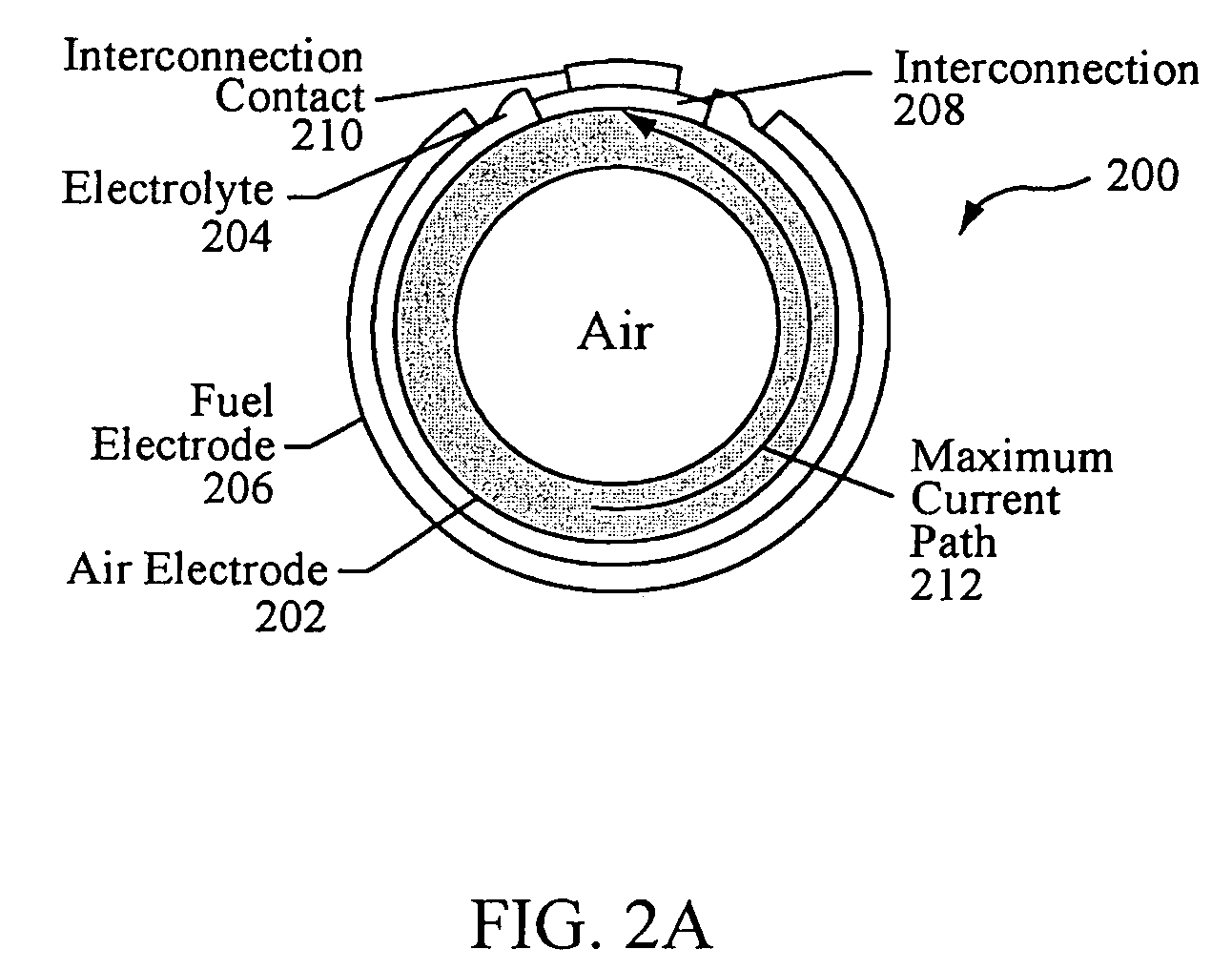

Fuel cell structures and assemblies

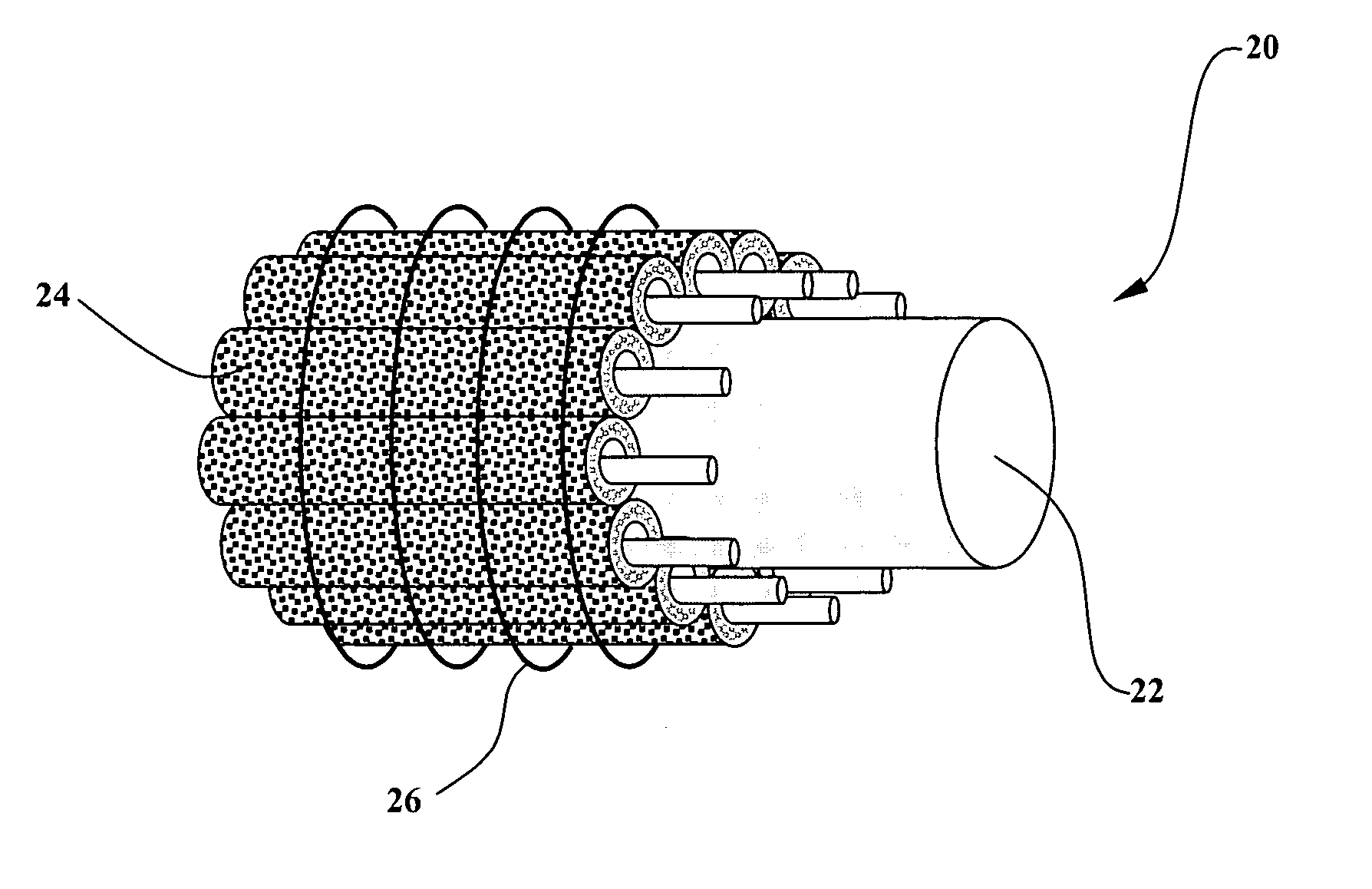

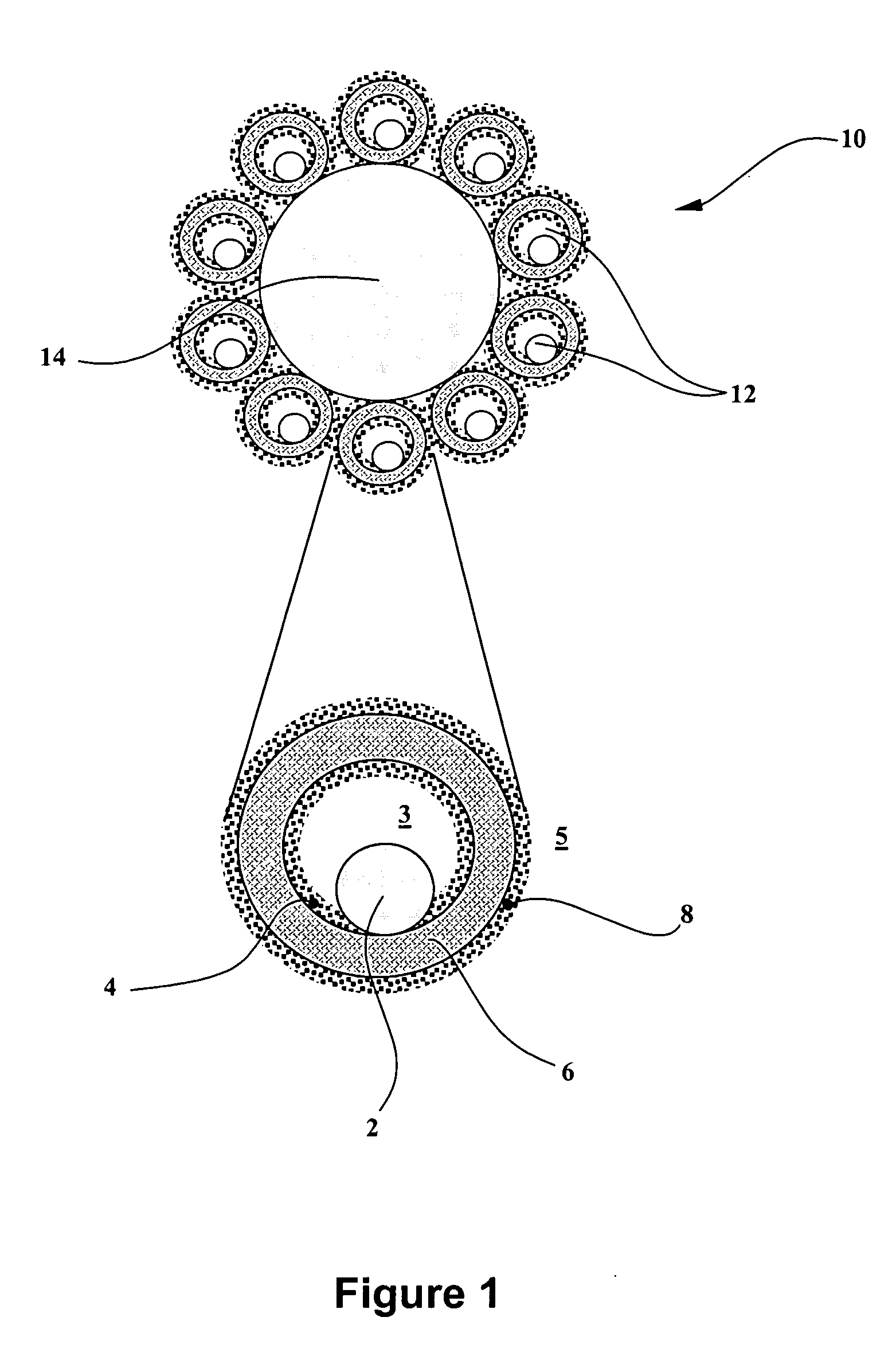

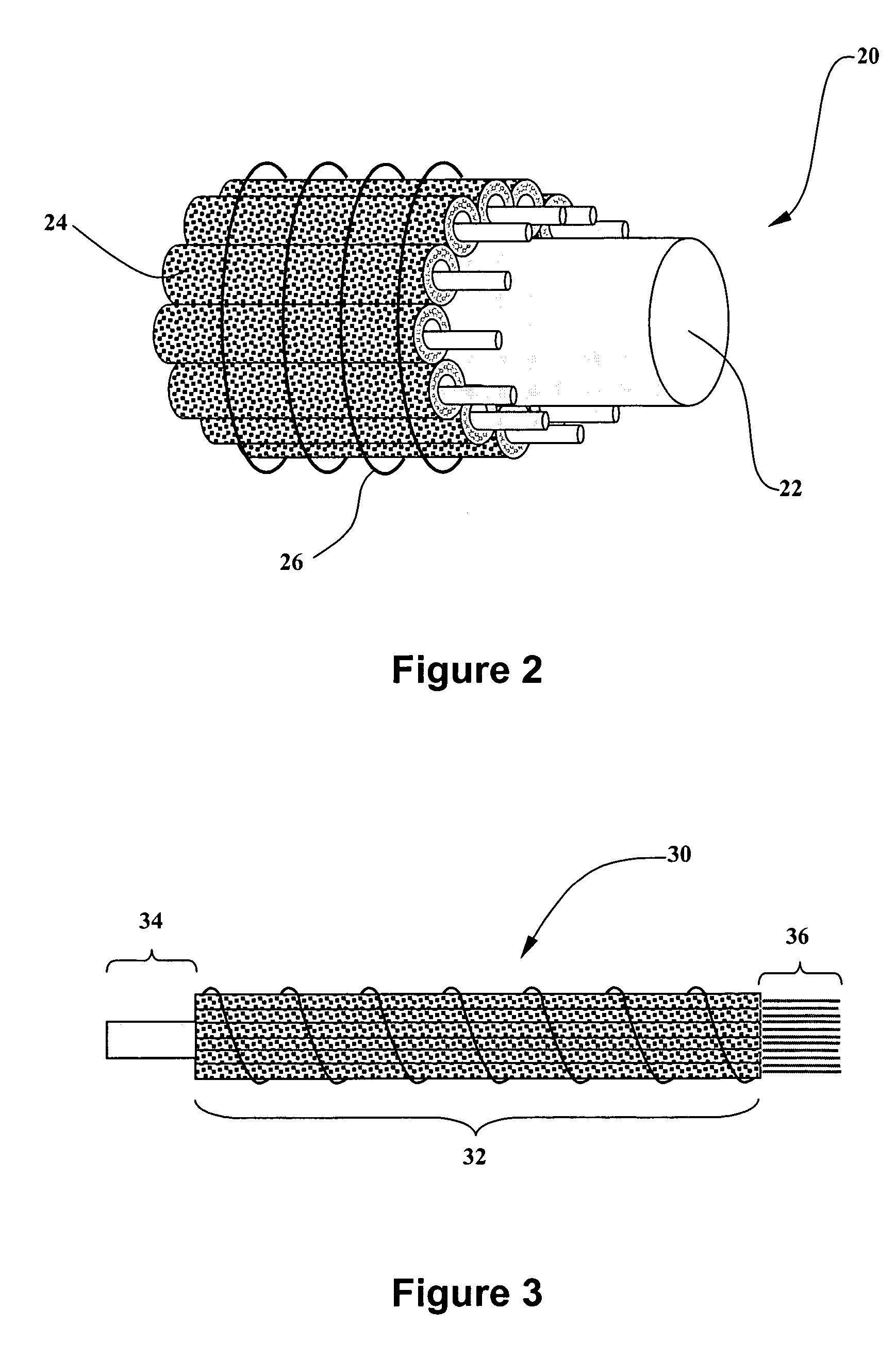

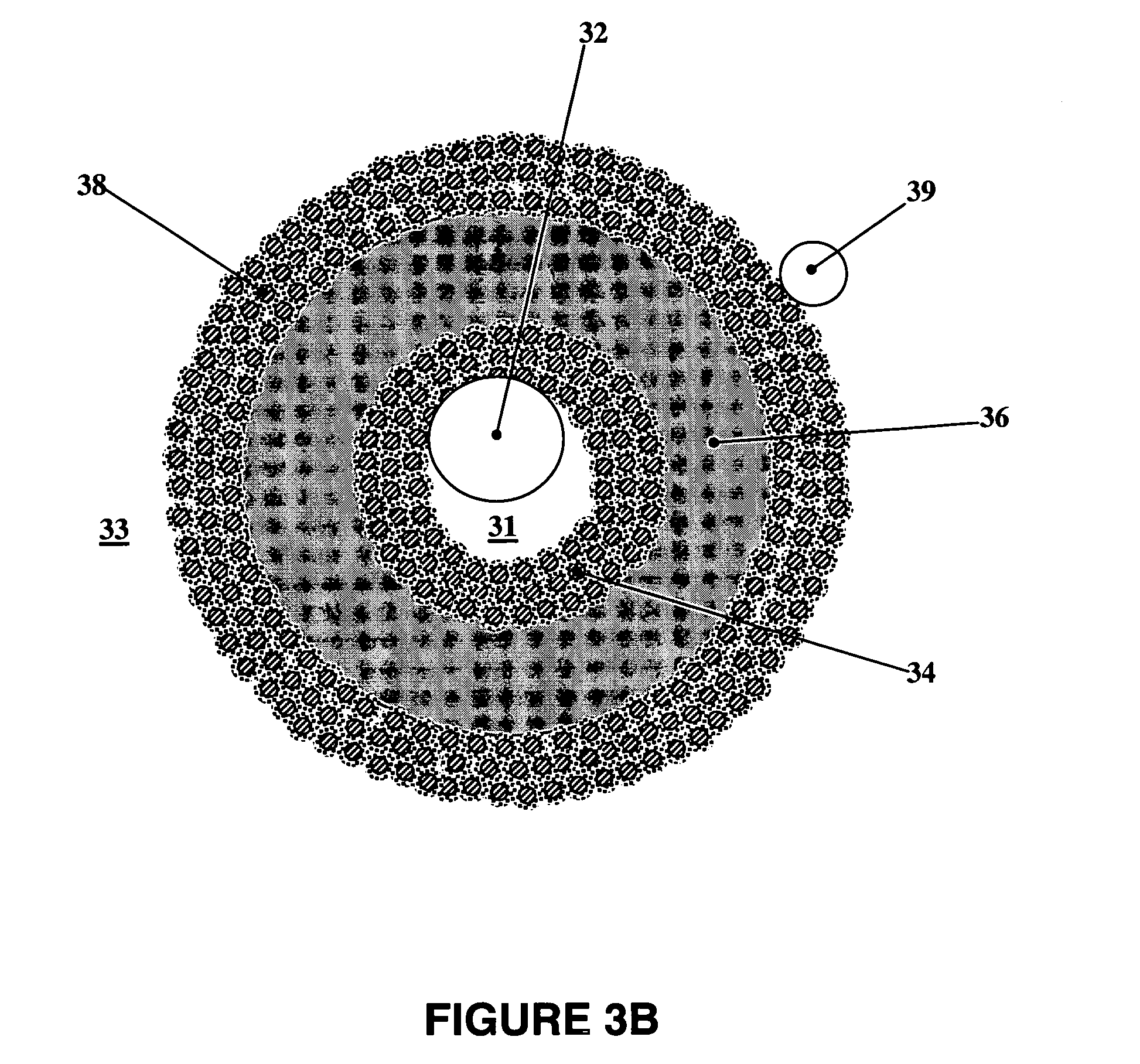

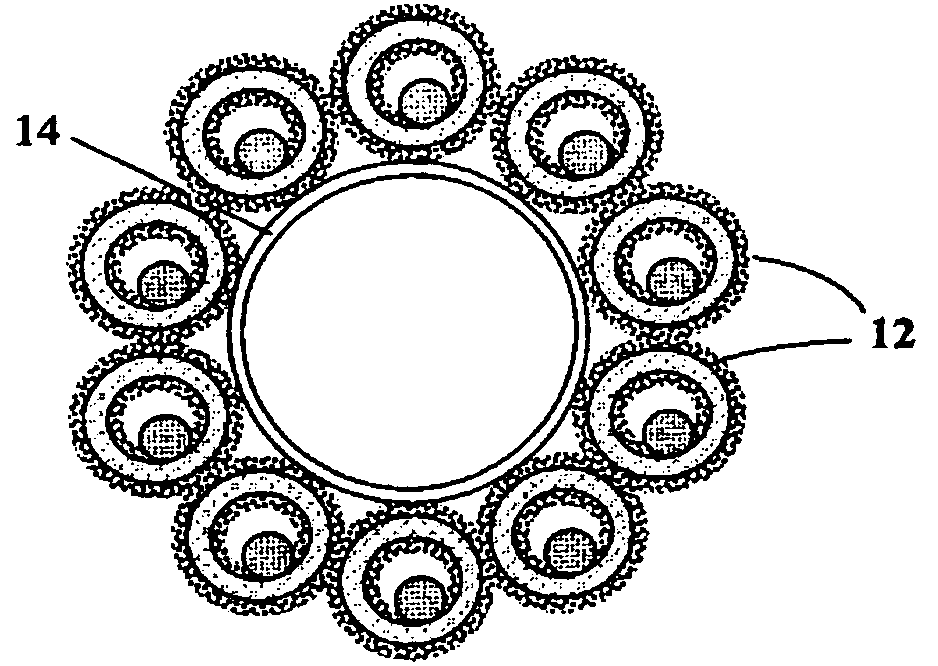

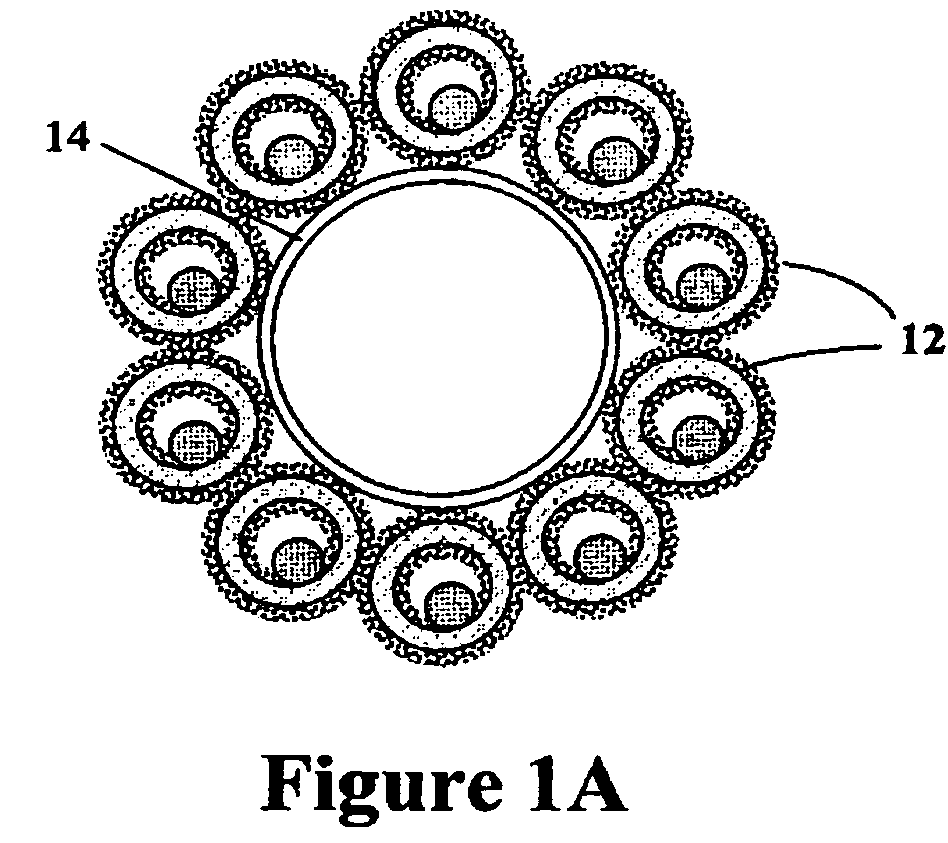

The present invention relates to microfibrous fuel cell sub-bundle structures, fuel cell bundles and fuel cell assemblies formed by such fuel cell sub-bundles and bundles. Specifically, a fuel cell sub-bundle is provided, which comprises multiple microfibrous fuel cells. Each microfibrous fuel cell comprises: (a) a hollow microfibrous membrane separator comprising an electrolyte medium, (b) an inner electrocatalyst layer in contact with an inner surface of such membrane separator, (c) an outer electrocatalyst layer in contact with an outer surface of such membrane separator, and (d) an individual current collector in electrical contact with the inner surface of such membrane separator. Each of such multiple microfibrous fuel cells is in electrical contact with a common current collector at the outer surface of its membrane separator.

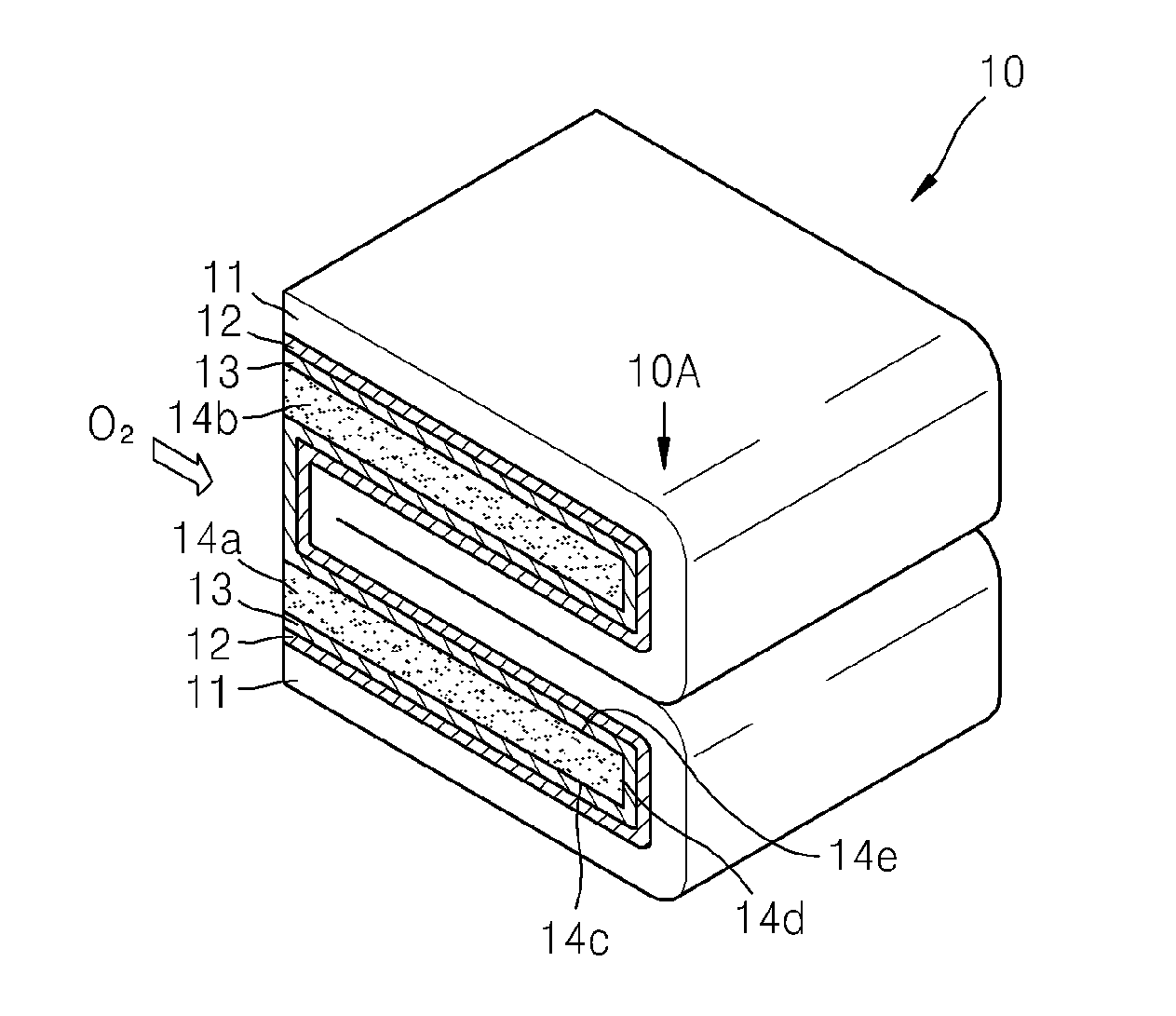

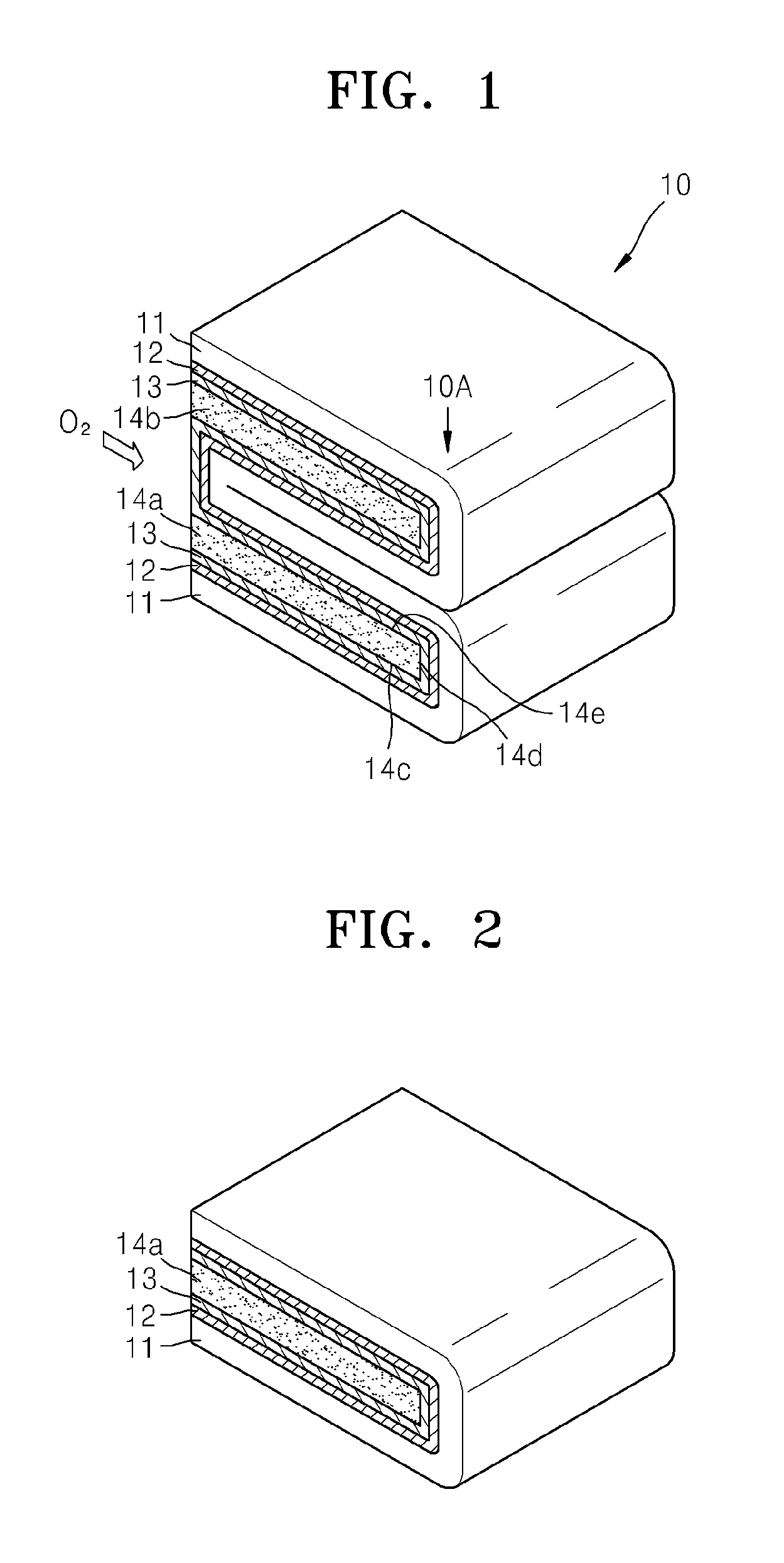

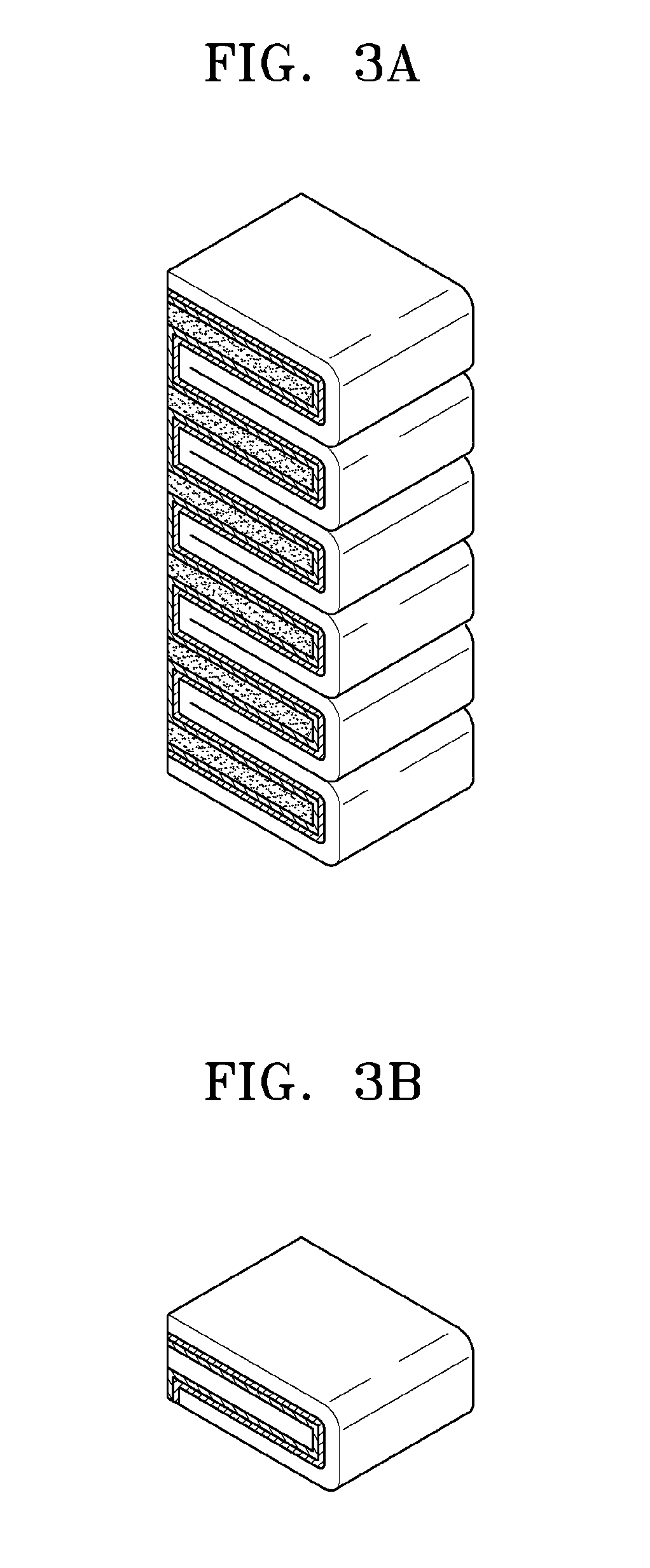

Metal-air battery having folded structure and method of manufacturing the same

A metal-air battery including: a negative electrode metal layer; a negative electrode electrolyte layer disposed on the negative electrode metal layer; a positive electrode layer disposed on the negative electrode electrolyte layer, the positive electrode layer comprising a positive electrode material which is capable of using oxygen as an active material; and a gas diffusion layer disposed on the positive electrode layer, wherein the negative electrode electrolyte layer is between the negative electrode metal layer and the positive electrode layer; wherein the negative electrode metal layer, the negative electrode electrolyte layer, and the positive electrode layer are disposed on the gas diffusion layer so that the positive electrode layer contacts a lower surface and an opposite upper surface of the gas diffusion layer, and wherein one side surface of the gas diffusion layer is exposed to an outside.

Owner:SAMSUNG ELECTRONICS CO LTD

Fuel cell and fuel cell stack

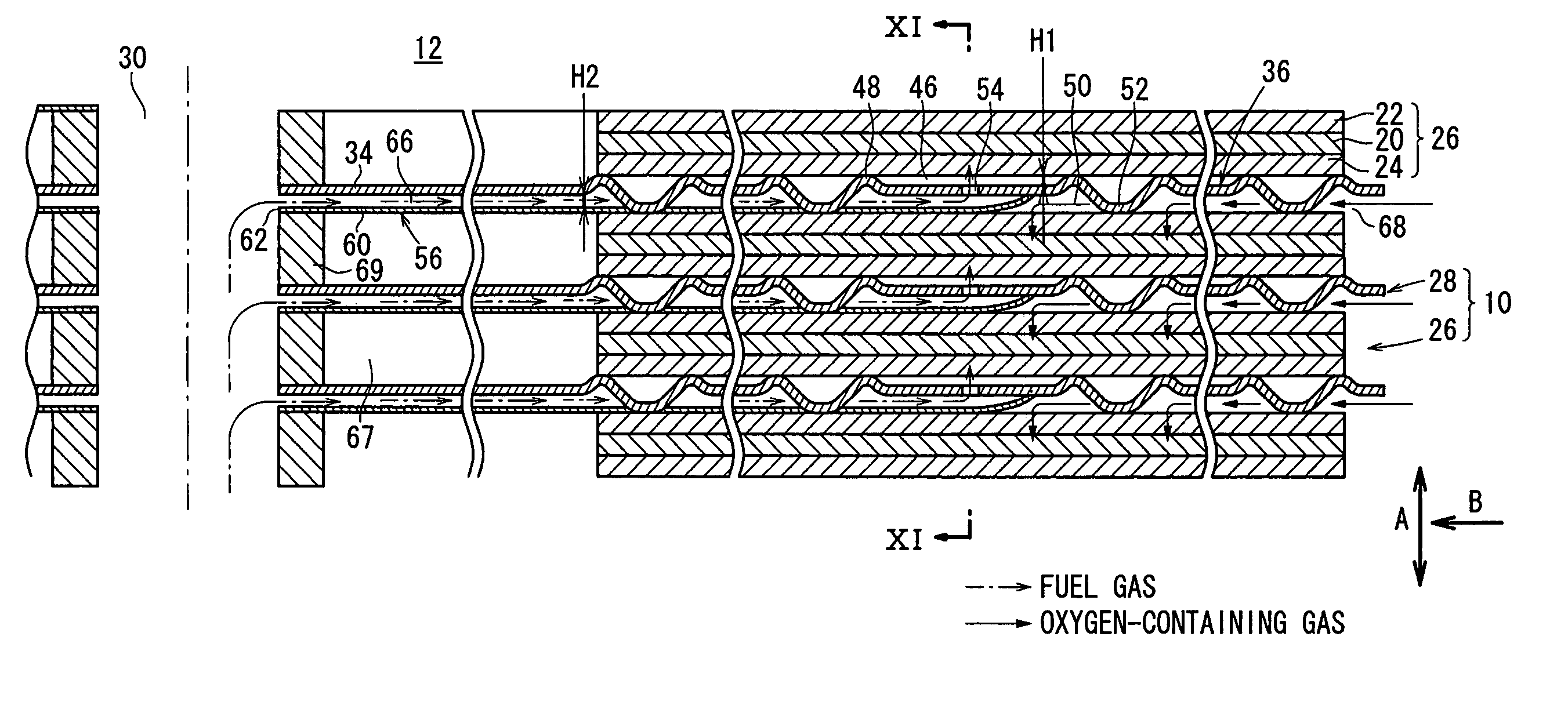

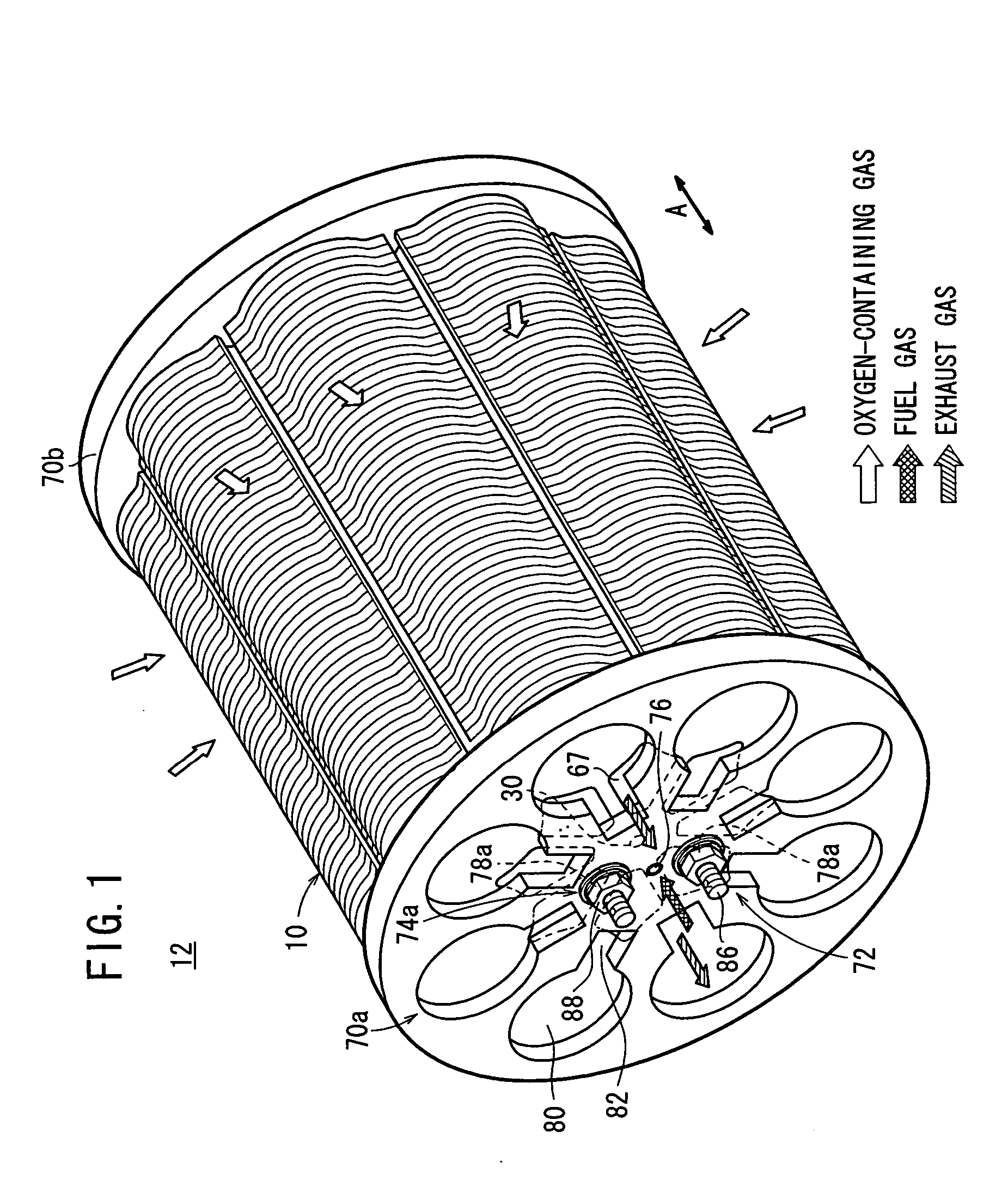

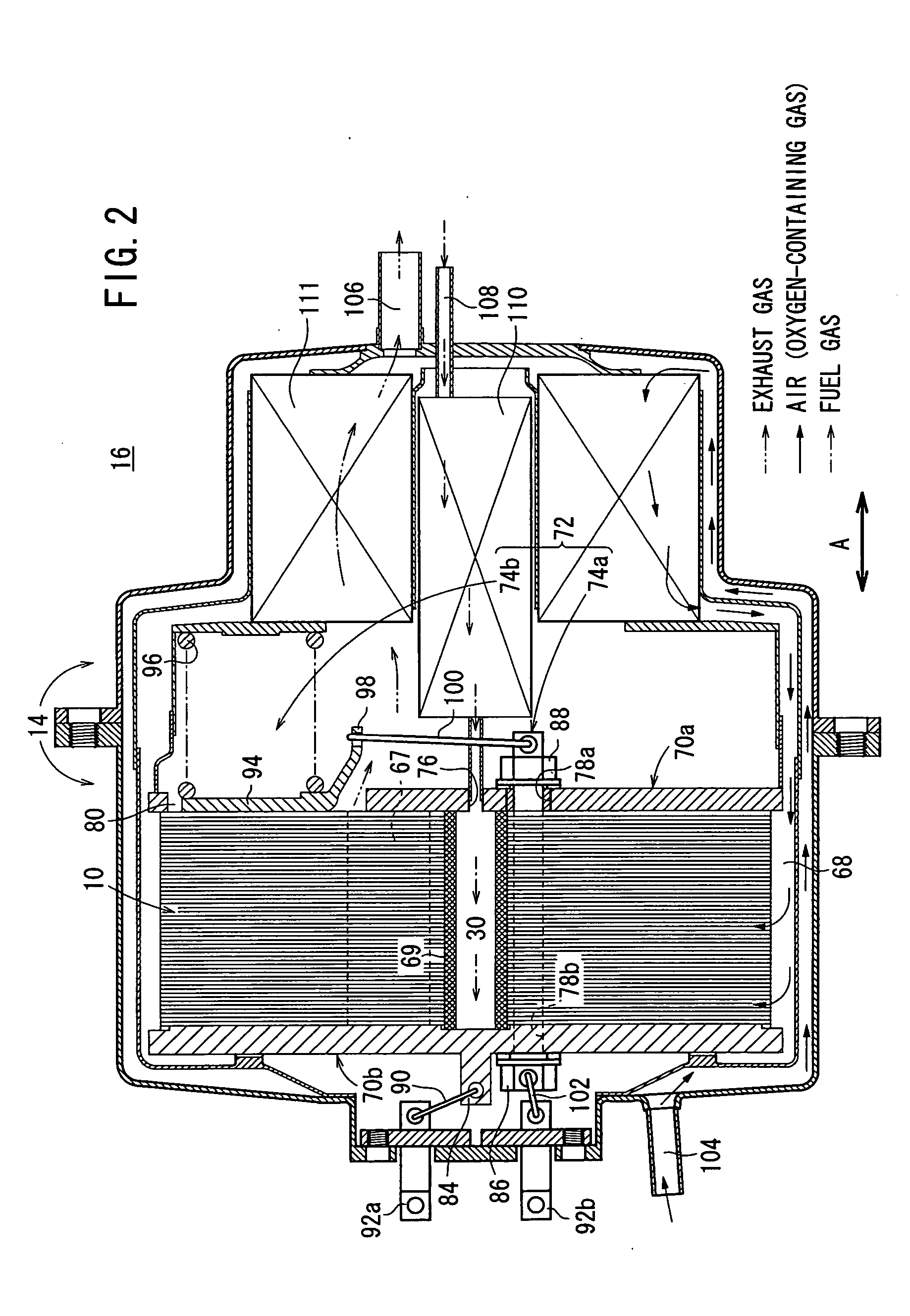

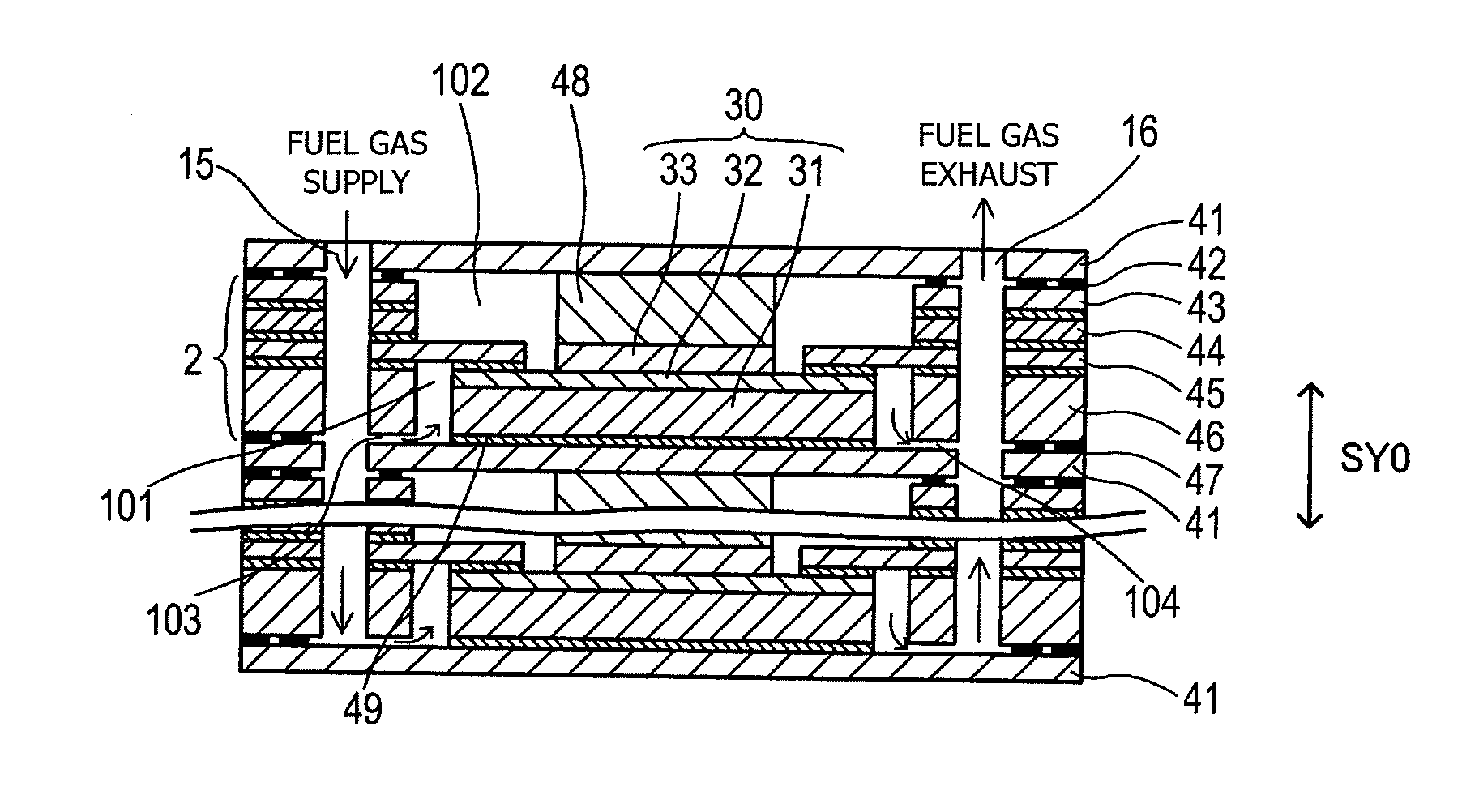

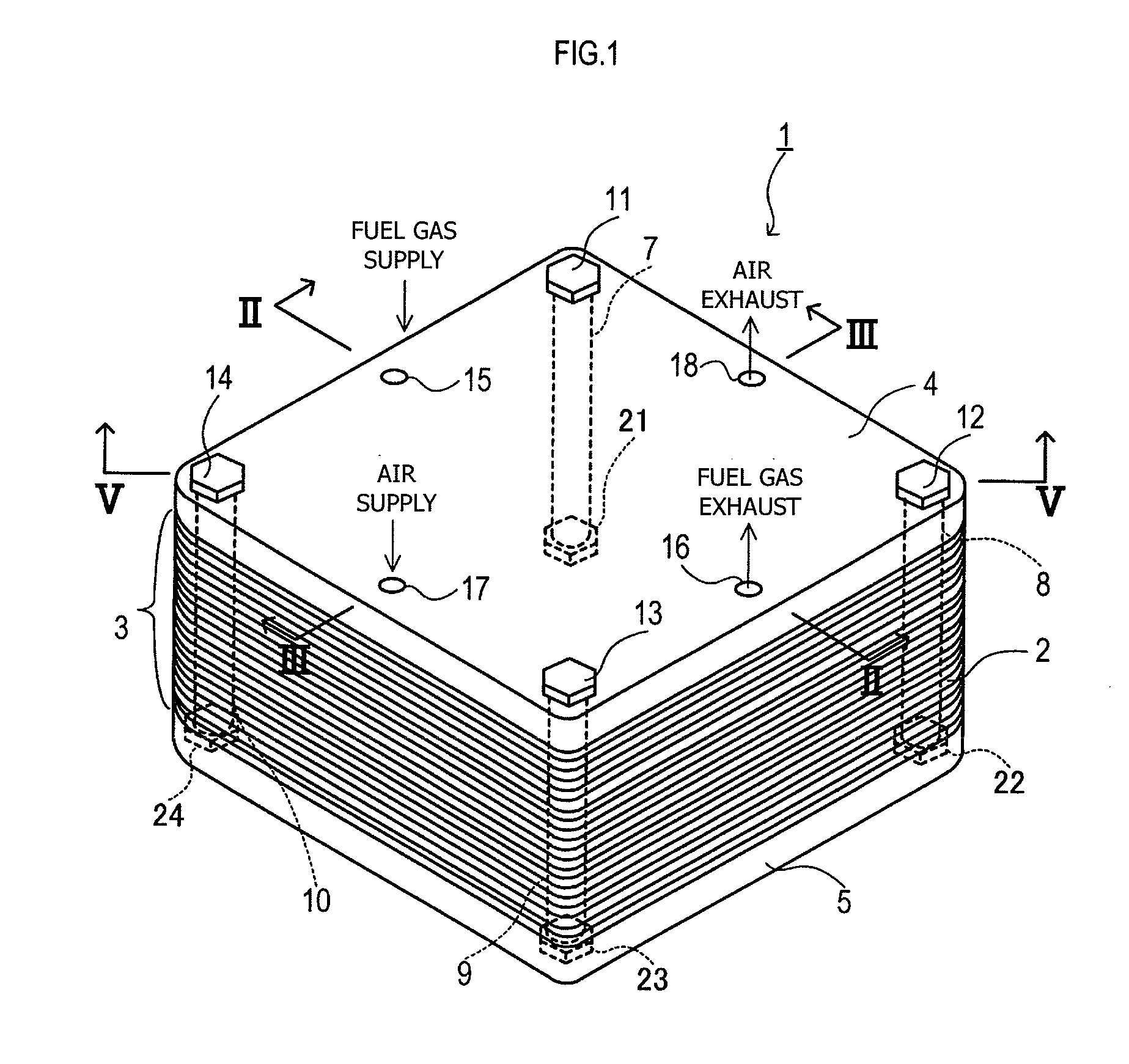

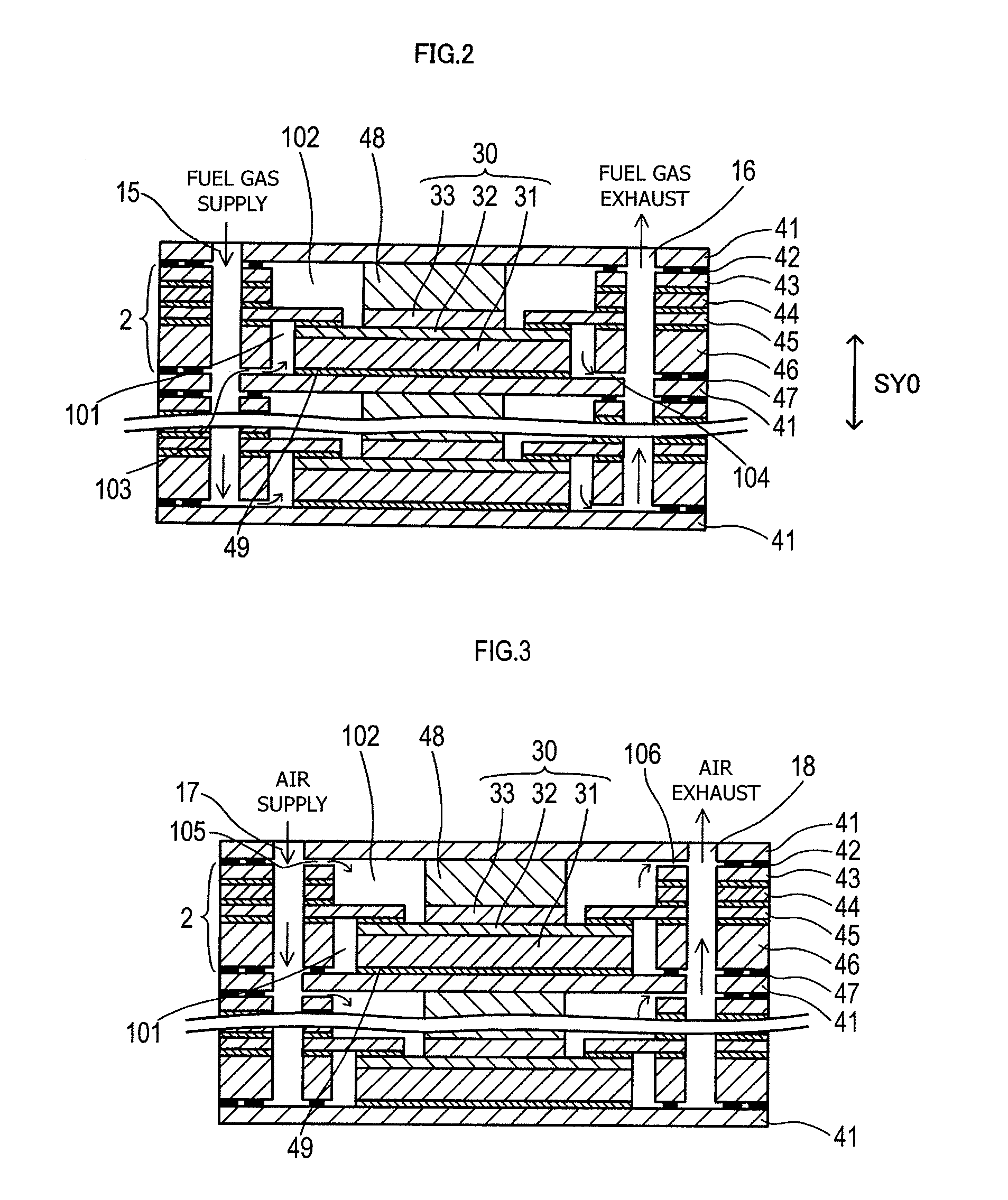

InactiveUS20050142424A1Simple and compact structureLoad is appliedFuel cell heat exchangeFuel cells groupingFuel cellsEngineering

A fuel cell includes electrolyte electrode assemblies and a pair of separators sandwiching the electrolyte electrode assemblies. Each of the separators includes a plurality of circular disks. First protrusions and second protrusions are provided on both surfaces of the circular disk. The first protrusions contact an anode of the electrolyte electrode assembly, and the second protrusions contact a cathode of the electrolyte electrode assembly. The area of the separators is divided into portions corresponding to the respective electrolyte electrode assemblies. Each of the divided portions of the separators forms a fuel gas flow field and an oxygen-containing gas flow field by sandwiching the electrolyte electrode assembly.

Owner:HONDA MOTOR CO LTD

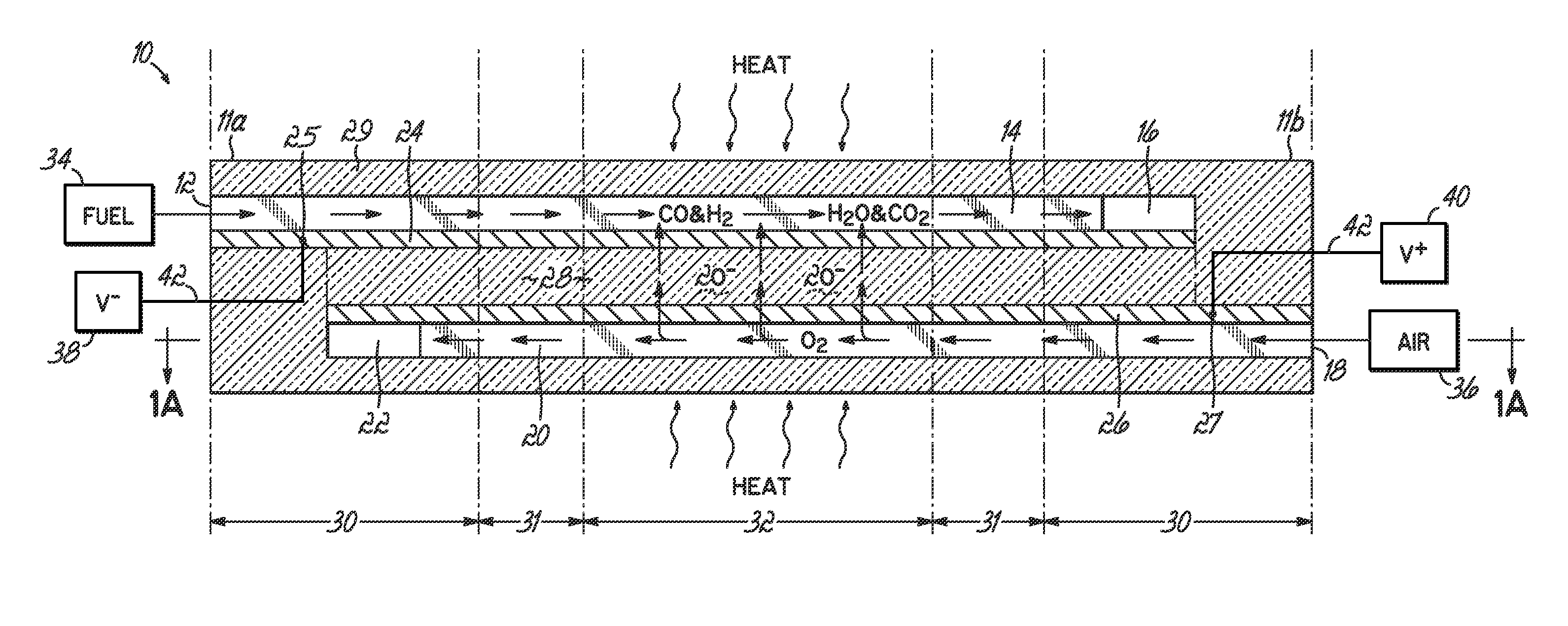

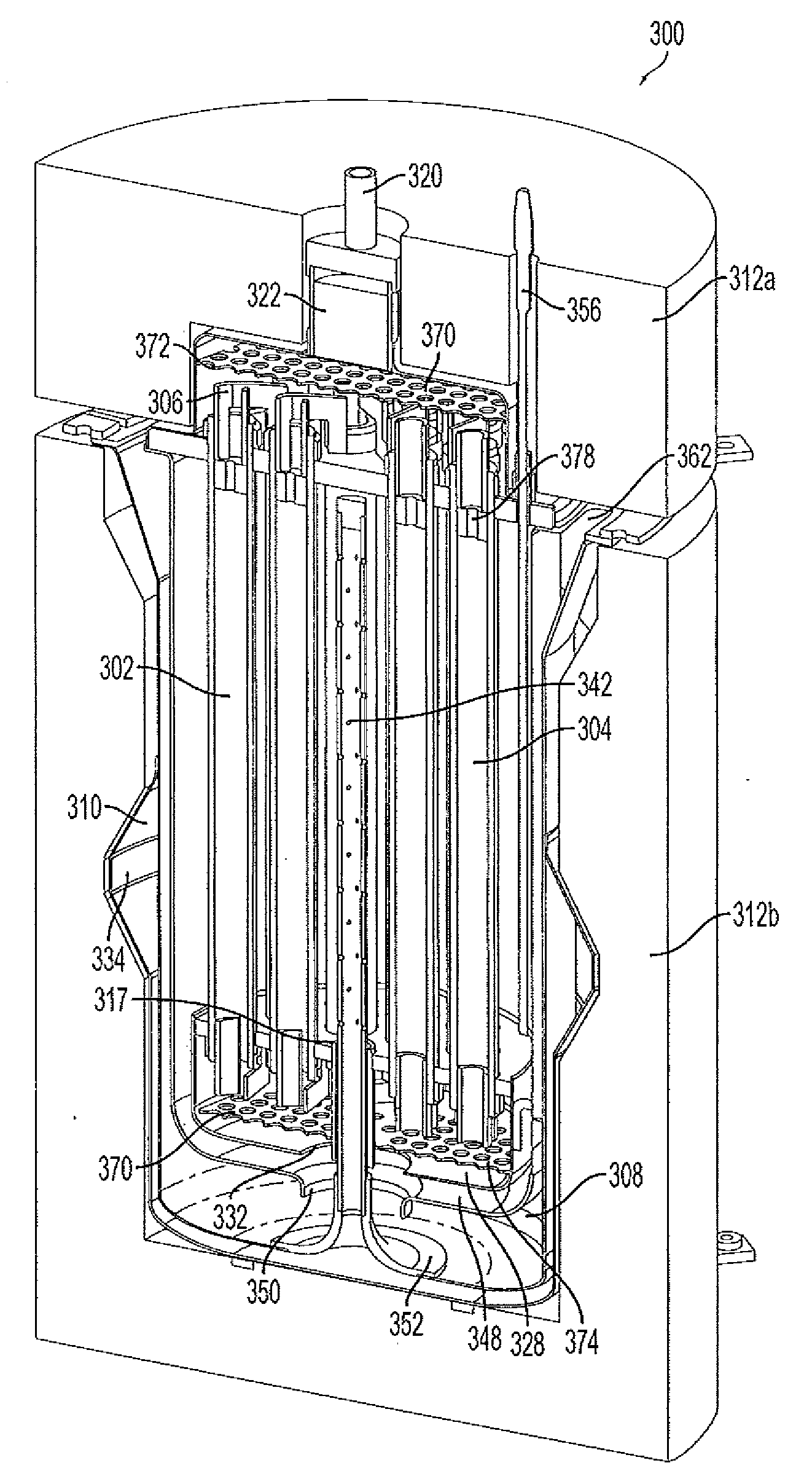

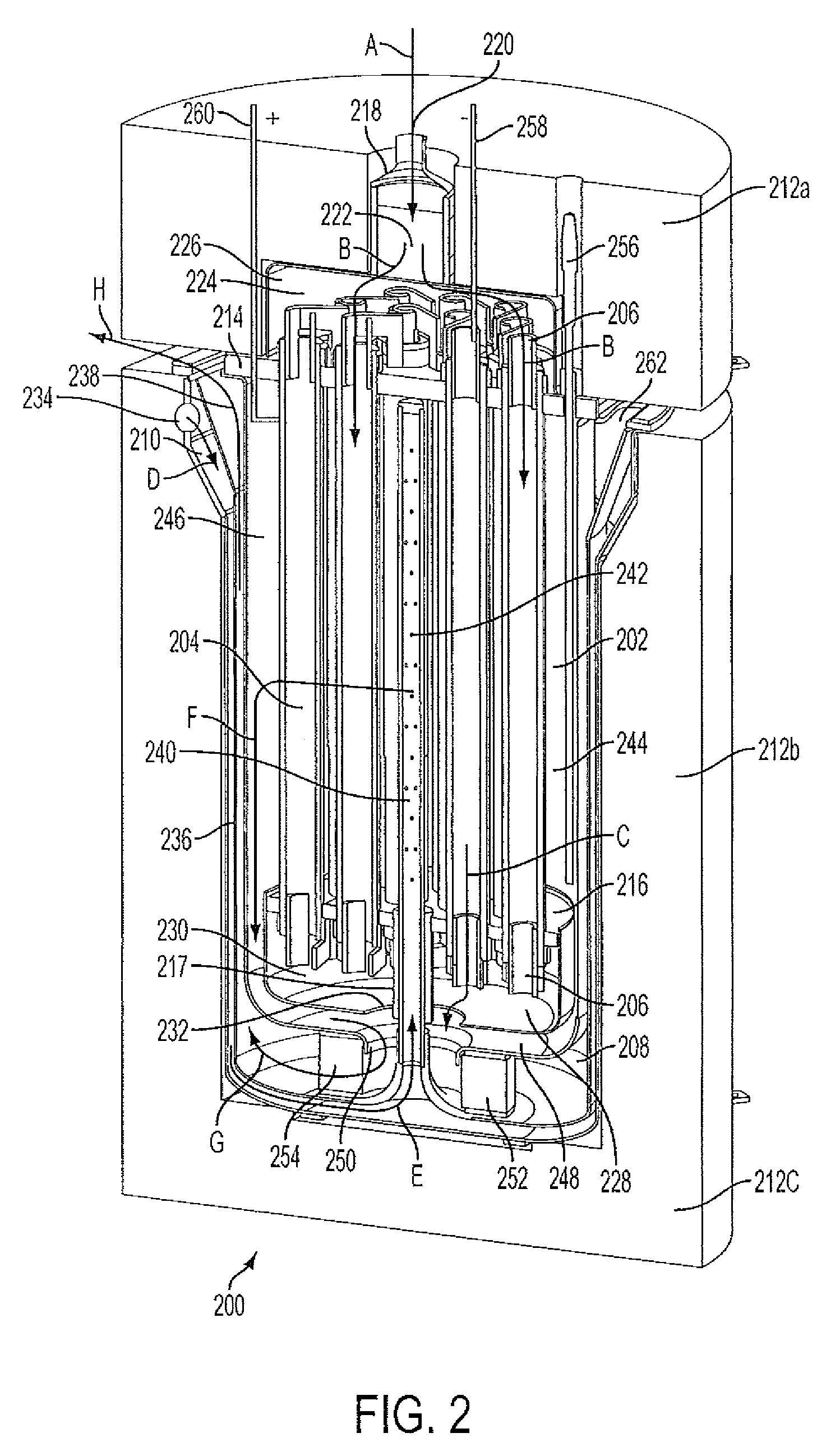

Solid oxide fuel cell device and system

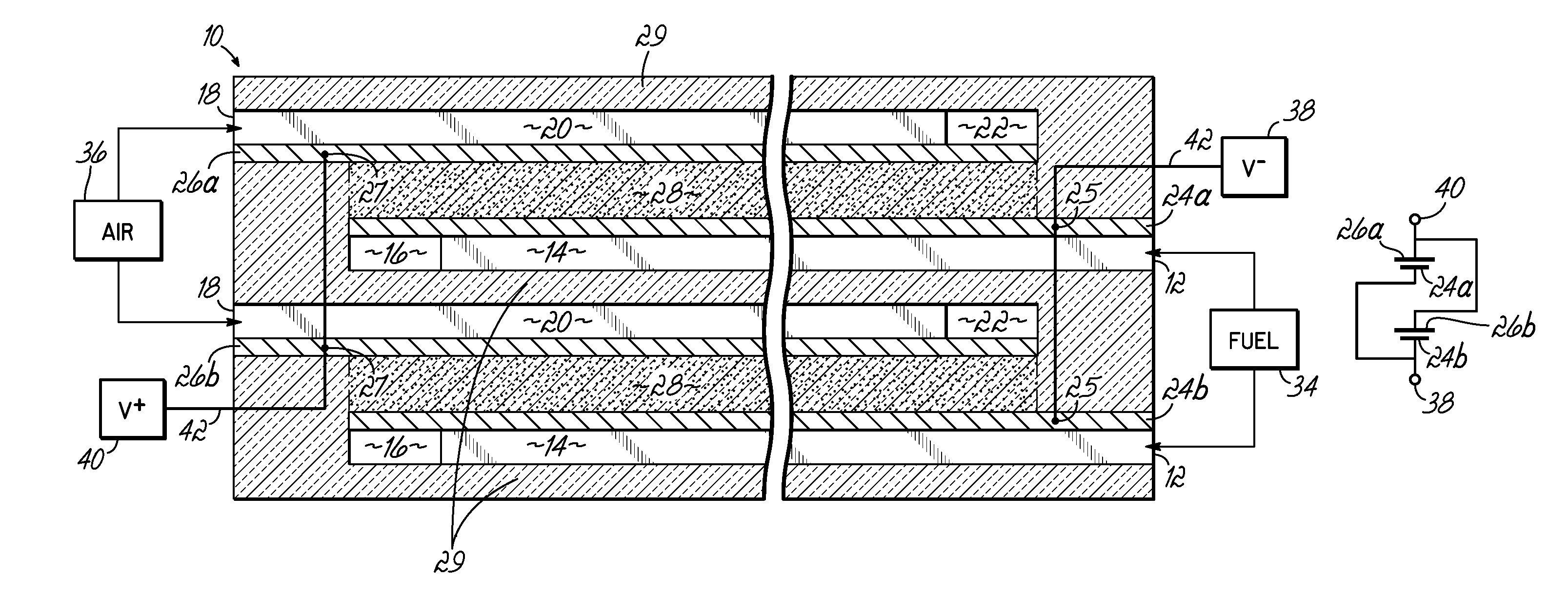

InactiveUS7838137B2Avoid layeringAvoid obstructionFuel cell heat exchangeReactant parameters controlFuel cellsElectrical connection

The invention provides a fuel cell device having first and second cold end regions with a reaction zone therebetween. Fuel and oxidizer inlets are positioned in the first and second cold end regions with respective fuel and oxidizer outlets positioned in either the reaction zone or the opposite cold end region, and respective elongate fuel and oxidizer passages are coupled between the respective inlets and outlets at least partially extending through the reaction zone within an interior solid ceramic support structure in parallel and opposing relation. Electrodes are positioned adjacent the fuel and oxidizer passages in the reaction zone within the interior solid ceramic support structure and are electrically coupled to exterior contact surfaces in at least one of the cold end regions to which electrical connections are made. An electrolyte between the electrodes is monolithic with the interior solid ceramic support structure.

Owner:DEVOE ALAN +1

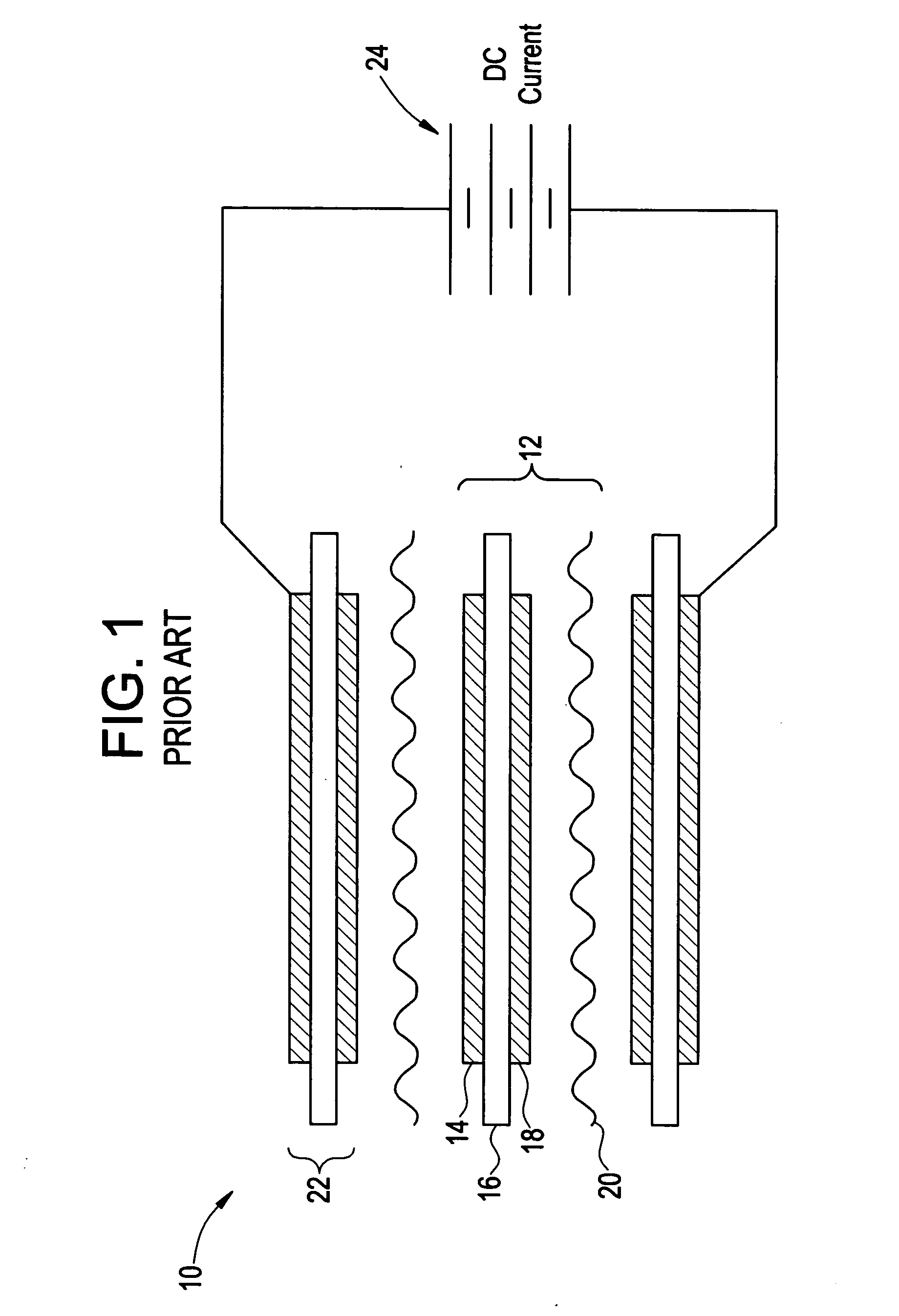

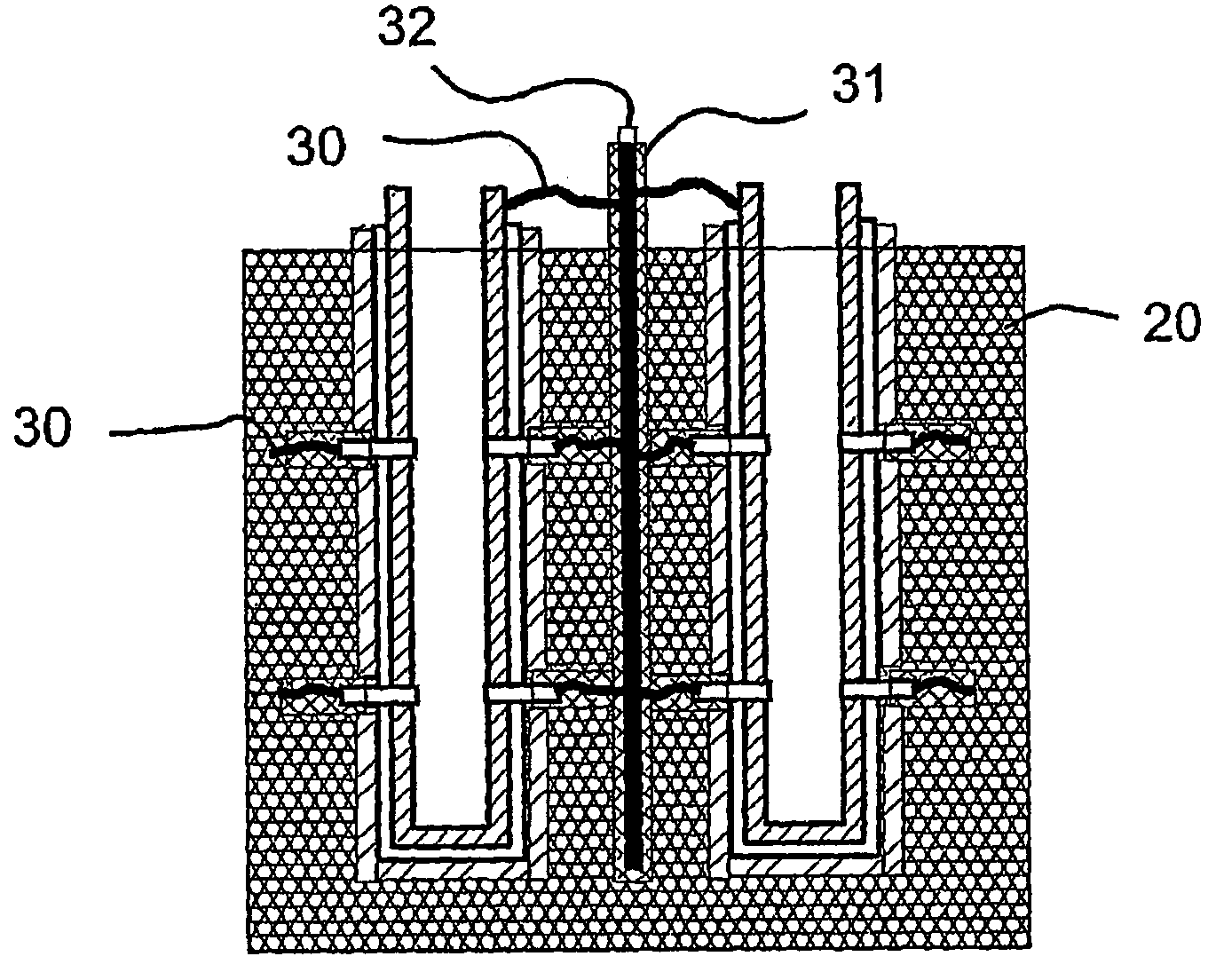

Pressurized electrolyzer stack module

A structural reinforcement for a pressurized plastic electrochemical cell stack is described with a first endplate and a second endplate, wherein the first endplate and the second endplate are each connected to a structural reinforcement along an axial direction such that the reinforcement extends through the first endplate and the second endplate and provides for compressing the first endplate and the second endplate against a bilithic or monolithic plastic electrochemical cell stack internal to the reinforcement, thereby sealing a gas generation cell within the reinforcement and thus providing enhanced creep resistance of the electrochemical cell stack.

Owner:GENERAL ELECTRIC CO

Solid oxide fuel cell system

InactiveUS20050196657A1Solve Porosity InsufficiencyReduce deliveryFuel cells groupingFuel cell shape/formPorosityFuel cells

Owner:INNOTECH ALBERTA INC

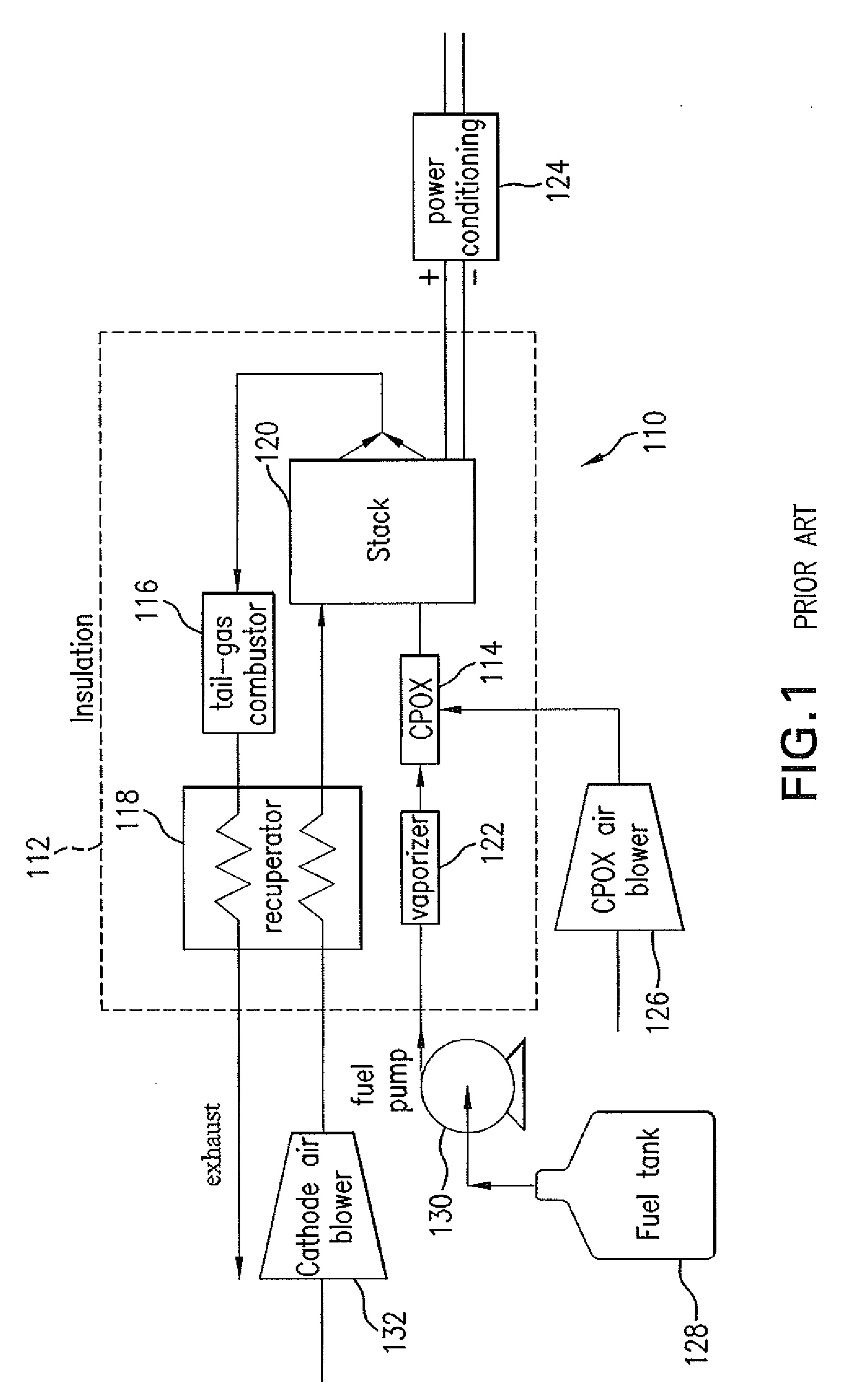

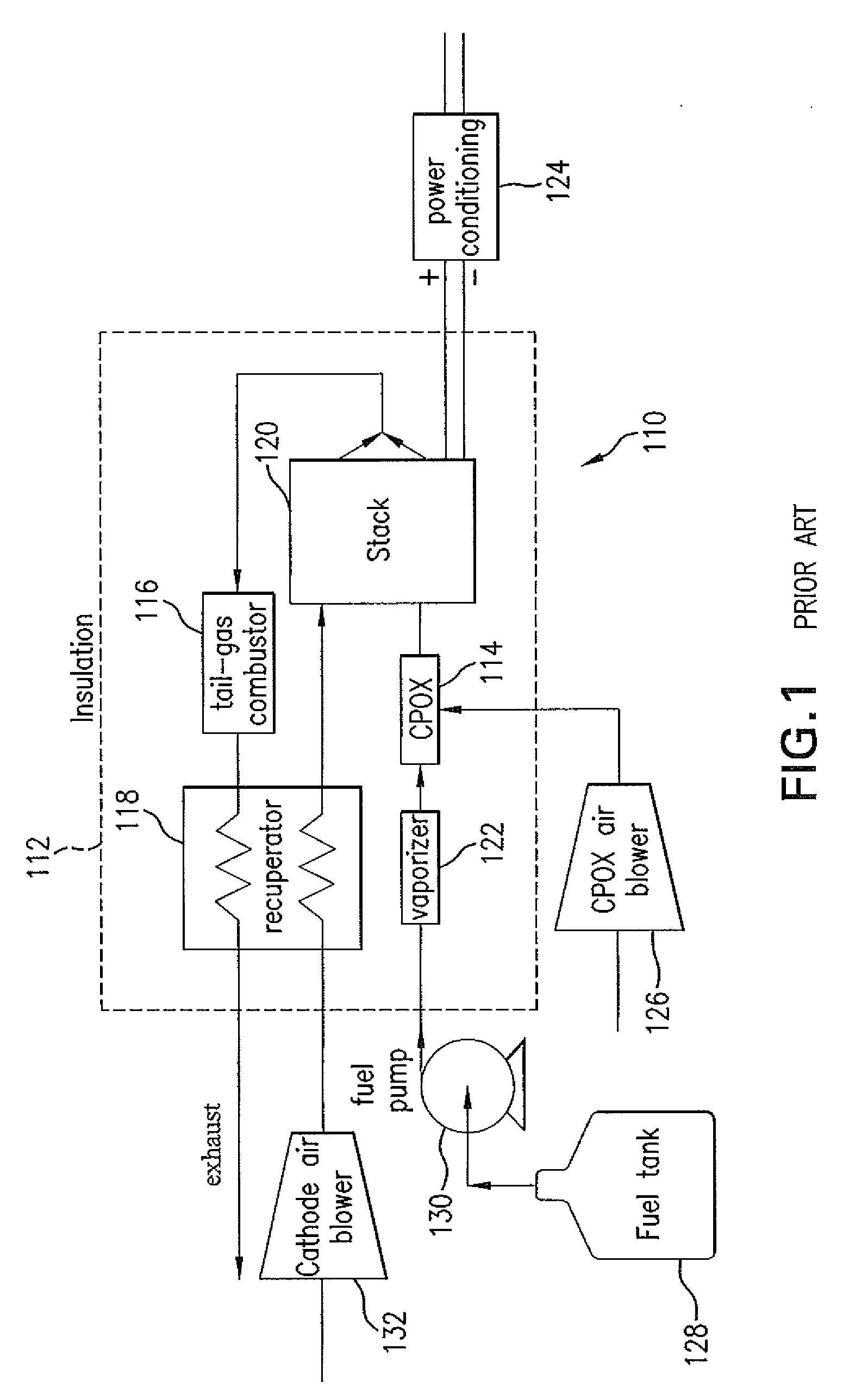

Solid oxide fuel cell systems with hot zones having improved reactant distribution

ActiveUS20100203399A1Easy accessMinimize regionReactant parameters controlFuel cell shape/formCounter flowCombustor

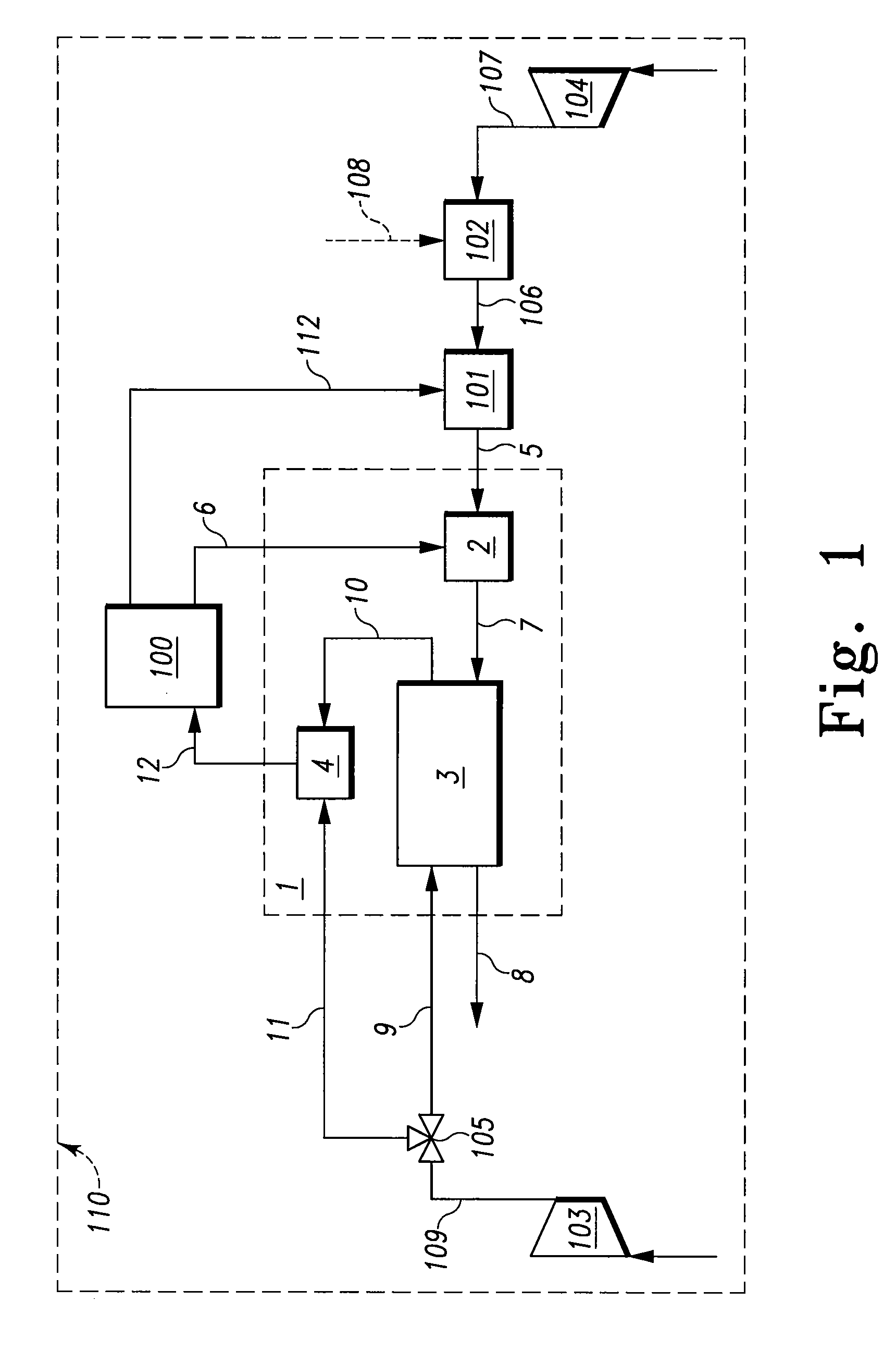

A Solid Oxide Fuel Cell (SOFC) system having a hot zone with a center cathode air feed tube for improved reactant distribution, a CPOX reactor attached at the anode feed end of the hot zone with a tail gas combustor at the opposing end for more uniform heat distribution, and a counter-flow heat exchanger for efficient heat retention.

Owner:SILICON VALLEY BANK +1

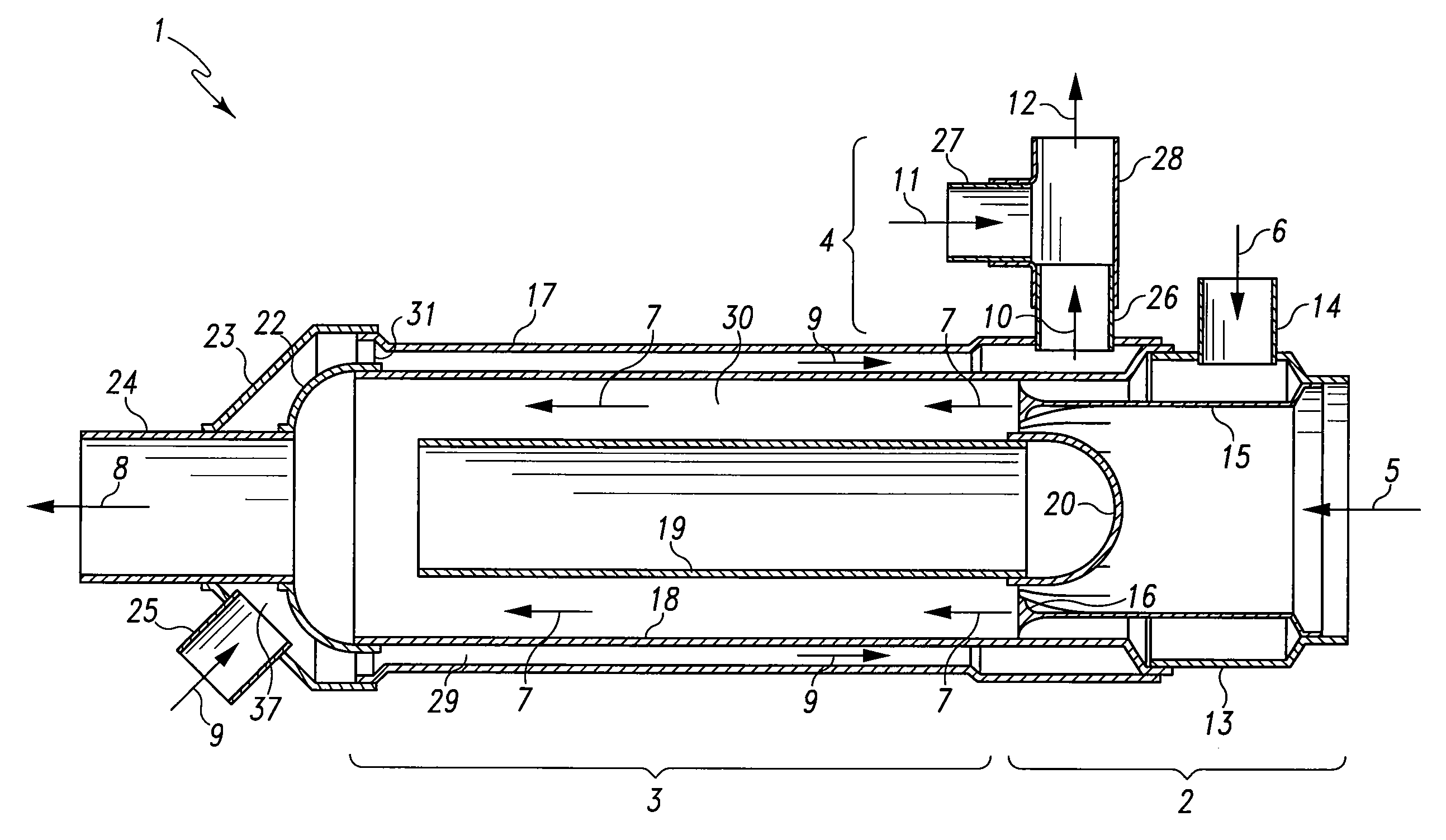

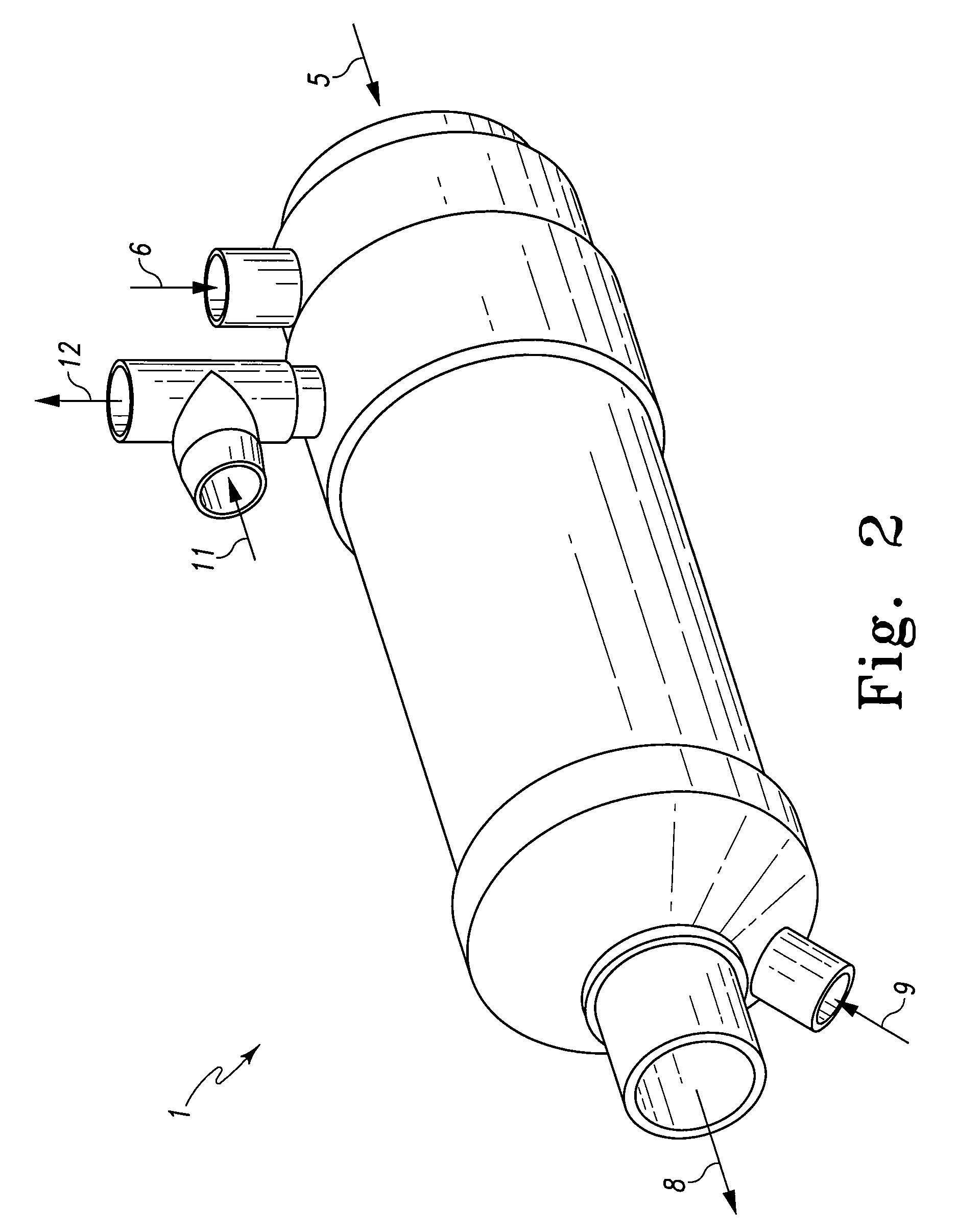

Compact air preheater for solid oxide fuel cell systems

InactiveUS20080020247A1Structural failureRemove heatFuel cells groupingRecuperative heat exchangersAir preheaterFuel cells

The present invention provides, among other things, a method of operating a solid oxide fuel cell system including a fuel cell stack. The method can include the acts of combining an exhaust flow from an anode side of the fuel cell stack and an exhaust flow from a cathode side of the fuel cell stack, transferring heat from the combined exhaust flow to a first air flow, and combining a second air flow and the heated first air flow upstream from the fuel cell stack to control a temperature of the combined air flow entering the cathode side of the solid oxide fuel cell.

Owner:MODINE MFG CO

Solid oxide fuel cell systems with hot zones having improved reactant distribution

ActiveUS8304122B2Easy accessMinimize regionReactant parameters controlFuel cell shape/formCounter flowCombustor

A Solid Oxide Fuel Cell (SOFC) system having a hot zone with a center cathode air feed tube for improved reactant distribution, a CPOX reactor attached at the anode feed end of the hot zone with a tail gas combustor at the opposing end for more uniform heat distribution, and a counter-flow heat exchanger for efficient heat retention.

Owner:SILICON VALLEY BANK +1

Structures and fabrication techniques for solid state electrochemical devices

Provided are low-cost, mechanically strong, highly electronically conductive porous substrates and associated structures for solid-state electrochemical devices, techniques for forming these structures, and devices incorporating the structures. The invention provides solid state electrochemical device substrates of novel composition and techniques for forming thin electrode / membrane / electrolyte coatings on the novel or more conventional substrates. In particular, in one embodiment the invention provides techniques for co-firing of device substrate (often an electrode) with an electrolyte or membrane layer to form densified electrolyte / membrane films 5 to 20 microns thick. In another embodiment, densified electrolyte / membrane films 5 to 20 microns thick may be formed on a pre-sintered substrate by a constrained sintering process. In some cases, the substrate may be a porous metal, alloy, or non-nickel cermet incorporating one or more of the transition metals Cr, Fe, Cu and Ag, or alloys thereof.

Owner:RGT UNIV OF CALIFORNIA

Structures and fabrication techniques for solid state electrochemical devices

Low-cost, mechanically strong, highly electronically conductive porous substrates and associated structures for solid-state electrochemical devices, techniques for forming these structures, and devices incorporating the structures provide solid state electrochemical device substrates of novel composition and techniques for forming thin electrode / membrane / electrolyte coatings on the novel or more conventional substrates. In particular, in one aspect the invention provides techniques for co-firing of device substrate (often an electrode) with an electrolyte or membrane layer to form densified electrolyte / membrane films 5 to 20 microns thick. In another aspect, densified electrolyte / membrane films 5 to 20 microns thick may be formed on a pre-sintered substrate by a constrained sintering process. In some cases, the substrate may be a porous metal, alloy, or non-nickel cermet incorporating one or more of the transition metals Cr, Fe and Cu, or alloys thereof.

Owner:RGT UNIV OF CALIFORNIA

Joined concentric tubes

ActiveUS20100038012A1Easy to manufactureEasy to joinCell electrodesFinal product manufactureAdhesiveFriction force

Tubular objects having two or more concentric layers that have different properties are joined to one another during their manufacture primarily by compressive and friction forces generated by shrinkage during sintering and possibly mechanical interlocking. It is not necessary for the concentric tubes to display adhesive-, chemical- or sinter-bonding to each other in order to achieve a strong bond. This facilitates joining of dissimilar materials, such as ceramics and metals.

Owner:RGT UNIV OF CALIFORNIA

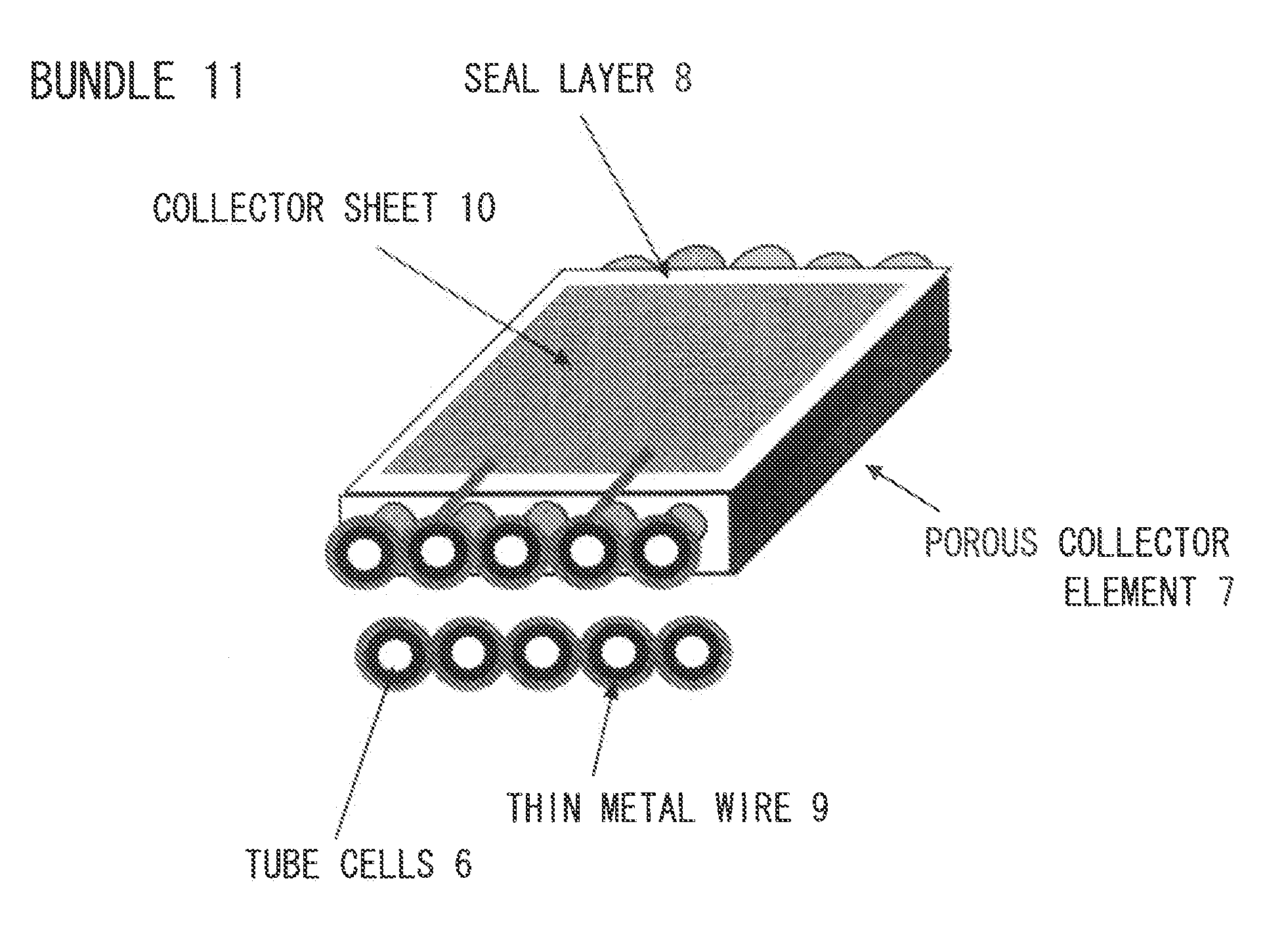

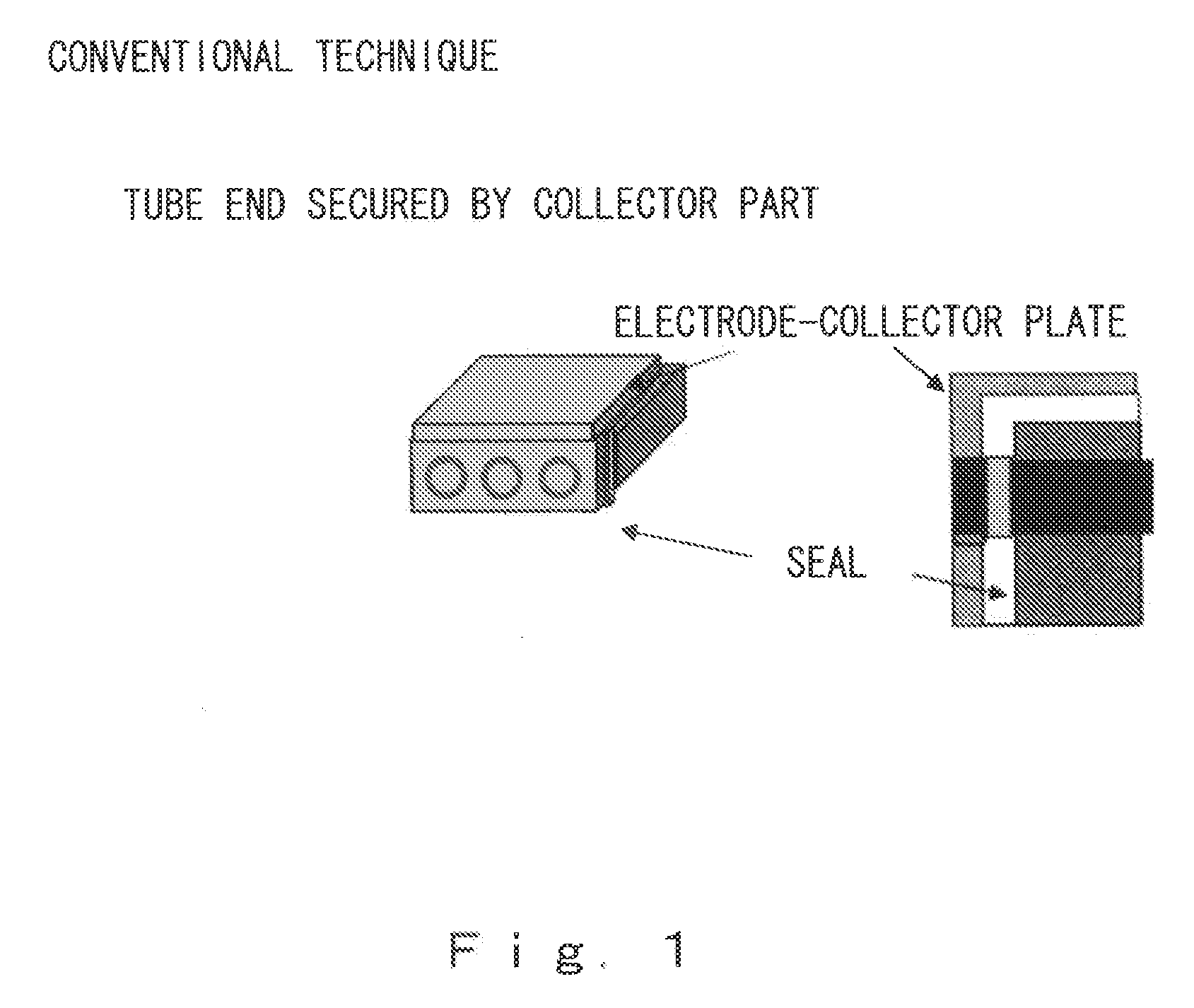

Electrochemical reactor bundles, stacks, and electrochemical reactor systems consisting of these components

InactiveUS20090214919A1Easy to stackEfficient collectionCellsElectrolyte moving arrangementsElectrochemical responseReactor system

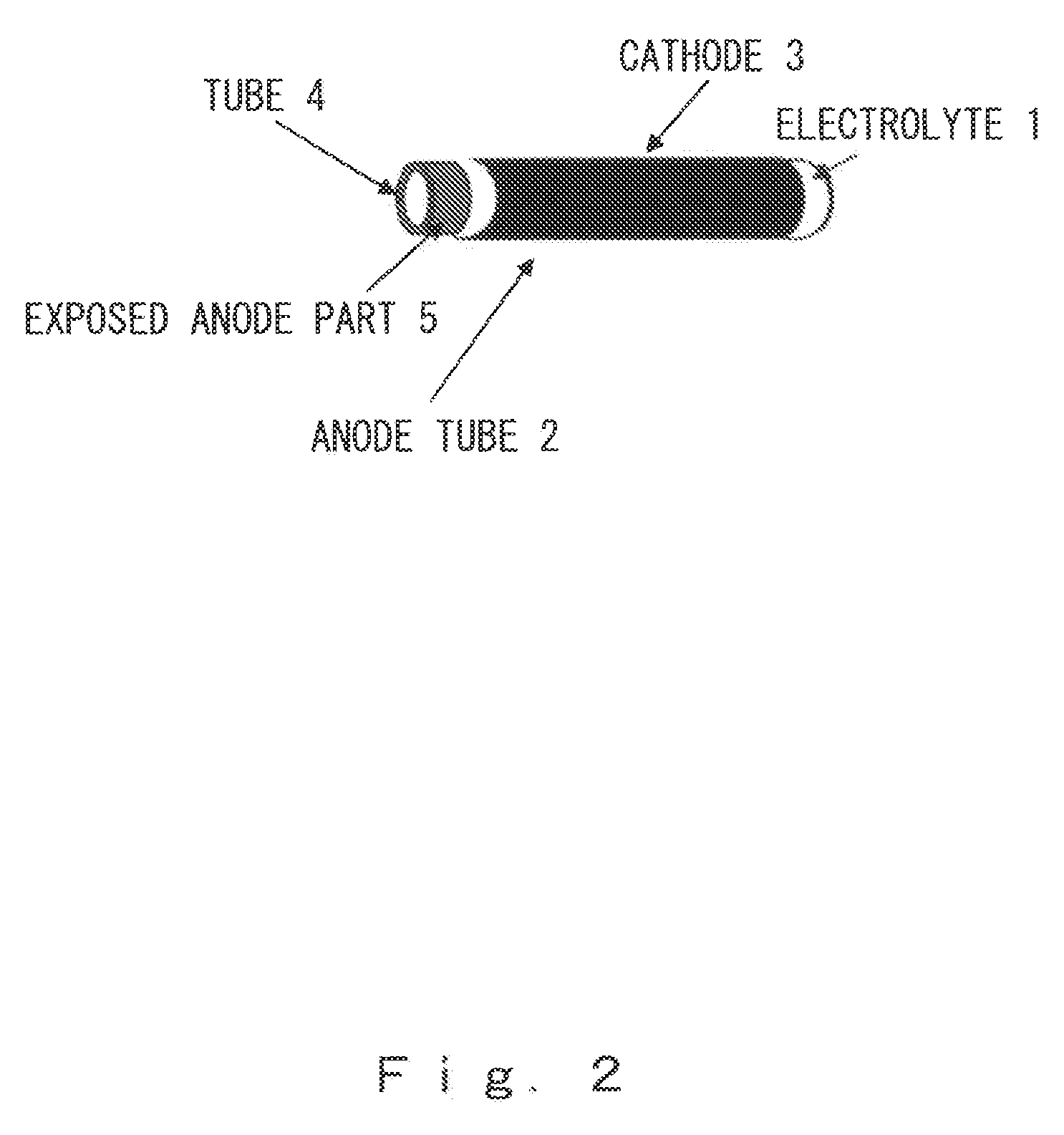

Tube electrochemical reactor bundle or stack, having a structure, in which a plurality of tube fuel cells, formed of a dense ion conductor (electrolyte) and cathode (air electrode) laminated to an anode (fuel electrode) material having a tube structure, are electrically connected by a thin metallic wire, and an electrochemical reactor system using them are provided.

Owner:NAT INST OF ADVANCED IND SCI & TECH

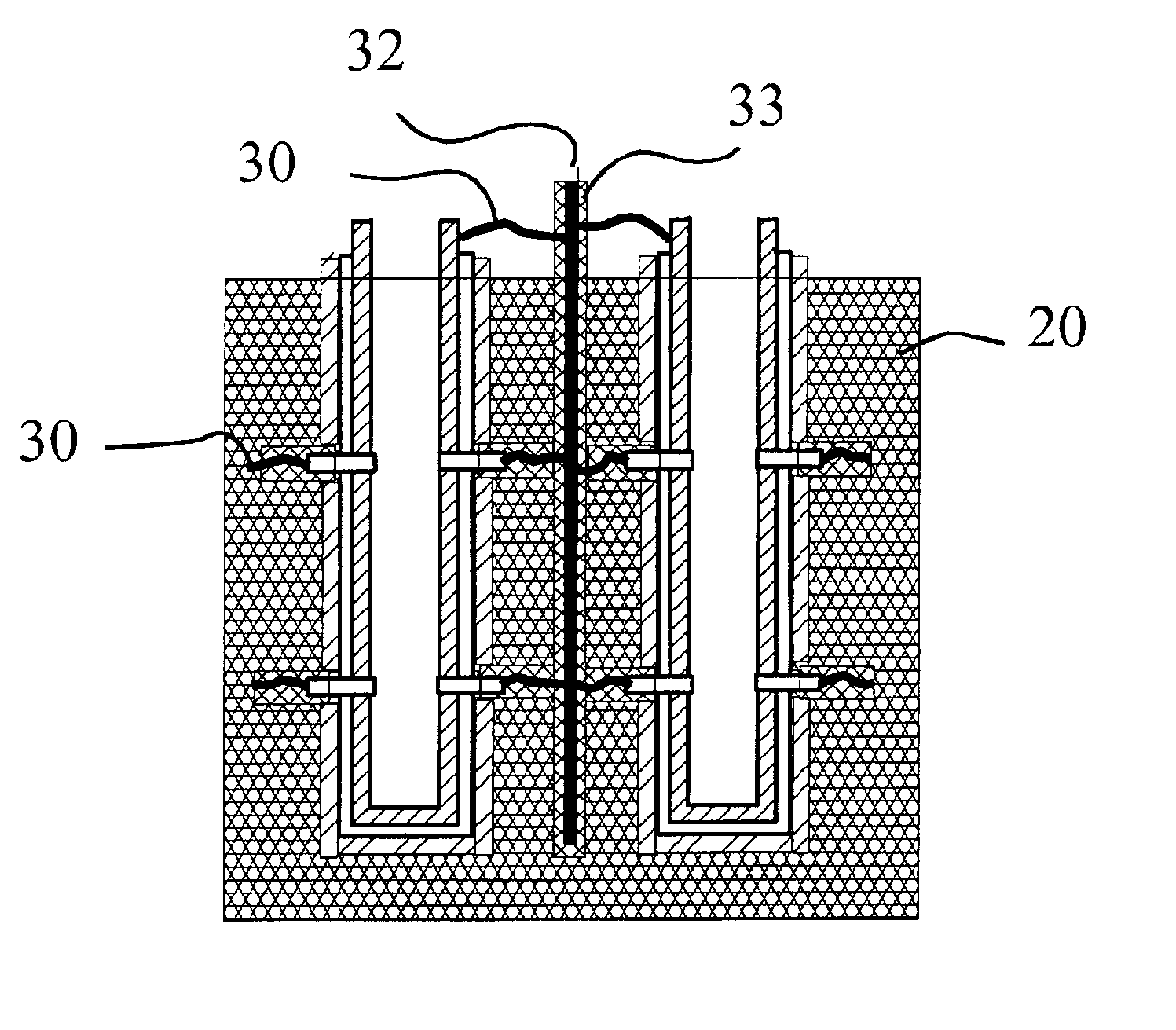

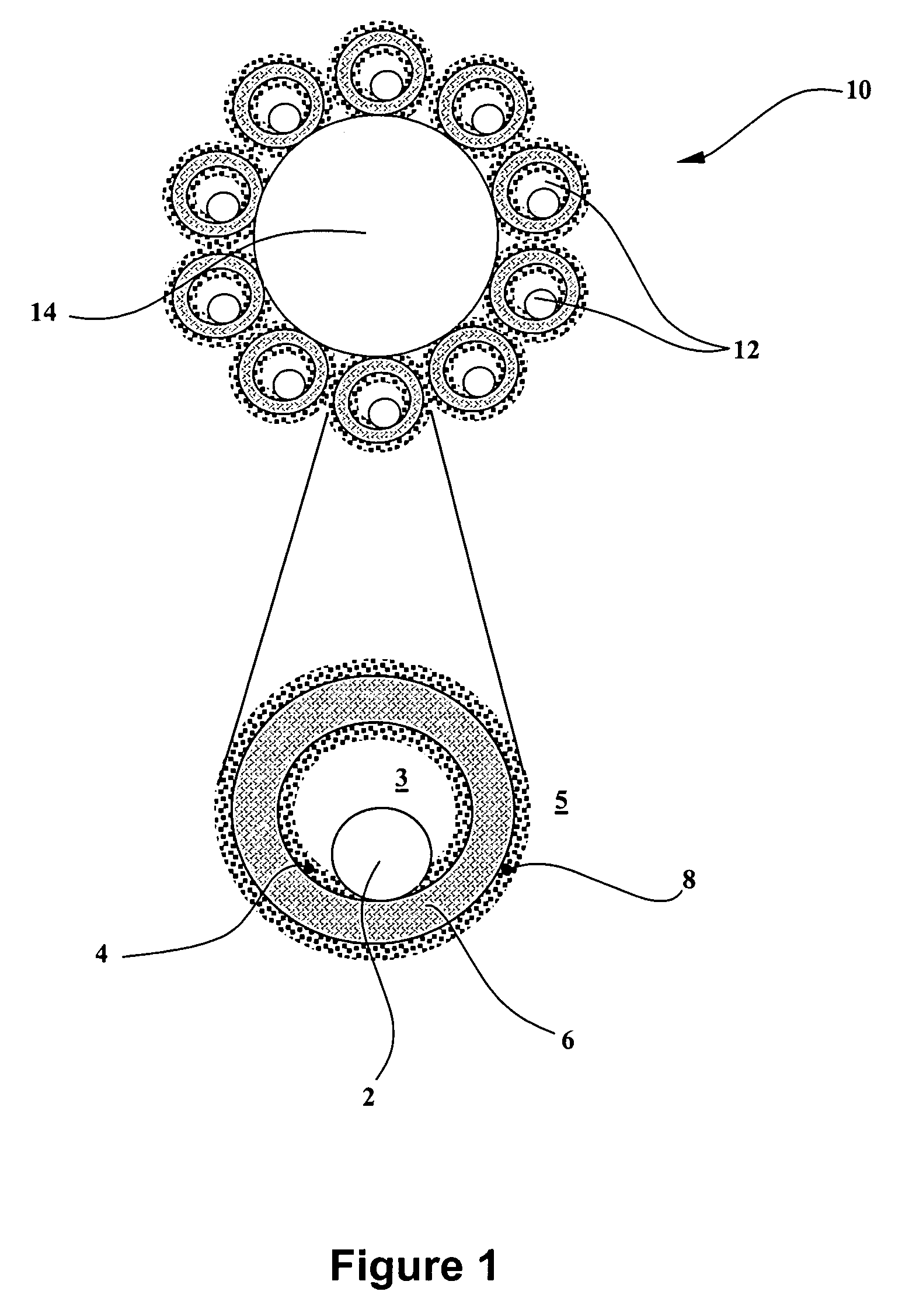

Solid oxide fuel cell system

This invention relates to a fuel cell system comprising a fuel cell stack, external circuit electrical leads coupled to the fuel cell electrodes, and a thermal enclosure assembly enclosing the stack. The stack includes a plurality of inner tubular solid oxide fuel cells, the inside of the inner fuel cells being fluidly couplable to a first reactant source, and a porous support matrix embedding the inner fuel cells and being fluidly couplable to a second reactant source such that a second reactant is flowable through the matrix and to the outer surface of the embedded fuel cells. The stack may also include an outer tubular solid oxide fuel cell surrounding the matrix and the inner fuel cells such that the second reactant is flowable through the matrix and to an inside surface of the outer fuel cell and wherein the outer surface of the outer fuel cell is fluidly couplable to a first reactant source.

Owner:INNOTECH ALBERTA INC

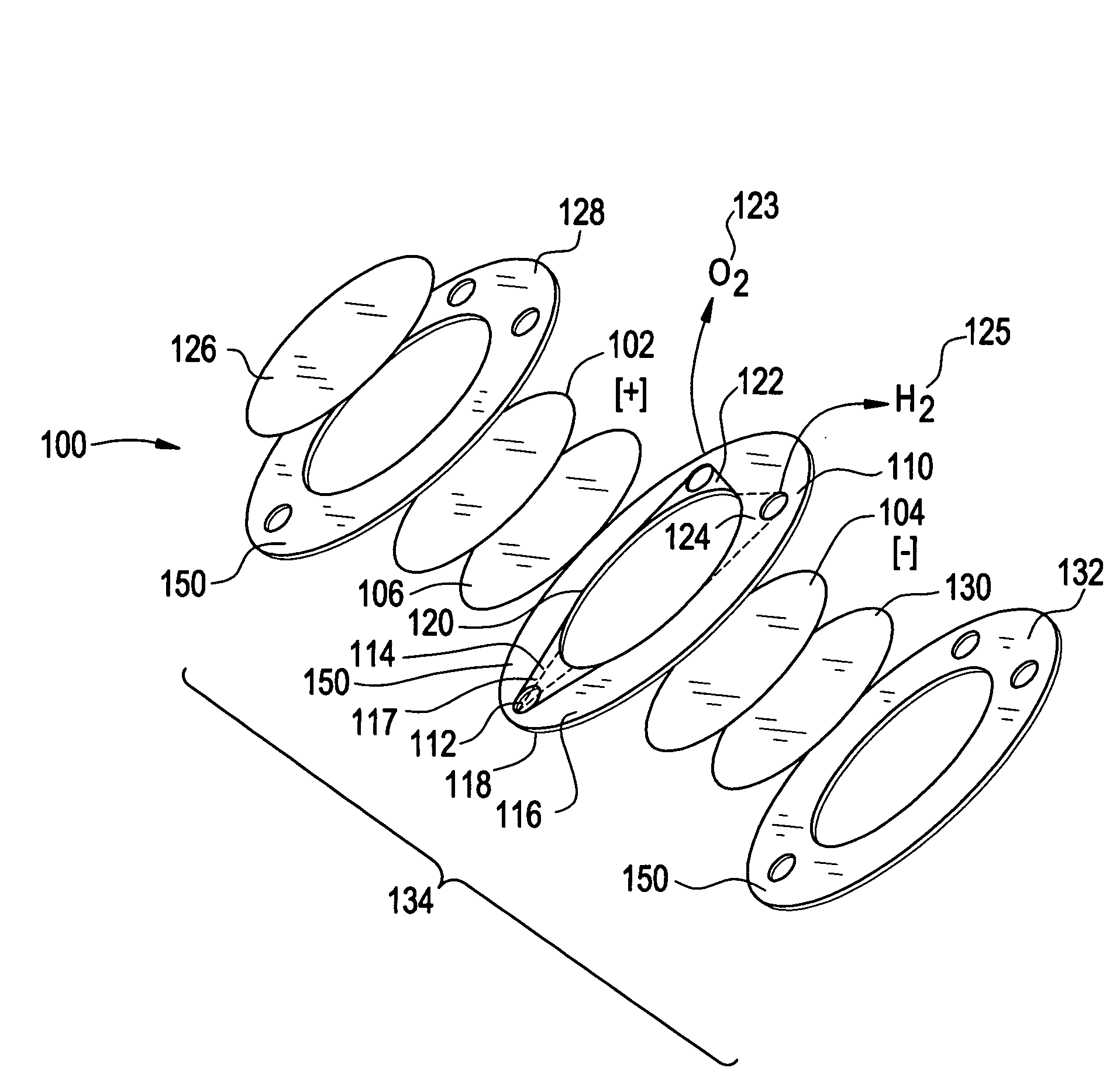

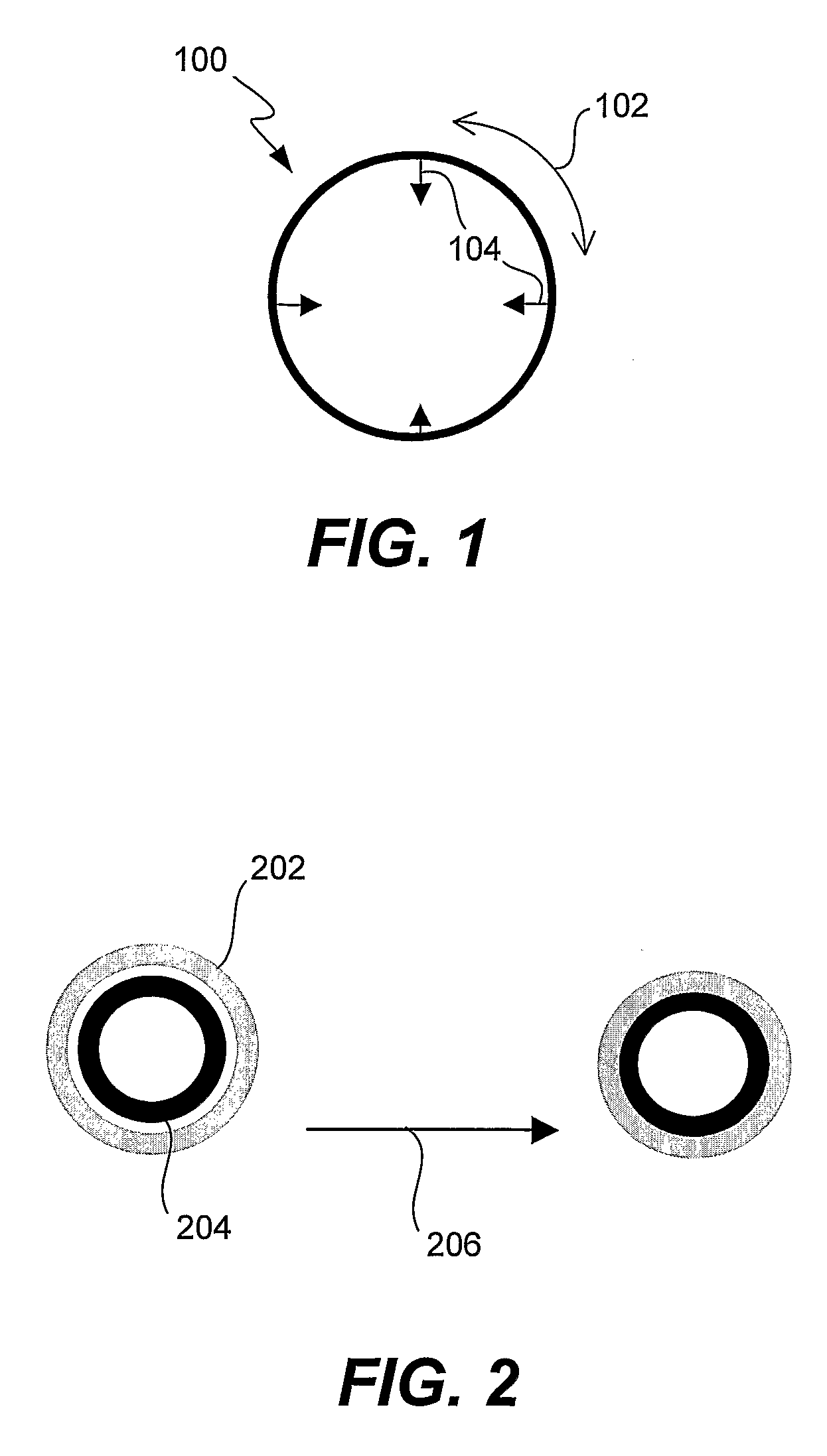

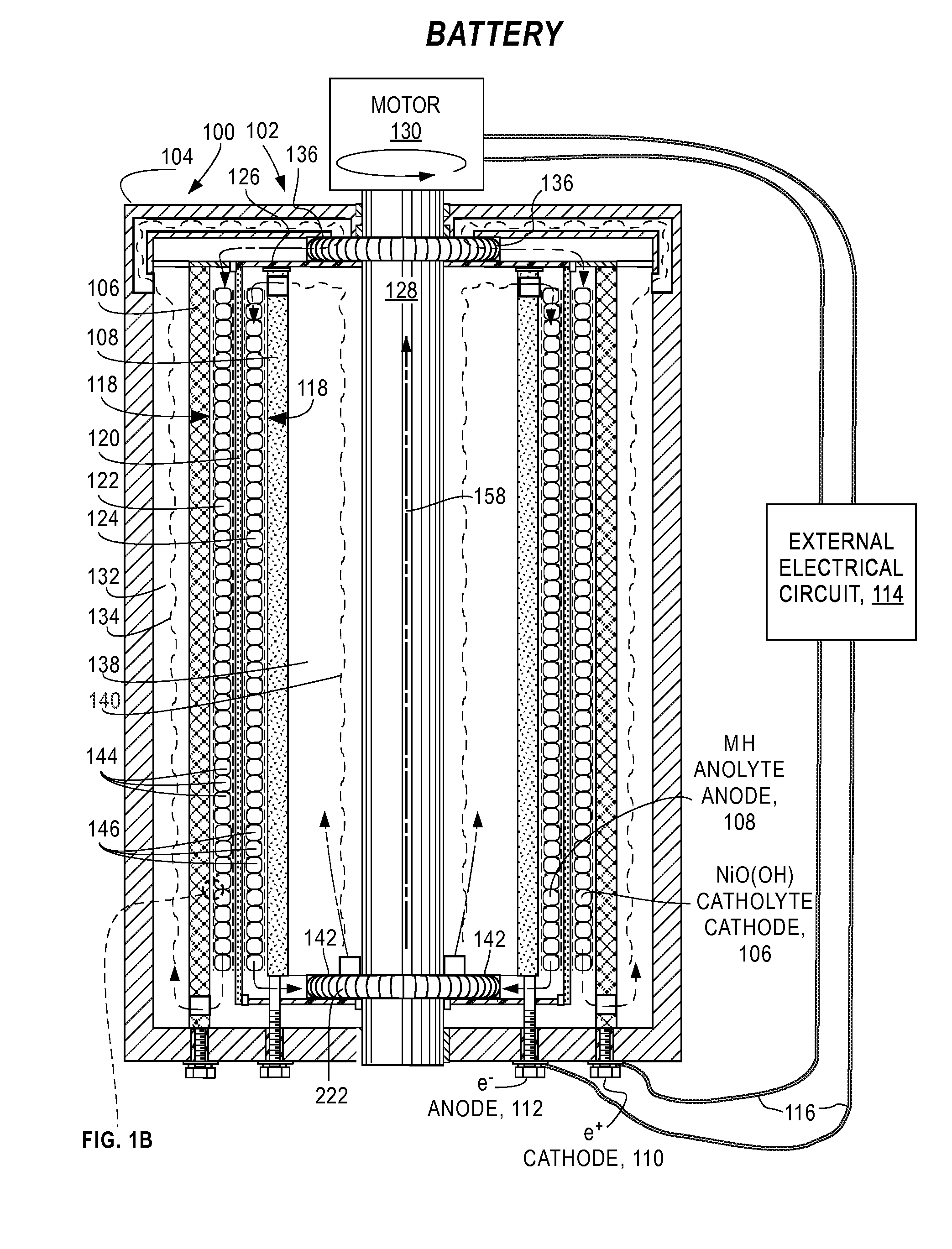

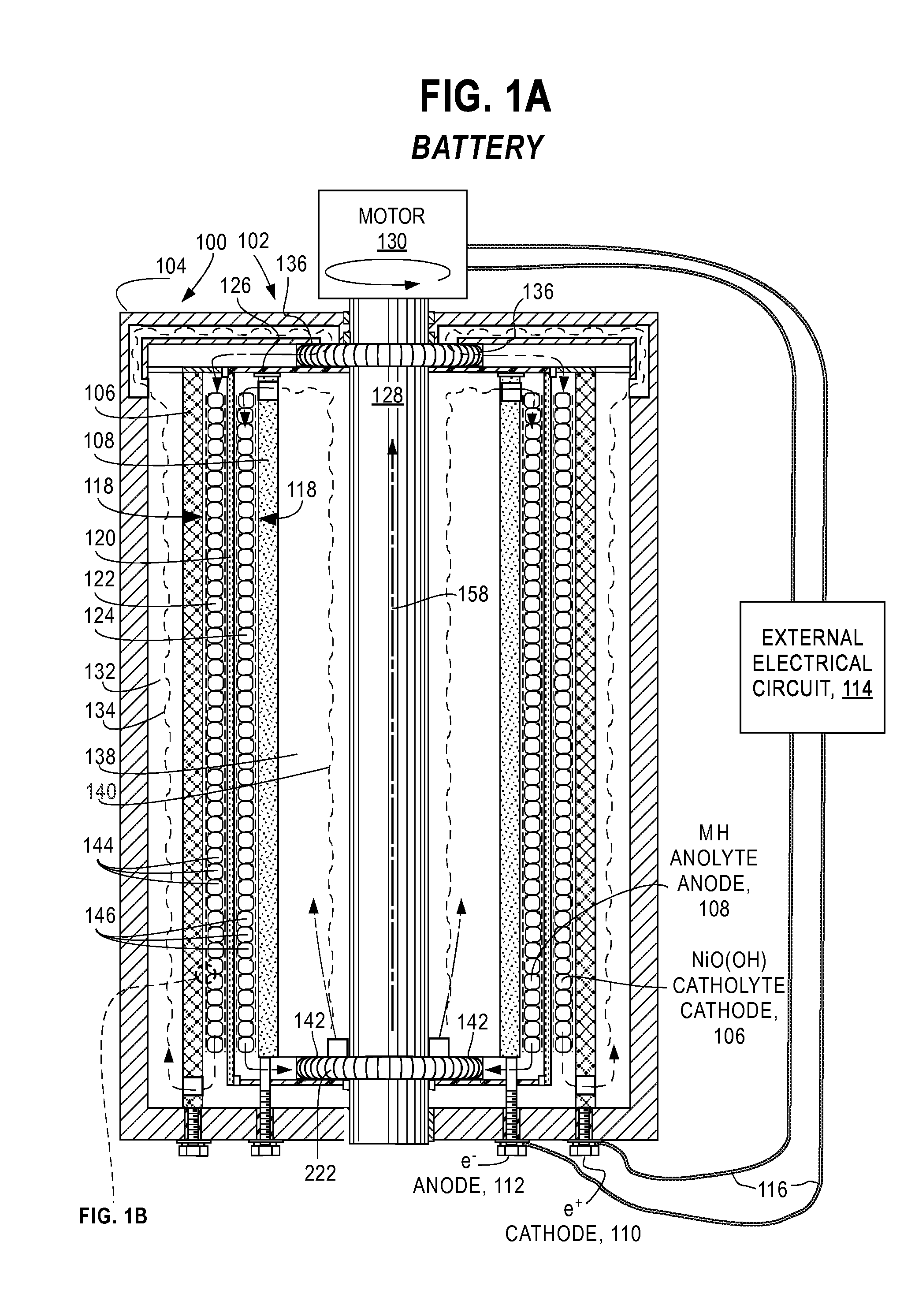

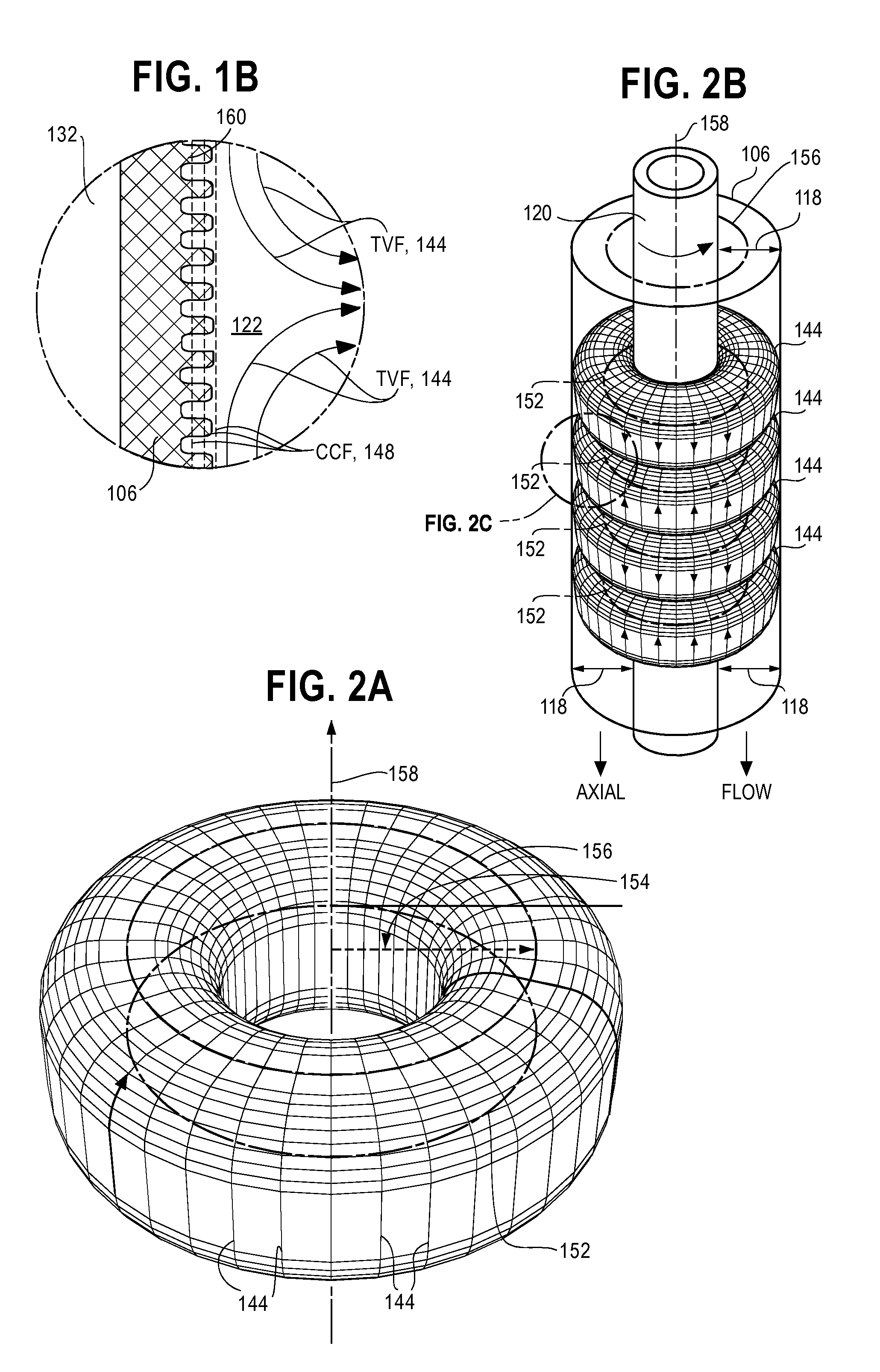

Galvanic electrochemical cells utilizing taylor vortex flows

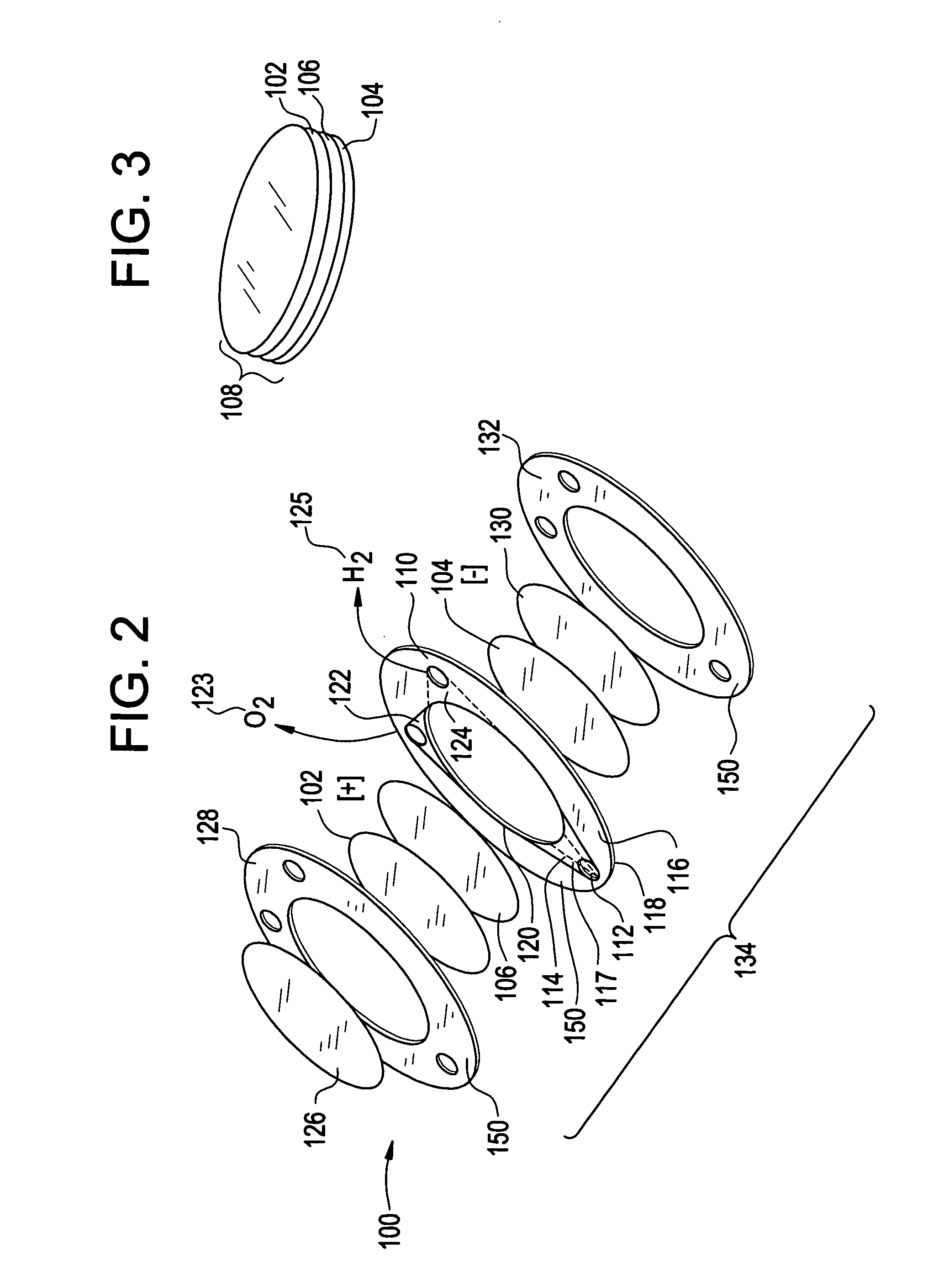

Electrochemical cells (100, 500, 600) for converting chemical energy into electrical energy, such as batteries (102), flow cells (502) and fuel cells (602) with a cylindrical rotating ion-permeable filter (120, 414, 520, 620) that generates Taylor Vortex Flows (144, 146, 404, 544, 546, 664, 666) and Circular Couette Flows (148, 150, 568, 570, 668, 670) in thixotropic catholytes and anolytes between a cylindrical current collector (106, 506, 606, 108, 508, 608) and the filter (120, 414, 520, 620) are disclosed.

Owner:GLOBAL ENERGY SCI CALIFORNIA

Fuel cell and method for fabricating same

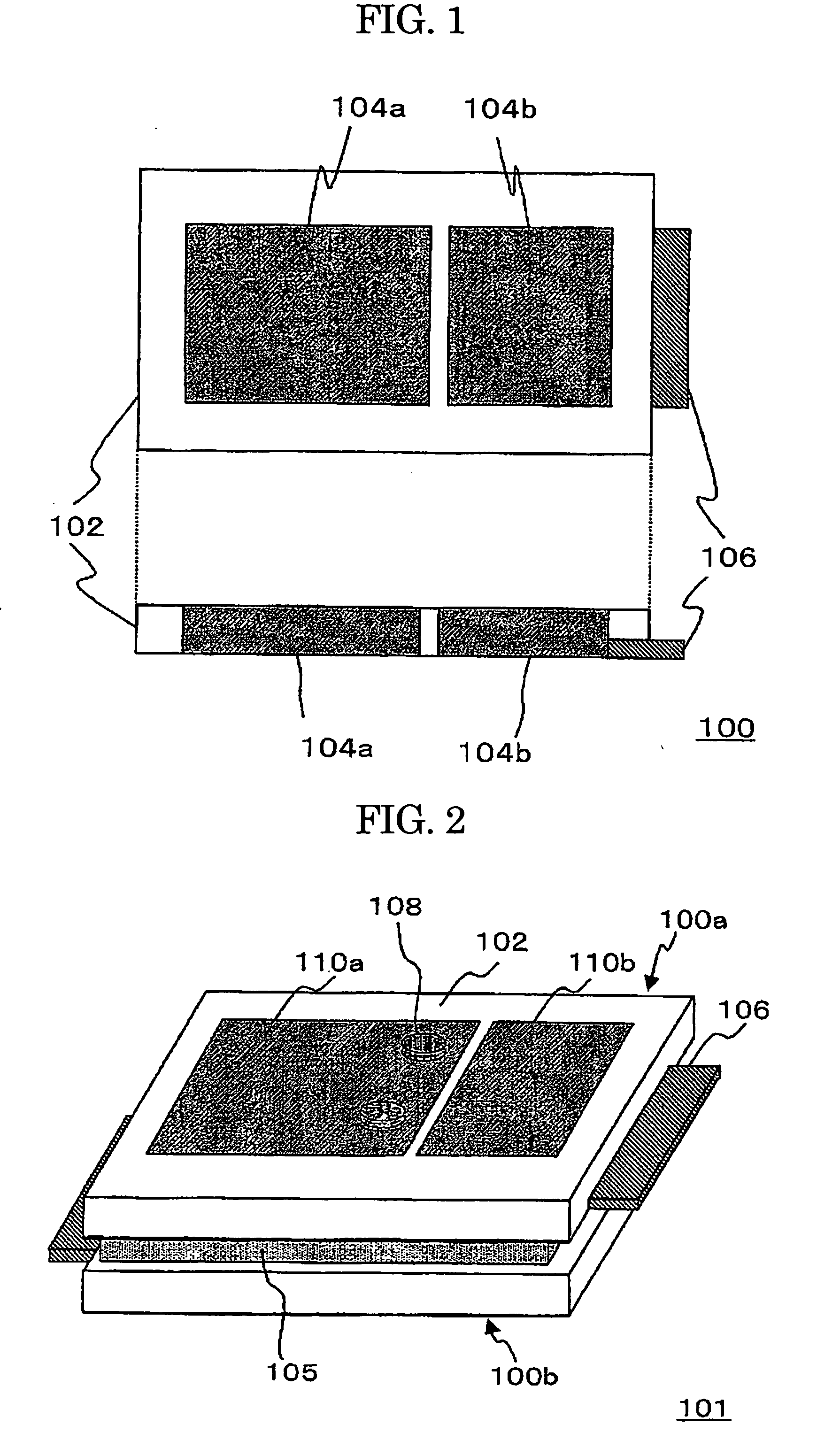

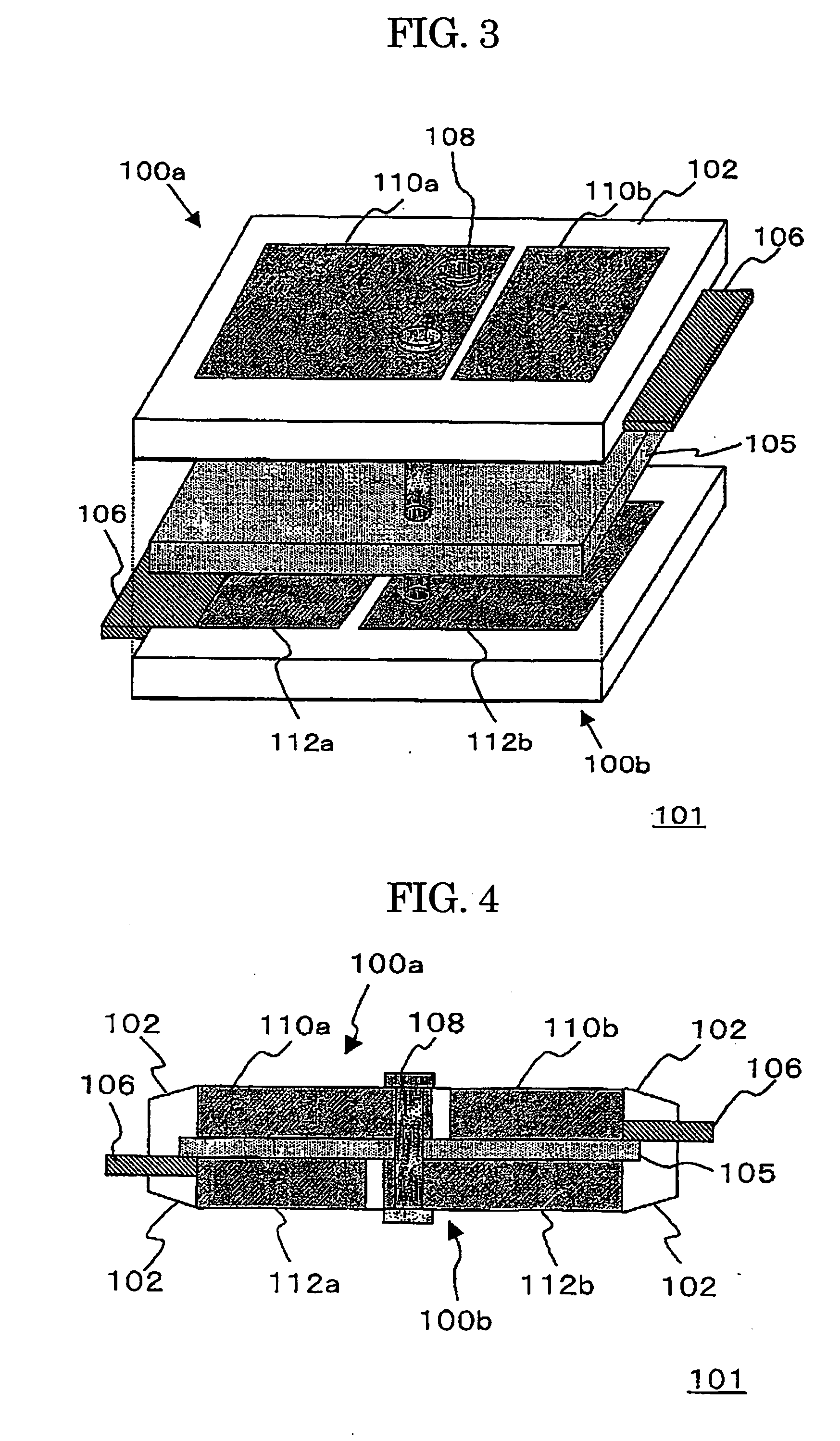

InactiveUS20070134531A1Increase productionFuel cells groupingFuel cell shape/formFuel cellsMiniaturization

[Problems] Miniaturization and weight-saving of a fuel cell including a plurality of unit cells are intended together with higher integration of the unit cells. [Means for Solving Problems] A pair of electrode sheet 100a, 100b, each having a plurality of fuel electrodes 110a, 110b or a plurality of oxidant electrodes 112a, 112b supported by a resin section 102, are disposed on a single plane on the respective surfaces of a solid electrolyte membrane 105 to configure a plurality of unit cells. The fuel electrode and the oxidant electrode of the adjacent two unit cells existing on the respective surfaces of the solid electrolyte membrane are connected in series by using an electroconductive member penetrating the solid electrolyte membrane. Since the electroconductive member 108 extends along the stacking direction of the cell, no excess space is required to achieve the miniaturization of the fuel cell.

Owner:NEC CORP +1

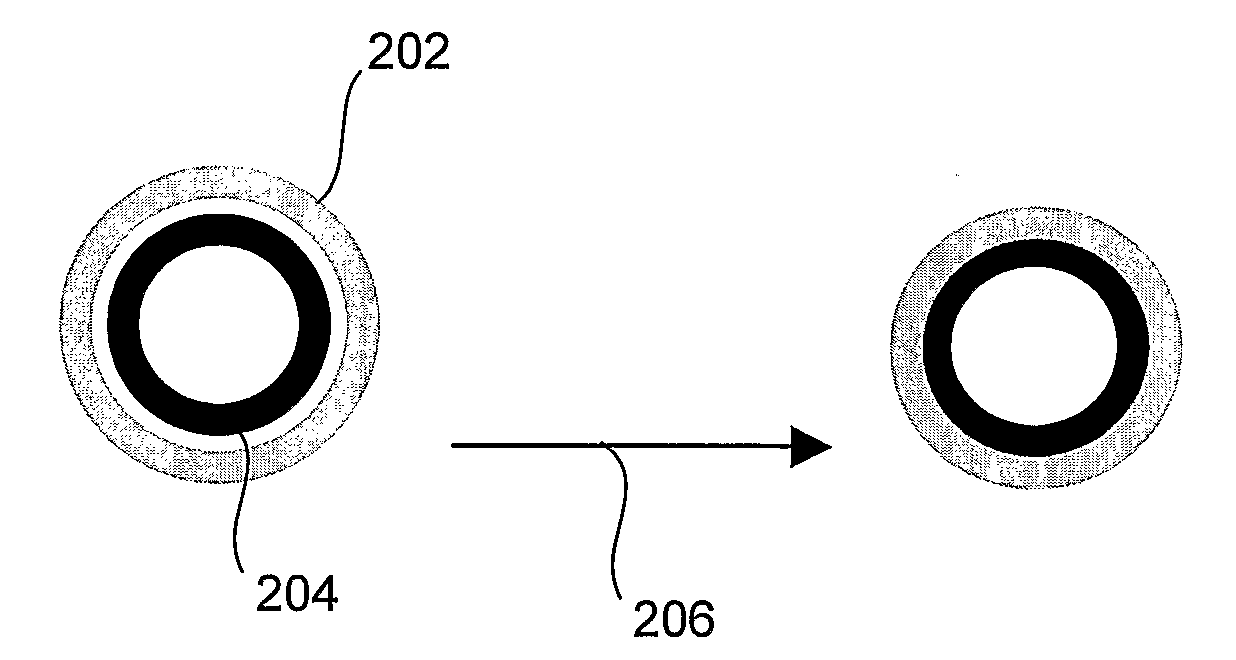

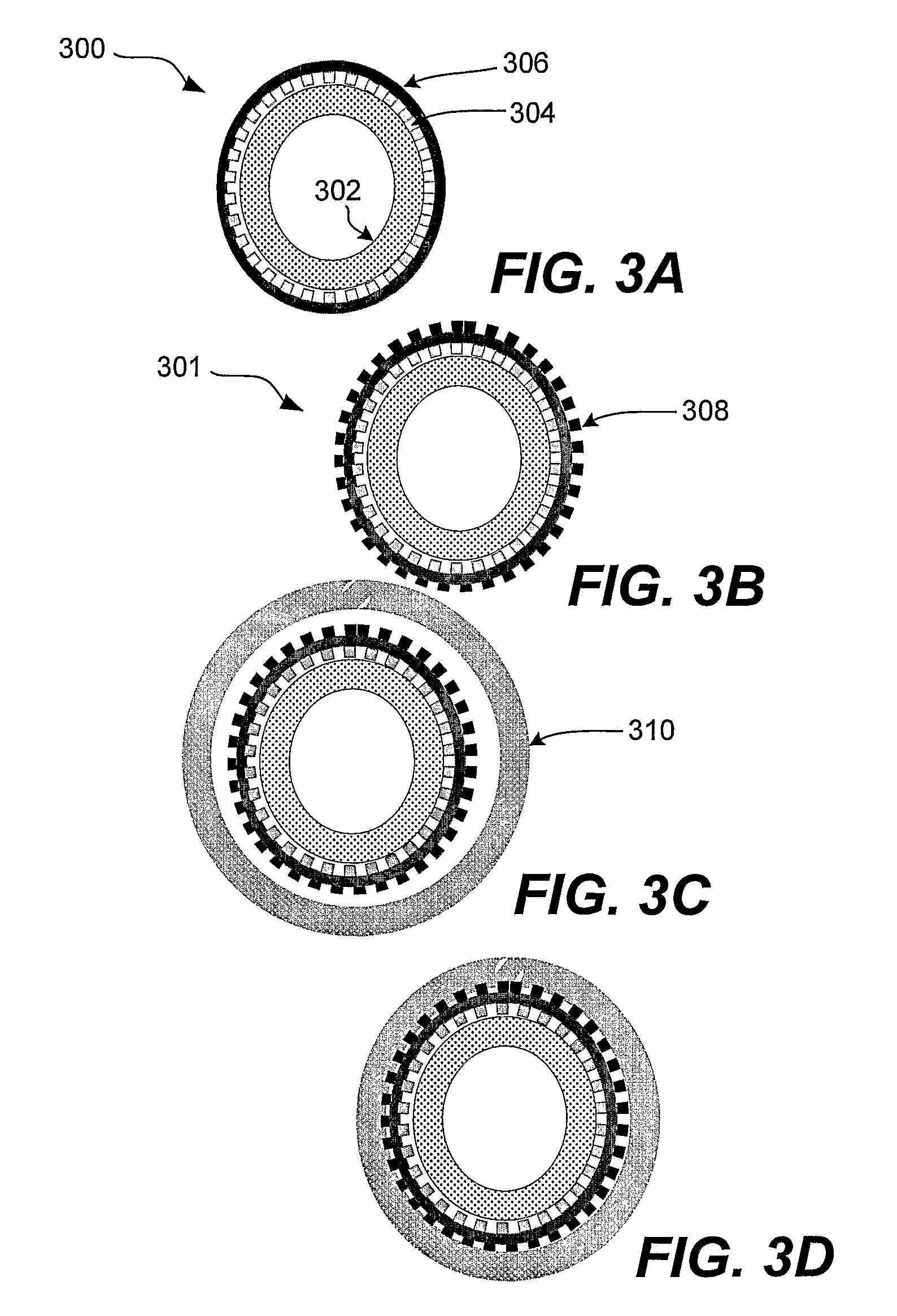

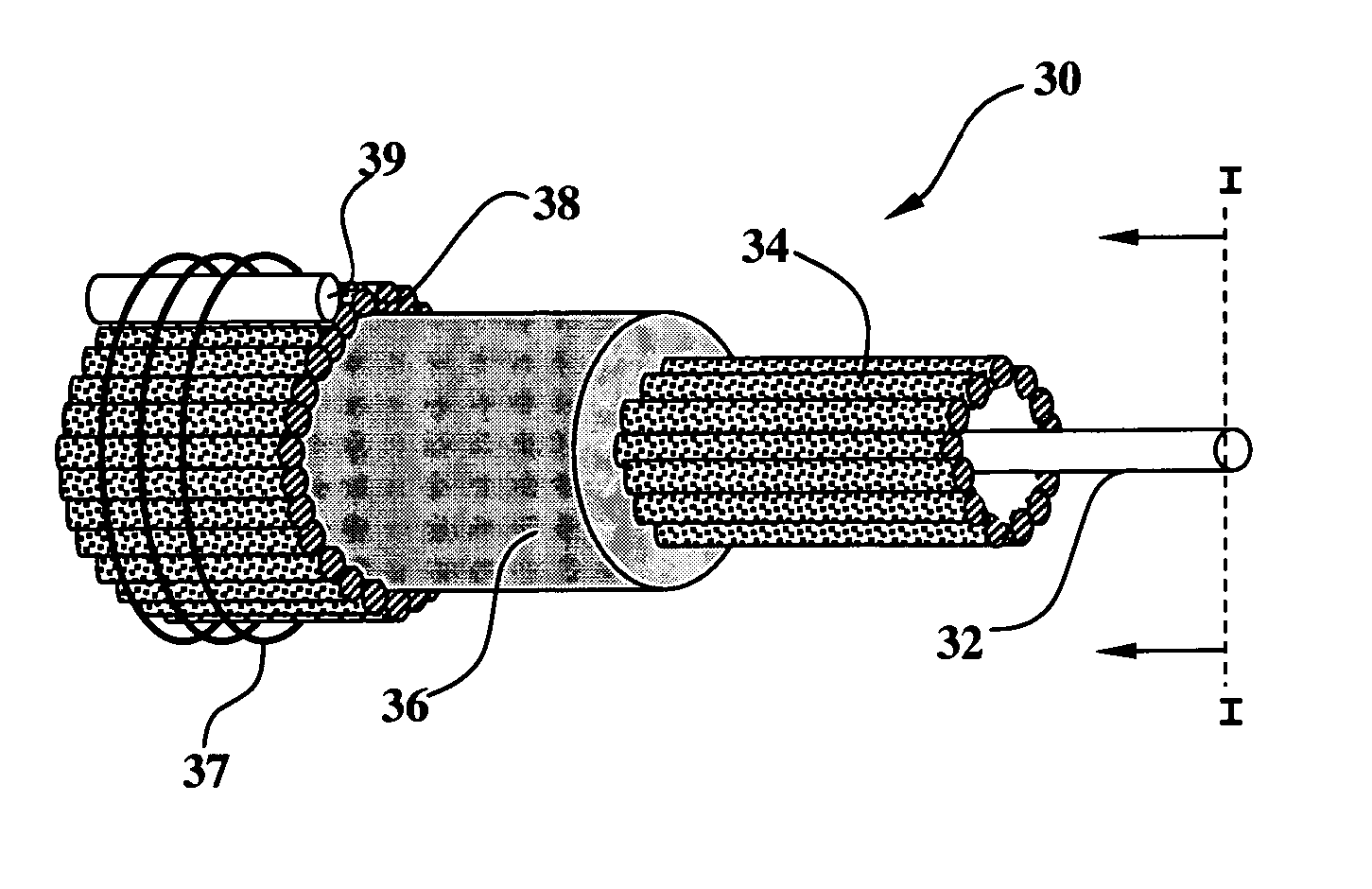

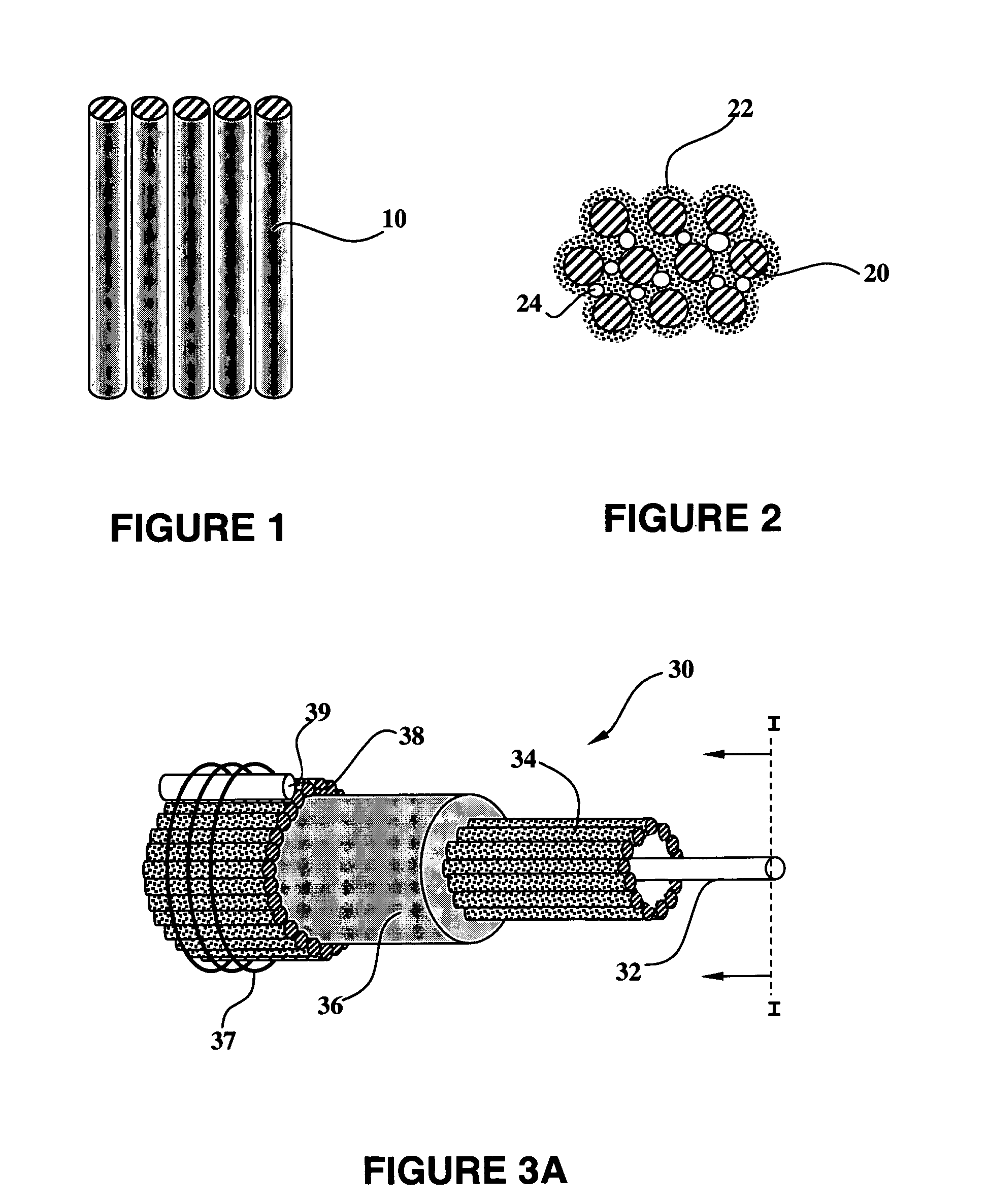

Microfibrous fuel cell assemblies comprising fiber-supported electrocatalyst layers, and methods of making same

ActiveUS20050181269A1Facilitates conformationMinimize damageFuel cells groupingIon-exchanger regenerationFuel cellsFiber network

The present invention relates to a microfibrous fuel cell structure of elongated form with a longitudinal axis. Such microfibrous fuel cell comprises electrocatalyst layers supported by a fiber network formed of unidirectional or substantially unidirectional conductive fibers. The conductive fibers of such fiber network are oriented parallelly or substantially parallelly to the longitudinal axis of the fuel cell, therefore allowing such fiber network to conform to the curvature of the microfibrous fuel cell along the radial direction but without causing overbending of the individual fibers.

Owner:MICROCELL CORP

Fuel cell structures and assemblies

The present invention relates to microfibrous fuel cell sub-bundle structures, fuel cell bundles and fuel cell assemblies formed by such fuel cell sub-bundles and bundles. Specifically, a fuel cell sub-bundle is provided, which comprises multiple microfibrous fuel cells. Each microfibrous fuel cell comprises: (a) a hollow microfibrous membrane separator comprising an electrolyte medium, (b) an inner electrocatalyst layer in contact with an inner surface of such membrane separator, (c) an outer electrocatalyst layer in contact with an outer surface of such membrane separator, and (d) an individual current collector in electrical contact with the inner surface of such membrane separator. Each of such multiple microfibrous fuel cells is in electrical contact with a common current collector at the outer surface of its membrane separator.

Owner:MICROCELL CORP

Solid oxide fuel cell apparatus

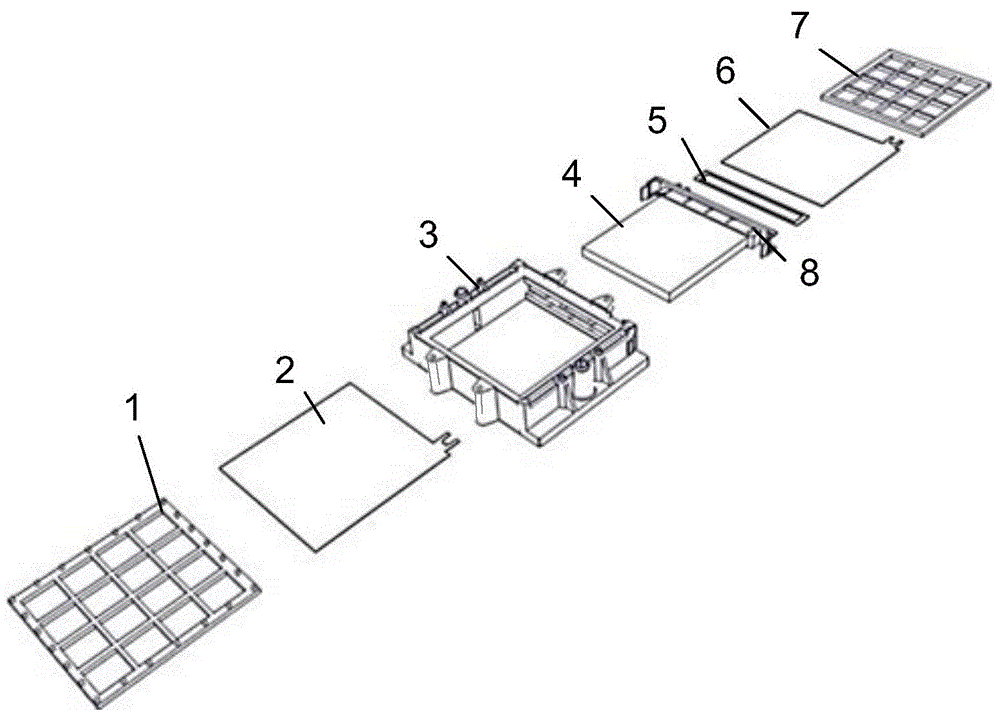

ActiveUS20110171554A1RemissionAvoid it happening againFuel cells groupingFuel cell shape/formFuel cellsDifferential pressure

[Means for Solution] A solid oxide fuel cell apparatus including a fuel cell having a plate-shaped first solid electrolyte, an anode provided on one side of the first solid electrolyte and coming in contact with fuel gas, and a cathode provided on the other side of the first solid electrolyte and coming in contact with oxidizer gas. The solid oxide fuel cell apparatus further includes a cell-follow-up deformation member located on at least one of opposite sides of the fuel cell with respect to a first stacking direction along which the anode, the first solid electrolyte, and the cathode are stacked together. The cell-follow-up deformation member deforms according to a deformation of the fuel cell on the basis of at least one of physical quantities including differential thermal expansion coefficient and differential pressure.

Owner:MORIMURA SOFC TECH CO LTD

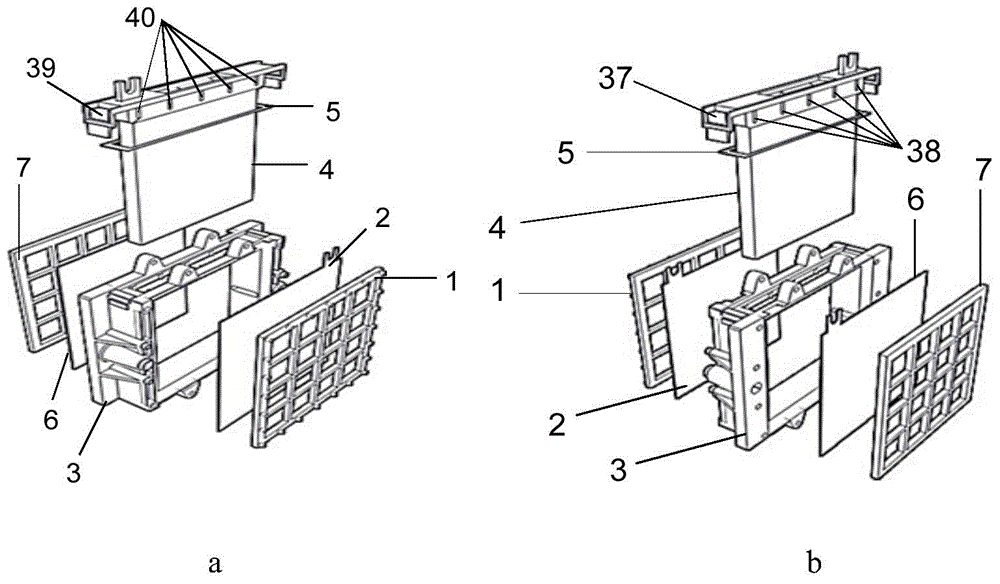

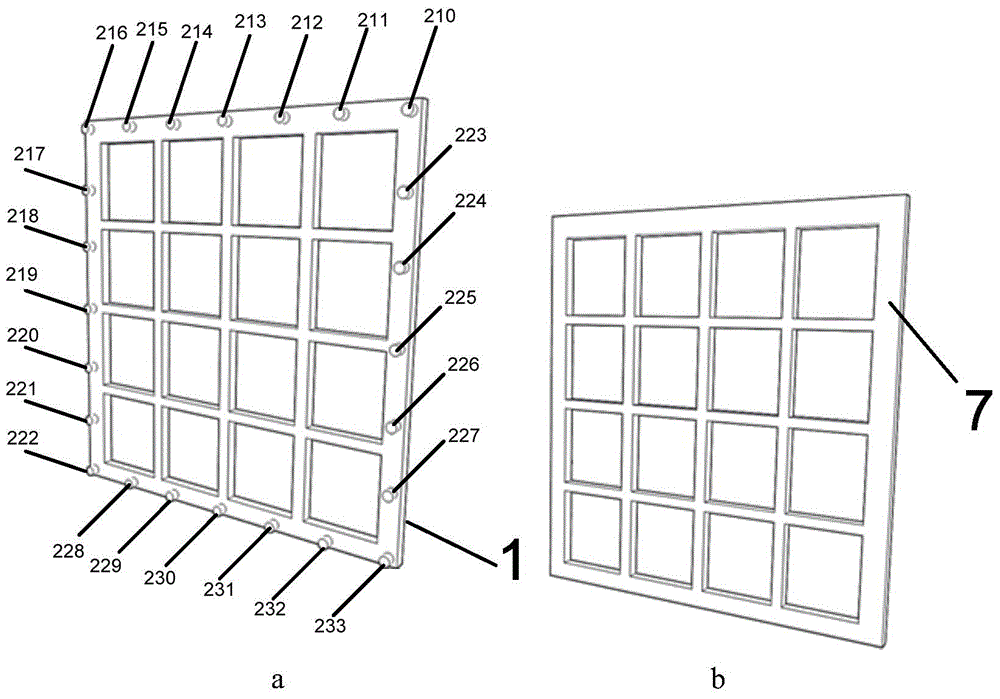

Liquid circuit built-in aluminium air fuel cell monomer and cell stack

InactiveCN104577262ASmooth entryReduce interaural distanceFuel and primary cellsFuel cells groupingFuel cellsMonomer

The invention relates to a liquid circuit built-in aluminium air fuel cell monomer and a cell stack. The liquid circuit built-in aluminium air fuel cell monomer comprises a first flat grid mesh, a first air electrode, a matrix frame, a second air electrode and a second flat grid mesh which are sequentially arranged, wherein the first air electrode is used as a cathode; the matrix frame is provided with a side port for enabling an aluminium alloy electrode used as an anode to be inserted in; a first electrolyte pipe orifice and a second electrolyte pipe orifice are also formed outside the matrix frame. The cell stack comprises a plurality of liquid circuit built-in aluminium air fuel cell monomers which are connected in series and a gap is reserved between every two adjacent cell monomers; support pillars are arranged at the edges of the first flat grid meshes; the first electrolyte pipe orifice in each cell monomer is connected with the second electrolyte pipe orifice in the adjacent cell monomer; the first and second air electrodes in each cell monomer are connected with the aluminium alloy electrode used as the anode in the adjacent cell monomer. According to the invention, a fuel cell pipeline is simple, the engineering degree is high, the guarantee is simple, the operation is convenient, the processing consistency is good, and the recycling and reusing can be realized.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

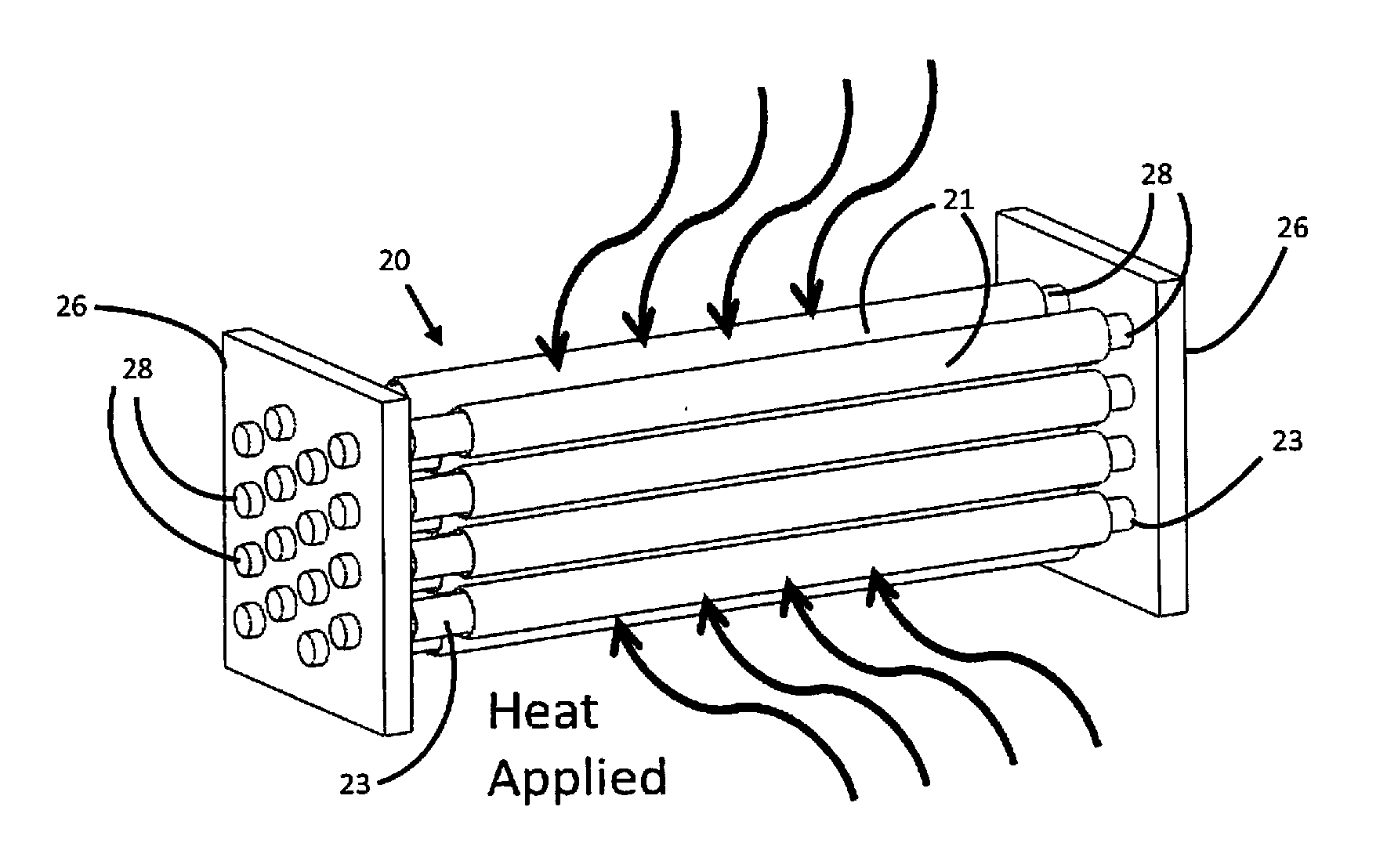

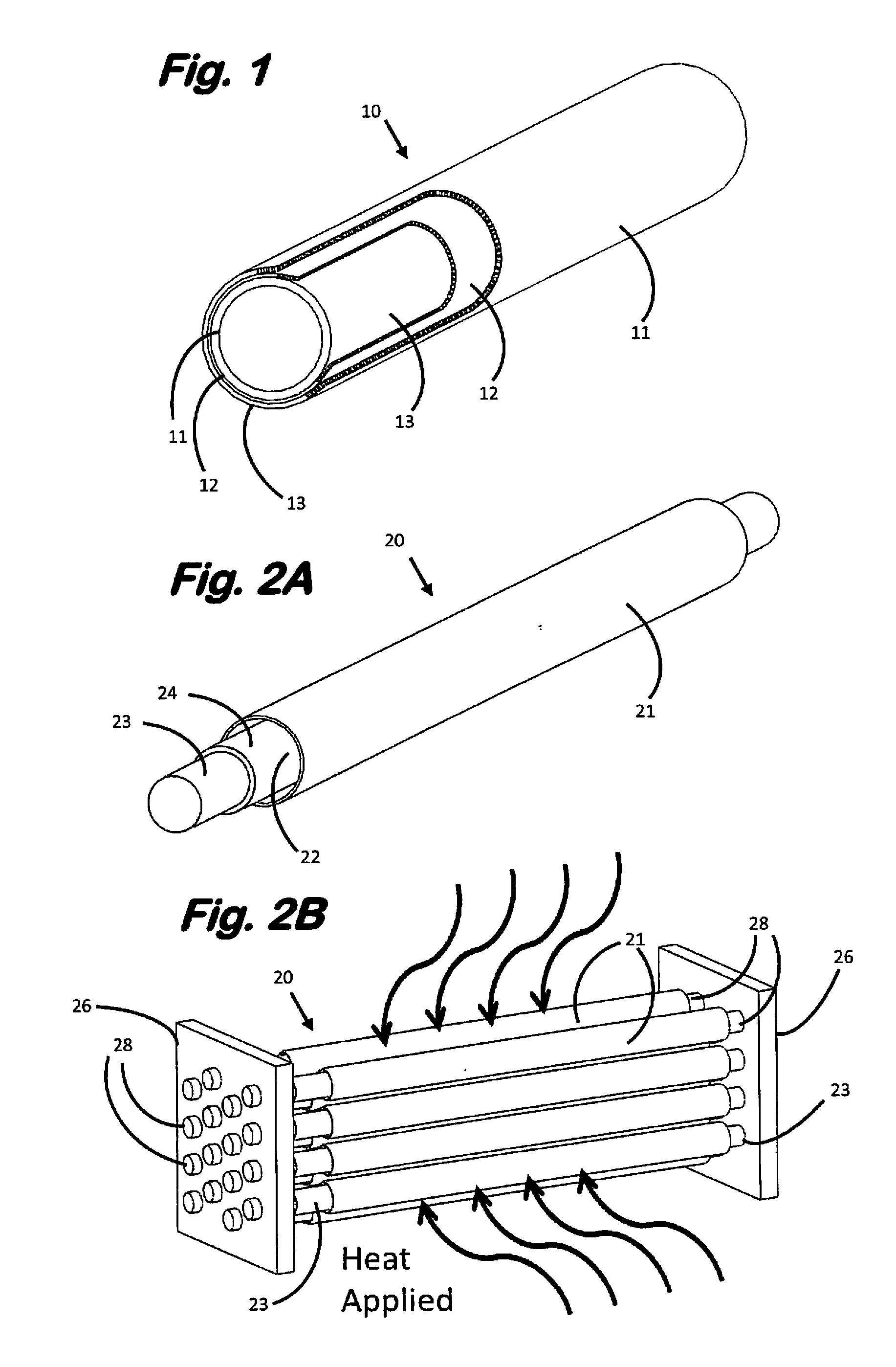

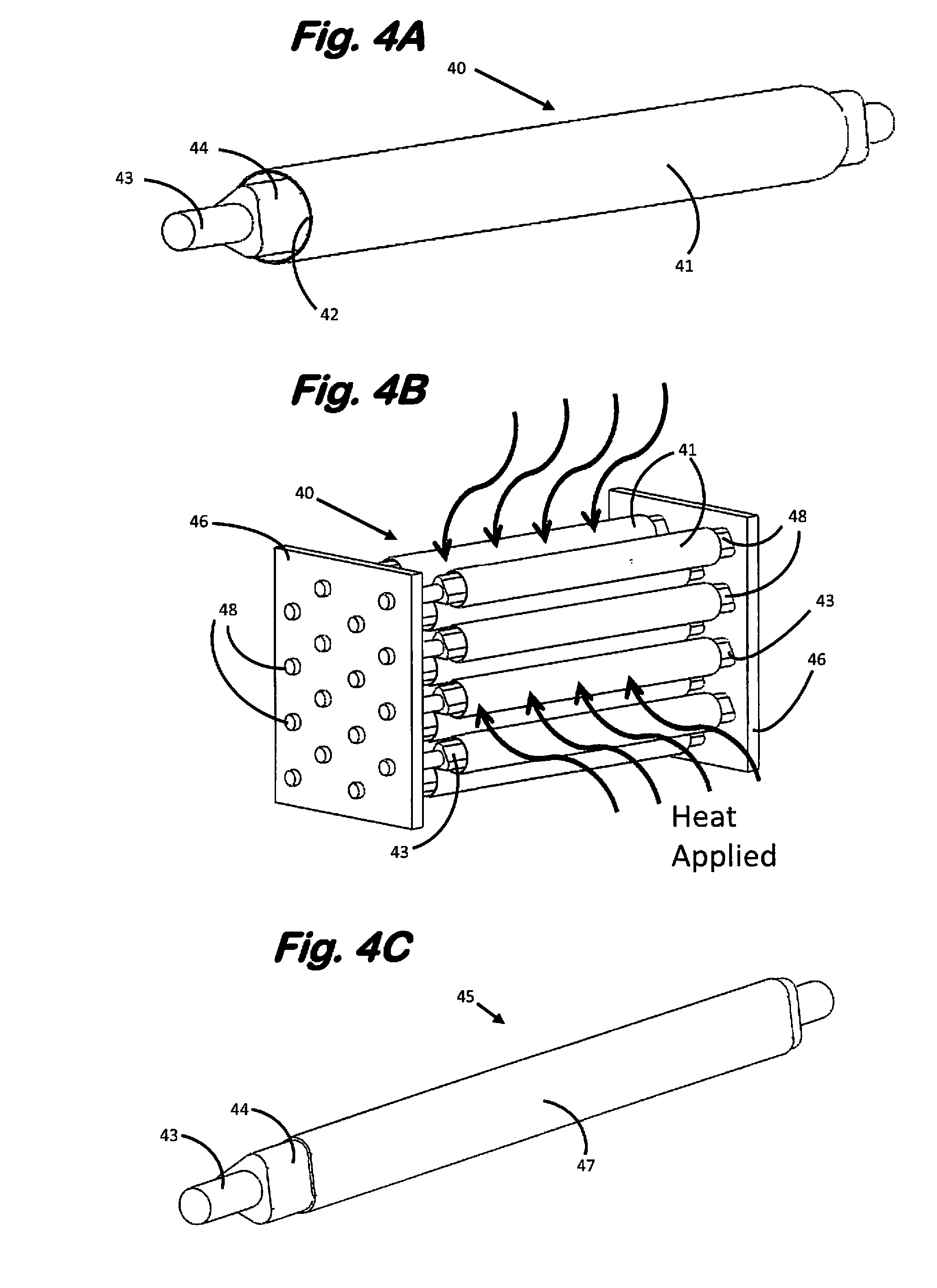

Process for producing tubular ceramic structures

ActiveUS20130056911A1Small sizeEasy to disassembleLiquid surface applicatorsMolten spray coatingFuel cellsComposite material

Tubular ceramic structures, e.g., anode components of tubular fuel cells, are manufactured by applying ceramic-forming composition to the external surface of the heat shrinkable polymeric tubular mandrel component of a rotating mandrel-spindle assembly, removing the spindle from said assembly after a predetermined thickness of tubular ceramic structure has been built up on the mandrel and thereafter heat shrinking the mandrel to cause the mandrel to separate from the tubular ceramic structure.

Owner:WATT FUEL CELL CORP

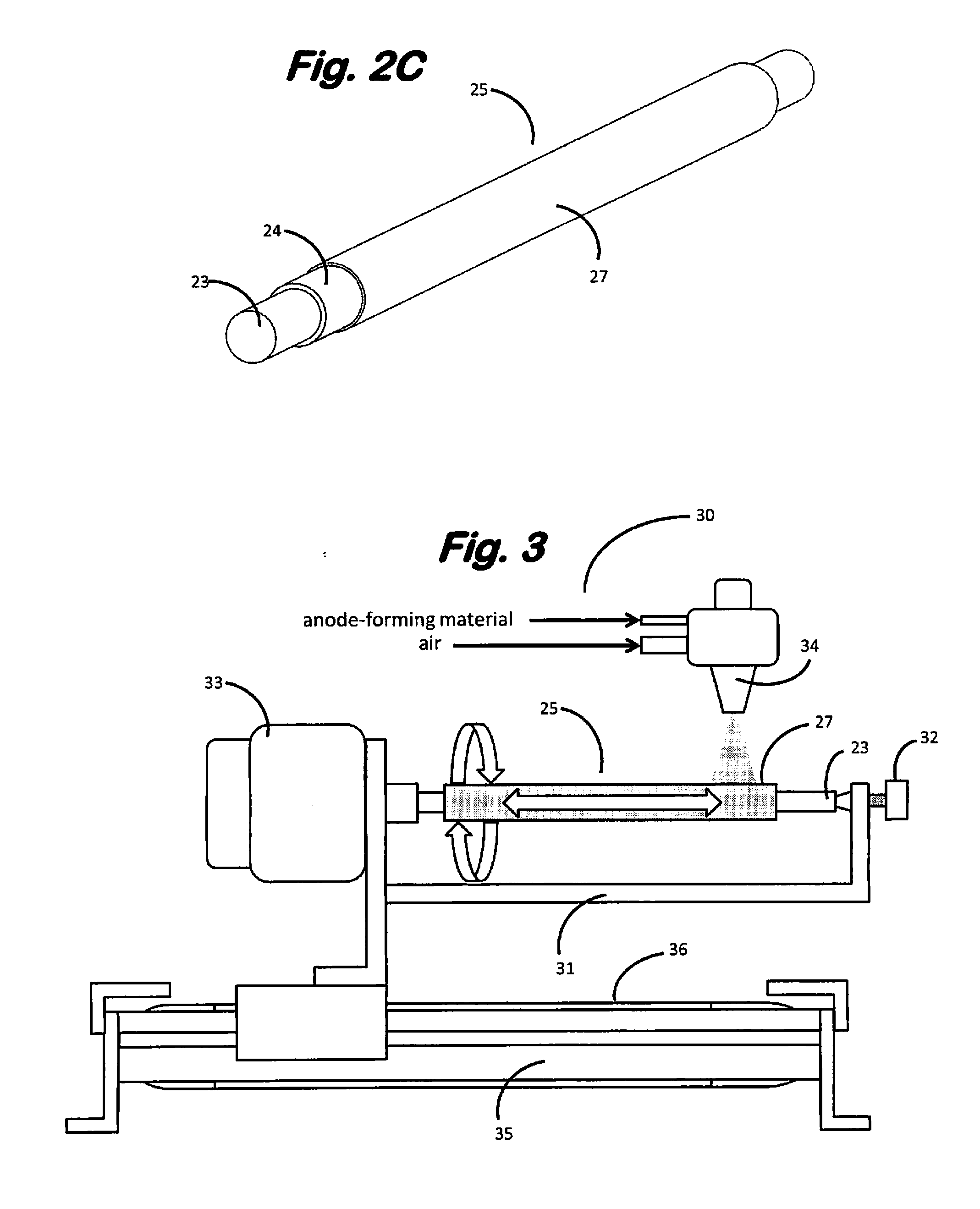

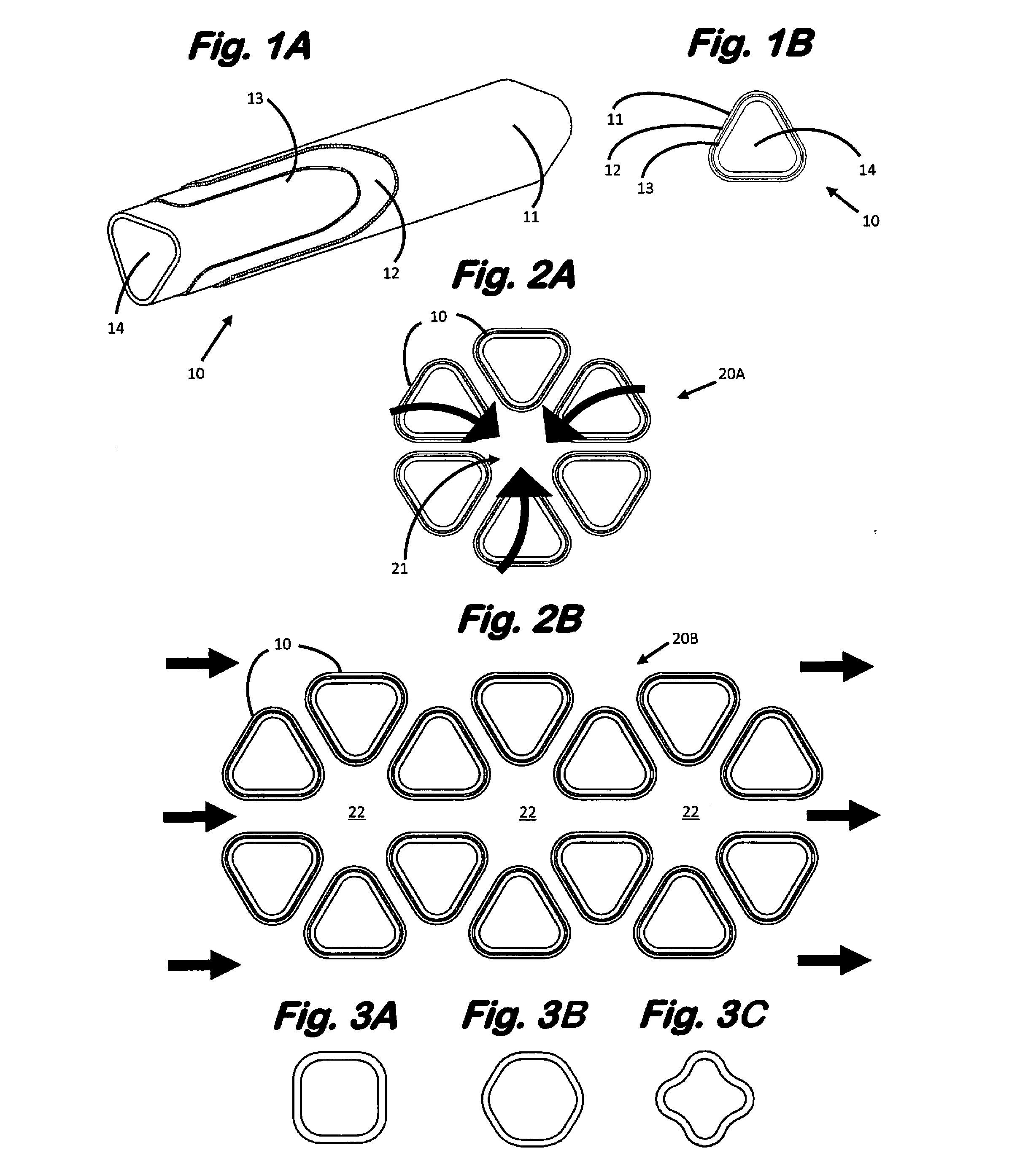

Process for producing tubular ceramic structures of non-circular cross section

ActiveUS20130059223A1Small sizeEasy to disassembleMolten spray coatingElectrode manufacturing processesFuel cellsMetallurgy

Tubular ceramic structures of non-circular cross section, e.g., anode components of tubular fuel cells of non-circular cross section, are manufactured by applying ceramic-forming composition to the external non-circular surface of the heat shrinkable polymeric tubular mandrel component of a rotating mandrel-spindle assembly, removing the spindle from said assembly after a predetermined thickness of tubular ceramic structure of non-circular cross section has been built up on the mandrel and thereafter heat shrinking the mandrel to cause the mandrel to separate from the tubular ceramic structure of non-circular cross section.

Owner:WATT FUEL CELL CORP

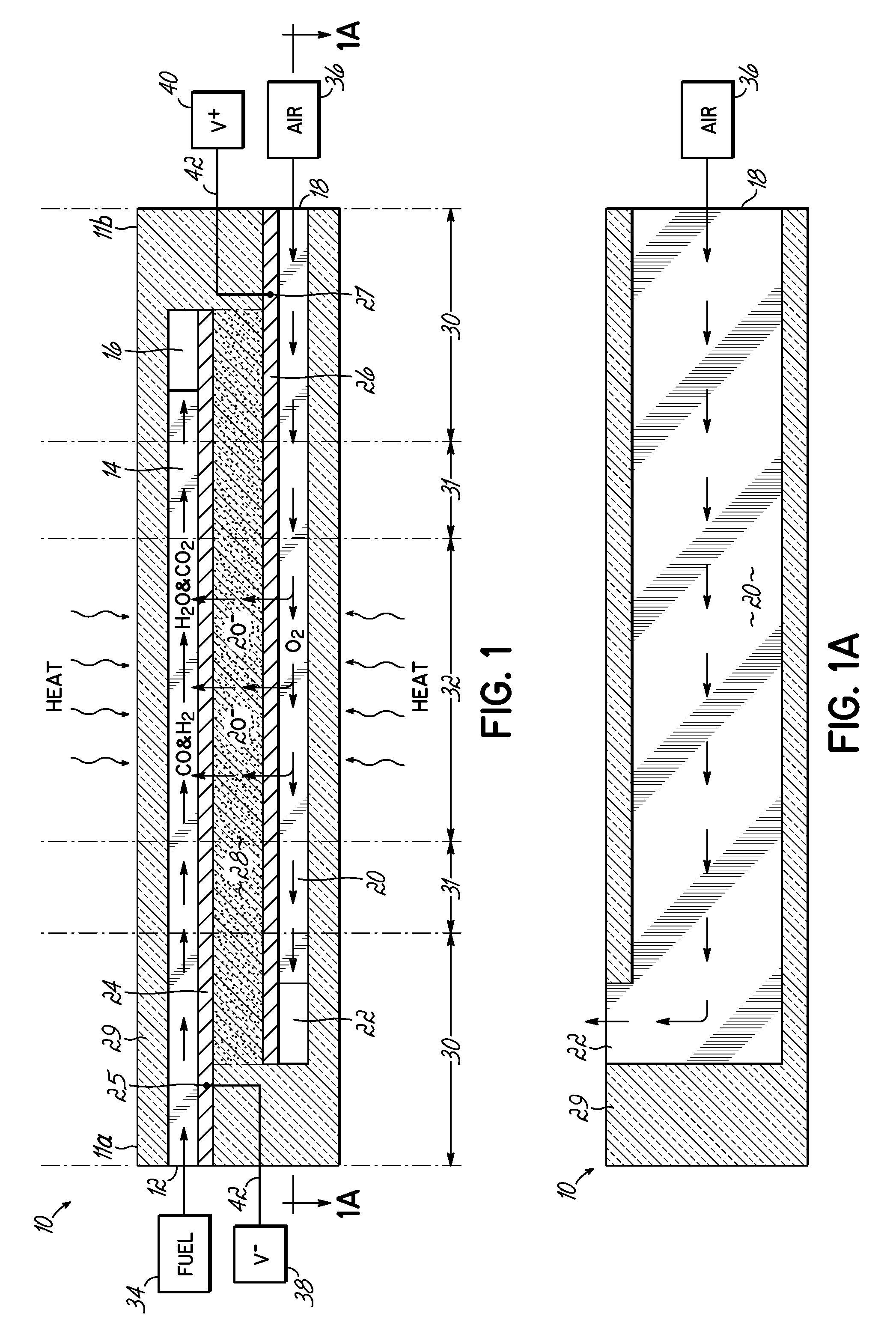

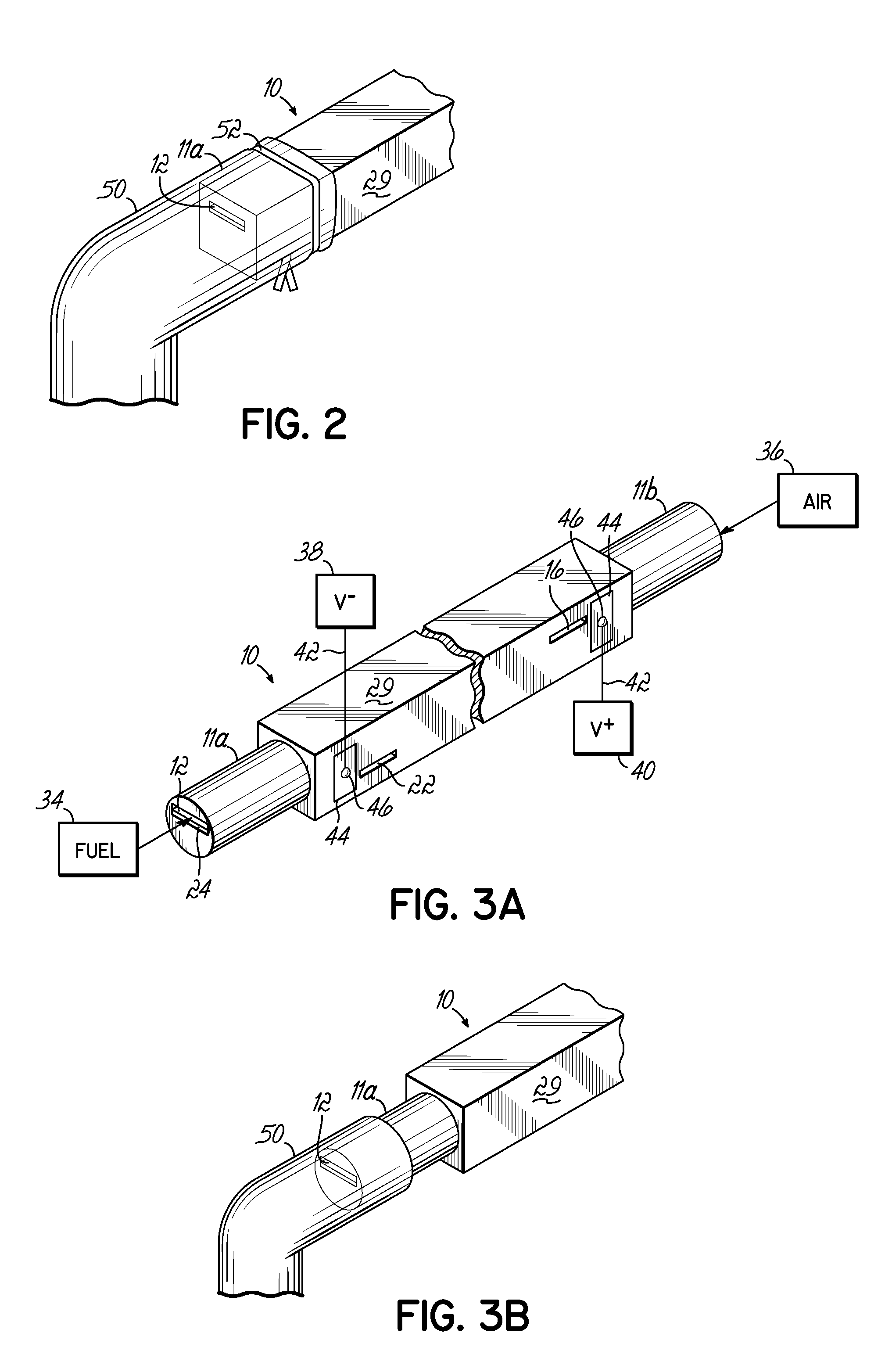

Solid Oxide Fuel Cell Device and System, Method of Using and Method of Making

InactiveUS20070105012A1Avoid layeringAvoid obstructionFuel cell heat exchangeDeferred-action cellsReaction temperatureElectrical connection

A solid oxide fuel cell device that includes an elongate substrate having a first end and an opposing second end with a length therebetween, a cold zone along a first portion of the length adjacent the first end, and a hot reaction zone along a second portion of the length adjacent the second end. The hot reaction zone is configured to be heated to an operating reaction temperature, and the cold zone is configured to remain at a low temperature below the operating reaction temperature. A fuel inlet and air inlet are each positioned in the cold zone and coupled to respective elongate fuel and oxidizer passages that extend through the hot reaction zone within the elongate substrate in parallel and opposing relation to respective fuel and air outlets adjacent the first end. An anode and a cathode are each positioned adjacent a respective fuel and oxidizer passage in the hot reaction zone within the elongate substrate and each is electrically coupled to a respective first and second exterior contact surface on the elongate substrate in the cold zone. A solid electrolyte is positioned between the anode and cathode, and negative and positive electrical connections are made to the respective first and second exterior contact surfaces. A fuel cell system is also provided incorporating a plurality of the fuel devices with their hot reaction zones positioned in a hot zone chamber and their cold zones extending outside the hot zone chamber. A heat source is coupled to the hot zone chamber to heat the reaction zones to the operating reaction temperature. Fuel and air supplies are coupled outside the hot zone chamber to the cold zones for supplying fuel and air flows into the respective fuel and oxidizer passages. A method of making a solid oxide fuel cell device is also provided in which fluid anode and cathode materials are flowed into passages followed by liquid removal to thereby form anodes and cathodes in the passages.

Owner:DEVOE ALAN +1

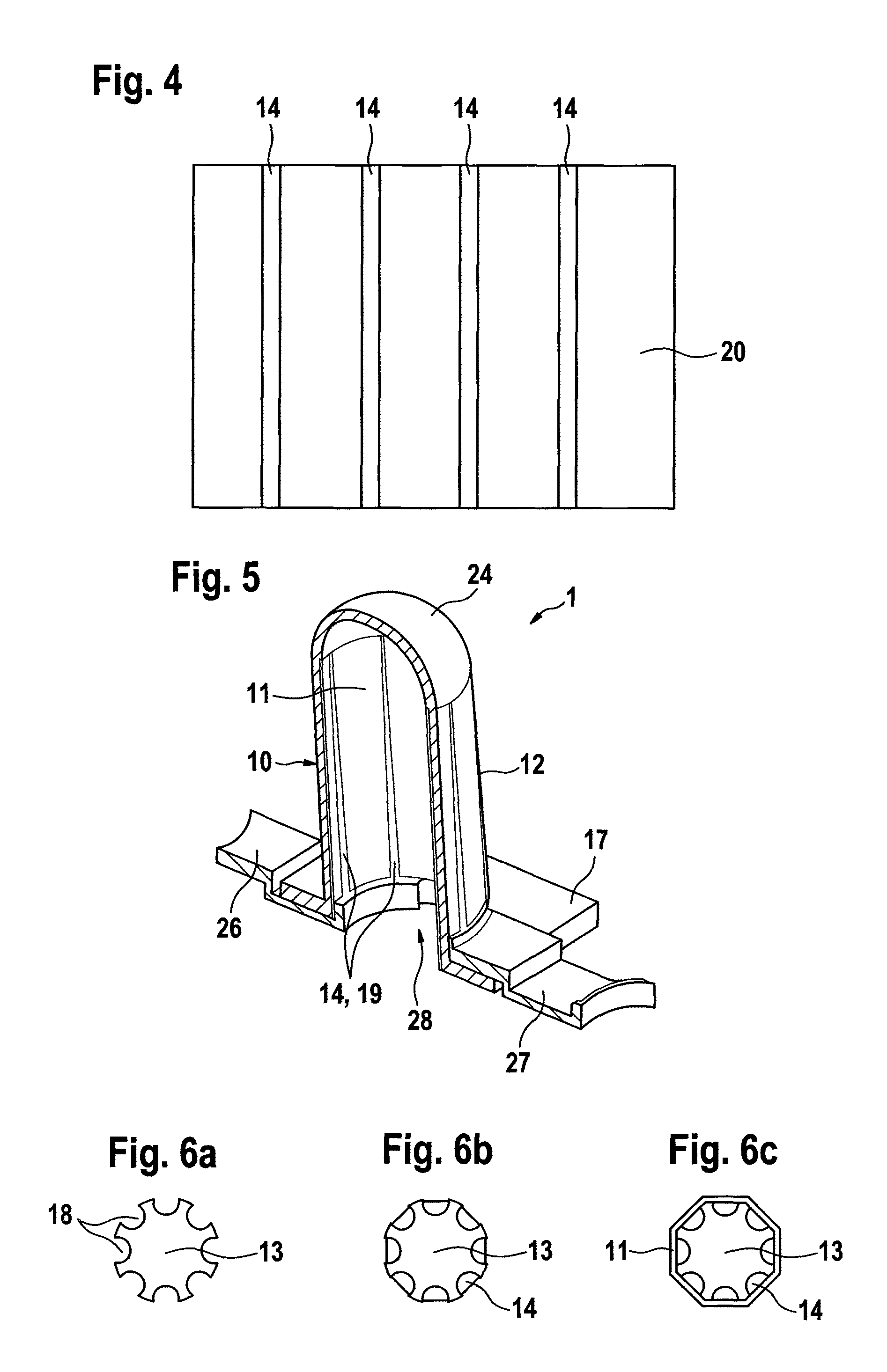

Method for production of a solid oxide fuel cell (SOFC)

InactiveUS8574791B2Simple wayOvercome disadvantagesFinal product manufactureFuel cell shape/formElectrolysisFuel cells

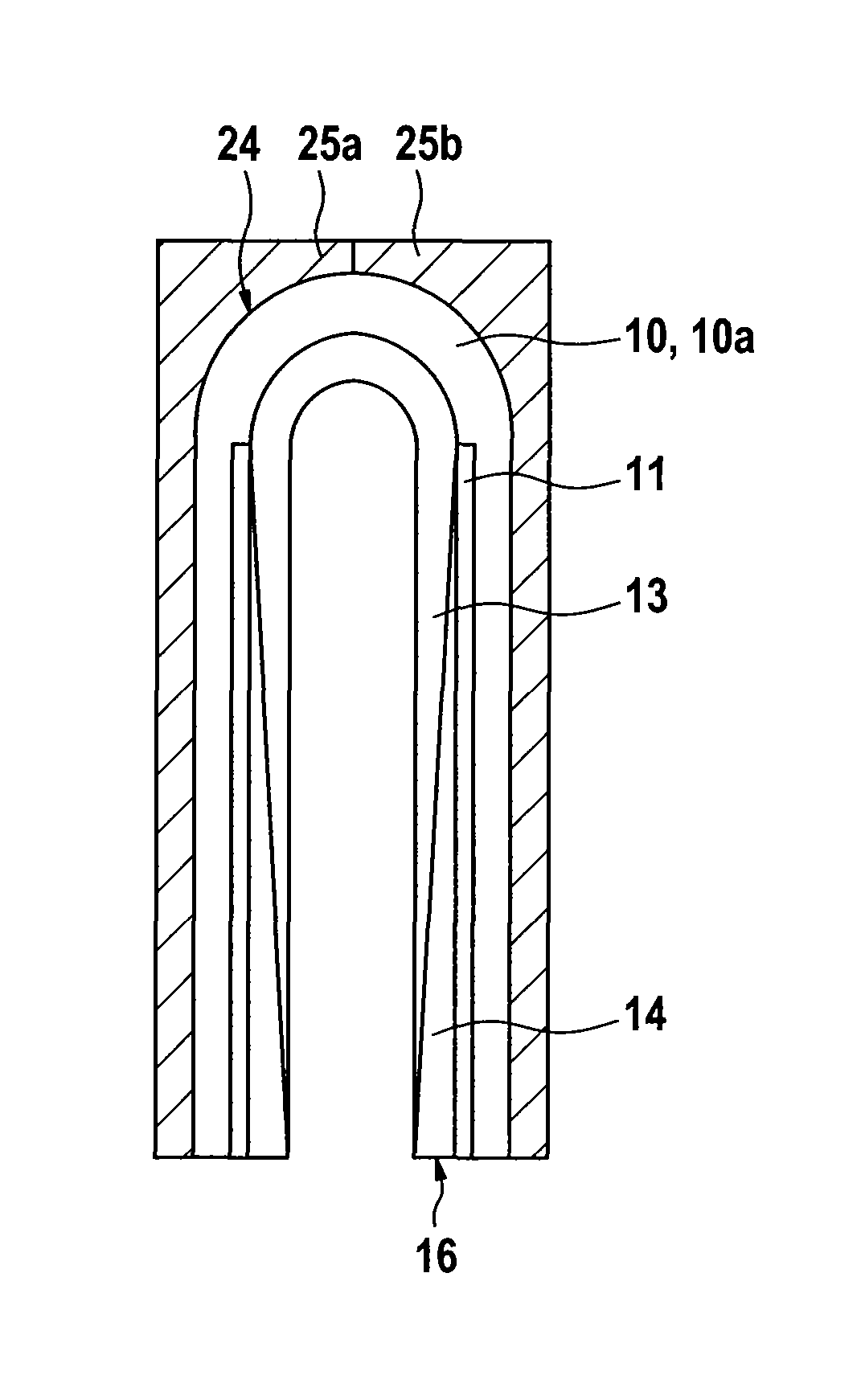

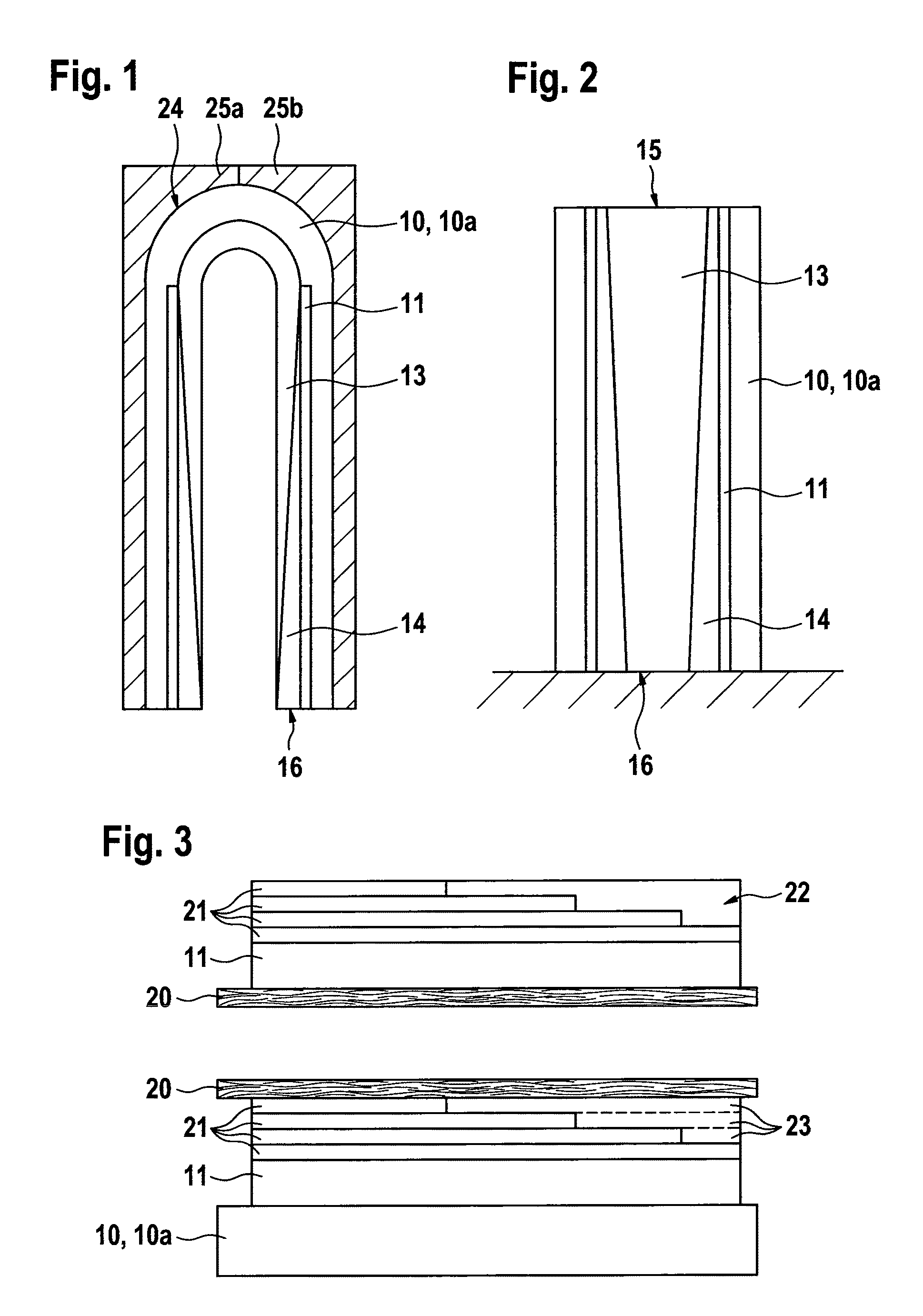

A method for production of a solid oxide fuel cell (SOFC) (1), having an electrolyte body (10) with a tubular structure, wherein at least one internal electrode (11) and one external electrode (12) are applied to the tubular electrolyte body, with the method having at least the following steps: provision of an injection molding core (13) on which at least one interconnector material (14) and the internal electrode (11) are mounted, arrangement of the injection molding core (13) in an injection mold (25a, 25b), injection molding of an electrolyte compound (10a) in order to form the electrolyte body (10), and removal of the injection molding core (13) in the form of a casting process with a lost core.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com