Fuel cell and method for fabricating same

a fuel cell and cell technology, applied in the field of fuel cells, can solve the problems of insufficient cell output for driving power sources, above miniaturization and weight saving of fuel cells, and achieve high hydrogen ion conductivity, high mechanical strength, and high output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

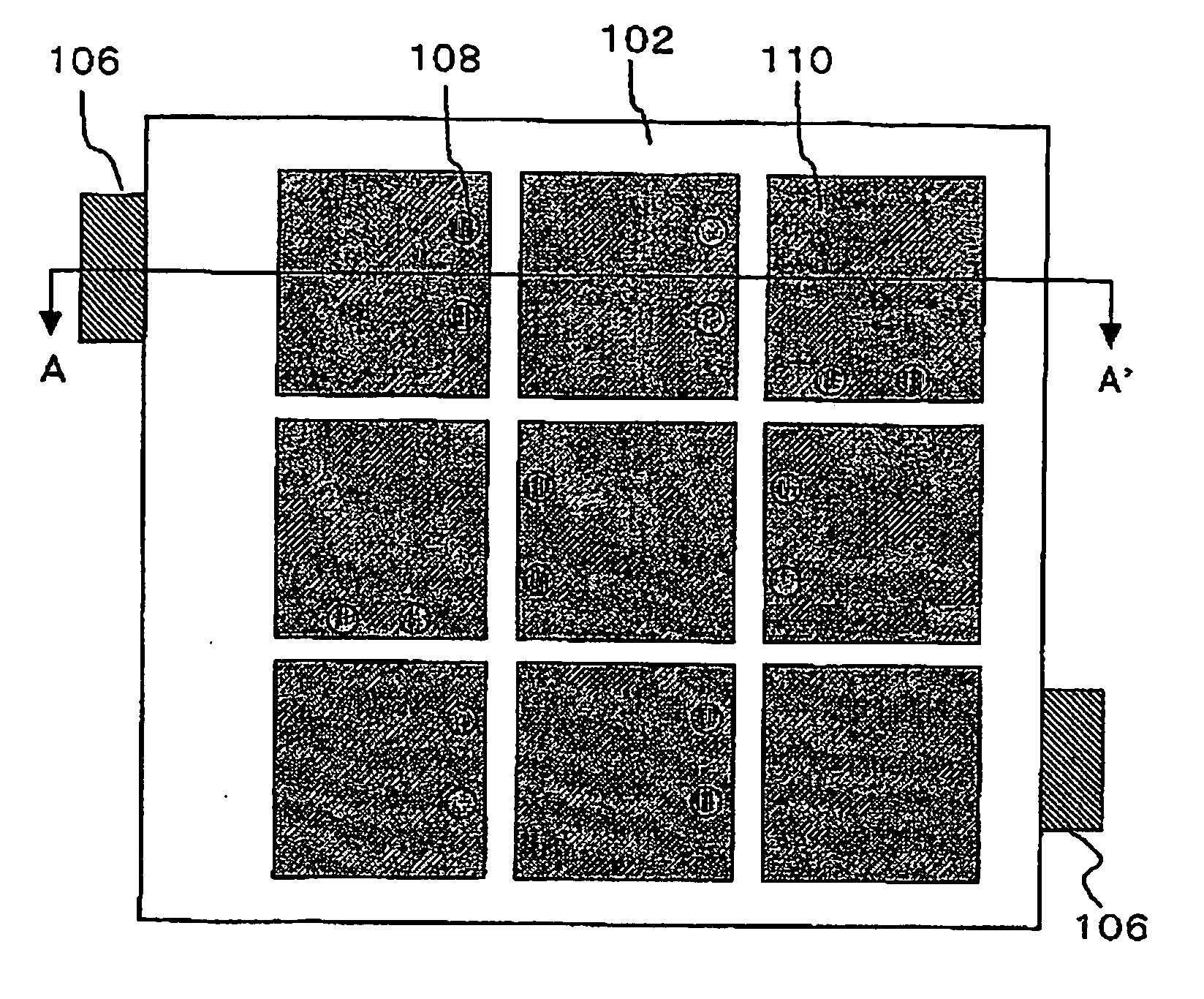

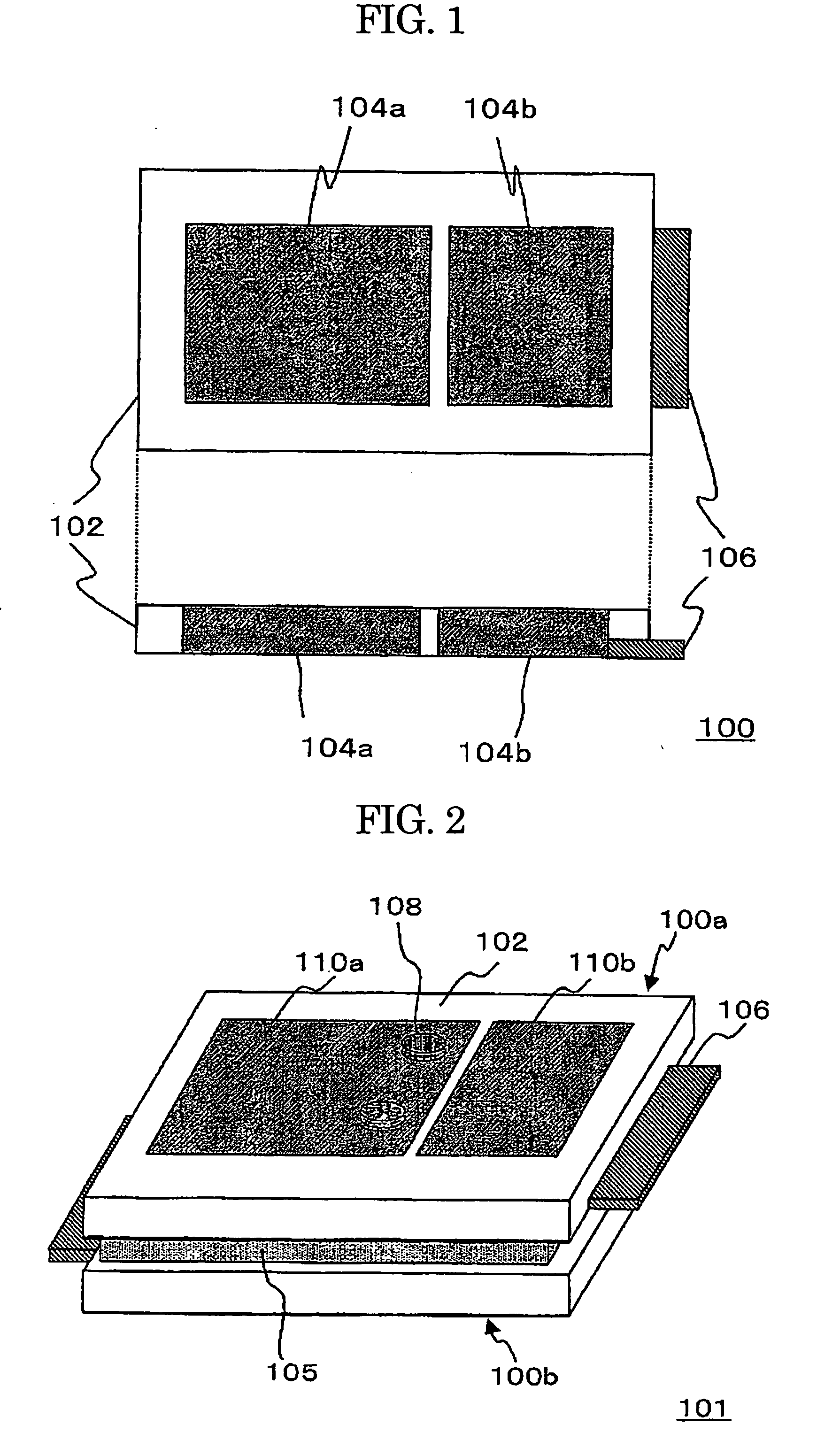

[0049] The present Embodiment exemplifies a fuel cell including two unit cells connected in series. FIG. 1 shows a schematic structure of an electrode sheet 100 constituting a fuel cell in accordance with the present Embodiment. In FIG. 1, the above drawing is an front elevation view and the bottom drawing is a side elevation view.

[0050] The electrode sheet 100 includes a plurality of electrodes 104a, 104b containing catalyst and disposed on a single plane, and a resin section 102 surrounding the electrodes. The electrode 104b is equipped with a draw-out electrode 106. The electrodes 104a, 104b are prepared by forming a catalyst layer on porous metal. While specific materials for forming the electrodes 104a, 104b and the resin section 102 are illustrated above, the electrodes 104a, 104b are made of foamed metal of SUS316 belonging to stainless steel and the resin section 102 is made of polyethylene in this Embodiment.

[0051] For example, the electrode sheet 100 can be fabricated as...

second embodiment

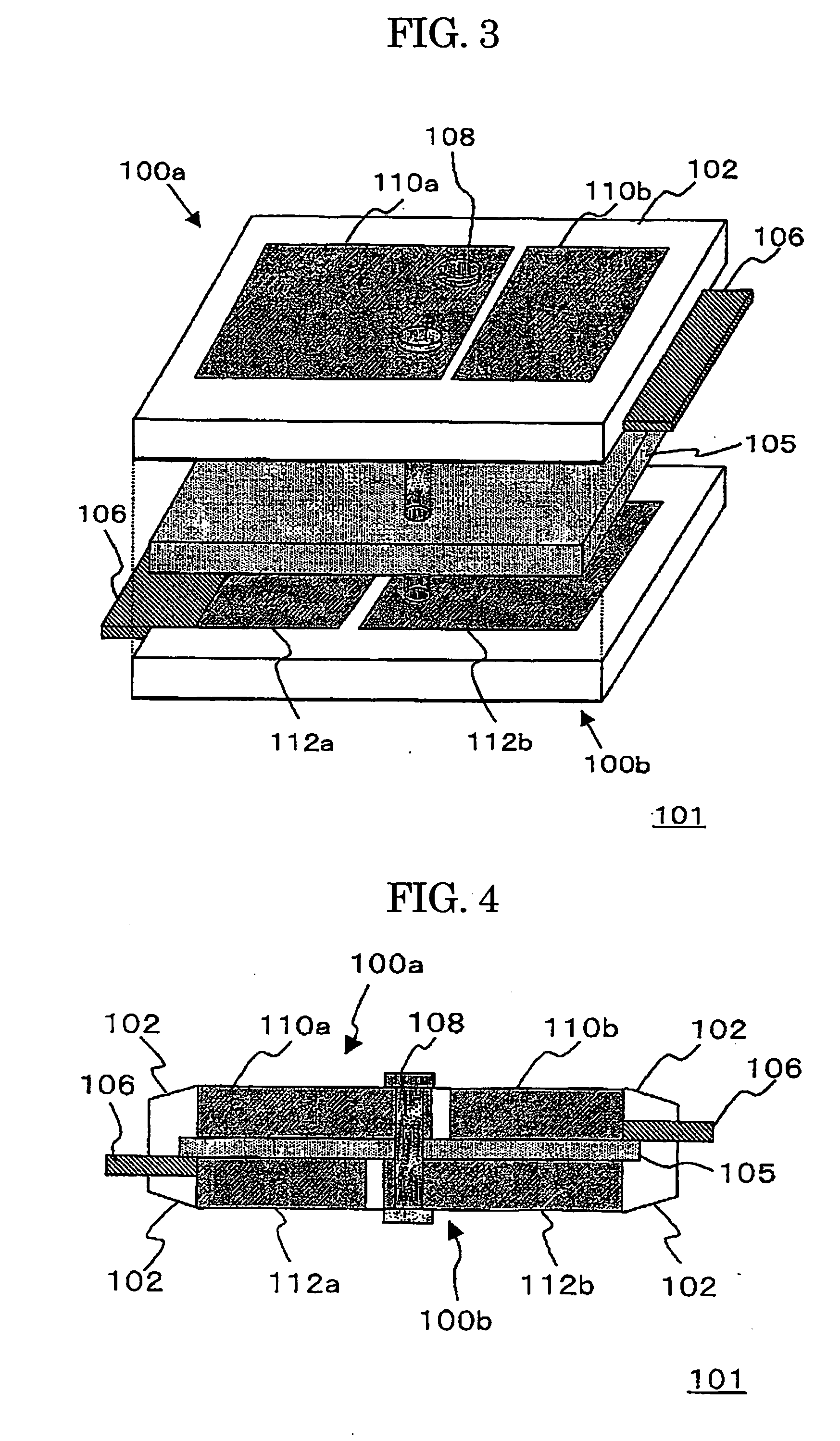

[0070] In this Embodiment, a fuel cell including electrodes and cells in matrix on a single plane is exemplified.

[0071] Before the description of the fuel cell of the present Embodiment, the structure of a conventional fuel cell will be shown. FIG. 6 is an example of a conventional fuel cell in an electrode-connection system. In the fuel cell, unit cells 120 are disposed in “2×2” in a resin section 102. A draw-out electrode 106 is mounted and connected to two adjacent unit cells 120 outside of an electrolyte membrane. In the fuel cell shown therein, the four unit cells are connected in series to take out the total output.

[0072] However, in this configuration, the draw-out electrodes outward extend around the resin section 102 so that there remains a problem regarding the miniaturization of the fuel cell and the higher integration. Further, since the respective unit cells are disposed along the respective edges of the resin section, each of the unit cells can be connected to the dr...

third embodiment

[0078] In the present Embodiment, as shown in FIG. 10, a metal frame 126 is disposed along the peripheries of the fuel electrode 110 and the oxidant electrode 112, and the rivet 108 is positioned through the metal frame to connect the cells. In this manner, a contact resistance between the rivet 108 and the cell can be reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| open-circuit voltage | aaaaa | aaaaa |

| input voltage | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com