Liquid circuit built-in aluminium air fuel cell monomer and cell stack

A fuel cell and built-in technology, applied in the direction of fuel cells, fuel cell half-cells, primary battery half-cells, fuel cell groups, etc., can solve the problems of not finding, inconvenient operation, and not finding invention cases, etc. To achieve the effect of reducing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

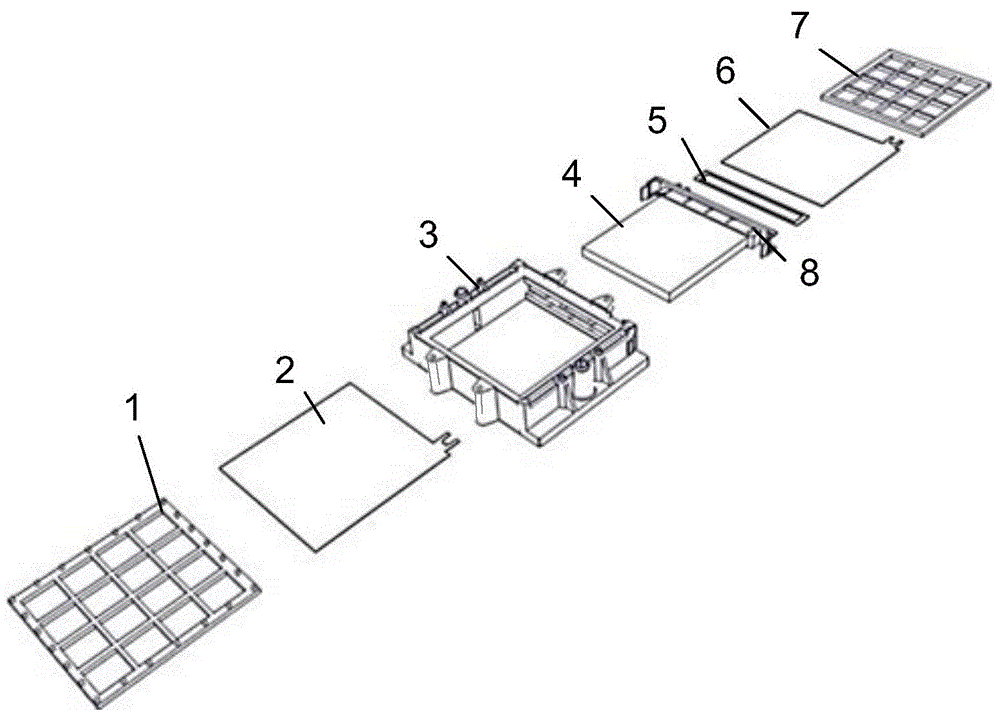

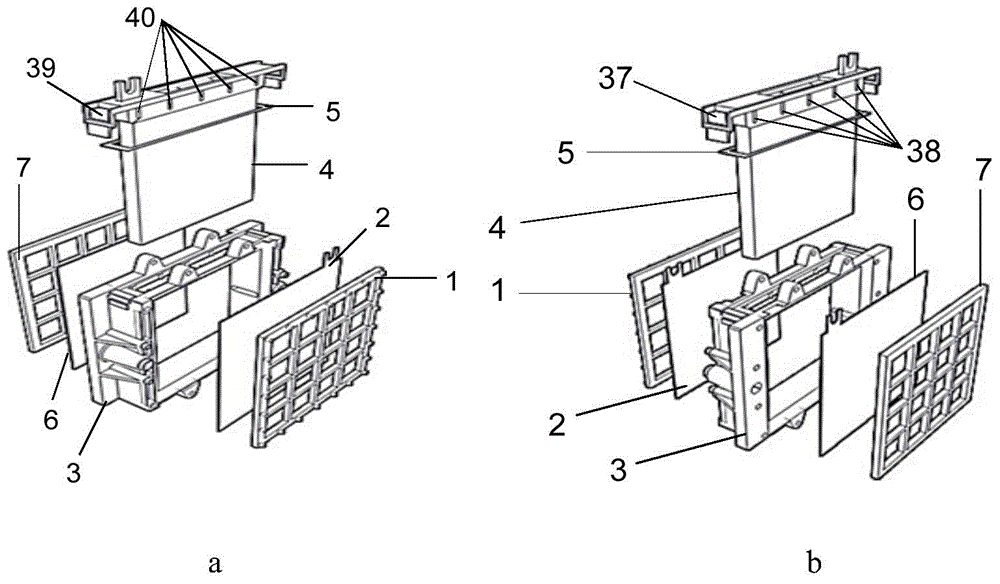

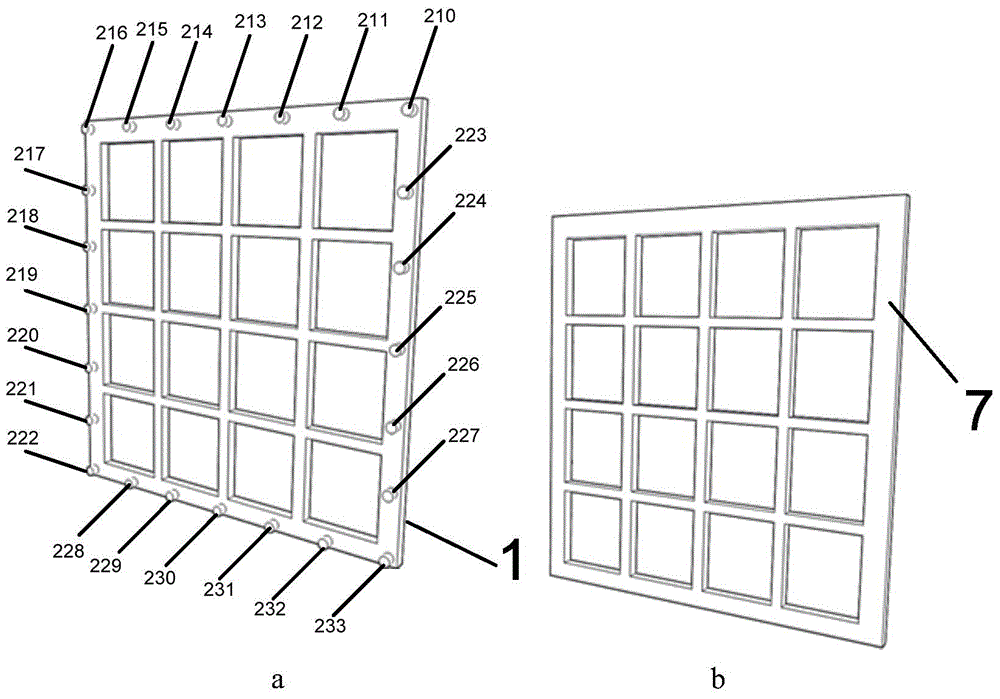

[0040] see Figure 1-10 According to the present invention, a single aluminum-air fuel cell with a built-in liquid circuit includes a single grid, an air cathode, a basic frame 3 and an anode aluminum alloy electrode 4 covered with a sealing ring 5 . The single grid includes the first and second flat grids 1, 7, and the edge of the first flat grid is uniformly arranged with a number of top pillars. The air cathode includes the first air electrode 2 and the second air electrode 6; and the built-in liquid circuit aluminum The specific structure of the air fuel cell unit includes the first flat grid 1, the first air electrode 2, the base frame 3, the second air electrode 6 and the second flat grid 7 arranged in sequence; There is a side port for inserting the anode aluminum alloy electrode 4, and the outside of the basic frame 3 is also provided with a first el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com