Patents

Literature

34results about How to "No getting stuck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

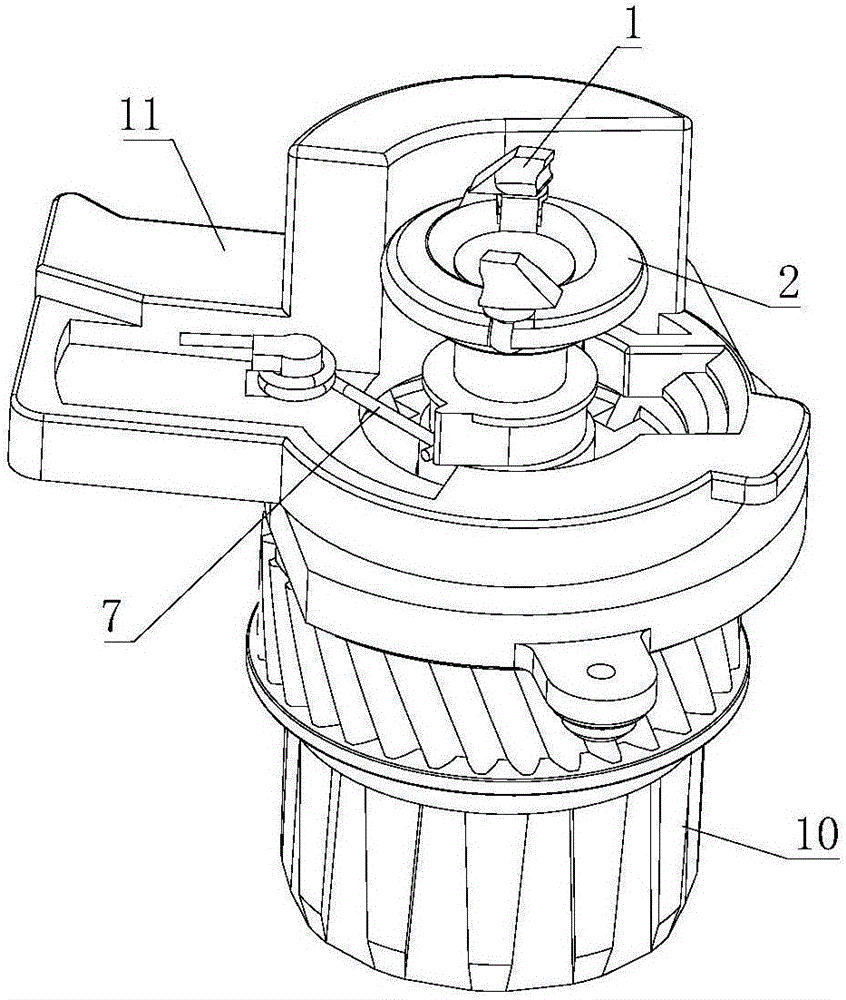

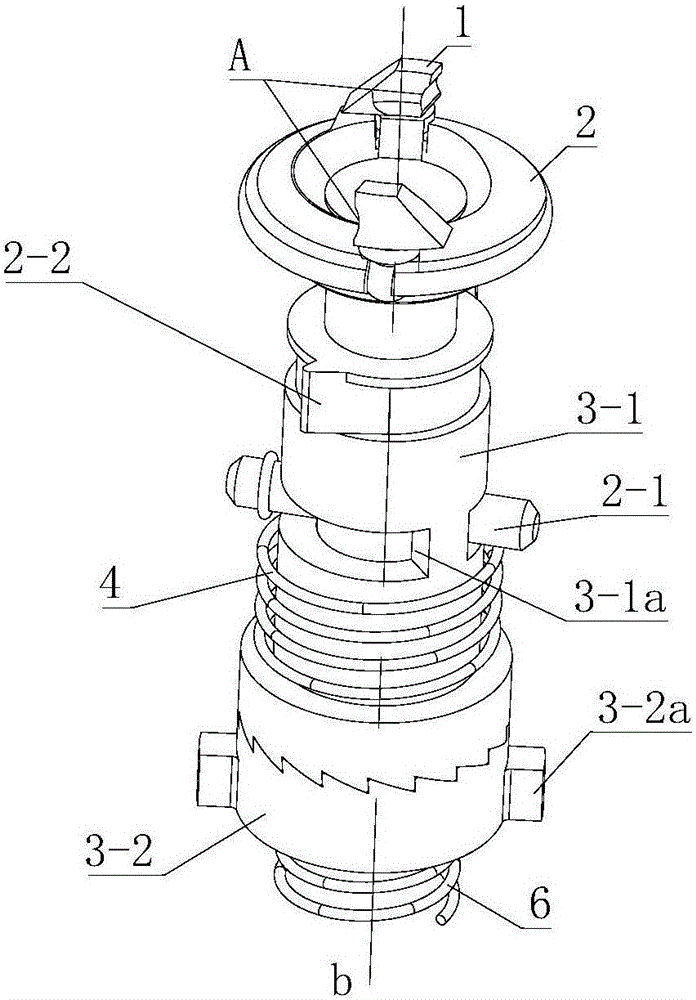

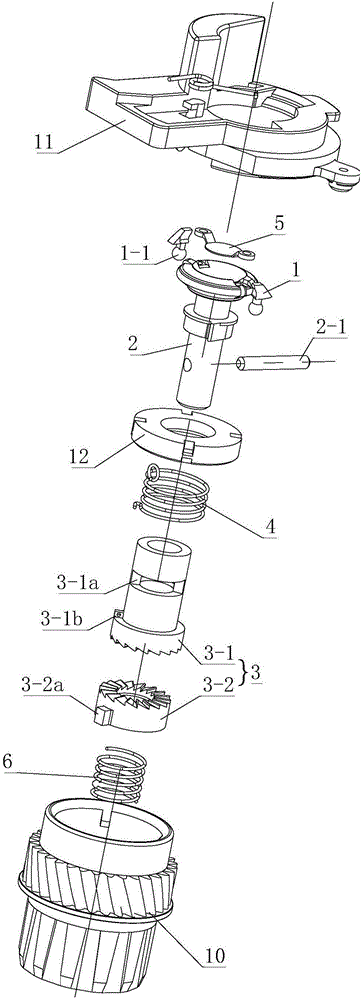

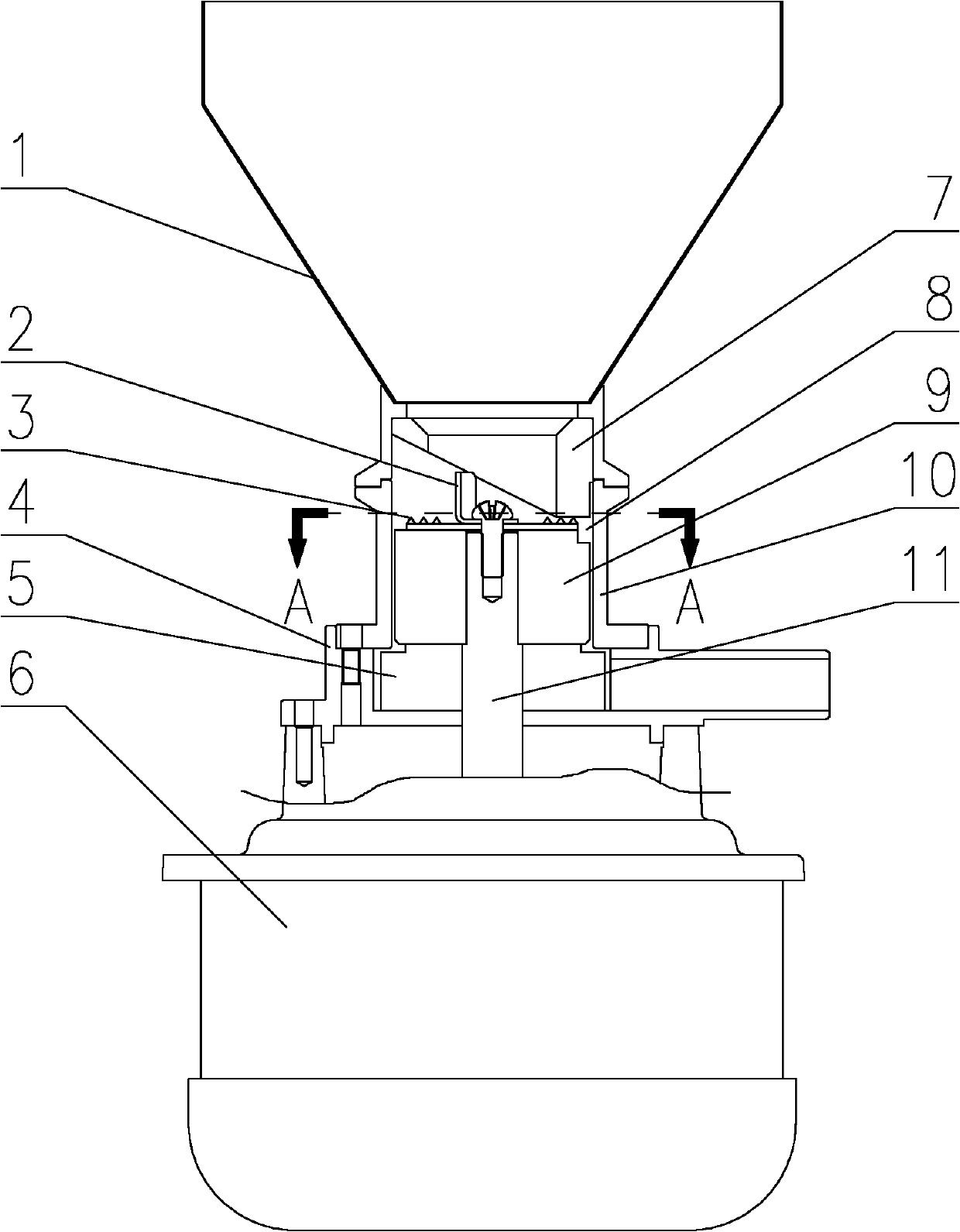

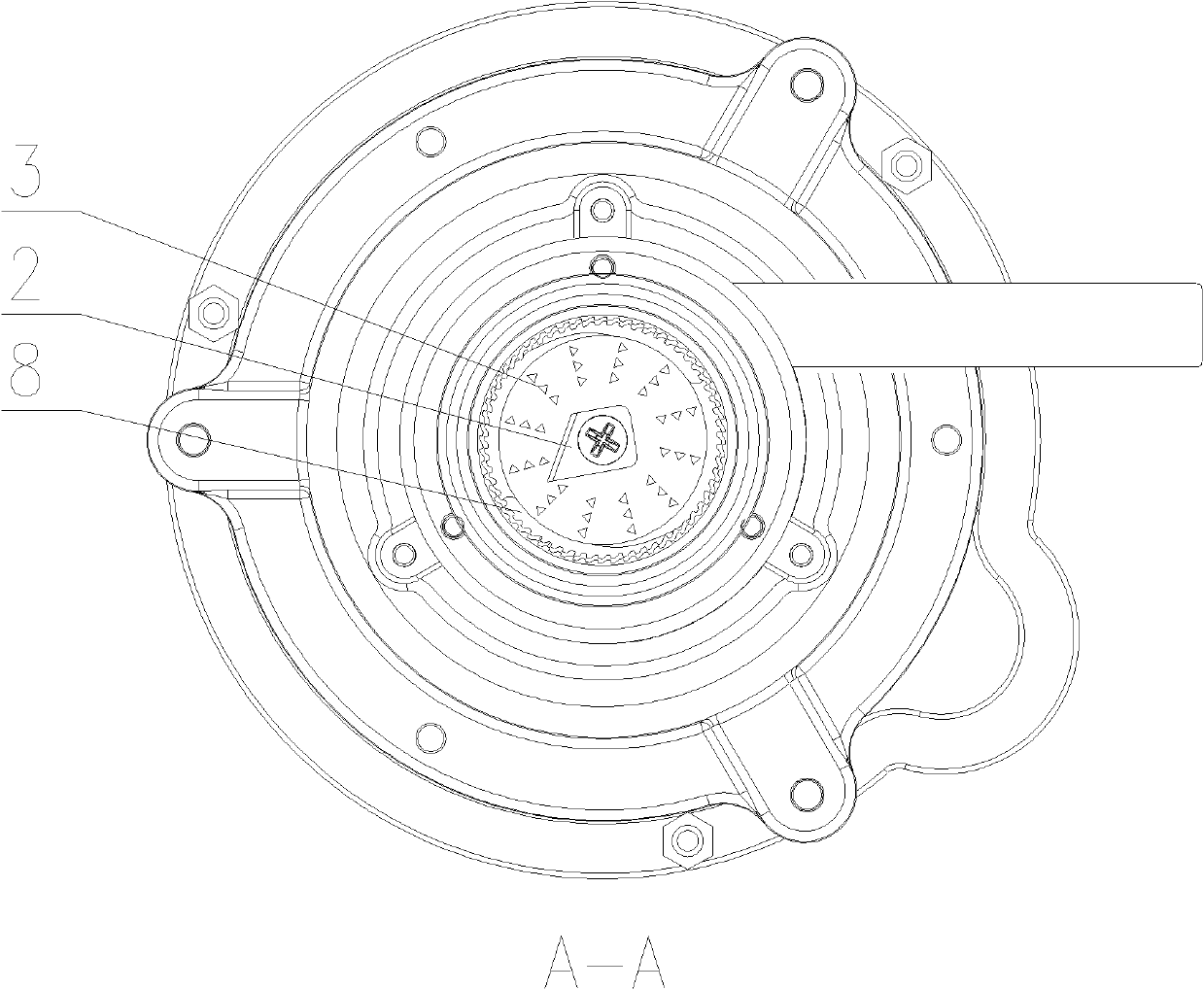

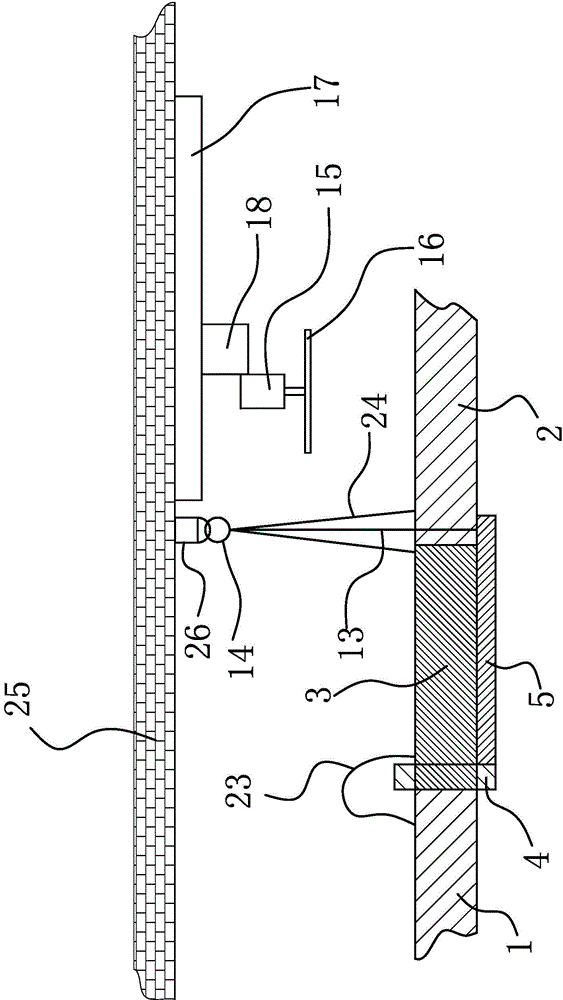

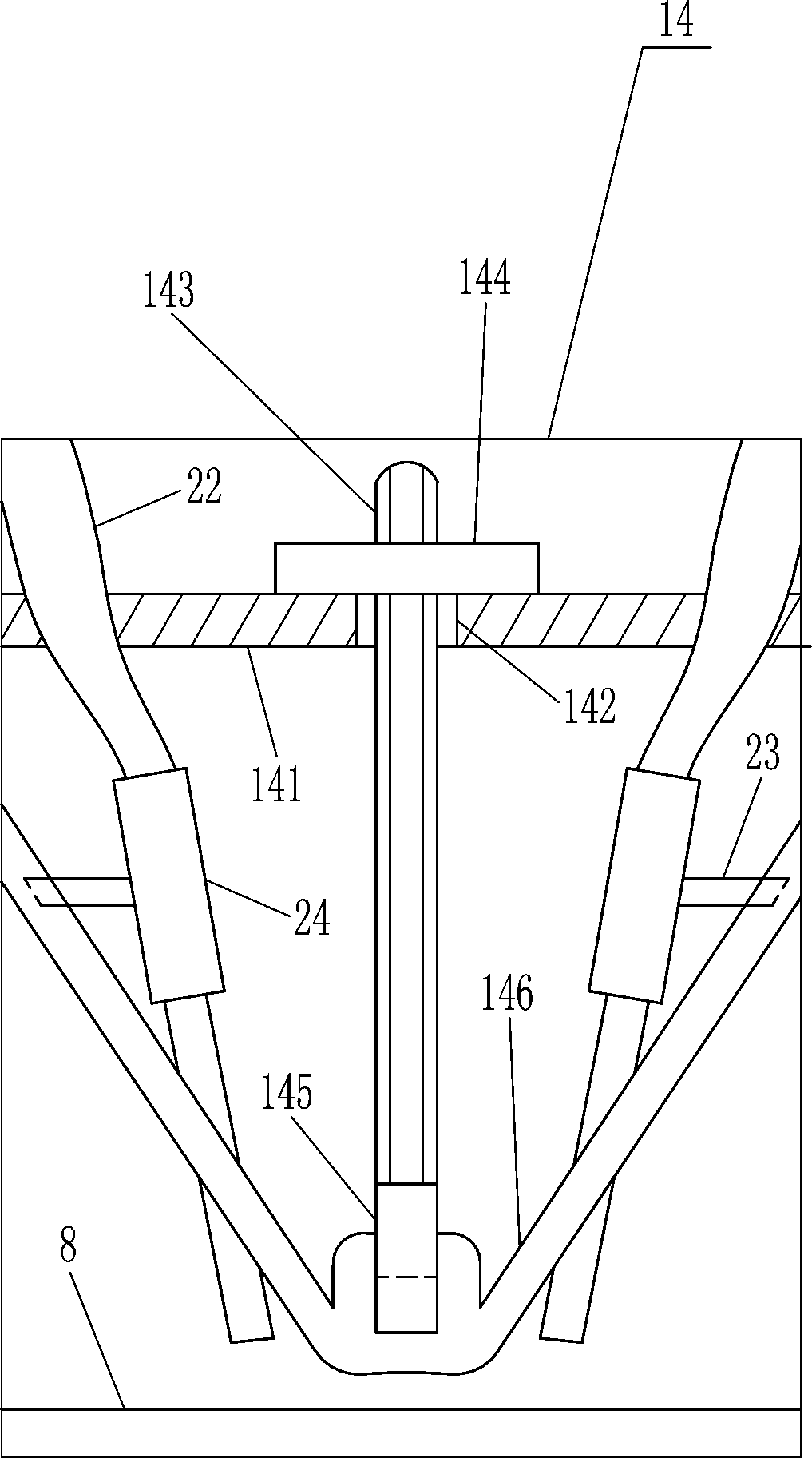

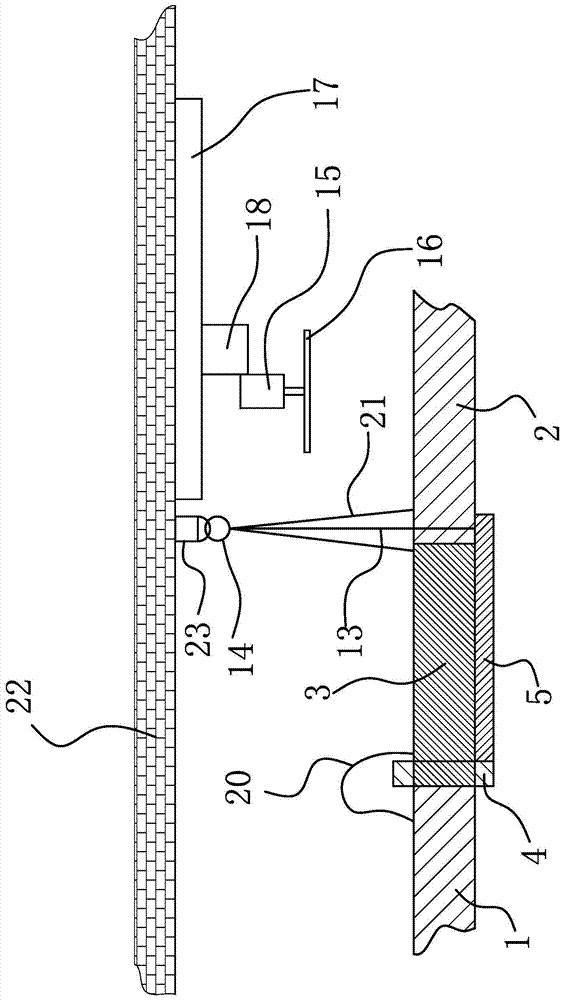

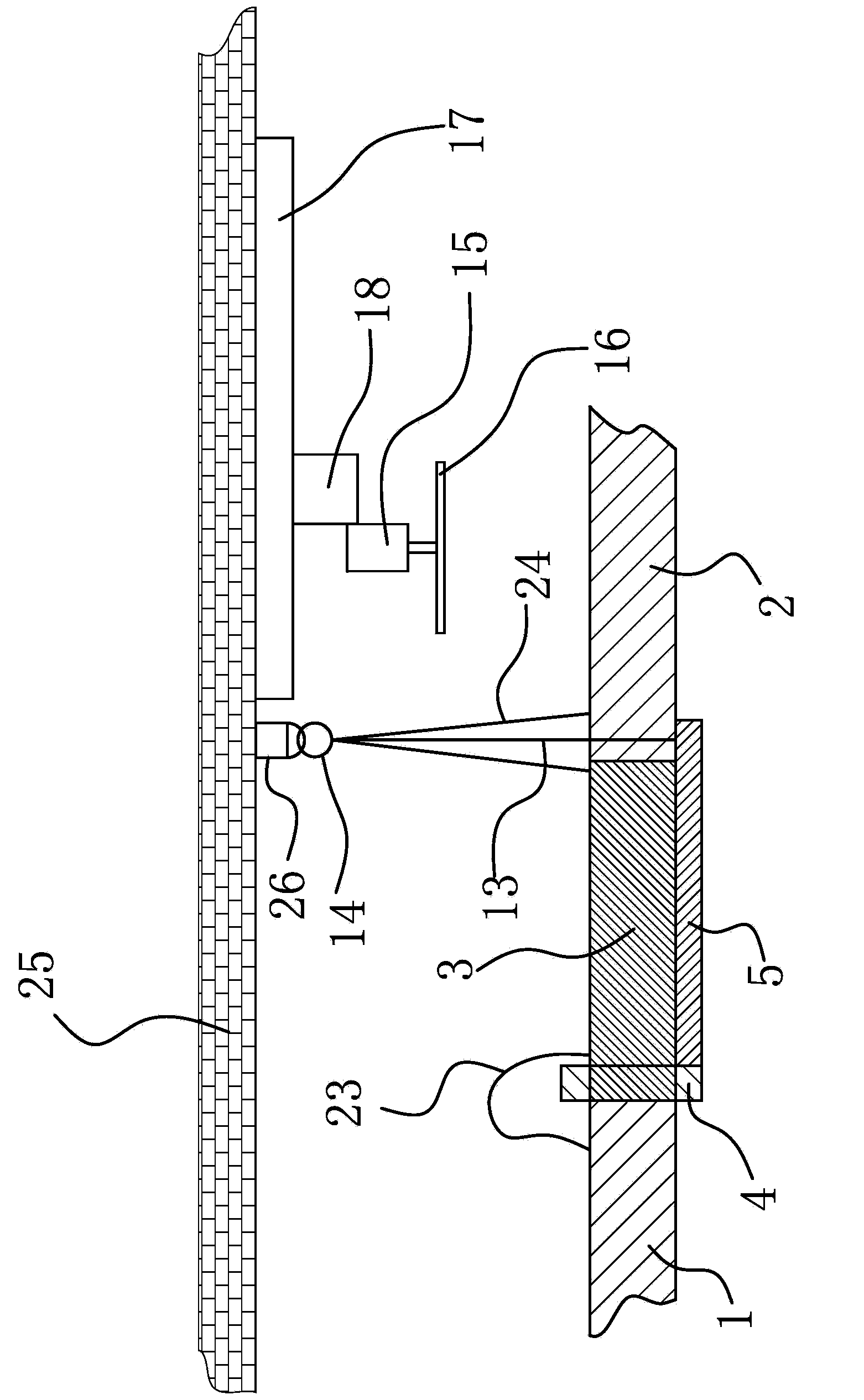

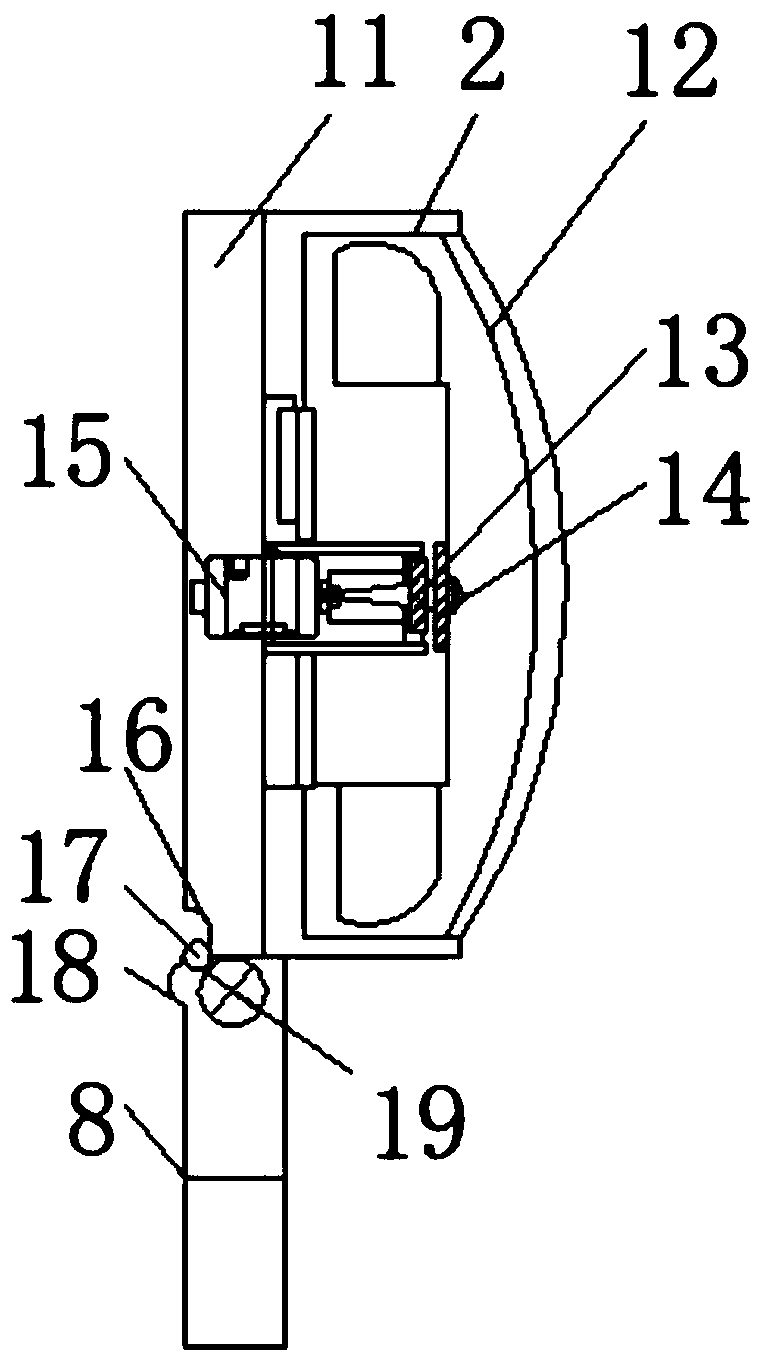

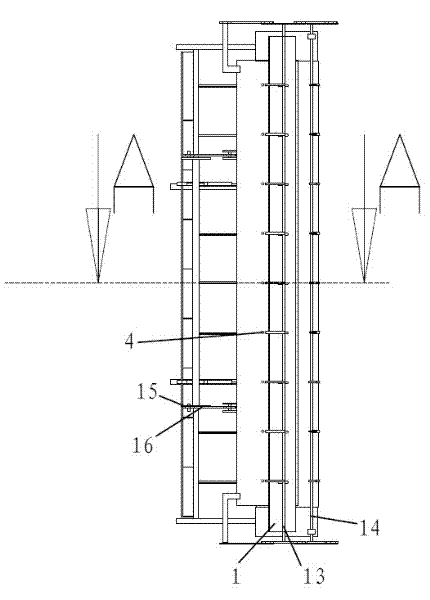

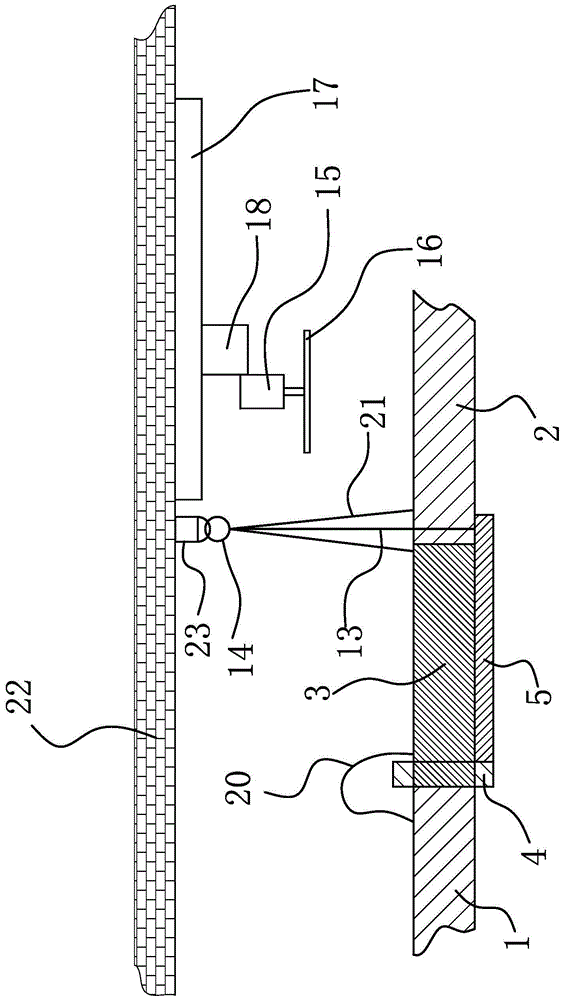

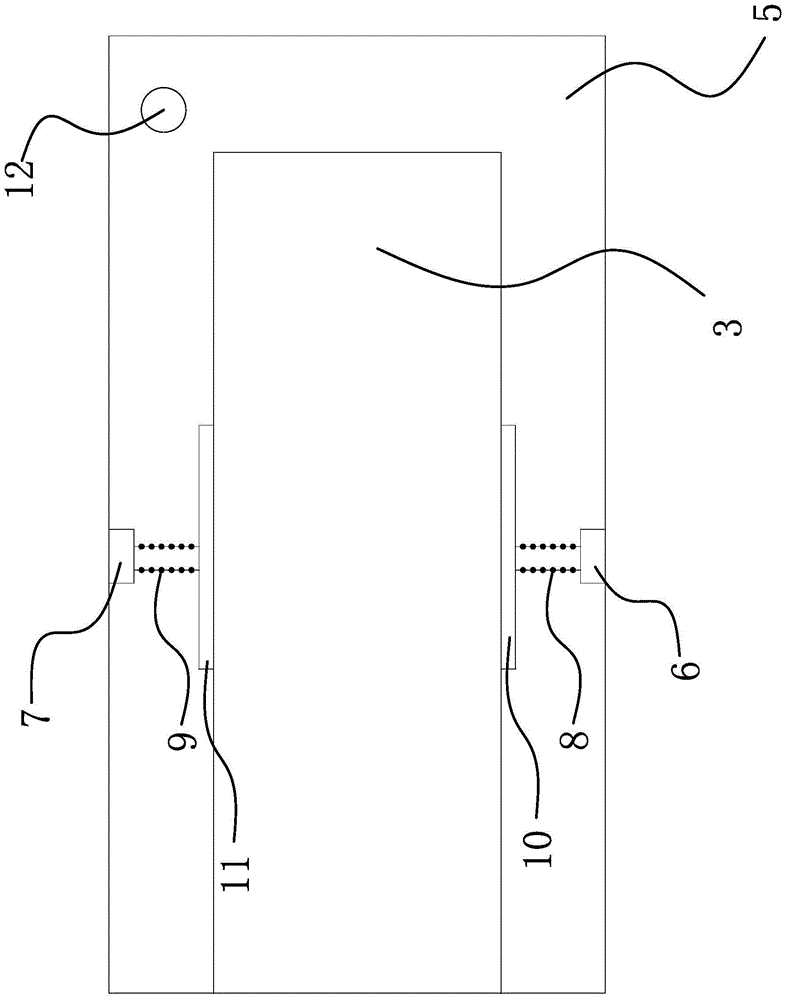

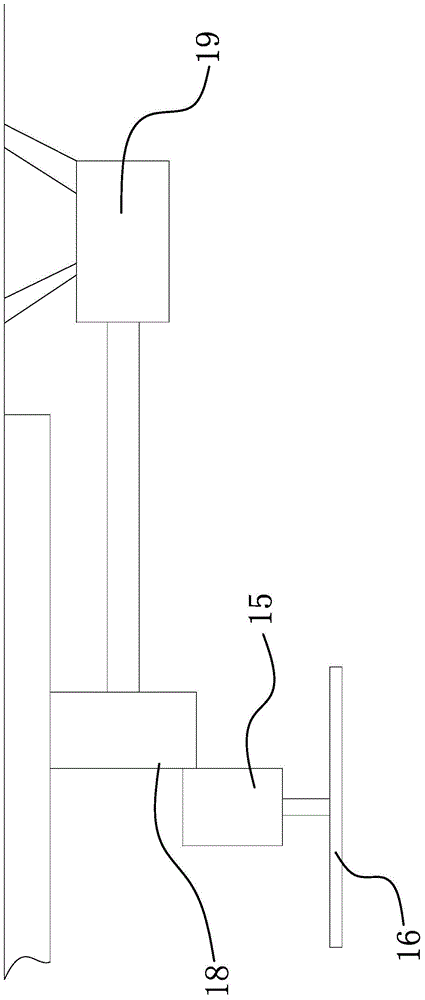

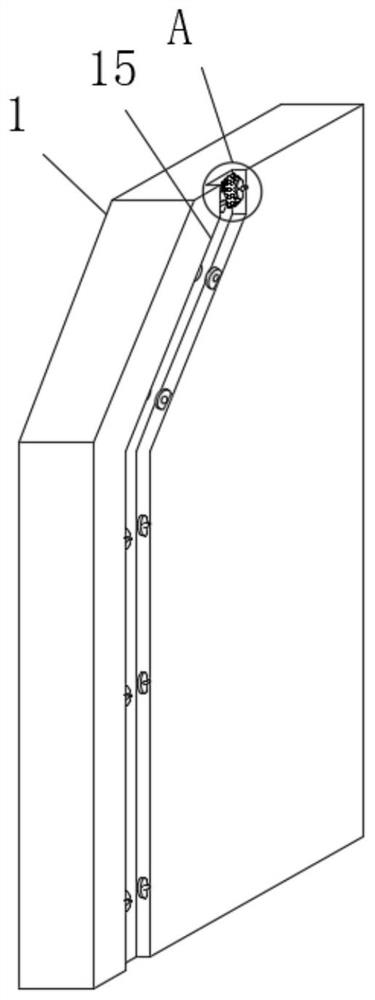

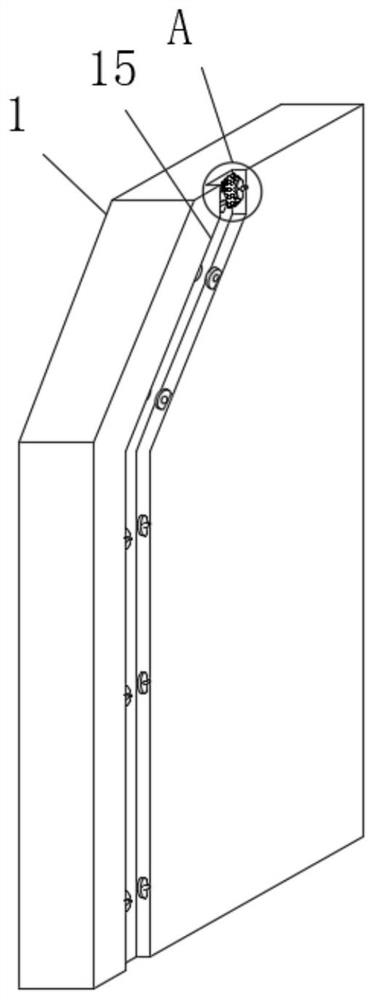

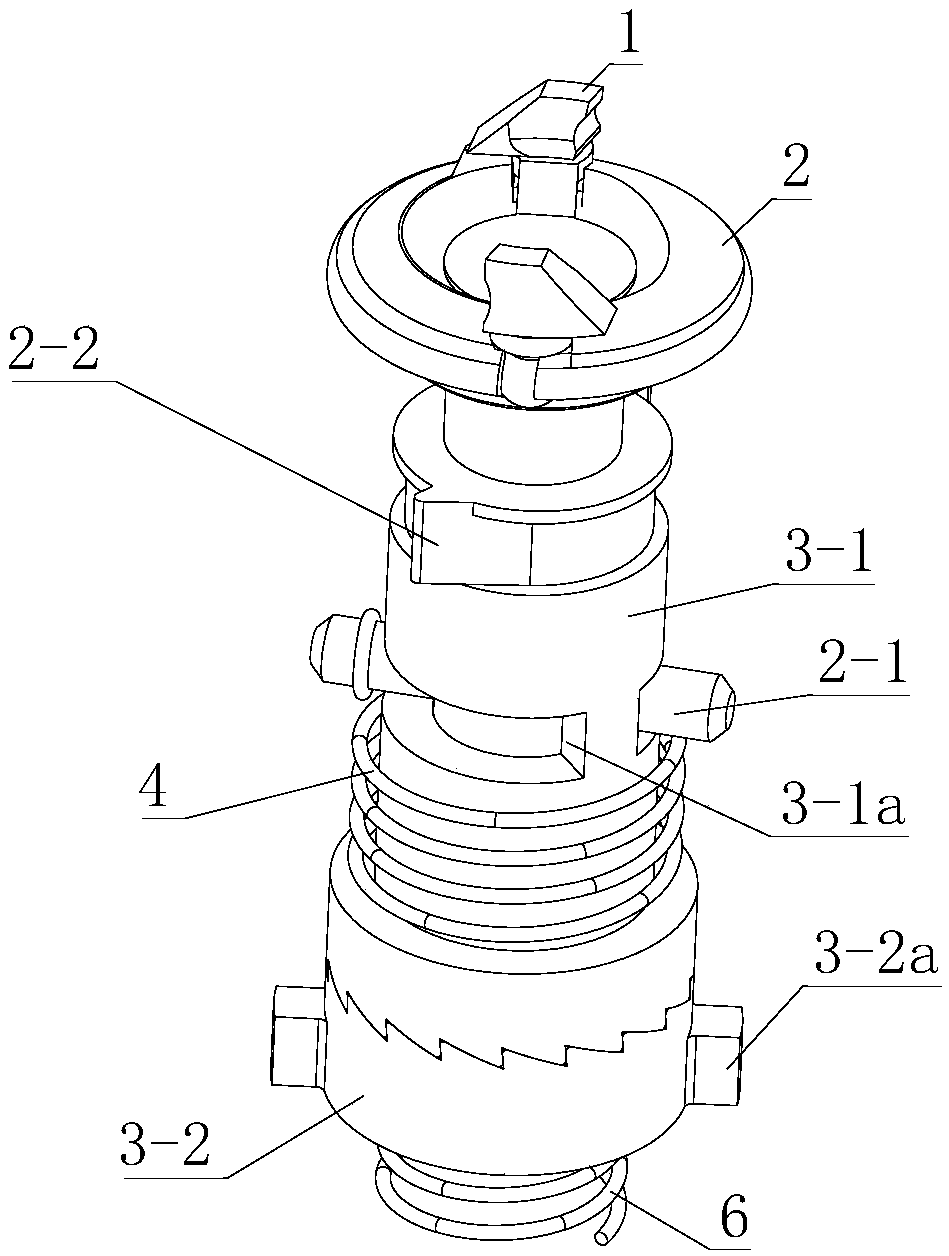

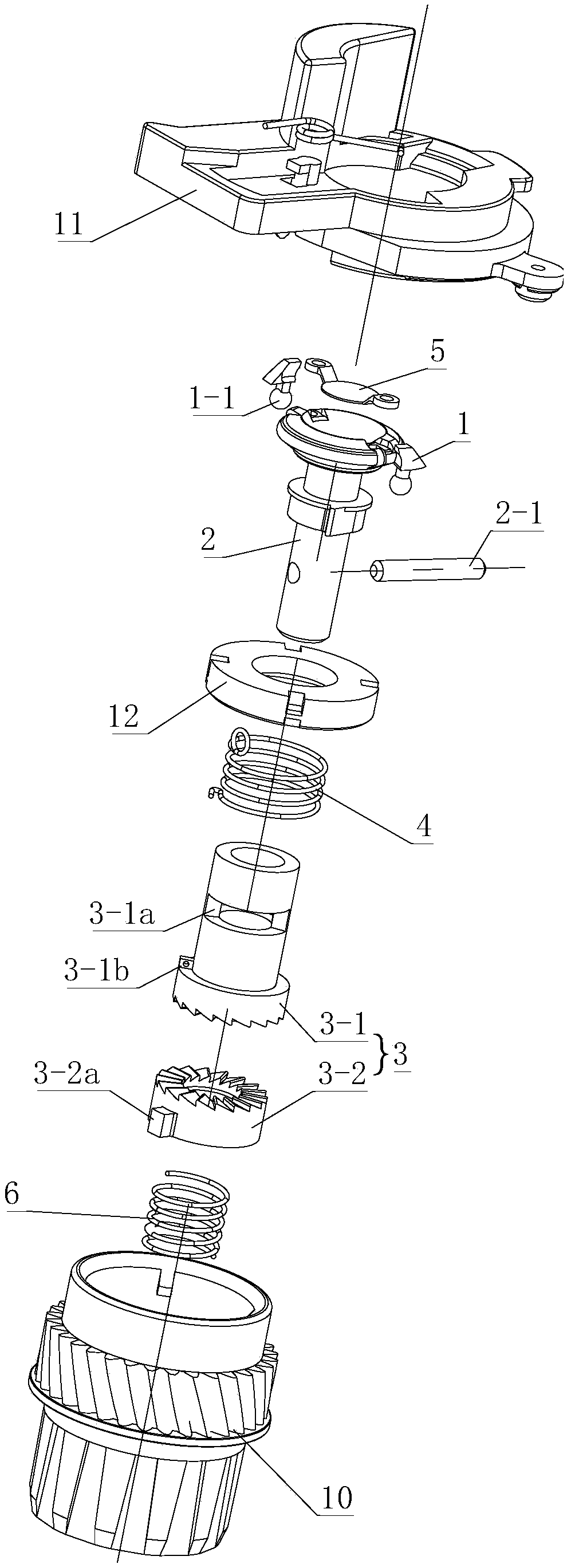

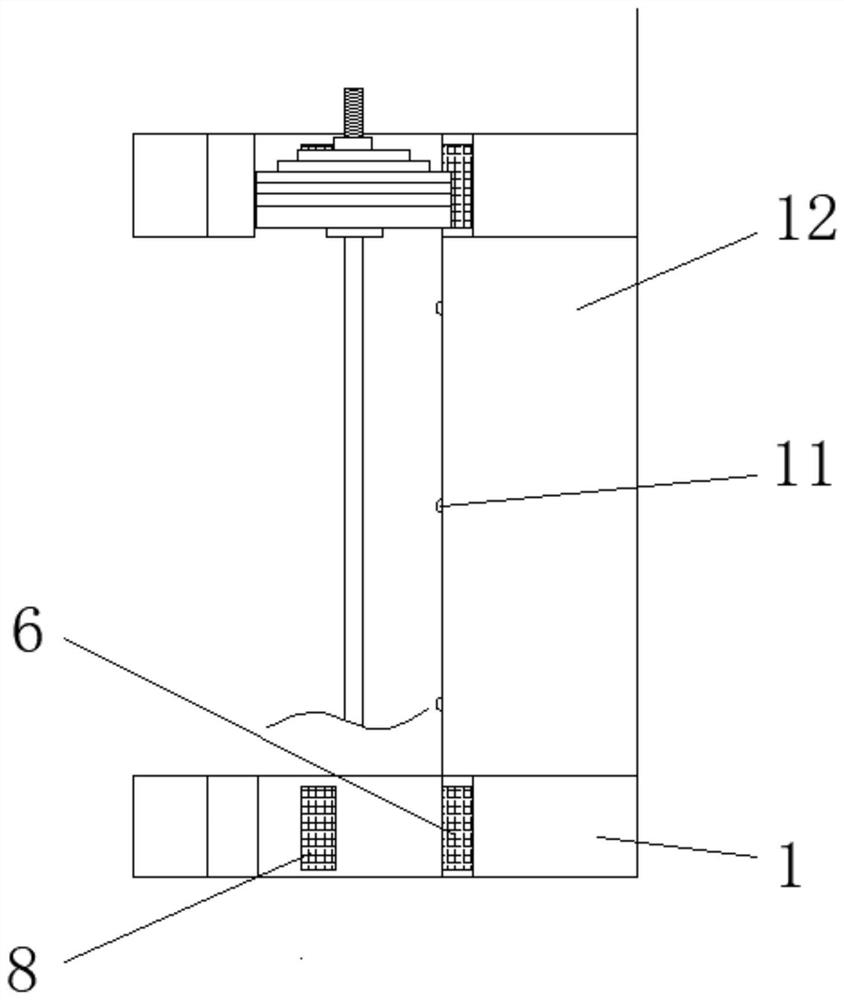

Driving force receiving assembly of photosensitive drum

ActiveCN105843008ASmooth entryNo getting stuckElectrographic process apparatusStress pointEngineering

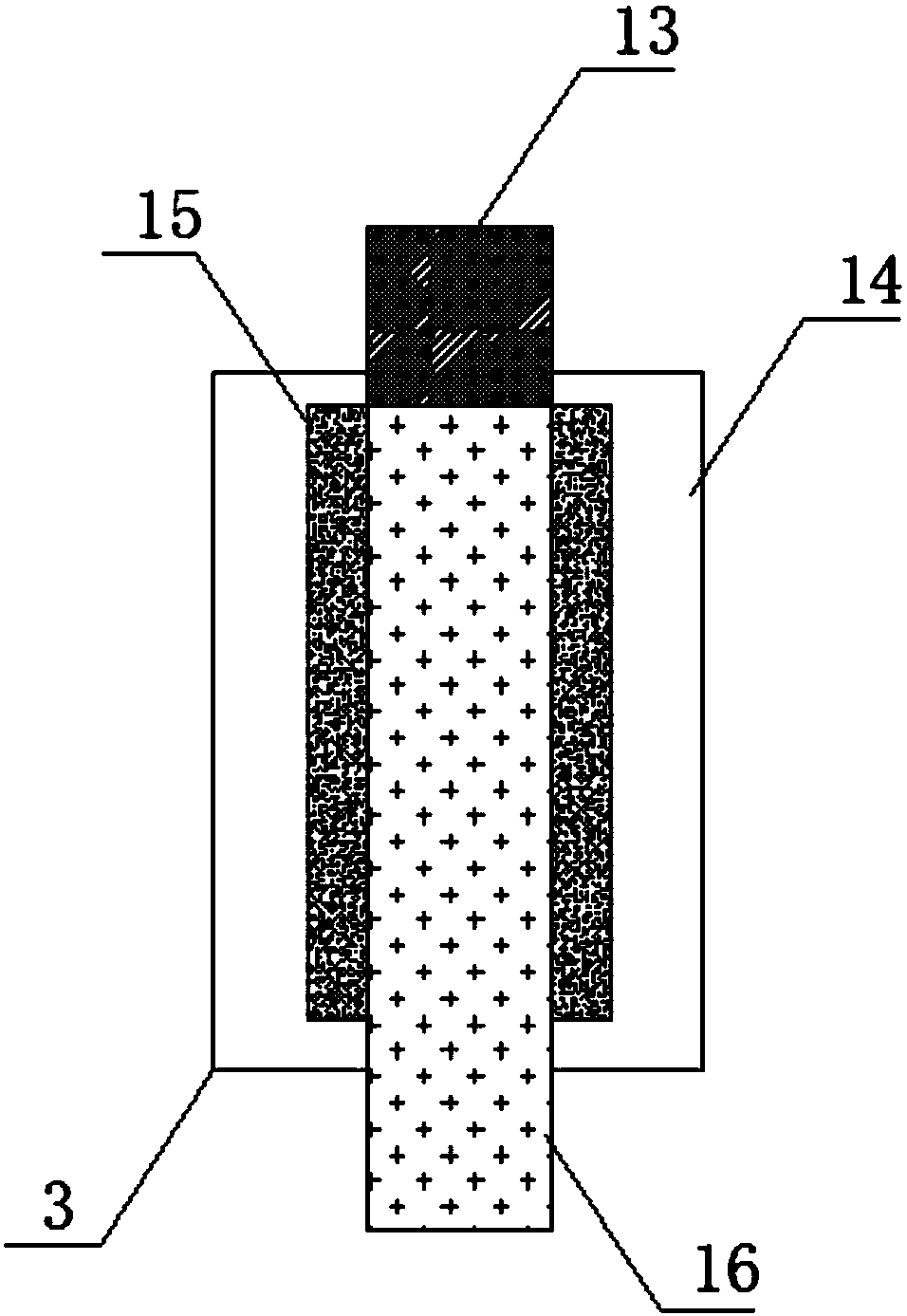

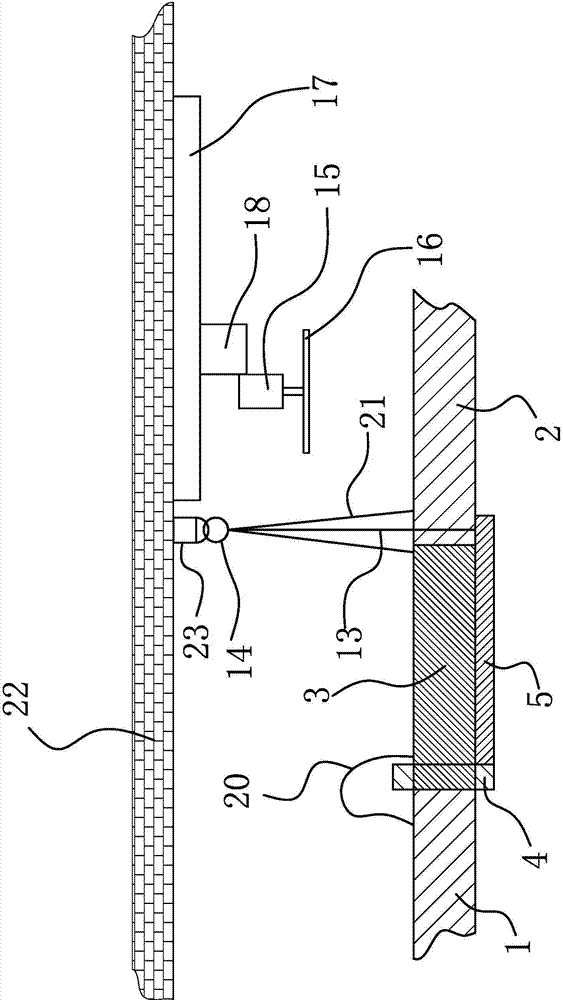

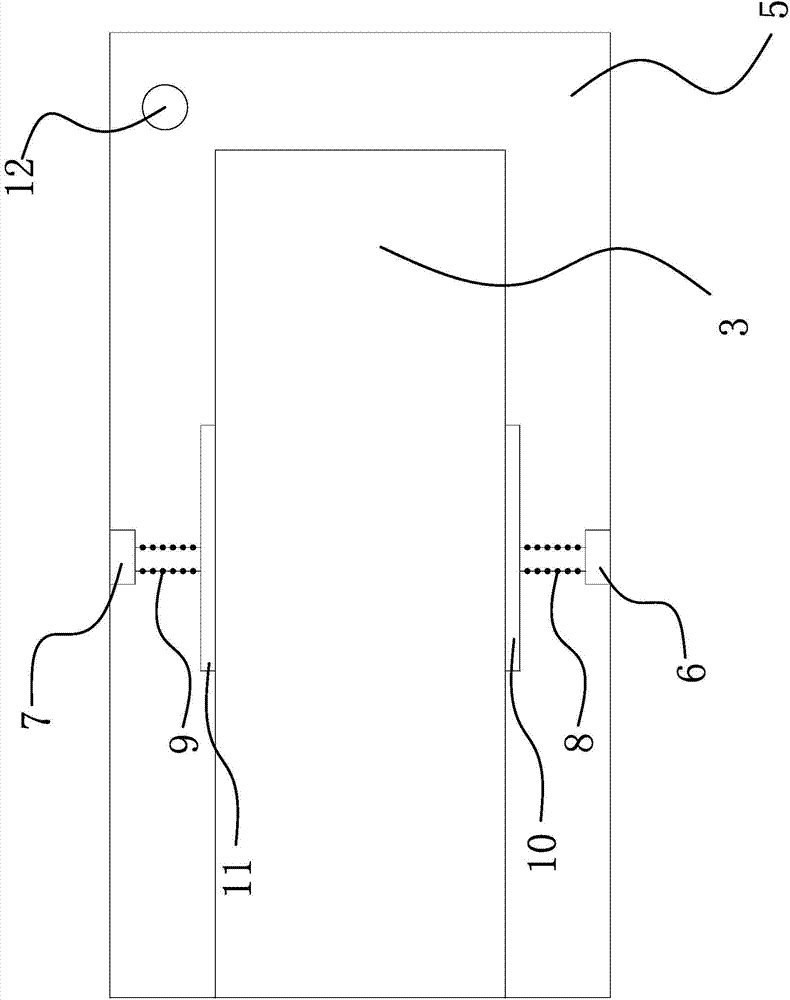

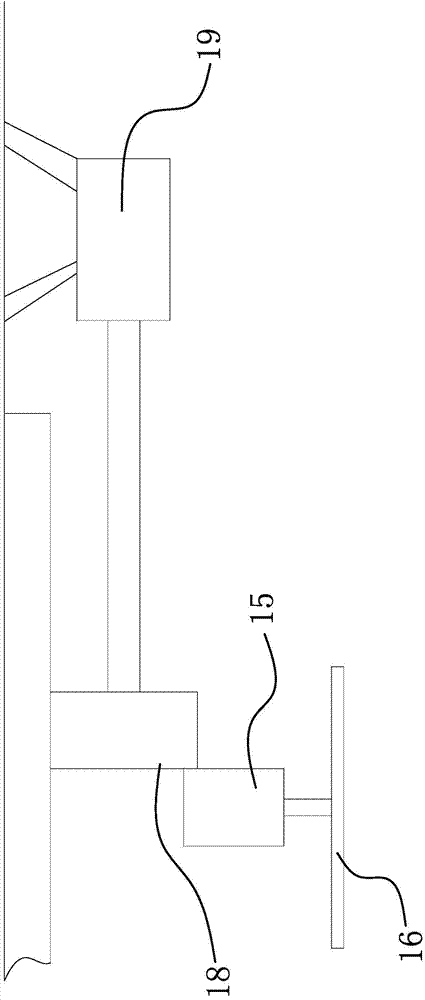

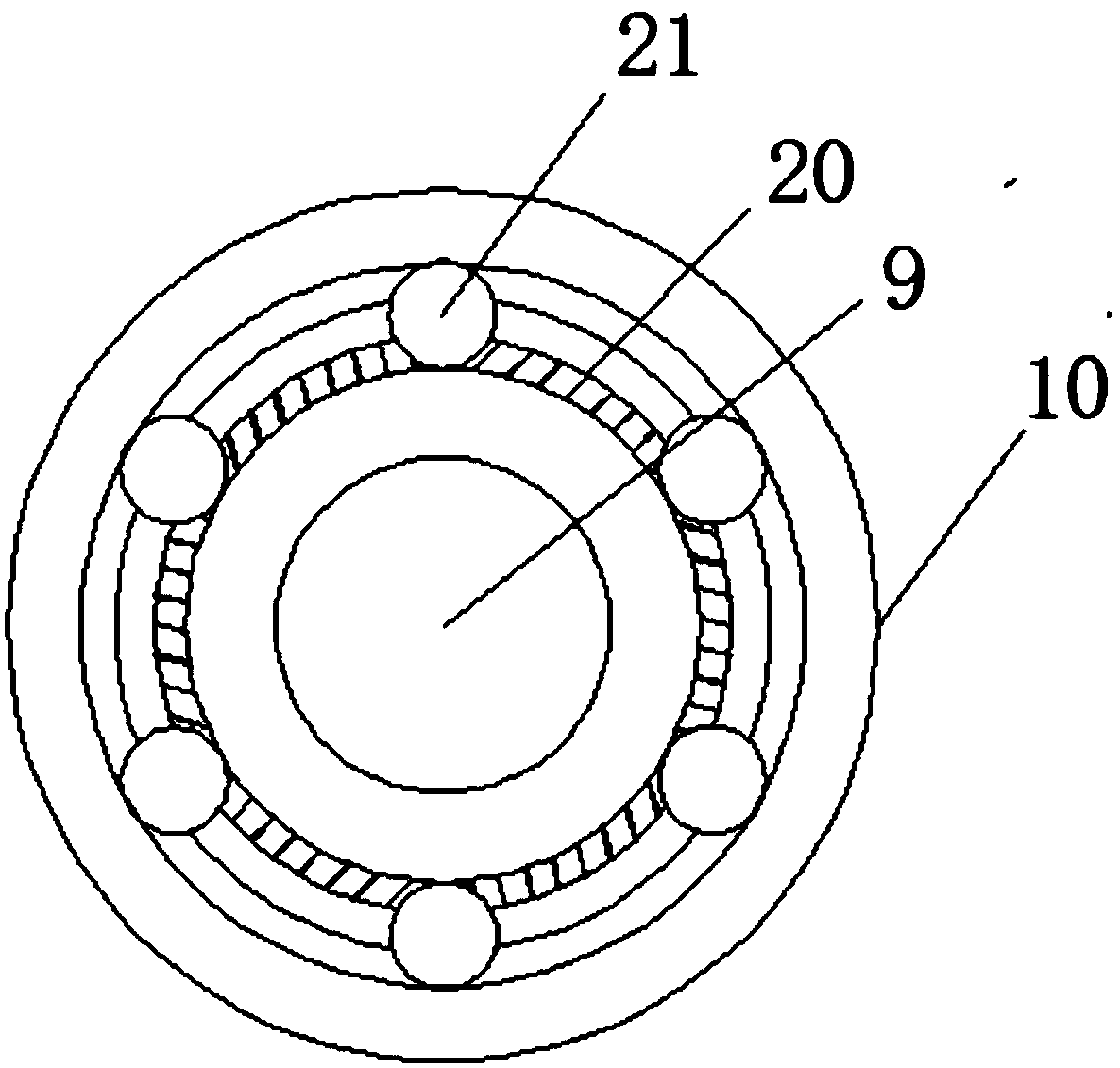

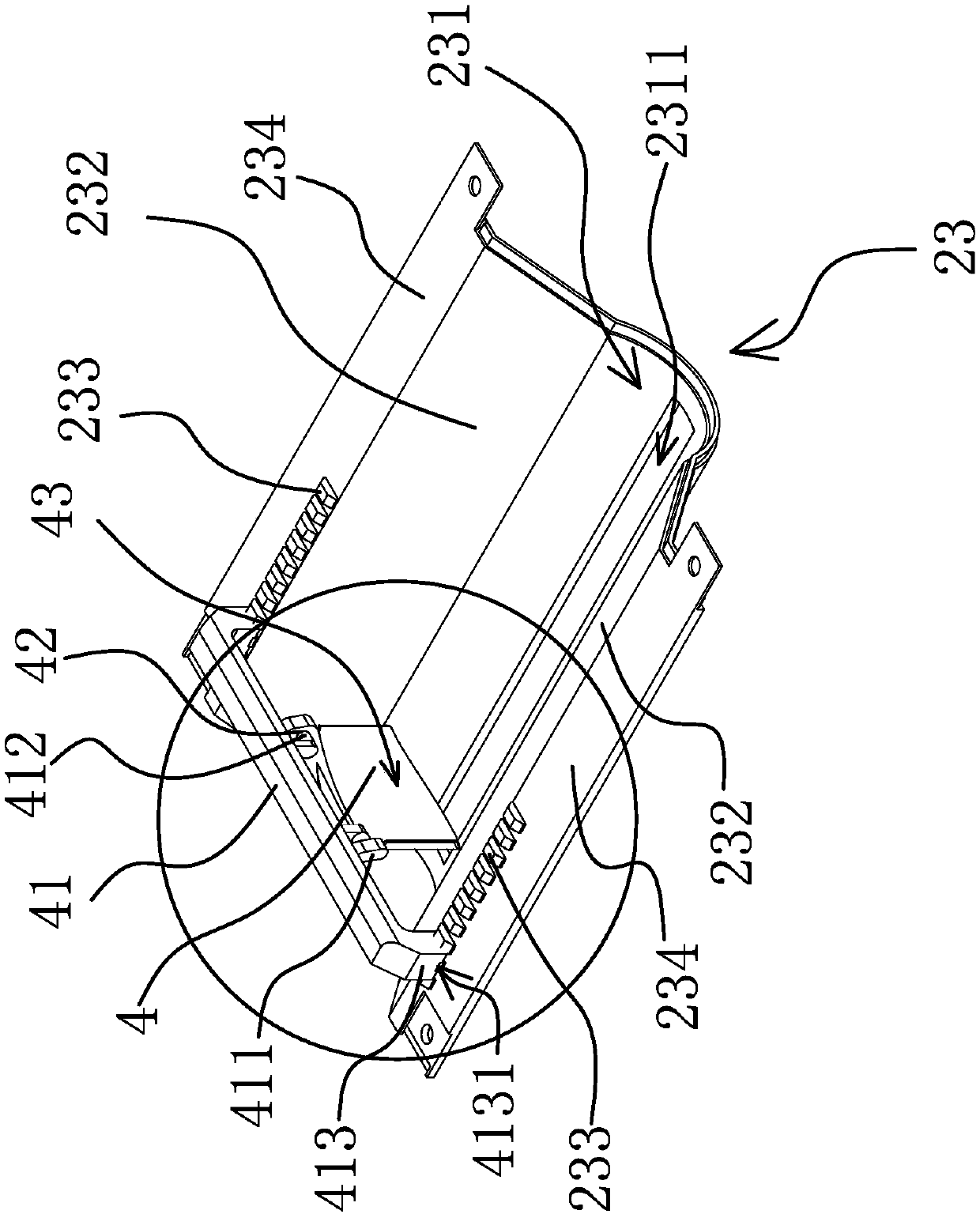

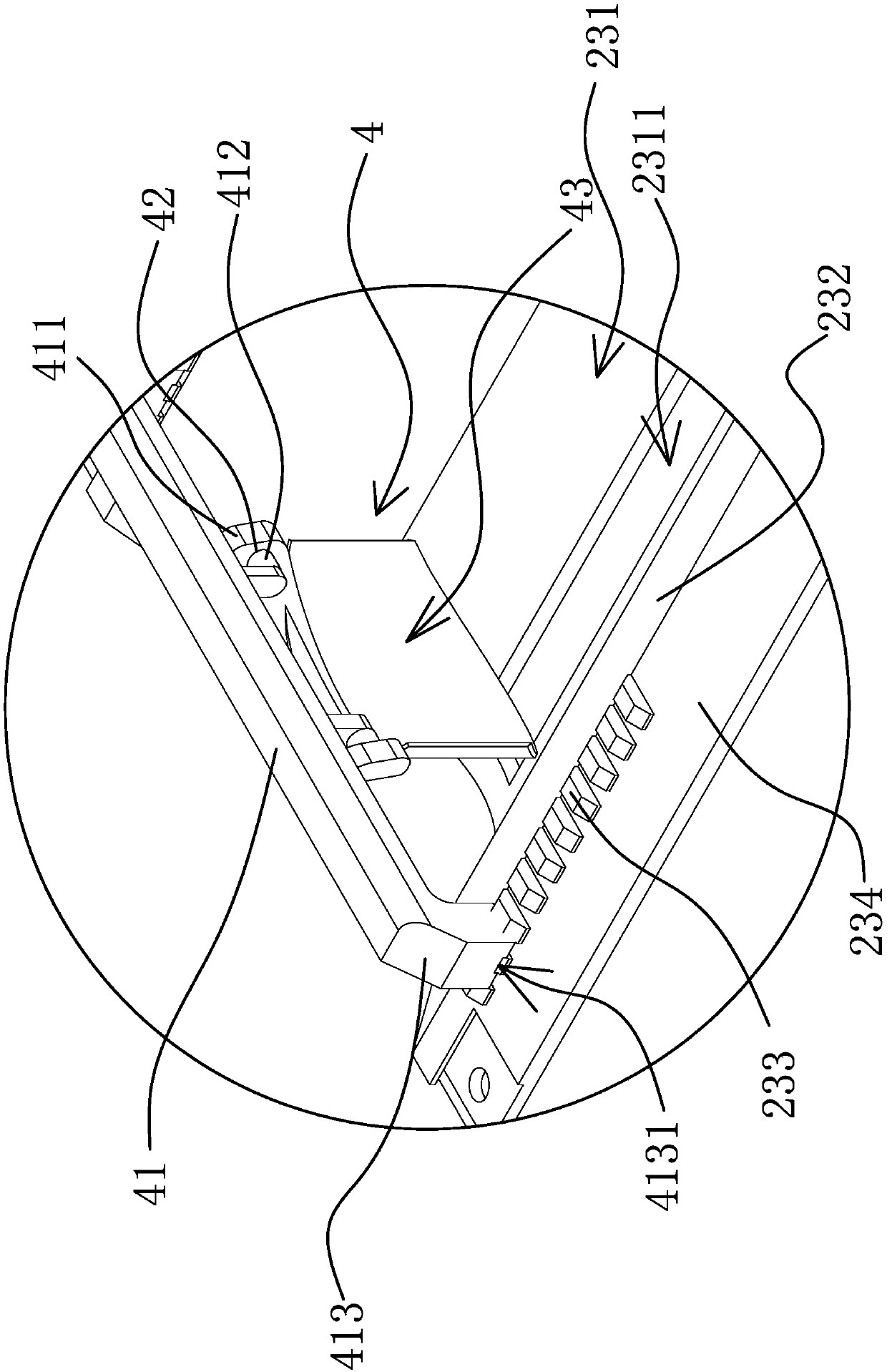

The invention discloses a driving force receiving assembly of a photosensitive drum. The driving force receiving assembly of the photosensitive drum is used for receiving rotating force of a driving head of an image forming device and transmitting the rotating force to the photosensitive drum through a photosensitive drum gear arranged at the end part of the photosensitive drum to drive the photosensitive drum to rotate. The driving force receiving assembly comprises a driving force receiving part, a driving force transmission part and a gear matching part, wherein the driving force receiving part is engaged with an engaging part of the driving head of the image forming device; the driving force transmission part is connected with the driving force receiving part and the gear matching part; the gear matching part is matched with the photosensitive drum gear; and the driving force receiving assembly is engaged with the driving head in a manner of forming a fixed angle by a vertical intersection line of the center point of the engaging part and the rotating center line of the driving head and the vertical intersection line of a stress point of the driving force receiving part and the rotating center line of the driving force transmission part. By the driving force receiving assembly, driving force transmission can be stably and reliably achieved; and the condition that a process cartridge is smoothly put in / taken out can be ensured.

Owner:ZHUHAI UN TERN IMAGING PROD

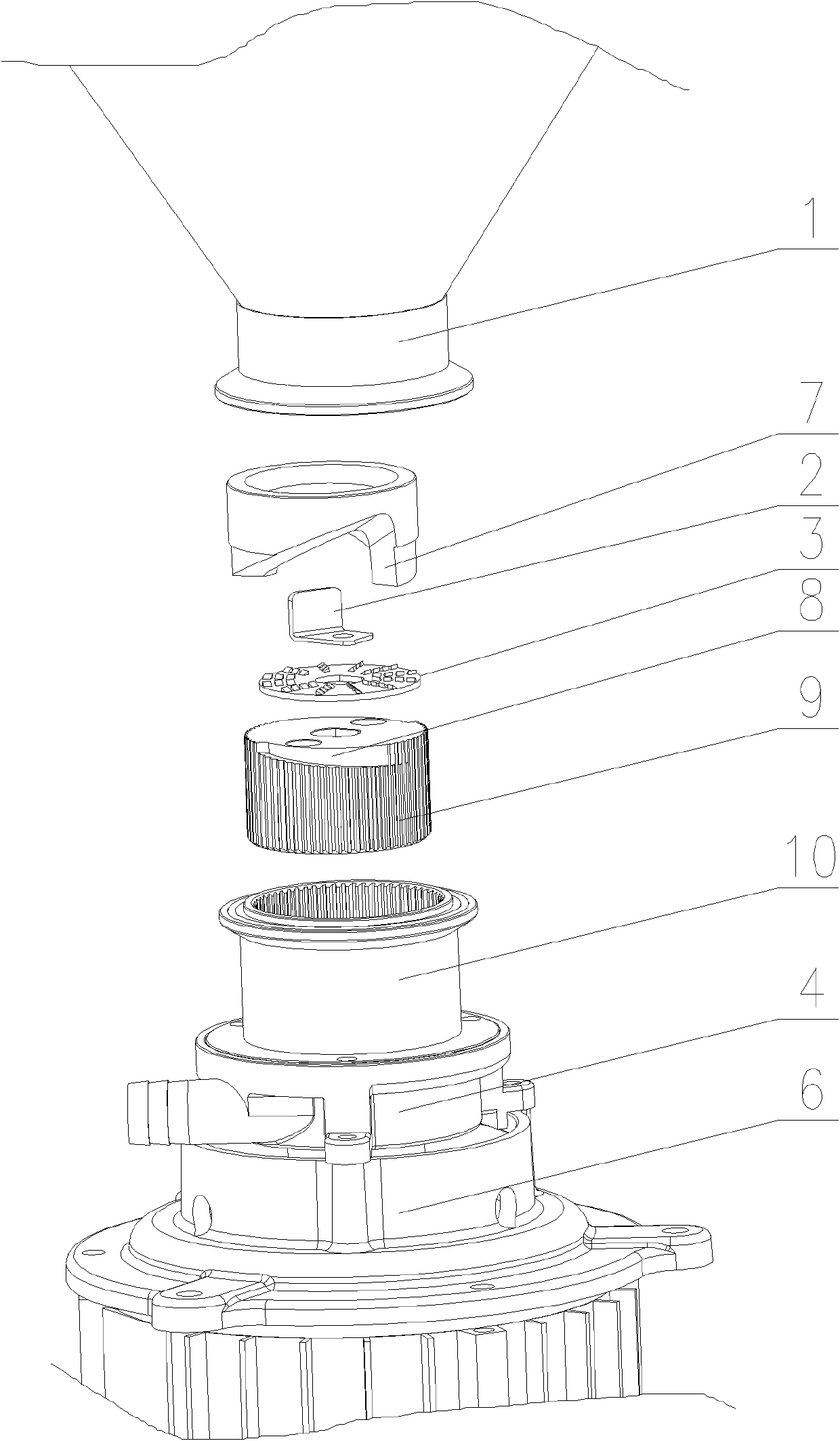

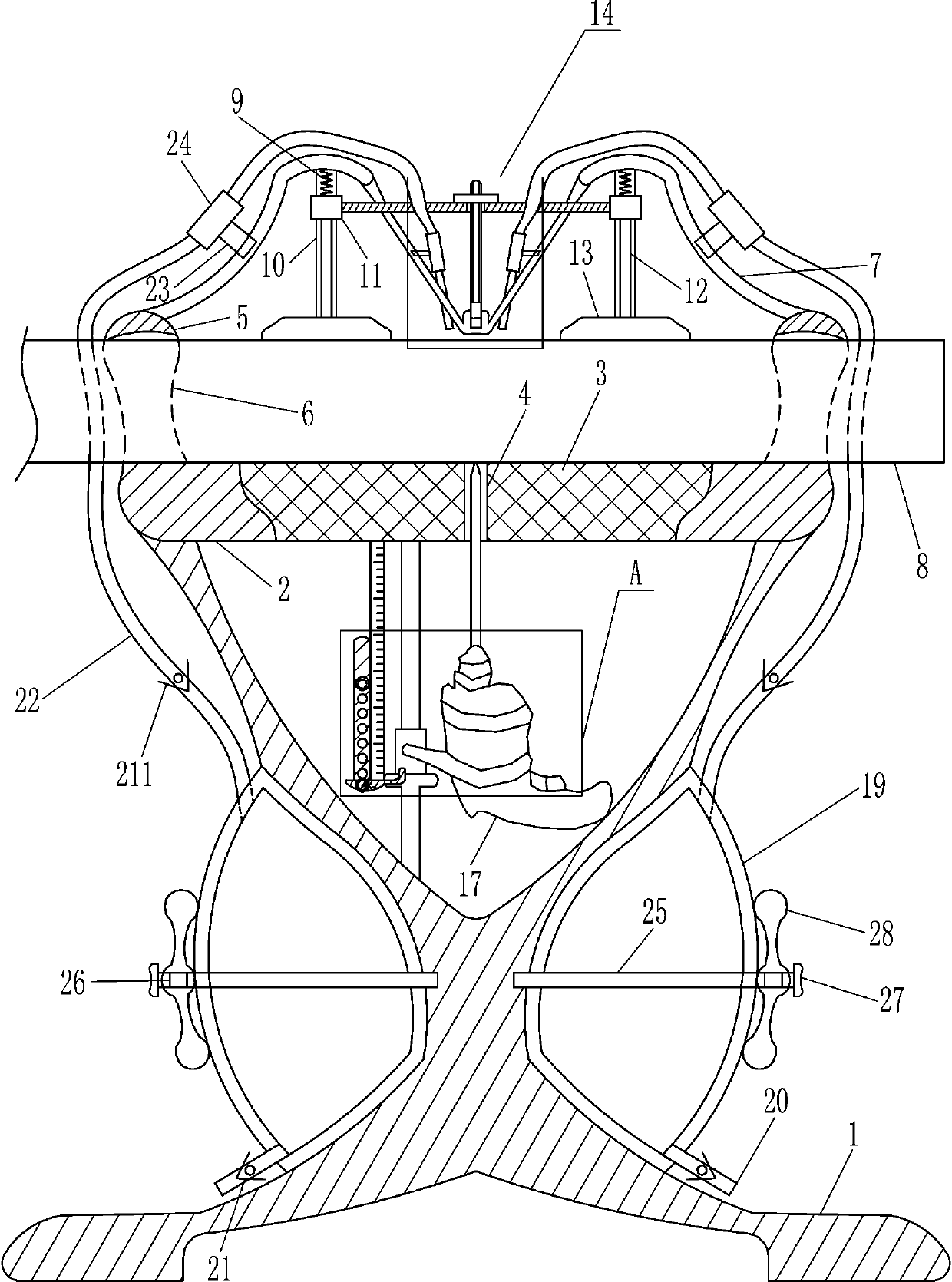

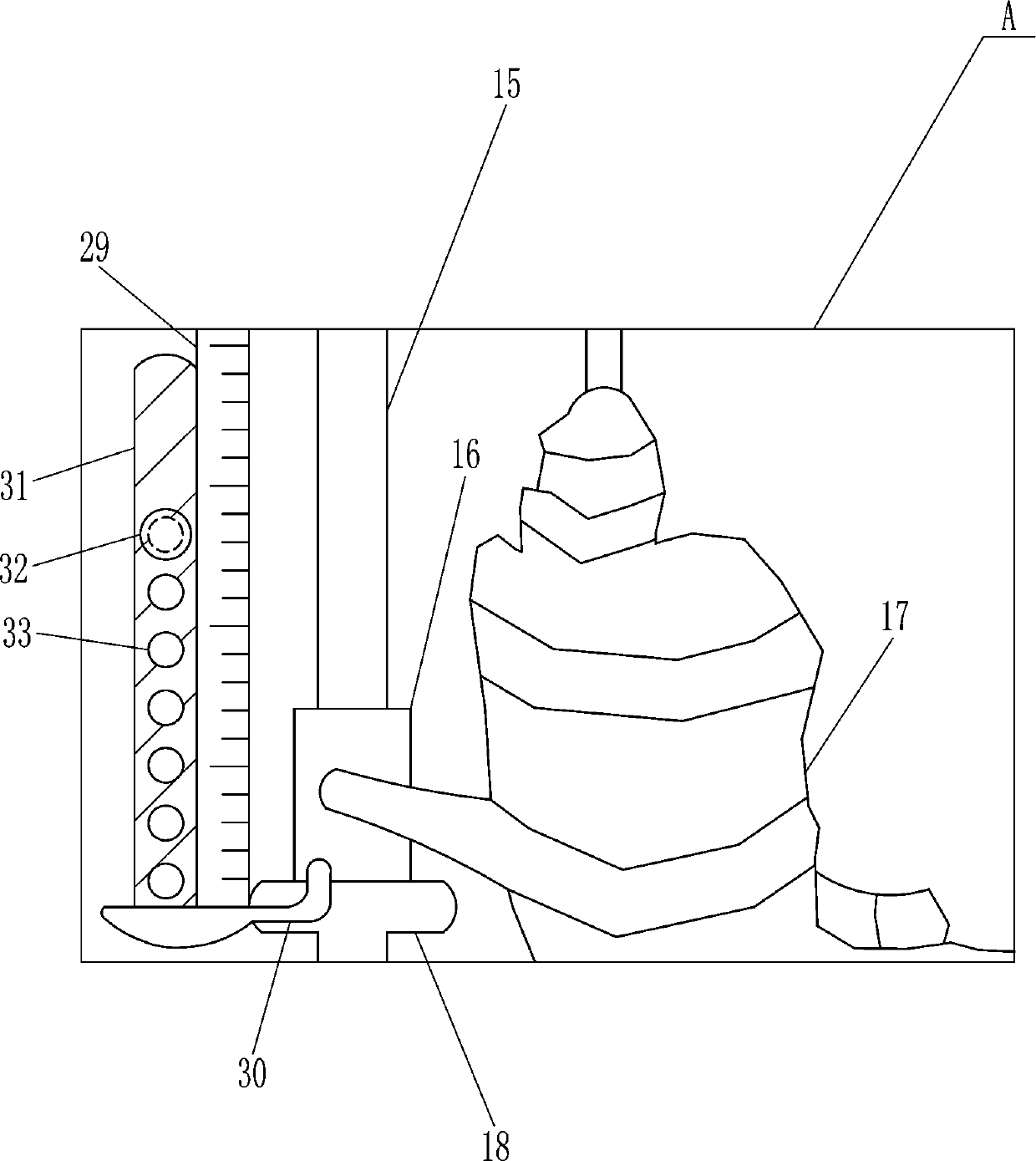

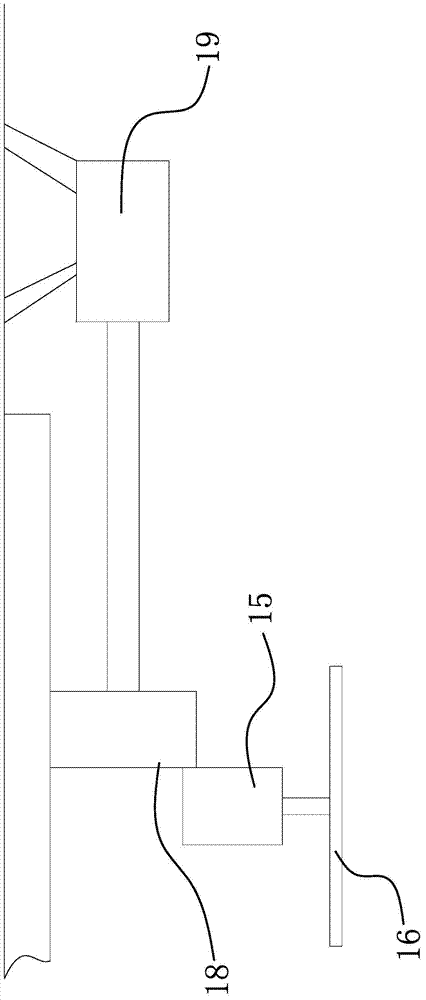

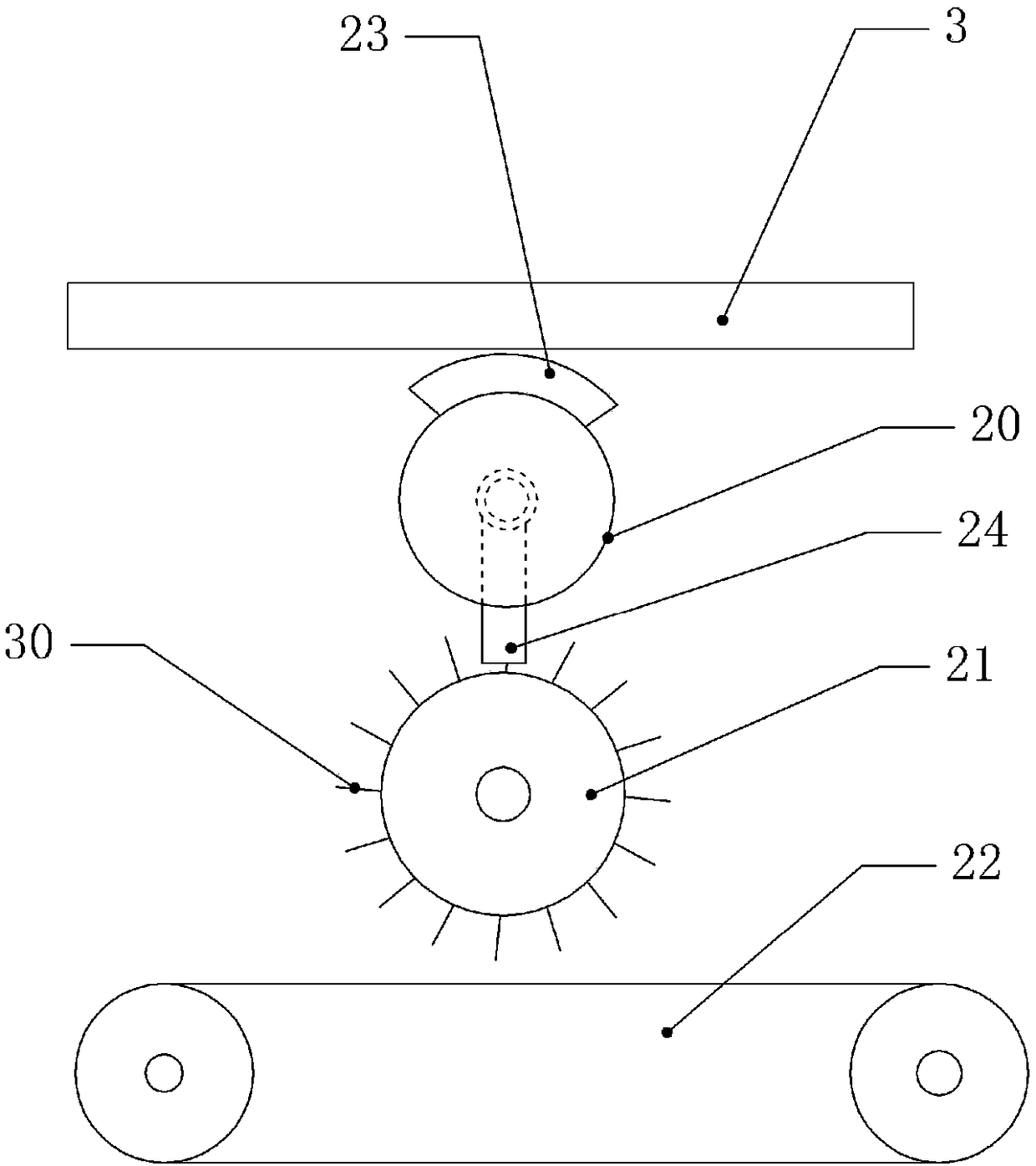

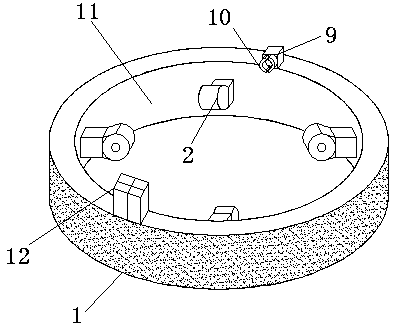

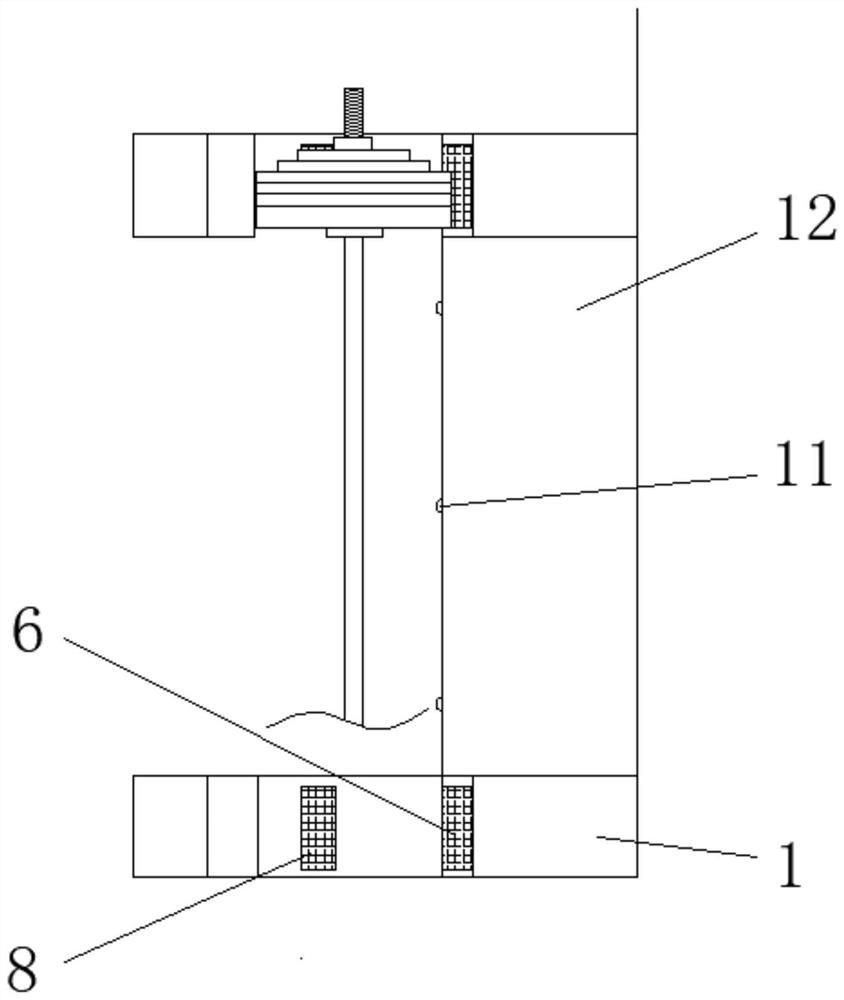

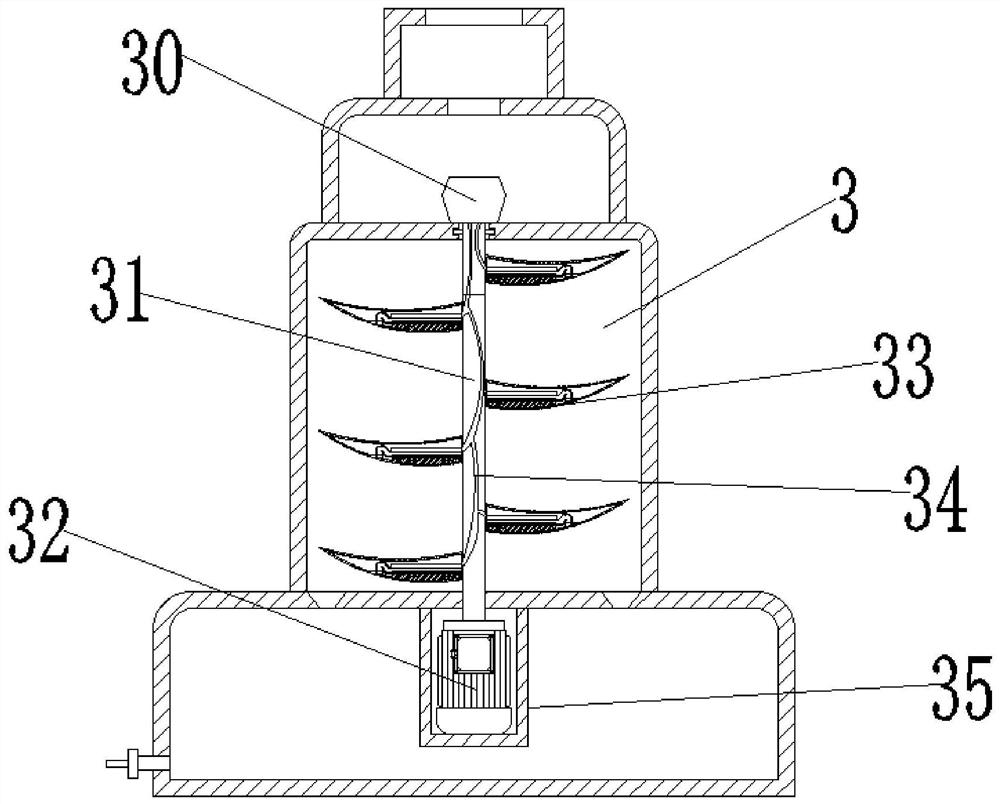

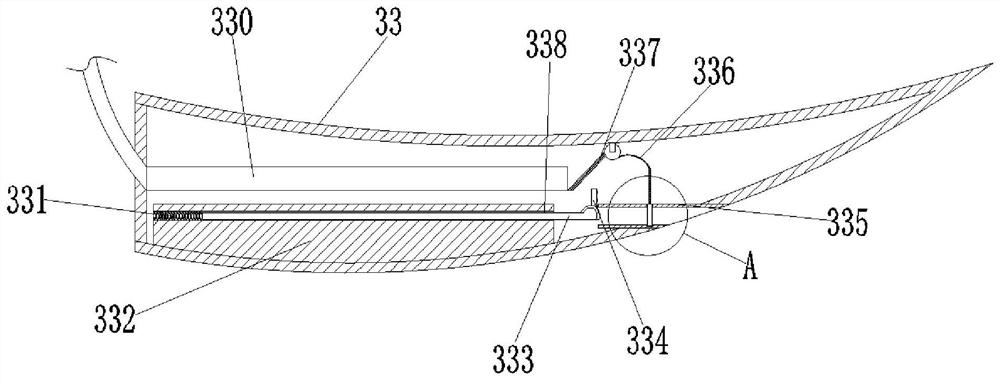

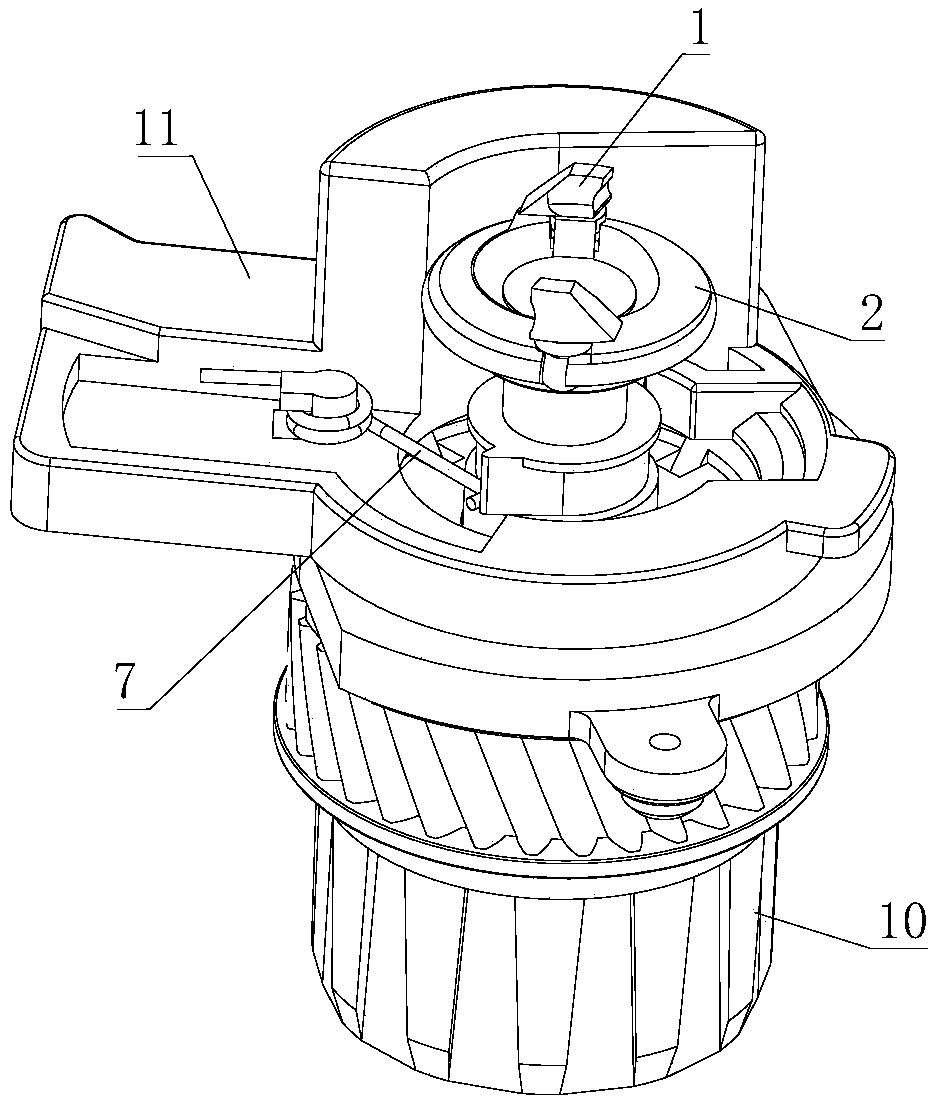

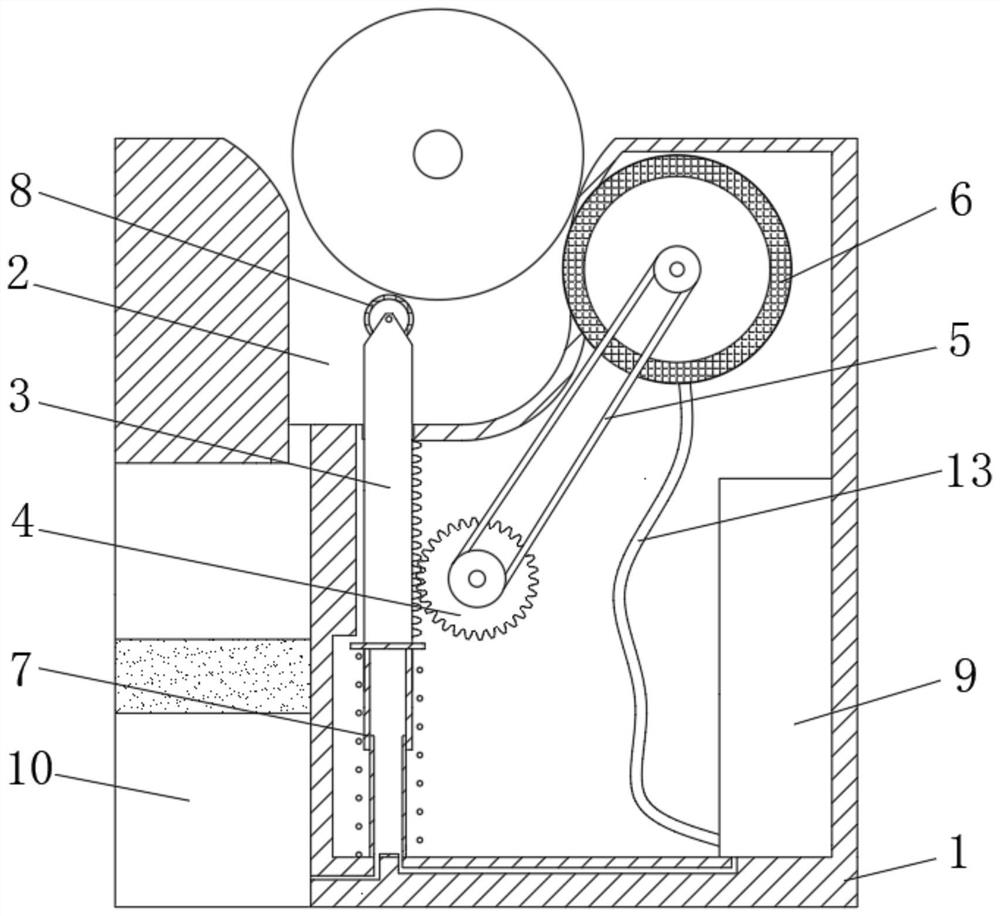

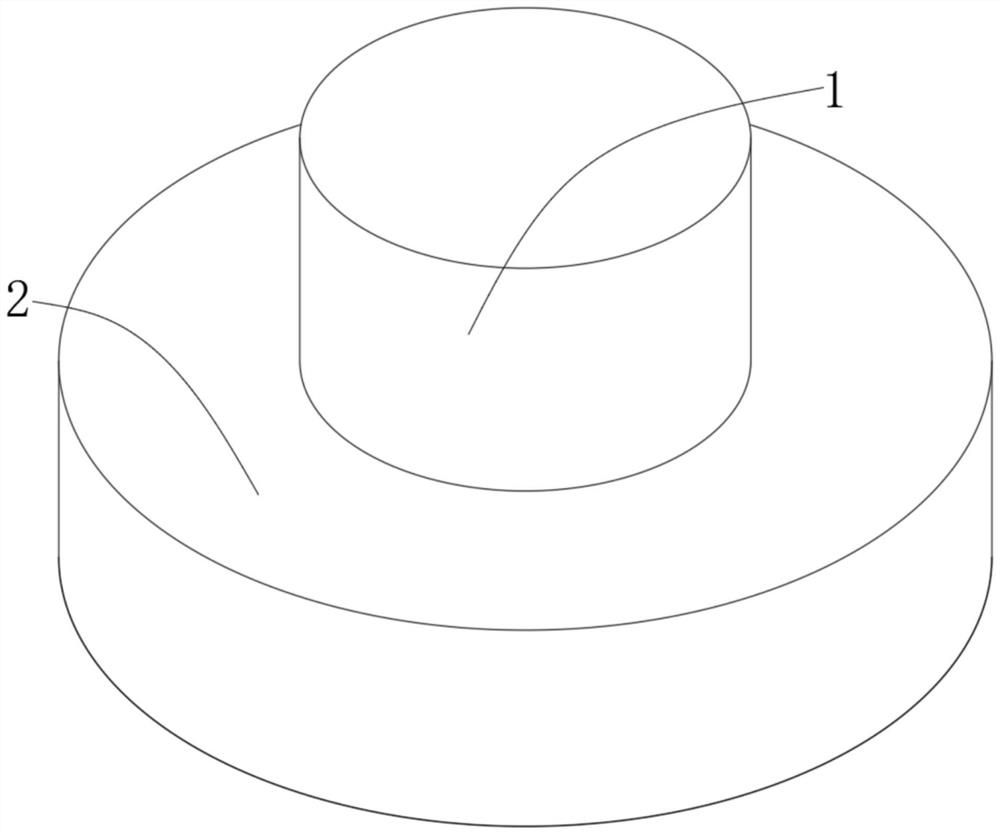

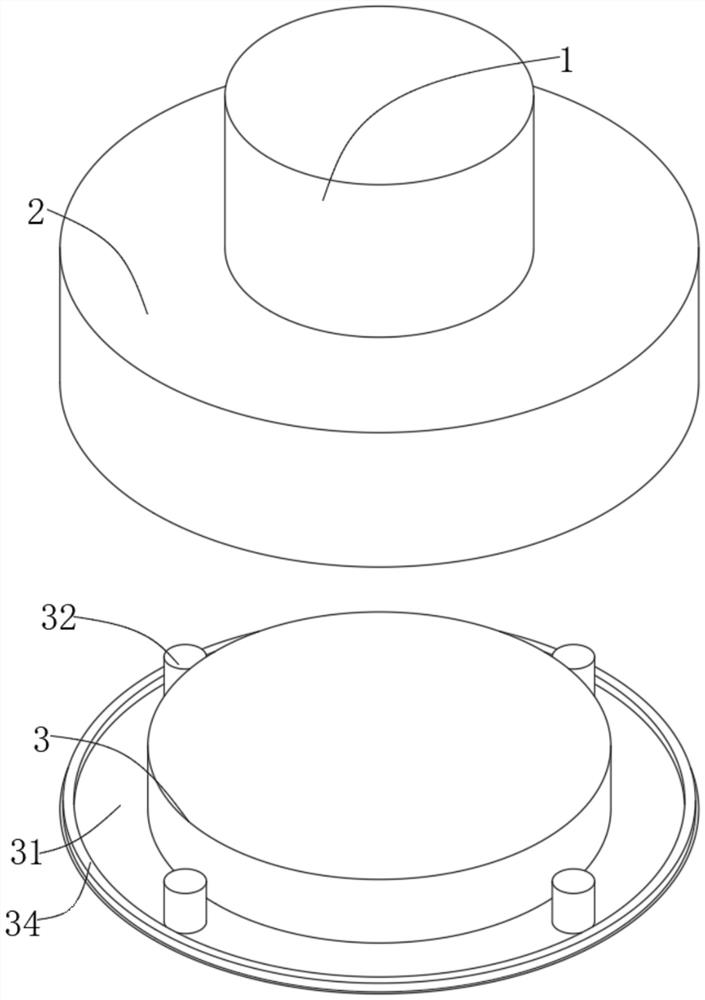

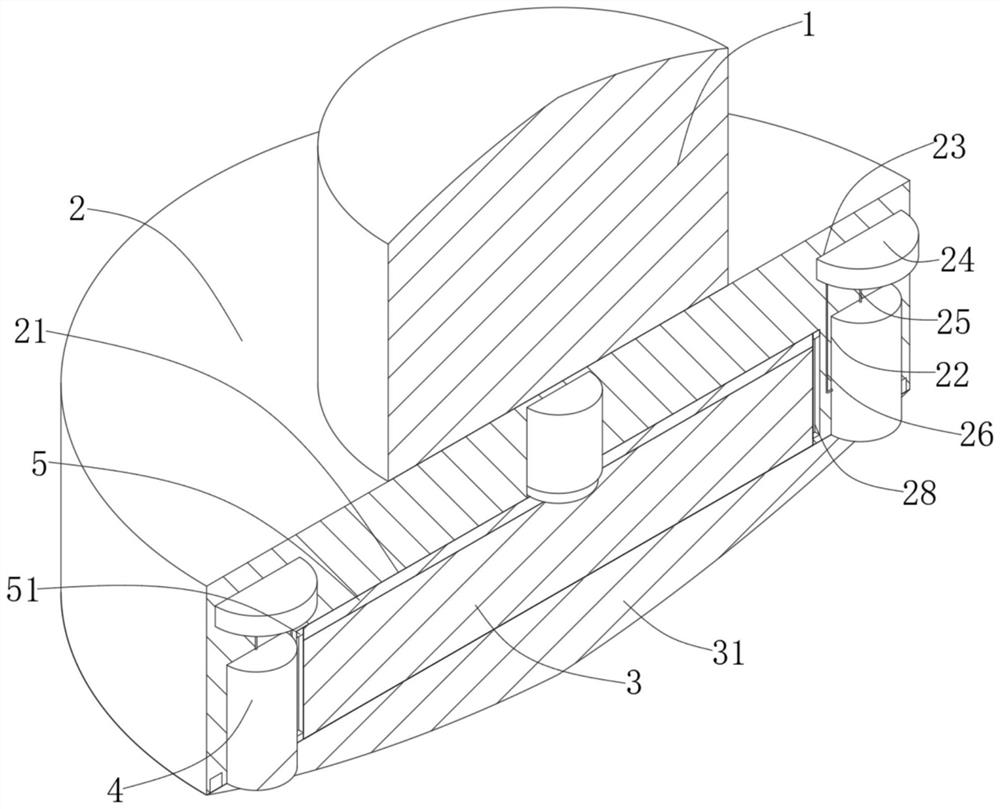

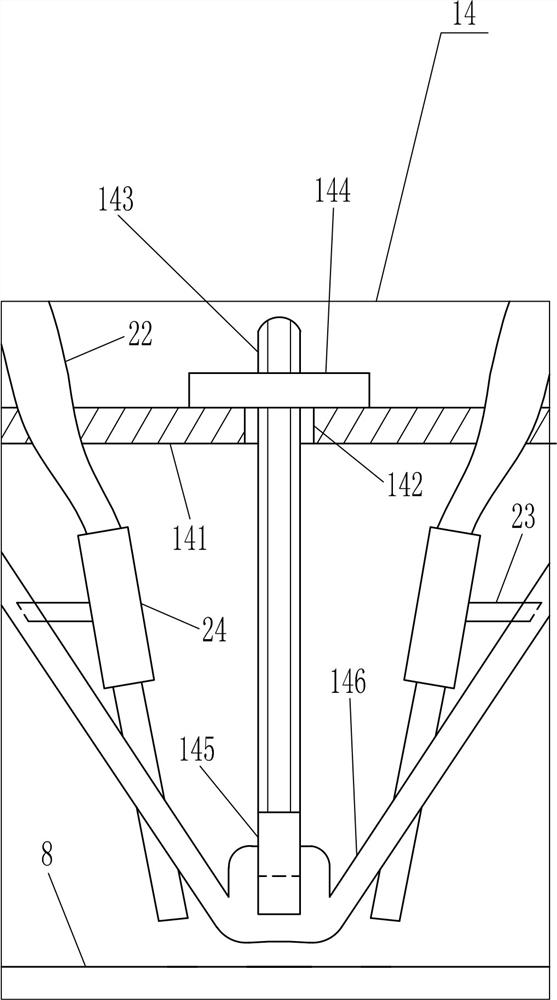

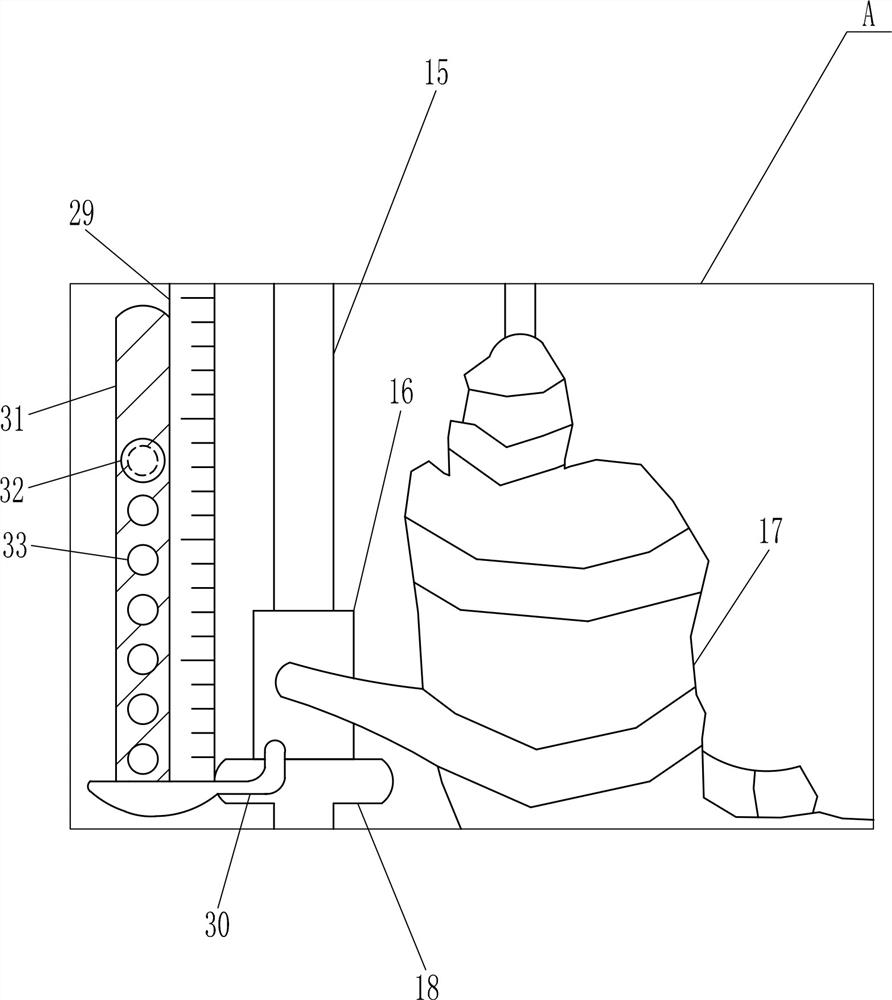

A crushing grinder

InactiveCN102553699AWon't squeezeSolve technical problems that are easy to get stuckGrain treatmentsEngineeringRing effect

The invention relates to a crushing grinder, which comprises a motor, a hopper and a crushing grinding part. The crushing grinding part comprises a coarse cracking part and a smooth grinding part. The smooth grinding part consists of a dynamic grinding head and a static grinding head. The coarse cracking part comprises a cutter head with a blade provided at the upper surface of the dynamic grinding head upper end and a pressing ring arranged between a hopper and the cutter head. The crushed objects are coarse cracked by their own gravity and having effect with the blade under the pressing ring effect, even hard crushed objects can be also coarse cracked by having effect with the blade for multitime and the seized phenomenon can not appear.

Owner:卢志丽

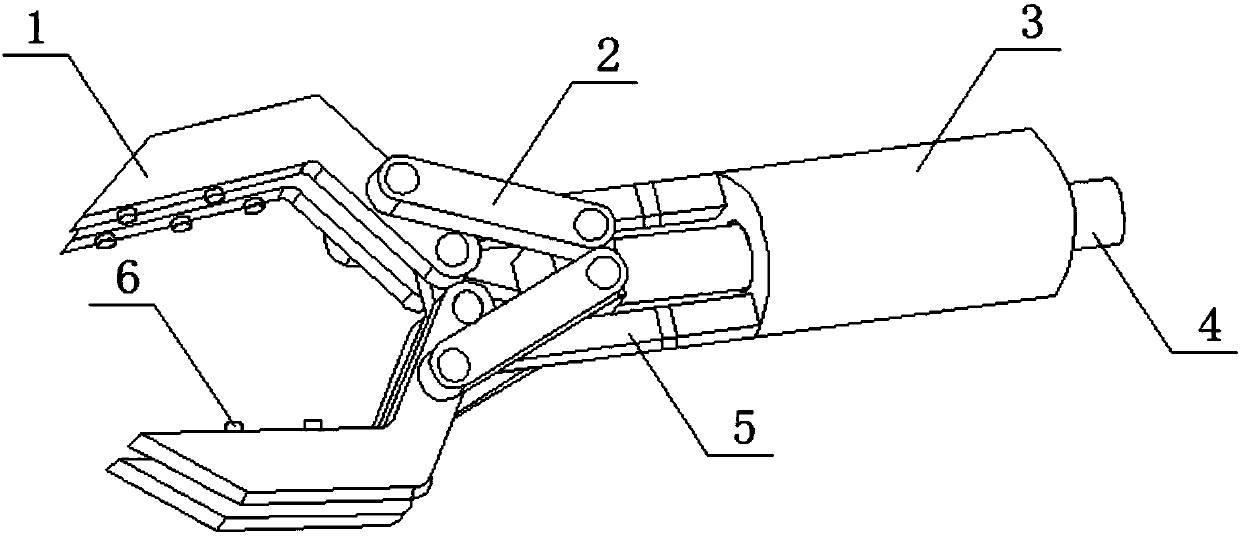

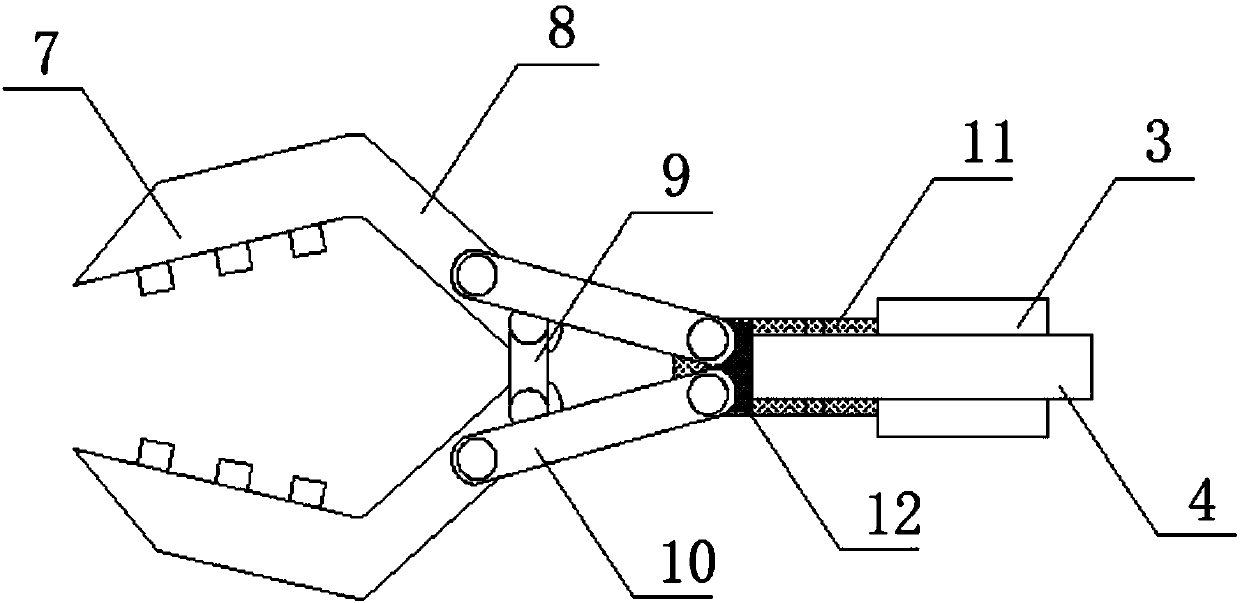

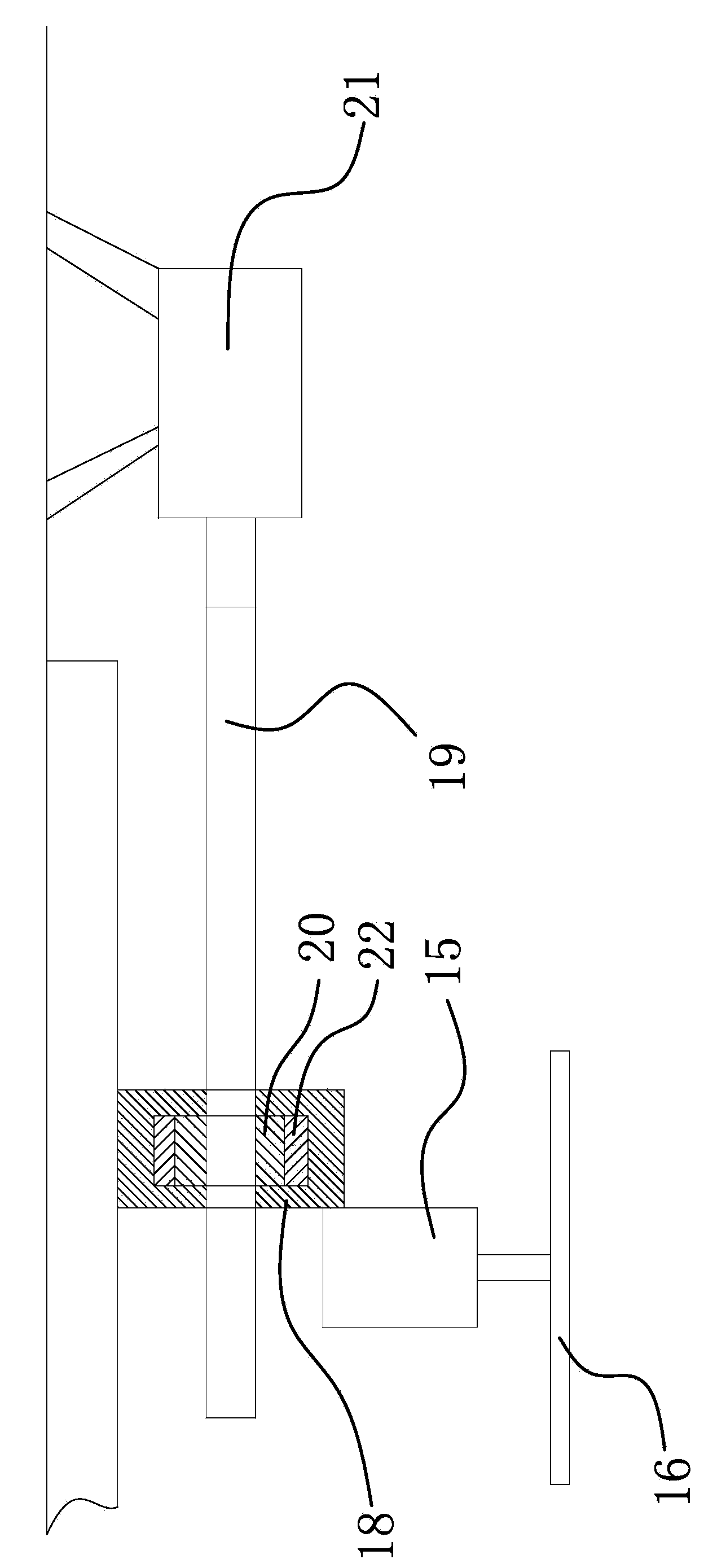

Mechanical arm used for hardware product production

The invention discloses a manipulator used in the production of hardware products, comprising a gripper, a transmission mechanism, a power supply device, a transmission rod, a limit mechanism, an electromagnet, fingertips, knuckles, connecting strips, stretching strips, limiting rails, sliding blocks, conductive posts, containment tubes, relay boxes and insulating posts. The beneficial effect of the present invention is: the top and bottom of the connecting bar are connected with grippers, and the several electromagnets arranged on one side of the two grippers are mutually misaligned, and the electromagnets can assist in attracting and fixing hardware parts in all directions; Several electromagnets on one side are electrically connected to the relay box, and several electromagnets are connected in parallel with each other, each electromagnet can work independently, even if one electromagnet is damaged, it will not affect the normal operation of the device; two When the distance between the fingertips of the gripper is the smallest, the conductive column is located inside the relay box, and the electromagnet starts to work after the gripper grabs the part, so as to avoid attracting unnecessary parts.

Owner:惠州市利尔康精密五金有限公司

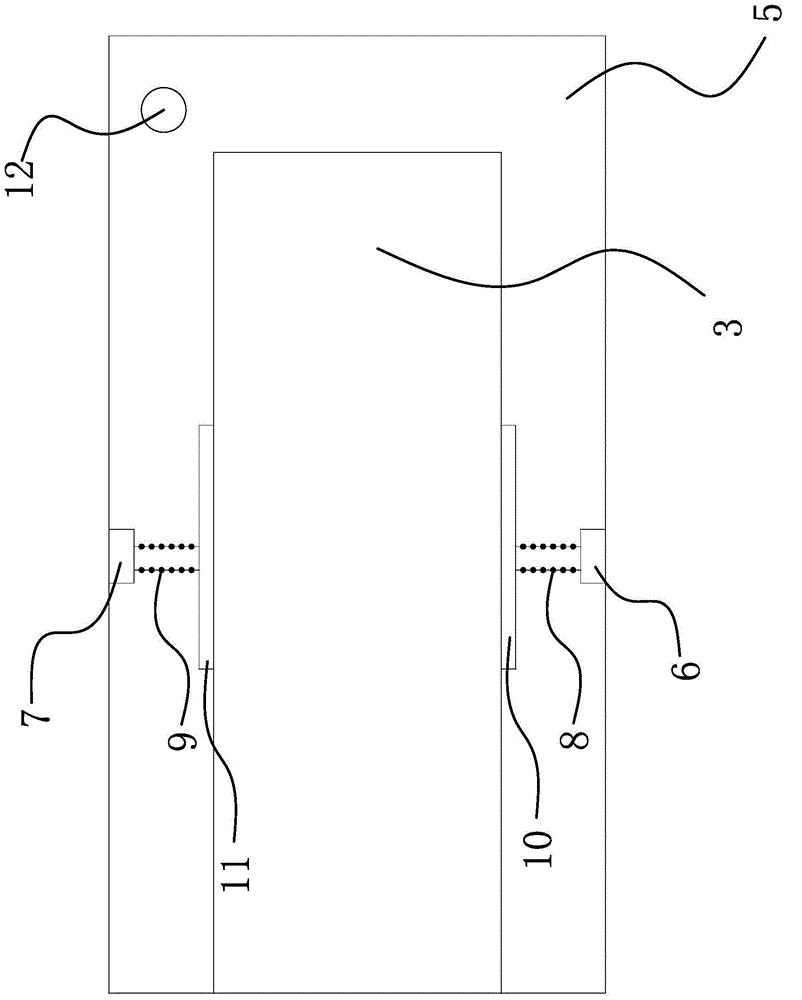

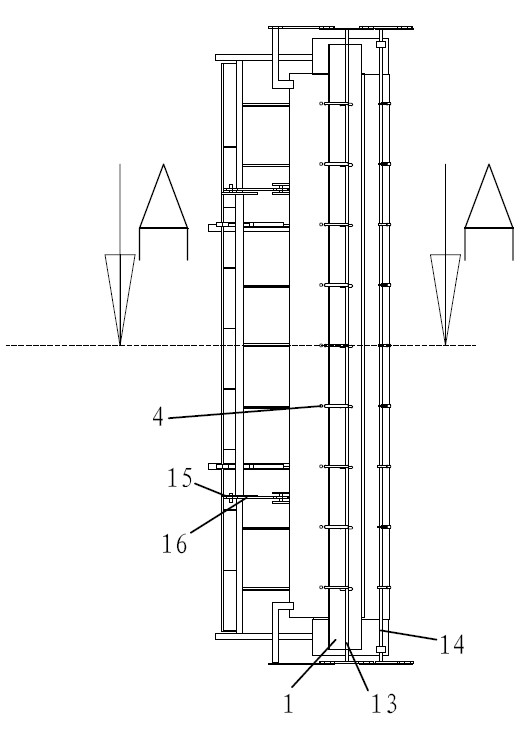

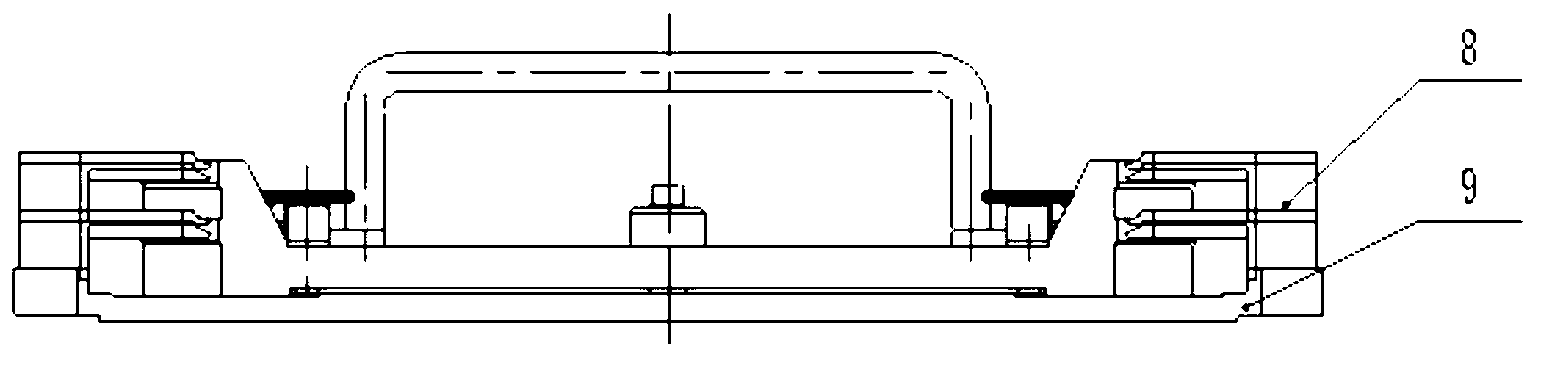

Busbar connector device of subway tunnel

The invention provides a busbar connector device of a subway tunnel. The device solves the technical problem that a connecting section of an existing busbar connector device of the subway tunnel can not fall down smoothly. The device comprises a left busbar section, a right busbar section and a connecting section detachably arranged between the left busbar section and the right busbar section and used for connection, a flood gate is hinged to the inner wall of a tunnel body, and the connecting section is located on the closing track of the flood gate. The device has the advantages of being capable of saving time, higher in efficiency, high in stability, safer in use and the like.

Owner:ZHEJIANG OCEAN UNIV

Subway tunnel of improved structure

The invention provides a subway tunnel which solves the technical problems that a submerging prevention door in an existing subway tunnel can not be closed, and connecting sections can not fall smoothly. The subway tunnel comprises a tunnel body, a busbar structure used for supplying power for trains and a submerging prevention door capable of closing the tunnel. The tunnel body and the busbar structure are arranged in the tunnel body, the busbar structure comprises a busbar left section, a busbar right section, and a connecting section, wherein the connecting section is arranged between the busbar left section and the busbar right section and used for connection, the connecting section is detachably arranged between the busbar left section and the busbar right section, the submerging prevention door is hinged to the inner wall of the tunnel body, and the connecting section is located at the closing track of the submerging prevention door. The subway tunnel has the advantages that time is saved, efficiency is higher, stability is good, and using is safer.

Owner:中泰恒邦工程技术有限公司

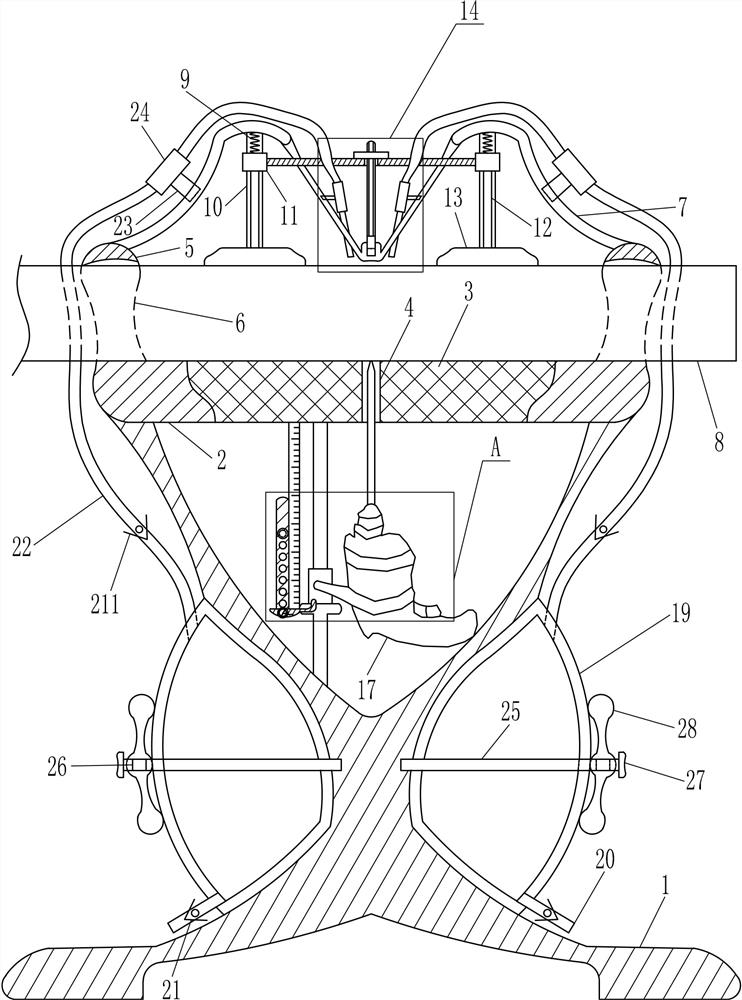

Wood block punching instrument for solid wood sofa machining

ActiveCN110434942AEasy to moveNo getting stuckOperator-supported drilling machinesBark-zones/chip/dust/waste removalSolid woodPunching

The invention relates to a punching instrument, in particular to a wood block punching instrument for solid wood sofa machining. The invention provides the wood block punching instrument for solid wood sofa machining, and the instrument has the characteristics that a wood block can be fixed more stably, the discomfort of the body of people can be reduced, and wood chips can be blown away. According to the technical scheme, the wood block punching instrument for solid wood sofa machining comprises a mounting frame, a placement block and the like, wherein the placement block is arranged at the top of the mounting frame, and a filter screen is arranged in the middle of the placement block. According to the instrument, a pressing block is arranged so that a wood block body can be pressed during drilling by people, and the increased burden, caused by the fact that people need to manually control the wood block body, on people is avoided; a sliding sleeve and a guide rail are arranged so that an electric drill can be vertically lifted, and a hole drilled by the electric drill is straight, so that the situation that the assembly is affected by an inclined drilled hole is avoided; and an air bag is arranged so that the wood chips on the surface of the wood block body can be blown away, and the wood block body can be conveniently moved and cannot be jammed.

Owner:深圳市艾丽特家具有限公司

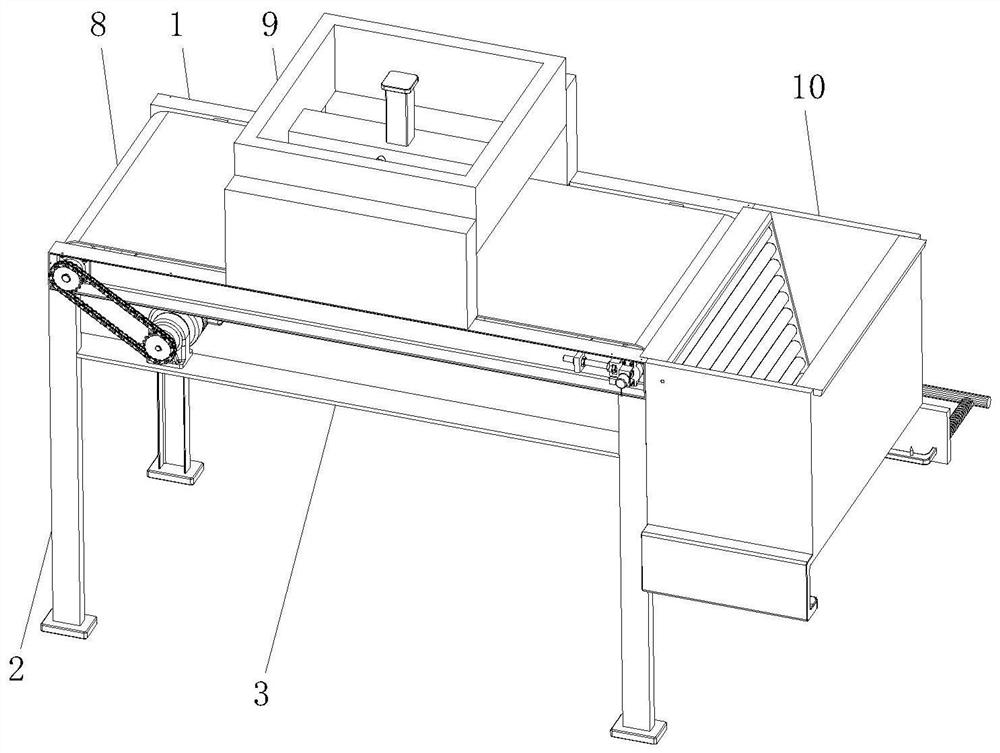

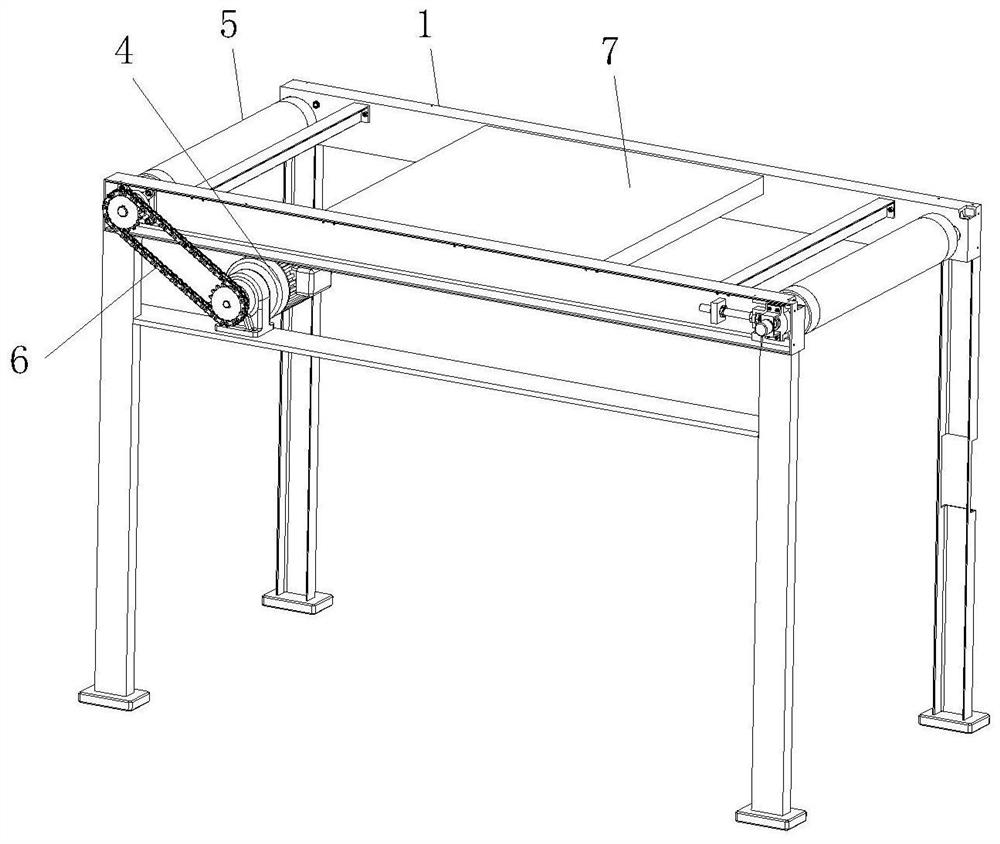

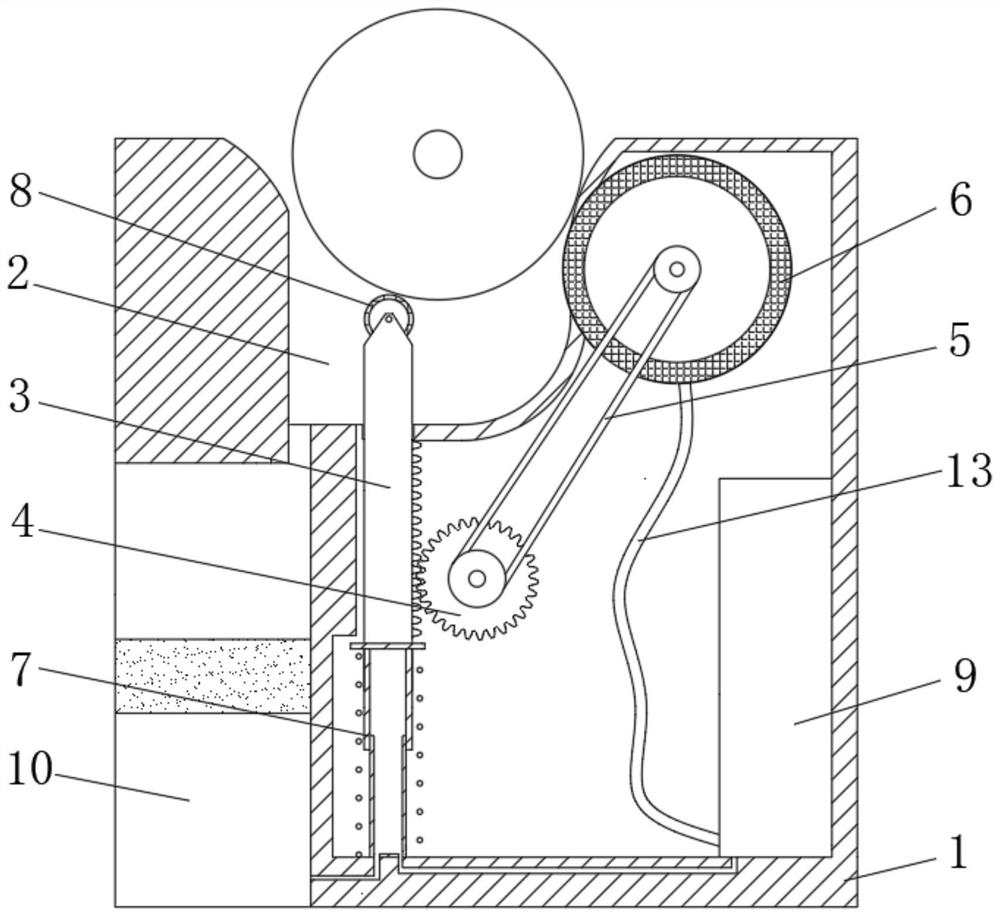

Textile compressor capable of packaging

InactiveCN112340153AAchieve the purpose of compressionImprove compression efficiencyPackagingElectric machineryDrive motor

The invention relates to the technical field of textile compressors, in particular to a textile compressor capable of packaging. The textile compressor comprises a base conveying body, wherein supporting legs are arranged at the lower end of the conveying body; a mounting plate is fixedly arranged at the inner sides of the supporting legs; a driving motor is fixedly arranged at the upper end of the mounting plate; a rotary drum is arranged at the inner side of the conveying body; a transmission mechanism is arranged between the driving motor and the rotary drum; a supporting plate is fixedly arranged at the side, close to the rotary drum, of the inner side of the conveying body; a conveyor belt is arranged at the outer side of the rotary drum and the outer side of the supporting plate; a compression mechanism is arranged over the portion, close to the supporting plate, of the upper end of the conveying body; a discharging frame is arranged at one end of the conveying body; a material guiding mechanism is arranged in the discharging frame; and a supporting framework is arranged at the lower end of the discharging frame. According to the textile compressor capable of packaging, the textile compression efficiency can be improved, a packing bag does not need to be opened manually in the textile packaging process, and the textile compressor is practical.

Owner:诸暨市惠联精密机械制造有限公司

Busbar joint mechanism of subway tunnel

The invention provides a bus bar joint device of a subway tunnel. With the adoption of the bus bar joint device, the technical problem that a connecting segment of the existing bus bar joint device in the subway tunnel drops out and is unsmooth is solved. The bus bar joint device of the subway tunnel comprises a left bus bar segment, a right bus bar segment and the connecting segment arranged between the left bus bar segment and the right bus bar segment and used for connecting; the connecting segment can be detachably arranged between the left bus bar segment and the right bus bar segment; a flood gate is hinged on the inner wall of a tunnel body; and the connecting segment is on a gate closing track of the flood gate. The bus bar joint device of the subway tunnel has the advantages of saving time, and being high in efficiency, good in stability and safer in use and the like.

Owner:ZHEJIANG OCEAN UNIV

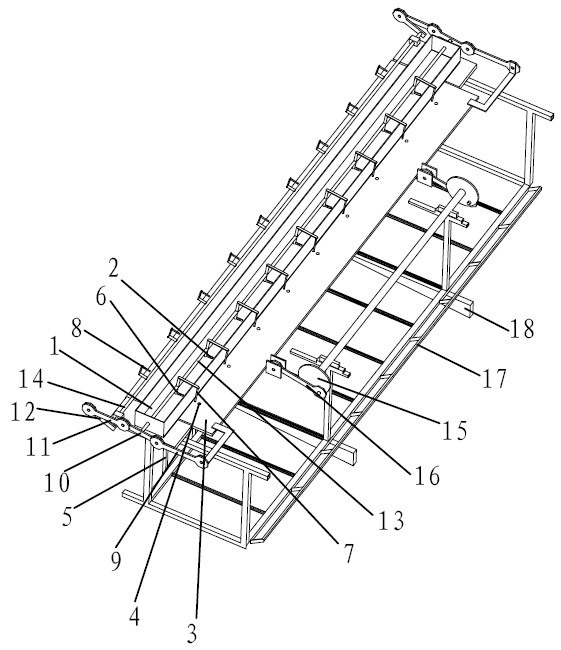

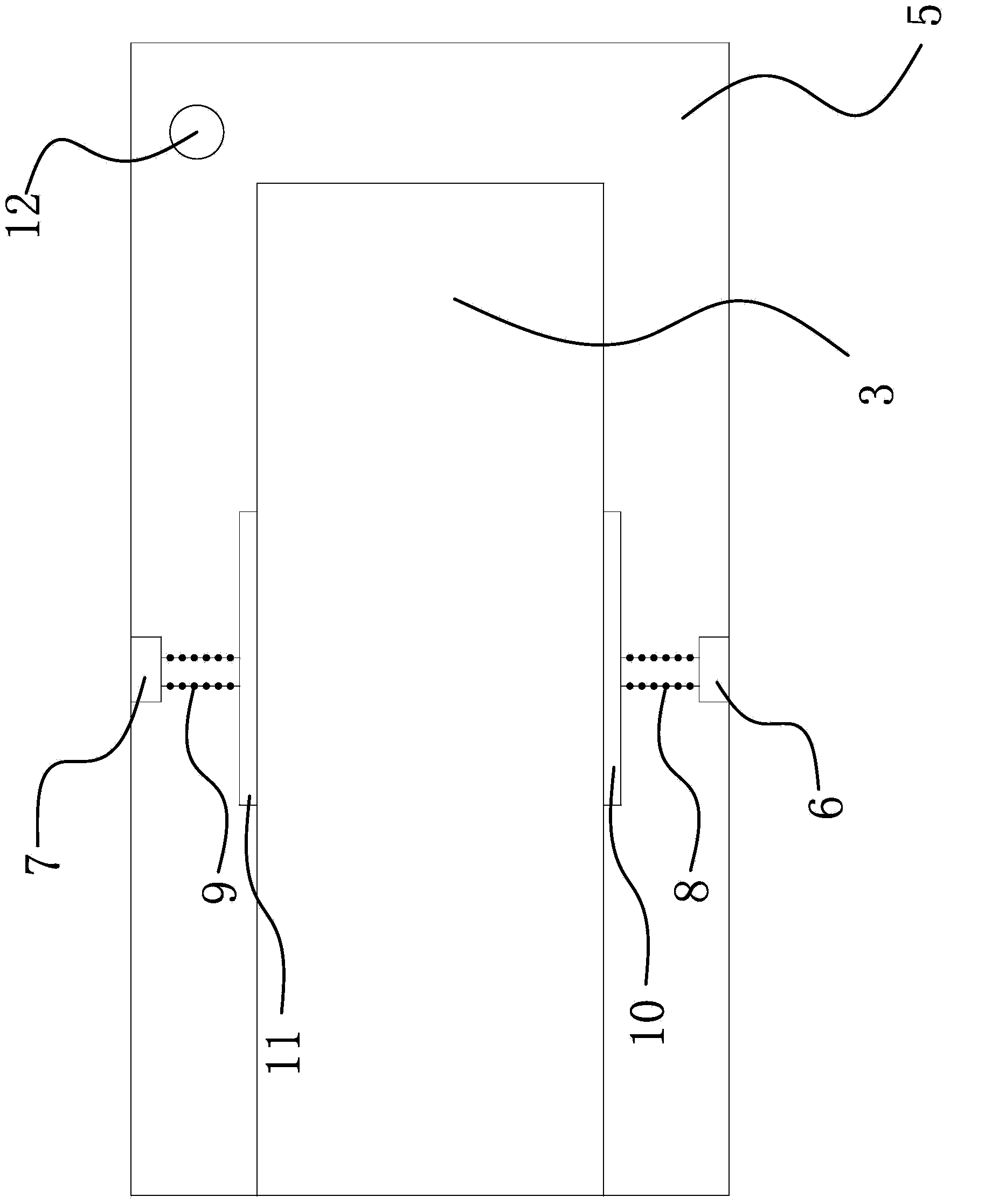

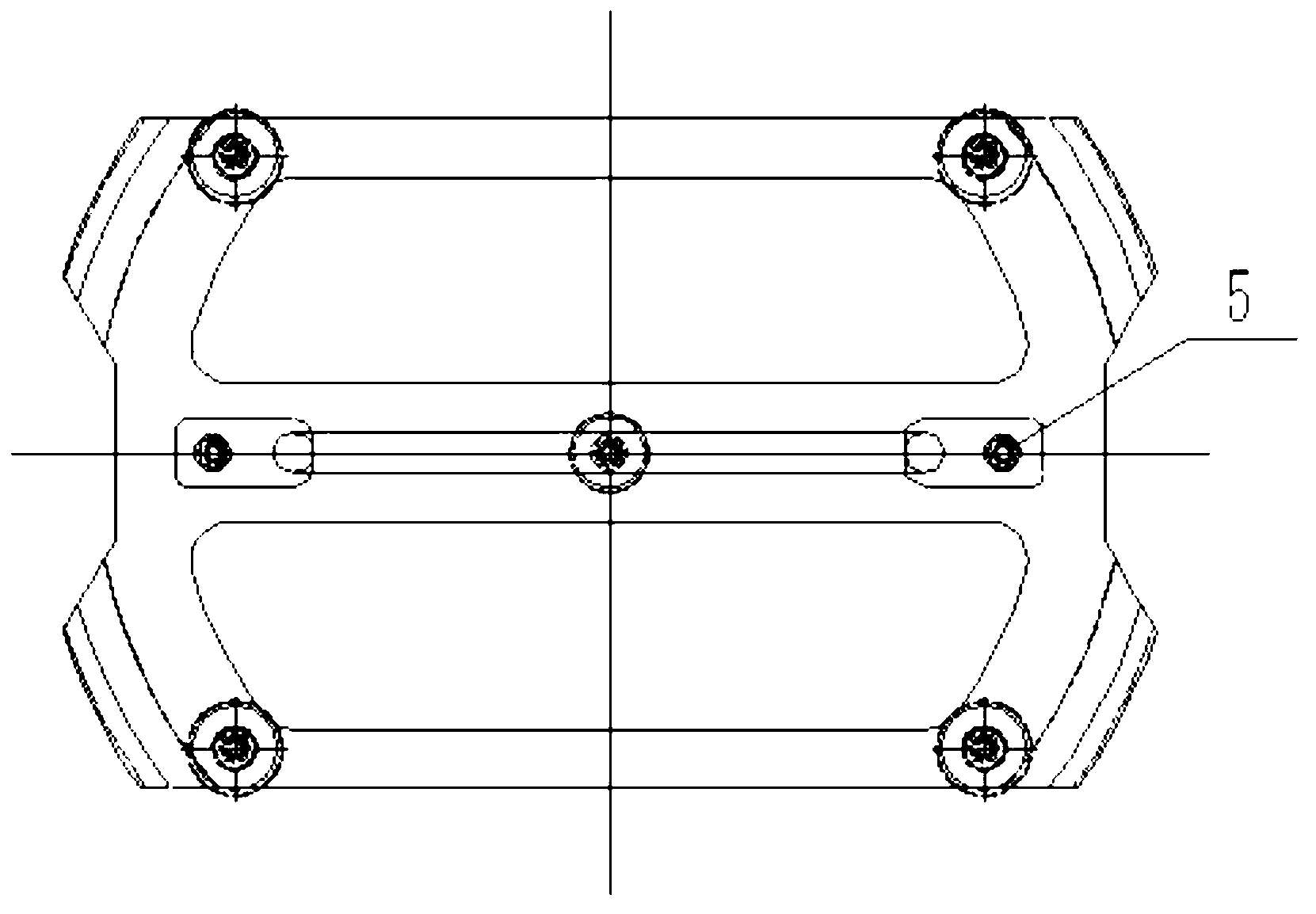

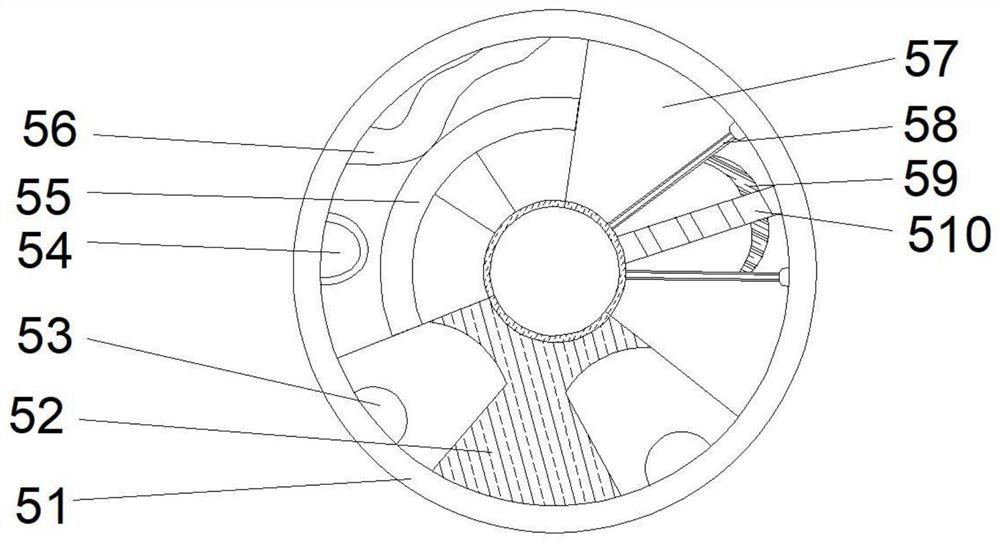

Pierced type material receiving device with machine tool material removal function

PendingCN108580931AFor automatic dischargeQuick and non-destructive removalAutomatic conveying/guiding stockMetal working apparatusMaterial removalMachine tool

The invention relates to the technical field of machine tools, and discloses a pierced type material receiving device with the machine tool material removal function. The pierced type material receiving device with the machine tool material removal function comprises a fixed rack, and further comprises a rotary material receiving disk and a fixed material receiving disk. The fixed material receiving disk is arranged in a downwards inclined manner and is connected to the fixed rack. The high end of the fixed material receiving disk is hinged to the rotary material receiving disk. A material outlet is formed in the low end of the fixed material receiving disk. The fixed rack is provided with a driving mechanism to drive the rotary material receiving disk to rotate. A guide plate is arrangedon one side of the rotary material receiving disk. The guide plate is arranged in a downwards inclined manner. A pressure sensor and a controller are arranged on the side, close to the guide plate, ofthe rotary material receiving disk. Multiple scrap discharge holes are formed in the rotary material receiving disk. Multiple scrap discharge holes are formed in the fixed material receiving disk. Afirst jet head and an air supply mechanism are installed on one side of the fixed material receiving disk. The pierced type material receiving device with the machine tool material removal function can discharge waste materials in circular grooves out in time.

Owner:CHONGQING HONGGANG CNC MACHINE TOOL

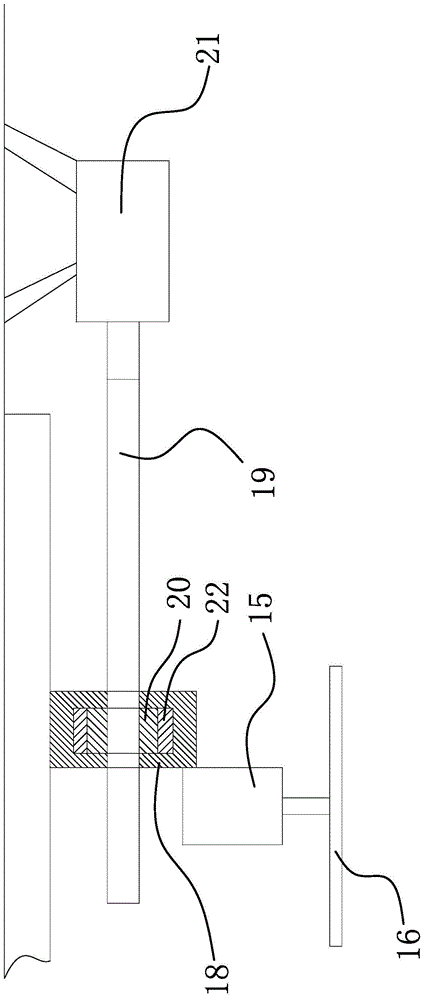

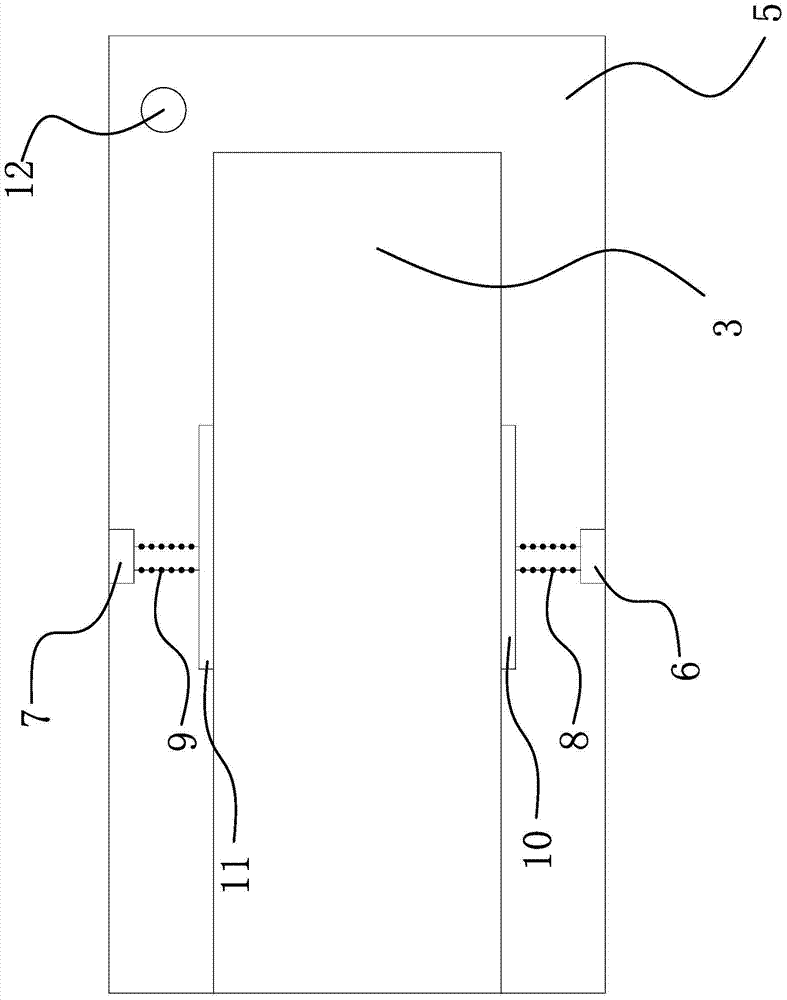

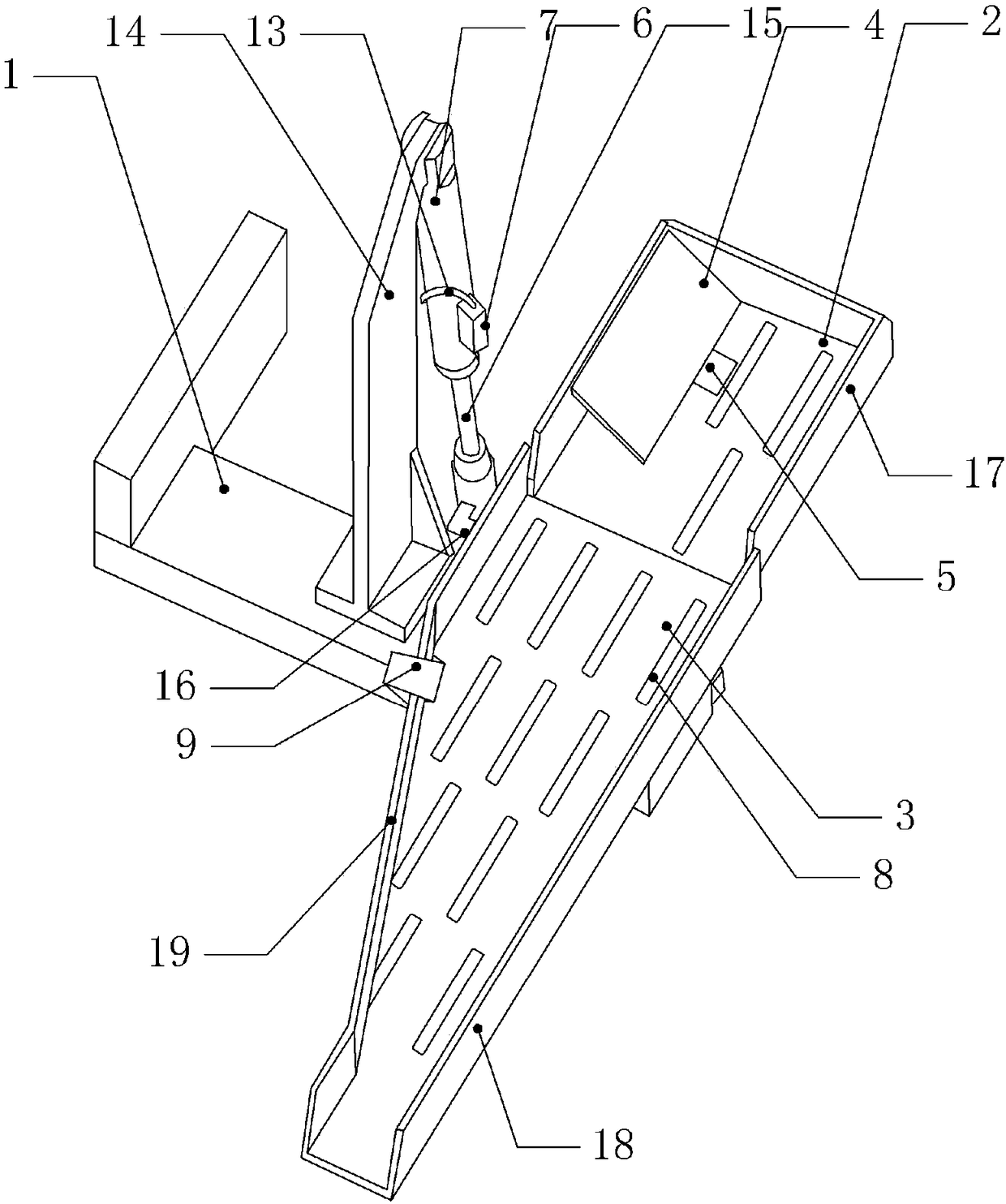

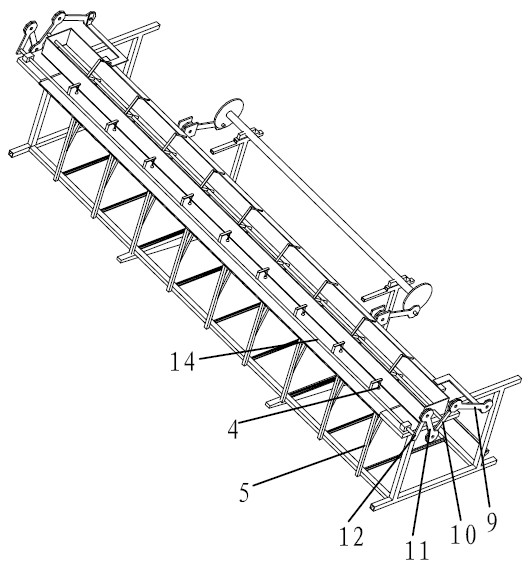

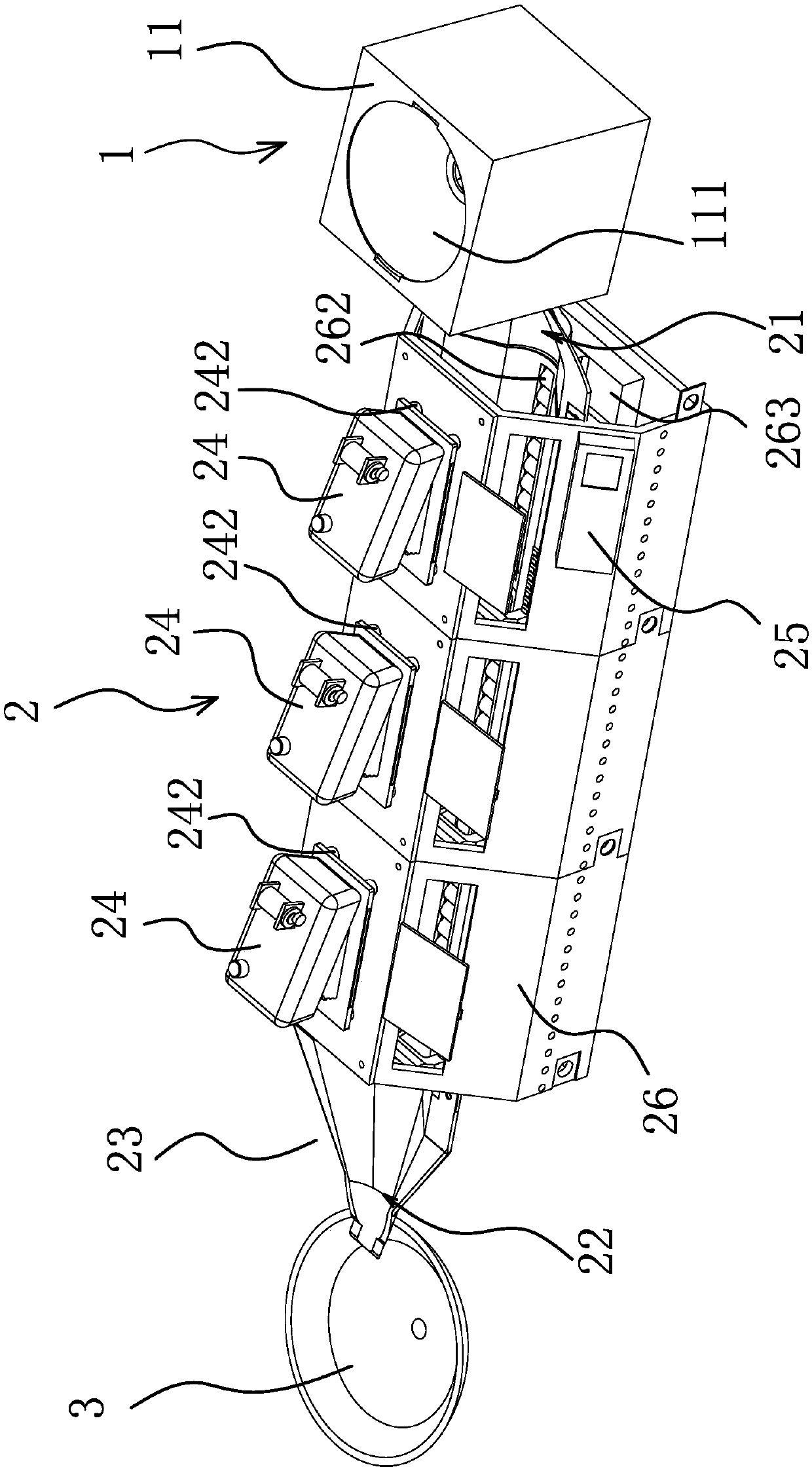

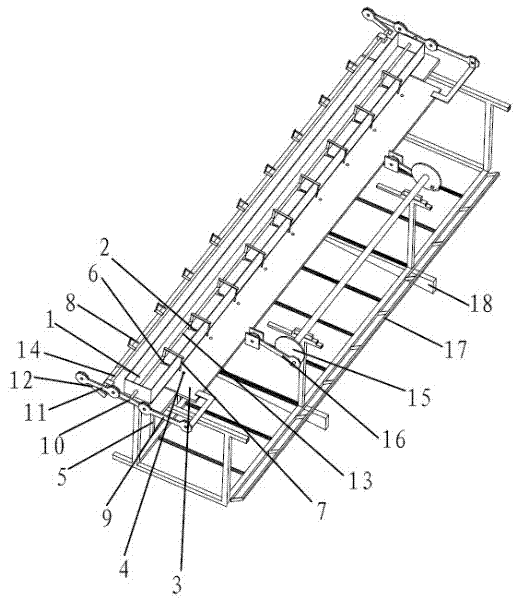

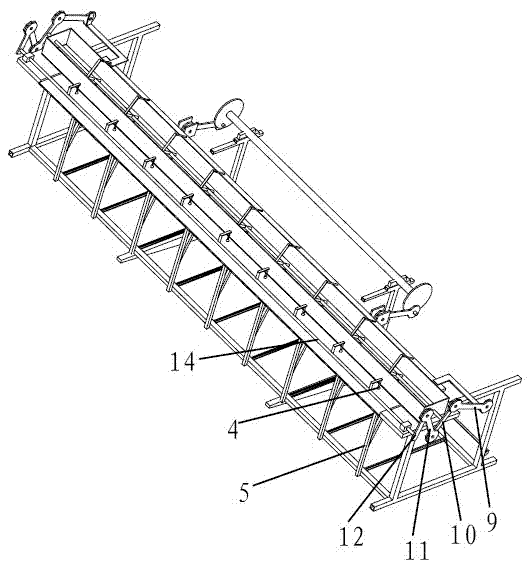

Automatic seeder

The invention provides an automatic seeder, which comprises a plurality of sets of seeding units. Each seeding unit comprises a seeding groove for containing seeds; a material port is arranged at the lower part of the seeding groove; a seeding plate capable of reciprocating is installed below the seeding groove; a seeding hole matching with the material port is arranged on the seeding plate; the seeding plate reciprocates so that the material port and the seeding hole are switched between a connected state and a mutually closed state; and the seeding plate is connected with a driver making the seeding plate reciprocate. The seeding plate is driven by an external power to reciprocate, so that the material port and the seeding hole are switched between the connected state and the mutually closed state to automatically implement the seeding operation. Compared with the manual seeding, the automatic seeding is more efficient, faster and more uniform. The invention can be used for seeding many kinds of seeds by adjusting the size of the seeding hole and the thickness of the seeding plate, adopts a plurality of different seeding speeds and accurately adjusts the seed number of each seeding operation.

Owner:XINJIANG WEST LIJING ECOLOGICAL CONSTR

Subway tunnel

InactiveCN103434419AClose in timeImprove securityMining devicesTrolley linesElectrical and Electronics engineering

The invention provides a subway tunnel which solves the technical problems that a submerging prevention door in an existing subway tunnel can not be closed, and connecting sections can not fall smoothly. The subway tunnel comprises a tunnel body, a busbar structure used for supplying power for trains and a submerging prevention door capable of closing the tunnel. The tunnel body and the busbar structure are arranged in the tunnel body, the busbar structure comprises a busbar left section, a busbar right section, and a connecting section, wherein the connecting section is arranged between the busbar left section and the busbar right section and used for connection, the connecting section is detachably arranged between the busbar left section and the busbar right section, the submerging prevention door is hinged to the inner wall of the tunnel body, and the connecting section is located at the closing track of the submerging prevention door. The subway tunnel has the advantages that time is saved, efficiency is higher, stability is good, and using is safer.

Owner:ZHEJIANG OCEAN UNIV

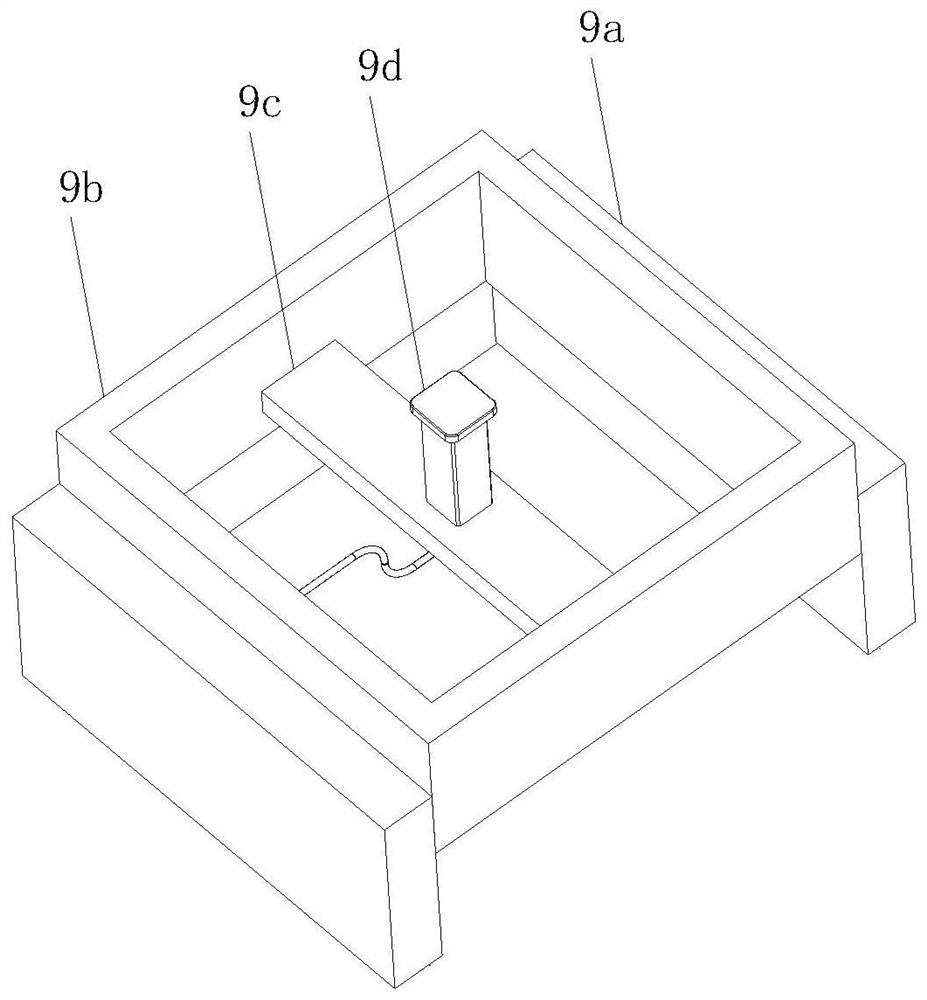

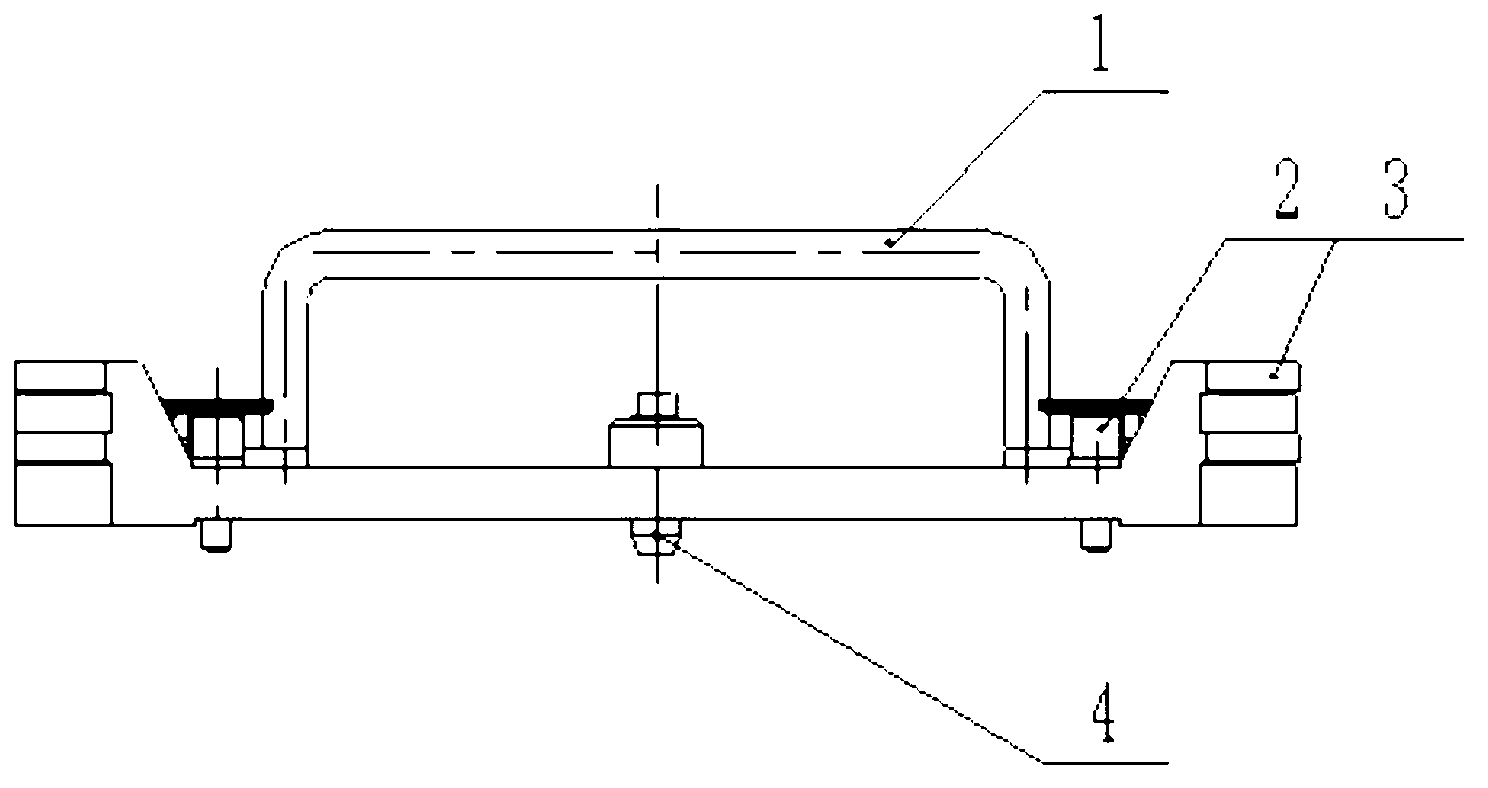

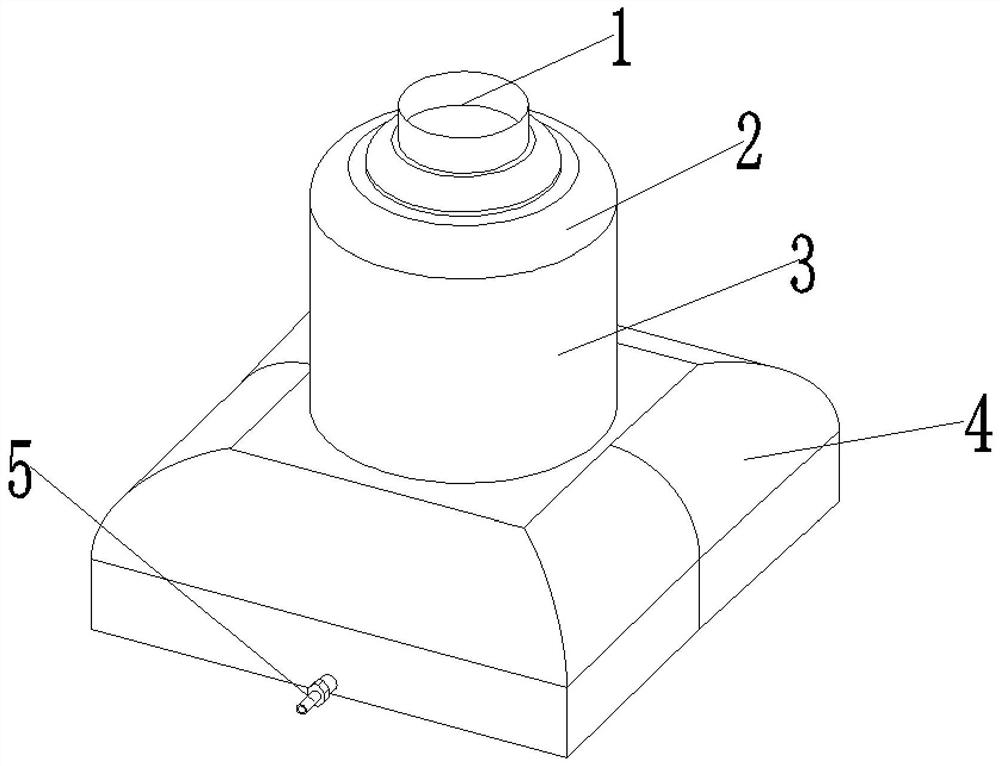

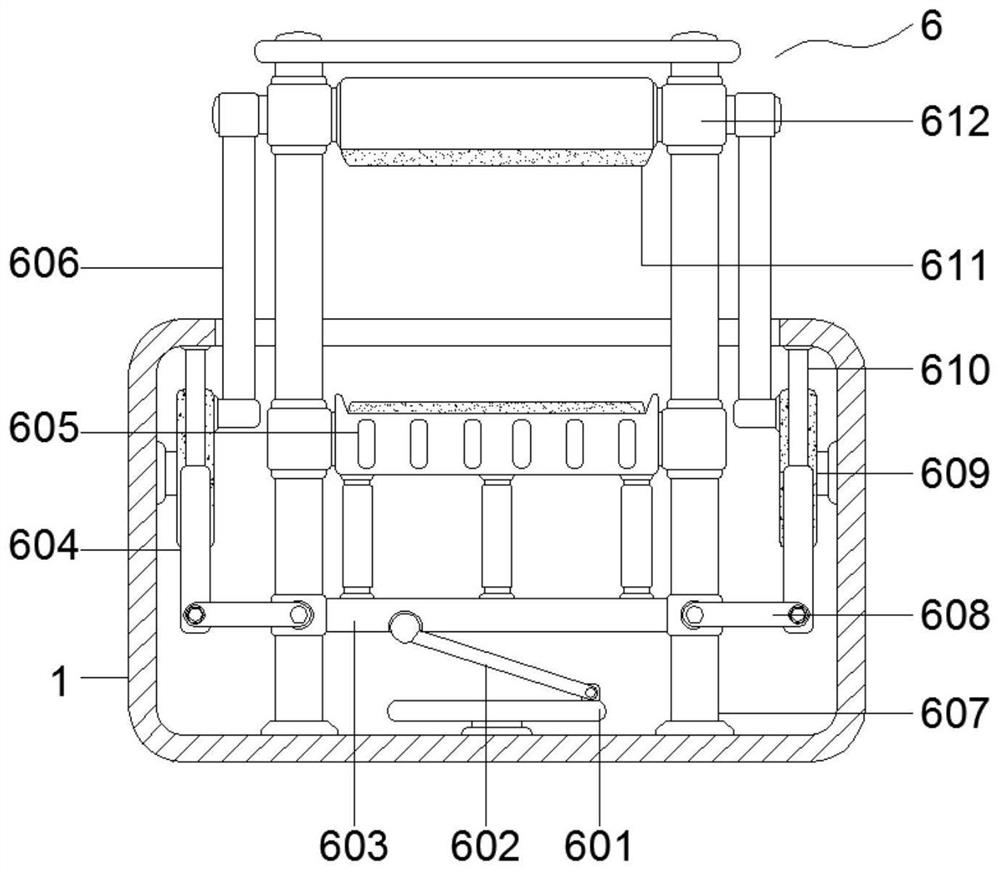

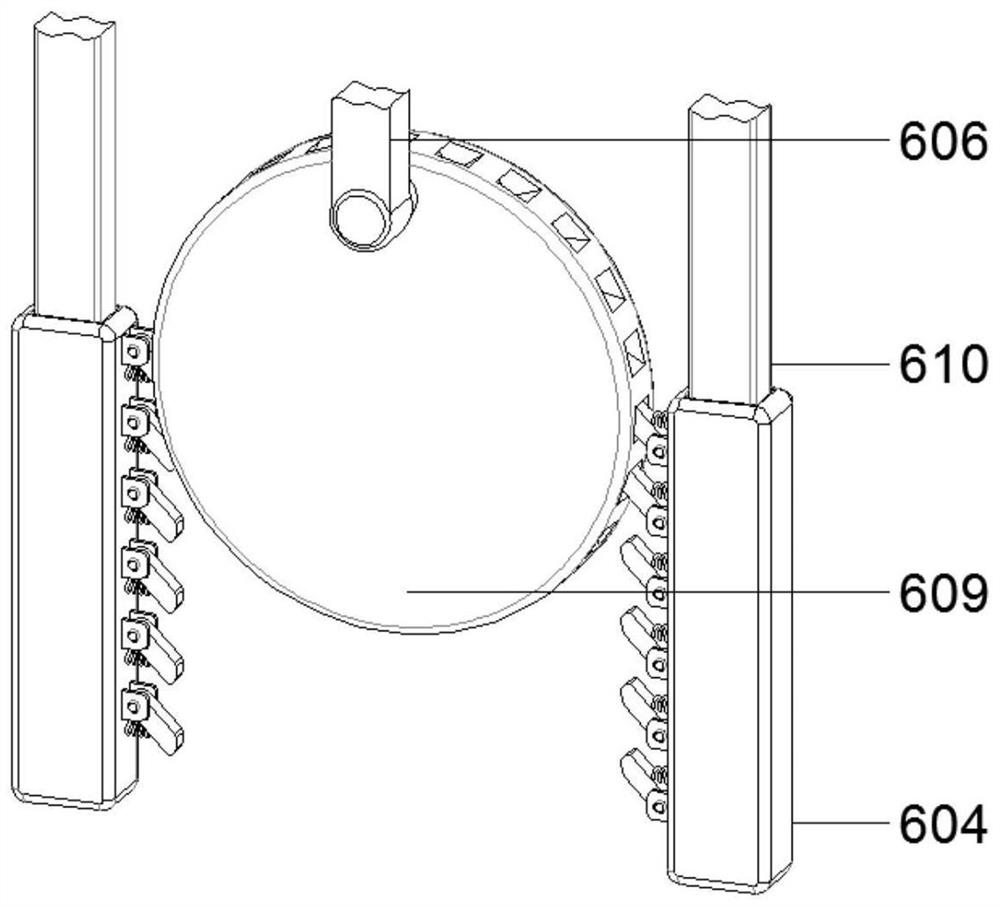

Special tool for installing wafer bracket and method for installing special tool

ActiveCN102747341BPrecise positioningAccurately determine the installation locationVacuum evaporation coatingSputtering coatingArchitectural engineeringSemiconductor

The invention discloses a special tool for installing a wafer bracket and a method for installing the special tool and belongs to the technical field of semiconductor film deposition devices. The technical problems that the exchanging position of wafers in existing brackets cannot be accurately positioned and the efficiency is low are solved. The special tool for installing the wafer bracket comprises a wafer bracket installation rack, wherein an installation rack handle is arranged on the wafer bracket installation rack and the installation rack handle is fixed on the wafer bracket installation rack through bolts. A positioning pin is arranged in the center of the wafer bracket installation rack and bolts are in threaded connection with the wafer bracket installation rack. The method comprises that the positioning pin penetrates through a wafer installation disk, the wafer installation disk and the wafer bracket installation rack are positioned to guarantee that the wafer installation disk and the wafer bracket installation rack share the same center, the wafer installation disk and the wafer bracket installation rack are fixed, the wafer bracket installation rack is placed in a circular groove of a loadlock chamber, the wafer bracket installation rack and the loadlock chamber are fixed after alignment, finally bolts are screwed off, and the wafer bracket installation rack is taken down. By the aid of the special tool and the method, the installation is time-saving and convenient, and wafers can be positioned precisely.

Owner:PIOTECH CO LTD

Thread guiding device applied to embroidery machine

InactiveCN110923977AFast off-line processEffective clampingEmbroidering machines apparatusHydraulic cylinderEngineering

The invention discloses a thread guiding device applied to an embroidery machine. The thread guiding device comprises a device body, a thread fixing structure and a mechanical clamp arm, wherein a guide rail is fixedly connected to the inner side of the device body; an air cylinder is movably connected to the upper end of the guide rail; thread fixing structures are movably connected to the periphery of the inner side of the guide rail; a movably sliding block is arranged on one side of each thread fixing structure, while a thread fixing ring is fixedly connected to the other side of the movable sliding block; a thread fixing pipe is arranged on the inner side of each thread fixing ring; hydraulic cylinders are fixedly connected to two sides in each thread fixing pipe; a hydraulic rod is fixedly connected to an output end on one side of each hydraulic cylinder, while a clamping plate is fixedly connected to the other end of the hydraulic rod; and a fixing block is fixedly connected tothe upper end of the device body. The thread guiding device is novel in structure, simple to operate and convenient to use; and when in thread guiding, stability of the device is ensured, work efficiency of the device is greatly improved, a thread loosening process can become quickly, and thus practicability of the whole device is improved.

Owner:湖南望轶工程设备租赁有限公司

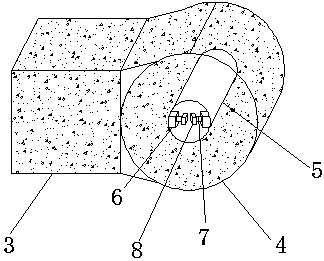

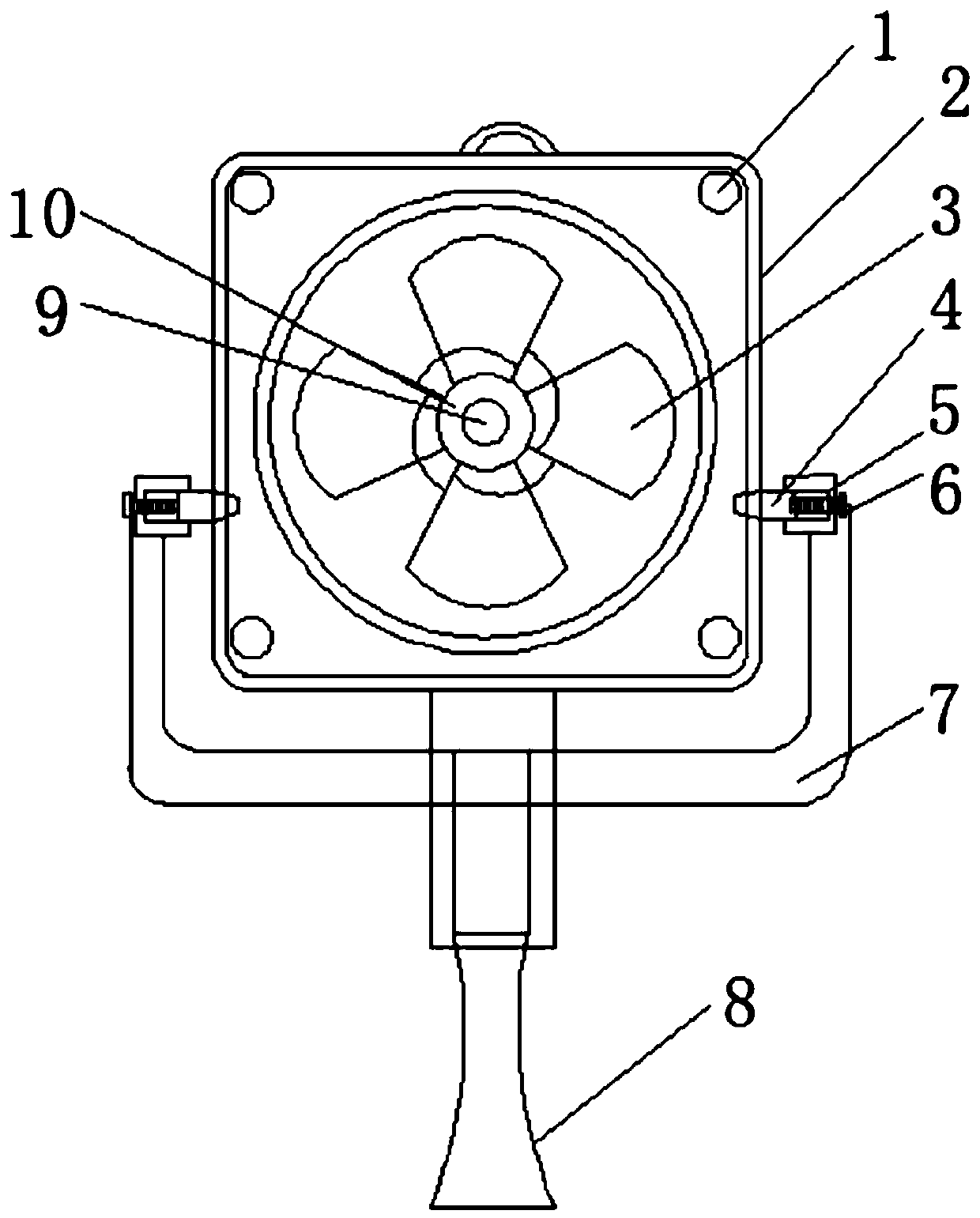

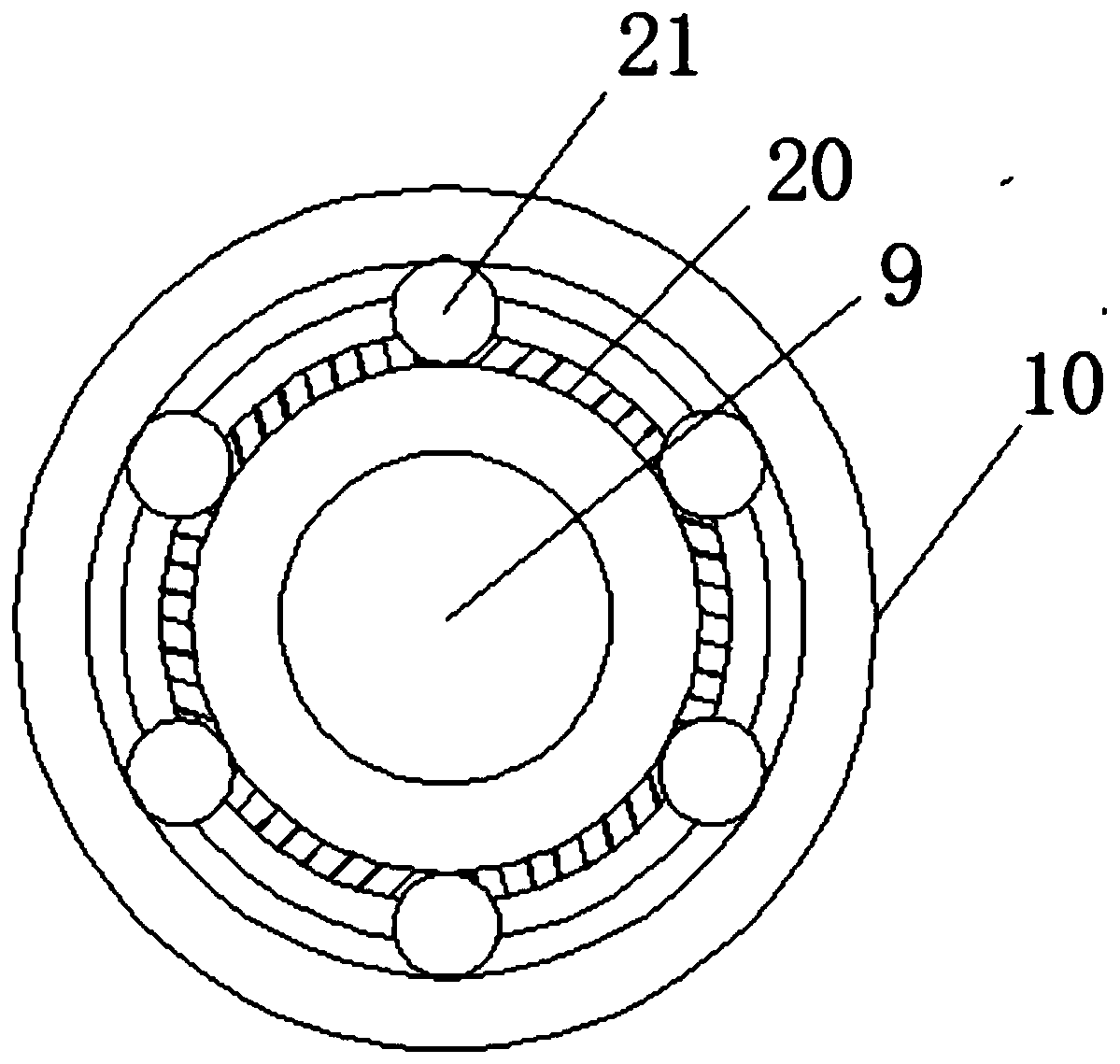

Portable fan with adjustable vertical angle

ActiveCN108678977APrevent falling offSave spacePump componentsCooling/ventillation arrangementFront coverVertical angle

The invention discloses a portable fan with the adjustable vertical angle. The portable fan comprises a front cover and a rear cover. Locking screws are fixed to the periphery of the surface of the front cover. A shaft core is arranged in the middle of the front cover. The outer side of the shaft core is provided with a shaft sleeve. Fan blades are arranged on the surface of the shaft sleeve. Rotation shafts are fixed to the right side wall of the front cover. Clamping bases are arranged on the outer sides of the rotation shafts. First screws are arranged in the rotation shafts. A base is connected to the lower portions of the clamping bases. A telescopic handle is fixed to the lower portion of the base. A protection hood is arranged in front of the front cover. A motor is arranged in themiddle of the rear cover, the rear cover is located behind the front cover, a damping frame is arranged on the right side of the motor, and a heat dissipation plate is arranged between the shaft coreand the shaft sleeve. The portable fan is provided with the rotation shafts, the size of the rotation shafts coincides with the size of the clamping bases, the rotation shafts can drive the clamping bases to rotate, the clamping bases and the rotation shafts are mutually fixed through the first screws, and the vertical angle of the fan is convenient to adjust.

Owner:马鞍山安慧智电子科技有限公司

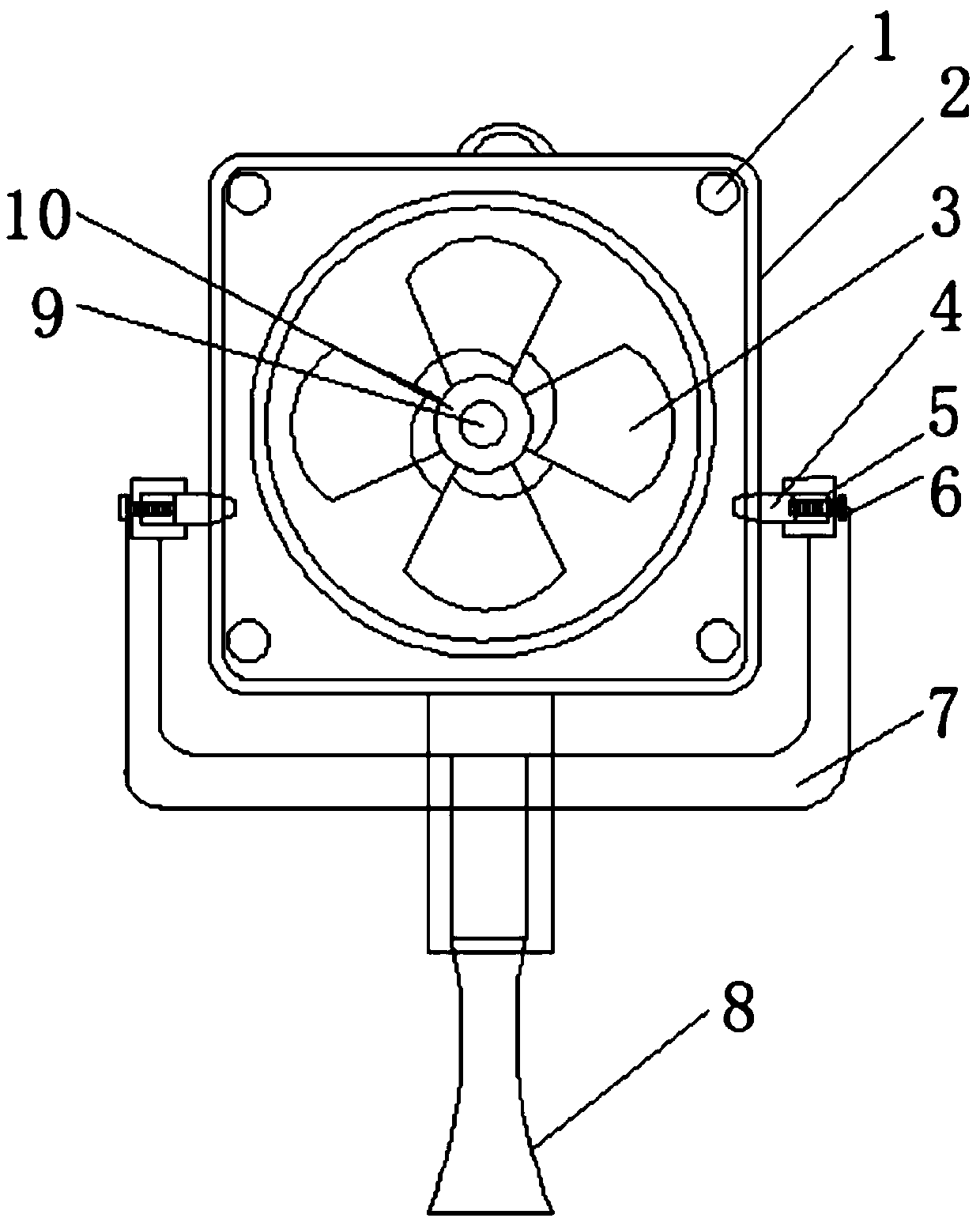

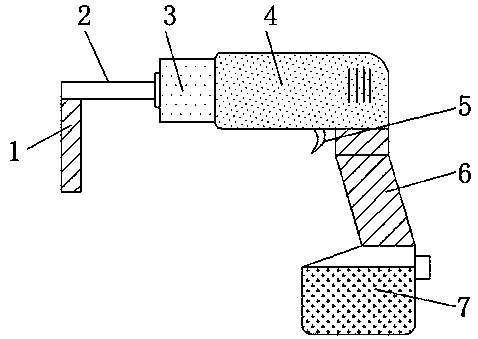

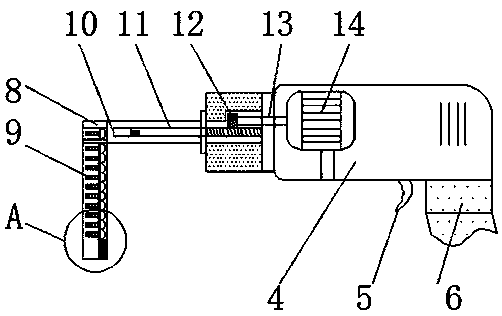

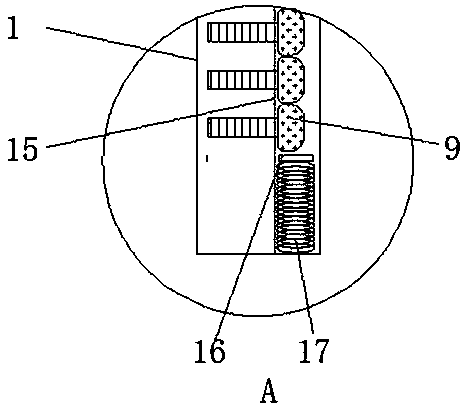

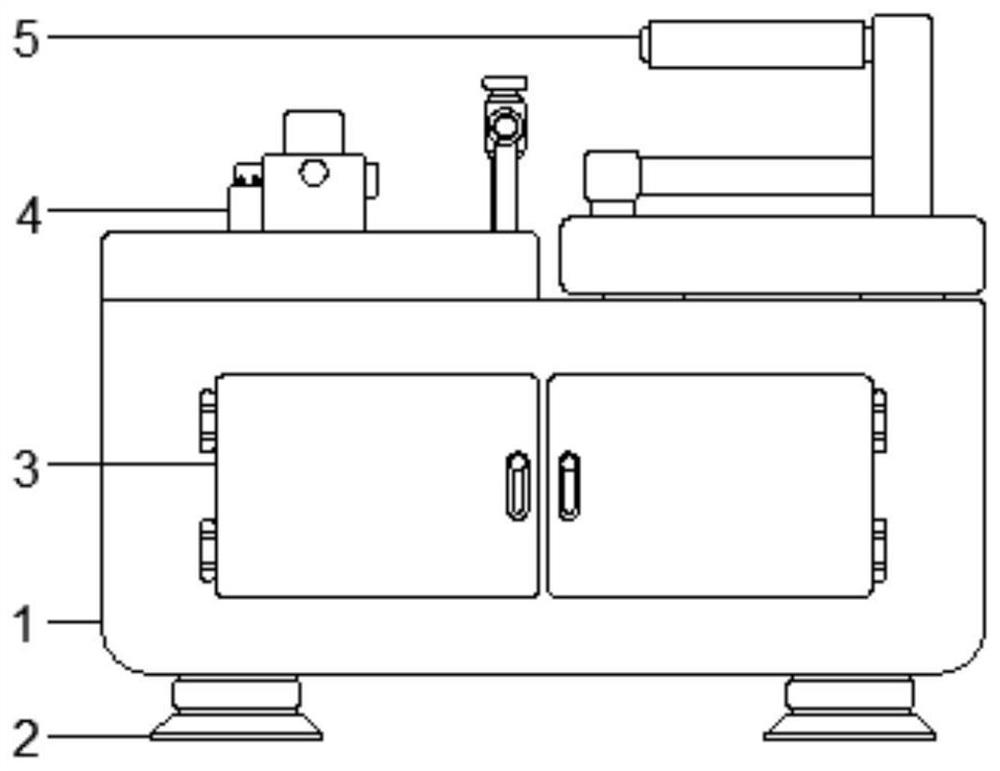

Hand-held automatic screw driving machine

InactiveCN109834639AHigh degree of automationImprove efficiency efficiencySpannersWrenchesGear wheelHand held

The invention discloses a hand-held automatic screw driving machine. The hand-held automatic screw driving machine comprises a screw box, a magnet, screws, a batch head and a screw fixing plate, wherein a screw box fixing rod is connected to the outer part of the screw box; a gear outer shell is connected to the outer part of the screw box fixing rod; a motor outer shell is mounted on the outer part of the gear outer shell; a battery is arranged at the bottom of a handle; the screw box fixing rod is connected to the outer part of the magnet; the screw box is mounted on the outer parts of the screws; a batch head transmission rod is mounted on the outer part of the batch head; a transmission gear is connected to the outer part of the batch head transmission rod; a motor transmission rod ismounted in the transmission gear; a motor is arranged on the outer part of the motor transmission rod; and a spring is arranged at the bottom of a screw ejecting plate. The hand-held automatic screw driving machine is provided with the screw box, the screws can be driven without the need for man-made screw aligning, and moreover, the machine adopts a hand-held type, staff can work more easily in structure, the automation degree is high, and a lot of manpower and material resources are saved.

Owner:广西明福科技有限公司

Metal cutting machine tool

PendingCN112355719AEasy to collectNot easy to splashMetal working apparatusMaintainance and safety accessoriesEngineeringMachine tool

The invention discloses a metal cutting machine tool. The metal cutting machine tool comprises a main body, wherein a working cavity is formed in the middle of the top of the front face of the main body; a box door is arranged on the left side of the top of the front face of the main body; a controller is fixedly connected to the right side of the top of the front face of the main body; a workingmechanism is arranged at the top of an inner cavity of the working cavity; a cutter is fixedly connected to the bottom of the front face of the working mechanism; a communicating device is fixedly connected to the middle position of the bottom of the inner cavity of the working cavity; and a transition device is fixedly connected to the top of the communicating device. The invention relates to thetechnical field of the metal cutting machine tool. According to the metal cutting machine tool, a workpiece is cut in the working cavity, trace cutting is conducted during cutting, cut chippings areconvenient to collect, and the chippings are not prone to splashing everywhere; the service life of the metal cutting machine tool is prolonged; the surface of a contact column is provided with fixingthreads, so that friction is increased during contact, the contact column can be matched with fixing teeth conveniently, thus, the fixing is conducted, and the shaking phenomenon is not prone to occurring after fixing; and loosening is convenient, and damage to the device is reduced.

Owner:闫玉乐

A production line for fish egg spreading

The invention provides a production line for sprinkling fish eggs, which belongs to the technical field of production equipment. It solves the problem of uneven sprinkling of the existing fish eggs during the sprinkling process. This production line for fish egg spreading includes feeder, spreader and feeder. The spreader includes a linear guide plate, one end of the linear guide plate is the feed end, and the other end of the linear guide plate is the discharge end. The feeding machine is aligned with the feeding end of the linear guide plate, and the linear guide plate is concave to form a guide groove for fish eggs to roll. There are several baffles on the linear guide plate, and several baffle plates are distributed along the length direction of the linear guide plate. Several baffle plates can Separate the material guide trough, there is an actuator between the linear guide plate and the baffle plate that can turn the baffle plate over and allow the fish eggs to pass through, the bottom of the material guide trough is provided with a discharge port, and the front of each section of the material guide trough A material spreading box is arranged on the top, and a material spreading port is arranged on the bottom surface of the material spreading box. This production line for fish egg spreading can make the coating of fish eggs even in the spreader.

Owner:杭州量创科技咨询有限公司

Automatic seeder

The invention provides an automatic seeder, which comprises a plurality of sets of seeding units. Each seeding unit comprises a seeding groove for containing seeds; a material port is arranged at the lower part of the seeding groove; a seeding plate capable of reciprocating is installed below the seeding groove; a seeding hole matching with the material port is arranged on the seeding plate; the seeding plate reciprocates so that the material port and the seeding hole are switched between a connected state and a mutually closed state; and the seeding plate is connected with a driver making the seeding plate reciprocate. The seeding plate is driven by an external power to reciprocate, so that the material port and the seeding hole are switched between the connected state and the mutually closed state to automatically implement the seeding operation. Compared with the manual seeding, the automatic seeding is more efficient, faster and more uniform. The invention can be used for seeding many kinds of seeds by adjusting the size of the seeding hole and the thickness of the seeding plate, adopts a plurality of different seeding speeds and accurately adjusts the seed number of each seeding operation.

Owner:XINJIANG WEST LIJING ECOLOGICAL CONSTR

Busbar connector device for subway tunnel

The invention provides a busbar connector device of a subway tunnel. The device solves the technical problem that a connecting section of an existing busbar connector device of the subway tunnel can not fall down smoothly. The device comprises a left busbar section, a right busbar section and a connecting section detachably arranged between the left busbar section and the right busbar section and used for connection, a flood gate is hinged to the inner wall of a tunnel body, and the connecting section is located on the closing track of the flood gate. The device has the advantages of being capable of saving time, higher in efficiency, high in stability, safer in use and the like.

Owner:ZHEJIANG OCEAN UNIV

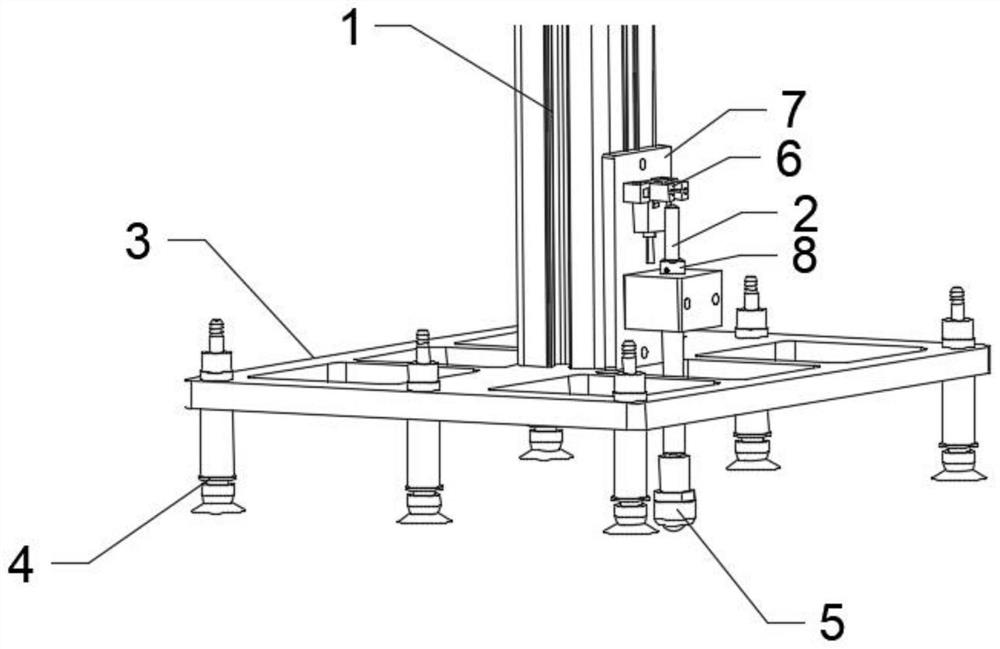

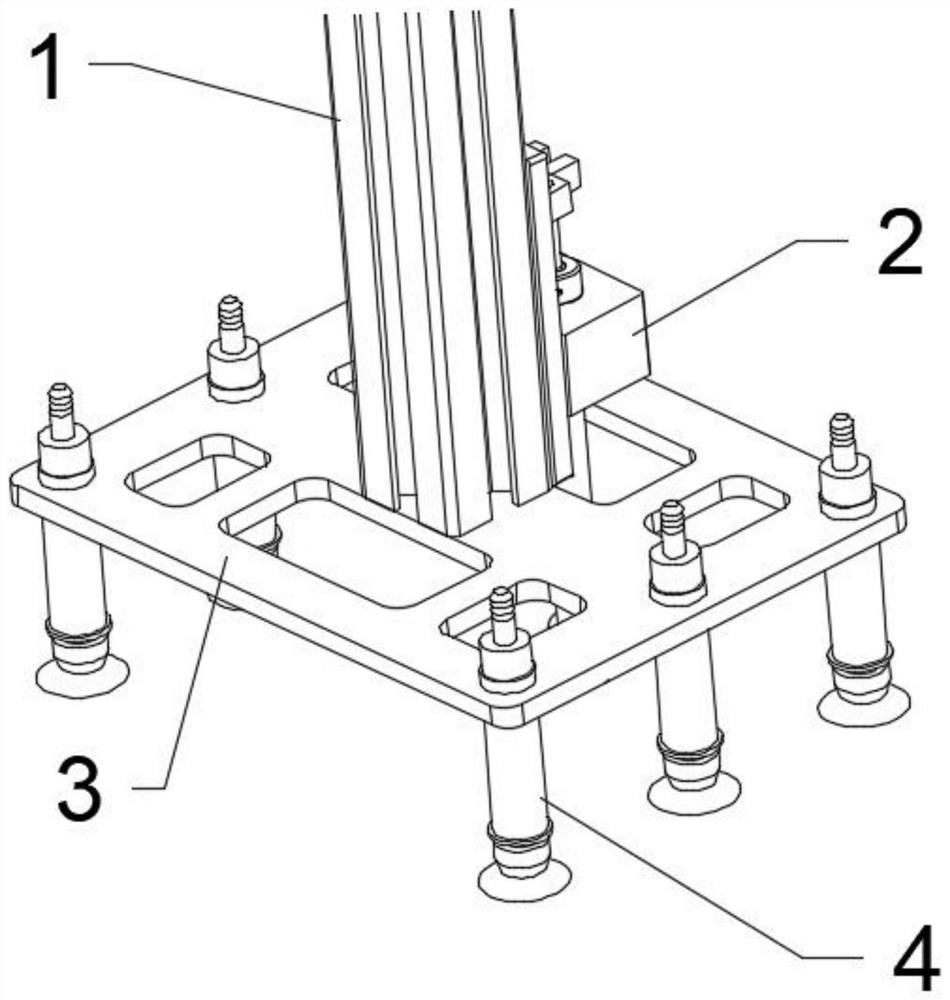

Efficient frame grabbing structure

PendingCN113385430APrevent pinned situationsNo getting stuckConveyorsControl devices for conveyorsLogistics managementEngineering

The invention relates to an efficient frame grabbing structure, and belongs to the field of logistics automatic frame feeding. The efficient frame grabbing structure comprises a fixed support, a sucker support and miniature vacuum suckers, the fixed support is vertically connected with the sucker support, the miniature vacuum suckers are distributed at two ends of the sucker support, a probe rod support is arranged on the fixed support, a sensor probe rod is mounted on the probe rod support, a U-shaped photoelectric sensor is installed on the upper part of the probe rod support, and the U-shaped photoelectric sensor is perpendicular to the sensor probe rod. The positions of the suckers can be accurately fed back, the suction time point of the suckers can be accurately controlled, a universal ball is selected as a contact piece, the situation that the sensor probe rod is pinned when a material frame is uneven can be effectively prevented, in addition, an oil-free bushing is additionally arranged between the probe rod and the probe rod support, so that the wear resistance and the assembly precision are ensured, the sensor probe rod is prevented from being stuck, manual nursing is not needed, the labor cost is reduced, and the working efficiency of a whole logistics assembly line is improved.

Owner:上海发网云物流科技有限公司

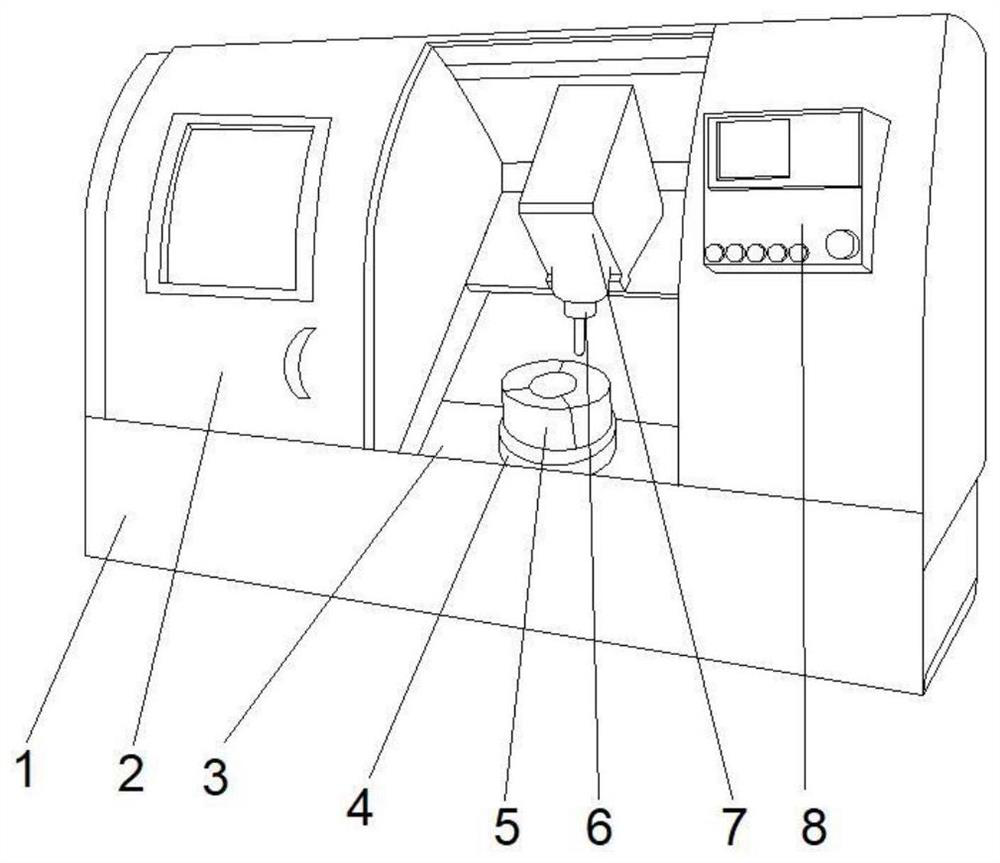

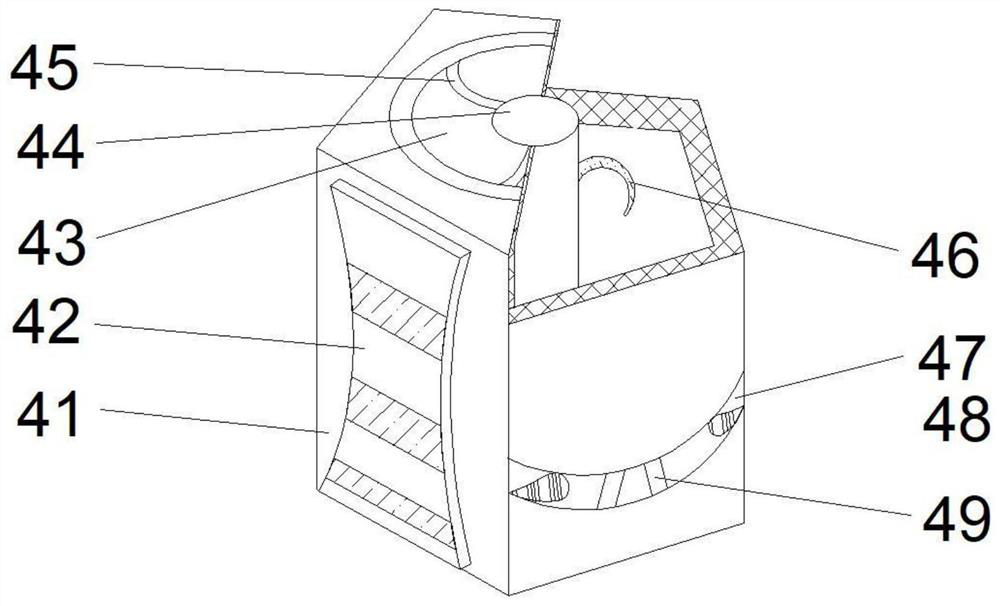

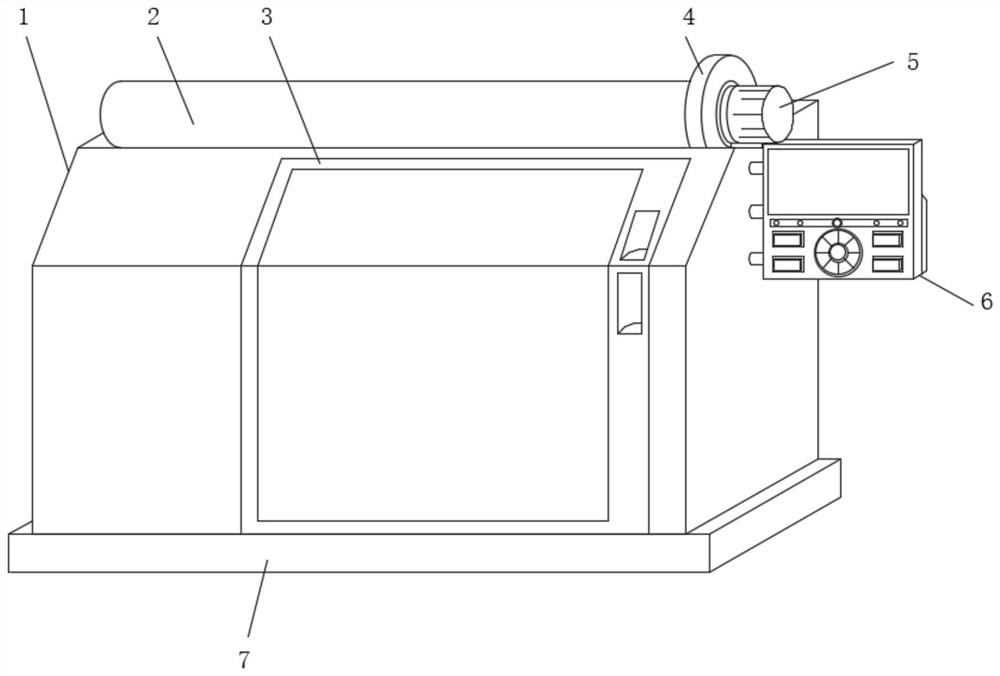

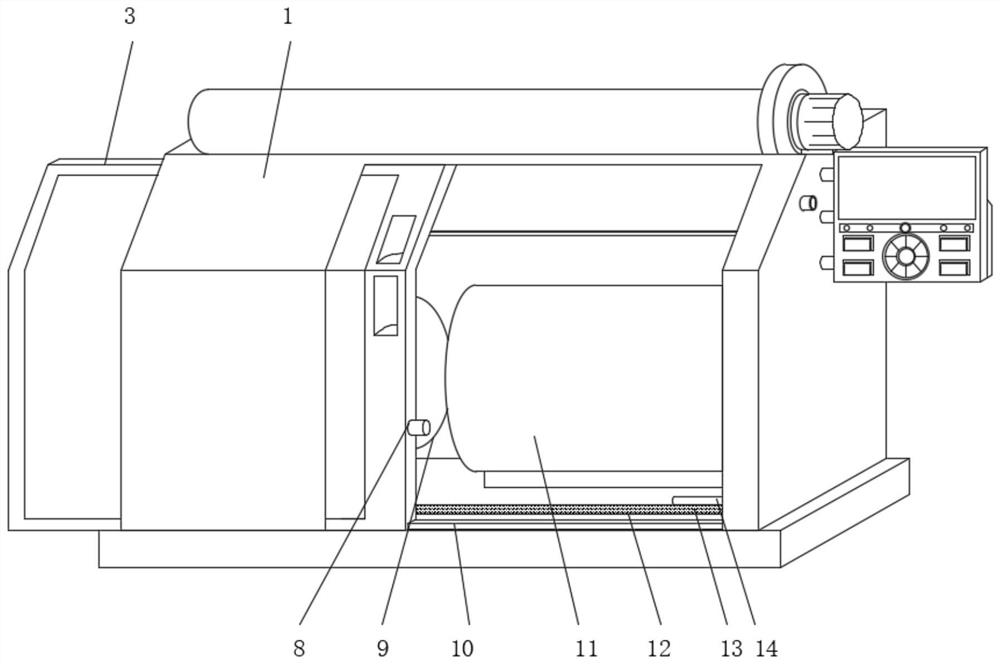

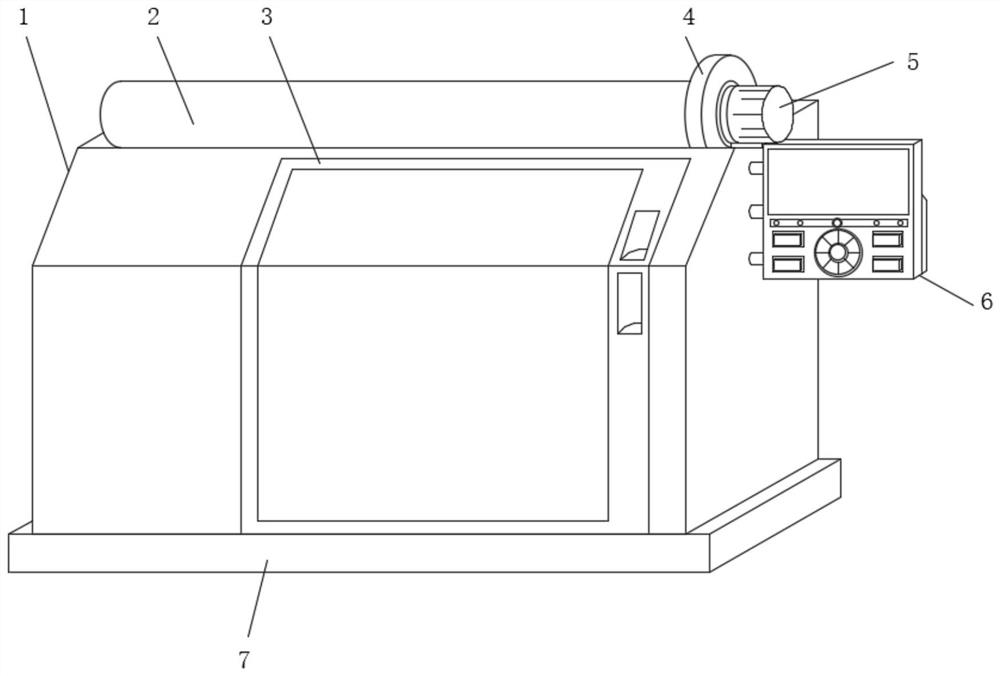

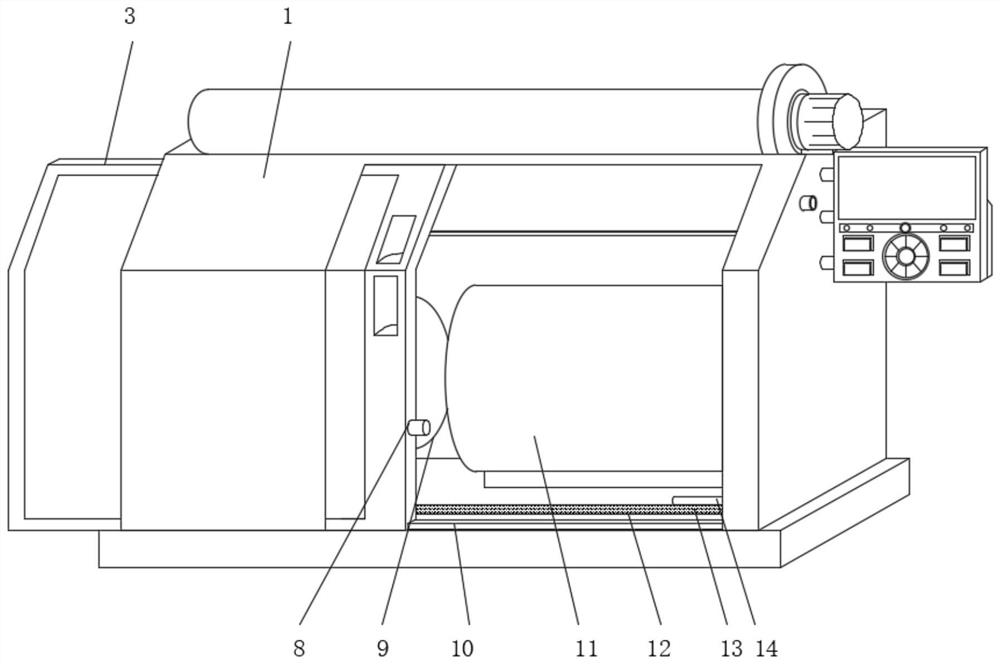

A high-performance and low-noise CNC machine tool

ActiveCN113199294BEffective contactEffective sound insulationMaintainance and safety accessoriesNumerical controlLow noise

The invention discloses a high-performance and low-noise numerical control machine tool, which belongs to the technical field of numerical control machine tools, and comprises a casing, a top case, a tool seat, a winding roller, a lubricating component, a built-in transparent sound insulation board, a limit component and a guide wheel. A top case is fixedly installed on the top of the case, and an outer cover is arranged on the outside of the top case, a drive motor is fixedly installed on one side of the top case, and a controller is fixedly installed on one side of the outer wall of the case through a connecting rod; In the present invention, by installing a winding shaft with a transparent sound-insulating pad on the top and a switch contact on the side wall of the machine door, the machine door will be closed when the machine tool is normally opened, and when the door is closed, The switch contacts can effectively contact the contacts of the machine case, thereby controlling the opening of the drive motor, and the drive motor can automatically drive the winding roller to rotate, and put down the transparent sound-proof pad, which realizes that the machine door is closed and the transparent sound-proof pad is automatically put down while the machine is working. , to achieve an effective sound insulation effect.

Owner:肇庆市高要区益美五金科技有限公司

Barbell placing rack capable of conducting automatic disinfection

ActiveCN113332695AAchieve disinfectionReach clearDumb-bellsLavatory sanitoryRotational axisLeather belt

The invention relates to the technical field of sports goods, and discloses a barbell placing rack capable of conducting automatic disinfection. The barbell placing rack comprises rack bodies, clamping grooves and fixing plates, wherein the clamping grooves are formed in the upper surfaces of the two rack bodies so as to achieve the functions of placing and fixing a barbell; ejector rods vertically penetrate through and movably sleeve the bottoms of the clamping grooves; clamping teeth are arranged on the surface of one side, shrunk in the rack bodies, of the ejector rods; transmission gears are fixedly clamped to the surfaces of the two sides of the middle of inner cavities in the rack bodies through rotating shafts; the clamping teeth on the side faces of the ejector rods are meshed with the transmission gears; rotating wheels are fixedly clamped to the surfaces of the two sides of the inner cavities in the rack bodies through rotating shafts; the transmission gears and the rotating wheels are fixedly clamped through a belt to achieve synchronous transmission; and contact faces of the rotating wheels and a barbell rod and the contact faces of pulleys and the barbell rod are made of rubber materials. According to the invention, linear motion of the ejector rods is converted into circular motion of the transmission gears and the rotating wheels through the gravity of the barbell so as to drive the barbell to rotate, so a worker can complete comprehensive disinfection of the barbell rod only by spraying a disinfectant fluid at fixed positions.

Owner:淮北智行信息科技有限公司

Automatic cleaning type animal feed crushing and drying device

The invention discloses an automatic cleaning type animal feed smashing and drying device which comprises a water inlet, the bottom of the water inlet communicates with a water tank, the bottom of the water tank is provided with a crushing box, the bottom of the crushing box is provided with a storage box, and the left side of the storage box communicates with a discharging port. The crushing box comprises a water discharging mechanism, a rotating rod, a stepping motor, a crushing cutter, a water pipe and a motor box, the motor box is fixedly connected with the top of the inner wall of the storage box, and the motor is fixedly connected with the bottom of the inner wall of the motor box. According to theautomatic cleaning type animal feed smashing and drying device, due to the fact that a straight water rod is arranged to make contact with a push rod, due to the impact force generated when water flow flows out and the throwing force of the rotating rod, the water flow pushes the push rod, through the rotation of a bearing, an arc lifting rod is moved upwards, a sliding groove is formed in a sliding groove block, the sliding groove and a through pipe are horizontally arranged, the top of a sliding rod makes contact with the interior of the through pipe, the clamping condition is avoided, and use is convenient.

Owner:吴应芬

High-performance low-noise numerical control machine tool

ActiveCN113199294AEffective contactEffective sound insulationMaintainance and safety accessoriesNumerical controlLow noise

The invention discloses a high-performance low-noise numerical control machine tool, and belongs to the technical field of numerical control machine tools. The high-performance low-noise numerical control machine tool comprises a machine shell, a top shell, a tool base, a winding roller, a lubricating assembly, a built-in transparent sound insulation plate, a limiting assembly and a guide wheel, wherein the top shell is fixedly mounted at the top of the machine shell, and an outer cover is arranged outside the top shell; and a driving motor is fixedly installed on the outer wall of one side of the top shell, and a controller is fixedly mounted on the outer wall of one side of the machine shell through a connecting rod. According to the machine tool, the winding shaft with the transparent sound insulation pad is mounted at the top, meanwhile, a switch contact is mounted on the side wall of a machine door, when the machine tool is started to work at ordinary times, the machine door can be closed, and when the machine door is closed, the switch contact can effectively make contact with a contact of the machine shell, so that the driving motor is controlled to be started; and the driving motor can automatically drive the winding roller to rotate, the transparent sound insulation pad is put down, the transparent sound insulation pad is automatically put down while the machine tool with the closed machine door works, and the effective sound insulation effect is achieved.

Owner:肇庆市高要区益美五金科技有限公司

A portable fan with adjustable vertical angle

ActiveCN108678977BEasy to adjust the vertical angleAvoid big vibrationsPump componentsCooling/ventillation arrangementElectric machineryEngineering

The invention discloses a portable fan with the adjustable vertical angle. The portable fan comprises a front cover and a rear cover. Locking screws are fixed to the periphery of the surface of the front cover. A shaft core is arranged in the middle of the front cover. The outer side of the shaft core is provided with a shaft sleeve. Fan blades are arranged on the surface of the shaft sleeve. Rotation shafts are fixed to the right side wall of the front cover. Clamping bases are arranged on the outer sides of the rotation shafts. First screws are arranged in the rotation shafts. A base is connected to the lower portions of the clamping bases. A telescopic handle is fixed to the lower portion of the base. A protection hood is arranged in front of the front cover. A motor is arranged in themiddle of the rear cover, the rear cover is located behind the front cover, a damping frame is arranged on the right side of the motor, and a heat dissipation plate is arranged between the shaft coreand the shaft sleeve. The portable fan is provided with the rotation shafts, the size of the rotation shafts coincides with the size of the clamping bases, the rotation shafts can drive the clamping bases to rotate, the clamping bases and the rotation shafts are mutually fixed through the first screws, and the vertical angle of the fan is convenient to adjust.

Owner:马鞍山安慧智电子科技有限公司

driving force receiver

ActiveCN106444316BSmooth entryNo getting stuckElectrographic process apparatusEngineeringMechanical engineering

Owner:ZHUHAI UN TERN IMAGING PROD

An automatic sterilizable barbell rack

ActiveCN113332695BAchieve disinfectionReach clearDumb-bellsLavatory sanitoryRotational axisGear wheel

Owner:淮北智行信息科技有限公司

Load rejection structure for underwater equipment

The load rejection structure comprises an equipment body, a load rejection part is fixedly connected to the bottom face of the equipment body, a cylindrical sliding cavity is formed in the center of the bottom face of the load rejection part, a cylindrical weight block is slidably connected into the cylindrical sliding cavity, and a weight arc-shaped bottom is fixedly connected to the bottom face of the cylindrical weight block. The top face of the arc-shaped bottom of the heavy object makes contact with the bottom face of the load rejection part, four load rejection columns are evenly and fixedly connected to the top face of the arc-shaped bottom of the heavy object, and four installation column grooves are formed in the positions, corresponding to the four load rejection columns, of the bottom face of the load rejection part respectively. The four load rejection columns and the four load rejection sleeves corresponding to the four load rejection columns are uniformly arranged, so that load rejection stress is uniform, the jamming condition is avoided, after load rejection is completed, a sealing push plate is mutually fixed with a third electromagnet on the inner side wall of the bottom surface of a load rejection cavity through a second electromagnet on the side wall, the load rejection cavity is sealed, and the load rejection efficiency is improved. And meanwhile, the hydraulic cylinder is started to push the sealing circular plate down to the bottom surface of the cylindrical sliding cavity, so that the cylindrical sliding cavity is sealed, and the sealing after the load rejection work is completed is ensured.

Owner:HANGZHOU DIANZI UNIV

A wood block punching device for solid wood sofa processing

ActiveCN110434942BEasy to moveNo getting stuckOperator-supported drilling machinesBark-zones/chip/dust/waste removalSolid woodPunching

The invention relates to a punching device, in particular to a wood block punching device for processing solid wood sofas. Therefore, the technical problem of the present invention is: provide a kind of solid wood sofa processing wood block punching instrument that can fix wood blocks more stably, can reduce people's physical discomfort and can blow away sawdust. The technical scheme of the present invention is: a wooden block punching device for processing solid wood sofas, including a mounting frame, a placing block, etc.; The present invention can realize that people can press the wooden block body tightly when drilling through the set pressing block, which does not require people to manually control the wooden block body, which increases people's burden; the set sliding sleeve and guide rail can make the electric drill vertical The hole drilled by the electric drill is also straight, and the assembly will not be affected by the inclination of the drilled hole; the sawdust on the surface of the wooden block body can be blown away by the air bag provided, which facilitates the movement of the wooden block body, and there will be no wood chips. The case where the block body is stuck.

Owner:深圳市艾丽特家具有限公司

Clothing packaging machine and packaging method for carrying out edge sealing and opening sealing treatment on packaging film

InactiveCN113320736AImprove work efficiencyEasy to moveWrapper twisting/gatheringCircular discEngineering

The invention relates to the technical field of clothing packaging, and discloses a clothing packaging machine for carrying out edge sealing and opening sealing treatment on a packaging film. The clothing packaging machine comprises a box body, a sealing and cutting assembly and a sliding assembly, wherein supporting legs are fixedly installed at the two sides of the bottom end of the box body, a box door is fixedly formed in the front surface of the box body, and an edge sealing machine is fixedly installed at the top end of the box body. According to the clothing packaging machine and packaging method for carrying out the edge sealing and opening sealing treatment on the packaging film, a connecting rod is installed at the top end of an electric rotating disc, a sliding rod is installed at the top end of the connecting rod, a heating piece is connected with the sliding rod through a guide rod, a sleeve rod is connected with the sliding rod through a fixing rod, then a clamping column is installed on the sleeve rod, an inclined groove is formed in the outer wall of a disc, and the clamping column is connected with the inclined groove; and movable rods are installed on the disc, sliding sleeves are installed at the top ends of the movable rods, cutters are installed on the opposite sides of the two sliding sleeves, and an edge sealing machine is installed at the top end of the box body, so that the edge sealing and opening sealing treatment can be carried out on the packaging film, and then the working efficiency of workers is increased.

Owner:嘉兴市衡威科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com