Clothing packaging machine and packaging method for carrying out edge sealing and opening sealing treatment on packaging film

A technology of packaging film and packaging machine, which is applied in the field of clothing packaging, can solve the problems of reduced work efficiency, inconsistent packaging, and high work intensity of staff, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A garment packaging method for performing edge sealing on a packaging film, the steps are as follows:

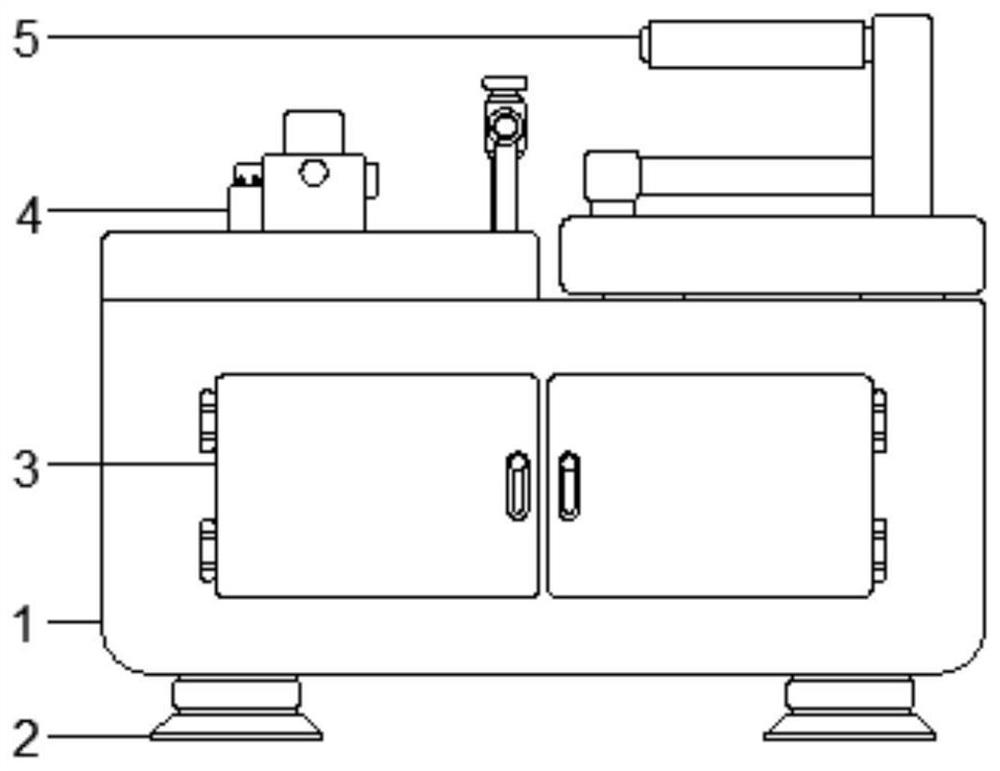

[0044] S1: Turn on the power supply of the device to make the conveyor belt run, and place the packaging film on the packaging film support 5 at the same time;

[0045] S2: On the basis of S1, the staff places the clothes to be packaged on the conveyor belt, makes it move with the conveyor belt, and packs it through the packaging film;

[0046] S3: On the basis of S2, start the edge banding machine 4, so that the clothes move with the conveyor belt, and then drive the packaging film to move, so that the edge banding machine 4 performs edge sealing on the packaging film;

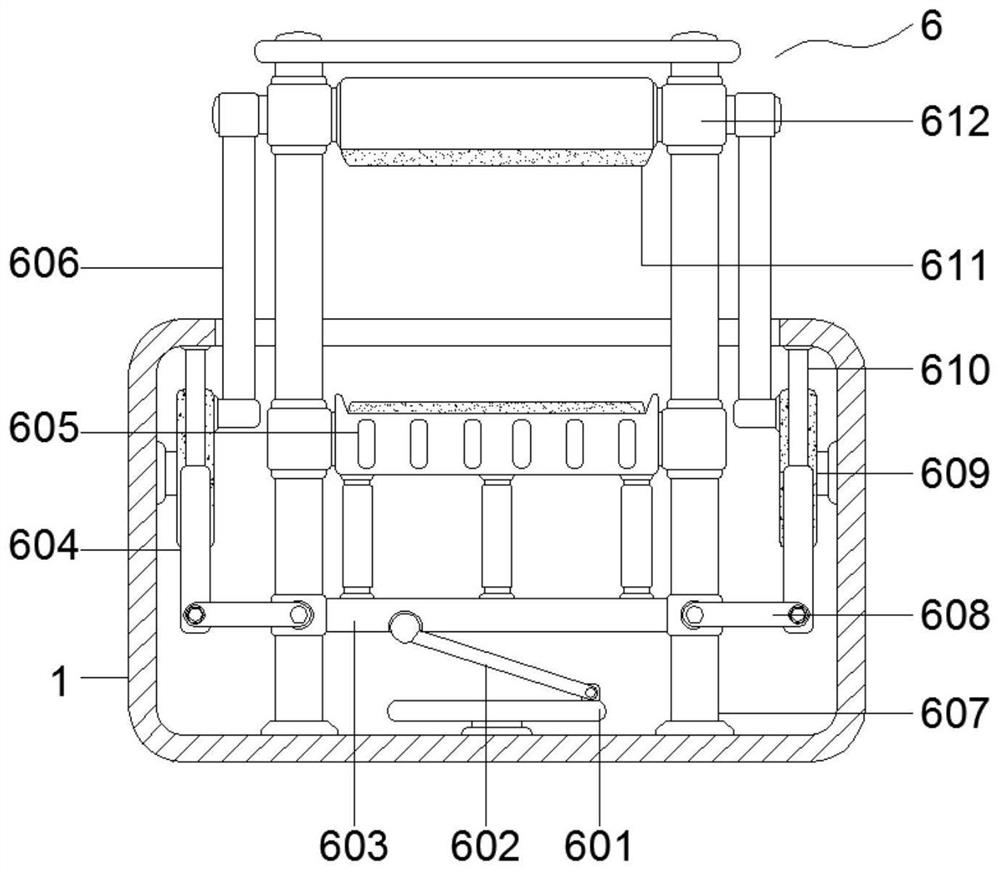

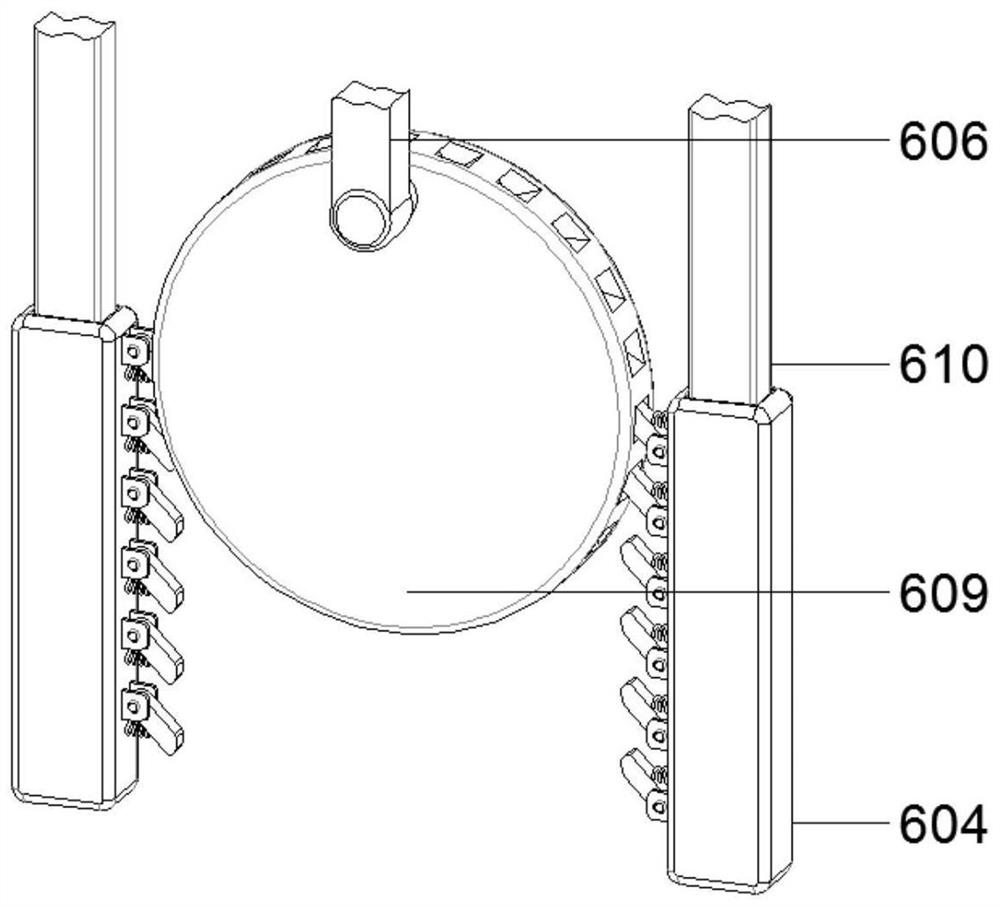

[0047] S4: On the basis of S3, start the electric turntable 601 to drive its speed to 0.5rpm / s, and then drive the sliding rod 603 to move upward through the connecting rod 602, and the sliding rod 603 drives the heating element 605 to move upward through the guide rod;

[0048] S5: On the basis of ...

Embodiment 2

[0052] A garment packaging method for performing edge sealing on a packaging film, the steps are as follows:

[0053] S1: Turn on the power supply of the device to make the conveyor belt run, and place the packaging film on the packaging film support 5 at the same time;

[0054] S2: On the basis of S1, the staff places the clothes to be packaged on the conveyor belt, makes it move with the conveyor belt, and packs it through the packaging film;

[0055] S3: On the basis of S2, start the edge banding machine 4, so that the clothes move with the conveyor belt, and then drive the packaging film to move, so that the edge banding machine 4 performs edge sealing on the packaging film;

[0056] S4: On the basis of S3, start the electric turntable 601 to drive its speed to 1.2rpm / s, and then drive the sliding rod 603 to move upward through the connecting rod 602, and the sliding rod 603 drives the heating element 605 to move upward through the guide rod;

[0057] S5: On the basis of ...

Embodiment 3

[0061] A garment packaging method for performing edge sealing on a packaging film, the steps are as follows:

[0062] S1: Turn on the power supply of the device to make the conveyor belt run, and place the packaging film on the packaging film support 5 at the same time;

[0063] S2: On the basis of S1, the staff places the clothes to be packaged on the conveyor belt, makes it move with the conveyor belt, and packs it through the packaging film;

[0064] S3: On the basis of S2, start the edge banding machine 4, so that the clothes move with the conveyor belt, and then drive the packaging film to move, so that the edge banding machine 4 performs edge sealing on the packaging film;

[0065] S4: On the basis of S3, start the electric turntable 601 to drive its speed to 2rpm / s, and then drive the sliding rod 603 to move upward through the connecting rod 602, and the sliding rod 603 drives the heating element 605 to move upward through the guide rod;

[0066] S5: On the basis of S4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com