Patents

Literature

154results about How to "Prevent sucking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

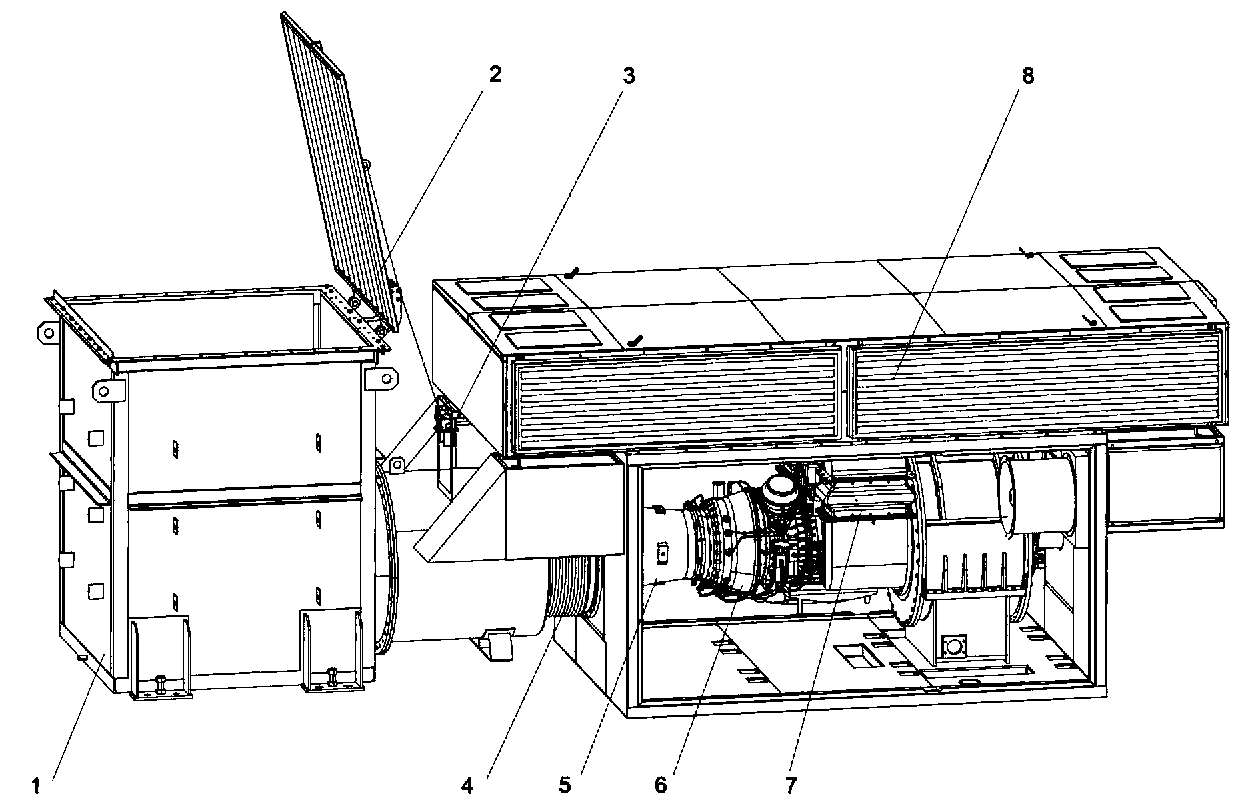

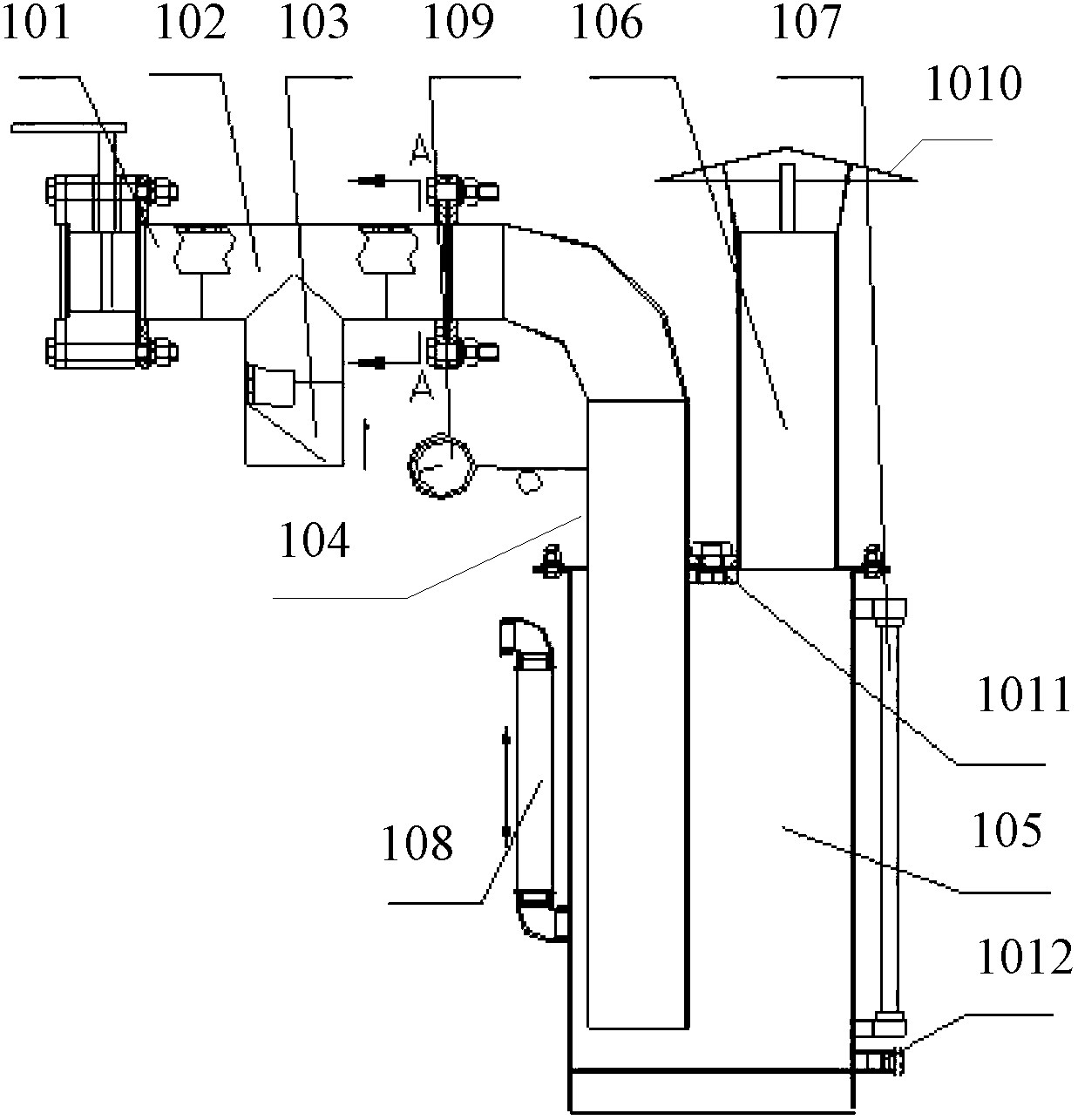

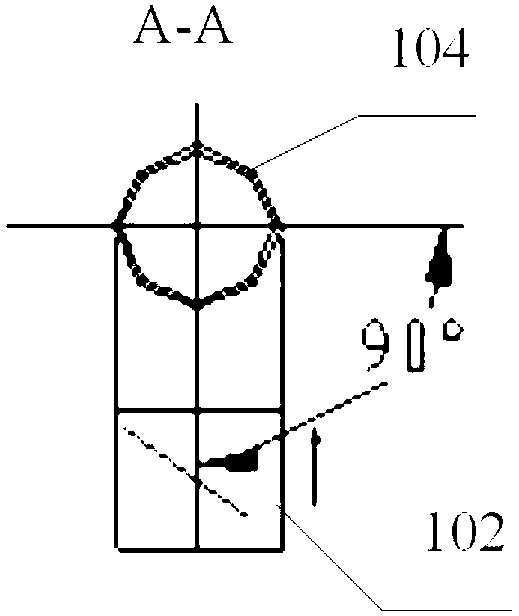

Intake and exhaust system of turbine engine

PendingCN111206994AMeet air intake needsAvoid damageGas turbine plantsTurbine/propulsion air intakesAir filterExhaust fumes

The invention discloses an intake and exhaust system of a turbine engine. The intake and exhaust system of the turbine engine comprises an intake system and an exhaust system, wherein the intake system is connected with an intake port of the turbine engine, the exhaust system is connected with an exhaust port of the turbine engine, the intake system comprises an intake filter and an intake pipeline, the intake filter is connected with the intake pipeline, the intake filter adopts a V-shaped structure, and a rain shielding cap is arranged at the exhaust tail end of the exhaust system. The intake and exhaust system of the turbine engine has the beneficial effects that the air inlet area is large, the air inlet flow speed is lower, the service life of an air filter is long, the rain shieldingcap additionally arranged at the exhaust port avoids the rainwater deposition in an exhaust silencer, the condition that rainwater possibly flows backwards is avoided and damages the turbine engine,and an opening of the rain shielding cap is away from the intake port, so that exhausted waste gas is prevented from being sucked by the intake port, and the quality of inlet air is ensured.

Owner:美国杰瑞国际有限公司

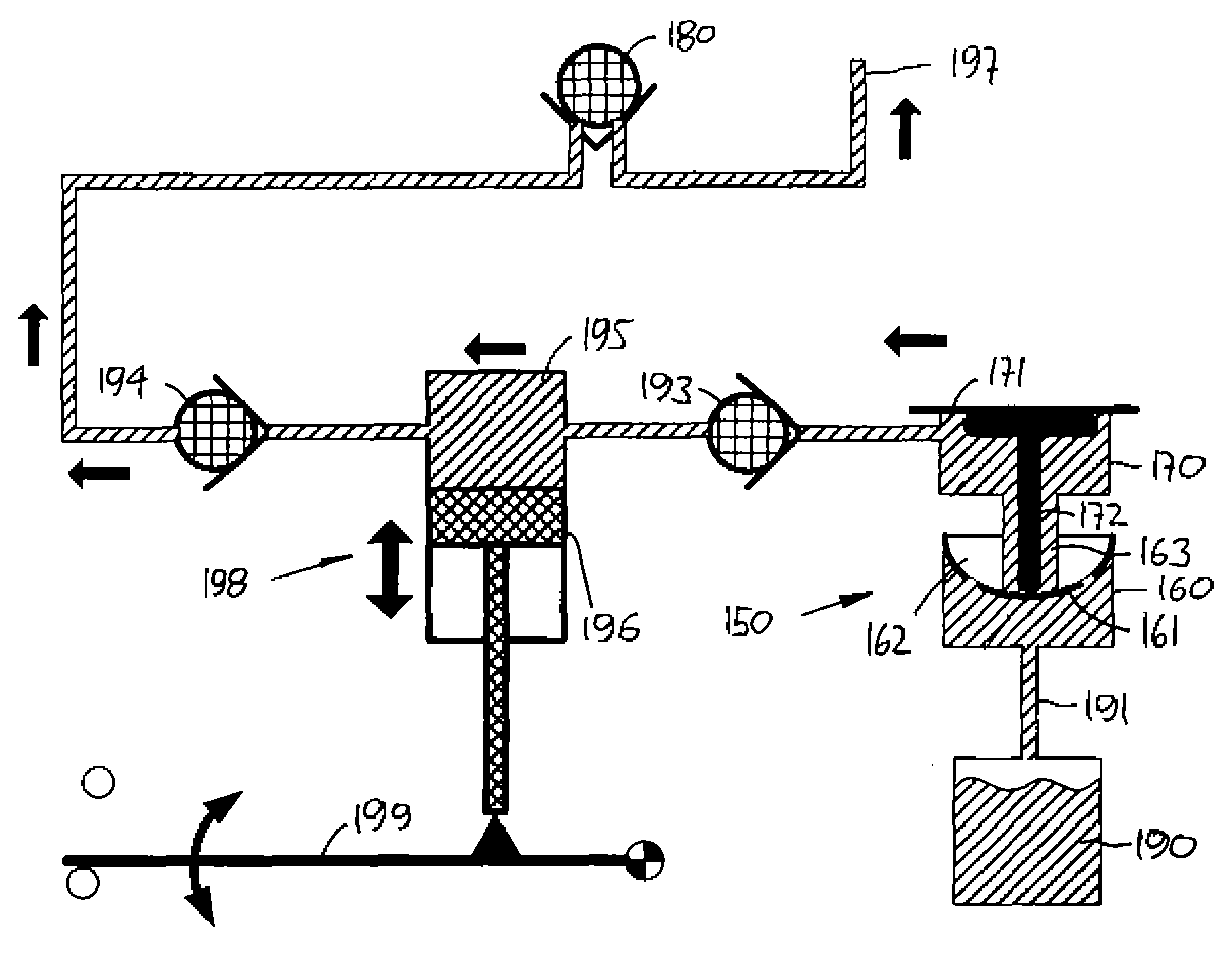

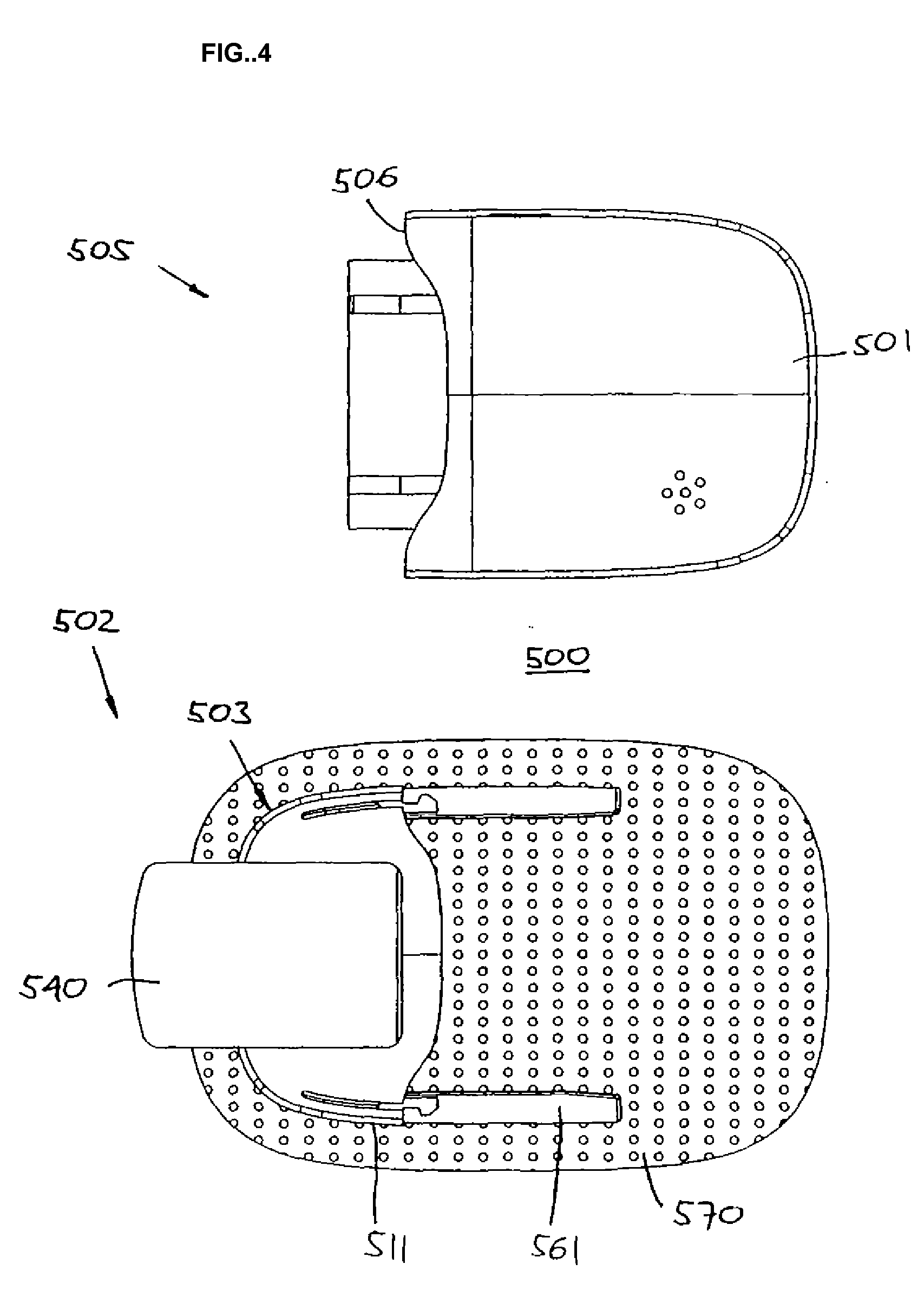

Pump Assembly With Safety Valve

InactiveUS20080188810A1High protection levelPrevent suckingPressure infusionPump installationsInlet valveSafety valve

The invention provides a pump assembly comprising a suction pump and a safety valve arranged between the pump inlet and a fluid inlet for the assembly. The safety valve comprises an inlet valve and a moveable control member acting on the safety inlet valve, wherein the control member is operatable between an initial position in which the safety inlet valve is closed, and an activated position in which the safety inlet valve is open, and wherein the control member is moved from the initial to the activated position by means of suction action from the pump. By this arrangement the opening of the safety valve is positively controlled by the suction provided by the pump whereas the safety valve is closed during non-operation of the pump.

Owner:NOVO NORDISK AS

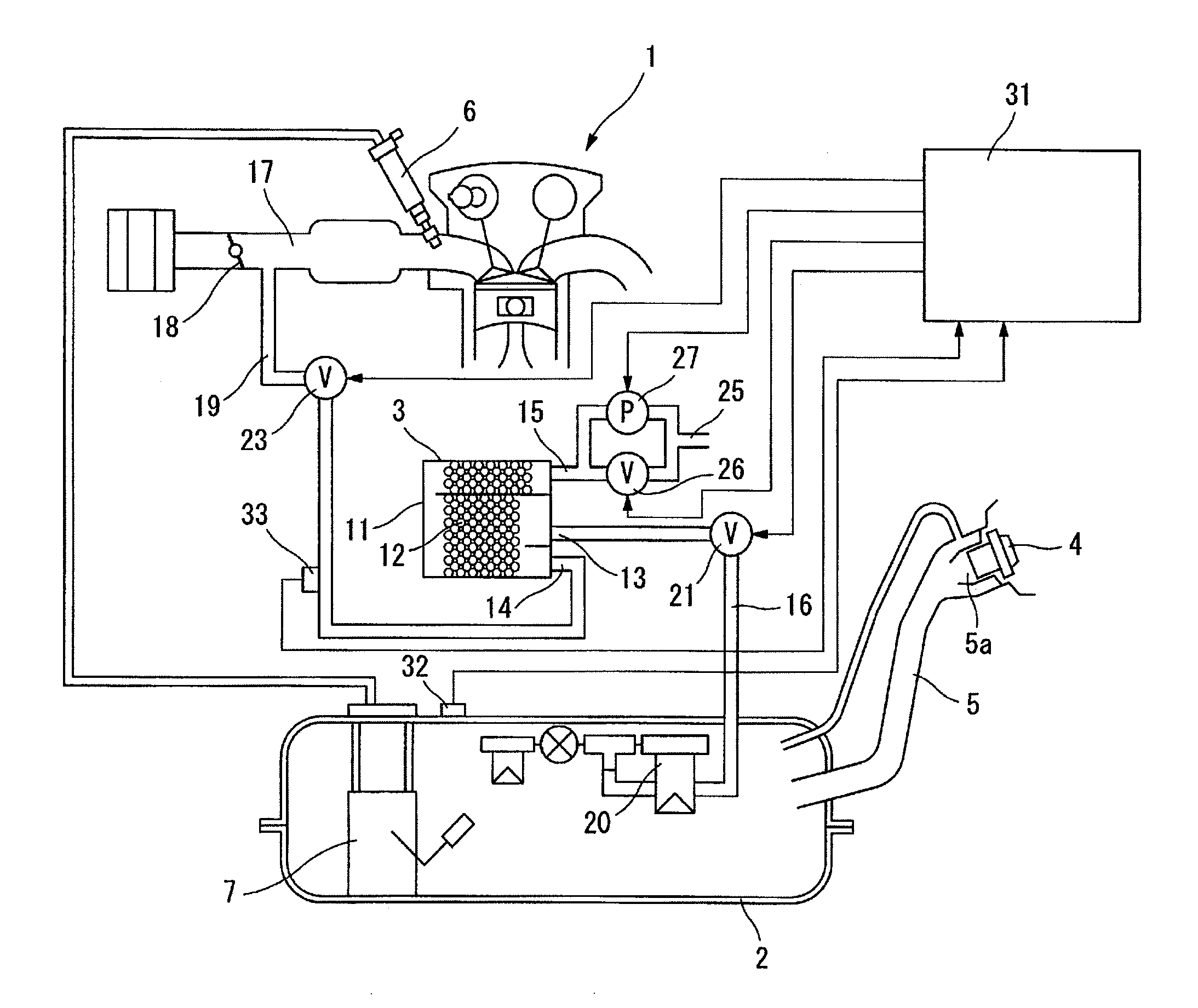

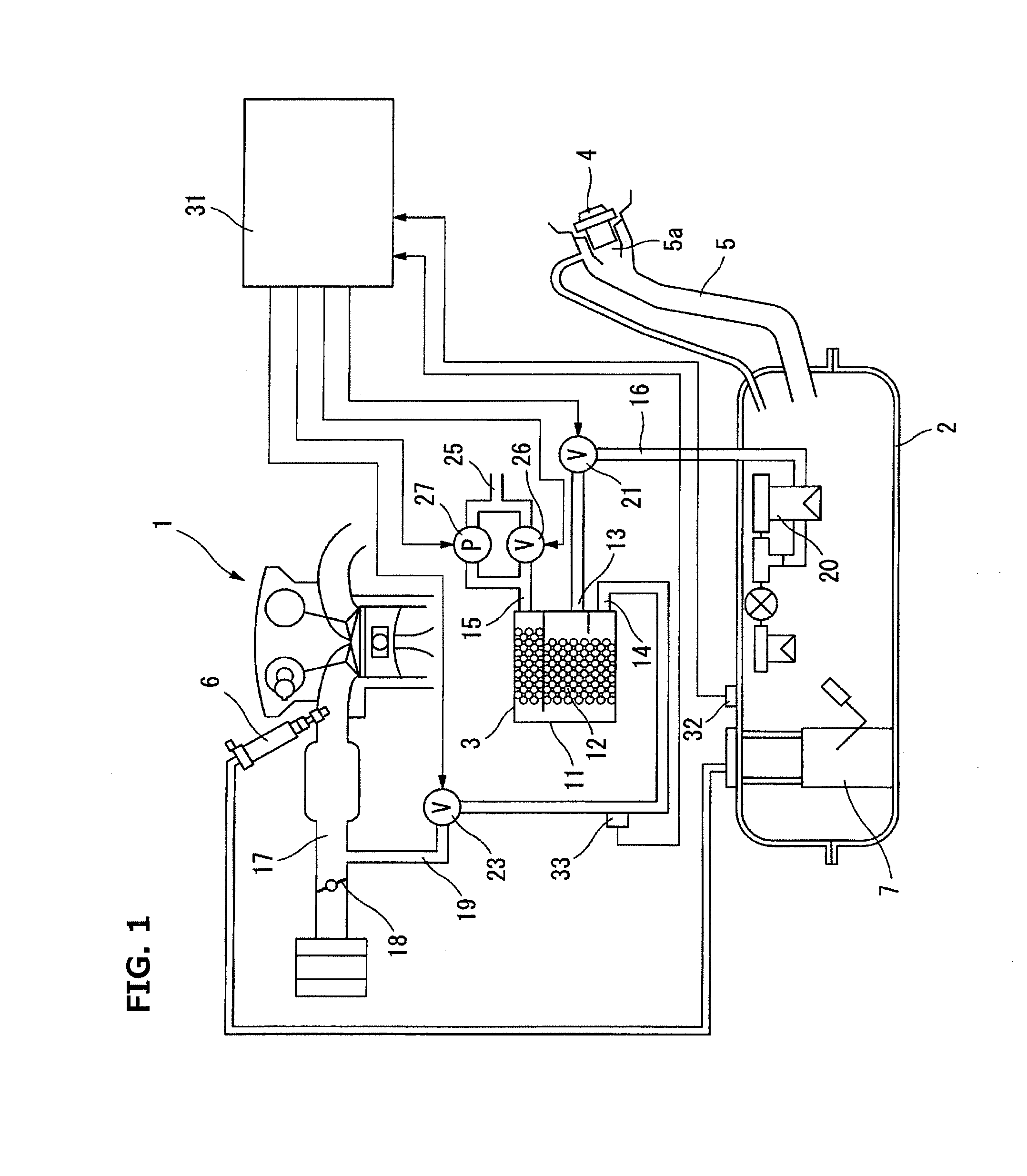

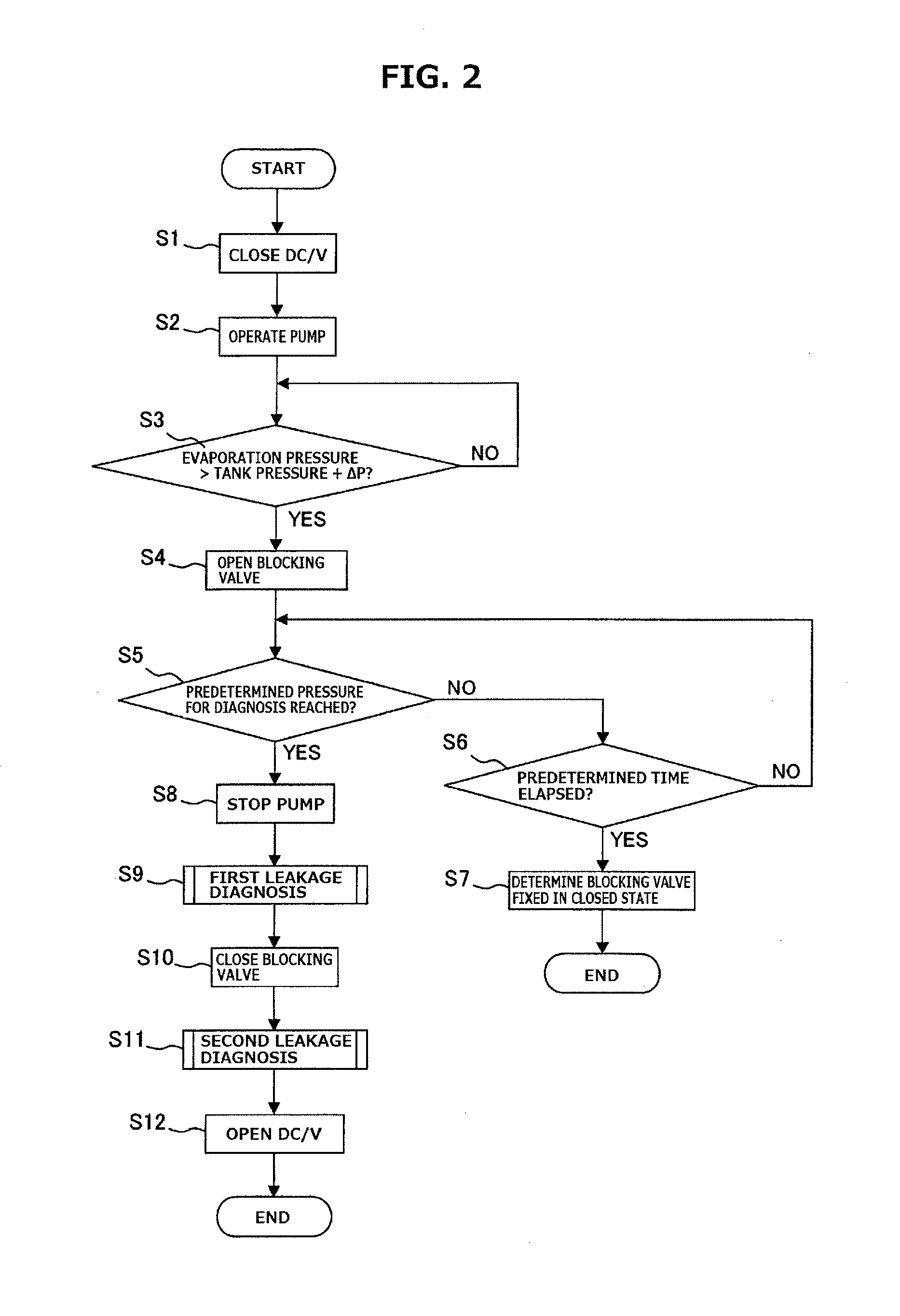

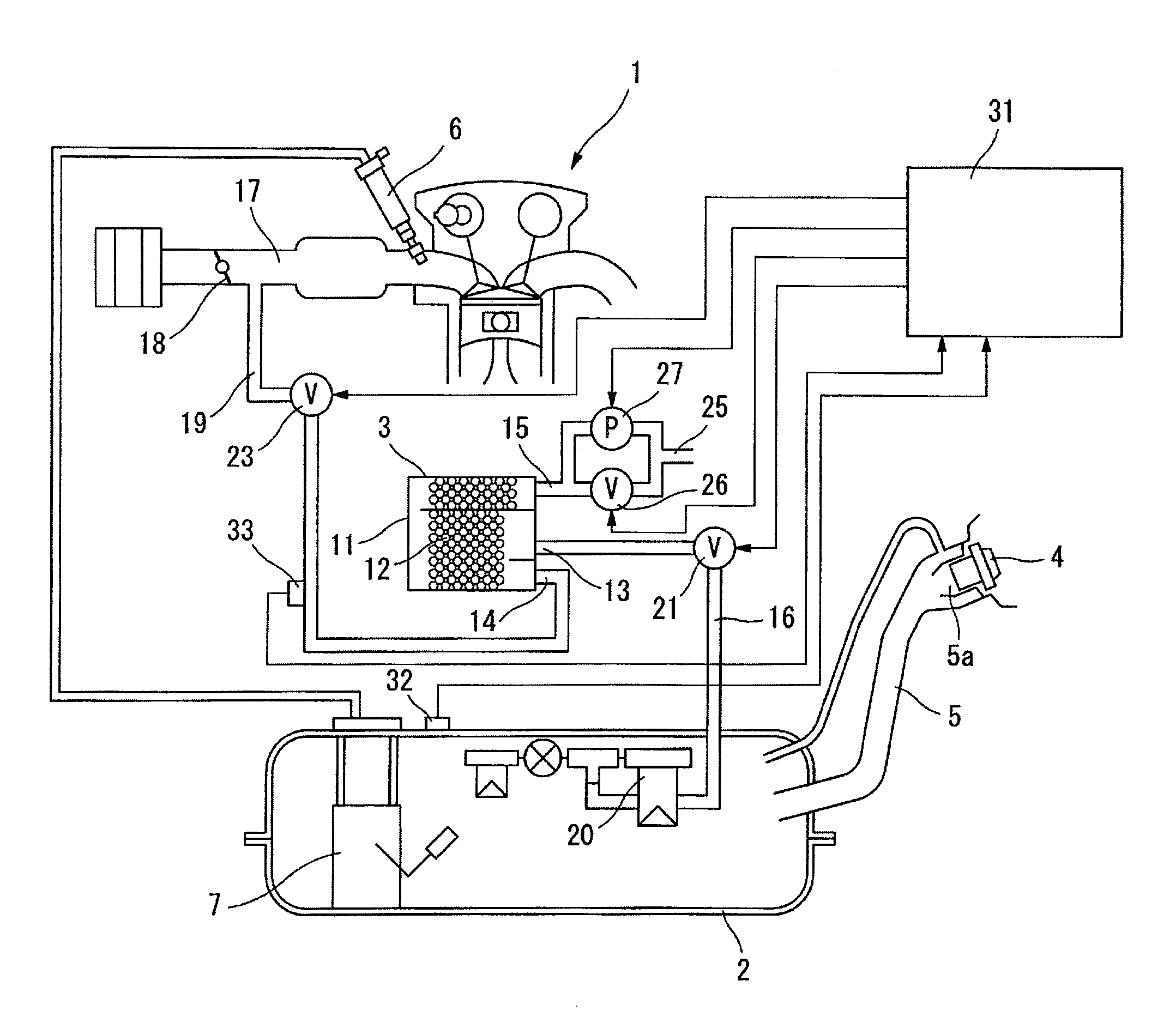

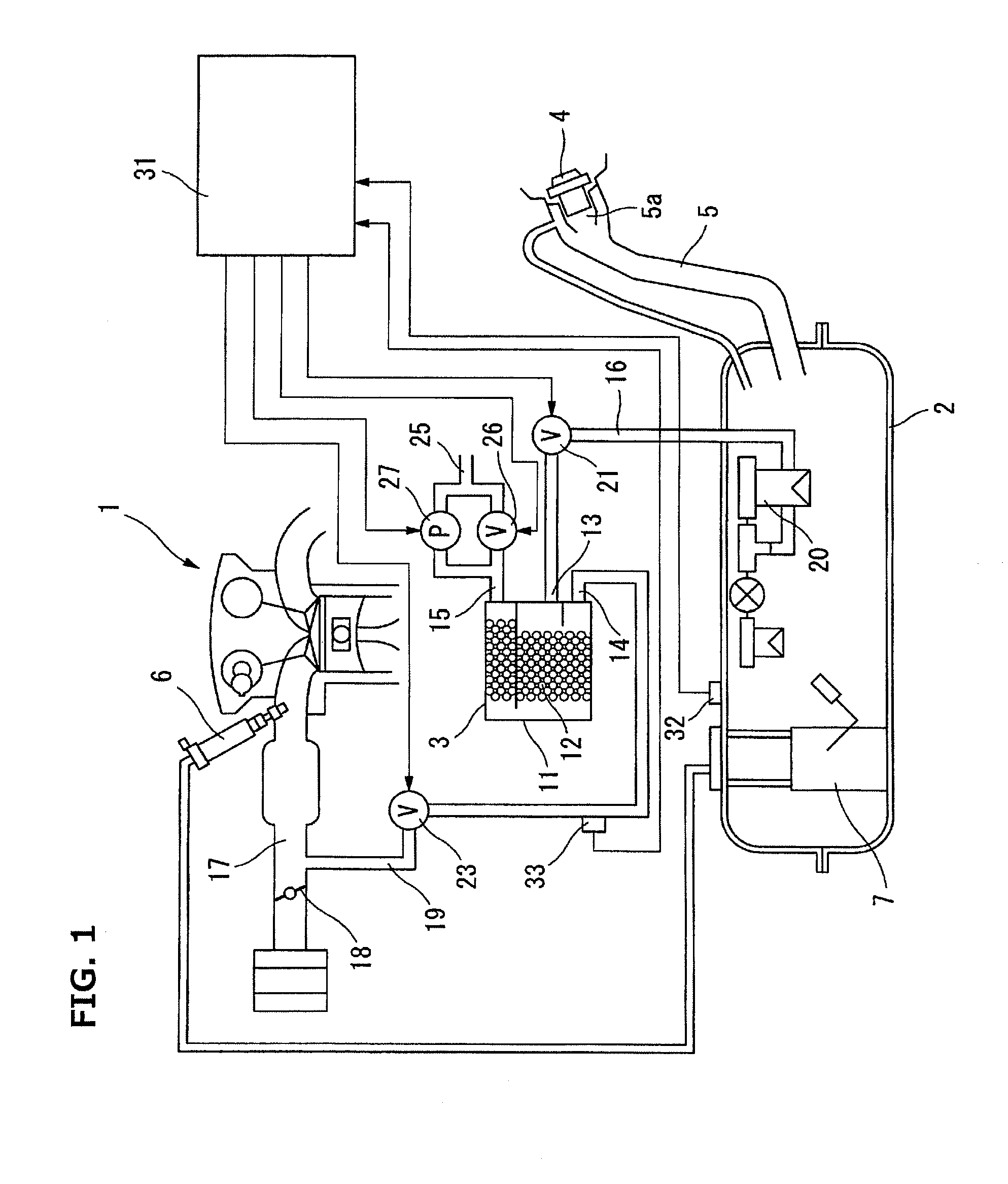

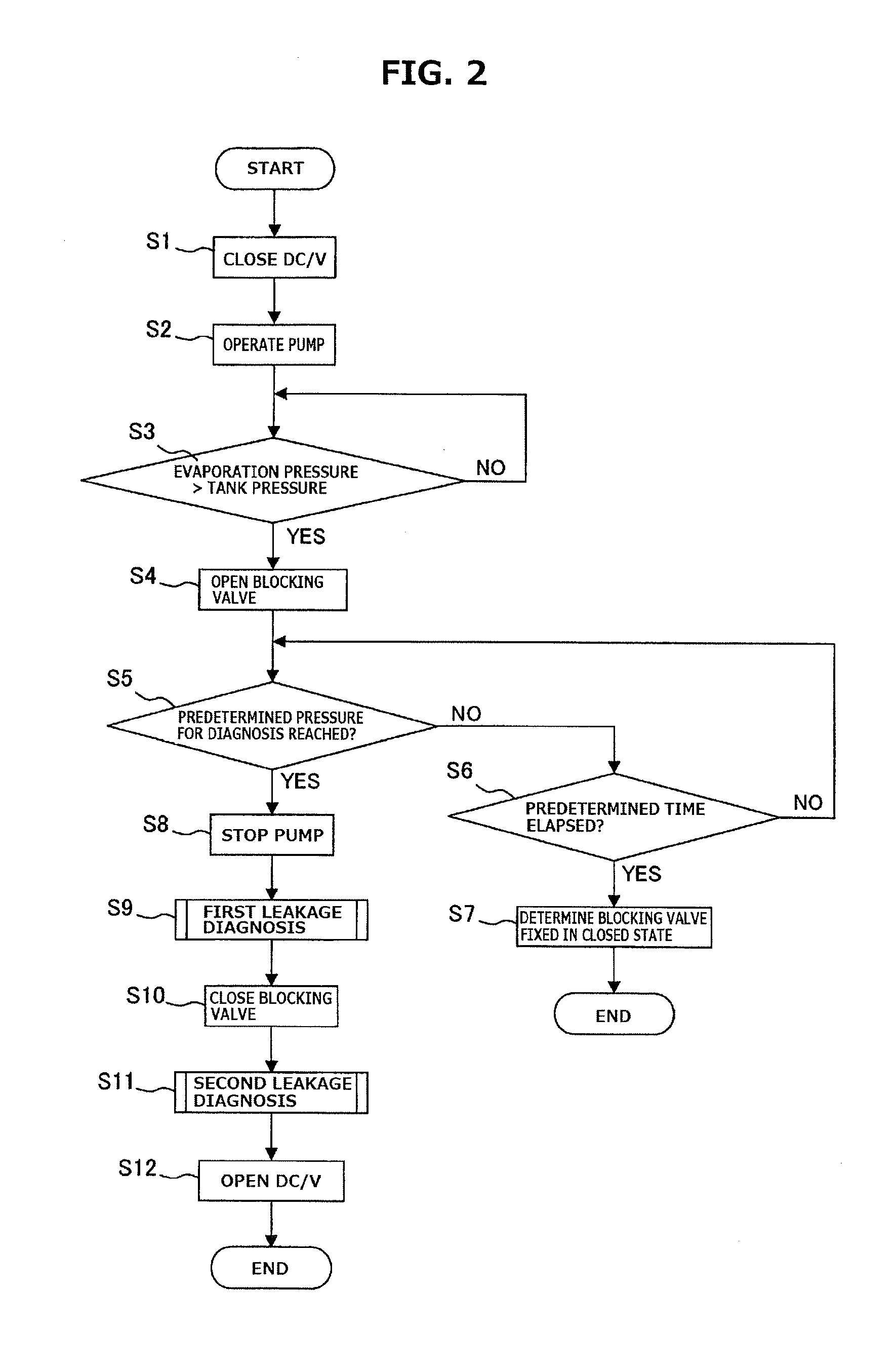

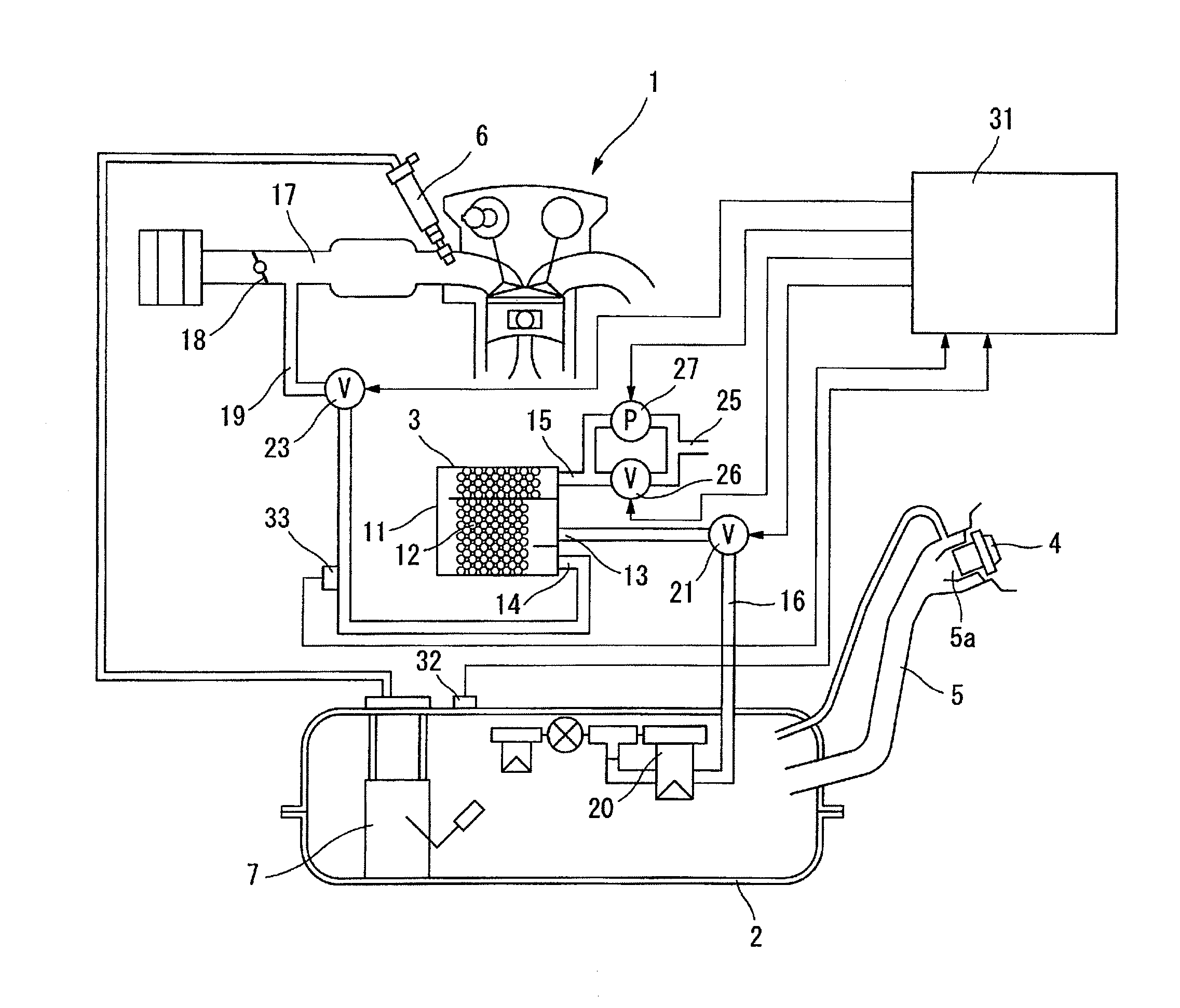

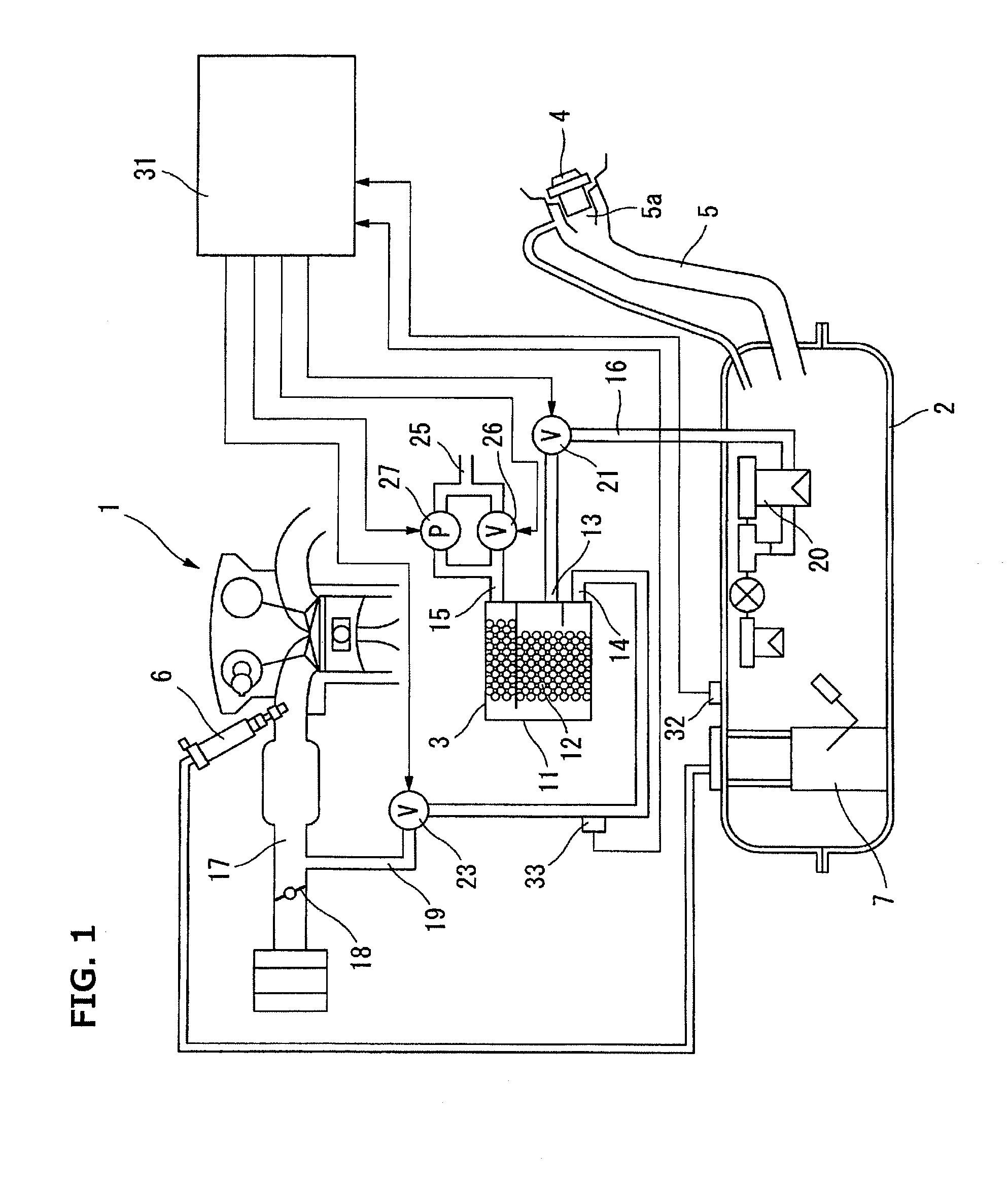

Device and method for diagnosing evaporated fuel processing device

ActiveUS20150013437A1High internal pressureSuppress increase of adsorbed amountDetection of fluid at leakage pointMeasurement of fluid loss/gain rateAutomotive engineeringFuel tank

An evaporated fuel processing apparatus includes a valve between a canister and a fuel tank, and maintains the fuel tank in hermetic state by closing the valve while a vehicle is stationary, and adsorbs evaporated fuel by the canister by opening the valve during fuel filling, wherein the evaporated fuel occurs in the fuel tank. A diagnostic apparatus includes: a pump connected to a canister-side region with respect to the valve, and configured to pressurize a system of the canister and the fuel tank; and a pressure sensor for sensing an internal pressure of the system. The diagnostic apparatus starts pressurization by the pump with the valve closed; brings the system into a pressurized state by opening the valve with a delay after the start of pressurization; and performs a leakage diagnosis based on a change in the internal pressure of the system from the pressurized state.

Owner:NISSAN MOTOR CO LTD

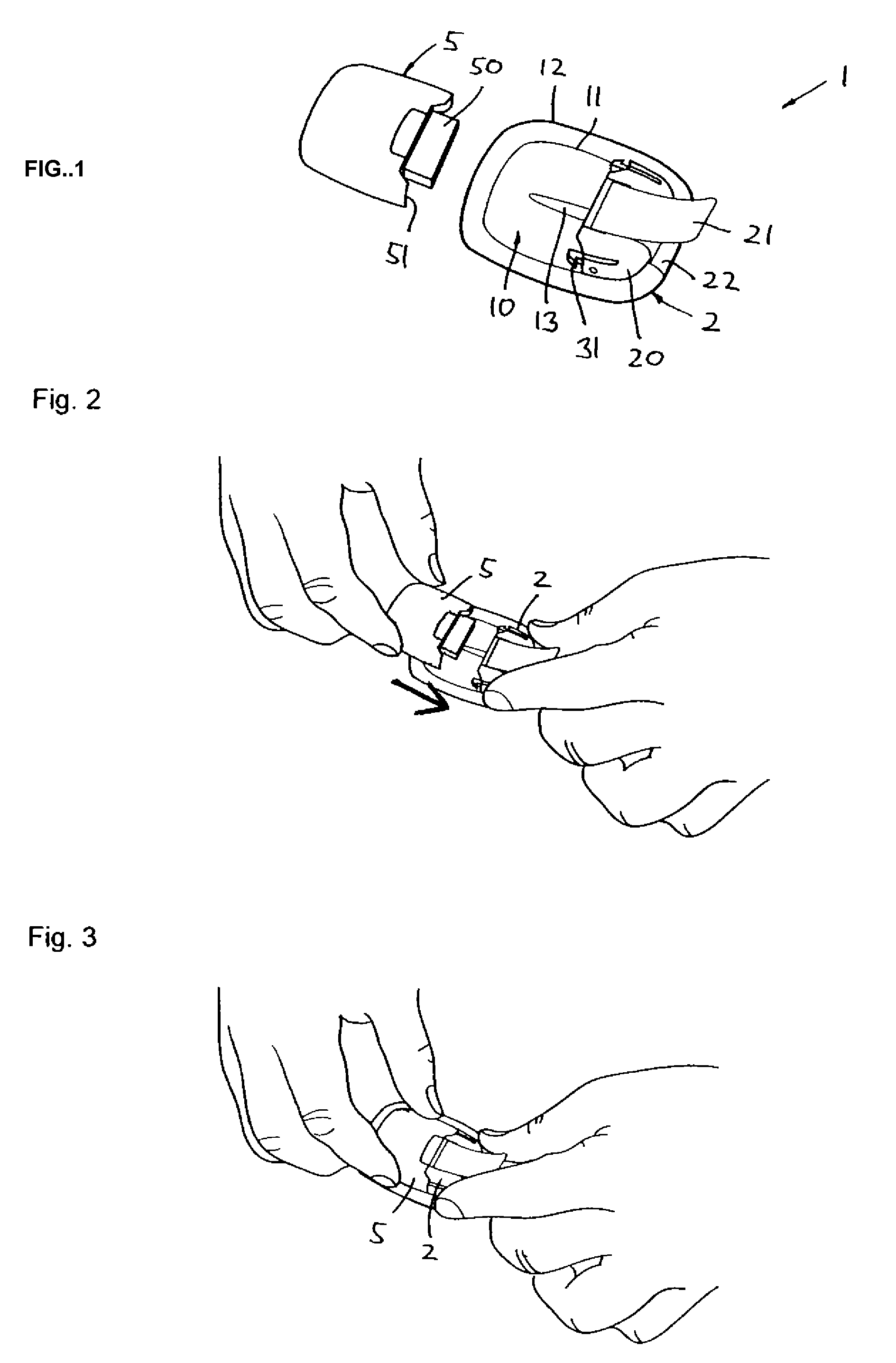

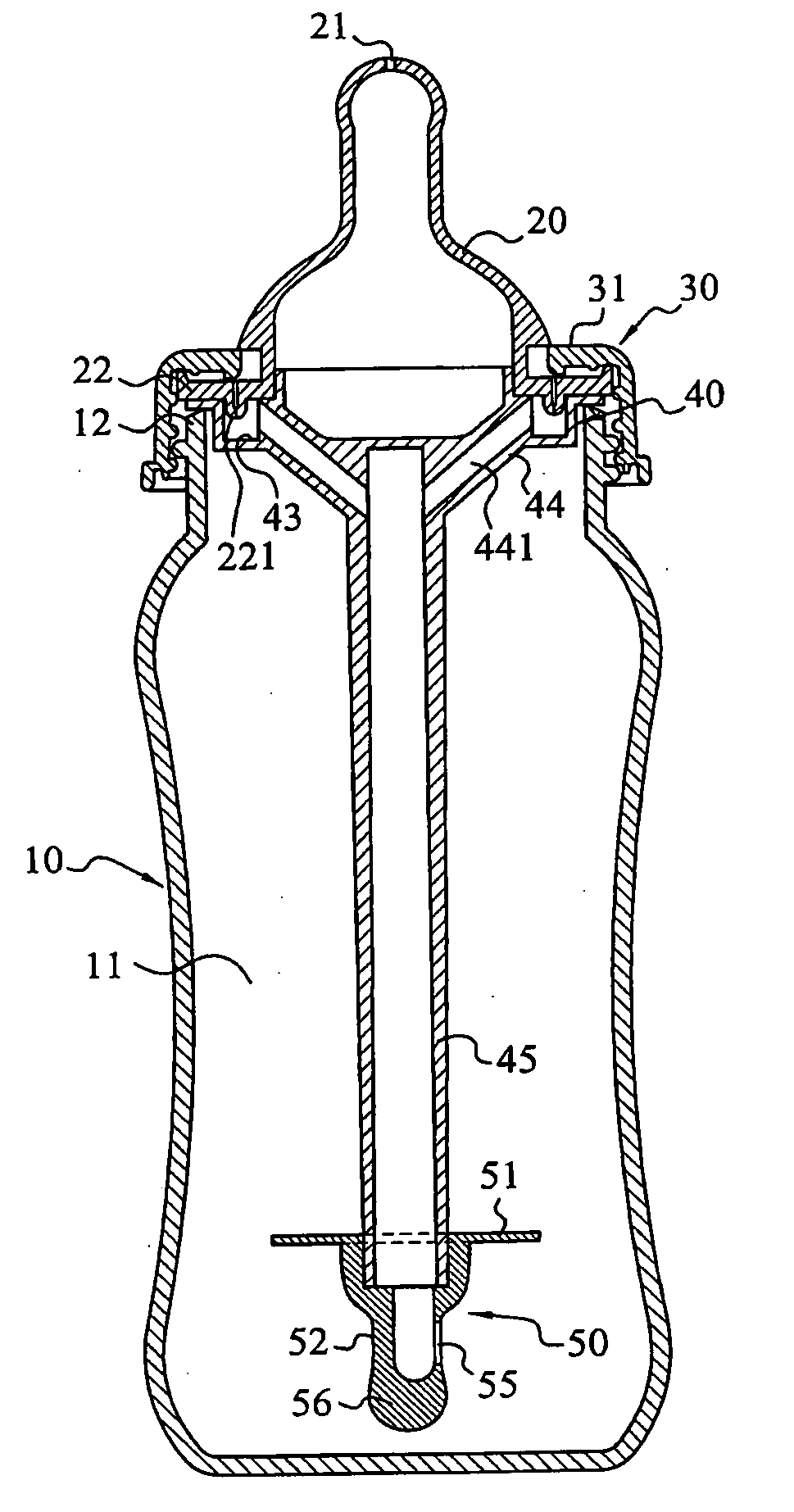

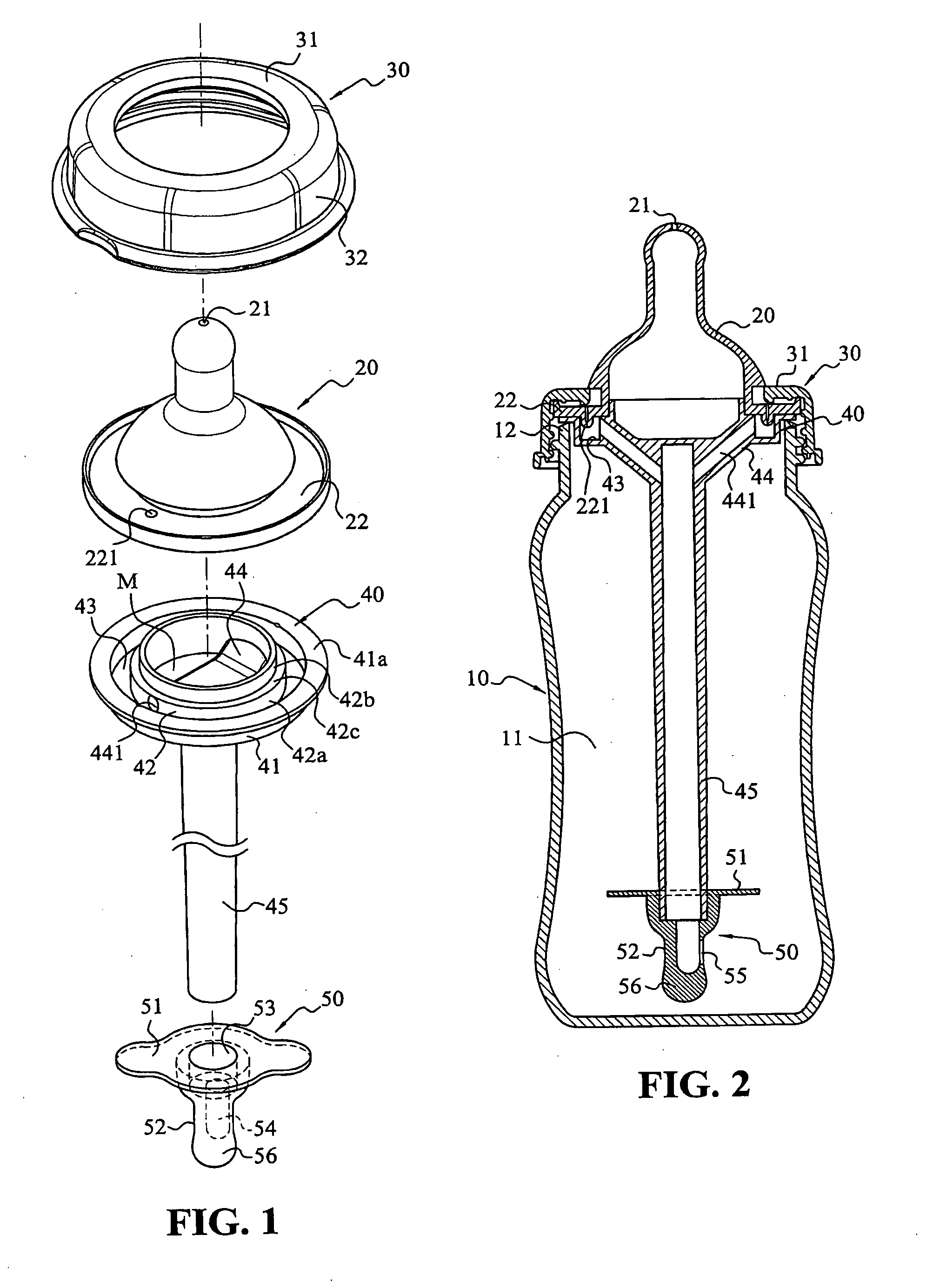

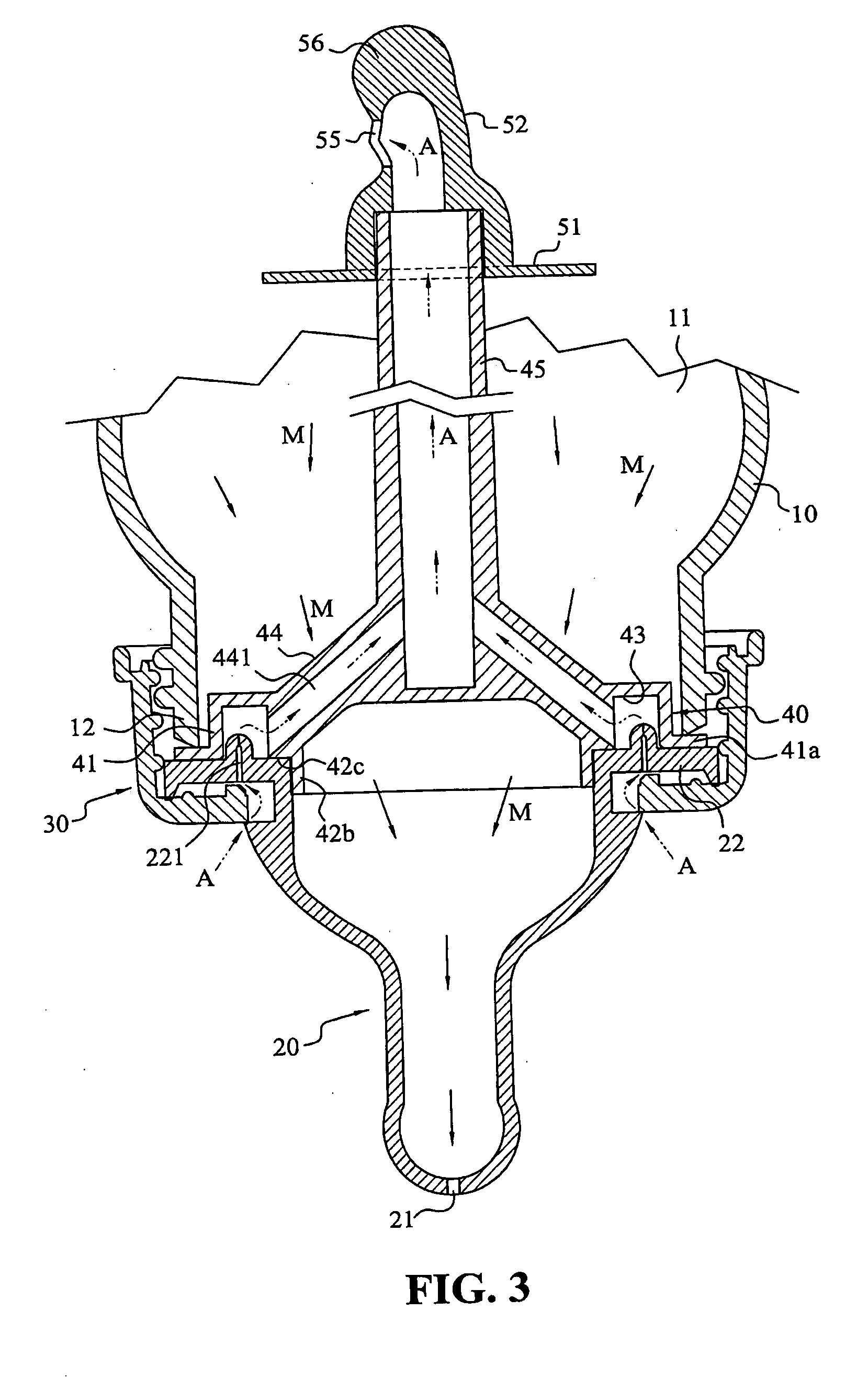

Liquid and air flow dividing arrangement for baby bottle

InactiveUS20090014403A1Less effortAvoid mixing and dissolvingFeeding-bottlesTeatsInternal pressurePositive pressure

A liquid and air flow dividing arrangement for baby bottle, comprising a bottle body, a nipple and a cover, and a plurality of check valve being provided on the base of the nipple, wherein said liquid and air flow dividing arrangement includes: a disk body fixed between the base of the nipple and the bottle opening by the fastening of the cover, which has a first sleeve provided on the outer side end to insert within the bottle opening of the bottle body and a second sleeve provided on the inner side end to insert on the inner side of the nipple, a recess being formed between the first sleeve and the second sleeve for receiving the check valve; and a pair of branched pipes extended from the side wall of the second sleeve in the center direction, each branched pipe having an air inlet hole communicated with the recess, both branched pipes being combined at the inside to form an air vent pipe extending towards the bottom of the bottle. The milk liquid during the baby feeding moves from the bottle body along one flow passage M, simultaneously the air enters from the other flow passage A into the bottle for quick supplement so as to balance the internal pressure. The interior of the baby bottle thus maintains a positive pressure all the time, so that the baby can suck milk smoothly without much effort.

Owner:LU CHIEN CHIH

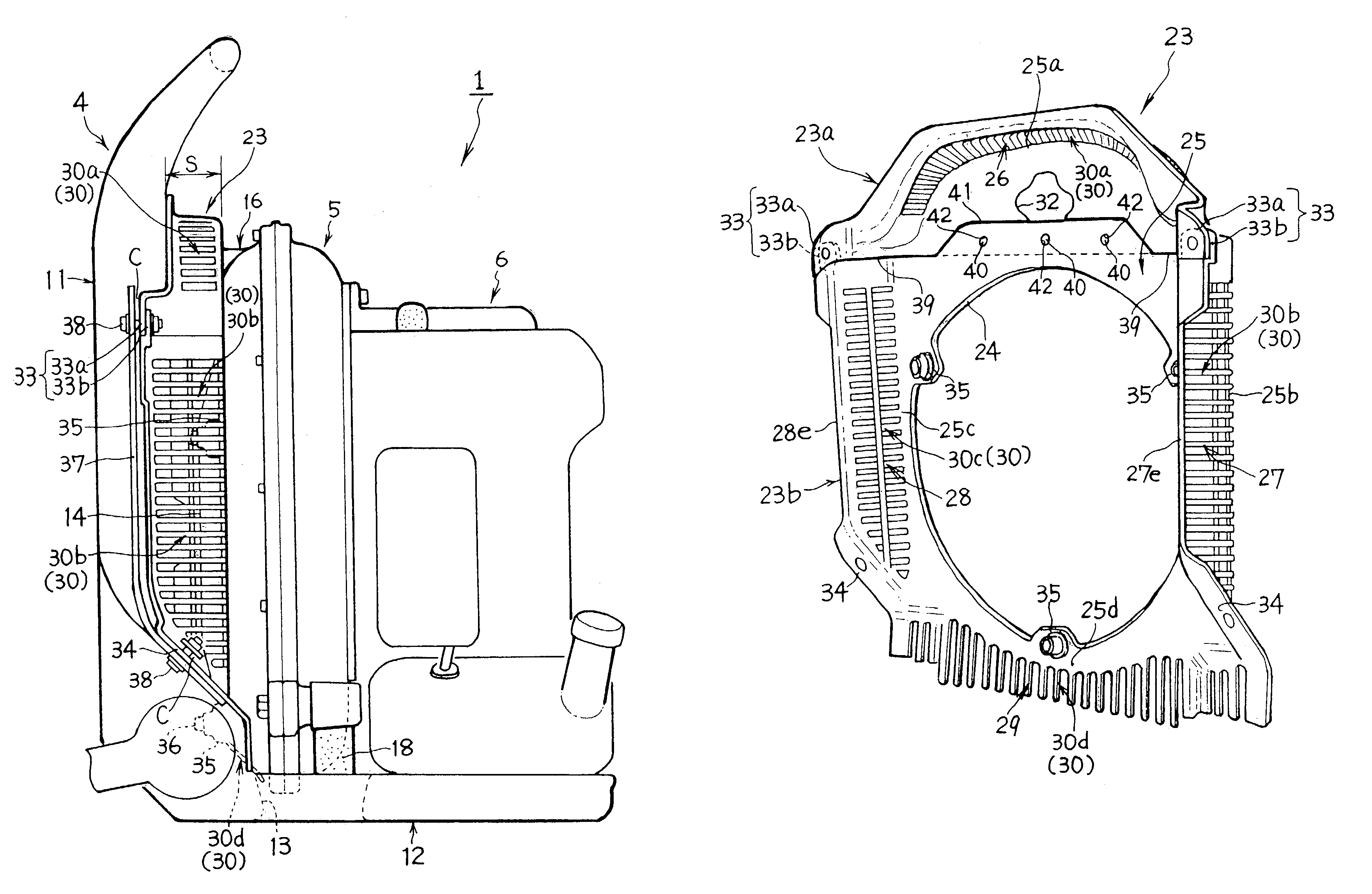

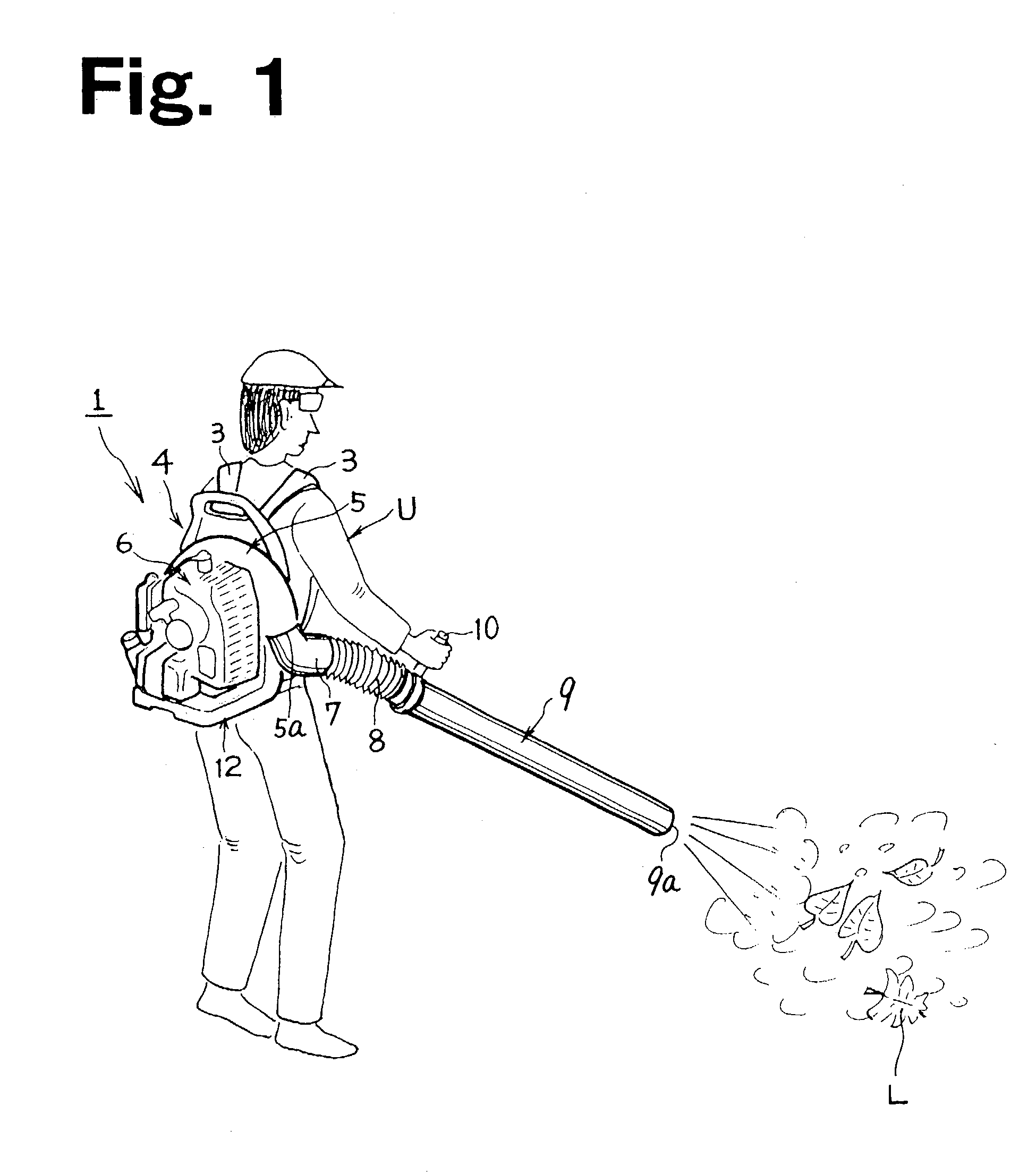

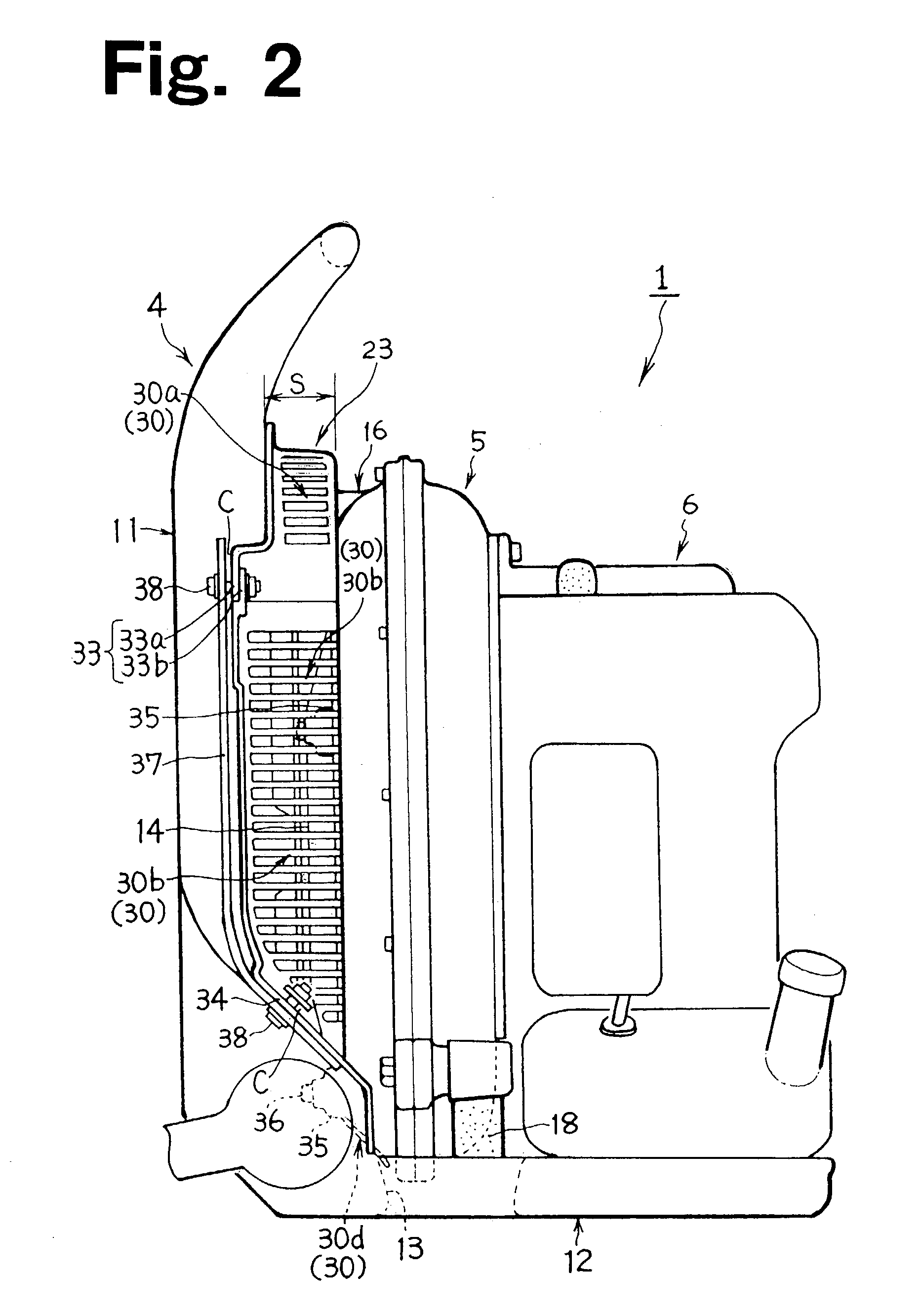

Power blower having a debris-catching cover

ActiveUS7055213B2Avoid it happening againEasy to disassemble and operatePump componentsHops/wine cultivationAerospace engineering

Owner:KIORITZ

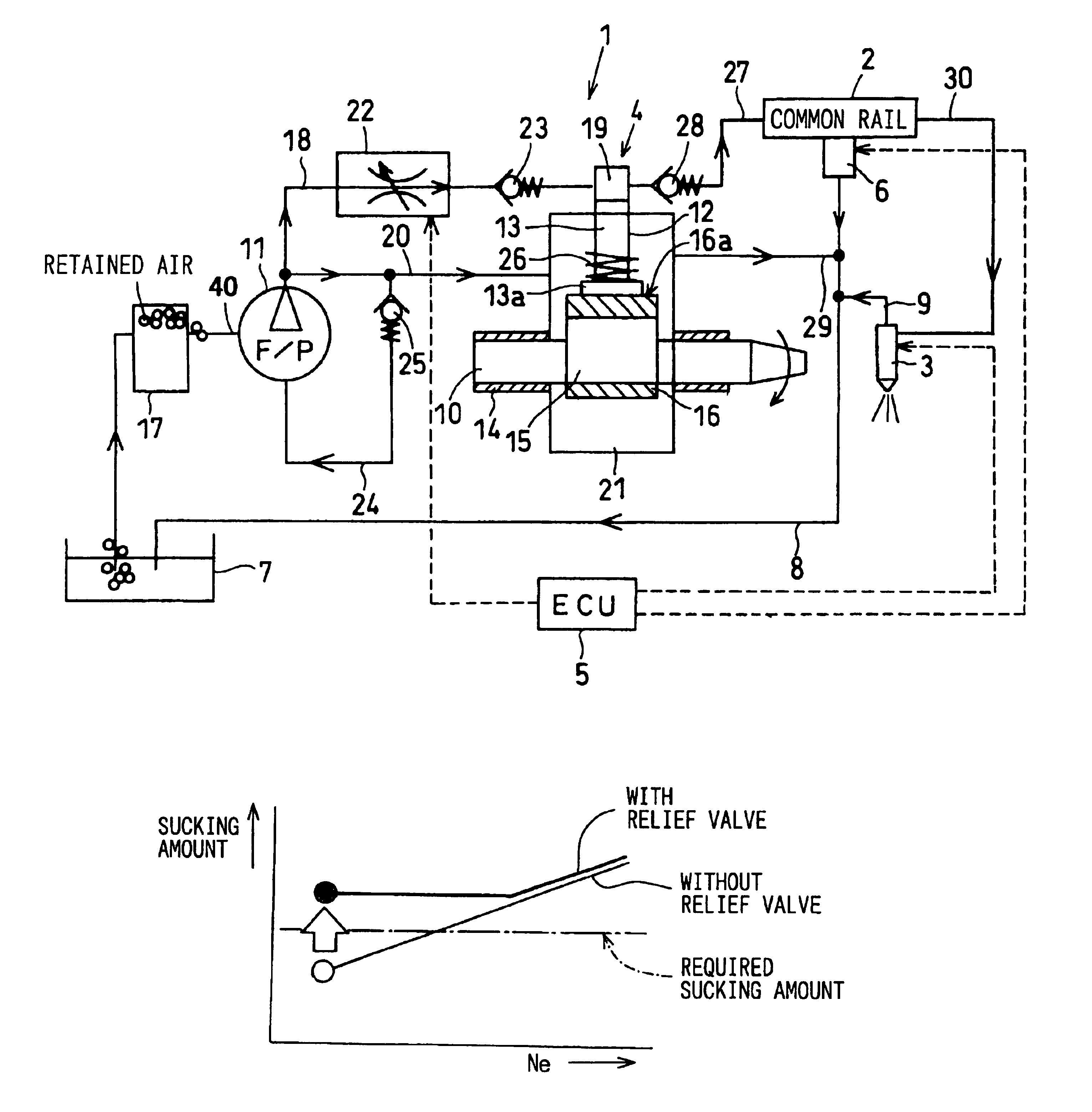

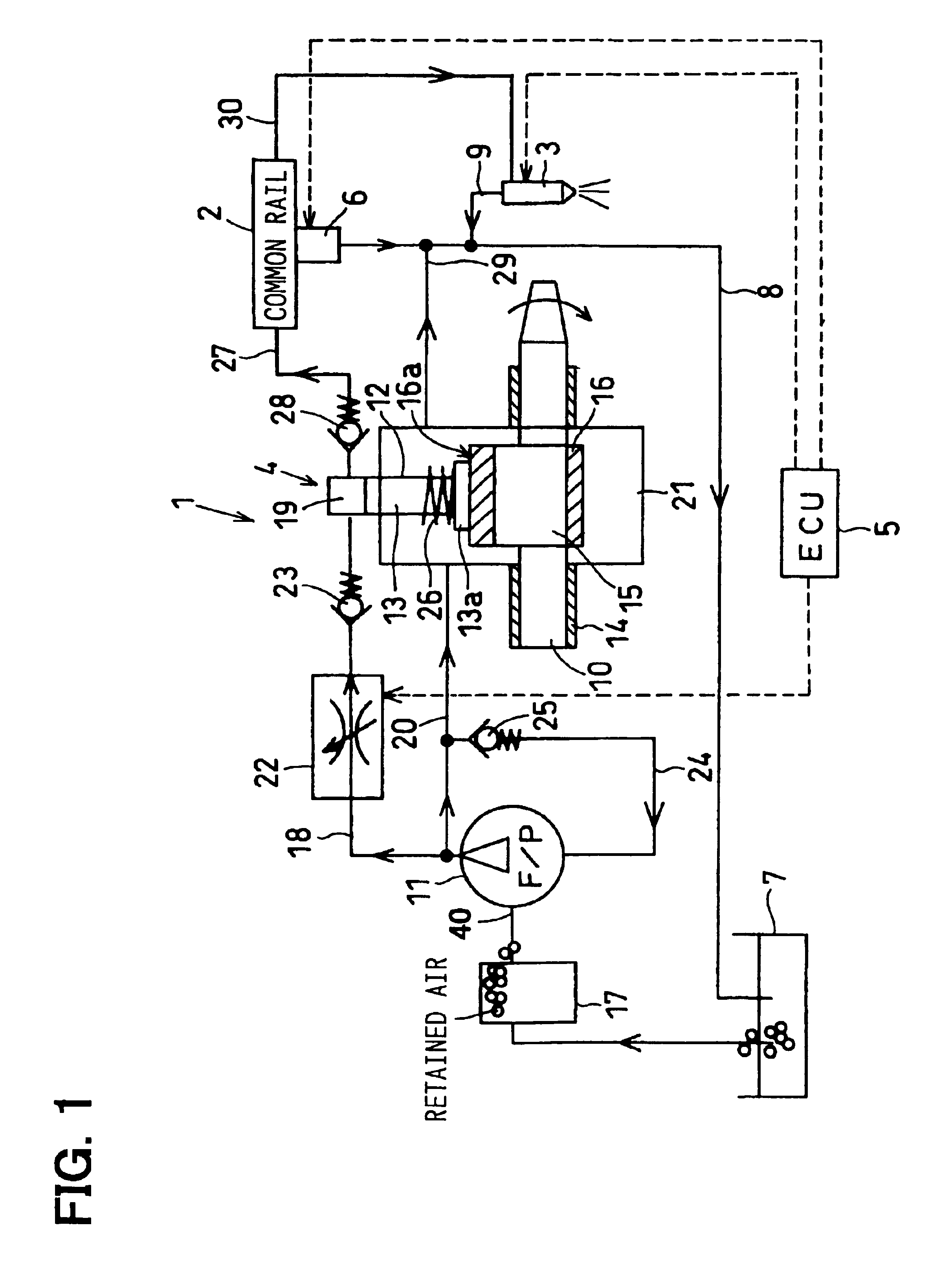

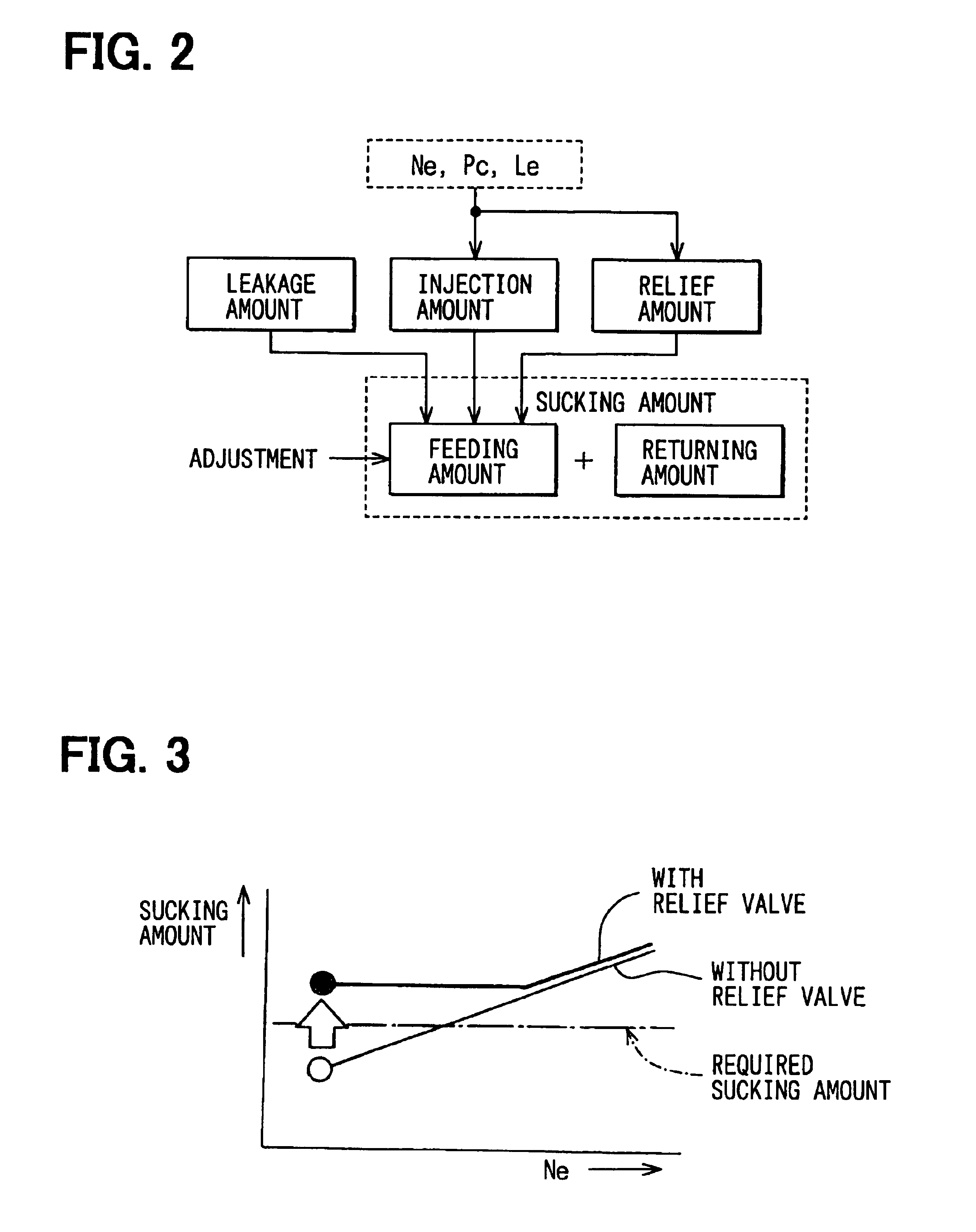

Common rail type fuel injection system

ActiveUS6895936B2Large amount of air is preventedLarge amount of airElectrical controlLow-pressure fuel injectionCommon railFuel tank

In a common rail type fuel injection system, fuel in a fuel tank is sucked by a feed pump and fed to a pressurizing pump. Fuel pressurized in the pressurizing pump is supplied to a common rail. The pressurized fuel accumulated in the common rail is injected into a cylinder of an internal combustion engine from an injector. All of these operations are electronically controlled by an electronic control unit. To gradually suck air in the fuel tank together with fuel and to avoid air accumulation in a fuel filter, a relief valve is connected to the common rail. The relief valve is opened when the engine is idling thereby to increase an amount of fuel sucked by the feed pump and to gradually suck the air together with the fuel. The relief valve is opened only in interval periods in which fuel is not injected from the injector.

Owner:DENSO CORP

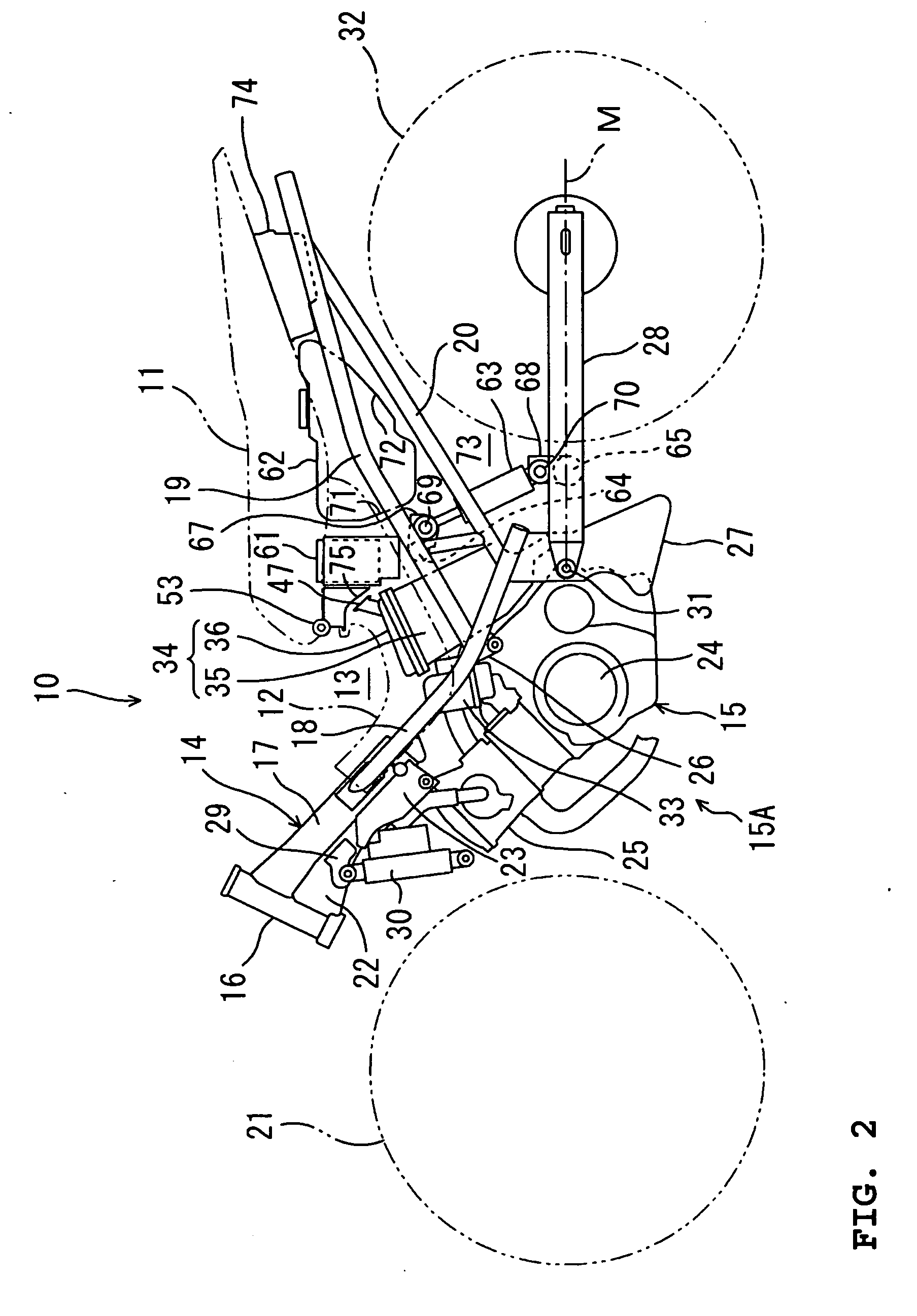

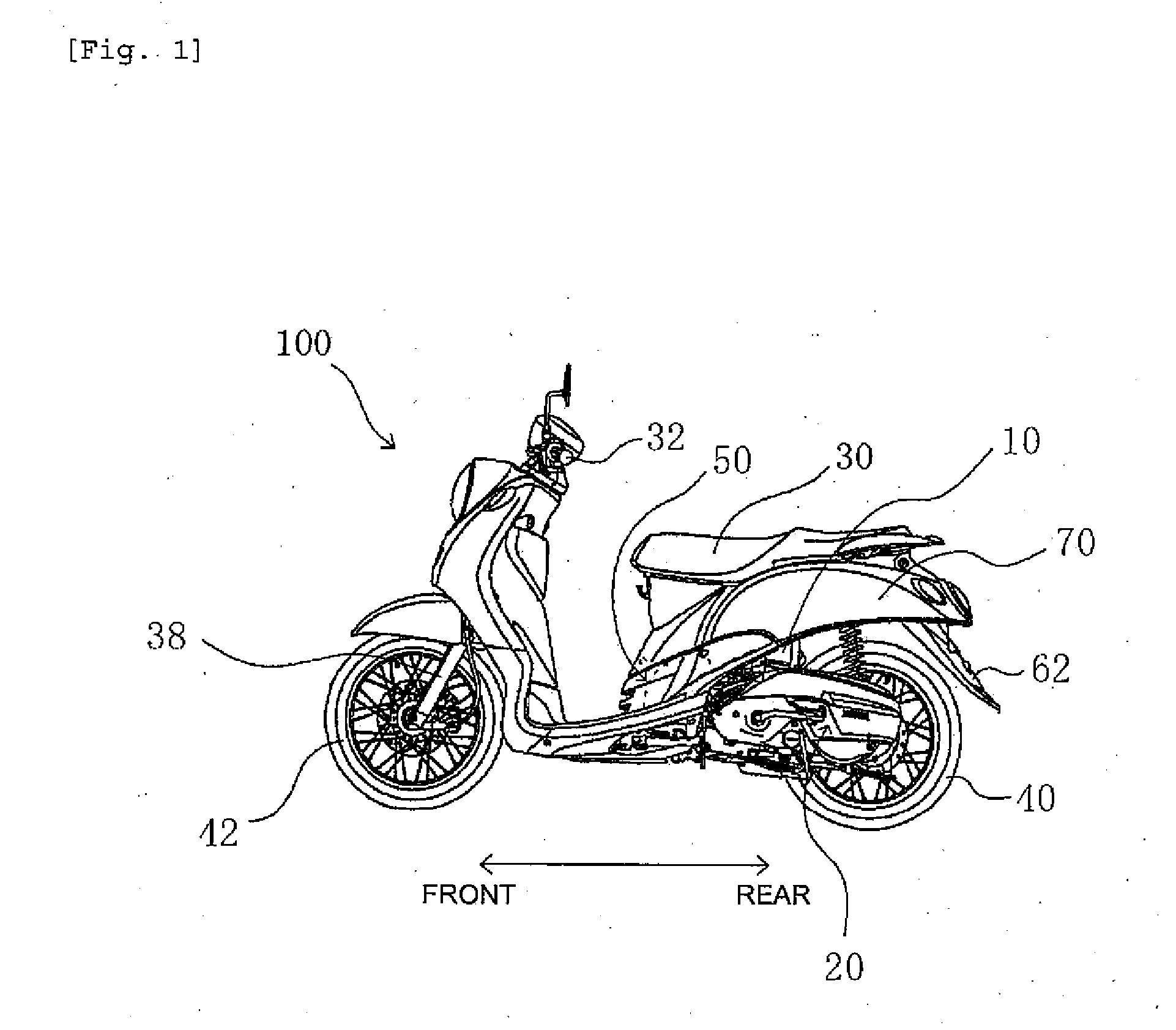

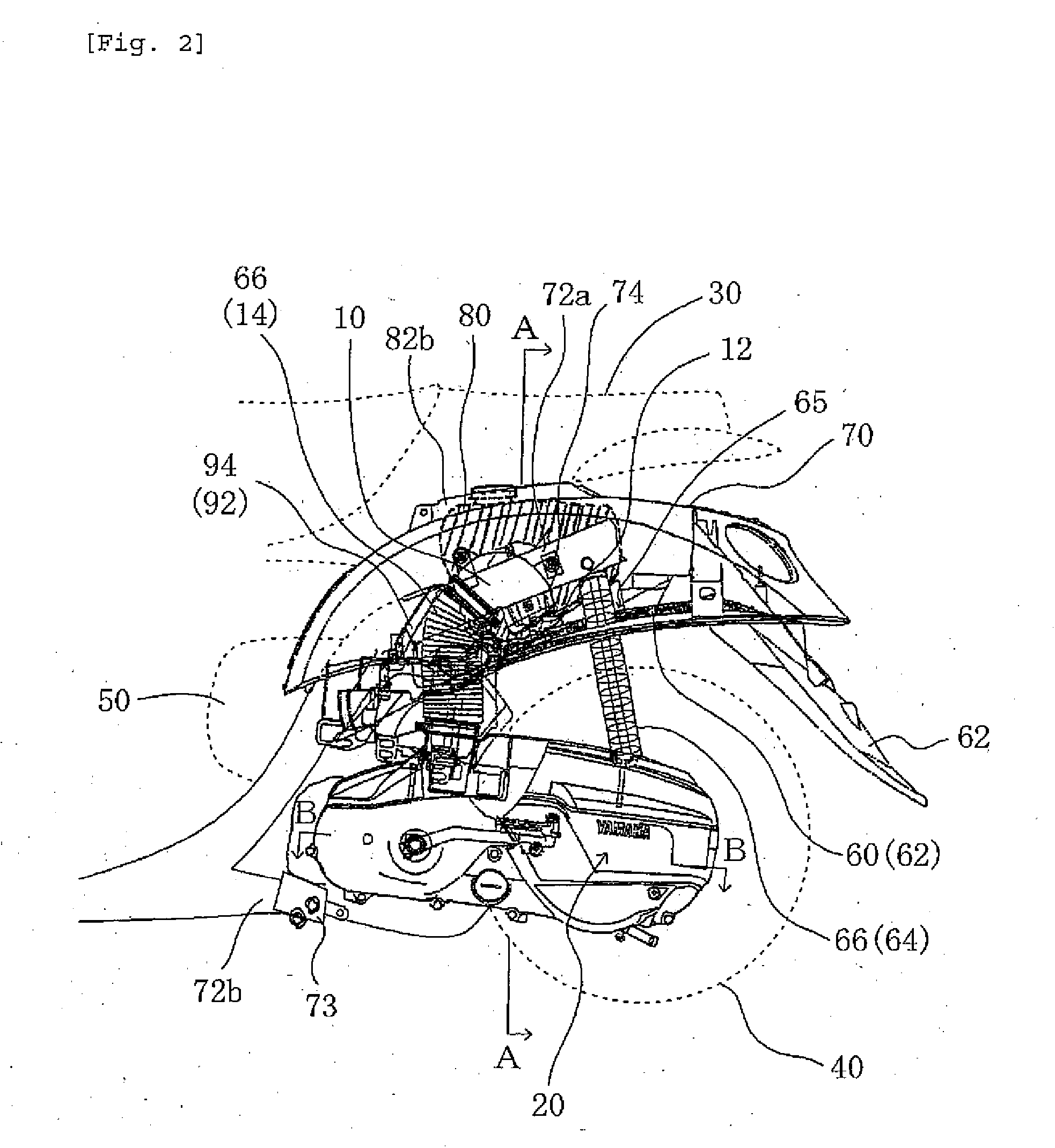

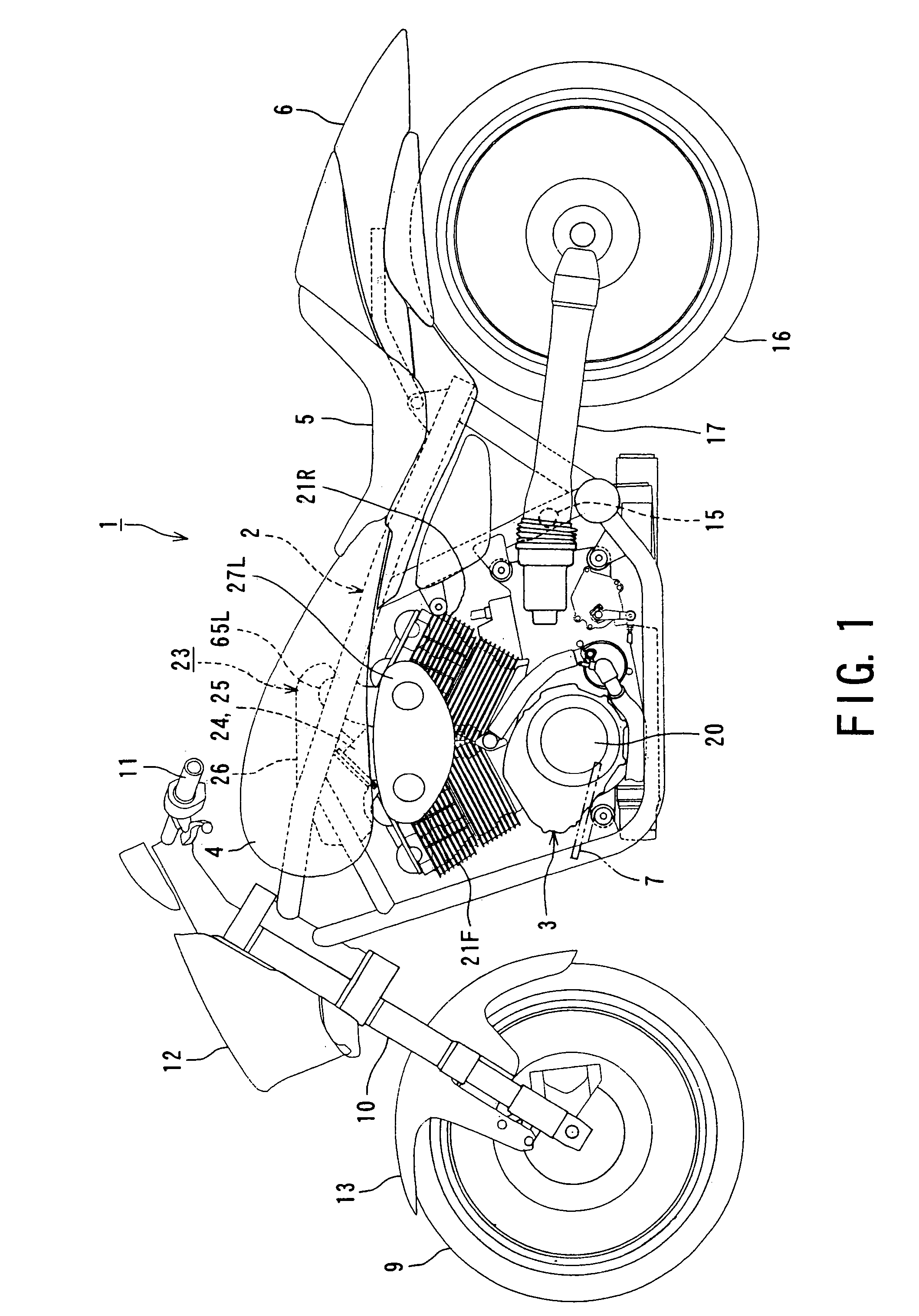

Straddle type vehicle

InactiveUS20060065457A1Big spaceEasy to useNon-fuel substance addition to fuelInternal combustion piston enginesCylinder blockFront cover

An air cleaner is prevented from sucking mud etc., while a relatively large space is ensured in front of a seat, in an under bone type straddle type vehicle which has an area recessed downward in front of the seat. An air cleaner is disposed in the rear of a cylinder block of an engine. The air cleaner includes a cleaner case that is taller than it is broad and a lid that covers a top of the cleaner case. An intake pipe is positioned at a rear side of the lid. The intake pipe is disposed within a space surrounded by the seat and a forward descending portion of a seat front cover, and opens obliquely upward rearward. A labyrinth structure is formed above the intake pipe for preventing drops of water from entering the intake pipe from the seat.

Owner:YAMAHA MOTOR CO LTD

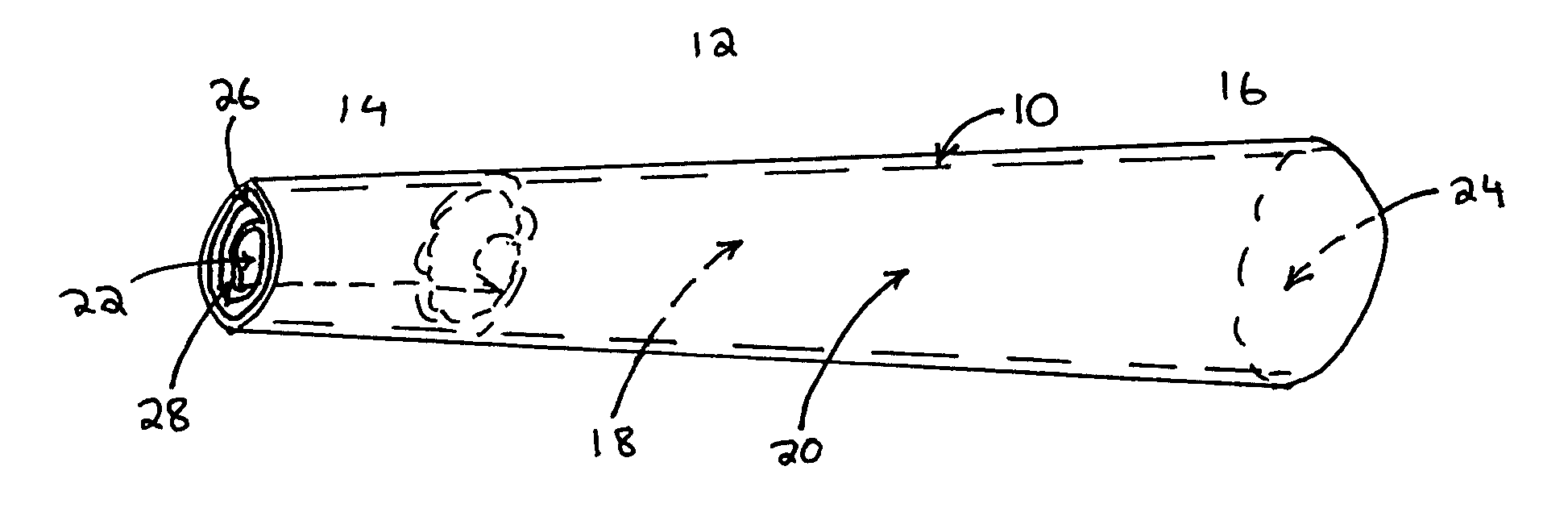

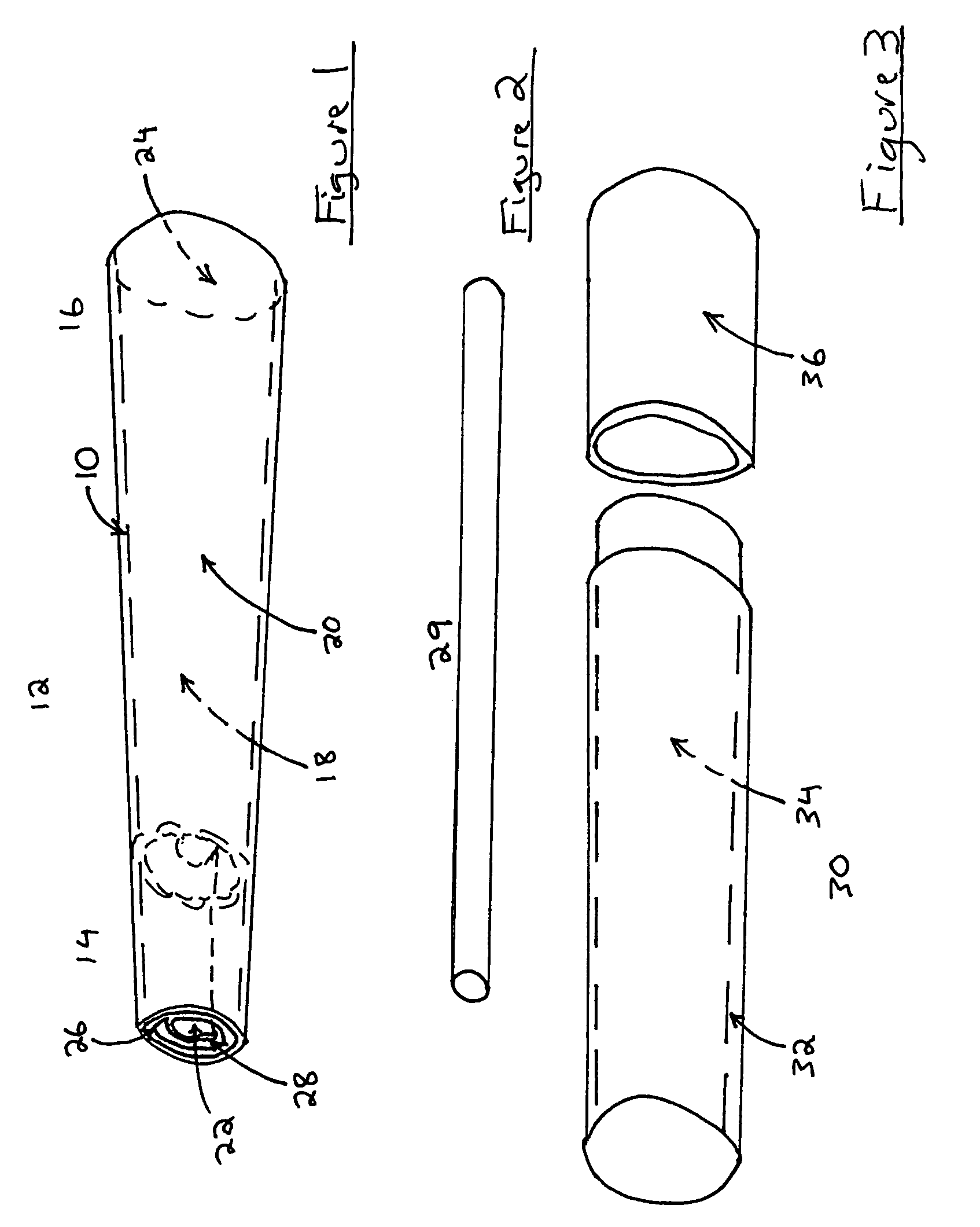

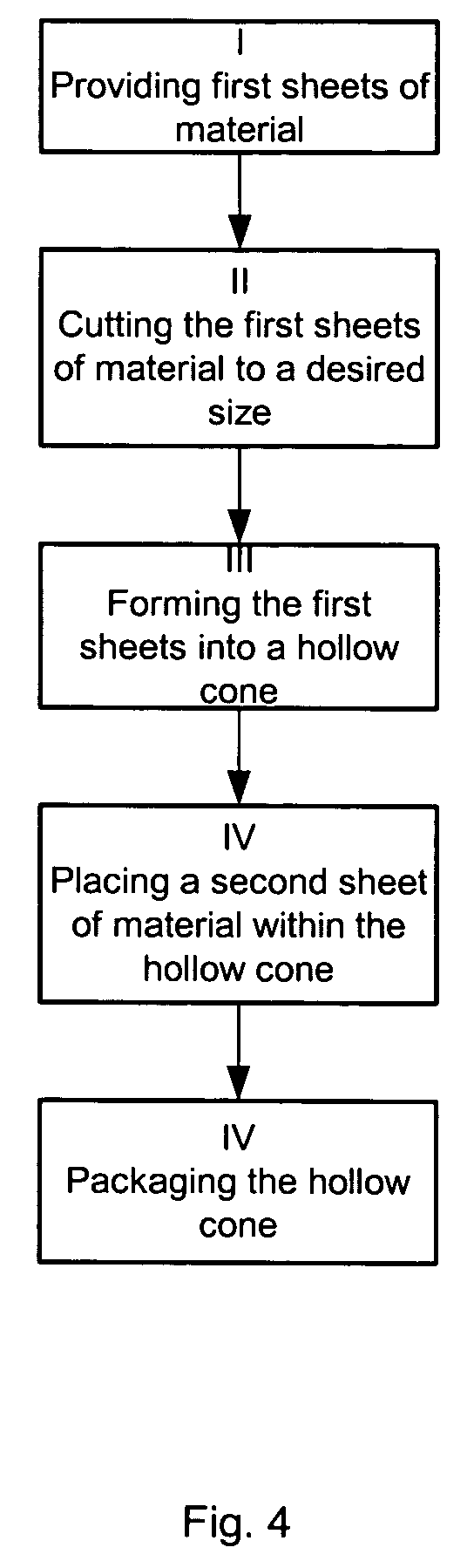

Cone wrapper for the consumption of smokable substances

ActiveUS7377281B2Easy to useSlower prolonged burnTobacco preparationNon-fibrous pulp additionEngineeringNicotine

The present invention provides a product and method of making thereof for the consumption of smokable substances such as tobacco or herbs. The product is comprised of tobacco, homogenized tobacco and / or natural leaf materials and has a hollow conical shape that allows for the easy insertion of smokable substances and further provides for larger amounts of smokable substances in the end of the product the consumer lights, resulting in an initial slower prolonged burn and more even distribution of nicotine. Additionally, the placement of a structure into one end of the hollow cone permits the consumer to consume the majority, if not all, of the smokable substance. This structure also prevents debris and other unwanted materials from being sucked through the end of the product and into the mouth and respiratory system of the consumer.

Owner:BBK TOBACCO & FOODS LLP

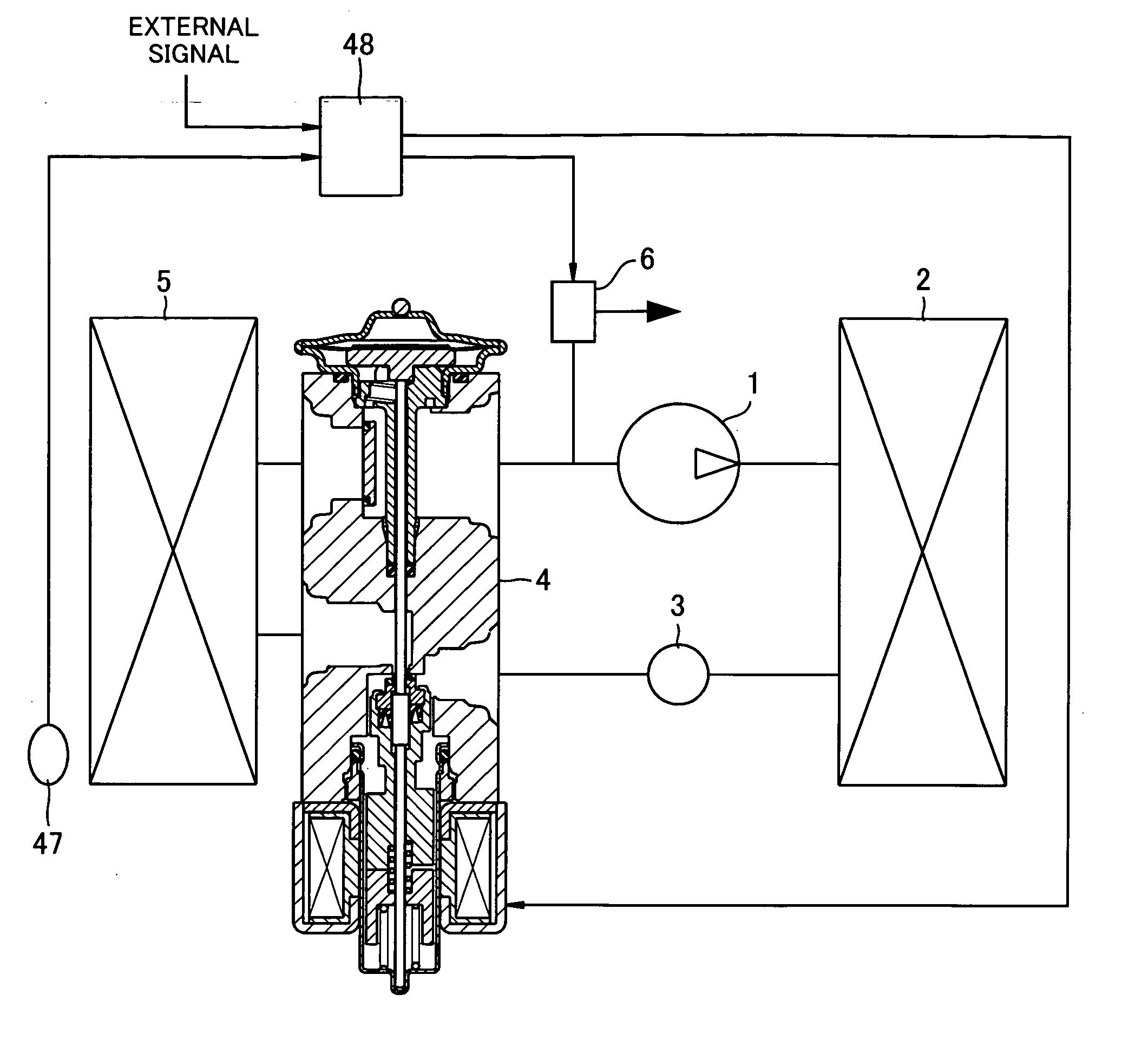

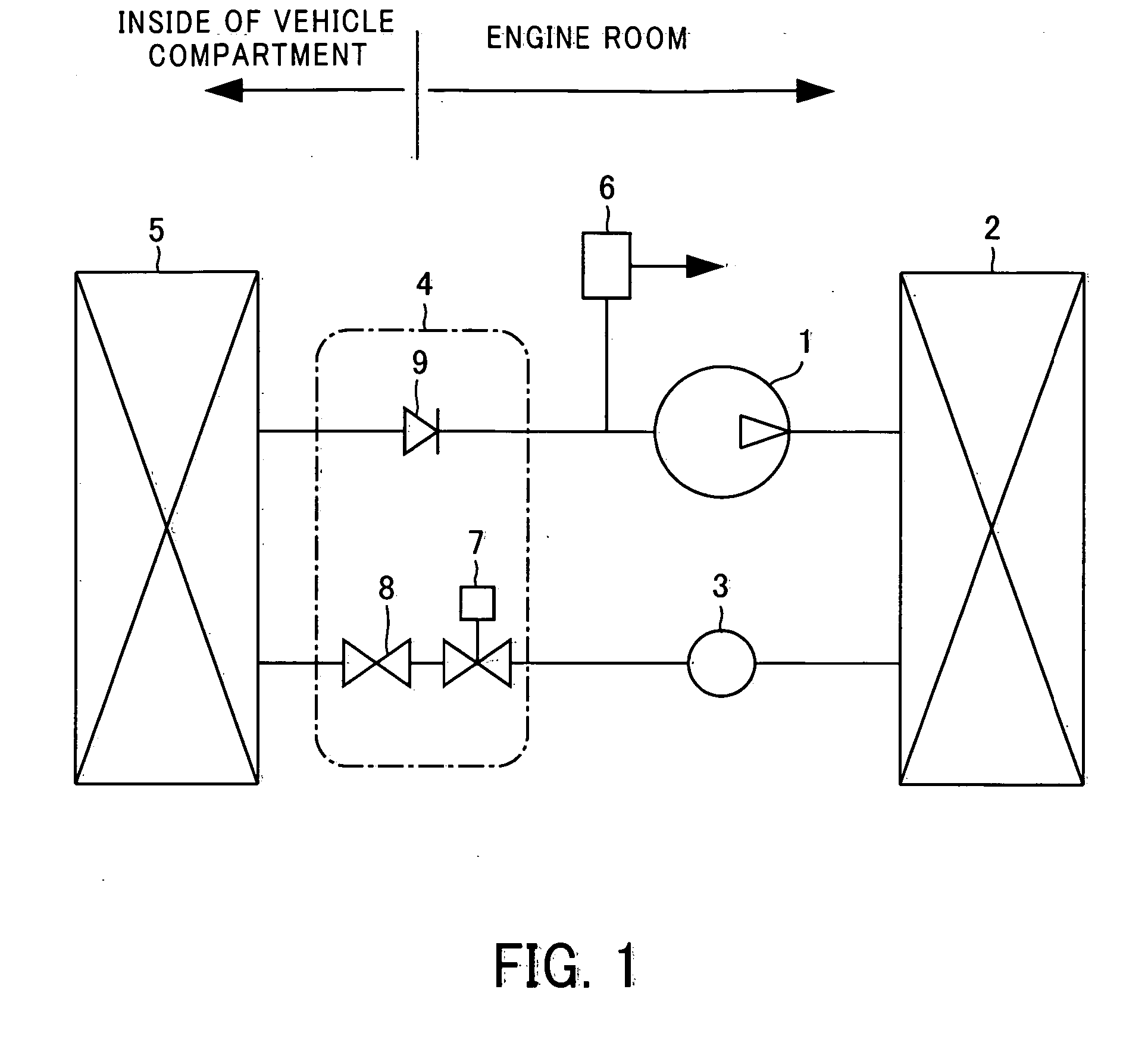

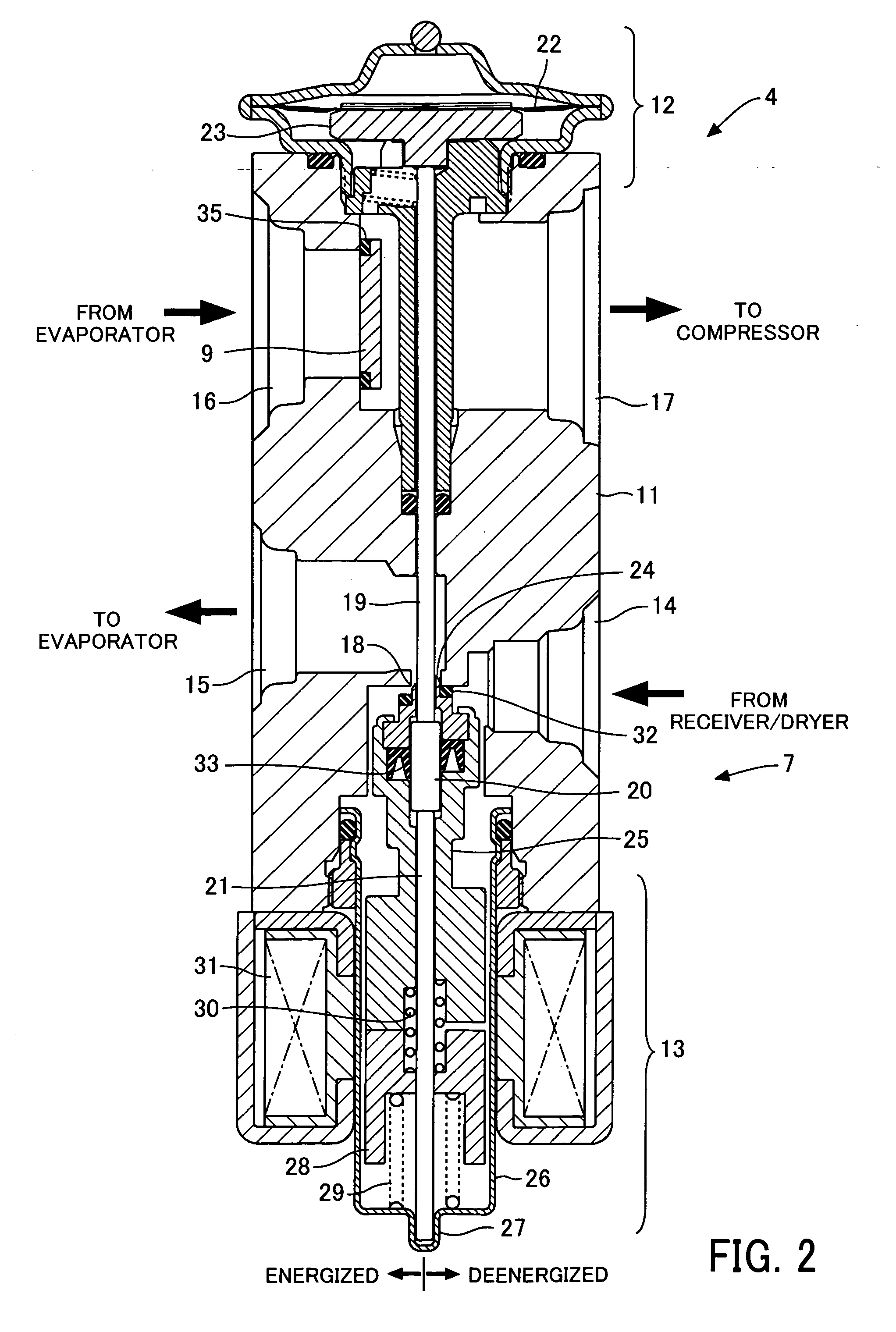

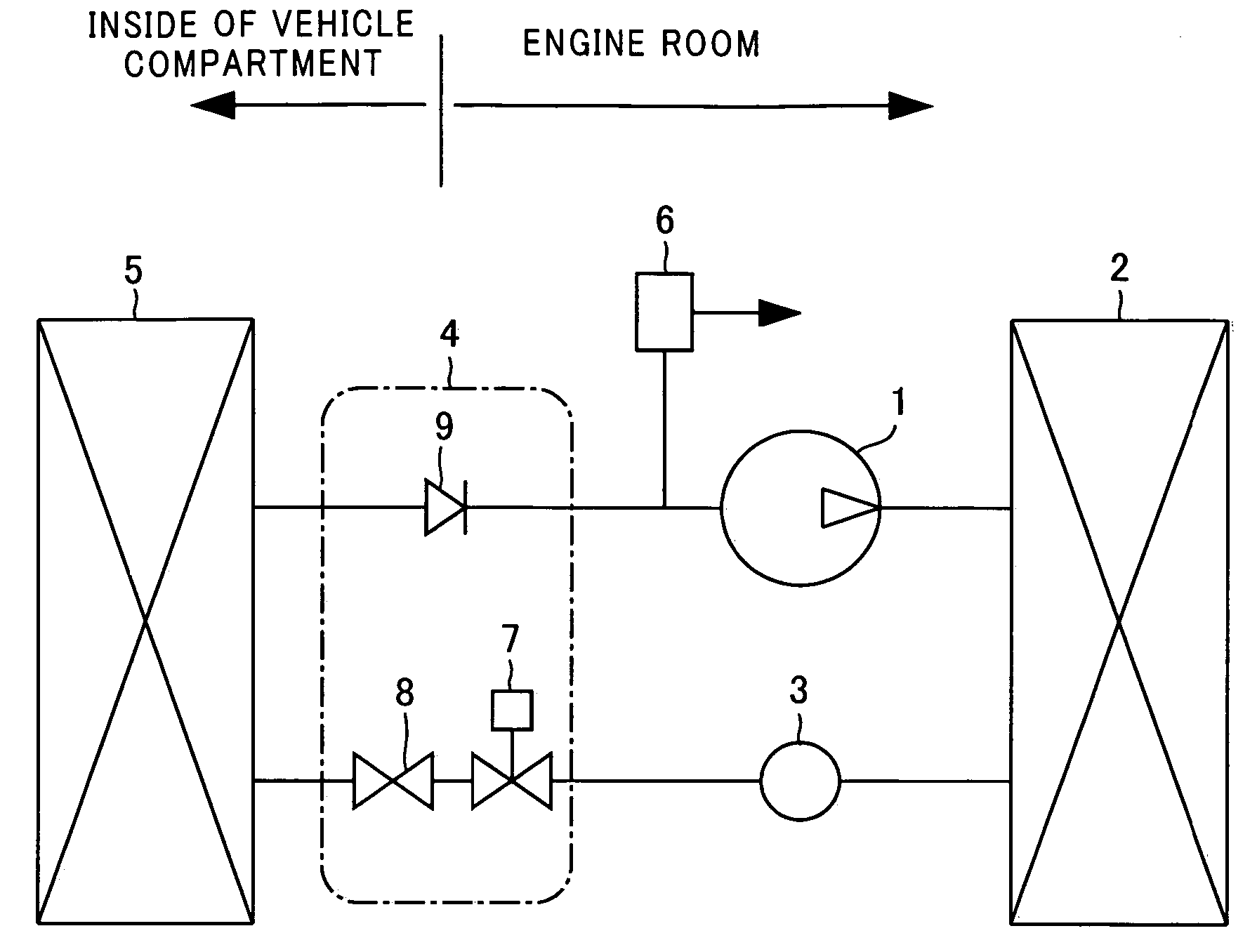

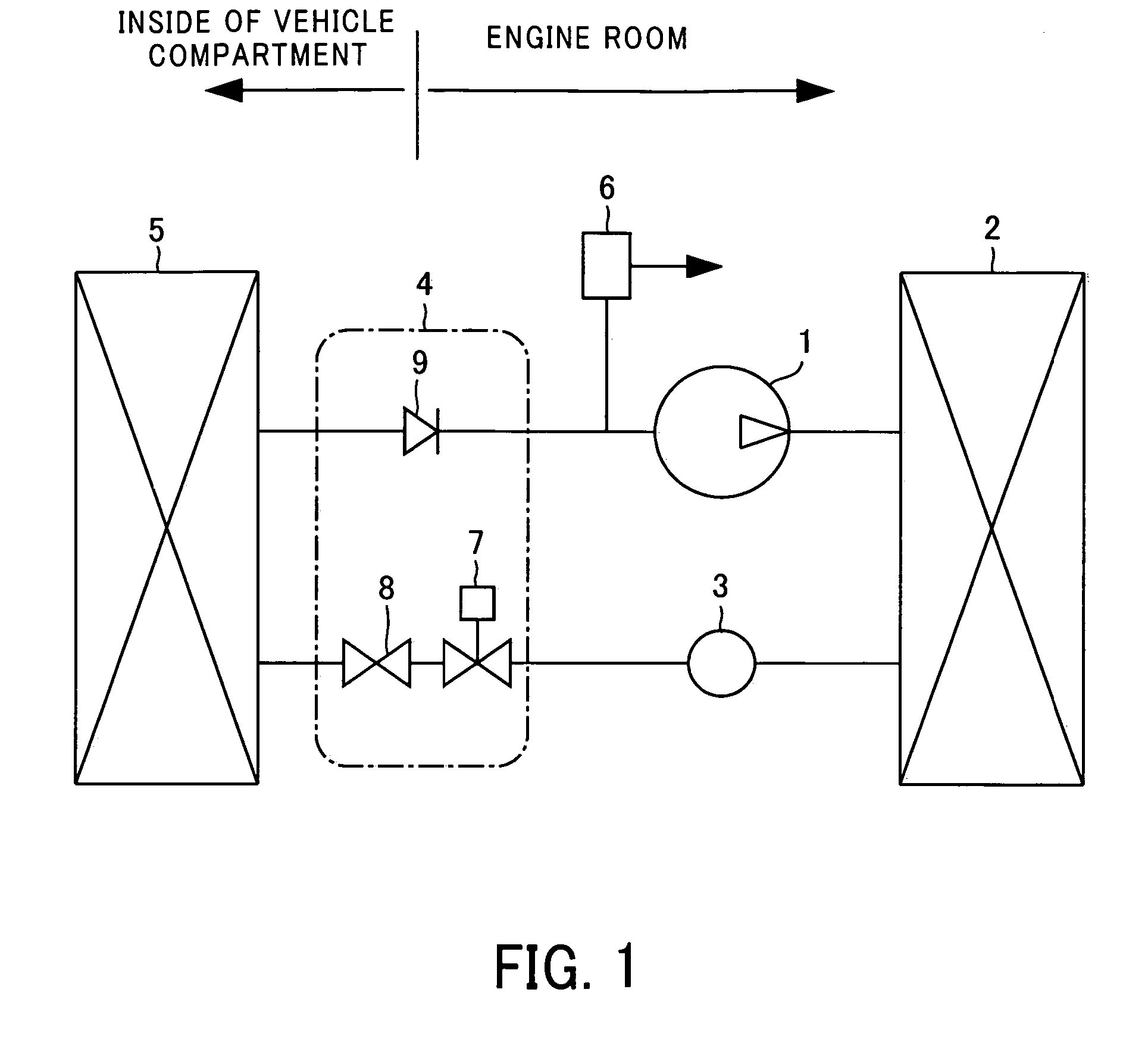

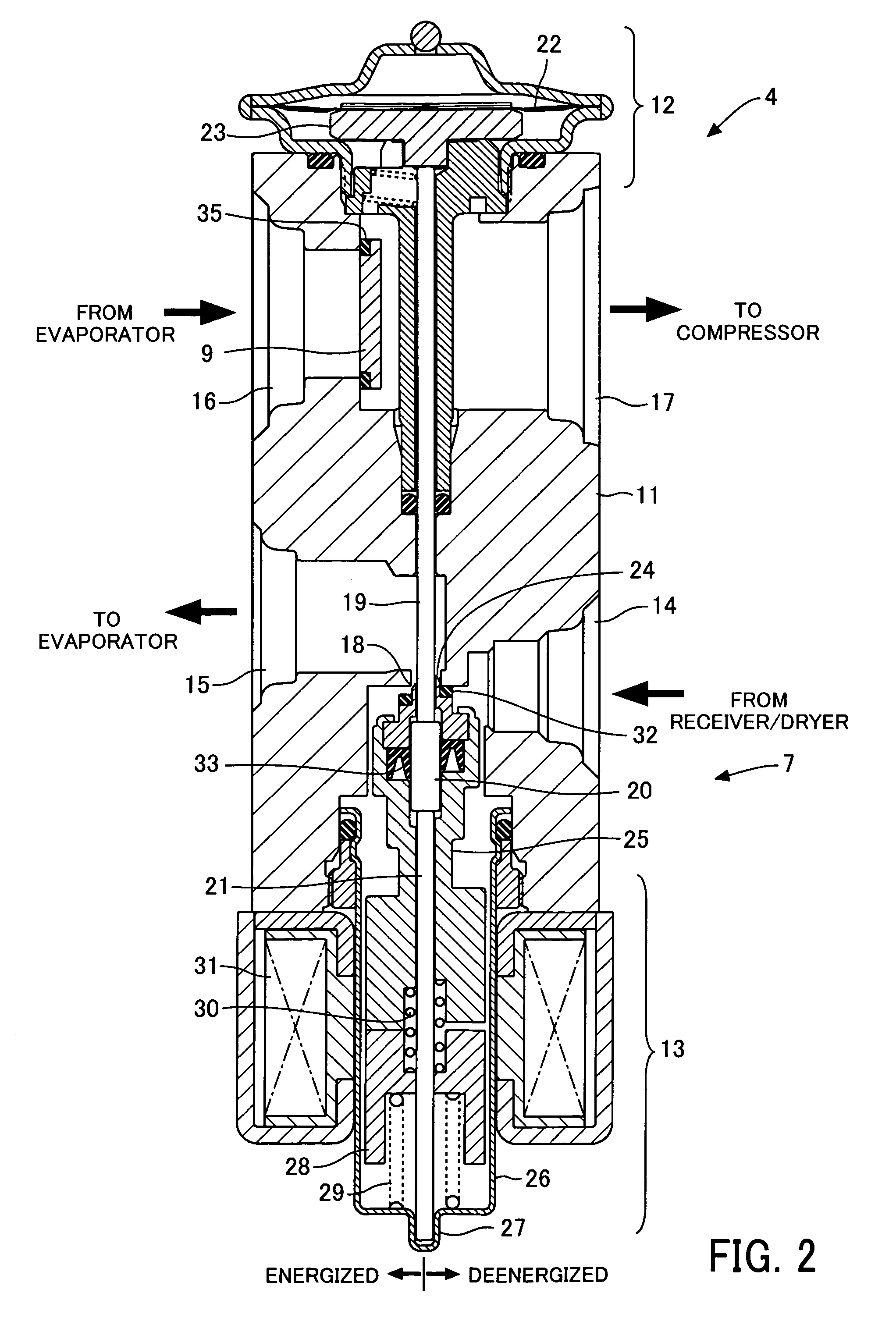

Refrigeration system

InactiveUS20050217313A1Inhibition releasePrevent suckingAir-treating devicesCompression machines with non-reversible cycleEngineeringHigh pressure

To prevent refrigerant in a refrigeration cycle from releasing into a vehicle compartment, in large amounts, due to breakage of an evaporator disposed on a compartment side or piping thereto. An expansion device is formed by an expansion valve that supplies throttled and expanded refrigerant to an evaporator, an electromagnetic valve connected in series to the expansion valve, and a check valve that prevents backflow of refrigerant flowing out of the evaporator, and a release-to-atmosphere device is provided in low-pressure piping connected to the compressor, for allowing the refrigerant therein to be released into the atmosphere. As a result, when refrigerant in the evaporator has released, or when there is a possibility of refrigerant releasing from the same, the electromagnetic valve is closed to isolate the evaporator from high-pressure piping of the refrigeration cycle, and at the same time the release-to-atmosphere device is opened to thereby dispose of the refrigerant in the low-pressure piping, outside the vehicle compartment. As a result, safety of occupants is ensured.

Owner:TGK

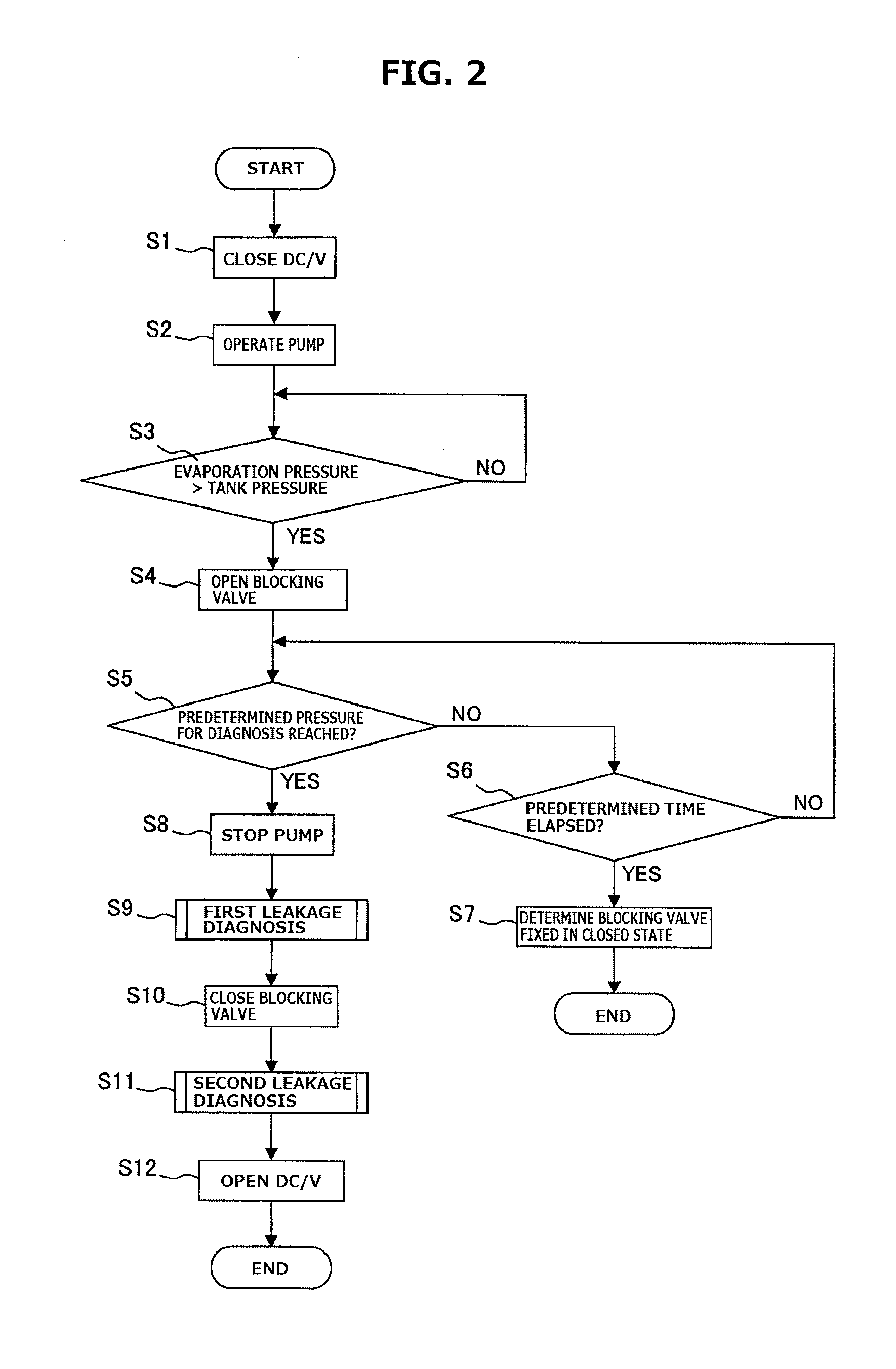

Device and method for diagnosing evaporated fuel processing device

ActiveUS20150040645A1Reduce the amount requiredPrevent suckingDetection of fluid at leakage pointMeasurement of fluid loss/gain rateAutomotive engineeringFuel tank

An evaporated fuel processing apparatus includes a valve between a canister and a fuel tank, and adsorbs evaporated fuel by the canister during fuel filling, and introduces into an intake air line of an internal combustion engine and processes the evaporated fuel while the internal combustion engine is operating. A diagnostic apparatus includes: a pump for pressurizing a system including the fuel tank and the canister; and a pressure sensor for sensing an internal pressure of the system. The diagnostic apparatus diagnoses whether or not leakage is present, based on a change in the internal pressure of the system from a pressurized state, wherein the pressurized state is a state pressurized to a predetermined pressure for diagnosis that is higher than a tank pressure at start of diagnosis; and maintains the fuel tank in the pressurized state by closing the valve after termination of the diagnosis.

Owner:NISSAN MOTOR CO LTD

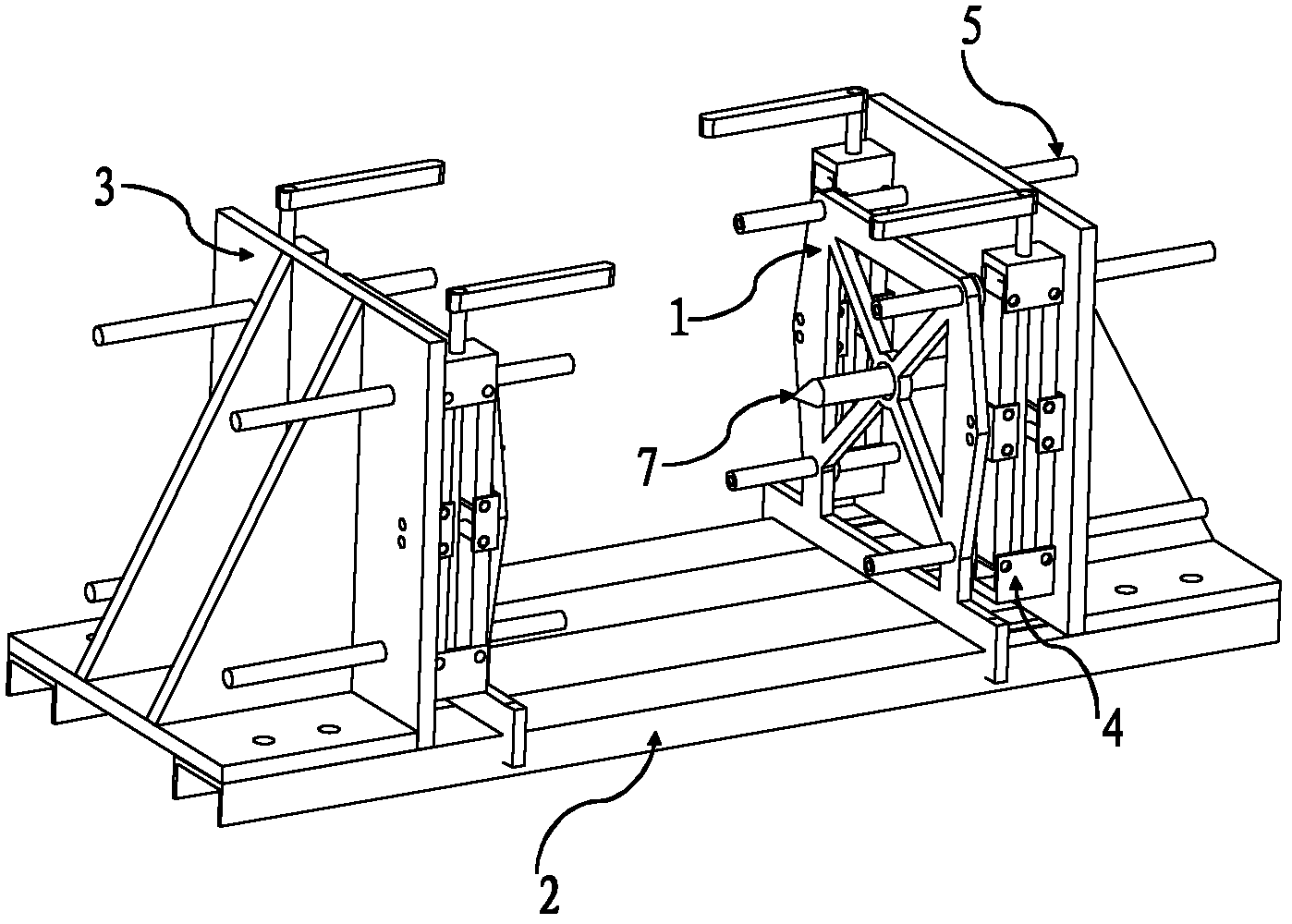

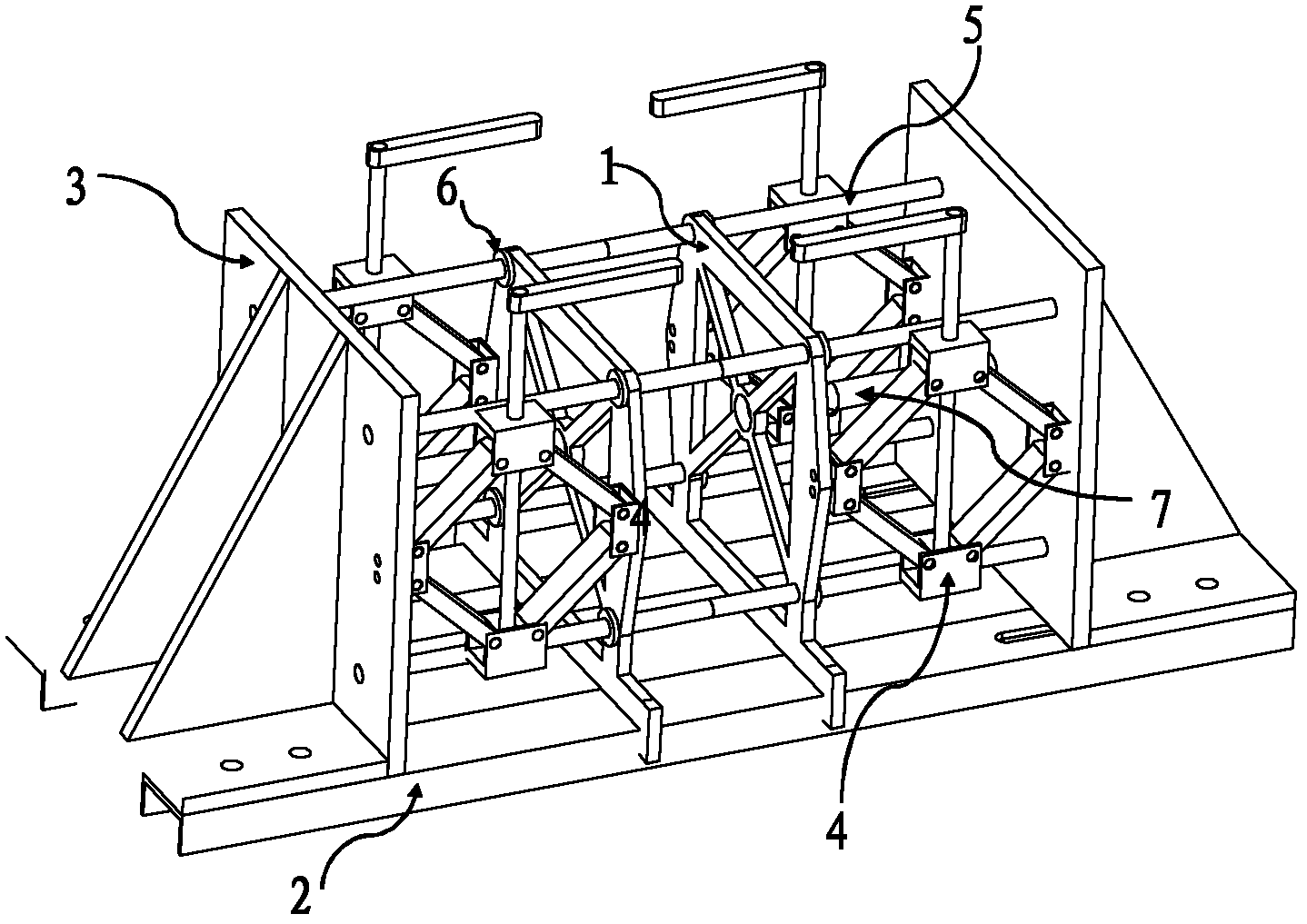

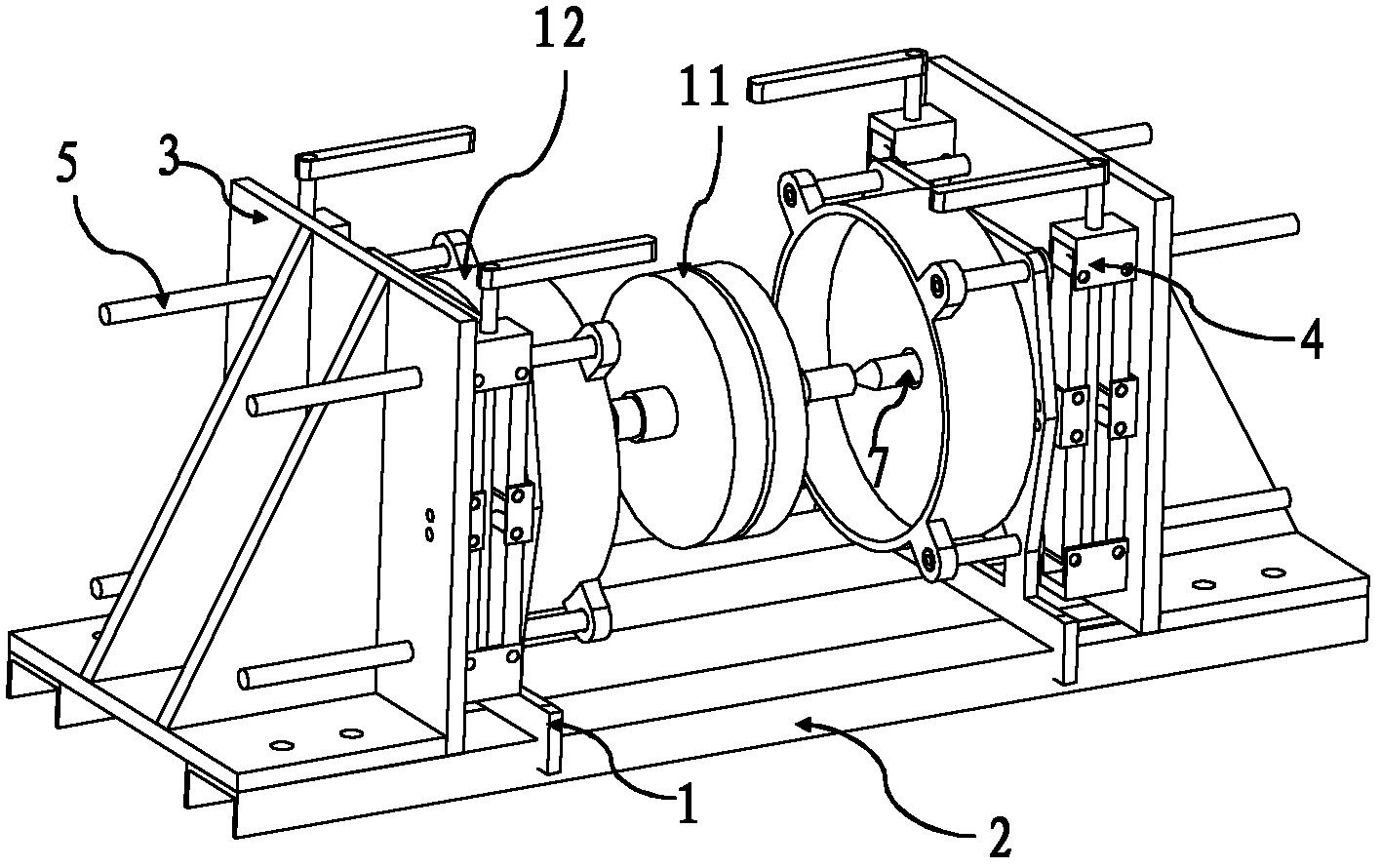

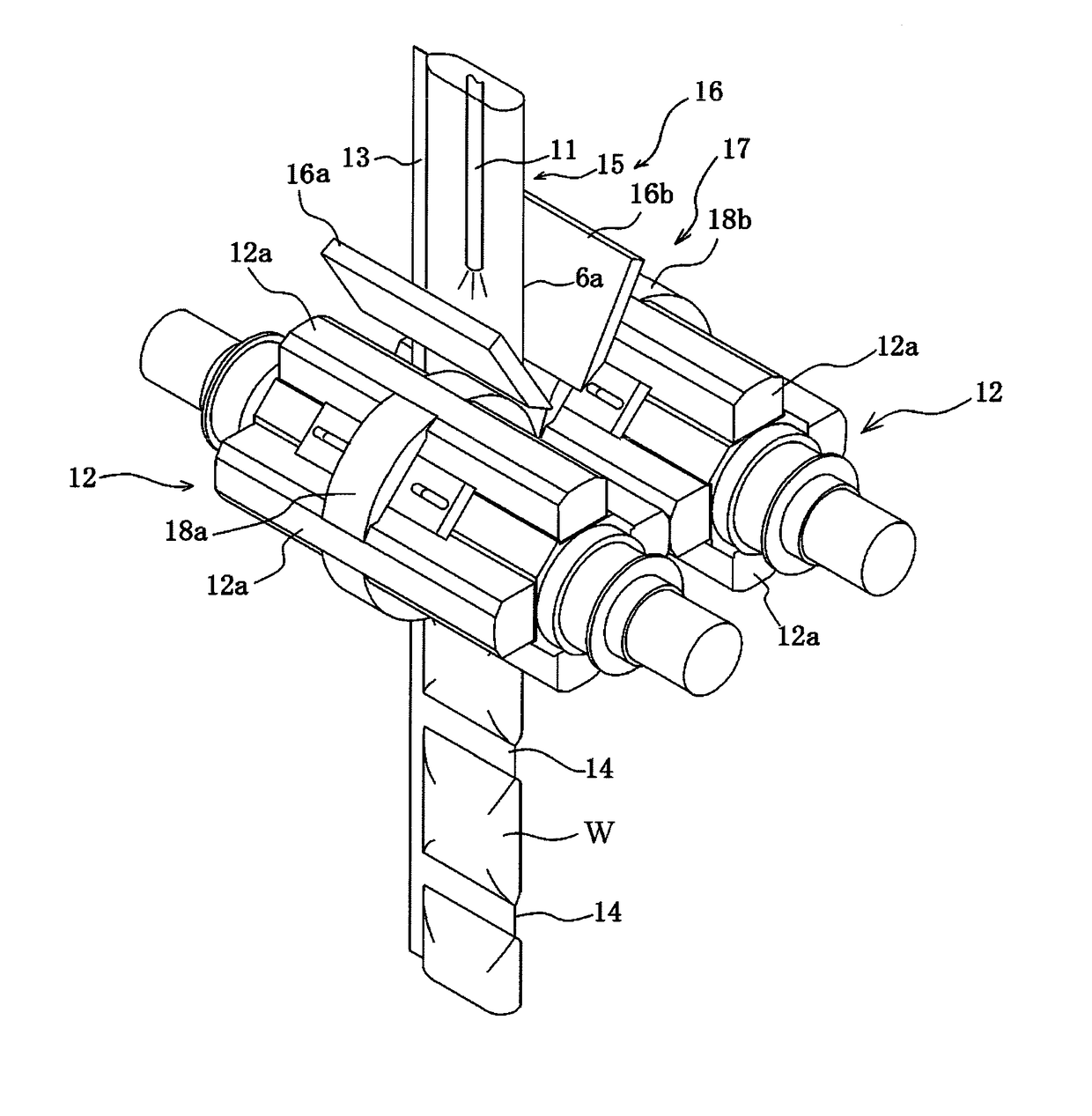

Assembling and disassembling tool for disk type permanent magnet motors and method for installing motor end covers

InactiveCN103001400AEasy to installQuick installationManufacturing stator/rotor bodiesPermanent magnet motorEngineering

The invention discloses an assembling and disassembling tool for disk type permanent magnet motors. The assembling and disassembling tool is used in the field of disk type permanent magnet motors and comprises guide rails, two seat frames, two fixing plates and fixing devices, wherein the seat frames perpendicular to the guide rails are respectively positioned at two ends of the guide rails, the two fixing plates are positioned between the two seat frames, and motor end covers can be fixed onto the fixing plates by the fixing devices; and the fixing plates at the two ends of the guide rails are connected with the seat frames by two pair of scissor jacks, apexes perpendicular to the seat frames are arranged in centers of the seat frames, through holes which are concentric with the apexes are arranged in centers of the fixing plates, and the apexes penetrate through the through holes of the centers of the fixing plates when the scissor jacks contract. The assembling and disassembling tool has the technical advantages that a rotor can be effectively prevented from being sucked onto the motor end cover on an optional side of the rotor under the action of magnetic force, and a step for adjusting a gap between each motor end cover and the rotor is omitted; the motor end covers of a disk type permanent magnet motor can be accurately and quickly installed; and collision of coils due to single-side absorption is prevented, fingers of operators cannot be pinched due to high attractive force of magnetic steel, and the safety is greatly improved during motor assembly.

Owner:SHANGHAI NANYANG ELECTRICAL MACHINERY

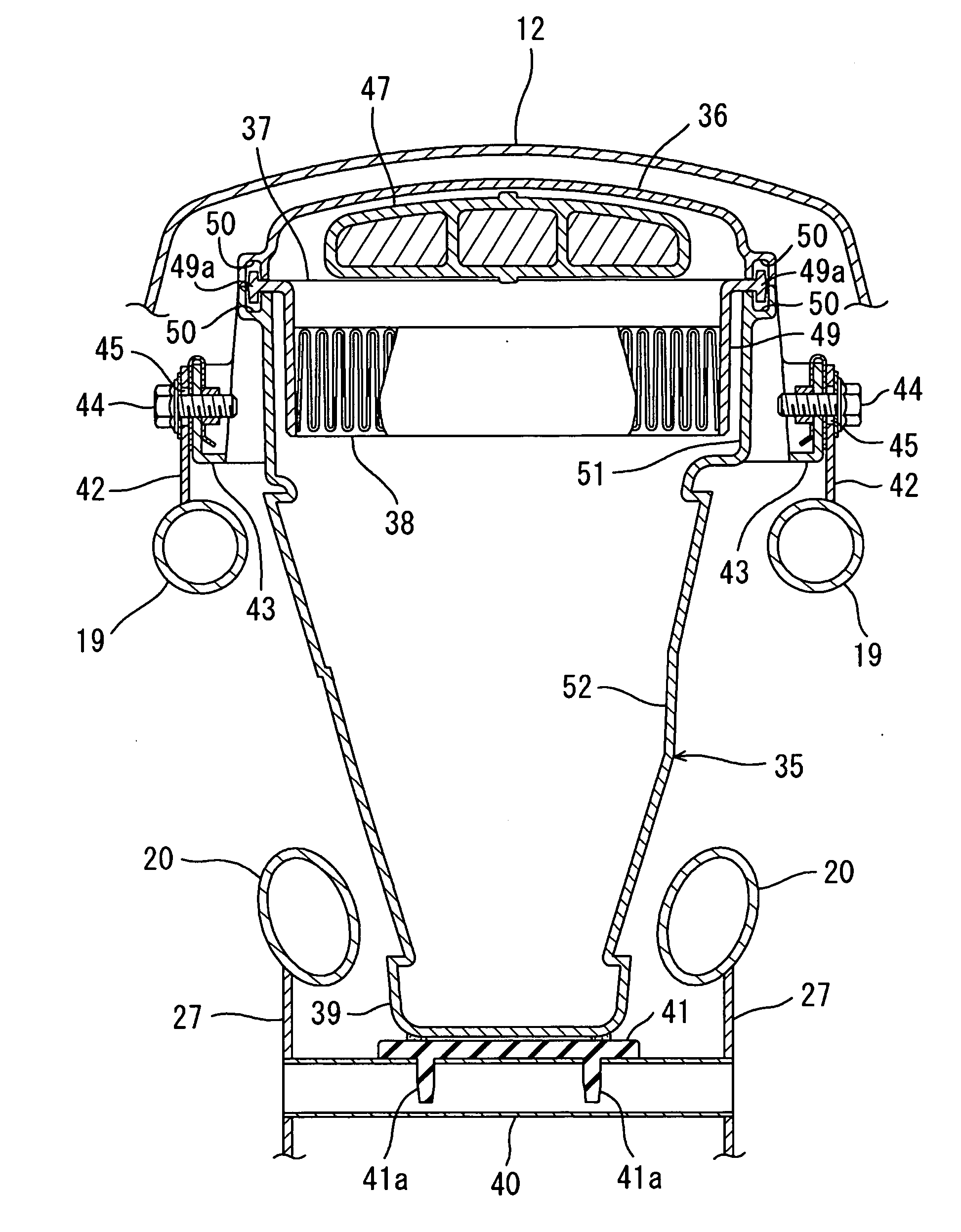

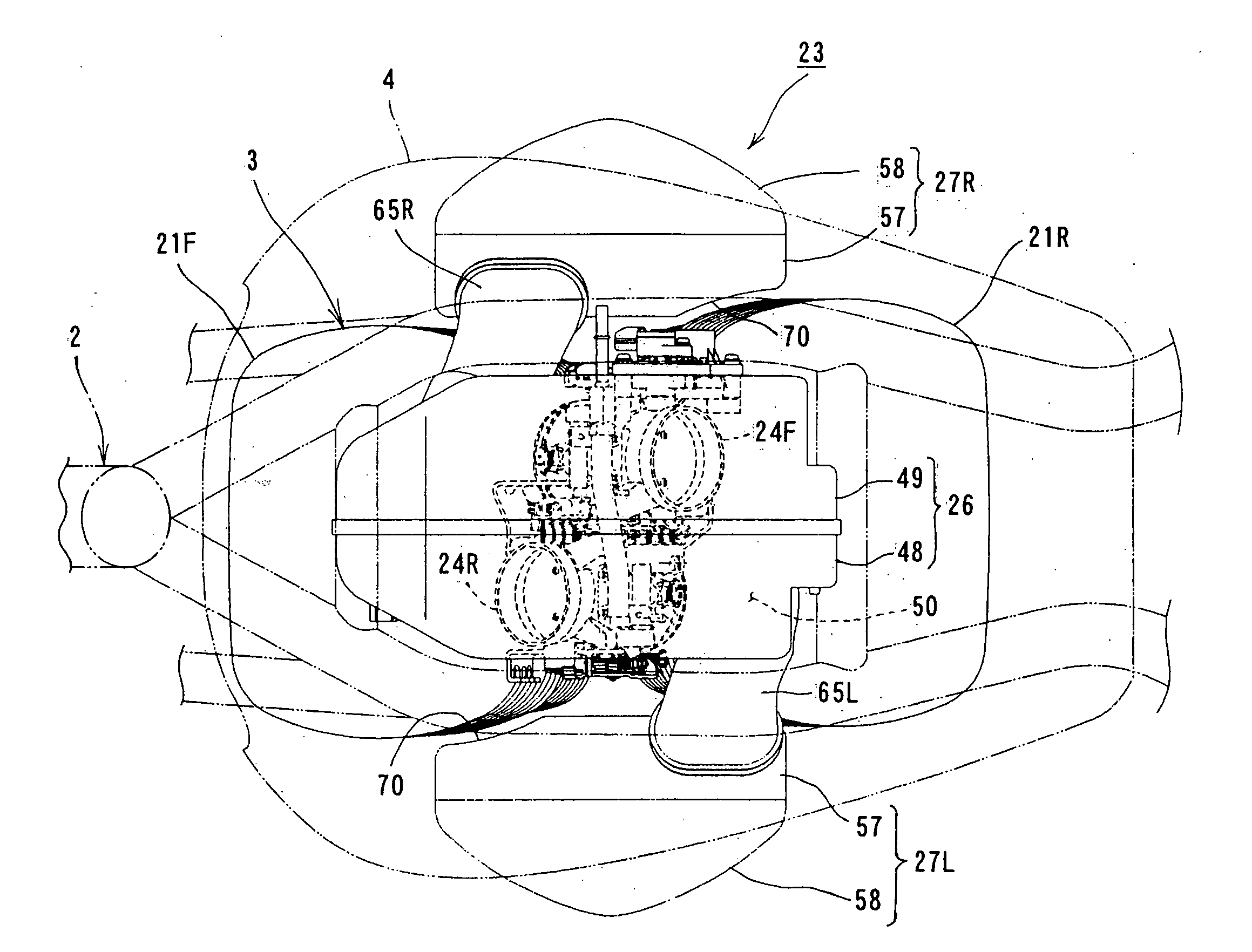

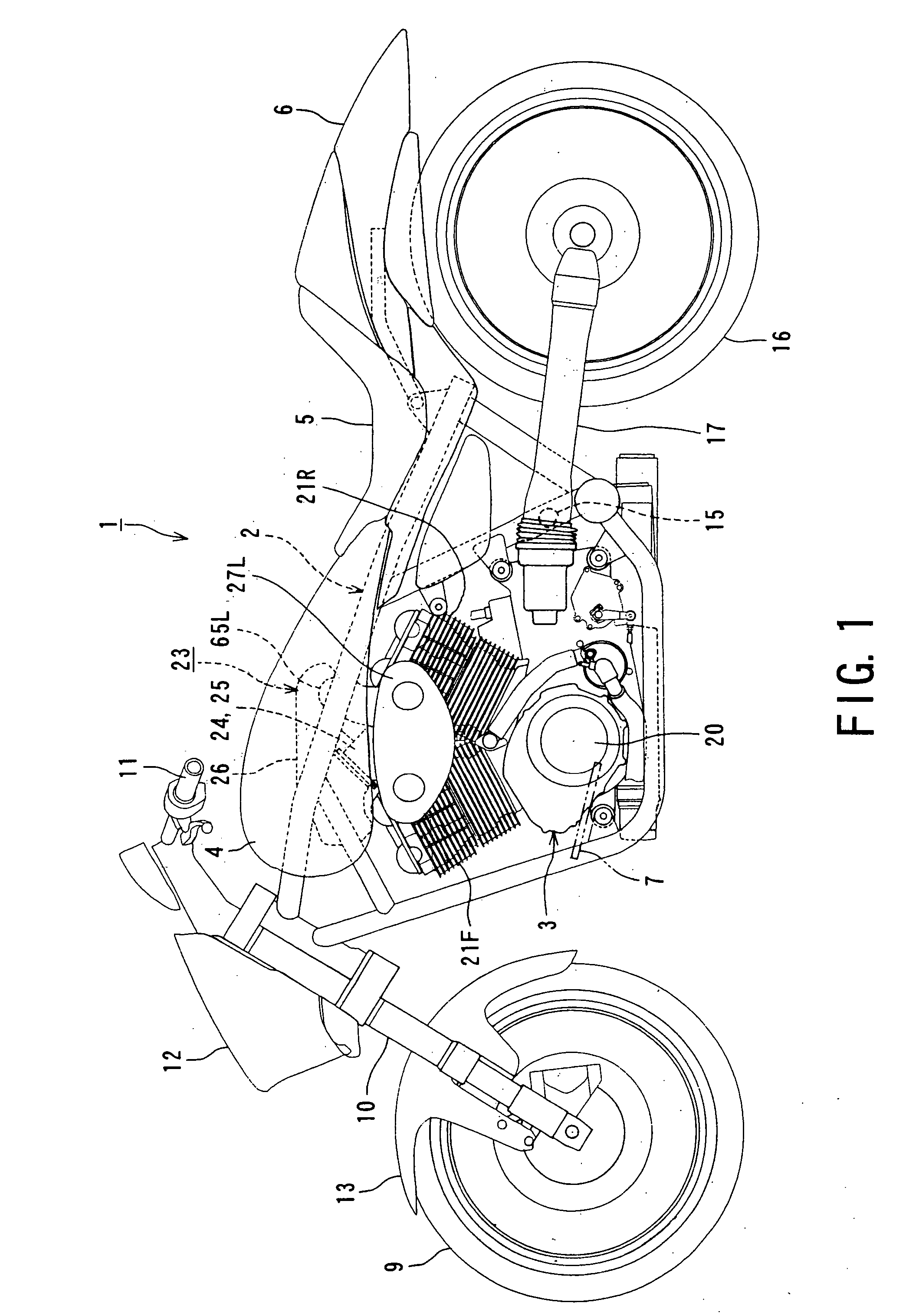

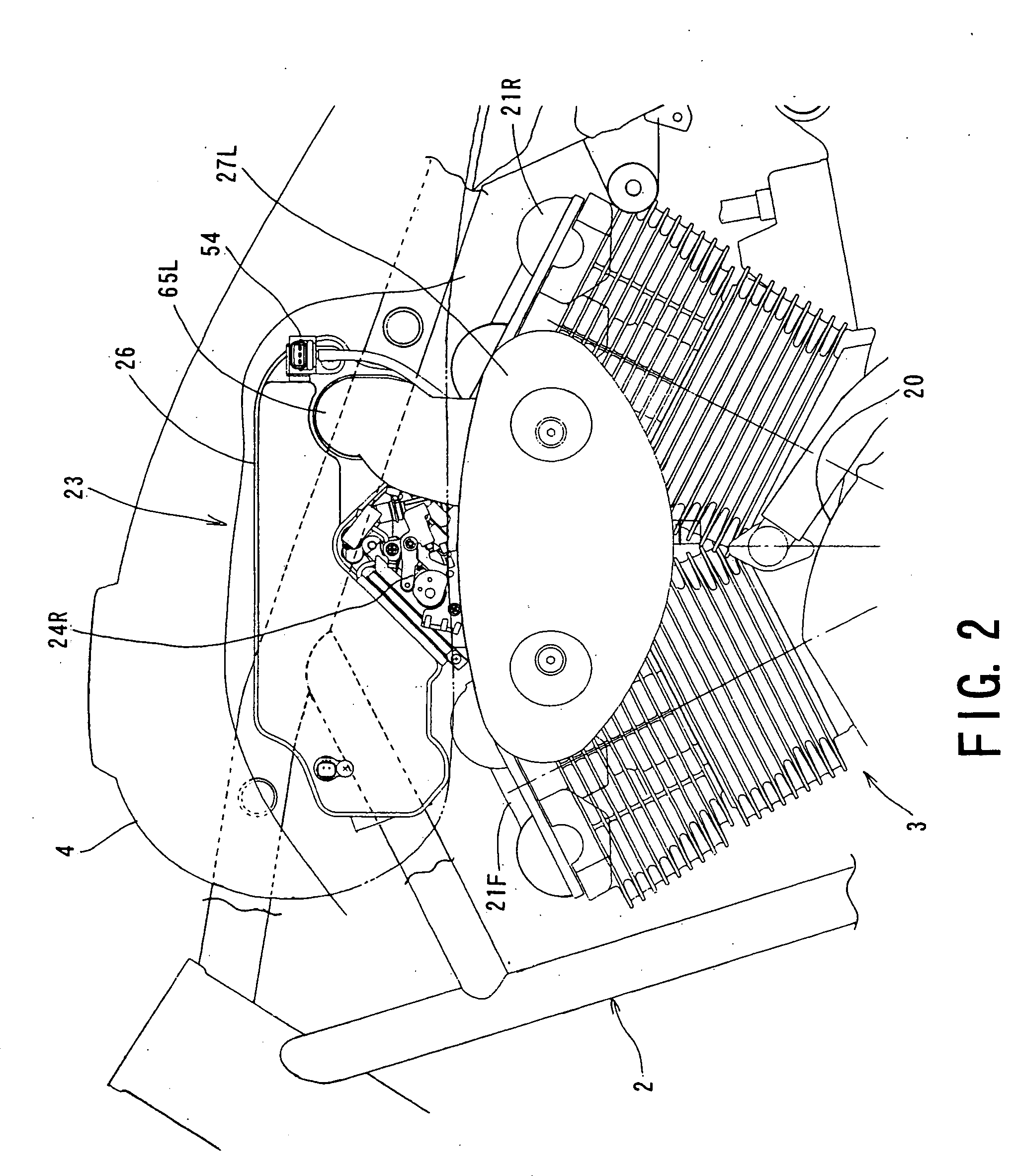

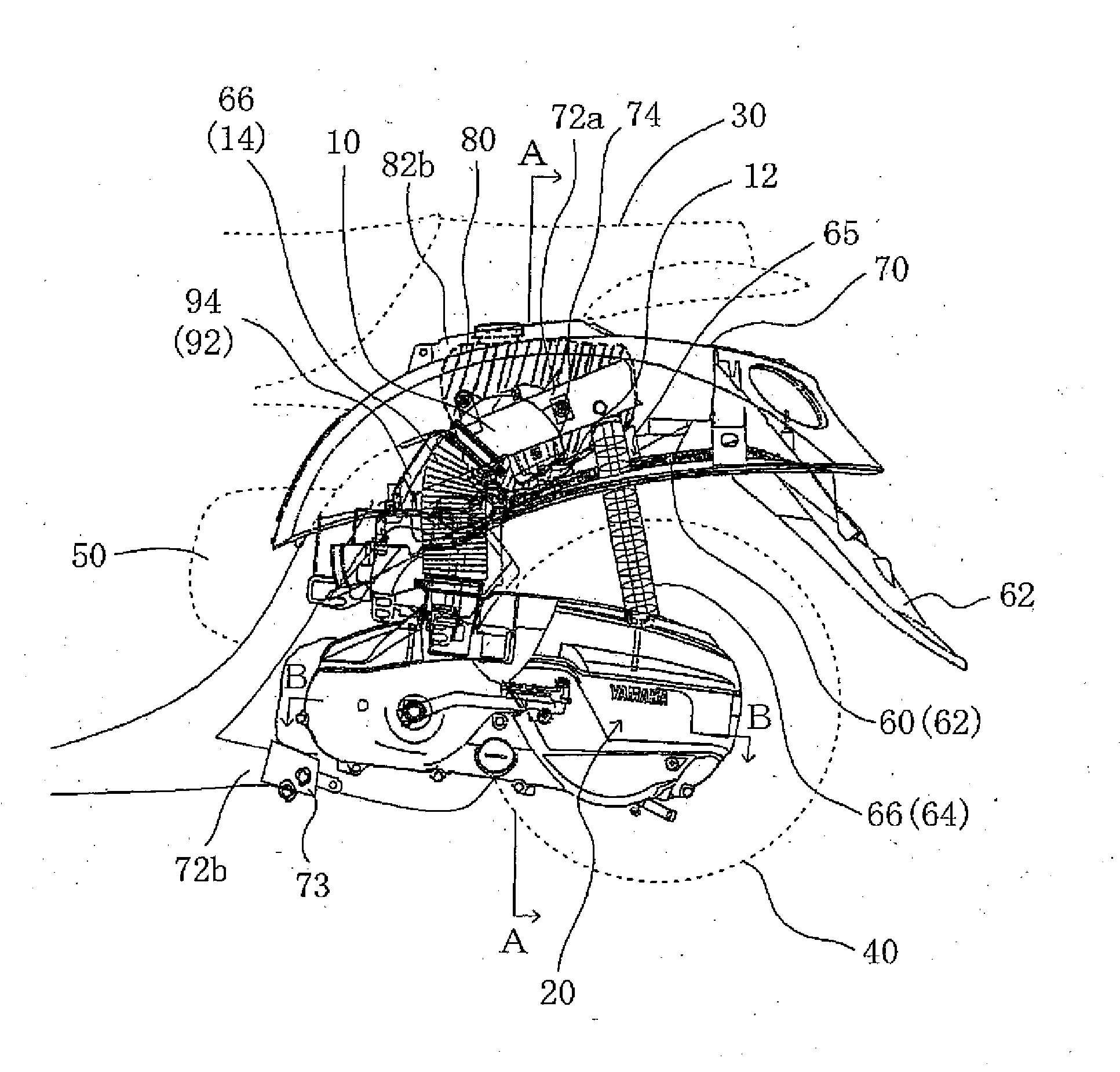

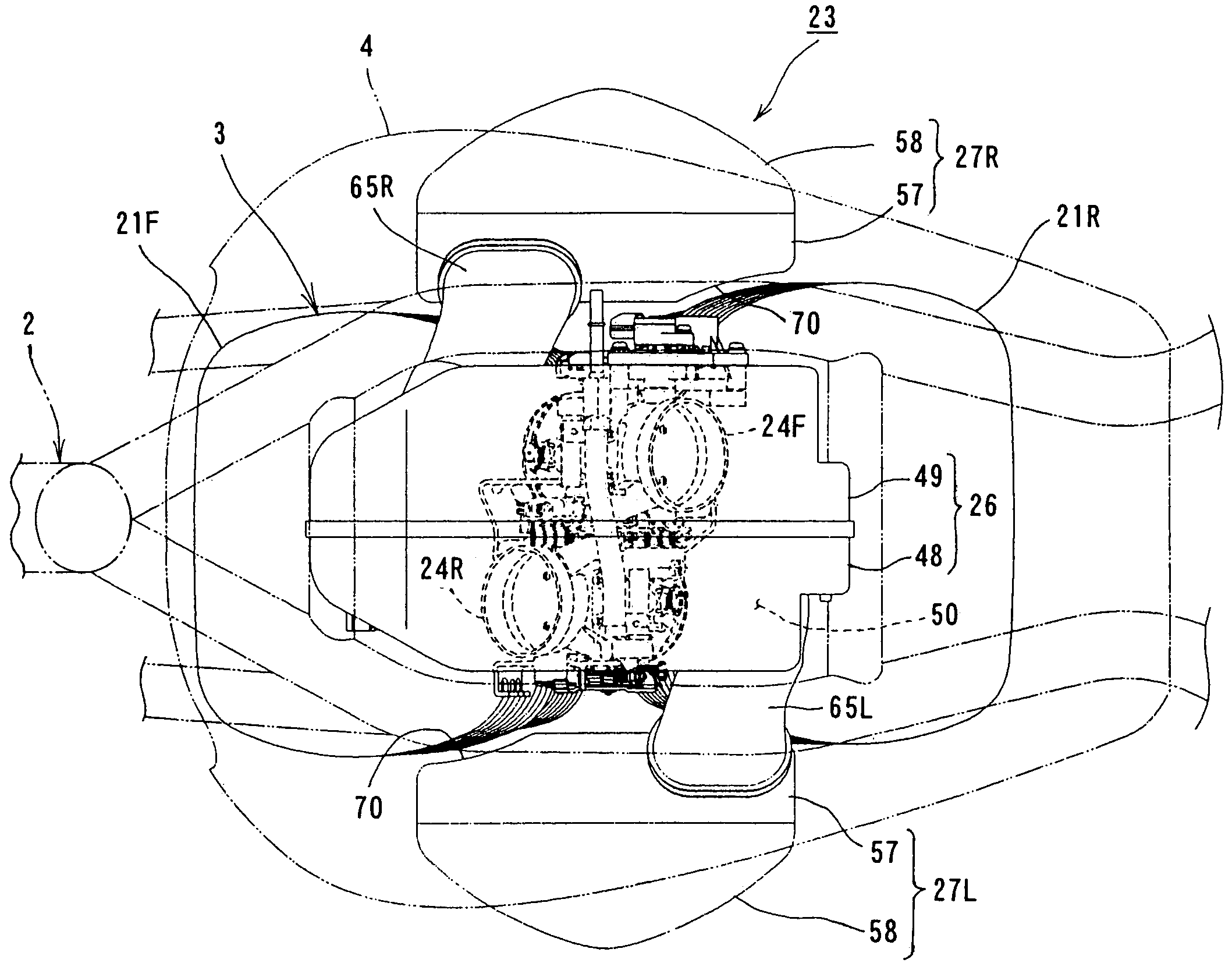

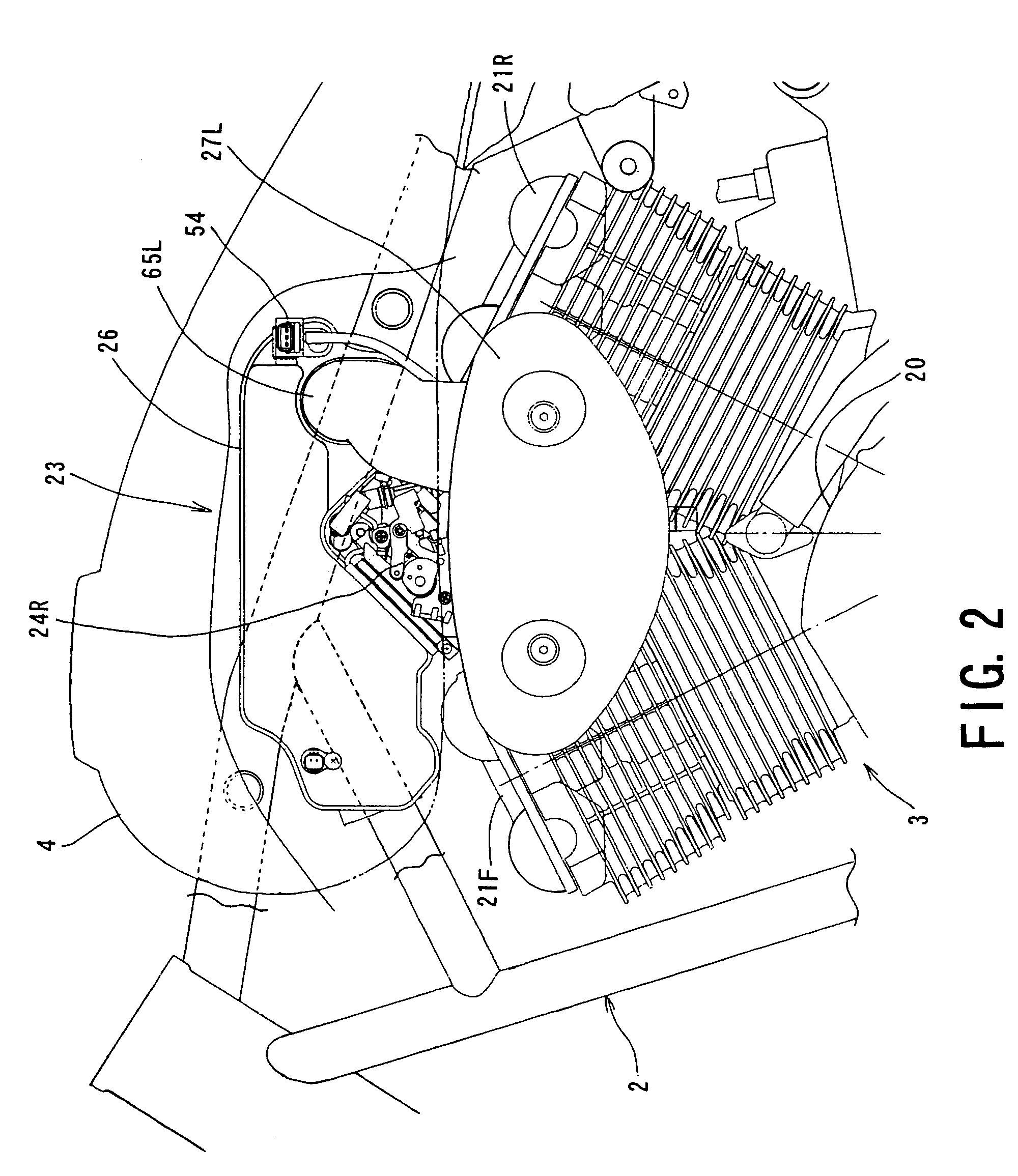

Intake device of V-type engine of motorcycle

ActiveUS20060213475A1Improve air intake efficiencyPromoting quietnessNon-fuel substance addition to fuelInternal combustion piston enginesInterior spaceAir filter

An intake device of a V-type engine provided with two cylinders inclining in a longitudinal direction of a motorcycle includes a center air cleaner arranged above a V-bank space formed between the two cylinders, a pair of right and left side air cleaners arranged on both sides of the V-bank space, and an air / fuel mixture supply device disposed between the center air cleaner and the V-bank space. An internal space of the center air cleaner is communicated with an intake port of each of the cylinders through the air / fuel mixture supply device. The internal space of the side air cleaner is divided into a dirty side and a clean side with an air filter being interposed therebetween, in which the clean side is connected to the center air cleaner and the dirty side is provided with an intake port communicating with an outside. The intake port is opened so as to face the V-bank space side.

Owner:SUZUKI MOTOR CORP

Fill packaging method and fill packaging machine for liquid packing material

InactiveUS20170247130A1Prevent suckingImprove productivityWrapper twisting/gatheringSuccessive articlesThin membraneEngineering

In a method for forming a lateral sealed portion, a liquid packing material can be filled without biting bubbles, granulates and so on included in the liquid packing material into the lateral sealed portion. In a method for forming a lateral sealed portion with a pair of lateral sealing rolls after a packaging film fed and run is folded at its central portion and a vertical sealing is performed at their side edge parts to shape into a cylindrical form and a liquid packing material is filled into an inside of the cylindrically formed packaging film, at least a folded side part of the cylindrically formed packaging film is pushed with a pushing means arranged between heat sealing bars located at equal intervals in a circumferential direction of the lateral sealing roll and the lateral sealed portion is formed at a pushed position with the pair of lateral sealing bars.

Owner:TAISEI LAMICK

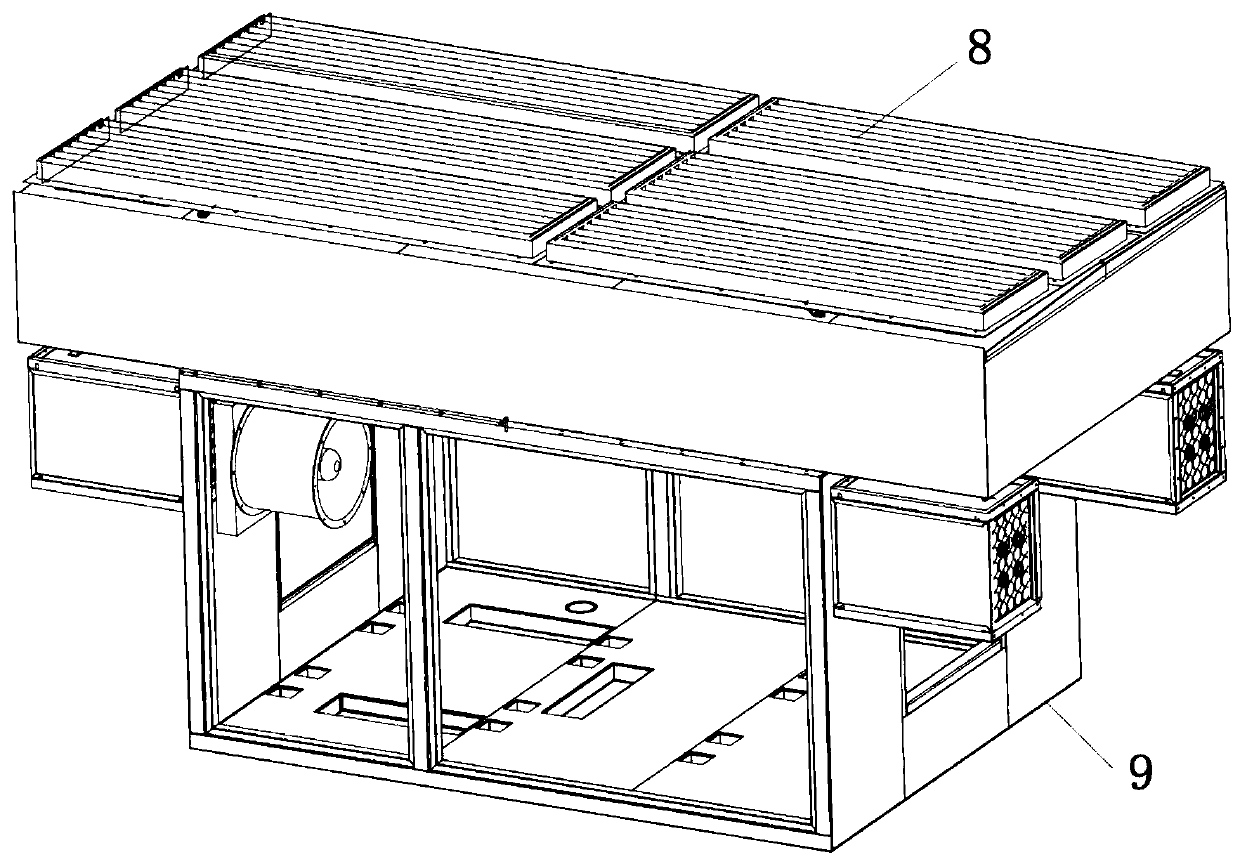

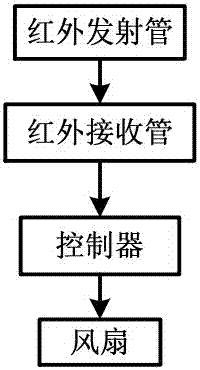

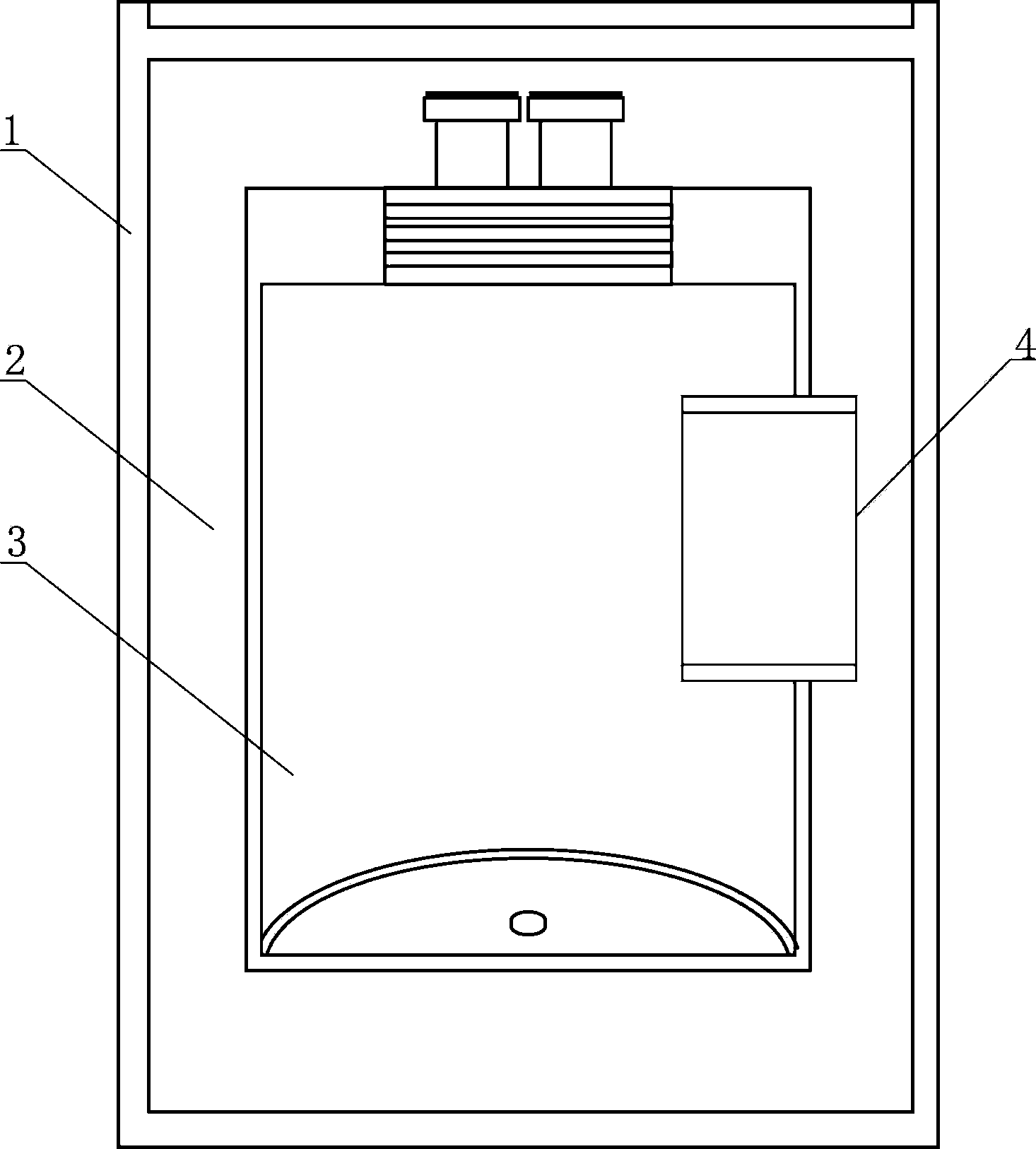

Distribution box capable of automatically dissipating heat

ActiveCN107579446APrevent suckingGuaranteed suctionSubstation/switching arrangement cooling/ventilationInfrared emitterElectromagnet

The invention relates to the technical field of electrical accessories, in particular to a distribution box capable of automatically dissipating heat. The distribution box comprises a box body and a box cover on the box body, a fan is arranged in the box body, and a plurality of heat dissipation holes protruding from the surface of the box cover are formed in the position, close to a heat source,of the box cover; each heat dissipation hole is provided with a fixing plate and a moving plate capable of automatically returning, an electromagnet is fixed to the side, toward the inner wall of thecorresponding heat dissipation hole, of each moving plate, an air bag is fixed to the inner wall of each heat dissipation hole, and an iron block attracting the corresponding electromagnet during heating expansion of the air bag is fixed to the air bag; an infrared emitter and an infrared receiver which can be covered by the corresponding moving plate are arranged on the inner wall of each heat dissipation hole, and each infrared receiver is used for receiving the infrared rays of the corresponding infrared emitter; the distribution box further comprises a controller, and the controller is used for controlling the fan to improve the rotational speed based on the signals of the infrared receivers. According to the distribution box, while the moving plates are adsorbed to the air bags to enlarge the heat dissipation holes, increase of the rotational speed of the fan is controlled to accelerate heat dissipation, and more heat is conducted out of the distribution box with the air by the enlargement of the heat dissipation holes, so that the heat dissipation effect is better.

Owner:广东智信电气有限公司

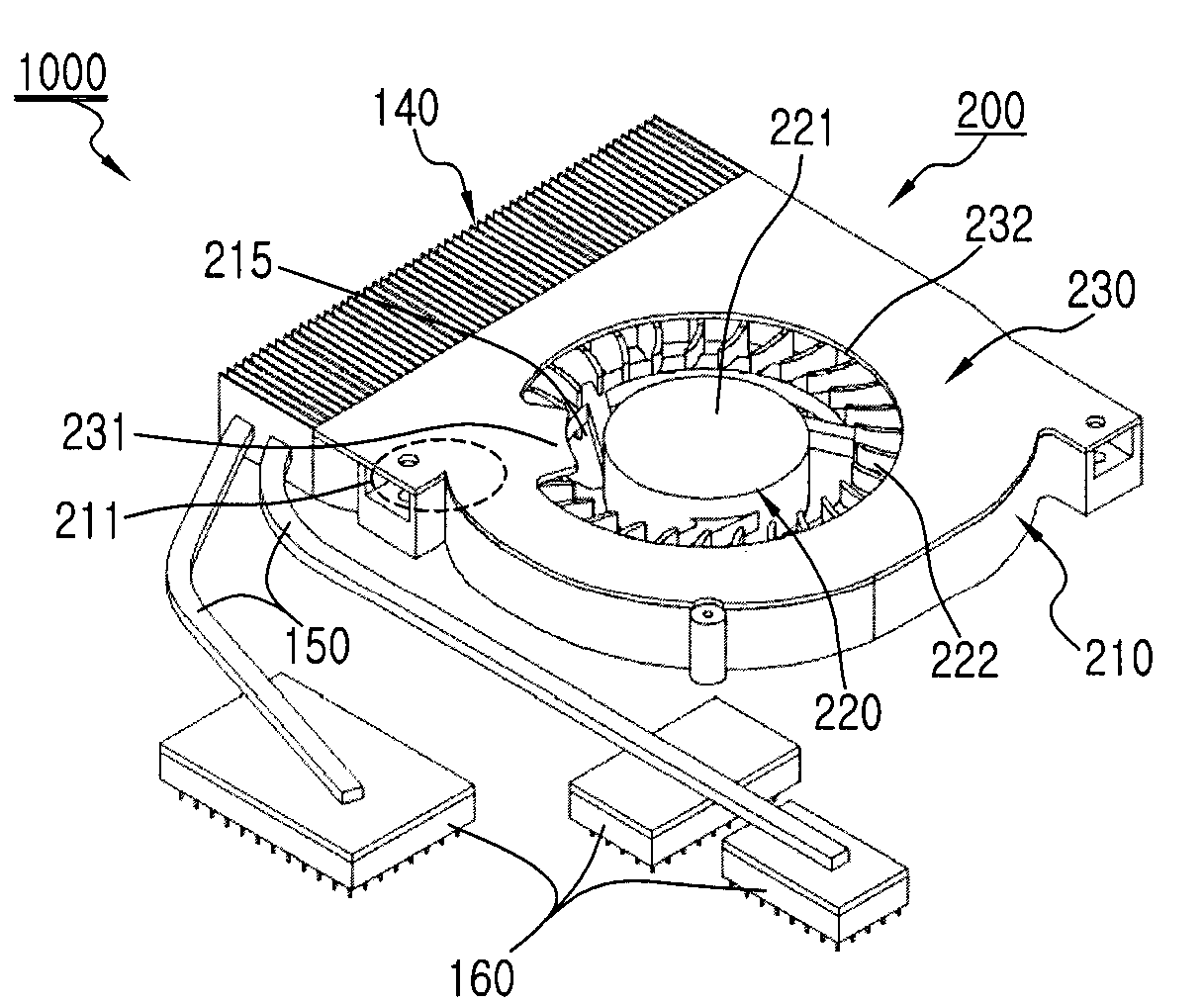

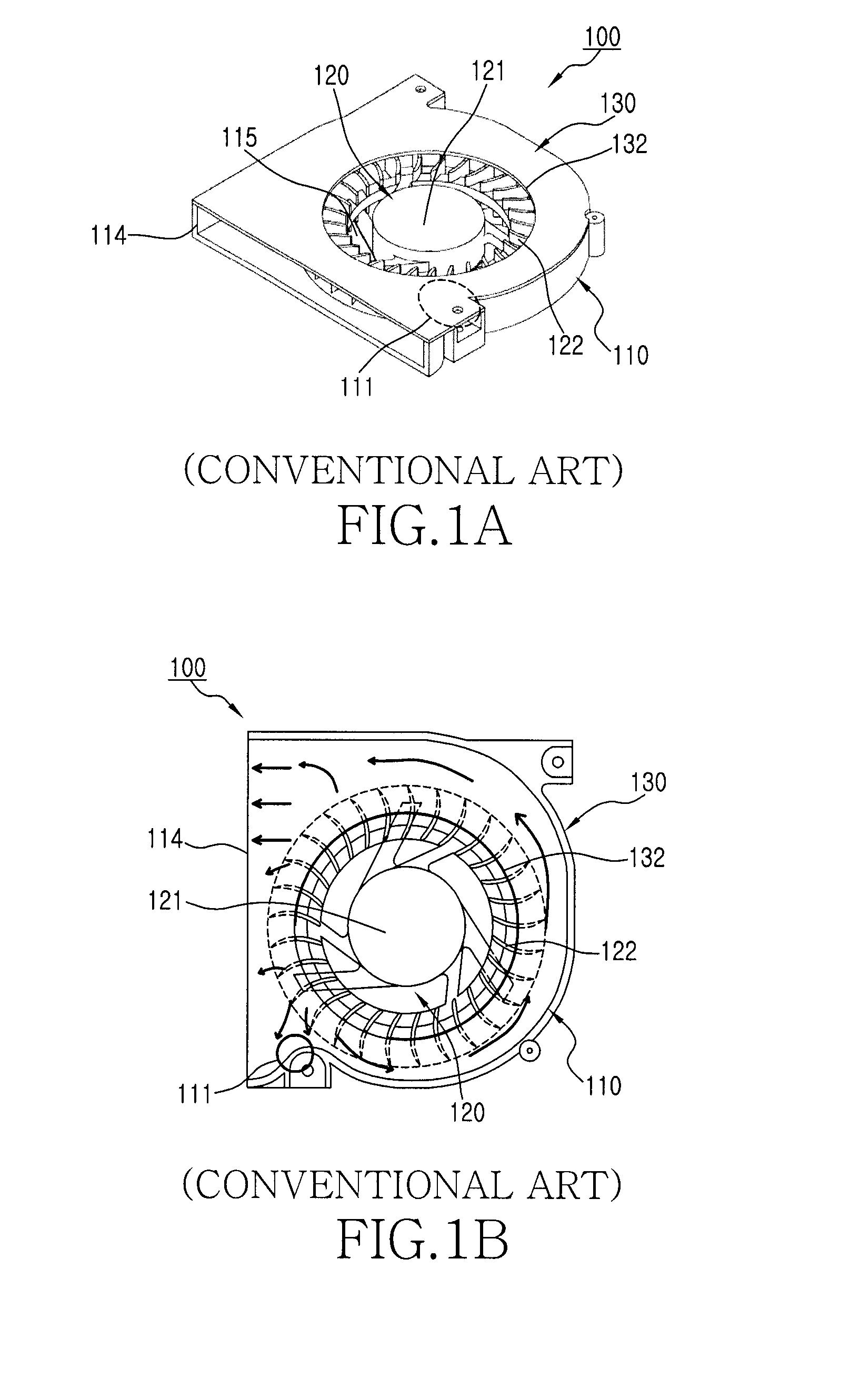

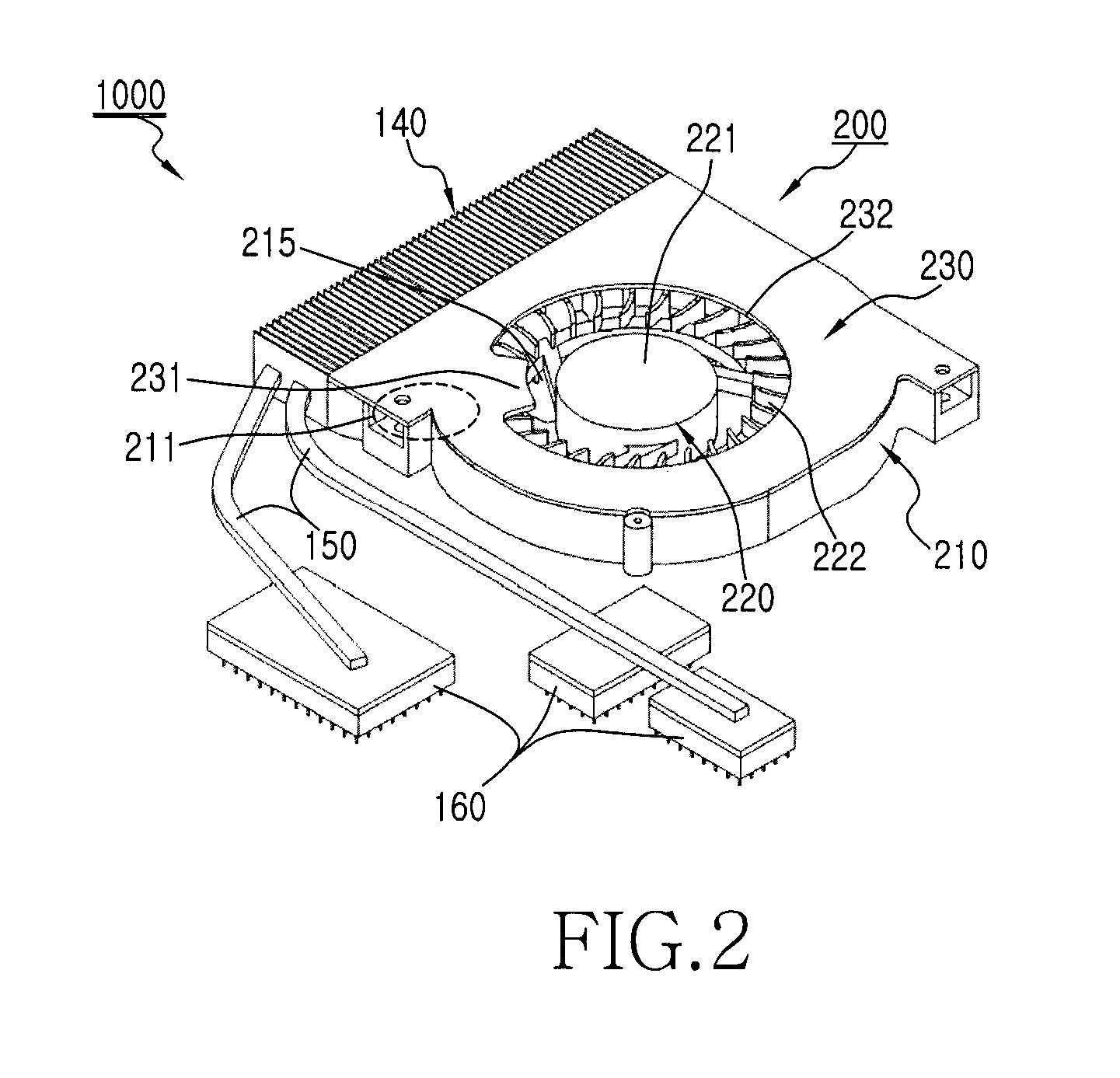

Centrifugal fan

InactiveUS20100074742A1Reduce noisePrevent suckingPump componentsWorking fluid for enginesImpellerEngineering

A centrifugal fan includes a housing, a spiral impeller, a suction interrupting member. The housing includes a suction port and a discharge port. The housing further includes an outwardly curved cutoff portion at a side of the discharge port. The spiral impeller is coupled with a motor to suck air through the suction port of the housing in a rotation-axis direction and discharge the sucked air through the discharge port in a direction perpendicular to a rotation-axis. The suction interrupting member prevents air from being sucked into a neighborhood of the cutoff portion through the suction port.

Owner:SAMSUNG ELECTRONICS CO LTD

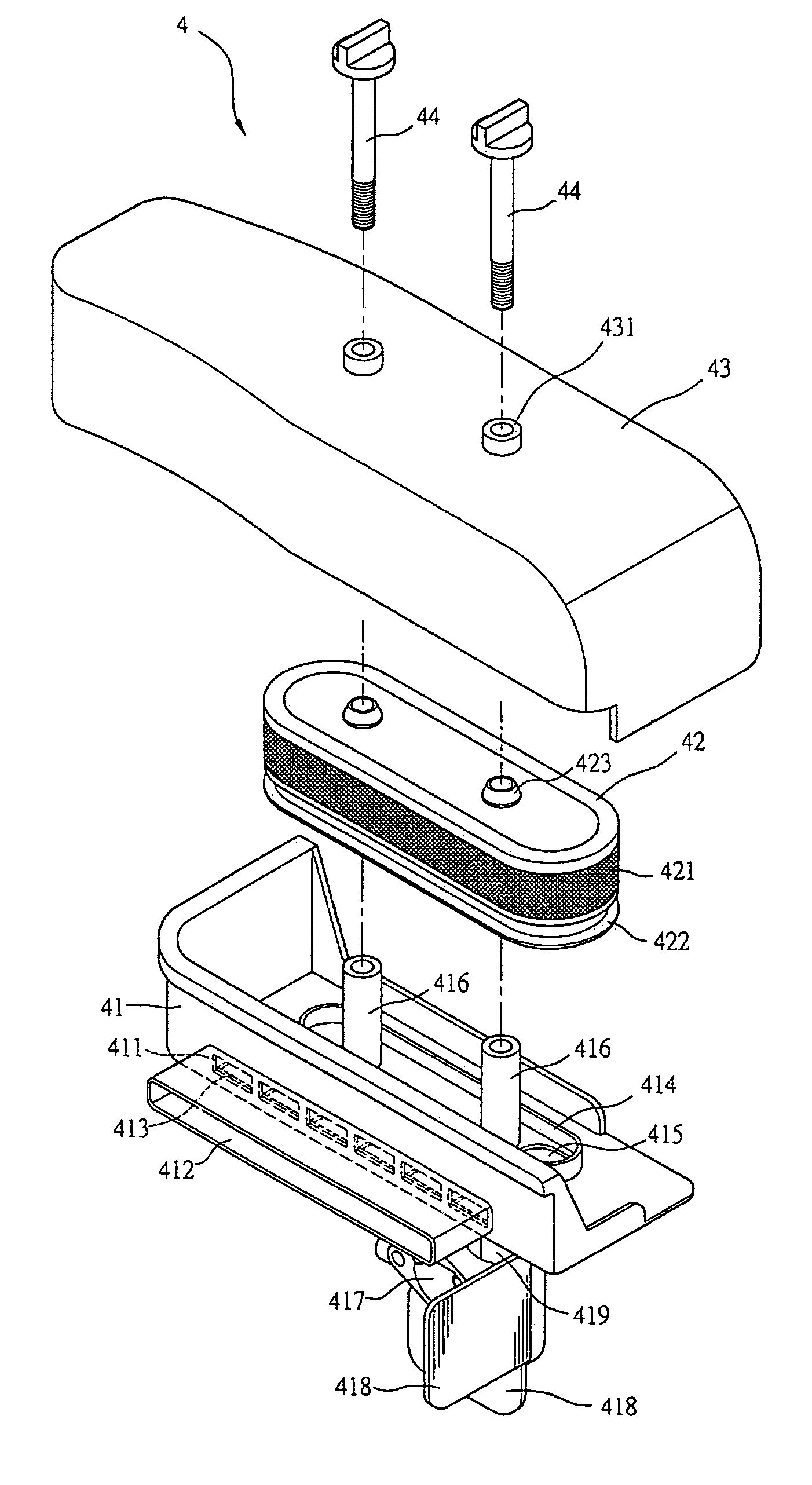

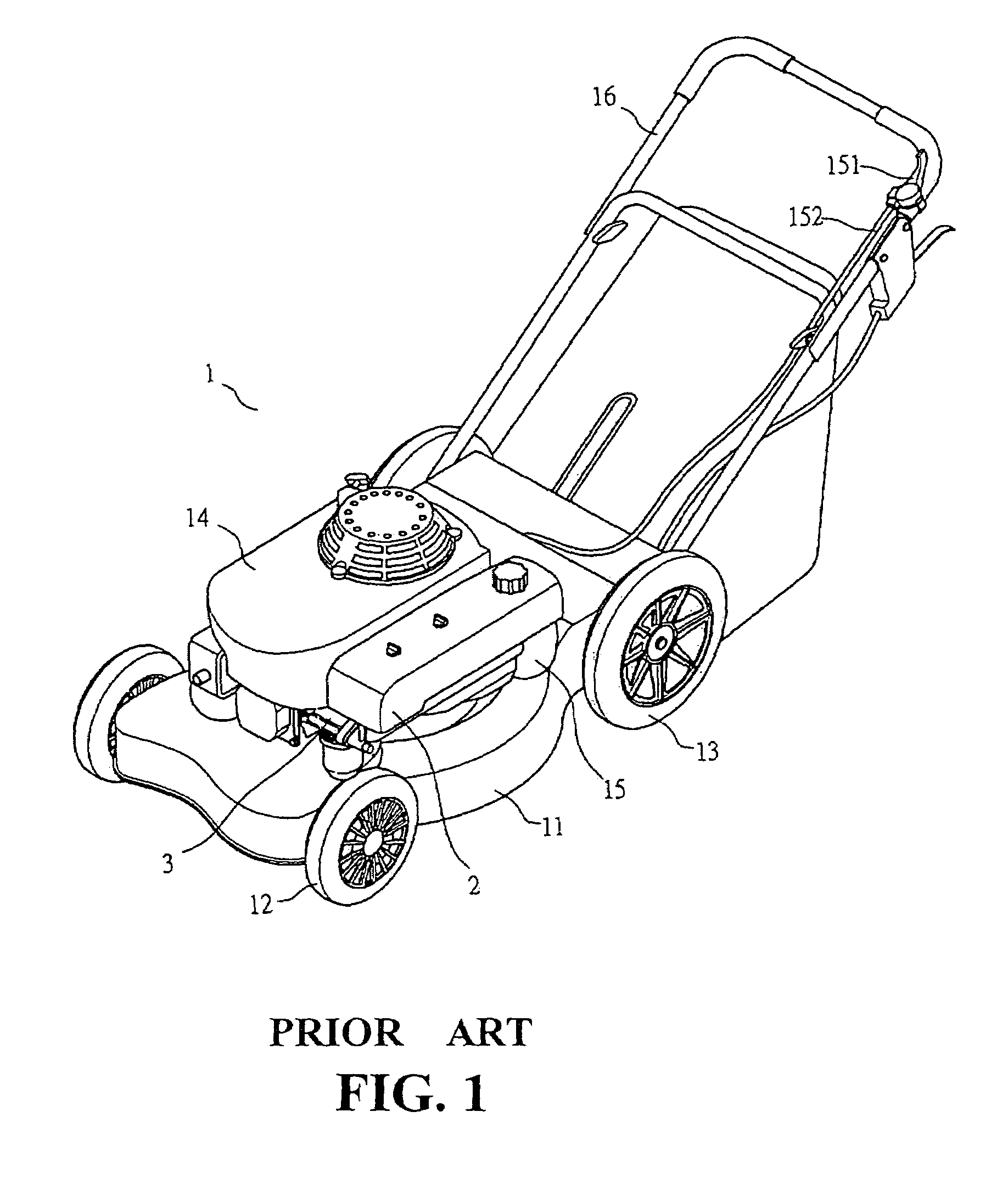

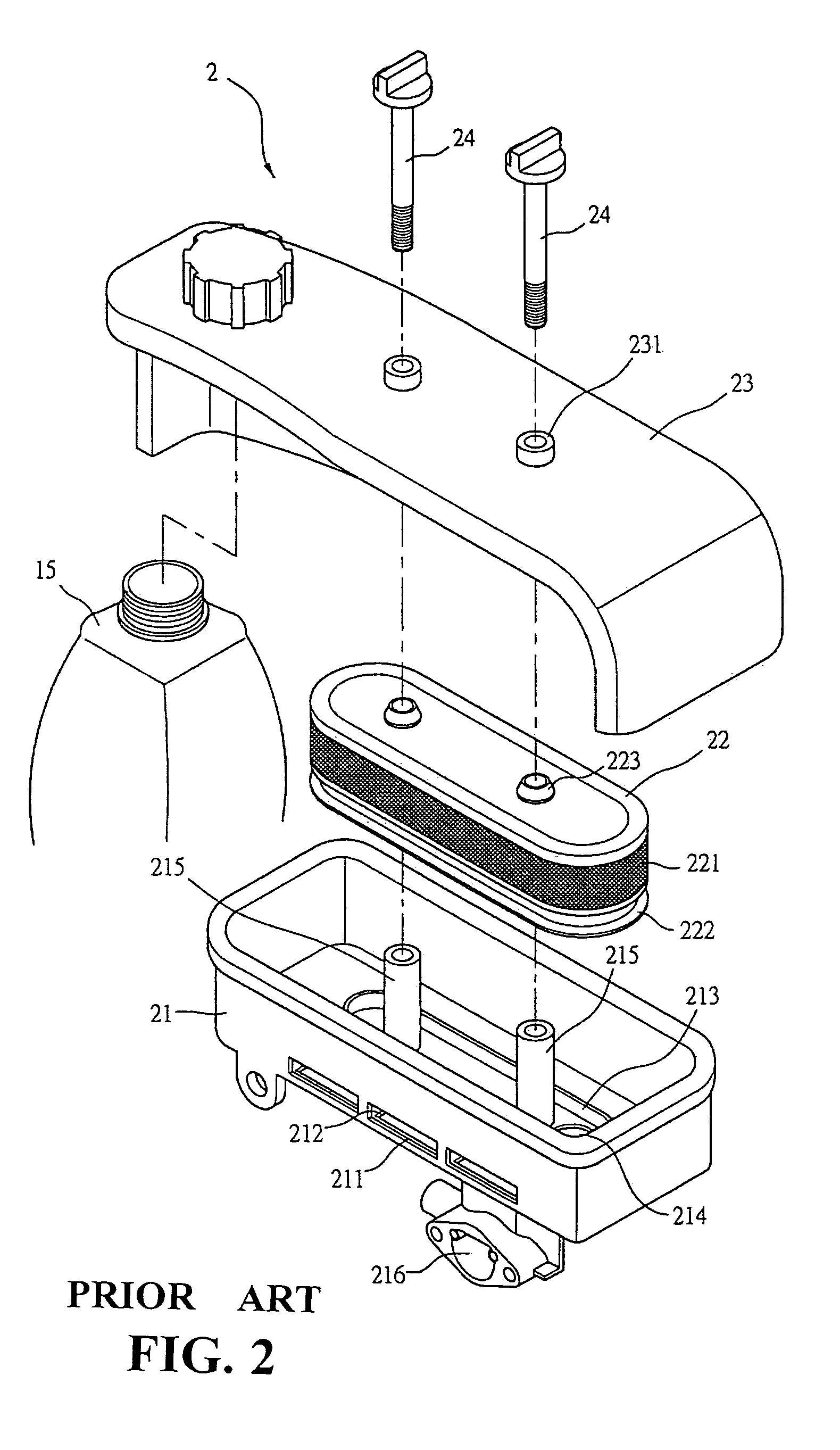

Air cleaner for engines

InactiveUS6955697B1Contaminating carburetorGuaranteed continuous supplyCombination devicesNon-fuel substance addition to fuelForeign matterCarburetor

Owner:KYMCO

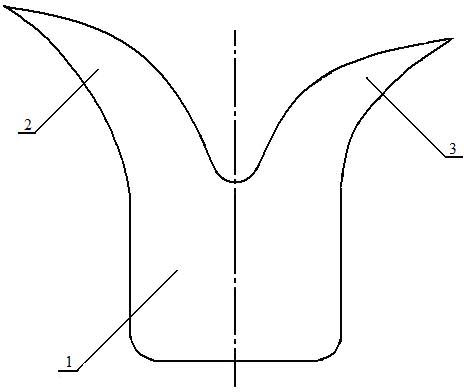

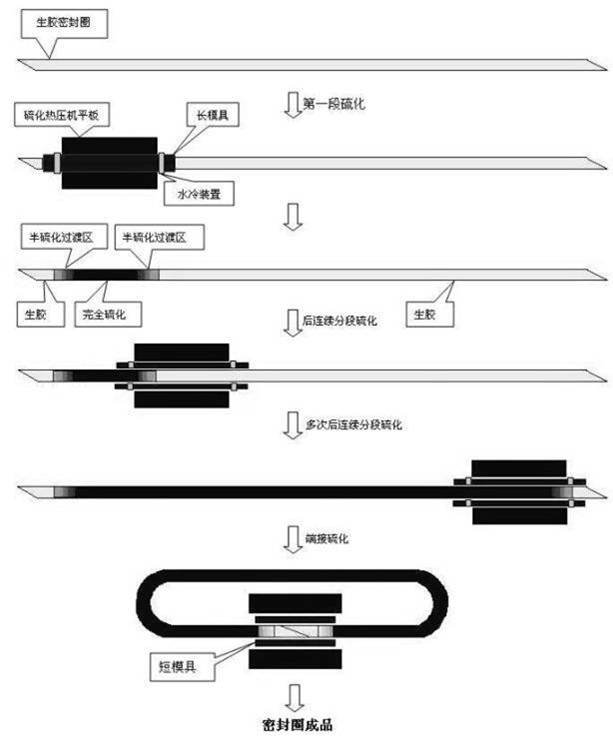

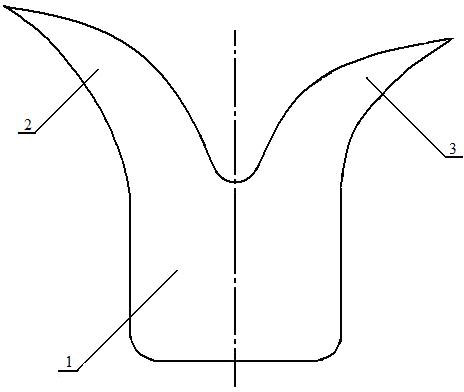

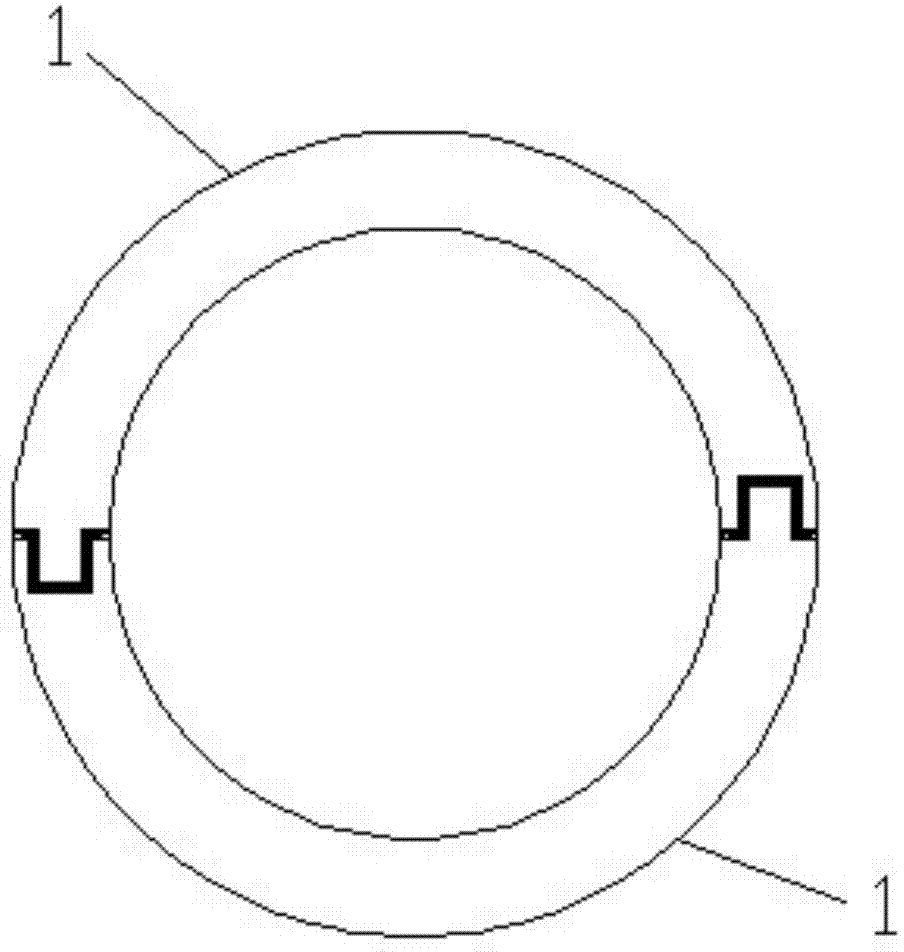

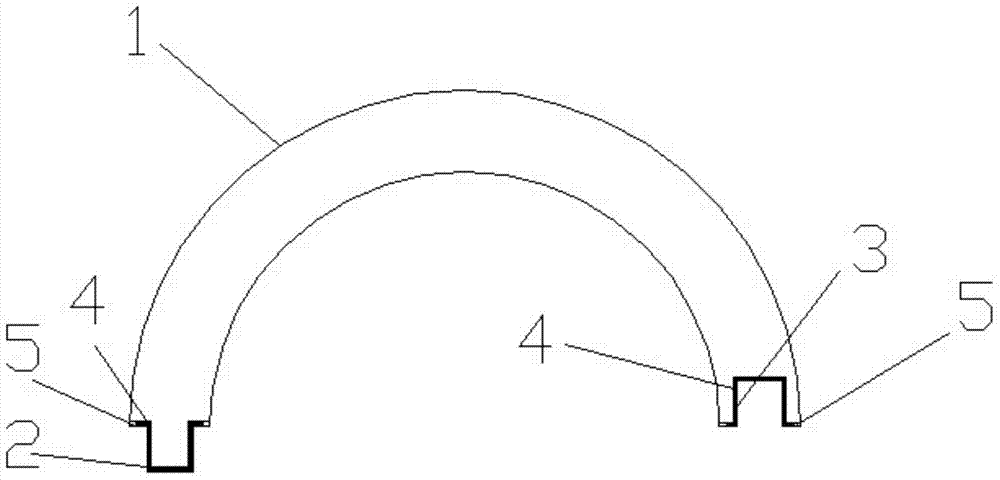

Y-shaped rubber dynamic sealing ring with long and short lips for unilateral sealing and sectional vulcanization process for sealing ring

InactiveCN102563080AReliable airtight protectionAvoid salt spray corrosionEngine sealsBearing componentsPolymer chemistryHot press

The invention relates to a Y-shaped rubber dynamic sealing ring with long and short lips for unilateral sealing and a sectional vulcanization process for the sealing ring. A V-shaped groove is formed between an inner sealing lip and an outer sealing lip, the inner sealing lip is shorter than the outer sealing lip, the height difference between the inner sealing lip and the outer sealing lip ranges from 1.5mm to 3.5mm, the outer sealing lip functions in sealing while the inner sealing lip does not function in sealing under the action of deformation pressing force, unilateral sealing is realized, and the inner sealing lip functions in storing lubricating greases. The process includes the steps: extruding mixed rubber into a straight-bar rubber blank through a rubber extruder, setting a vulcanization starting point and a vulcanization finishing point for sectional vulcanization on a machining section according to the widths of vulcanization moulds and a hot press table top during vulcanization by using the two vulcanization moulds and a rubber plate vulcanization hot press matched with the table top, wherein Y-shaped sections of mould cavities of the vulcanization moulds are the same in shape and different in length; ensuring non-defective link and transition of rubber, semi-vulcanized rubber and vulcanized rubber in previous mould stripping, next mould feeding and mould closing during vulcanization; and performing vulcanization after ensuring the rubber to enter the moulds at end connection ring positions, and ensuring the strength and the appearance of a joint to be no different from other positions.

Owner:SHANGHAI UNIV

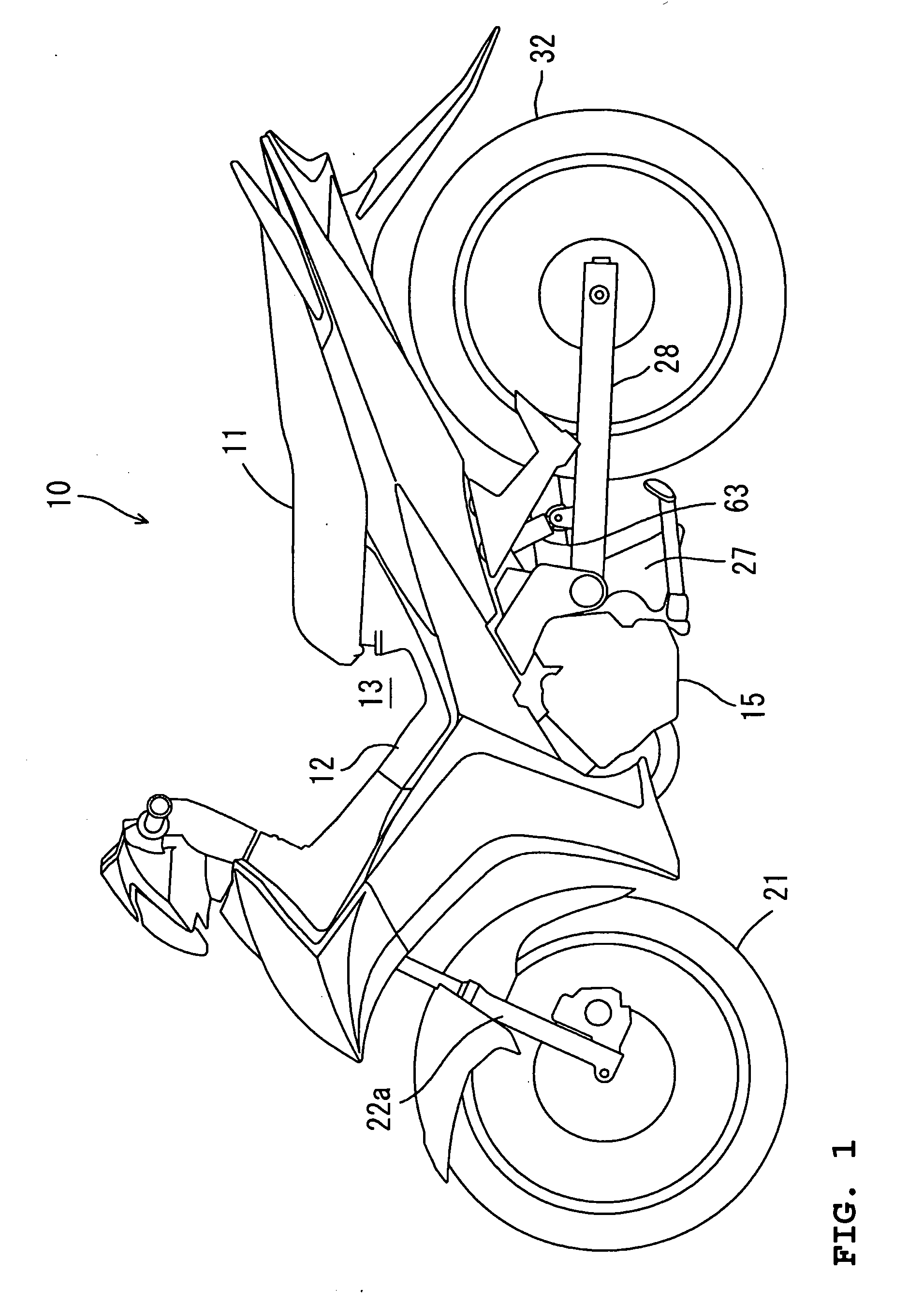

Motorcycle

InactiveUS20070251744A1Easy constructionPrevent intrusionWheel based transmissionFrictional rollers based transmissionLeather beltBuilding construction

A motorcycle has a duct that is simple in construction to introduce cooling air into a belt chamber while simultaneously preventing invasion of dust, etc. into the belt chamber. A rear fender defines a wall that separates the seat and a rear tire. An outside-air intake port of the duct is arranged in a space formed between the seat and the wall.

Owner:YAMAHA MOTOR CO LTD

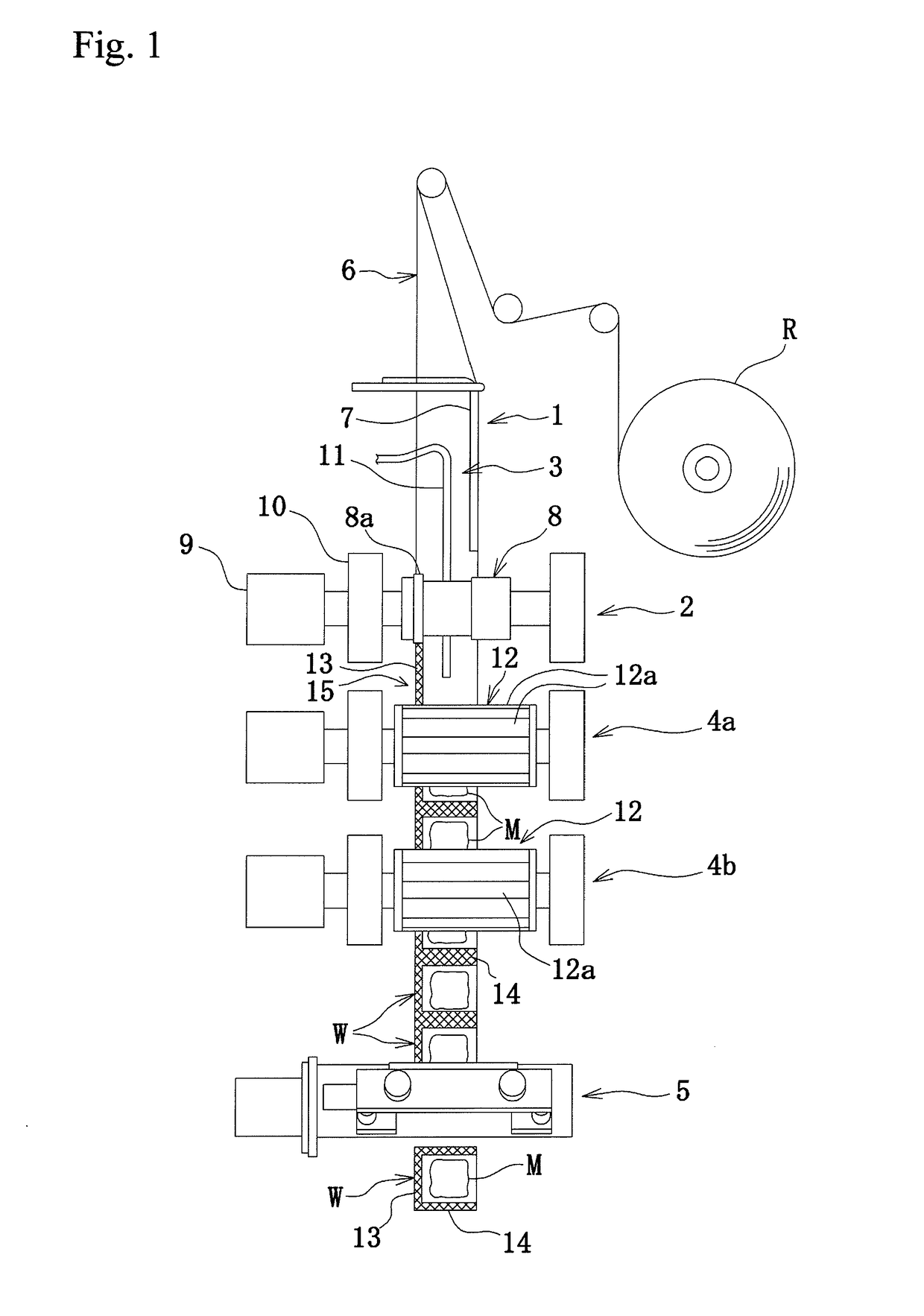

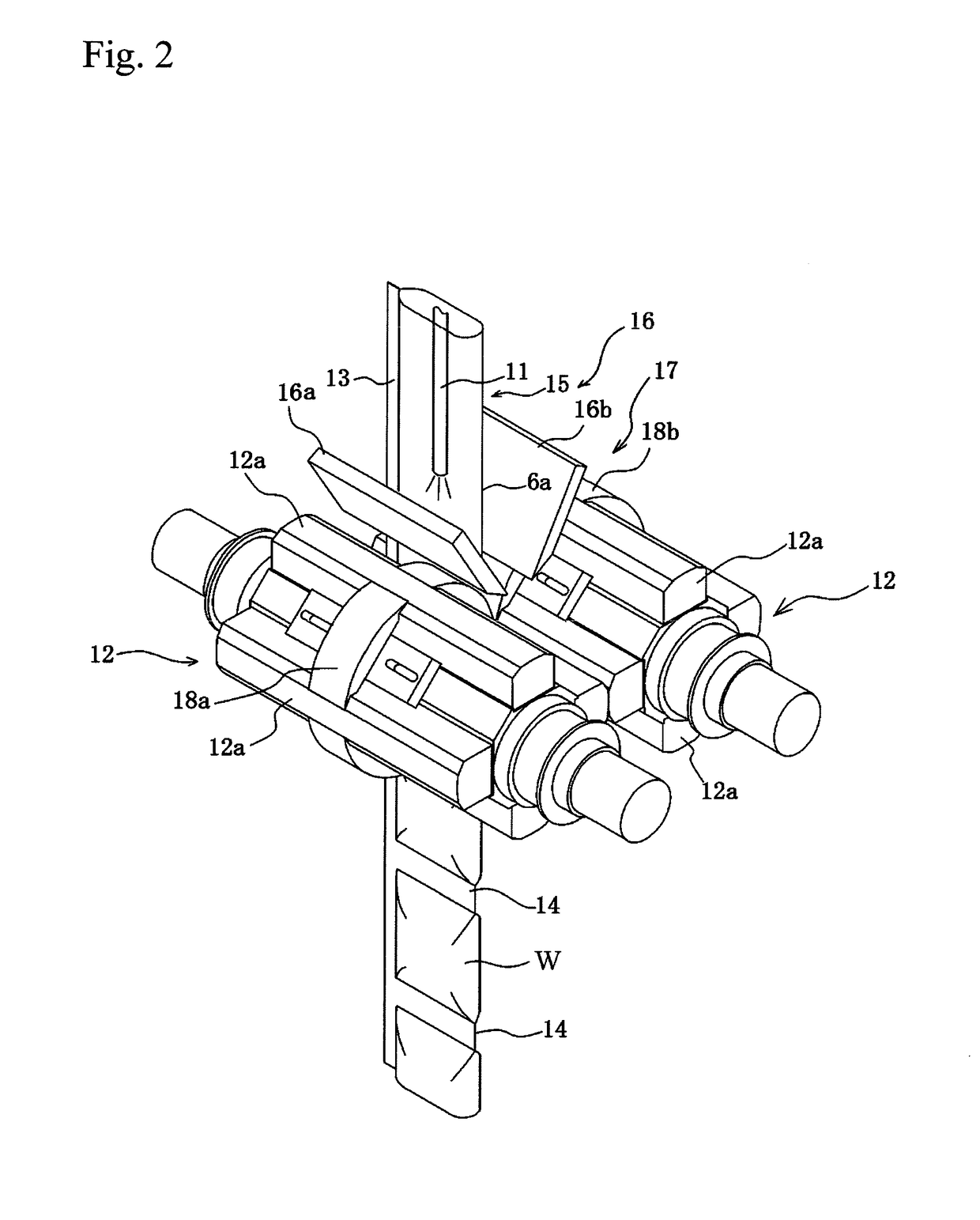

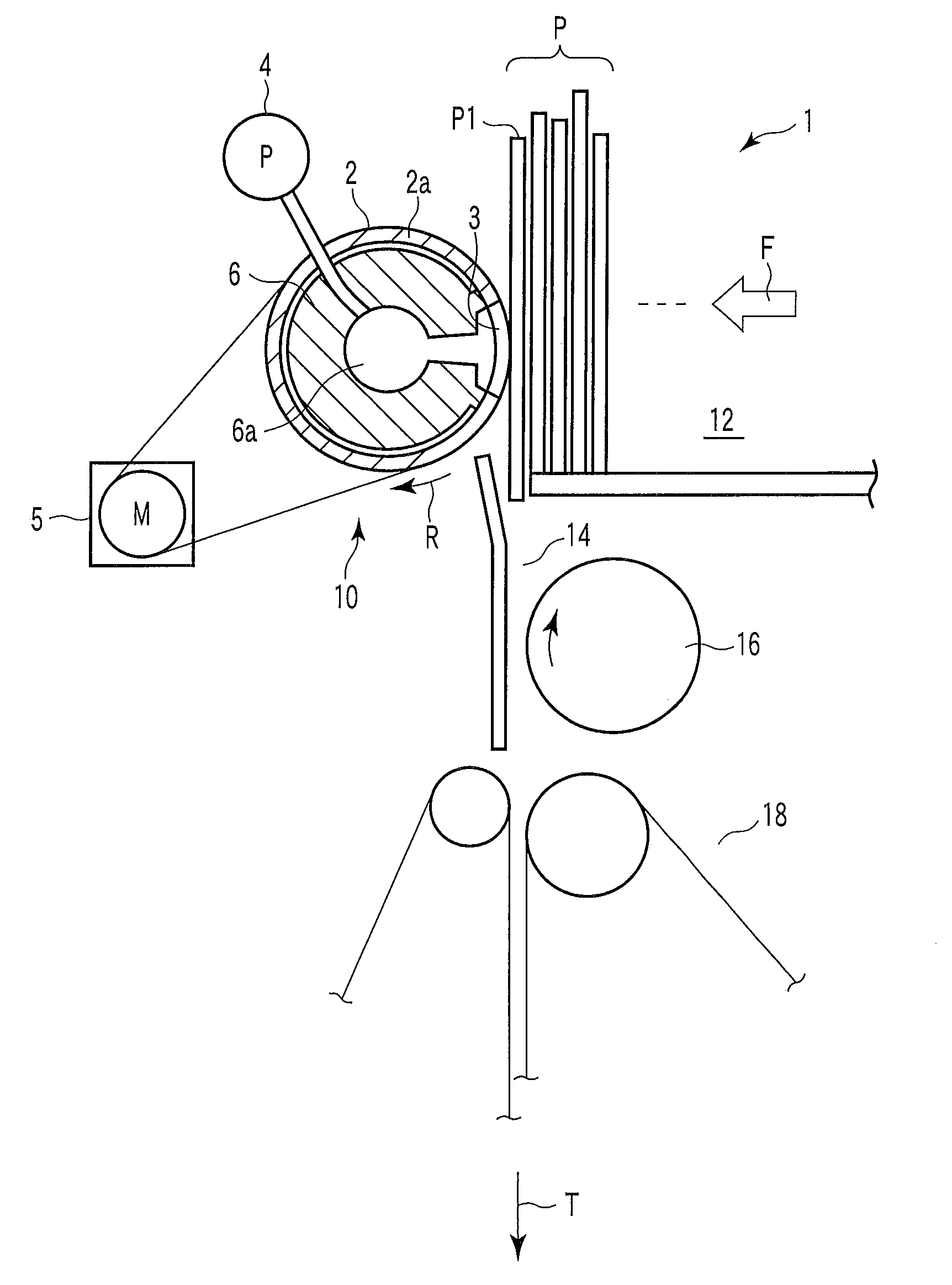

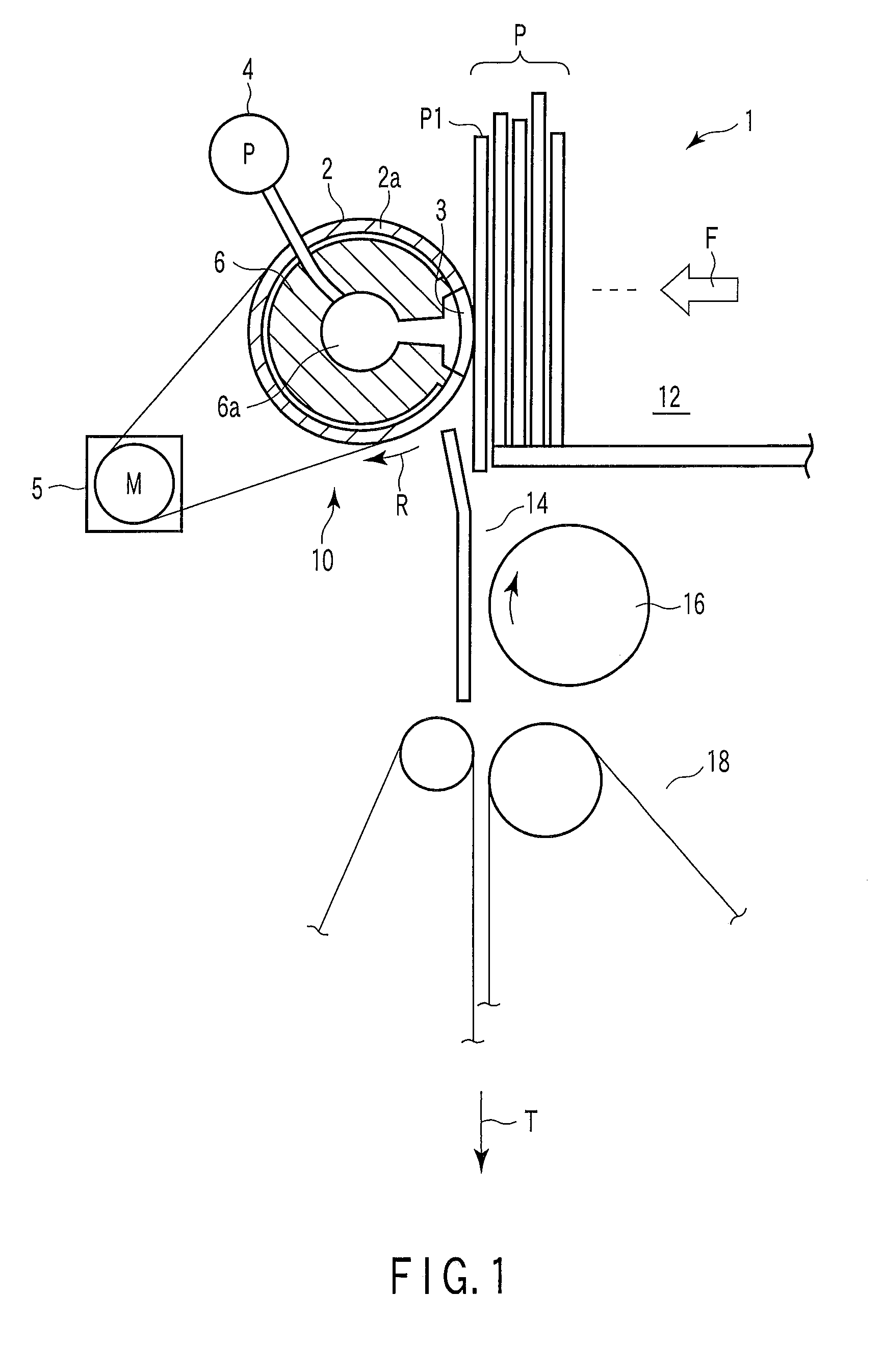

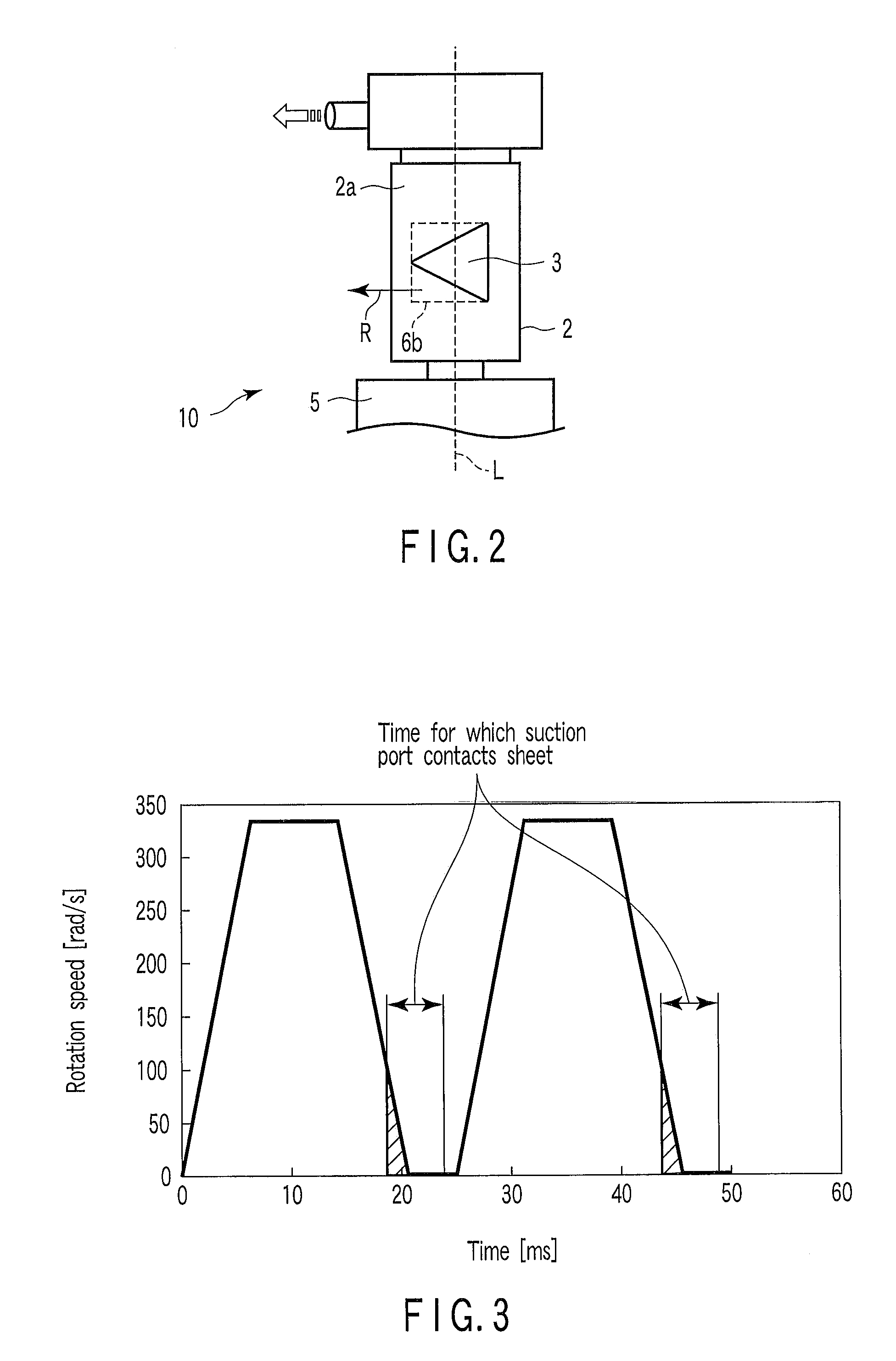

Sheet takeout device

A sheet takeout mechanism has a takeout roller that rotates in contact with a sheet located at a takeout position, and a motor that intermittently rotates the takeout roller. A triangular suction port is formed on a suction surface of the takeout roller and has a vertex located downstream in a rotation direction of the takeout roller. When a negative pressure is exerted on the sheet via the suction port, the suction force is weak at the beginning of suction and then increases gradually.

Owner:KK TOSHIBA

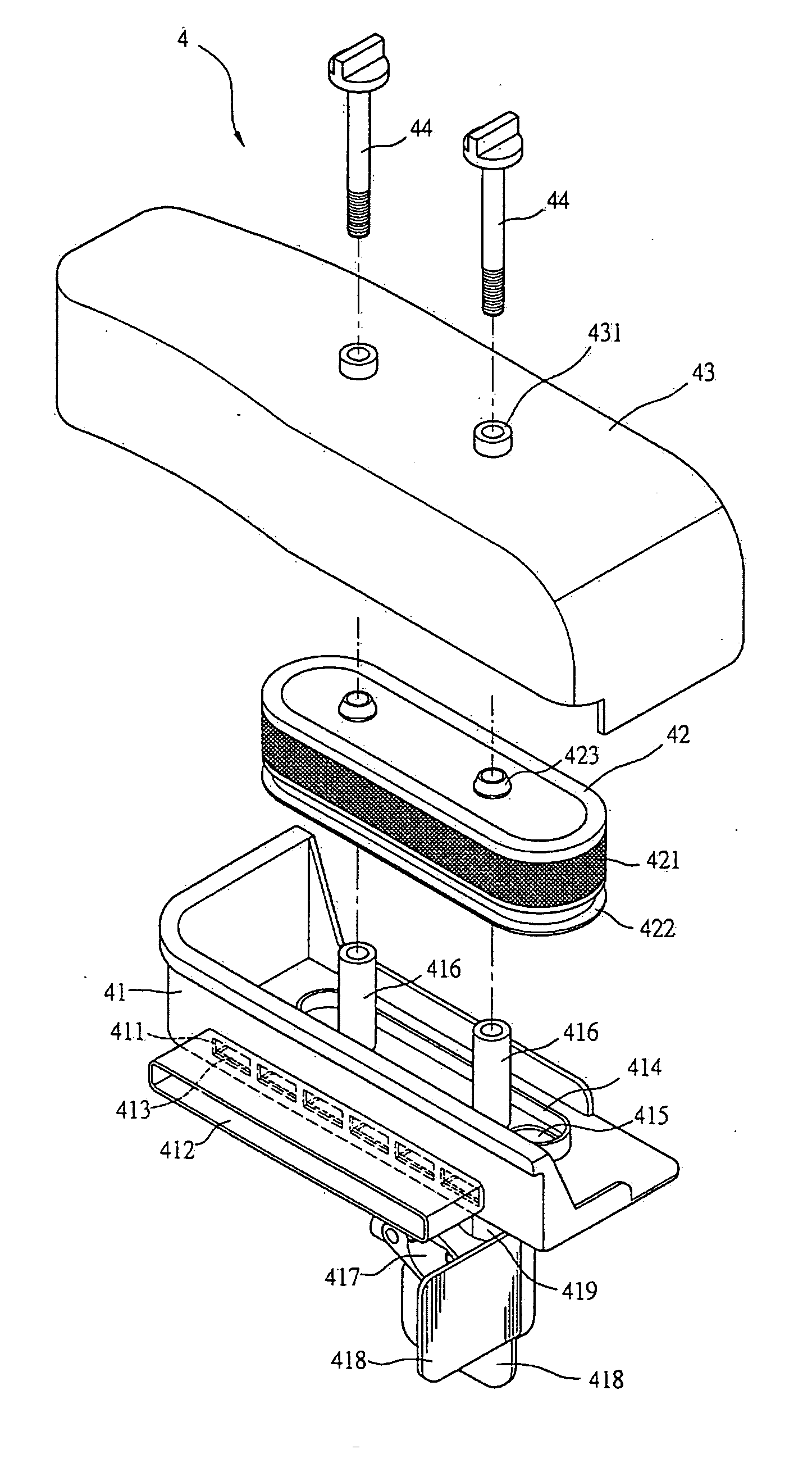

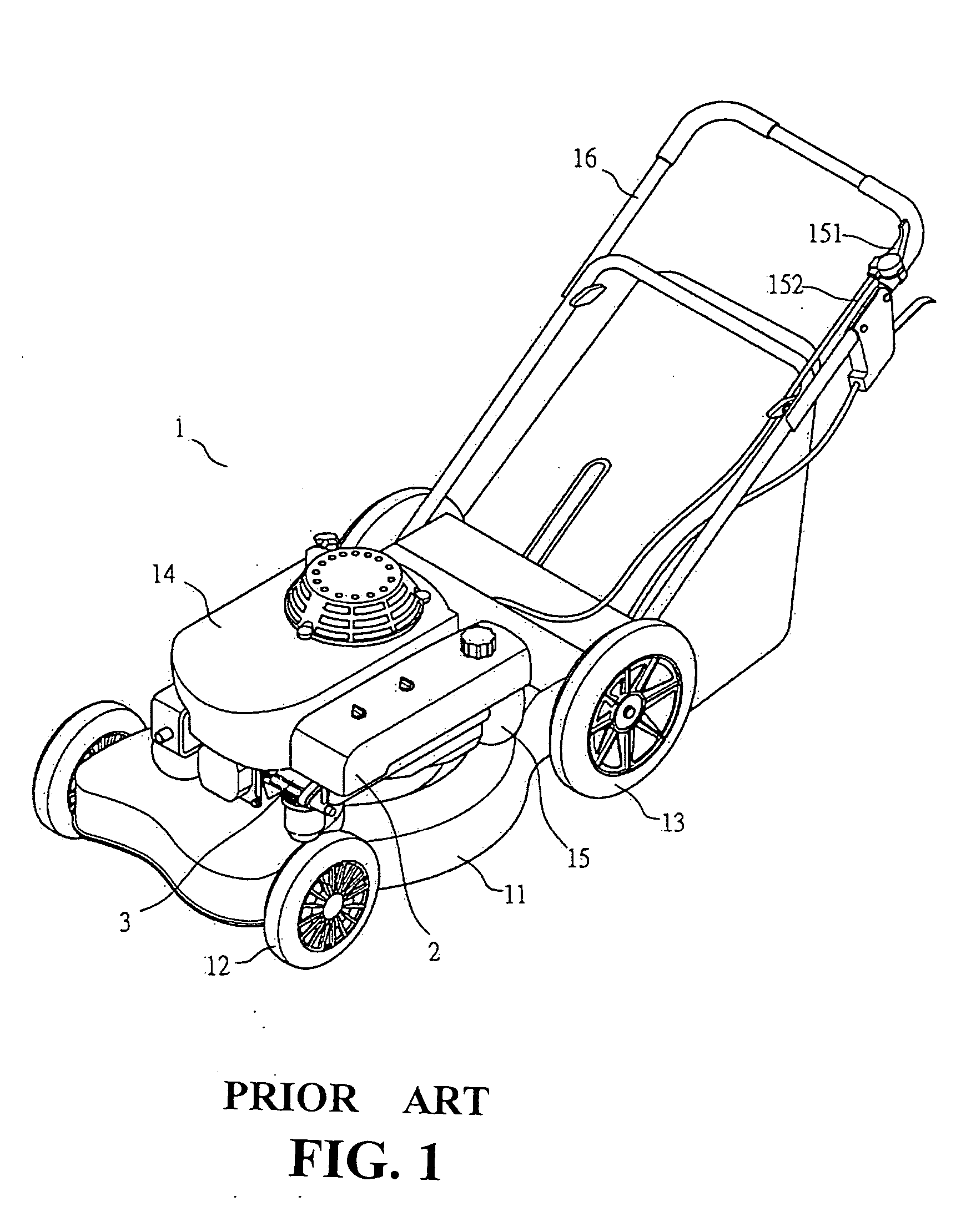

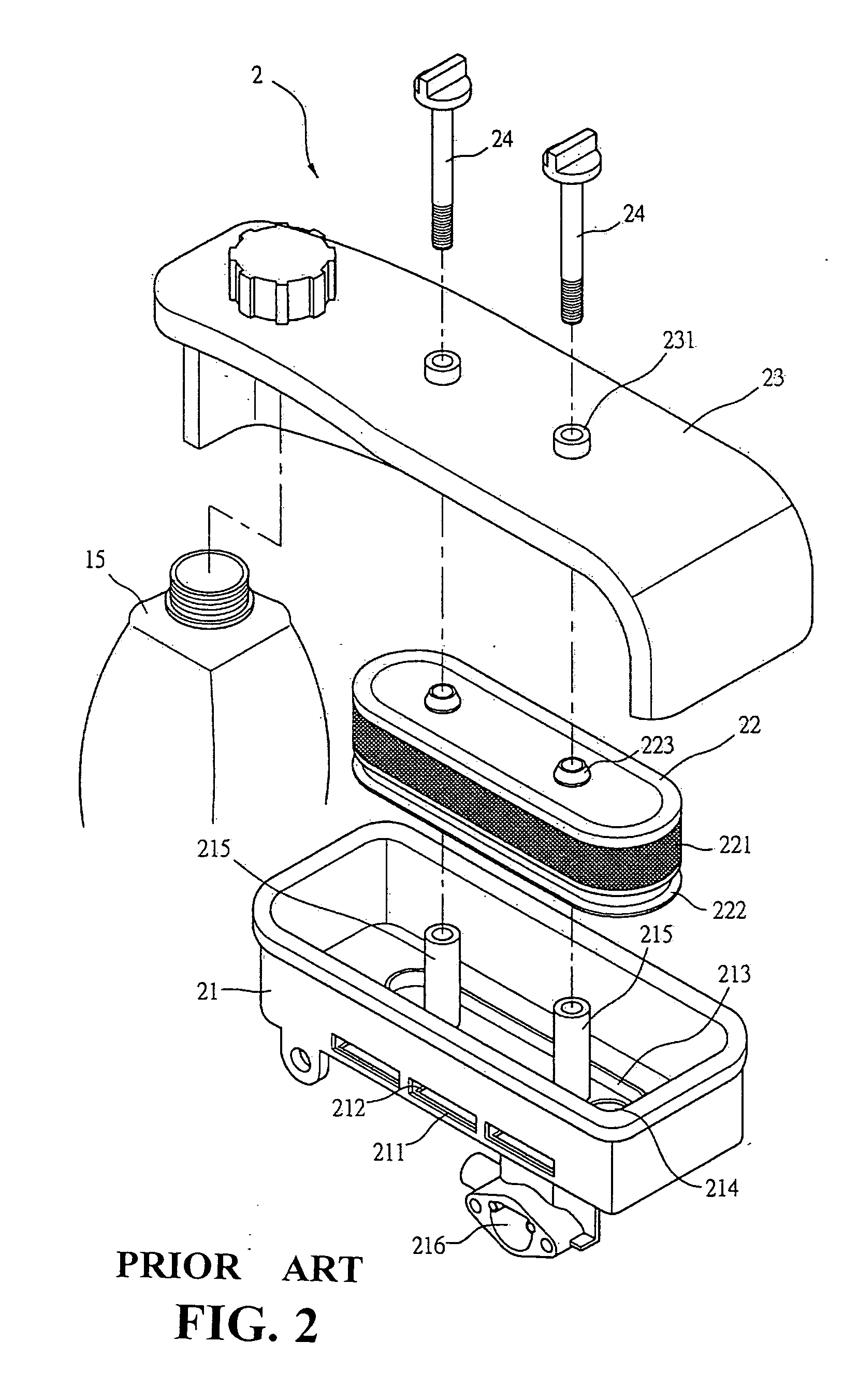

Air cleaner for engines

InactiveUS20050217222A1Contaminating carburetorPrevent suckingCombination devicesMowersForeign matterEngineering

An air cleaner for engines includes a fender provided on the side of the air inlet and the air passage, and a hollow tube adapted to the air inlet to prevent weeds, dust, and pebbles from entering into the air cleaner for enabling clean air to be delivered to the engine continuously and protecting the carburetor from being contaminated by foreign matter.

Owner:KYMCO

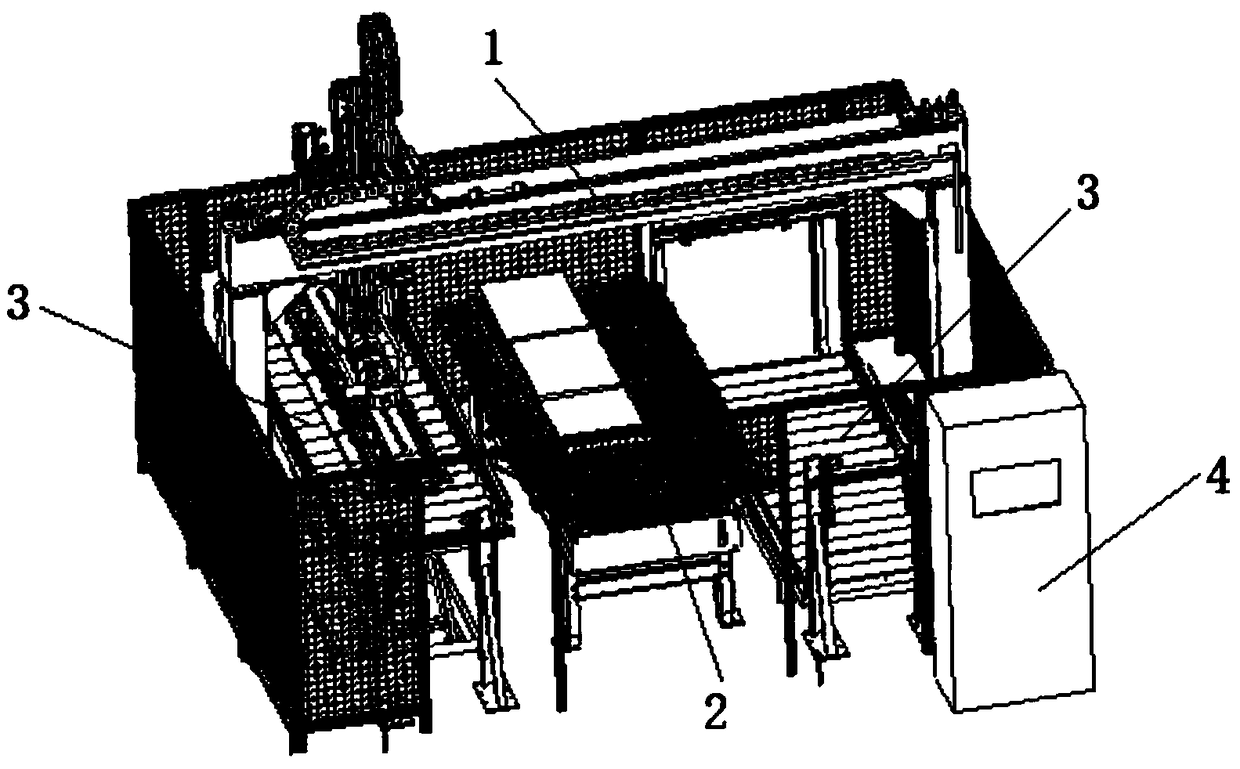

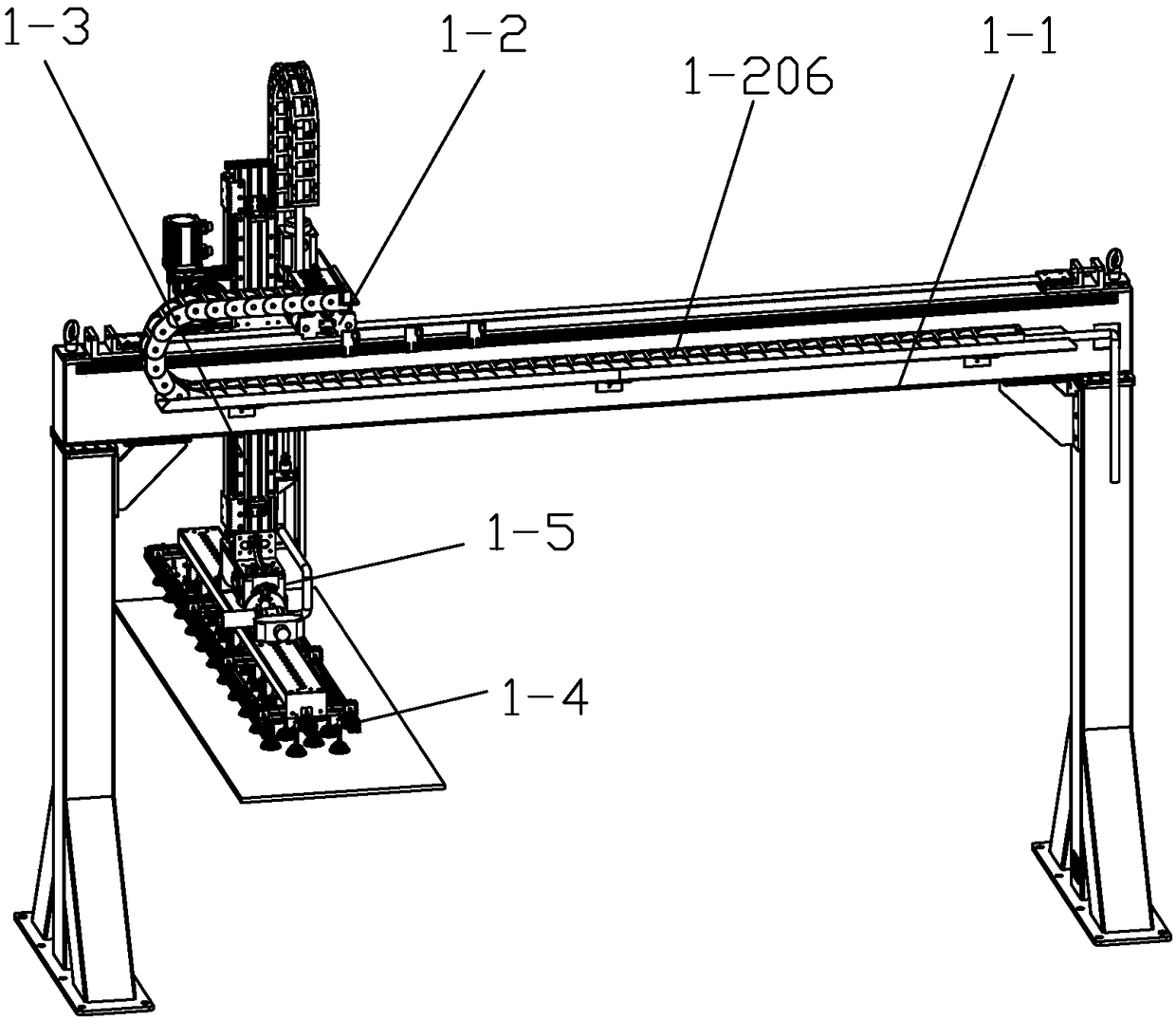

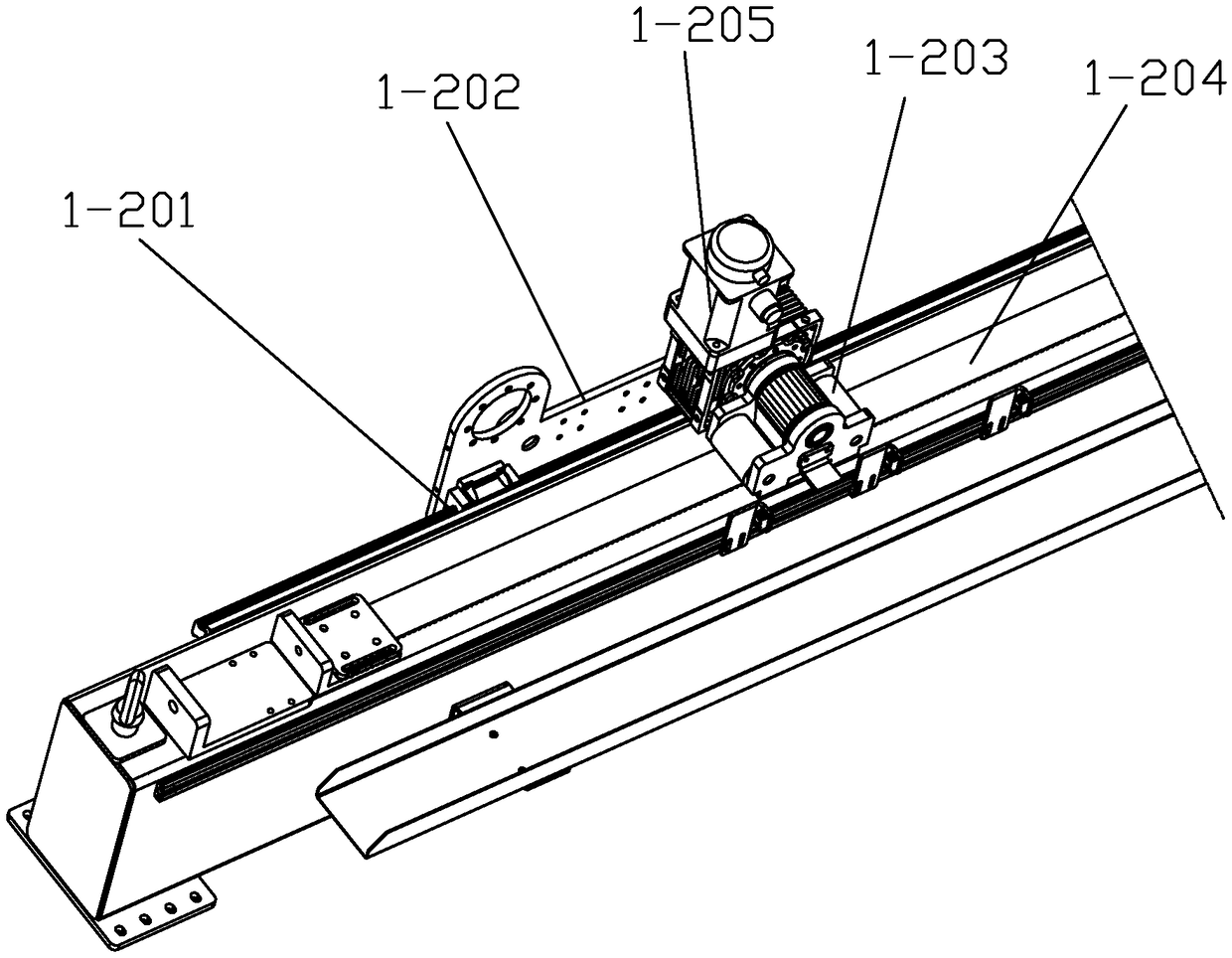

Gantry sucker automatic loading system

The invention discloses a gantry sucker automatic loading system, and relates to the field of furniture plate machining. The gantry sucker automatic loading system comprises a gantry sucker transfer machine, a belt and roller combined vertical and horizontal translation machine, two hydraulic lifting roller machines and a control system; the belt and roller combined vertical and horizontal translation machine is arranged in middle; the hydraulic lifting roller machines are separately arranged on two sides of the belt and roller combined vertical and horizontal translation machine; the gantry sucker transfer machine stretches over the belt and roller combined vertical and horizontal translation machine and the hydraulic lifting roller machines; and the gantry sucker transfer machine, the belt and roller combined vertical and horizontal translation machine and the hydraulic lifting roller machines are controlled by the control system. The gantry sucker automatic loading system solves theproblems of high labor intensity and boring and complicated work in manual loading.

Owner:JIANGSU LIWEI LOGISTICS MACHINERY

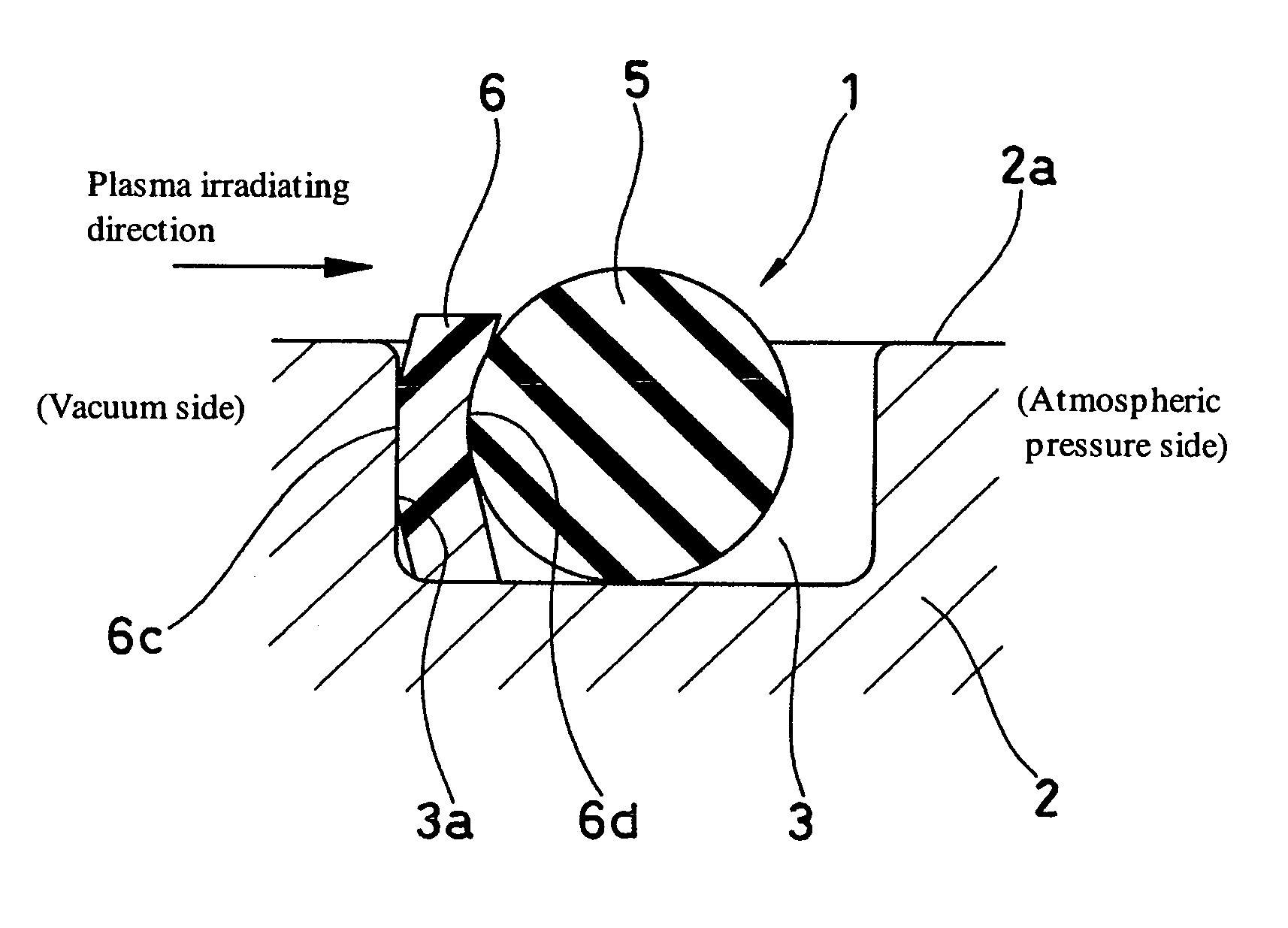

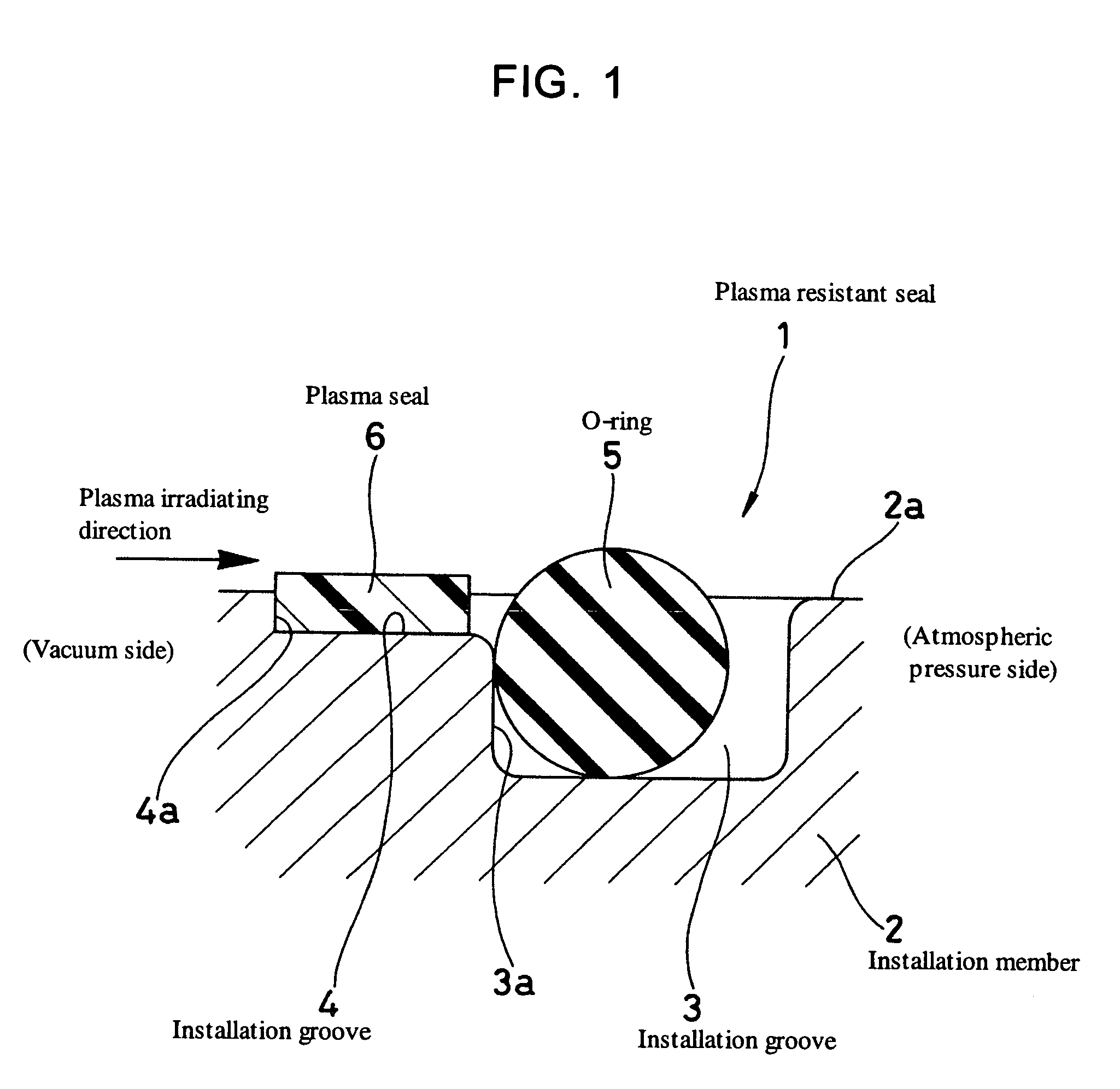

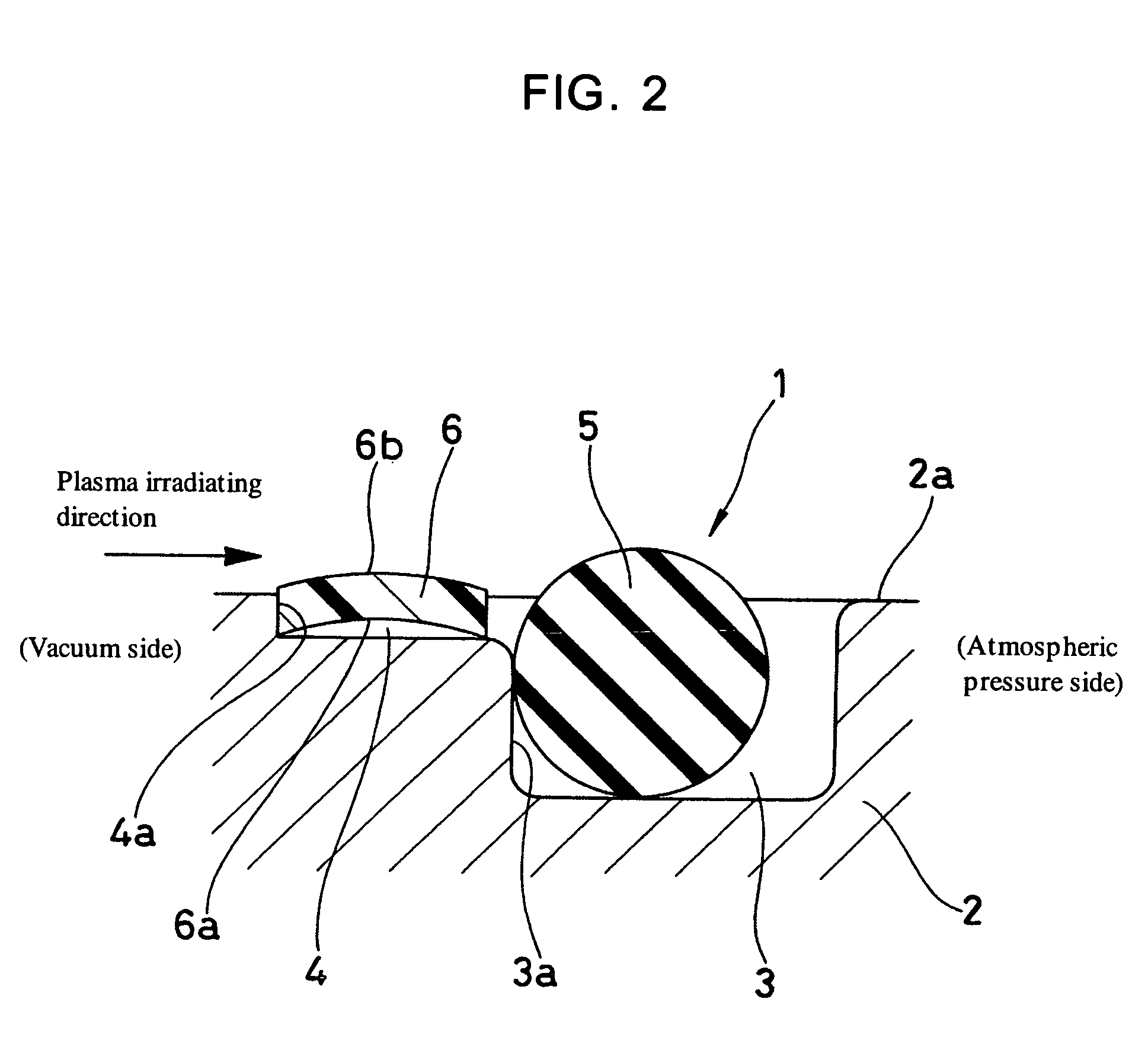

Plasma resistant seal

InactiveUS7942425B2Improve shielding effectPrevent suckingEngine sealsOther chemical processesEngineeringPlasma irradiation

To make a plasma resistant seal excellent in both a plasma resisting performance and a sealing performance, and prevent an O-ring from protruding to a vacuum side gap, a plasma seal (6) made of PTFE having a plasma resisting performance is provided in a plasma irradiating side of an O-ring (5) as a main seal made of a rubber-like elastic material, an installation groove (4) shallower than a depth of an installation groove (3) provided in an installation member (2) is continuously provided in a plasma irradiation side of the installation groove (3), the O-ring (5) is attached to the installation groove (3), and the plasma seal (6) is attached to the installation groove (4) in a compressed state, or the O-ring is attached to the installation groove and the plasma seal is attached to the plasma irradiation side of the same installation groove (3) in a compressed state.

Owner:NOK CORP

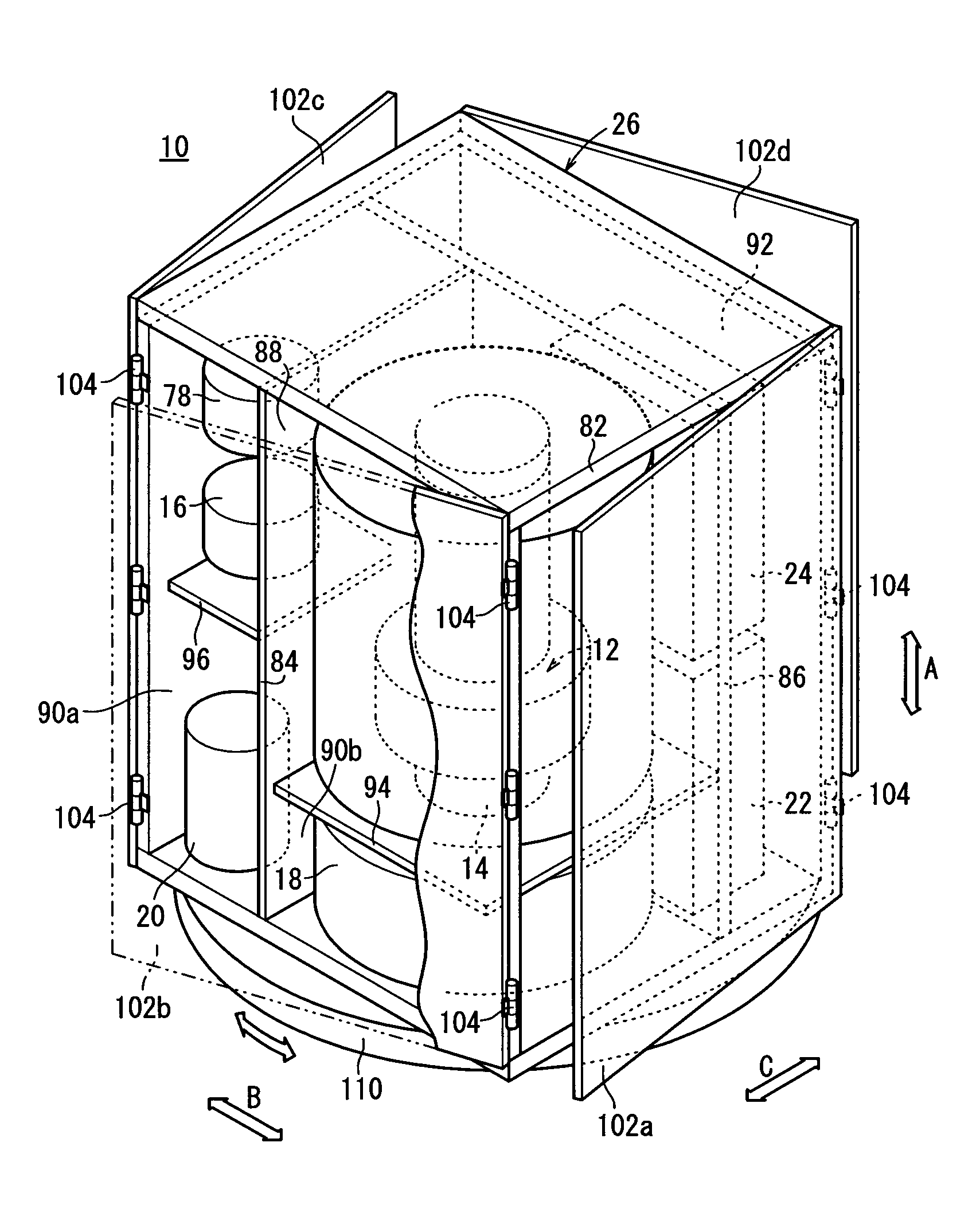

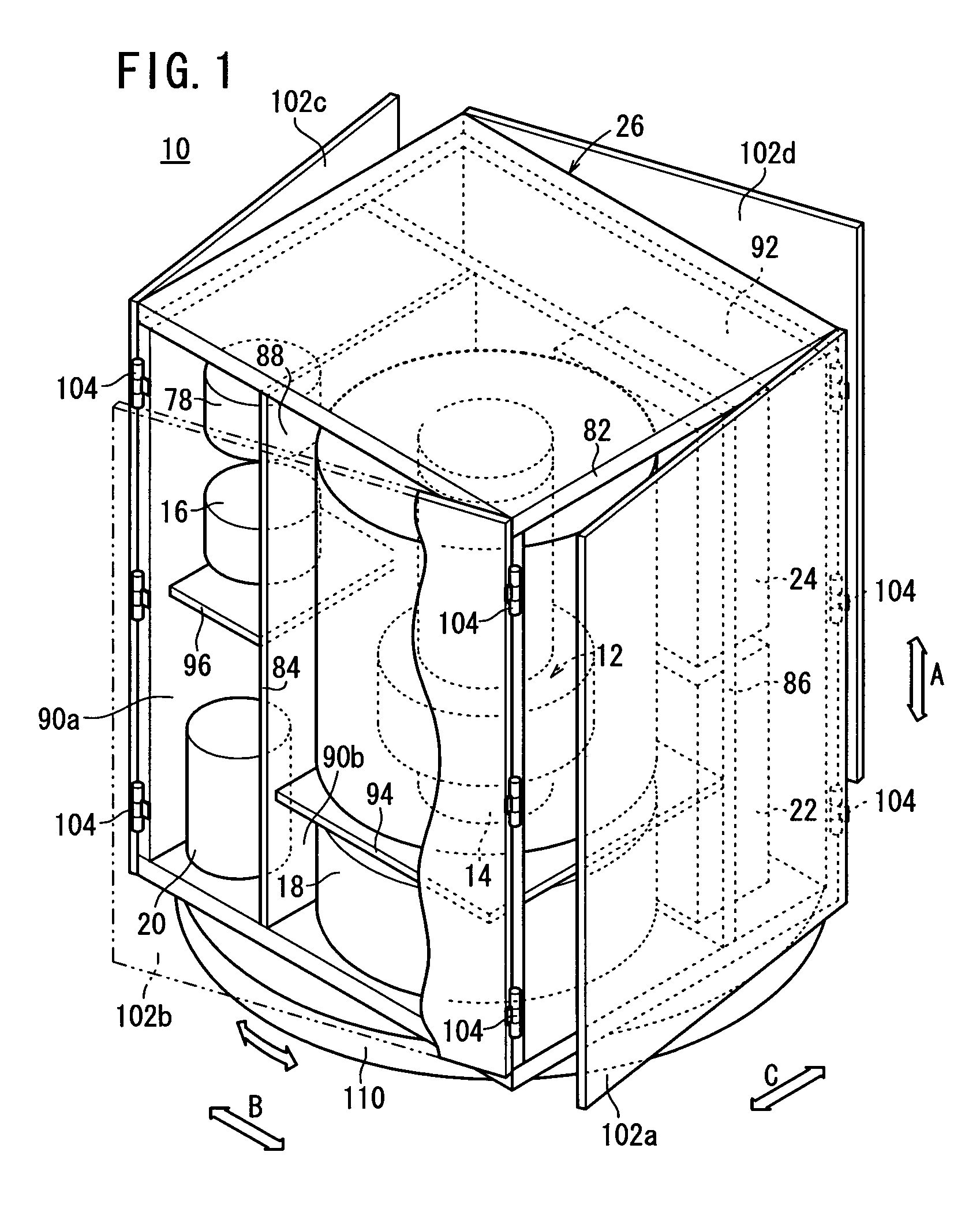

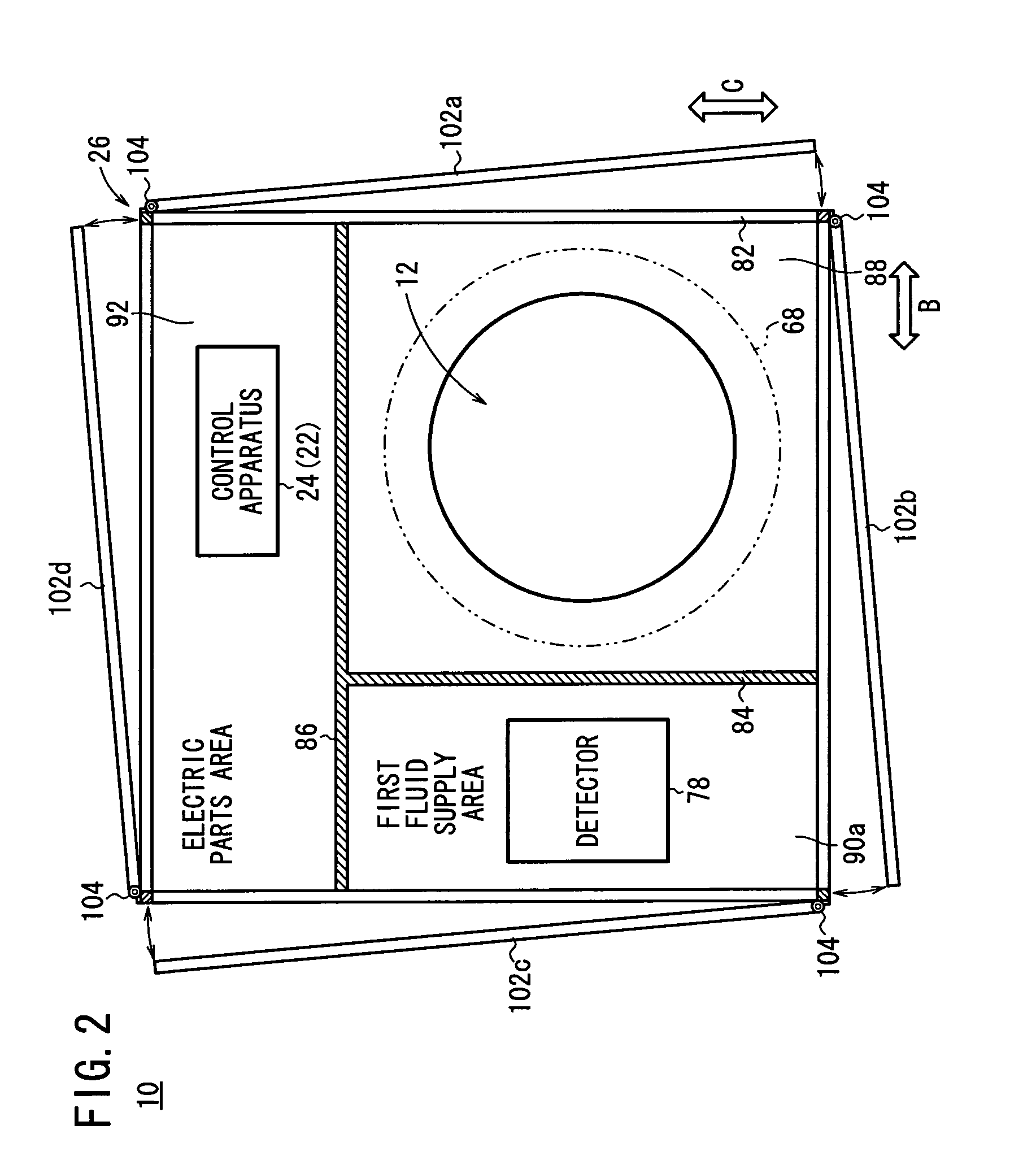

Fuel cell system

ActiveUS8178256B2Minimize diffusionAvoid thermal effectsFuel cell heat exchangeFuel cells groupingCombustorFuel cells

A casing of a fuel cell system is divided into a module area, a first fluid supply area, a second fluid supply area, and an electric parts area. The first fluid supply area is provided on a first side surface of the module area, and an electric parts area is provided on a second side surface of the module area. The second fluid supply area is provided under a bottom surface of the module area. A fuel cell module and a combustor are provided in the module area.

Owner:HONDA MOTOR CO LTD

Positive and negative pressure protector

ActiveCN103062624AEasy to adjustPrevent suction deflation and swellingContainer filling methodsVariable capacity gas holdersEngineeringPositive pressure

The invention discloses a positive and negative pressure protector. The protector concretely comprises a gas inlet tube, a triplet, a negative pressure valve, a gas guide tube, an outer cylinder, a diffusion tube, a liquidometer and an overflow tube. The length of the overflow tube is adjusted to change the liquid seal height, so the positive pressure of a container is adjusted; and the triplet is adjusted and the angle of the negative valve is changed to adjust the negative pressure of the container, so the positive and negative pressures in the container are conveniently adjusted, thereby the suck-shriveling and expansion-cracking of the container are effectively prevented.

Owner:BEIJING SANYI GREEN ENERGY DEV

Automobile steering wheel cover

The invention relates to an automobile steering wheel cover, comprising a steering wheel body. The steering wheel body is composed of two identical semicircular covers; one end of each semicircular cover is provided with a protrusion which is protruded outwards; a magnetic device is arranged in each protrusion; an insulation layer is arranged between each magnetic device and the surface of the corresponding semicircular cover; the other end of each semicircular cover is provided with a groove adaptive to the corresponding protrusion; the magnetic devices are arranged on the peripheries of the grooves; the insulation layers are arranged between the magnetic devices and the surfaces of the corresponding semicircular covers. The automobile steering wheel cover has the characteristics of simple structure, low cost, convenience in installation and detachment and the like.

Owner:常州时代精工刃具有限公司

Refrigeration system

InactiveUS7165421B2Inhibition releasePrevent suckingAir-treating devicesVehicle heating/cooling devicesAtmospheric airHigh pressure

Owner:TGK

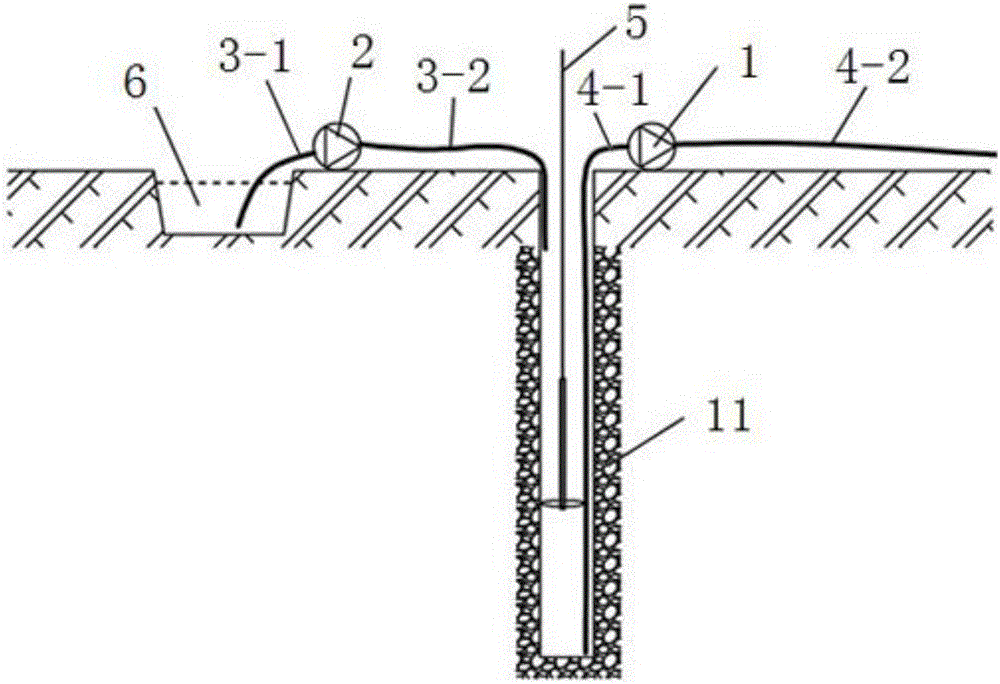

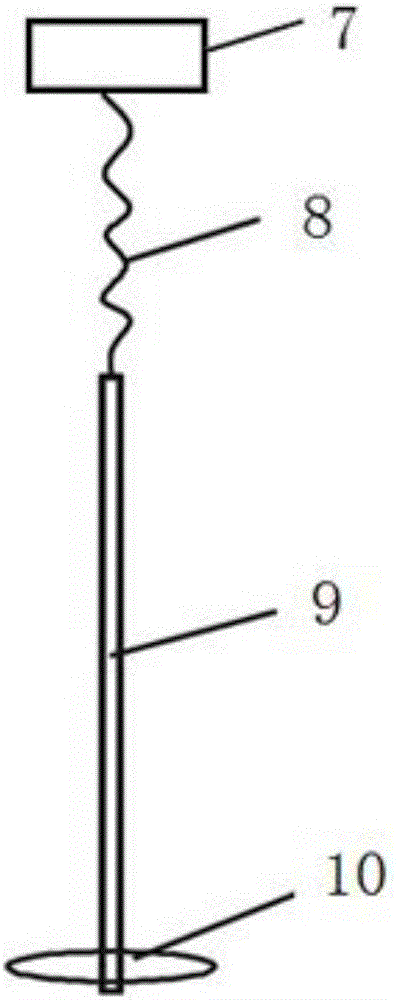

Simple hydrological-hole dredging device

InactiveCN105064312AImprove dredging efficiencyImprove dredging effectFlushingIn situ soil foundationEngineeringGroundwater

The invention discloses a simple hydrological-hole dredging device. The simple hydrological-hole dredging device comprises a first dieselized pumping machine, a second dieselized pumping machine and a stirrer. The first dieselized pumping machine is connected with hard plastic pipes and used for pumping out underground water at the bottom of a hydrological hole. The second dieselized pumping machine is connected with soft plastic pipes and used for injecting water into the hydrological hole. The stirrer comprises a thin rope and a metal rod. The thin rope is connected with one end of the metal rod. A cloth strip or a sponge is arranged at the other end of the metal rod and used for stirring the underground water in the hydrological hole. According to the simple hydrological-hole dredging device, circulating of the water in the hydrological hole is achieved through the two dieselized pumping machines; and as the underground water in the hydrological hole is stirred through the stirrer, the hole dredging efficiency is greatly improved, and the hole dredging time is shortened. The simple hydrological-hole dredging device is simple in structure and convenient to install, and can be repeatedly used.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Vacuum leak-detection sterile dual-valve soft bag transfusion combined bag

InactiveCN103961260AThoroughly sterilizedEfficient sterilizationPharmaceutical containersMedical packagingLeak detectionBiomedical engineering

The invention relates to a vacuum leak-detection sterile dual-valve soft bag transfusion combined bag. A manufacturing process of the vacuum leak-detection sterile dual-valve soft bag transfusion combined bag comprises the following steps of sterilizing a material membrane of a liquid medicine bag, feeding the material membrane into a packing workshop, welding the material membrane with a transfusion valve to form an inner packaging bag, filling the inner packaging bag with liquid medicine to form soft bag transfusion, performing sterilization for a second time and performing drying; performing lamp detection for a first time to remove unqualified products with wrong package printing, wrong welding and large impurities in the packaging bag; covering the liquid medicine bag with an outer packaging bag, vacuumizing space between the outer protective bag and the liquid medicine bag or filling space between the outer packaging bag and the liquid medicine bag with protective gas preparations or liquid preparations or solid preparations, performing sterilization for a third time, packing the combined bag in a case, and putting the case in storage for later use; performing lamp detection for a second time to remove leaked products. By means of the vacuum leak-detection sterile dual-valve soft bag transfusion combined bag, bacteria cannot retain in an interlayer, microleaked large volume injection formed in the inner packaging bag can be discharged effectively and conveniently, and the liquid leakage rate when the combined bag leaves the factory is reduced below 0.029%. The period of validity of the vacuum leak-detection sterile dual-valve soft bag transfusion combined bag is prolonged to five years from two years.

Owner:SICHUAN TAIPINGYANG PHARMA

Intake device of V-type engine of motorcycle

ActiveUS7380534B2Improve air intake efficiencyPromoting quietnessNon-fuel substance addition to fuelInternal combustion piston enginesInterior spaceAir filter

An intake device of a V-type engine provided with two cylinders inclining in a longitudinal direction of a motorcycle includes a center air cleaner arranged above a V-bank space formed between the two cylinders, a pair of right and left side air cleaners arranged on both sides of the V-bank space, and an air / fuel mixture supply device disposed between the center air cleaner and the V-bank space. An internal space of the center air cleaner is communicated with an intake port of each of the cylinders through the air / fuel mixture supply device. The internal space of the side air cleaner is divided into a dirty side and a clean side with an air filter being interposed therebetween, in which the clean side is connected to the center air cleaner and the dirty side is provided with an intake port communicating with an outside. The intake port is opened so as to face the V-bank space side.

Owner:SUZUKI MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com