Y-shaped rubber dynamic sealing ring with long and short lips for unilateral sealing and sectional vulcanization process for sealing ring

A dynamic sealing ring, segmented vulcanization technology, applied in the direction of engine seals, engine components, bearing components, etc., can solve the problems of increased dynamic friction and operating damping, difficulty, and high processing costs, reducing dynamic friction and running. Increased damping, keeping running, reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

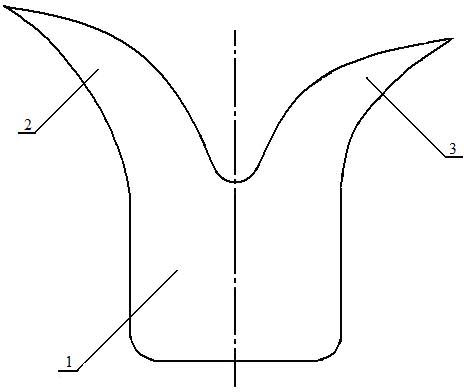

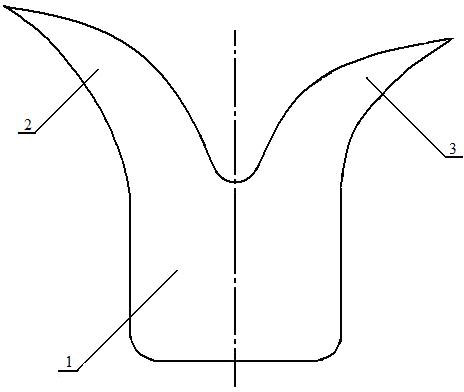

[0017] see figure 1 , the Y-shaped rubber dynamic sealing ring with long and short lip unilateral seal is characterized in that: the cross section of the sealing ring is Y-shaped, a V-shaped groove is formed between the inner and outer sealing lips, and the length of the inner sealing lip is longer than that of the outer sealing lip. The lip is short, and the height difference between the inner and outer sealing lips is: 1.5mm to 3.5mm; under the deformation and compression force, the outer sealing lip plays a sealing role, while the inner sealing lip does not function as a seal, achieving unilateral sealing, while the inner sealing lip acts as a seal. The function of storing grease.

Embodiment 2

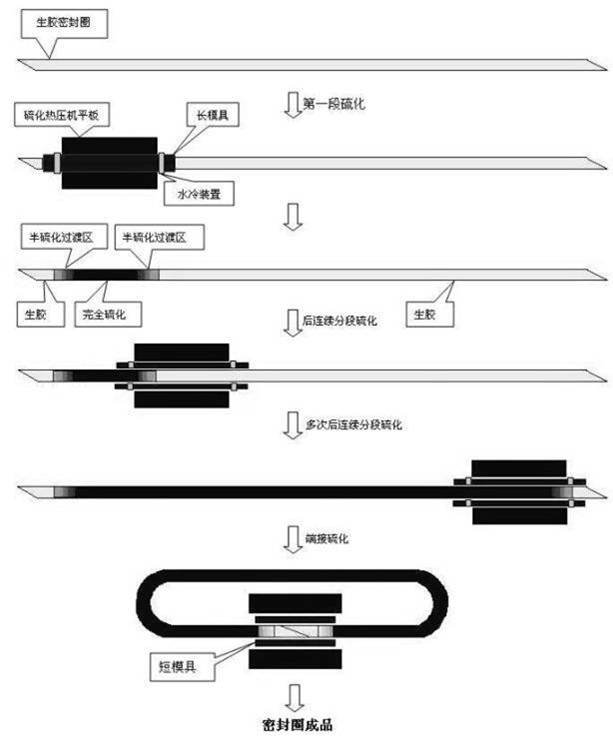

[0019] see figure 2 , the segmental vulcanization process of the Y-shaped rubber dynamic sealing ring with long and short lip unilateral seals. The vulcanization molds with the same Y-shaped cross-section and different lengths and the rubber flat vulcanization hot press with matching table tops. During the vulcanization process, the starting point and end point of vulcanization are set in the processing section according to the width of the vulcanization mold and the table top of the hot press machine. Carry out segmental vulcanization; during the vulcanization process, the previous mold release, the next mold entry and mold closing must ensure the defect-free connection and transition of raw rubber, semi-vulcanized and vulcanized rubber; the looping parts of the terminations must ensure the butt joint of raw rubber into the mold Then vulcanize to ensure that the interface strength and appearance are no different from other parts.

Embodiment 3

[0021] see figure 2 , The specific operation steps of the segmental vulcanization process of the Y-shaped rubber dynamic seal ring with long and short lip unilateral seals are as follows: Design a mold according to the caliber of the Y-shaped rubber dynamic seal ring (diameter: Φ1000mm) processed according to the requirements, and first machine the whole , and then cut off two sets of molds with different lengths and lengths. The length range of the long mold is: 1200mm, and the length range of the short mold is: 1000mm. The uniform vulcanization process parameters are adopted in the staged vulcanization process. The Y-shaped raw rubber billet extruded by the extruder is placed in the mold and placed on a rubber flat vulcanizer. The vulcanization time is 10 minutes and the vulcanization temperature is 150°C. The initial first-stage vulcanization is processed by a long mold, starting from a section of the raw rubber blank belt, and a 150mm raw rubber blank is reserved at the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com