Patents

Literature

39results about How to "Keep running" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

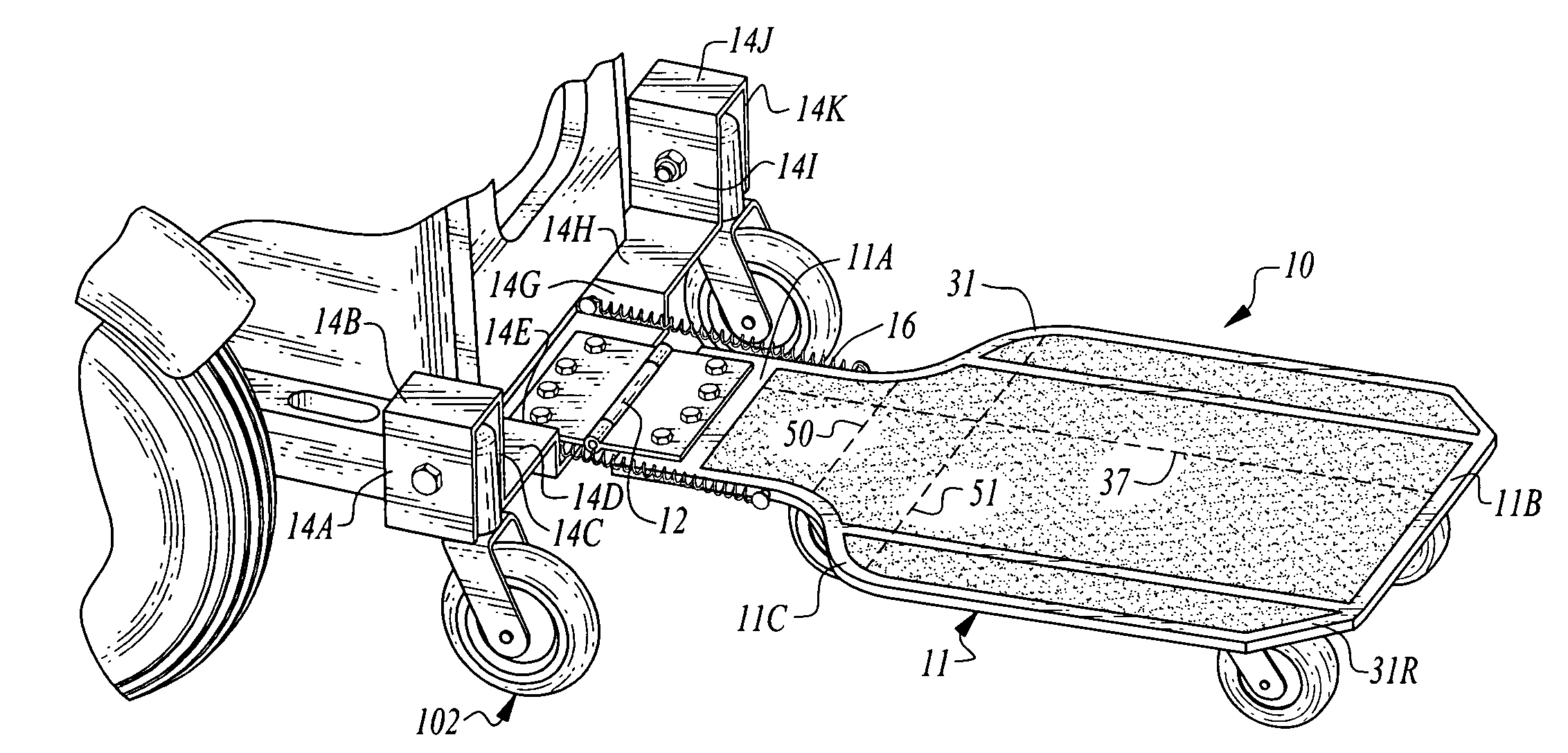

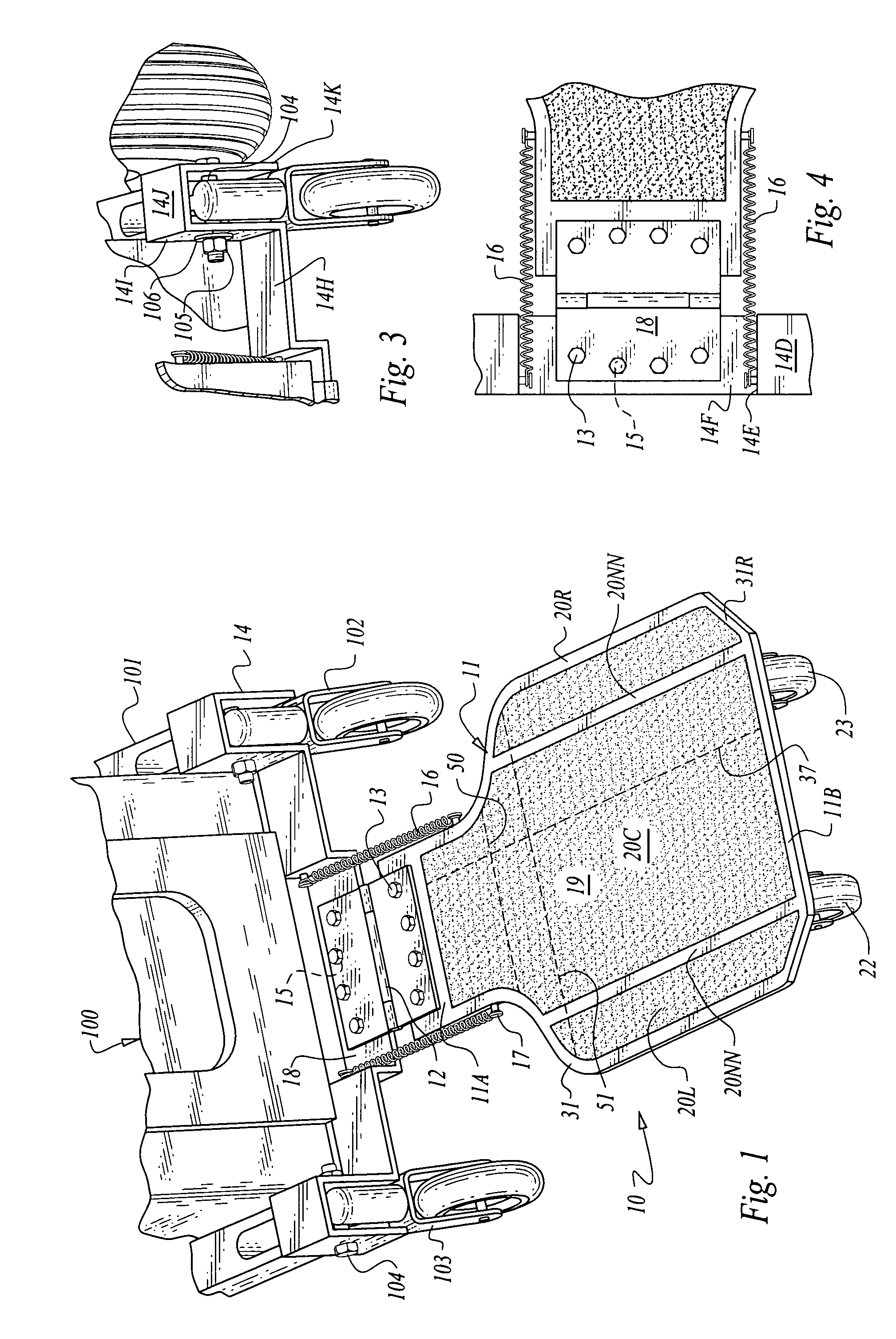

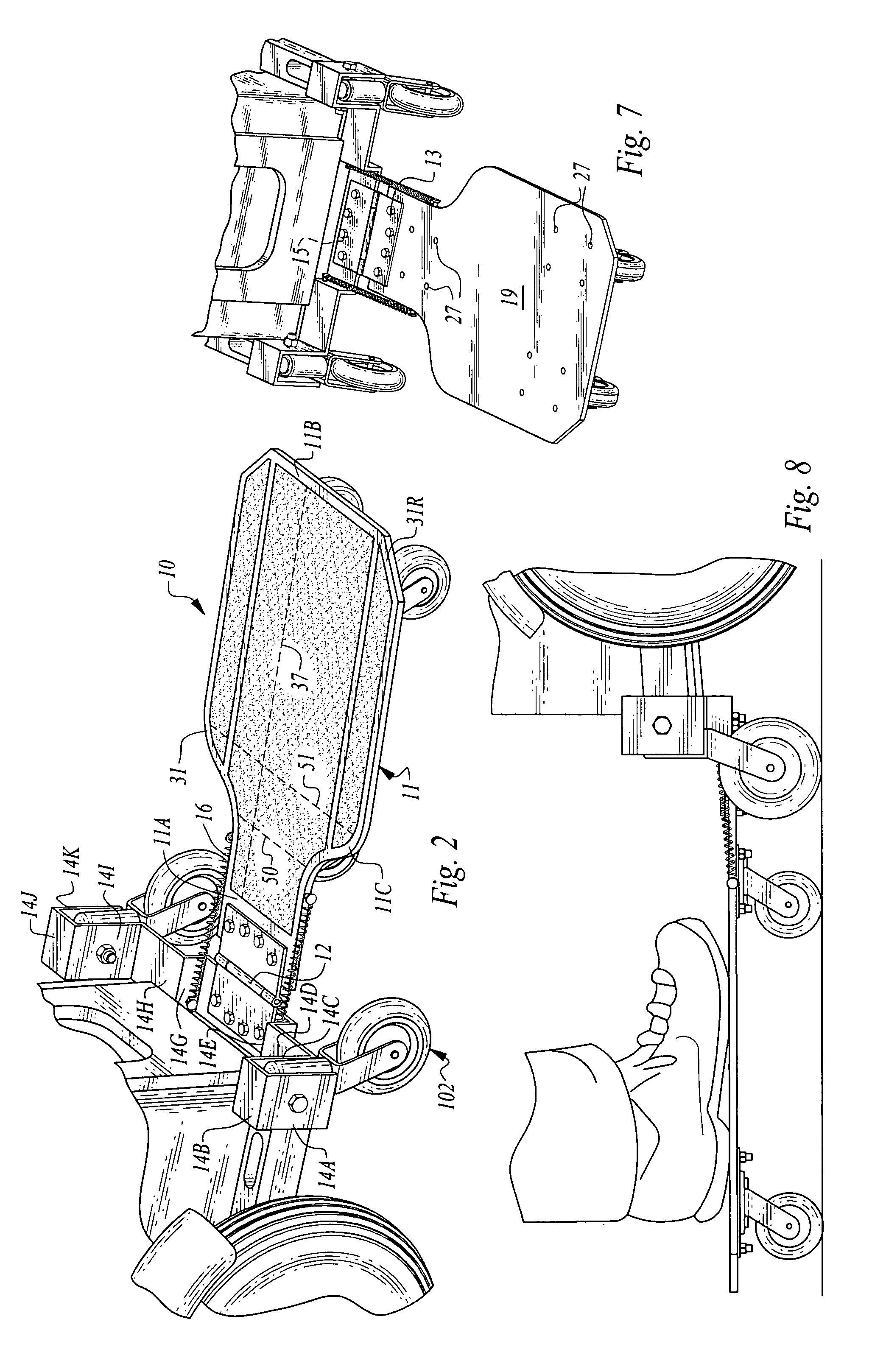

Personal standing platform for motorized wheel chair

ActiveUS8006786B1Keep runningElectric propulsion mountingWheelchairs/patient conveyanceCoil springWheelchair

A passenger standing platform for attachment to a mobility vehicle that provides improved support for the rider, increased weightload, and easy mountability and storage capability, The unit has a paddle shape platform base with 3 fully rotating caster assemblies attached to its underside in a triangular configuration and a non-skid mat attached to its obverse side. The platform base is hingedly attached to a mount plate that connects to the mobility vehicle, and is retained in a non-use generally vertical position off the ground by a pair of spaced coil springs attached at opposite ends to the mount plate and to the platform base.

Owner:2001 BYRON L CHAPMAN & JUDI A CHAPMAN REVOCABLE TRUST

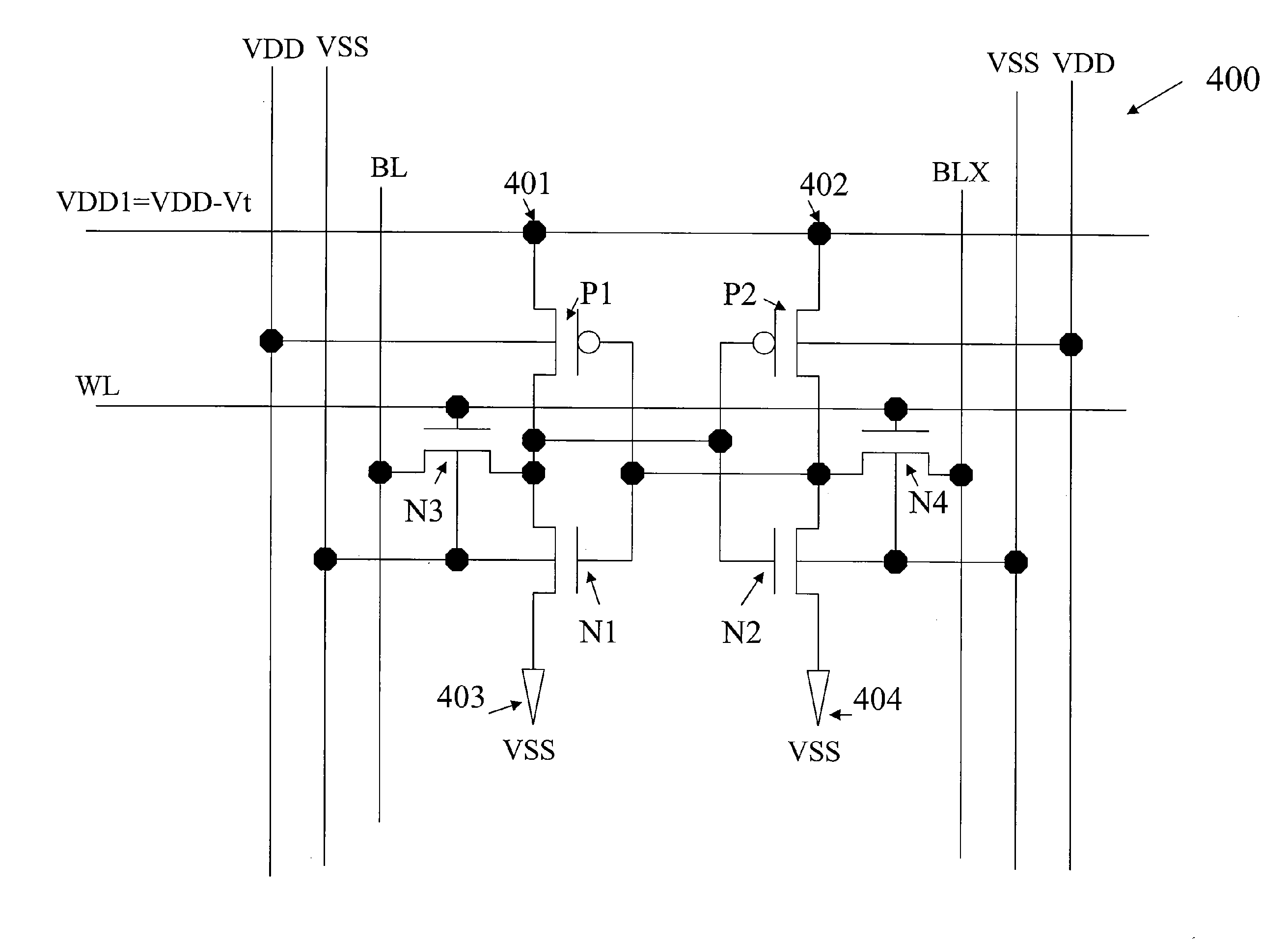

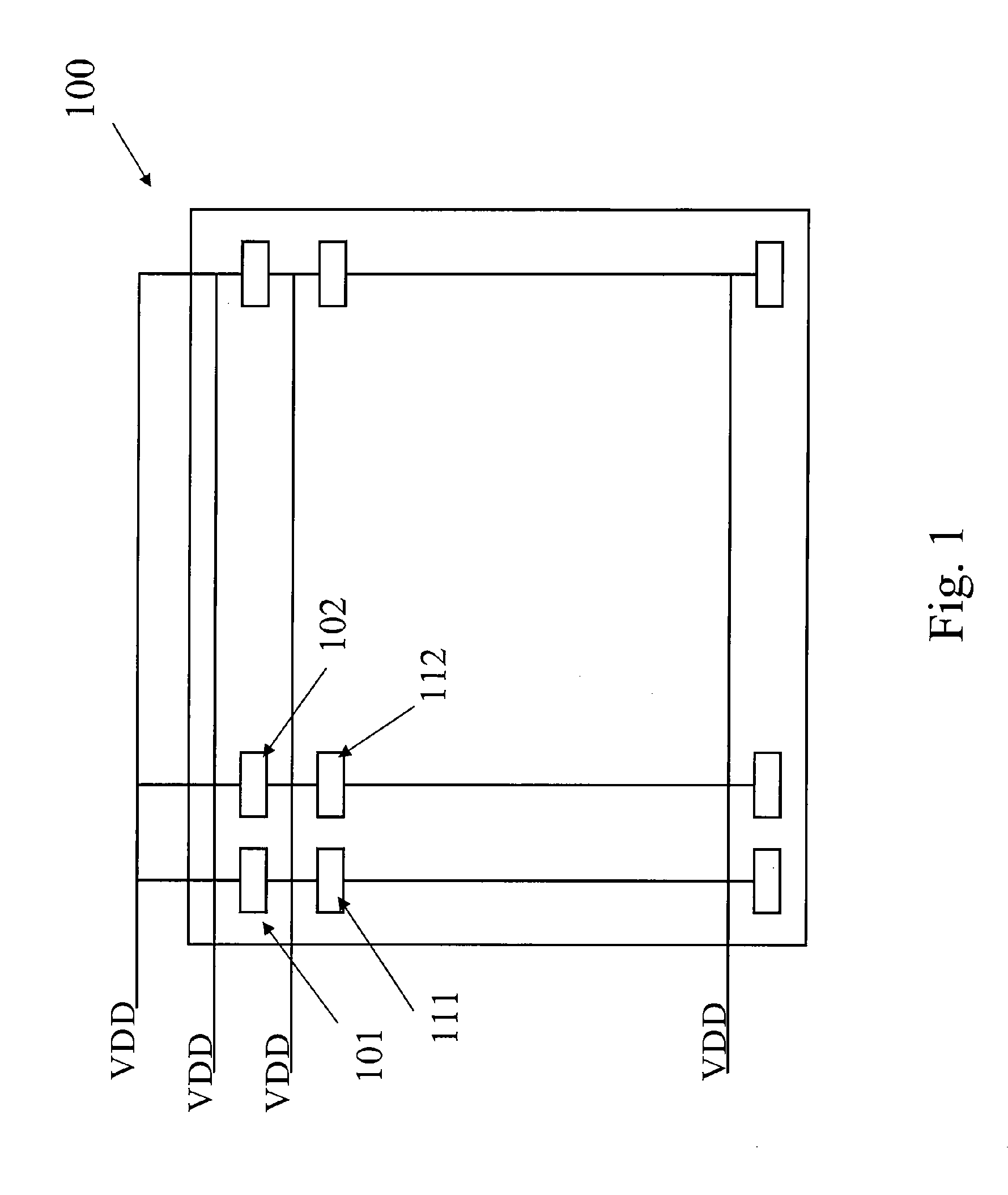

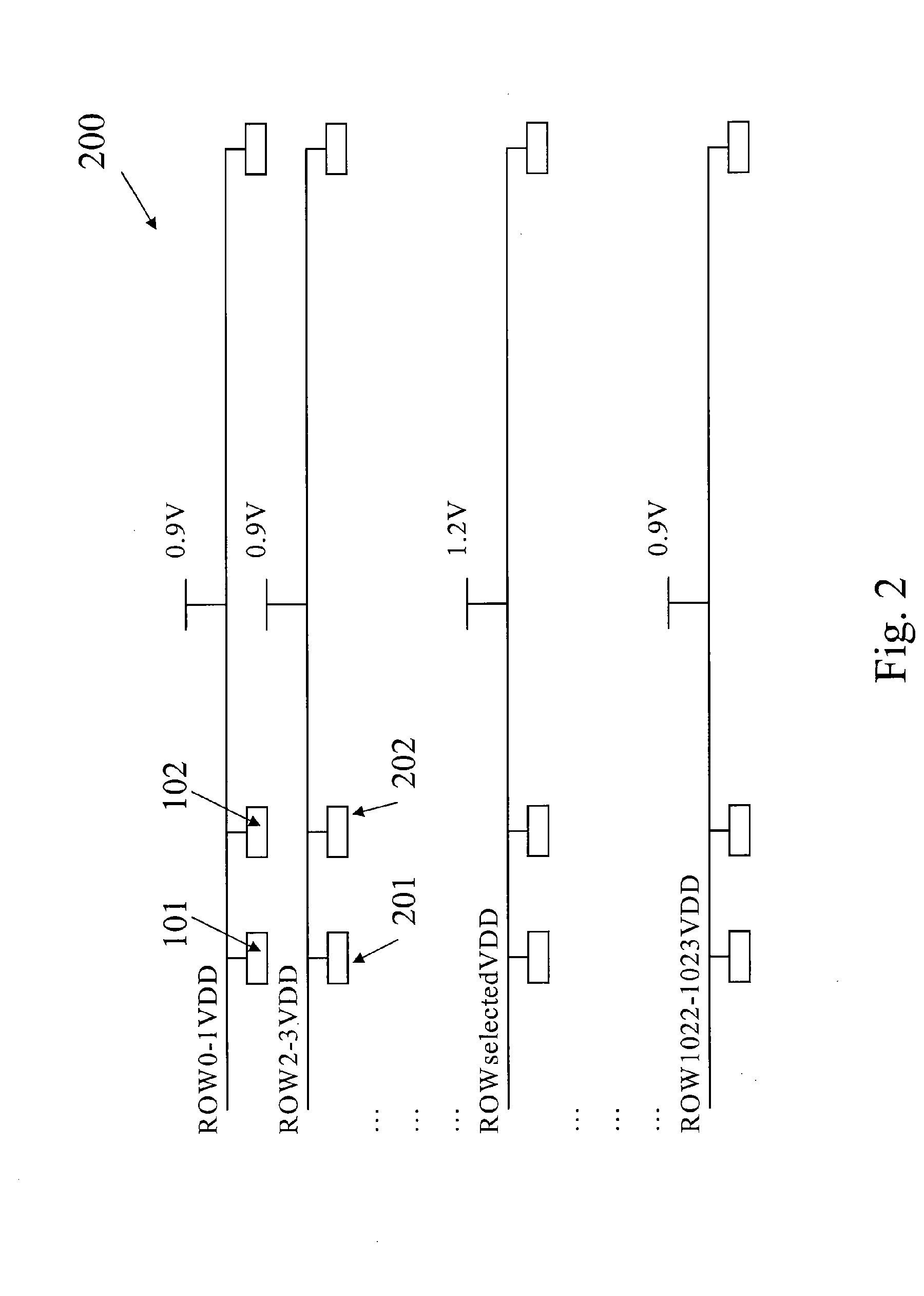

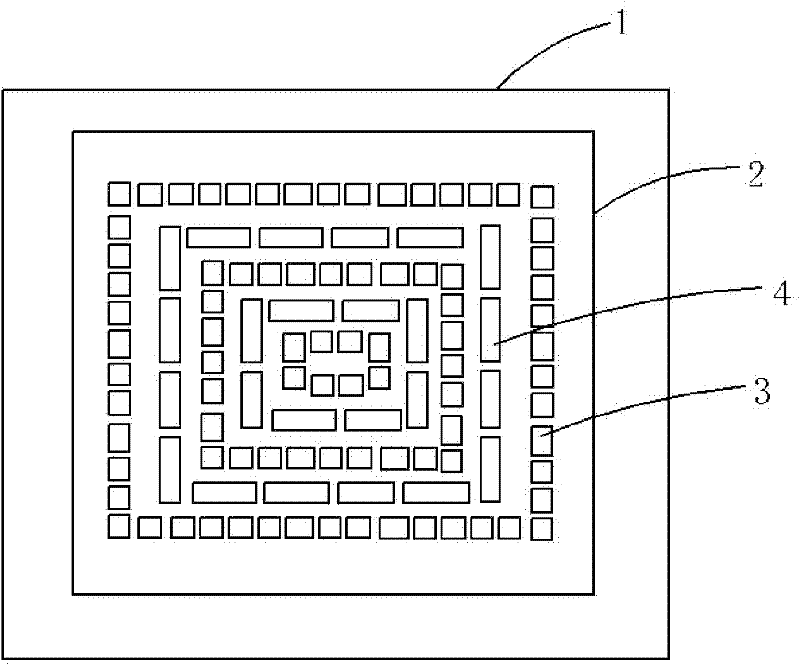

Power line decoding method for an memory array

InactiveUS20100103759A1Simple designLow cost implementationDigital storageIntegrated circuitStorage cell

A method for selectively providing power supply voltage to a memory device. The method provides an integrated circuit memory device including a first plurality of memory cells. Each memory cell includes a power terminal and a ground terminal. The method includes selecting a second plurality of memory cells from the first plurality of memory cells. The method provides a first power voltage to the power terminal of each of the selected memory cells and a second power voltage to the power terminal of each of the unselected memory cells. The second power voltage is lower than the first power voltage. In an embodiment, the method applies a first ground voltage to the ground terminal of each of the selected memory cells and applies a second ground voltage to the ground terminal of each of the unselected memory cells. The second ground voltage is higher than the first ground voltage.

Owner:SEMICON MFG INT (SHANGHAI) CORP

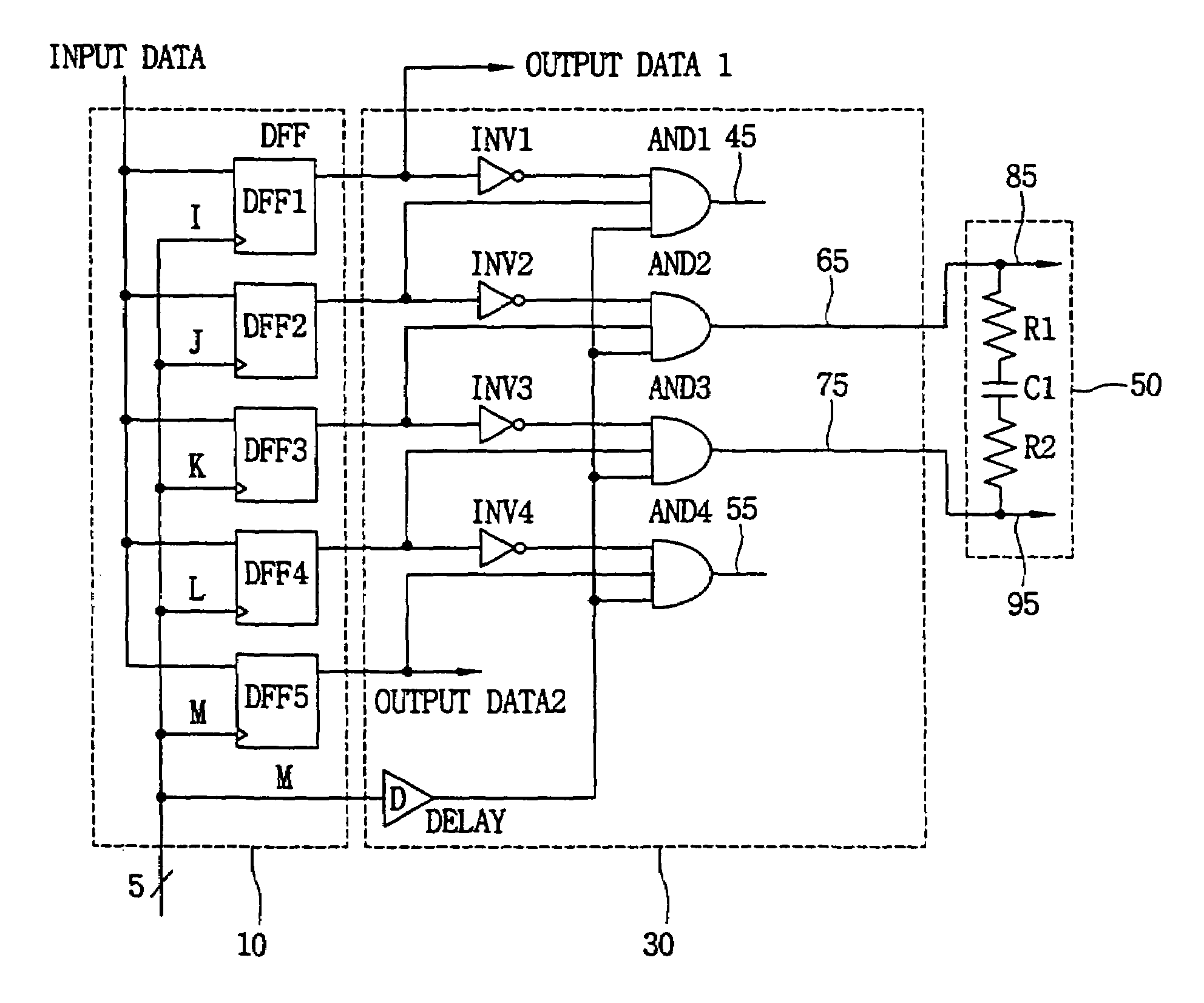

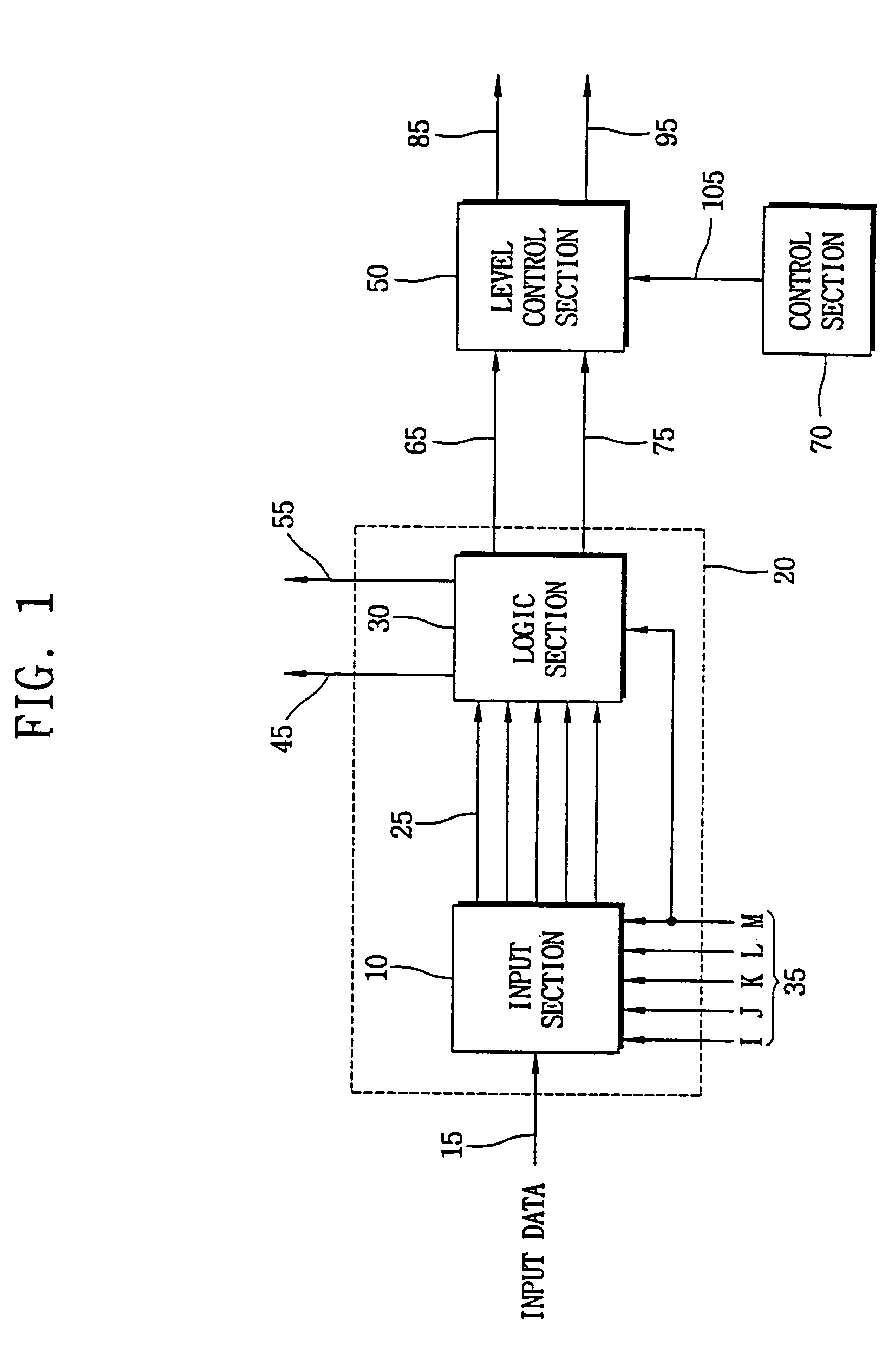

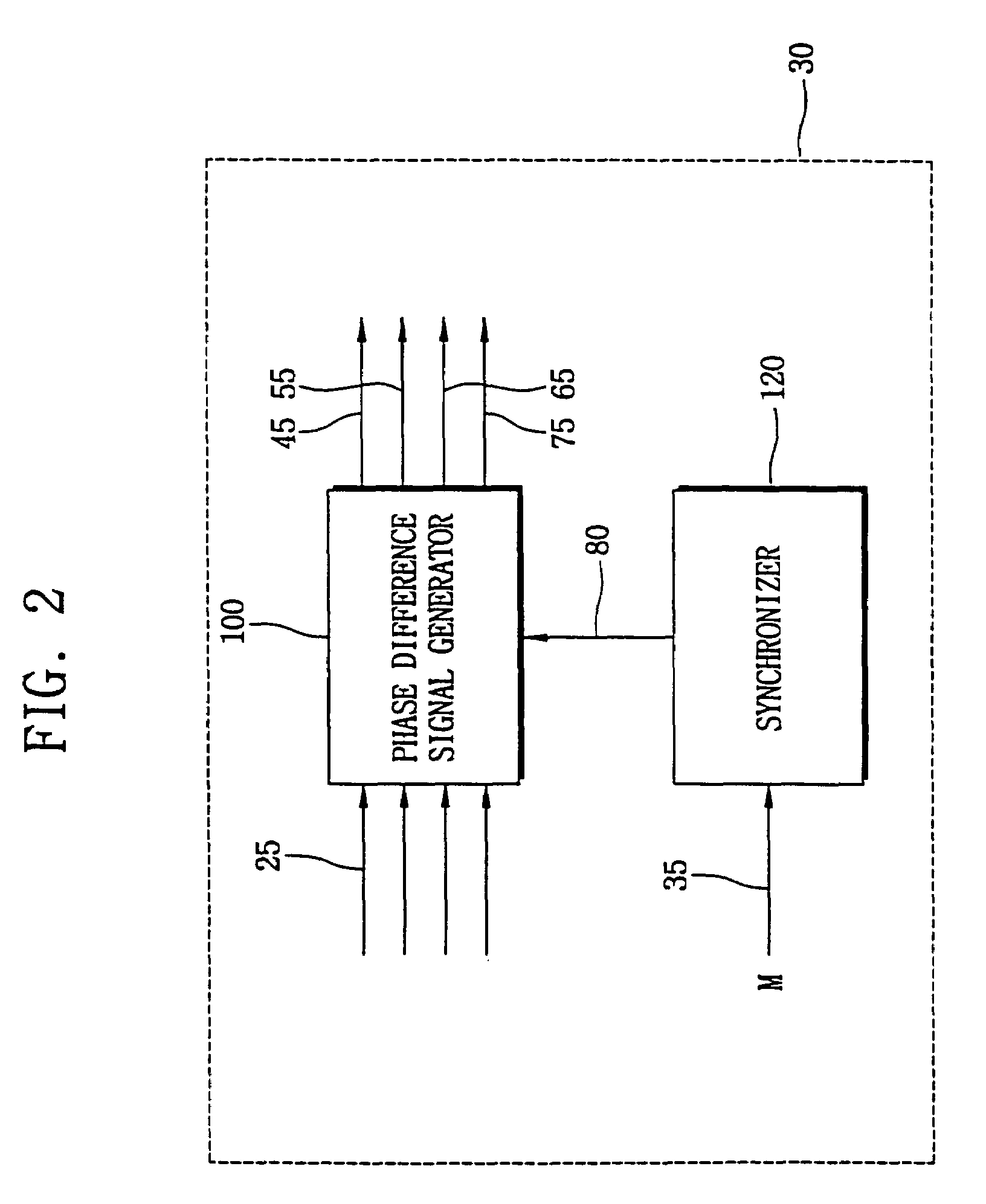

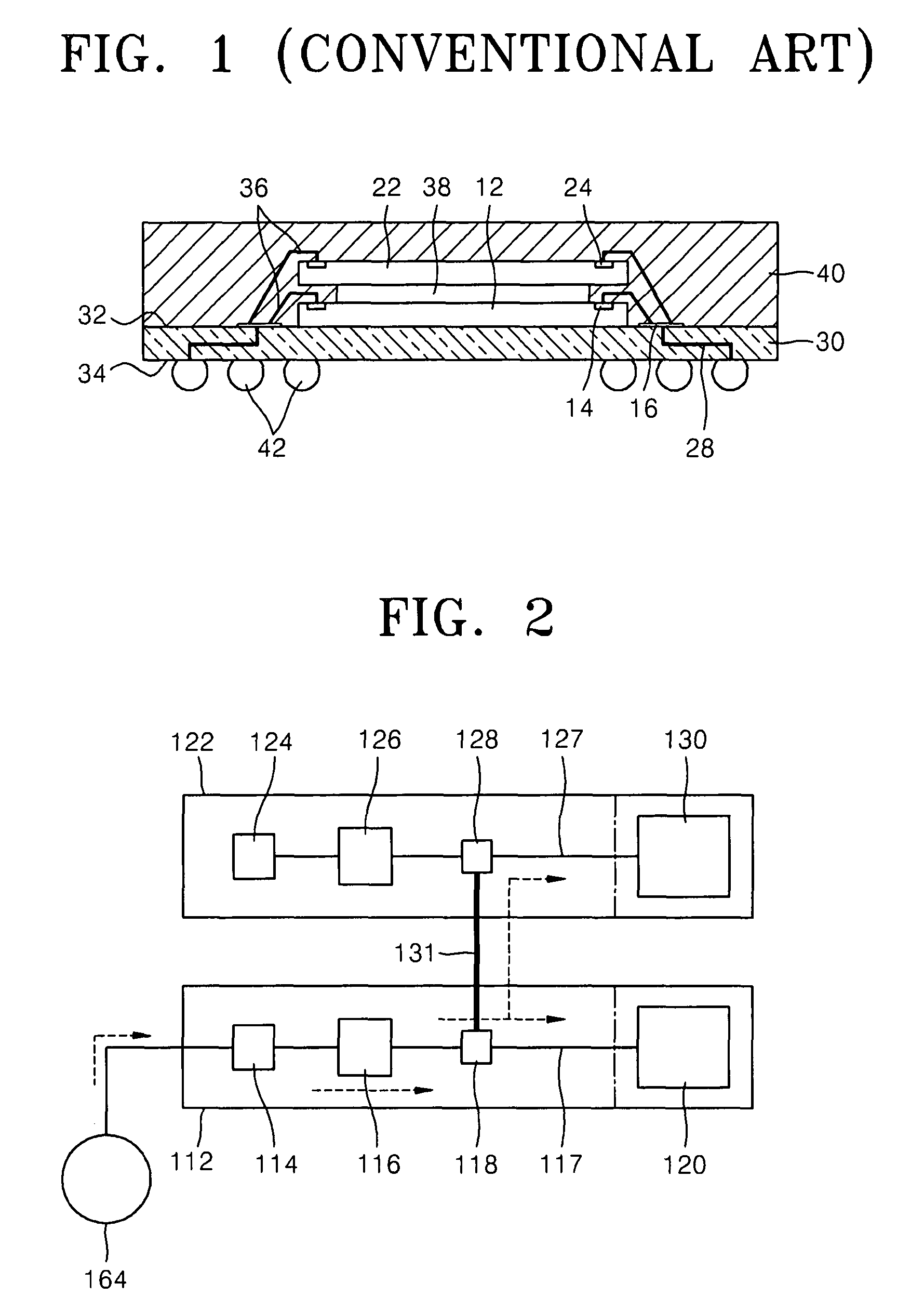

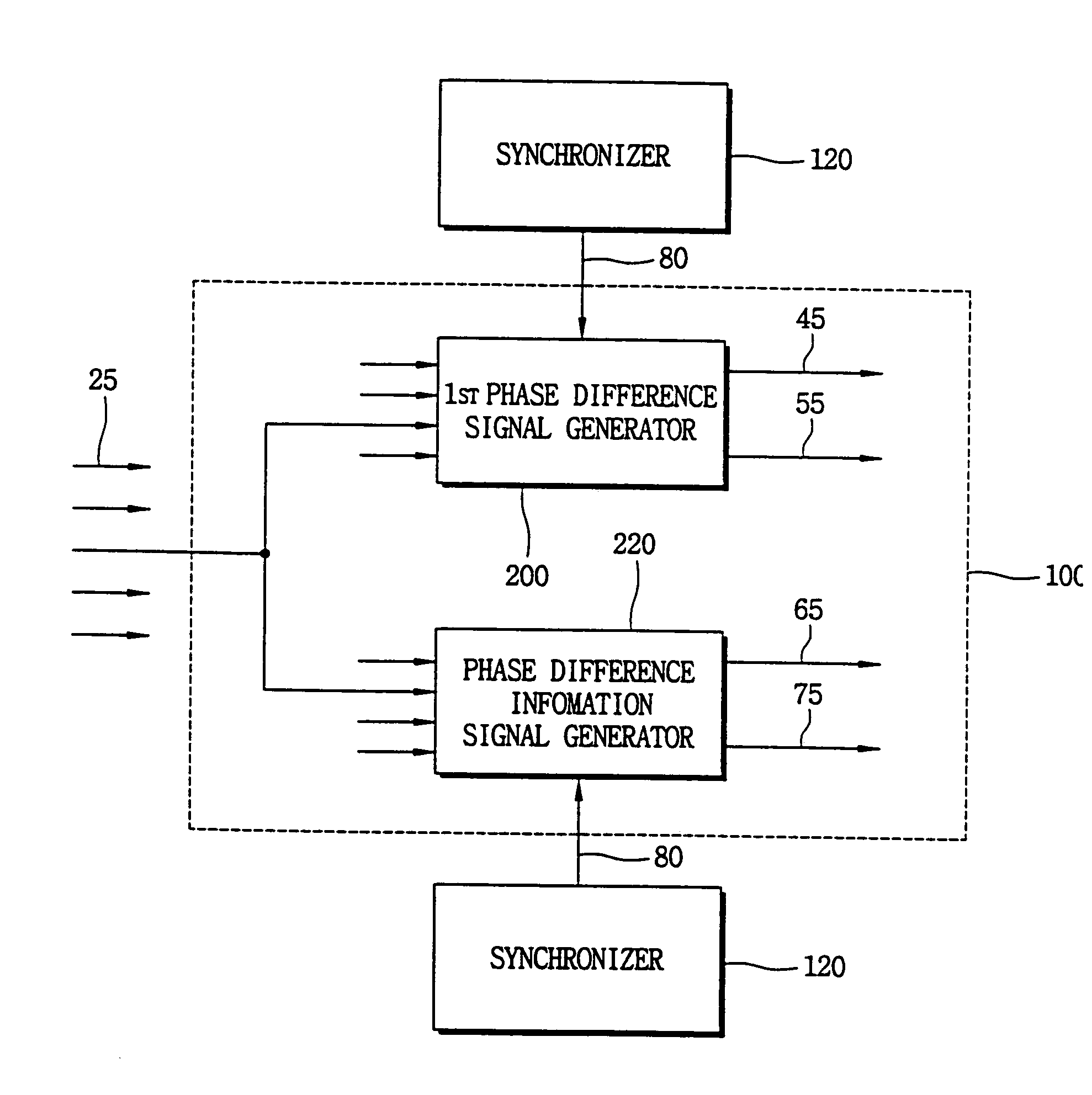

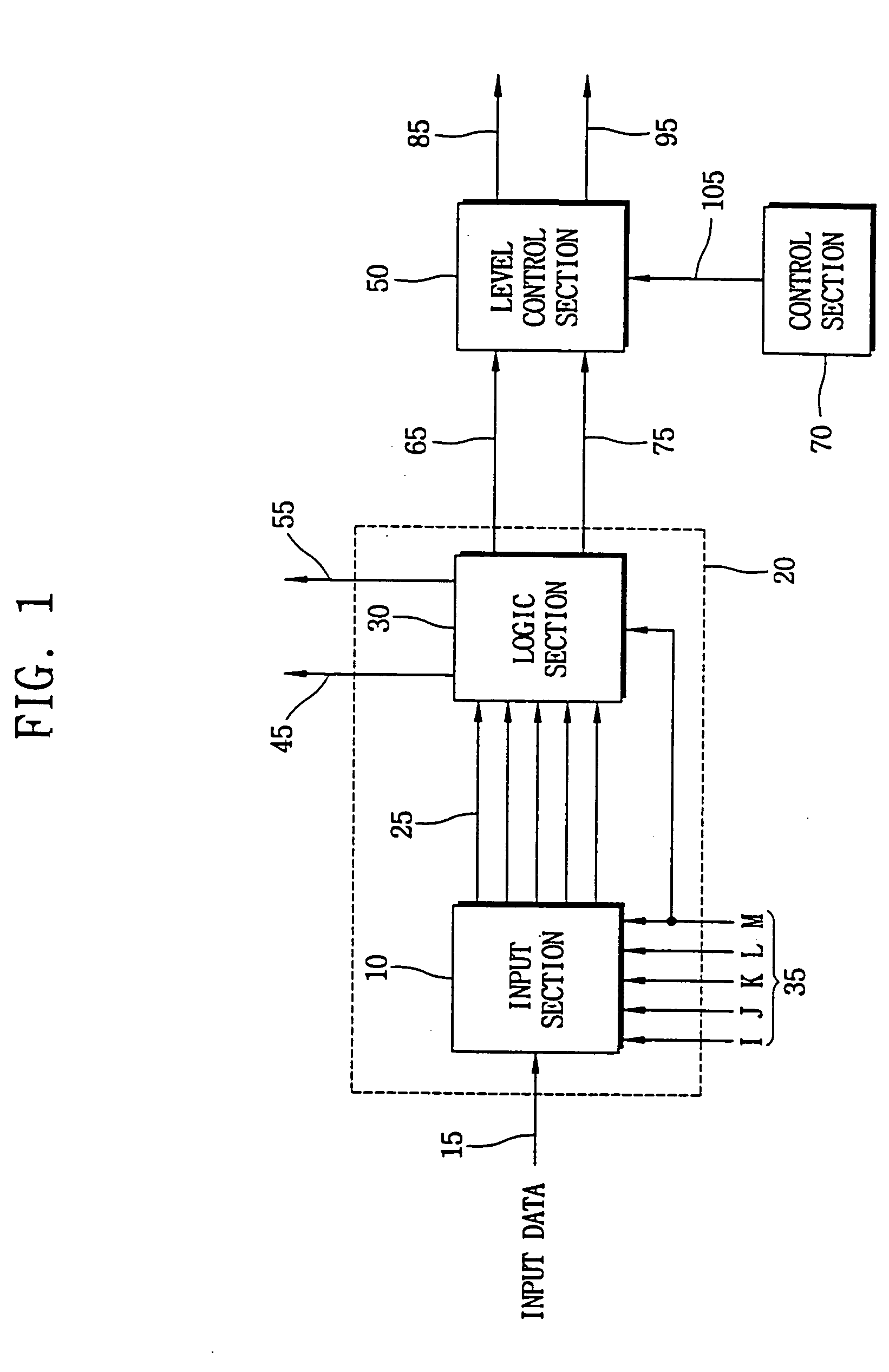

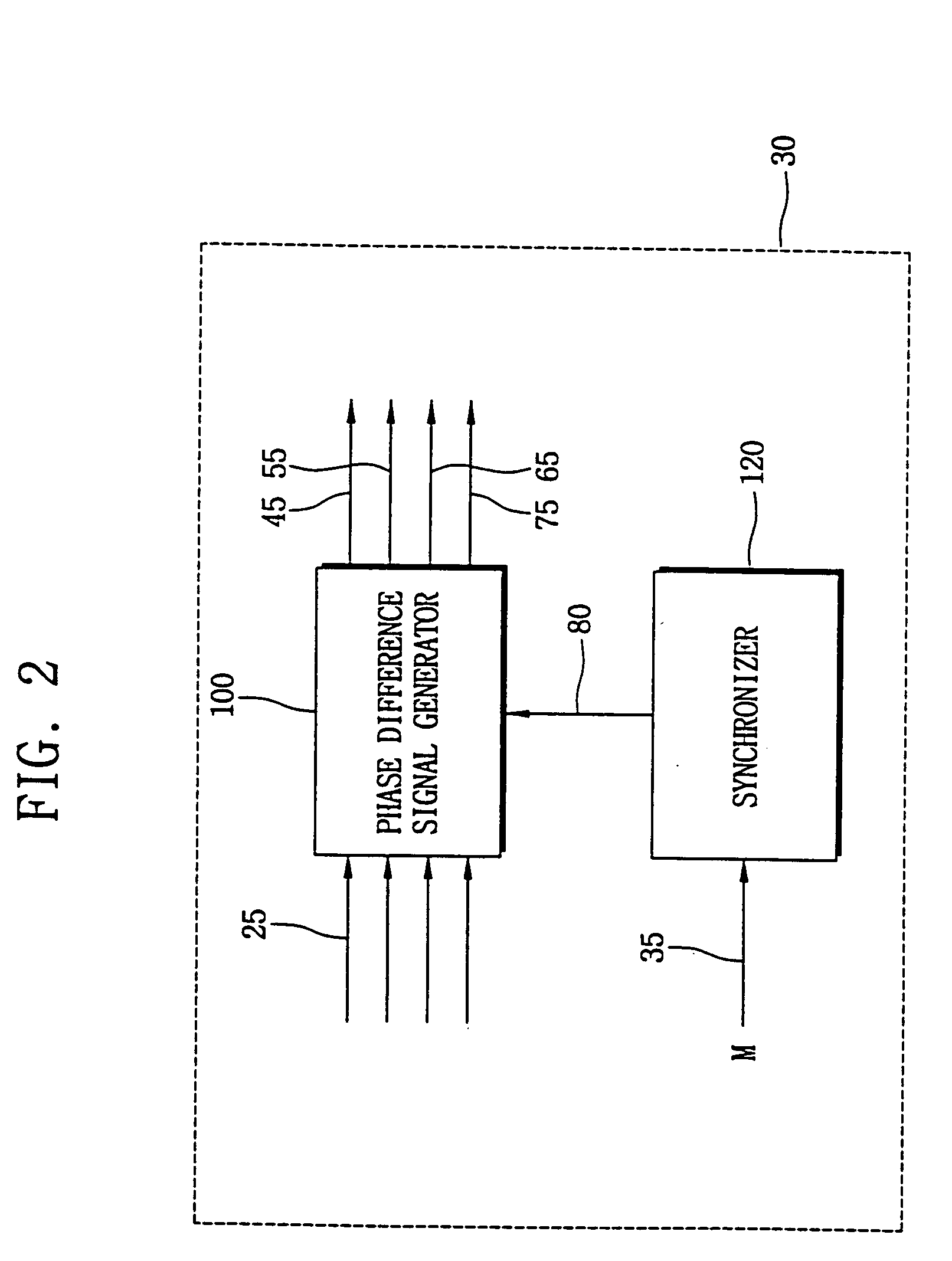

Method of detecting phase difference, phase detector for performing the same and clock-and-data recovering device including the phase detector

InactiveUS7078938B2Reduce jitterImprove featuresPulse automatic controlVoltage-current phase anglePhase detectorPhase difference

Owner:SAMSUNG ELECTRONICS CO LTD

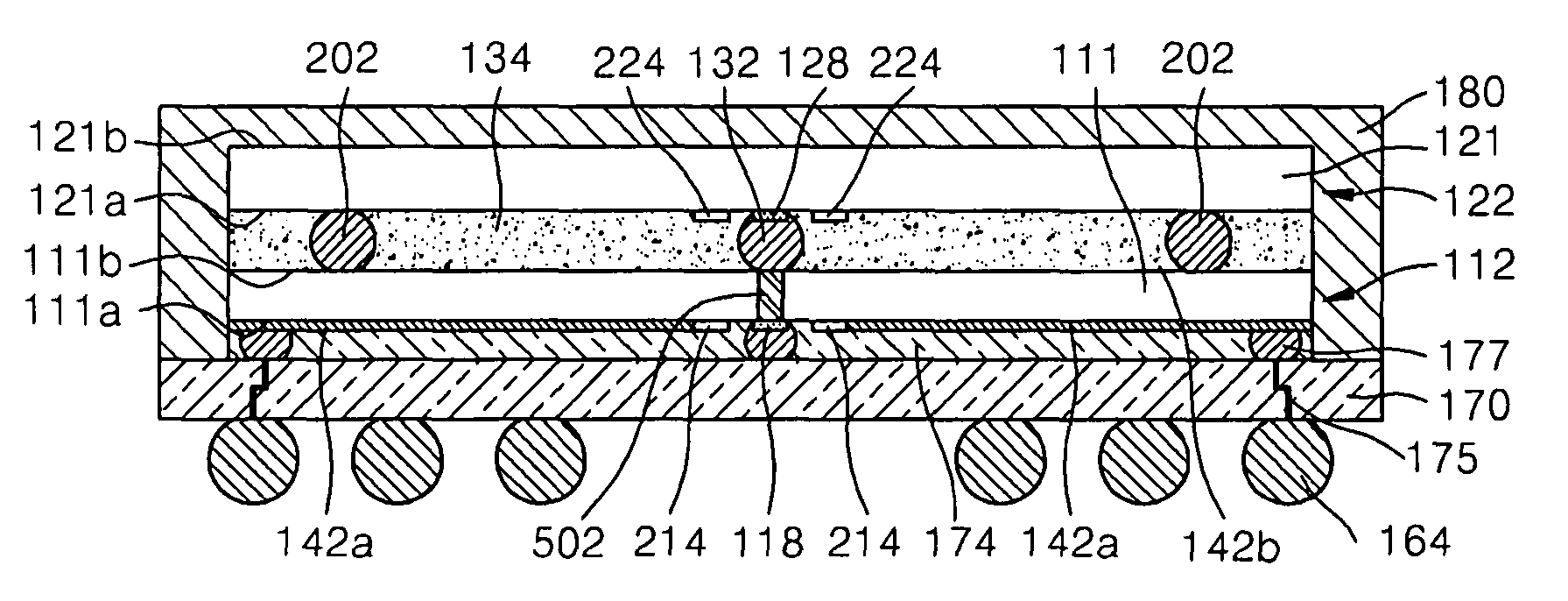

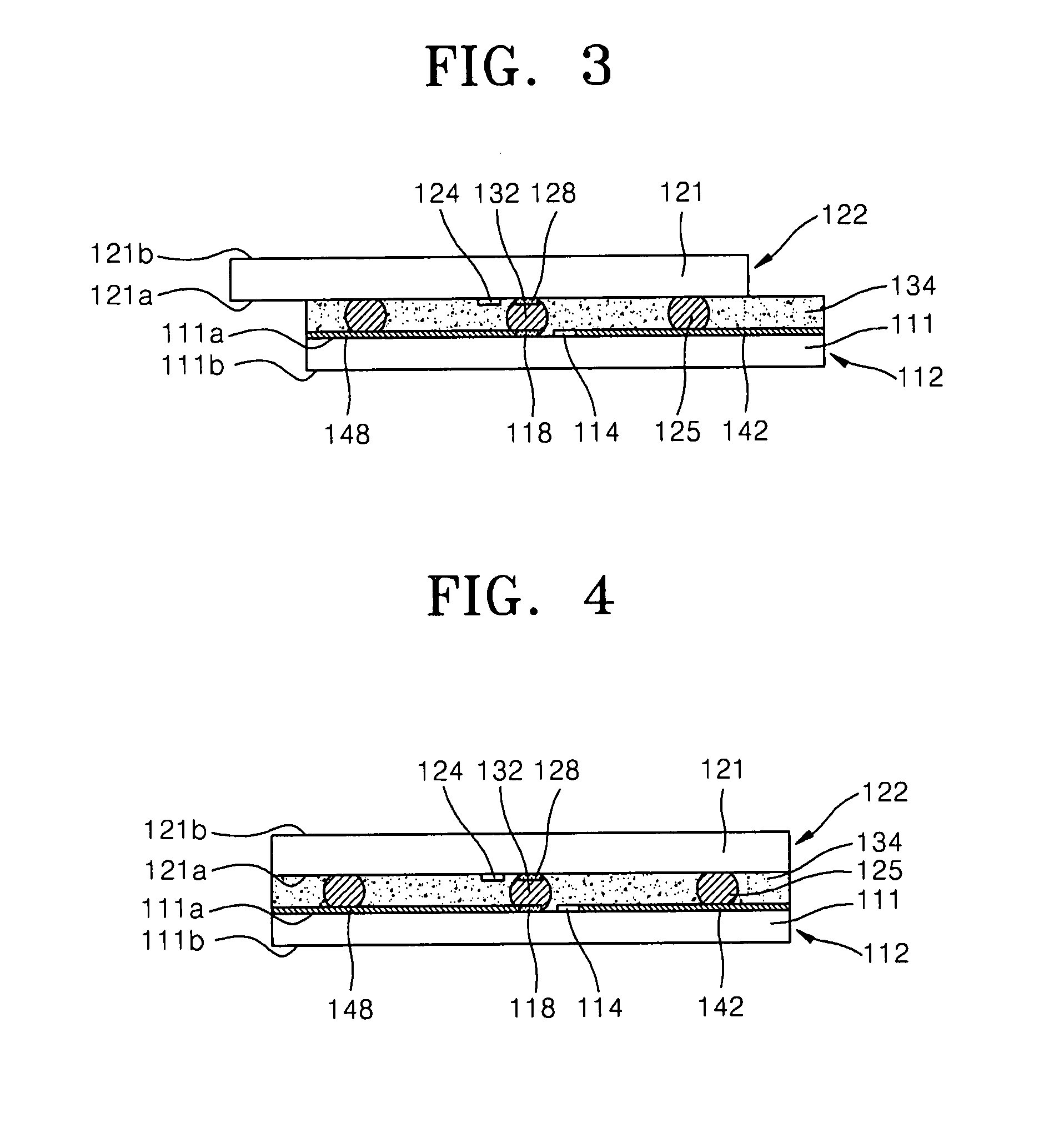

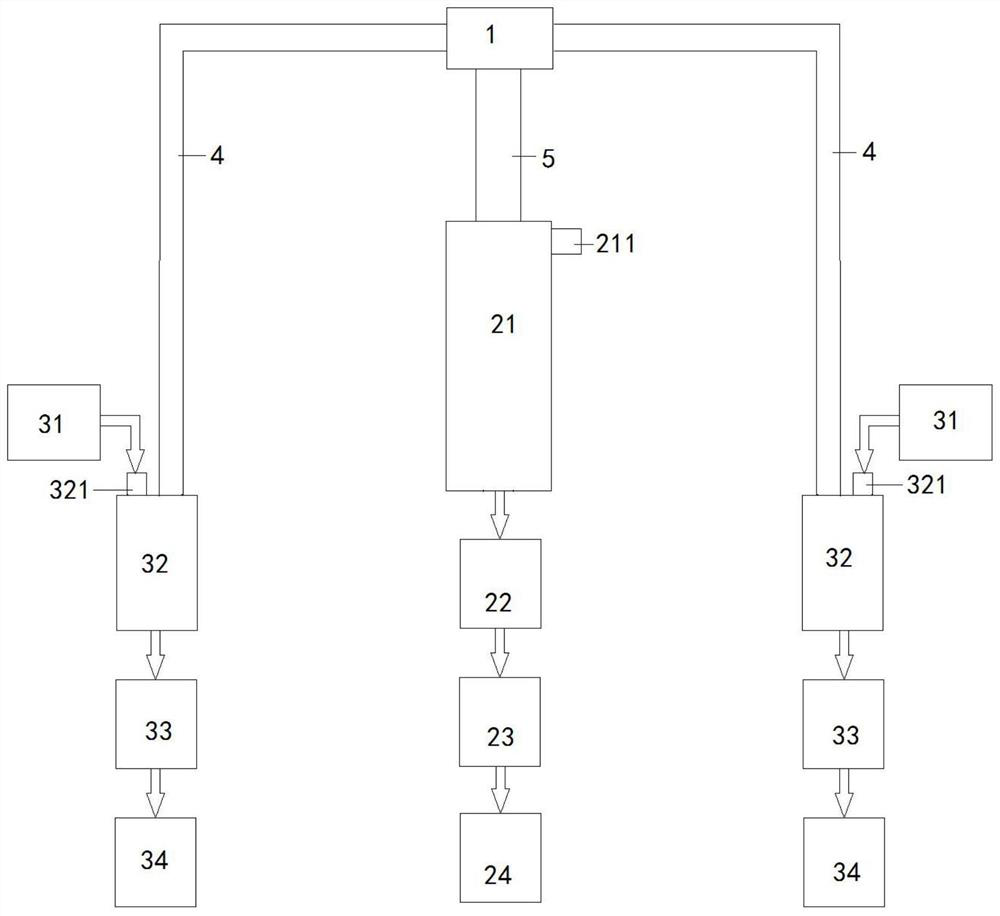

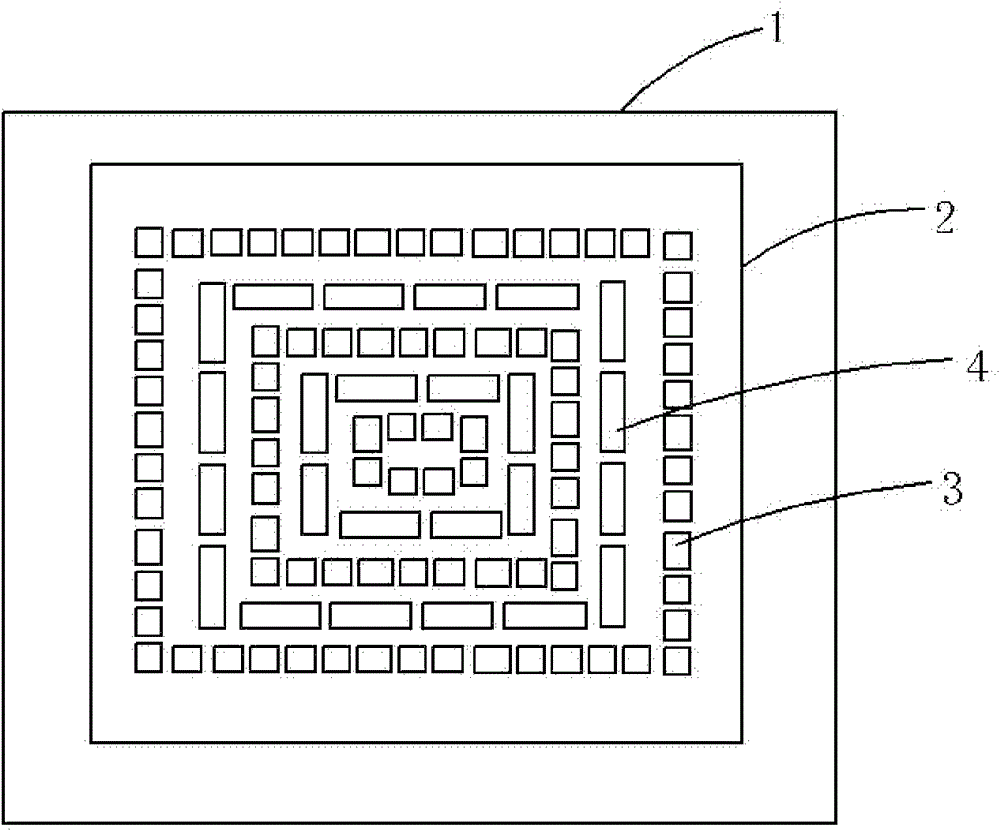

Chip stack, chip stack package, and method of forming chip stack and chip stack package

ActiveUS7964948B2Increase device capacityKeep runningSemiconductor/solid-state device detailsSolid-state devicesEngineeringChip stacking

A chip stack may include a first chip and a second chip stacked on the first chip. Each of the first and second chips may include a substrate having an active surface and an inactive surface opposite to the active surface; an internal circuit in the active surface; an I / O chip pad on the active surface and connected to the internal circuit through an I / O buffer; and a I / O connection pad connected to the I / O chip pad through the I / O buffer by a circuit wiring. A redistributed I / O chip pad layer may be on the active surface of the first chip, the redistributed I / O chip pad layer redistributing the I / O chip pad. The I / O connection pads of the first chip and the second chip may be electrically connected to each other by an electrical connecting part.

Owner:SAMSUNG ELECTRONICS CO LTD

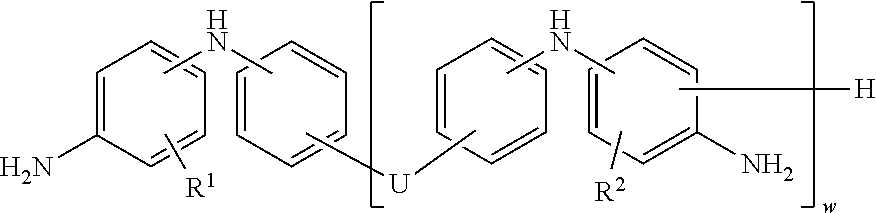

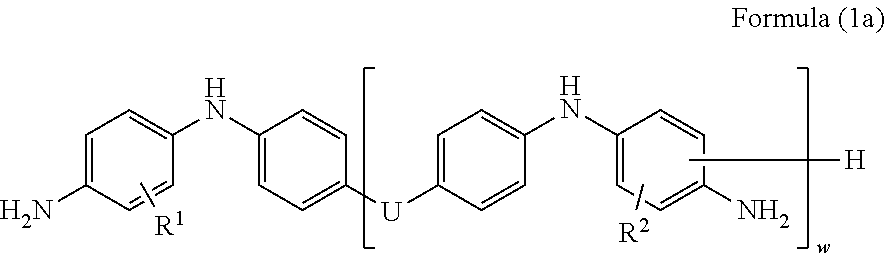

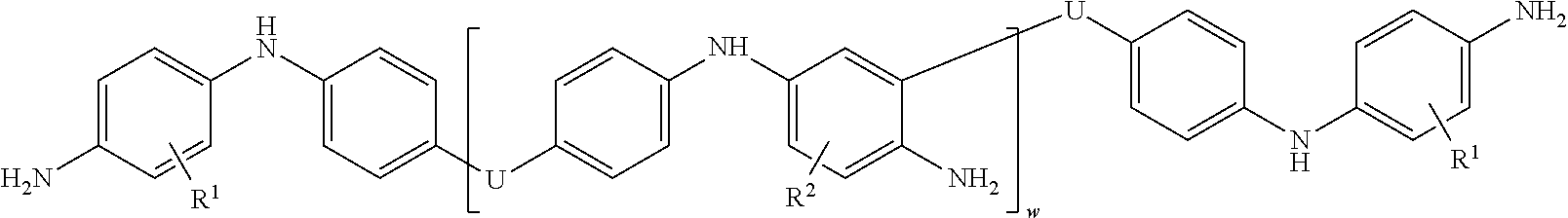

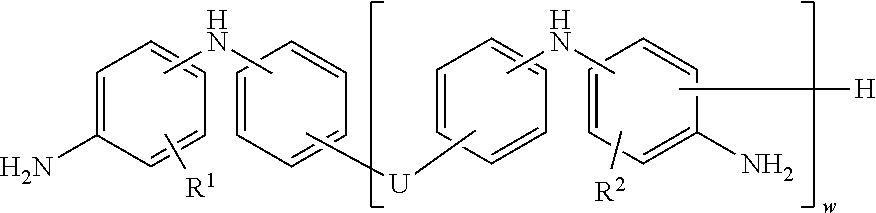

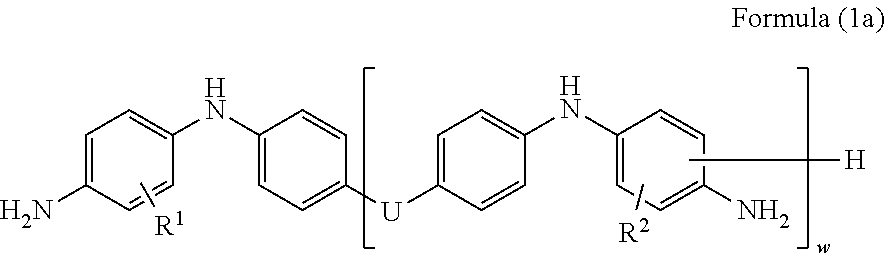

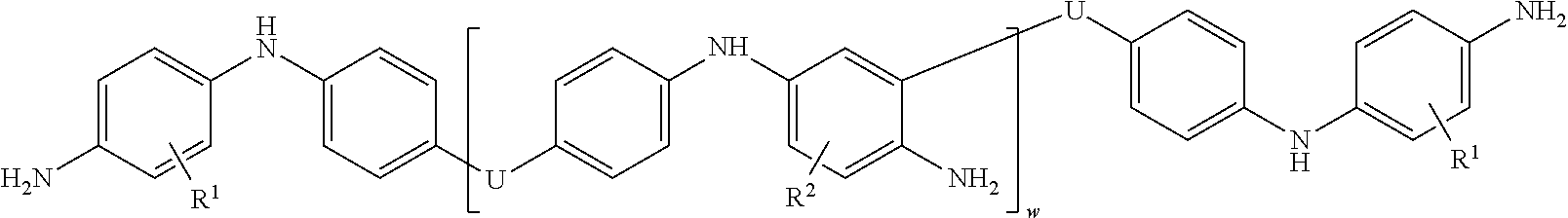

Lubricating composition containing a carboxylic functionalised polymer

ActiveUS8969266B2High oxidationIncrease resistanceOrganic chemistryLiquid carbonaceous fuelsOxidation stabilityThermal stability

The invention provides a lubricating composition comprising an oil of lubricating viscosity and an amine-functionalized additive, wherein the amine-functionalized additive is derived from an amine having at least 3 aromatic groups, at least one —NH2 functional group, and at least 2 secondary or tertiary amino groups. The invention further provides for the additive to have improved thermal and oxidative stability modifying properties. The lubricating composition may include circulating oils, turbine oils, hydraulic fluids, transformer oils and greases as well as others that require good oxidation stability and good rust inhibition properties.

Owner:THE LUBRIZOL CORP

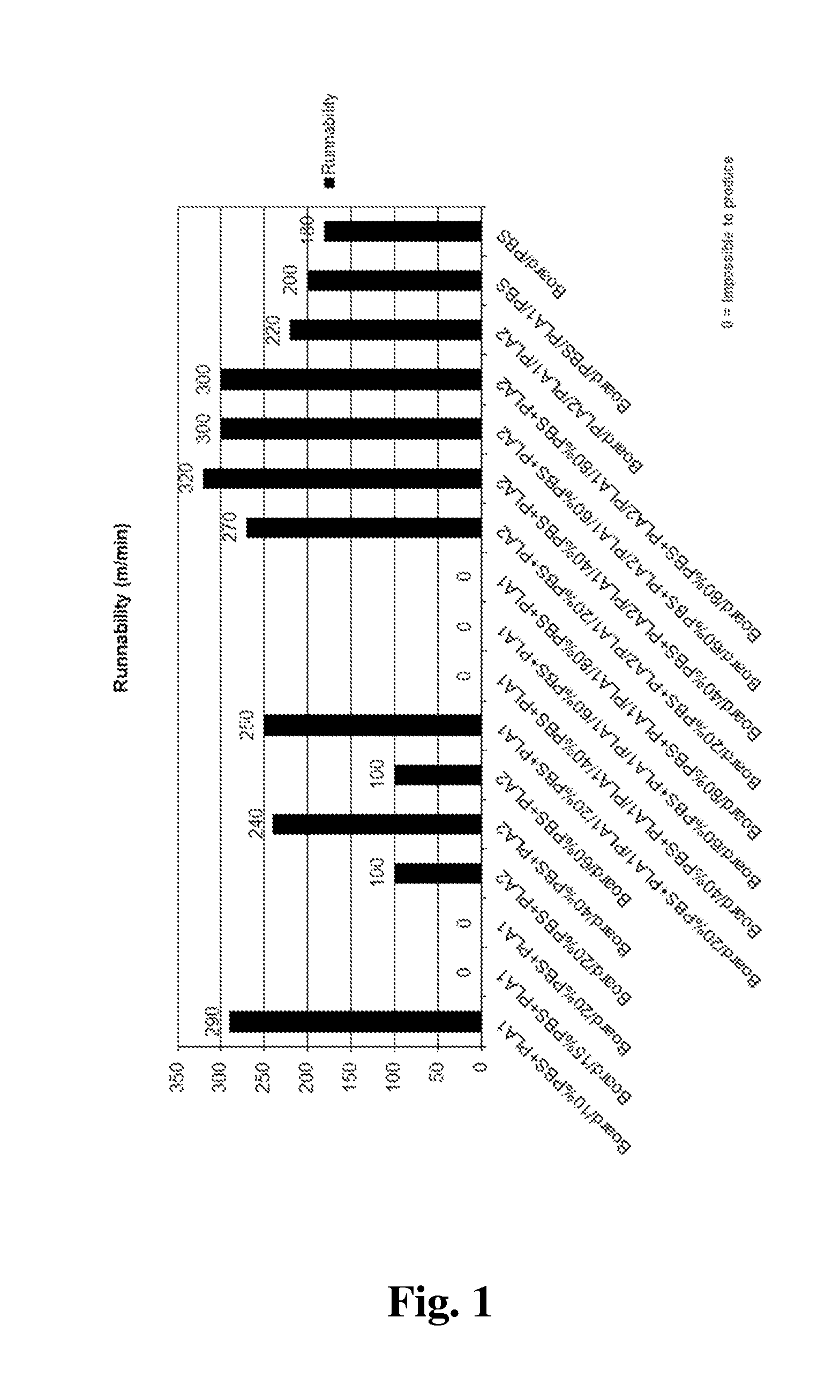

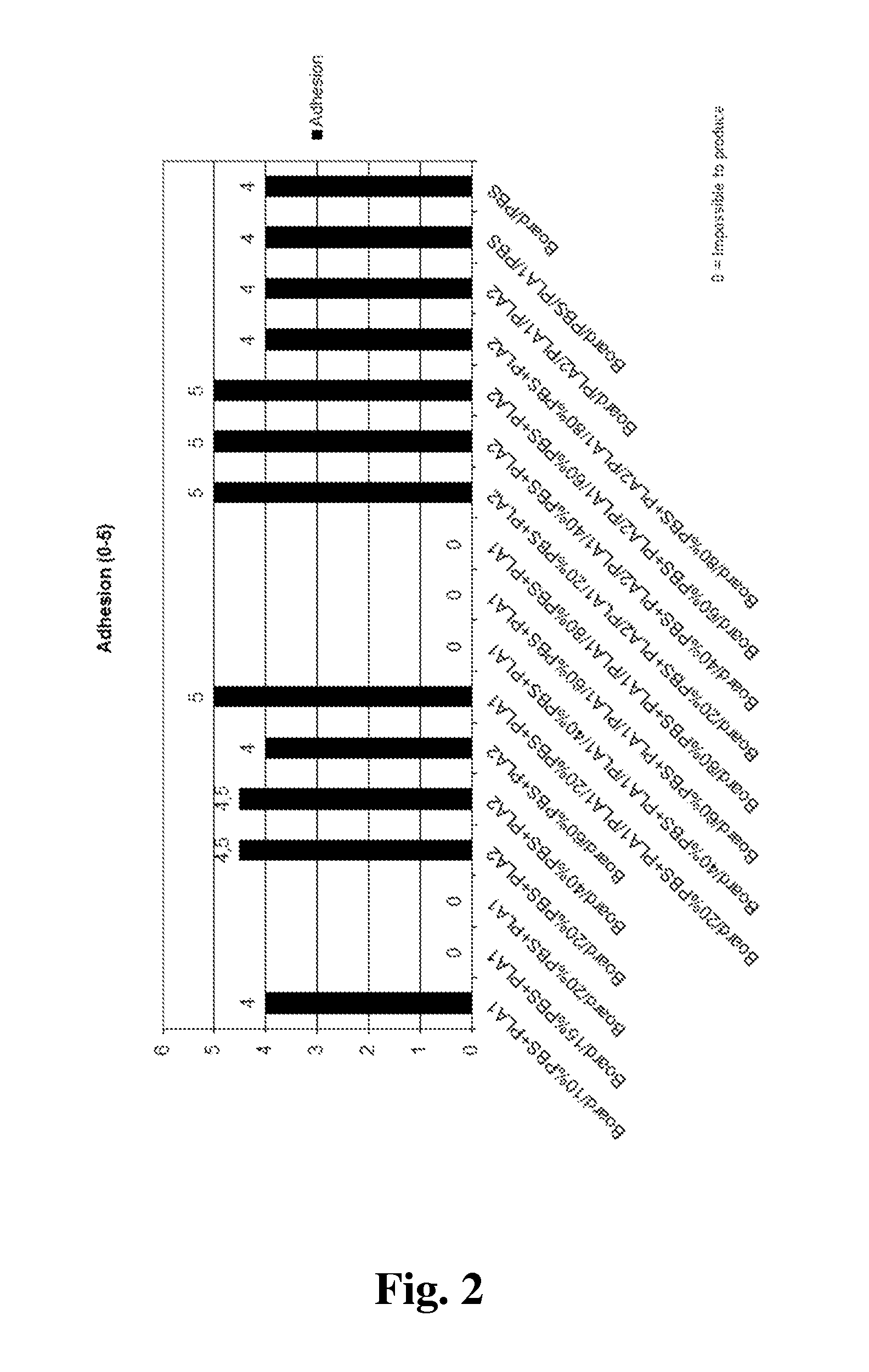

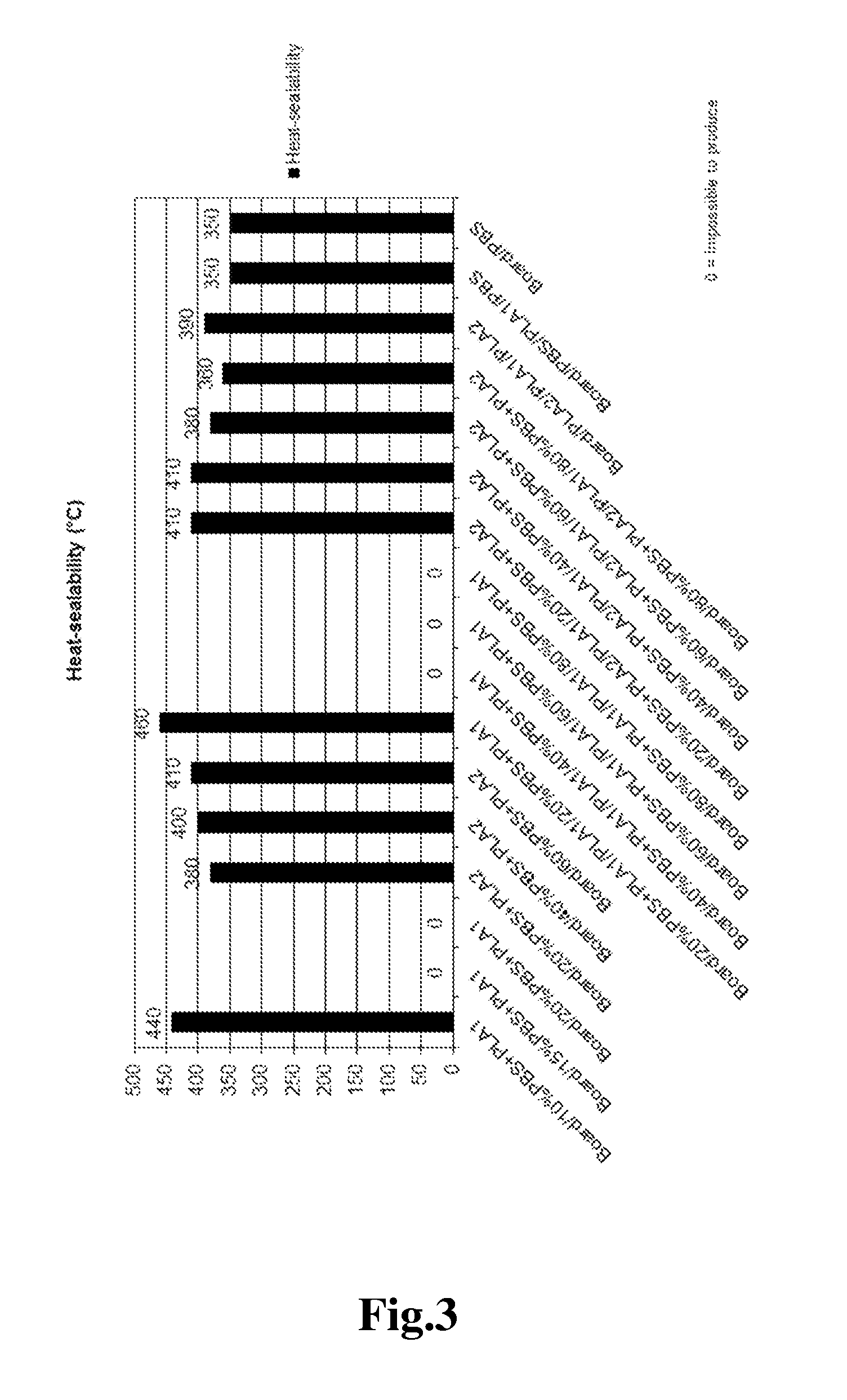

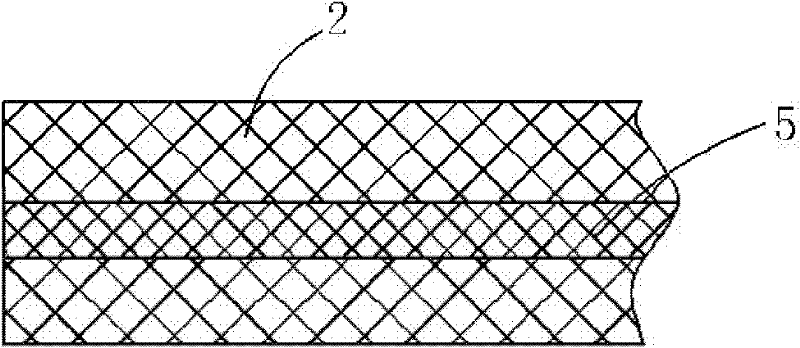

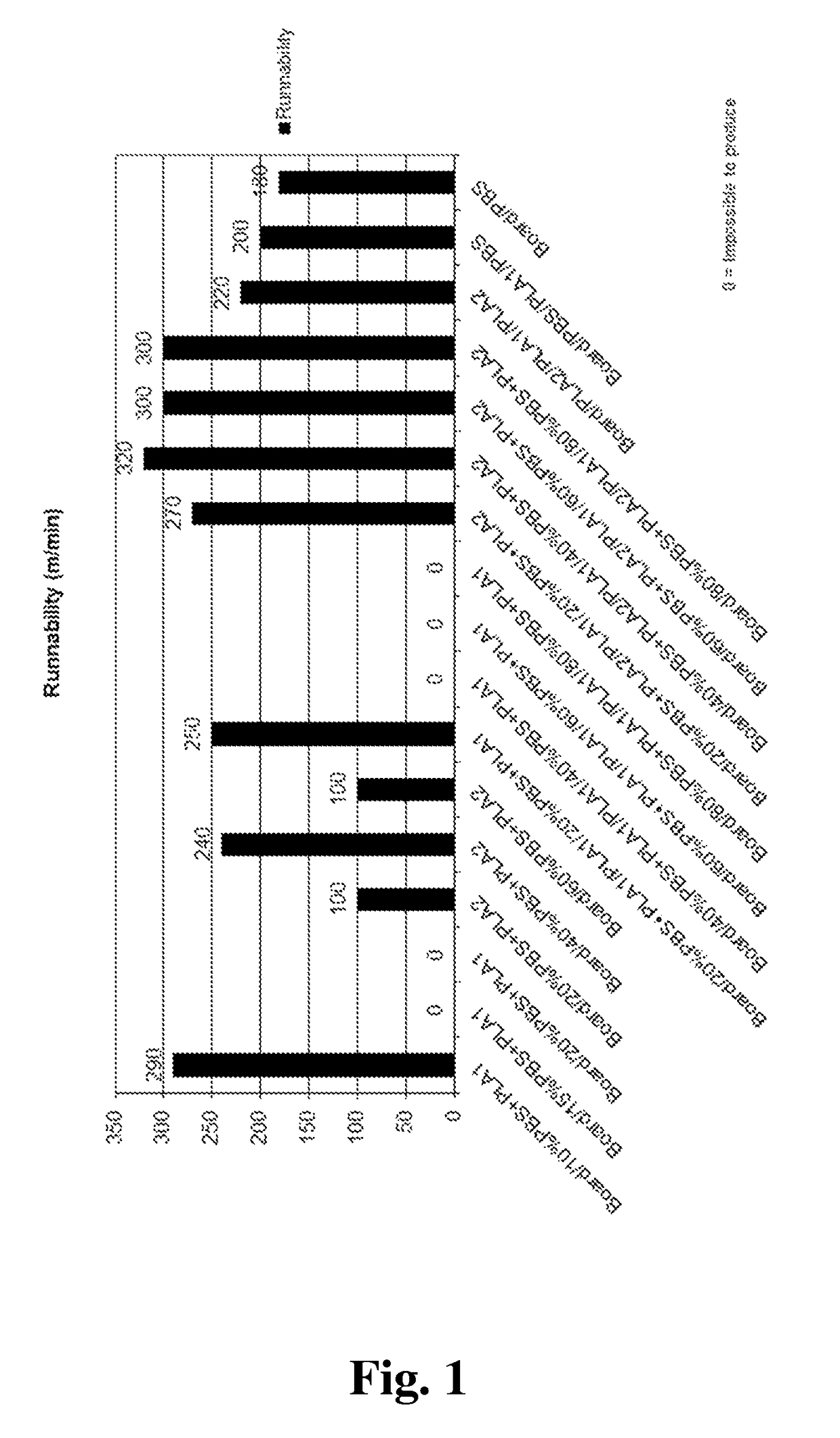

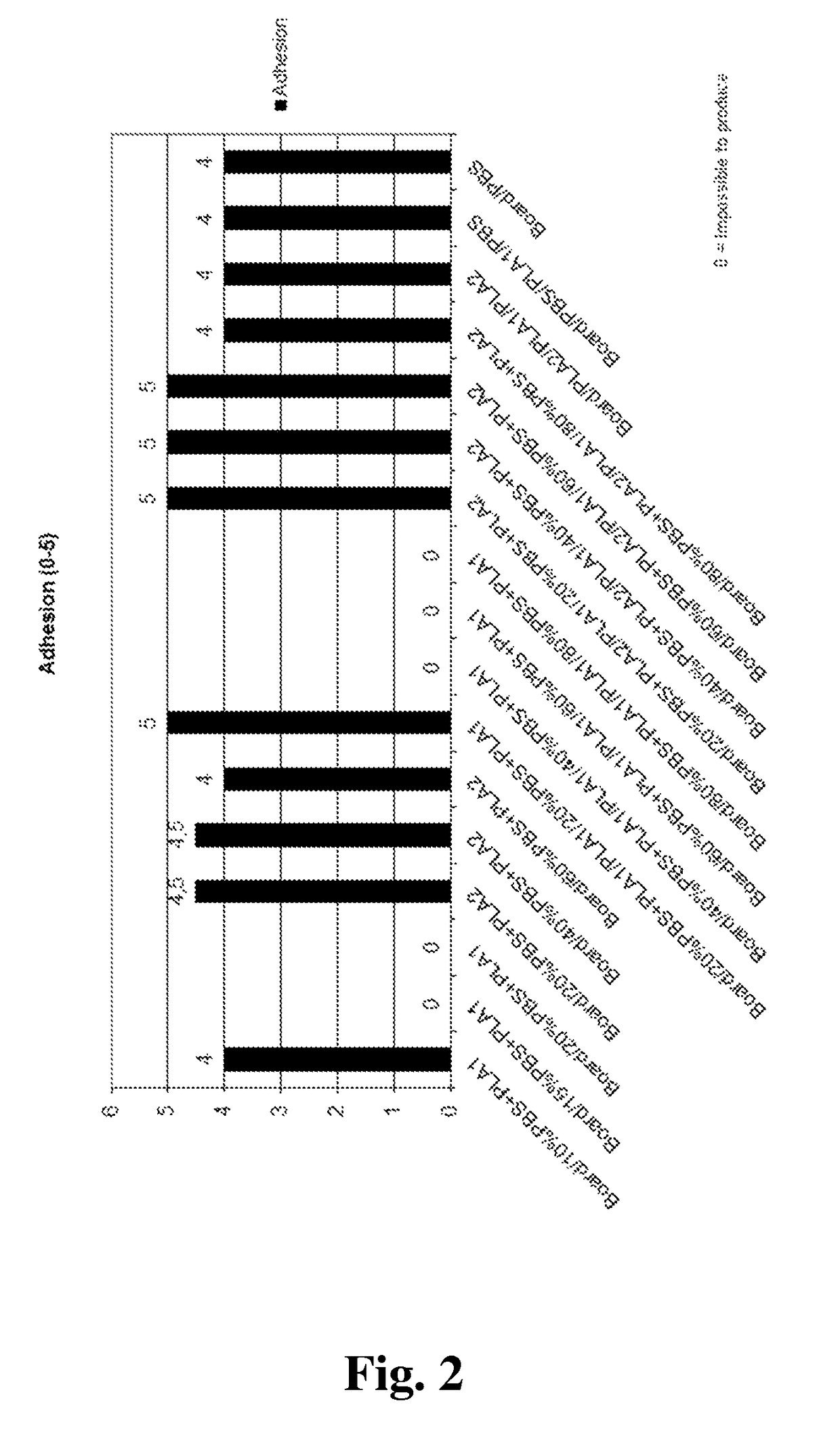

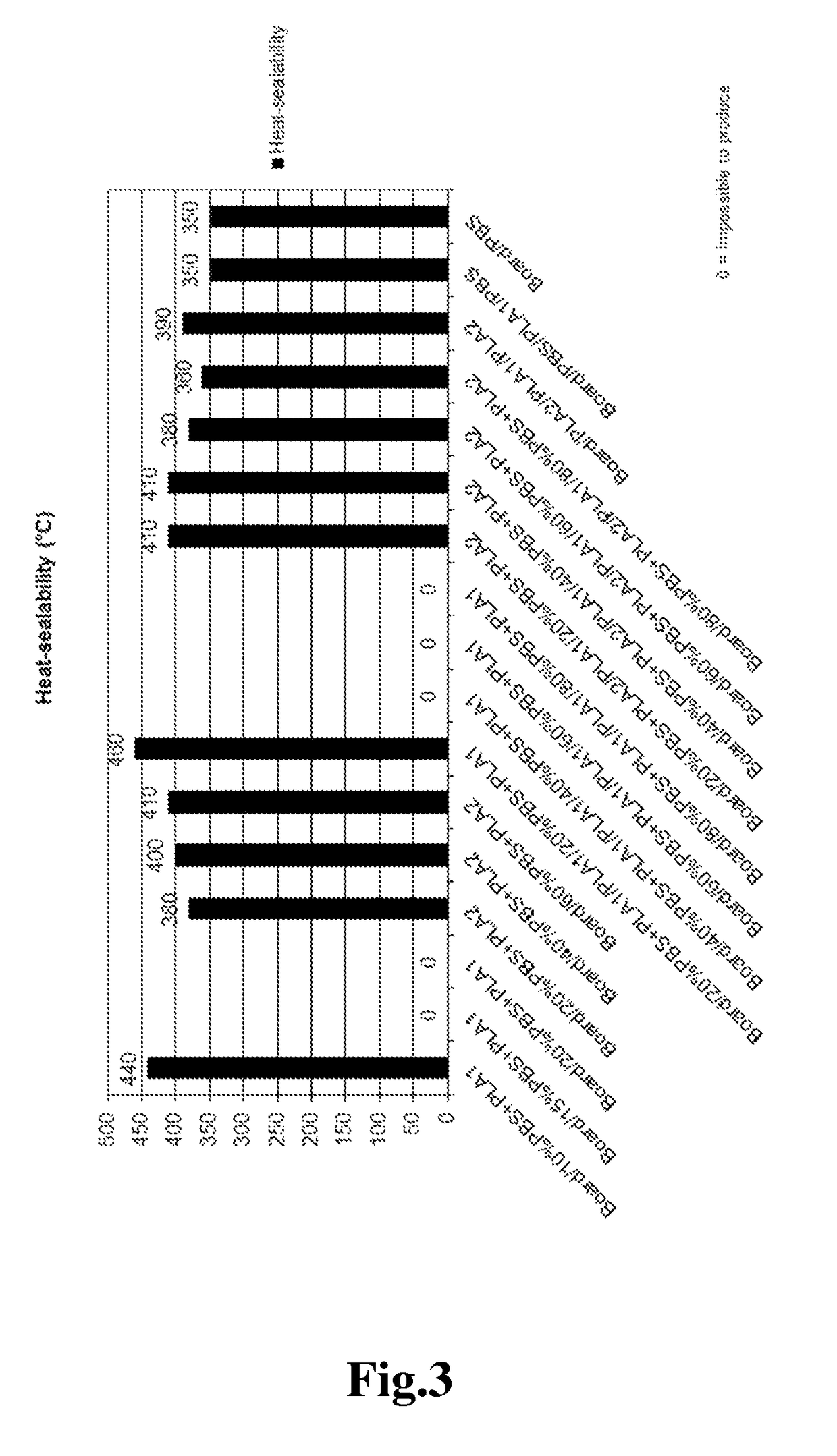

Method for manufacturing biodegradable packaging material, biodegradable packaging material and a package or a container made thereof

ActiveUS20150274367A1Easy extrusionKeep runningLiquid surface applicatorsWrappersFiberPolymer science

A biodegradable packaging material, a method of manufacturing the same, as well as products made of the material wherein the manufacture comprises extrusion onto a fibrous substrate one or more polymer coating layers including at least one layer of a polymer blend consisting of (i) 20-95 wt-% of polylactide having a high melt index of more than 35 g / 10 min (210° C.; 2.16 kg), (ii) 5-80 wt-% of polybutylene succinate (PBS) or a biodegradable derivate thereof, and (iii) 0-5 wt-% of one or more polymeric additives. The components of the blend are melted and blended in connection with the extrusion step. The goal is to improve extrudability, increase machine speed in extrusion and maintaining good adhesiveness to the substrate and good heat-sealability of the coating. The products include disposable drinking cups and board trays, as well as sealed carton packages for solids and liquids.

Owner:STORA ENSO OYJ

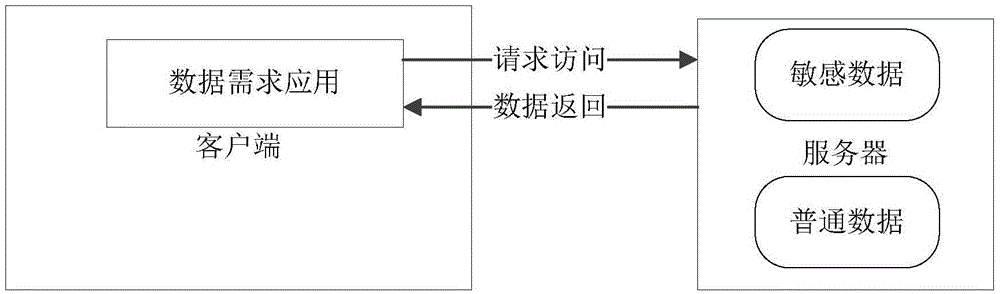

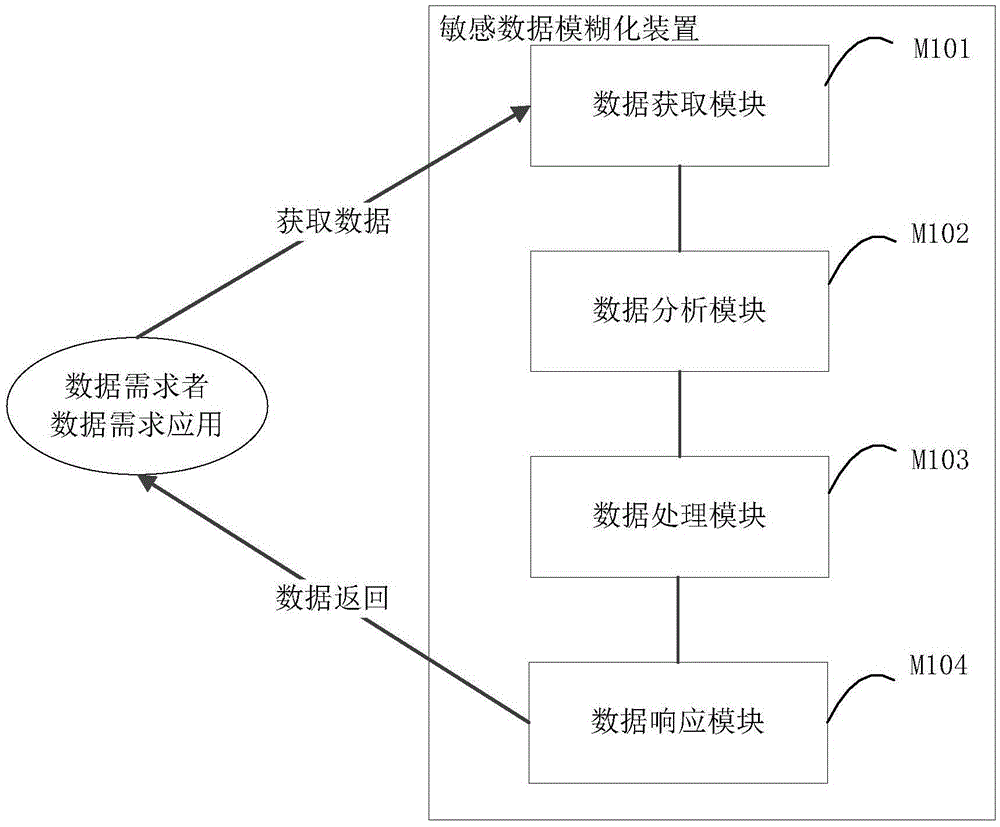

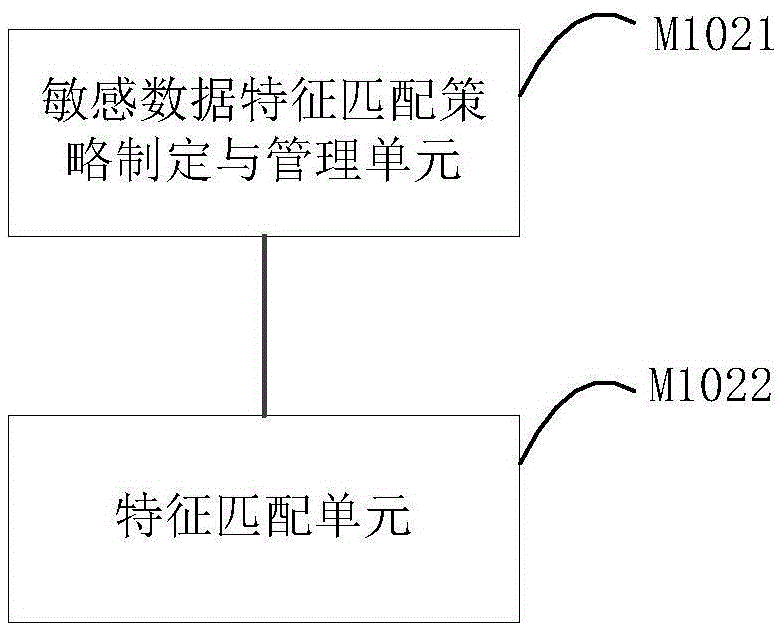

Fuzzification device and method of sensitive data

The invention discloses a fuzzification device of sensitive data. The device is used as the auxiliary accessory of the data demand application of a client which can access the server in which the sensitive data is located. The device comprises that a data obtaining module is used for obtaining the return data from a data demander or the data demand application; the return data is the data obtained through requesting to the server for accessing by the data obtaining module; a data analyzing module is used for making and managing a sensitive data feature matching strategy, matching the data transmitted from the data obtaining module according to the sensitive data feature matching strategy and finding out the sensitive data fitting with features; a data processing module is used for making and managing a sensitive data fuzzification strategy fitting with the sensitive data feature matching strategy made by the data analyzing module, carrying out fuzzification processing to the sensitive data transmitted from the data analyzing module according to the sensitive data fuzzification strategy, thus obtaining fuzzified non-sensitive data; and a data response module is used for returning the fuzzified non-sensitive data to the data demander or the data demand application. The invention also discloses a fuzzification method of the sensitive data.

Owner:亿阳安全技术有限公司

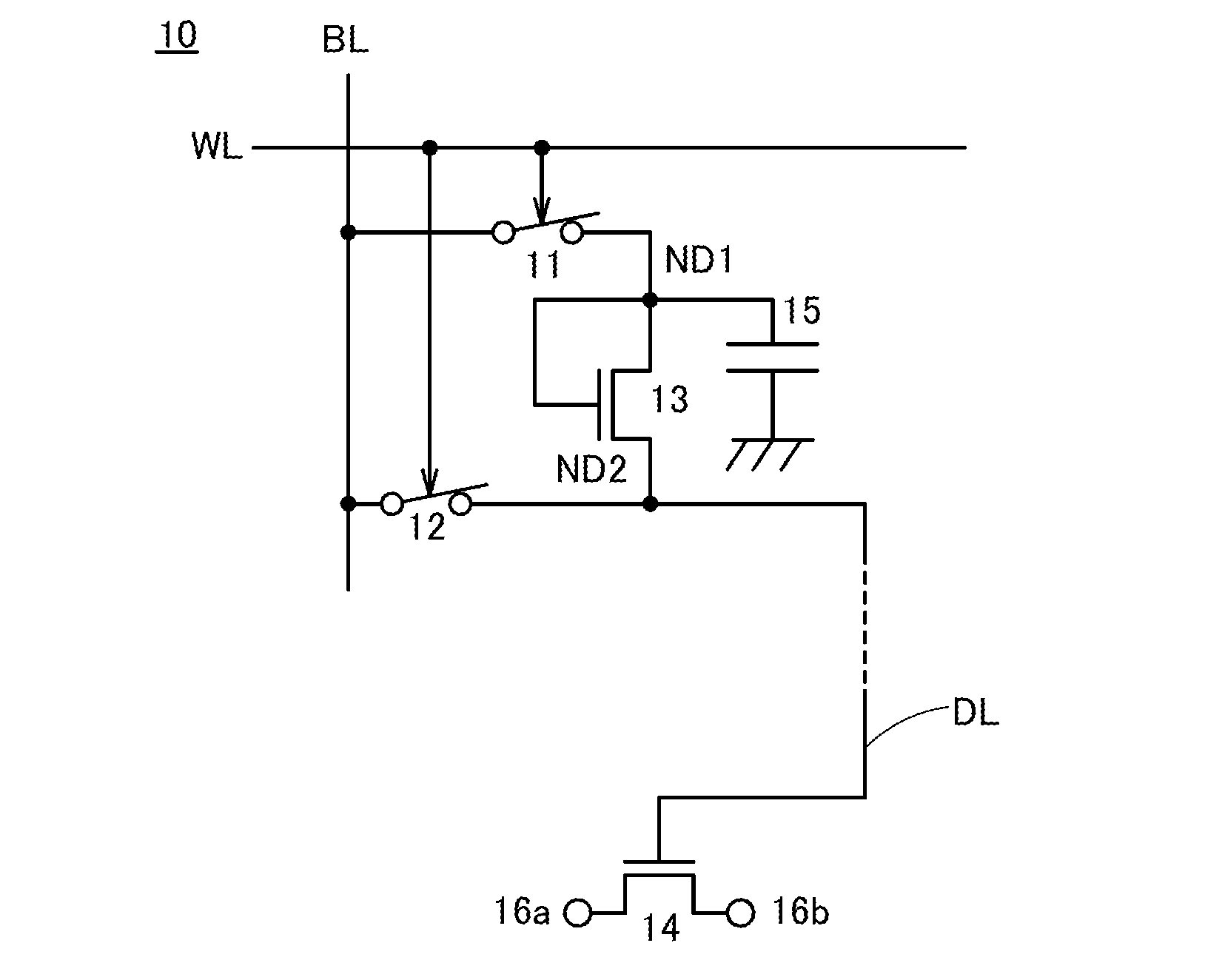

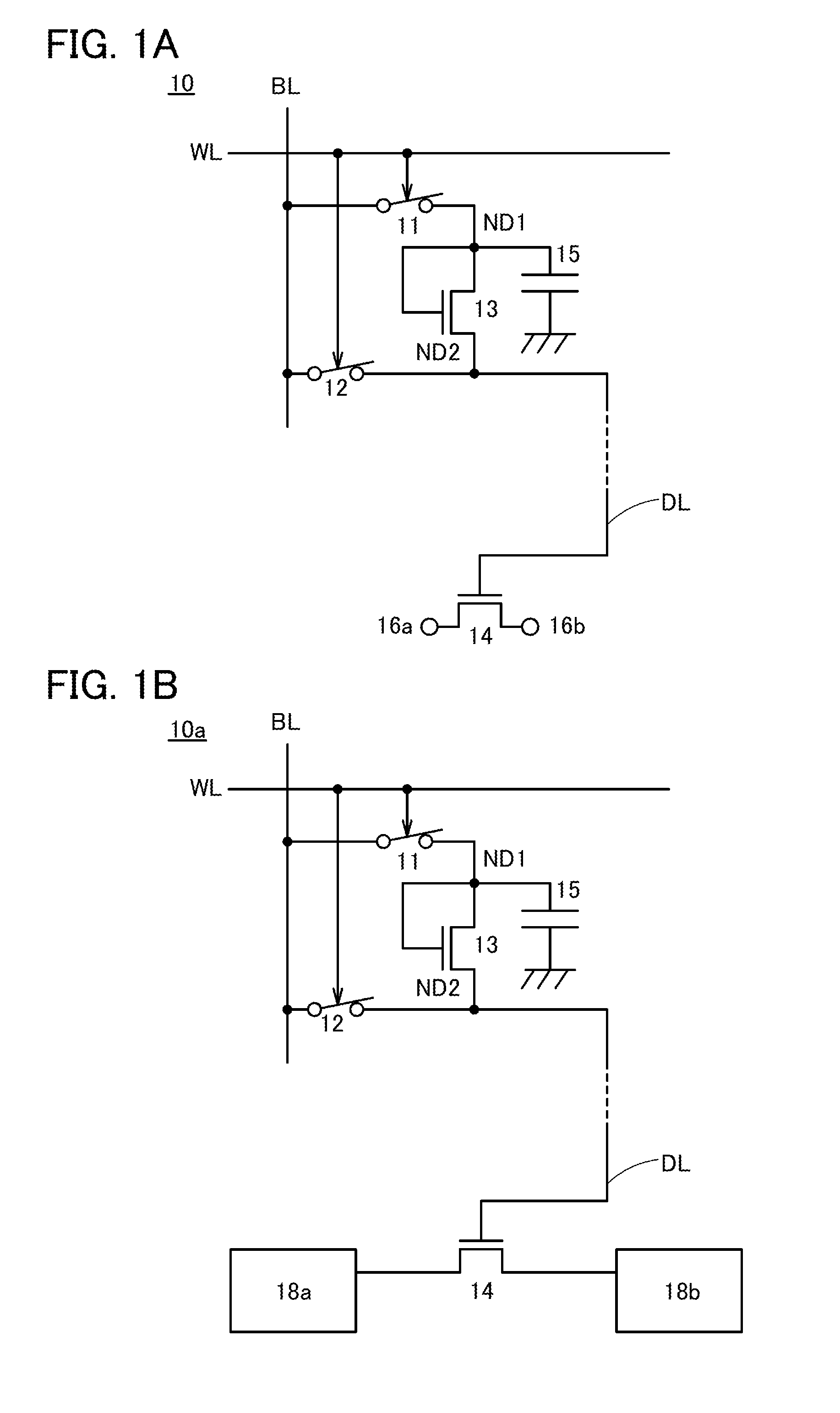

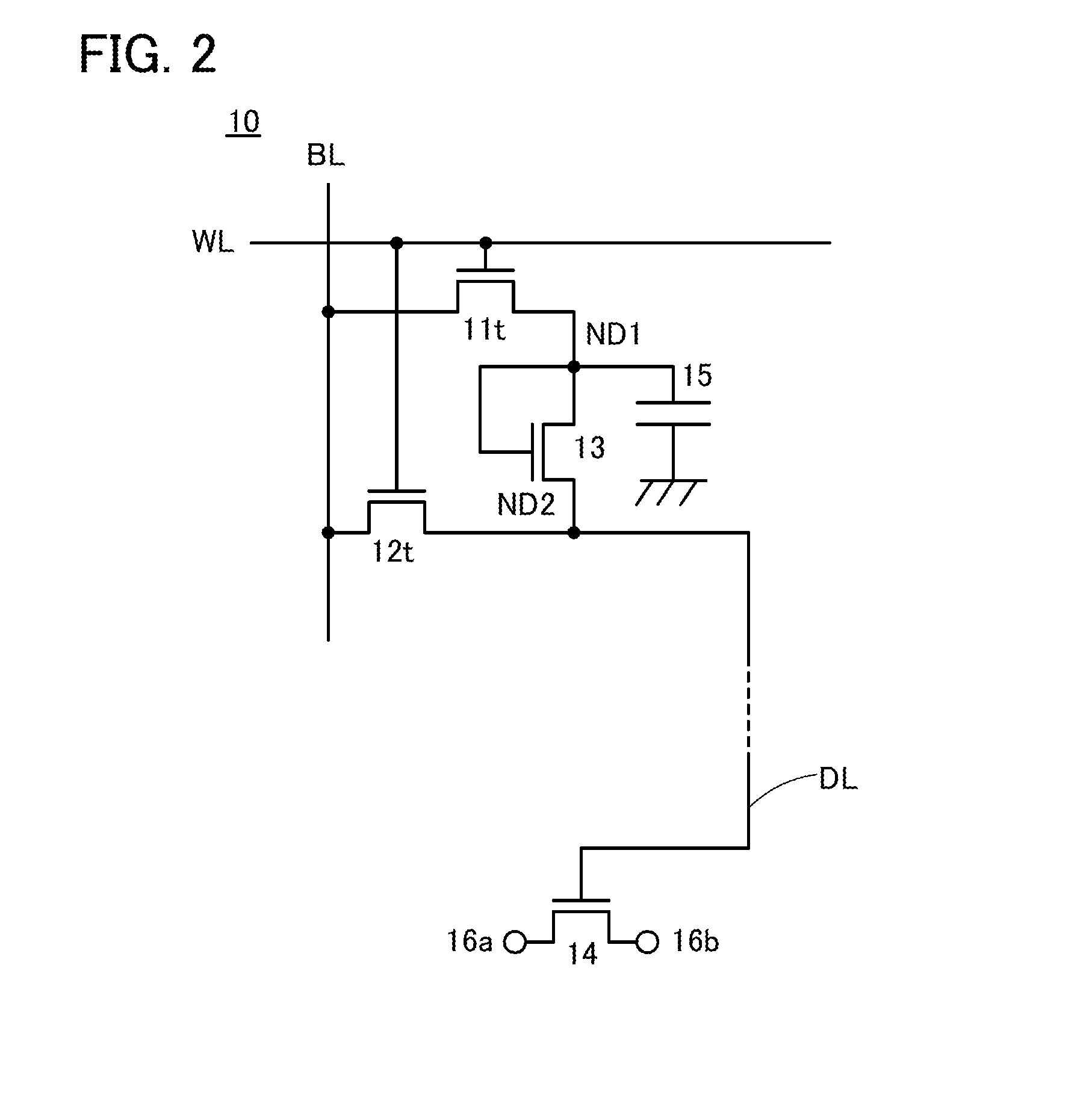

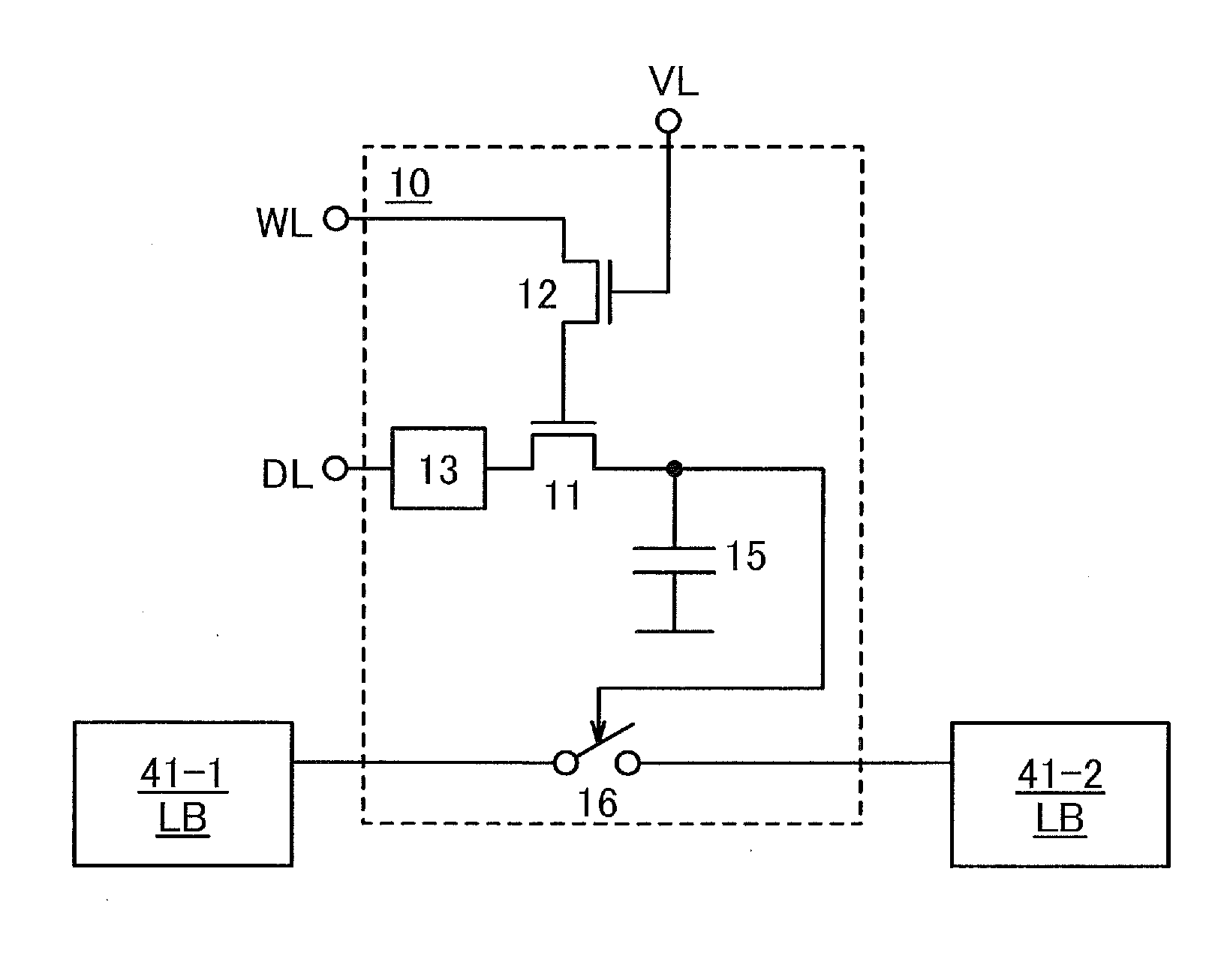

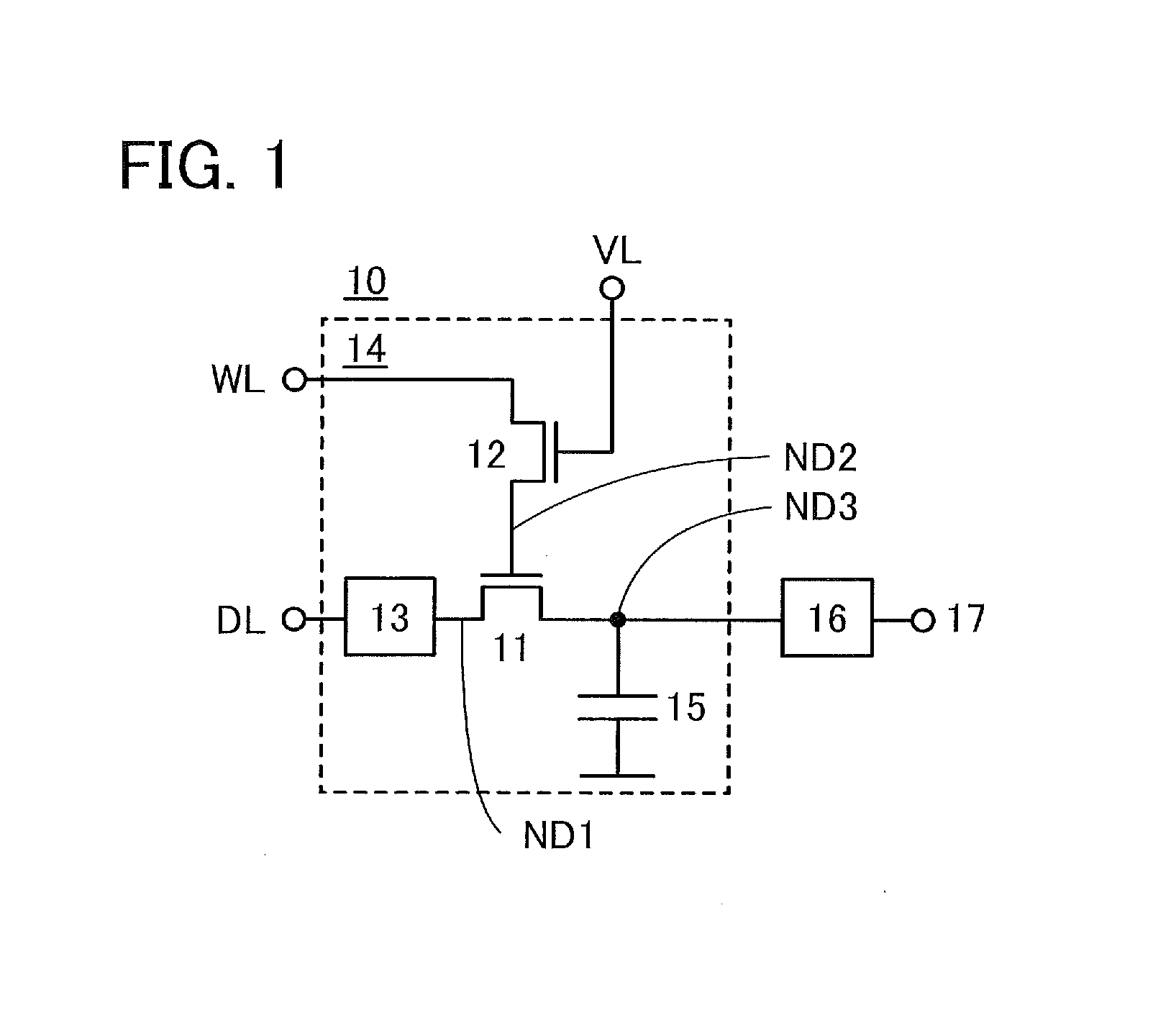

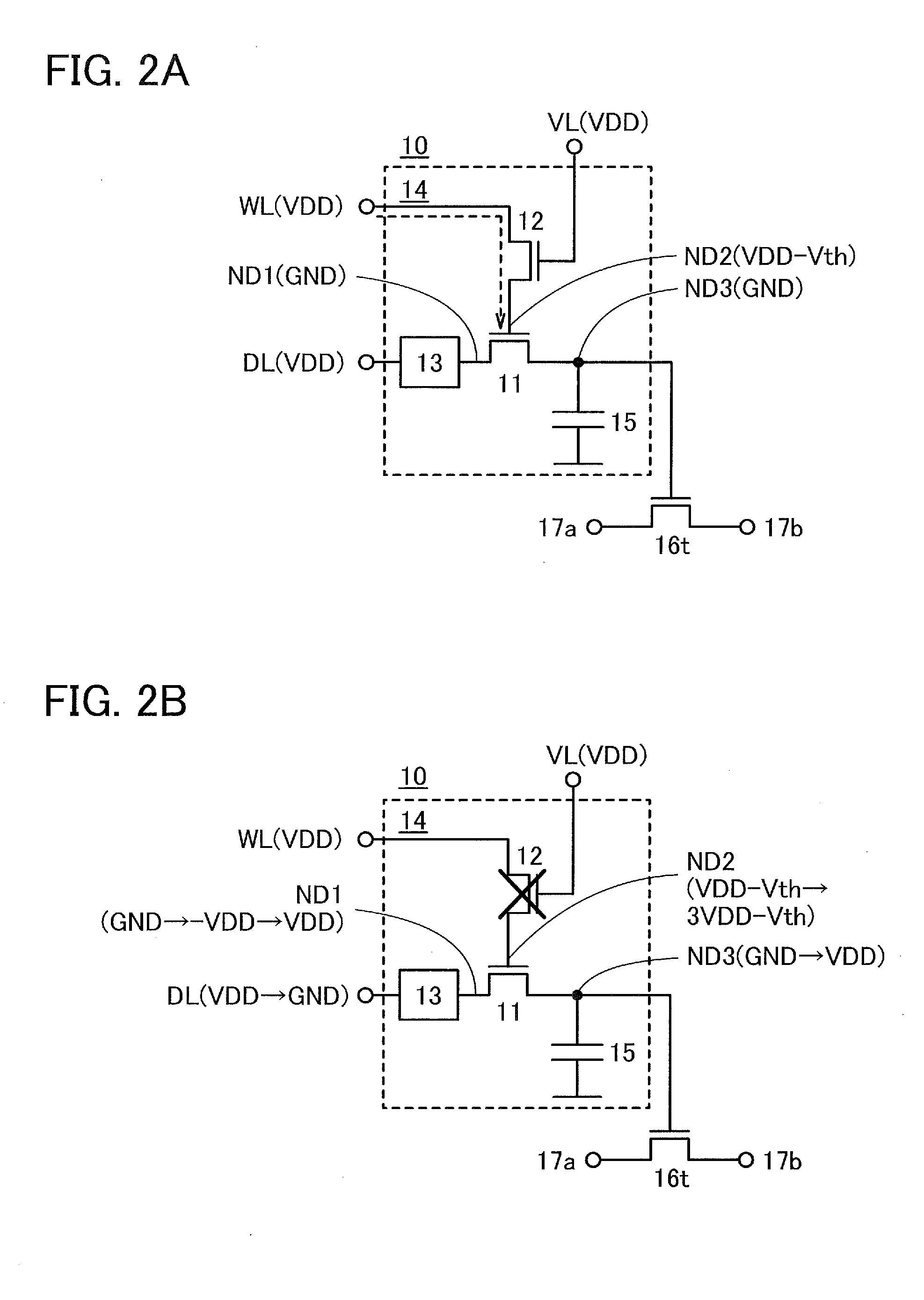

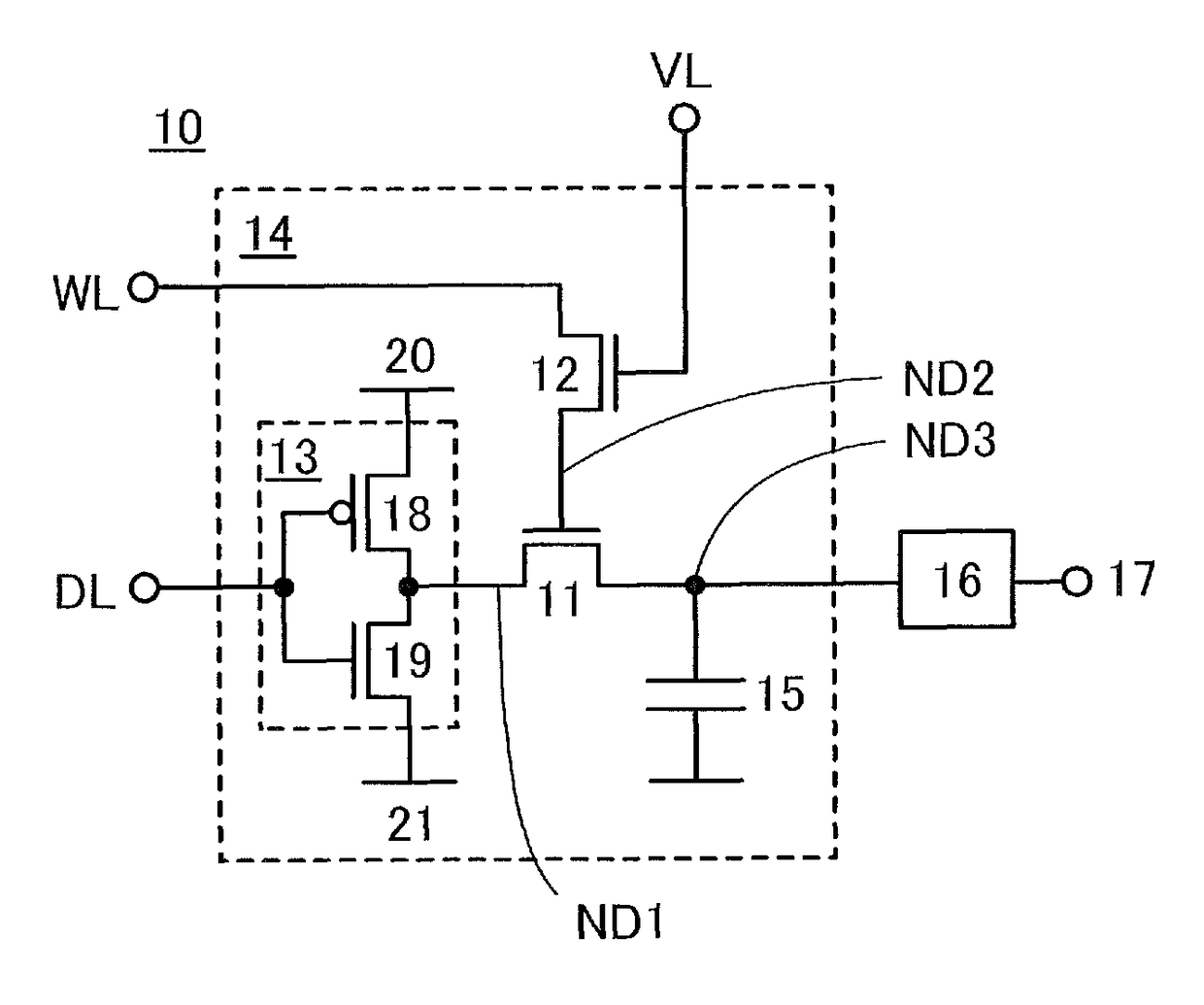

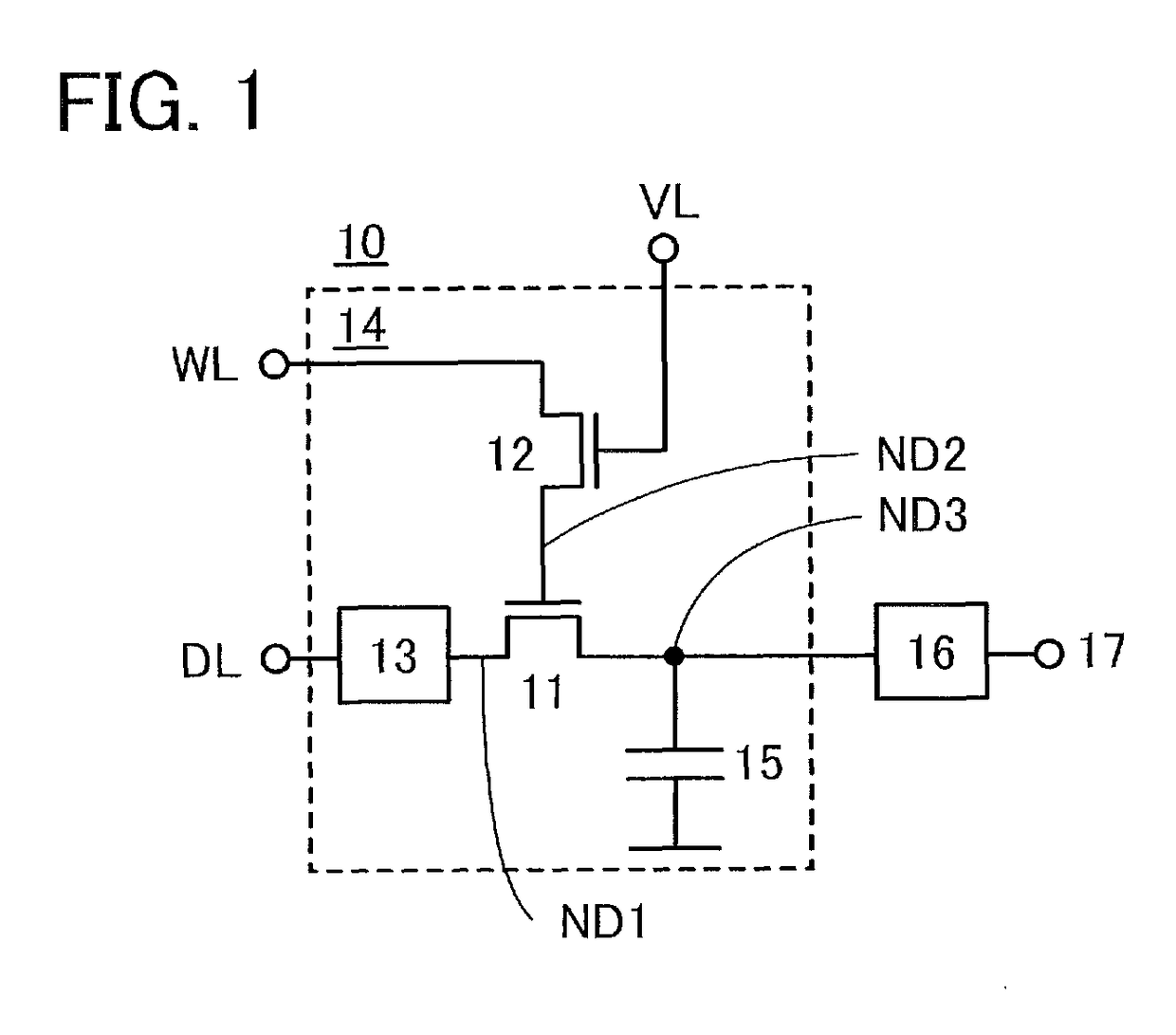

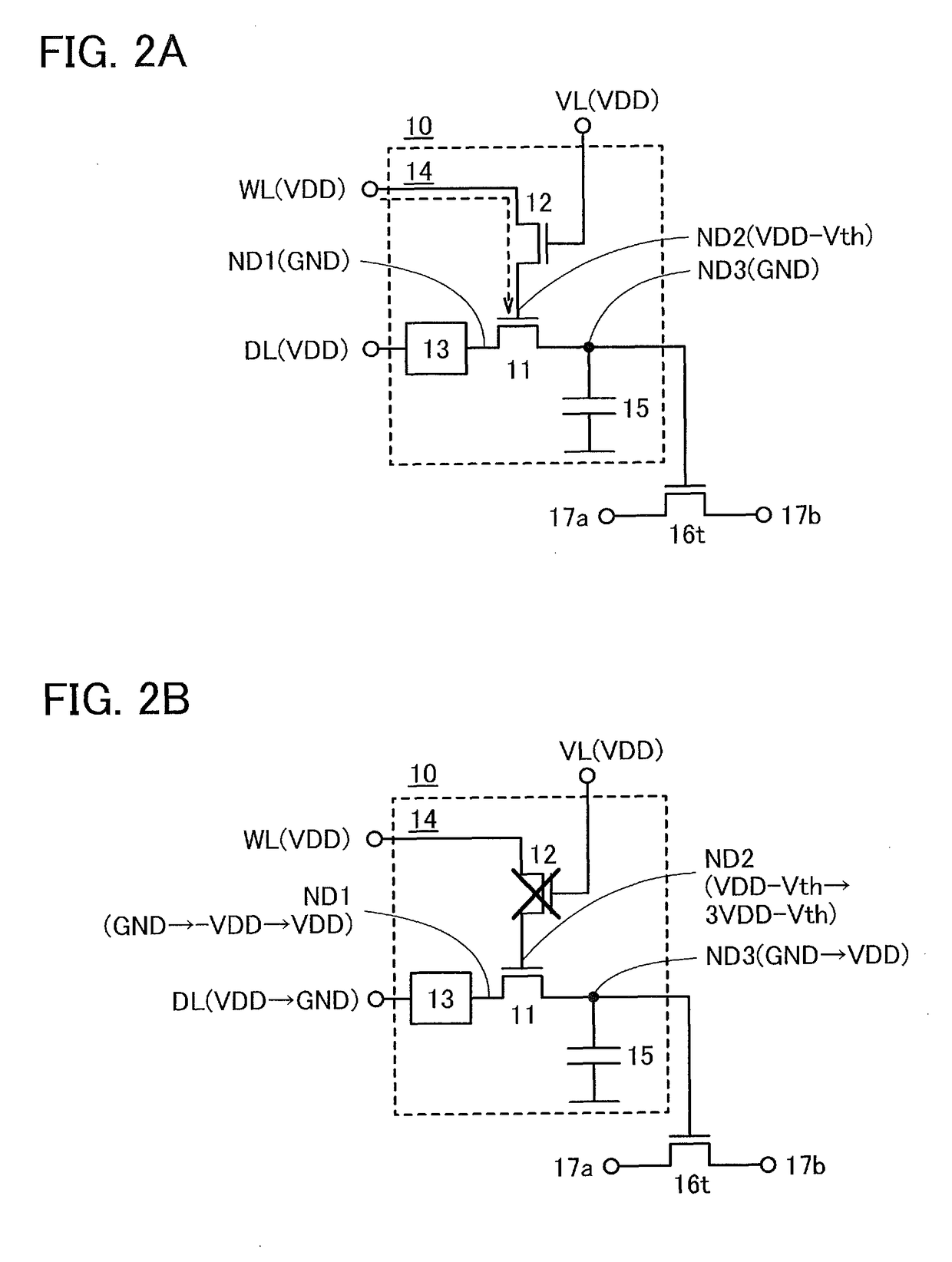

Programmable logic device and semiconductor device

ActiveUS20140340116A1Reduce power consumptionGuaranteed normal operationPower consumption reductionStatic indicating devicesProgrammable logic deviceControl signal

A programmable logic device having low power consumption with operation speed maintained is provided. The programmable logic device includes a first circuit; a second circuit; a first transistor making electrical connection between the first circuit and the second circuit depending on a potential of a gate of the first transistor; a first switch configured to control supply of a signal to a first node; a second switch configured to control supply of the signal to a second node; a second transistor having a gate and one of a source and a drain that are electrically connected to the first node and having the other of the source and the drain that is electrically connected to the second node; and a capacitor that holds a potential of the signal supplied to the first node.

Owner:SEMICON ENERGY LAB CO LTD

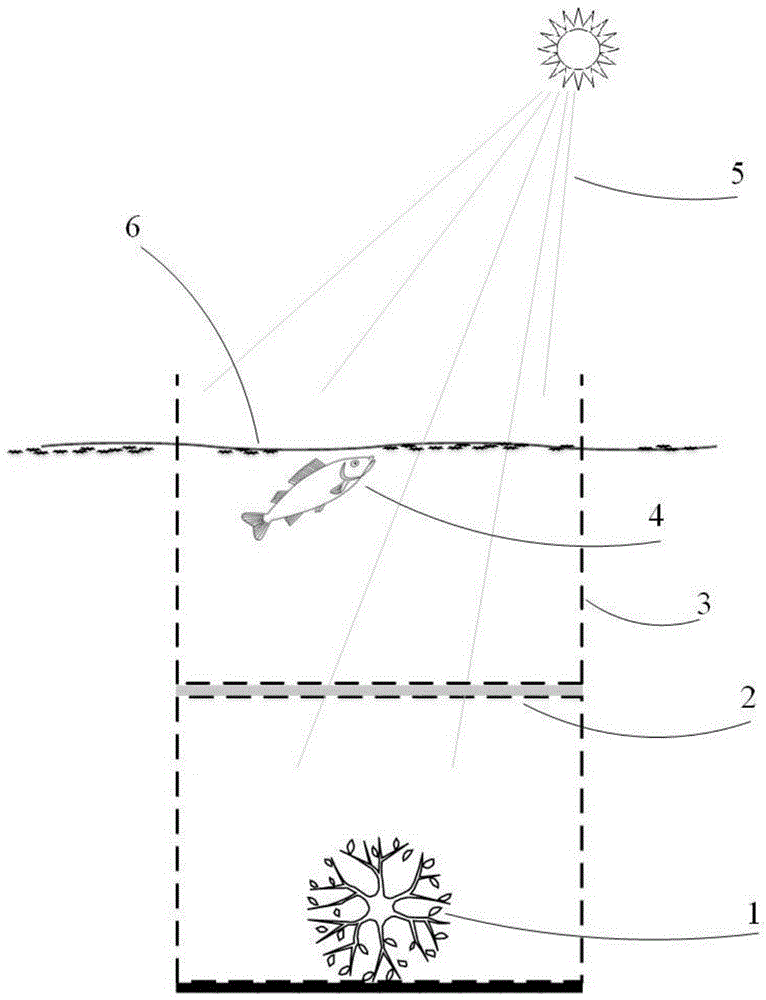

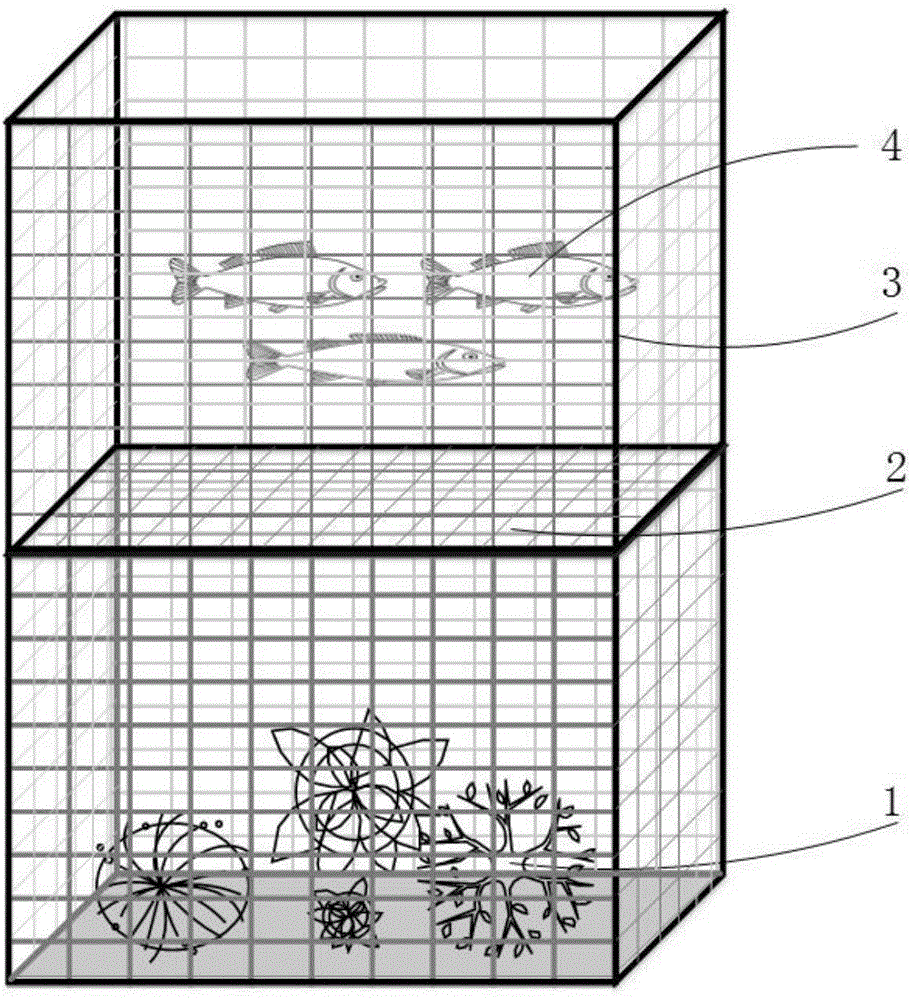

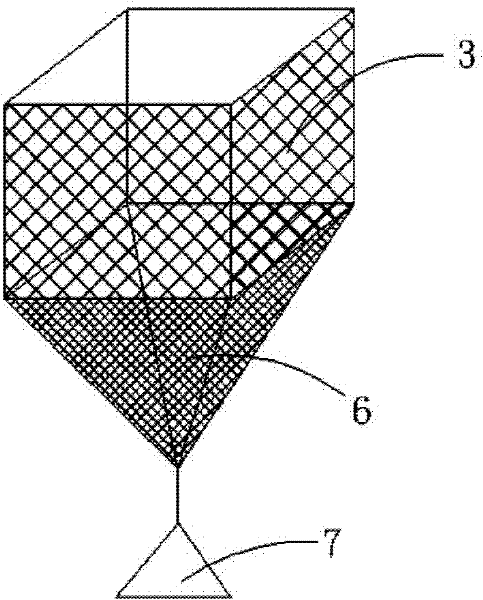

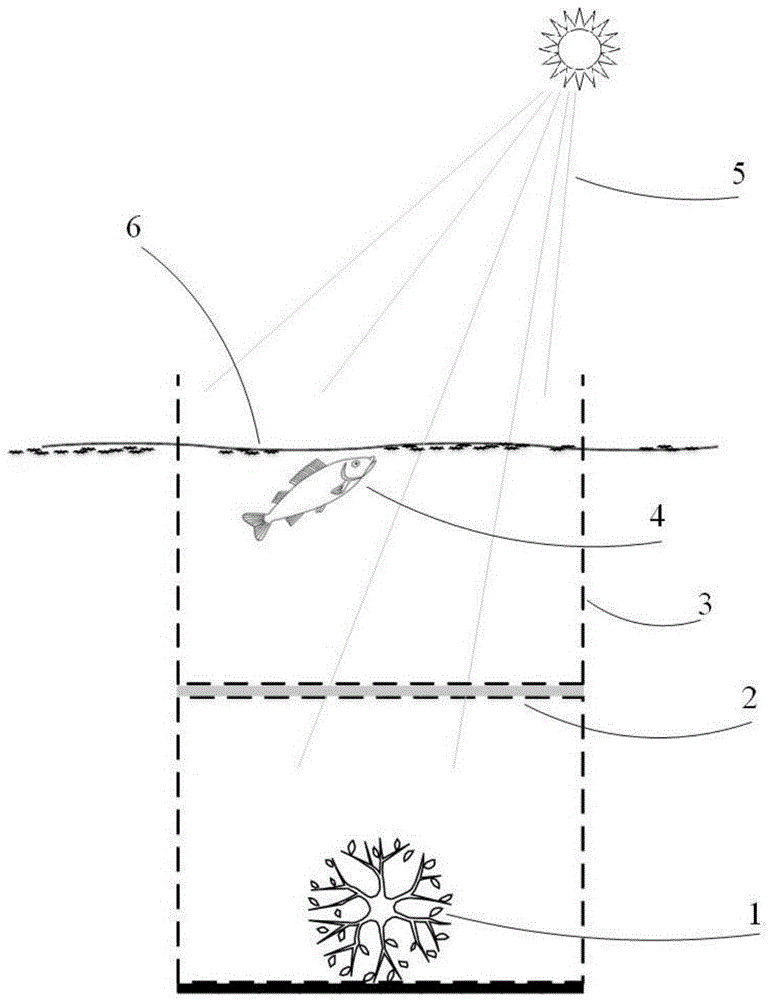

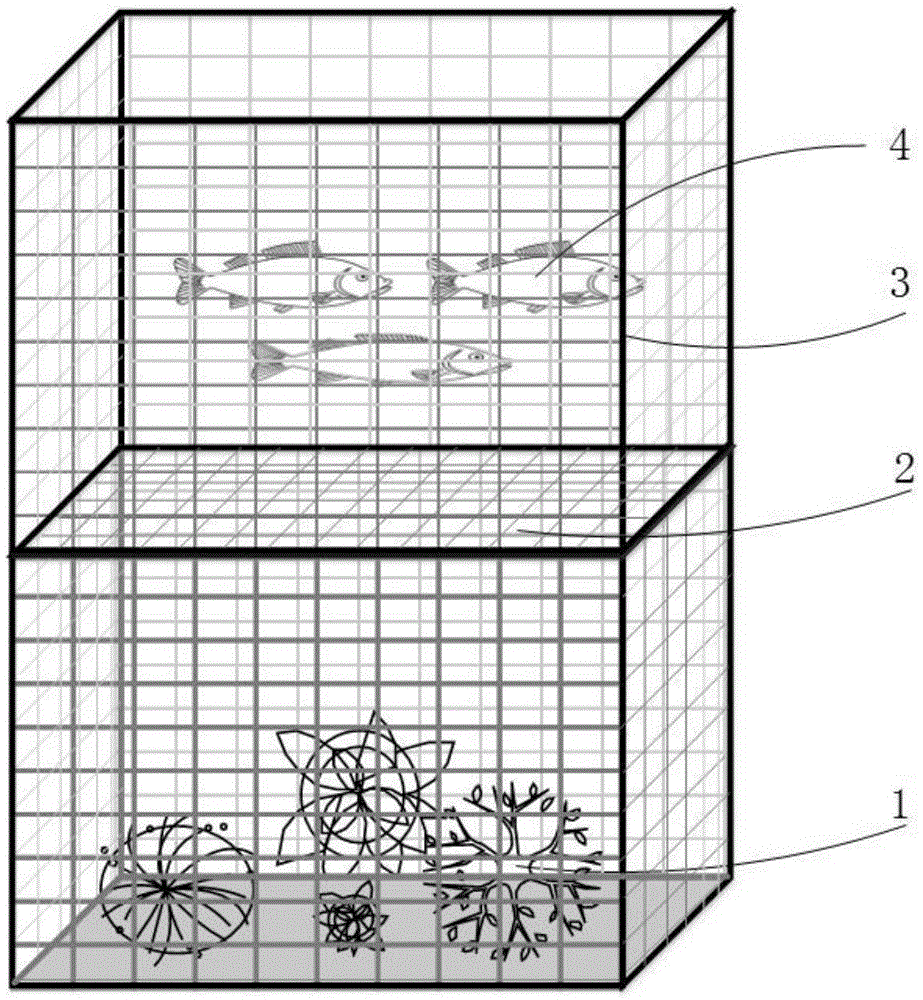

Ecological net cage-based water purification method

ActiveCN104003523AImprove eutrophication statusEasy to operateBiological water/sewage treatmentPhosphorus concentrationAlgal bloom

The invention discloses an ecological net cage-based water purification method; a double-layer net cage is used as a carrier; filter-feeder fish is fed in the upper-layer cage; submerged plants are fixed in the lower-layer cage; the net cage is put into a water area for water purification. The method of the invention is based on the net cage and the comprehensive utilization of water environment ecological systems; no additional energy is necessary; only solar energy and biological energy in the water environment are used to maintain the operation of the net cage module; and no secondary pollution problem is generated. The method can relieve the water bloom problem caused by water eutrophication, can effectively decrease nitrogen and phosphorus concentrations of water body, needs little manual intervention, has the advantages of simple operation and low cost, and is suitable for ecological management and improvement of water of lakes, rivers, reservoirs.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Lubricating Composition Containing a Carboxylic Functionalised Polymer

ActiveUS20130203638A1High oxidationIncrease resistanceOrganic chemistryLiquid carbonaceous fuelsOxidation stabilityCarboxylic acid

The invention provides a lubricating composition comprising an oil of lubricating viscosity and an amine-functionalised additive, wherein the amine-functionalised additive is derived from an amine having at least 3 aromatic groups, at least one —NH2 functional group, and at least 2 secondary or tertiary amino groups. The invention further provides for the additive to have improved thermal and oxidative stability modifying properties. The lubricating composition may include circulating oils, turbine oils, hydraulic fluids, transformer oils and greases as well as others that require good oxidation stability and good rust inhibition properties.

Owner:THE LUBRIZOL CORP

Storage device and semiconductor device

ActiveUS20140312932A1Operating speedAccurate operationPower reduction in field effect transistorsSolid-state devicesEngineeringSemiconductor device

A low-power storage device is provided. The storage device includes a first transistor, a second transistor, a logic element, and a semiconductor element. The second transistor controls supply of a first signal to a gate of the first transistor. When the potential of a second signal to be input is changed from a first potential into a second potential lower than the first potential, the logic element changes the potential of a first terminal of the first transistor from a third potential lower than the second potential into the first potential after the logic element changes the potential of the first terminal of the first transistor from the second potential into the third potential. The semiconductor element has a function of making a second terminal of the first transistor floating. The first transistor includes a channel formation region in an oxide semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

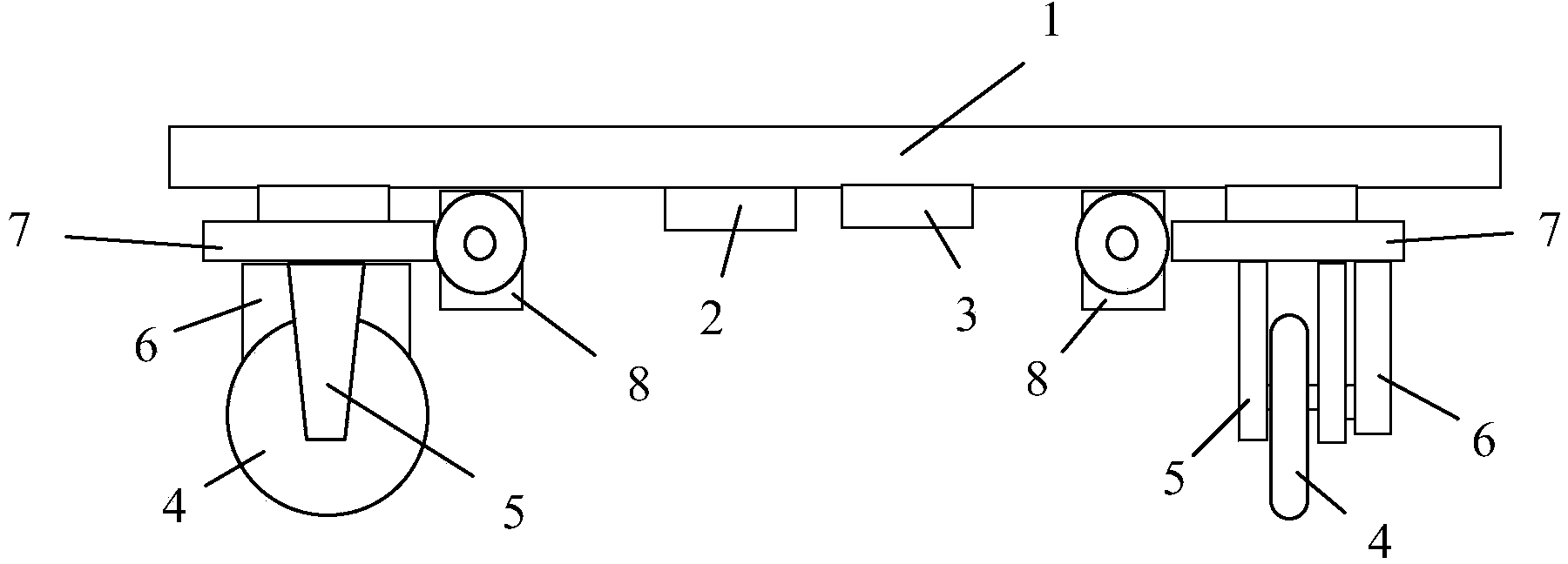

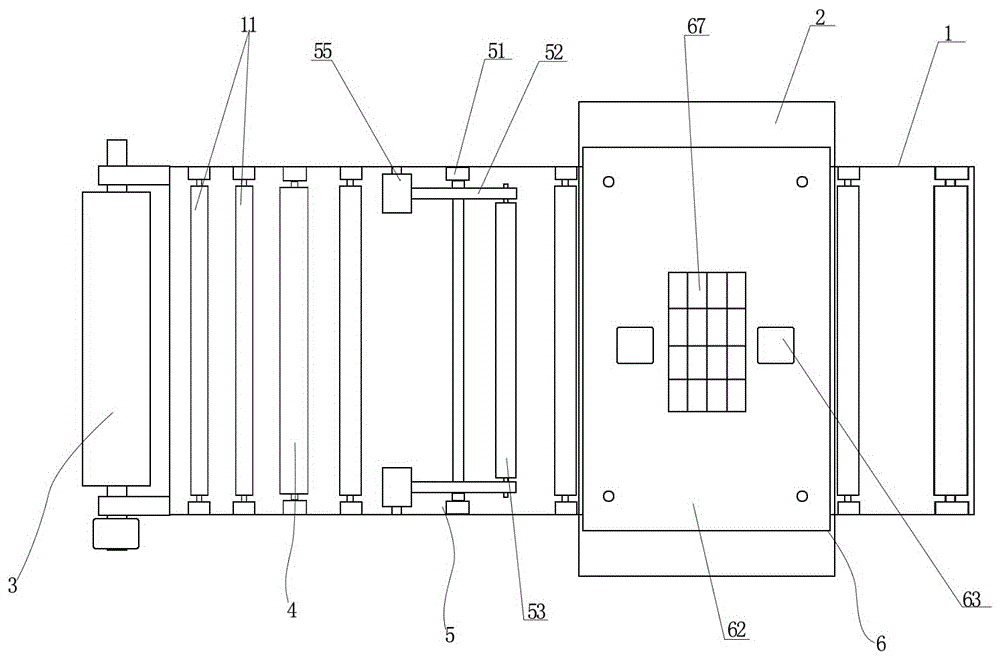

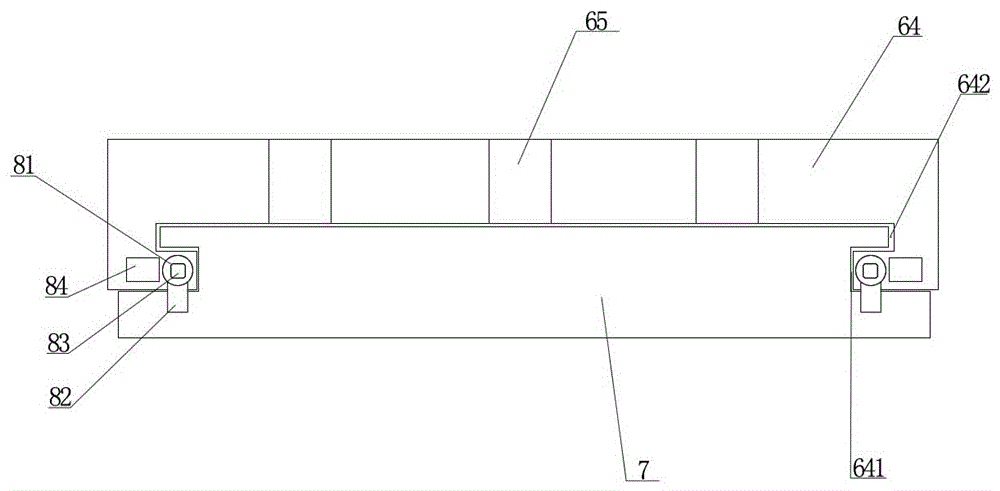

Four-wheel independent drive transfer trolley

A four-wheel independent drive transfer trolley comprises an objective table, a battery and a master controller. Four wheel type supporting devices are arranged in the bottom face of the objective table. Any one of the wheel type supporting devices comprises a wheel, a wheel suspension gear, a wheel driving mechanism, a wheel mounting base and a wheel steering driving mechanism. Each wheel suspension gear and each wheel driving mechanism are fixedly connected to the corresponding wheel mounting base, each wheel driving mechanism is connected with the corresponding wheel, and each wheel mounting base is connected with the bottom face of the objective table through a rotating shaft and a thrust bearing. Each wheel steering driving mechanism is fixed in the bottom face of the objective table, and each wheel steering driving mechanism is connected with the corresponding wheel mounting base. According to the four-wheel independent drive transfer trolley, needed turning radius limitation in the moving process is greatly reduced, the trolley is suitable for narrow areas with extremely compact space, the four wheels are respectively connected with one independent driving mechanism, when a work environment swings, enough road holding force can be generated, and stable operation can be kept.

Owner:SHANGHAI DESHENG MIGAO ELEVATOR

Method for collecting blue algae and purifying water quality

InactiveCN102219308AControl biomassReduce N and P contentBiological water/sewage treatmentWater sourceWater quality

The invention discloses a method for collecting blue algae and purifying water quality by breeding algae-eating fishes in a water body. The method provided by the invention is characterized in that a plurality of uniformly distributed net cages used for breeding algae-eating fishes are arranged in an algae-controlling water area; the bottom of each net cage is equipped with a fish manure collector which is made from a dense net; the algae-eating fishes are bred in the net cages; and an algae manure interception net is arranged on the edge of the water area in which the net cages are disposed.According to the invention, the algae manure interception net, a fish-interception and blue algae-capture module and an ecological floating-island water quality purification module are arranged in local water areas, so as to effectively control the biomass of blue algae in water source areas, effectively reduce the content of N and P in a water body, improve the safety of water consumption, and obtain the cycling support economically.

Owner:ANHUI AGRICULTURAL UNIVERSITY

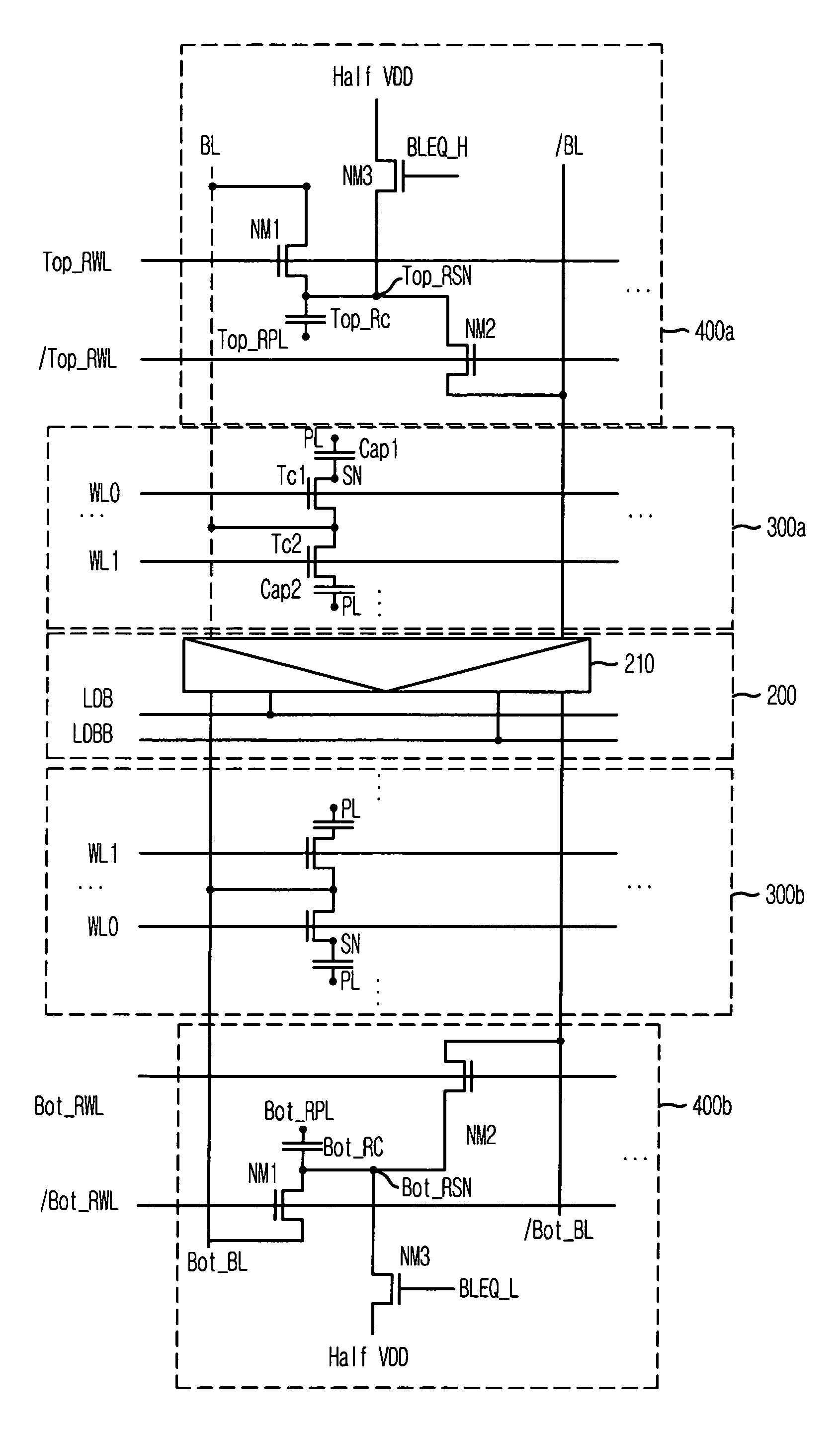

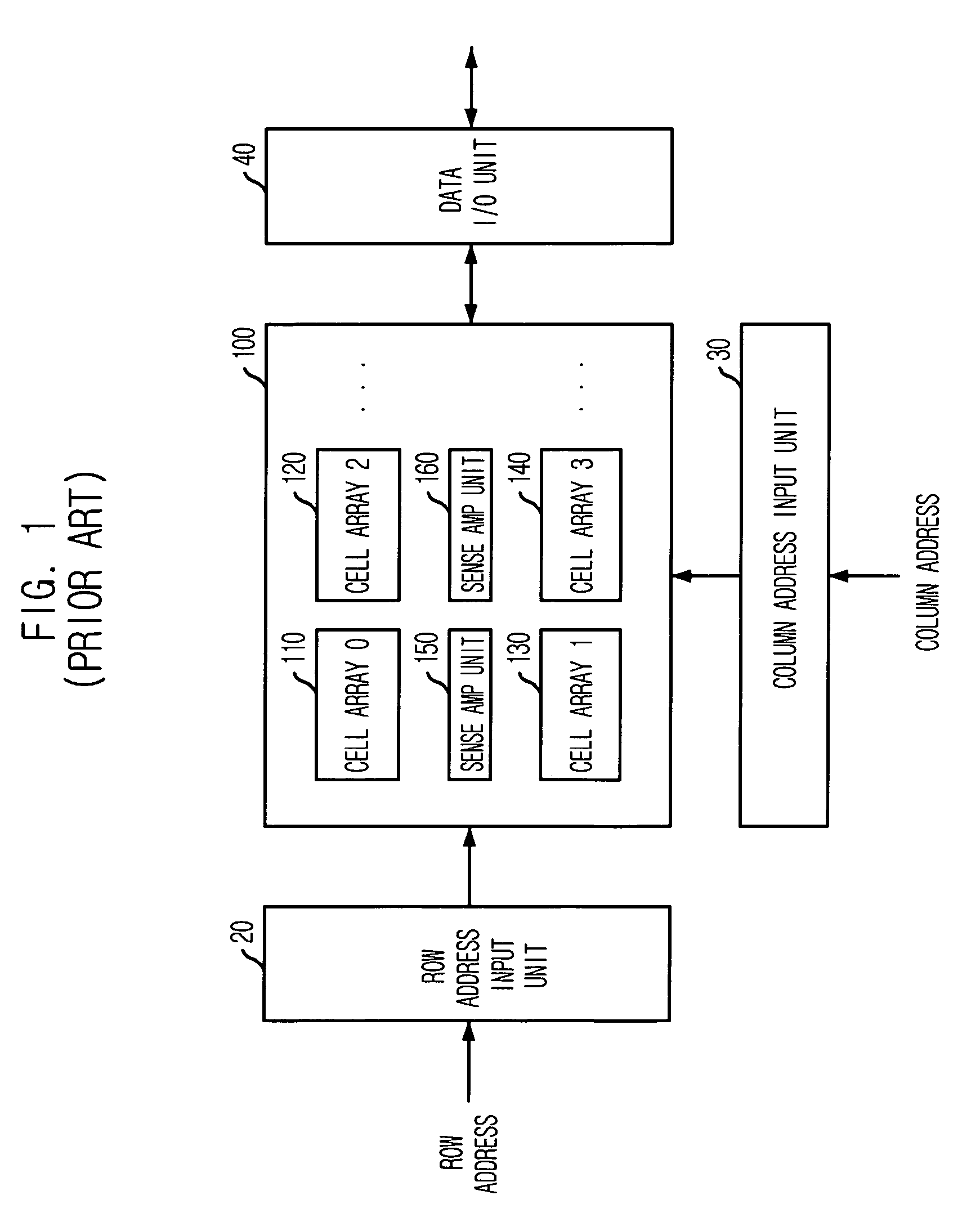

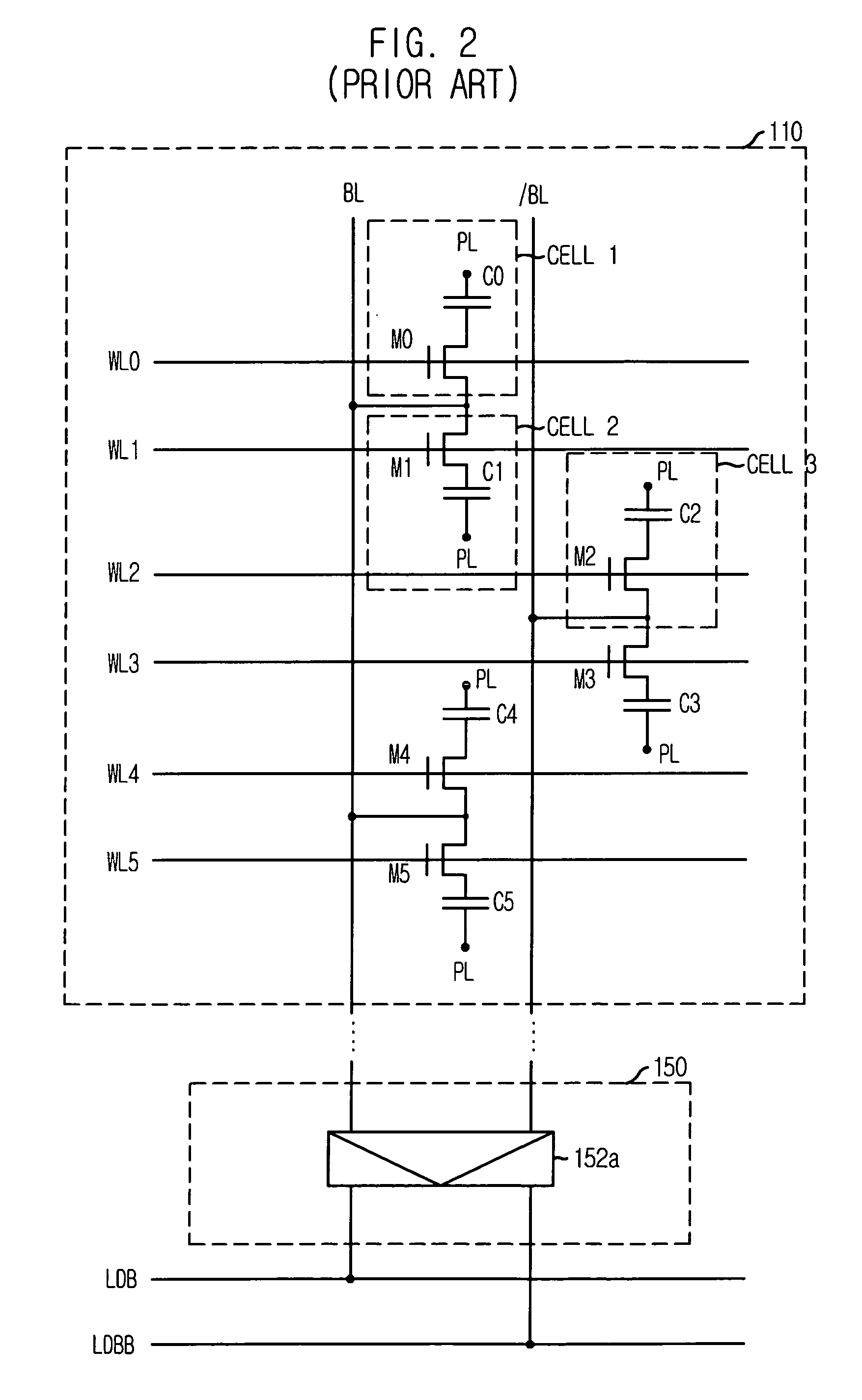

Semiconductor memory device for a low voltage operation

A semiconductor memory includes first and second cell arrays for applying a data signal onto pairs of first bit lines and second bit lines, respectively, first and second reference cell blocks each of which applies a reference signal onto a corresponding bit line bar or a corresponding bit line when the data signal is inputted to the corresponding bit line or the corresponding bit line bar, and a sense amp for sensing and amplifying a difference of data signals applied onto one pair of bit lines connected thereto of the pairs of first and second bit lines, wherein each bit line maintains a floating state without an input of an extra pre-charge voltage upon a pre-charge operation, and the other pair of bit lines disconnected to the sense amp are pre-charged with the reference signal by the corresponding reference cell block.

Owner:SK HYNIX INC

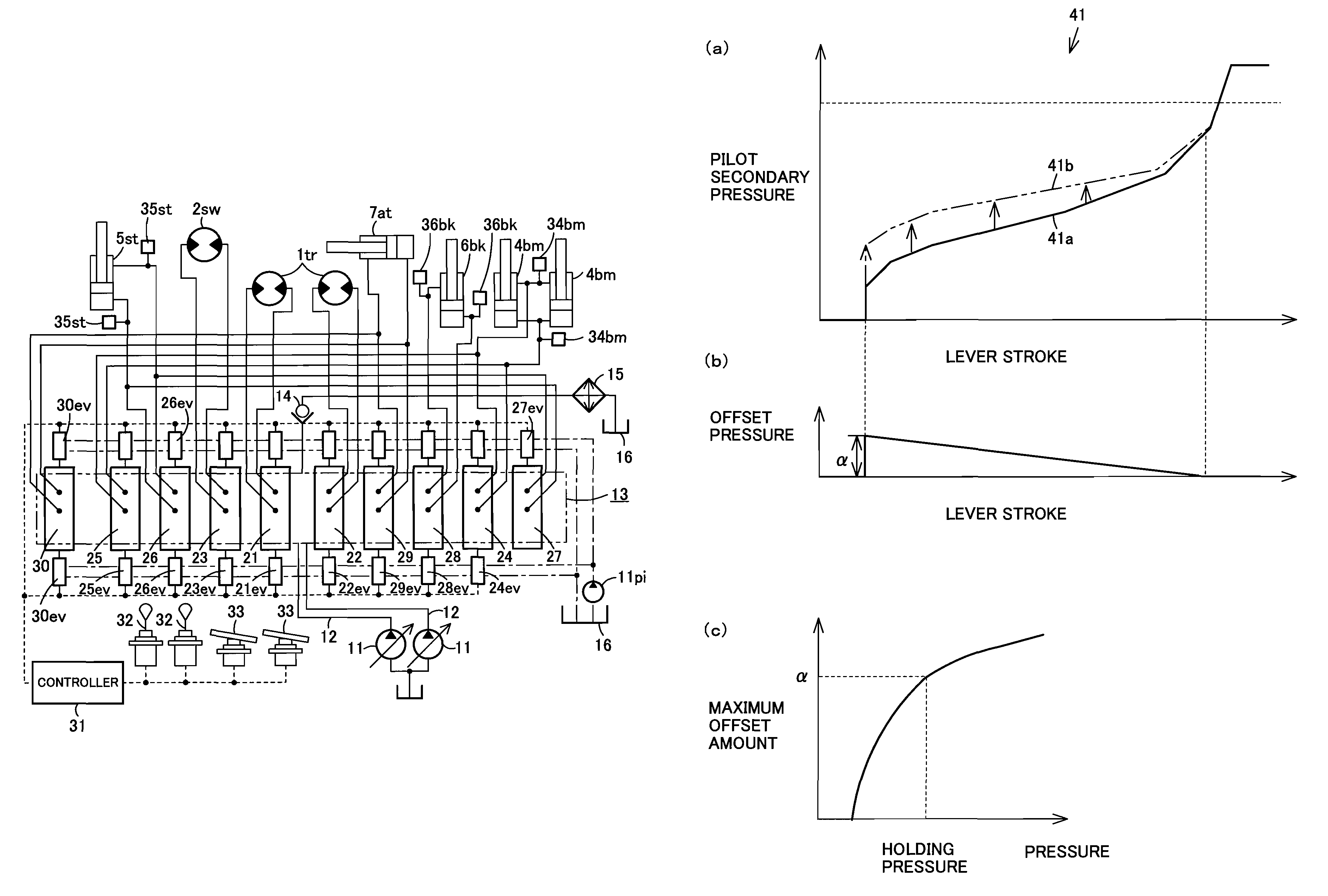

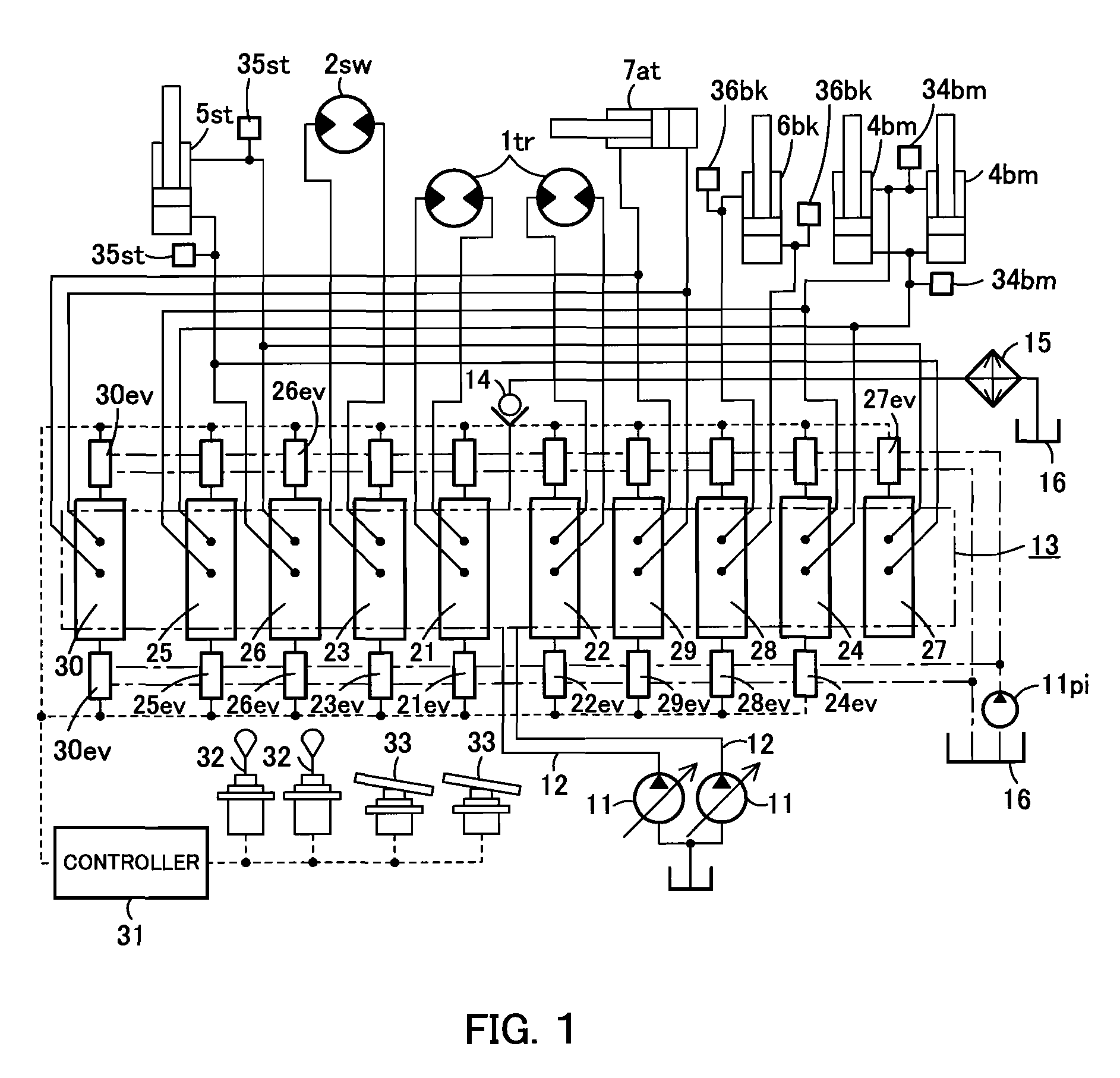

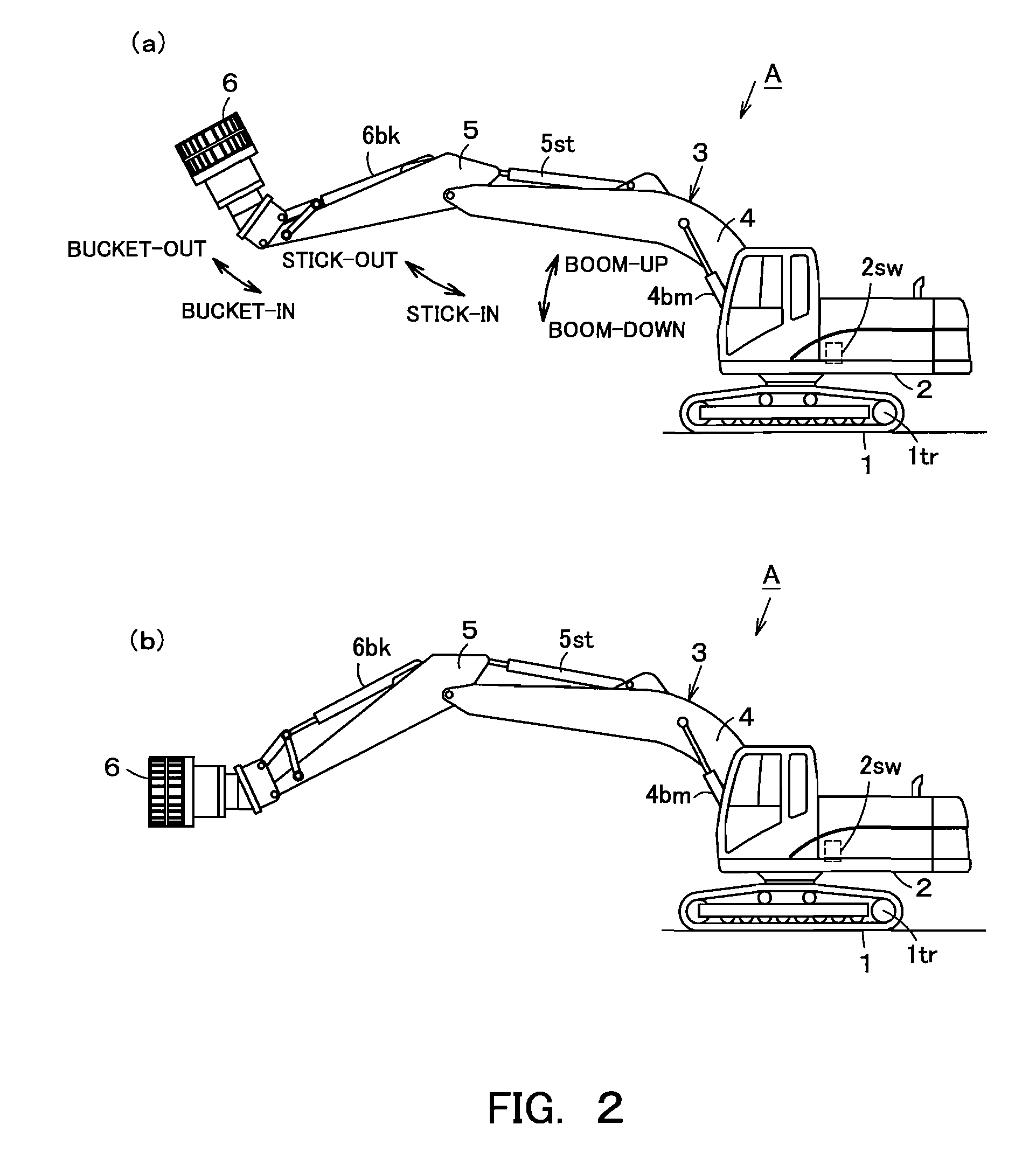

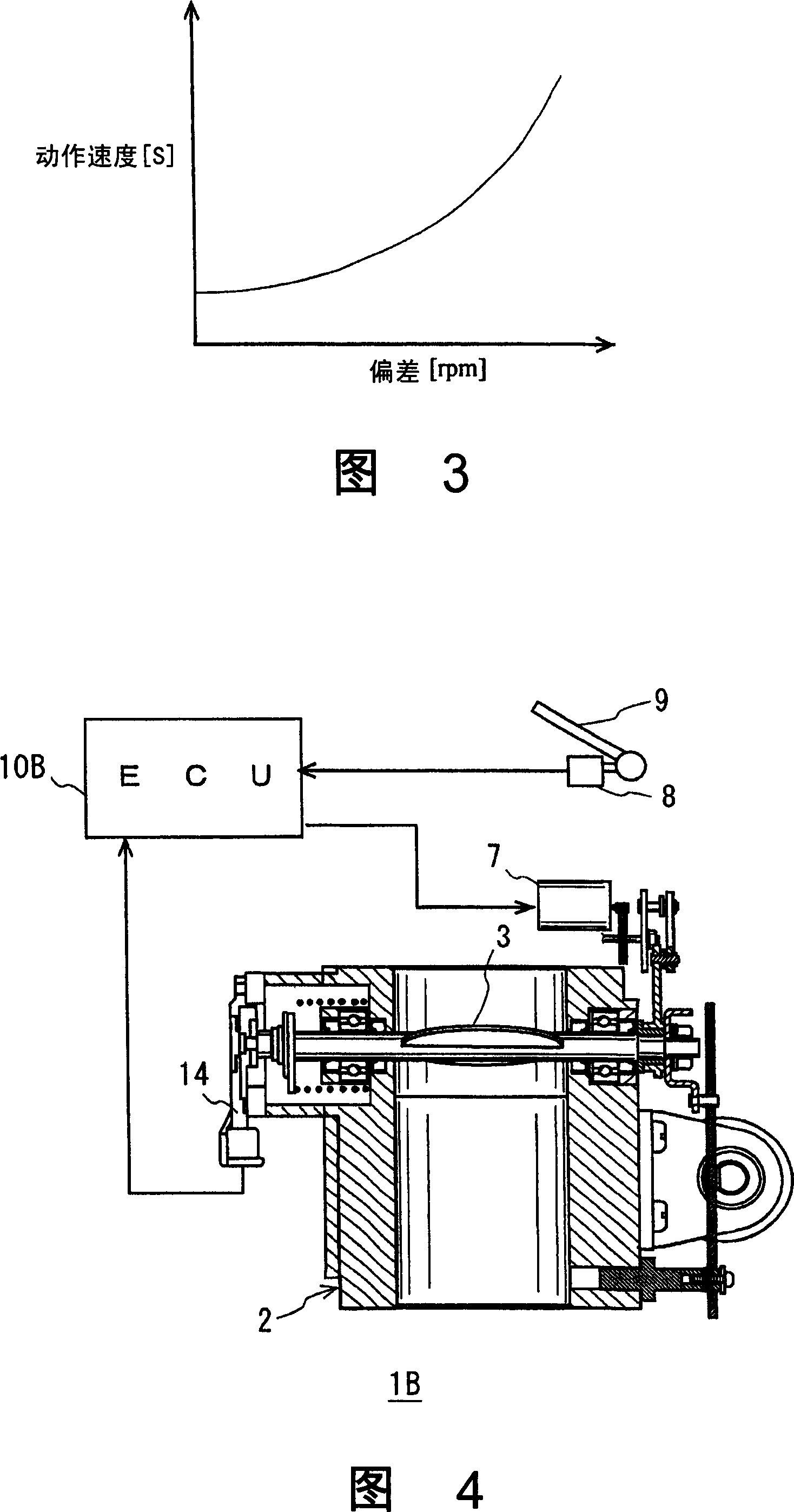

Control unit for work machine

InactiveUS7930970B2Easy to operateKeep runningServomotor componentsServomotorsSolenoid valveEngineering

A control unit for a work machine that allows automatically obtaining optimal operability even when the weight of a work arm in the work machine is changed. In a work machine where at least a part of a work arm to be operated by a fluid pressure actuator is provided so as to be replaceable, a control unit for a work machine includes: a pilot-operated control valve that controls the fluid pressure actuator; a proportional solenoid valve that pilot-controls the pilot-operated control valve by a pilot control pressure according to an electrical signal corresponding to a manual operation amount; a measuring means that measures a weight of at least the part of the work arm; and a controller that converts characteristics between the manual operation amount and the pilot control pressure of the proportional solenoid valve to characteristics according to the weight of the work arm measured by the measuring means.

Owner:CATEPILLAR SARL

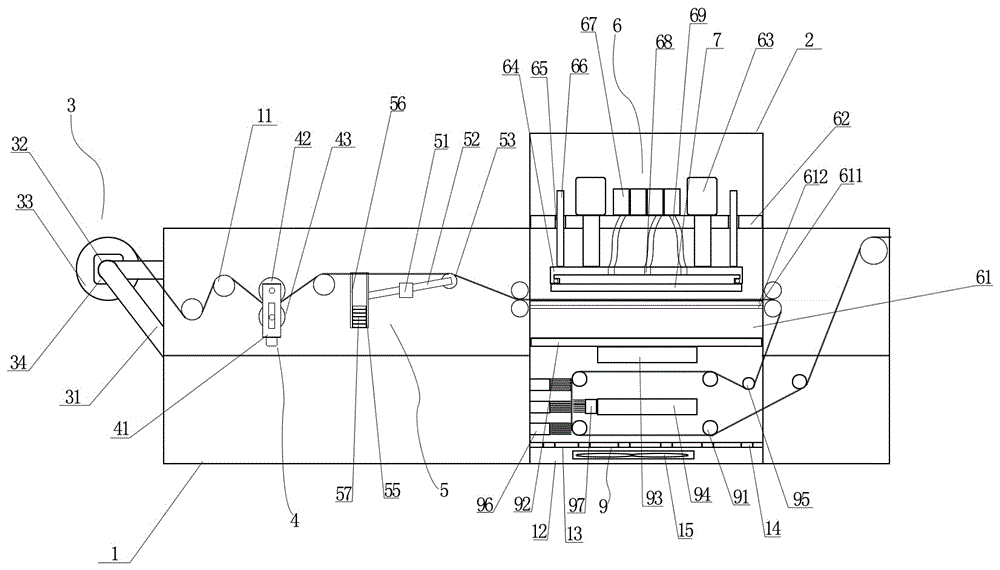

Dust collection type woven fabric printing device for spinning

InactiveCN106004025AKeep shapeGuaranteed cleanlinessRotary pressesPrinting press partsMechanical engineeringImpurity

The invention discloses a dust collection type woven fabric printing device for spinning. A delivery device is assembled in a first rack and used for delivering woven fabric. The delivery device comprises a woven fabric dragging machine for dragging and shifting the woven fabric and a tensioning mechanism used for keeping the woven fabric in a tensioned state in the delivery process, so that the woven fabric is kept in the tensioned and smooth state when moving to a printing mechanism so as to be better printed. The printing mechanism comprises printing plates which are connected into a connection plate. A drying and dust collecting assembly arranged on the lower portion of a second rack is used for woven fabric drying and woven fabric dust collection after printing is completed. Through the drying procedure, patterns can be reserved on the woven fabric quickly, the shape of the patterns can be kept, and the printing quality is improved. Through the dust collection procedure, batting and dust on the surface of the woven fabric are cleaned up conveniently after the woven fabric is dried, and cleanness of the woven fabric is ensured. An interlayer arranged on the lower portion of the second rack is used for collecting the impurities such as the batting and dust removed from the surface. A worker cleans the interlayer layer once after collection is carried out for a period of time, and cleanness and normal operation of the woven fabric printing device are maintained.

Owner:WUJIANG HUAYUN TEXTILE

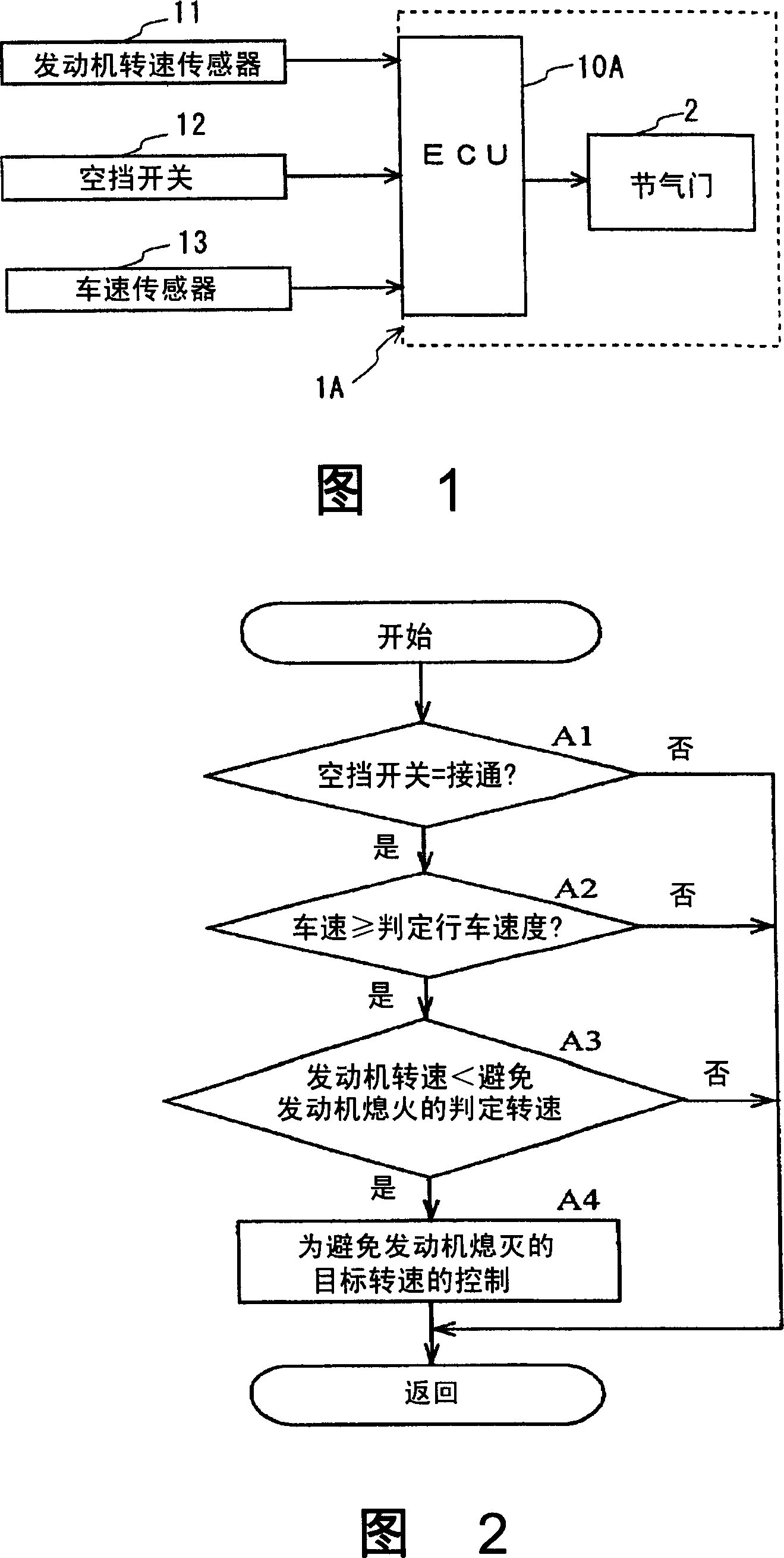

Electronic control method for choker and electronic control choker device

InactiveCN101122261AAvoid stallingKeep runningVehicle fittingsInternal combustion piston enginesActuatorChange positions

The engine system arranged with electronic control air throttle device can well maintain the running state of the engine as the system can reliably avoid the engine stall which is generated by the rotating speed descending of the engine. In the air throttle electronic control method which is executed by the electronic control air throttle device 1A to do on-and-off controlling to the air throttle 3 by the actuator 7 according to the instruction of the electronic control unit 10A, the electronic control unit 10A detects the output signal of the neutral position switch, the signal of the engine speed sensor, and the signal of vehicle speed sensor, when the speed changing box is at the stage changing position and the gear is at the connecting condition, besides, the vehicle speed is above the scheduled determinant rotary speed and the engine speed is below the scheduled determinant rotary speed when the engine stall is likely to happen, the system does controlling to the air throttle to hold the engine speed above the target rotary speed which is specified to avoid the engine stall.

Owner:NIKKI CO LTD

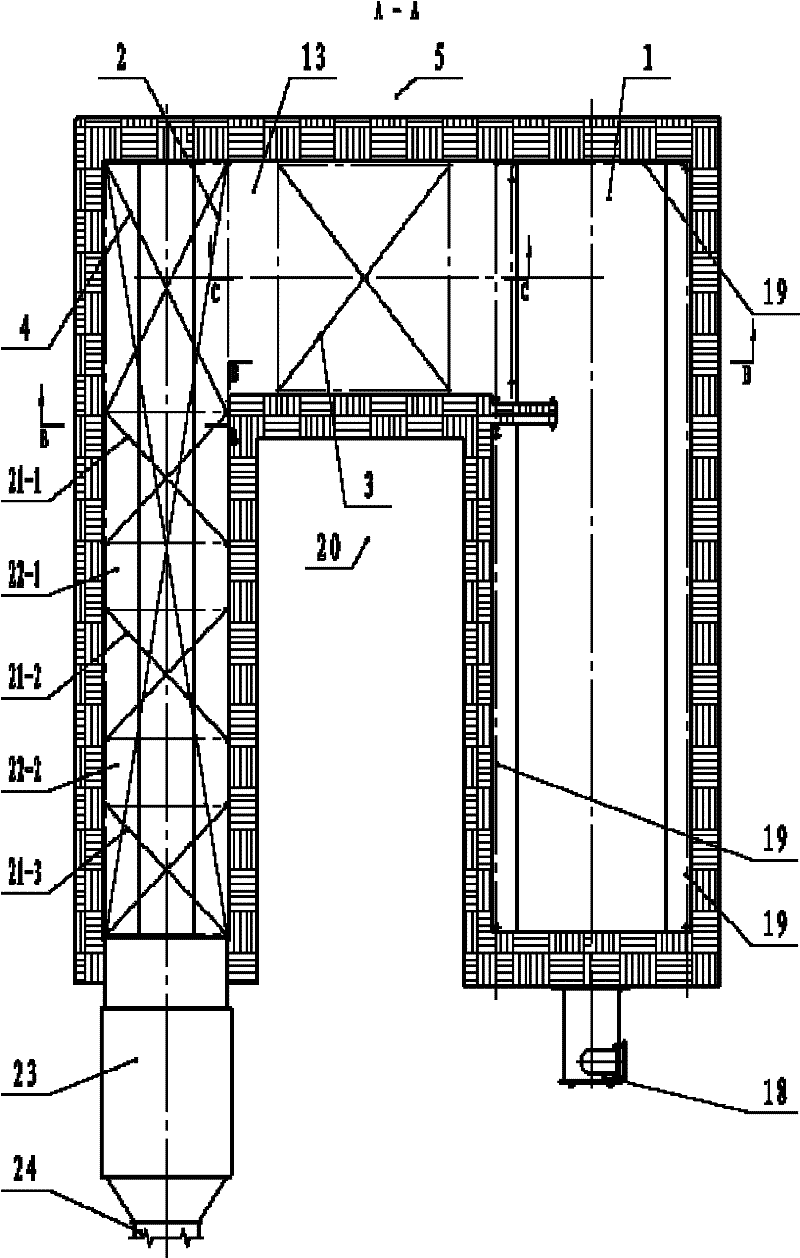

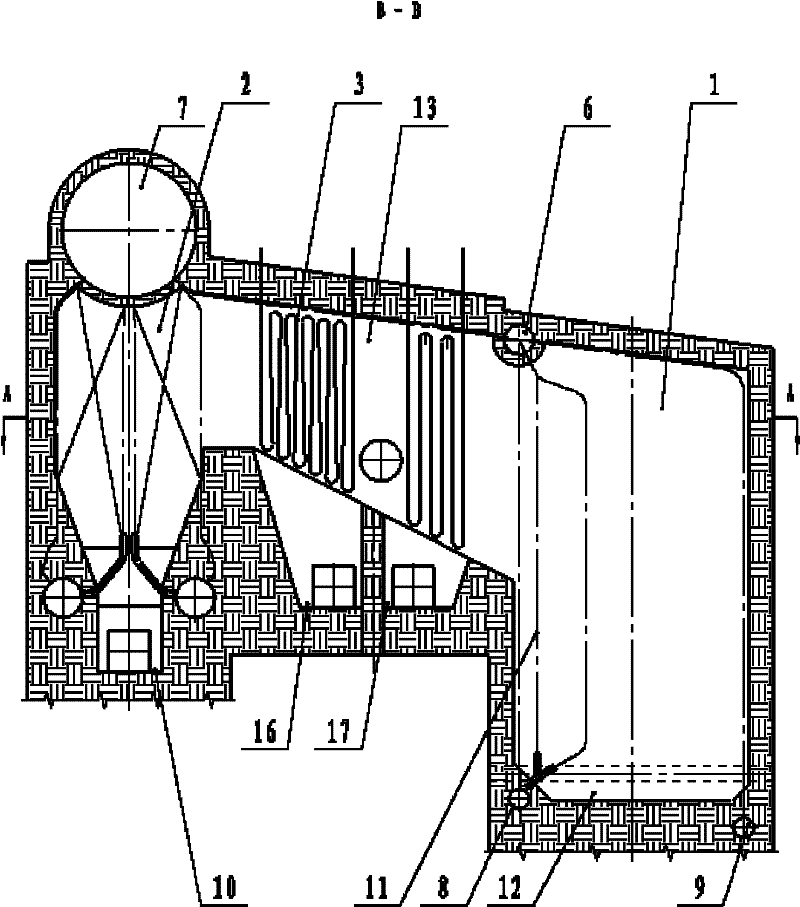

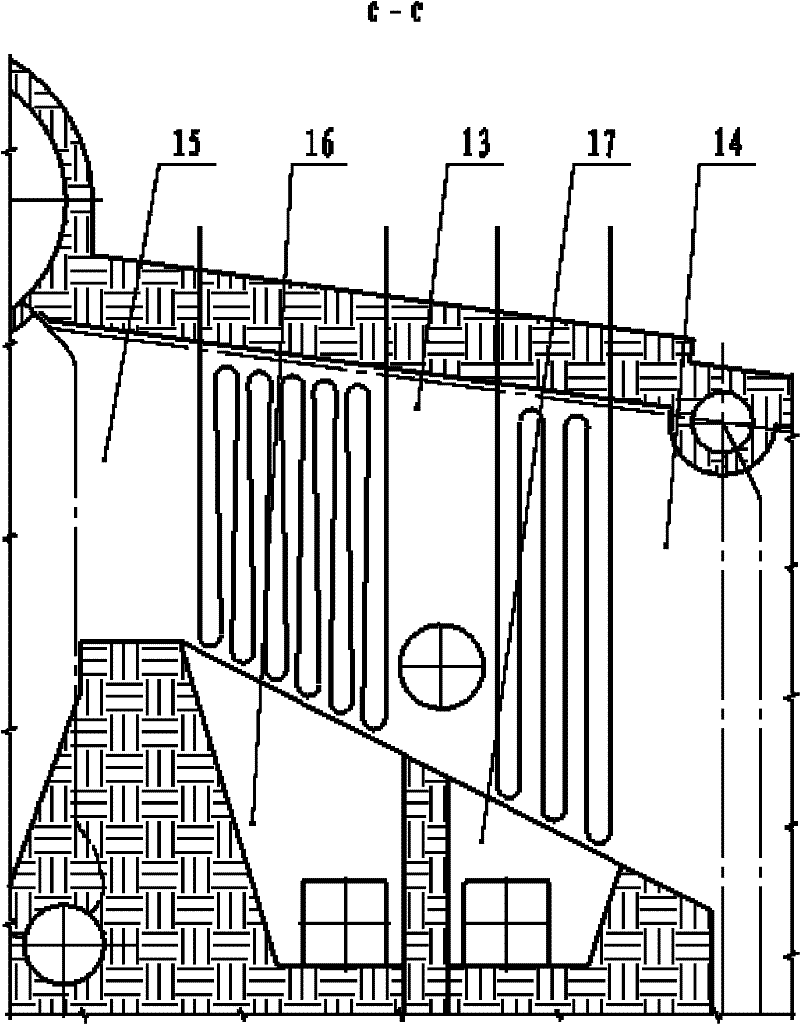

Boiler for generating power by combusting exhausting gas of yellow phosphorus

The invention discloses a boiler for generating power by combusting exhausting gas of yellow phosphorus, belonging to the field of boilers. A boiler body is integrally of as a novel boiler structure arranged in a horizontal n shape, a boiler convection tube bank and a boiler hearth are respectively arranged at the left side and the right side of the boiler body, an overheater is arranged in a transverse straight flue at the rear parts of the boiler convection tube bank and the hearth, and the boiler convection tube bank is a straight flue; because smoke linearly flows for scouring a tube, possibility of condensing various corrosive matters on the tube because the smoke generates a vortex zone at a corner is avoided; and the hearth is provided with a corrosion-preventing water-cooling wall and controls smoke temperature at an outlet of the boiler convection tube bank, corrosion related to the tube of the boiler body is reduced furthest completely due to the adoption of the boiler, problems of failure in an early phase and long service life caused by serious corrosion due to the adoption of the exhausting gas of yellow phosphorus as the fuel in the power generating boiler are solved actually, heat energy of the exhausting gas of yellow phosphorus is effectively recycled, energy resources are greatly saved and environment is favorably protected.

Owner:WUHAN TIANYUAN BOILER +1

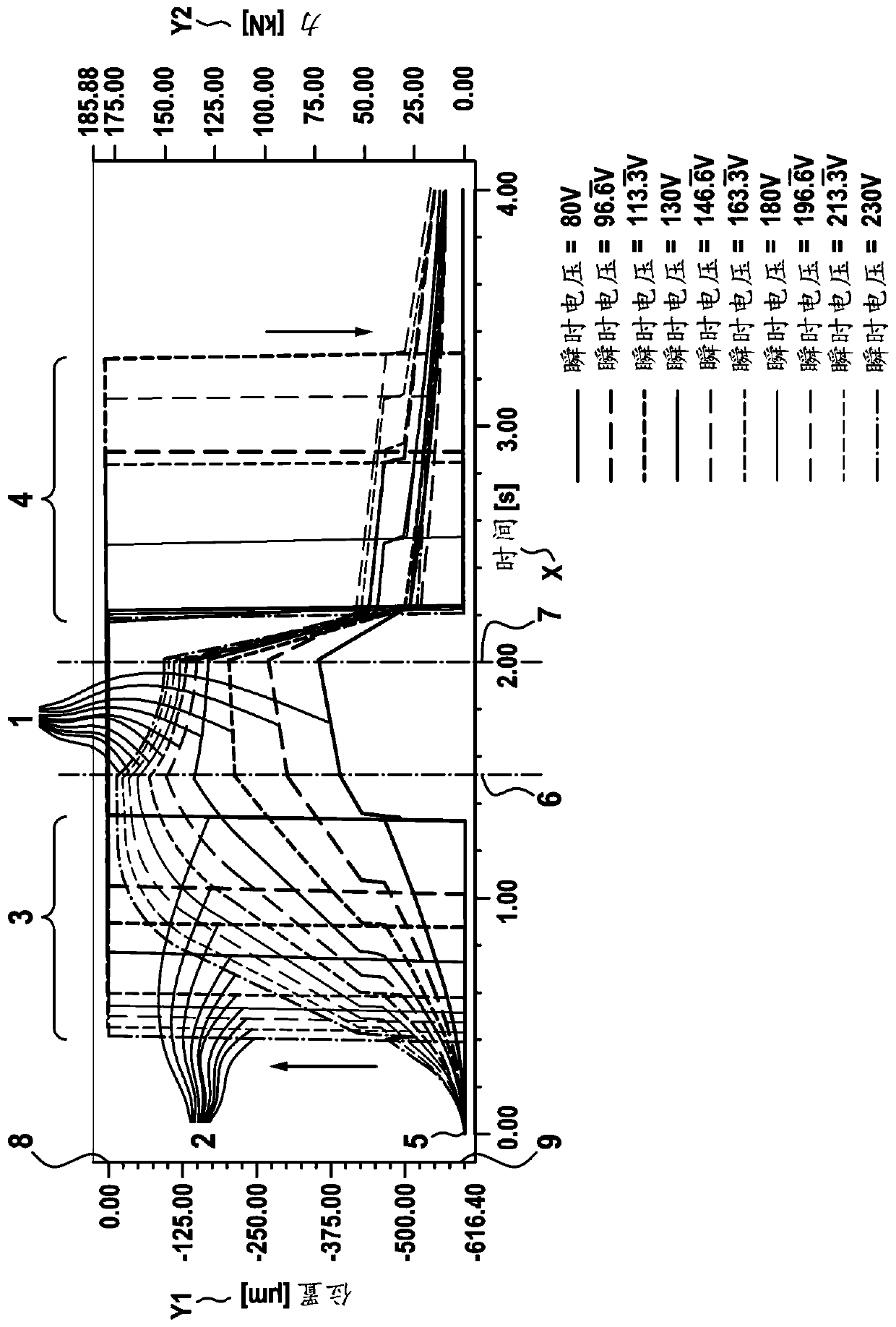

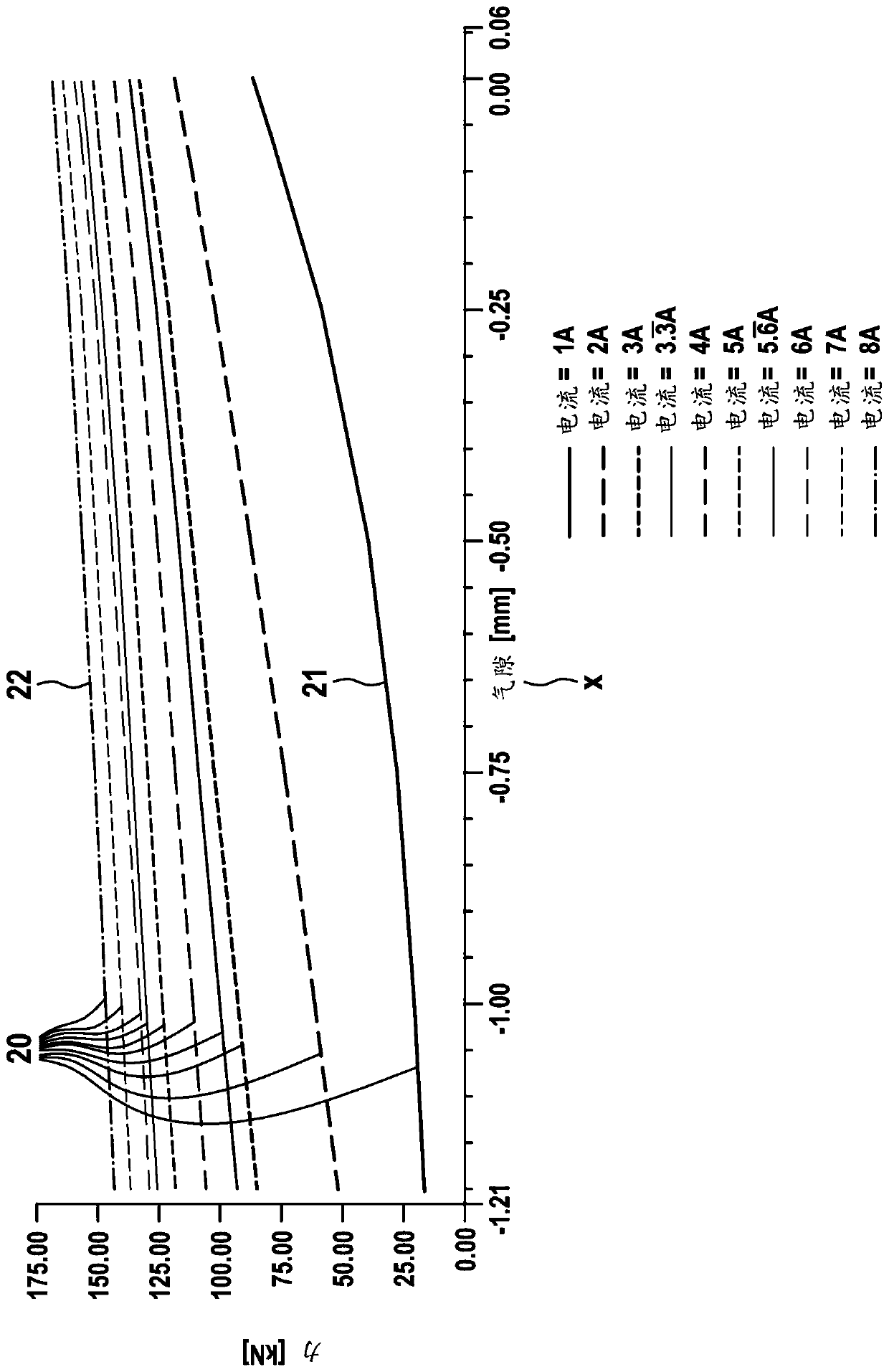

Method for diagnosis and/or maintenance of a brake of a transportation system, software program, and brake apparatus

The invention relates to a method for diagnosis and / or maintenance of a brake configured to apply braking force to a hoisting machine of a transportation system. The method comprises:- controlling thebrake to start a brake control action, e.g. an opening and / or a closing action of the brake;- monitoring the brake to detect a response of the brake to the brake control action, wherein in case of the response the response is detected in a predefined manner;- measuring a brake operating time interval from a first point in time of starting of the brake control action until a second point in time of monitoring the brake to detect the response; and,- if either the response has not been detected until the brake operating time interval reaches and / or exceeds a predetermined threshold or the response has been detected after the brake operating time interval reaches and / or exceeds the predetermined threshold, establishing an information indicating that an operation of the brake should be modified. Another aspect of the invention is a computer program realizing the method and a brake apparatus configured to execute the method.

Owner:KONE CORP

A water purification method based on ecological cages

InactiveCN104003523BAvoid the pitfalls of manipulationReduce biomassBiological water/sewage treatmentEutrophicationPurification methods

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Method for manufacturing biodegradable packaging material, biodegradable packaging material and a package or a container made thereof

A biodegradable packaging material, a method of manufacturing the same, as well as products made of the material wherein the manufacture comprises extrusion onto a fibrous substrate one or mote polymer coating layers including at least one layer of a polymer blend consisting of (i) 20-95 wt-% of polylactide having a high melt index of more than 35 g / 10 min (210° C.; 2.16 kg), (ii) 5-80 wt-% of polybutylene succinate (PBS) or a biodegradable derivate thereof, and (iii) 0-5 wt-% of one or more polymeric additives. The components of the blend are melted and blended in connection with the extrusion step. The goal is to improve extrudability, increase machine speed in extrusion and maintaining good adhesiveness to the substrate and wood heat-sealability of the coating. The products include disposable drinking cups and board trays, as well as sealed carton packages for solids and liquids.

Owner:STORA ENSO OYJ

PDA automatic power-off method

InactiveCN107479680AKeep runningThermometer detailsVolume/mass flow measurementSensor arraySimulation

The invention relates to a PDA automatic power-off method. The method includes the steps that a PDA automatic power-off platform is provided and used, and the platform includes temperature sensing equipment, timing equipment, a first sensor array and a second sensor array; the temperature sensing equipment is used for detecting and outputting the real-time temperature of the environment where intelligent equipment is positioned as the real-time environmental temperature, the timing equipment is used for providing real-time timing signals, the first sensor array is arranged above the intelligent equipment and used for conducting image data collection on the upper scene of the intelligent equipment to obtain and output first on-site images, and each sensor in the first sensor array outputs a high-definition real-time image; the second sensor array is arranged above the intelligent equipment and used for conducting image data collection on the upper scene of the intelligent equipment to obtain and output second on-site images, and each sensor in the second sensor array outputs a high-definition real-time image.

Owner:NANYANG NORMAL UNIV

Method of detecting phase difference, phase detector for performing the same and clock-and-data recovering device including the phase detector

InactiveUS20050017758A1Reduce jitterImprove featuresPulse automatic controlVoltage-current phase anglePhase detectorPhase difference

First and fourth phase difference signals, and first and second phase difference information signals respectively having first, fourth, second and third phase differences may be generated using an input signal and a plurality of clock signals each of which has different phase with each other. A level of the first phase difference information signal may be lowered, and a second phase difference signal having a first level less than levels of the first and fourth phase difference signals may be generated. A level of the second phase difference information signal may be lowered, and a third phase difference signal having a second level less than the levels of the first and fourth phase difference signals may be generated. The level of the phase difference signals having a phase difference lower than 45° may be lowered, and thus the operational speed of a CDR device may be maintained and / or the jitter characteristics may be enhanced.

Owner:SAMSUNG ELECTRONICS CO LTD

A processing system and process of soybean meal for feed

The invention discloses a processing system and process of soybean meal for feed, and relates to the technical field of feed processing. The processing system includes a hot blast furnace, a monolithic processing line and a powder processing line; the monolithic processing line includes sequentially connected first drum-type feed drying Dryer, the first pulverizer, the first screening machine and the first drying mechanism, the powder processing line includes the second pulverizer, the second drum feed dryer, the second screening machine and the second drying mechanism connected in sequence mechanism. The soybean meal processing system for feed provided by the present invention adopts the processing mode of one furnace for multiple lines, which reduces the energy consumption of the equipment under the premise of ensuring the drying effect; the whole material processing line and the powder processing line are set at the same time, which can The moisture content of the raw materials is different, and the corresponding production line is selected to meet the processing needs of soybean meal raw materials with different moisture contents; at the same time, multiple production lines can be used together to keep the equipment in operation as a whole, and will not cause problems due to the uneven moisture content of soybean meal raw materials. Equipment down.

Owner:广东省佰益科技有限公司

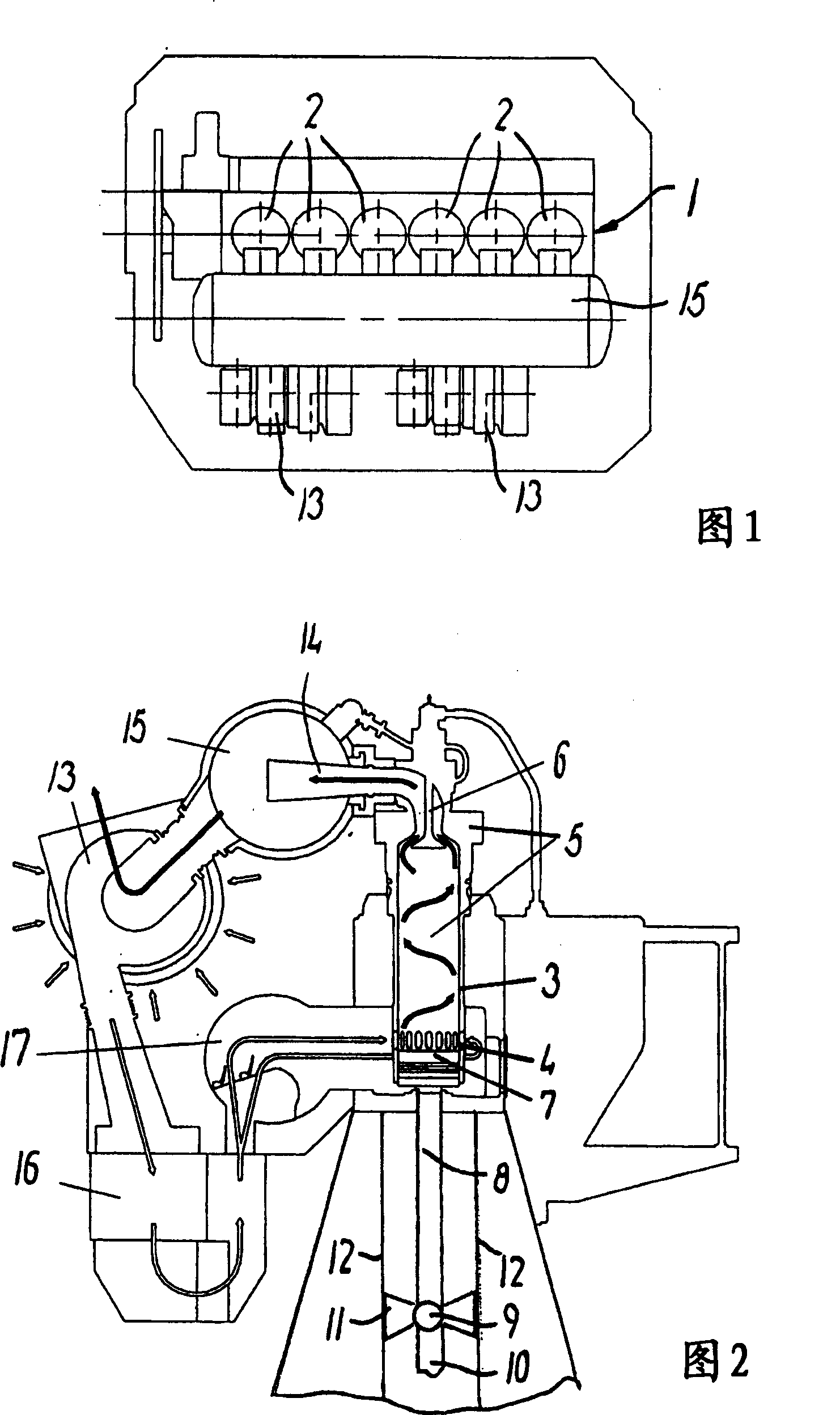

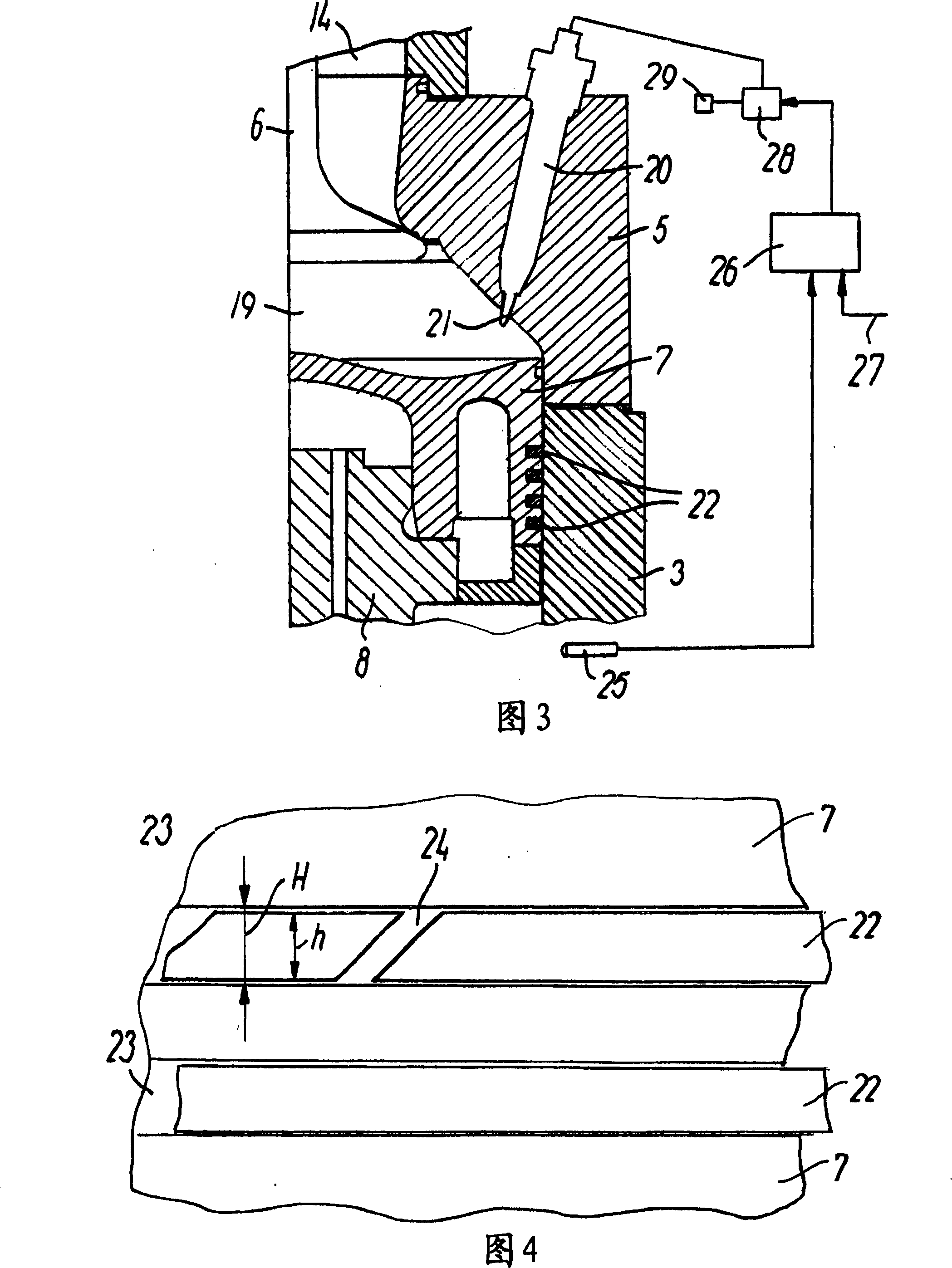

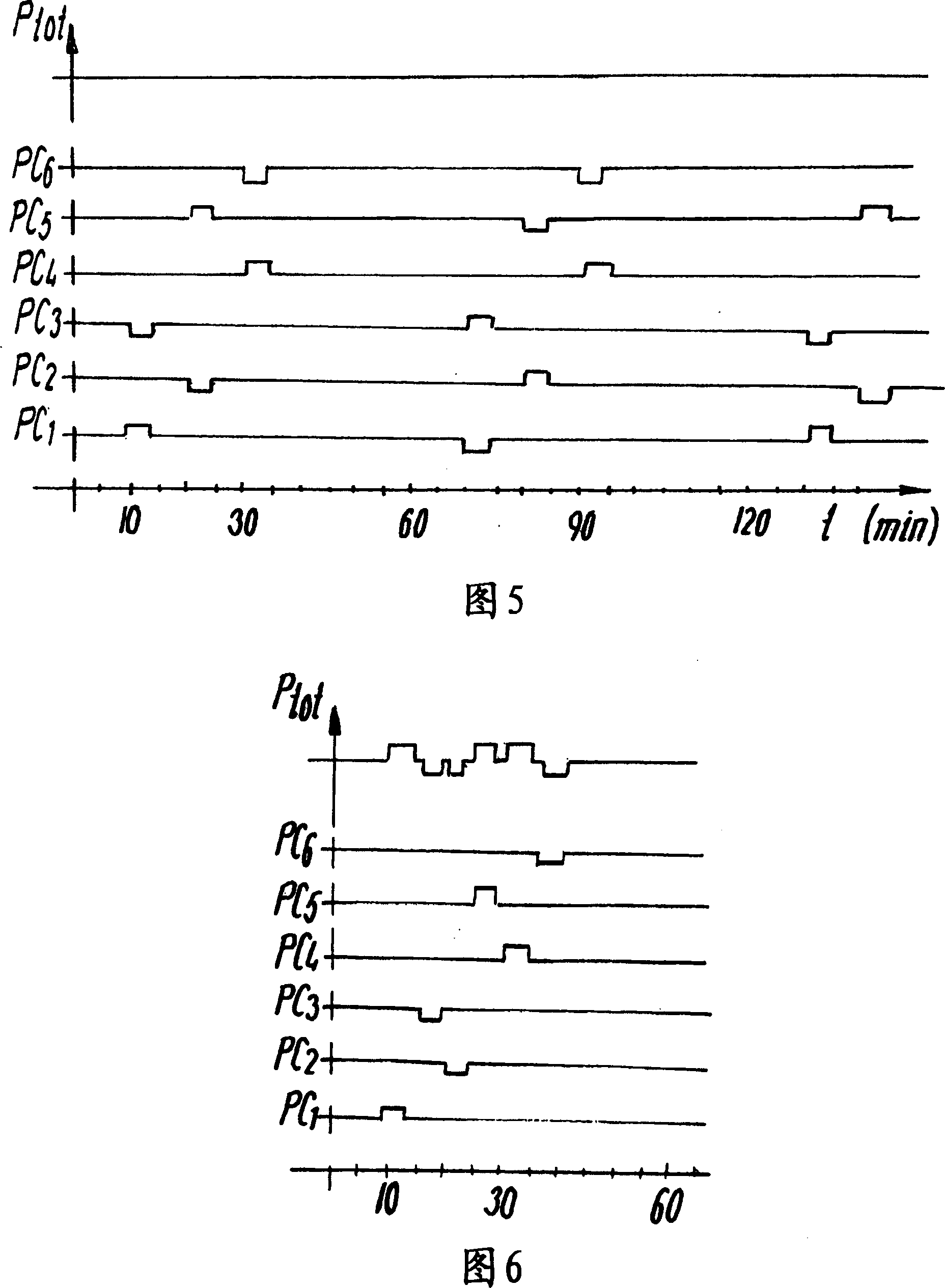

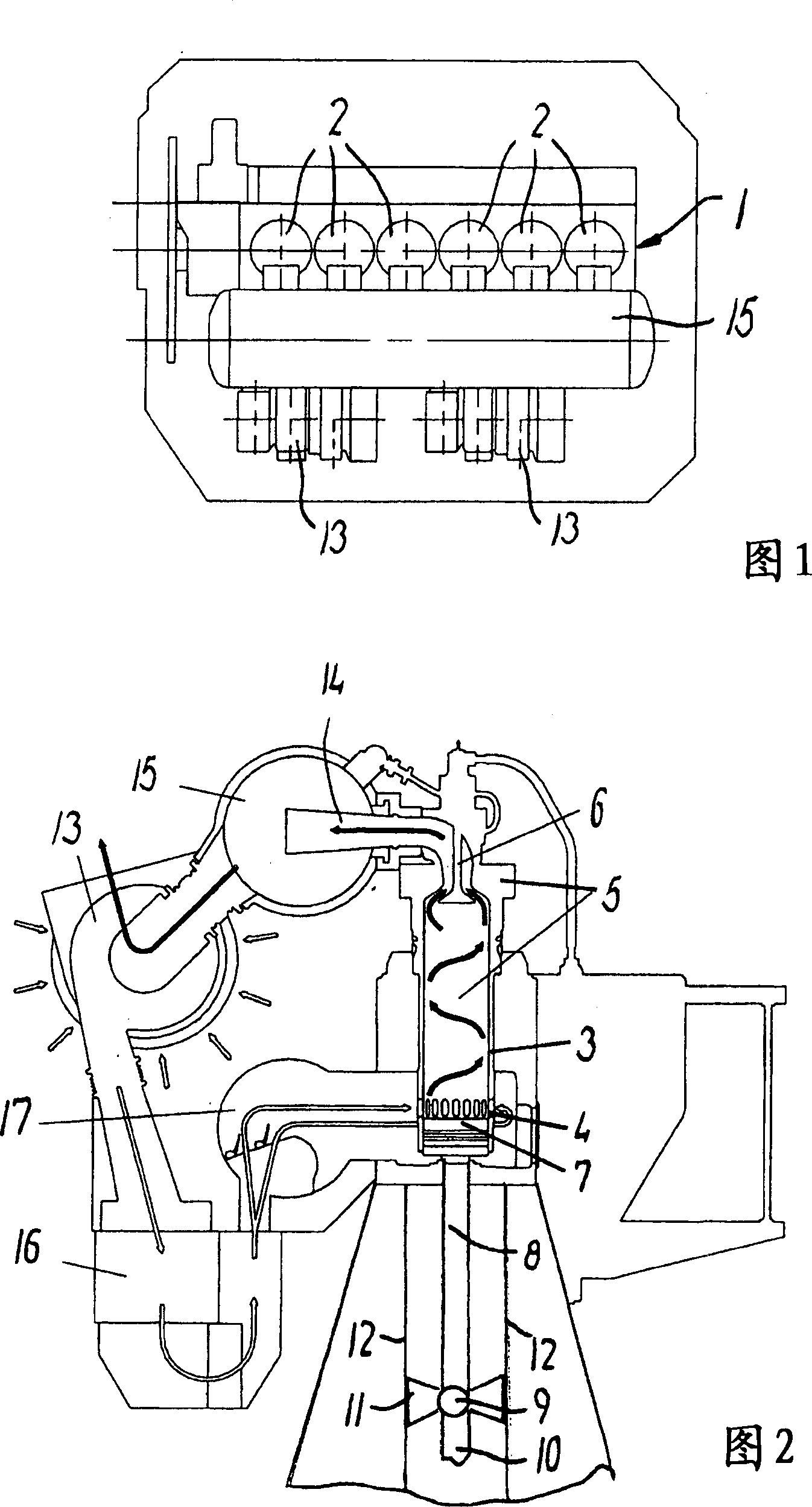

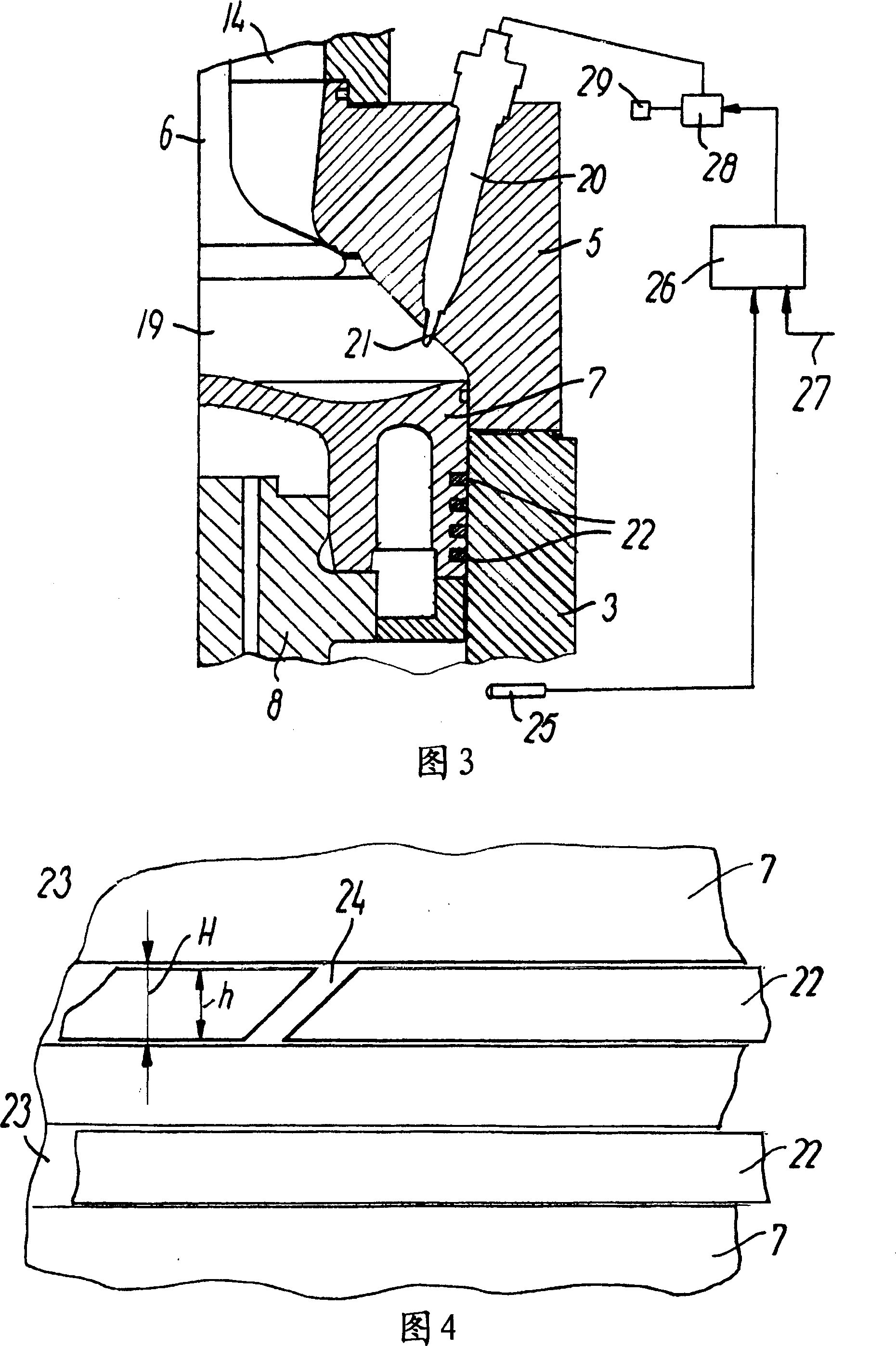

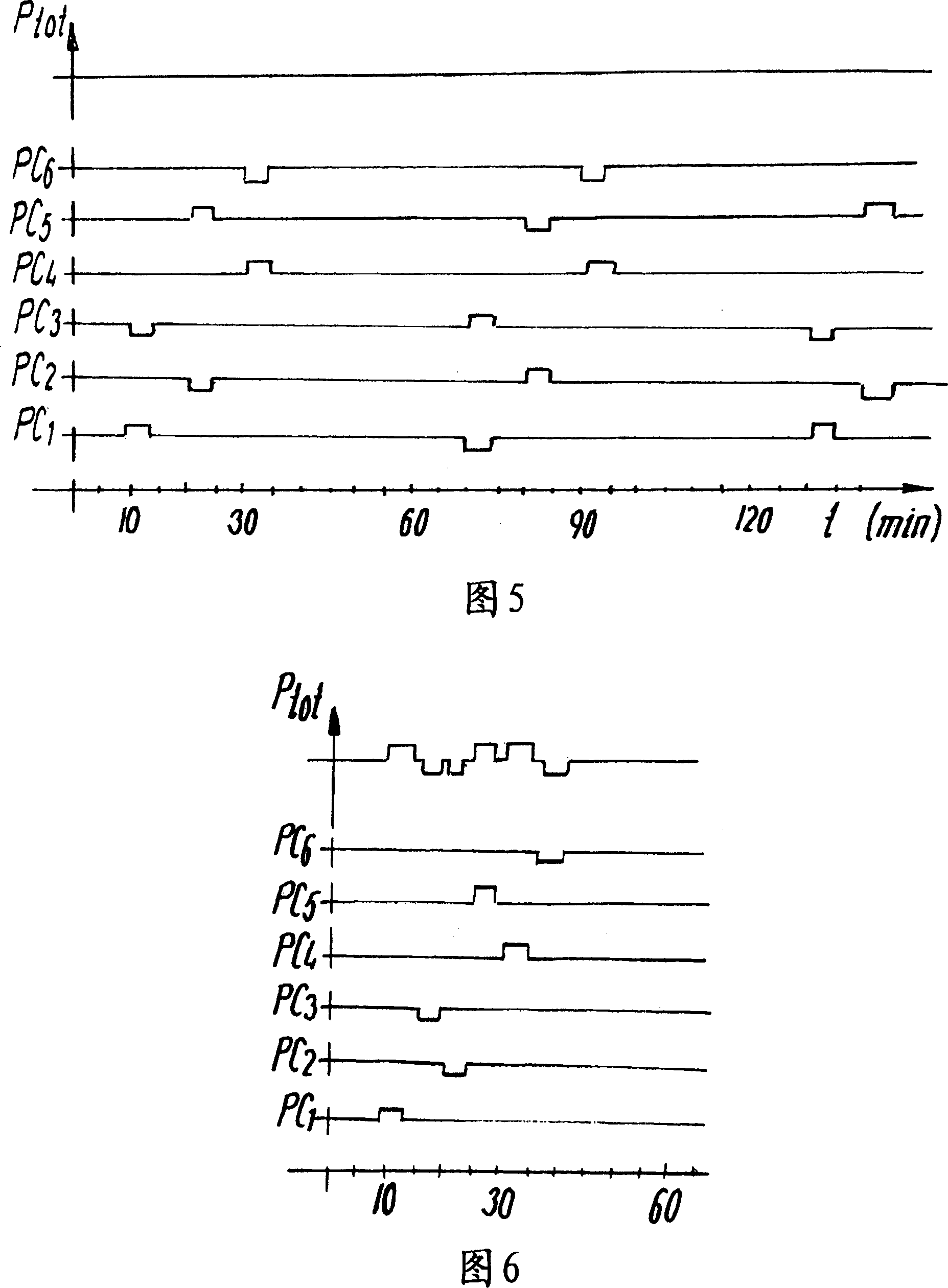

Method for forcibly changing rotating position of piston ring and cross-type two-stroke diesel engine

In a crosshead type two-stroke internal combustion engine, the rotation position of piston ring relative to adjacent piston is forcibly changed in the below way. Because the engine is set to continuously run at preset constant load or constant speed, the forcible change of the rotation position of piston in cylinder is effected by at least load fluctuation on the cylinder, so that the mean effective pressure in the cylinder changes at least 0.5bar, and is effected by keeping the changed load for a certain time in the said cylinder.

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

Method for collecting blue algae and purifying water quality

InactiveCN102219308BControl biomassImprove water qualityBiological water/sewage treatmentWater sourceWater quality

The invention discloses a method for collecting blue algae and purifying water quality by breeding algae-eating fishes in a water body. The method provided by the invention is characterized in that a plurality of uniformly distributed net cages used for breeding algae-eating fishes are arranged in an algae-controlling water area; the bottom of each net cage is equipped with a fish manure collector which is made from a dense net; the algae-eating fishes are bred in the net cages; and an algae manure interception net is arranged on the edge of the water area in which the net cages are disposed.According to the invention, the algae manure interception net, a fish-interception and blue algae-capture module and an ecological floating-island water quality purification module are arranged in local water areas, so as to effectively control the biomass of blue algae in water source areas, effectively reduce the content of N and P in a water body, improve the safety of water consumption, and obtain the cycling support economically.

Owner:ANHUI AGRICULTURAL UNIVERSITY

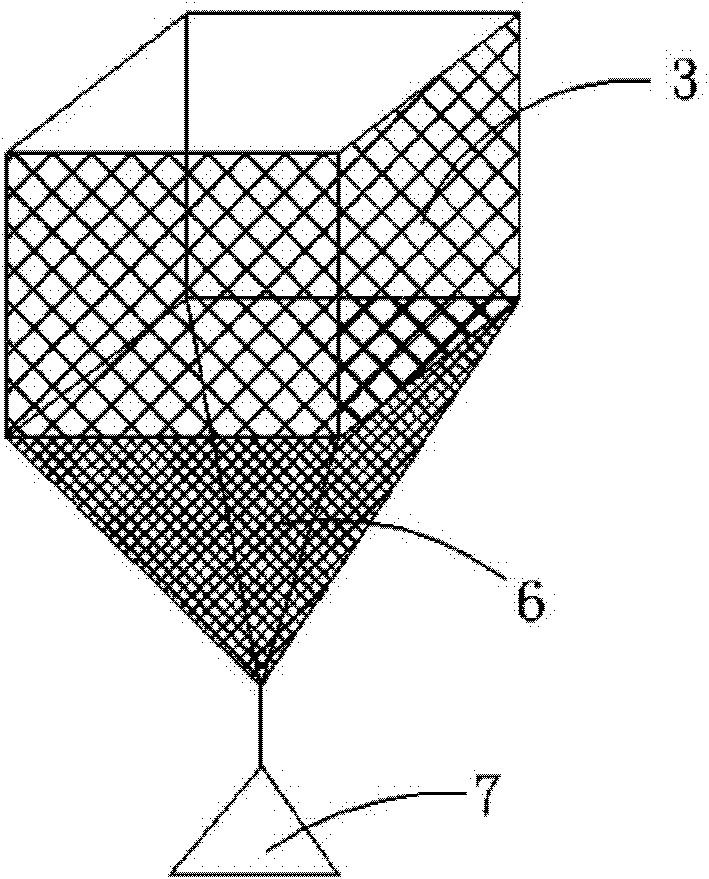

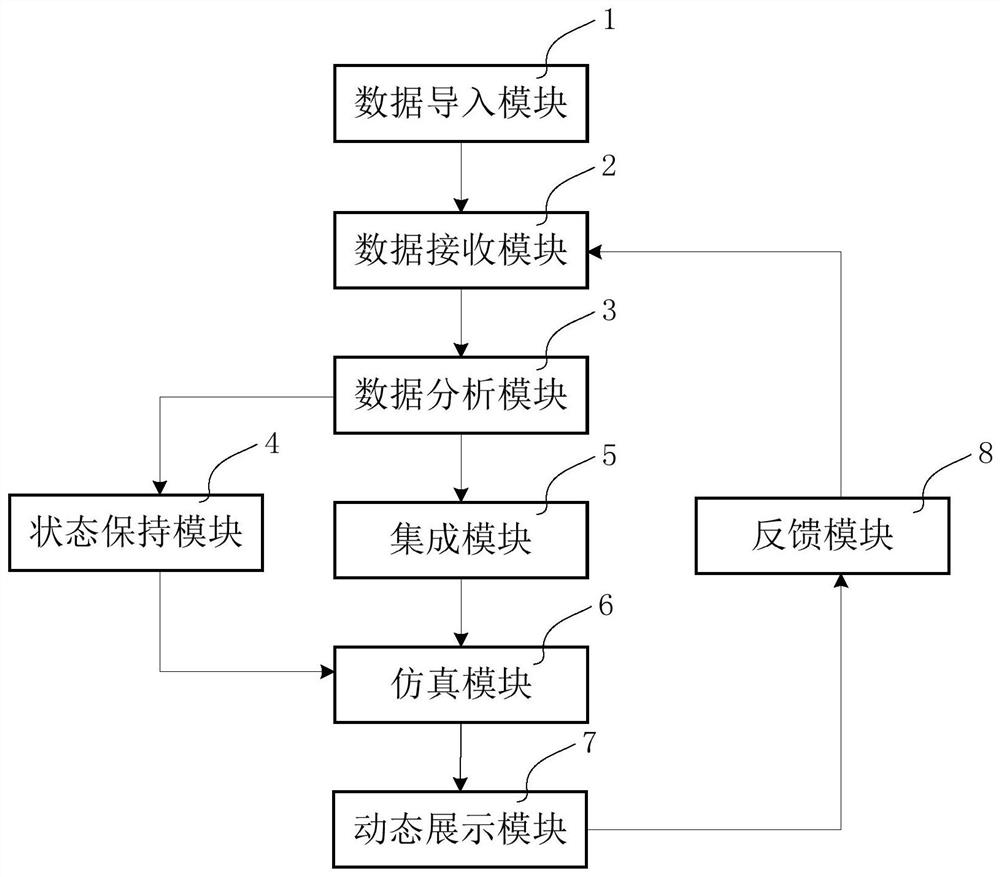

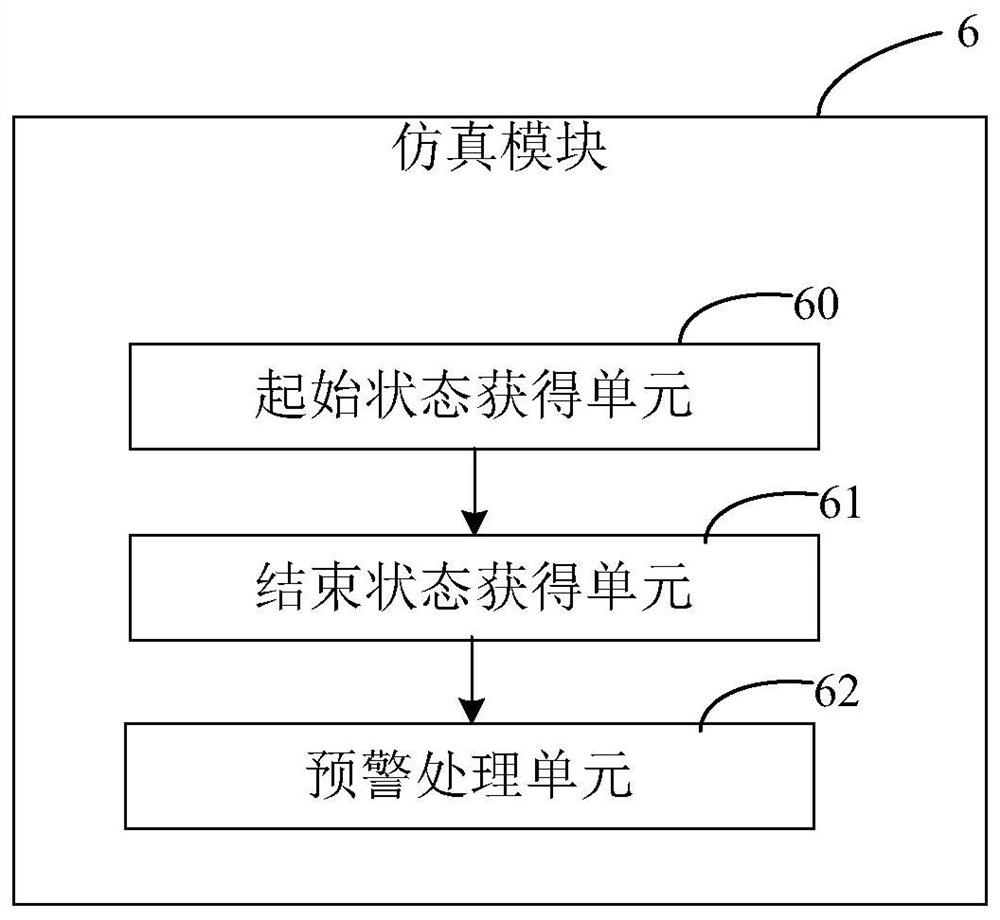

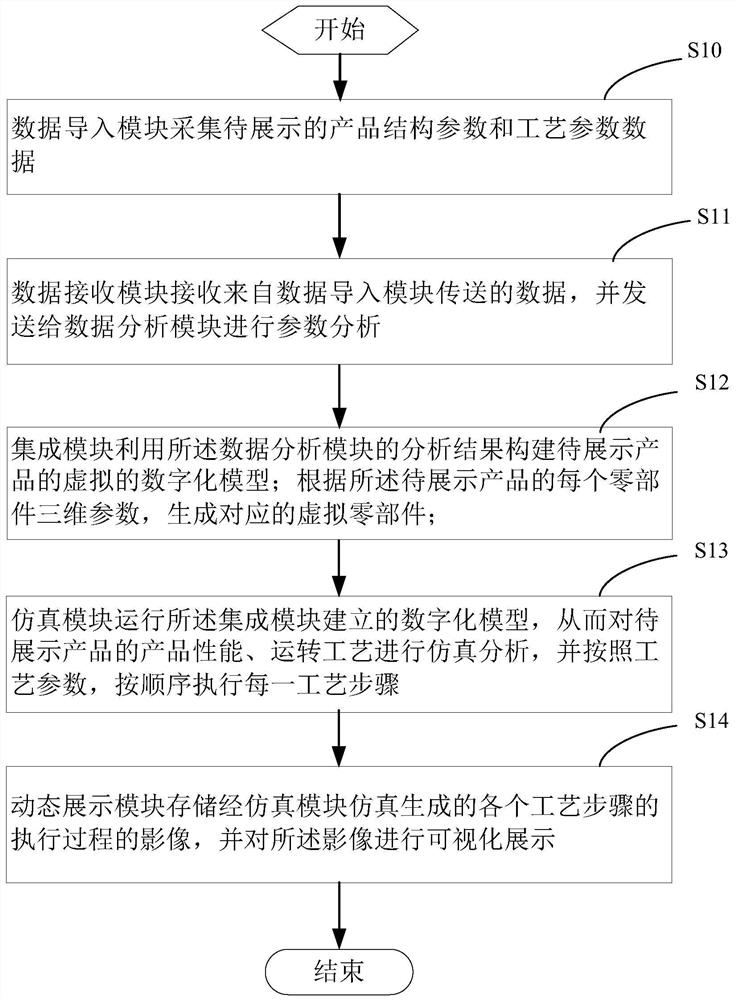

Model display system and method based on digital twinborn technology

PendingCN113627031AMaintain Integrity and IndependenceKeep runningDesign optimisation/simulationSpecial data processing applicationsDynamic displayParameter analysis

The invention discloses a model display system based on a digital twinning technology. The system comprises a data import module, a data receiving module, a data analysis module, an integration module, a simulation module and a dynamic display module, wherein an operator imports data such as performance and operation process of a product into the data import module, the data receiving module receives the data from the data import module and then transmits the data to the data analysis module, the data analysis module analyzes product parameters and then establishes a virtual model of a product by using a digital twinning technology in the integration module, and after the model is established, the simulation module dynamic display module is used for dynamically displaying the operation process of the product. The invention further discloses a corresponding method. By implementing the invention, the model display efficiency can be improved, and the workload of model adjustment can be reduced.

Owner:SHENZHEN POWER SUPPLY BUREAU

Method for forcibly changing rotating position of piston ring and cross-type two-stroke diesel engine

In a crosshead type two-stroke internal combustion engine, the rotation position of piston ring relative to adjacent piston is forcibly changed in the below way. Because the engine is set to continuously run at preset constant load or constant speed, the forcible change of the rotation position of piston in cylinder is effected by at least load fluctuation on the cylinder, so that the mean effective pressure in the cylinder changes at least 0.5bar, and is effected by keeping the changed load for a certain time in the said cylinder.

Owner:MAN DIESEL & TURBO FILIAL AF MAN DIESEL & TURBO SE TYSKLAND

Low power storage device in which operation speed is maintained

ActiveUS9729149B2Reduce power consumptionRun at high speedPower reduction in field effect transistorsDigital storageLogic elementOxide semiconductor

Owner:SEMICON ENERGY LAB CO LTD

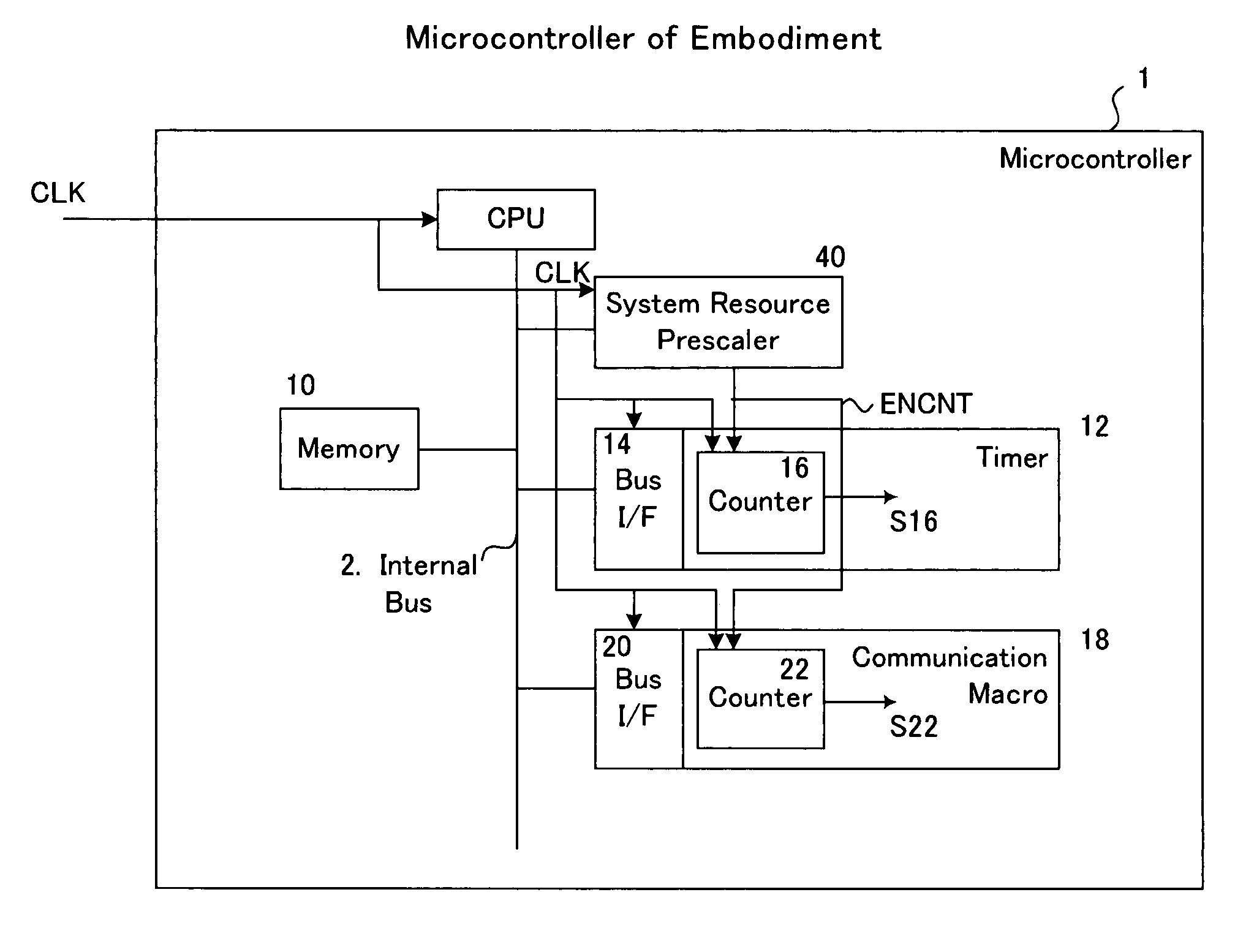

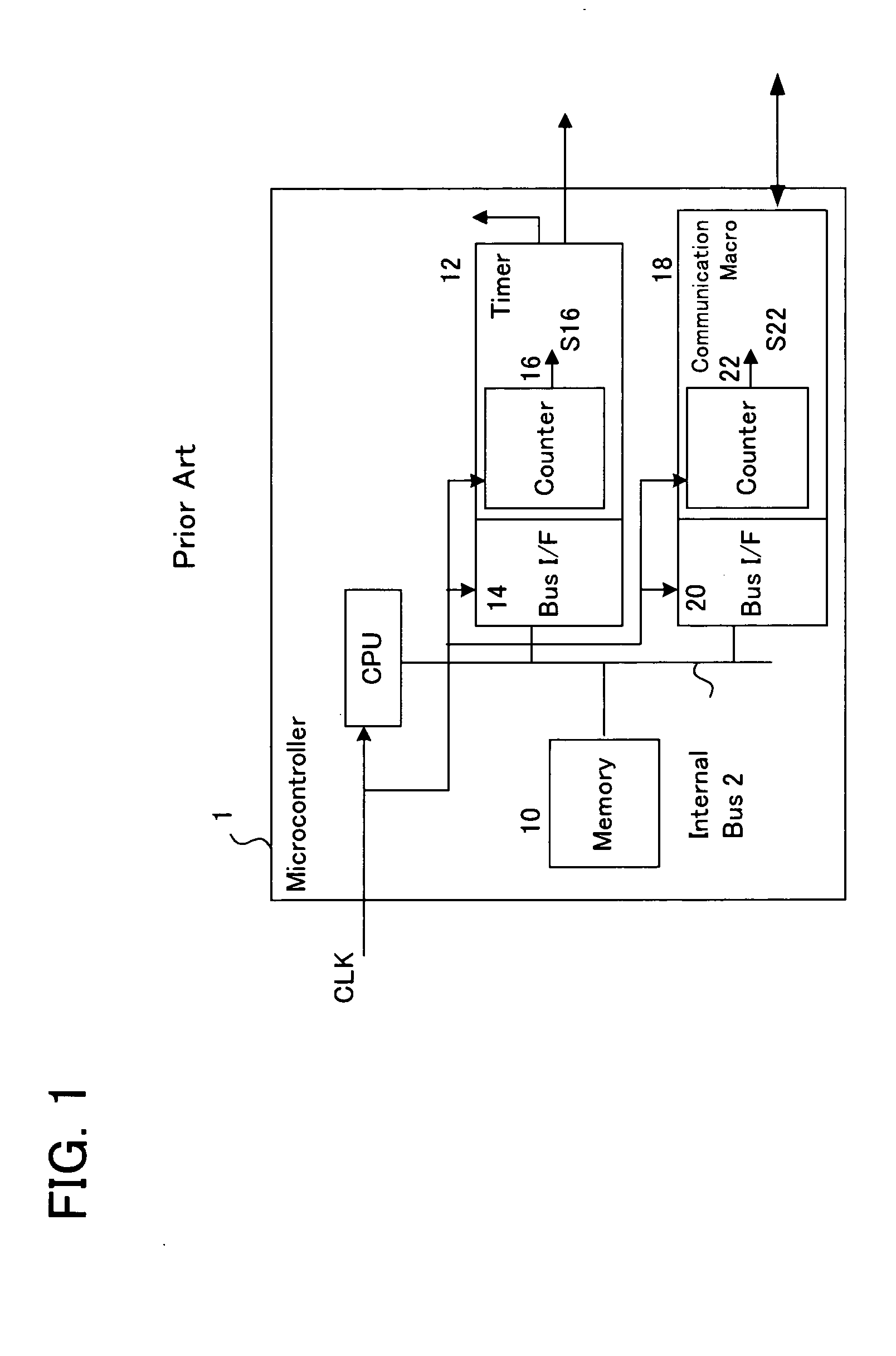

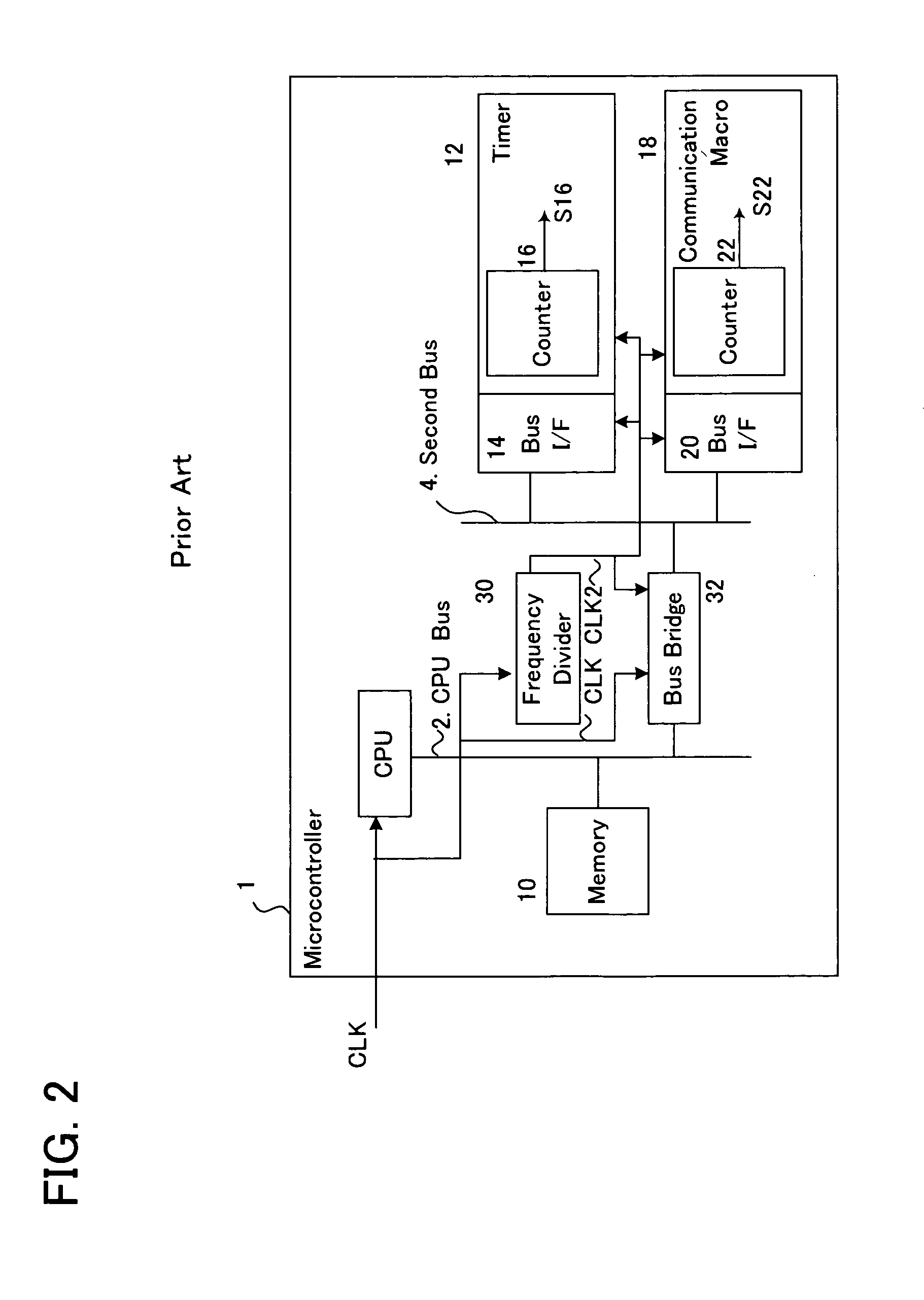

Microcontroller havng a system resource prescaler thereon

InactiveUS20050080826A1Keep runningGenerating/distributing signalsArchitecture with single central processing unitMicrocontrollerBus interface

A microcontroller operating in synchronization with clock includes: an arithmetic unit operating in synchronization with the clock; an internal resource being connected to the arithmetic unit via a bus, and having at least a bus interface, and an internal circuit operating in synchronization with the clock; and a system resource prescaler which generates from the clock an operation permission signal denoting an operation permission state in m cycles out of n cycles of the clock (m=<n), and supplies the operation permission signal to the internal circuit of the internal resource. The above-mentioned internal circuit operates in synchronization with the clock when the operation permission signal denotes the operation permission state.

Owner:MONTEREY RES LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com