Patents

Literature

85 results about "Mean effective pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The mean effective pressure is a quantity relating to the operation of a reciprocating engine and is a valuable measure of an engine's capacity to do work that is independent of engine displacement. When quoted as an indicated mean effective pressure or IMEP (defined below), it may be thought of as the average pressure acting on a piston during the different portions of its cycle.

Lubricating oil compositions

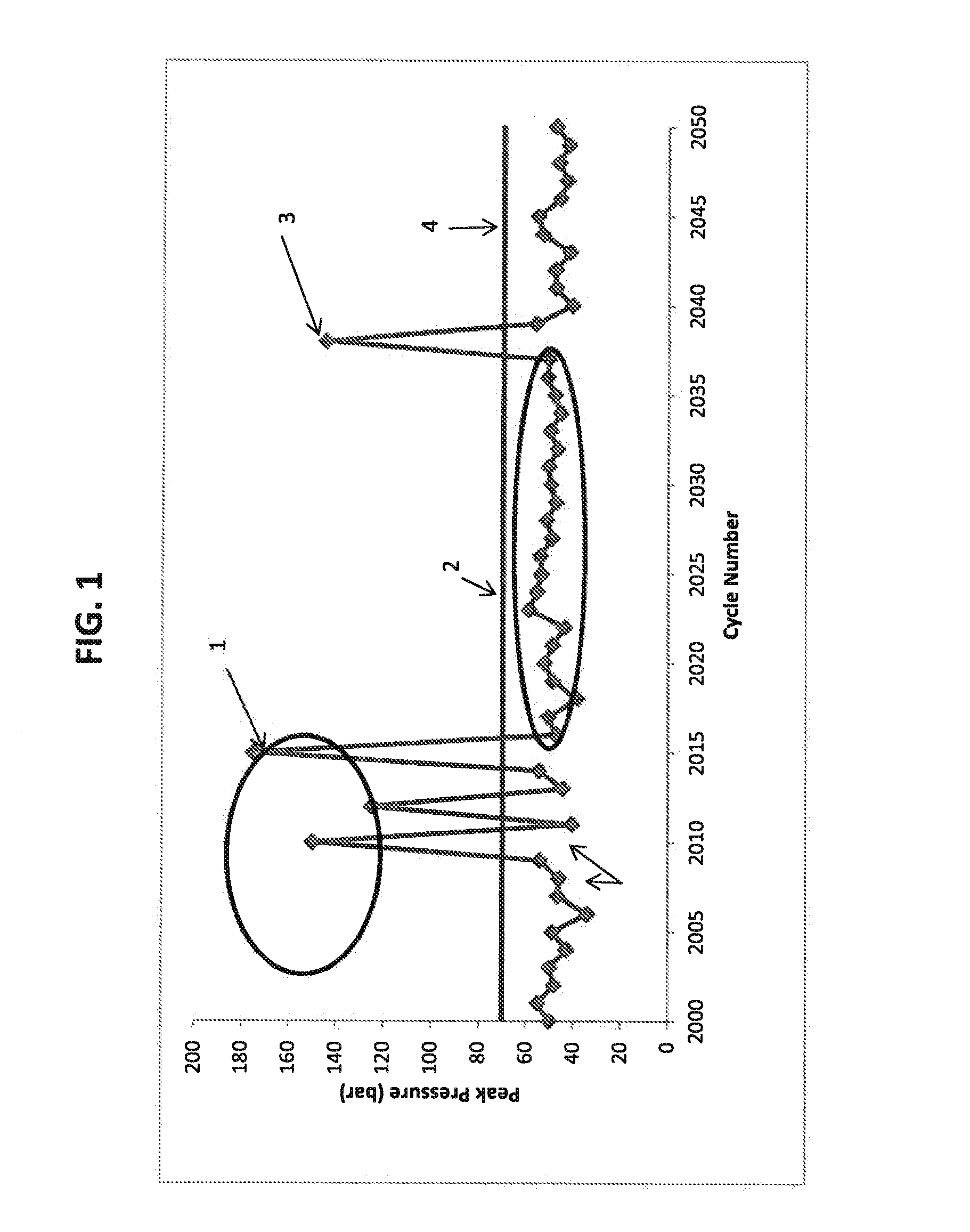

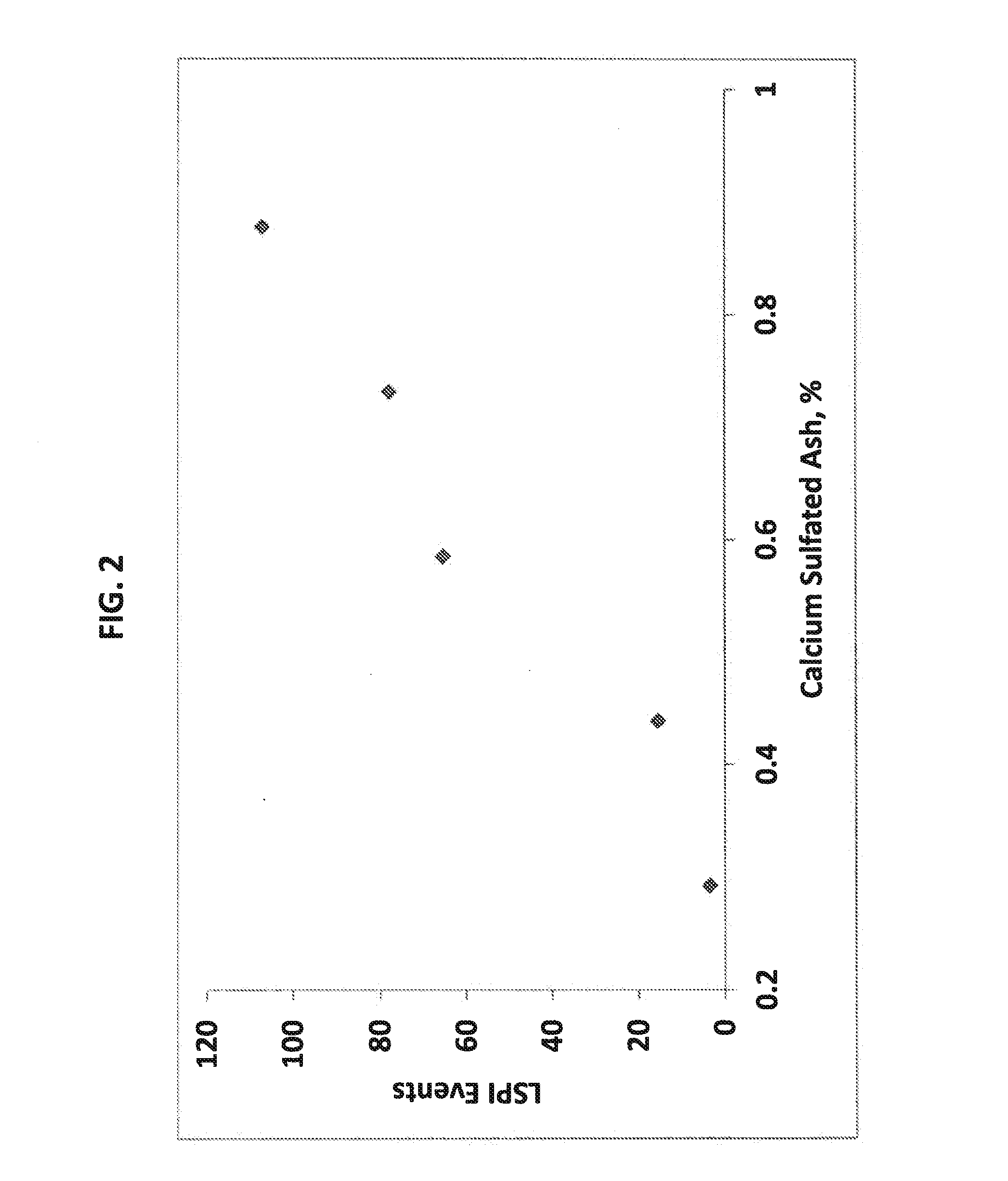

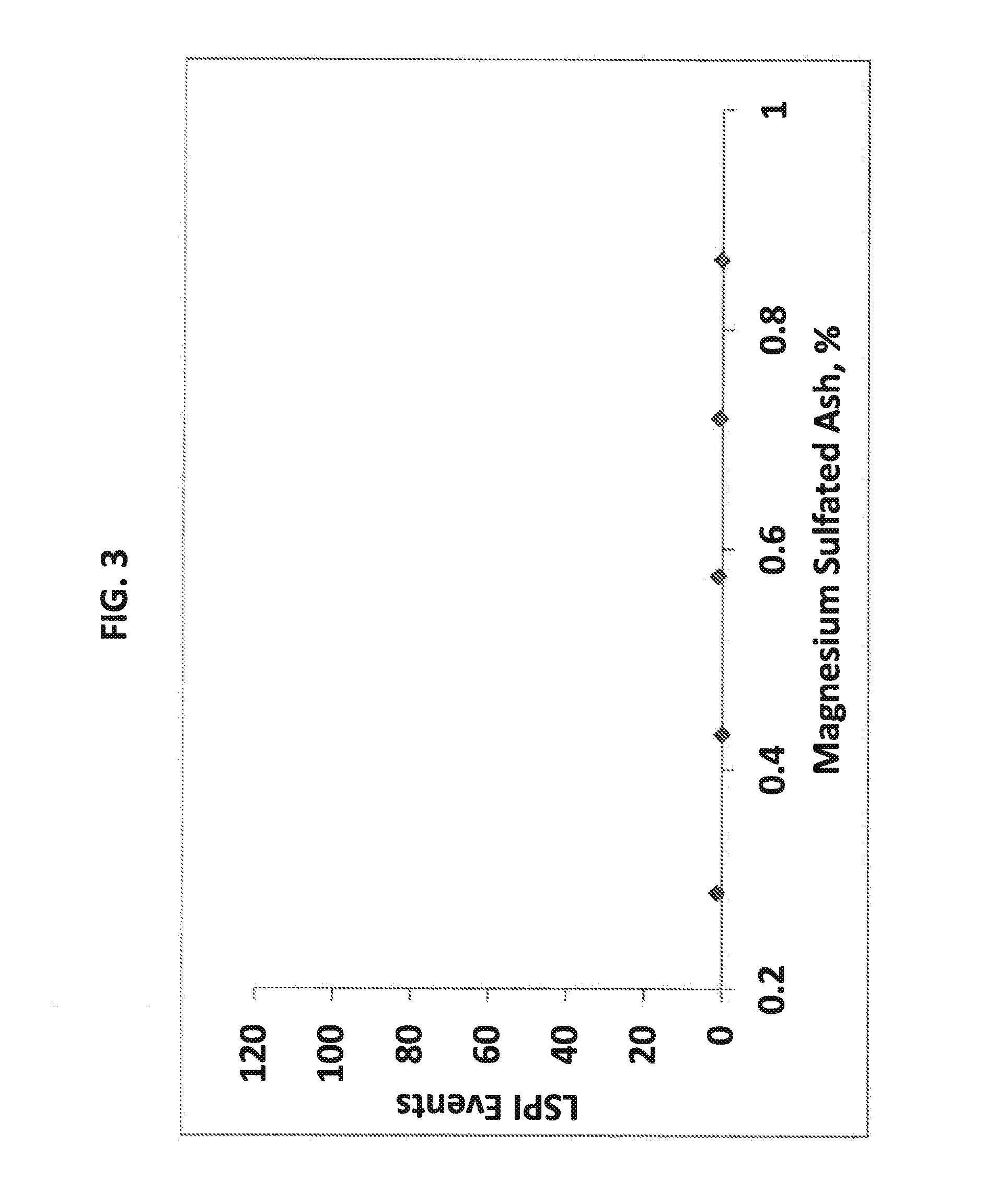

A method of preventing or reducing the occurrence of Low Speed Pre-Ignition (LSPI) in a direct-injected, boosted, spark-ignited internal combustion engine that, in operation, generates a break mean effective pressure level of greater than about 15 bar, at an engine speed of from about 1500 to about 2500 rotations per minute (rpm), in which the crankcase of the engine is lubricated with a lubricating oil composition containing at least about 0.2 mass % of magnesium sulfated ash.

Owner:INFINEUM INT LTD

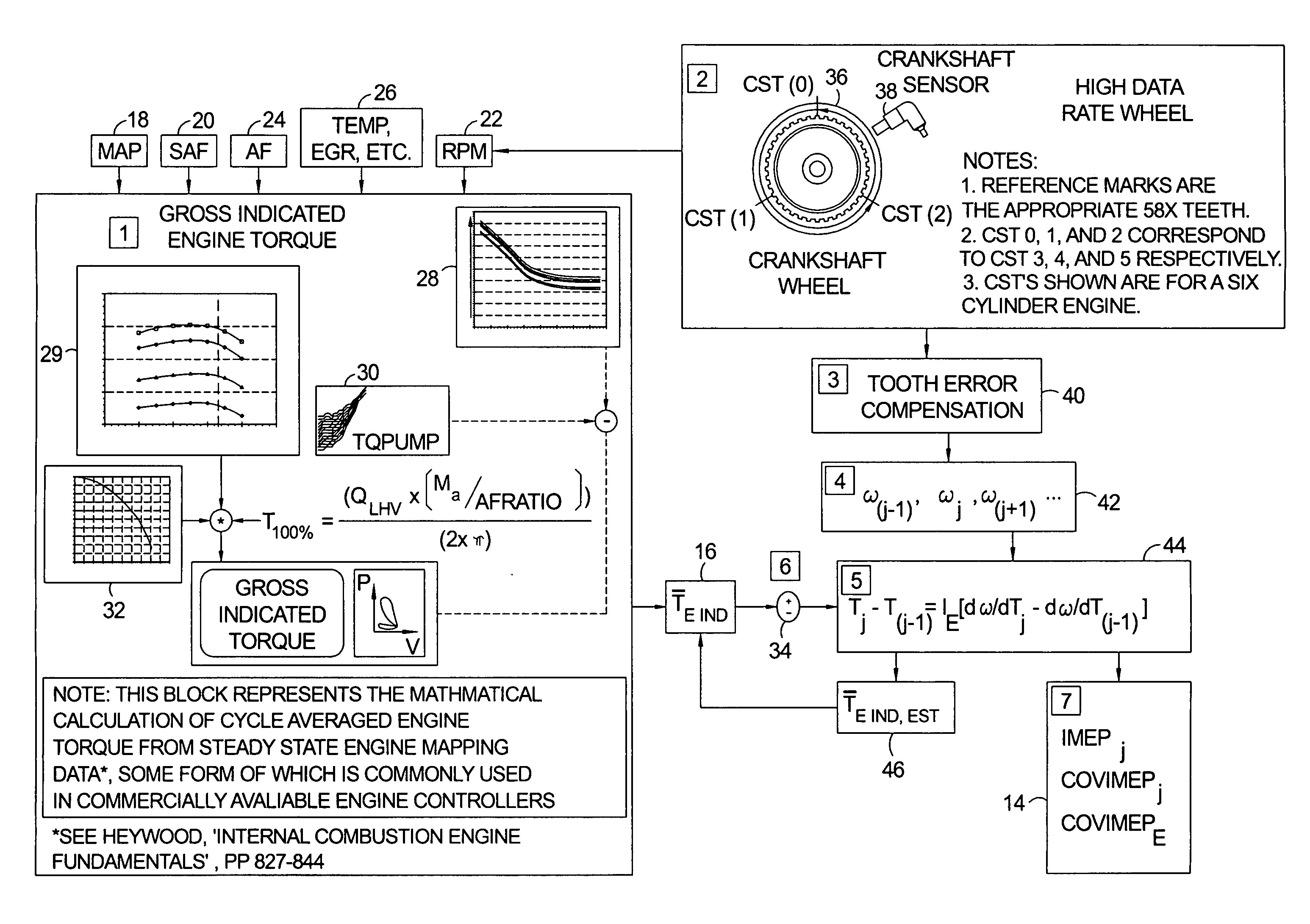

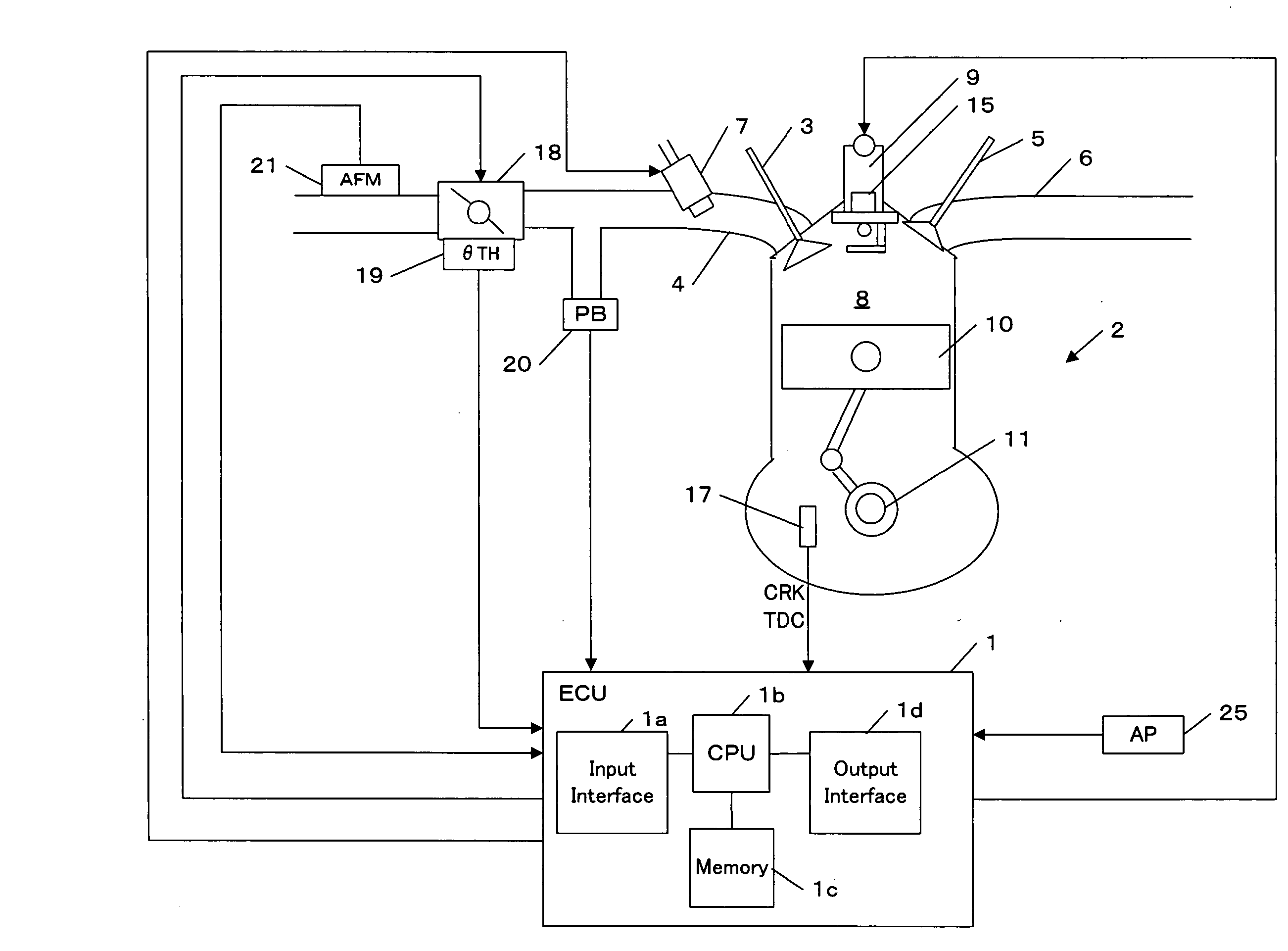

Method for estimation of indicated mean effective pressure for individual cylinders from crankshaft acceleration

ActiveUS20090276143A1Eliminates expense and intrusivenessDecrease in levelAnalogue computers for vehiclesElectrical controlInternal combustion engineMechanics

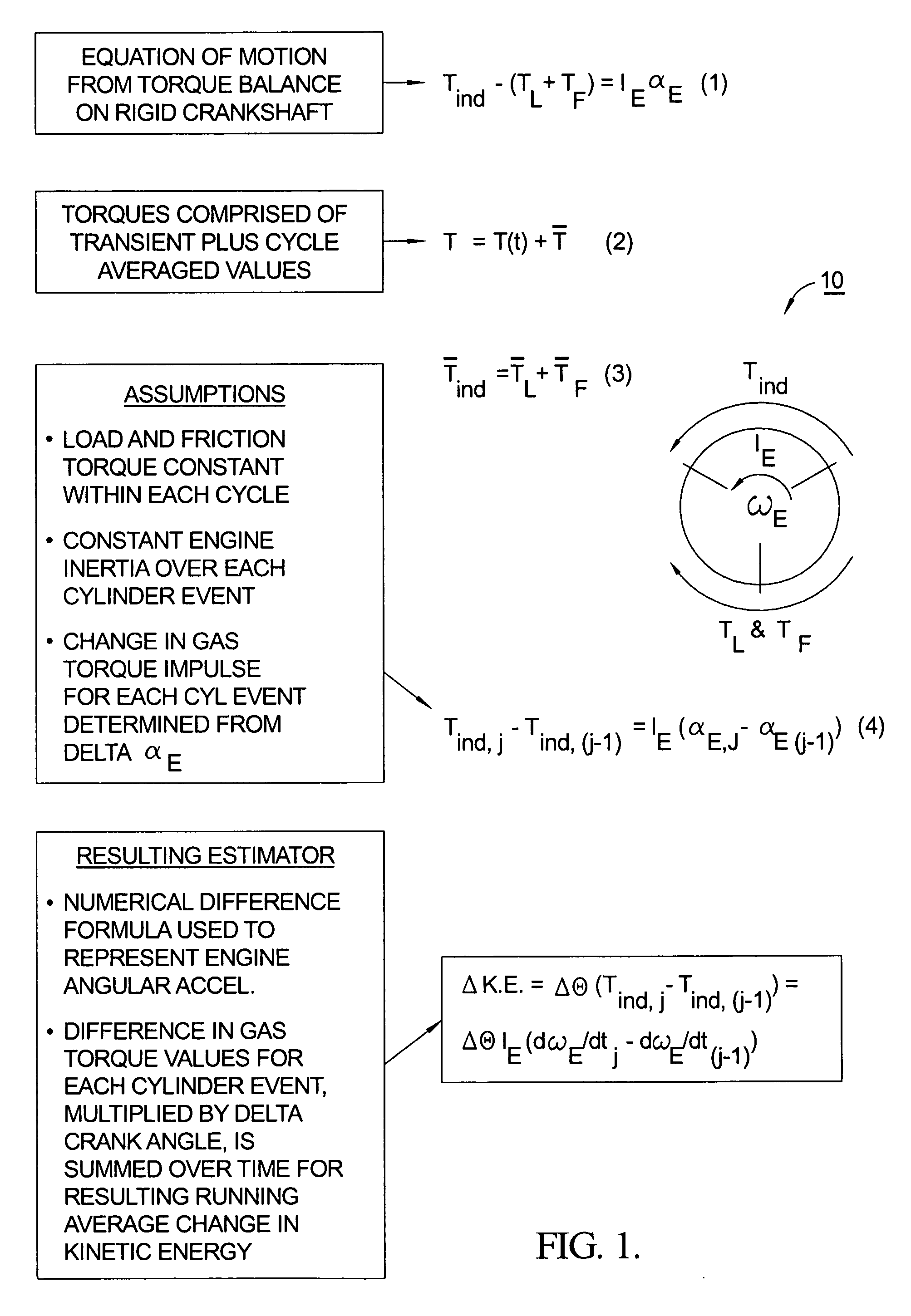

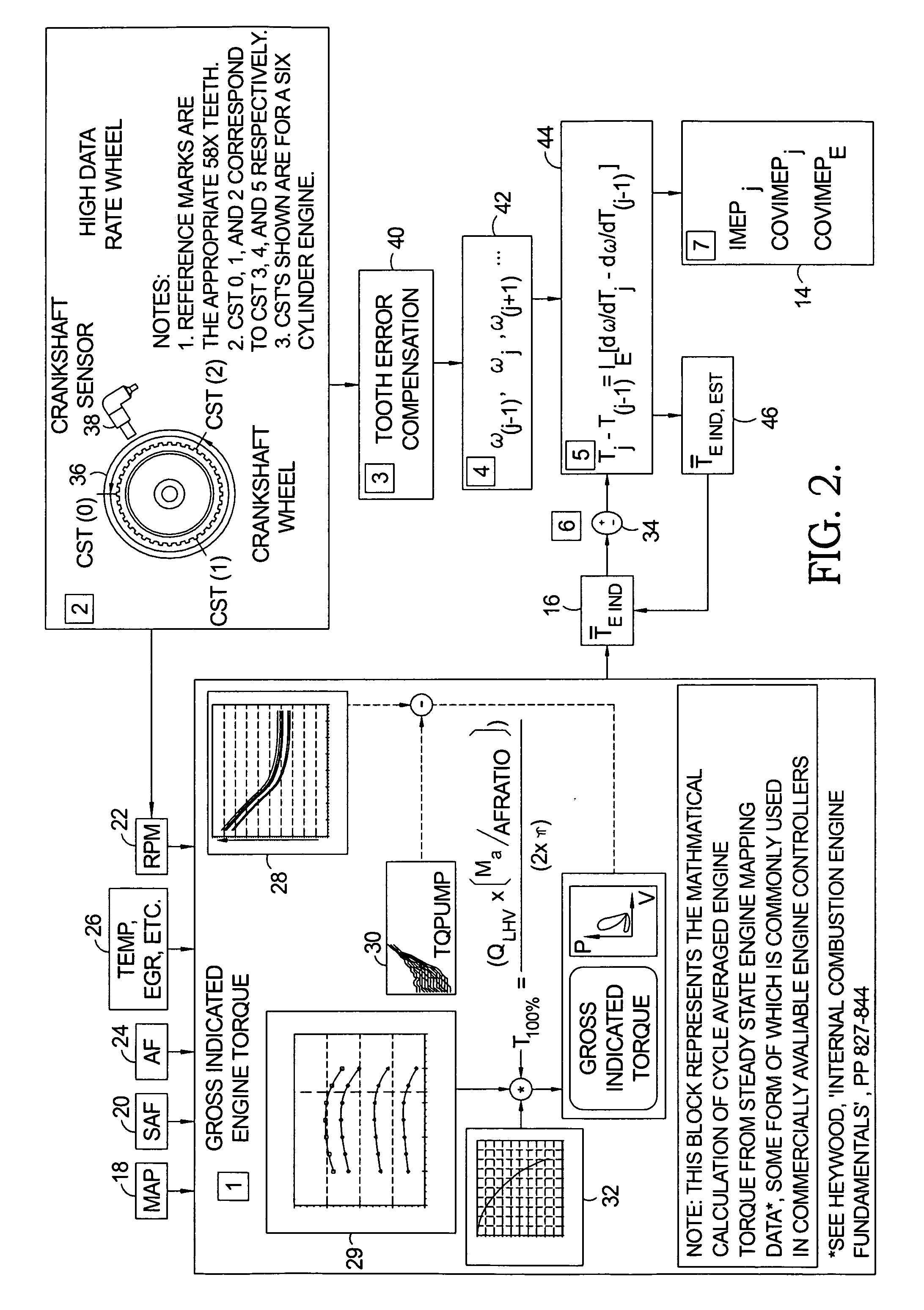

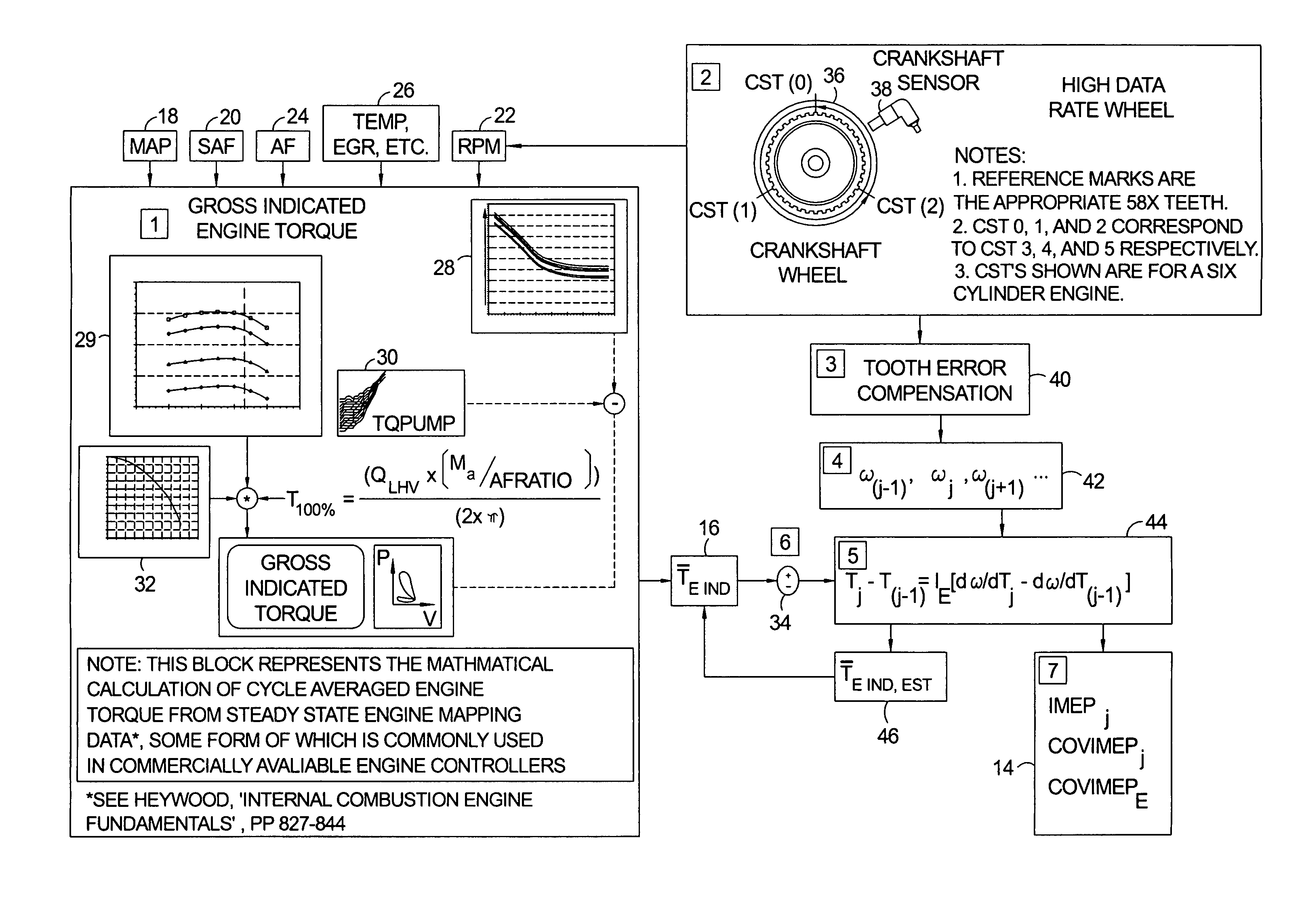

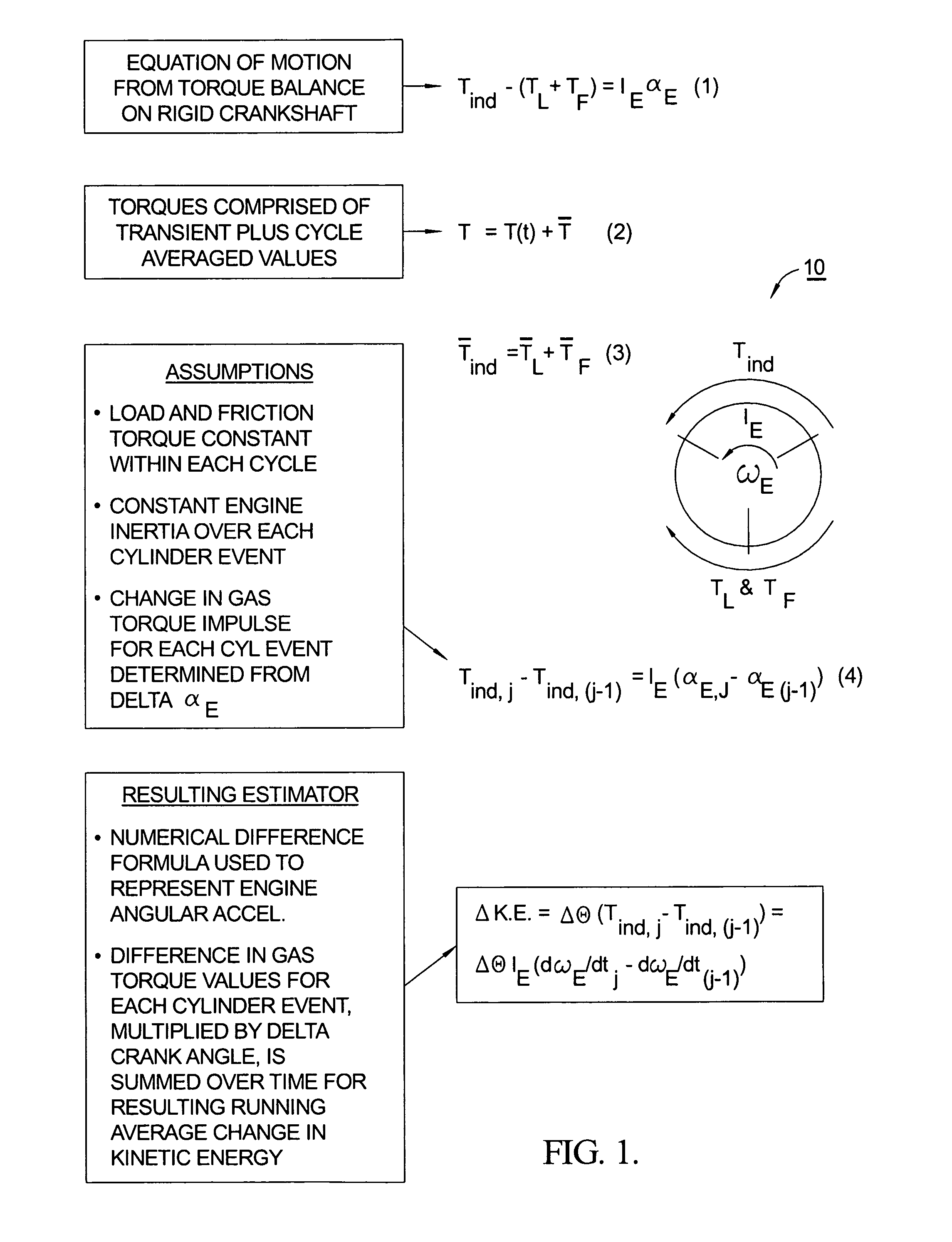

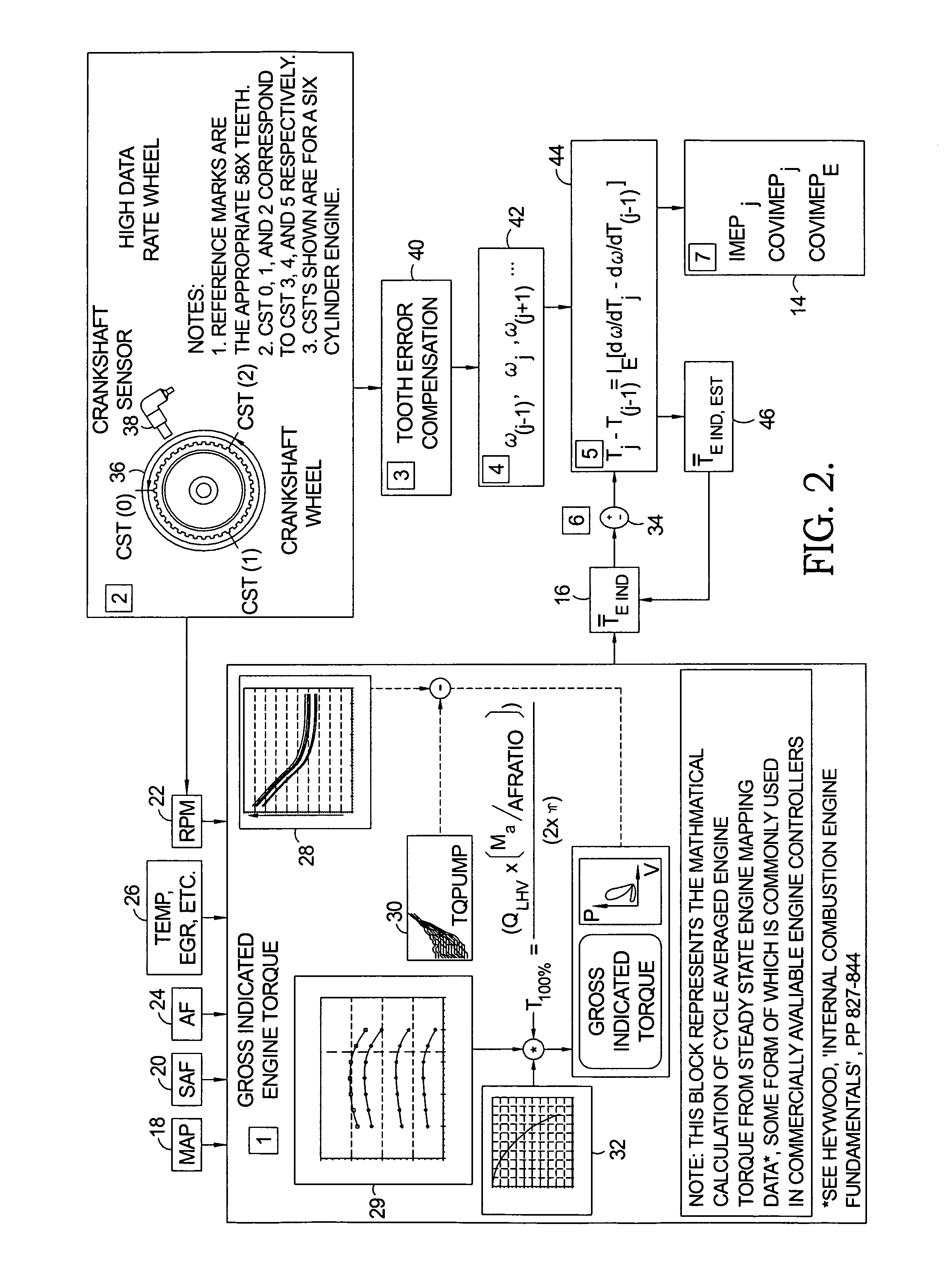

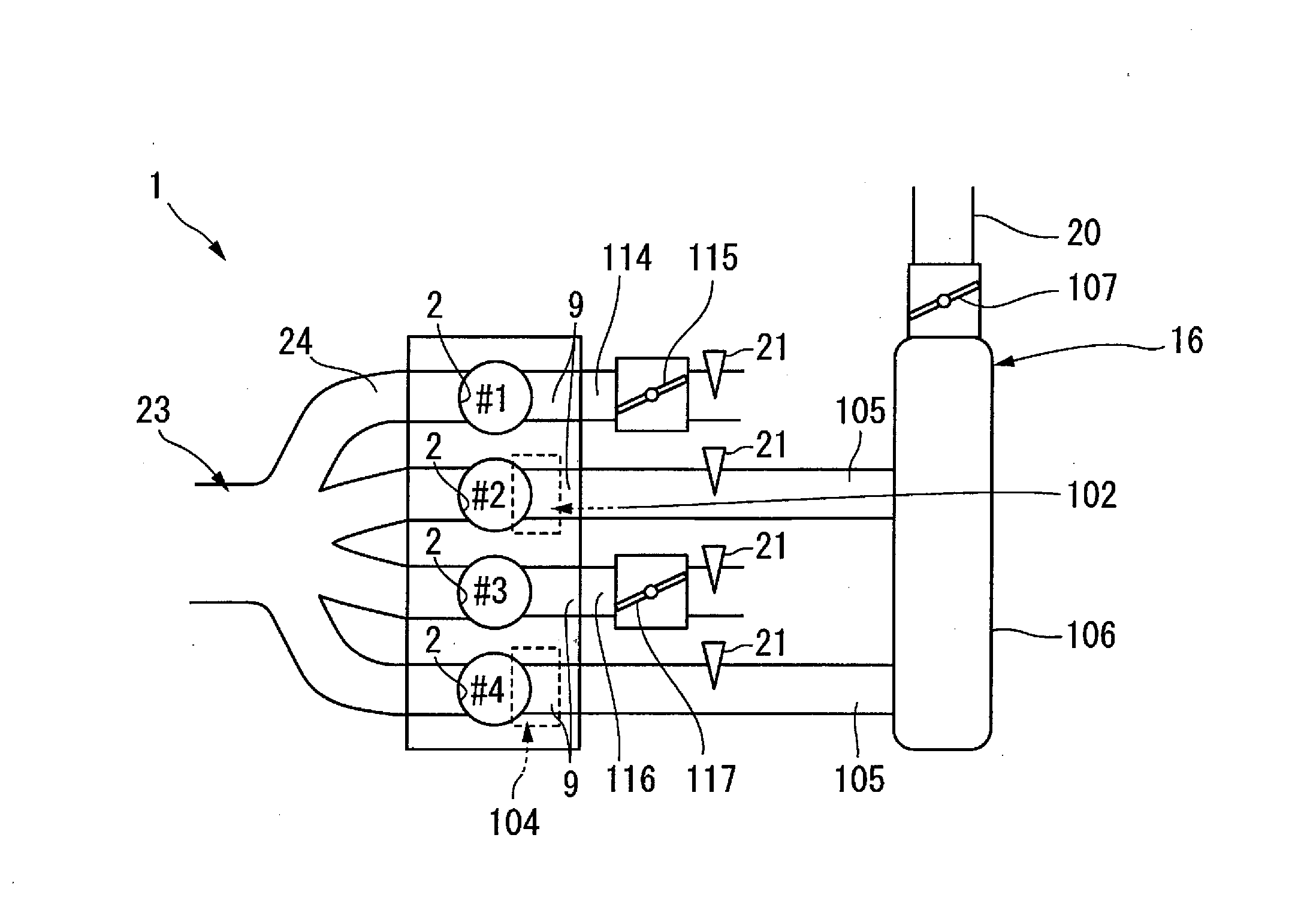

A method for inferring Indicated Mean Effective Pressure as total transient indicated engine torque in an internal combustion engine, comprising the steps of acquiring at least one crankshaft time stamp for use in determining a cylinder-specific engine velocity; calculating an incremental change in engine kinetic energy from the previously fired cylinder (j−1st) to the currently fired (jth) cylinder using the cylinder-specific engine velocity; equating the incremental change in engine kinetic energy to a change in energy-averaged cylinder torque (IMEP) from the previously-fired (j−1st) to a currently-fired (jth) cylinder; summing a plurality of the incremental changes in engine kinetic energy over time to determine a value of the transient component of indicated torque; determining a value of the quasi-steady indicated engine torque; and adding the value of transient component of indicated torque to the value of quasi-steady indicated engine torque to yield the Indicated Mean Effective Pressure.

Owner:DELPHI TECH IP LTD

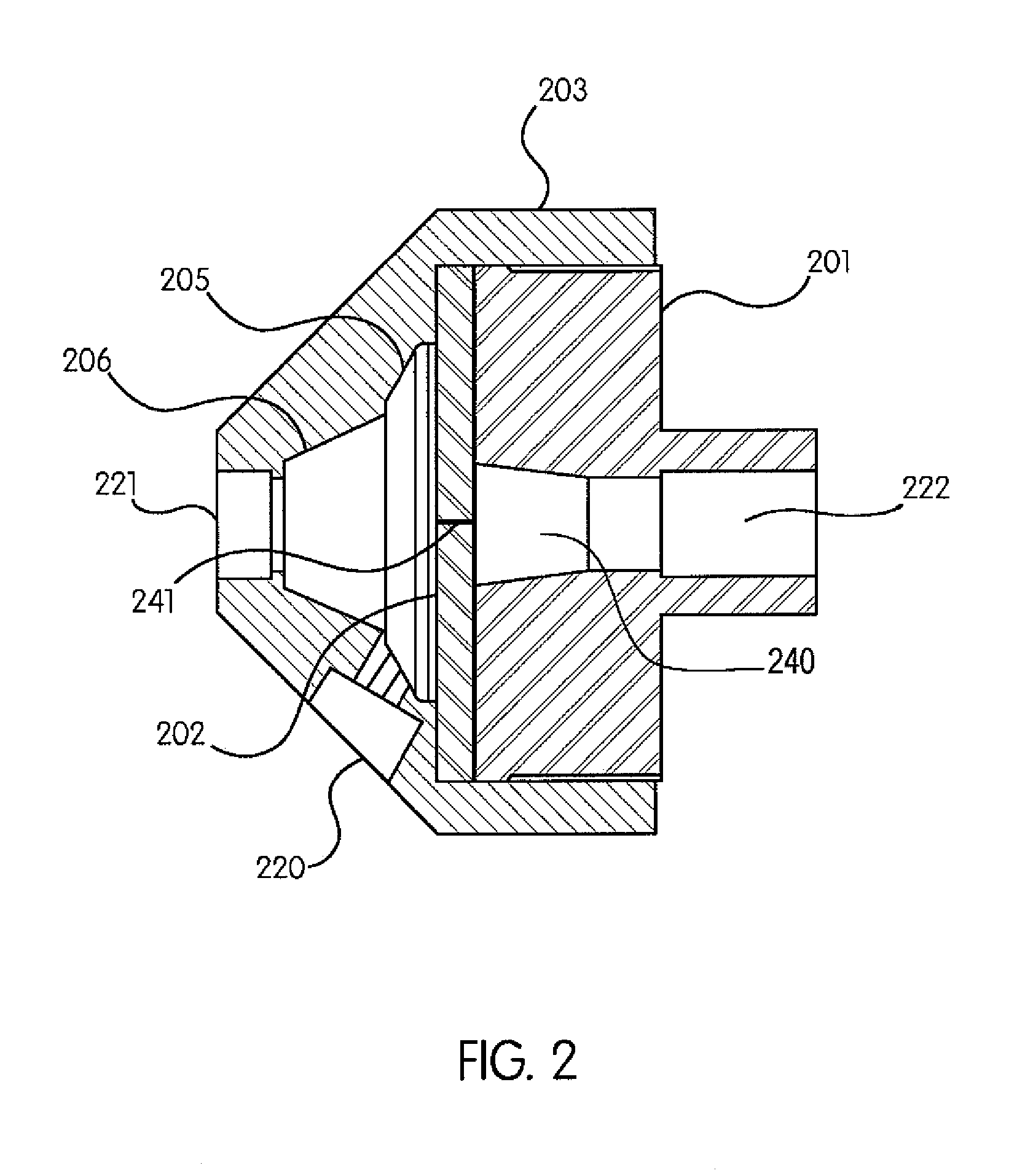

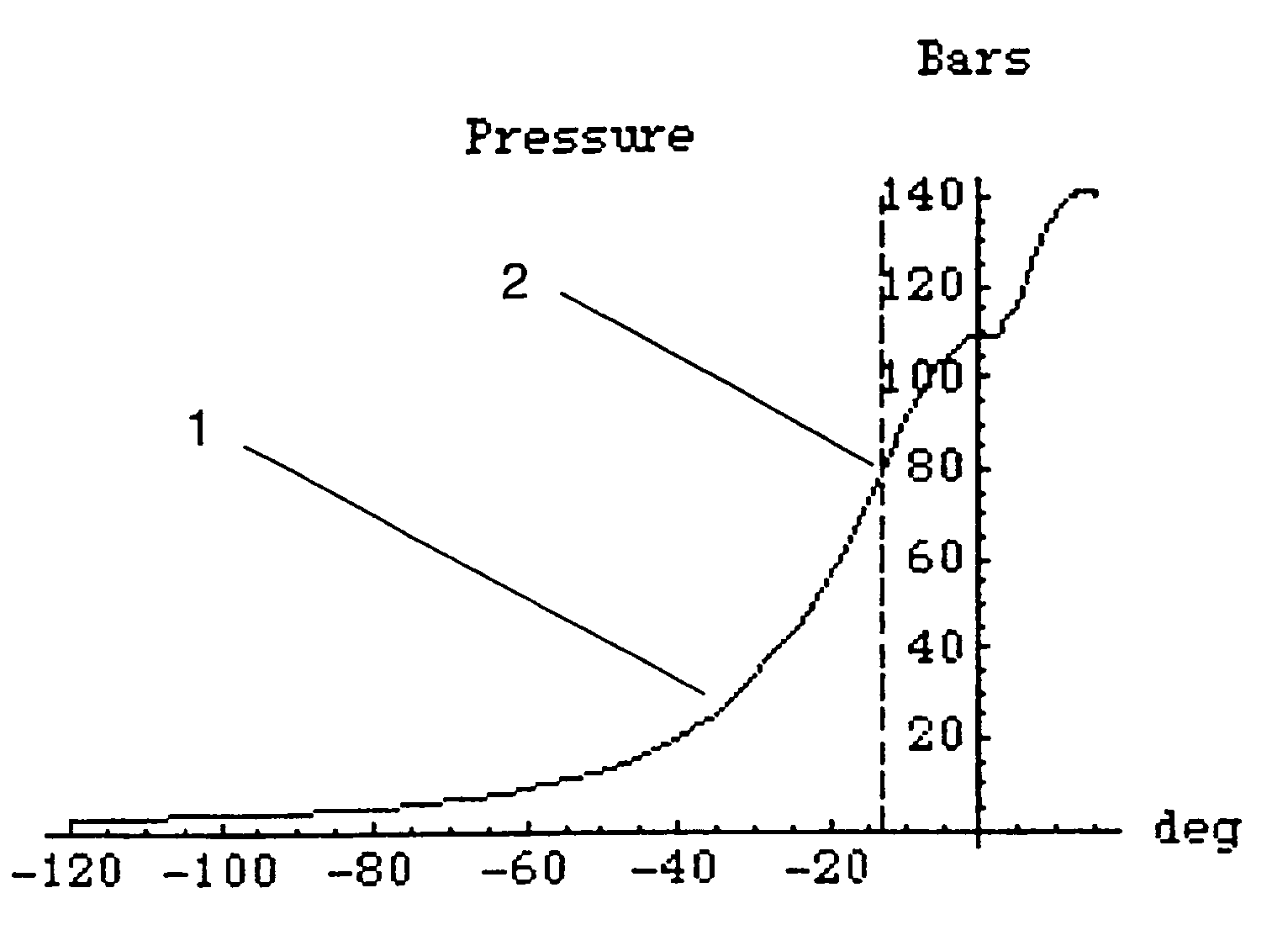

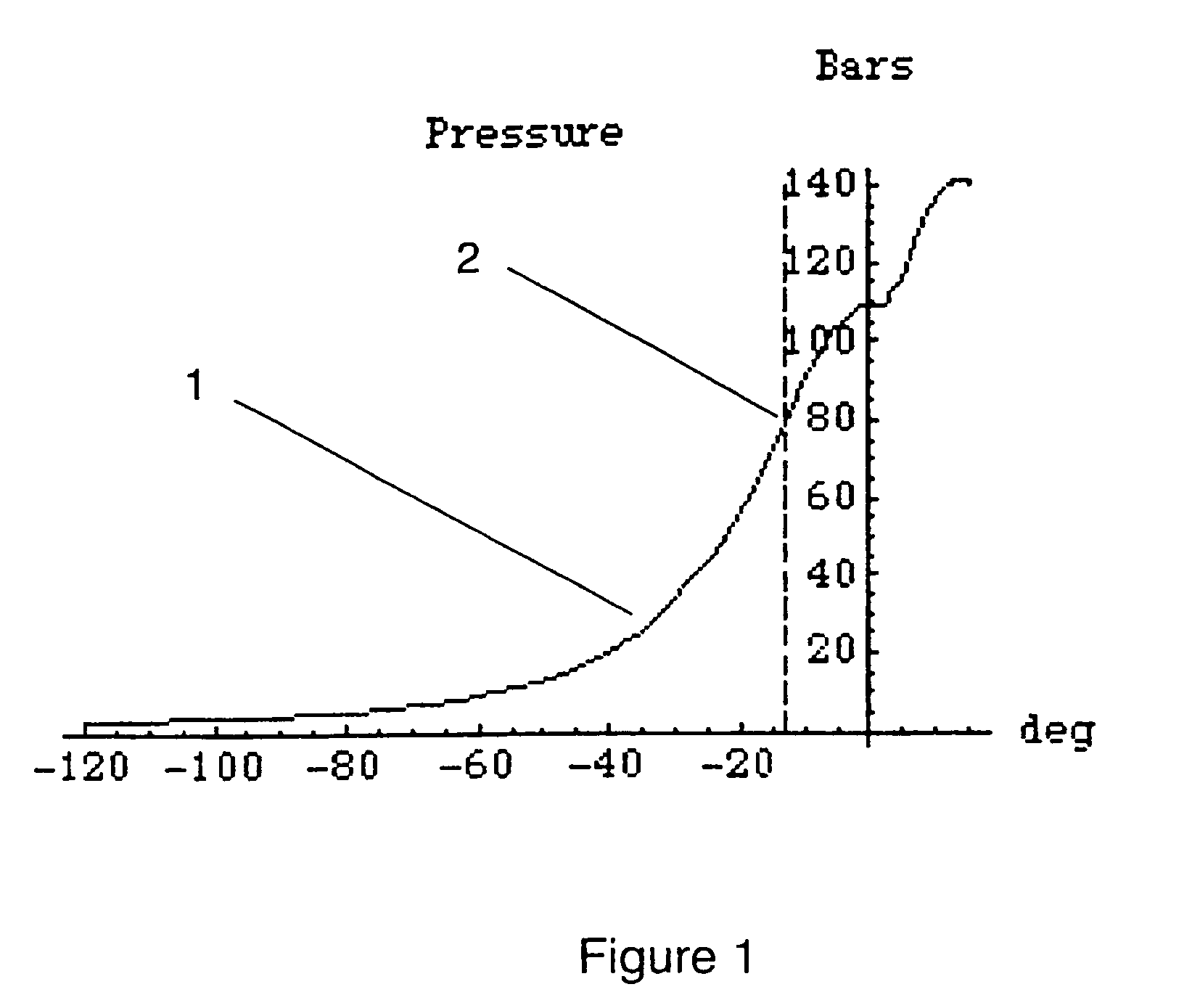

Method to determine tdc in an internal combustion engine

InactiveUS20040236496A1Efficient developmentReduce fuel consumptionInternal-combustion engine testingAnalogue computers for vehiclesFlywheelInternal combustion engine

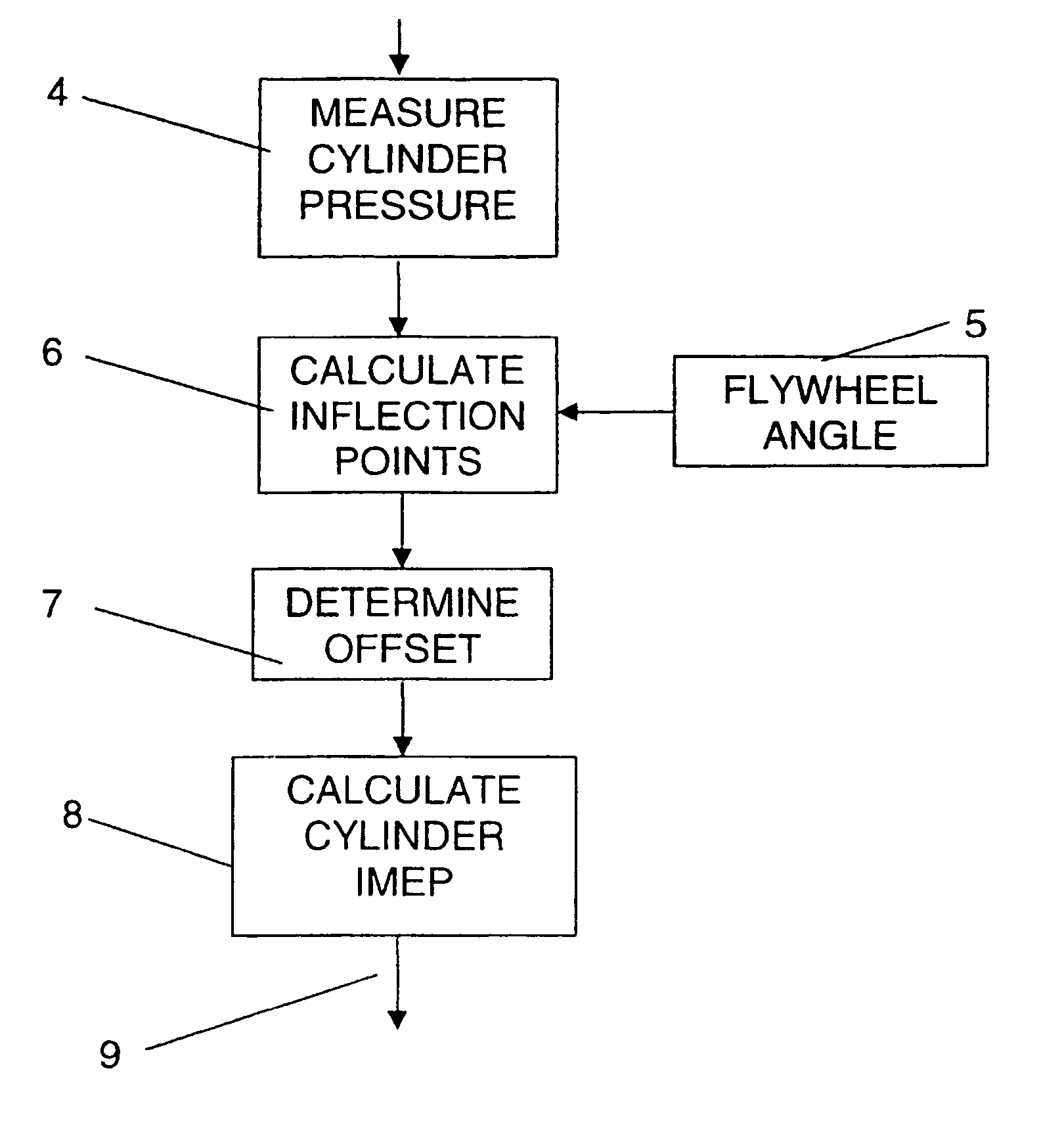

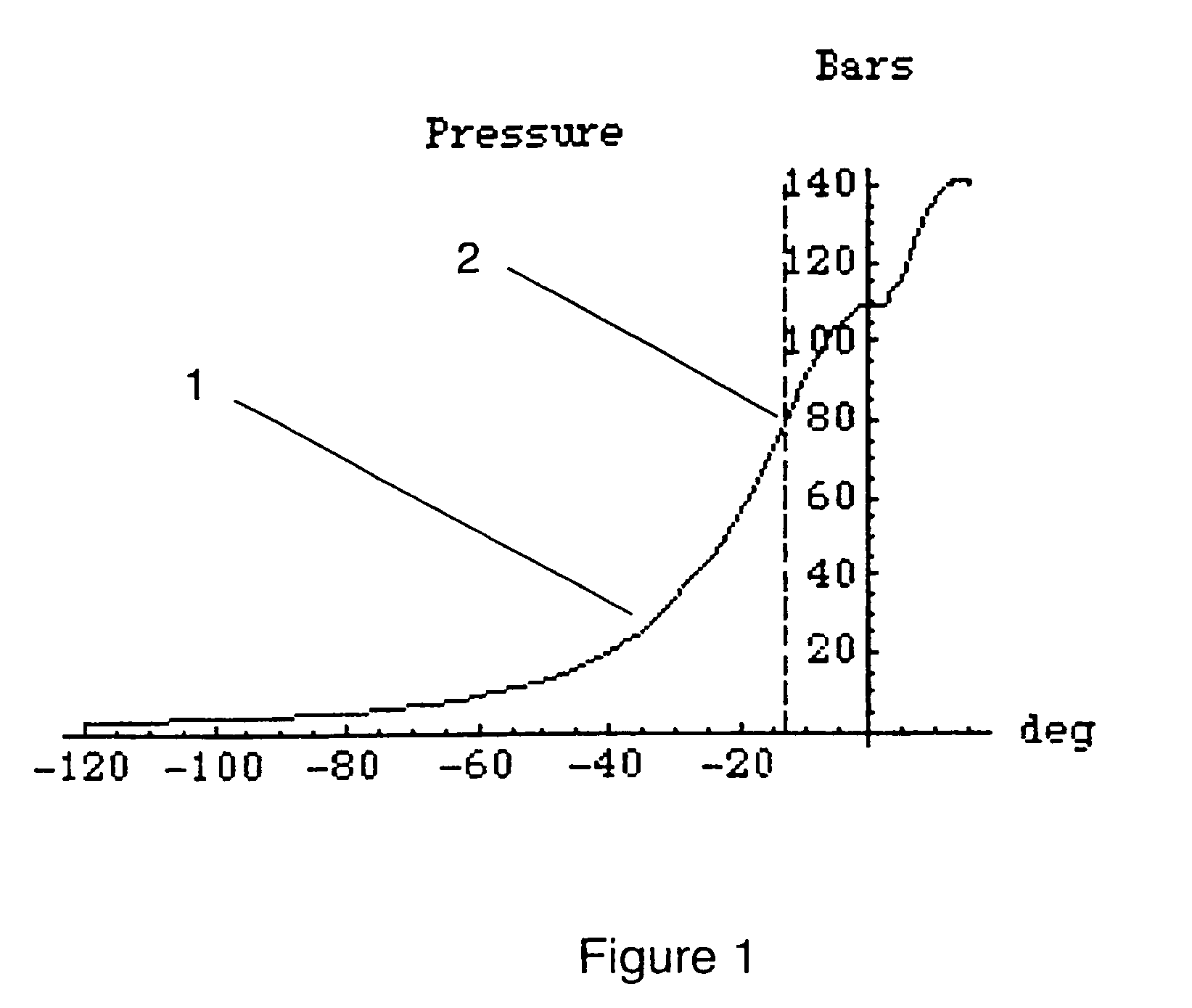

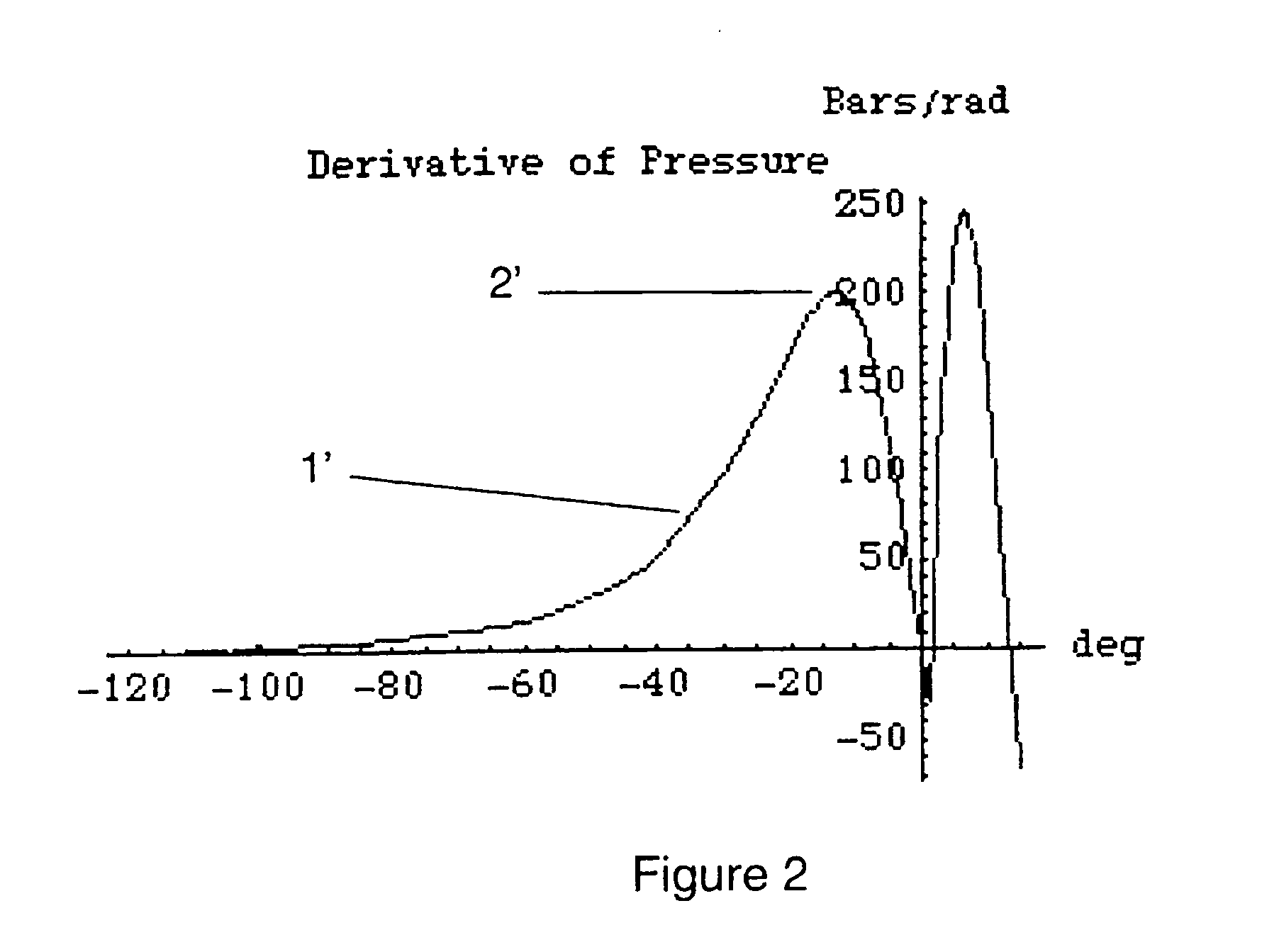

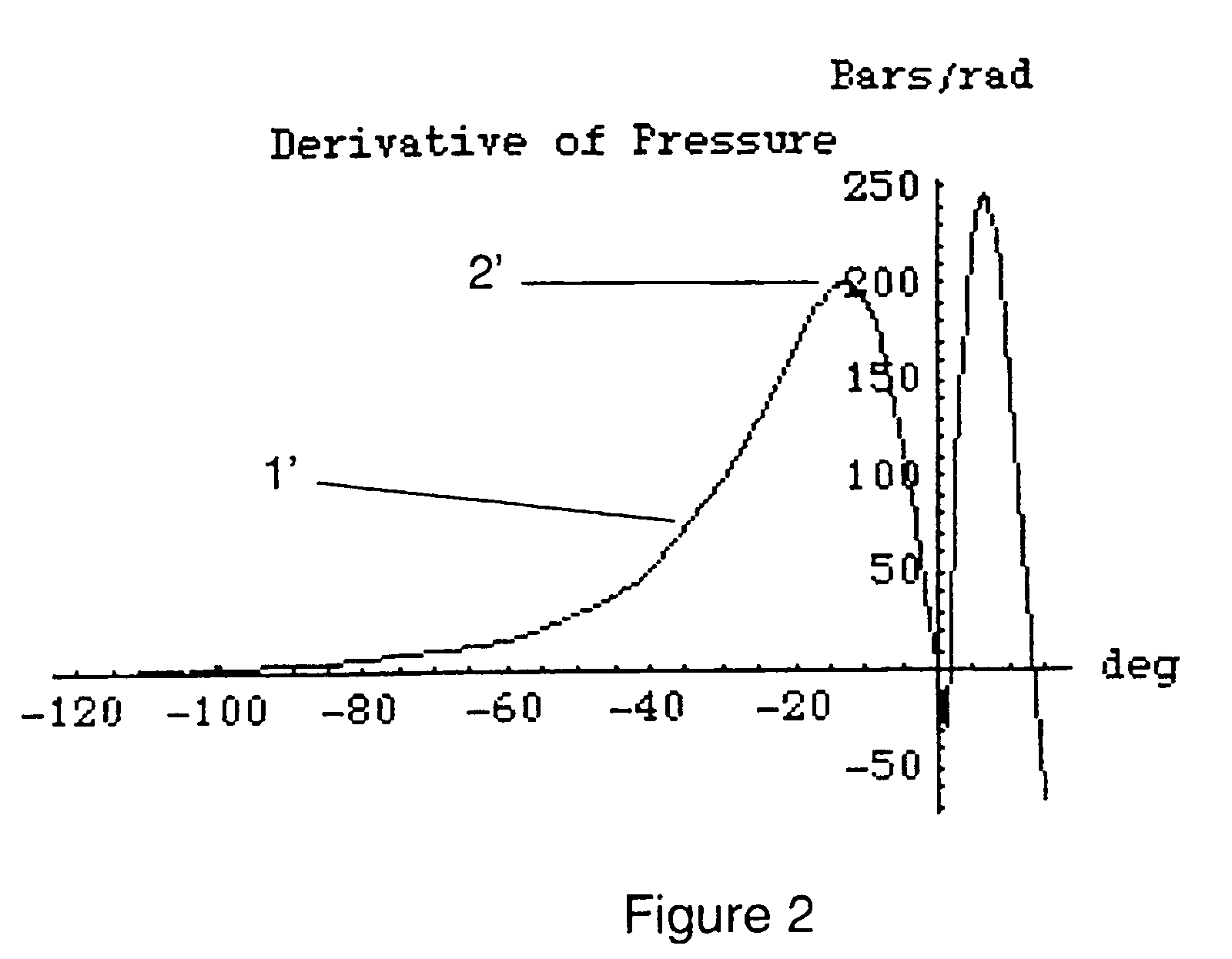

A method and apparatus for accurately determining TTX: in a cylinder of an internal combustion engine. Gas pressure is measured in the cylinder relative to crank angle, giving rise to a curve of gas pressure with crank angle. An offset is found by first computing the angular position of an inflexion point of the compression pressure curve measured as a function of the crank angle, and then computing the offset as the difference between the angular position of a piston in the cylinder and a theoretical value for said angular position of the piston dependent on a known or measured flywheel angle. The value of TDC corrected by the offset is then used to calculate a value of work output such as the indicated Mean Effective Pressure (IMEP) which may be used for diagnostic and / or control purposes.

Owner:ABB (SCHWEIZ) AG

Method for estimation of indicated mean effective pressure for individual cylinders from crankshaft acceleration

ActiveUS7623955B1Eliminates expense and intrusivenessDecrease in levelAnalogue computers for vehiclesInternal-combustion engine testingEngineeringInternal combustion engine

A method for inferring Indicated Mean Effective Pressure as total transient indicated engine torque in an internal combustion engine, comprising the steps of acquiring at least one crankshaft time stamp for use in determining a cylinder-specific engine velocity; calculating an incremental change in engine kinetic energy from the previously fired cylinder (j−1st) to the currently fired (jth) cylinder using the cylinder-specific engine velocity; equating the incremental change in engine kinetic energy to a change in energy-averaged cylinder torque (IMEP) from the previously-fired (j−1st) to a currently-fired (jth) cylinder; summing a plurality of the incremental changes in engine kinetic energy over time to determine a value of the transient component of indicated torque; determining a value of the quasi-steady indicated engine torque; and adding the value of transient component of indicated torque to the value of quasi-steady indicated engine torque to yield the Indicated Mean Effective Pressure.

Owner:DELPHI TECH IP LTD

Low pressure measurement devices in high pressure environments

The present invention presents various novel approaches to solving the problems inherent in measuring biological pressures in high pressure systems. Thus, to protect a pressure transducer exposed to fluid flows at higher pressures than its overpressure rating, a novel valve is used that closes a protected leg in which the transducer is located. The various exemplary embodiments of such valves each have a high pressure input, one or more low pressure inputs, and an output. In operation, when a high pressure fluid flow occurs at a high pressure input, such valves automatically close the low pressure inputs. Alternatively, a novel transducer system is presented, which automatically limits the effective pressure sensed by a transducer to a certain maximum.

Owner:ACIST MEDICAL SYST

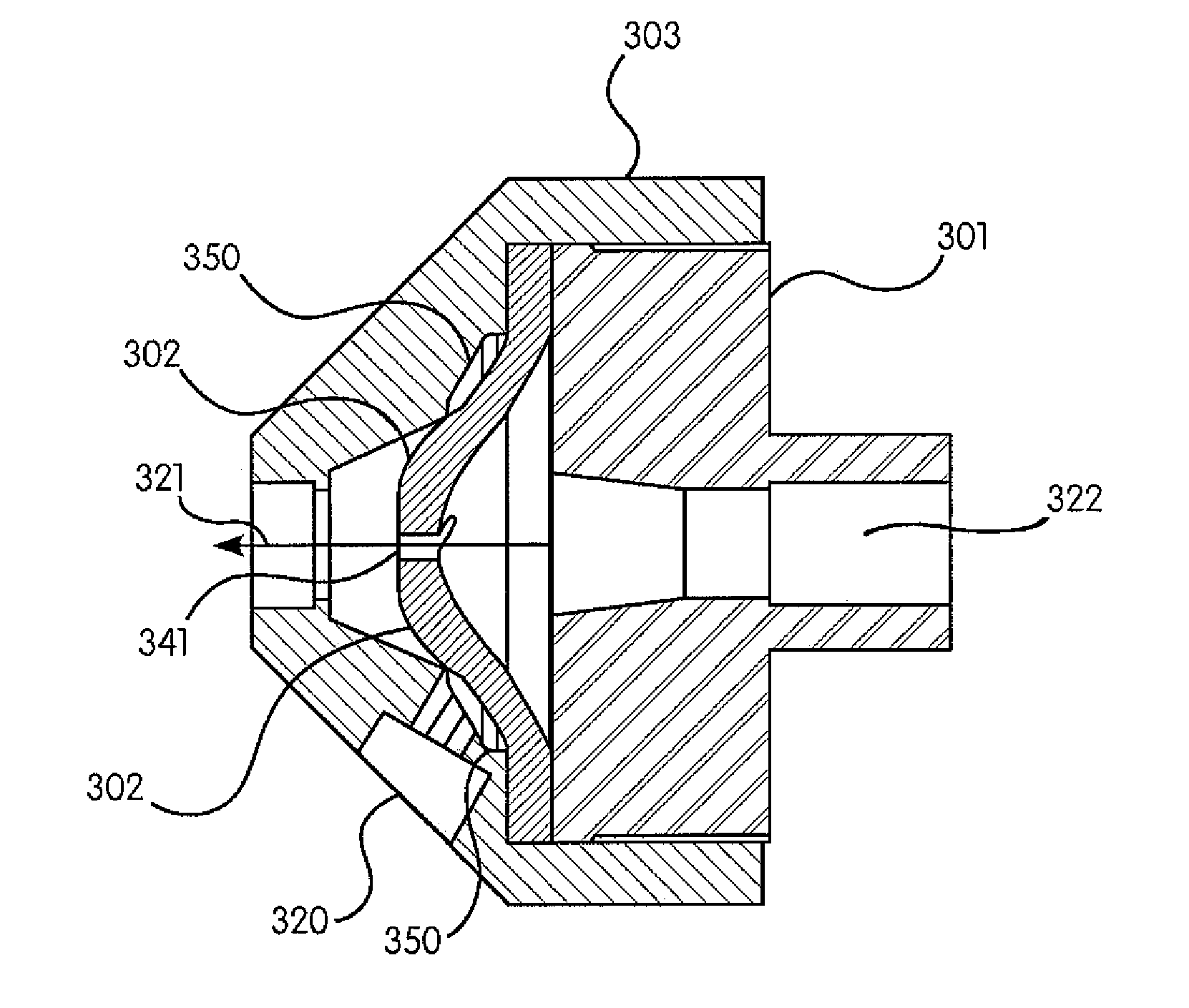

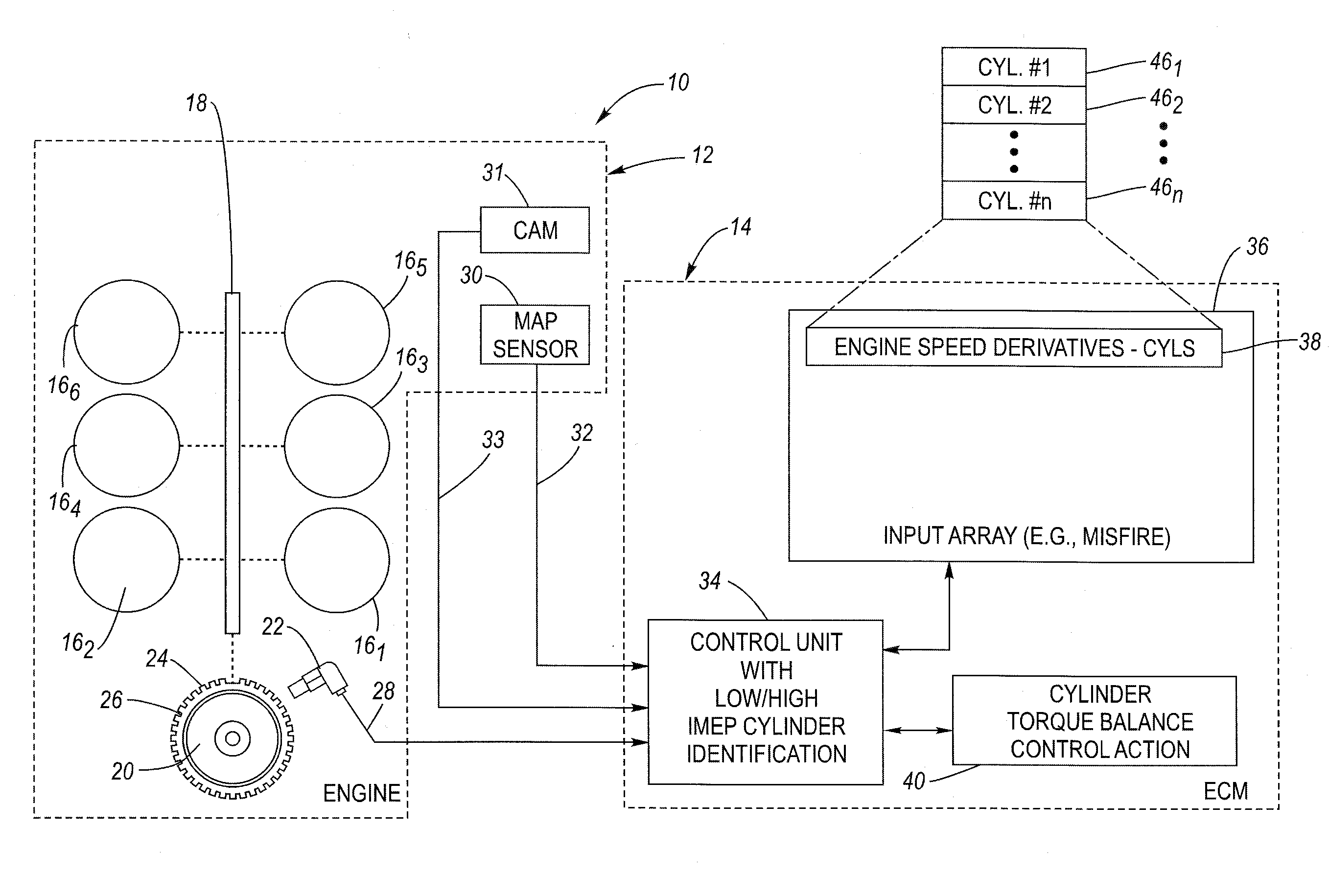

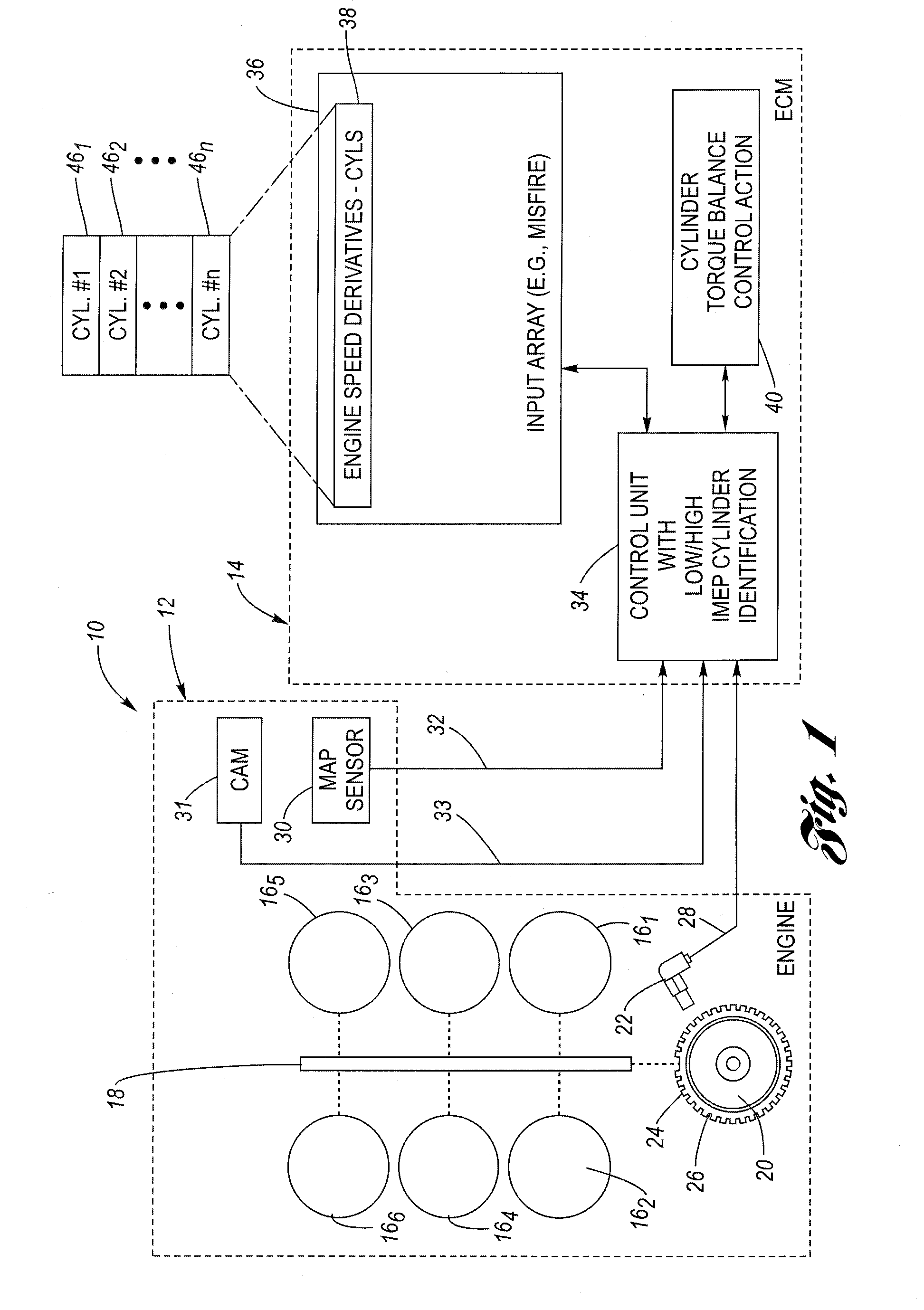

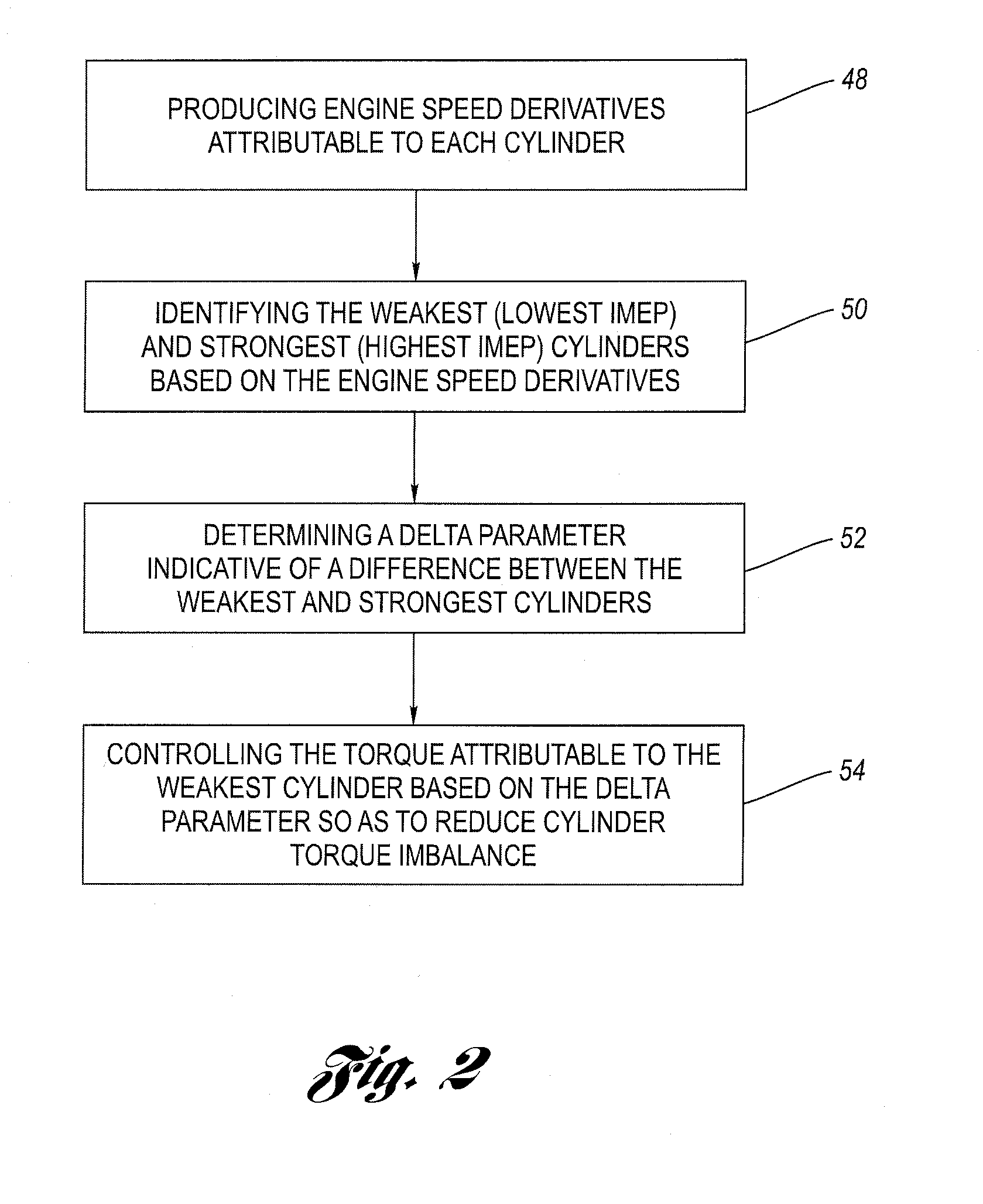

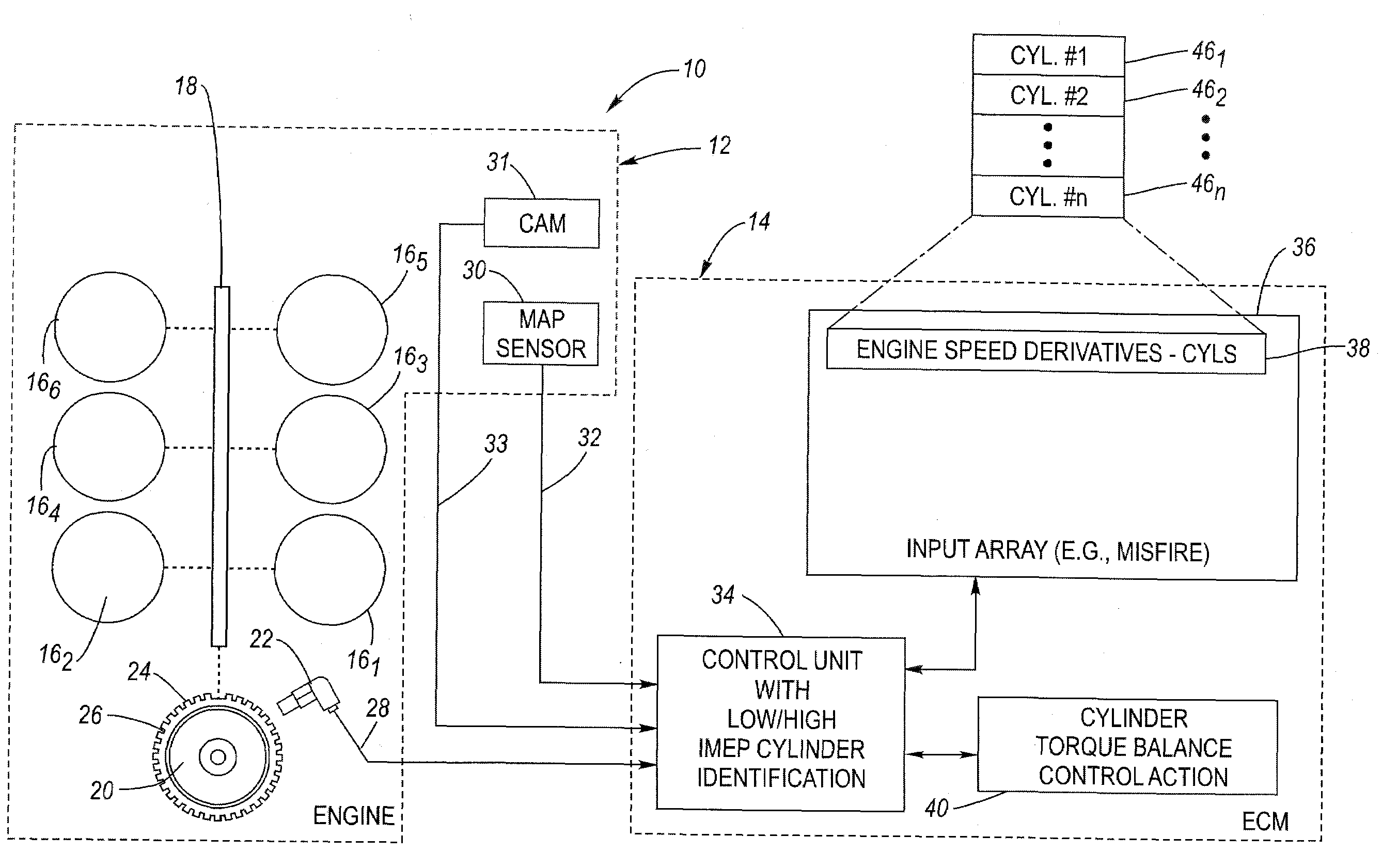

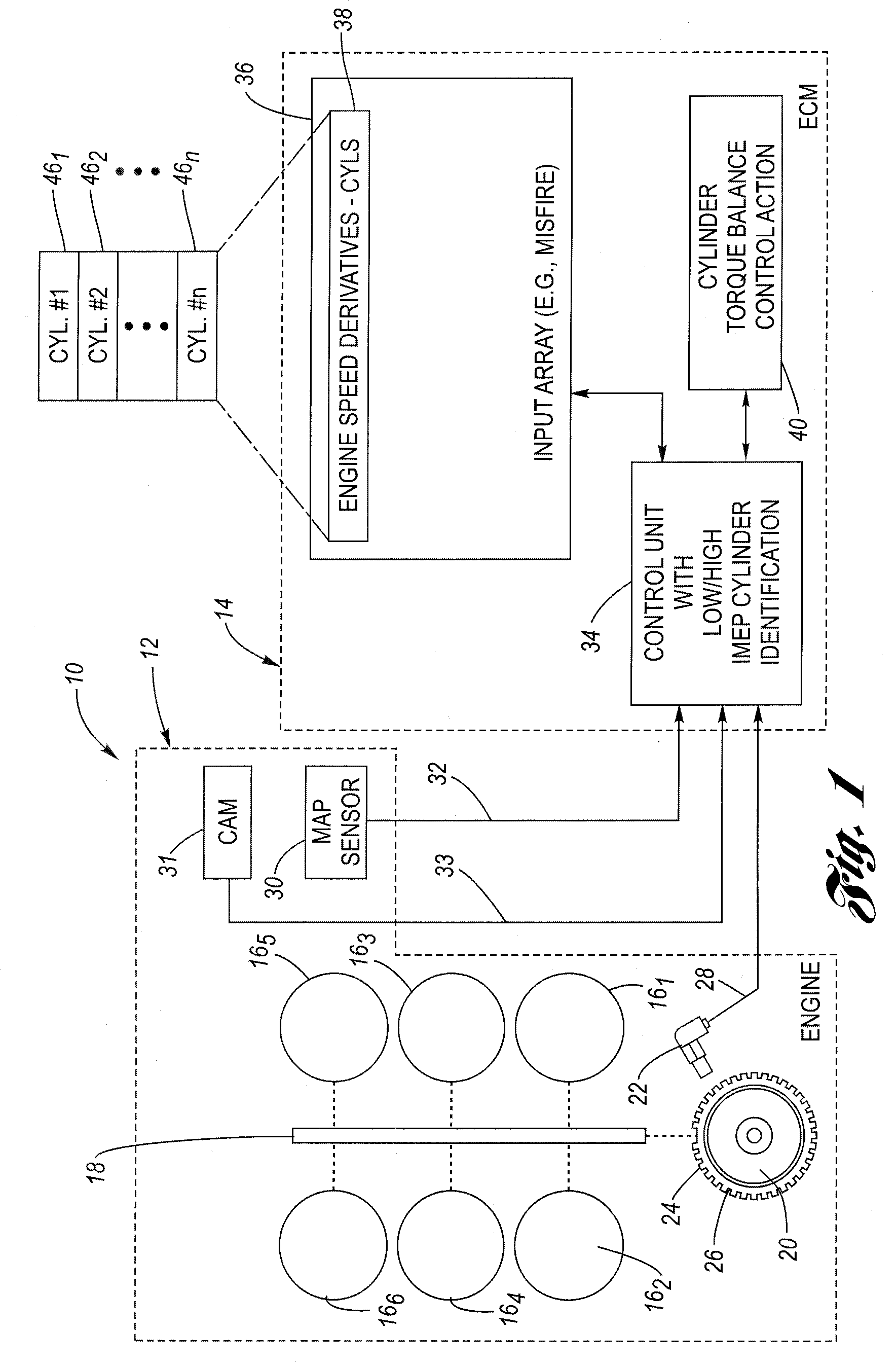

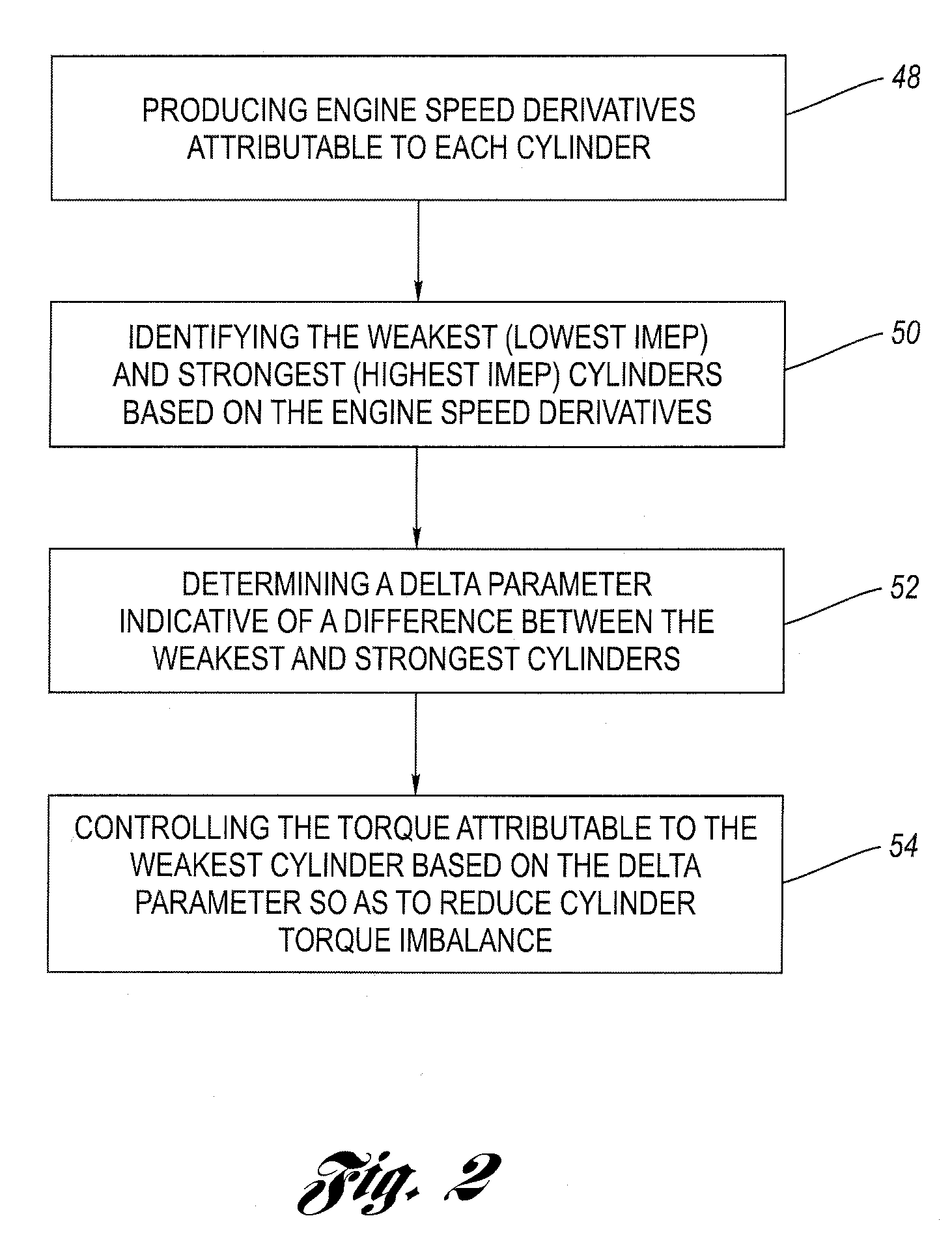

Method for low and high imep cylinder identification for cylinder balancing

ActiveUS20090259382A1Reduce cylinder torque imbalanceImprove performanceAnalogue computers for vehiclesElectrical controlControl theoryMean effective pressure

A system and method for identifying the cylinders having the lowest (“weakest”) and highest (“strongest”) Indicated Mean Effective Pressure (IMEP) utilizes engine speed derivative and / or higher order derivative values typically available in an engine control module by virtue of the need to detect misfire. A delta parameter is calculated that is indicative of the difference between the engine speed derivatives and / or higher order derivatives for the “weakest” and the “strongest” cylinders. Control action is then taken to balance the cylinders, based on the delta parameter, by first increasing torque for the “weakest” cylinder, by at least one increasing spark advance, increasing fuel, decreasing dilution (EGR) or slowing decay of fuel control on cold start. Once the weakest cylinder has been balanced, the control action is then directed to increasing torque of the new “weakest” cylinder.

Owner:DELPHI TECH IP LTD

Method to determine TDC in an internal combustion engine

InactiveUS7117080B2Efficient developmentHigh in technologyInternal-combustion engine testingAnalogue computers for vehiclesInternal combustion engineFlywheel

A method and apparatus for accurately determining TDC in a cylinder of an internal combustion engine. Gas pressure is measured in the cylinder relative to crank angle, giving rise to a curve of gas pressure with crank angle. An offset is found by first computing the angular position of an inflexion point of the compression pressure curve measured as a function of the crank angle, and then computing the offset as the difference between the angular position of a piston in the cylinder and a theoretical value for said angular position of the piston dependent on a known or measured flywheel angle. The value of TDC corrected by the offset is then used to calculate a value of work output such as the Indicated Mean Effective Pressure (IMEP) which may be used for diagnostic and / or control purposes.

Owner:ABB (SCHWEIZ) AG

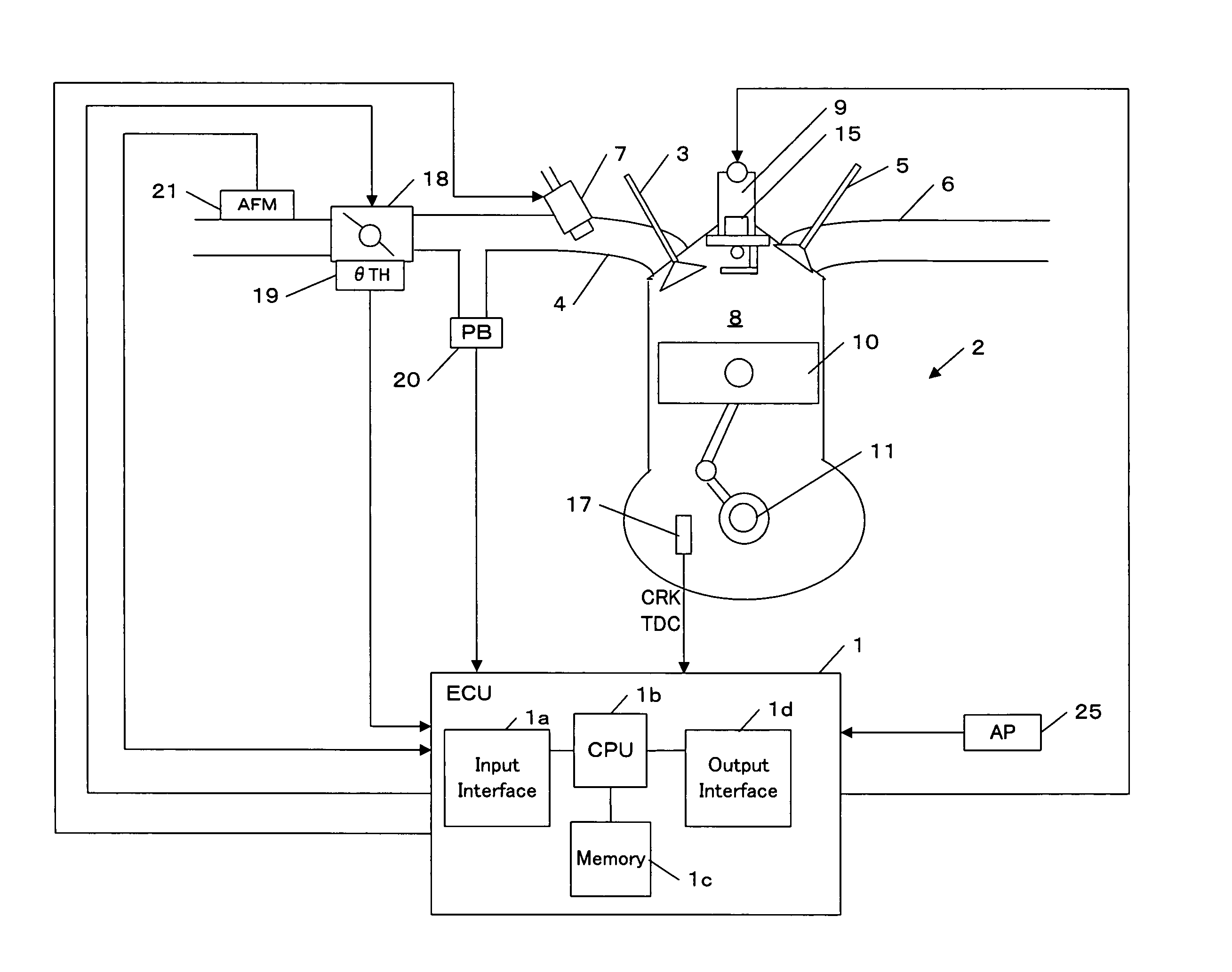

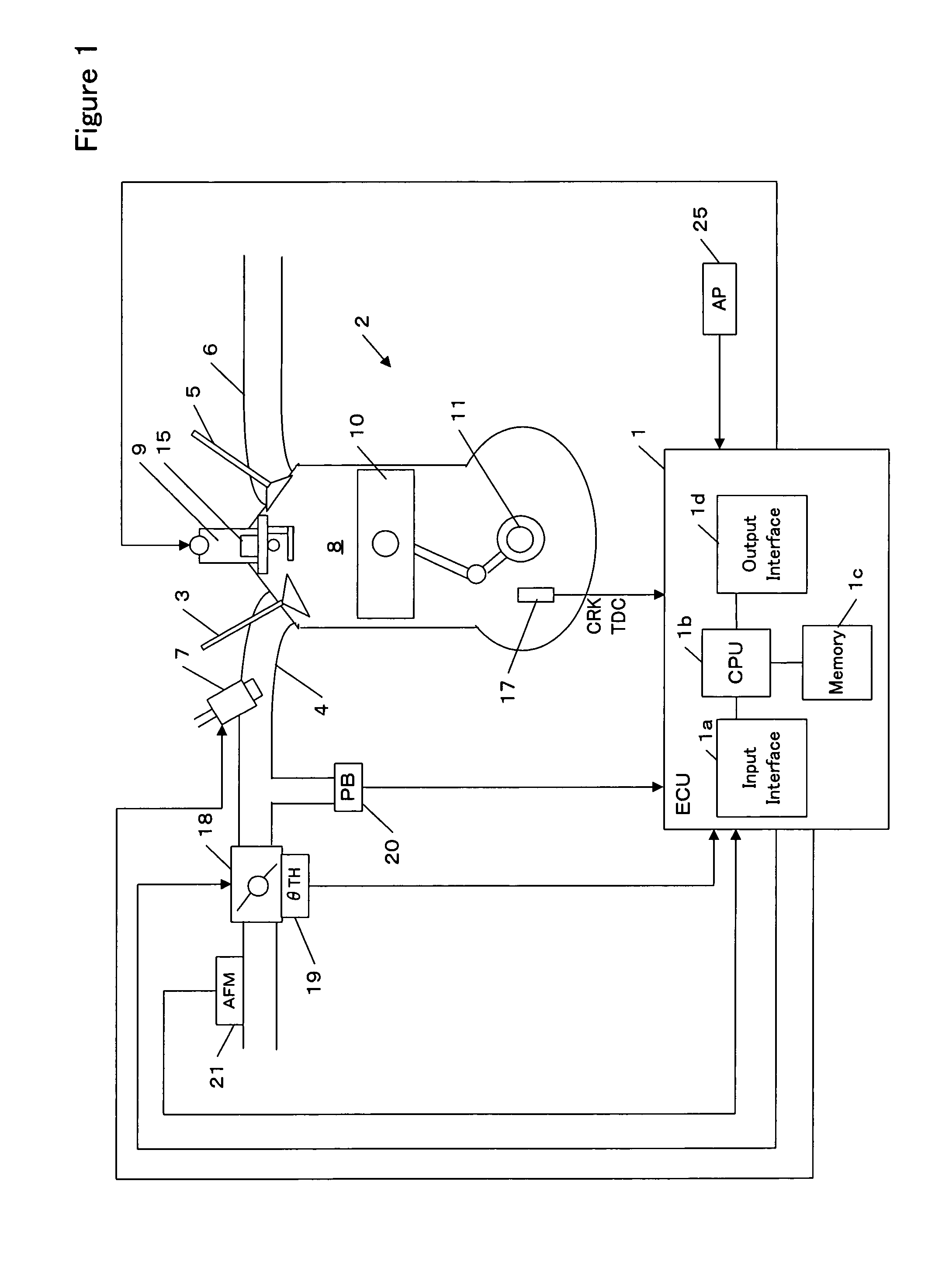

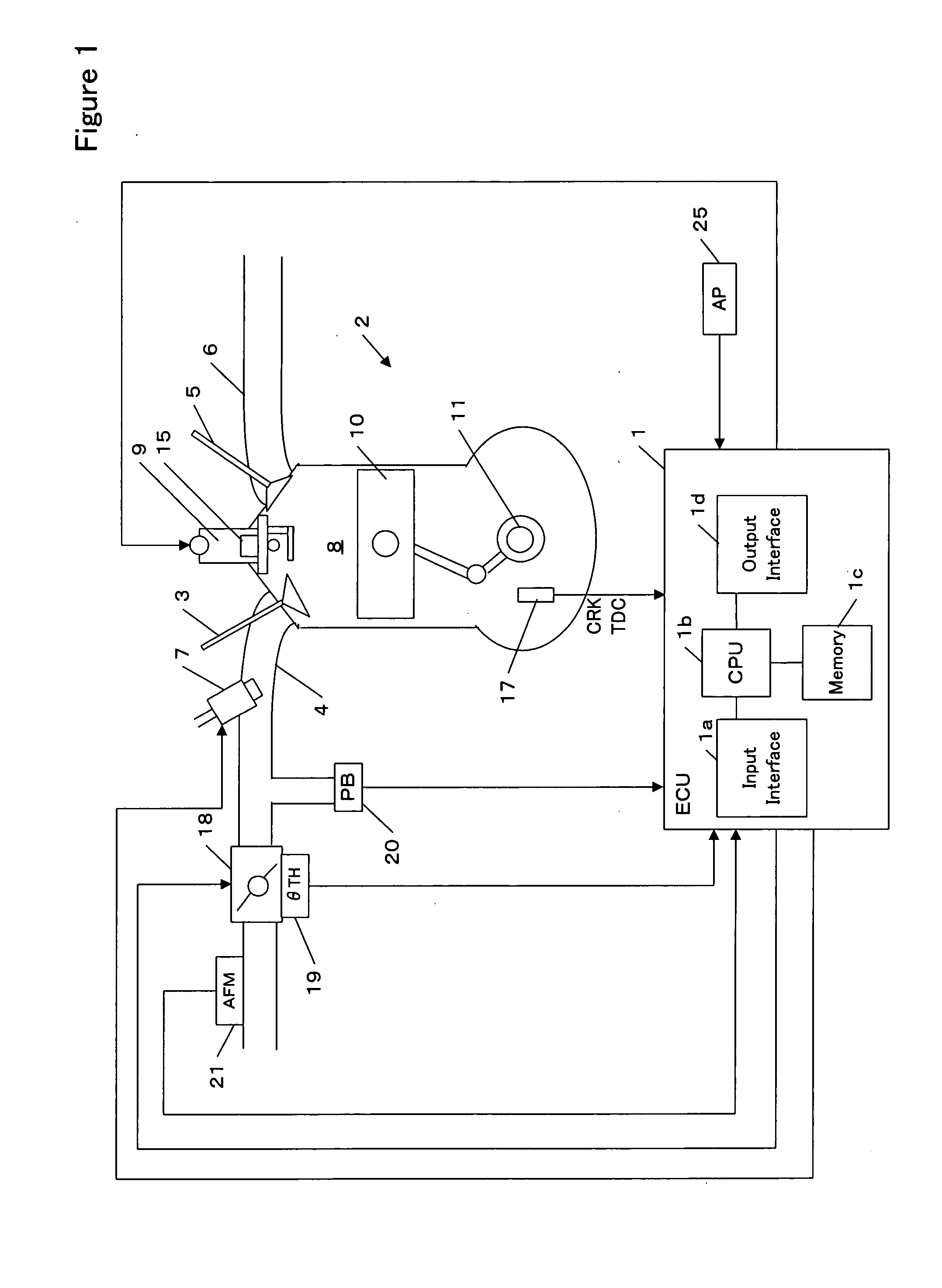

Control apparatus, control method, and engine control unit

ActiveUS20070270983A1Quickly accommodate modeling errorImprove calculation accuracyAnalogue computers for vehiclesElectrical controlComputer scienceMean effective pressure

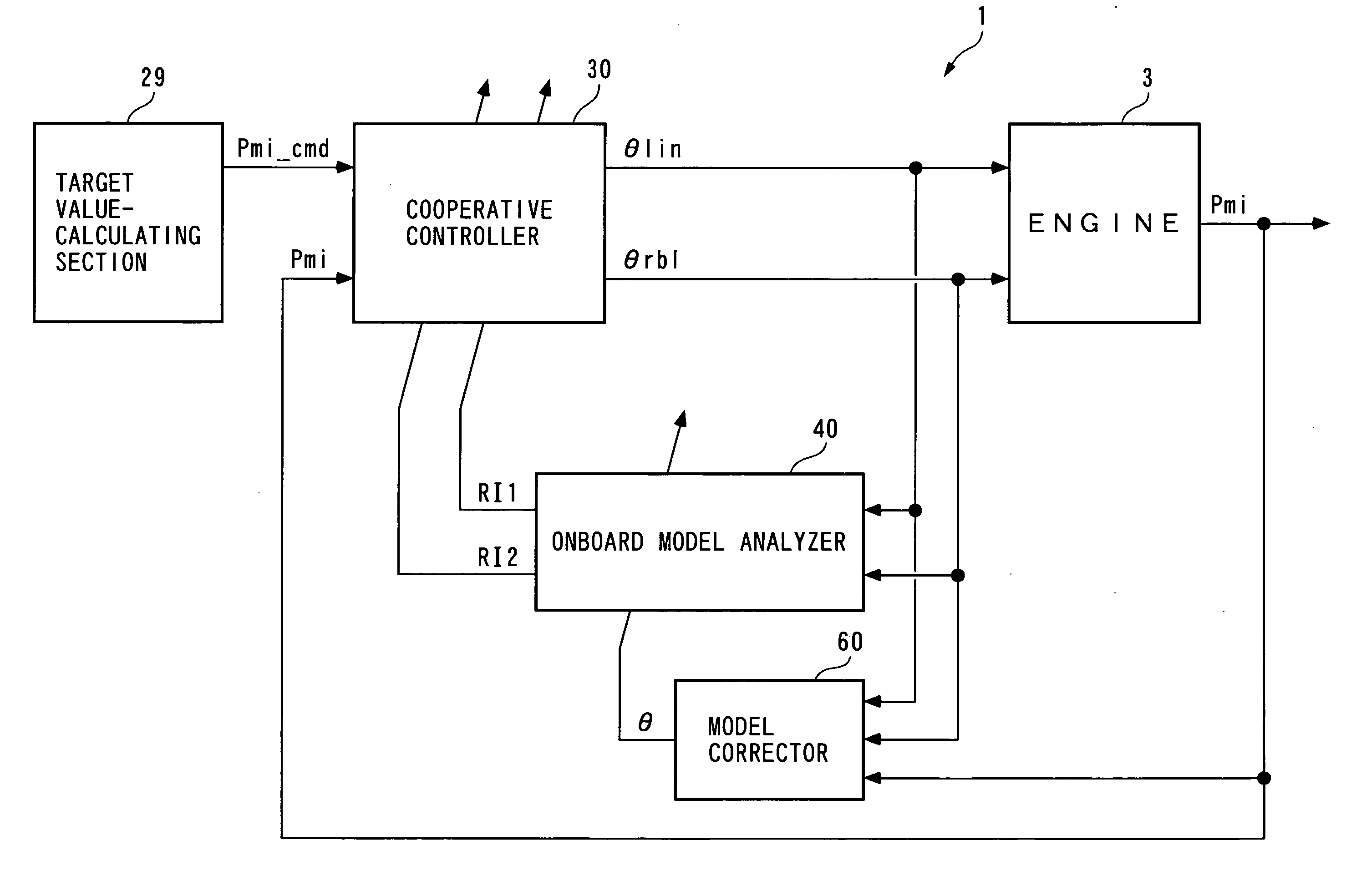

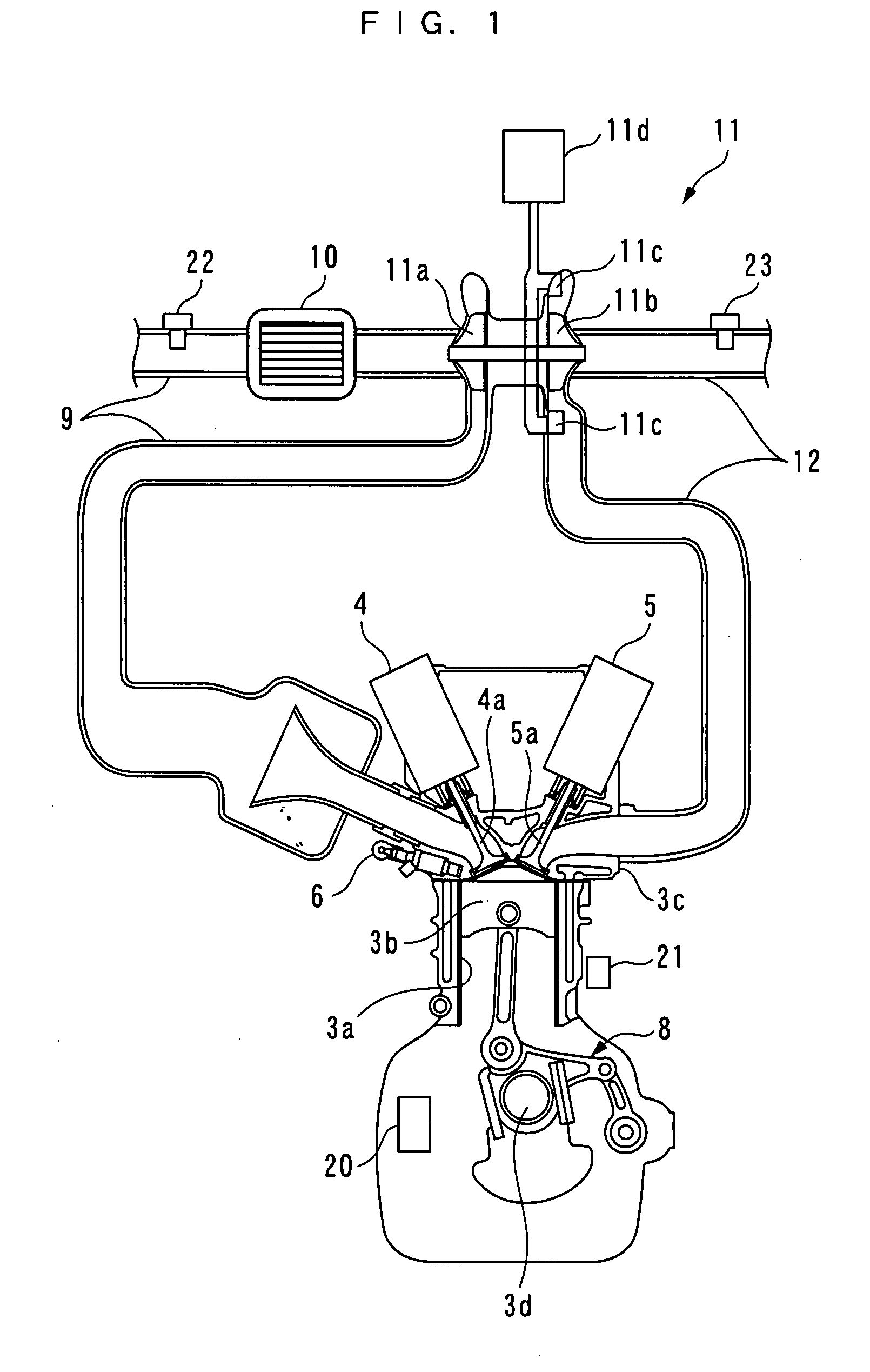

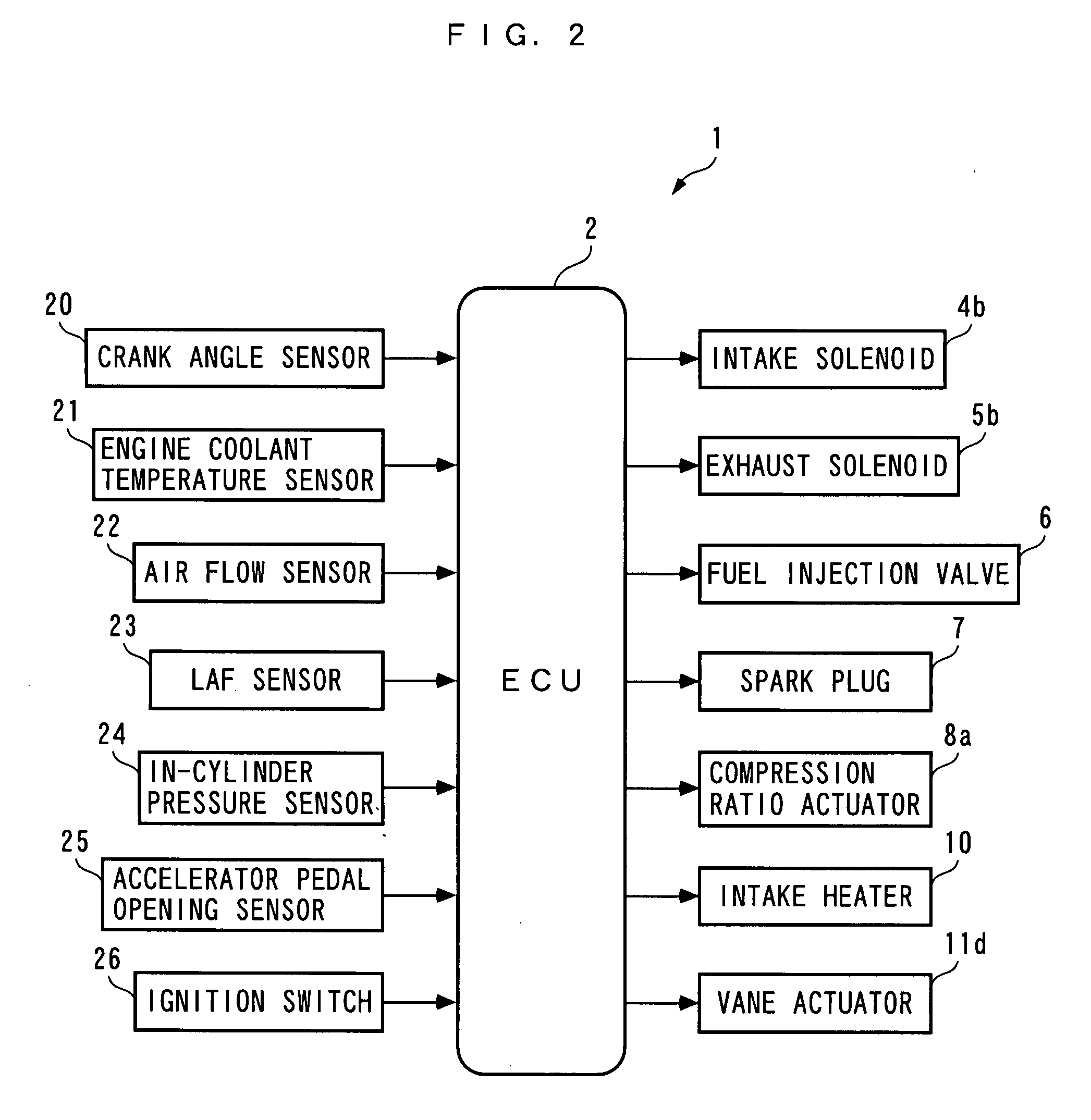

A control apparatus which is capable of ensuring both high-level stability and accuracy of control, even when controlling a controlled object having extremal characteristics or a controlled object a controlled object model of which cannot be represented. The control apparatus 1 includes a cooperative controller 30, an onboard model analyzer 40, and a model corrector 60. The model corrector 60 calculates the model correction parameter matrix θ, so as to correct the controlled object model defining the relationship between the intake opening angle θlin and the exhaust reopening angle θrbl and the indicated mean effective pressure Pmi. The onboard model analyzer 40 calculates first and second response indices RI1 and RI2 representative of correlations between θlin, θrbl, and Pmi, based on the controlled object model corrected using θ. The cooperative controller 30 calculates the θlin and θrbl such that Pmi is caused to converge to a target value Pmi_cmd, and determines an increasing / decreasing rate and increasing / decreasing direction of θlin and θrbl according to RI1 and RI2.

Owner:HONDA MOTOR CO LTD

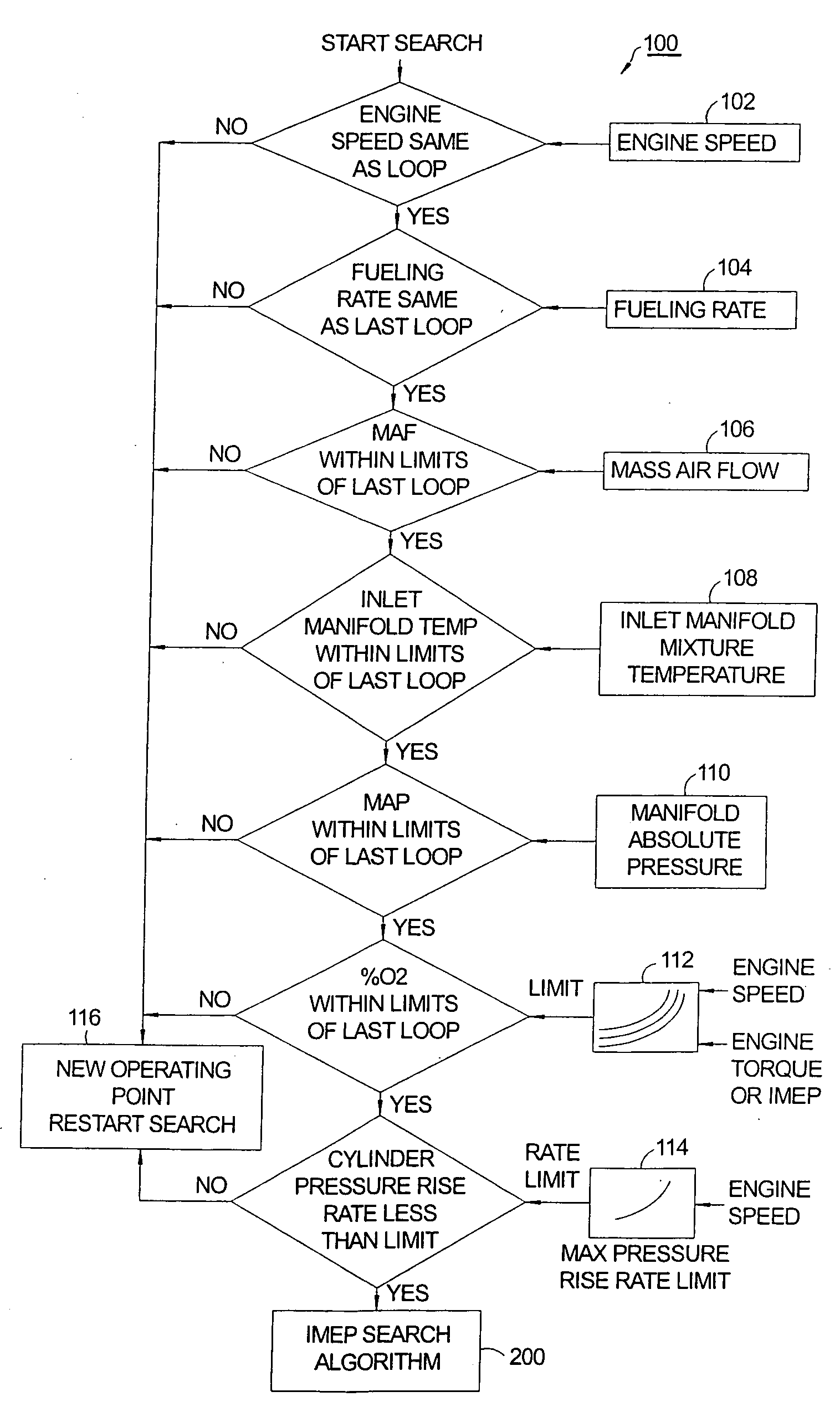

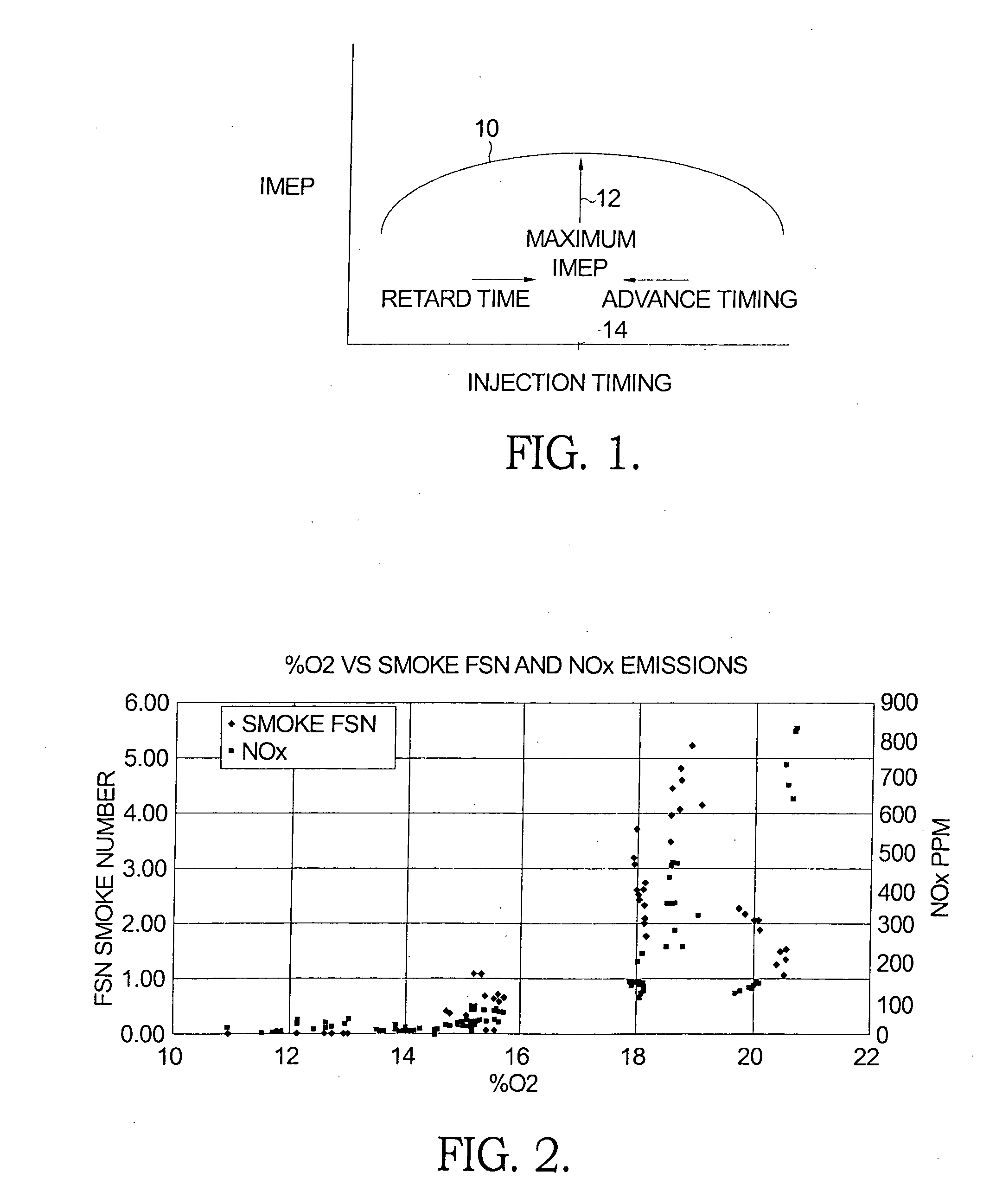

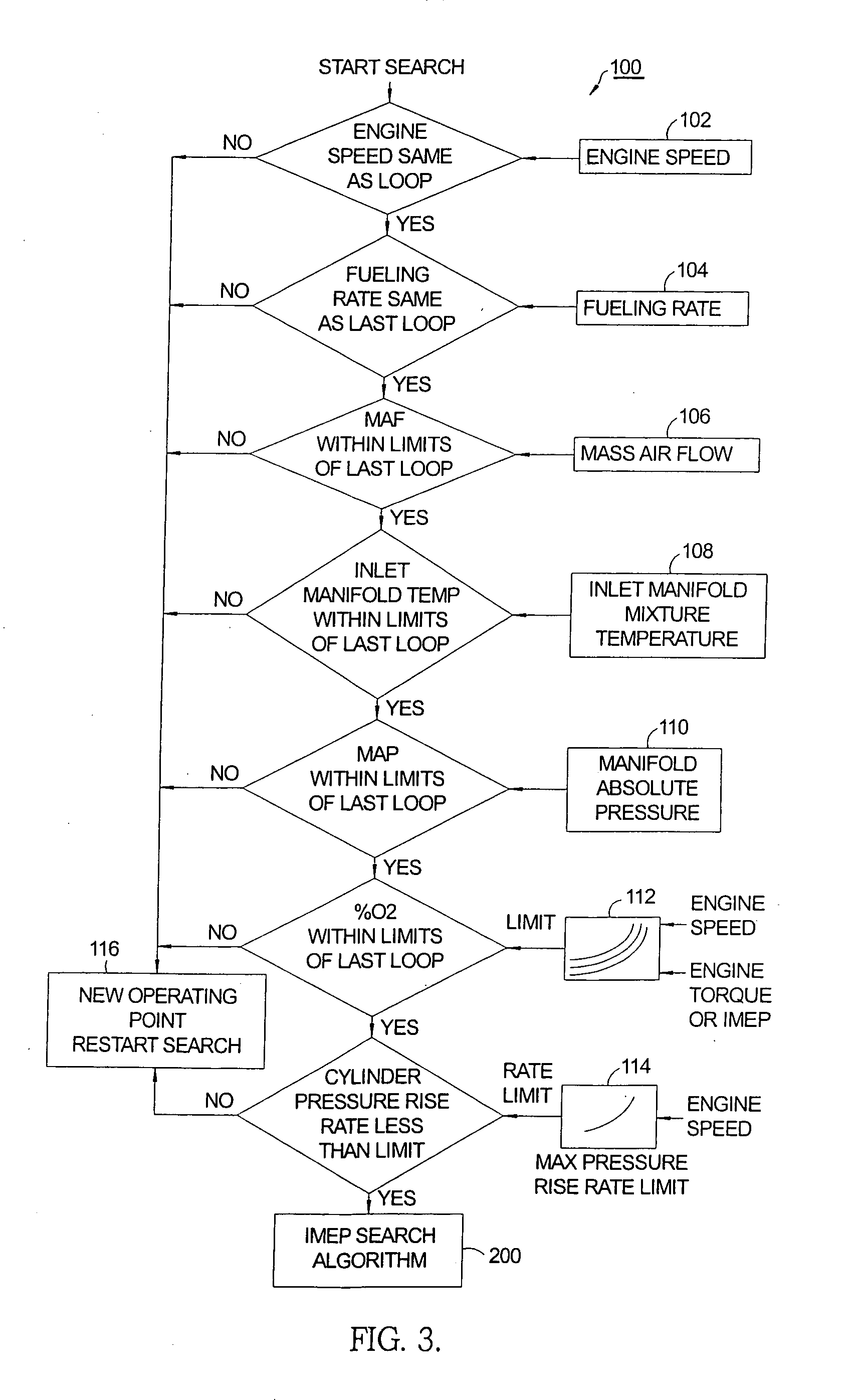

Method for optimizing fuel injection timing in a compression ignition engine

ActiveUS20090177368A1Increase or decreaseMaximize fuel economyElectrical controlInternal combustion piston enginesNarrow rangeMaximum torque

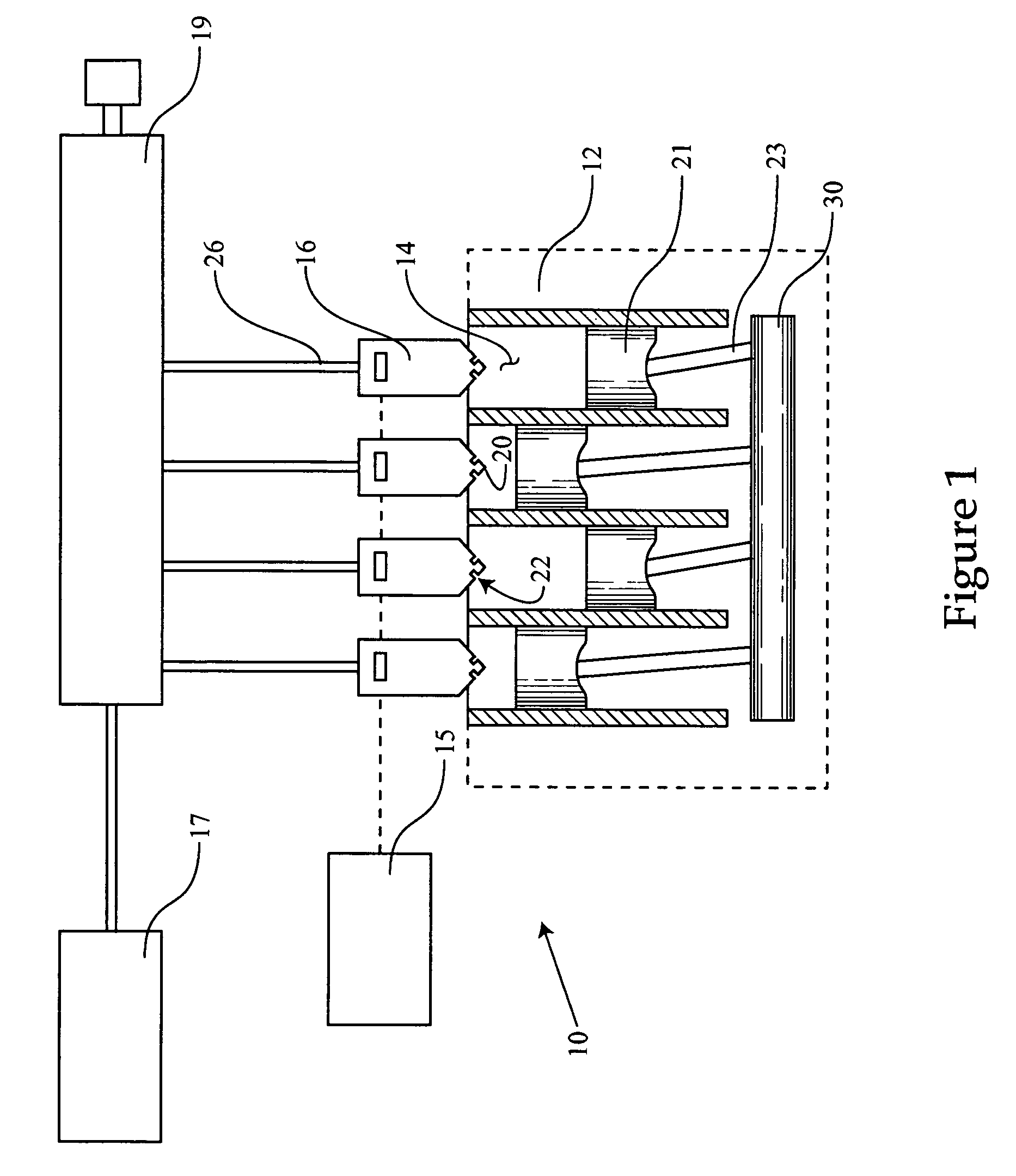

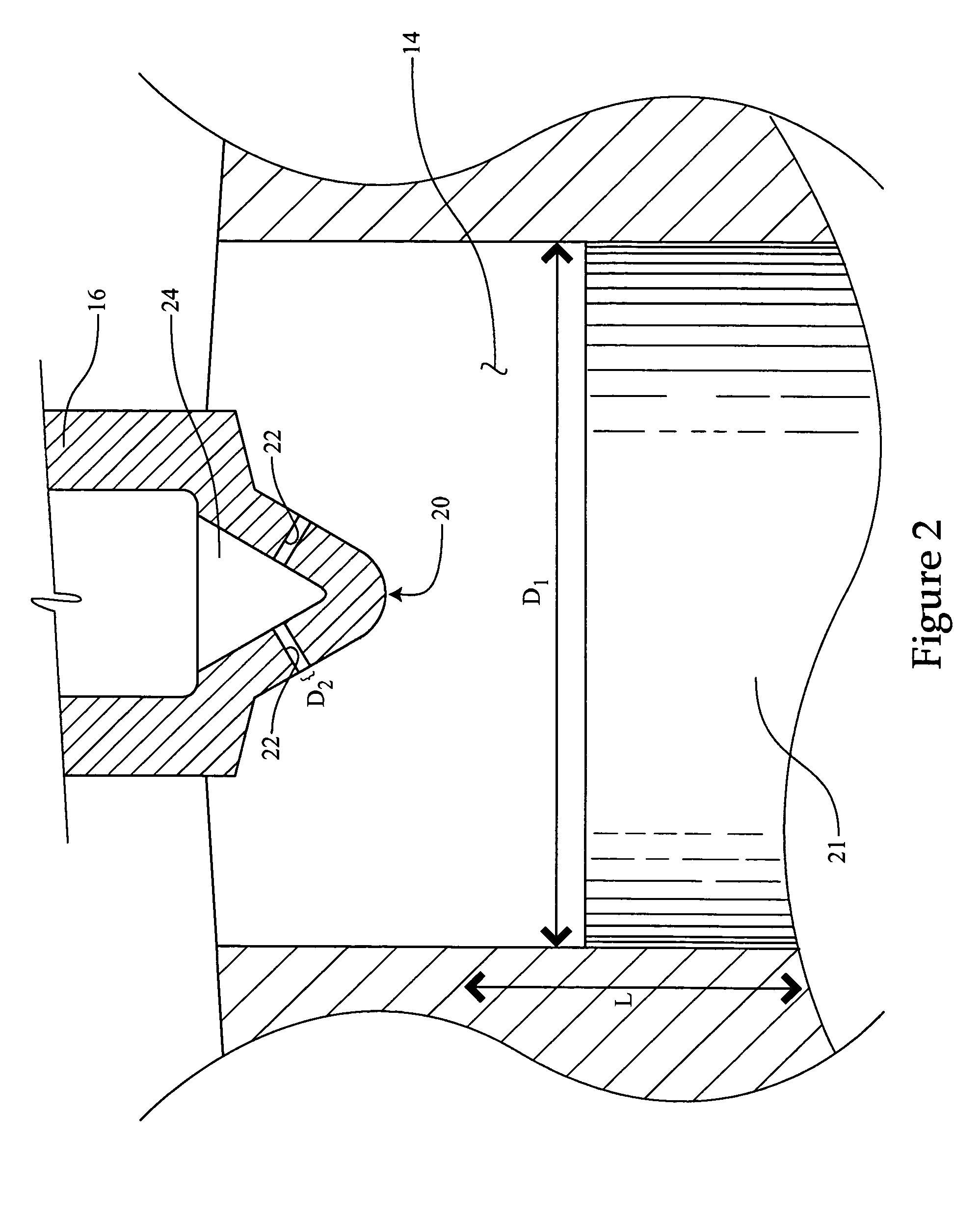

A method for determining the optimum fuel injection timing angle in a CI engine provided with means disposed in one or more cylinders for measuring Indicated Mean Effective Pressure. The pressure level during the power stroke of a piston is a direct correlate of engine torque being generated, and the timing of fuel injection can increase or decrease the amount of torque. Thus, maximum torque can be obtained by optimizing the timing of fuel injection. An algorithm in the ECM varies the timing of fuel injection in a narrow range until a IMEP maximum is achieved, which timing is then retained and employed until the engine operating conditions change. Thus, the invention can optimize fuel economy by optimizing the torque obtained from each injection of fuel into the cylinders.

Owner:DELPHI TECH IP LTD

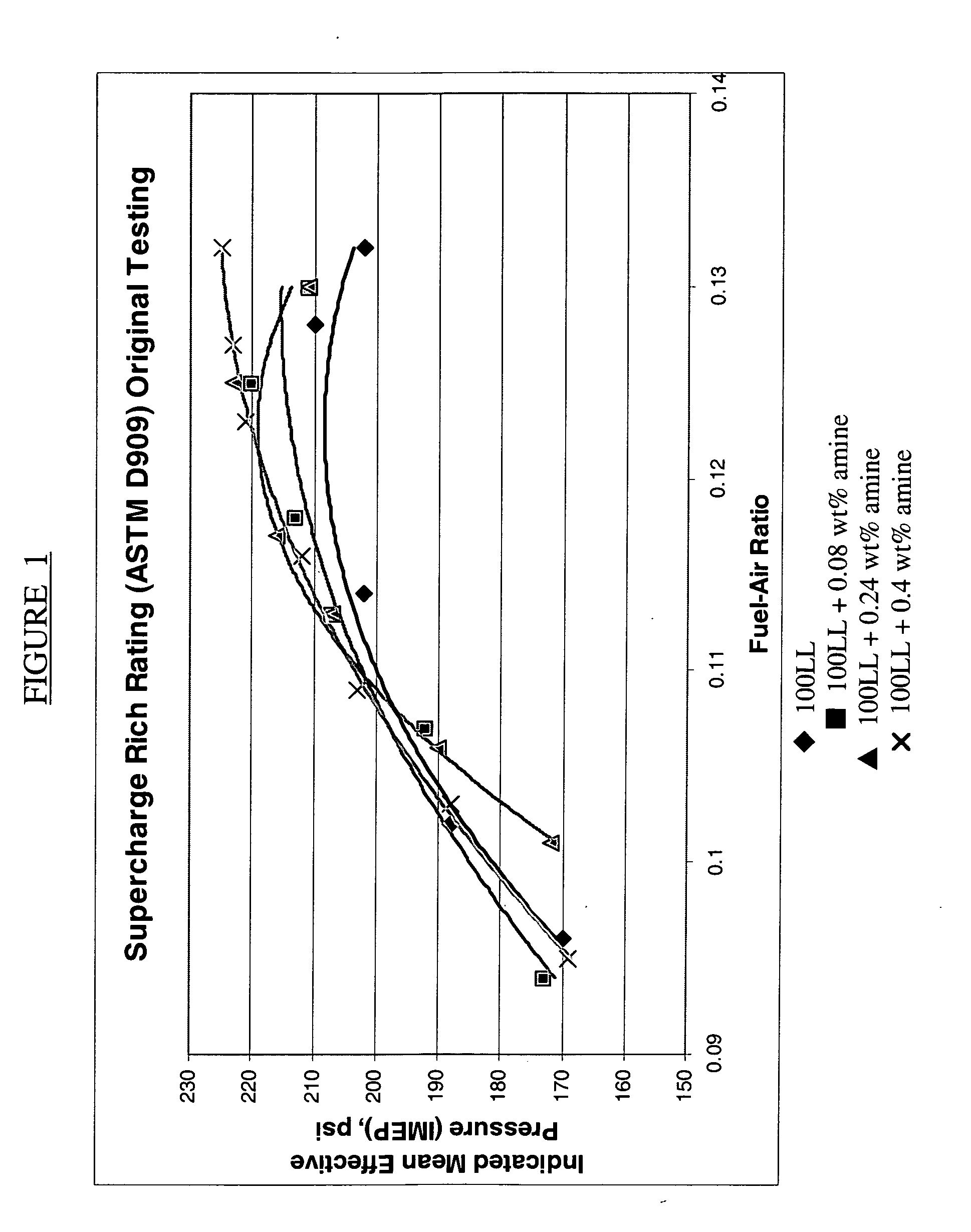

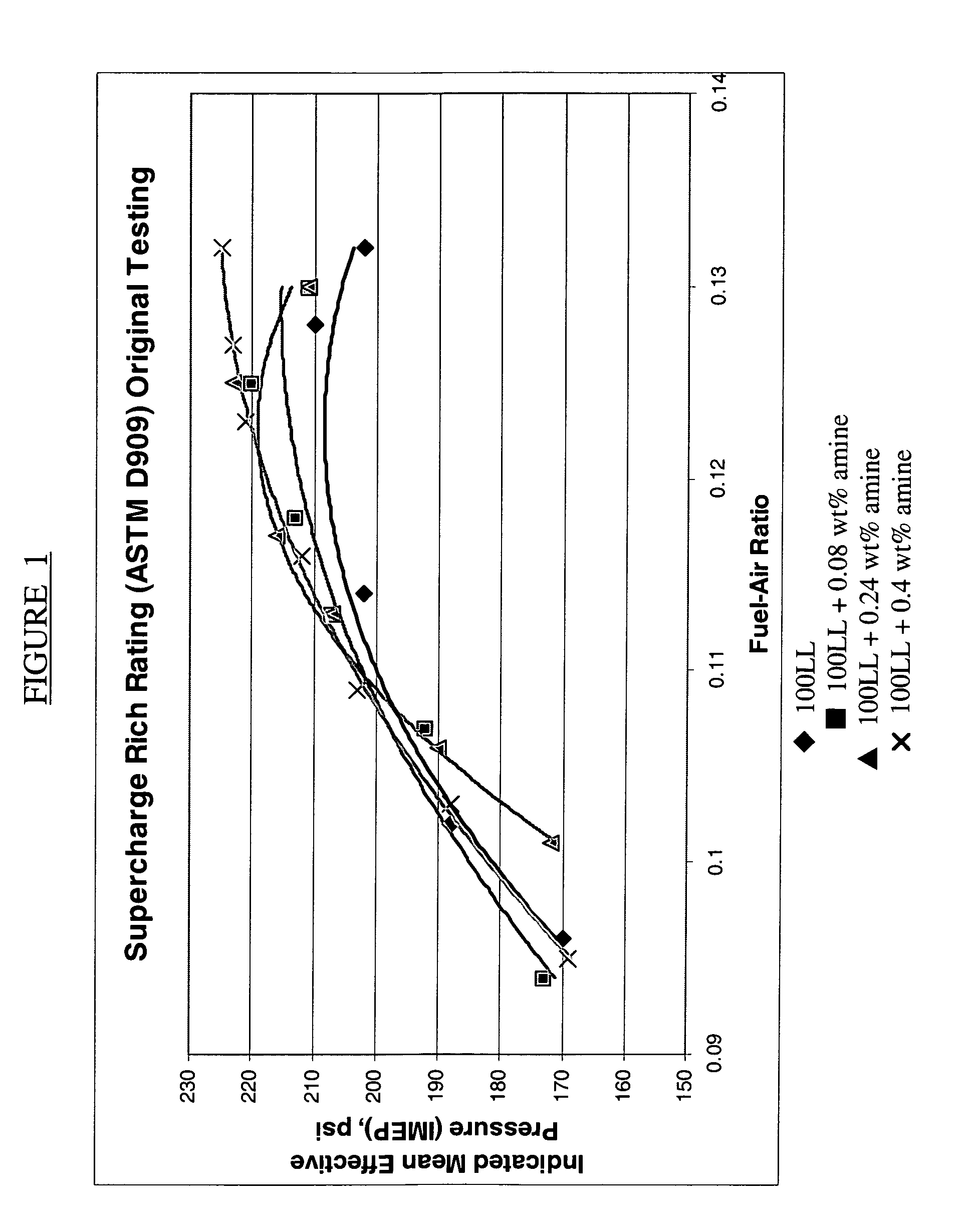

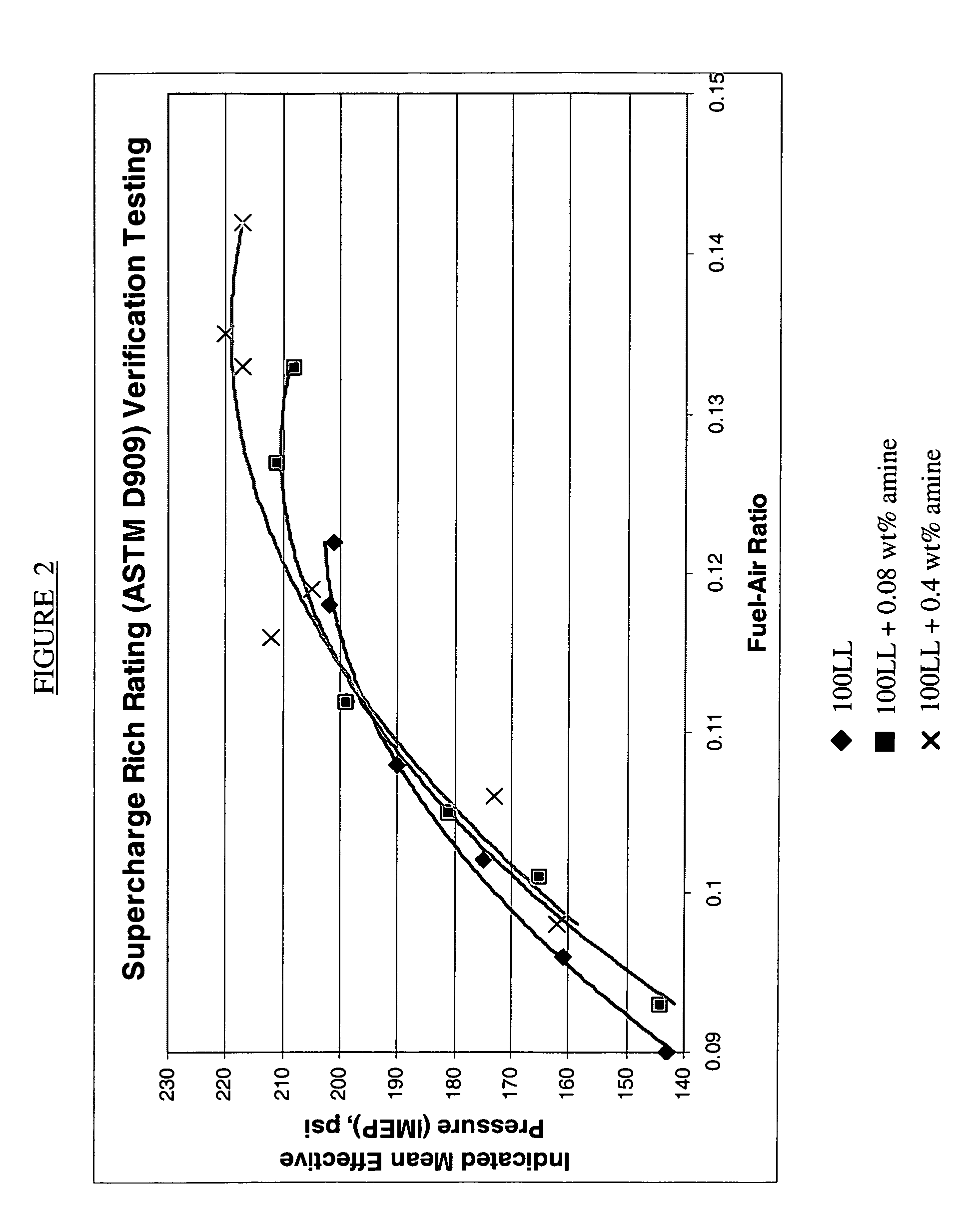

Leaded aviation gasoline

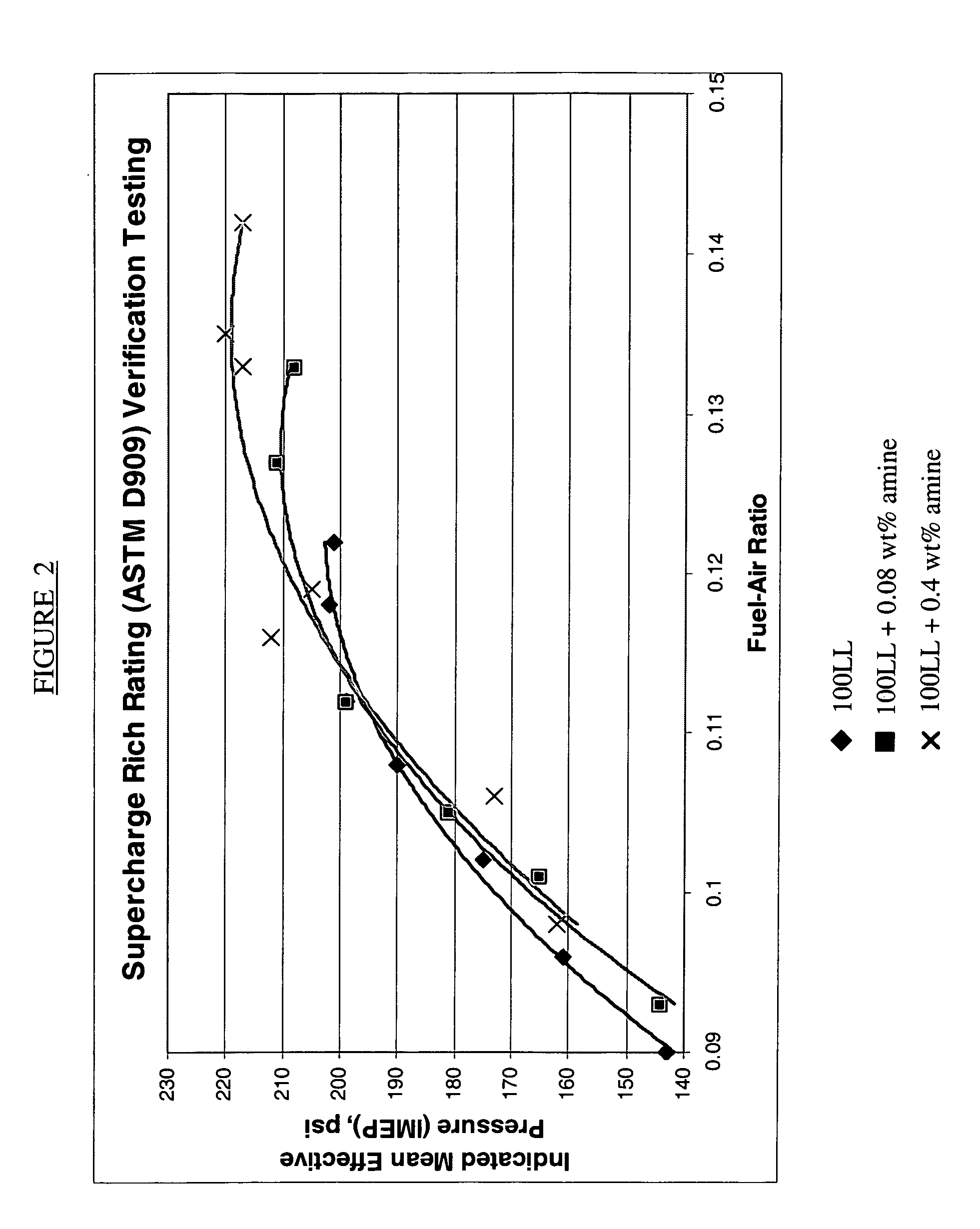

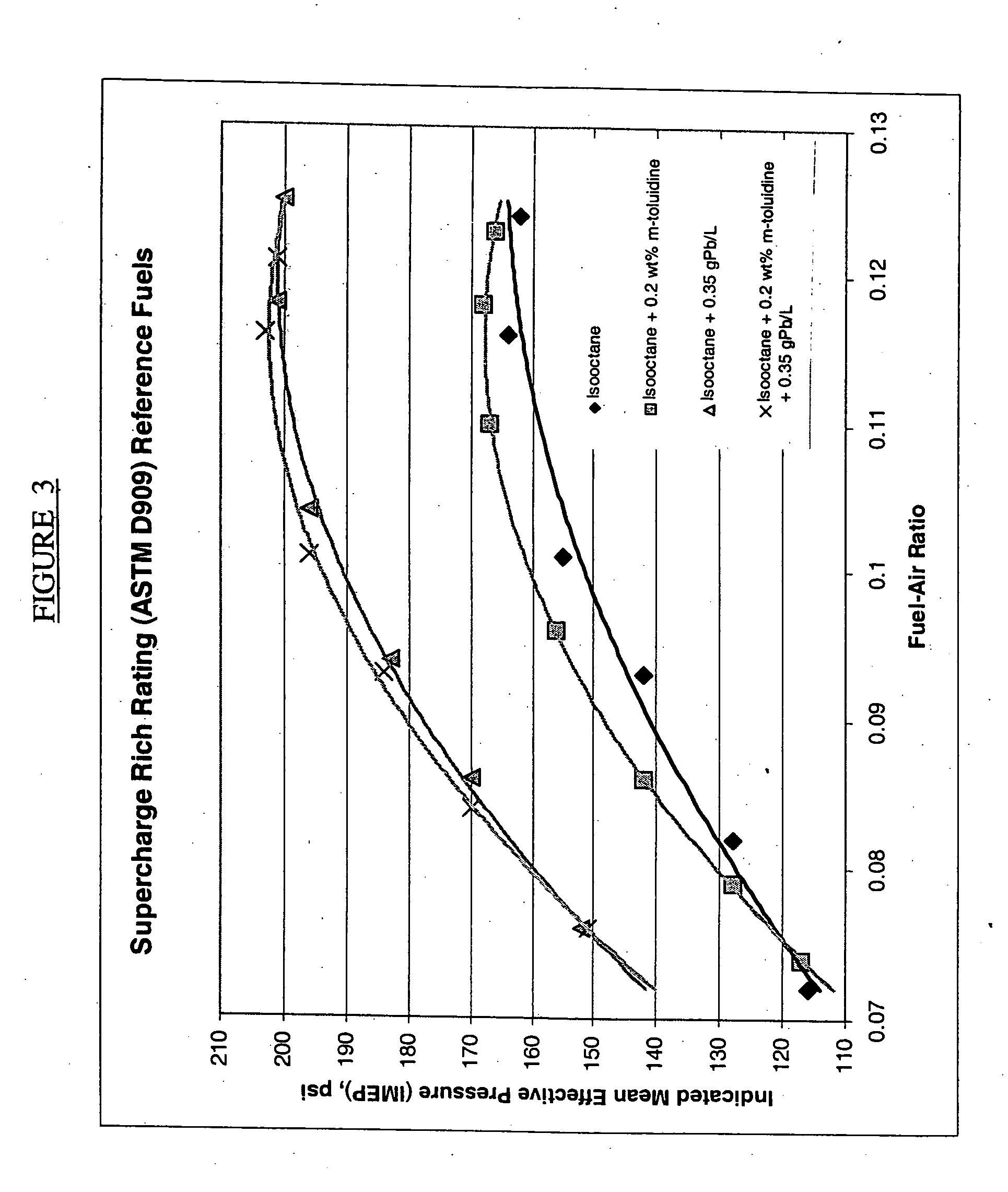

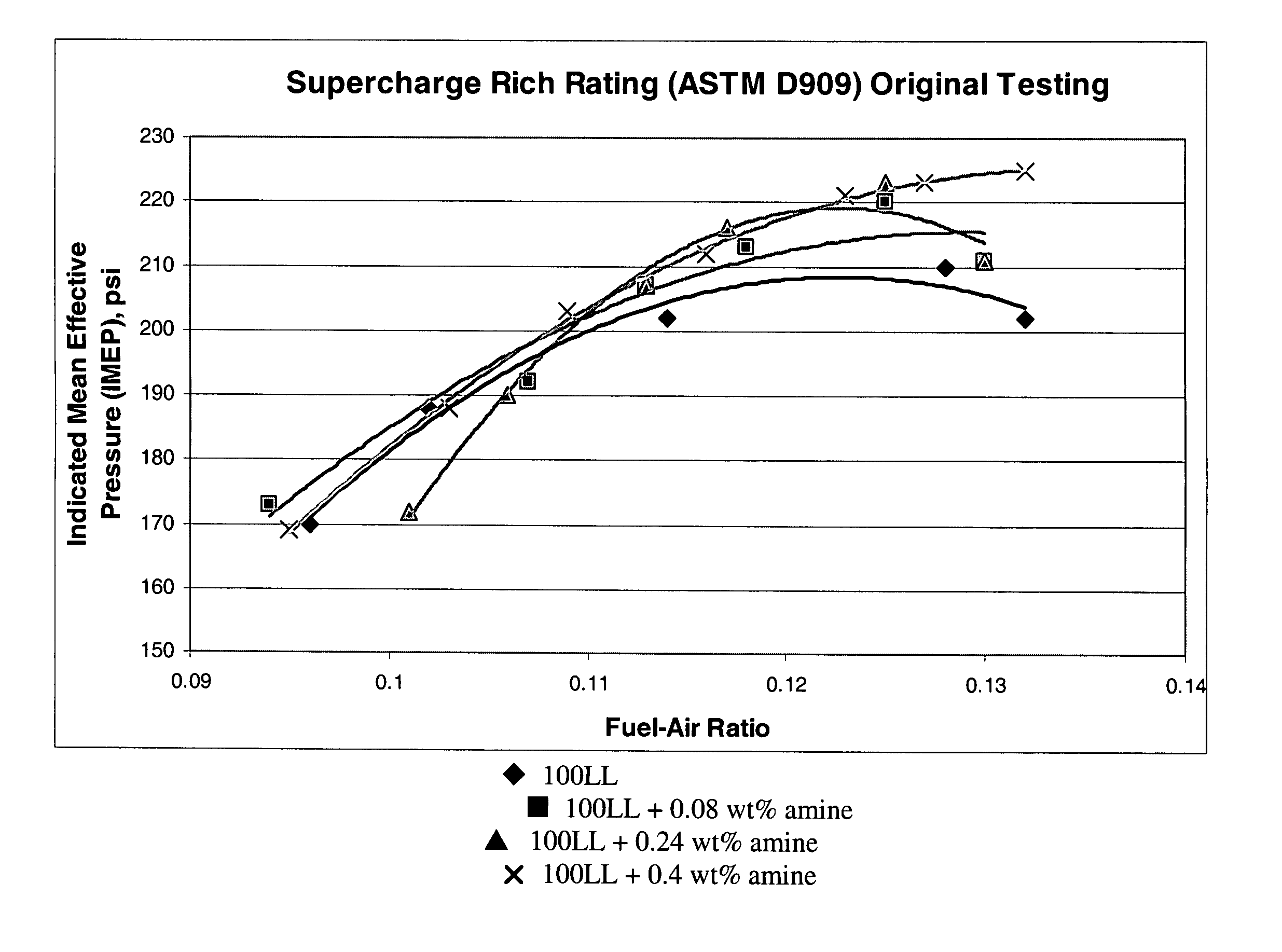

Aviation gasolines having an enhanced peak indicated mean effective pressure are provided by admixing with a leaded base aviation gasoline an aromatic amine of the formula NH2—Ar—(R1)n wherein R1 is selected from C1-C10 alkyl, halogen, and mixtures thereof provided that when R1 is alkyl it occupies the meta- or para-positions on the aromatic ring, Ar is a phenyl aromatic group and n is an integer from 0 to 3 to provide an aviation gasoline having a peak indicated mean effective pressure as determined by ASTM D-909 of greater than about 200 psi.

Owner:EXXON RES & ENG CO

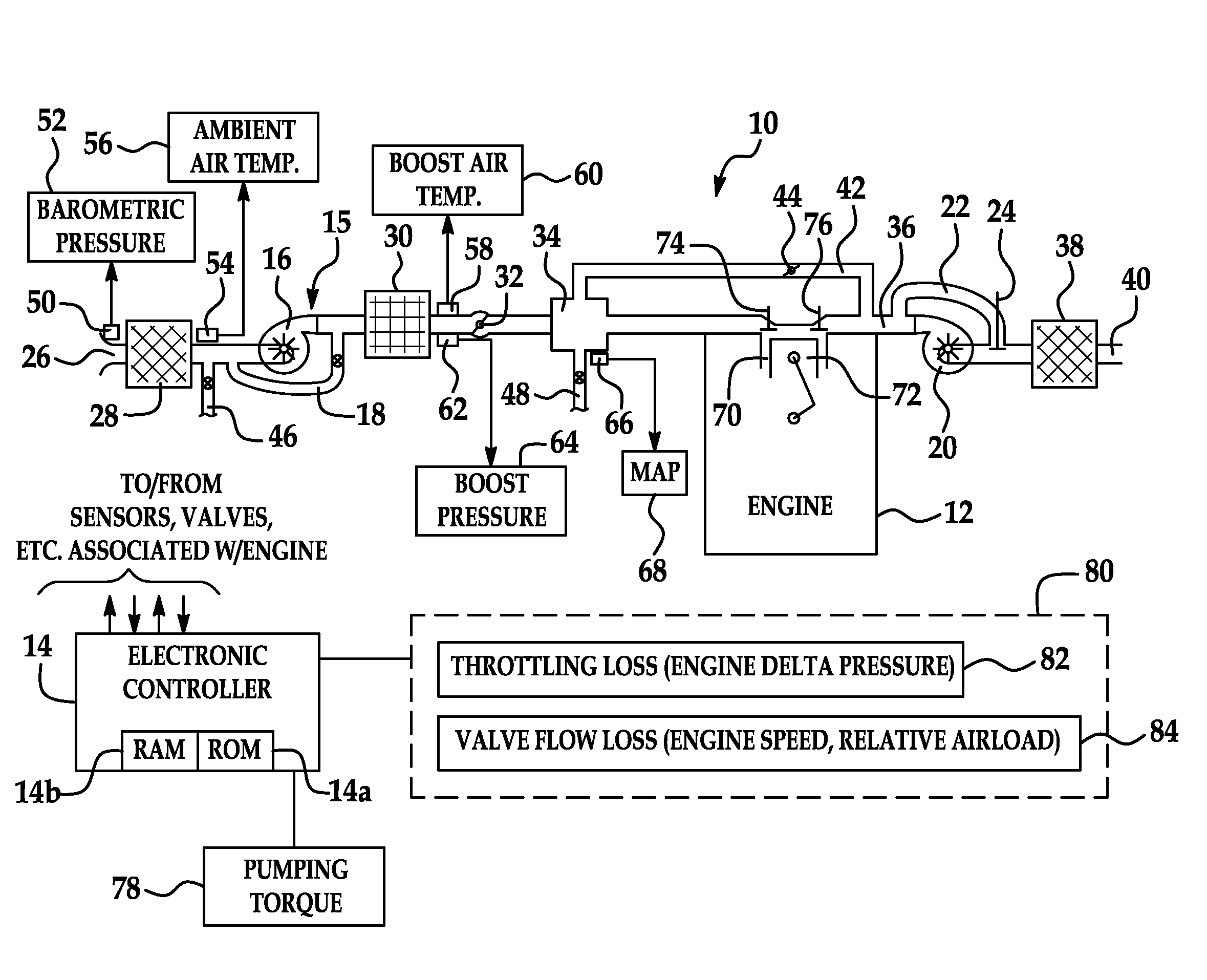

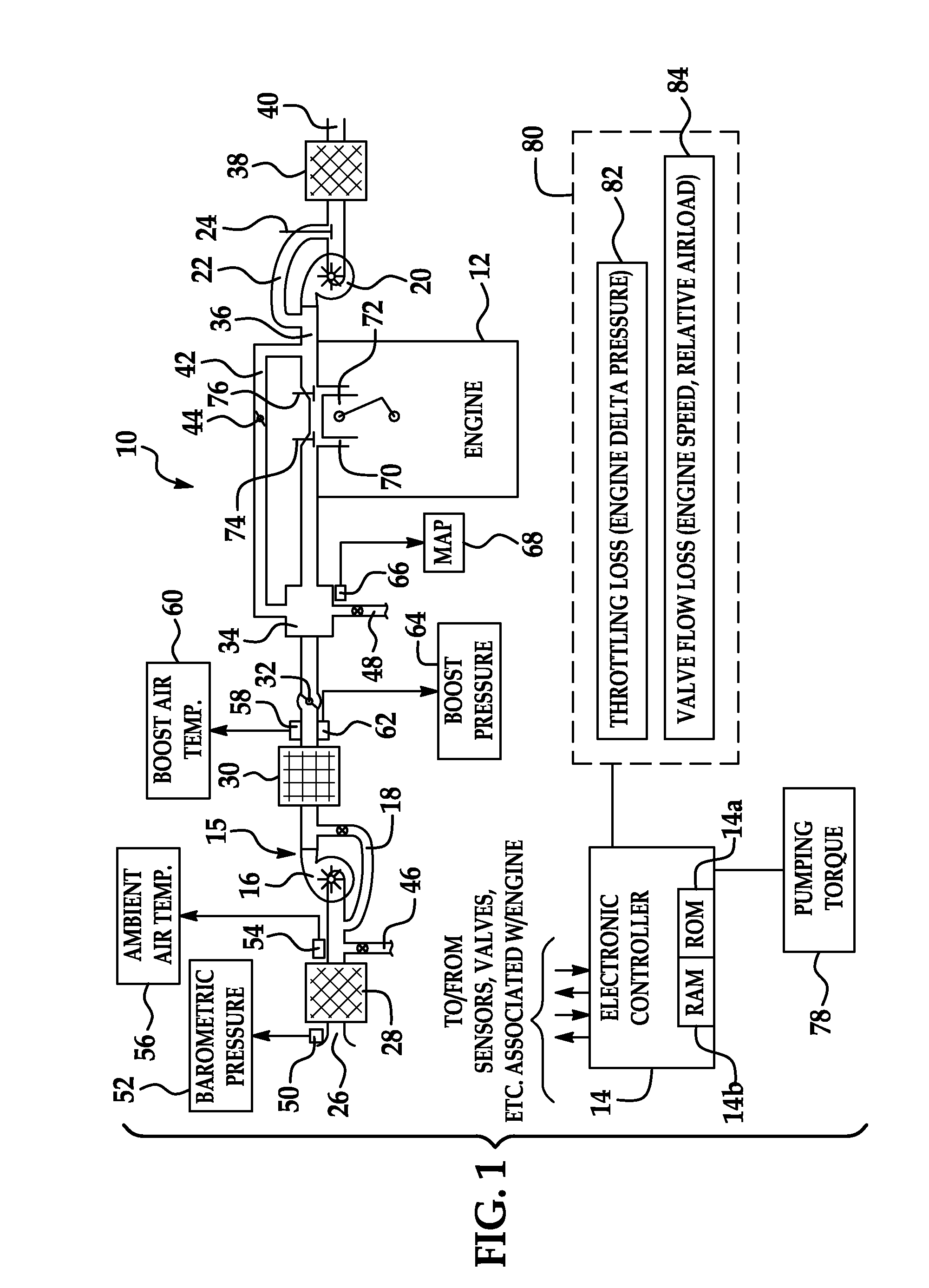

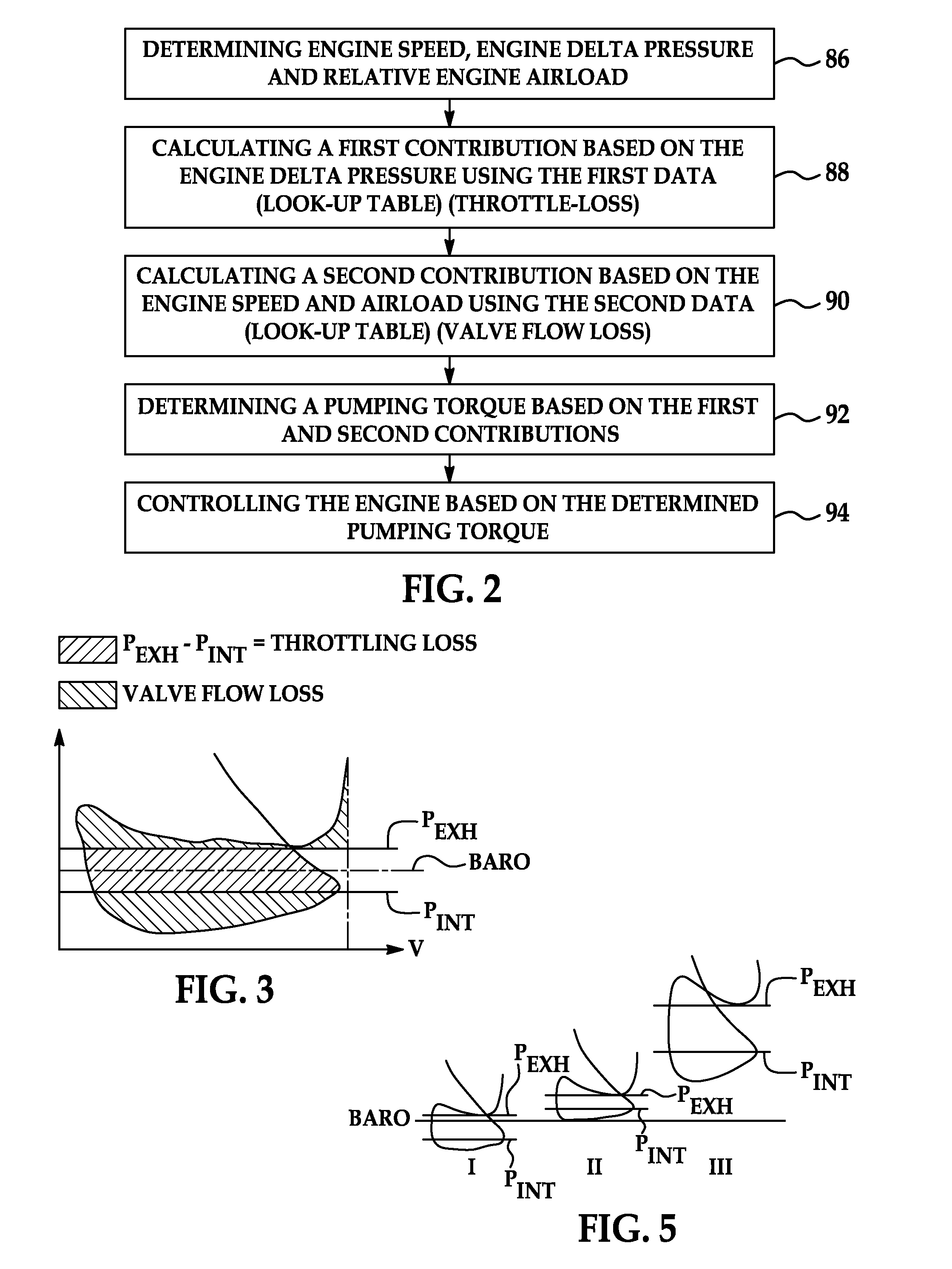

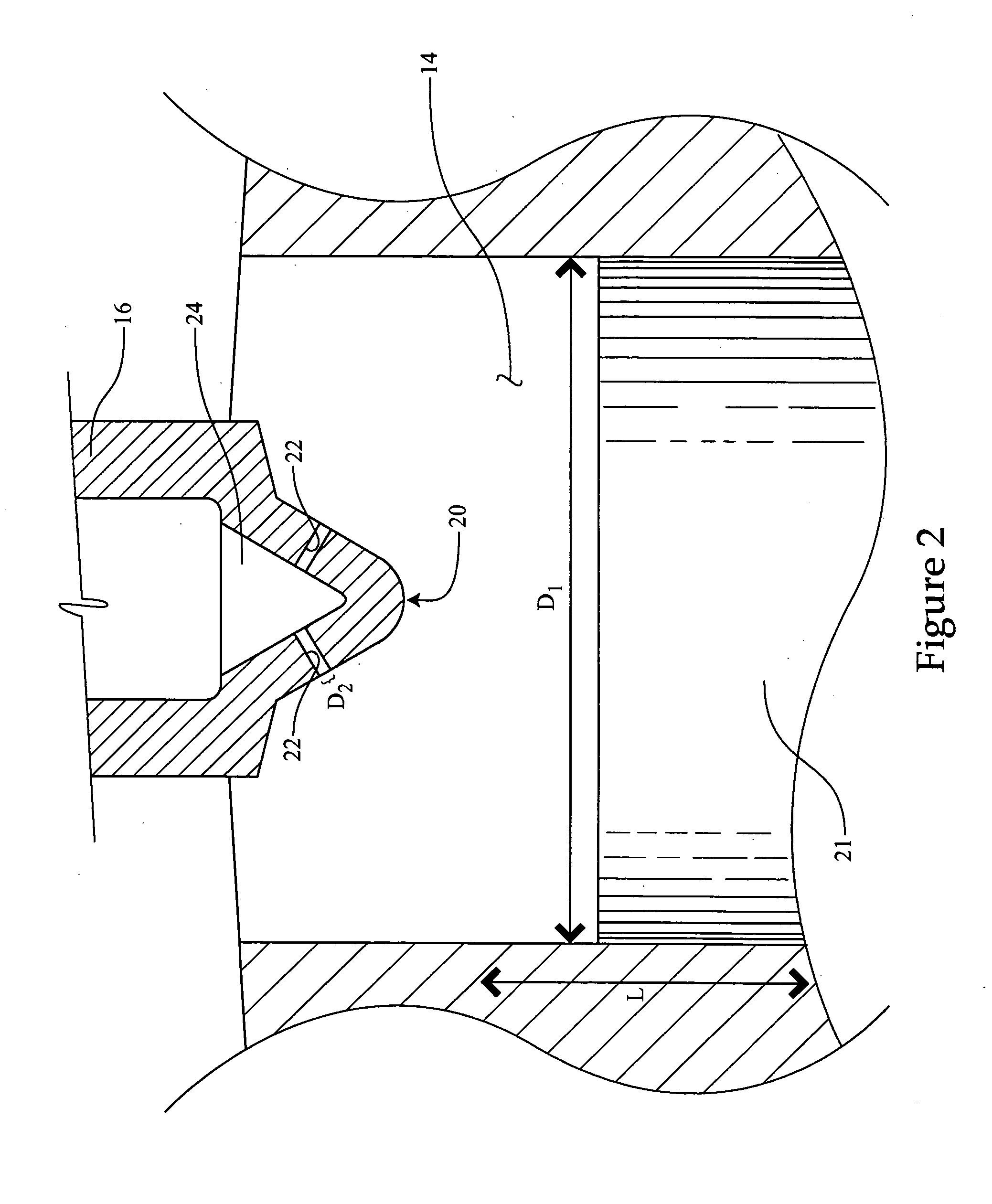

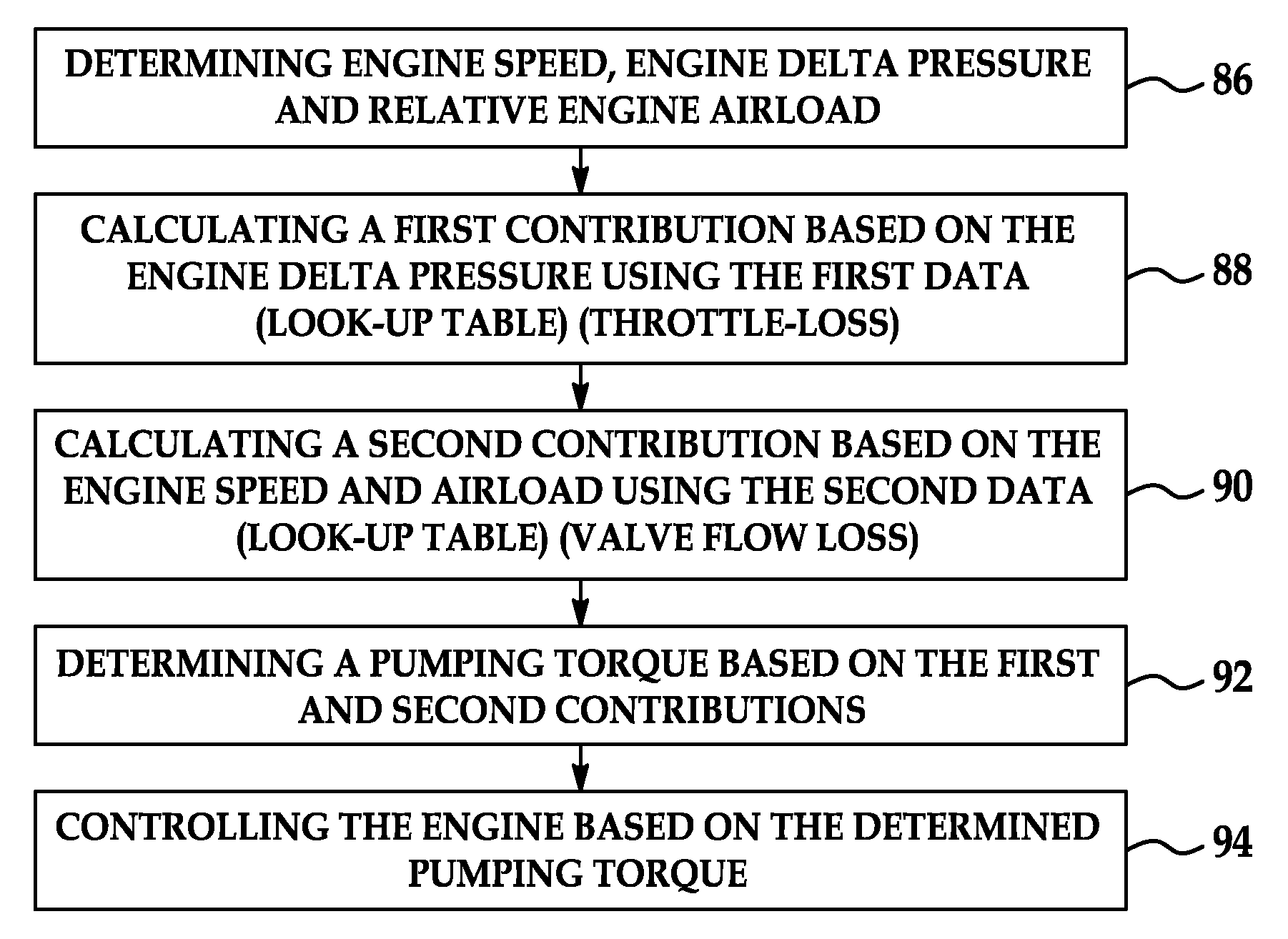

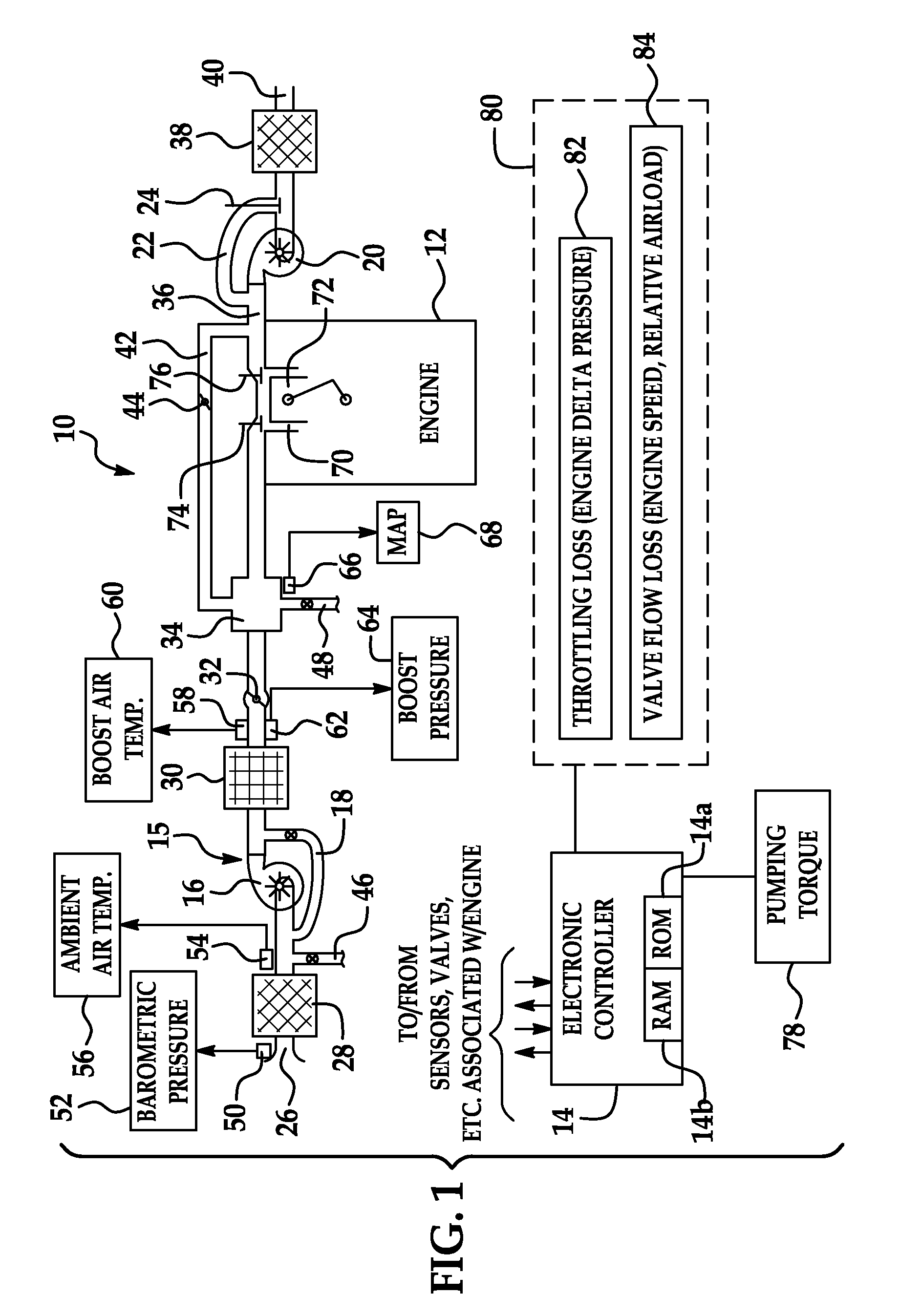

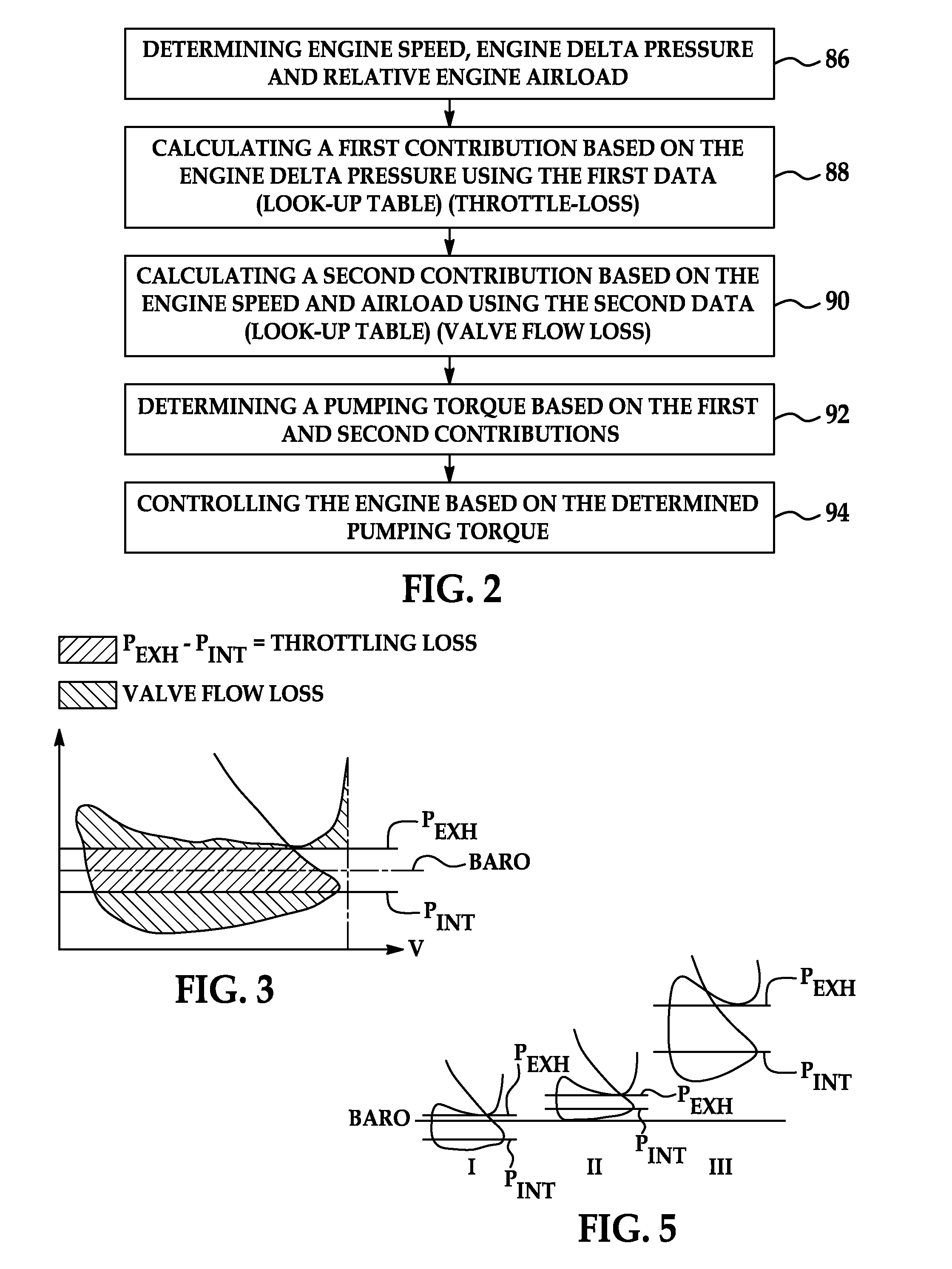

System and method for a pumping torque estimation model for all air induction configurations

InactiveUS20090018748A1Analogue computers for vehiclesElectrical controlControl theoryMean effective pressure

A system and method for controlling an engine involves providing a pumping torque estimation model. The model distinguishes between pumping losses due to throttling and pumping losses due to valve flow losses. The model is implemented by a pair of look-up tables. The data in each look-up table reflect Pumping Mean Effective Pressure (PMEP), which is indicative of the pumping work. The throttling loss table provides a first contribution based on an engine delta pressure. The valve flow loss table provides a second contribution based on an engine speed and a relative airload. The first and second contributions are summed and then multiplied by a predetermined factor to convert the pumping work (PMEP) into pumping torque. The model will work with naturally-aspirated, turbo-charged and super-charged air induction configurations and provides improved altitude compensation. The model will also work with both spark-ignition and compression-ignition configurations.

Owner:DELPHI TECH INC

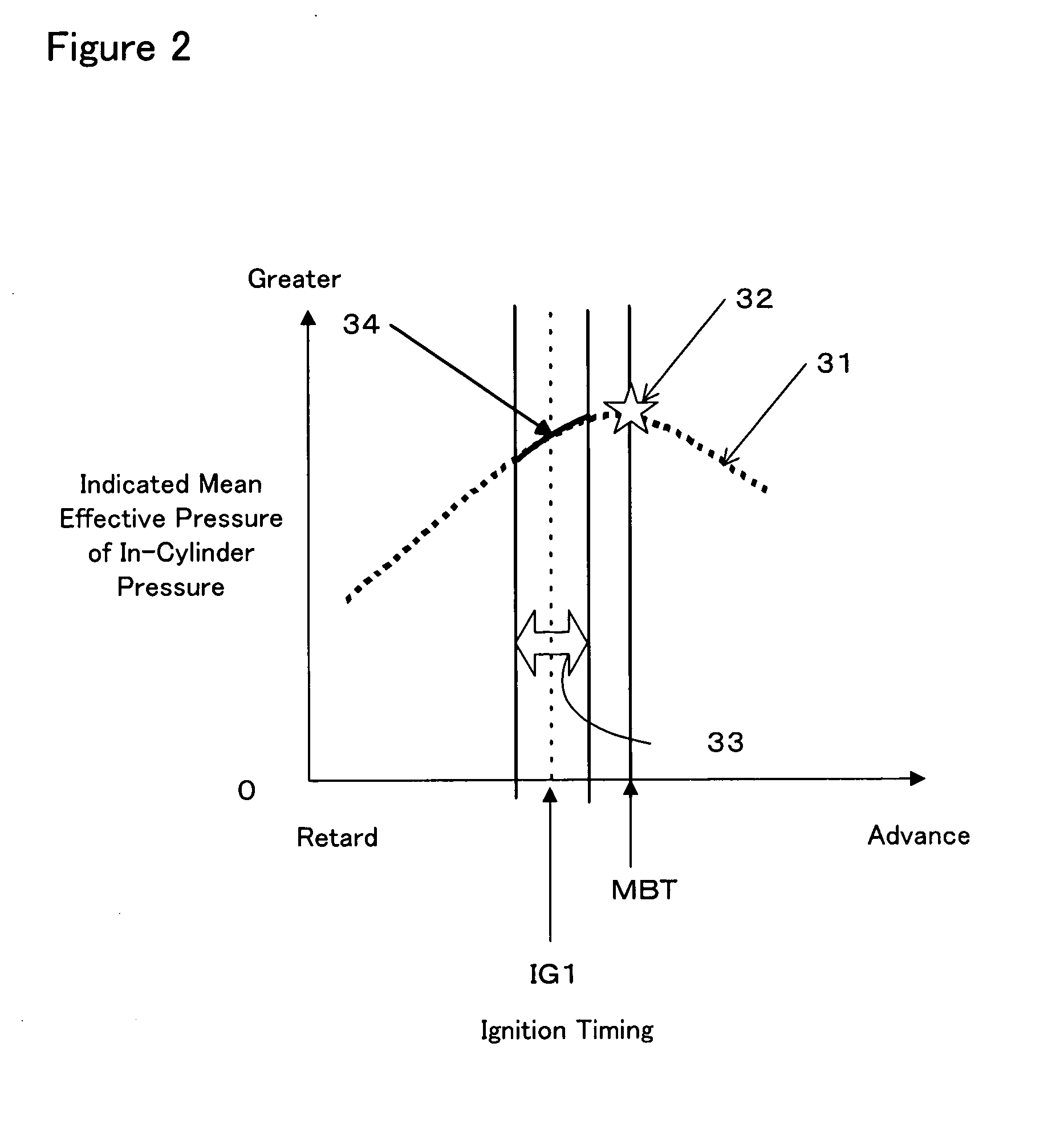

Ignition timing controlling device and method

InactiveUS7437233B2Increase pressureAvoid efficiencyAnalogue computers for vehiclesElectrical controlIgnition timingFeedback control

Owner:HONDA MOTOR CO LTD

Method for monitoring combustion stability of an internal combustion engine

ActiveUS20070021903A1Reduce quality problemsReduce in quantityAnalogue computers for vehiclesElectrical controlOperating pointCombustion

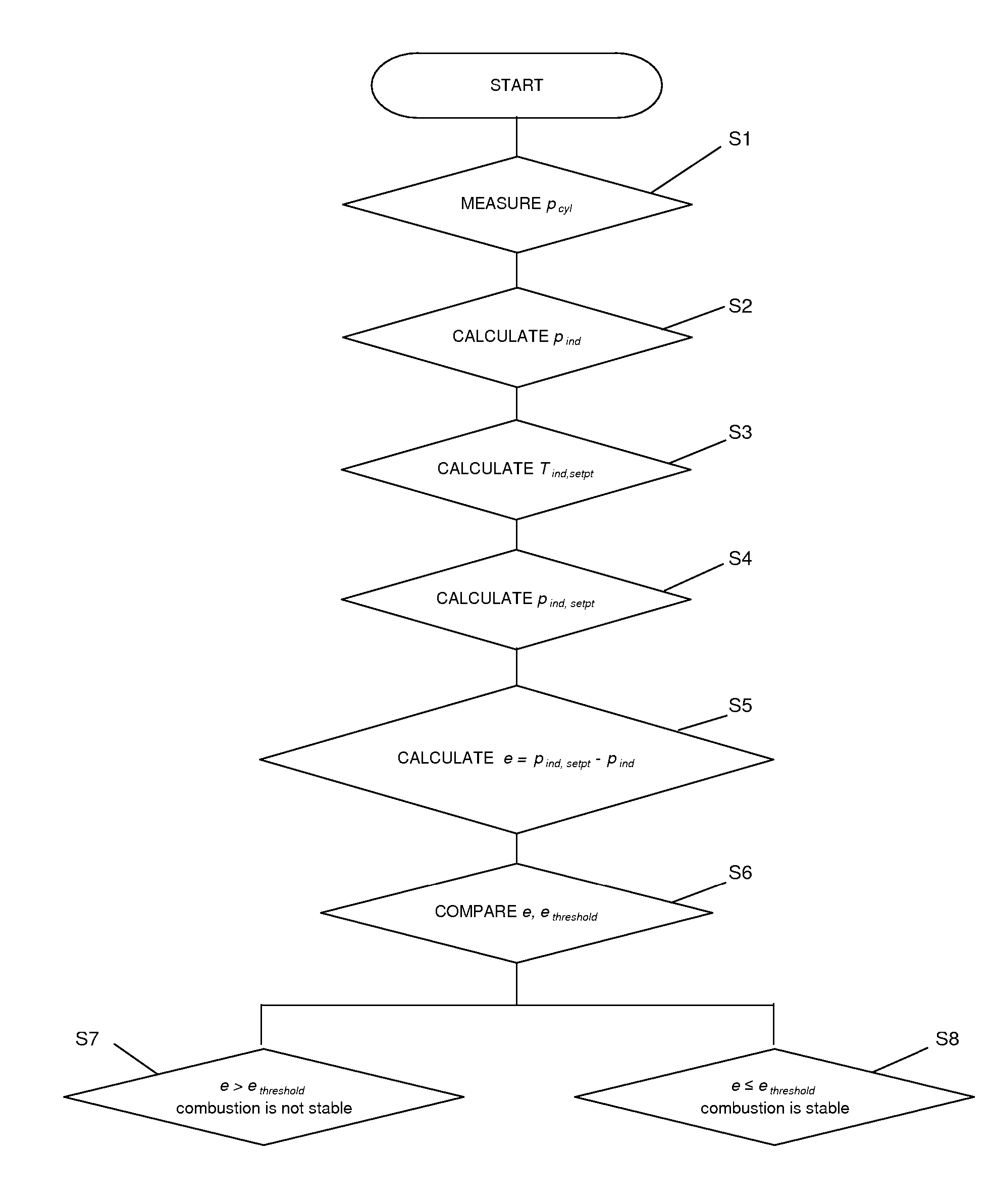

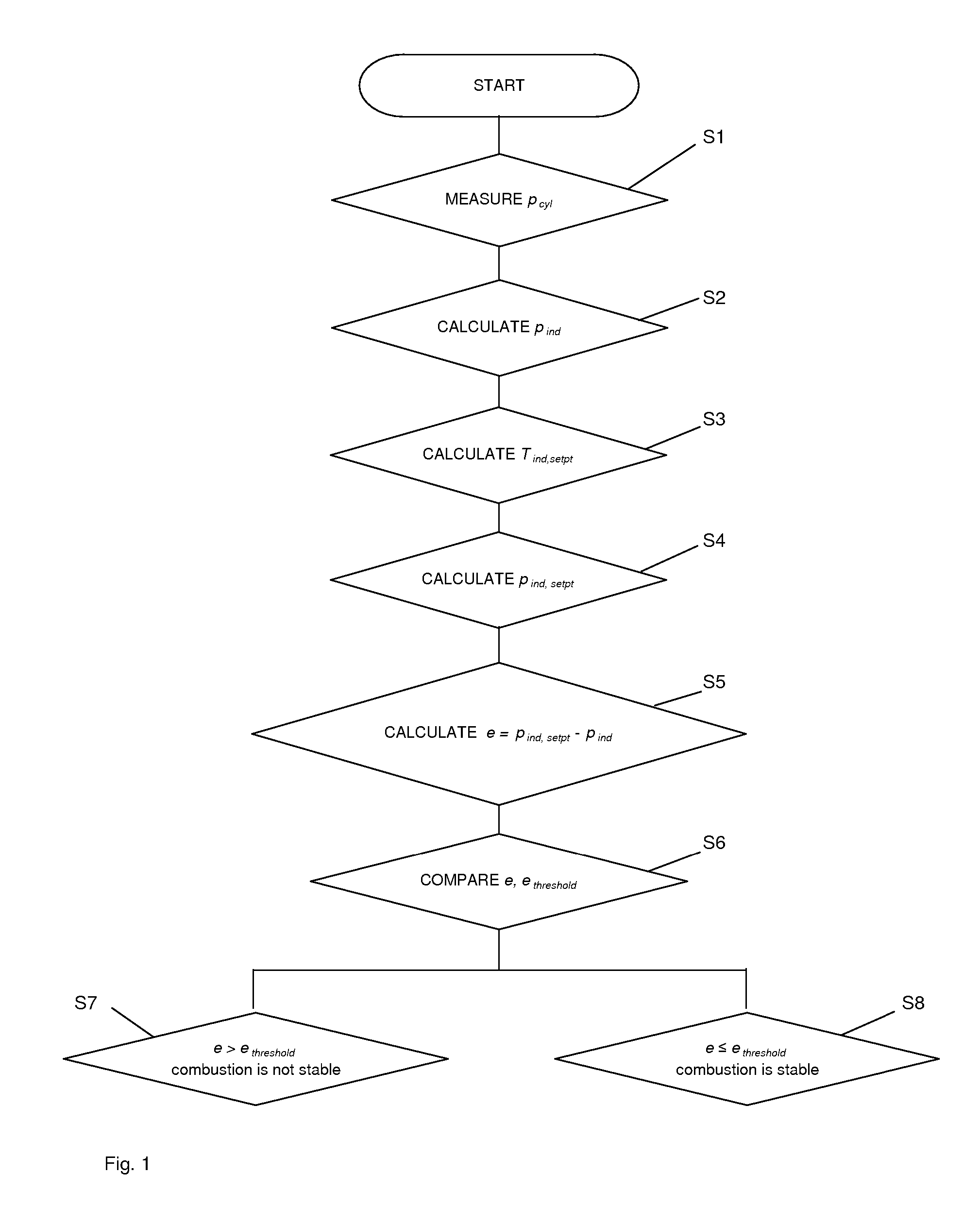

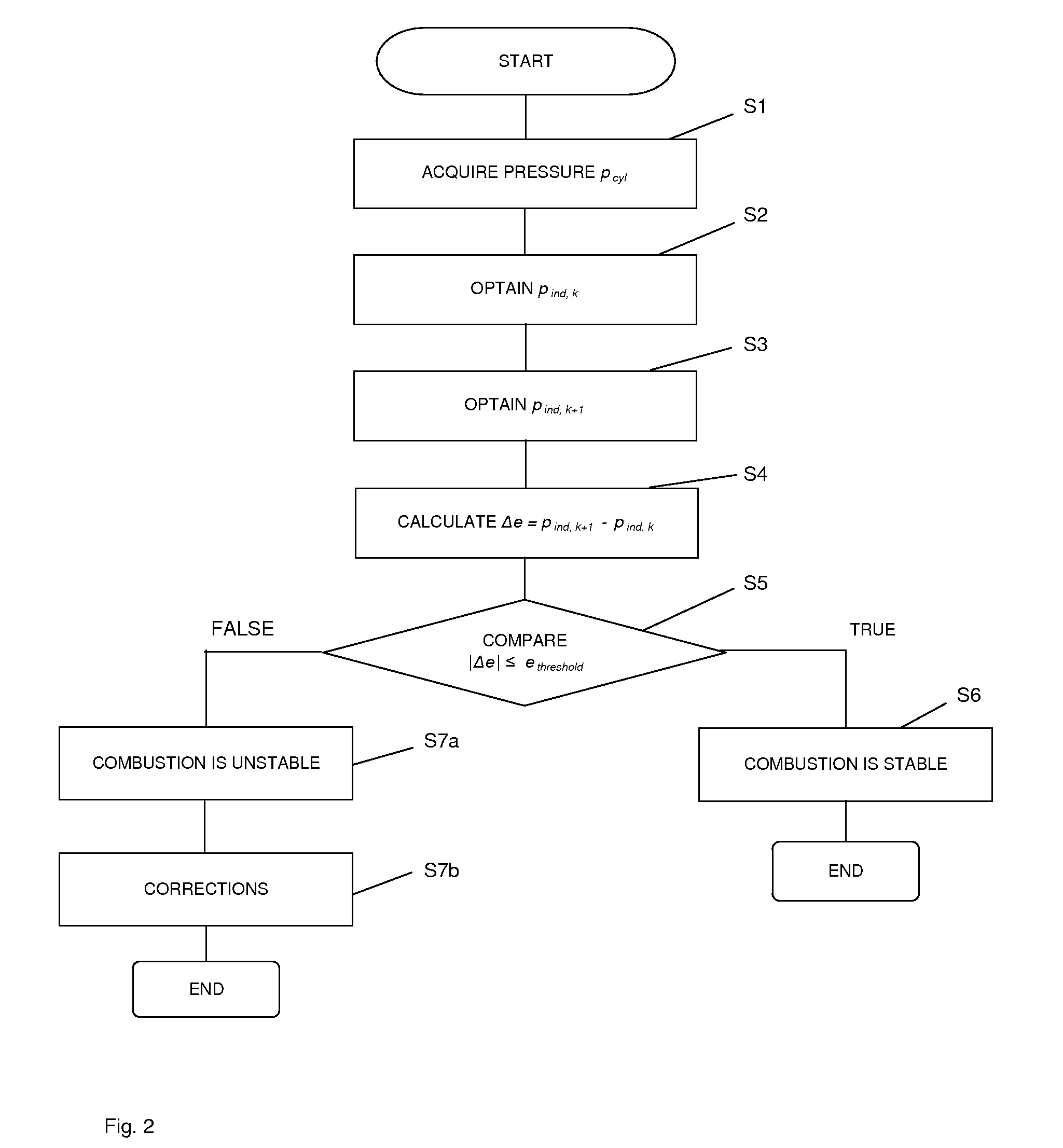

The present invention relates to a method for monitoring combustion stability of an internal combustion engine equipped with a crankshaft, an intake manifold and at least one cylinder, including the following steps: determining the absolute deviation e of indicated mean effective pressure pind or indicated torque Tind with respect to their actual set point, i.e., with respect to actual indicated mean effective pressure set point pind,setpt or actual indicated torque set point Tind,setpt, namely Δpind or ΔTind, or alternatively determining the relative change Δe in said deviation between two consecutive combustion cycles k, k+1 of said at least one cylinder, i.e., determining (Δpind,k+1−pind,k) or (ΔTind,k+1−ΔTind,k) or determining the relative change Δe in angular acceleration ω′ of the crankshaft between two consecutive combustion cycles k, k+1, i.e., (Δω′k+1−Δω′k), and comparing said determinated deviation e or said change Δe with a predetermined engine operating point dependent threshold ethreshold or Δethreshold in order to decide if the combustion is stable or not by means of the following inequalities: |e|>ethreshold or |Δe|>Δethreshold means combustion is not stable, |e|≦ethreshold or |Δe|≦Δethreshold means combustion is stable. The method is preferably applied to homogeneous charge combustion ignition engines (HCCI).

Owner:FORD GLOBAL TECH LLC

Leaded aviation gasoline

Aviation gasolines having an enhanced peak indicated mean effective pressure are provided by admixing with a leaded base aviation gasoline an aromatic amine of the formula NH2—Ar—(R1)n wherein R1 is selected from C1-C10 alkyl, halogen, and mixtures thereof provided that when R1 is alkyl it occupies the meta- or para-positions on the aromatic ring, Ar is a phenyl aromatic group and n is an integer from 0 to 3 to provide an aviation gasoline having a peak indicated mean effective pressure as determined by ASTM D-909 of greater than about 200 psi.

Owner:EXXON RES & ENG CO

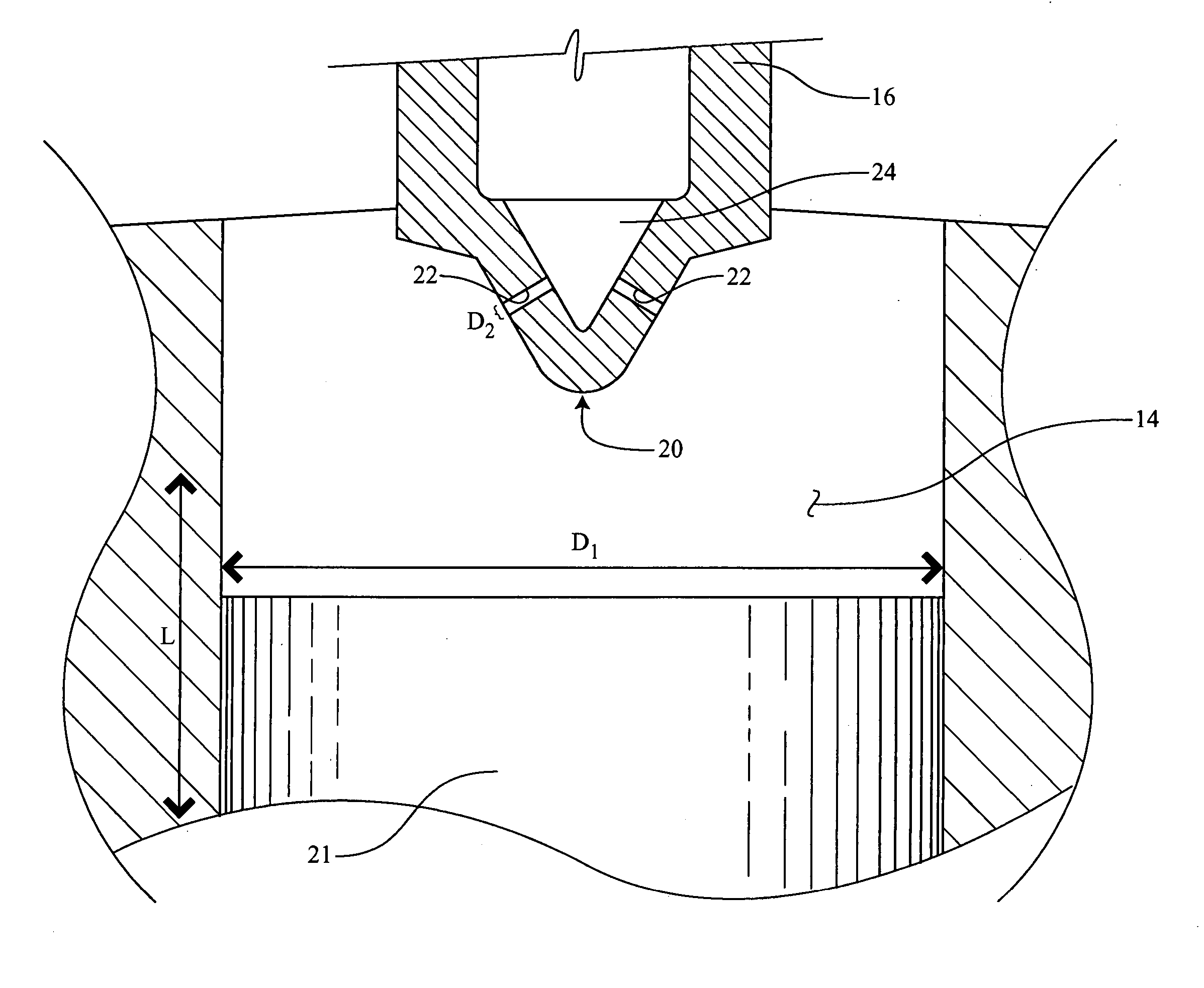

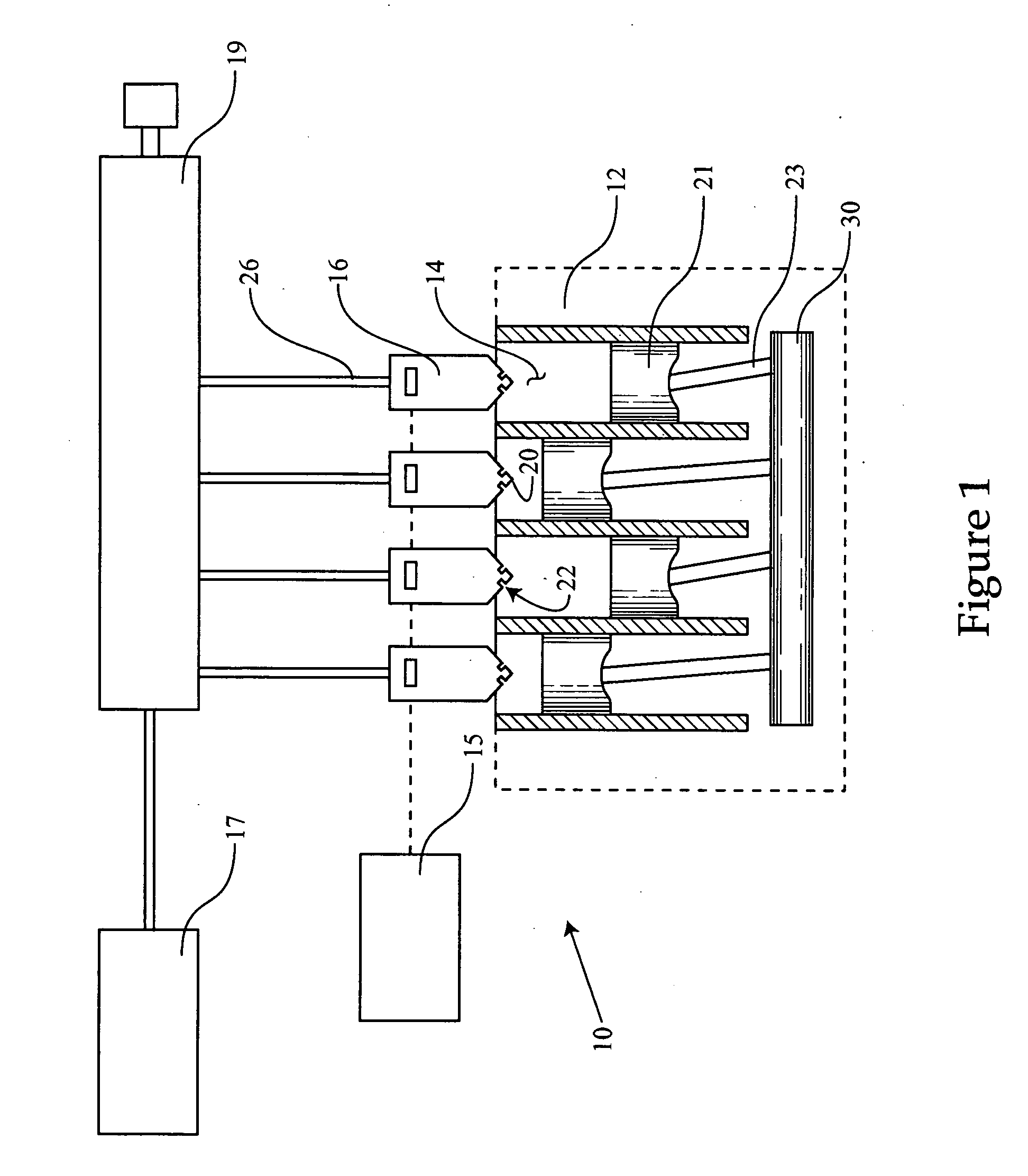

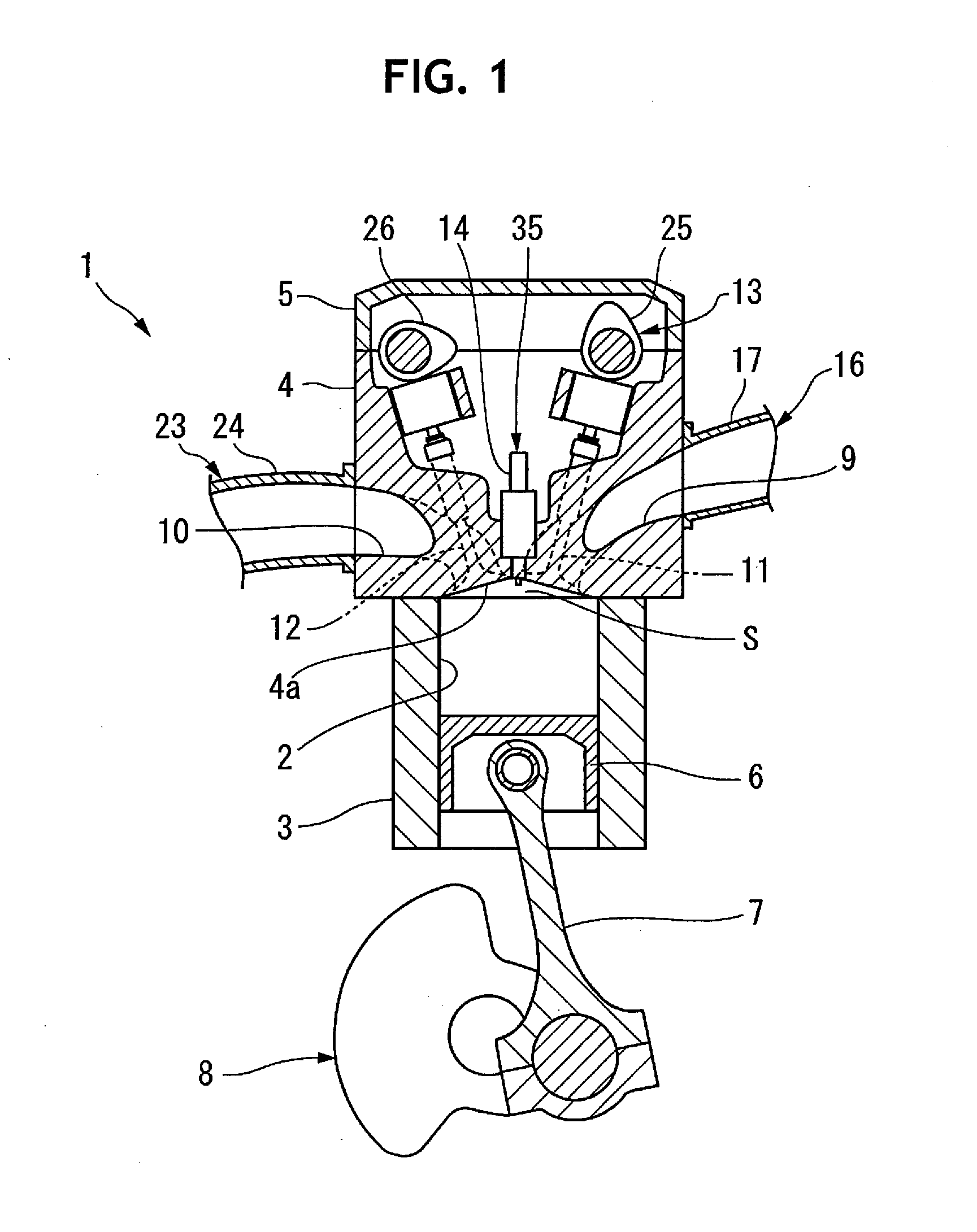

Internal combustion engine

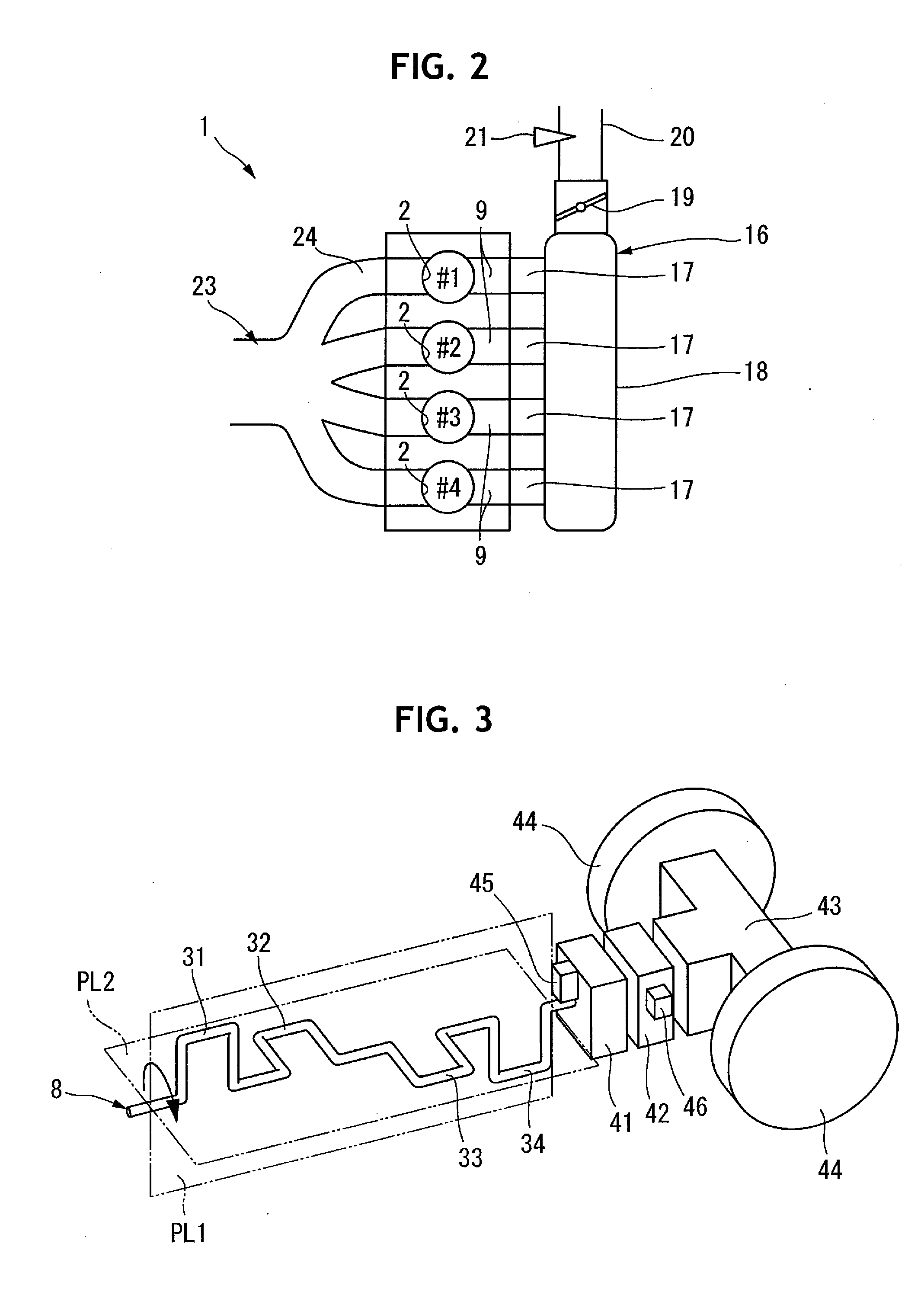

ActiveUS20060201478A1Sufficient quantityInternal combustion piston enginesSpray nozzlesInternal combustion engineCrankshaft

The present disclosure provides an internal combustion engine having an engine housing with at least one cylinder that has diameter less than about 3 inches. A fuel injector is provided and disposed at least partially within the at least one cylinder, and includes a plurality of outlet orifices having a diameter between about 50 microns and about 110 microns. The disclosure further provides a method of operating an internal combustion engine. The method includes the steps of rotating an engine crank shaft of the engine at a speed greater than about 5000 revolutions per minute, injecting a quantity of fuel into each of the cylinders, and burning at least every fourth piston stroke a sufficient quantity of the injected fuel to yield a brake mean effective pressure of at least about 200 lbs. per square inch.

Owner:CATERPILLAR INC

System and method for a pumping torque estimation model for all air induction configurations

A system and method for controlling an engine involves providing a pumping torque estimation model. The model distinguishes between pumping losses due to throttling and pumping losses due to valve flow losses. The model is implemented by a pair of look-up tables. The data in each look-up table reflect Pumping Mean Effective Pressure (PMEP), which is indicative of the pumping work. The throttling loss table provides a first contribution based on an engine delta pressure. The valve flow loss table provides a second contribution based on an engine speed and a relative airload. The first and second contributions are summed and then multiplied by a predetermined factor to convert the pumping work (PMEP) into pumping torque. The model will work with naturally-aspirated, turbo-charged and super-charged air induction configurations and provides improved altitude compensation. The model will also work with both spark-ignition and compression-ignition configurations.

Owner:DELPHI TECH INC

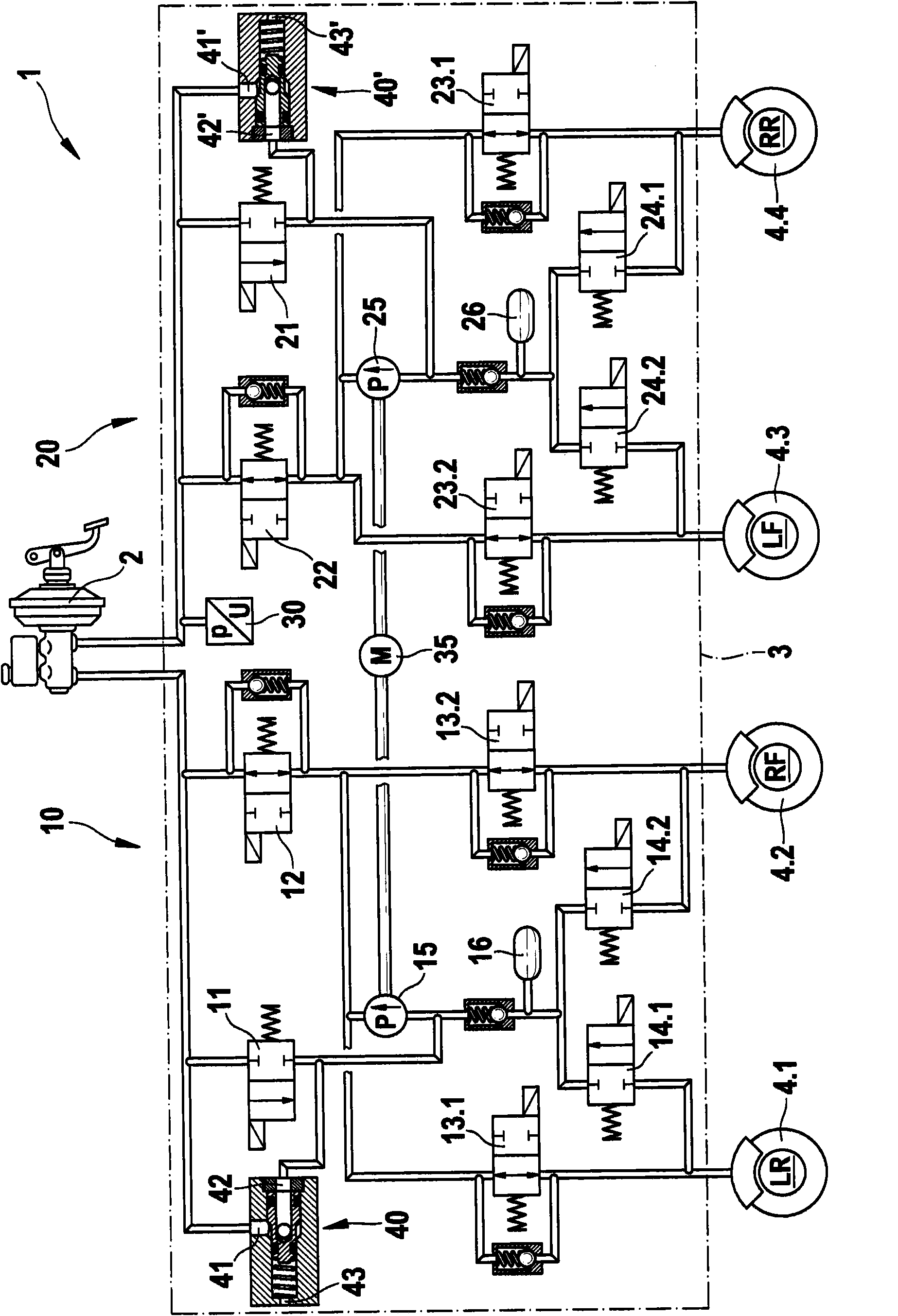

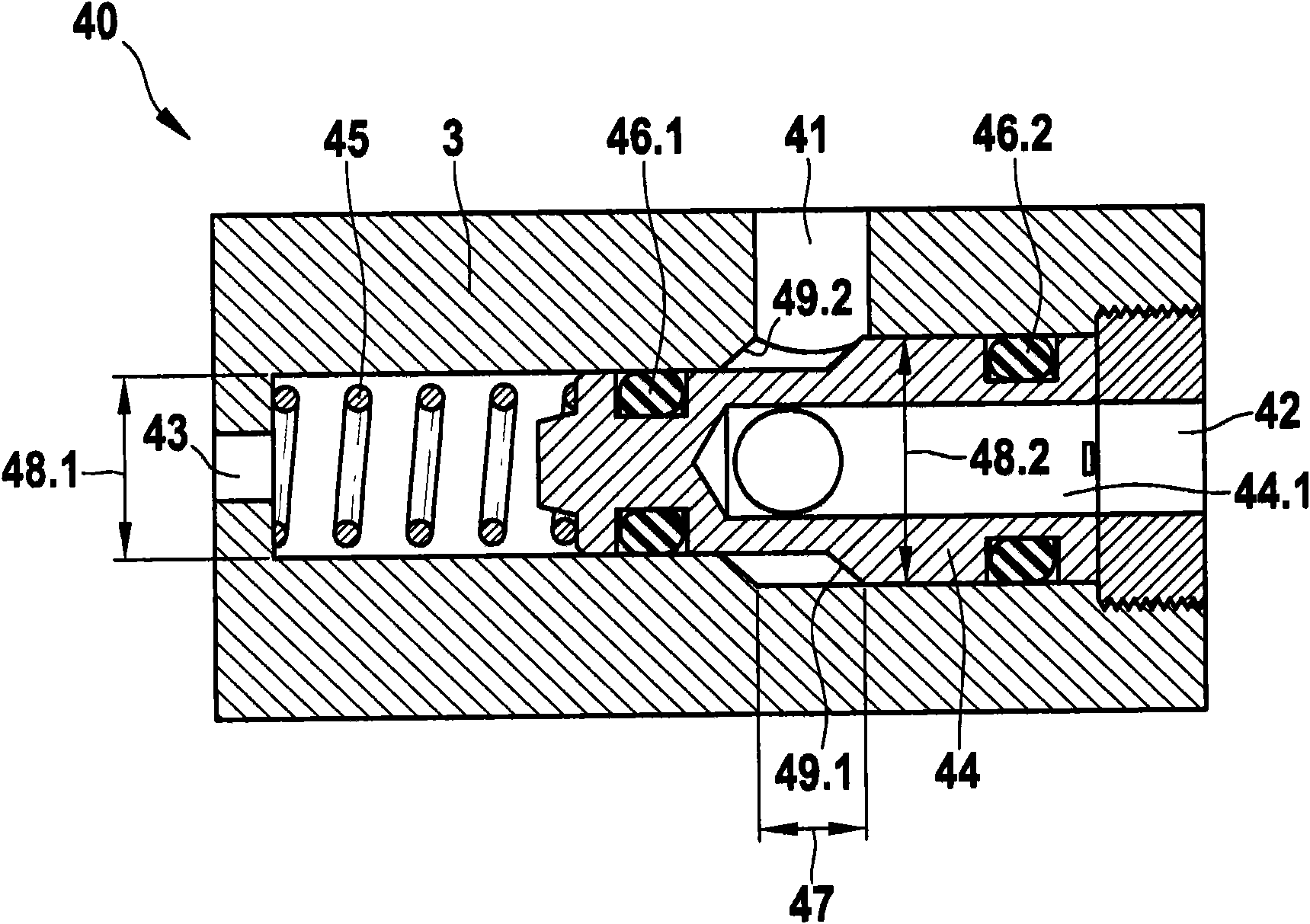

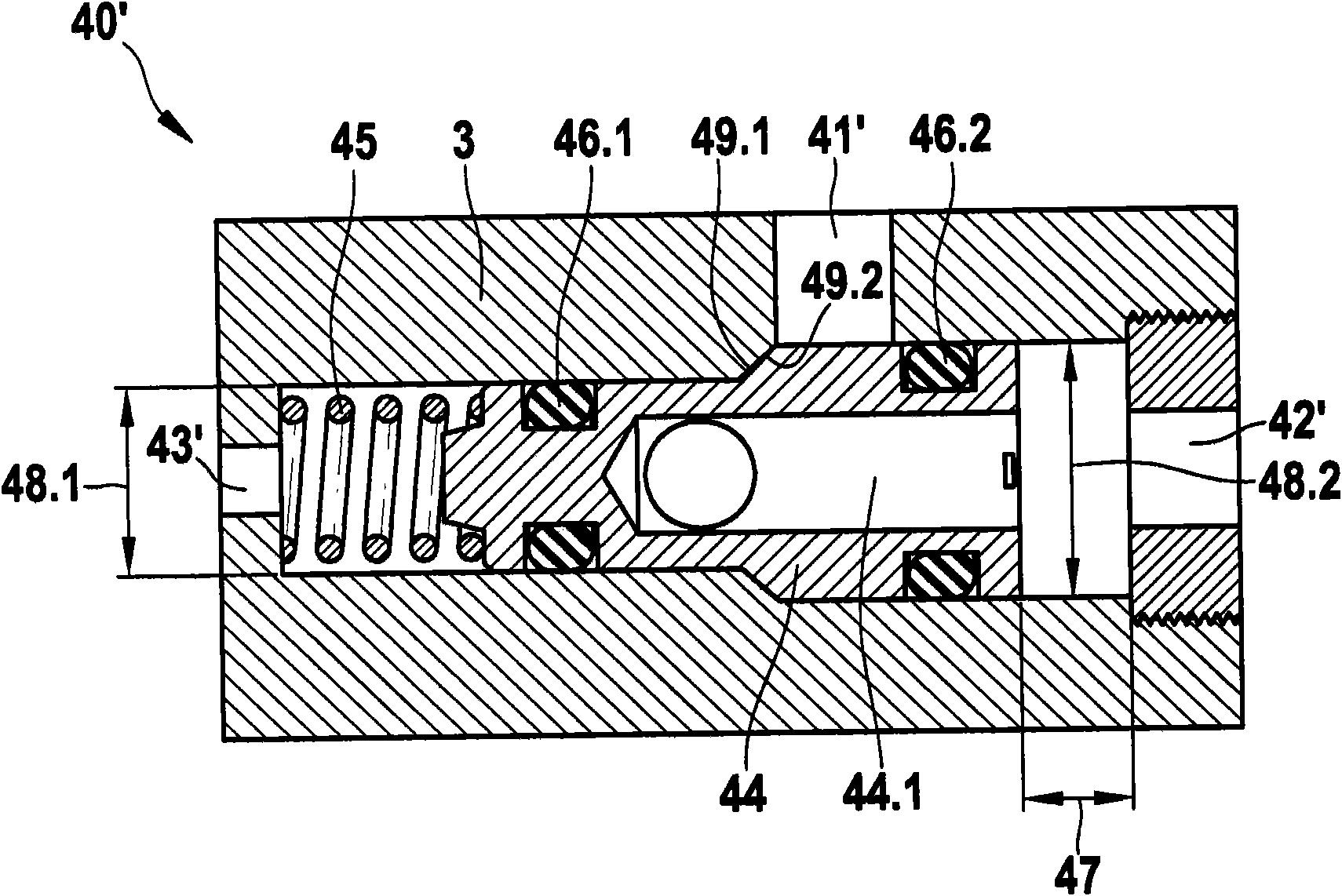

Control valve for a vehicle brake system and vehicle brake system comprising such a control valve

ActiveCN102066169AClose reliableAvoid Radial PreloadOperating means/releasing devices for valvesServomotor componentsEngineeringControl valves

Owner:ROBERT BOSCH GMBH

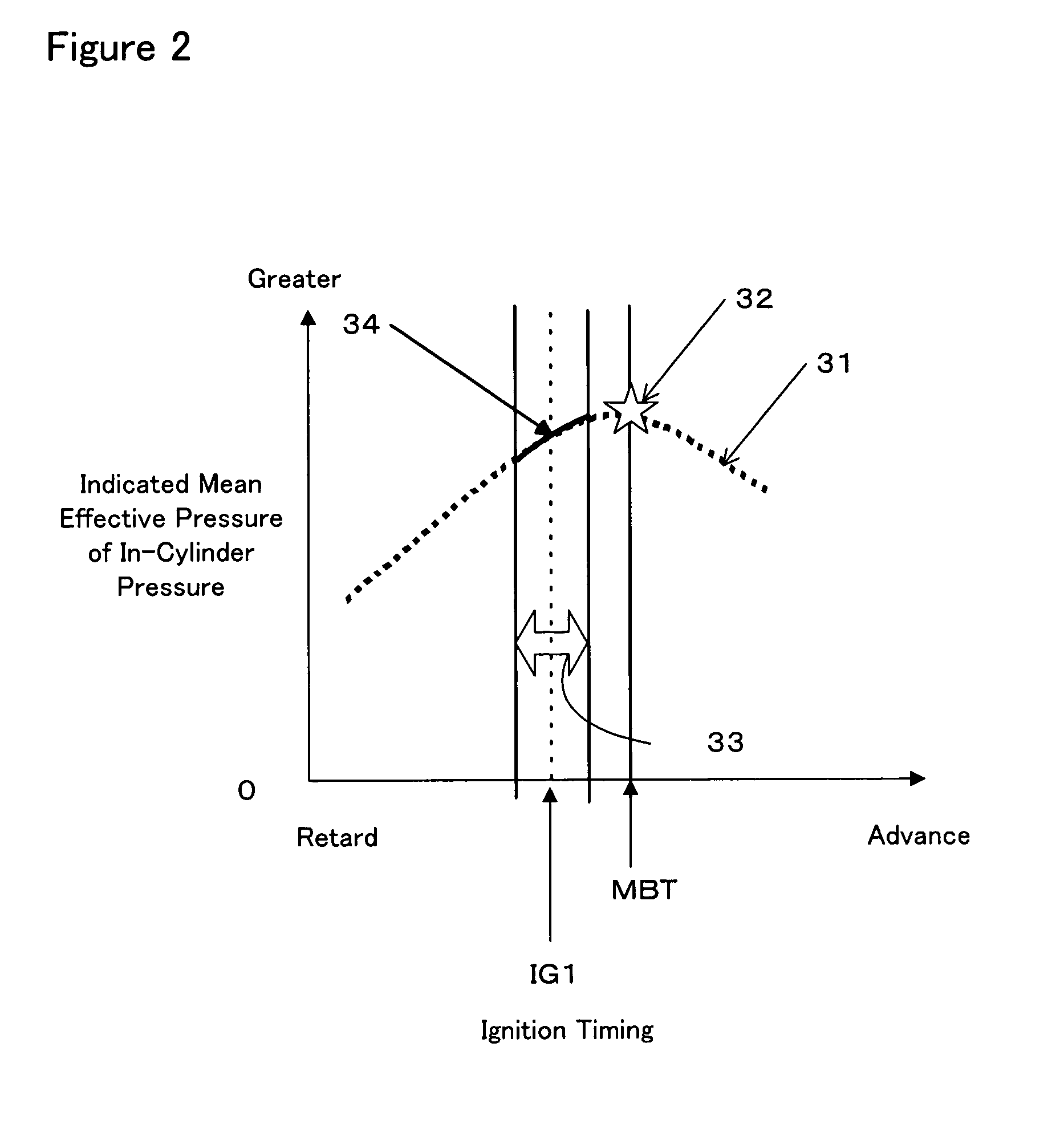

Ignition Timing Controlling Device and Method

InactiveUS20070271025A1Exclude influenceImprove combustion efficiencyAnalogue computers for vehiclesElectrical controlThermodynamicsIgnition timing

A method of controlling ignition timing of an engine. In the control method, final ignition timing for performing ignition is calculated by adding a variation component to a set ignition timing. According to the final ignition timing, an indicated average effective pressure of an in-cylinder pressure detected when ignition is performed is calculated. An ignition timing characteristic curve indicating the correlation between the indicated average effective pressure and the variation component is estimated and optimal ignition timing is calculated from the characteristic curve. Feedback control for converging the set ignition timing to the optimal ignition timing is then performed. Consequently, the ignition timing is controlled to an optimal ignition timing corresponding to a current operational state of the engine.

Owner:HONDA MOTOR CO LTD

Four-cylinder engine and method of operating four-cylinder engine

ActiveUS20160333801A1Driving energyElectrical controlInternal combustion piston enginesCylinder headCylinder block

An engine includes a cylinder body, a cylinder head, and an ignition device including spark plugs. The engine also includes an intake device connected to intake ports, an exhaust device connected to exhaust ports, pistons, and a crankshaft connected to the pistons by connecting rods. Explosion intervals of the cylinders are 270°, 180°, 90°, and 180° as crank angles. The engine further includes a discomfort eliminator which, when the engine speed is lower than a predetermined value, makes the indicated mean effective pressure of at least one of two cylinders having an explosion interval of 90° lower than the indicated mean effective pressures of the other cylinders having an explosion interval of not 90°. The engine causes unequal-interval explosions but produces little change in the driving energy per unit time during an operating state in which an occupant is liable to feel torque fluctuations.

Owner:YAMAHA MOTOR CO LTD

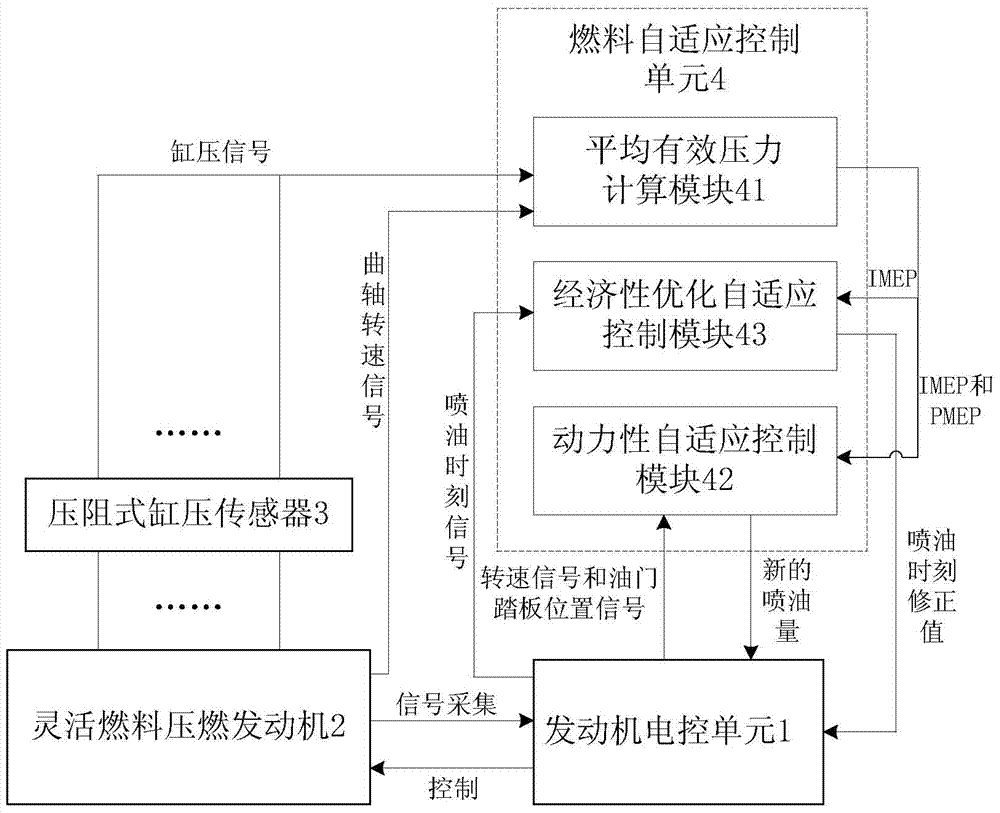

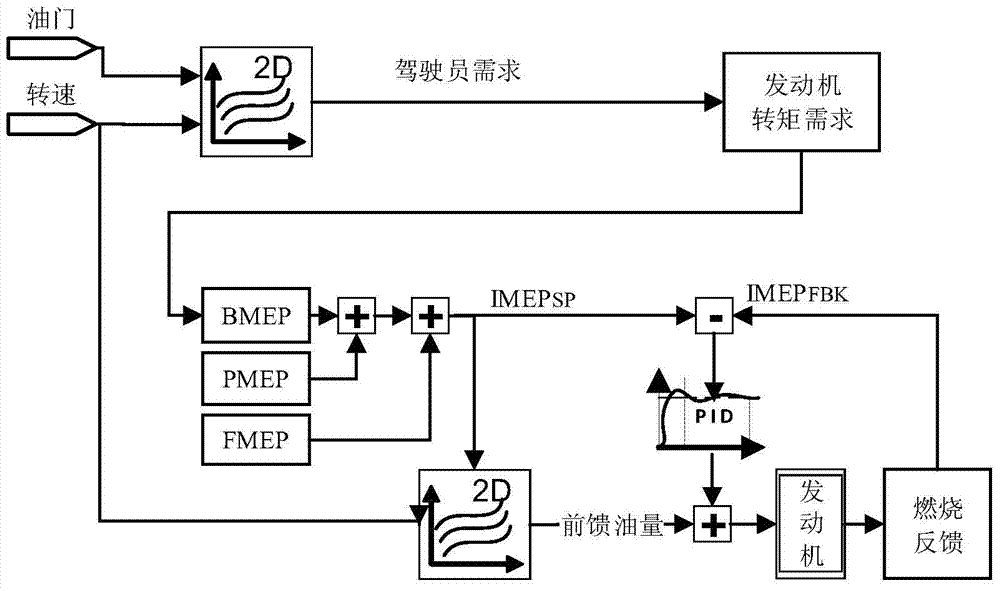

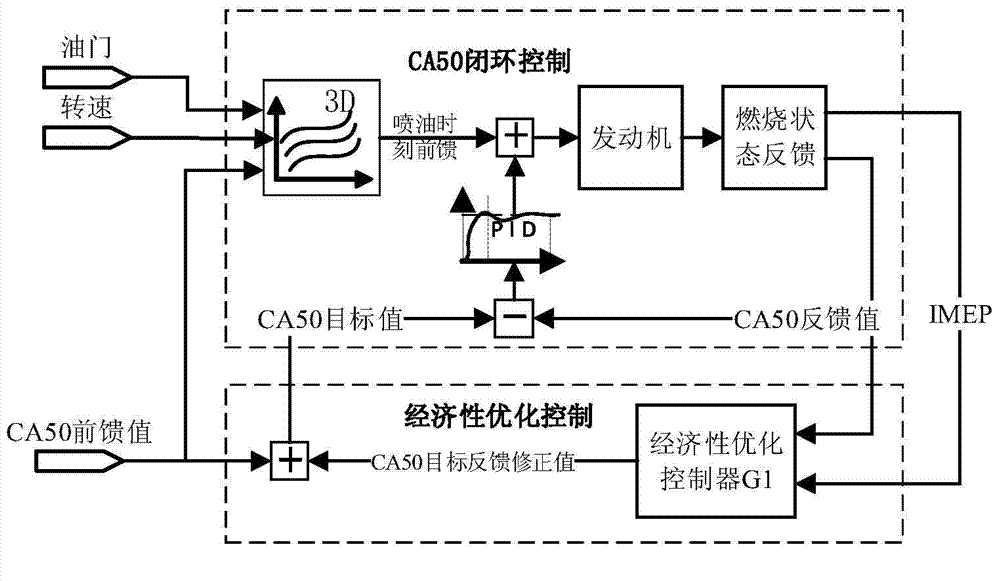

Fuel self-adaptation control method for flexible fuel engine

ActiveCN104727963AImprove powerImprove economyElectrical controlMachines/enginesLoop controlClosed loop

The invention relates to a fuel self-adaptation control method for a flexible fuel engine. The fuel self-adaptation control method comprises the steps that a gasoline and diesel mixing flexible fuel engine combustion closed-loop control system which comprises an engine electronic control unit, a flexible fuel compression-ignition engine, a piezoresistive cylinder pressure sensor and a fuel self-adaptation control unit is arranged, wherein the fuel self-adaptation control unit comprises a power performance self-adaptation control module, an economical efficiency optimizing self-adaptation control module and a mean effective pressure calculating module; an IMEP and an PMEP are obtained by the mean effective pressure calculating module and are transmitted to the power performance self-adaptation control module, and meanwhile, the IMEP is transmitted to the economical efficiency optimizing self-adaptation control module; a new fuel-injection amount is obtained by the power performance self-adaptation control module and is transmitted to the engine electronic control unit, and the self-adaptation control is carried out on fuel power performance by the engine electronic control unit; a fuel-injection time corrected value is obtained by the economical efficiency optimizing self-adaptation control module and is transmitted to the engine electronic control unit, and the optimized self-adaptation control is carried out on fuel economical efficiency by the engine electronic control unit.

Owner:TSINGHUA UNIV

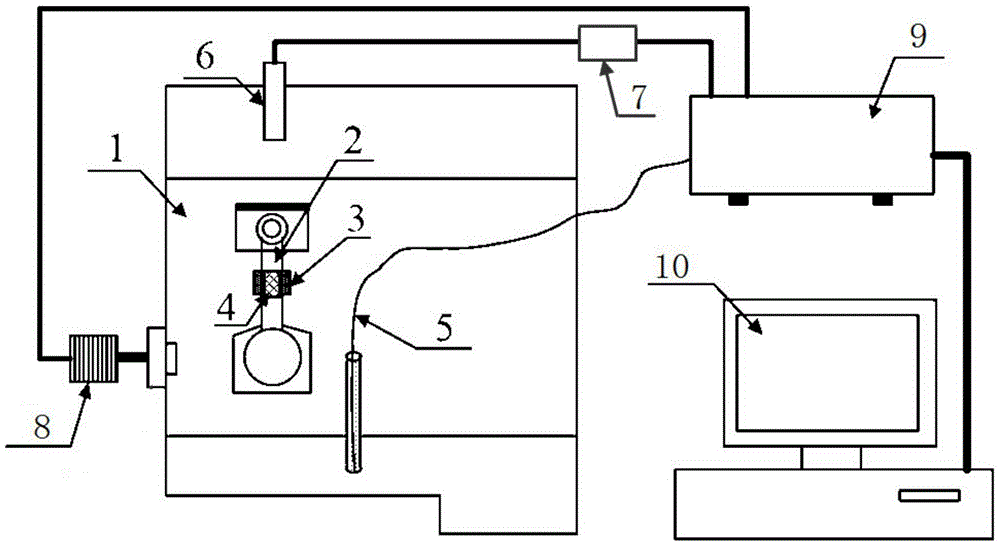

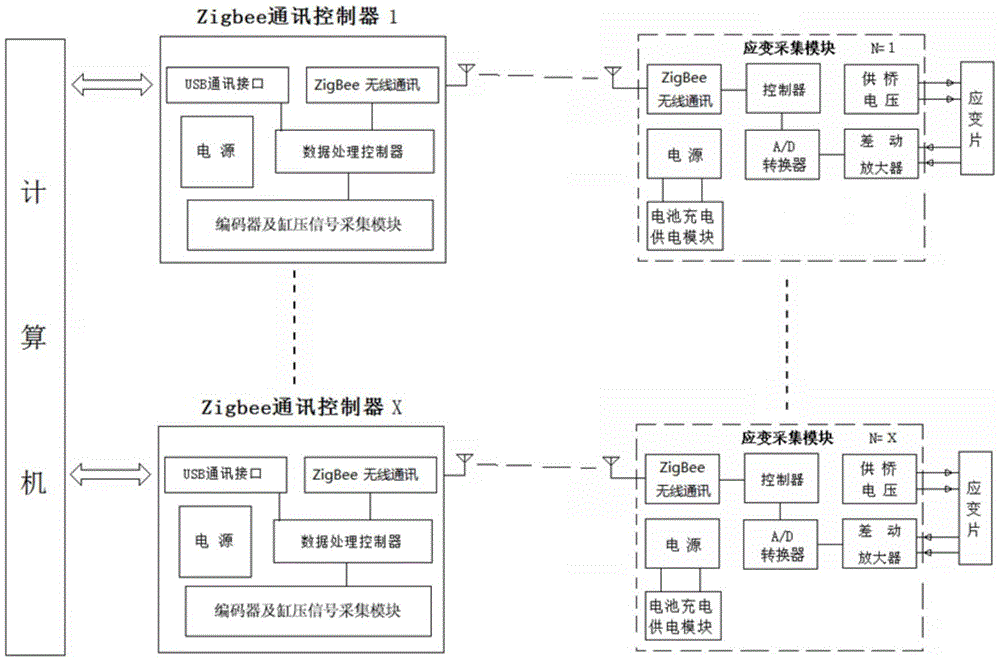

Piston group cylinder sleeve friction force wireless measuring method and implement device

InactiveCN105486440AThere is no breakage problemLow costApparatus for force/torque/work measurementEngineeringInternal combustion engine

The invention provides a piston group cylinder sleeve friction force wireless measuring method and an implement device, which belong to the technical field of an internal combustion engine. The wireless measuring device comprises strain gauges, a wireless sending module, a receiving antenna, a pressure sensor, a charge amplifier, a photoelectric encoder, a signal acquisition module and a computer. The train gauges are attached to the two sides of the middle portion of a connection rod, and is connected with the wireless sending module; the receiving antenna extends into an engine cylinder through a signal hole in an engine oil pan; and the receiving antenna is connected with the signal acquisition module. The piston group cylinder sleeve friction force wireless measuring method and device are provided on the basis of a mean effective pressure indication method (IMEP), and thus the problem that in the wired measuring process, the connecting rod is always in a high-velocity motion state with a bent axle under the working condition of an engine, and it is necessary to design a special line-leading device to lead out a signal line, however, the line can be damaged easily, and the measuring system is disabled. The measuring method and device are reasonable in design, simple in structure and suitable for optimization design of a piston group cylinder sleeve friction force measuring system.

Owner:SHANGHAI JIAO TONG UNIV

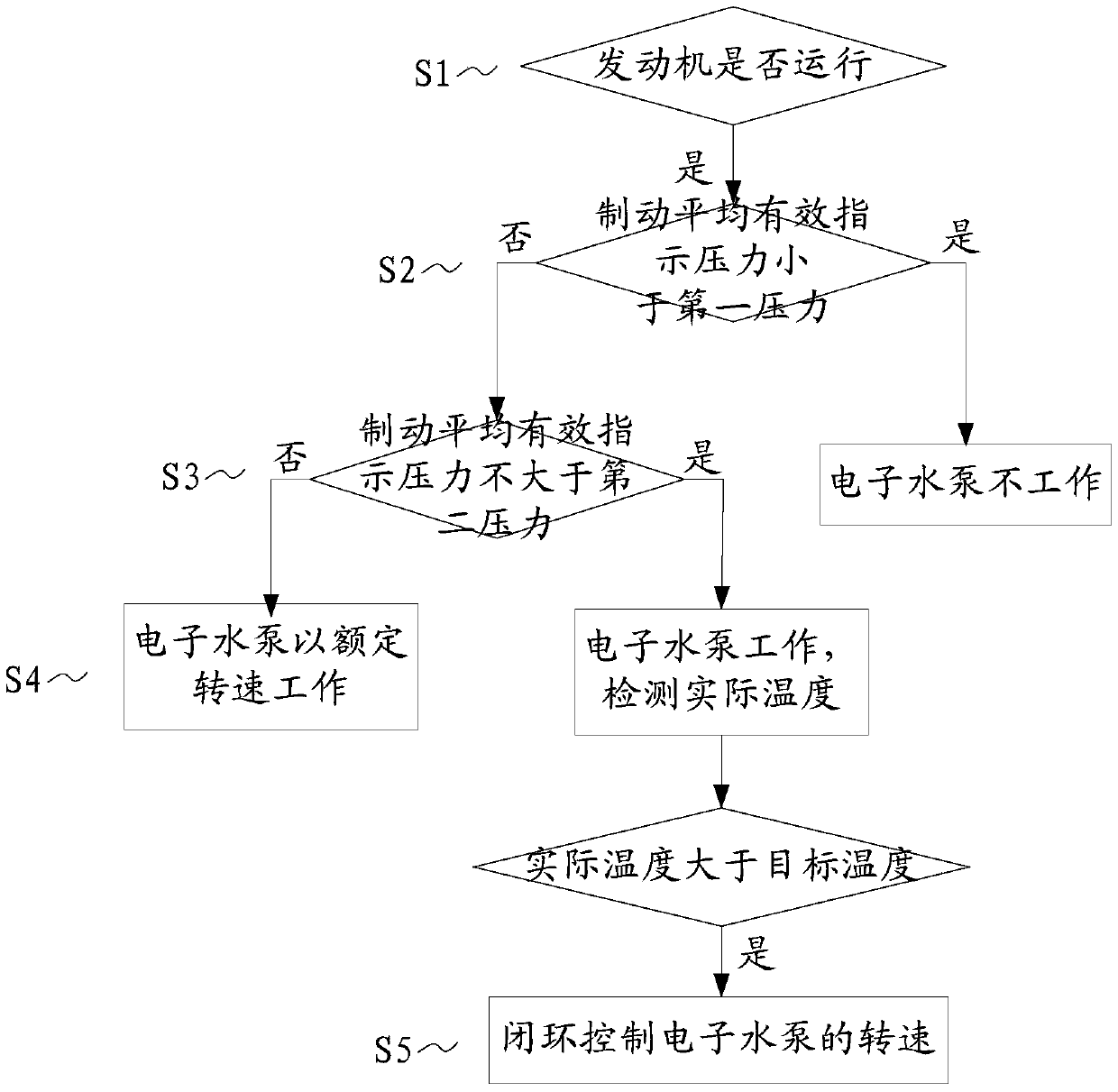

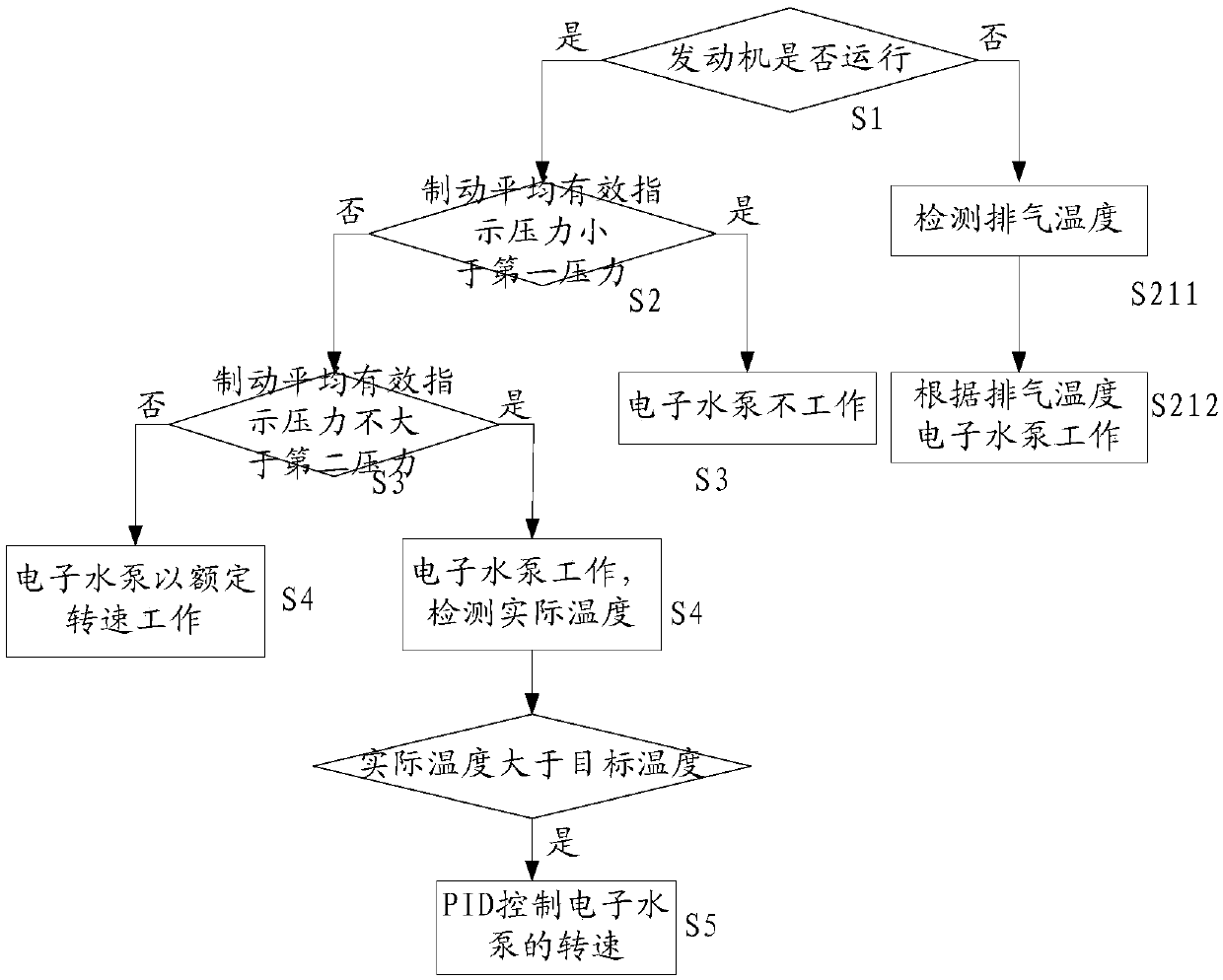

Electronic water pump control method

ActiveCN105508019AGuaranteed to workImprove economyCoolant flow controlInternal combustion piston enginesLoop controlClosed loop

The invention belongs to the technical field of automobile control, and provides an electronic water pump control method, which comprises the following steps that an ECU (Electronic Control Unit) calculates indicated mean effective brake pressure according to an engine estimation model if an engine runs; if the indicated mean effective brake pressure is lower than first pressure, an electronic water pump does not work; if the indicated mean effective brake pressure is not lower than the first pressure and not higher than second pressure, the electronic water pump works, and practical temperature after inter-cooling is detected; if the practical temperature is higher than target temperature, rotating speed of the electronic water pump is regulated by adopting closed loop control until an absolute value of a difference between the practical temperature and the target temperature is lower than a preset value; if the indicated mean effective brake pressure is higher than the second pressure, the electronic water pump works at rated rotating speed. According to the method, the ECU calculates the indicated mean effective brake pressure according to the engine estimation model, and the indicated mean effective brake pressure is compared with a minimum load threshold of the indicated mean effective brake pressure to control the electronic water pump to ensure that a booster and an inter-cooler work at optimal temperature, save energy resources and improve economy of fuel.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

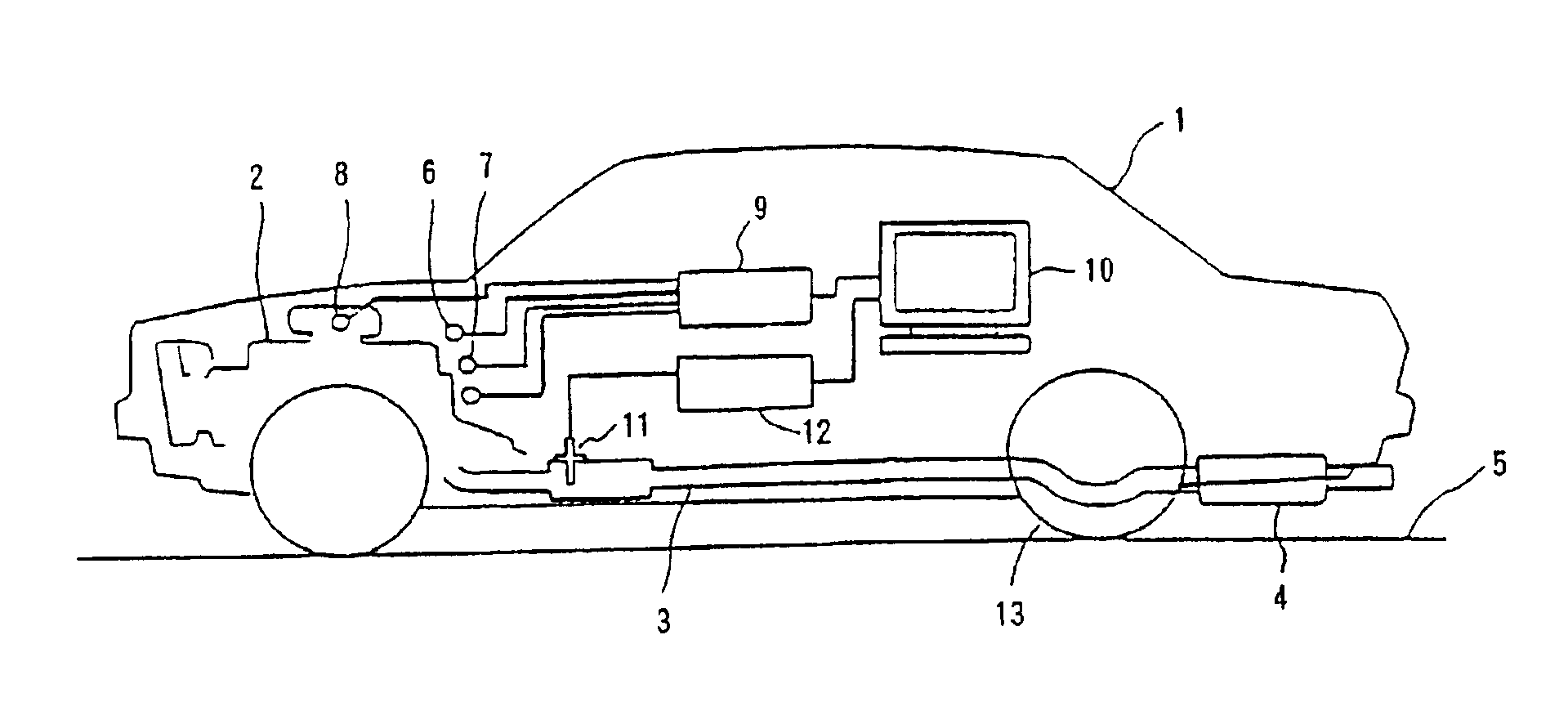

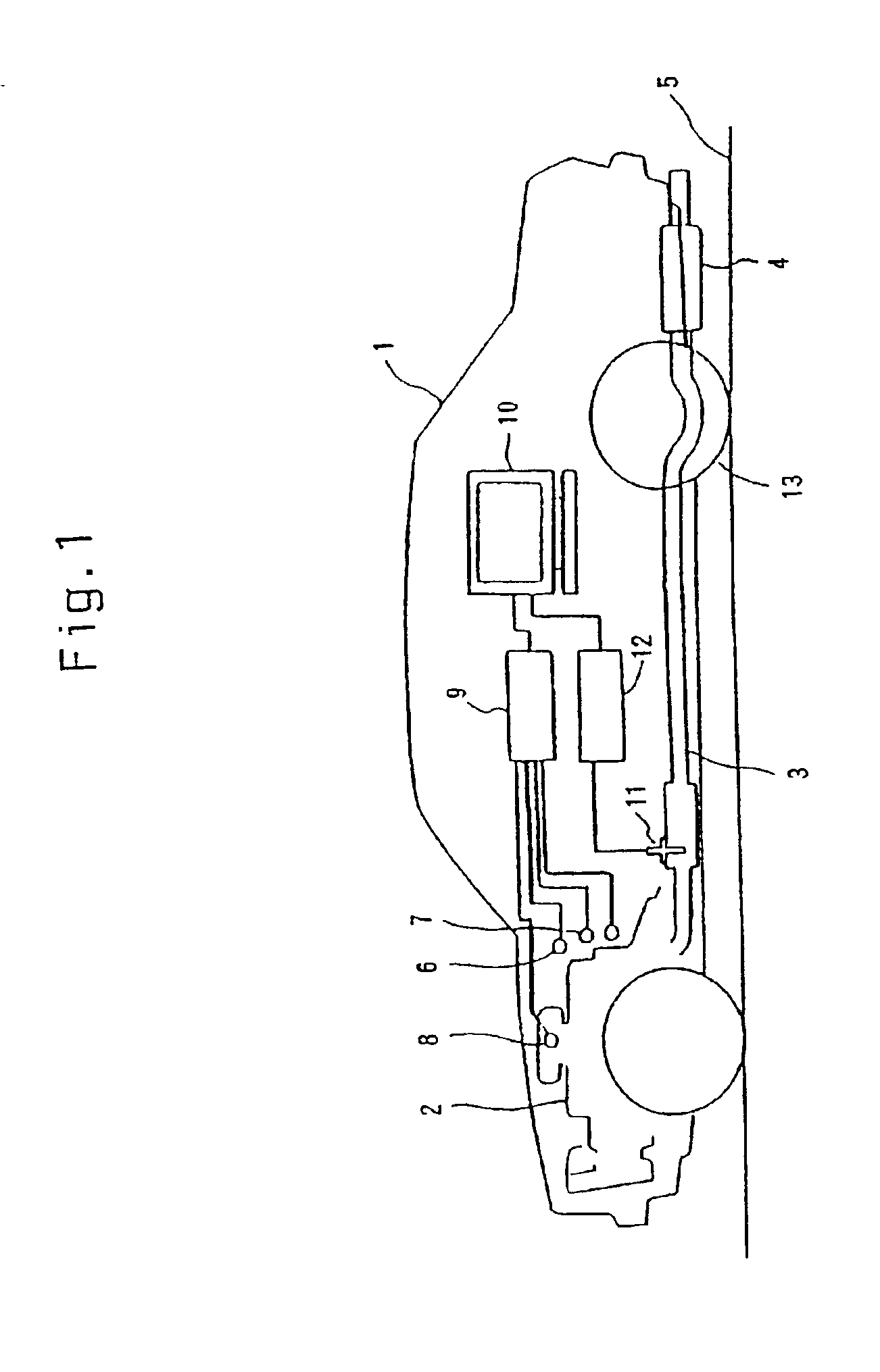

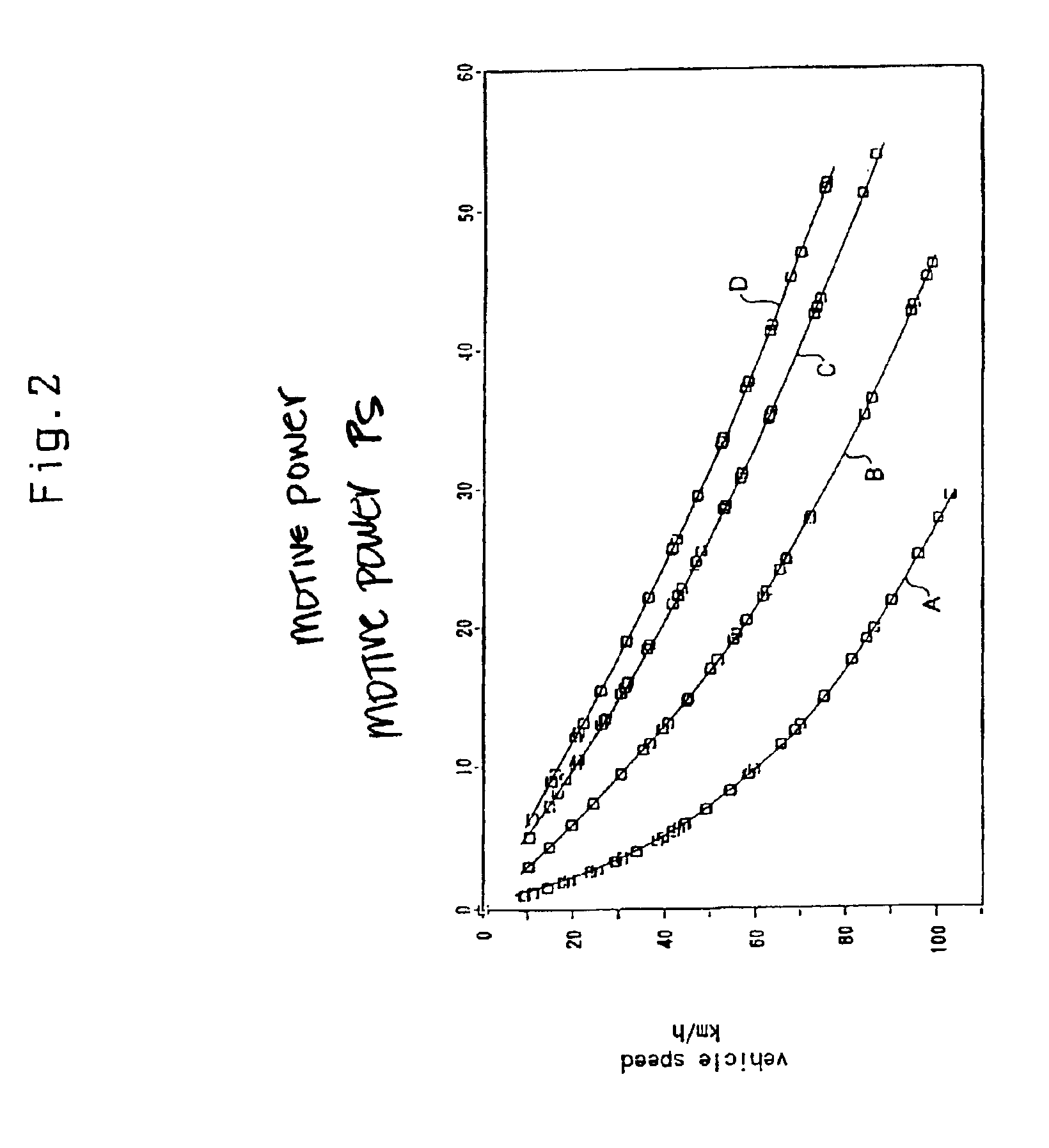

System and method for measuring brake mean effective pressure in a running vehicle

InactiveUS6877367B2Easy to measureVolume/mass flow by thermal effectsEngine testingRoad surfaceData collecting

The present invention provides a method for easily measuring a brake mean effective pressure of a running vehicle. An air flow sensor, a λ sensor and a data collecting apparatus are mounted to the vehicle. A running speed and engine speed from the vehicle while actually running on a road surface, and output of the air flow sensor an the λ sensor are inputted to the data collecting apparatus. Specific fuel consumption is obtained from an intake air amount and ratio of excessive air in exhaust gas. Output of an engine is obtained from a relation between the specific fuel consumption and the engine speed.

Owner:HORIBA LTD

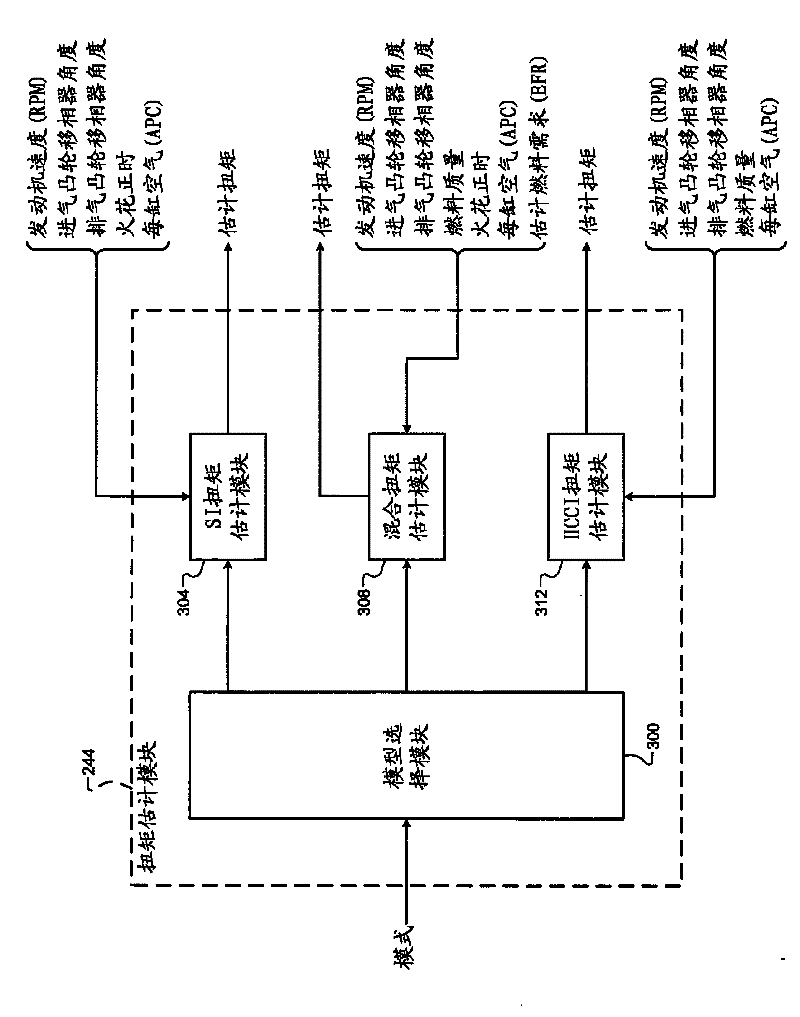

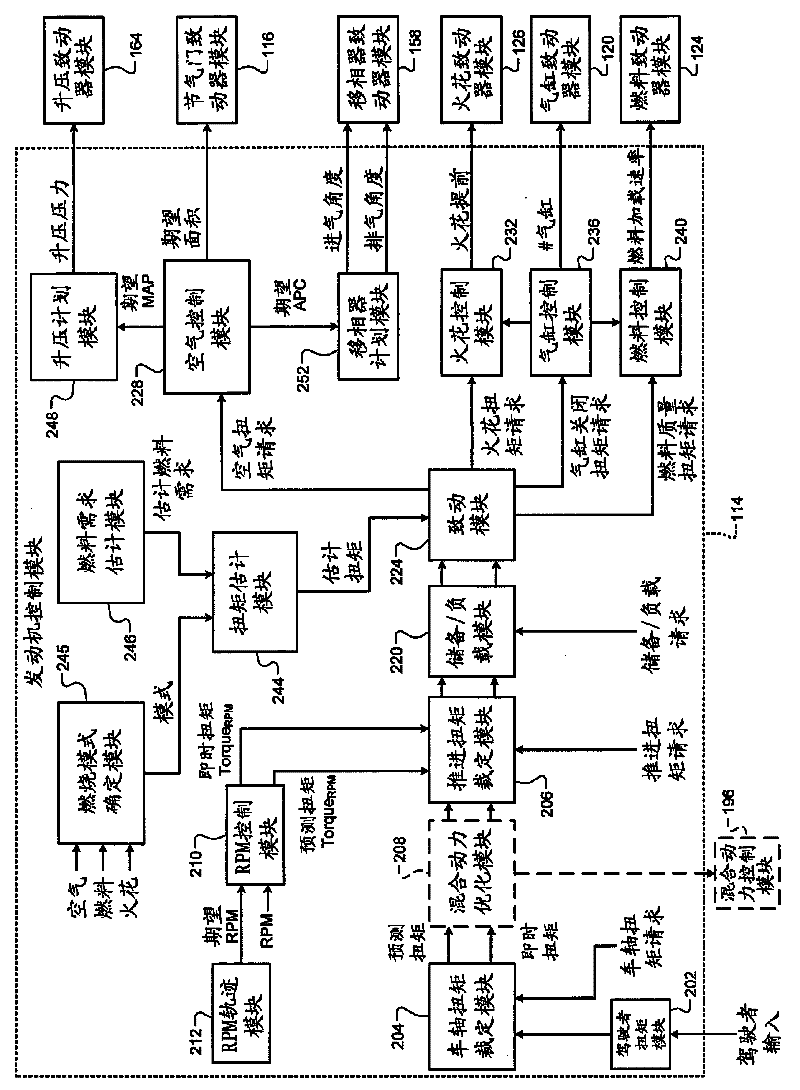

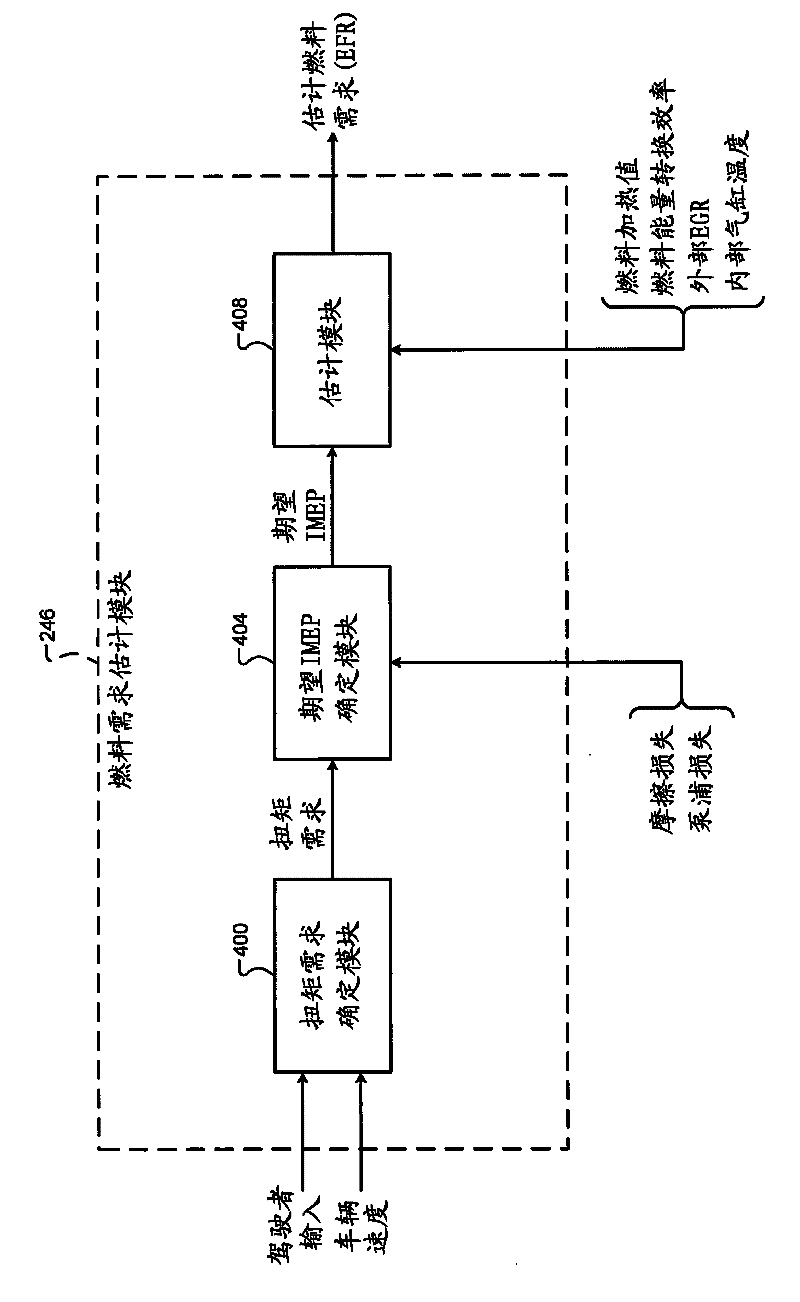

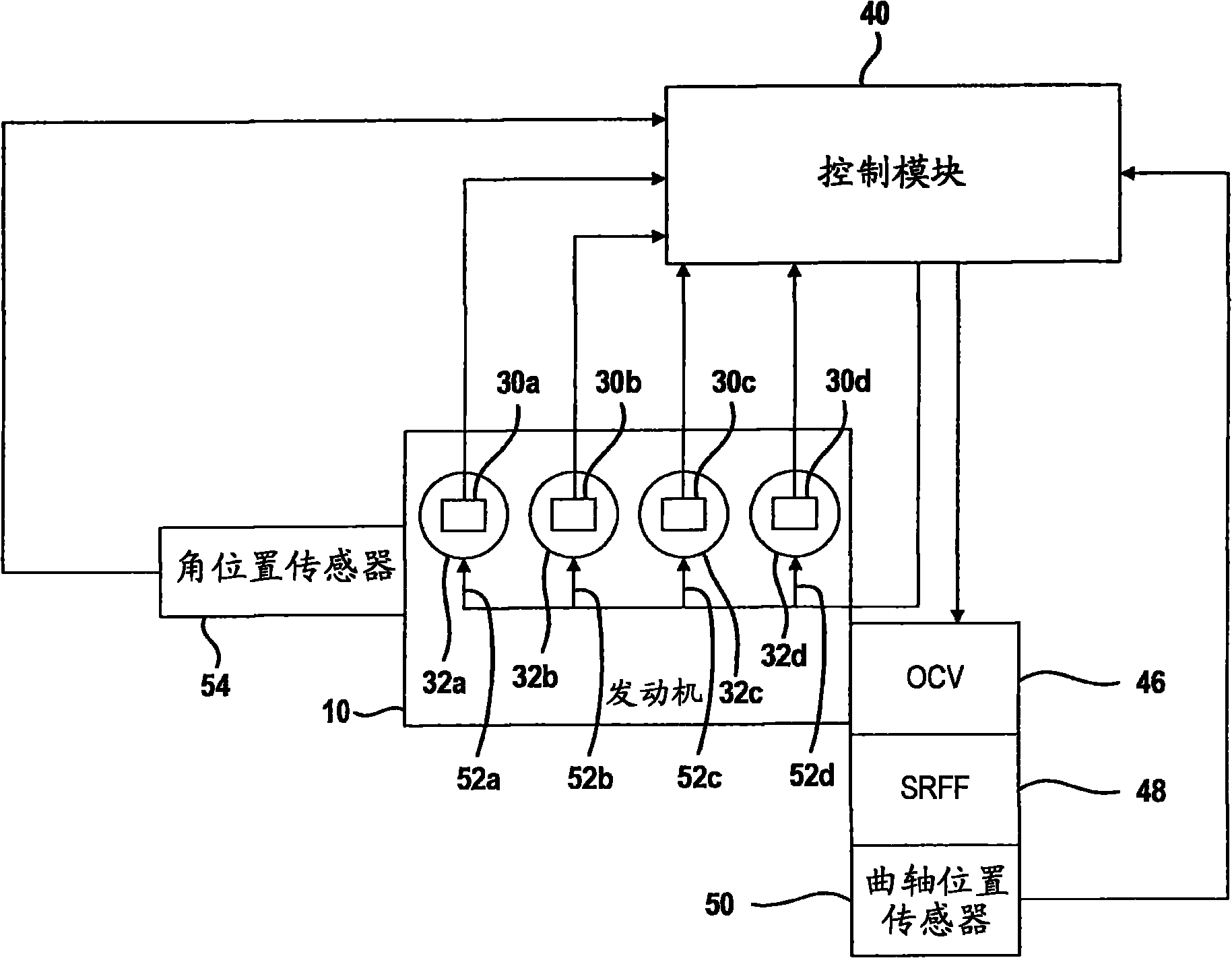

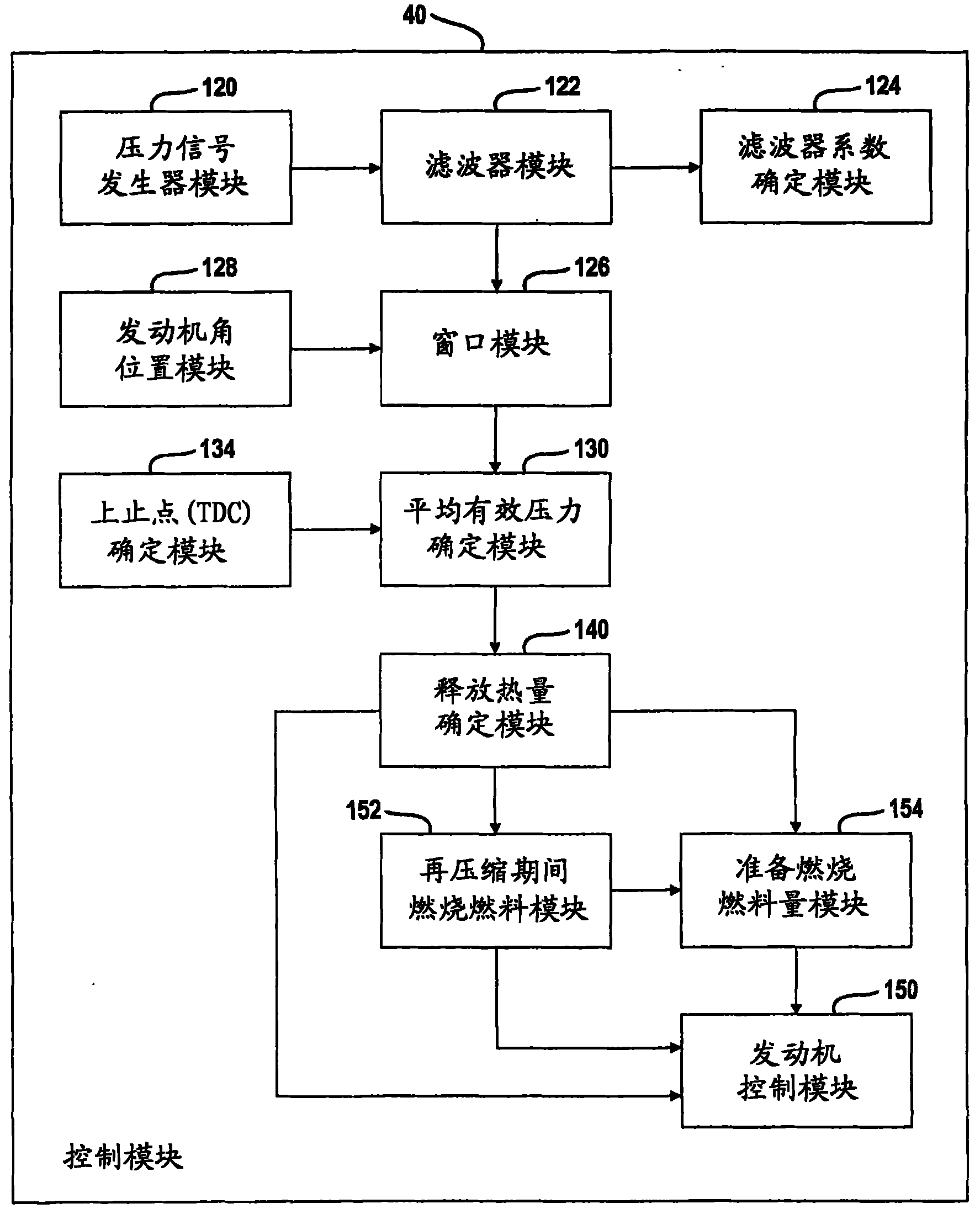

System and method for estimating torque output of a homogeneous charge compression ignition engine

ActiveCN102200062AElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionControl system

The invention relates to a system and a method for estimating torque output of a homogeneous charge compression ignition engine, and concretely provides a control system for a homogeneous charge compression ignition (HCCI) engine including a fuel requirement estimation module, a torque estimation module, and a torque control module. The fuel requirement estimation module estimates a fuel requirement of the HCCI engine based on a desired indicated mean effective pressure (IMEP) of cylinders in the HCCI engine. The torque estimation module estimates a torque output of the HCCI engine based on the estimated fuel requirement. The torque control module adjusts the torque output of the HCCI engine based on the estimated torque output and a desired torque output.

Owner:GM GLOBAL TECH OPERATIONS LLC

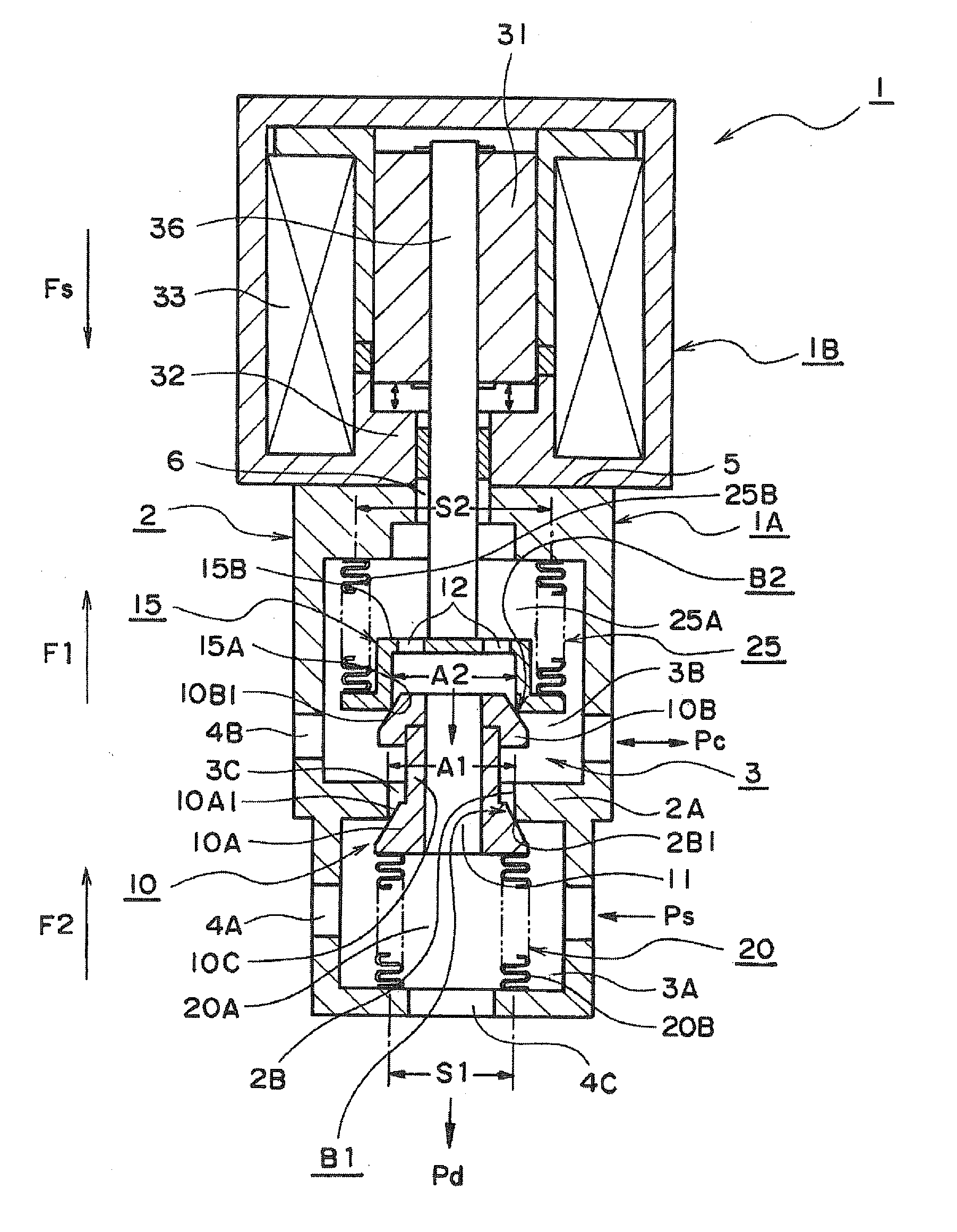

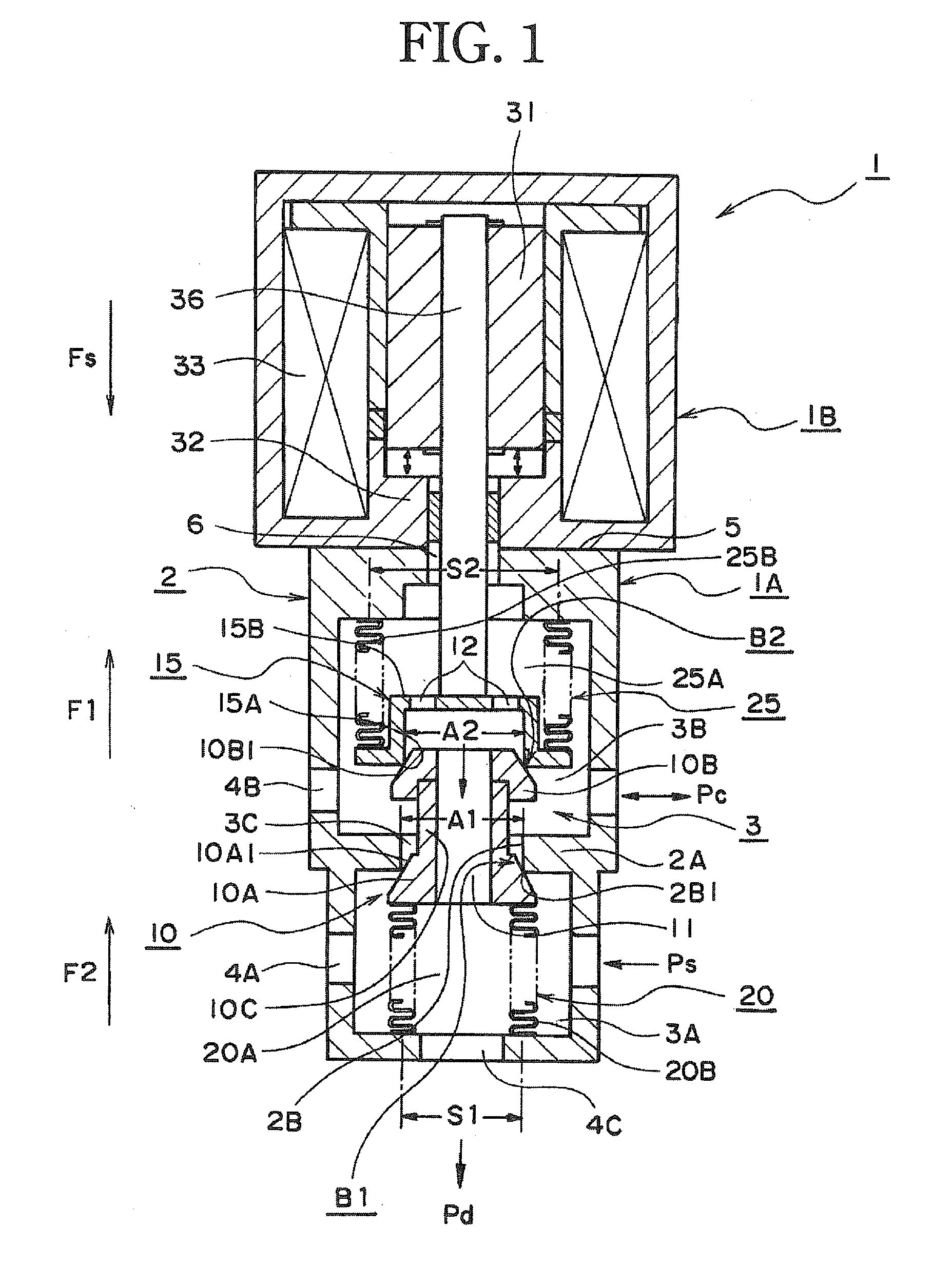

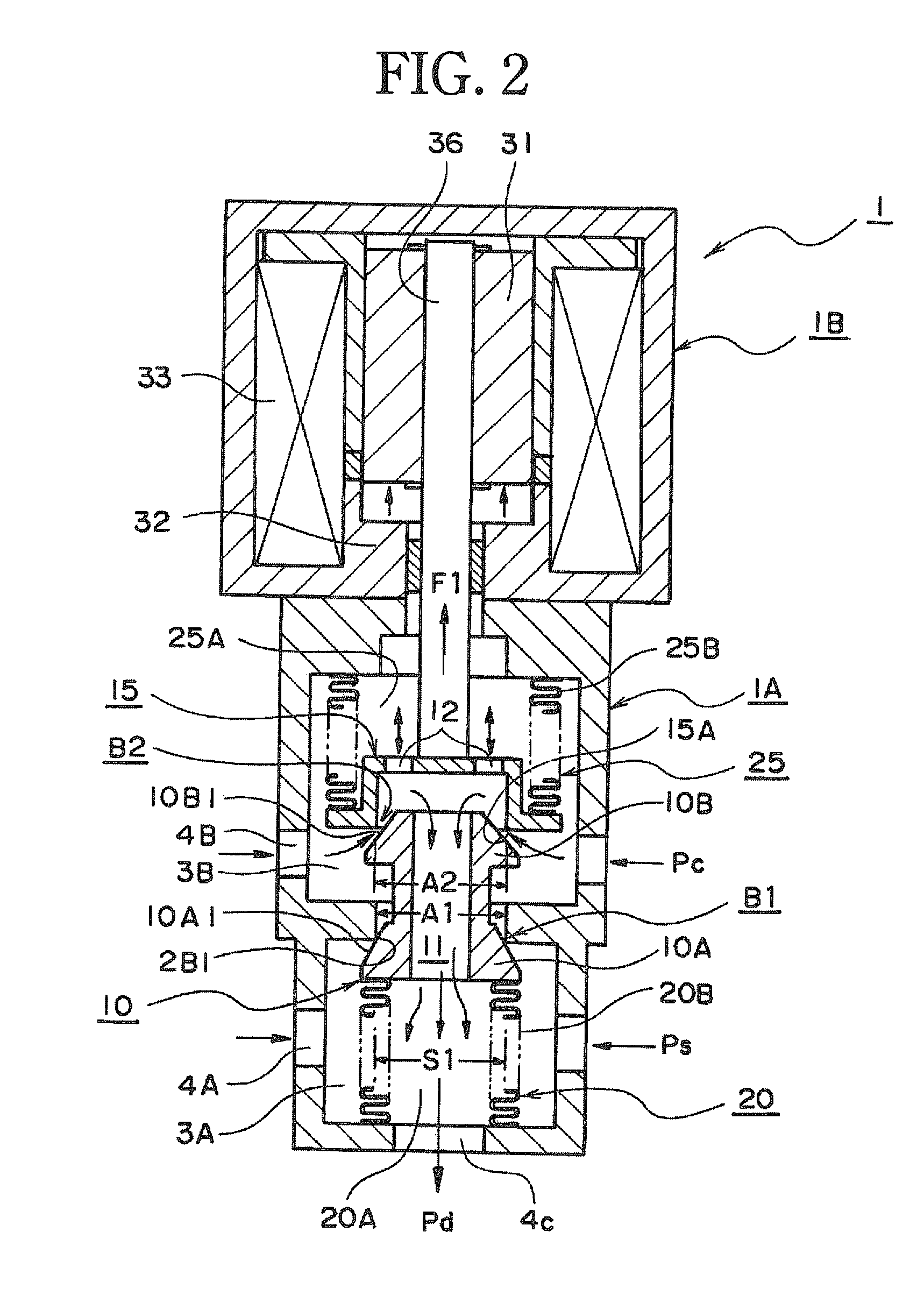

Control valve

ActiveUS8434518B2Reduce resistanceImprove responsivenessOperating means/releasing devices for valvesMultiple way valvesControl valvesPressure sensing

The control valve has a body; a supply port, an output port, and a discharge port; a first pressure-sensing device; the valve body having a first valve section surface that forms a first valve seat surface; a valve seat body having a second valve seat surface that forms the second valve section surface; a second pressure-sensing device; and a solenoid section. The first effective pressure-receiving area, the first pressure-receiving area on the inner side of a portion where the first valve seat surface and the first valve section surface are in contact with each other, and the second pressure-receiving area on the inner side of a portion where the second valve seat surface and the second valve section surface are in contact with each other are set to be substantially the same, and the second effective pressure-receiving area is set greater than the first effective pressure-receiving area.

Owner:EAGLE INDS

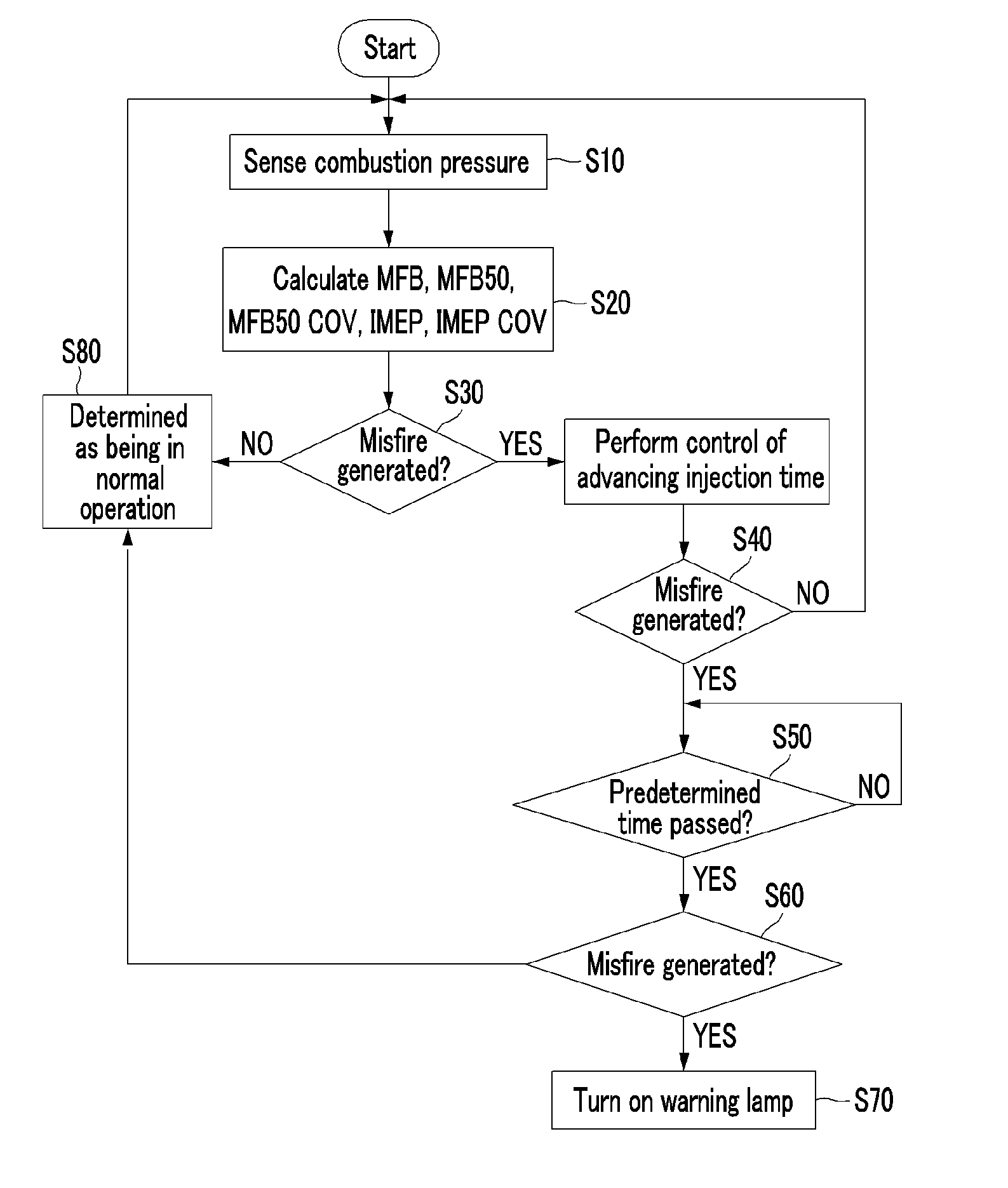

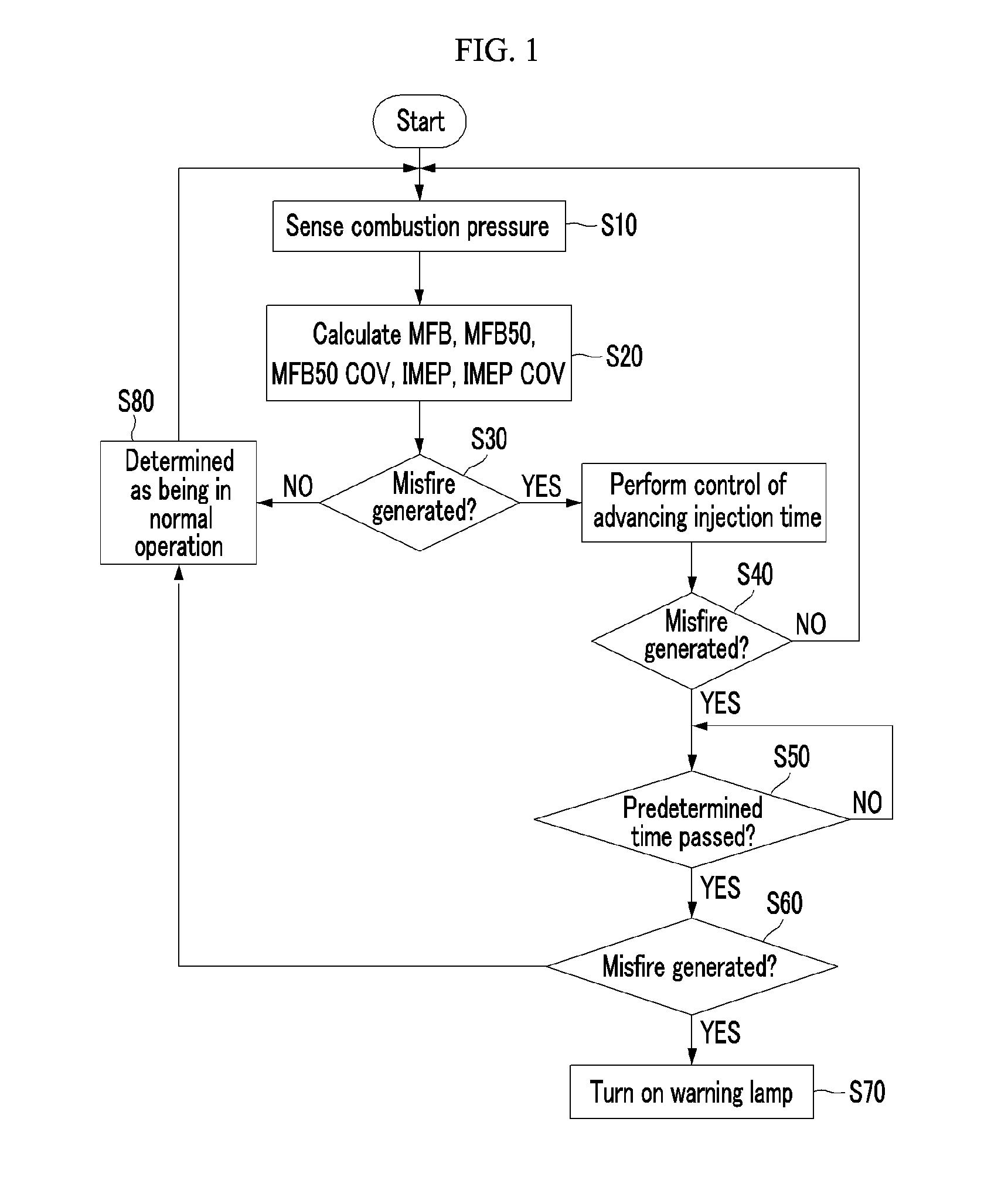

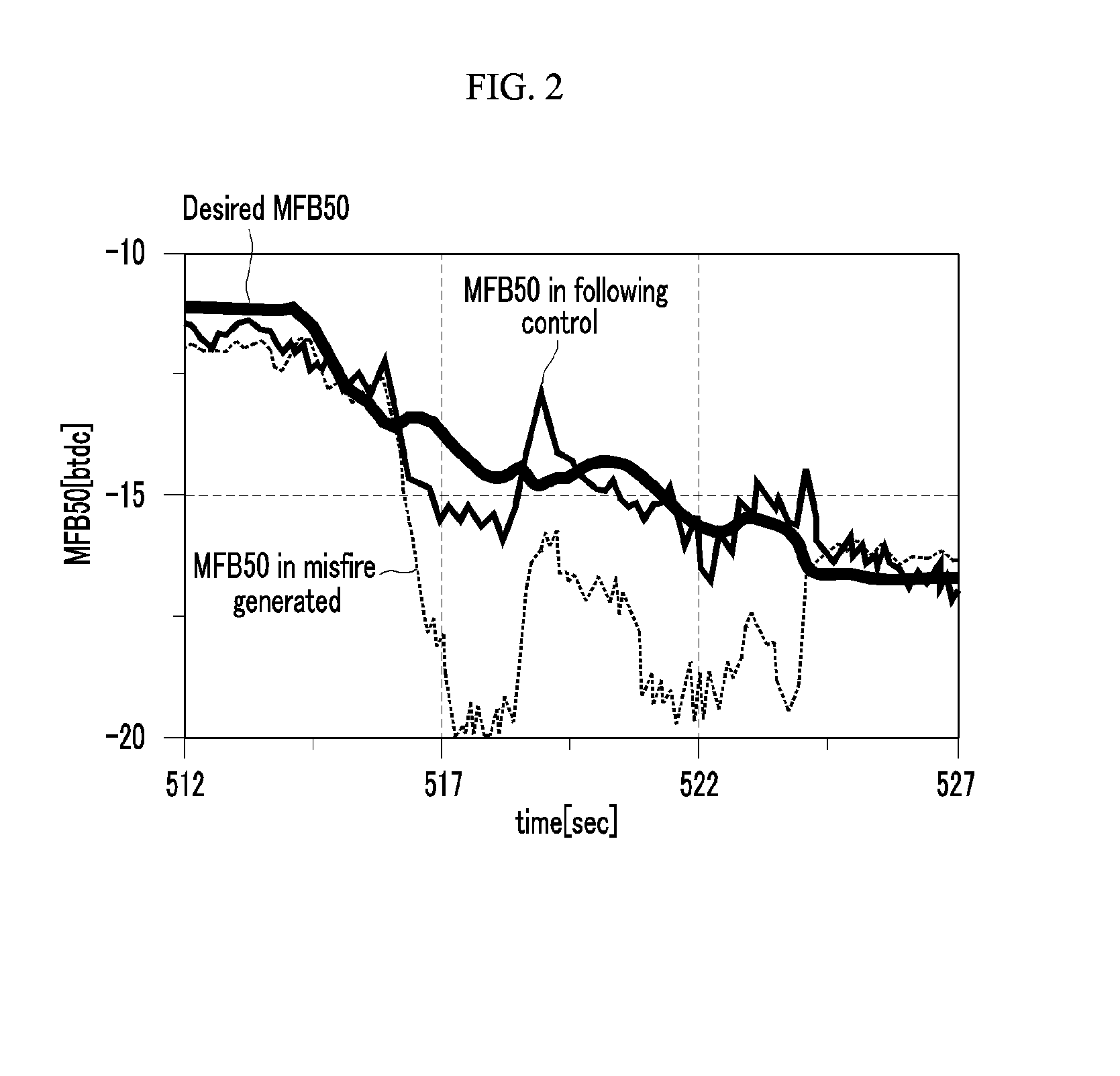

Device and method for determining and controlling combustion misfire of vehicle engine

InactiveUS20140116385A1Accurately determinePrevent deterioration of stabilityInternal-combustion engine testingElectrical controlCombustion chamberEngineering

A method of determining and controlling misfire in an engine. The method and device sense combustion pressure in a combustion chamber of an engine while the engine is operated; calculate MFB (a ratio of the amount of combustion heat at a specific point of time to the total amount of combustion heat), MFB50 (a point of time at which the amount of combustion heat is 50% of the total amount of combustion heat), MFB50 COV (Coefficient of Variation), IMEP (Indicated Mean Effective Pressure) and IMEP COV, from the combustion chamber; set a desired MFB50; and determine that there is misfire when a crank angle is delayed at 5 degrees or more, the MFB50 COV is 20% or more, or the IMEP COV is 20% or more, by comparing the calculated MFB50 with the desired MFB50; and then advance an injection time such that the MFB follows the desired MFB.

Owner:HYUNDAI MOTOR CO LTD

Method for low and high IMEP cylinder identification for cylinder balancing

ActiveUS7680583B2Reduce cylinder torque imbalanceImprove performanceAnalogue computers for vehiclesElectrical controlControl theoryMean effective pressure

A system and method for identifying the cylinders having the lowest (“weakest”) and highest (“strongest”) Indicated Mean Effective Pressure (IMEP) utilizes engine speed derivative and / or higher order derivative values typically available in an engine control module by virtue of the need to detect misfire. A delta parameter is calculated that is indicative of the difference between the engine speed derivatives and / or higher order derivatives for the “weakest” and the “strongest” cylinders. Control action is then taken to balance the cylinders, based on the delta parameter, by first increasing torque for the “weakest” cylinder, by at least one increasing spark advance, increasing fuel, decreasing dilution (EGR) or slowing decay of fuel control on cold start. Once the weakest cylinder has been balanced, the control action is then directed to increasing torque of the new “weakest” cylinder.

Owner:DELPHI TECH IP LTD

Internal combustion engine

ActiveUS7201135B2Internal combustion piston enginesSpray nozzlesInternal combustion engineRevolutions per minute

The present disclosure provides an internal combustion engine having an engine housing with at least one cylinder that has diameter less than about 3 inches. A fuel injector is provided and disposed at least partially within the at least one cylinder, and includes a plurality of outlet orifices having a diameter between about 50 microns and about 110 microns. The disclosure further provides a method of operating an internal combustion engine. The method includes the steps of rotating an engine crank shaft of the engine at a speed greater than about 5000 revolutions per minute, injecting a quantity of fuel into each of the cylinders, and burning at least every fourth piston stroke a sufficient quantity of the injected fuel to yield a brake mean effective pressure of at least about 200 lbs. per square inch.

Owner:CATERPILLAR INC

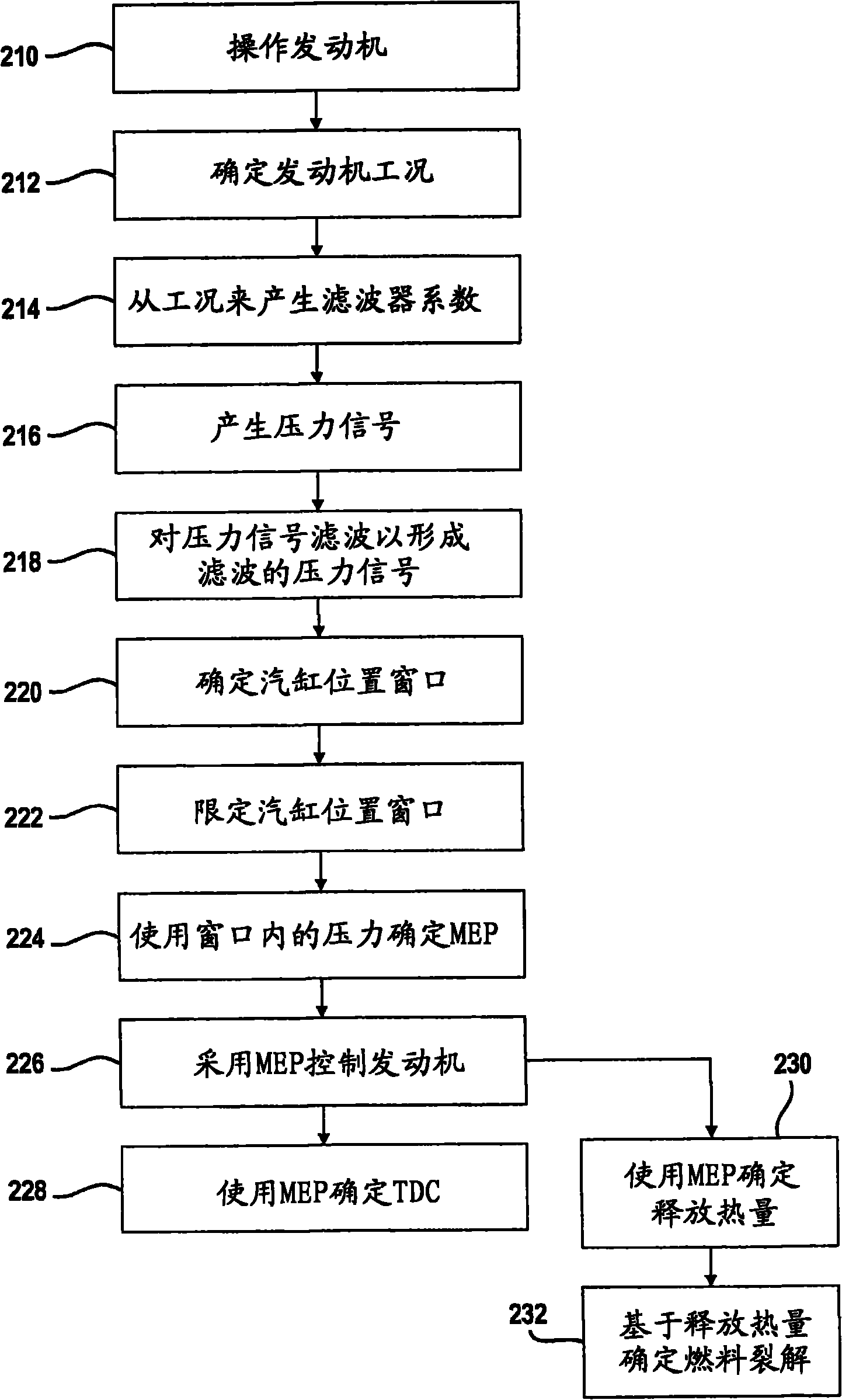

Method and system for controlling an engine using in-cylinder pressure sensor signals

A method and a control system that includes a window module that determines a piston position window, a mean effective pressure determination module that generates a mean effective pressure with in-cylinder pressure signals within the piston position window and an engine control module that controls the engine using the mean effective pressure.

Owner:GM GLOBAL TECH OPERATIONS LLC

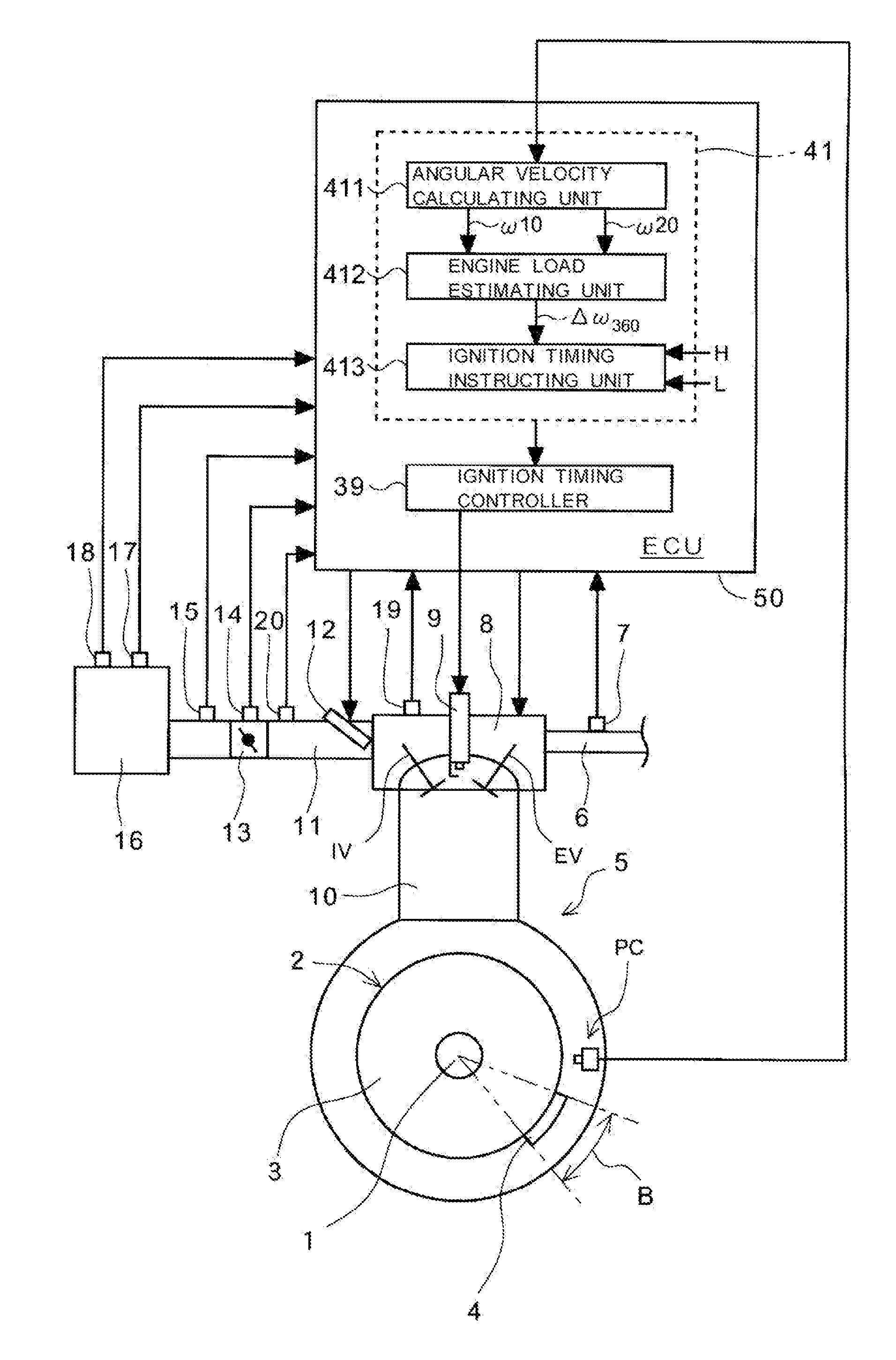

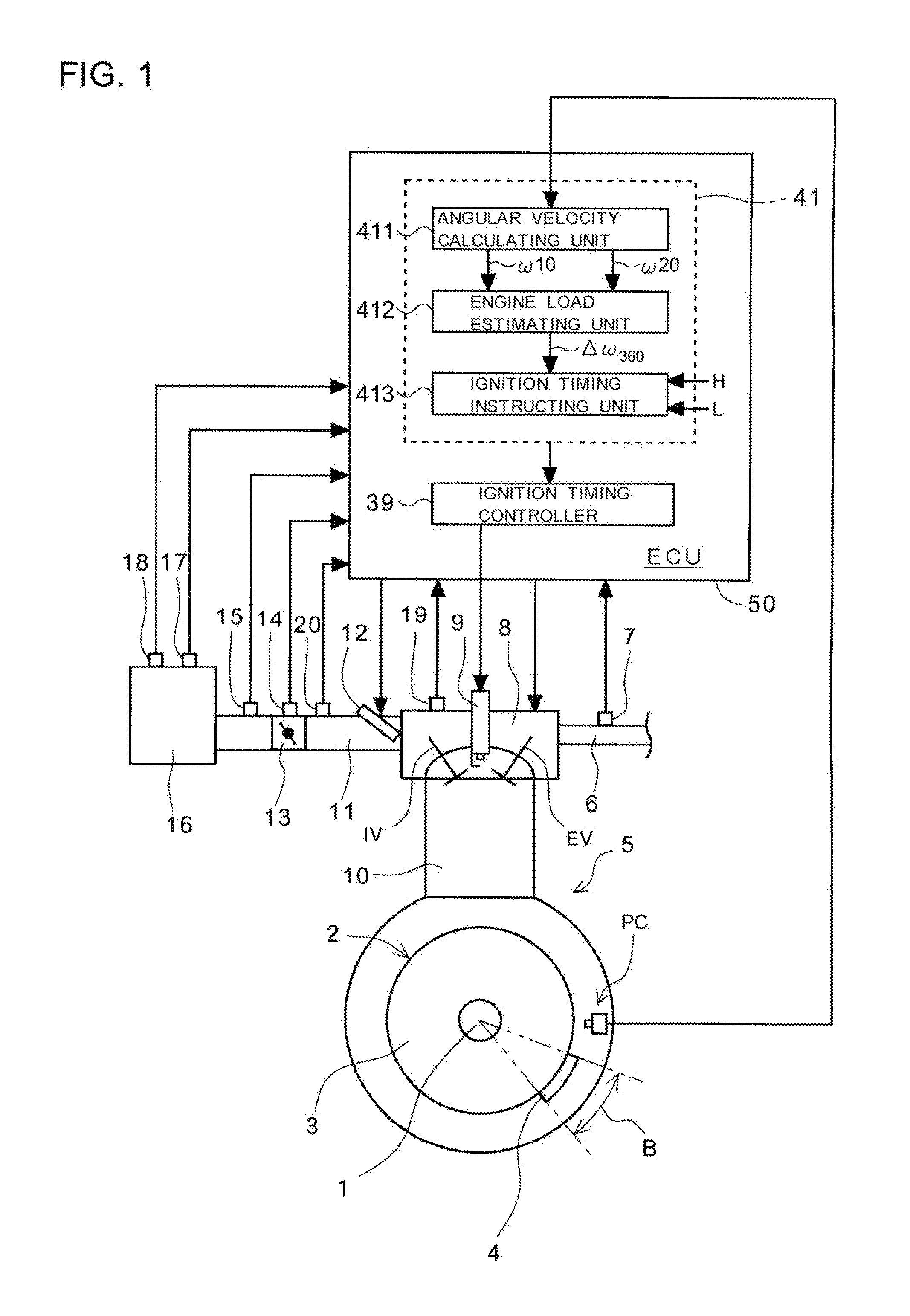

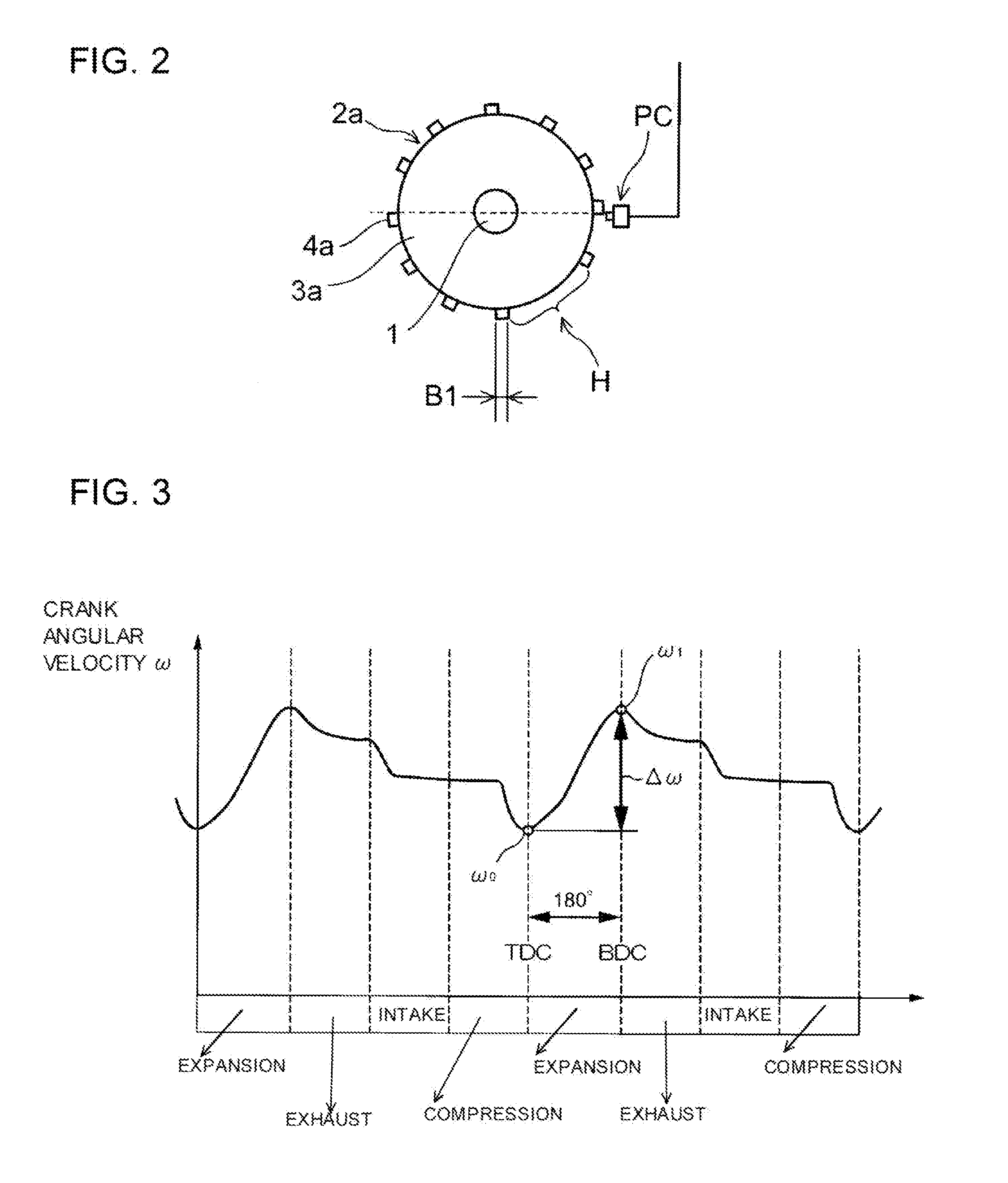

Engine control unit

ActiveUS20120158320A1Improve estimation accuracyExclude influenceInternal-combustion engine testingElectrical controlTop dead centerAngular velocity

To prevent a reduction in engine load detection accuracy due to variations in reluctor size within mass production tolerances, an engine control unit includes a pulse generator PC that detects a reluctor to output crank pulses. An angular velocity calculating unit calculates a first crank angular velocity on the basis of an interval between two crank pulses output in a predetermined section near compression top dead center TDC, and detects near overlap top dead center OLP the same reluctor used for calculating the first crank angular velocity to calculate a second crank angular velocity on the basis of an interval between generated two crank pulses. An engine load estimating unit calculates, as an engine load, a difference between the first crank angular velocity and the second crank angular velocity. The engine load is indicated mean effective pressure over a whole cycle including negative work done by the engine.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com