Piston group cylinder sleeve friction force wireless measuring method and implement device

A technology of wireless measurement and piston group, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of easy breakage of wires and measurement failure, and achieve the effect of low cost and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

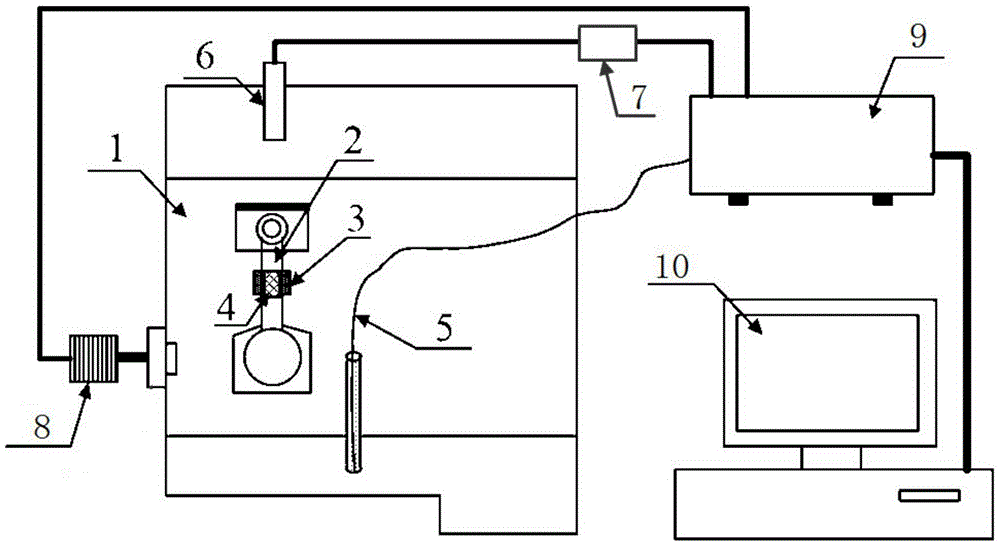

[0015] Examples of the present invention are figure 1 , figure 2 As shown, the present invention includes an experimental engine 1, a connecting rod 2, a strain gauge 3, a wireless transmission module 4, a receiving antenna 5, a pressure sensor 6, a charge amplifier 7, a photoelectric encoder 8, a signal acquisition module 9, a computer 10, and a strain gauge 3 Attached to both sides of the middle part of the connecting rod 2 and connected to the wireless transmission module 4, the receiving antenna 5 extends into the engine cylinder through the signal hole processed in the oil pan, the receiving antenna 5 is connected to the signal acquisition module 9, the photoelectric encoder 8 It is connected with the output shaft of the experimental engine 1 , the signal line of the photoelectric encoder 8 is connected with the signal acquisition module 9 , and the signal acquisition module 9 is connected with the computer 10 .

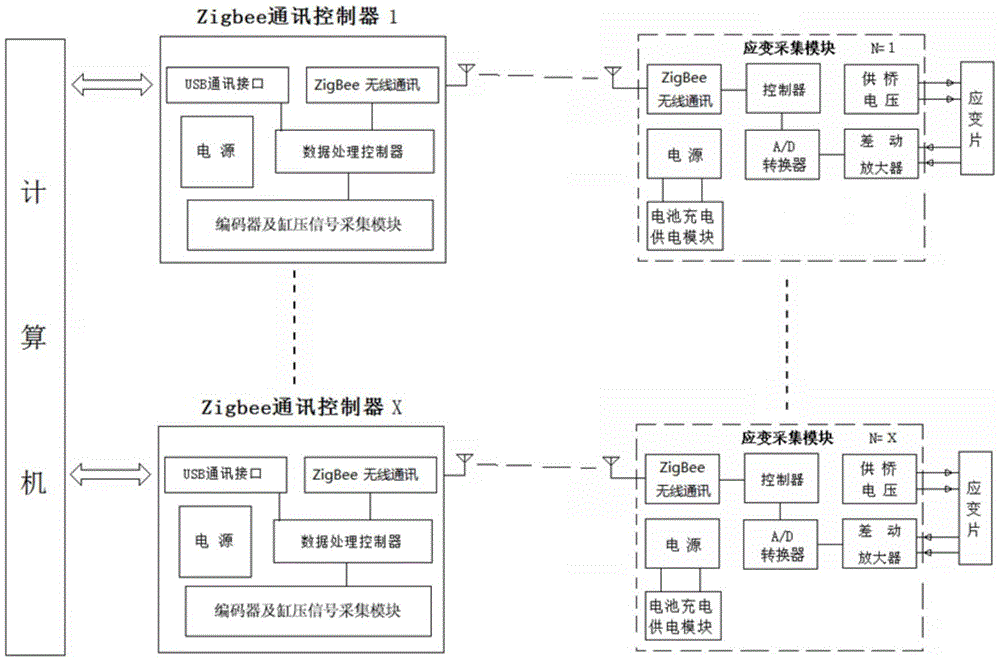

[0016] like figure 2 As shown, the working principle d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com