Method for estimation of indicated mean effective pressure for individual cylinders from crankshaft acceleration

a technology of internal combustion engine and effective pressure, which is applied in the direction of electrical control, process and machine control, etc., can solve the problems of inability to carry, large amount of analysis equipment on the rack, and inability to accurately estimate the effective pressure of individual cylinders, so as to reduce the level of calibration effort, eliminate the expense and intrusion of direct imep measurement, and reduce the effect of calibration parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

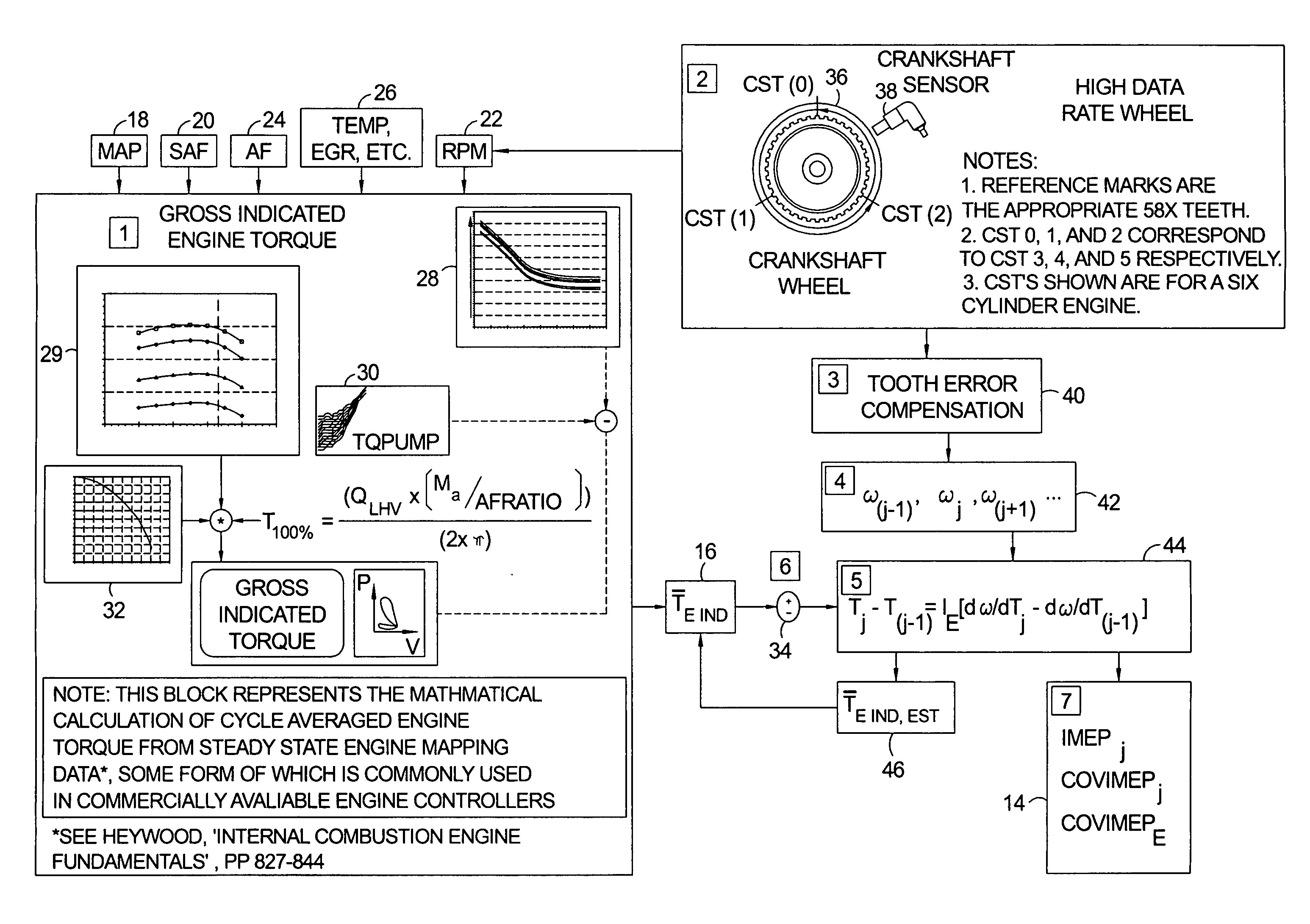

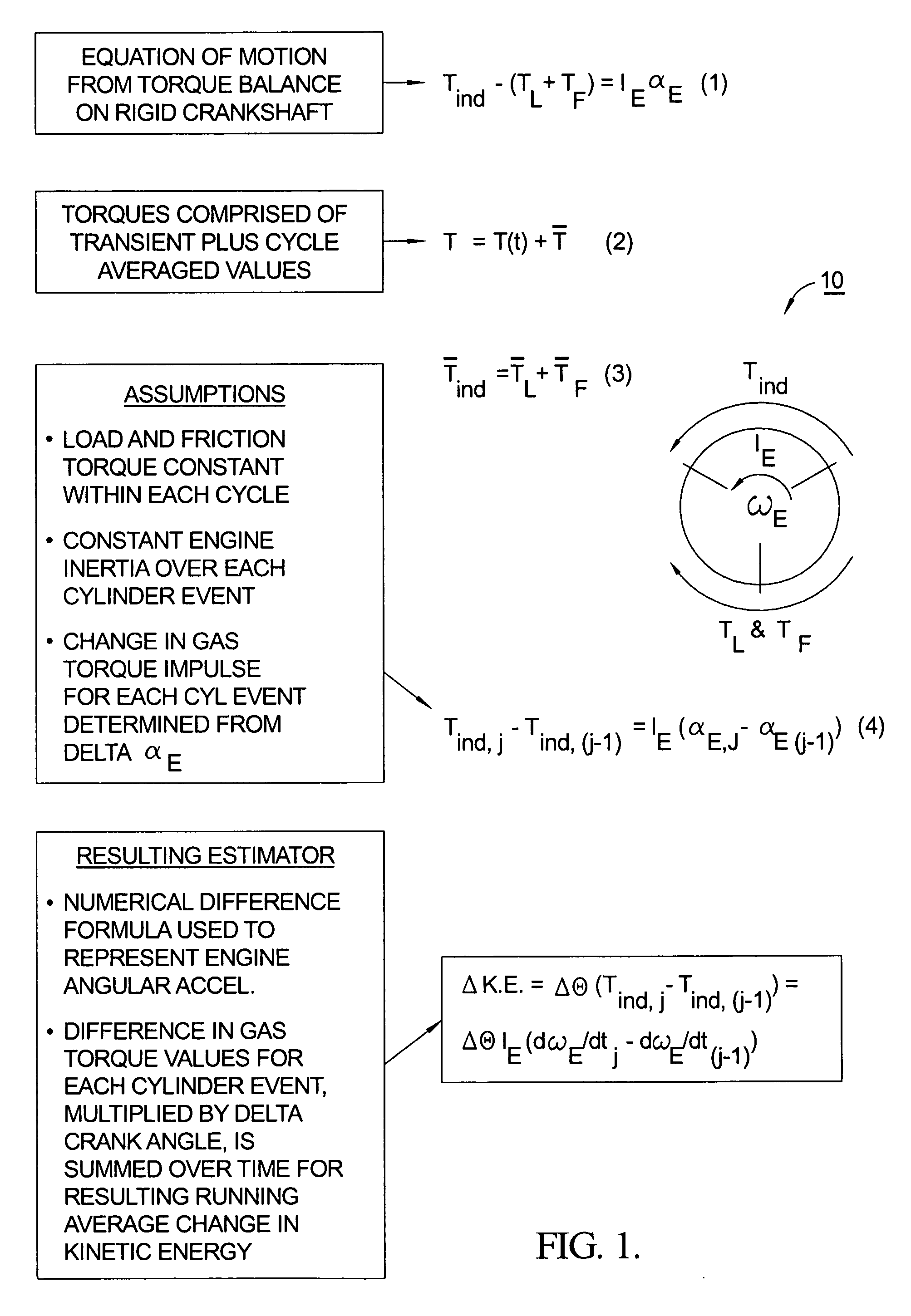

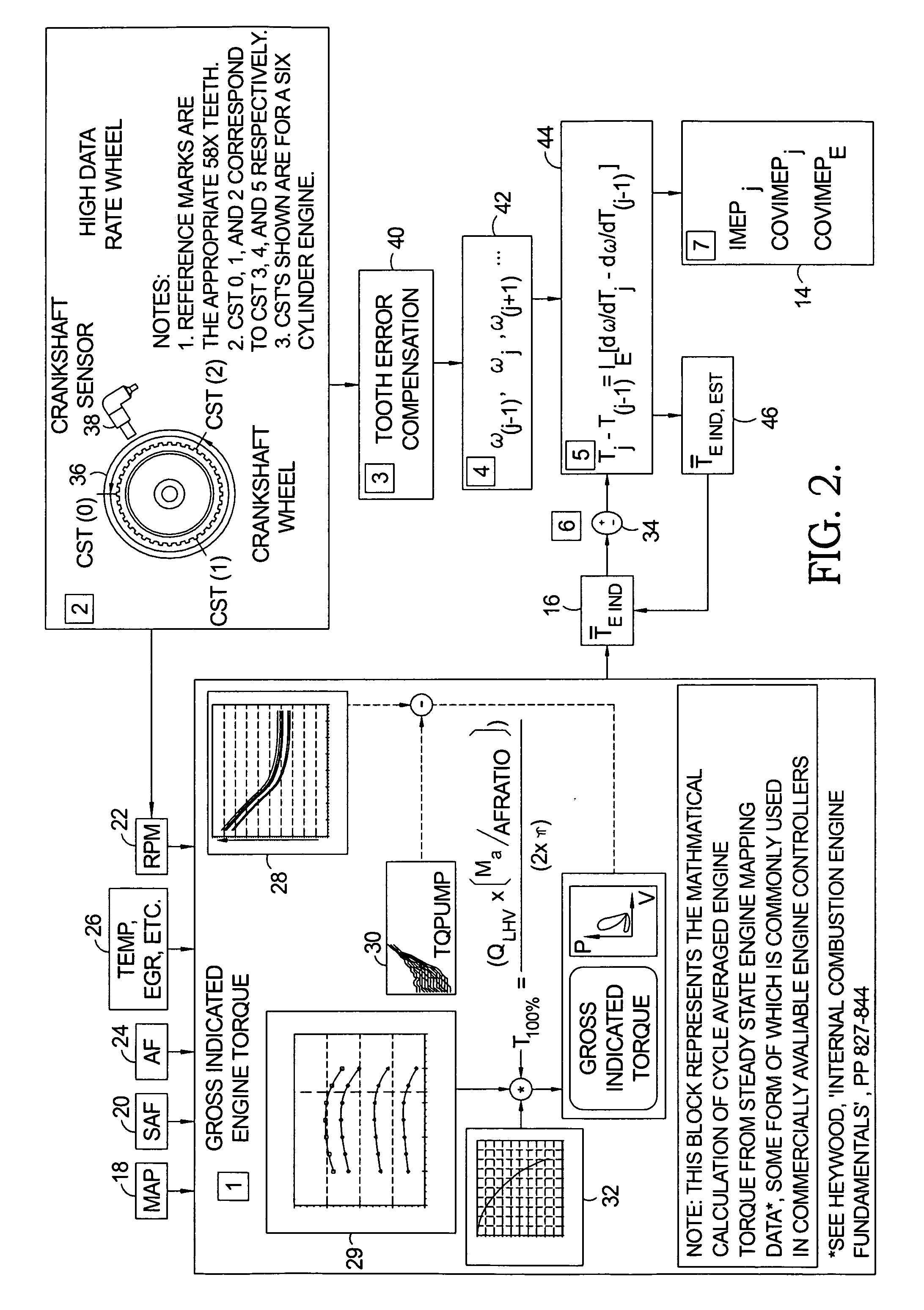

[0037]The transient inter-cycle indicated torque component may be determined in two ways: either indirectly, through calculation of engine kinetic energy change via the difference in average torque from one cylinder event to the next multiplied by the crank angle over which average torque difference acts, or directly, through changes in measured instantaneous crank shaft velocities from one cylinder event to the next. For illustration purposes, the development of average torque changes (indirect method) will be described in detail here.

[0038]Referring to FIG. 1, a torque balance on a rigid crankshaft of an internal combustion engine is illustrated in Diagram 10. Gas or indicated torque (Tind) is assumed to act through the piston and connecting rod assembly at the crank / connecting rod interface. As a first approximation, an average cylinder torque is assumed to act over a crank angle range (ωE), the location of which is optimized for capturing the total energy contribution of the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com