Method for forcibly changing rotating position of piston ring and cross-type two-stroke diesel engine

A technology of two-stroke internal combustion engine, rotating position, applied in the direction of piston rings, mechanical equipment, engine components, etc., capable of solving problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

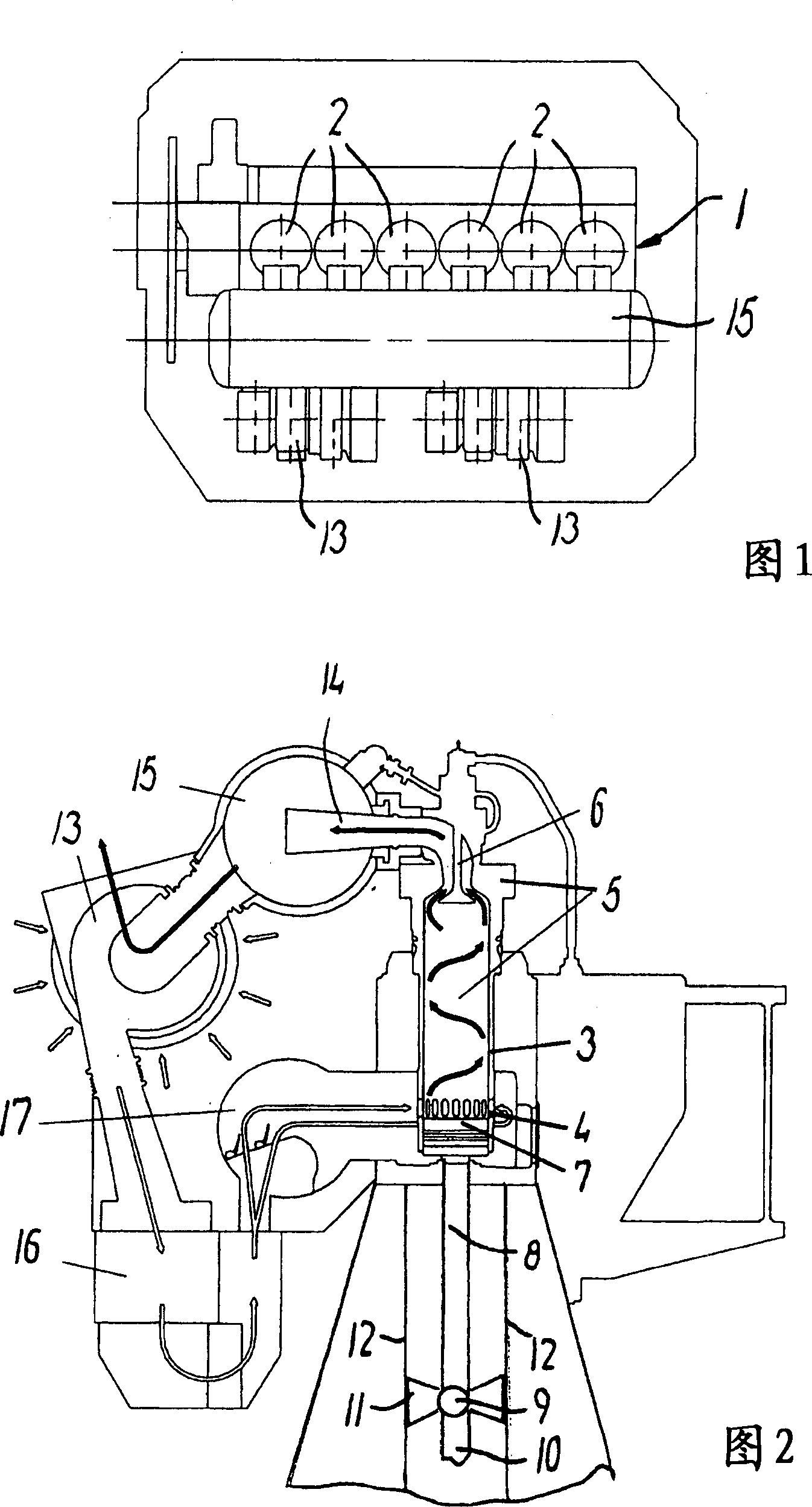

[0030] In the exemplary embodiment of FIG. 1 , a two-stroke internal combustion engine 1 has six cylinders 2 arranged in a single row (tandem engine). The engine may have other numbers of cylinders, for example 4 to 15 cylinders. The engine can be made, for example, from MAN B&W diesels and MC or ME type diesels, or from W_rtsil_ of the Sulzer RT-flex or Sulzer RTA type, or from Mitsubishi. These cylinders may have a bore diameter in the range of eg 25-120 cm, preferably 35-120 cm, more preferably 50-110 cm. The engine has a power range of, for example, 270-8500 kW per cylinder, preferably 1000-7000 kW. Therefore, the engine of the present invention is a large engine.

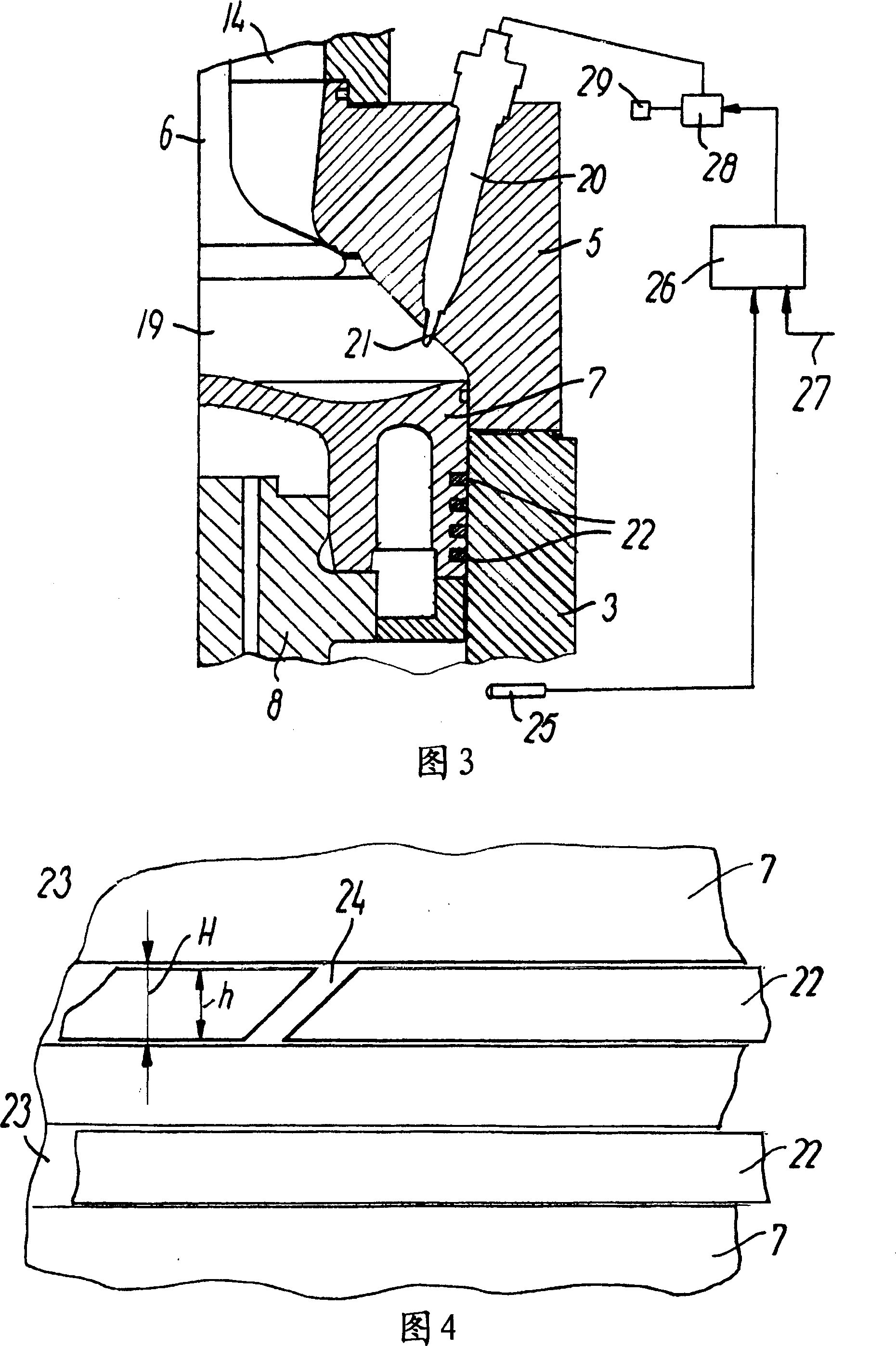

[0031] Each cylinder 2 has a cylinder liner 3 with a row of exhaust holes 4 at its lower end, a cylinder head 5 and an exhaust valve 6 positioned at the upper end of the cylinder liner. The piston 7 is mounted on a piston rod 8 . The piston rod is conventionally connected to a crankpin on a crankshaft (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com