Patents

Literature

1276results about How to "Increased bending stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

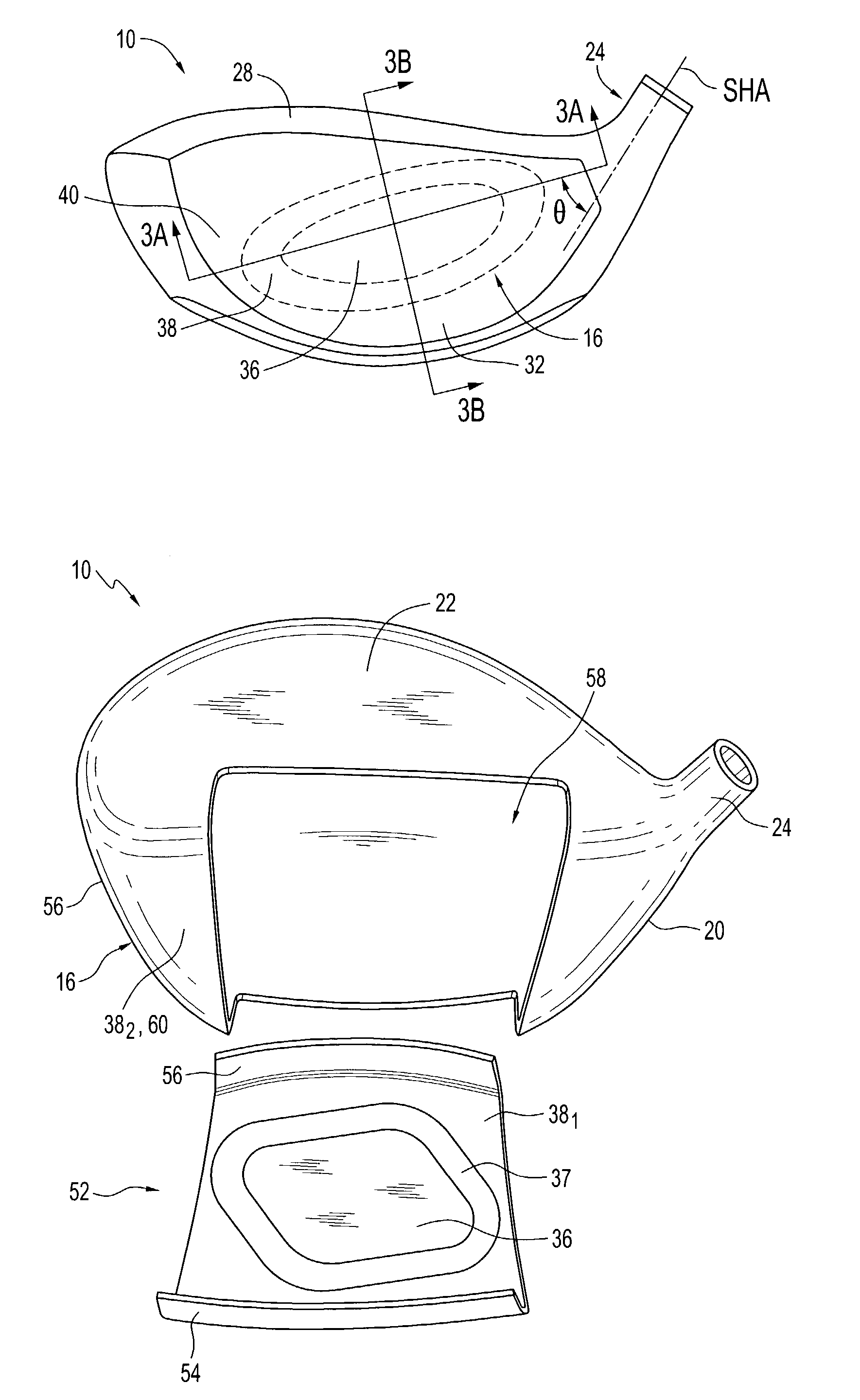

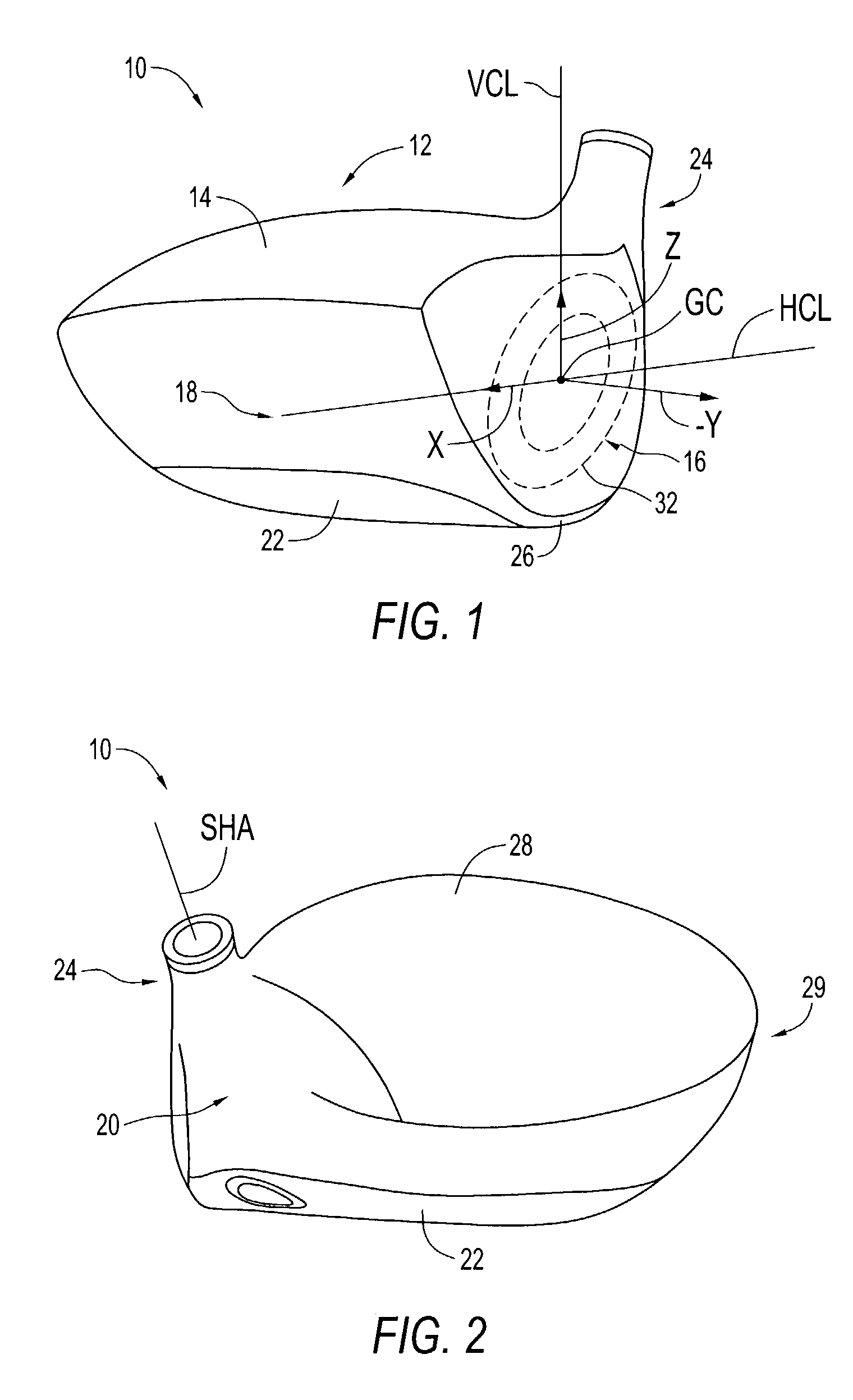

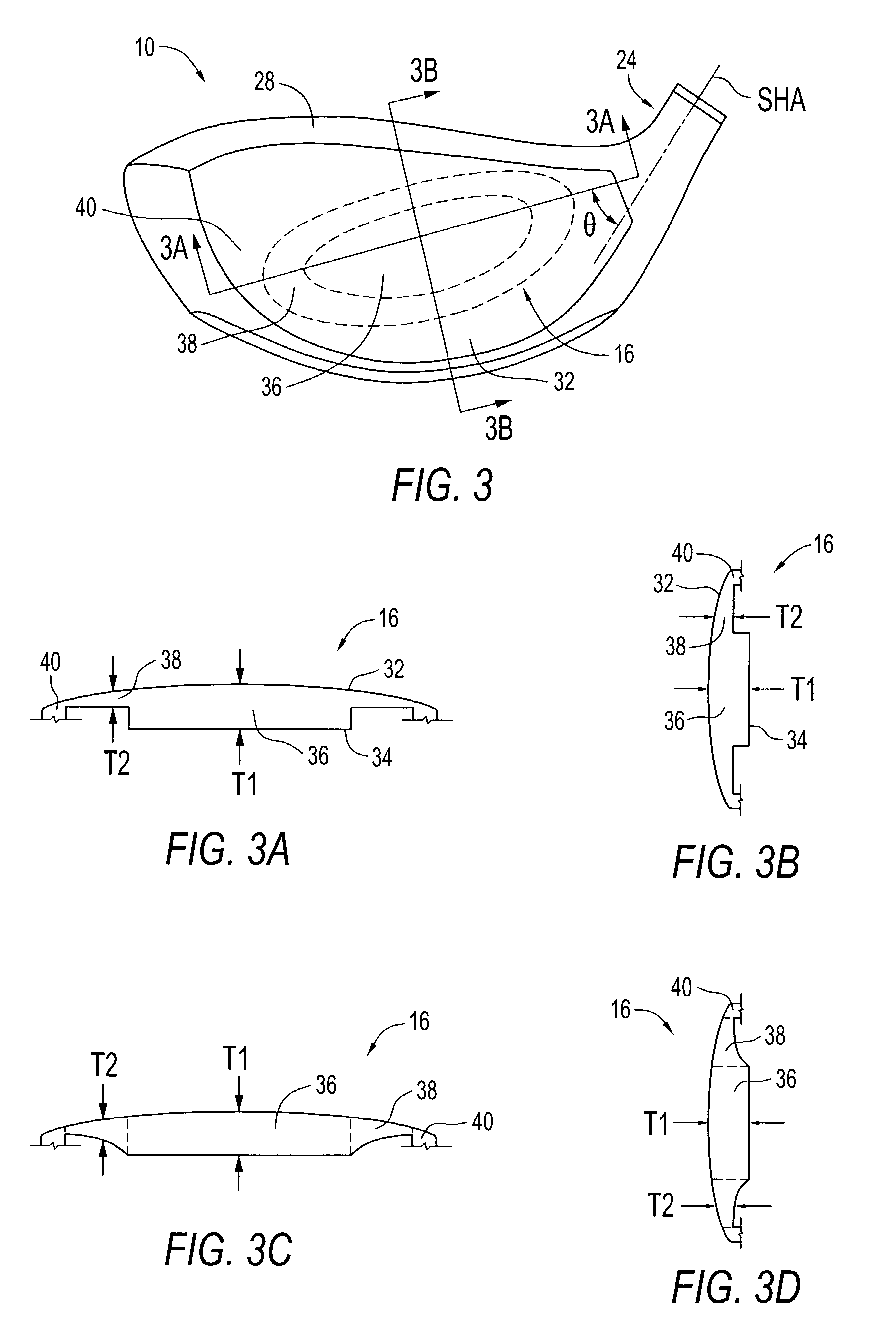

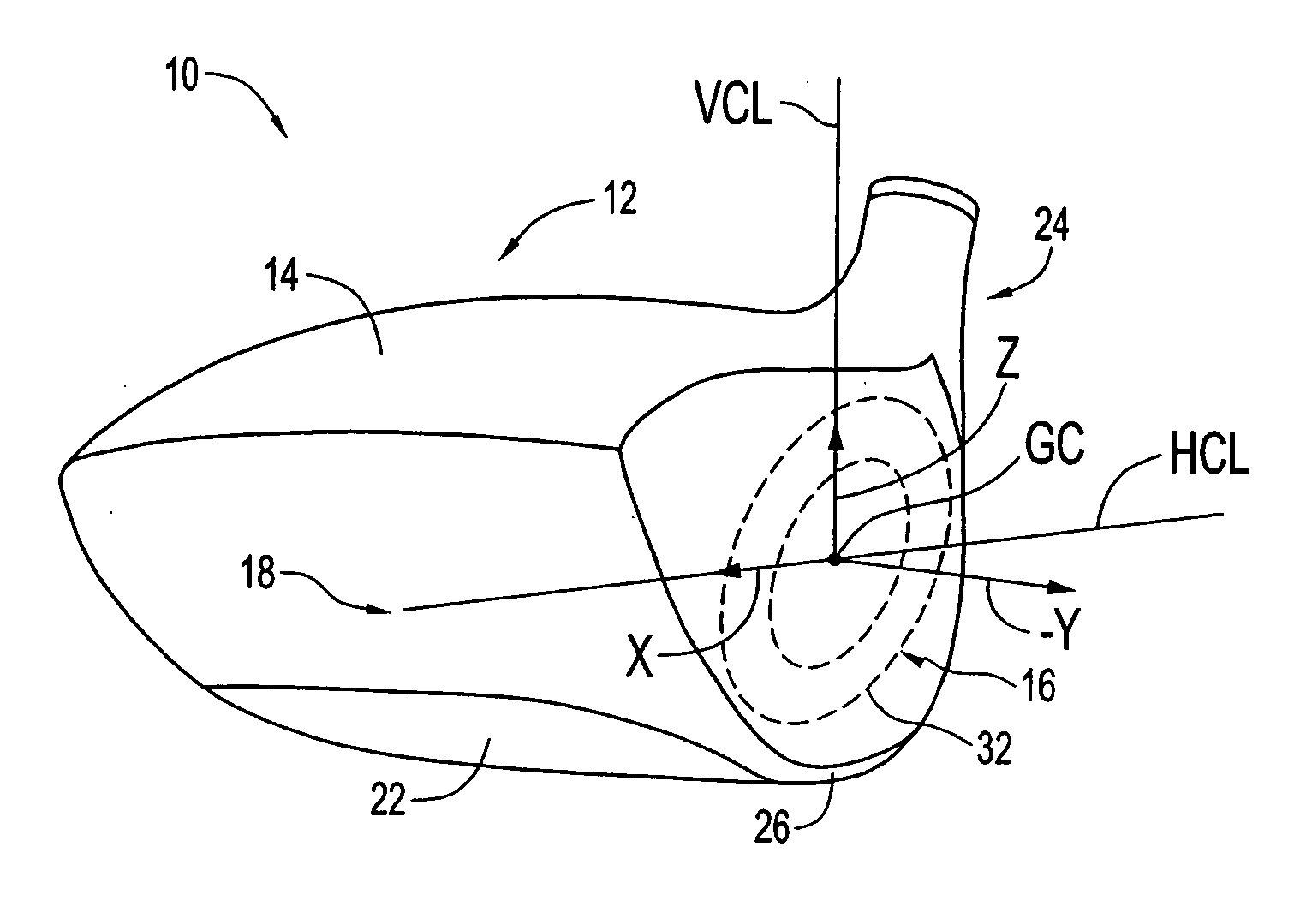

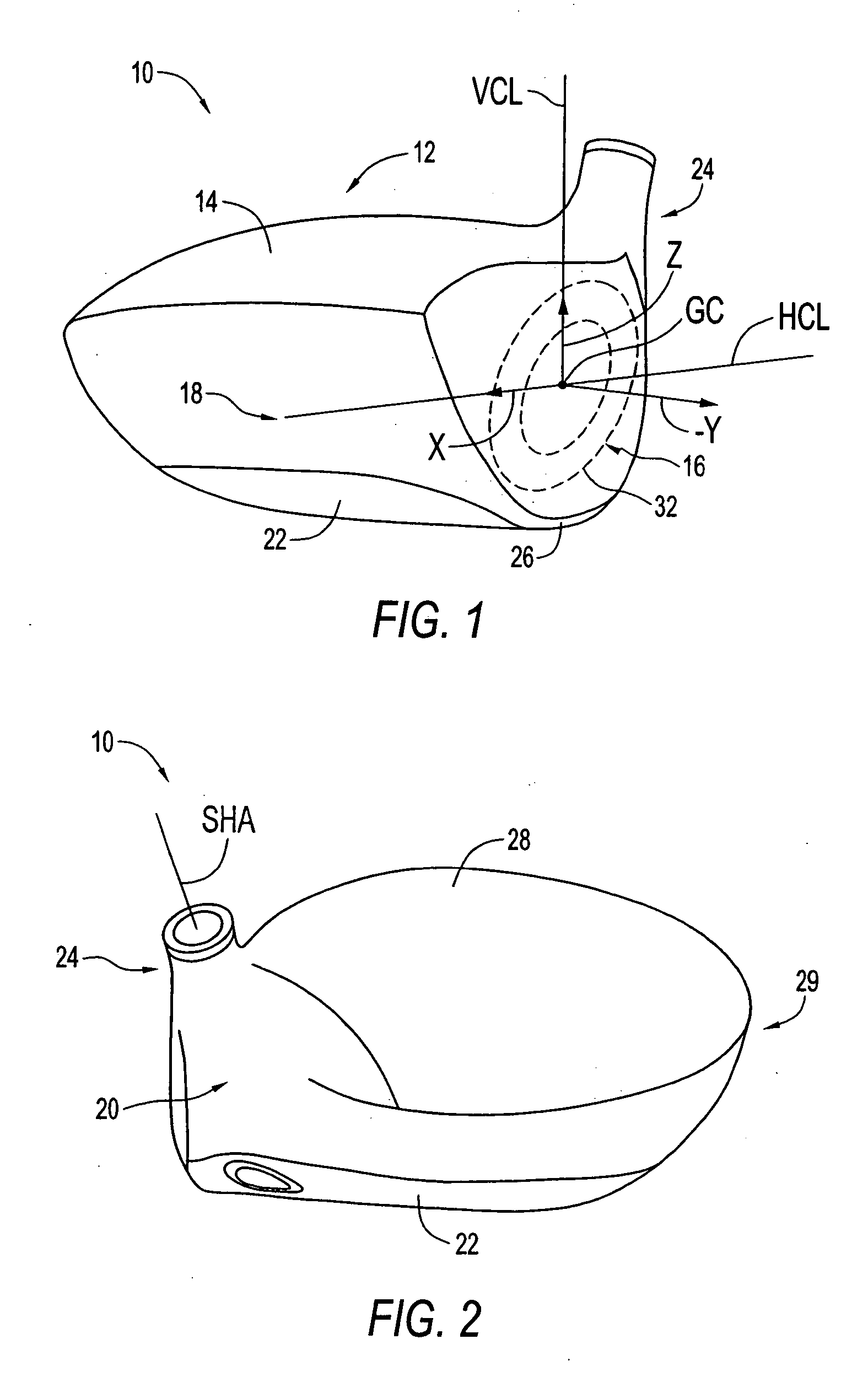

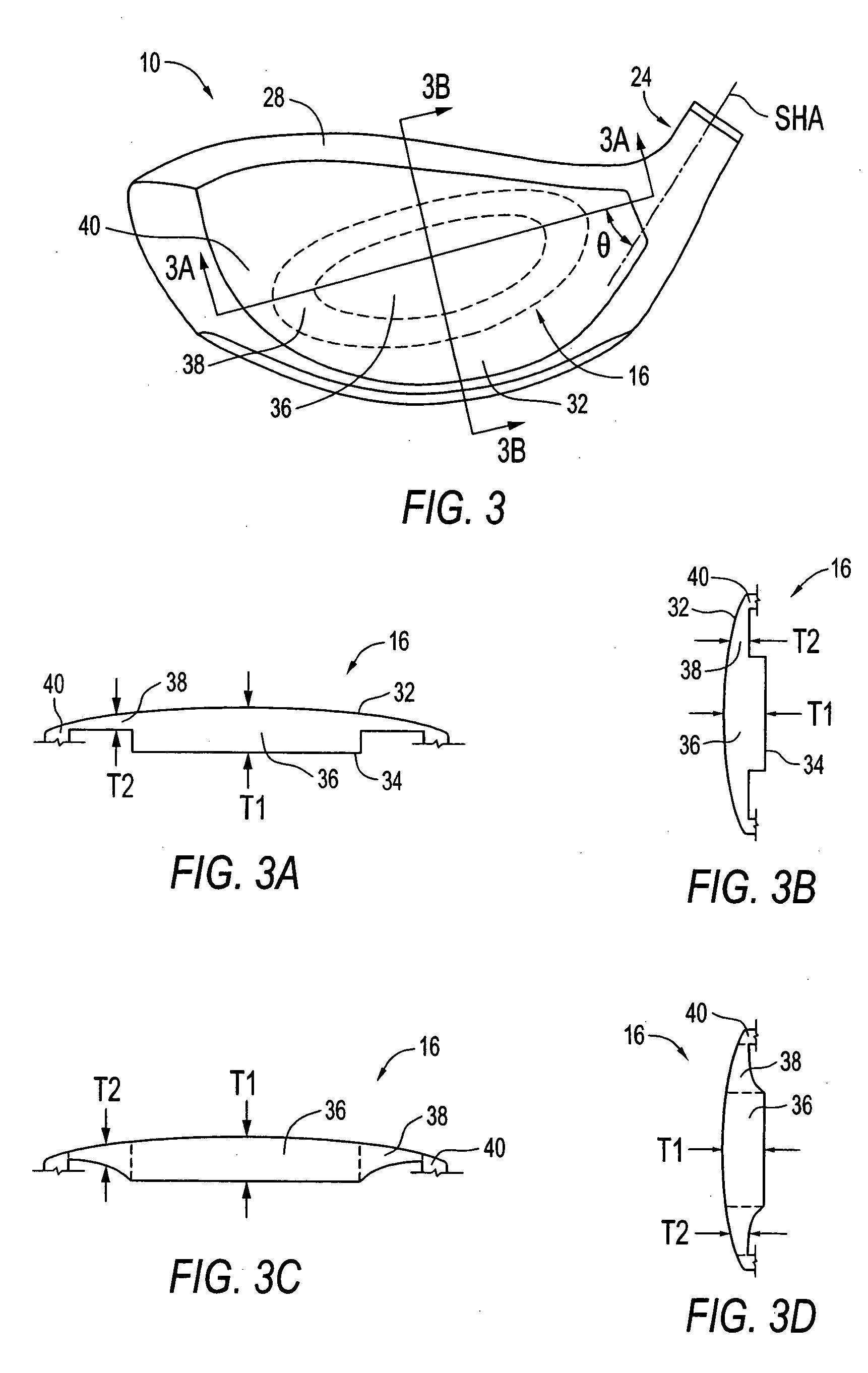

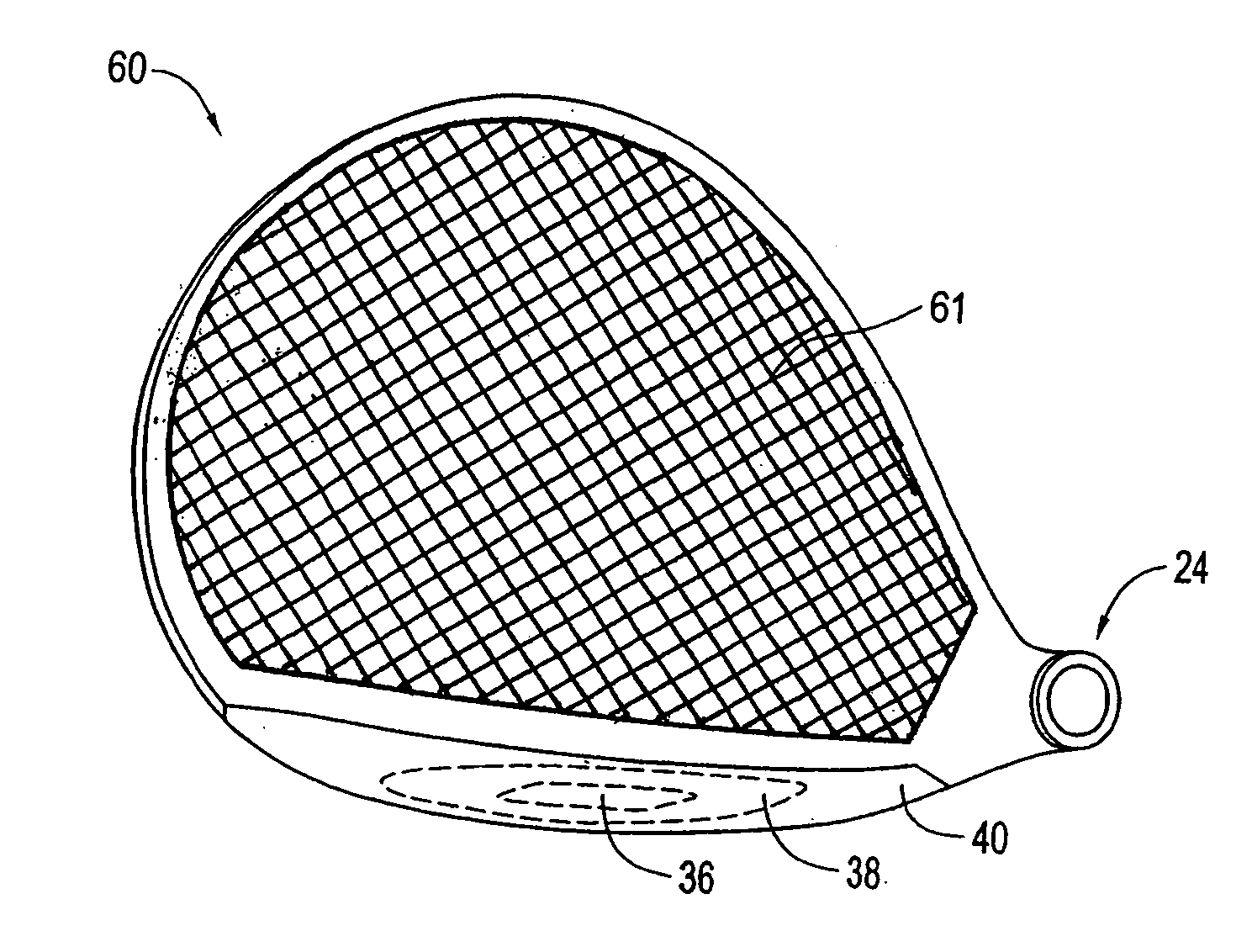

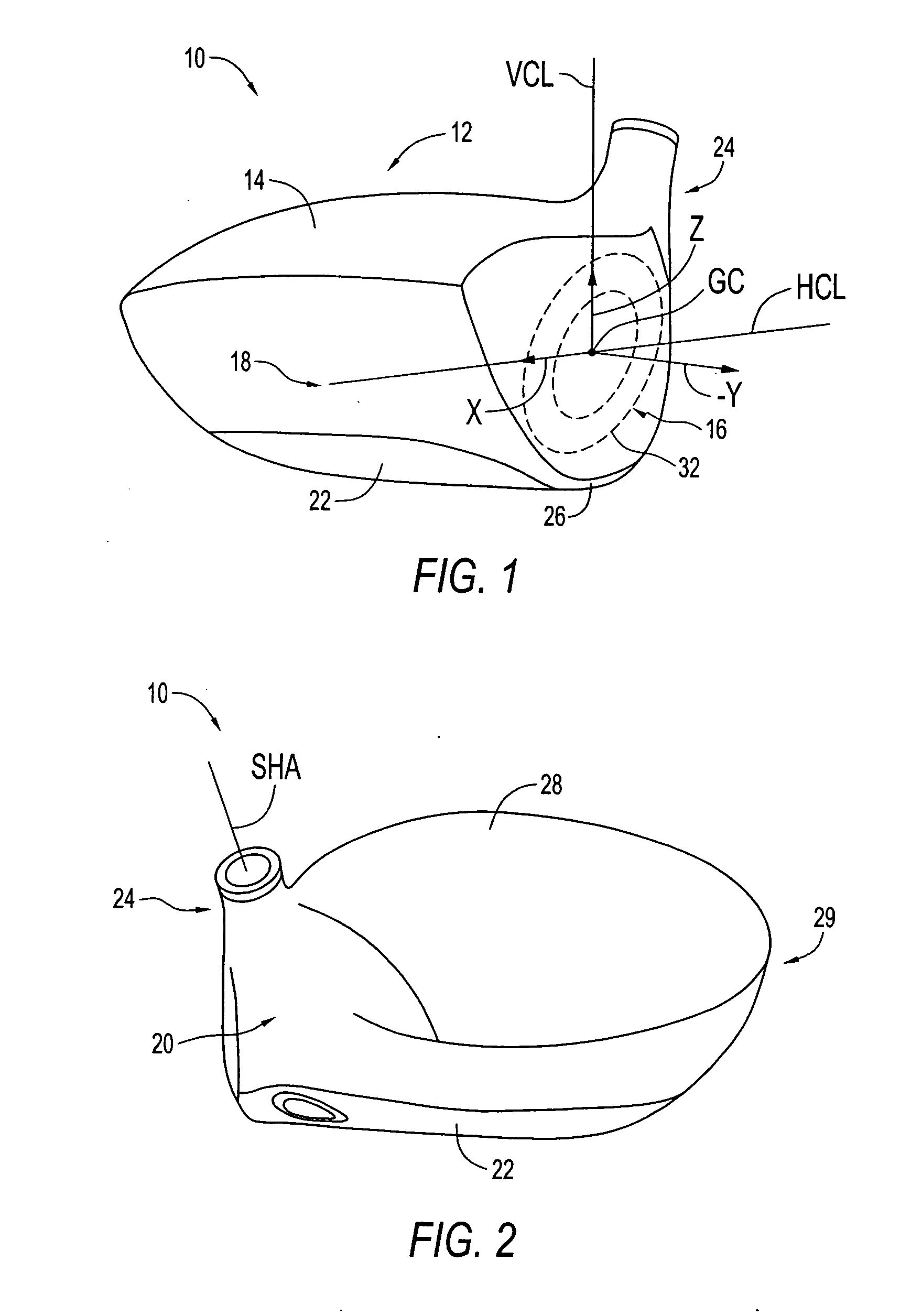

Metal wood club with improved hitting face

InactiveUS7029403B2Increased bending stiffnessIncrease elasticityAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsEllipseBall impact

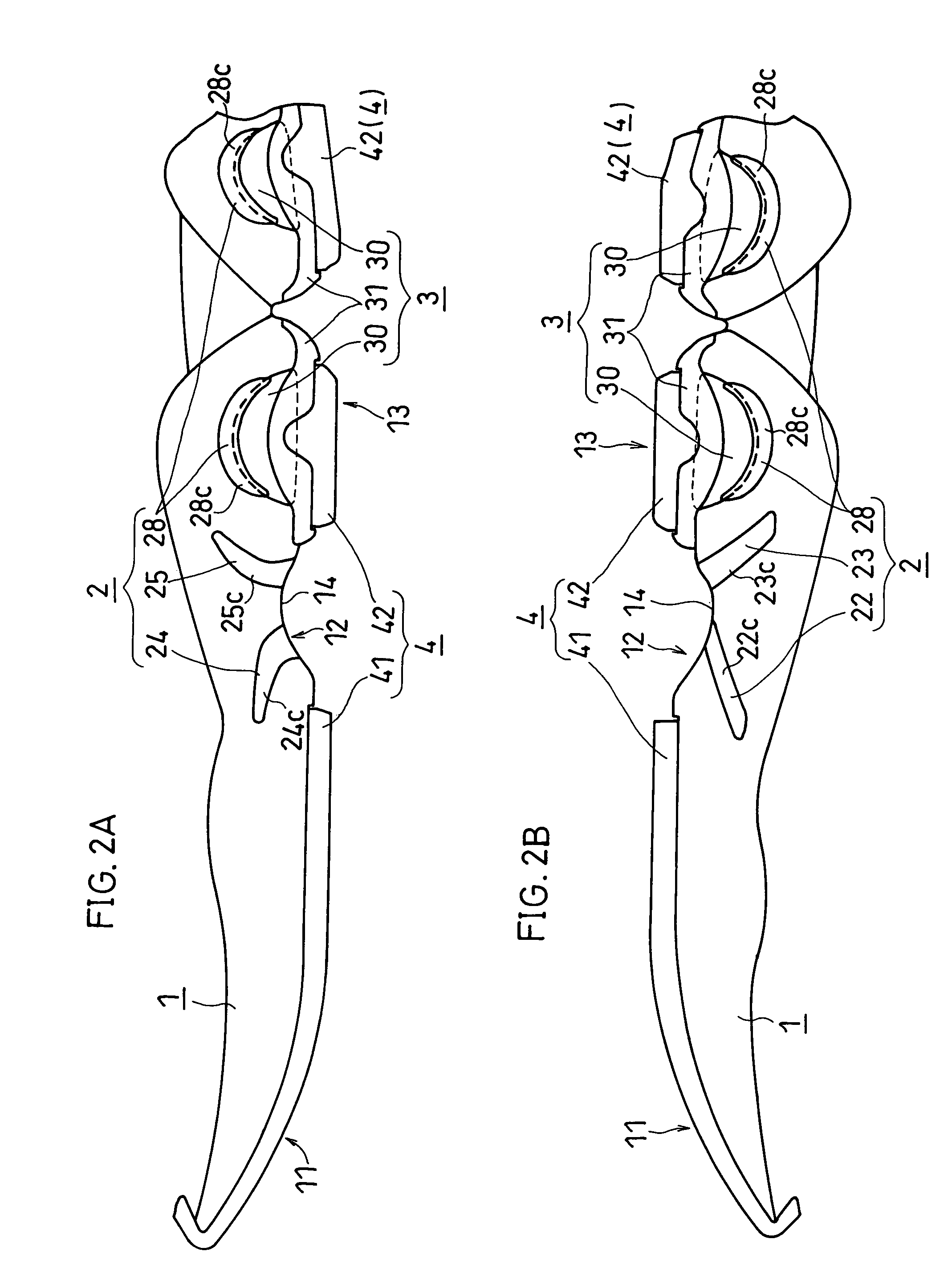

A golf club head having selectively oriented zones of relatively high flexural stiffness is disclosed. The hitting face is configured and dimensioned so that it includes an inner zone and a concentric intermediate zone. The inner zone has relatively high flexural stiffness and the intermediate zone has relatively lower flexural stiffness. The inner zone may have an elliptical shape or a substantially parallelogram shape. Preferably, the inner zone has a shape that comprises a major axis and a minor axis and the major axis aligns substantially in the direction of high heel to low toe. This arrangement of inner and intermediate zones creates a gradient of flexural stiffness in the direction of high toe to low heel and produces a desirable manipulation COR in that direction. This area of high coefficient of restitution advantageously coincides with the ball impact pattern that golfers typically make on the hitting face. The hitting face also comprises a measurement zone wherein the lowest COR is at least 93% of the highest COR.

Owner:ACUSHNET CO

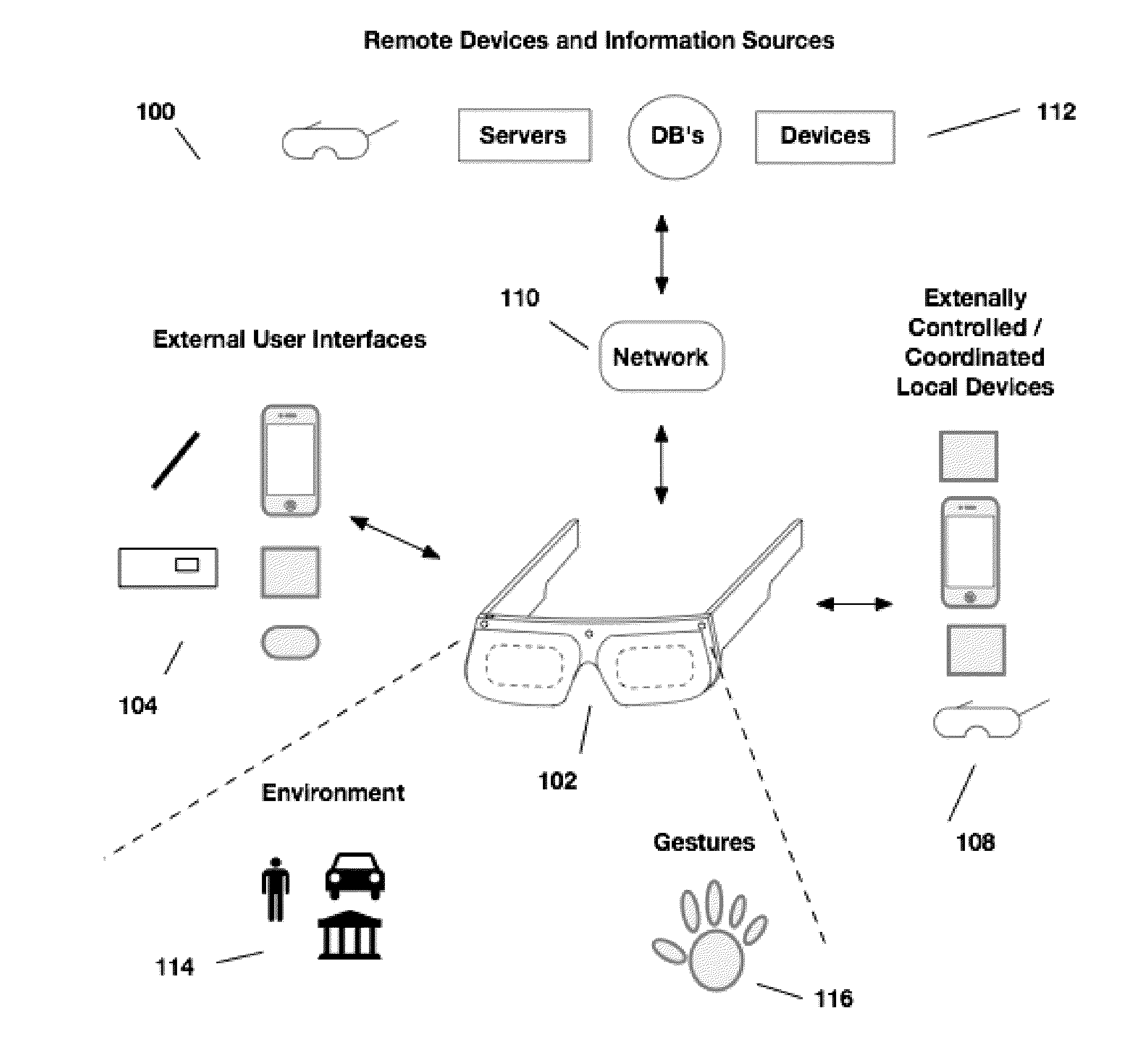

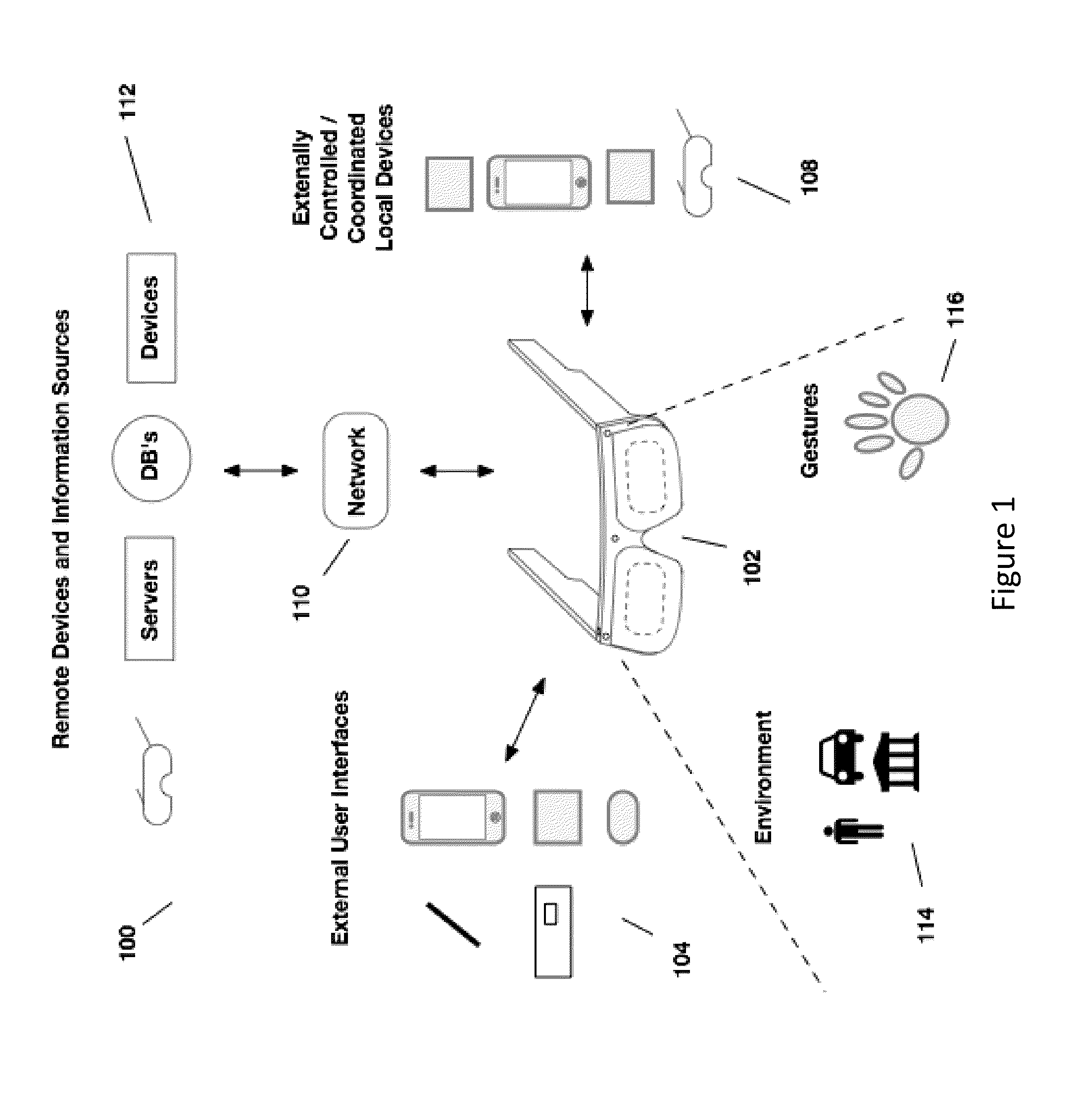

Head worn computer display systems

ActiveUS20160246055A1Improve cooling effectIncrease airflowDetails for portable computersImage data processingOptical mountDisplay device

Aspects of the present disclosure relate to mounting electronics and optical systems in head-worn see-through computer displays. In embodiments, a head worn computer includes an optical chassis with a rigid open box structure configured to provide a stable optical mounting reference plane and a plurality of image source reference planes. The head worn computer further includes a first image source mounted on one of the image source reference planes to project first image light through a first hole in the optical mounting reference plane and a second image source mounted on a second of the image source reference planes and configured to project second image light through a second hole in the optical mounting reference plane. An outer frame holds the optical chassis such that, when worn by a user, the first and second image light is aligned with the eyes of the user.

Owner:OSTERHOUT GROUP INC

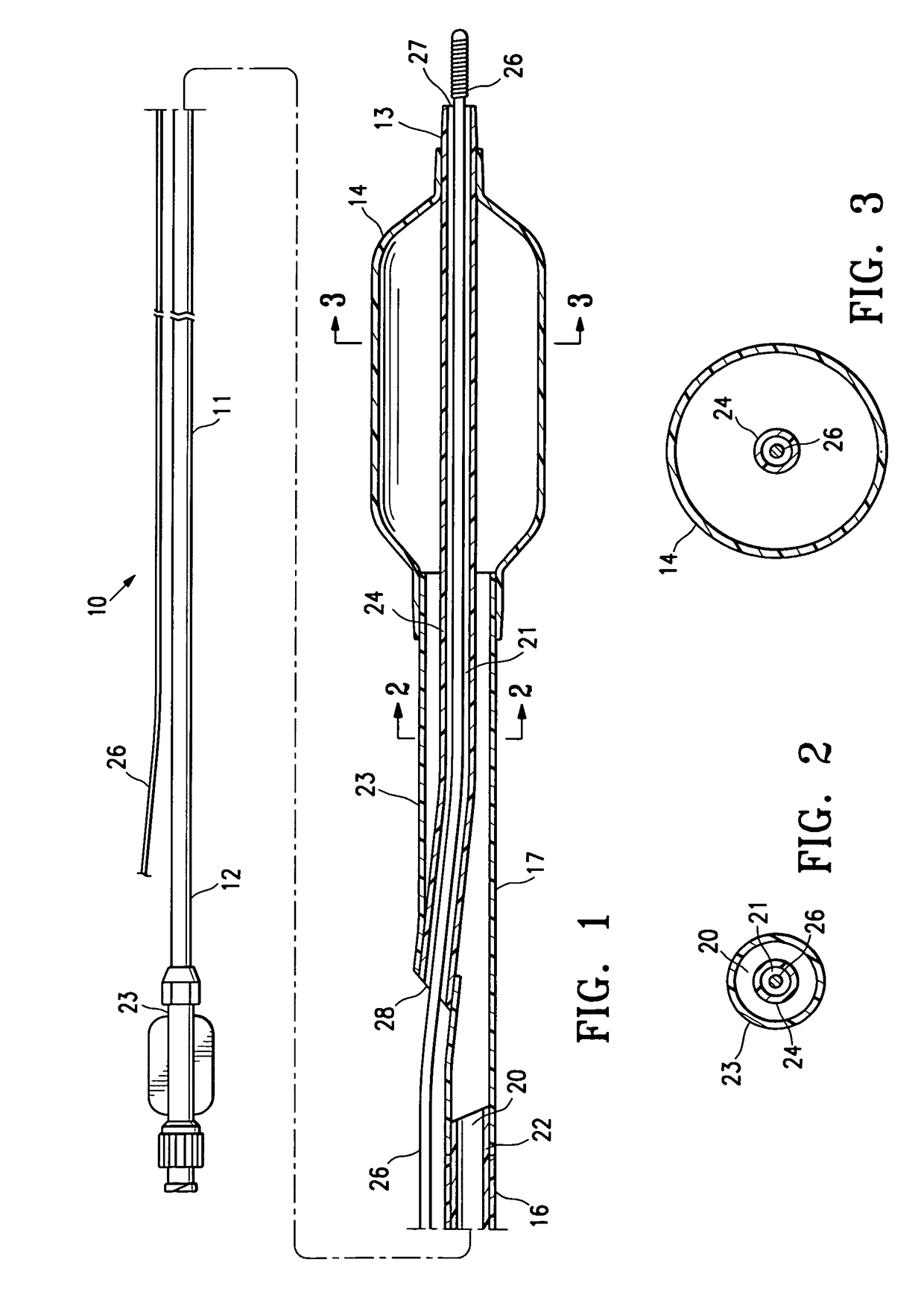

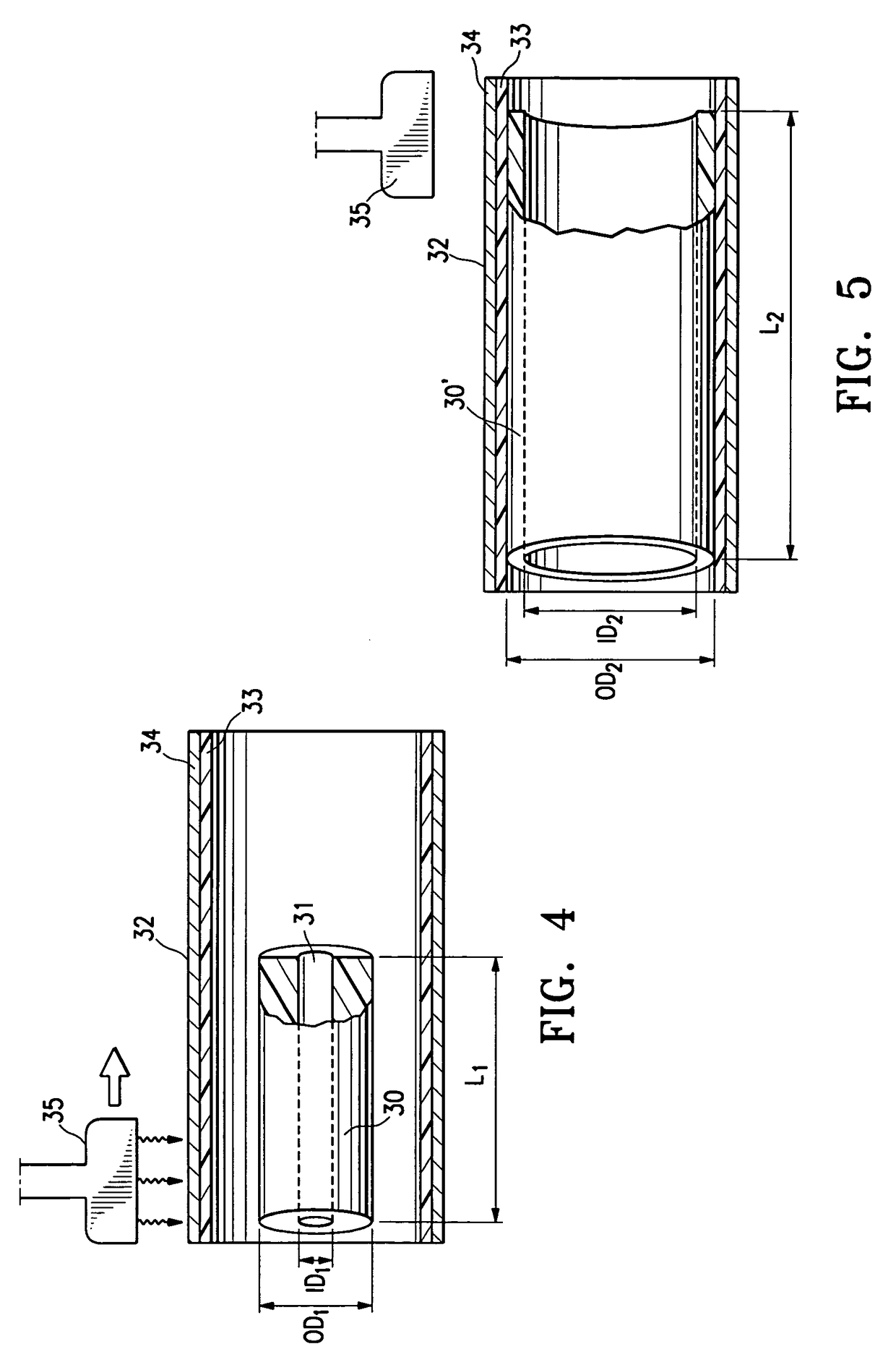

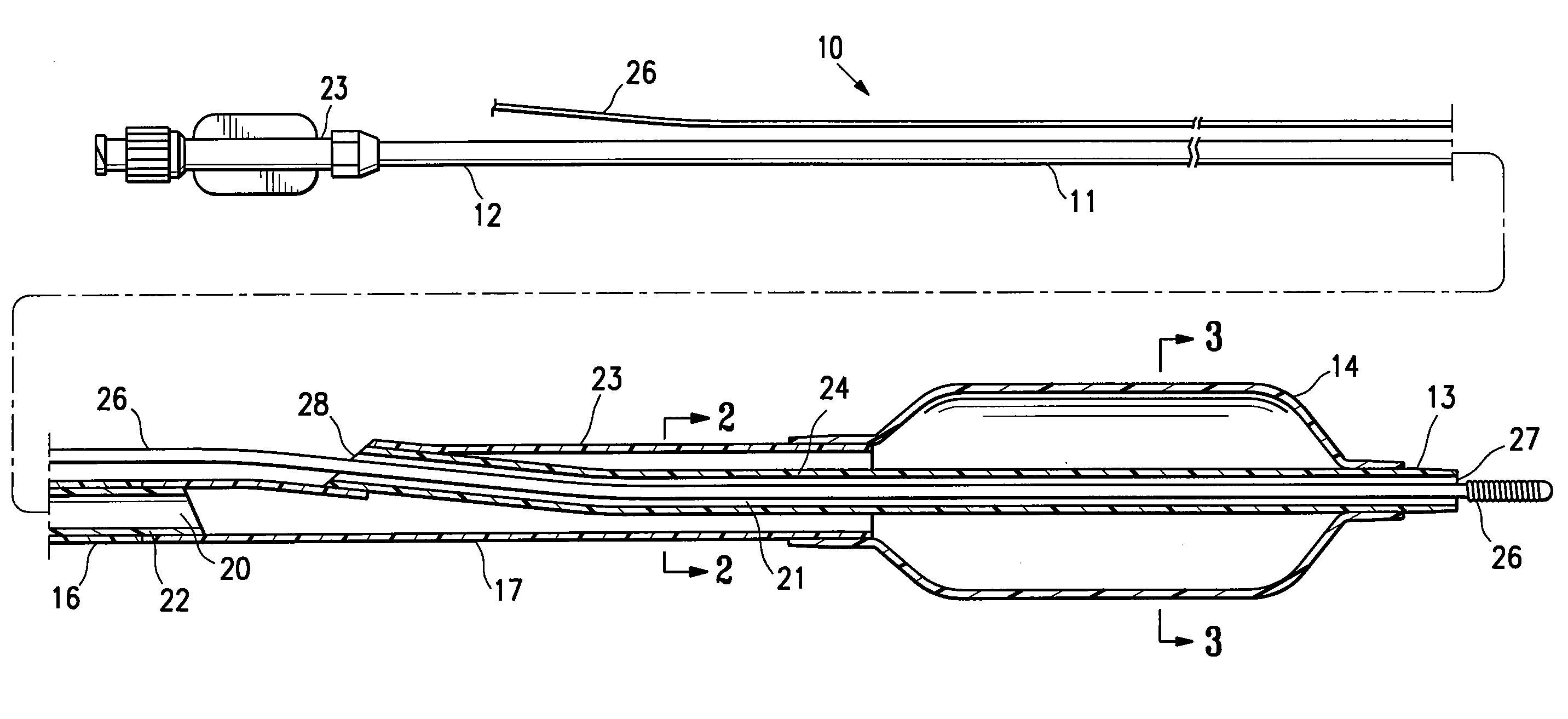

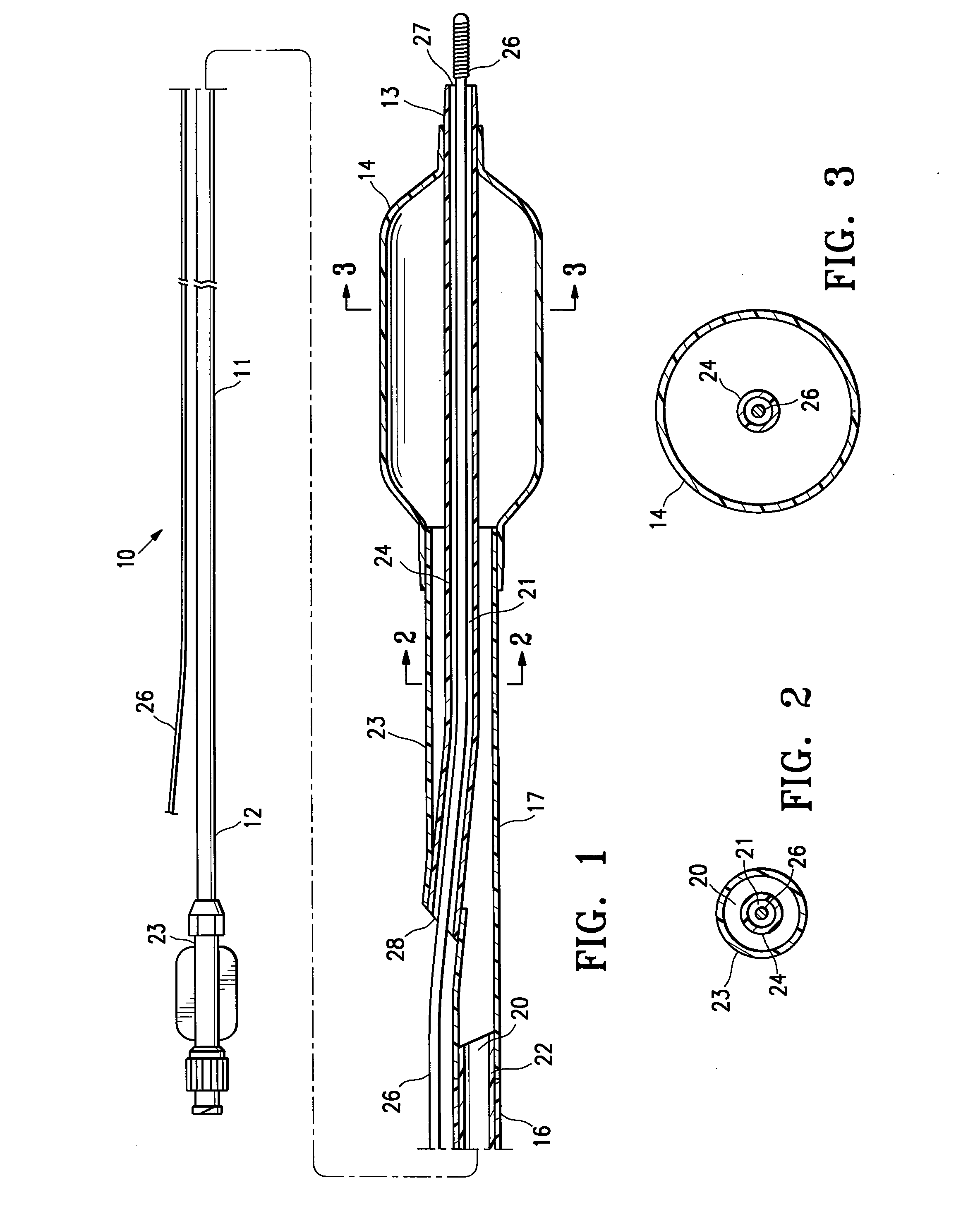

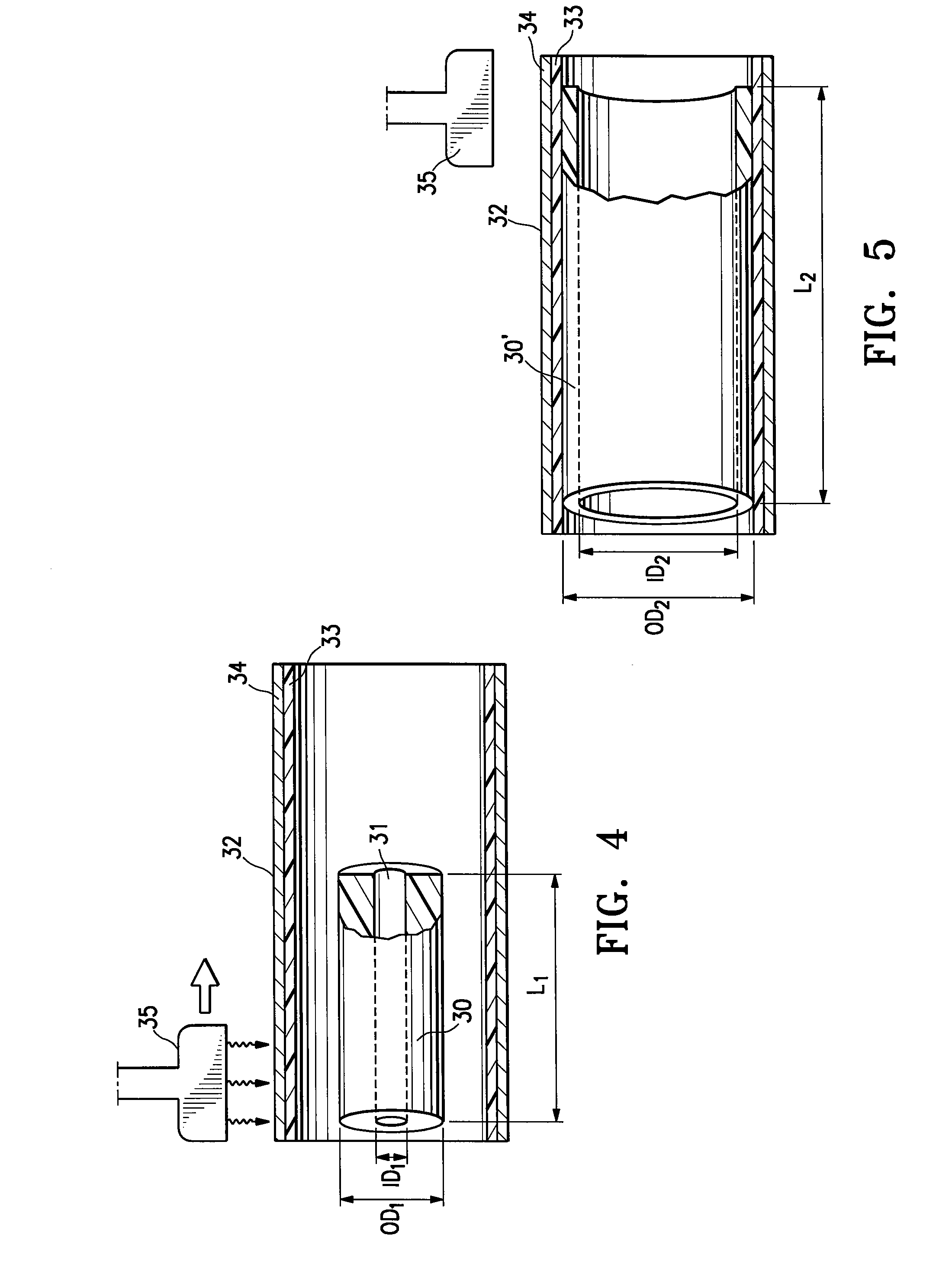

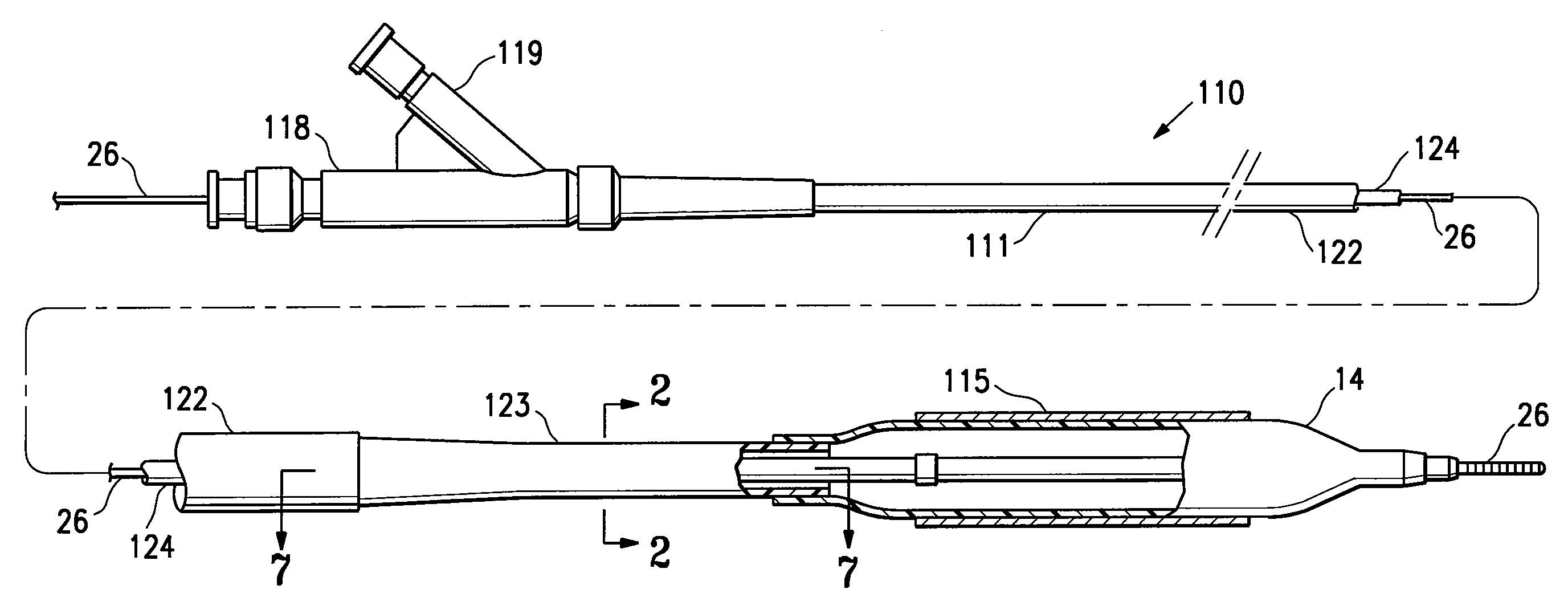

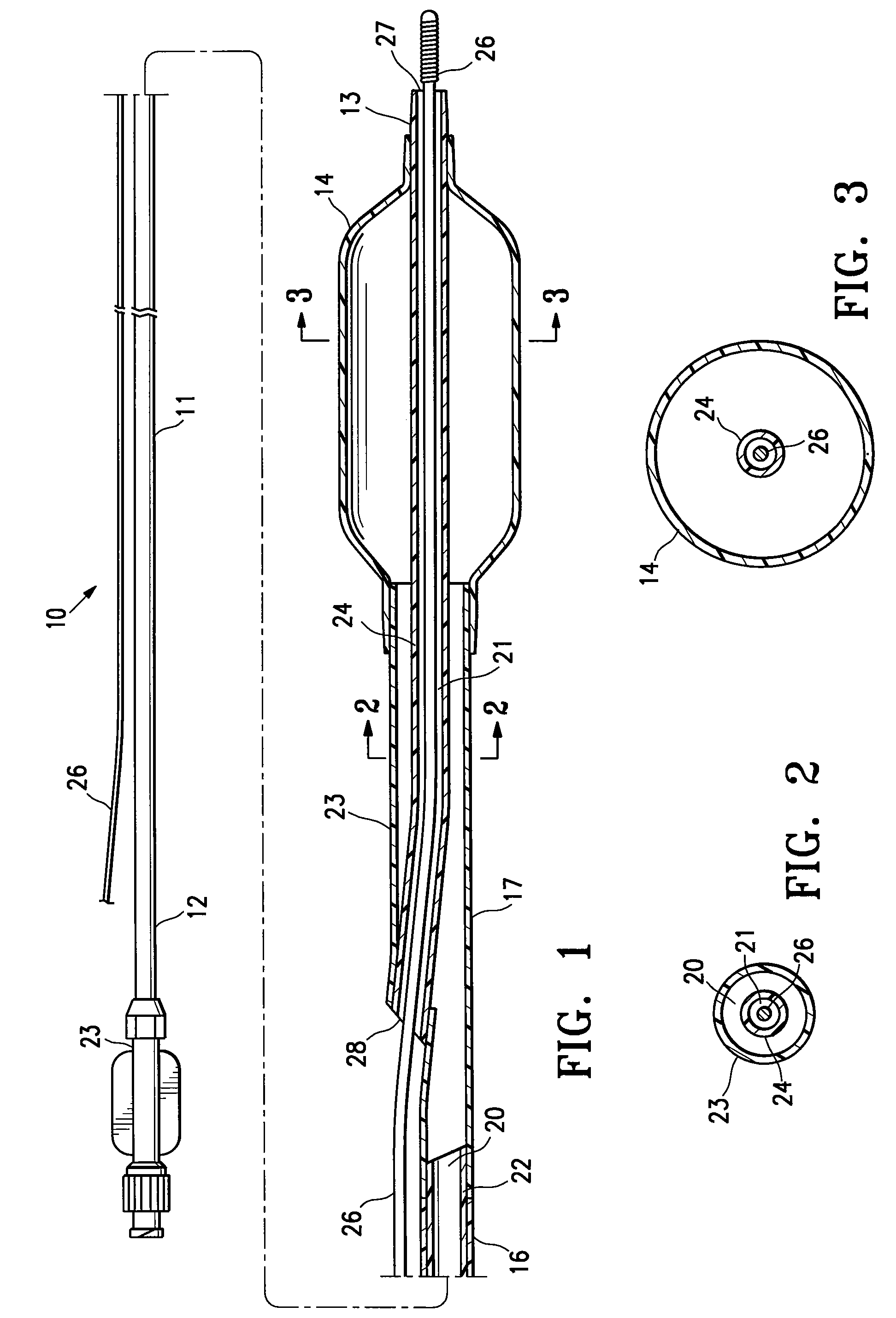

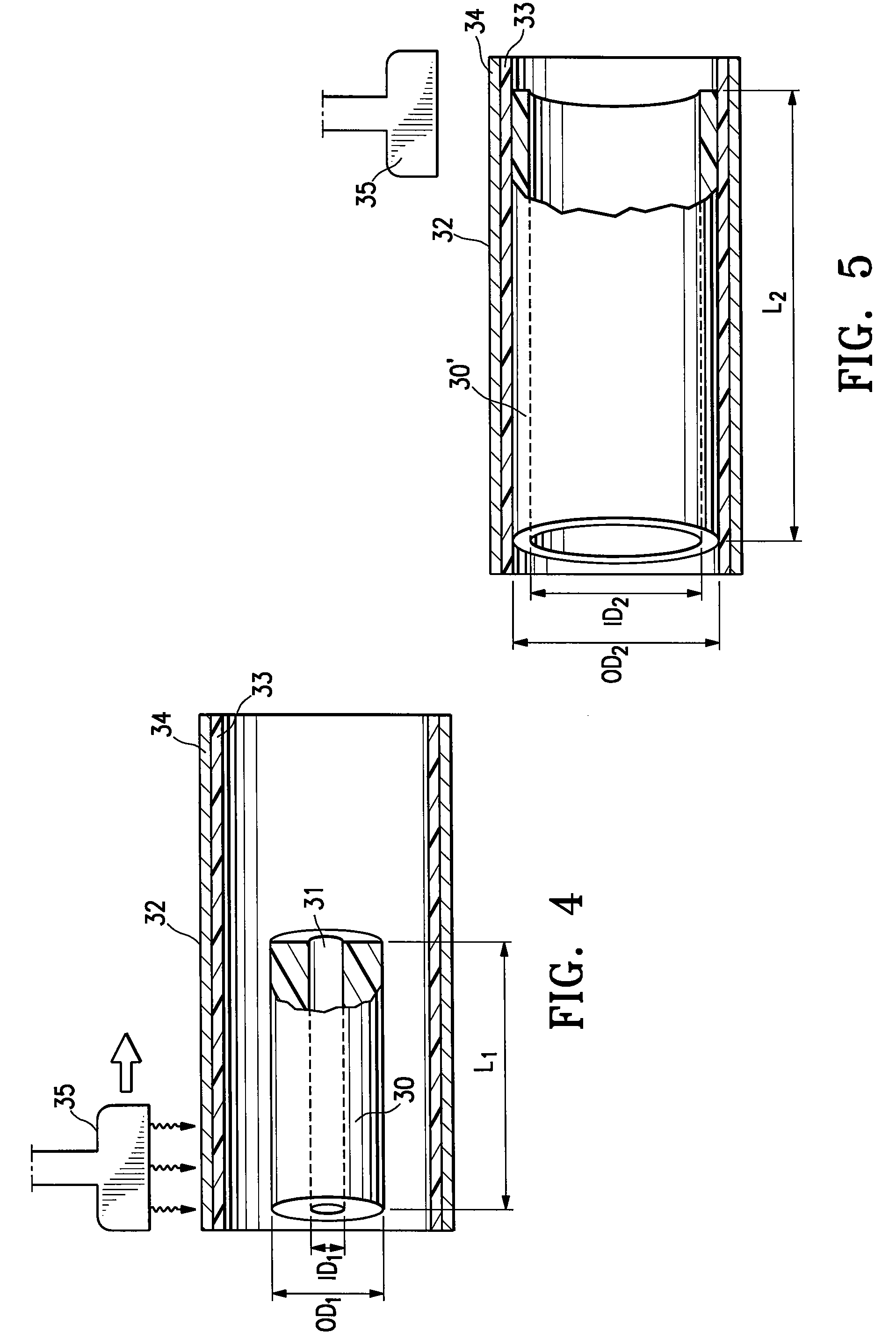

Method of making a balloon catheter shaft having high strength and flexibility

A catheter having an elongated shaft with a tubular member which forms at least a portion of the shaft and which is formed of a biaxially oriented thermoplastic polymeric material, and a method of forming the catheter shaft by radially and longitudinally expanding the tubular member to biaxially orient the polymeric material. A catheter of the invention has an improved combination of low bending stiffness, high rupture pressure, and high tensile strength, for improved catheter performance.

Owner:ABBOTT CARDIOVASCULAR

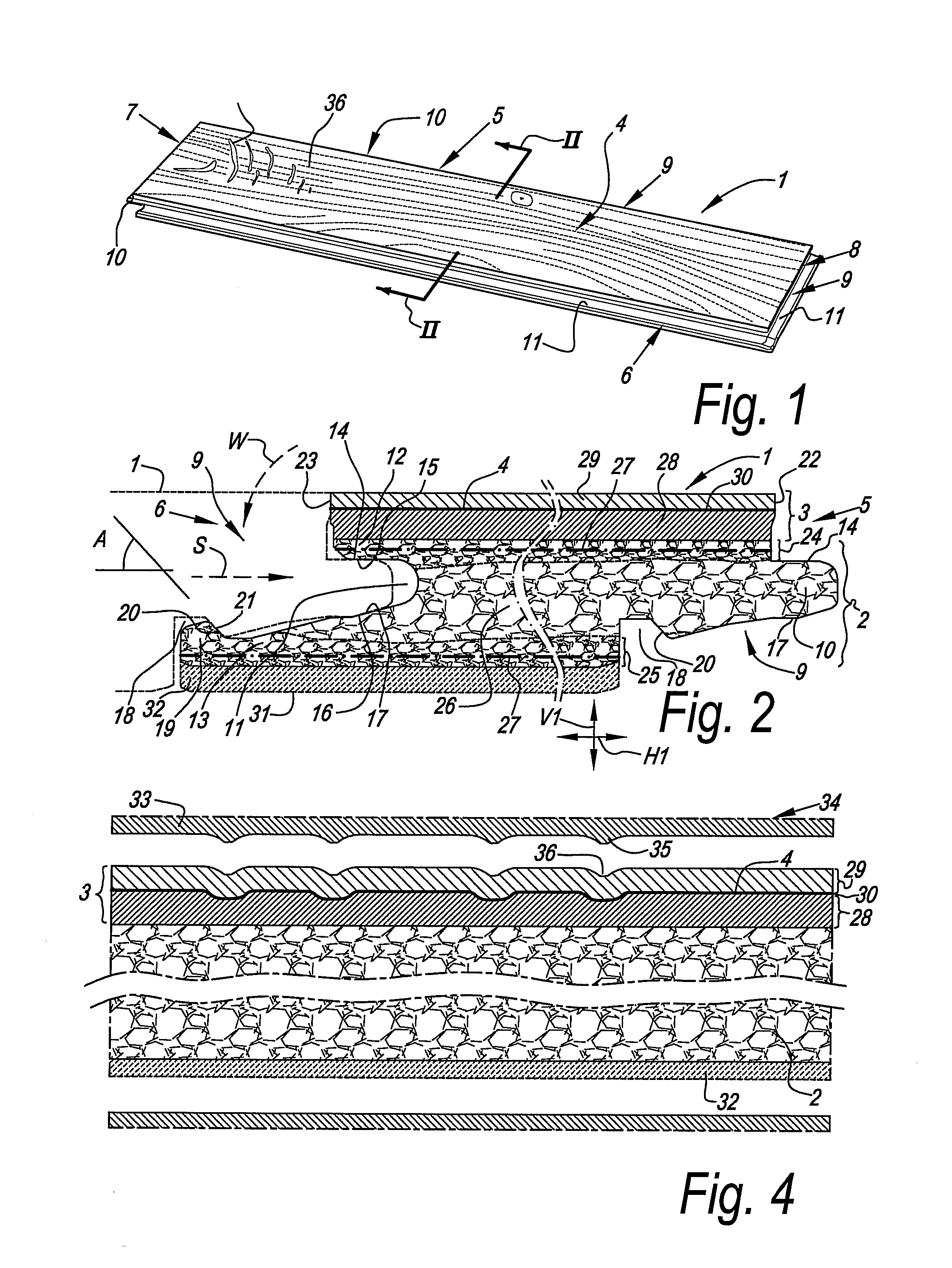

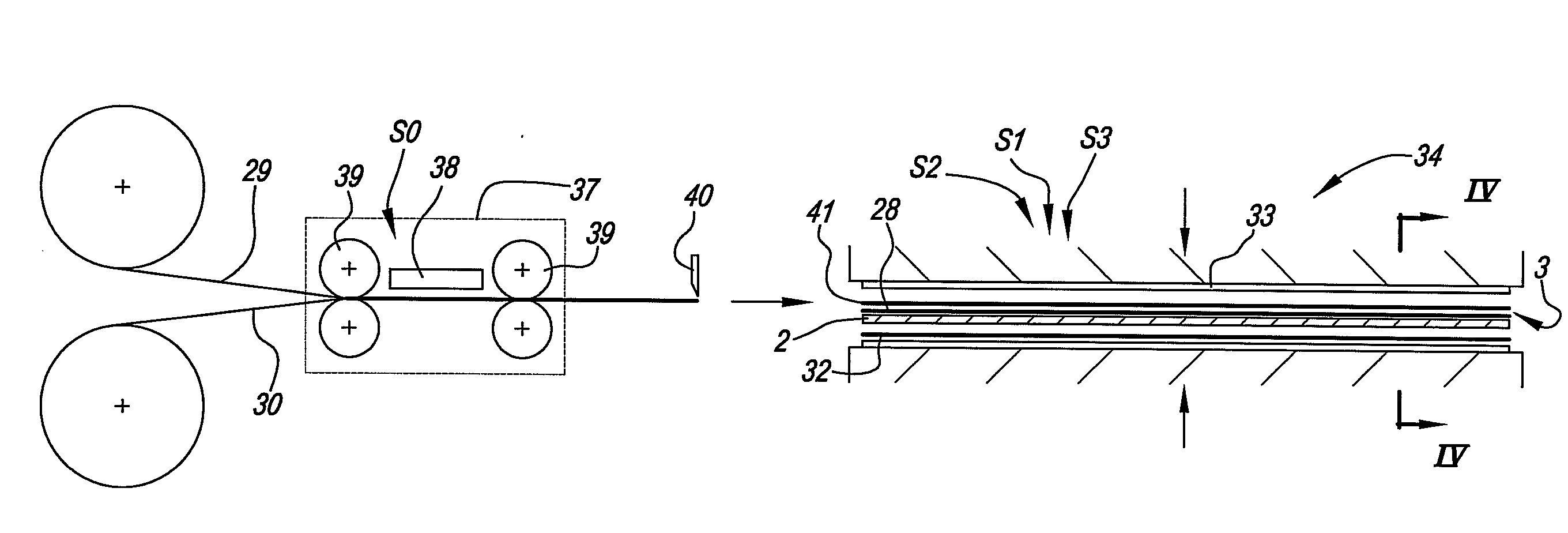

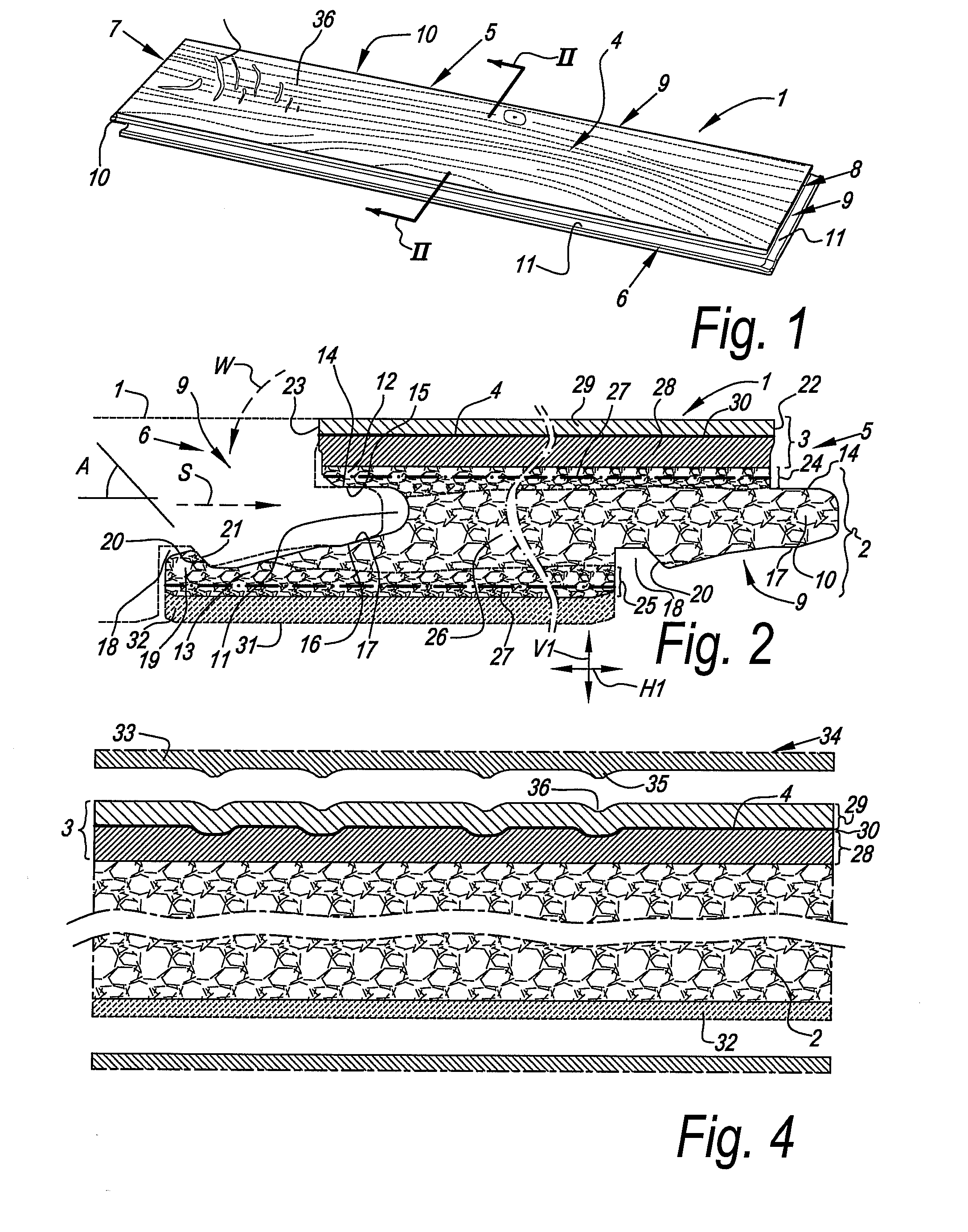

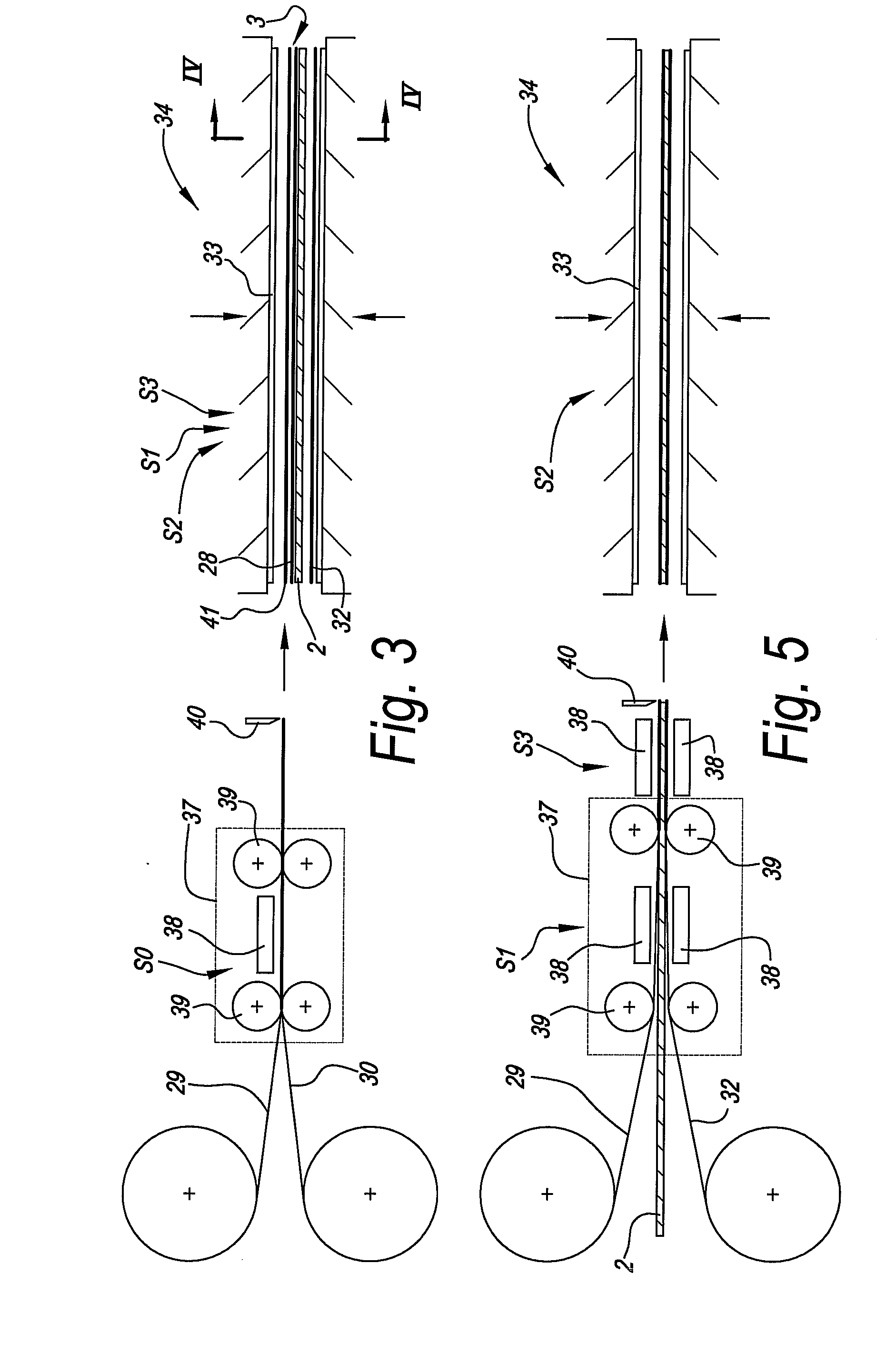

Floor panel and methods for manufacturing floor panels

ActiveUS20130067842A1High densityHigh sensitivityCovering/liningsDecorative surface effectsPanellingEngineering

In a method for manufacturing floor panels that have at least a substrate and a top layer provided on the substrate, the top layer including a thermoplastic layer that is translucent or transparent, the method may involve providing the top layer, including the thermoplastic layer, on the substrate. The method may also involve heating at least the thermoplastic layer, and structuring the thermoplastic layer using a mechanical press element.

Owner:FLOORING IND LTD

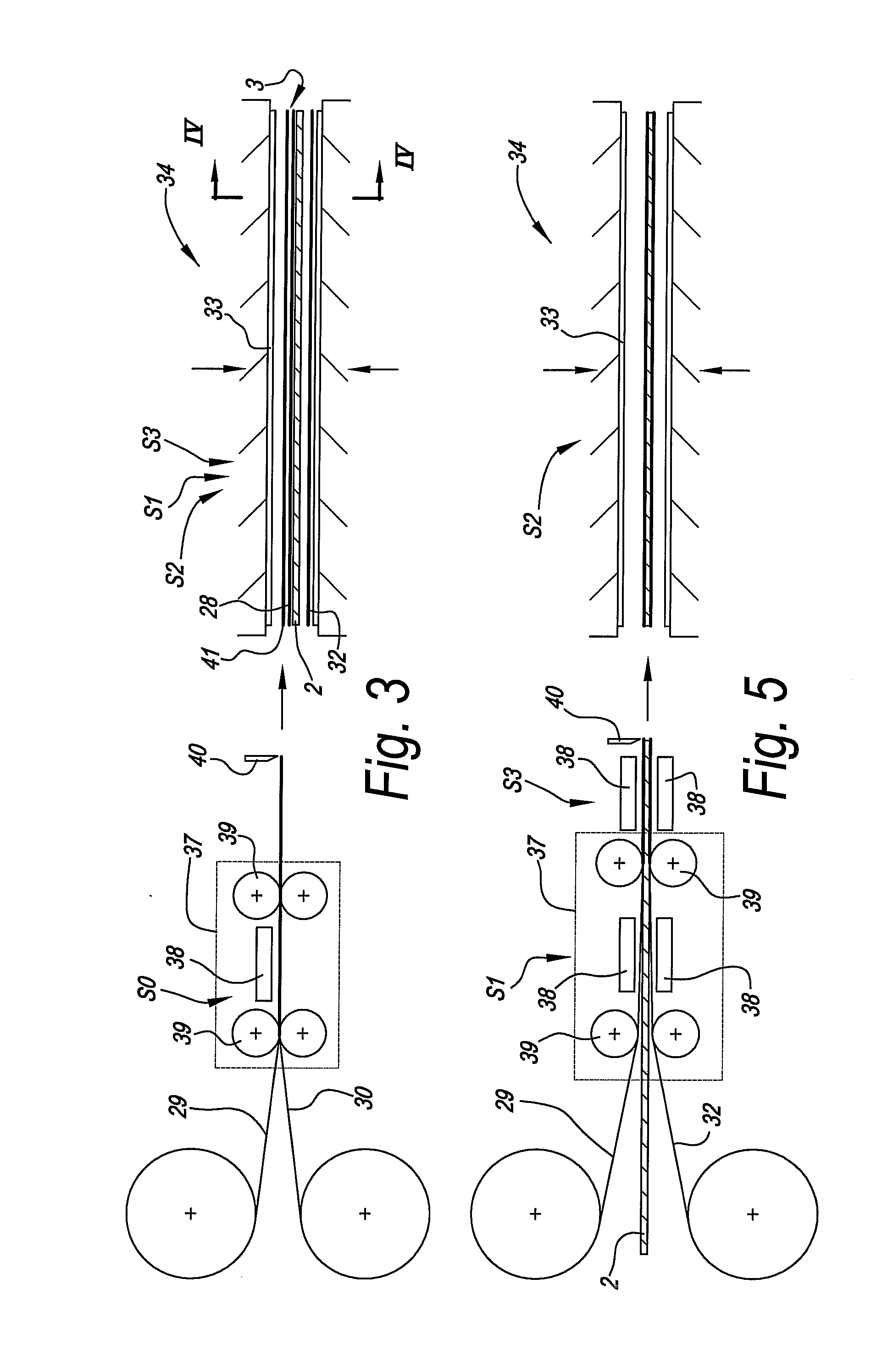

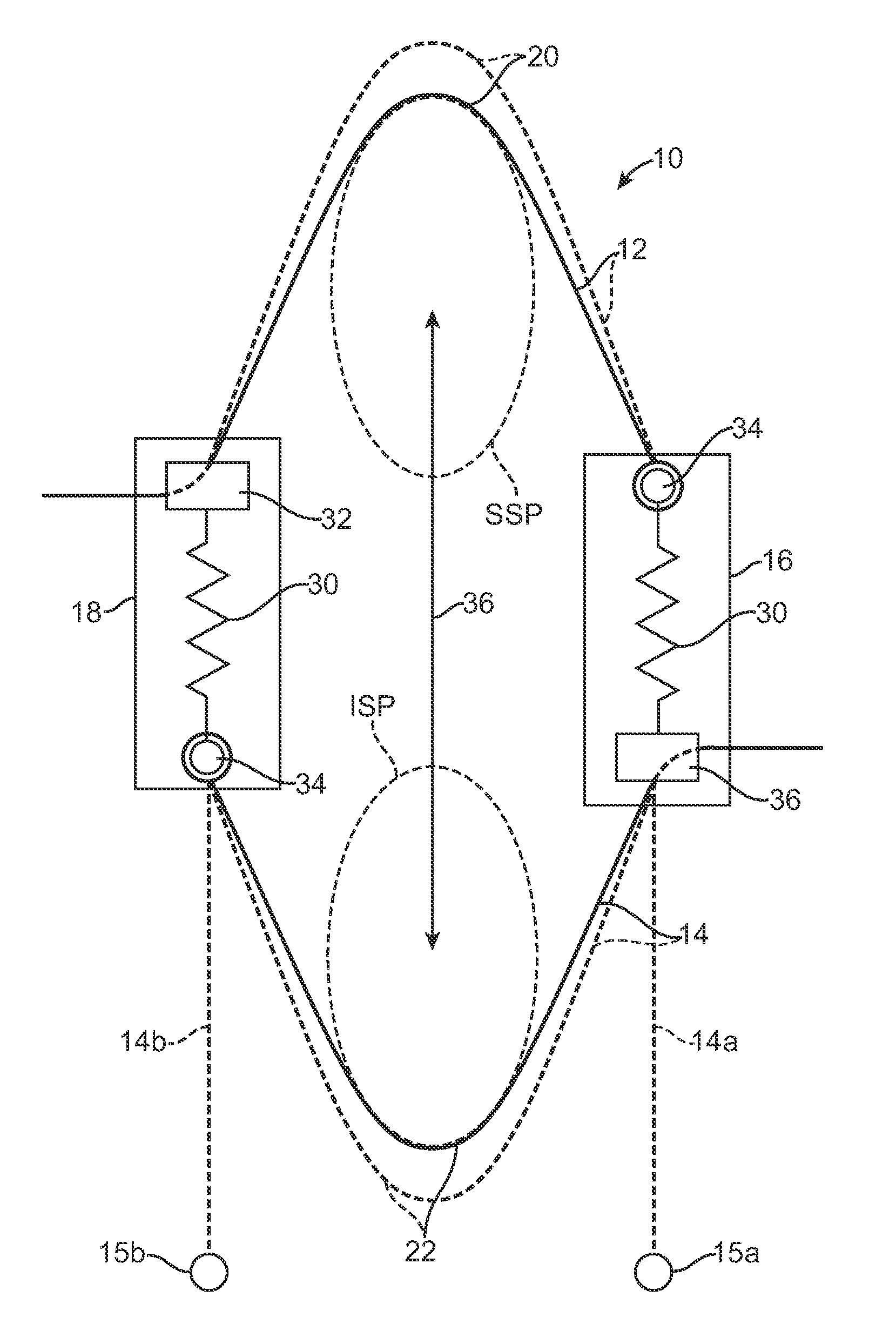

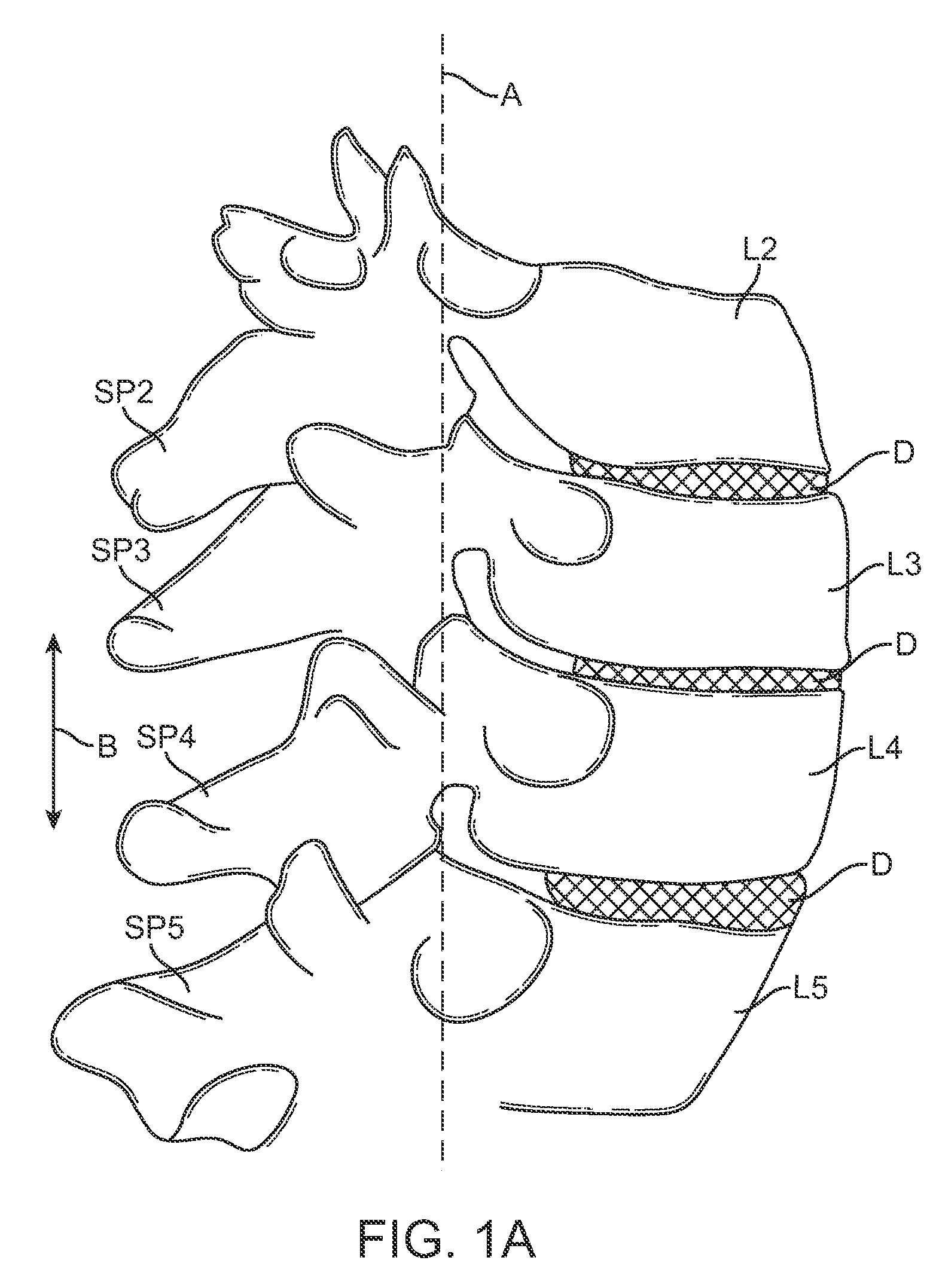

Methods and systems for increasing the bending stiffness and constraining the spreading of a spinal segment

InactiveUS20100036424A1Increased bending stiffnessRelieve instabilityInternal osteosythesisDiagnosticsMedicineTension member

A system for restricting spinal flexion includes superior and inferior tether structures joined by a pair of compliance members. Compliance members comprise tension members which apply a relatively low elastic tension on the tether structures. By placing the tether structures on or over adjacent spinous processes, flexion of a spinal segment can be controlled in order to reduce pain.

Owner:SIMPIRICA SPINE

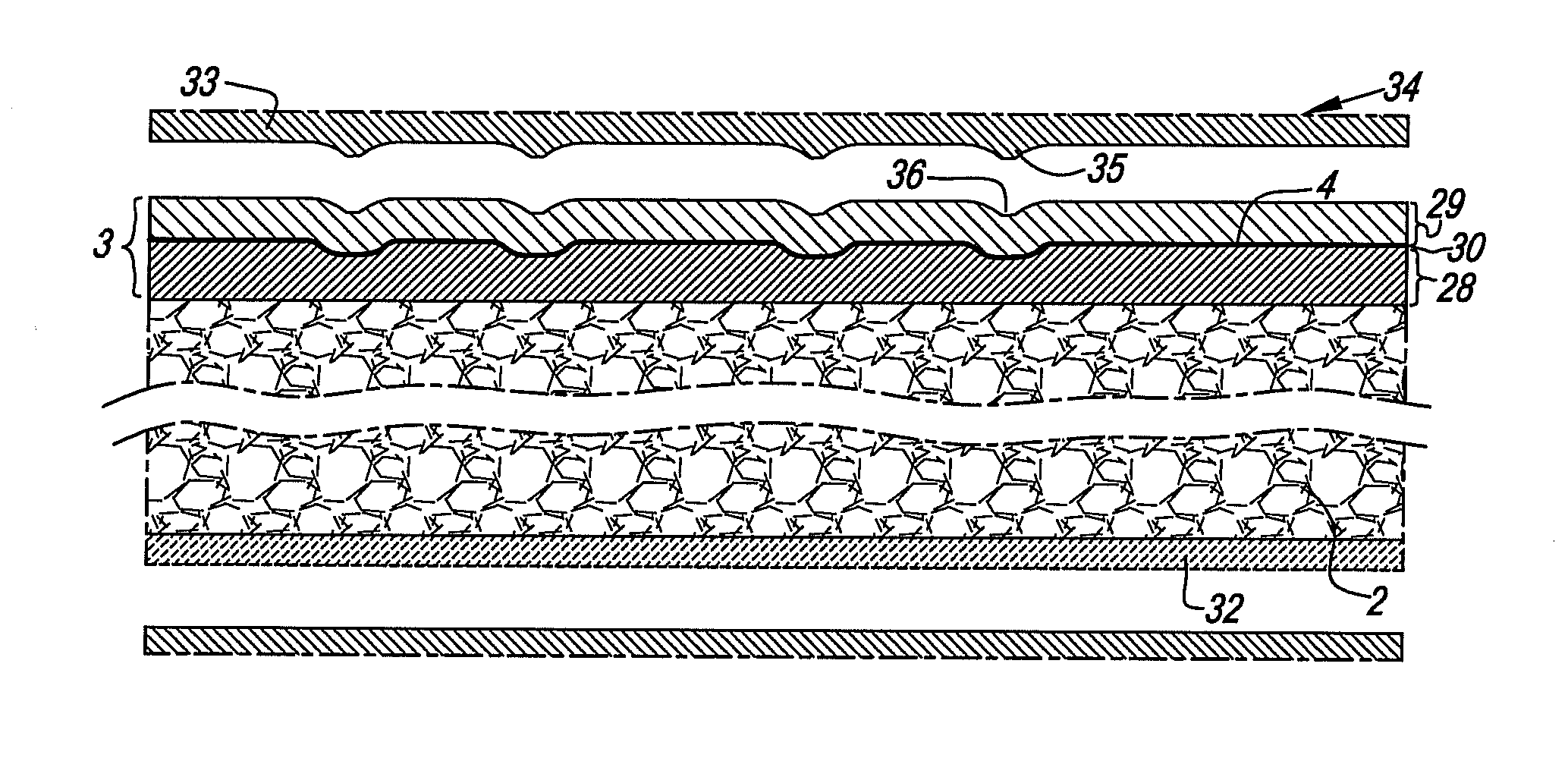

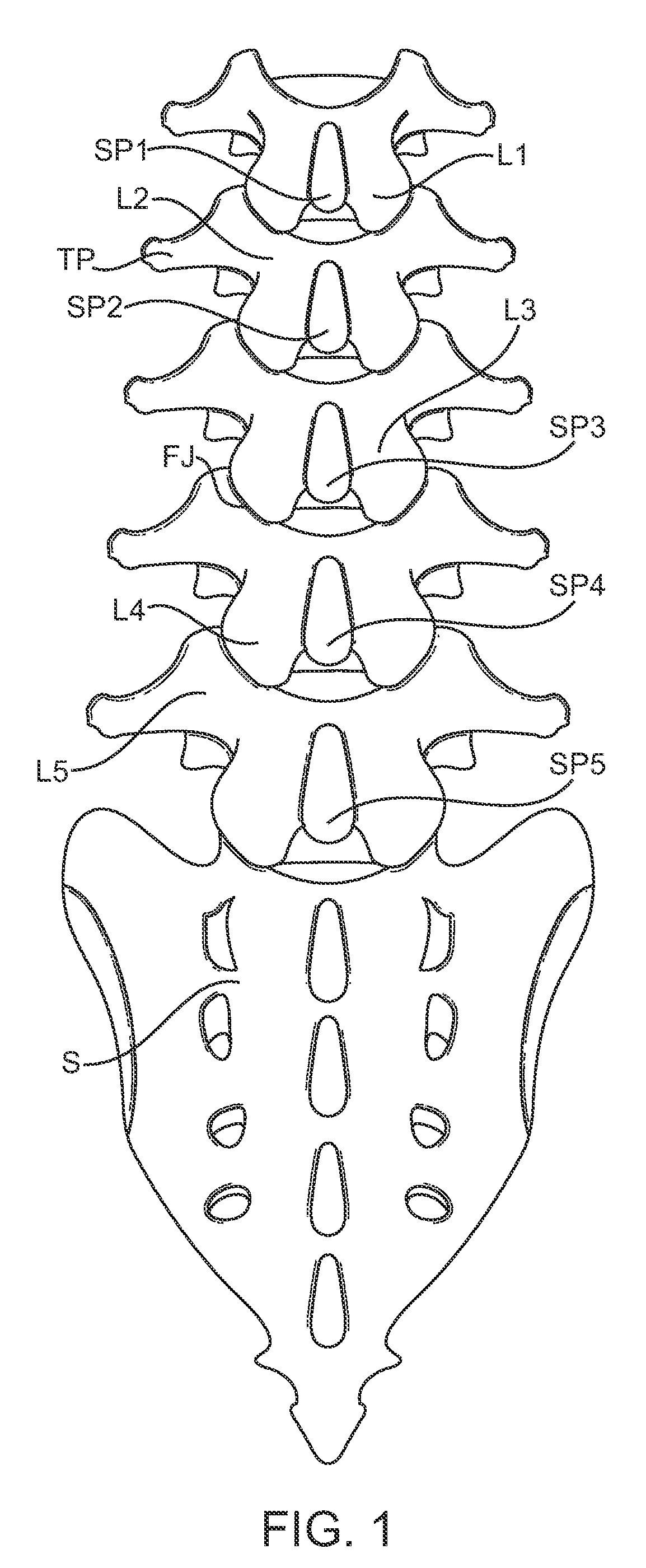

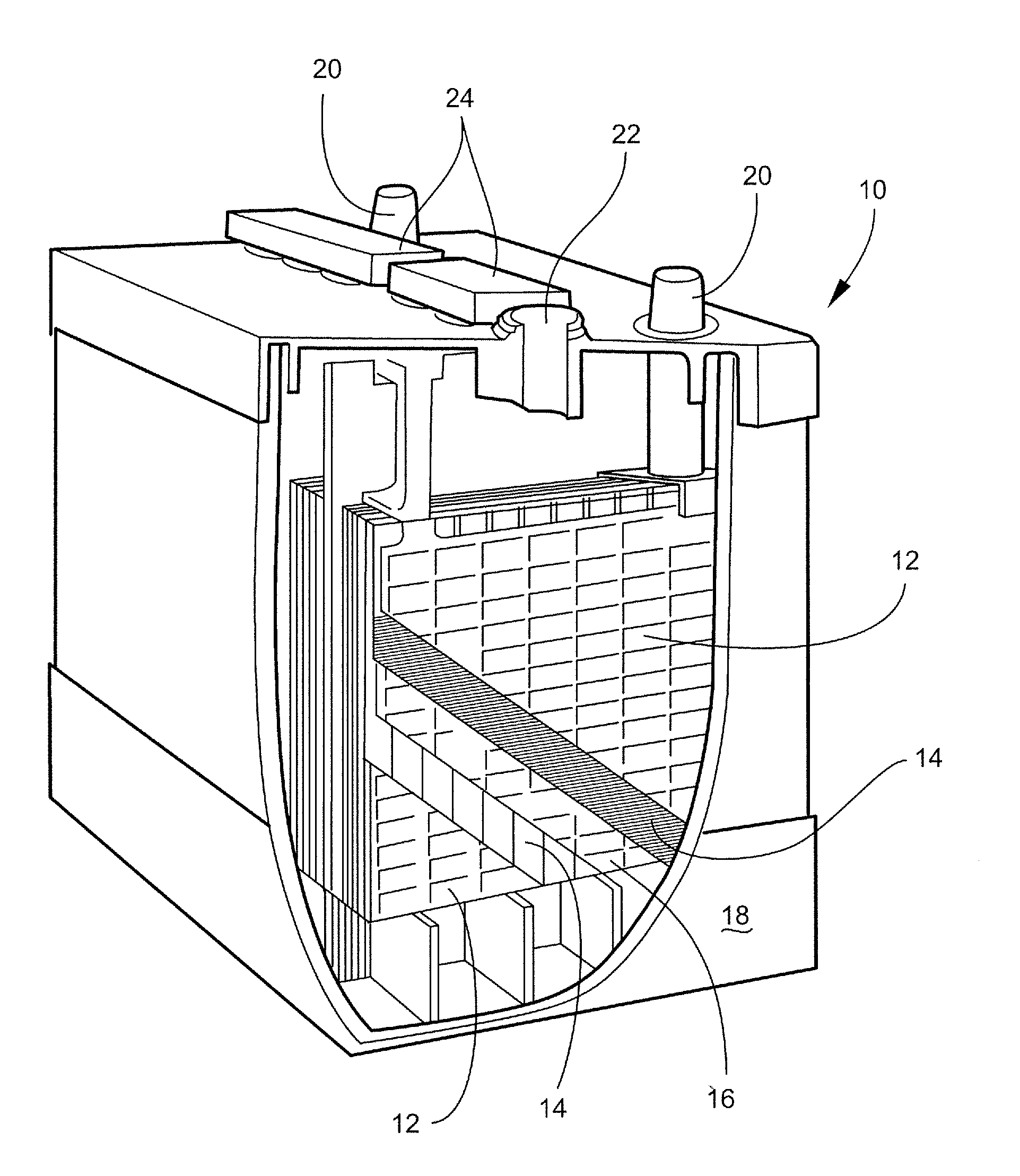

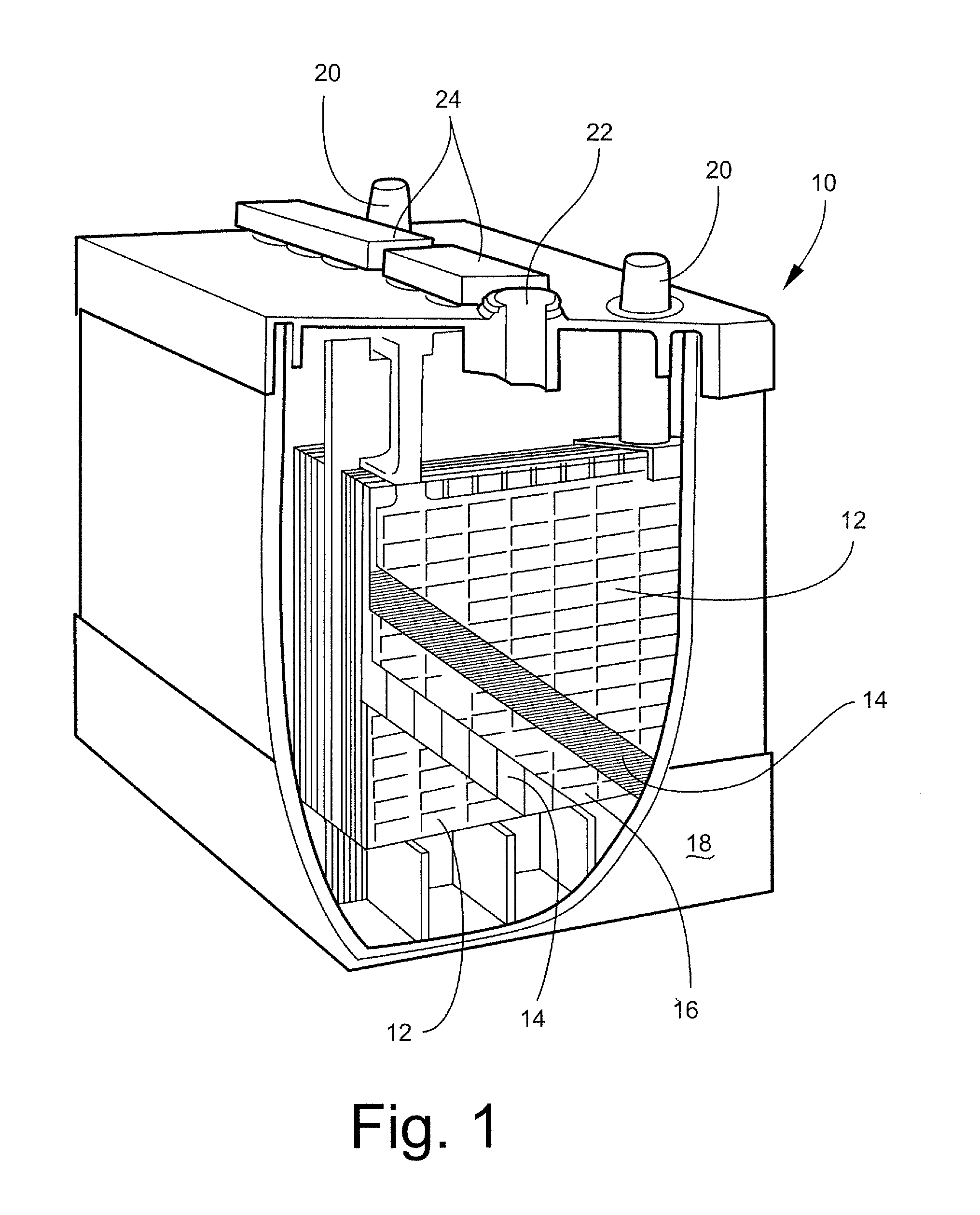

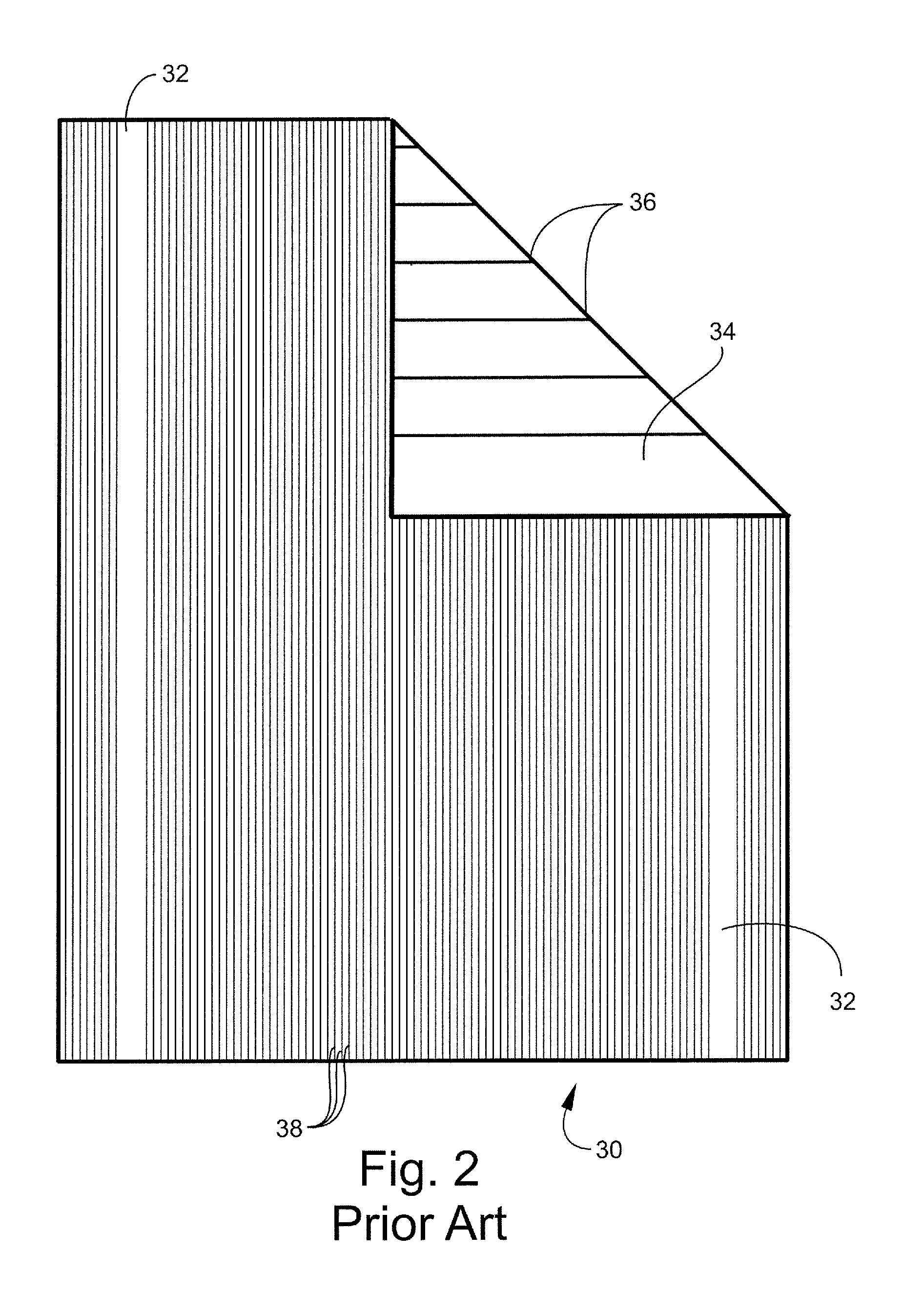

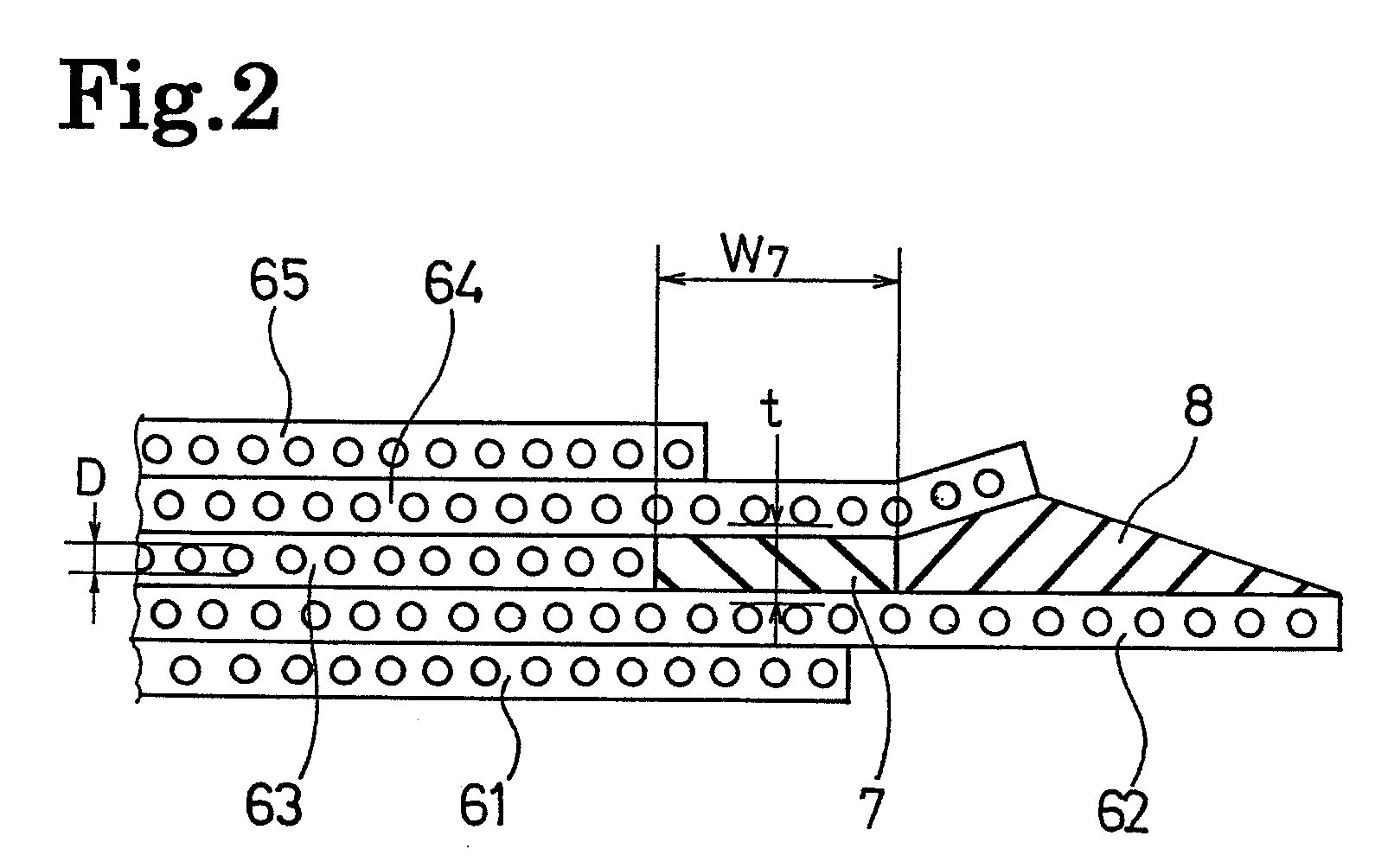

Battery separators with cross ribs and related methods

ActiveUS20110091761A1Increased bending stiffnessEasy to prepareCell seperators/membranes/diaphragms/spacersFinal product manufacturePorous membraneBiomedical engineering

A separator for a lead acid battery is a porous membrane having a positive electrode face and a negative electrode face. A plurality of longitudinally extending ribs, a plurality of protrusions or a nonwoven material may be disposed upon the positive electrode face. A plurality of transversely extending ribs are disposed upon the negative electrode face. The transverse ribs disposed upon the negative electrode face are preferably juxtaposed to a negative electrode of the lead acid battery, when the separator is placed within that battery.

Owner:DARAMIC LLC

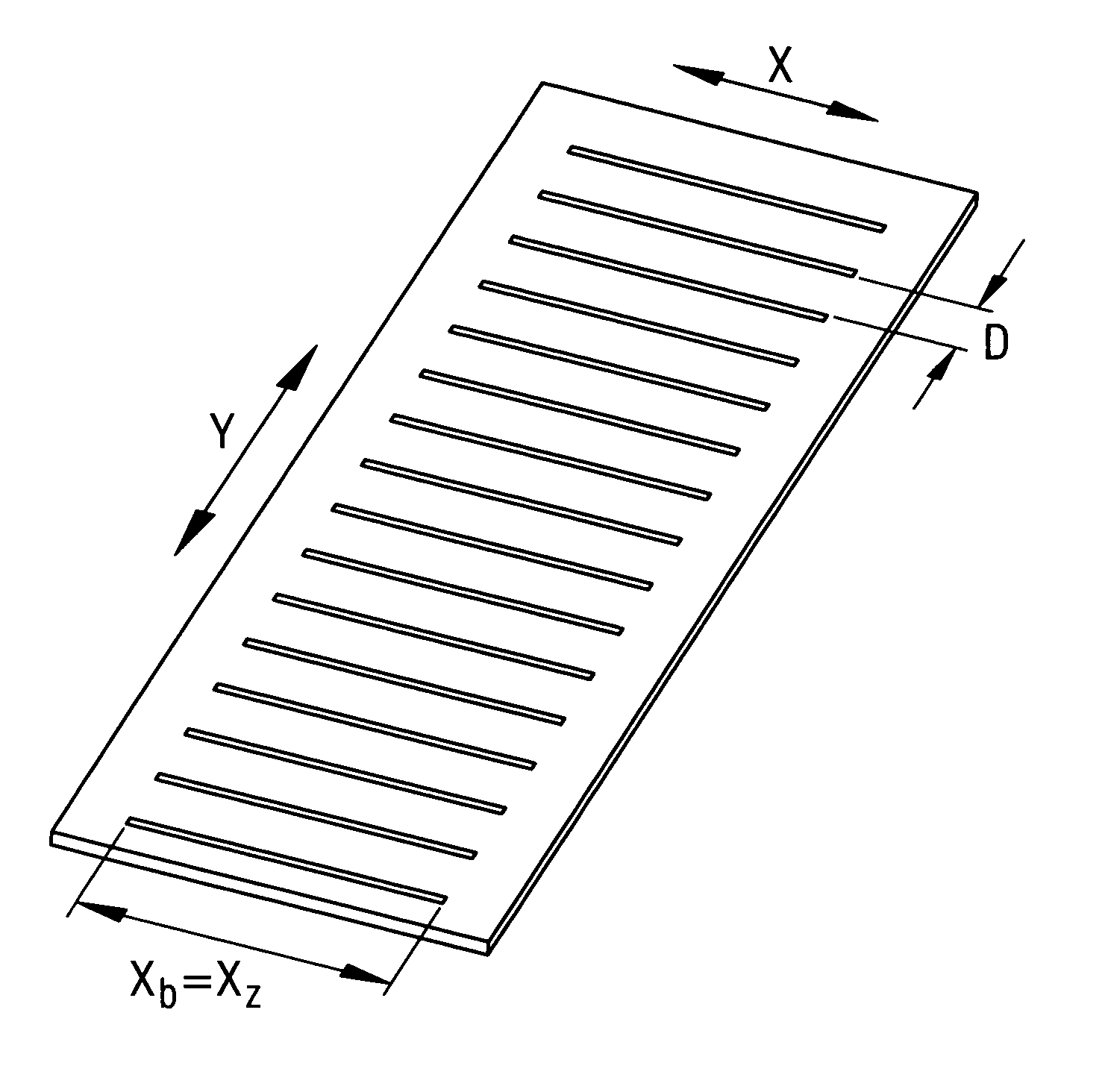

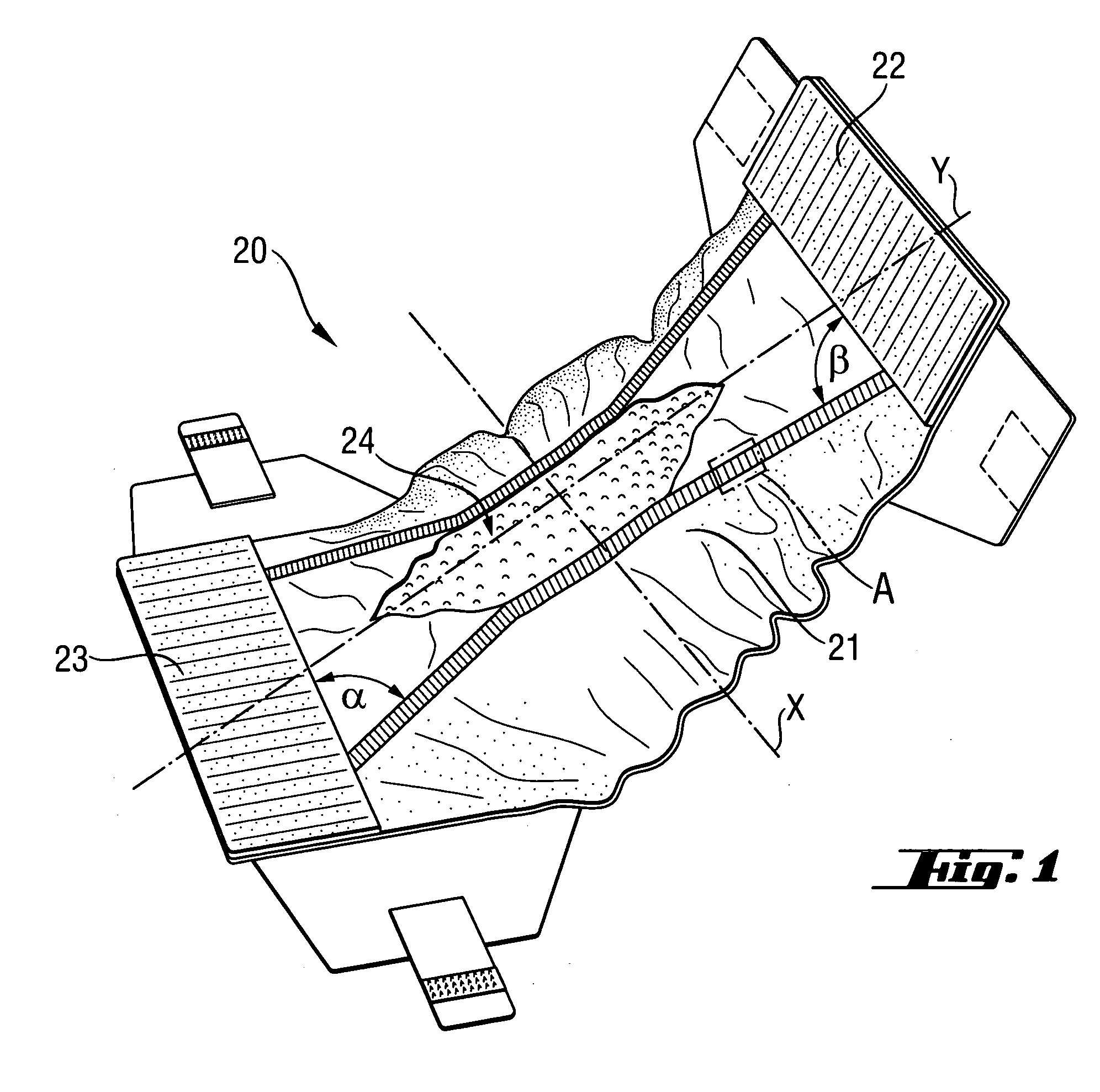

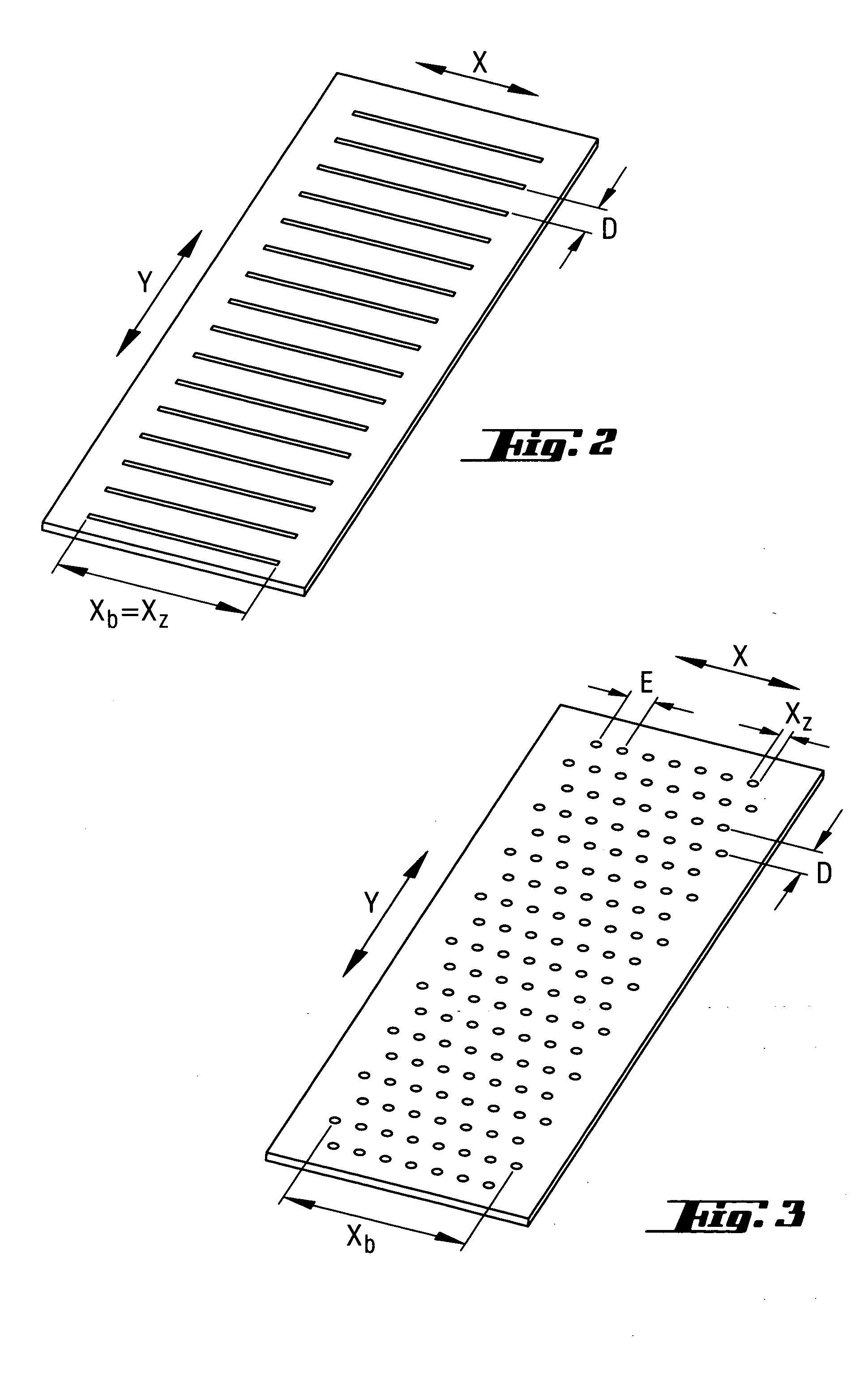

Elasticated materials

This invention relates to an elasticated materials comprising a stiff carrier material that is satisfactorily elasticated with one or more elastic strands with a low load force, due to the use of a specific bonding pattern, with specific bonding areas. The bonding areas are typically separate bonding areas positioned on separate intervals along the length direction of the carrier material, whereby each bonding area comprises one or more separate bonding zones, extending in the width (X) direction. The invention also relates to absorbent articles comprising this elasticated material and processes for making the elasticated material.

Owner:THE PROCTER & GAMBLE COMPANY

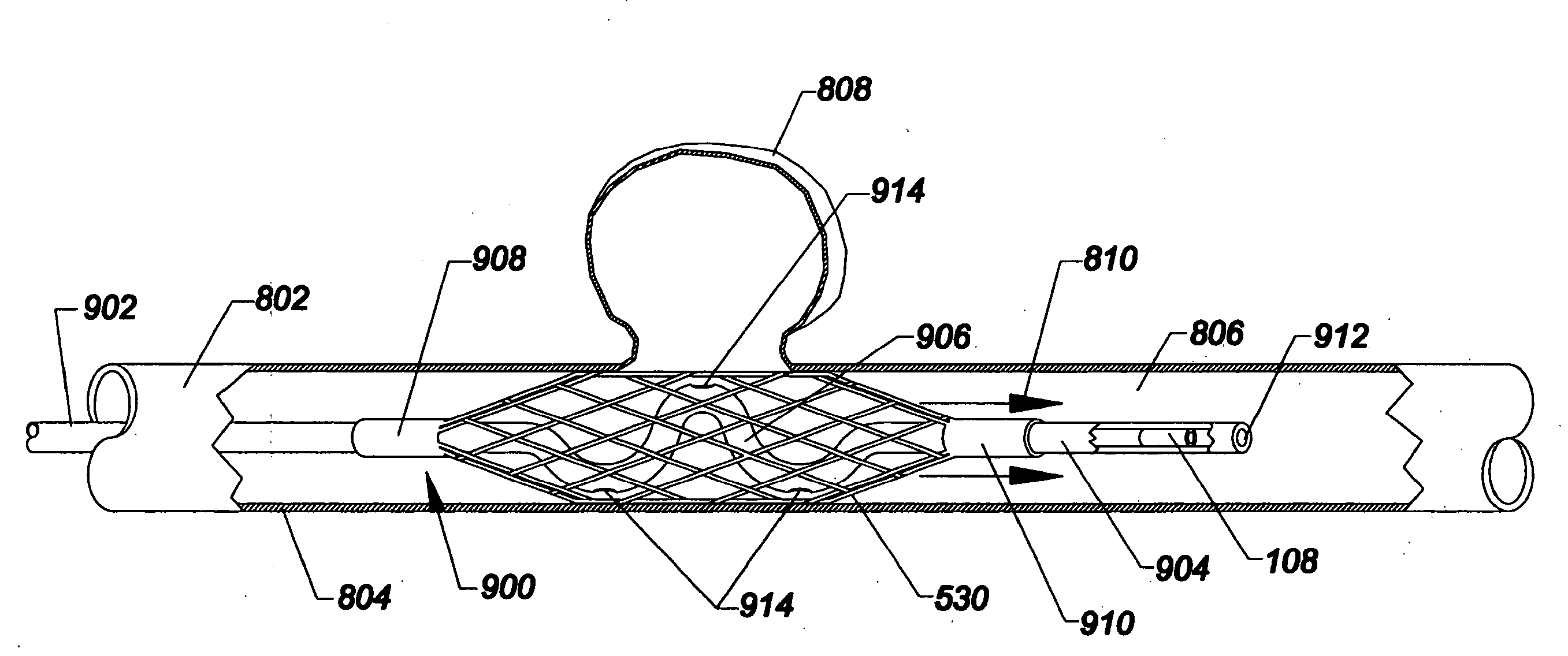

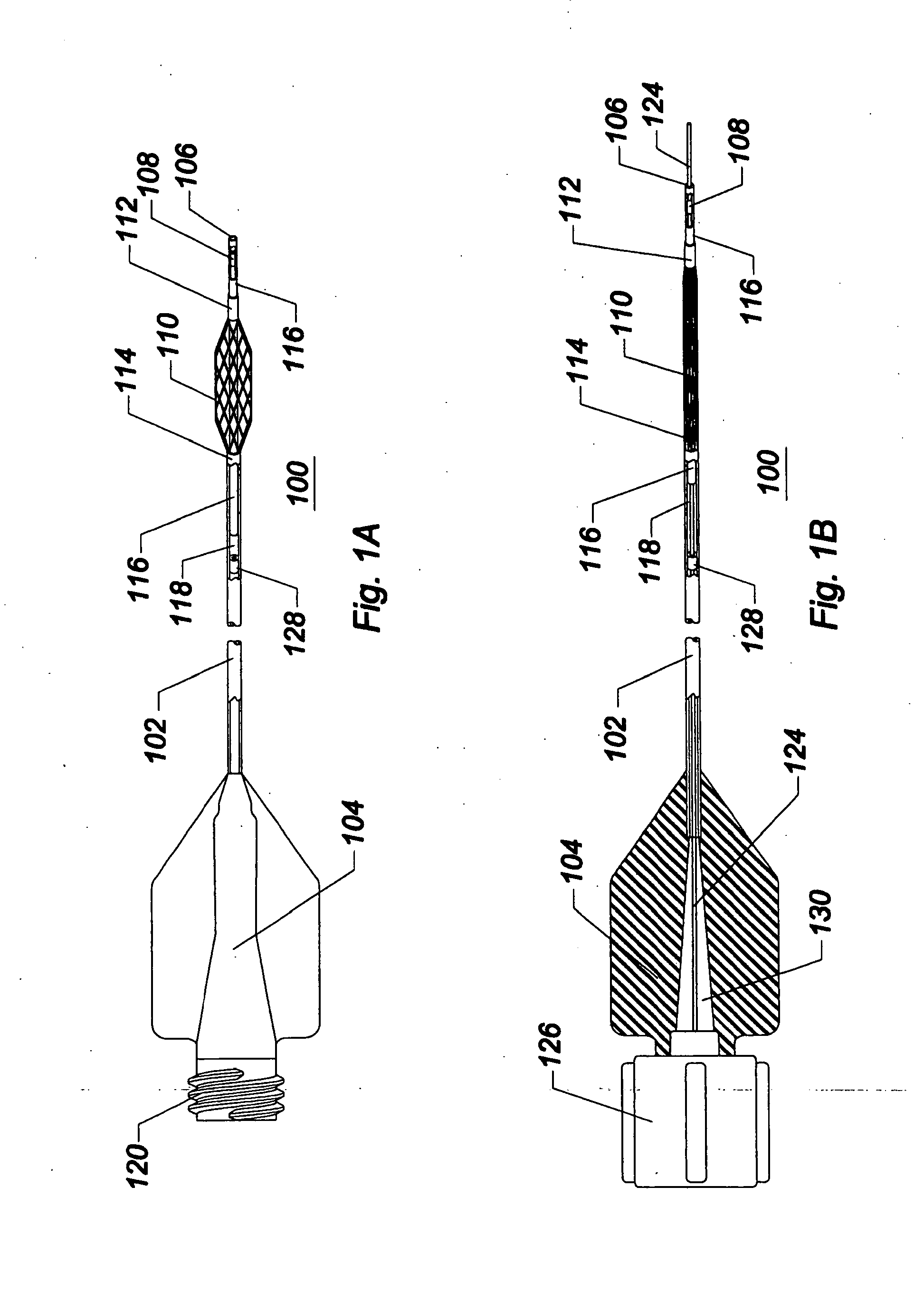

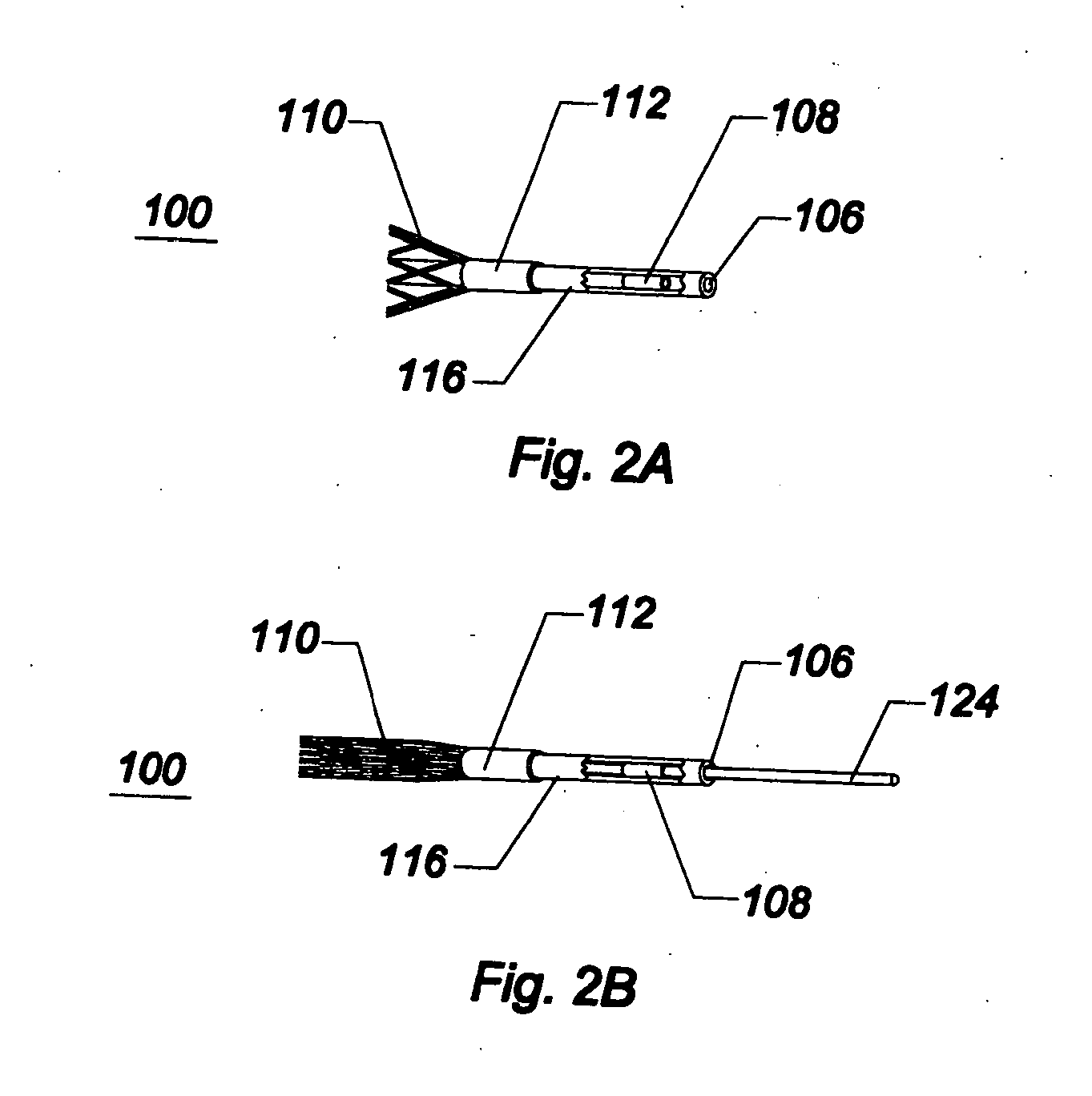

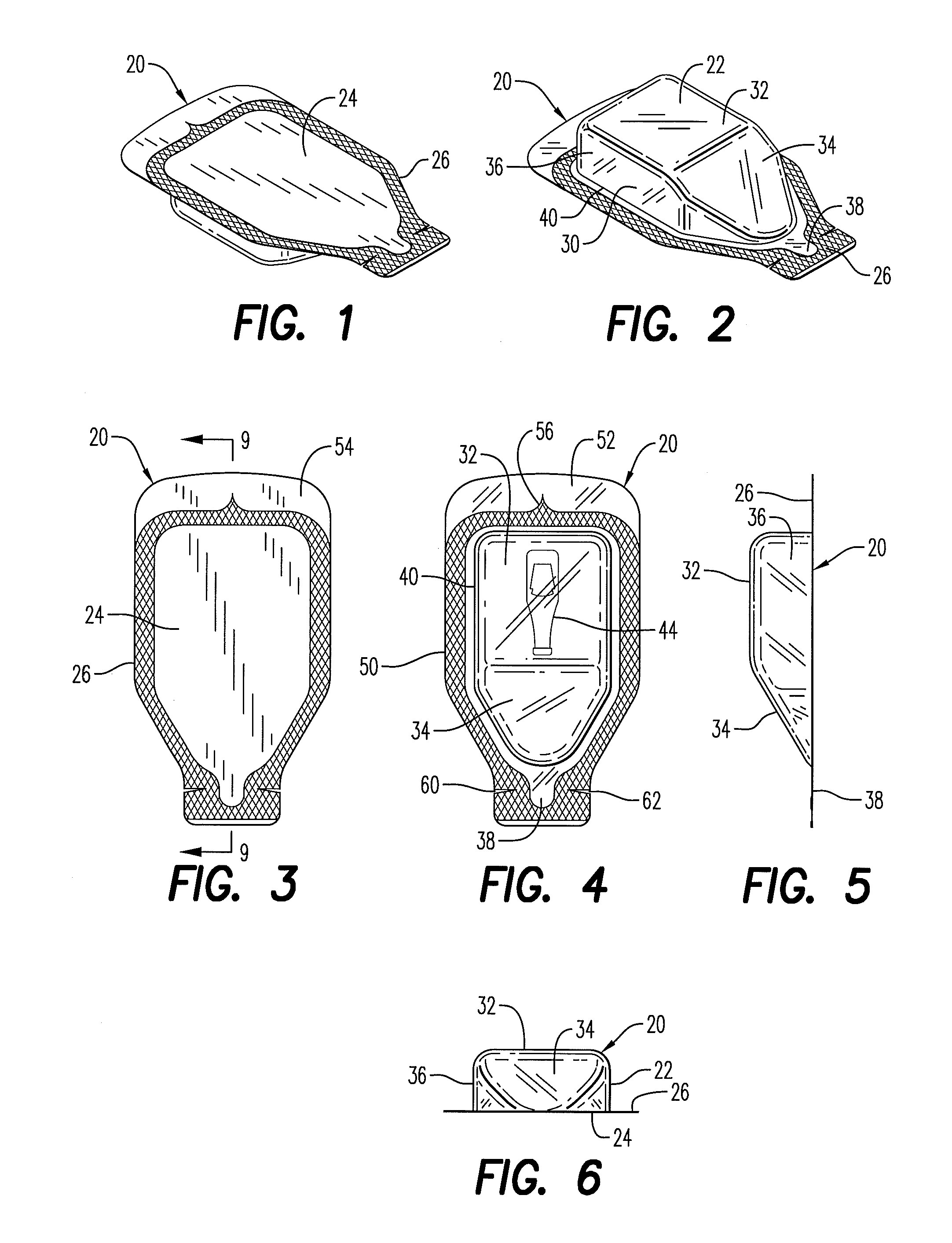

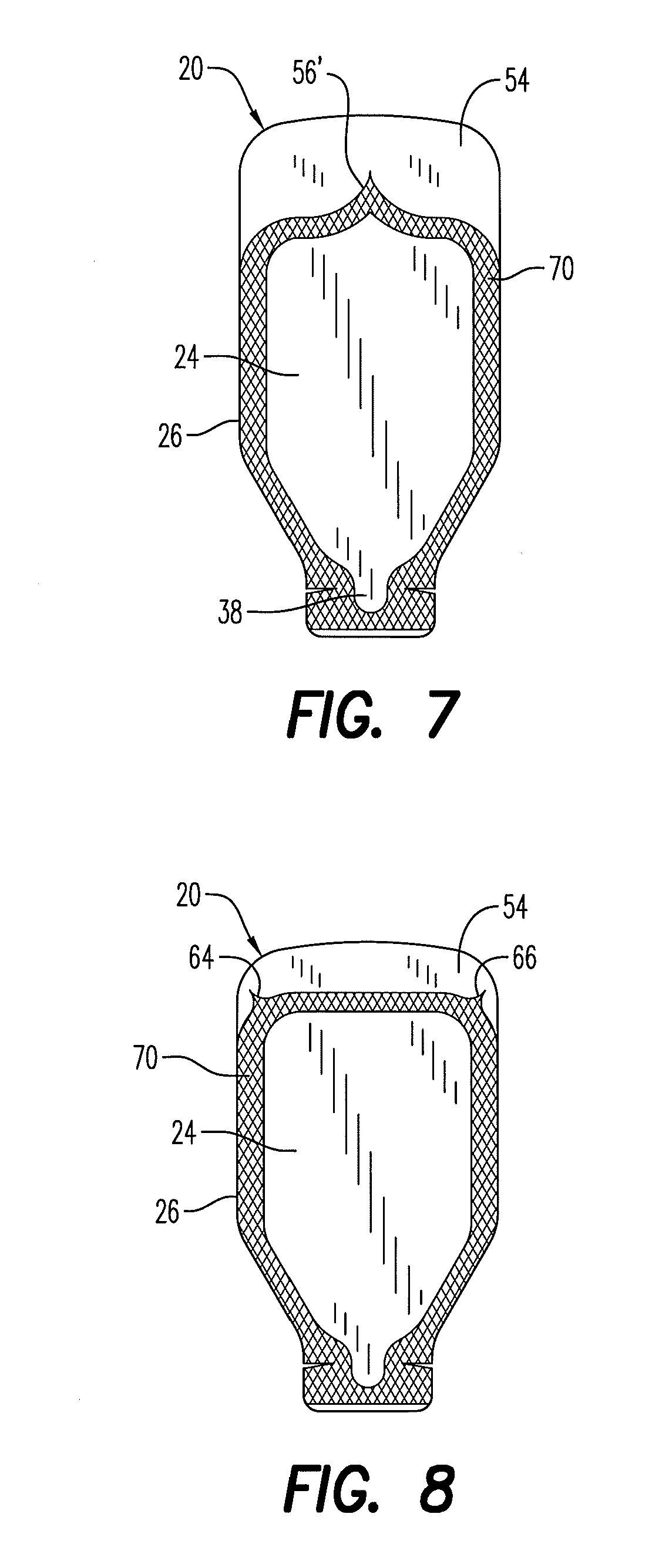

Multi-utilitarian microcatheter system and method of use

InactiveUS20110264132A1Easy to navigateIncreased bending stiffnessDilatorsCatheterDistal portionThrombus

A device for performing therapeutic or diagnostic procedures within the cerebrovasculature includes a catheter having a distal portion, a proximal portion and a lumen extending therebetween, the catheter including an expandable region for engaging the vessel wall, thrombus, atheroma, or other structures. The device further includes an elongate stretching member, which can be a guidewire, insertable longitudinally through the lumen of the catheter, the elongate stretching member being configured for stretching at least a portion of the catheter and causing the expandable region to transition from an expanded state to a collapsed state, and wherein the elongate stretching member is retracted proximally relative to the catheter causes the expandable region to transition from the radially collapsed state to a radially, or laterally expanded state.

Owner:REVERSE MEDICAL CORP

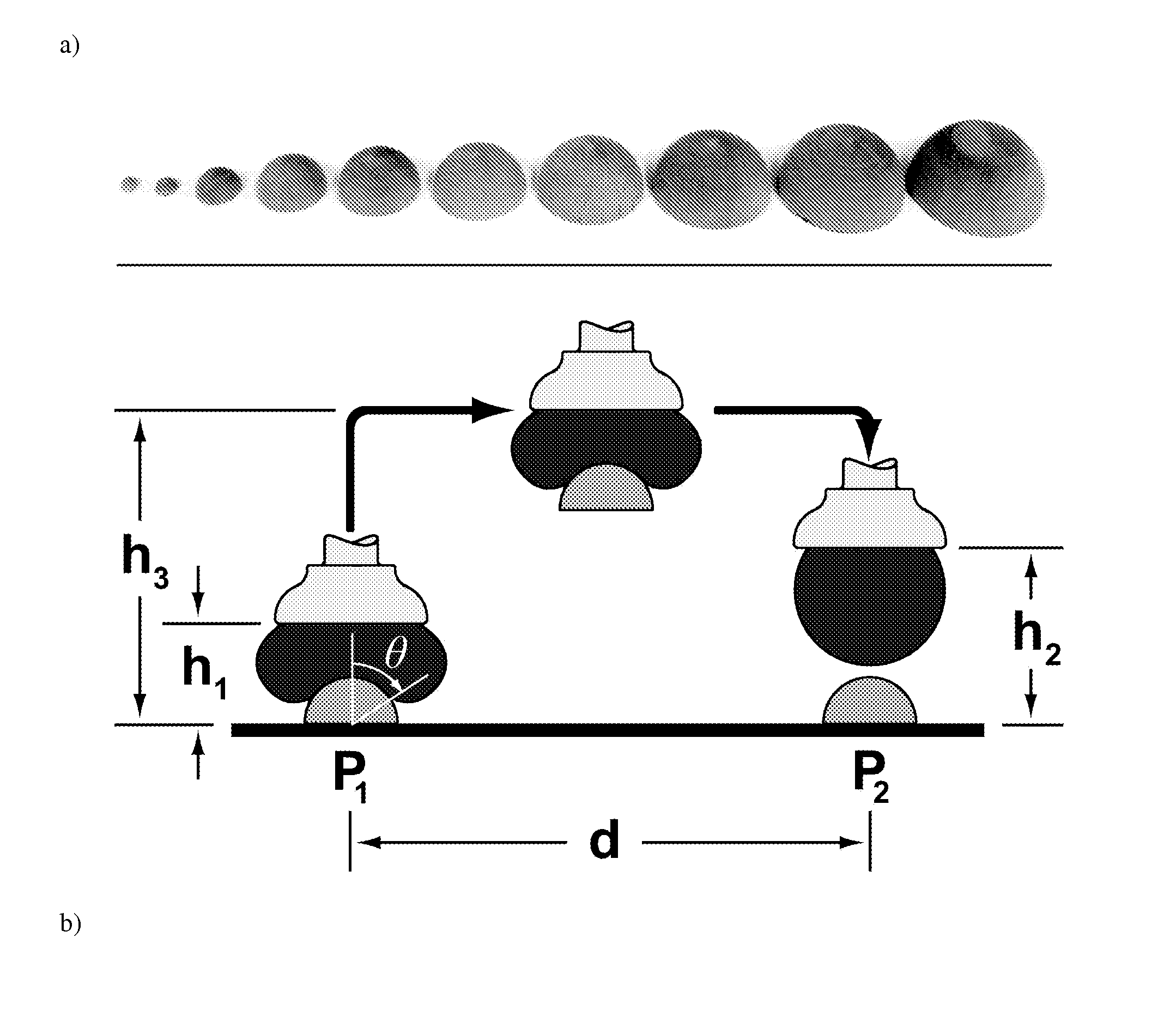

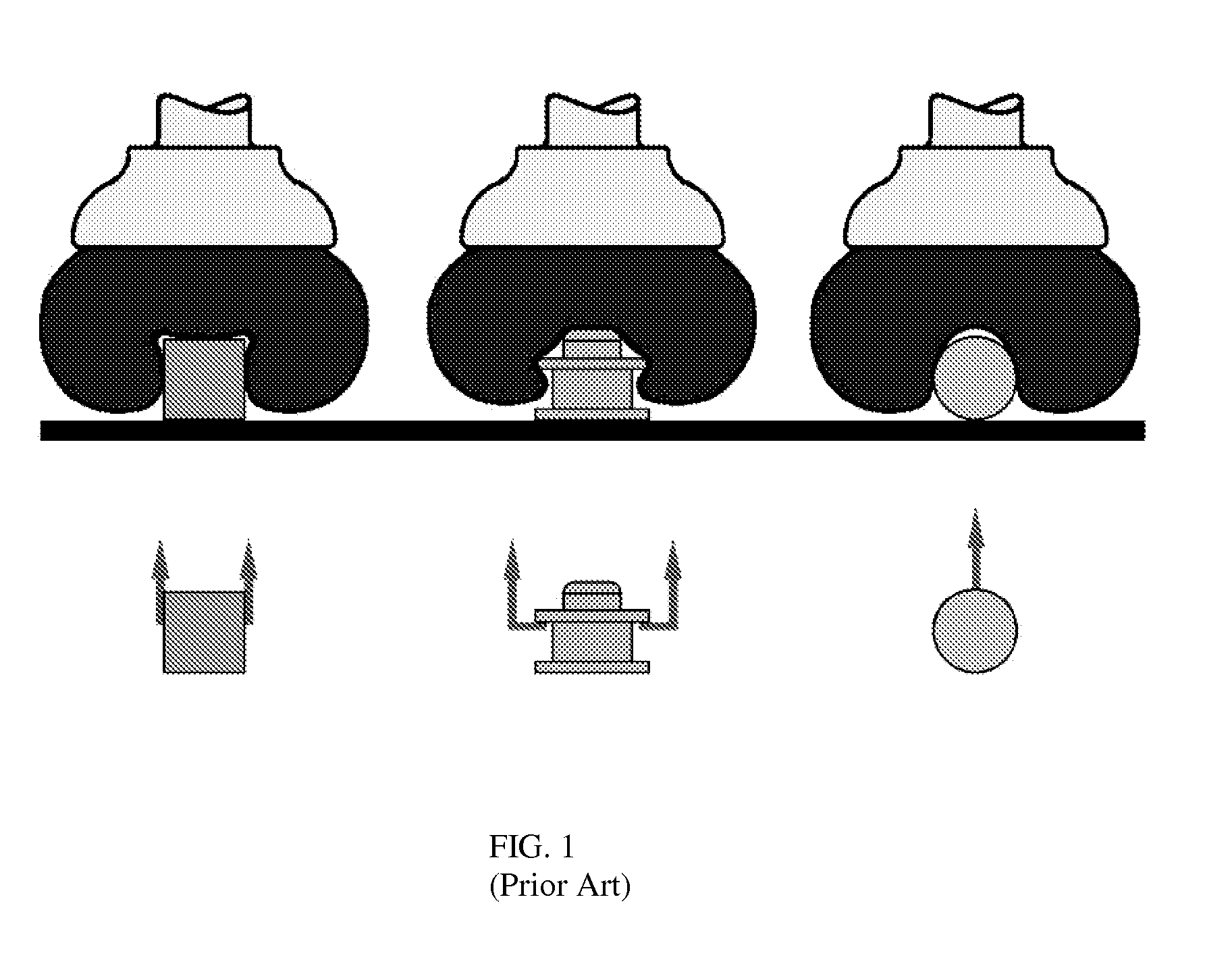

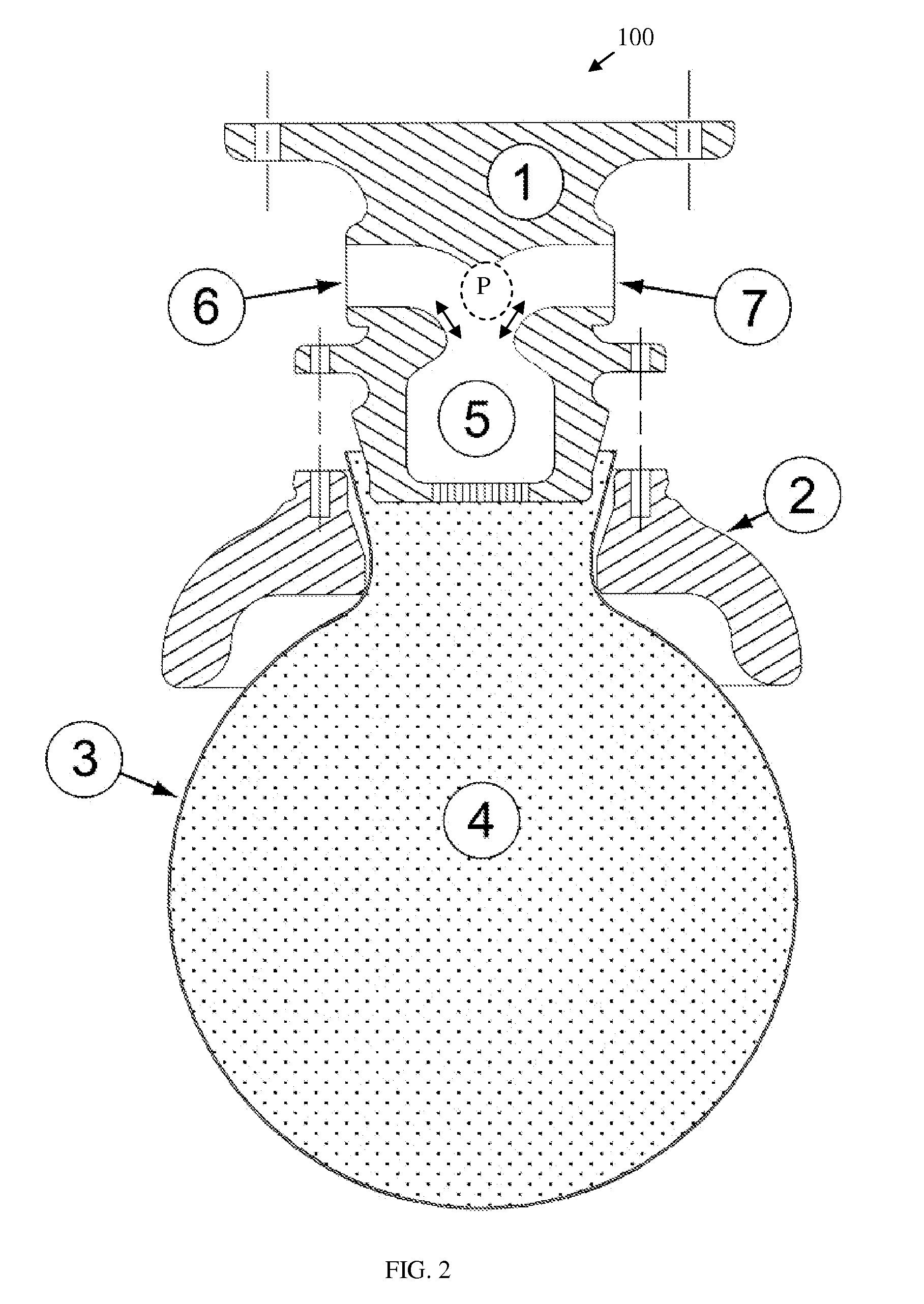

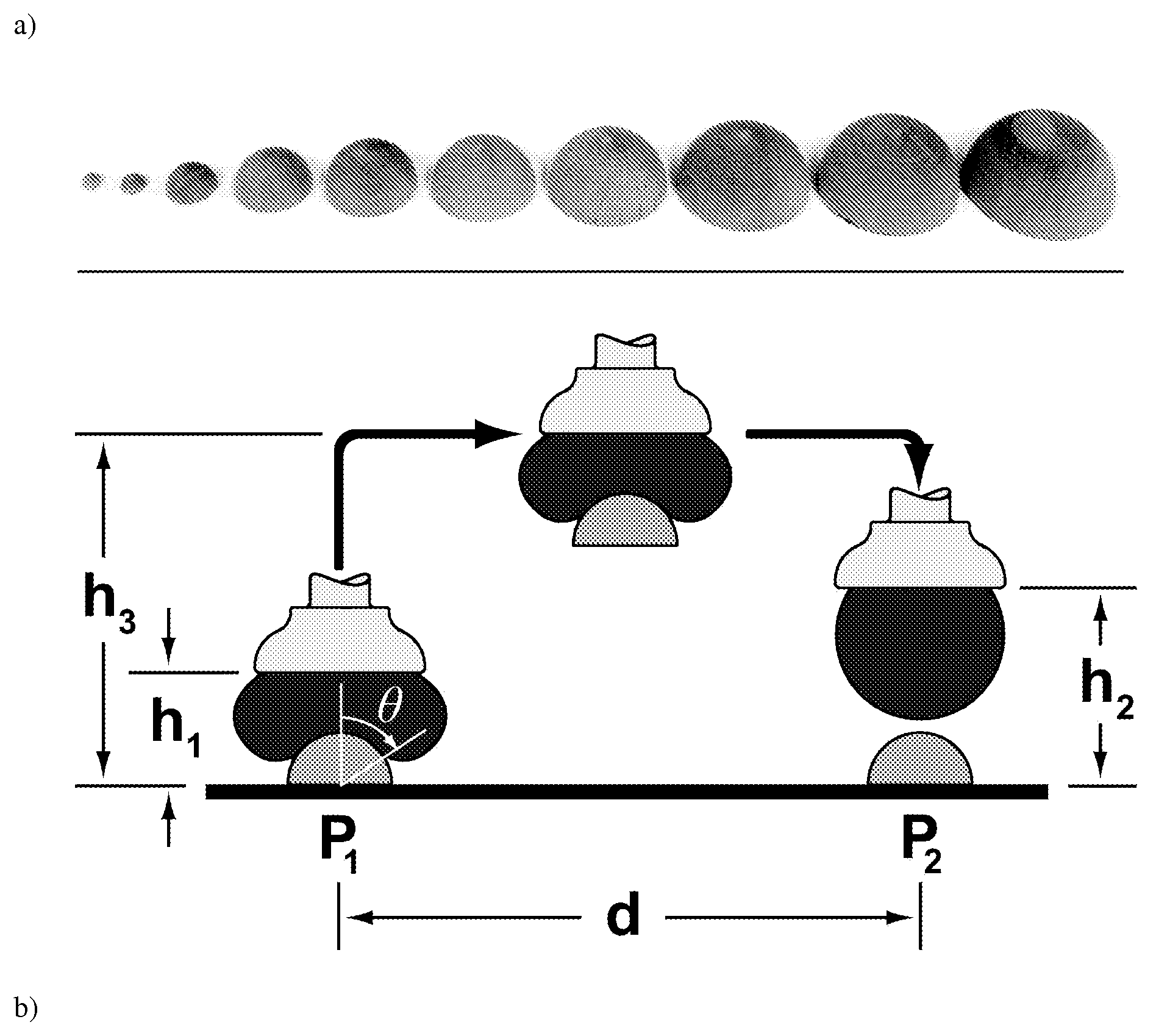

Gripping and releasing apparatus and method

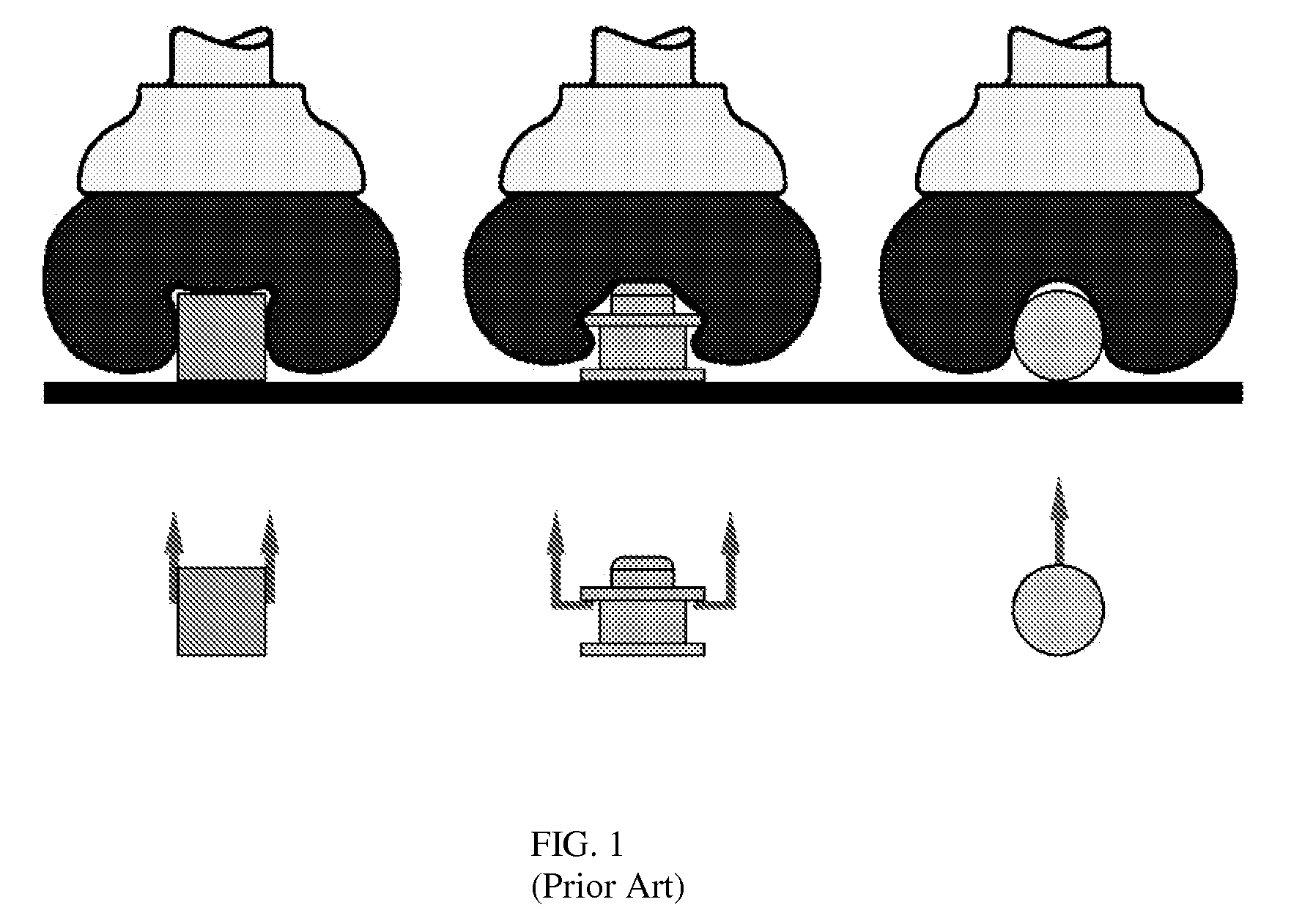

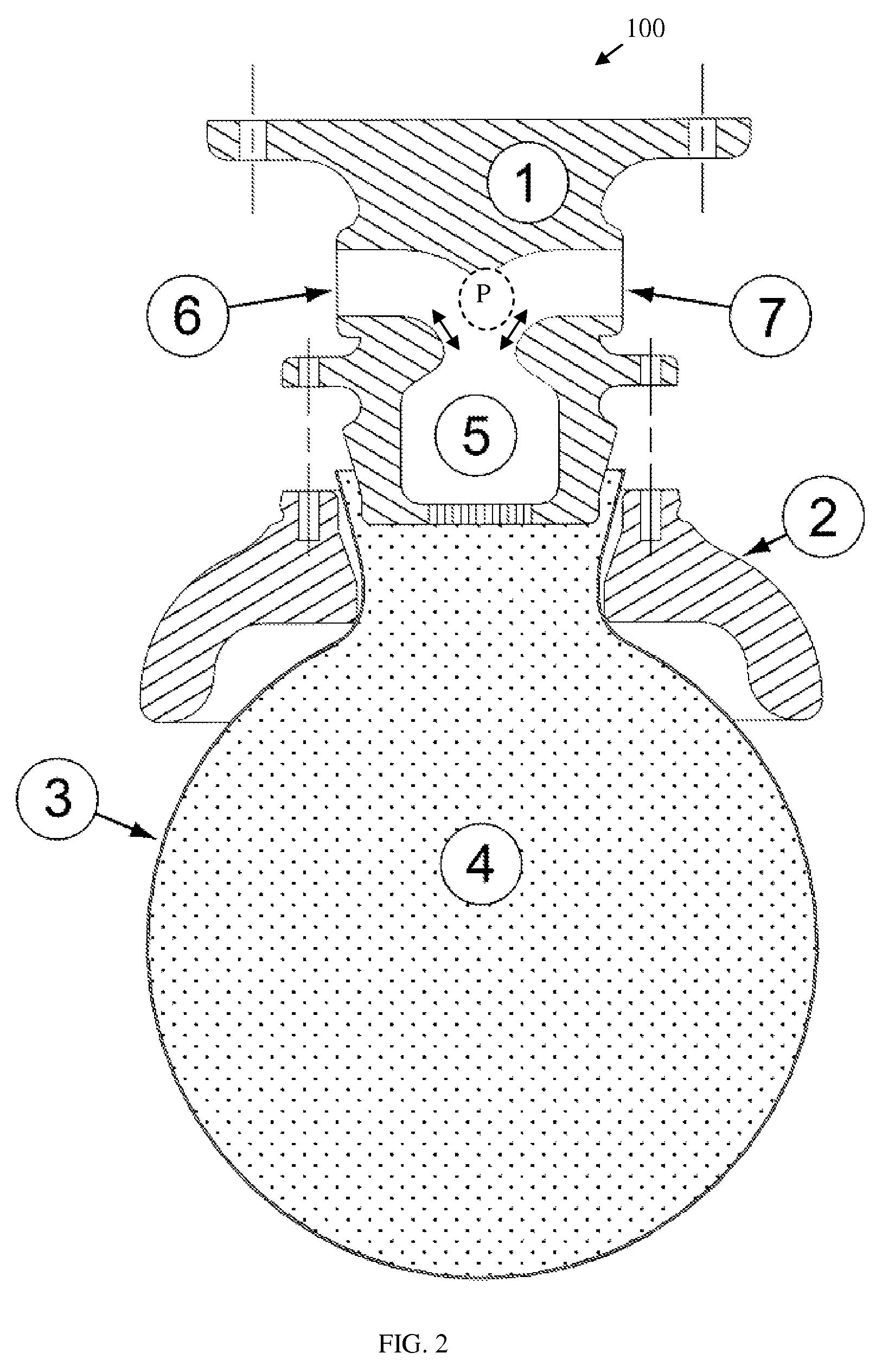

ActiveUS20130106127A1Improvement factorImprove performanceGripping headsRobotPositive pressureEngineering

A passive universal gripper includes a mass of granular material encased in an elastic membrane. Using a combination of positive and negative pressure, the gripper can rapidly grip and release a wide range of objects that are typically challenging for conventional universal grippers, such as flat objects, soft objects, or objects with complex geometries. The gripper passively conforms to the shape of a target object, then vacuum-hardens to grip it rigidly; later using positive pressure to reverse this transition-releasing the object and returning to a deformable state. The apparatus and method enable the fast ejection of objects from the gripper, as well as essentially instantaneous reset time between releasing and gripping.

Owner:CORNELL UNIVERSITY +1

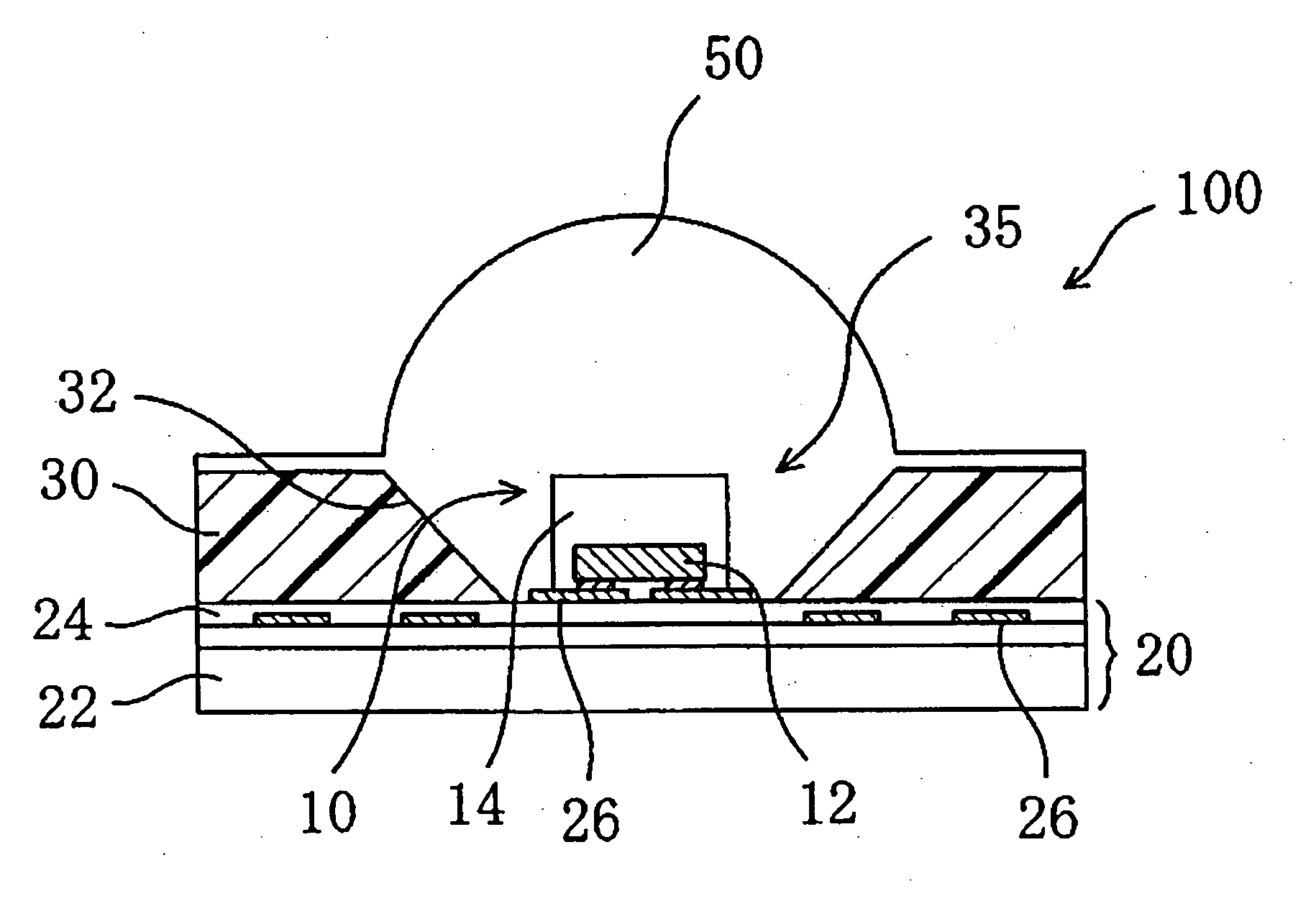

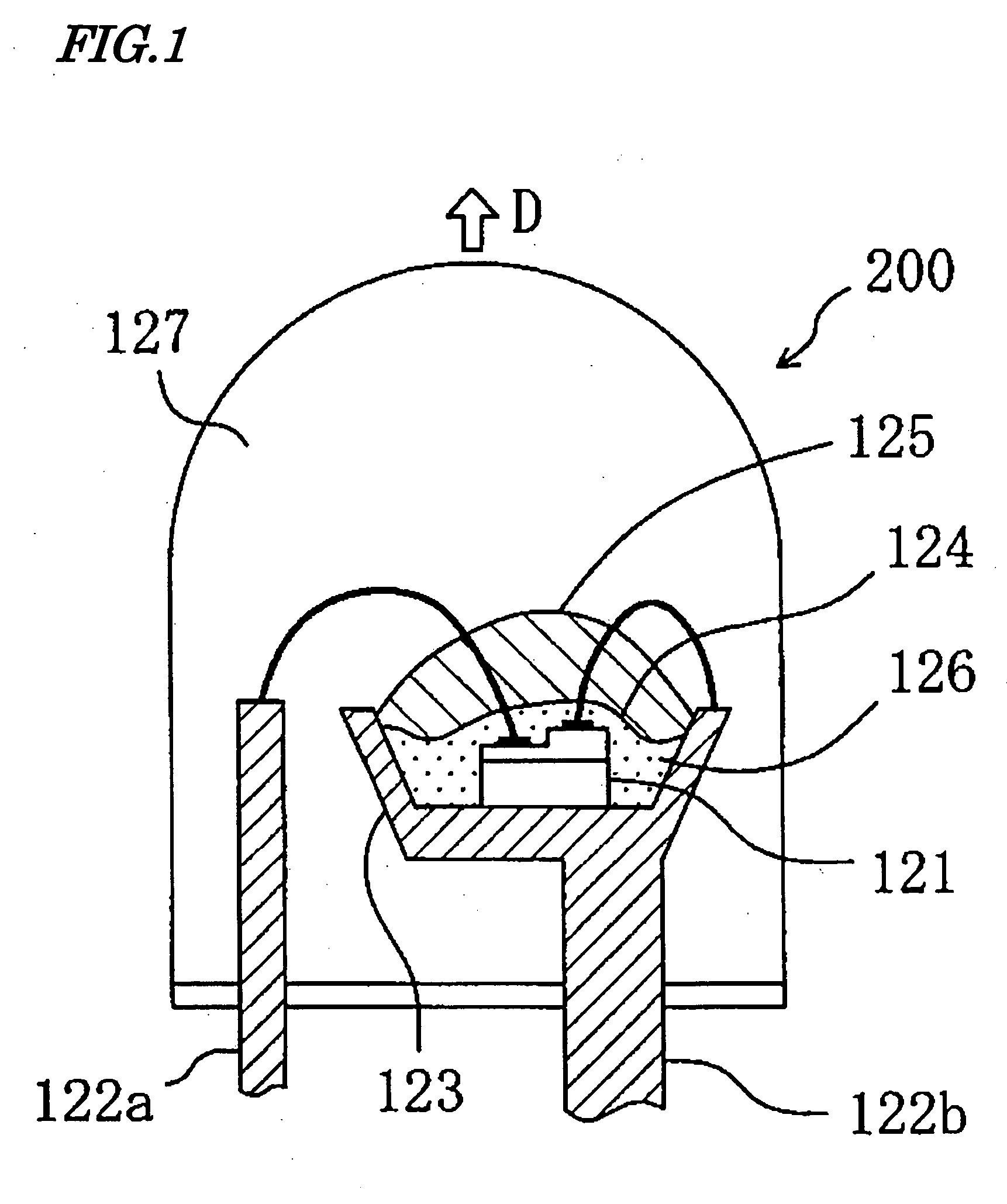

LED lamp

InactiveUS20060186425A1Increased bending stiffnessImprove rigidityPlanar light sourcesPoint-like light sourceEngineeringLED lamp

An LED lamp 100 according to the present invention includes: a substrate 20 with an upper surface; a plurality of LED chips 10, which are arranged on the upper surface of the substrate 20; and a reflector 30, which has reflective surfaces that reflect emissions of the respective LED chips 10 at least partially. The reflector 30 includes a resin and a framework that is made of a material having a higher flexural rigidity than the resin.

Owner:PANASONIC CORP

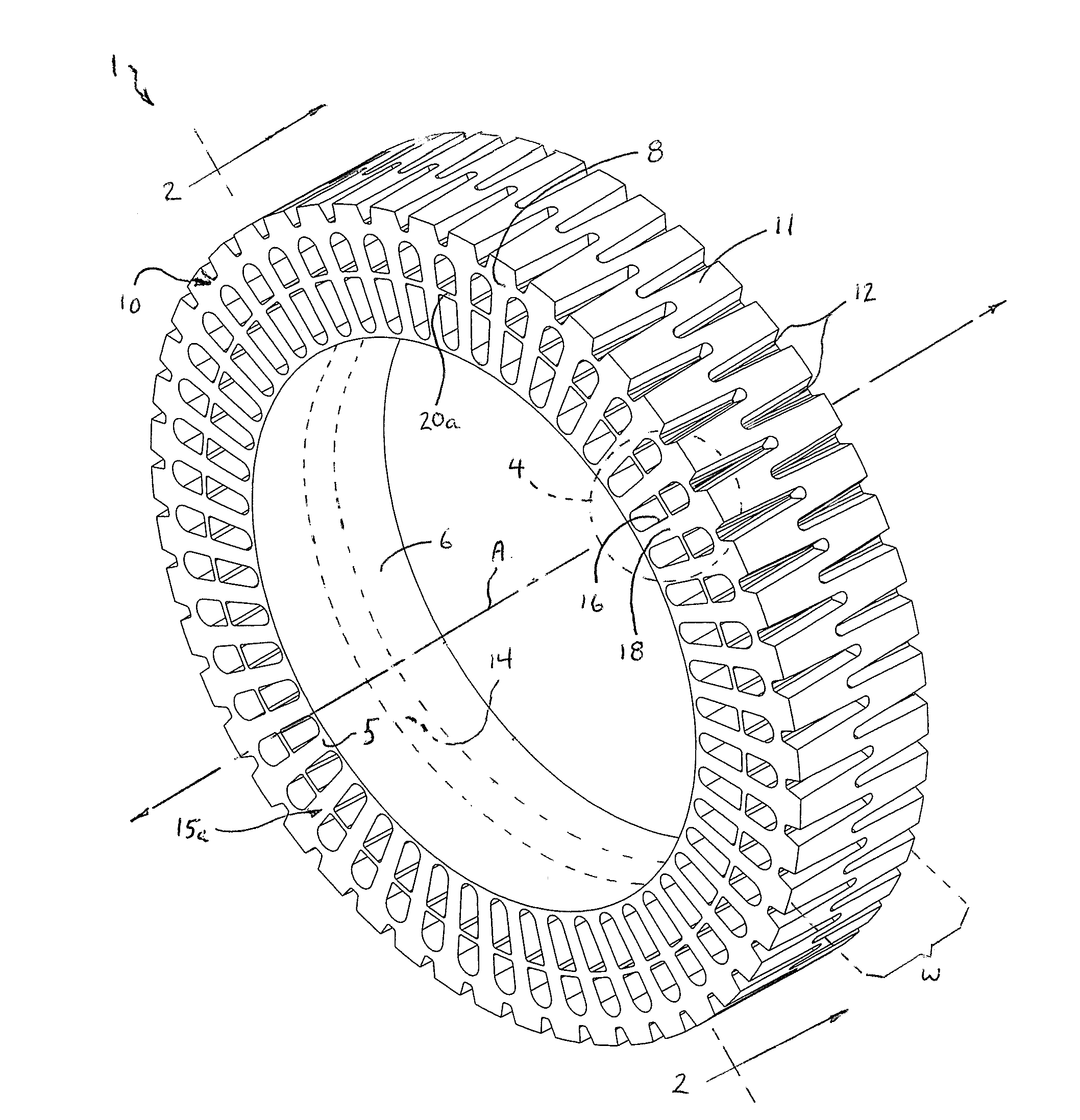

Non-pneumatic tire with annular spoke reinforcing web

InactiveUS20120234444A1Increased bending stiffnessIncrease the maximum loadNon-inflatable tyresLoad carryingEngineering

A non-pneumatic tire is provided with an annular reinforcing web that reduces the bending of compression spokes formed in the tire and reduces stresses and strains in the tire. The non-pneumatic tire includes an inner hoop member having an inner surface that defines the inner diameter of the tire, and an outer hoop member having a tread groove region that defines the outer diameter of the tire. A disc-shaped central web portion connects the inner and outer hoop members. A plurality of elongated, radially aligned cavities on either side of the central web defines integrally-formed compression spokes which connect the inner and outer hoop members. The annular reinforcing web is located on and affixed to either side of the central web portion and interconnects a mid portion of each spoke to a mid portion of the spokes on either side of it. Preferably, the annular reinforcing web is reinforced with fiber webbings on its outer side for added strength. The annular reinforcing web allows the tire to be made with less polyurethane material with no reduction in load carrying capability.

Owner:CATERPILLAR INC

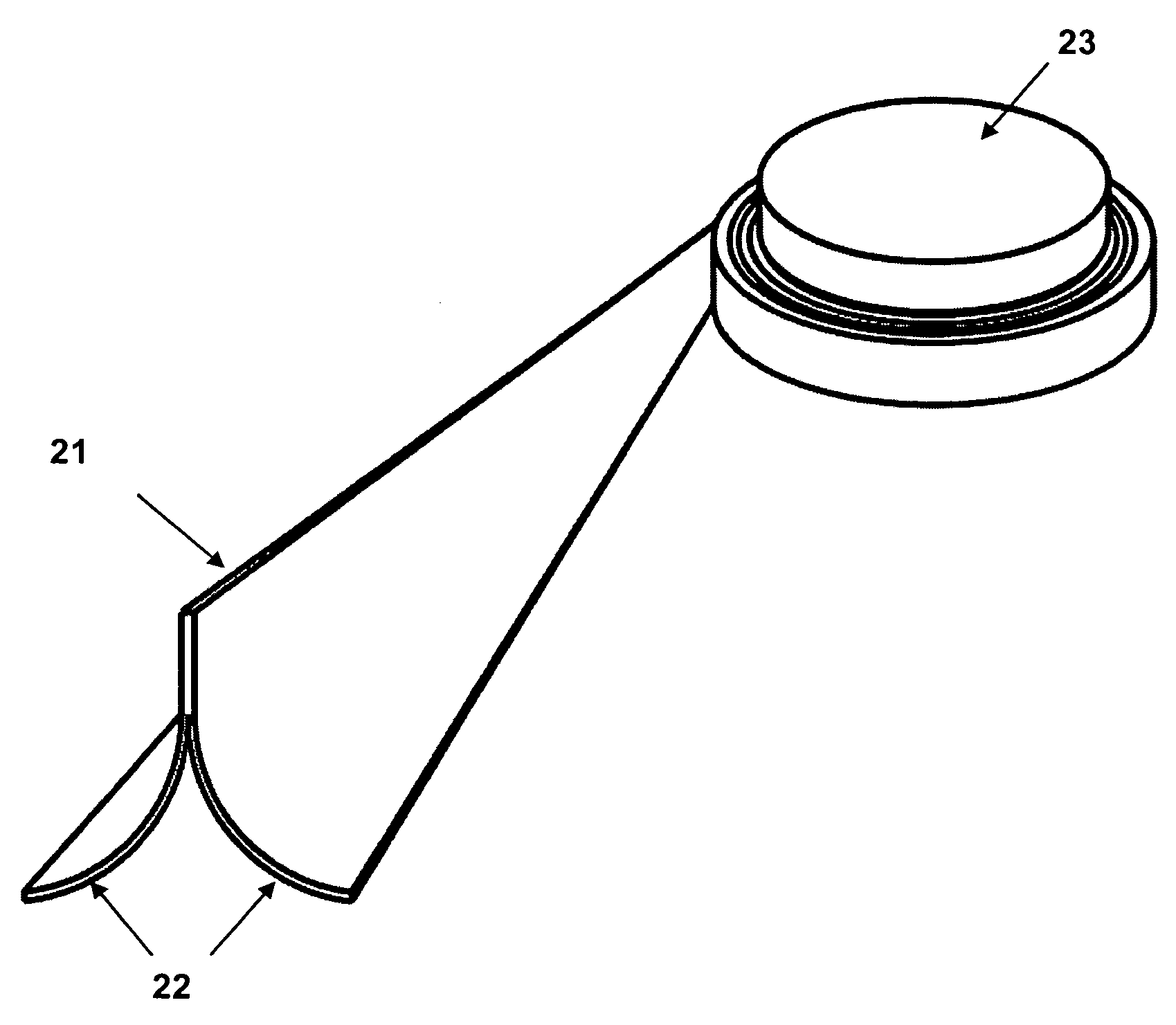

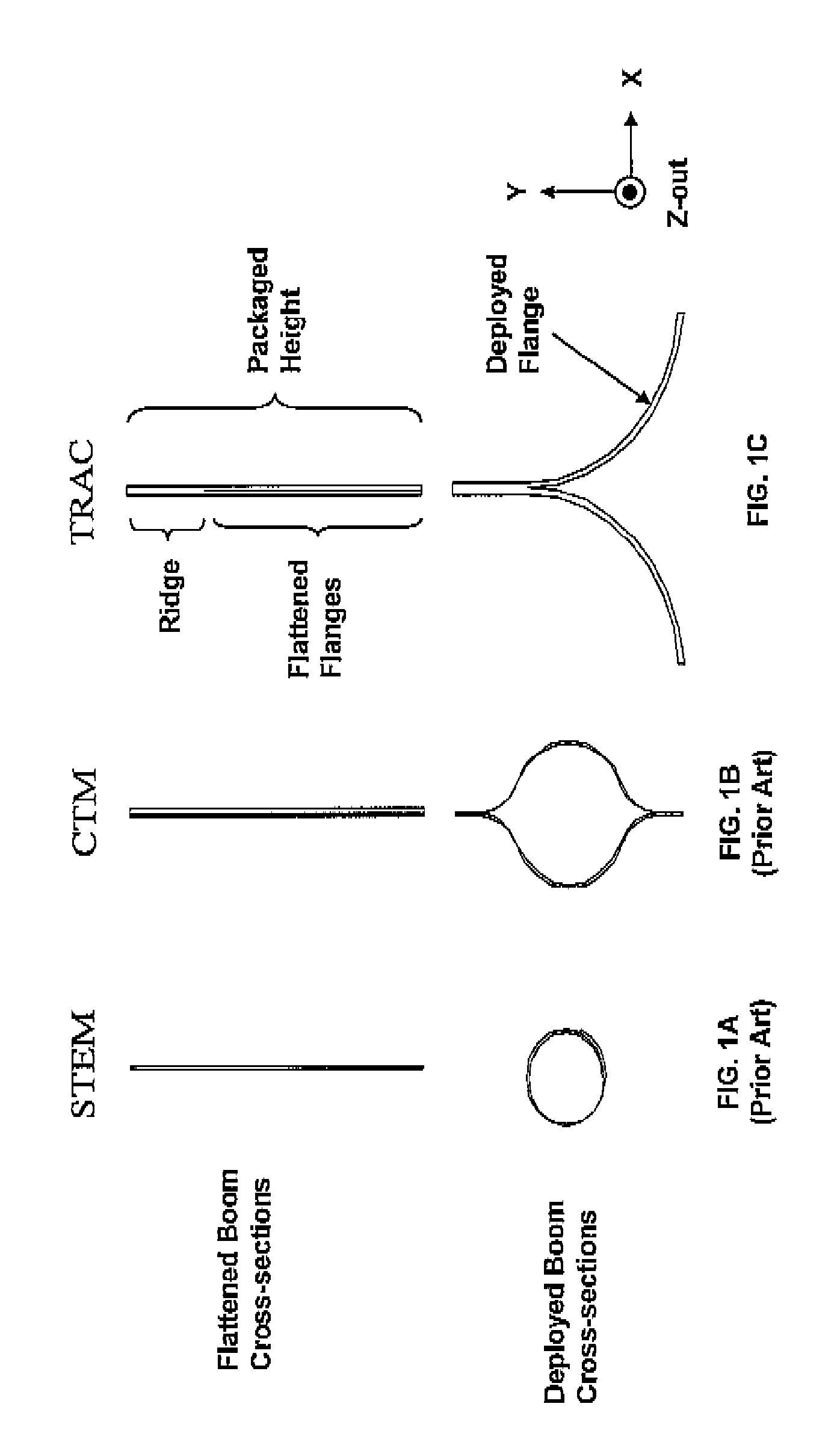

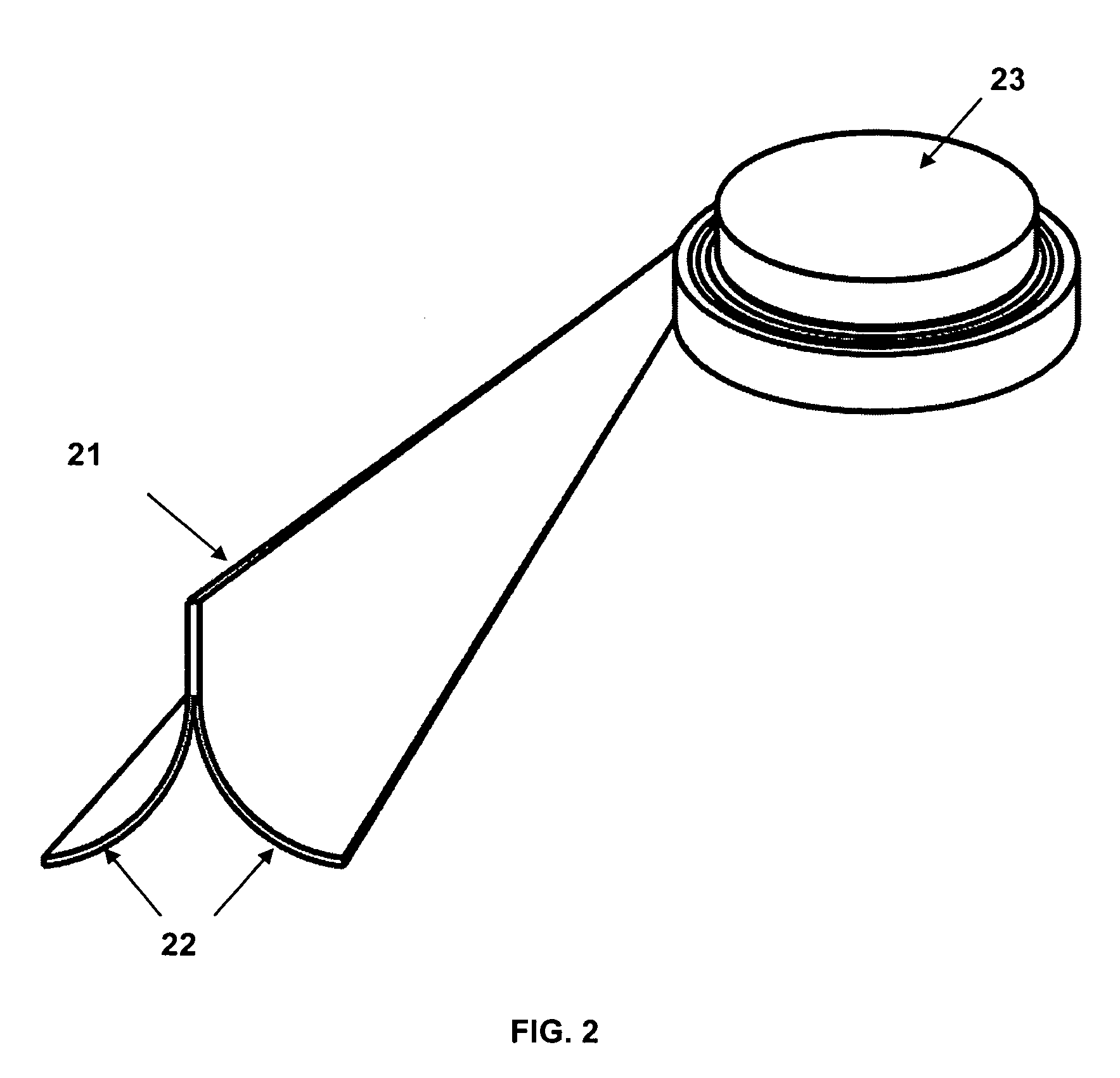

Triangular rollable and collapsible boom

ActiveUS7895795B1Reduced torsional stiffnessIncreased bending stiffnessCosmonautic vehiclesCosmonautic partsFiberCarbon fibers

An elastic space-deployable boom of carbon fiber reinforced plastic or other resilient material having an open substantially triangular cross-section when deployed and stowed with a flattened cross-section about a circular hub.

Owner:THE GOVERNMENT OF THE UNITED STATES AS REPSESENTED BY THE SEC OF THE AIR FORCE

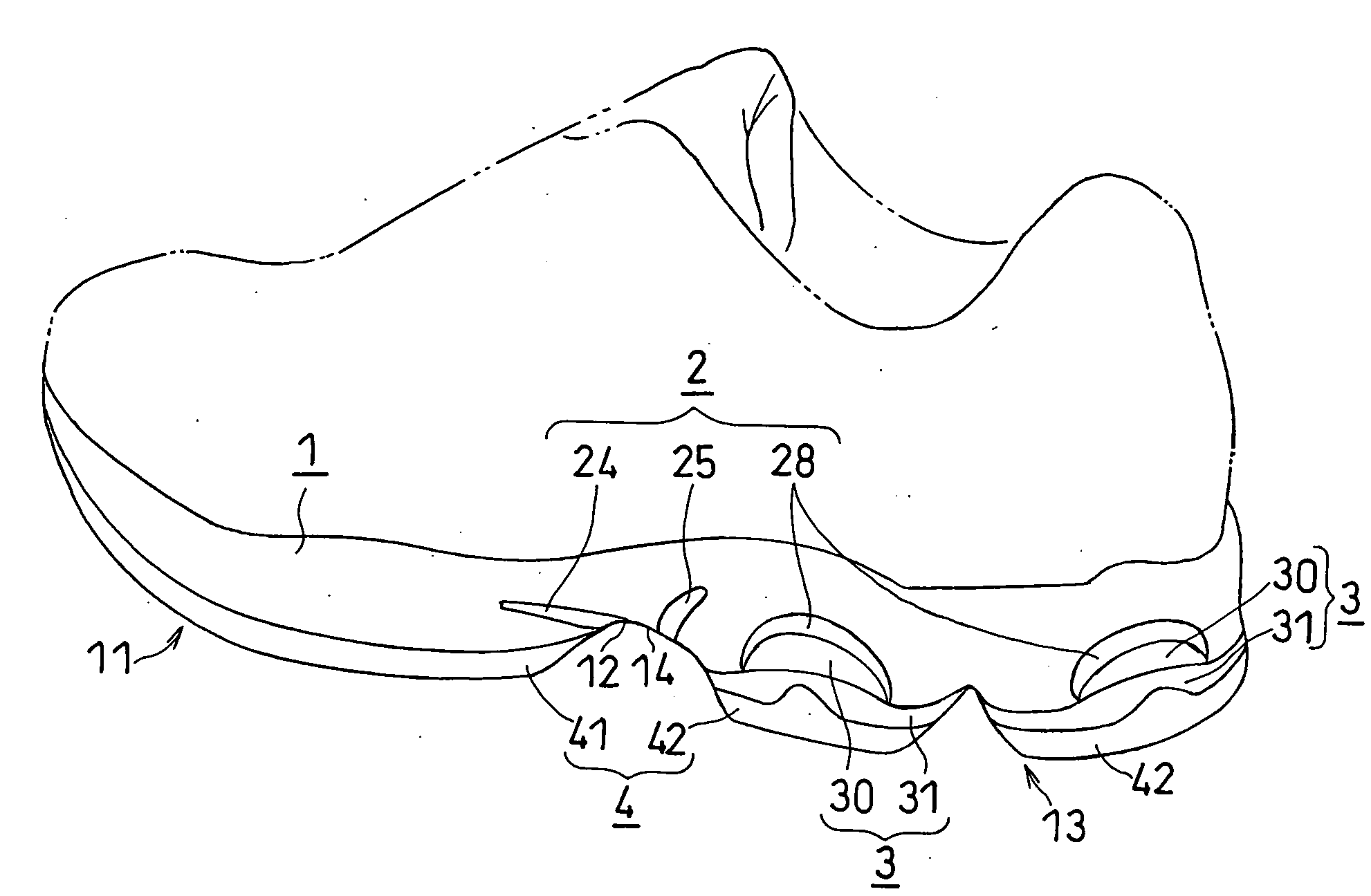

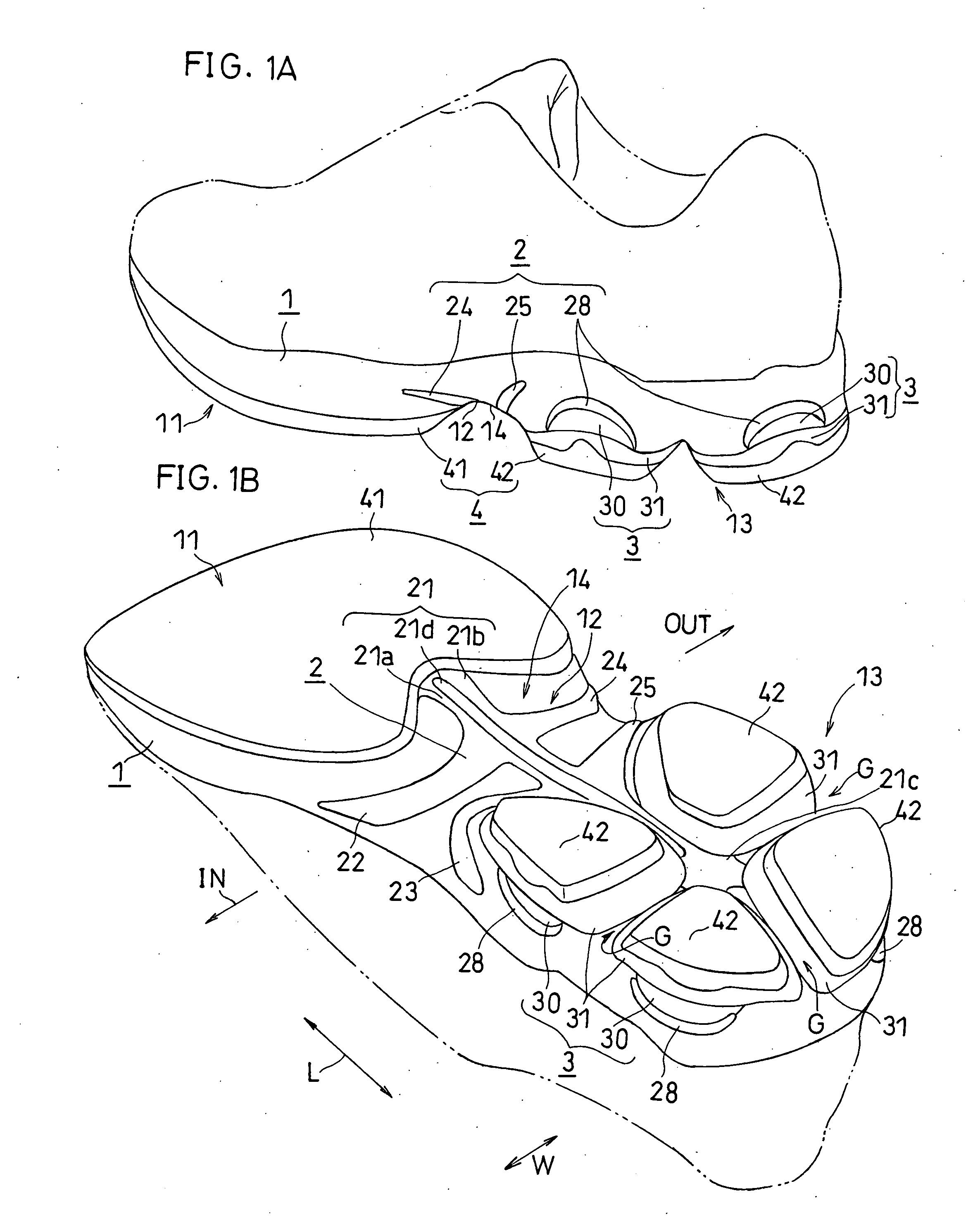

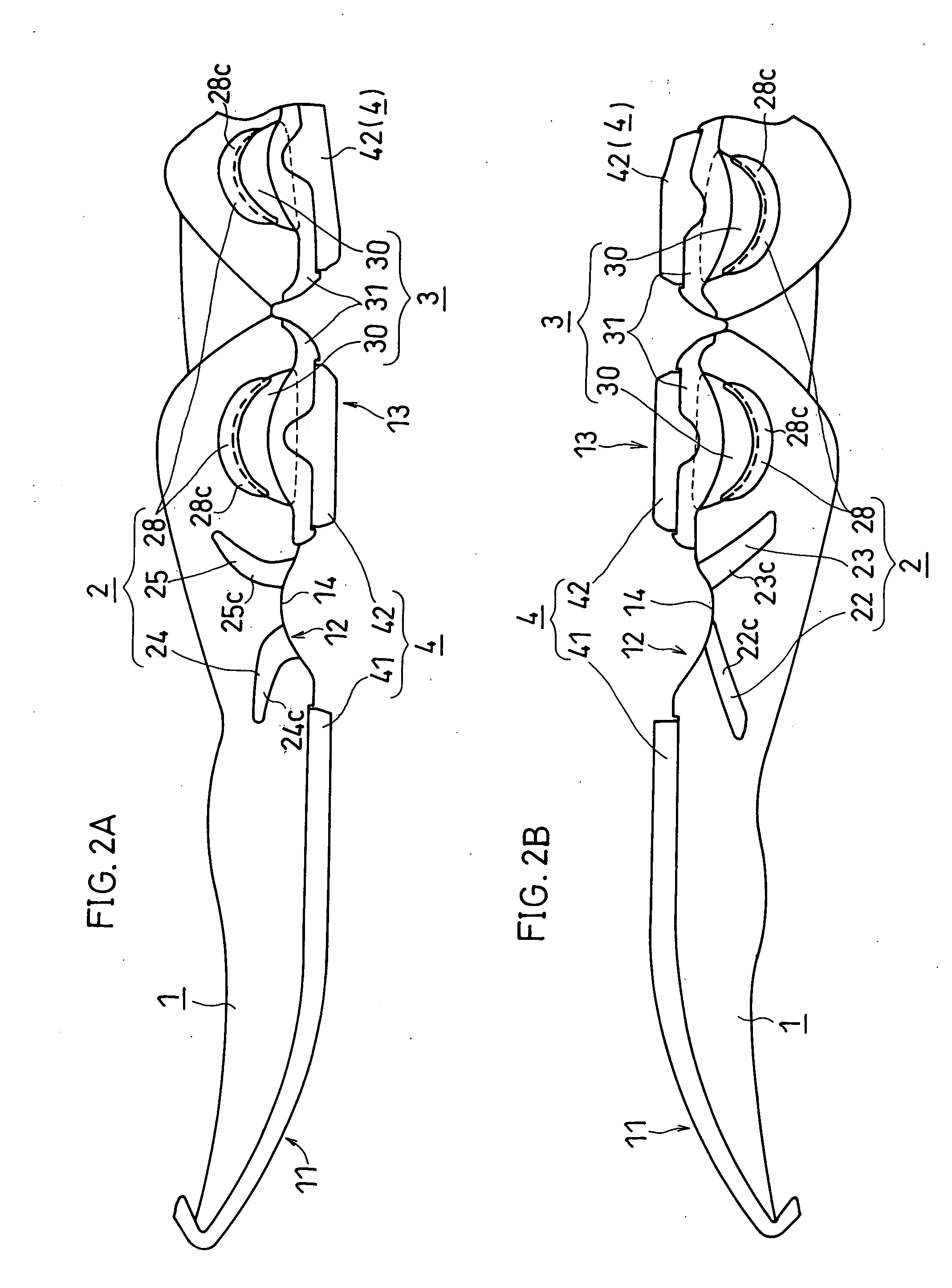

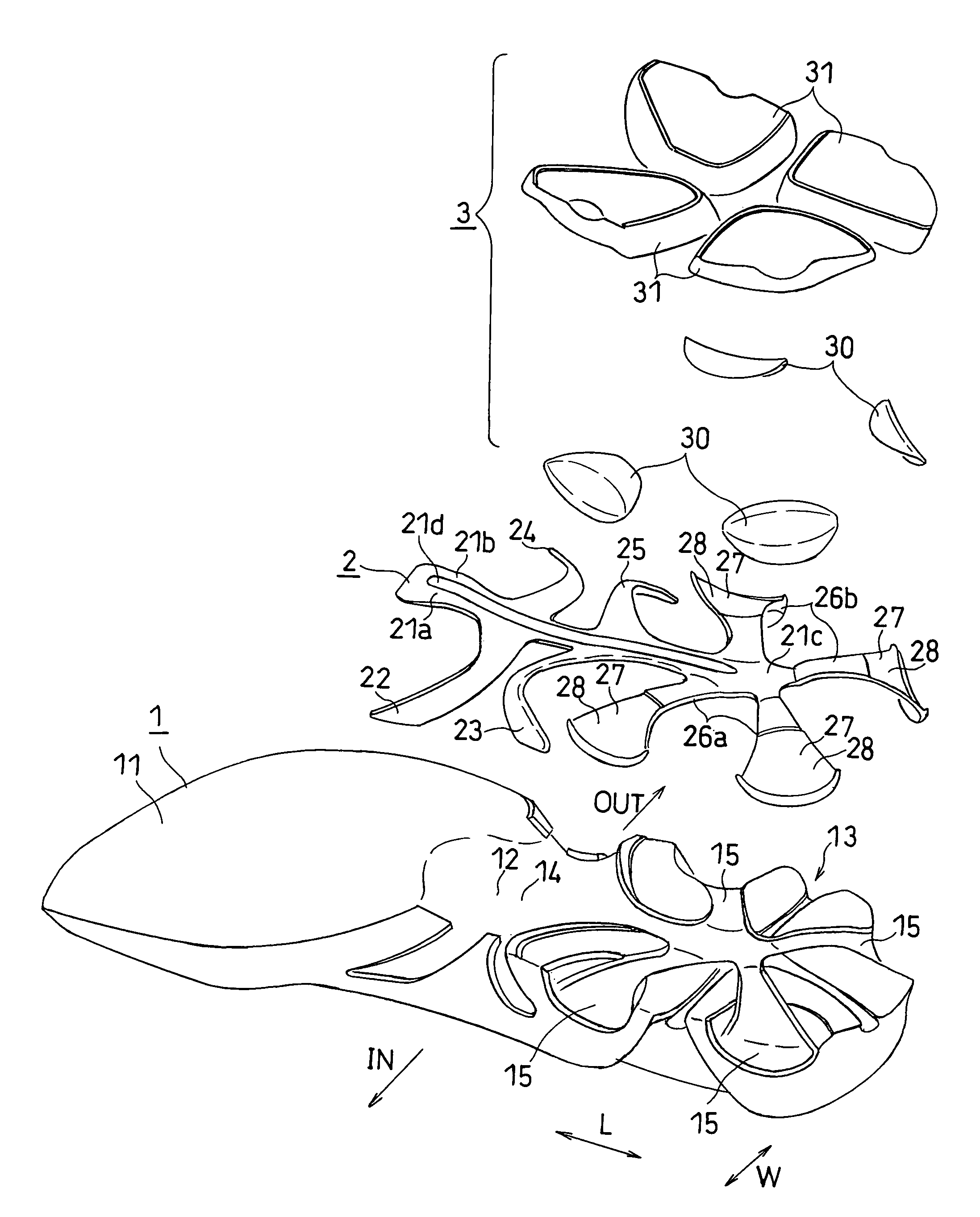

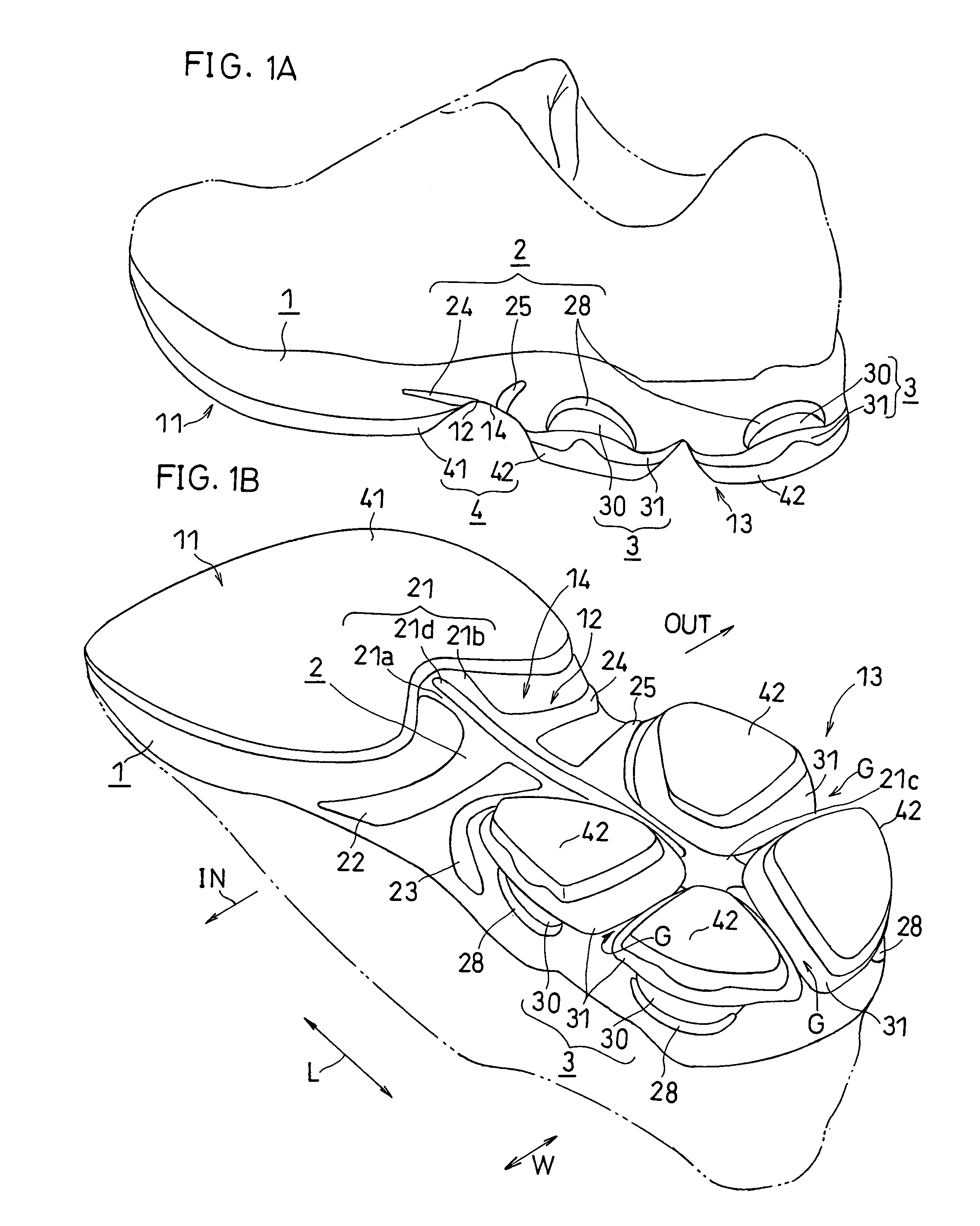

Shoe sole with reinforcing structure and shoe sole with shock-absorbing structure

ActiveUS8453344B2Inhibition decreasedImprove holding rigiditySolesHeelsEngineeringMechanical engineering

Owner:ASICS CORP

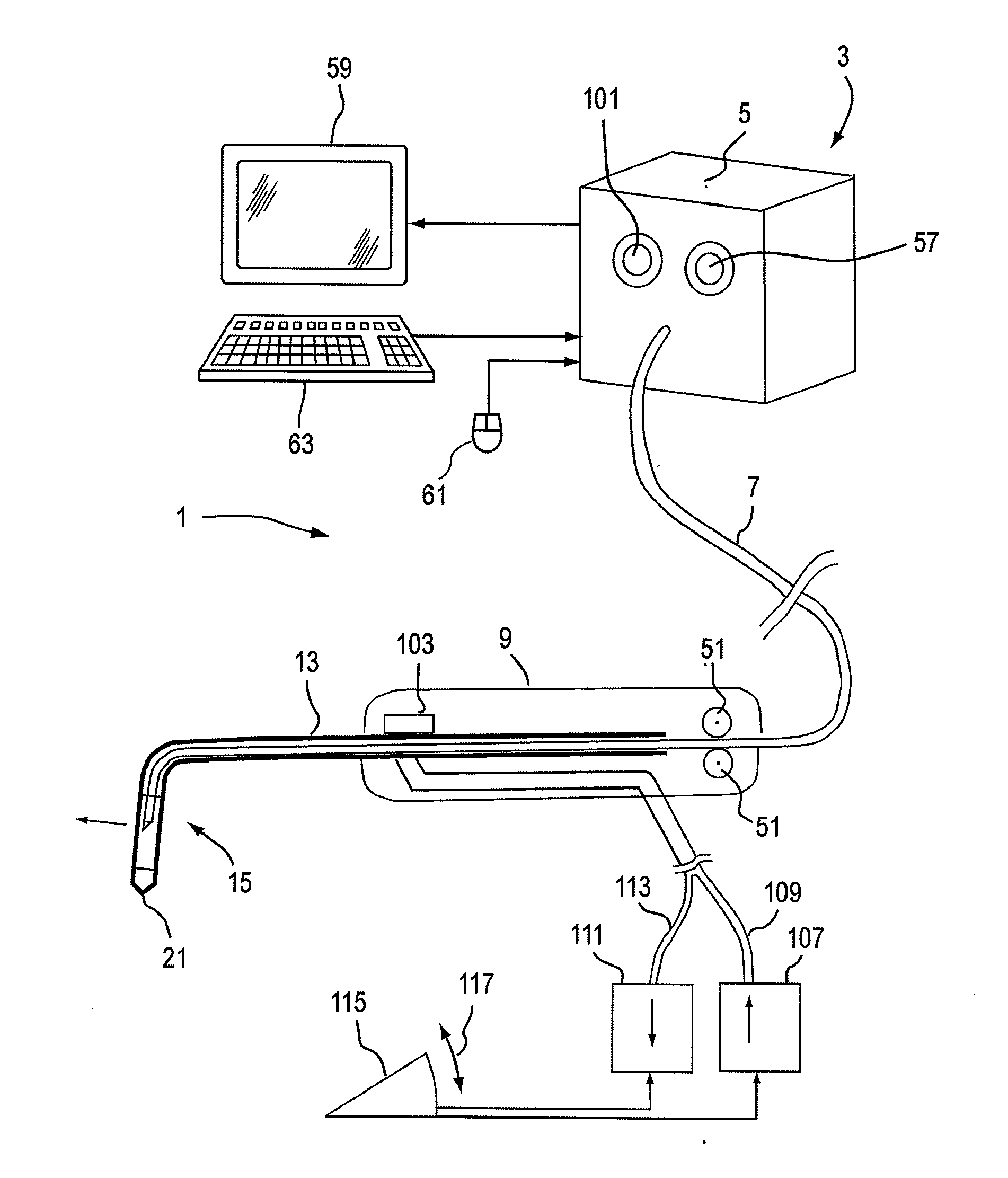

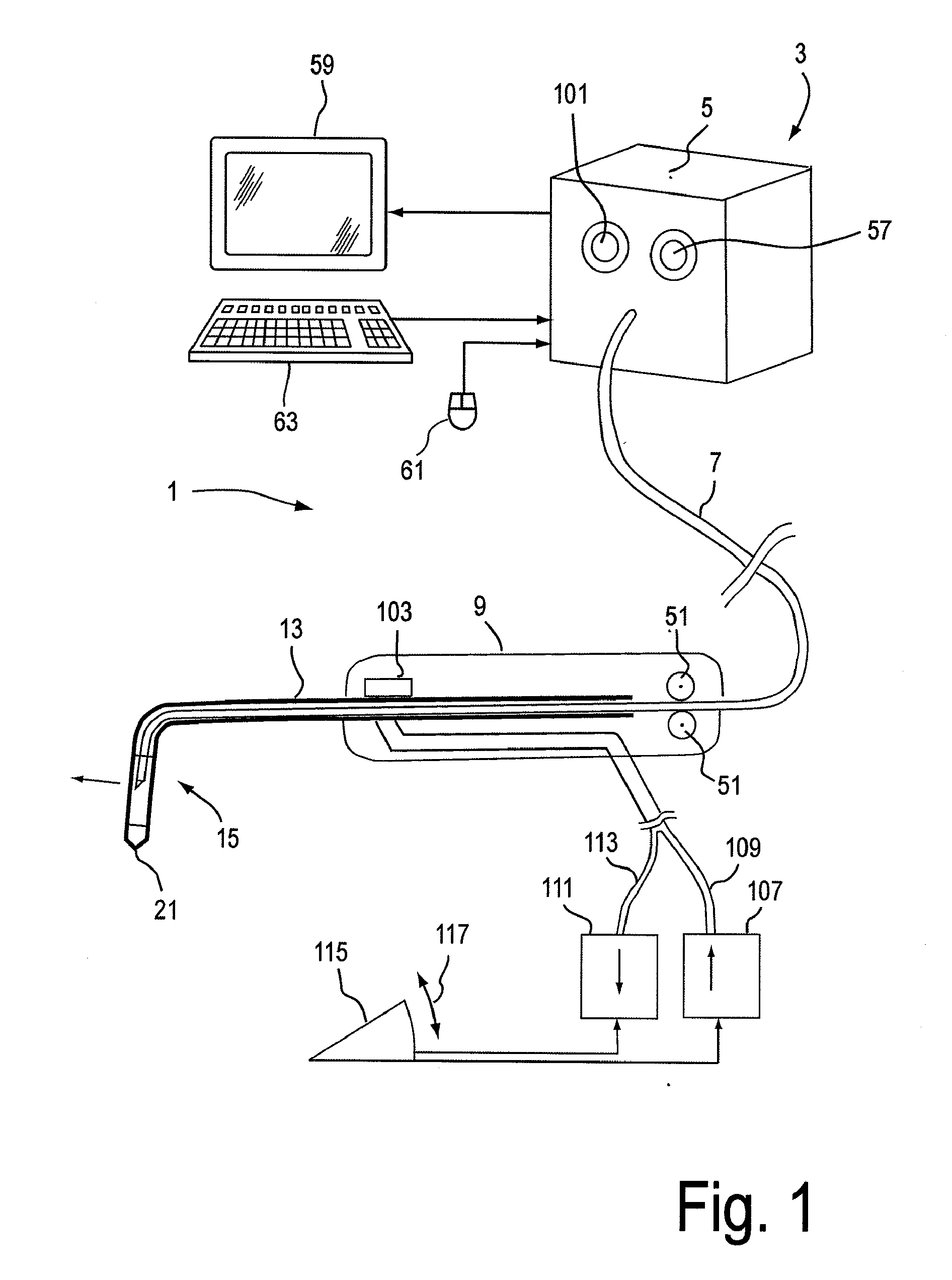

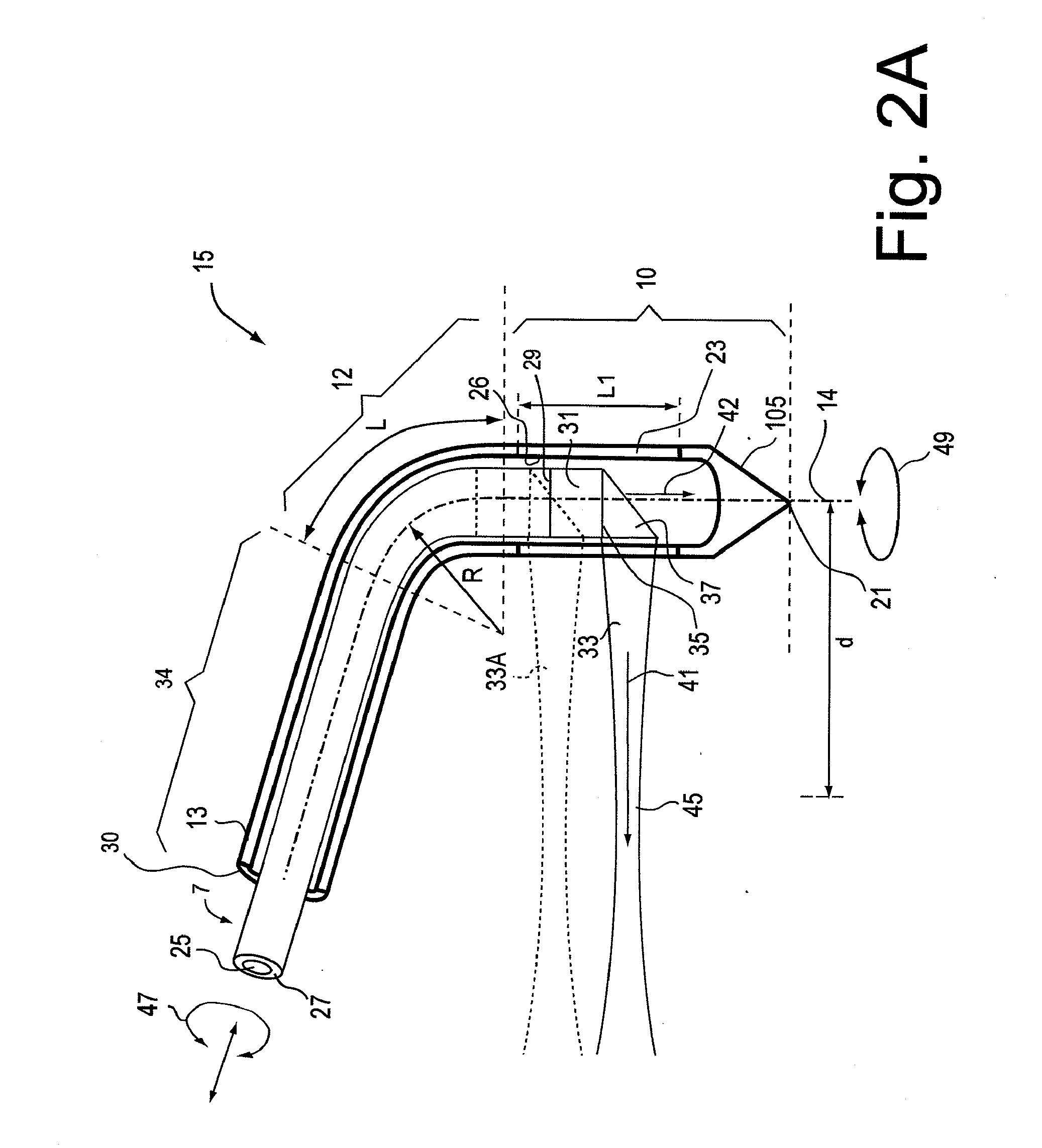

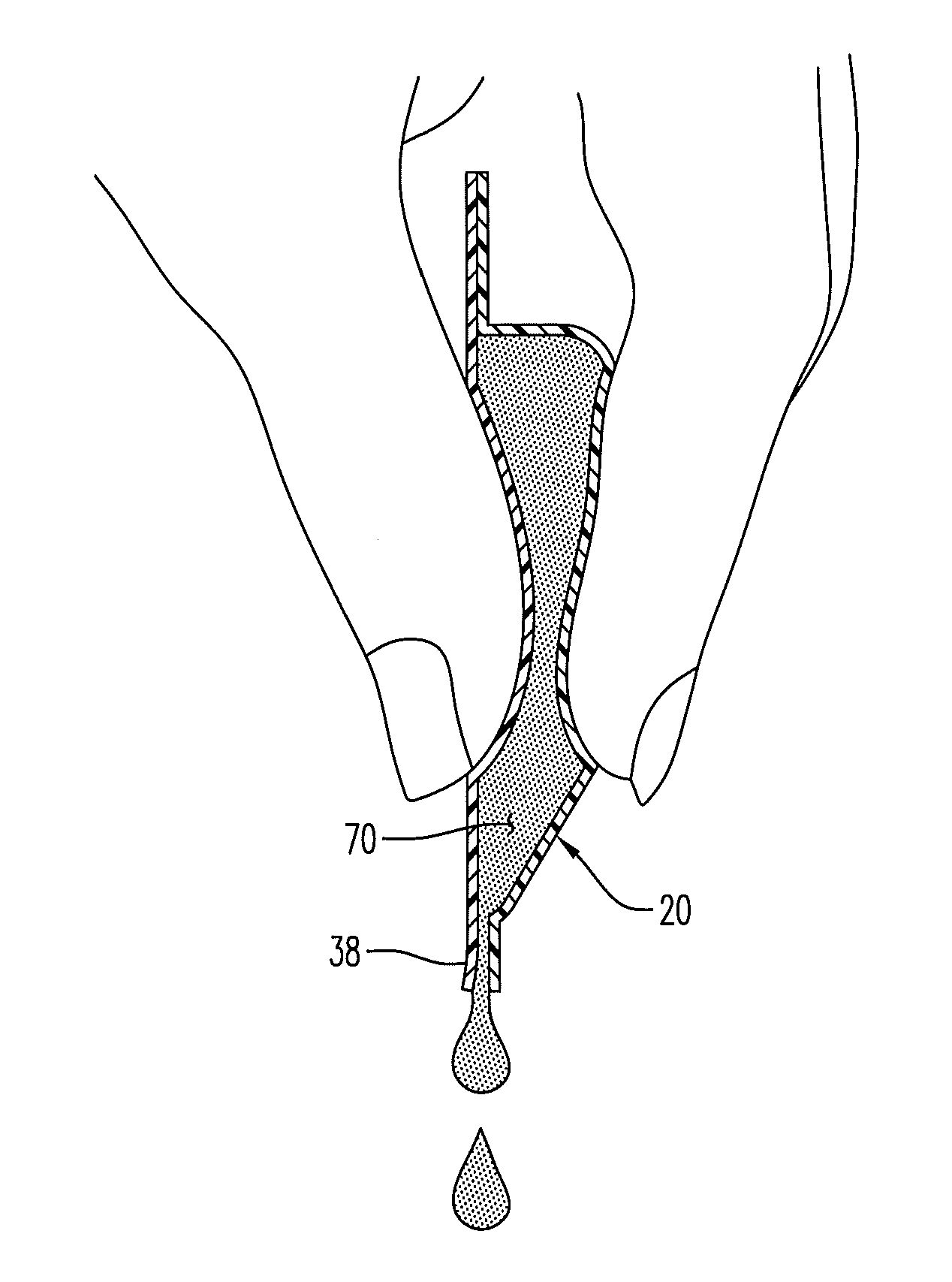

Surgical Device and Surgical Method

ActiveUS20120226267A1Precise alignmentImprove accuracyEye surgerySurgical instrument detailsOphthalmologyDistal portion

A surgical instrument system for ophthalmic surgery in an eye is provided, comprising: an OCT apparatus including an interferometer; an optical fiber coupled to the OCT apparatus and extending a probe arm of the interferometer; a hand tool comprising: a hand piece, a tube extending away from the hand piece and comprising a distal end portion having a longitudinal axis, wherein a distal portion of the optical fiber is received within the tube; a beam emitter coupled to a tip end of the optical fiber and configured to emit an OCT measuring beam into an emission direction; and an actuator configured to change the emission direction of the OCT measuring beam relative to a tip end of the distal end portion.

Owner:CARL ZEISS MEDITEC AG

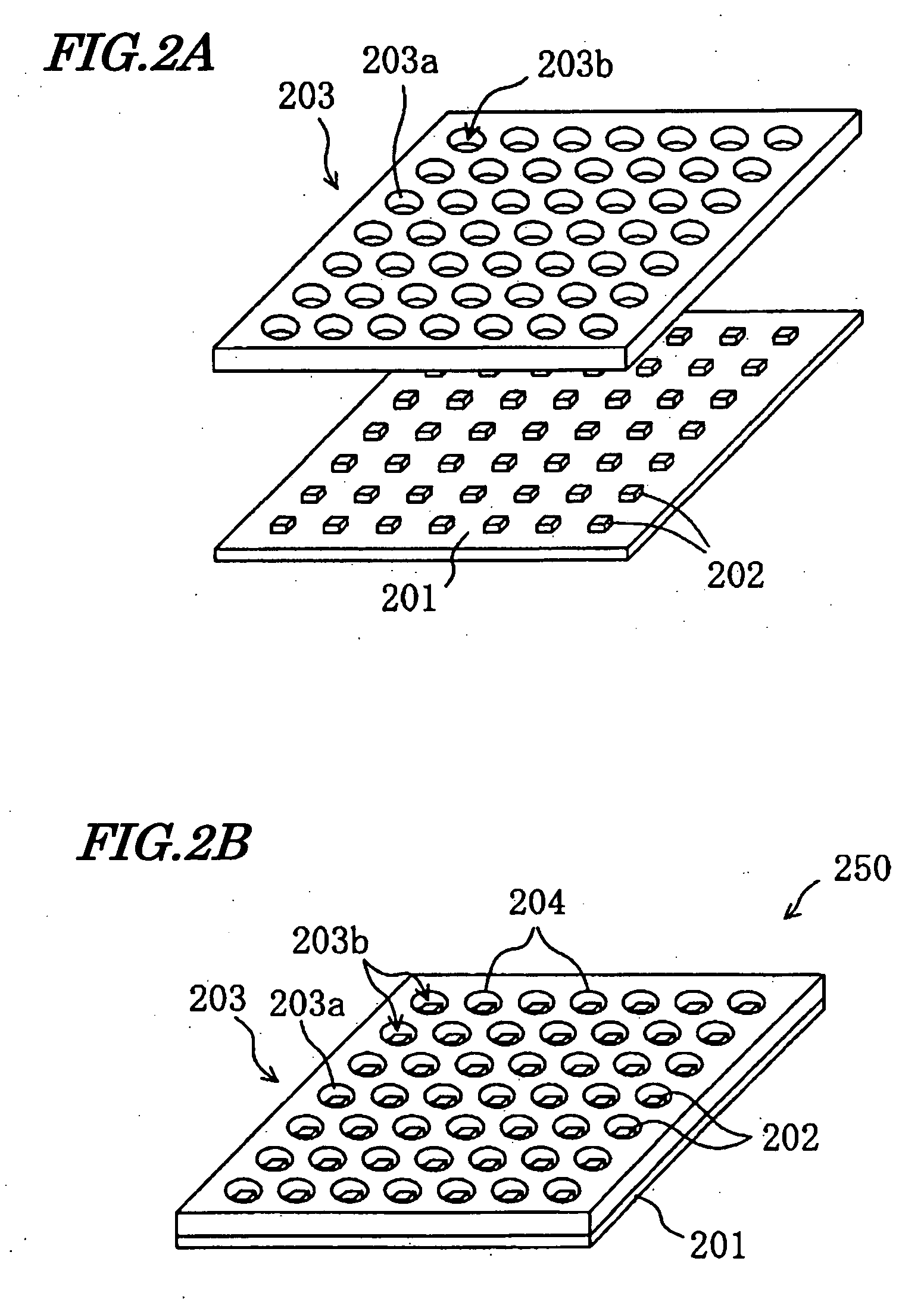

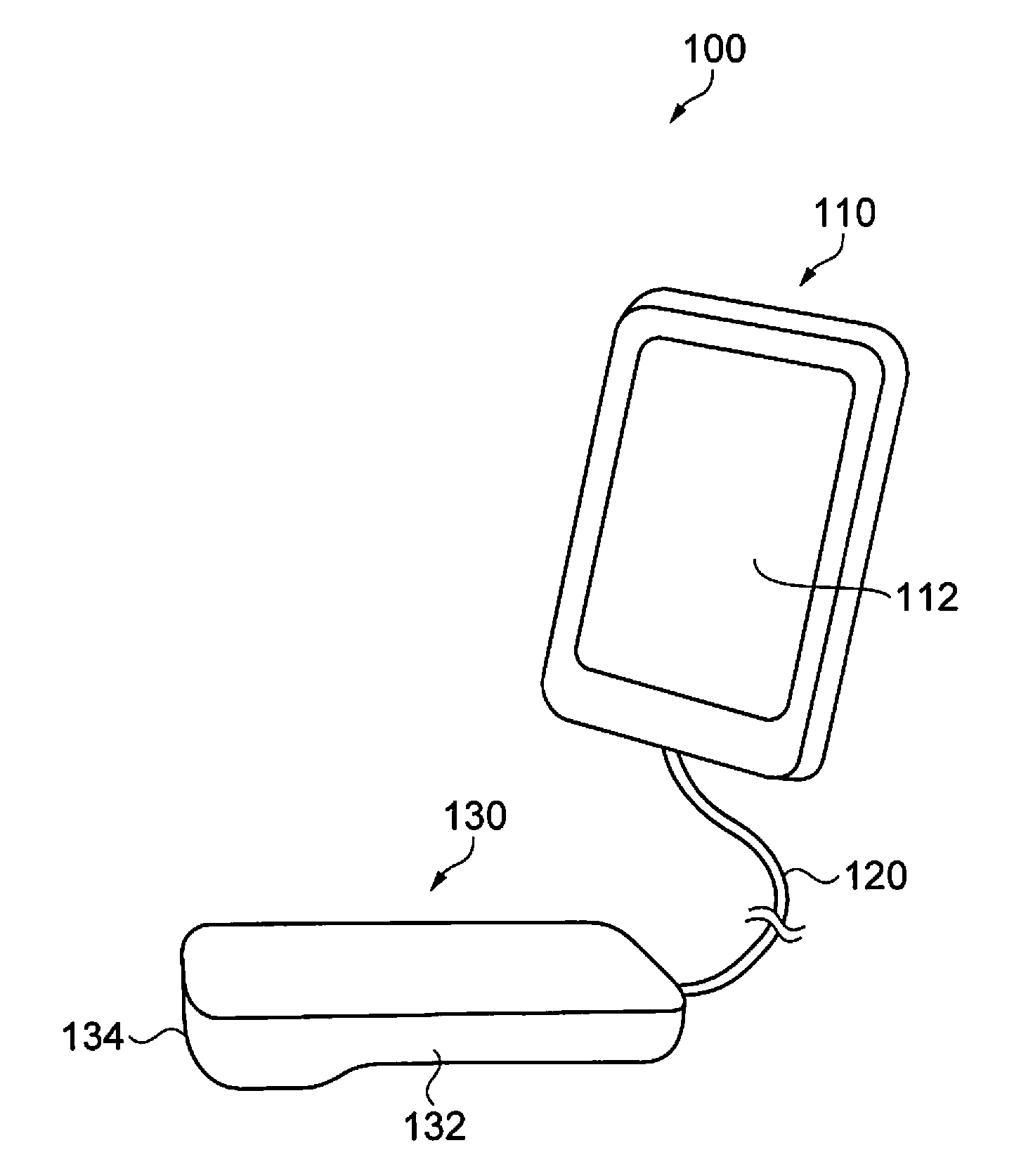

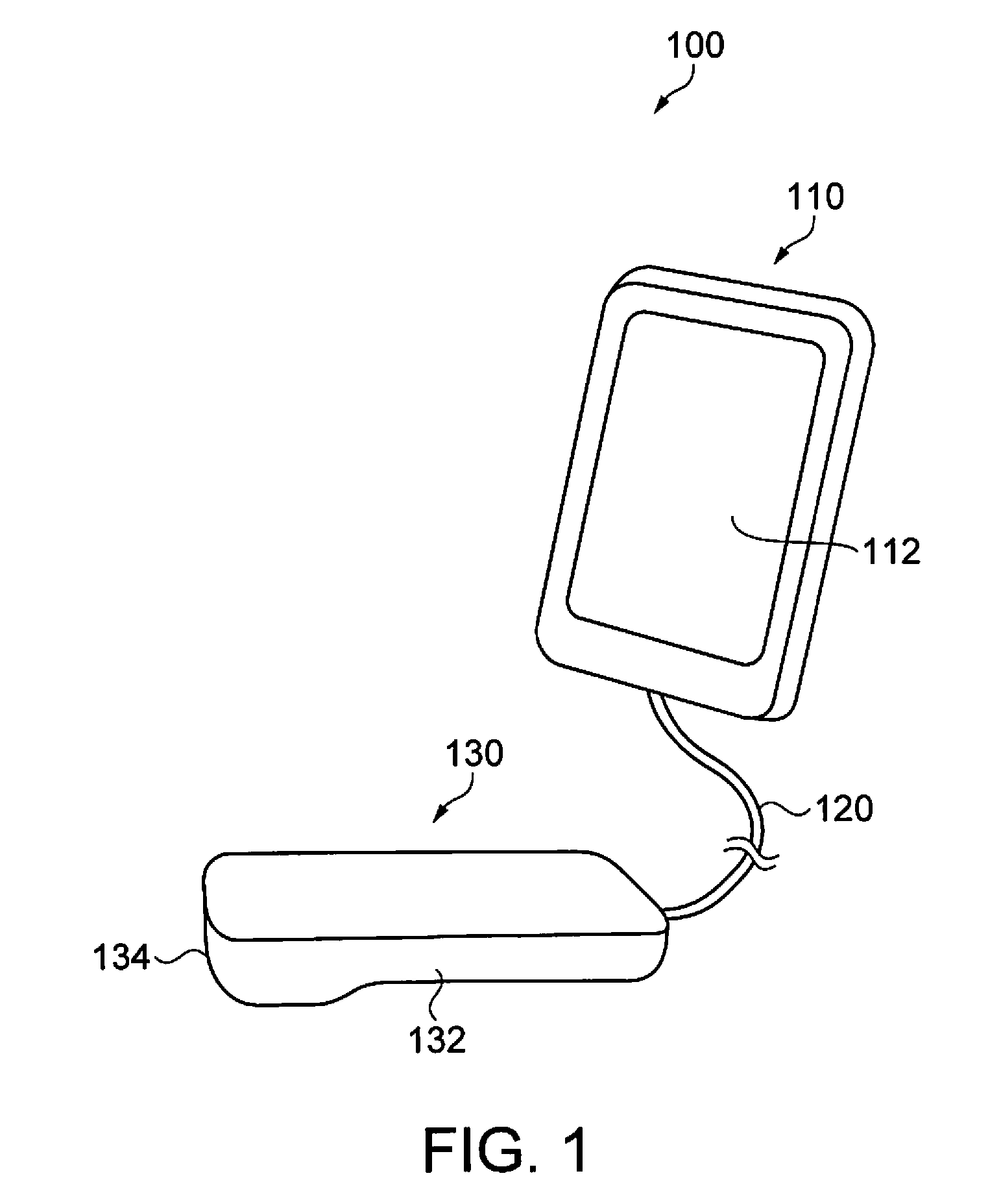

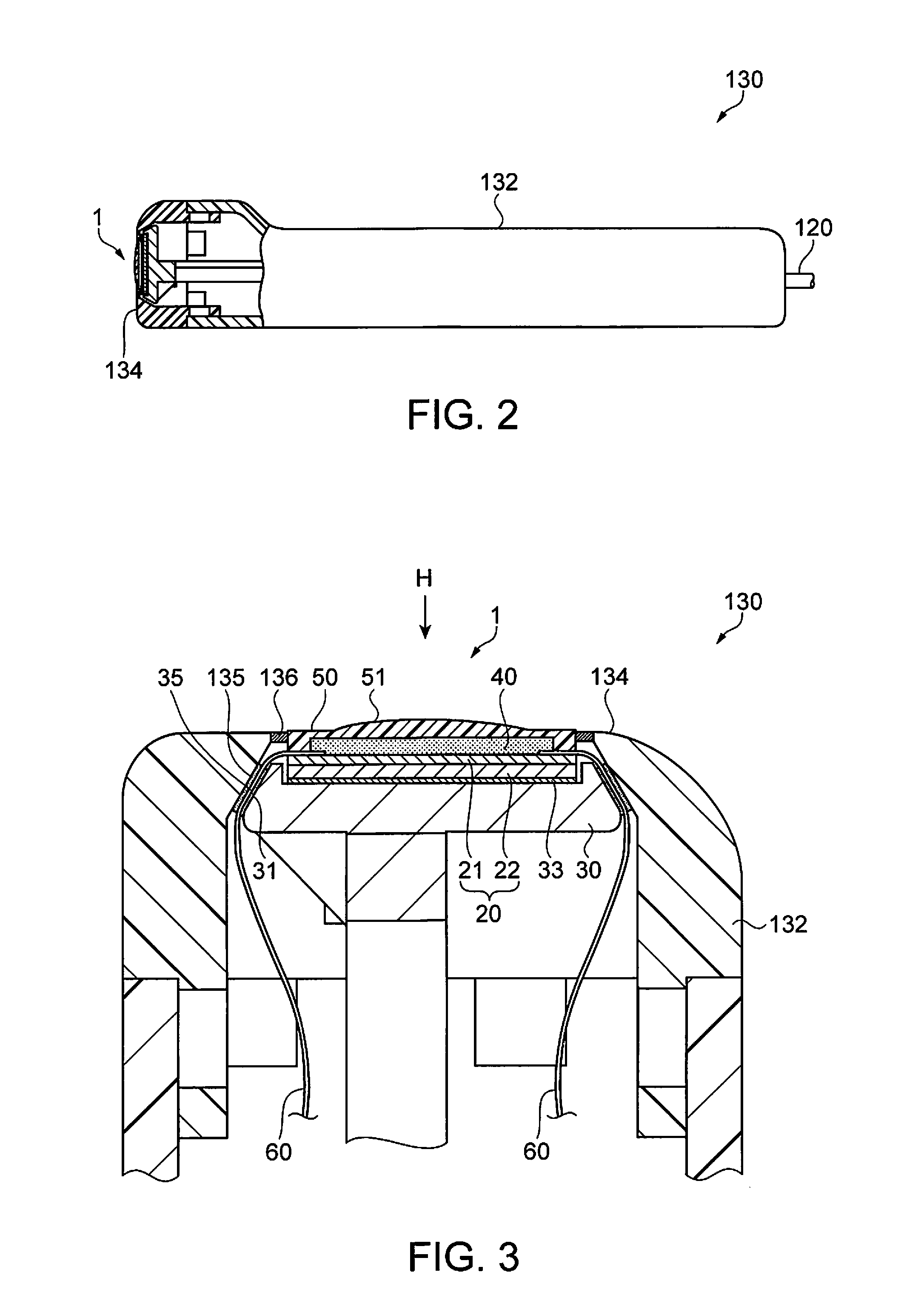

Ultrasonic device, ultrasonic probe, electronic equipment, and ultrasonic imaging apparatus

ActiveUS20140208853A1Improve reliabilityAvoid damageAnalysing solids using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesUltrasonic imagingAcoustic lens

Provided is an ultrasonic device including: an ultrasonic element array substrate having a plurality of ultrasonic elements that each include a piezoelectric body; an acoustic lens secured via an acoustic matching layer to a surface, formed with the ultrasonic elements, of the ultrasonic element array substrate; and a support member secured to a surface, opposite to the surface formed with the ultrasonic elements, of the ultrasonic element array substrate, wherein the support member is formed to have a larger area, in plan view in the thickness direction of the ultrasonic element array substrate, and a higher bending stiffness than the ultrasonic element array substrate, and the acoustic lens is formed to have a lower bending stiffness than the ultrasonic element array substrate. The above-described ultrasonic device further includes an acoustic matching layer filled between the ultrasonic element array substrate and the acoustic lens.

Owner:SEIKO EPSON CORP

Gripping and releasing apparatus and method

ActiveUS8882165B2Improvement factorImprove performanceGripping headsRobotPositive pressureEngineering

A passive universal gripper includes a mass of granular material encased in an elastic membrane. Using a combination of positive and negative pressure, the gripper can rapidly grip and release a wide range of objects that are typically challenging for conventional universal grippers, such as flat objects, soft objects, or objects with complex geometries. The gripper passively conforms to the shape of a target object, then vacuum-hardens to grip it rigidly; later using positive pressure to reverse this transition—releasing the object and returning to a deformable state. The apparatus and method enable the fast ejection of objects from the gripper, as well as essentially instantaneous reset time between releasing and gripping.

Owner:CORNELL UNIVERSITY +1

Balloon catheter tapered shaft having high strength and flexibility and method of making same

ActiveUS20080045928A1Low bending stiffnessIncrease pressureStentsBalloon catheterPliabilityHigh intensity

A catheter having an elongated shaft with a tubular member which forms at least a portion of the shaft and which is formed of a biaxially oriented thermoplastic polymeric material, and a method of forming the catheter shaft by radially and longitudinally expanding the tubular member to biaxially orient the polymeric material, and, in one embodiment, tapering the tubular member to form a bending stiffness transition. A catheter of the invention has an improved combination of low bending stiffness, high rupture pressure, and high tensile strength, for improved catheter performance.

Owner:ABBOTT CARDIOVASCULAR

Methods for manufacturing floor panels

ActiveUS20140020820A1High densityHigh sensitivityDecorative surface effectsOrnamental structuresEngineeringMechanical press

In a method for manufacturing floor panels that have at least a substrate and a top layer provided on the substrate, the top layer including a thermoplastic layer that is translucent or transparent, the method may involve providing the top layer, including the thermoplastic layer, on the substrate. The method may also involve heating at least the thermoplastic layer, and structuring the thermoplastic layer using a mechanical press element.

Owner:UNILIN BV

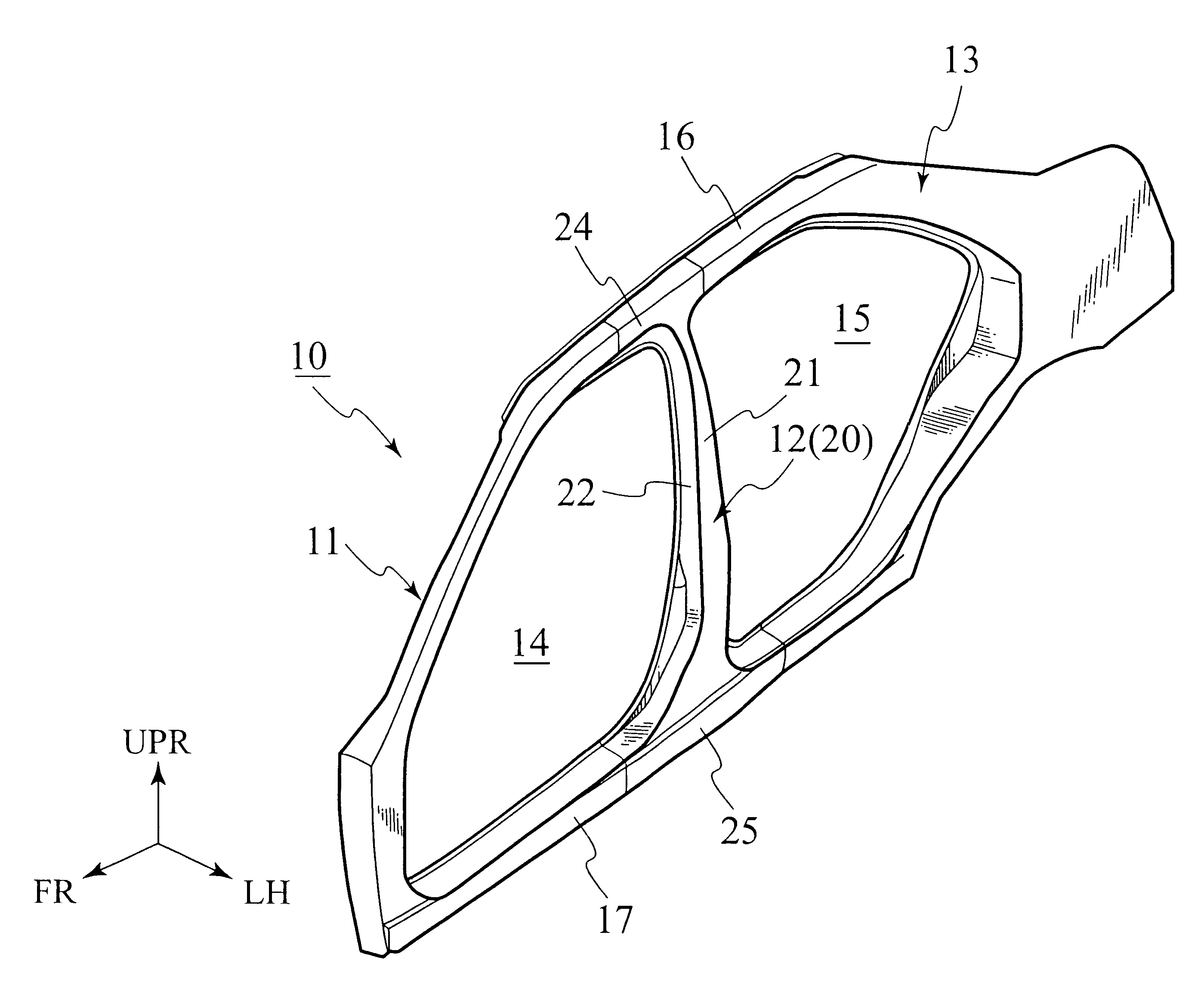

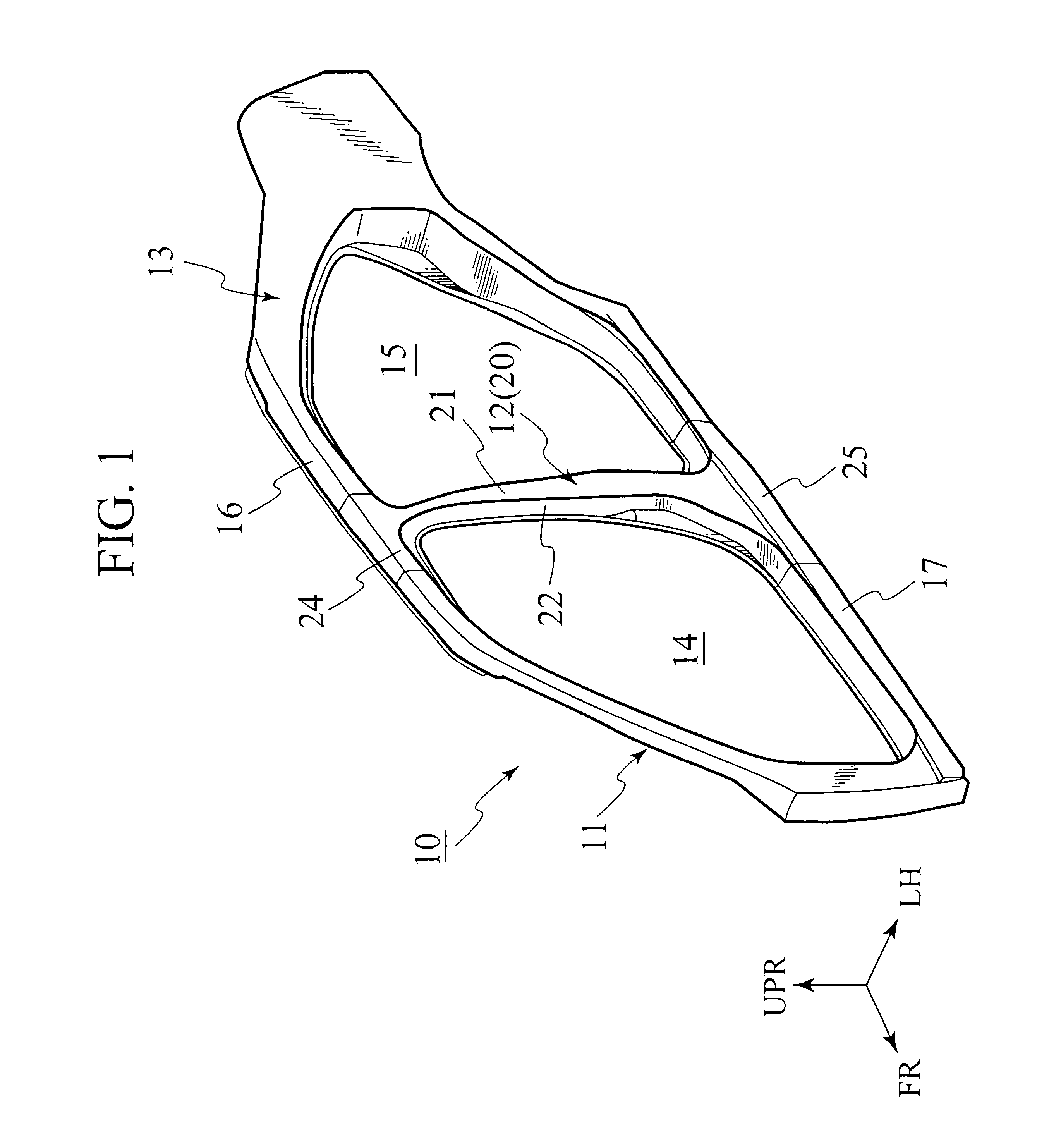

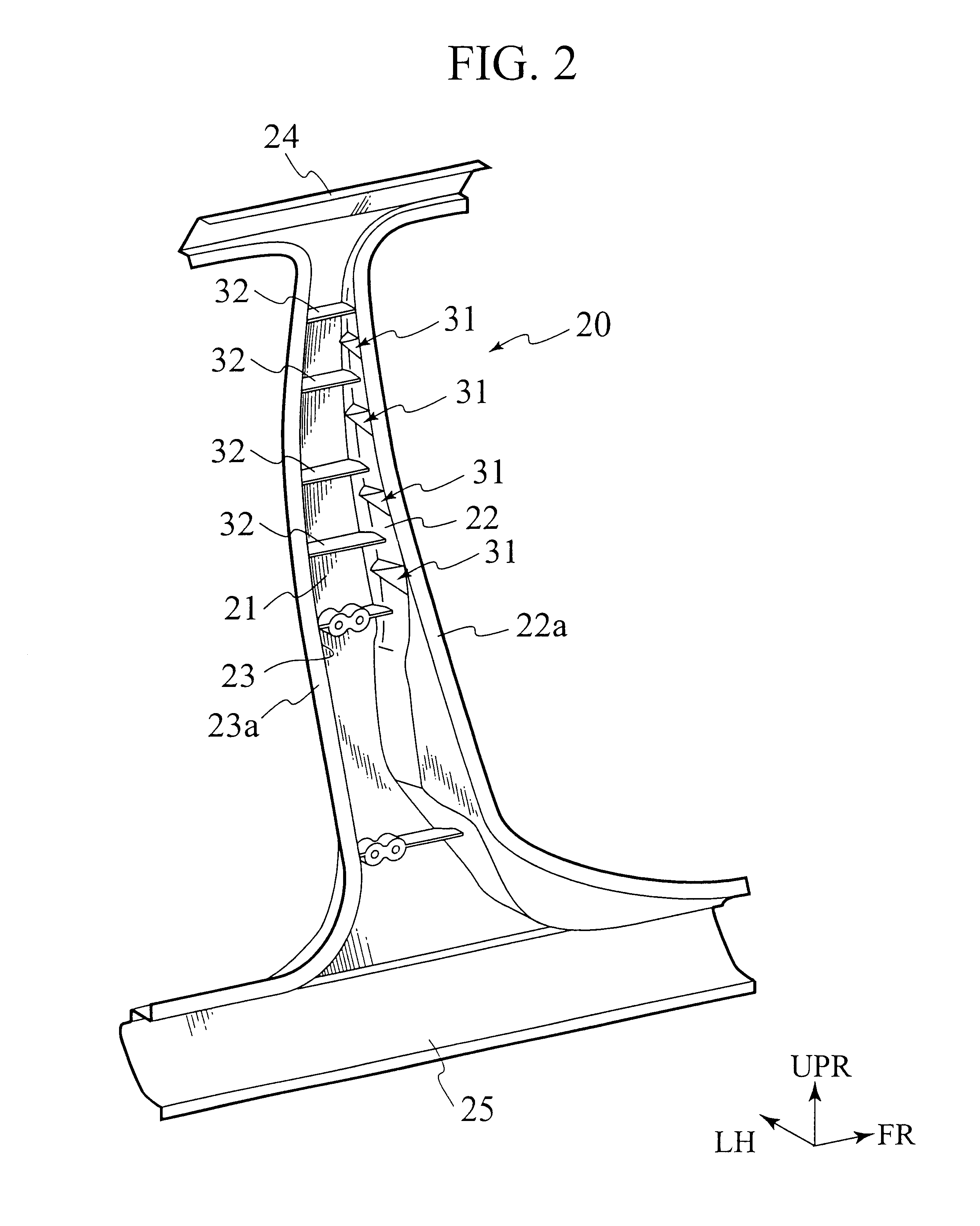

Pillar structure of a vehicle

InactiveUS6702368B1Control deformationIncrease a geometrical moment of inertiaVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

Owner:NISSAN MOTOR CO LTD

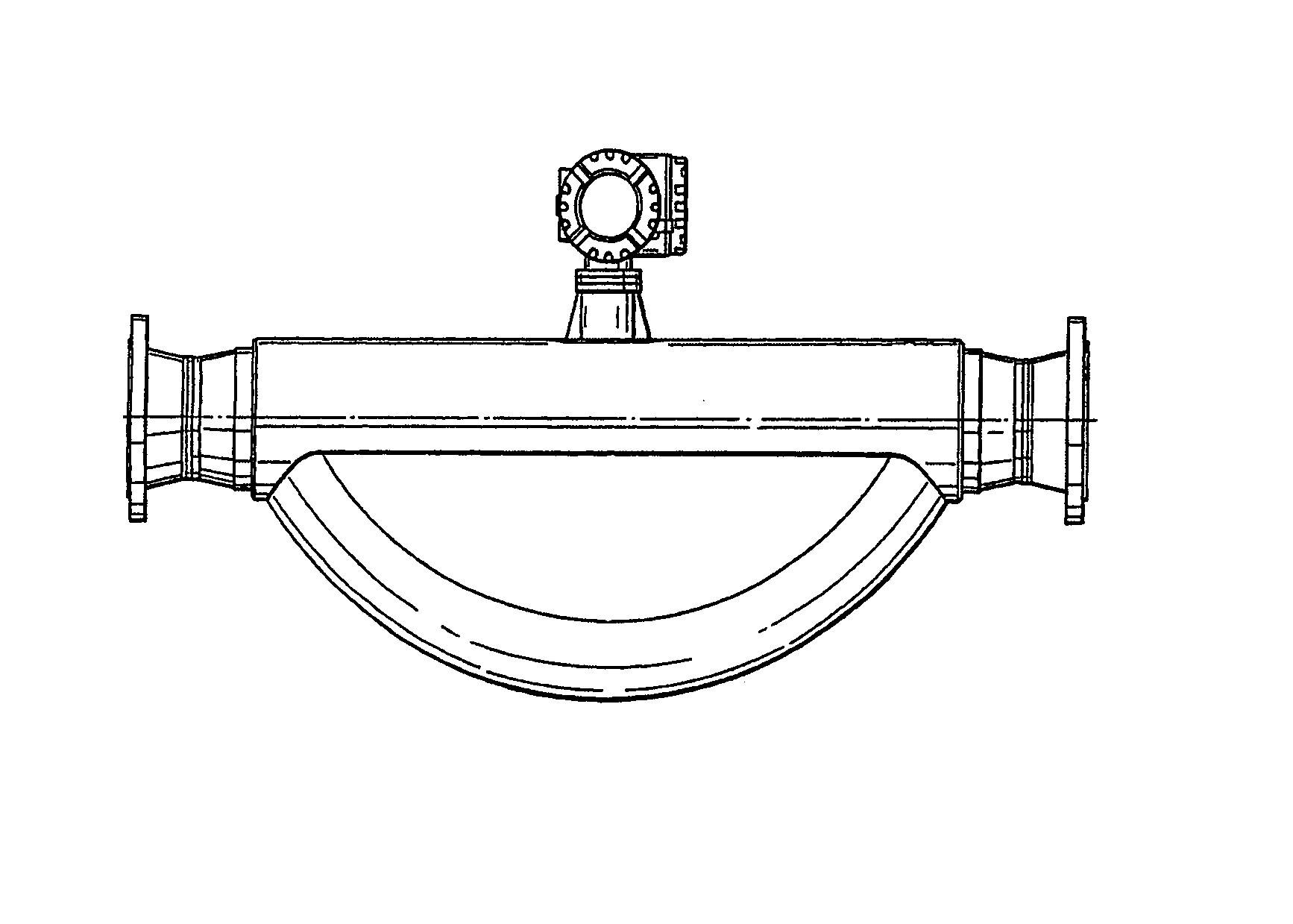

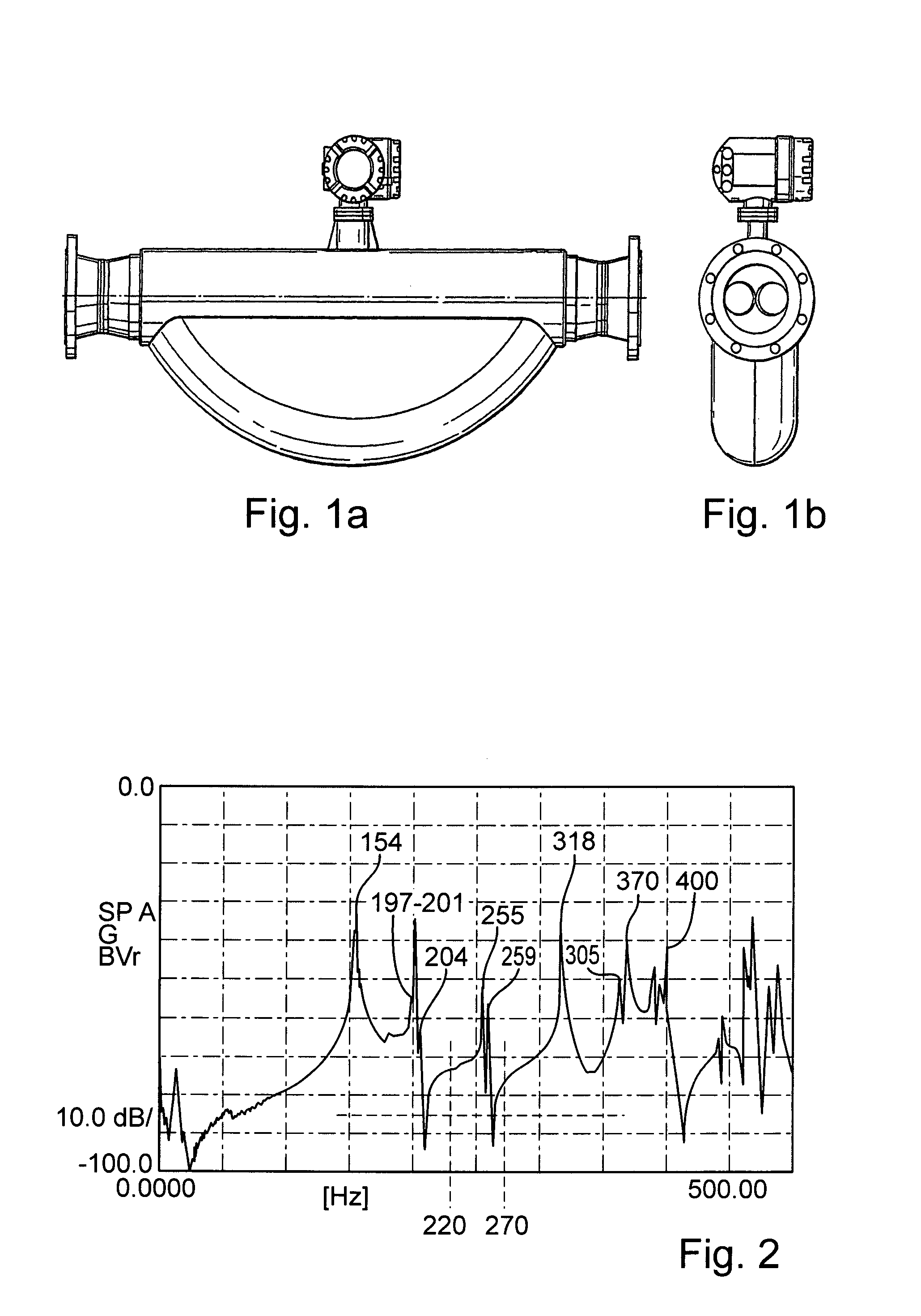

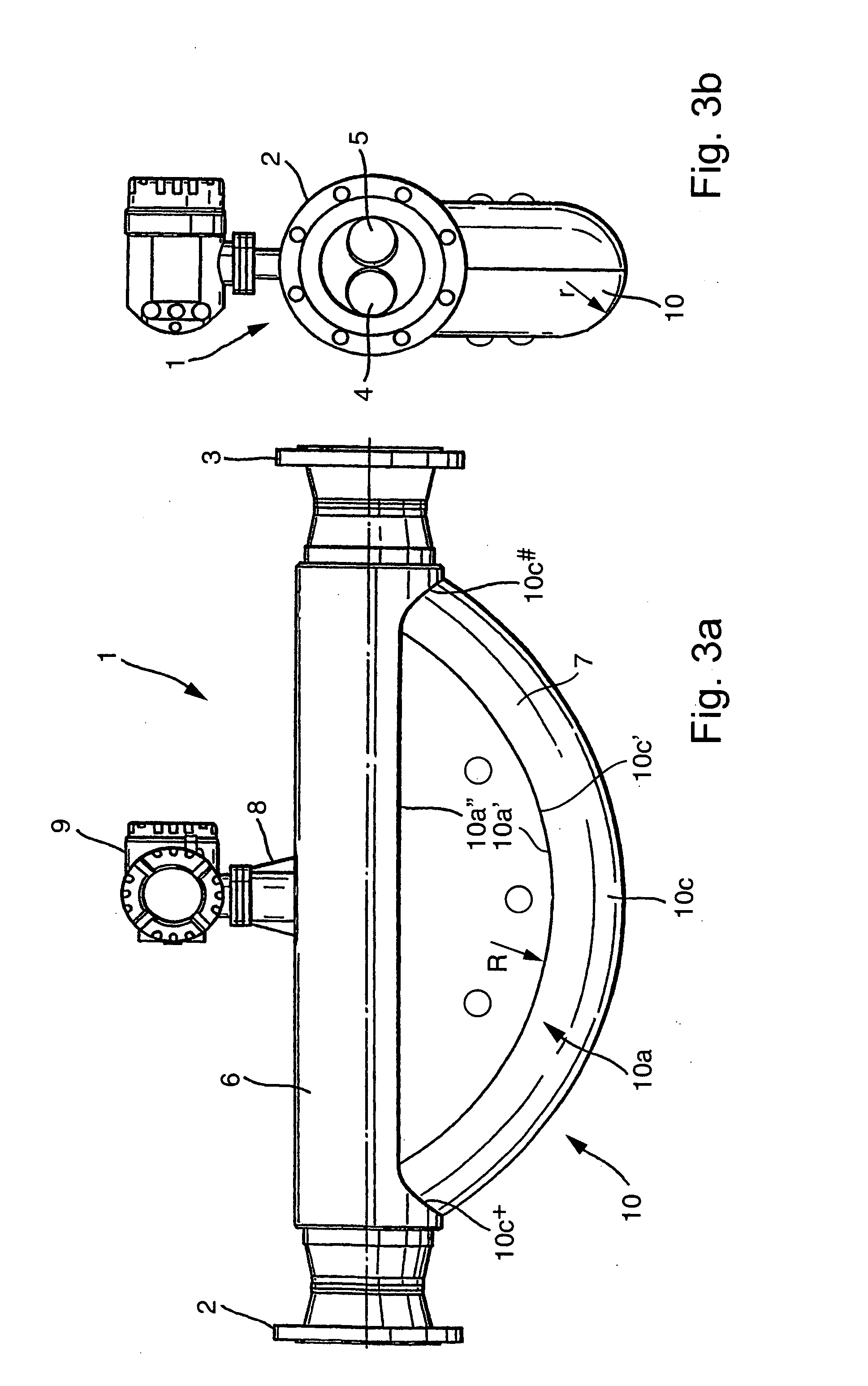

Vibration-type measurement transducer

ActiveUS7216549B2Increased bending stiffnessSignificant complexityDirect mass flowmetersTransducerVolume fraction

A measurement transducer includes a transducer housing, which exhibits a multiplicity of natural oscillation modes and at least a first measuring tube for conveying at least a volume fraction of the medium to be measured. The measuring tube is held to oscillation in the transducer housing and vibrator, at least at times. Also included is an electromechanical, exciter mechanism acting on the at least one measuring tube and a sensor arrangement reacting to movements, i.e. bending oscillations, of the measuring tube. Also included is a first support element fixed, i.e. directly, to the transducer housing and serving for the formation of essentially locationally fixed oscillation nodes in the transducer housing for suppressing or erasing at least one natural oscillation mode of the transducer housing. An outer oscillation system is formed by the transducer housing and at least the at least one support element and an inner oscillation system is formed by the at least one measuring tube, the medium at least instantaneously conveyed therein, and, at least in part, by the exciter mechanism and the sensor arrangement. The inner oscillation system, executes, at least at times during operation of the measurement transducer, mechanical oscillations, especially in the form of lateral oscillations.

Owner:ENDRESS HAUSER FLOWTEC AG

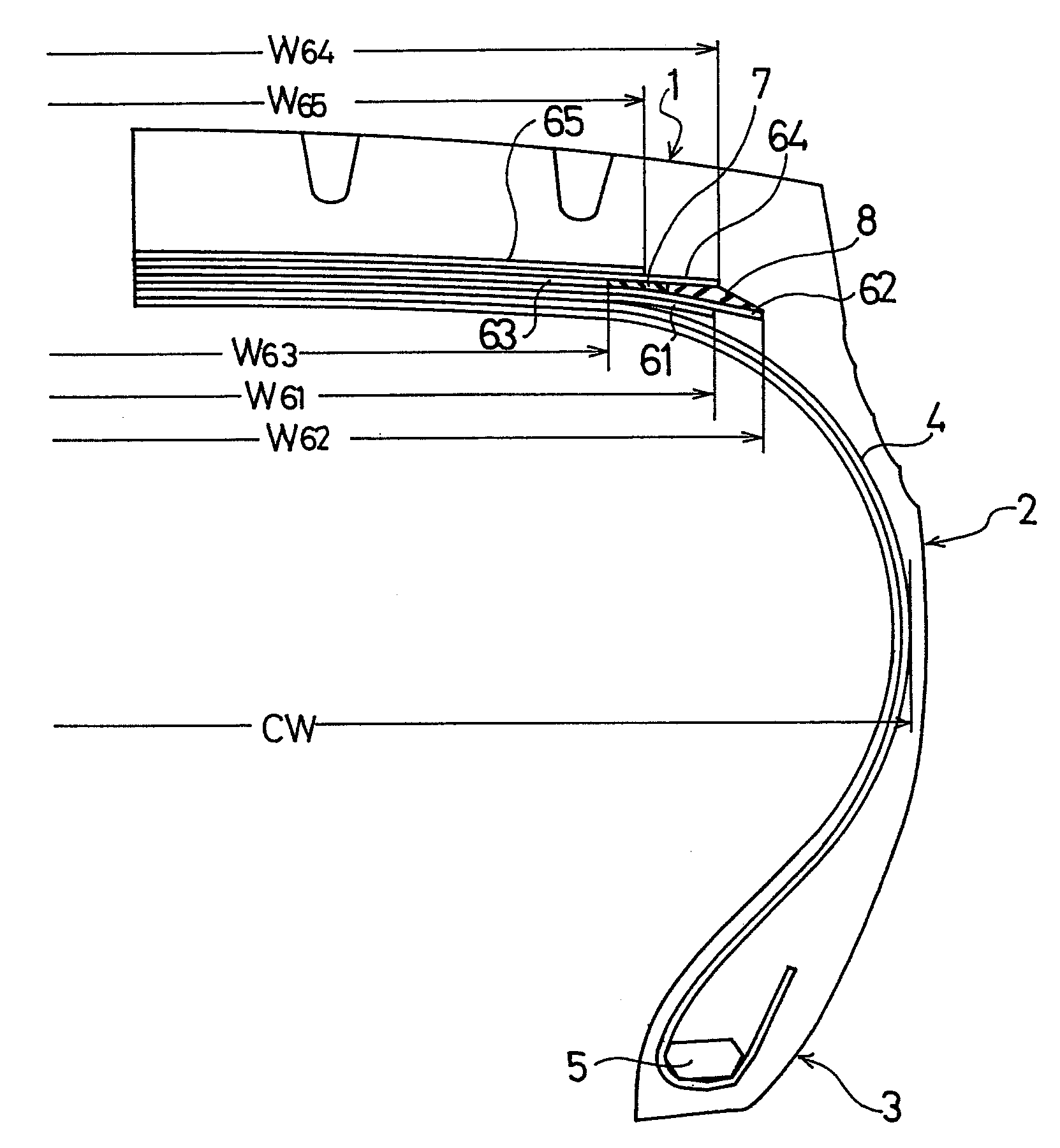

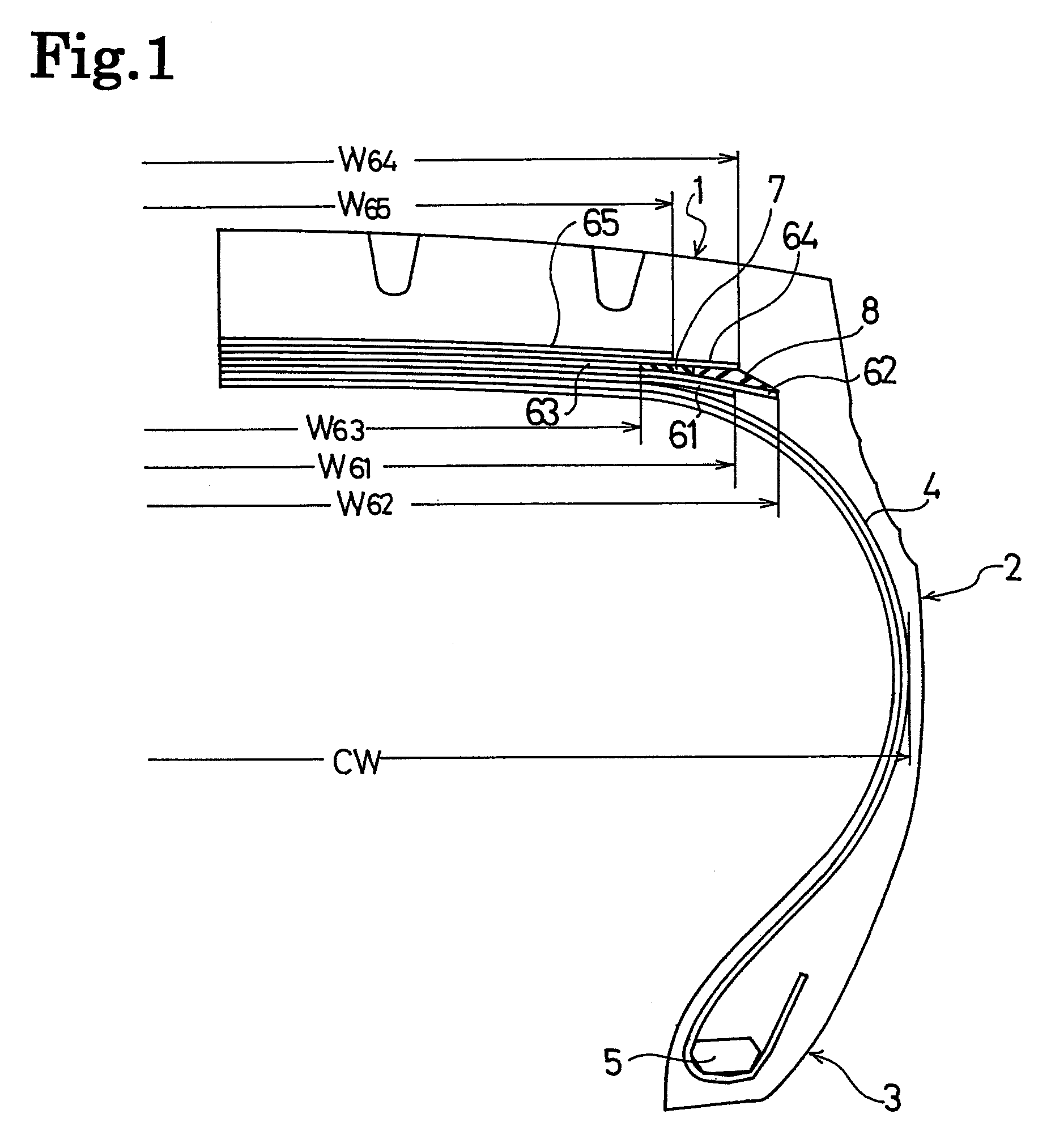

Pneumatic tire

ActiveUS20090277557A1Avoid fatigue fractureIncrease widthHeavy duty tyresHeavy duty vehicleEngineeringStress relaxation

The present invention provides a pneumatic tire that inhibits any fatigue rupture at an edge portion of a circumferential-direction reinforcing belt layer and also inhibits any separation at an edge portion of crossed belt layers. In the pneumatic tire, at least two crossed belt layers are disposed on the outer circumferential side of a carcass layer in a tread portion. At least one circumferential-direction reinforcing belt layer with a width smaller than those of the crossed belt layers is disposed between the crossed belt layers. Moreover, a stress relaxation layer of a rubber composition having a fixed thickness is disposed between the crossed belt layers while lying adjacent to an edge portion of and outside, in the width directions of, the circumferential-direction reinforcing belt layer.

Owner:THE YOKOHAMA RUBBER CO LTD

Multi-Function Condiment Container

ActiveUS20100270330A1Improve gripReduce and eliminate degradationClosuresLiquid transferring devicesAdhesiveFlange

A container for condiments includes a container portion having generally planar bottom, a generally parallel flange, a discharge spout, and a sidewall extending between the bottom and the flange. A generally planar cover portion is secured to the flange by an adhesive such that there exists a non-bonded region between the cover and the flange. At least one section of the flange in the non-bonded region is bent downwardly away from the cover portion to form therebetween a finger-access gap. The sidewall includes a front portion disposed below the spout and extending downwardly with respect thereto. The sidewall front portion is configured to prevent the spout from becoming displaced upwardly in response to the sidewall front portion being contacted by the rear portion of another container in a package of the containers.

Owner:H J HEINZ COMPANY BRANDS

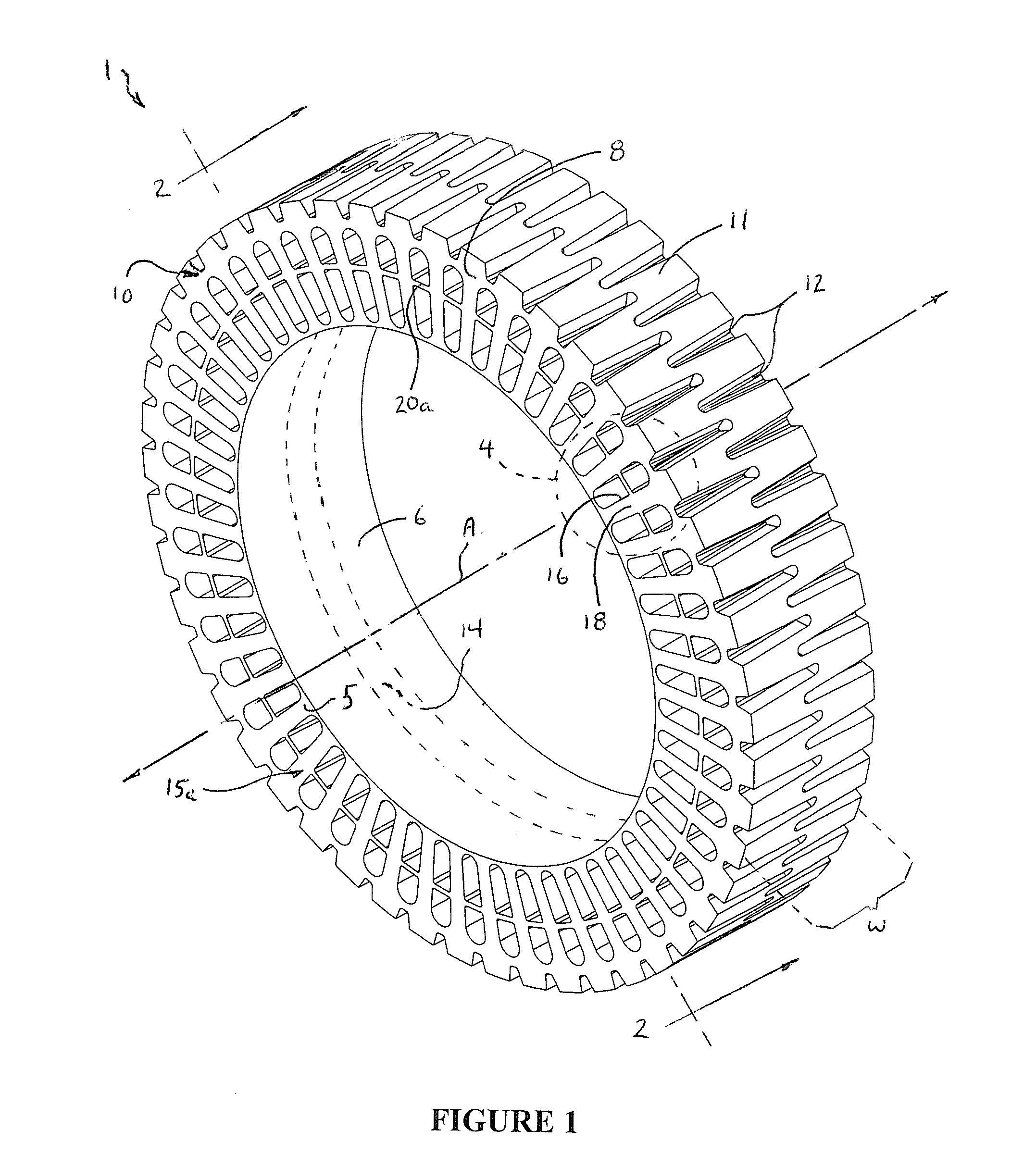

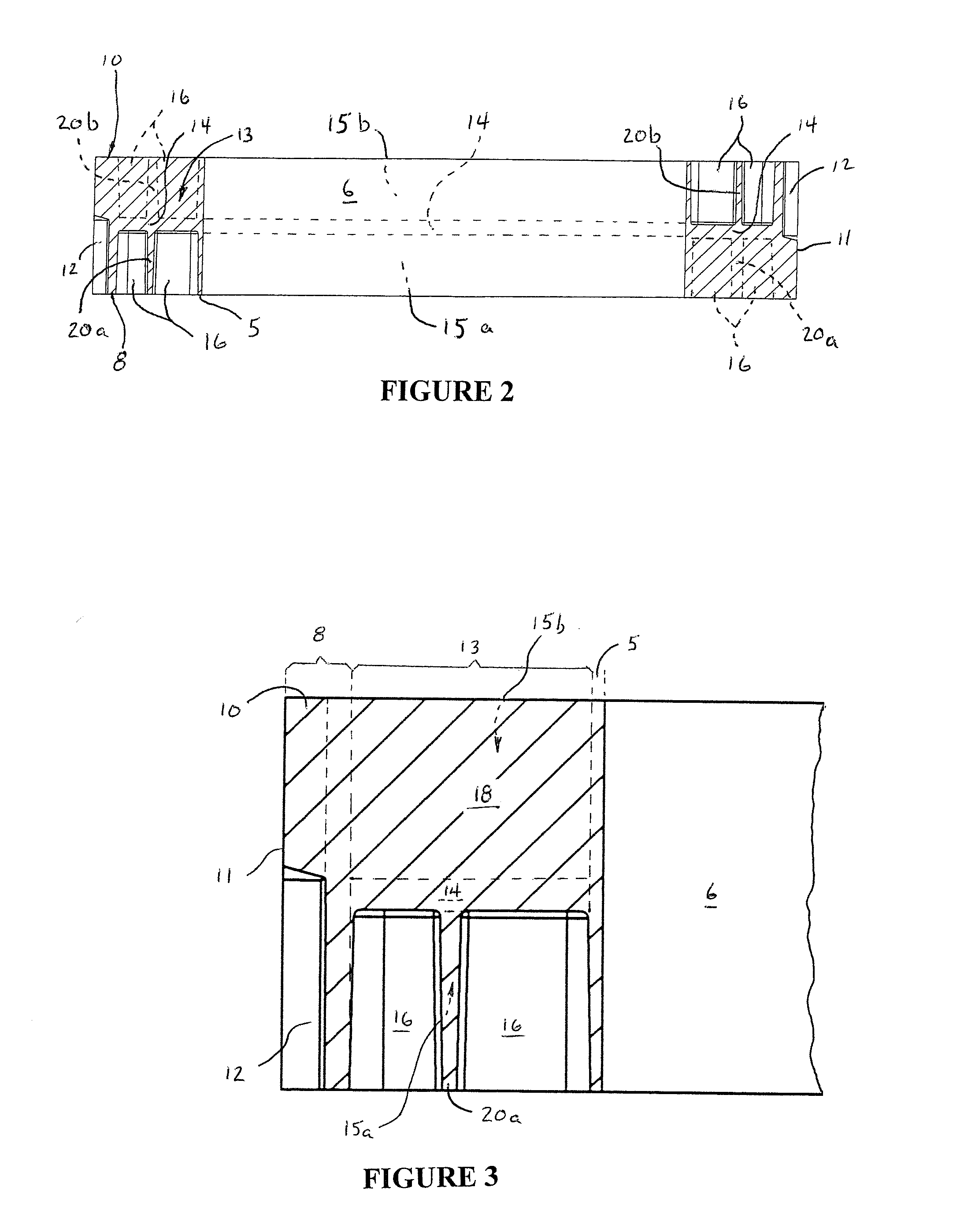

Metal wood club with improved hitting face

InactiveUS20050192118A1Variable thicknessIncreased bending stiffnessAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsEllipseEngineering

A golf club head having selectively oriented zones of relatively high flexural stiffness is disclosed. The hitting face is configured and dimensioned so that it includes an inner zone and a concentric intermediate zone. The inner zone has relatively high flexural stiffness and the intermediate zone has relatively lower flexural stiffness. The inner zone may have an elliptical shape or a substantially parallelogram shape. Preferably, the inner zone has a shape that comprises a major axis and a minor axis and the major axis aligns substantially in the direction of high heel to low toe. This arrangement of inner and intermediate zones creates a gradient of flexural stiffness in the direction of high toe to low heel and produces a desirable manipulation COR in that direction.

Owner:ACUSHNET CO

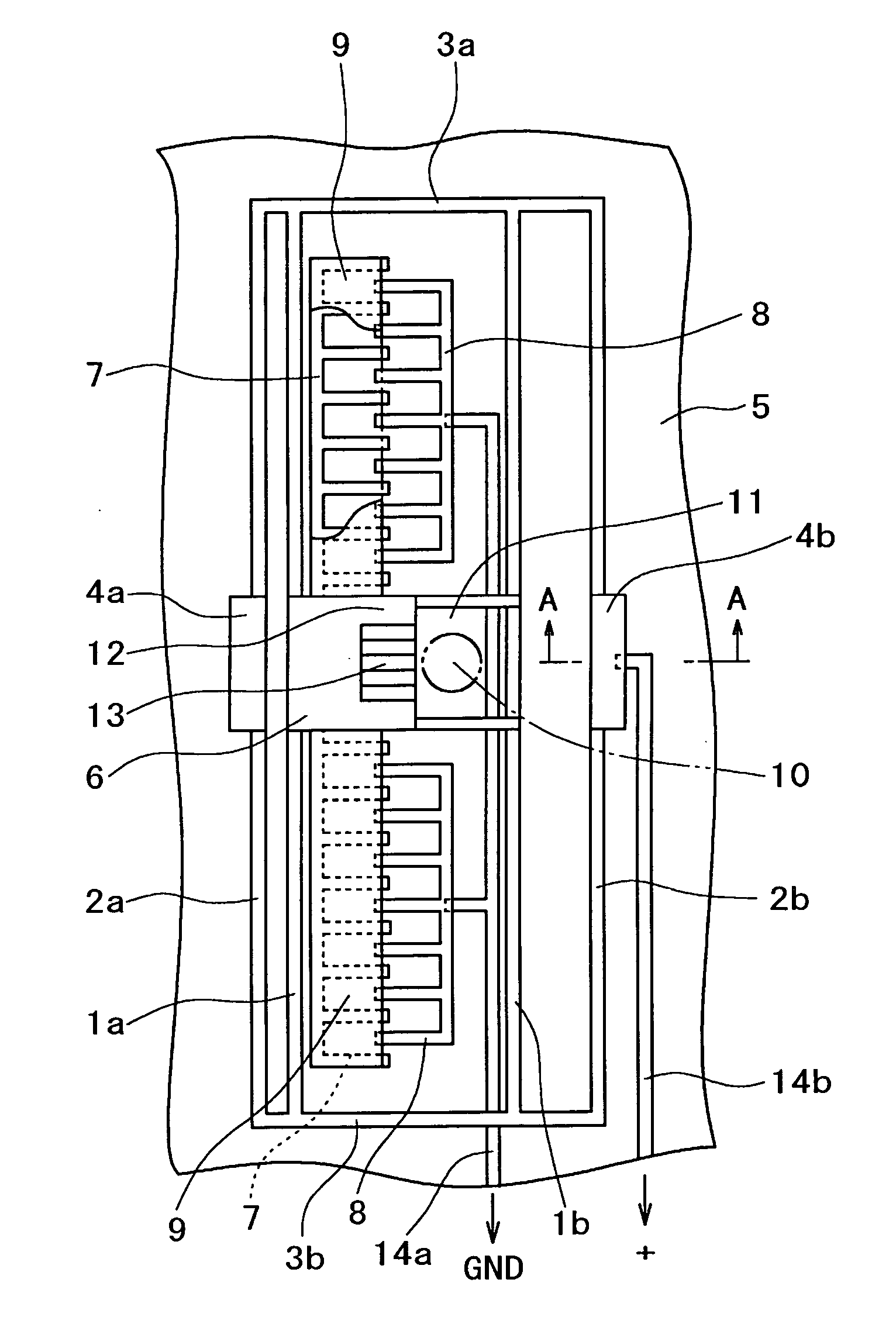

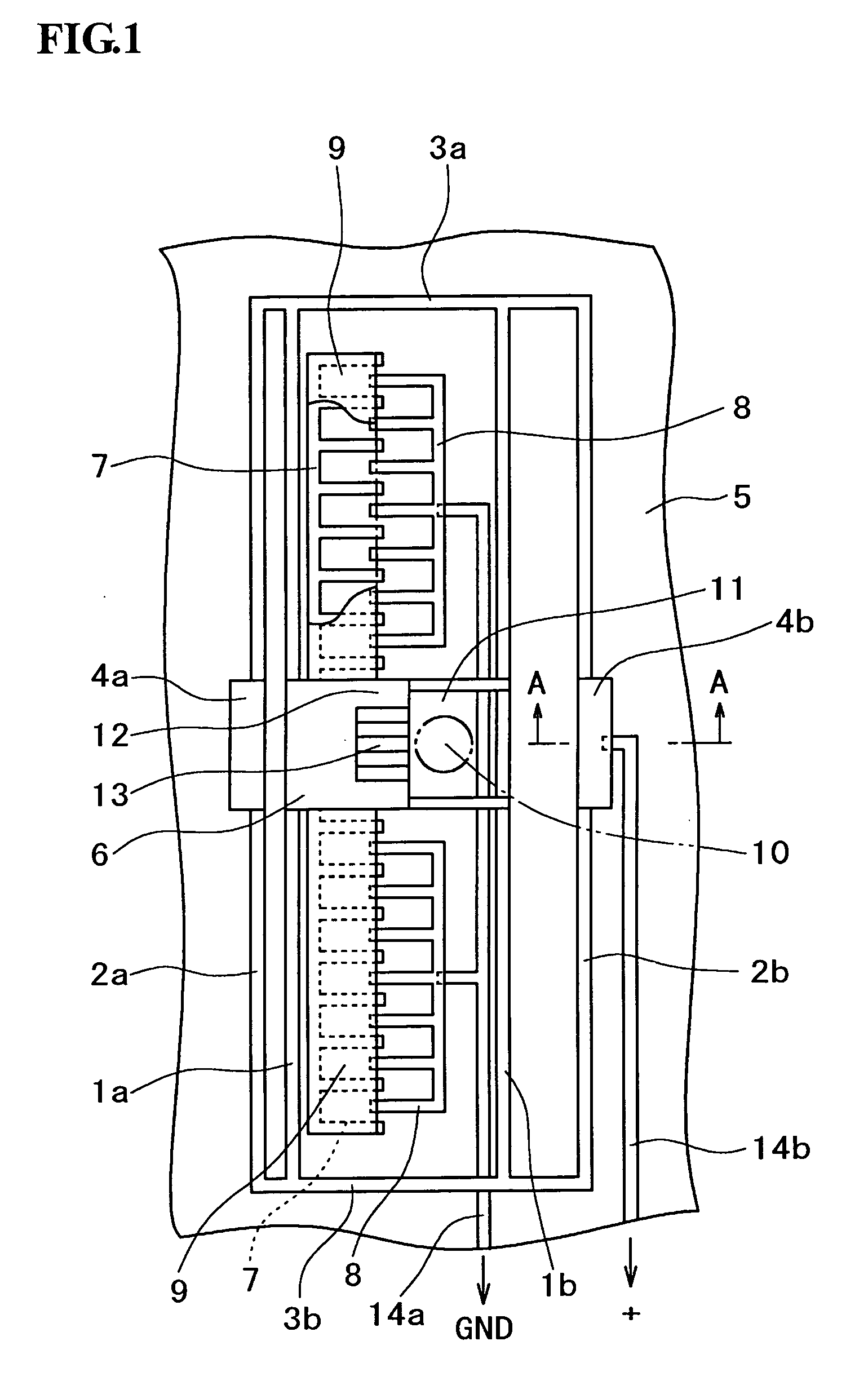

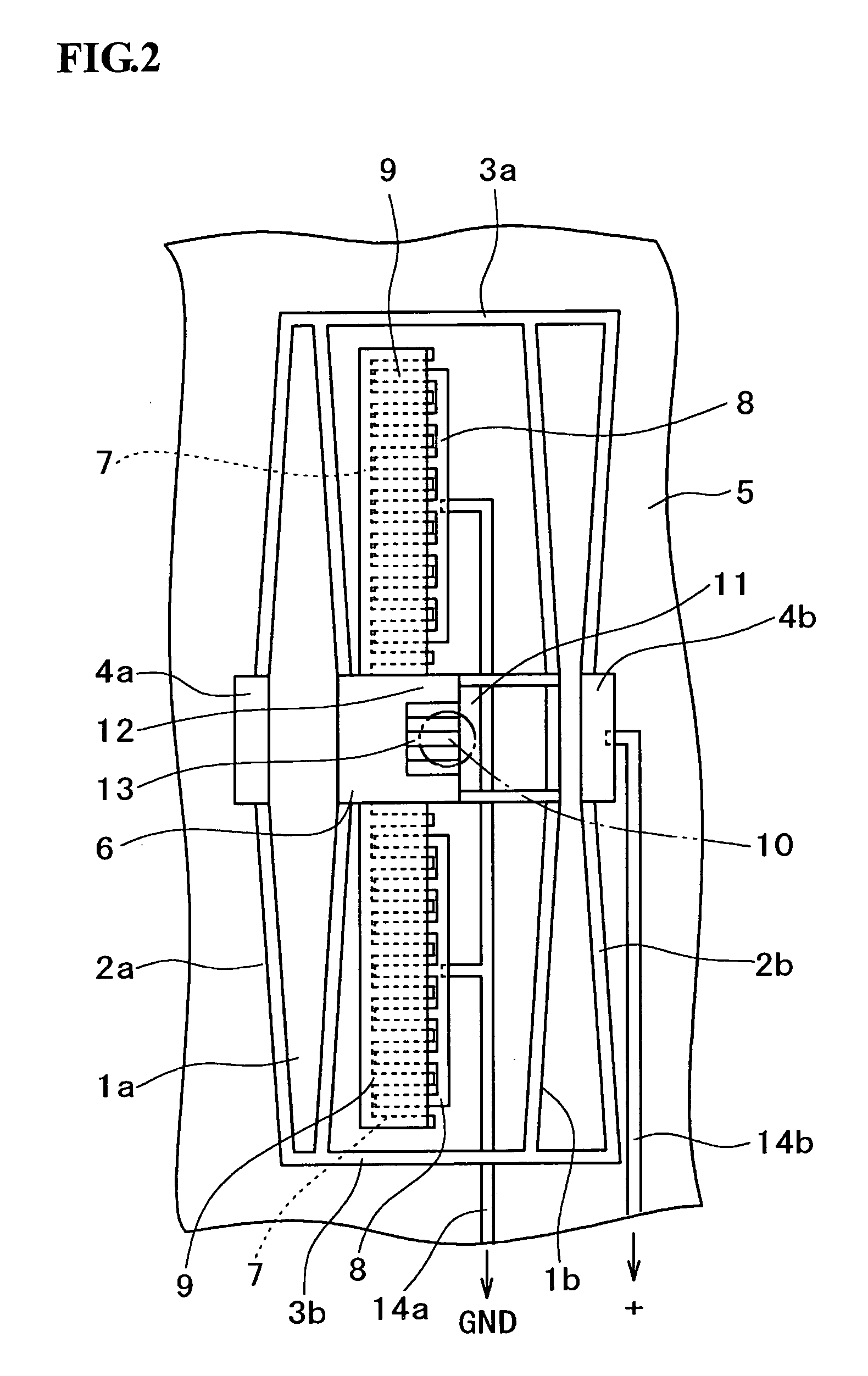

Electrostatic comb drive actuator, and optical controller using the electrostatic comb drive actuator

InactiveUS20050052723A1Preventive effectIncreased bending stiffnessPiezoelectric/electrostrictive devicesFlexible microstructural devicesComb driveEngineering

An electrostatic comb drive actuator, characterized in that plural outer suspended elastic beams 2a and 2b are disposed in parallel to and outside plural inner suspended elastic beams 1a and 1b disposed in parallel to each other; the ends of the inner suspended elastic beams and the outer suspended elastic beams on both sides are connected with end connecting beams 3a and 3b; the outer suspended elastic beams are supported at their centers on a board 5; the inner suspended elastic beams are connected with each other at their centers by means of a working section 6; a movable comb electrode 7 is supported on the working section; and a fixed comb electrode 8 is supported on the board.

Owner:MORITEX CORP +1

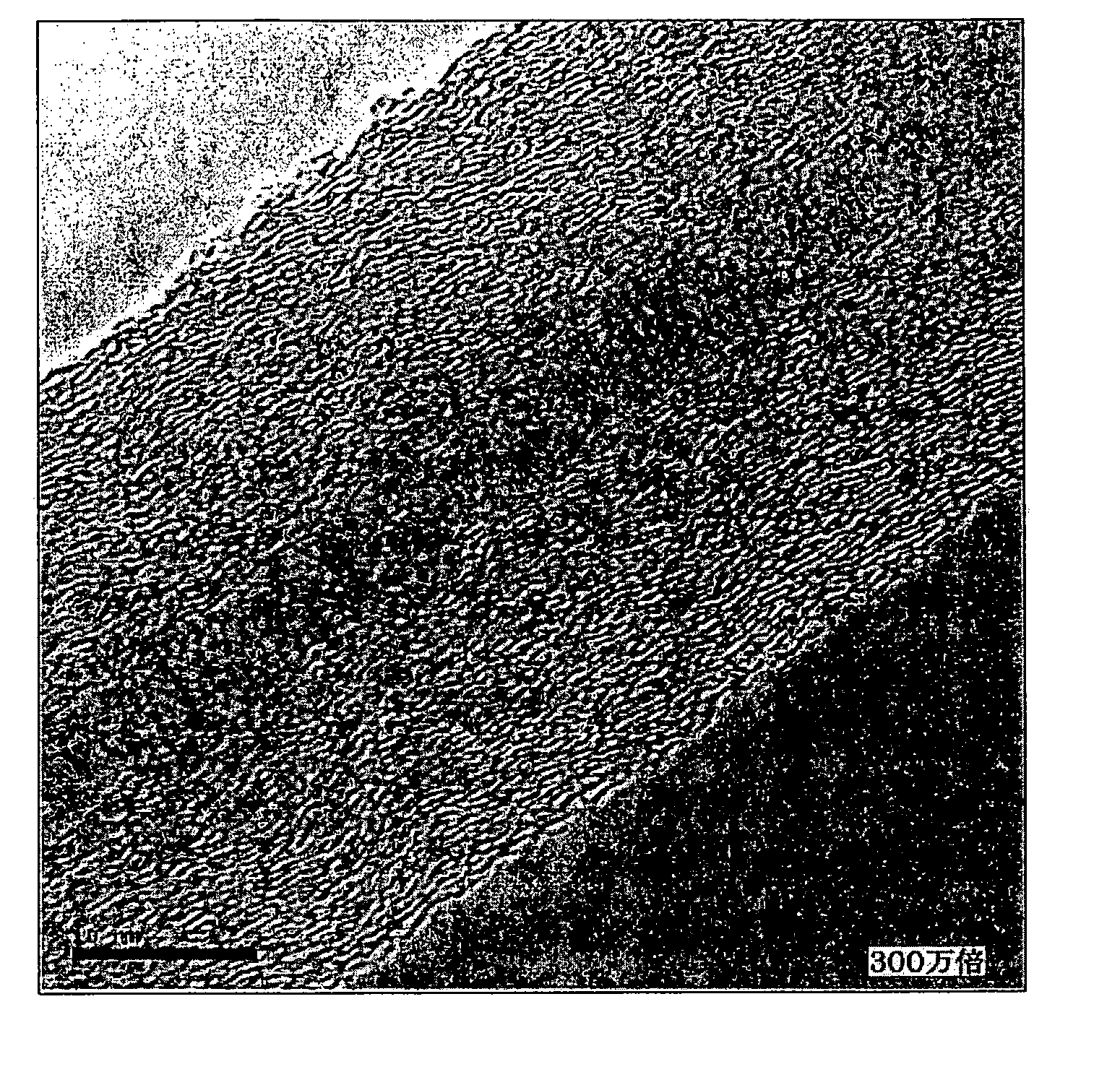

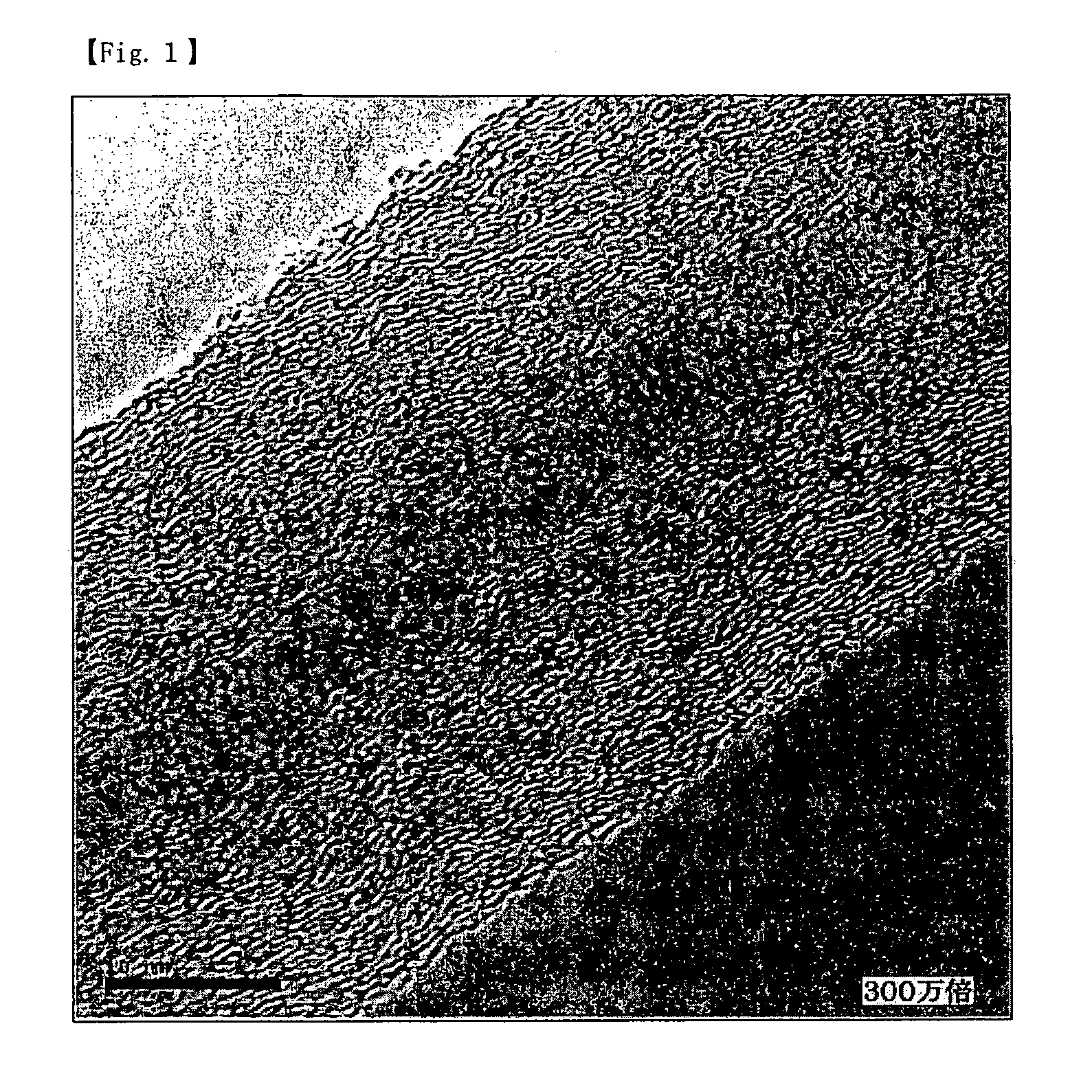

Ultrathin carbon fibers

InactiveUS20060062715A1Increased bending stiffnessSolving the Insufficiency of ElasticityMaterial nanotechnologyCarbon compoundsAspect ratioRaman spectroscopy

An ultrathin carbon fiber having two or more tubular graphene sheets layered is disclosed. The tubular graphene sheets has a polygonal cross section in a direction substantially orthogonal to the axis of the ultrathin carbon fibers, a diameter of the fiber is 15 to 100 nm, an aspect ratio of the carbon fiber is not more than 105, and ID / IG of the carbon fiber as determined by Raman spectroscopy is not more than 0.2.

Owner:HODOGAYA KAGAKU IND

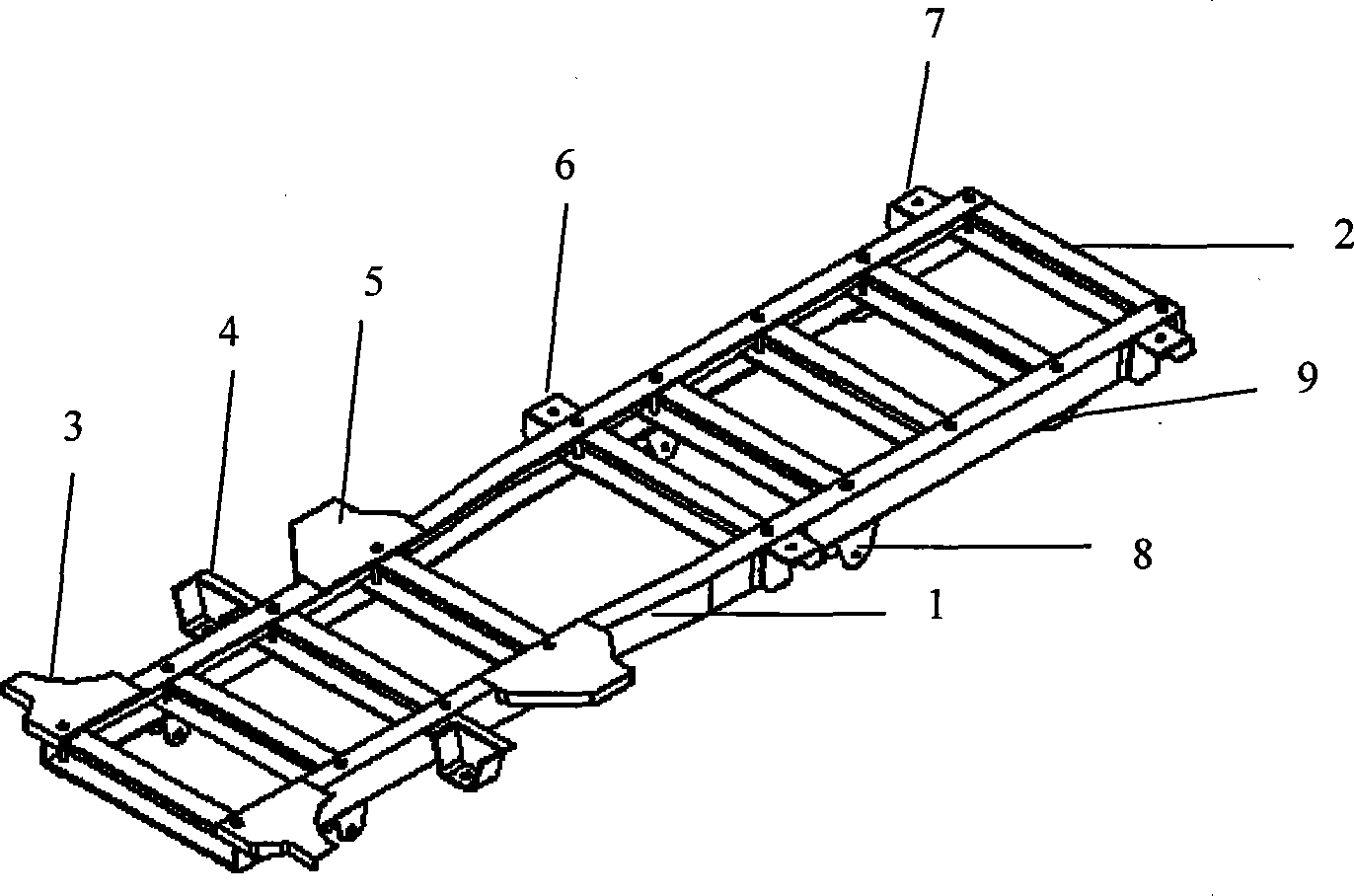

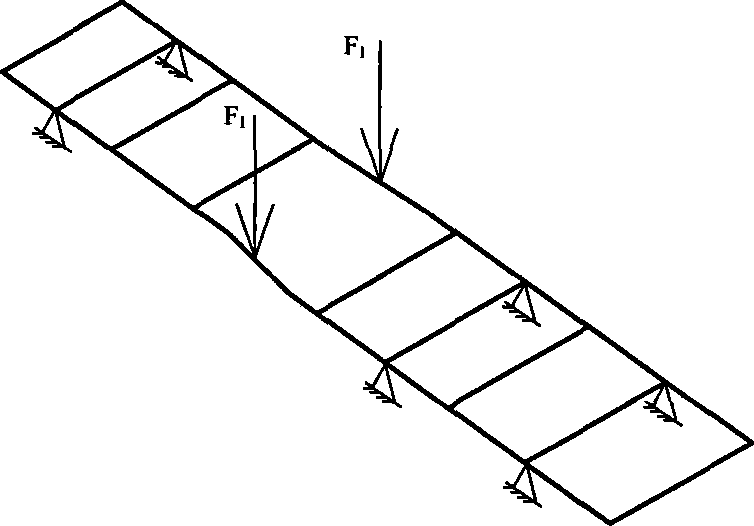

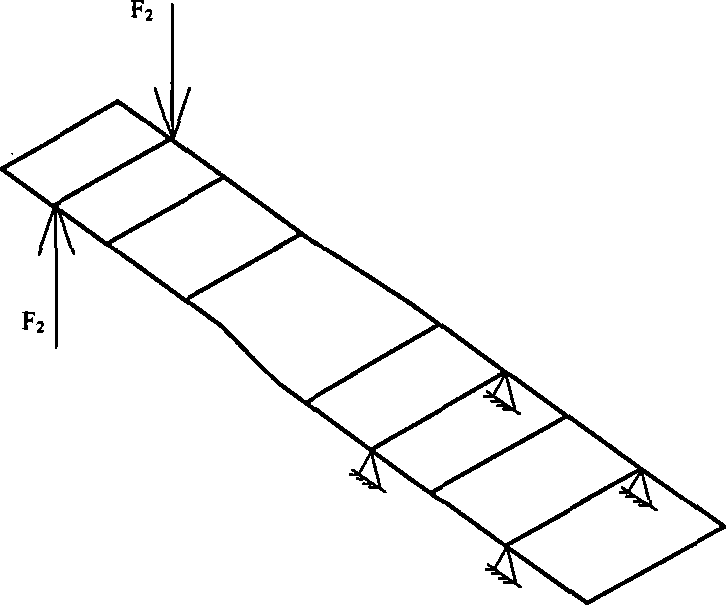

Optimum design method of non-bearing frame structure of light vehicle

InactiveCN104112050AIncreased bending stiffnessIncrease stiffnessSpecial data processing applicationsVehicle frameData file

The invention provides an optimum design method of a non-bearing frame structure of a light vehicle. The optimum design method comprises the steps of establishing a three-dimensional geometrical model of the original frame structure of the light vehicle by use of SolidWorks software and outputting the model in the IGES (Initial Graphics Exchange Specification) data file format, thereby obtaining the IGES model of the frame structure, next, reading the IGES model of the frame structure in Hypermesh software, performing geometrical processing and dividing finite element meshes by use of the Hypermesh software, and performing topological optimization on the cross beam structure of the frame by use of the structure optimization function of the Hypermesh software without changing the structural forms of the longitudinal beam and the attached seats of the frame, thereby realizing the optimum design of the arrangement position and the structural form of the cross beam structure. The optimum design method of the non-bearing frame structure of the light vehicle is capable of improving the bending rigidity and torsional rigidity of the frame of the light vehicle and the inherent frequency of the frame structure without increasing the weight of the frame structure, thereby ensuring that the frame has relatively high overall rigidity and improving the reliability, security, operation stability and vibration property of the vehicle.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Balloon catheter tapered shaft having high strength and flexibility and method of making same

ActiveUS8382738B2Low bending stiffnessIncrease pressureStentsBalloon catheterBalloon catheterUltimate tensile strength

A catheter having an elongated shaft with a tubular member which forms at least a portion of the shaft and which is formed of a biaxially oriented thermoplastic polymeric material, and a method of forming the catheter shaft by radially and longitudinally expanding the tubular member to biaxially orient the polymeric material, and, in one embodiment, tapering the tubular member to form a bending stiffness transition. A catheter of the invention has an improved combination of low bending stiffness, high rupture pressure, and high tensile strength, for improved catheter performance.

Owner:ABBOTT CARDIOVASCULAR

Composite metal wood club

InactiveUS20060293118A1Increased bending stiffnessIncrease elasticityAnalysing solids using sonic/ultrasonic/infrasonic wavesGolf clubsSurface layerHigh density

A metal wood golf club head adapted for attachment to a shaft, comprising of a body portion and a crown portion, each portion constructed of a different density material. Combining a high-density material in the body portion, with a low-density material in the crown portion, creates an ultra-low center of gravity relative to the geometric face center, resulting in higher launch angles and spin rate ratios. The material for the crown portion is preferably a composite. The crown portion comprises an inner surface layer of a vibration dampening material. The transverse surfaces of the crown and body portions creating a gap that is filled with a shock absorption material such as putty or a rubber based structural adhesive.

Owner:ACUSHNET CO

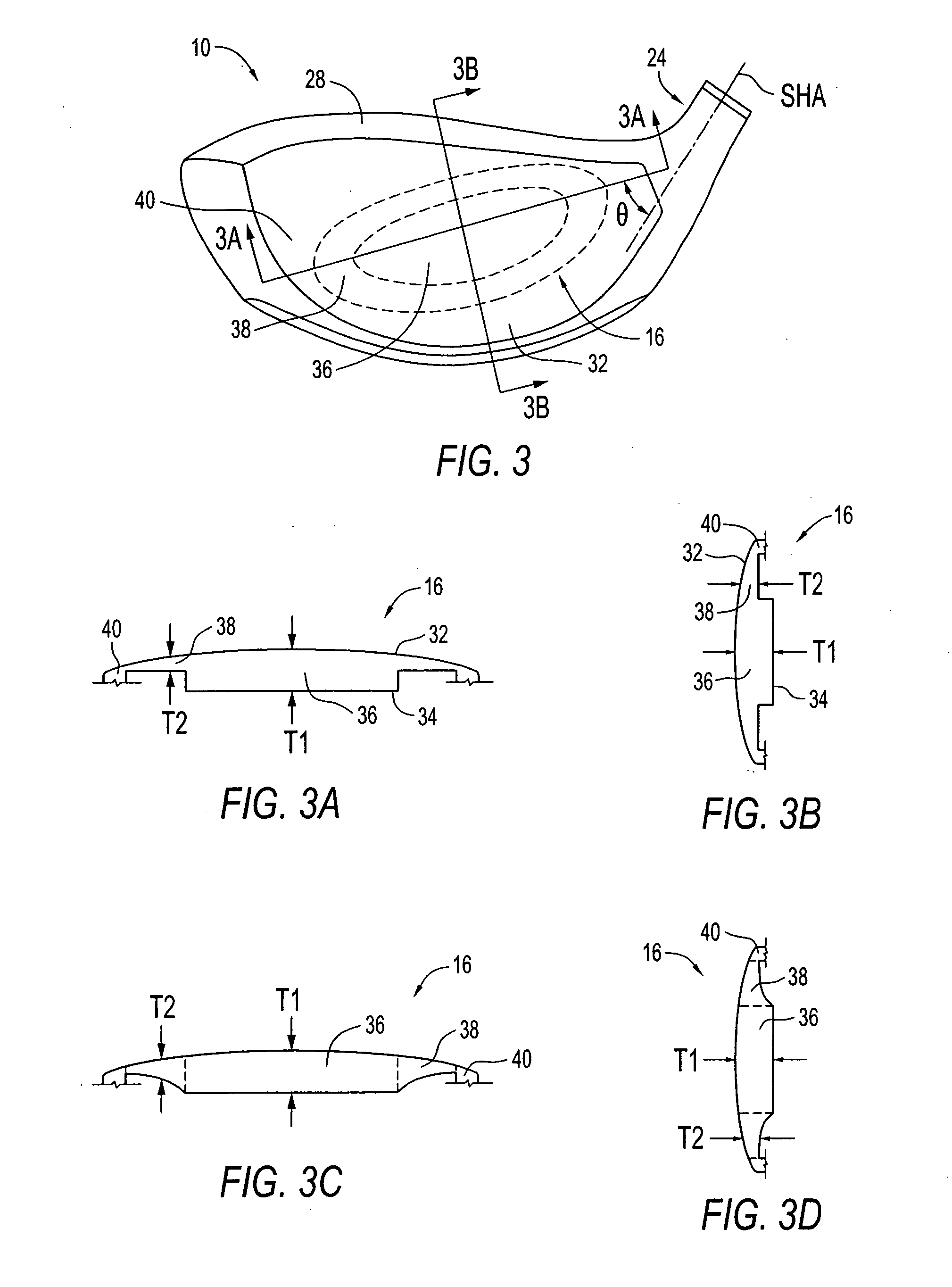

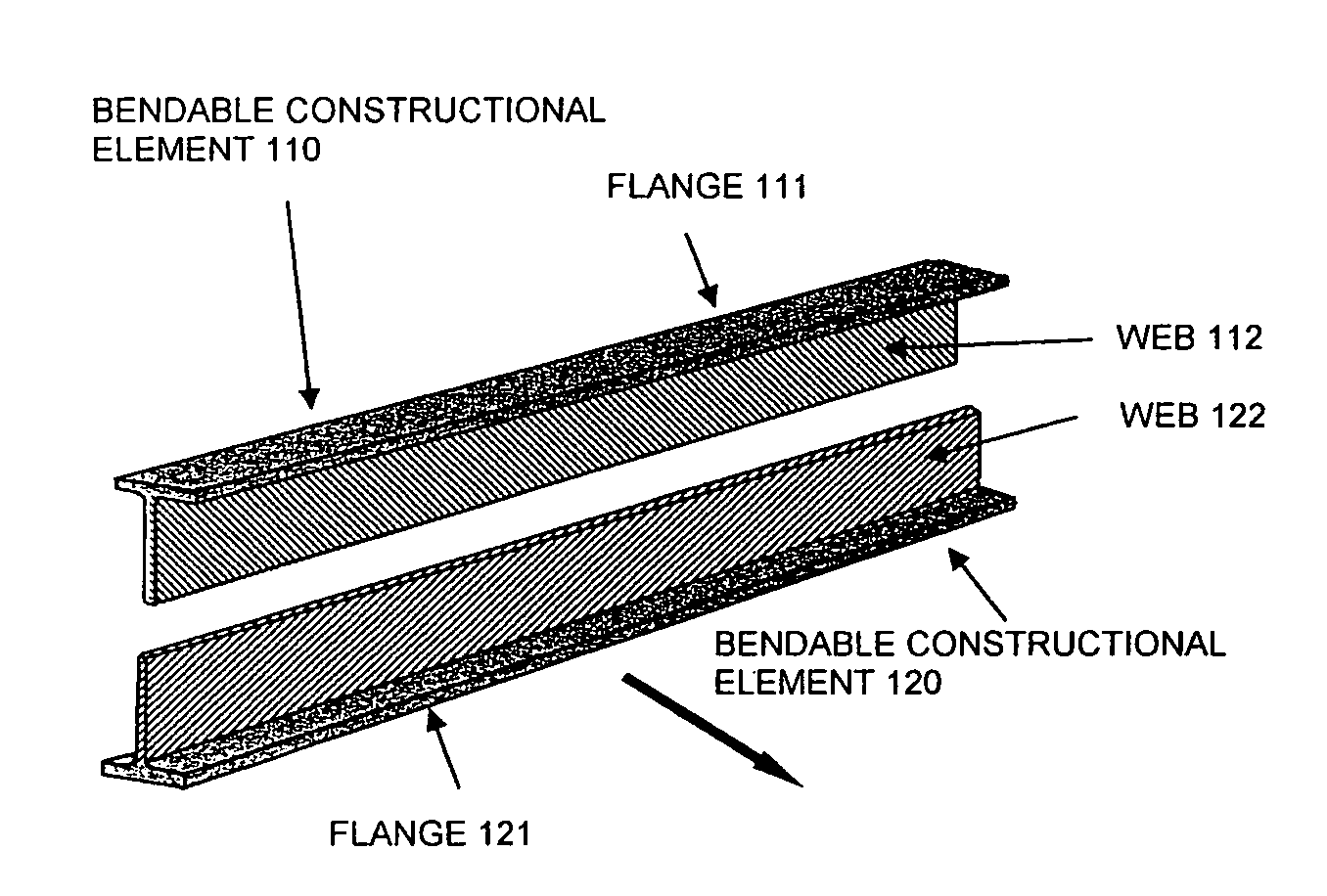

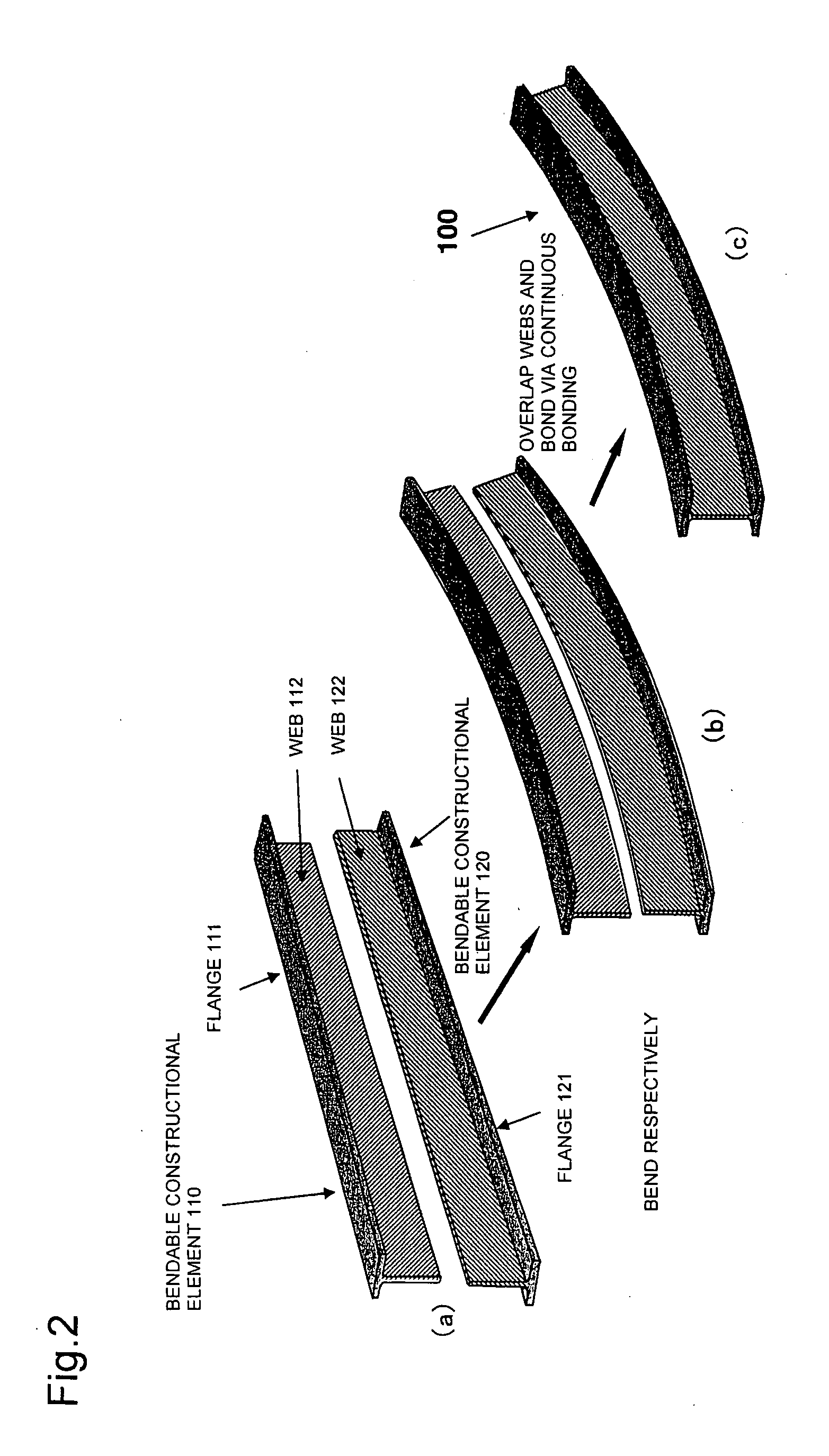

Method for continuously forming structural member

ActiveUS20080099131A1Increased bending stiffnessLower areaMechanical working/deformationGirdersFiberEpoxy

The invention provides an improved method for forming a composite material mainly composed of carbon fiber. It is difficult to form an H-shaped structural member formed of a prepreg material having carbon fiber fabric impregnated with epoxy resin into a member having curvature. Thus, the structural member is divided into two bendable constructional elements 110 and 120, which are bent to given curvature then adhesively-bonded to form a structural member having curvature.

Owner:JAMCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com