Patents

Literature

880results about How to "Increased torsional stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

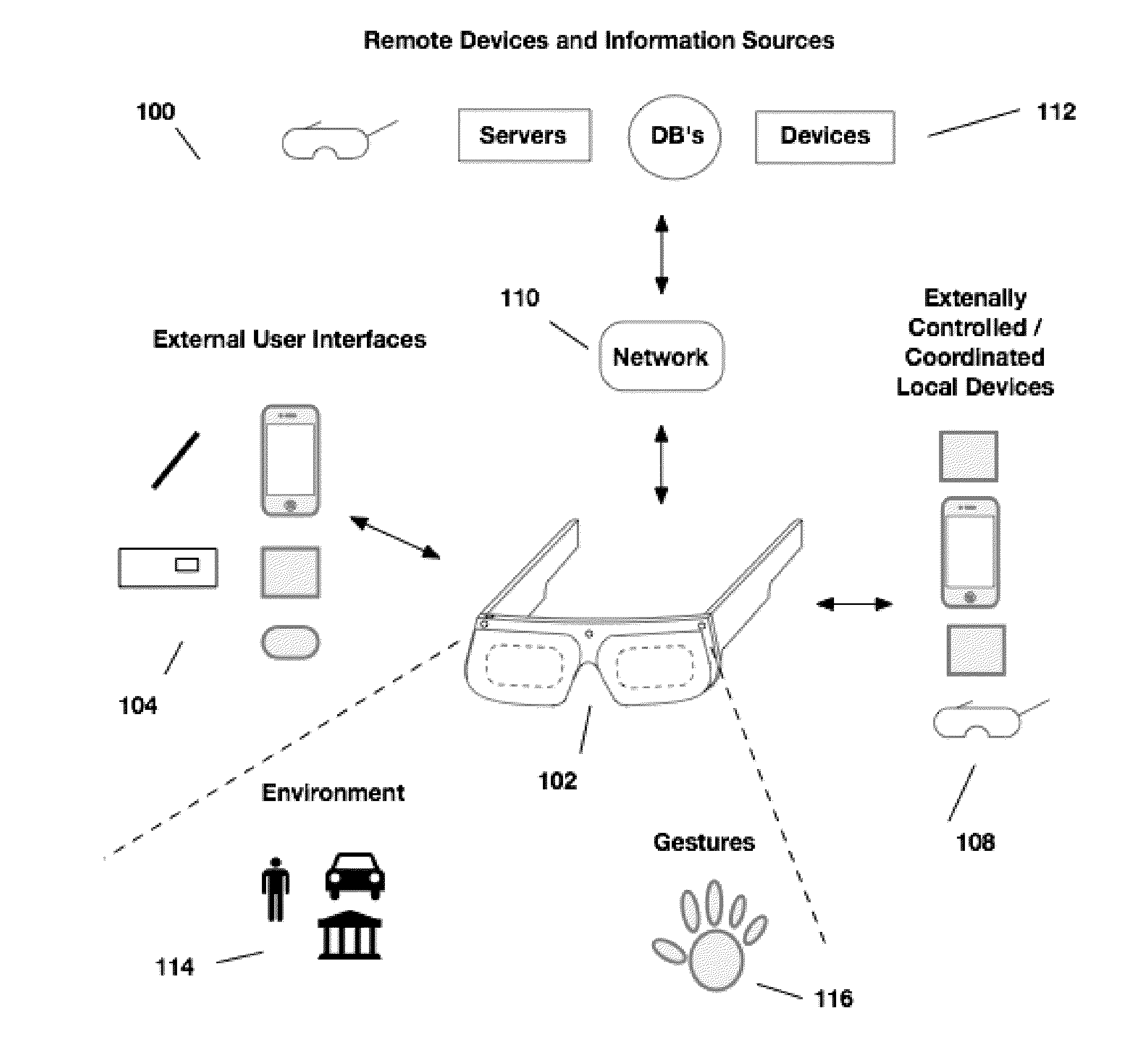

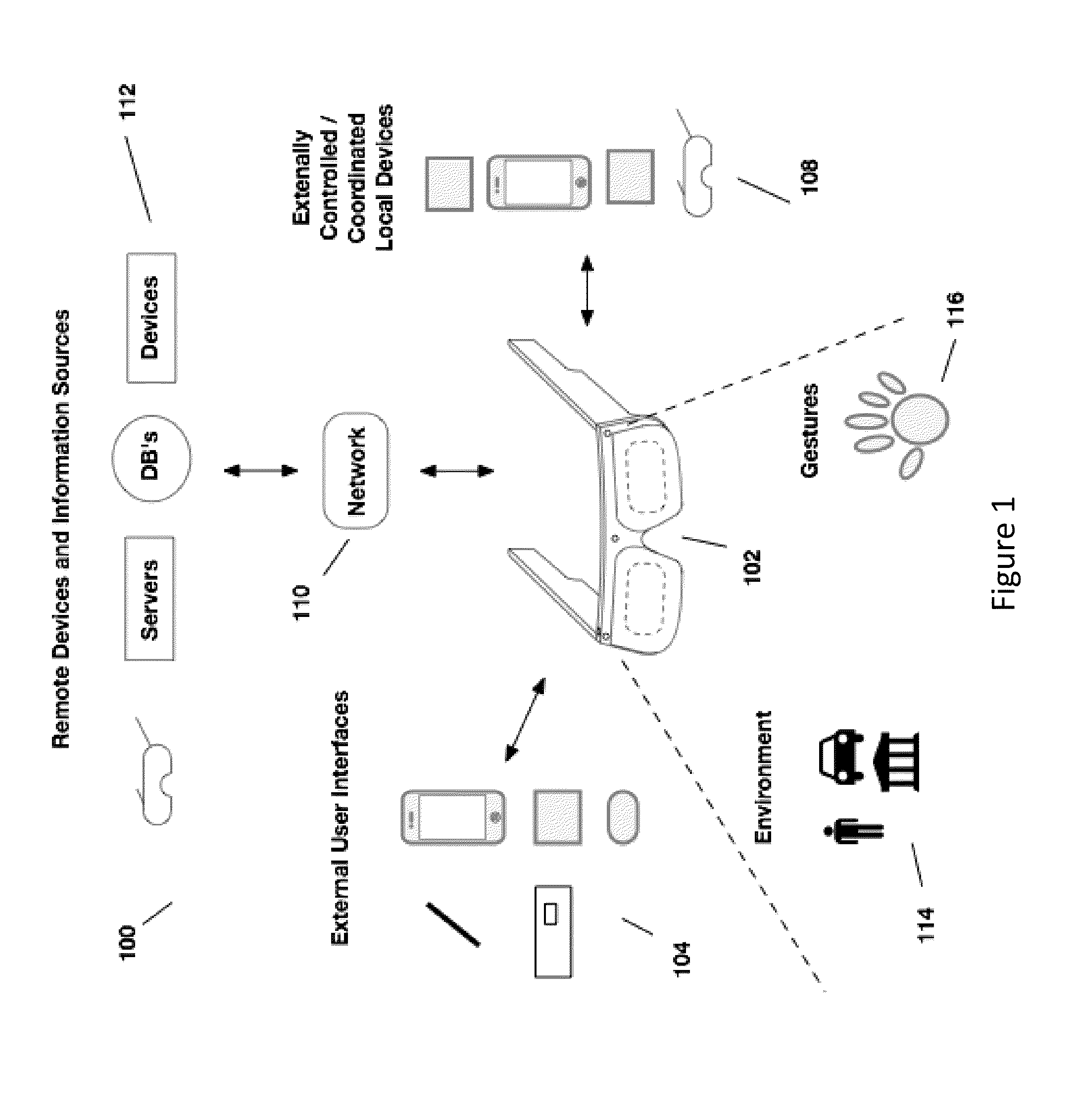

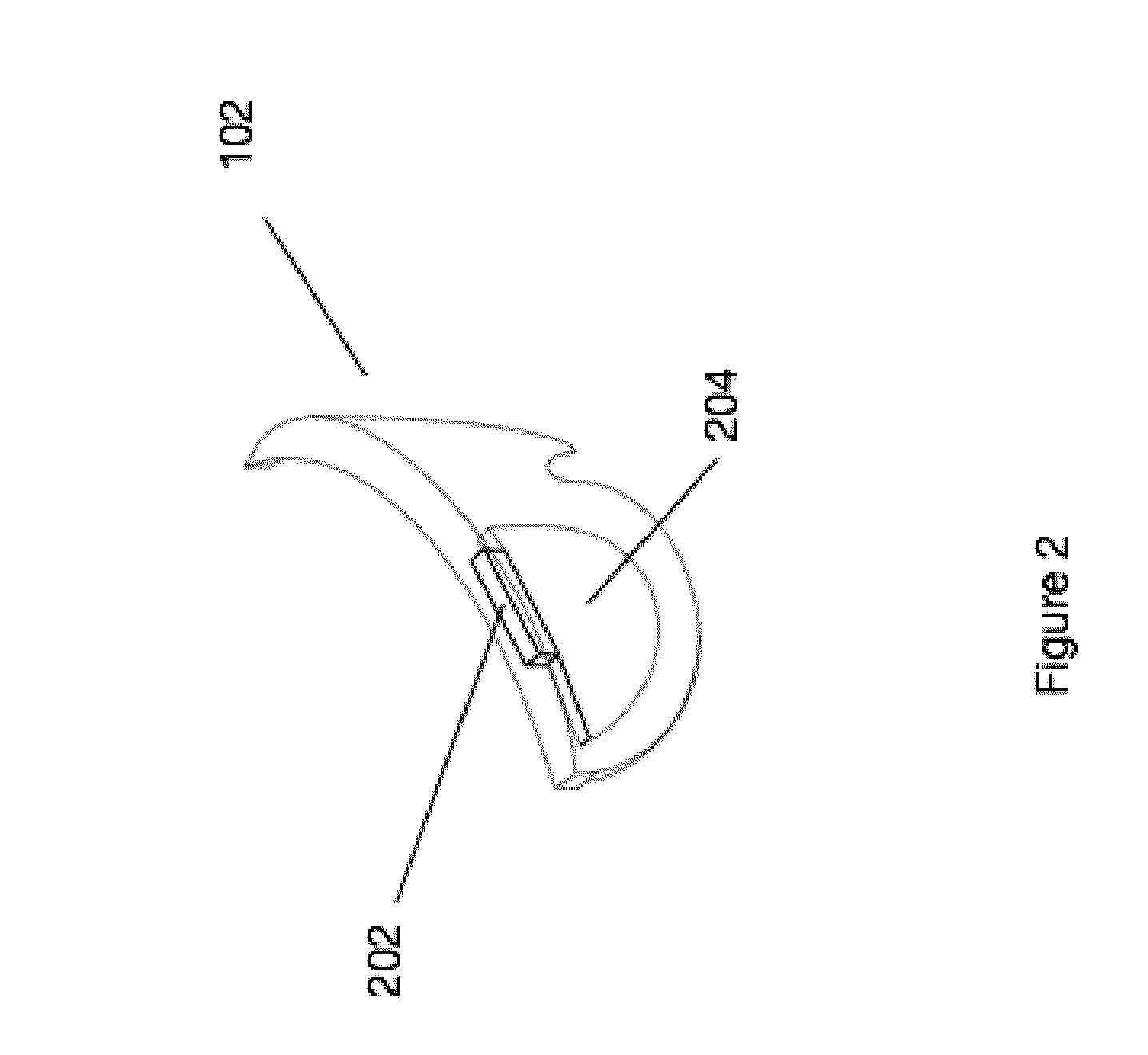

Head worn computer display systems

ActiveUS20160246055A1Improve cooling effectIncrease airflowDetails for portable computersImage data processingOptical mountDisplay device

Aspects of the present disclosure relate to mounting electronics and optical systems in head-worn see-through computer displays. In embodiments, a head worn computer includes an optical chassis with a rigid open box structure configured to provide a stable optical mounting reference plane and a plurality of image source reference planes. The head worn computer further includes a first image source mounted on one of the image source reference planes to project first image light through a first hole in the optical mounting reference plane and a second image source mounted on a second of the image source reference planes and configured to project second image light through a second hole in the optical mounting reference plane. An outer frame holds the optical chassis such that, when worn by a user, the first and second image light is aligned with the eyes of the user.

Owner:OSTERHOUT GROUP INC

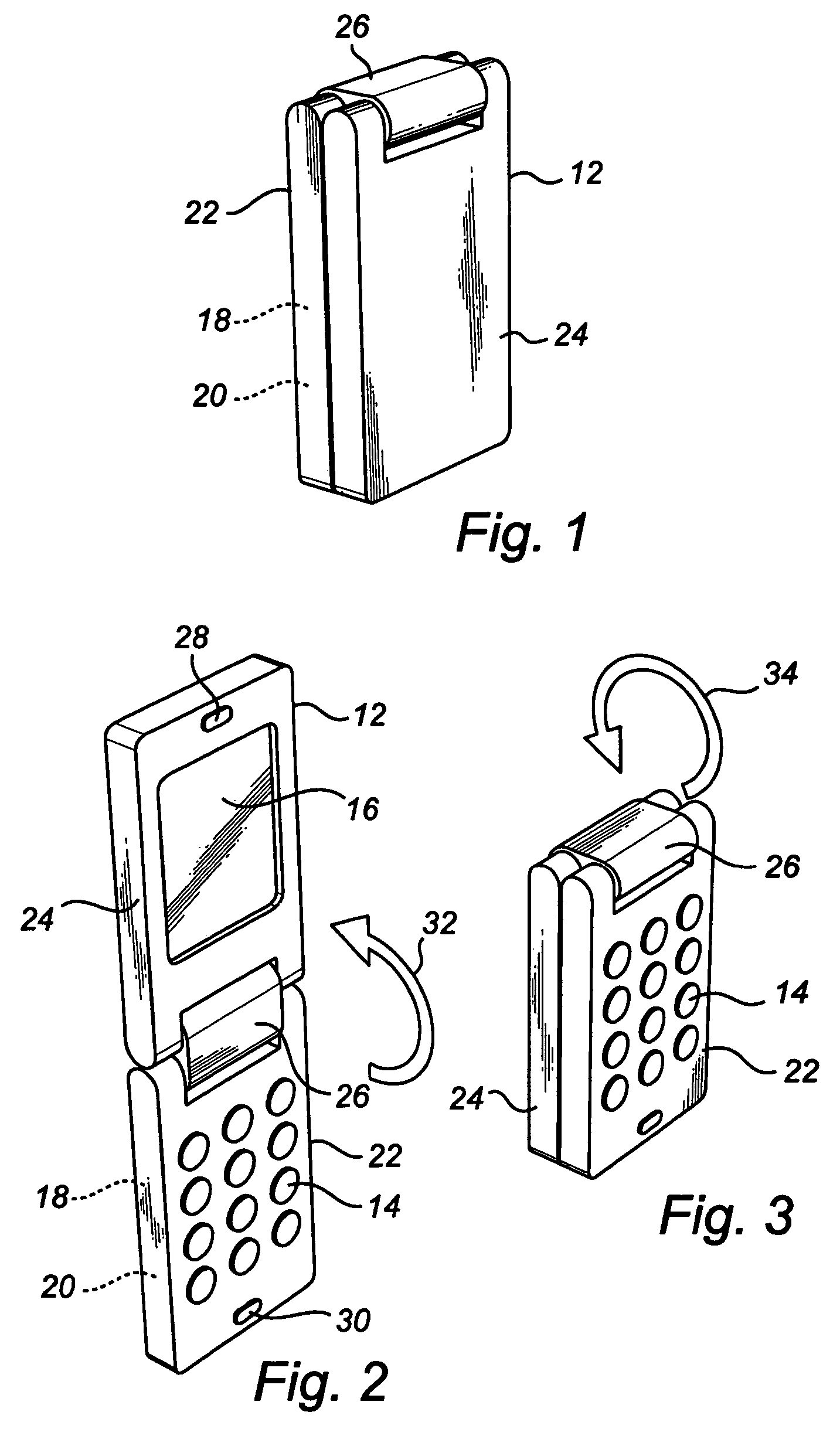

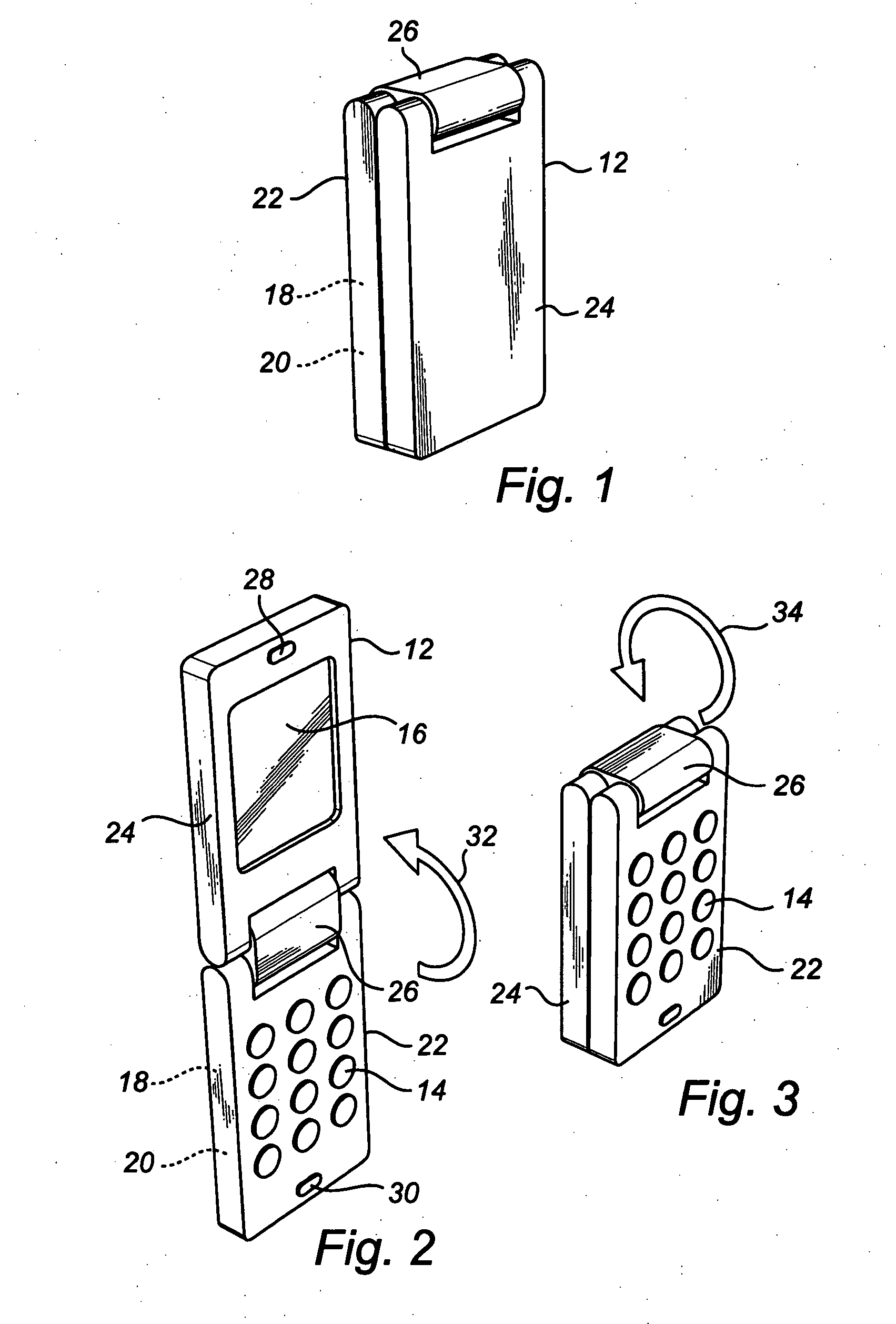

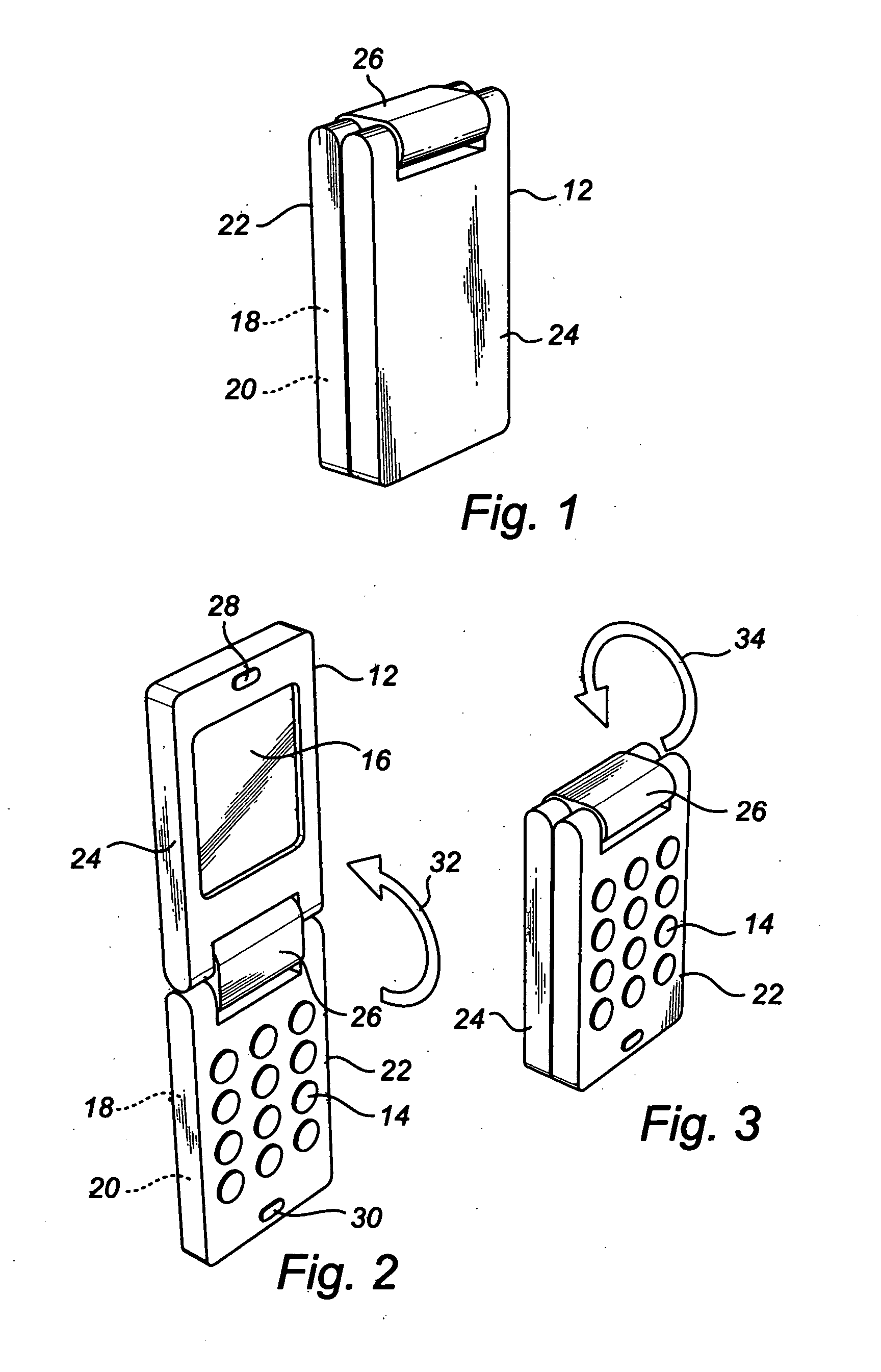

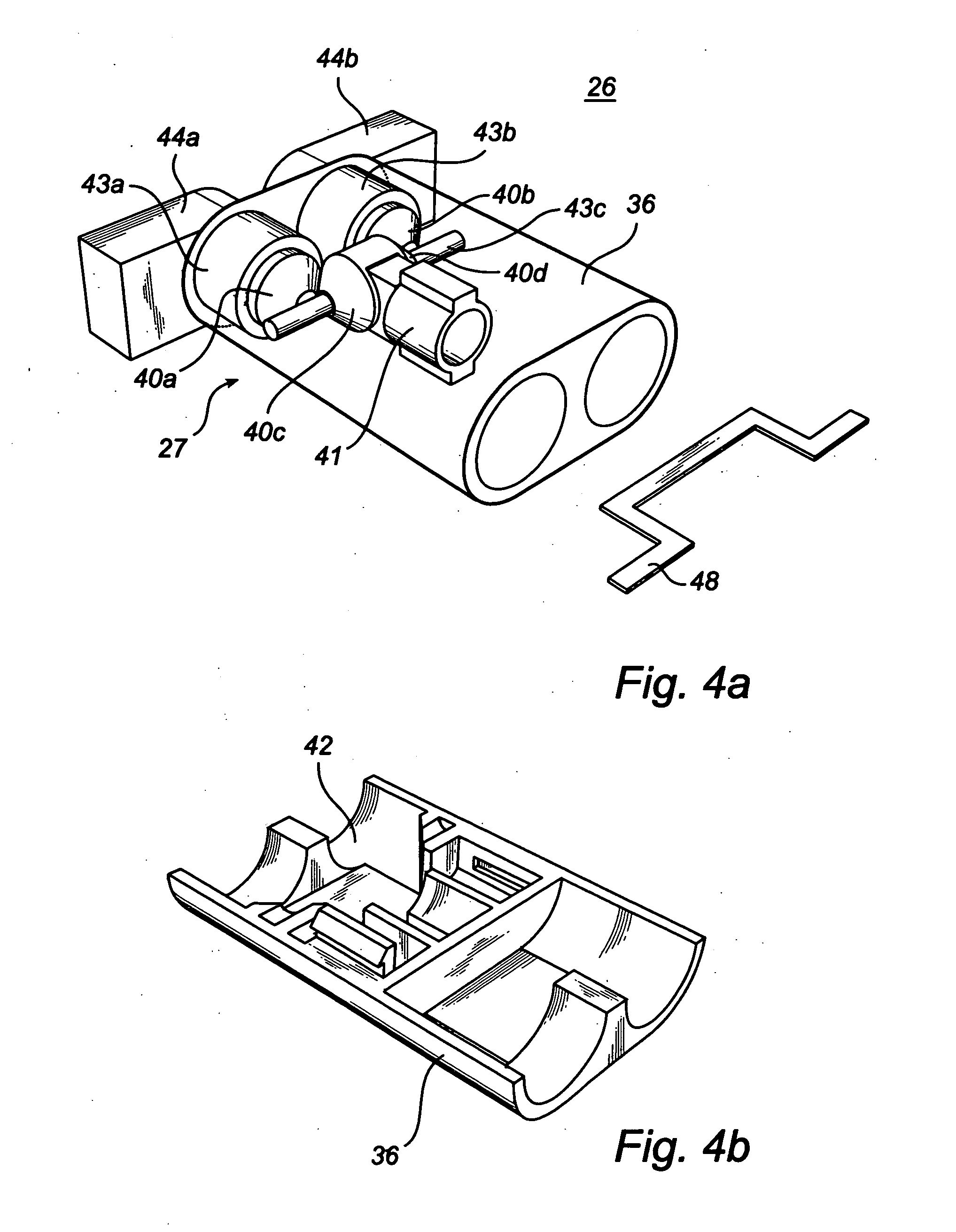

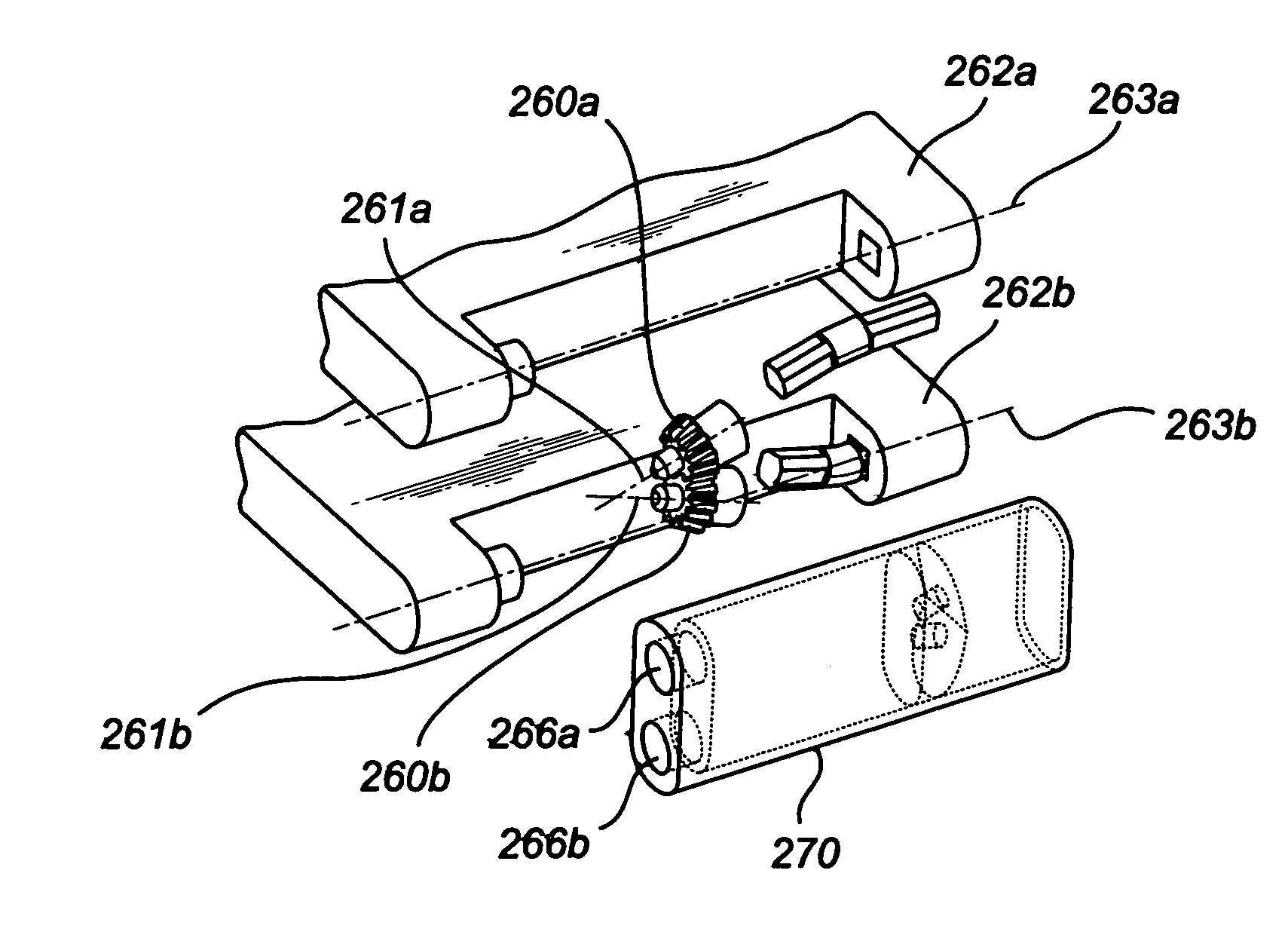

Mobile communications device with synchronising hinge

InactiveUS7512426B2Reduce thicknessRisk minimizationTelevision system detailsDevices with multiple display unitsTransceiverDisplay device

The invention relates to a mobile communications device comprising a housing, a transceiver in the housing, a keypad connected to the housing, and a display connected to the housing, wherein the housing comprises a first section movably connected to a second section of the housing by a multi-axis hinge, wherein a first axis of rotation of the hinge is provided at the first section of the housing and a second offset axis of rotation of the hinge is provided at the second section of the housing, and wherein the hinge comprises means for synchronizing rotation of the first and second sections relative to the hinge through a path of about 360 degrees. The invention further relates to a hinge for use therein.

Owner:NOKIA TECH OY

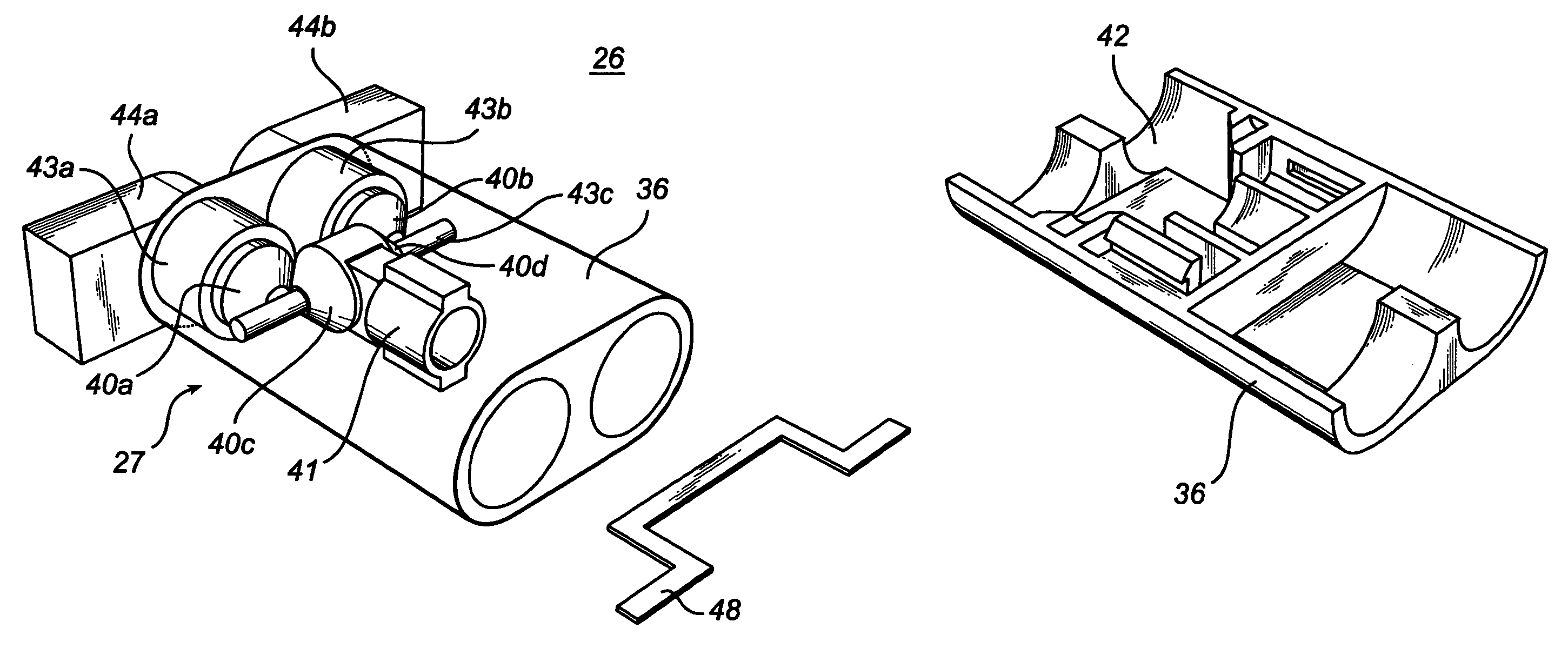

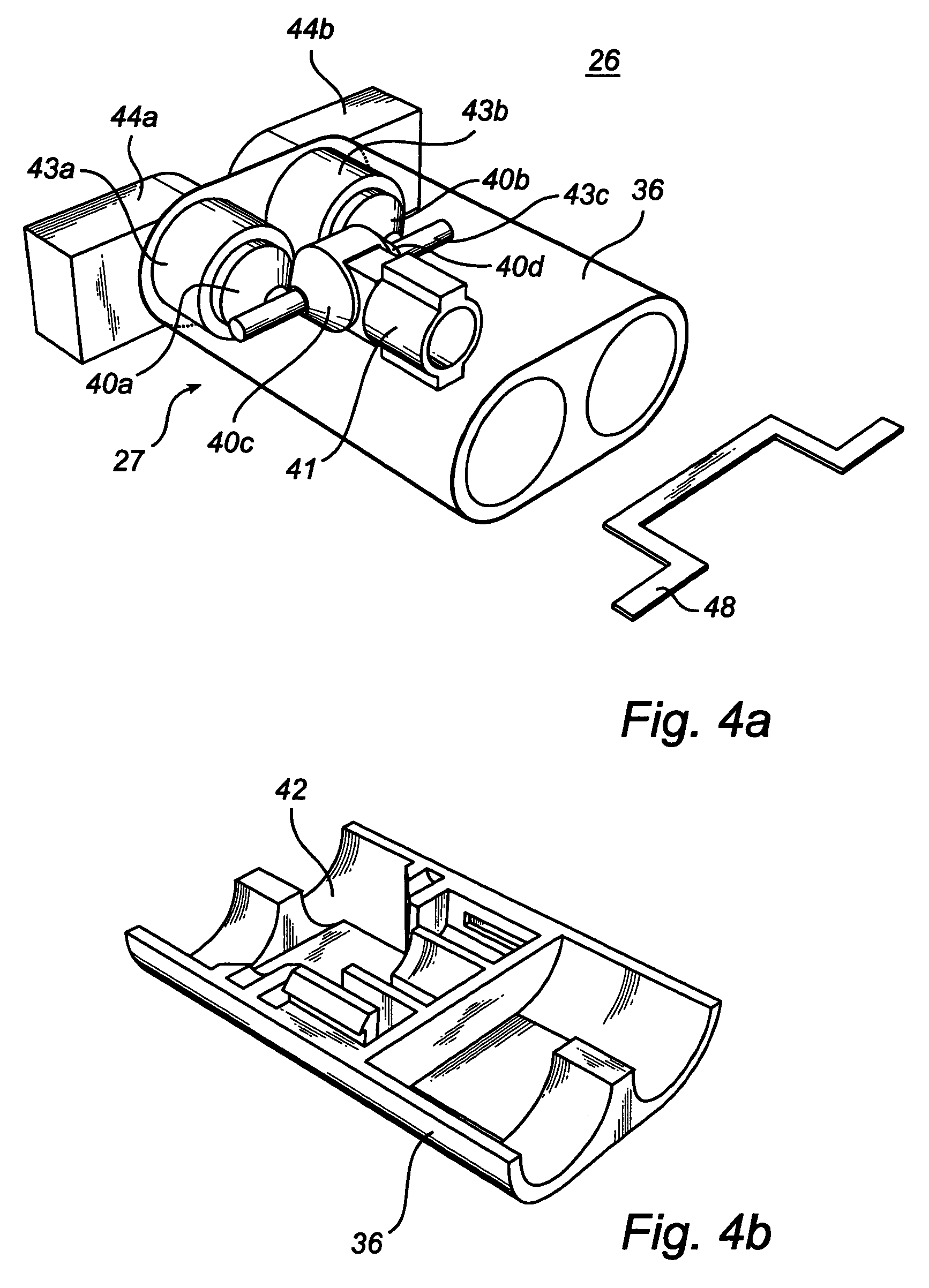

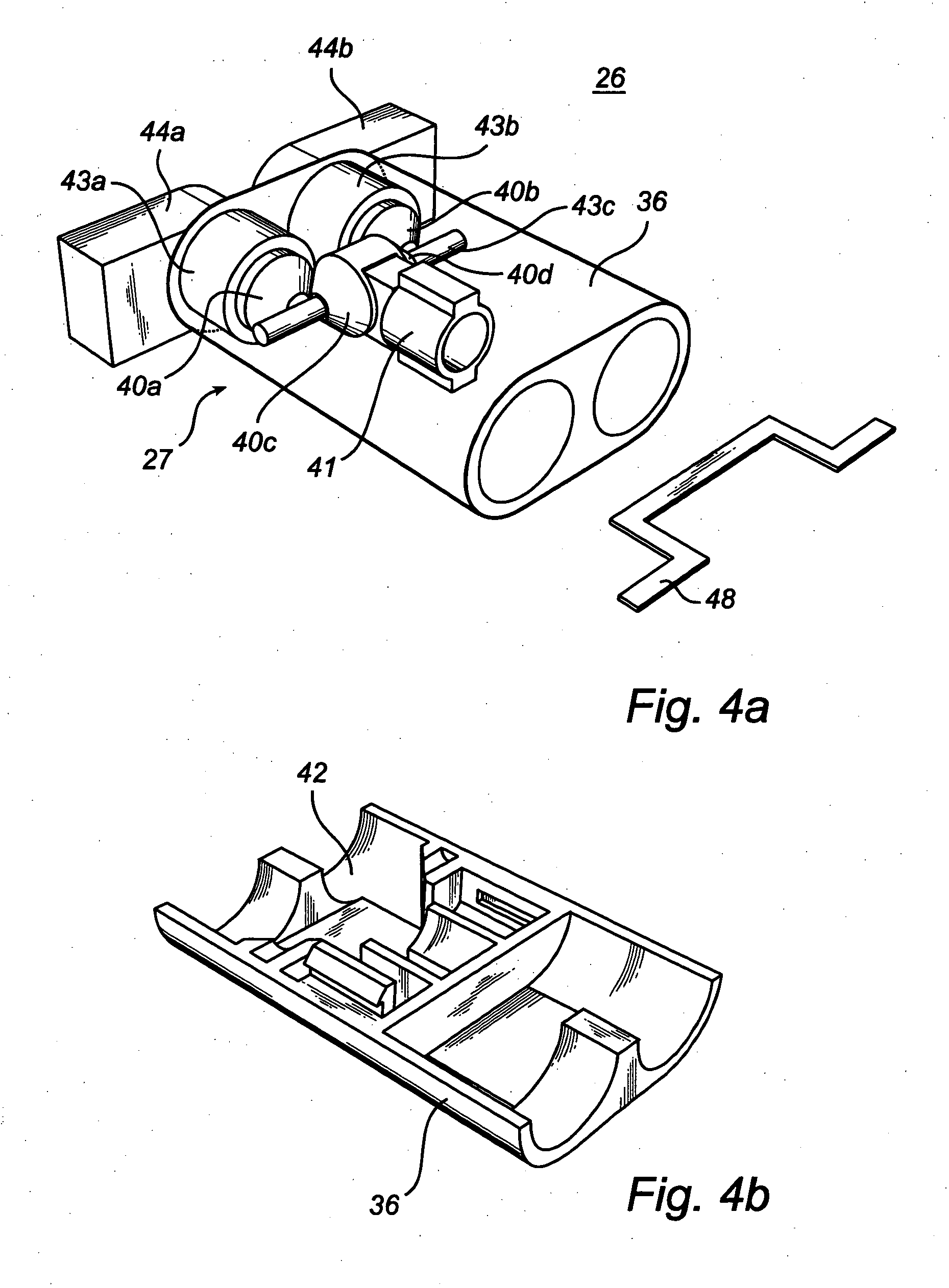

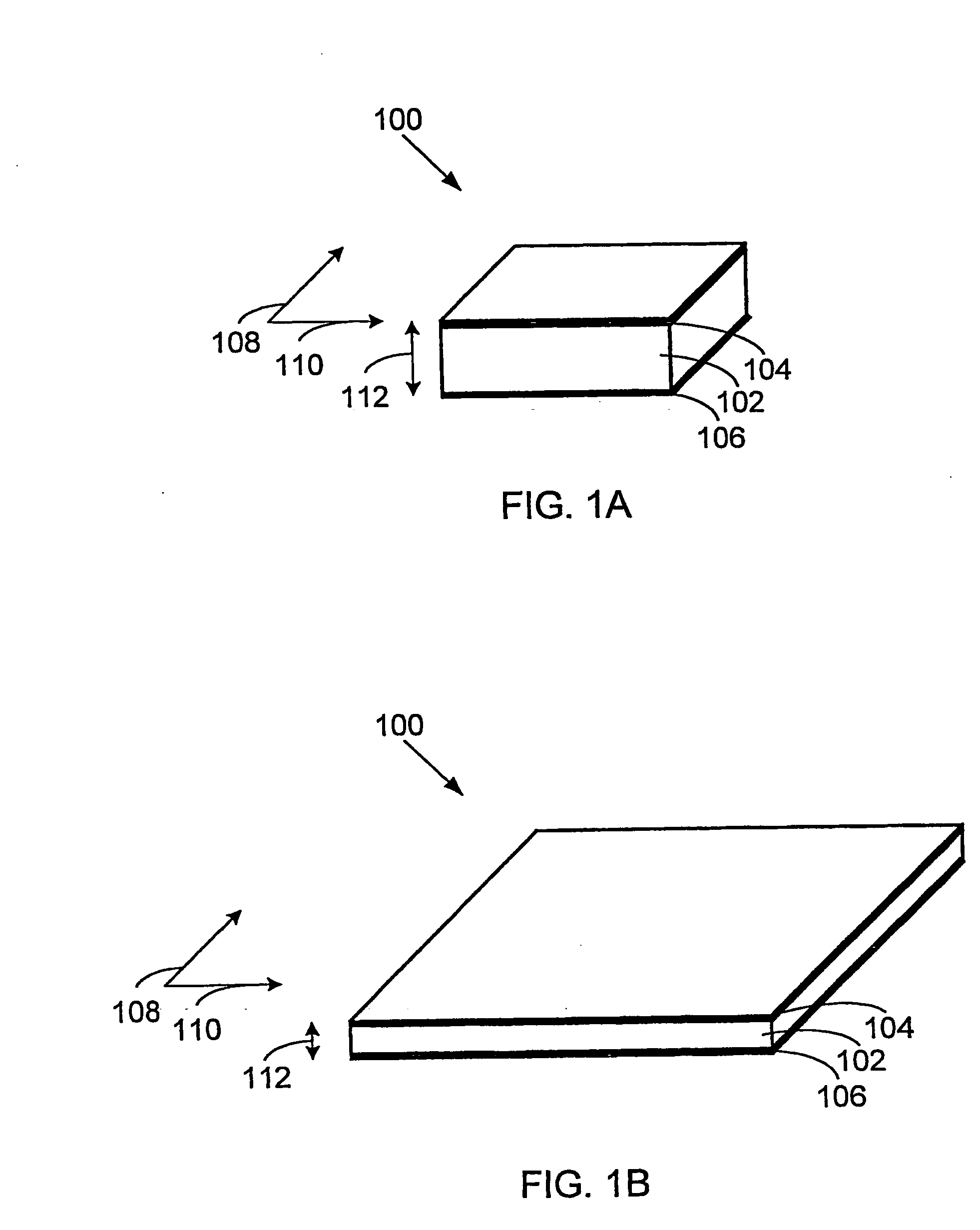

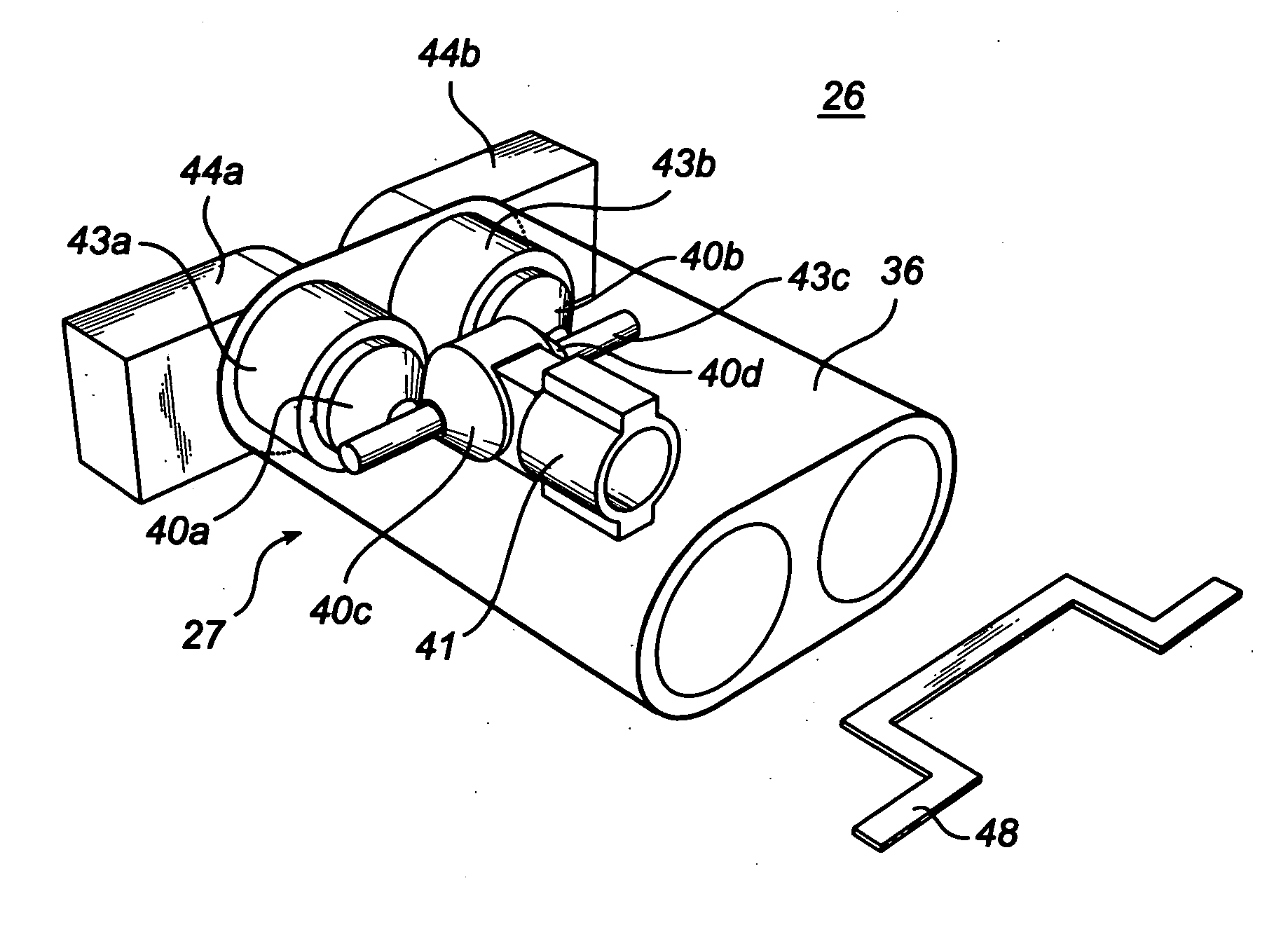

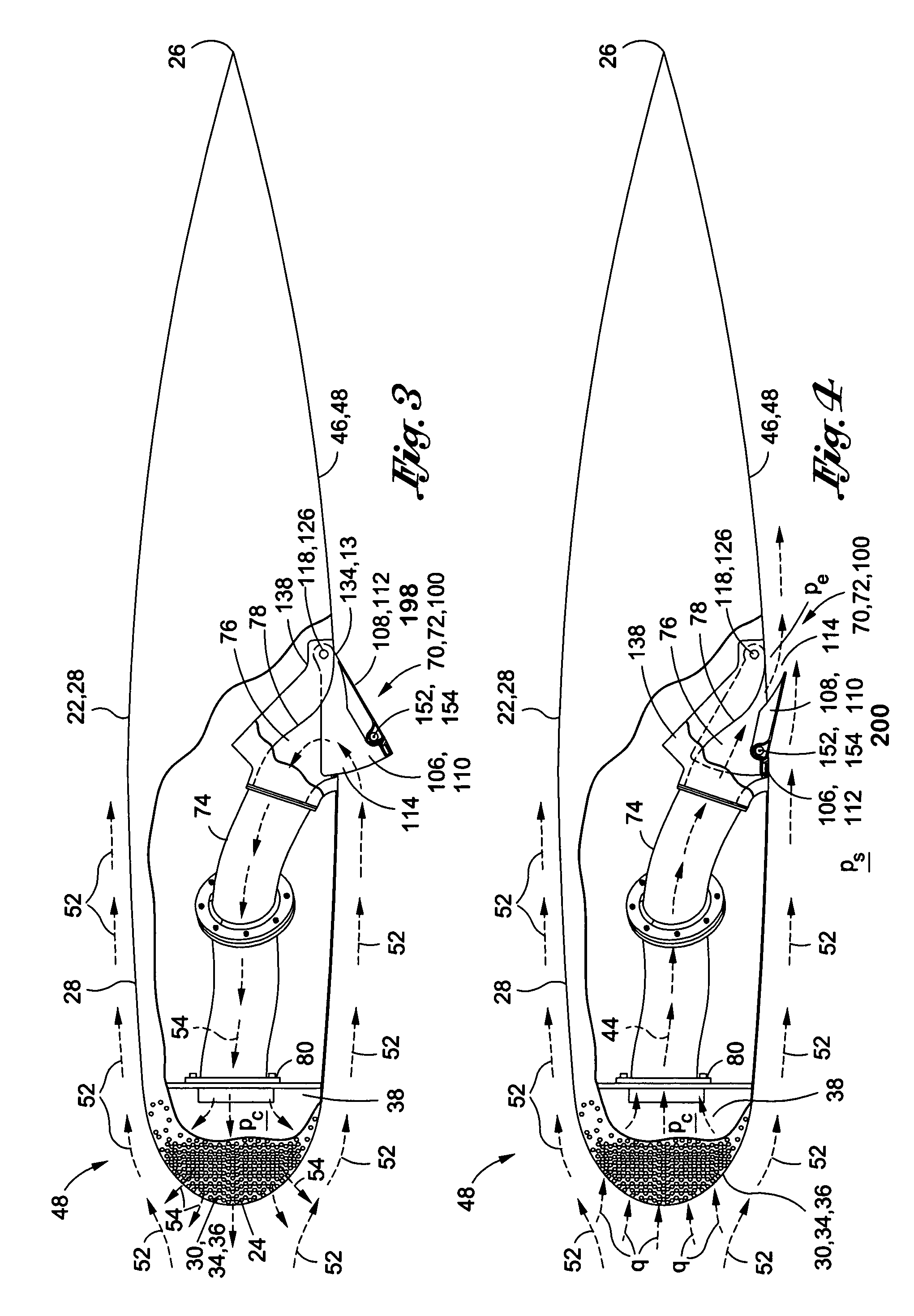

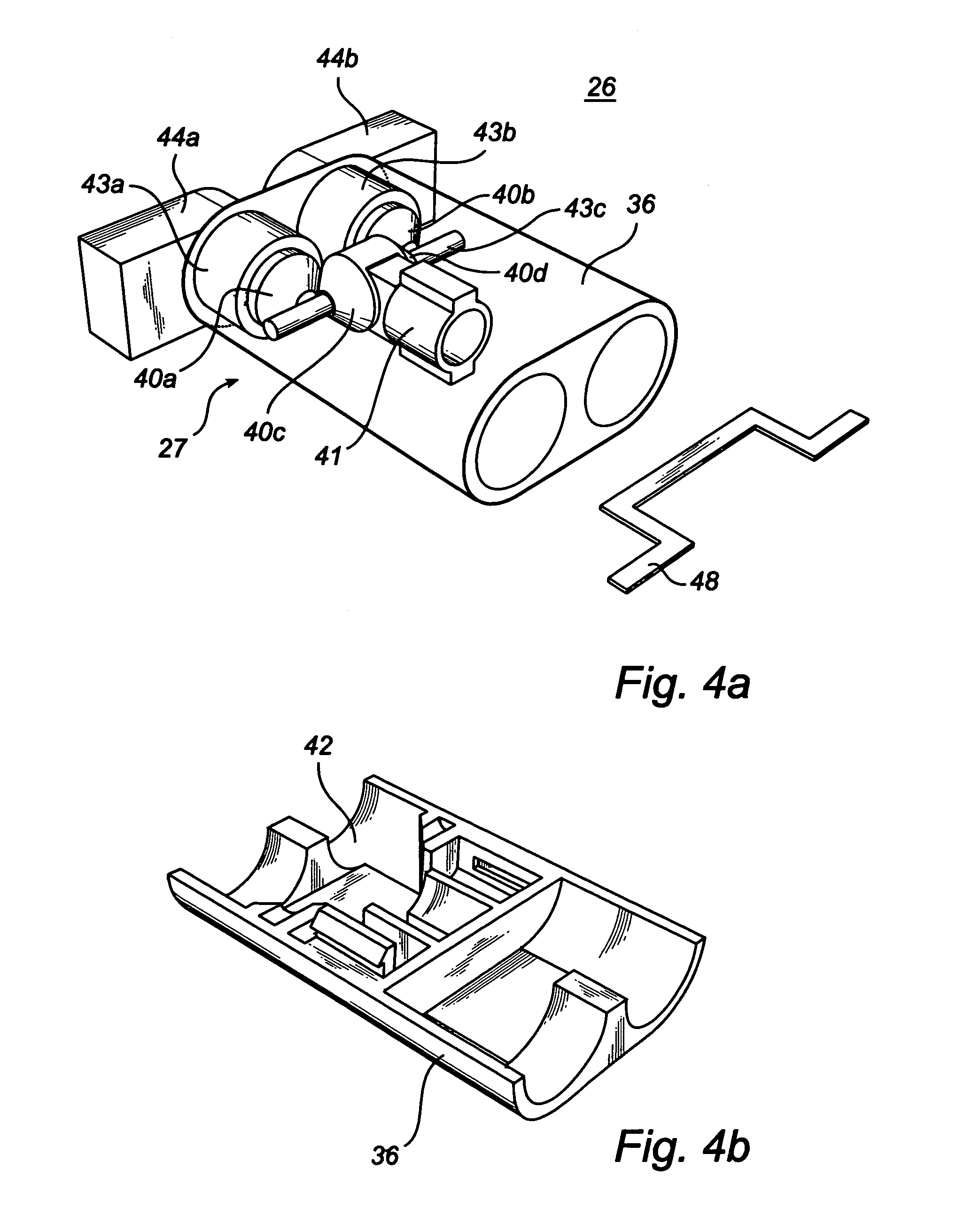

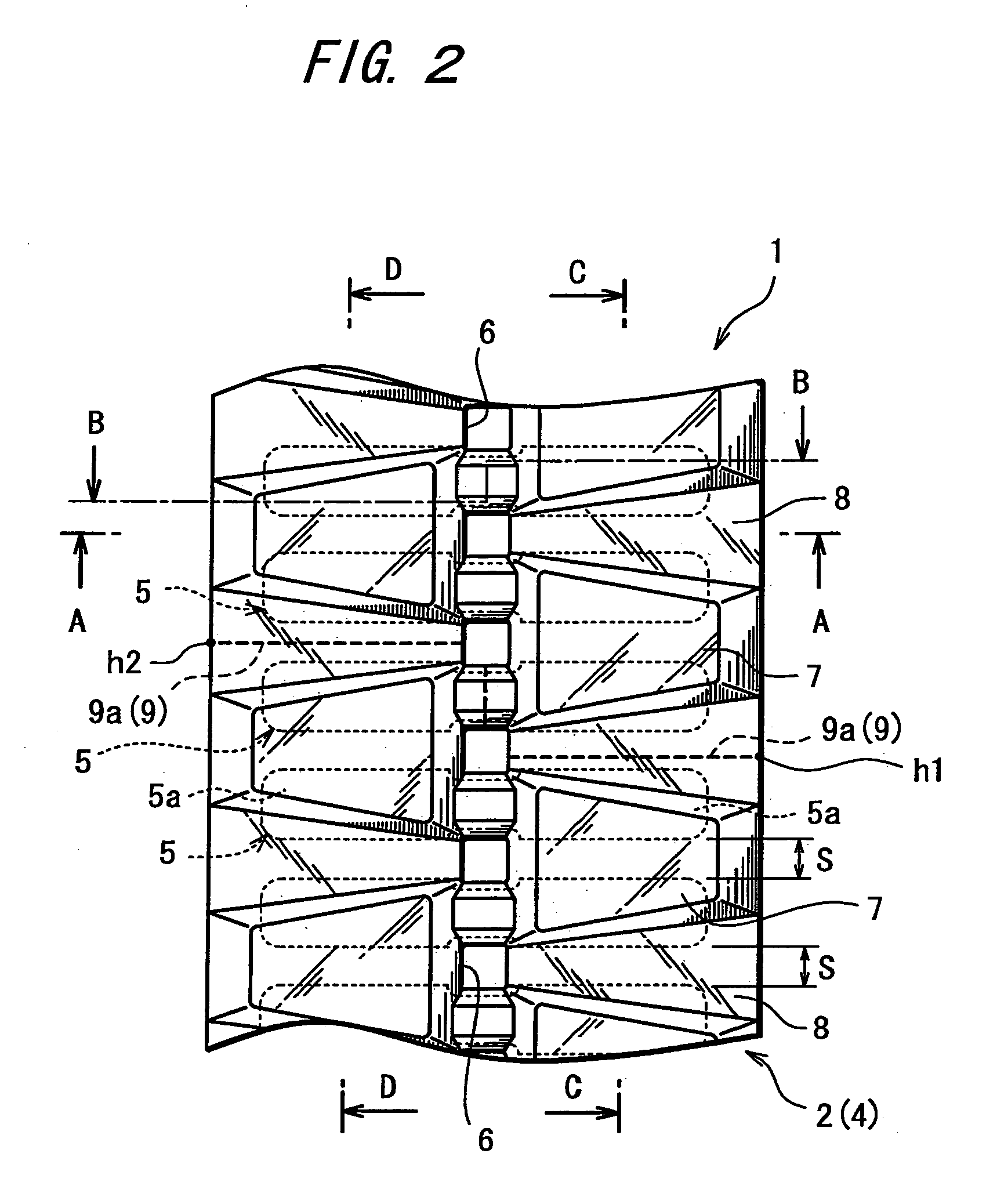

Electroactive polymer rotary clutch motors

ActiveUS7166953B2Increased torsional stiffnessPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesActive polymerMechanical energy

The present invention relates to mechanical-electrical power conversion systems. The systems comprise one or more electroactive polymers that convert between electrical and mechanical energy. When a voltage is applied to electrodes contacting an electroactive polymer, the polymer deflects. This deflection may be converted into rotation of a power shaft included in a motor. Repeated deflection of the polymer may then produce continuous rotation of the power shaft.

Owner:SRI INTERNATIONAL

System and method for implant delivery

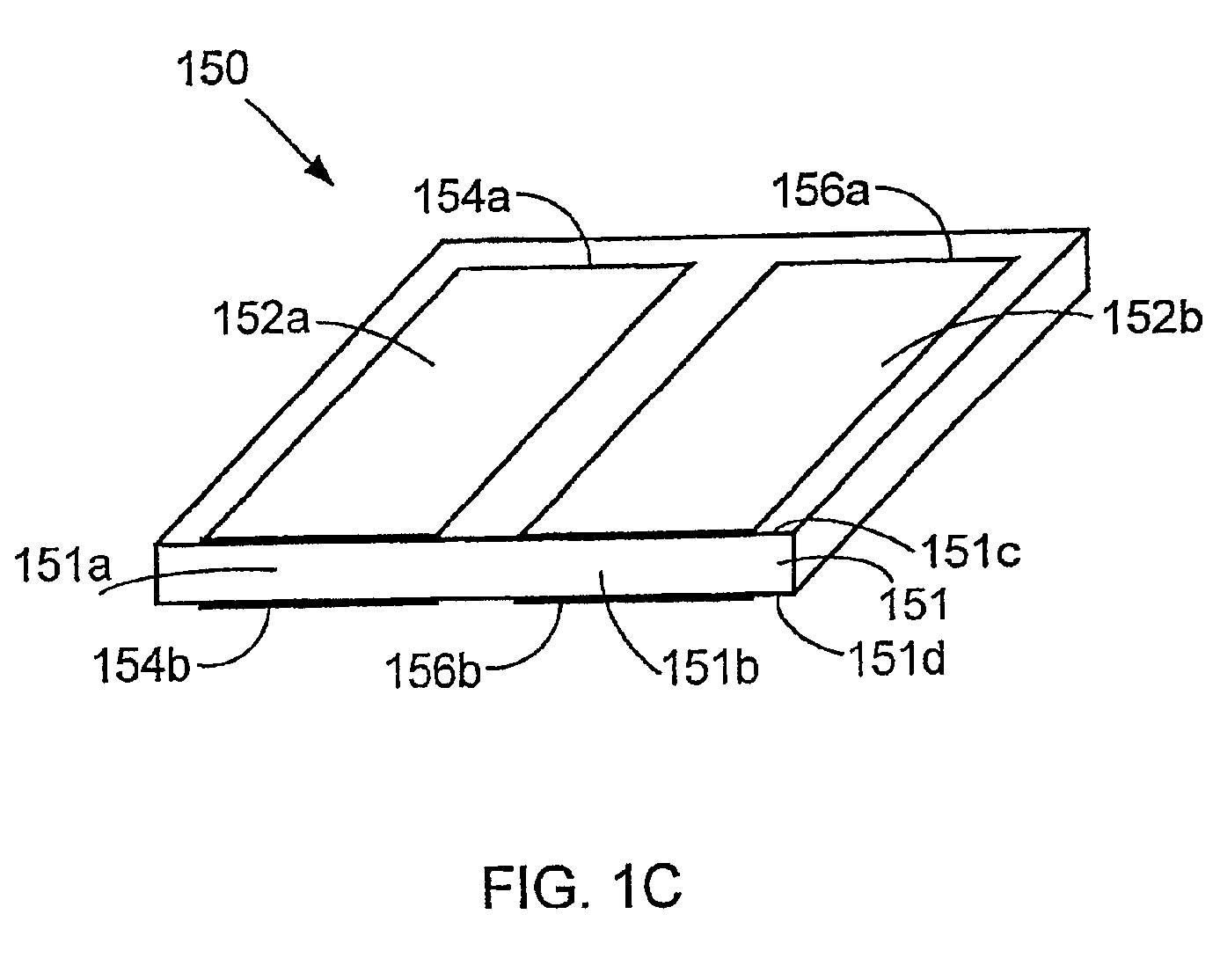

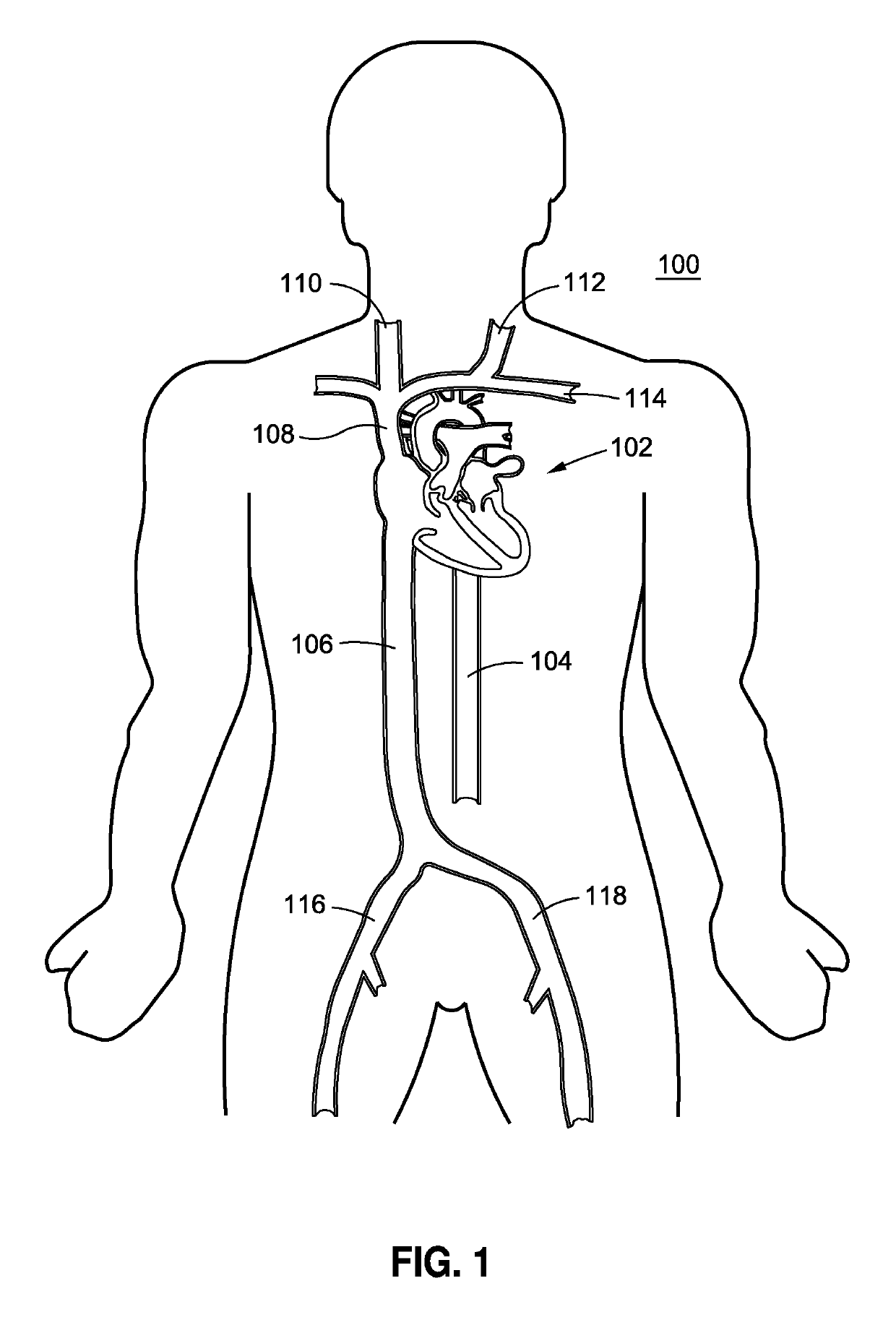

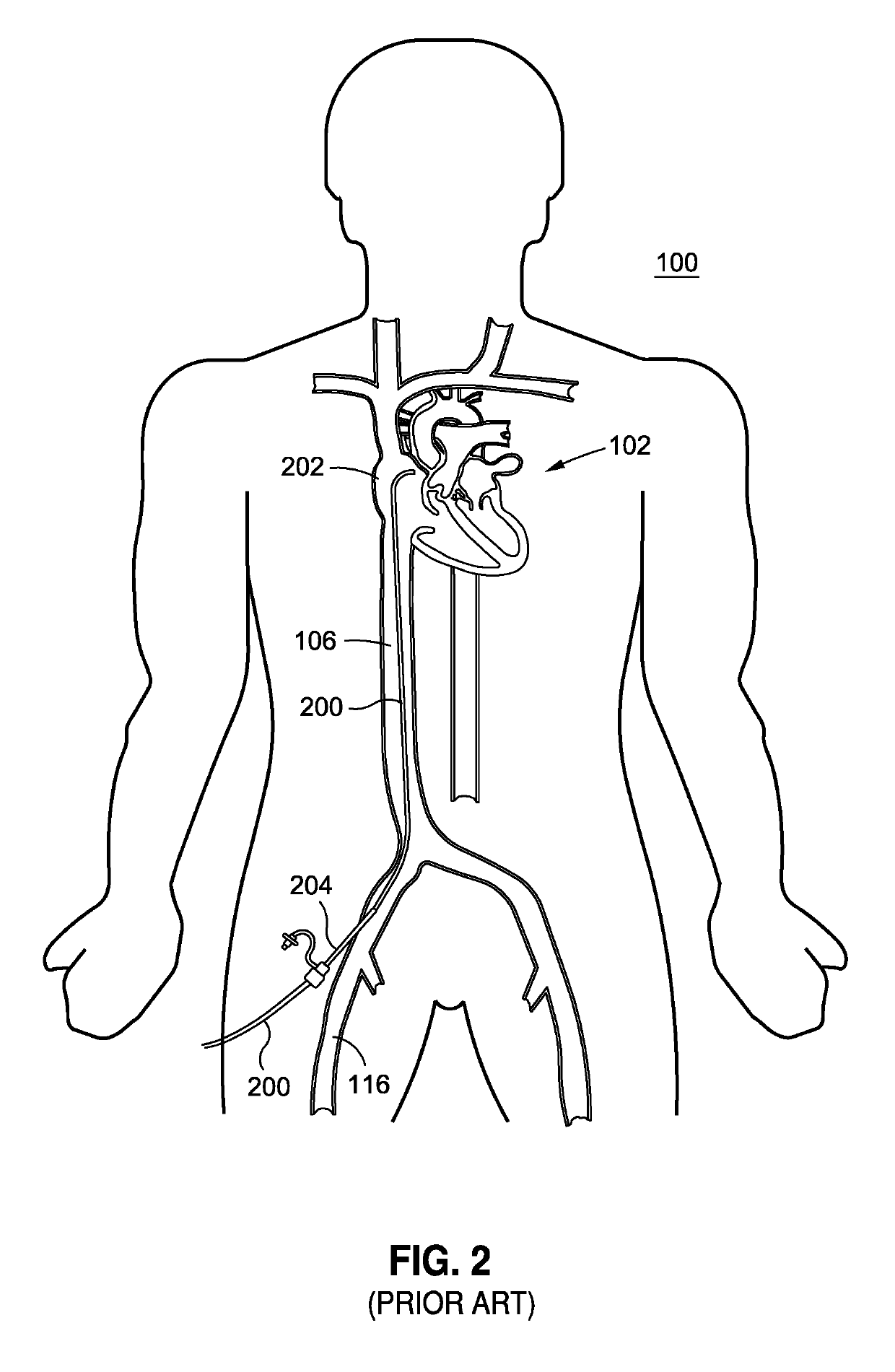

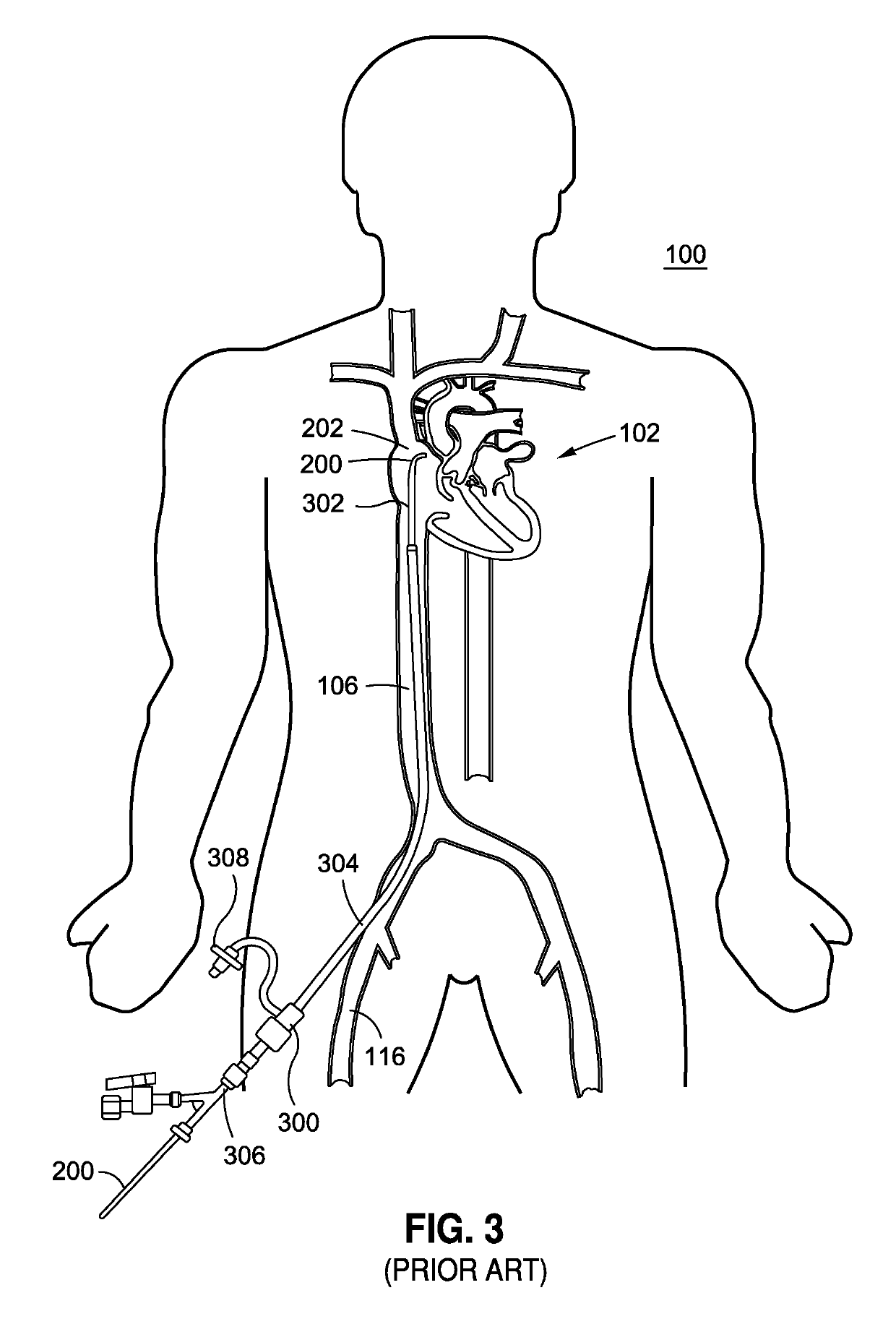

ActiveUS10299924B2Reduce in quantityIncreased torsional stiffnessStentsHeart valvesMedicineSacroiliac joint

A method for delivering an implant including, a catheter having a shaft defined by a proximal end and a distal end and a bore extending therethrough; a first joint in the shaft, and a second joint in the shaft located distal of the first joint. The first joint and the second joint are separated by a first digit sized to receive the implant and located between the first joint and the second joint. The second joint and the distal end are separated by a second digit being sized to receive the implant. The implant is advanced through the first digit and into the second digit without bending the implant or the first and second digits by rotating the digits at the first joint and the second joint.

Owner:ABBOTT CARDIOVASCULAR

Mobile communications device with synchronising hinge

InactiveUS20060238968A1Non-collapsibility can be strengthenedSmall thicknessTelevision system detailsDevices with multiple display unitsTransceiverDisplay device

The invention relates to a mobile communications device comprising a housing, a transceiver in the housing, a keypad connected to the housing, and a display connected to the housing, wherein the housing comprises a first section movably connected to a second section of the housing by a multi-axis hinge, wherein a first axis of rotation of the hinge is provided at the first section of the housing and a second offset axis of rotation of the hinge is provided at the second section of the housing, and wherein the hinge comprises means for synchronizing rotation of the first and second sections relative to the hinge through a path of about 360 degrees. The invention further relates to a hinge for use therein.

Owner:NOKIA TECHNOLOGLES OY

Electroactive polymer motors

InactiveUS20060119225A1Increased torsional stiffnessIncrease distancePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesMechanical energyElectrode Contact

The present invention relates to mechanical-electrical power conversion systems. The systems comprise one or more electroactive polymers that convert between electrical and mechanical energy. When a voltage is applied to electrodes contacting an electroactive polymer, the polymer deflects. This deflection may be converted into rotation of a power shaft included in a motor. Repeated deflection of the polymer may then produce continuous rotation of the power shaft.

Owner:SRI INTERNATIONAL

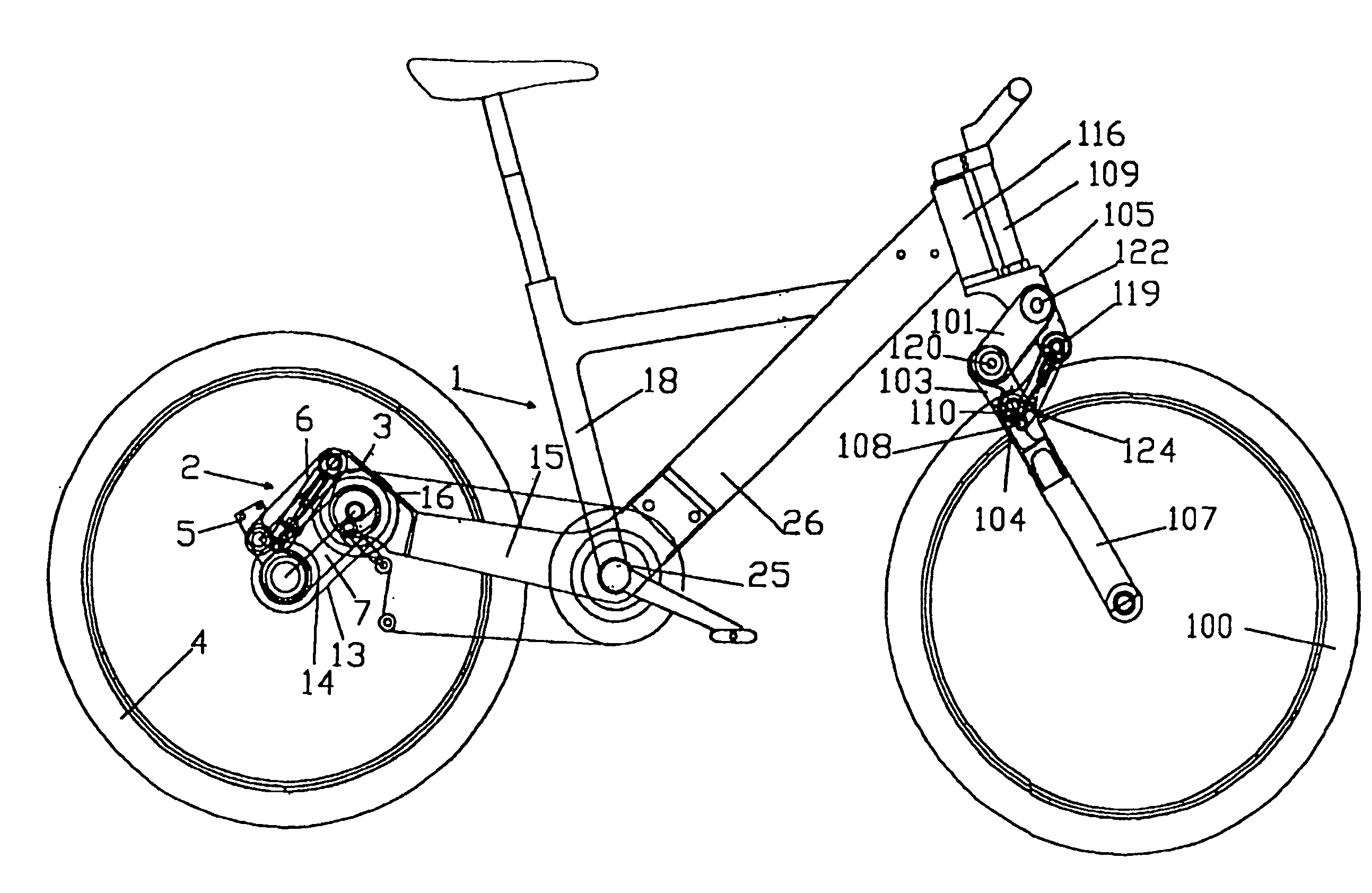

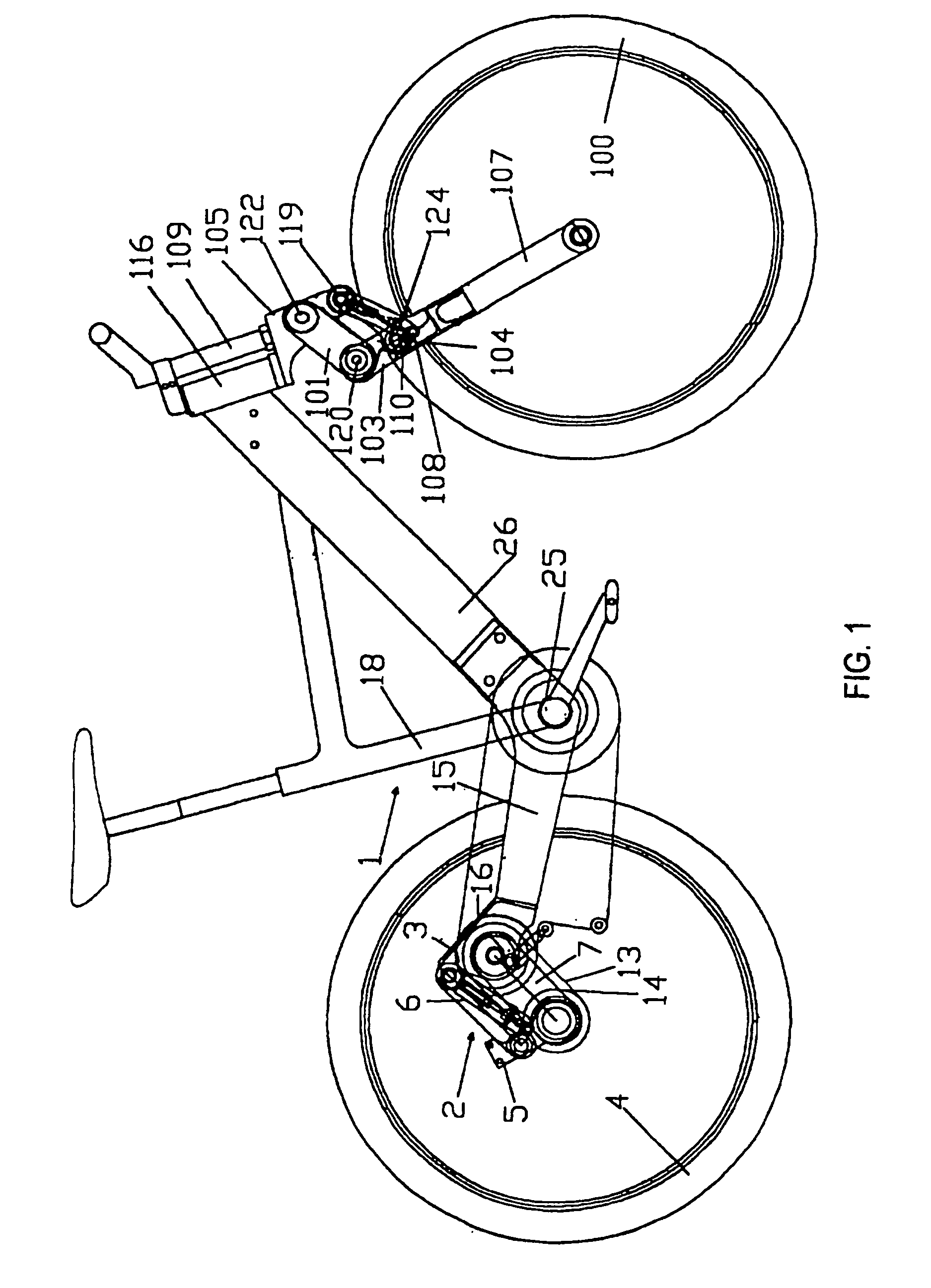

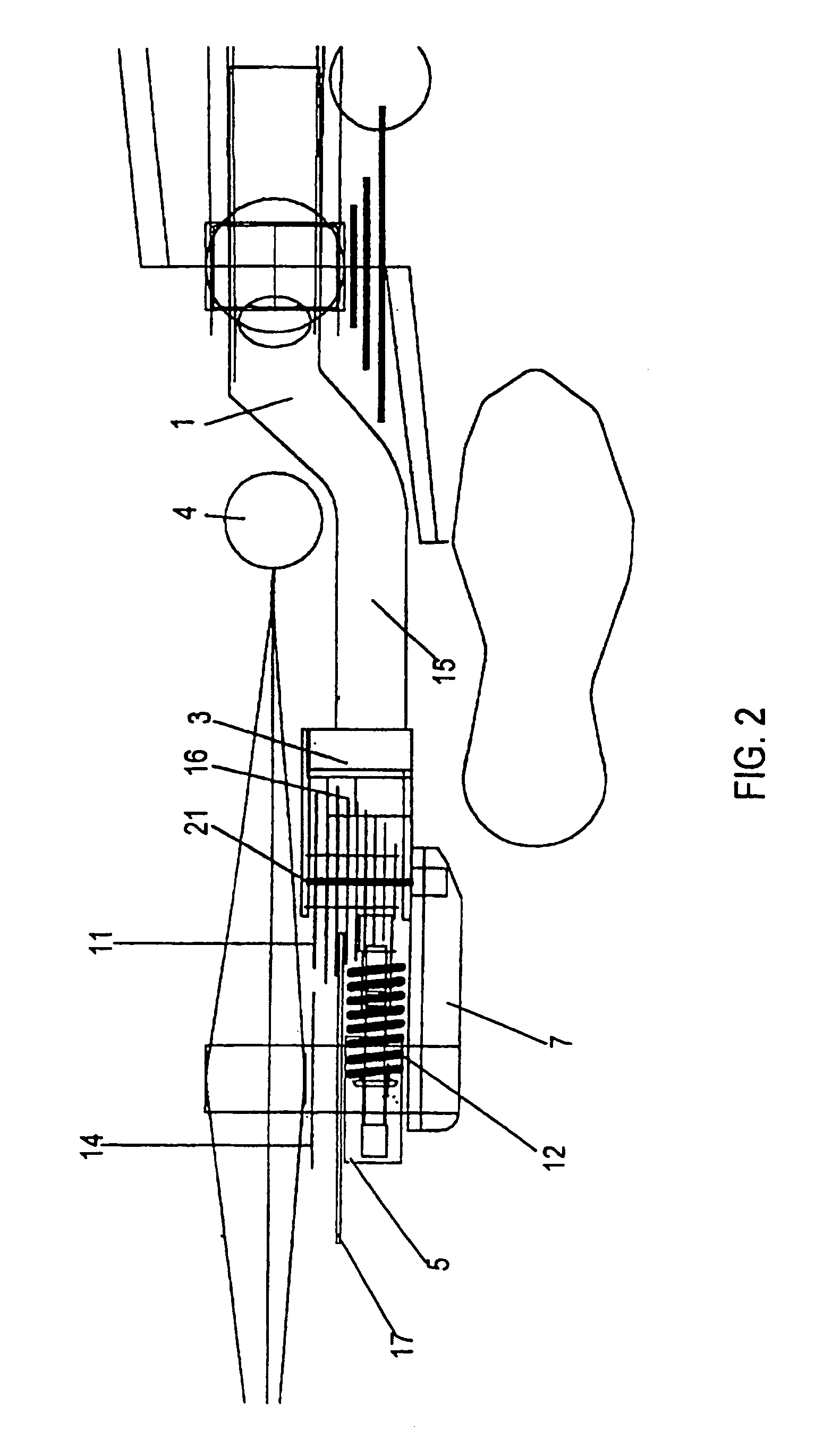

All-suspension bicycle frame with isolated drive gear

InactiveUS6910702B1Dampen undesirable rocking movementReduce frictionPassenger cyclesChildren cyclesVehicle frameGear wheel

A frame assembly for a two-wheel vehicle includes a front wheel fork and chainstays. Between the front wheel fork and the chainstays, the frame assembly further includes a saddle tube, a crank housing, and a lower tube connecting the crank housing to a steering tube. A parallelogram-shaped suspension assembly is attached to a rear end of the chainstays.

Owner:HALS CATO

Mobile communications device with synchronising hinge

InactiveUS20060236505A1Simple and robust solutionImprove reliabilityDigital data processing detailsWing accessoriesTransceiverDisplay device

The invention relates to a mobile communications device comprising a housing, a transceiver in the housing, a keypad connected to the housing, and a display connected to the housing, wherein the housing comprises a first section movably connected to a second section of the housing by a multi-axis hinge, wherein a first axis of rotation of the hinge is provided at the first section of the housing and a second offset axis of rotation of the hinge is provided at the second section of the housing, and wherein the hinge comprises means for synchronizing rotation of the first and second sections relative to the hinge through a path of about 360 degrees. The invention further relates to a hinge for use therein.

Owner:NOKIA TECHNOLOGLES OY

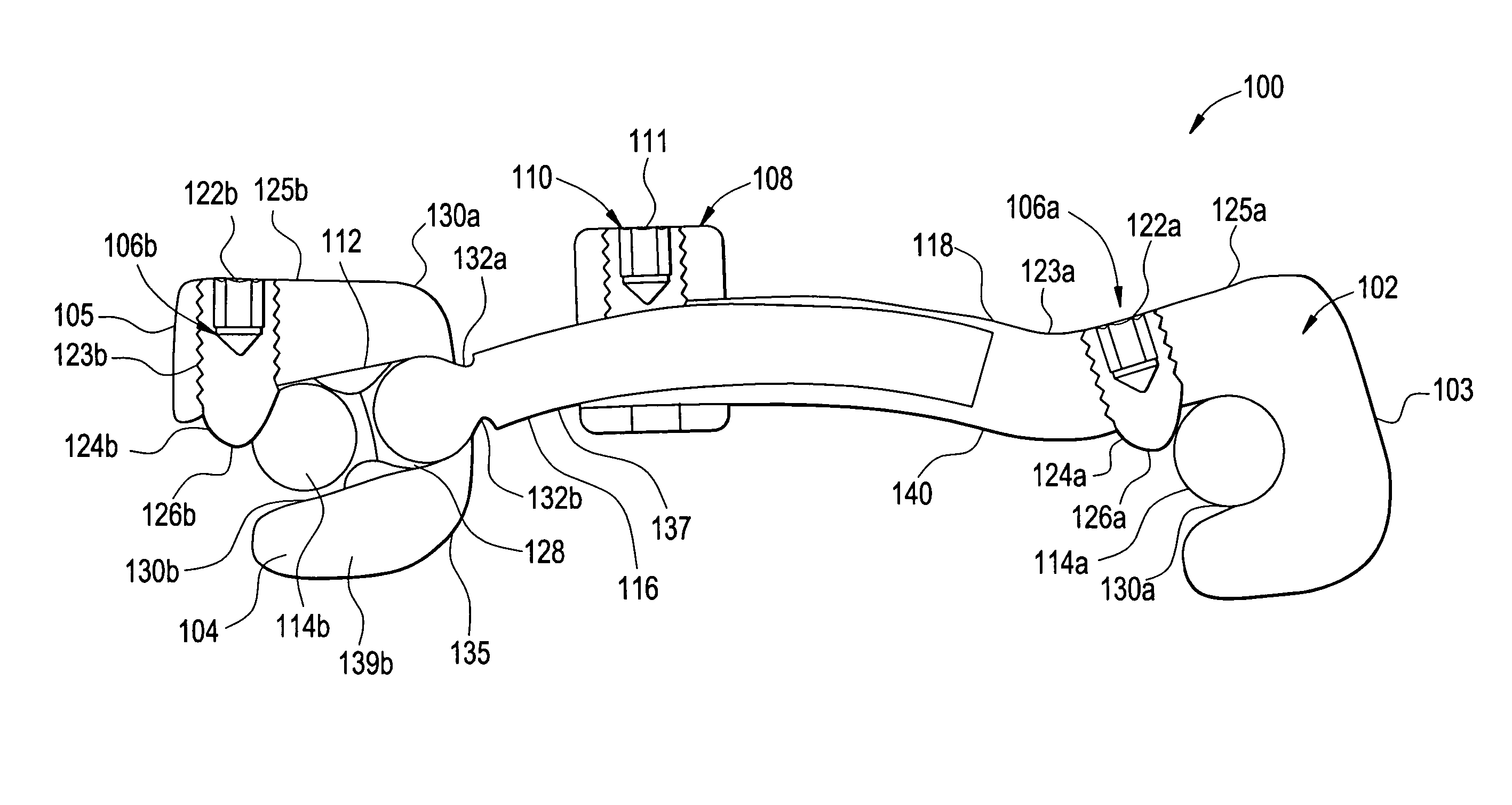

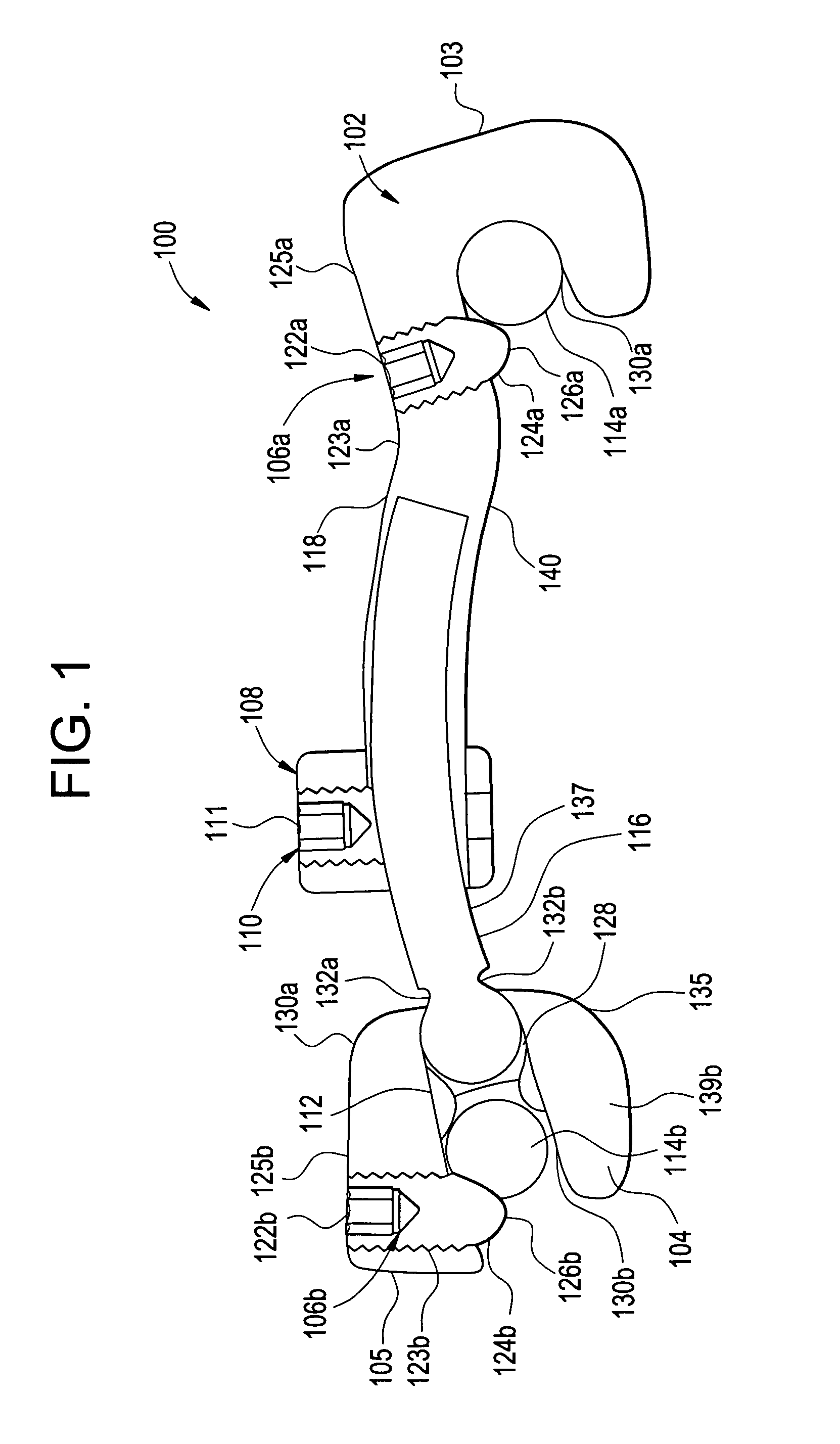

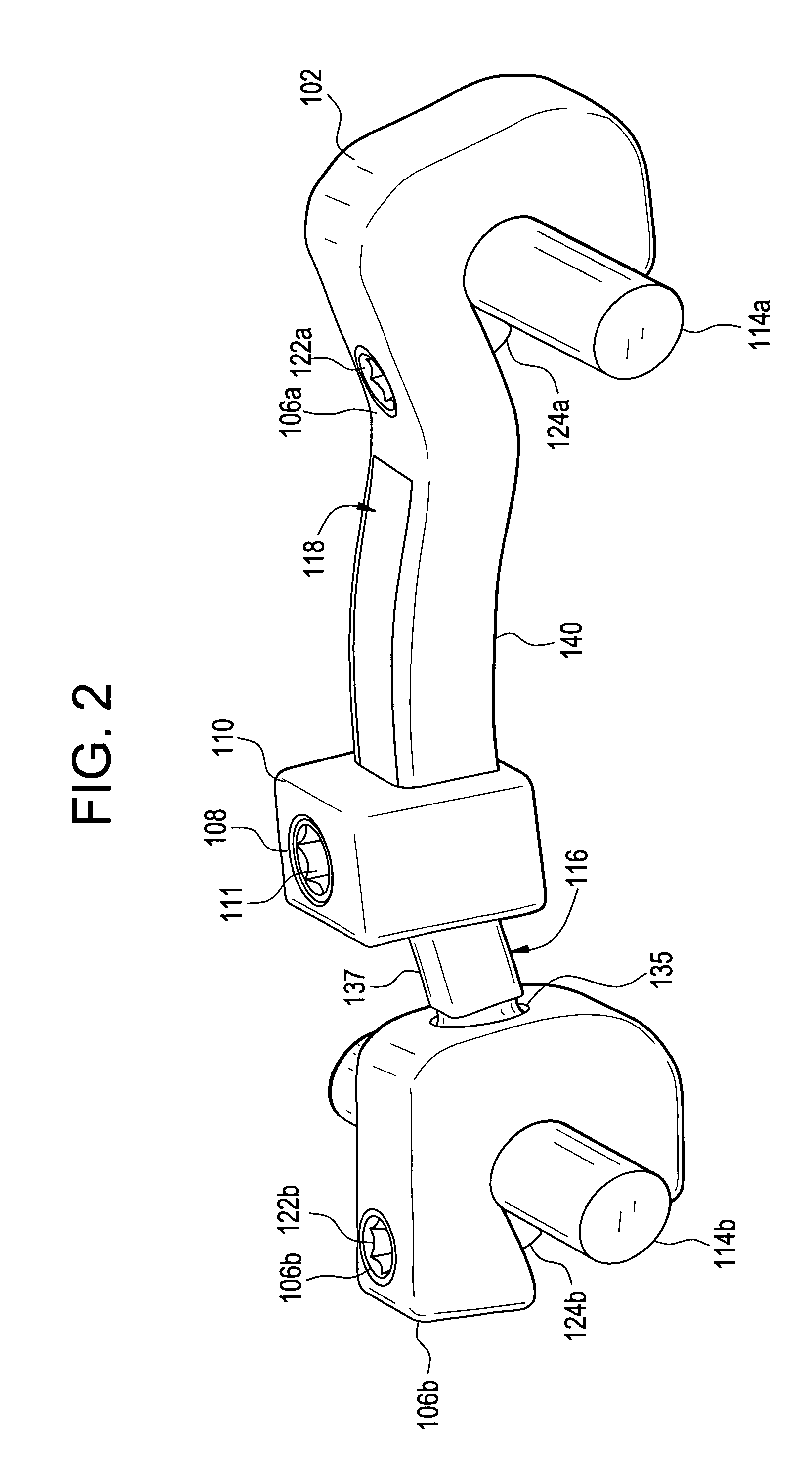

Multi-axial transverse rod connector

ActiveUS8075594B2Increased torsional stiffnessLimited angulationInternal osteosythesisJoint implantsEngineeringMechanical engineering

A multi-axial rod connector for connecting spinal rods is provided. The rod connector includes a poly-axial rod assembly configured to include a lateral translation mechanism and a fixed hook configured to be rigidly coupled to one end of the poly-axial rod assembly. The fixed hook includes a fixed hook cavity configured to secure a spinal rod. The rod connector also includes a variable hook configured to be rotatably coupled another end of the poly-axial rod. The variable hook includes a variable hook cavity configured to secure another spinal rod. The lateral translation mechanism is configured to change distance between the fixed hook and the variable hook.

Owner:ALPHATEC SPINE INC

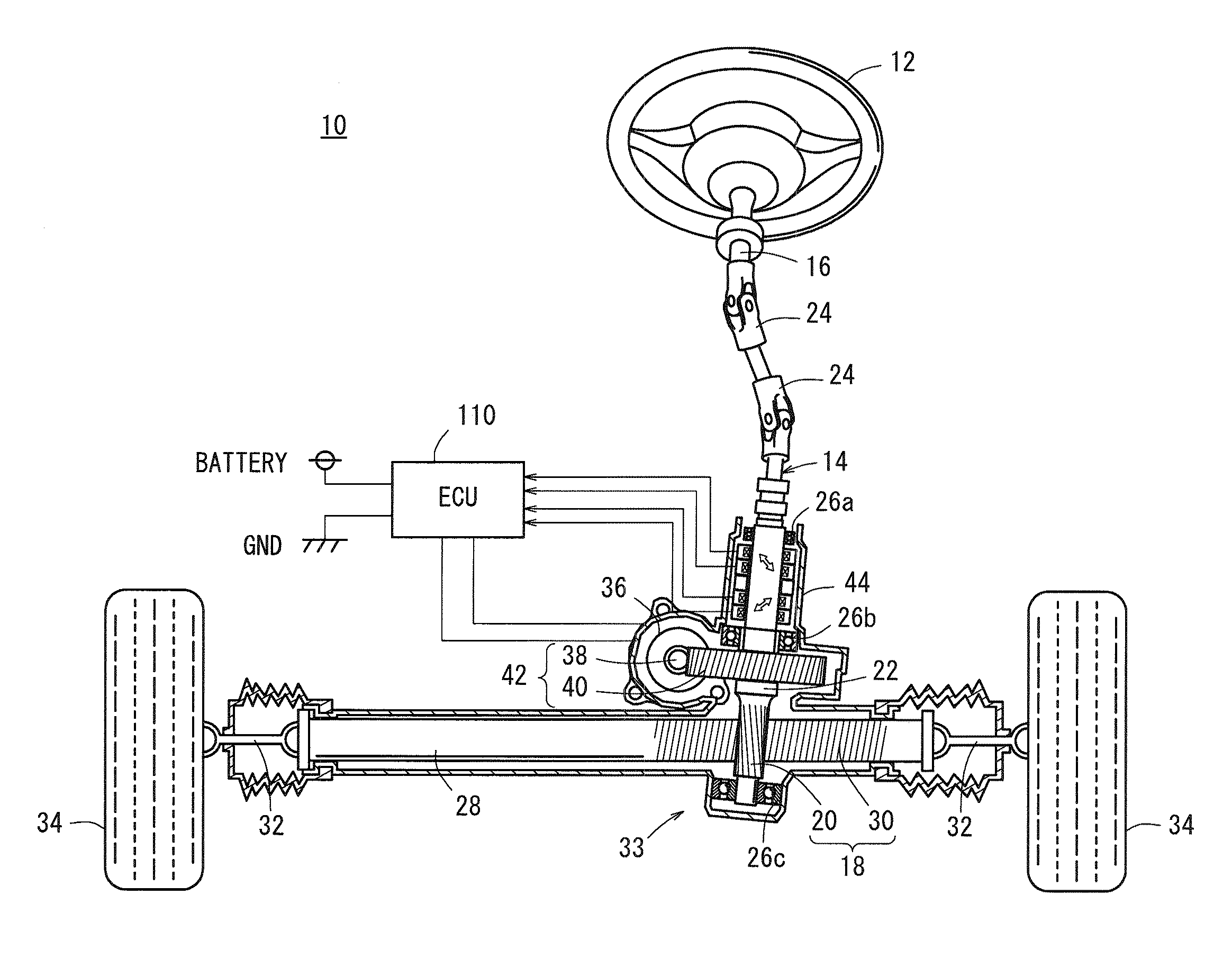

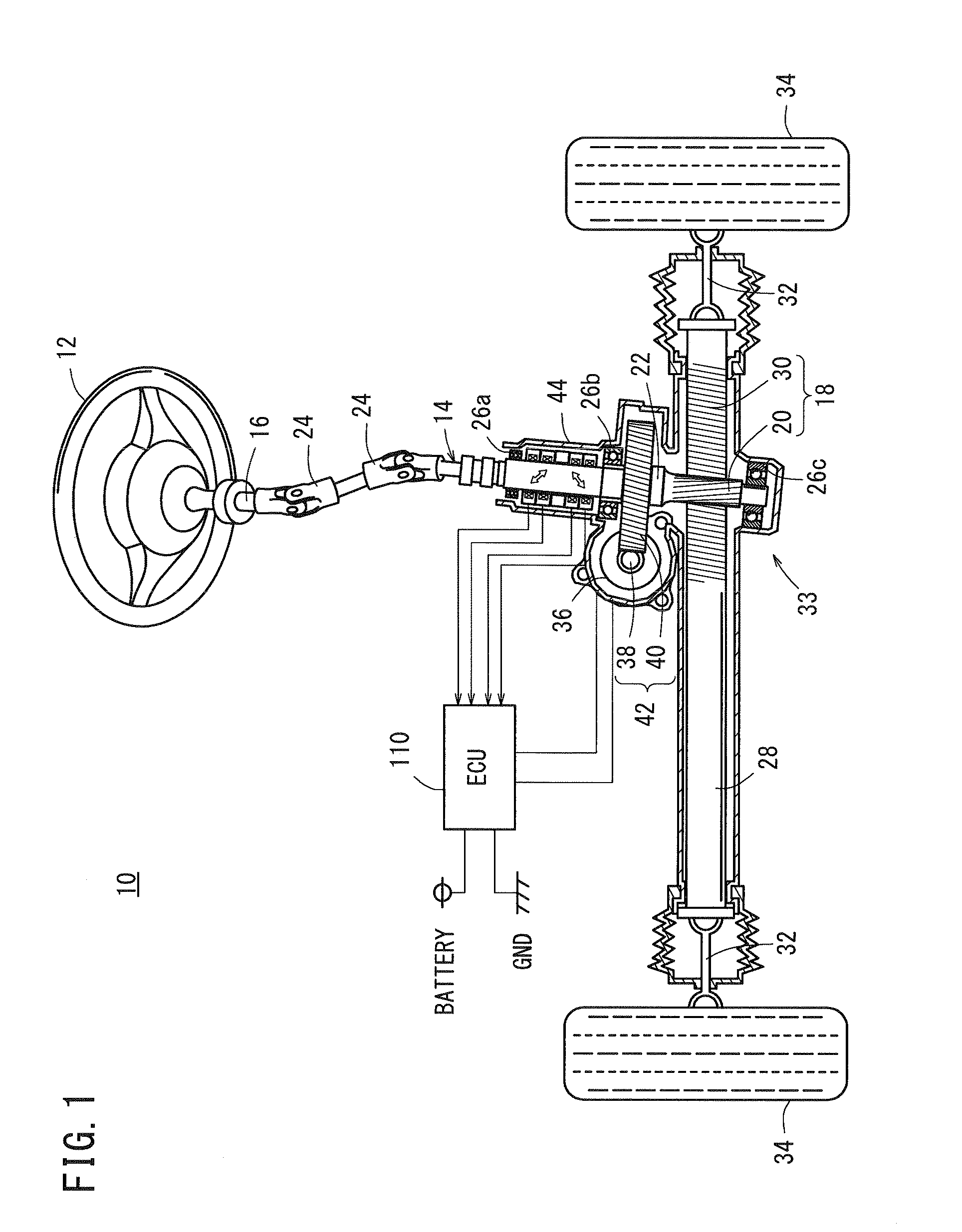

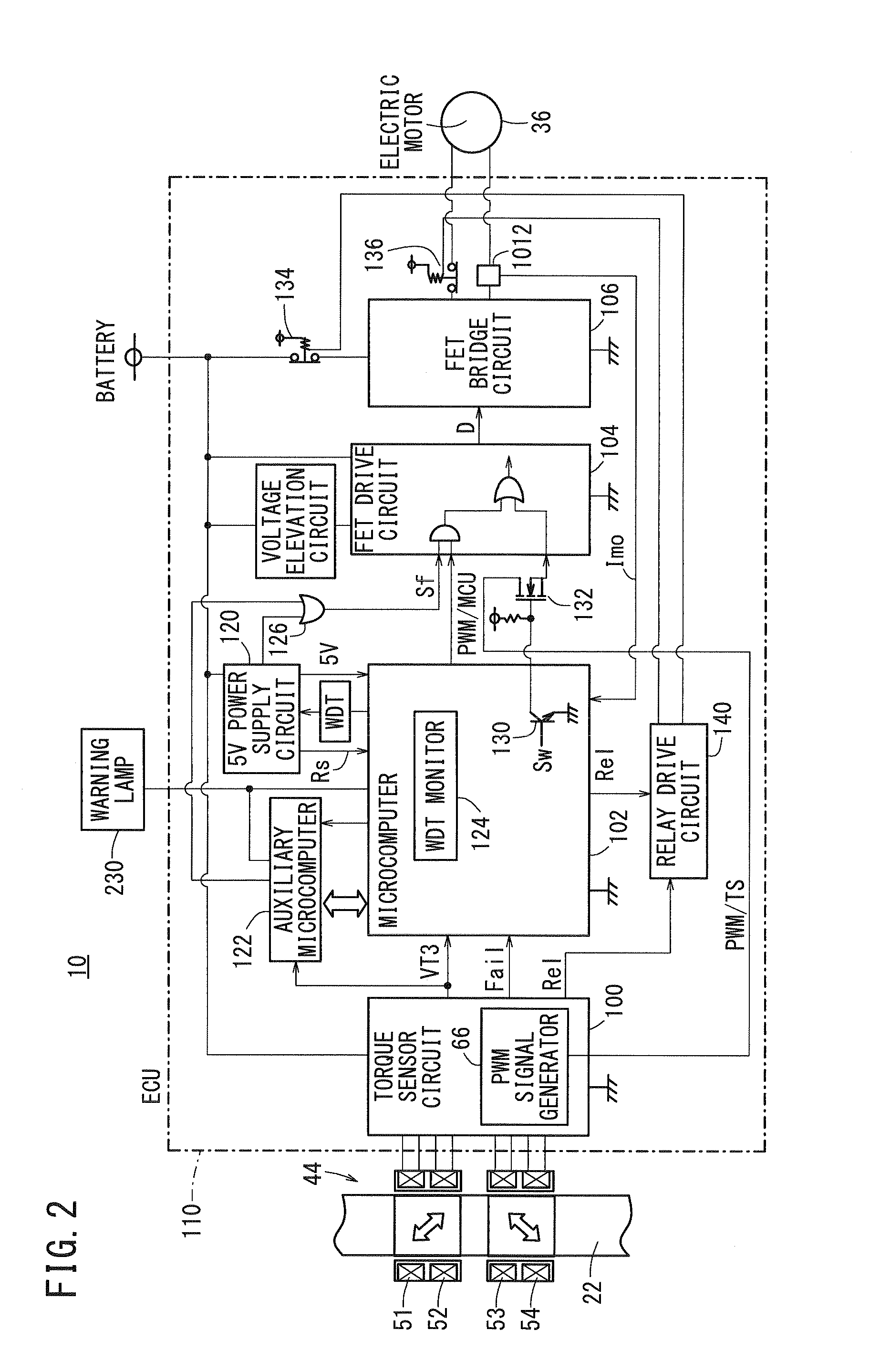

Electric power steering apparatus

InactiveUS20120271513A1Guarantee continuous and stable operationPromote generationSteering initiationsDigital data processing detailsMicrocomputerElectric power steering

In the event of a failure of a first electric motor drive signal generator, e.g., the microcomputer, which generates a first electric motor drive signal for performing a feedback control, a second electric motor drive signal generator, e.g., a PWM signal generator, which is made up of discrete circuit components, directly converts a steering torque signal into a second electric motor drive signal. An electric motor, which generates the assistive steering force, is driven by the second electric motor drive signal.

Owner:HONDA MOTOR CO LTD

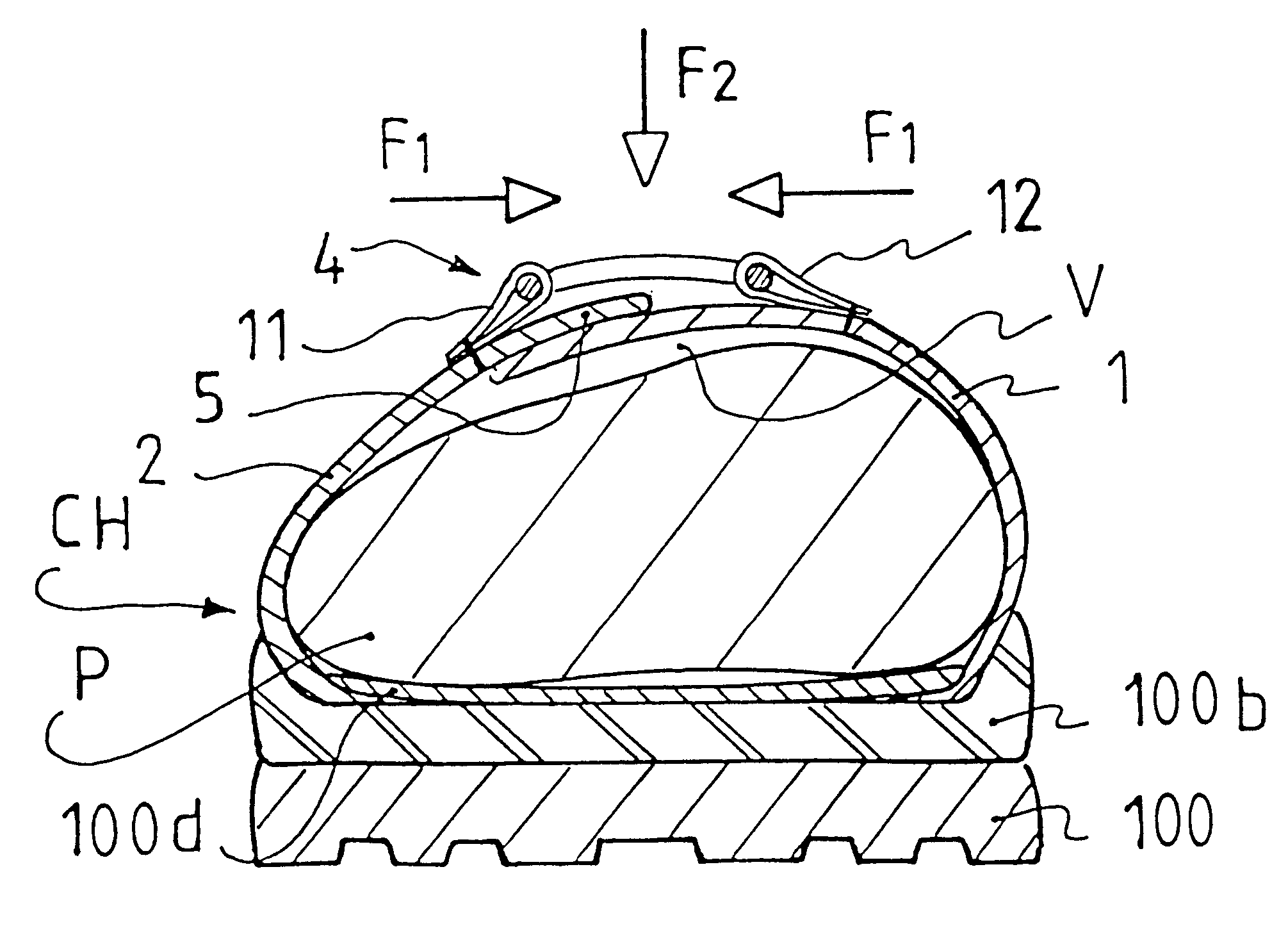

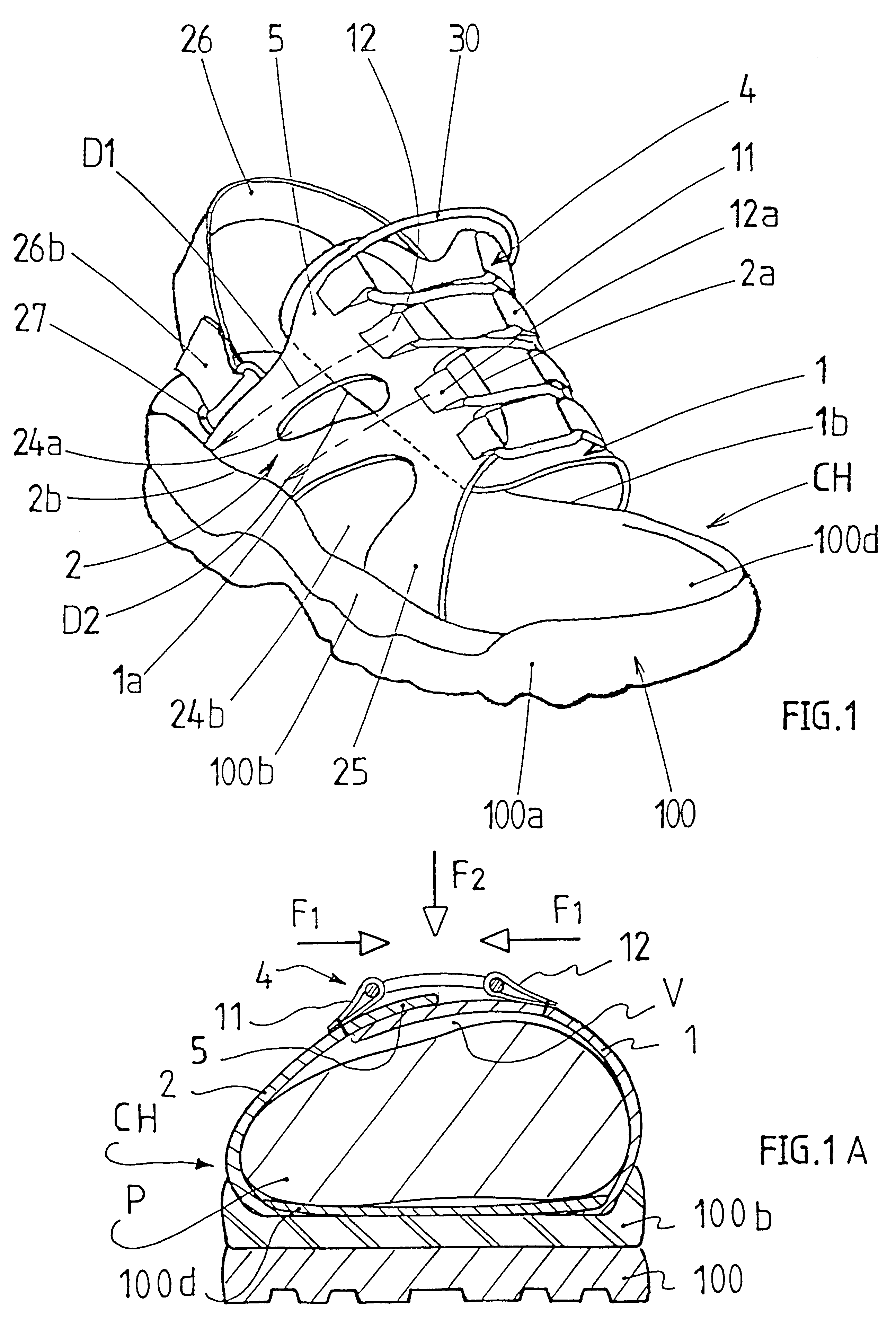

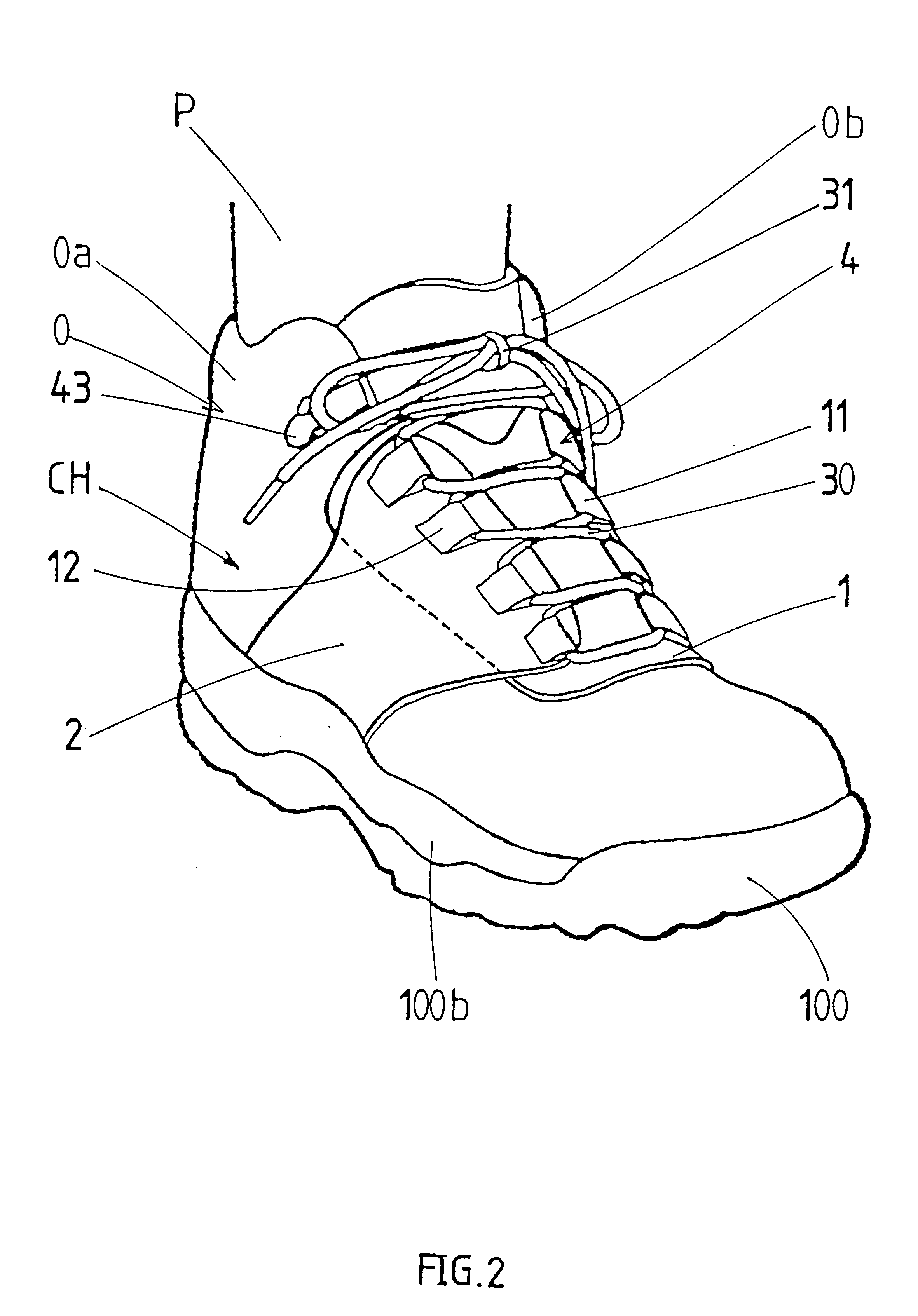

Tightening device for footwear, and an article of footwear incorporating such tightening device

InactiveUS6860035B2Distribute pressureImprove torsional rigidityShoe lace fasteningsUpperEngineering

Owner:SALOMON SA

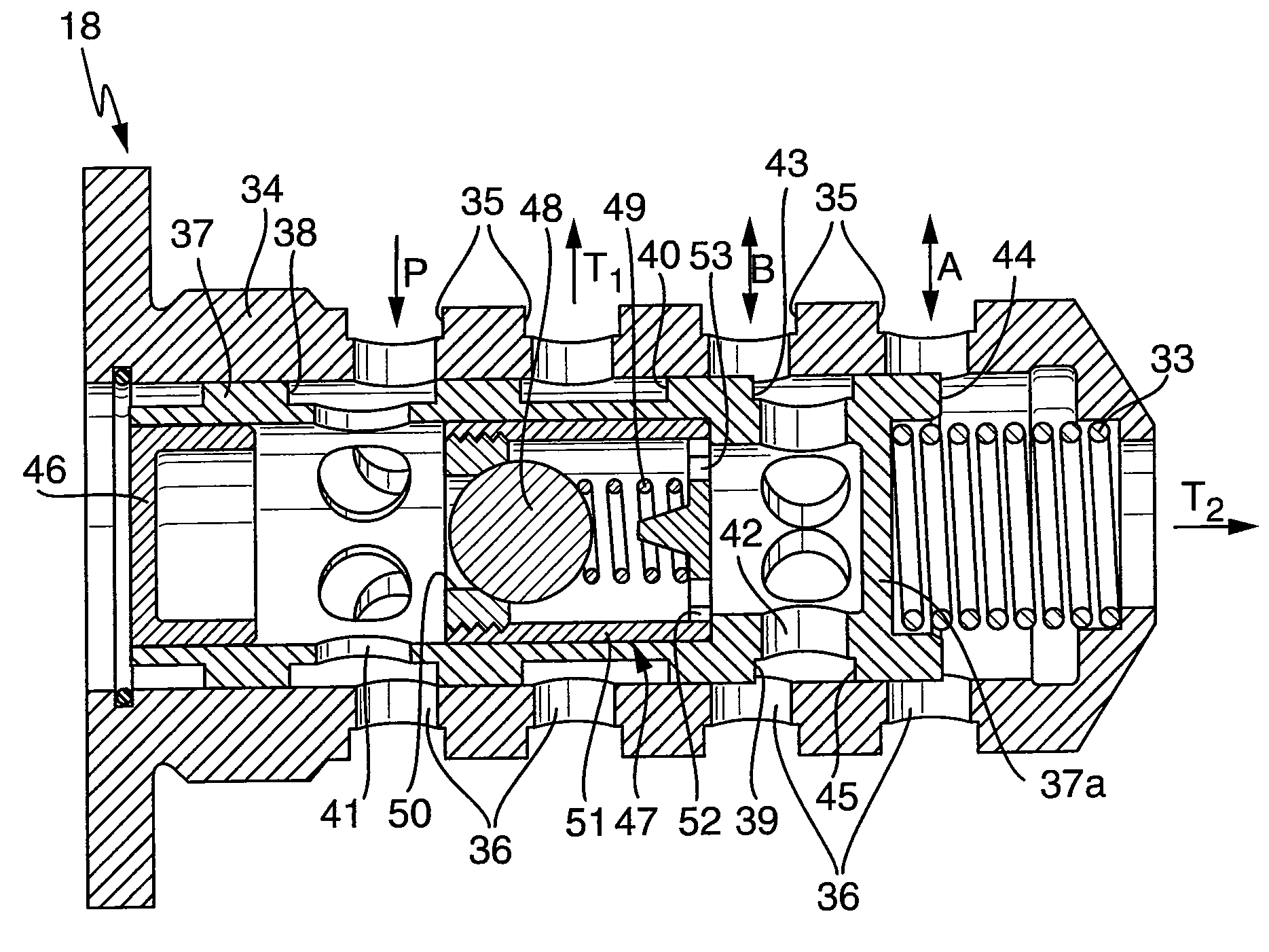

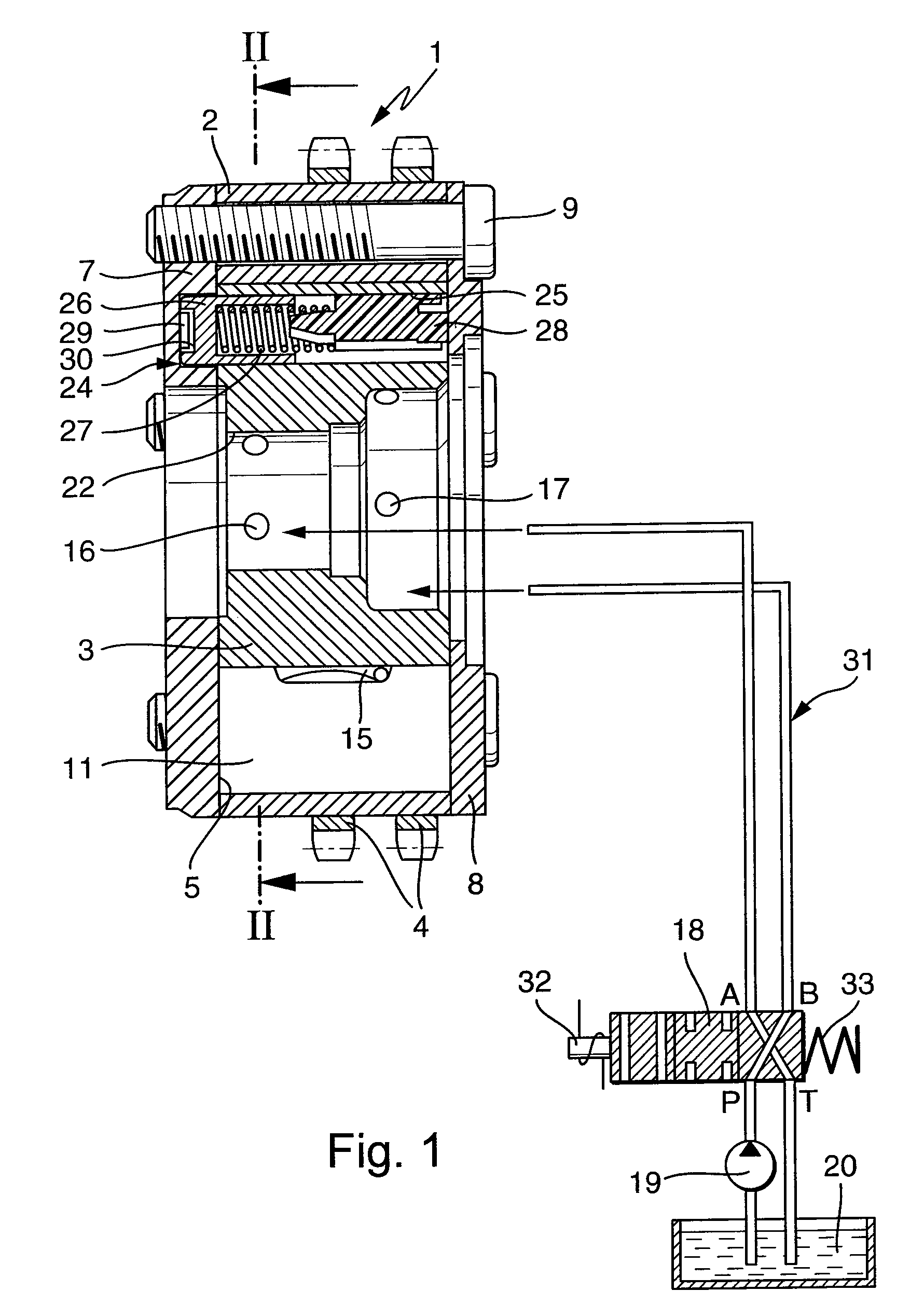

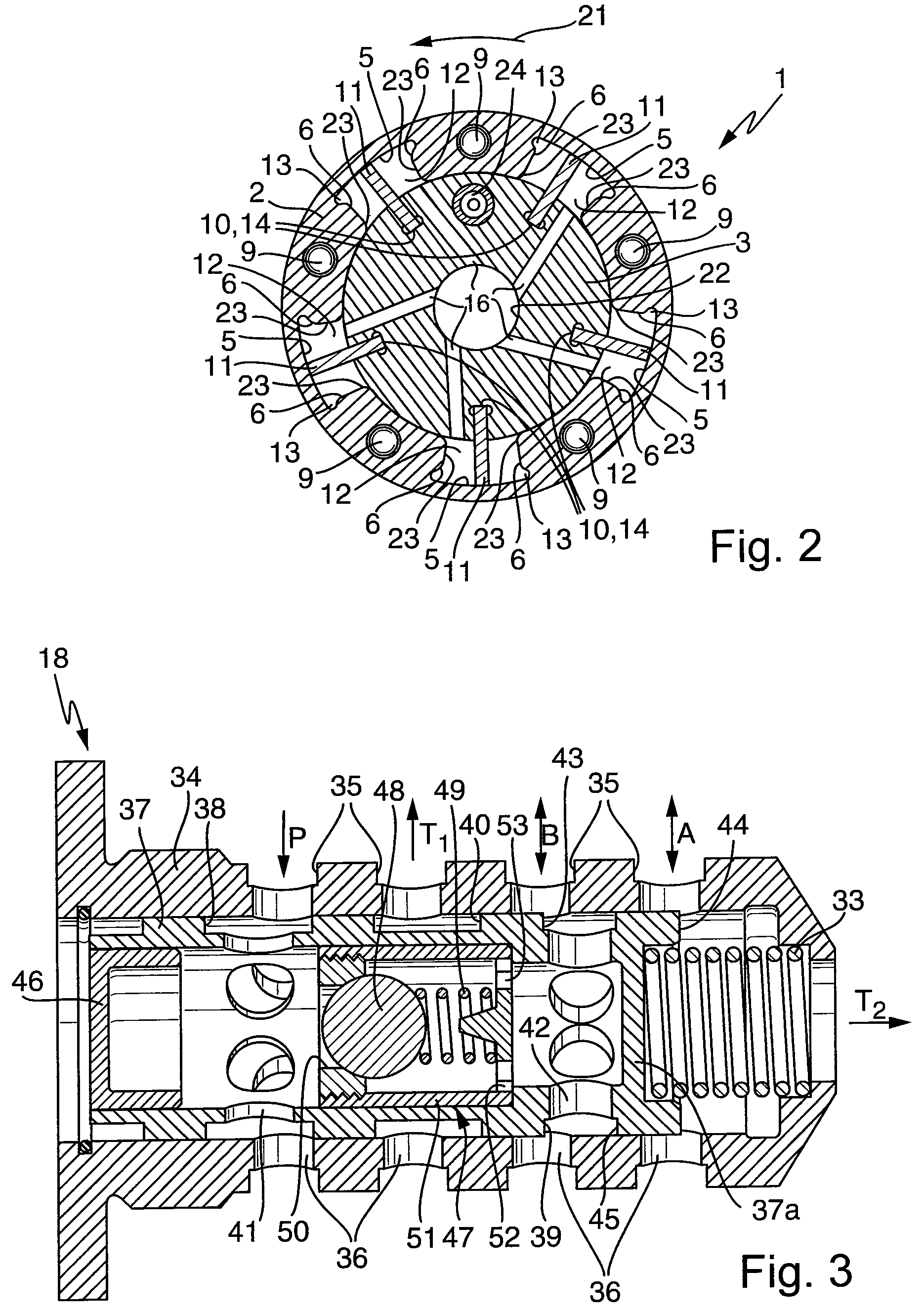

Control valve for a device for changing the control times of an internal combustion engine

InactiveUS7533695B2Easy to integrateAxial spacing reducedServomotor componentsMultiple way valvesAxial displacementExternal combustion engine

Owner:SCHAEFFLER TECH AG & CO KG

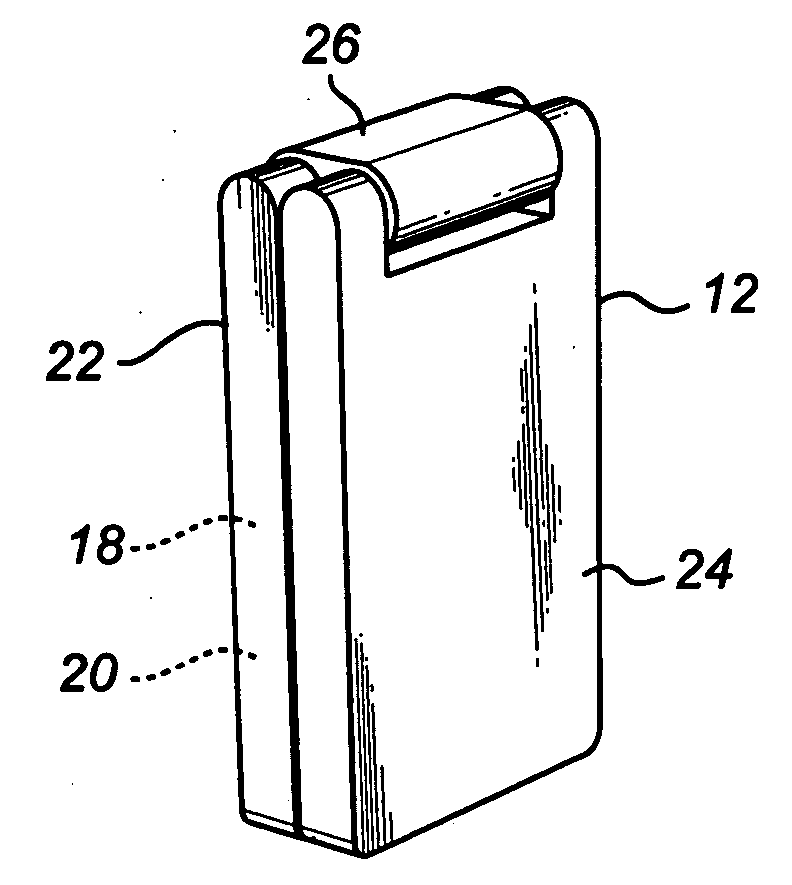

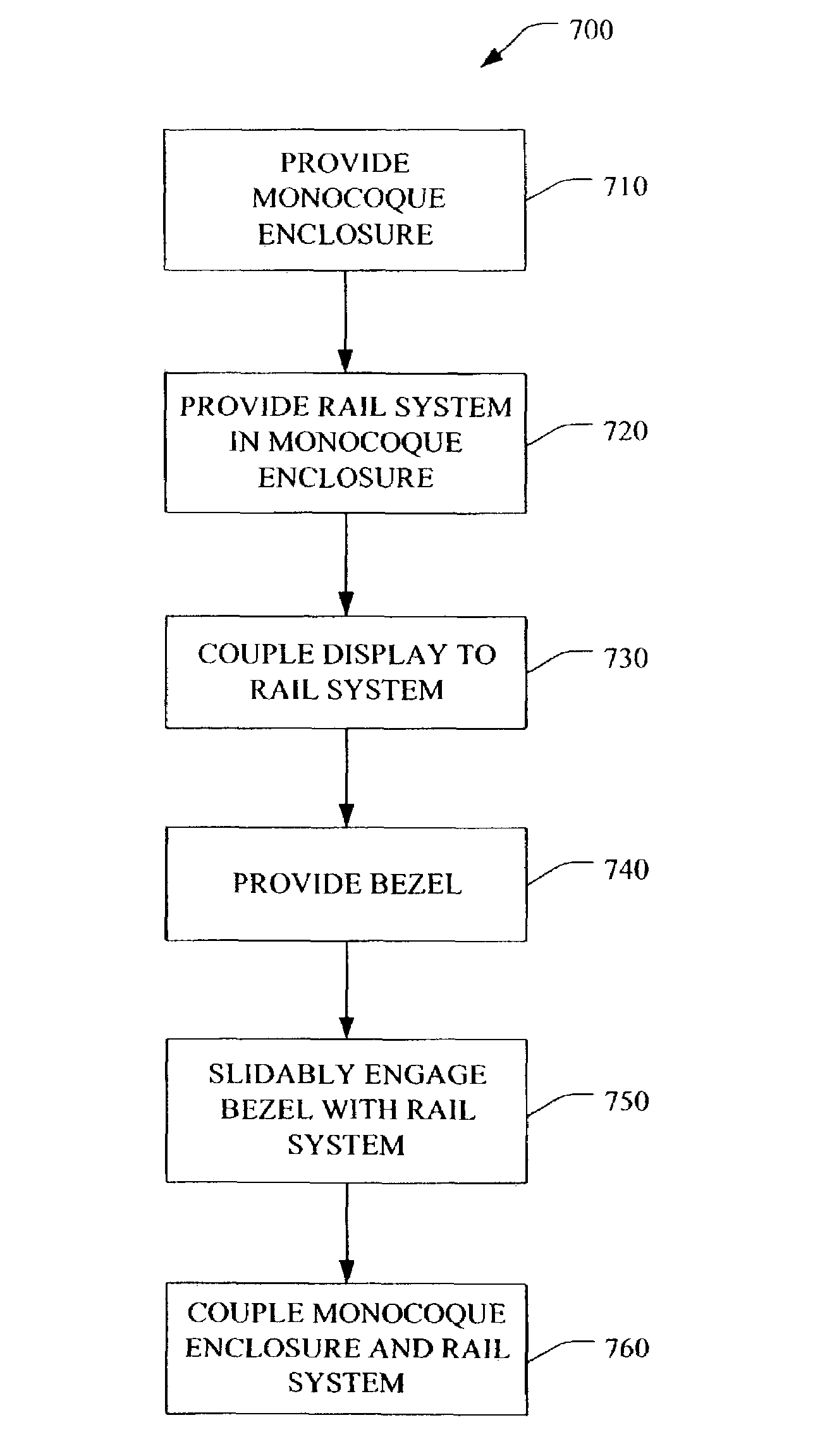

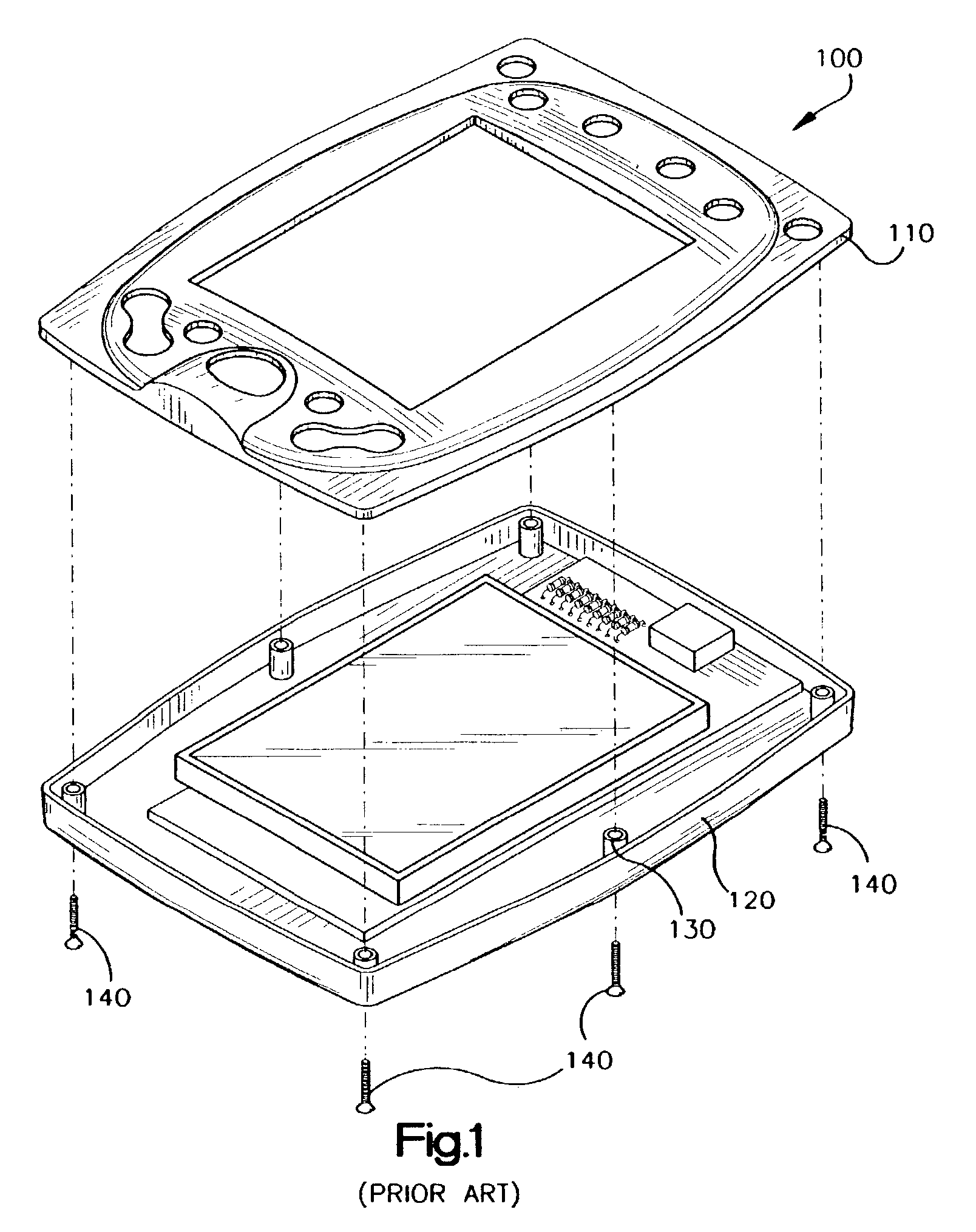

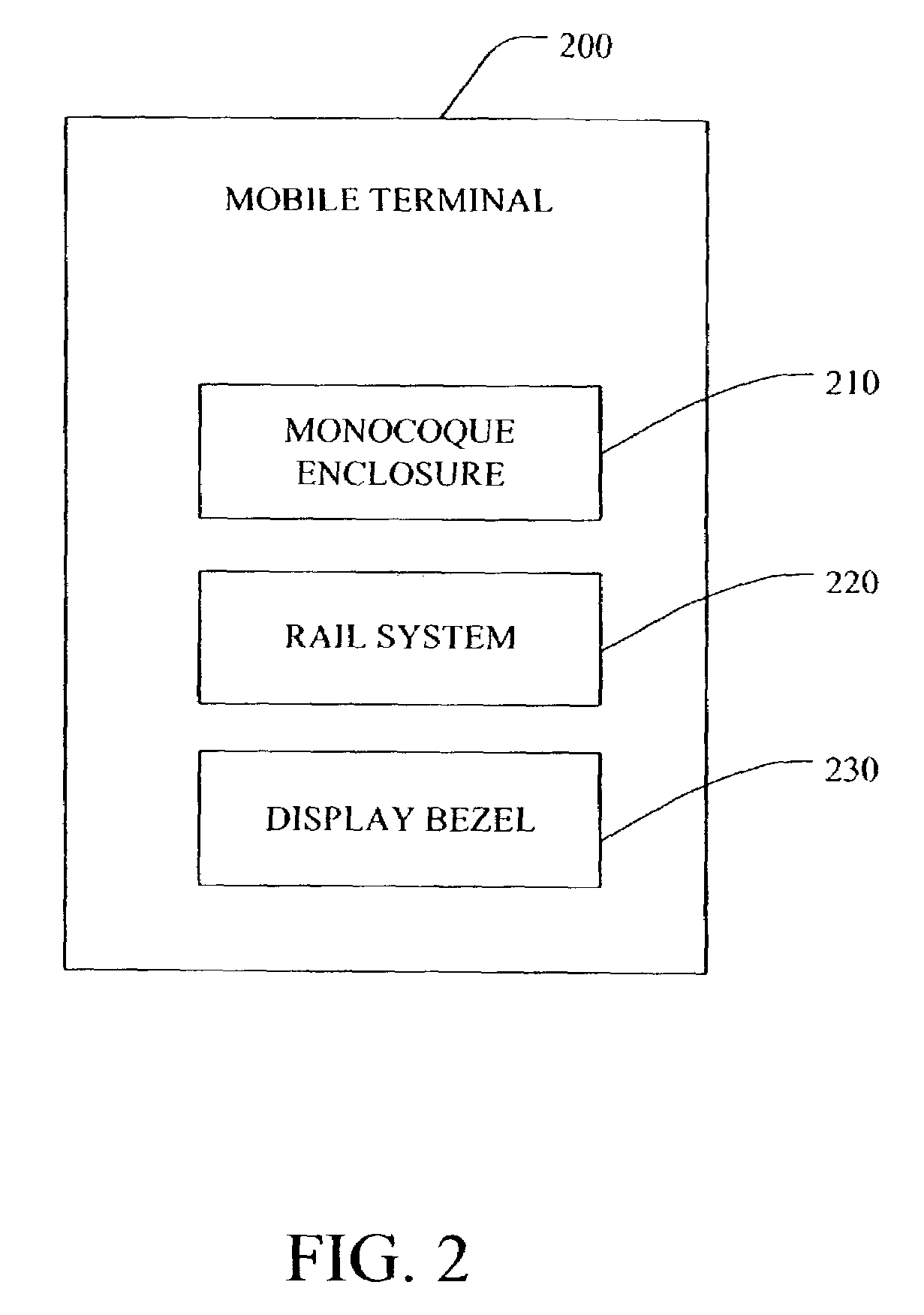

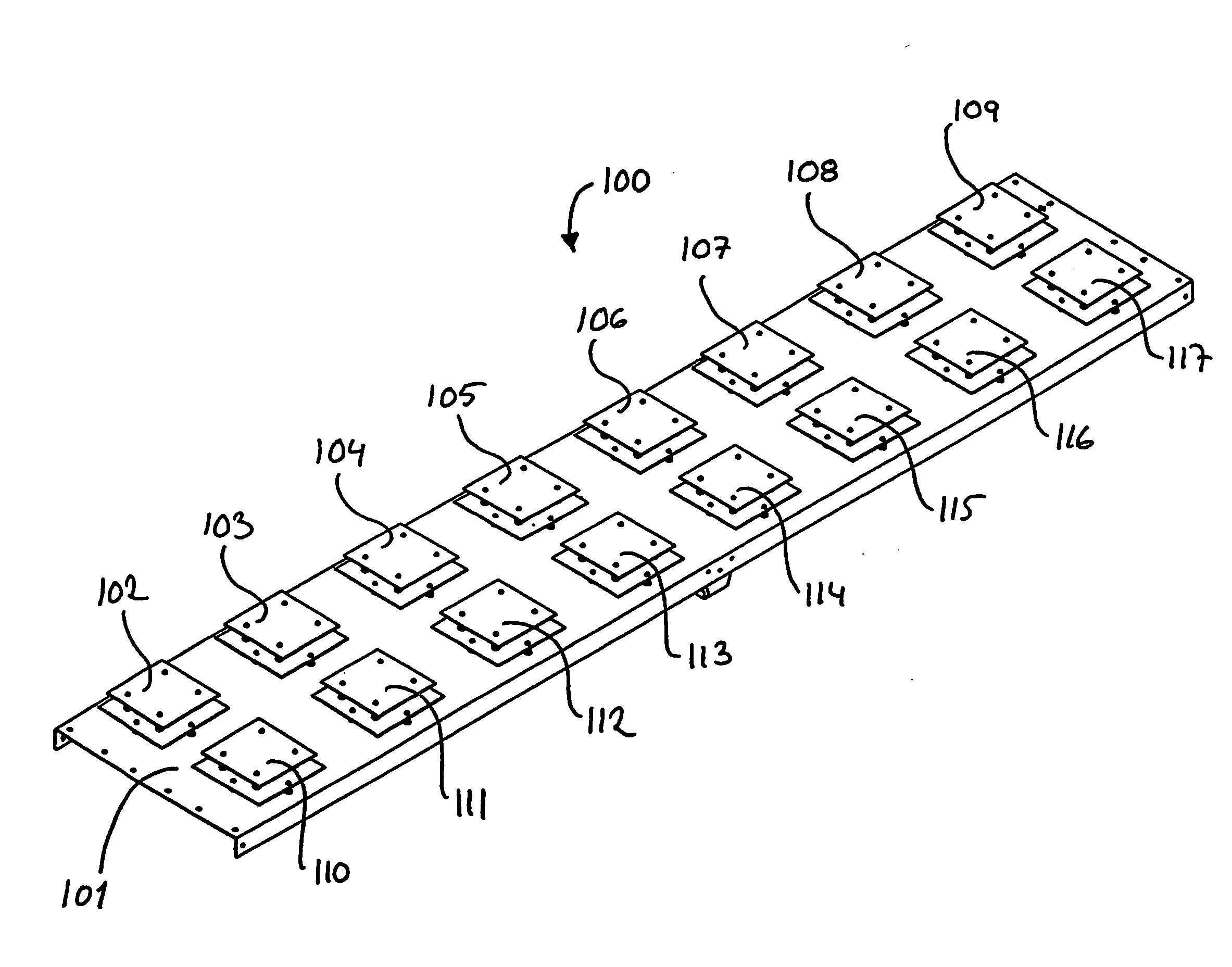

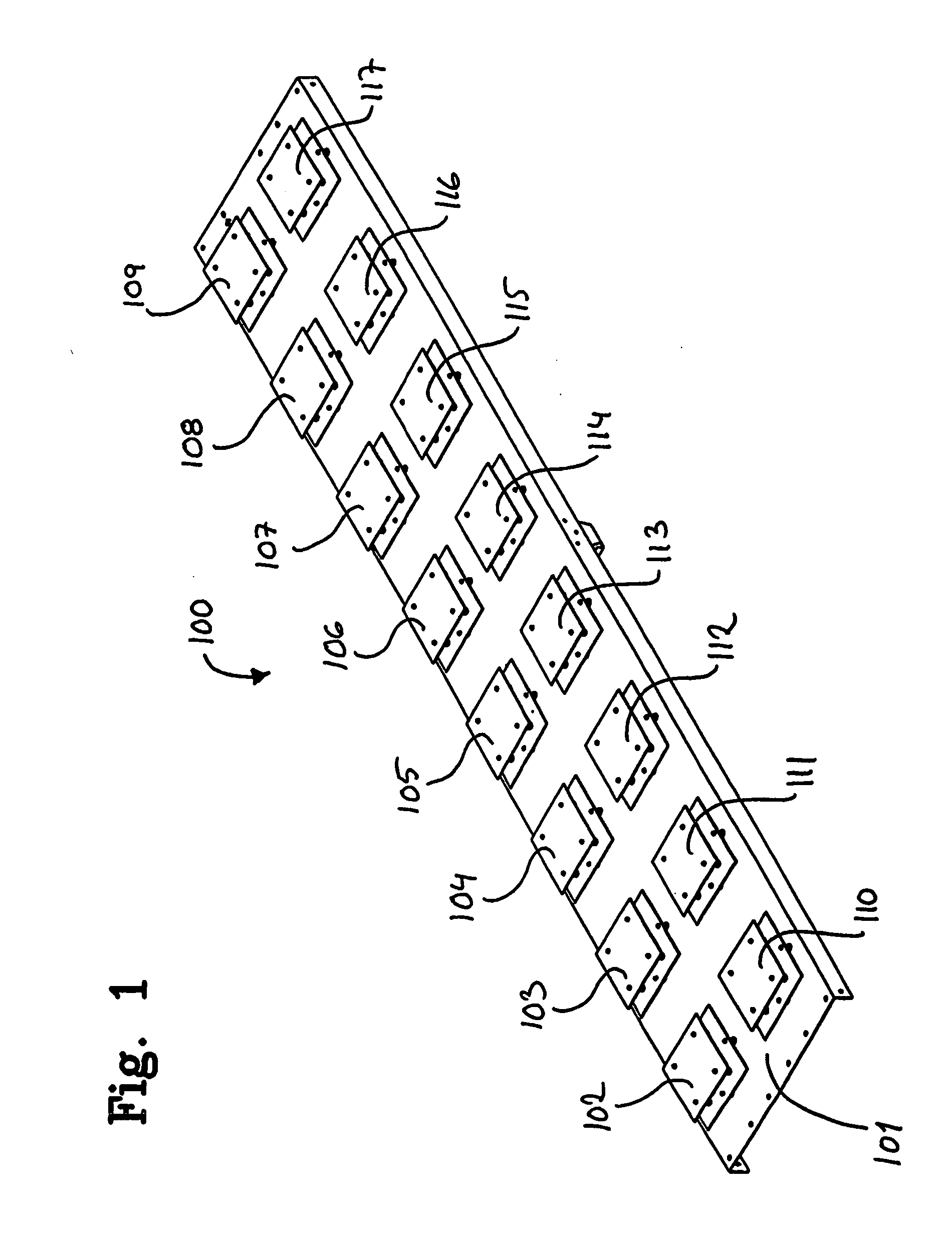

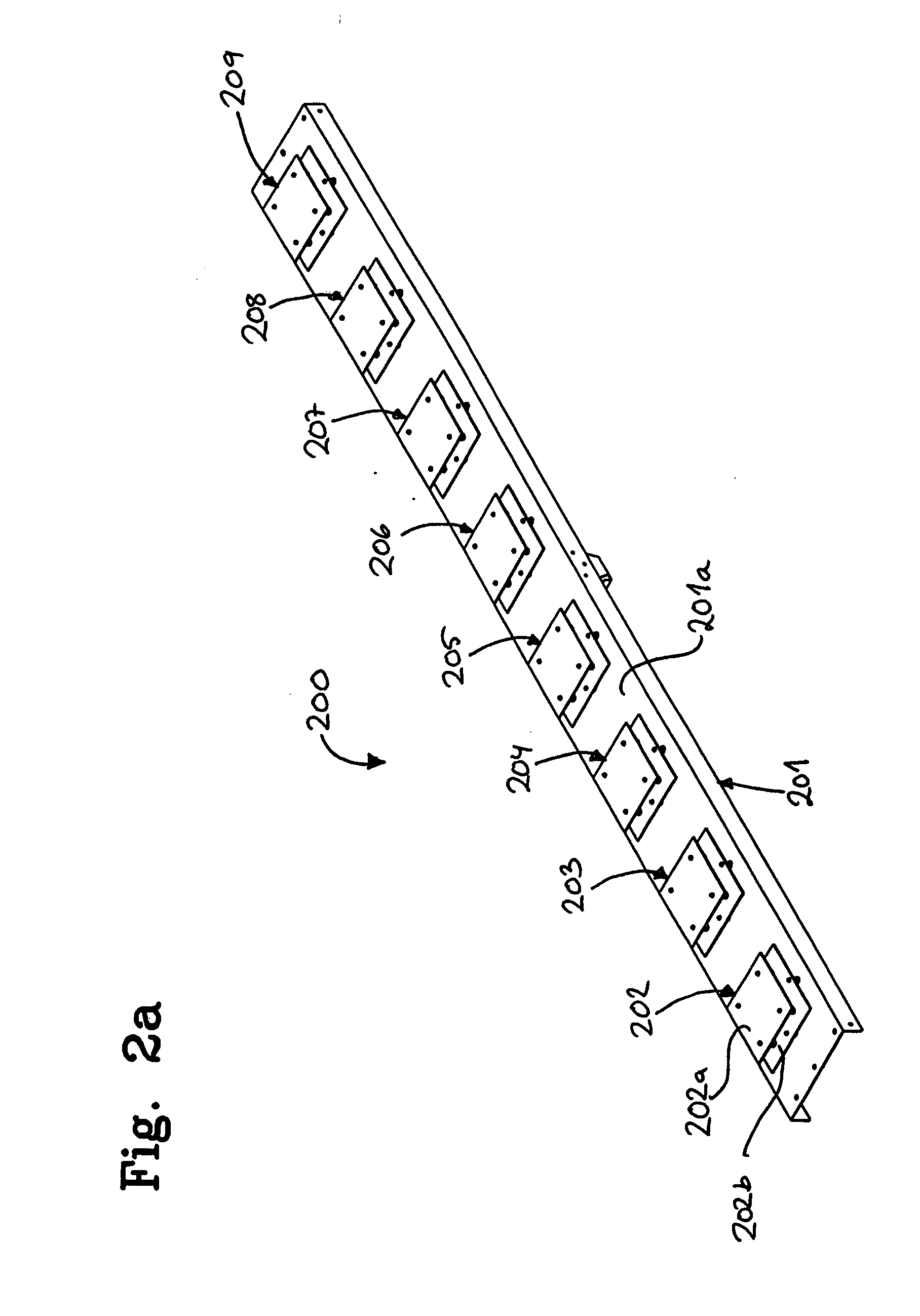

Rugged design for hand held mobile terminals

ActiveUS7522889B2Increased torsional stiffnessEasy to assembleInterconnection arrangementsMounting boards securingDisplay deviceHand held

Systems and methods for a rugged hand held mobile terminal design are provided. The mobile terminal design includes a monocoque enclosure for housing electronic components. The electronic components are mounted on a rail system, which is positioned within an interior portion of the enclosure through an open end of the enclosure. The mobile terminal design also includes a display bezel. The display bezel and the rail system have mating parts for securing the assembly together.

Owner:SYMBOL TECH LLC

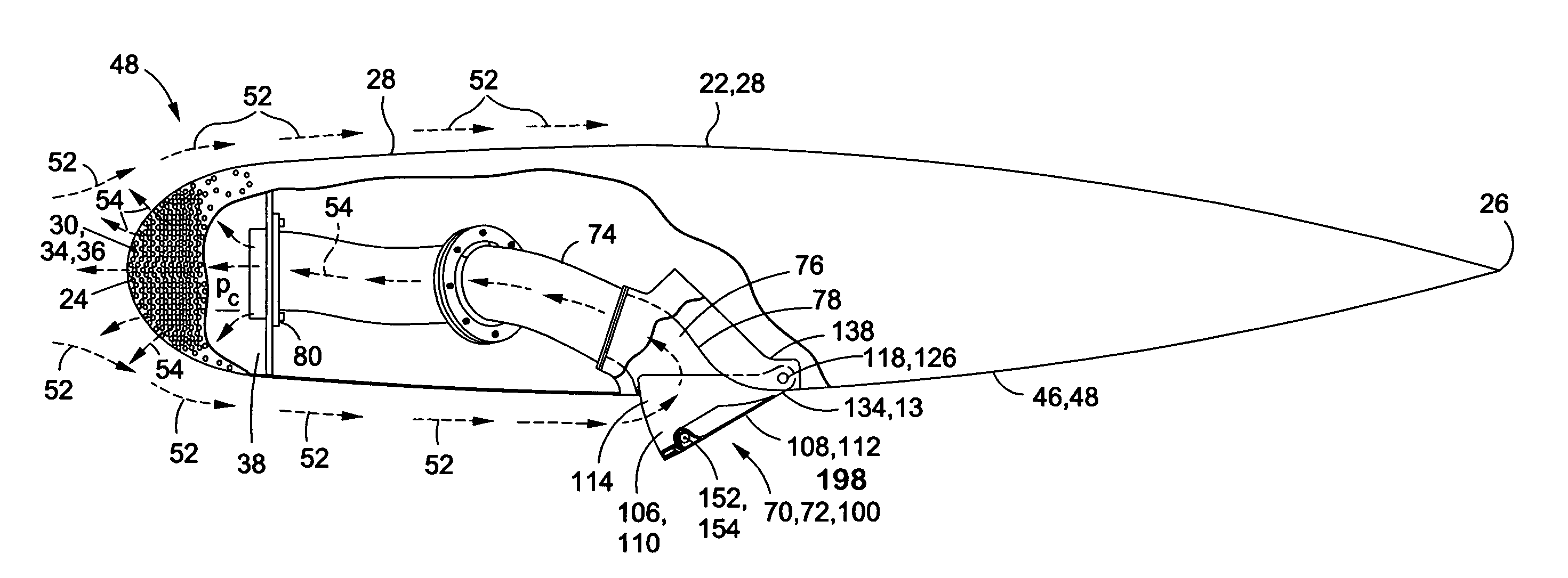

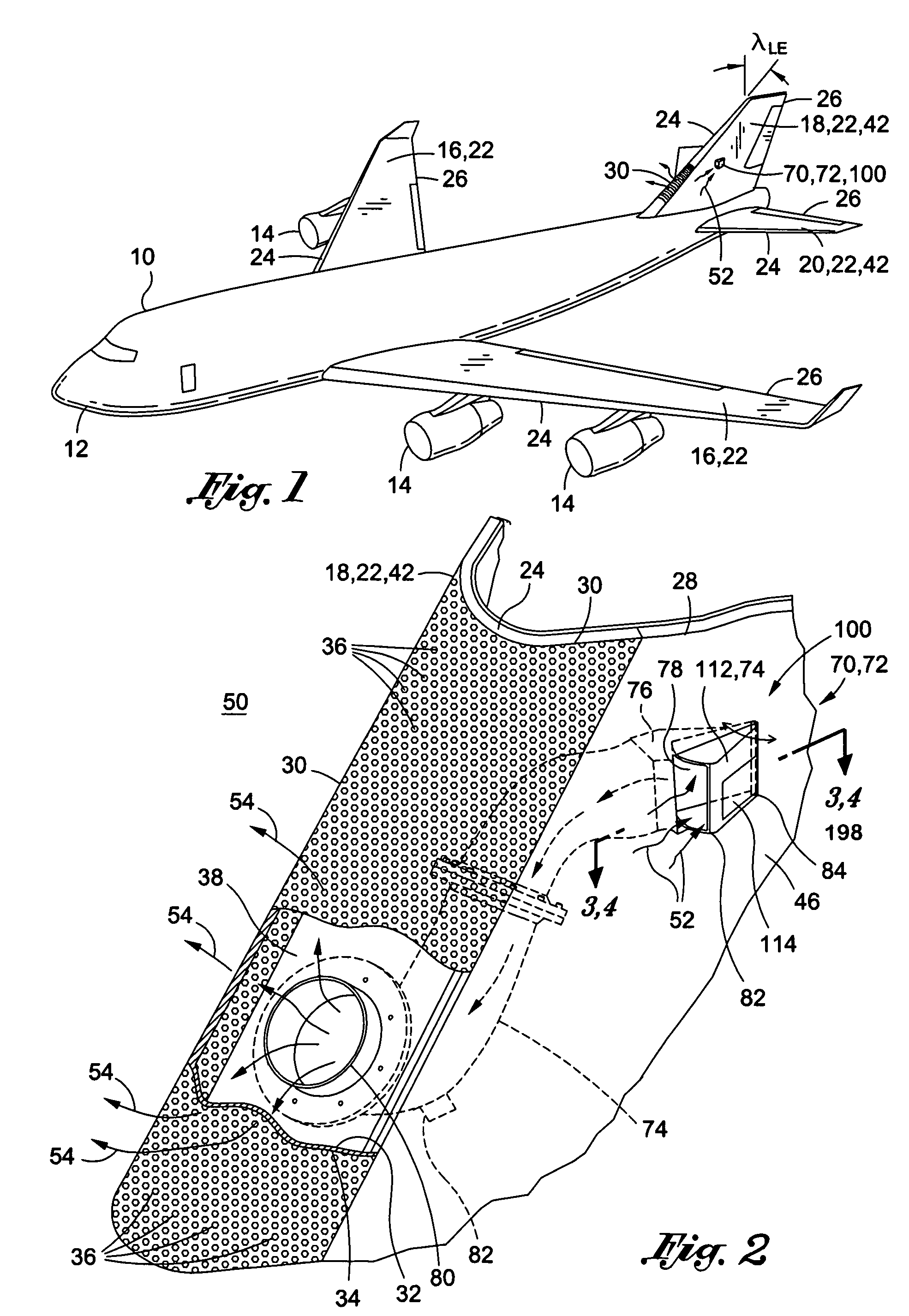

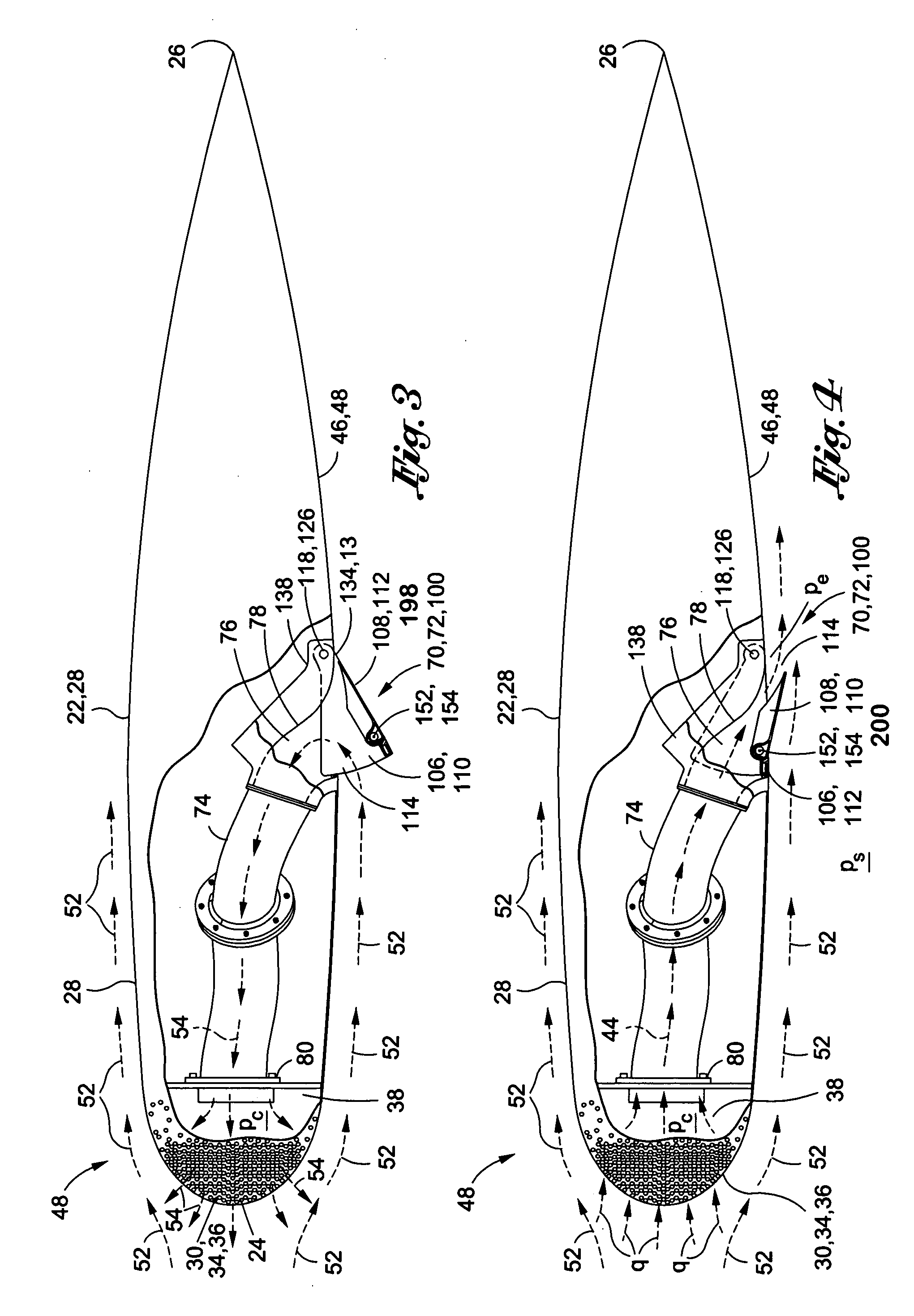

Door assembly for laminar flow control system

ActiveUS8245976B2Efficient removalReduced effectivenessNACA type air intakesPower installationsControl systemActuator

Owner:THE BOEING CO

Mobile communications device with synchronising hinge

InactiveUS7426406B2Simple and robust solutionImprove reliabilityDigital data processing detailsWing accessoriesTransceiverDisplay device

The invention relates to a mobile communications device comprising a housing, a transceiver in the housing, a keypad connected to the housing, and a display connected to the housing, wherein the housing comprises a first section movably connected to a second section of the housing by a multi-axis hinge, wherein a first axis of rotation of the hinge is provided at the first section of the housing and a second offset axis of rotation of the hinge is provided at the second section of the housing, and wherein the hinge comprises means for synchronizing rotation of the first and second sections relative to the hinge through a path of about 360 degrees. The invention further relates to a hinge for use therein.

Owner:NOKIA TECHNOLOGLES OY

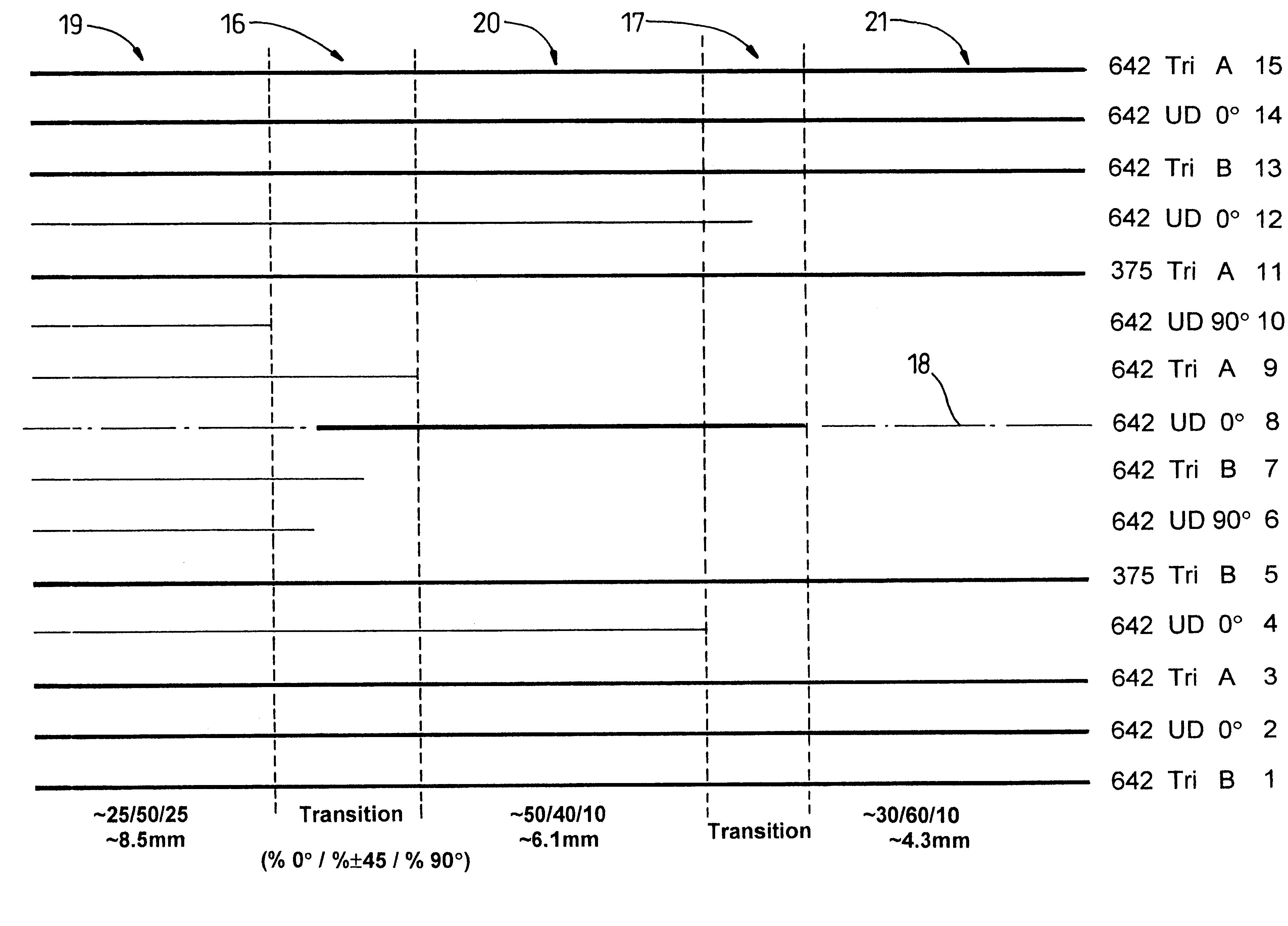

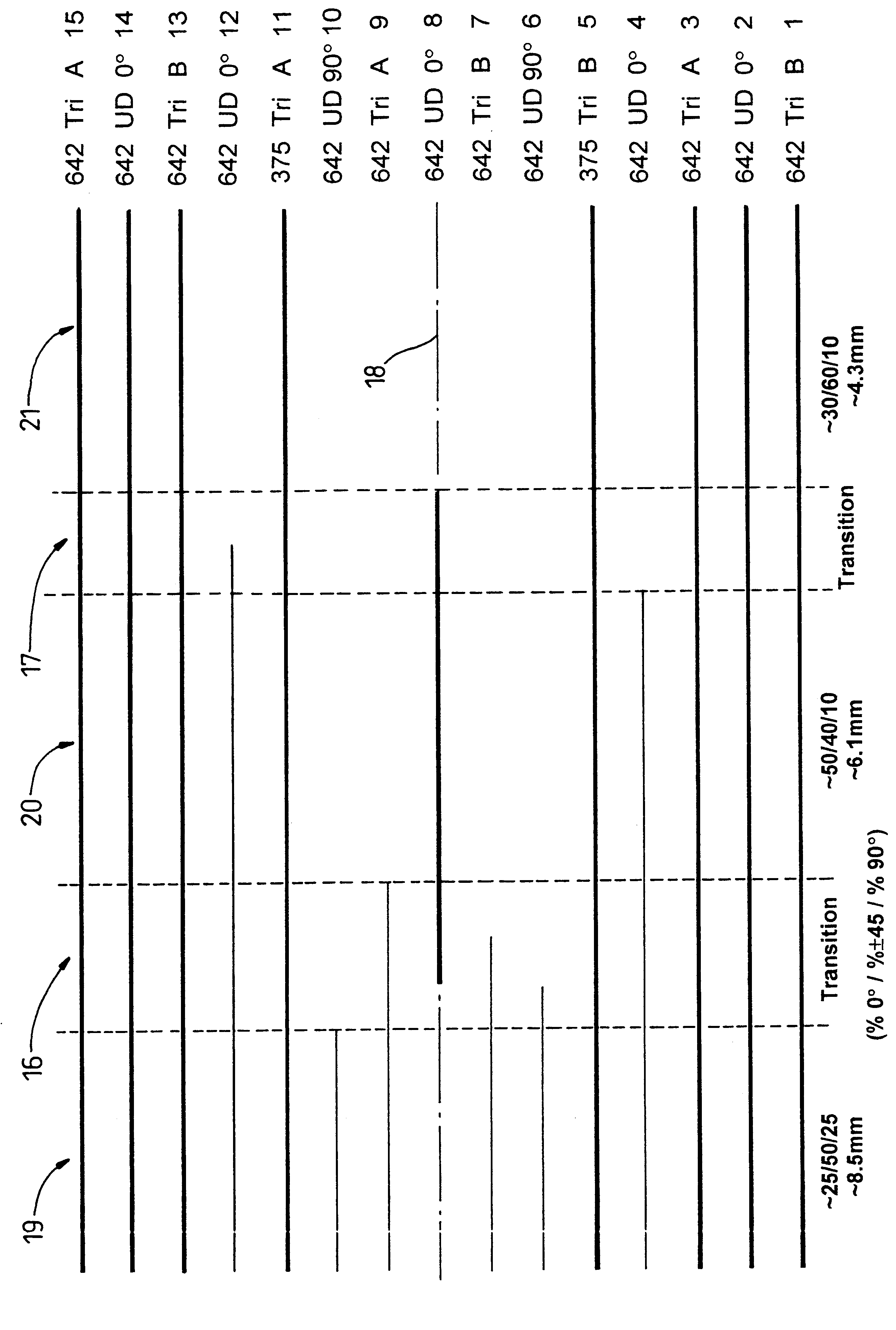

Composite laminate manufacture with multiaxial fabrics

Owner:AIRBUS OPERATIONS LTD

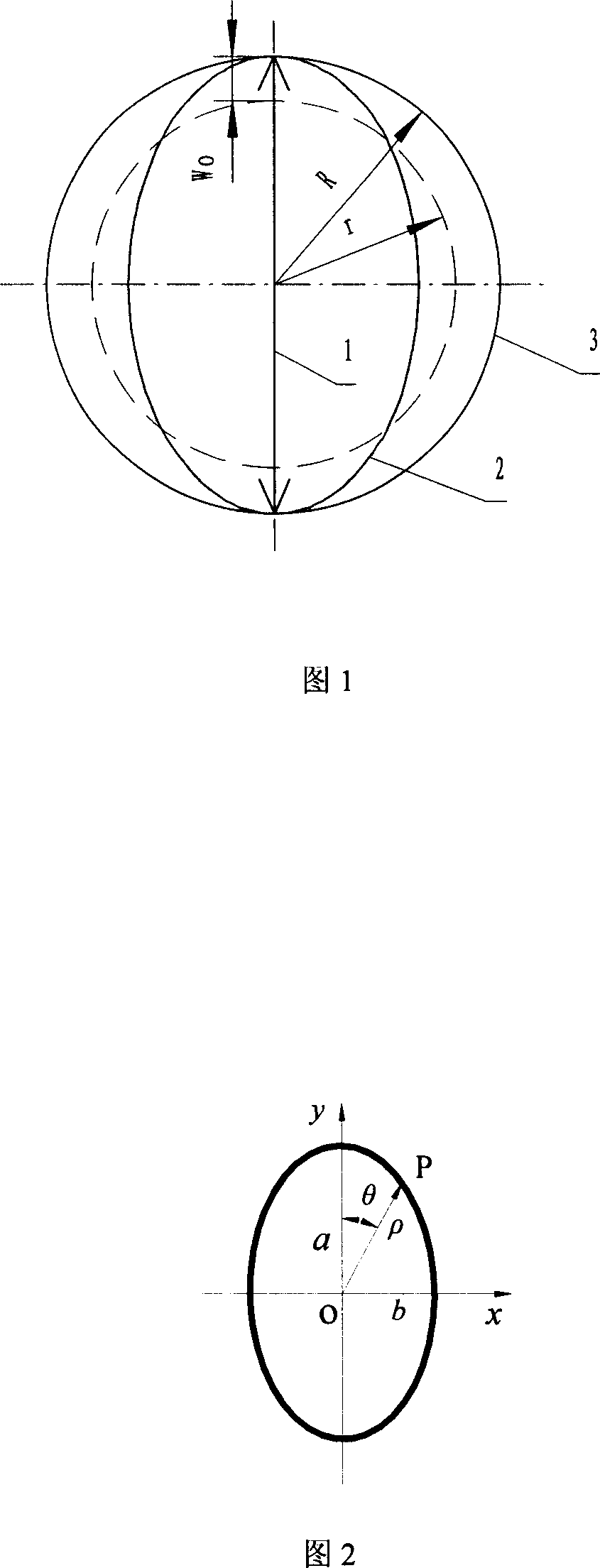

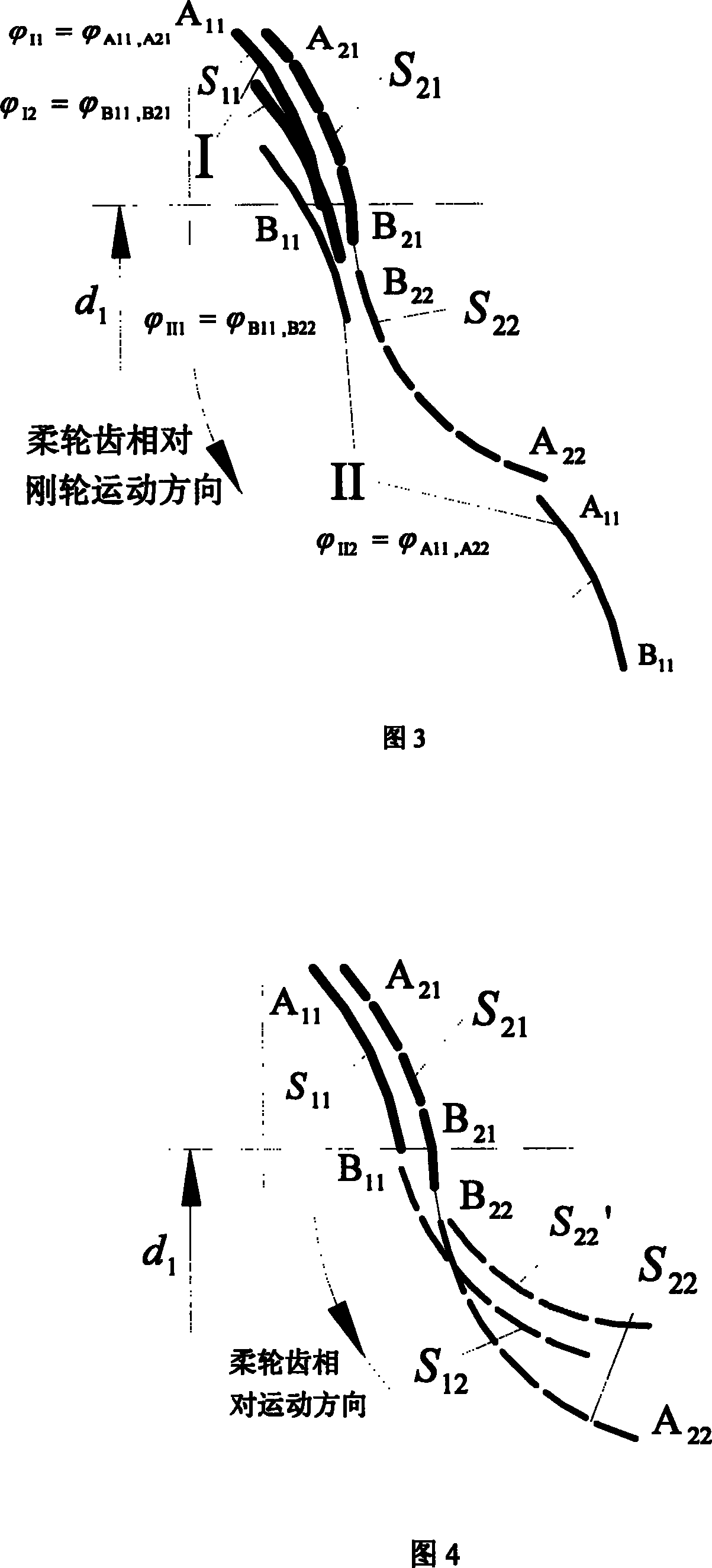

Harmonic gear power transmission with double circular arc tooth outline

InactiveCN101135357AImprove carrying capacityIncreased torsional stiffnessToothed gearingsStress conditionsHarmonic

The harmonic wave gear driver with two-arc teeth profile comprises wave generator, flexible wheel and rigid wheel. The wave generator is in form of elliptic cam, the flexible wheel and the rigid wheel has a two-arc teeth profile respectively which can realize conjugation motion. The driver can effectively improve the stress condition of the flexible wheel tooth-root and drive quality and increase load-bearing ability and torque rigidity of harmonic wave driver, and further lower minimum drive ratio of harmonic wave driver. Advantages: good processing property.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

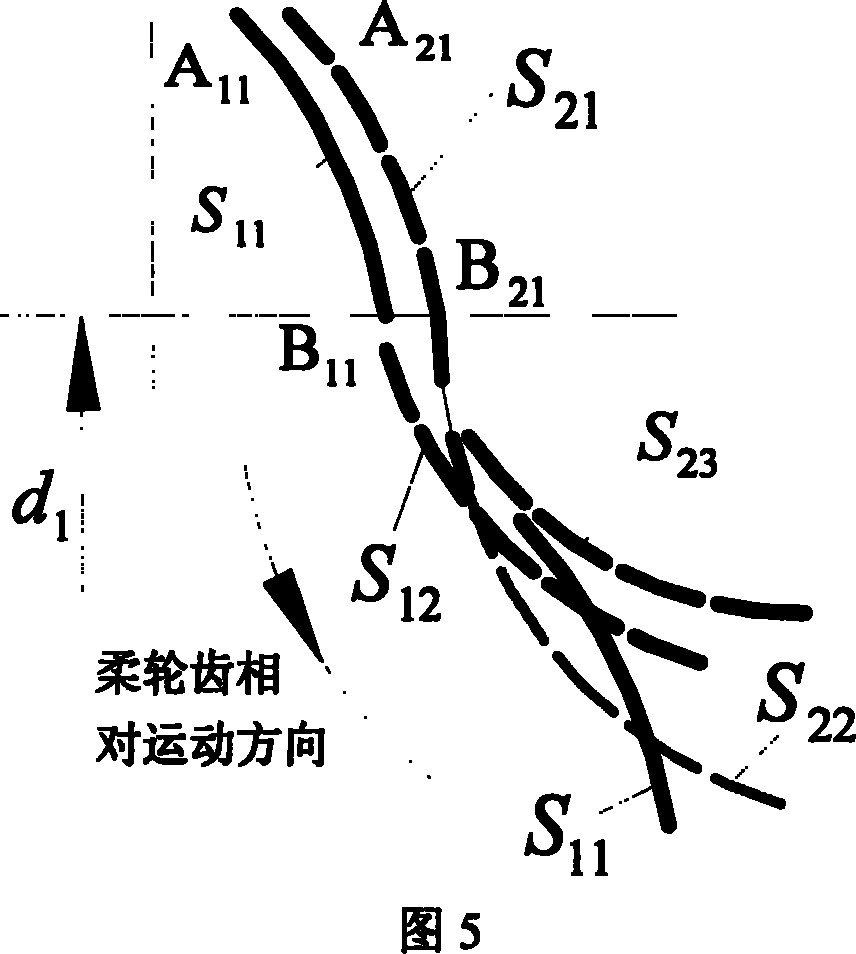

Rubber crawler

InactiveUS20050168069A1Small thicknessImprove joint strengthDriving beltsAlighting gearElastic componentEngineering

Owner:SUMITOMO RUBBER IND LTD

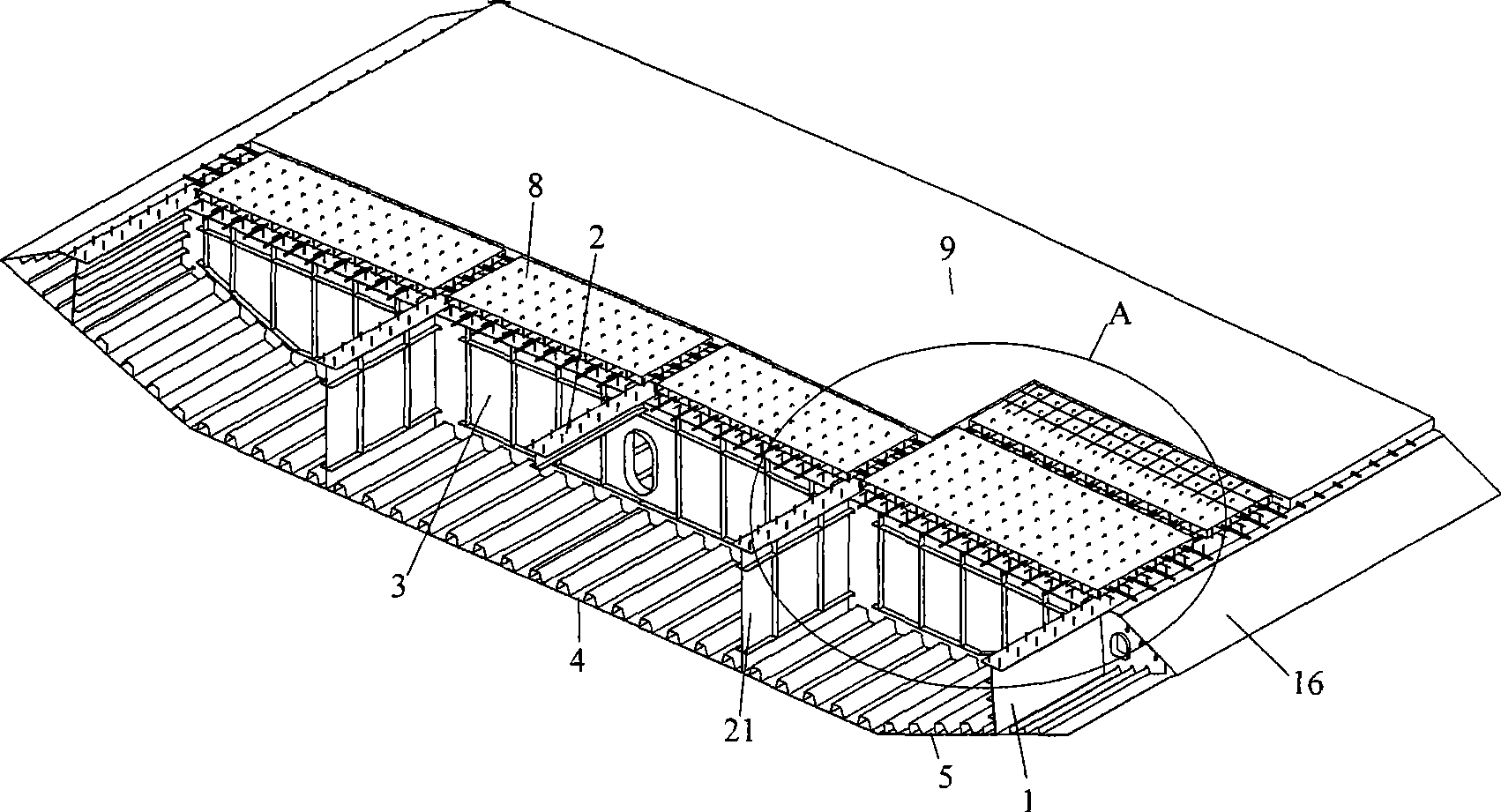

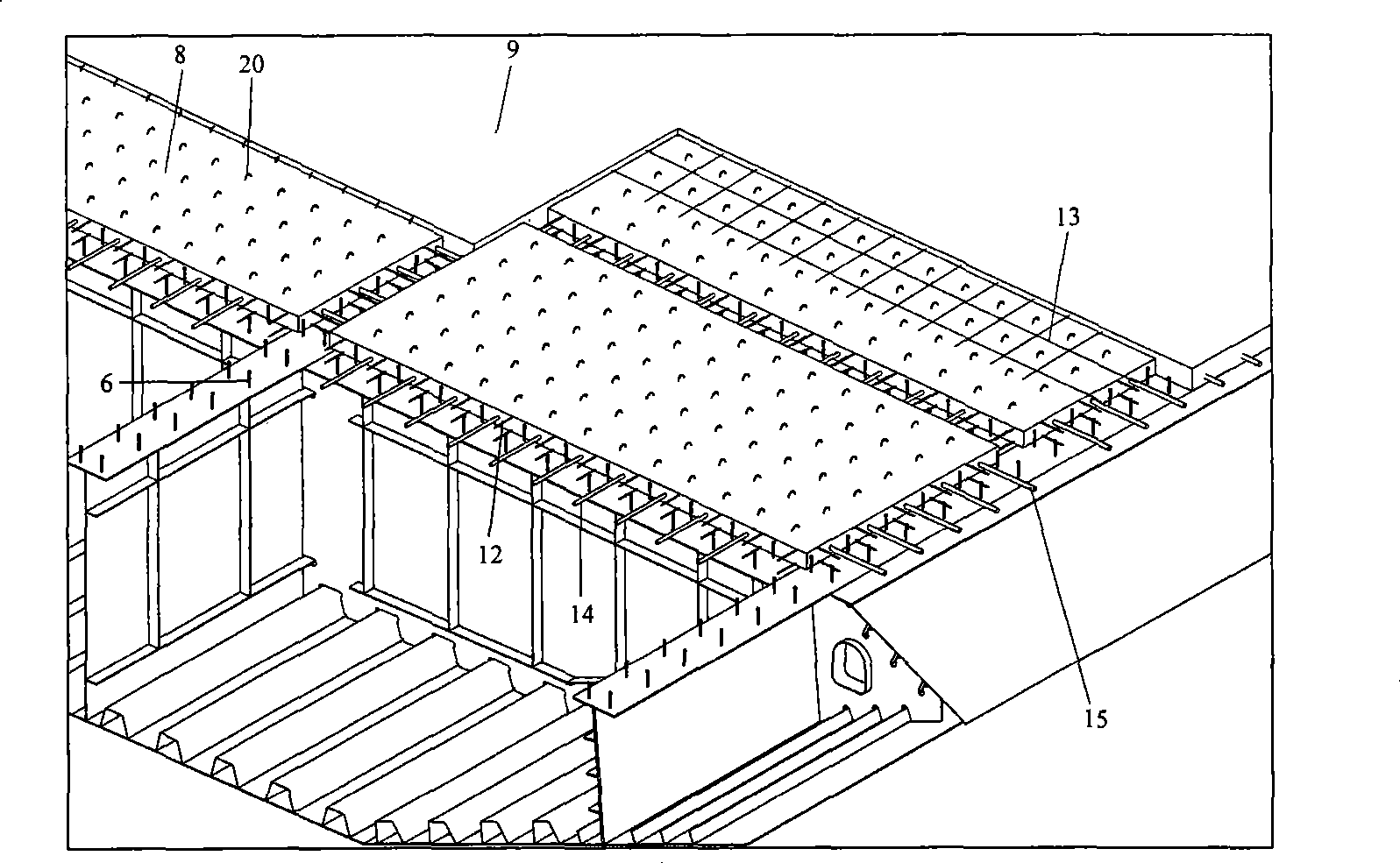

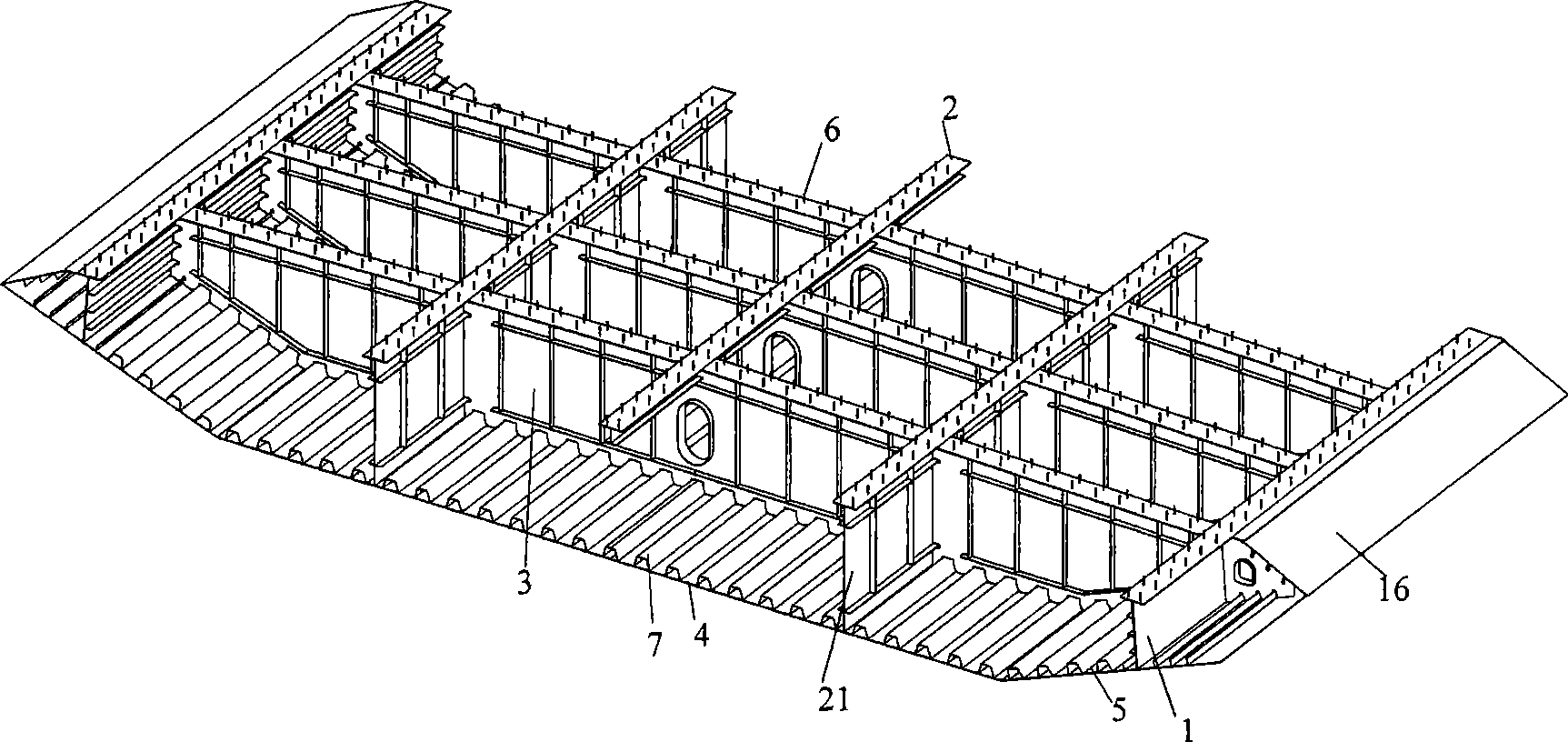

Streamline steel-concrete folding case beam

InactiveCN101413247AIncreased torsional stiffnessImprove wind resistanceBridge materialsBridge engineeringCable stayed

The invention discloses a streamlined steel-concrete superimposed box girder, which relates to the technical field of bridge engineering and is used for a long-span bridge girder. Two sides of the superimposed box girder are provided with tuyere structures, and a bridge panel adopts a superimposed structure consisting of prefabricated concrete slabs and a post-poured concrete layer. When the box girder is in use, the superimposed box girder is a streamlined single-box single-chamber or single-box multi-chamber cross section; the tuyere structures are polygonal open thin-walled structures; and longitudinal-transverse prestress is applied in the superimposed bridge panel. The box girder effectively improves the torsional rigidity and wind-resistant stability of the section of the girder, remarkably improves the integrity and durability of the bridge panel, and expands the application of superimposed girders in cable-stayed bridges and other long-span bridges.

Owner:CCCC HIGHWAY CONSULTANTS

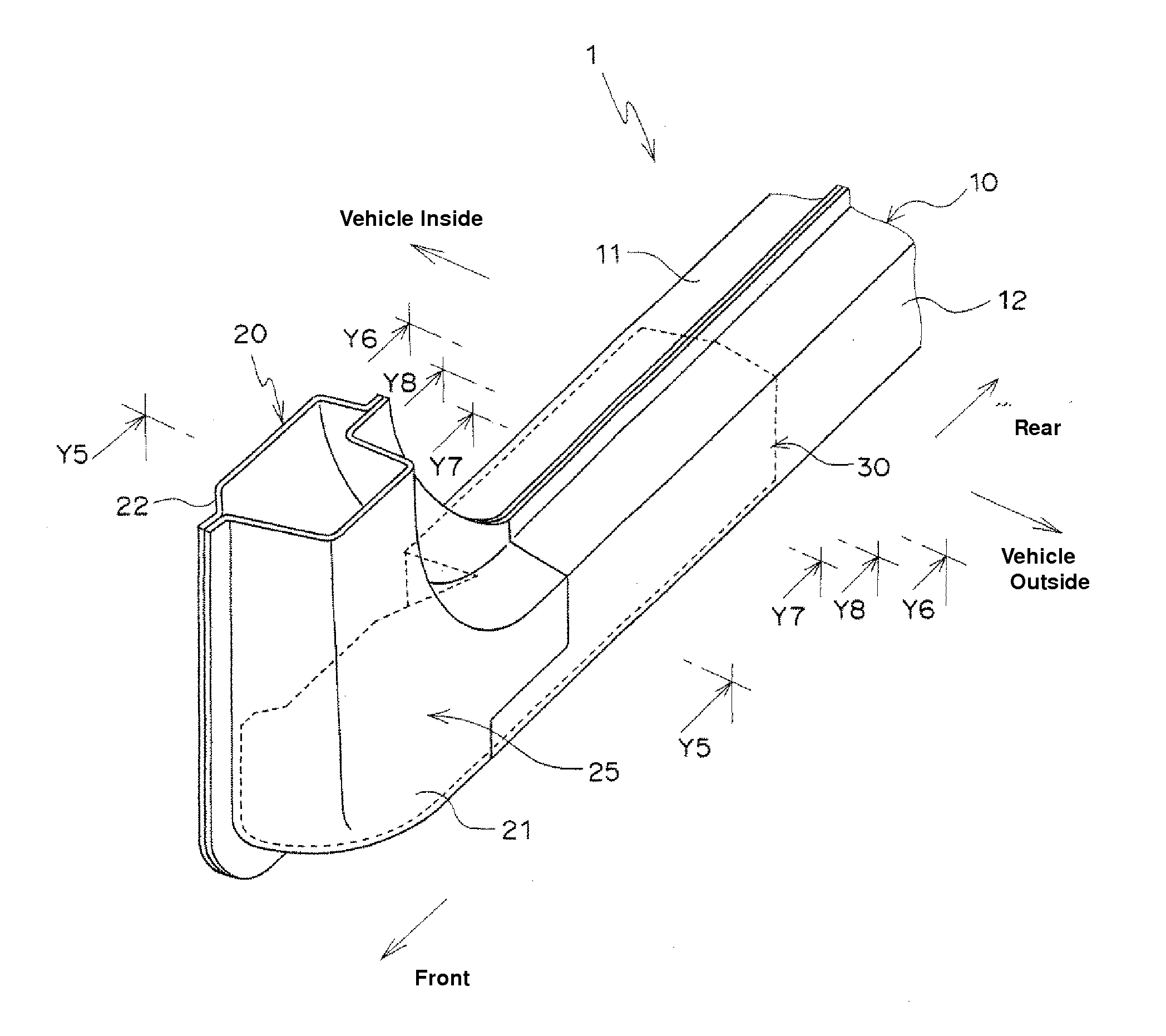

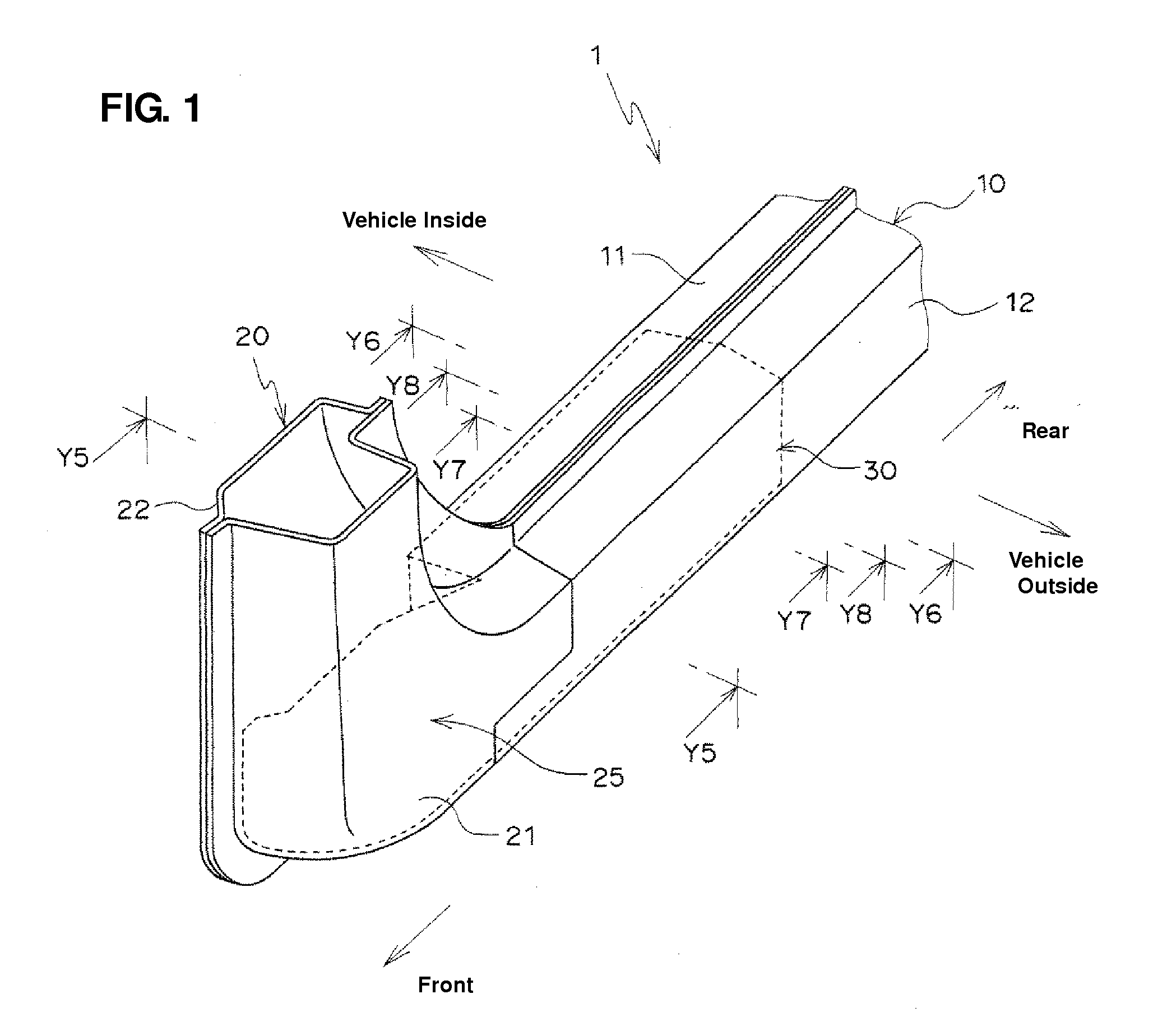

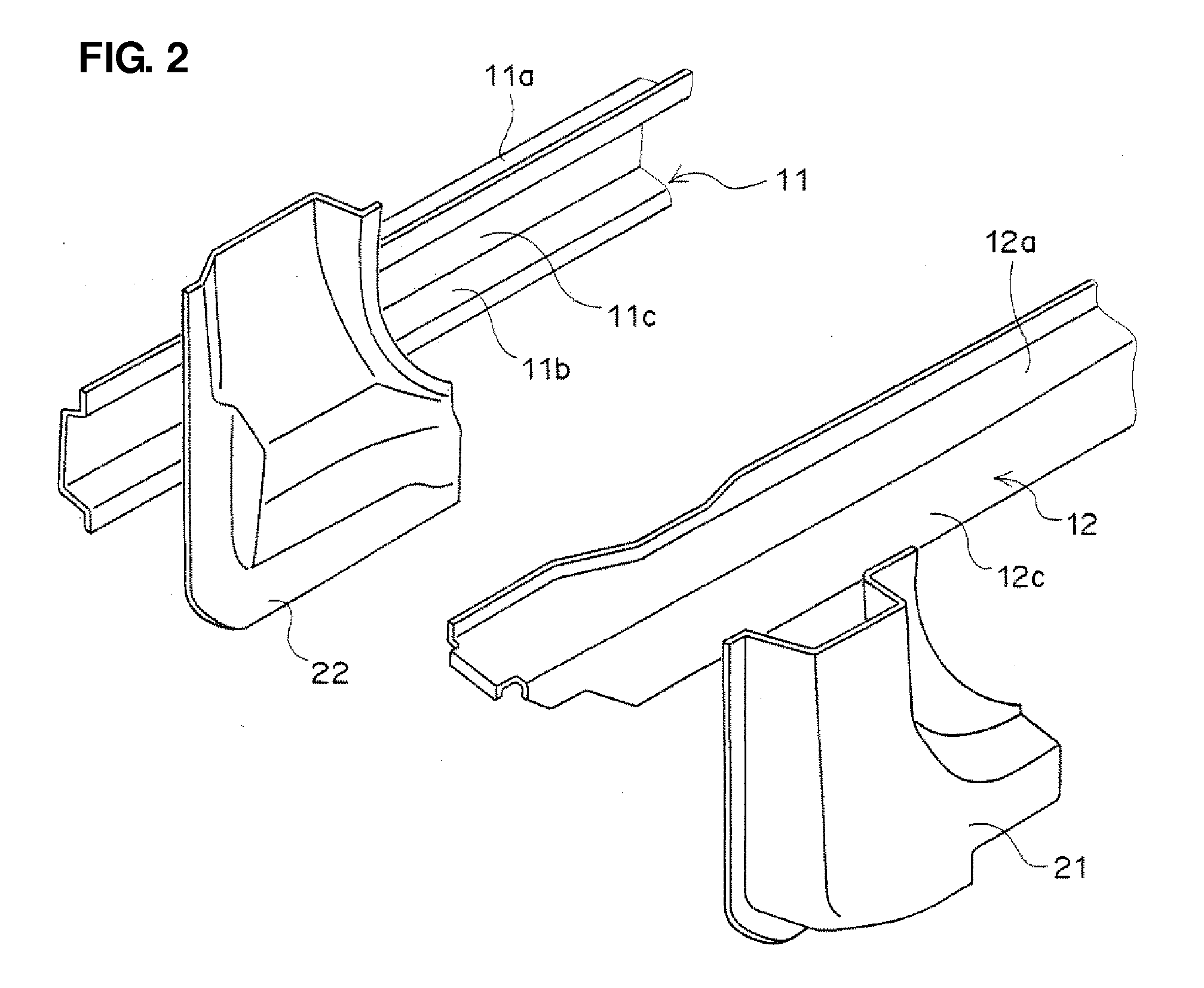

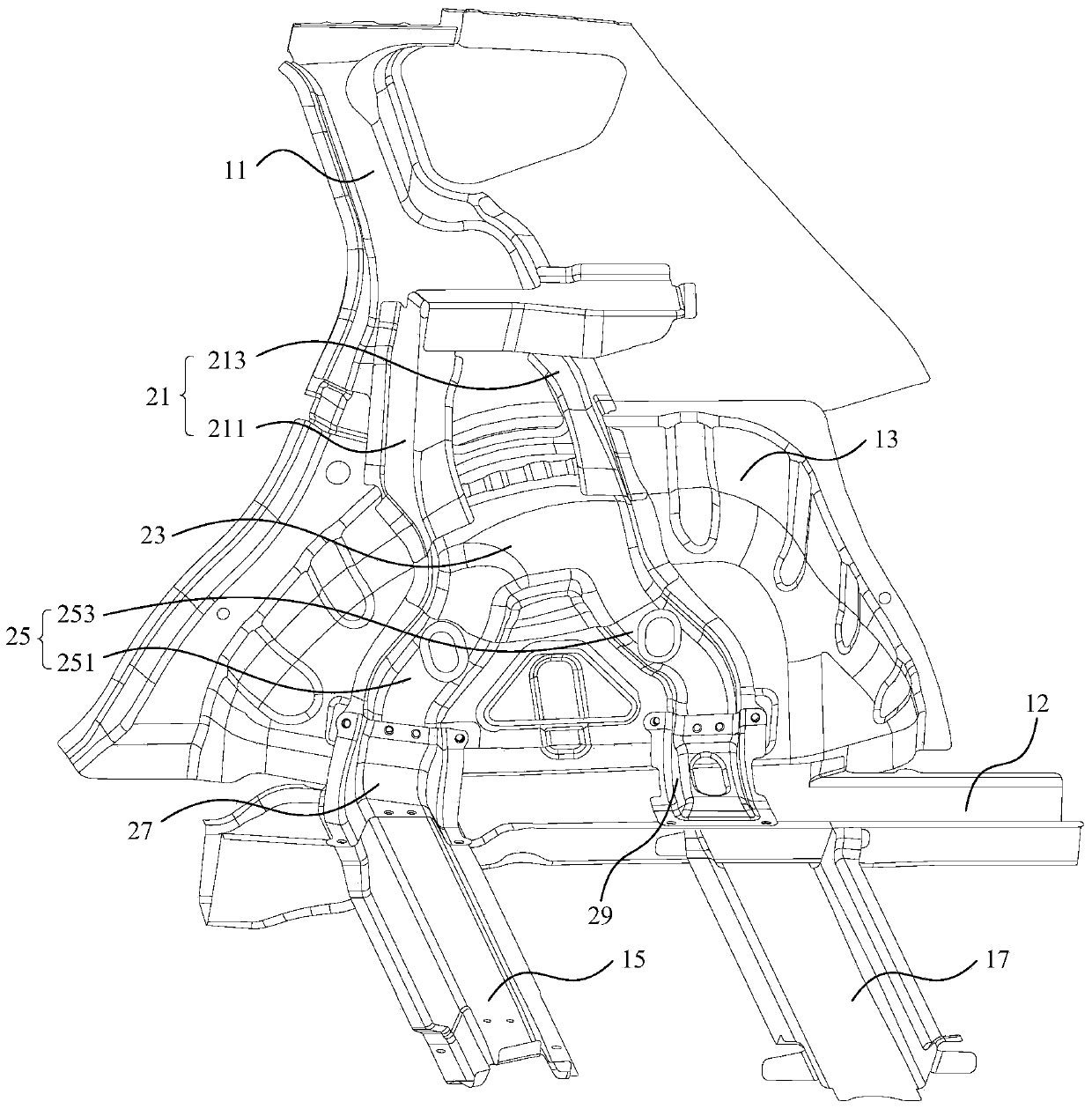

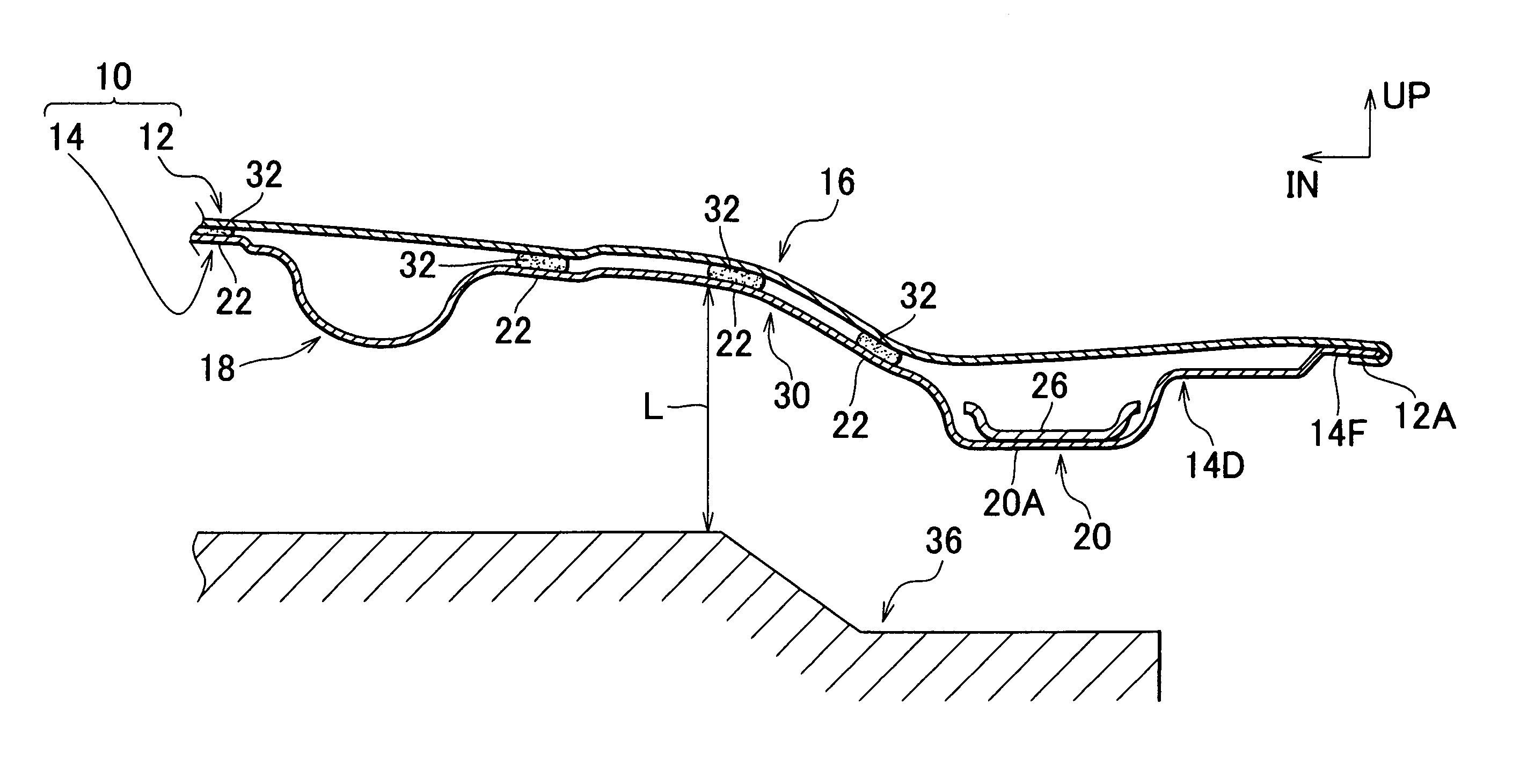

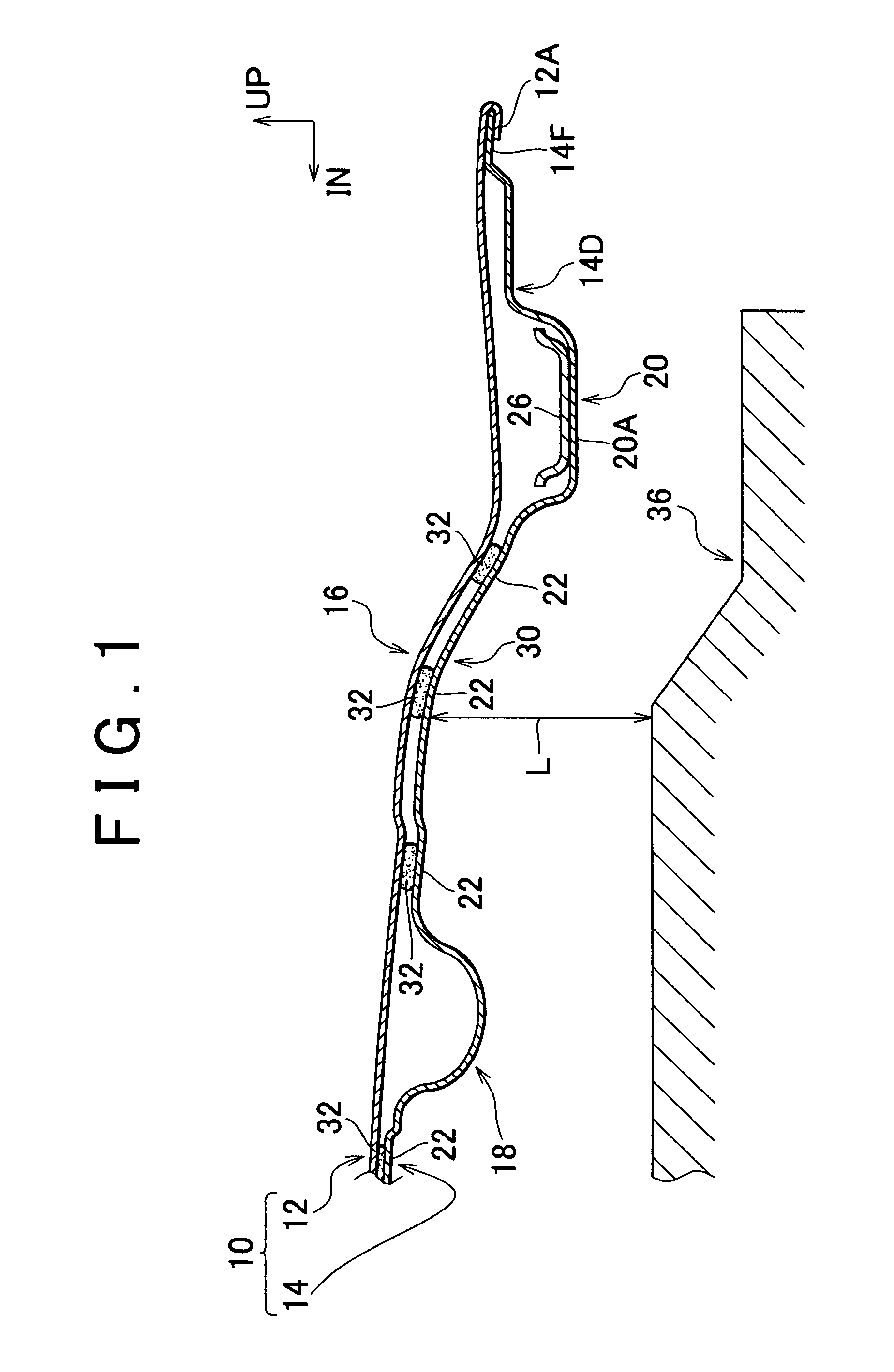

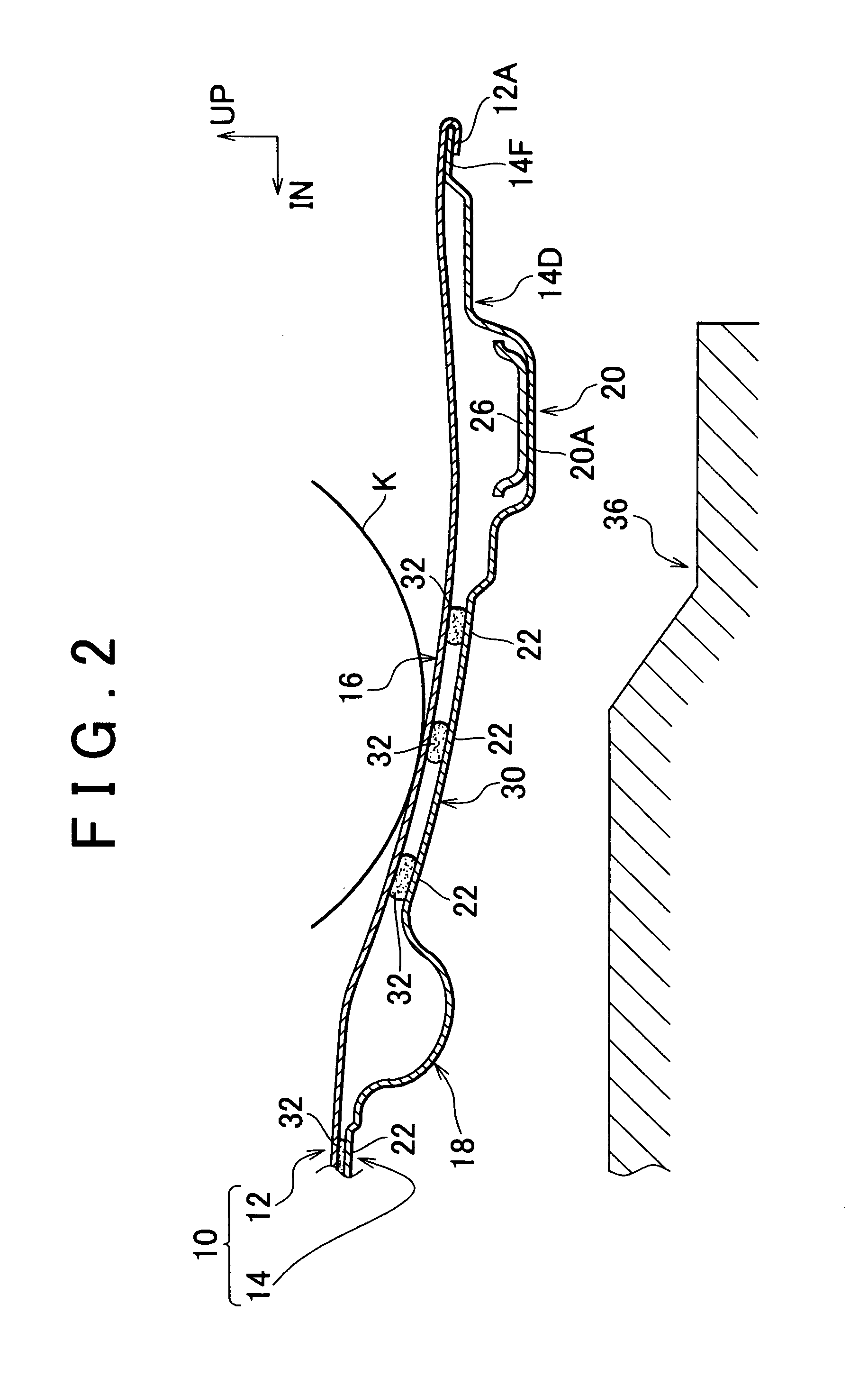

Frame structure for vehicle

InactiveUS20120119546A1Increased torsional stiffnessInhibit weight gainVehicle seatsSuperstructure subunitsRotational axisEngineering

In a frame structure for a vehicle having a reinforcement body provided inside a frame body, the frame body comprises a first face portion and a second face portion extending in a direction substantially perpendicular to a rotational-axis direction of a bending moment occurring when a torsional load acts on a vehicle body, and third face portions positioned between the first and second face portions, and the reinforcement body comprises third-face connection portions connected to the third face portions, a first-face connection portion connected to the first face portion at a corner portion, a first-face non-contact portion provided away from the first face portion, a second-face connection portion connected to the second face portion at a corner portion, and a second-face non-contact portion provided away from the second face portion.

Owner:MAZDA MOTOR CORP

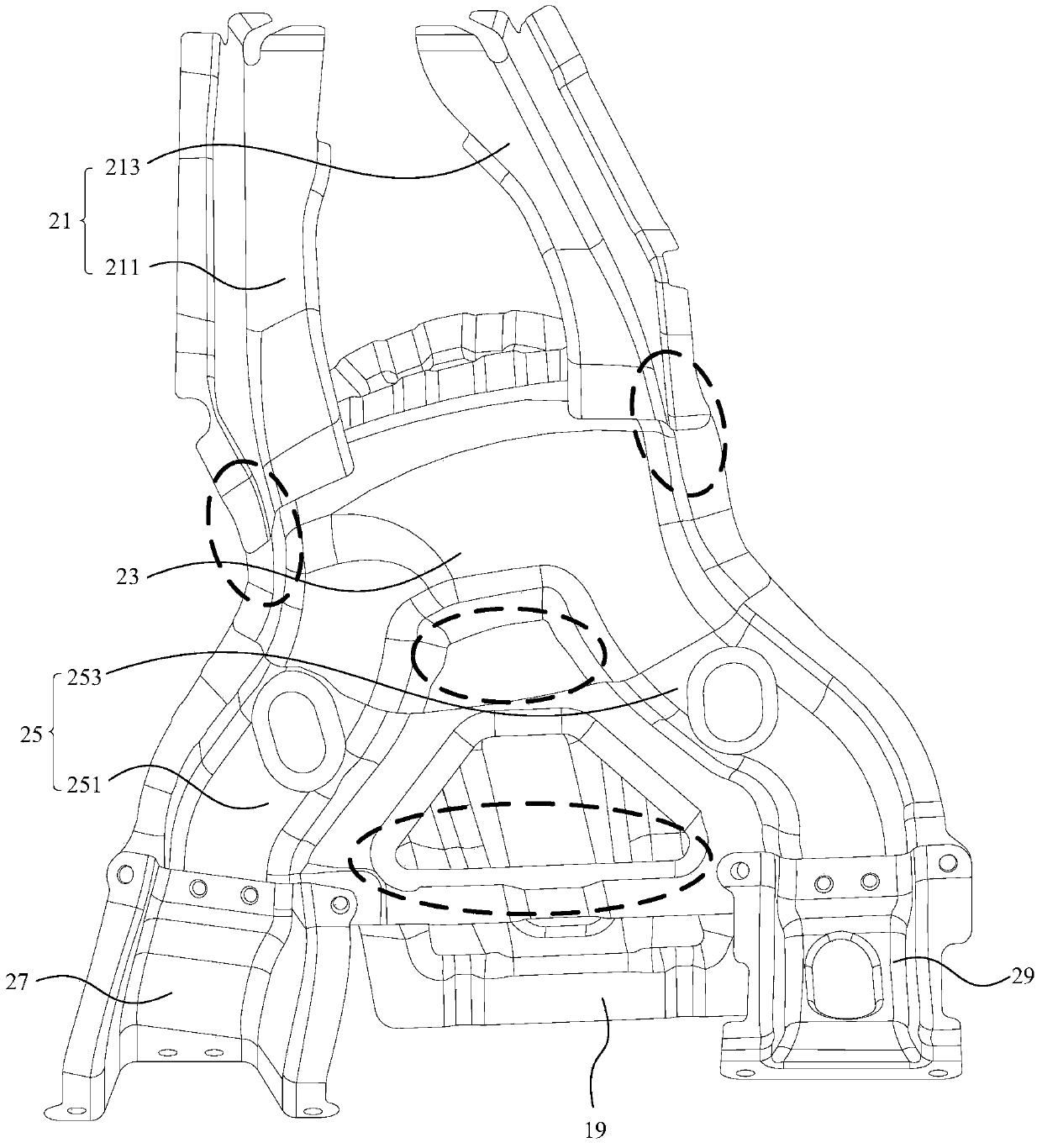

Automobile and reinforcing device for inner plate of rear wheel casing of automobile

ActiveCN103693115AIncreased torsional stiffnessIncreased durabilitySuperstructure subunitsControl theoryMechanical engineering

Owner:GREAT WALL MOTOR CO LTD

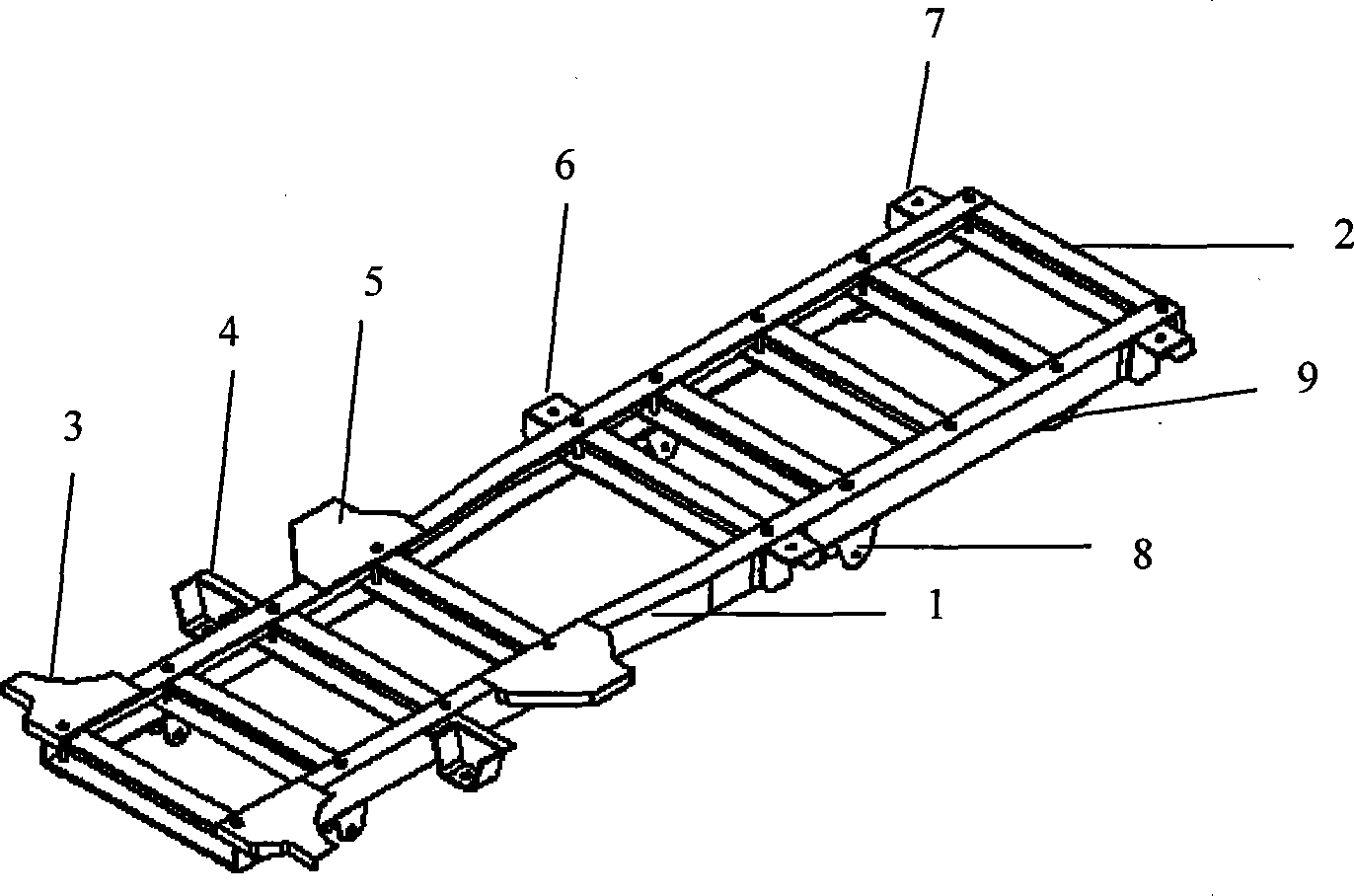

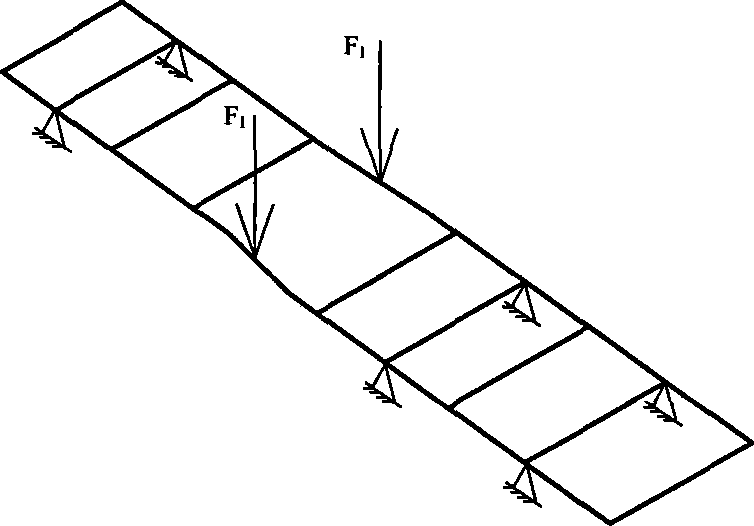

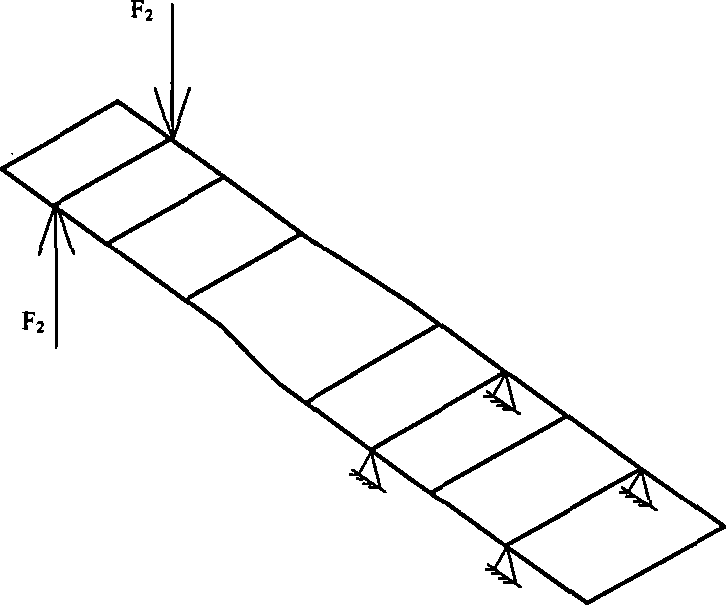

Optimum design method of non-bearing frame structure of light vehicle

InactiveCN104112050AIncreased bending stiffnessIncrease stiffnessSpecial data processing applicationsVehicle frameData file

The invention provides an optimum design method of a non-bearing frame structure of a light vehicle. The optimum design method comprises the steps of establishing a three-dimensional geometrical model of the original frame structure of the light vehicle by use of SolidWorks software and outputting the model in the IGES (Initial Graphics Exchange Specification) data file format, thereby obtaining the IGES model of the frame structure, next, reading the IGES model of the frame structure in Hypermesh software, performing geometrical processing and dividing finite element meshes by use of the Hypermesh software, and performing topological optimization on the cross beam structure of the frame by use of the structure optimization function of the Hypermesh software without changing the structural forms of the longitudinal beam and the attached seats of the frame, thereby realizing the optimum design of the arrangement position and the structural form of the cross beam structure. The optimum design method of the non-bearing frame structure of the light vehicle is capable of improving the bending rigidity and torsional rigidity of the frame of the light vehicle and the inherent frequency of the frame structure without increasing the weight of the frame structure, thereby ensuring that the frame has relatively high overall rigidity and improving the reliability, security, operation stability and vibration property of the vehicle.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

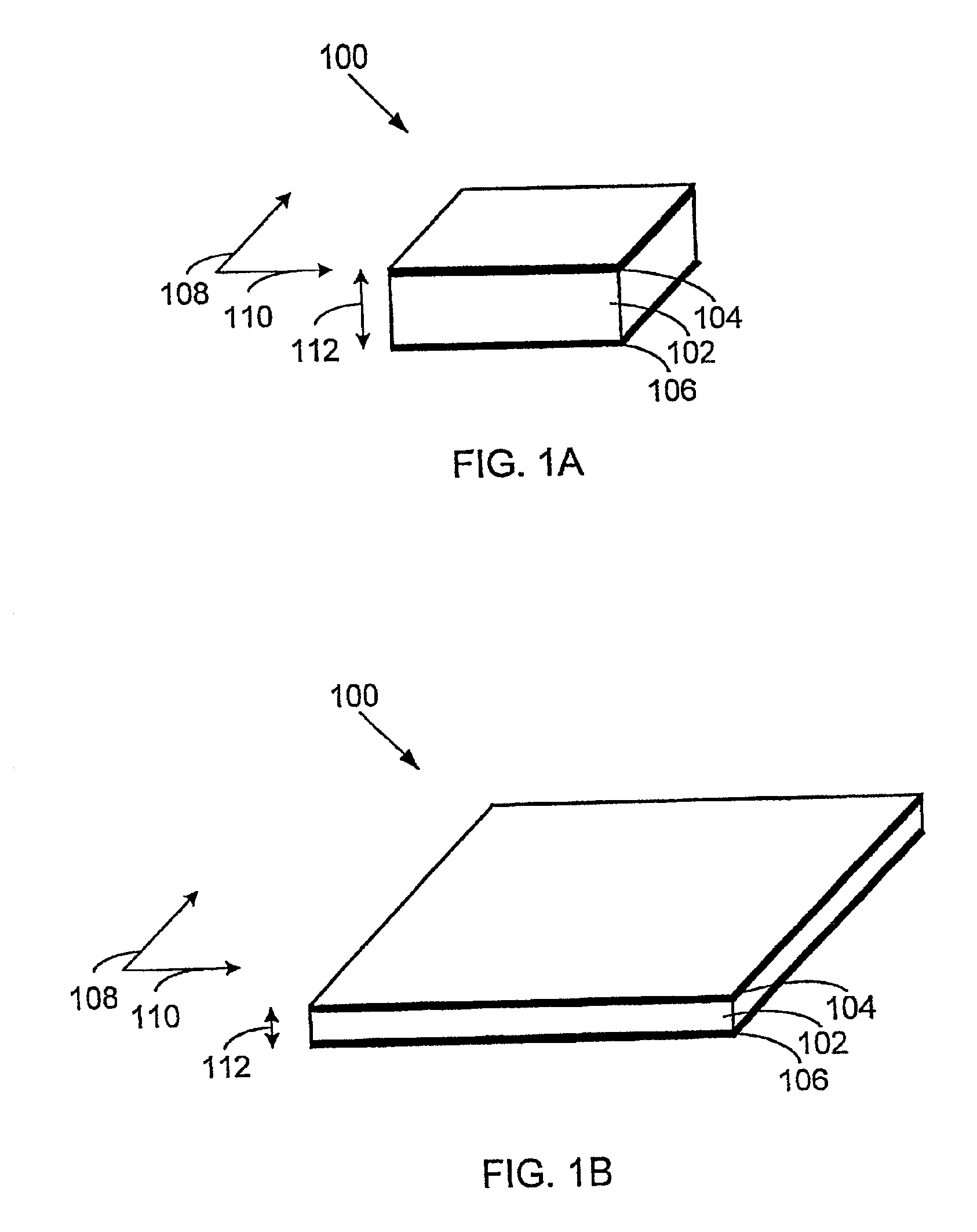

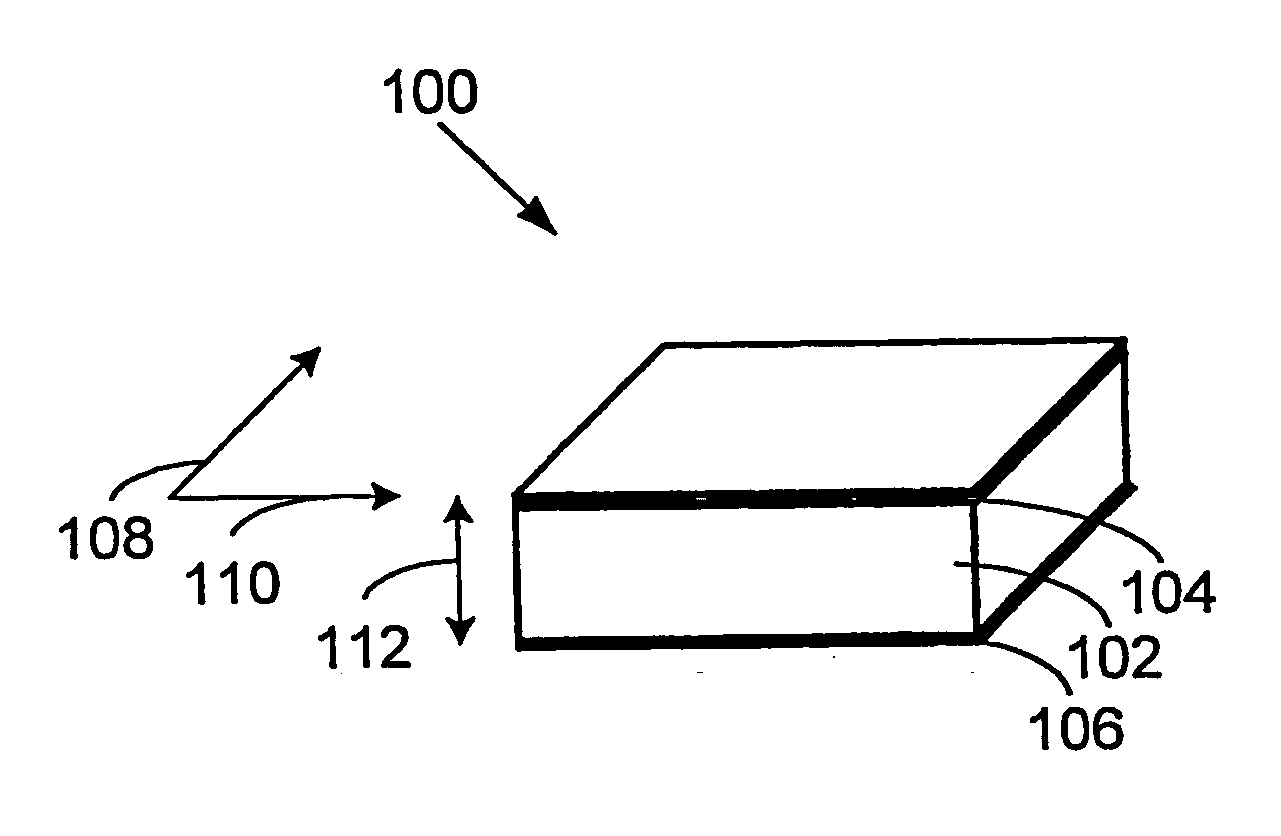

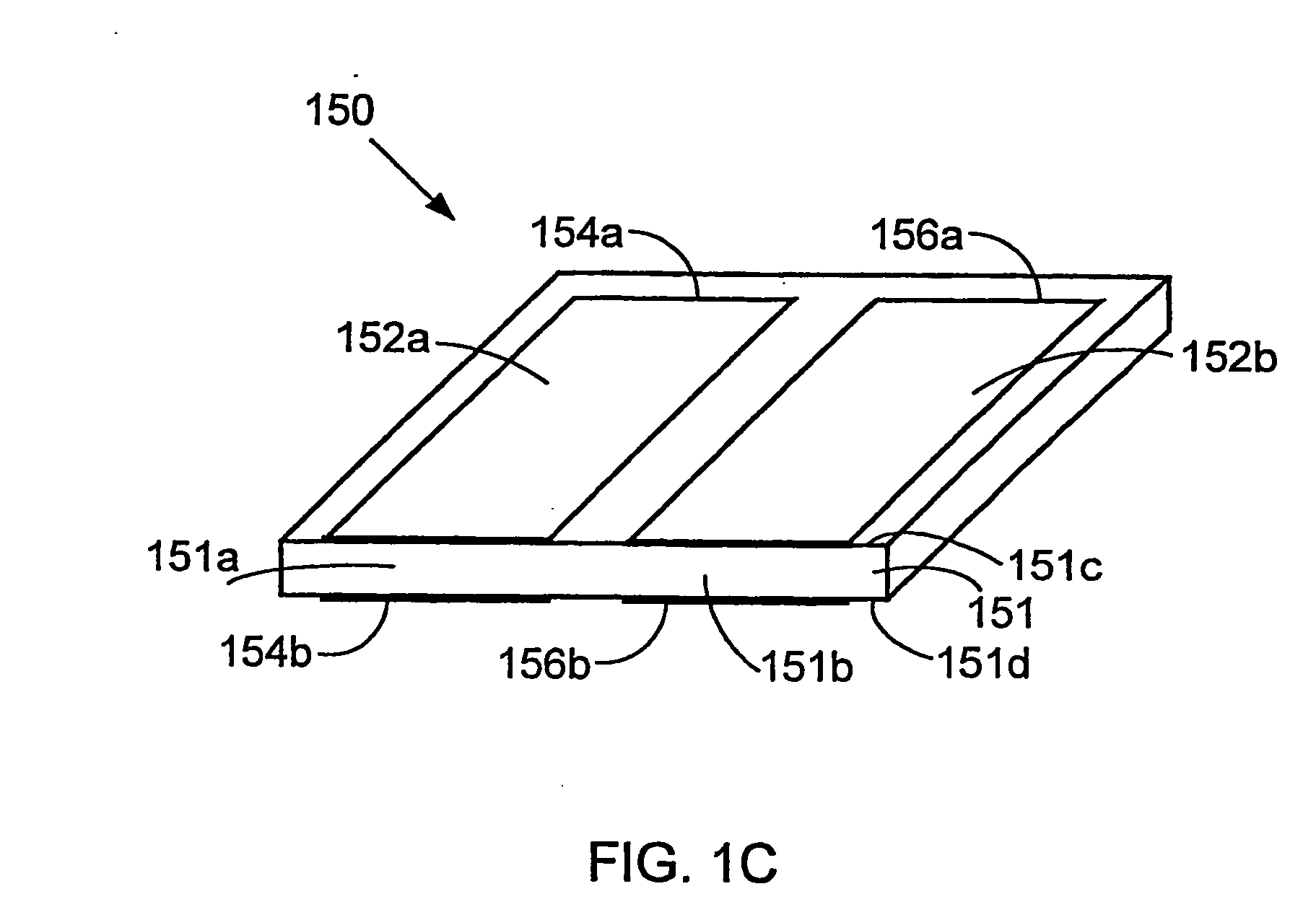

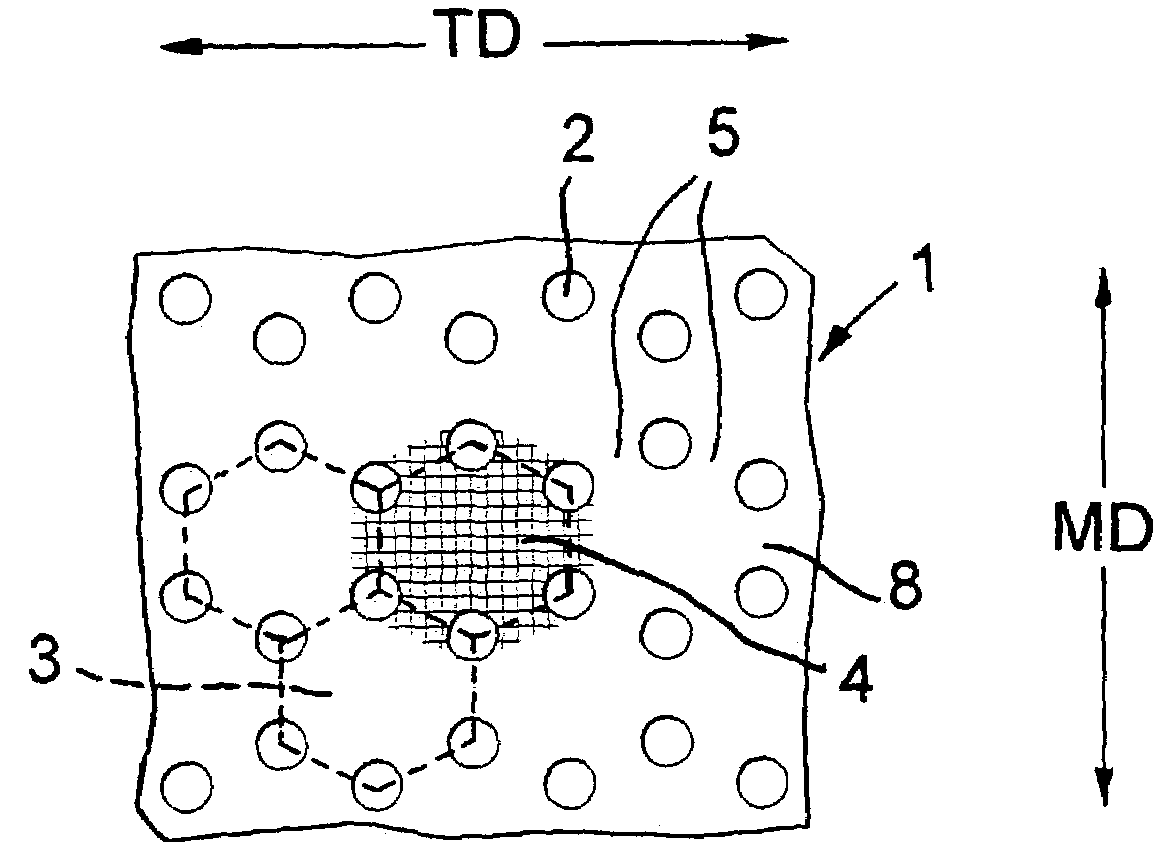

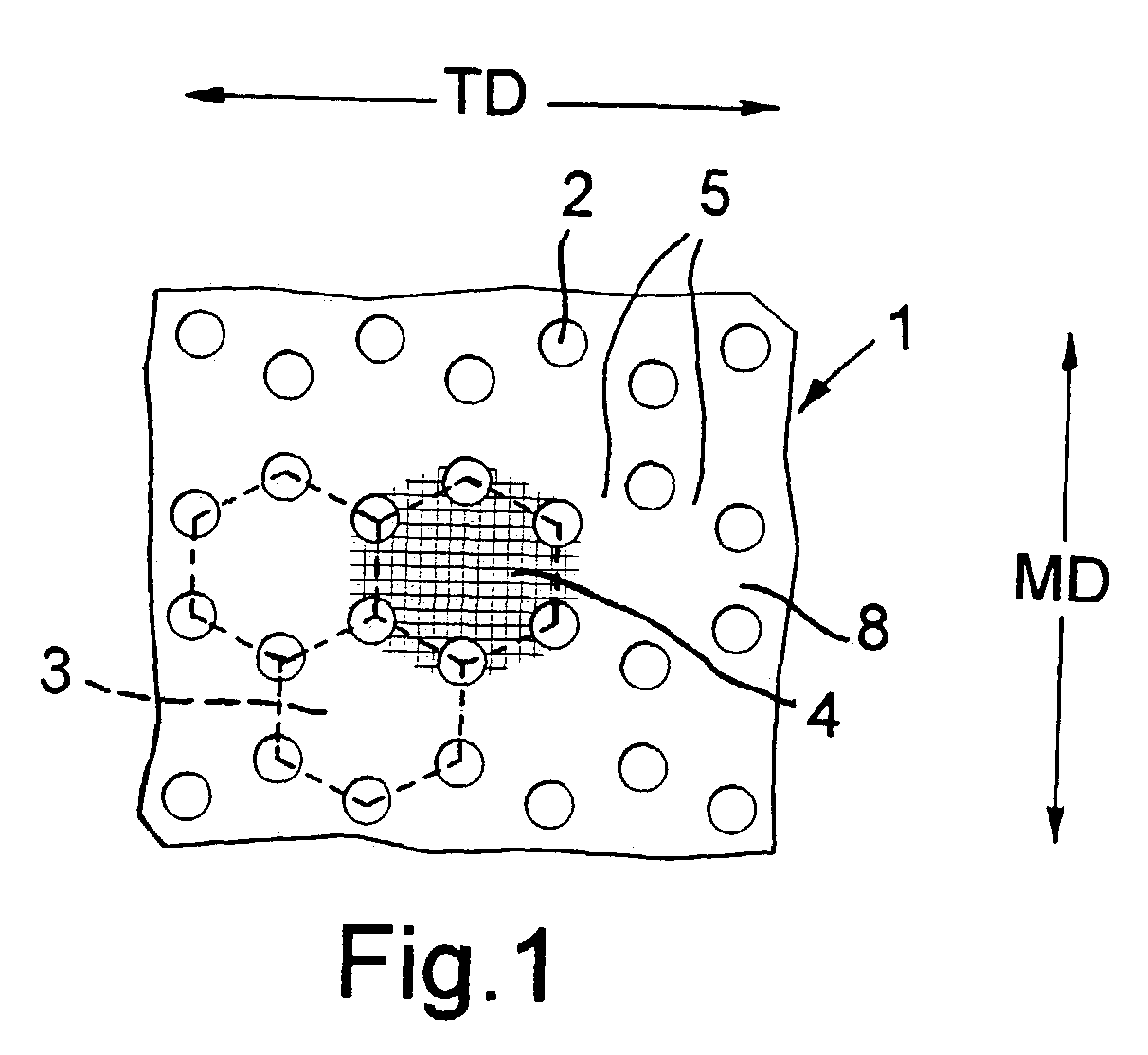

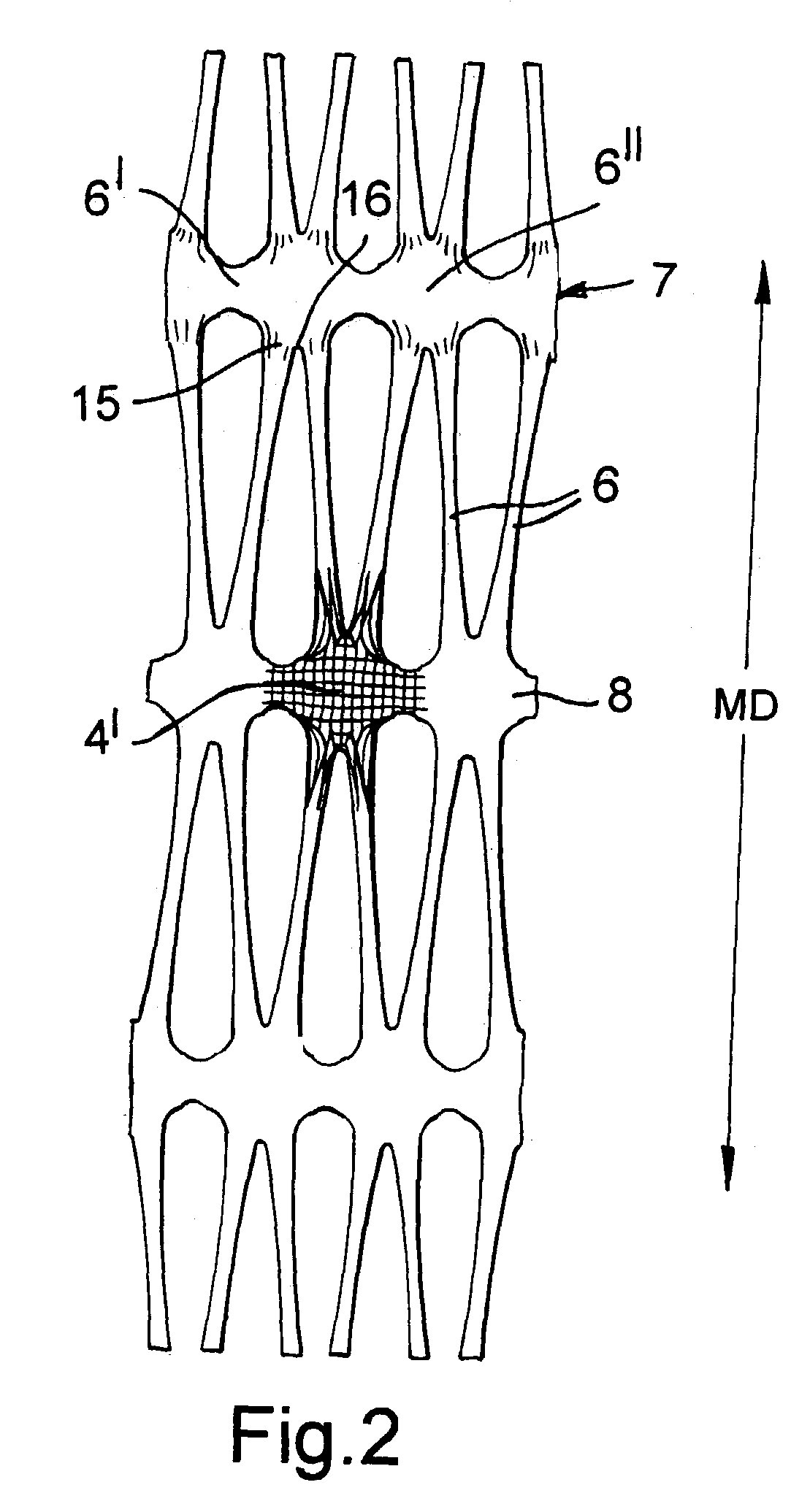

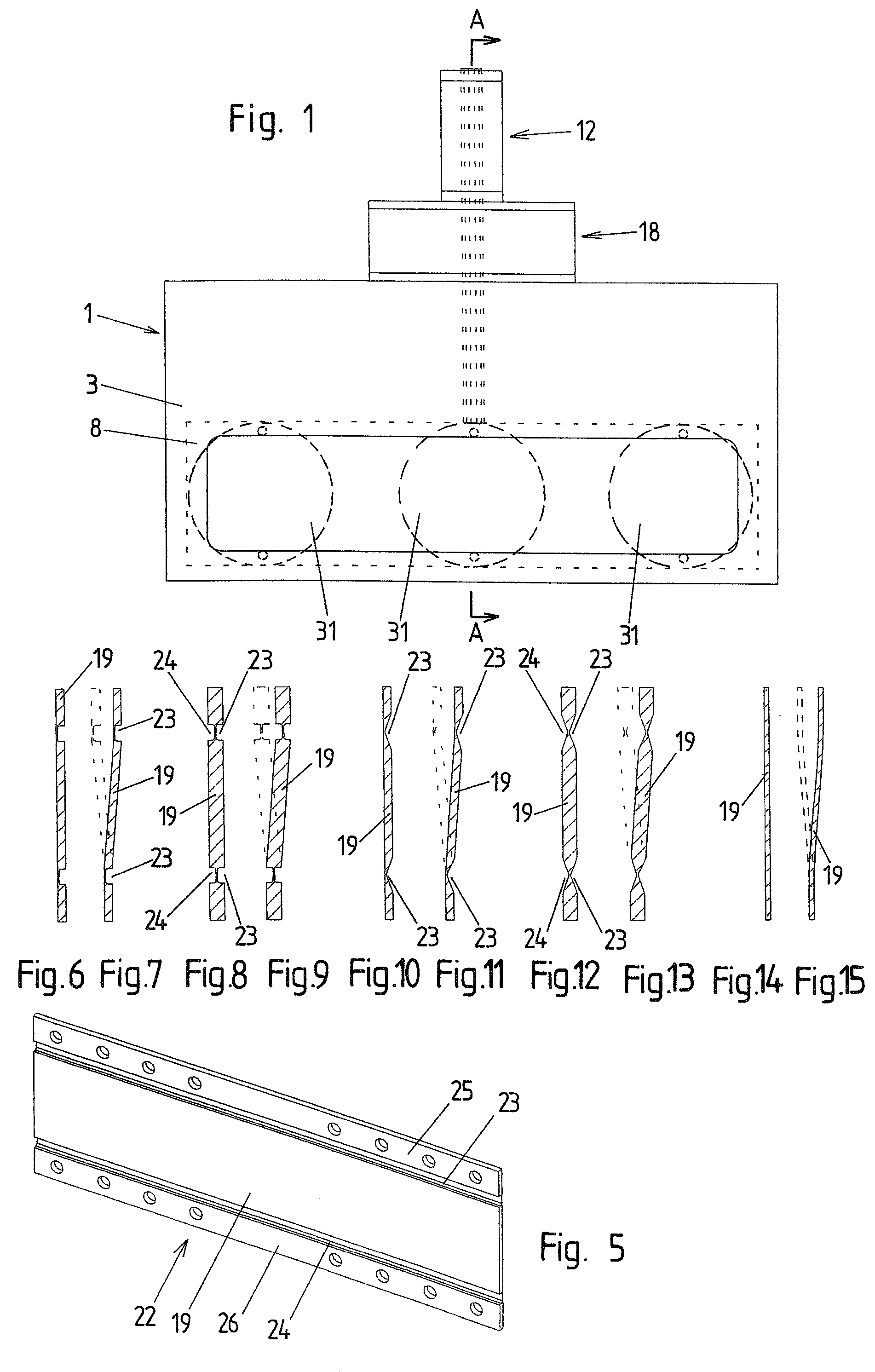

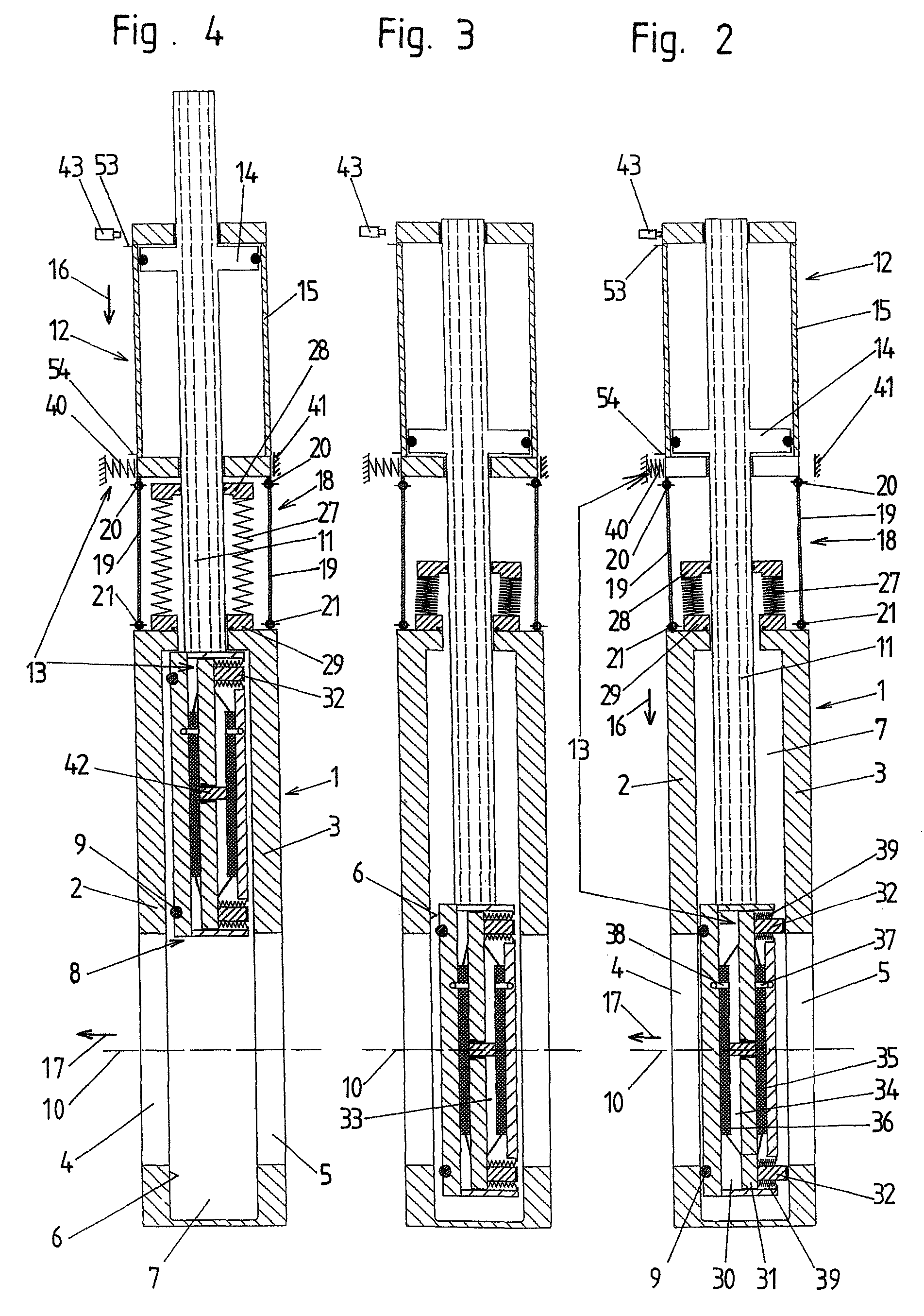

Geogrid or mesh structure

ActiveUS7001112B2Increase torsional stiffnessEnhance abilityArtificial islandsLayered productsEngineeringPlastic materials

To make an oriented plastics material geogrid 10 in which oriented strands 6, 9 form triangular meshes with a junction 11 at each corner and six of the strands 6, 9 meet at each junction 11, a plastics material sheet starting material 1 has holes 2 in an array of hexagons 3, opposite holes 2 of each hexagon being aligned in the machine direction, and the starting material 1 is stretched first in the machine direction and secondly in the transverse direction. In the eventual geogrid 10, the centre portions of the hexagons in the starting material 1 form the junctions 11. The centres of the junctions 11 are slightly biaxially oriented, but at the edges of the junctions 11, the orientation of the edge of substantially each strand 6 or 9 runs around the edge of the respective junction 11 and into the edge of the next strand 6 or 9. During the second stretch, restraint can be applied in the first stretch direction and discontinued before the material is allowed to relax in the second stretch direction. If desired, the procedure can be terminated after the first stretch, to produce a uniaxially-oriented geogrid. By using a starting material 21 which has through holes 22 and weakened zones 23, it is possible to form the geogrid of the invention from a starting material 21 having a rectangular array of through holes 22.

Owner:TENSAR TECH

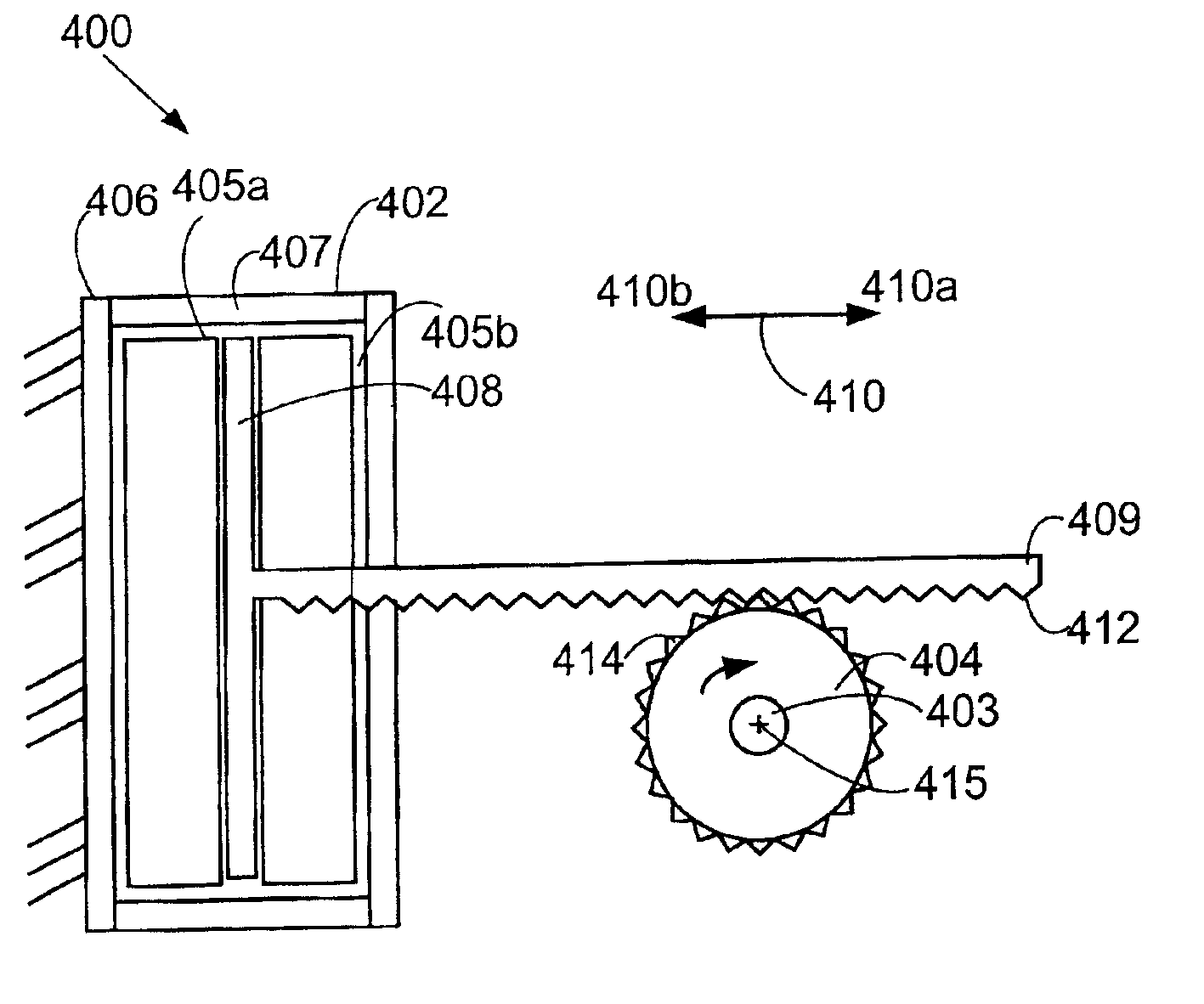

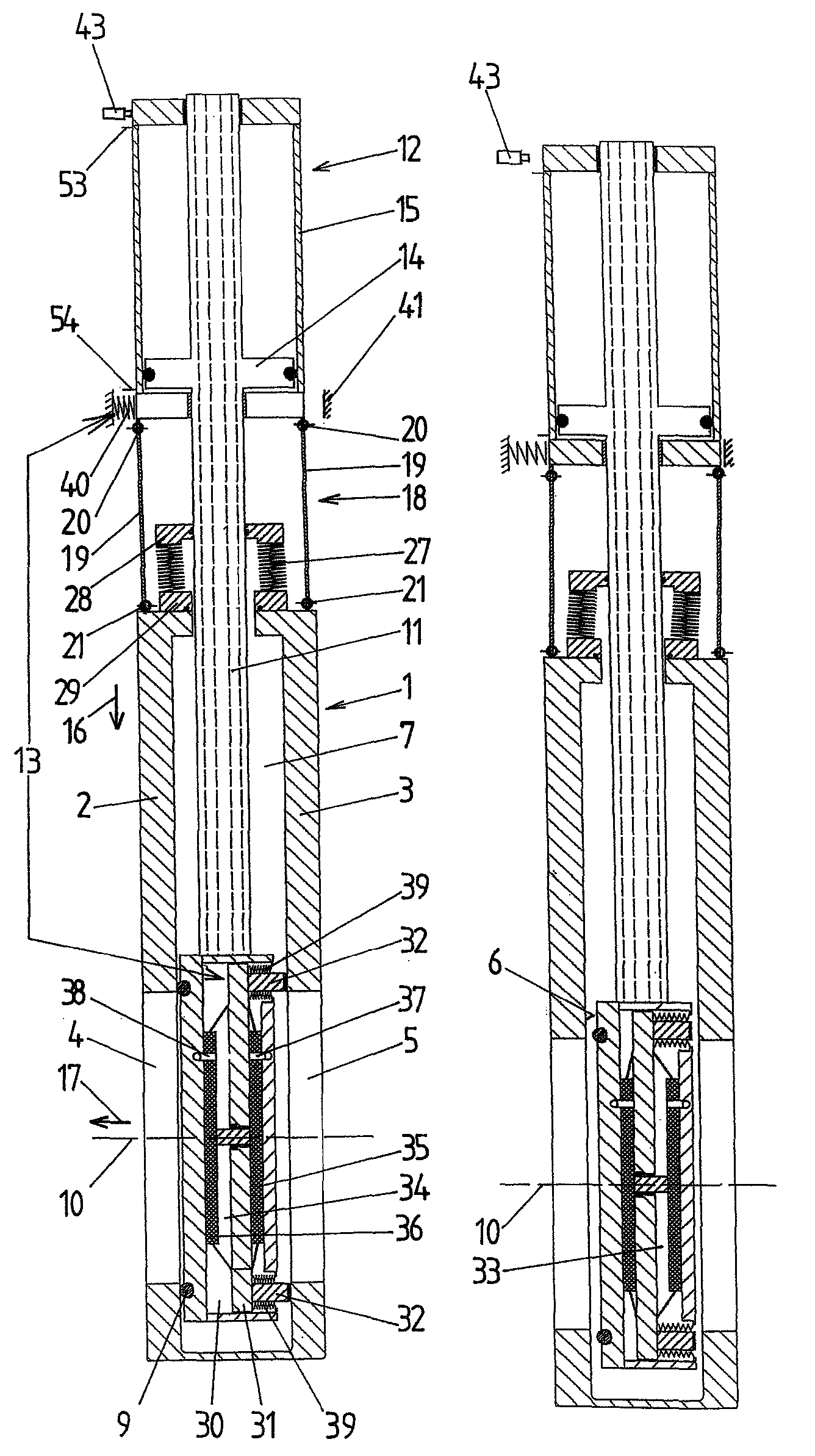

Vacuum valve

InactiveUS7762527B2Easy constructionIncreased torsional stiffnessOperating means/releasing devices for valvesSlide valveEngineeringValve opening

A vacuum valve comprises a valve body with a valve opening, a valve plate which is adjustable from an open position, in which it releases the valve opening, to an intermediate position, in which it covers the valve opening but is lifted from the valve seat, into a closed position in which it contacts the valve seat, and from the closed position to the intermediate position into the open position, a valve rod carrying the valve plate, a transverse drive unit by which the valve plate can be displaced in a transverse adjusting direction extending transverse to the longitudinal axis of the valve opening, a longitudinal drive unit by which the valve plate can be displaced in a longitudinal adjusting direction extending parallel to the longitudinal axis of the valve opening and opposite the longitudinal adjusting direction, and a guide device by which the transverse drive unit is guided so as to be displaceable relative to the valve body parallel to the longitudinal adjusting direction. The transverse drive unit is displaced relative to the valve body parallel to the longitudinal adjusting direction when the valve plate is adjusted from its intermediate position to its closed position and from its closed position to its intermediate position.

Owner:VAT HLDG AG

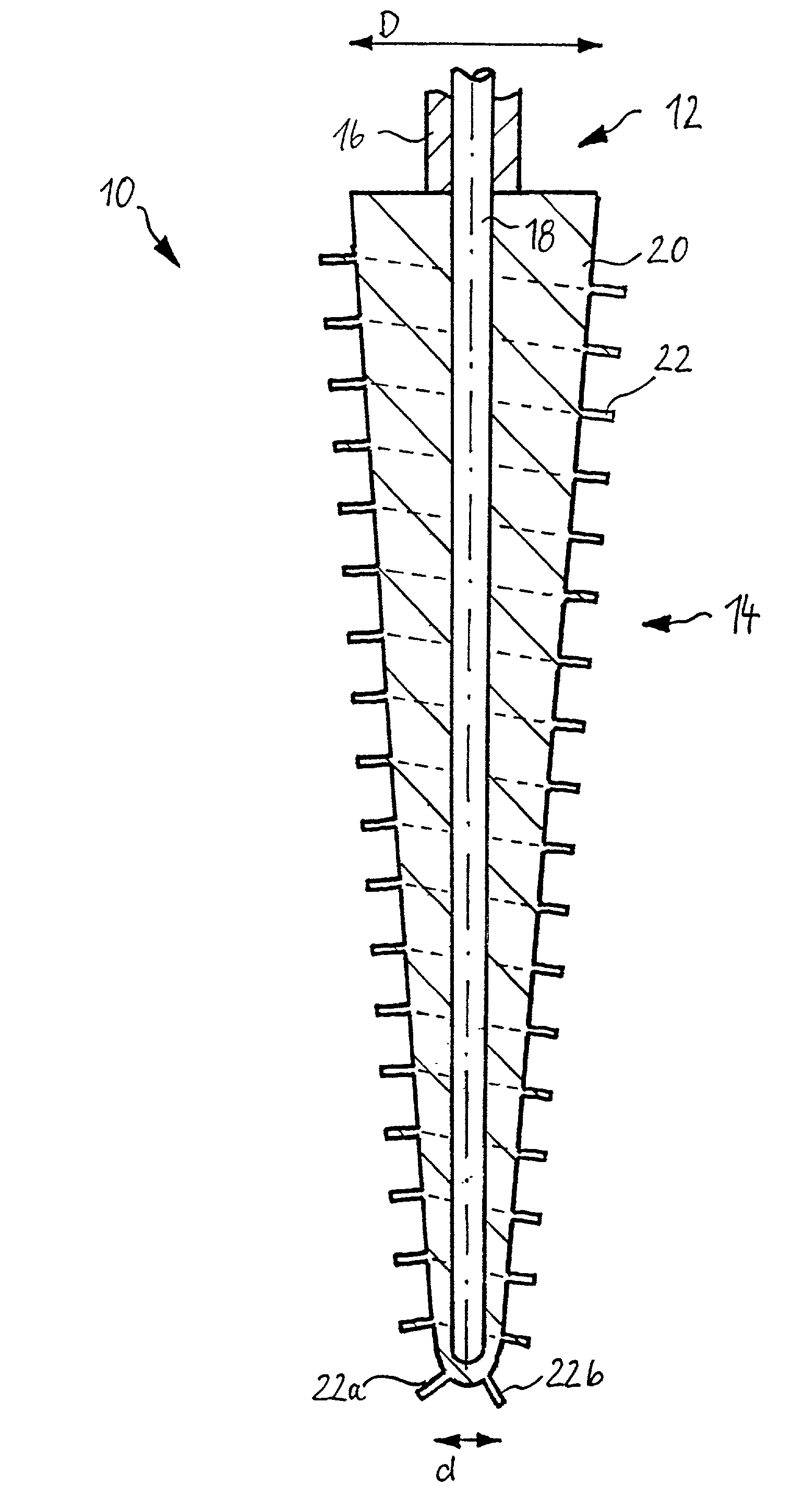

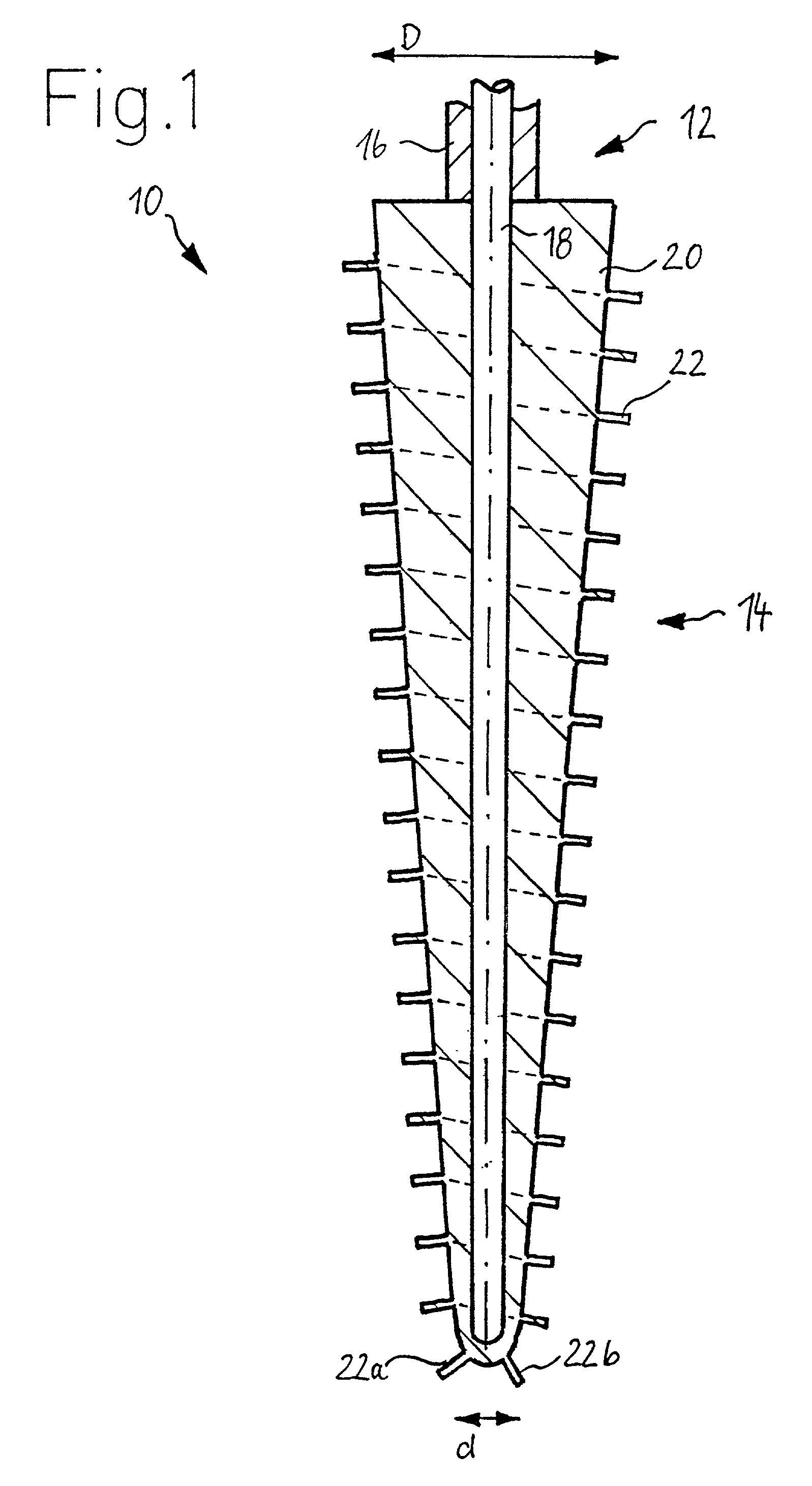

Cleaning instrument for a tooth root canal

InactiveUS20020172922A1Easy to cleanIncreased torsional rigidityGum massageBrush bodiesBristleEngineering

The cleaning instrument (10) comprises a head portion (10) and, adjacent thereto, a cleaning portion (14) having a shank (20), which is provided with bristles (22) on its external surface. In order that especially the tooth root canal or also a tooth interstice can be reliably cleaned using the cleaning instrument (10), the shank (20) is of integral construction with the bristles (22).

Owner:ROEKO & DENTALERZEUGNISSE

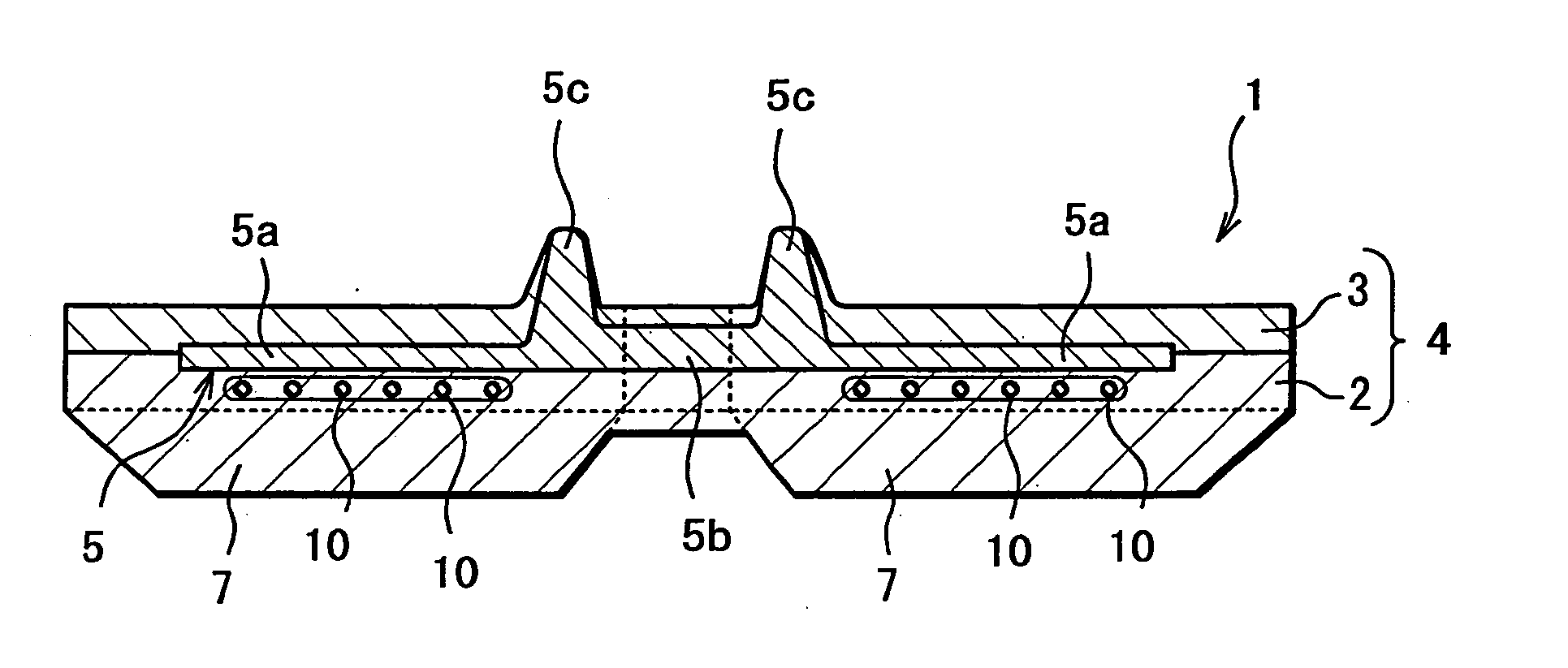

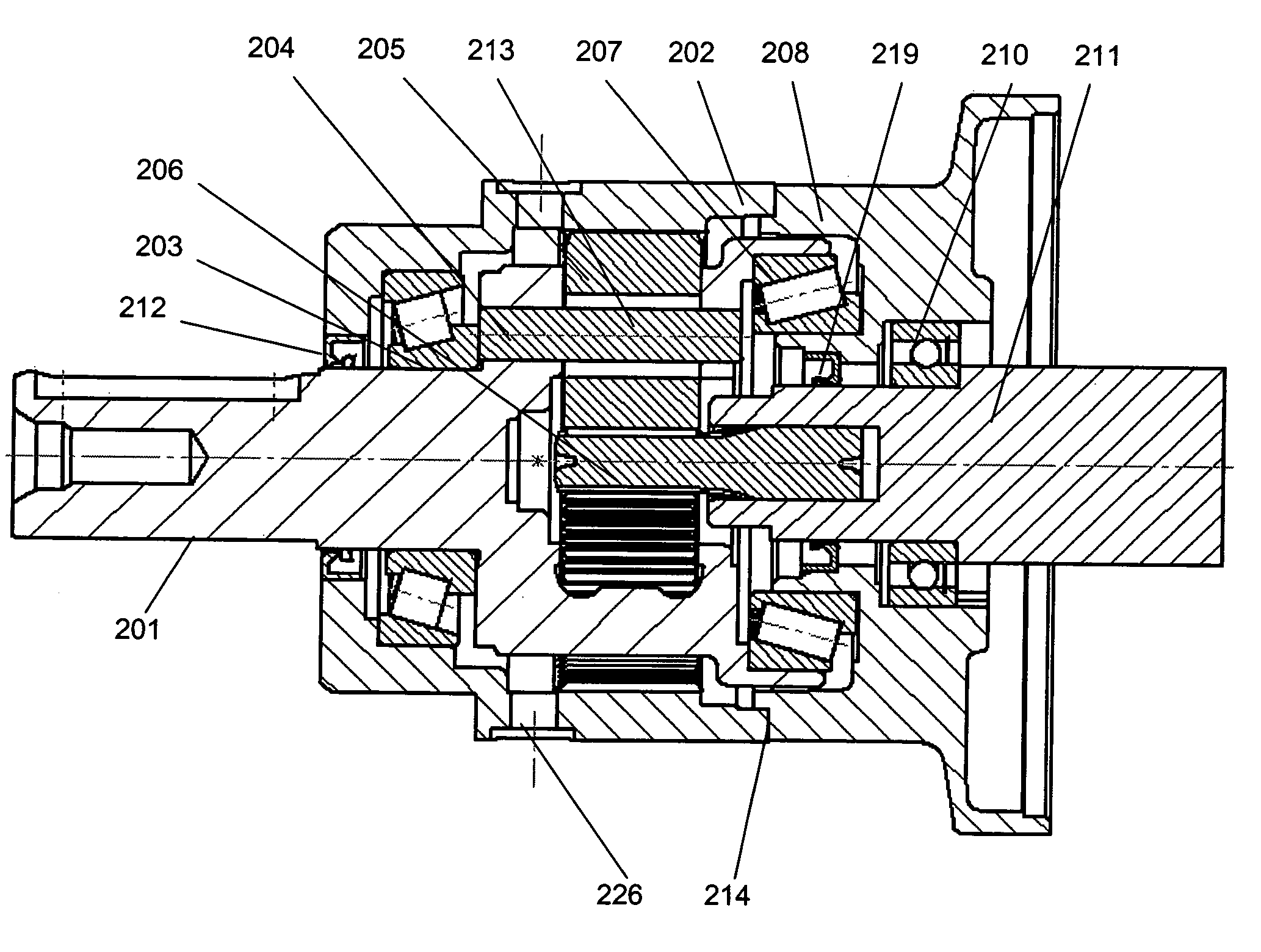

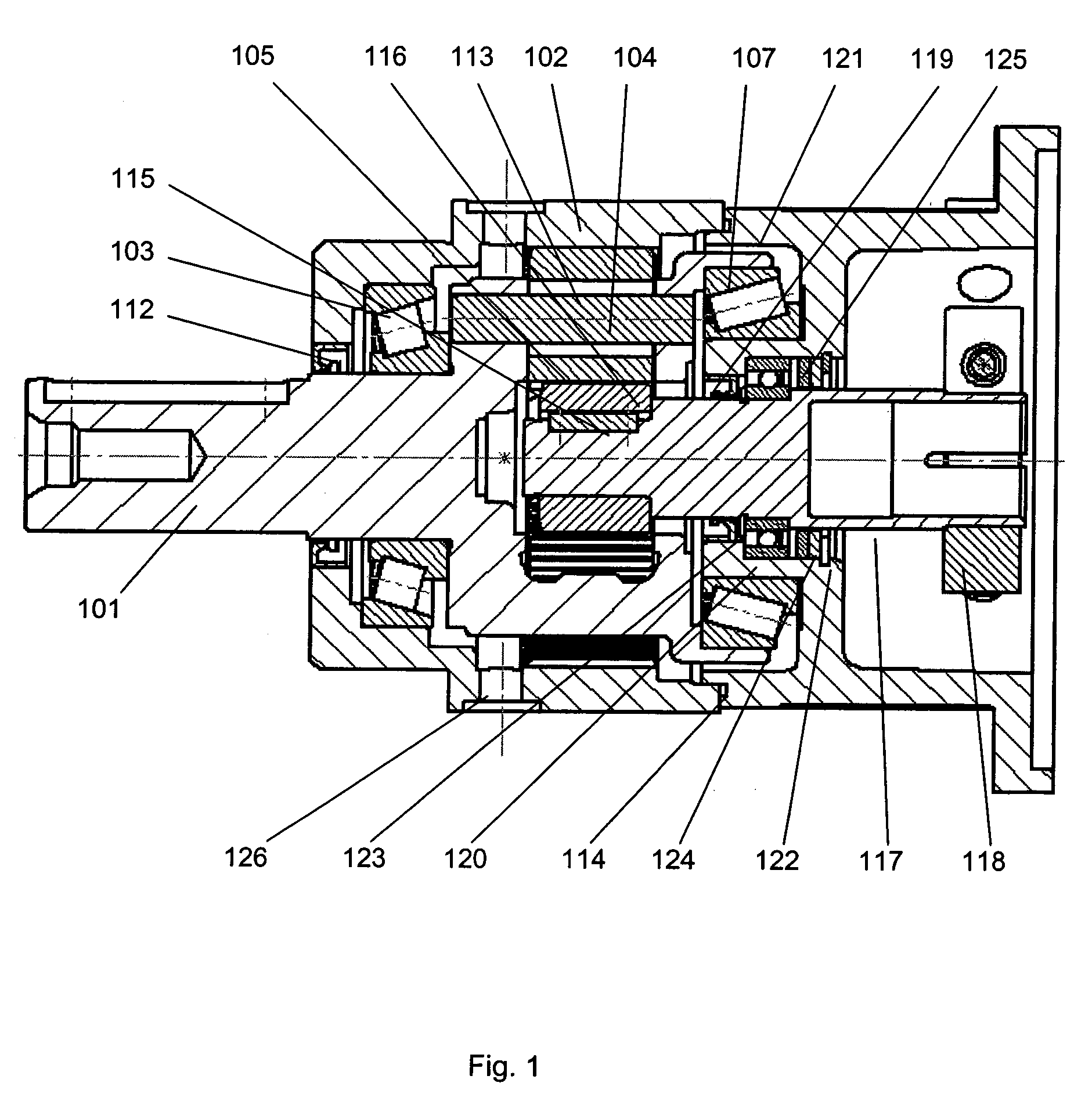

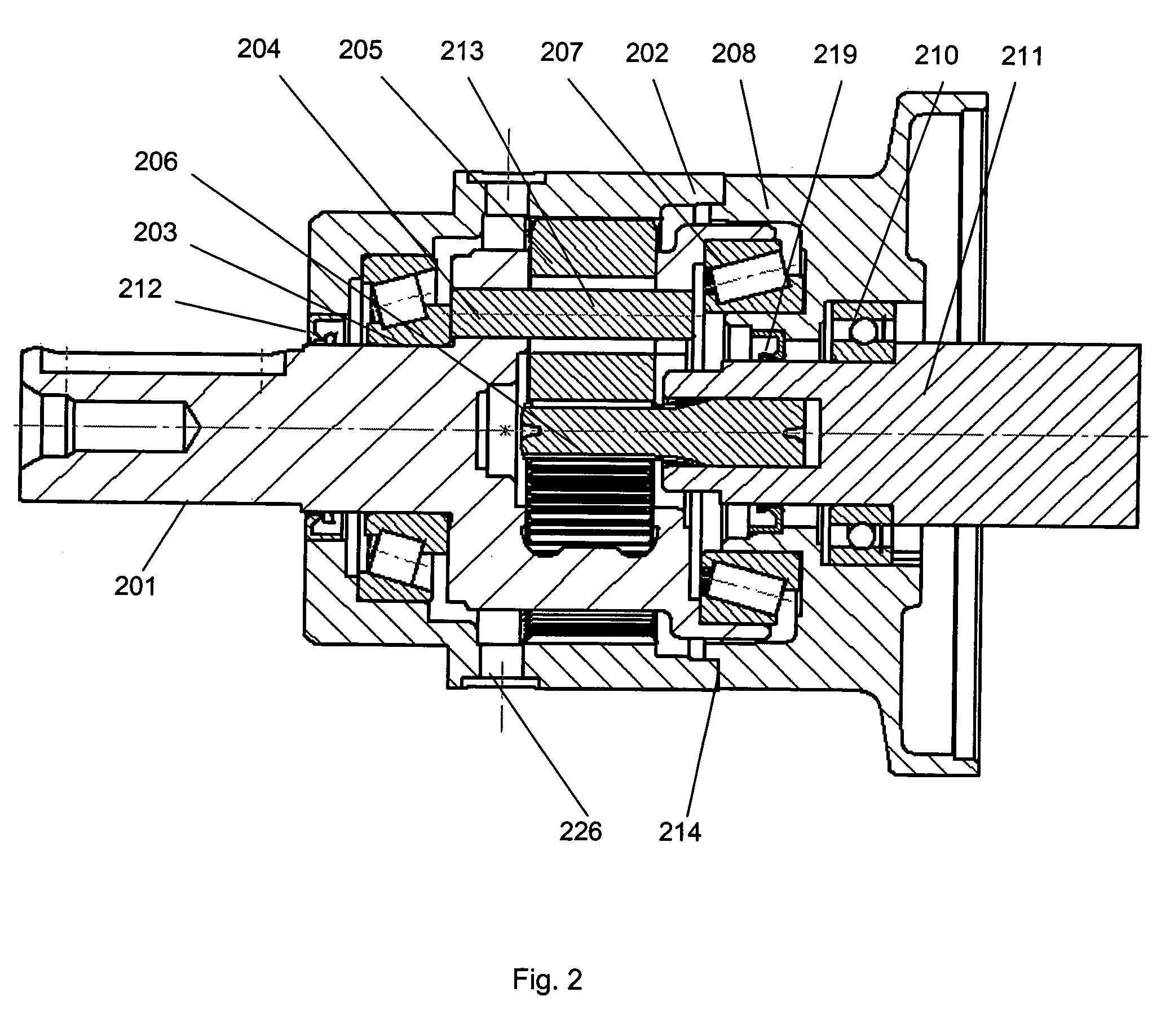

Planetary gear, gear motor and series of gear motors

InactiveUS7182709B2Reduce in quantityDecreased varietyToothed gearingsMechanical energy handlingEngineeringGear tooth

A series of gear motors, a gear motor, and a planetary-gear stage includes planet wheels that mesh with a sun wheel and inner gear teeth provided for the gear housing. The planet wheels are supported in a rotatable planet carrier, which forms the power take-off, and to which a sealing element is assigned on the output side. The planetary-gear stage is assigned a further sealing element on the input side. The gear housing is shaped on the input side such that an interface is formed for connection to further components, which include at least one shaft connected to the sun wheel.

Owner:SEW-EURODRIVE GMBH & CO KG

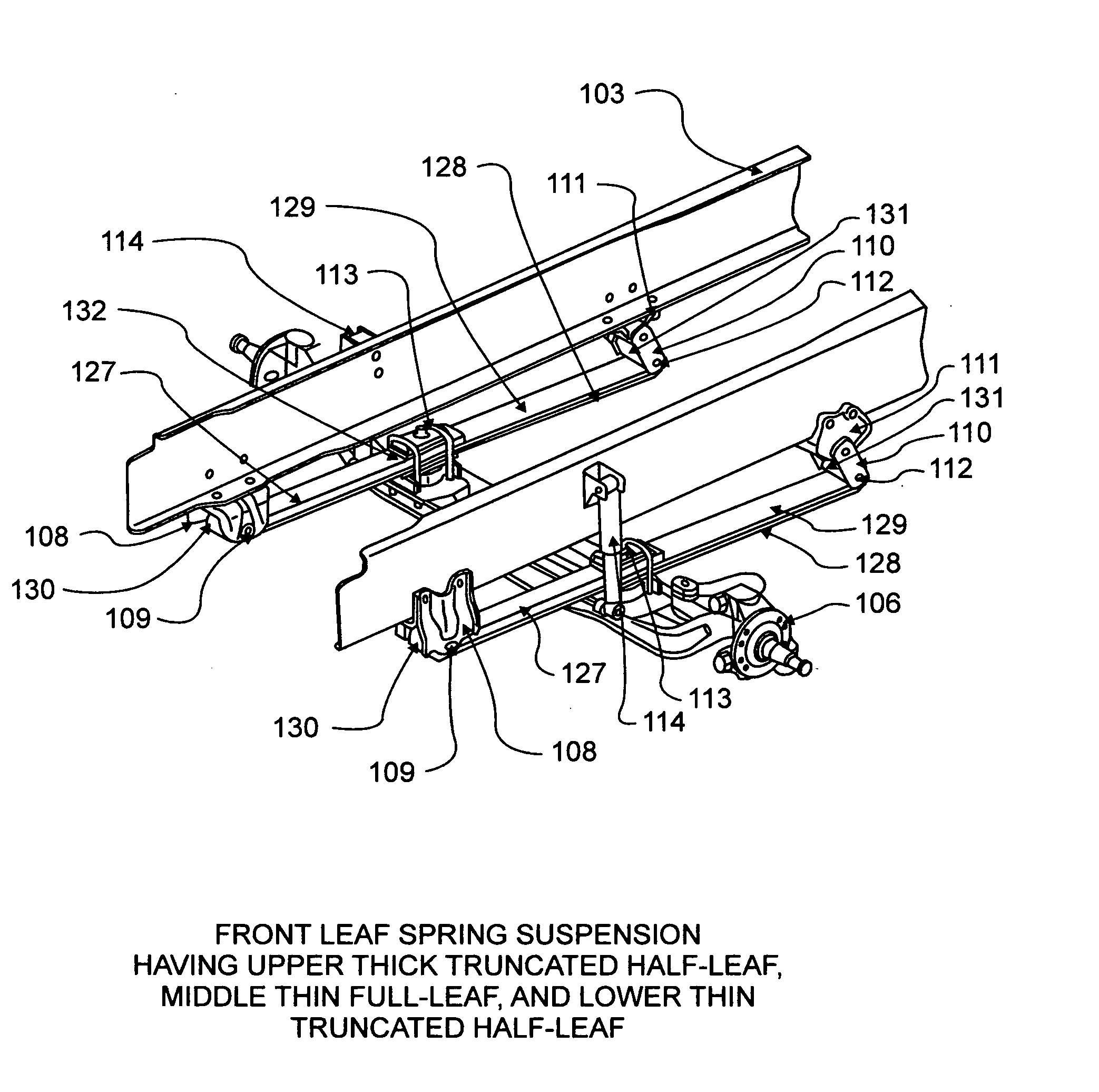

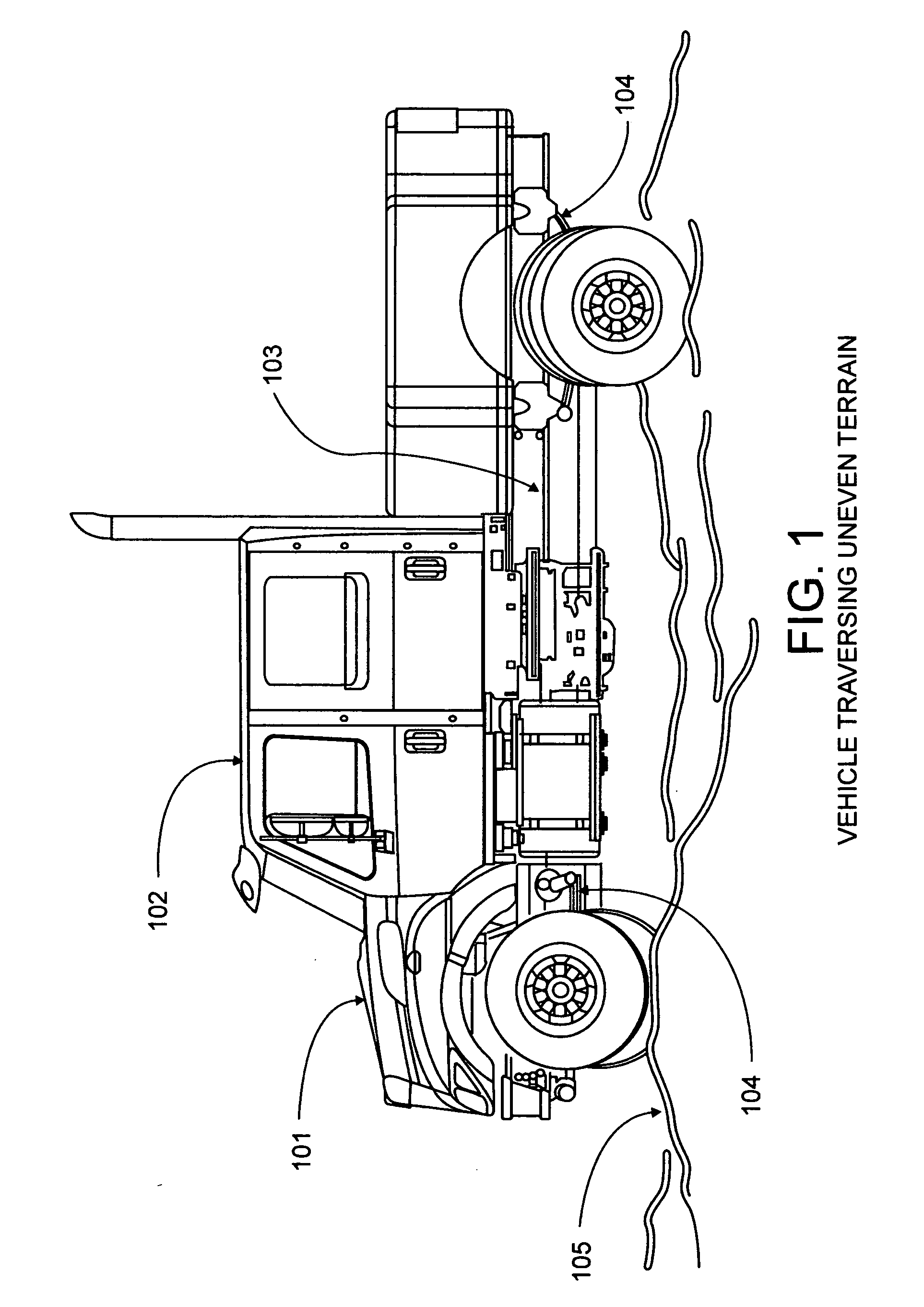

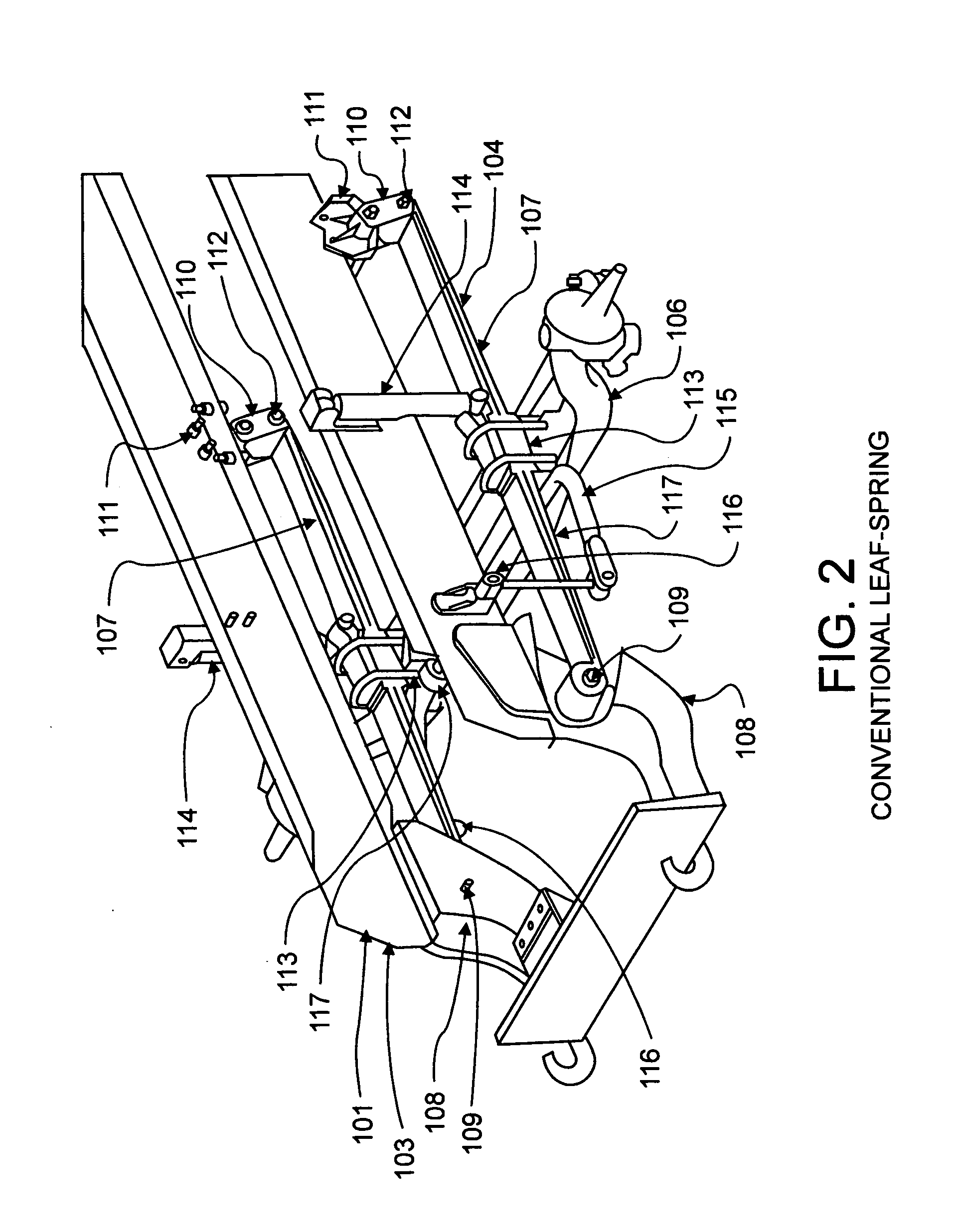

Leaf spring with high auxiliary roll stiffness

InactiveUS20070262547A1Robust and simple to manufacturePositive attributeLeaf springsInterconnection systemsEngineeringBending stiffness

A vehicle suspension provides increased auxiliary roll stiffness by utilizing spring assemblies having a thick truncated half-leaf, a thin full-leaf, and a thin truncated half-leaf located opposite the thick truncated half-leaf. The thick truncated half-leaf increases the torsional rigidity of the spring assembly in order to increase the leaf twist sub-component of auxiliary roll stiffness and increases the bending rigidity of half of the spring assembly in order to increase the axle torsion sub-component of auxiliary roll stiffness. The thin full-leaf provides structural integrity, and the thin half-leaf allows tuning of the overall vertical spring rate of the suspension and limits the leaf stresses in the thin full-leaf.

Owner:INT TRUCK INTPROP LLC

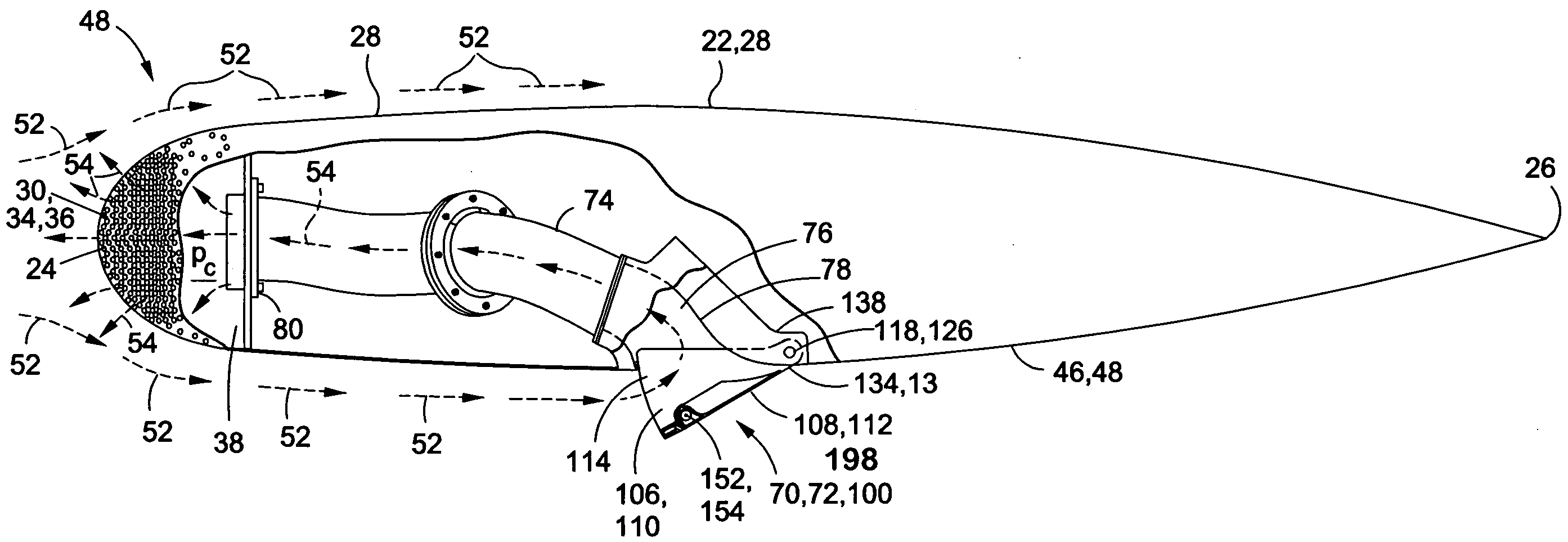

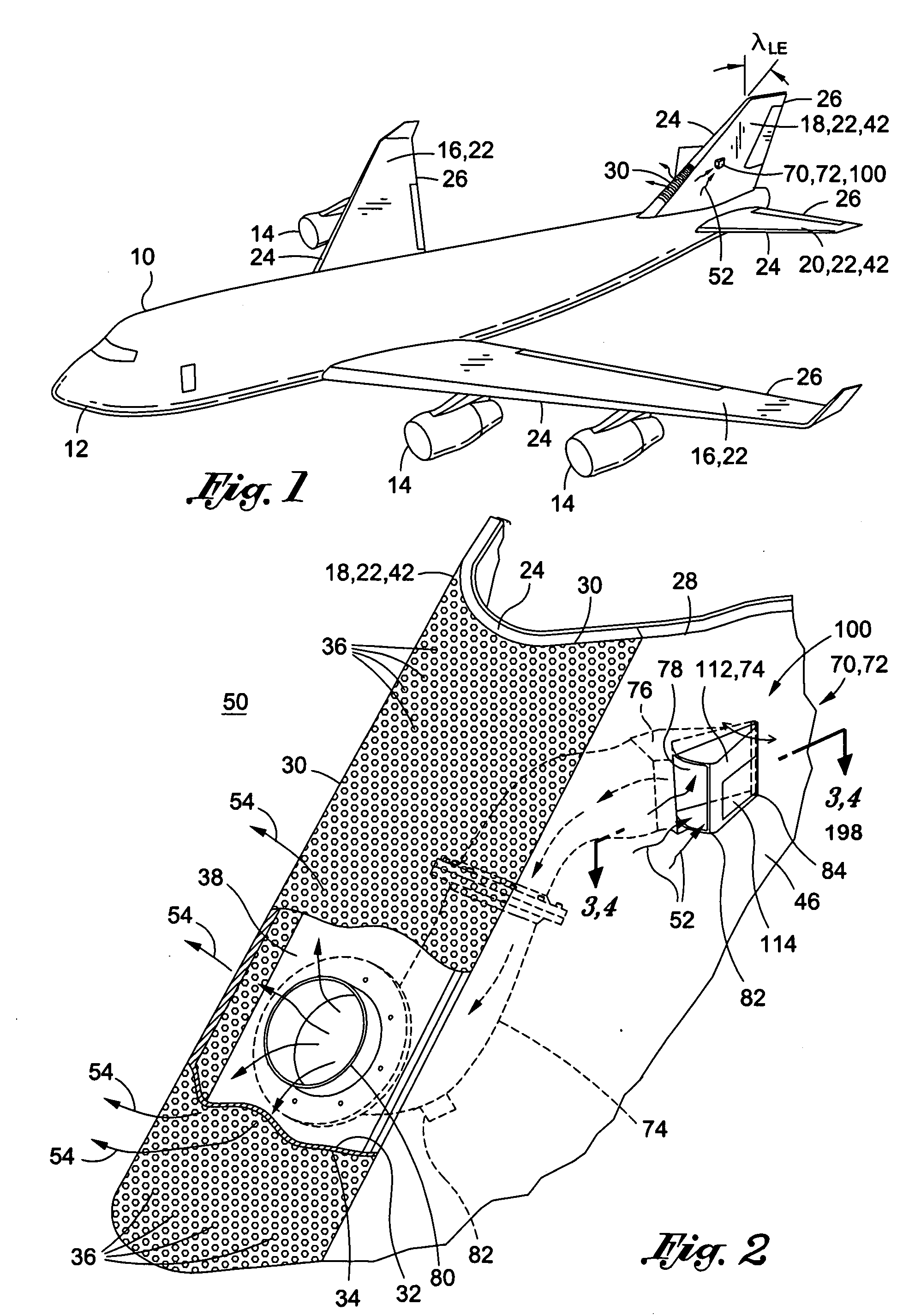

Door assembly for laminar flow control system

ActiveUS20100181435A1Increased torsional stiffnessMinimize distortionNACA type air intakesPower installationsControl systemActuator

A door assembly has a first door integrated with a second door. The first door has a first door cowl. The second door is pivotably mounted to the first door and has a second door cowl forming at least a portion of the first door cowl. The door assembly includes at least one actuator coupled to the first and second doors. Each one of the first and second doors is pivotable between open and closed positions and defines an opening when moved to the open position. The openings of the first and second doors face in opposite directions. The actuator is operative to pivotably move at least one of the first and second doors between the open and closed positions.

Owner:THE BOEING CO

Antenna Assembly

ActiveUS20100265150A1Reduce decreaseIncreased torsional stiffnessAntenna arrays manufactureWaveguide type devicesEngineeringAntenna element

An antenna assembly and a method of mounting such an assembly are disclosed. A first and a second assembly portion are joined together, wherein the assembly portions each comprise a elongated reflector body serving as a reflector for electromagnetic power radiated by the antenna assembly portion, and a set of antenna element receiving means located in a linear row along a longitudinal direction of the reflector body for respectively receiving an antenna element, and side portions along the long sides of the said reflector body. The assembly method comprises the step of fastening the first and second assembly portions to each other along a respective side portion of the said assembly portions so as to form a dual array antenna assembly.

Owner:INTEL CORP

Hood structure for vehicle

ActiveUS7140673B2Improve absorption efficiencyIncreased torsional stiffnessVehicle seatsPedestrian/occupant safety arrangementEngineeringFlange

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com