Streamline steel-concrete folding case beam

A streamlined steel and laminated box technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of easy cracking of concrete and high torsional rigidity, and achieve concrete cracking, high torsional rigidity, and good wind resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

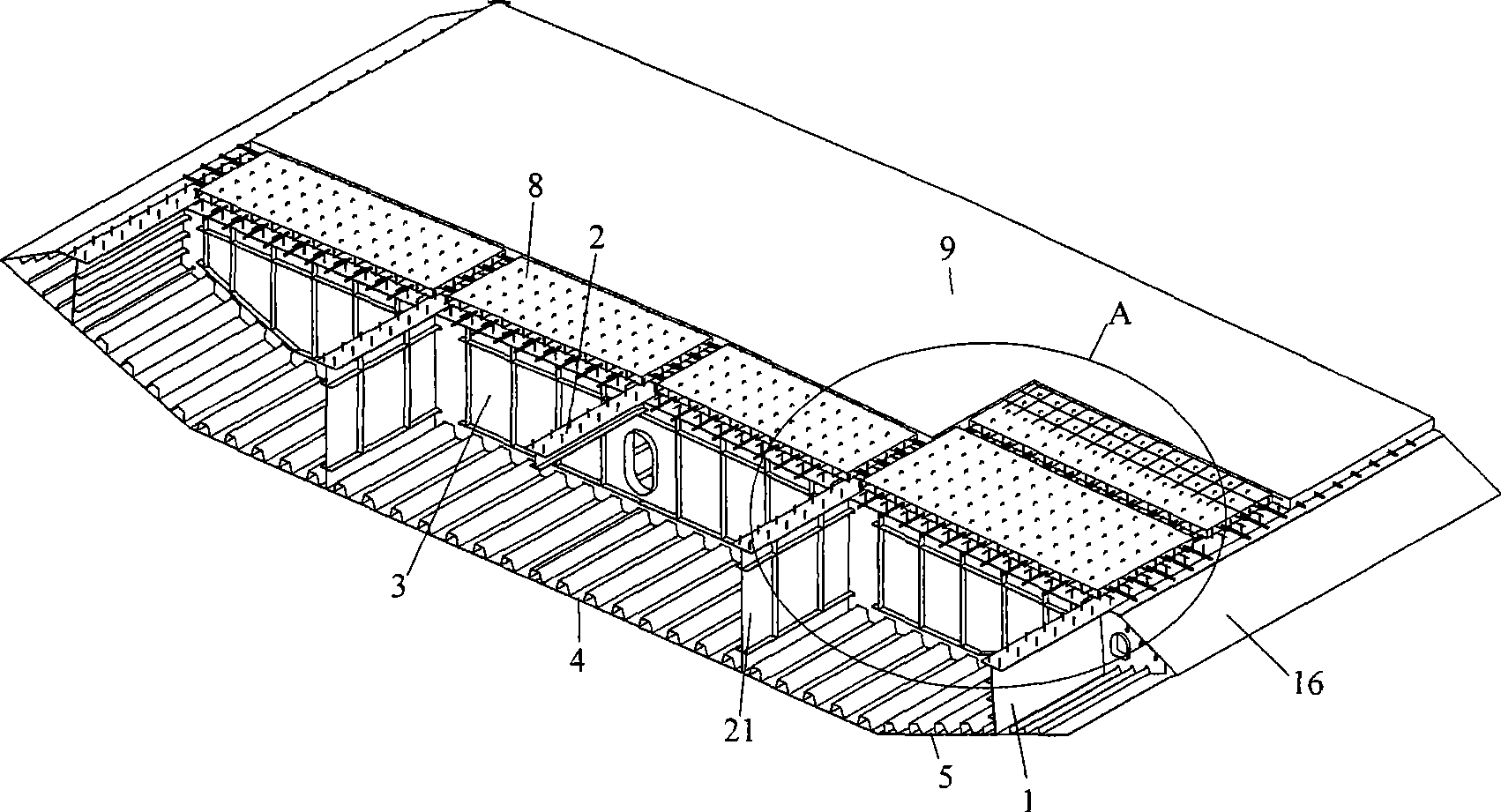

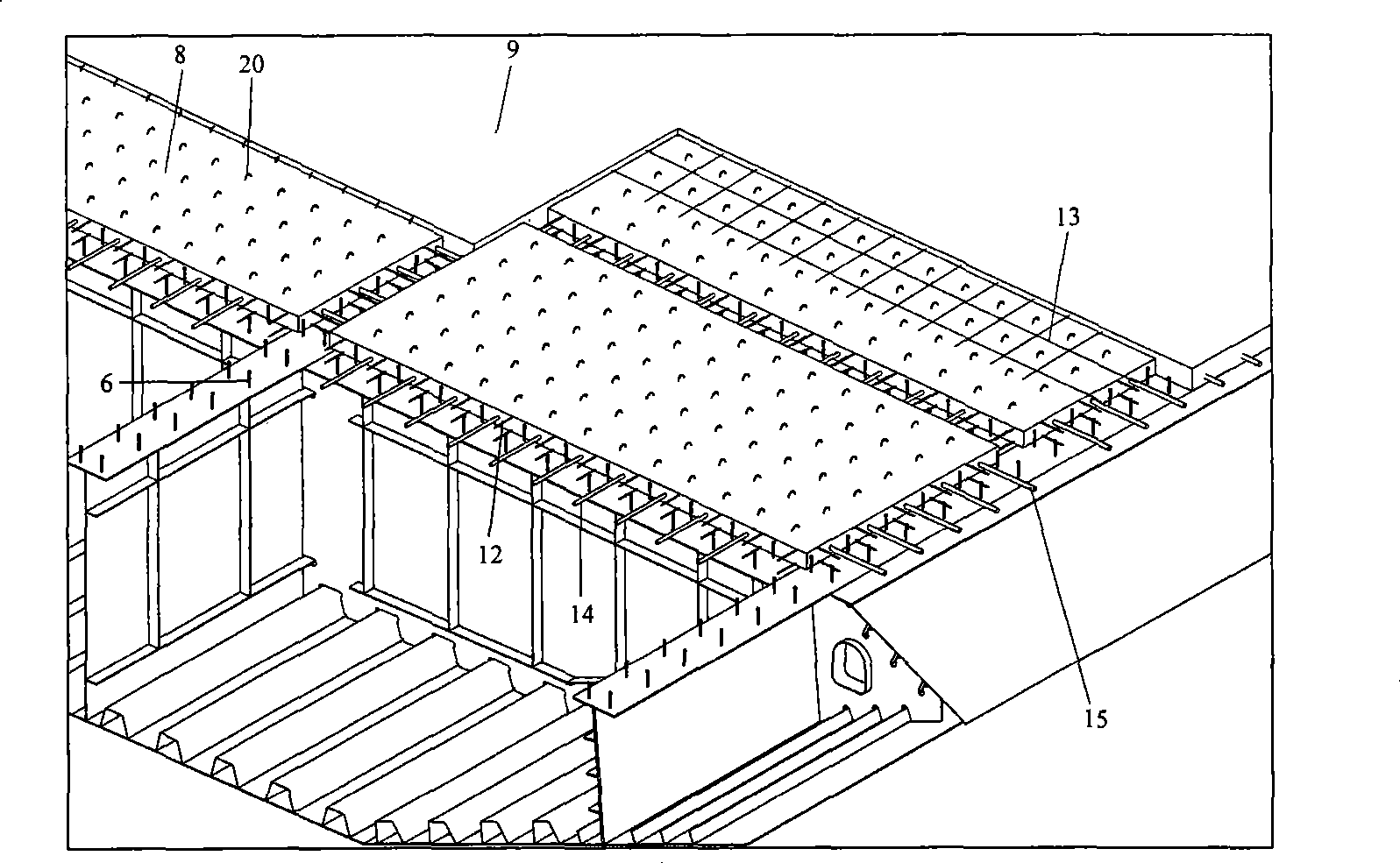

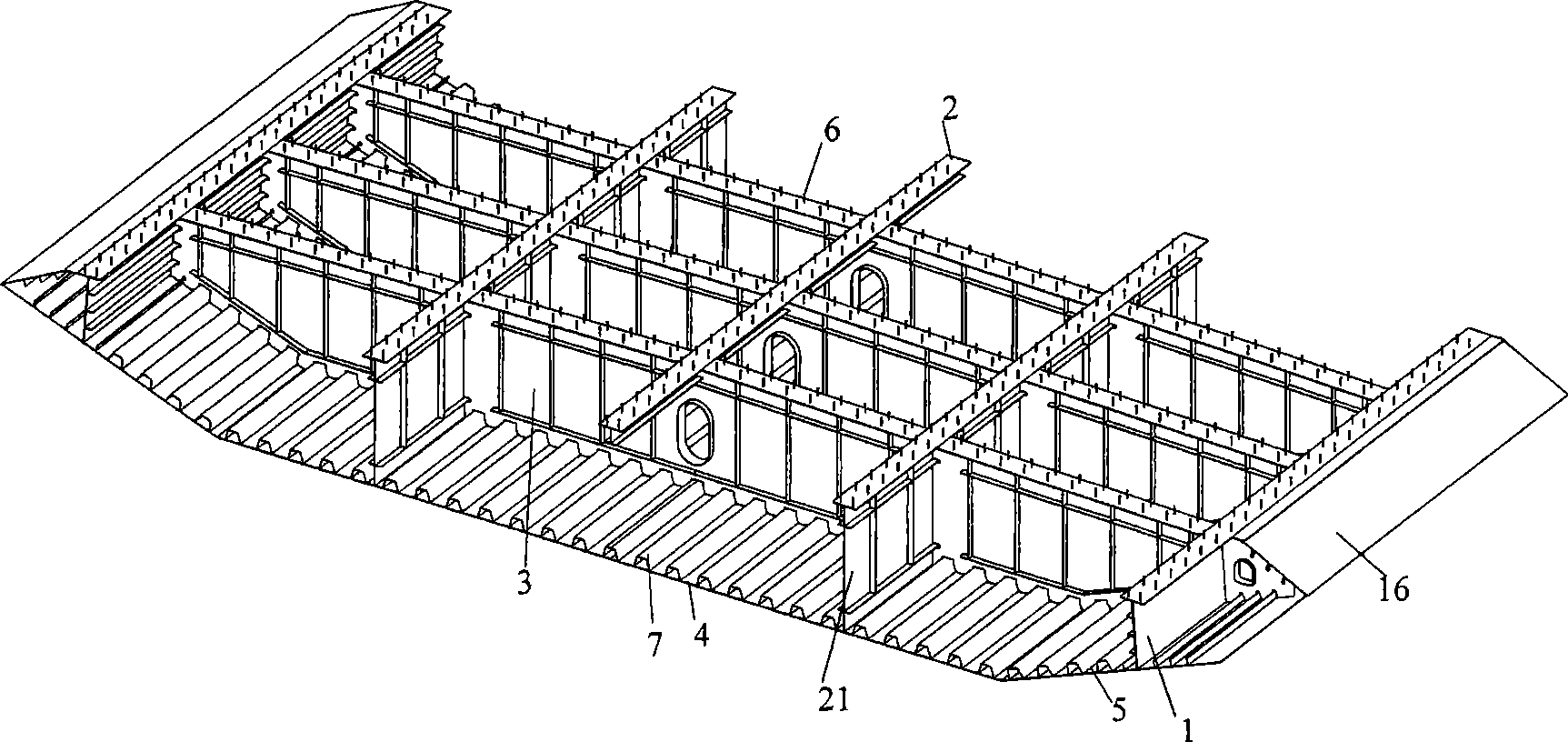

[0029] See Figure 1~6Shown is a streamlined steel-concrete composite box girder of the present invention. The laminated box girder is composed of steel girder structure, laminated bridge deck and air nozzle structure 16; the air nozzle structure 16 is placed on both sides of the laminated box girder, and the entire laminated box girder presents a streamlined single-box cross-section. The main steel girder structure is composed of outer steel longitudinal beam 1, inner steel longitudinal beam 21, steel small longitudinal beam 2, steel cross beam 3, steel floor 4 and steel inclined floor 5; outer steel longitudinal beam 1, inner steel longitudinal beam 21, steel The small longitudinal beams 2 and the steel cross beams 3 are arranged orthogonally to form a steel beam grid; the inner steel longitudinal beams 21 and the steel cross beams 3 divide the laminated box girder into several chambers. The outer steel longitudinal beam 1, the inner steel longitudinal beam 21, and the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com