Patents

Literature

95 results about "Monocoque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monocoque (/ˈmɒnəˌkɒk, -ˌkoʊk/), also structural skin, is a structural system where loads are supported through an object's external skin, similar to an egg shell. The word monocoque is a French term for "single shell" or (of boats) "single hull". First used in boats, a true monocoque carries both tensile and compressive forces within the skin and can be recognised by the absence of a load-carrying internal frame.

Monocoque jaw design

Owner:TYCO HEALTHCARE GRP LP

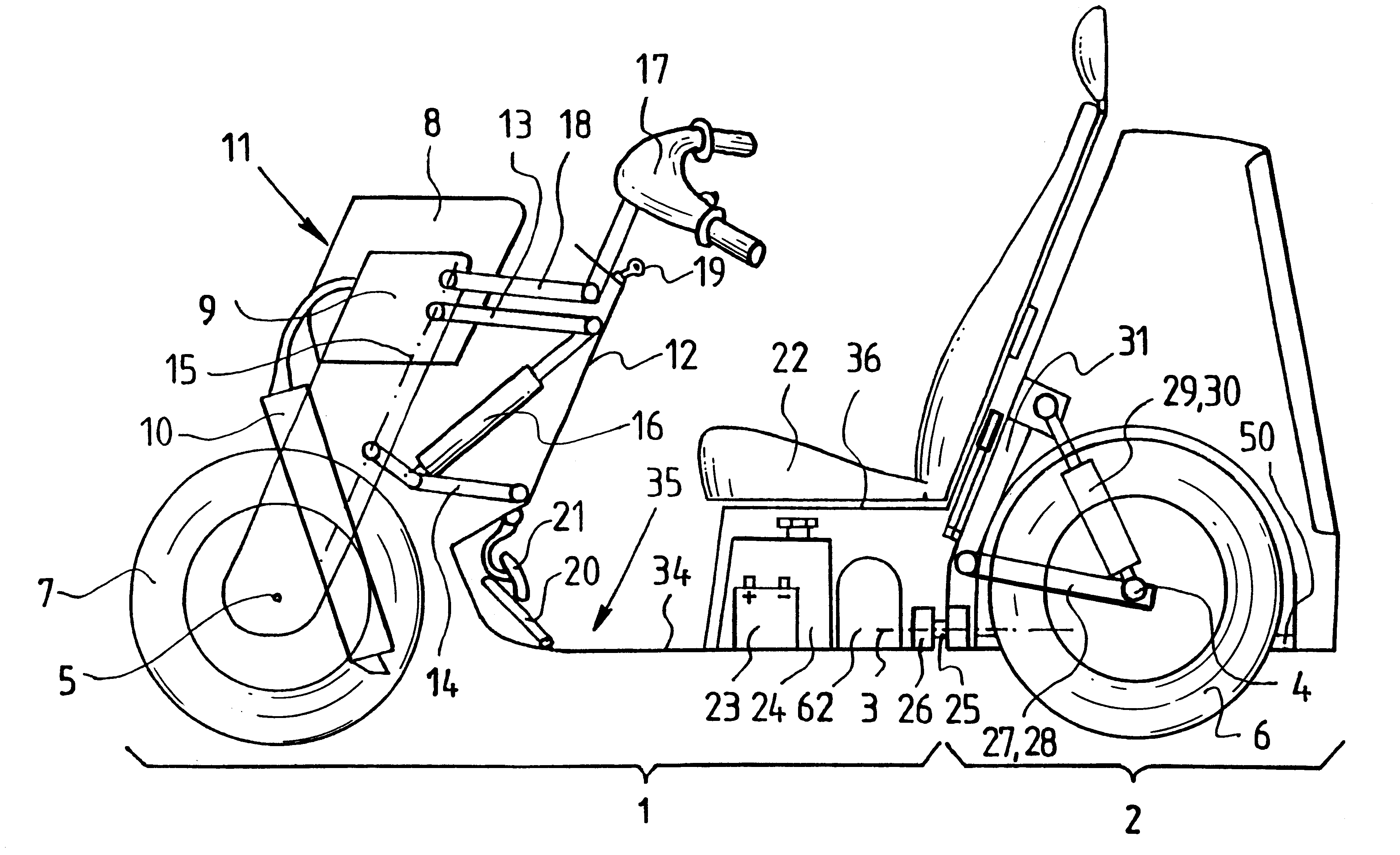

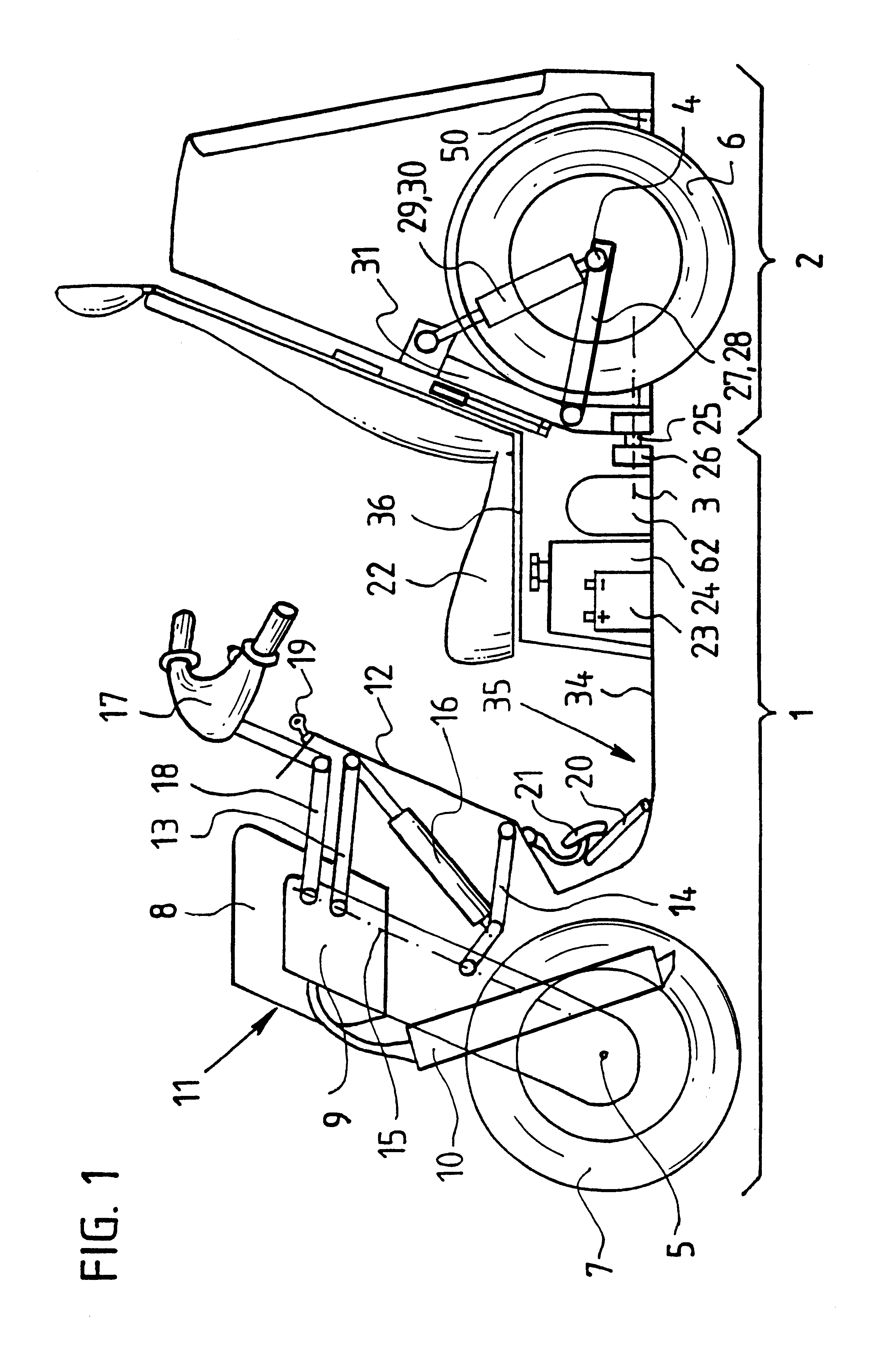

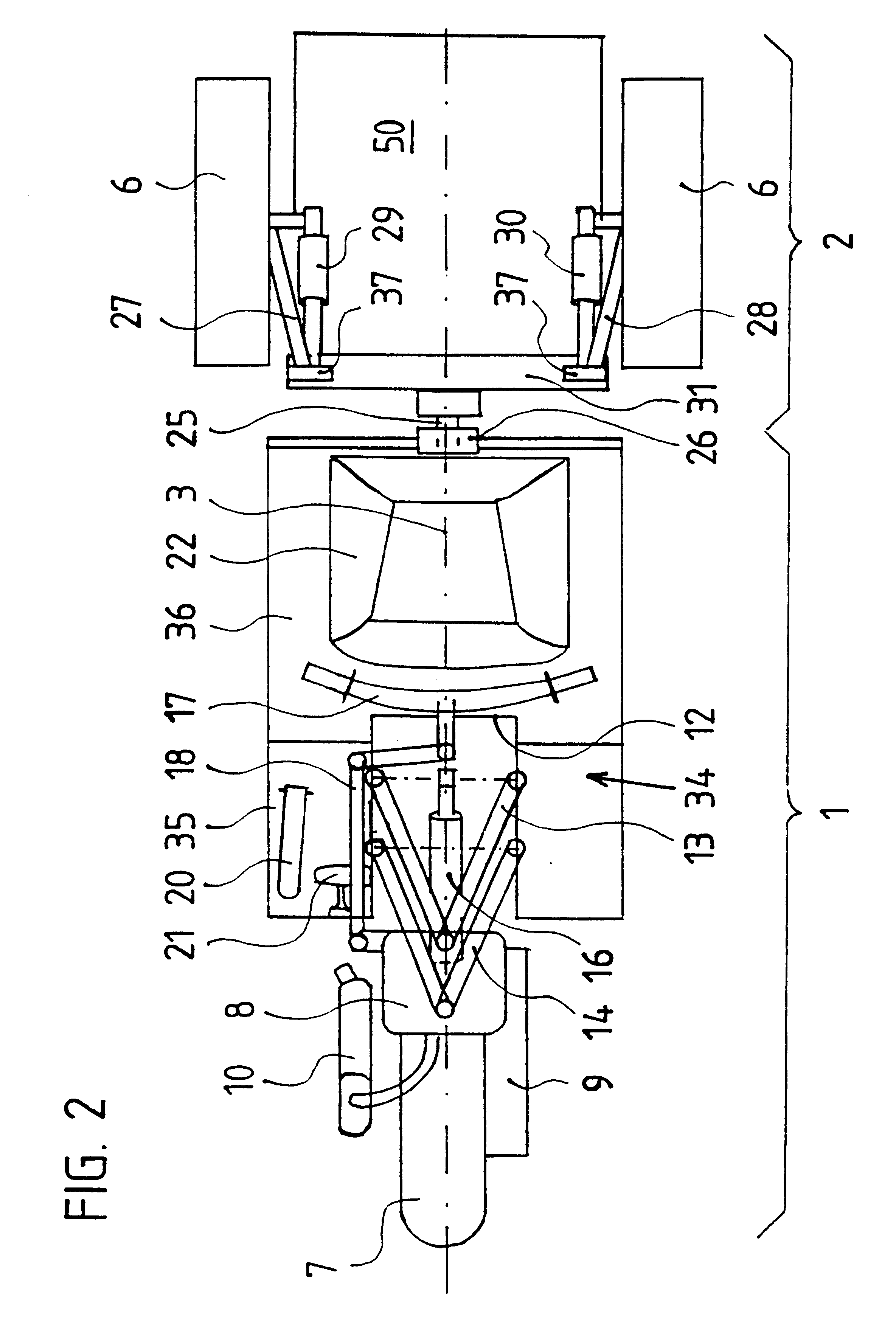

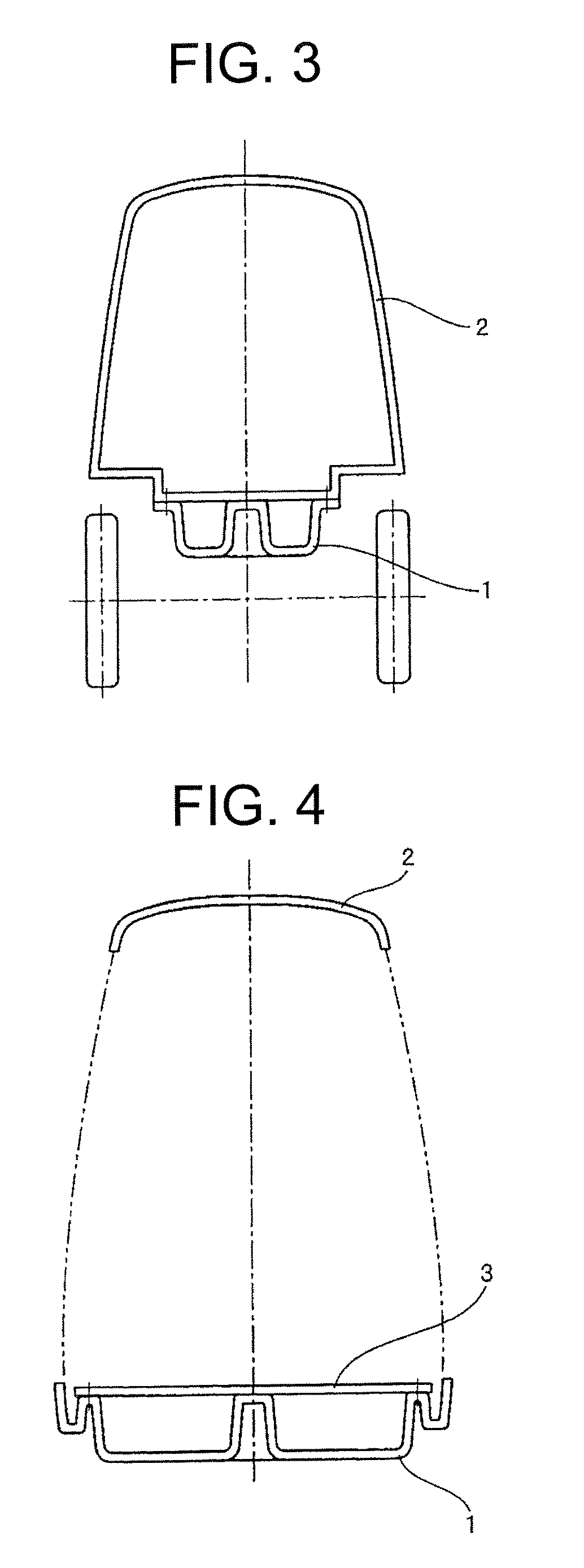

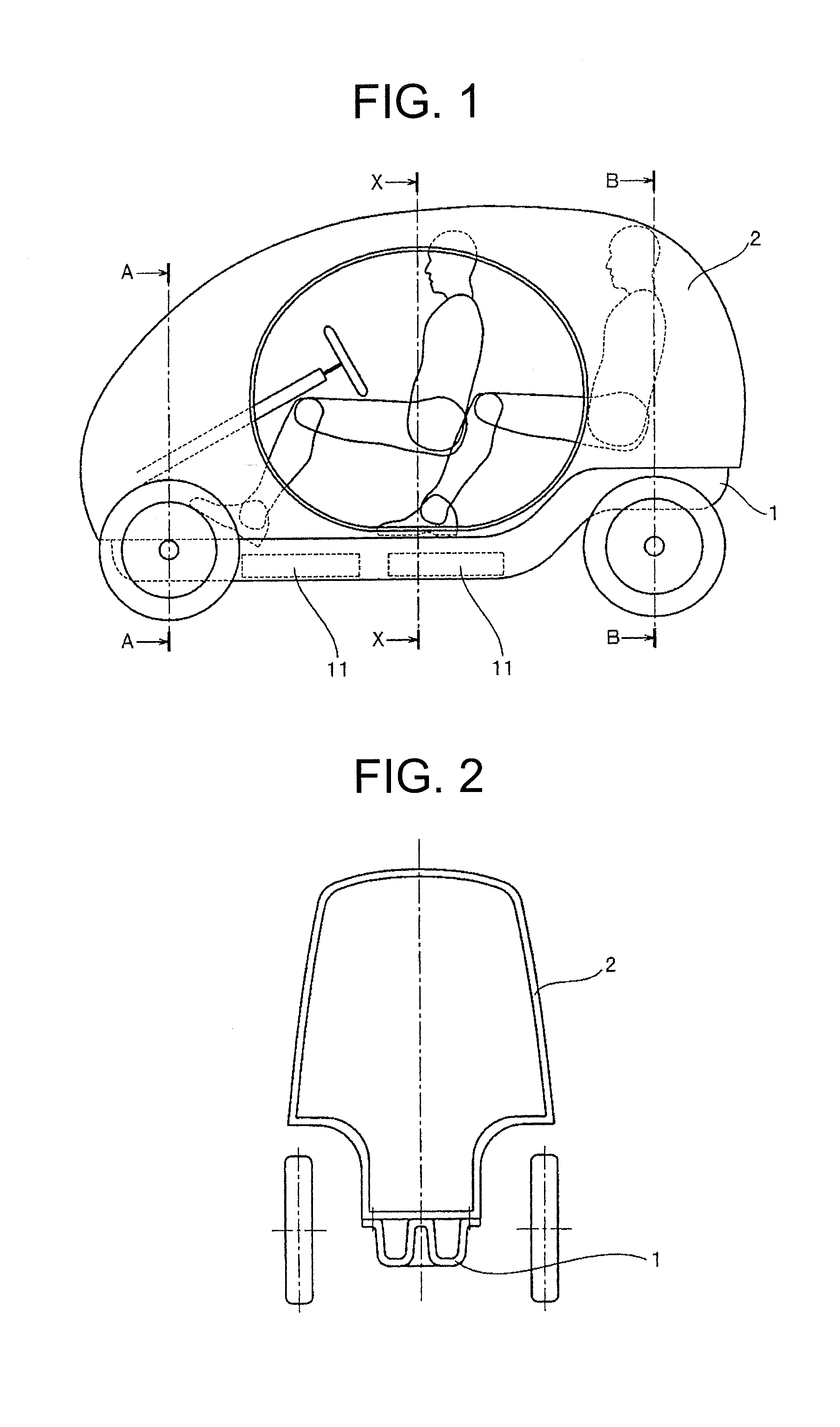

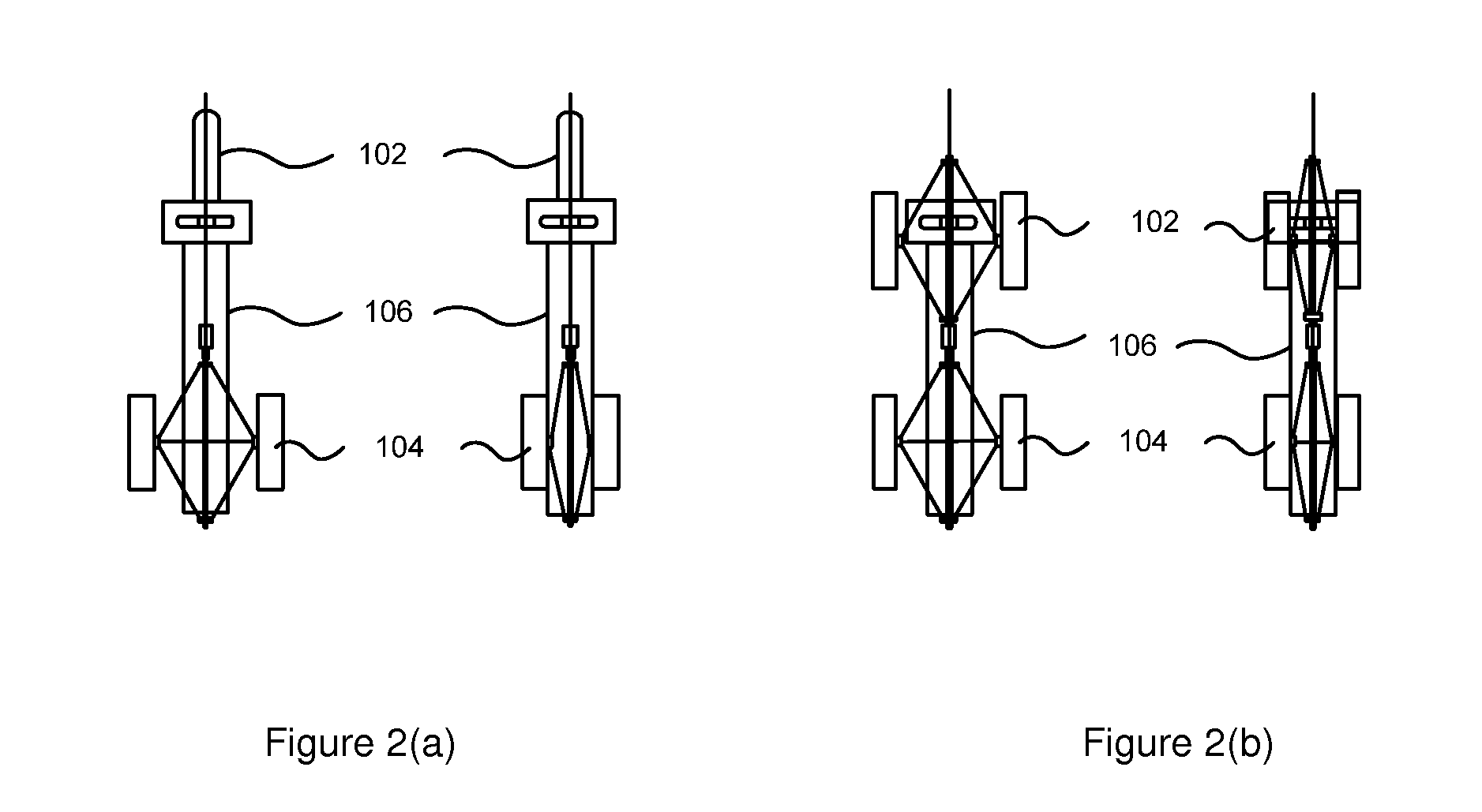

Three-wheel motor vehicle

A three-wheeled vehicle having two parts that can be tilted around a longitudinal axis. A rear part has a chassis for two-track wheels and the front part, which can be tilted relative to the rear part, accommodates a driver seat. Connected to a front end of the front part is a tiltable front wheel suspension to which a front wheel and an engine and gears for the front-wheel drive are attached. The two vehicle parts that can be tilted relative to each other each support or form a body which can also be designed for the front part as a monocoque and forms a closed and heatable driver cabin.

Owner:CITYMOBIL

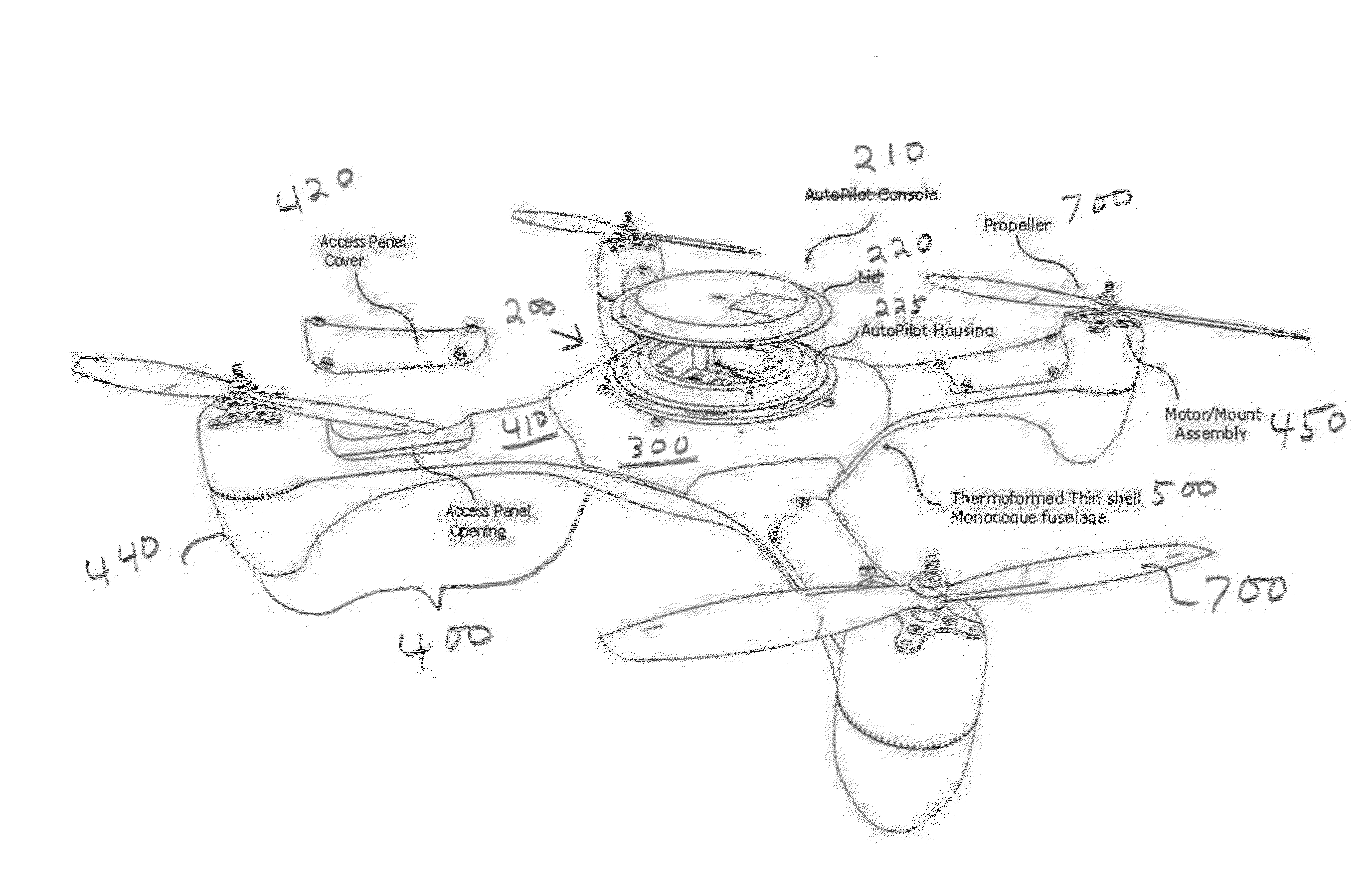

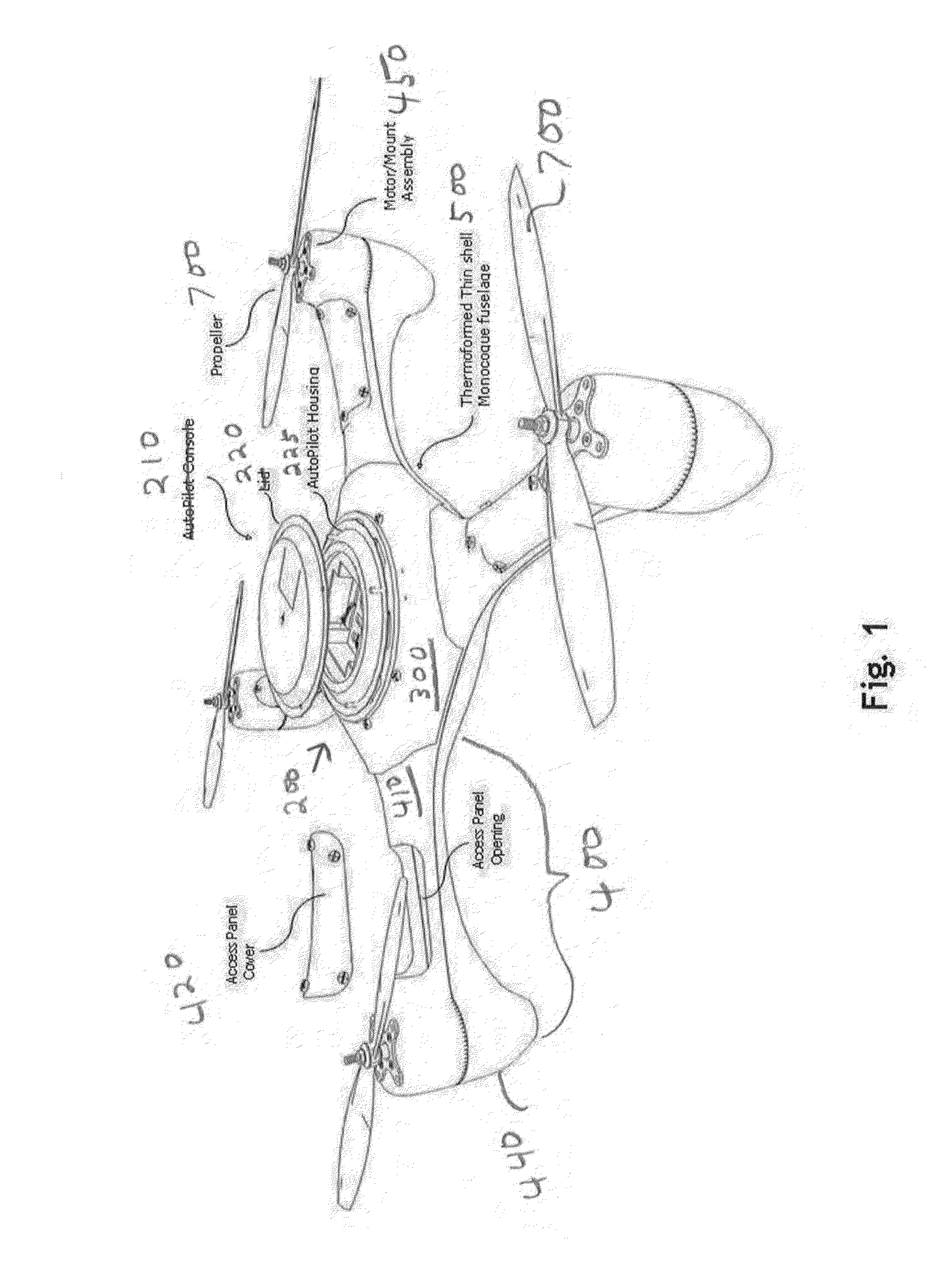

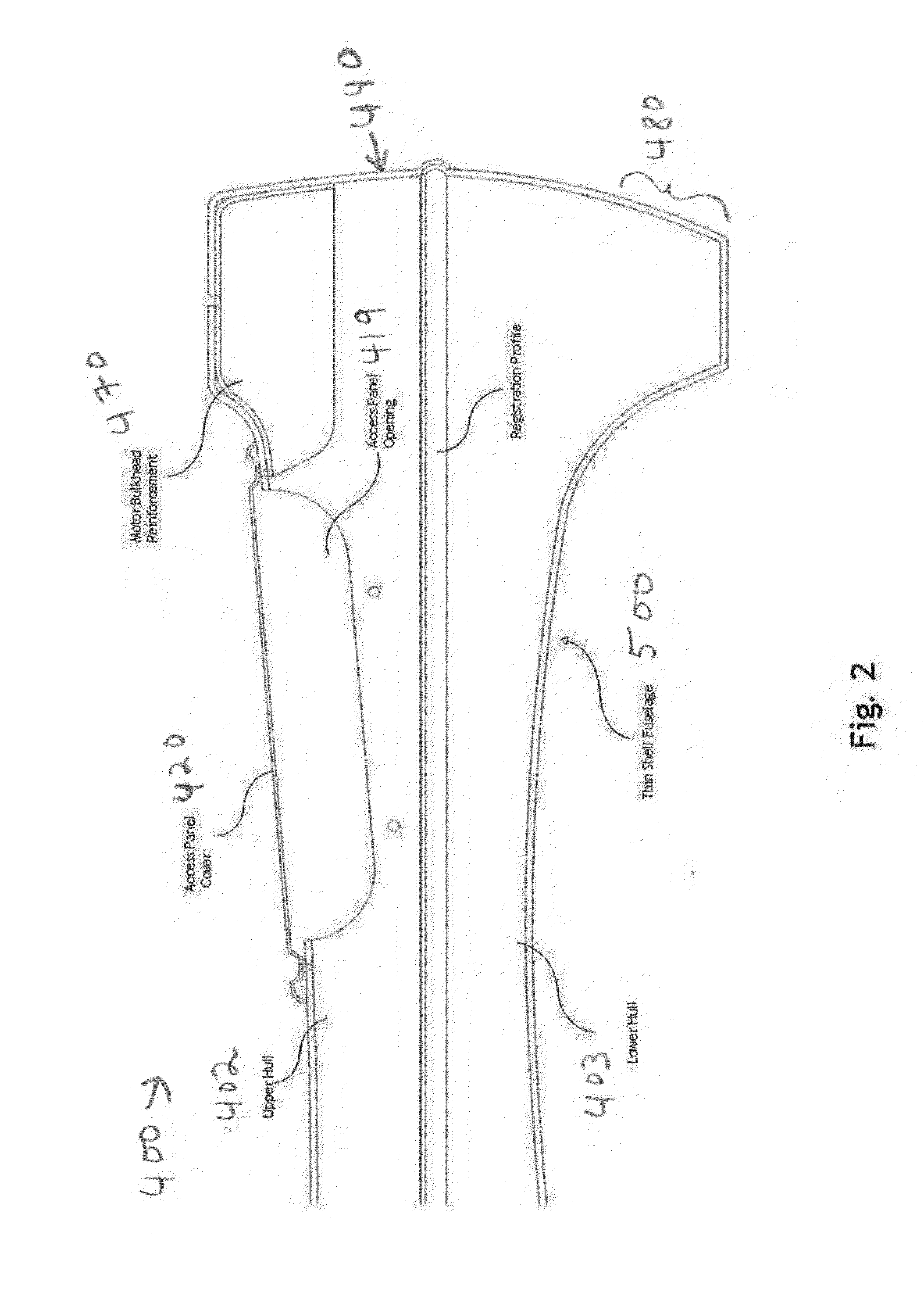

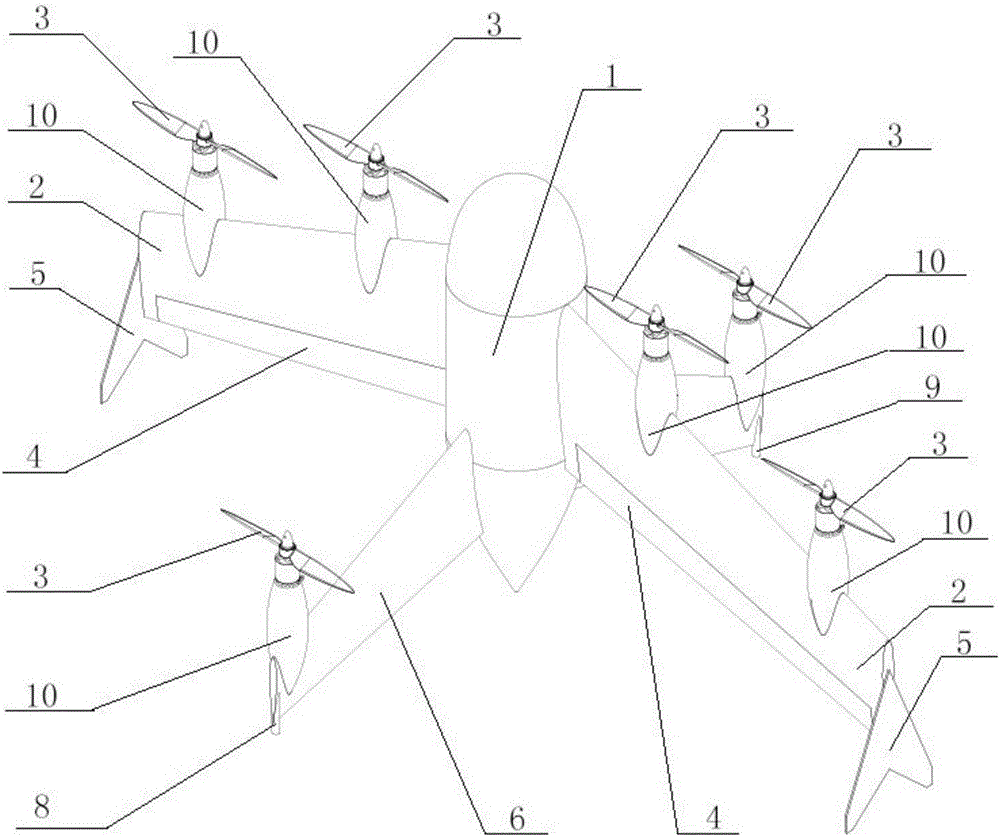

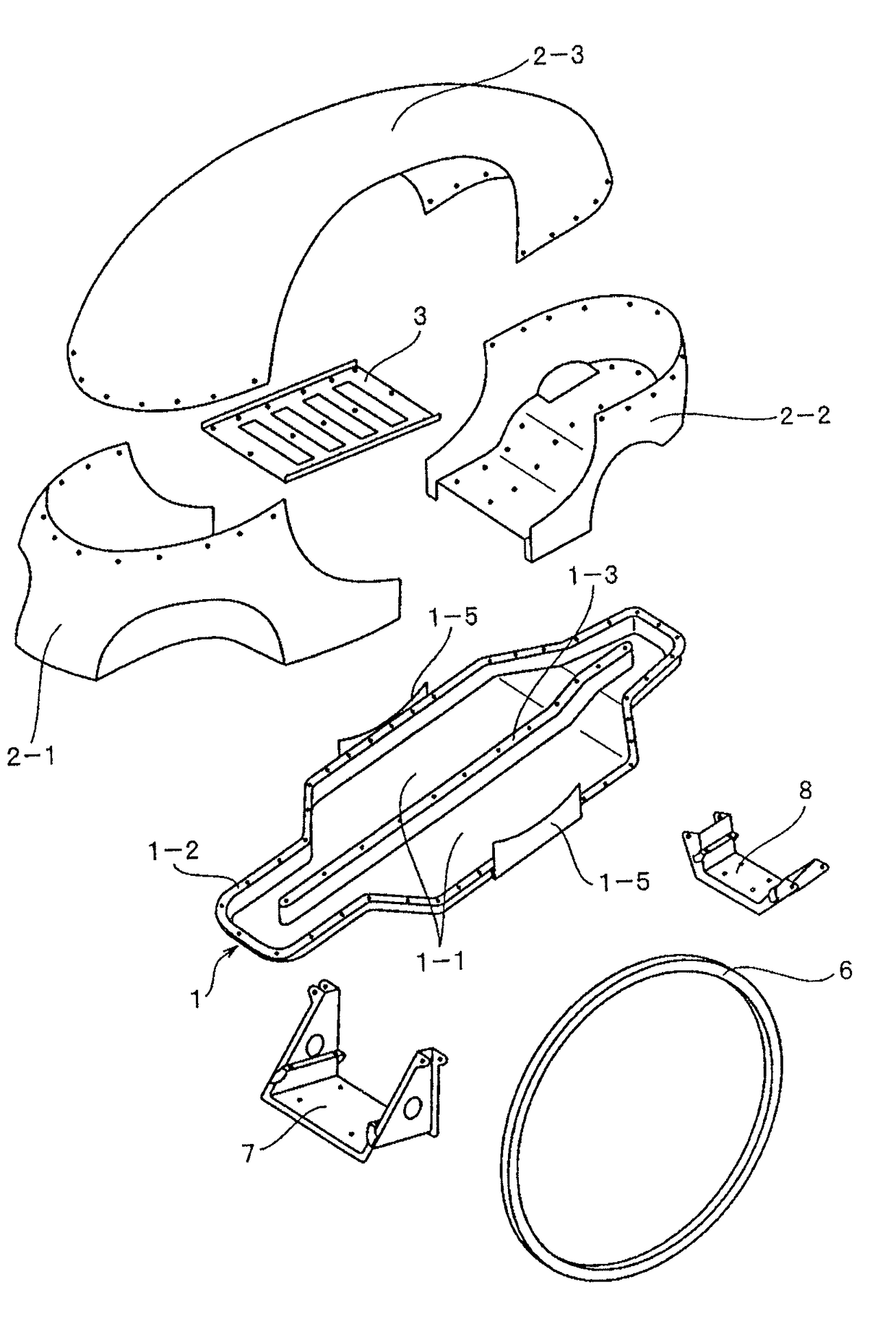

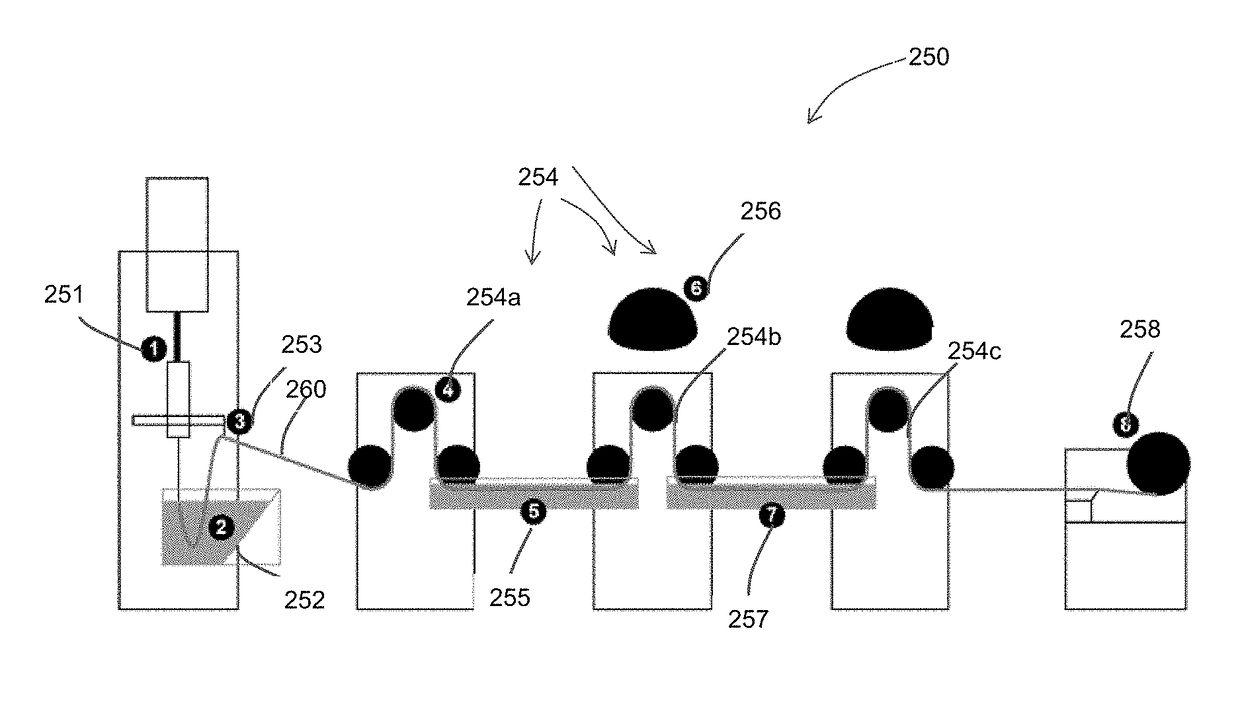

Methods and Systems of Constructing a Multi Rotor Aircraft Fuselage

InactiveUS20140231582A1Dissipating loadImprove efficiencyPower plant arrangements/mountingRemote controlled aircraftThin shellsFuselage

A lower hull 403 and an upper hull 402 may form a multi rotor aircraft fuselage system comprising a comprising a thermoformed thin shell monocoque fuselage 500, center console assembly 200, the center console assembly comprising a center console cover 210, an auto pilot housing cover 220 and an auto pilot housing 225. A center fuselage area 300 contains the center console assembly 200. The center fuselage area is part of a plurality of arm assemblies 400. Each arm assembly may comprise a distal end 440 and a proximal end 410, an access panel cover 420 which may expose a access panel opening 419. An access panel opening 419 may lead to an arm void area 430, with the arm void area 430 further defined by the interior sections of the thin shell fuselage 500.

Owner:HEADRICK SEAN

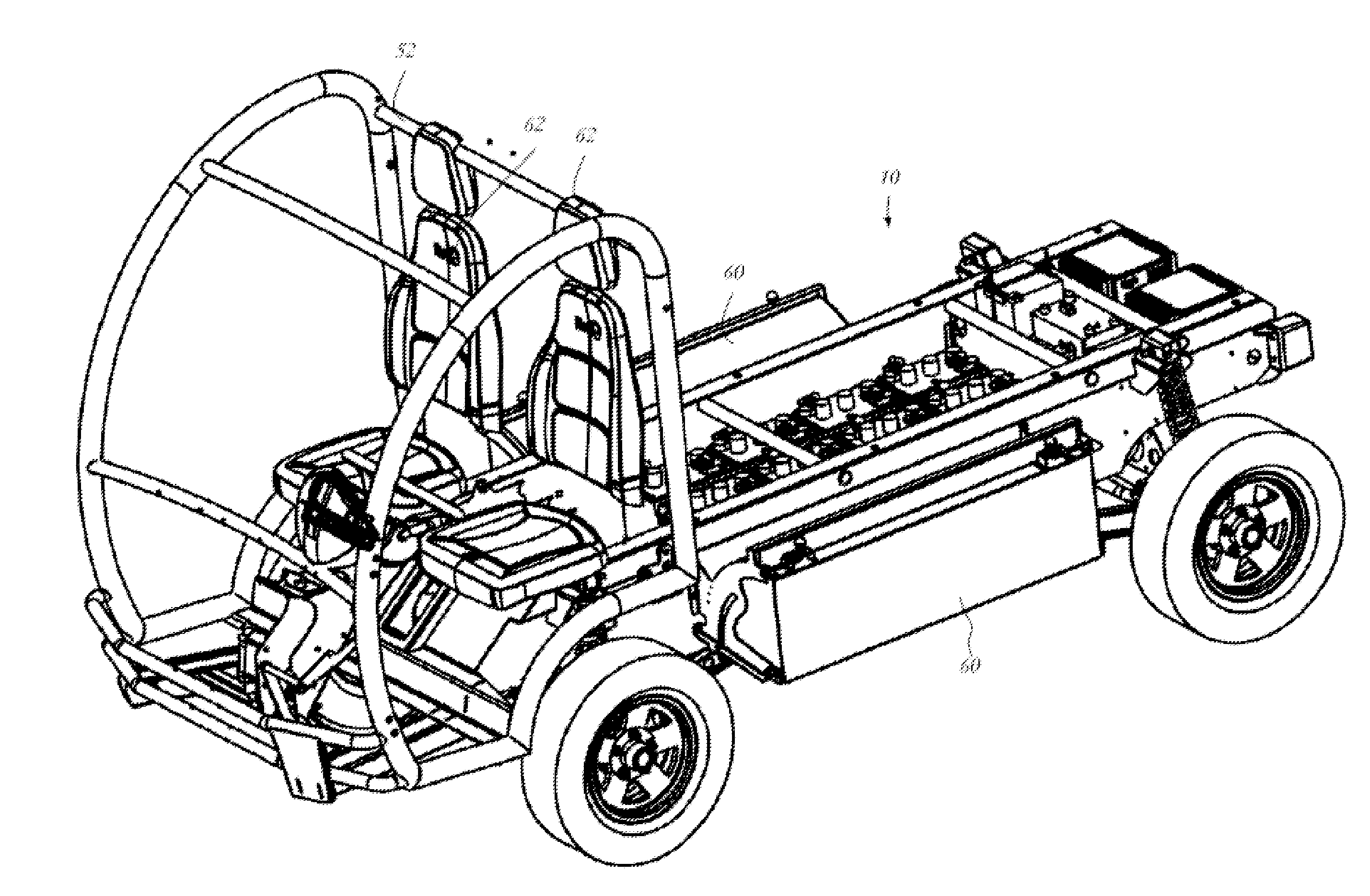

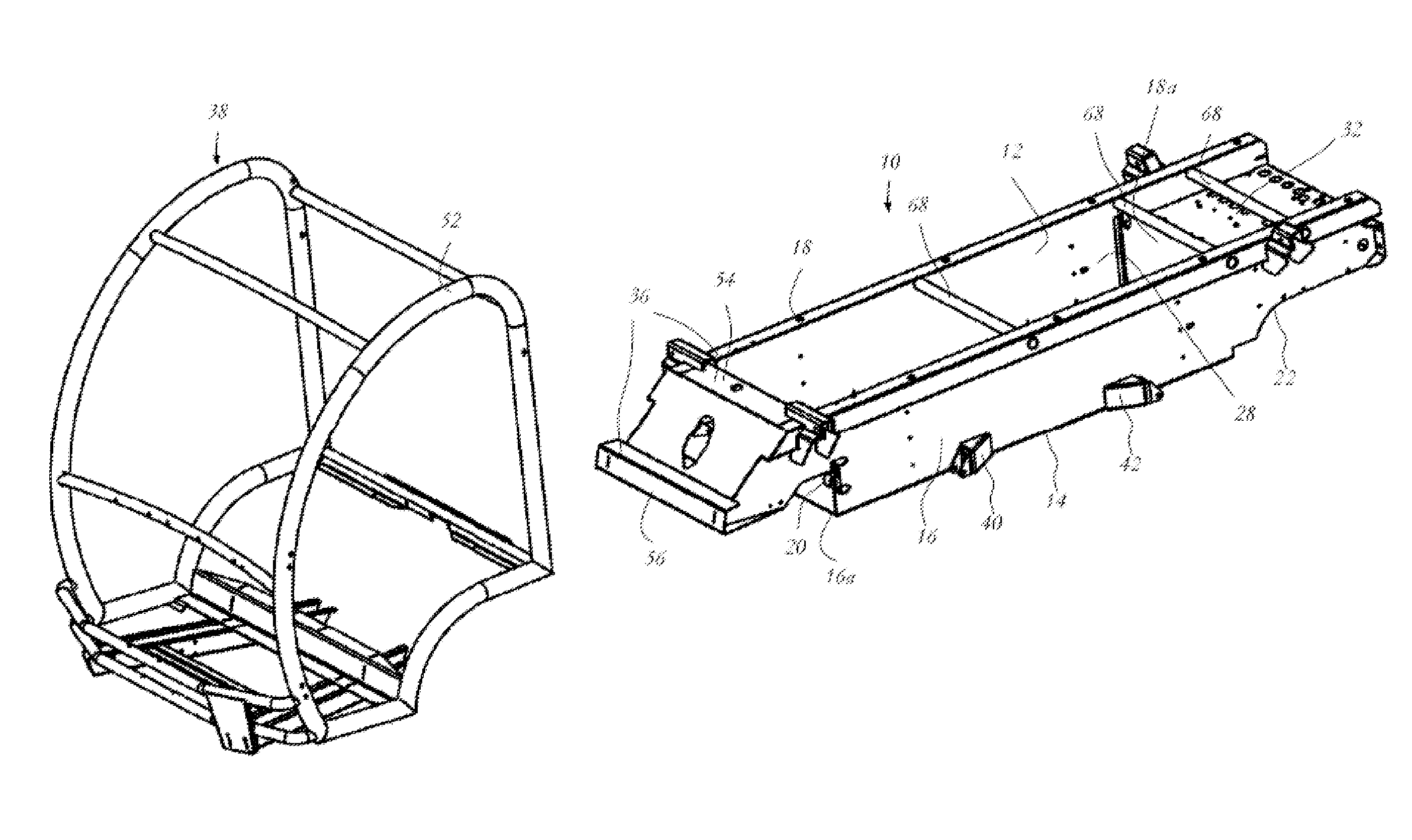

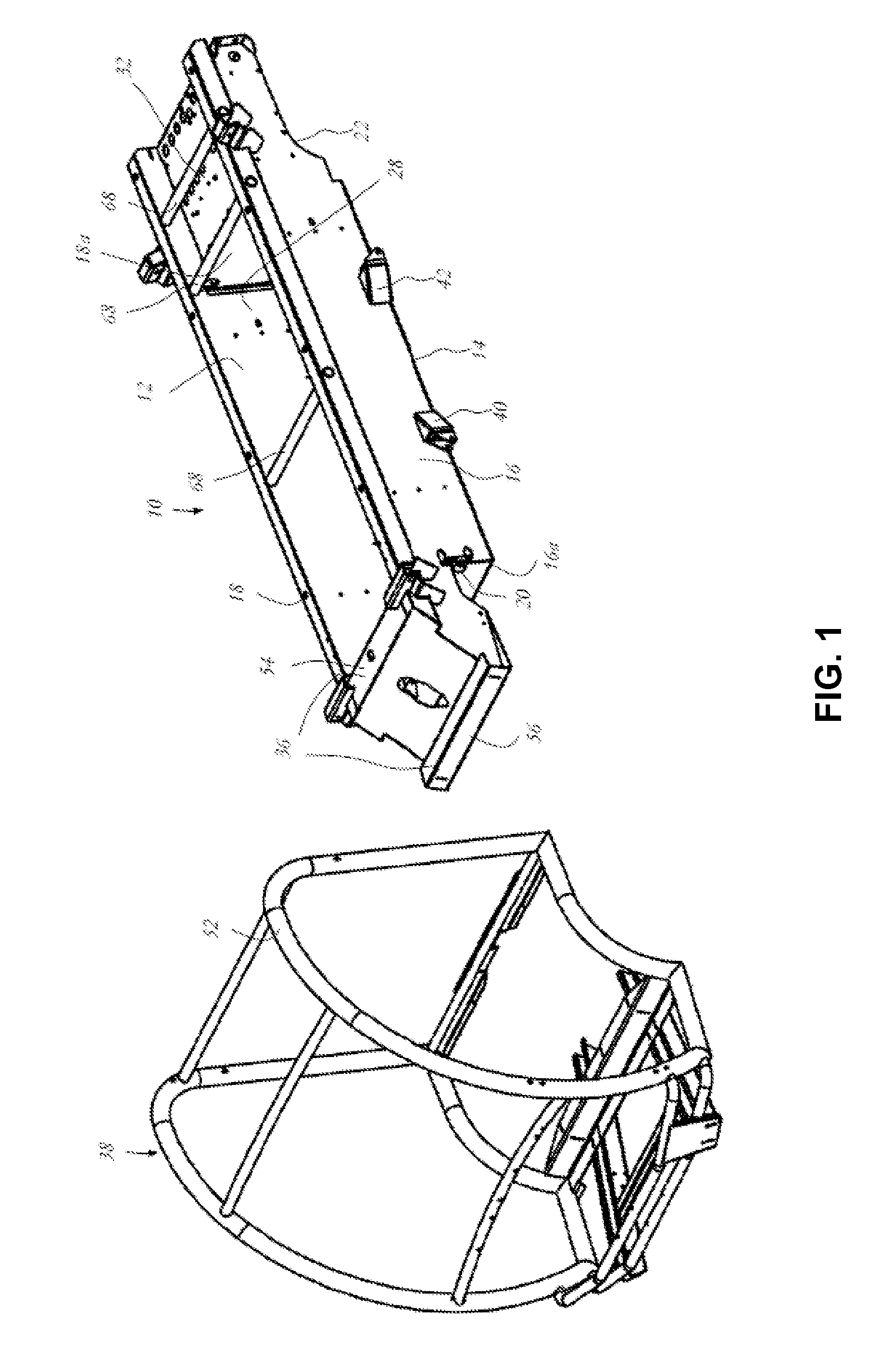

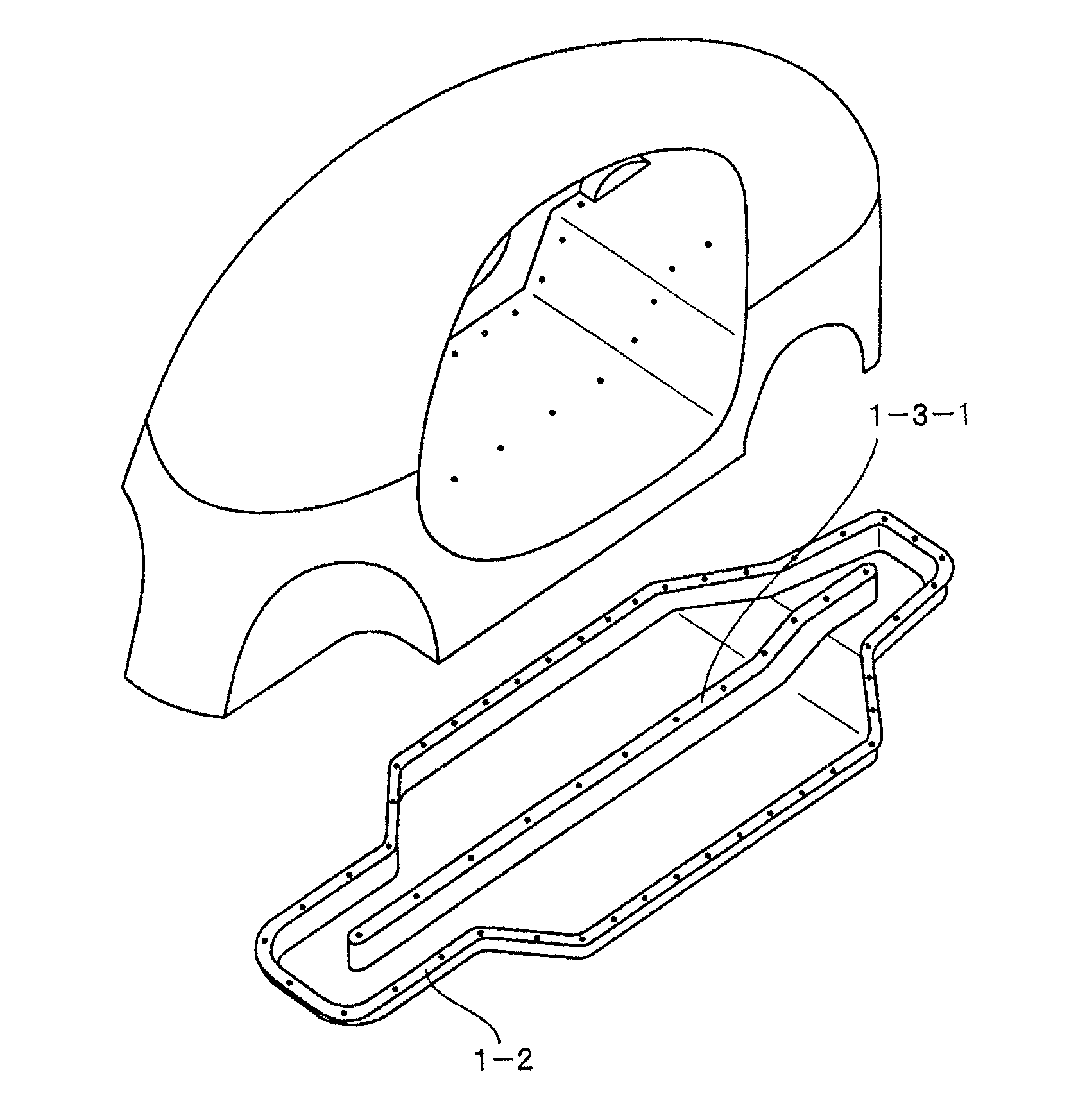

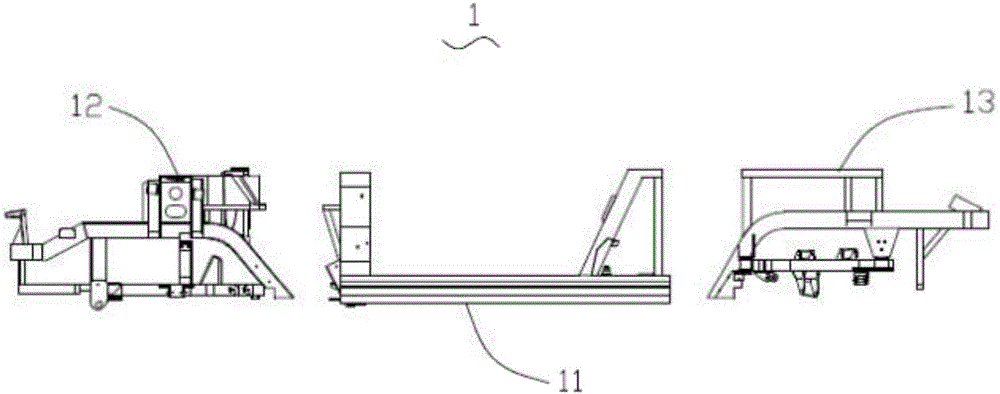

Vehicle Monocoque Body Assembly

A vehicle self-supporting monocoque body assembly comprising a base frame structure is provided. The body assembly also comprises a pair of wheel axles interfaces located at generally front and rear locations of the base frame structure for receiving a pair of wheel axles. The body assembly also has an energy storage element compartment positioned between front and rear wheel axles interfaces. The body assembly also includes an engine compartment for completely housing an engine system. The body assembly also comprises a vehicle outer frame interface. The body assembly also includes front and rear suspension arm interfaces for interfacing with two pairs of front and rear symmetrical suspension arms extending along a length of the base frame structure. The bottom surface of the base frame structure is positioned at or below a horizontal plane between the wheel axles. Preferably, the vehicle outer frame interface is shaped to receive a cabin frame structure.

Owner:VEHICULES NEMO

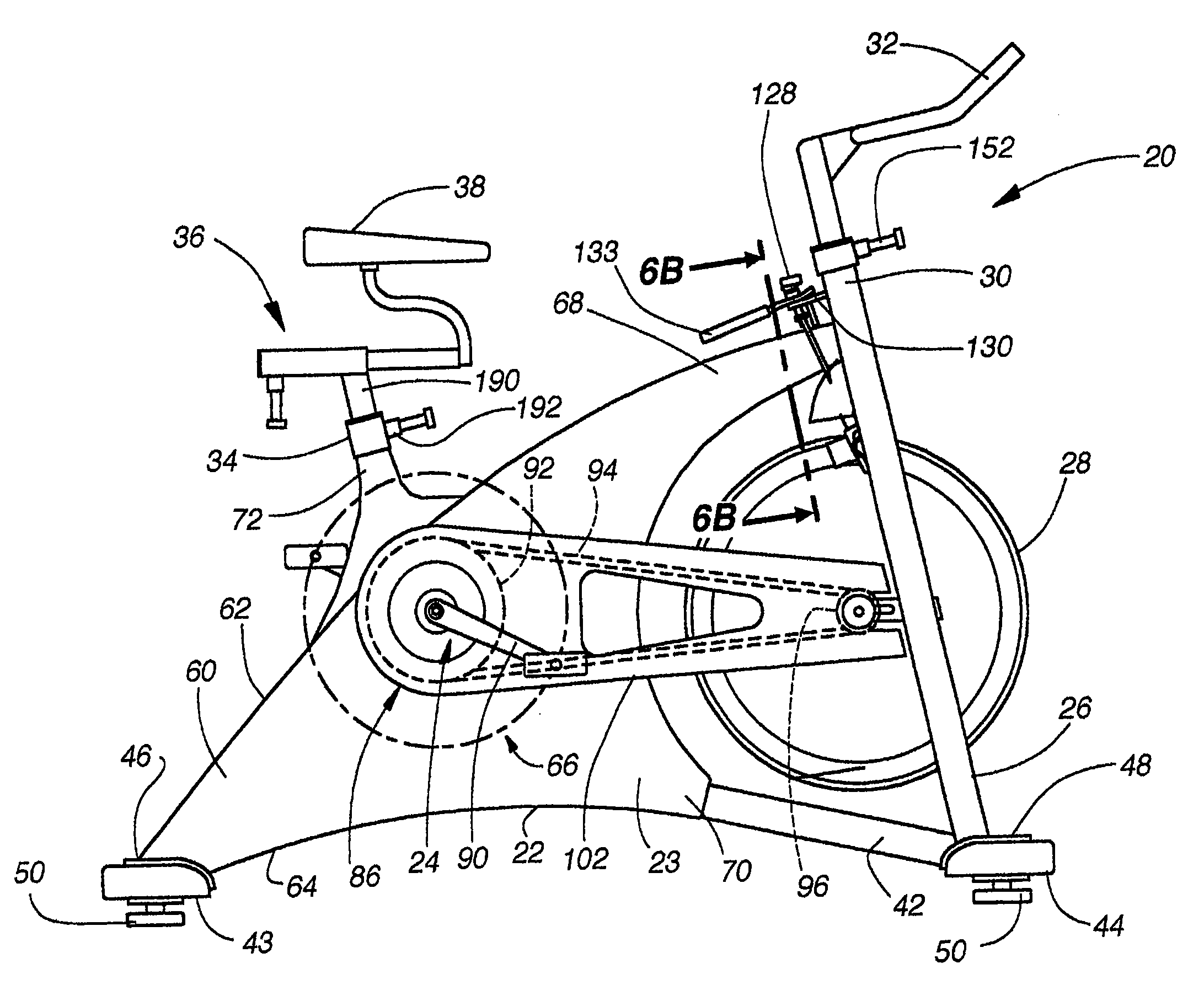

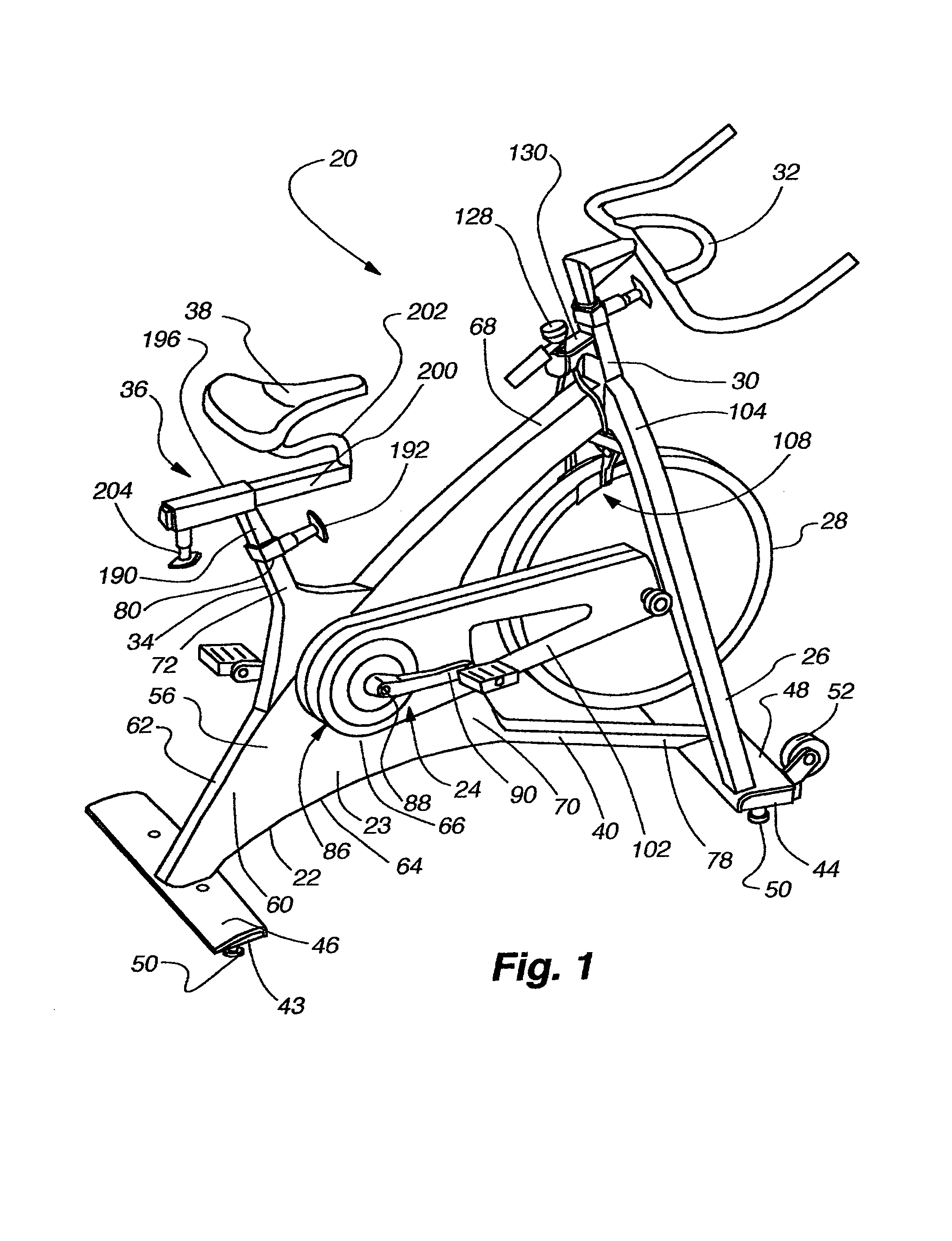

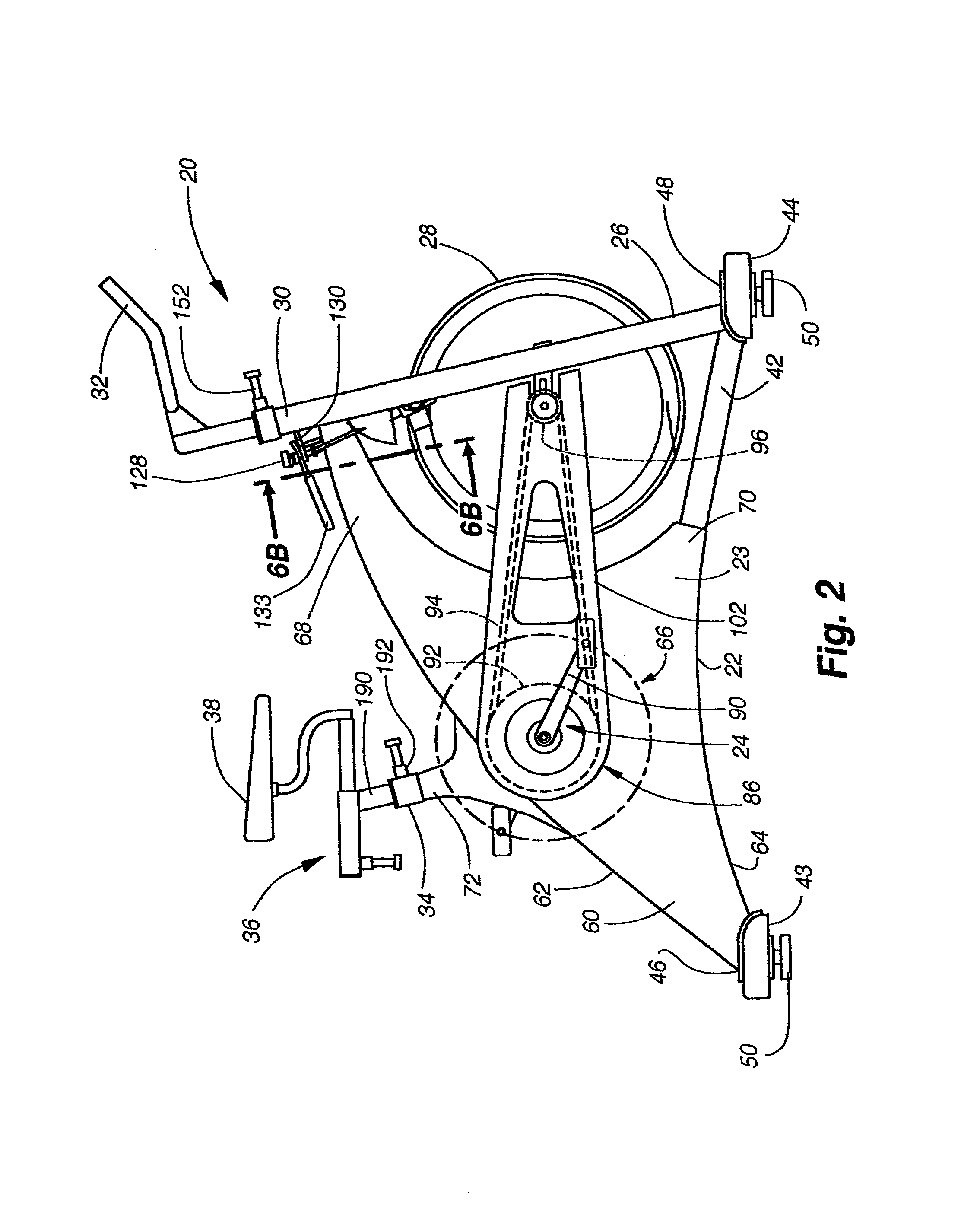

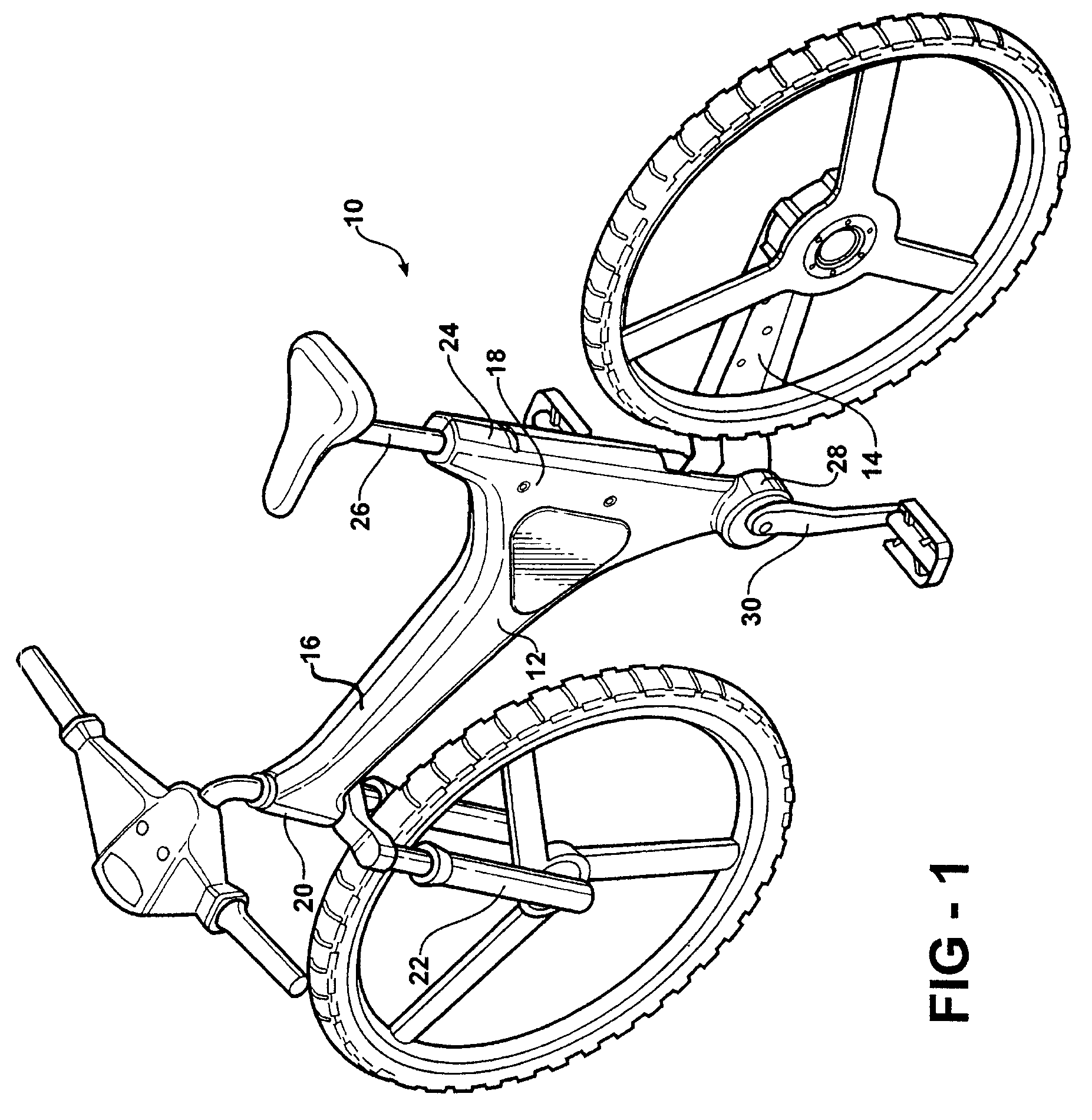

Exercise bicycle

InactiveUS7226393B2Easy to manufactureEasy to movePassenger cyclesChildren cyclesEngineeringUltimate tensile strength

A unique structure for an indoor exercise bike that provides strength in its design, as well as the flexibility to create an aesthetically appealing frame structure. The monocoque frame design, including two symmetrical halves joined together, forms a very strong, light shell that can take on a variety of shapes and sizes. The seat structure, handlebar structure, drive train and support platforms are all able to be readily attached to the primary frame structure to provide an exercise bicycle that is sturdy, easy to manufacture, and light enough to easily move when necessary.

Owner:NAUTILUS INC

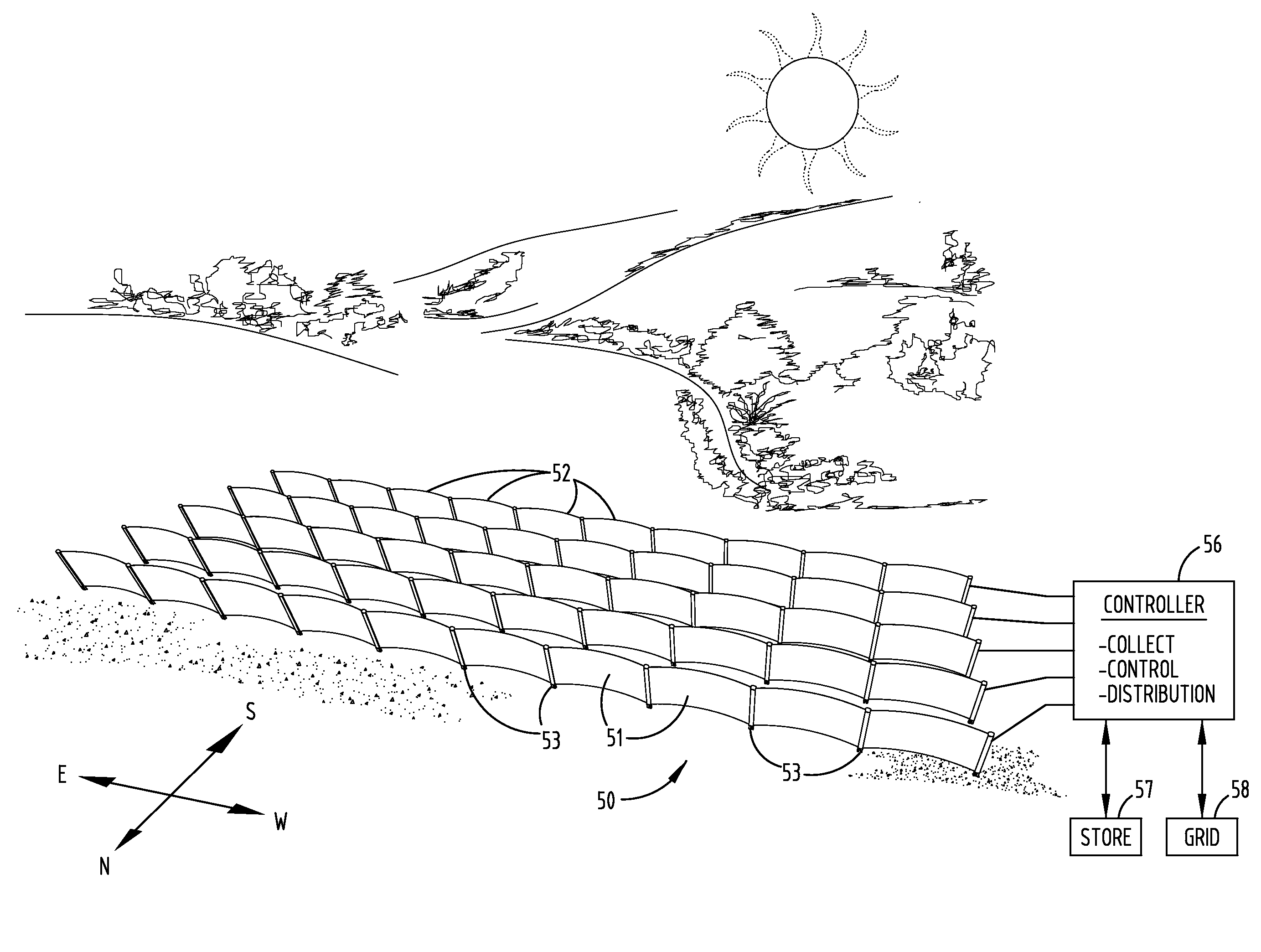

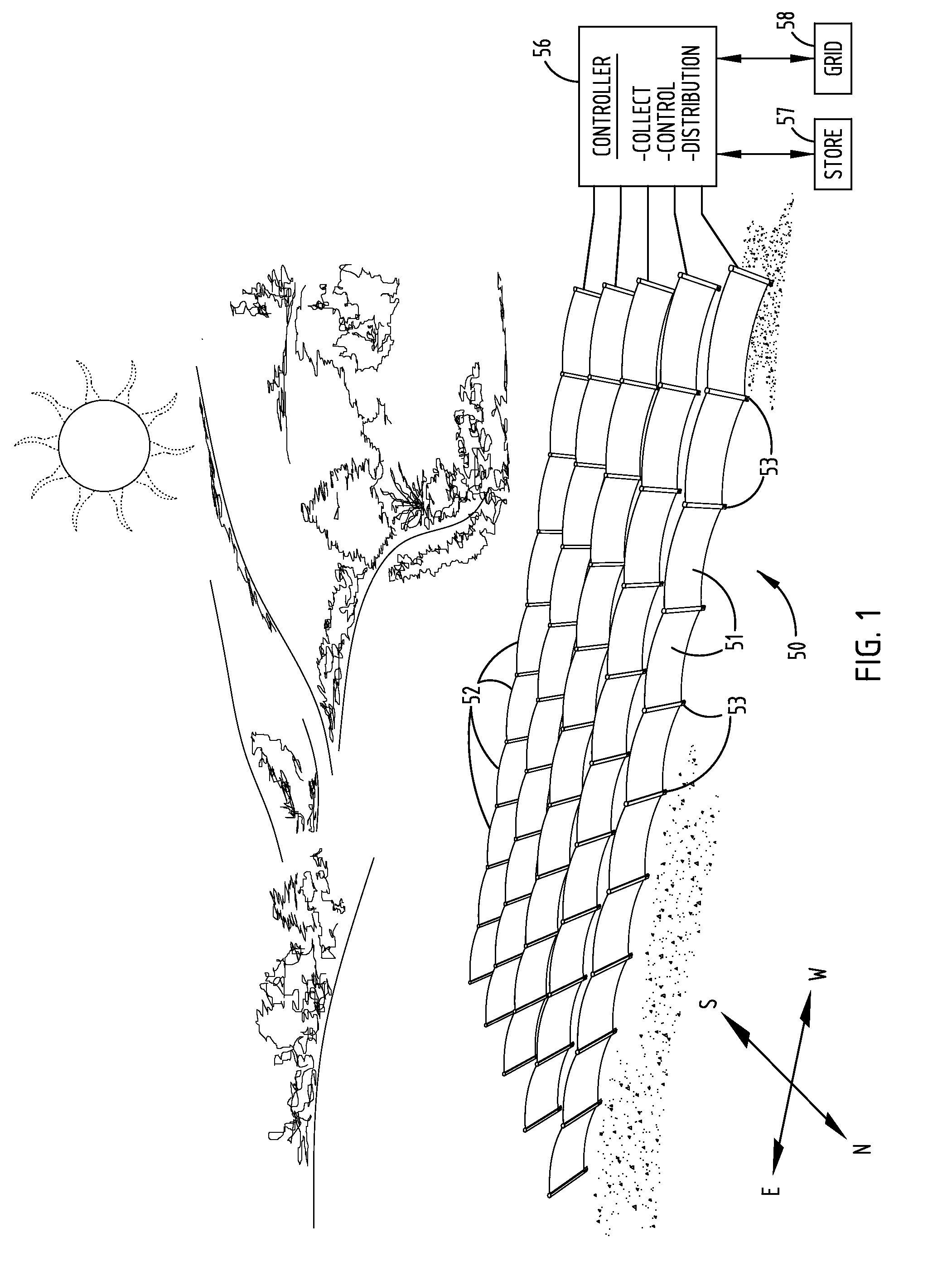

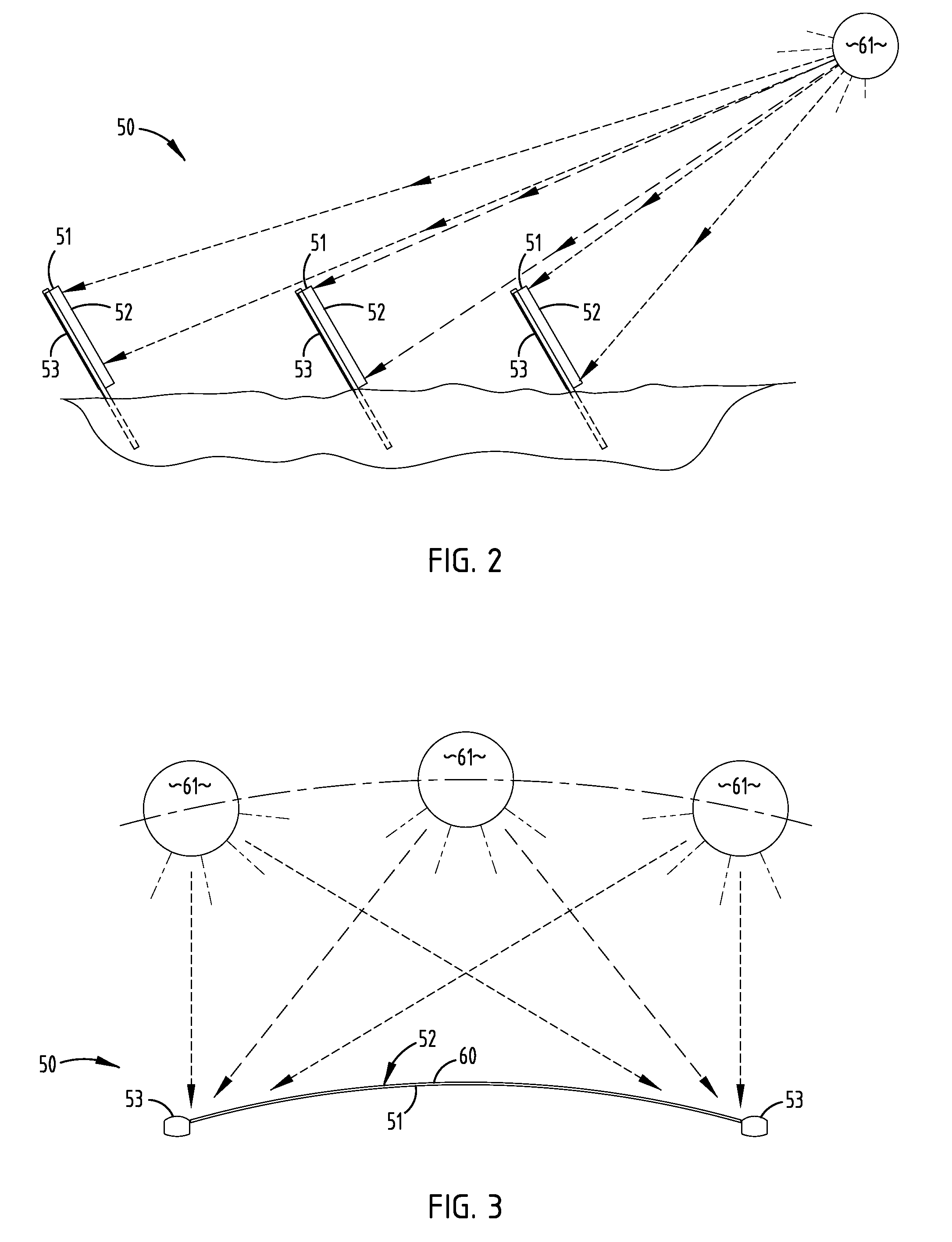

Solar panel system with monocoque supporting structure

ActiveUS20110303262A1Rapidly deployableSignificant and reliablePhotovoltaic supportsSolar heating energyControl powerElectrical battery

A solar panel system comprises a monocoque forming an enlarged solar-facing generally-convex outer support surface when in an installed position and that supports solar cells at optimal angles for capturing solar energy. The monocoque provides a stressed-skin support reducing weight while maintaining strength, optimal support surface, and minimizing cost. A post engages and supports adjacent edges of a pair of adjacent monocoques. An electrical circuit connects the solar cells for electrical flow and power management, and preferably includes a controller for controlling power from the solar cells, including combining them in series or parallel as optimal for a given systems configuration. The illustrated monocoque includes a roll formed sheet or a number of sheets, stacked vertically together and anchored to spaced posts using connectors in a “fence-like” pattern.

Owner:WOLTER JAMES F

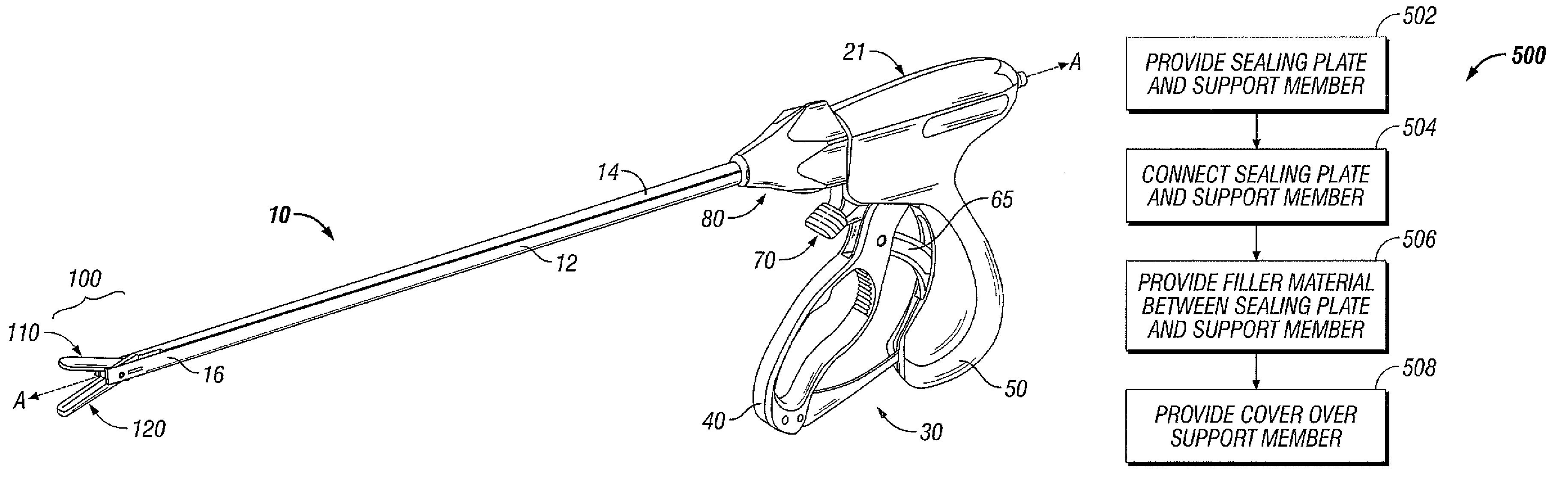

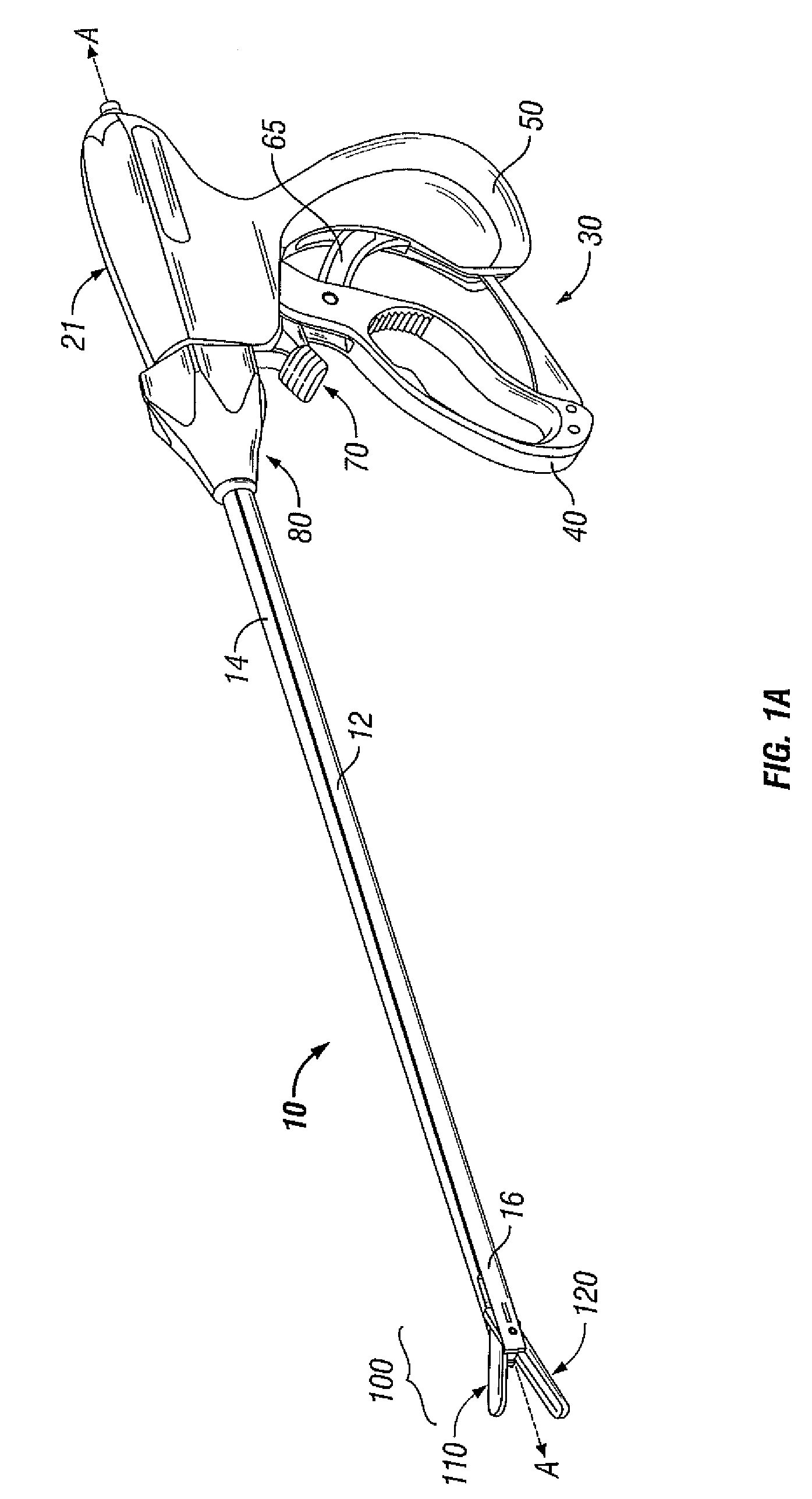

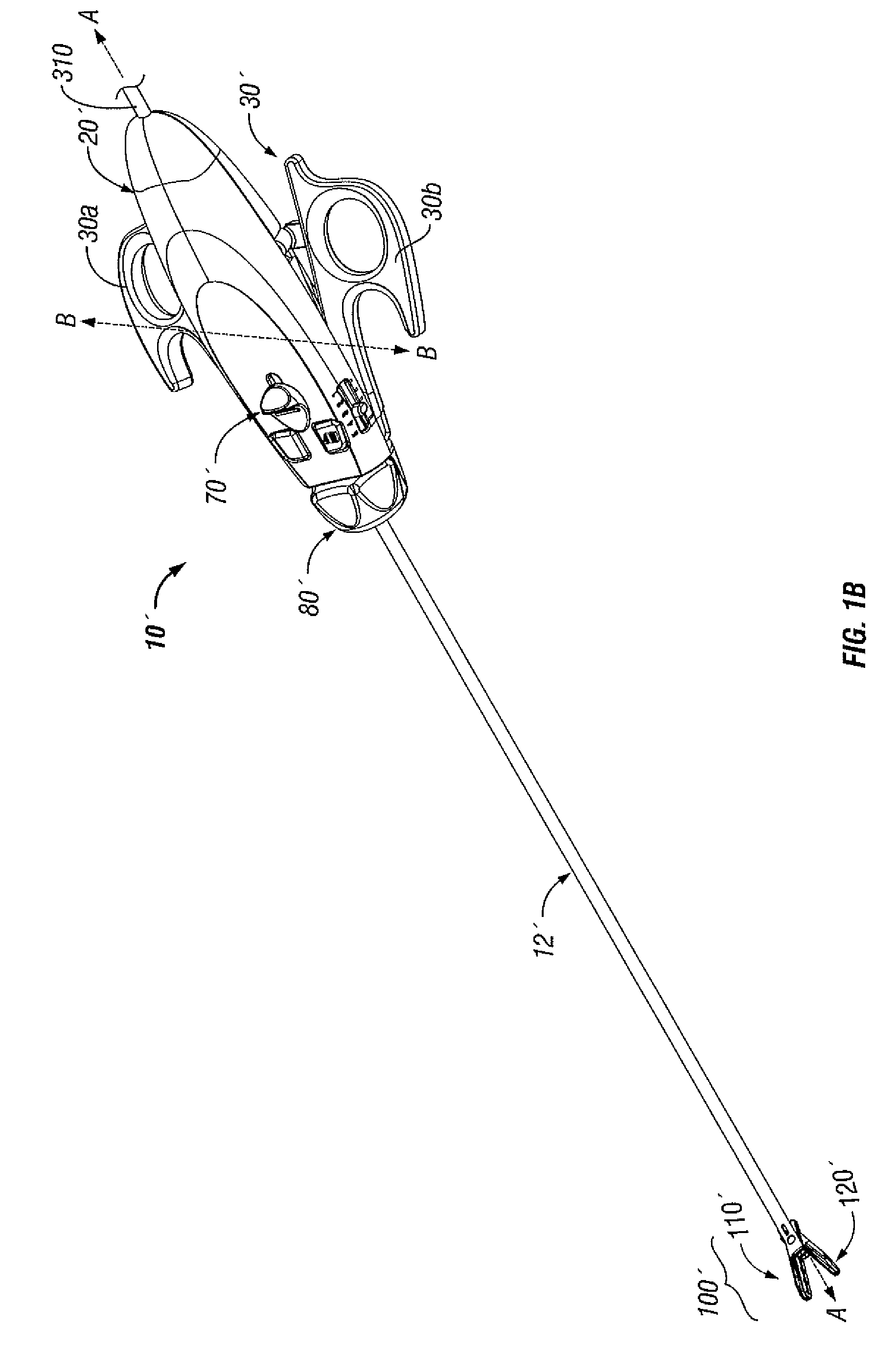

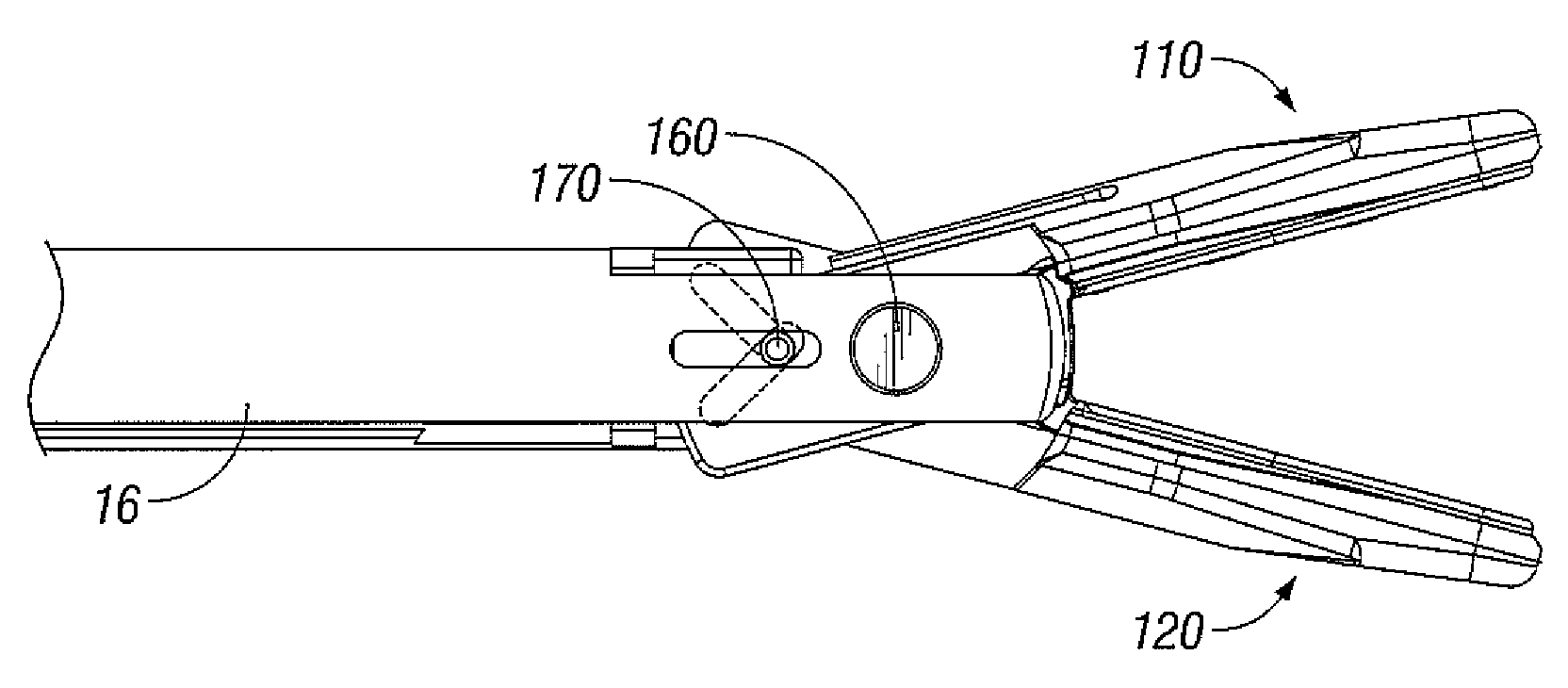

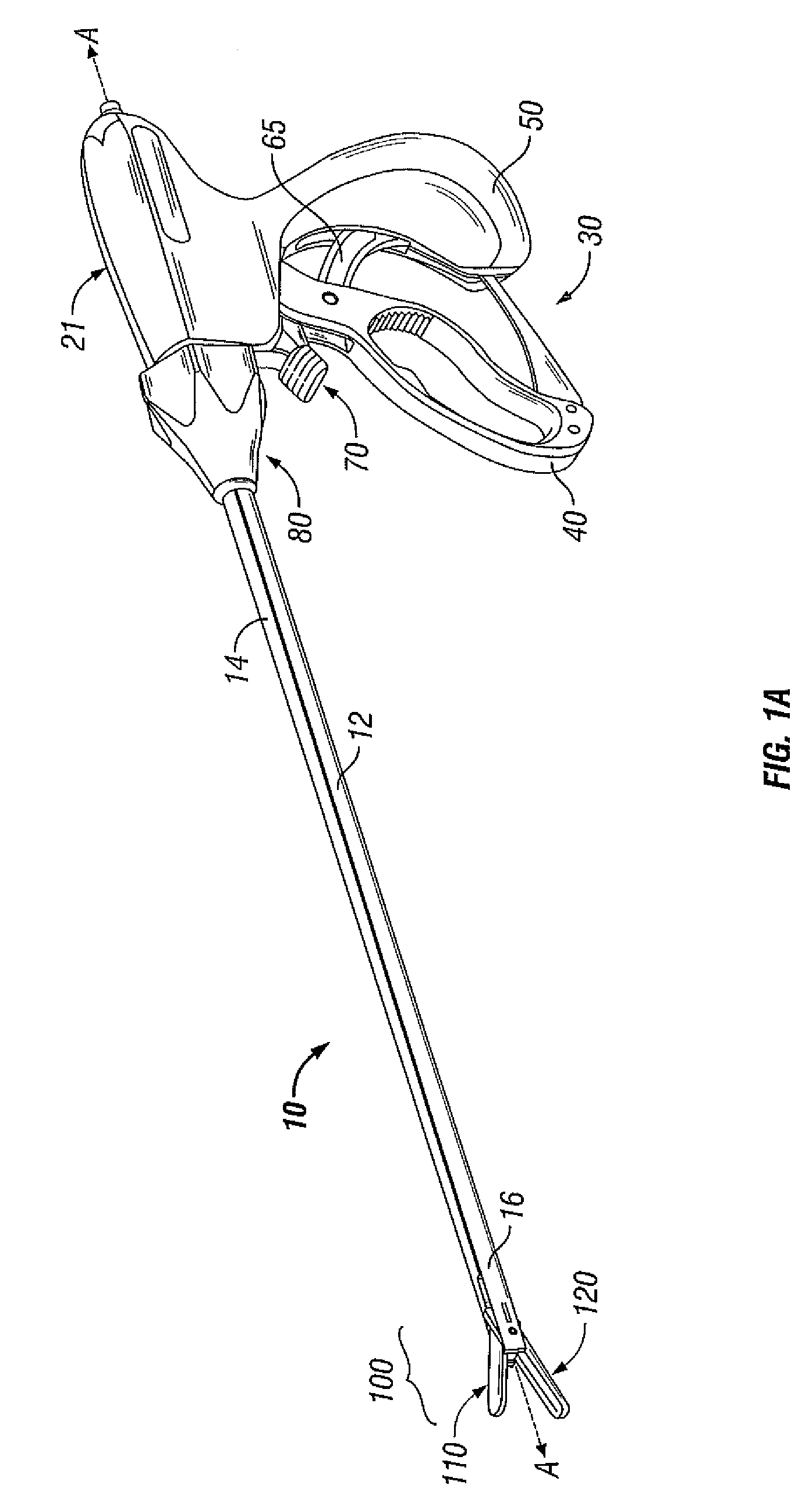

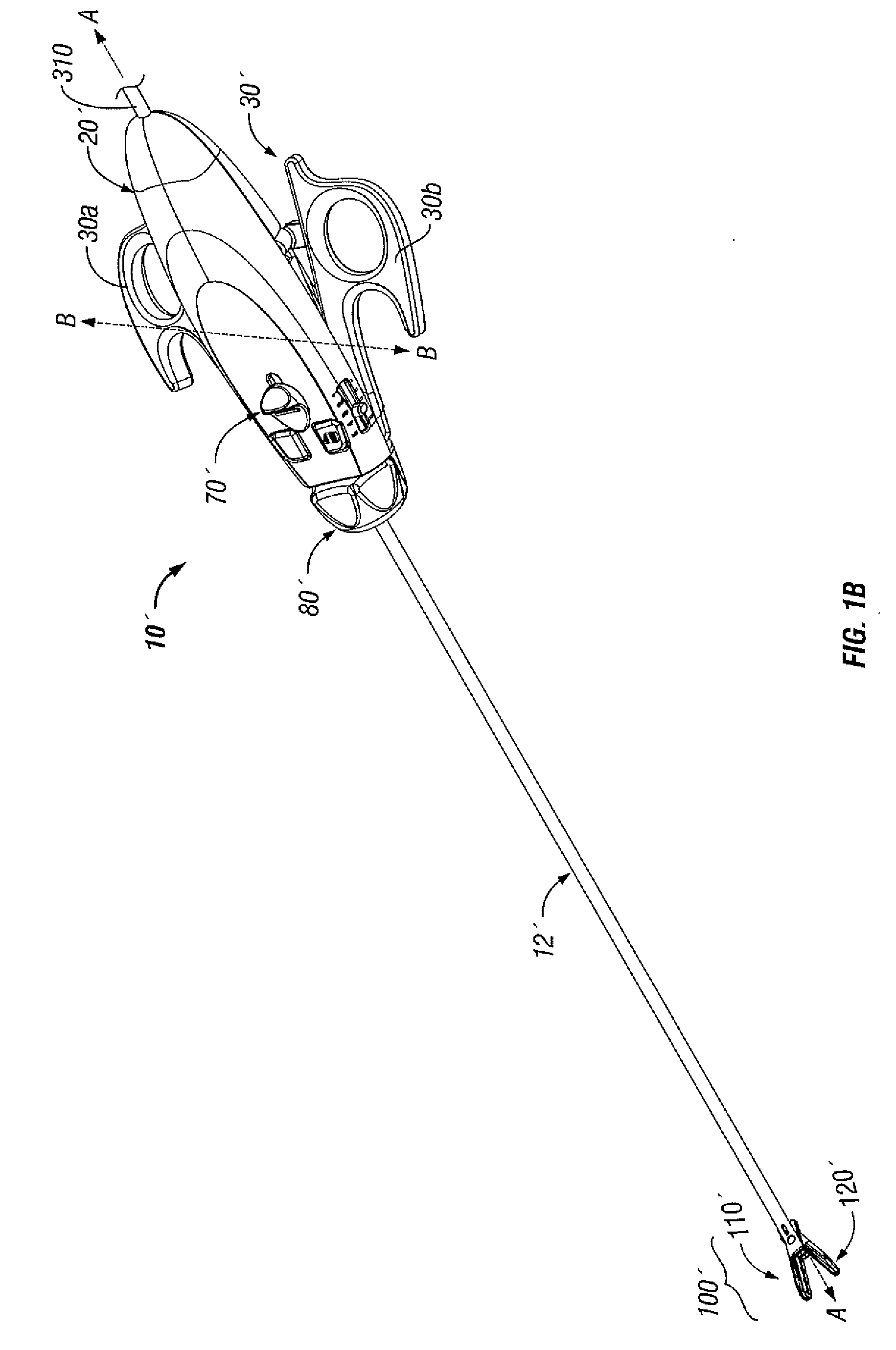

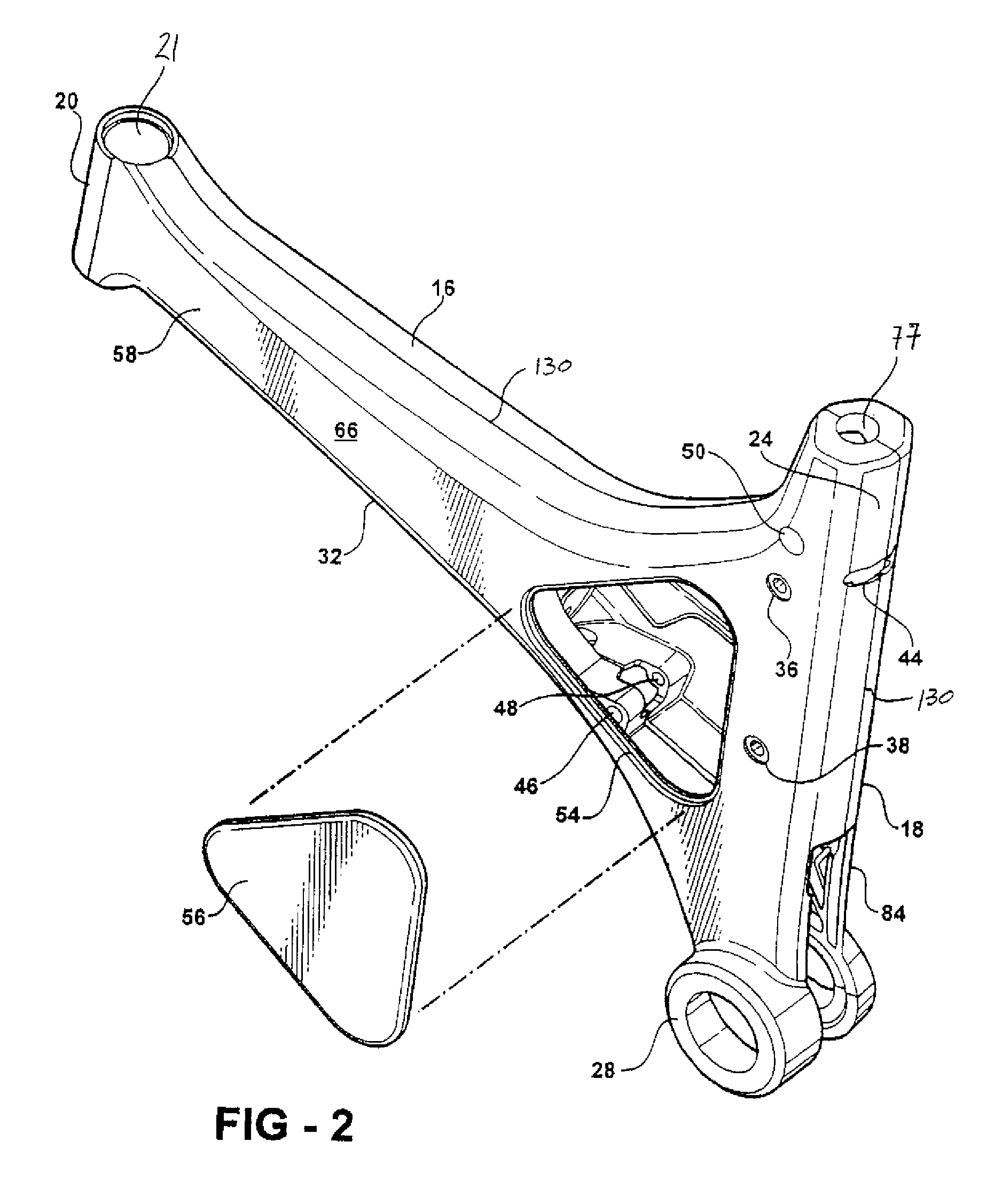

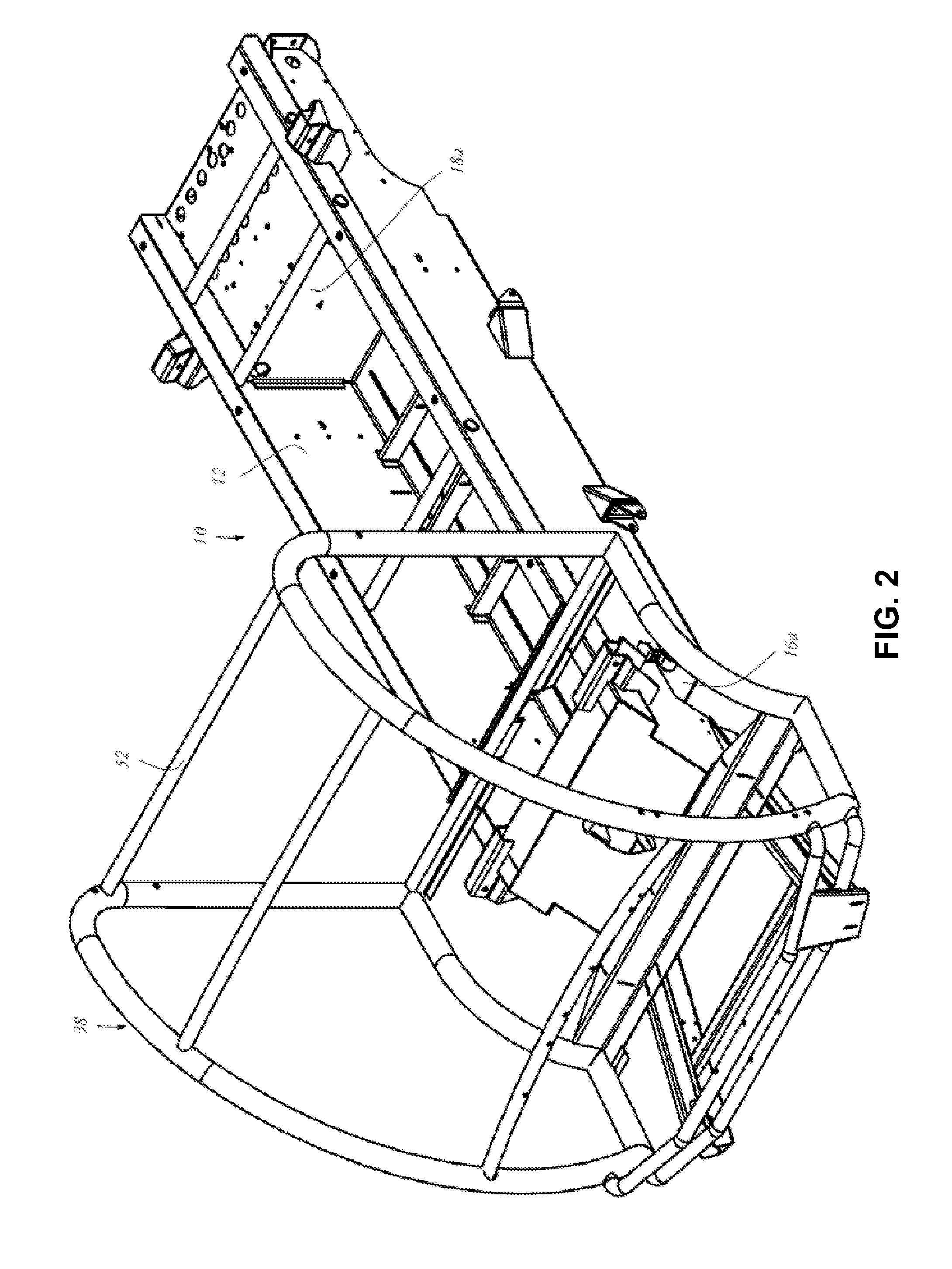

Monocoque Jaw Design

ActiveUS20090216229A1High strengthMetal rolling stand detailsSurgical instrument detailsForcepsEngineering

A jaw member for use with an electrosurgical forceps includes a support member having a first surface and a pair of depending sides which extend therefrom forming a generally U-shaped configuration. The free end of the sides each including a flange which extends outwardly therefrom which is designed to attach to an electrically conductive plate such that the plate bridge the two flanges to enclose the U-shaped support member to form a box-like skeleton having a cavity defined therein. An insulative material is disposed within the cavity and an insulative cover is disposed about a periphery of the box-like support skeleton to insulate surrounding tissue during activation of the conductive plate.

Owner:TYCO HEALTHCARE GRP LP

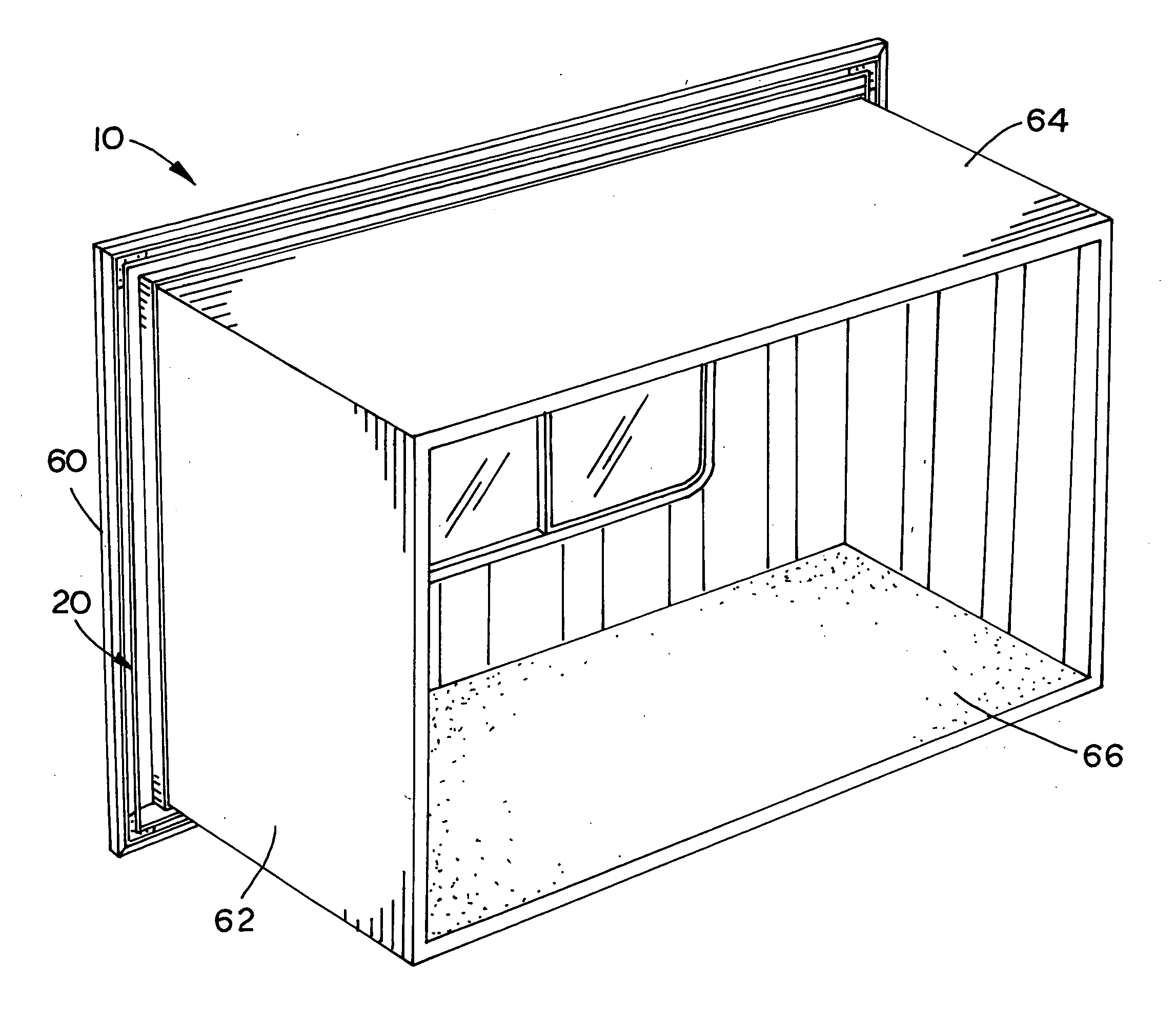

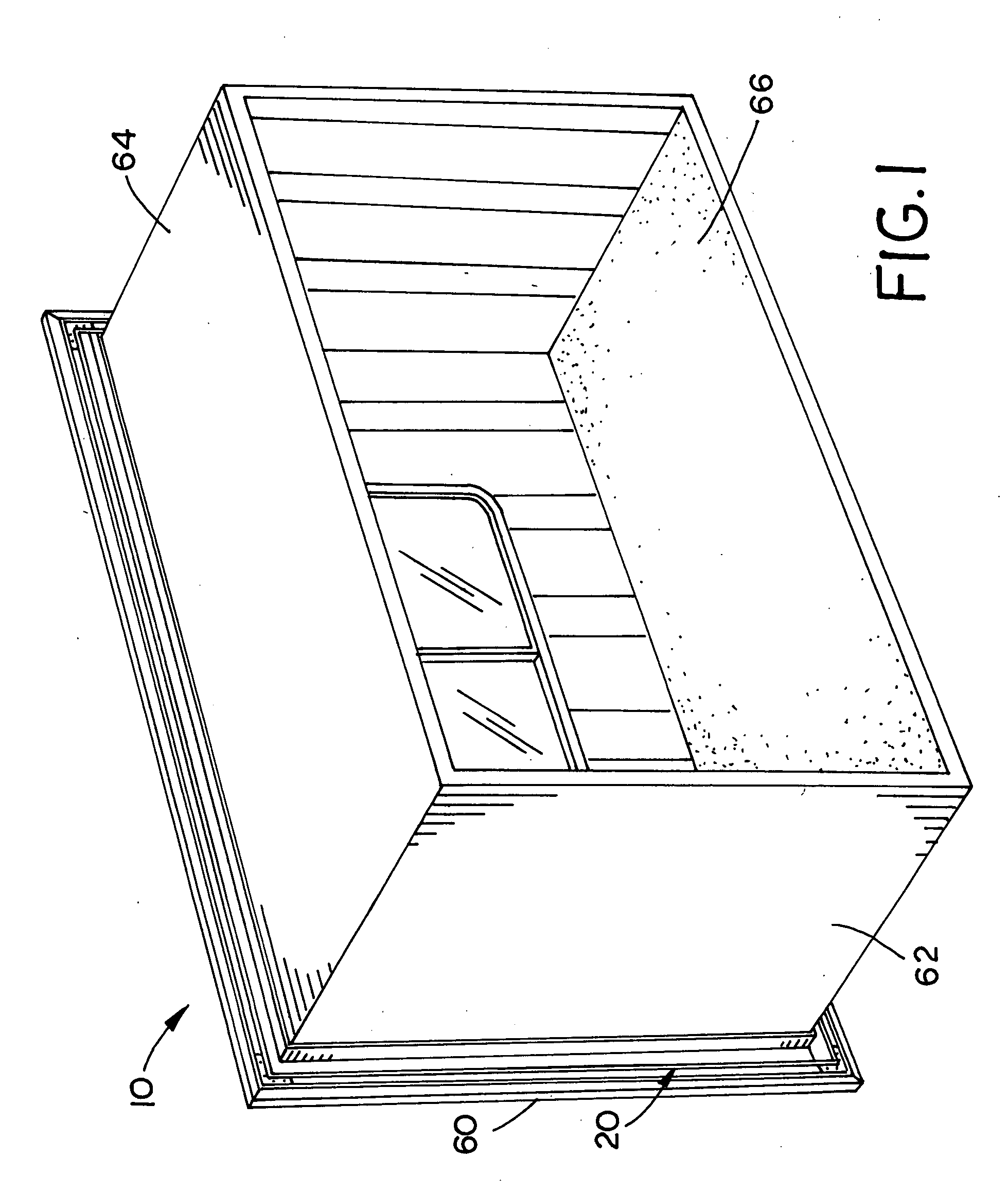

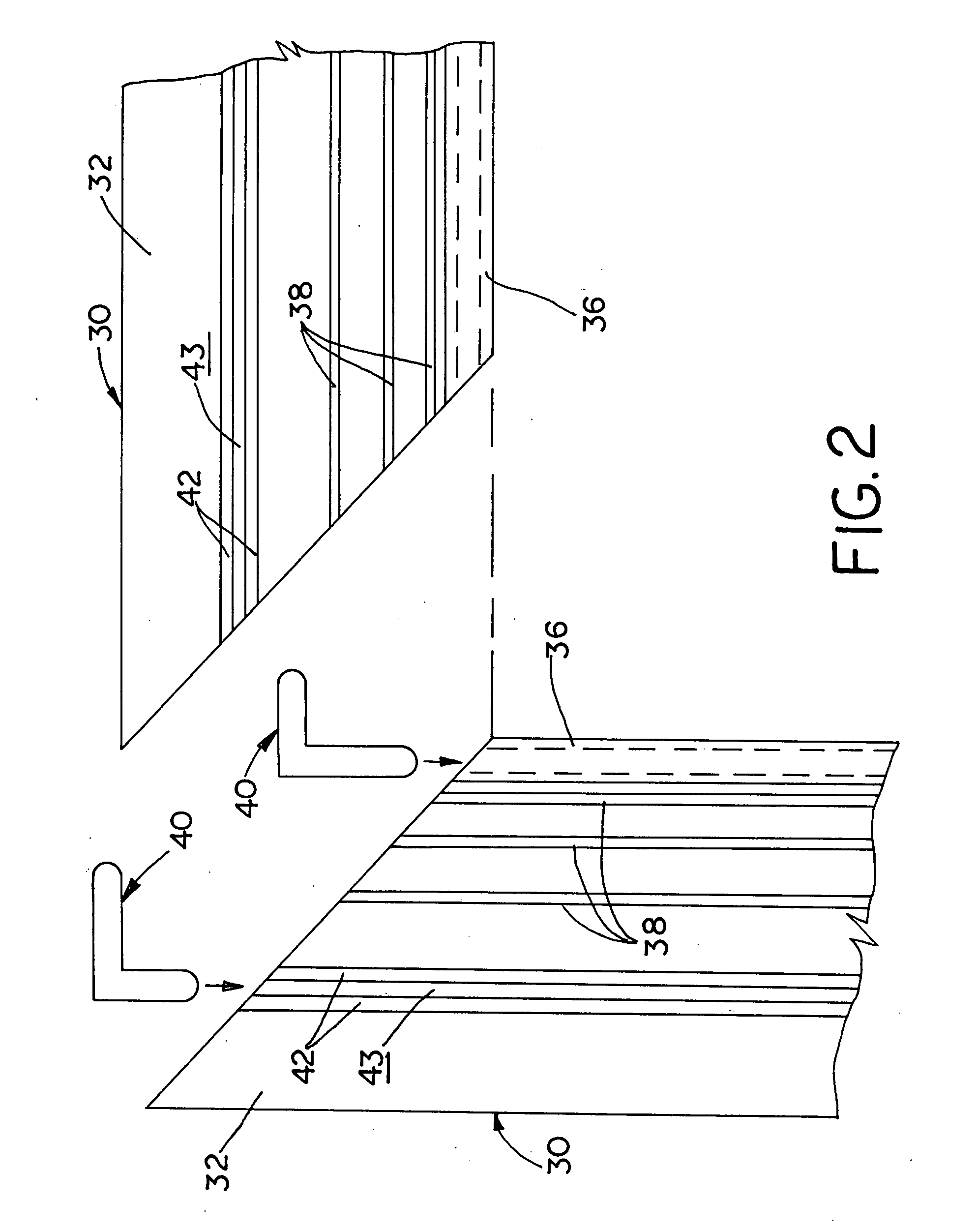

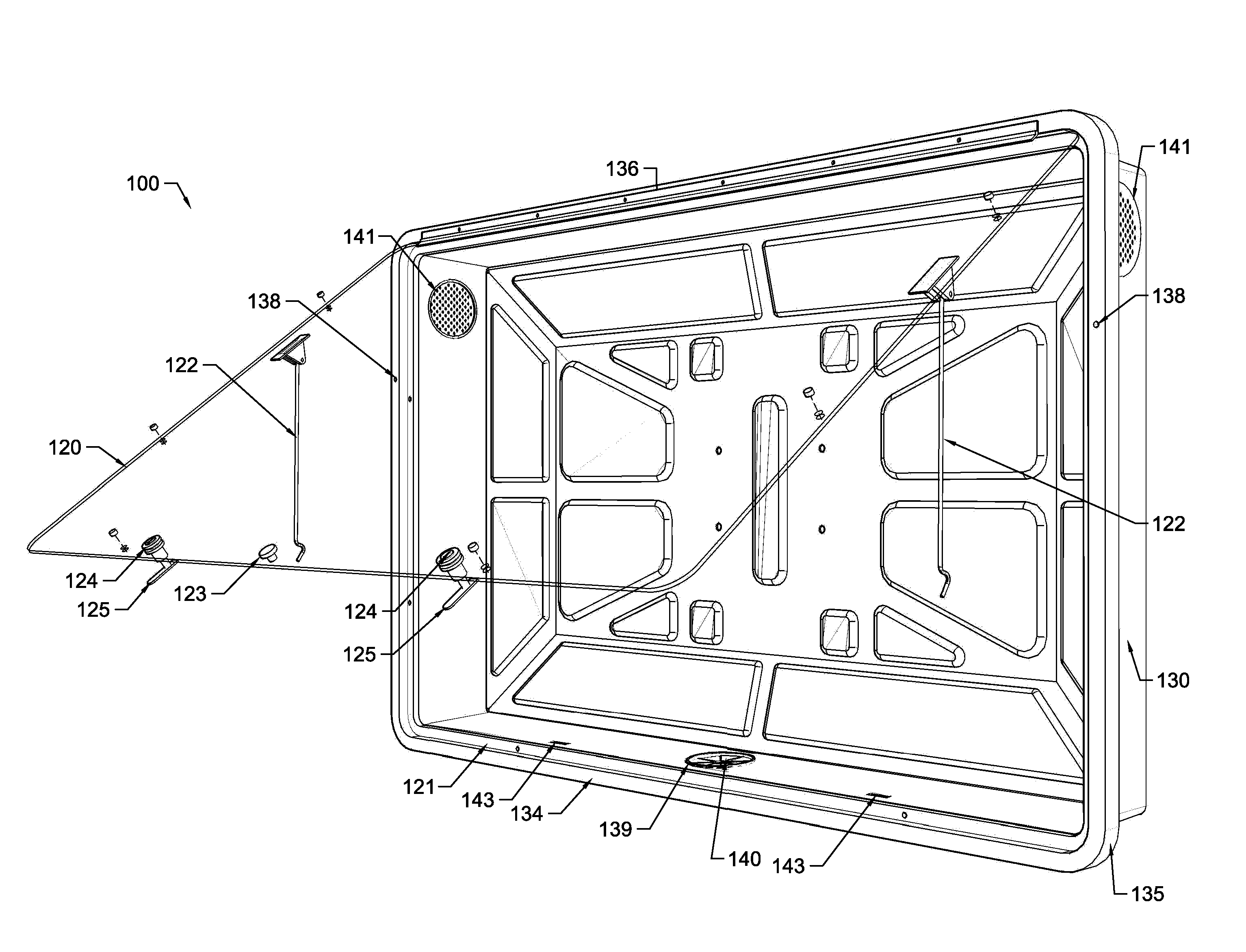

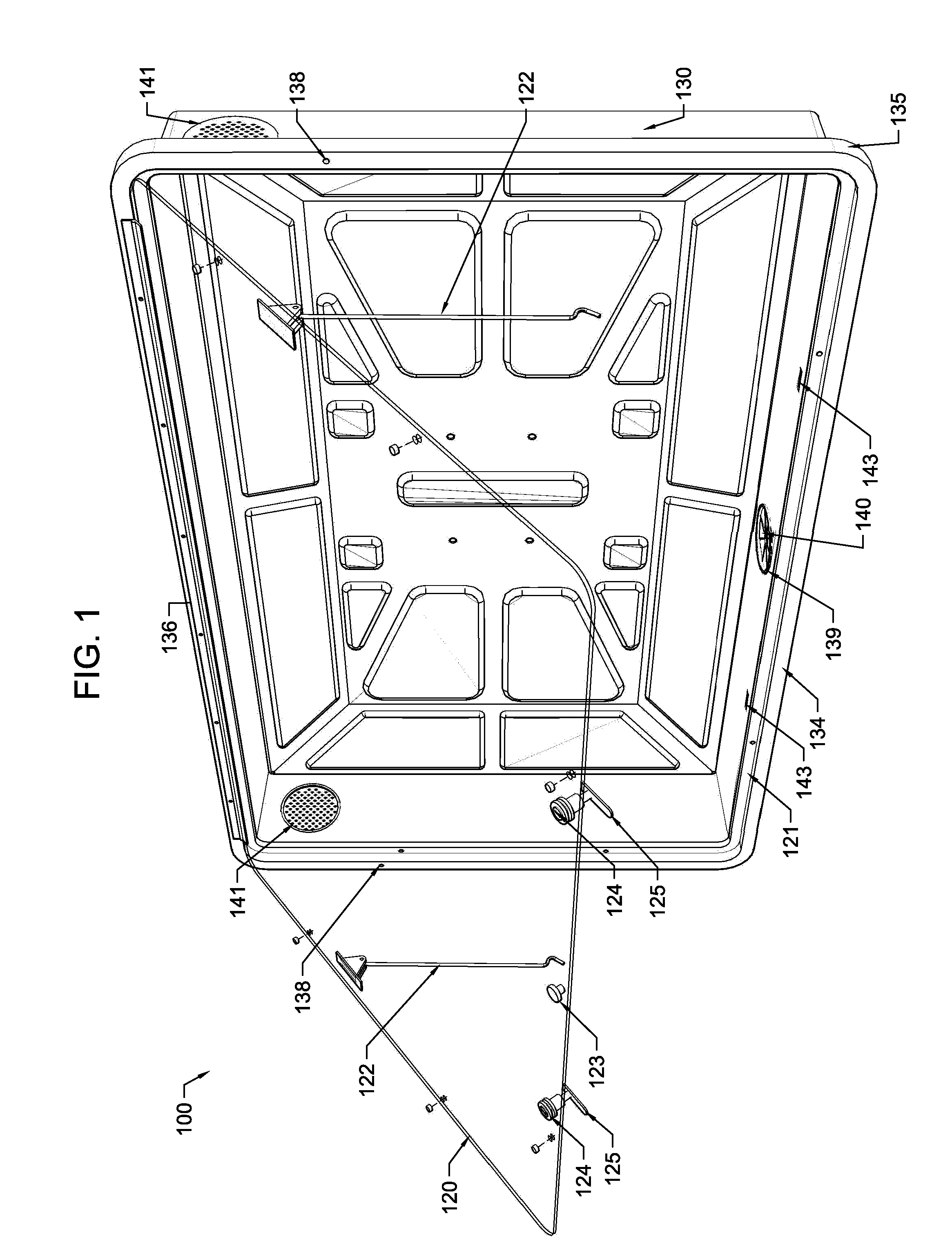

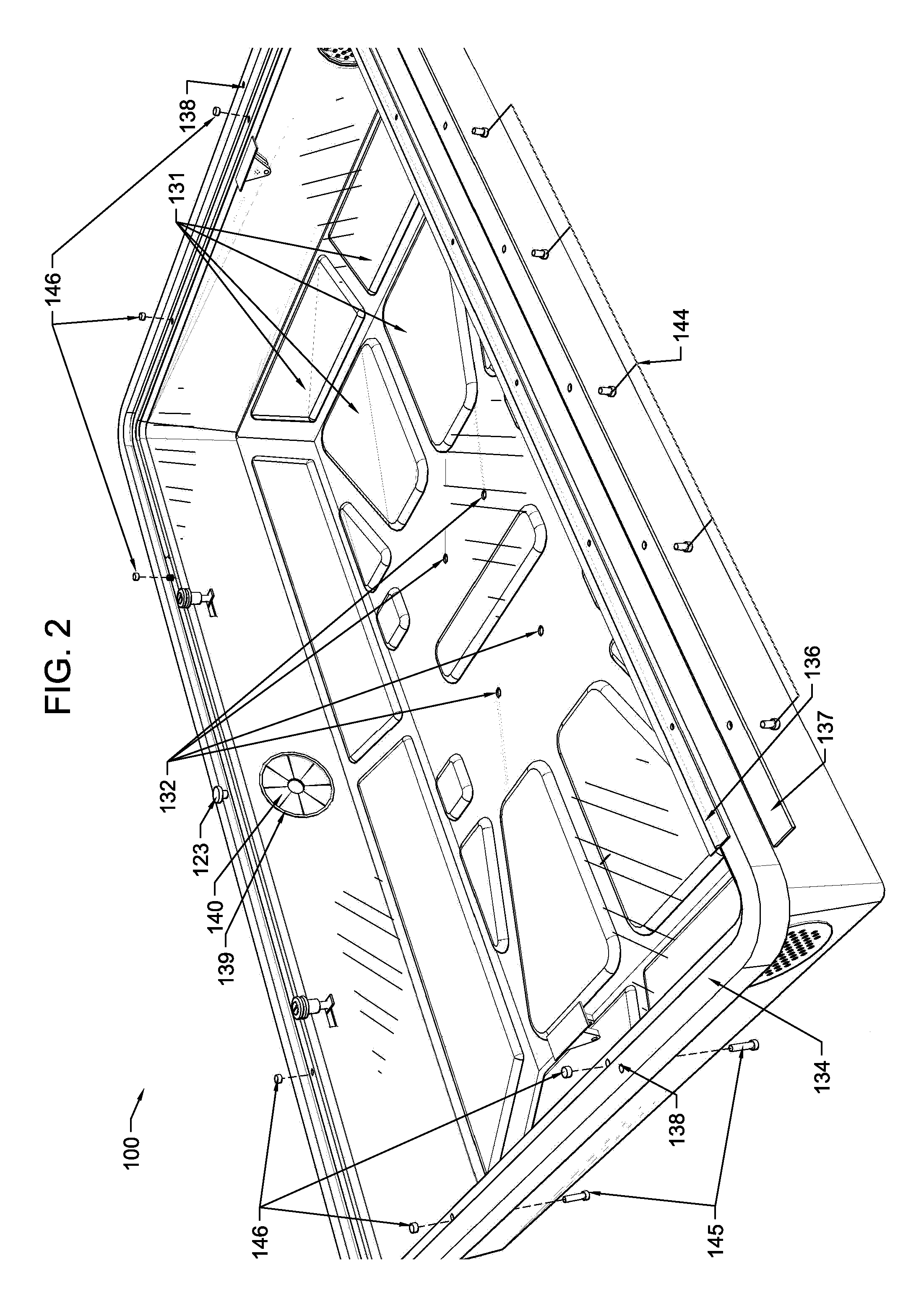

Slide-out room and components used in the manufacture of the same

InactiveUS20070194586A1Easy to adaptEliminate needVehicle with living accommodationItem transportation vehiclesLap jointMiter joint

The slide-out room is constructed from monocoque laminate wall panels interconnected by an end wall sub-frame. The end wall sub-frame is constructed from unique main extrusion members that are interconnected using key-locked miter joints. Each main extrusion member has a generally Z-shaped cross section, which allows the members to be joined using two joint keys fitted into spaced parallel key channels formed in the main extrusion members. The end wall sub frame also includes secondary extrusion members welded to the main extrusion members and interconnected using a lap joint. The secondary extrusion members have legs that are spaced from the legs of the main extrusion so that the monocoque panels can be fitted and secured between the legs to and from the side walls, ceiling and floor of the slide-out room. A monocoque panel is bonded directly to the outside of the end wall sub-frame to form the slide-out room end wall.

Owner:R N R INT

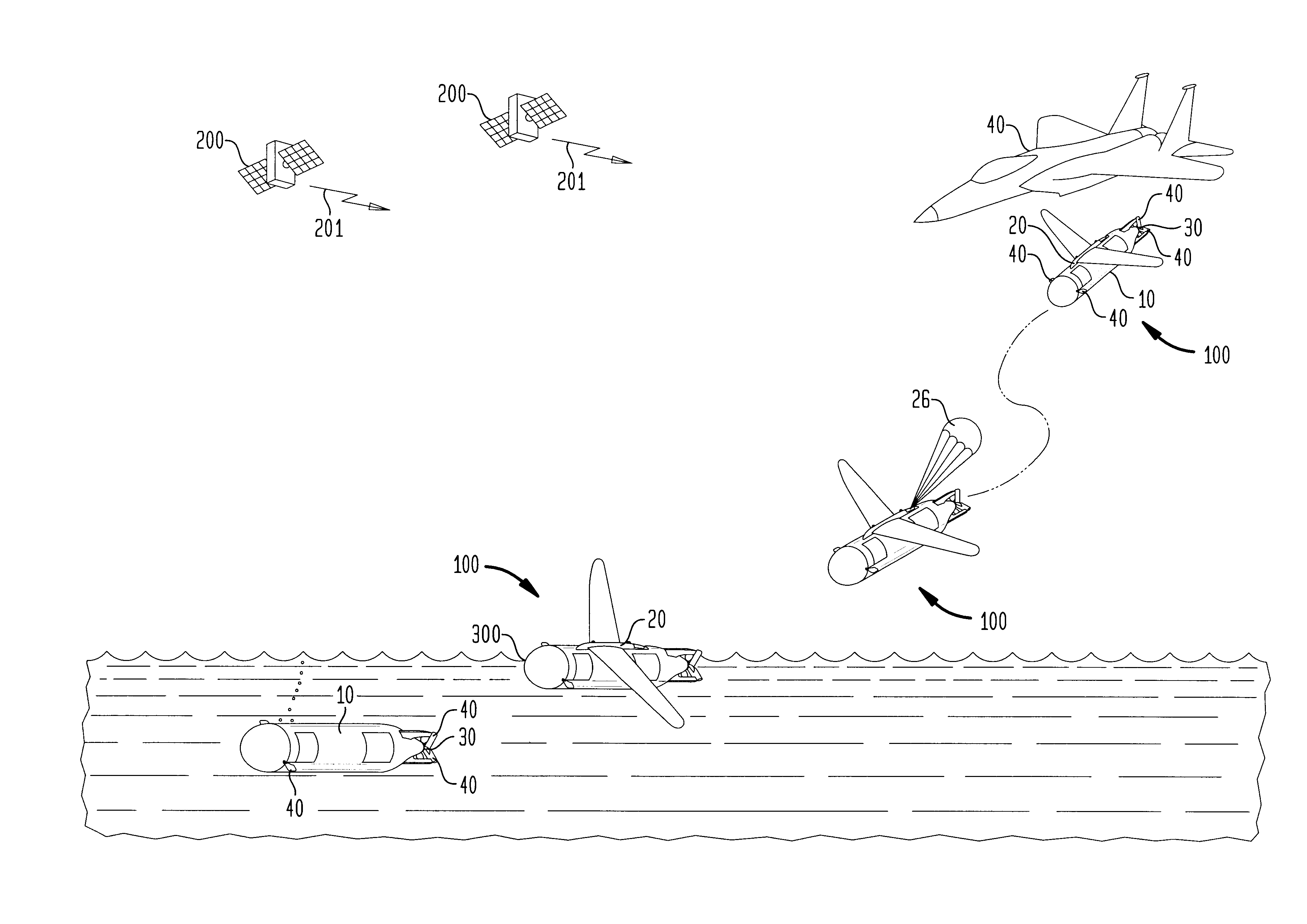

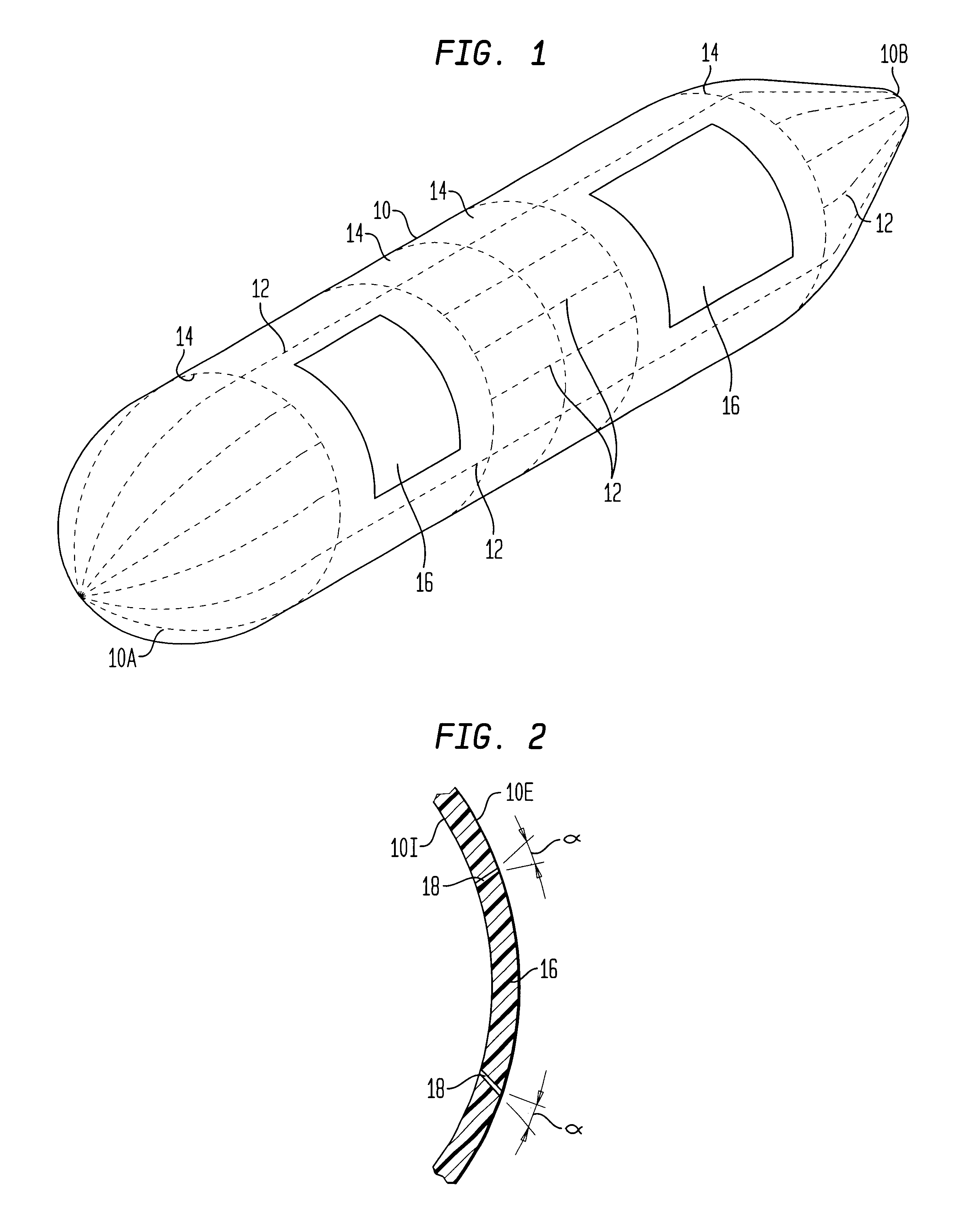

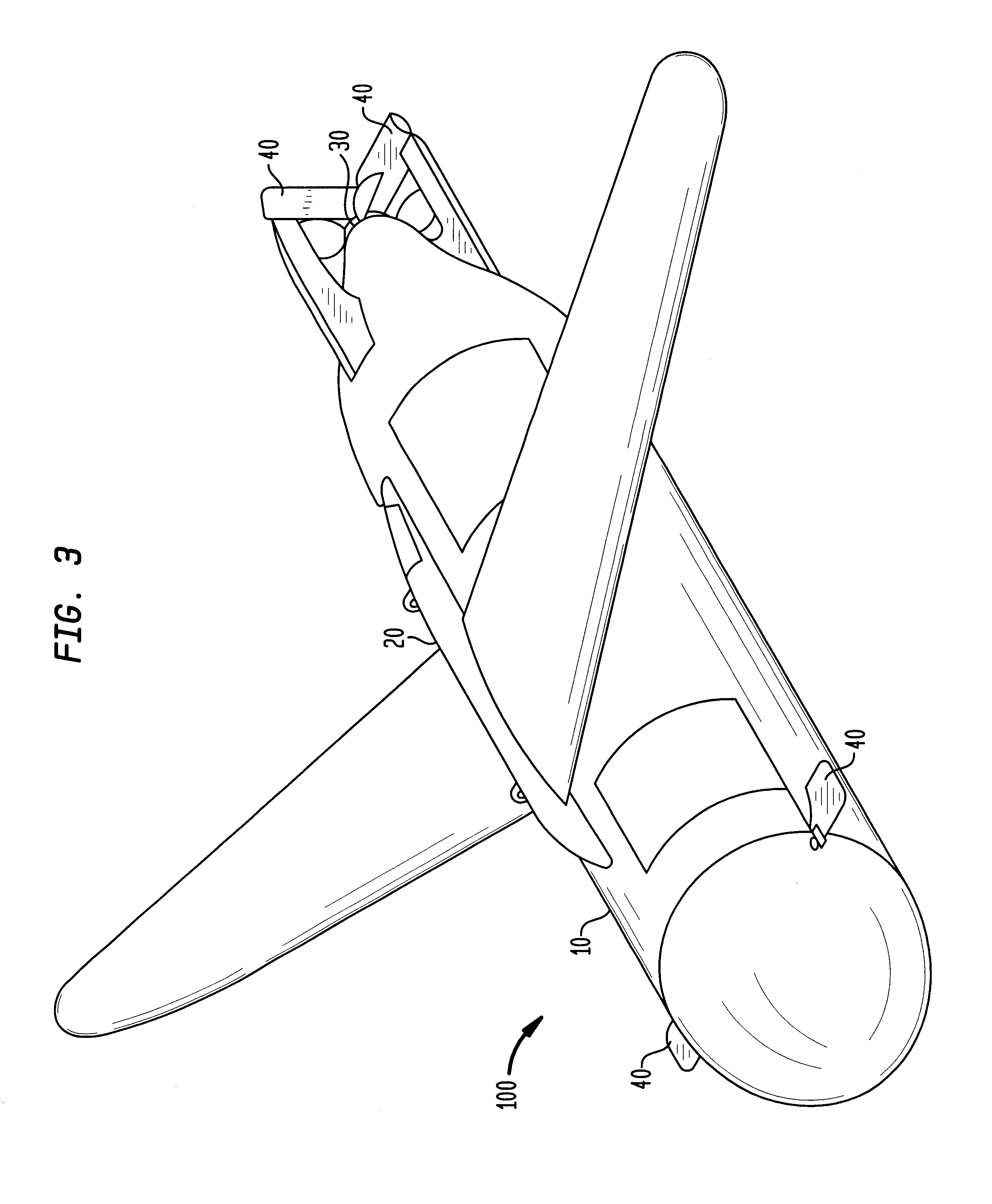

Air-delivered monocoque submersible vehicle system

InactiveUS6640739B2Improved hull constructionSimplifies and expands for deploymentMarine minesBuoysFiberThermoplastic

An air-delivered submersible vehicle system has a monocoque-construction shell made from a fiber-reinforced plastic material selected from the group consisting of thermoplastics and thermoset plastics. The shell is equipped with a wing kit so that it can be deployed from an aircraft and fly through the air to a destination at a surface of a body of water. The shell is further equipped as a submersible vehicle so that it can be propelled through the water once it has reached its water destination.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY

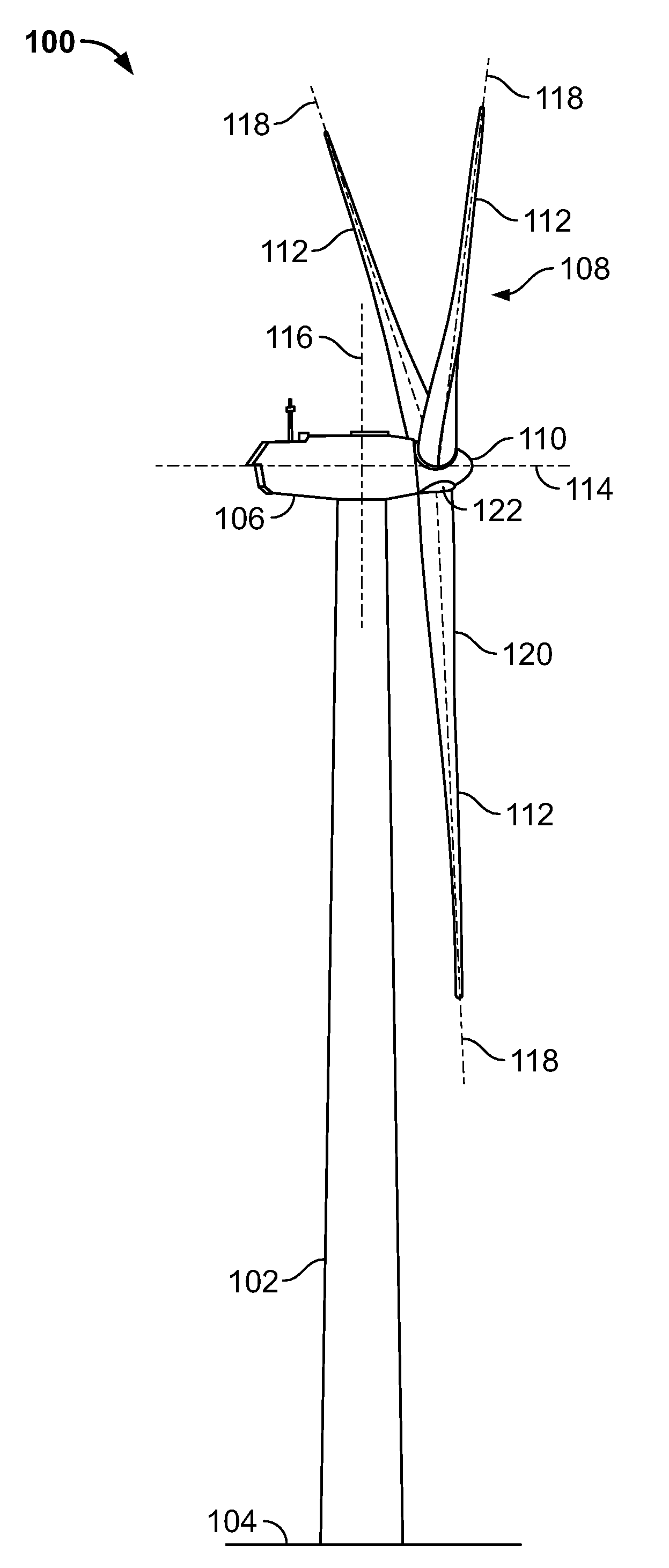

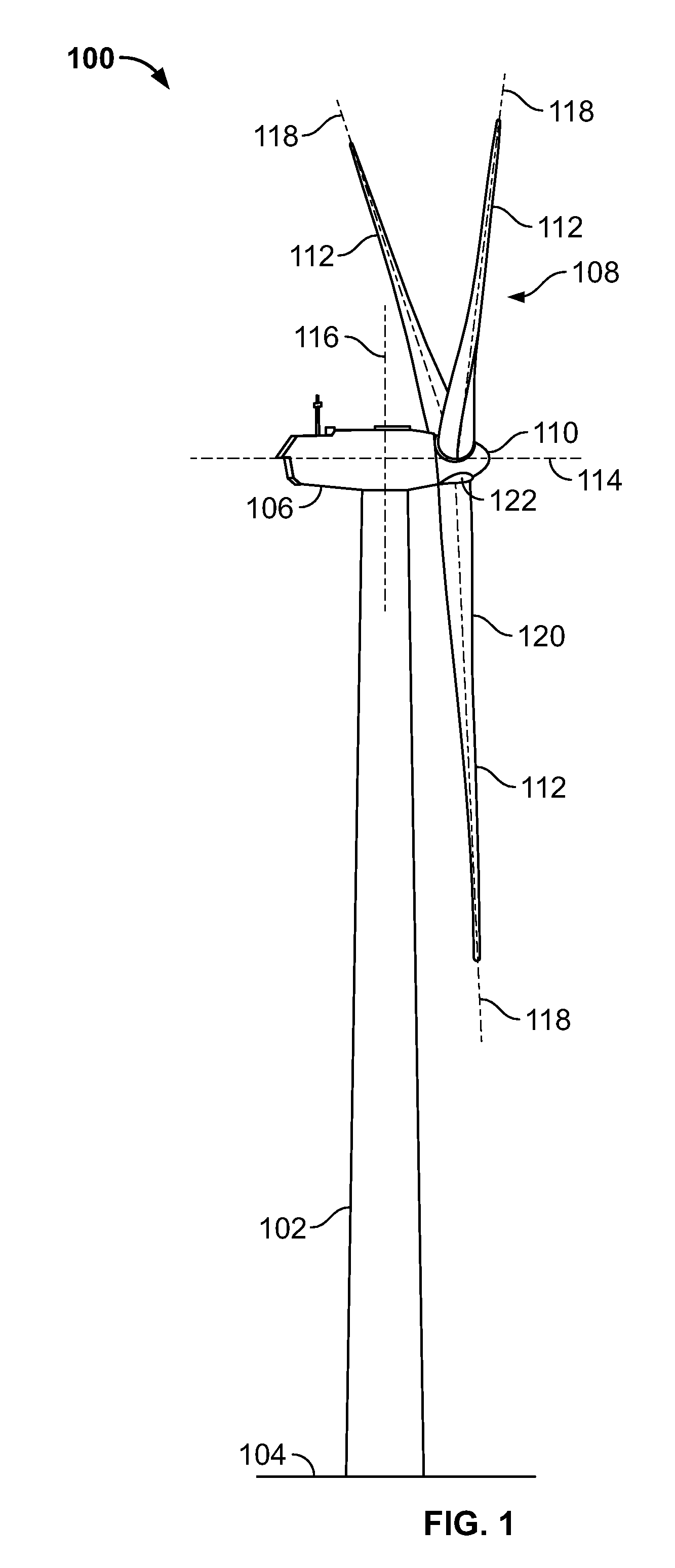

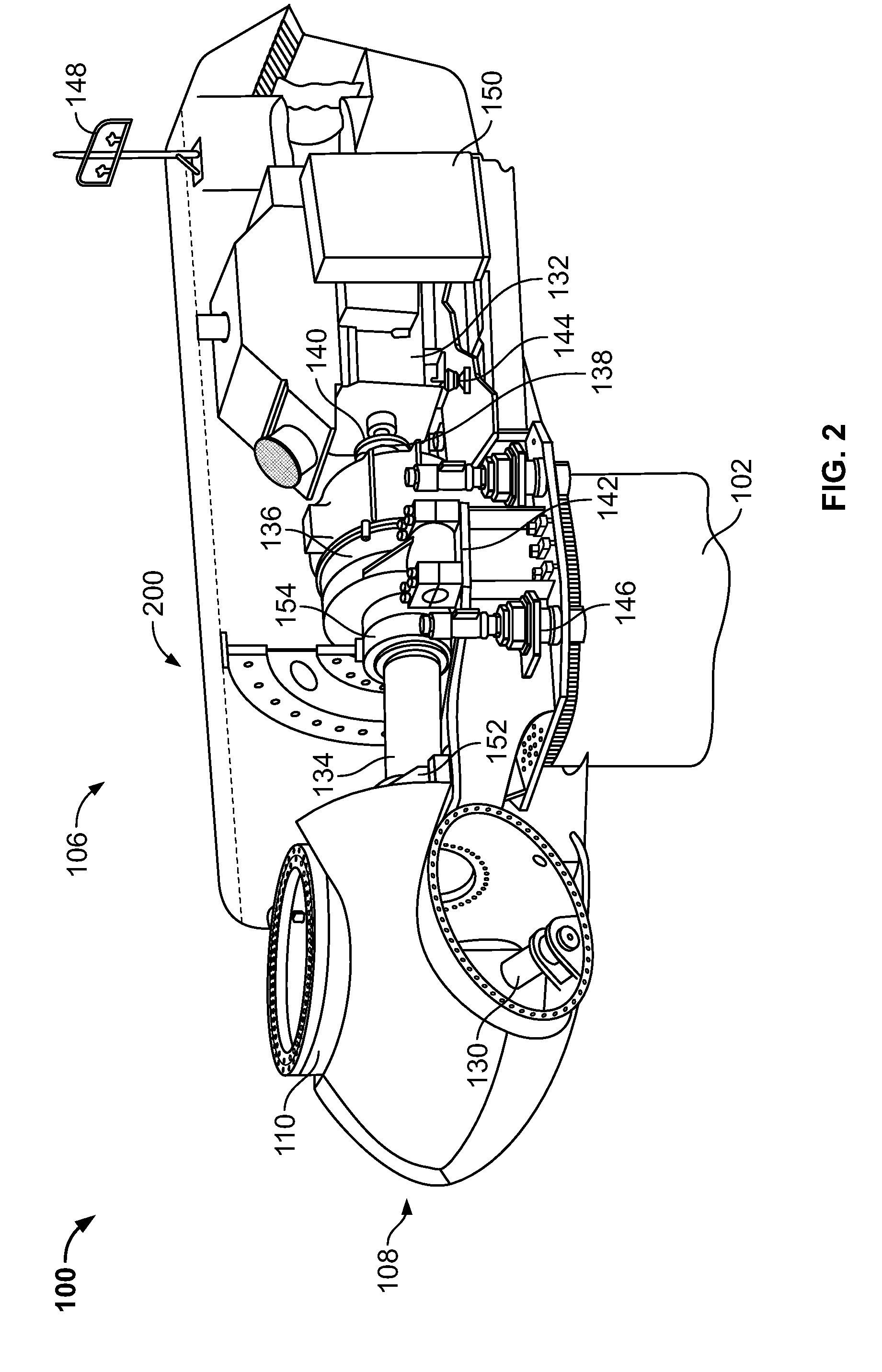

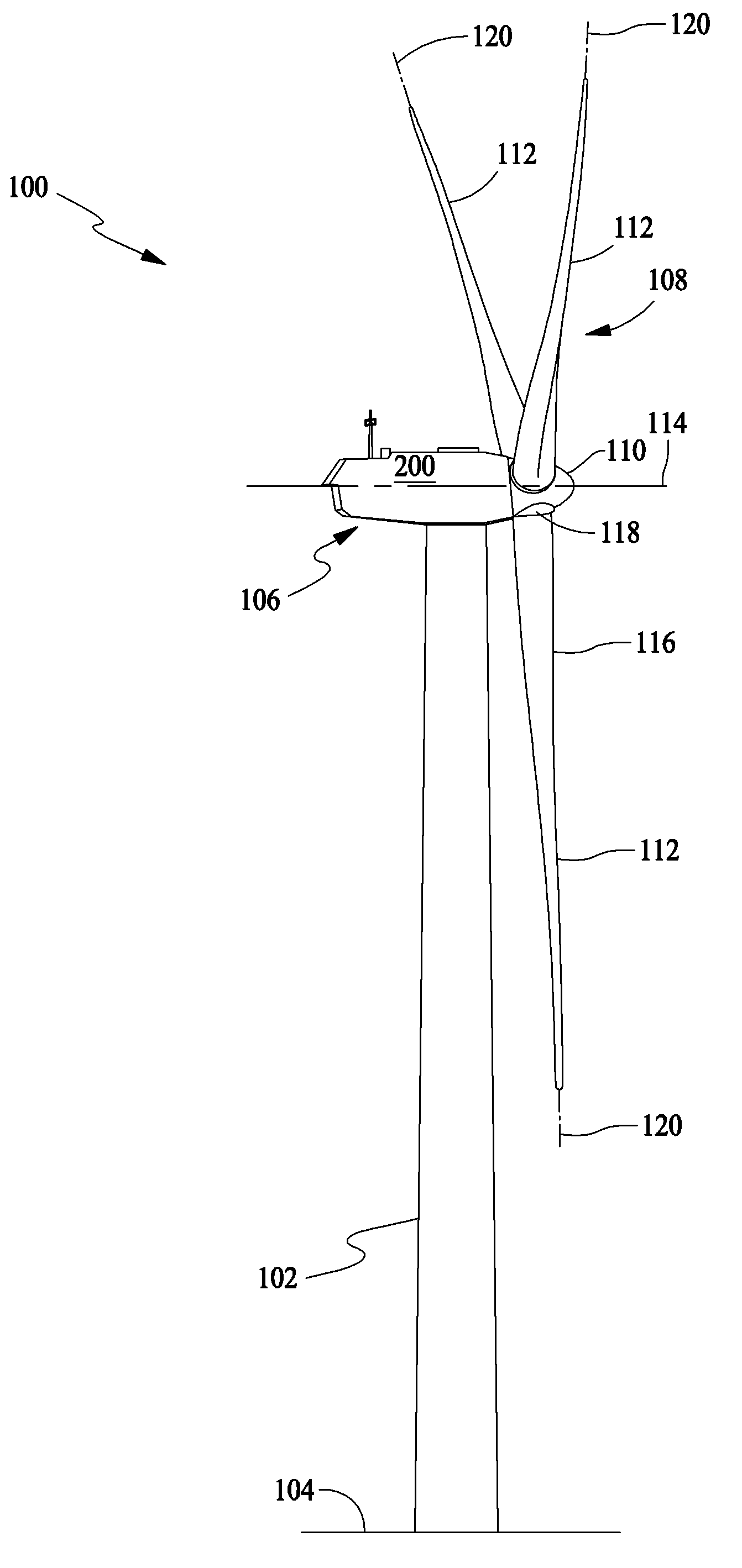

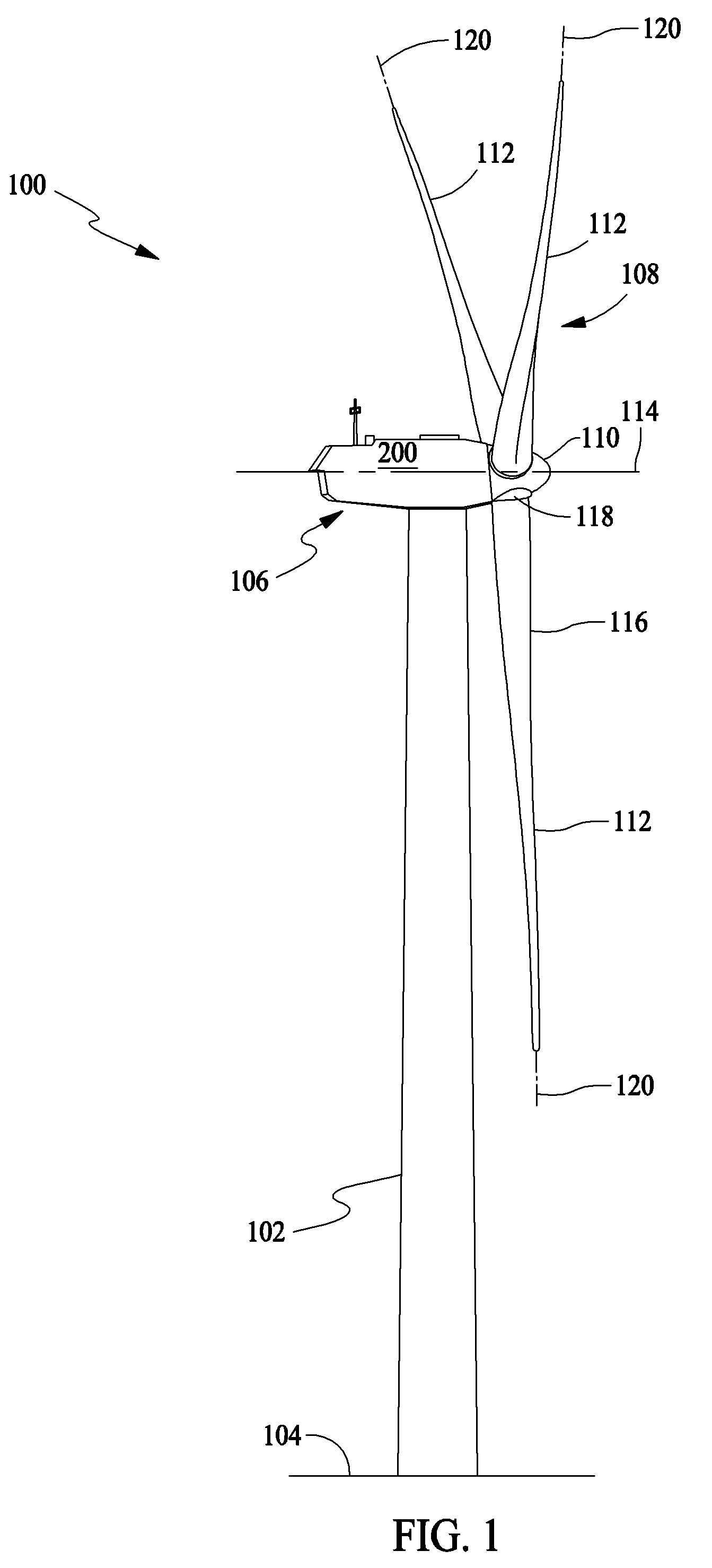

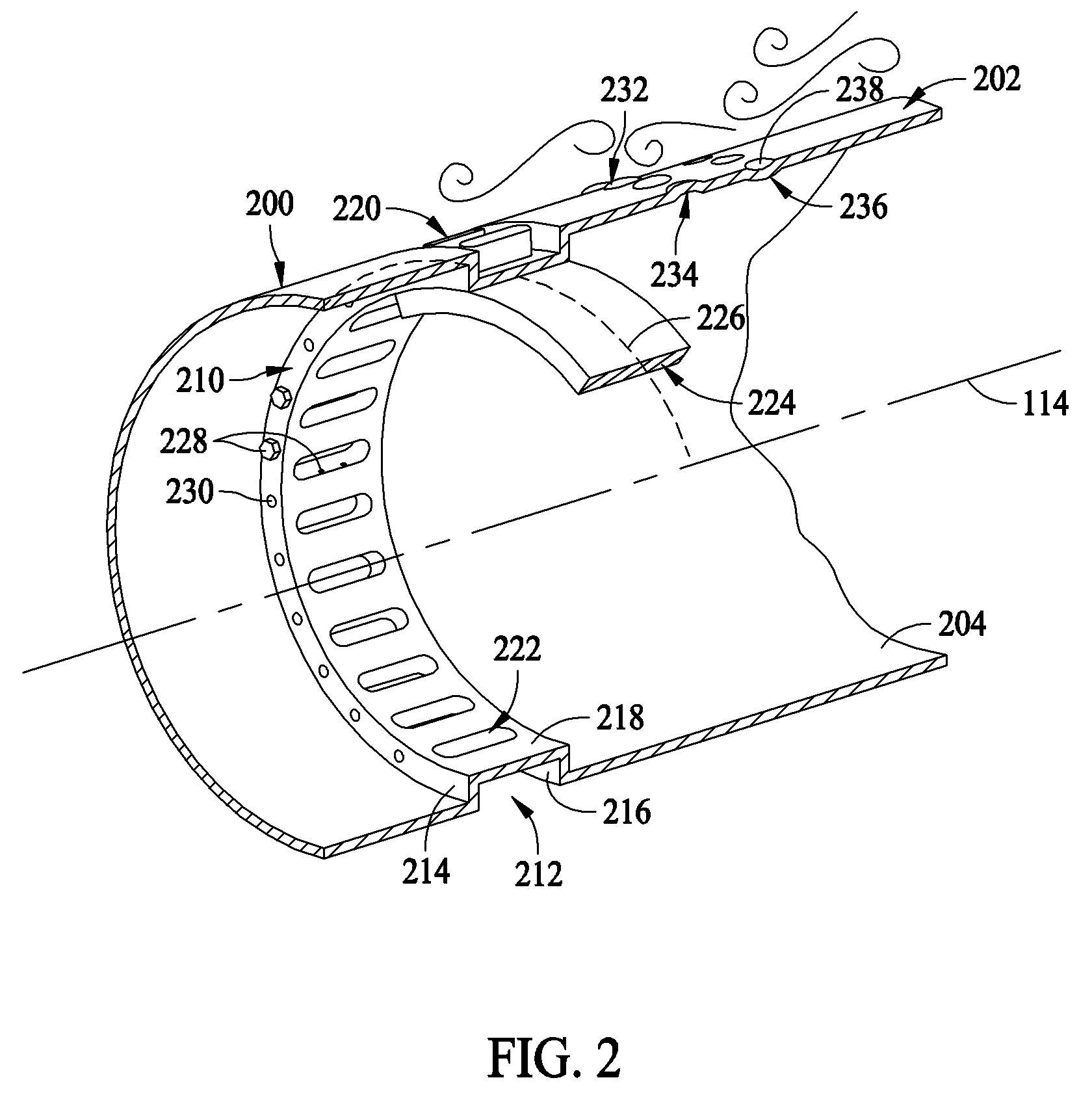

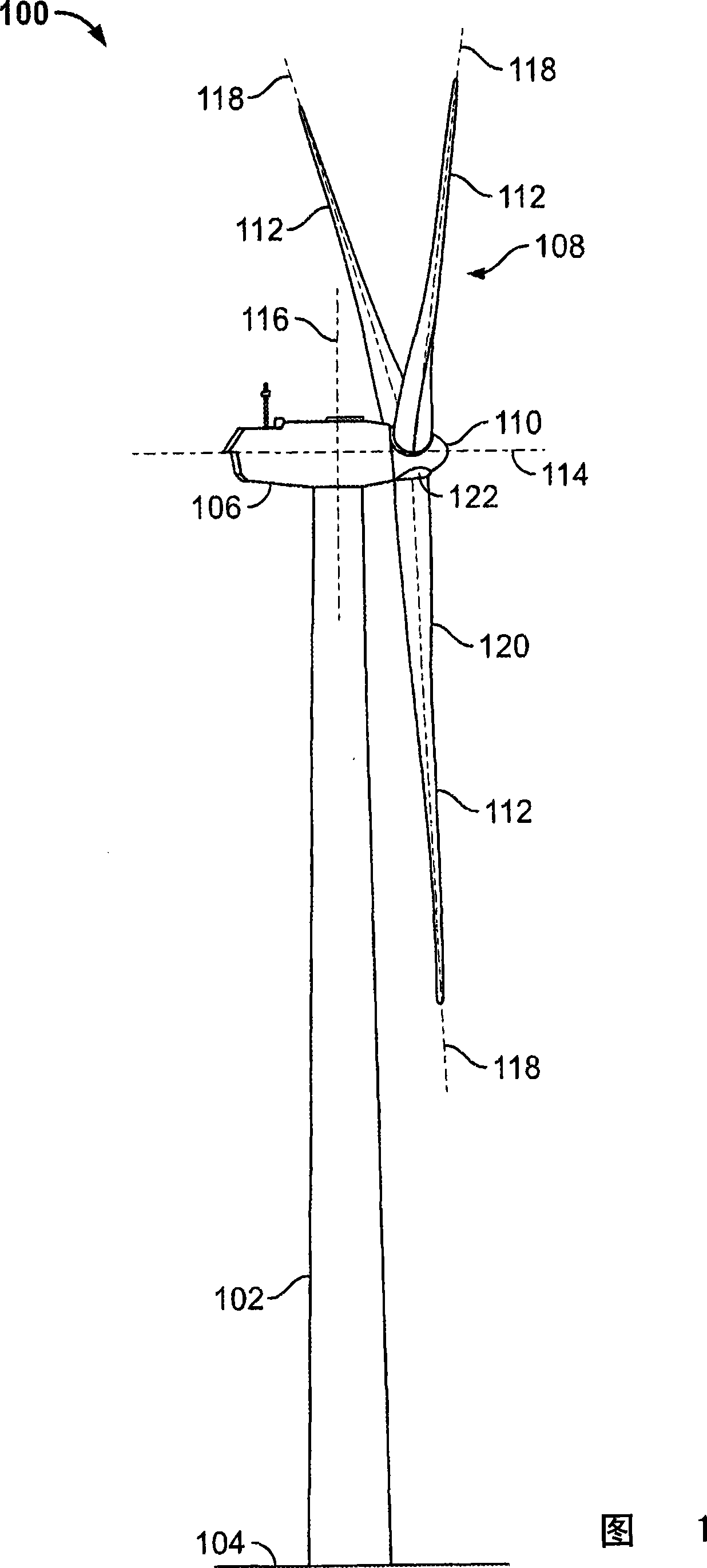

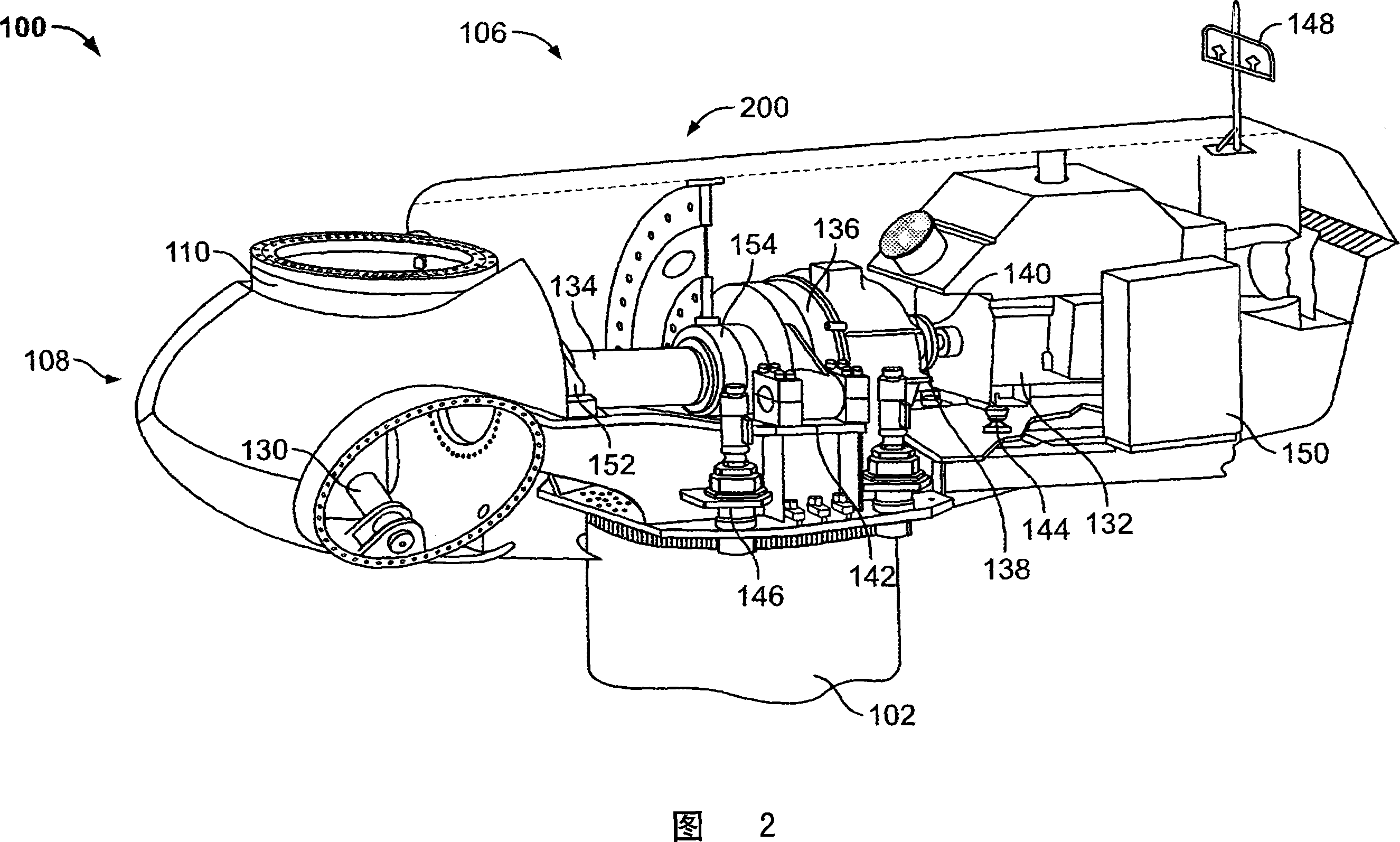

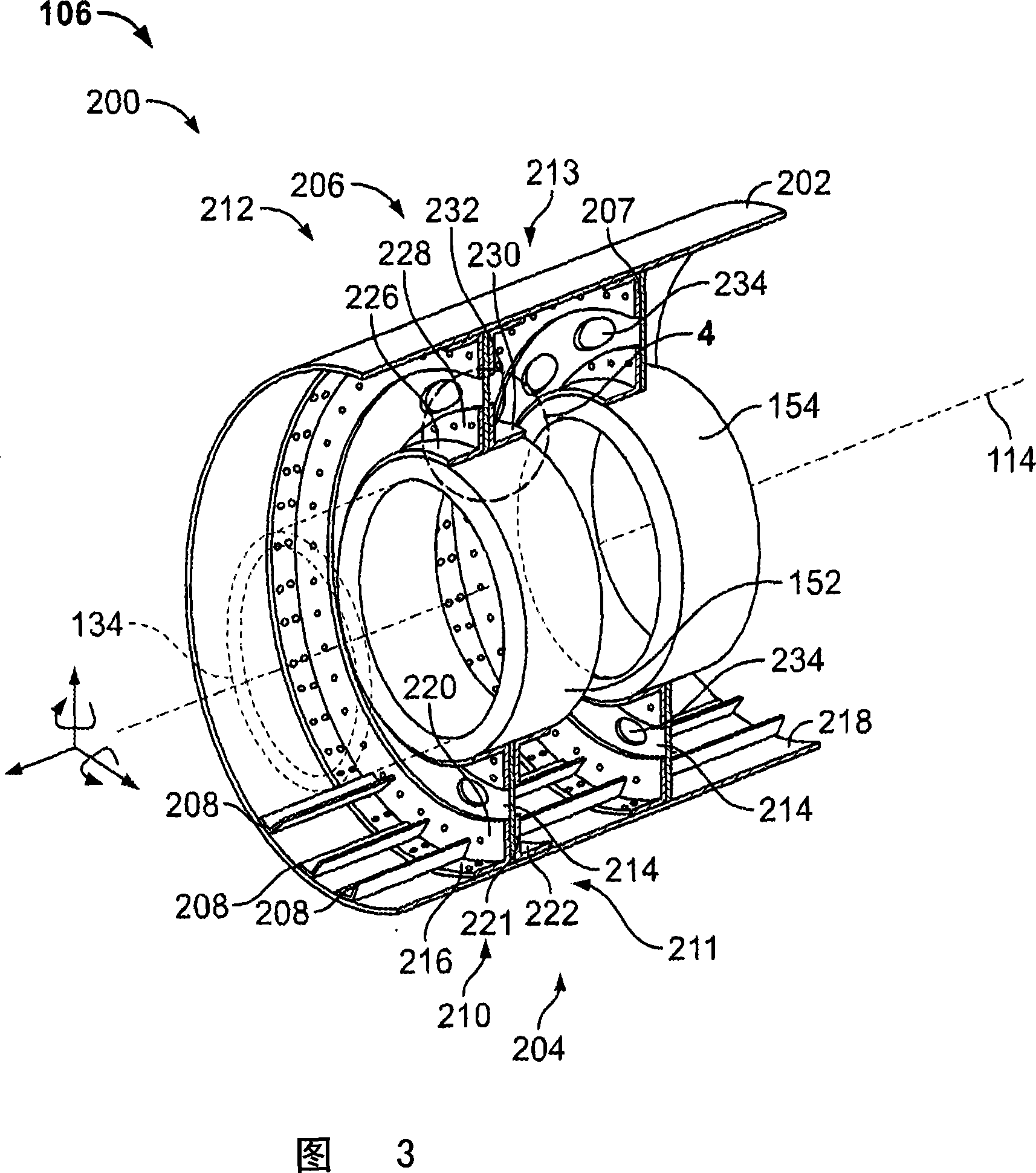

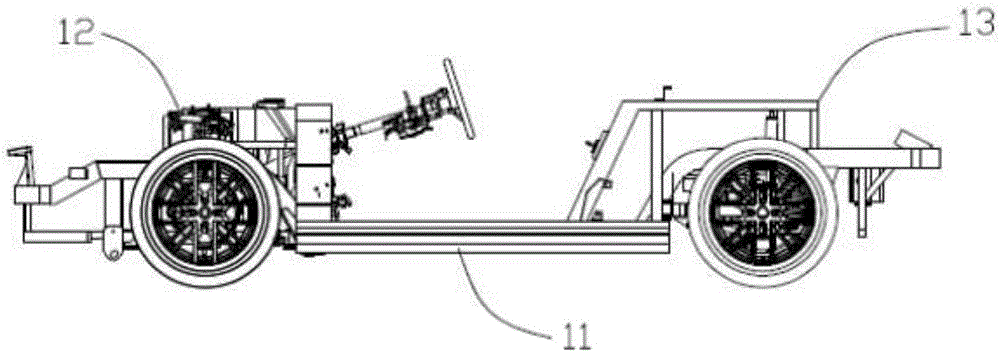

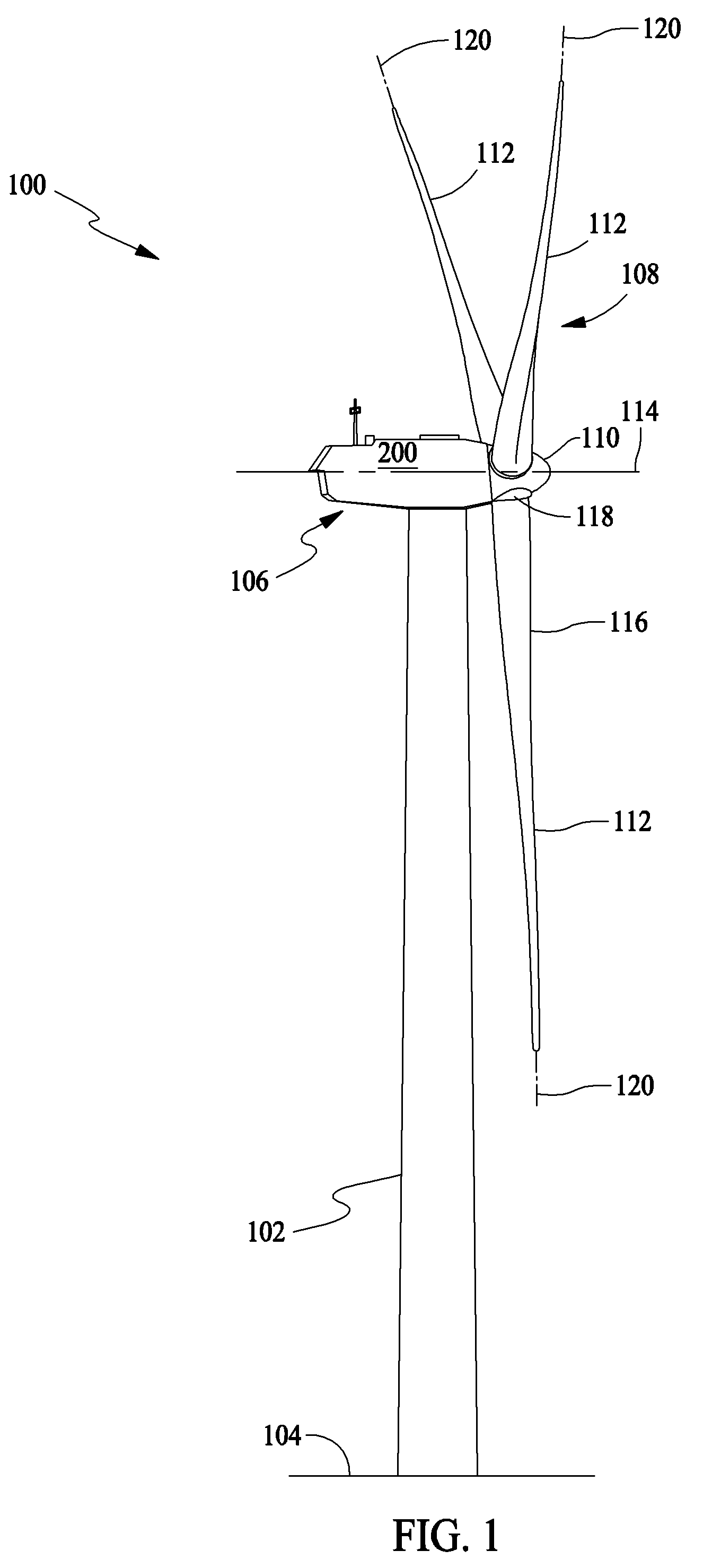

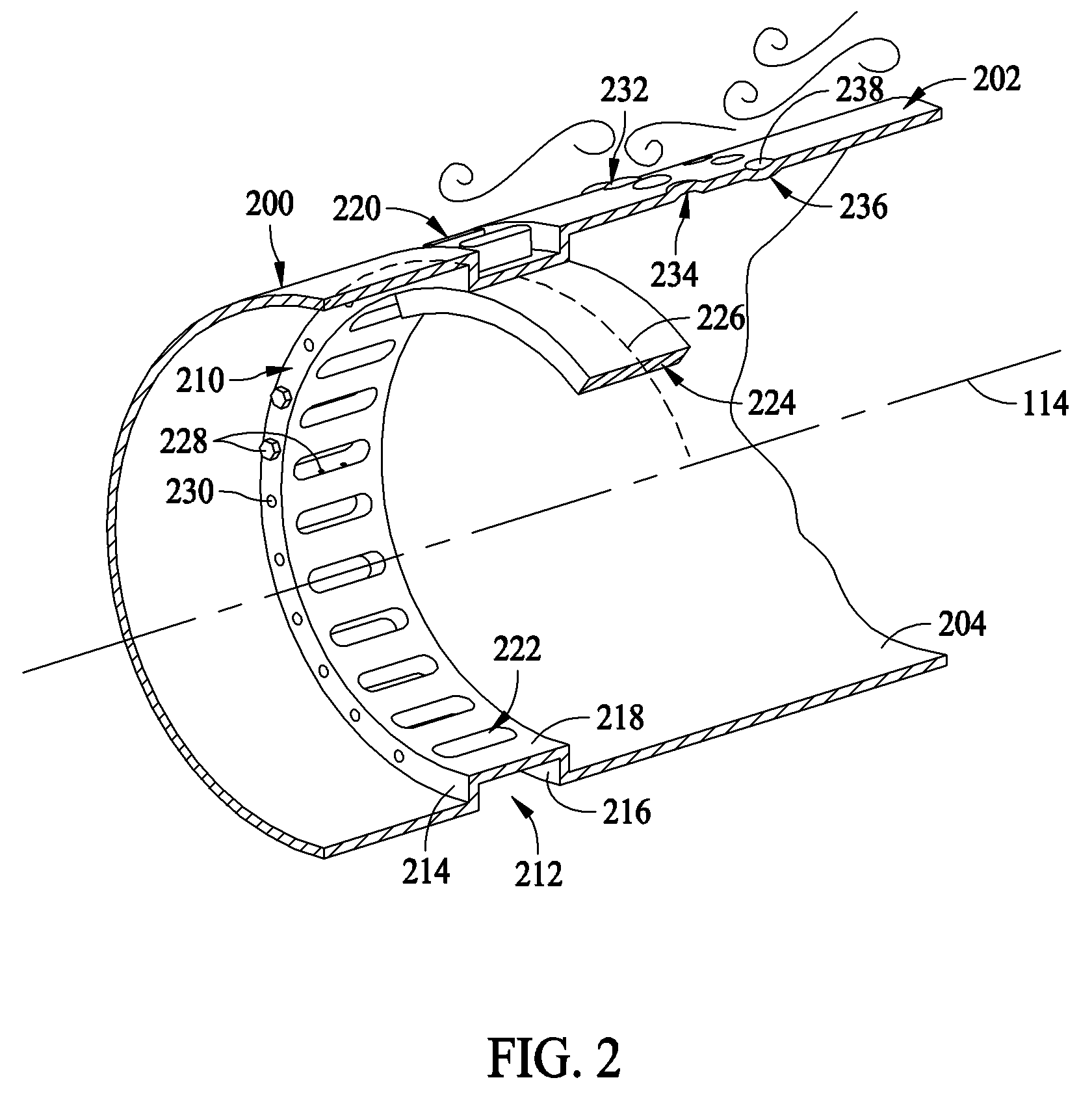

Methods and apparatus for assembling and operating semi-monocoque rotary machines

A wind turbine generator includes at least one rotating member and a semi-monocoque nacelle structure that includes at least one stationary member extending over at least a portion of the rotating member. A method of operating the wind turbine generator includes transmitting loads to the semi-monocoque nacelle structure.

Owner:GENERAL ELECTRIC CO

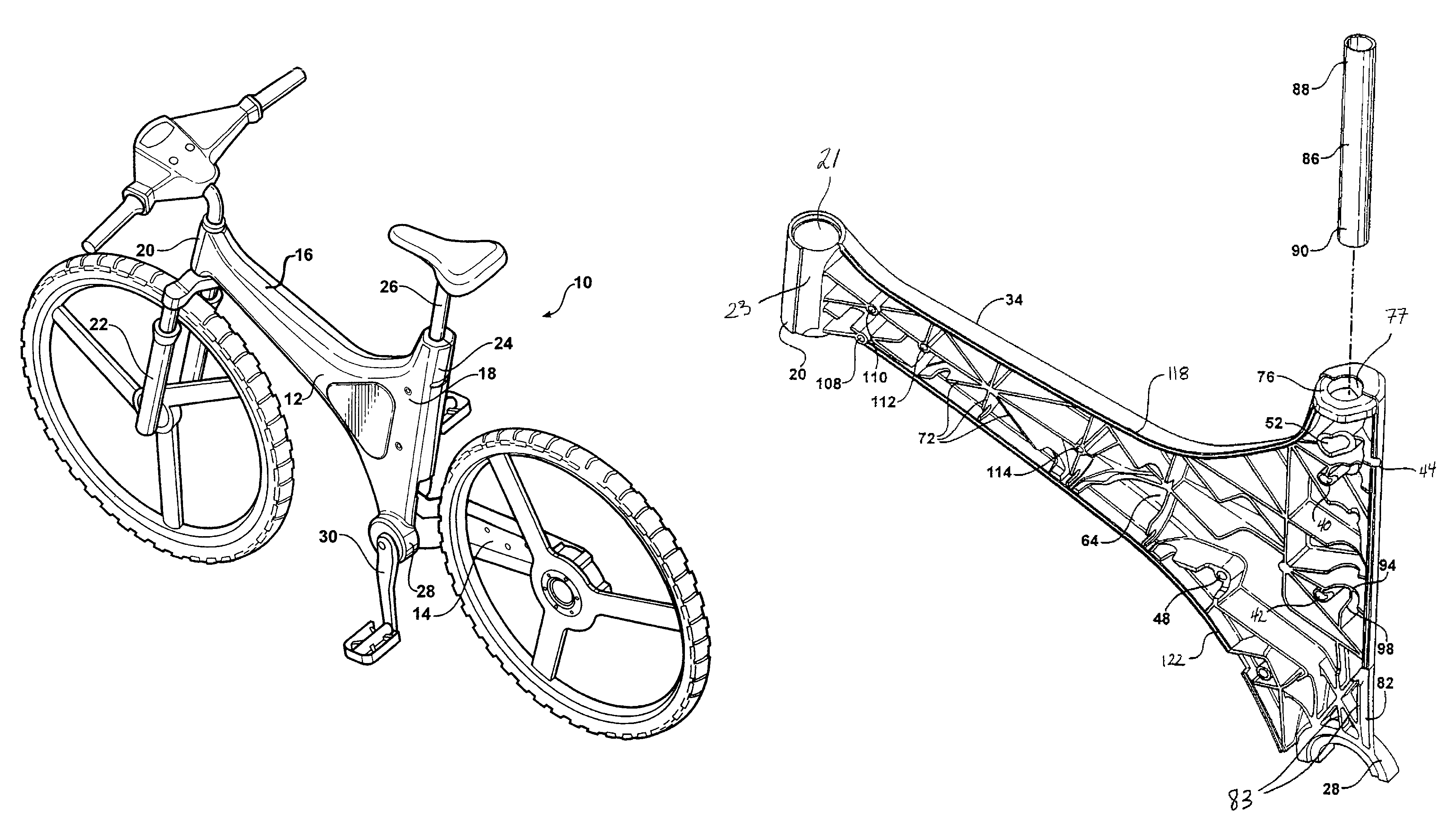

Bicycle frame construction

A unitary monocoque frame is provided for a bicycle including a right half shell having a peripheral edge and a left half shell having a peripheral edge symmetrical with the peripheral edge of the right half shell. The right half shell includes an integrally formed head tube portion and an integrally formed seat tube collar. The left half shell includes a curved surface to join with the head tube portion and a cupped recess to receive the seat tube collar. A tongue extends along at least a portion of the peripheral edge of one of the right and left half shells. A groove extends along at least a corresponding portion of the peripheral edge of the other one of the right and left half shells. The tongue and groove are in mating engagement to join the right and left half shells forming the unitary monocoque frame.

Owner:BIONX CANADA

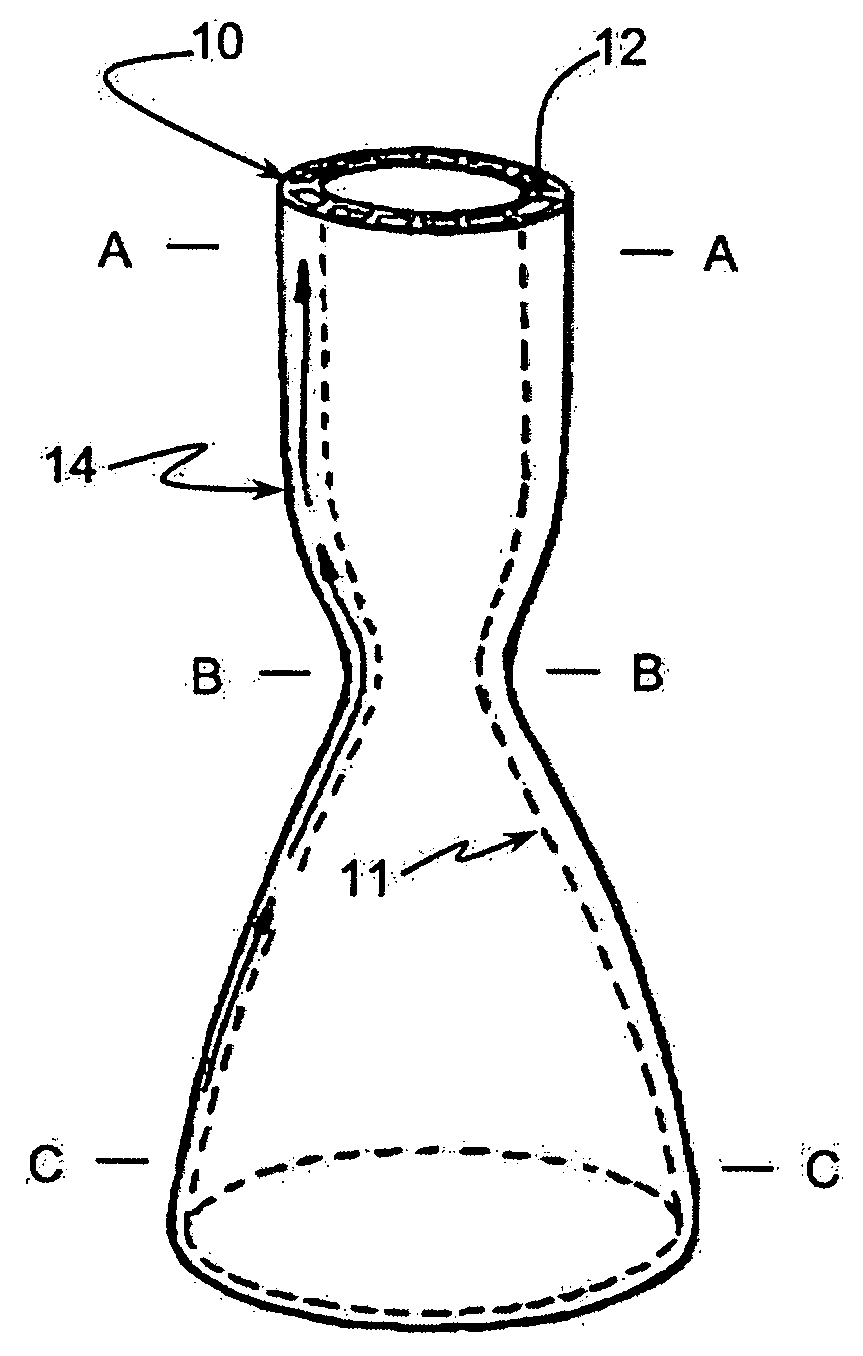

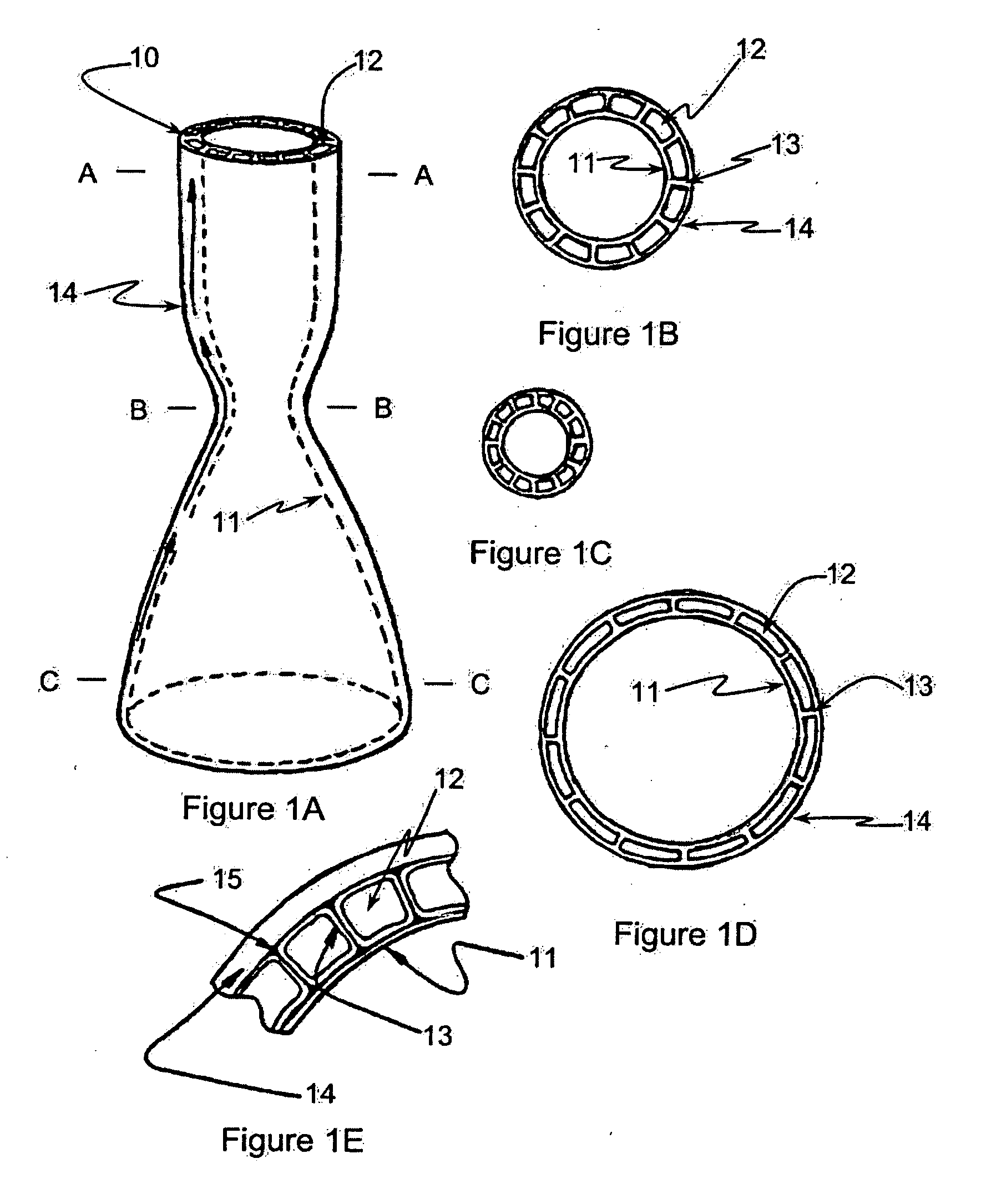

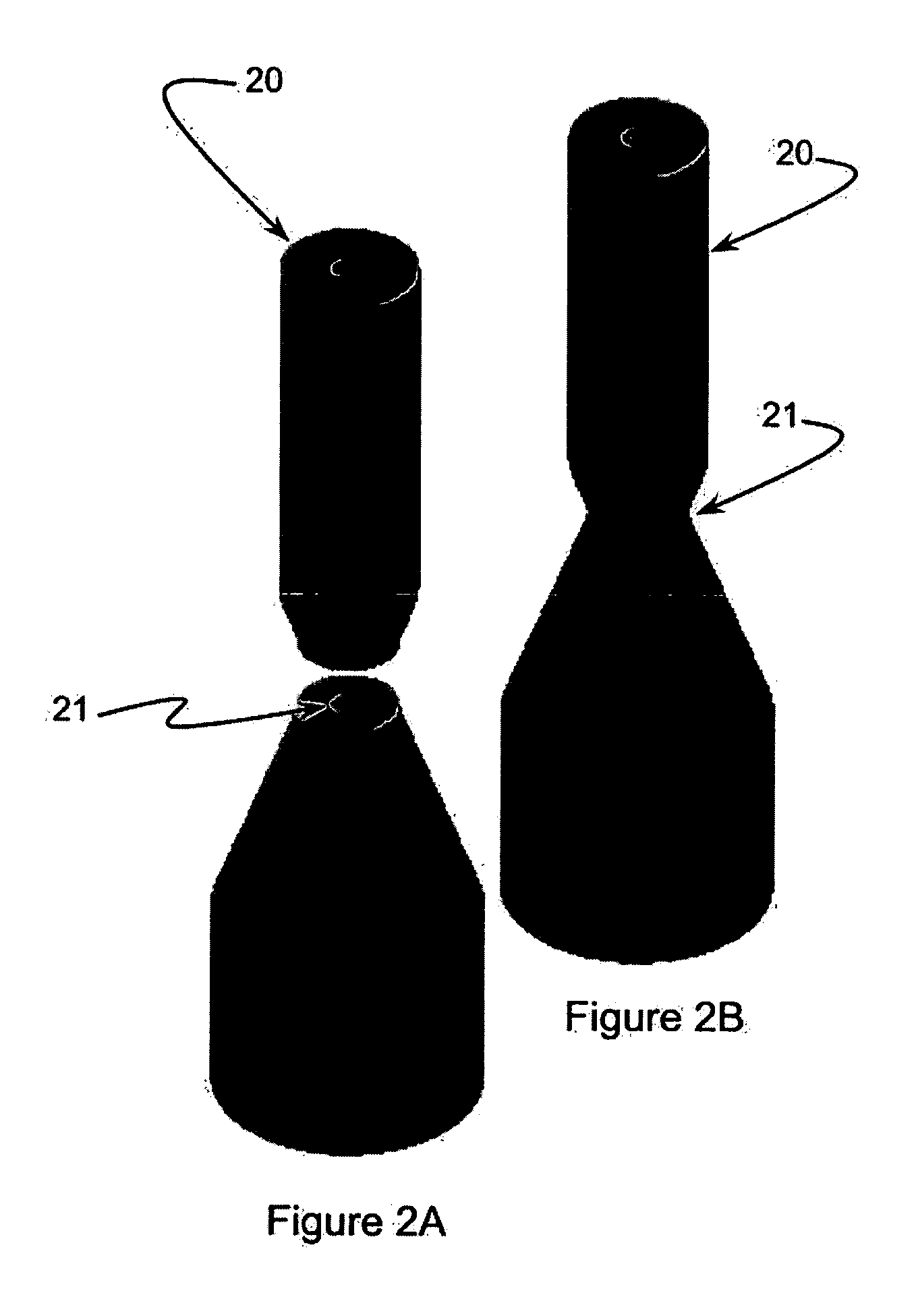

Actively-cooled fiber-reinforced ceramic matrix composite rocket propulsion thrust chamber and method of producing the same

InactiveUS20040222571A1Ceramic shaping apparatusStationary tubular conduit assembliesThrust chamberActive cooling

An actively-cooled, fiber-reinforced ceramic matrix composite thrust chamber for liquid rocket propulsion systems is designed and produced with internal cooling channels. The monocoque tubular structure consists of an inner wall, which is fully integrated to an outer wall via radial coupling webs. Segmented annular void spaces between the inner wall, outer wall and adjoining radial webs form the internal trapezoidal-shaped cooling channel passages of the tubular heat exchanger. The manufacturing method enables producing any general tubular shell geometry ranging from simple cylindrical heat exchanger tubes to complex converging-diverging, Delaval-type nozzle structures with an annular array of internal cooling channels. The manufacturing method allows for transitioning the tubular shell structure from a two-dimensional circular geometry to a three-dimensional rectangular geometry. The method offers the flexibility of producing internal cooling channels of either constant or continuously variable cross-sectional area, in addition to orienting the cooling channels either axially, helically or sinusoidally (e.g., undulating) with respect to the longitudinal axis of the tubular shell structure with without significant added manufacturing complication.

Owner:ROLLS ROYCE HIGH TEMPERATURE COMPOSITES INC

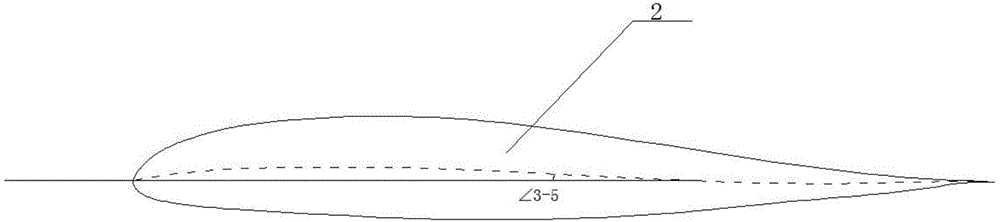

Vertical take-off and landing aircraft with distributed power unit configuration

InactiveCN106218887AGood technical effectLow paddle loadVertical landing/take-off aircraftsRotocraftEngineeringWing configuration

The invention discloses a vertical take-off and landing aircraft with distributed power unit configuration. The vertical take-off and landing aircraft with the distributed power unit configuration comprises an aircraft body, aircraft wings, an empennage and propellers. The aircraft body is of a semi-monocoque structure, and comprises a nose, a middle fuselage and an aircraft tail. The middle fuselage of the aircraft body is a cargo bay. The aircraft wings are arranged on the two sides of the aircraft body in a left-right symmetry mode. The aircraft wings are of double-beam semi-monocoque structures and connected with the aircraft body through reinforced frames. Auxiliary lifting wings are arranged at the rear edges of the aircraft wings correspondingly. End-plate type winglets are arranged at the wingtips of the aircraft wings correspondingly. According to the vertical take-off and landing aircraft with the distributed power unit configuration, the distributed propelling unit configuration is adopted, so that the aircraft can have a low rotor disk load and the high propelling efficiency during the vertical take-off and landing processes; a combined control mode combining the motor rotating speed / the propeller pitch with a propeller slip flow rudder is adopted, so that the control efficacy is high; tailless flying wing configuration is adopted for a fixed wing face, the size of the aircraft is decreased, the structure is more compact and easy to detach and maintain, and the wind resistance is good in the vertical take-off and landing stages compared with conventional configuration and a canard configuration.

Owner:杭州迅蚁网络科技有限公司

Vehicle of monocoque construction formed from thermoplastic resin members

ActiveUS9802650B2Increase awarenessImprove securityElectric propulsion mountingVehicle sub-unit featuresEngineeringField of view

Owner:TEIJIN LTD

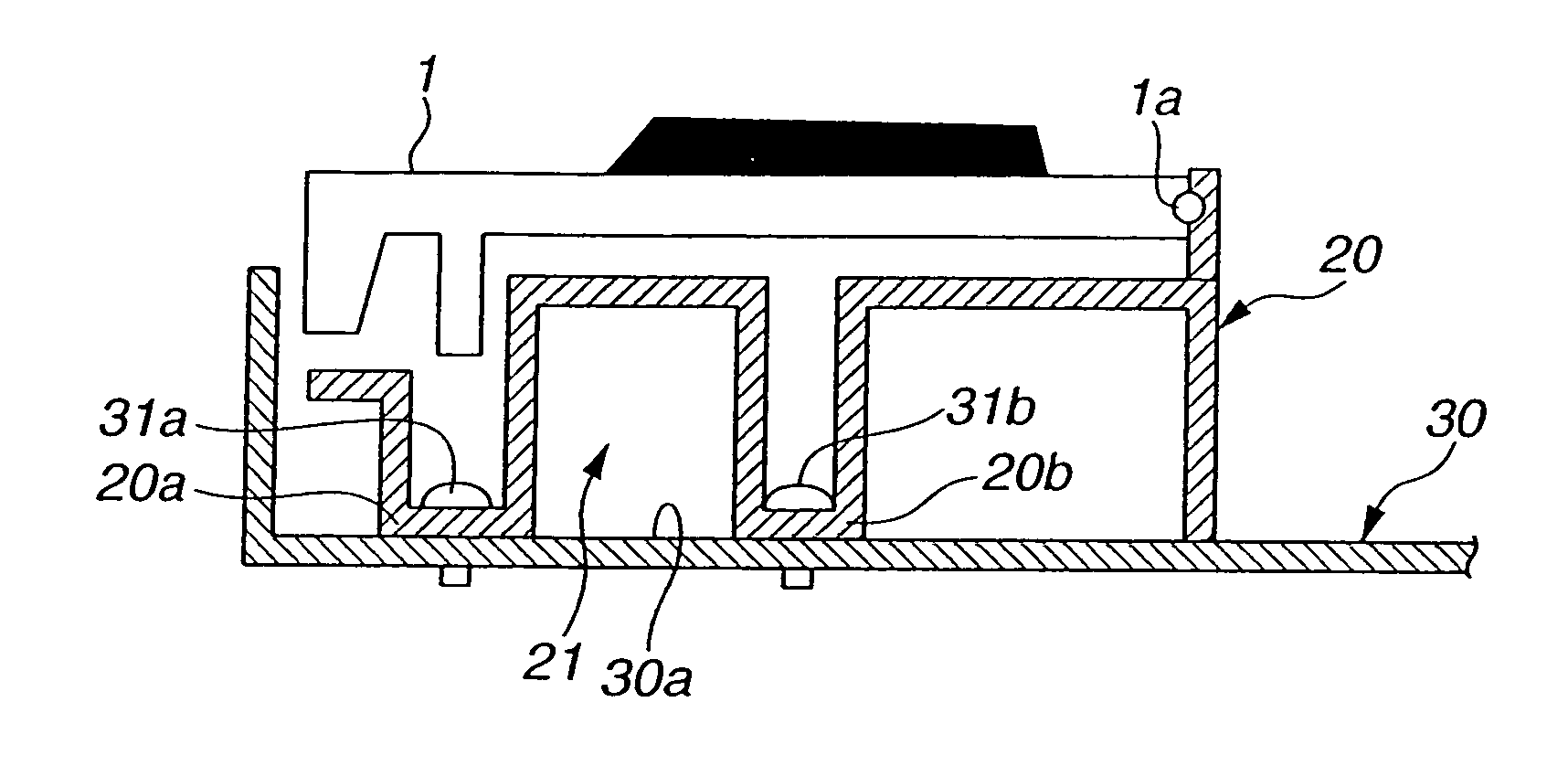

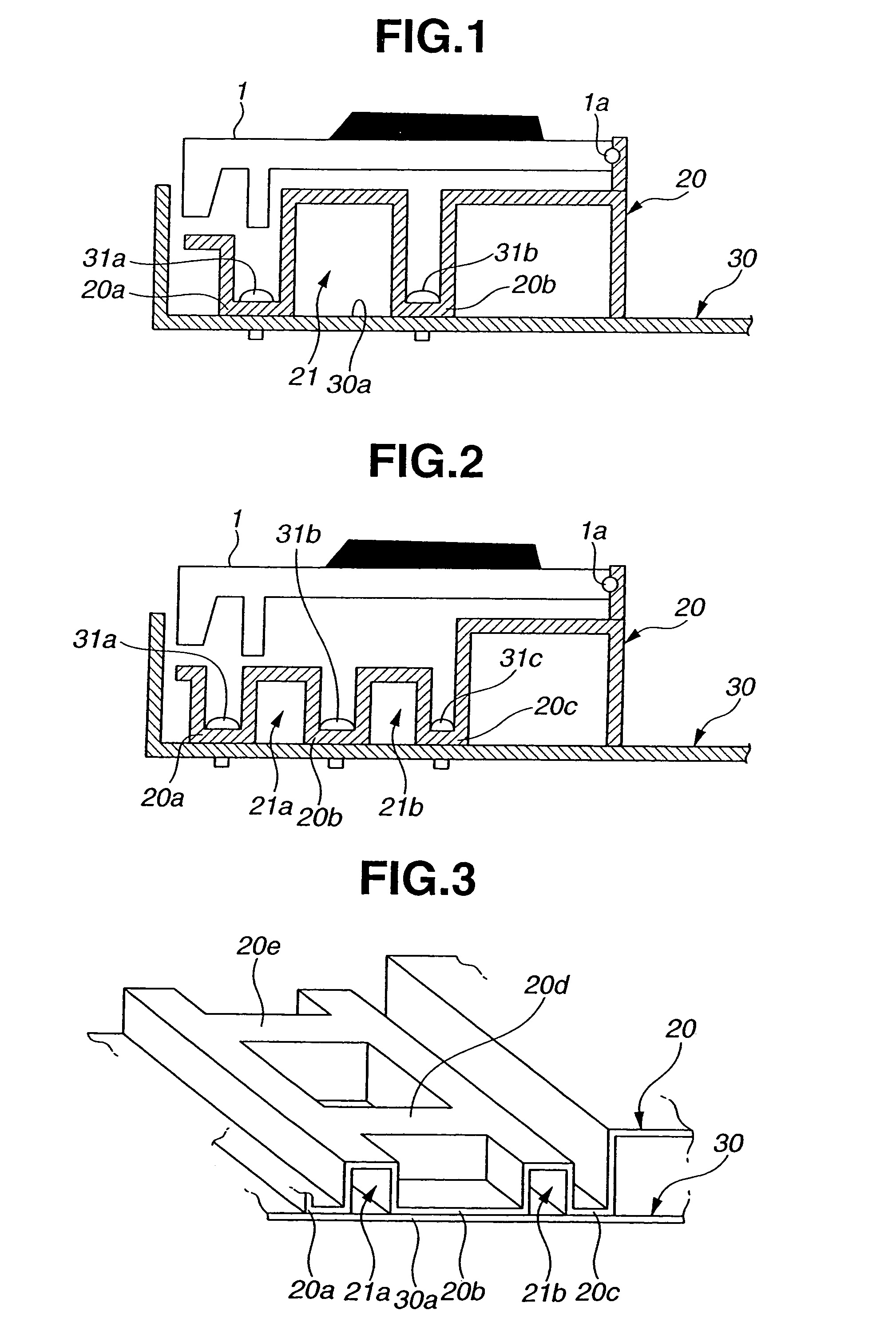

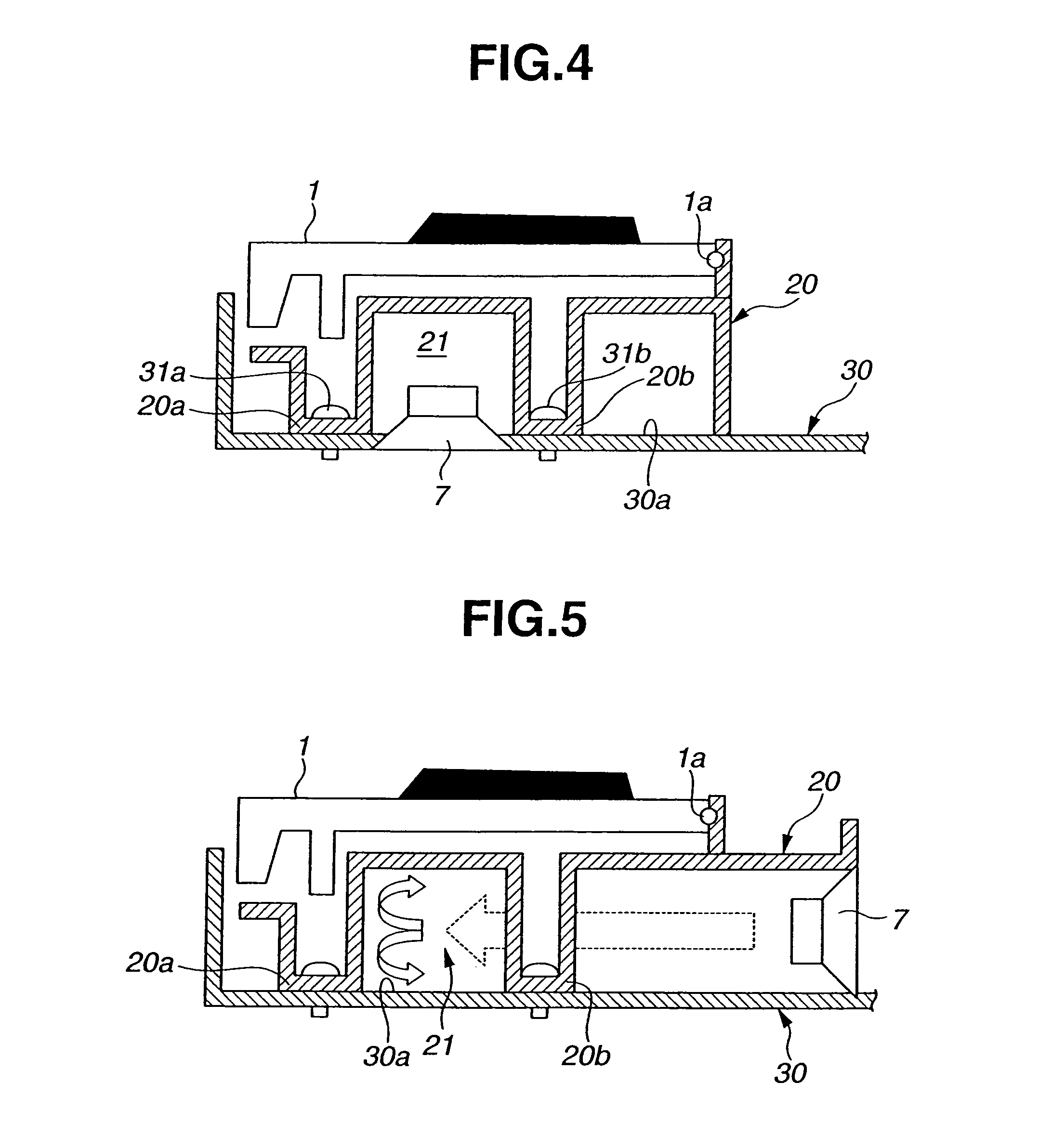

Keyboard apparatus

ActiveUS7326844B2Improve rigidityReduce weightElectrophonic musical instrumentsPercussion musical instrumentsEngineeringBending stiffness

Owner:YAMAHA CORP

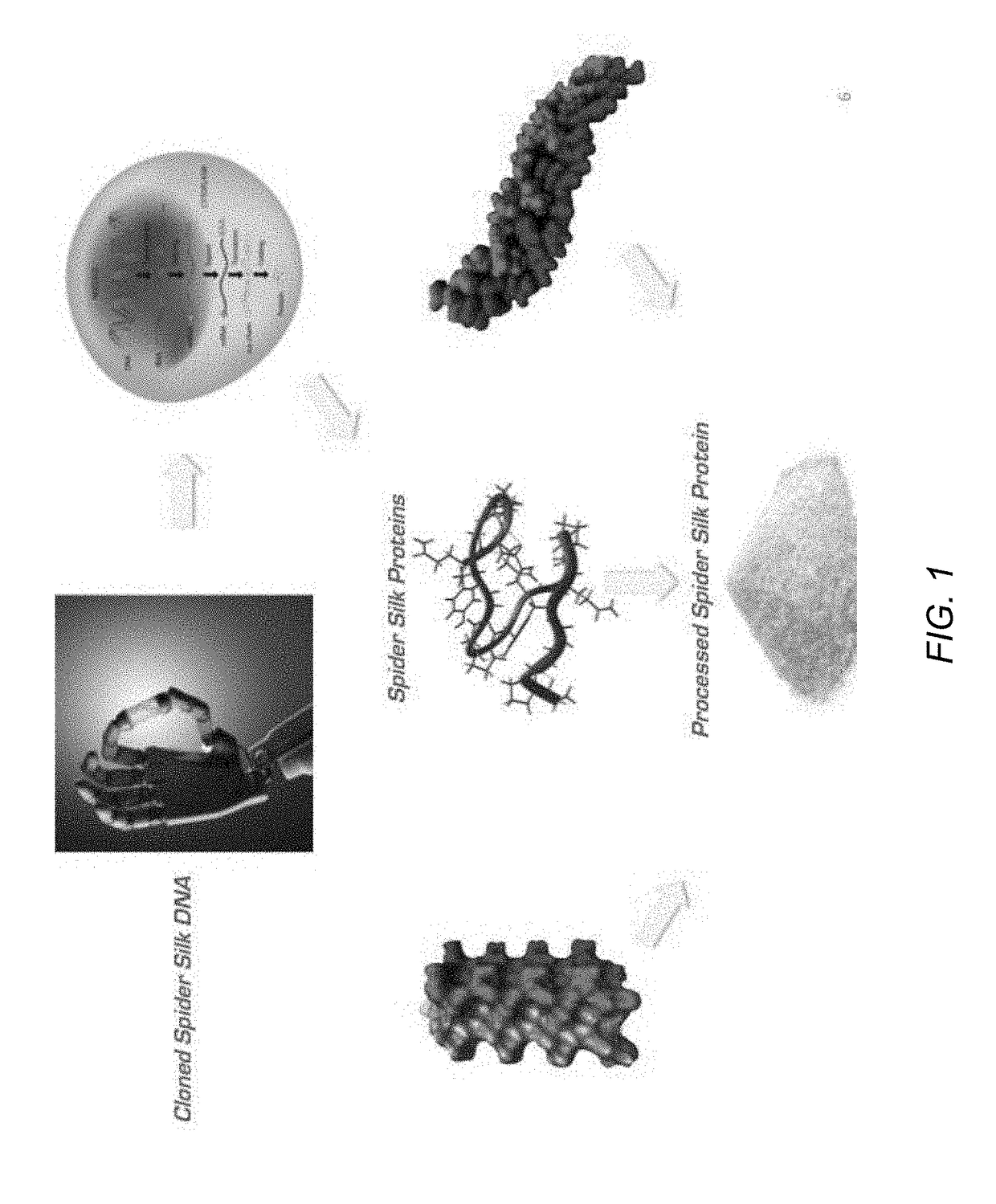

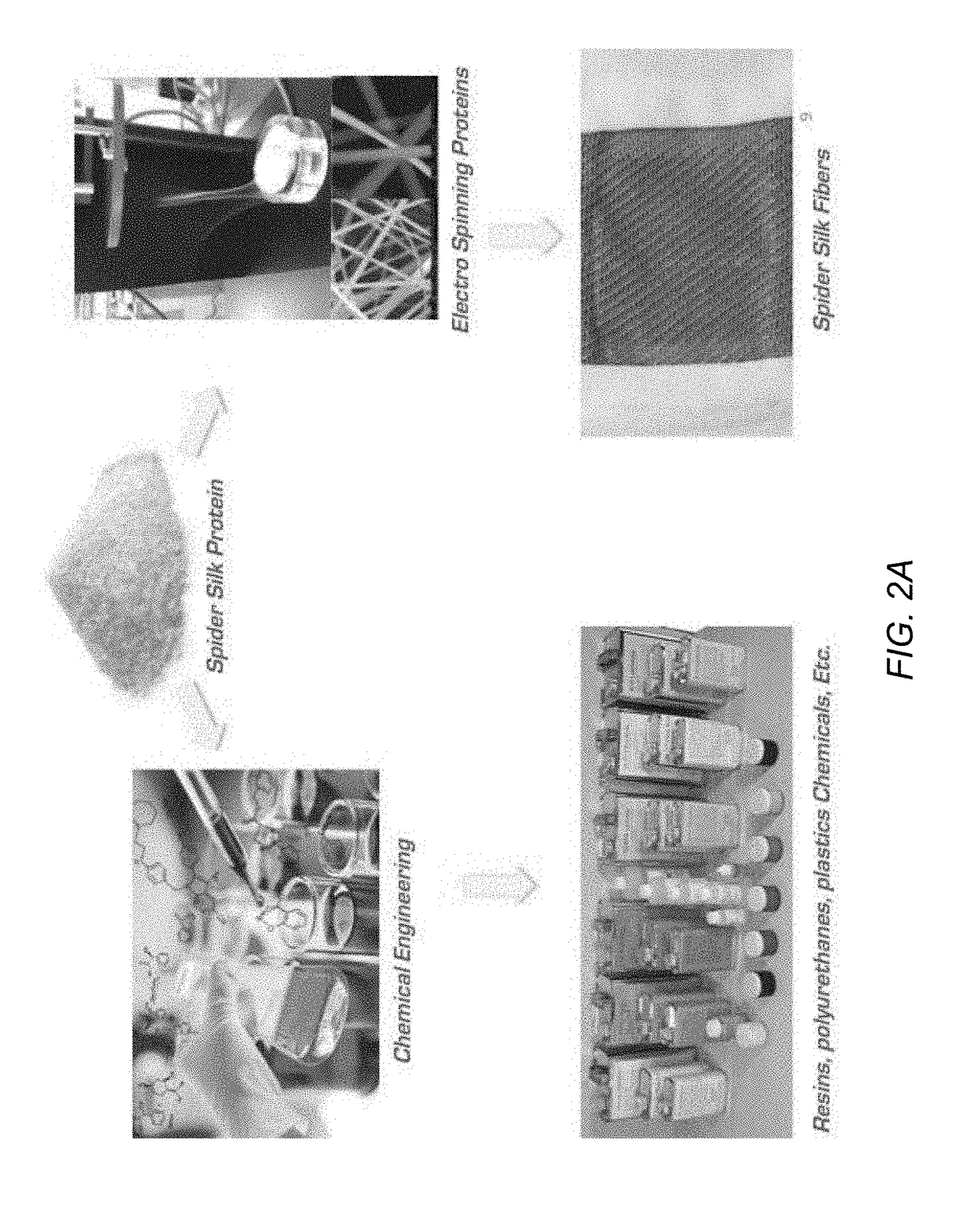

Load-bearing composite panels, materials, products, and processes to make and use same

Load-bearing composite panels, materials, and products made by surrounding with a long fiber and / or fiber cloth reinforced polyurethane resin, an assembly containing one or more load-bearing members, graphene, a structural polyurethane / resin sandwich composite and / or spider silk protein fiber-cloth-continuous fibers. The composite structures can provide stronger, lighter-weight structural items such as vehicle floor and body panels, bullet-proof anti-ballistic panel products, vehicle bullet-proof anti-ballistic body panel structures and floors, bullet-proof vests, vehicle chassis, monocoque chassis, motor homes chassis-bodies, fuselage floors and frames for aircraft and / or UAV's, bicycle and motorcycle frames, wind turbine blades frames and structures, ship or boat haul body structures, shipment containers, pre-fabricated walls of buildings, train structure body or floor panels, solar panel supports, battery housings, mobile home walls, roof modules, truck beds, and truck trailer floors. Such composite panels, materials, and products can also be utilized in artificial organs, ligaments or tendons, artificial disc vertebrae, ropes, and 3D printing parts.

Owner:JEREZ ROBERTO VELOZZI

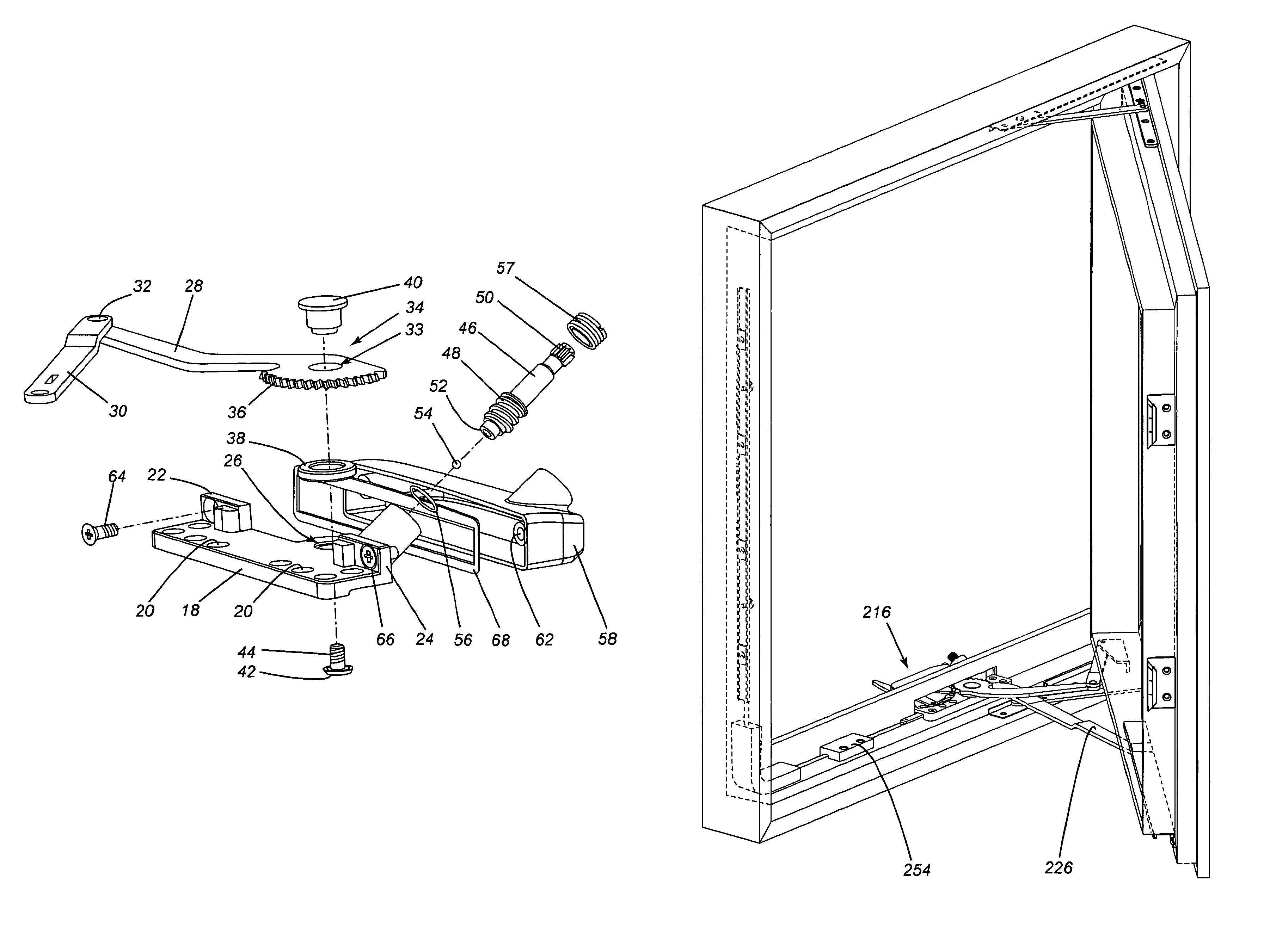

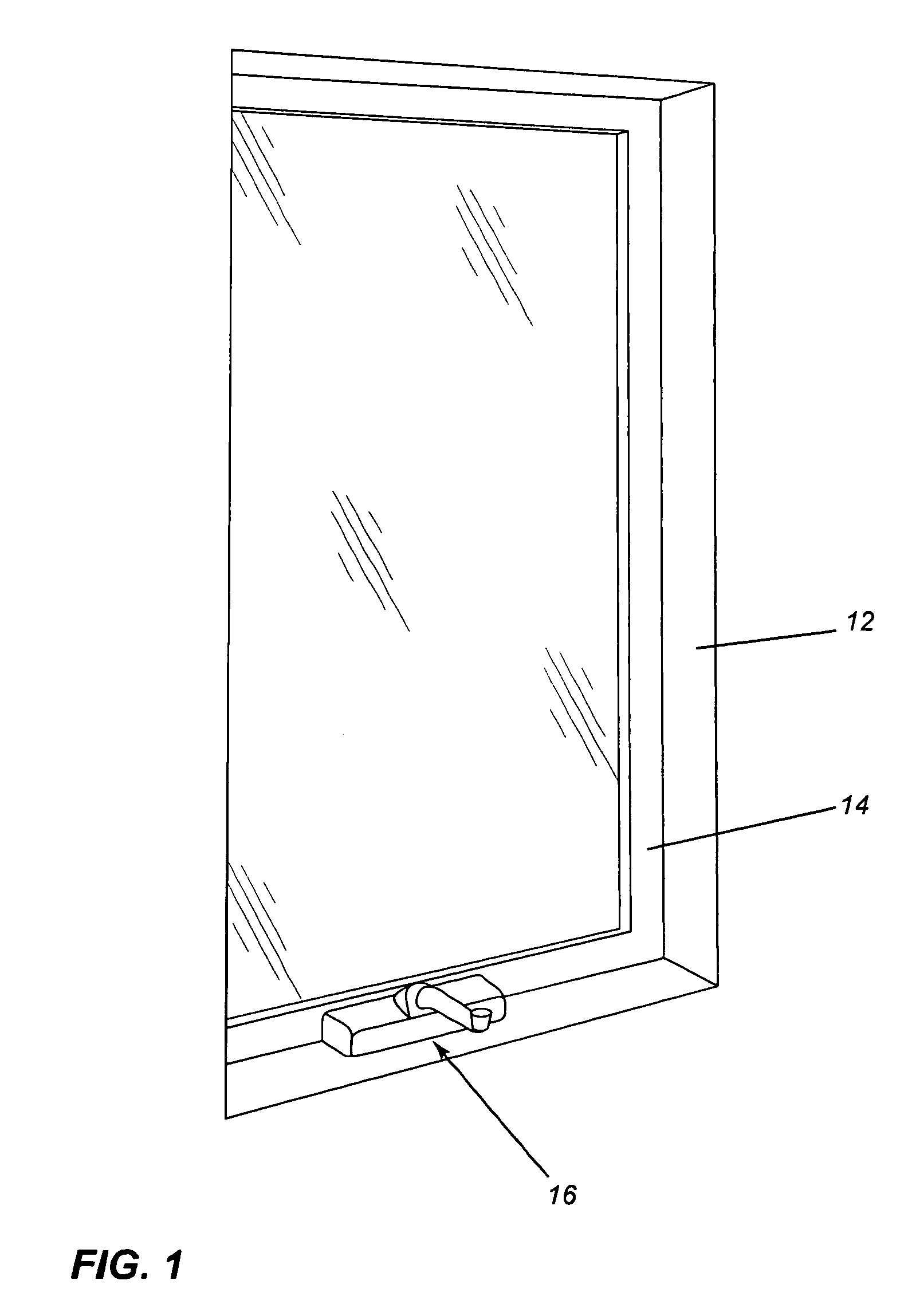

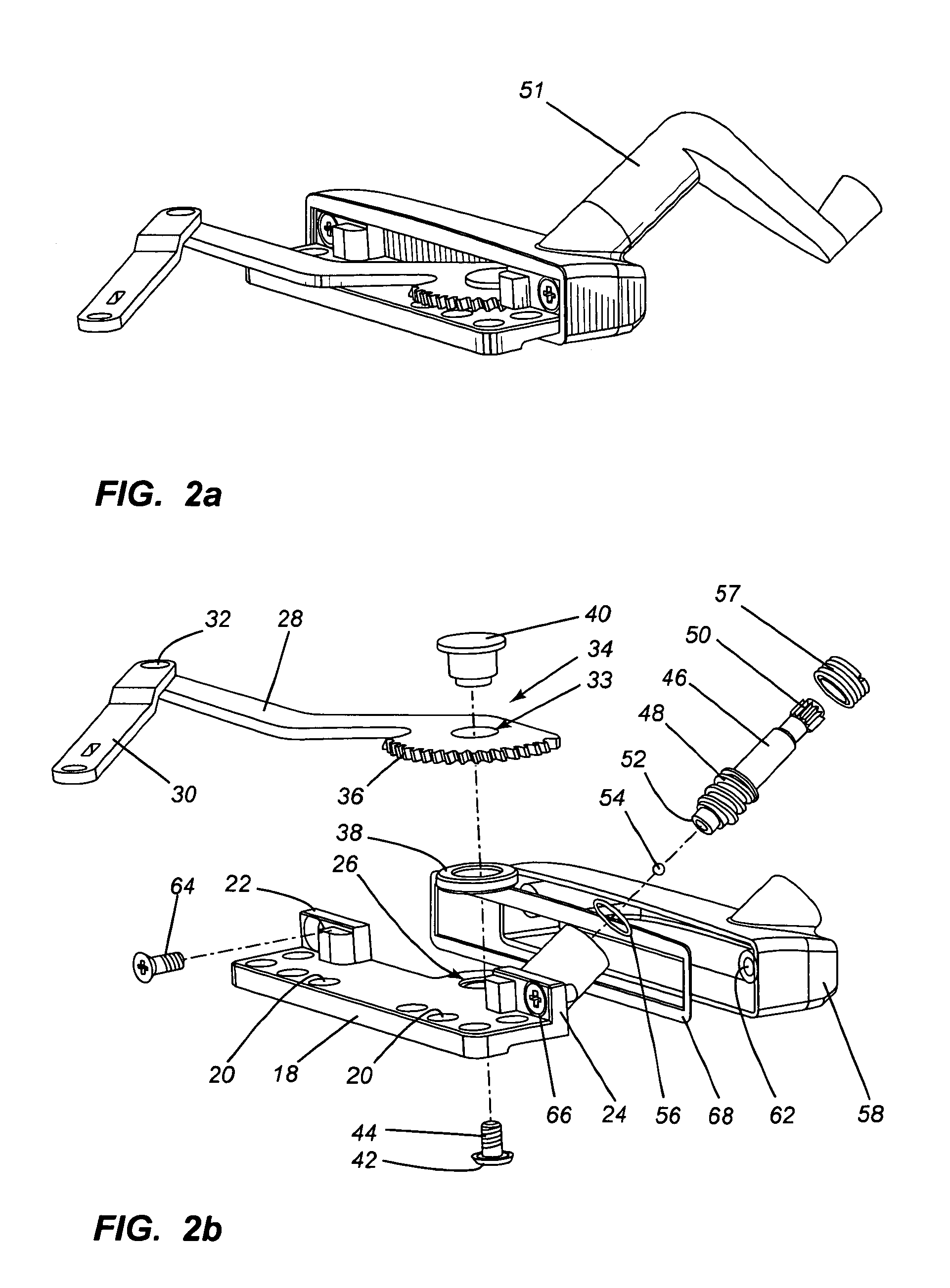

Casement window operator

ActiveUS8141295B2Reduce penetrationMan-operated mechanismWing suspension devicesEngineeringMechanical engineering

Owner:CARRIER CHRISTIAN

Vehicle monocoque body assembly

A vehicle self-supporting monocoque body assembly comprising a base frame structure is provided. The body assembly also comprises a pair of wheel axles interfaces located at generally front and rear locations of the base frame structure for receiving a pair of wheel axles. The body assembly also has an energy storage element compartment positioned between front and rear wheel axles interfaces. The body assembly also includes an engine compartment for completely housing an engine system. The body assembly also comprises a vehicle outer frame interface. The body assembly also includes front and rear suspension arm interfaces for interfacing with two pairs of front and rear symmetrical suspension arms extending along a length of the base frame structure. The bottom surface of the base frame structure is positioned at or below a horizontal plane between the wheel axles. Preferably, the vehicle outer frame interface is shaped to receive a cabin frame structure.

Owner:VEHICULES NEMO

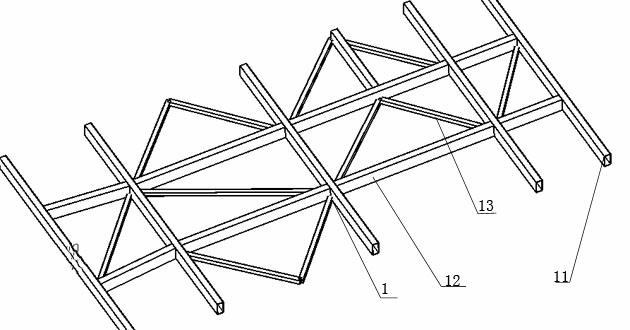

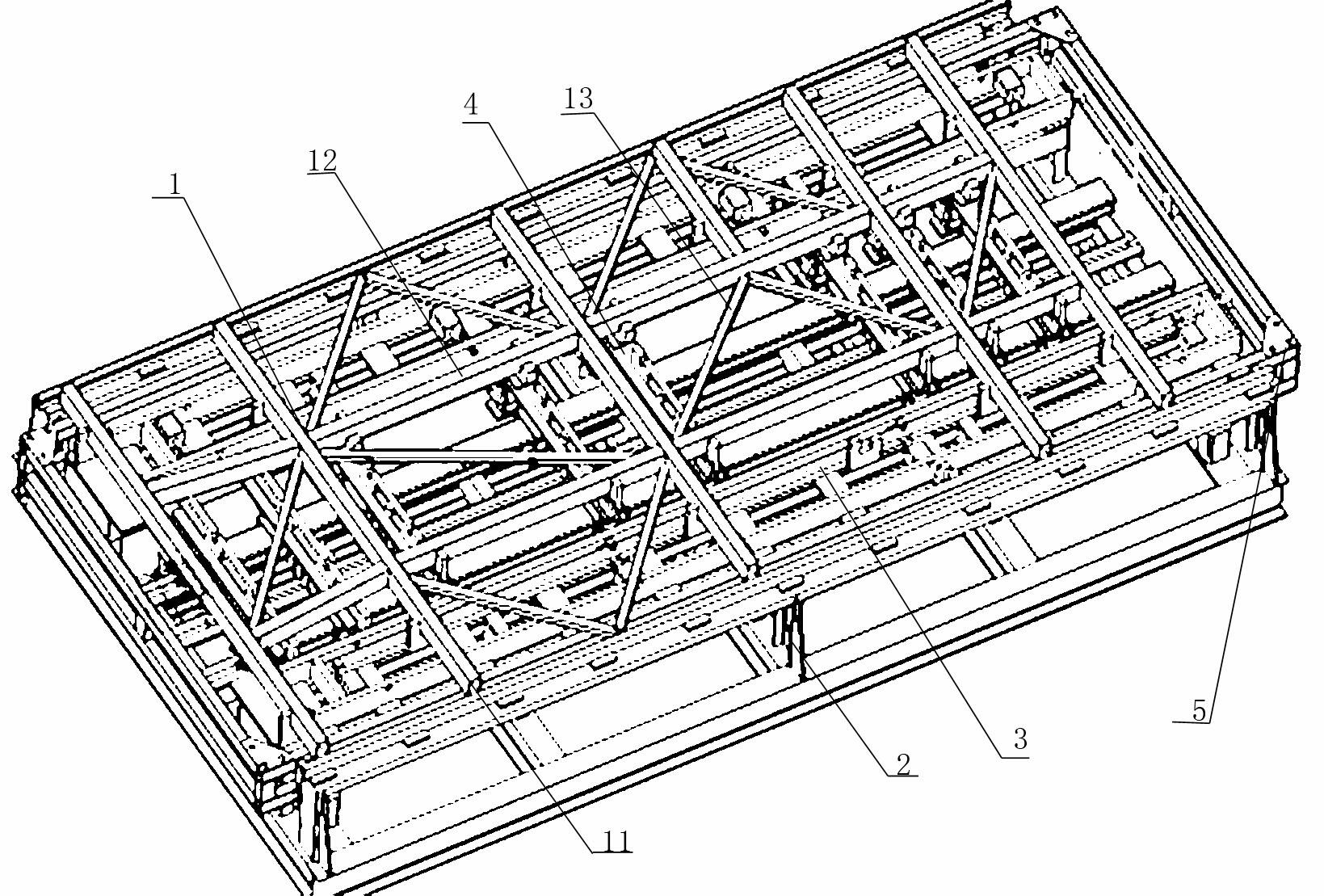

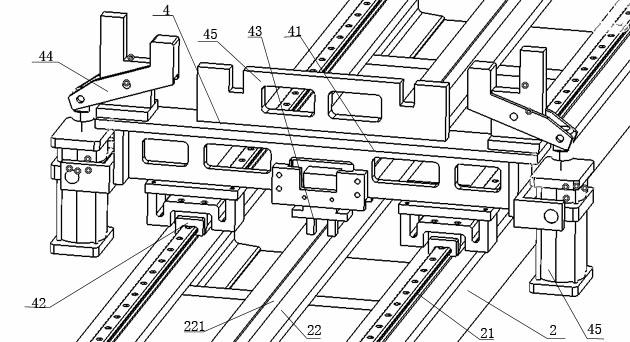

Welding clamping fixture for midpiece of monocoque bus frame

InactiveCN102380735AGeneralizationImprove generalizationWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention relates to a welding clamping fixture for a midpiece of a monocoque bus frame. The welding clamping fixture comprises an underframe on which two guide rails are arranged in parallel, wherein at least two longitudinal beam positioning devices perpendicular to the guide rails are arranged on the guide rails, each longitudinal beam positioning device comprises a bracket, slider blocks which are matched with the guide rails in a guiding manner along the length direction of the guide rails are arranged at the bottoms of the brackets, a longitudinal beam clamping seat is arranged at the top of each bracket, and a diagonal-bracing clamping seat is arranged between the two longitudinal beam clamping seats; and traverse beam positioning devices are arranged at outer sides of the both ends of each longitudinal beam positioning device on the underframe, and each traverse beam positioning device comprises an adapting pole on which a traverse beam clamping seat is arranged. When the welding clamping fixture is in use, the longitudinal beam positioning devices can be used for positioning the longitudinal beams and the diagonal bracings of the bus frame, and the traverse beam positioning devices are used for positioning the traverse beams of the bus frame, the longitudinal beam positioning devices can be regulated according to different spacing distances among the traverse beams of the bus frame, and the traverse beam positioning devices can be replaced according to different bus frame structures, therefore, the welding clamping fixture can satisfy the welding requirements of bus frames of various structures through simple regulation.

Owner:ZHENGZHOU YUTONG BUS CO LTD

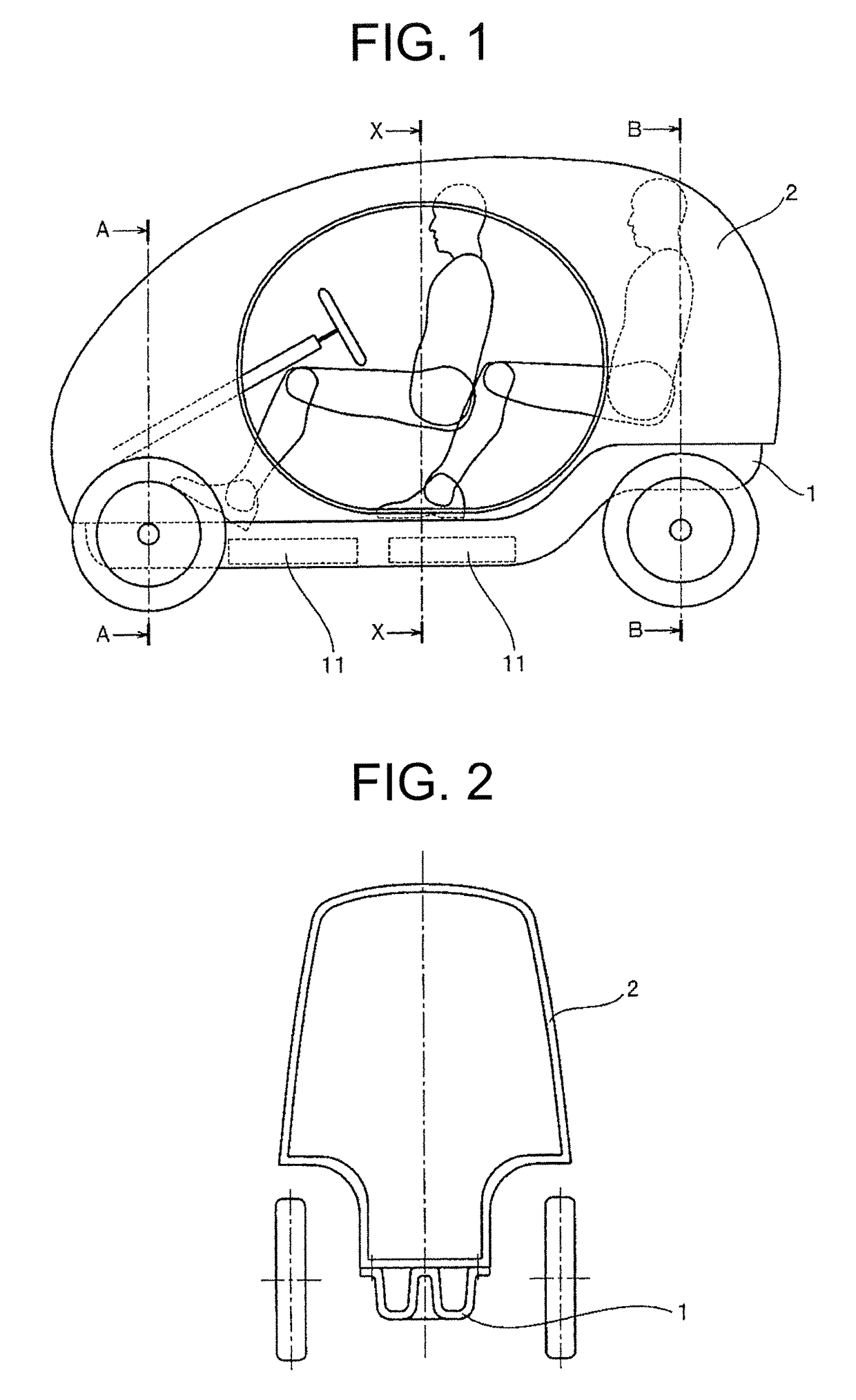

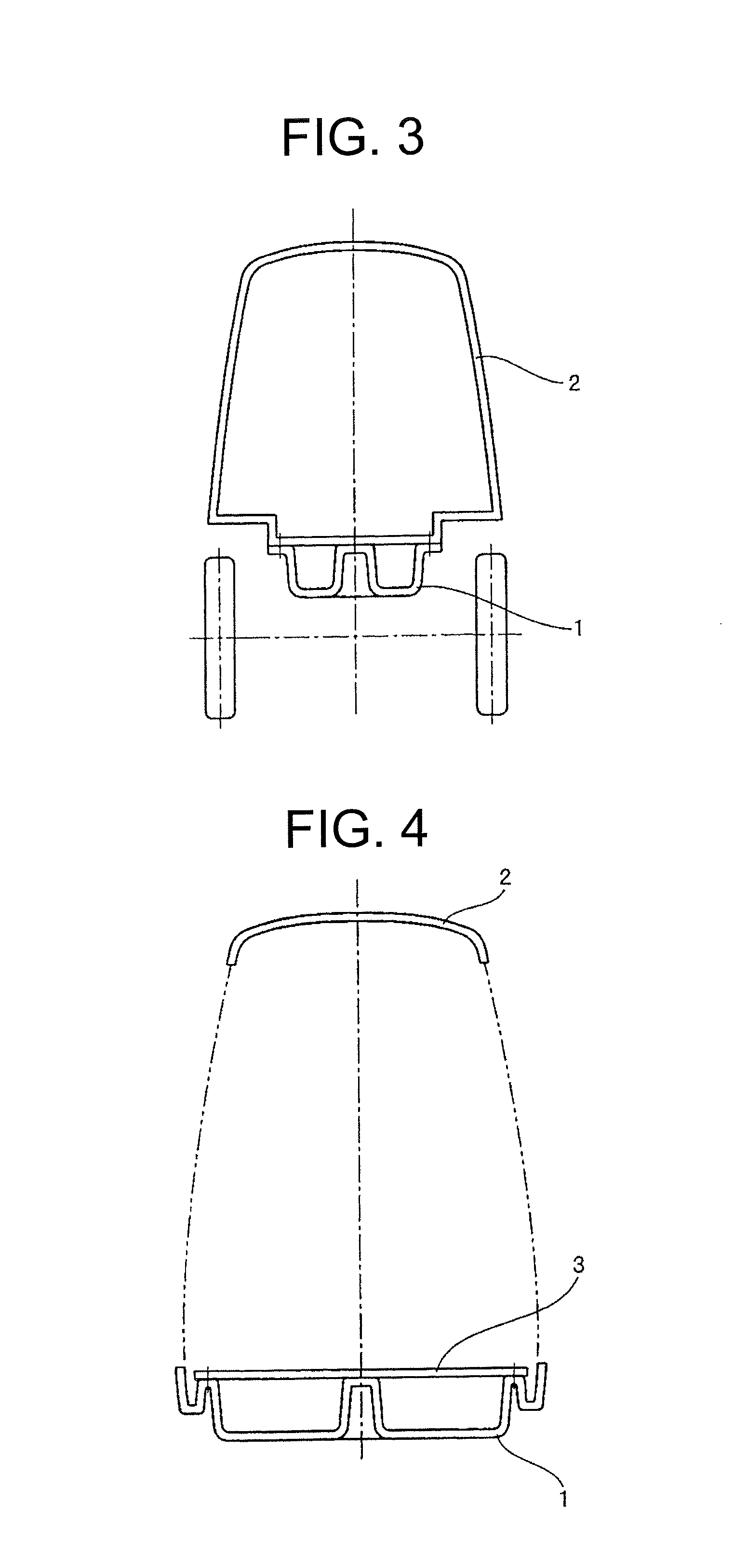

Vehicle of monocoque construction formed from thermoplastic resin members

ActiveUS20160137229A1Driving safetyIncrease awarenessElectric propulsion mountingUnderstructuresEngineeringField of view

This vehicle of monocoque construction is formed by fastening together resin parts which are an upper body integrally made of a transparent thermoplastic resin composition, a lower body integrally made of a thermoplastic resin composition and a floor integrally made of a thermoplastic resin composition, wherein the vehicle is characterized in that the lower body is provided with a flange part rising up from the entire perimeter of the bottom surface and, in the center of the bottom surface, a convex rib part that continues rearward from the front of the vehicle, and the upper body and the floor being fastened to the flange part and the convex rib part of the lower body. In so doing, there can be provided a vehicle which is lightweight, affords a good field of view during driving, is simple in construction, and has the necessary rigidity.

Owner:TEIJIN LTD

Methods and apparatus for assembling and operating monocoque rotary machines

A method and apparatus of assembling a rotary machine includes providing at least one component. The component is at least one of a rotating member and a stationary member. The method and apparatus also includes coupling the component to a monocoque nacelle structure. The monocoque nacelle structure includes an outer shell that extends over at least a portion of the component.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for assembling and operating semi-monocoque rotary machines

A wind turbine generator (100) includes at least one rotating member and a semi- monocoque nacelle structure (200) that includes at least one stationary member extending over at least a portion of the rotating member. During operation the wind turbine generator transmits loads to the semi-monocoque nacelle structure.

Owner:GENERAL ELECTRIC CO

All-weather enclosure for flat panel displays

ActiveUS9235232B2Improve structural rigidityTelevision system detailsCasings/cabinets/drawers detailsDisplay devicePrism

A lightweight, weatherproof, protective enclosure for flat panel displays comprising a containing element in the form of an open, shallow rectangular prism with a regular network of shallow reinforcing depressions formed in its outer surface and a substantially transparent planar viewing element hingedly connected to the containing element such that when the viewing element is closed over, and sealed to, the containing element the protective enclosure forms a lightweight, monocoque structure with enhanced structural rigidity.

Owner:PROTECTIVE ENCLOSURES CO LLC

Monocoque electric vehicle and assembling method thereof

InactiveCN105691462AGuaranteed StrengthReduce harmMonocoque constructionsVehicle frameModular design

The invention provides a load-bearing electric vehicle and an assembly method thereof. The load-bearing electric vehicle includes a frame assembly, a front compartment assembly and a driver's cab assembly; the frame assembly includes a magnesium alloy welded The main body of the frame and the front suspension and rear suspension made of aluminum alloy welding, the front suspension and rear suspension are fixedly connected to the main body of the frame; the front warehouse assembly and cab assembly are mainly made of carbon fiber composite materials have to. By adopting the load-bearing electric vehicle and its assembly method of the present invention, the frame assembly is jointly made of magnesium alloy and aluminum alloy to ensure the strength of the main body of the frame, and effectively absorb the impact of collisions through the collapse of the aluminum alloys of the front suspension and rear suspension. Kinetic energy, reducing occupant injuries, combined with the front cabin assembly and cab assembly made of carbon fiber composite materials, effectively reducing the weight of the vehicle; simplifying the assembly and manufacturing process through modular design, improving efficiency, and also helping to speed up the follow-up of electric vehicles Industrialization development.

Owner:SUZHOU EAGLE ELECTRIC VEHICLE MFG

Methods and apparatus for assembling and operating monocoque rotary machines

A method and apparatus of assembling a rotary machine includes providing at least one component. The component is at least one of a rotating member and a stationary member. The method and apparatus also includes coupling the component to a monocoque nacelle structure. The monocoque nacelle structure includes an outer shell that extends over at least a portion of the component.

Owner:GENERAL ELECTRIC CO

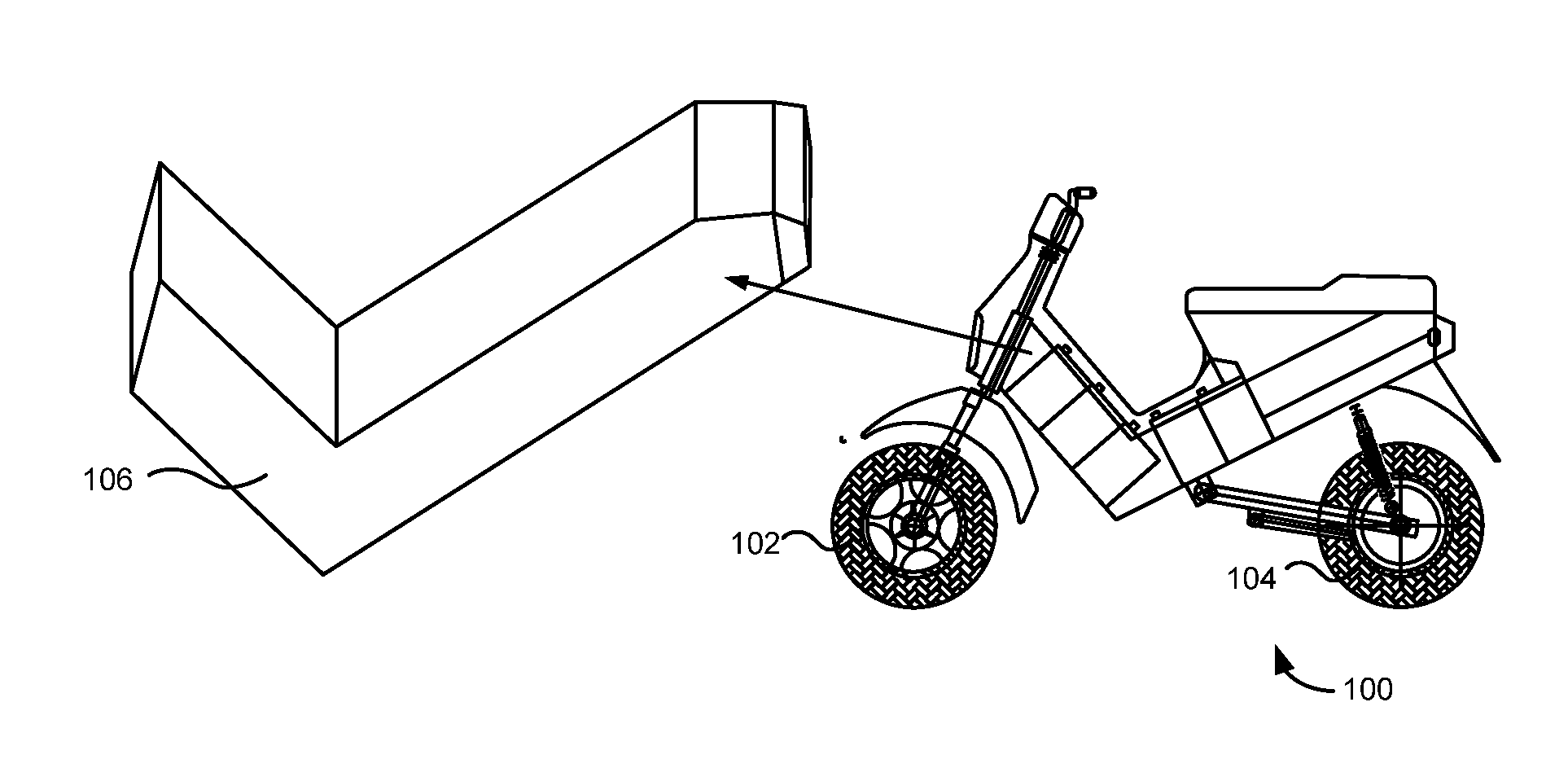

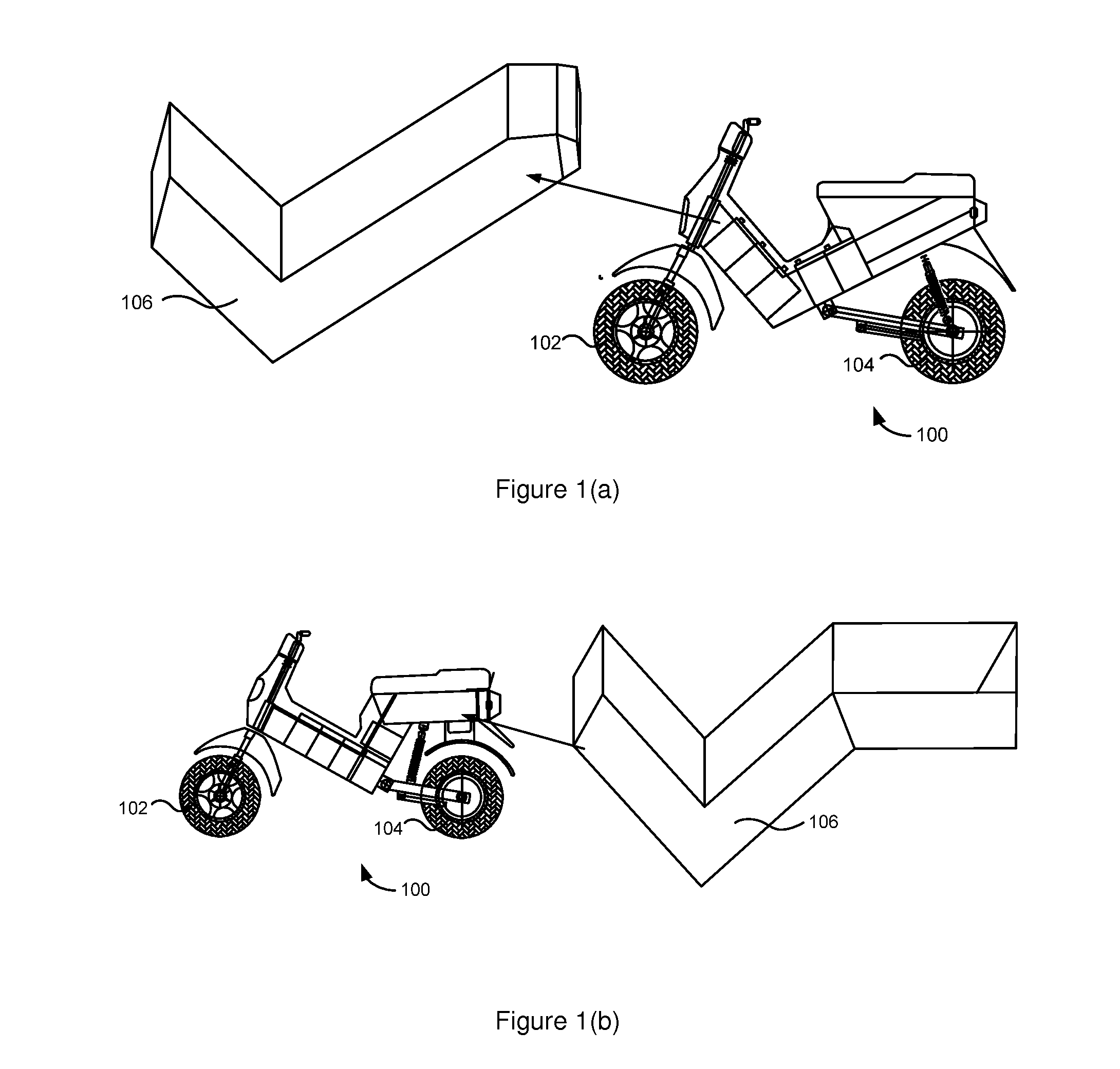

Monocoque structure of an electrically powered motorized vehicle

InactiveUS20110042916A1Improve performanceRigid enoughPassenger cyclesChildren cyclesDie castingControl switch

The present invention describes a unique monocoque structure of an electrically powered motorized vehicle. In one embodiment, the structure includes at least two front wheels, wherein the pitch of the front wheels can be extended; at least two rear wheels, wherein the pitch of the rear wheels can be extended; and a monocoque frame suspended between the front wheels and the rear wheels. Further, a control switch is mounted on the monocoque fame to convert two wheeled vehicle to three or four wheeled vehicle and vice versa. Furthermore, the monocoque frame is built with combinations of die-cast, extrusions of high strength plastic and light metal alloys to provide light weight and sufficient rigidity.

Owner:ANANTHAKRISHNA ANIL

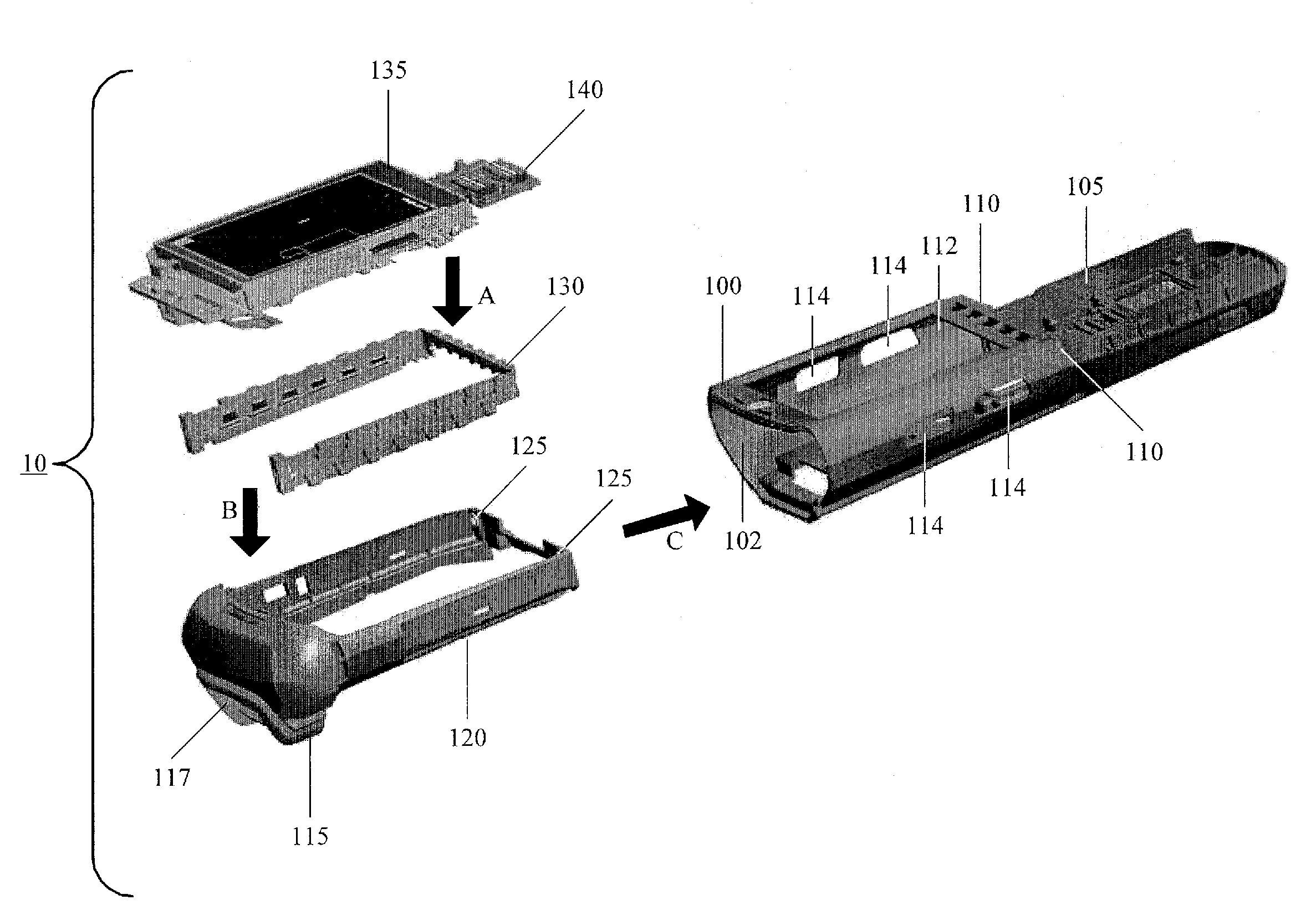

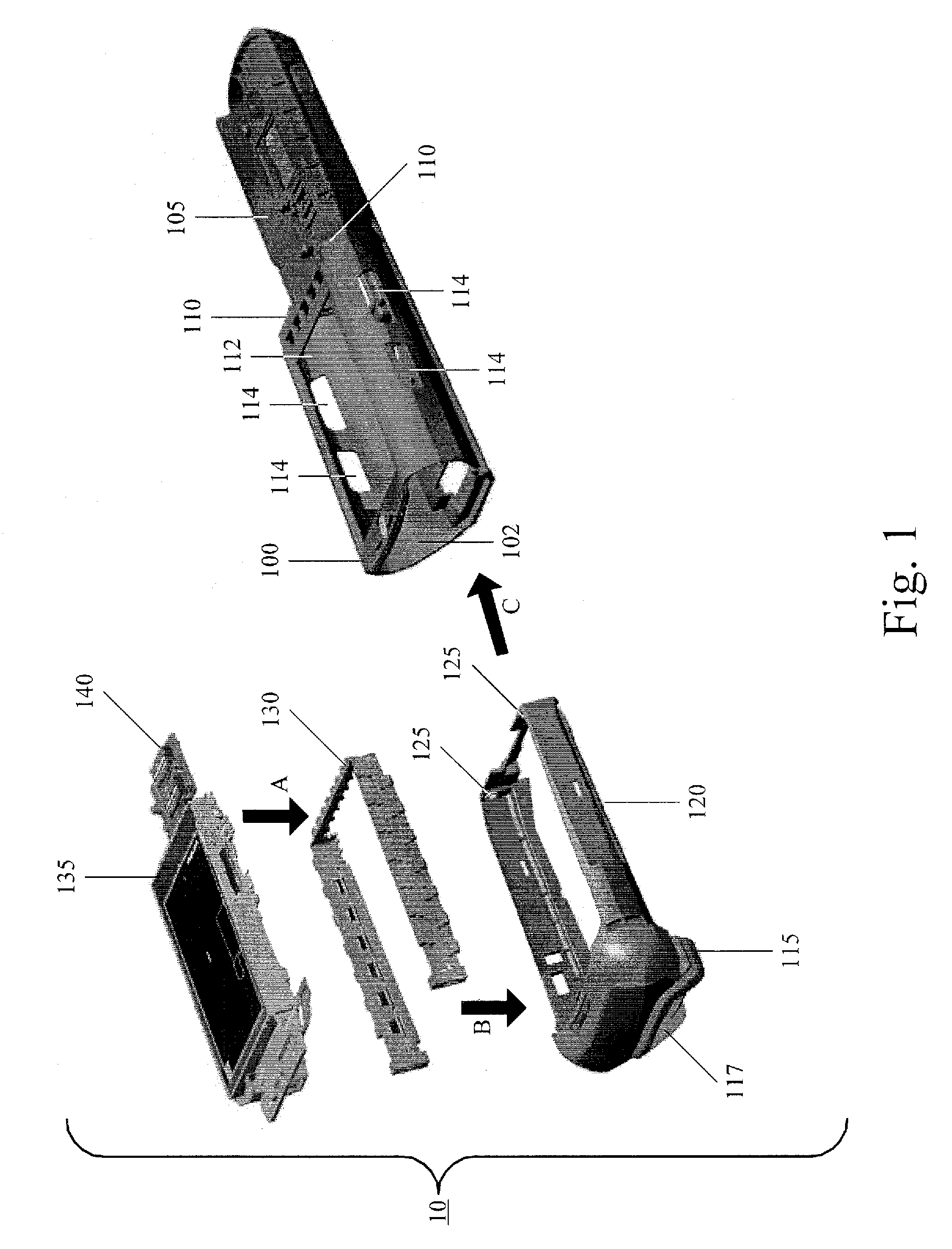

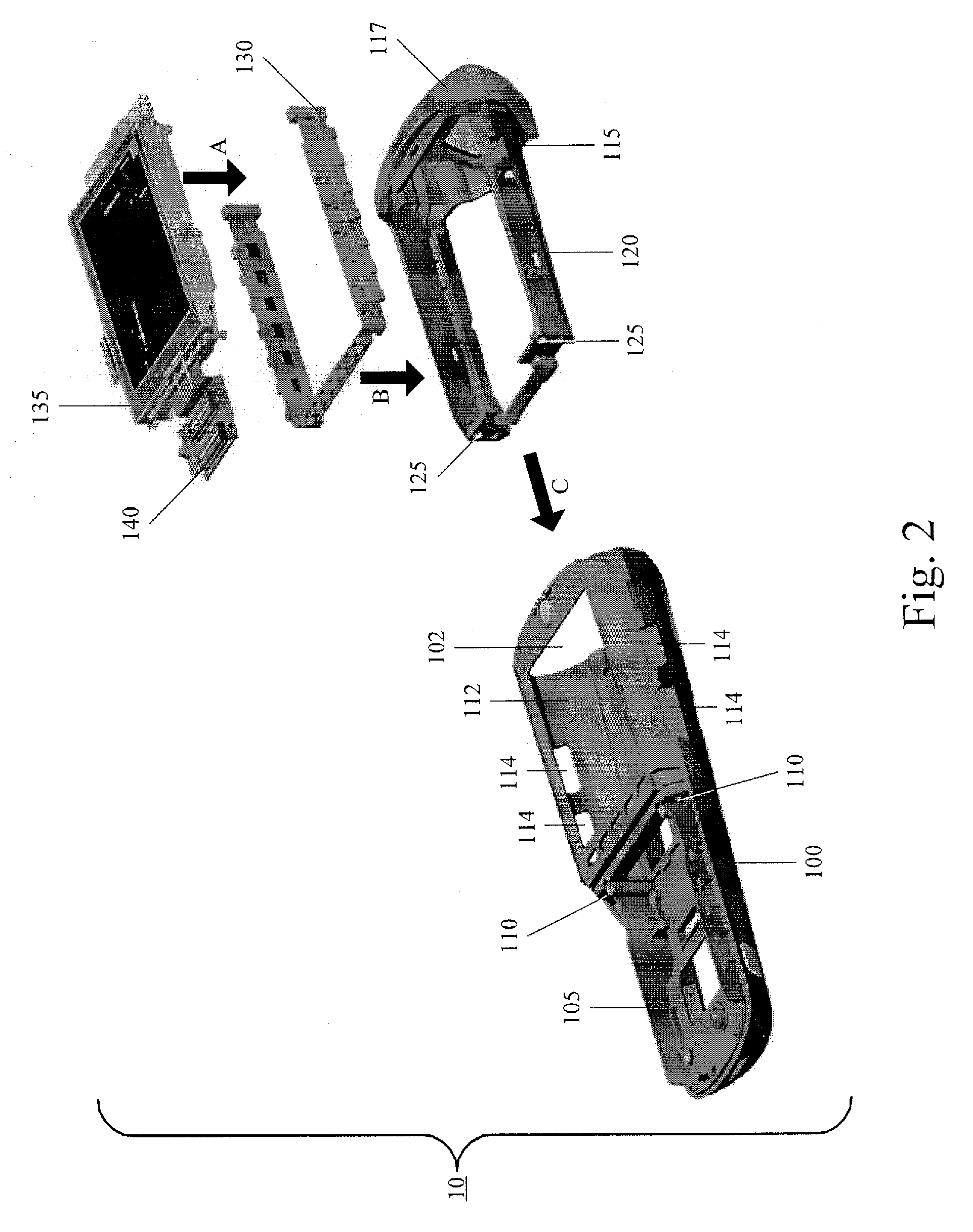

Shock Isolation System for a Mobile Unit with a Monocoque Housing

A monocoque housing for a mobile unit comprises a base, an end cap, and an isolation gasket. The mobile unit includes an electronic stack assembly. The base has an opening. The end cap is adapted to removably couple with the base. The end cap includes a cap and a frame where the frame is received by the base through the opening so that the cap covers the opening. The isolation gasket is disposed between the frame and the electronic stack assembly. The electronic stack assembly is not mechanically fastened to the isolation gasket. When the mobile unit experiences a shock load, the isolation gasket absorbs the shock load to reduce the shock load on the electronic stack assembly.

Owner:SYMBOL TECH INC

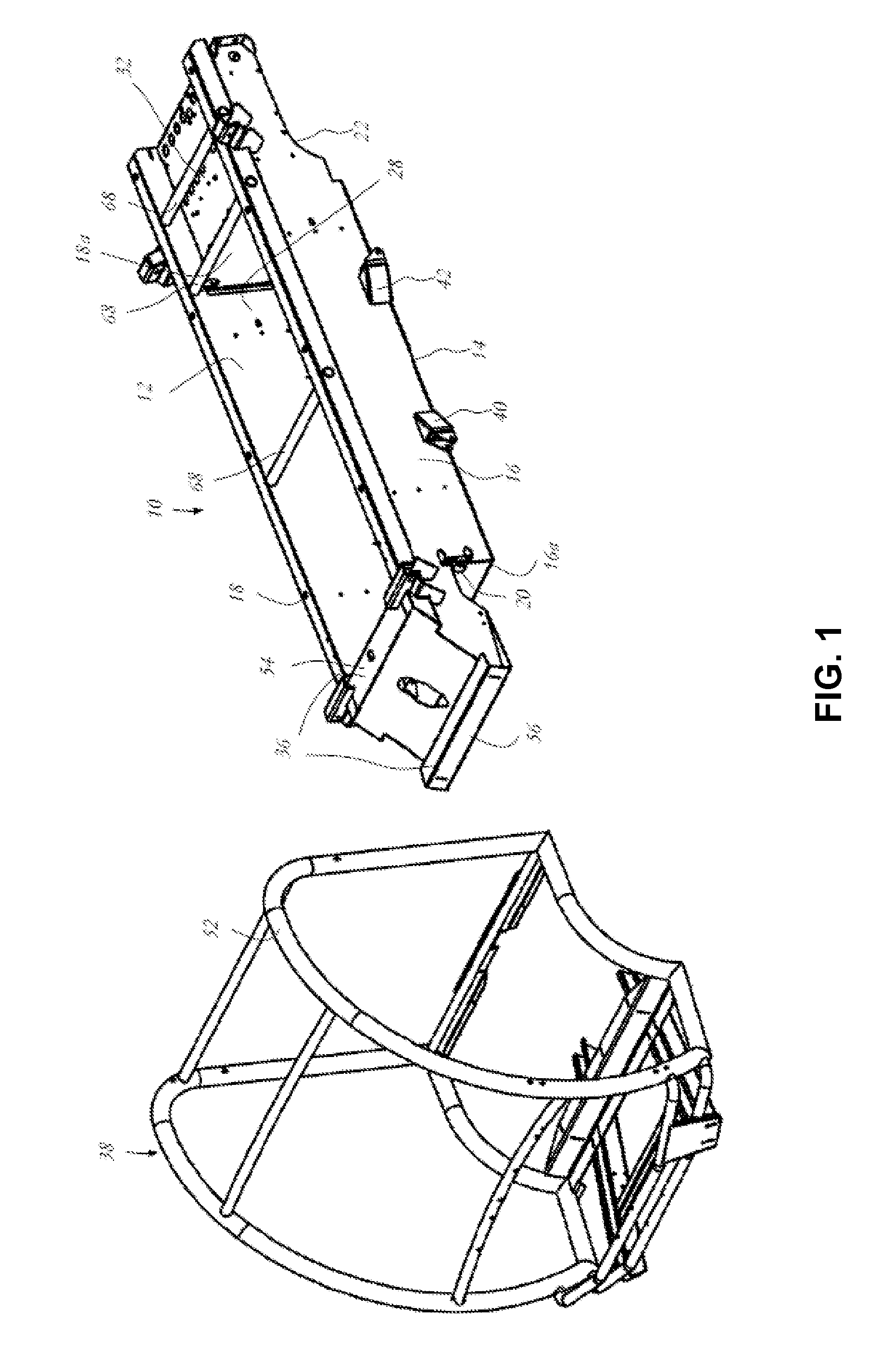

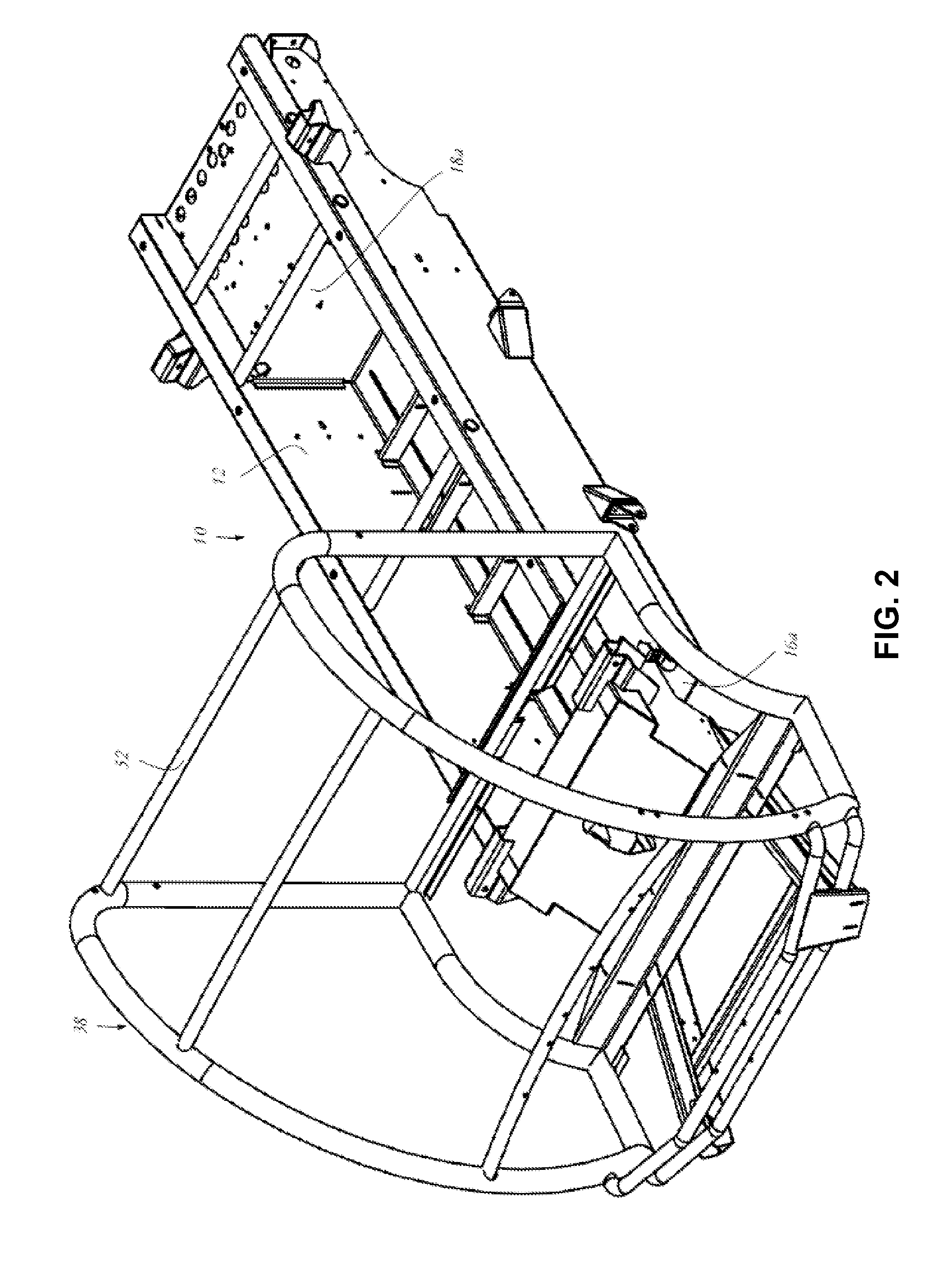

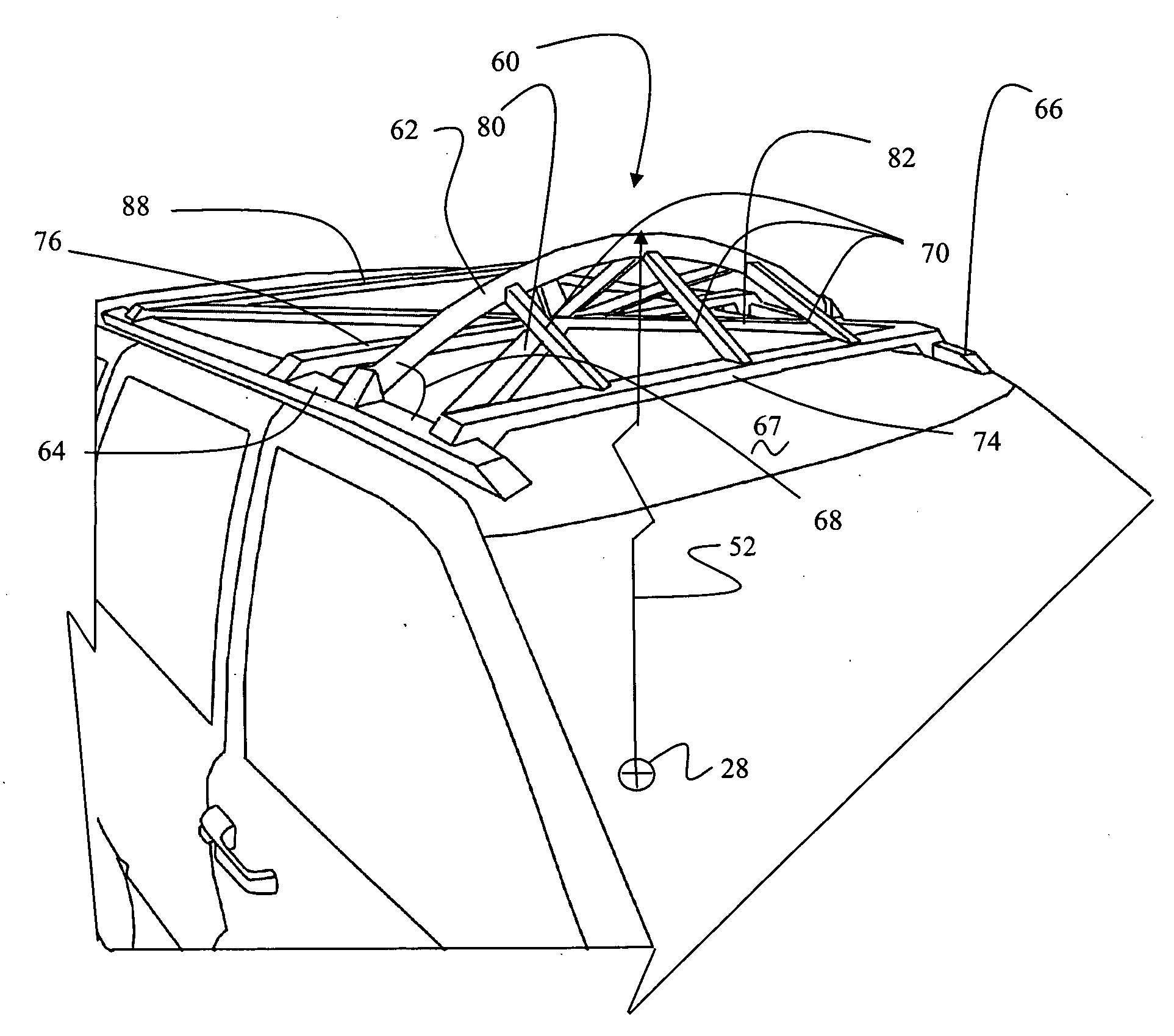

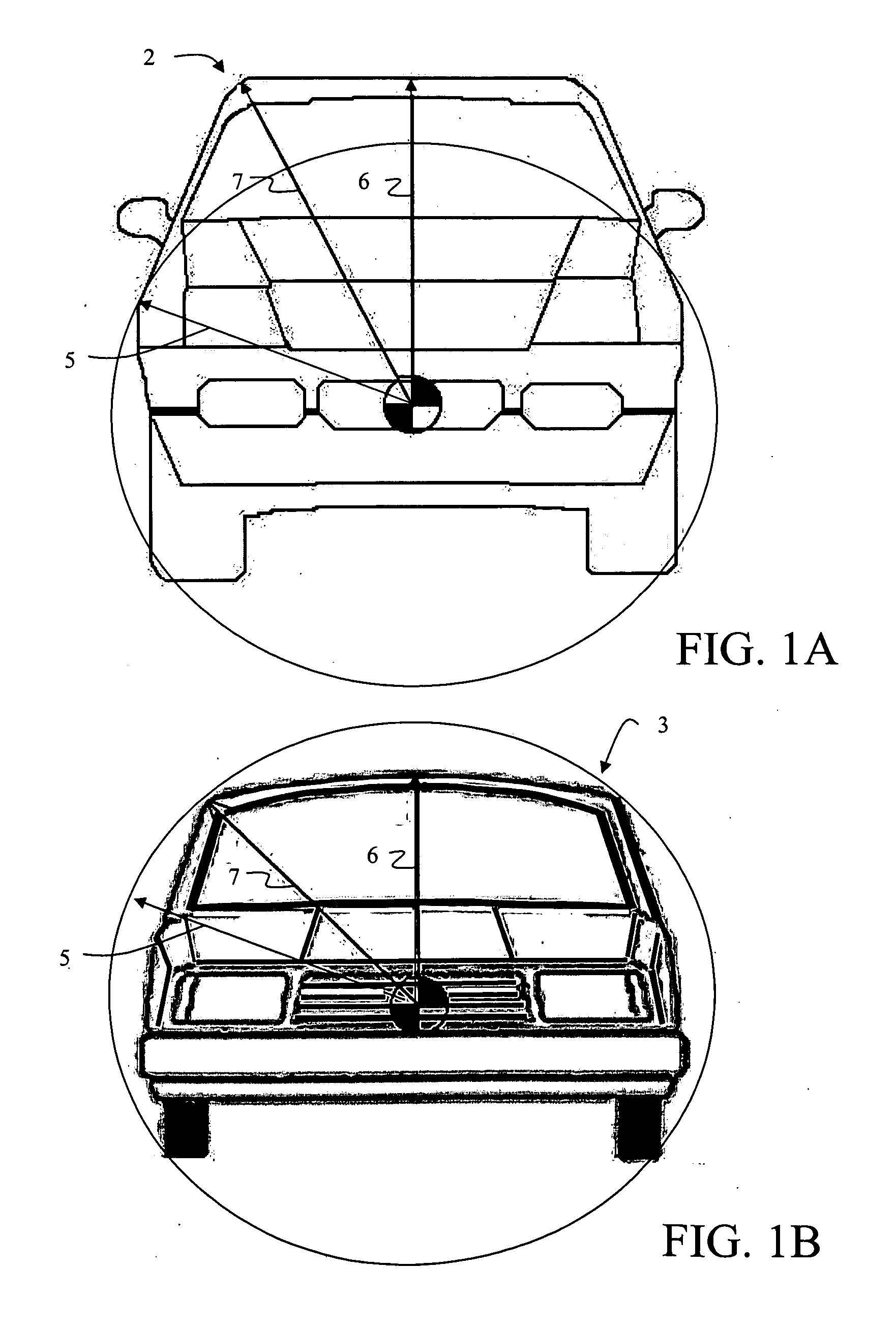

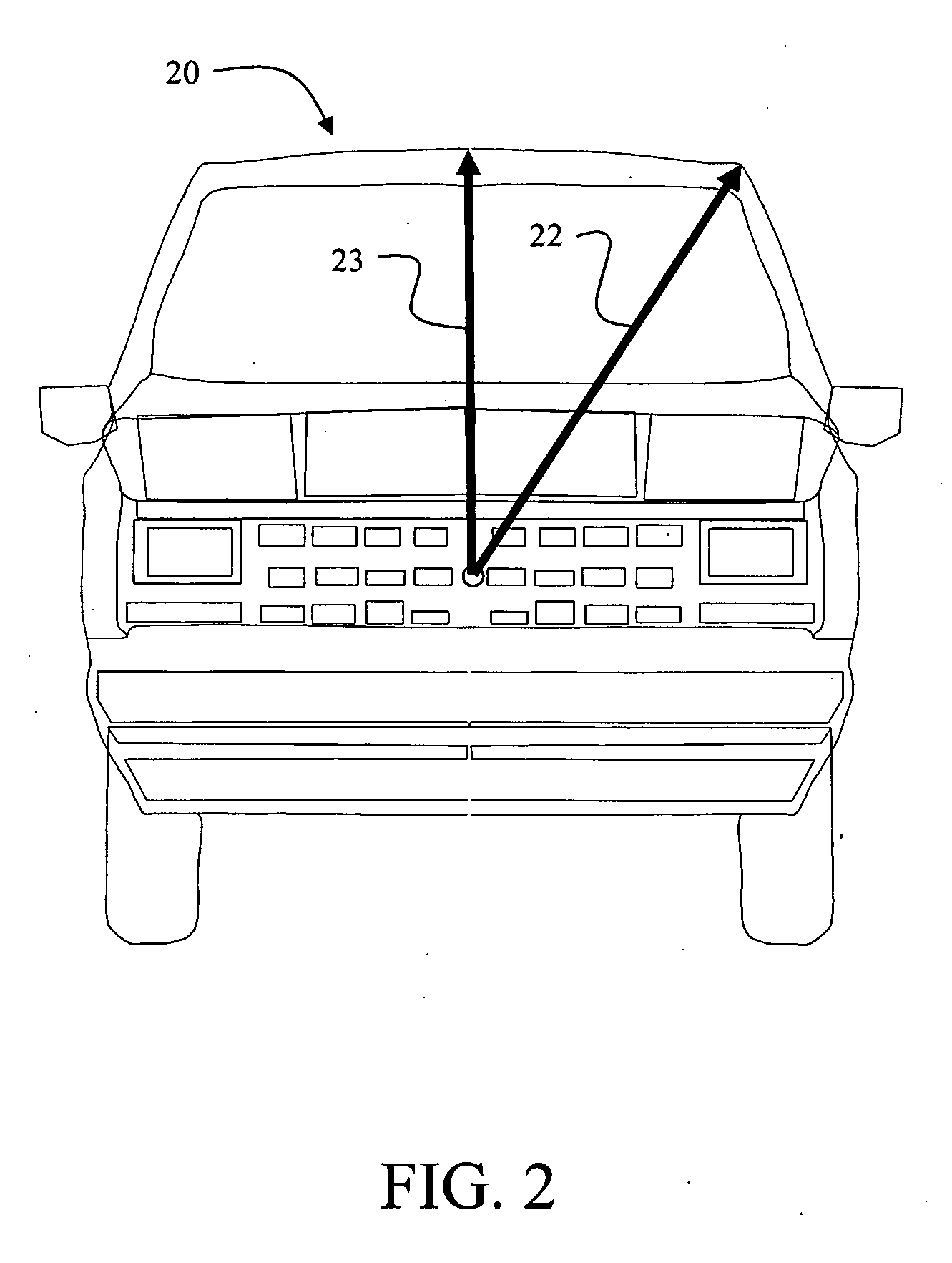

Vehicle rollover protection roof geometry and structure

ActiveUS20100045074A1Pedestrian/occupant safety arrangementSuperstructure subunitsRolloverEngineering

A vehicle geometry for rollover crush resistance is created by determining a center of mass providing a roll axis and establishing a roof line contact surface spaced from the center of mass by a hoop radius substantially equal to a major radius of roll contact from the roll axis. As a first embodiment, the roof line contact surface is established in original designs for vehicles as a monocoque structure. As a second embodiment, provided as an original equipment manufacture (OEM) item or retrofit structural assembly, an arcuate member shaped as a byte of the hoop radius is employed and is mounted between two side rails with additional structural supports for the arcuate member on a nominally flat roofline.

Owner:SAFETY TESTING INT

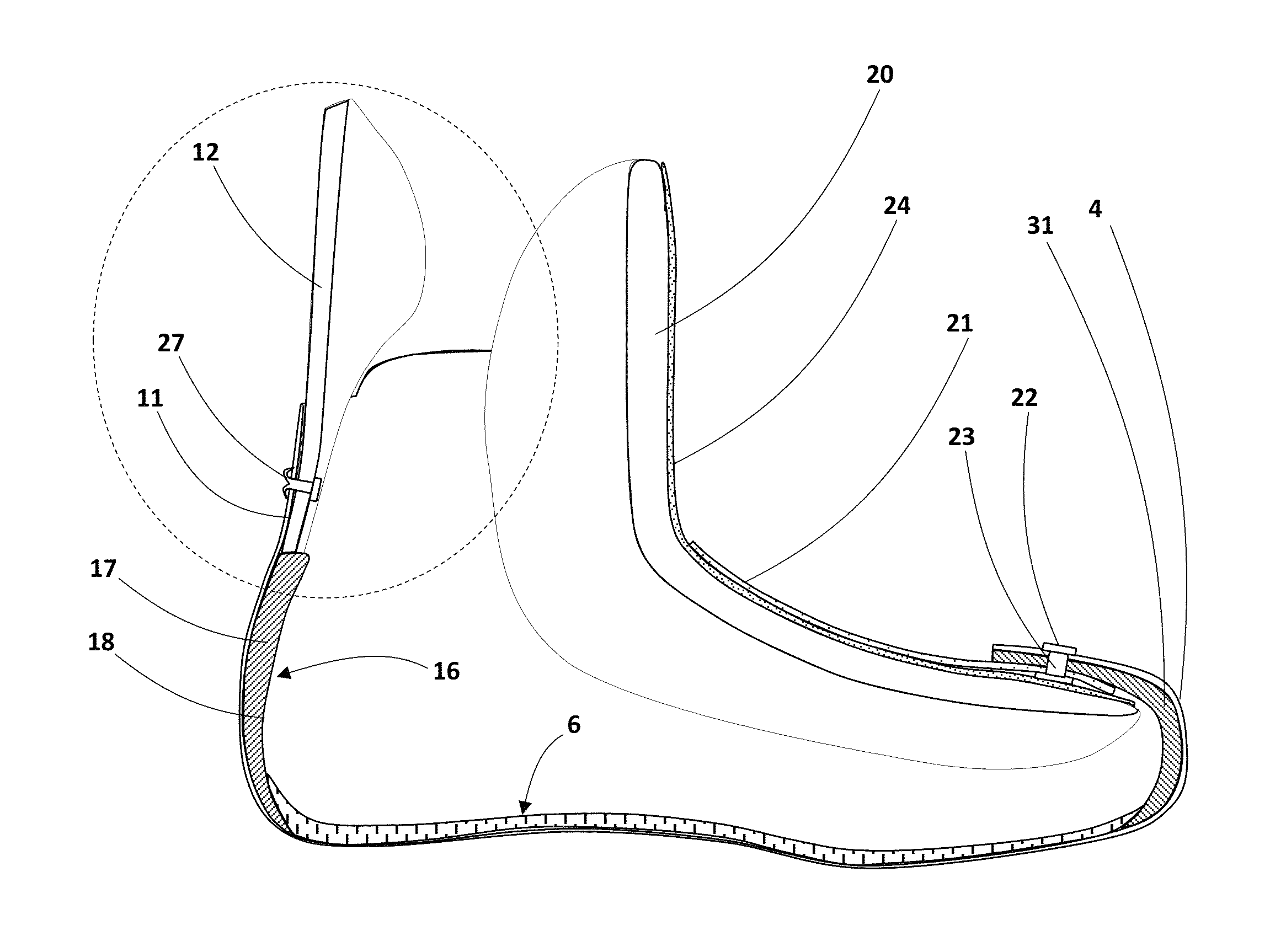

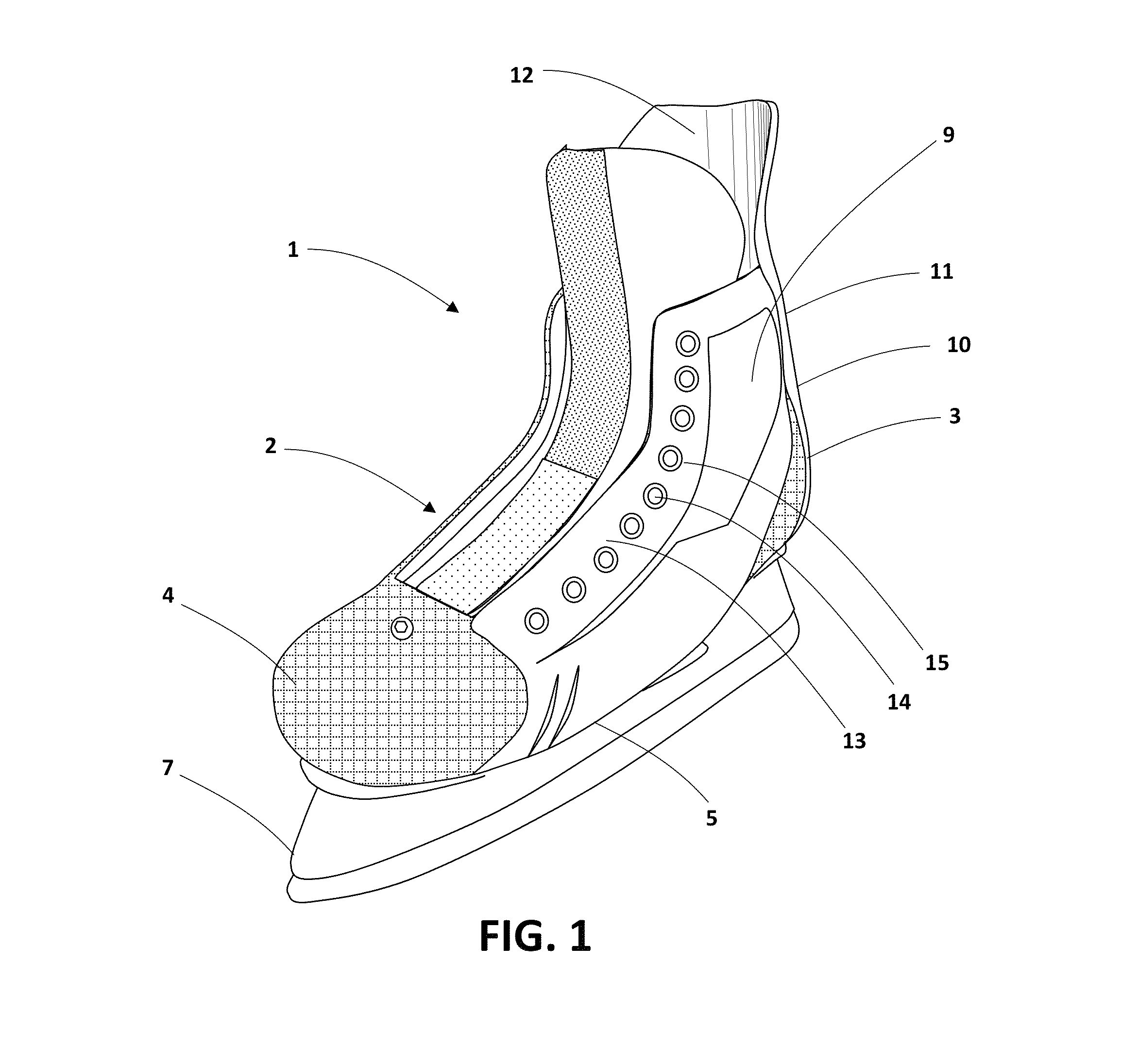

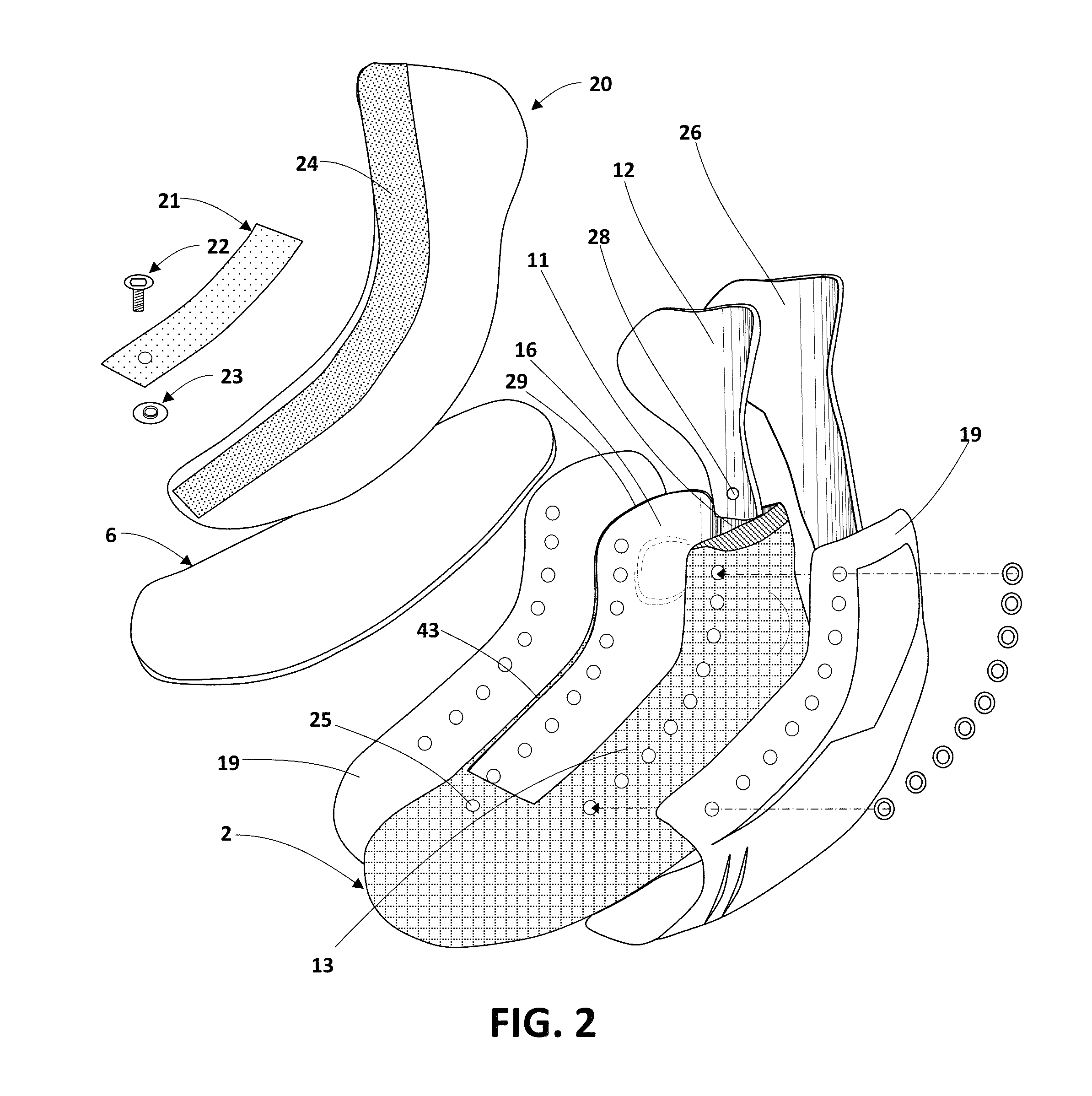

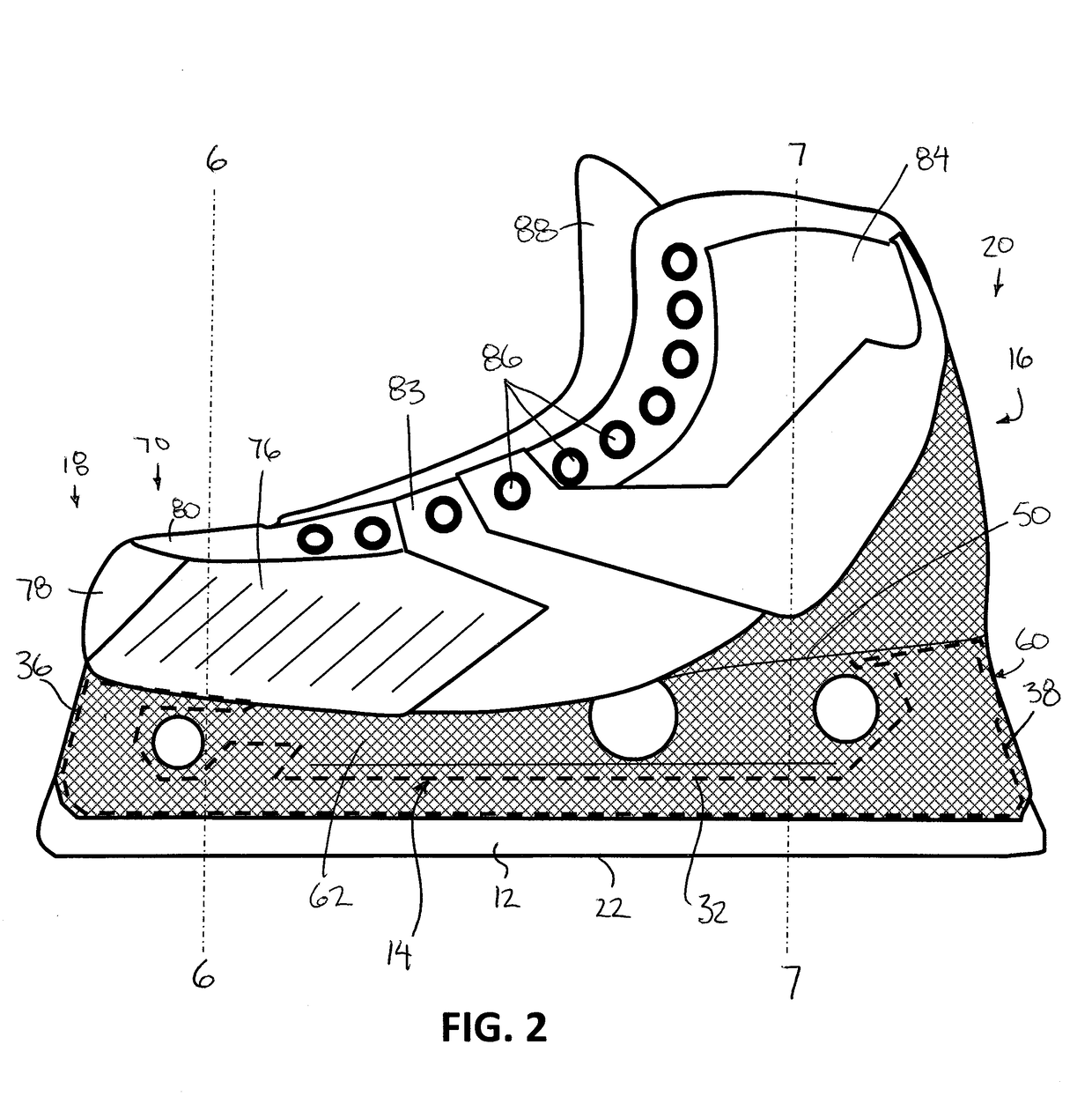

Skate boot with monocoque body

ActiveUS9320315B2Superior protection and durabilitySupport moreLastingDomestic footwearMedicinePlantaris tendon

A skate boot for receiving a wearer's foot comprising: a monocoque skate boot body comprising a heel portion; a toe box portion; a sole portion; an ankle portion; a lower Achilles tendon portion located directly above the heel portion; an upper Achilles tendon portion for receiving a tendon guard; an eyelet cuff portion, the eyelet cuff portion houses the eyelet holes, through which eyelets are installed, through which a lace is utilized to tighten the skate boot to the wearer's foot. Also included, a liner portion, integrated into the monocoque skate boot body, comprised of foam for cushioning the wearer's foot, bonded to a material layer for providing comfort against the wearer's skin, an outer shell bonded and stitched to the outer surface of the monocoque skate boot body, a tendon guard secured to the upper Achilles tendon portion with freedom to adjust the position, and a tongue attached to the toe box portion with freedom to adjust the position.

Owner:VH FOOTWEAR INC

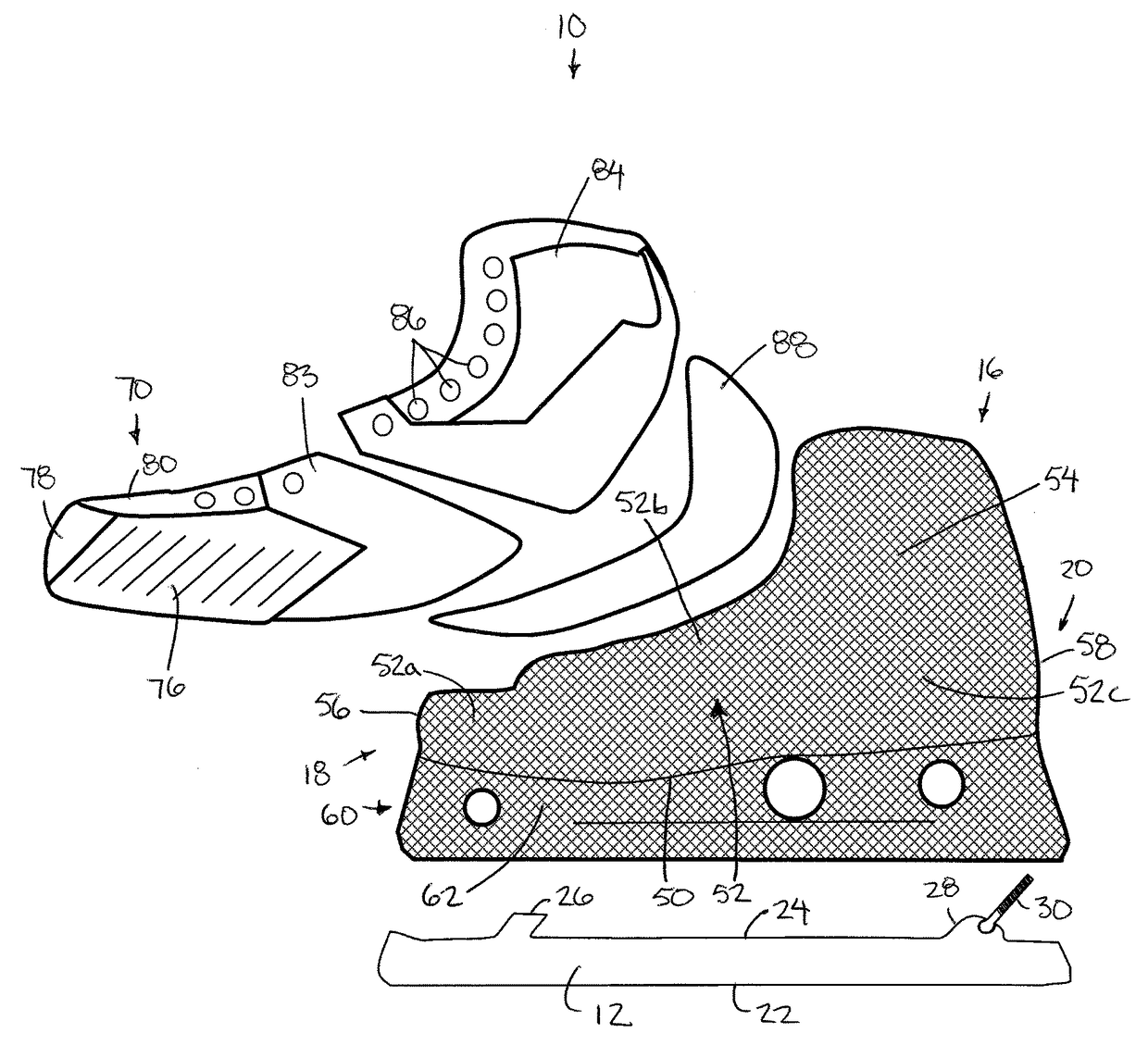

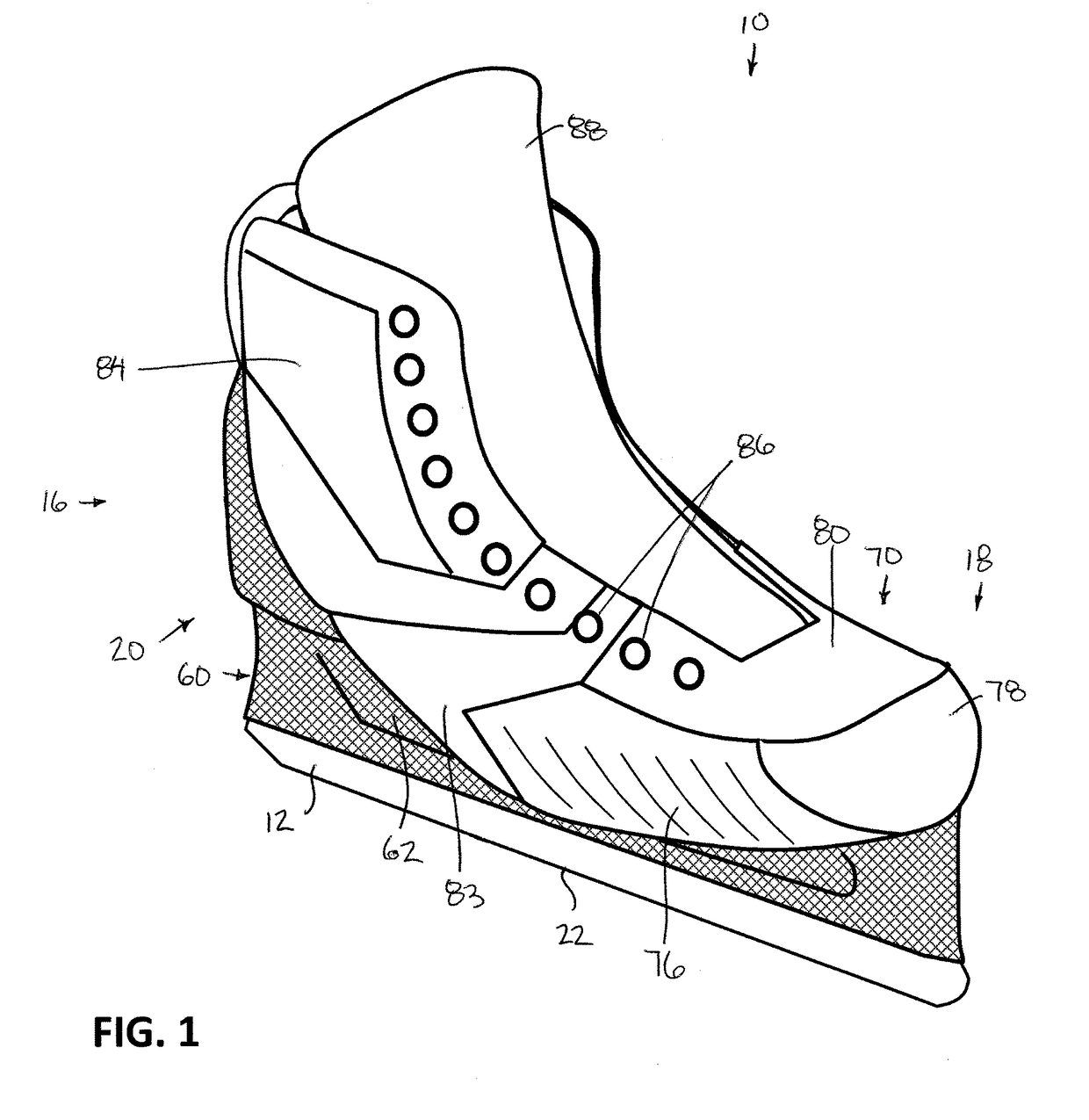

Protective goalie skate boot body with integral blade mounting channel

A goalie skate assembly has i) a plastic blade mounting member adapted to releasably receive a metal skate blade therein, and ii) a monocoque carbon fiber and resin composite skate boot body for receiving a foot of the user therein. The unitary structure of the skate boot body includes i) a sole portion, ii) a heel portion extending upwardly from the sole portion for receiving a heel of the user therein, iii) a pair of side portions extending upwardly from opposing sides of the sole portion, and iv) a lower portion extending downwardly from a bottom side of the sole portion so as to surround at least a portion of the blade mounting member. A toe cap mounted on the skate boot body includes a molded plastic outer shell and a liner formed of a fiber and resin composite material bonded to an inner surface of the outer shell.

Owner:VH FOOTWEAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com