Monocoque electric vehicle and assembling method thereof

An assembly method and technology of electric vehicles, applied in load-bearing body structures, vehicle parts, transportation and packaging, etc., can solve the problems that electric vehicles are difficult to meet, difficult to achieve driving performance, etc., to ensure strength, reduce occupant injuries, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings. However, this embodiment does not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to this embodiment are included in the protection scope of the present invention.

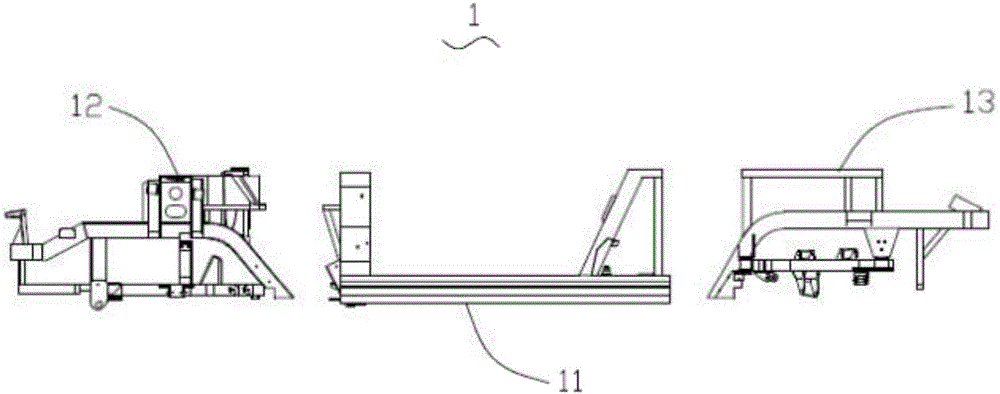

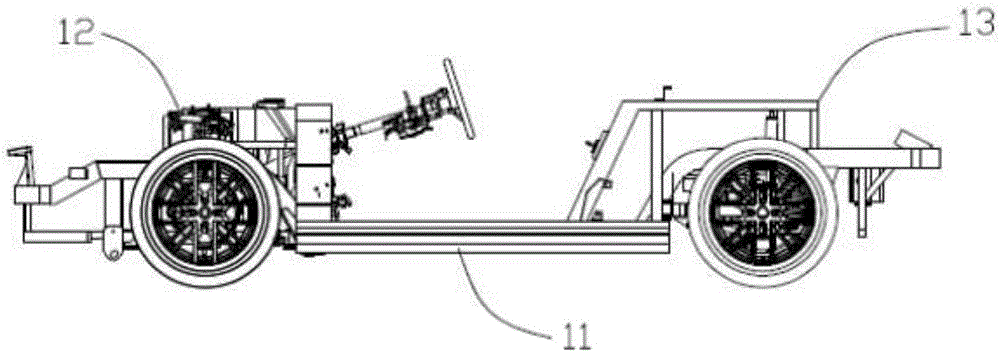

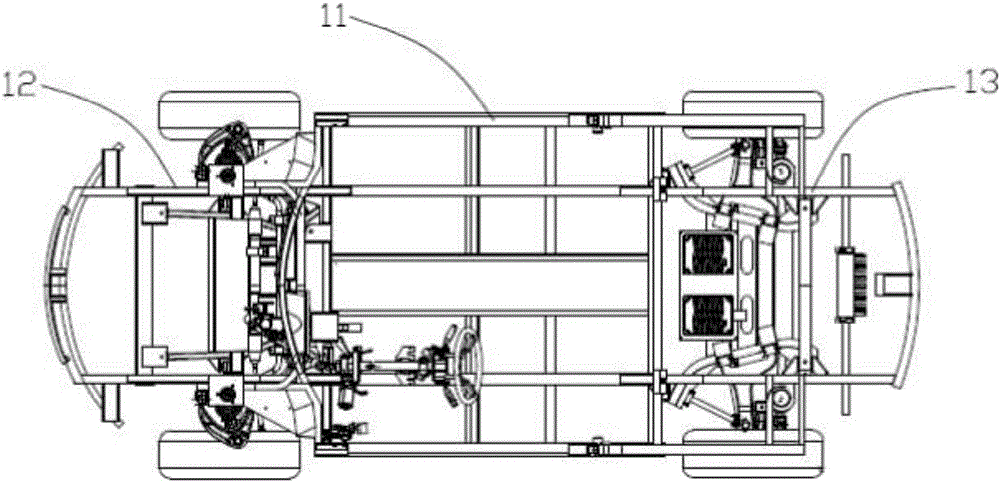

[0046] like Figure 1-14 Shown is a preferred embodiment of the load-carrying electric vehicle 100 of the present invention. The load-bearing electric vehicle 100 includes a frame assembly 1 , a front compartment assembly 2 and a driver's cab assembly 3 which are modularly designed and assembled in sequence.

[0047] The frame assembly 1 includes a frame body 11 made of magnesium alloy welding and a front suspension 12 and a rear suspension 13 made of aluminum alloy welding. The front suspension 12 and the rear suspension 13 are fixedly connected to the The vehicle frame main body 11 is described. Magnesium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com