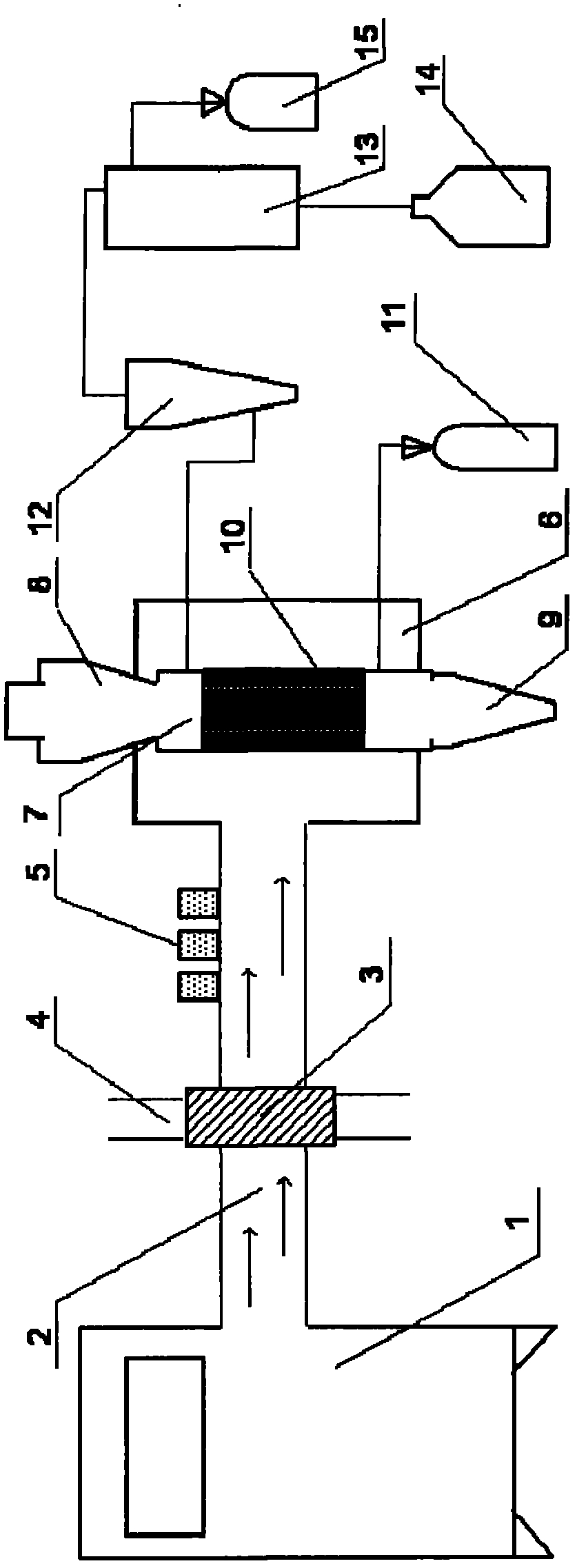

Continuous reaction device and method for microwave biomass pyrolysis

A technology of biomass pyrolysis and microwave reaction, which is applied in the preparation of biofuels, liquid hydrocarbon mixtures, chemical/physical/physicochemical processes of energy application, etc. Biomass pyrolysis, small, only less than 5 kg, etc., to achieve industrial application, good effect, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The broad-leaved poplar sawdust is used as raw material, the particle size distribution is 0.025-0.8mm, the single-mode resonant cavity and the screw are used to advance the feeding mode, and the microwave pyrolysis experiment is carried out with the above steps of the present invention. The microwave power is 2kW, and the biomass is reacting The residence time in the vessel was 5min, the feed rate was 10kg / h, and the reaction temperature was 400°C. Liquid and gaseous products were collected. The yield of pyrolysis liquid bio-oil is 44%, the yield of gas products is 29%, and the low calorific value is 22.68MJ / Nm 3 .

Embodiment 2

[0068] Using sawdust as raw material, particle size distribution is 0.025-0.8mm, adding 5wt% activated carbon, using multi-mode resonant cavity, carrying out microwave pyrolysis experiment according to the above steps of the present invention, microwave power 1kW, feed rate 20kg / h, biomass The residence time in the reactor was 3 min, and the liquid and gaseous products were collected. The yield of pyrolysis liquid bio-oil is 39%, the yield of gas products is 40%, and the low calorific value is 16.07MJ / Nm 3 .

Embodiment 3

[0070] Using sawdust as raw material, the particle size distribution is 0.025-0.8mm, adding 5wt% potassium carbonate, using a multi-mode resonant cavity, carrying out microwave pyrolysis experiments according to the above steps of the present invention, the feed rate is 20kg / h, and the biomass is in the reactor The medium residence time is 3min, the microwave power is 1kW, and the liquid product and gas product are collected. The yield of pyrolysis liquid bio-oil is 37%, and the yield of gas product is 47%.

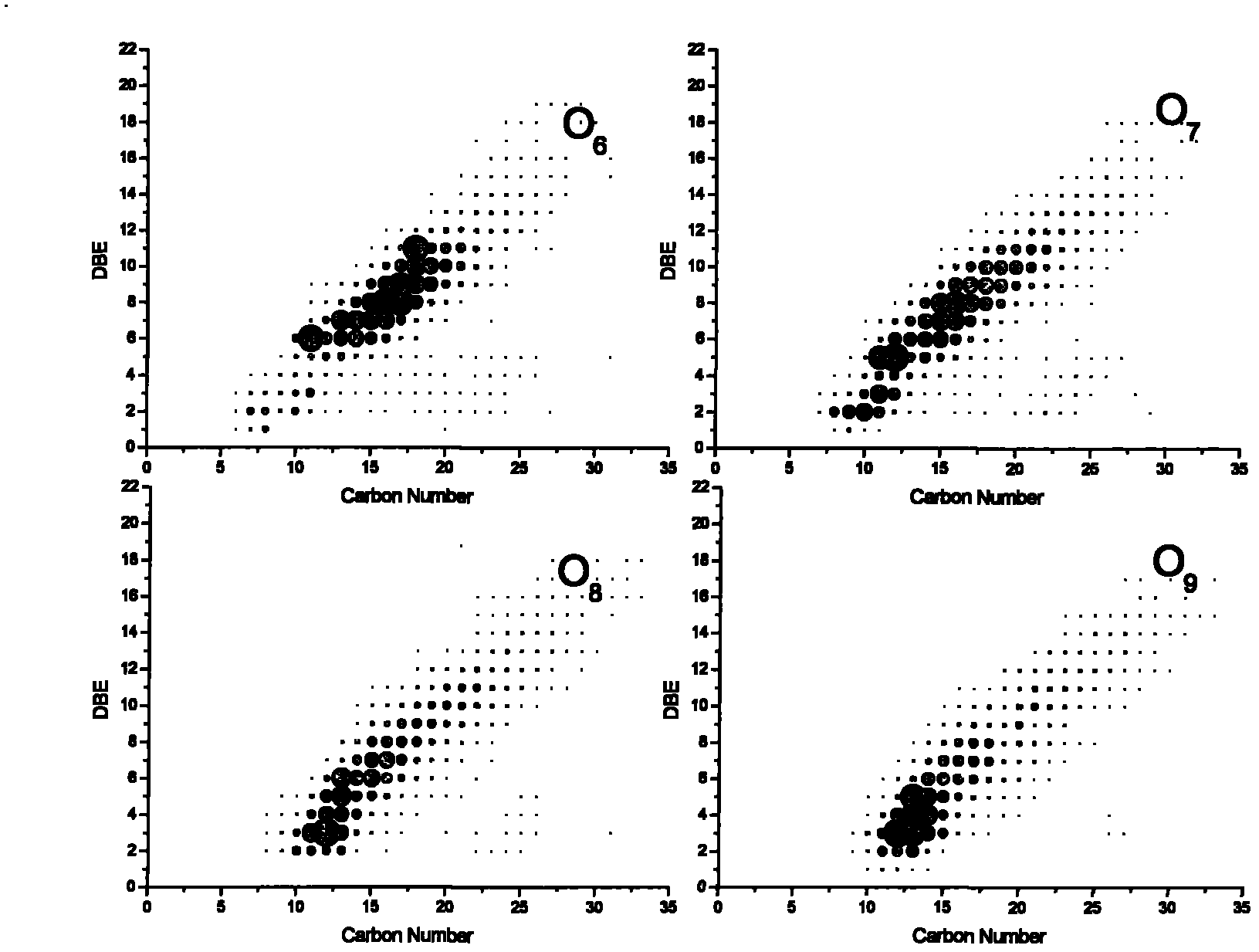

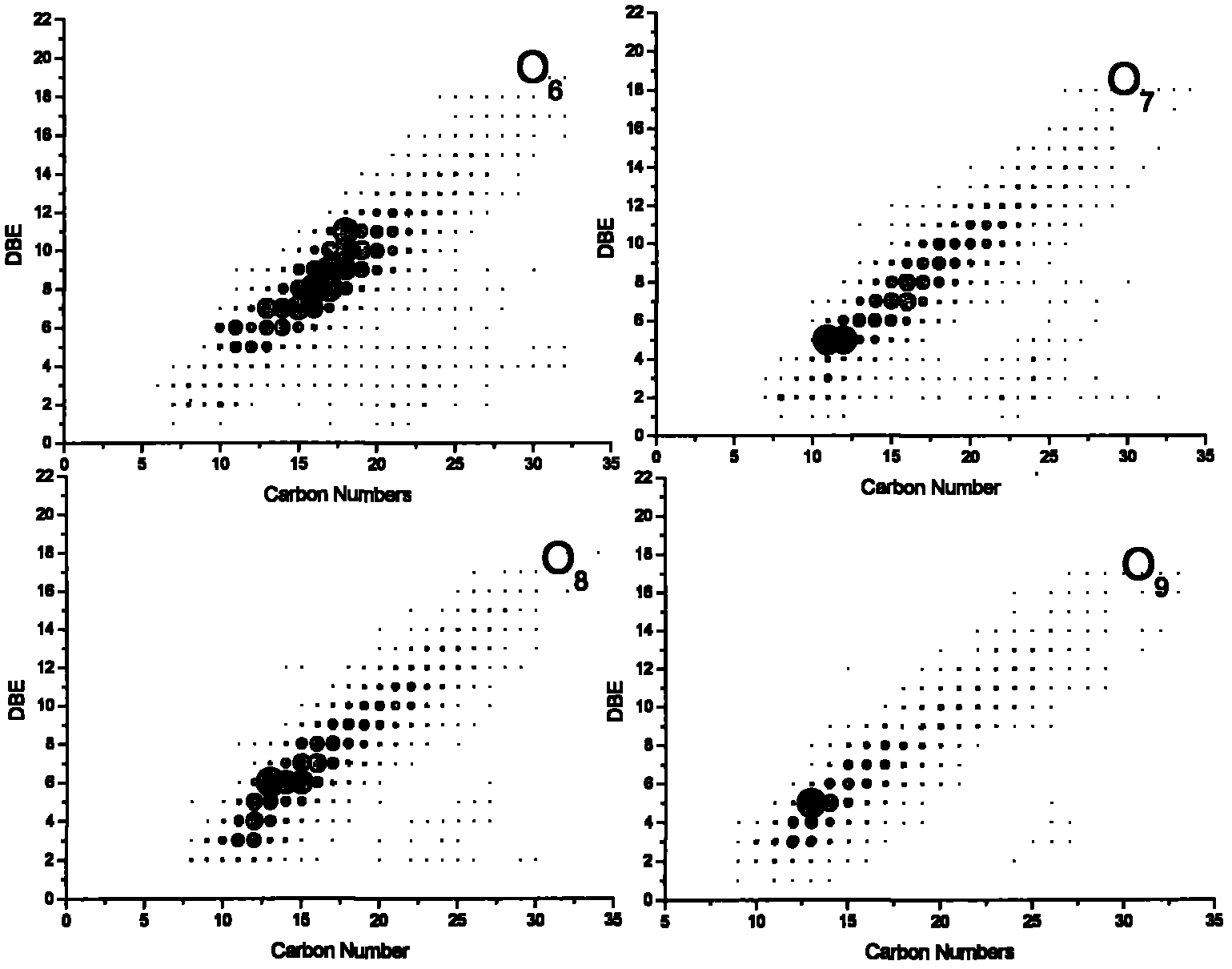

[0071] The bio-oil composition generated in Example 2 is more complex than that in Example 3, so adding potassium carbonate can simplify the bio-oil composition. Fourier transform ion cyclotron resonance mass spectrometry results are as follows figure 2 and image 3 as shown, figure 2 and image 3 The ordinate DBE of is the equivalent double bond (DBE), which is defined as the sum of the double bond and the number of naphthenes. If the molecular formula of the compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com