Preparation method of loading iron based metal organic skeleton out phase Fenton catalyst and application thereof

An iron-based metal, organic framework technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. It can improve the Fenton treatment effect, excellent adsorption performance and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

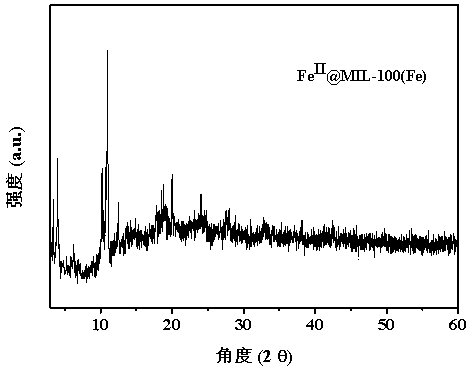

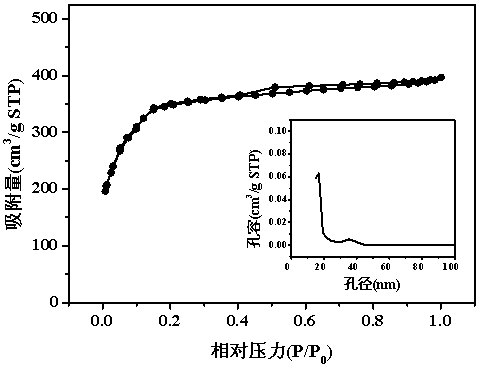

[0030] (1) Preparation of substrate MIL-100(Fe)

[0031] Hydrothermal method, the molar ratio of iron powder, trimesic acid, hydrofluoric acid, nitric acid and deionized water is 1.0:0.66:2.0:1.2:280; the constant temperature reaction temperature is 150°C, and the time is 12 h The temperature of hot water purification is 80°C, and the stirring time is 5 h; the temperature of ethanol purification is 60°C, and the stirring time is 3 h; the temperature of vacuum drying is 70°C, and the time is 12 h.

[0032] (2) The construction process and characterization of the supported Fe-based metal-organic framework heterogeneous Fenton catalyst, the specific steps are as follows:

[0033] Add 0.1 g of MIL-100(Fe) prepared in (1), 0.6 g of polyvinylpyrrolidone, and 13 mL of deionized water into a 20 mL polytetrafluoroethylene reactor, stir well, then add 0.028 g of anhydrous Ferric chloride, stir well, then add 0.38 g of potassium iodide. The mixed solution was stirred on a magnetic stir...

Embodiment 2

[0038] A supported iron-based metal-organic framework heterogeneous Fenton catalyst Fe II The preparation method of MIL-100(Fe), using MIL-100(Fe) as the matrix, supports the divalent iron component by hydrothermal method, and obtains Fe II MIL-100(Fe) is a supported iron-based metal-organic framework heterogeneous Fenton catalyst.

[0039] The method includes the following steps:

[0040] (1) Preparation of matrix MIL-100(Fe): Mix iron powder, trimesic acid, hydrofluoric acid, nitric acid and deionized water evenly, then place in a polytetrafluoroethylene hydrothermal reactor, react at constant temperature, and filter After the light orange solid product was obtained, it was washed with deionized water. It was then further purified by two steps: 1) hot water purification; 2) hot ethanol purification. Finally the solid was dried in a vacuum oven.

[0041] (2) Mix MIL-100(Fe) prepared in step (1) with dispersant, anhydrous ferric chloride, deionized water, and reducing agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com