Affinity chromatography fixed phase of immobilization metal and its preparation method

A chromatographic stationary phase and metal immobilization technology, which is applied in the field of separation and purification to achieve the effects of reducing non-specific adsorption, improving detection limit and sensitivity, and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

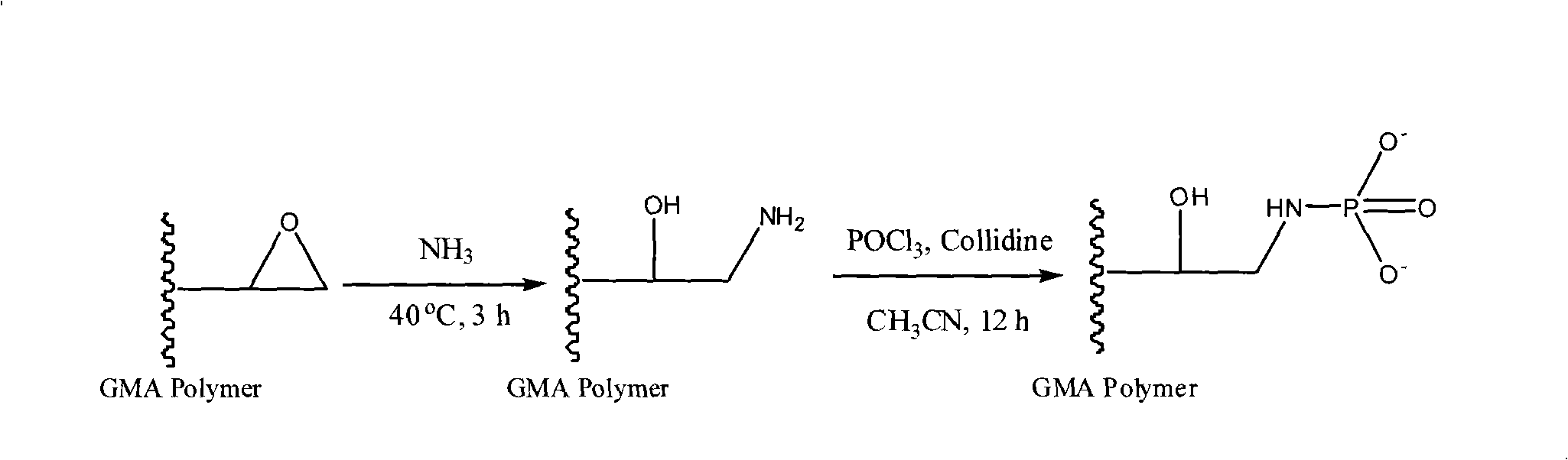

[0031] The preparation method of stationary phase comprises the following steps:

[0032] Preparation of GMA Polymer microspheres: microspheres obtained from polyglycidyl methacrylate and vinyl glycidyl methacrylate, by swelling method, with polyvinylbenzene as seed (0.5g), by methacrylic acid shrinkage Glyceride (9.0g) is polymerized with vinyl glycidyl methacrylate (3.5g) on the seed, 2% (w / w) of AIBN is the initiator, and reacts in 120mL of 0.1% SDS (w / w) solution, Ultrasonic vibration until solidified, to obtain non-porous polymer microspheres with a particle size of 8-12um. (See Boling Gong, Jinxia Zhu, Long Li, Kejuan Qiang, Li Ren, Synthesis of non-porous poly(glycidylmethacrylate-co-ethylenedimethacrylate) beads and their application in separation of biopolymers, Talanta, 2006, 68:666-672.

[0033] 1) Amination reaction: use 25% (mass concentration) concentrated ammonia water as an amination reagent and mix it with 10ml / 1g of the above-prepared GMA Polymer microsphe...

Embodiment 2

[0043] The difference from Example 1 is:

[0044] Preparation of GMA Polymer microspheres: By swelling method, polyvinylbenzene is used as the seed, and glycidyl methacrylate and vinyl glycidyl methacrylate are polymerized on the seeds to obtain macroporous polymer microspheres. Particle size 8-12um. (Boling Gong, Lili Wang, Chaozhan Wang, Xindu Geng, Preparation of hydrophobic interaction chromatographic packings based on monodyspersepoly(glycidylmethacrylate-co-ethylenedimethacrylate) beads and their application, Journal of ChromatographyA, 2004, 1022: 33-39.)

[0045] 1) Amination reaction: Dissolve 20g of 3,3-diaminopropylimine in 100mL of anhydrous acetone, and add polyglycidyl methacrylate polymer microspheres into the anhydrous acetone solution (1g / 10mL) , reacted at room temperature for 4 hours, washed the product with water until neutral after the reaction, and obtained aminated microspheres;

[0046] Or replace the above-mentioned GMA Polymer microspheres with the ...

Embodiment 3

[0055] The difference from Example 1 is:

[0056] Preparation of GMA Polymer microspheres: by swelling method, with polyvinylbenzene as seed (0.5g), by glycidyl methacrylate (9.0g) and vinyl glycidyl methacrylate (3.5g) on the seed Polymerization, 2% (w / w) AIBN as initiator, react in 120mL 0.1% SDS (w / w) solution, ultrasonically vibrate until solid, and obtain non-porous polymer microspheres with a particle size of 8-12um. (Boling Gong, Jinxia Zhu, Long Li, Kejuan Qiang, Li Ren, Synthesis of non-porous poly(glycidylmethacrylate-co-ethylenedimethacrylate) beads and their application in separation of biopolymers, Talanta, 2006, 68: 666-672).

[0057] 1) Amination reaction: Dissolve 40 g of ethylenediamine in 100 mL of morpholine ethaneiodic acid (MES) at a pH of about 5, add polyglycidyl methacrylate polymer microspheres into the solution (1 g / 10 mL), and heat at room temperature Under the condition of reaction for 3 hours, the product after the reaction was washed with water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com