Manufacturing method of unimolecular sequencing chip

A single-molecule sequencing and chip technology, applied in biochemical equipment and methods, determination/inspection of microorganisms, bioreactors/fermenters for specific purposes, etc. , complex processing technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

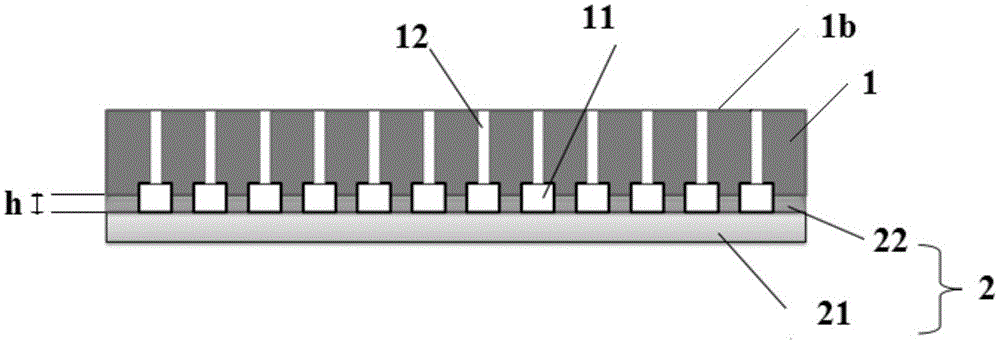

[0074] A kind of preparation method of single-molecule sequencing chip (see attached image 3 The schematic diagram of the preparation method), comprises the following steps:

[0075] (1) Get a silicon chip as the substrate, according to the graphic template of the designed reaction cell array, adopt photolithography to make the positive film of the reaction cell array on the surface of the silicon chip, specifically comprising the following steps;

[0076] a. Take a silicon wafer, wash the surface of the substrate with absolute ethanol and water in sequence, and then heat the cleaned silicon wafer on a hot plate at 150°C for 10 minutes to completely evaporate the surface moisture; place the treated silicon wafer on Spin-coat negative photoresist SU-82150 on the rotary stage of the coating machine, start the coating machine, spread the photoresist evenly on the silicon wafer, and obtain the silicon wafer after coating, in which the surface of the silicon wafer is The thicknes...

Embodiment 2

[0100] A method for preparing a single-molecule sequencing chip, comprising the following steps:

[0101] (1) Get a silicon chip as the substrate, according to the graphic template of the designed reaction cell array, adopt photolithography to make the positive film of the reaction cell array on the surface of the silicon chip, specifically comprising the following steps;

[0102] a. Take a silicon wafer, wash the surface of the substrate with absolute ethanol and water in sequence, and then heat the cleaned silicon wafer on a hot plate at 150°C for 10 minutes to completely evaporate the surface moisture; place the treated silicon wafer on Spin-coat negative photoresist SU-82150 on the rotary stage of the coating machine, start the coating machine, spread the photoresist evenly on the silicon wafer, and obtain the silicon wafer after coating, in which the surface of the silicon wafer is The thickness of the photoresist layer is 650 μm, the acceleration time of the uniform glue...

Embodiment 3

[0114] A method for preparing a single-molecule sequencing chip, comprising the following steps:

[0115] (1) Take a glass as the substrate, according to the graphic template of the designed reaction cell array, adopt photolithography to make the positive film of the reaction cell array on the surface of the glass, specifically comprising the following steps;

[0116] a. Take a piece of glass, wash the surface of the substrate with absolute ethanol and water in sequence, and then heat the cleaned silicon wafer on a hot plate at 150°C for 10 minutes to completely evaporate the surface moisture; place the treated silicon wafer on a uniform Spin-coat negative photoresist SU-82150 on the rotating stage of the glue machine, start the glue leveler, spread the photoresist evenly on the silicon wafer, and obtain the silicon wafer after the glue leveling, in which the surface of the silicon wafer The thickness of the photoresist layer is 620 μm, the acceleration time of the uniform glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com