Multitubular slurry bed reactor and reaction system

A reaction system and reactor technology, applied in the chemical industry, can solve problems such as difficult temperature control, uneven gas-liquid-solid three-phase mixing, short contact time of reaction raw materials, etc., achieve uniform liquid level, improve gas-liquid flow field distribution, The effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementations of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments, so as to better understand the solutions of the present invention and the advantages of various aspects thereof. However, the specific embodiments and examples described below are only for illustrative purposes, rather than limiting the present invention.

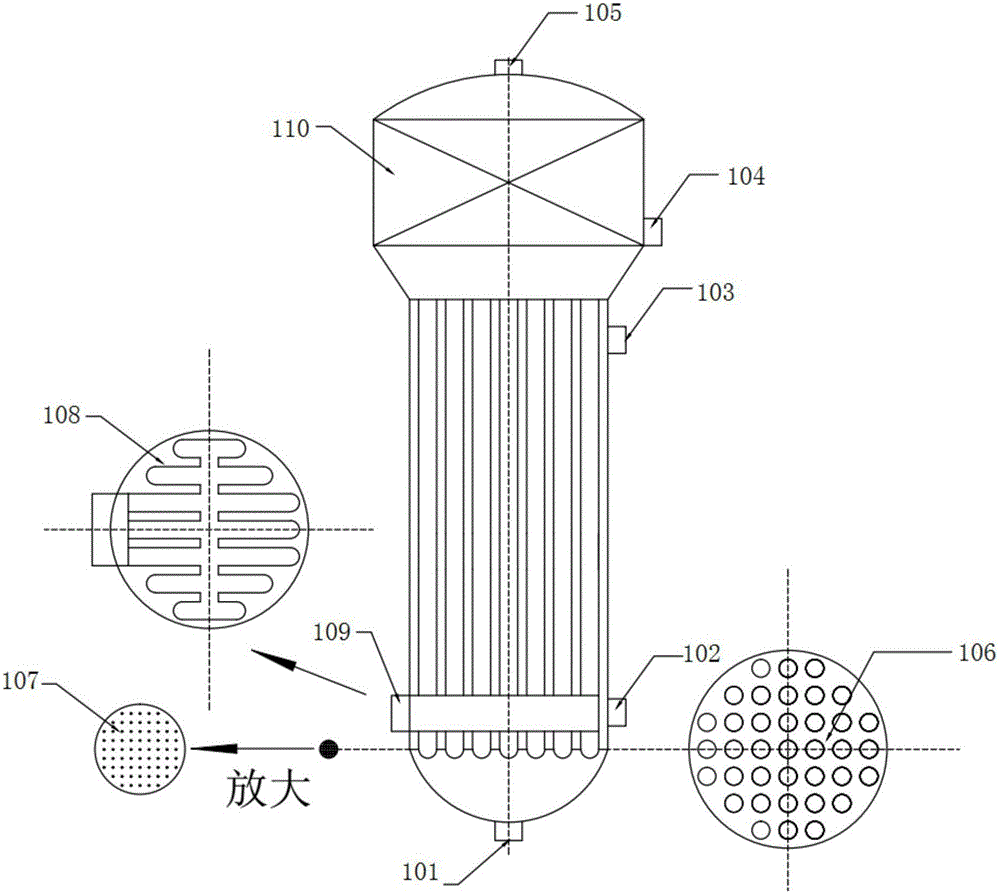

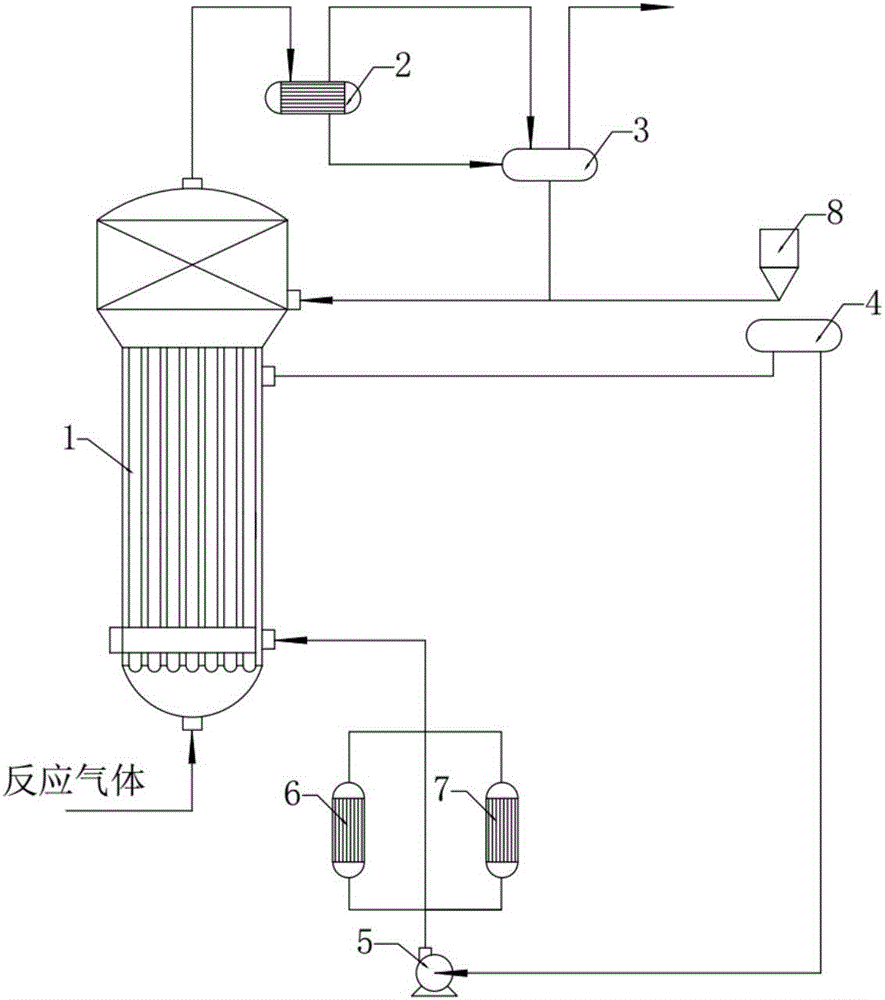

[0032] Such as figure 1 As shown, the tubular slurry-bed reactor 1 of the present invention is used as a reactor for the selective hydrogenation of acetylene to produce ethylene. The slurry-bed reactor 1 includes an inlet section, a tubular distribution section and an enlarged Three parts in paragraph.

[0033] Such as figure 1 As shown, at the bottom of the reactor 1 is an inlet section, and there is a gas inlet 101 at the bottom for the reaction gas to enter the reactor 1 for use.

[0034] Such as figure 1 As shown, above the intake section is a tube distribution sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com