Patents

Literature

99results about How to "No reflux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

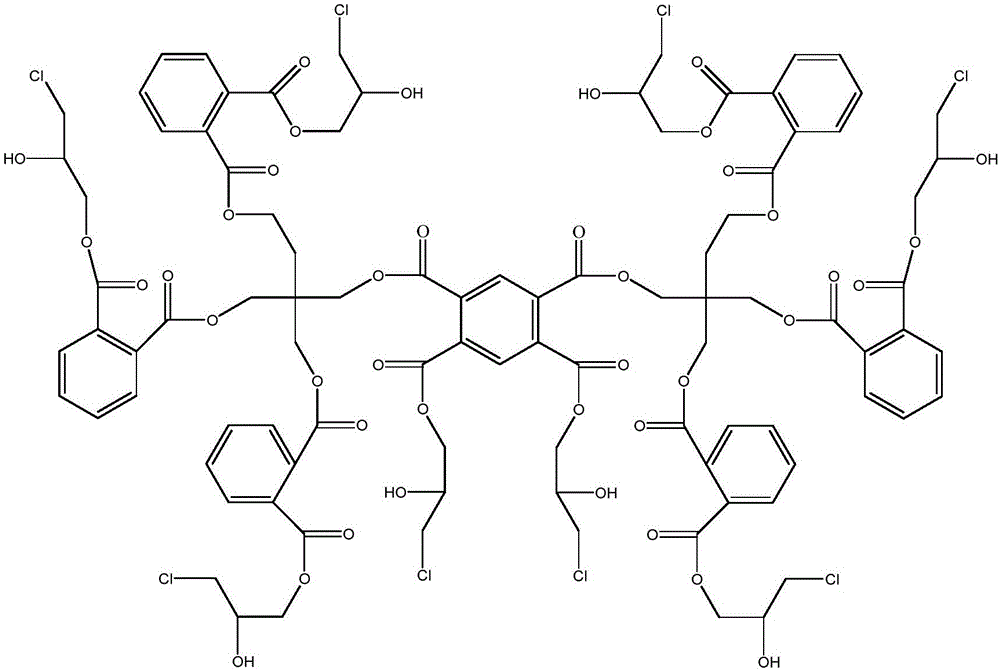

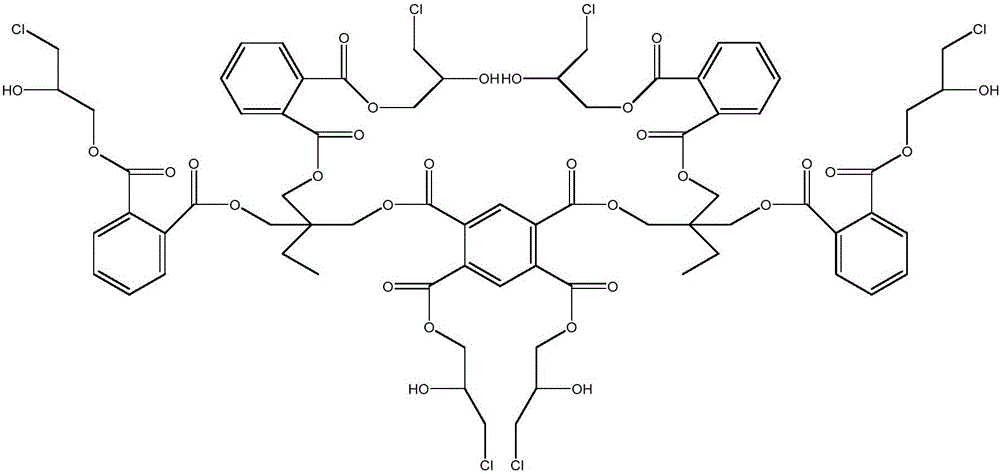

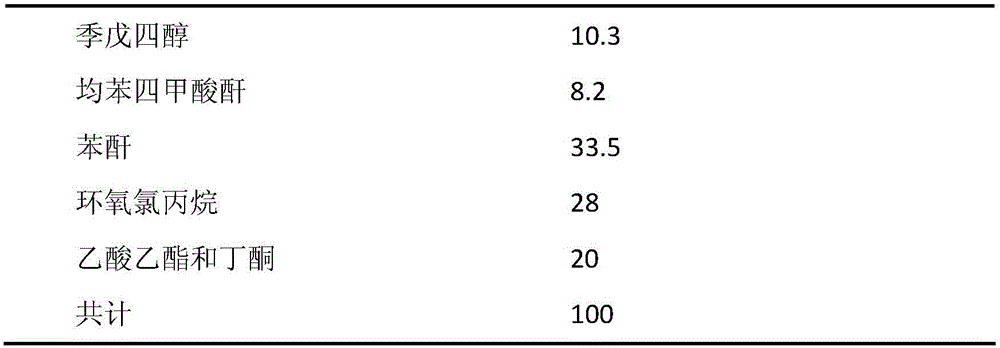

Hyperbranched hydroxyl polyester resin, and preparation method and application of hyperbranched hydroxyl polyester resin

ActiveCN106565965AAnhydrousNo refluxAnti-corrosive paintsPolyurea/polyurethane coatingsNitrogen gasDolichol

The invention discloses hyperbranched hydroxyl polyester resin, and a preparation method and an application of the hyperbranched hydroxyl polyester resin.The preparation method of the hyperbranched hydroxyl polyester resin comprises the following steps: 1) according to molar fraction, 1 part of dicarboxylic anhydride and 2-4 parts of polyhydric alcohol are mixed in a reaction kettle, paratoluenesulfonic acid and an organic solvent are added for reaction at 105-125 degrees under nitrogen protection, then 4-10 parts of phthalic anhydride are added, and reaction for 2-3h is carried out; and 2) according to molar fraction, 6-10 parts of epoxy compounds are added to a matrix prepared in the step 1), a catalyst and an organic solvent are added for reaction for 4-6h at 105-1130 degrees under the nitrogen protection till an acid value is less than 10mgKOH / g, and cooling and discharging are carried out. The solid content of the hyperbranched hydroxyl polyester resin reaches above 70%, and the viscosity is 3000-12000mPa.s. High solid-content bi-component polyurethane dope prepared with the adoption of the hyperbranched hydroxyl polyester resin has high construction solid content, low VOC content, high film hardness, good heat resistance and outstanding anti-corrosion property.

Owner:SOUTH CHINA UNIV OF TECH

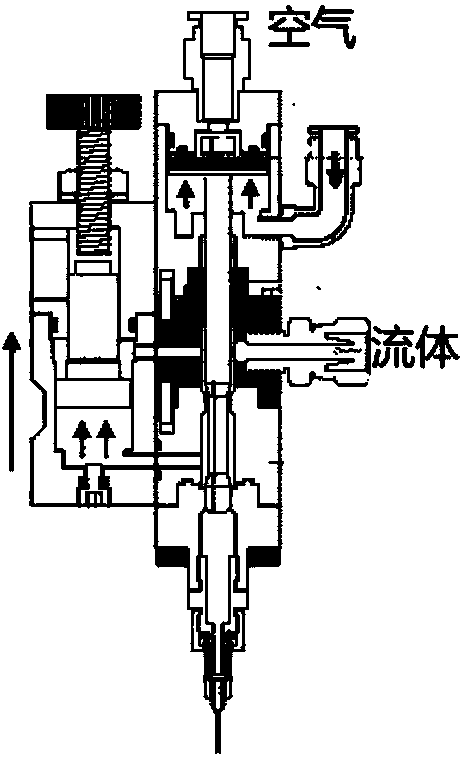

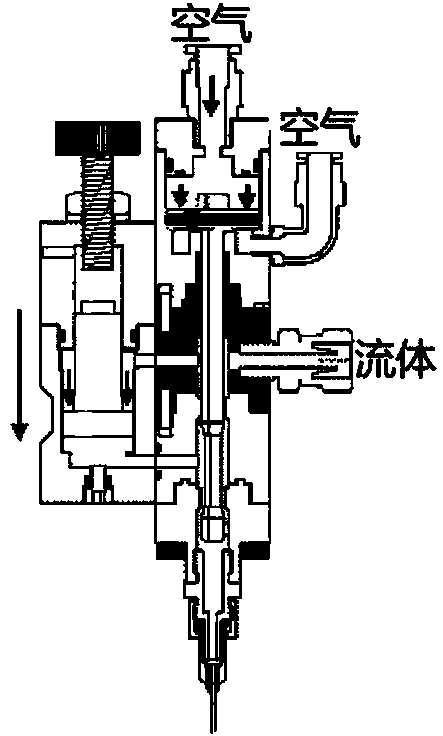

Jetting glue dispensing valve device and jetting glue dispensing method

InactiveCN103464342AAchieve continuous injectionJet realizationLiquid surface applicatorsCoatingsSingle processMechanical engineering

The invention discloses a jetting glue dispensing valve device and a jetting glue dispensing method. The jetting glue dispensing valve device comprises a jetting glue dispensing valve, a glue supply pipeline and a glue supply valve, wherein a turntable capable of being closed / opened quickly is mounted at the bottom of the glue supply valve. During a glue jetting course, the glue supply valve is closed, and a channel allowing a glue solution to flow back to the glue supply valve from the glue supply pipeline is intercepted, so that glue jetting with precise volume is achieved. After a single glue jetting course is finished, the glue supply valve is opened, and the glue supply channel is opened for filling, so that continuous jetting of the glue solution is achieved. When the device and the jetting glue dispensing method are used for glue dispensing, no backflow occurs, so that an effective utilization rate of striker movement is increased, and jetting of a high-viscosity glue solution is facilitated; the device is simple in structure and easy to process; the turntable has the characteristic of periodic rotation, and can stir the glue solution, so that precipitation of fluorescent powder in the glue solution is avoided effectively; the fluid velocity in the jetting glue dispensing valve is distributed more uniformly; and the glue dispensing quality is ensured.

Owner:CENT SOUTH UNIV

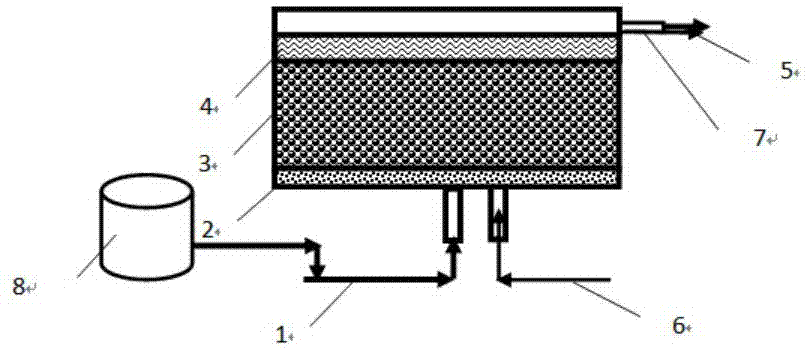

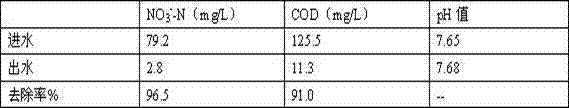

Mixed nutritional type denitrifying filler and preparation and application thereof

ActiveCN107151050AIncrease hydraulic retention timeSolve the problem that the dosage is difficult to controlWater contaminantsTreatment with anaerobic digestion processesActivated carbonSolid carbon

The invention specifically relates to a mixed nutritional type denitrifying biological filler and a preparation and application thereof. The mixed nutritional type denitrifying biological filler adopts the technical principle that activated carbon, sulfur and solid carbon source are used as raw materials to prepare the denitrifying biological filler, and the denitrifying biological filler and anionic clay are mixed and loaded into an applicable reactor; the filter simultaneously has the heterotrophism and autrophism denitrifying effects, so that the problem of secondary pollution caused by adding of liquid carbon sources is effectively solved, and the production of sulfur autrophism byproducts is flexibly controlled.

Owner:知和环保科技有限公司

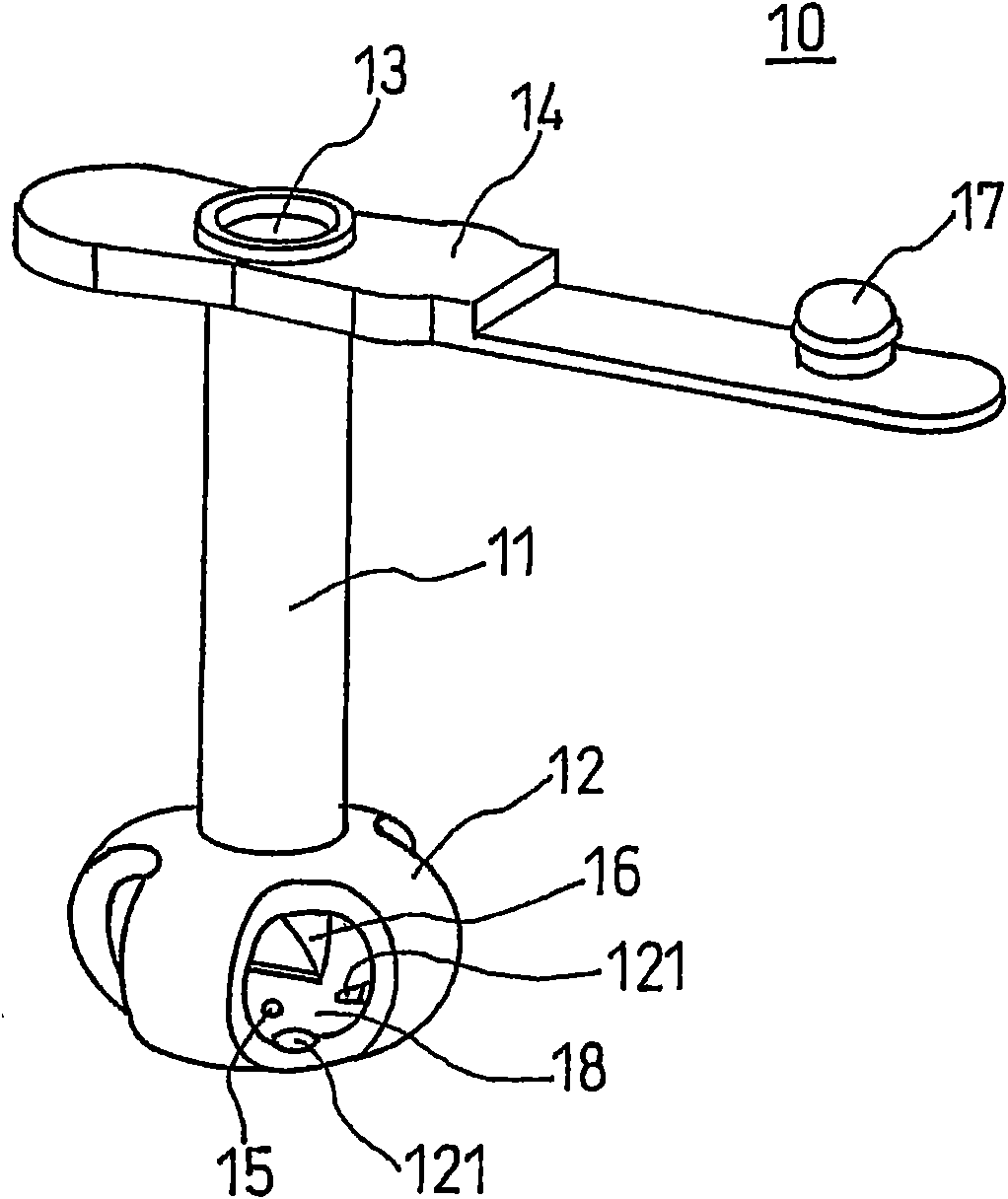

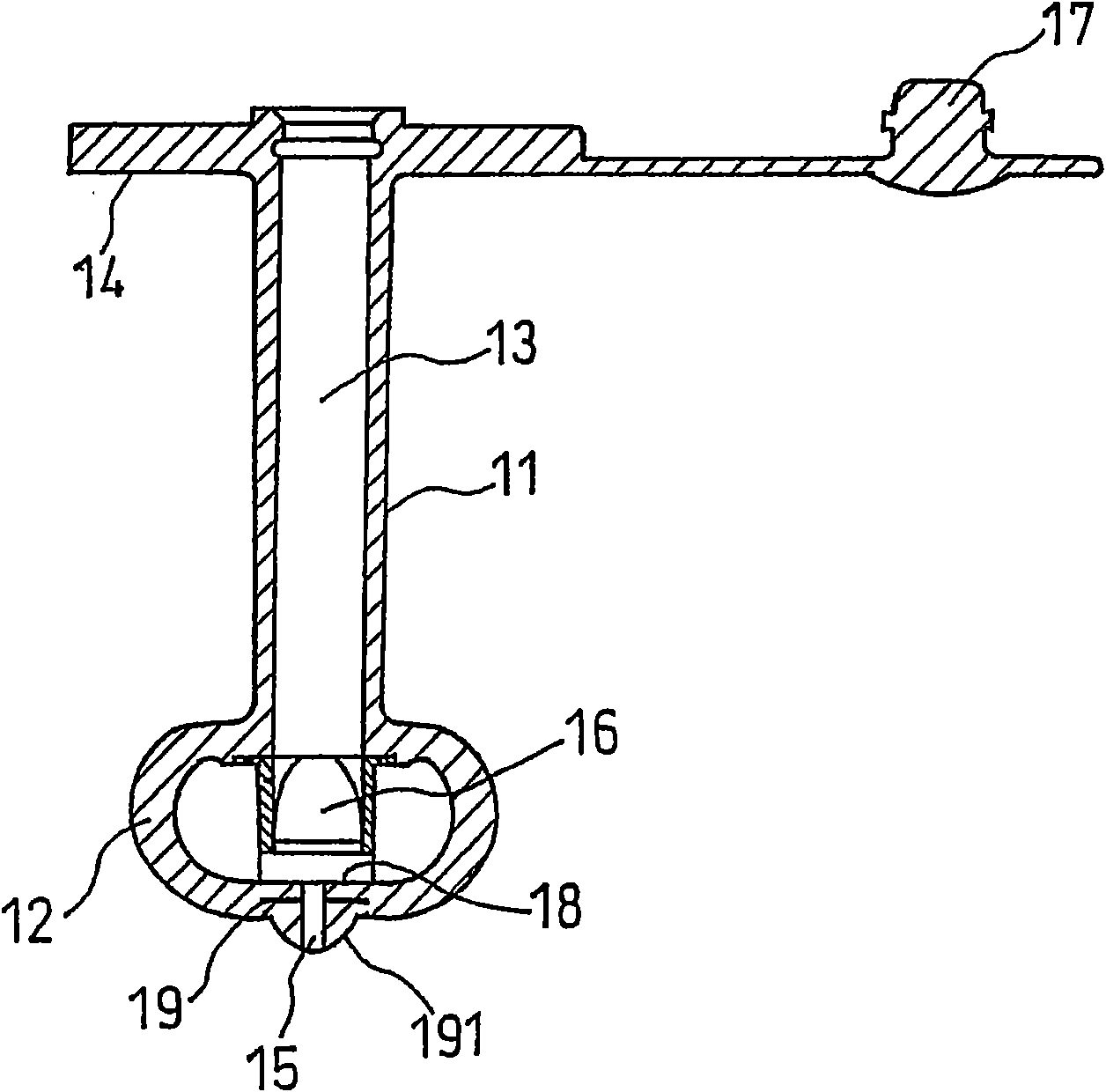

Catheter kit for burrow

Disclosed is a catheter tool for fistula with excellent operability including a catheter and a sealing device. The catheter has a flexible tube and an indwelling part in the body. The flexible tube extends along the wall of the fistula hole. A nutrition passage is provided inside the fistula hole to introduce nutrition or medicinal liquid into the stomach. The indwelling part in the body is attached to the soft tube. The protruding shape of the front end of the tube is a non-balloon indwelling part in the stomach in the body buried state while shrinking from the protruding state due to the external force caused by the sealing device. The sealing device is pulled out A sealing device that may be matched to the aforementioned catheter, which has a guide wire passage and an operation part, the guide wire passage is used to insert the guide wire attached from the front end to the middle of the guide wire, and the operation part is used to insert the guide wire attached to the rear end of the guide wire passage. The indwelling part in the body transmits the external force, and the rear end part of the guide wire channel and the operation part are arranged in a separated state.

Owner:SUMITOMO BAKELITE CO LTD +1

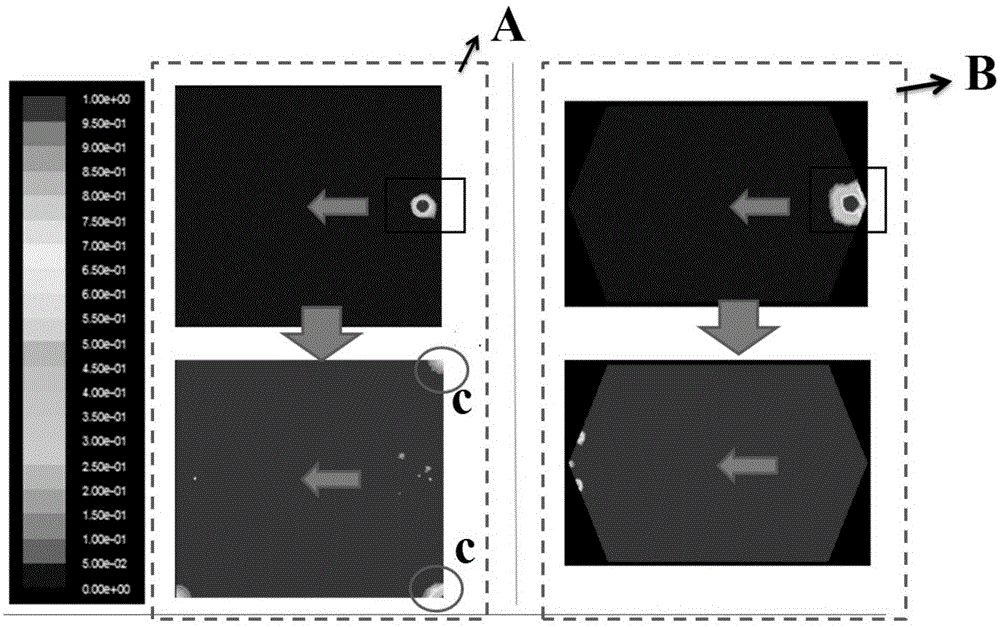

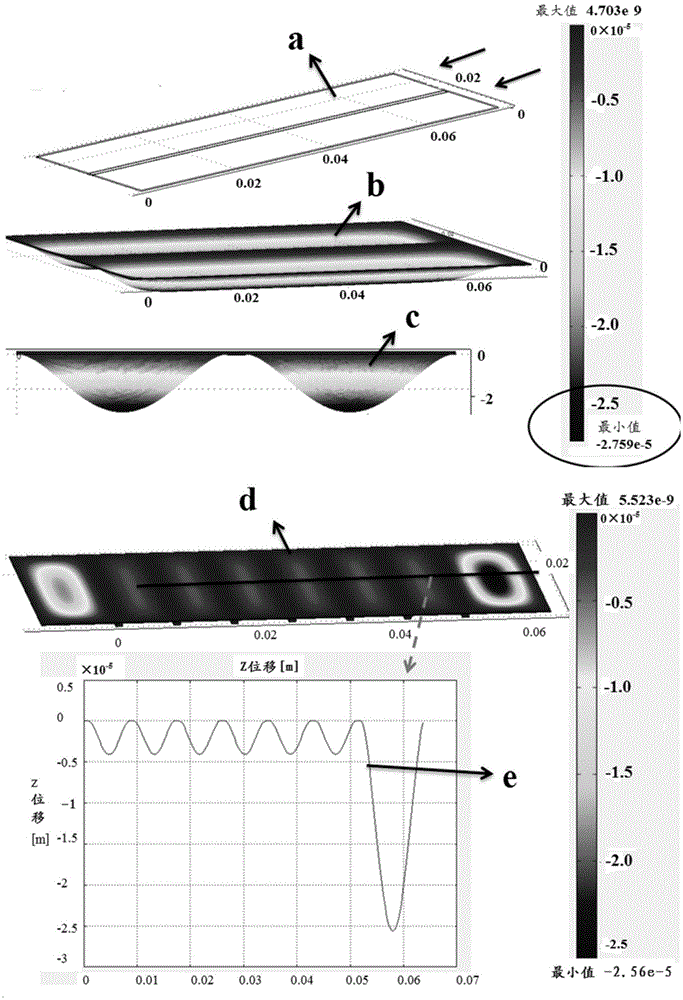

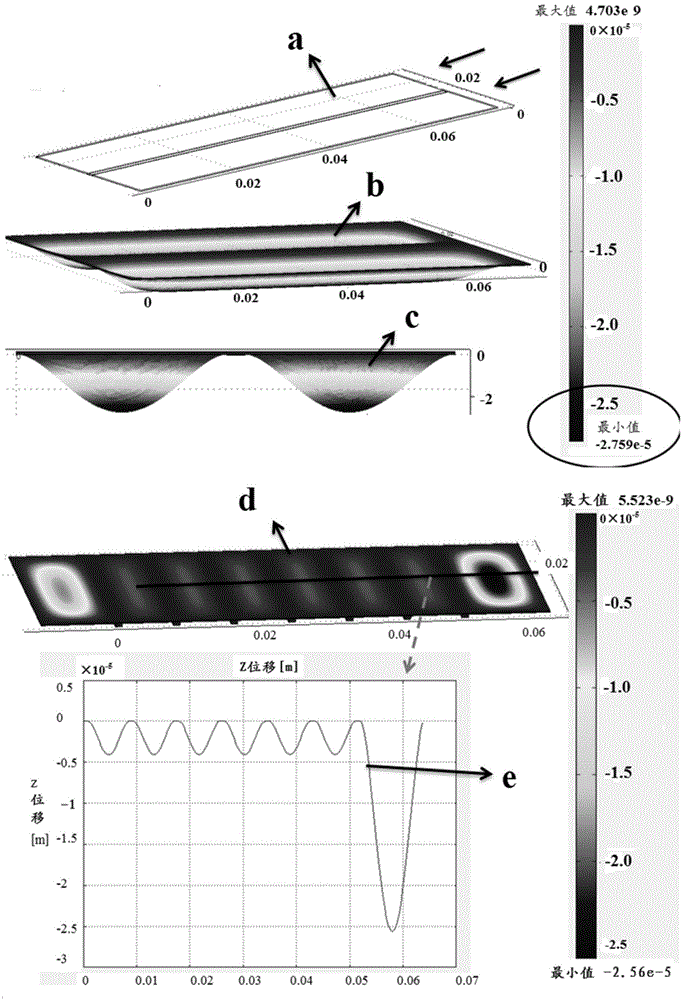

Manufacturing method of unimolecular sequencing chip

ActiveCN105112290AImprove flow field distributionIncrease the support pointBioreactor/fermenter combinationsBiological substance pretreatmentsOxygen plasmaEngineering

The invention provides a manufacturing method of a unimolecular sequencing chip. The manufacturing method includes the following steps: (1), taking a baseplate, and adopting a photoetching method to make an anodic film of a reaction tank array on the surface of the baseplate; (2), using model glue to pour the anodic film, curing for 1-3h at 90-100 DEG C after vacuum degassing, uncovering the anodic film to obtain a groove with multiple runners, punching a hole in each of two ends of each runner to form fluid input and output holes, and obtaining a substrate; (3), taking a transparent base, and preparing a polymethylglutarimide (PMGI) layer on the surface of the transparent base to obtain a transparent base with the surface modified; (4), subjecting the substrate and the transparent base to oxygen plasma cleaning and press-fitting, and injecting a reagent into each runner to clean the corresponding PMGI layer contacting with each runner to obtain the unimolecular sequencing chip. The manufacturing method is simple in process and low in manufacturing cost.

Owner:GENEMIND BIOSCIENCES CO LTD

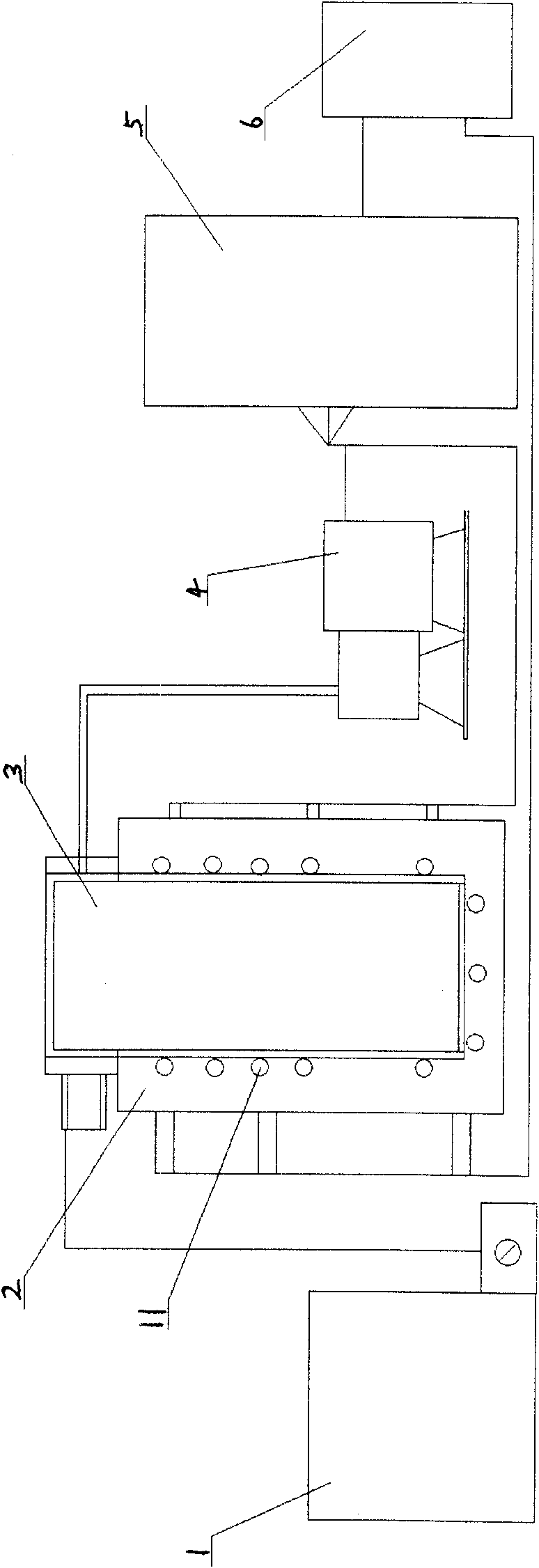

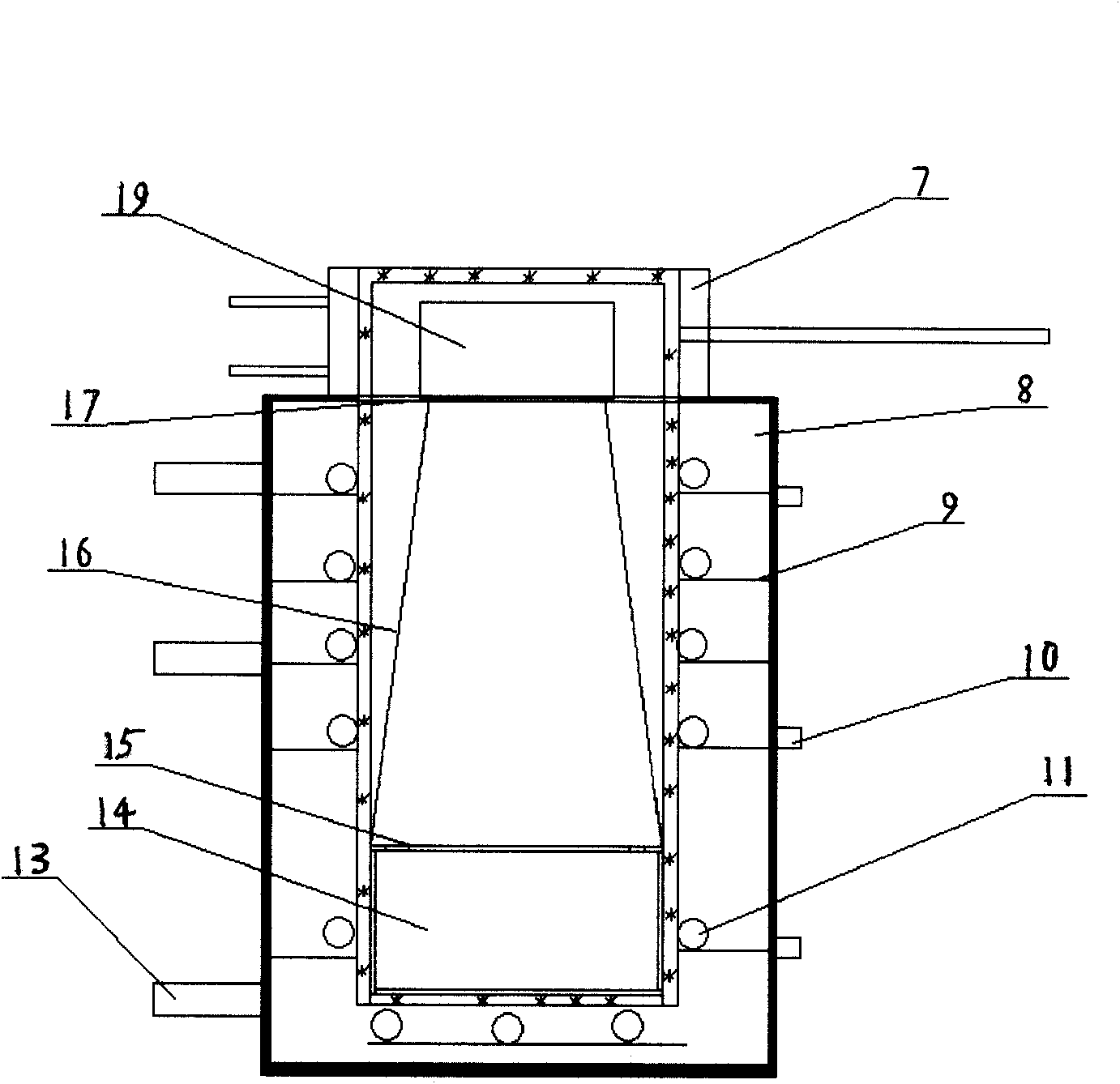

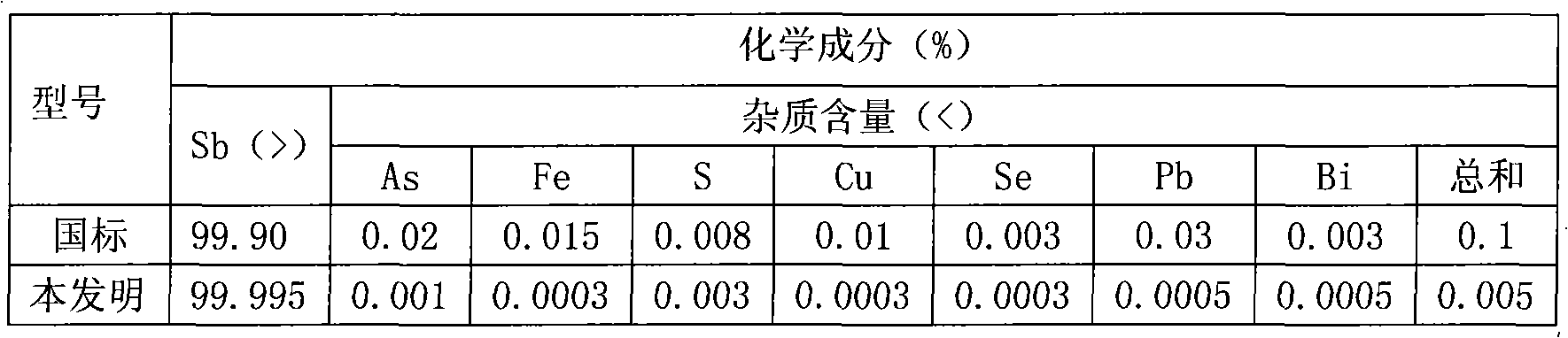

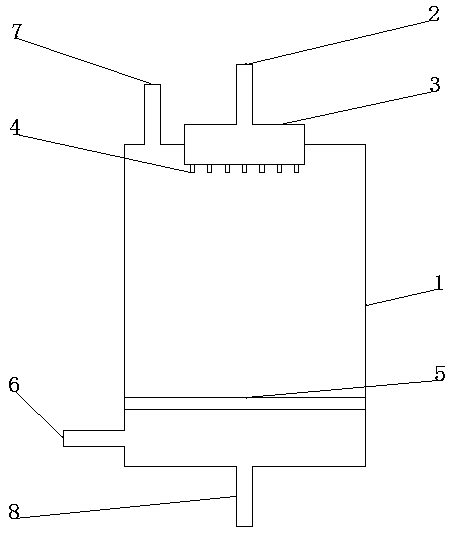

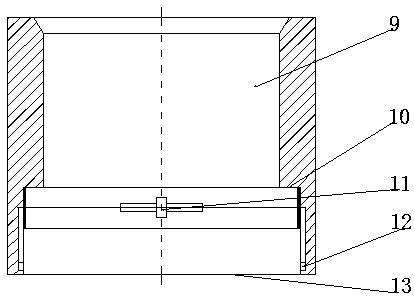

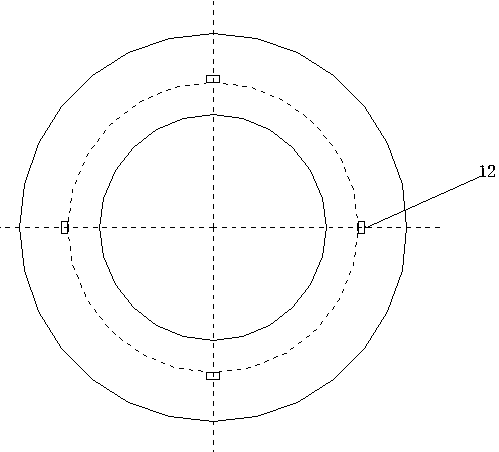

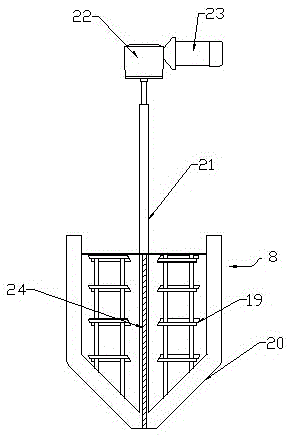

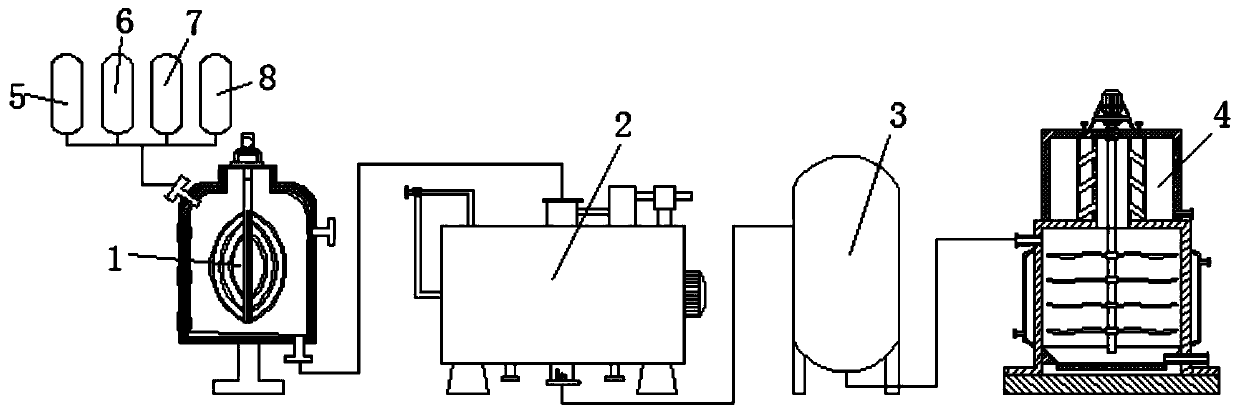

Method and device for producing high-purity antimony

The invention relates to a method and device for producing high-purity antimony, and belongs to the field of high-purity non-ferrous metal metallurgy in the smelting industry. The method comprises the following technological steps: 1, putting needle antimony in a crucible, arranging the crucible into a vacuum tank, starting a water cooling system and a vacuum pump, and controlling the vacuity below 13 Pa; 2, controlling the bottom temperature of the crucible to between 600 and 900 DEG C, the medium temperature to between 500 and 650 DEG C and the top temperature to between 350 and 450 DEG C, and preserving the temperature for 1 to 3 hours; and 3, continuously raising the temperature of the bottom of the crucible to between 650 and 900 DEG C, volatilizing the antimony through holes, contacting the antimony with a conical titanium plate, condensing the antimony on the titanium plate, preserving the temperature to completely volatilize the antimony, and remaining impurities with high boiling point such as lead in the crucible. The method and the device have high production speed, low energy consumption and simple equipment processing, and are suitable for requirement of mass production. A water jacket is adopted for cooling, so the condensing effect is good; and the impurities are not refluxed basically, the purity of products is high, and the production process has no pollution and no pollutant emission.

Owner:株洲科迪亚实业有限公司

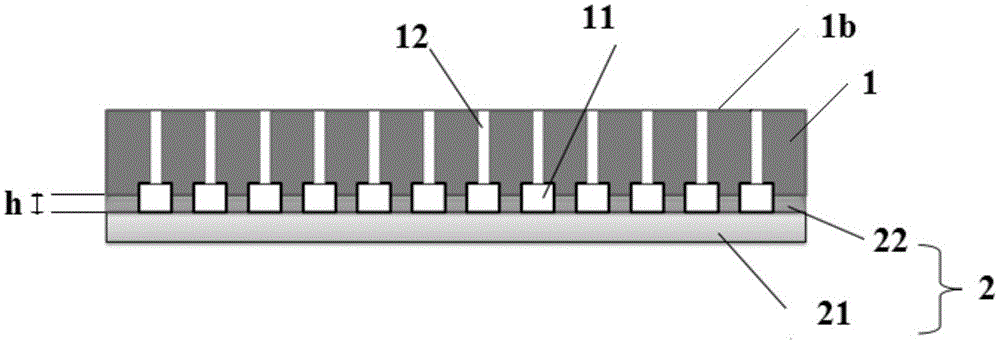

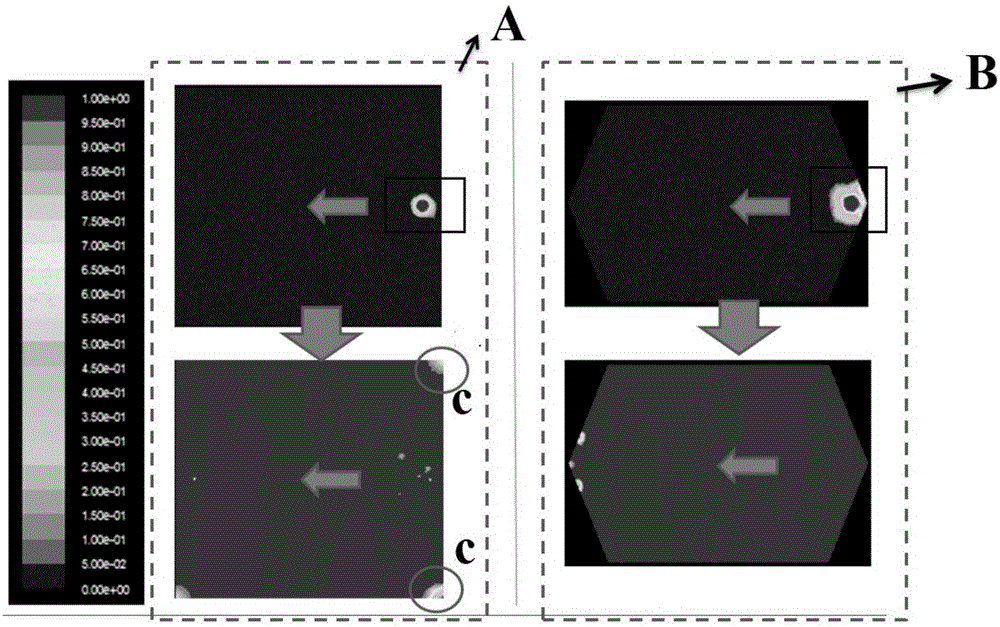

Single-molecule sequencing chip

ActiveCN105154323AImprove flow field distributionIncrease the support pointBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFluid input

The invention provides a single-molecule sequencing chip, which comprises a substrate and a base layer which is arranged in a mode of being laminated with the substrate, wherein the substrate comprises a first surface and a second surface which are oppositely arranged; a reaction tank array which is formed by a plurality of runners is arranged on the first surface of the substrate in a spacing mode; two opposite sidewalls of each runner extend in the length direction of the runner and are intersected at two ends of the runner to form two conical tail ends having included angles; fluid input holes and fluid output holes which are communicated with the second surface of the substrate are respectively formed in the surfaces of the two conical tail ends; the base layer comprises a transparent base and a spacing layer which is arranged on the surface of the transparent base; and the spacing layer is contacted with the first surface of the substrate and the spacing layer, corresponding to the locations of the runners, is formed with corrosion grooves. The chip is good in flow field distribution, the base in the chip is low in deformation rate and fluid in the chip is thorough in flushing switching.

Owner:GENEMIND BIOSCIENCES CO LTD

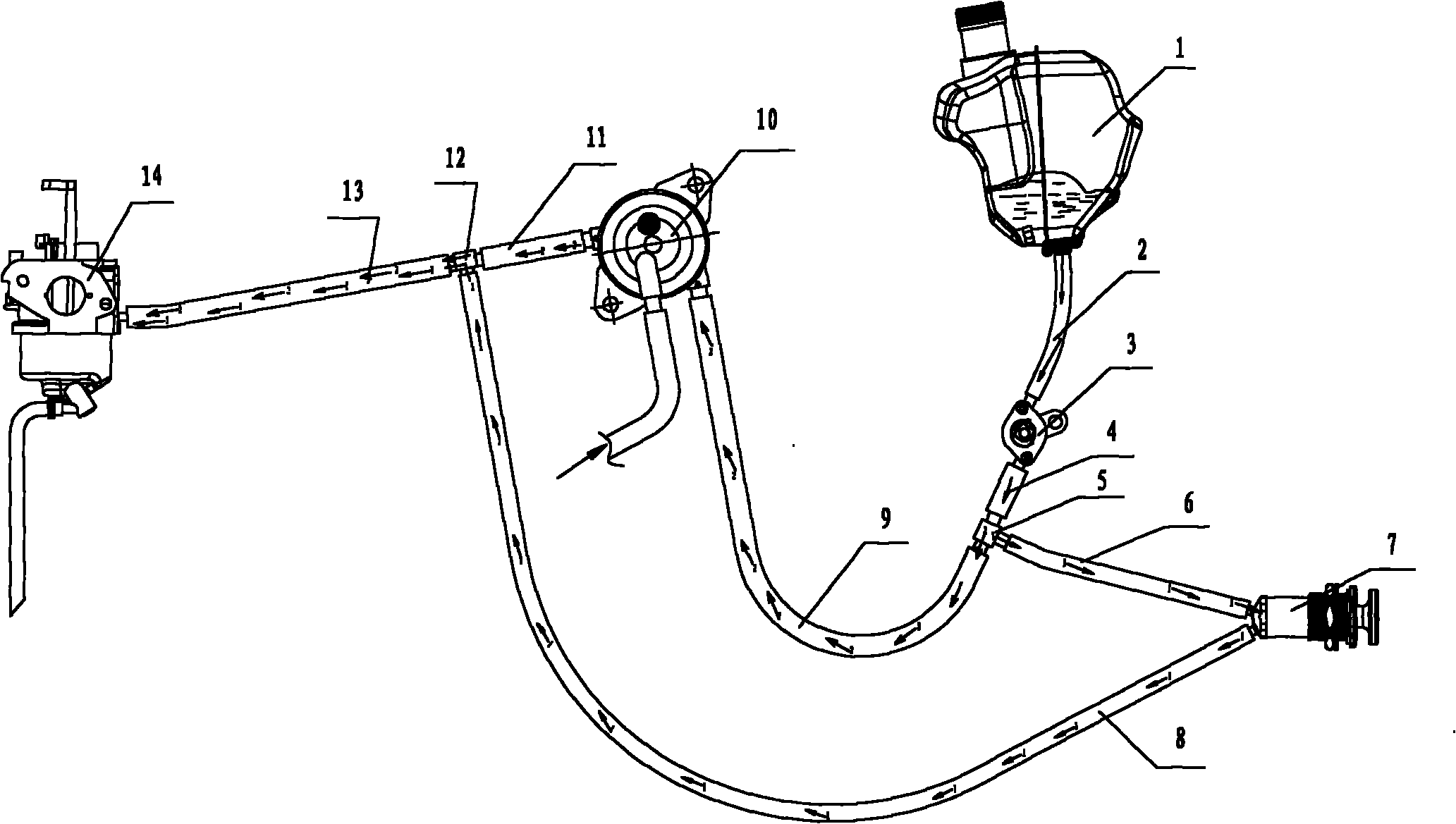

Quick-start oil circuit system for digital portable generator

InactiveCN101886593AShorten the timeSave energyMachines/enginesLiquid fuel feedersCarburetorTransport fuel

The invention discloses a quick-start oil circuit system for a digital portable generator, which comprises an oil tank, an oil switch, an automatic oil suction pump and a carburetor which are sequentially connected together through oil delivery pipelines. The quick-start oil circuit system is characterized by further comprising a manual oil suction pump, wherein, the oil inlet and the oil outlet of the manual oil suction pump are respectively communicated with the oil delivery pipelines at two ends of the automatic oil suction pump through the oil inlet pipe and the oil outlet pipe of the manual oil suction pump. In the invention, as the quick-start oil circuit system is provided with a manual oil circuit, a user can more rapidly transport fuel oil in the oil tank to the carburetor by the additional manual oil suction pump to ensure that an engine can be quickly started without frequent hand-pulling recoil like the conventional technology, thus greatly saving time and effort of the user and providing more convenience for the user to use the digital portable generator.

Owner:SUZHOU ERMA MECHNICAL & ELECTRICAL

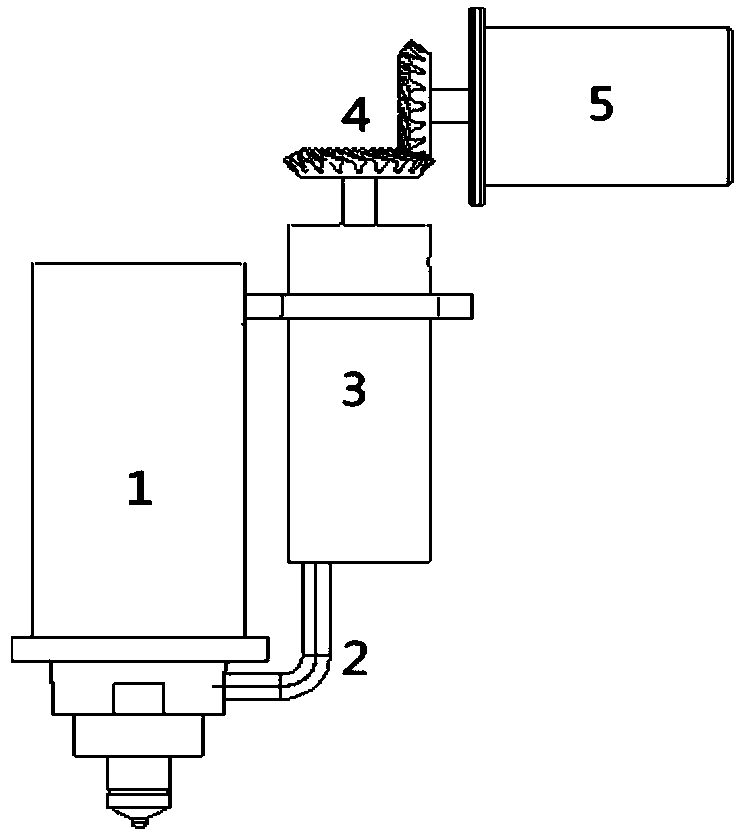

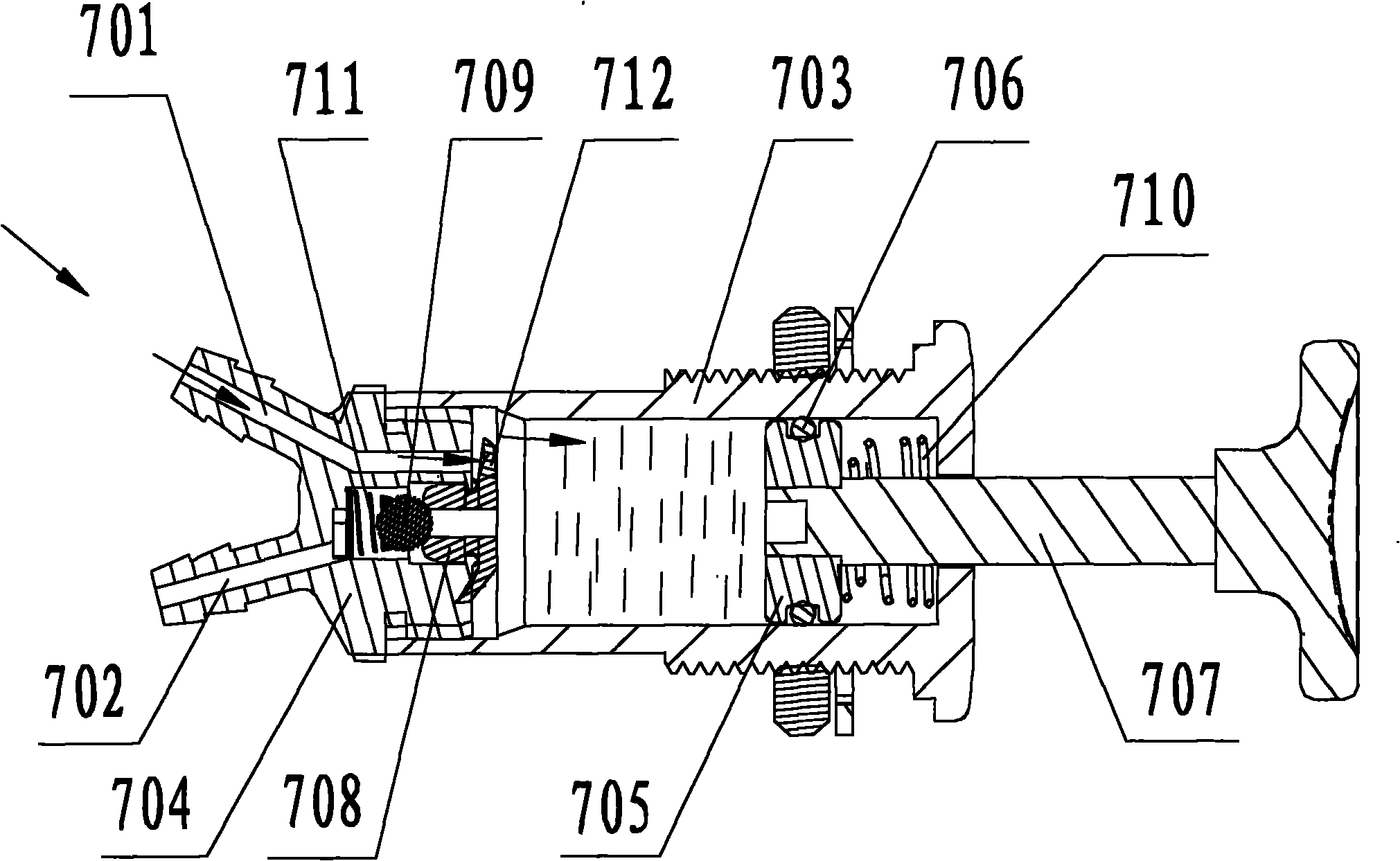

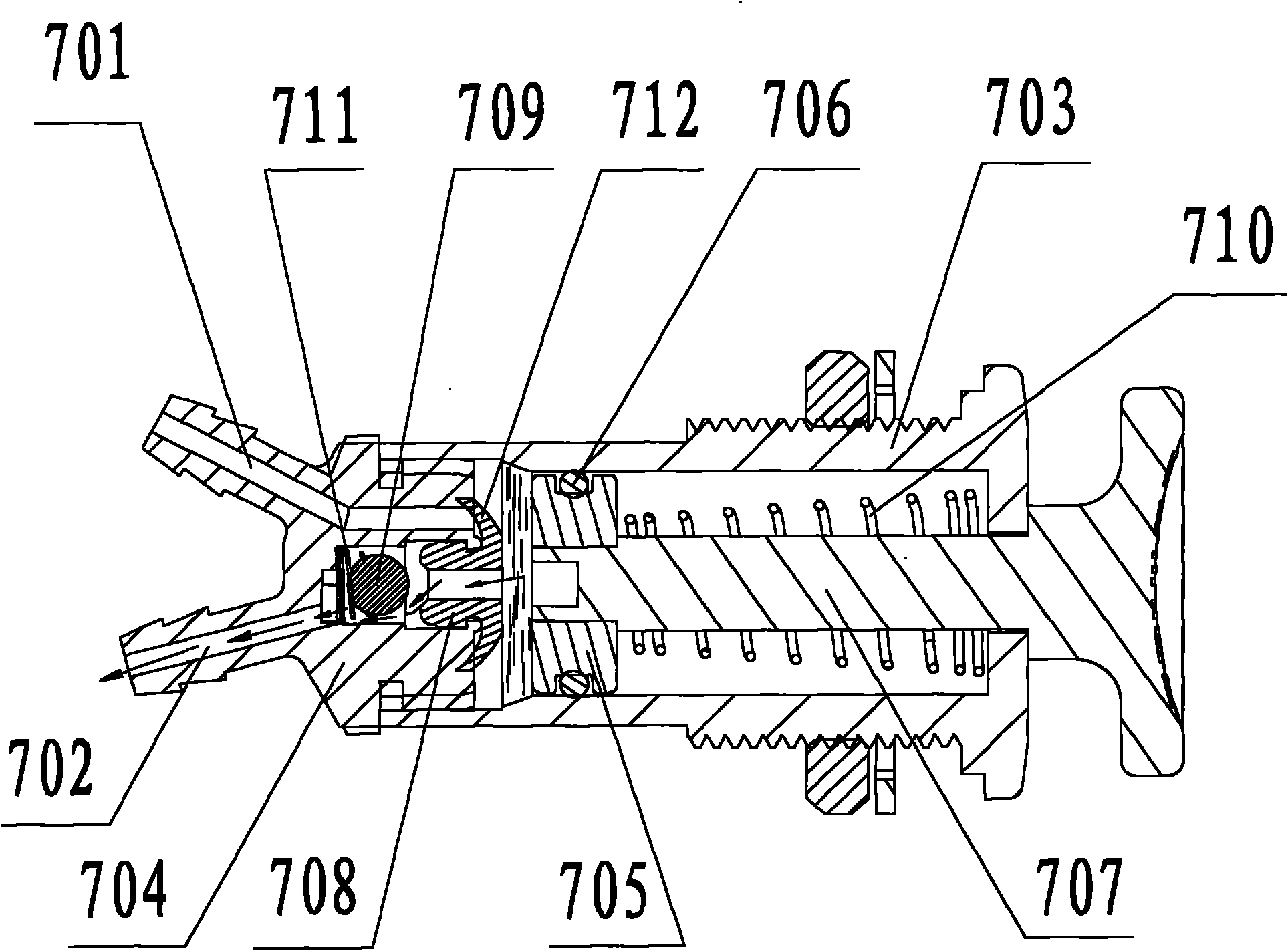

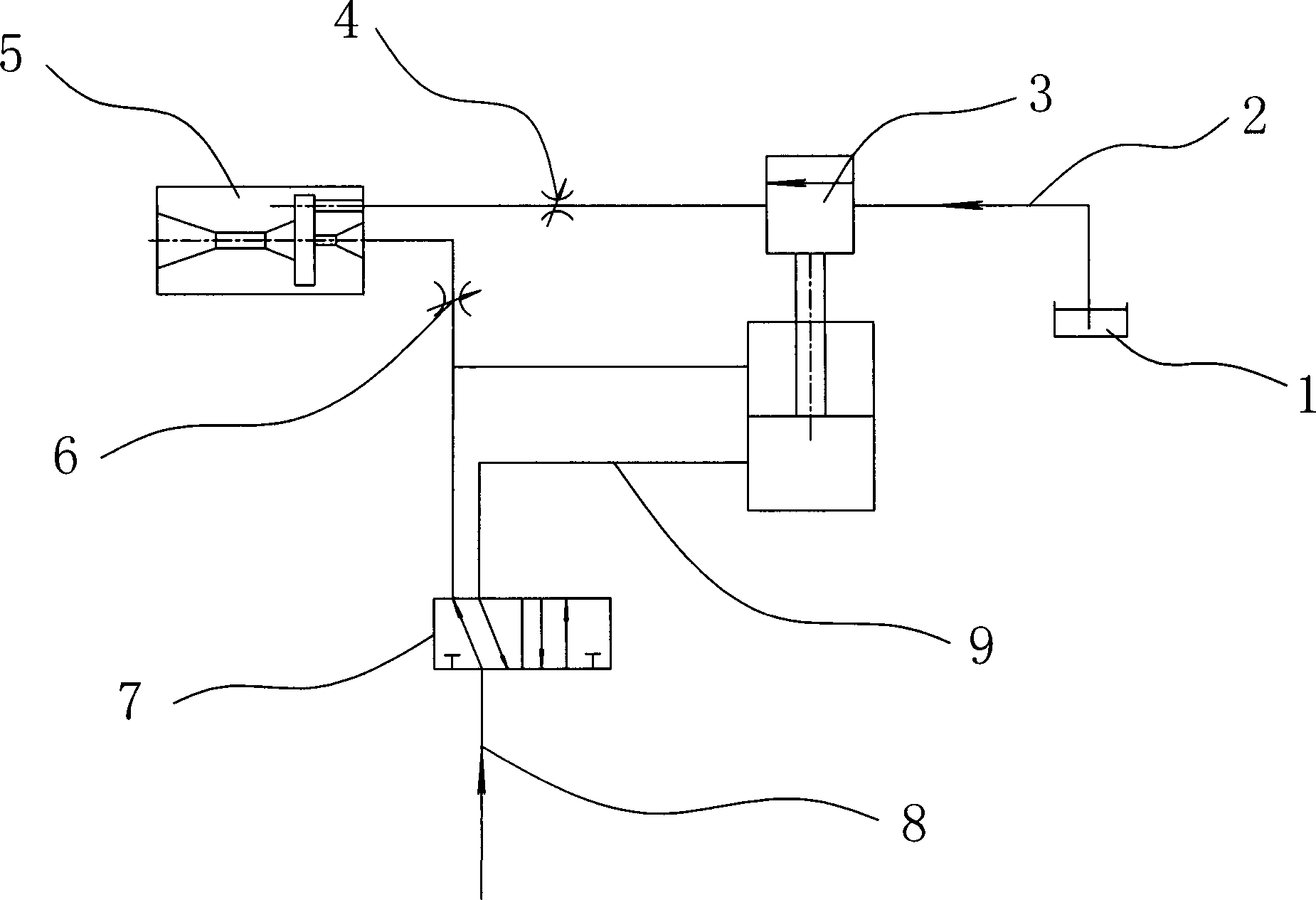

Near-dry cutting supersonic jet apparatus and control method thereof

InactiveCN103551915AReduce the temperatureNo refluxServomotor componentsMetal working apparatusSolenoid valveSpray nozzle

The invention provides a near-dry cutting supersonic jet apparatus and a control method thereof. The near-dry cutting supersonic jet apparatus comprises a control circuit board, a supersonic jet injector, a nozzle, a cutting fluid delivery pipe, a compressed air delivery pipe and an adjusting block. The supersonic jet injector is mounted on the nozzle, the adjusting block comprises a pneumatic cutting fluid one-way stop valve, a cutting fluid adjusting valve and a compressed air adjusting valve, the cutting fluid delivery pipe is connected with a cutting fluid storage tank and the supersonic jet injector, the pneumatic cutting fluid one-way stop valve and the cutting fluid adjusting valve are sequentially arranged on the cutting fluid delivery pipe from the cutting fluid storage tank to the supersonic jet injector, the compressed air delivery pipe is connected with a compressed air source and the supersonic jet injector, a control solenoid valve and the compressed air adjusting valve are sequentially arranged on the compressed air delivery pipe from the compressed air source to the supersonic jet injector, and the control solenoid valve is connected with the pneumatic cutting fluid one-way stop valve through a connecting pipe.

Owner:陈建军 +1

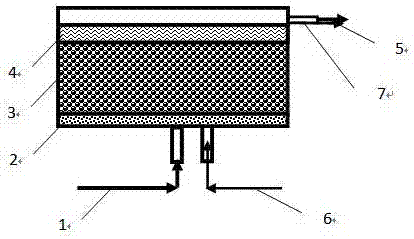

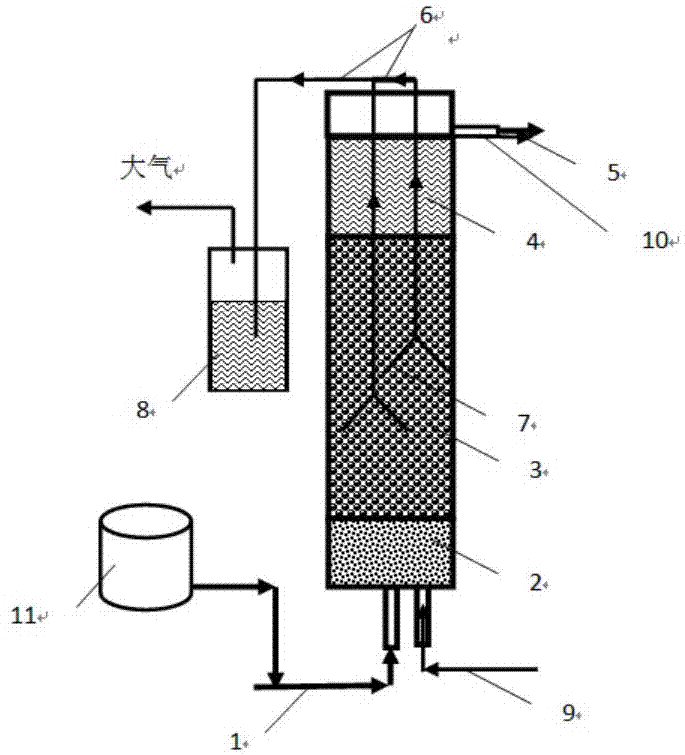

Denitrification slow release filler as well as preparation and application methods thereof

ActiveCN107117706AExtended stayImprove nitrogen removal efficiencyWater treatment compoundsWater contaminantsActivated carbonSolid carbon

The invention particularly relates to biological denitrification filler as well as preparation and application methods thereof. The technical principle of the filler is that activated carbon and solid carbon are used as raw materials for preparation of biological denitrification filler, and the raw materials are mixed with anionic clay to be accommodated in an adaptive reactor; the reactor is equipped with a medicine adding system, a small amount of (lower than theoretical stoichiometric ratio) organic carbon is added from a water inlet position of the reactor to enhance removal of nitrate.The filler has a good denitrification effect, can also effectively solve the problem of secondary pollution caused by excessive liquid carbon.

Owner:知和环保科技有限公司

Dressing process of gold ores

InactiveCN101898167ASolve the floating speed problemSolve the problem that the sulfide particles with large specific gravity cannot be floatedFlotationWet separationAutomatic controlAutomated control system

A dressing process of gold ores comprises the step of pulp particle size grading. The difference lies in that the dressing process also comprises the steps of ore dressing and pulp washing, dispensing and stirring at fixed time for reaction, ore floating at fixed time, tailing discharging at fixed time, etc, therefore, in the ore floating procedure, the pulp viscosity does not affect the floating upward speed of the sulfides, the sulfide particles with high proportion do not exist, the floatation concentrate pulp does not flow back in the opposite direction, the heavy metals and the valuable elements can be maximally recovered and the discharged tailings do not contain sulfides and heavy metals. The single floatation ore groove circulating linkage mechanism is adopted and is automatically monitored and regulated by an automatic control system, thus greatly shortening the ore floating process. Compared with the prior art, the dressing process can save energy by more than 50% and is especially suitable for the gold mine industry.

Owner:孙宝海

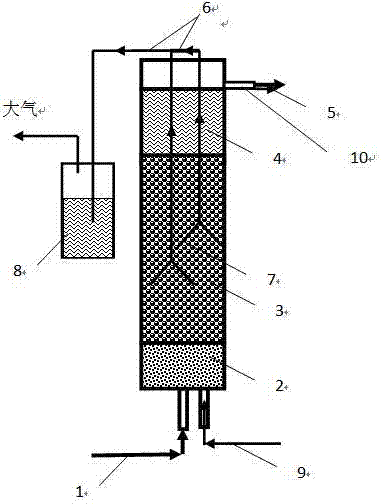

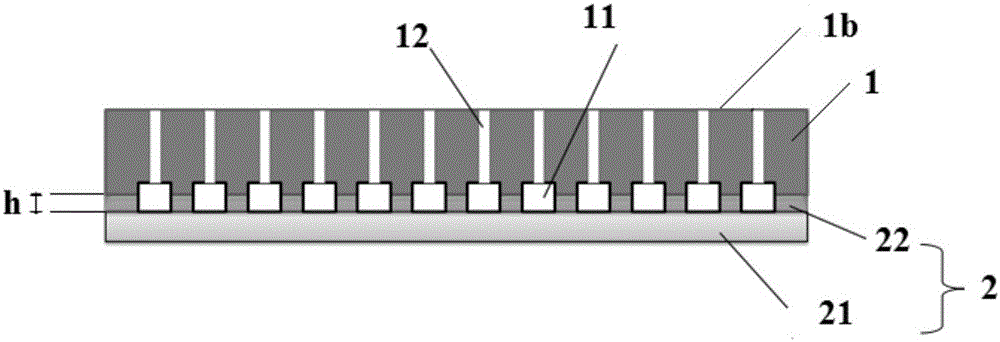

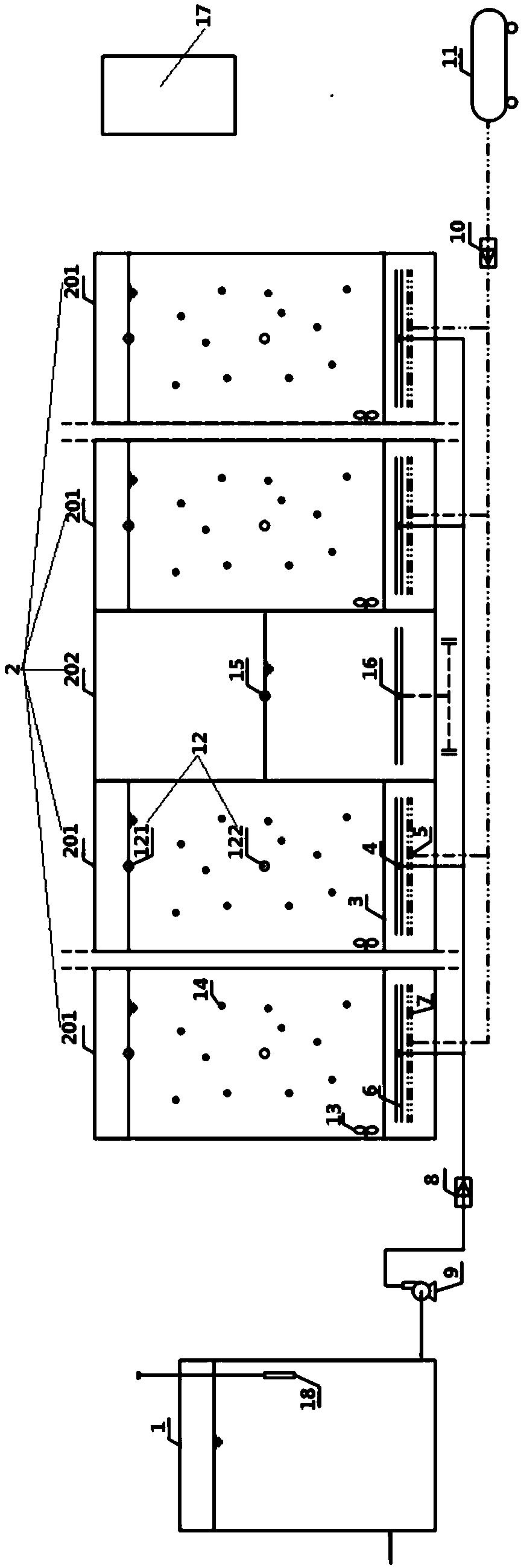

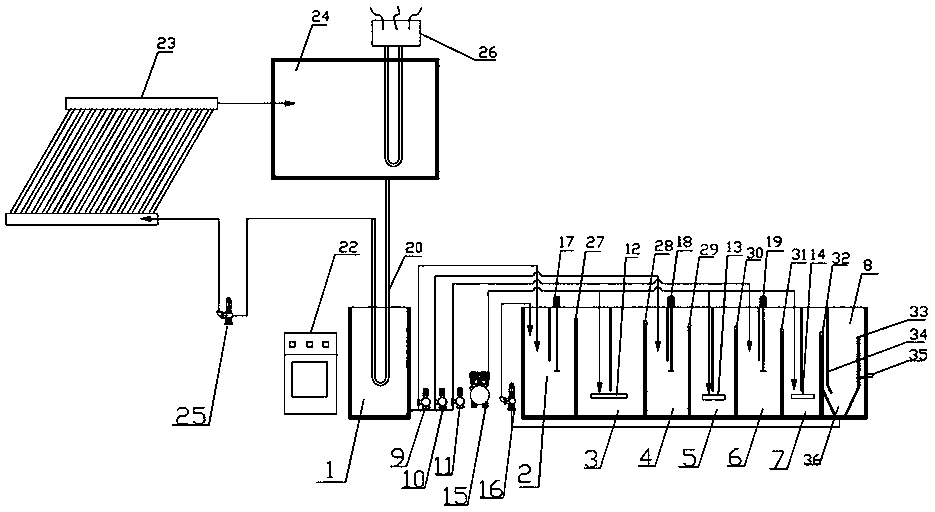

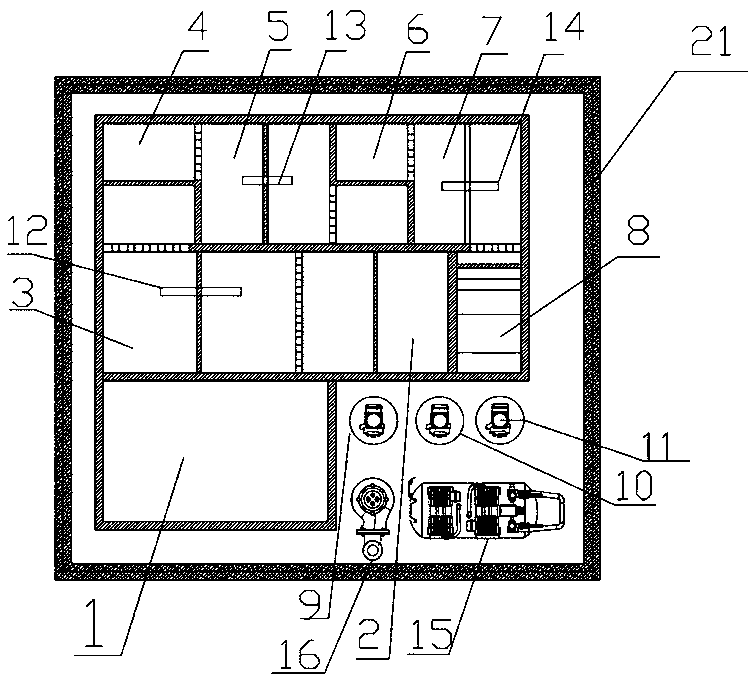

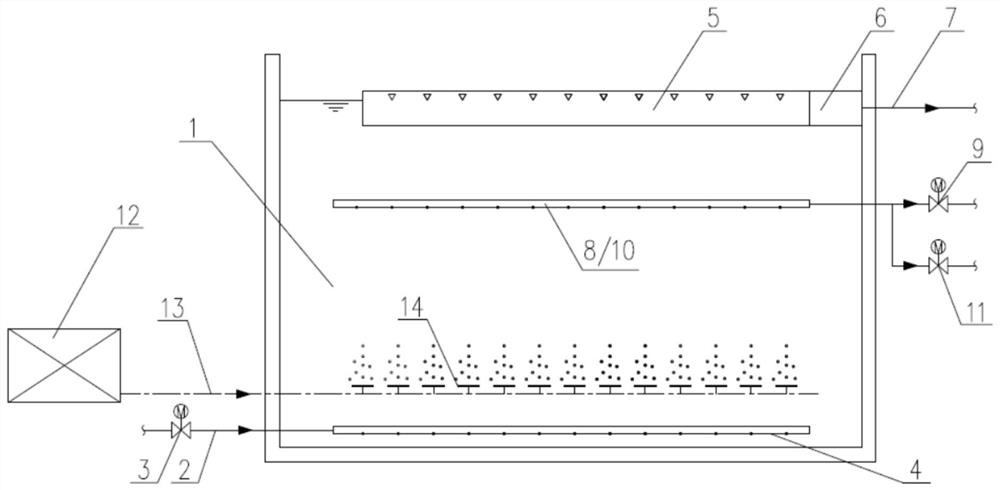

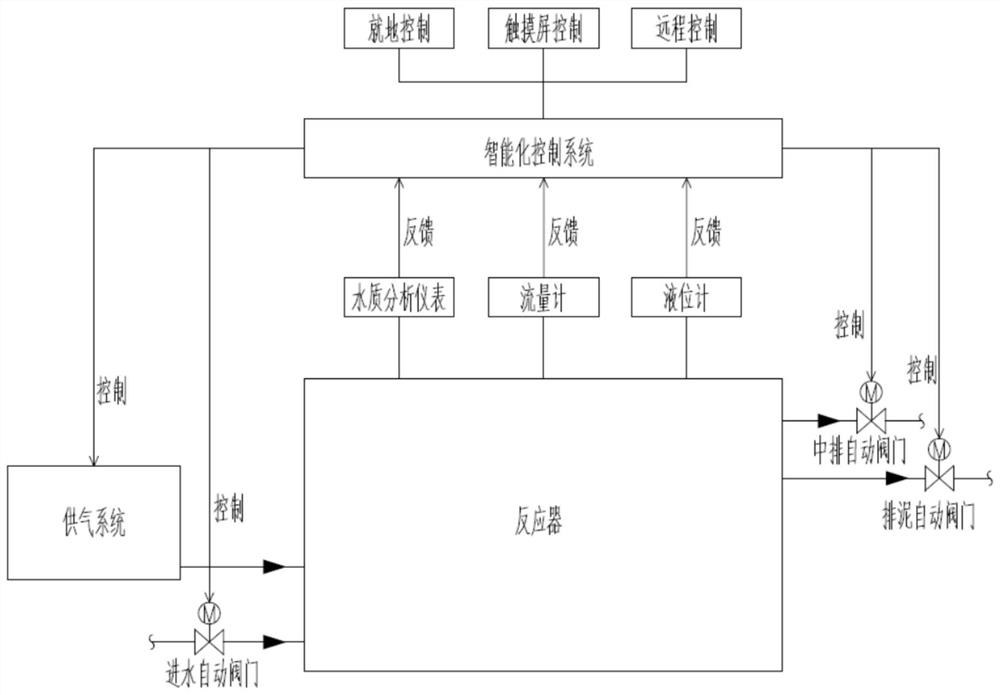

Continuous flow intermittent aeration type biological film nitrogen and phosphorus removal device and method

PendingCN107915312AIncrease profitReduce dosageTreatment using aerobic processesSustainable biological treatmentPhysical spaceSludge

The invention discloses a continuous flow intermittent aeration type biological film nitrogen and phosphorus removal device and method. The device comprises an adjusting tank (1) and a reactor (2), wherein the reactor (2) is integrally constructed by a plurality of reaction regions (201) and a water outlet region (202); the reaction regions (201) are filled with suspending fillings (14) and work in a sequencing batch manner so as to realize intermittent aeration; and the integrated reactor is capable of realizing processes of continuous inflow and continuous effluent. The device has the beneficial effects that the process chain is short, the carbon source in raw water is adequately utilized, and the nitrogen and phosphorus removal and mud-water separation processes are synchronously realized in the same physical space of a single-state bioreactor; and the device is extremely low in sludge output, low in treatment cost, convenient to manage, suitable for the small-scale decentralized treatment of town sewage and particularly suitable for the treatment of low-carbon-nitrogen-ratio town sewage in the south.

Owner:CENT & SOUTHERN CHINA MUNICIPAL ENG DESIGN & RES INST

Catheter kit for burrow

Owner:SUMITOMO BAKELITE CO LTD +1

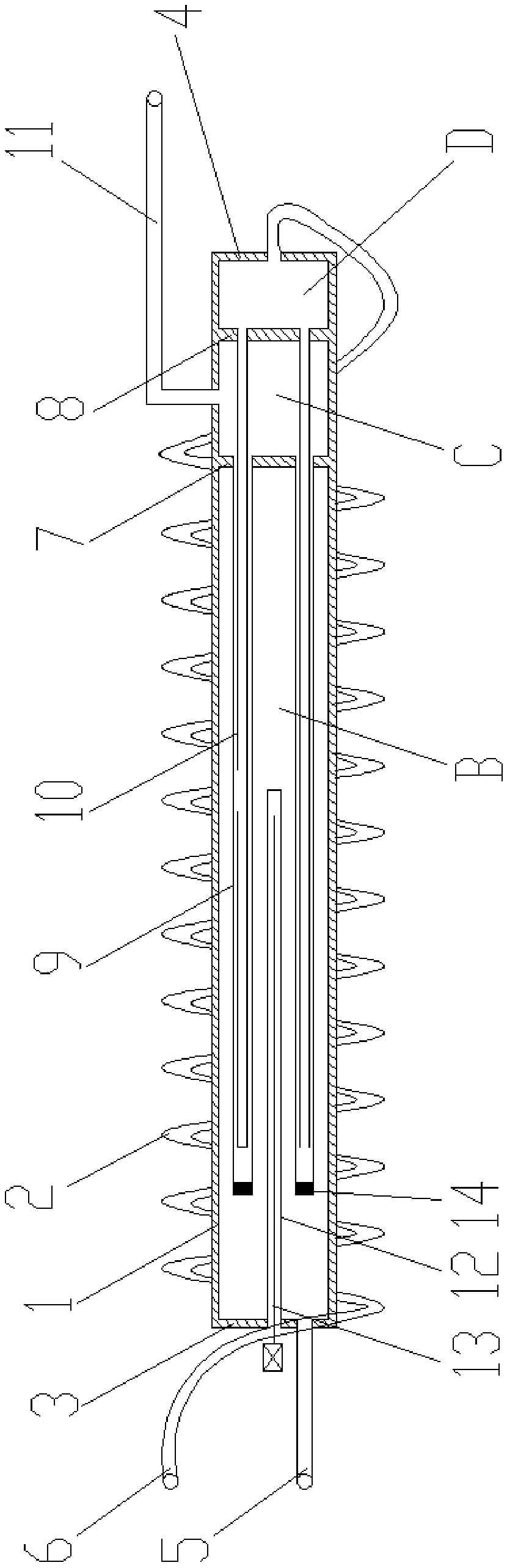

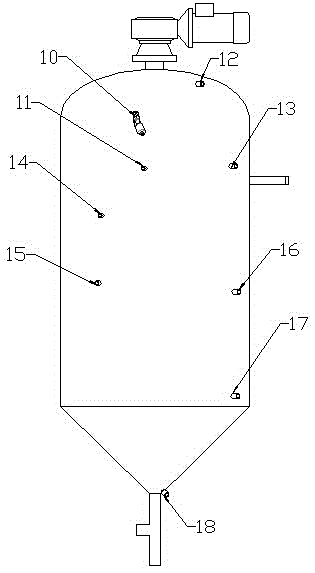

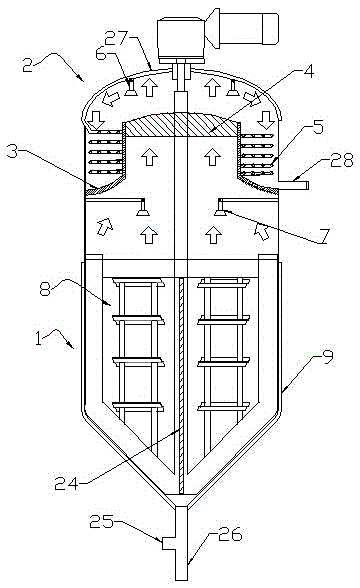

Ultra-high purity hydrogen separator

ActiveCN107585741ASimplify the separation systemImprove separation efficiencyHydrogen separationDispersed particle separationEngineeringProcess engineering

The invention provides an ultra-high purity hydrogen separator. The ultra-high purity hydrogen separator comprises a shell taking the shape of a circular pipe and a coil spirally wound outside the shell, a first plug and a second plug are arranged at the end part of the shell, the first plug is provided with an ultra-high purity hydrogen outlet, the outlet is communicated with an ultra-high purityhydrogen outlet pipe, the second plug is provided with a mixed hydrogen inlet, the inlet is communicated with a mixed hydrogen inlet pipe through the coil, the shell is divided into three cavities bya first baffle plate and a second baffle plate, a working cavity is internally provided with a palladium membrane pipe and a liner pipe, a waste gas outlet is arranged on the outer wall of the shell,and the outlet is communicated with a waste gas outlet pipe and a waste gas collecting cavity. The disclosed ultra-high purity hydrogen separator has the characteristics of simple and compact structure, safety, reliability and long service life, and is suitable for separating various mixed hydrogen systems; the separating efficiency of hydrogen reaches more than 90%, and the purity of the hydrogen reaches more than 99.9999%.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Low-temperature-resistant dispersing type sanitary sewage treatment integrated device and treatment method thereof

InactiveCN110282741AInhibition of swellingNo refluxBiological treatment apparatusTreatment with aerobic and anaerobic processesThermal insulationCollection system

Owner:沈阳工大蓝金环保产业技术研究院有限公司

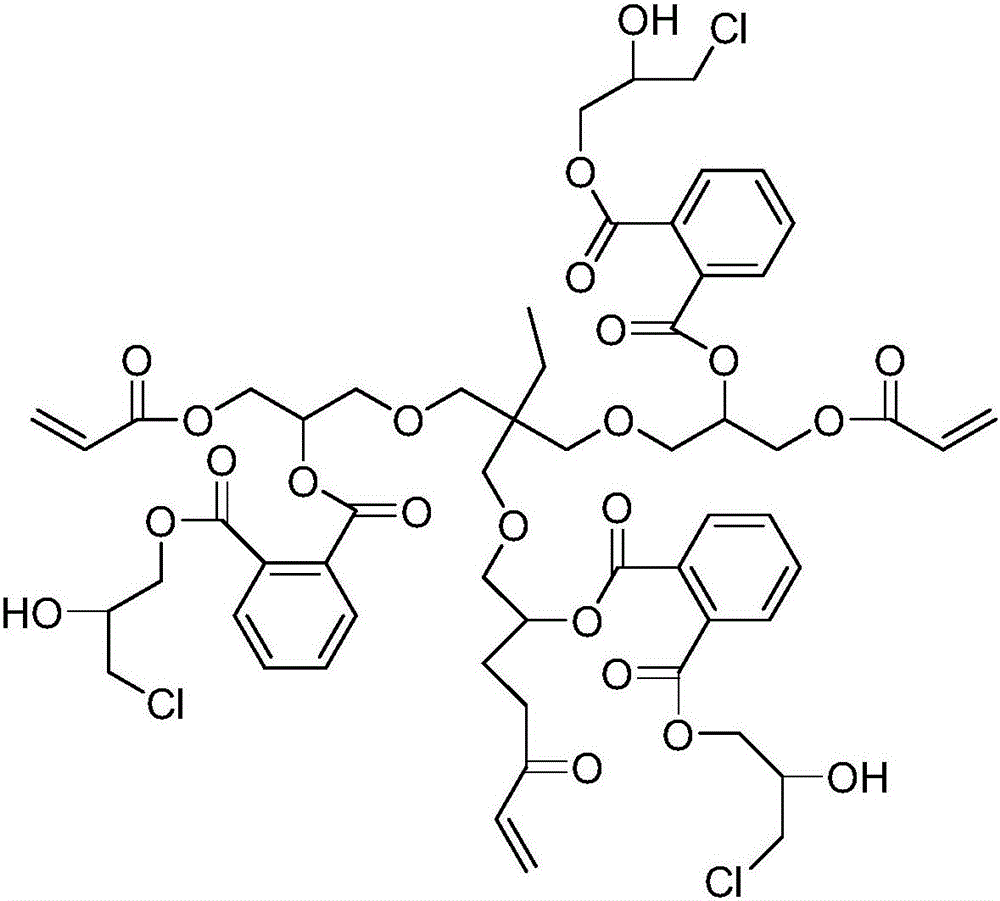

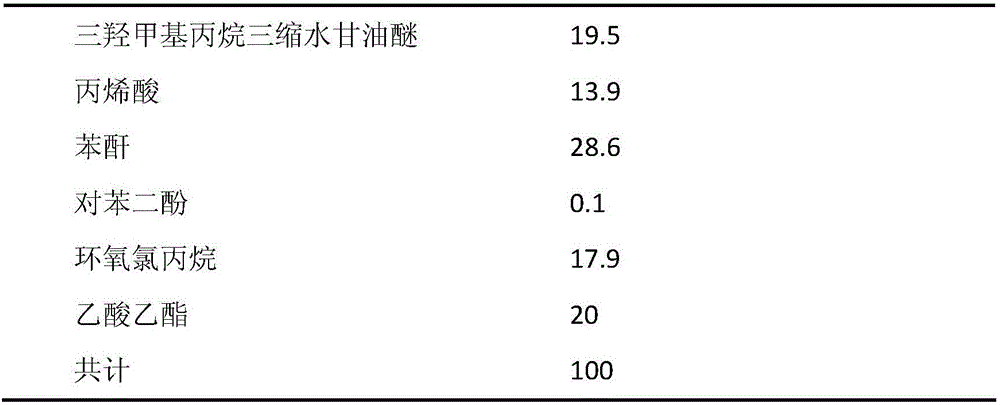

UV (Ultraviolet) curable polyester as well as preparation method and application of UV curable polyester

ActiveCN106748765ALow viscosityAnhydrousOrganic compound preparationCarboxylic acid esters preparationPolyesterP-Toluenesulfonic acid

The invention discloses UV (Ultraviolet) curable polyester as well as a preparation method and application of the UV curable polyester. The preparation method of the UV curable polyester comprises the following steps: 1) mixing 1 part of triglycidyl ether and 3 to 4 parts of an acrylic monomer into a reaction kettle according to a mole fraction; adding a quaternary ammonium salt catalyst, a polymerization inhibitor and an organic solvent and reacting at 105 DEG C to 125 DEG C until the acid value is less than 10mgKOH / g; 2) adding acid anhydride, a polymerization inhibitor and p-toluenesulfonic acid into a matrix prepared by the step 1), and reacting at 105 DEG C to 130 DEG C for 2h to 4h; adding an epoxy compound which is 0.9 to 1.2 times of the mole fraction of the acid anhydride and adding the quaternary ammonium salt catalyst and the organic solvent to react until the acid value is less than 10mgKOH / g; decompressing and distilling to remove the solvent, and cooling and discharging a material, wherein the solid content of the resin reaches 100 percent or more and the viscosity is 3000mPa.s to 30000mPa.s. UV curable paint prepared by the polyester has excellent coating film performance and relatively low cost.

Owner:SOUTH CHINA UNIV OF TECH

CO2-trapping spray device and technology

ActiveCN109569241ANo refluxEliminate wall lossDispersed particle separationAir quality improvementSpray towerEngineering

The invention discloses a CO2-trapping spray device and a technology. The device comprises a spray tower. The top of a tower body is provided with a liquid inlet and a gas discharging port, and the bottom is provided with a liquid discharging port and a gas inlet. A gas distributor is installed above the gas inlet. The liquid inlet is connected with a nozzle device. The nozzle device is formed byorderly distributing nozzle units. Each nozzle unit is formed by a double-layer nozzle plate, a rotation driving component and a pressure sensor. The double-layer nozzle plate comprises a nozzle frontplate and a nozzle rear plate. The nozzle front plate and the nozzle rear plate are uniformly provided with nozzle holes. The rotation driving component comprises a spin core and a rotating ring. Thespin core is provided with an electro-magnetic induction device. The pressure sensor is capable of, through the electro-magnetic induction device, transmitting a signal of a liquid pressure size to the spin core so as to rotate the spin core and drive the nozzle rear plate to be correspondingly rotated, and enabling the nozzle holes of the nozzle front plate and the nozzle rear plate to form dynamic overlapping and interlacing.

Owner:山西恒鑫宇环保科技服务有限公司

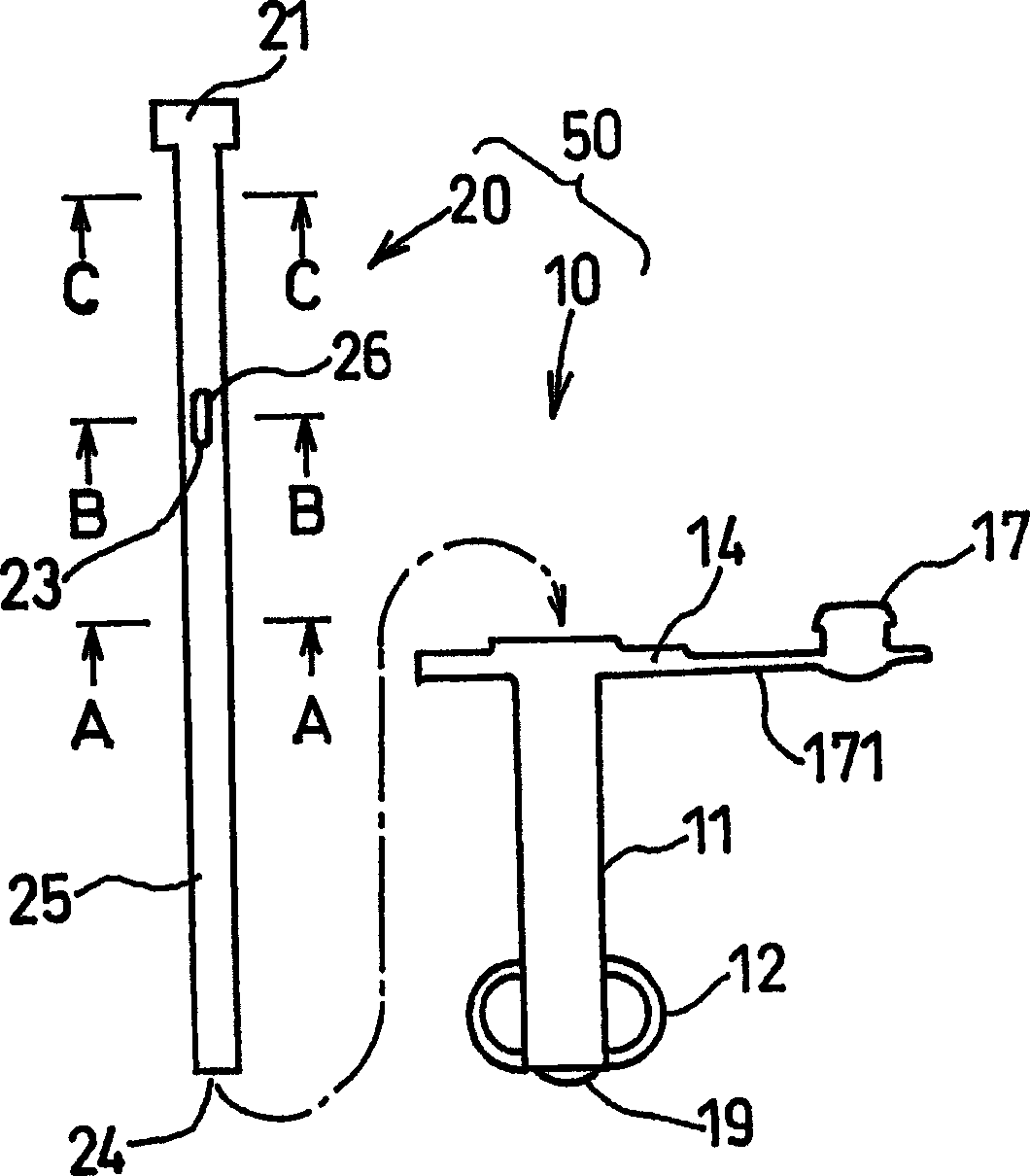

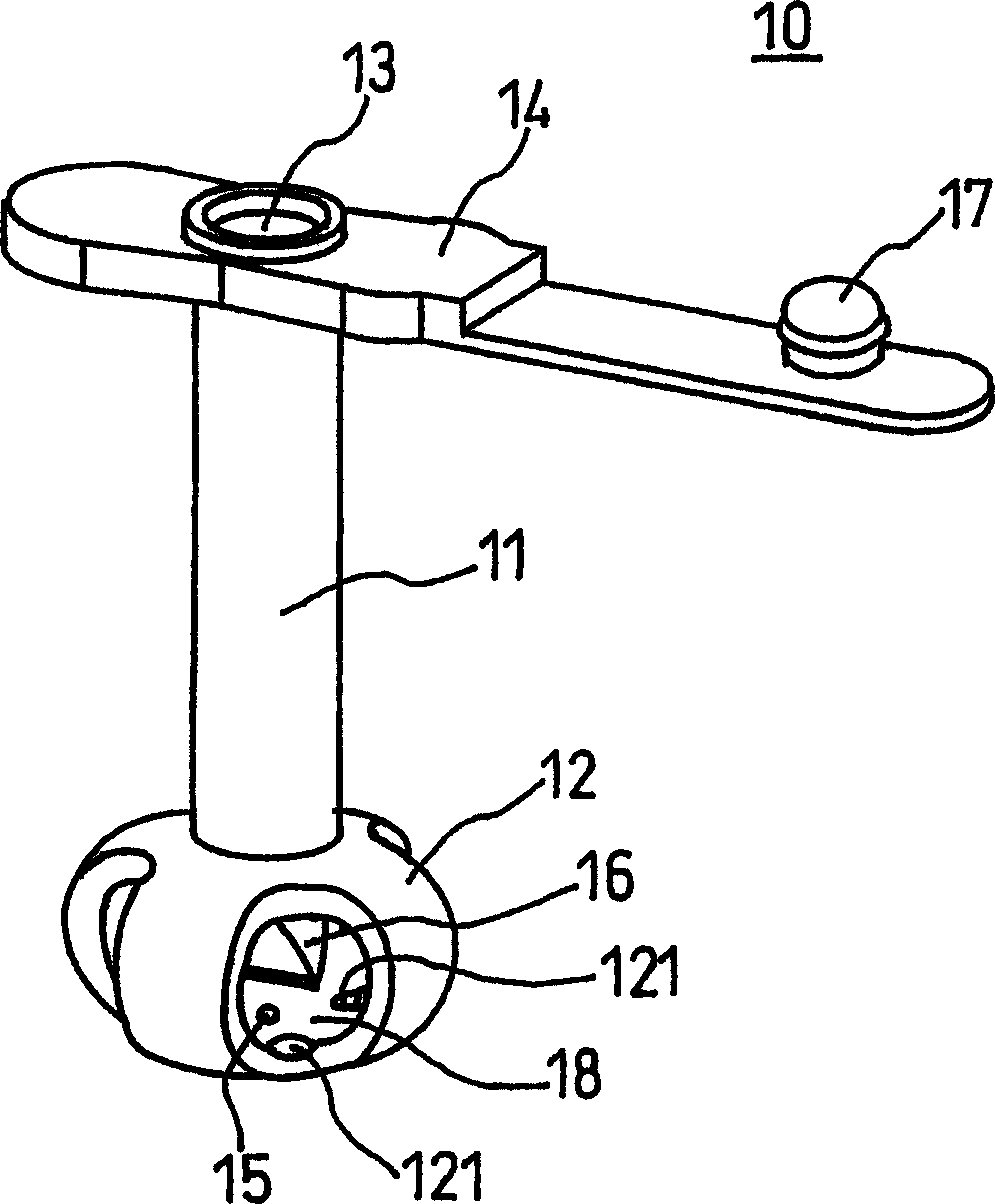

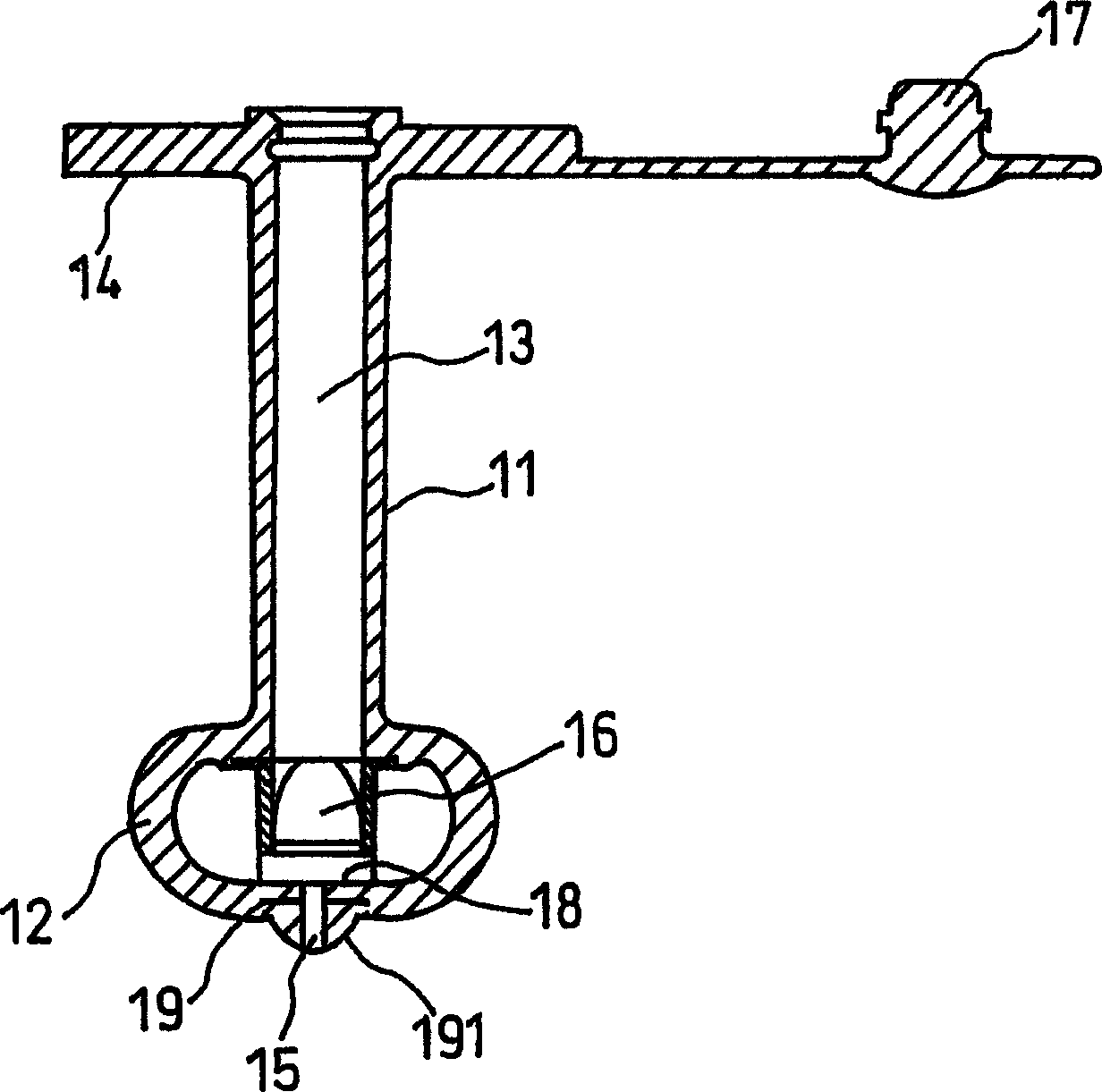

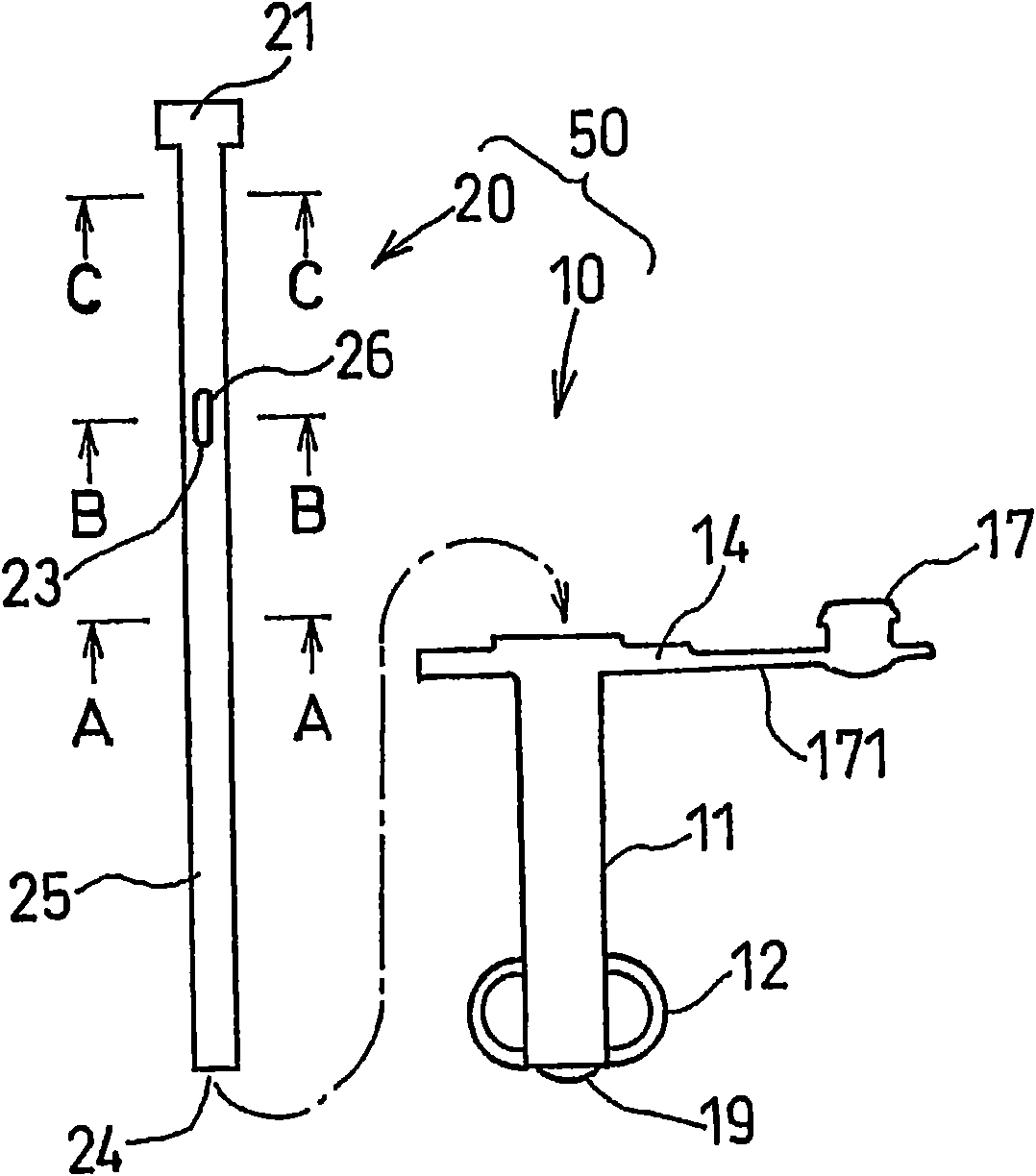

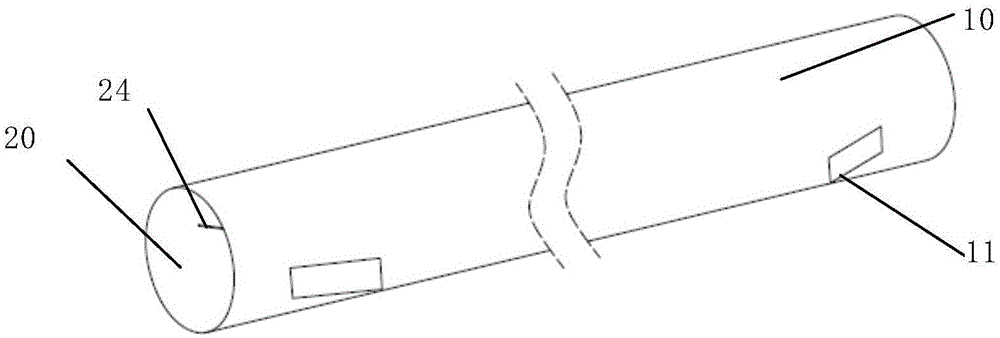

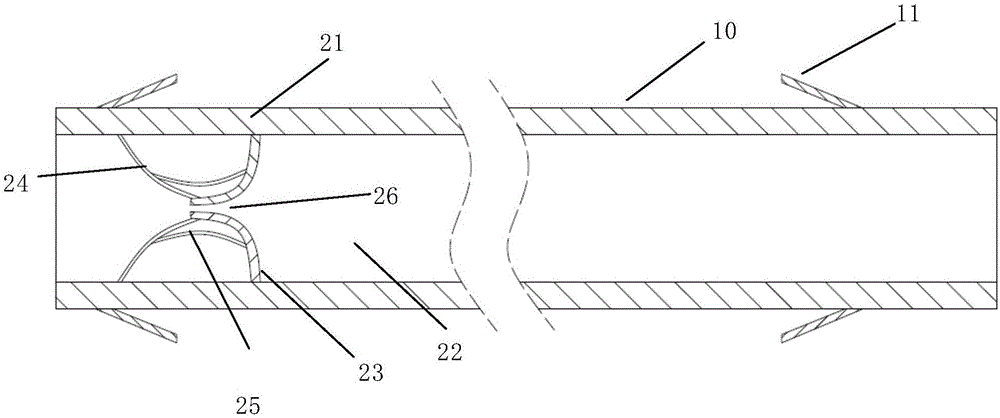

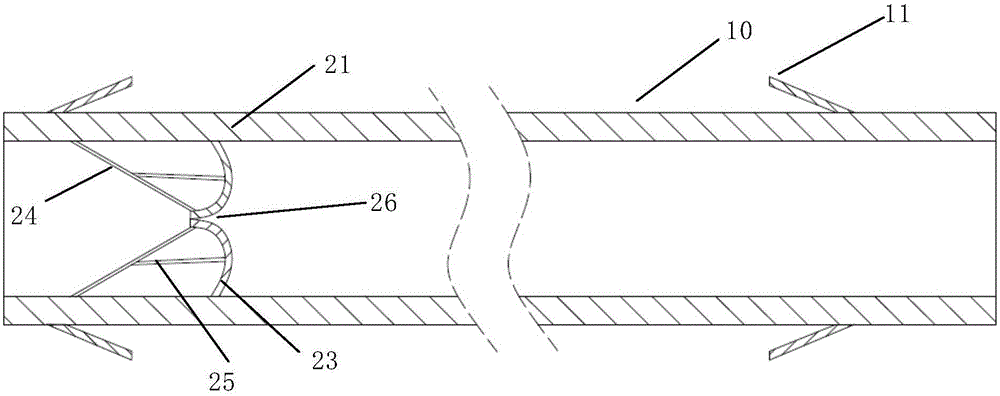

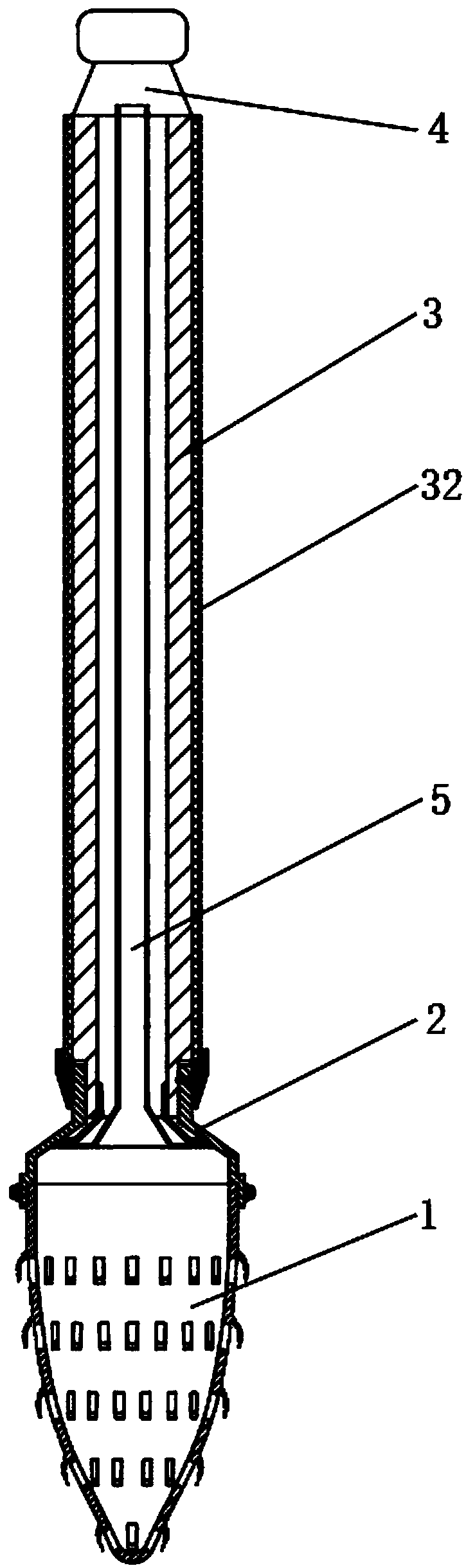

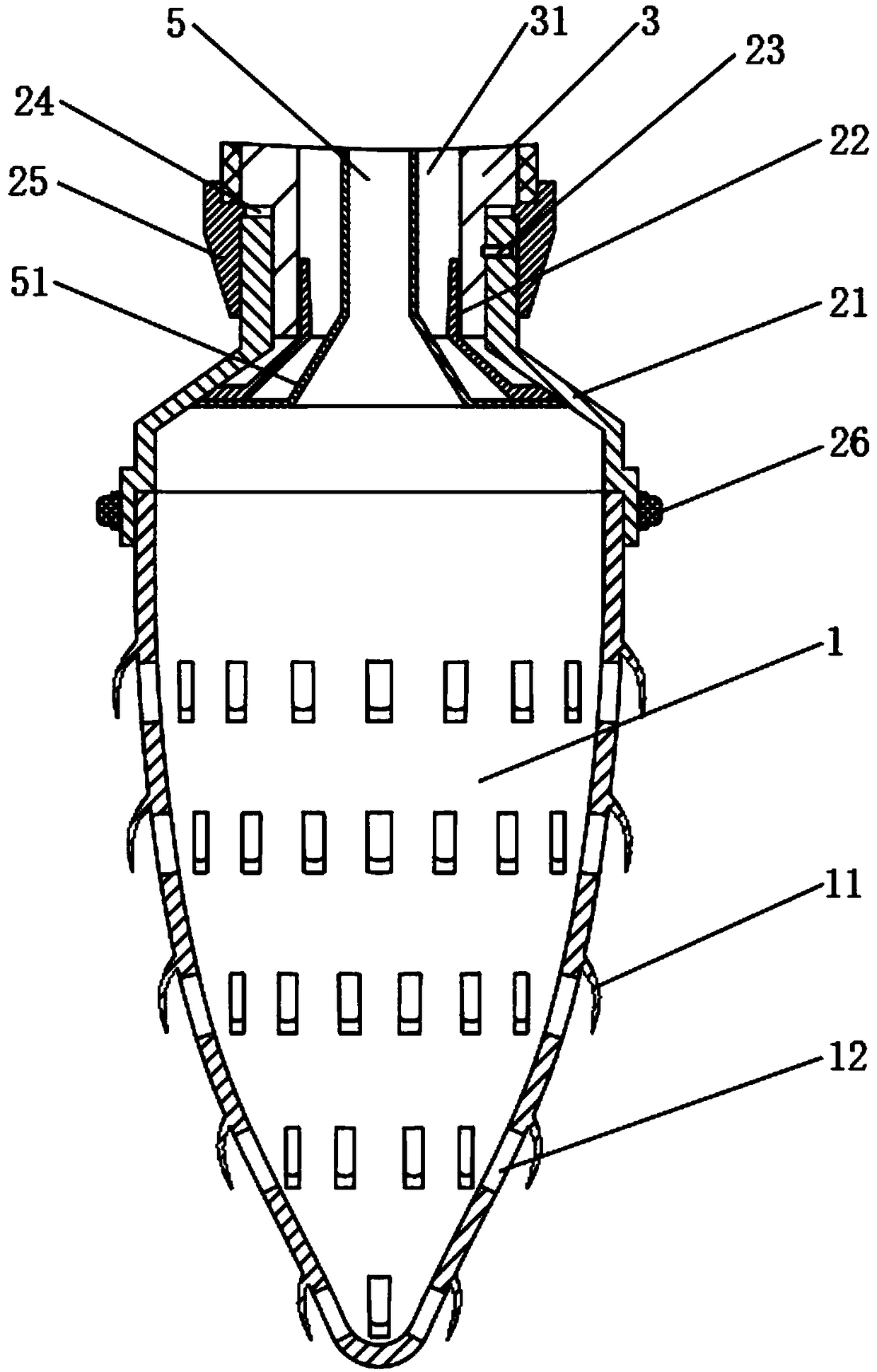

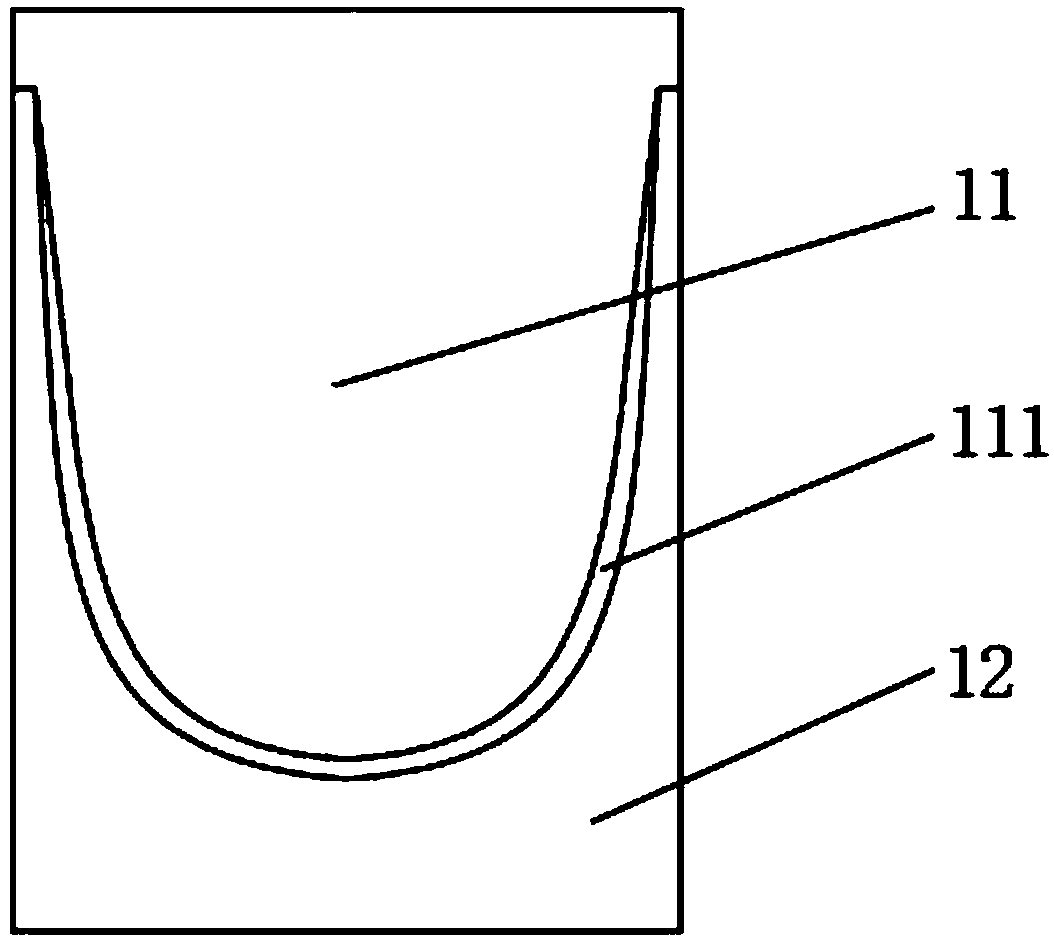

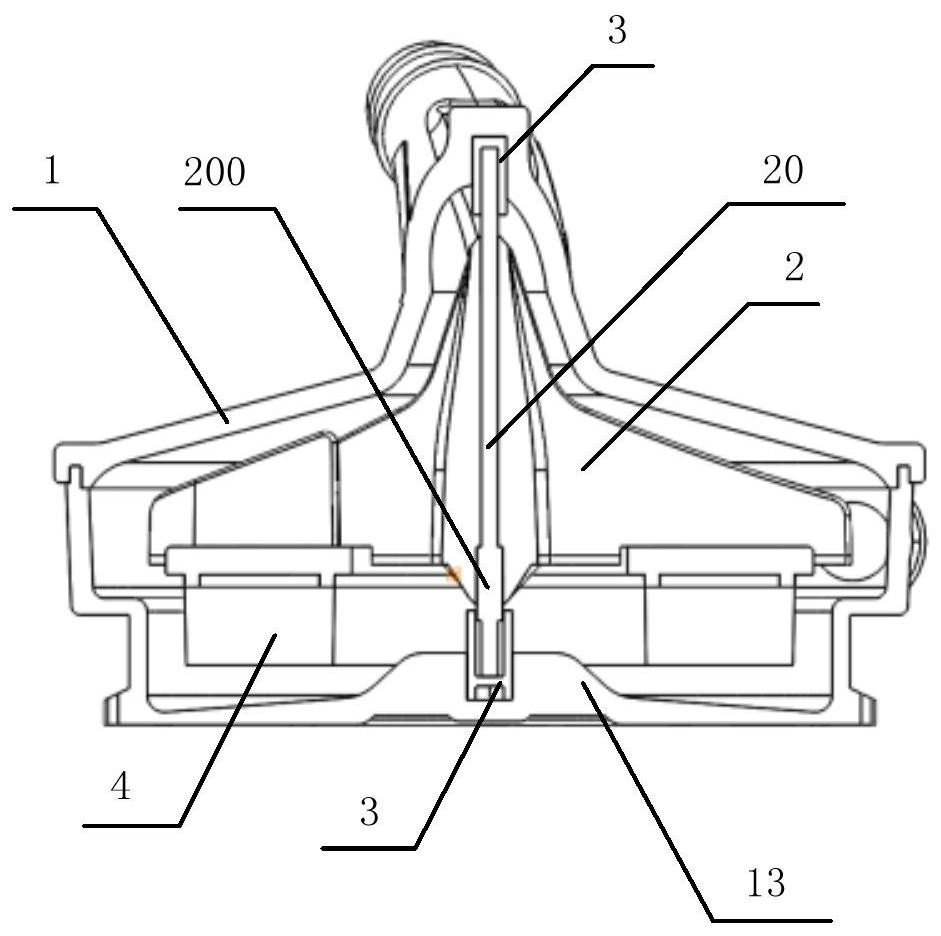

Anti-backflow biliary tract drainage support

The invention provides an anti-backflow biliary tract drainage support. The biliary tract drainage support includes (a) a support section (10) of a hollow tube-shaped structure; and (b) a drainage section (20), wherein the drainage section (20) includes a base (21) connected to the support section (20), petaloid members (23) (22) which extend from the base to a far end, and block-like structures (25) positioned at a near side. The biliary tract drainage support can ensure drainage of the biliary tract, can effectively prevent backflow of content of duodenums, and then can reduce the opportunities of support blocking and biliary tract infections.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Reactor for treating village and town sewage based on aerobic granular sludge and sewage treatment method

PendingCN113371822ASimple processSmall footprintWater treatment parameter controlBiological treatment regulationSludgeSewage

The invention provides a reactor for treating village and town sewage based on aerobic granular sludge and a sewage treatment method. The reactor comprises a water inlet system, a drainage system, an intermediate drainage system, a sludge discharge system, a gas supply system and an intelligent control system; the invention also relates to the sewage treatment method of the reactor. Compared with other village and town sewage treatment processes, the reactor for treating the village and town sewage based on the aerobic granular sludge has the advantages of more efficient biological nitrogen and phosphorus removal capacity, simple process structure, no need of a secondary sedimentation tank, small occupied area, good sludge settleability, easiness in mud-water separation, less mechanical equipment, strong impact load resistance, high automation and intelligence degree, simple operation and management, low operation energy consumption and the like.

Owner:许孝瑜

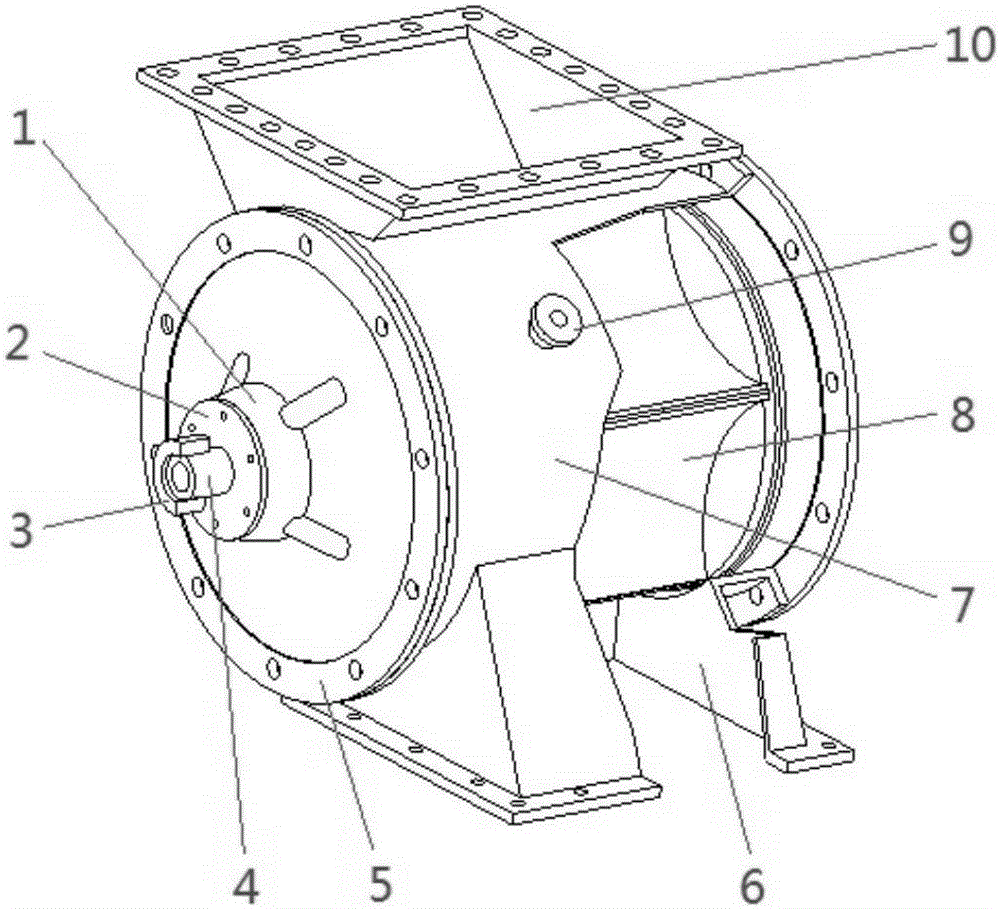

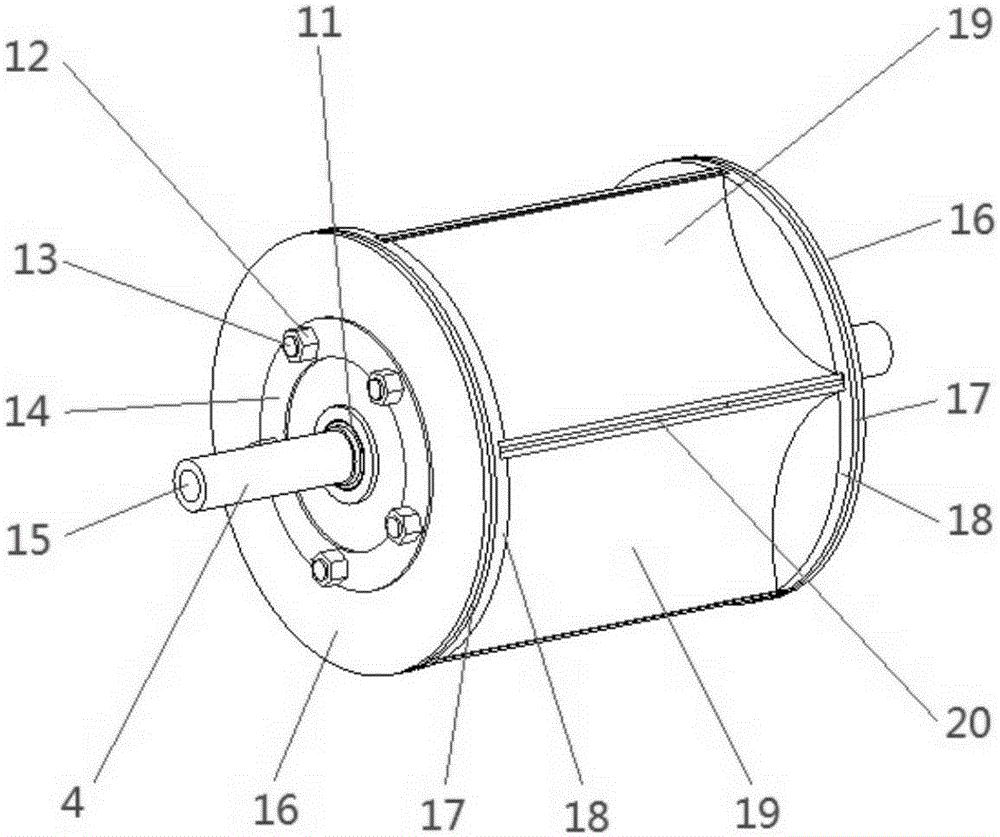

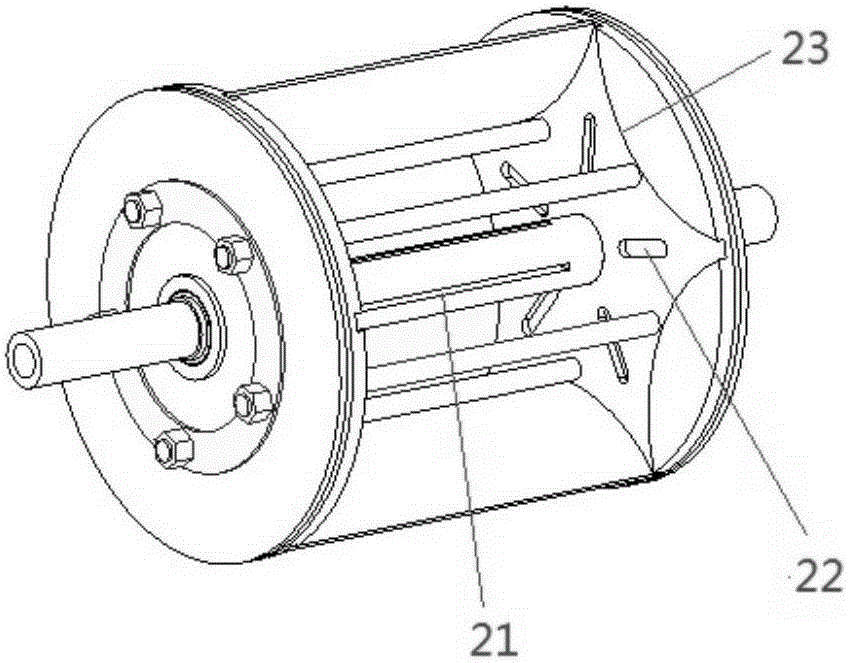

Rotary feeder sealed through air curtains

The invention provides a rotary feeder sealed through air curtains. The rotary feeder comprises a cambered impeller rotor, a shell body, a pressure limiting valve, a feeding inlet, a discharging outlet, rotating joints, externally-arranged bearings, big end caps, small end caps and conical sleeves. The cambered impeller rotor is of a hollow structure, and is provided with cambered plates evenly distributed along the circumference. An axial clearance taken as an airflow channel for the axial sealing air curtain is arranged between the tops of every two adjacent cambered plates. Annular clearances taken as airflow channels for the end face sealing air curtains are arranged between inner side plates and outer side plates. A hollow shaft, the cambered plates, the inner side plates and the outer side plates are connected into a whole. The cambered impeller rotor is detachably connected through the conical sleeves, studs, nuts, annular gaskets, arc-shaped grooves and the like. Compared with an existing feeder, the closed air curtains formed in the rotary feeder are good in sealing effect. The rotor does not make contact with the inner surface of the shell body, and the rotor is free of abrasion, so that the service life of parts and components is long. The rotor is flexible in operation and convenient to disassemble and clean. The rotary feeder can be taken as a non-contact rotary sealed feeding device which is capable of achieving continuous conveyance of materials.

Owner:CHANGZHOU UNIV

Pen-shaped debridement device

The invention discloses a pen-shaped debridement device. The pen-shaped debridement device is characterized by comprising a debridement head which is hollow, a plurality of scrapers connected with thedebridement head and positioned on the outer side face of the same, an adsorption opening arranged on the debridement head, corresponding to the scrapers, communicated with a containing cavity and used for enabling substances scraped by the scrapers to enter the containing cavity, a holding rod and a connection portion, where the containing cavity is formed inside the debridement head, a cavity is formed inside the holding rod and penetrates the same, and one end of the connection portion is connected with the tail of the debridement head while the other end of the same is connected with theholding rod. The pen-shaped debridement device has the advantages of being simple in structure, portable and stable to operate and having elasticity and steering ability.

Owner:NINGBO FIRST HOSPITAL

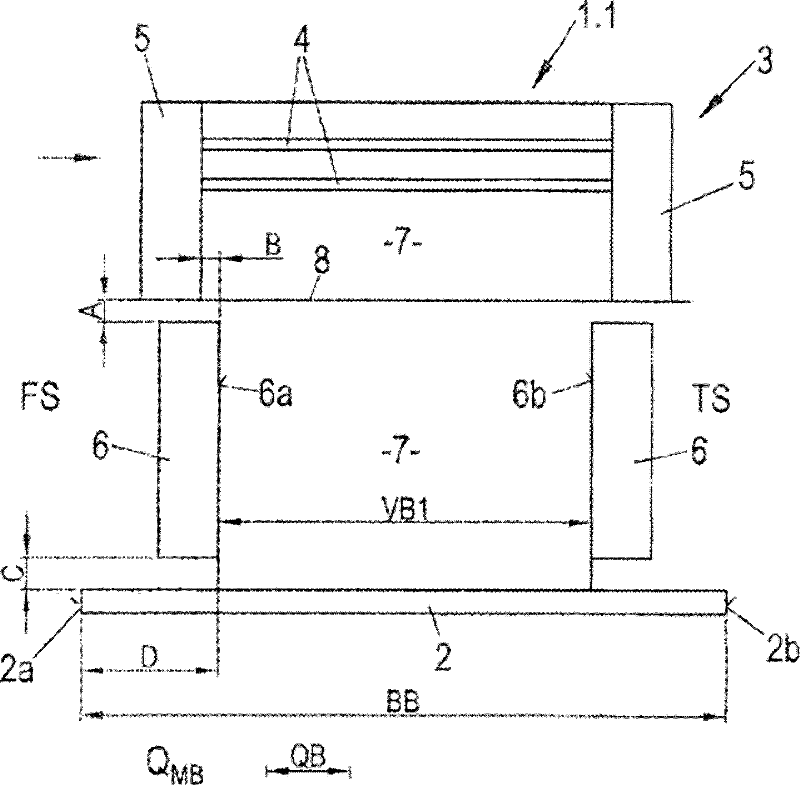

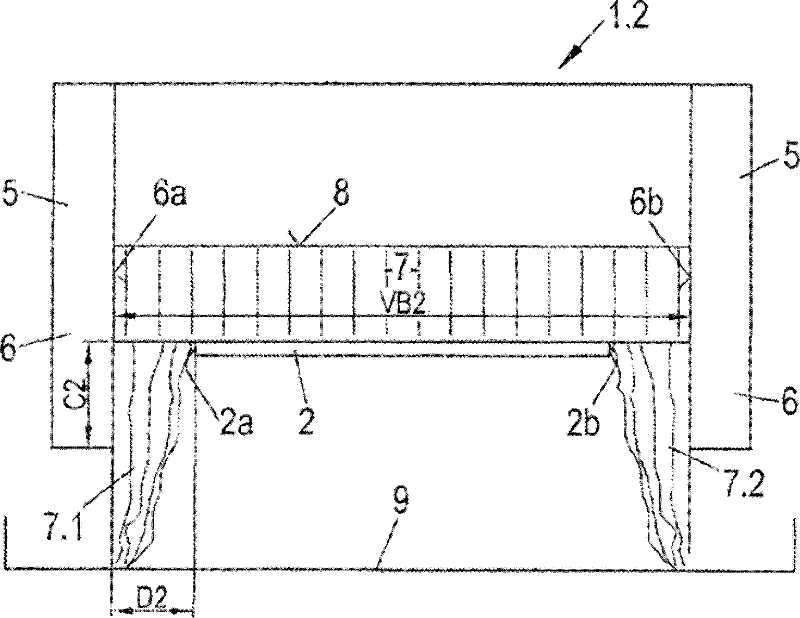

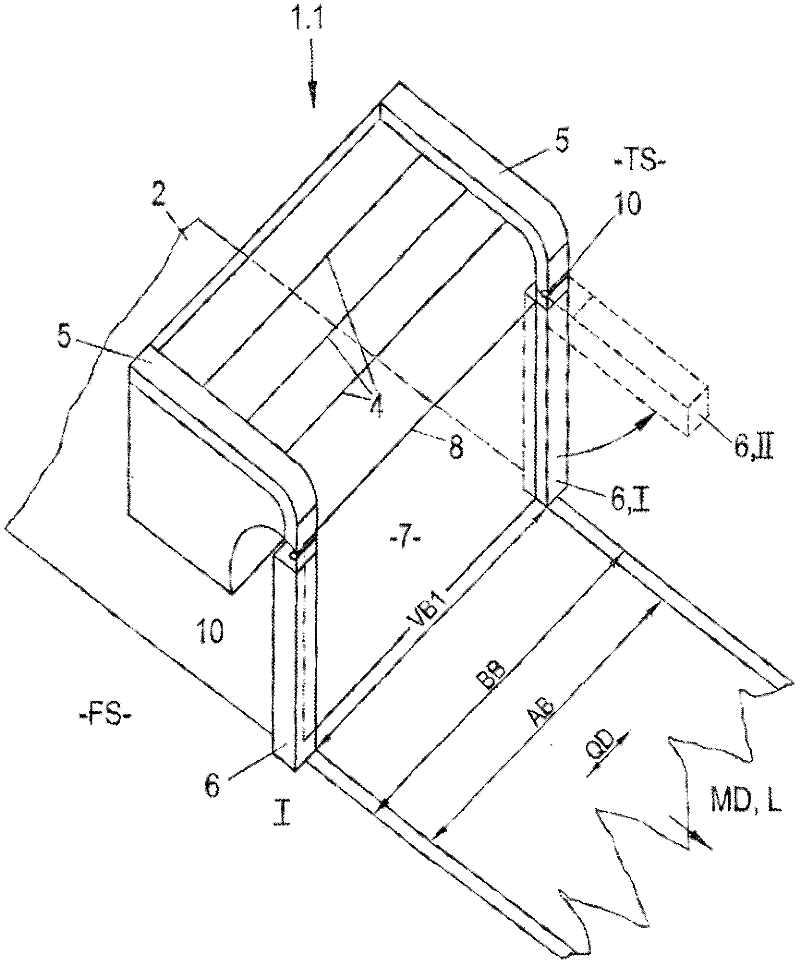

Curtain application unit

InactiveCN102316995AImprove protectionNot in operating positionLiquid surface applicatorsCoatingsFiberEngineering

running paper, board or other fibrous web (2) in a coating machine, having a curtain application head (3) arranged above the fibrous web (2) and corresponding at least to the width of the fibrous web (2) for dispensing at least one fluid to a paste-like application medium (M1, M2) in the form of a single or multi-layered curtain (7) that falls substantially as a result of gravity onto the fibrous web (2), wherein a curtain holder (6) is provided on at least one side edge of the curtain (7) to guide the curtain (7) through the path of fall thereof - that is, between a tear-off edge (8) of the application head (3) and the surface of the fibrous web (2) moving underneath the application head (3) in a longitudinal direction (MD), additionally having an application medium collection channel and an air boundary layer distance arrangement. According to the invention, the curtain holder (6) is movably arranged on a component of the coating machine or the curtain application unit (1.1, 1.2, 1.3) so that the curtain holder (6) is held in the operating position (I) thereof during operation of the application unit (1.1, 1.2, 1.3) but still allows it to leave the operating position (I) thereof.

Owner:VOITH PATENT GMBH

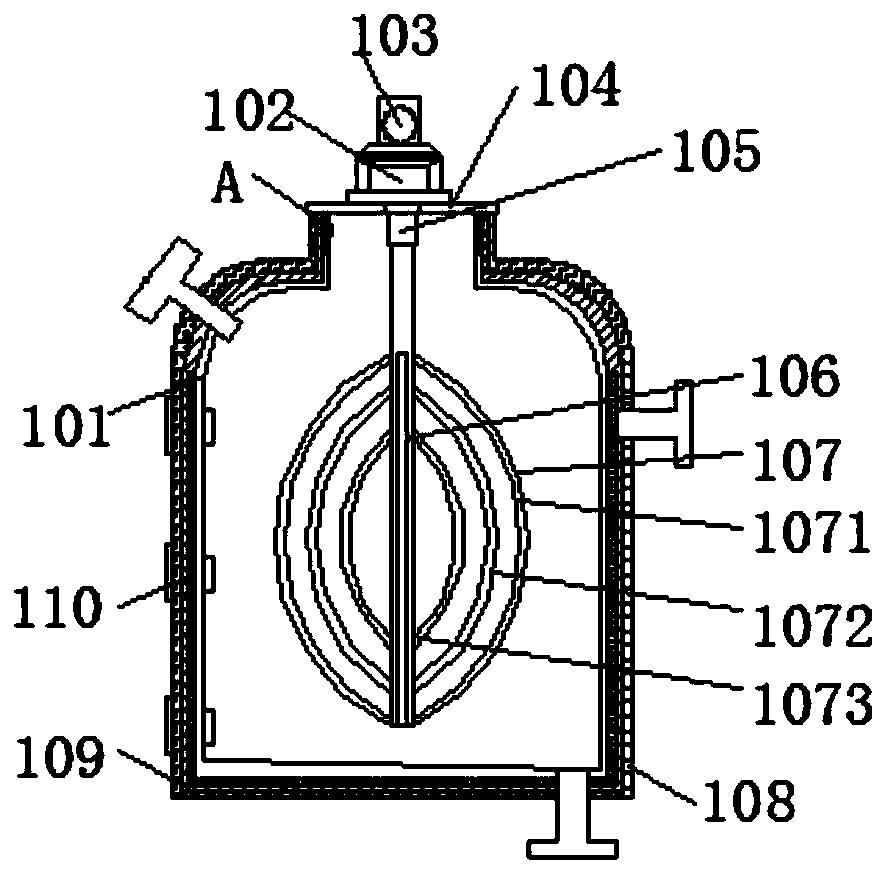

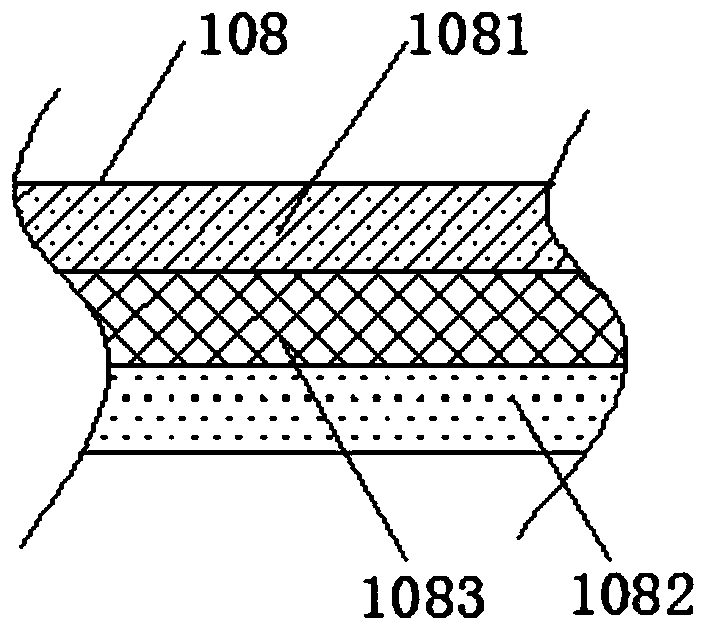

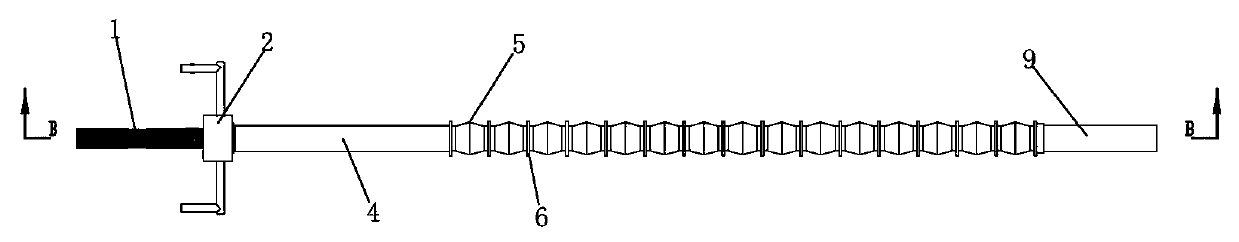

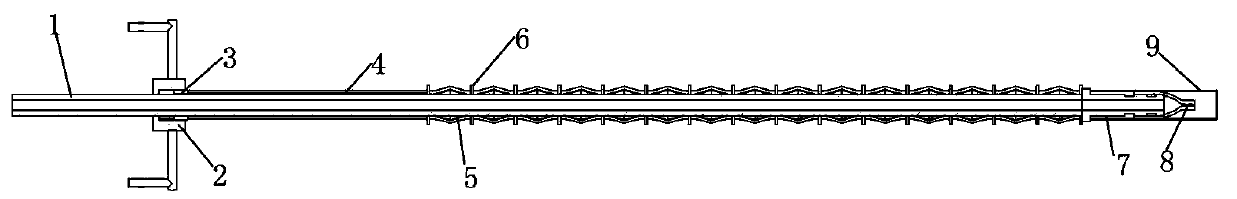

Liquid treatment equipment

ActiveCN105641963AImprove heat transfer efficiencySolve the difficult problem of fouling and cleaningDistillation regulation/controlEvaporator accessoriesMechanical engineeringEvaporation chamber

The invention discloses liquid treatment equipment. The liquid treatment equipment comprises an evaporation chamber, and a condensation chamber is arranged on the evaporation chamber. According to the technical scheme, compared with common distillation and concentration treatment equipment, the evaporation and condensation integrated design is adopted for the liquid treatment equipment, so that the liquid treatment equipment is compact in structure, and space occupied by the liquid treatment equipment is reduced by about 20% or above compared with that occupied by present common equipment; a scraper is arranged inside the equipment, so that the problem that scale is formed on the inner wall of the evaporation chamber in the evaporation process and is difficult to remove is solved.

Owner:HIMILE MECHANICAL MFG

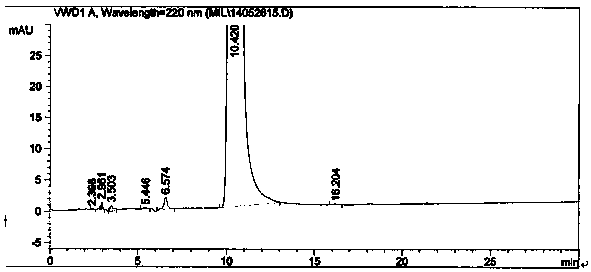

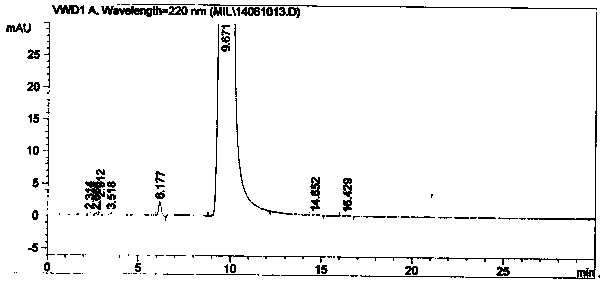

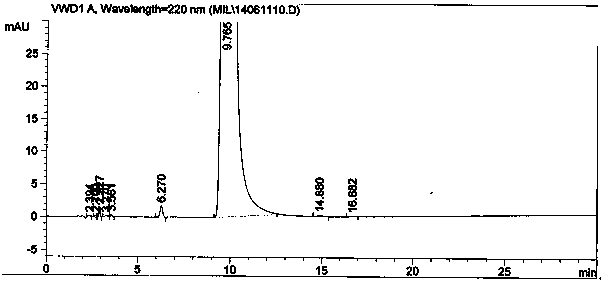

A kind of preparation method of high-purity milrinone

ActiveCN104387320BImprove crystal effectQuality improvementOrganic chemistrySolubilityAcetic anhydride

Owner:HUZHOU ZHANWANG PHARMA

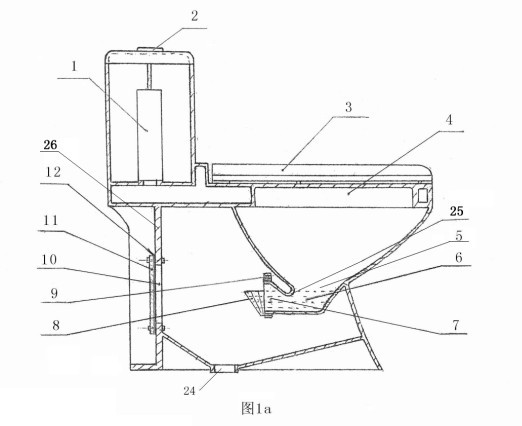

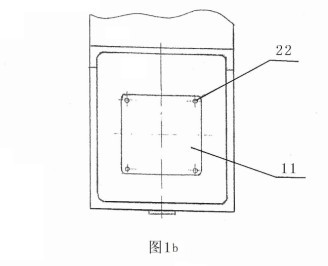

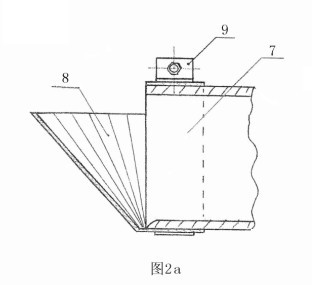

Direct-discharge water-saving pedestal pan with elastic water seal door by using water impact force

ActiveCN102094450AAvoid problems that are easy to block and affect useShort rinse timeWater closetsFlushing timeWater saving

The invention provides a direct-discharge water-saving pedestal pan with an elastic water seal door by using water impact force. In the invention, a horizontal water outlet is arranged on an outer end of a lower water port of a pelvic cavity ceramic main body; a downward bulge is arranged on the top end of a joint between the horizontal water outlet and the lower water port; and an elastic water seal door assembly is arranged on the horizontal water outlet and can reserve a sealing water level which is higher than the bulge in the horizontal water outlet under a balanced condition without an external force, and the elastic water seal door assembly is elastically and extensionally deformed to be opened under the action of the water impact force so that water and pollutants are rapidly discharged into a sewer. The pedestal pan or squat pan using the elastic water seal door device is very water-saving (1L of water is used in the case of low water mark and 3L of water is used in the case of high water mark), and is far superior to provisions of national and international water-saving standards; and the flushing time is very short, the pollutant backflow and peculiar smell are avoided, and 100% of sealed water is replaced, thus being beneficial to health and environmental protection, and effectively avoiding the problem that the traditional pedestal pan and squat pan are easily blocked to affect applications.

Owner:广东泰妮科技有限公司

Methyl salicylate preparation apparatus

InactiveCN110270285ARecycle thoroughlyStir wellOrganic compound preparationTransportation and packagingRefluxDistillation

The invention provides a methyl salicylate preparation apparatus. The apparatus comprises a reaction kettle, a dryer, a filtering apparatus and a distillation apparatus, wherein the reaction kettle is connected with a first material storage tank, a second material storage tank, a third material storage tank and a fourth material storage tank, salicylic acid is stored in the first material storage tank, anhydrous methanol is stored in the second material storage tank, concentrated sulfuric acid is stored in the third material storage tank, and a sodium carbonate solution is stored in the fourth material storage tank. The reaction kettle is stirred more uniformly, a reaction process is carried out quickly, the interior and internal components can be cleaned, and at the same time noise can be effectively reduced; methyl salicylate is more thoroughly recovered by the dryer; and methyl salicylate in the distillation apparatus is heated to evaporate water, distillation efficiency is high, and no reflux is carried out.

Owner:ZHENJIANG GAOPENG PHARMA

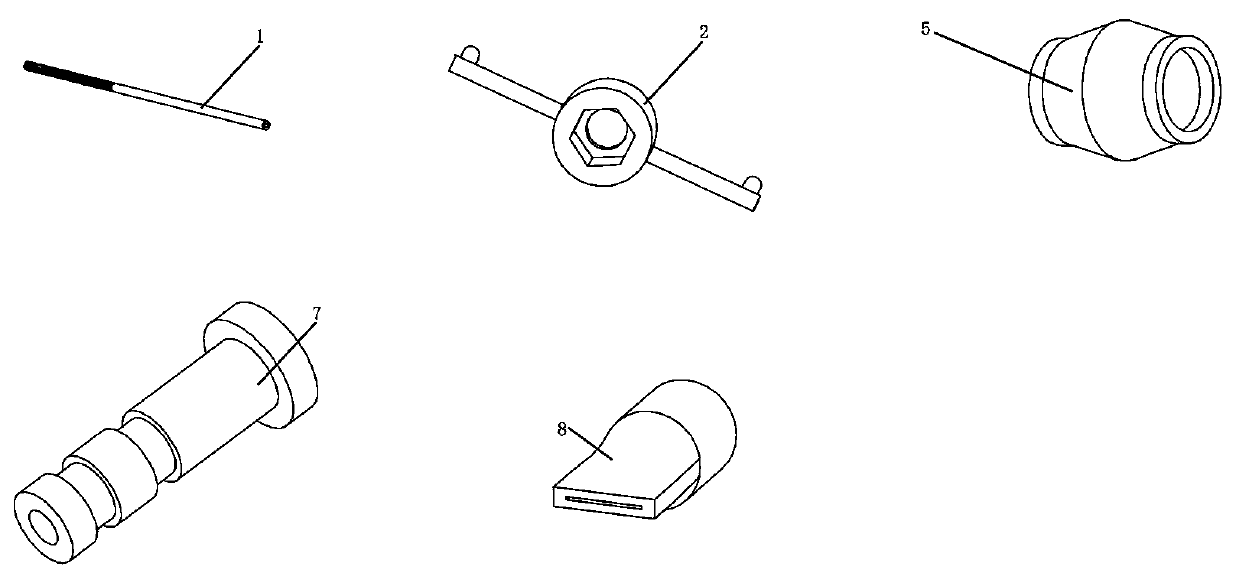

Device and method for sealing, grouting, and reinforcing broken coal-rock masses

InactiveCN110630292APromote expansionClose contactUnderground chambersSealing/packingSlurryEngineering

The invention belongs to the technical field of surrounding rock control in coal mining, and particularly relates to a device and method for sealing, grouting, and reinforcing broken coal-rock masses.Technical problems such as poor sealing and grouting effects and complex construction in the prior art are solved. The device mainly comprises a grouting pipe, a wrench, a nut, a casing pipe, a sealing sleeve, a gasket, a tail end joint, a duckbill valve, and a tail end protection tube, one end of the grouting pipe is provided with an external thread, the nut is in screw joint with the grouting pipe through the external thread, the wrench is connected to the outside of the nut in a sleeving mode, the other end of the grouting pipe is fixedly connected with the tail end joint, the tail end protection tube is fixed to the tail end joint, and the duckbill valve is mounted on the tail end joint in a sleeving mode and completely located in the protection tube at the tail end; and the casing pipe, the sealing sleeve and the gasket are mounted on the outer wall of the grouting pipe between the nut and the tail end joint in turn in a sleeving mode. According to the device and method for sealing, grouting, and reinforcing the broken coal-rock masses, the sealing effect is good, the grouting process is simple, slurry can be prevented from flowing back, the cost is low, the grouting speed ishigh, and the device for sealing, grouting, and reinforcing the soft and broken coal-rock masses can be widely used and promoted.

Owner:HENAN POLYTECHNIC UNIV

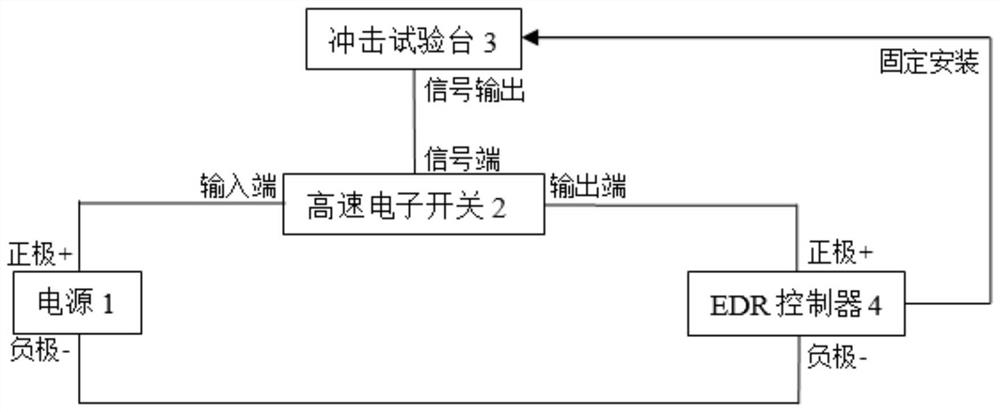

Power-off storage testing device and method for automobile event data recording system

ActiveCN112710911AImprove synchronicityNo battery backflowElectrical testingEvent data recorderImpact test

The invention provides an automobile event data recording system outage storage testing device. The device comprises a power supply, a high-speed electronic switch and an impact test bench, wherein a positive electrode of the power supply is connected with an input end of the high-speed electronic switch through a wire, and an output end of the high-speed electronic switch is connected with a positive electrode of the power supply of an EDR controller to be tested through a wire; a negative electrode of the power supply is connected with a negative electrode of the power supply of the EDR controller to be tested through a wire; a signal output end of the impact test bench is connected with a signal input end of the high-speed electronic switch through a signal line; and the table top of the impact test table is used for mounting a to-be-tested EDR controller. The device is advantaged in that power supply to the EDR controller is cut off through the high-speed electronic switch, synchronism is high, and power failure is thorough.

Owner:CATARC AUTOMOTIVE TEST CENT TIANJIN CO LTD +1

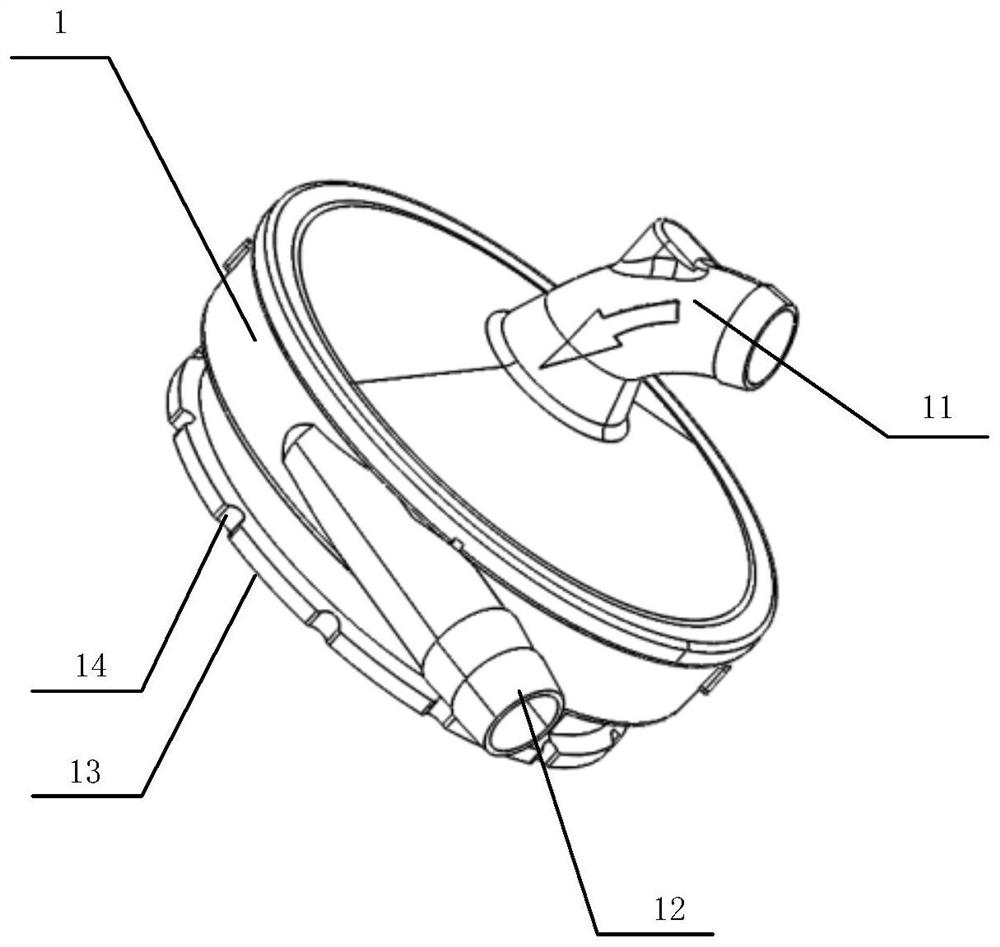

Medical centrifugal pump head

PendingCN113769258AReduce accelerationAvoid damageBlood pumpsIntravenous devicesBlood flowEngineering

The invention relates to the technical field of medical treatment, and particularly relates to a medical centrifugal pump head. The medical centrifugal pump head comprises a pump shell and an inducer rotationally installed in the pump shell; a magnet is arranged at the bottom of the inducer; the pump shell is provided with a liquid inlet and a liquid push-out opening; a top positioning sleeve and a bottom positioning sleeve are arranged in the pump shell; a positioning rod capable of rotating around the inducer is arranged at the axis of the inducer, and the two ends of the positioning rod are respectively connected with the top positioning sleeve and the bottom positioning sleeve; the section of the liquid inlet is gradually increased in the liquid inflow direction, and the liquid inlet is located in the center of the top of the pump shell; a plurality of blades with inclined side surfaces are arranged on the inducer, and an angle between the liquid push-out opening and the blades is 45 degrees; and a plurality of positioning notches capable of being connected with external equipment are formed in the bottom of the pump shell. The medical centrifugal pump head adopts the bearing-free design, is less in friction and lower in heat production, ensures that no vortex exists in a liquid inlet and the liquid push-out opening of the centrifugal pump head, is uniform in acceleration, and keeps the optimal blood flow.

Owner:卡迪美科北京生物科技有限公司

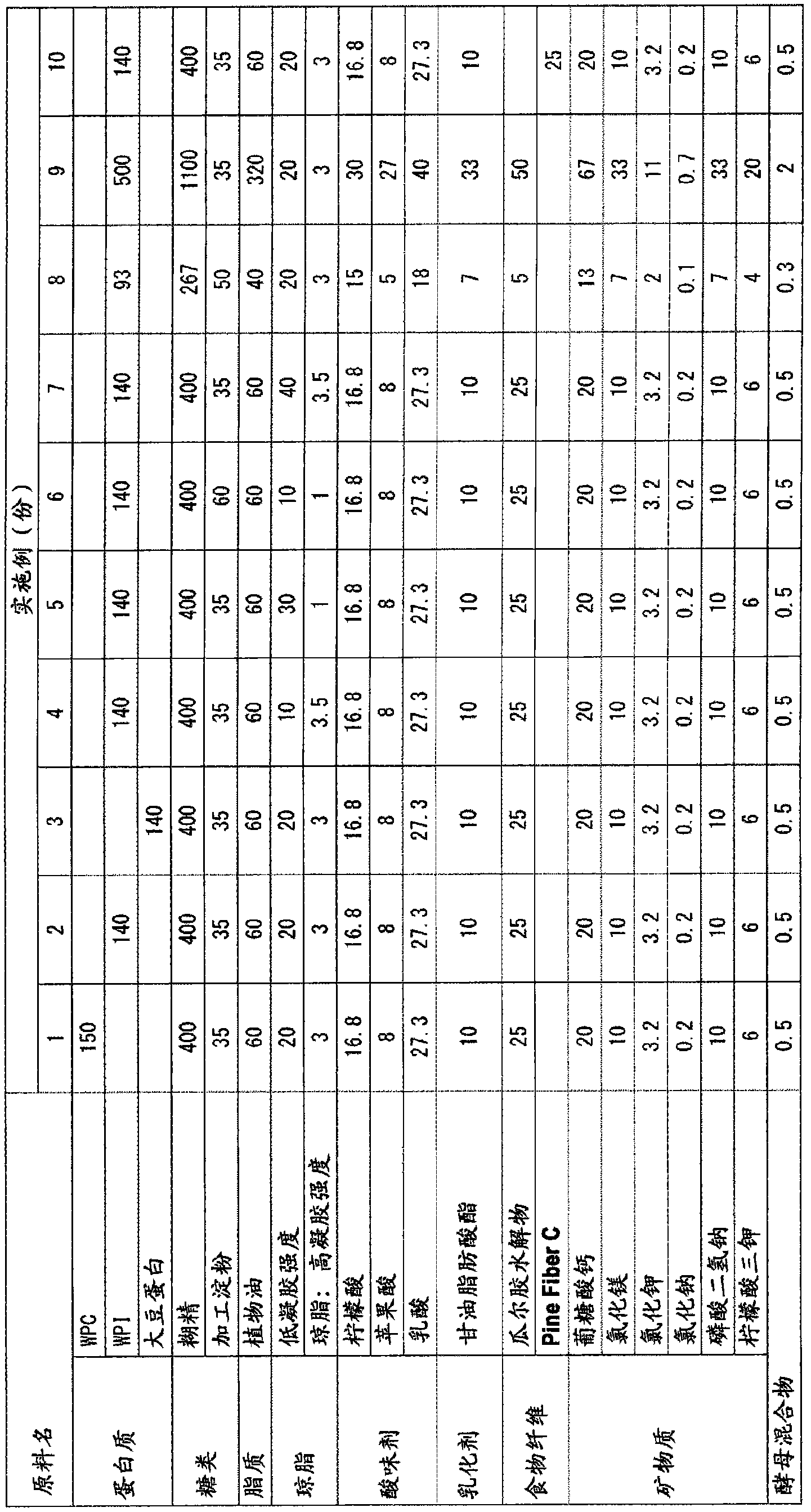

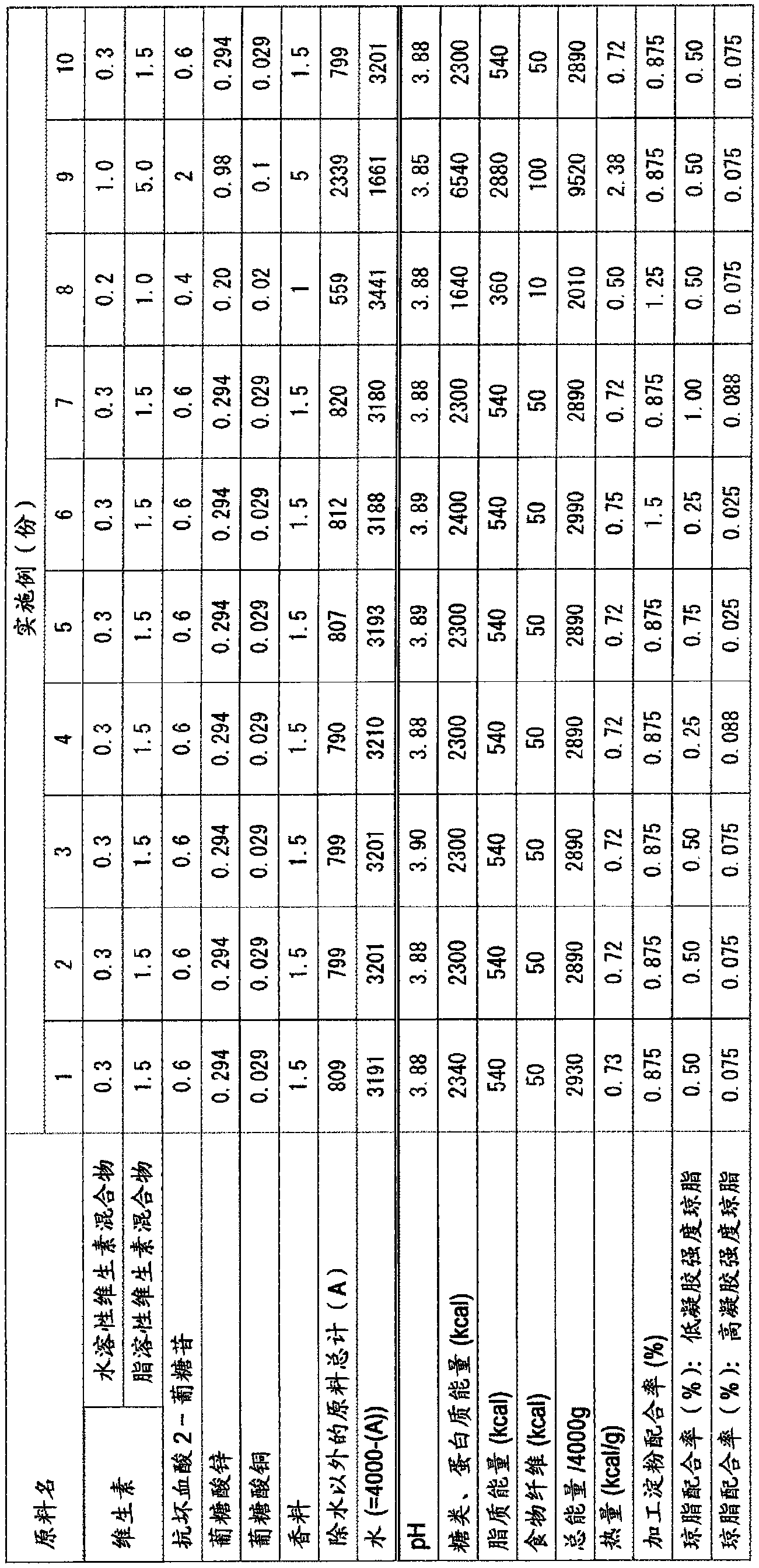

Semi-solidified nutrient for gastrostomy

ActiveCN104394844AGood shape retentionReduce resistanceMetabolism disorderPharmaceutical delivery mechanismUltimate tensile strengthNutrient

[Problem] To provide: a semi-solidified nutrient having good shape retention even when pushed out of a syringe, etc., having little adhesion to the tube, and having little resistance when pressed out of the tube; and a preparation method therefor. [Solution] A semi-solidified nutrient for gastrostomy, including: a nutrient; an agar having a jelly strength of no more than 10 kPa; an agar having a jelly strength of at least 30 kPa; and a processed starch. The content of the agar having a jelly strength of no more than 10 kPa is 0.1-1 mass% relative to the total amount of the semi-solidified nutrient for gastrostomy; the content of the agar having a jelly strength of at least 30 kPa is 0.01-0.2 mass% relative to the total amount of the semi-solidified nutrient for gastrostomy; and the processed starch content is 0.5-3 mass% relative to the total amount of the semi-solidified nutrient for gastrostomy.

Owner:NUTRI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com