Liquid treatment equipment

A technology for liquid treatment and treatment equipment, applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. Improved distillation and concentration efficiency, increased heat transfer efficiency, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

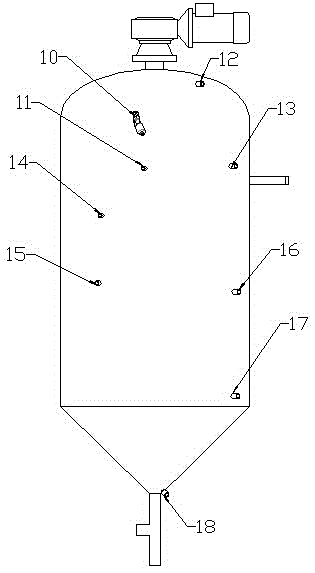

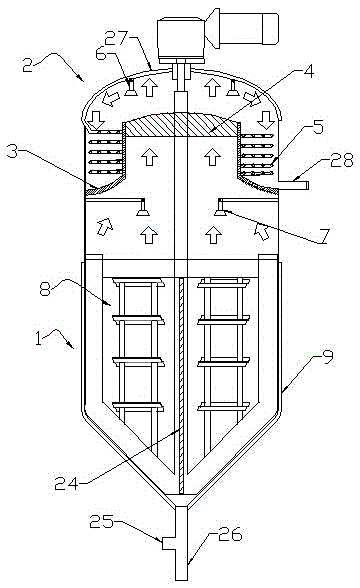

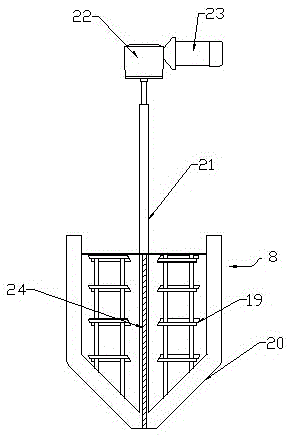

[0042] Examples such as figure 1 As shown, a liquid processing device includes an evaporation chamber 1, a condensation chamber 2 is arranged on the evaporation chamber 1, the evaporation chamber 1 is adjacent to the condensation chamber 2, and the evaporation chamber 1 and the condensation chamber 2 are integrally structured.

[0043] The evaporating chamber 1 and the condensing chamber 2 are separated by an interlayer 3 , and the interlayer 3 is used to avoid heat exchange between the evaporating chamber 1 and the condensing chamber 2 .

[0044] A vertical cylindrical passage is arranged in the middle of the interlayer 3, and the vertical cylindrical passage can ensure that the steam in the evaporation chamber 1 enters the condensation chamber 2 smoothly.

[0045] An annular cavity is formed between the interlayer 3 and the inner wall of the condensation chamber 2 to ensure that the condensed liquid will not flow back into the evaporation chamber 1 .

[0046] The liquid tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com