Mixed nutritional type denitrifying filler and preparation and application thereof

A technology of mixed nutrition and nitrification filler, applied in chemical instruments and methods, anaerobic digestion treatment, biological water/sewage treatment, etc., can solve problems such as unsatisfactory denitrification and denitrification effect, and achieve good wastewater treatment effect and operation effect. Good, the effect of speeding up the update

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

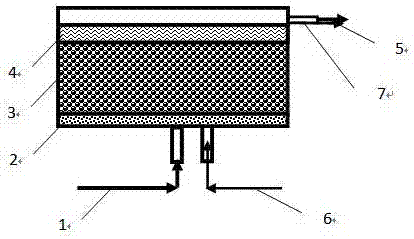

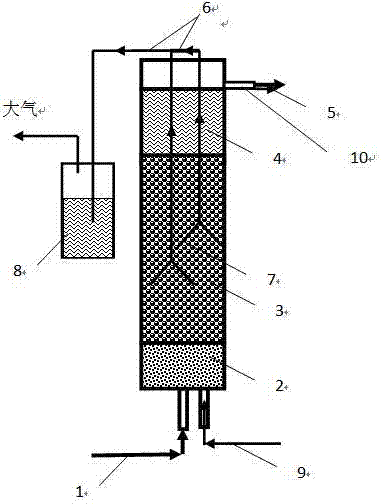

Embodiment 1

[0029] The filler and the reactor of the invention are used to treat simulated nitrate sewage. Activated carbon, sulfur, polybutylene succinate, polycaprolactone, and carboxymethyl cellulose are made into fillers of different particle sizes according to the mass ratio of 20:5:1:1:1, and the filling height is 3m. In the 0.5m ZHDN-B1 type reactor, the filler is packed in layers according to the particle size of 30mm, 20mm, 15mm, 10mm, and 5mm from bottom to top, and the filler and anionic clay are mixed into the reactor according to the ratio of 10:1. . Inoculate the domesticated activated sludge into the reactor, add sodium nitrate to tap water to make water with a concentration of nitrate nitrogen of 80 mg / L to simulate the water quality of sewage, and the raw water is poured into the reactor from the bottom of the reactor through a peristaltic pump. The hydraulic retention time of the sewage in the reactor is 60min, the detected nitrate nitrogen content in the water is less ...

Embodiment 2

[0033] The filler and the reactor of the invention are used to treat simulated nitrate sewage. Activated carbon, sulfur, polybutylene succinate, polycaprolactone and carboxymethyl cellulose are made into fillers of different particle sizes according to the mass ratio of 25:10:1:2:2, and the filling is up to 3m in height. In the 0.75m ZHDN-B2 type reactor, the fillers are filled in layers according to the particle size of 25mm, 10mm, 5mm, 3mm, and 1mm from bottom to top, and the filler and anionic clay are mixed into the reactor according to the ratio of 50:1. . Inoculate the domesticated activated sludge into the reactor, add sodium nitrate to tap water to make water with a concentration of nitrate nitrogen of 80 mg / L to simulate the water quality of sewage, and the raw water is poured into the reactor from the bottom of the reactor through a peristaltic pump. The hydraulic retention time of the sewage in the reactor is 60min, the detected nitrate nitrogen content in the wate...

Embodiment 3

[0037] The filler and the reactor of the invention are used to treat simulated nitrate sewage. Activated carbon, sulfur, polybutylene succinate, polycaprolactone and carboxymethyl cellulose are made into fillers of different particle sizes according to the mass ratio of 10:10:5:3:3, and the filling is up to 3m in height. In the 1m ZHBN-B2 reactor, the filler is packed in layers according to the particle size of 30mm, 25mm, 10mm, 5mm, and 3mm from bottom to top, and the filler and anionic clay are mixed into the reactor according to the ratio of 20:1. Inoculate the domesticated activated sludge into the reactor, add sodium nitrate to the tap water to prepare water with a concentration of nitrate nitrogen of 60mg / L to simulate the water quality of sewage, and the raw water is pumped into the reactor from the bottom of the reactor through a peristaltic pump. The hydraulic retention time of the sewage in the reactor is 45min, the nitrate nitrogen content in the water is detected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com