Patents

Literature

69results about How to "Jet realization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

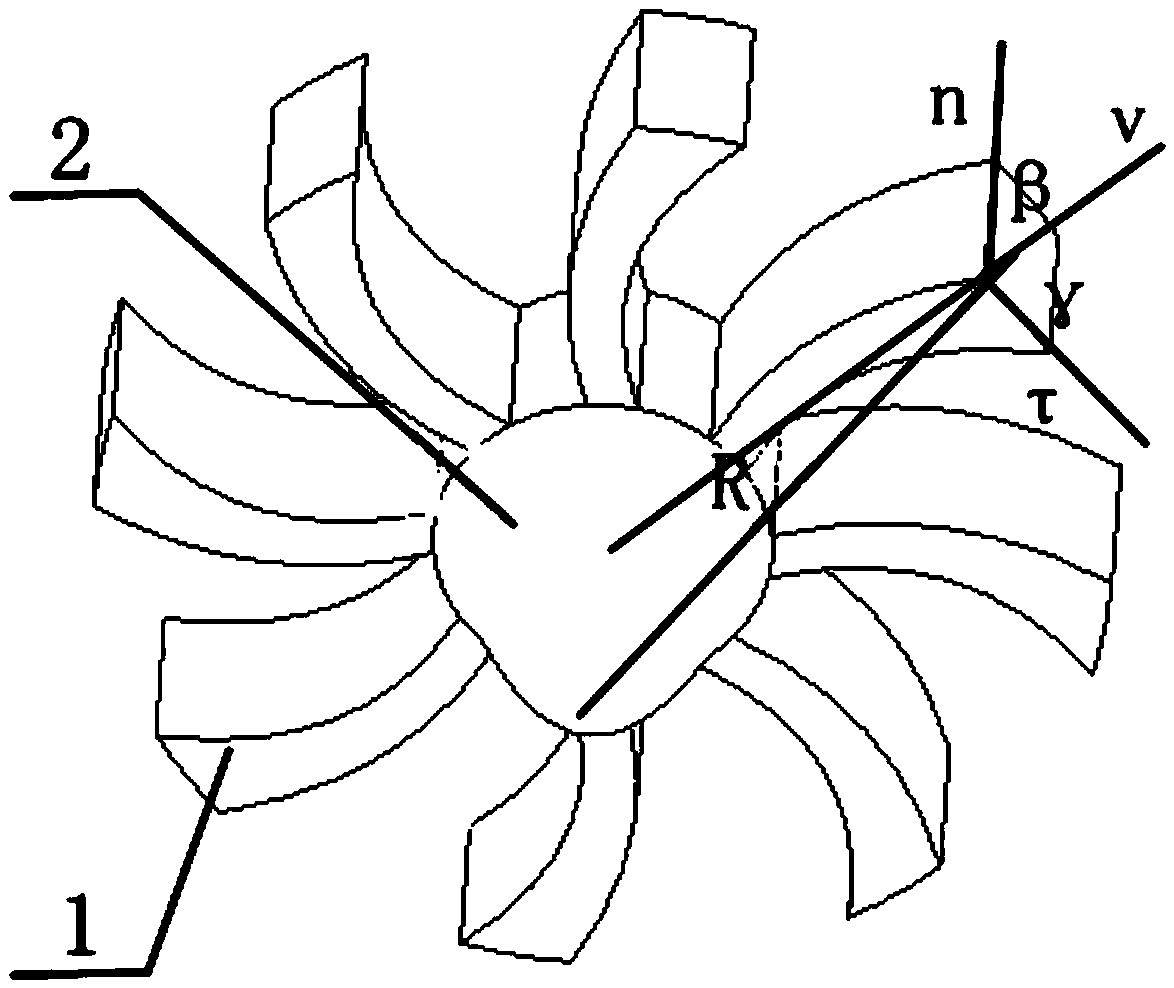

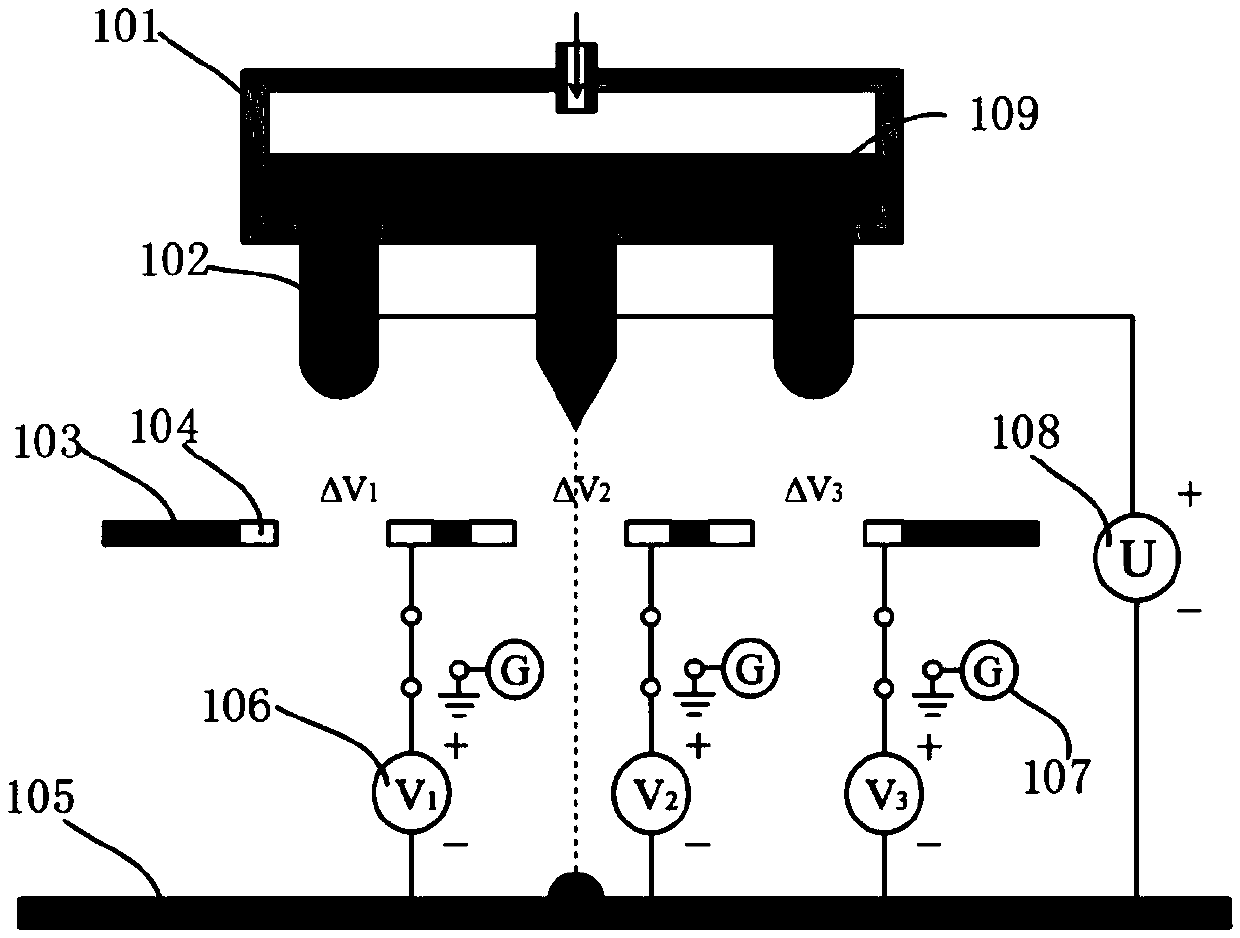

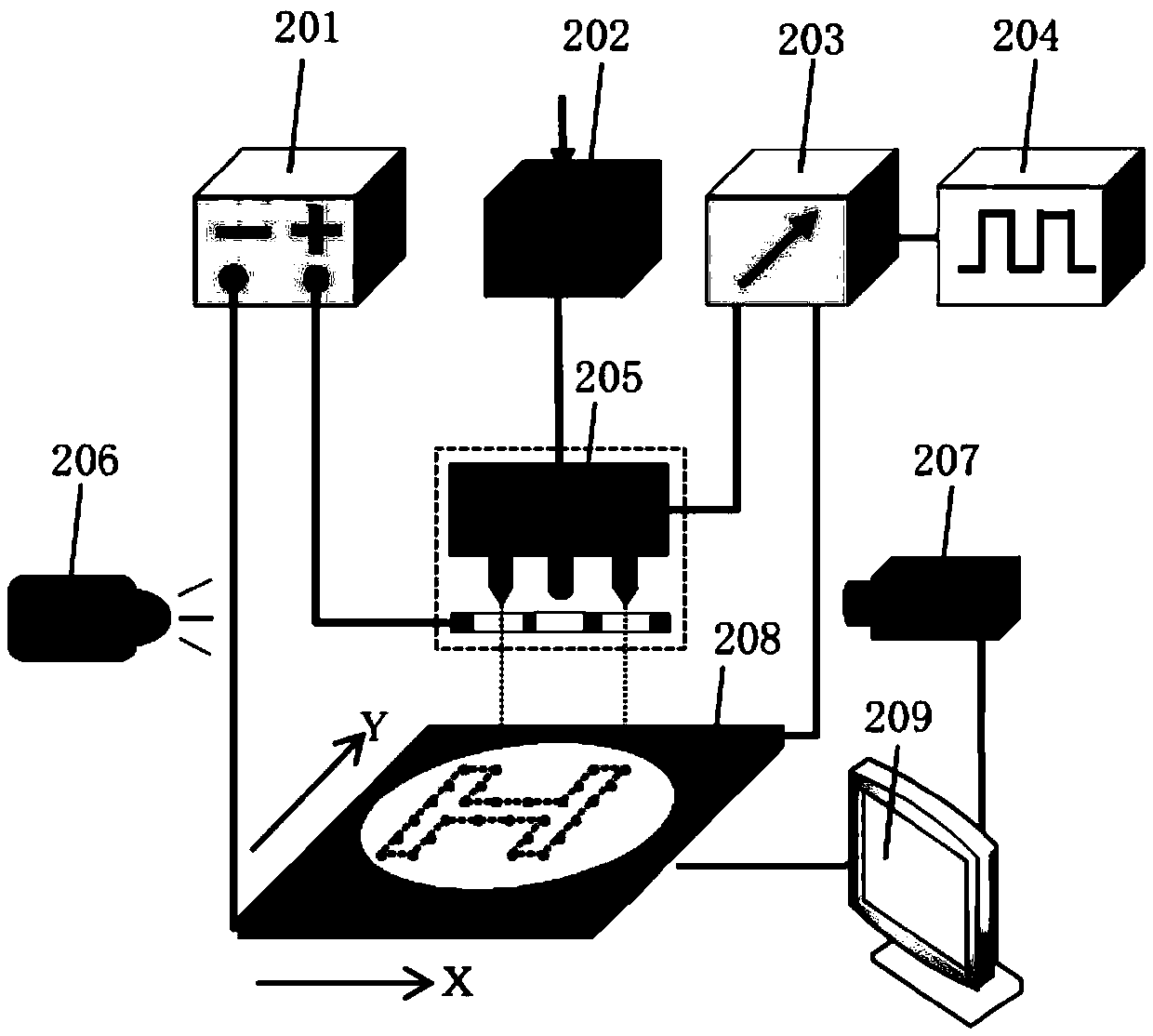

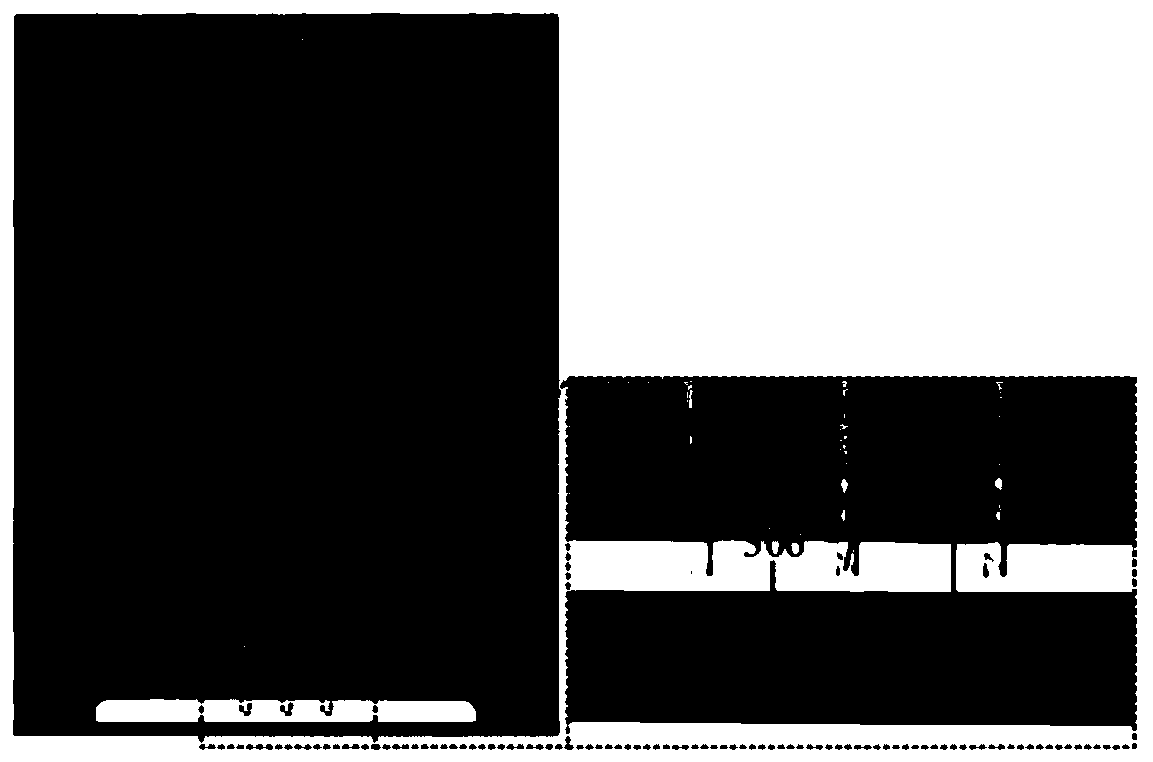

Array electric fluid jet printing head characterized by independently controllable nozzle jet and realization method of independent control of jet of nozzles

ActiveCN104191819AAchieve independent controllable injectionSimple structurePrintingSpray nozzleEngineering

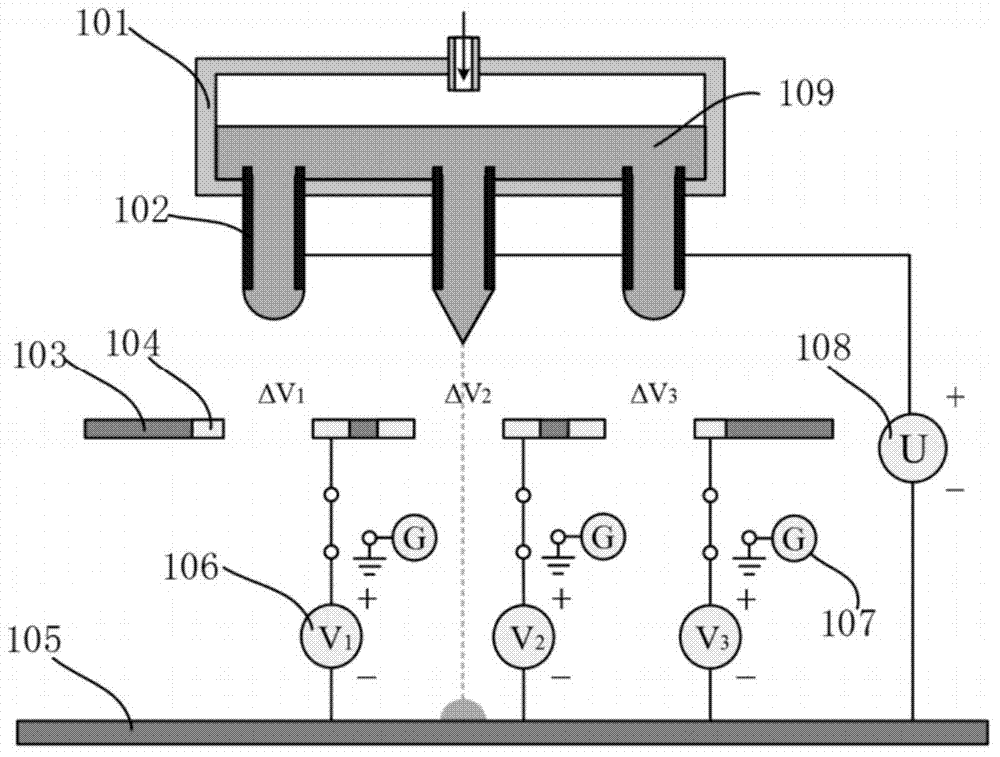

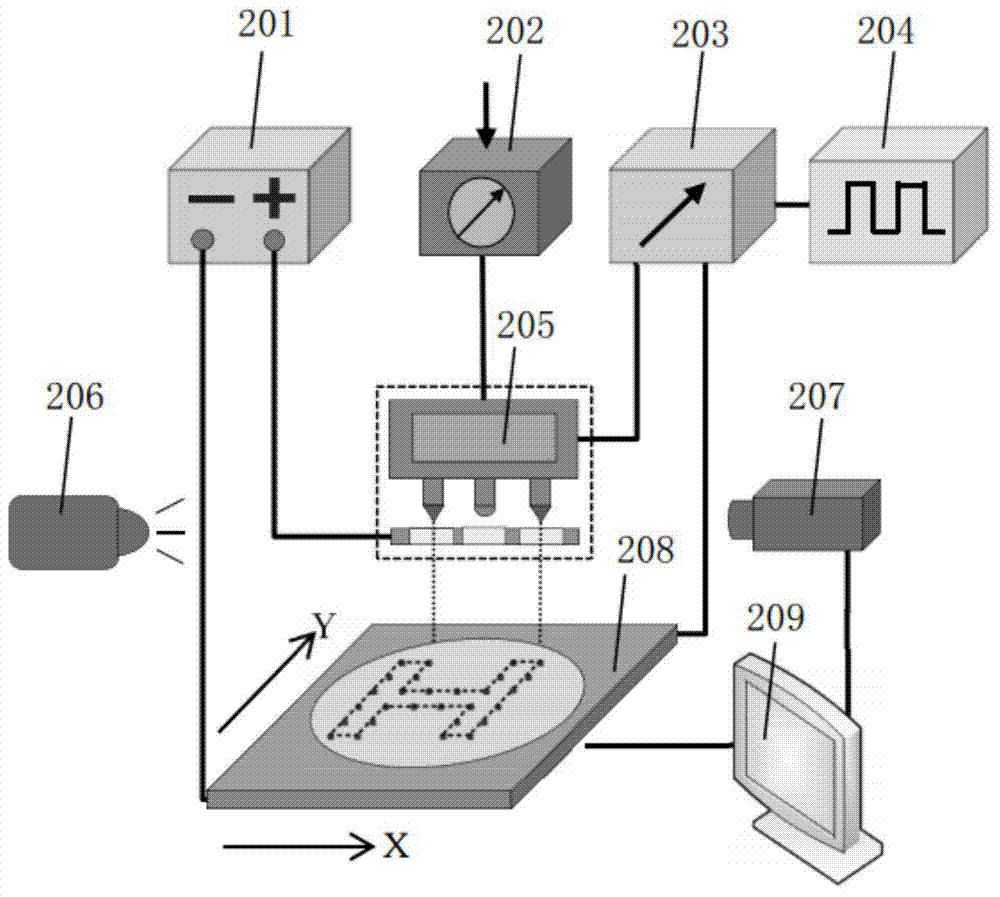

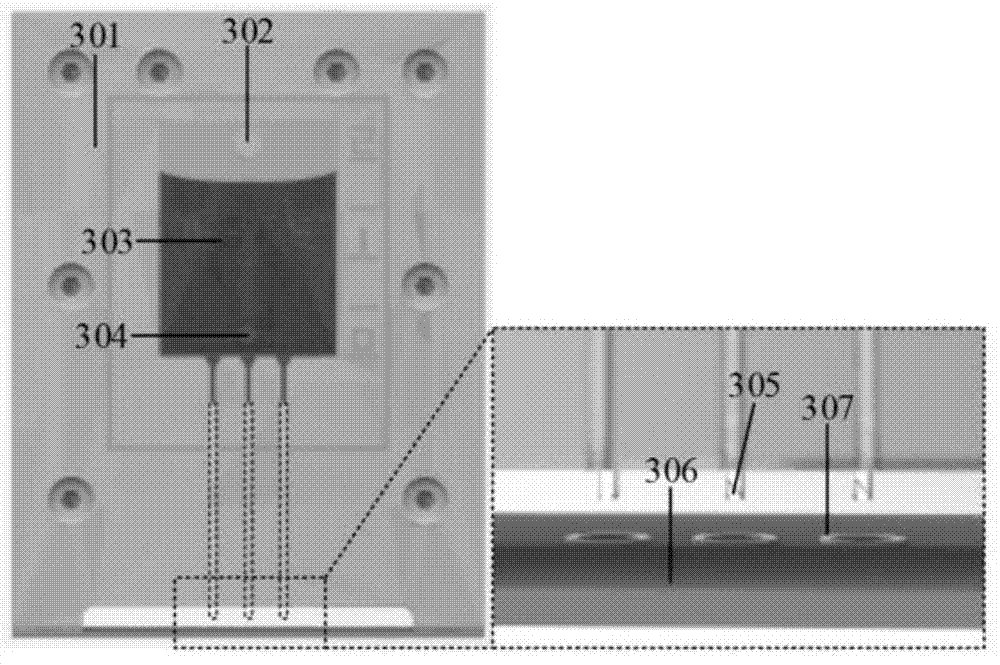

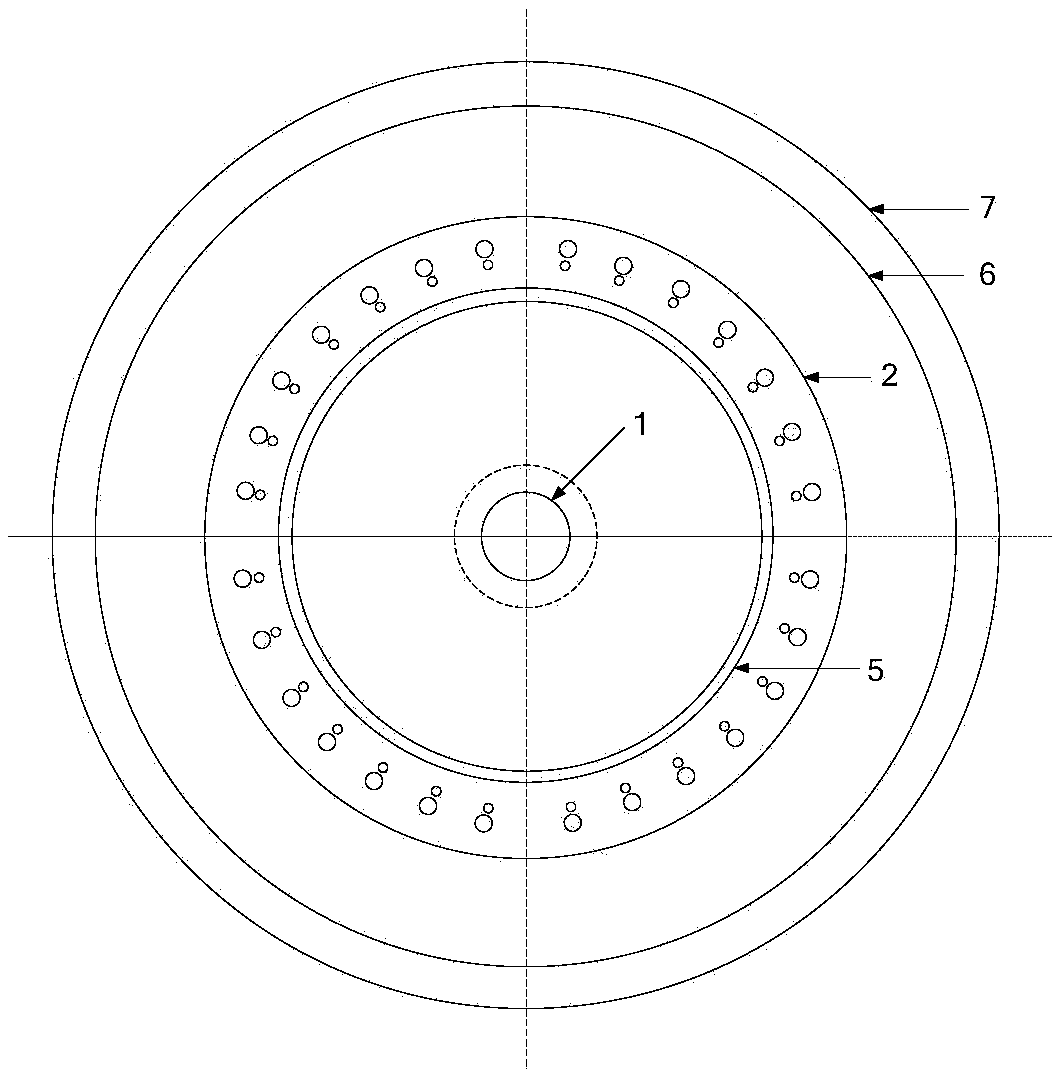

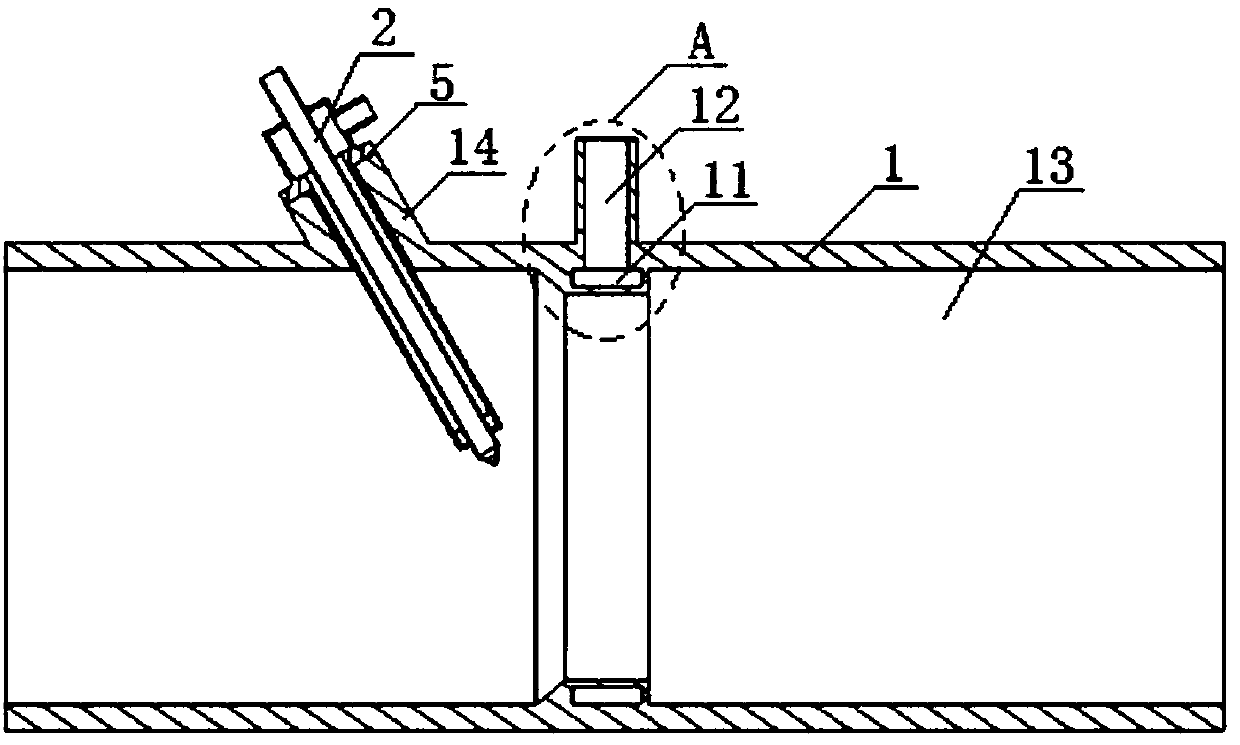

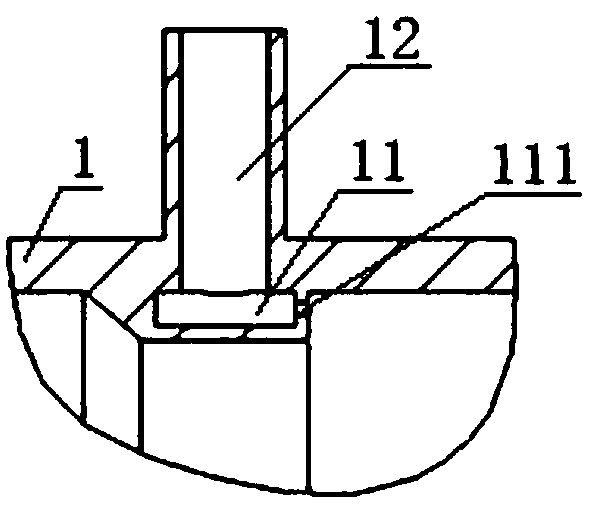

The invention discloses an array electric fluid jet printing head characterized by independently controllable nozzle jet. The array electric fluid jet printing head comprises a guide electrode layer arranged between a nozzle array and a receiving plate, and a plurality of round holes corresponding to nozzles in number are formed in the guide electrode layer; the centers of the round holes are collinear with the centers of the nozzles; a circle of conducting ring is coaxially disposed on the outer periphery of each round hole in the guide electrode layer, and is connected with one voltage source; and the nozzle array is connected with the jet voltage sources; and the voltage value of each voltage source is properly adjusted, so that the voltage differences of the nozzles required for jet printing and the corresponding conducting rings are greater than the voltage differences of the remaining nozzles, the field strength of the nozzles for jet is greater than the field strength needed to start the jetting, the field strength of the nozzles not required for jetting is lower than the field strength needed to start the jetting, and the independent control of all the nozzles can be realized. The invention further discloses a realization method of the independent control of the jet of the nozzles. The array electric fluid jet printing head and the realization method can solve the problems of complex structure and incapability of large-scale integrated use in the conventional independent jet control to printing heads.

Owner:HUAZHONG UNIV OF SCI & TECH

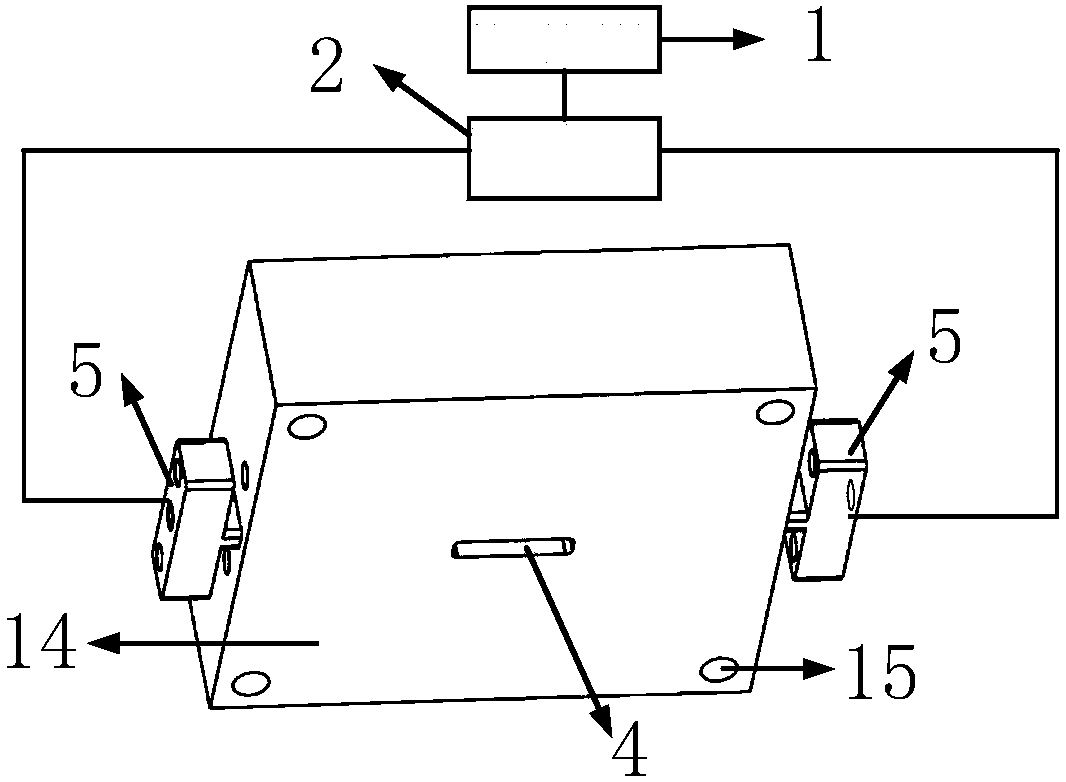

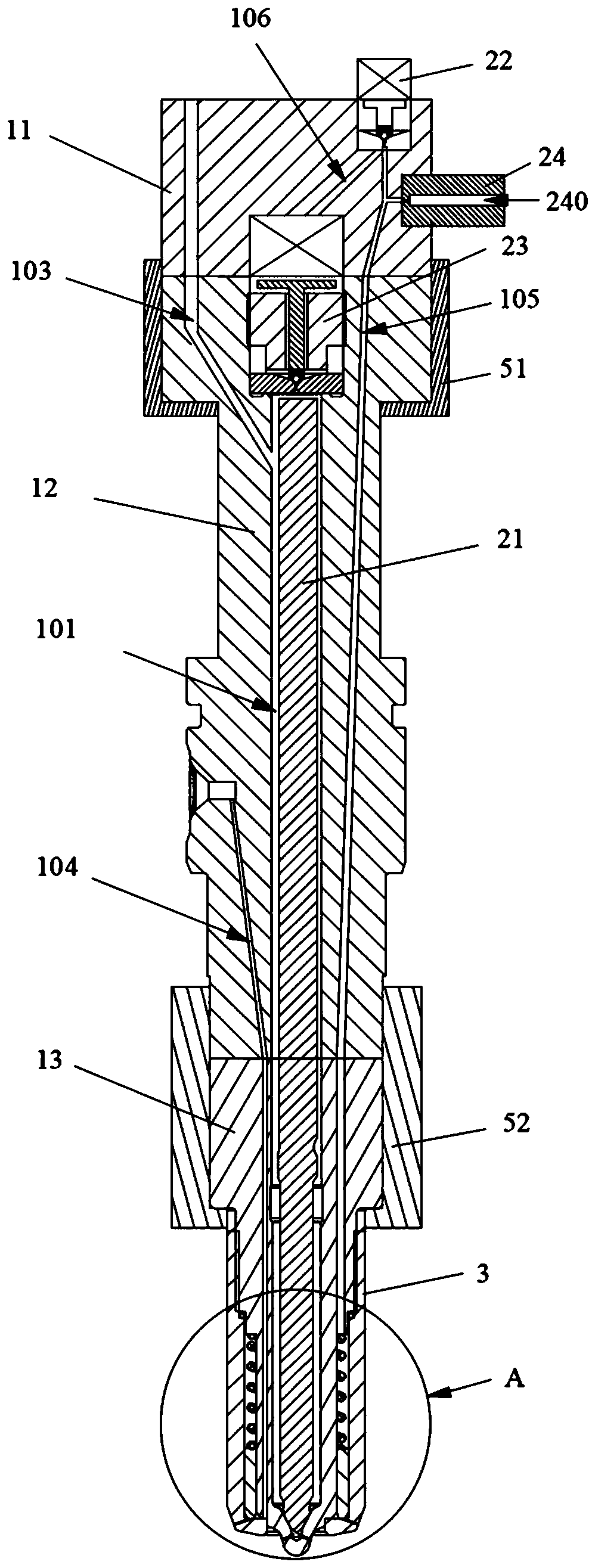

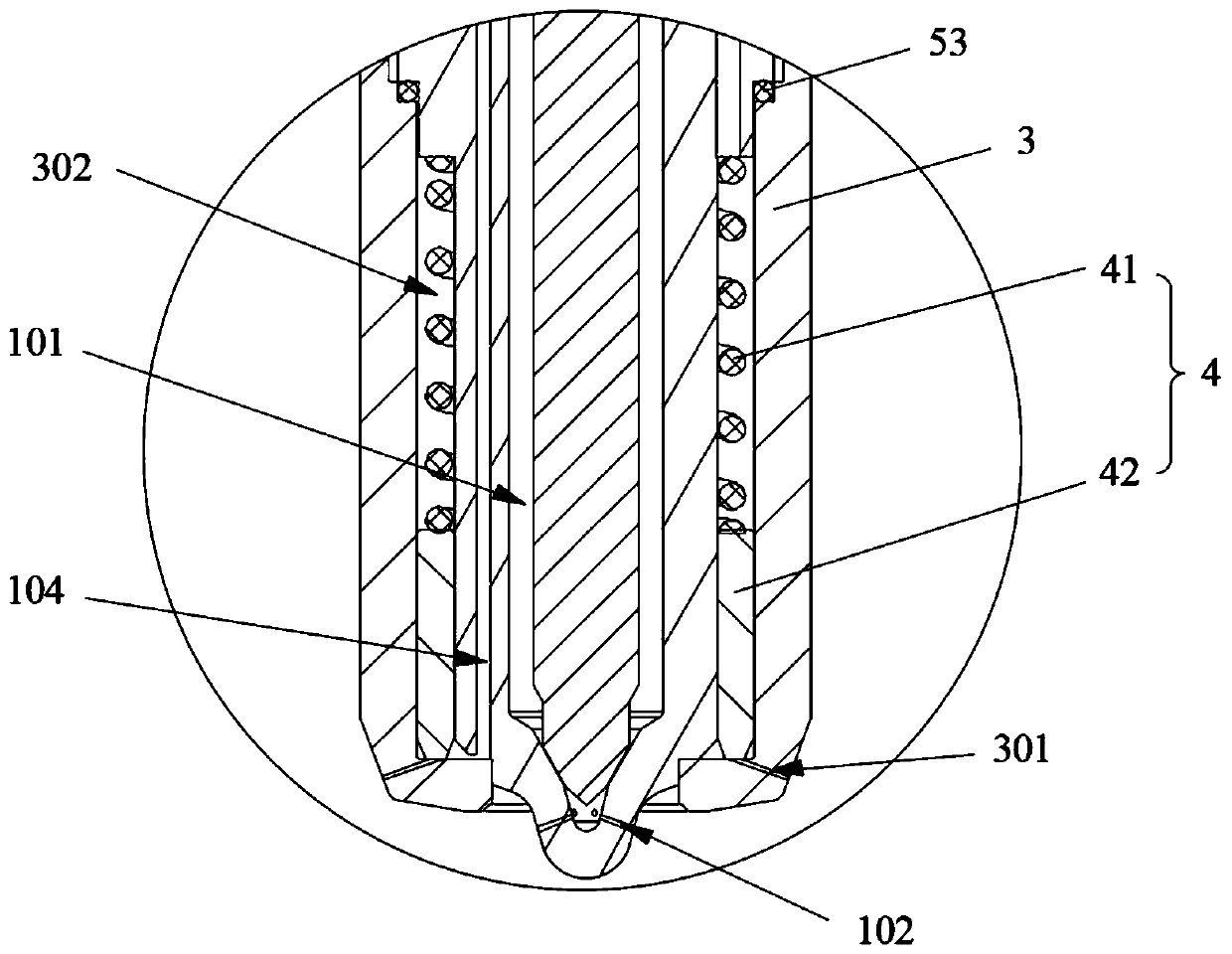

Microdroplet spray device, and method for preparing CNTs film by deposition through microdroplet spray device

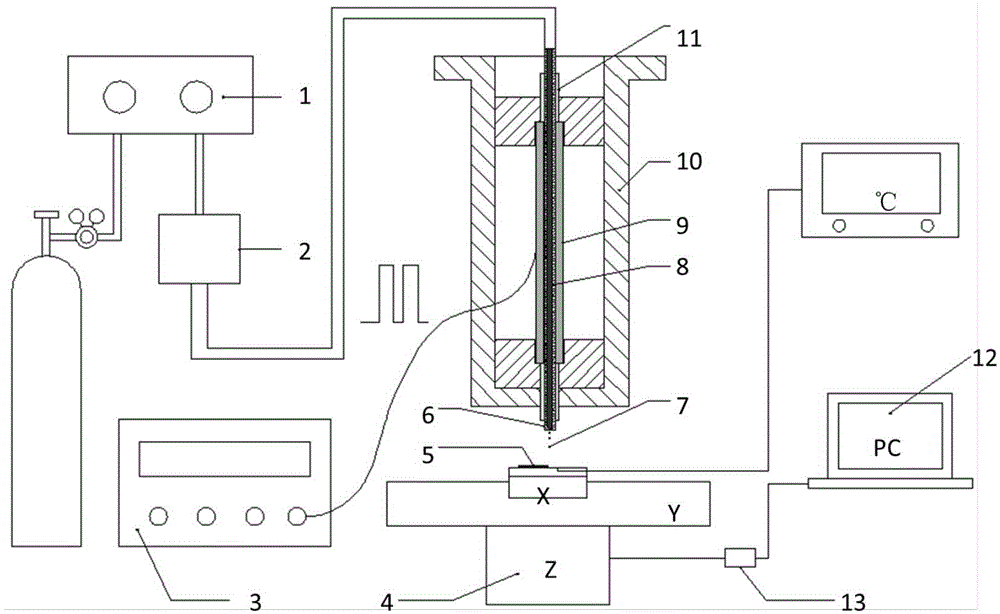

The invention discloses a microdroplet spray device, and a method for preparing a CNTs film by deposition through the microdroplet spray device, and aims to solve the technical problem that the CNTs film prepared by a current microdroplet spray device is poor in quality. According to the technical scheme adopted by the invention, the microdroplet spray device comprises a pressure controller, a vibration driver, a three-dimensional motion base plate, a spray nozzle, a resonant glass tube, a piezoelectric ceramic tube, a computer, and a three-dimensional motion base plate controller. The method for preparing the CNTs film by deposition through the microdroplet spray device comprises: regulating the pressure controller, so that a CNTs suspension liquid at the spray nozzle has back pressure; then, driving the piezoelectric ceramic tube to generate quick vibration by virtue of the vibration driver, transmitting the vibration to the CNTs suspension liquid in a micro-channel resonant cavity through the resonant glass tube, thereby realizing spraying of tiny microdroplets of the CNTs suspend liquid; and controlling the three-dimensional motion base plate to carry out three-dimensional motion by virtue of the computer, thereby completing preparation of the CNTs film. The preparation of the CTNs film with a controllable dimension is carried out, according to a designation part, in an open environment, so that quality of the CNTs film is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

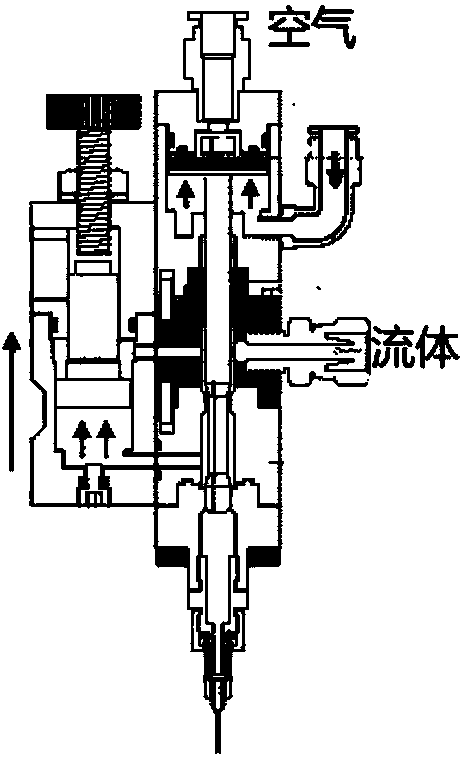

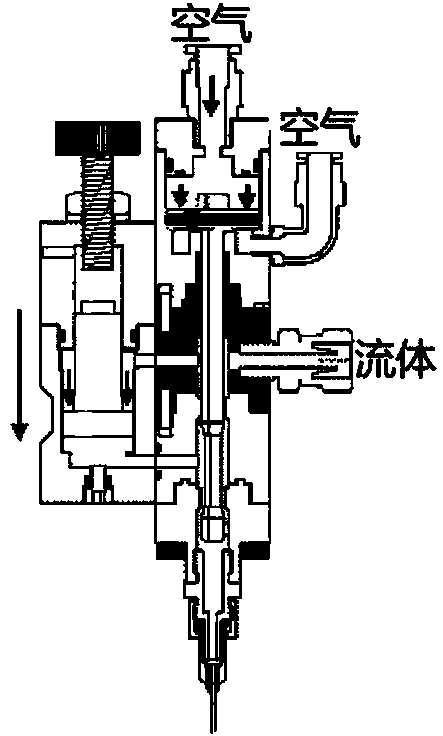

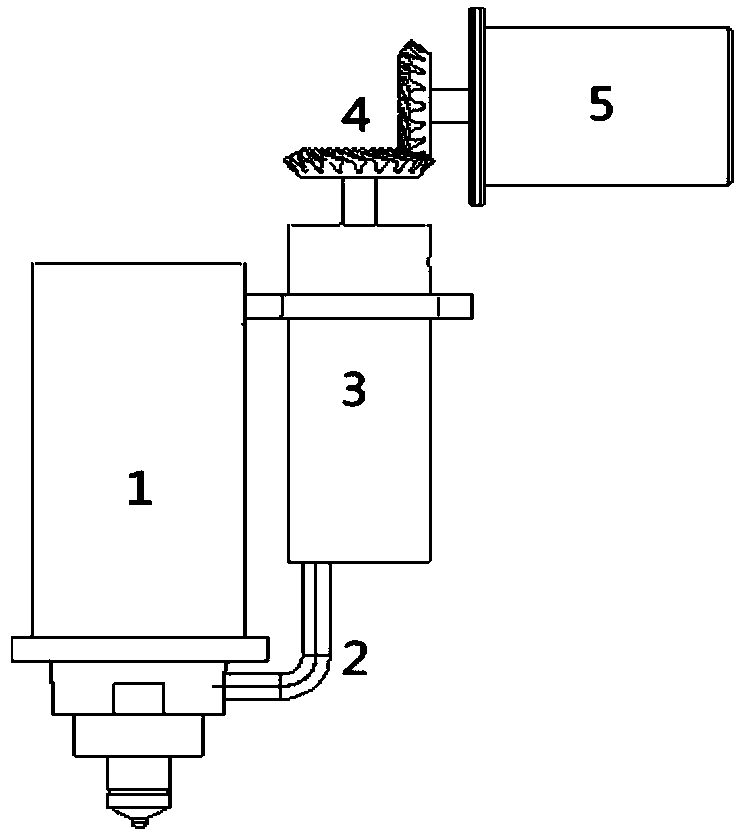

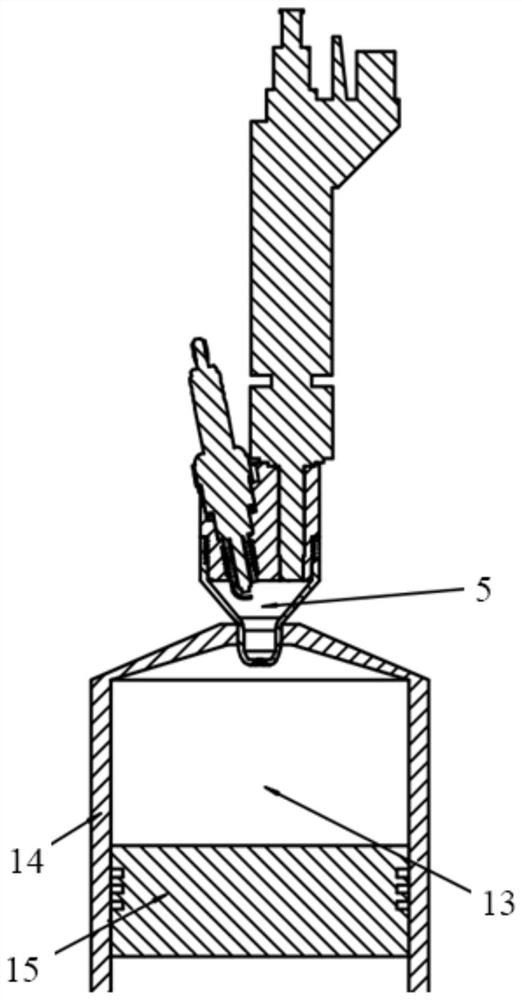

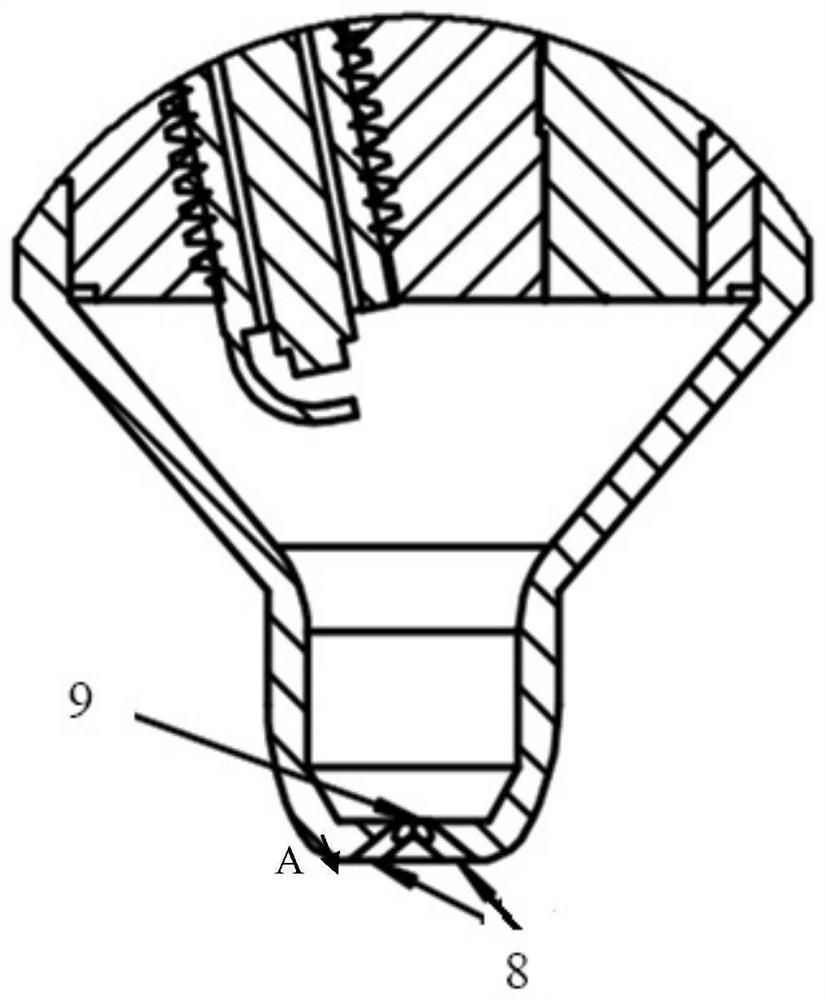

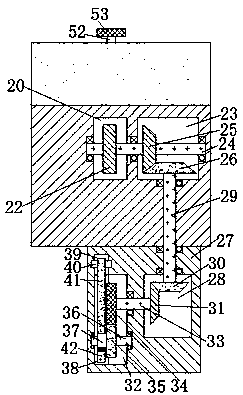

Jetting glue dispensing valve device and jetting glue dispensing method

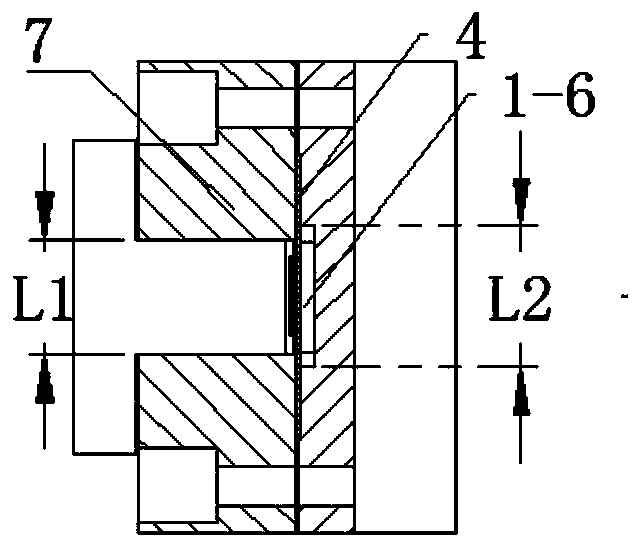

InactiveCN103464342AAchieve continuous injectionJet realizationLiquid surface applicatorsCoatingsSingle processMechanical engineering

The invention discloses a jetting glue dispensing valve device and a jetting glue dispensing method. The jetting glue dispensing valve device comprises a jetting glue dispensing valve, a glue supply pipeline and a glue supply valve, wherein a turntable capable of being closed / opened quickly is mounted at the bottom of the glue supply valve. During a glue jetting course, the glue supply valve is closed, and a channel allowing a glue solution to flow back to the glue supply valve from the glue supply pipeline is intercepted, so that glue jetting with precise volume is achieved. After a single glue jetting course is finished, the glue supply valve is opened, and the glue supply channel is opened for filling, so that continuous jetting of the glue solution is achieved. When the device and the jetting glue dispensing method are used for glue dispensing, no backflow occurs, so that an effective utilization rate of striker movement is increased, and jetting of a high-viscosity glue solution is facilitated; the device is simple in structure and easy to process; the turntable has the characteristic of periodic rotation, and can stir the glue solution, so that precipitation of fluorescent powder in the glue solution is avoided effectively; the fluid velocity in the jetting glue dispensing valve is distributed more uniformly; and the glue dispensing quality is ensured.

Owner:CENT SOUTH UNIV

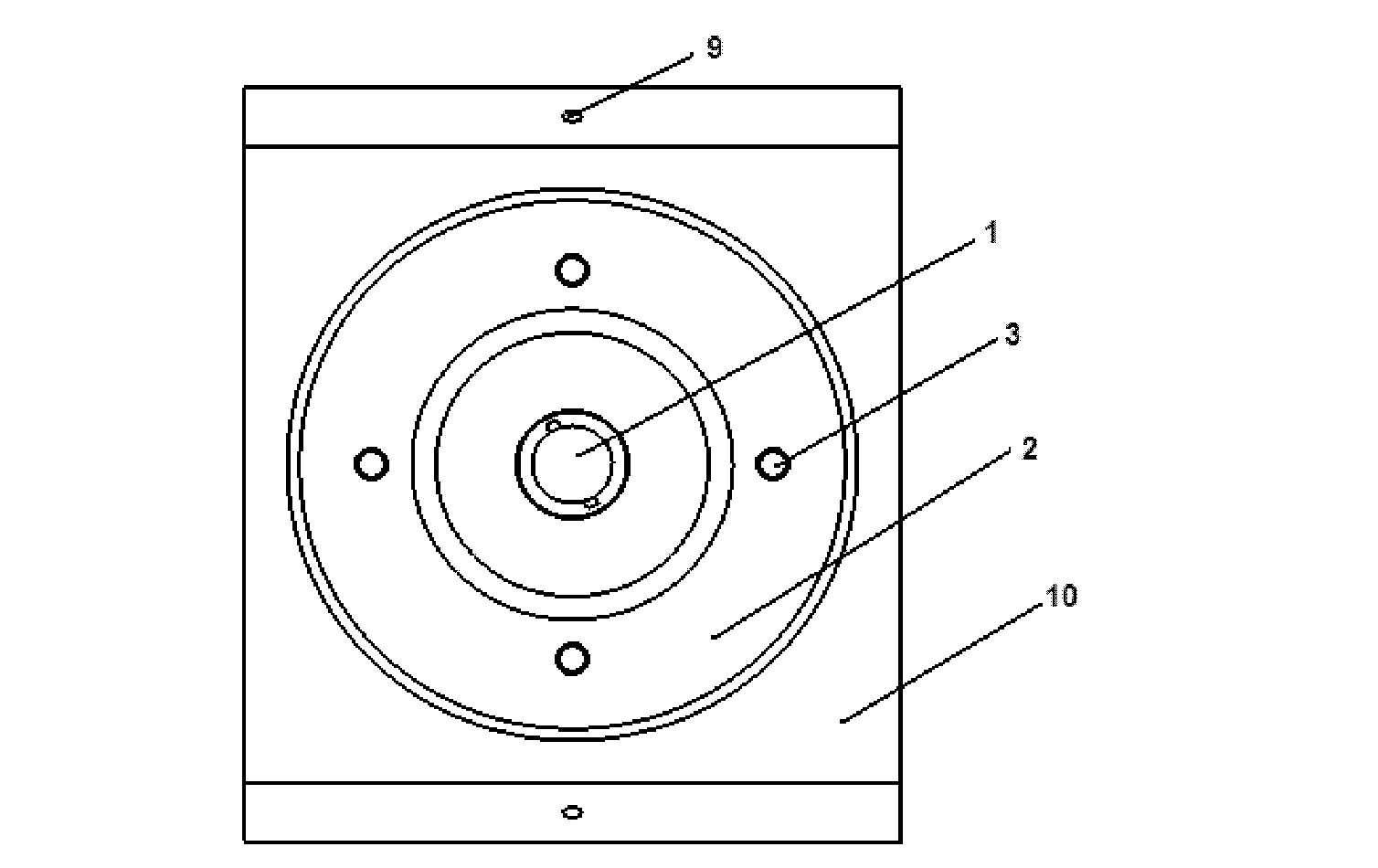

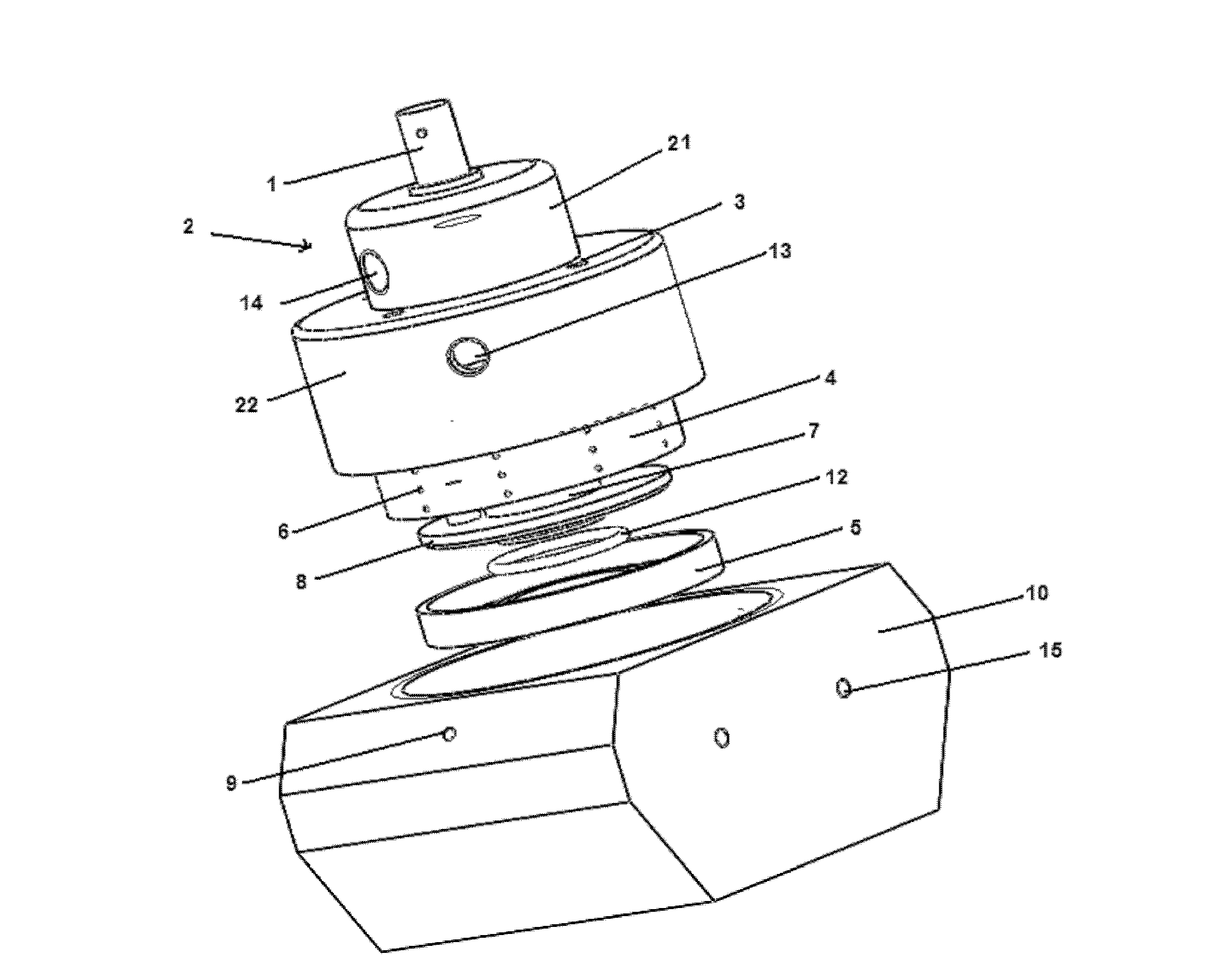

Atomizing jet device for cleaning

ActiveCN102641865ASimple structureHighly integratedLiquid spraying apparatusCleaning using liquidsSurface patternAudio power amplifier

The invention relates to the technical field of semiconductor chips, in particular to an atomizing jet device for cleaning, which comprises an upper casing and a lower casing connected with the upper casing. The upper casing is in the shape of a two-step cylinder including a first-step casing and a second-step casing, the cross section area of the first-step casing is smaller than that of the second-step casing, the first-step casing is provided with a cable joint capable of being connected with a power amplifier, and an energy transducer is arranged in the second-step casing. Vent holes are arranged on two side walls of the lower casing, an atomizing jet through hole is arranged at the center of the lower casing, and the vent holes are communicated with the atomizing jet through hole and form included angles with the same. The atomizing jet device for cleaning is simple in structure and high in integration degree, is capable of jetting ultra-micro-atomized liquid drops effectively and effectively cleaning the chips on the premise of protecting surface patterns of the chips while saving water resources to the utmost extent.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

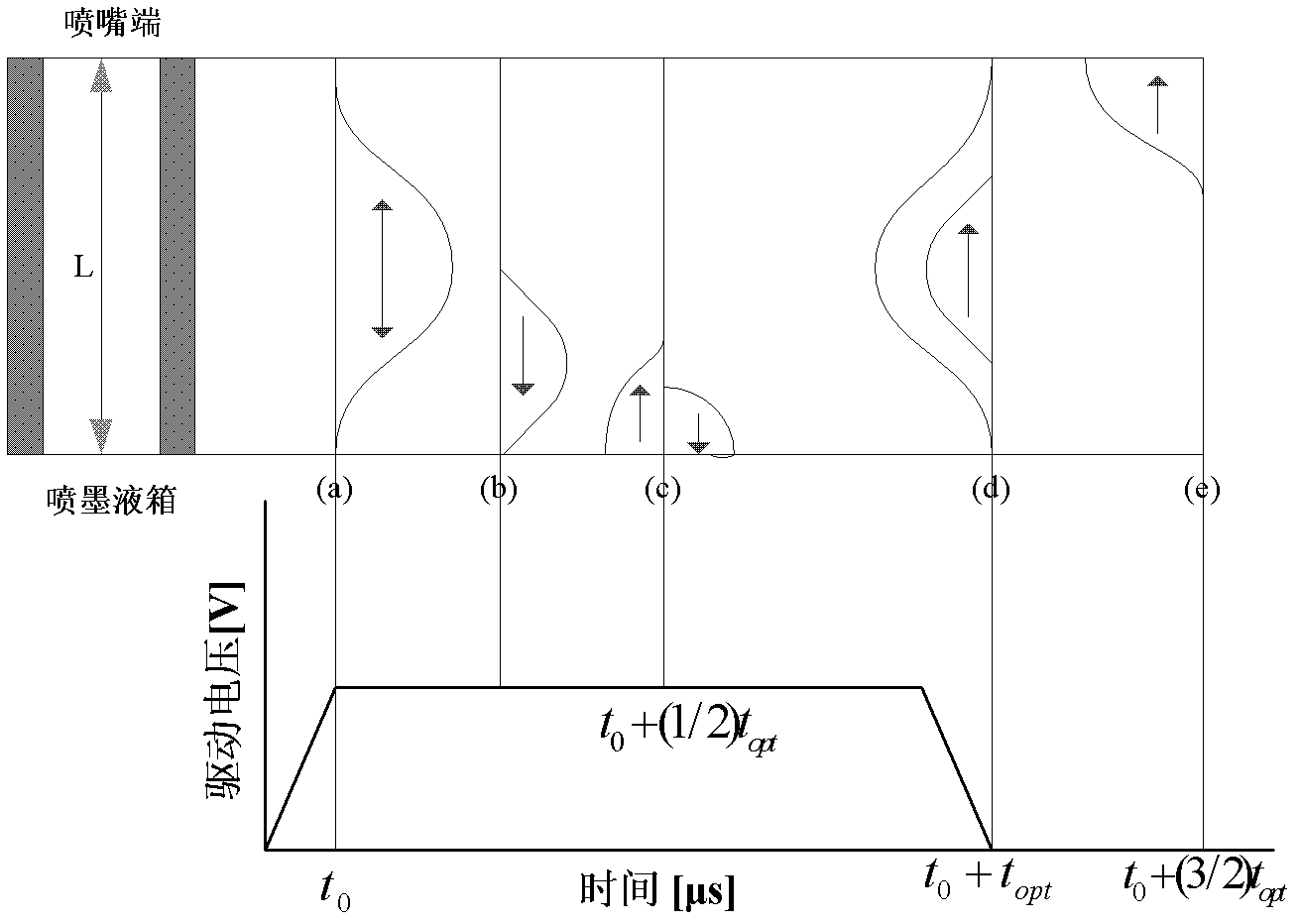

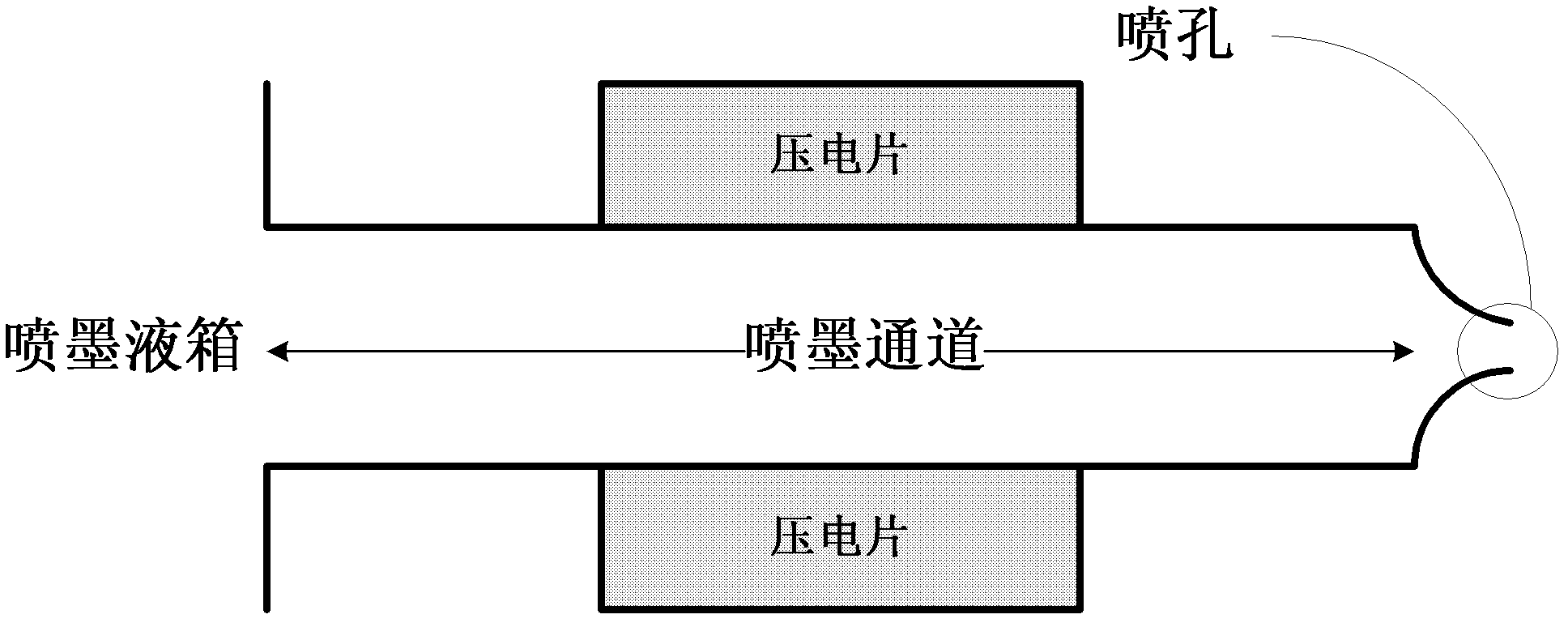

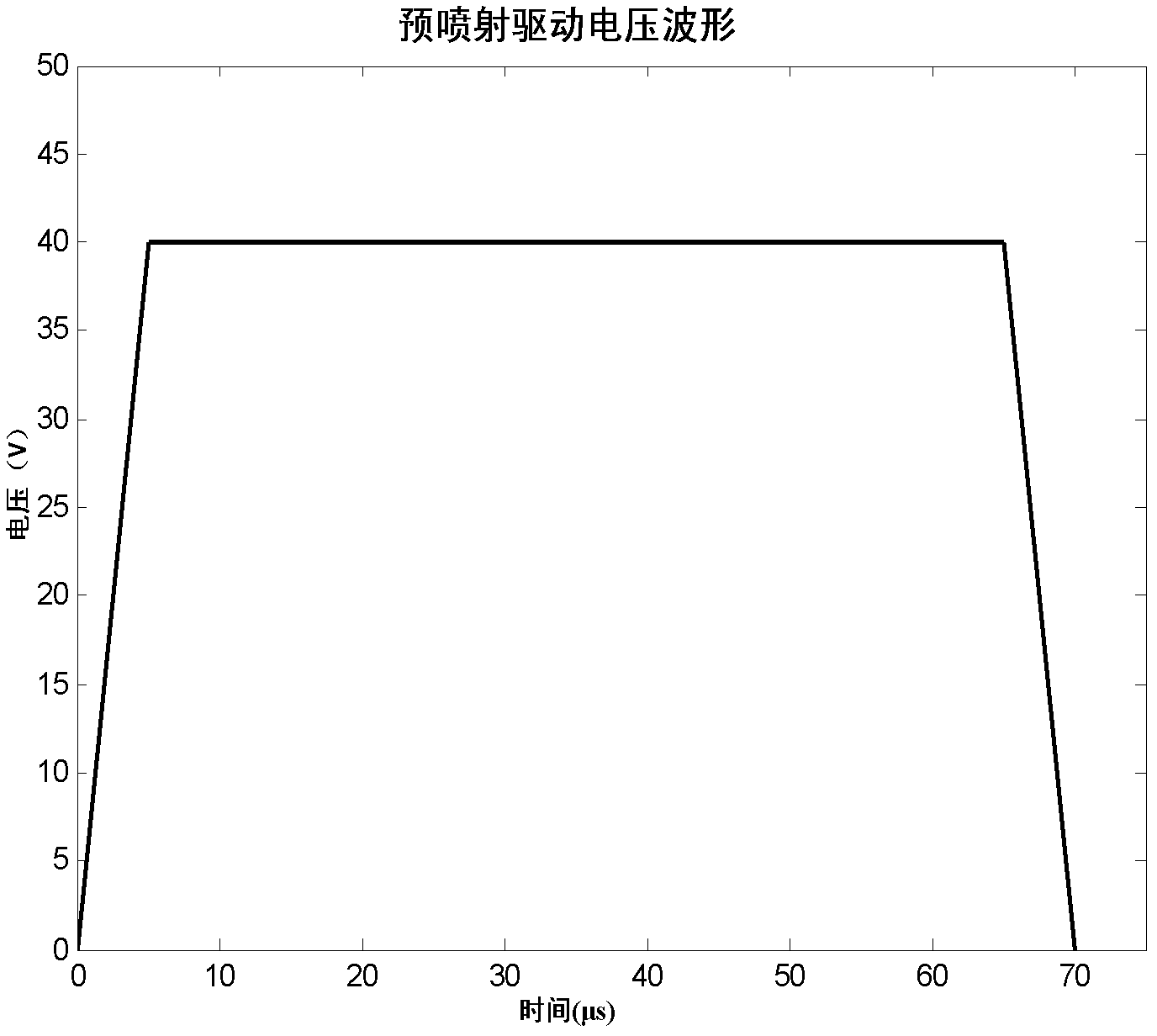

Cell printing self-adaptive inkjet driving control method

InactiveCN102555555AAvoid cloggingJet realizationTypewritersTissue/virus culture apparatusSelf adaptiveTissue engineering

The invention belongs to the field of the tissue engineering, and particularly discloses a cell printing self-adaptive inkjet driving control method in which a piezo printhead is used for controlling. The self-adaptive inkjet driving control method is characterized in that an inkjet liquid tank, an inkjet passage, a spray orifice and piezoelectric plates are adopted; one end of the inkjet passageis communicated to the spray orifice and the other end of the inkjet passage is communicated with the inkjet liquid tank; the piezoelectric plates are arranged outside the inkjet passage; and the piezoelectric plates are distributed on and under the inkjet passage. The cell printing self-adaptive inkjet driving control method is used for implementing the jetting of a high-viscosity biological agent and for solving the phenomenon of blocking.

Owner:XIDIAN UNIV

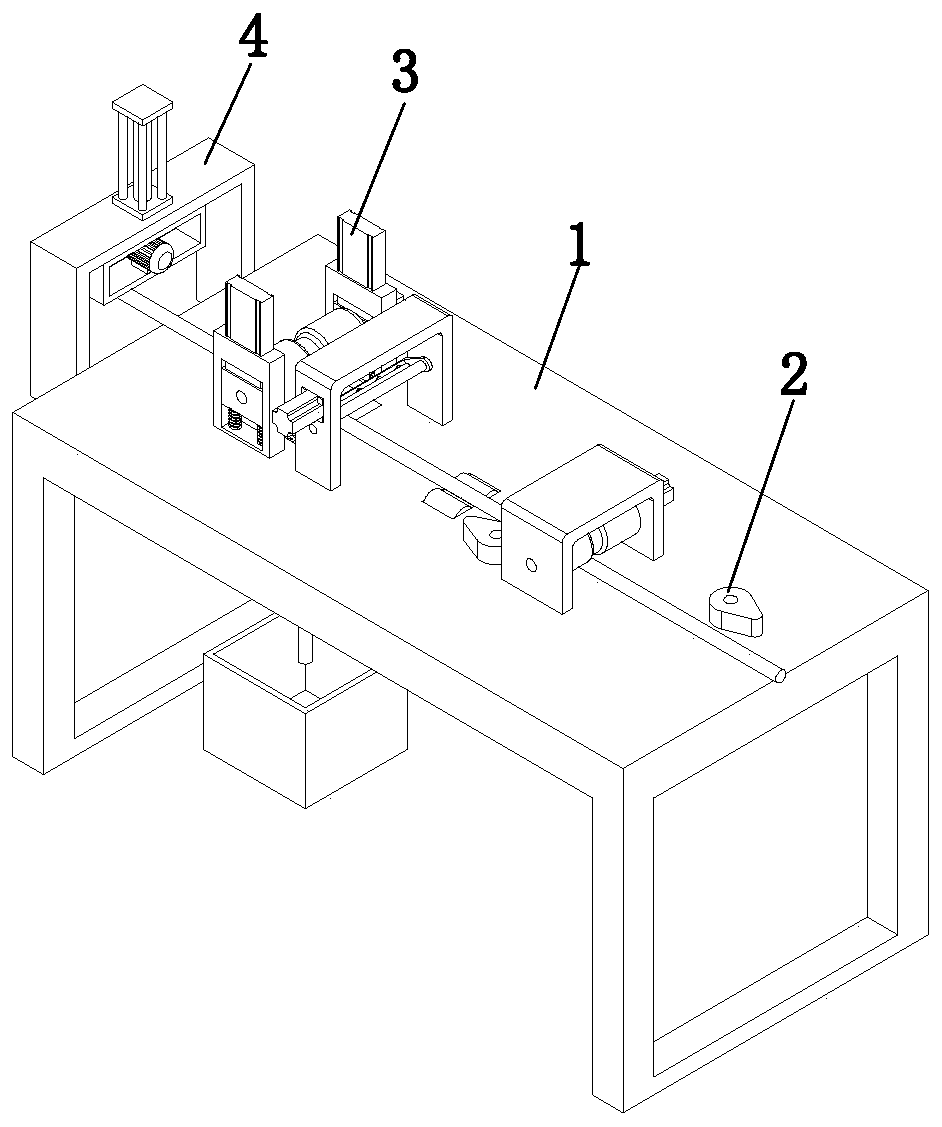

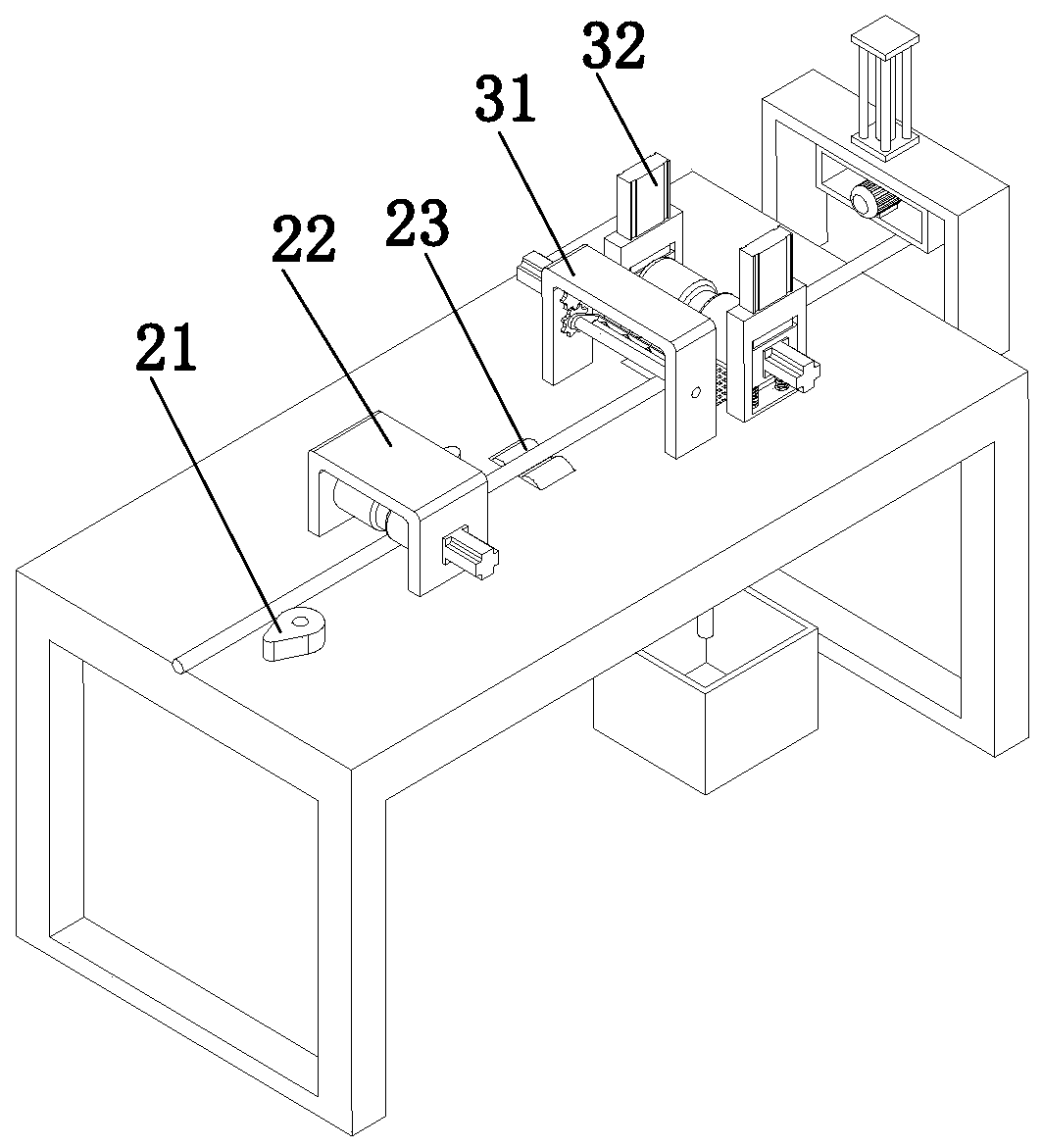

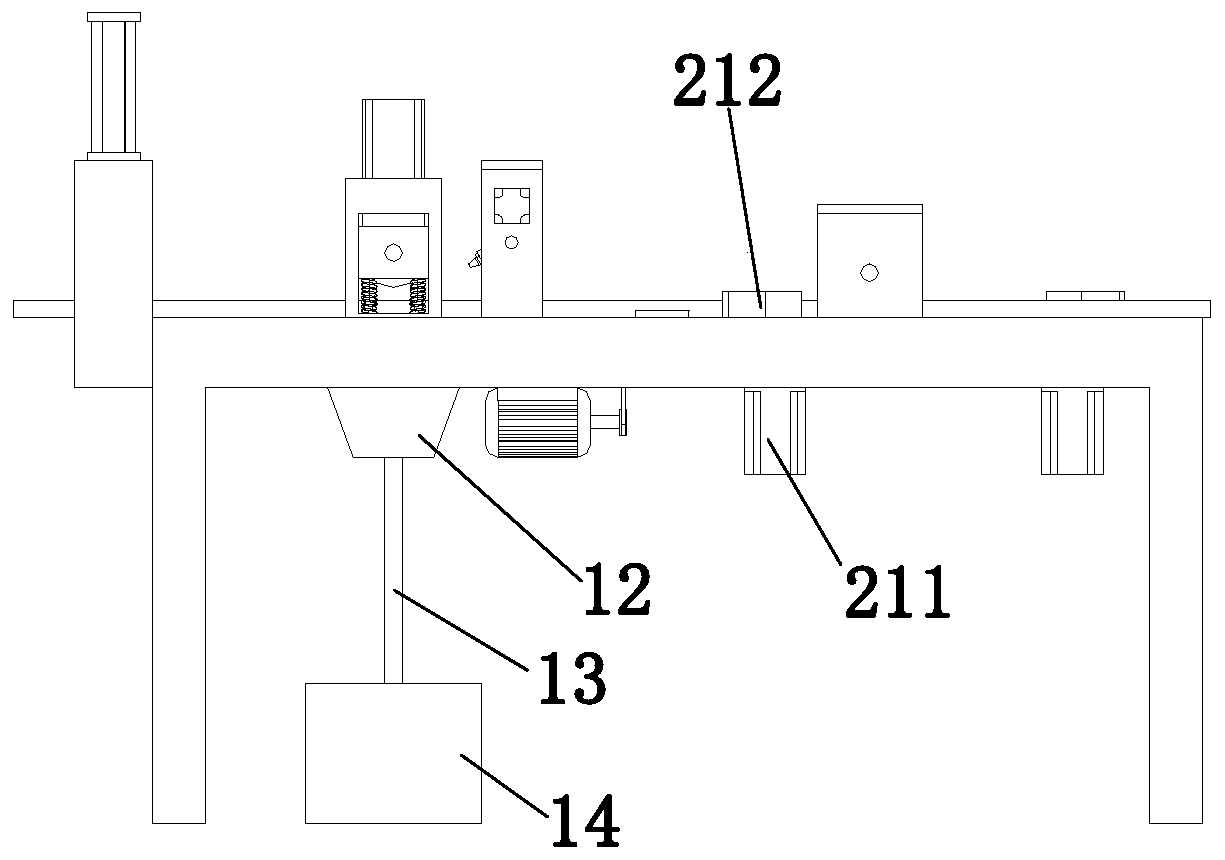

Stainless steel corrugated pipe machining device

InactiveCN111002171AAffect processing operationsFull sanding jobGrinding carriagesGrinding machinesElectric machineryStructural engineering

The invention discloses a stainless steel corrugated pipe machining device, which belongs to the technical field of corrugated pipe machining equipment. The device comprises a mounting frame, a corrugated pipe conveying and fixing assembly, a grinding assembly and a cutting assembly, wherein the corrugated pipe conveying and fixing assembly comprises a fixing piece, a conveying piece and an overturning piece; the fixing piece is arranged on the mounting frame; the conveying piece is arranged at the top of the mounting frame; the overturning piece is arranged on the mounting frame; the grindingassembly comprises a grinding piece and a water spraying piece; the grinding piece is arranged at the top of the mounting frame and located above a waste groove; and the water spraying piece is arranged at the top of the mounting frame. The overturning motor works to drive a first rotating wheel to rotate, the first rotating wheel rotates to drive two second rotating wheels to rotate through a belt, two second rotating wheels rotate to drive two overturning wheels to rotate on two overturning grooves, the two overturning wheels rotate to drive the stainless steel corrugated pipe to rotate, and the stainless steel corrugated pipe can be comprehensively polished through rotation of the stainless steel corrugated pipe.

Owner:深圳市领域精密制造有限公司

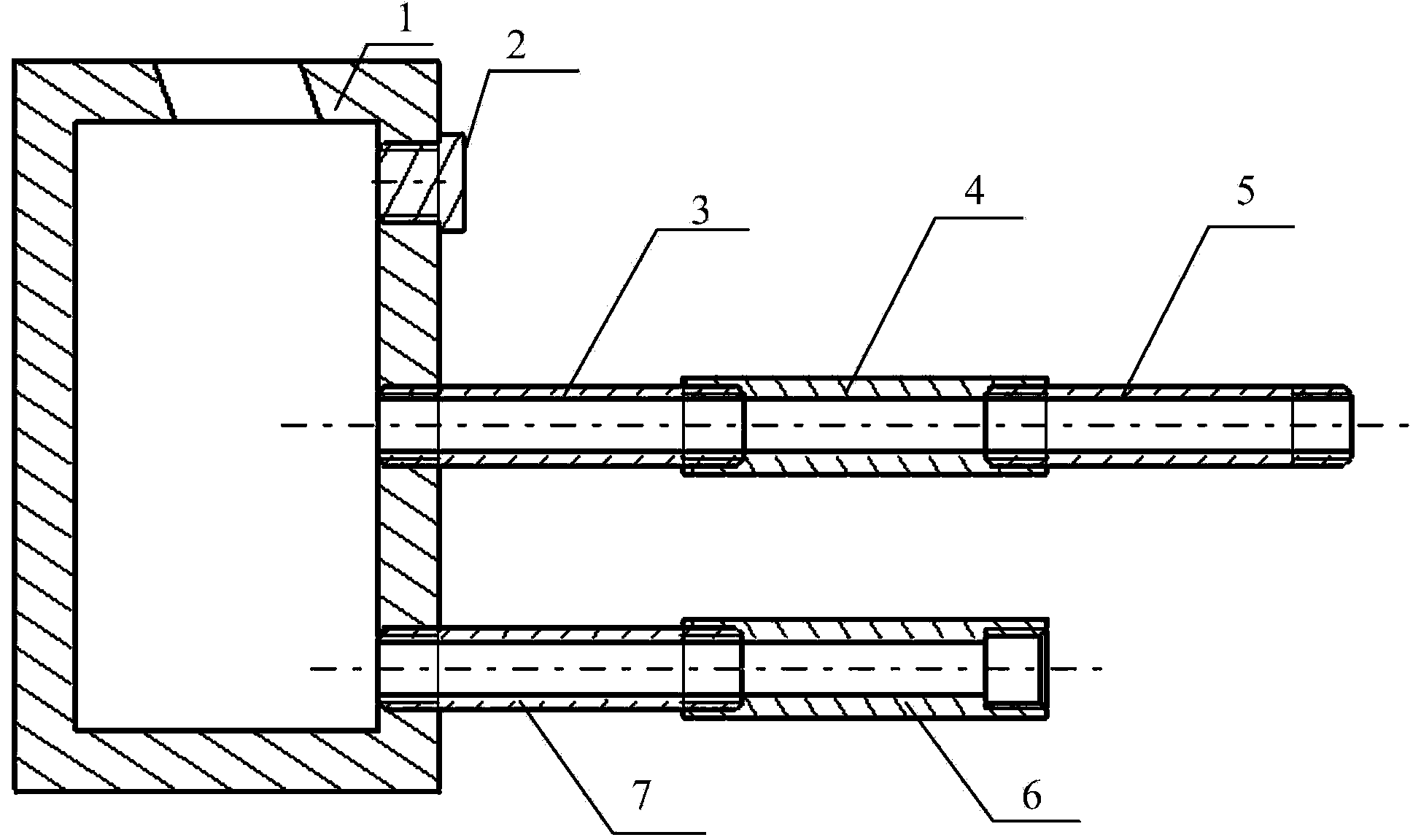

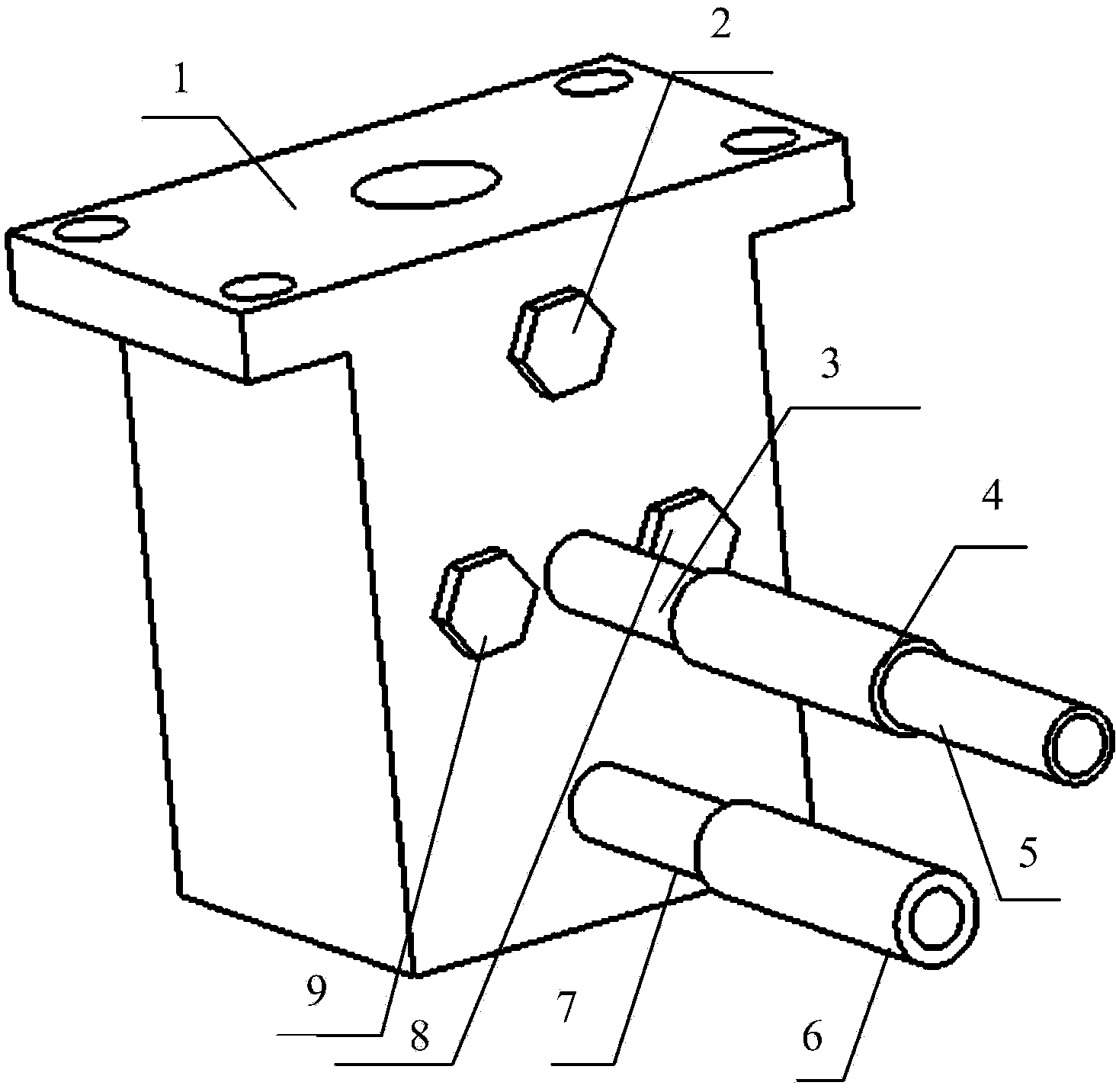

Device with changeable gas injection direction and nozzle number

ActiveCN103470404AStrong installation and removal flexibilitySimple structureInternal combustion piston enginesFuel supply apparatusNozzleEngineering

The invention discloses a device with a changeable gas injection direction and a changeable nozzle number, and aims to solve the problems that the gas injection direction and the nozzle number cannot be changed in the prior art. The device with the changeable gas injection direction and nozzle number is composed of a base (1), a nozzle subassembly and a sealing subassembly. The nozzle subassembly comprises a No. 1 nozzle, a No. 2, nozzle and a No. 3 nozzle with the same structure, wherein one end of one or two or three of the three nozzles is arranged in different gas orifices on the base (1) in a threaded connection manner. The sealing subassembly is composed of a No. 1 sealing bolt, a No. 2 sealing bolt, ellipsis, and a No. N-1 sealing bolt, wherein one or two ellipsis or N-1 of the No. 1 sealing bolt, No. 2 sealing bolt, ellipsis, and No. N-1 sealing bolt is / are arranged in different gas orifices on the base (1) in the threaded connection manner; N is the number of the gas orifices formed in the base (1), and N is greater than or equal to 1 and less than or equal to 9.

Owner:JILIN UNIV

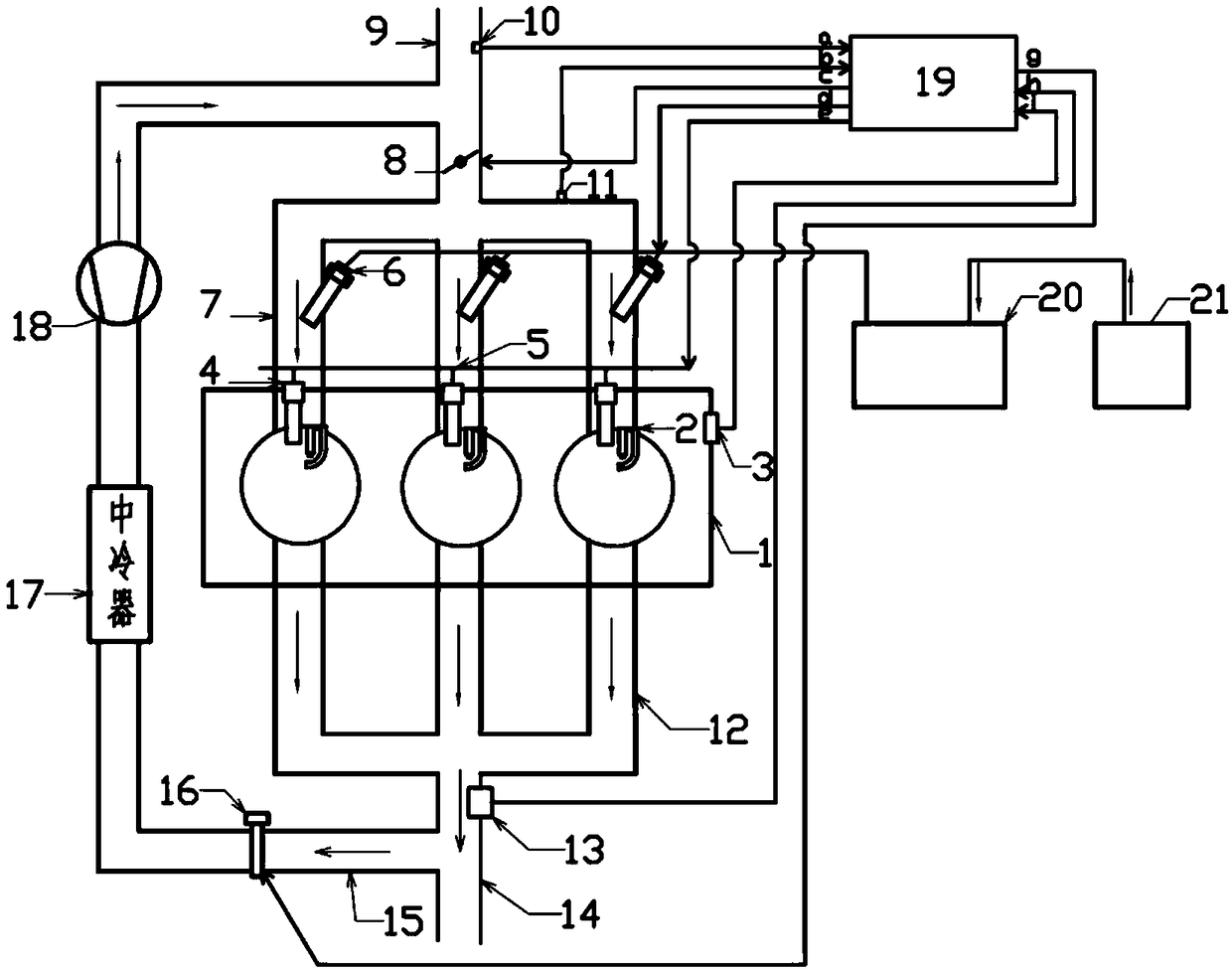

Gasoline engine combustion control method and gasoline engine suitable for medium and heavy vehicle

PendingCN108843446AExpand the scope ofReduce dependenceInternal combustion piston enginesExhaust gas recirculationThermal efficiencySpark plug

The invention discloses a gasoline engine combustion control method and a gasoline engine suitable for a medium and heavy vehicle. On a traditional diesel engine platform, a gas inlet sprinkler systemand a spark plug are reconstructed and additionally mounted on the basis of a gas inlet channel and a cylinder cover, meanwhile, a set of EGR system is arranged in a matched mode, so that the modified gasoline engine adopts EGR strategy in the small and medium load working conditions and adopts EGR and gas inlet channel and sprinkler coupling strategies in the heavy load condition. The problem oflow displacement and low thermal efficiency of a traditional gasoline engine can be overcome, the detonation can be suppressed through EGR coupling gas inlet channel and sprinkler in the heavy load condition, the range of efficient clean combustion can be effectively widened, so that the application need in the medium and heavy vehicle can be met, and meanwhile, the strict emission regulations can be met by using a ternary catalytic converter.

Owner:TIANJIN UNIV

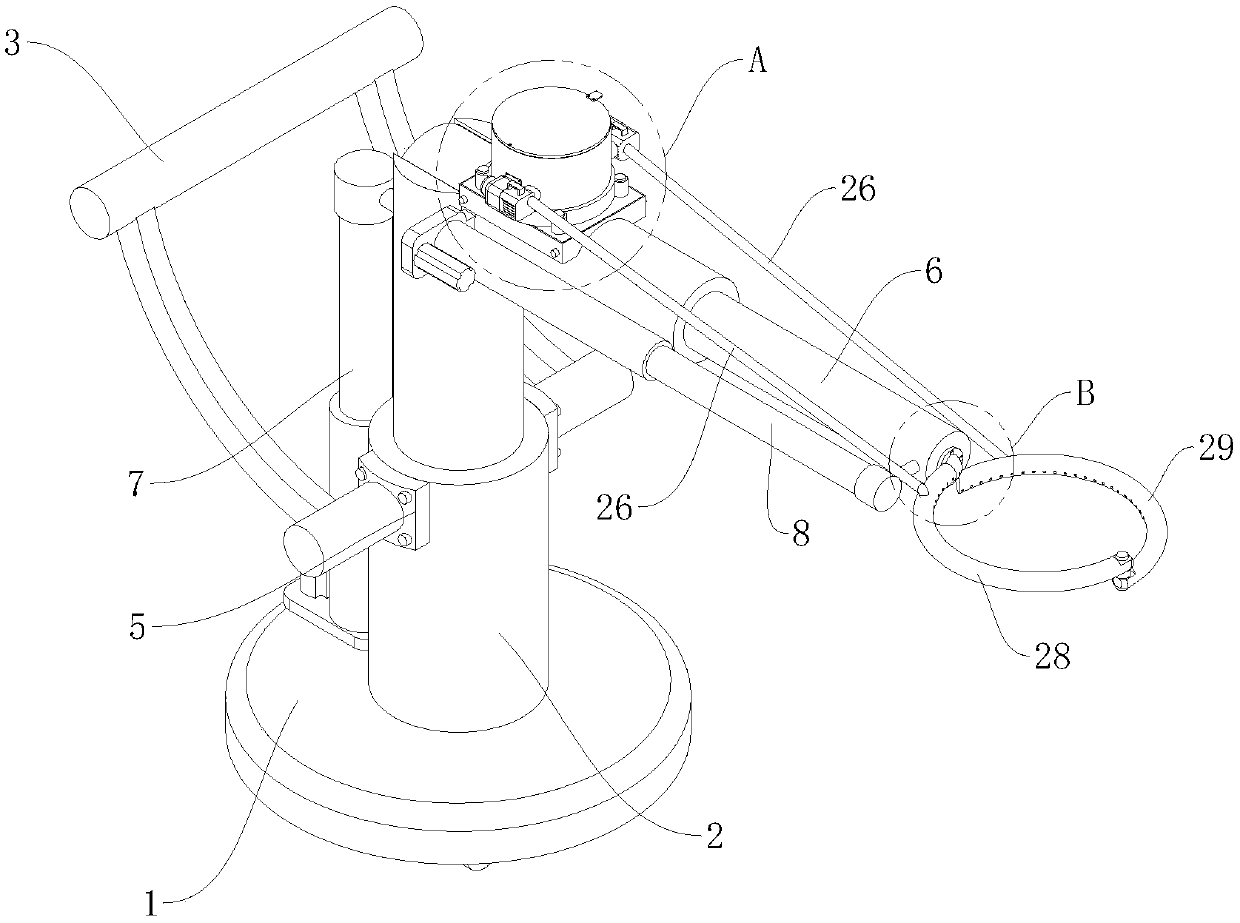

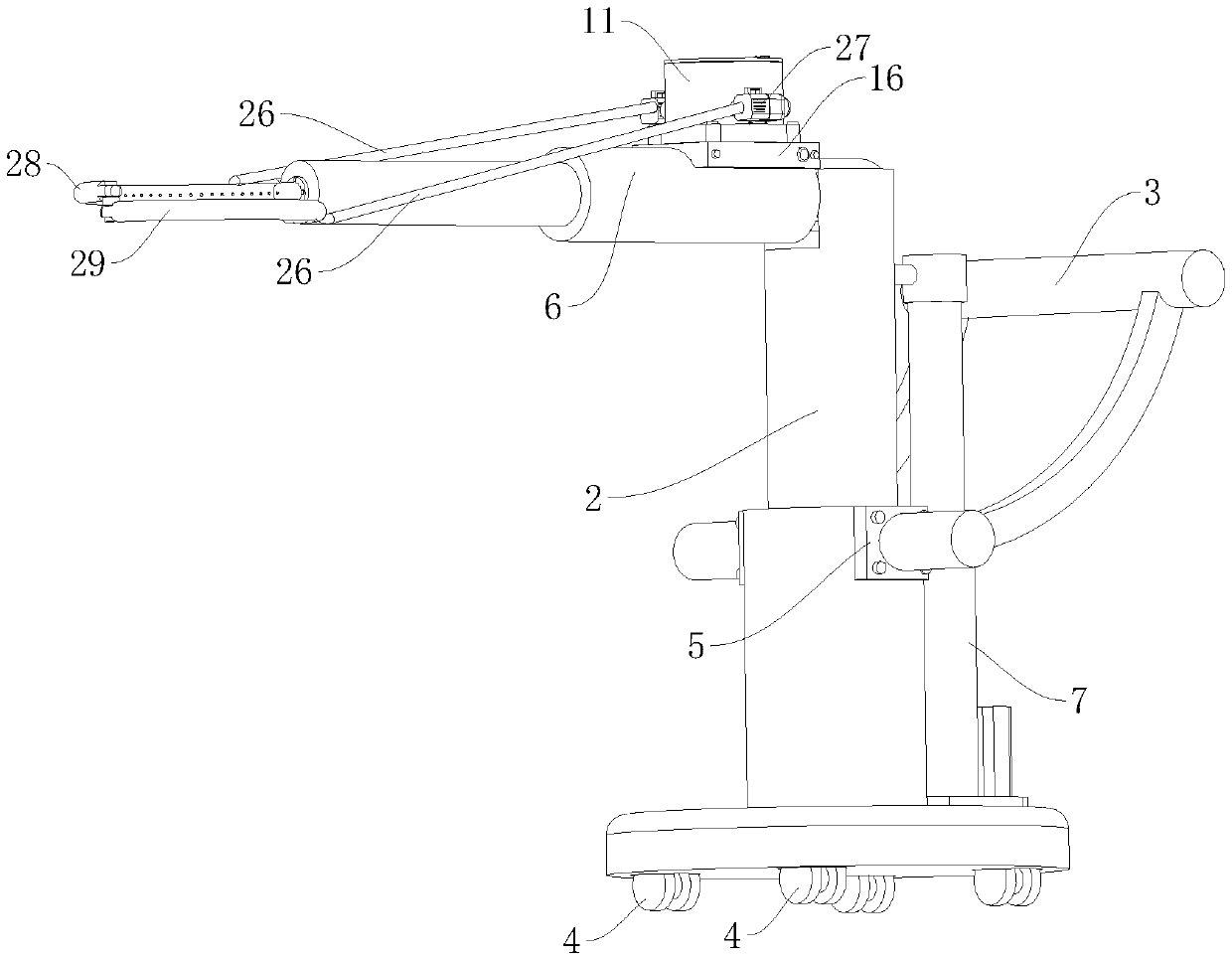

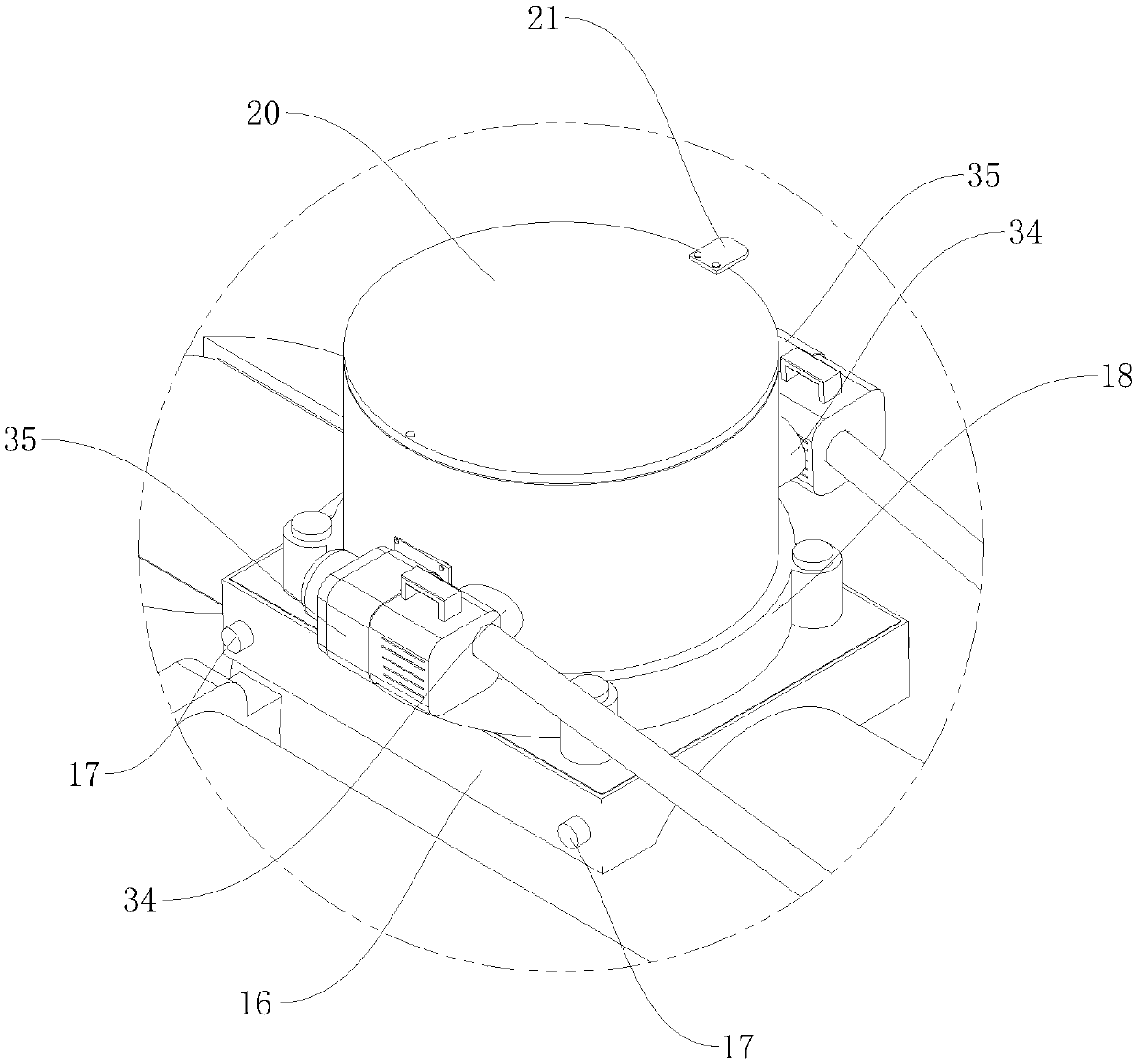

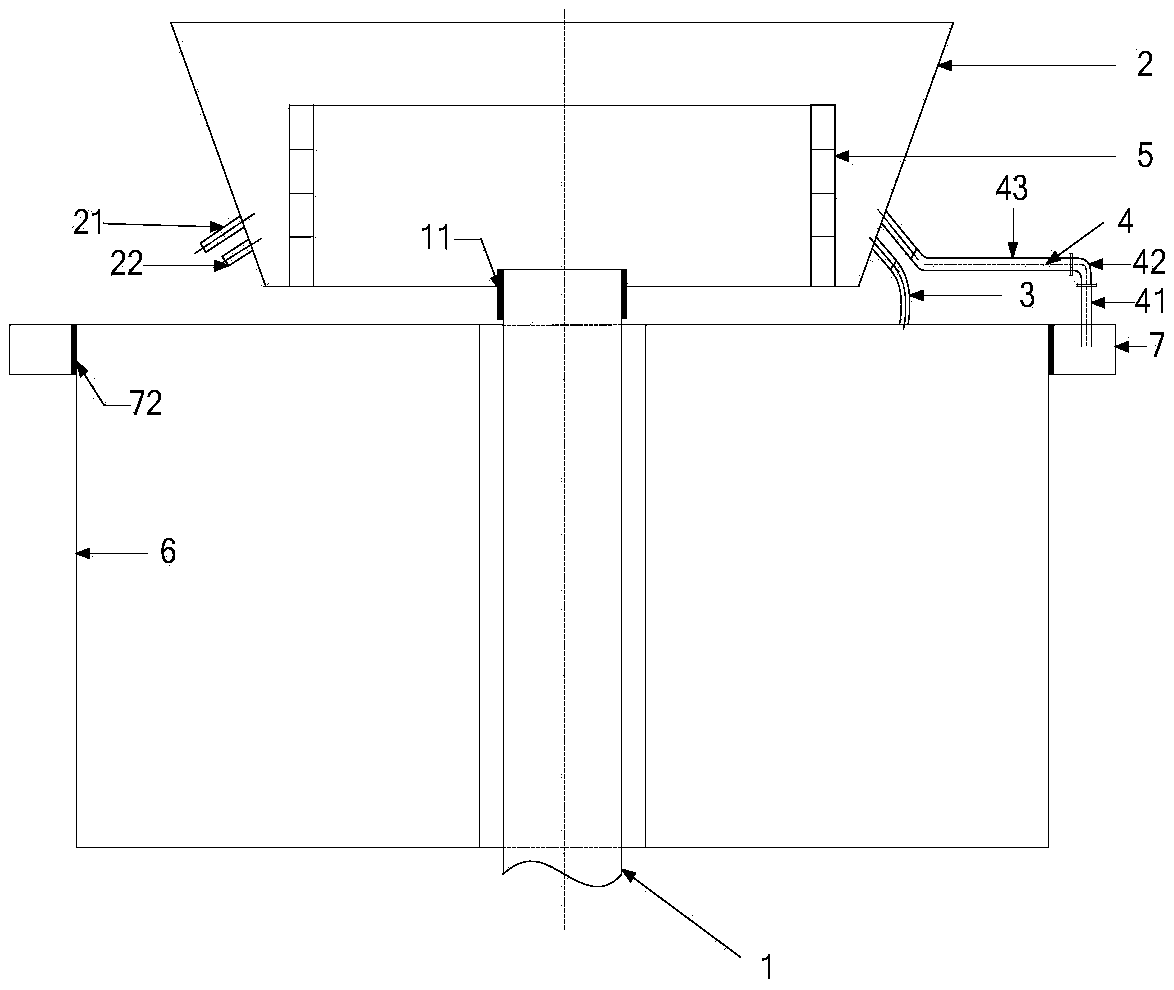

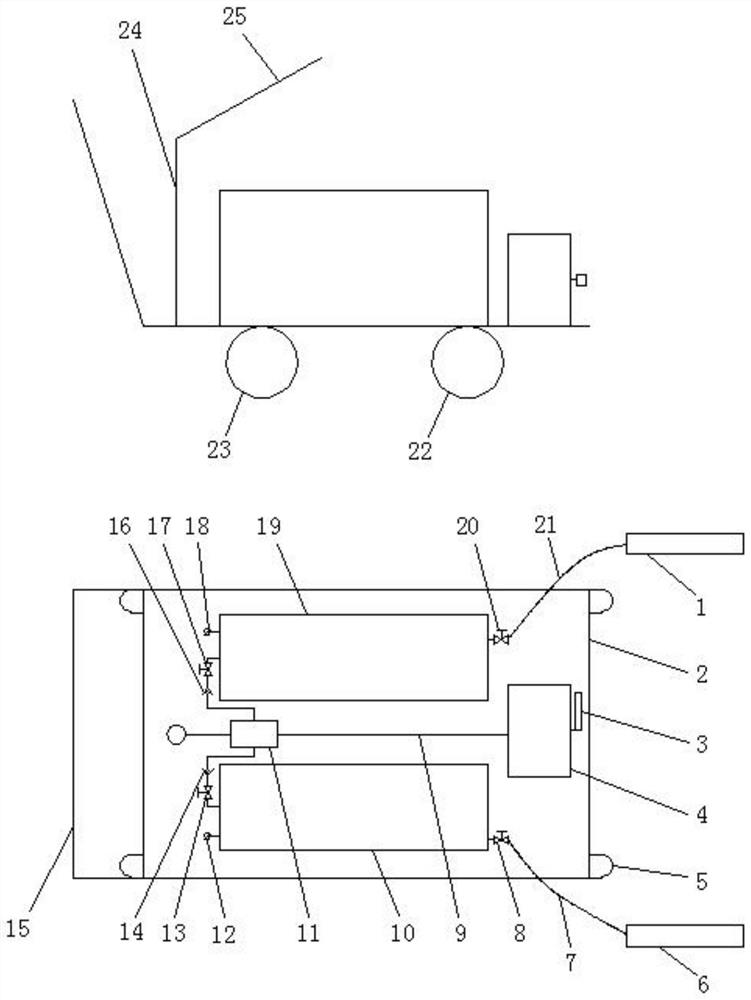

Whitening agent injection equipment used for afforestation tree root protection

InactiveCN109590125AStir wellJet realizationLiquid spraying apparatusPlant protectionTree rootWhitening Agents

The invention relates to the technical field of environmental protection equipment, in particular to whitening agent injection equipment used for afforestation tree root protection. The whitening agent injection equipment comprises a base, a machine body, a push handle, a stirring mechanism and an injection mechanism. The base is arranged in a horizontal state. Multiple universal wheels are arranged at the bottom of the base. The machine body is vertically arranged at the top of the base and is fixedly connected with the base. The push handle is arranged over the base and is fixedly connectedwith the middle of the machine body through a first fixed cover. A machine arm is hinged to the top of the machine body. The stirring mechanism is horizontally arranged on the outer wall of the machine arm and is fixedly connected with the outer wall of the machine arm. The injection mechanism is arranged at the end, away from the top of the machine body, of the machine arm. The machine body and the machine arm are each of a telescopic structure. The whitening agent injection equipment used for afforestation tree root protection is simple in use, convenient to carry and good in whitening effect, whitening agent manufacturing equipment can be arranged for whitening, and the problems that existing whitening equipment is thick and heavy and hard to carry and has no whitening agent manufacturing function are solved.

Owner:李元珍

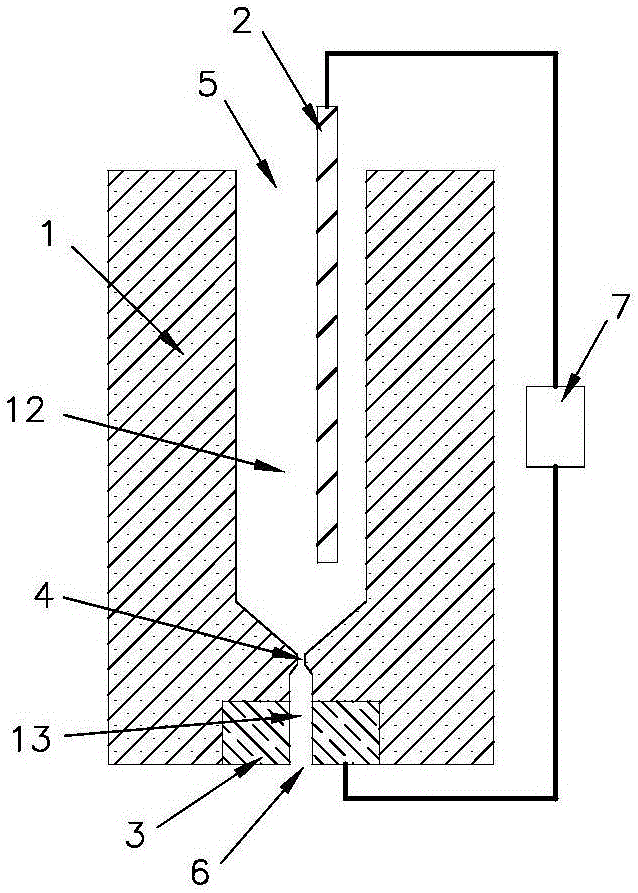

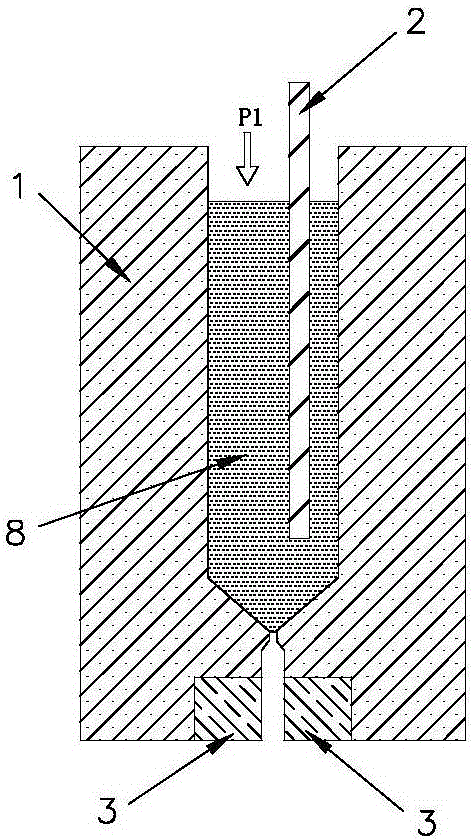

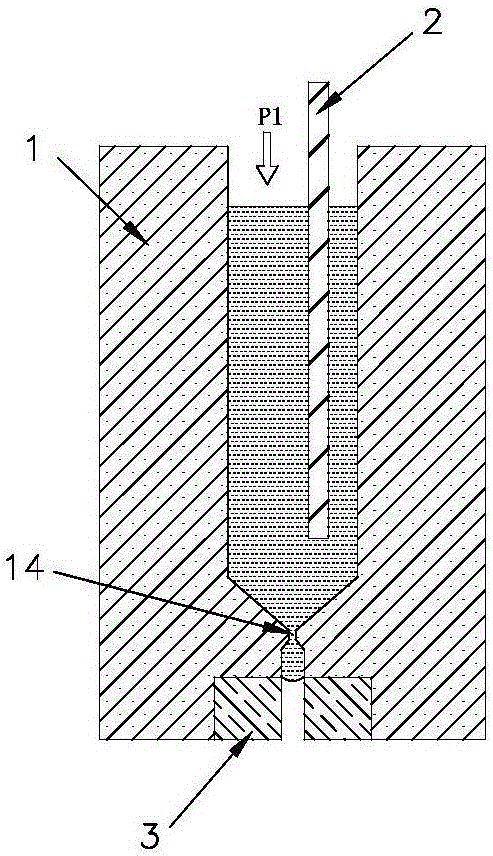

Water jet source apparatus with constant pressure

ActiveCN105371946AReduce the impactIsolation impactSubsonic/sonic/ultrasonic wave measurementWater storage tankSpray nozzle

The invention discloses a water jet source apparatus with constant pressure. The apparatus comprises a water pump guide pipe, a guiding gutter, a guiding pipe, an overflow pipe, a current stabilizing grid, a water storage tank and an overflow groove, and is characterized in that one end of the water pump guide pipe is connected with a submersible pump, the other end of the water pump guide pipe is connected with the guiding gutter, the guiding gutter is connected with the guiding pipe and the overflow pipe, one end of the guiding pipe is connected with the guiding gutter, the other end of the guiding pipe is connected with the water storage tank, the outer side of the water storage tank is connected with the overflow groove, and water in the overflow groove flows to the submersible pump. According to water jet source apparatus with the constant pressure, by means of a water level difference between the water storage tank and a jet nozzle, jet pressure is generated due to the effect of gravity, additional vibration and noise are not caused, the pressure is constant, and the water jet source apparatus is suitable for a jet source in an underwater jet research process.

Owner:HARBIN ENG UNIV

SCR urea injection protective system

ActiveCN107916973APlay a role in heat preservationPrevent hitting a wallInternal combustion piston enginesExhaust apparatusInlet channelInjection air

An SCR urea injection protective system comprises an exhaust pipe and a urea nozzle assembly of which the urea injection end is inserted into the exhaust pipe; the exhaust pipe is provided with an annular air cavity along the inner wall of the exhaust pipe; one side of the annular air cavity communicates with the outside of the exhaust pipe through an air inlet channel, and the other side of the annular air cavity is provided with a plurality of first air injection holes communicating with the interior of the exhaust pipe; and the urea nozzle assembly comprises a urea injection pipe and an aircooling pipe which coaxially sleeves the urea injection pipe, an air channel is formed between the interior of the air cooling pipe and the exterior of the urea injection pipe, and the air inlet endand the air outlet end of the air cooling pipe communicate with the interior of an air connector and the interior of the exhaust pipe correspondingly. Through the design, waste gas heat preservation is achieved, meanwhile, the working efficiency of an SCR system is improved, and a urea nozzle can be cooled.

Owner:DONGFENG COMML VEHICLE CO LTD

Liquid raw material spraying method and device used for three-dimensional printing

ActiveCN106513682AImprove controllabilityQuick squirtAdditive manufacturing apparatusIncreasing energy efficiencyHigh resistanceLiquid state

Owner:NANJING TAITAO INTELLIGENT SYST CO LTD

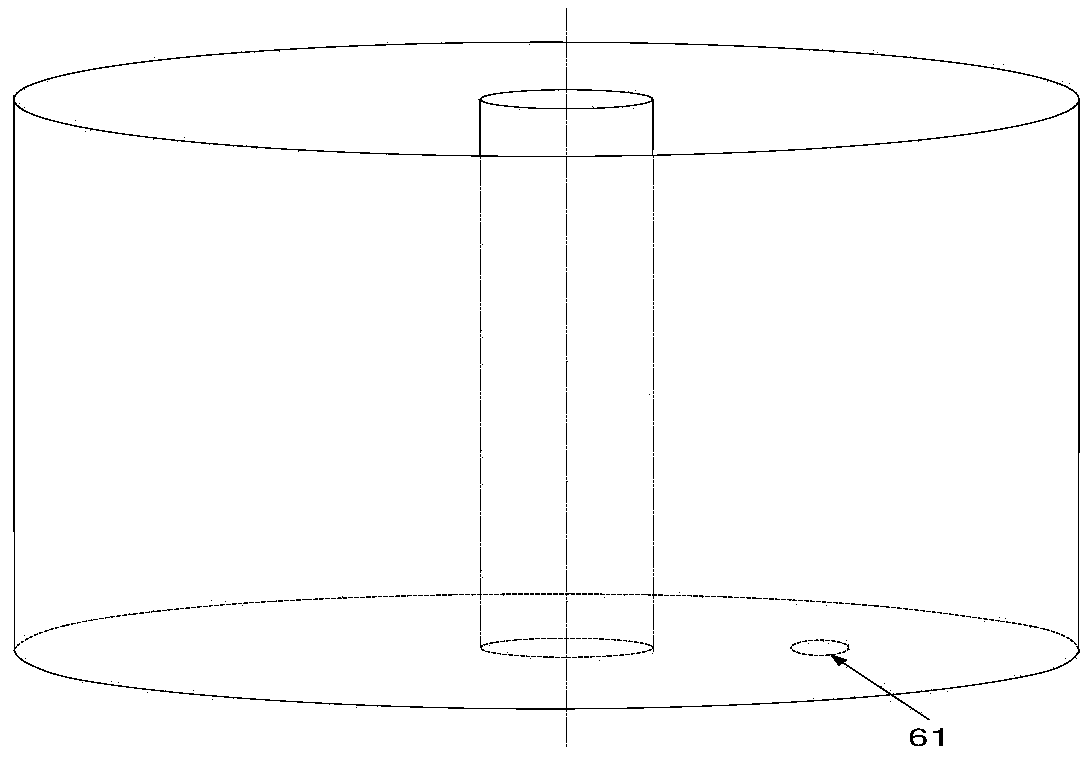

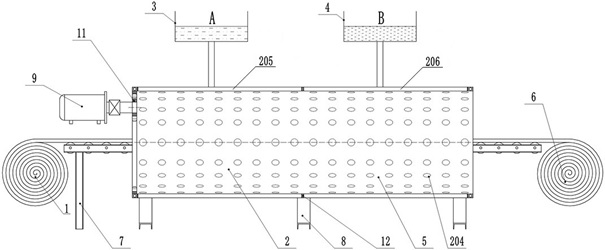

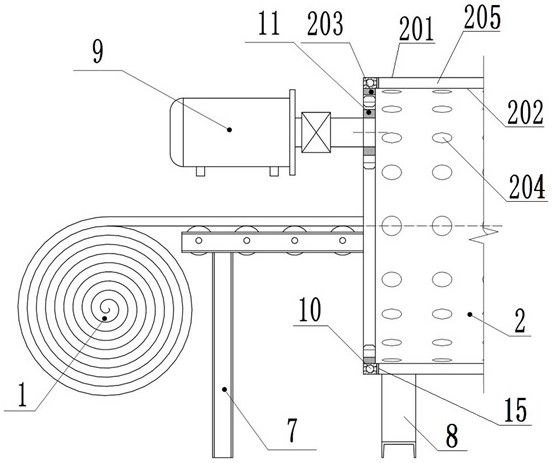

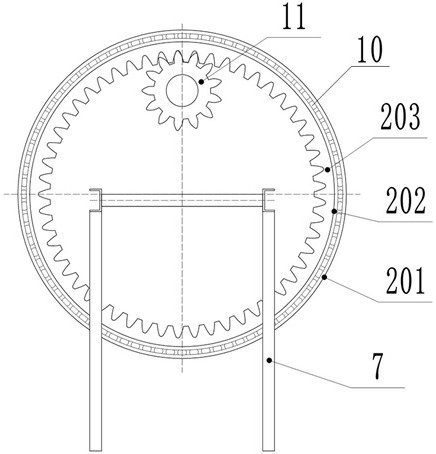

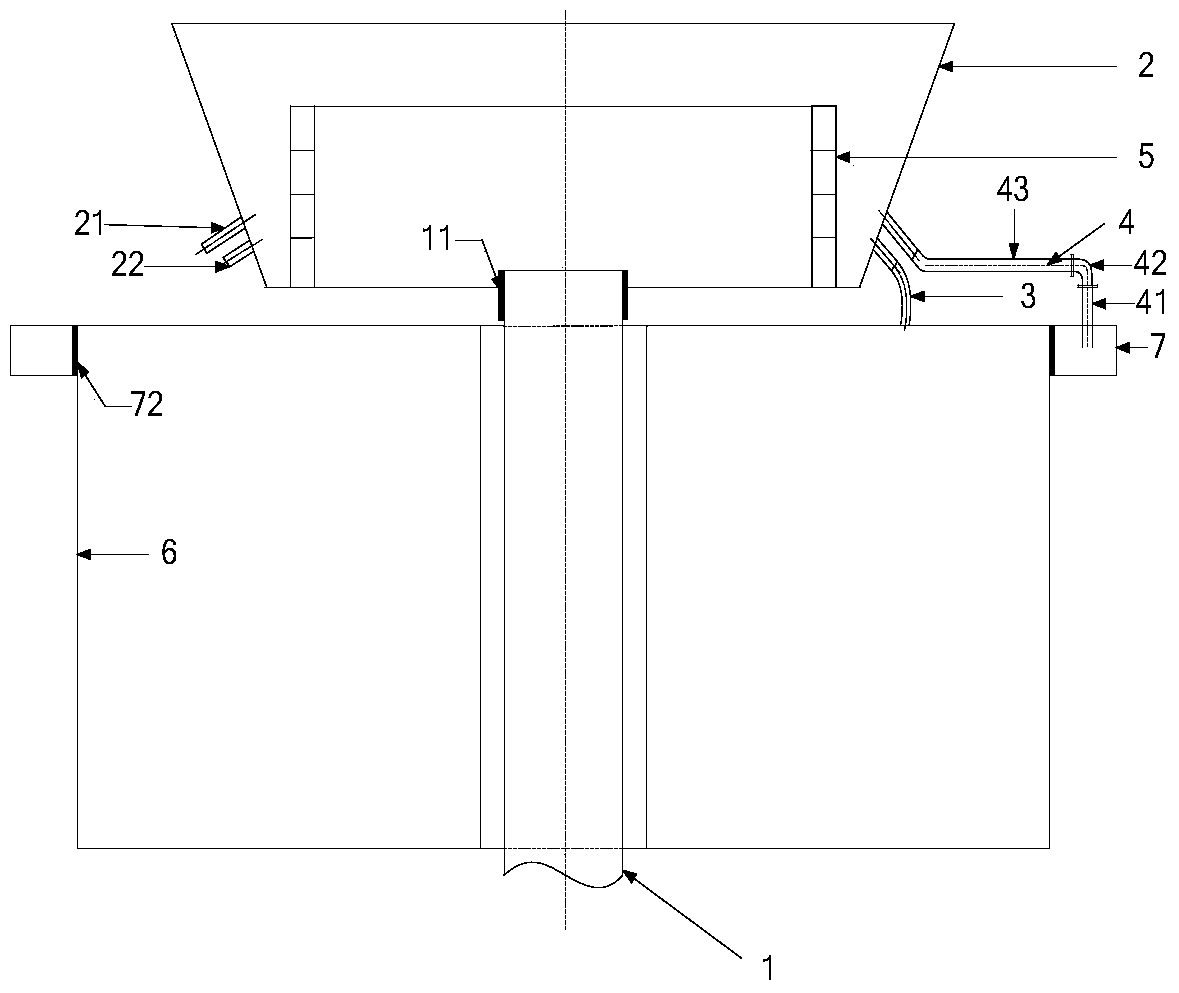

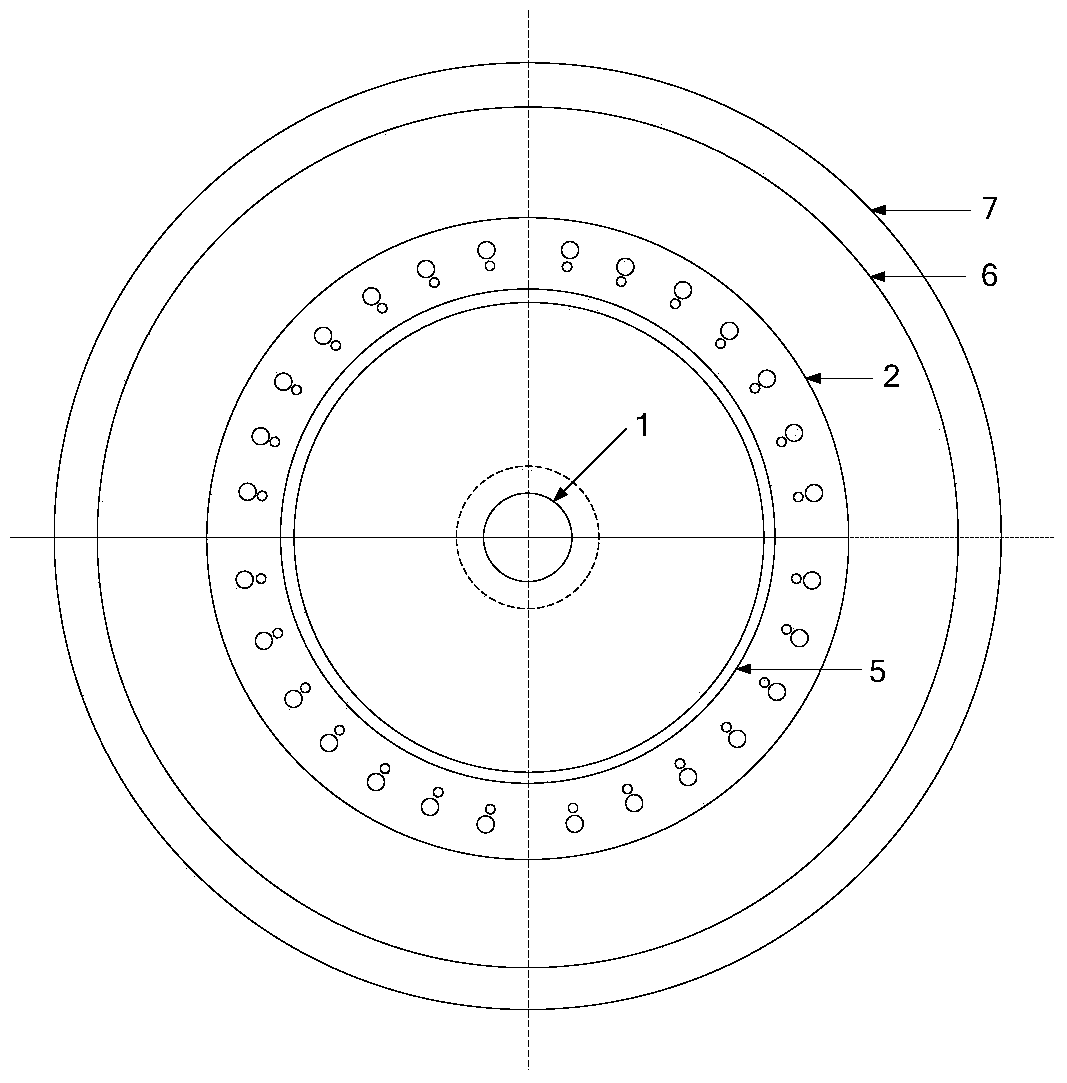

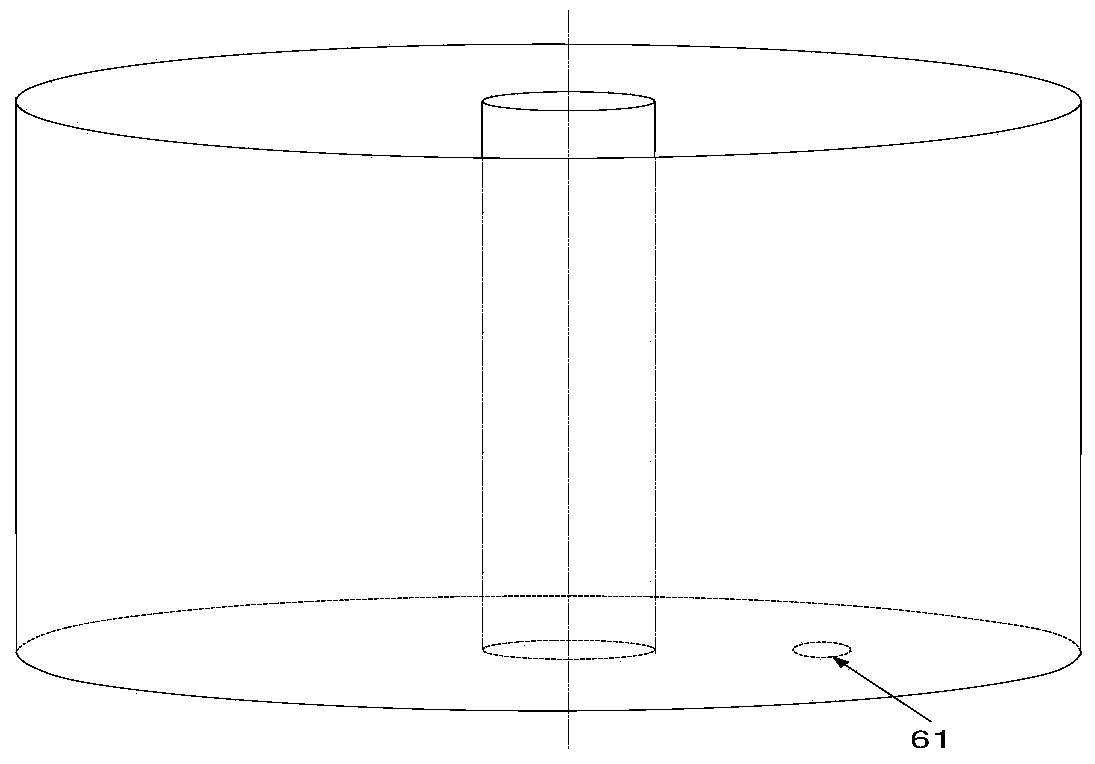

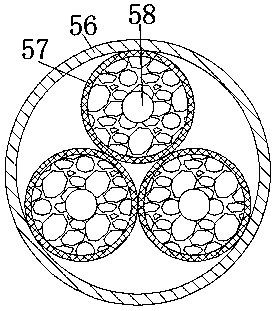

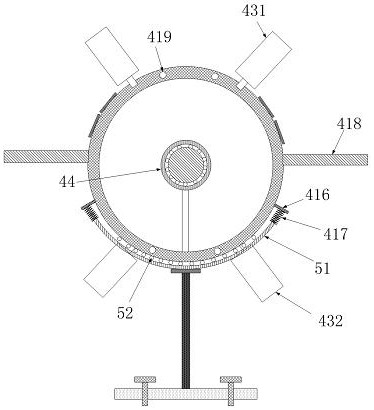

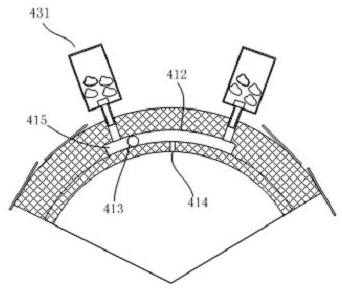

Equipment and method for rapidly preparing gel felt

The invention provides equipment and method for quickly preparing a gel felt. The equipment for quickly preparing the gel felt comprises an outer cylinder, an inner cylinder rotationally arranged in the outer cylinder and provided with an inner cavity for an unfolded fiber felt to penetrate through the inner cylinder, and a driving device which is in transmission connection with the inner cylinder and used for driving the inner cylinder to rotate; the inner cylinder and the outer cylinder are arranged in a spaced mode to form an annular cavity; the two axial ends of the annular cavity are closed; an inlet allowing silica sol, a catalyst or catalytic sol to enter the annular cavity is formed in the outer cylinder; a plurality of communicating holes for communication between the inner cavity of the inner cylinder and the annular cavity are formed in the inner cylinder; and when the inner cylinder rotates, the silica sol, the catalyst or the catalytic sol entering the annular cavity enters the inner cavity of the inner cylinder through the communicating holes and is sprayed to the surfaces of the two sides of the fiber felt under the rotation action of the inner cylinder. The all-directional spraying effect can be achieved, so that it is guaranteed that the silica sol, the catalyst or the catalytic sol is fully and evenly immersed into the fiber felt, and the good heat preservation and heat insulation performance of the gel felt is guaranteed.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

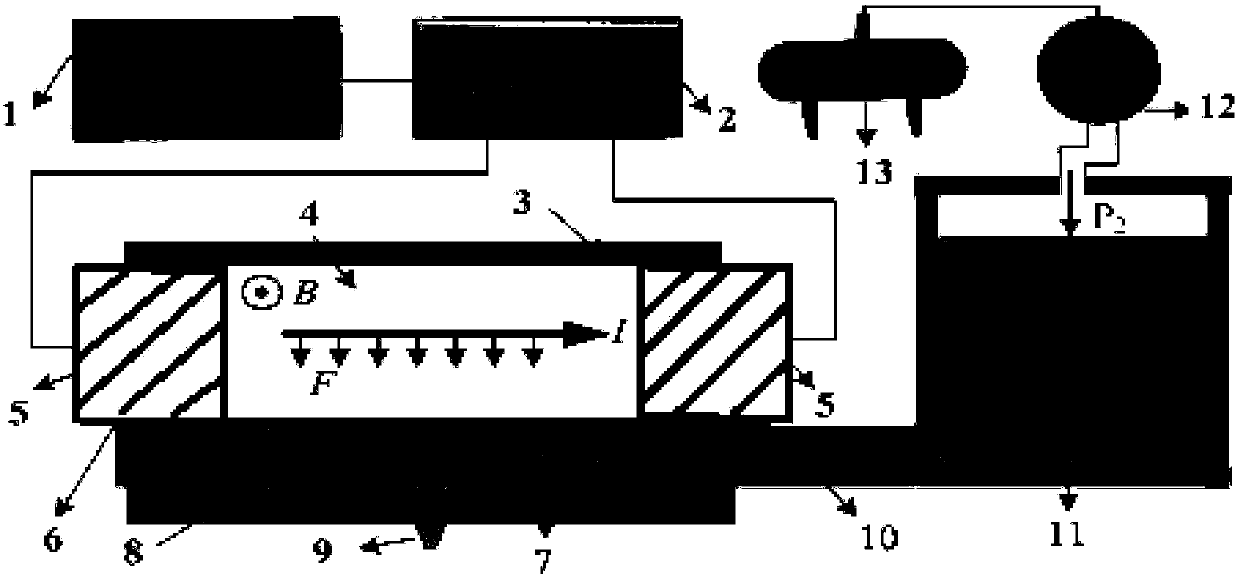

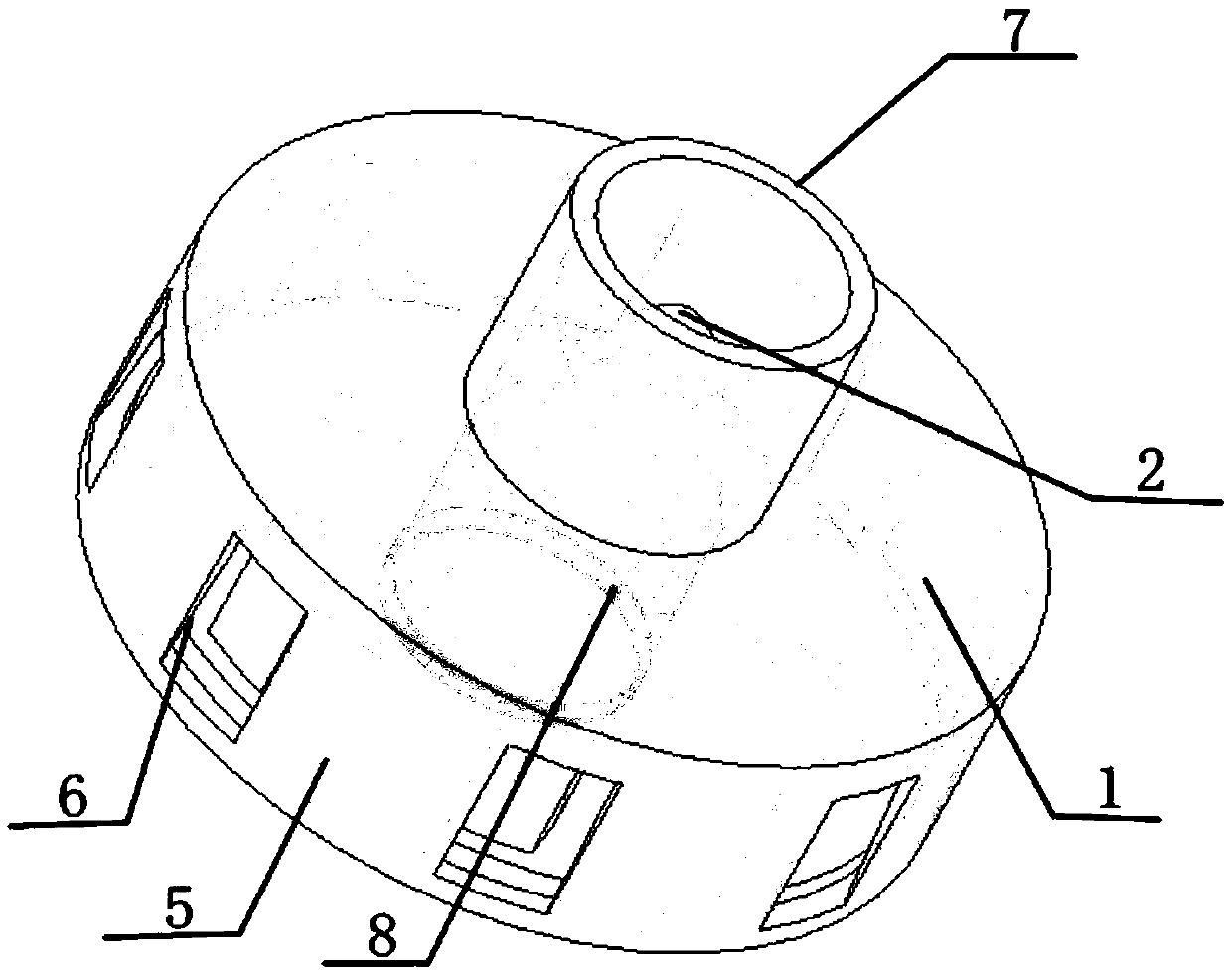

Device for preparing microdroplets based on magnetofluid excitation technology jet breakup

ActiveCN108031848AIncrease contactJet realizationAdditive manufacturing apparatusBreakupLiquid metal

The invention discloses a device for preparing microdroplets based on magnetofluid excitation technology jet breakup, relates to a micro-jetting device, and provides a preparing method applicable to the liquid microdroplets. According to the method, a disturbance generator and a jetting cavity are separated through a membrane. The cavity above the membrane is filled with a liquid metal solution, and high-frequency electromagnetic force generated by high-frequency pulse current flowing through liquid metal in a constant magnetic field serves as excitation waves. When the excitation waves are applied to a micro liquid column jetted out of a nozzle under a constant atmosphere condition, the micro liquid column can be fractured to form the uniform microdroplets. The micro-jetting device is implemented, and an adjacent excitation wave generator and the jetting cavity are processed in a main cavity. A disturbance wave generator is composed of permanent magnets, liquid metal, the membrane, electrodes, a signal source, a power amplifier and the like. The excitation wave generator is fixed between the permanent magnets, the electrodes are arranged inside the permanent magnets, and it is guaranteed that current is uniformly distributed; high-frequency electric signals are generated through the signal source and the power amplifier.

Owner:BEIJING UNIV OF TECH

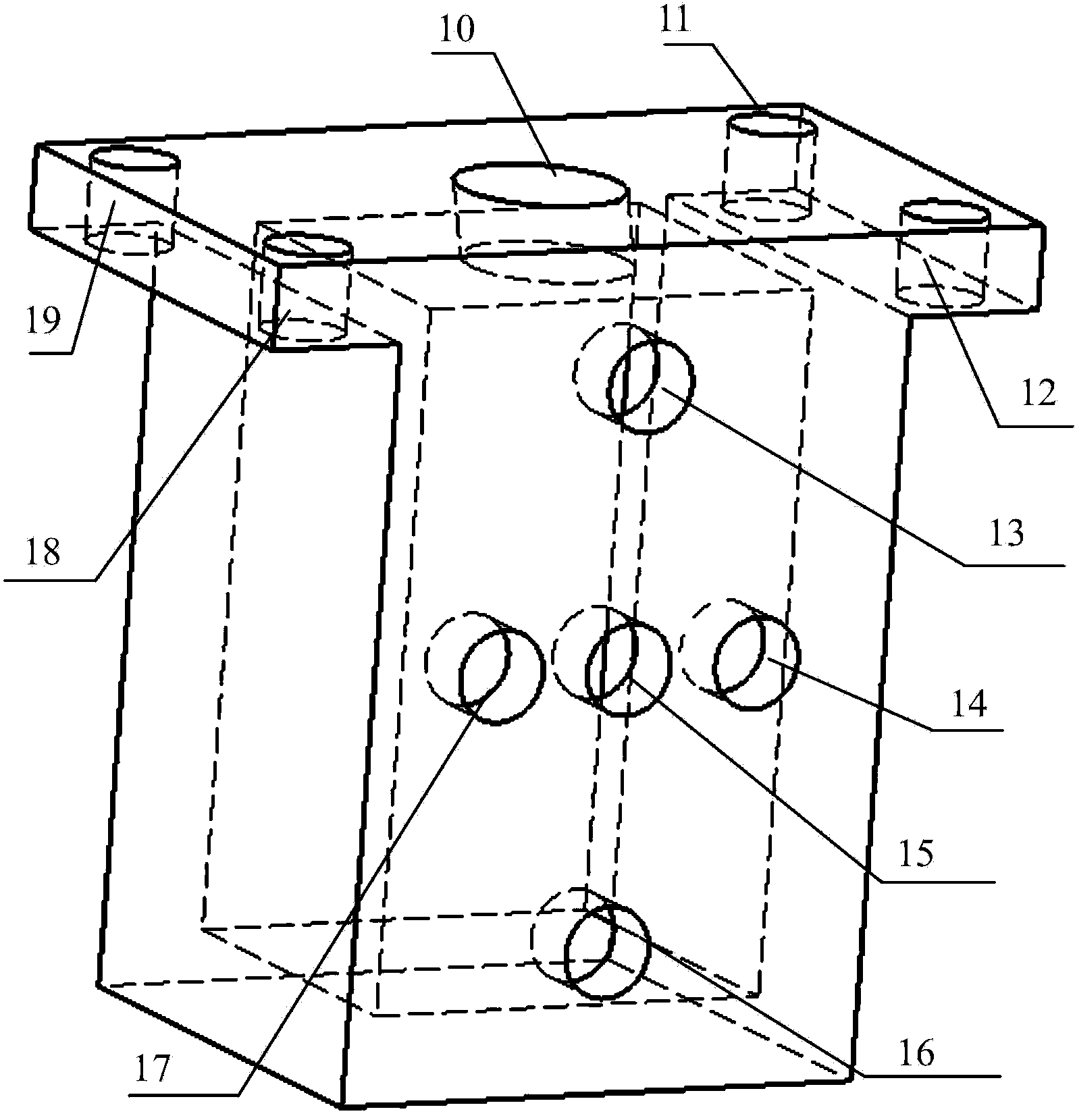

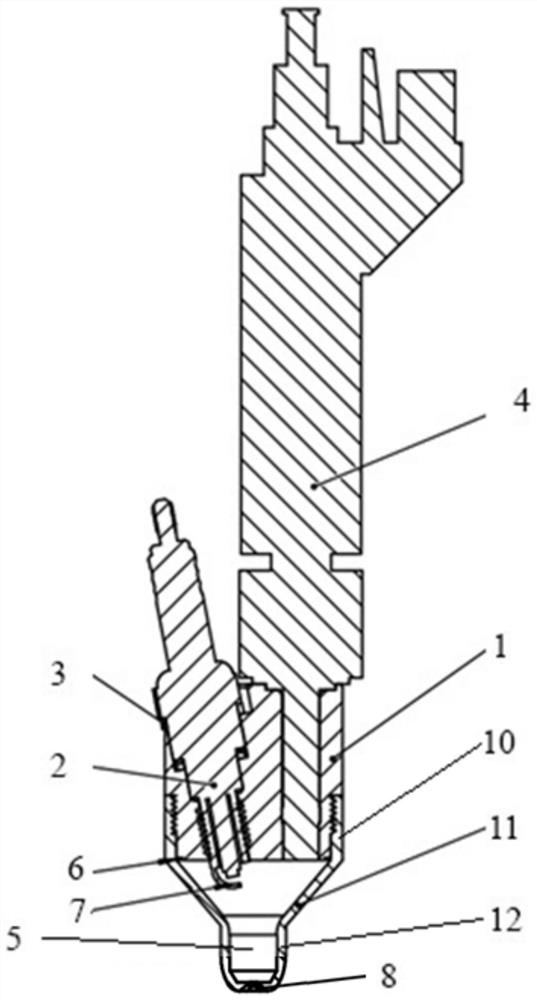

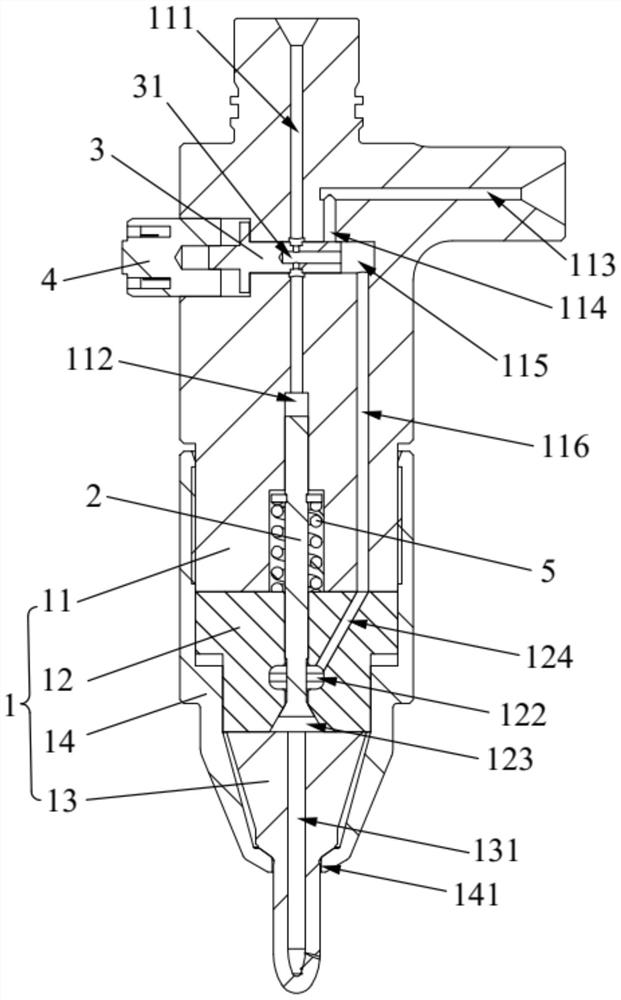

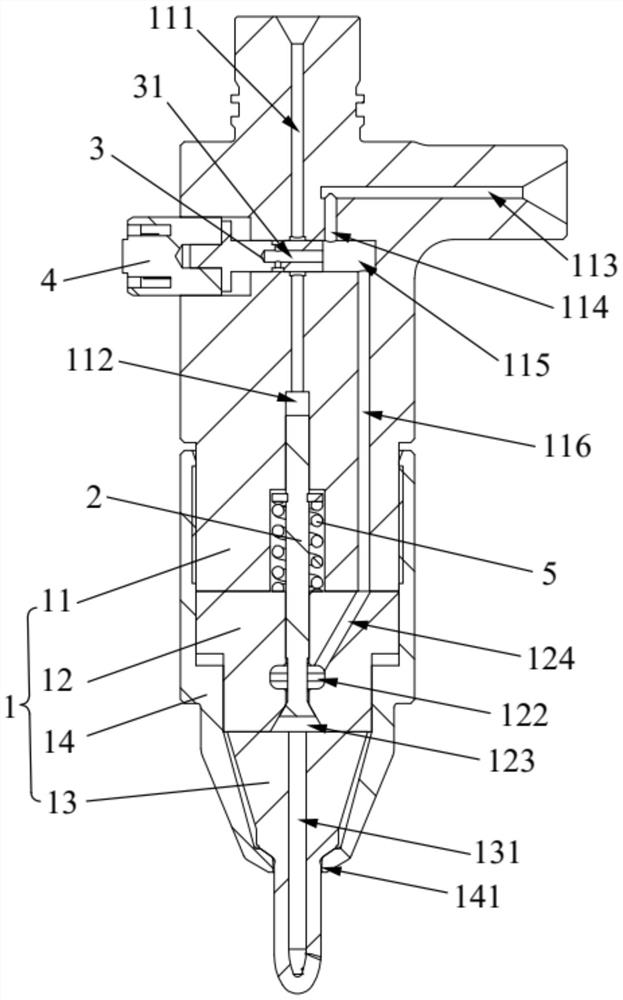

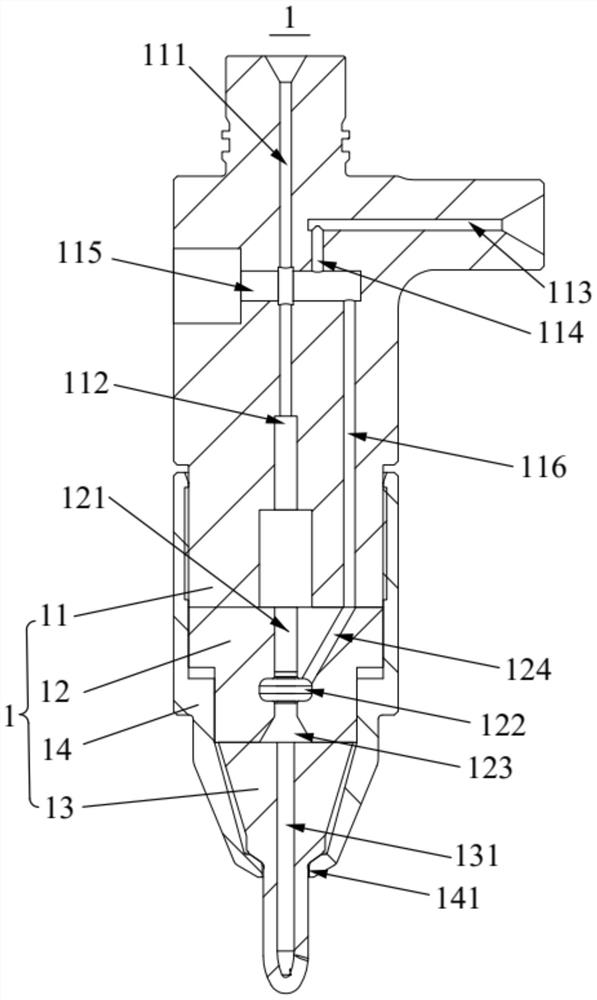

Integrated double-fuel injector and injection method thereof

ActiveCN111535957ASimple structureLow costFuel injection apparatusMachines/enginesEngineeringControl valves

Disclosed are an integrated double-fuel injector and an injection method thereof, which relate to the technical field of double-fuel injectors. The integrated double-fuel injector comprises: a valve body provided with an oil cavity, an oil injection hole, an oil injection way, an intake channel, an oil control inlet channel, and an oil control return channel; a valve rod disposed in the oil cavity; a nozzle sleeve provided with a gas injection hole, the nozzle sleeve and the valve body defining a pressure adjustment cavity, and the pressure adjustment cavity communicating with the oil controlinlet channel, the oil control return channel and the gas injection hole, respectively; a pressure adjustment component disposed in the pressure adjustment cavity, the gas injection hole being isolated from the intake channel when the pressure adjustment component abuts against the end portion of the nozzle sleeve, and the pressure adjustment component being capable of moving relative to the nozzle sleeve to enable the intake channel to communicate with the gas injection hole when gas is introduced into the intake channel; and an oil control valve disposed on the oil control return channel. The integrated double-fuel injector disclosed in the present invention not only can implement three work modes, but also has the advantages of simple structure, low cost, better injection effect and noneed of modifying an engine.

Owner:FAW JIEFANG AUTOMOTIVE CO

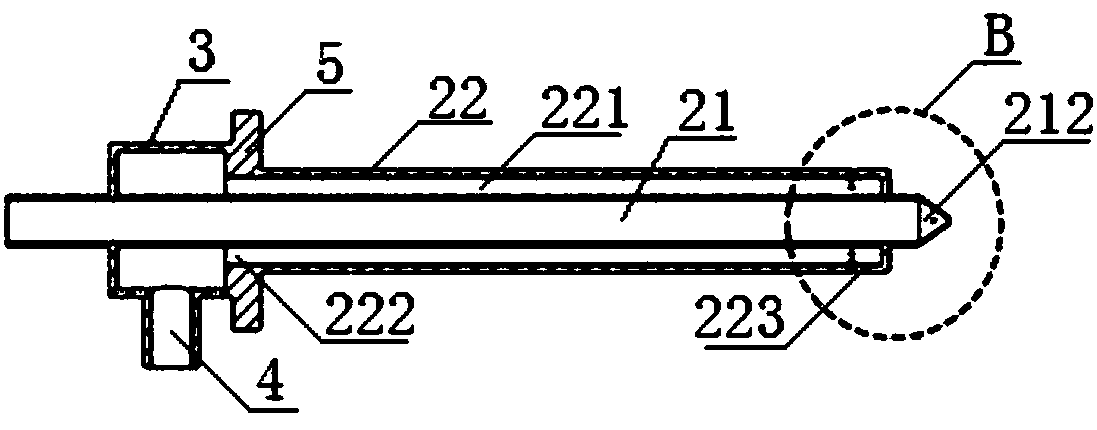

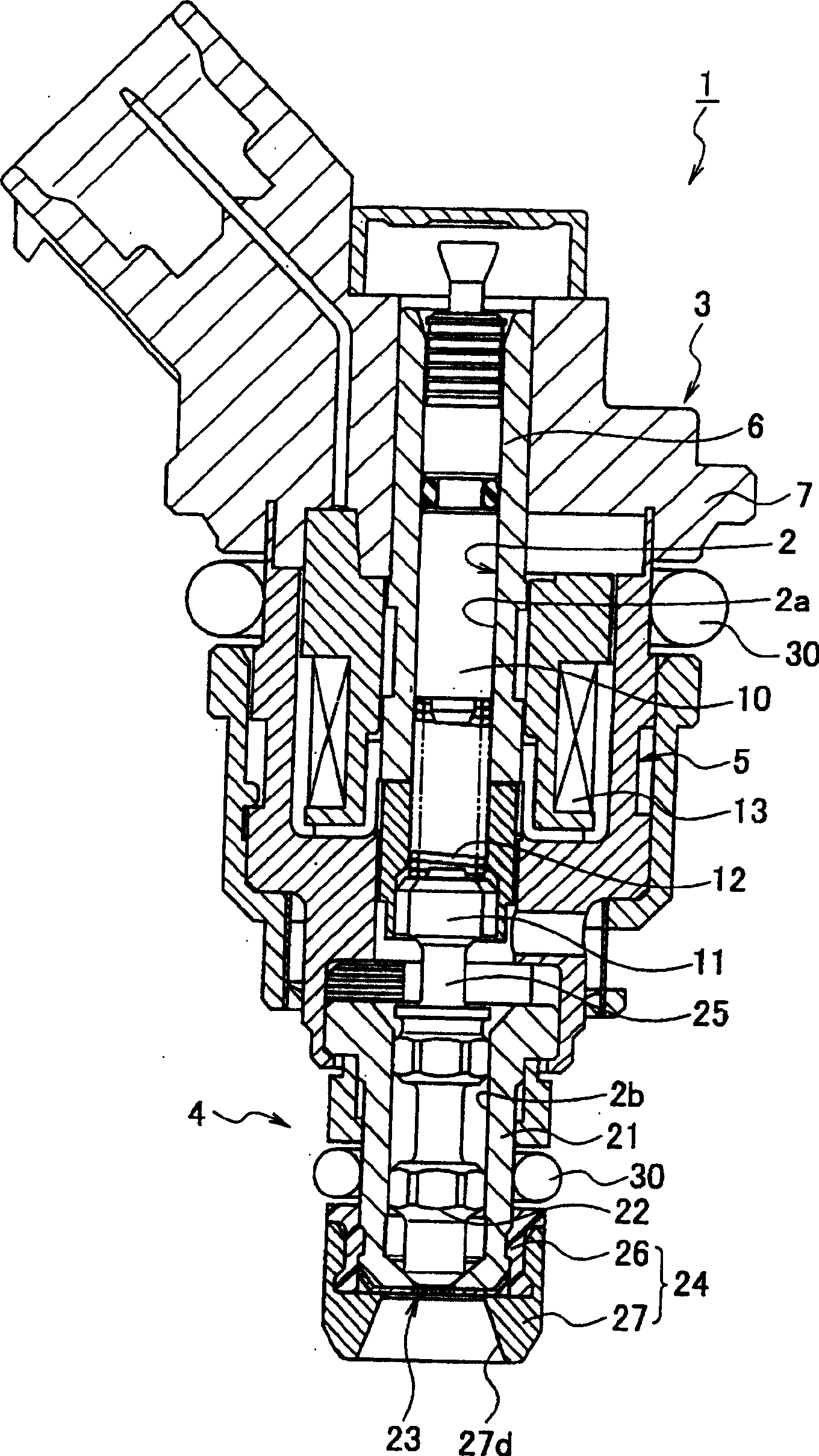

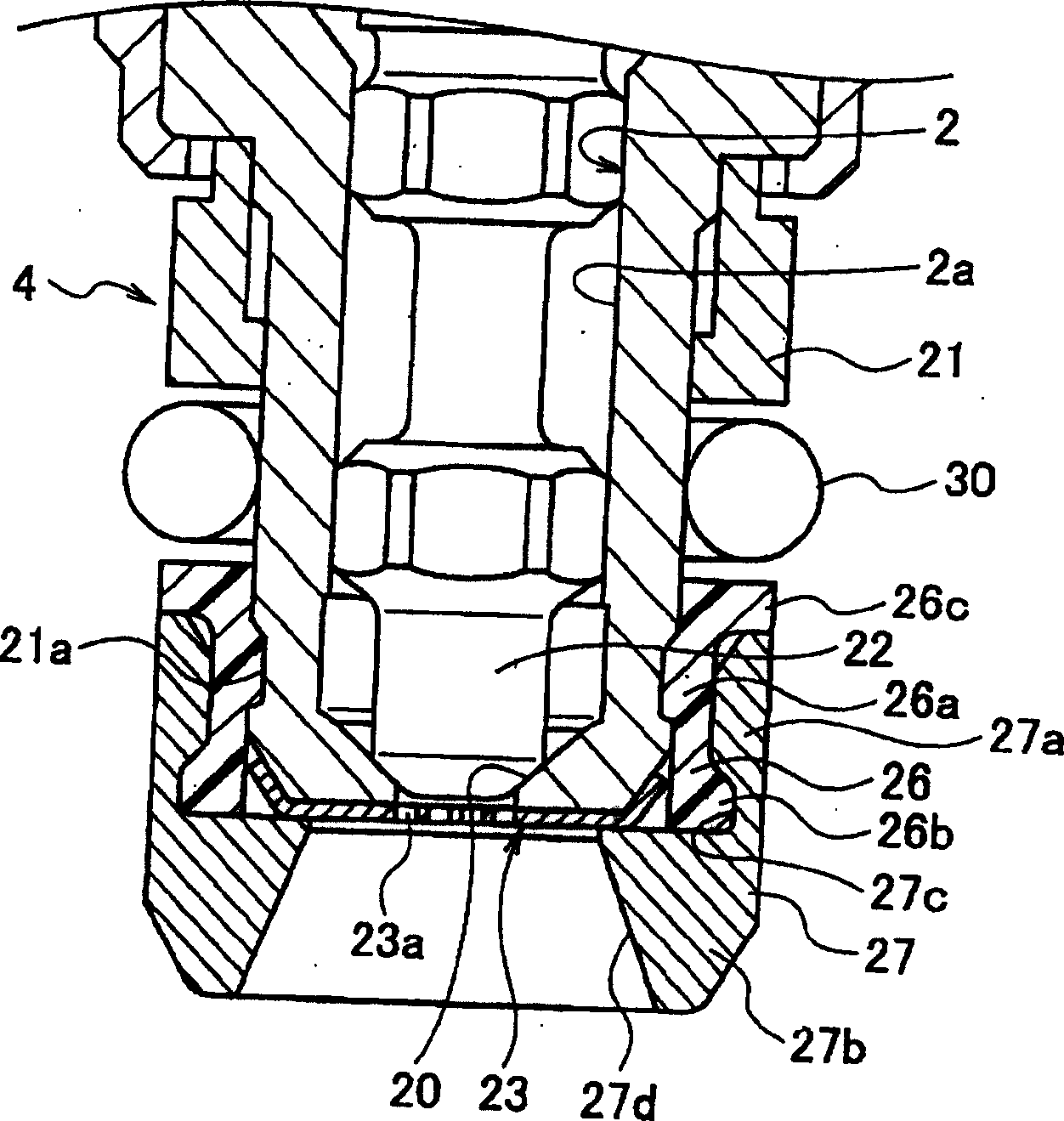

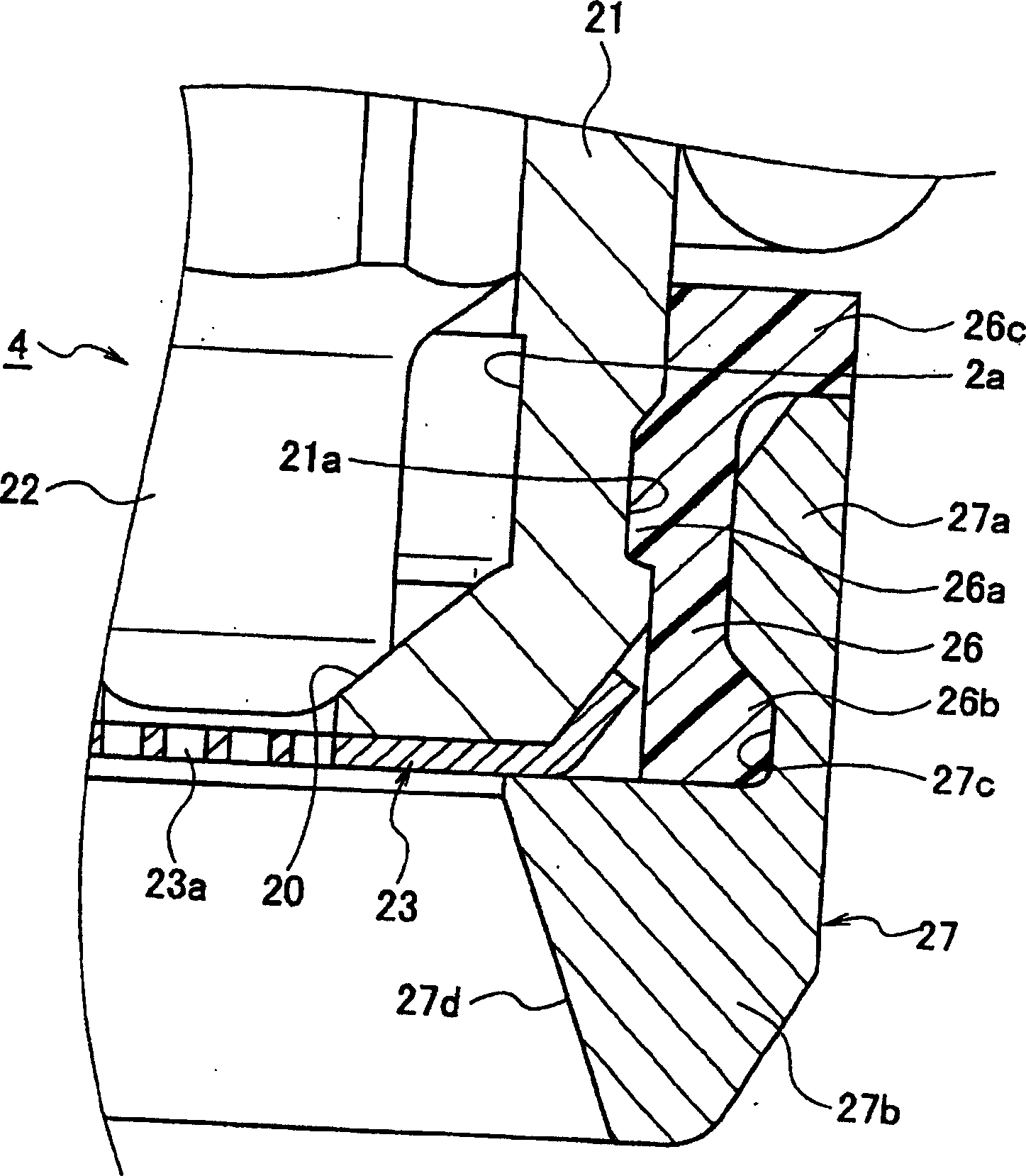

Fuel shooting valve

InactiveCN1626789AWon't fall offDoes not condense or freezeFuel injection apparatusMachines/enginesFuel injectionValve seat

The invention discloses a fuel injection valve. The technical problem to be solved by the invention is to provide a fuel injection valve which can prevent dew condensation and icing on a nozzle plate through a protective body. The technical solution to solve the technical problem is a fuel injection valve comprising a valve body (21) with a valve seat surface (20) formed on the wall surface of the fuel flow passage (2), and a valve body (21) arranged in the fuel flow passage (2). A plug (22), a nozzle plate (23) mounted on the front end face of the valve body (21) and having a plurality of nozzle holes (23a), and a nozzle plate (23) mounted on the outer periphery of the valve body (21) to surround the nozzle plate (23) The protective body (24) configured in the manner of the outer circumference of the valve body (21), wherein the protective body (24) is pressed into the outer circumference of the valve body (21) and the locking protrusion (26a) on the inner circumference locks the locking groove of the valve body (21) The resin shield part (26) of (21a), and the peripheral locking protrusion (26b) that is pressed into the outer periphery of the resin shield part (26) and locks the resin shield part (26) in the locking groove part (27c) And it is constituted by a metal shield member (27) having a shield portion (27b) surrounding the outer periphery of the nozzle plate (23).

Owner:HITACHI LTD

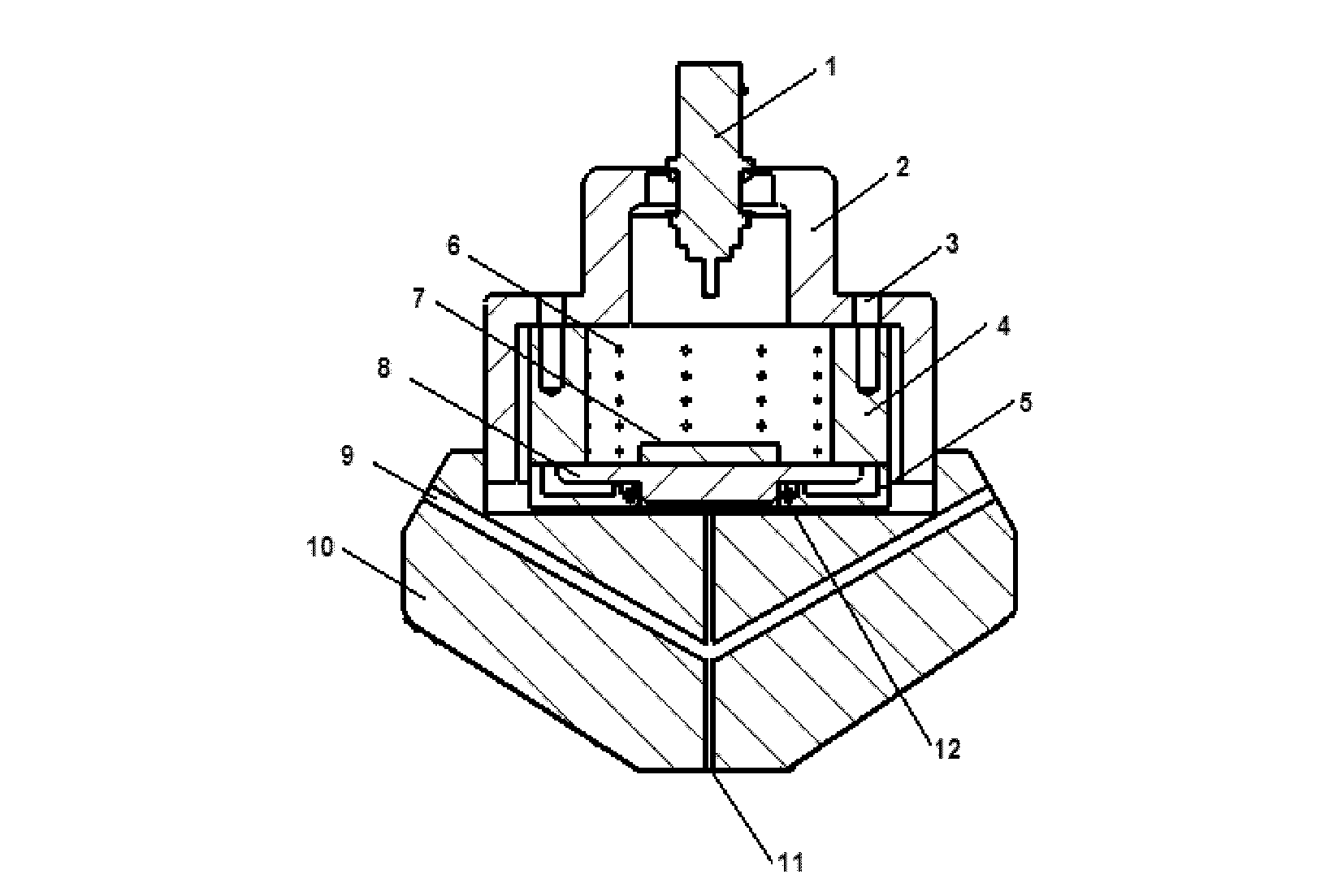

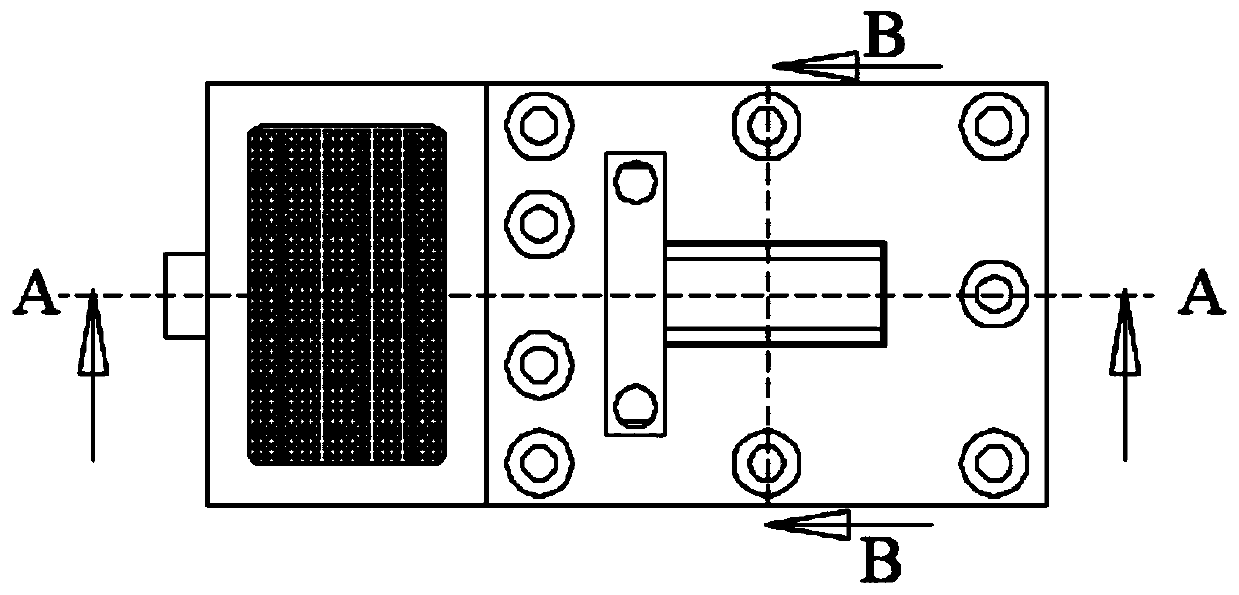

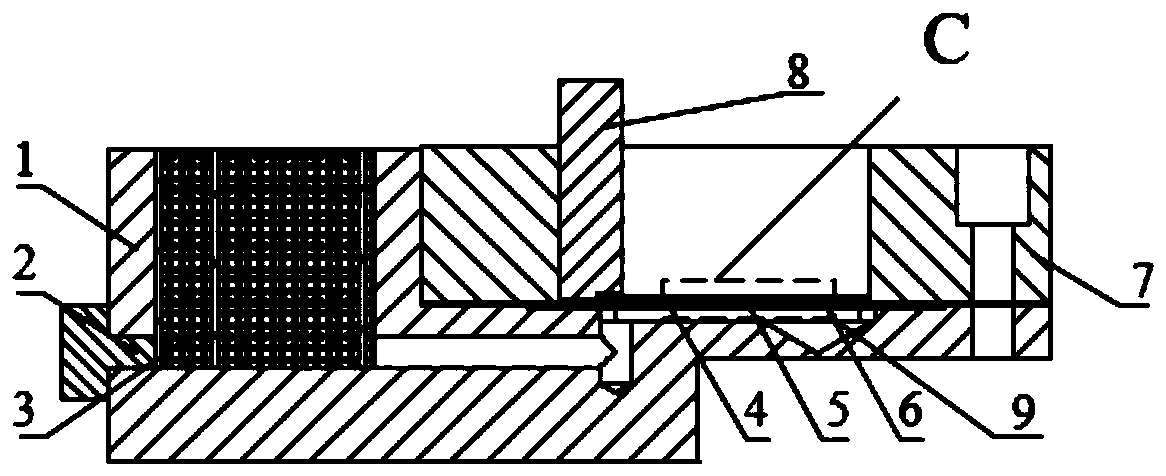

Cantilever beam piezoelectric microspray mechanism capable of spraying high-viscosity fluid

ActiveCN110038763AReduce the voltage amplitudeJet realizationLiquid spraying apparatusCeramicCantilevered beam

The invention provides a cantilever beam piezoelectric microspray mechanism capable of spraying high-viscosity fluid. The mechanism comprises a base, a porous liquid storage structure, a flexible thinfilm, a copper sheet, piezoelectric ceramic, an upper cover plate, a copper sheet pressing plate and spray nozzles. A liquid storage tank is formed in the left side of the upper surface of the base,a mounting groove is formed in the right side of the upper surface of the base, a fluid circulating groove is formed in the bottom of the mounting groove, the liquid storage tank communicates with thefluid circulating groove through a liquid storage tank outlet and a fluid flow channel inlet in sequence, the porous liquid storage structure is arranged in the liquid storage tank, the flexible thinfilm is arranged in the positioning groove and completely covers the fluid circulating groove, the upper cover plate constrains the normal outward freedom degree of the flexible thin film, the coppersheet is attached to the flexible thin film, the piezoelectric ceramic is attached to the copper sheet, the copper sheet pressing plate penetrates through the upper cover plate and is tightly pressedto the left end of the copper sheet to form a cantilever beam structure, the spray nozzles are formed in the lower surface of the base and communicate with a fluid channel, and a closed cavity accommodating the high-viscosity fluid is defined between the flexible thin film and the base. By means of the cantilever beam piezoelectric microspray mechanism, the high-pressure high-viscosity fluid canbe sprayed.

Owner:HARBIN INST OF TECH

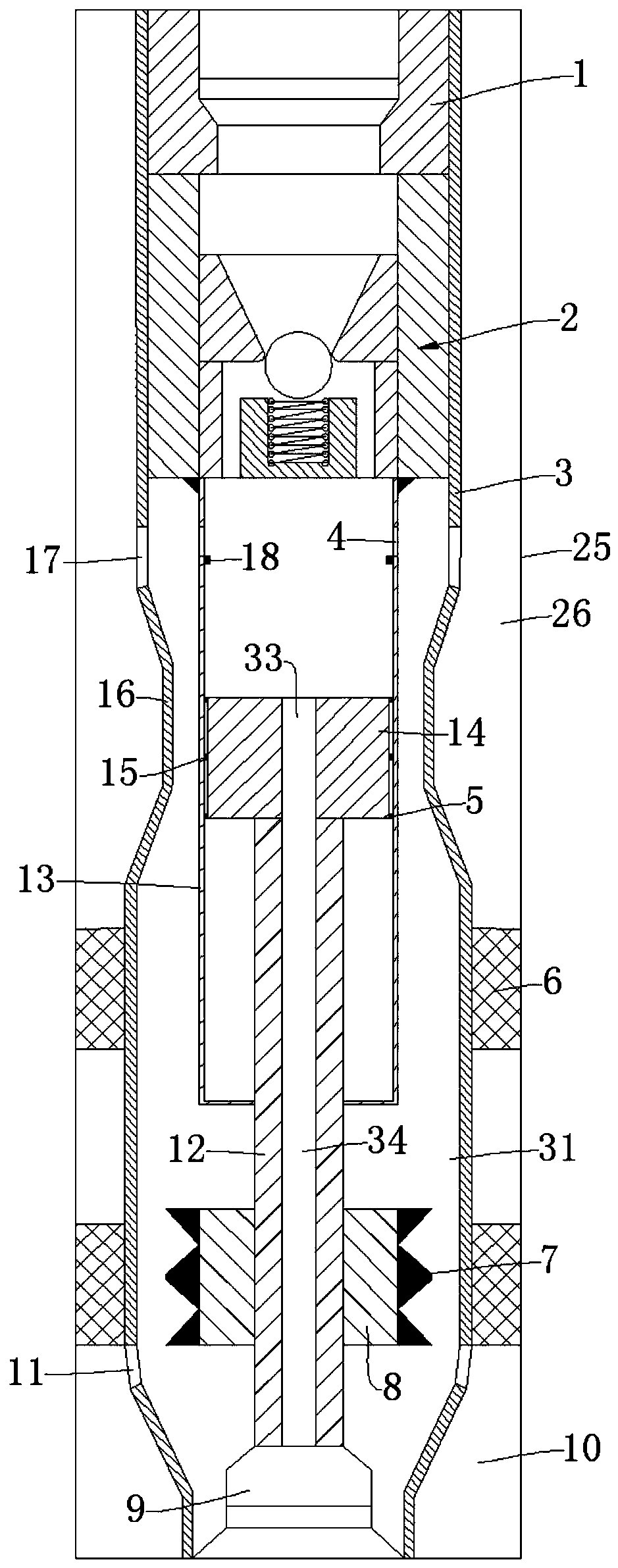

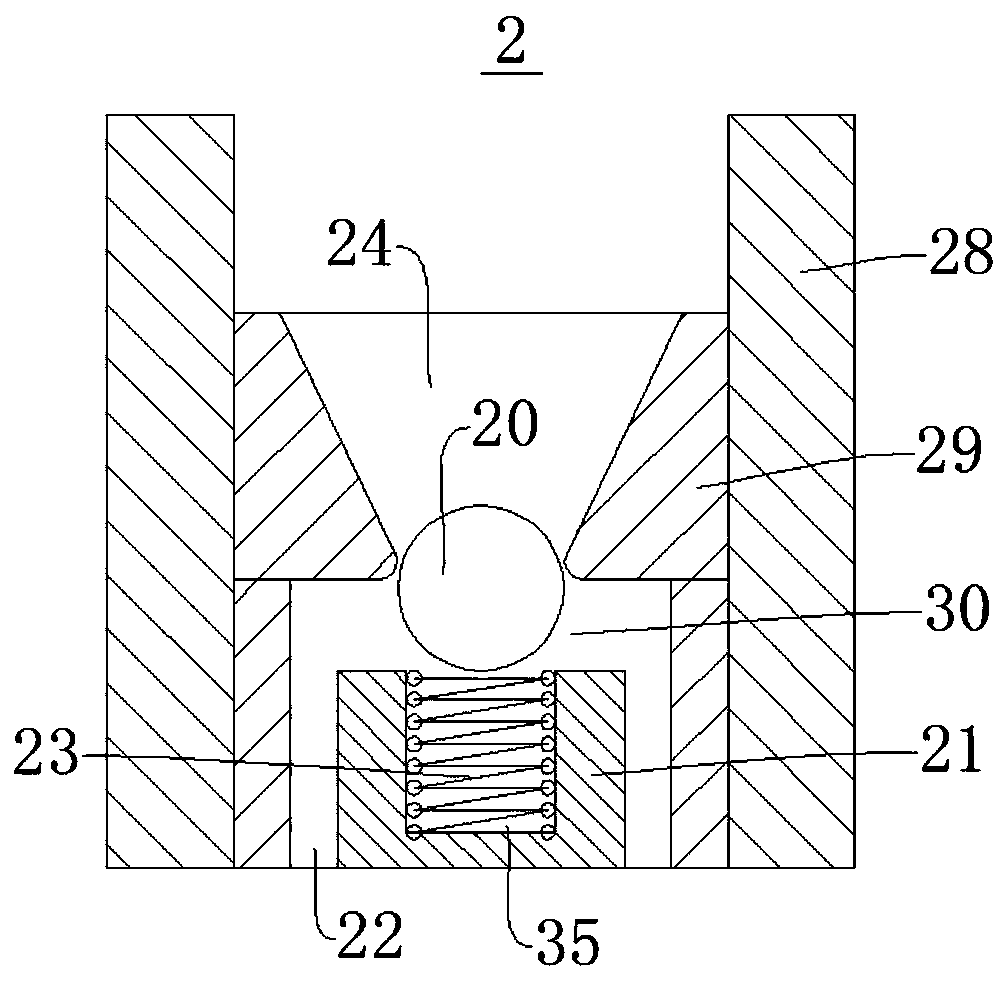

Tool for reducing equivalent circulating density

The invention provides a tool for reducing the equivalent circulating density. The tool comprises an outer cylinder, a one-way check valve assembly, an inner shell and a piston rod, wherein the outercylinder is put in a borehole, and a first annulus is formed between the outer cylinder and the borehole; the outer cylinder is sleeved with a sealing mechanism sealed on the inner wall of the borehole, and the first annulus is separated into an upper annulus and a lower annulus; the sidewall close to the upper end of the outer cylinder is provided with jet holes communicating with the upper annulus, and the sidewall close to the lower end of the outer cylinder is provided with inflow holes communicating with the lower annulus; the one-way check valve assembly is arranged in the outer cylinder, the inner shell is connected with the lower end of the one-way check valve assembly , and a second annulus is formed between the inner shell and the outer cylinder; the sidewall of the inner shell is provided with pressure relief holes, and the bottom wall of the inner shell is provided with a through hole; the piston rod is arranged in the inner shell, the lower end of the piston rod is arranged in the through hole in a penetrating manner, and a piston is arranged at the upper end of the piston rod; and a first flow channel is arranged in the piston, and a second flow channel communicatingwith the first flow channel in a butt joint manner is arranged in the piston rod. The tool for reducing the equivalent circulating density can reduce the equivalent circulating density, realizes the purpose of depressurization and guarantees safe and efficient well drilling.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

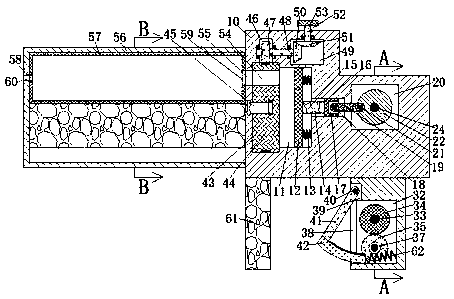

Gasoline engine ignition mechanism comprising pre-combustion chamber with shared jet orifice

The invention relates to a gasoline engine ignition mechanism comprising a pre-combustion chamber with a shared jet orifice. The ignition mechanism comprises a cylindrical connecting piece, an oil sprayer mounting hole, a spark plug mounting hole, the pre-combustion chamber connected with the outer circumferential face of the connecting piece through threads, a pre-combustion chamber oil sprayer matched with the oil sprayer mounting hole to work and a pre-combustion chamber spark plug matched with the spark plug mounting hole to work; the pre-combustion chamber is formed by combining three sections, namely a first cylindrical sleeve body, a conical sleeve body and a second cylindrical cavity body in sequence from top to bottom; N evenly-distributed jet flow spraying holes are formed in the center of the bottom of the second cylindrical cavity, the center lines of all the spraying holes intersect with the center line of the second cylindrical cavity, and the intersection points coincide with one another; and all the spraying holes are converged into a spraying opening at the upper bottom surface of the second cylindrical cavity, namely the shared jet orifice. According to the gasoline engine ignition mechanism, the jet flow of flames can be simultaneously carried out by six jet flow spraying openings.

Owner:TIANJIN UNIV

Test device and method of cement mortar fluidity

The present invention discloses a test device and method of cement mortar fluidity. The device includes a cement mortar sprayer, a housing, a shaft, a turbine, a speed friction control strip, a support, and a height-adjustable baffle. The center of the housing front is provided with a cement mortar inlet; an outlet of the cement mortar sprayer is communicated with the cement mortar inlet; the side of the housing is provided with a plurality of injection orifices; the turbine is located within the housing; the front of the turbine has a projection in conical structure; the projection is right opposite to the cement mortar inlet; one side of the speed friction control strip is fixed to the back of the turbine; one side of the baffle is movably connected to the inner wall of the housing, and the other side of the baffle contacts with the other side of the speed friction control strip; the support is fixed to the inner surface of the housing; and one end of the shaft is movably connected to the support, and the other end of the shaft penetrates through the baffle and the speed friction control strip, and is connected to the turbine. The invention can realize the injection of cement mortar and can measure fluidity of the cement mortar.

Owner:CHANGAN UNIV

Arrayed electrofluid jet printing head with independently controllable nozzle ejection and its realization method

ActiveCN104191819BAchieve independent controllable injectionSimple structurePrintingSpray nozzleEngineering

Owner:HUAZHONG UNIV OF SCI & TECH

A water jet source device with constant pressure

ActiveCN105371946BIsolation impactReduce vibrationSubsonic/sonic/ultrasonic wave measurementWater storage tankWater flow

The invention discloses a water jet source apparatus with constant pressure. The apparatus comprises a water pump guide pipe, a guiding gutter, a guiding pipe, an overflow pipe, a current stabilizing grid, a water storage tank and an overflow groove, and is characterized in that one end of the water pump guide pipe is connected with a submersible pump, the other end of the water pump guide pipe is connected with the guiding gutter, the guiding gutter is connected with the guiding pipe and the overflow pipe, one end of the guiding pipe is connected with the guiding gutter, the other end of the guiding pipe is connected with the water storage tank, the outer side of the water storage tank is connected with the overflow groove, and water in the overflow groove flows to the submersible pump. According to water jet source apparatus with the constant pressure, by means of a water level difference between the water storage tank and a jet nozzle, jet pressure is generated due to the effect of gravity, additional vibration and noise are not caused, the pressure is constant, and the water jet source apparatus is suitable for a jet source in an underwater jet research process.

Owner:HARBIN ENG UNIV

Manufacturing method of liquid injector head

InactiveCN108940637AJet realizationExtend the spray timeLiquid spraying apparatusMating connectionSlide plate

The invention discloses a manufacturing method of a liquid injector head. The liquid injector head comprises a device body, an injection device arranged in the device body and a switching device arranged in the device body. The switching device comprises a first working cavity formed in the device body. A slide plate is connected into the first working cavity in a sliding fit mode. First springs are fixedly arranged on the right end surface of the slide plate and symmetric up and down, and the right ends of the first springs are fixedly connected with the right side end surface of the first working cavity. The right side end wall of the first working cavity communicates with a connecting rod cavity. A first connecting rod extending rightwards is fixedly arranged on the right end surface ofthe slide plate. A slide block connected with the connecting rod cavity in a sliding fit mode is fixedly arranged at the right end of the first connecting rod. An internal connecting groove with a rightward opening is formed in the slide block. First fixing shafts are fixedly arranged on the front and rear side end walls of the internal connecting groove correspondingly. According to the device,a plurality of water tanks are integrated, an increase of the water storage amount can prolong the injection time of a water gun, liquid in different colors can be injected, and the experience feelingof a player is improved.

Owner:余名宪

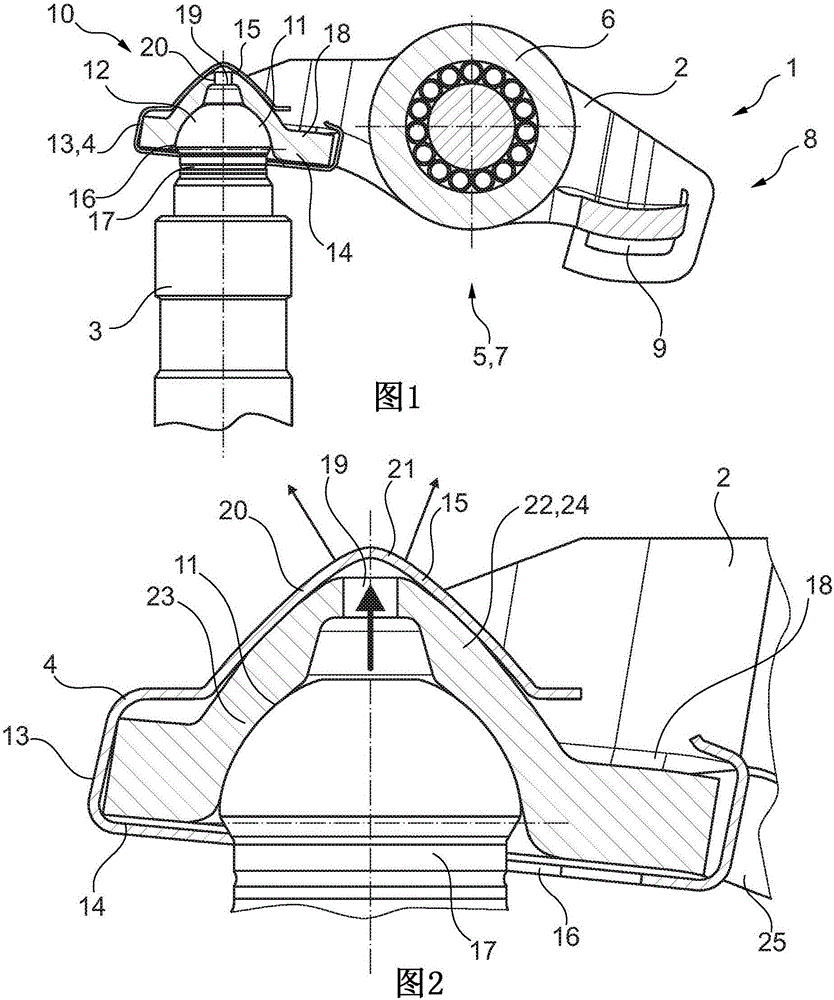

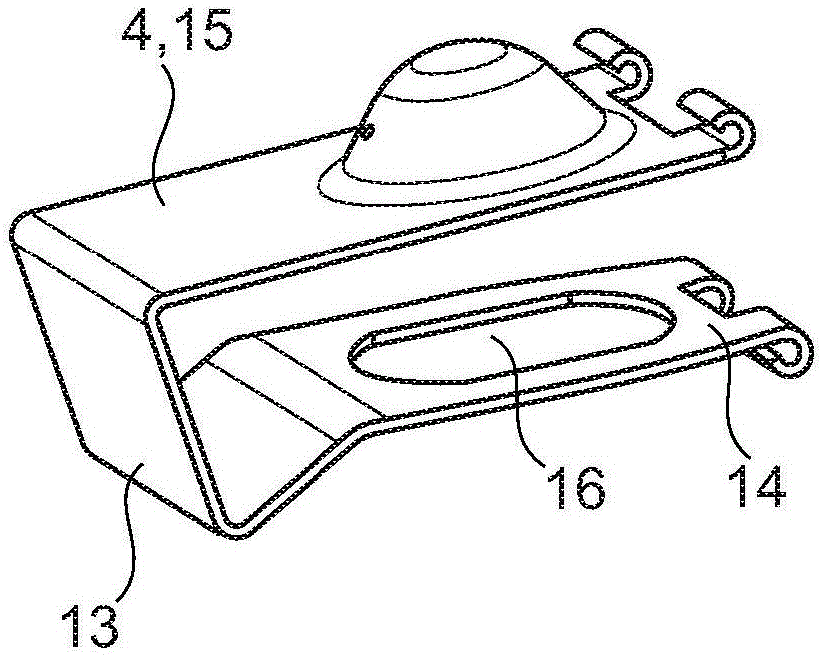

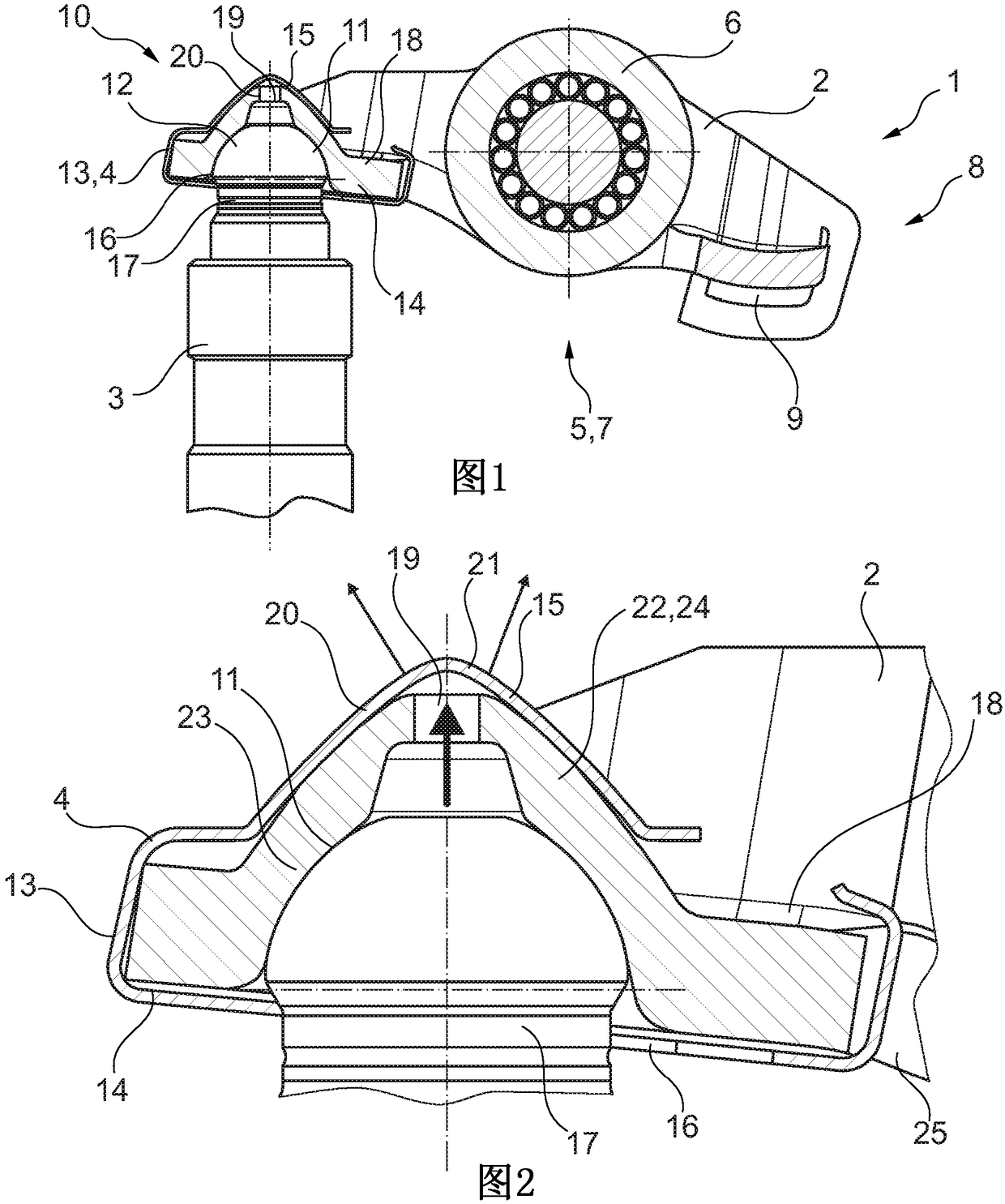

Method and apparatus for indicating d2d resource pool in wireless communication system

InactiveCN106255808AEasy stampingReduce trimmingValve arrangementsMachines/enginesResource poolCommunications system

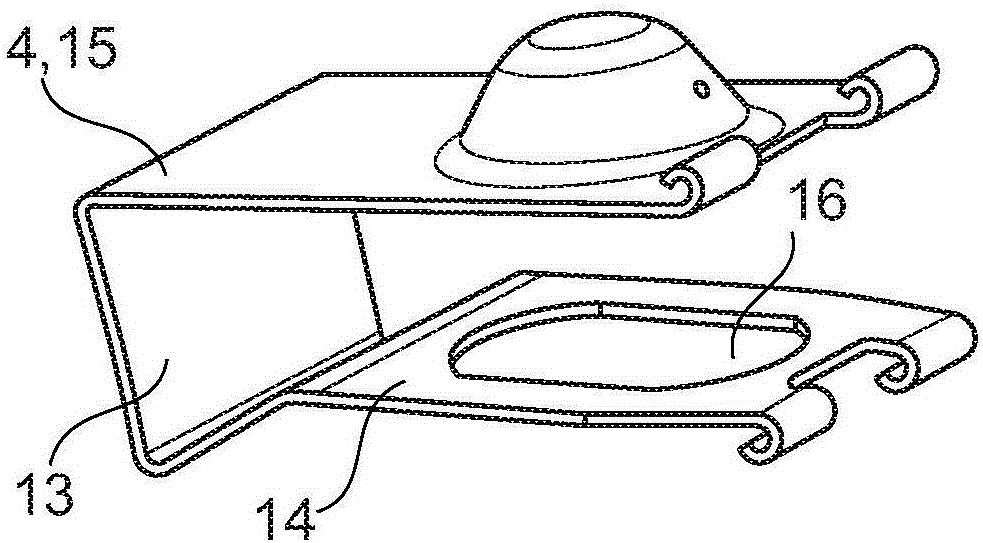

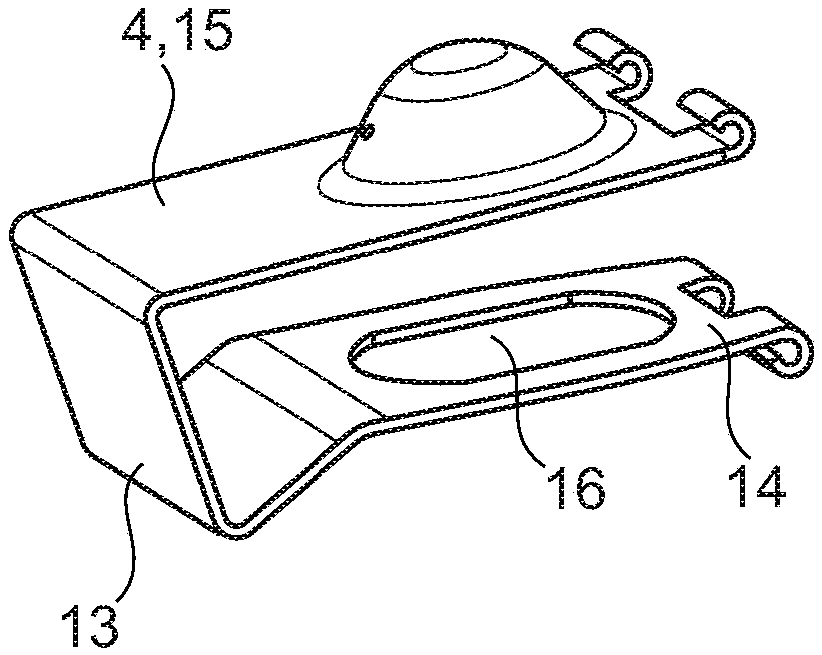

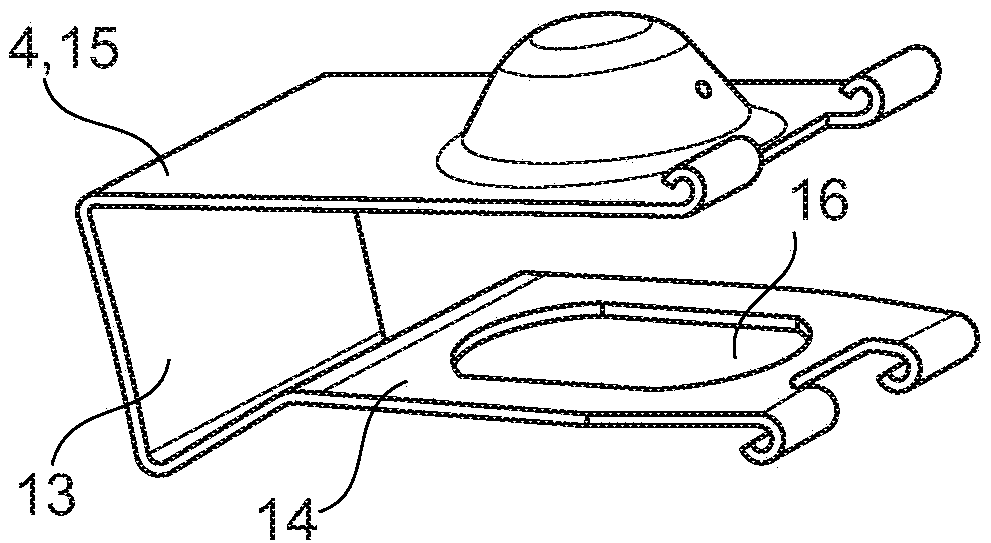

A connection clip (4) fixes a dome-shaped recess located at the end of a drag lever on a head (12) of a support element (3). The connection clip consists of two spring limbs (14, 15) which are connected at one end by a transverse bracket (13). One spring limb (14) rests on the lower face (7) of the drag lever (2), and a recess (16) of said spring limb engages around a retaining region (17) of the support element (3) below the support element head (13). The other spring limb (15) runs on an upper face (18) of the drag lever (2). A channel (19) which is provided by the support element (3) leads through the recess (11) for an injection oil lubrication. The other spring limb (15) of the connection clip (4) lies on the upper face (18) of the drag lever (2) over the dome-shaped recess (11) in a closed manner and has an injection oil bore (20) which is fluidically connected to the channel (19) and which faces away from the drag lever (2) via the second end (10) thereof.

Owner:SCHAEFFLER TECH AG & CO KG

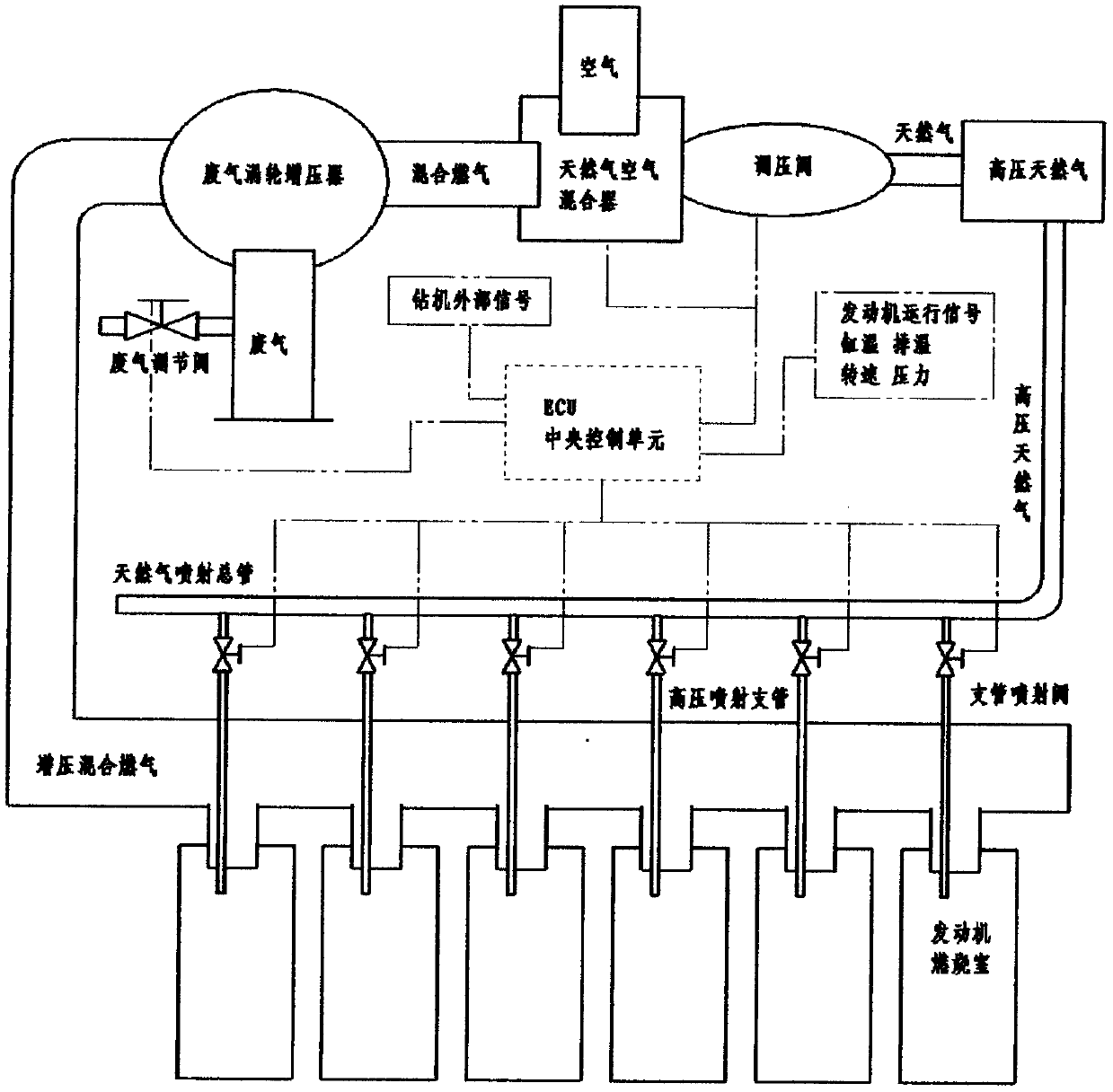

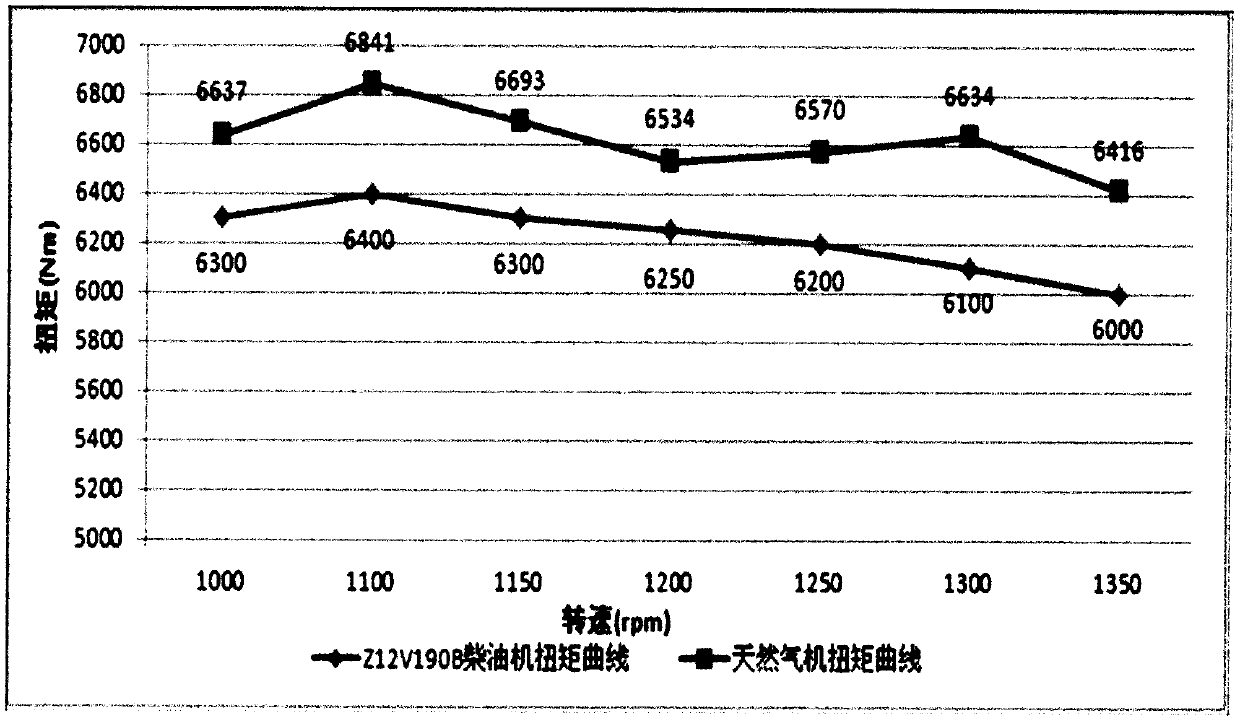

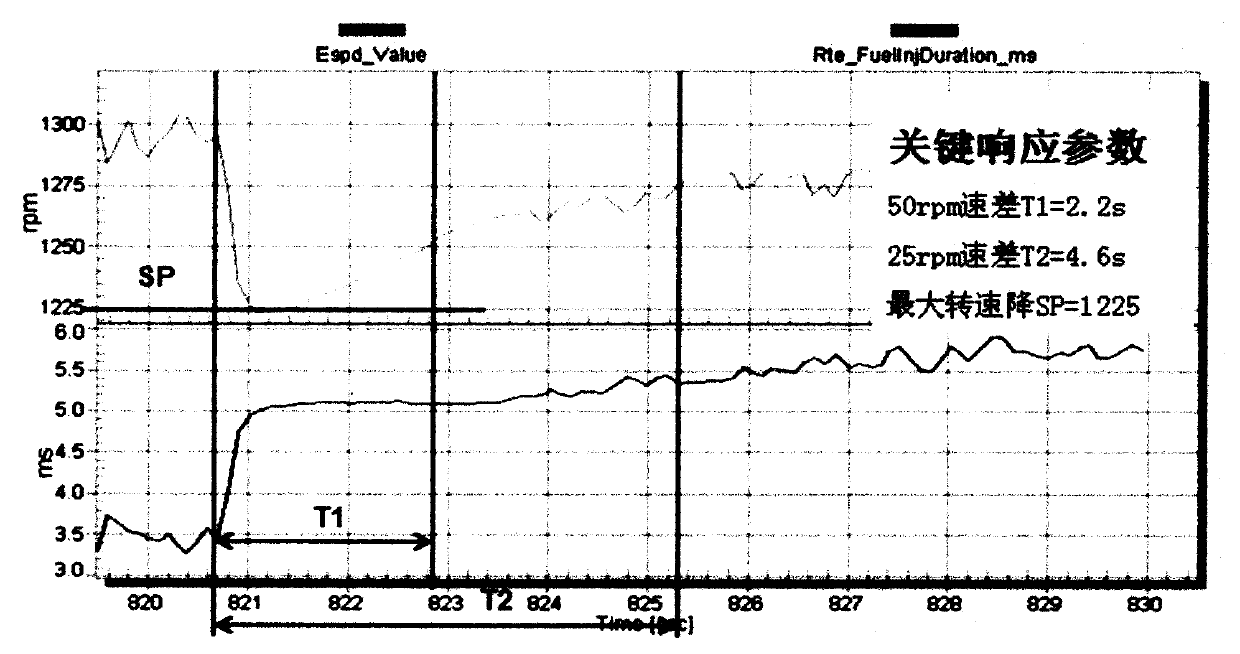

Gas engine for realizing rapid power response by utilizing electronic fuel injection

InactiveCN111561387AJet realizationLower jetElectrical controlInternal combustion piston enginesNatural gas fuelControl theory

The invention discloses a gas engine for realizing rapid power response by utilizing electronic fuel injection. The gas engine can effectively solve the problem of insufficient power response of a natural gas engine by adopting a high-pressure electronic fuel injection technology. The problem of fuel transient supply is solved by using the electronic injection technology, meanwhile, the supply ofa combustion improver is ensured by using a supercharging backflow technology, the supply of natural gas fuel under the special working condition of sudden load rise is ensured to be sufficient, and anatural gas mixed combustion mode is prevented from being knocking and misfiring states by adjusting the supply amount of the combustion improver. Besides the supply and control of the fuel and the combustion improver, effective prediction and pre-control are carried out on the power demand signal of the sudden rise, and the timeliness and effectiveness of the response are guaranteed. By means ofa fuel emergency cut-off device, major accident sources such as engine overspeed and the like when load demand signals are disturbed are prevented and controlled, and major accidents are avoided.

Owner:北京奥尔斯玛特能源有限公司

Dual-fuel injector and ship

PendingCN114135429ASimple structureOptimize structure layoutInternal combustion piston enginesFuel injection apparatusInjectorNeedle valve

The invention relates to the technical field of internal combustion engines, and discloses a dual-fuel injector and a ship. The dual-fuel injector comprises a valve body, a needle valve element and a sliding valve element. The ship adopts the dual-fuel injector, when the sliding valve element is located at the first position, the diesel oil channel, the inner cavity channel and the mold cavity are sequentially communicated, diesel oil enters from the diesel oil channel, and part of the diesel oil enters the injection cavity through the diesel oil channel, the inner cavity channel, the mold cavity and the injection channel. And the other part of the diesel enters the switch channel, the needle valve core moves under the pressure of the diesel and opens the injection orifice, and the diesel in the injection cavity is injected from the injection orifice. And when the sliding valve element is located at the second position, the natural gas enters the injection cavity through the natural gas channel, the cavity and the injection channel. Part of diesel oil enters the switch channel, the needle valve element moves under the pressure of the diesel oil, the injection opening is opened, and natural gas in the injection cavity is injected out of the injection opening. According to the dual-fuel injector, dual-fuel injection of diesel oil and natural gas can be achieved, and the structure of the dual-fuel injector is simplified.

Owner:CSSC POWER INST CO LTD

Bird repellent spraying device for high-voltage power transmission line tower

ActiveCN113273563AJet realizationExpand the scope of diffusionAnimal repellantsAnimal scienceEngineering

The invention discloses a bird repellent spraying device for a high-voltage transmission line tower. The bird repellent spraying device comprises a base, a supporting rod located above the base, a platform, a bird repellent spraying device located above the platform and a supporting assembly. Compared with the prior art, by means of smaller upper bottom surface area of a circular truncated cone, air in a cylinder is compressed, bird repellents can be sprayed, the diffusion range of the bird repellents can be expanded, meanwhile, the solid bird repellent and the liquid bird repellent can be used at the same time, the application range is wider, different kinds of bird repellents can be added into a solid bird repellent bottle and a liquid bird repellent bottle, the bird repelling operation for various birds is realized, and the birds are prevented from generating resistance; and through wing plates on the outer side of the cylinder, shaking of the cylinder is achieved by the wing plates, the solid bird repellent in the solid bird repellent bottle is moved, the problems that the solid bird repellent is accumulated at a screen and consequently the screen is blocked, the bird repellent cannot be discharged in time and the angle of a reflective lens on the outer side of the cylinder is changed are solved, and therefore, the purpose of adjusting the bird repelling angle is achieved.

Owner:XIANGYANG POWER SUPPLY COMPANY OF STATE GRID HUBEI ELECTRIC POWER

Hand-push dual-agent fire extinguishing device for ship deck

The invention discloses a hand-push dual-agent fire extinguishing device for a ship deck. The hand-push dual-agent fire extinguishing device for the ship deck comprises a vehicle frame, wherein two directional wheels are symmetrically arranged on the front portion of the vehicle frame, two steering wheels are symmetrically arranged on rear portions of the vehicle frame, a dry powder tank and a foam tank are arranged over the vehicle frame in parallel, the dry powder tank is provided with a first outlet and is connected with a dry powder gun through a first spray pipe, the foam tank is providedwith a first outlet and is connected with a foam gun through a second spray pipe, a second outlet of the dry powder tank and a second outlet of the foam tank are connected with a mixer through pipes,a first one-way valve is arranged on the pipe between the mixer and the dry power tank, a second one-way valve is arranged on the pipe between the mixer and the foam tank, the mixer is connected witha dual-agent sprayer through a third spray pipe and is connected with a hose reel through a fourth pipe, and a dual-agent spray gun is arranged on the hose reel. The hand-push dual-agent fire extinguishing device for the ship deck has the beneficial effects that dry powder and foam liquid can be mixed to be sprayed, and the dry power and foam can also be separately sprayed; and the device can beflexibly pushed by 1-2 persons to extinguish a fuel fire on the deck.

Owner:九江中船长安消防设备有限公司

Structural unit of the valve train of an internal combustion engine

InactiveCN106255808BAchieve jettingEasy stampingValve arrangementsMachines/enginesExternal combustion engineEngineering

The connecting clip (4) fixes the rocker arm with its ball-and-socket-shaped indentation at its end on the head (12) of the support element (3), wherein the connecting clip consists of two cross-bow frames at one end. (13) Formed by connected spring arms (14, 15), and wherein the spring arm (14) rests on the underside (7) of the rocker arm (2) and surrounds the support element ( 3) in the holding area (17) below its head (13), and wherein an additional spring arm (15) extends on the upper side (18) of the rocker arm (2), wherein the support element ( 3) The supply channel (19) leads through the inner recess (11) for oil spray lubrication, wherein the additional spring arm (15) of the connecting clip (4) is closed in the ball-and-socket-shaped inner recess (11) is placed on the upper side (18) of the rocker arm (2) and has an oil injection hole (20) in fluid connection with the channel (19), the oil injection hole (20) passing through the rocker arm in the longitudinal direction The second end (10) of the arm is pointed away from the rocker arm (2).

Owner:SCHAEFFLER TECH AG & CO KG

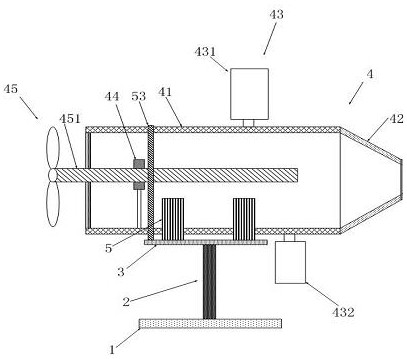

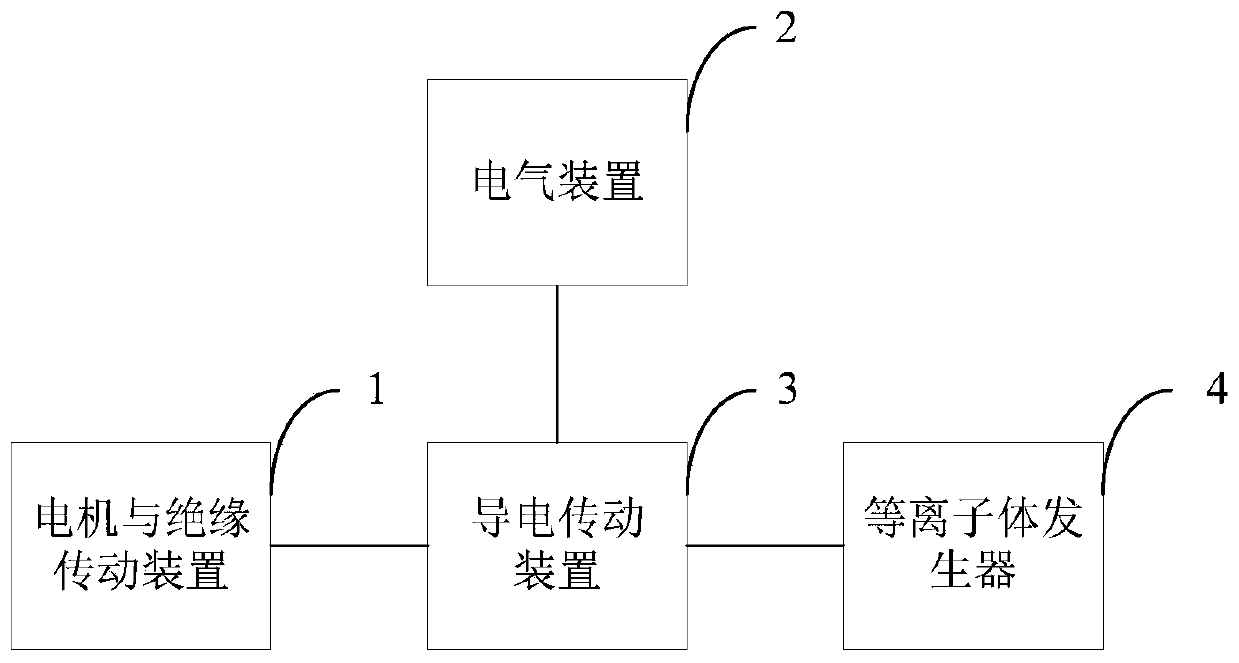

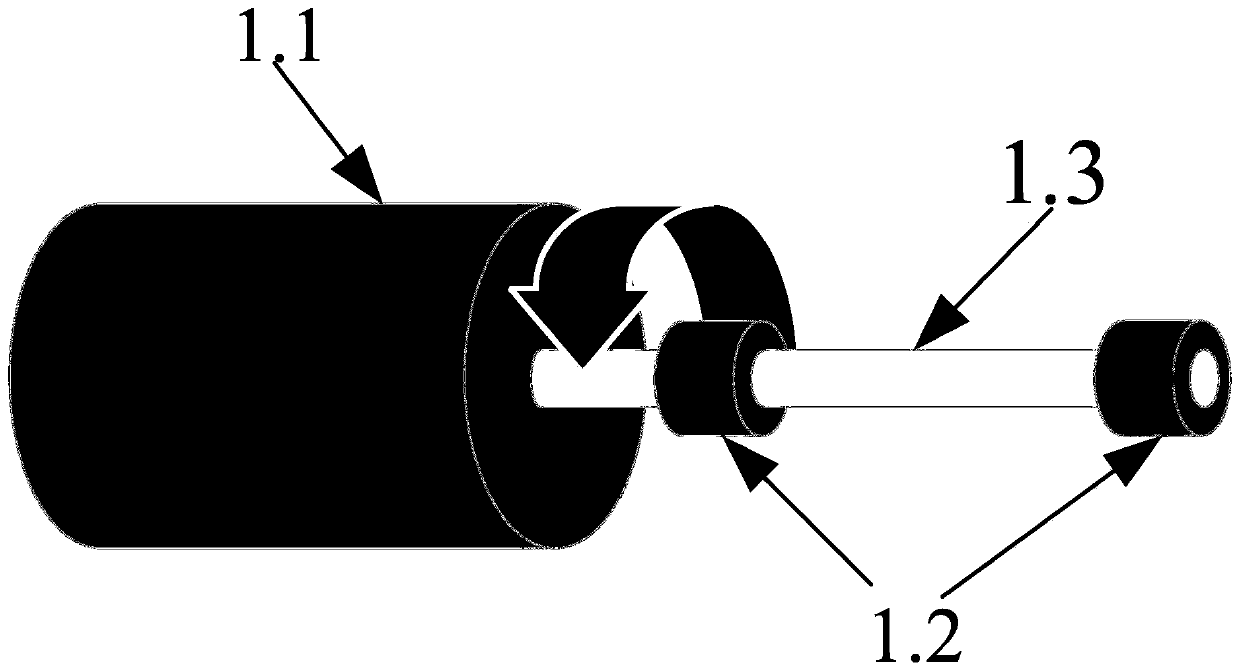

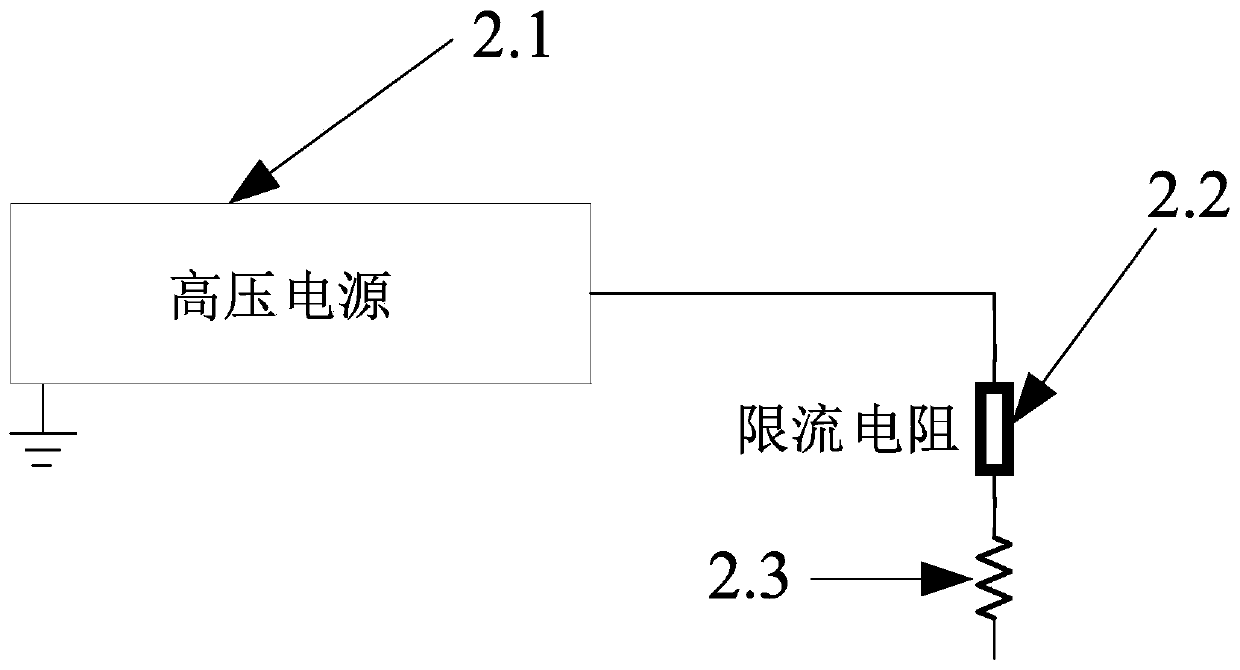

Atmospheric pressure plasma jet device

ActiveCN110913550AEasy to productizeIncrease particle concentrationPlasma techniquePlasma jetElectric machine

The invention discloses an atmospheric pressure plasma jet device. The device comprises a motor and insulation transmission device, an electrical device, a conductive transmission device and a plasmagenerator, the motor and insulation transmission device comprises a motor and an insulation transmission device, and the electrical device is used for providing high voltage, adjusting current, adjusting plasma temperature, controlling impact current and stabilizing discharge; the conductive transmission device is used for guiding high voltage of the electrical device into the plasma generator andguiding torque of the motor and the insulation transmission device into the plasma generator; the plasma generator is used as a discharge chamber, plasmas are generated in the generator, the plasma flow is lengthened after the plasmas are blown out along with airflow, and plasma jet flow with various kinds of gas serving as working gas under the atmospheric pressure condition is formed. The device is adopted to drive the electrode to lengthen the discharge channel, and then the discharge channel is blown out by airflow, so that jet flow of various working gases can be realized.

Owner:武汉海思普莱生命科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com