Structural unit of the valve train of an internal combustion engine

A technology of structural units and valve trains, applied in the direction of engine components, machines/engines, mechanical equipment, etc., which can solve problems such as the problem of continuous clamping of connecting clips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

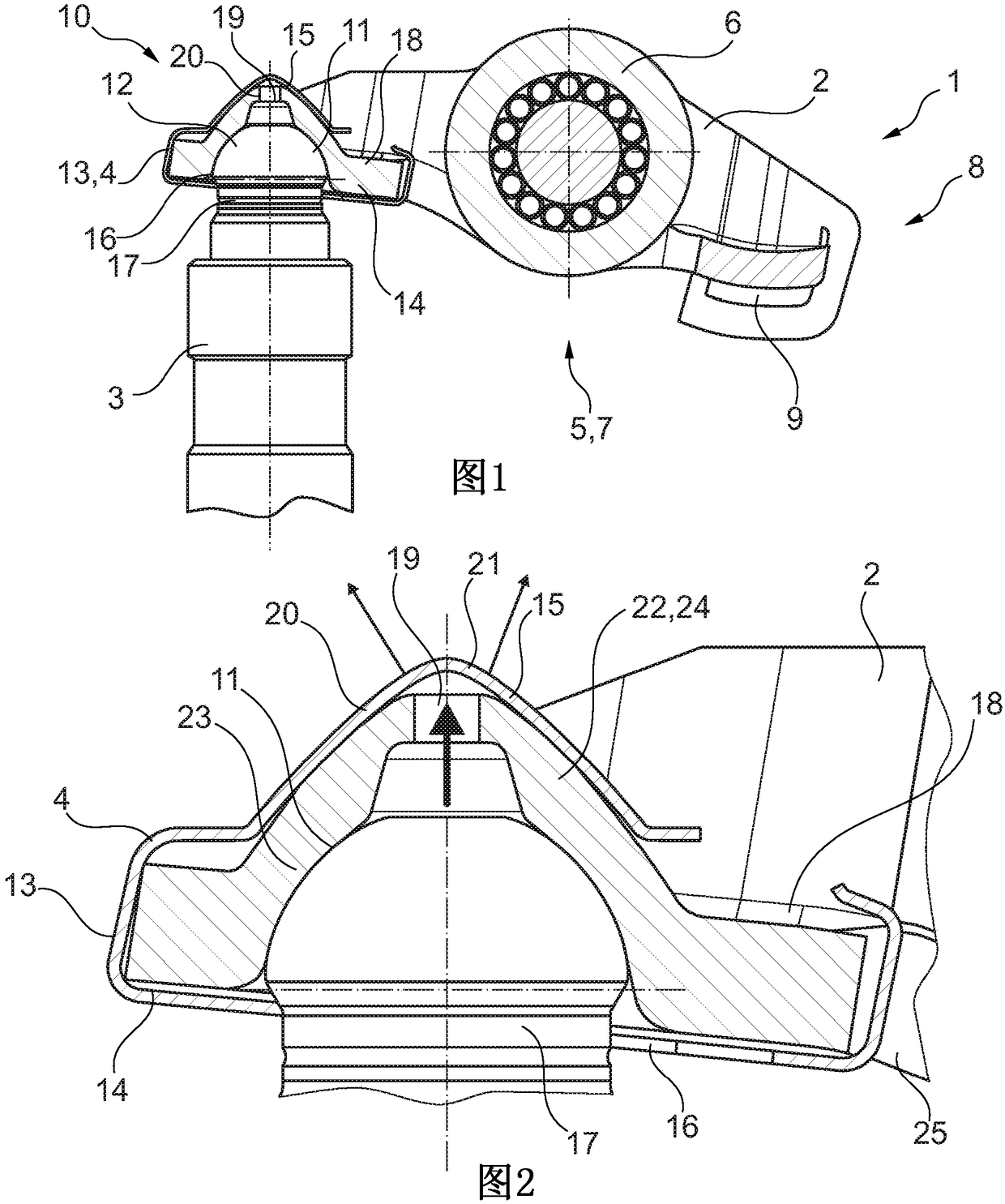

[0018] figure 1 A structural unit 1 of a valve train of an internal combustion engine is disclosed. The structural unit 1 comprises a rocker 2 made of thin-walled steel sheet metal, a support element 3 and a connecting clip 4 made of spring sheet metal.

[0019] The rocker arm 2 is U-shaped in cross section. In its central region 5 , the rocker arm has a cutout 25 with a cam impact surface 6 present as a roller. On its underside 7 , the rocker arm 2 has on the one hand a stop 9 for the gas exchange valve in the first end 8 and on the other hand a ball-and-socket-shaped indentation 11 at the second end 10 .

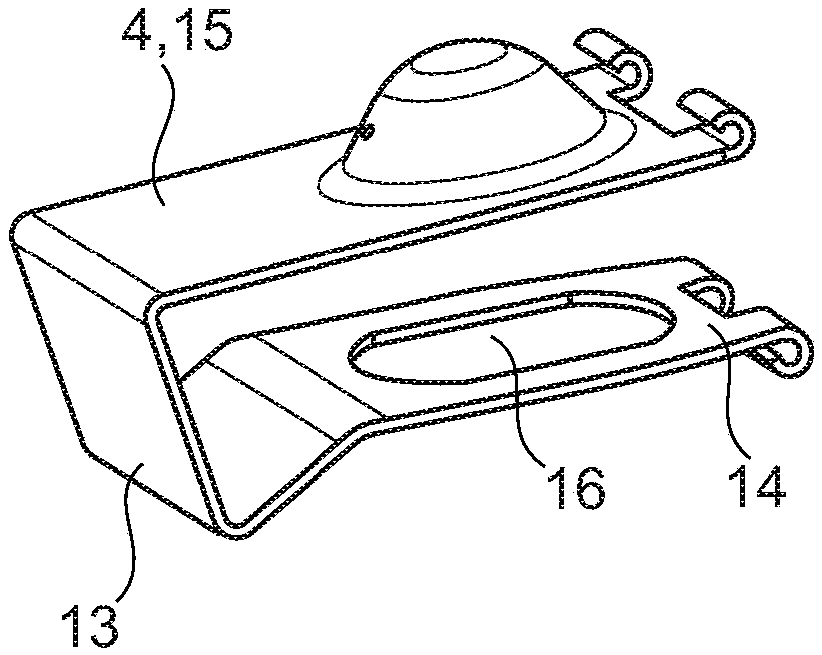

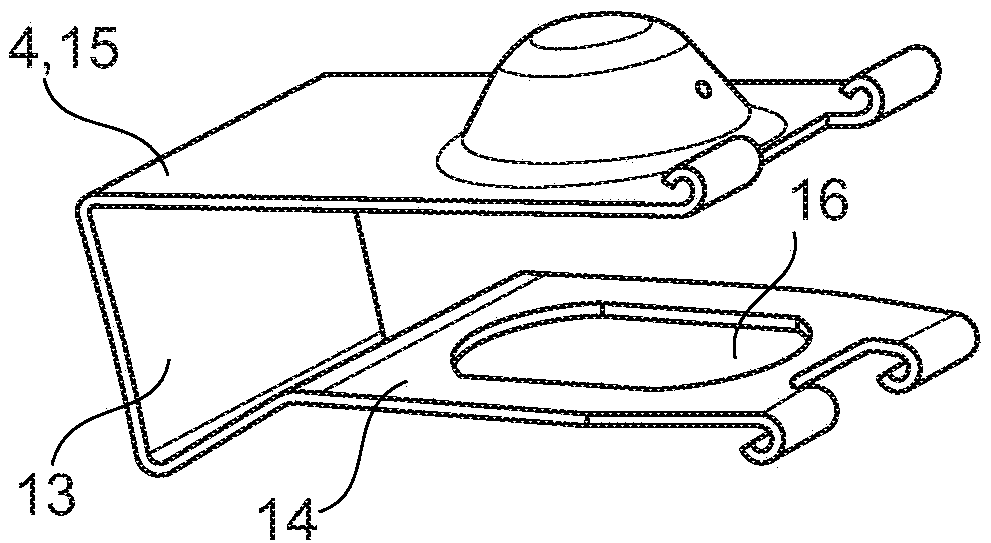

[0020] For example in figure 1 , figure 2 It can be seen in the figure that the head 12 of the support element 3 rests in the last-mentioned inner recess 11 . Here, the rocker arm 2 is fastened in an articulated manner to the head 12 of the support element 3 via a connecting clip 4 in a manner that prevents it from falling out.

[0021] The connecting clip 4 is impl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com