Eyedrop capsule

A technology of eye drops and capsules, which is applied in the field of eye drop packaging, can solve problems such as danger, air inhalation, bacteria, and environmental pollution, and achieve the effects of low transportation costs, extended shelf life, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment —

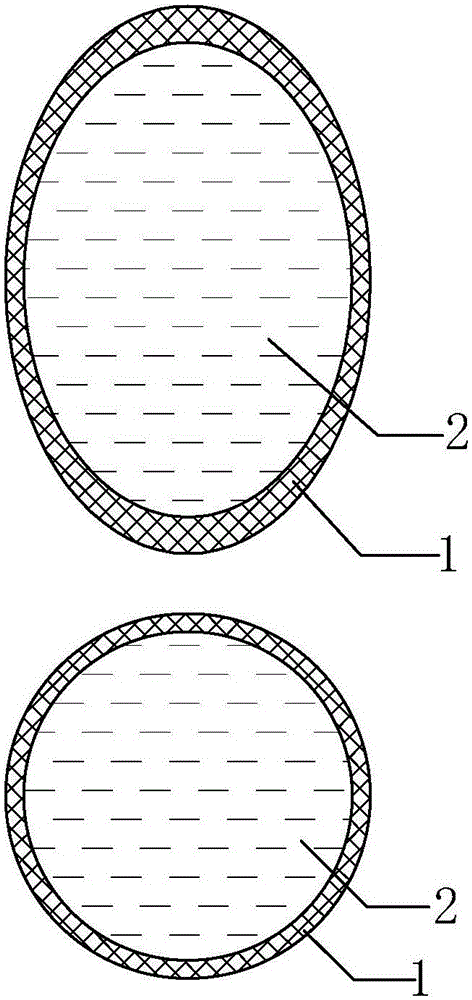

[0023] Such as figure 1 As shown, the invention provides an eye drop capsule. The eye drop capsule is composed of a capsule skin 1 made of flexible plastic material and an eye drop 2 contained inside it. The two ends of the capsule skin 1 are thicker and the middle is thinner. The shape is roughly ellipsoid, and a solution cavity is formed on its inner surface, and the solution cavity is filled with eye drops 2, and the eye drops 2 are completely isolated from the air. When in use, first use a pin to pierce one or more small holes at one end of the capsule skin 1, and then squeeze the eye drop capsule against the eyes to drip the eye drop 2 into the eyes. By changing the size of the force and the number of pinholes, it is also possible to achieve such Figure 4 The three usage forms of dripping, spraying and spraying are shown.

specific Embodiment 2

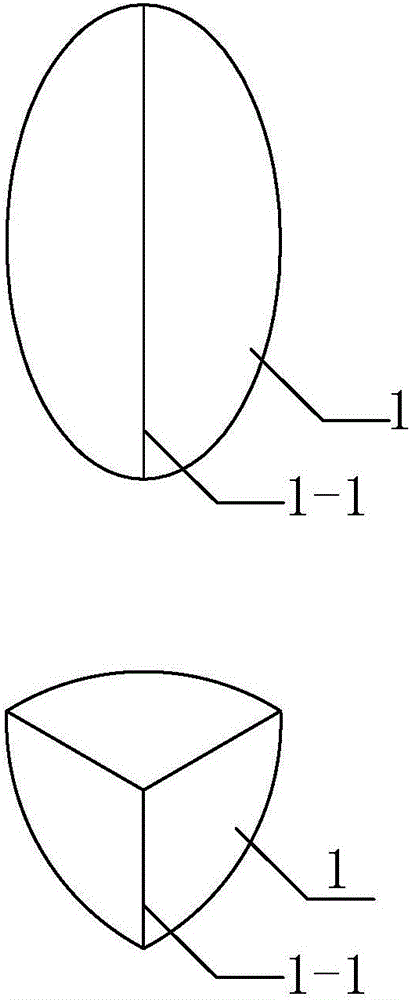

[0024] figure 2 Shown is an eye drop capsule provided with an edge corner structure 1-1 with an anti-rollover function according to the present invention. The edge and corner structure 1-1 is formed by extrusion of a mold when the capsule skin 1 is integrally formed. The edge and corner structure 1-1 can effectively prevent the eye drop capsule from rolling on the plane, and it will be more convenient to store the eye drop capsule. figure 2 What is shown is an eye drop capsule provided with three edge corner structures 1-1, which is only a preferred embodiment selected for convenience of description, and one or more edge corner structures 1-1 can be set as required in actual production. 1.

specific Embodiment 3

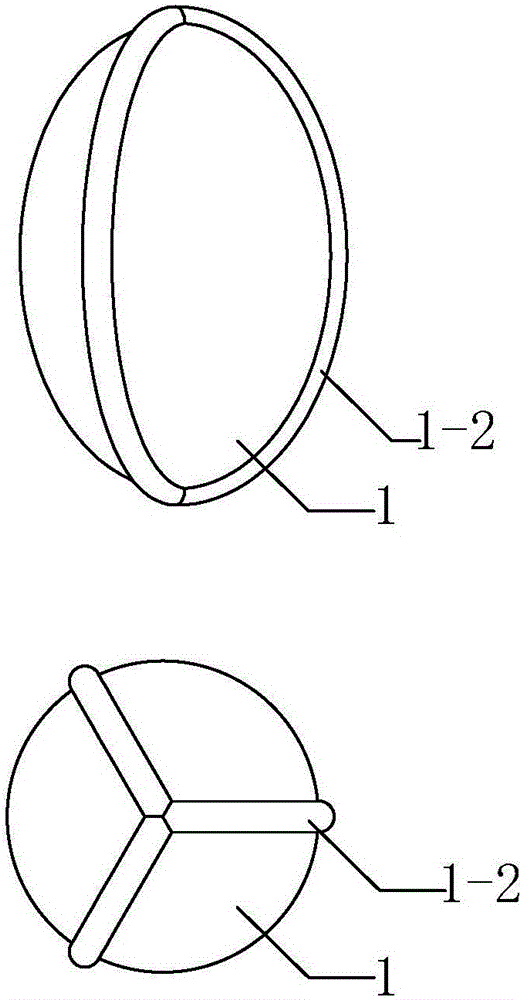

[0025] image 3 Shown is an eye drop capsule provided with the anti-rolling function of the edge protrusion structure 1-2 of the present invention. The protruding edge structure 1-2 is formed by extrusion of a mold when the capsule skin 1 is integrally molded. The protruding edge structures 1-2 may also be retained when a thermoplastic elastomer tube with three protruding edge structures is thermally expanded and molded. image 3 The figure shows three edge protruding structures 1-2, which are only preferred embodiments selected for convenience of description, and one or more edge protruding structures 1-2 can be provided in actual production according to needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com