Patents

Literature

812 results about "Edge structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

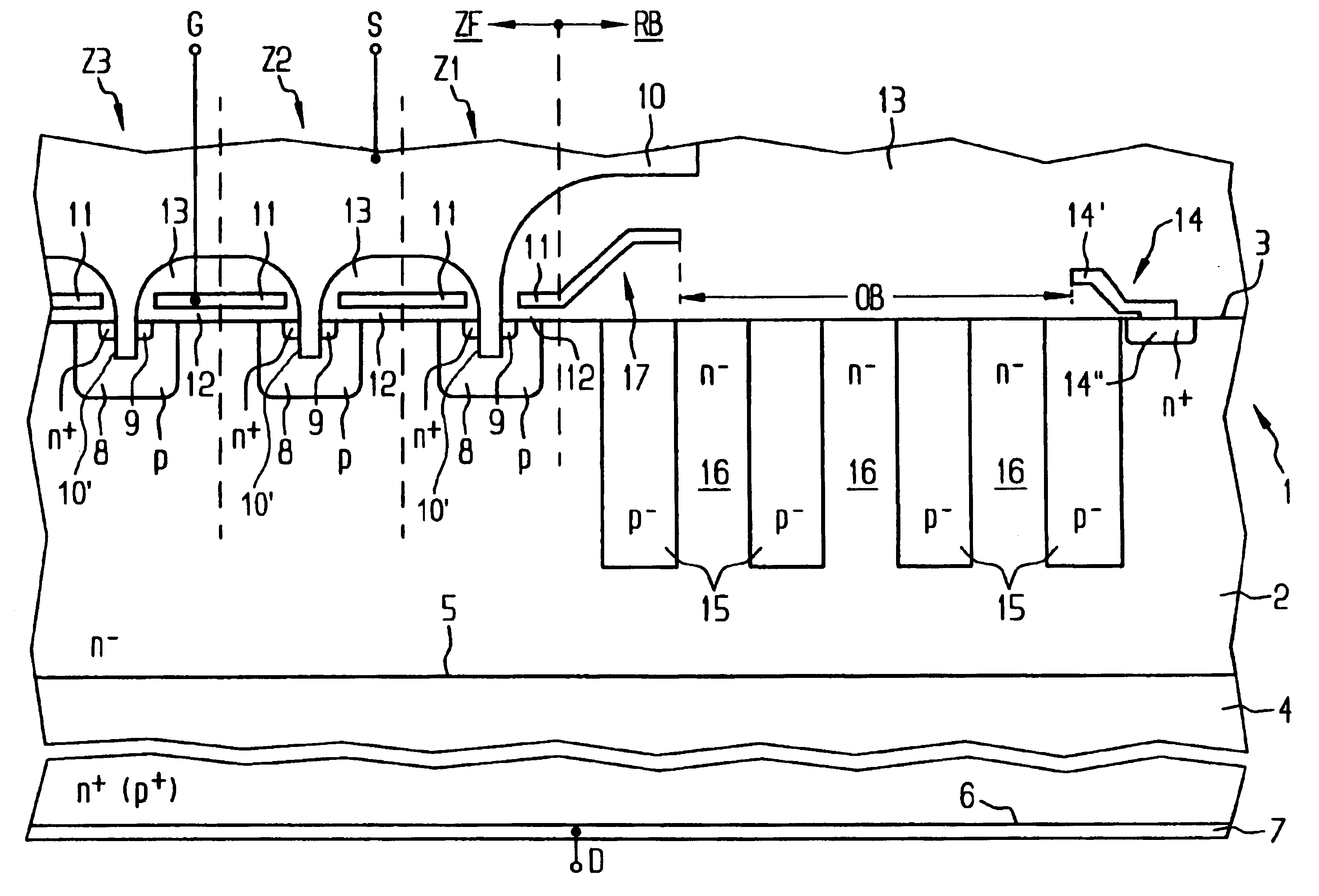

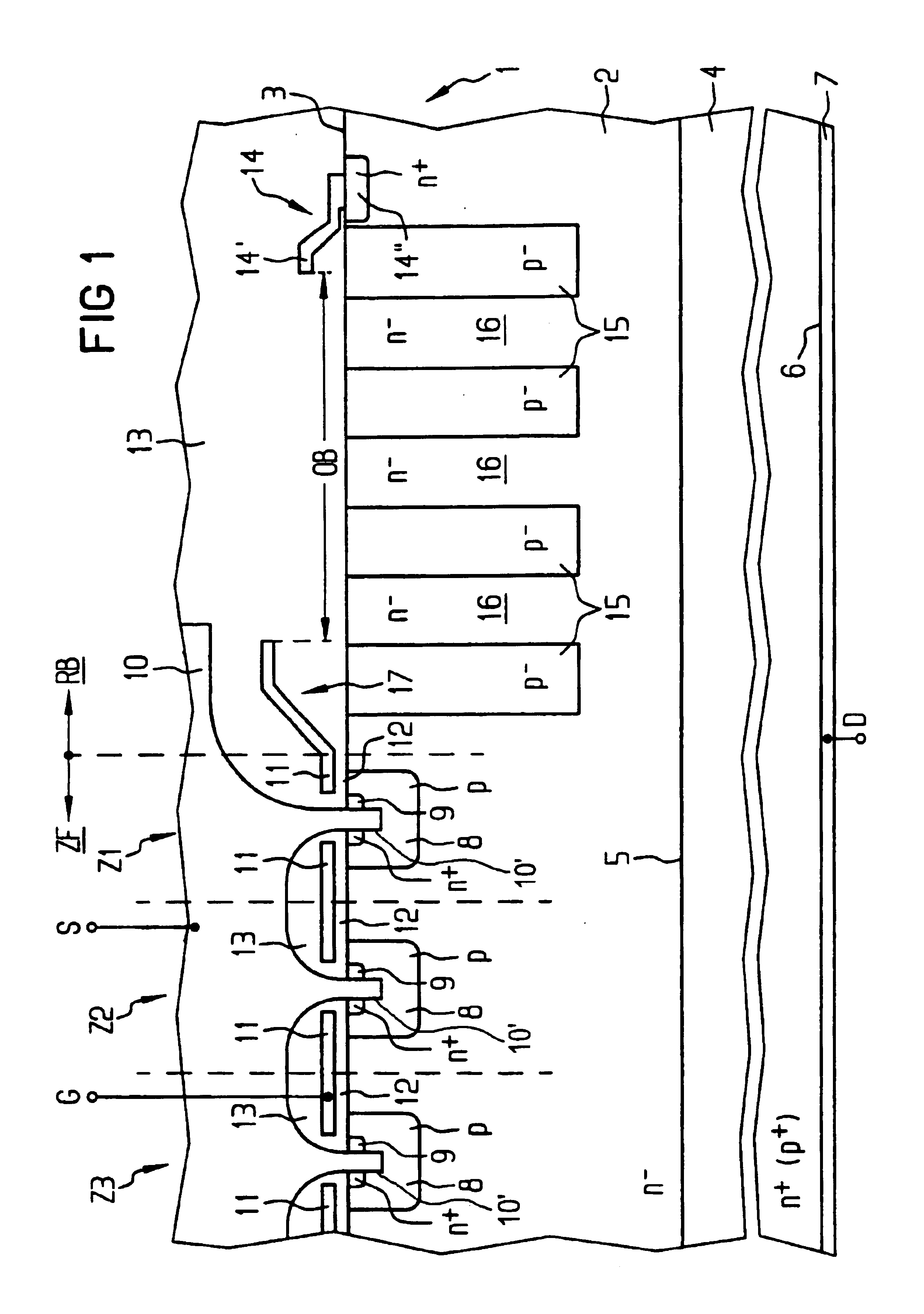

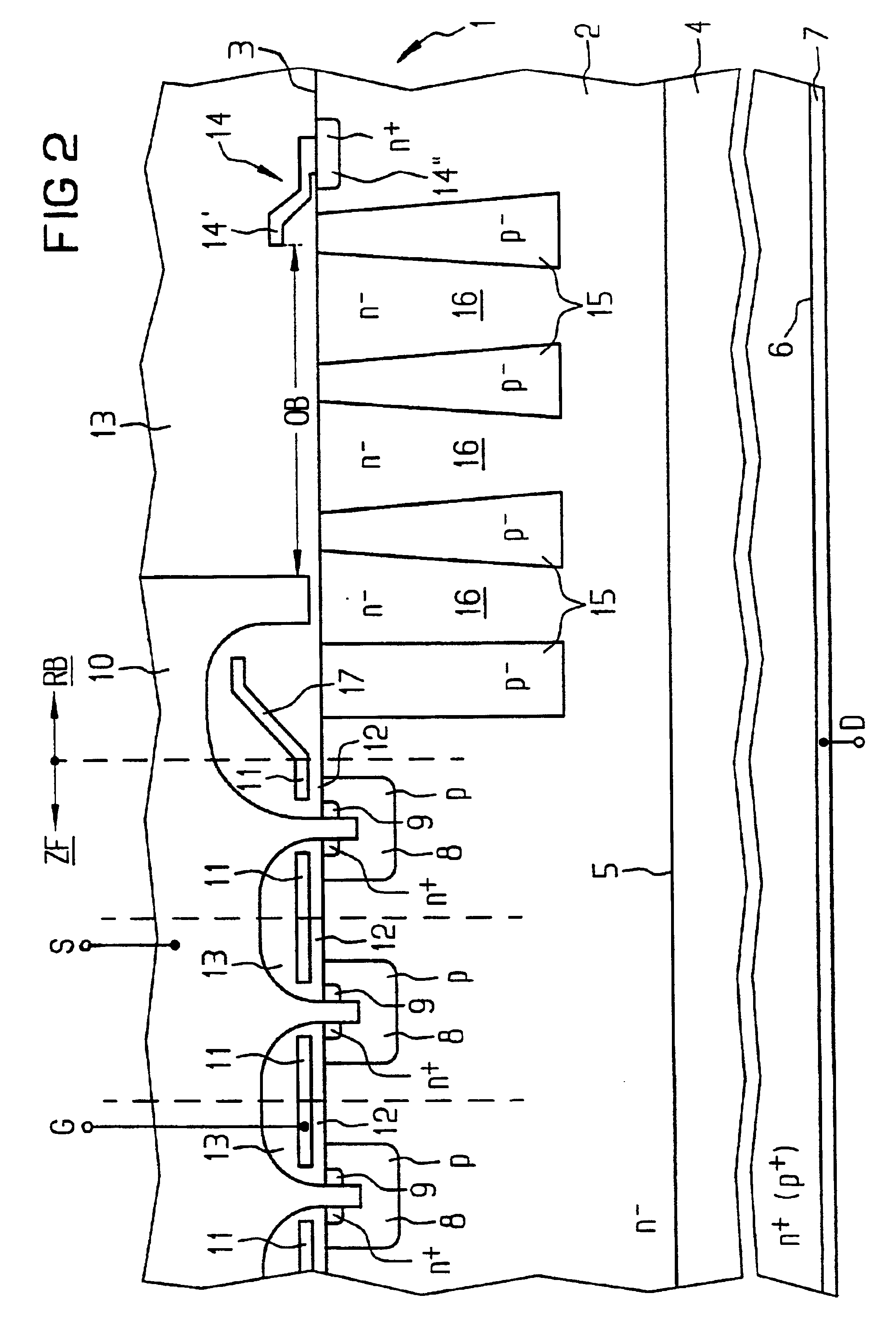

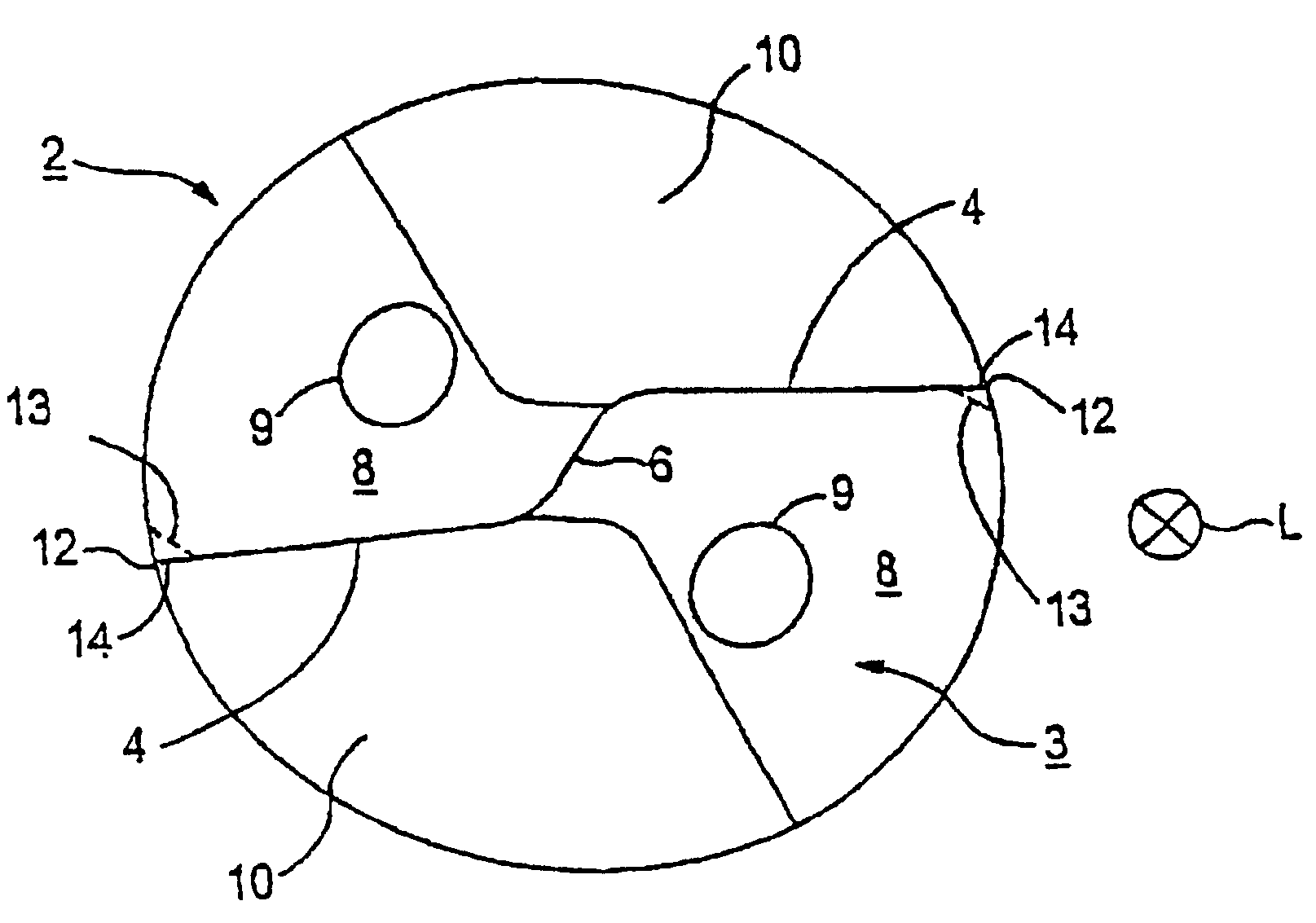

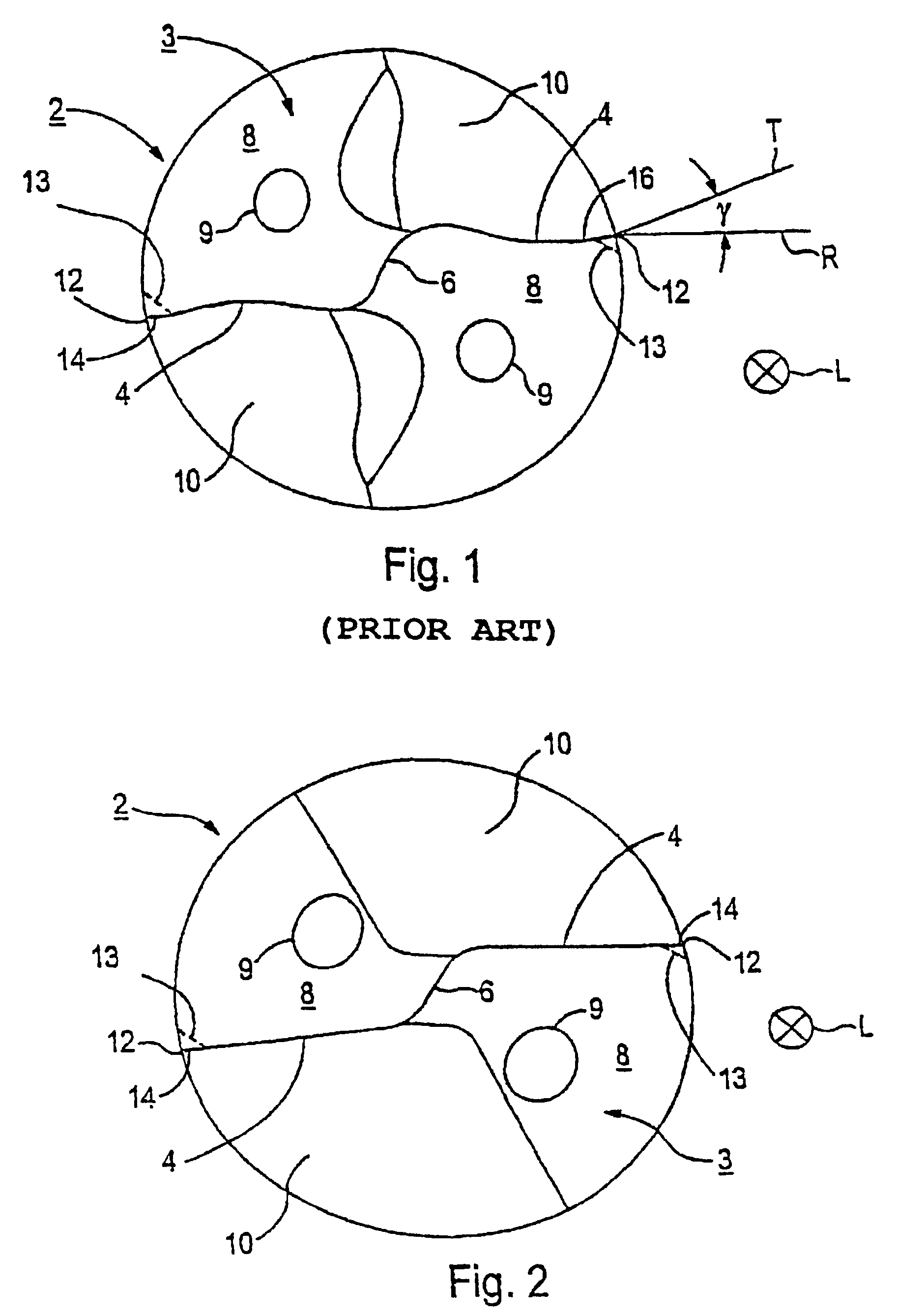

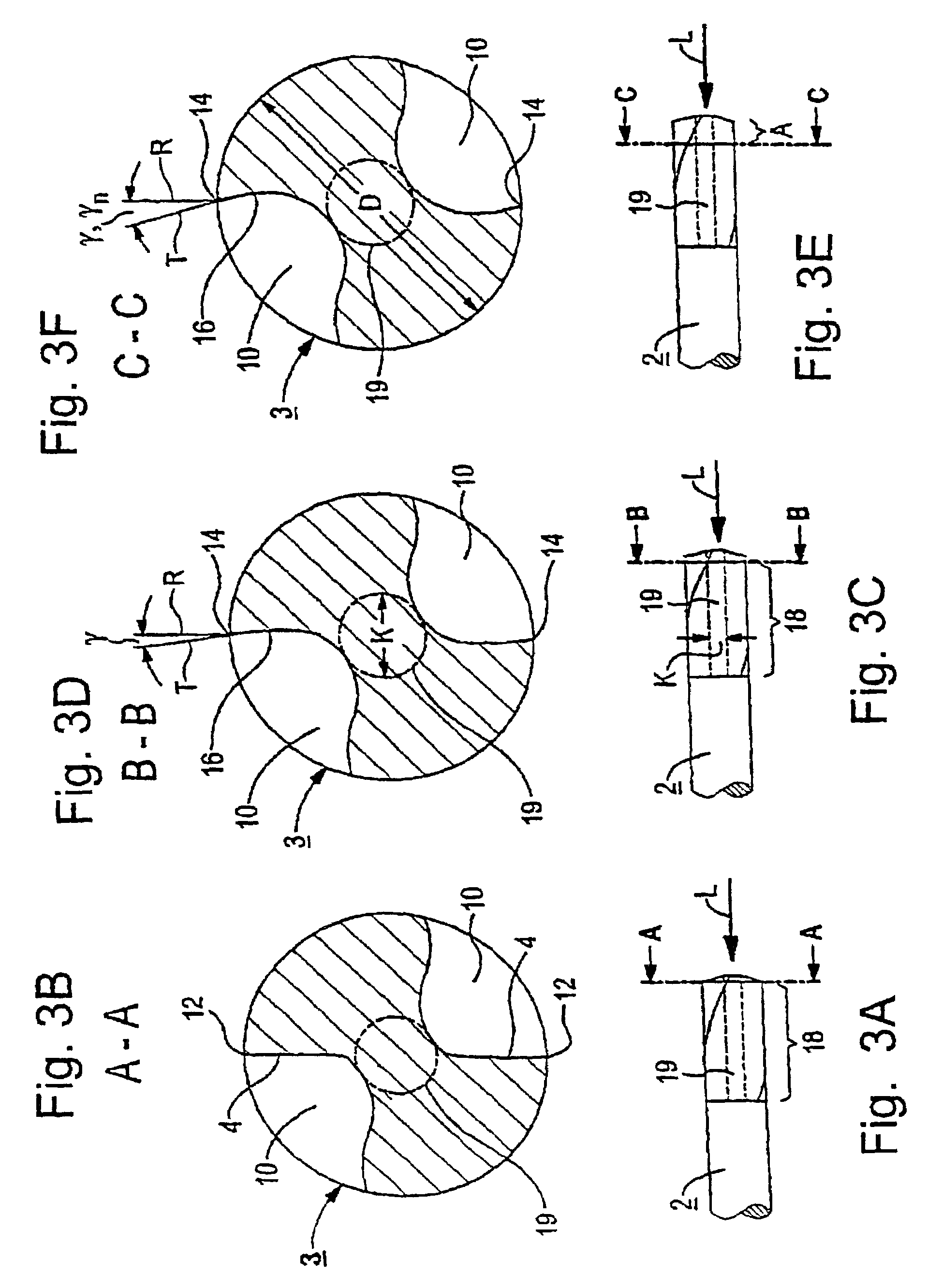

High voltage resistant edge structure for semiconductor components

The invention relates to a high voltage resistant edge structure in the edge region of a semiconductor component which has floating guard rings of the first conductivity type and inter-ring zones of the second conductivity type which are arranged between the floating guard rings, wherein the conductivities and / or the inter-ring zones are set such that their charge carriers are totally depleted when blocking voltage is applied. The inventive edge structure achieves a modulation of the electrical field both at the surface and in the volume of the semiconductor body. If the inventive edge structure is suitably dimensioned, the field intensity maximum can easily be situated in the depth; that is, in the region of the vertical p-n junction. Thus, a suitable edge construction which permits a “soft” leakage of the electrical field in the volume can always be provided over a wide range of concentrations of p and n doping.

Owner:INFINEON TECH AG

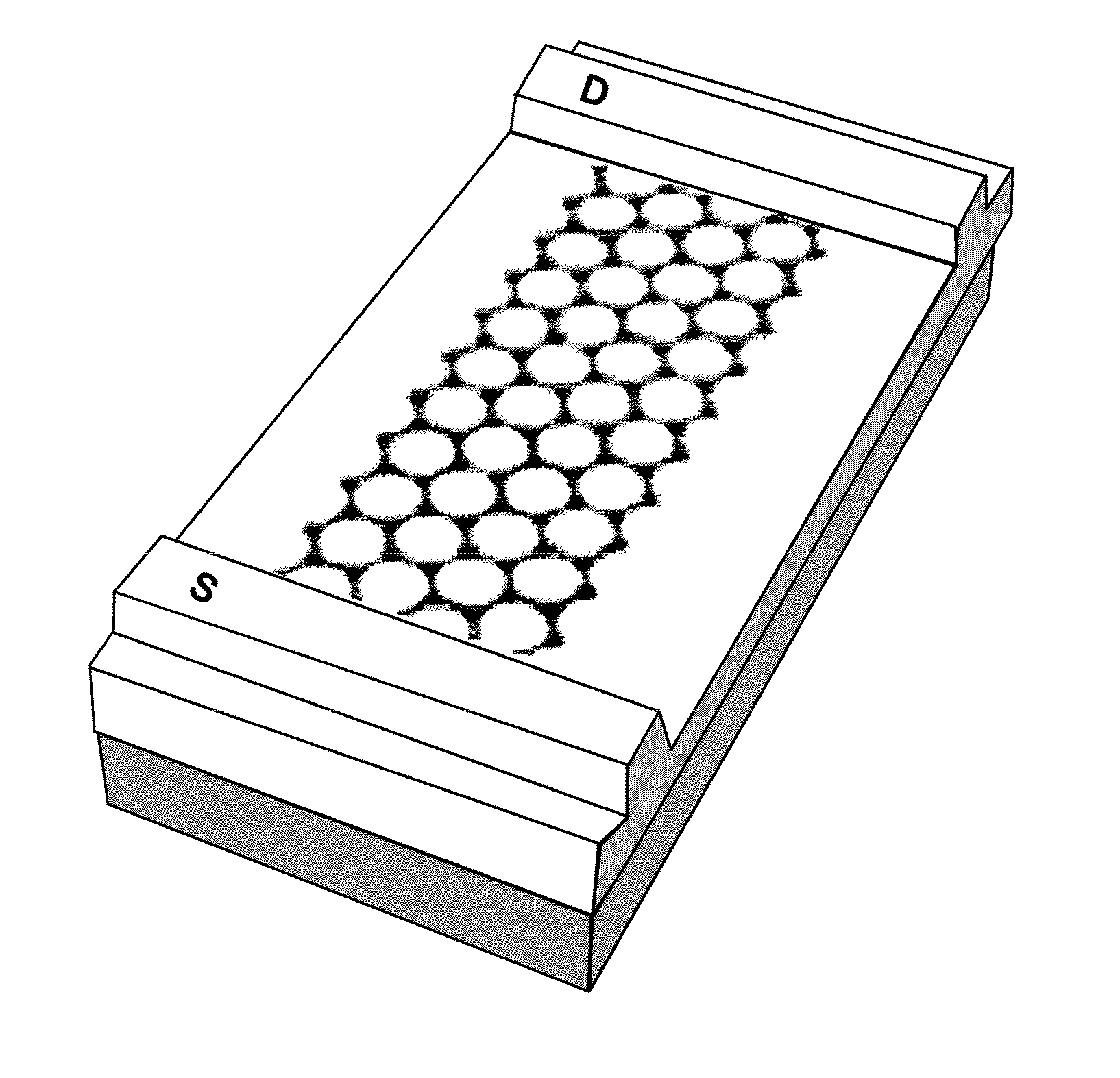

Narrow Graphene Nanoribbons from Carbon Nanotubes

ActiveUS20110253969A1Longer treatmentMaterial nanotechnologyDecorative surface effectsNanostructureNanotube

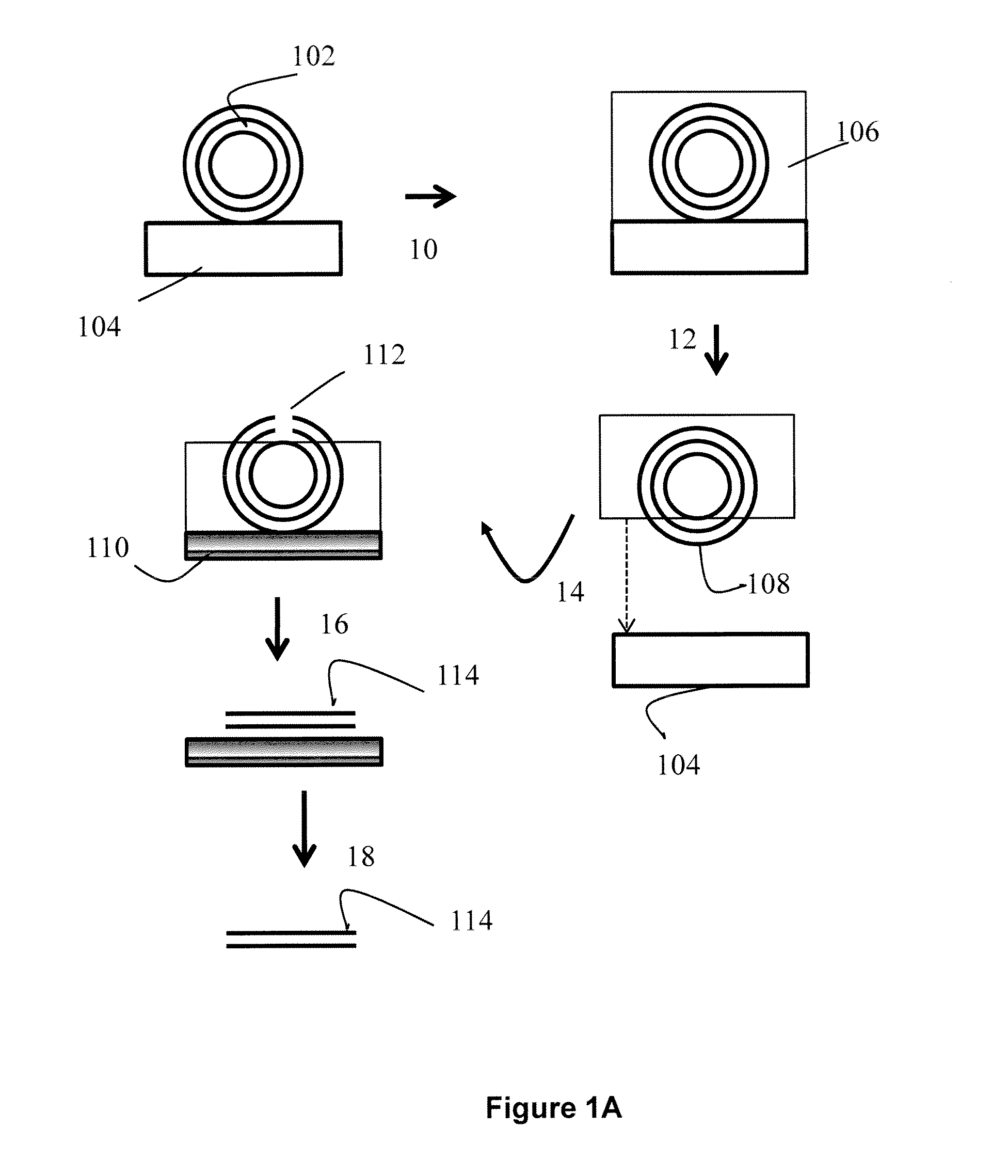

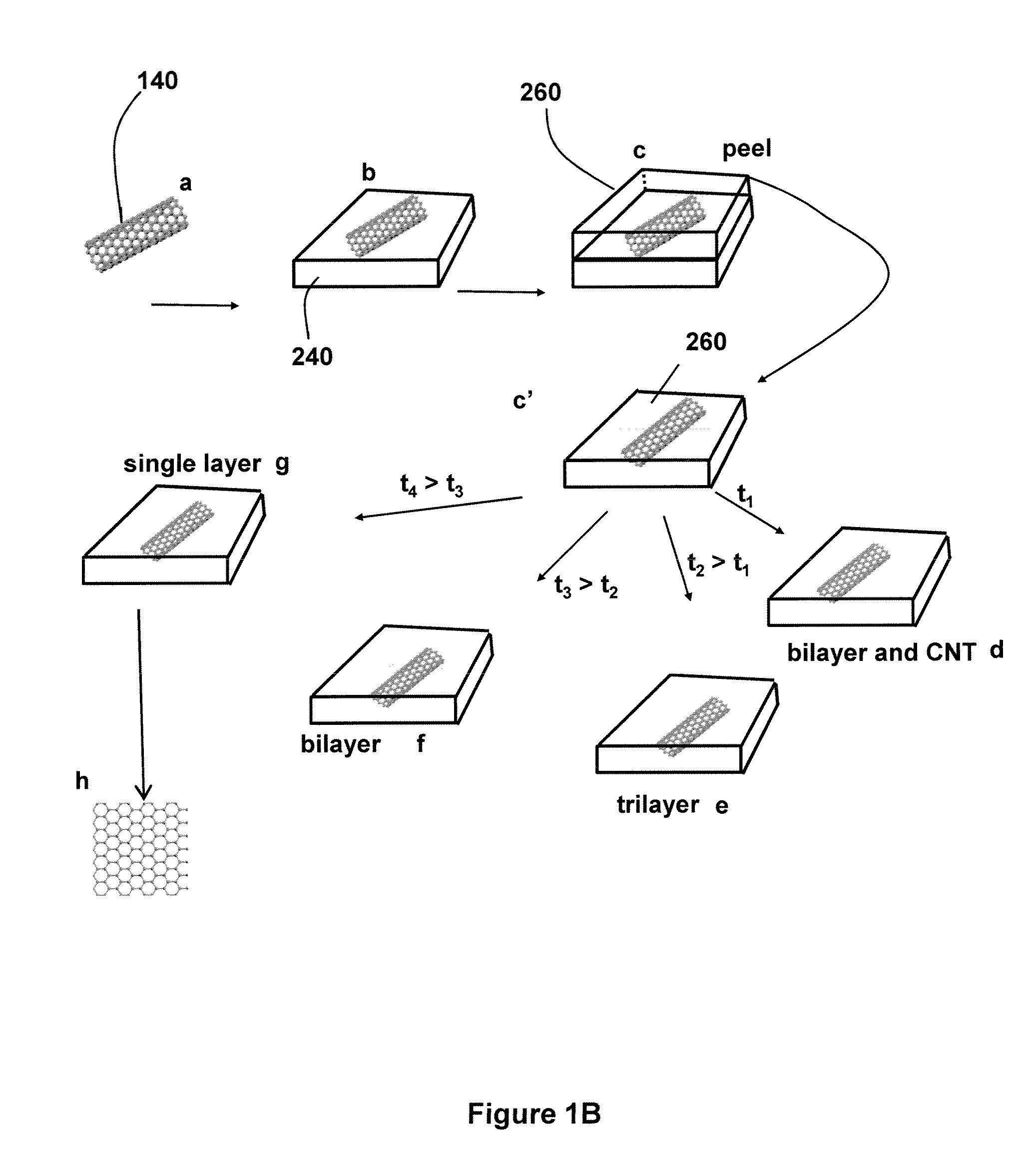

Disclosed is a method for making graphene nanoribbons (GNRs) by controlled unzipping of structures such as carbon nanotubes (CNTs) by etching (e.g., argon plasma etching) of nanotubes partly embedded in a polymer film. The GNRs have smooth edges and a narrow width distribution (2-20 nm). Raman spectroscopy and electrical transport measurements reveal the high quality of the GNRs. Such a method of unzipping CNTs with well-defined structures in an array will allow the production of GNRs with controlled widths, edge structures, placement and alignment in a scalable fashion for device integration. GNRs may be formed from nanostructures in a controlled array to form arrays of parallel or overlapping structures. Also disclosed is a method in which the CNTs are in a predetermined pattern that is carried over and transferred to a substrate for forming into a semiconductor device.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

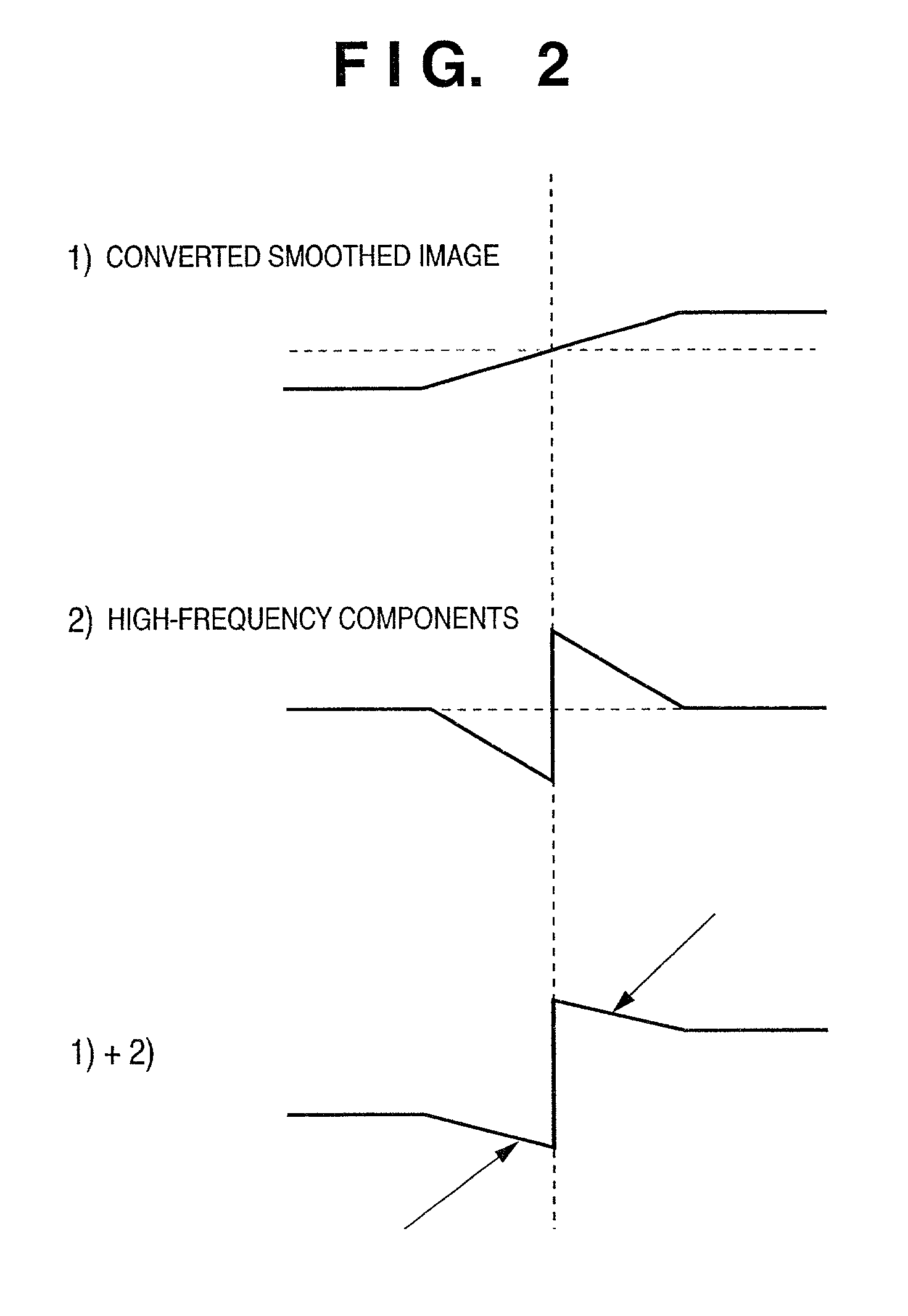

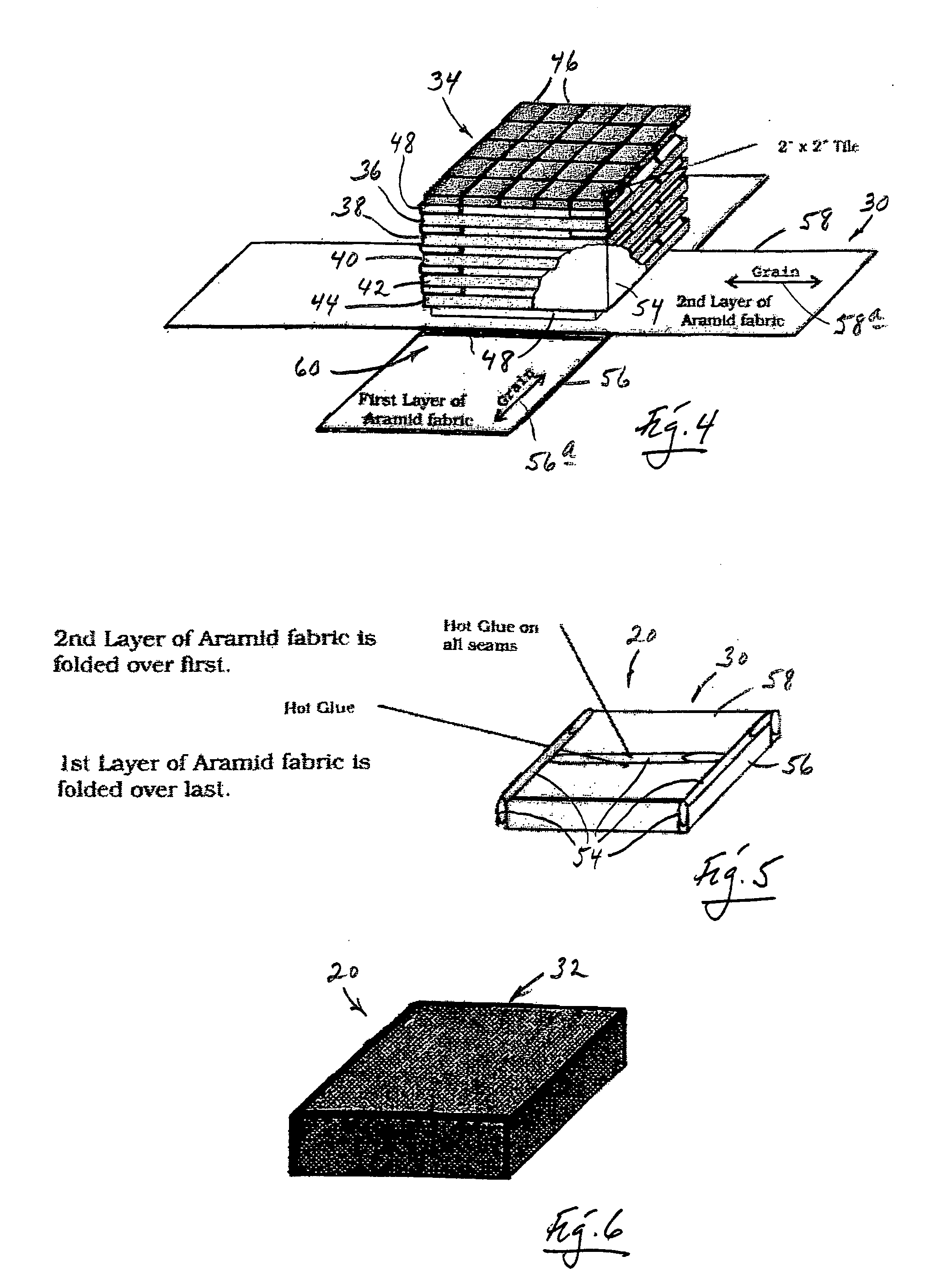

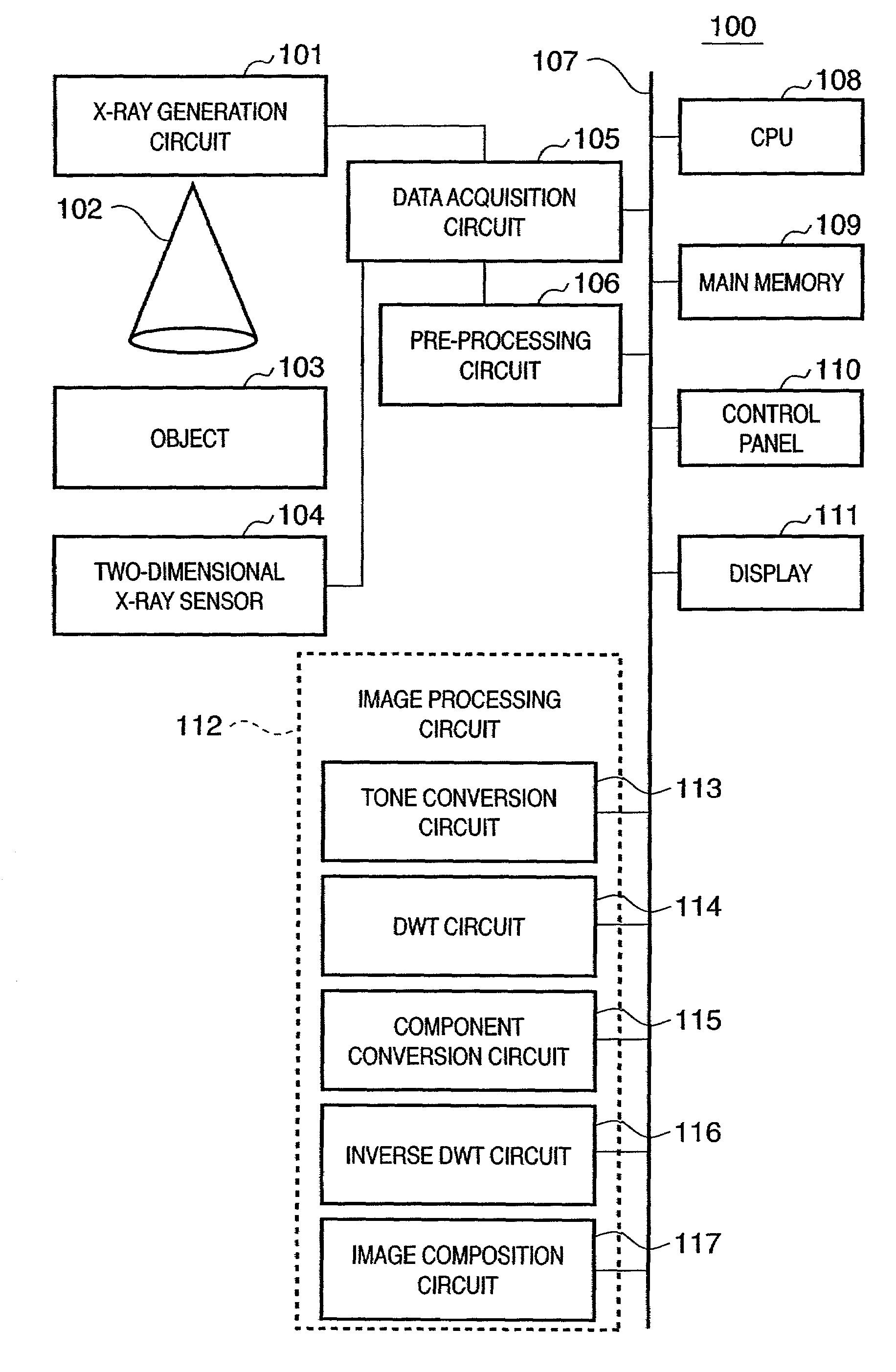

Image processing apparatus, image processing method, storage medium, and program

InactiveUS20030016855A1Suppressing and avoiding collapseHigh quality imagingImage enhancementImage analysisPattern recognitionImaging processing

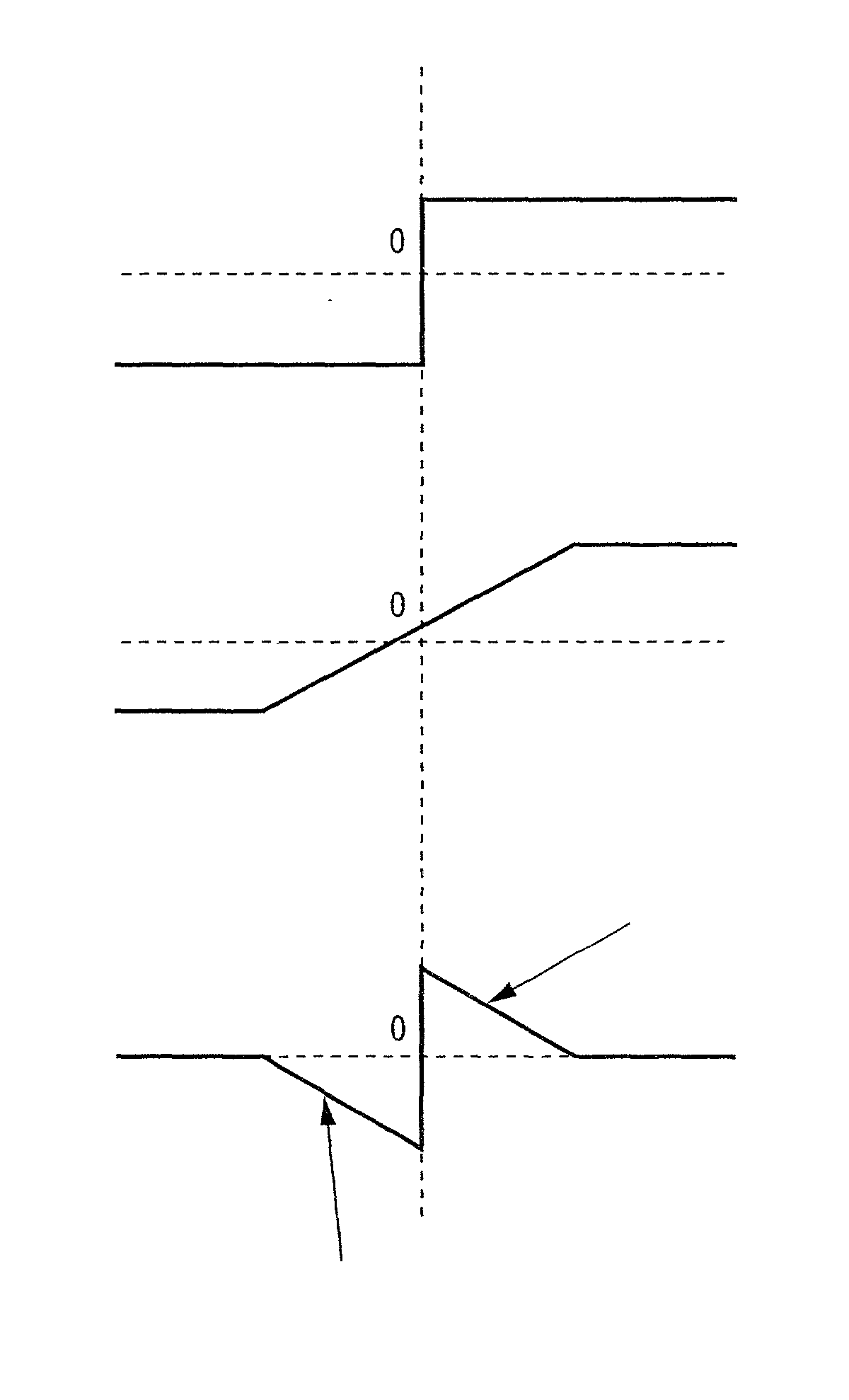

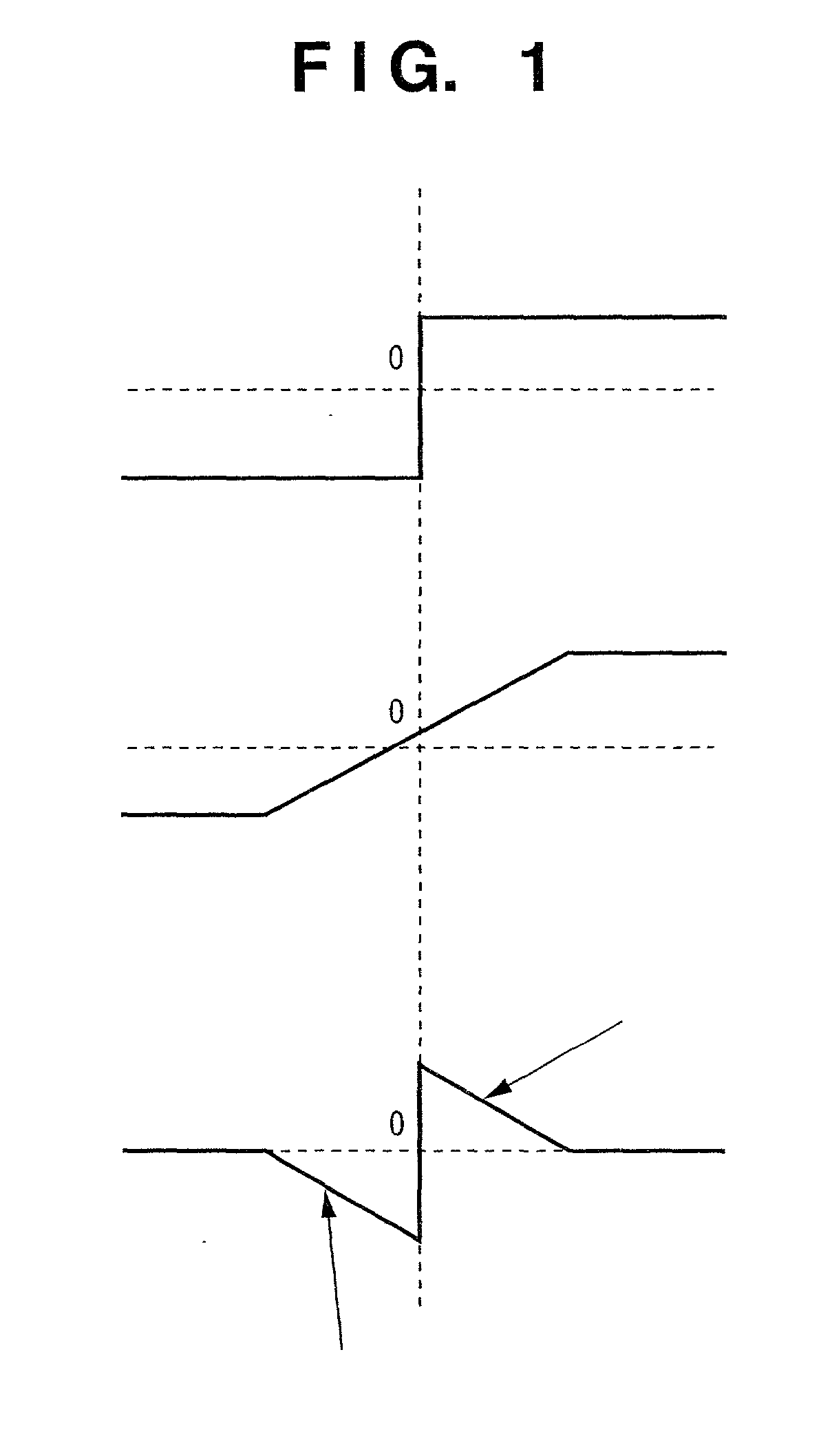

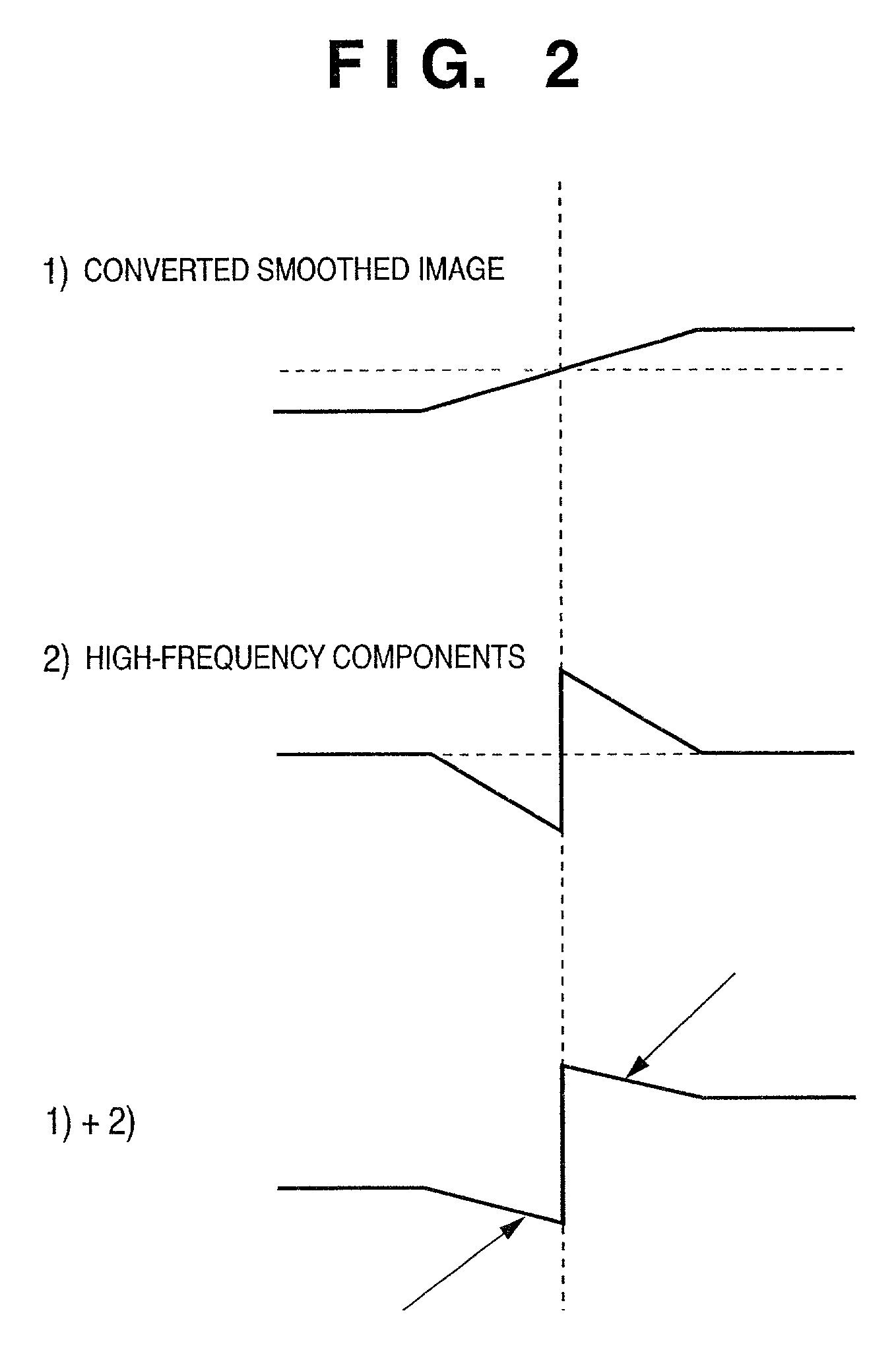

There are disclosed an image processing apparatus and method, and the like, which can obtain a high-quality image, the dynamic range or partial pixel value range of which has been changed while suppressing or avoiding collapse of the edge structure of an image or generation of overshoot. Also, there are disclosed an image processing apparatus and method, and the like, which can obtain a high-quality image, desired spatial frequency components of which have been emphasized or suppressed while suppressing or avoiding collapse of the edge structure of an edge portion contained in an objective image. For example, an image processing apparatus includes tone conversion means for executing tone conversion of an image, frequency transformation means for decomposing the image that has undergone tone conversion by the tone conversion means into frequency components of a plurality of frequency bands, and component conversion means for converting the frequency components of the plurality of frequency bands obtained by the frequency transformation means, on the basis of values of the frequency components and the tone conversion characteristics of the tone conversion means.

Owner:CANON KK

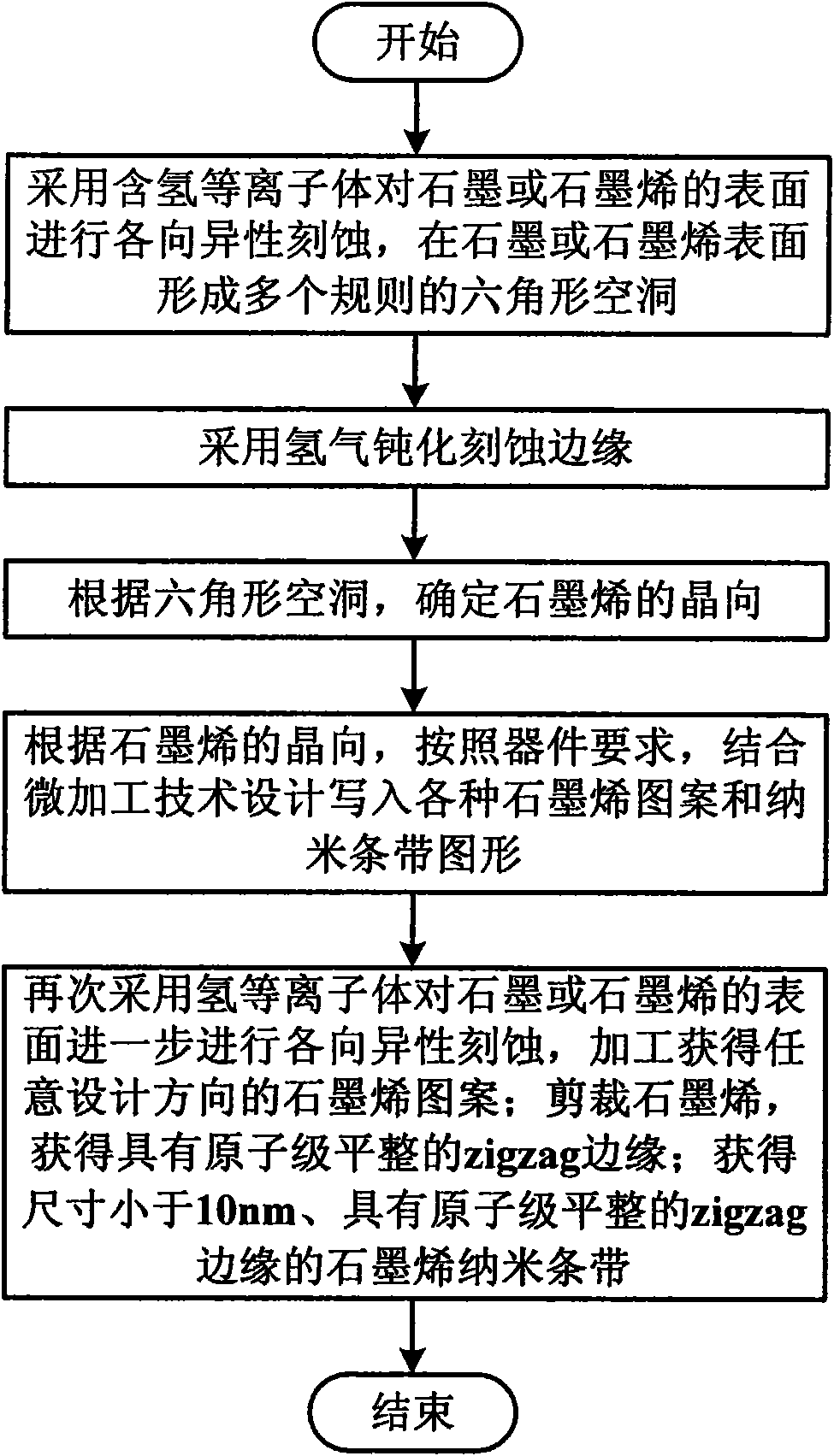

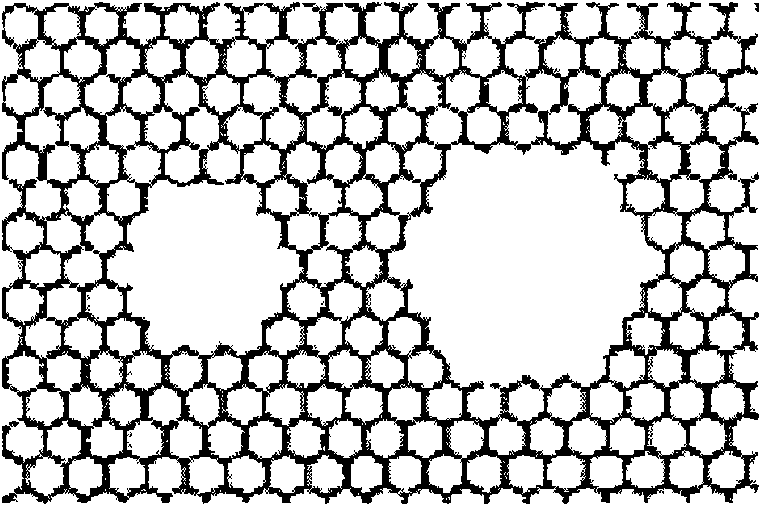

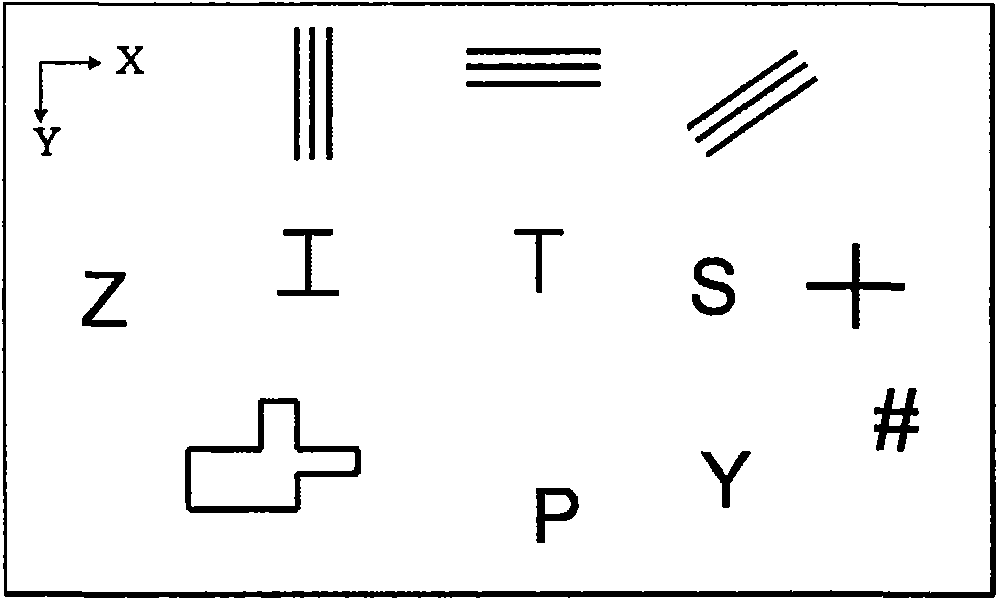

Anisotropic etching method of graphite or graphene

ActiveCN101996853AGood size controlRealize the processing effectNanostructure manufactureSemiconductor/solid-state device manufacturingHydrogenCrystal orientation

The invention discloses an anisotropic etching method of graphite or grapheme, which is used for realizing crystal orientation of graphene, graphene cutting and patterning. The method comprises the following steps of: performing anisotropic etching on the surface of graphite or grapheme by adopting hydrogen-containing plasma, and forming a plurality of regular hexagonal holes on the surface of graphite or grapheme. All the hexagonal holes have the same orientation, the orientation is matched with the crystal orientation of graphene, etched edges have atomic scale smoothness, and all the edge structures are zigzag configurations. The invention overcomes the limitations existing in the traditional etching method of graphite or grapheme and realizes cutting and patterning graphene with controllable size and atomic scale smooth edges.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Twist drill and method for producing a twist drill which method includes forming a flute of a twist drill

InactiveUS7201543B2Reduce disadvantagesQuickly and easily groundWood turning toolsTransportation and packagingFluteEdge structure

A twist drill and method for producing is provided. The cutting edge structure has a first portion at the drill tip portion and a second portion disposed away from the drill tip portion. The flute wall extends further into the land structure at the second portion of the cutting edge structure than at the tip portion to provide a greater amount of drill material at the tip portion than at the second portion of the cutting edge structure. The flute wall extends further into the land structure at the second portion of the cutting edge structure than at the tip portion to provide a greater flute volume per length at the second portion of the cutting edge structure than at the drill tip portion.

Owner:KENNAMETAL INC

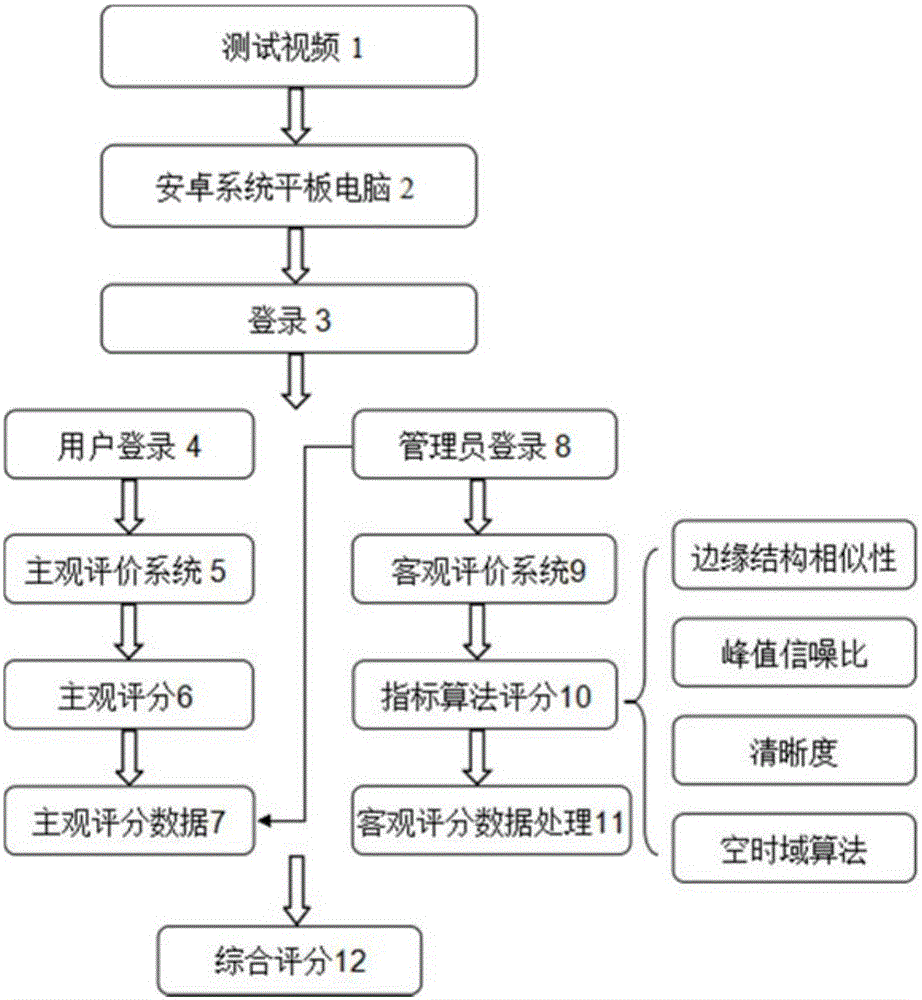

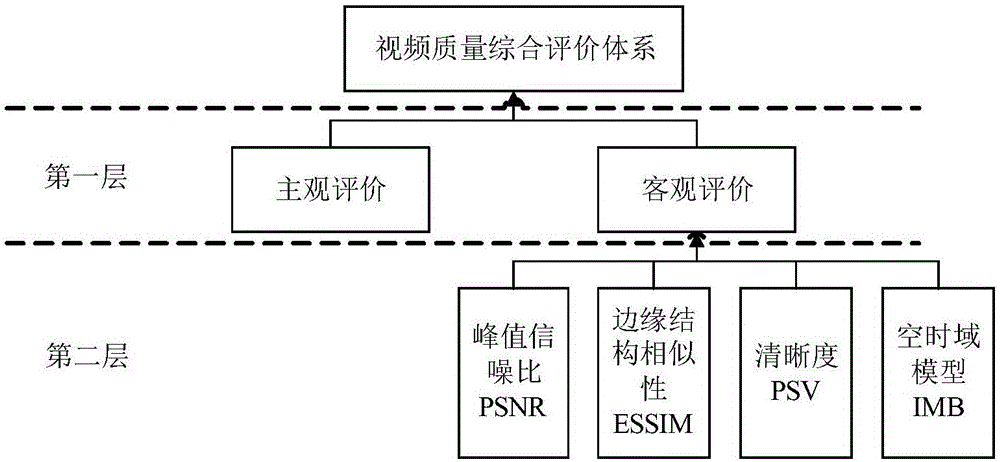

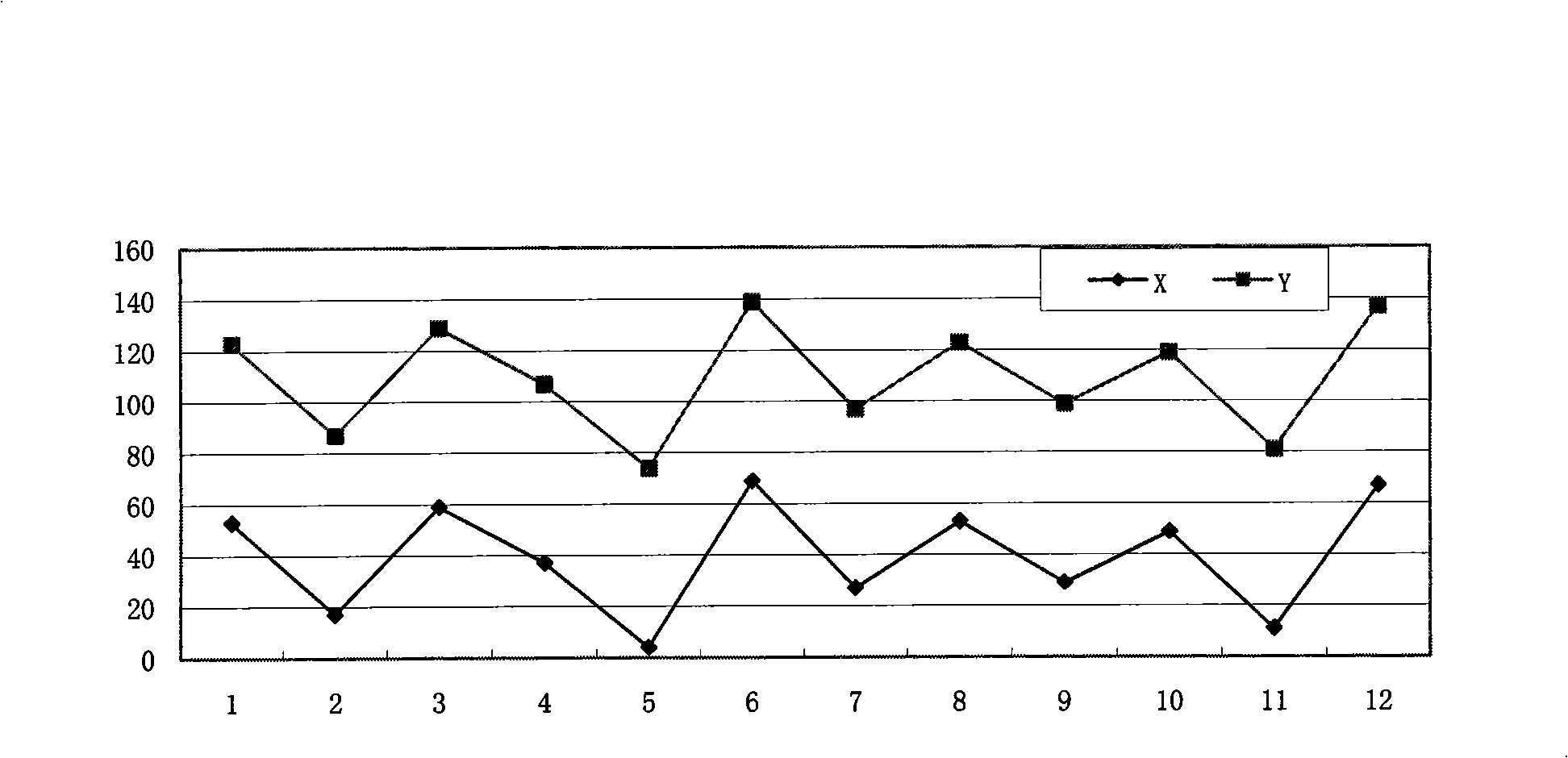

Method for evaluating video quality

ActiveCN105100789AGuaranteed accuracyEffective evaluationTelevision systemsPattern recognitionTime domain

The invention relates to a method for evaluating video quality. The method includes a first step of subjectively evaluating the video quality in nine scoring level, calculating average subjective scores of each scene among a plurality of video scenes, and finishing subjective evaluation of video quality to obtain a subjectively evaluating result; a second step of carrying out objective evaluating pretreatment on video quality, including peak value signal-to-noise ratio processing, edge structure similarity processing, sharpness processing and spatial-time domain value processing; a third step of objectively evaluating the video quality to obtain an objective evaluating result; and a fourth step of comprehensively evaluating the video quality. In the fourth step, subjective evaluating result and the objective evaluating result are combined to obtain a comprehensive result through comprehensive calculation. The accuracy of the video evaluation result is effectively improved, and high-efficient evaluation is realized.

Owner:TIANJIN UNIV OF SCI & TECH

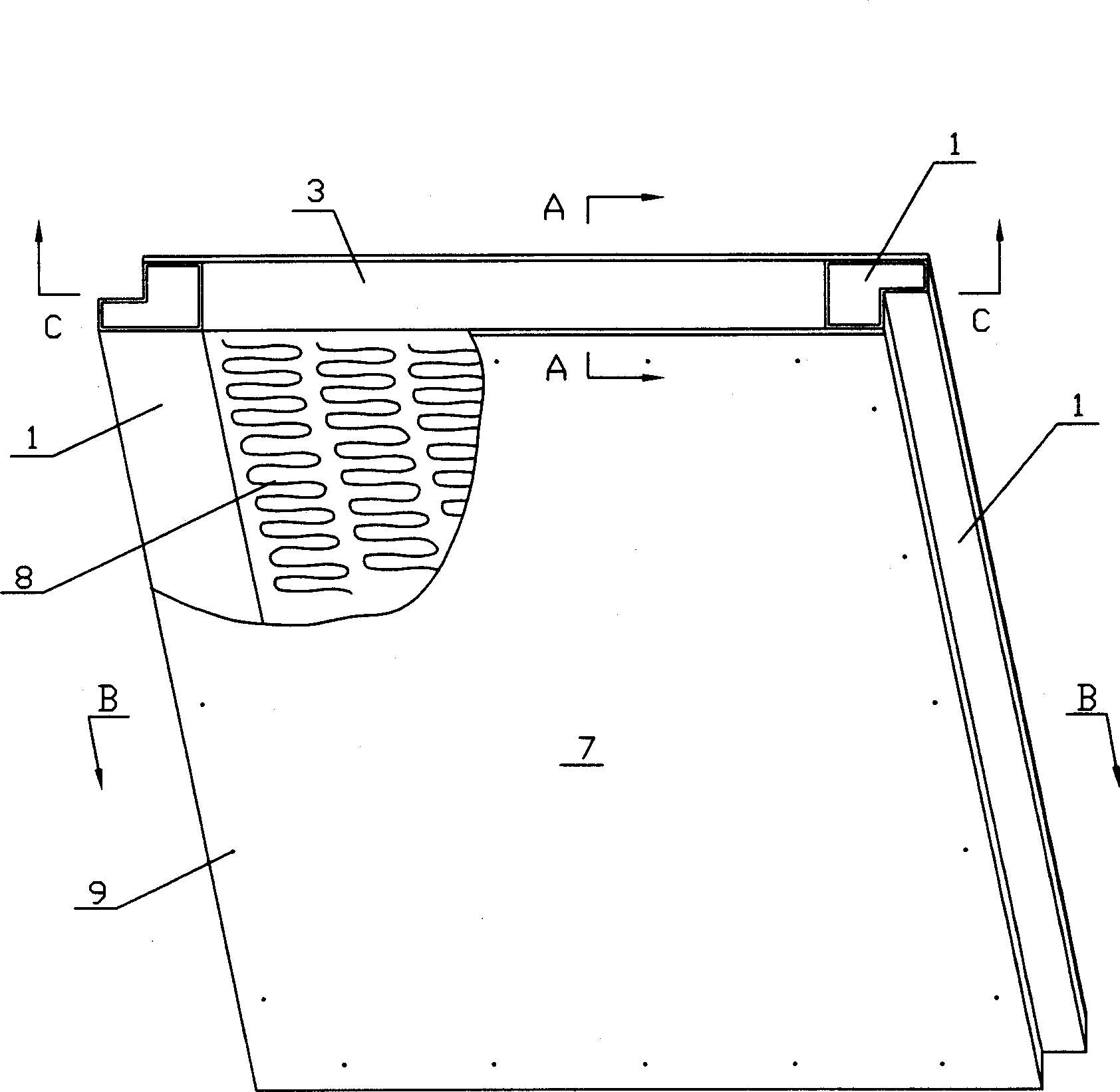

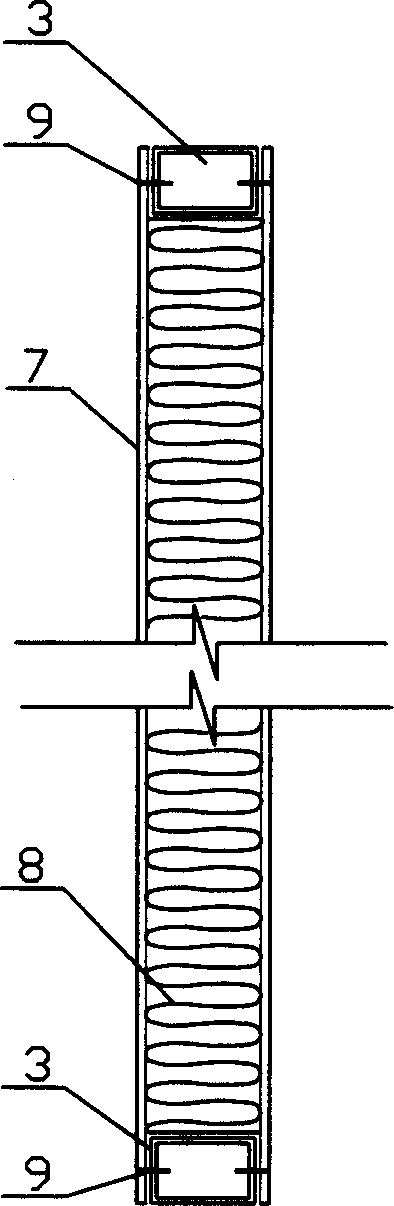

Assembled large-scale construction board with light frame and manufacturing process thereof

ActiveCN1884762AImprove structural performanceImprove seismic performanceBuilding componentsKeelEdge structure

The invention relates to an assembly light frame large-scale building sheet material and relative preparation, wherein said invention comprises: two plates and one core plate clamped between them; said core plate comprises a light frame at the edge to form sealed edge structure, and light thermal-insulated material filled into the chamber surrounded by said light frame; the plate and the light frame are connected via self-threading screw. And the preparation comprises filling type, rolling type and model compress type. The inventive sheet is preformed with light keel, which can confirm better structure of room, with anti-wind, anti-vibration and anti-theft functions (it arranges steel bar network inside the plate).

Owner:广州益群板业有限公司

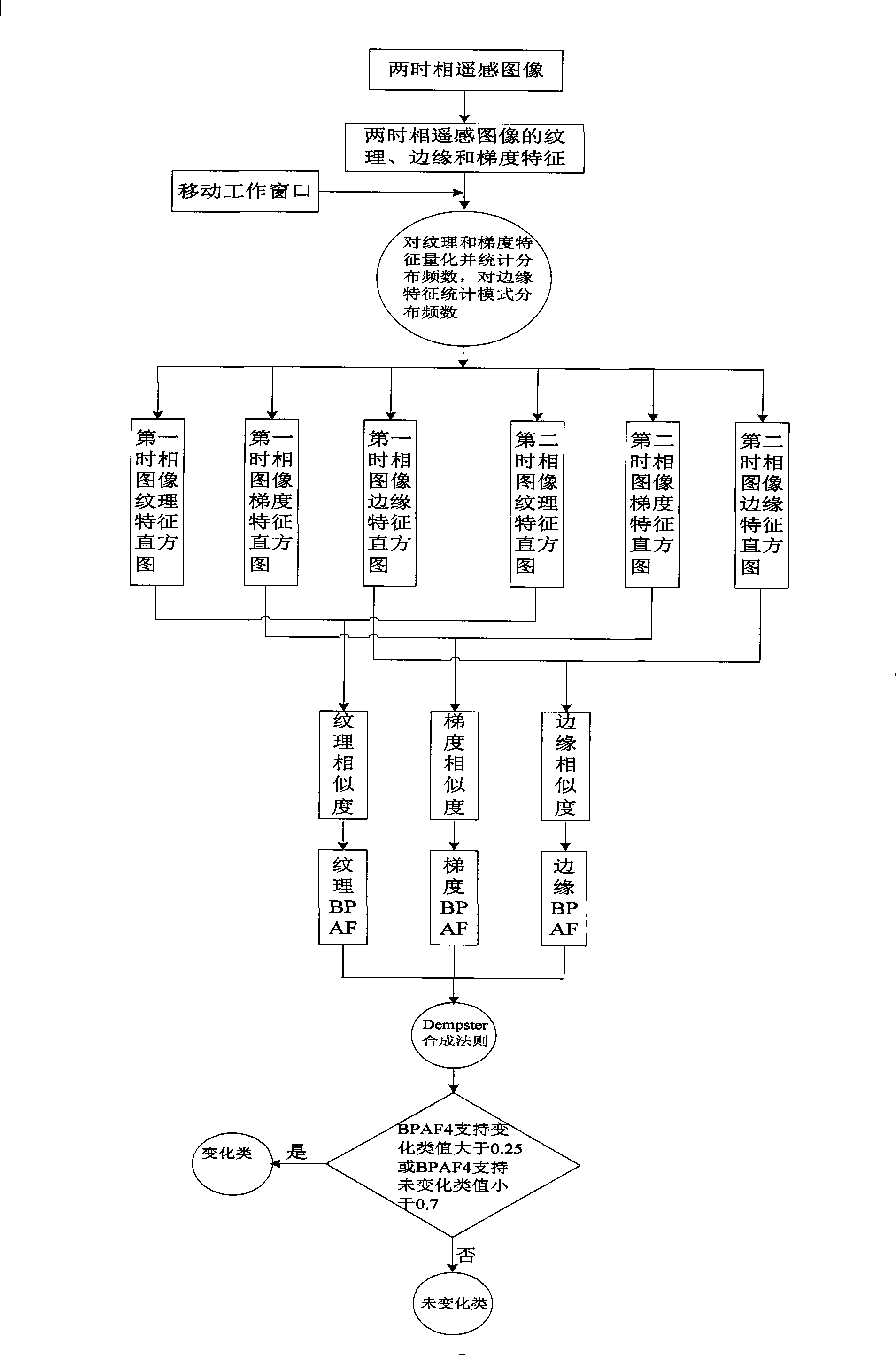

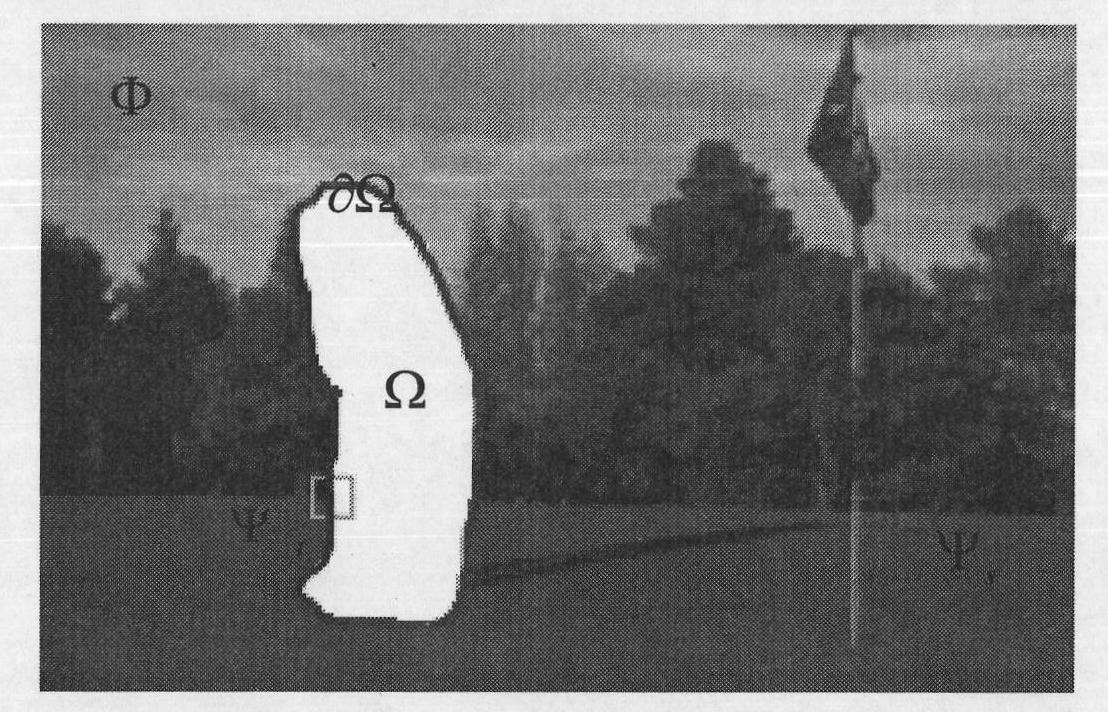

Remote sensing image change detection method based on multi-feature evidence integration and structure similarity

InactiveCN101539629AImprove immunityImprove robustnessElectromagnetic wave reradiationFeature extractionEdge structure

The invention discloses a remote sensing image change detection method based on multi-feature proof integration and structure similarity, comprising the following steps: A. data preparation: selecting remote sensing images to be carried out with change detection in different time phase and in the same spatial scope; B. feature extraction: respectively extracting features of textures, grads and edges of images in two time phases; C. structure similarity calculation: calculating the texture structure similarity, grads structure similarity and edge structure similarity of the remote sensing images in two time phases in a working window; D. basic probability assignment function determination: building basic probability assignment function (BPAF) of evidence theory based on texture structure similarity, the grads structure similarity and edge structure similarity; and E. forming evidence and obtaining change areas to realize change detection. The method carries out change detection based on the area statistic features of edges, texture sand grads of images and can effectively avoid detection miss and false detection caused by the change detection using single feature; and the algorithm has robustness.

Owner:NANJING NORMAL UNIVERSITY

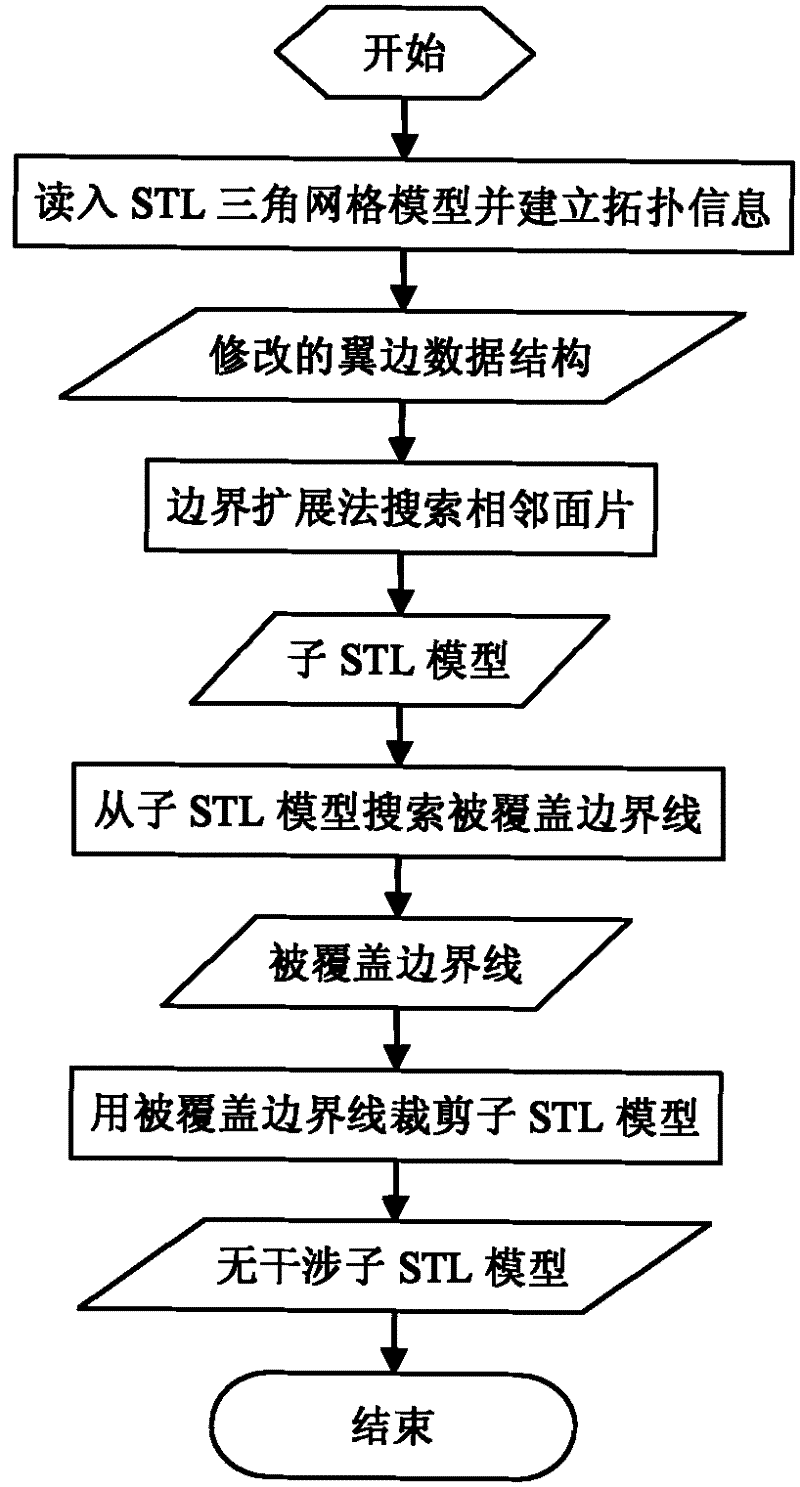

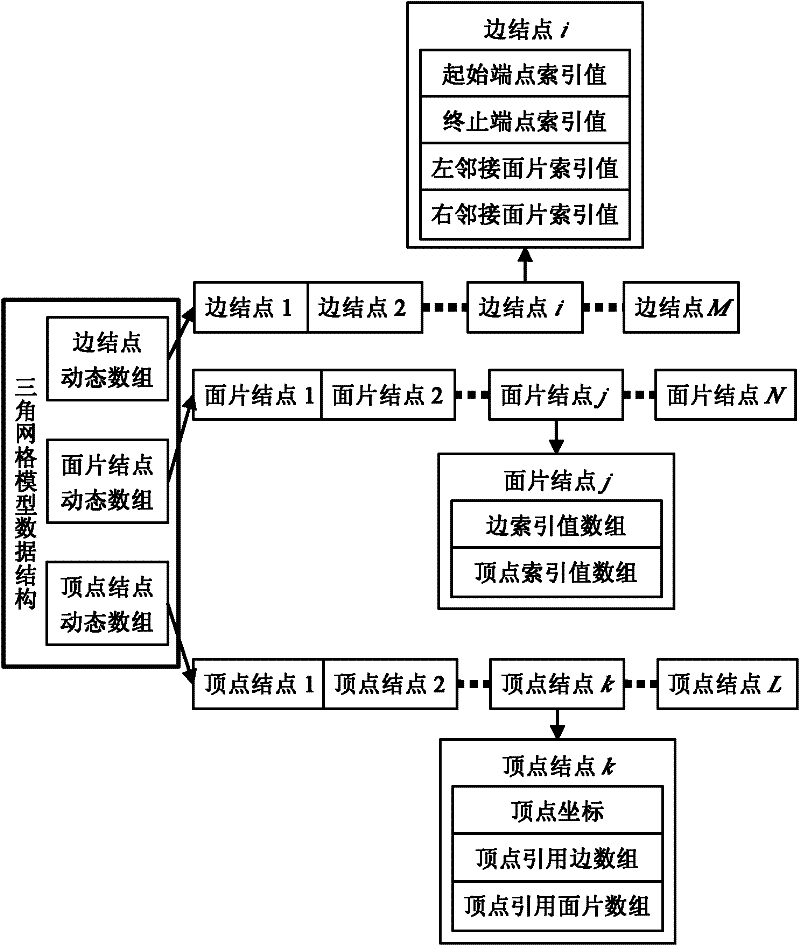

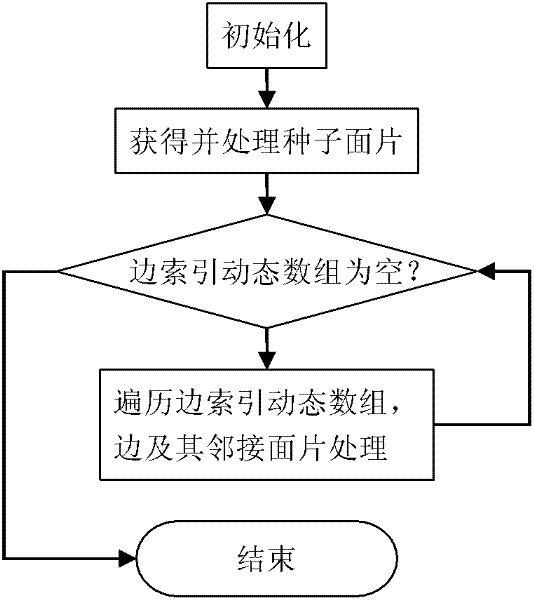

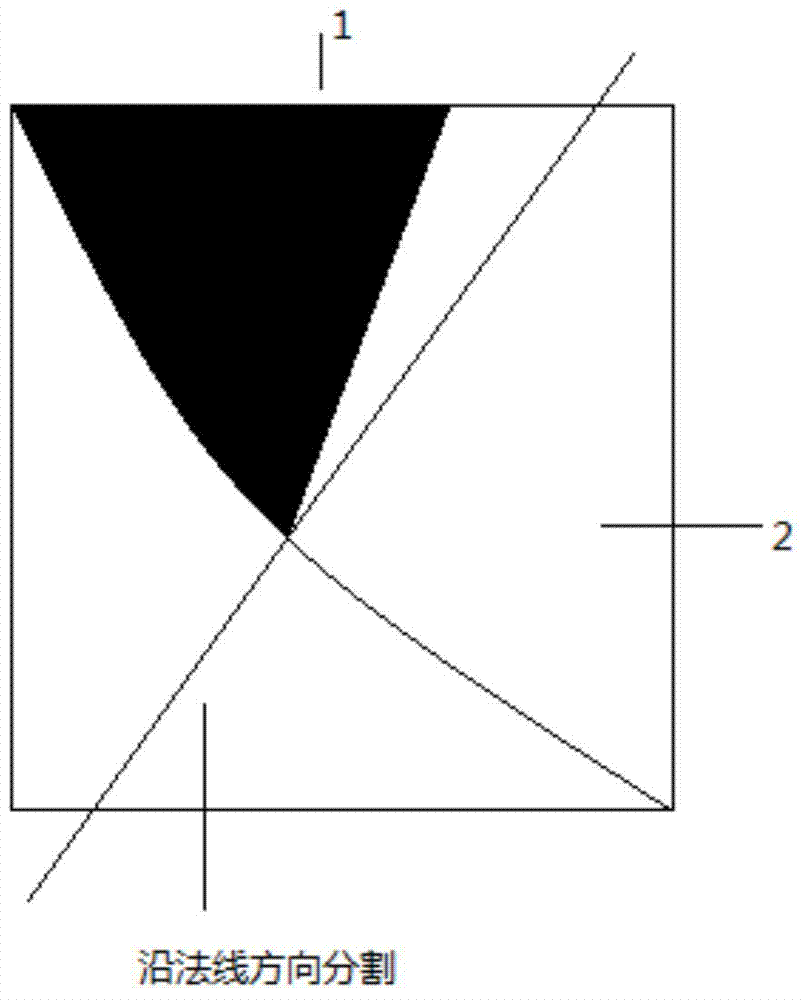

3D segmentation method for stl triangular mesh model

The invention discloses a three-dimensional segmenting method for an STL (Standard Template Library) triangular network model in rapid molding process. The three-dimensional segmenting method comprises the following steps of: firstly, reading the STL triangular network model from an STL file into an internal storage, and establishing complete topological information of a surface patch, a side and a peak in the STL model based on an improved wing-edge structure; secondly, repeatedly searching through information in the internal storage to obtain a highest position surface patch serving as a seed surface patch in an original STL model, and searching an adjacent surface patch having the same normal vector Z-axis component symbol as the seed surface patch with a boundary expansion method on the basis to obtain a plurality of sub-STL models having the same normal vector Z-axis component symbol; and lastly, checking the boundary of each sub-STL model, recognizing and extracting covered boundary lines, and segmenting the sub-STL model by using a vertical plane defined by the covered boundary lines to further generate non-interfered sub-STL models. By adopting the three-dimensional segmenting method, three-dimensional segmentation of the STL triangular network model can be realized effectively; and moreover, the triangular network model has the advantages of high adaptability, high efficiency and low resource consumption.

Owner:HUAQIAO UNIVERSITY

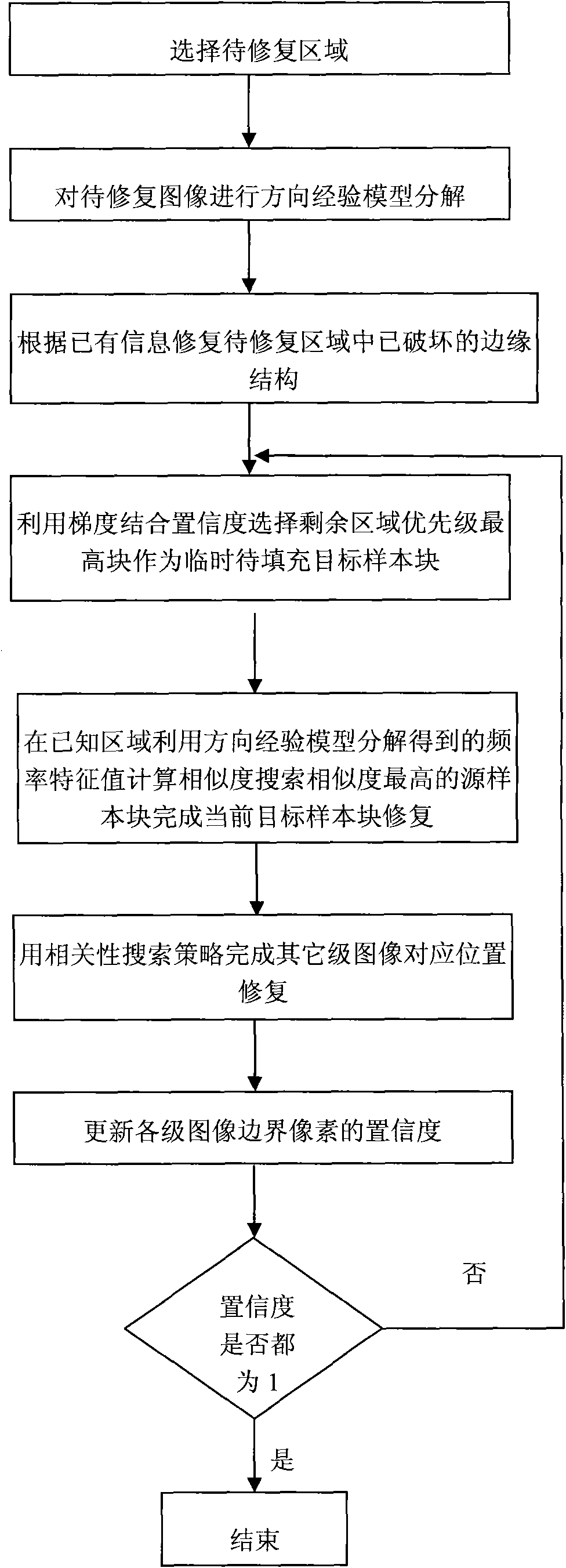

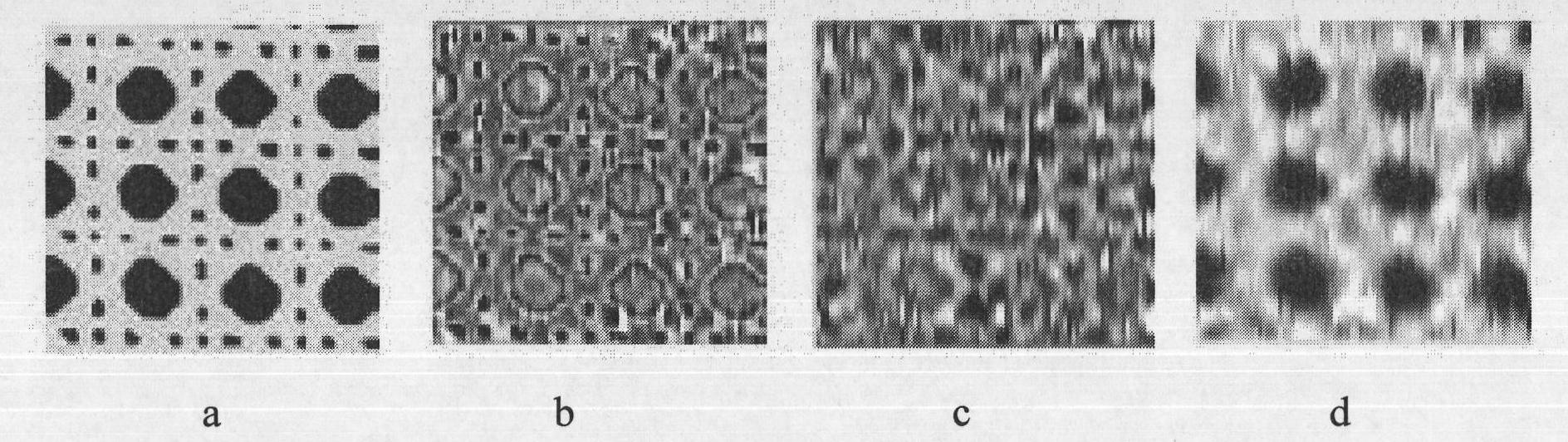

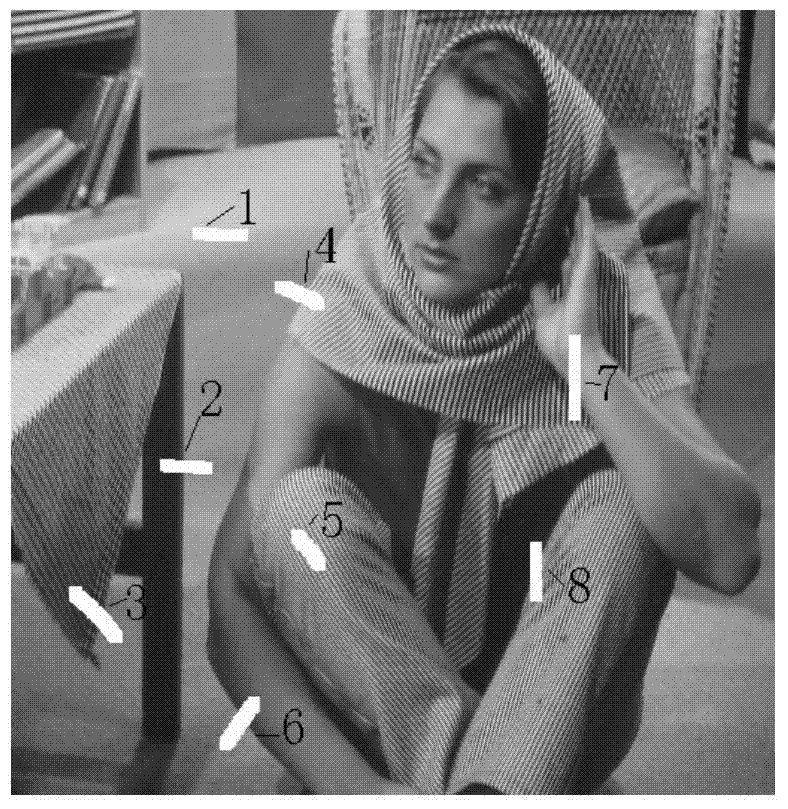

Image restoring method

InactiveCN101777178APrevent continuous expansionImprove repair effectImage enhancementAlgorithmDecomposition

The invention relates to an image restoring method, which comprises the following steps: firstly carrying out direction and experience model decomposition on a target image, allowing to draw damaged edge structure information in a given area to be restored according to the existing information, utilizing a frequency characteristic value obtained by the direction and experience model decomposition to calculate similarity so as to firstly finish edge structure restoration in the whole damaged area, then combining degree of confidence to calculate the priority of a residual filling area according to gradient characteristics of pixel points on the boundary of the area to be restored, and utilizing a frequency characteristic value obtained by the decomposition again to calculate similarity so as to finish the restoration of corresponding areas. The method not only can restore the structure and texture information in a larger-scale defective area, but also can restore the images with certain sheltering relation. The robustness in the restoring process is high, thus effectively preventing continuous expansion of error information.

Owner:NANJING UNIV

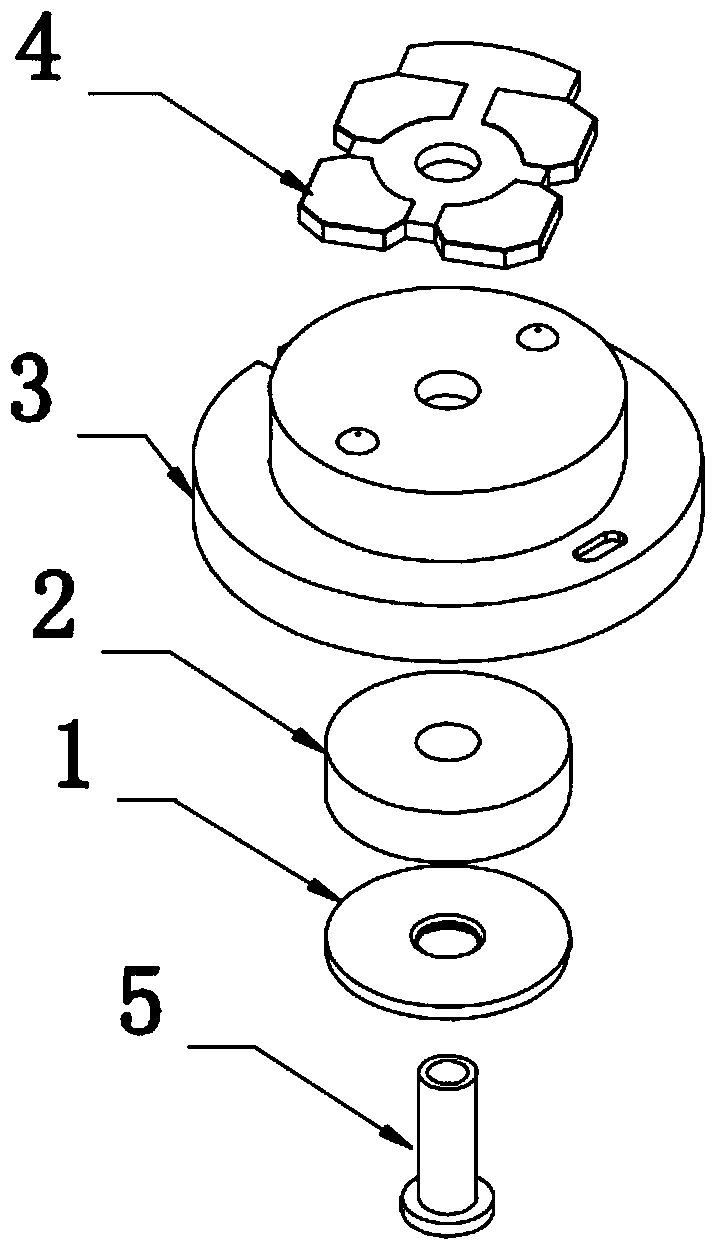

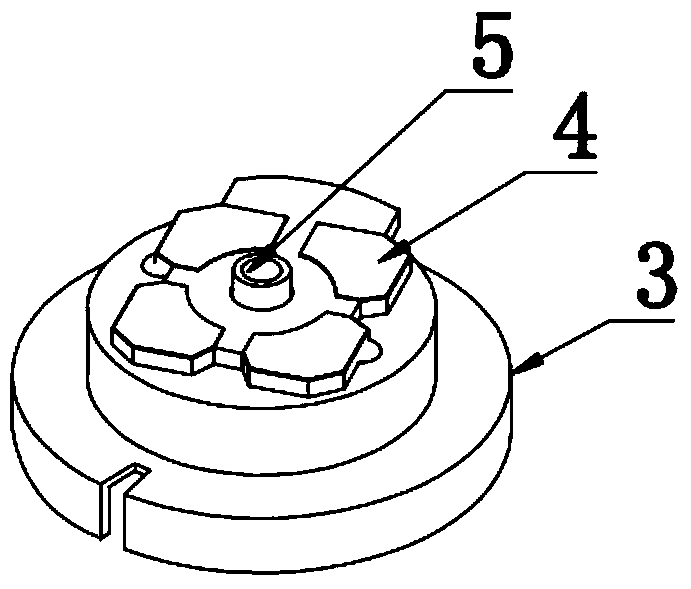

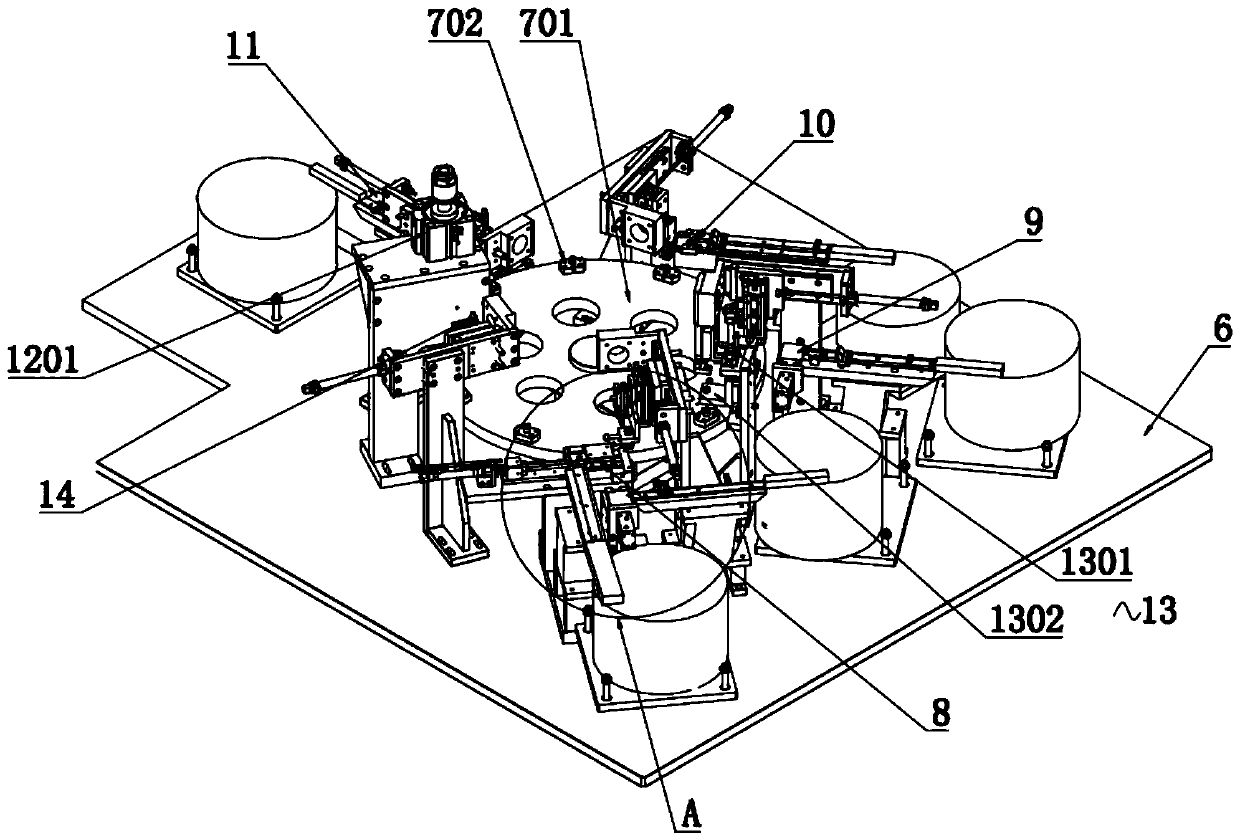

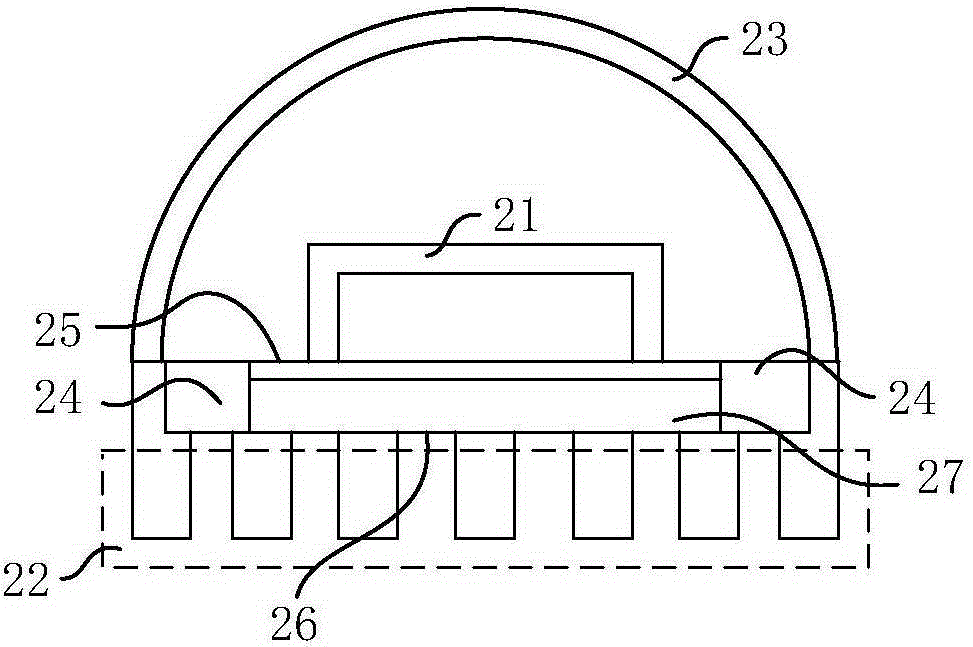

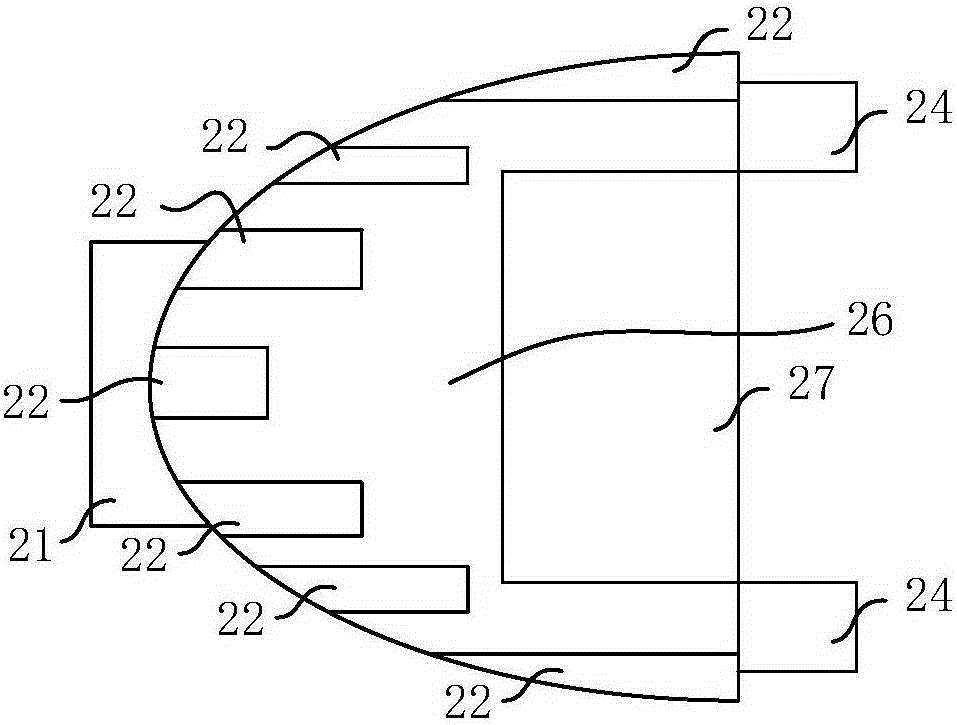

Automatic assembling equipment of magnetic circuit system of loudspeaker

ActiveCN103731791AImprove efficiencyReduce labor costsElectrical transducersEdge structureEngineering

The invention relates to automatic assembling equipment of a magnetic circuit system of a loudspeaker. The automatic assembling equipment comprises a bottom plate, wherein a feeding mechanism and a washer and rivet combined mechanism are arranged on the bottom plate; the feeding mechanism comprises a rotary table, clamps and a driver, the rotary table is equally divided in a multi-station mode, the clamps are arranged on the periphery of the rotary table at equal intervals to accumulate and position one end of a rivet cap of each rivet, and the driver drives the rotary table to step intermittently to replace stations; a magnet feeding structure, a T iron feeding structure, a PCB feeding structure and a riveting pressing mechanism are further sequentially arranged on the bottom plate and around the rotary table, the magnet feeding structure, the T iron feeding structure and the PCB feeding structure respectively enable a magnet, T iron and a PCB to be connected to the rivets in a sleeved mode, the riveting pressing mechanism opens a hollow folding edge structure end portion arranged at the other end, away from the rivet cap, of each rivet in a riveted mode, and the mechanisms are controlled by a master control circuit. A rotary table type production mode is adopted, a washer, the magnet, the T iron and the PCB can be assembled and riveted automatically, efficiency is improved because the stations work simultaneously, existing manual operation is replaced, labor cost is lowered, the mechanisms are mechanically controlled to achieve automatic positioning, alignment is accurate, and product consistency is good.

Owner:SANKYO PRECISION HUIZHOU

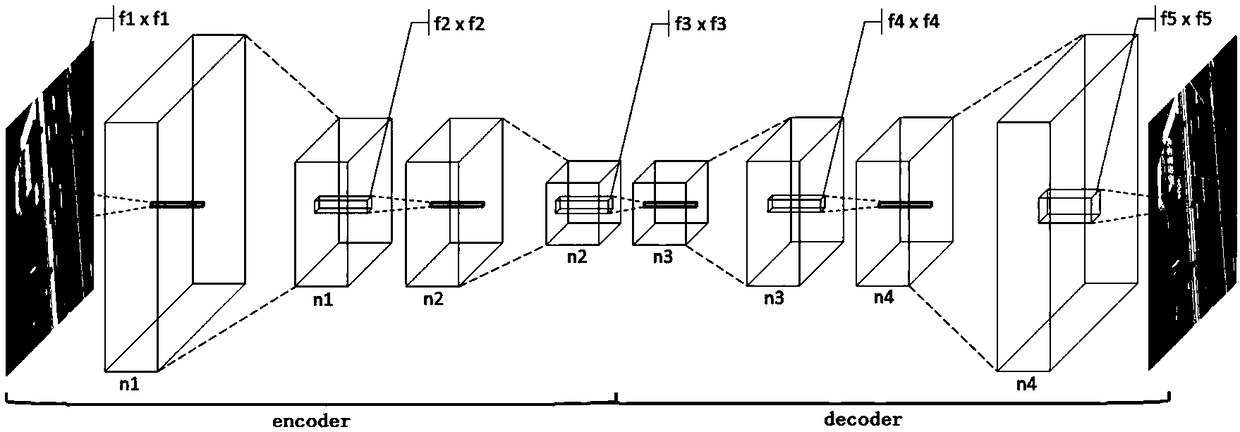

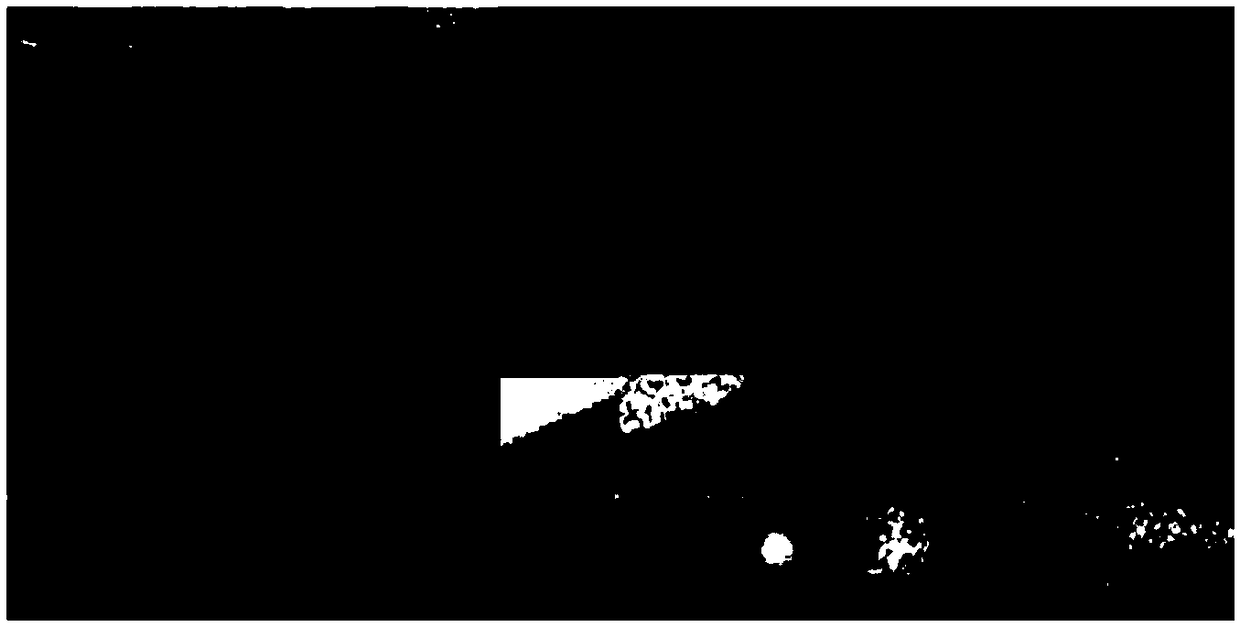

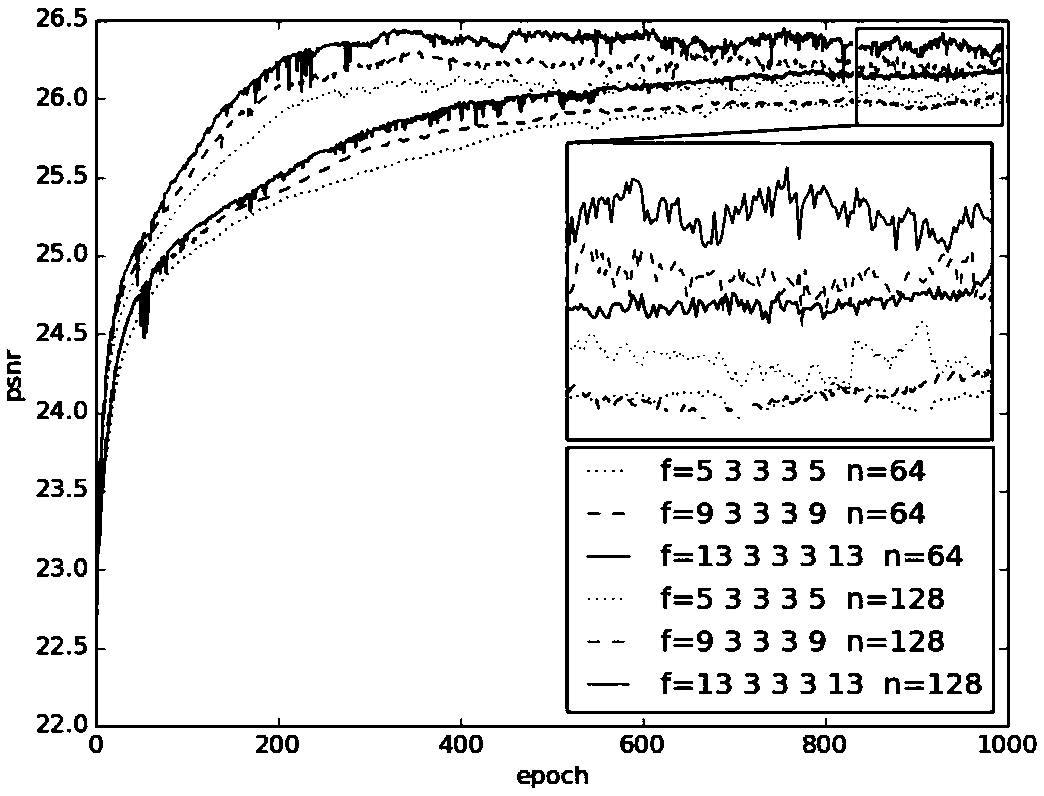

Space target image restoration method based on convolutional auto-encoding convolutional Neural Network

InactiveCN108765338AClear edge structureIncrease contrastImage enhancementNeural architecturesEdge structureNetwork model

The invention discloses a space target image restoration method based on a convolutional auto-encoding convolutional neural network. The method comprises the steps of establishing degraded images withdifferent degradation degree as input data, wherein the input data is used for learning and establishing a relatively robust CAE neural network model; and establishing simulation image sets of different types and different blurring degree through utilization of the prior knowledge with limited space target quantity and known part of models, and the feature that the similarity among the models ishigh, wherein the simulation image sets are used for carrying out training in the convolutional network. The method has the advantages that the images with clear edge structures can be restored; the method has excellent turbulence blurring removing capacity; the edge contrast of the restored images is high; the anti-noise capacity is excellent; the internal structures of the restored images are displayed relatively stably and clearly; and the efficiency is relatively high.

Owner:XIHUA UNIV

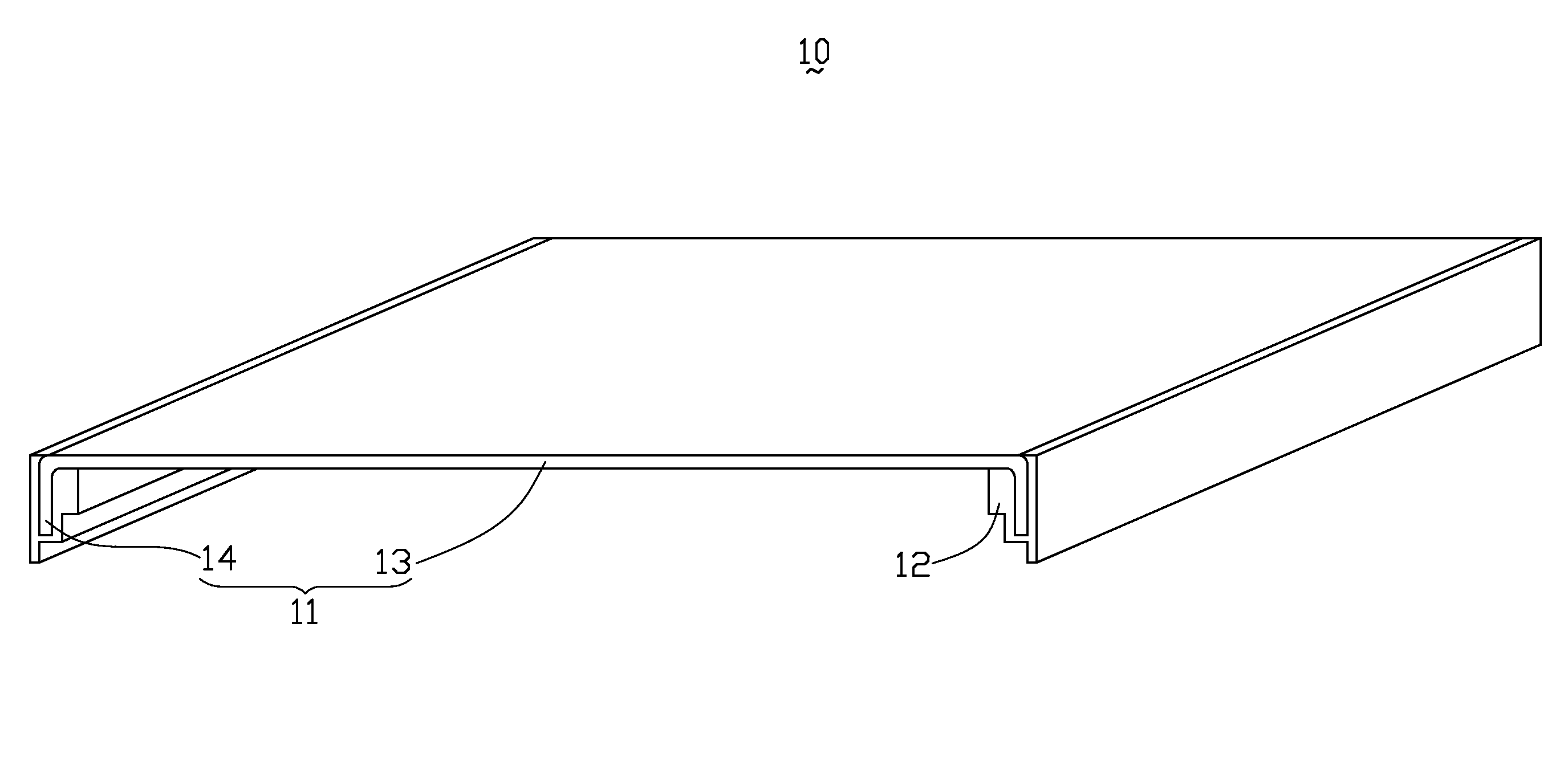

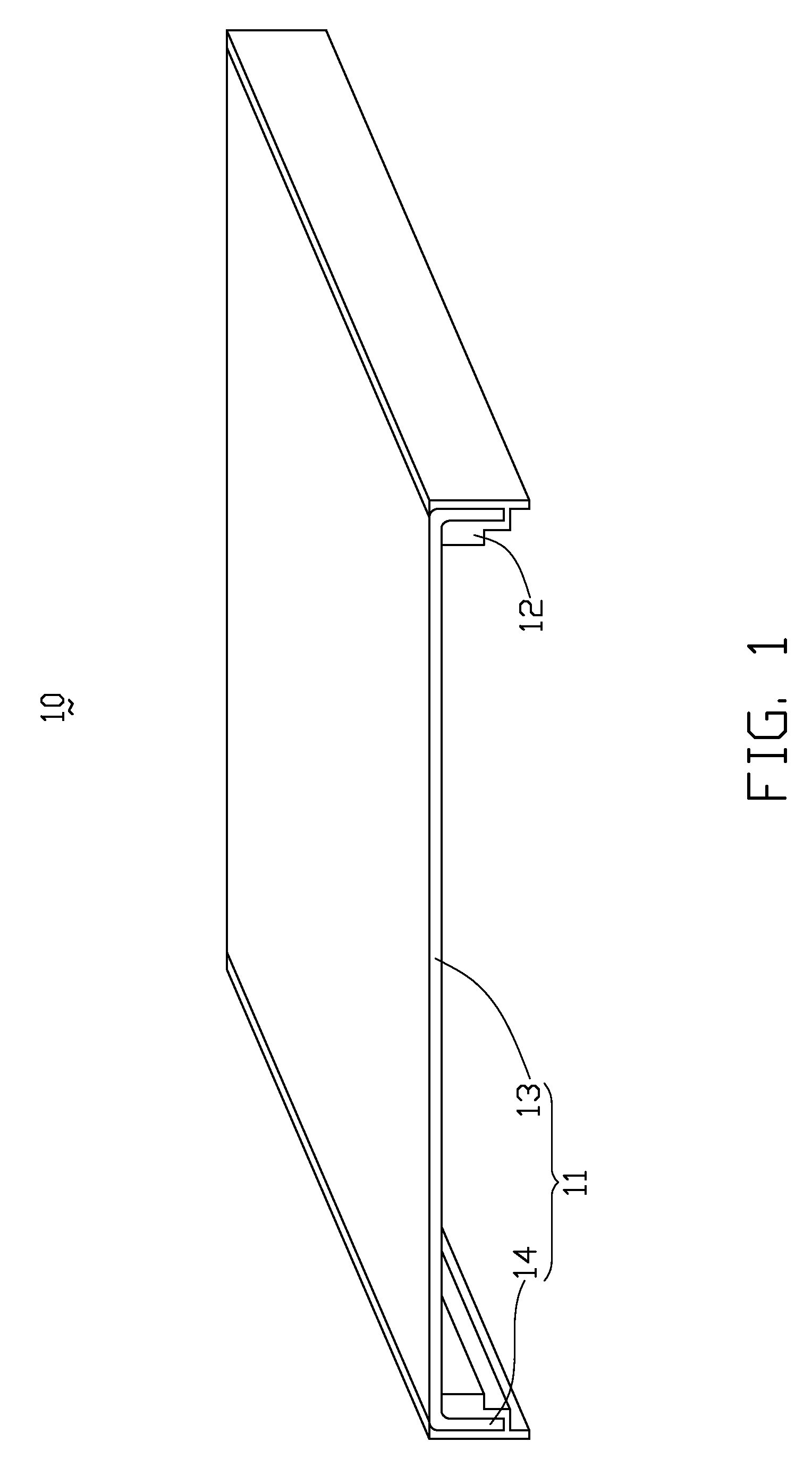

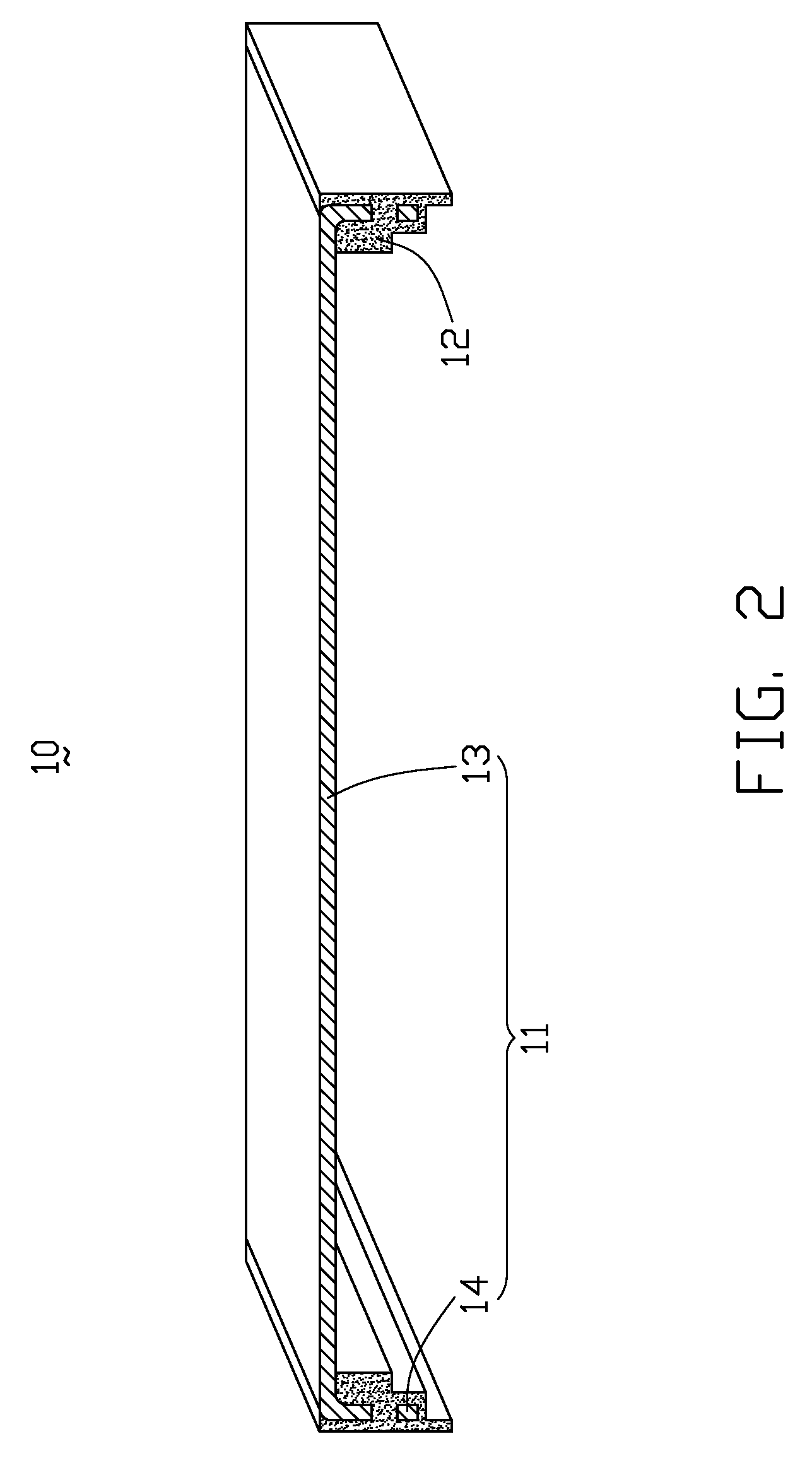

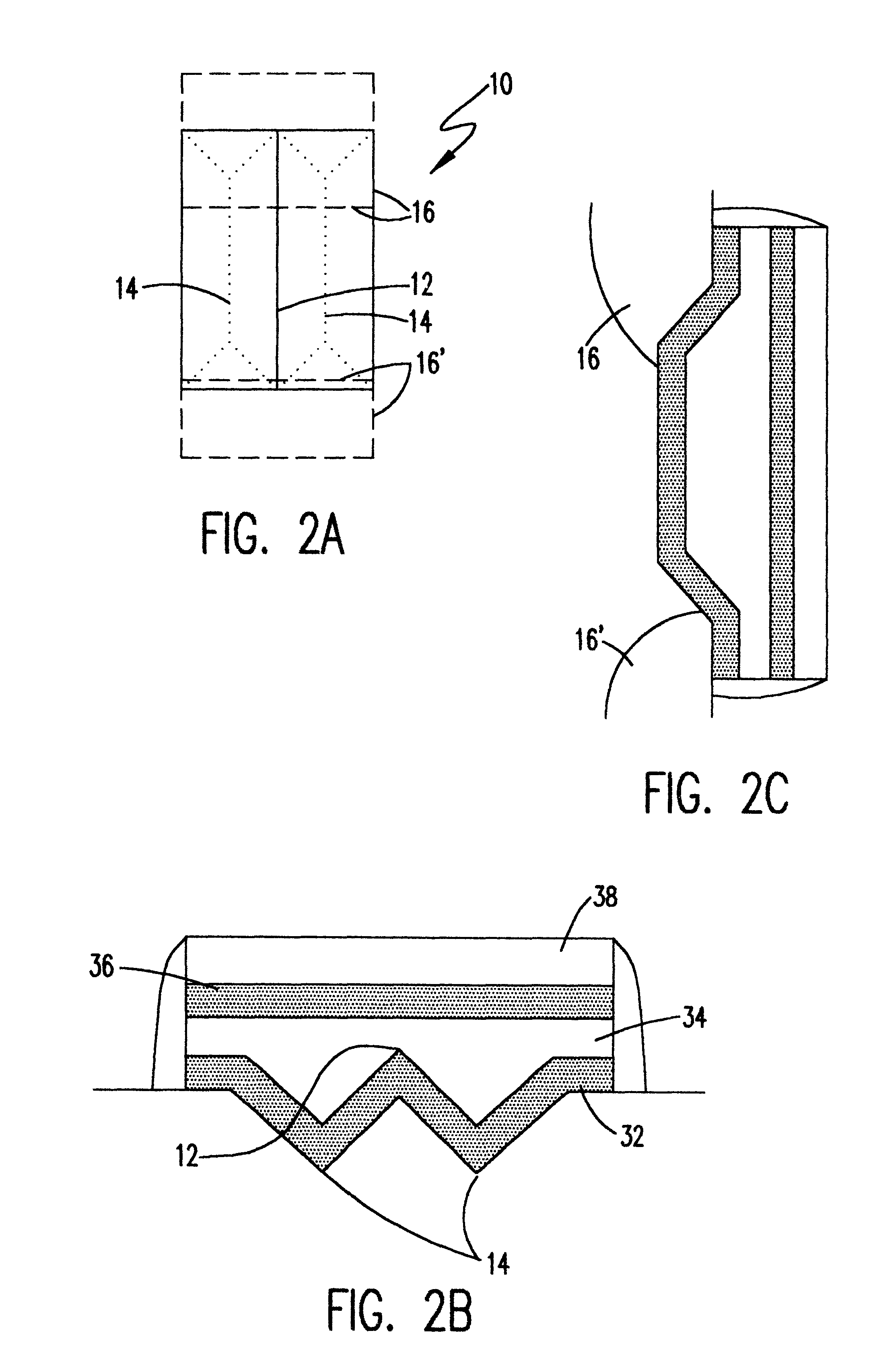

Plastic coated edge structure used for portable electronic device and method for making the same

An exemplary plastic coated edge structure (10) includes a base sheet (11) and a protective plastic layer (12). A fringe portion of the base sheet defines a plurality of through holes (15). The protective plastic layer coats the fringe portion, and part of the protective plastic layer engages in the through holes. A method for making a plastic coated edge structure includes: providing a base sheet including a fringe portion, the fringe portion defining a plurality of though holes; putting the base sheet into an injection mold; injecting a melted plastic material into the injection mold from a side of the fringe portion to an opposite side of the fringe portion from the through holes to form the protective plastic layer for coating the fringe portion; solidifying the plastic material to form a plastic coated edge structure; and taking the plastic coated edge structure out of the injection mold.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

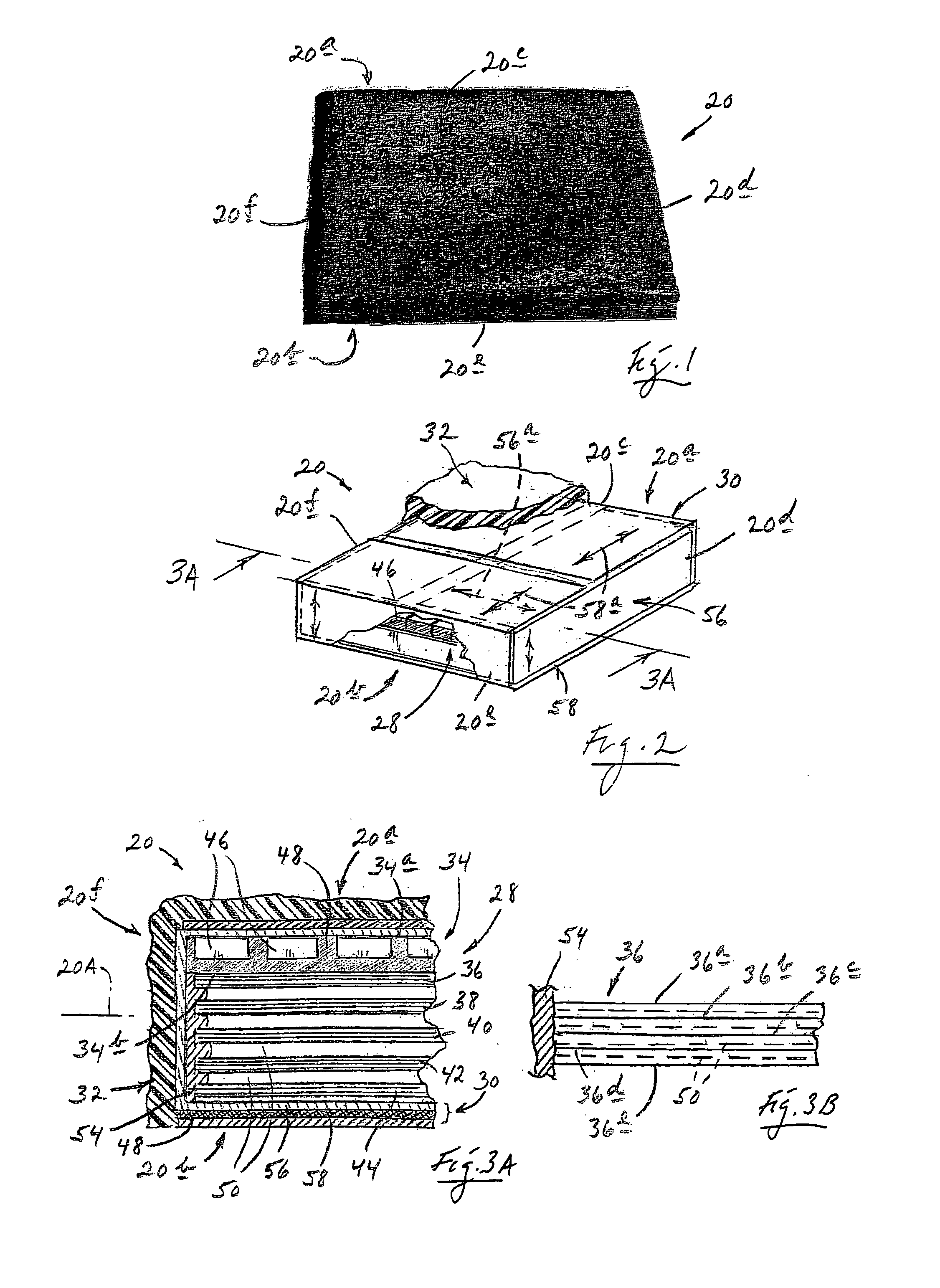

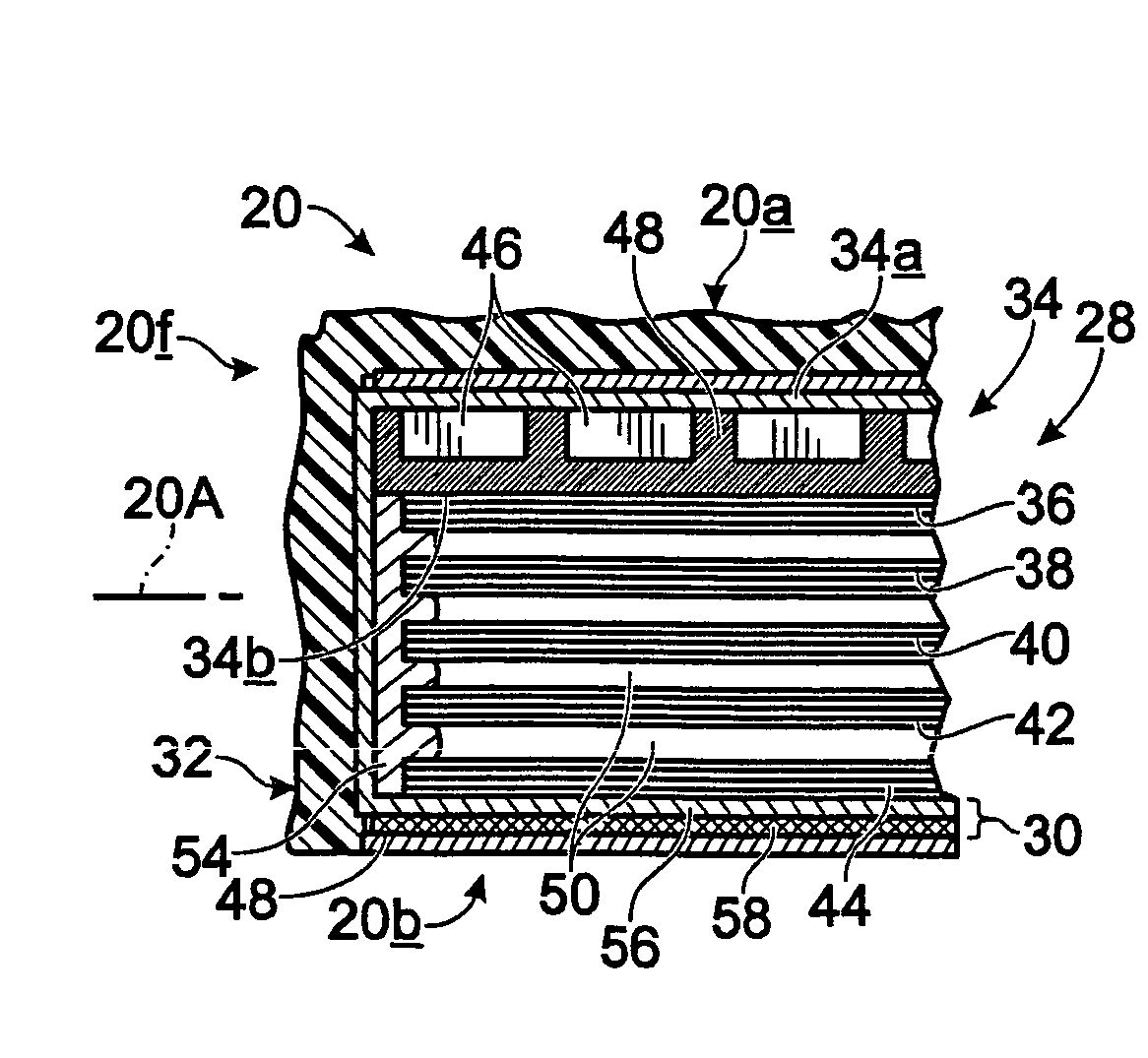

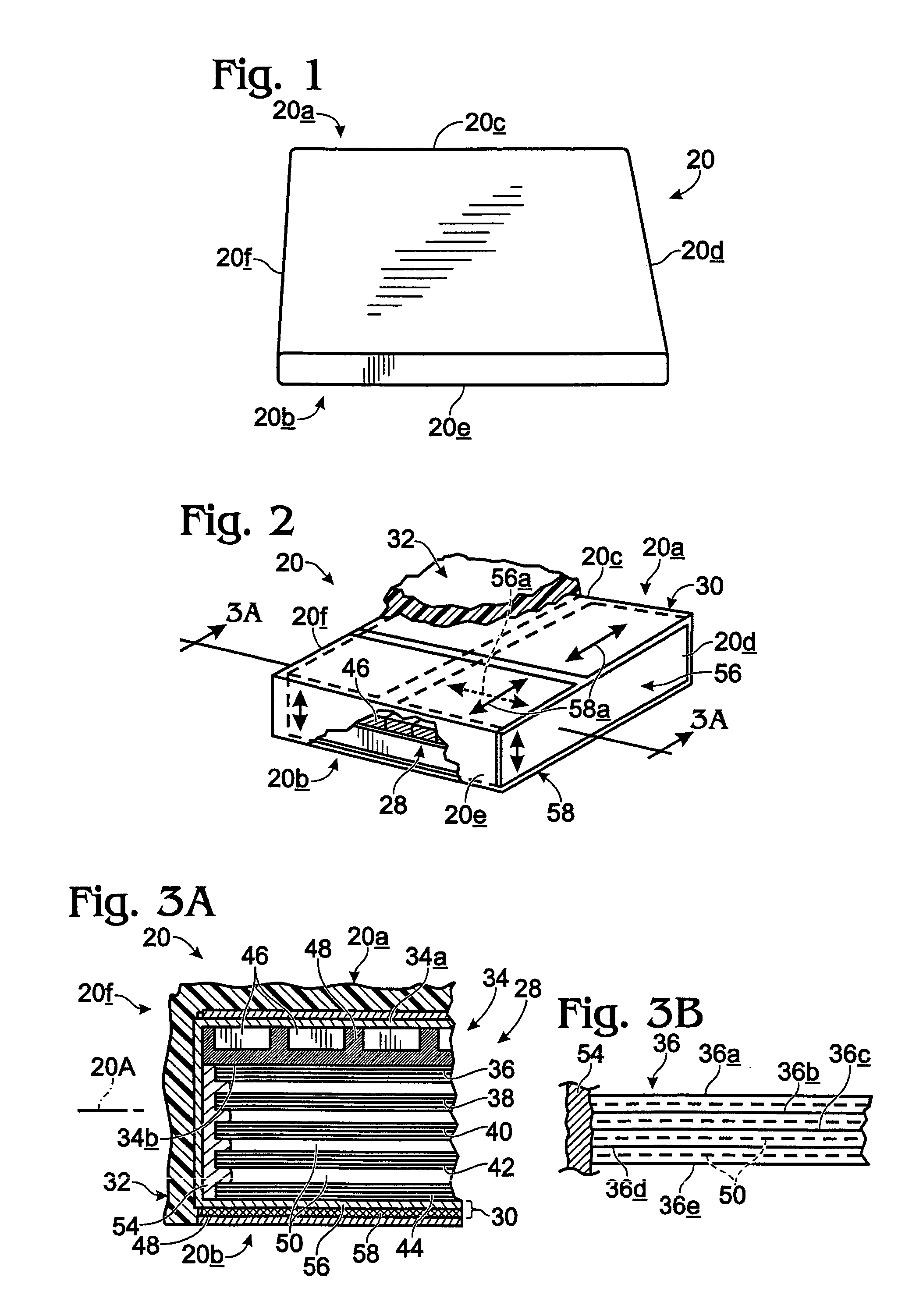

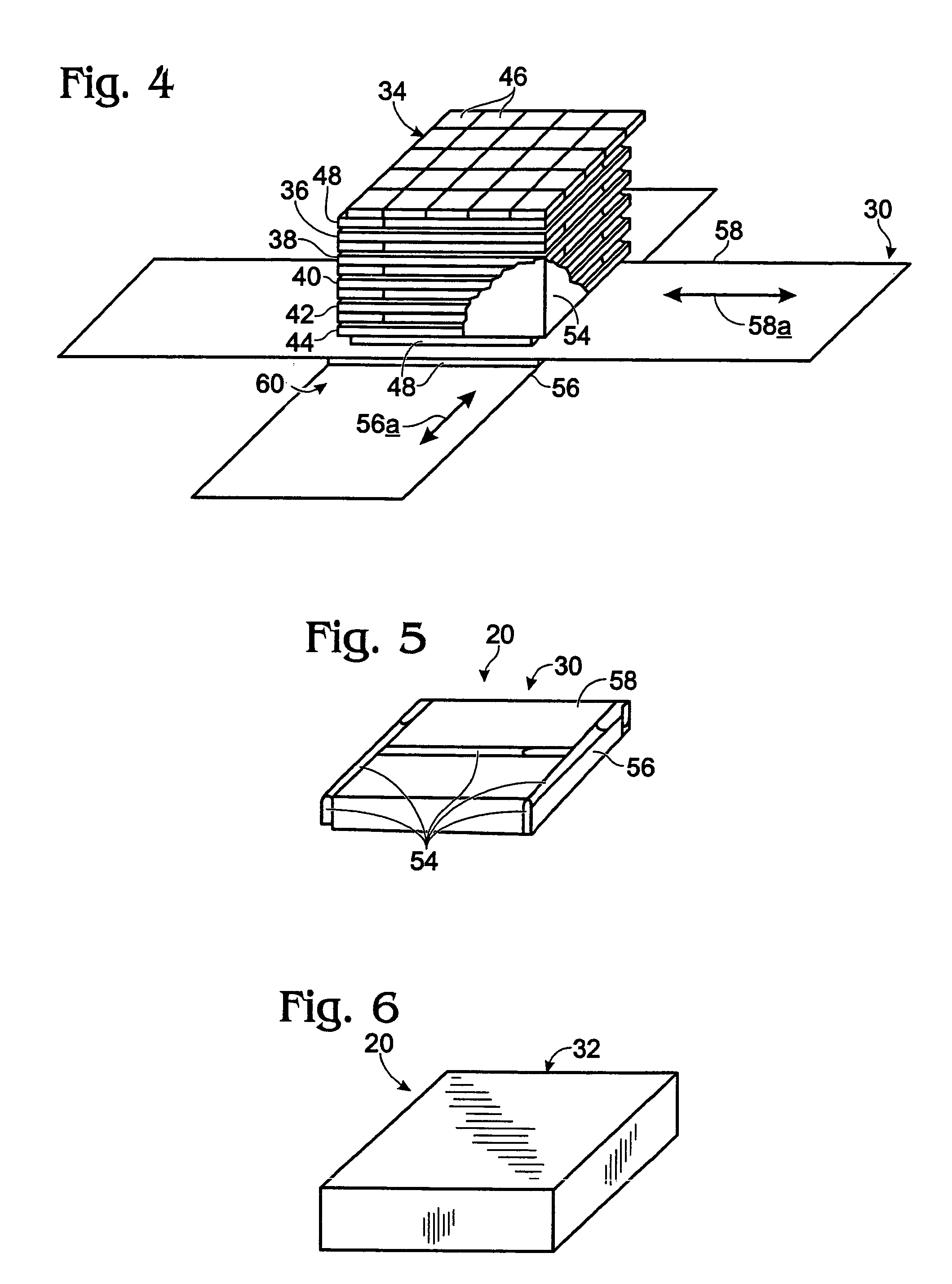

Trampoline response armor panel

InactiveUS20050193667A1Enhances trampoline actionImprove actionArmourDoor/window protective devicesClassical mechanicsEdge structure

An armor panel for defeating a projectile strike including (a) a substantially planar core structure having spaced, generally parallel-planar strike and opposite faces, and elongate, circumsurrounding edge structure extending generally normally between these faces to define a perimeter for the core structure, (b) stranded core-wrap structure substantially fully enveloping the core structure, and possessing elongate, tension-load-bearing (TLB) strands which extend at angles relative to one another across the mentioned faces, and substantially parallel to one another in a distribution along the perimeter defined by the edge structure, and (c) a high-elastomeric coating which is distributed over at least those portions of the core-wrap structure which are disposed adjacent the strike face and the edge structure.

Owner:HENRY JAMES JACKSON MILHAM +2

Image processing apparatus, image processing method, storage medium, and program

InactiveUS7079700B2Suppressing and avoiding collapseImage enhancementImage analysisPattern recognitionImaging processing

There are disclosed an image processing apparatus and method, and the like, which can obtain a high-quality image, the dynamic range or partial pixel value range of which has been changed while suppressing or avoiding collapse of the edge structure of an image or generation of overshoot. Also, there are disclosed an image processing apparatus and method, and the like, which can obtain a high-quality image, desired spatial frequency components of which have been emphasized or suppressed while suppressing or avoiding collapse of the edge structure of an edge portion contained in an objective image.For example, an image processing apparatus includes tone conversion means for executing tone conversion of an image, frequency transformation means for decomposing the image that has undergone tone conversion by the tone conversion means into frequency components of a plurality of frequency bands, and component conversion means for converting the frequency components of the plurality of frequency bands obtained by the frequency transformation means, on the basis of values of the frequency components and the tone conversion characteristics of the tone conversion means.

Owner:CANON KK

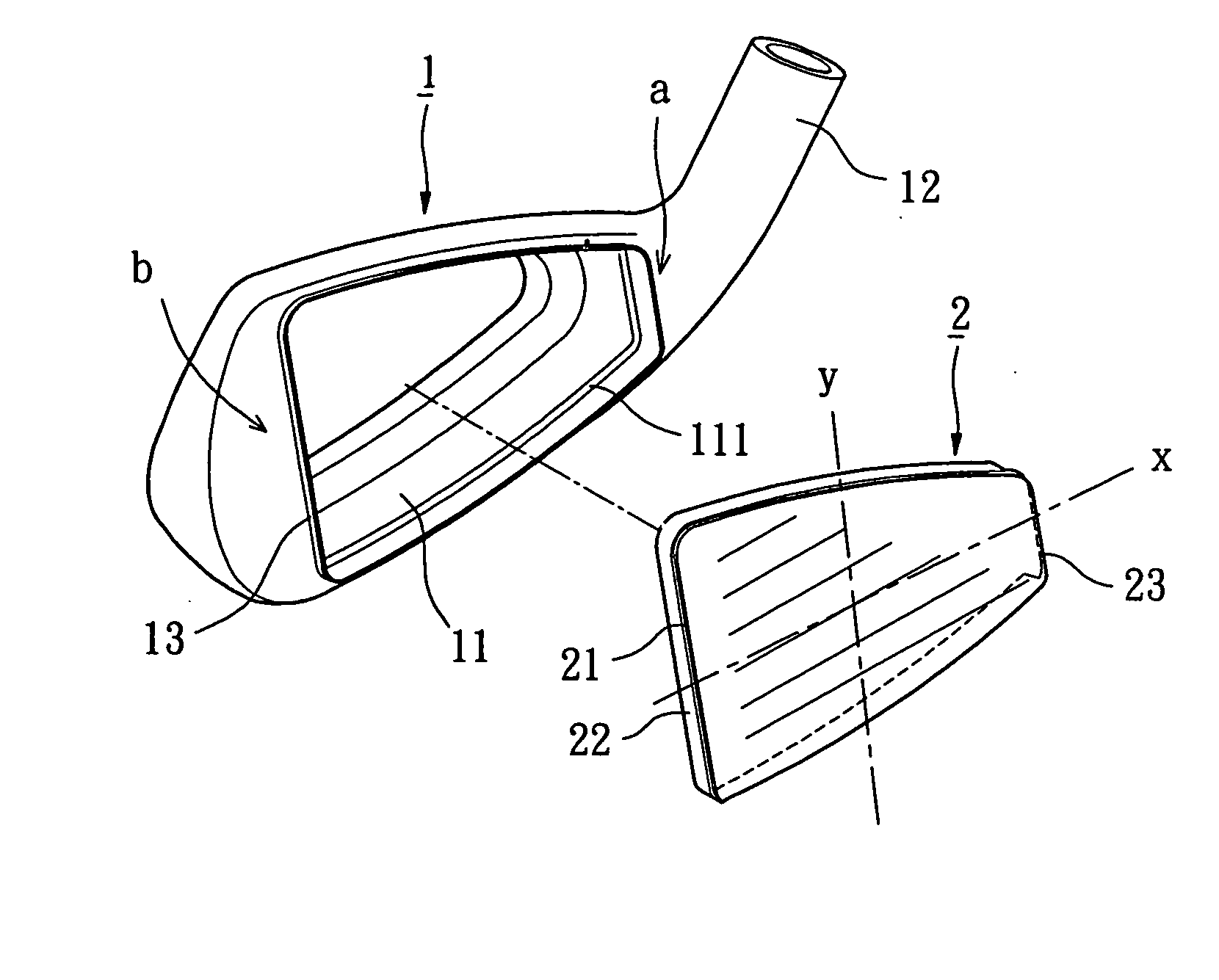

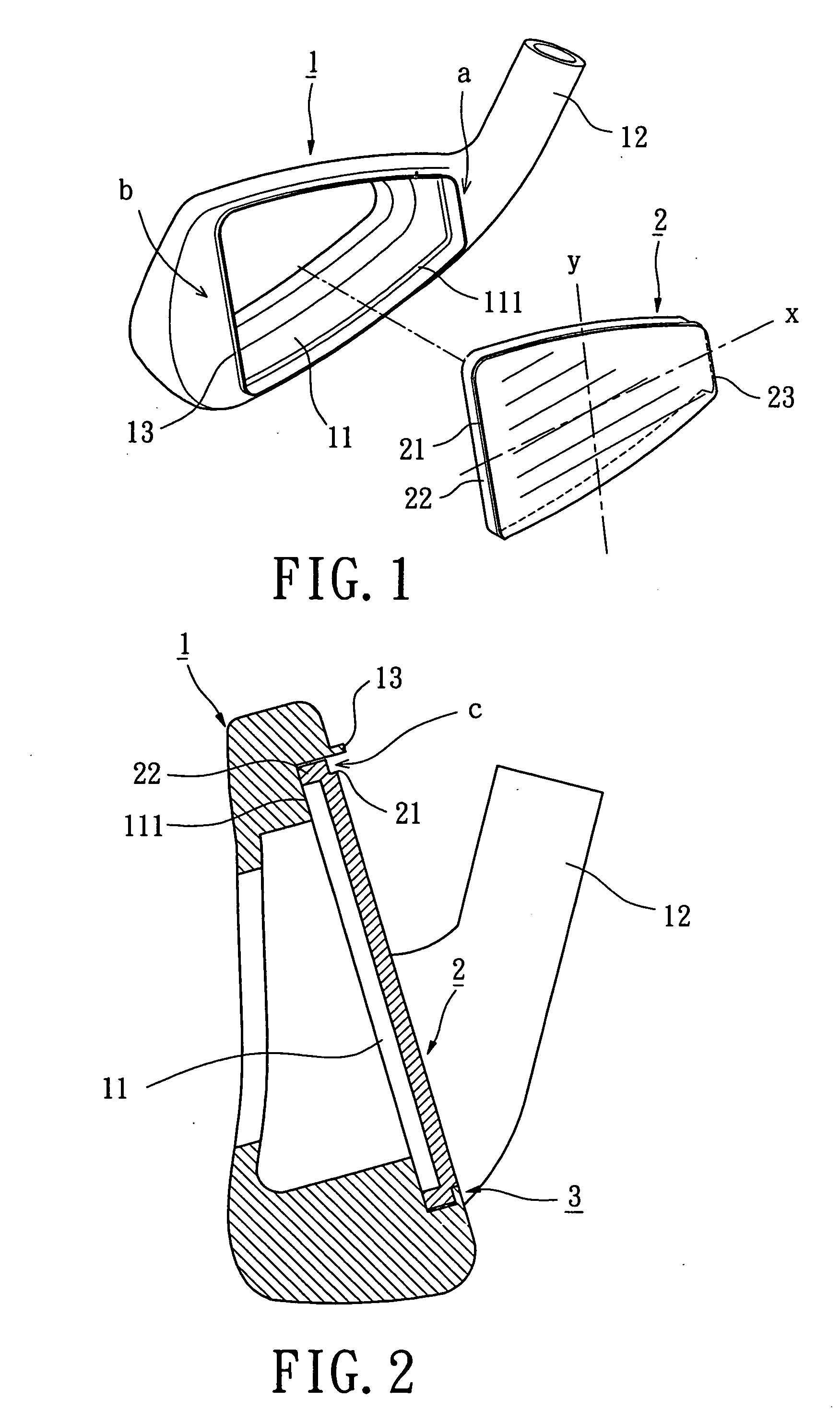

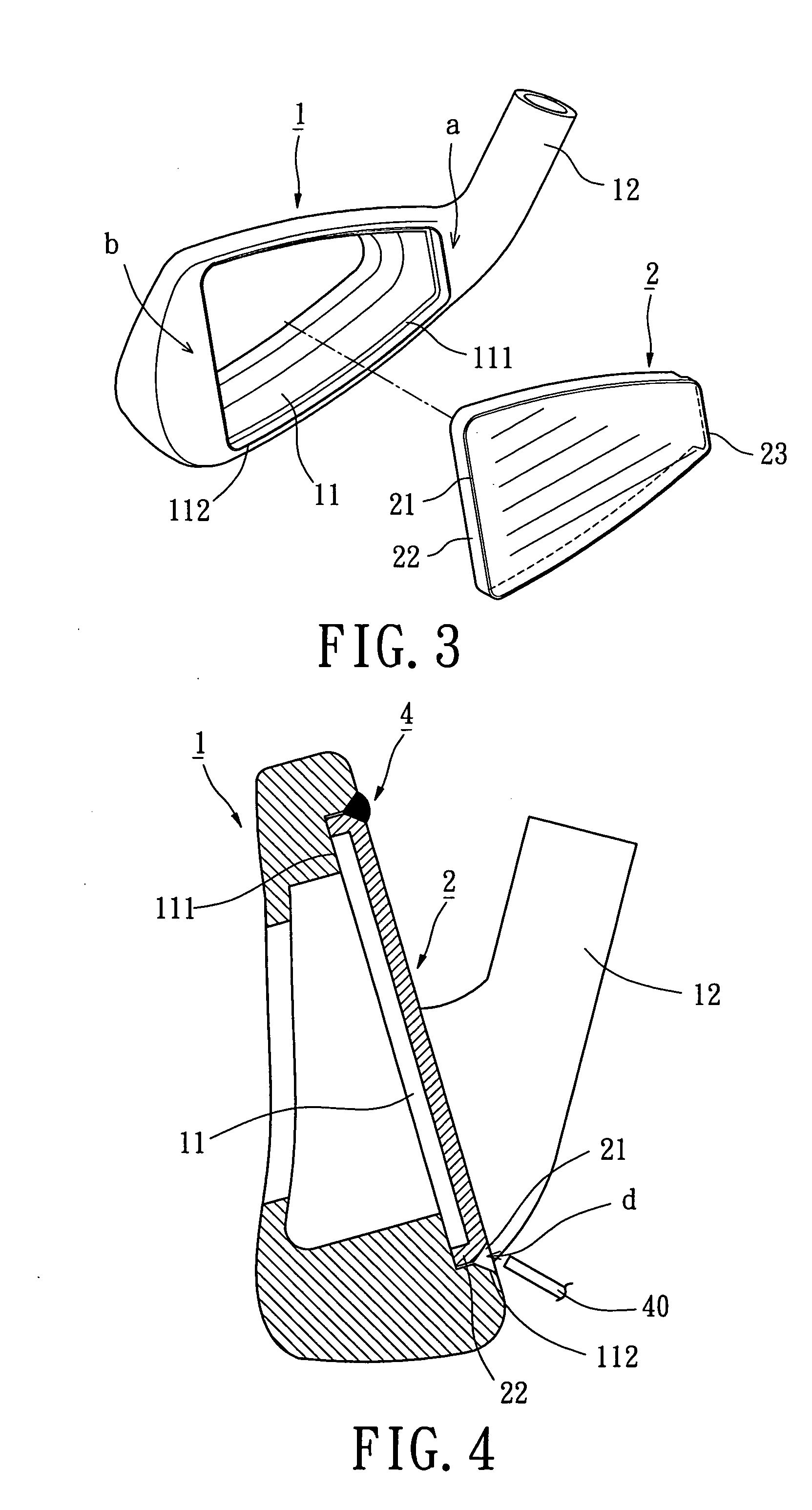

Upright bent edge structure of a striking plate for combing with a golf club head body

InactiveUS20060052179A1Design choice is expandedIncrease choiceGolf clubsRacket sportsEdge structureEngineering

A golf club head includes a golf club head body, a striking plate and a connecting portion. The golf club head body provides with an assembling recession at its front side. The striking plate provides with a main plate, an upright bent edge and a support wall to constitute a U-shaped or L-shaped configuration that can increase elastic deformation of the striking plate. In assembling, the support wall of the striking plate is initially inserted into the assembling recession of the golf club head body. The connection portion is located between the golf club head body and the striking plate, and securely connects the striking plate with the golf club head body.

Owner:NELSON PRECISION CASTING

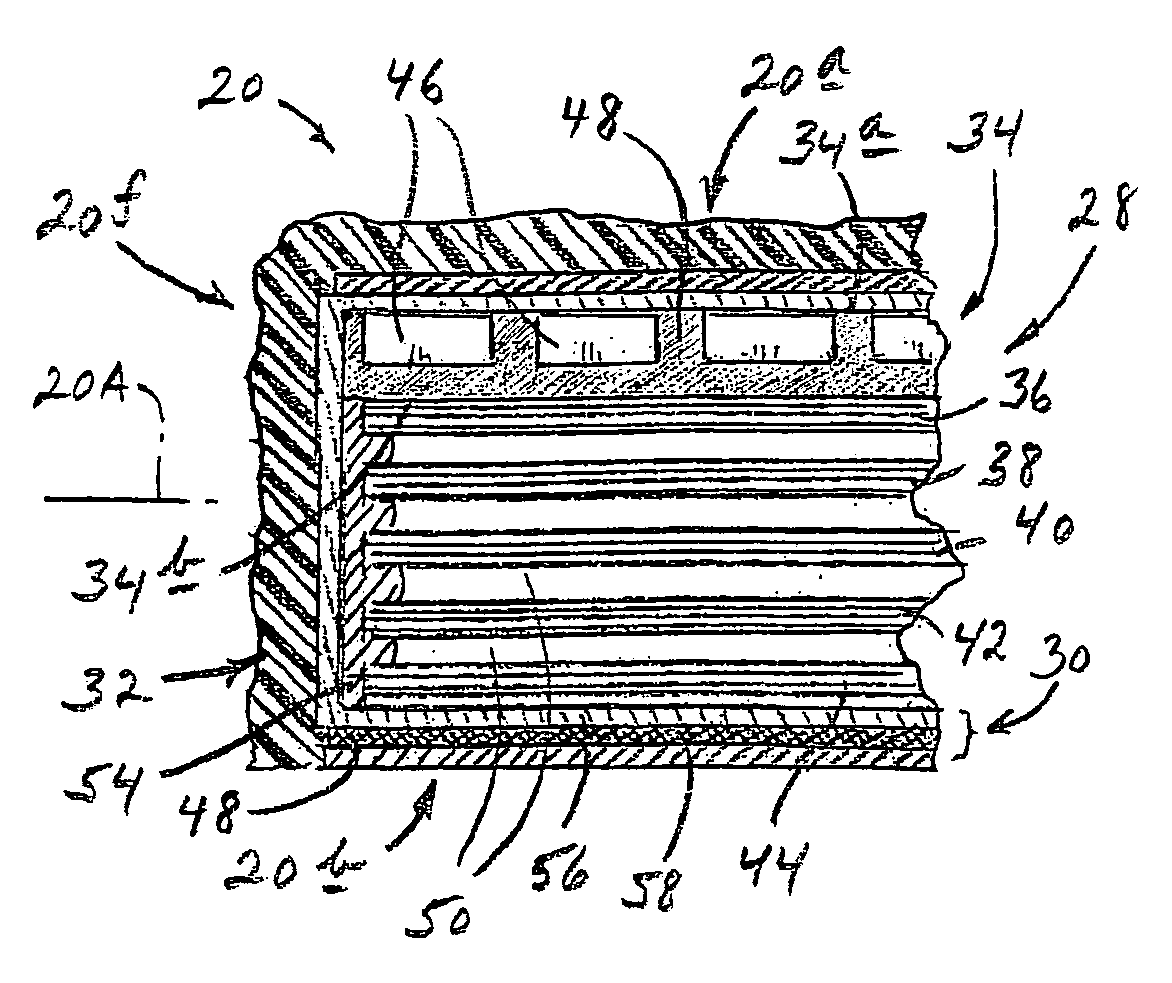

Trampoline responsive armor panel

InactiveUS7216576B2Improve actionEnhance the broad-beam trampoline-response behavior of the overall panelDoor/window protective devicesArmour platesEdge structureEngineering

An armor panel for defeating a projectile strike including (a) a substantially planar core structure having spaced, generally parallel-planar strike and opposite faces, and elongate, circumsurrounding edge structure extending generally normally between these faces to define a perimeter for the core structure, (b) stranded core-wrap structure substantially fully enveloping the core structure, and possessing elongate, tension-load-bearing (TLB) strands which extend at angles relative to one another across the mentioned faces, and substantially parallel to one another in a distribution along the perimeter defined by the edge structure, and (c) a high-elastomeric coating which is distributed over at least those portions of the core-wrap structure which are disposed adjacent the strike face and the edge structure.

Owner:HENRY JAMES JACKSON MILHAM +2

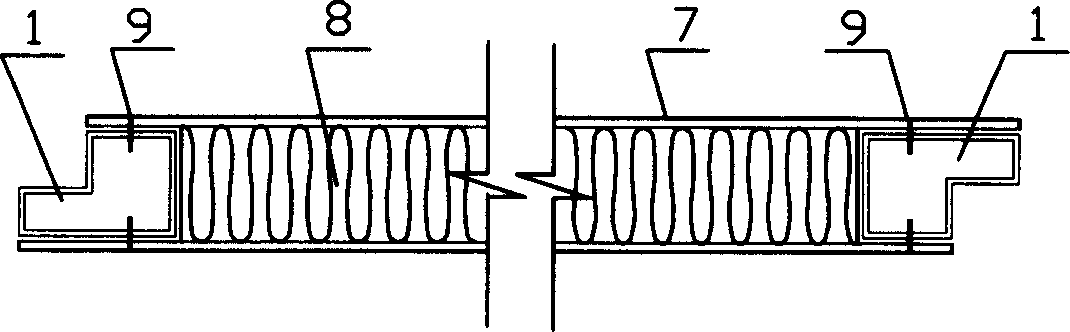

Variant flexible tail edge structure based on bionic conception

ActiveCN103387048AAchieving active deformationRealize the integrated design of drive/deformation/bearingWing adjustmentsHoneycombEdge structure

The invention provides a variant flexible tail edge structure based on a bionic conception, and belongs to the technical field of variant aircraft. The variant flexible tail edge structure provided by the invention is characterized in that an elastic base plate is arranged between a first flexible honeycomb and a second flexible honeycomb, a first air-operated muscle driver is arranged at the outer side of the first flexible honeycomb, and a first large transformation skin is arranged at the outer side of the first air-operated muscle driver; a second air-operated muscle driver is arranged at the outer side of the second flexible honeycomb, and a second large transformation skin is arranged at the outer side of the second air-operated muscle driver; a fracture surface combined by the first flexible honeycomb and the second flexible honeycomb is a put-down trapezoid, and a tail edge rigidity section is connected with an upper bottom of the trapezoid. The variant flexible tail edge structure provided by the invention realizes the driving / transformation / bearing integrated design, realizes the driving transformation of a flexible tail edge, and simplifies the tail edge structure. The variant flexible tail edge structure provided by the invention has the advantages that structure is simple, the weight is light, the driving / transformation / bearing are integrative.

Owner:哈尔滨烯创新材料有限公司

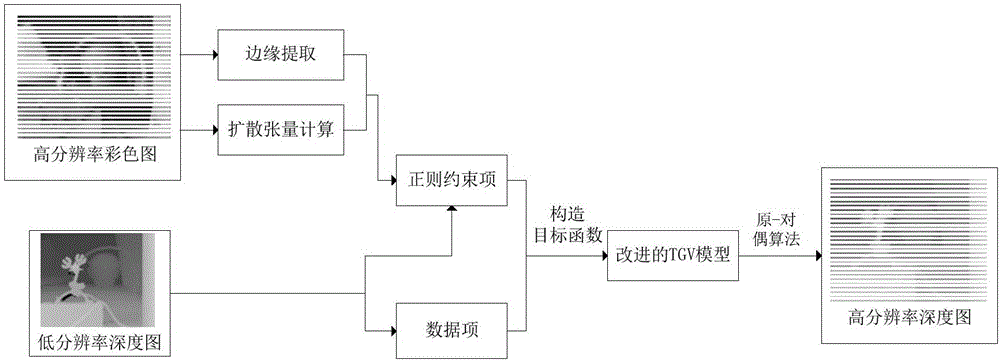

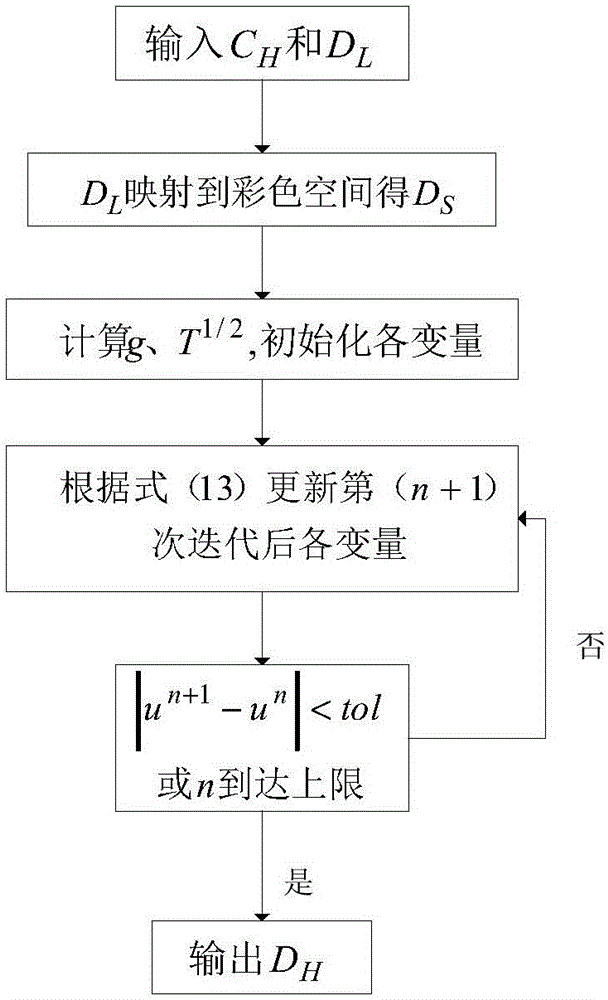

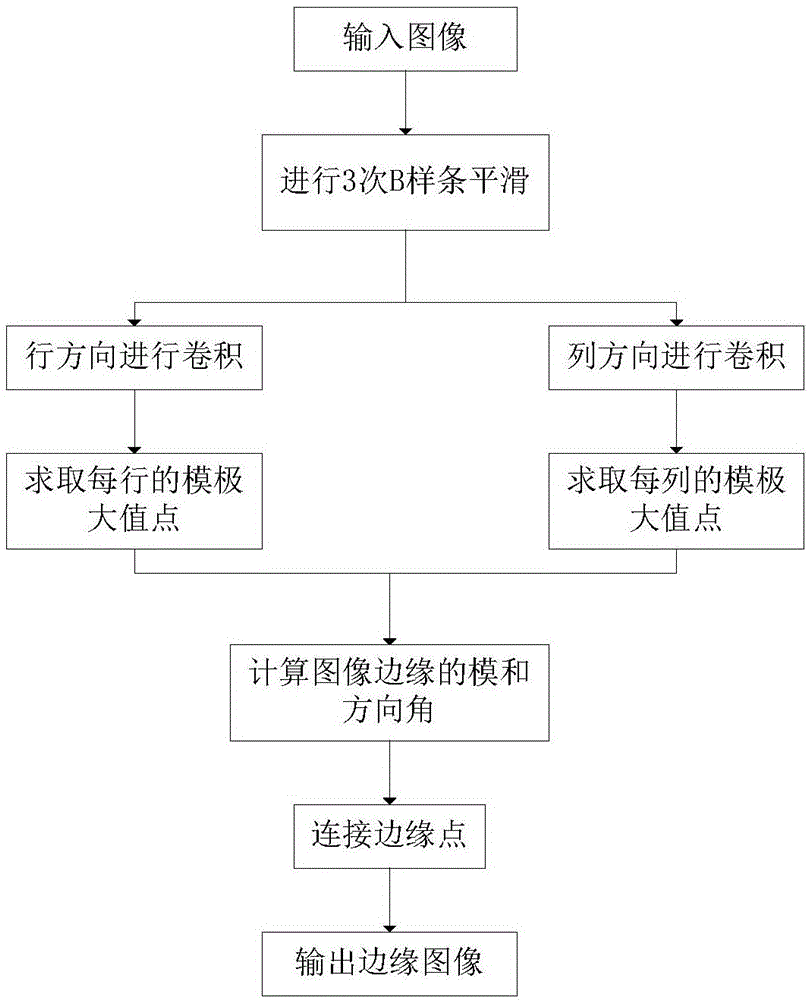

Two-dimensional image-assisted depth image enhancement method

InactiveCN106408524AGuaranteed Depth DiscontinuityGuaranteed depth uniformityImage enhancementImage analysisColor imageDiffusivity tensor

The invention discloses a two-dimensional image-assisted depth image enhancement method. The method includes the steps of utilizing a ToF camera and a high-resolution color camera to obtain a low-resolution depth image and a high-resolution color image of a same scene, and mapping a low-resolution depth map to a high-resolution color space; constructing data items of an objective function according to reconstruction constraints of a depth image; utilizing edge information of the color image to perform weighting on a regularization model, introducing diffusion tensor to a second-order generalized total variation model, and forming a regularization model for characteristics of the depth image; and solving through iterative reweighting and a primal-dual algorithm, so as to obtain a reconstruction result. The two-dimensional image-assisted depth image enhancement method provided by the invention can effectively solve the problems of low resolution, unclear margin and existence of noise of the depth image, and effectively protects the edge structure of the image.

Owner:NANJING UNIV OF SCI & TECH

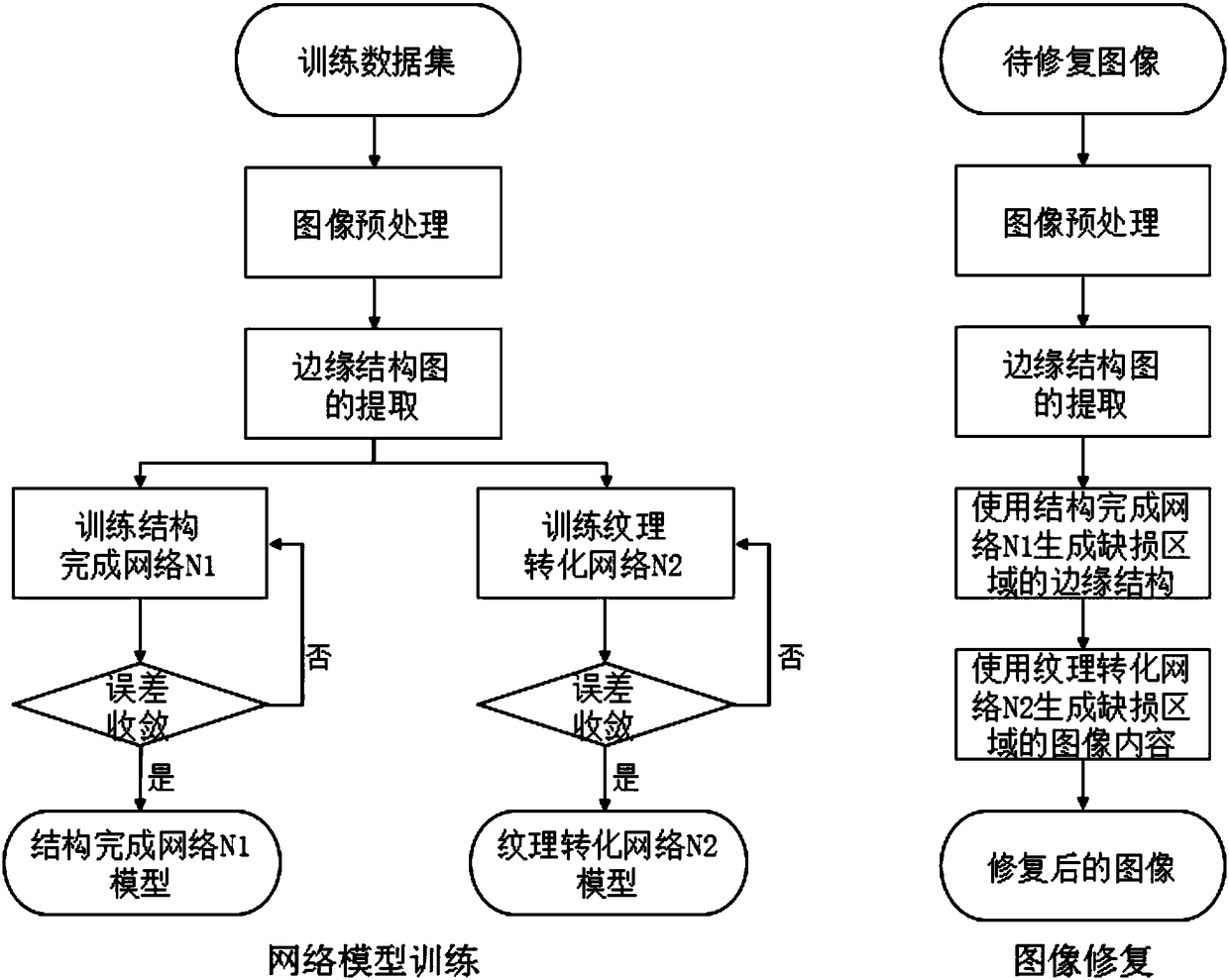

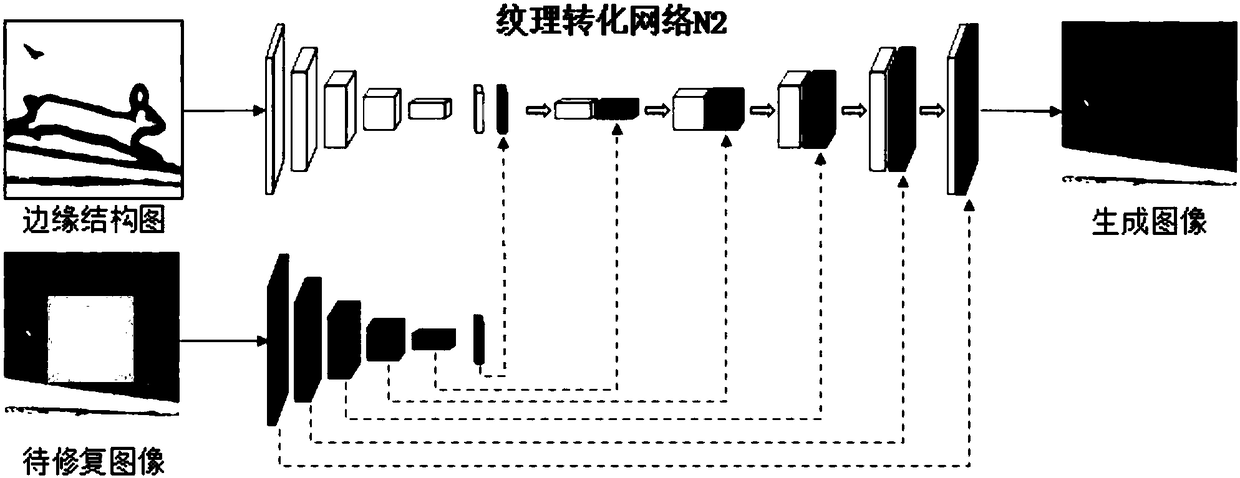

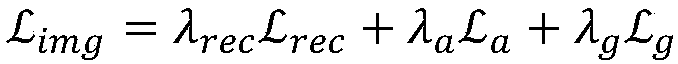

Image inpainting method based on structure and texture hierarchical prediction

ActiveCN108460746AAvoid confusionAvoid shape distortionImage enhancementNeural architecturesGenerative processPattern recognition

The invention discloses an image inpainting method based on structure and texture hierarchical prediction. The method comprises a network model training part and an image inpainting part. The networkmodel training part comprises the steps of pre-processing a training data set, extracting an edge structure chart, constructing and training a structure completion network N1, and constructing and training a texture conversion network N2; and the image inpainting part comprises the steps of inputting a tested image to be repaired and pre-processing, extracting the edge structure chart, using the structure completion network N1 to generate an edge structure of a defect area, using the texture conversion network N2 to generate image content of the defect area, and enabling the generated image content of the defect area to fill the image to be repaired. The method is capable of decomposing a problem of the image inpainting to problems of the structure and texture hierarchical prediction, automatically generating a defect structure, and using a repaired structure edge graph to constrain a texture generating process, thereby effectively avoiding the texture confusion and the shape distortion, and greatly improving the repairing capacity in allusion to a natural image large area defect problem.

Owner:WUHAN UNIV

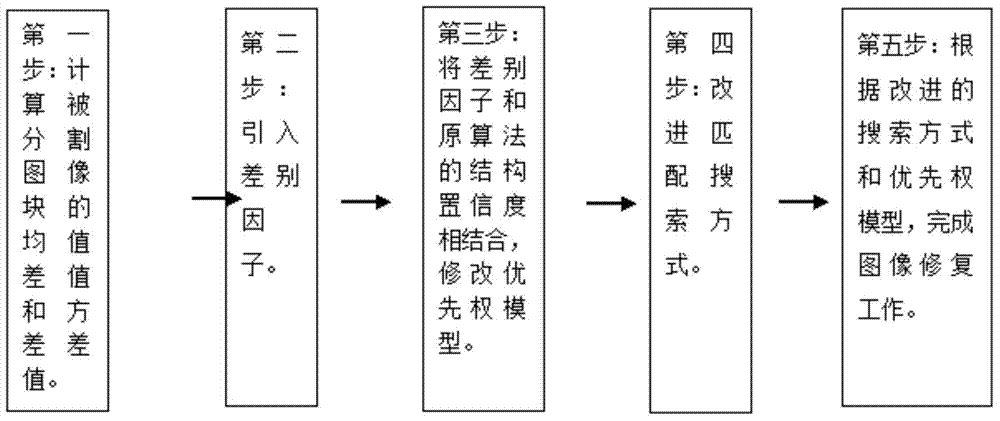

Criminisi image restoration method based on textures and edge features

InactiveCN103700093ASuppress Priority RepairAvoid destructionImage enhancementImage analysisPattern recognitionEdge structure

The invention discloses a criminisi image restoration method based on textures and edge features. A difference factor which enhances the discrimination capability for a structural part is introduced in a priority model to optimize priority calculation through analyzing texture structure features and edge structure features. The Criminisi image restoration method disclosed by the invention can effectively restrain priority repair of texture parts, and prevent the texture part from extending excessively to an edge part to result in image linear structural failure.

Owner:HANGZHOU DIANZI UNIV

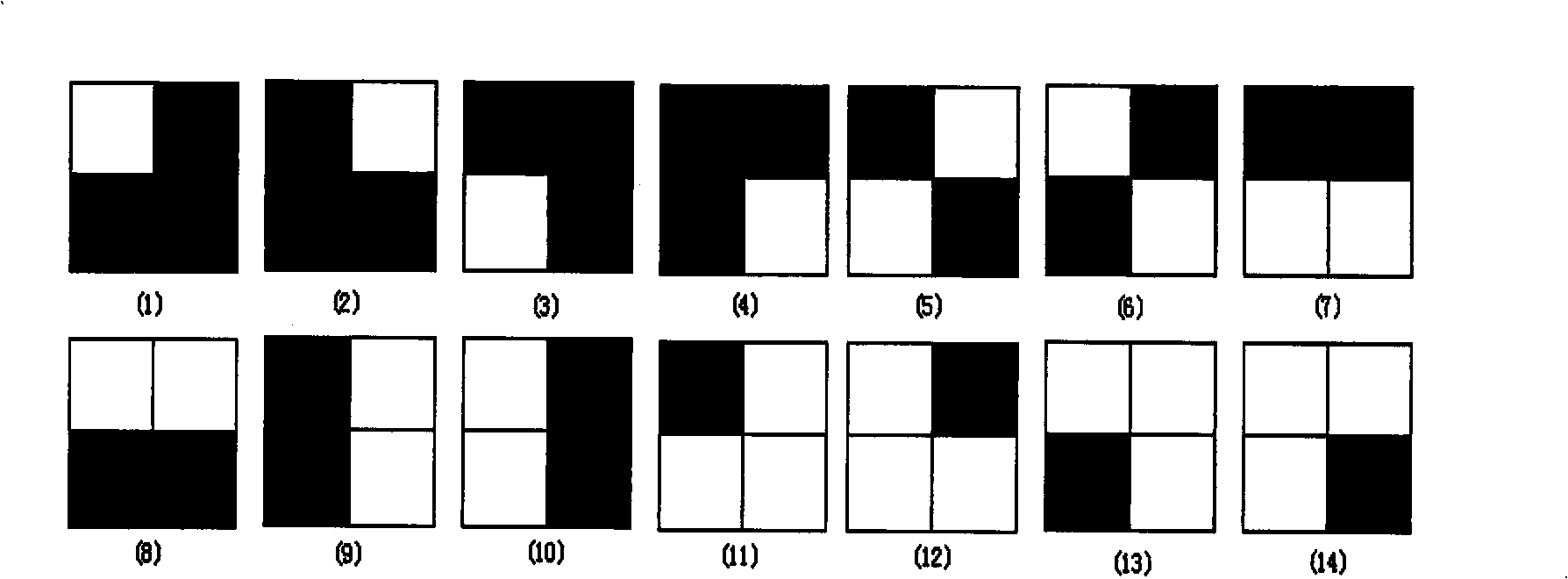

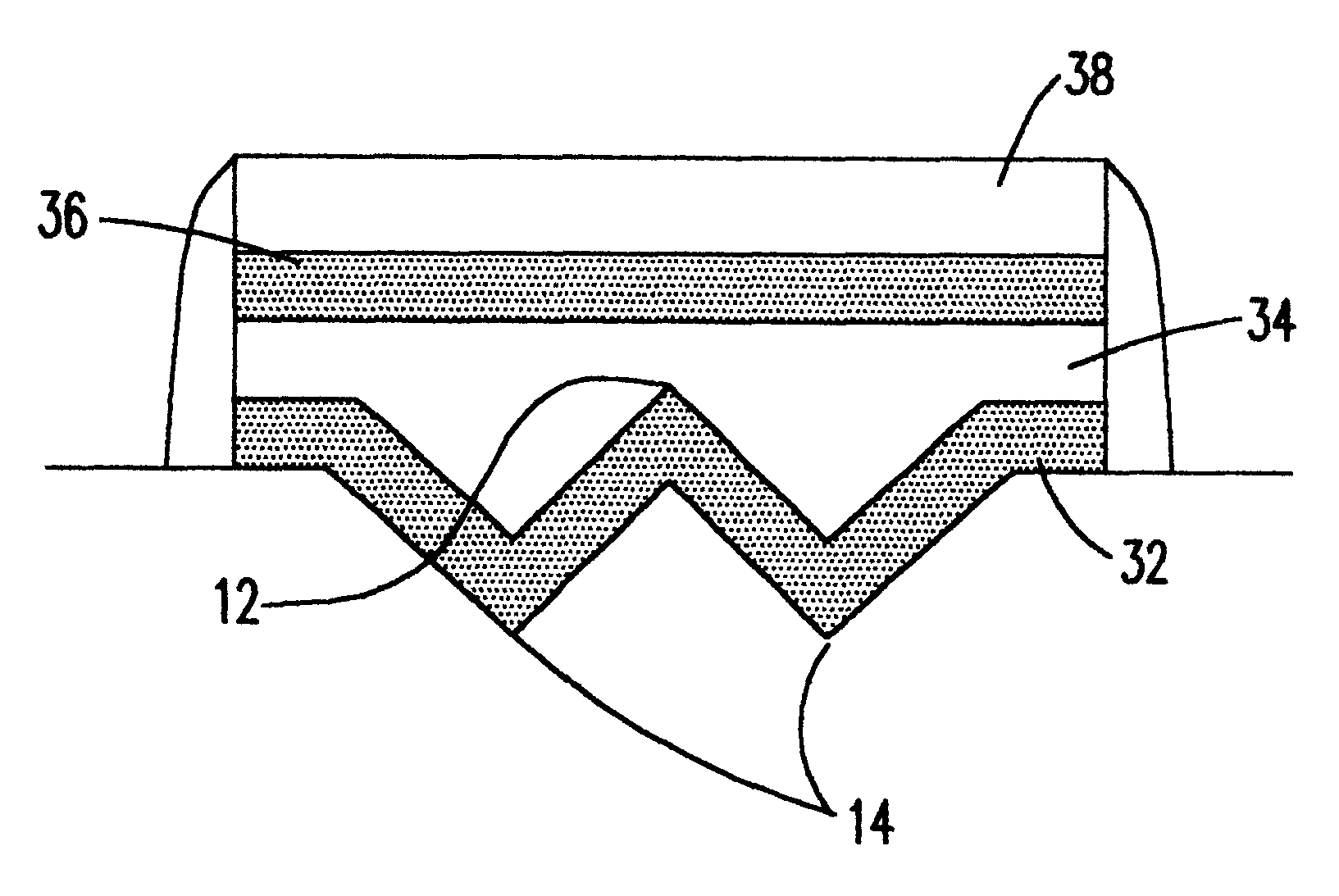

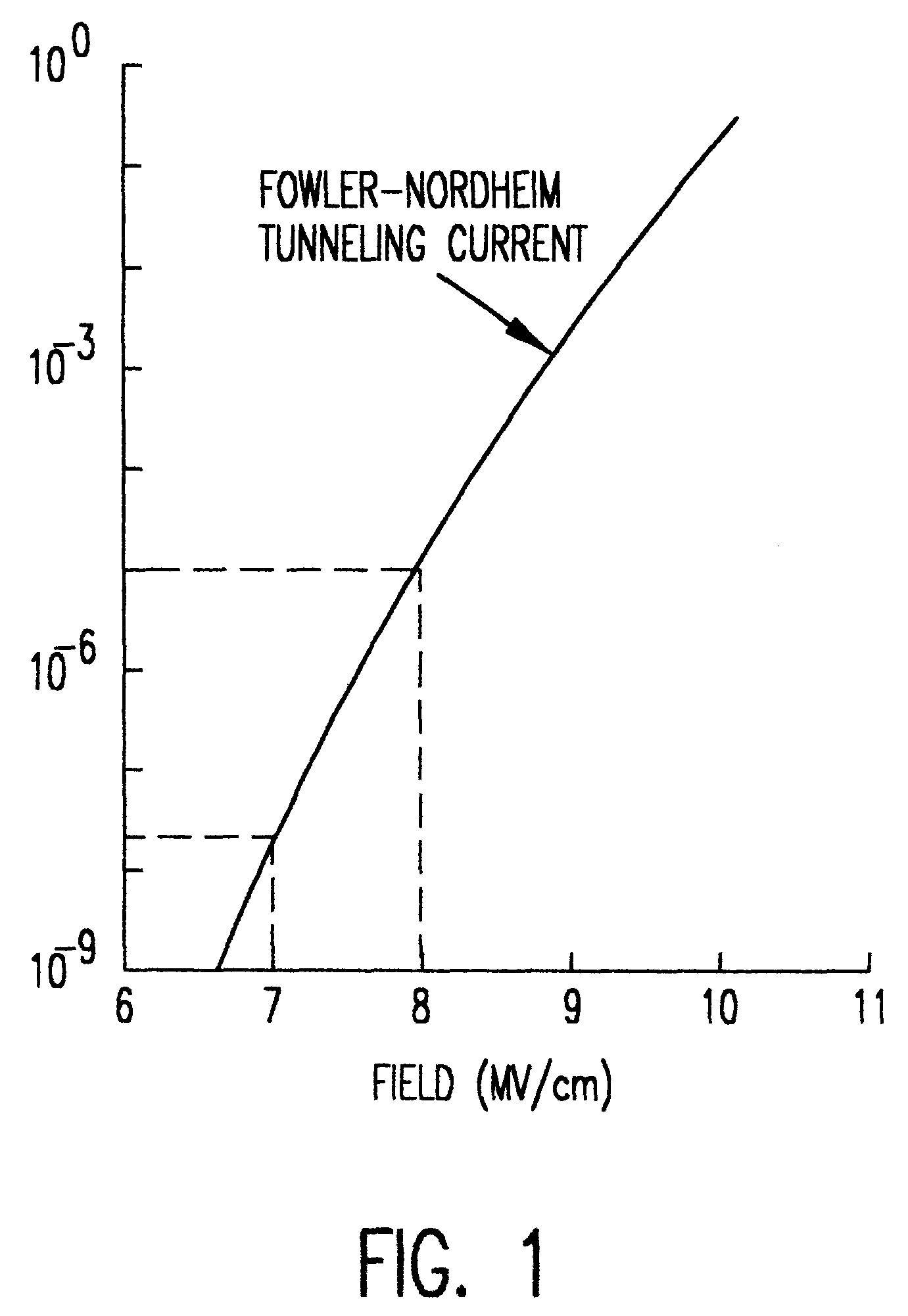

NVRAM array device with enhanced write and erase

InactiveUS6445029B1Increased write and erase tunnelling currentTransistorSolid-state devicesPreferential etchingGate insulator

Increased write and erase tunnelling currents are developed by enhancement of an electric field near a floating gate with a shaped edge structure overlapping a source / drain diffusion and developing increased floating gate area with angled regions joined by edges in order to reduce write and erase cycle times. The edge structure is formed by selective and preferential etching in accordance with the crystal structure of a monocrystalline semiconductor substrate. The sharpness of the edges and concentration of the electric field may be enhanced by consumption and stress effects of oxidation of the substrate to form a floating gate insulator.

Owner:GLOBALFOUNDRIES INC

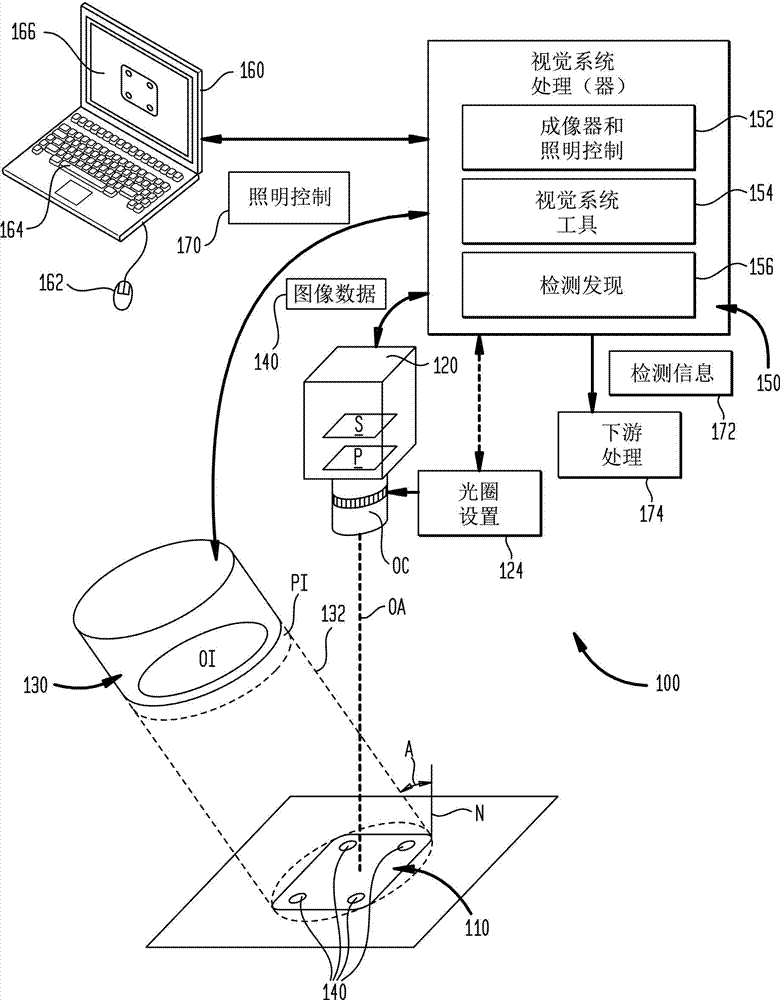

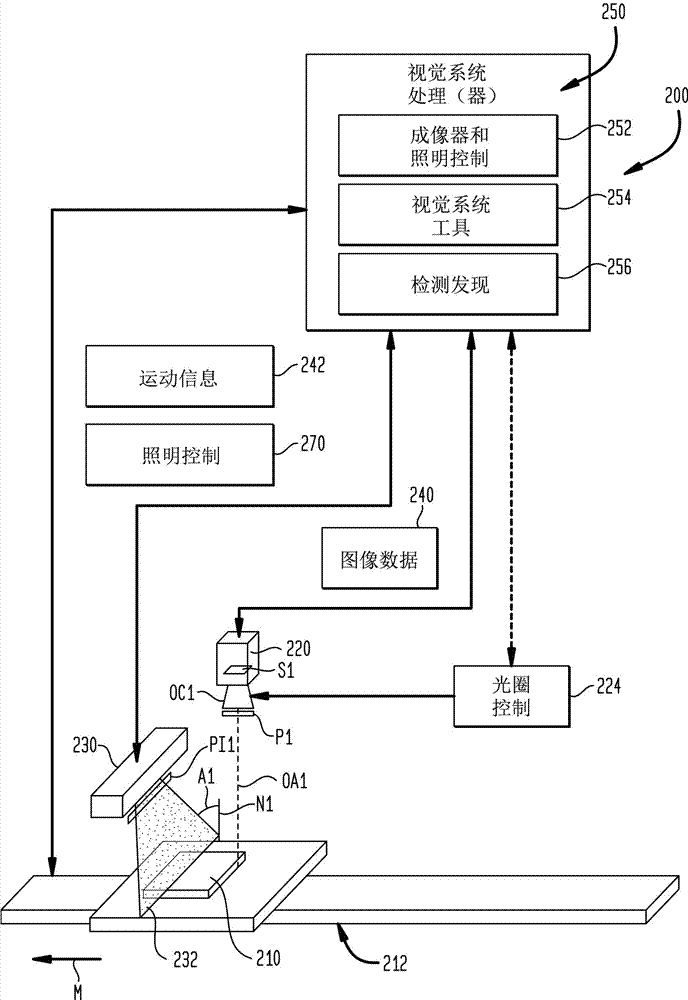

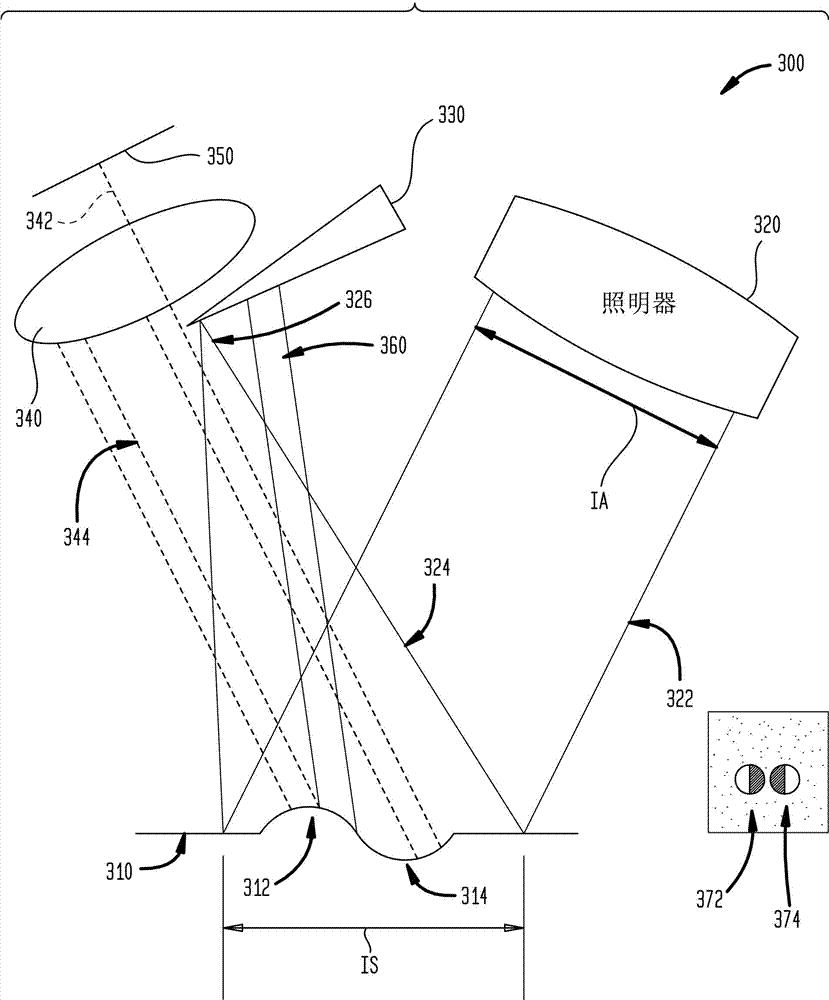

System and method for detecting defects on reflection surface through visual system

ActiveCN106959293AScattered light enhancement or suppressionPolarisation-affecting propertiesOptically investigating flaws/contaminationOptical axisLight beam

The invention relates to a system and a method for detecting and imaging reflection surface defects on a reflection surface through a blade edge technology. A camera aperture or an external device is arranged to form a physical blade edge structure in an optical path. The physical blade edge structure advantageously shields reflection rays from an illuminated reflection surface which has a preset slope value, and makes rays deflecting by different slopes reach a visual system camera sensor. Most light reflected from a flat part on a surface is blocked by the blade edge. Most light reflected from a defective slope part is reflected to an entrance aperture. An illumination beam forms a certain angle relative to the optical axis of the camera, to provide an incidence angle which is proper for an examined surface. The surface can be static or move relative to the camera.

Owner:COGNEX CORP

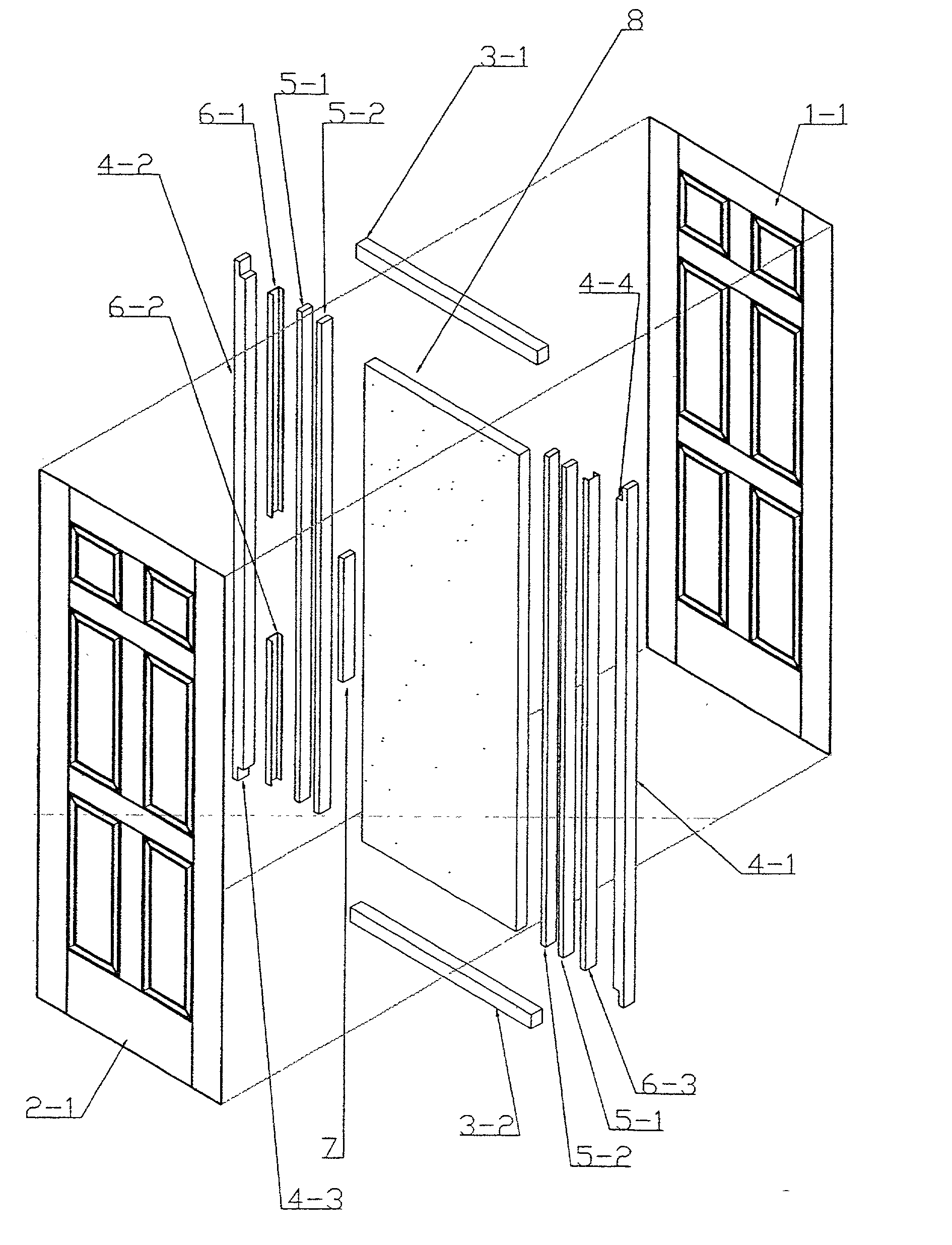

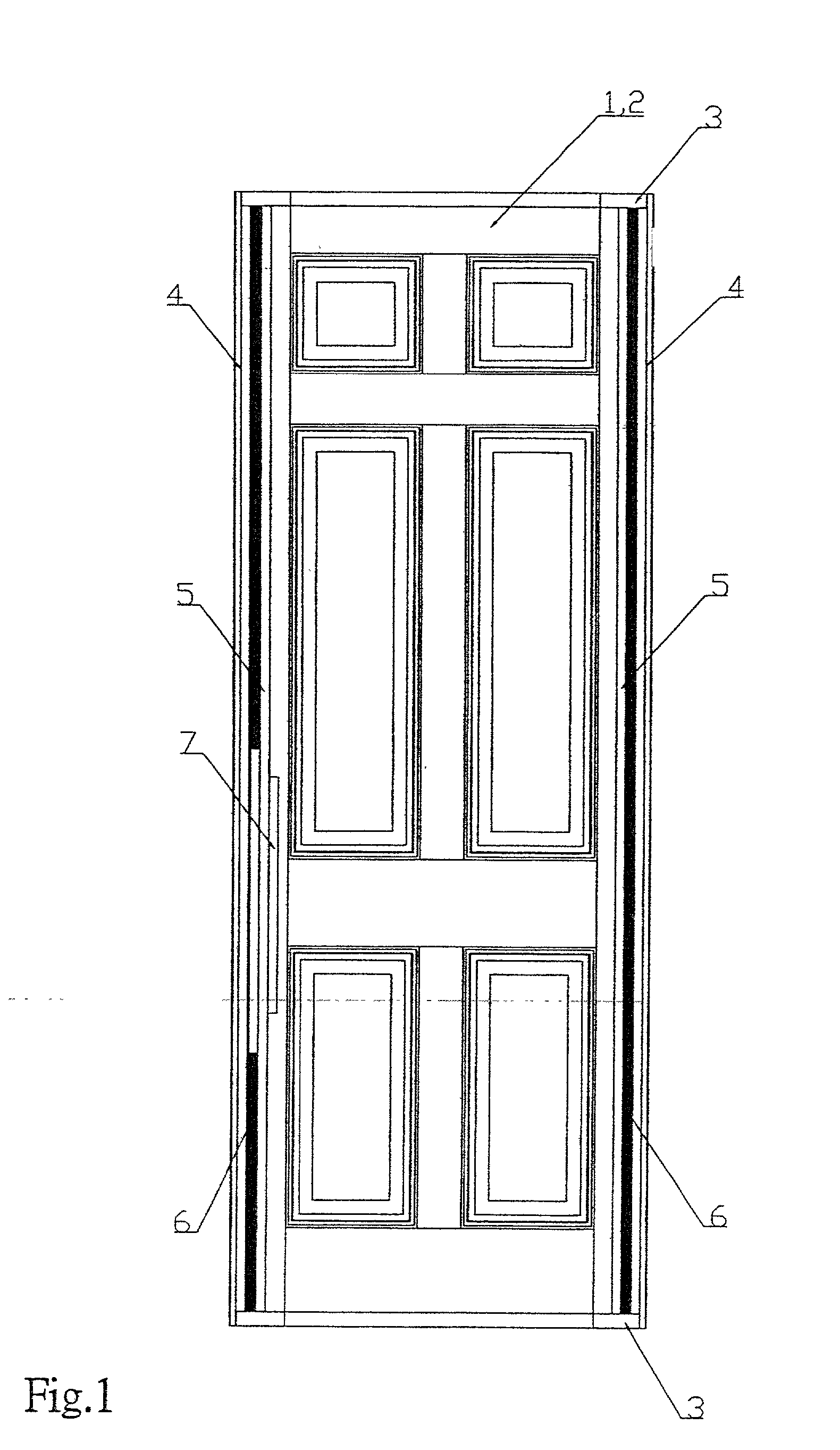

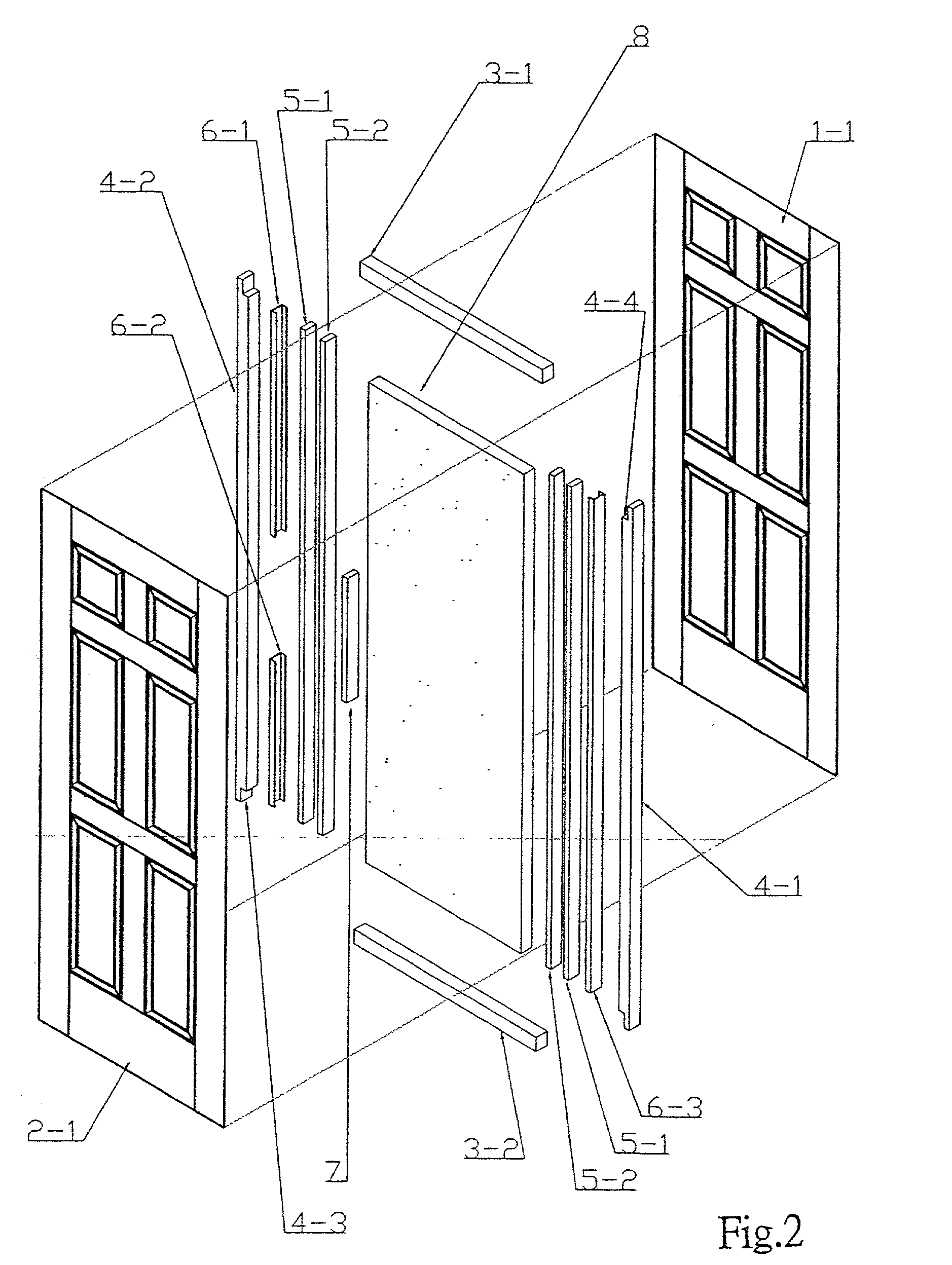

Assembly structure of super-high door

InactiveUS20030084639A1Optimize assembly structureImprove assembly structureDoor leavesAdhesiveEdge structure

The assembly structure of the super-high door of this invention comprises members of two hubbed door skins, a top edge-sealing angle bar, a bottom edge-sealing angle bar, a left edge-sealing angle bar, and a right edge-sealing angle bar. Said hubbed door skins are integrally molded flush-edged structures which are positioned by the flange ribs of the left edge-sealing angle bar and the right edge-sealing angle bar; meanwhile, the top edge-sealing angle bar and the bottom edge-sealing angle bar are positioned by the milled notches at the top and the bottom ends of the left edge-sealing angle bar and the right edge-sealing angle bar. This invention is characterized in: the inner side of the upper longer region (above the handle) of the left edge-sealing angle bar and the inner side of the lower shorter region (below the handle) of the left edge-sealing angle bar are respectively inlaid with two U-shape reinforcing irons of which each length is corresponding to each length of said two regions, then a wood strip with a length a little bit shorter than that of the left edge-sealing angle bar is inserted into the inner of the two U-shape reinforcing irons having different length, then closely joined, by a nail gun and an adhesive, to another wood strip of which the handle position is inlaid with a reinforcing angle bar; besides, the inner side of the right edge-sealing angle bar is inlaid with an U-shape reinforcing iron of which the length is a little bit shorter than that of the right edge-sealing angle bar, then a wood strip with a length corresponding to that of the U-shape reinforcing iron is inserted thereto and closely joined, by a nail gun and adhesives, to another wood strip; thereafter, said structure is coated with an adhesive and press-assembled with two hubbed door skins; after assembling, the bottom edge-sealing angle bar is drilled a hole thereof and filled up with ammonium polyester foamed plastic to form a super-high door structure which will not bent nor deform.

Owner:NANYA PLASTICS CORP

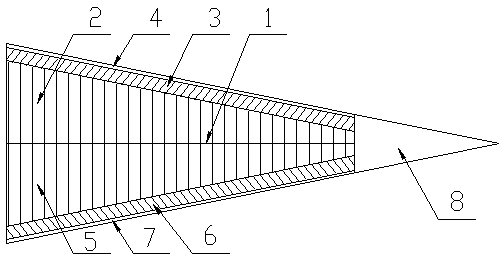

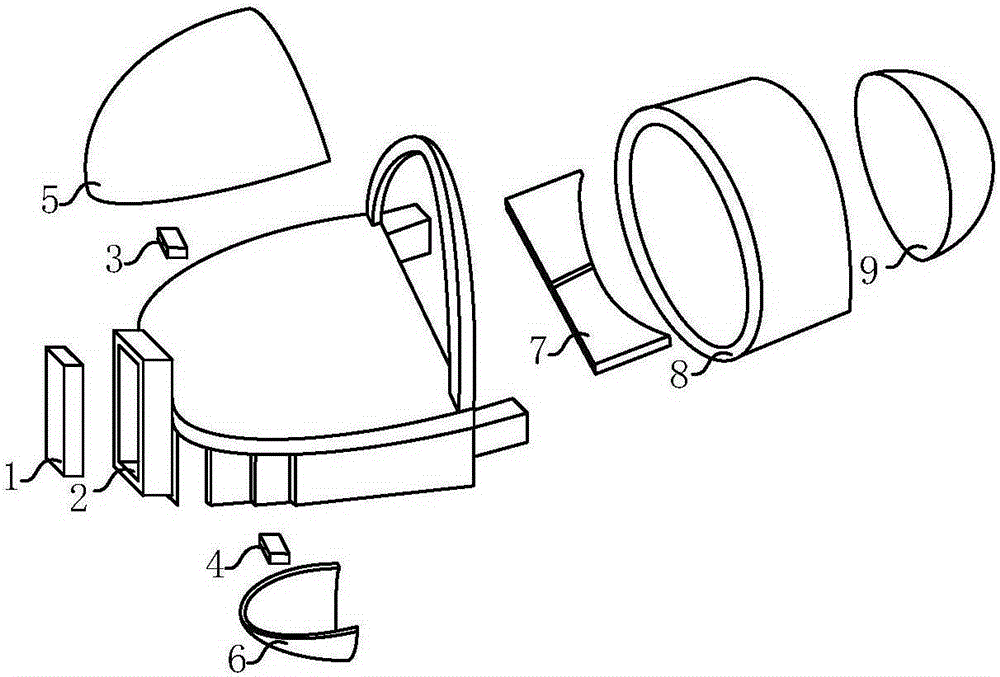

High beam and low beam integrated LED automobile lens

InactiveCN105276487ALight up fastIncrease brightnessNon-electric lightingVehicle headlampsEdge structureOptoelectronics

The invention discloses a high beam and low beam integrated LED automobile lens. The problems that an existing automobile headlamp is short in service life, large in size, unclear in cut-off line and low in brightness are mainly solved. According to the high beam and low beam integrated LED automobile lens, a cooling fan (1) is mounted at the tail of a cooling support (2), and a low beam lamp bead (3) and a low beam reflecting cup (5) are arranged on the upper surface of the cooling support (2); and a high beam lamp bead (4) and a high beam reflecting cup (6) are arranged on the lower surface of the cooling support (2), a shading plate (7) and a lens support (8) are mounted at the front end of the cooling support (2), and the front end of the shading plate (7) is of a crescent sharp knife edge structure, and used for blocking out a straight bright-dark clear cut-off line. The shading plate (7) is sleeved with the lens support (8), a lens (9) is mounted at the front end of the lens support (8), and the lens (9) is used for refracting light to be in the light types of low beams and high beams. According to the structure, the LED automobile lens is clear in cut-off line and high in brightness.

Owner:HAIYAN LIGUANG ELECTRONICS TECH CO LTD

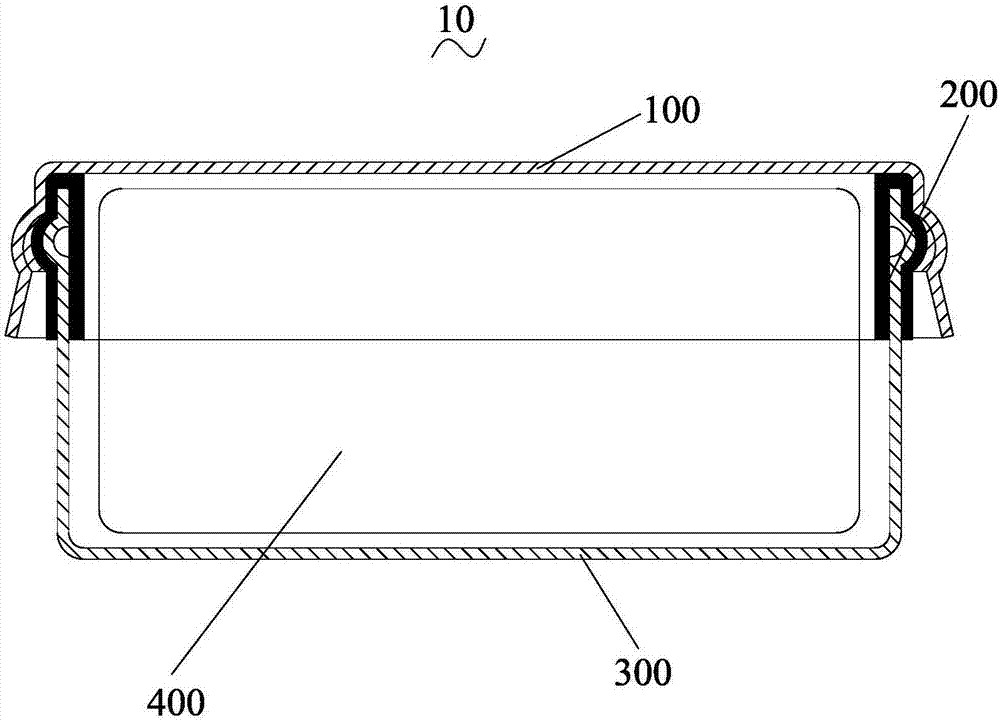

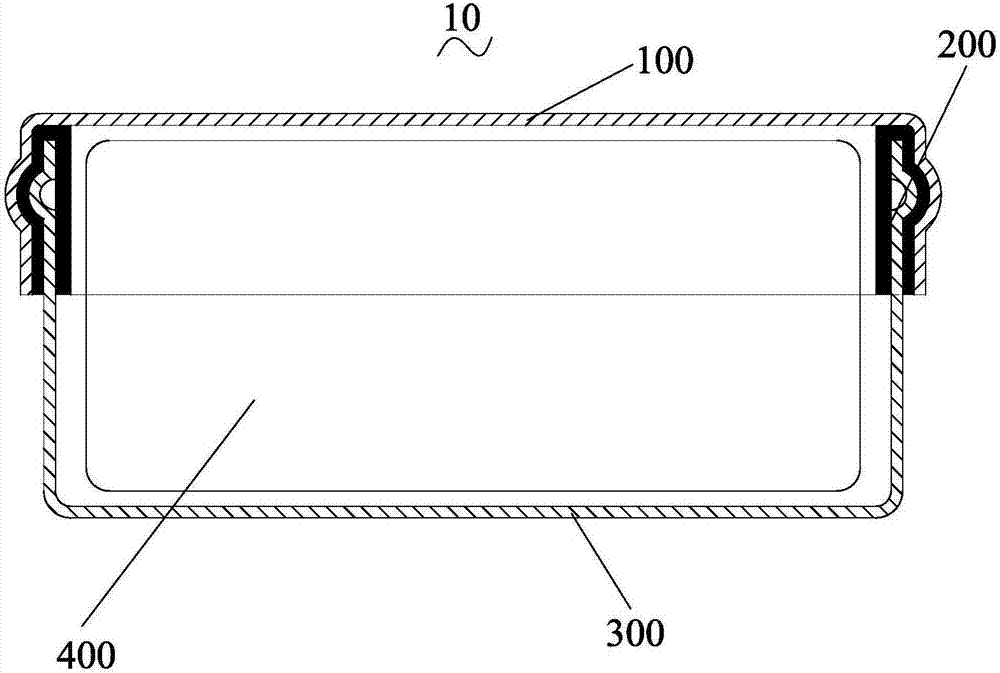

Button-type lithium cell sealing structure and sealing method

ActiveCN107425145APrevent liquid leakageImprove sealingFinal product manufactureNon-aqueous electrolyte cellsLithiumEdge structure

The invention discloses a button-type lithium cell sealing structure and sealing method. The button-type lithium cell sealing structure comprises a cell cover, a sealing ring and a cell shell. The cell cover is of a covered edge structure; the covered edge structure forms a first covered edge, a second covered edge and a third covered edge; a locked edge section and a sealed section are formed at the third covered edge; the cell shell is of a sealed edge structure, and the sealed edge structure forms a first sealed edge, a second sealed edge, a third sealed edge and a fourth sealed edge; and the first covered edge is pressed against the fourth sealed edge by a sealing ring, the second covered edge is pressed against the third sealed edge by a sealing ring, the locked edge section of the third covered edge is pressed against the second sealed edge by a sealing ring, and the sealed section of the third covered edge is pressed against the first sealed edge by a sealing ring. According to the button-type lithium cell sealing structure disclosed by the invention, the covered edge structure of the cell cover and the sealed edge structure of the cell shell are optimized, and a liquid leakage phenomenon caused by damage and breakage of the sealing rings in the sealing process is prevented, so that integral sealing performance is improved.

Owner:EVE ENERGY CO LTD

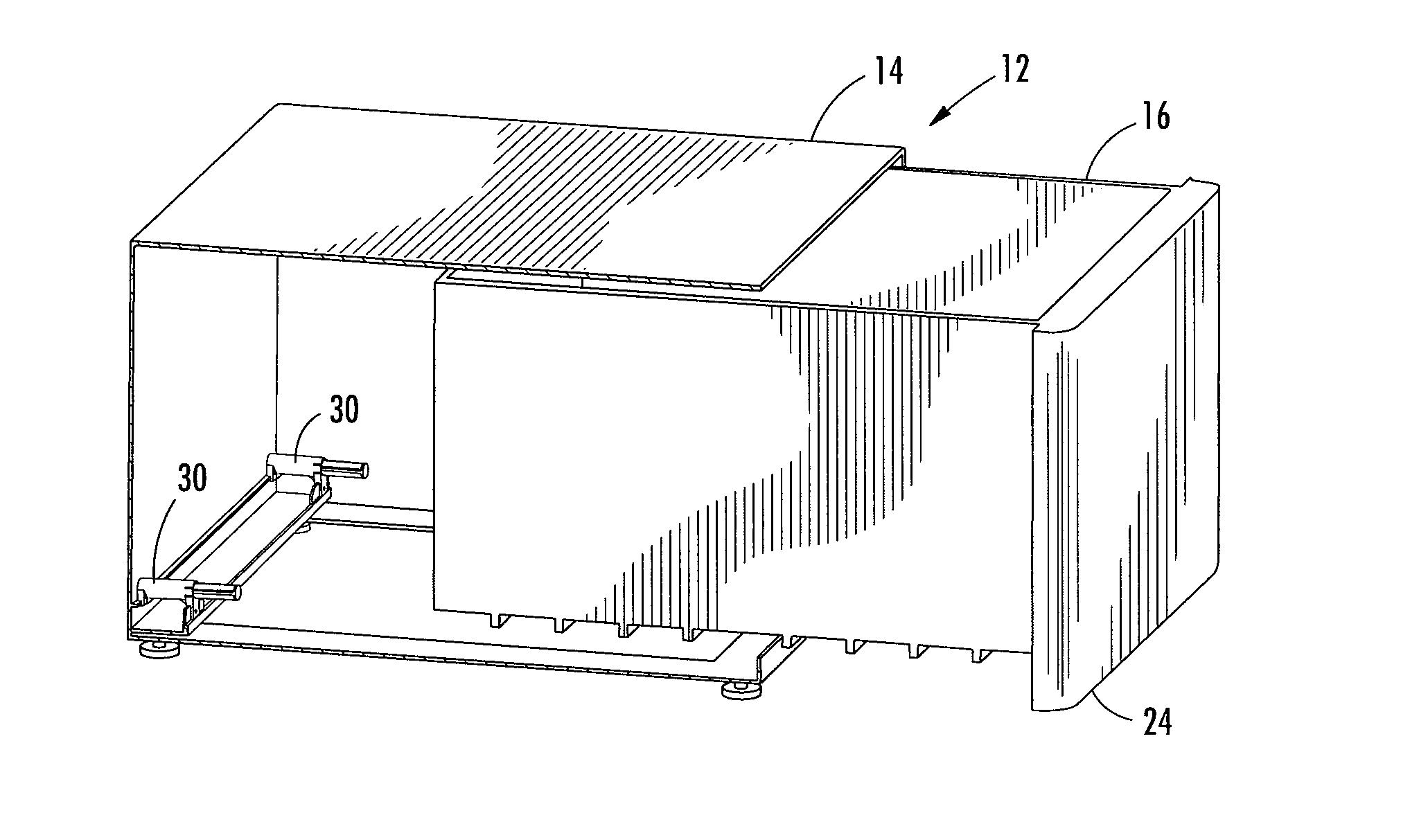

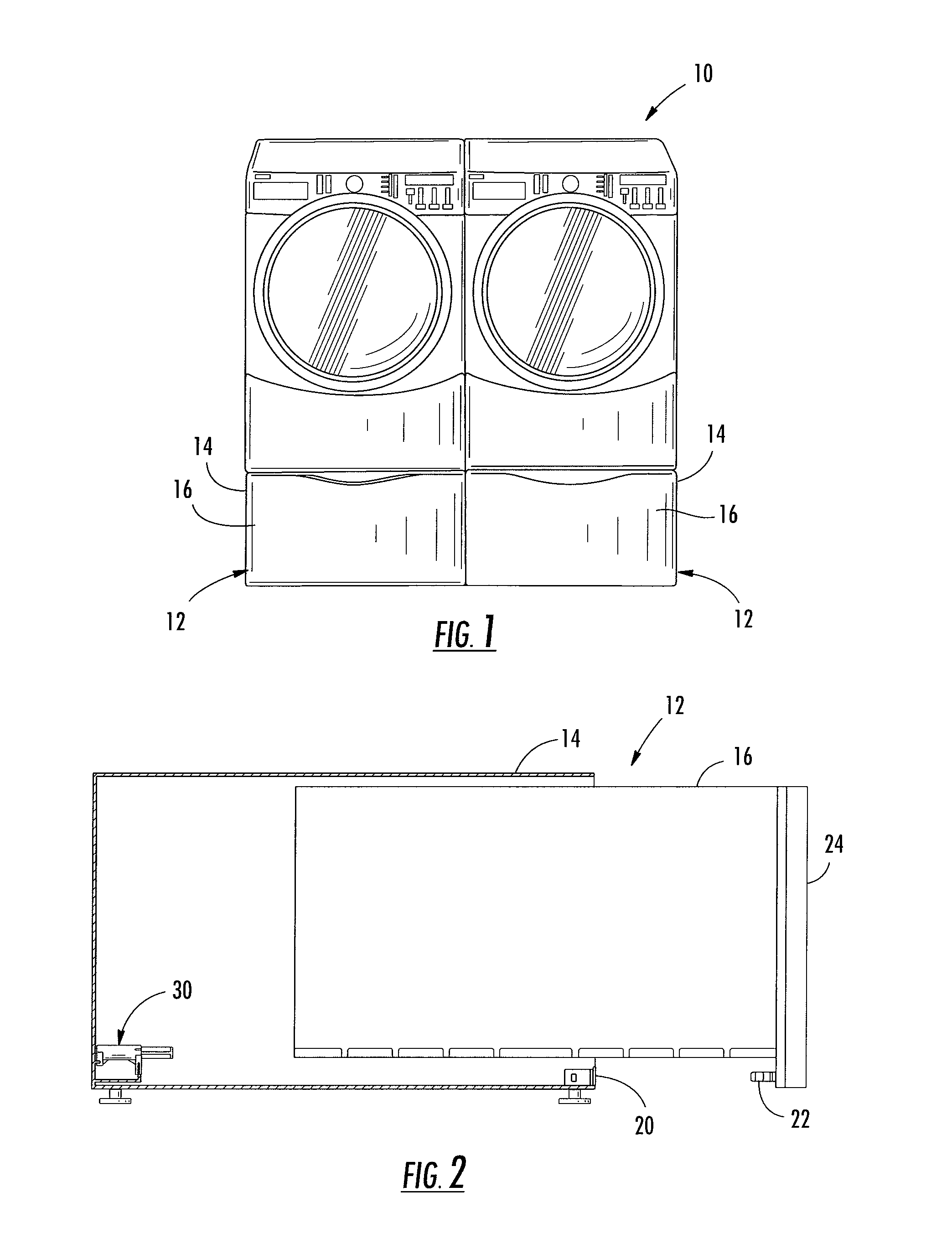

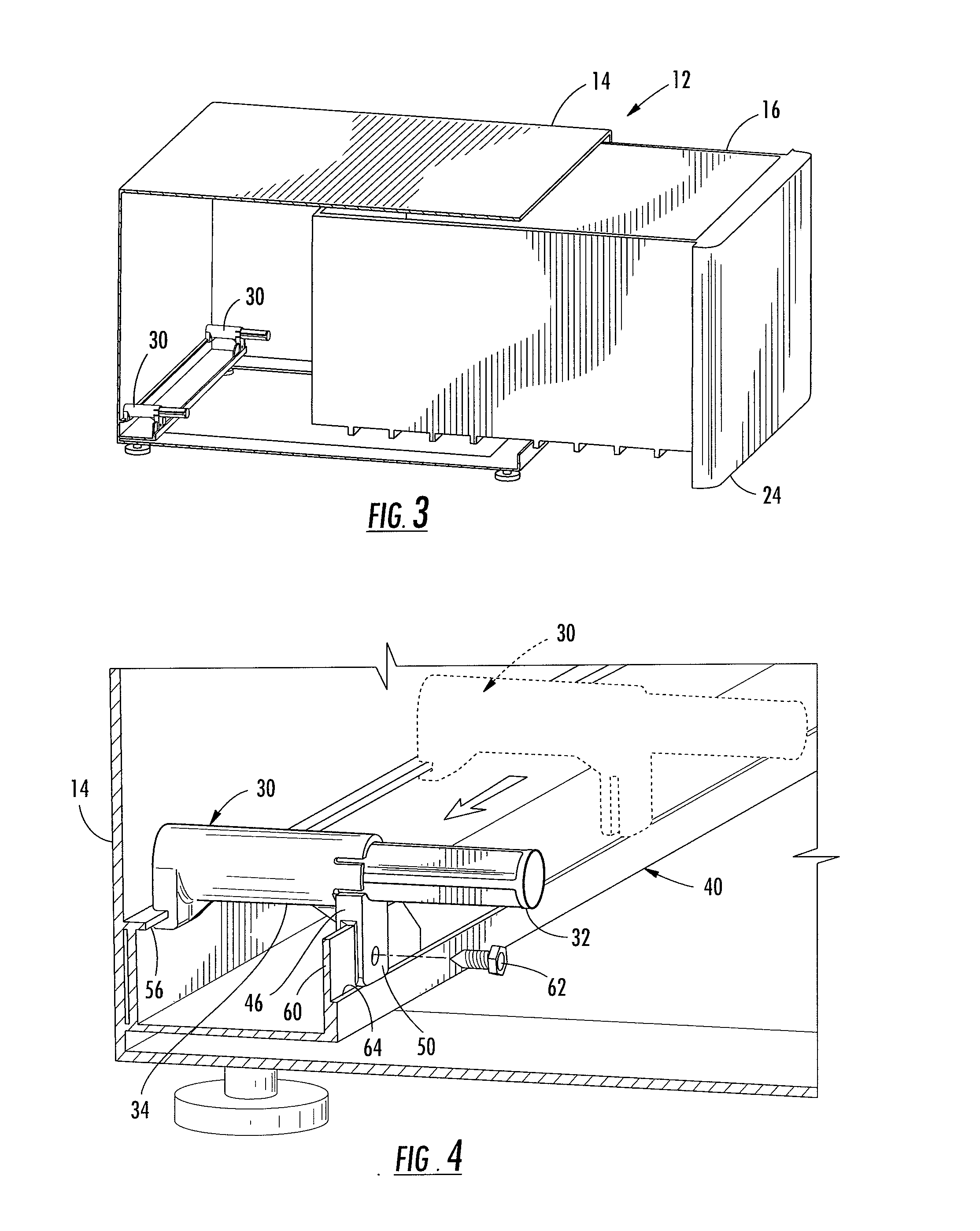

Drawer Actuator and Latch System

A drawer manipulation system adapted to facilitate opening of a drawer supported within a cabinet. The system includes at least one biasing actuator adapted for mounting in supported relation at projecting edge elements within the cabinet housing the drawer. The actuator incorporates an arrangement of slotted engagement surfaces adapted to accept supporting edge structures. The actuator may be used in conjunction with a push-push latch assembly.

Owner:ILLINOIS TOOL WORKS INC

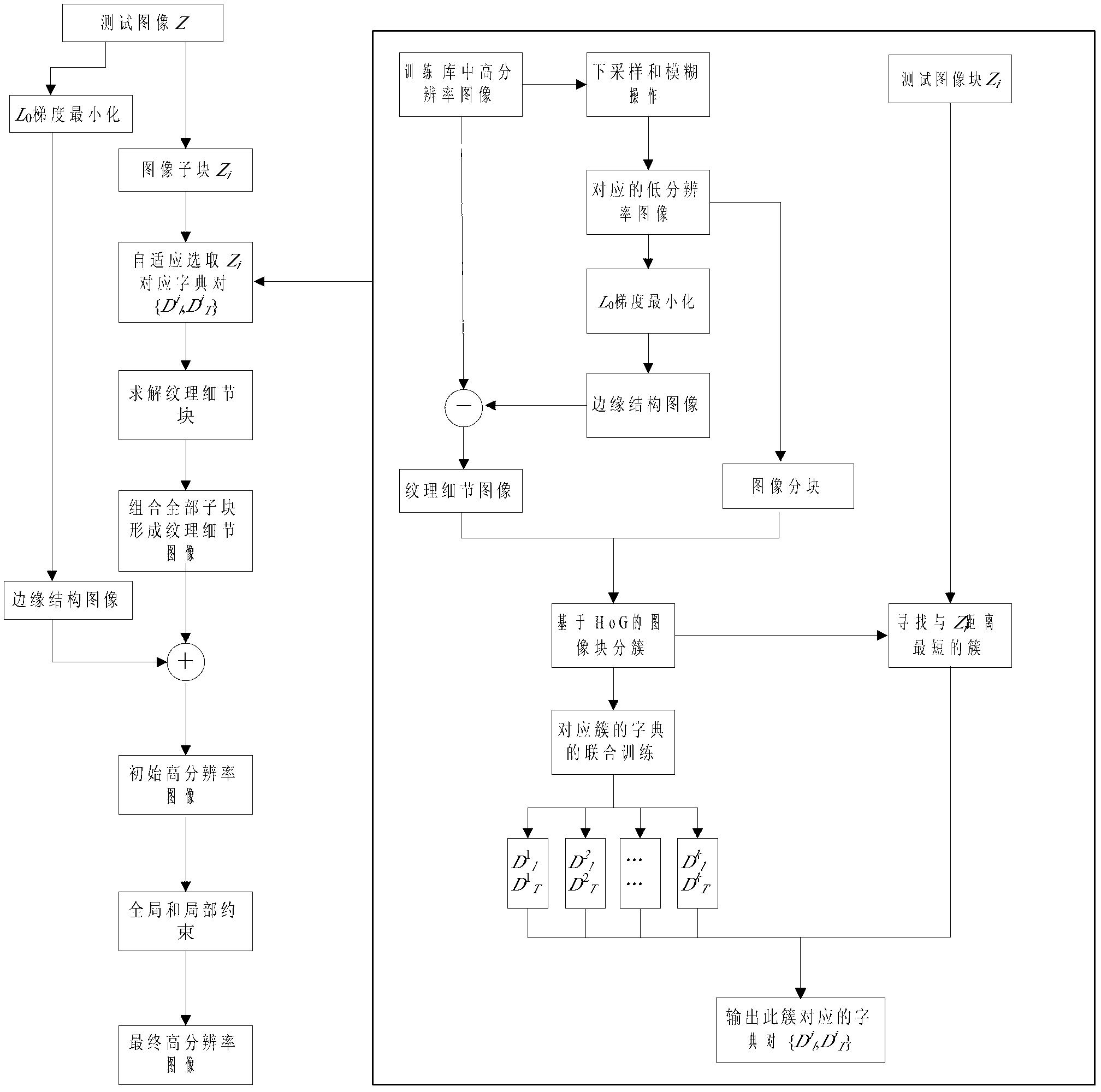

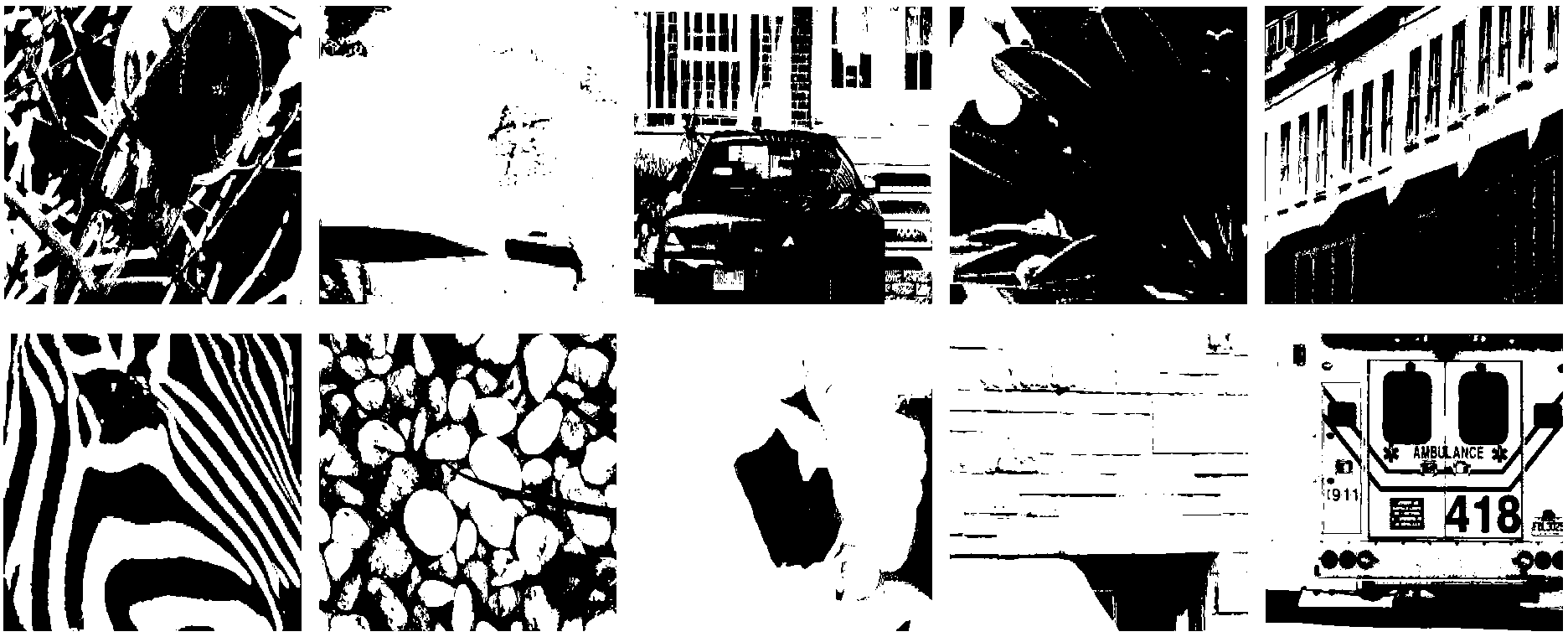

Method for reconstructing single-image super-resolution based on double-layer model

InactiveCN103279933AEasy maintenanceImage edges are sharpImage enhancementImage resolutionSingle image

The invention discloses a method for reconstructing a single-image super-resolution based on a double-layer model. The method comprises the following steps: (1) using the L0 gradient minimizing method and a HoG operator to generate K training clusters, then training corresponding dictionary pairs of the clusters, (2) selecting a geometrical dictionary pair corresponding to a low-resolution image block for testing in a self-adapting mode according to the HoG operator, solving a high-resolution line detail image corresponding to a low-resolution image, (3) using the L0 gradient minimizing method to solve a high-resolution edge structure image corresponding to the low-resolution image for testing, (4) adding the solved high-resolution line detail image to the high-resolution edge structure image to obtain an initial high-resolution image, and (5) carrying out global restriction and local restriction on the initial high-resolution image to obtain a final high-resolution image. According to the method for reconstructing the single-image super-resolution based on the double-layer model, a reconstructed image contour is clear, detail information is abundant, and quality of the reconstructed image is improved.

Owner:CHONGQING UNIV

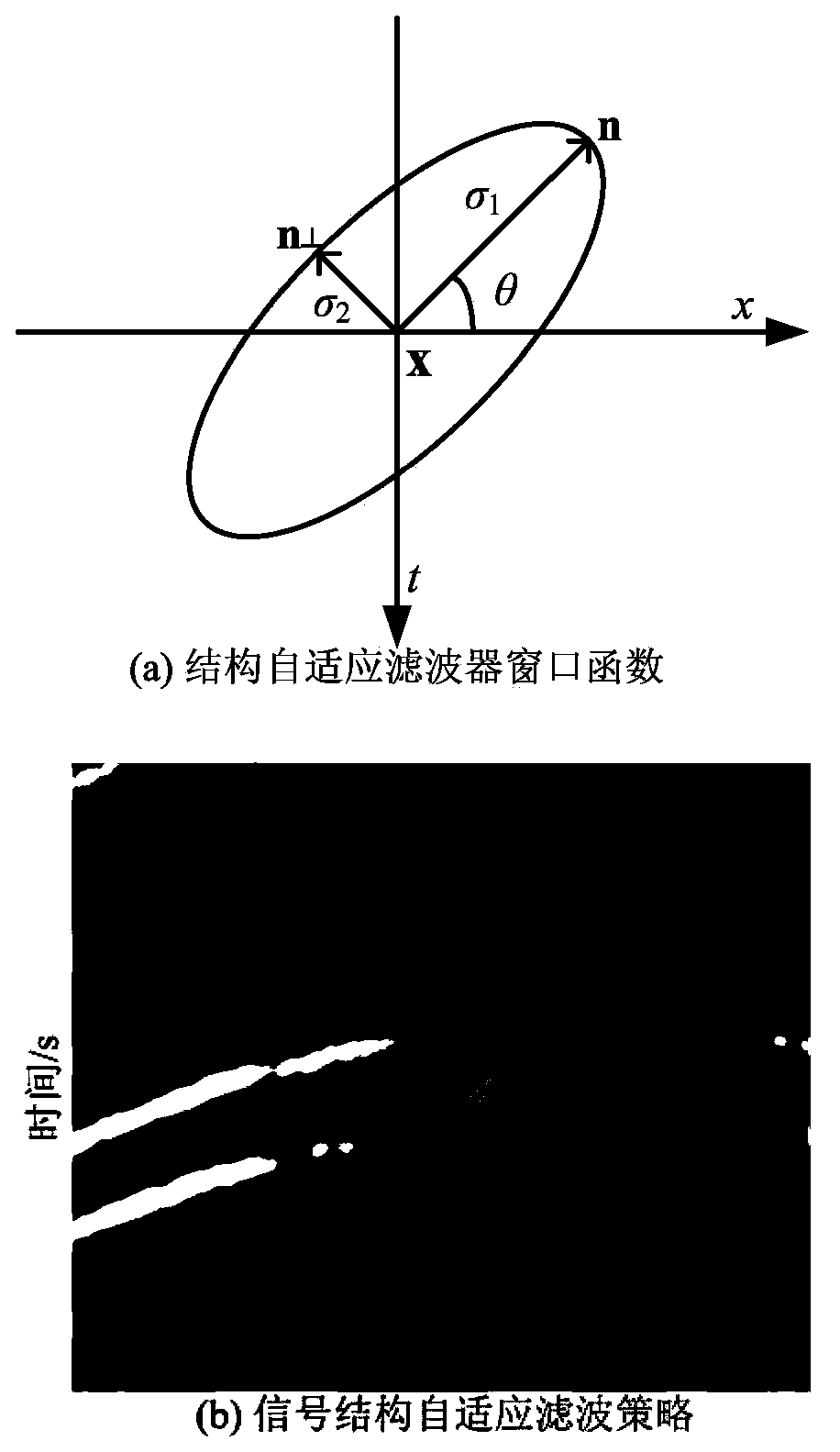

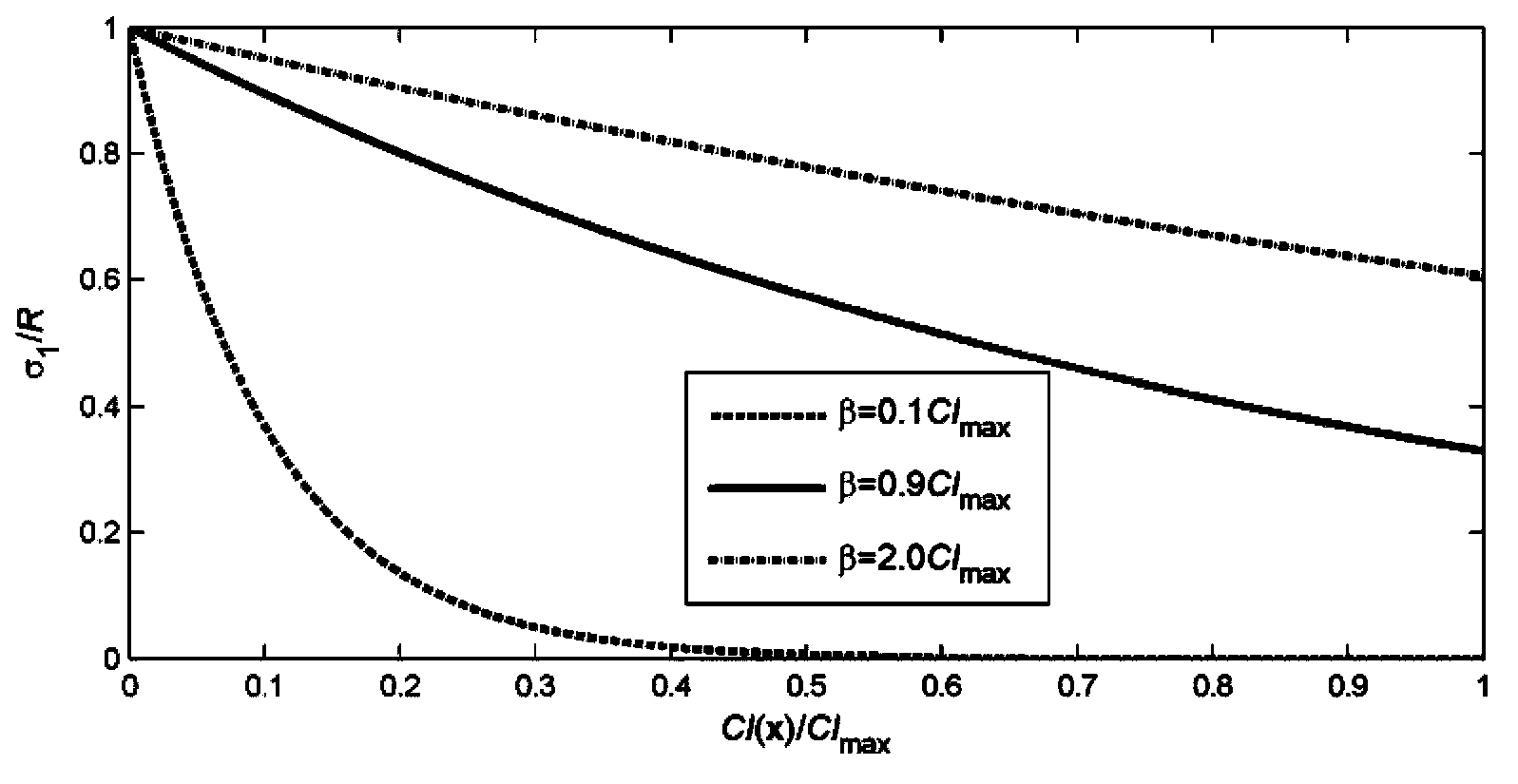

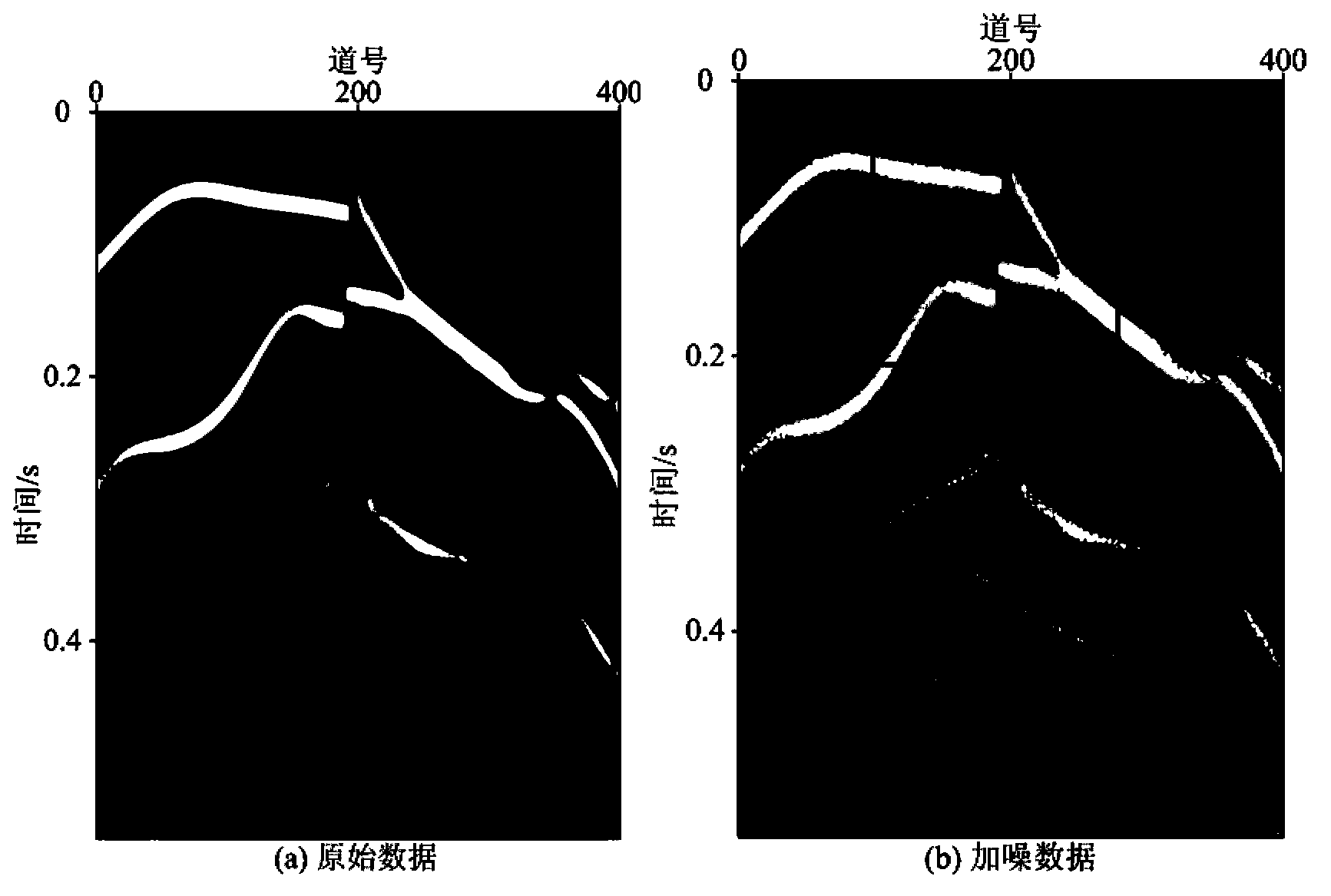

Stratum structure self-adaption median filtering method

InactiveCN103364835AAvoid Size Selection ProblemsImprove filtering effectSeismic signal processingEdge structureRandom noise

The invention discloses a stratum structure self-adaption median filtering method. The method comprises the steps of: 1, calculating a gradient structure tensor; 2, calculating a stratum lateral incontinuity measurement; 3, structuring a structure self-adaption median filtering device; and 4, performing structure self-adaption median filtering and processing. By utilizing the method, earthquake random noise and part coherent noise can be effectively attenuated, and stratum edge and detailed structure characteristics such as effective signals, geologic faults and amplitude abnormalities can be maintained in a filtering process; the algorithm of the technical scheme is easy to realize and has good operability; and moreover, a selection problem of a median filtering processing window size is avoided, the method meets the requirements of the median filtering processing of complicated signals, for data areas with good event extension, the filtering performance of the median filtering device is improved through adaptively controlling the direction characteristics of a filtering window, and for areas with geologic faults and angular unconformity, the maintaining performance of the median filtering device to stratum edge structures such as the geologic faults is improved through adaptively adjusting the size of the filtering window.

Owner:XI AN JIAOTONG UNIV

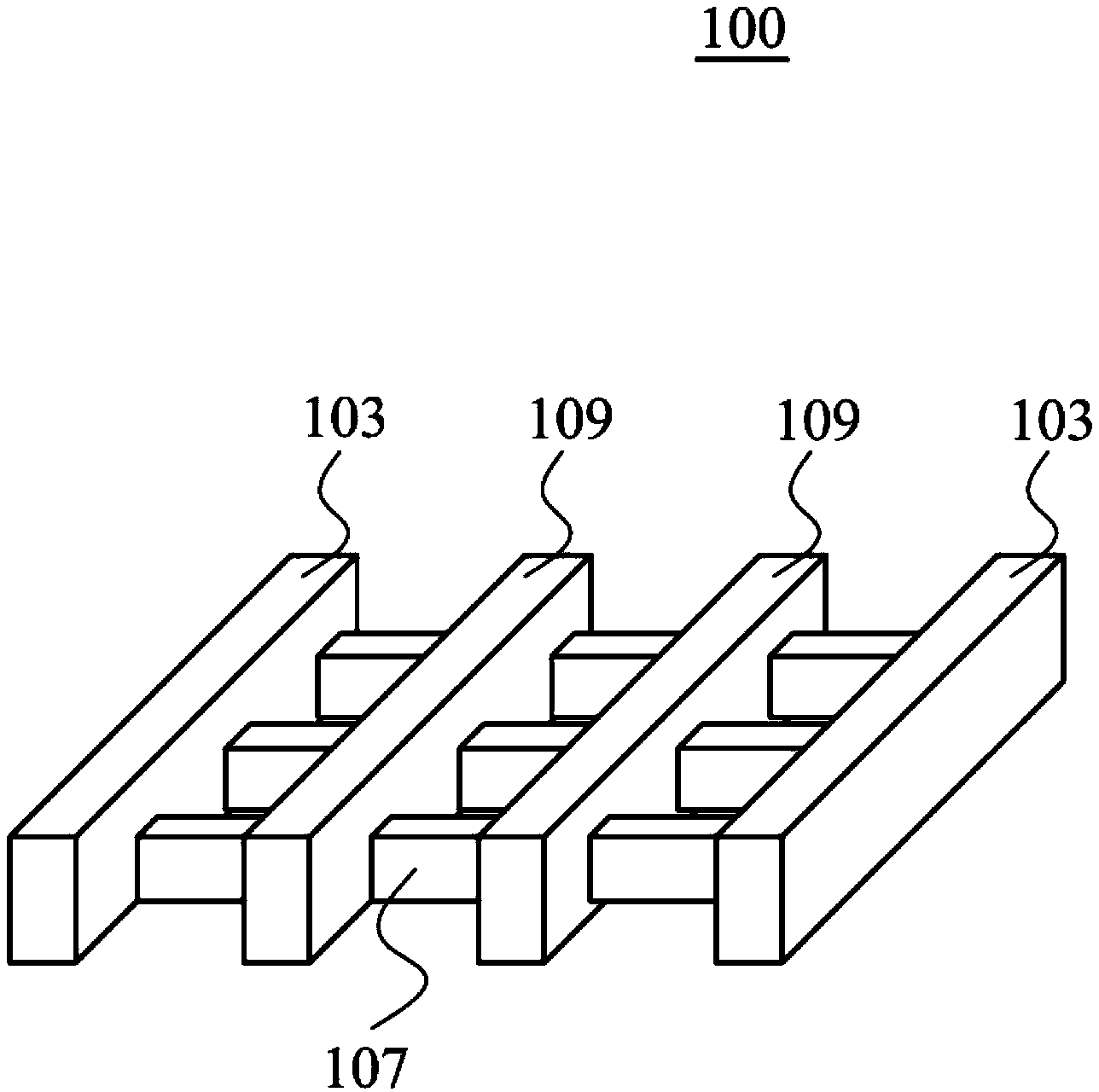

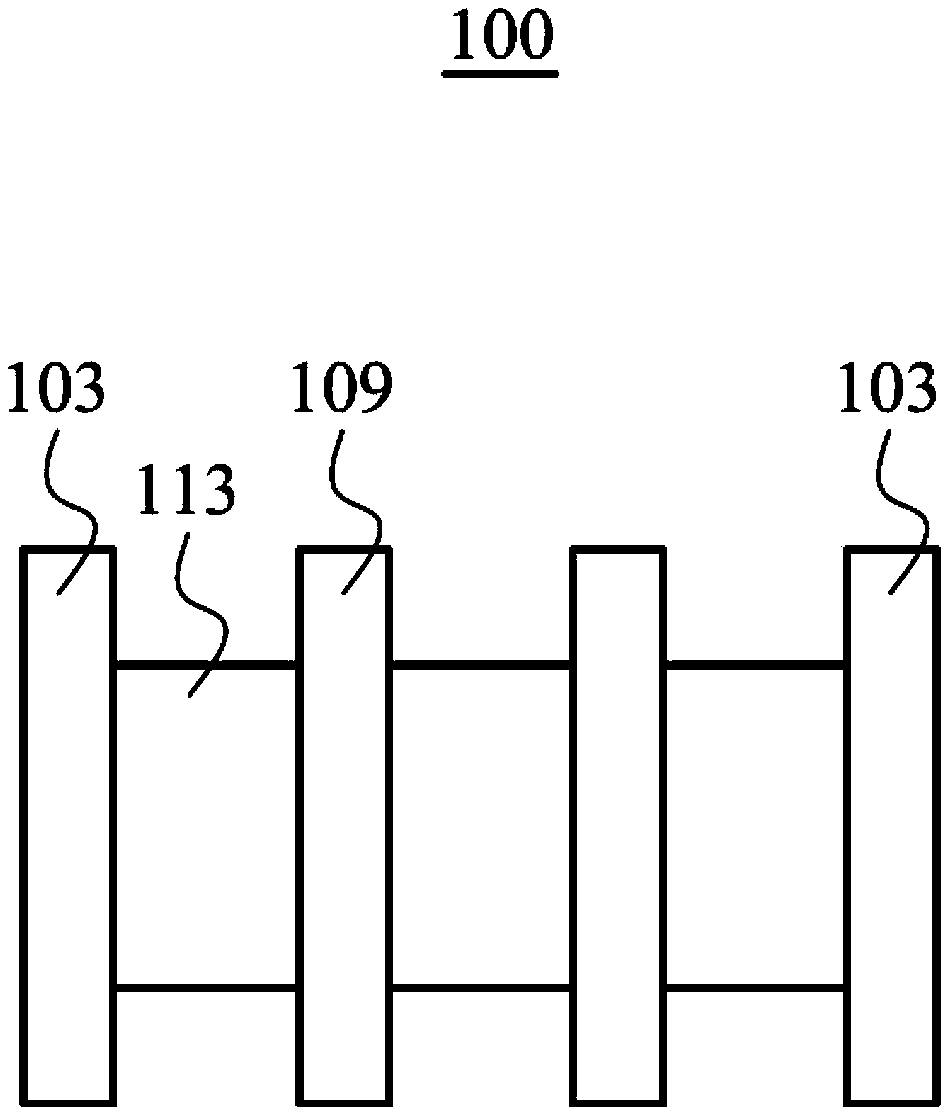

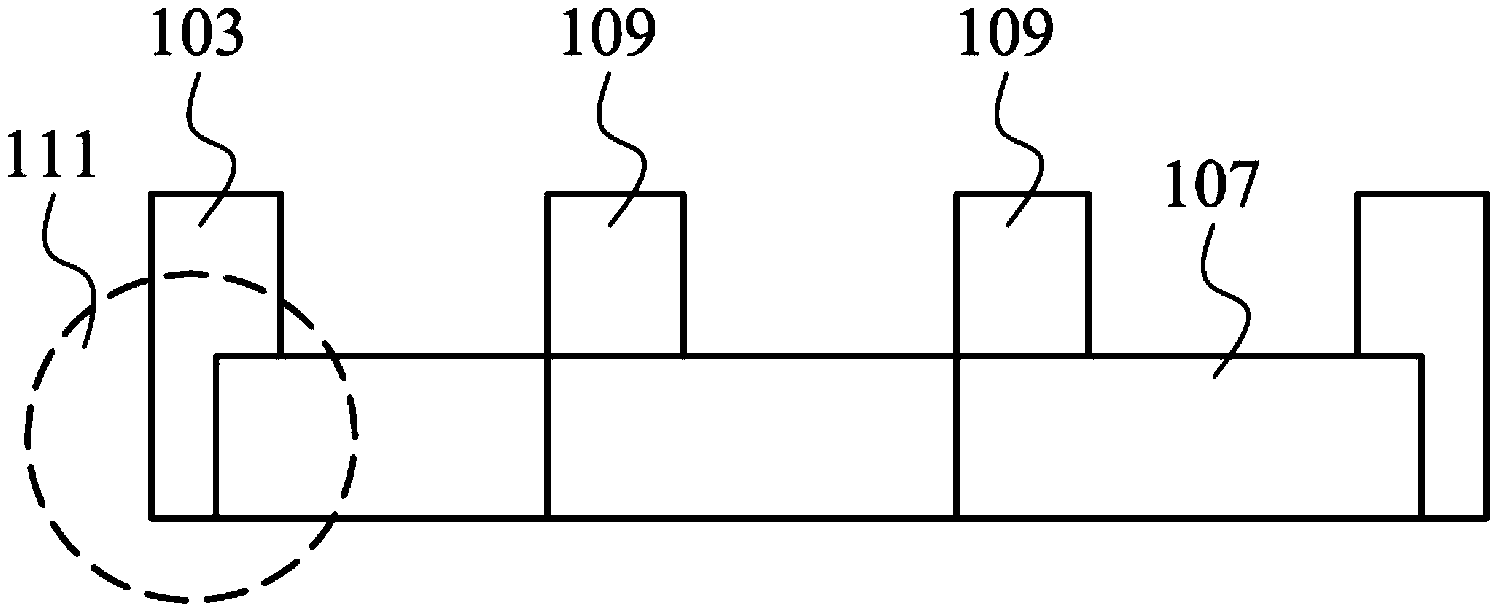

Layout verification method used for polysilicon cell edge structure in FinFET standard cells

The invention discloses a method for standard cells using an FinFET standard cell structure with polysilicon on OD edges. FinFET transistors are used to define the standard cells, and the standard cells comprise grid structures forming a transistor at a crossing point with a semiconductor fin. Polysilicon pseudo-structures are formed in active areas of the standard cells or edges of OD areas. In a design process, a pre-layout netlist schematic diagram for the standard cells includes a three-terminal MOS device corresponding to the polysilicon pseudo-structure at the edges of the standard cells. After automatic placement and routing processing, standard cells are employed to form a device layout, and a post-layout netlist is extracted. If two standard cells are contiguous, a single polysilicon pseudo-structure at the common boundary is formed. A layout-versus-schematic comparison is then performed in which the pre-layout netlist and the post-layout netlist are compared in order to verify the obtained layout. The invention also discloses a layout verification method used for a polysilicon cell edge structure in FinFET standard cells.

Owner:TAIWAN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com