System and method for detecting defects on reflection surface through visual system

A visual system and reflective technology, applied in the field of visual systems for inspecting reflective surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

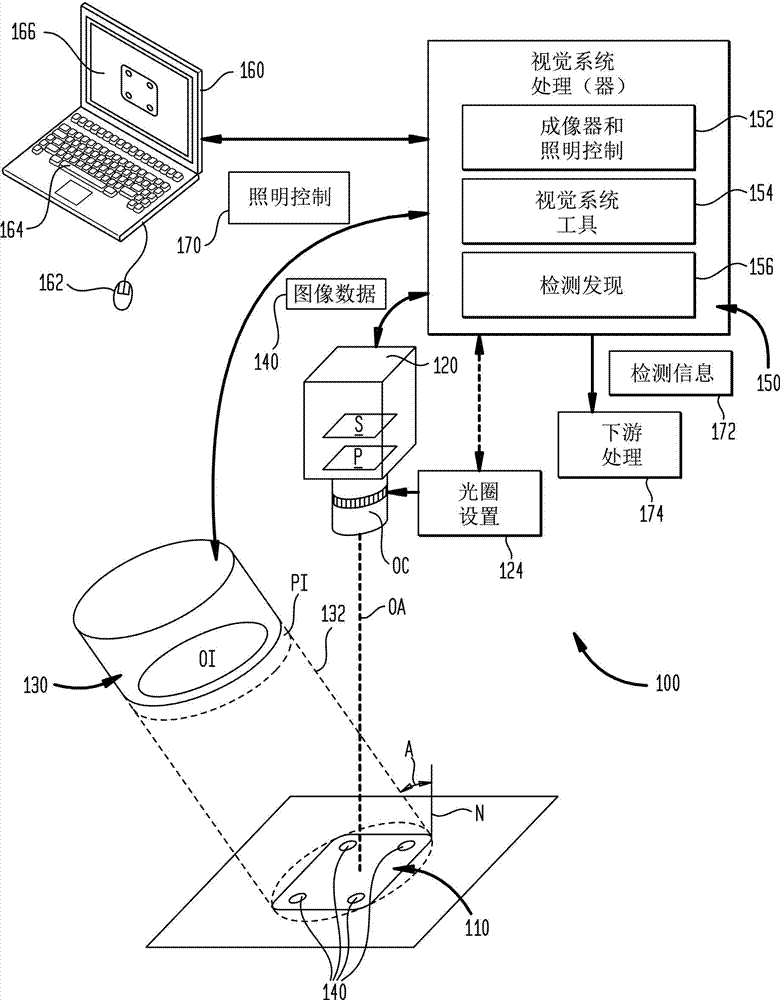

[0031] figure 1 is an illustration of an exemplary vision system arrangement 100 in which a scene includes a reflective object 110 positioned stationary relative to a stationary vision system camera 120 in accordance with an illustrative embodiment. In this embodiment, vision system camera 120 includes a two-dimensional (2D) image sensor S that includes an array of N×M pixels in, for example, a rectangular arrangement. The camera includes an optical package OC, which may include any acceptable lens assembly (eg, a lens with a C-type objective mount, F-type objective mount, or M12-type mount). In this embodiment, the lens includes a manual or automatic aperture control—for example, an iris, wherein a user or other external controller can enter an appropriate aperture setting 124 into the manual or automatic aperture control (as further described below). like that). Sensor S and optical package OC collectively define an optical axis OA, which is generally perpendicular to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com