High beam and low beam integrated LED automobile lens

A technology for far and near beams and automobiles, which is applied to the semiconductor devices of light-emitting components, light sources, and shading. It can solve the problems of not clear cut-off lines of light and shade, insufficient concentration of high beams, and insufficient brightness of low beams, etc., and achieve the cut-off line of low and dark light Clear, high brightness, fast switching speed between far and near light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawings and embodiments thereof.

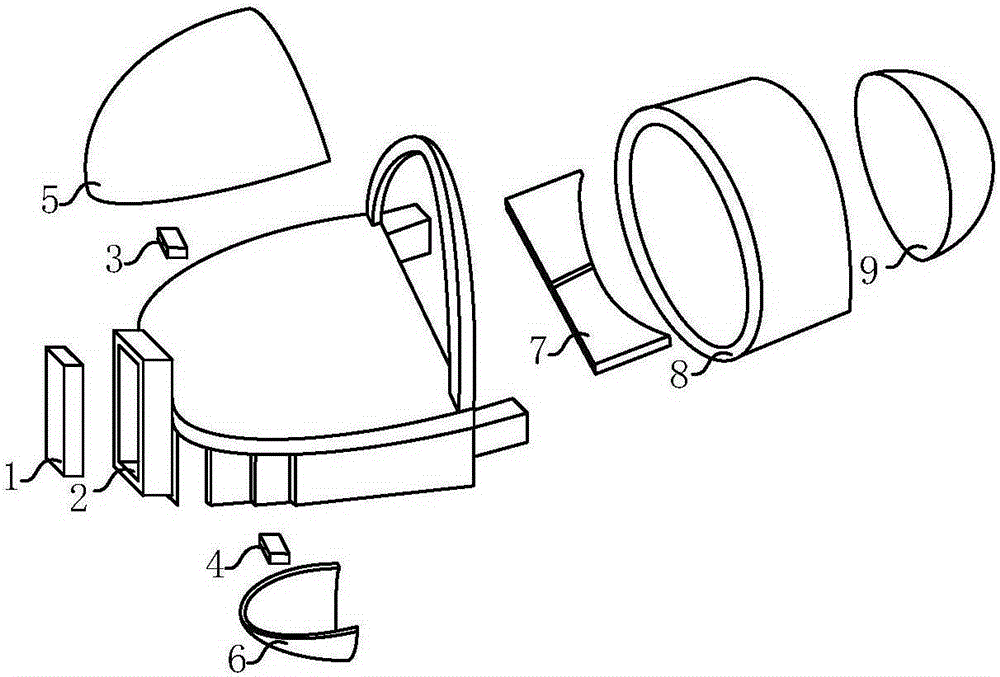

[0026] refer to figure 1 , the LED automotive lens of the present invention comprises a cooling fan 1, a cooling bracket 2, a low beam lamp bead 3, a high beam lamp bead 4, a low beam reflector cup 5, a high beam reflector cup 6, a light shield 7, a lens holder 8 and a lens 9; of which:

[0027] The heat dissipation fan 1 is installed at the tail of the heat dissipation support 2, forming a horizontal air flow to blow to the heat dissipation support 2 for its heat dissipation;

[0028] The upper surface of the heat dissipation bracket 2 is provided with a low beam lamp bead 3 and a low beam reflector cup 5; the lower surface of the heat dissipation bracket 2 is provided with a high beam lamp bead 4 and a high beam reflector cup 6;

[0029] The low-beam lamp bead 3 is a package of single or multiple LEDs as a lamp bead, installed horizontally with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com