Automatic assembling equipment of magnetic circuit system of loudspeaker

A magnetic circuit system and automatic assembly technology, applied in the direction of sensors, electrical components, etc., can solve the problems of high labor intensity, increased production costs, and low efficiency of workers, and achieve the effects of good product consistency, reduced labor costs, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

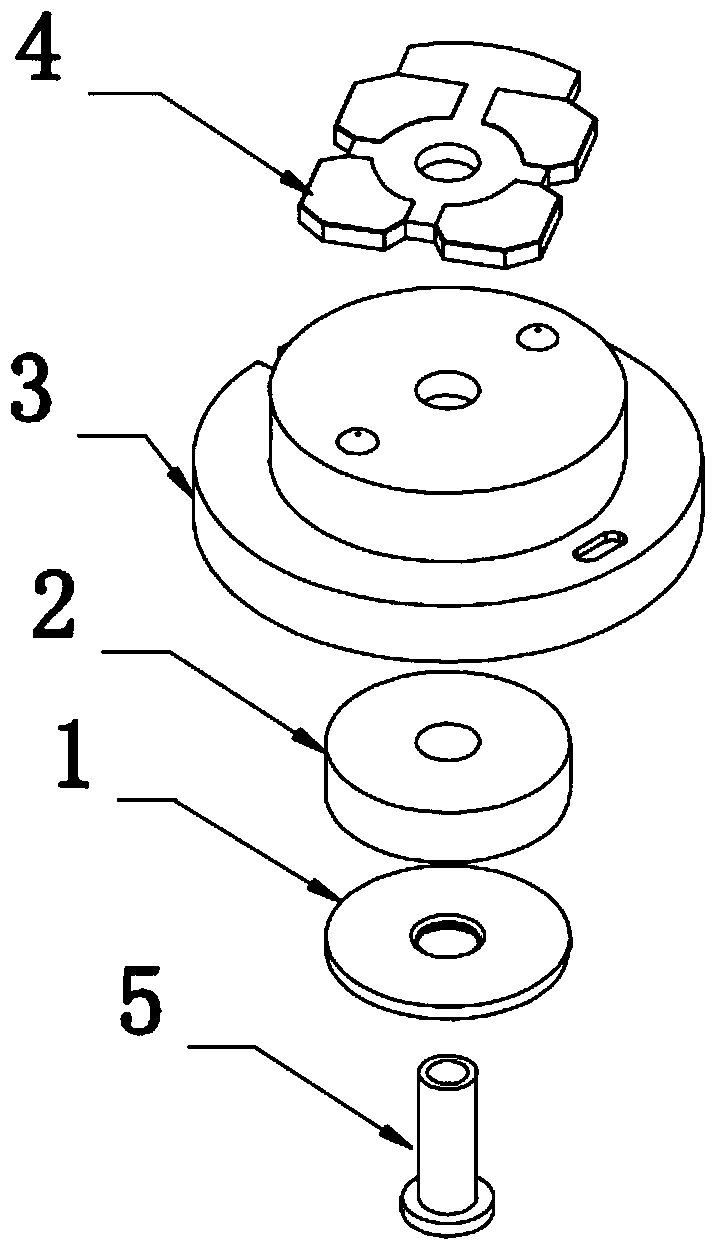

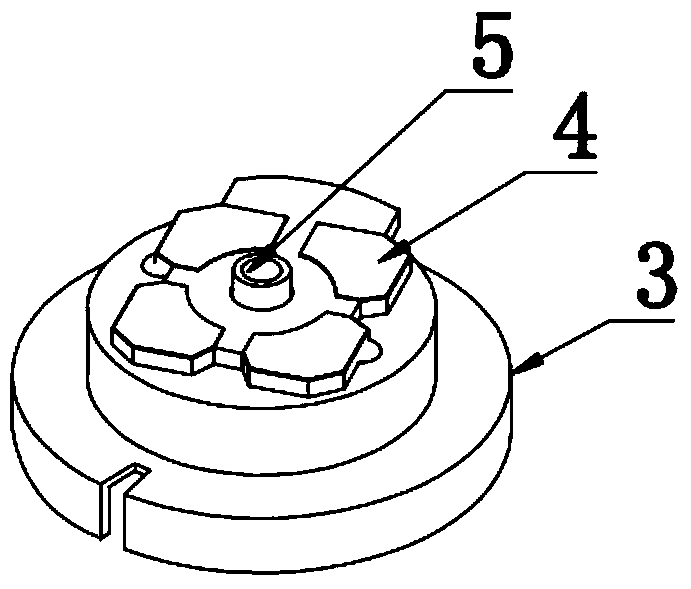

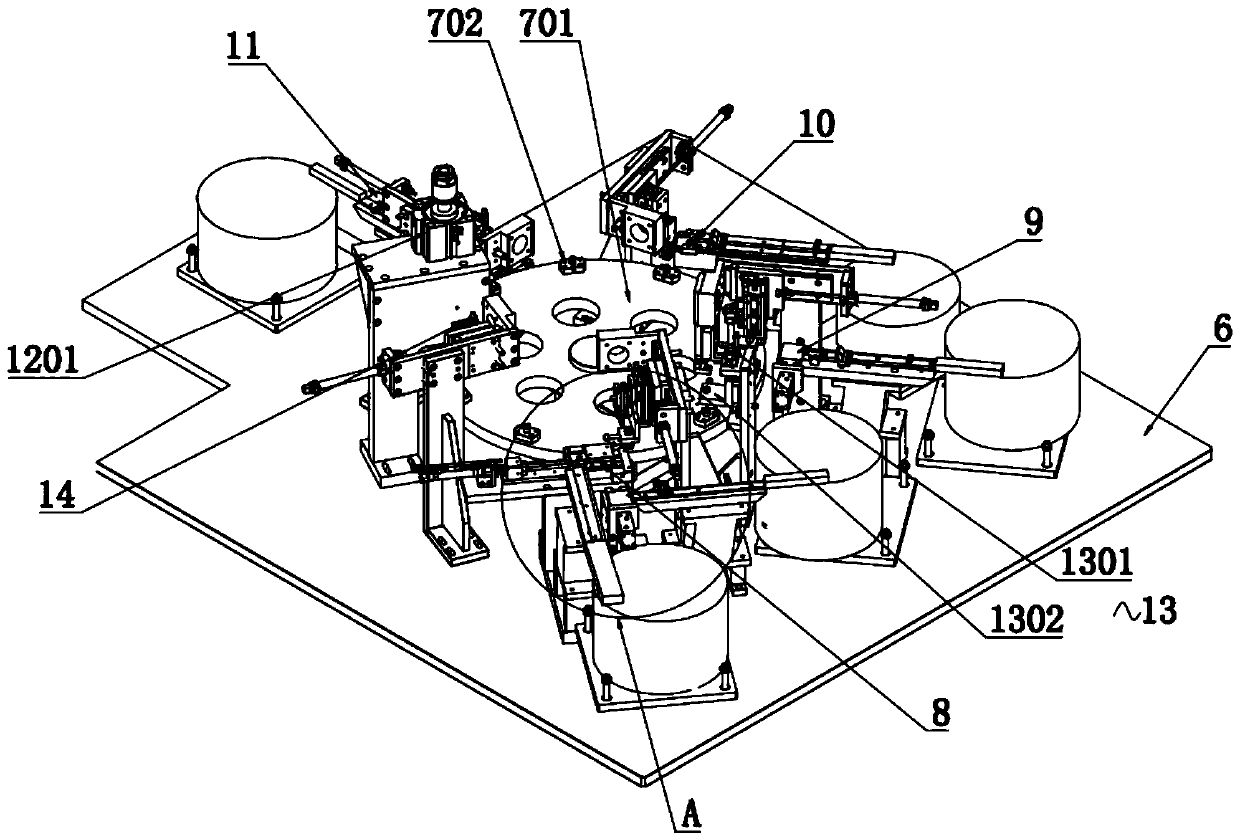

[0025] Such as Figure 3-5 As shown, the present embodiment provides an automatic assembly equipment for a loudspeaker magnetic circuit system. The assembly is to assemble the washer, magnet, T iron, and PCB board into a magnetic circuit system through rivets, including a bottom plate 6 on which With:

[0026] The feeding mechanism 7, the feeding mechanism 7 includes a multi-station equally divided turntable 701, clamps 702 and a driver (not shown in the figure), the clamps 702 are equidistantly arranged around the turntable 701 to accommodate and position one end of the rivet cap of the rivet, and the driver drives The turntable 701 intermittently steps to replace the station;

[0027] The washer and rivet combination mechanism 8 is set on one side of the feeding mechanism 7, and includes a combined workbench 801, an automatic rivet feeding device 802, and a washer automatic feeding device 803. The combined workbench 801 is provided with a rivet positioning mechanism 804. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com