Patents

Literature

684 results about "Image contour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

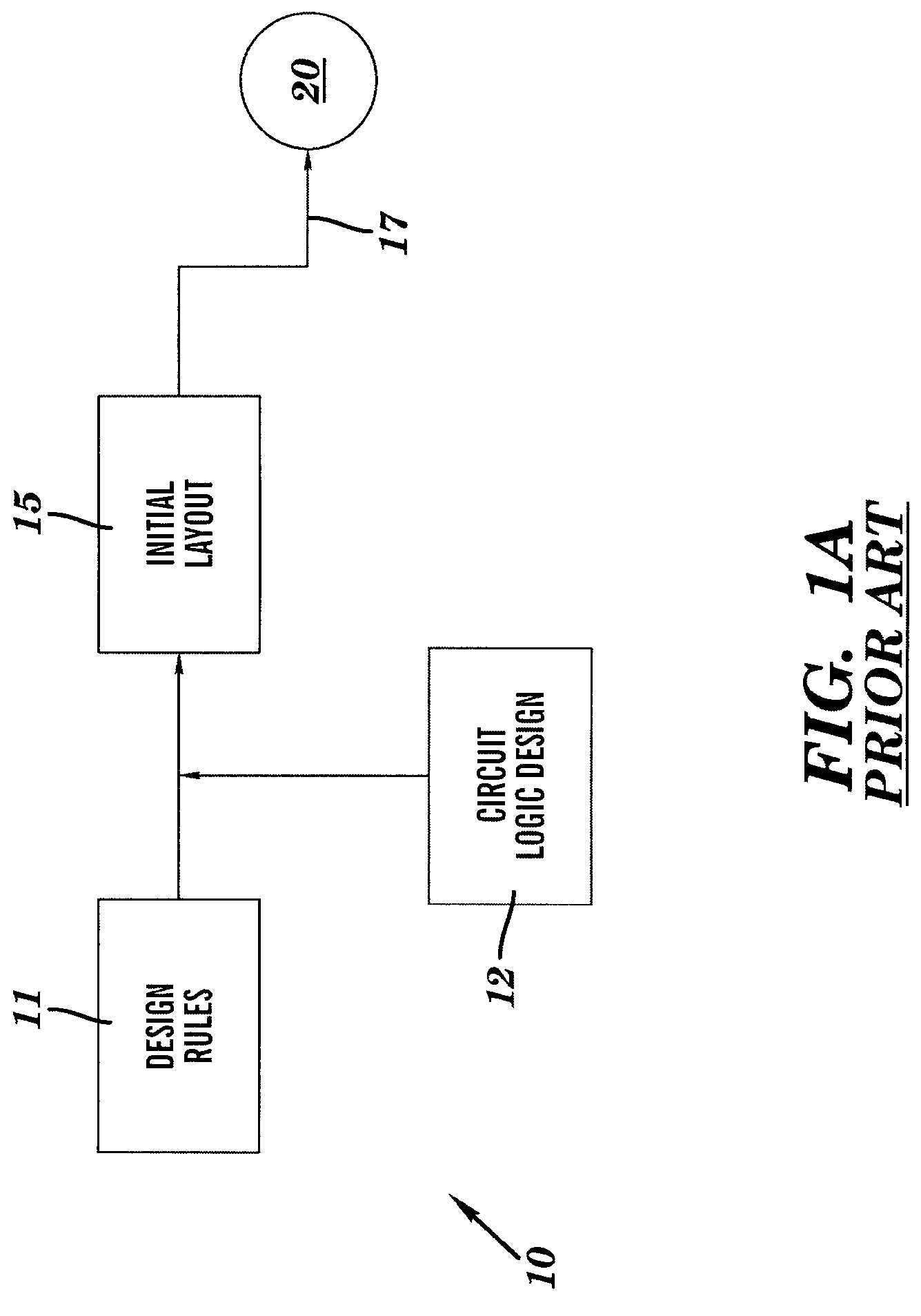

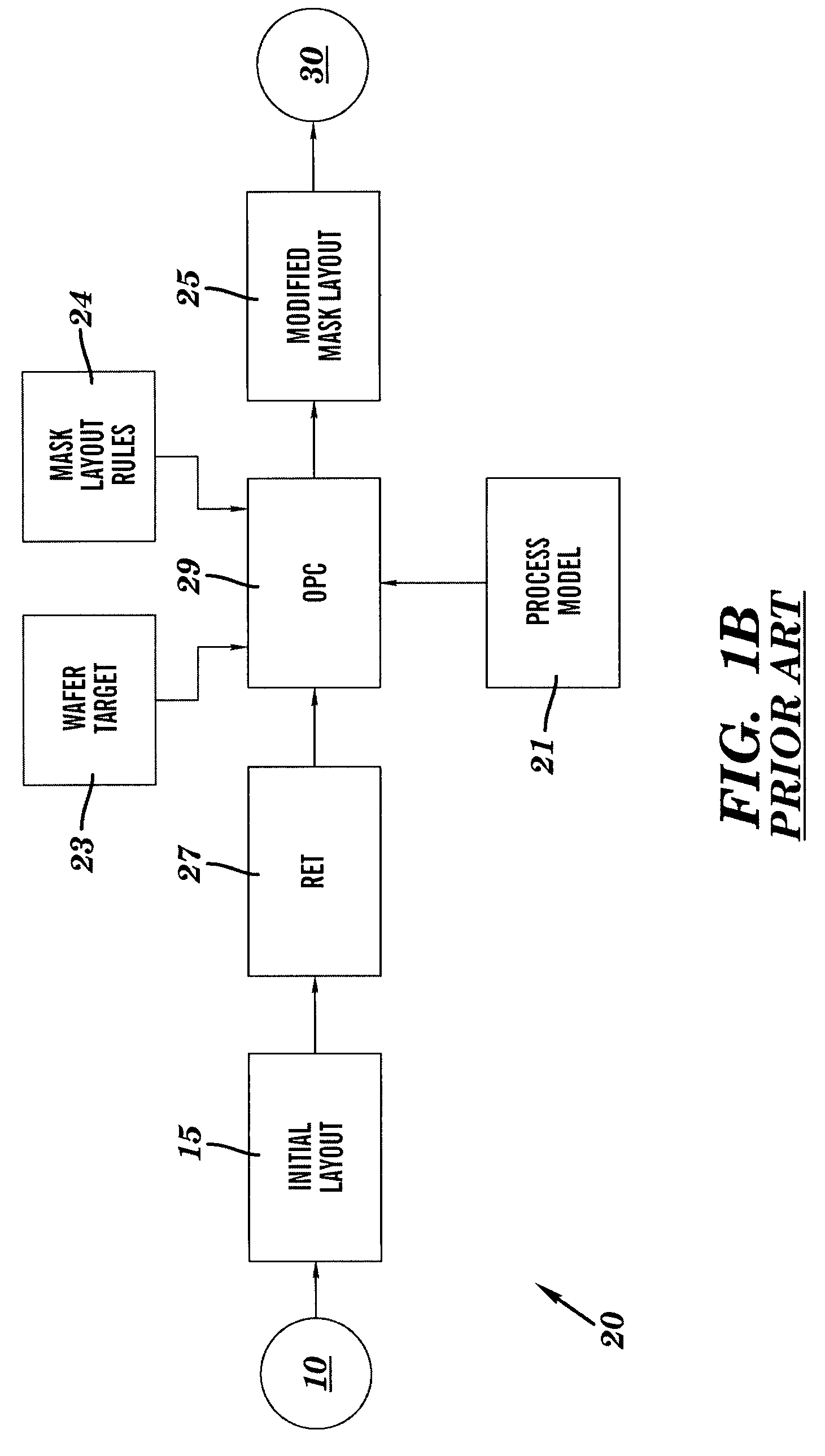

Closed-loop design for manufacturability process

InactiveUS20080127029A1Satisfy constraintsSimple methodOriginals for photomechanical treatmentSpecial data processing applicationsDesign phaseEngineering

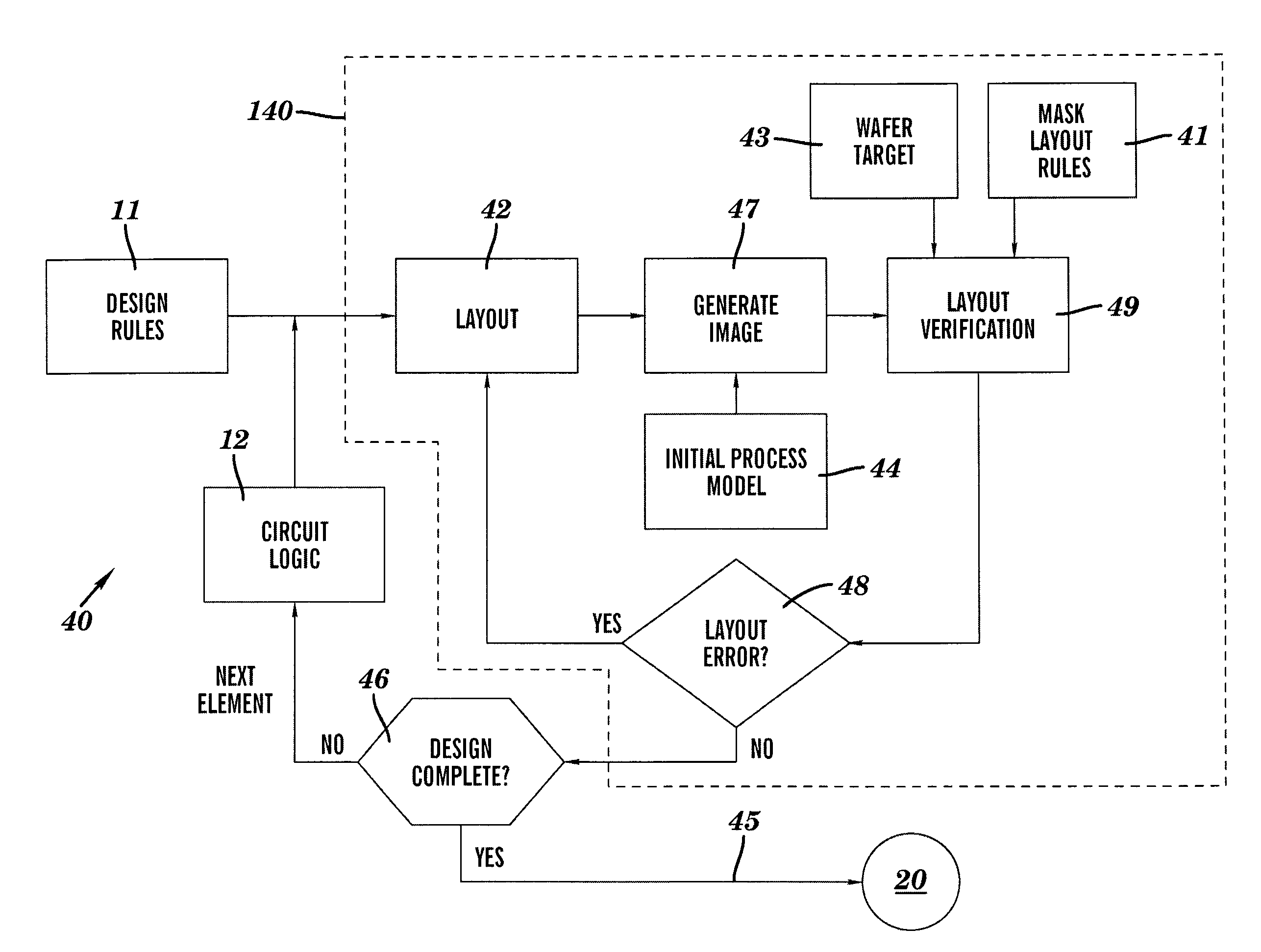

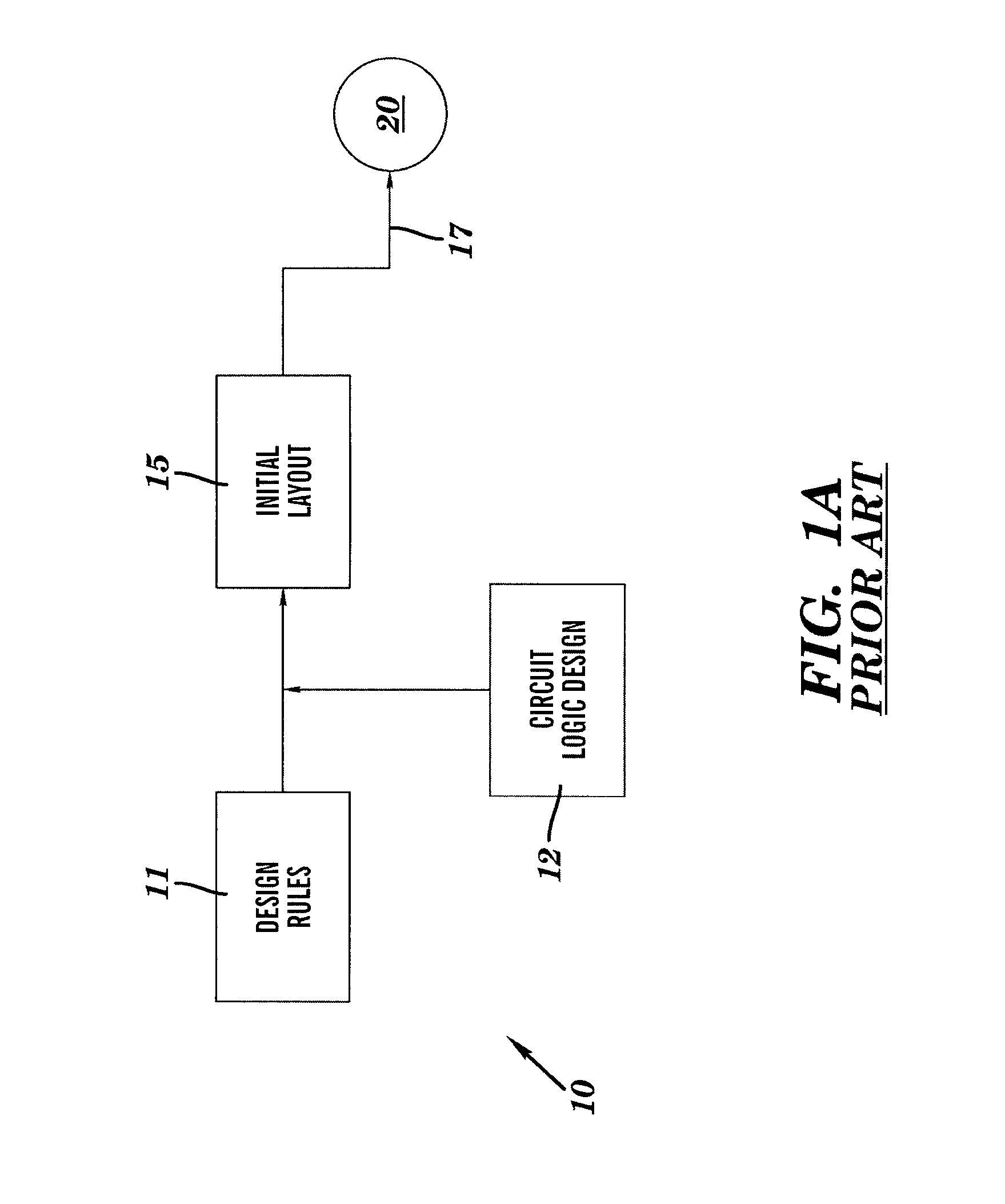

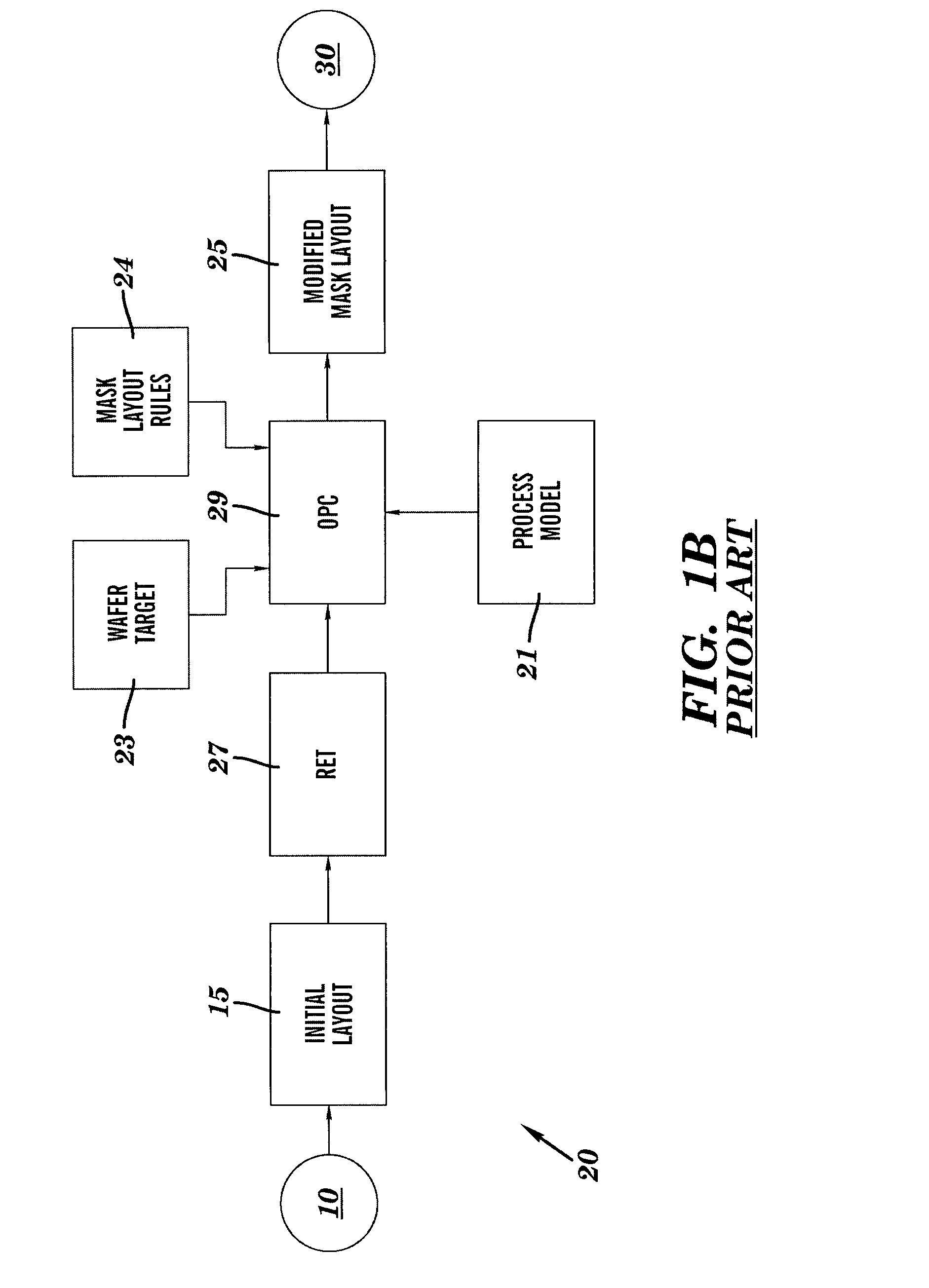

A method of designing an integrated circuit is provided in which the design layout is optimized using a process model until the design constraints are satisfied by the image contours simulated by the process model. The process model used in the design phase need not be as accurate as the lithographic model used in preparing the lithographic mask layout during data prep. The resulting image contours are then included with the modified, optimized design layout to the data prep process, in which the mask layout is optimized using the lithographic process model, for example, including RET and OPC. The mask layout optimization matches the images simulated by the lithographic process model with the image contours generated during the design phase, which ensures that the design and manufacturability constraints specified by the designer are satisfied by the optimized mask layout.

Owner:IBM CORP

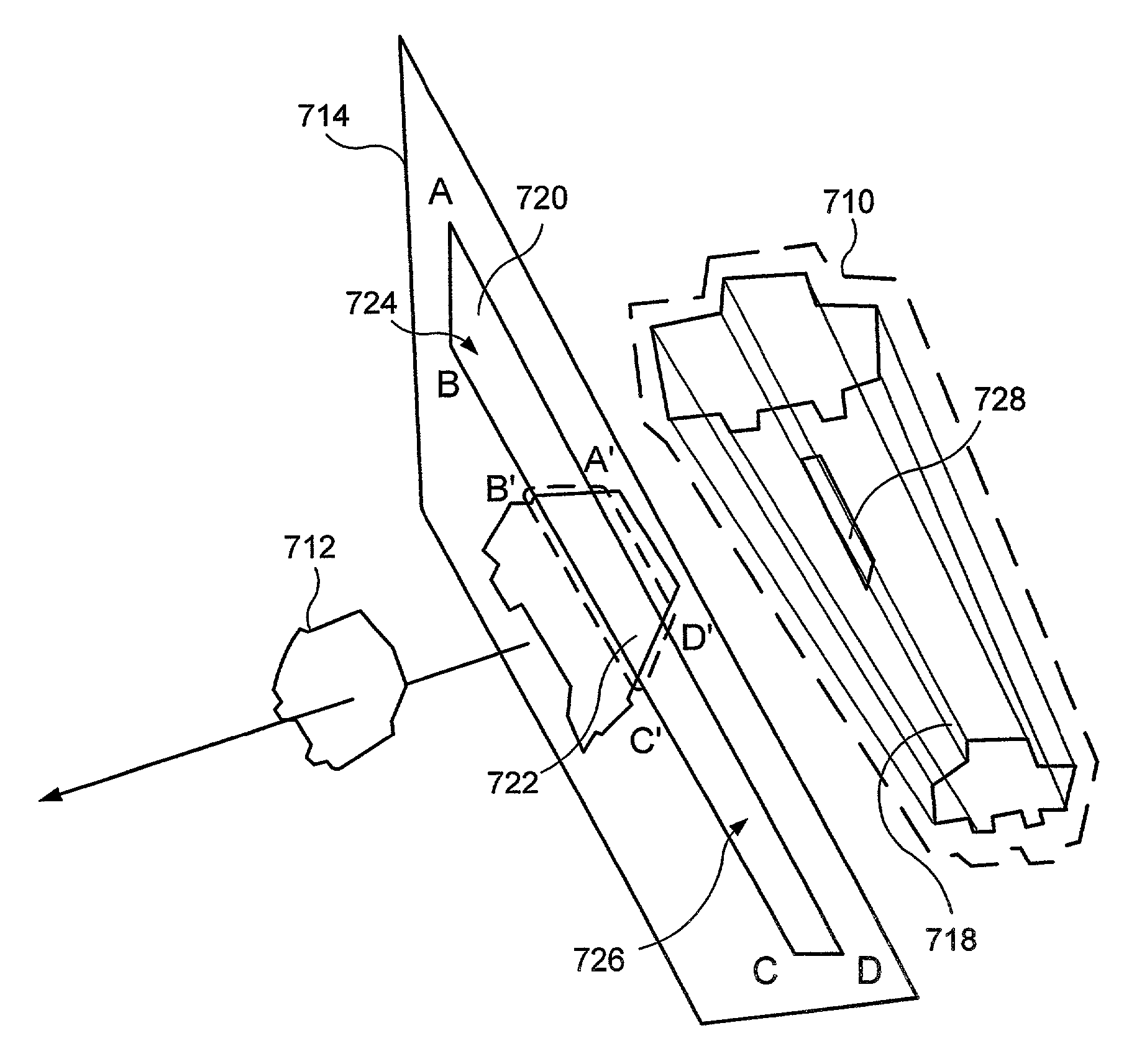

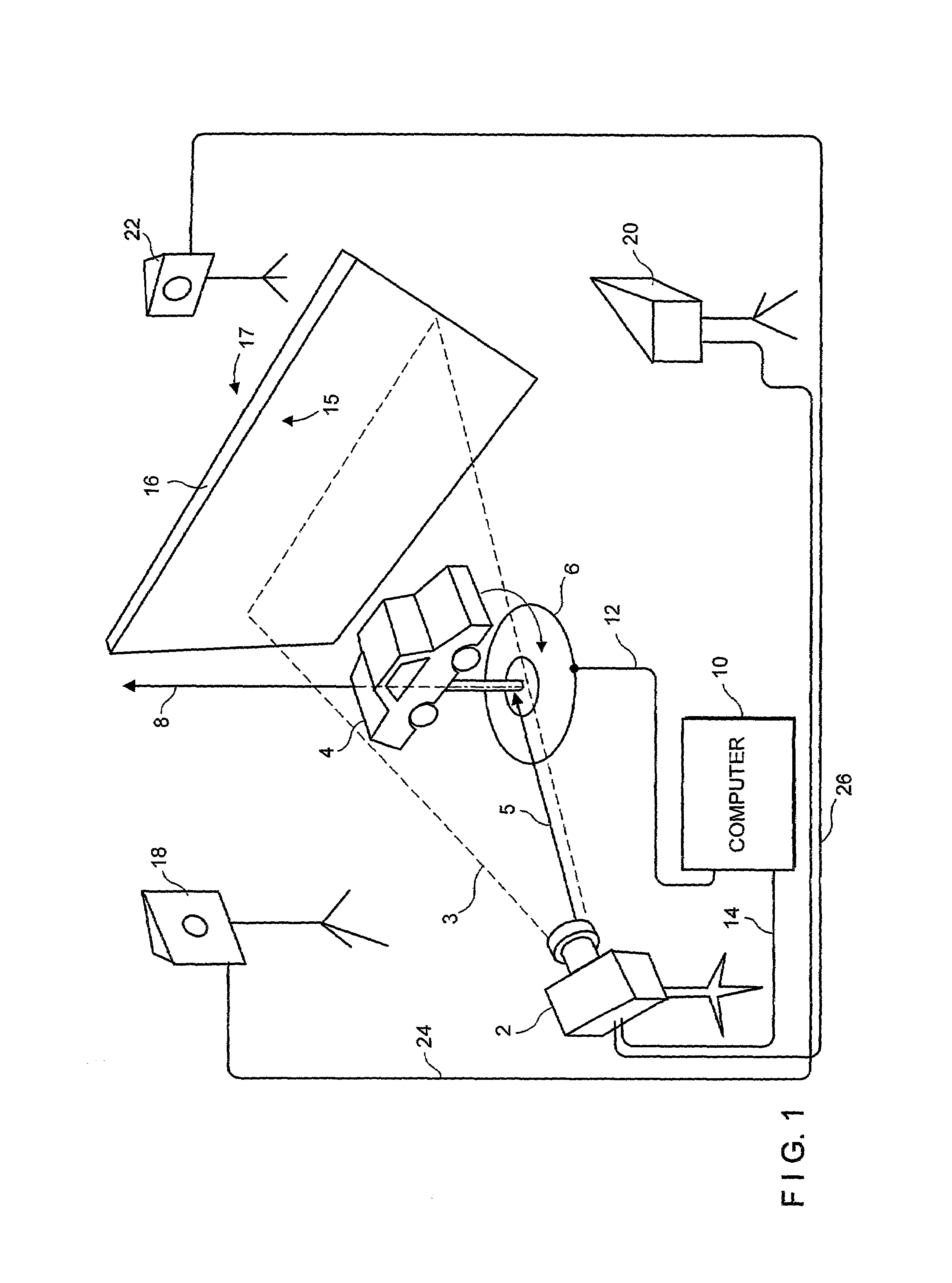

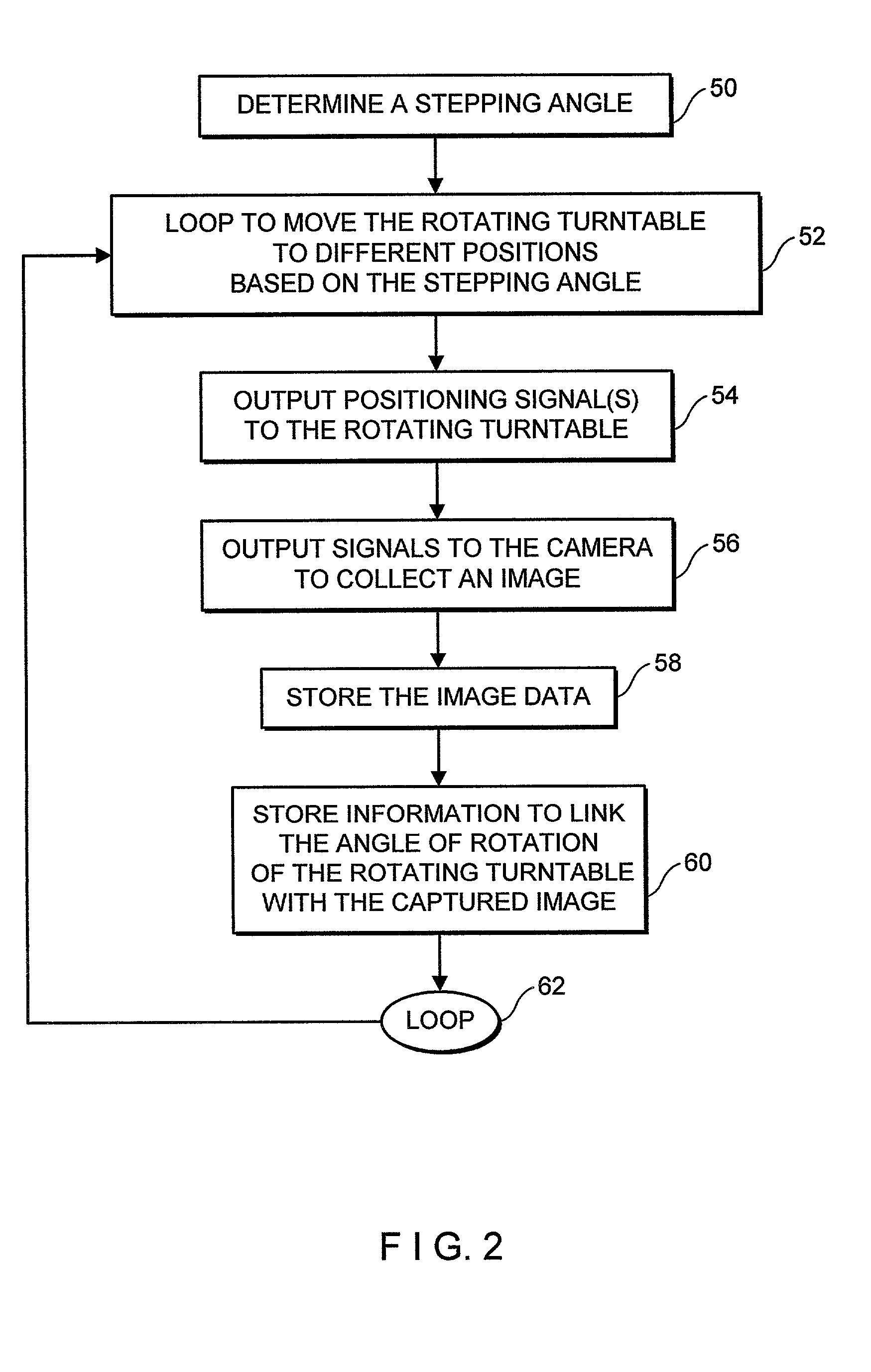

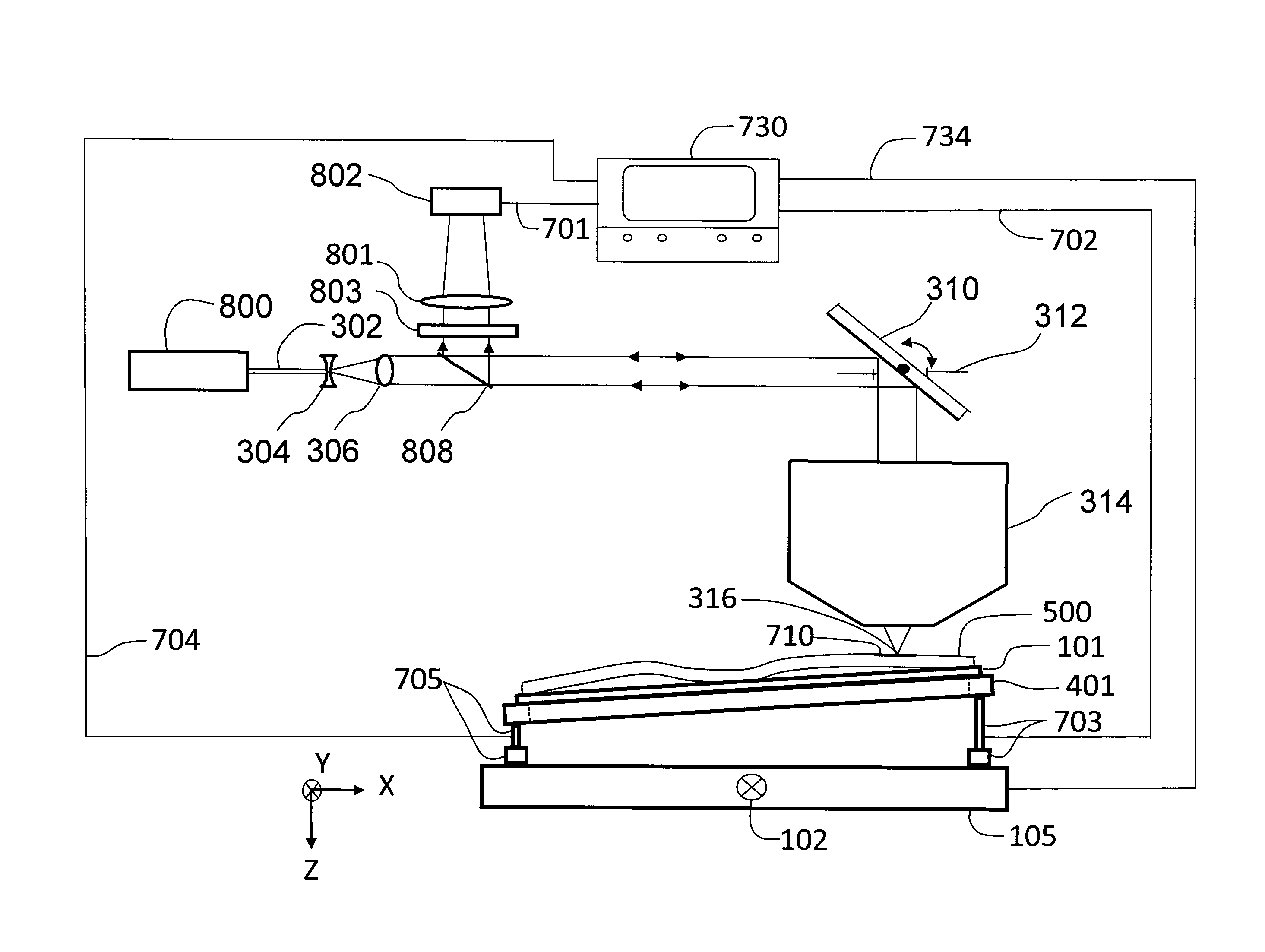

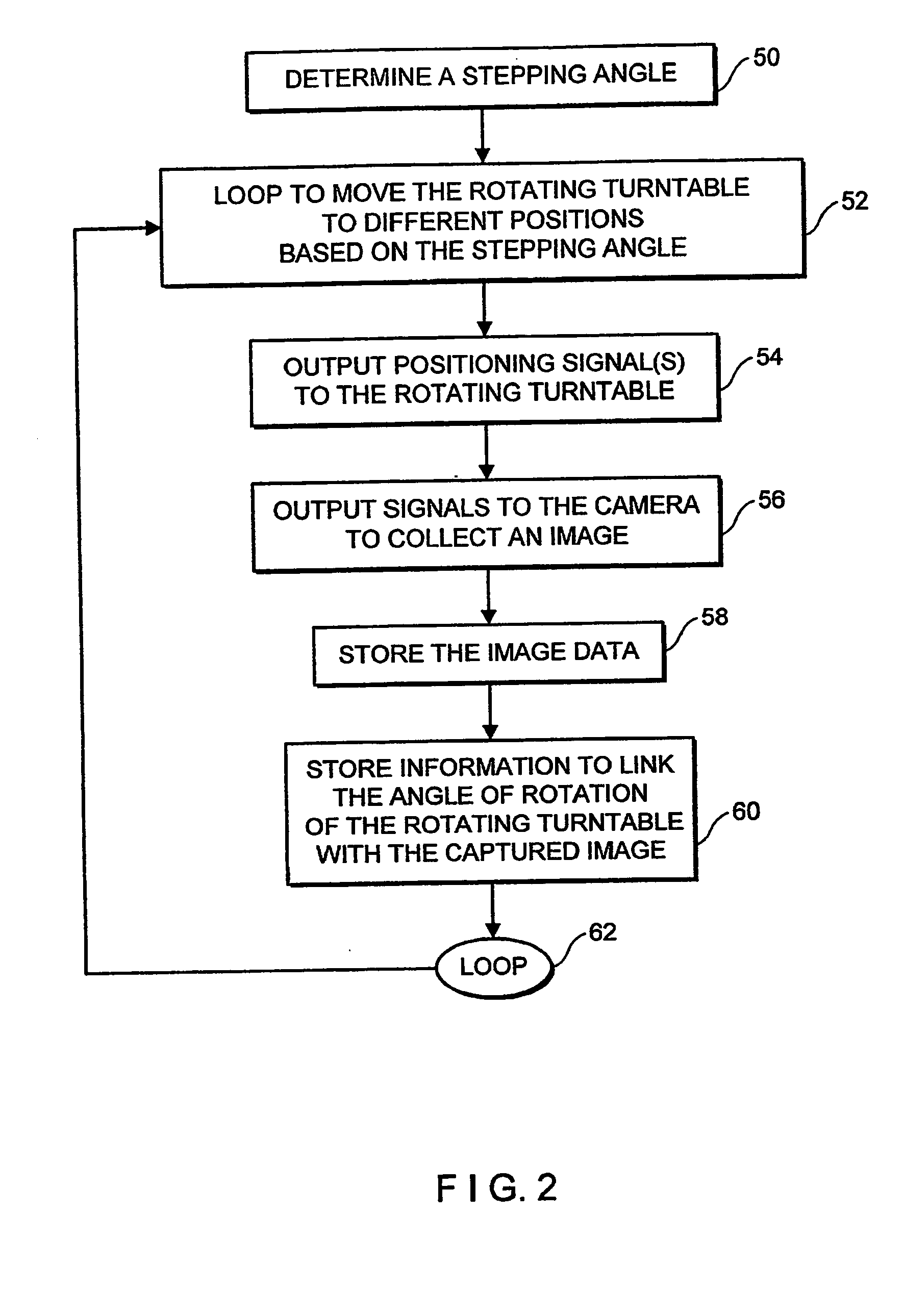

System and method of three-dimensional image capture and modeling

InactiveUS7065242B2Eliminate needImprove accuracyImage data processing detailsAquisition of 3D object measurementsOne passObject based

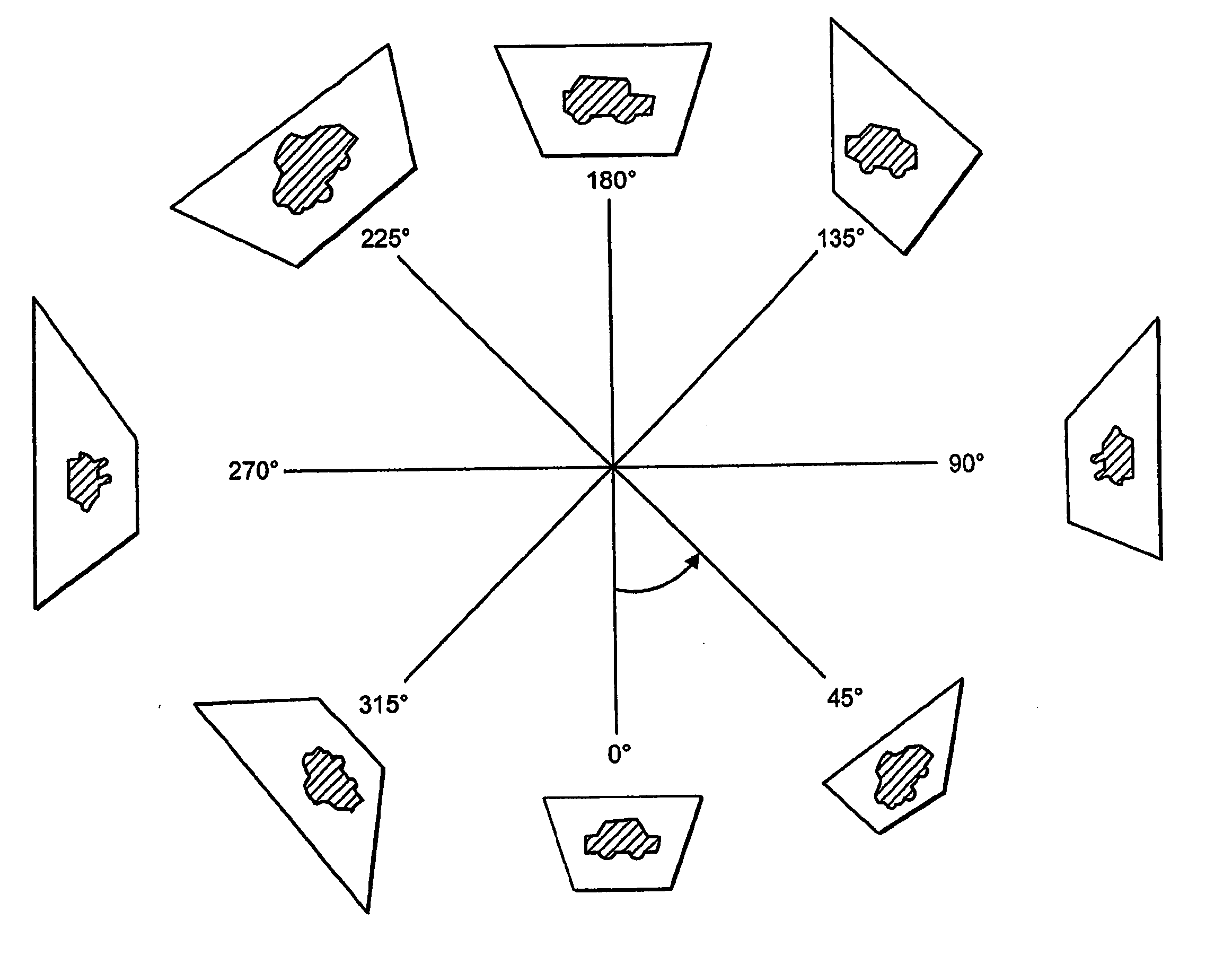

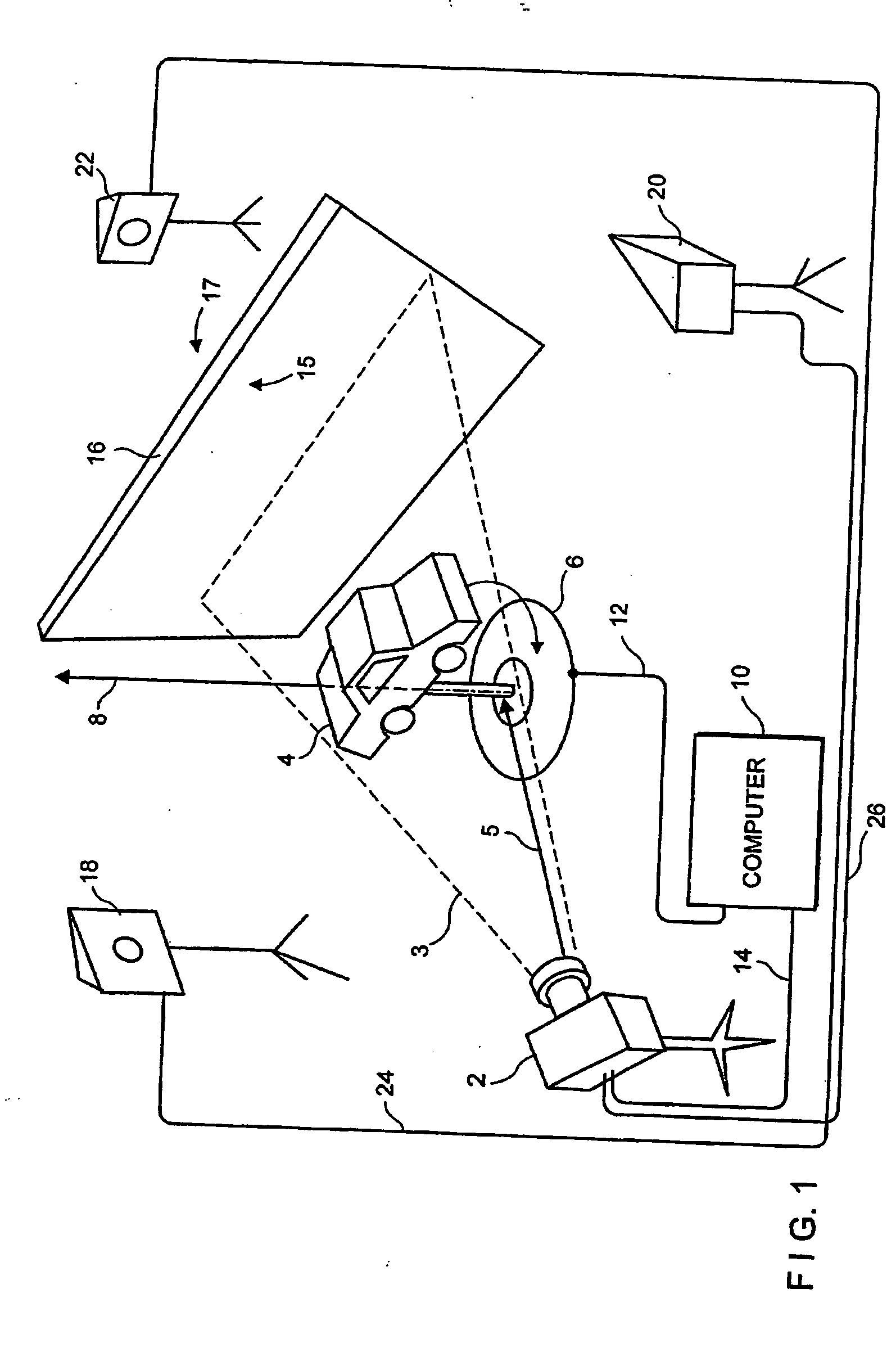

System and method for constructing a 3D model of an object based on a series of silhouette and texture map images. In the exemplary embodiment an object is placed on a rotating turntable and a camera, which is stationary, captures images of the object as it rotates on the turntable. In one pass, the system captures a number of photographic images that will be processed into image silhouettes. In a second pass, the system gathers texture data. After a calibration procedure (used to determine the camera's focal length and the turntable's axis of rotation), a silhouette processing module determines a set of two-dimensional polygon shapes (silhouette contour polygons) that describe the contours of the object. The system uses the silhouette contour polygons to create a 3D polygonal mesh model of the object. The system determines the shape of the 3D model analytically-by finding the areas of intersection between the edges of the model faces and the edges of the silhouette contour polygons. The system creates an initial, (rough) model of the 3D object from one of the silhouette contour polygons, then executes an overlaying procedure to process each of the remaining silhouette contour polygons. In the overlaying process, the system processes the silhouette contour polygons collected from each silhouette image, projecting each face of the (rough) 3D model onto the image plane of the silhouette contour polygons. The overlaying of each face of the (rough) 3D model onto the 2D plane of the silhouette contour polygons enables the present invention to determine those areas that are extraneous and should be removed from the (rough) 3D model. As the system processes the silhouette contour polygons in each image it removes the extraneous spaces from the initial object model and creates new faces to patch “holes.” The polygonal mesh model, once completed, can be transformed into a triangulated mesh model. In a subsequent step, the system uses a deterministic procedure to map texture from the texture images onto the triangles of the 3D mesh model, locating that area in the various texture map images that is “best” for each mesh triangle.

Owner:SIZMEK TECH

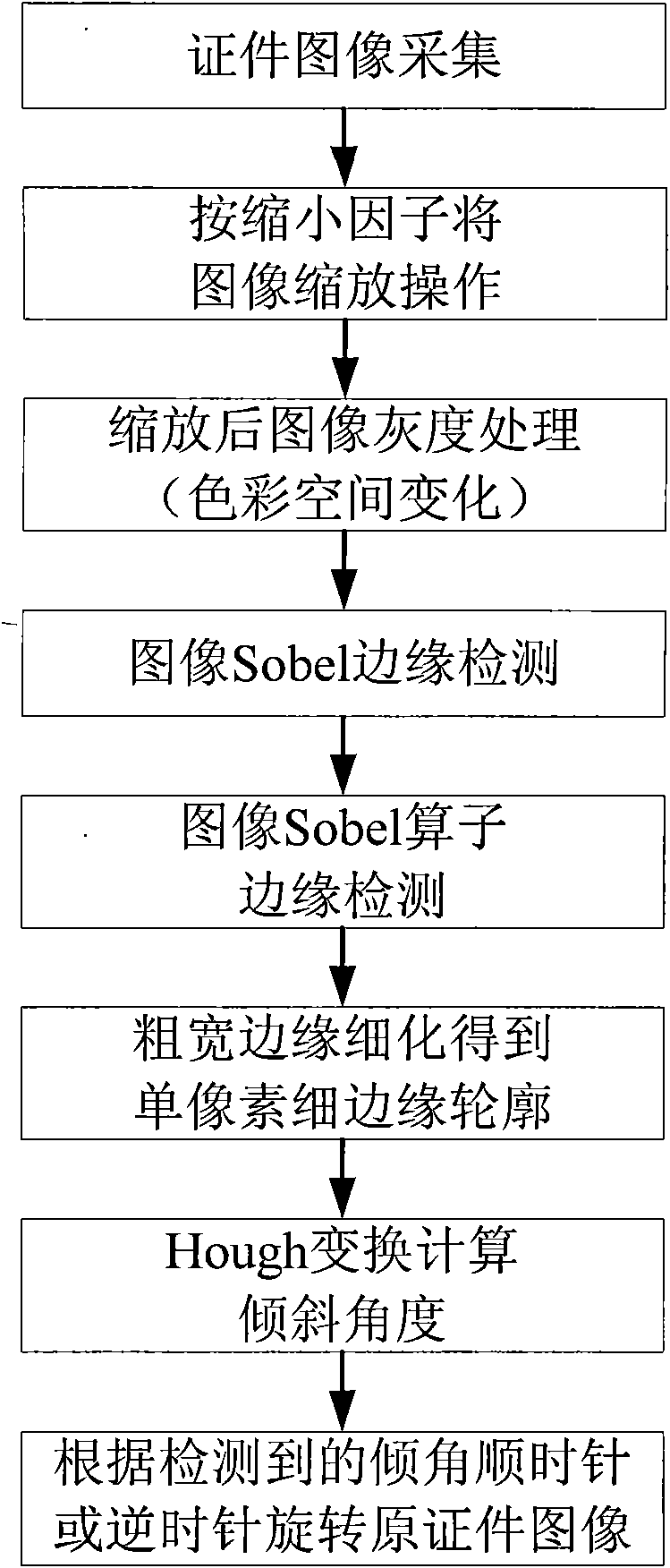

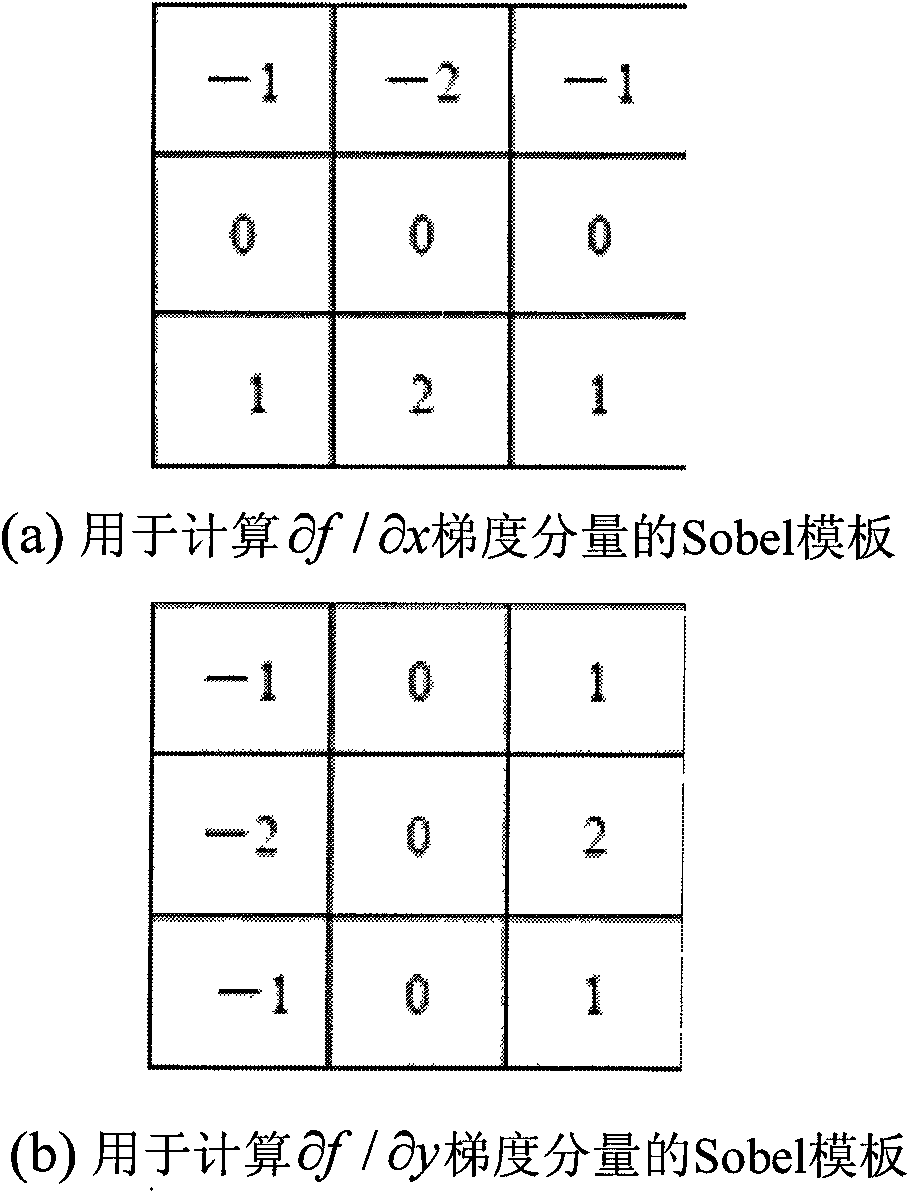

Method for correcting certificate image inclination

InactiveCN101625760AImprove efficiencyImprove accuracyImage analysisGeometric image transformationImproved algorithmImage contour

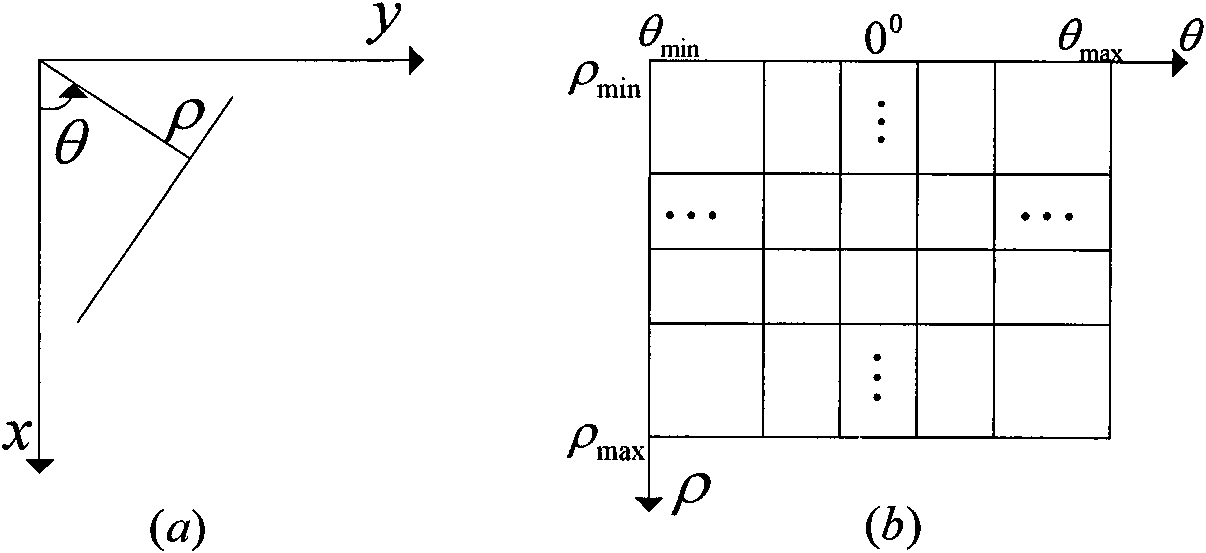

The invention discloses a method for calculating angle of inclination and correcting inclination by using image contour information and combing Hough conversion. The method comprises: a) using an image collection device to obtain a certificate image; b) reducing the obtained certificate image; c) carrying out grey treatment on the certificate image; d) using an Sobel operator module to detect the edges of the gray image to obtain a thicker wide profile image; e) carrying out detailing operation on the treated image to obtain a profile image with thin edges and one pixel width; f) carrying out Hough conversion on the obtained profile image with thin edges to detect the line parameter of a frame, and using detected parameter to calculate to obtain the angle of inclination of an original certificate; and g) using the obtained angle of inclination to rotate the image. The invention fully utilizes reduced image contour information and uses Hough conversion to calculate the angle of inclination, which greatly reduces points participating in operation, improves algorithm efficiency and ensures high accuracy, strong robustness and high reliability of algorithm detection.

Owner:谭洪舟

Intelligent defect diagnosis method

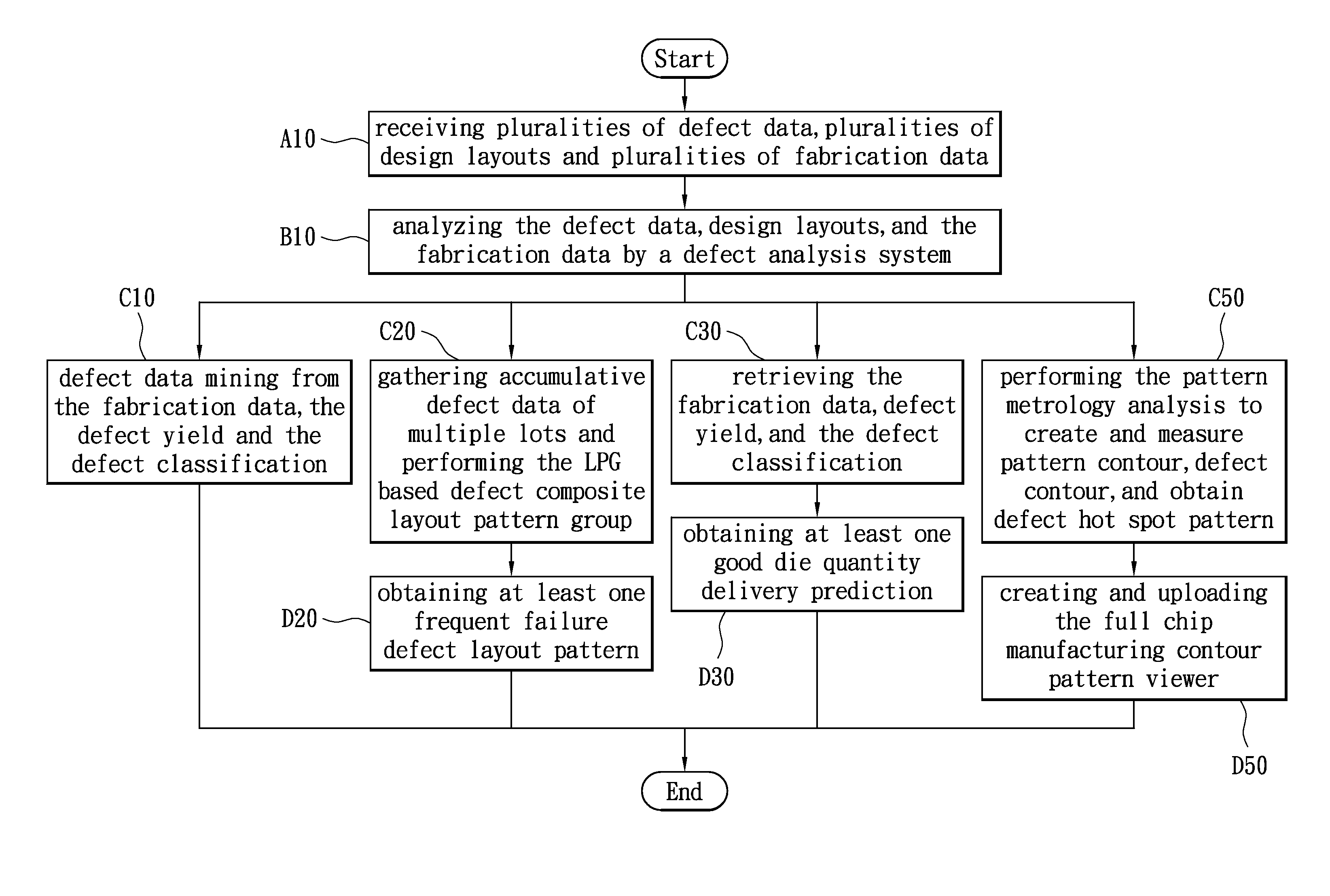

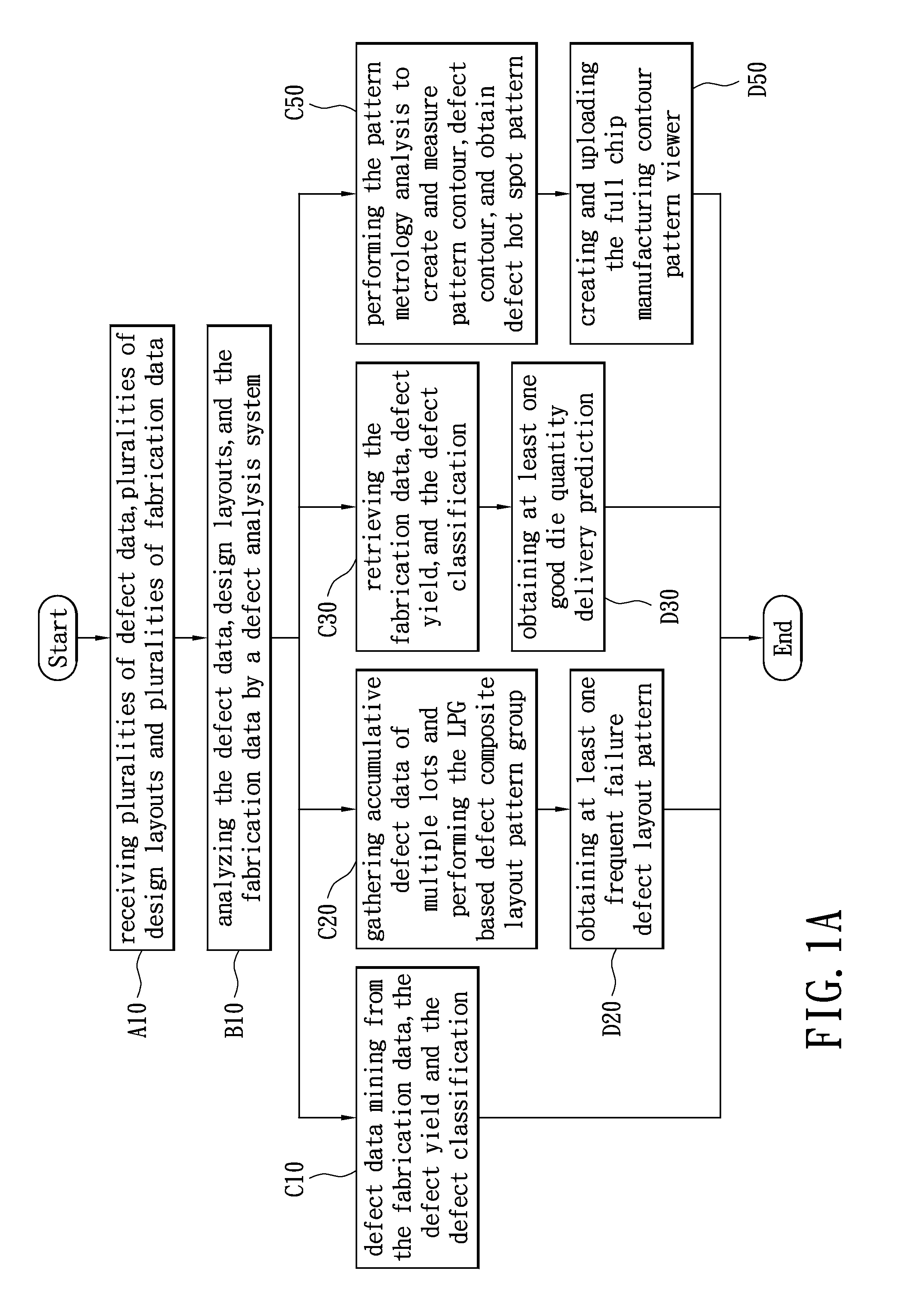

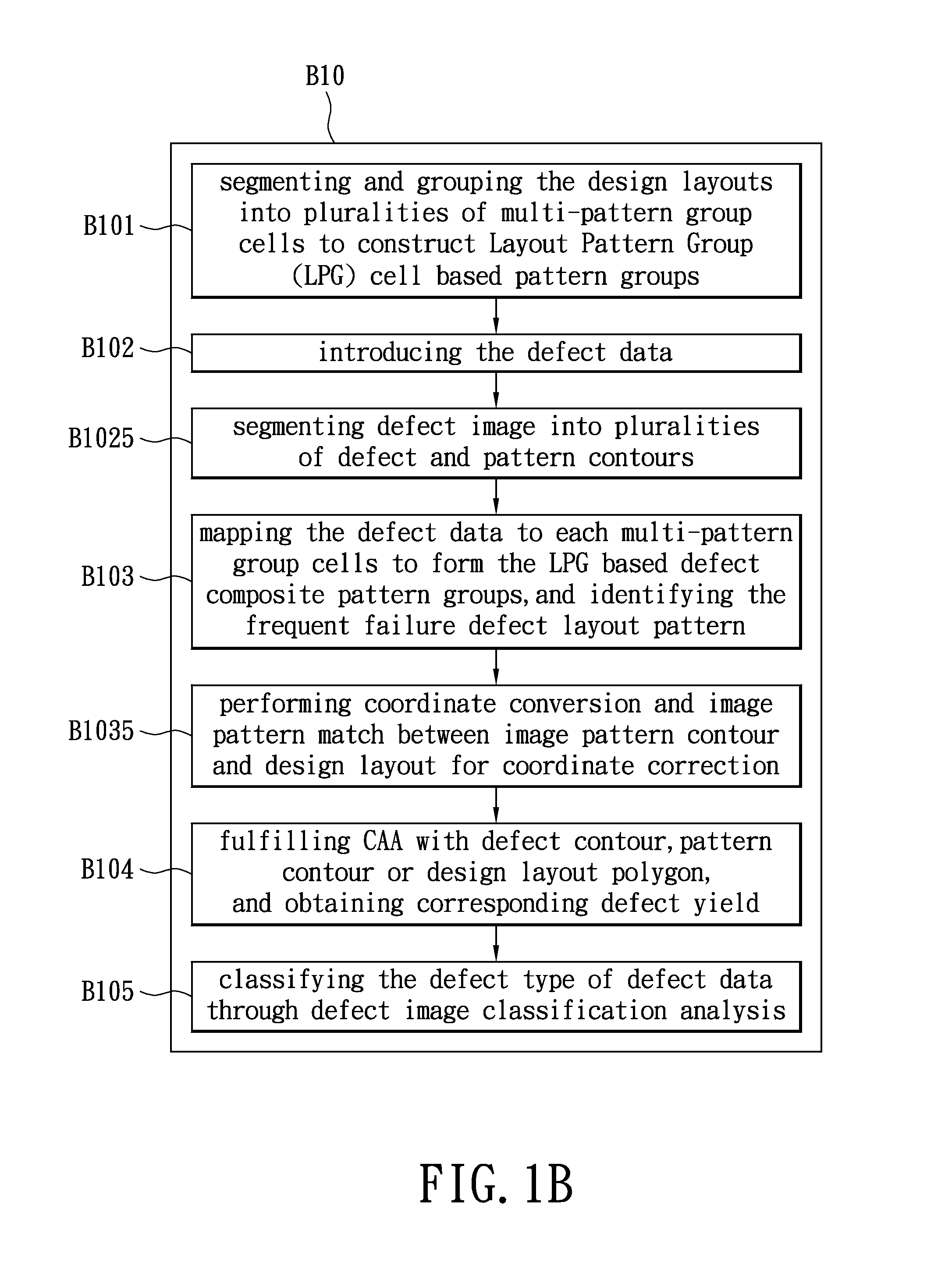

InactiveUS20130174102A1Quick monitoringRapid debugging defect yieldProgramme controlSemiconductor/solid-state device testing/measurementSystems analysisComposite pattern

An intelligent defect diagnosis method for manufacturing fab is provided. The intelligent defect diagnosis method comprises: receiving pluralities of defect data, design layouts and fabrication data; analyzing the defect data, design layouts, and the fabrication data by a defect analysis system, wherein the analyzing step further contains the sub-steps: segmenting and grouping the design layouts into pluralities of multi-pattern group cells to construct LPG cell based pattern groups; introducing the defect data; segmenting defect image into pluralities of defect and pattern contours; mapping the defect data to each multi-pattern group cell to form the LPG based defect composite pattern group; performing coordinate conversion and pattern match between image contour and design layout for coordinate correction; fulfilling CAA with defect contour, pattern contour and design layout, and obtaining corresponding defect yield; classifying the defect type of defect data through defect image classification analysis.

Owner:ELITETECH TECH

Biased curve indicator random field filters for enhancement of contours in images

InactiveUS7130484B2Image enhancementTelevision system detailsPattern recognitionNonlinear systems of equations

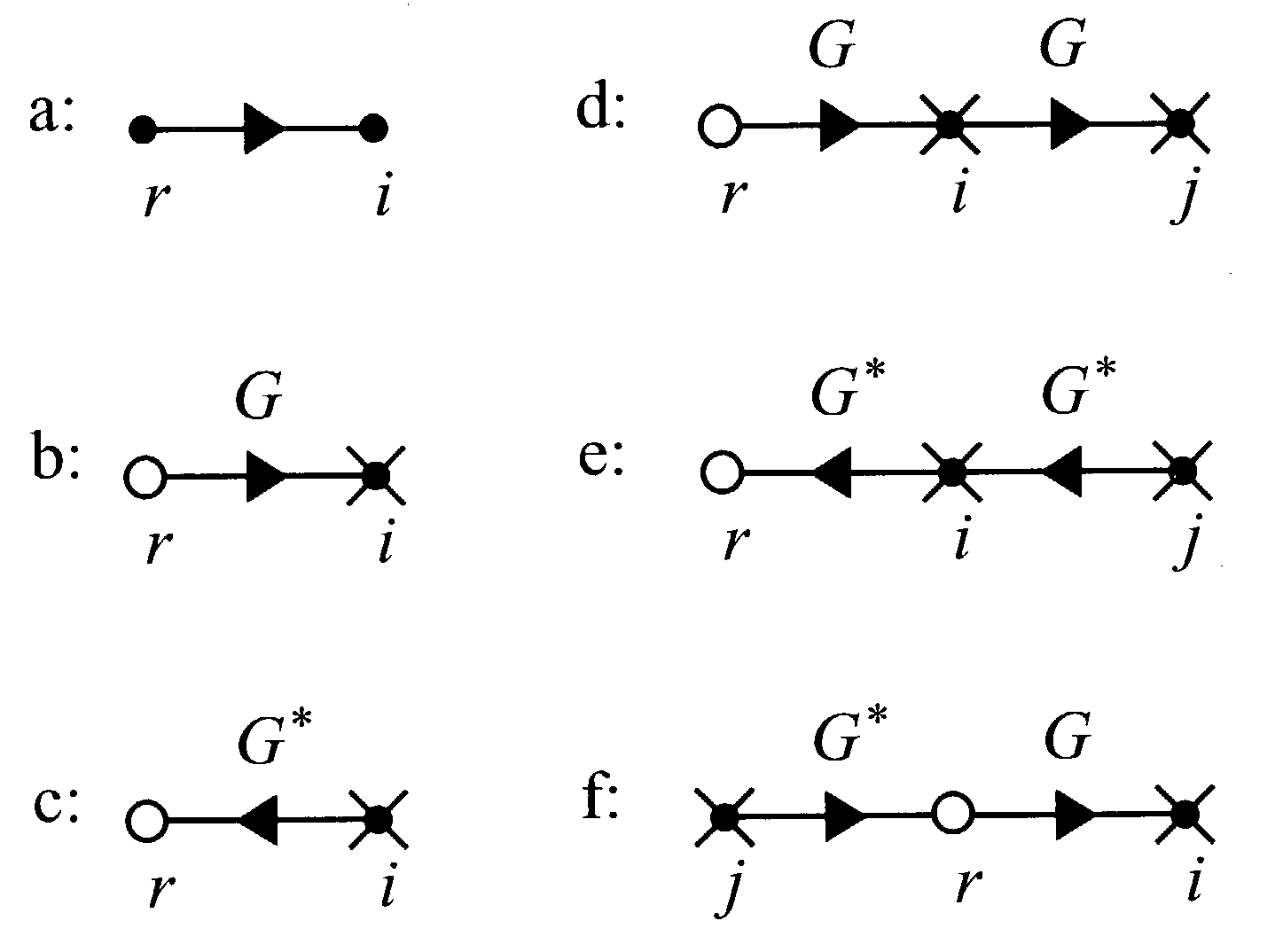

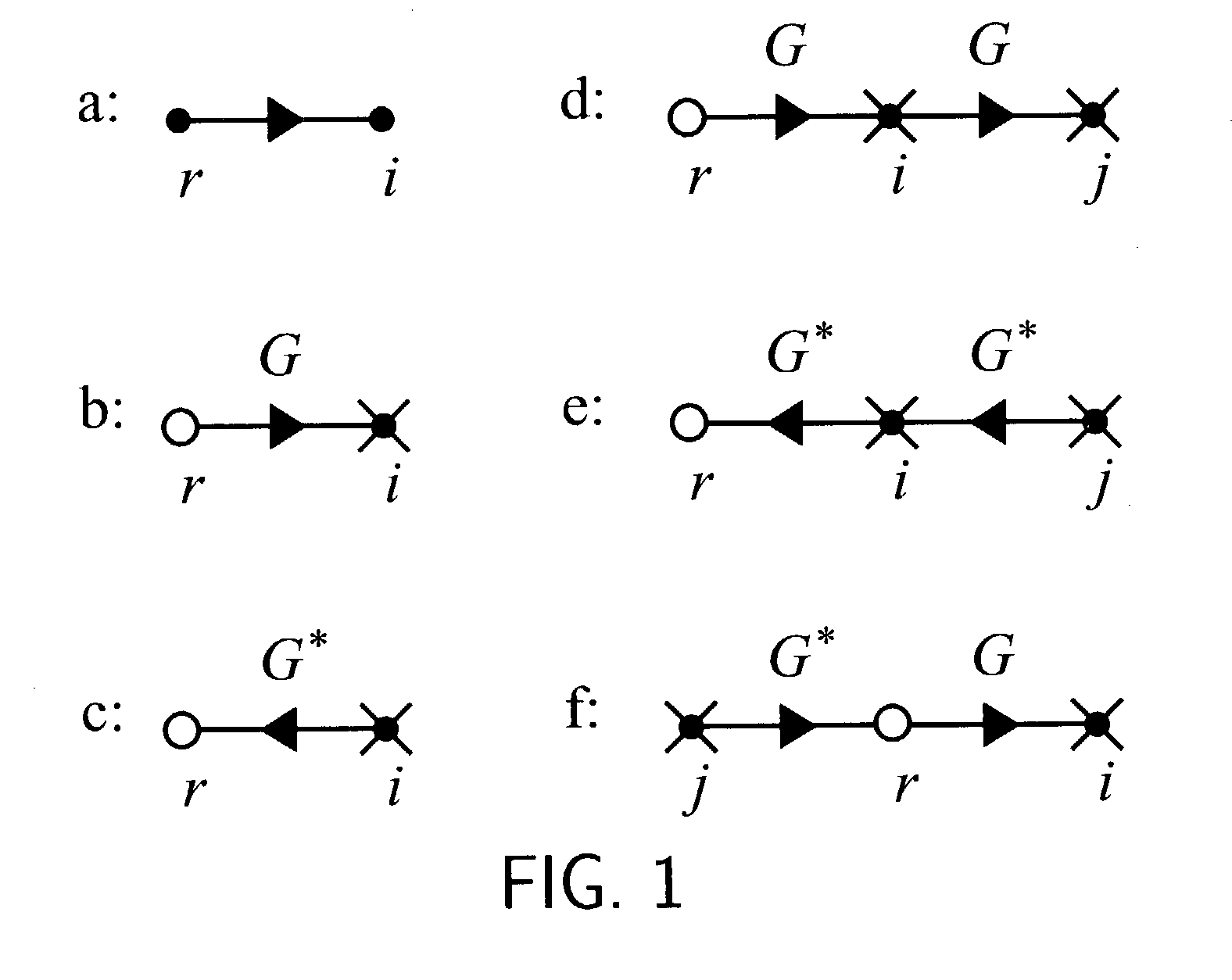

Enhancement of contours in images that are noisy or otherwise corrupted is important in medical imaging, scanning for weapons detection, and many other fields. Here, the Curve Indicator Random Field (CIRF) is used as a model of uncorrupted images of contours for constructing filters with biased CIRF posterior mean approximations involving a coupled nonlinear system of equations with a number of adjustable parameters.

Owner:AUGUST JONAS

Image registration and multi-resolution fusion-based panoramic image splicing method

InactiveCN108416732AReduce invalid areaUniform exposureImage enhancementImage analysisEqualizationMulti resolution

The invention discloses an image registration and multi-resolution fusion-based panoramic image splicing method. An adaptive threshold of sequence images is subjected to binary processing and image contour information is extracted by utilizing a pixel neighborhood relationship; a similar region of an image contour structure is quickly estimated through a similarity measurement method for Hu momentinvariant features; and SIFT feature point extraction is performed in a similar region part of two original images. Moreover, feature point initial matching is performed by using a bidirectional K-nearest classification algorithm; mismatched points are screened by an RANSAC algorithm; and an affine transformation matrix among the images is estimated. In addition, in an image fusion aspect, brightness equalization and local color mapping processing is adopted. Then, through an improved Laplacian pyramid multi-resolution fusion algorithm, spliced images are fused to realize seamless splicing. According to the method, the image splicing time is shortened, the image splicing efficiency is improved, the similar region can be quickly located, the mismatch in splicing is effectively improved, and the image registration precision is improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

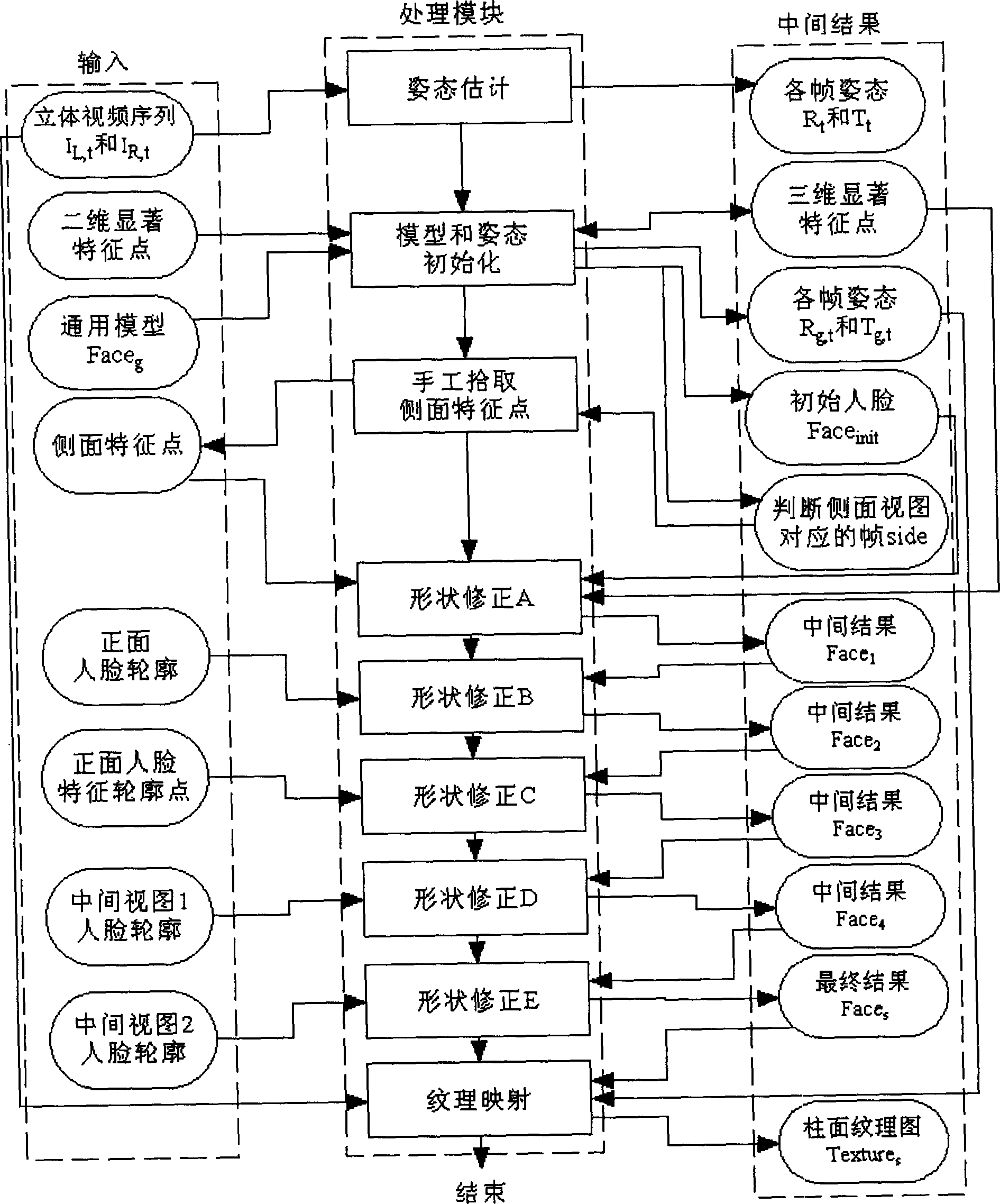

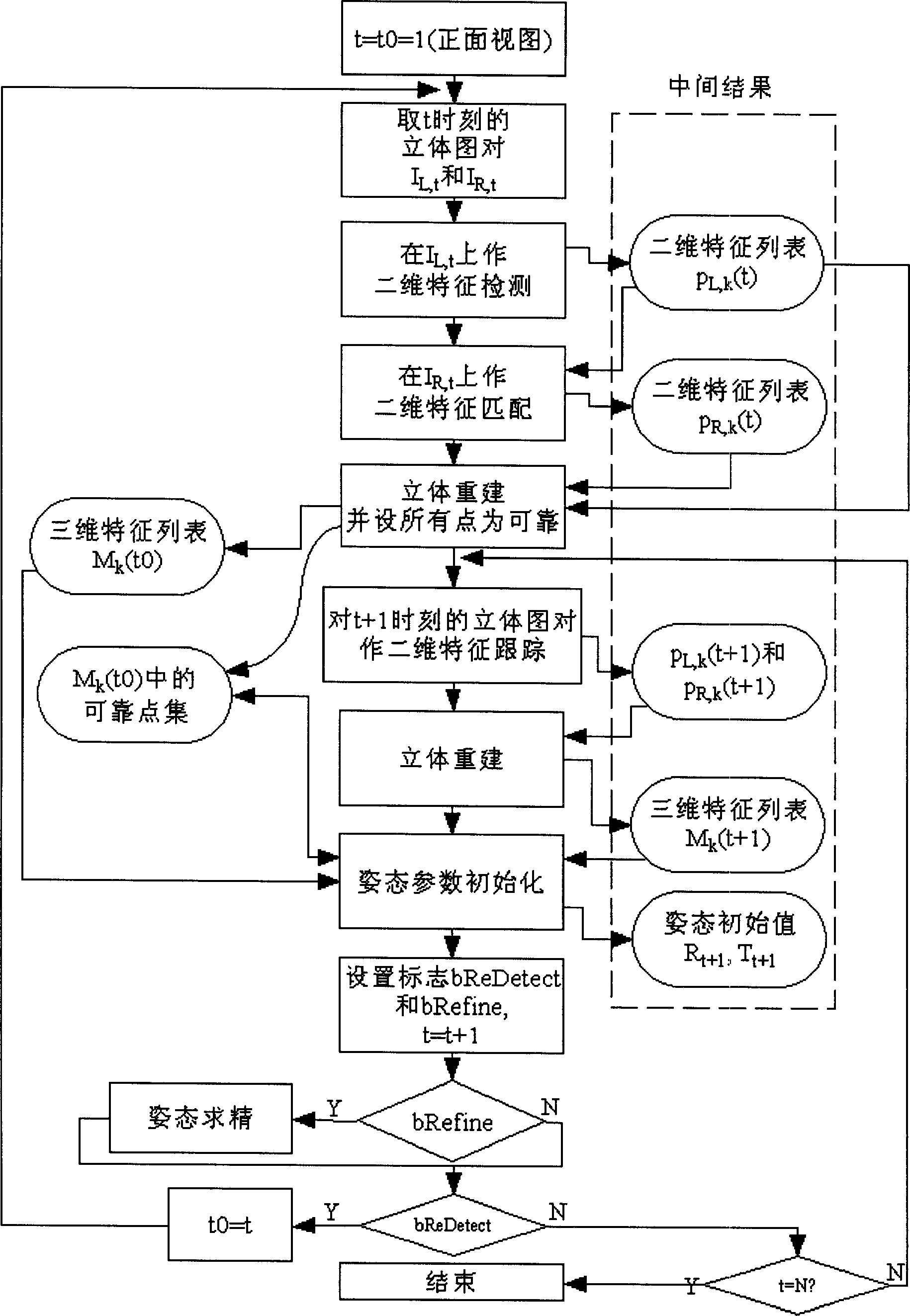

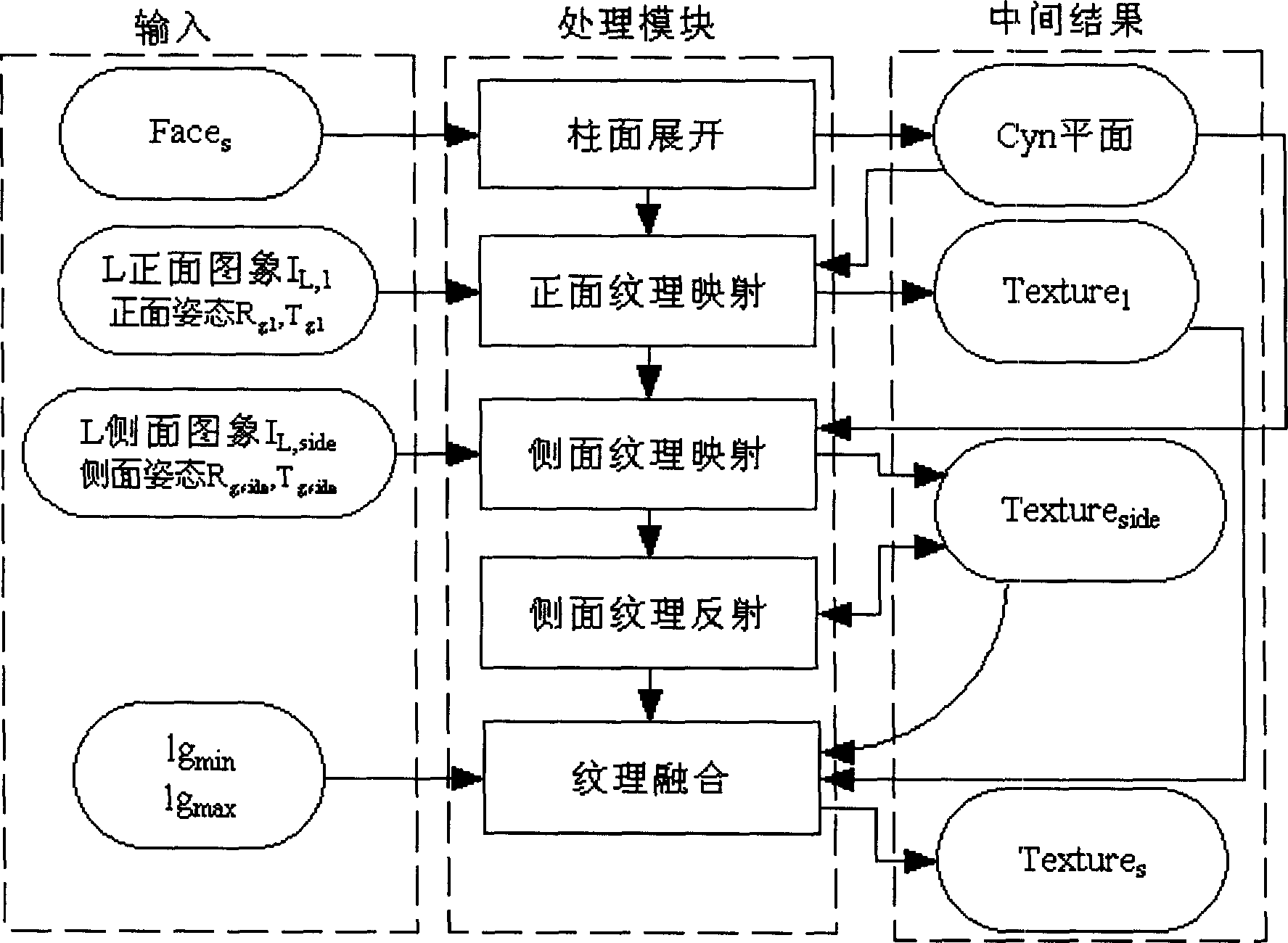

Establishing method of human face 3D model by fusing multiple-visual angle and multiple-thread 2D information

InactiveCN1404016AAchieve the expected purpose2D-image generation3D-image renderingPattern recognitionAnimation

The present invention belongs to the field of computer-aided human face image re-construction technology. The present invention features that human face as model establishing object is first photographed with two, one upper and one lower, stere ovideo cameras to obtain video sequence from the front to the side of the face with unchanged expression; the precise posture parameters in different times are then obtained via autoamtic posture estimating algorithm; after the initiation of model and posture, 3D information are extracted separately from two types of 2D threads including one stereo reconstruction type of the image and the other matching and correcting type of model projection contour and image contour; and the 3D face model is finally established.

Owner:TSINGHUA UNIV

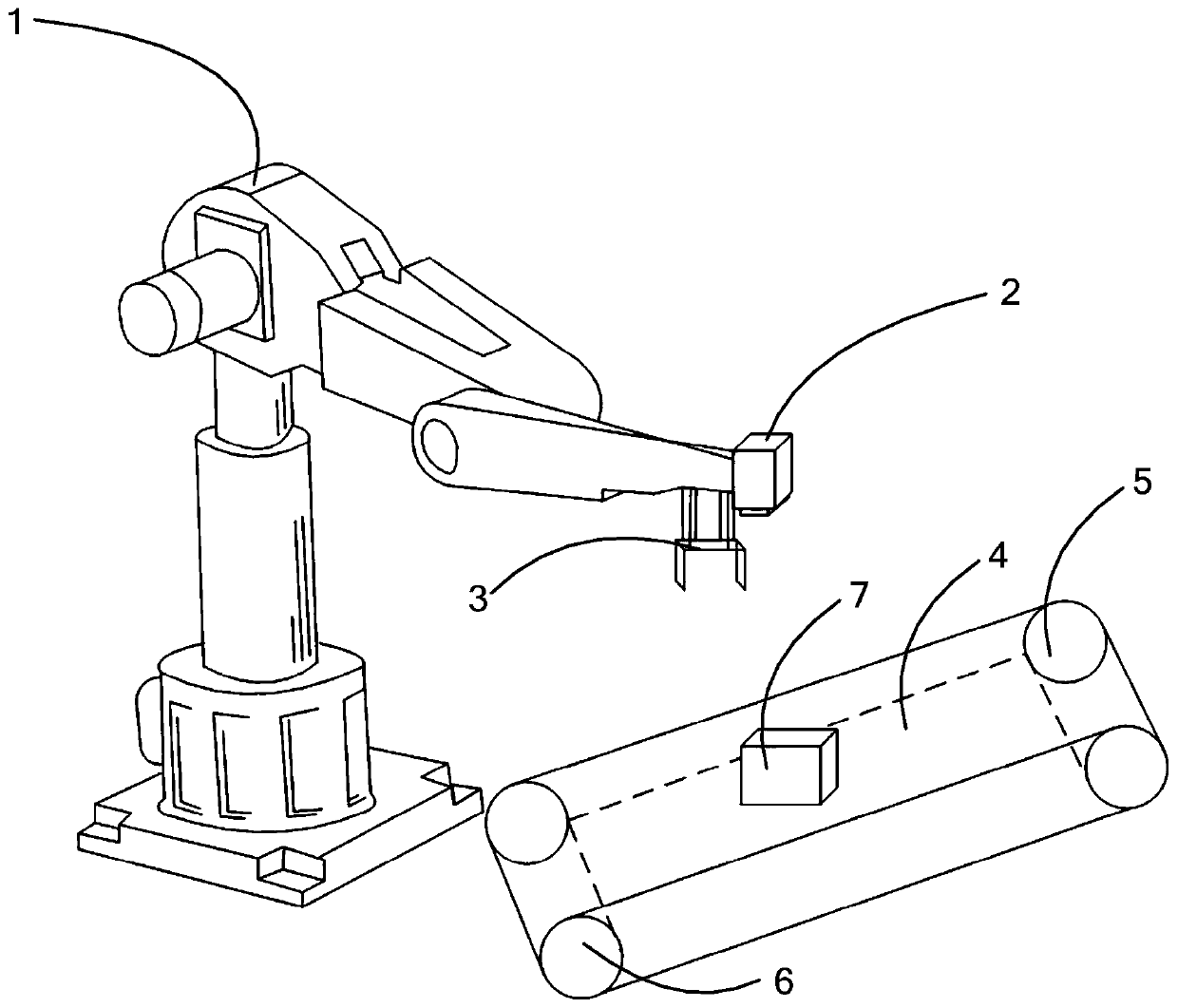

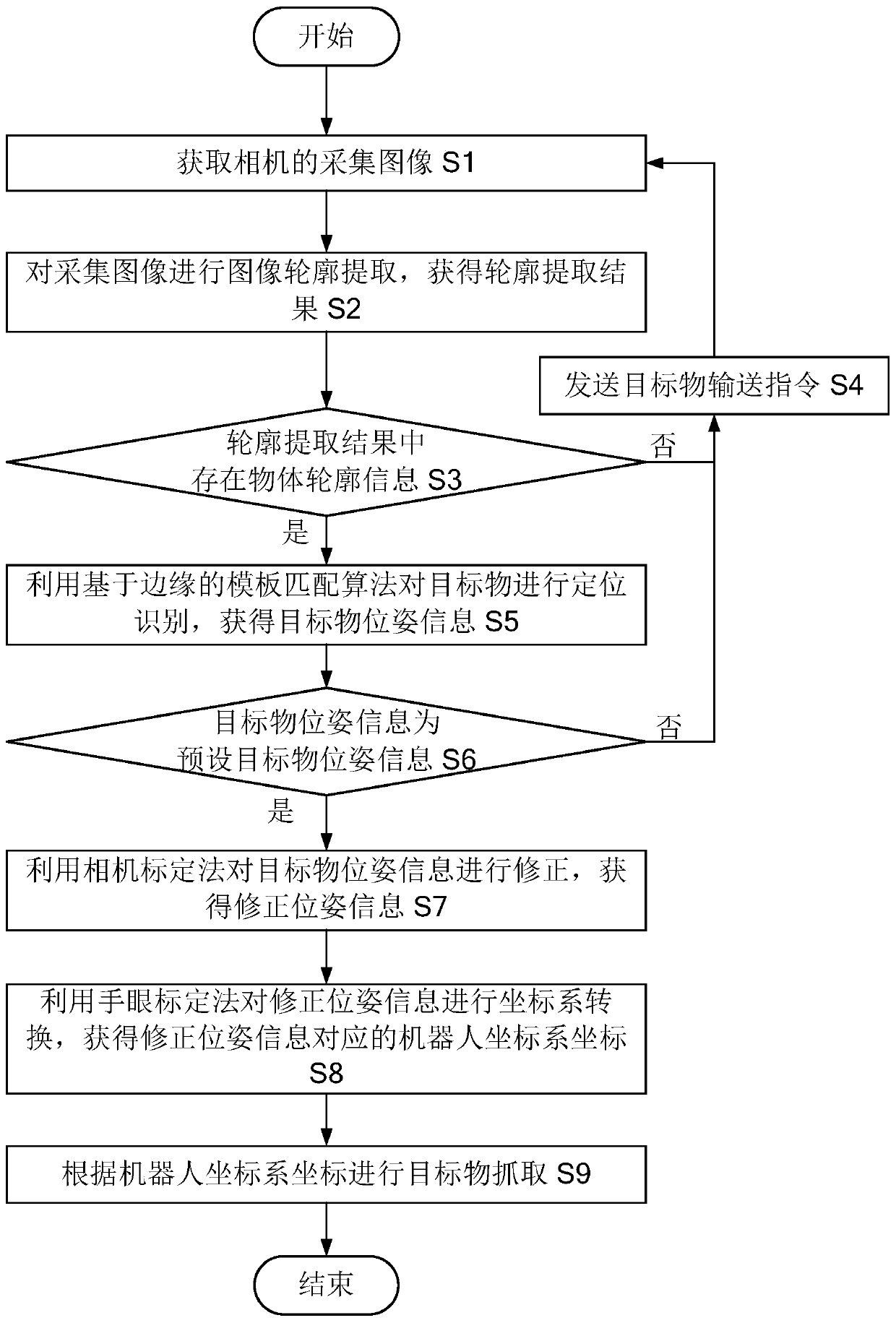

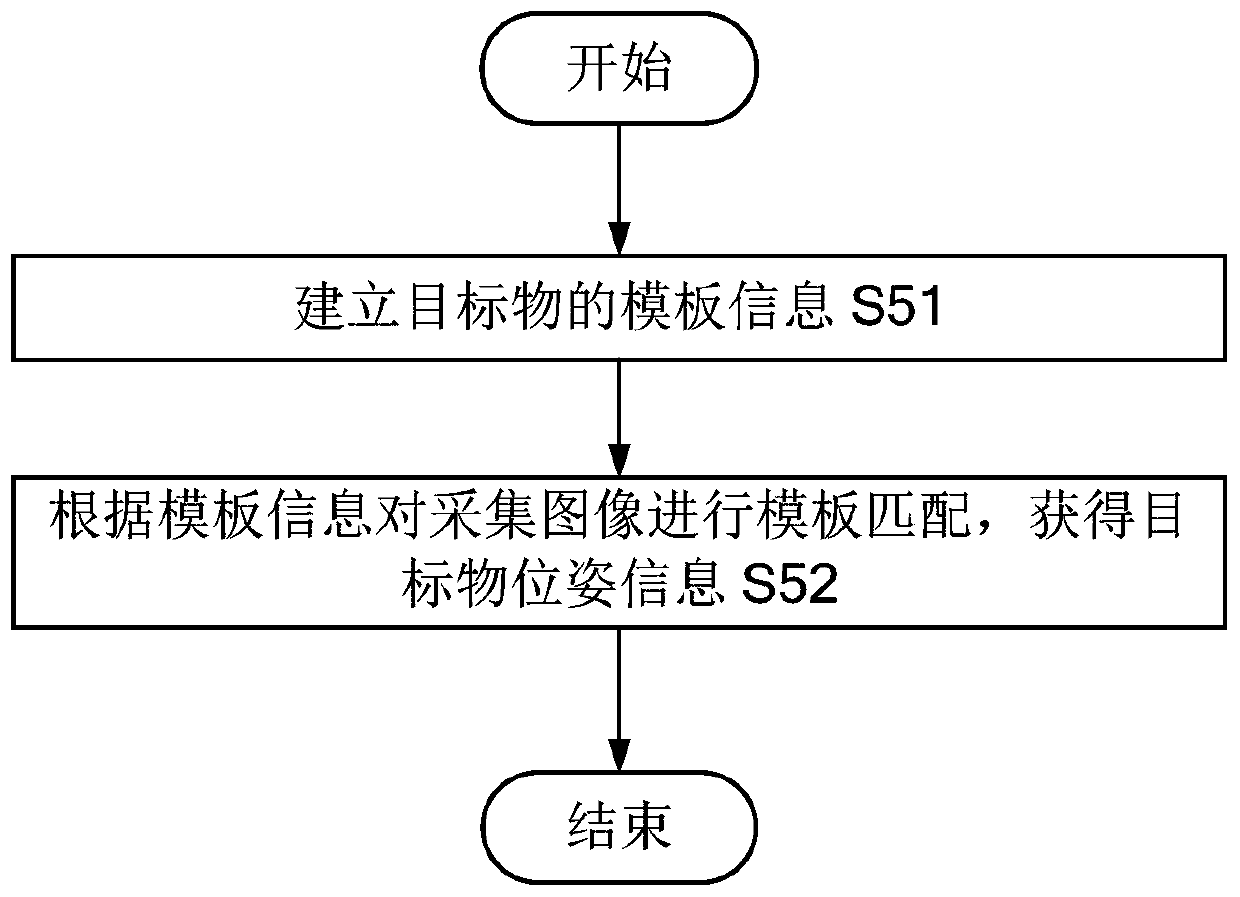

Industrial robot visual recognition positioning grabbing method, computer device and computer readable storage medium

InactiveCN110660104AImprove stabilityHigh precisionImage enhancementProgramme-controlled manipulatorComputer graphics (images)Engineering

The invention provides an industrial robot visual recognition positioning grabbing method, a computer device and a computer readable storage medium. The method comprises the steps that image contour extraction is performed on an acquired image; when the object contour information exists in the contour extraction result, positioning and identifying the target object by using an edge-based templatematching algorithm; when the target object pose information is preset target object pose information, correcting the target object pose information by using a camera calibration method; and performingcoordinate system conversion on the corrected pose information by using a hand-eye calibration method. The computer device comprises a controller, and the controller is used for implementing the industrial robot visual recognition positioning grabbing method when executing the computer program stored in the memory. A computer program is stored in the computer readable storage medium, and when thecomputer program is executed by the controller, the industrial robot visual recognition positioning grabbing method is achieved. The method provided by the invention is higher in recognition and positioning stability and precision.

Owner:GREE ELECTRIC APPLIANCES INC

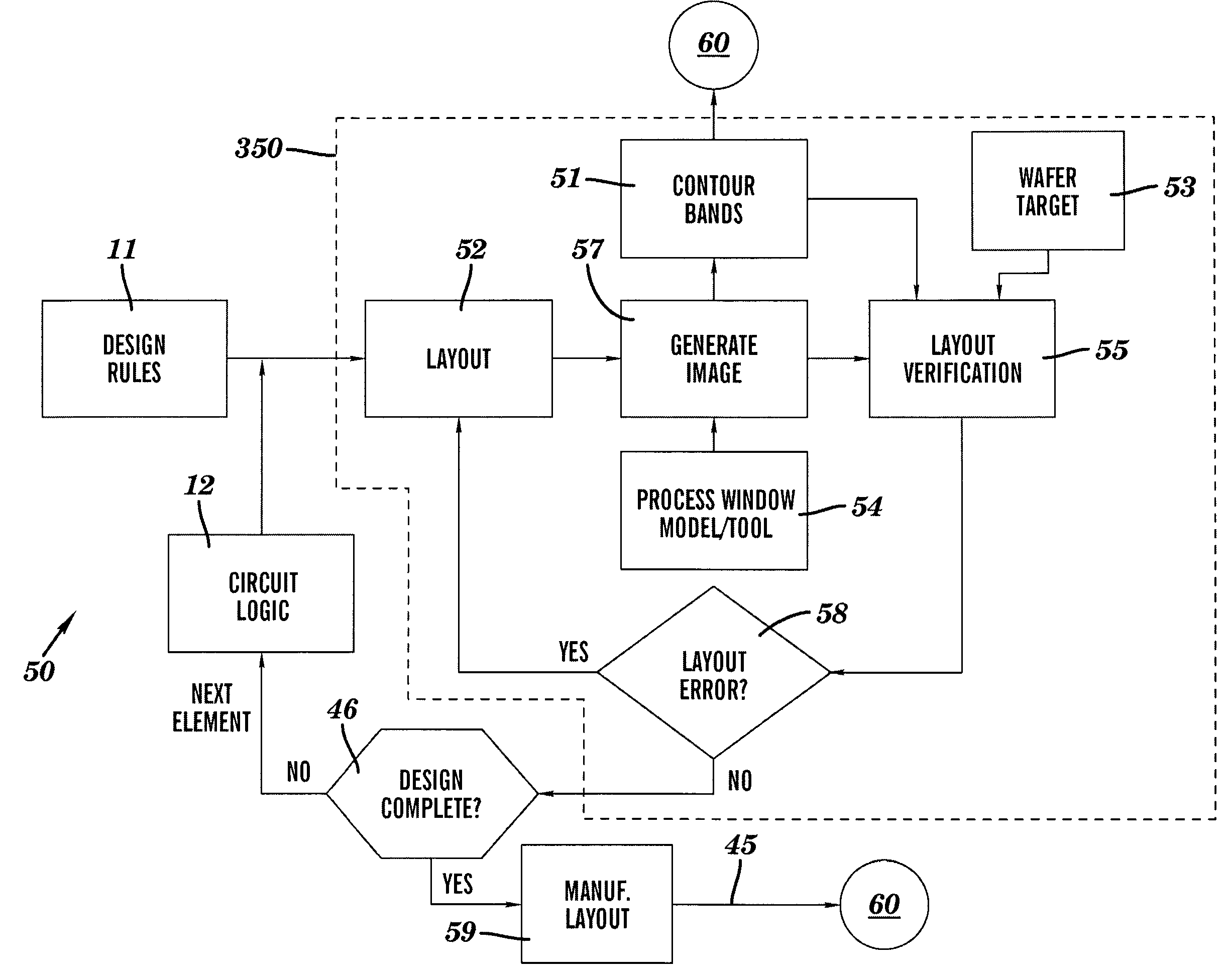

Closed-loop design for manufacturability process

InactiveUS7624369B2Simple methodSatisfy constraintsOriginals for photomechanical treatmentSpecial data processing applicationsDesign phaseLoop design

A method of designing an integrated circuit is provided in which the design layout is optimized using a process model until the design constraints are satisfied by the image contours simulated by the process model. The process model used in the design phase need not be as accurate as the lithographic model used in preparing the lithographic mask layout during data prep. The resulting image contours are then included with the modified, optimized design layout to the data prep process, in which the mask layout is optimized using the lithographic process model, for example, including RET and OPC. The mask layout optimization matches the images simulated by the lithographic process model with the image contours generated during the design phase, which ensures that the design and manufacturability constraints specified by the designer are satisfied by the optimized mask layout.

Owner:INT BUSINESS MASCH CORP

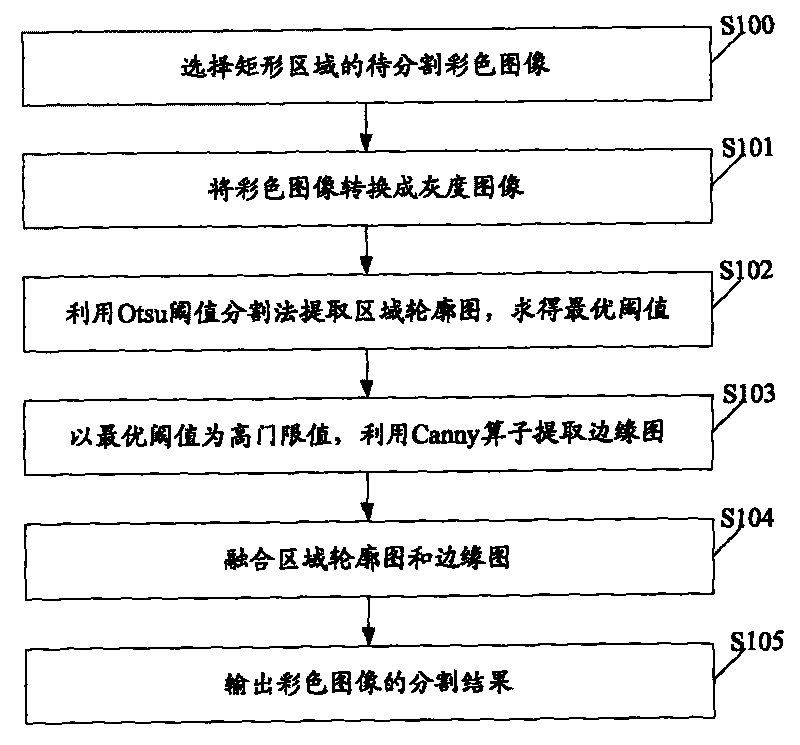

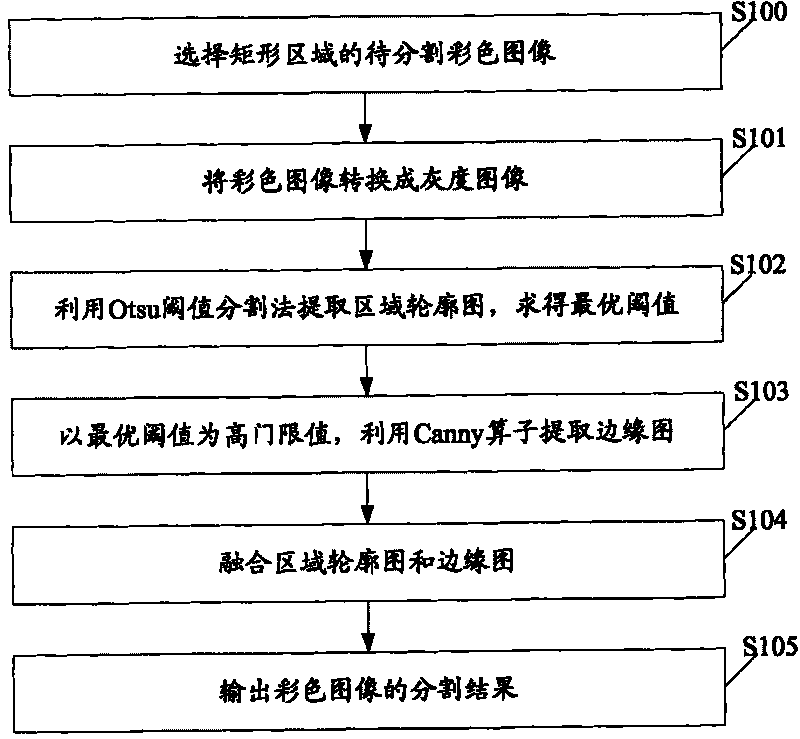

Color image segmentation method and system

InactiveCN101699511AImprove accuracyWork around application limitationsImage analysisColor imageEdge maps

The invention discloses a color image segmentation method, which comprises the following steps: processing an image to be segmented into a gray image; extracting a region profile map from the gray image by an Otsu threshold segmentation method, and determining an optimal threshold; taking the optimal threshold as a high threshold of a Canny operator, and extracting an edge map from the gray image by utilizing the Canny operator; and fusing the area profile map and the edge map, and outputting a segmentation result of a color image. The method adopts an operator threshold determining scheme combined with an adaptive strategy and an empirical value and overcomes the defect that an empirical value selecting method has application limitation; the local change intensity of a gray value is obtained through edge detection, so that over-segmentation of avoidable areas is limited; and residual edges are complemented through region segmentation, so that profiles of images after the segmentation are more clear and complete.

Owner:SHENZHEN SKYWORTH DIGITAL TECH CO LTD

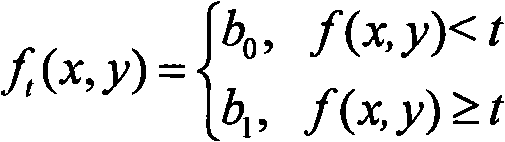

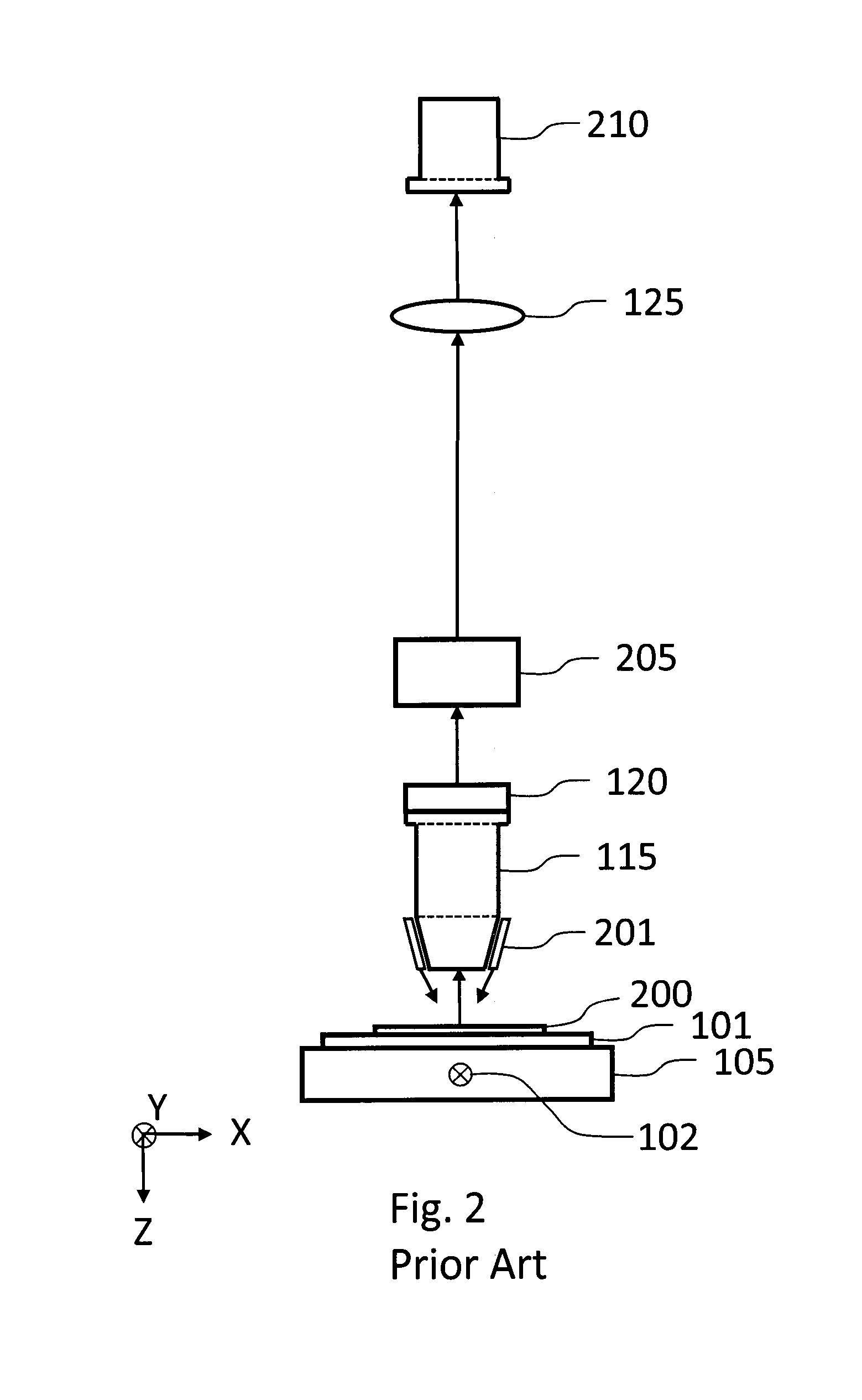

Slide scanner with dynamic focus and specimen tilt and method of operation

ActiveUS20150054921A1Avoid focusColor television detailsClosed circuit television systemsFluorescenceScan line

An instrument and method for scanning large microscope specimen on a specimen holder has a scanning optical microscope that is configured to scan the specimen in one of brightfield and fluorescence. The specimen is dynamically tillable about a scan direction during a scan to maintain focus along the length of each scan line as the scan proceeds. A three dimensional image of the specimen can be obtained wherein the specimen tilt and relative focus are maintained from a first image contour to a second image contour through a thickness of a specimen.

Owner:HURON TECH INT

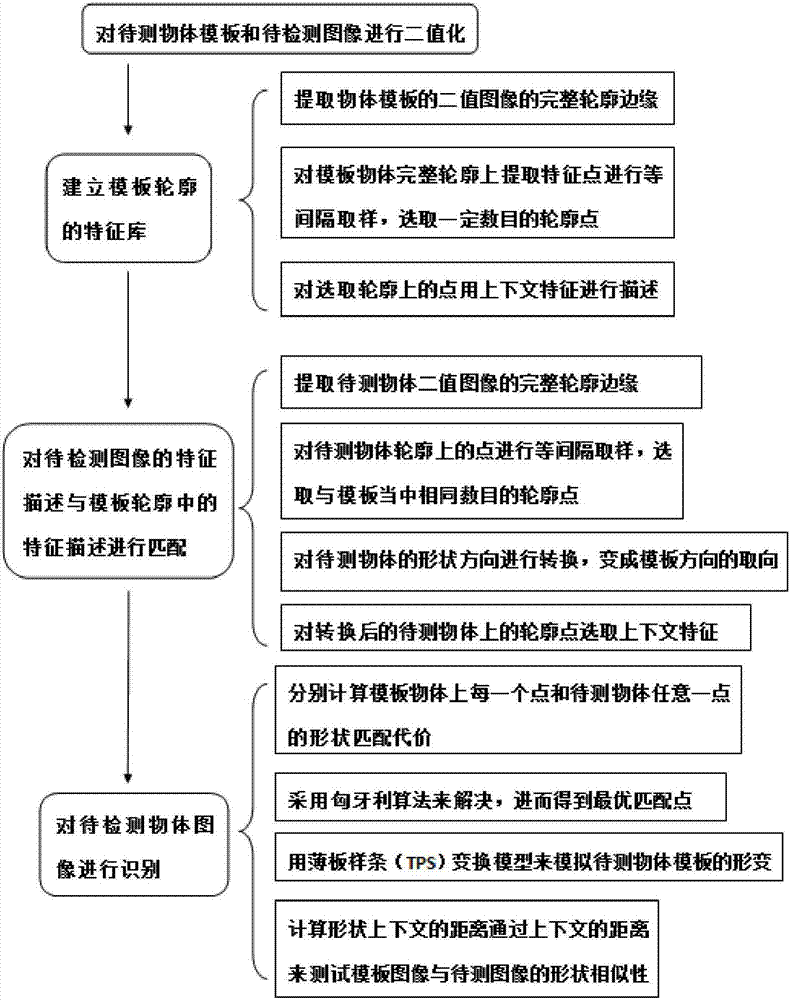

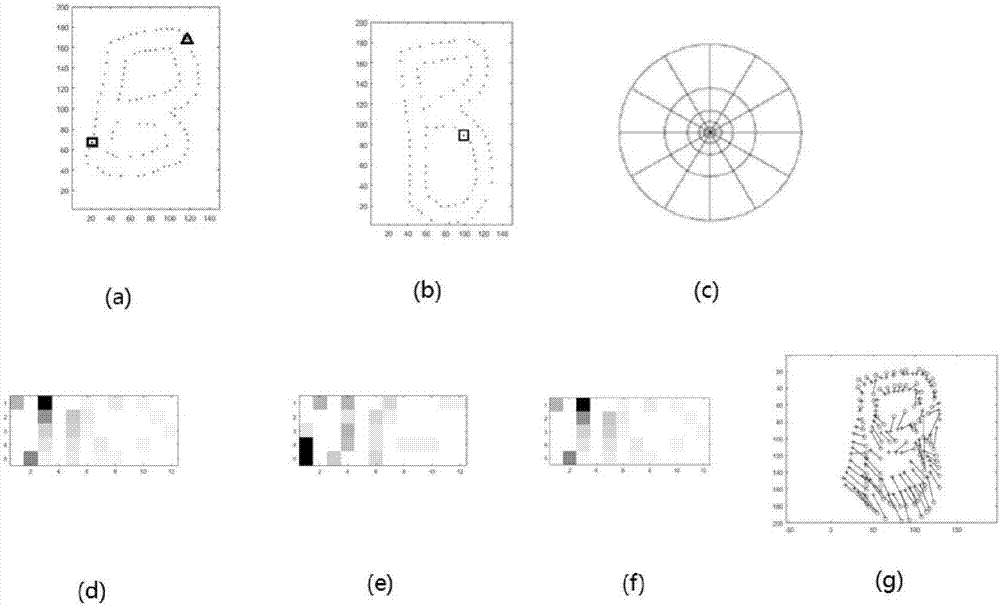

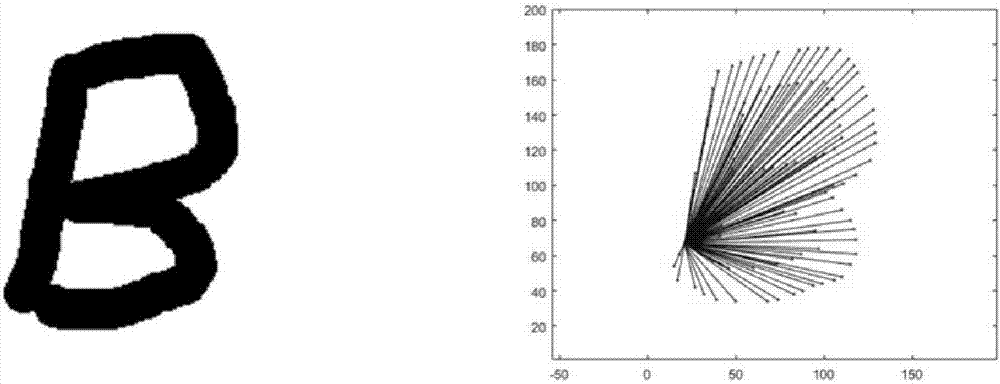

Target recognition method based on image contour characteristic

ActiveCN107103323ASolve the problem of rotation invarianceRotation invariance hasCharacter and pattern recognitionContour matchingImage contour

The invention discloses a target recognition method based on an image contour characteristic. The method comprises the steps of preprocessing a template image and a to-be-identified object image for generating a binary image; establishing a characteristic database of an object template contour; extracting a whole contour of an object template binary image, equidistantly acquiring a certain number of characteristic points on the contour, and describing the object contour by means of a context characteristic of the characteristic points; performing target recognition on the to-be-identified object image; extracting the contour edge of the to-be-identified binary image; selecting a certain number of characteristic points; converting the shape direction of the to-be-identified object to the direction of the template; describing the contour of the to-be-identified image after direction changing by means of the context characteristic of the selected points; and determining similarity between the to-be-identified object and the template object through matching cost. Compared with prior art, the target recognition method has advantages of settling a problem of rotational invariance in a contour matching process, realizing invariable rotation in the contour matching process, and realizing effective application in target recognition in the image.

Owner:SYSU CMU SHUNDE INT JOINT RES INST +1

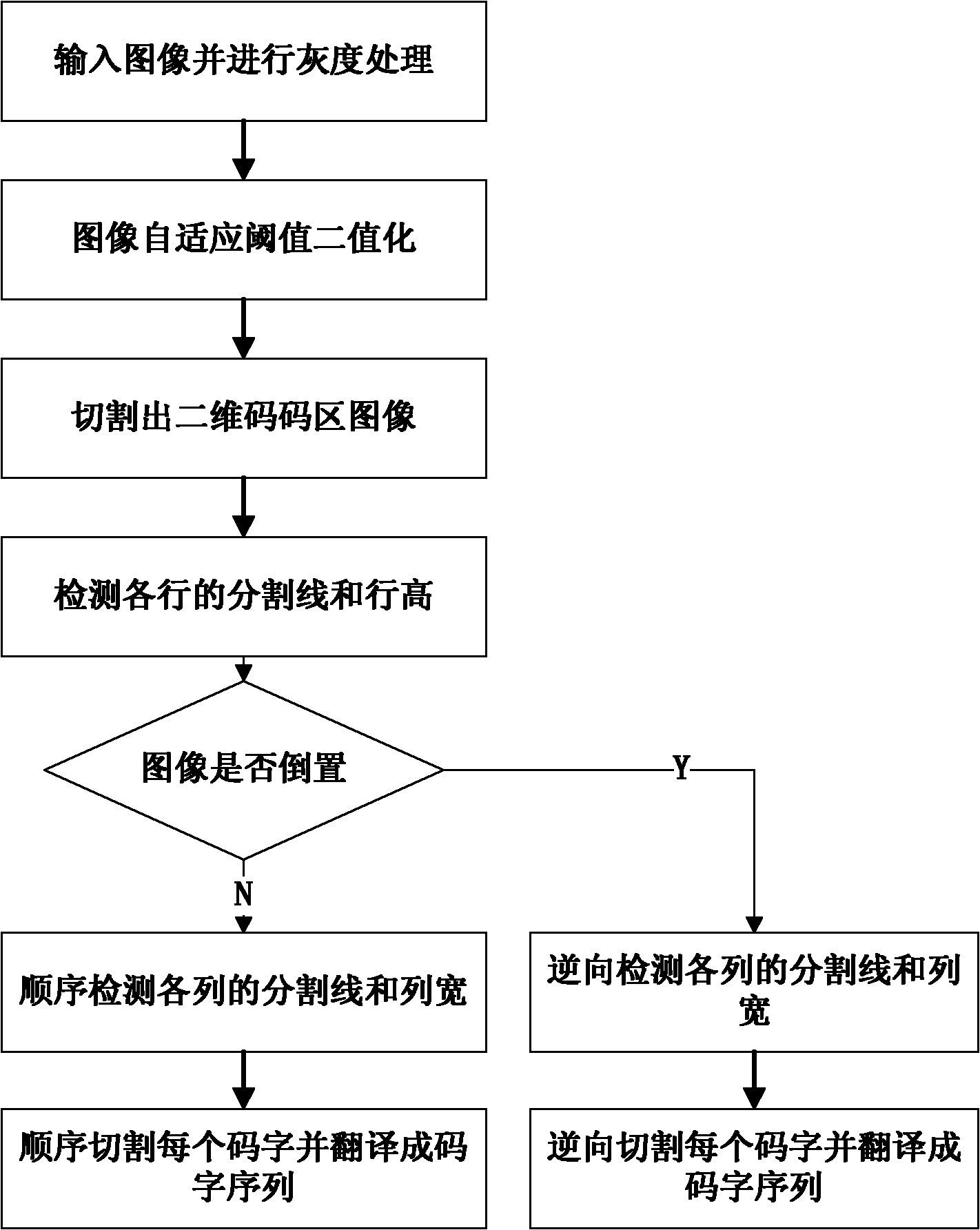

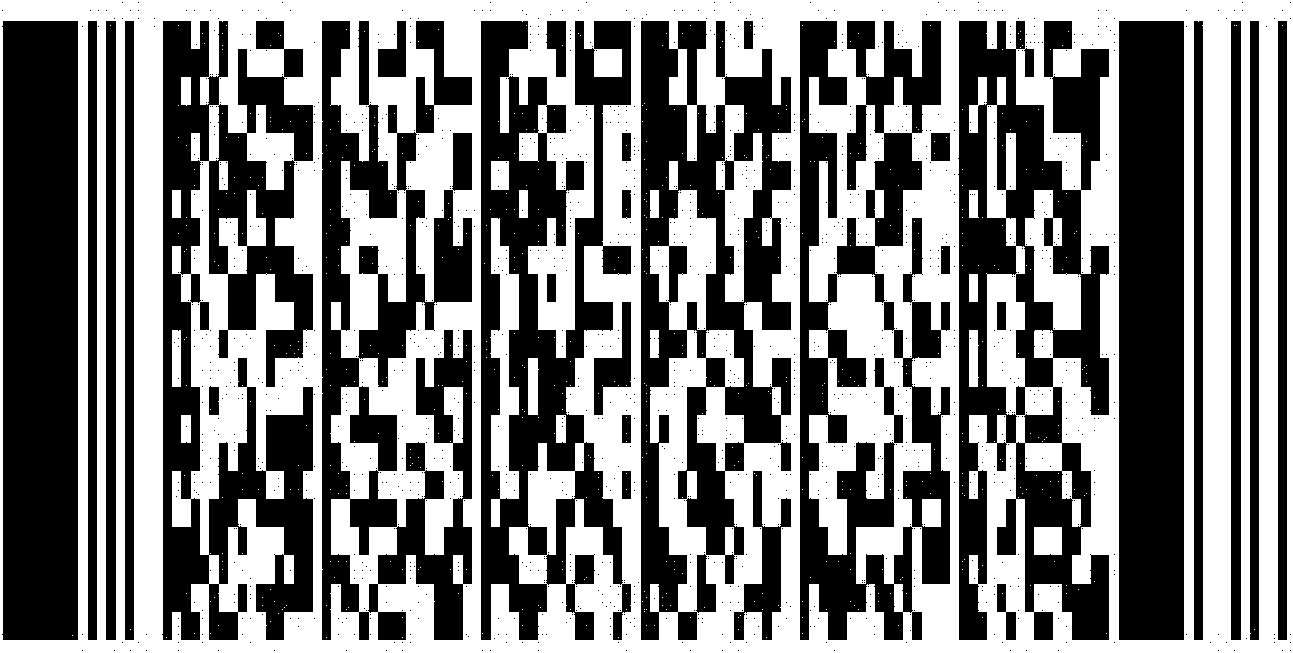

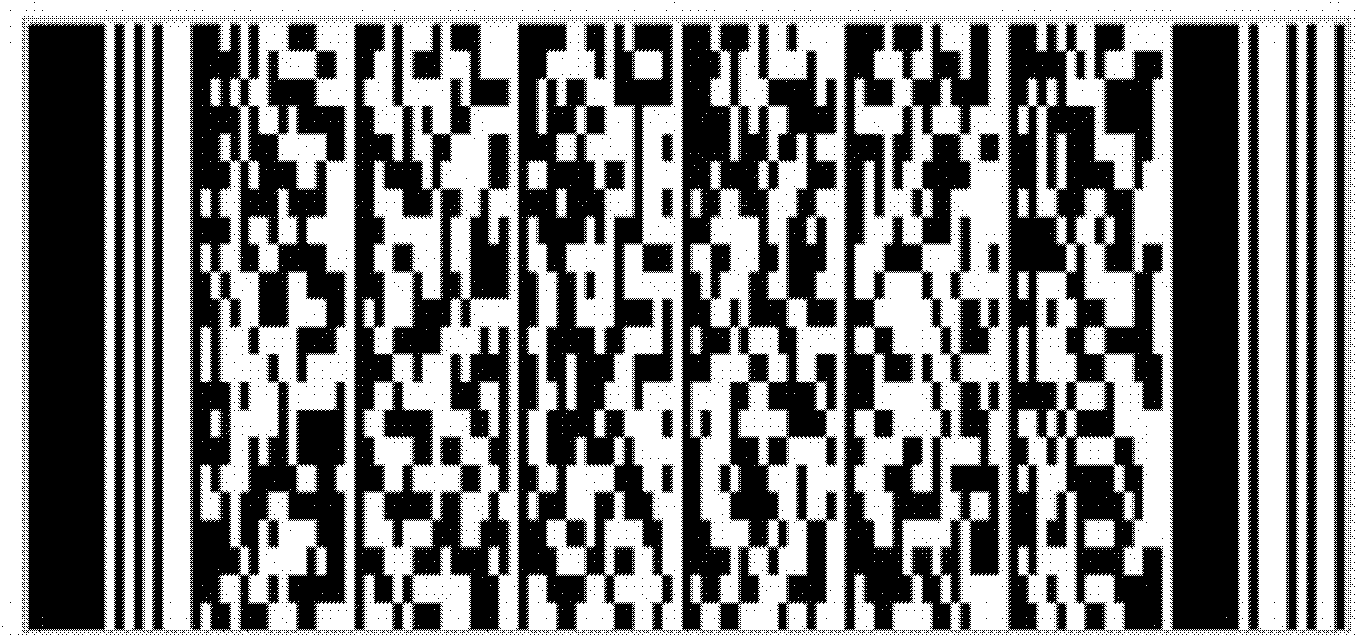

Method for cutting portable data file (PDF) 417 standard two-dimensional bar code image

InactiveCN102184378AImprove fouling resistanceImprove efficiencySensing by electromagnetic radiationSplit linesLine width

The invention discloses a method for cutting a portable data file (PDF) 417 standard two-dimensional bar code image based on a projection mode by using image profile information. The method comprises the following steps of: inputting the normal PDF417 standard two-dimensional bar code image, carrying out grey processing, and binarizing a grey image by using a self-adaptive global threshold value to obtain a two-dimensional code binary image; cutting two-dimensional code areas of the processed image to obtain the image which only has the code areas; identifying the obtained two-dimensional code image, detecting coordinates of partition lines of each row, and calculating row height; detecting whether the two-dimensional code image is inversed, cutting each code word image sequentially from top to bottom and from right to left according to the detected coordinates of the partition lines of the row, the row height, the coordinates of the partition lines of a line, and line width; and identifying code words from right to left reversely, and converting the code words into corresponding code word sequences. By the method, each code word can be cut accurately in the situation that the image is partially contaminated, lost or even inclined slightly at an angle of less than 0.1 degree. The method is high in robustness and high in reliability.

Owner:MAOMING POLYTECHNIC

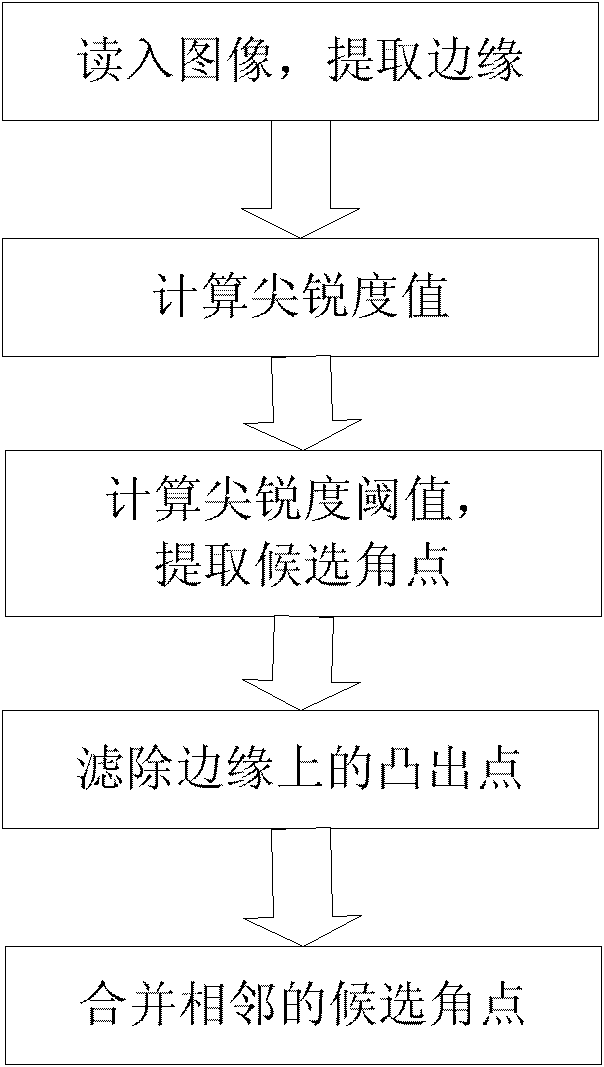

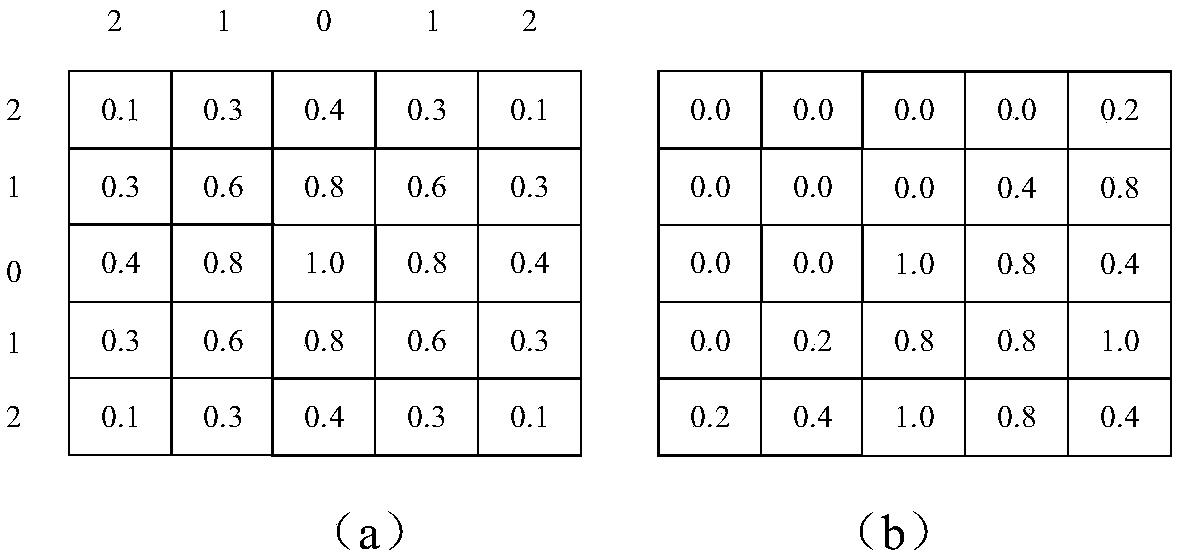

Self-adaptive angular-point detection method based on image contour sharpness

The invention relates to a self-adaptive angular-point detection method based on image contour sharpness, which comprises the following steps of: firstly extracting an image edge by utilizing an edge detection operator, and computing the sharpness of each point on the edge; for each edge, selecting the point with the sharpness larger than a threshold value as a candidate angular point by using the mean value of the sharpness of all points on the edge as a threshold value; then projecting the fitting straight line of the candidate angular point towards a supporting edge in the supporting region of the candidate angular point, computing the distance between the candidate angular point and a projected point thereof, setting a threshold value for the distance, and filtering the points with sharpness smaller than the threshold value as projected points; and finally combining the candidate angular points into one angular point when a plurality of candidate angular points are abutted according to the principle that a connection weight value is maximum and of priority and the sharpness is maximum and secondary to obtain a final image angular point. The invention has high detection accuracy and strong anti-interference capability, can not detect a false angular point when detecting a round boundary and can be applied to the aspects of 3D reconstruction, visual positioning and measurement and the like.

Owner:SHANGHAI JIAO TONG UNIV

System and method of three-dimensional image capture and modeling

InactiveUS20060227133A1Eliminate needImprove accuracyImage data processing detailsAquisition of 3D object measurementsOne passObject based

Owner:ANDREAS ACQUISITION LLC

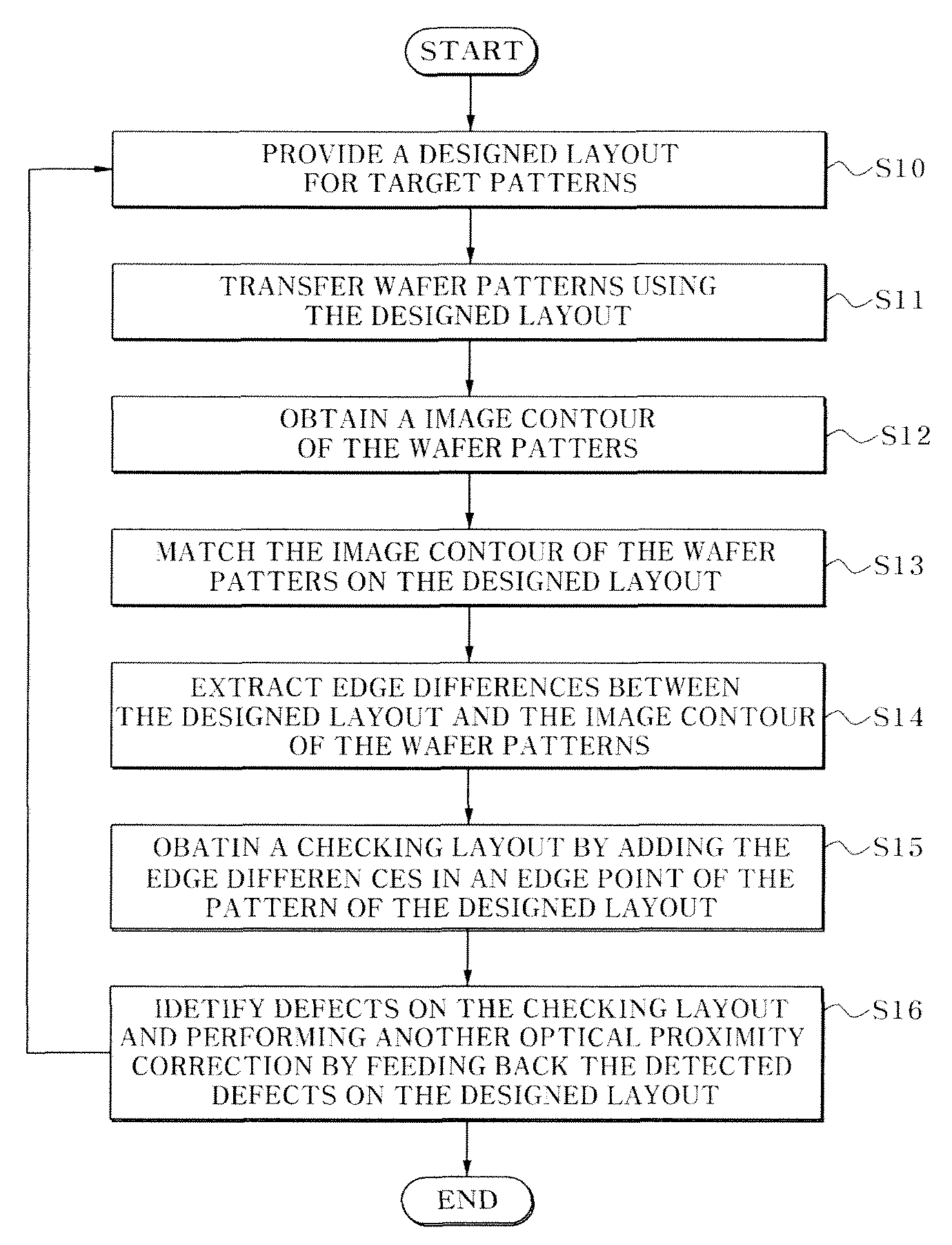

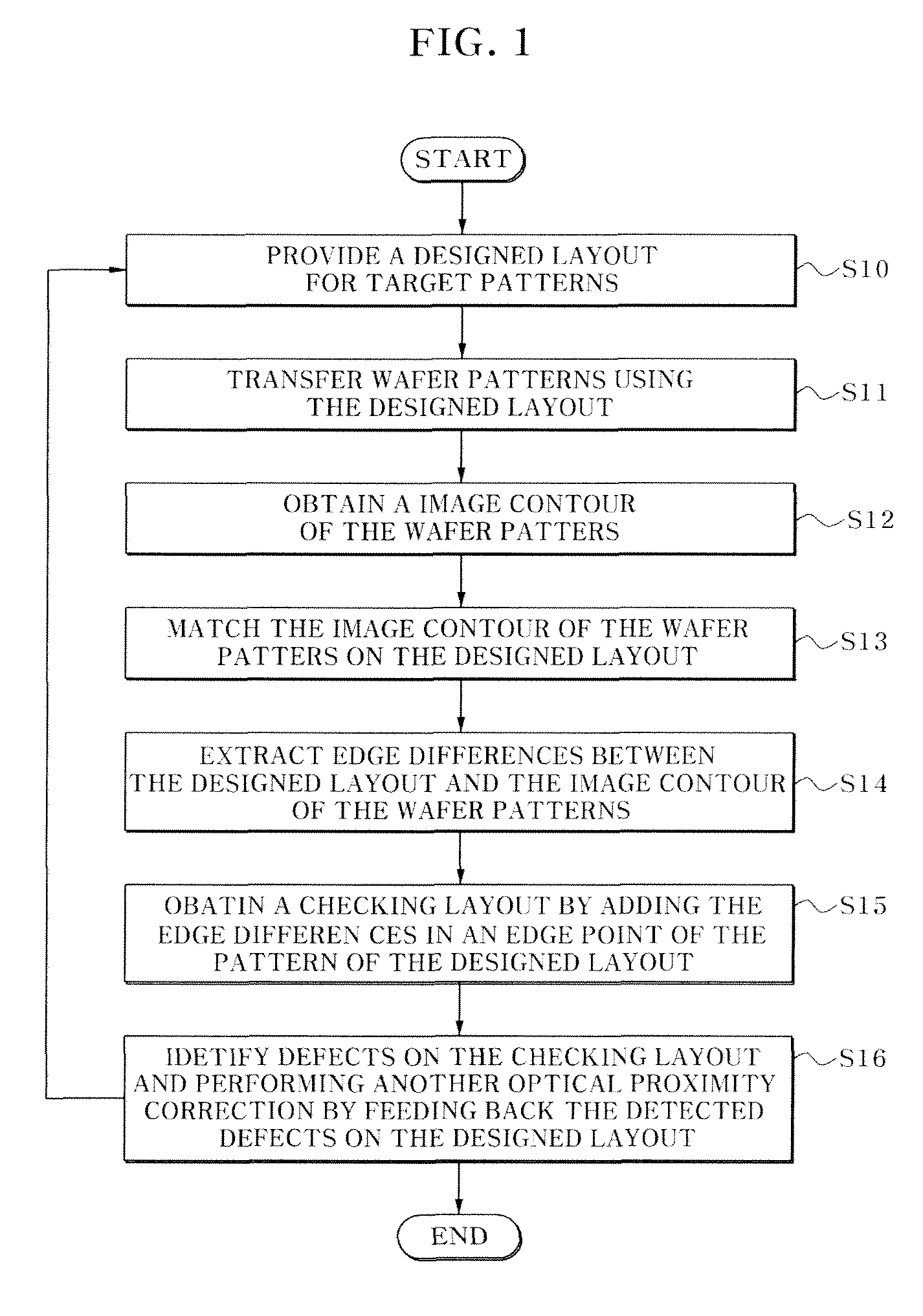

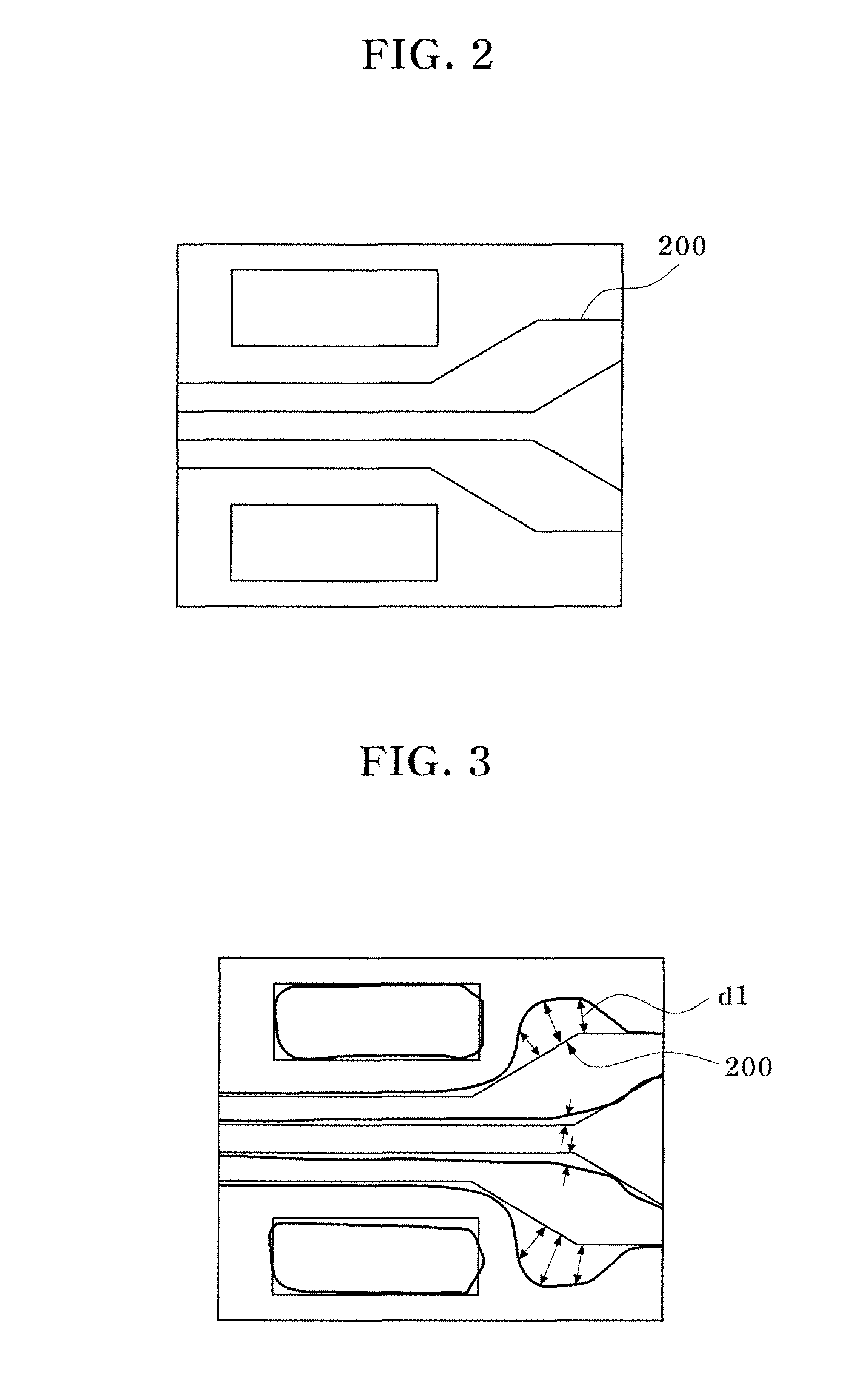

Method for verifying mask pattern of semiconductor device

ActiveUS7752584B2Photomechanical apparatusSemiconductor/solid-state device manufacturingImage contourSemiconductor

Owner:SK HYNIX INC

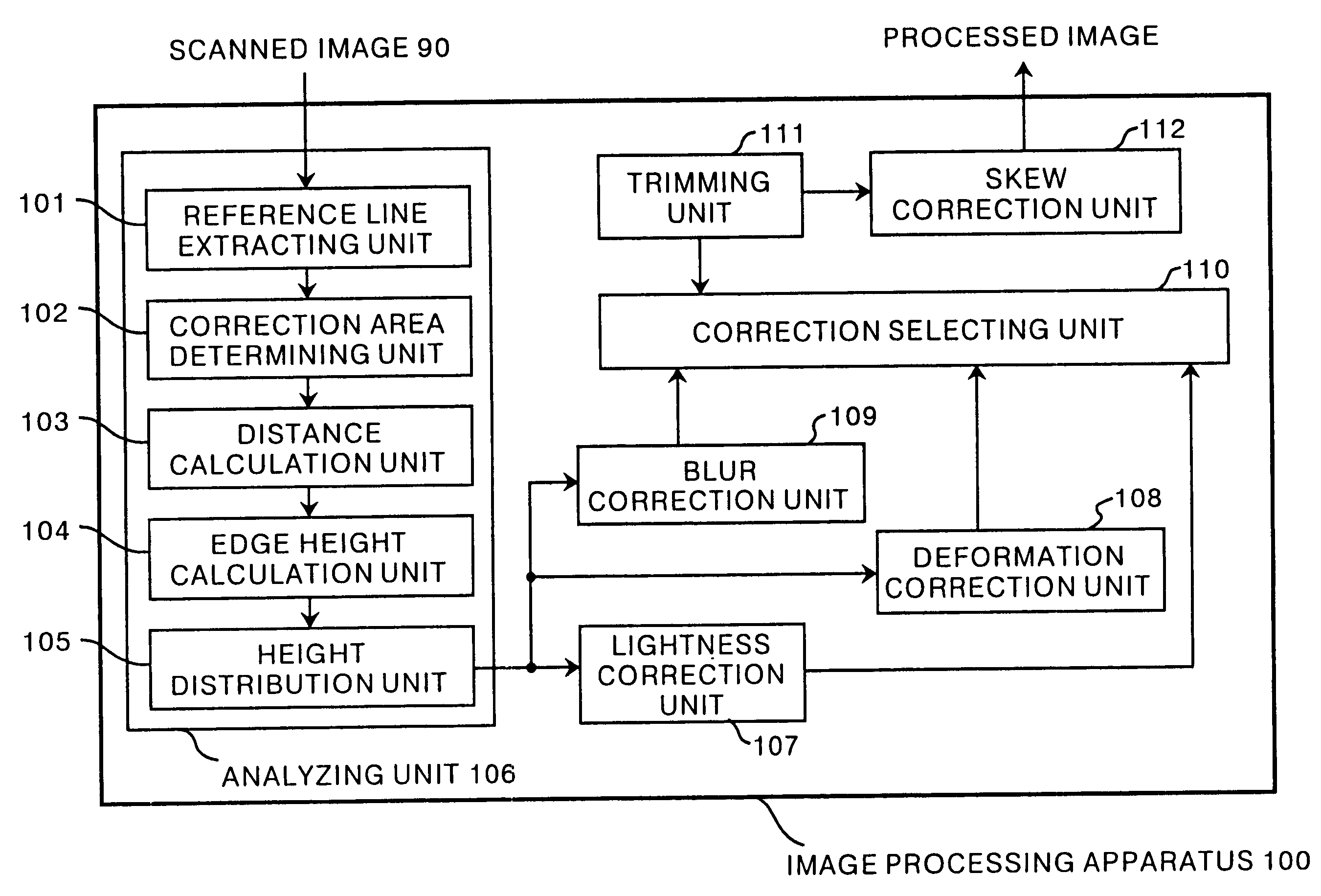

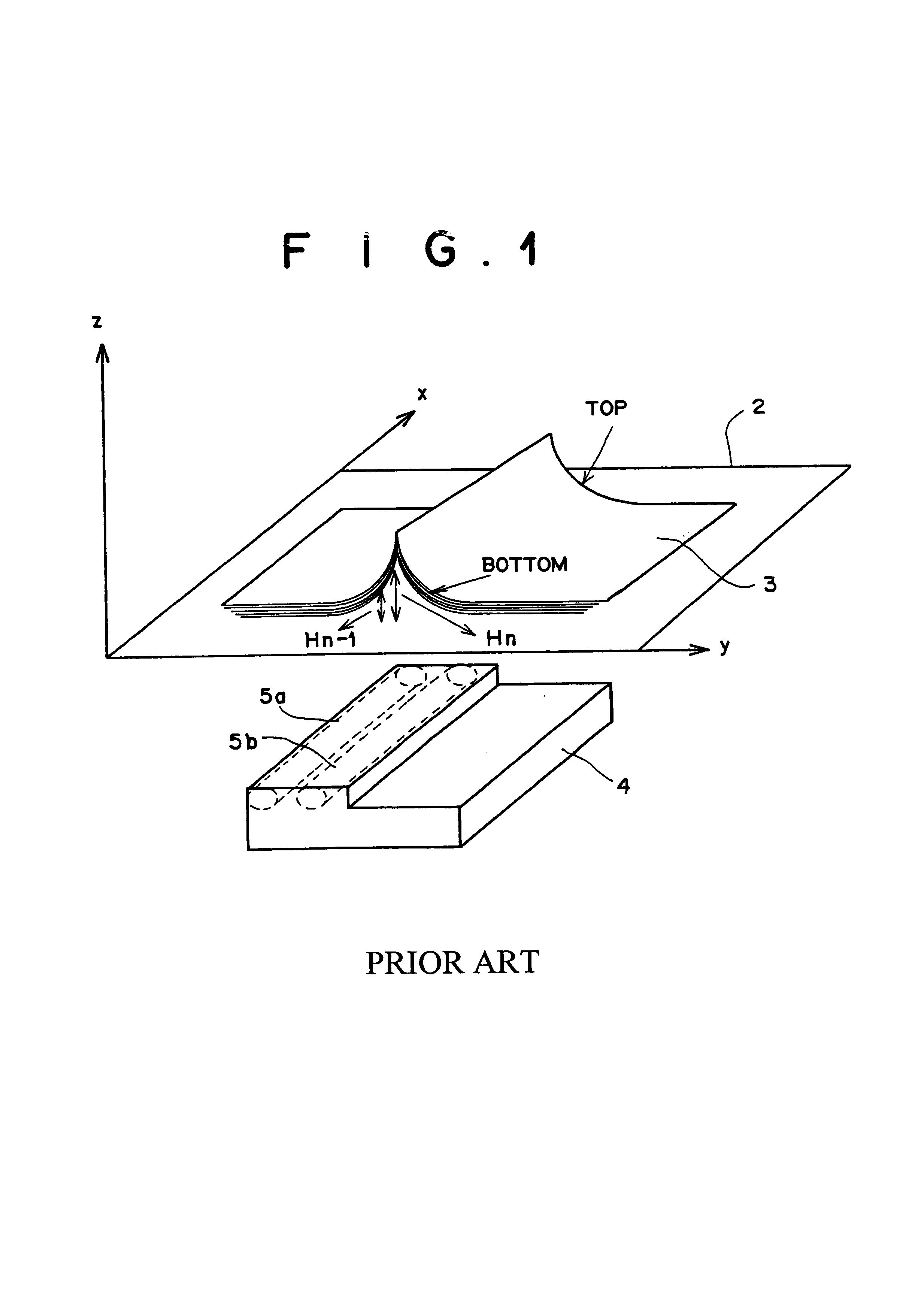

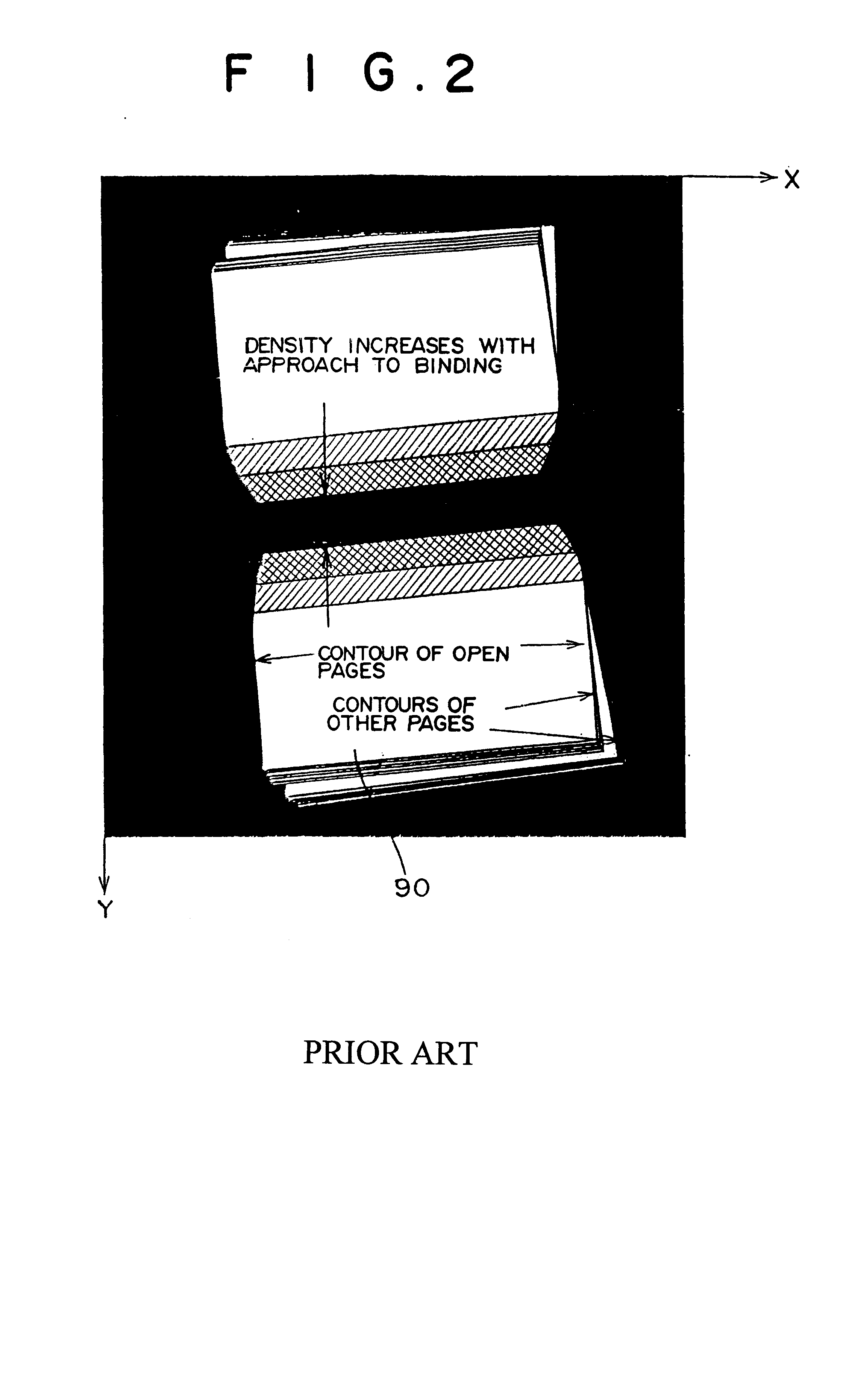

Method and apparatus for correcting degradation of book center image by image processing based on contour of book center image

InactiveUS6816624B1Character and pattern recognitionElectrographic process apparatusImage basedImaging processing

An image processing apparatus corrects degradation of an image of a pair of spread pages of a bound book placed on a document table. The image processing apparatus includes a height obtaining unit which obtains a plurality of heights, above the document table, of a plurality of points of the pair of spread pages, based on a contour of the pair of spread pages which appears in the image, and an image correcting unit which corrects the degradation of the image based on the plurality of heights obtained by the height obtaining unit. The degradation may be unevenness of lightness, deformation, a blur, or the like.

Owner:RISO KAGAKU CORP

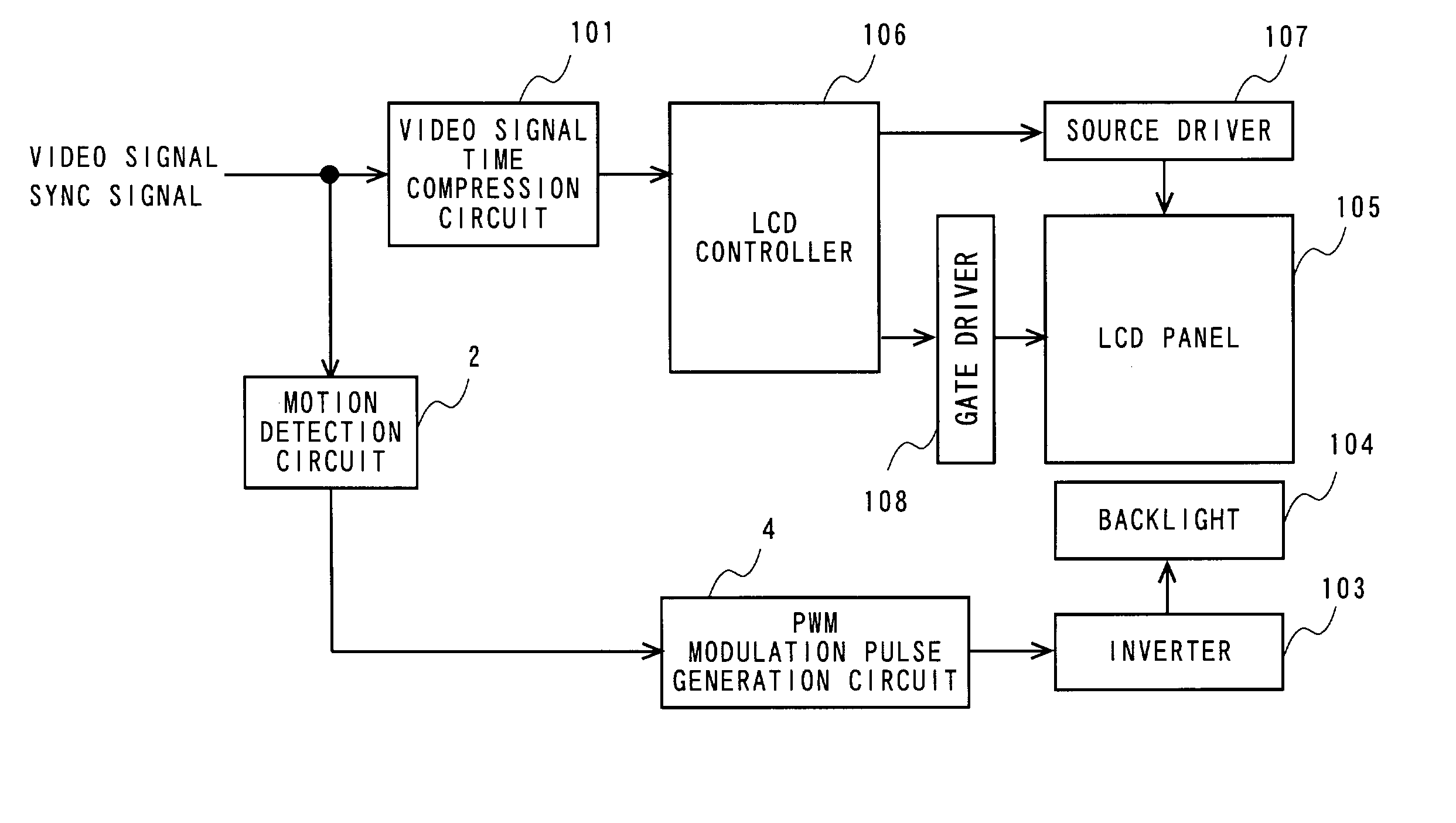

Image display apparatus and method

InactiveUS6980225B2Quality improvementHigher-quality image displayCathode-ray tube indicatorsNon-linear opticsLiquid-crystal displayDisplay device

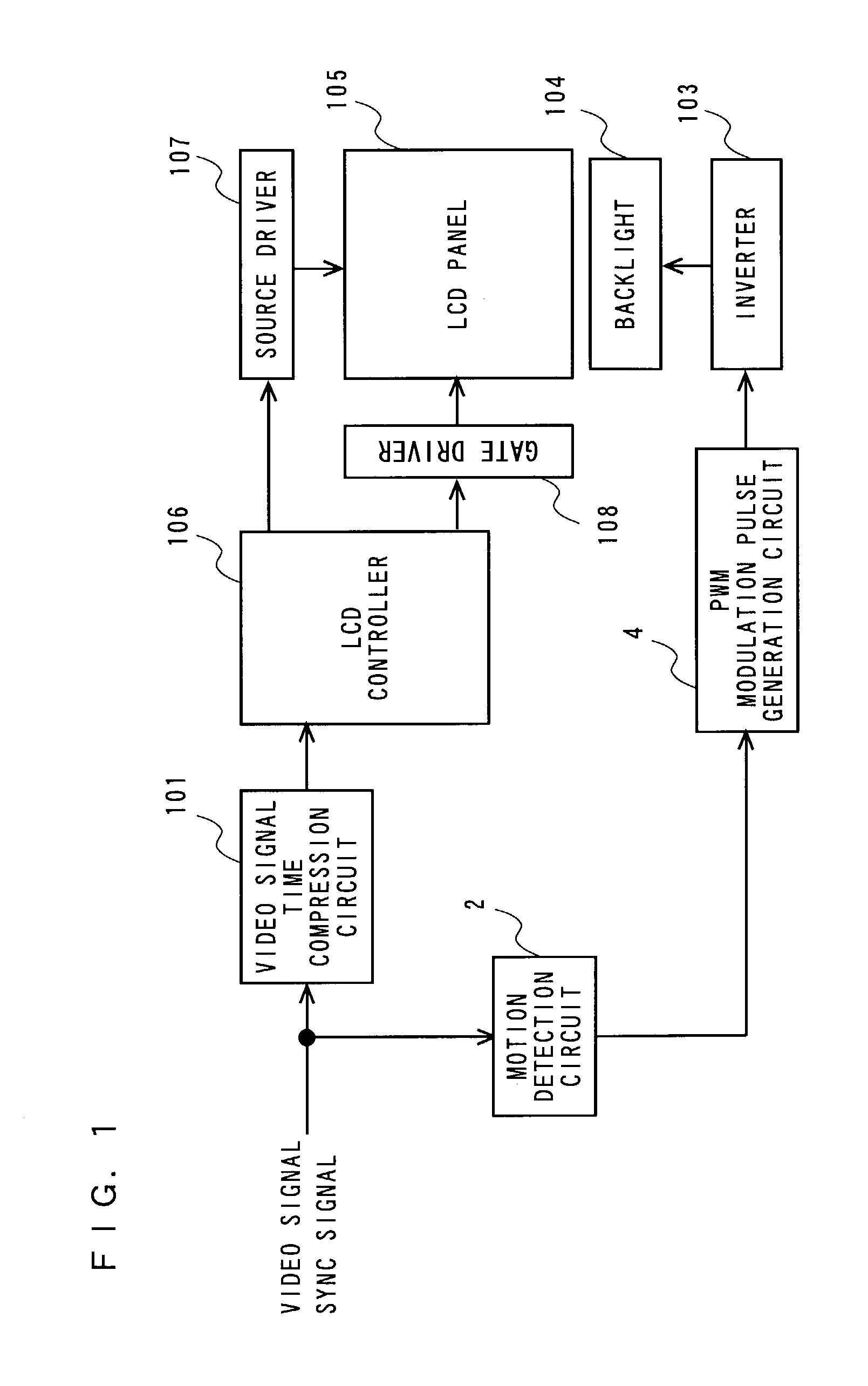

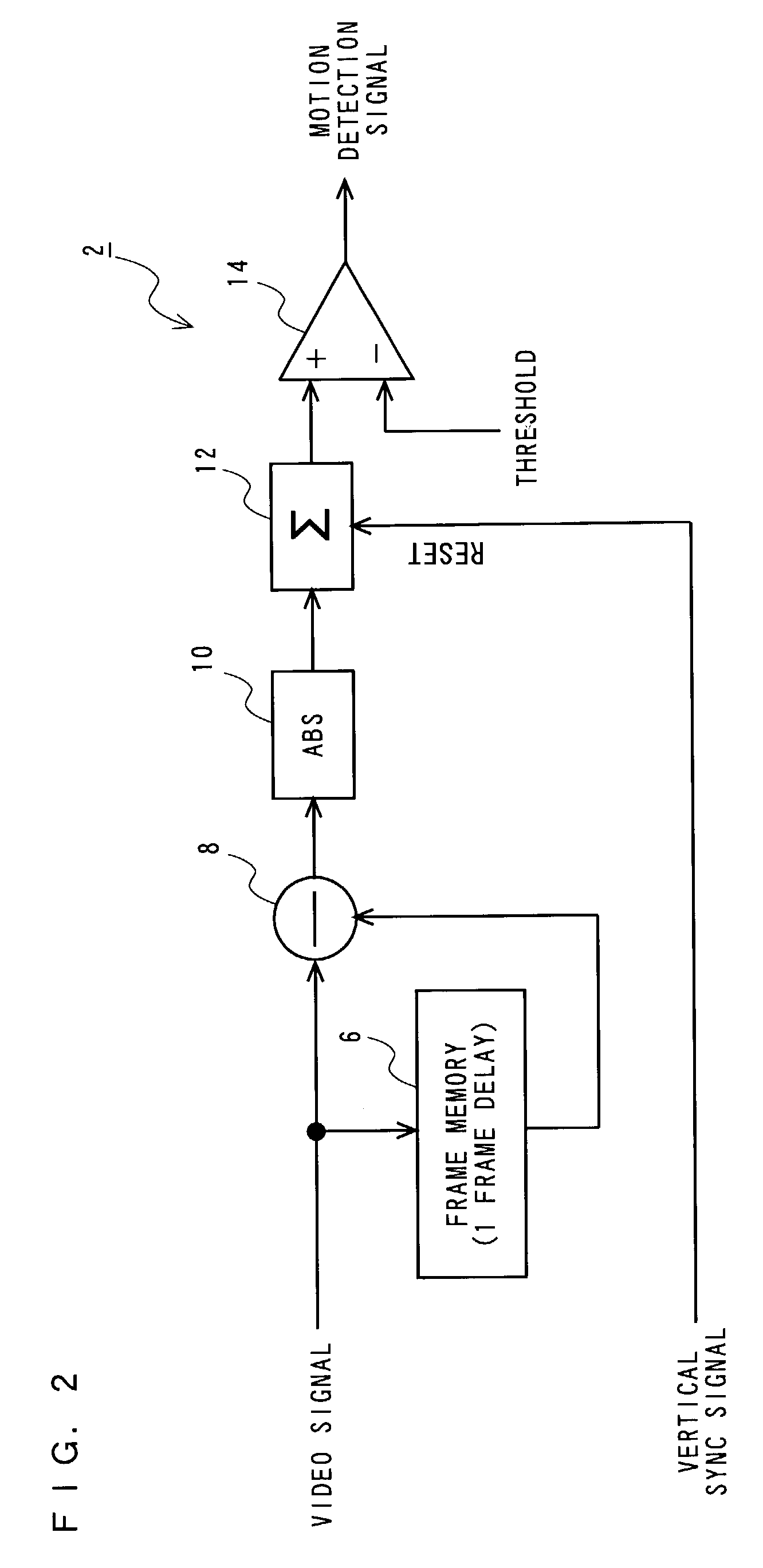

A liquid crystal display apparatus that uses a backlight for display includes a video signal time compression circuit for compressing a video signal in the time axis direction and outputting the time-compressed video signal, an LCD controller for driving a liquid crystal panel based on the time-compressed video signal, and a source driver and a gate driver. The liquid crystal display apparatus also includes a motion detection circuit for detecting the amount of motion of a display image based on the video signal, a PWM modulation pulse generation circuit for generating modulation pulses different in frequency according to the detection result from the motion detection circuit, and an inverter for lighting up the backlight based on the modulation pulses, to thereby enable reduction of image contour blurring in a moving image and reduction of flicker in a still image.

Owner:PANASONIC CORP

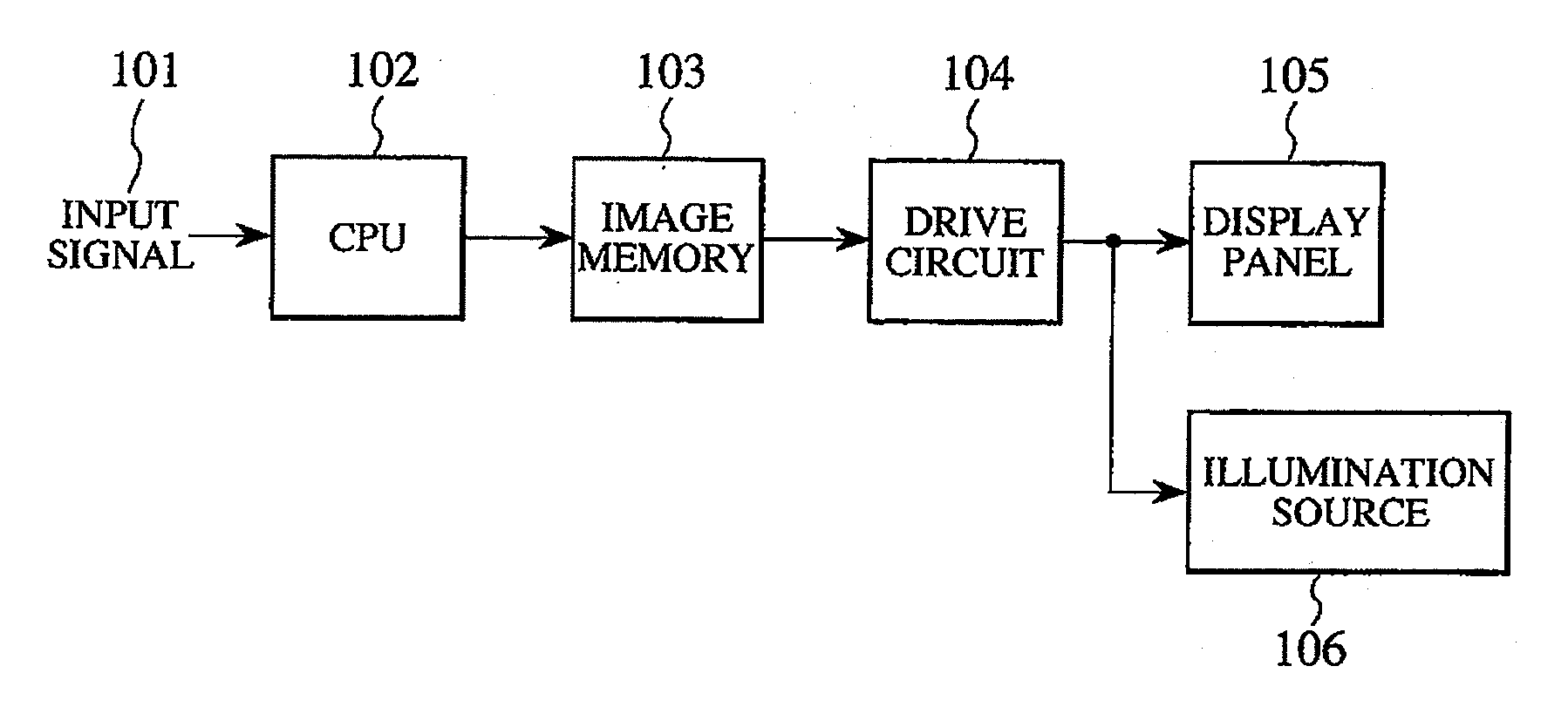

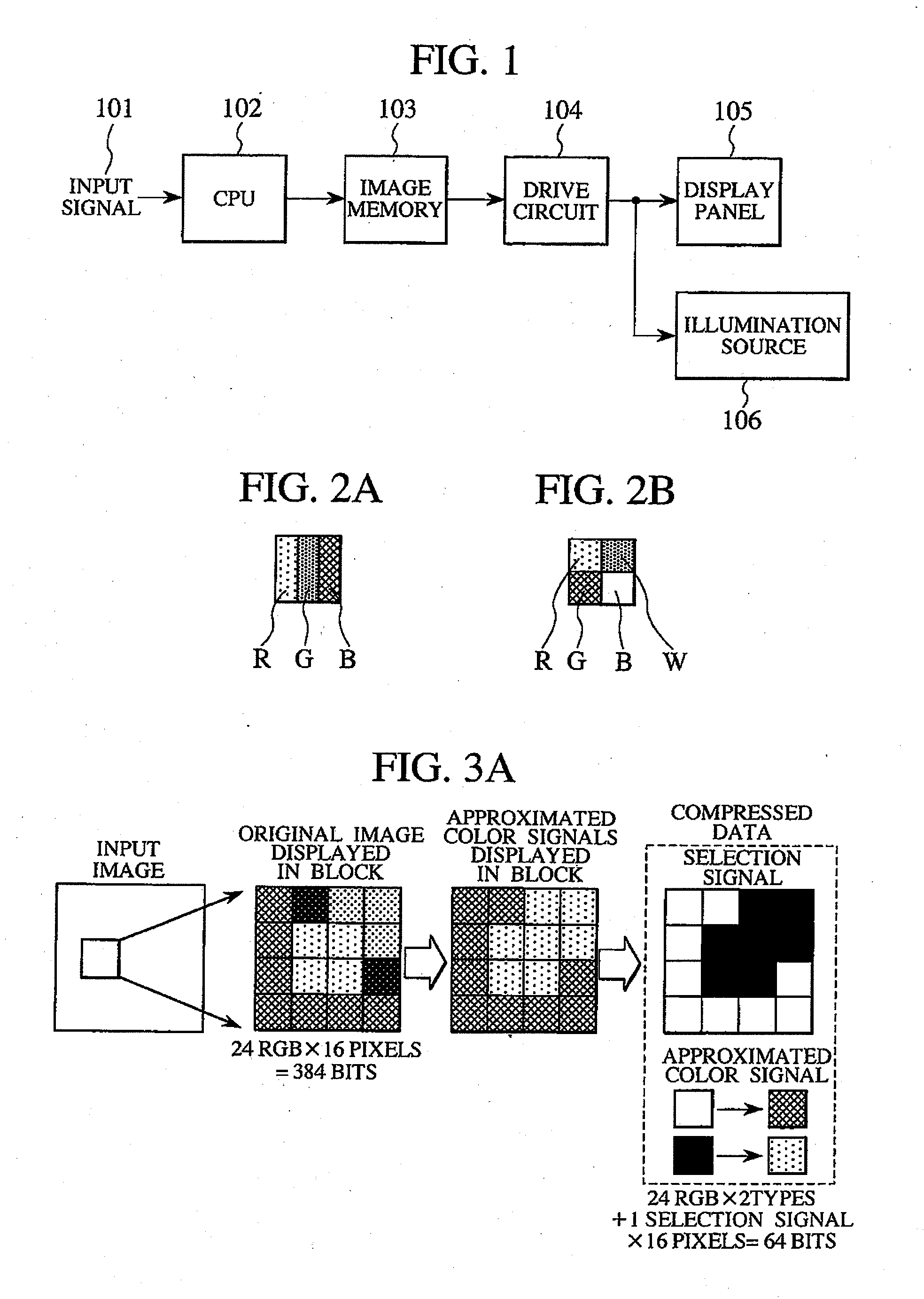

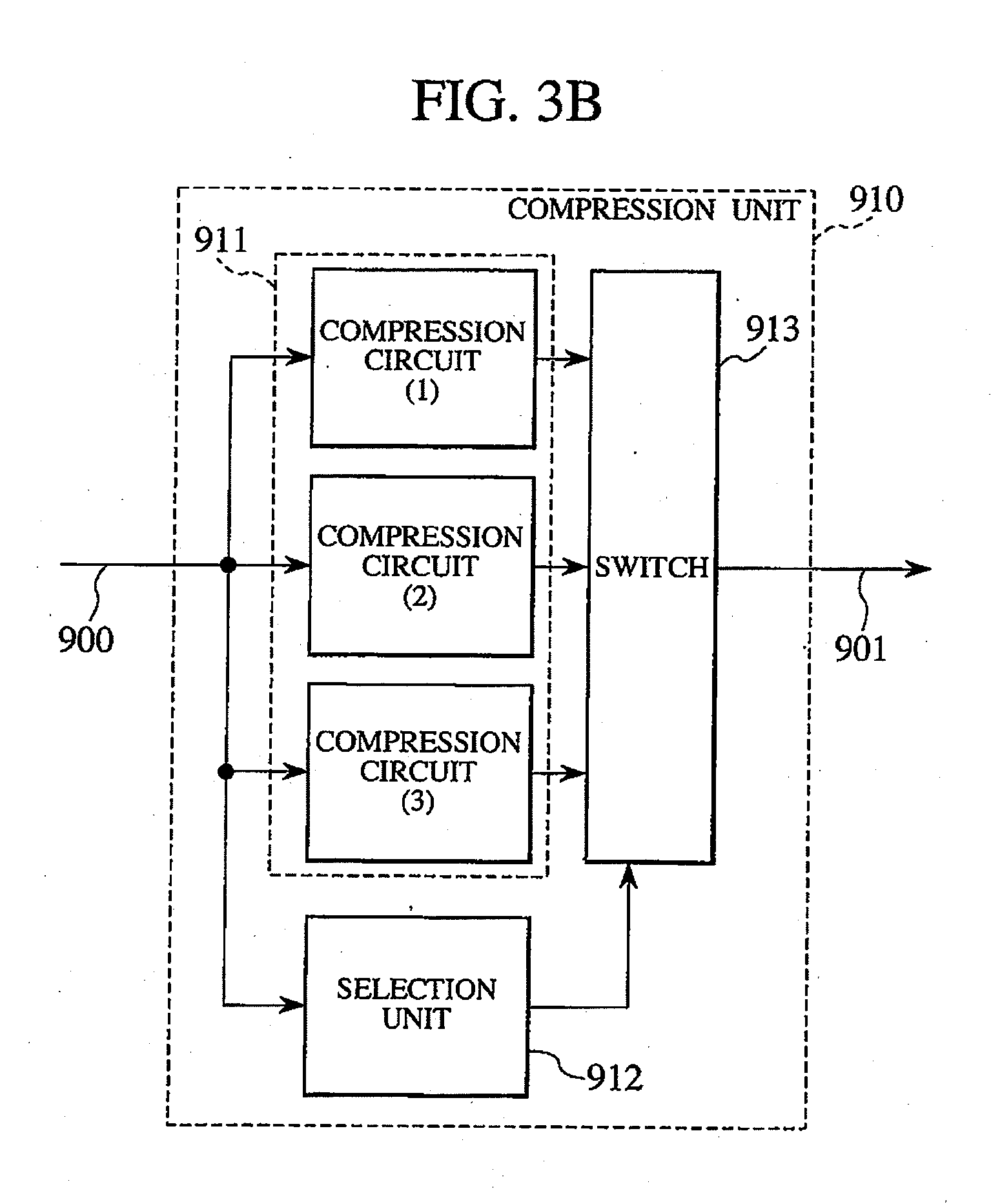

Multi-color display device

ActiveUS20090027410A1Reduce data volumeQuality improvementImage memory managementImage codingComputer graphics (images)Display device

It is expected to increase the size of a display panel and the number of tones to be displayed on the display panel, and it is requested to use a display panel displaying M (M>3) types of colors. This requires a large memory capacity and makes a circuit for performing signal conversion complex due to an increase in the amount of data to be subjected to the signal conversion. An image memory stores image data compressed at a fixed compression rate, and the signal conversion is performed on the compressed image data. This technique reduces a memory capacity and simplifies a signal conversion circuit. The signal conversion makes it possible to improve color reproducibility of an image displayed and the quality of the image due to smoothing of the outline of the image. In the case of a display panel having sub-pixels displaying M types of colors, the signal conversion is performed on a compressed signal for each sub-pixel to improve the quality of an image.

Owner:JAPAN DISPLAY INC +1

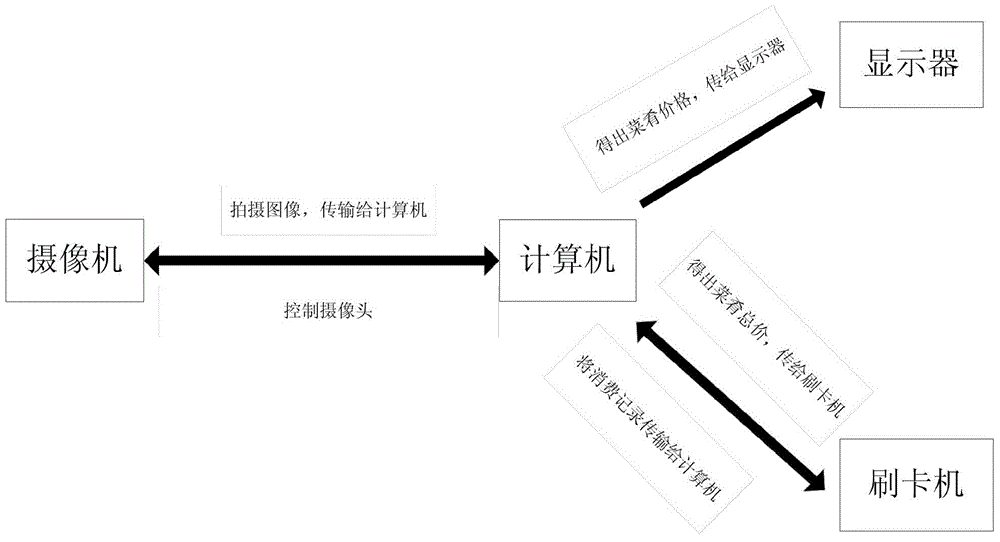

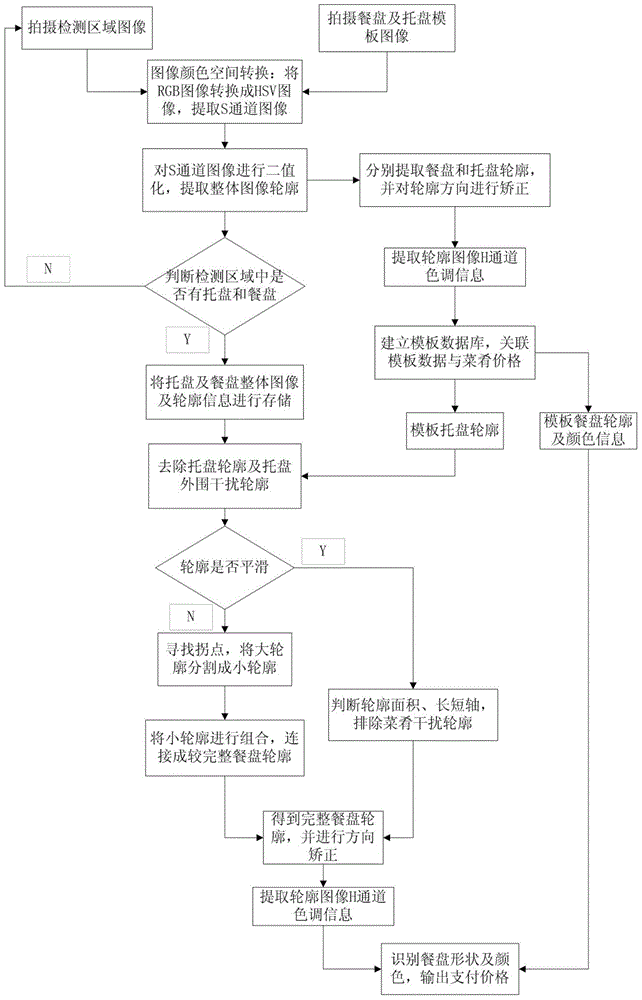

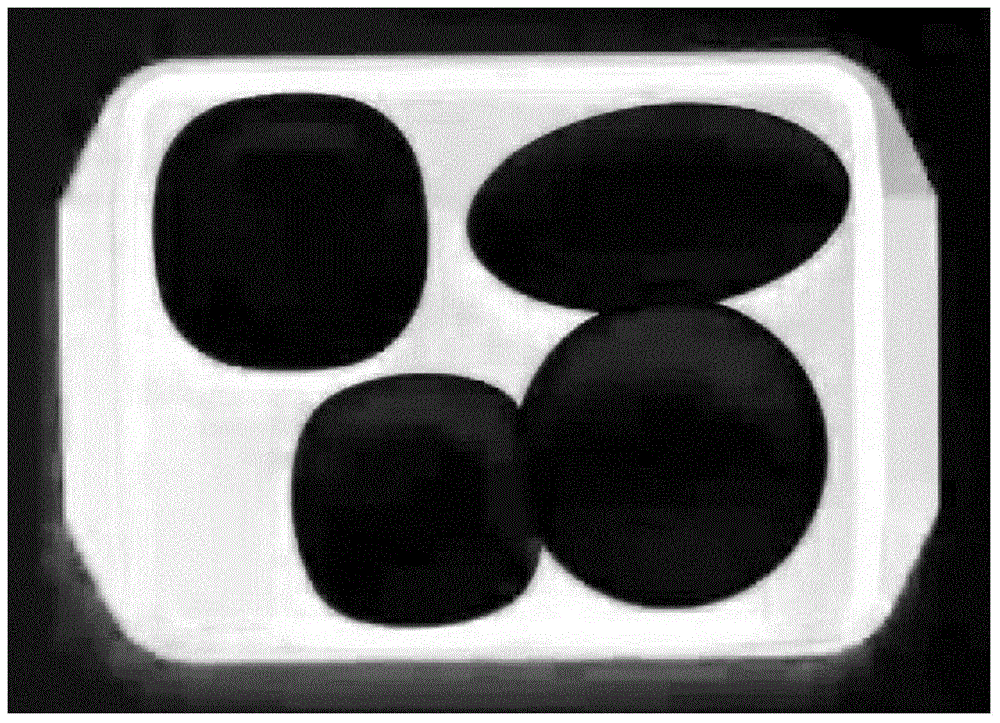

Automatic restaurant settlement method and system

ActiveCN104463167ALow costData processing applicationsCharacter and pattern recognitionGraphicsImaging processing

The invention relates to an automatic restaurant settlement method and system. The method includes the steps that a whole image in a detected area is shot, and the whole image contour is extracted through an image processing method; whether tray and service plate images exist in the detected area is judged through an image recognition technology by using the contour information, and the whole image and the contour information are stored; then the contour and tone information of service plates is extracted through the graphics and the image processing method; the contour and tone information of the service plates is matched with template information in a database to obtain the contour shapes and colors of the service plates; the total amount of dishes is obtained through the relevance of the shapes and the colors of the service plates and the prices of the dishes. The system comprises a camera, a computer, a machine point of sale machine (POS) and a display. According to the automatic restaurant settlement method and system, the service plates do not need to be customized or transformed, the automatic restaurant settlement method and system are suitable for the service plates of any shape and material, the cost is low, high efficiency and rapidness are achieved, certain robustness is achieved to the overlapping and blocking of the service plates, and no special requests for the service plate placing mode of repast personnel are needed.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI +1

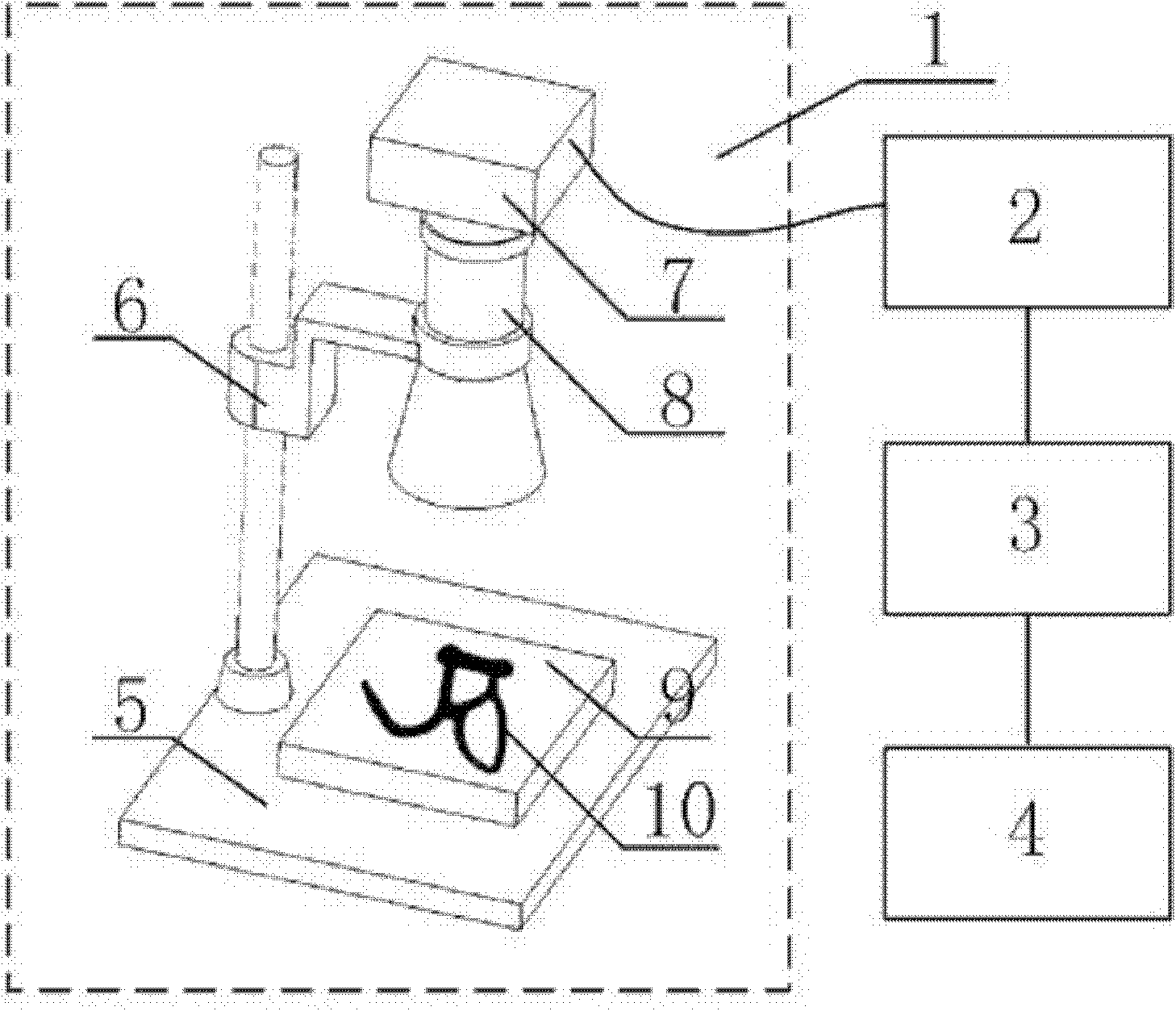

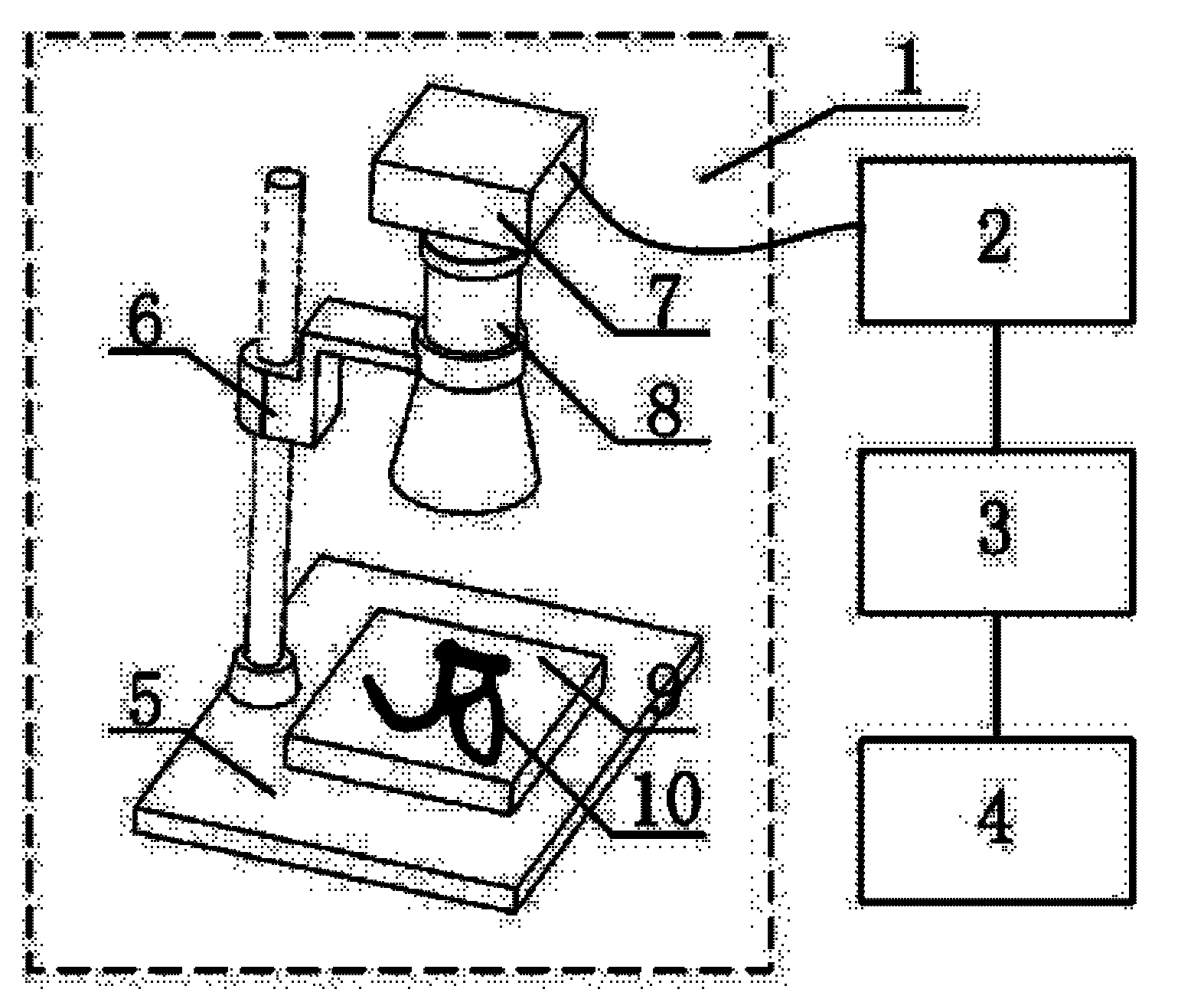

Method and device for measuring section contour of sealing strip of vehicle based on image matching

InactiveCN101806586AMeet the measurement requirementsHigh precisionUsing optical meansImage contourImage matching

The invention discloses a method and a device for measuring the section contour of a sealing strip of a vehicle in the technical field of automatic measurement. The device comprises an image acquiring system, an image preprocessing module, an image registering module and an error detecting module, wherein the image acquiring system is connected with the image preprocessing module for transmitting a section image of the sealing strip; the image preprocessing module is connected with the image registering module for transmitting a section contour chain code; and the image registering module is connected with the error detecting module for transmitting registered contour information. In the device and the method, a sectional slice image of an adhesive tape is acquired by adopting an industrial camera, the section contour of the sealed strip is acquired by processing the image, and the acquired contour is matched with a vehicle standard CAD image contour through data processing so that a specific error value at a specified contour segment of the sealed strip of the vehicle is accurately given; and therefore, rapid non-contact measurement for the section contour of the sealing strip of the vehicle is realized. The method has the advantages of rapidness and accuracy.

Owner:SHANGHAI JIAO TONG UNIV

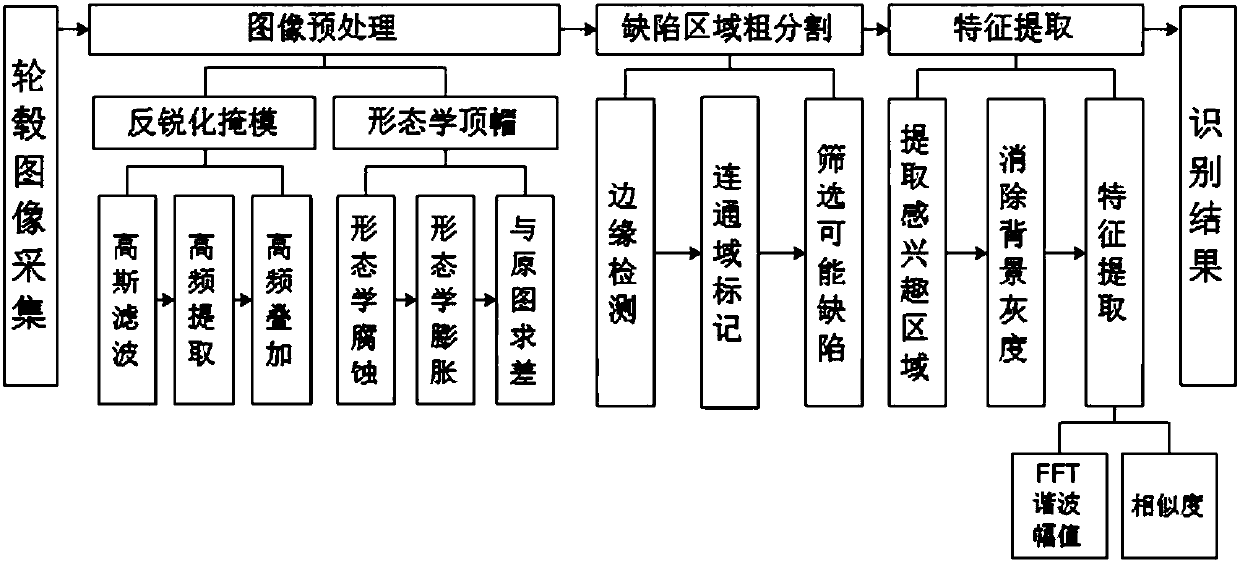

Method for detecting potential defects of complicated-structure castings on basis of vertical cross line contour features

ActiveCN107808378AReduce the impactImprove final defect detection rateImage enhancementImage analysisPattern recognitionSharpening

The invention discloses a method for detecting potential defects of complicated-structure castings on basis of vertical cross line contour features. The method comprises the following steps of: acquiring an X-ray image of a complicated-structure casting, sharpening the image by adoption of an anti-sharpening mask algorithm, and carrying out grayscale morphological top hat operation; marking a connected domain by adoption of Canny edge detection, preliminarily screening defect-possible areas through a pixel area of the connected domain; extracting interested areas, solving grayscale informationof cross lines passing the center of the interested area in eight directions, and screening two mutually vertical cross lines; and analyzing grayscale image contour change features of the two cross lines, eliminating background influences, and judging whether defects are real defects or not according to the contour change features. The method has the effects of highlighting fuzzy defect areas which are difficult to distinguish by human eyes, improving the defect edge detection effect, decreasing the influences of corner area structures of small castings and effectively improving the final defect detection rate.

Owner:ZHEJIANG UNIV

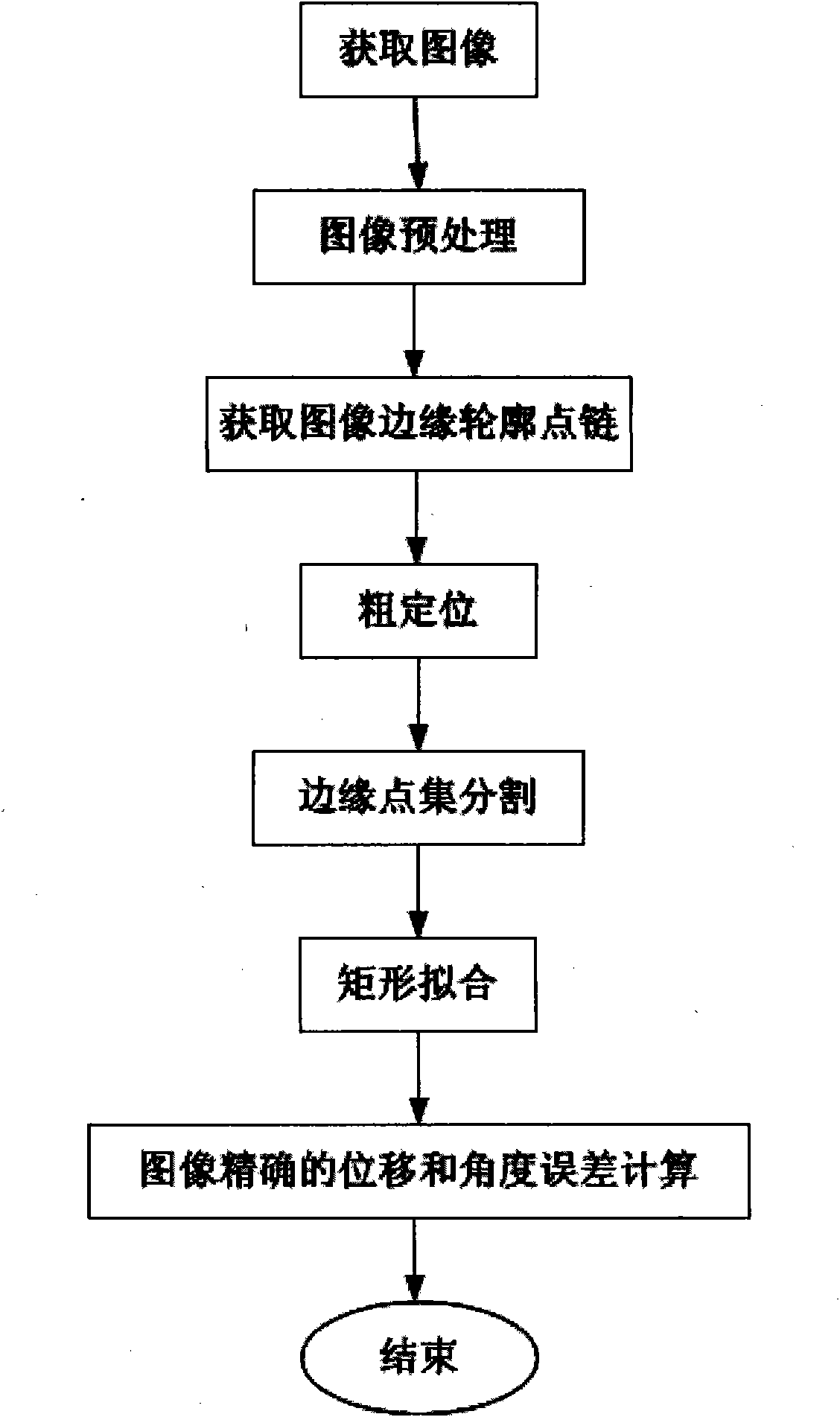

Visual inspection method for chip electronic component position error based on edge fitting

InactiveCN101839690ACalculation speedImage analysisUsing optical meansBoundary contourGravity center

The invention discloses a visual inspection method for chip electronic component position error based on edge fitting. The method is that a boundary contour point set of an entire image is obtained by adopting boundary following to generate the edge point chain structure of the image; the image center a chip electronic component is preliminarily calculated by adopting a contour gravity center method, a corner is roughly calculated by adopting a closest-to-center point method, two lines which pass through the image center and are perpendicular to each other are established, the two lines divides the image contour into four areas containing corner points, four corner points are obtained in each area respectively according to the distance from a point to the center and four line sides are formed, and the corresponding edge point set is extracted by using the four line sides to partition an edge; and the edge fitting is conducted to each edge point set by adopting an edge point set rectangle least square method to obtain the fitting rectangle of the edge, and the center coordinates of the fitting rectangle and the corner relative to a horizontal direction are calculated. The invention has the advantages that the center position and the corner of the chip surface mounting component can be accurately inspected and the calculation speed is fast.

Owner:HOHAI UNIV CHANGZHOU

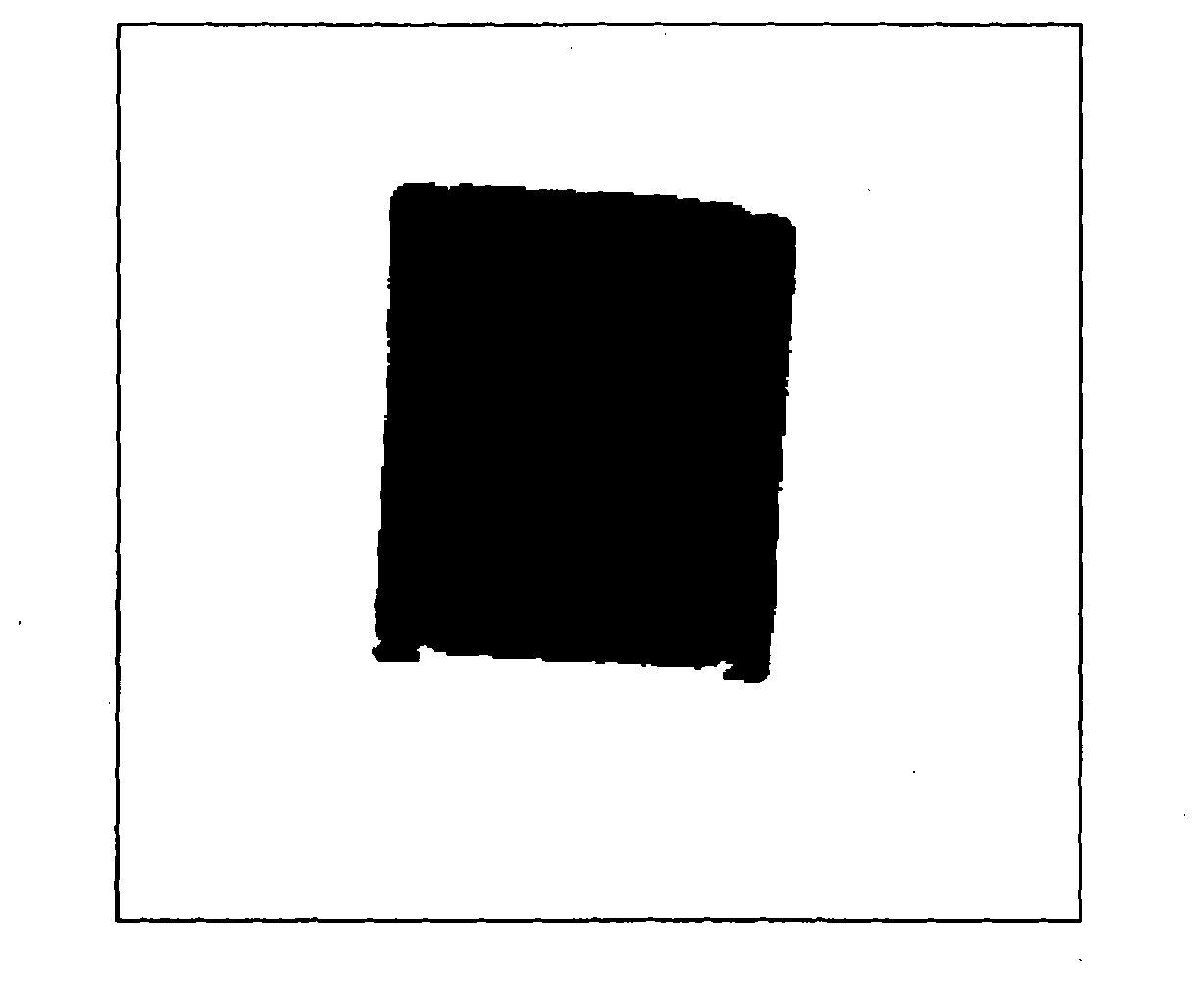

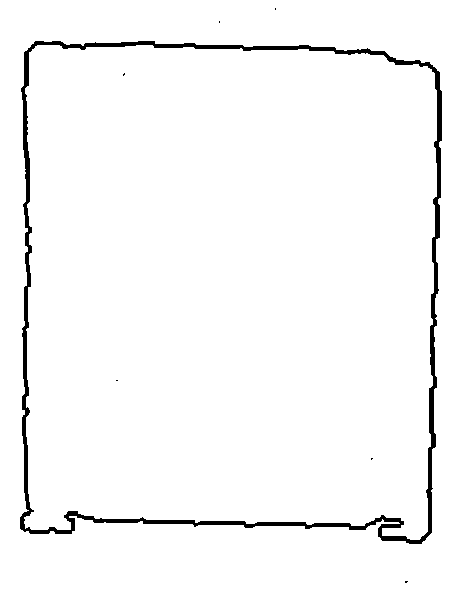

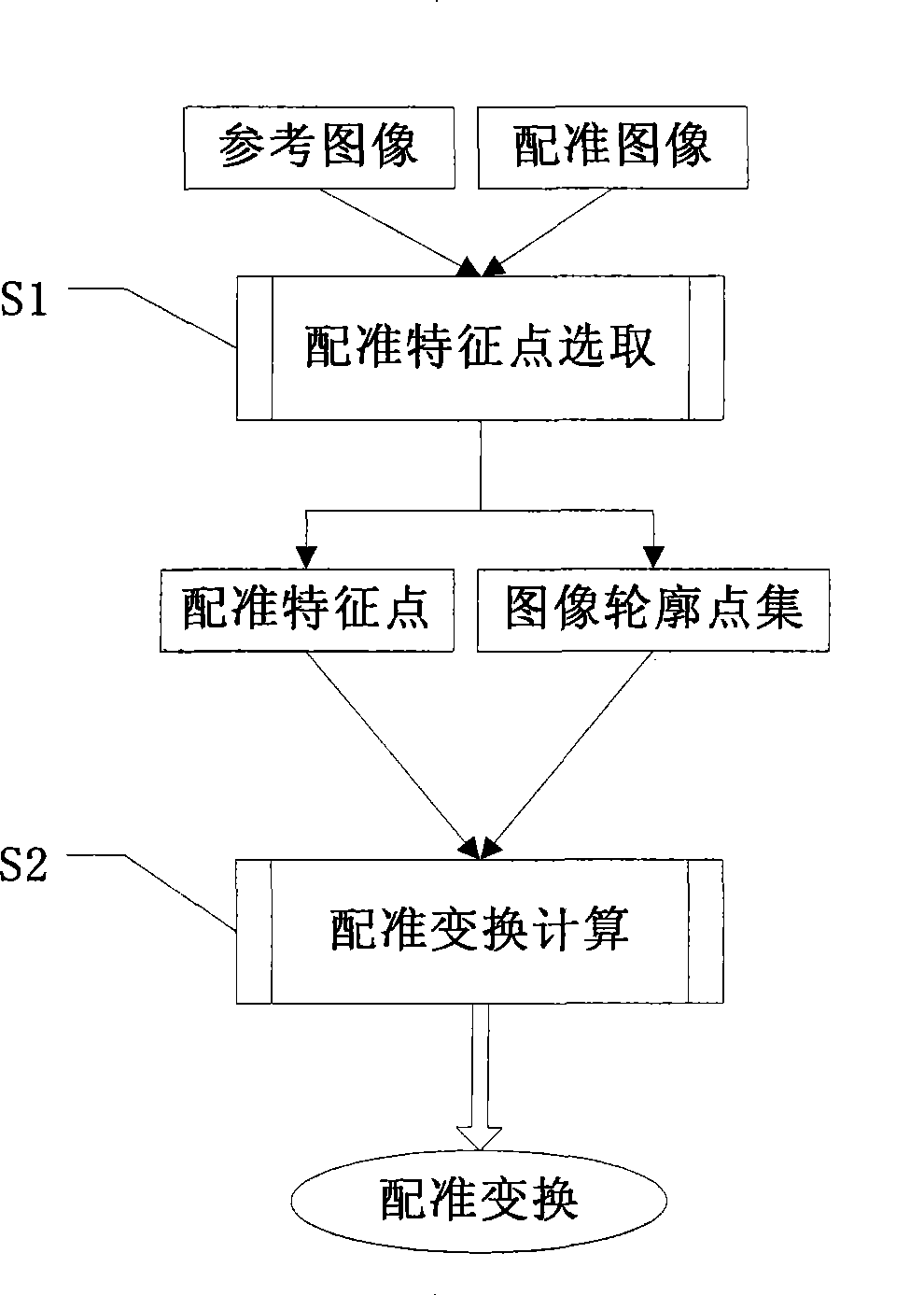

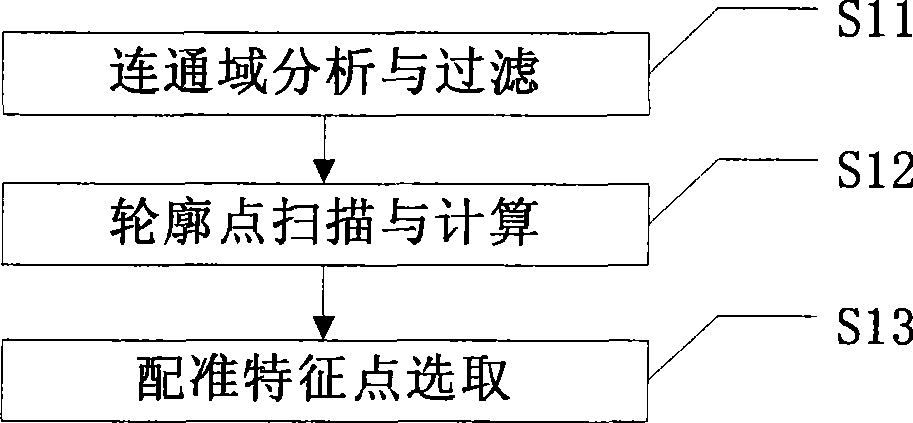

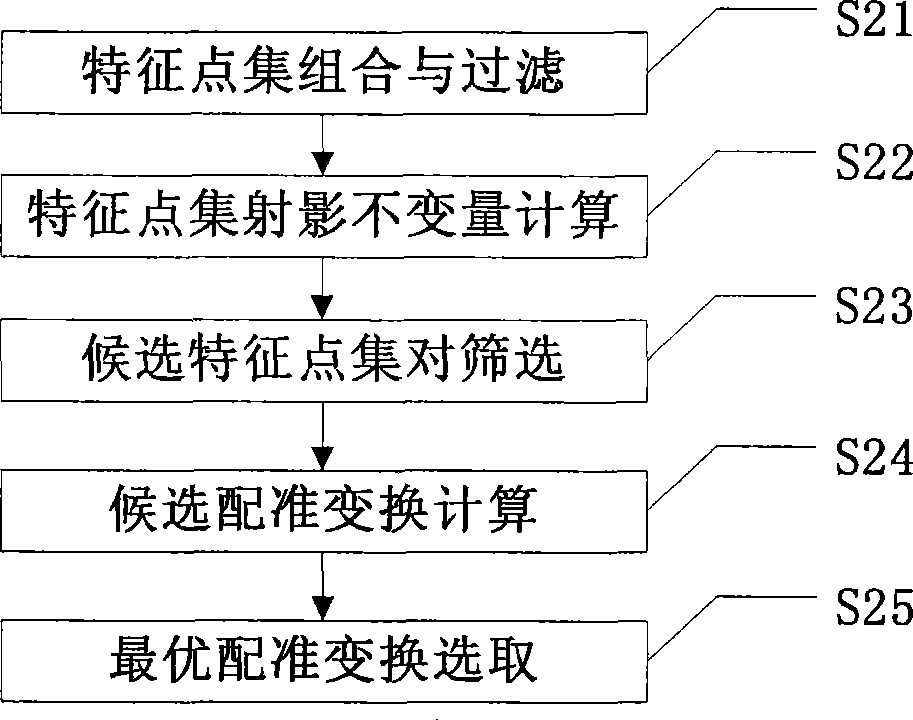

Method for registration of document image and selection of characteristic points

InactiveCN101377847AImprove usabilityImprove versatilityGeometric image transformationImaging processingReference image

The invention relates to the technical field of the image processing subject, in particular to a general document image registration and feature point selection method. In the method, image outlines are used as document image registration features and outline points are used for representing document image outlines. The method comprises the following steps: a plurality of points are selected automatically from a reference image and a registered image as image registration feature points with document image outline points as candidates by adopting the feature point selection method; subsequently, a plurality of candidate matching point set pairs are selected in a centralized way from the feature points with projective transformation invariables as similarities; geometric transformation corresponding to the point set pairs is figured out as candidate registration transformation; finally, being measured in outline matching degree, the optimal matching transformation is looked for from candidate registration transformation as the ultimate registration transformation for registration of document images. The method is applicable for registration of document images of different types, and is very efficient and robust.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

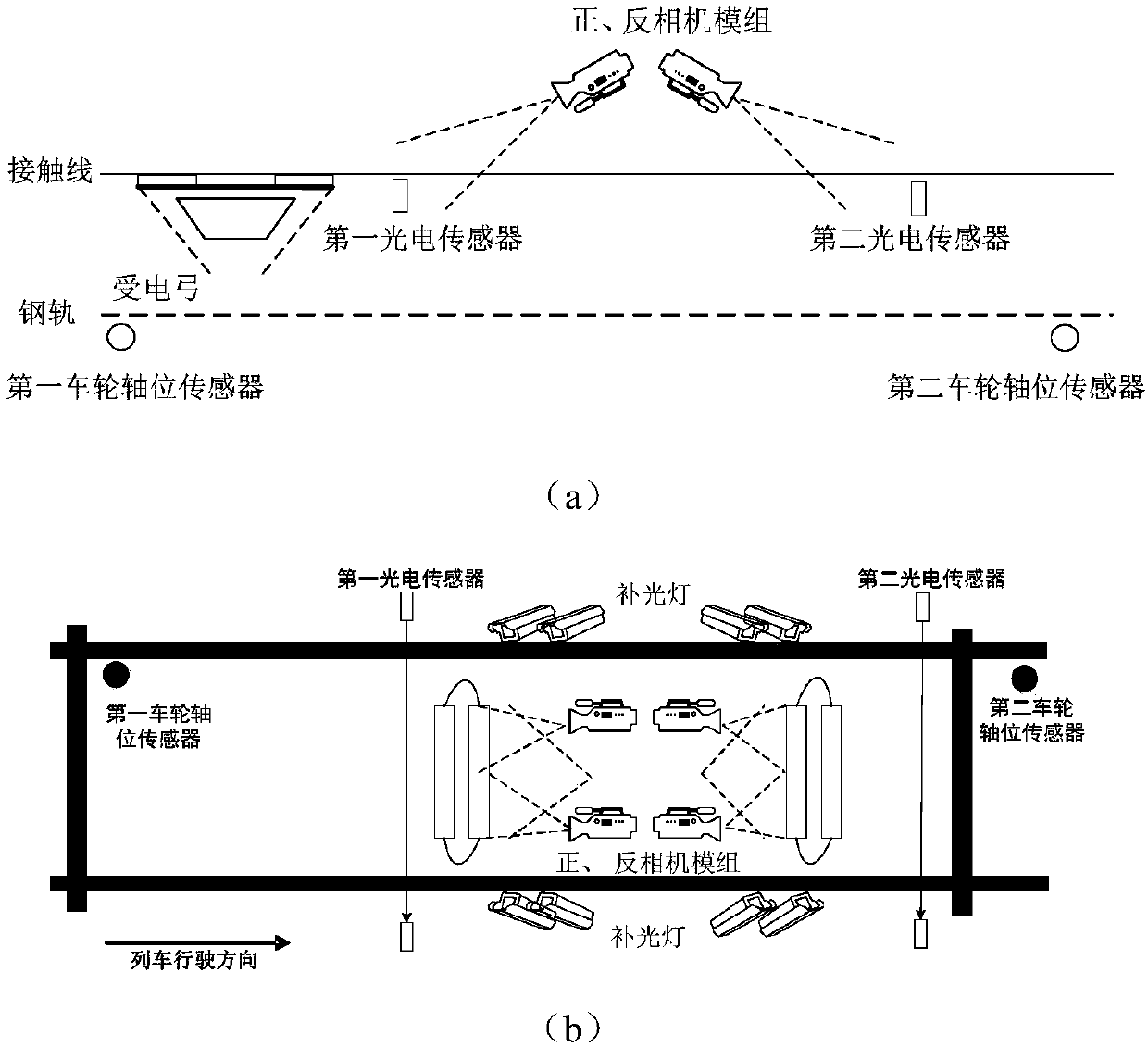

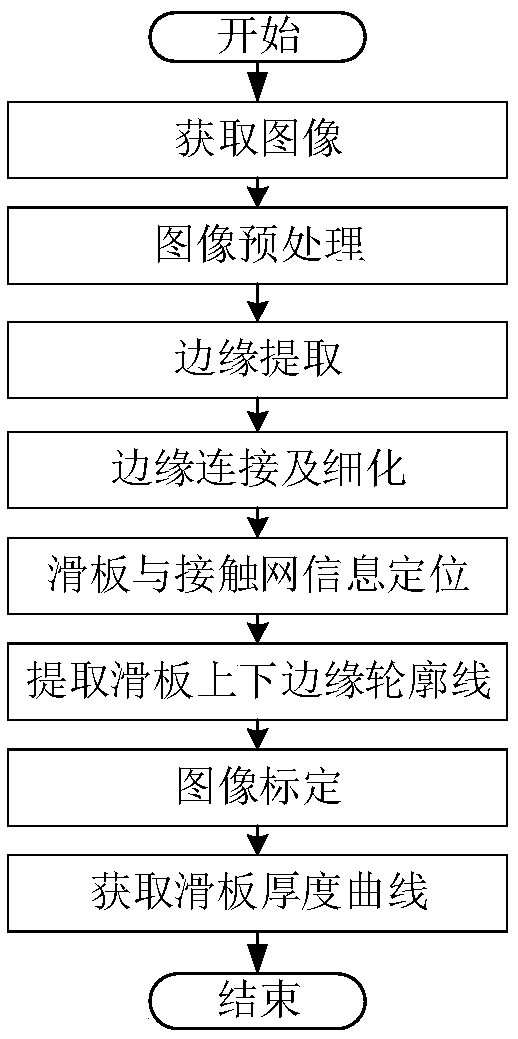

Online detection device and method for abrasion of pantograph sliding plate based on images

InactiveCN107588733AImprove detection accuracyImprove detection efficiencyUsing optical meansSlide plateImage contour

The invention discloses an online detection device and method for the abrasion of a pantograph sliding plate based on images. The device comprises an image acquisition module, a data transmission module and an image processing module, and is characterized in that the data transmission module transmits image data acquired by the image acquisition module to the image processing module to process. The method comprises the steps of firstly performing denoising on an original image based on a cascade filter capable of dynamically calibrating the filtering strength, and enhancing a target area by adopting a local contrast enhancement algorithm based on the local standard deviation; then extracting an image contour by using a threshold adapting Canny edge detection algorithm, positioning the edges on the sliding plate by using Hough transformation, and searching a datum line according to the edge positions on the sliding plate; and finally converting a pixel distance between the upper end lower edges of the sliding plate into the actual sliding plate residual thickness, and acquiring an abrasion curve of the sliding plate. The online detection device and method are convenient in structurelayout, stable in system and capable of performing high-precision online non-contact measurement.

Owner:NANJING UNIV OF SCI & TECH

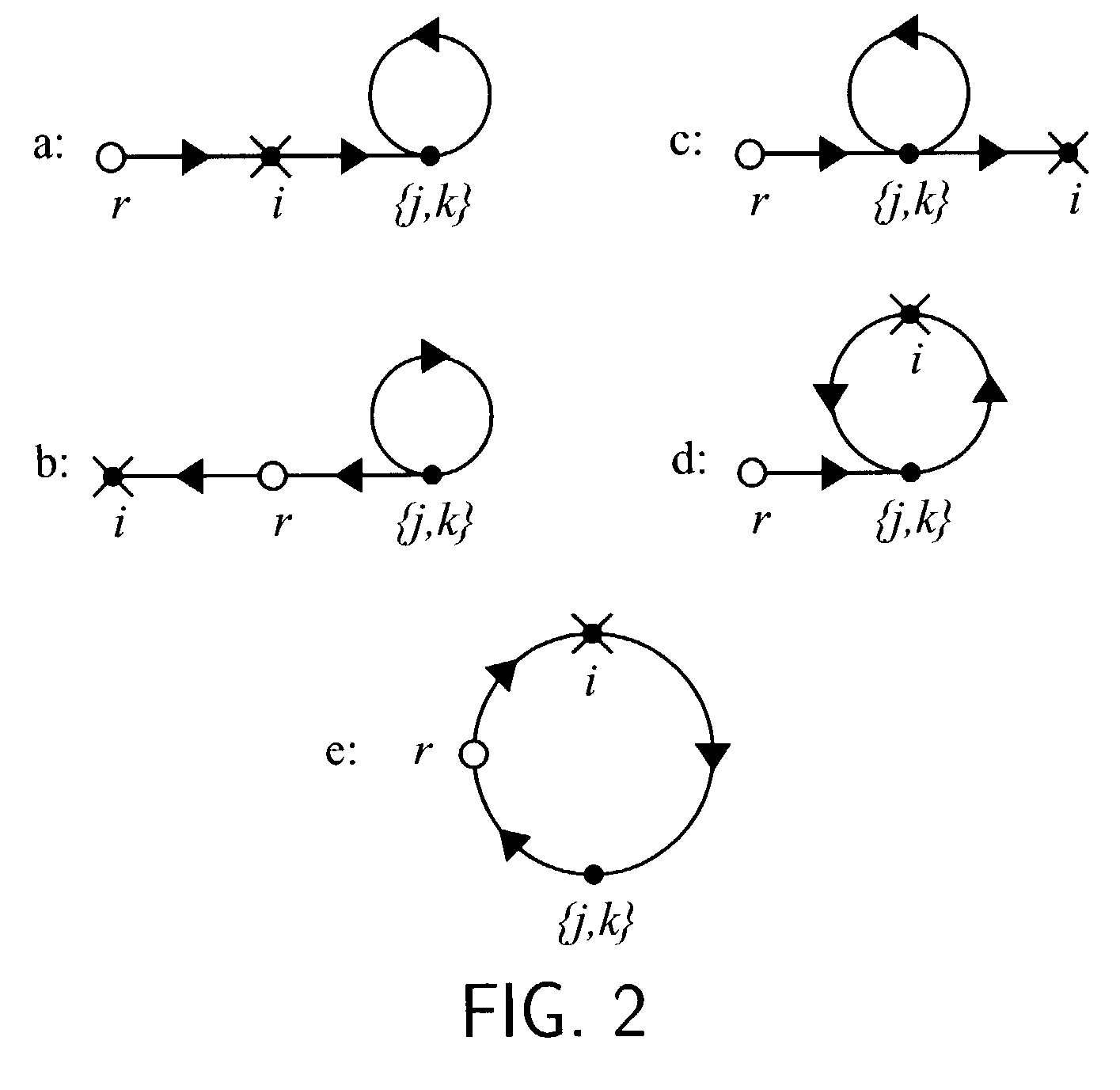

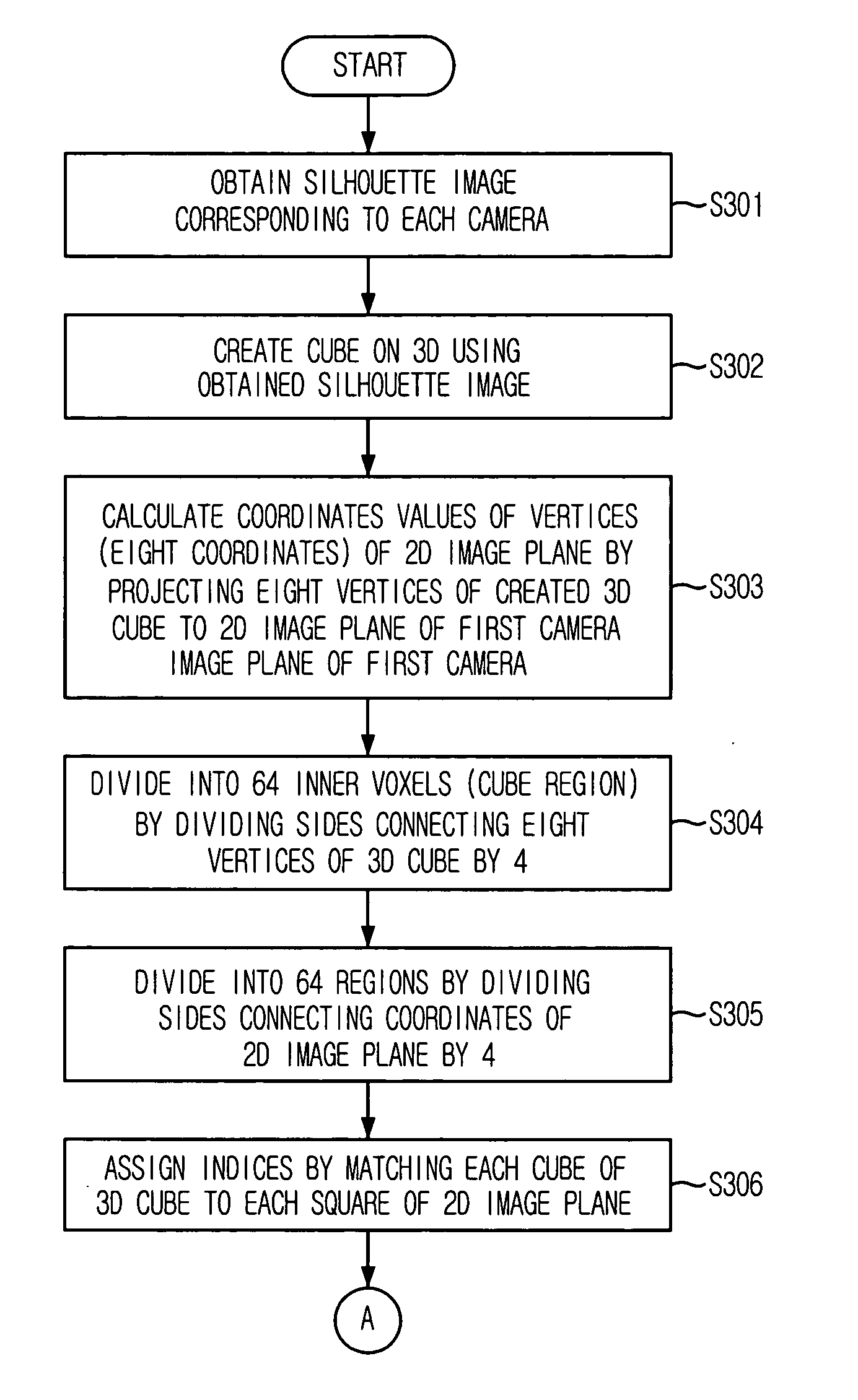

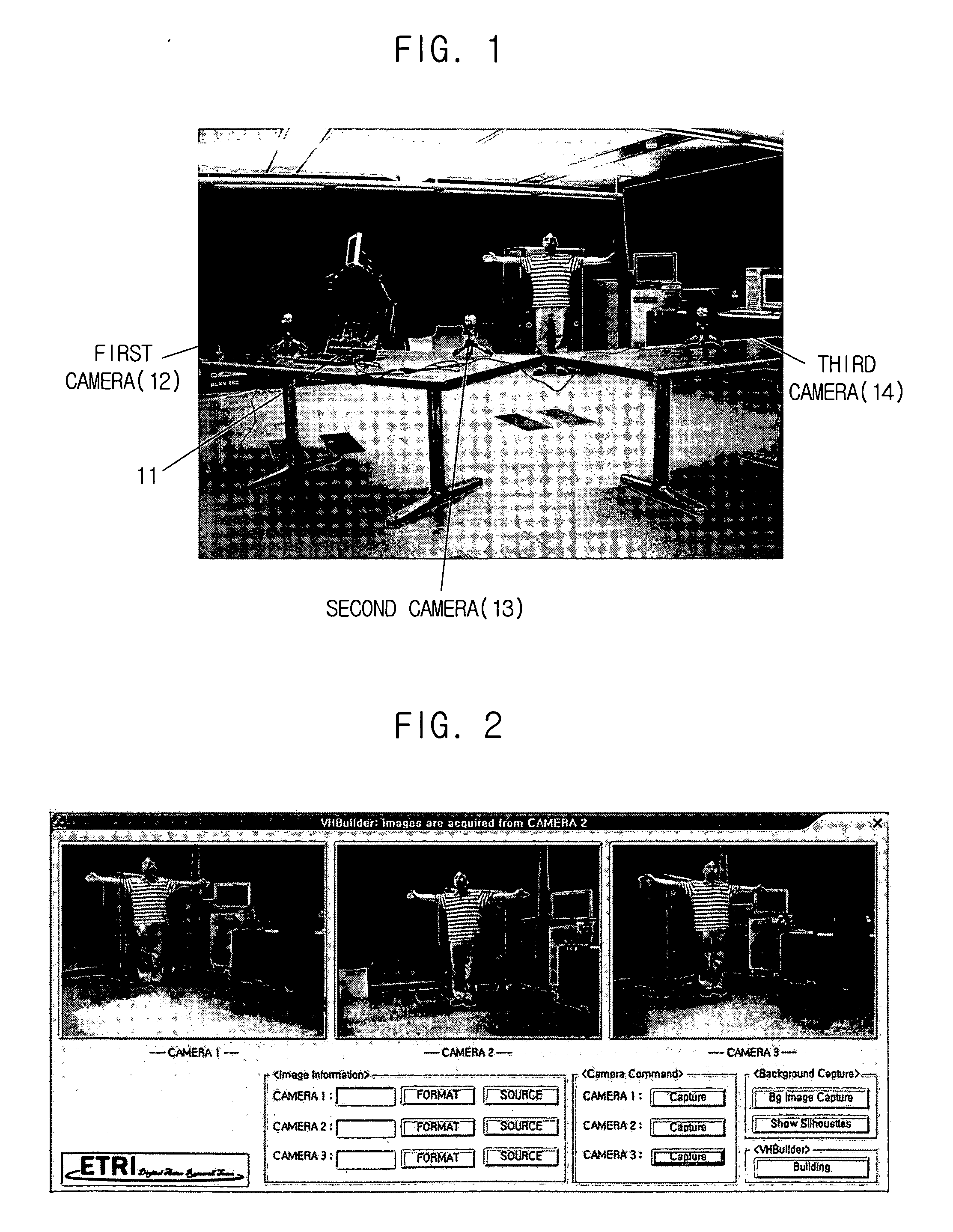

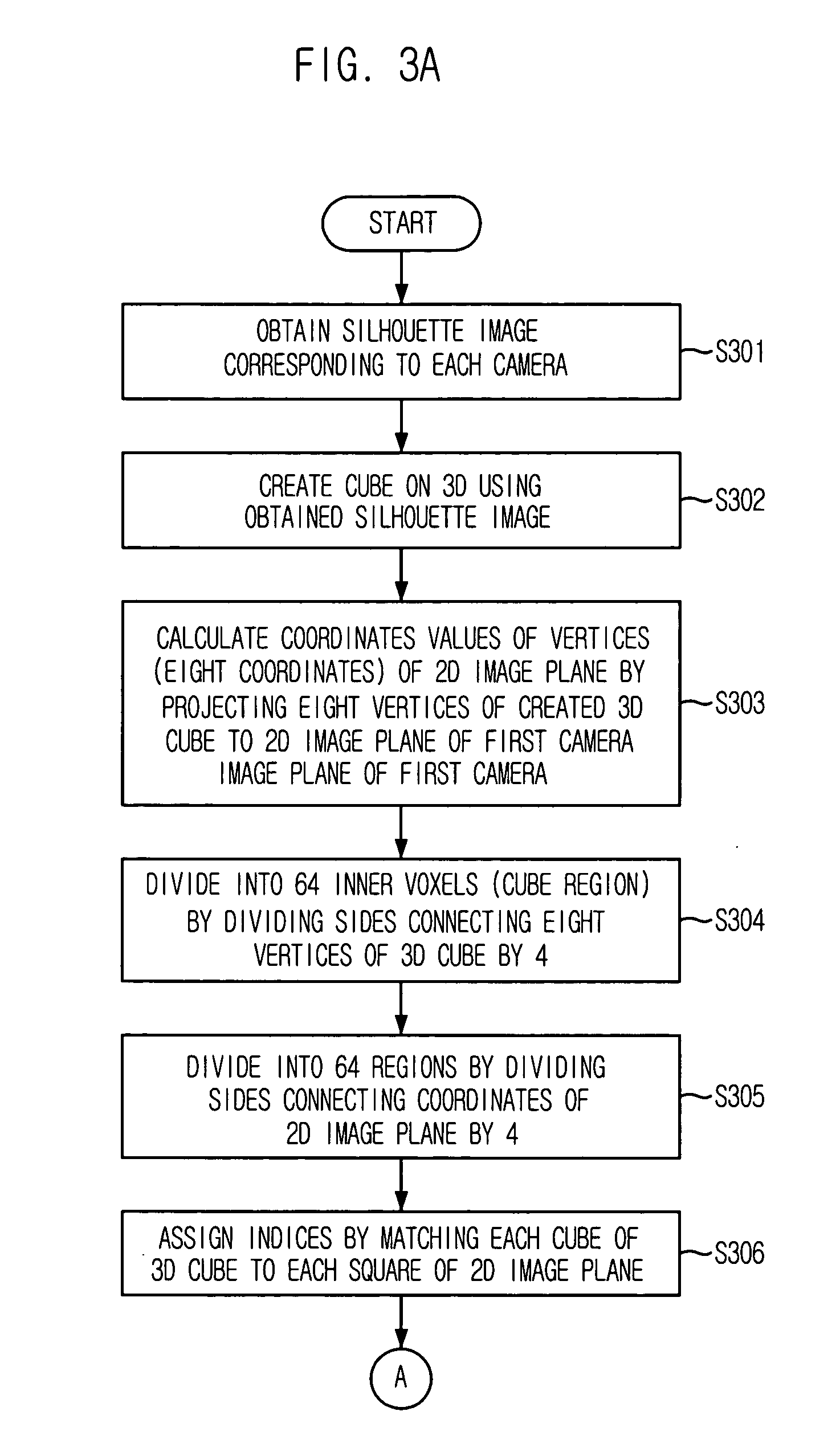

Method for reconstructing three-dimensional structure using silhouette information in two-dimensional image

A method for reconstructing a three-dimensional structure using silhouette information on a two-dimensional plane is provided. The method includes: obtaining silhouette images; creating a cube on a three-dimensional space using the silhouette images; calculating vertex coordinates on a two-dimensional image plane by projecting eight vertices of the three-dimensional cube on a two-dimensional image plane of a first camera; dividing into multiple inner voxels by dividing sides formed by the eight vertices by a divider; dividing into a predetermined number of regions by dividing sides connecting the coordinates by a predetermined divider; assigning indices by matching cubes of the three-dimensional cube to square regions on the two-dimensional image plane in one to one manner; storing indices of regions where the square regions meets with a first silhouette image; and reconstructing three-dimensional structure by finding common indices through repeatedly performing the steps using other silhouette images.

Owner:ELECTRONICS & TELECOMM RES INST

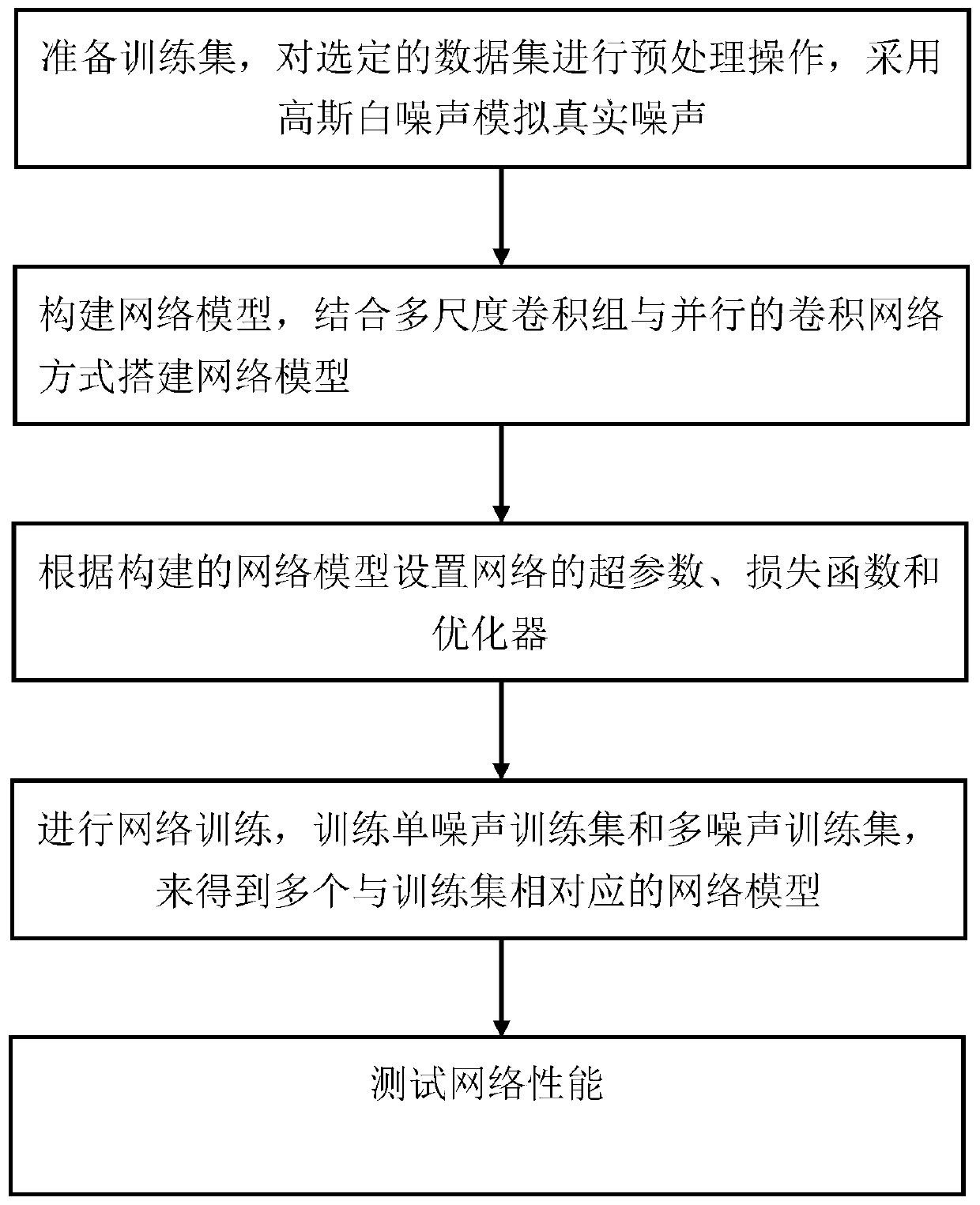

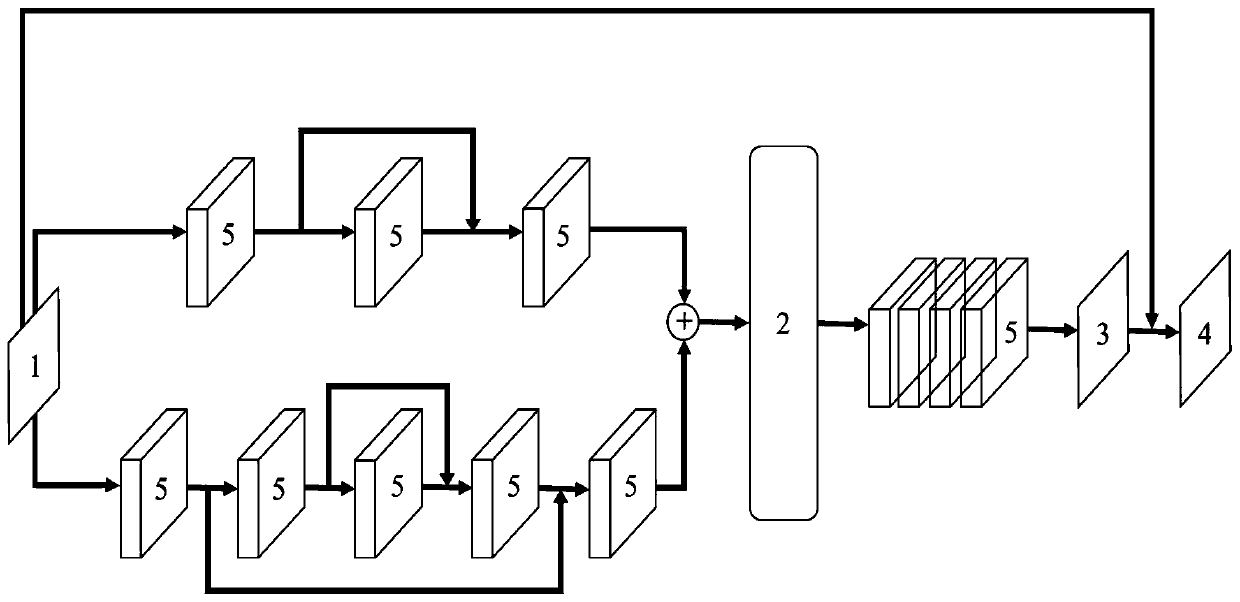

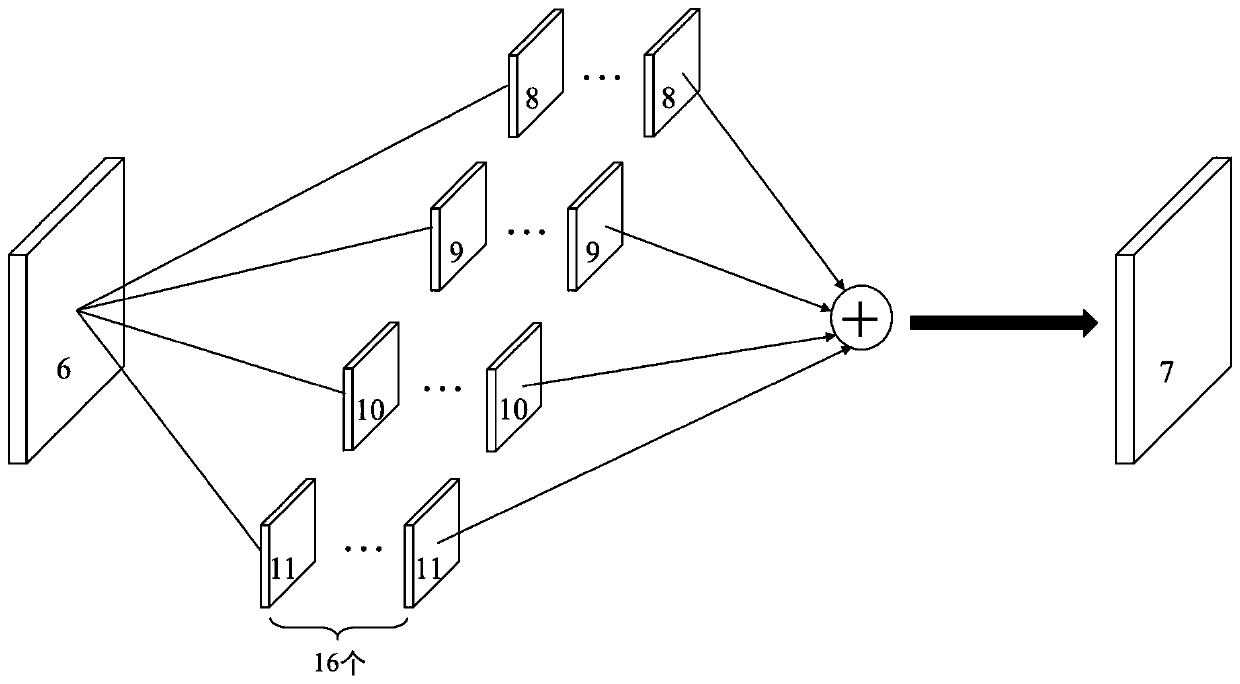

Convolutional neural network image denoising method based on multi-scale convolution groups and parallelism

The invention discloses a convolutional neural network image denoising method based on multi-scale convolution groups and parallelism. The method specifically comprises the following steps of 1, preparing a training set, selecting an appropriate data set as an original image in the training set, preprocessing the original image, simulating the real noise by adopting the Gaussian white noise, and adding the real noise into the original image as a noise image corresponding to the original image; 2, constructing a network model, and constructing a network model in combination with a convolution network mode of the multi-scale convolution group and the parallelism; 3, setting the hyper-parameters, a loss function and an optimization algorithm of the network according to the network model constructed in the step 2; 4, performing network training, and using the constructed network model in the step 2 to train a single-noise training set and a multi-noise training set respectively to obtain aplurality of network models corresponding to the training sets; and 5, testing the network performance. According to the method, more image contours and texture details can be reserved while the noise is eliminated.

Owner:XIAN UNIV OF TECH

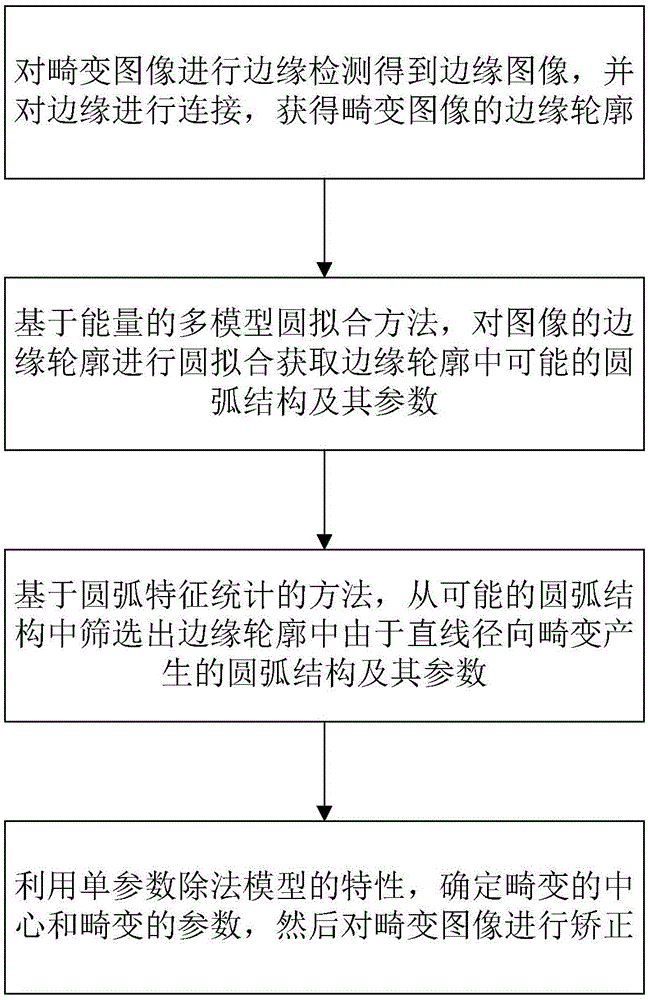

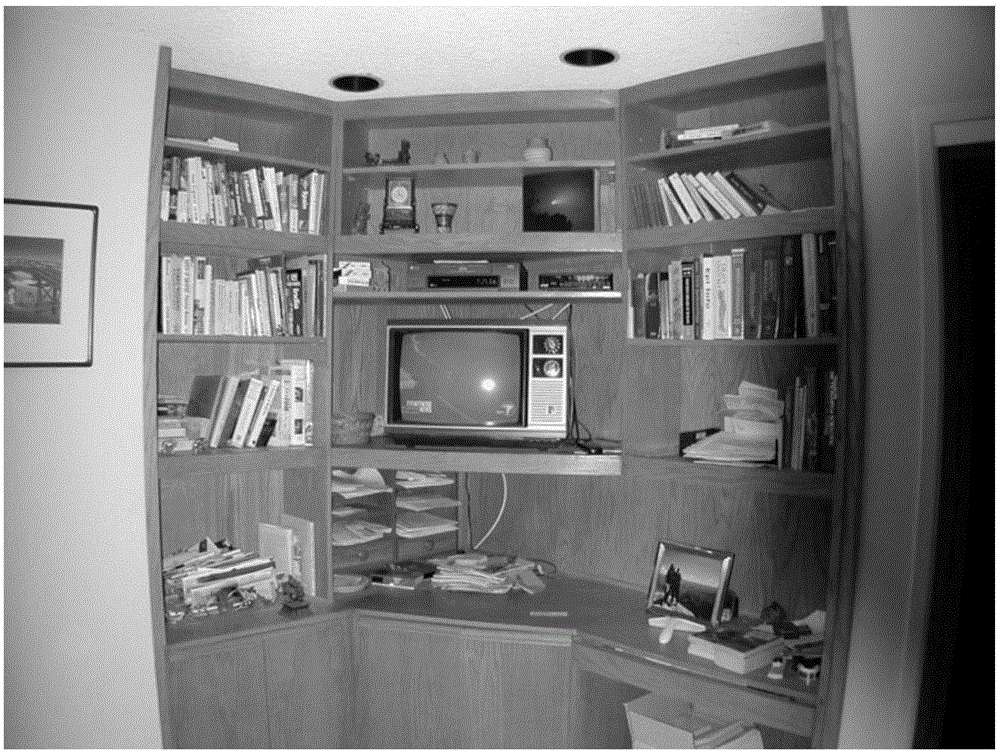

Radial image distortion rectifying method and system based on distorted linear structure detection

ActiveCN105096269ARealize automatic correctionImprove robustnessImage enhancementPattern recognitionImage contour

The invention discloses a radial image distortion rectifying method based on distorted linear structure detection. The method includes S1 extracting distorted image contours, S2 extracting arcs in an edge contour, S3 sorting arcs and S4 rectifying distorted images. The invention further discloses a radial image distortion rectifying system based on distorted linear structure detection. A solution for rectifying radial image distortion generated during an image obtaining process is provided in order to solve the problem radial distortion is generated when a camera takes images, and the keys of the solution are the distortion reasons and distortion rectifying difficulties. Automatic rectification of radial image distortion is realized based on distorted linear structure in distorted images, no artificial intervention and special template are needed, and the robustness is high.

Owner:北交智轨(北京)科技有限公司

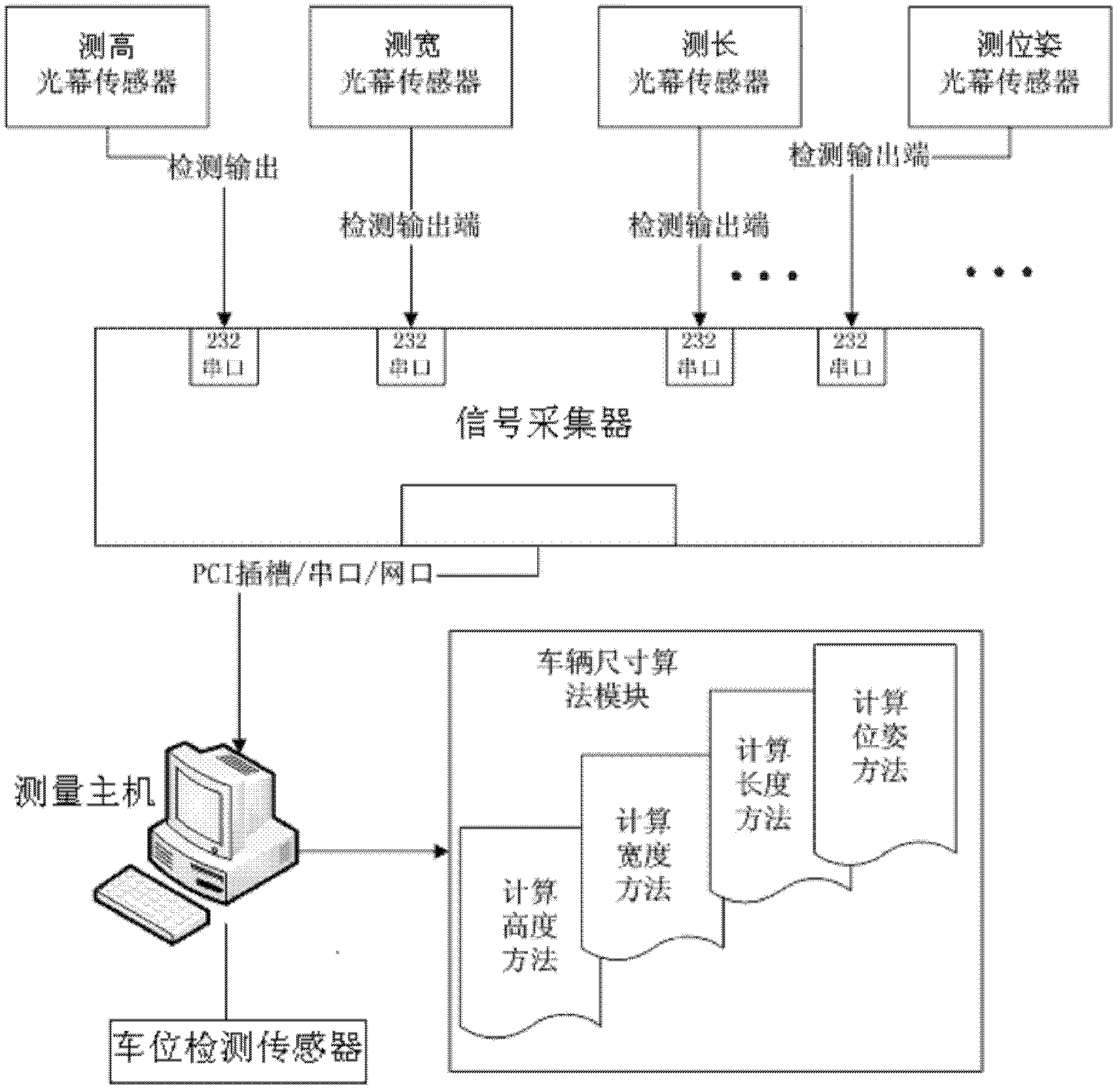

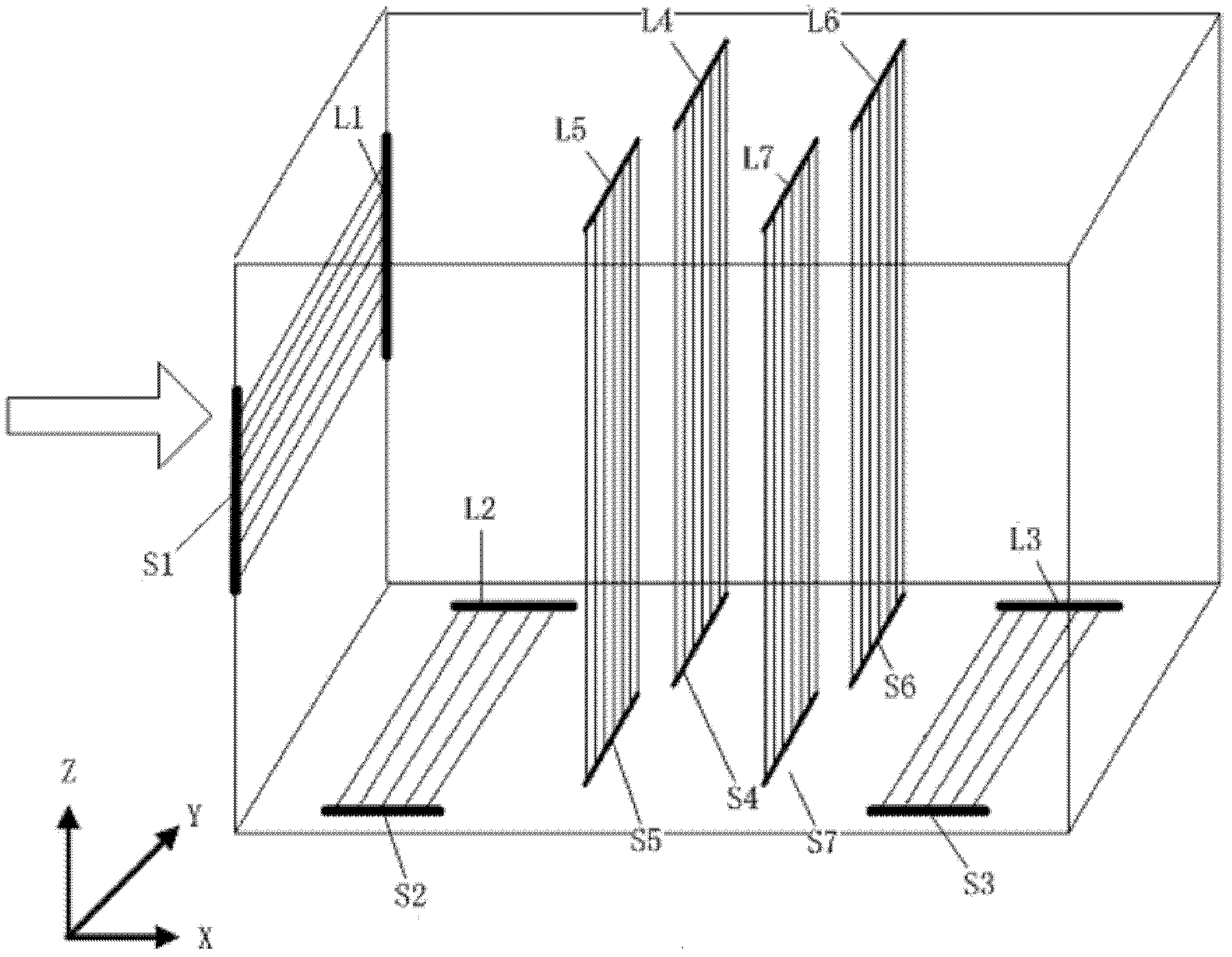

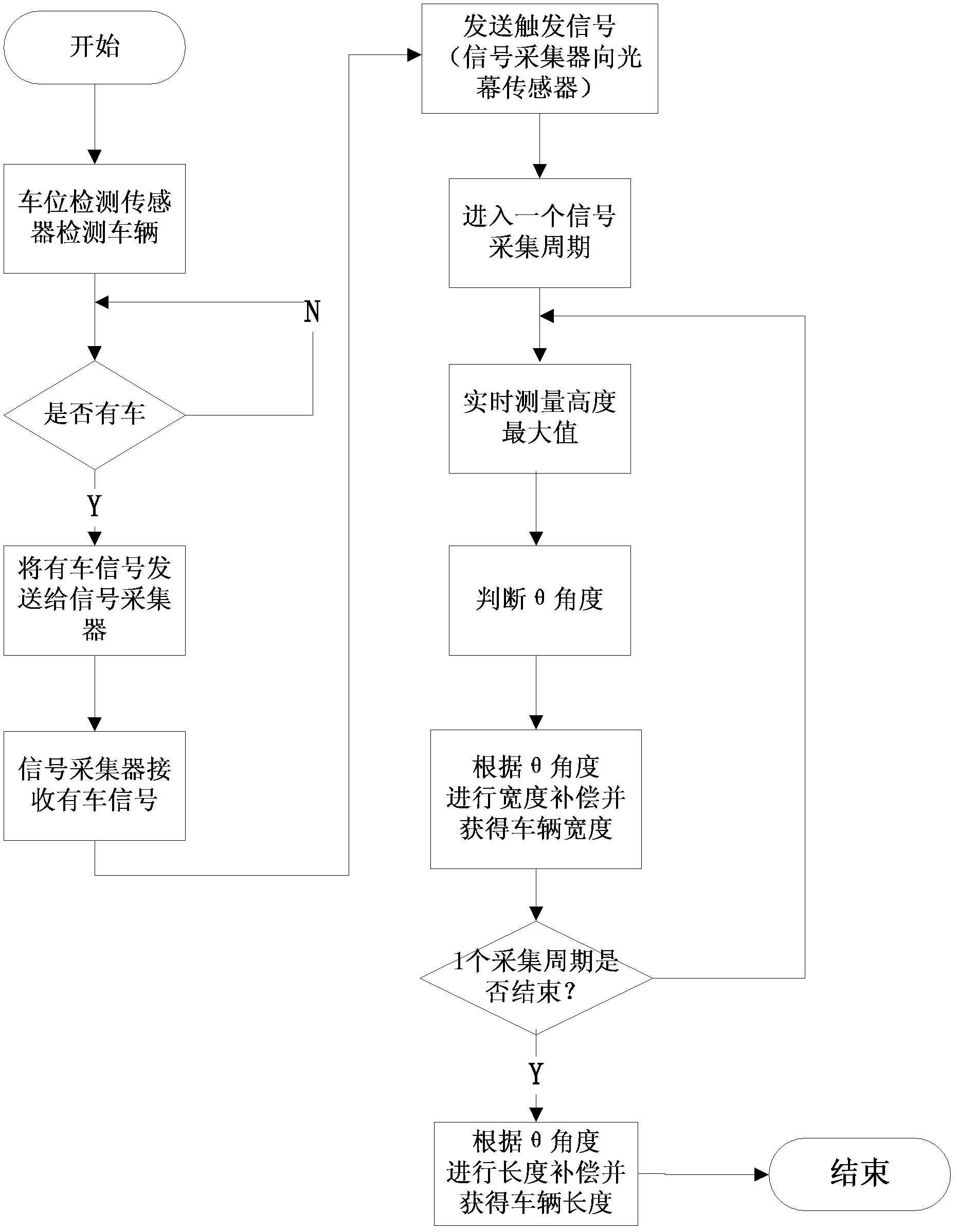

Light curtain-based vehicle size automatic measuring system and measuring method thereof

InactiveCN102620662ARealize accurate measurement functionAvoid errorsUsing optical meansSensor arrayCamera image

The invention relates to a light curtain-based vehicle size automatic measuring system and a measuring method thereof. The system consists of a measuring host, a signal acquisition device and a light curtain sensor array which are connected, wherein the light curtain sensor array is a three-dimensional structure which consists of a height measuring light curtain sensor, a width measuring light curtain sensor and a length measuring light curtain sensor; output ends of the height measuring light curtain sensor, the width measuring light curtain sensor and the length measuring light curtain sensor are connected with the signal acquisition device; and after a detection signal transmitted by the light curtain sensor array is received by the measuring host, the height, the width and the length of a vehicle to be measured are calculated by the measuring host. The system is rational in design; an accurate measuring function of the vehicle size is realized; the problem of error in image contour dimension caused by the fact that a camera screenshot is not in the same plane as a land mark and a vertical mark existing in a camera image photograph measuring method is solved; the measuring accuracy and stability are improved; and all the degree of difficulty for handling, the anti-interference capacity and the maintainability are dramatically improved.

Owner:SHENZHEN PUZHILIANKE ROBOT TECH CO LTD

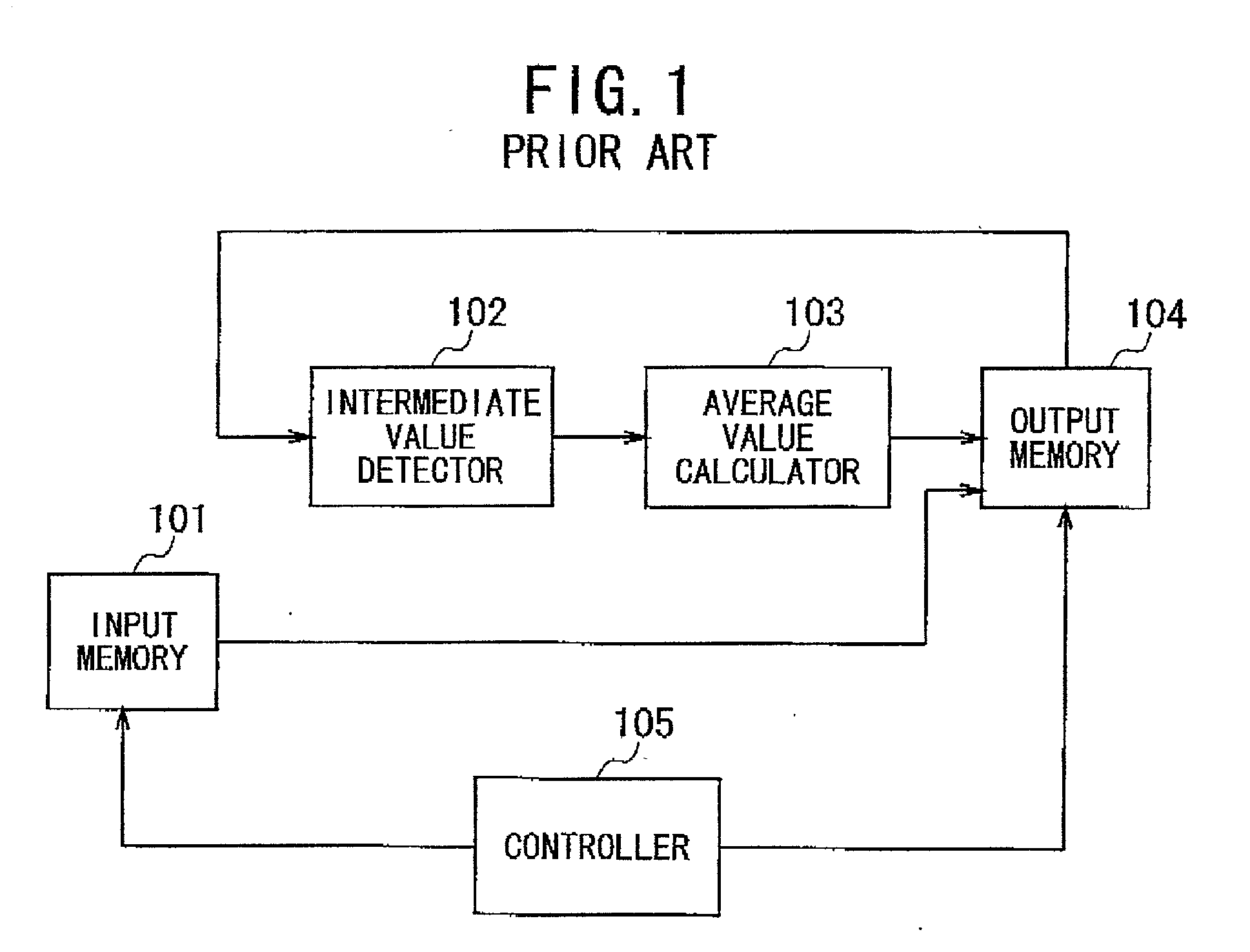

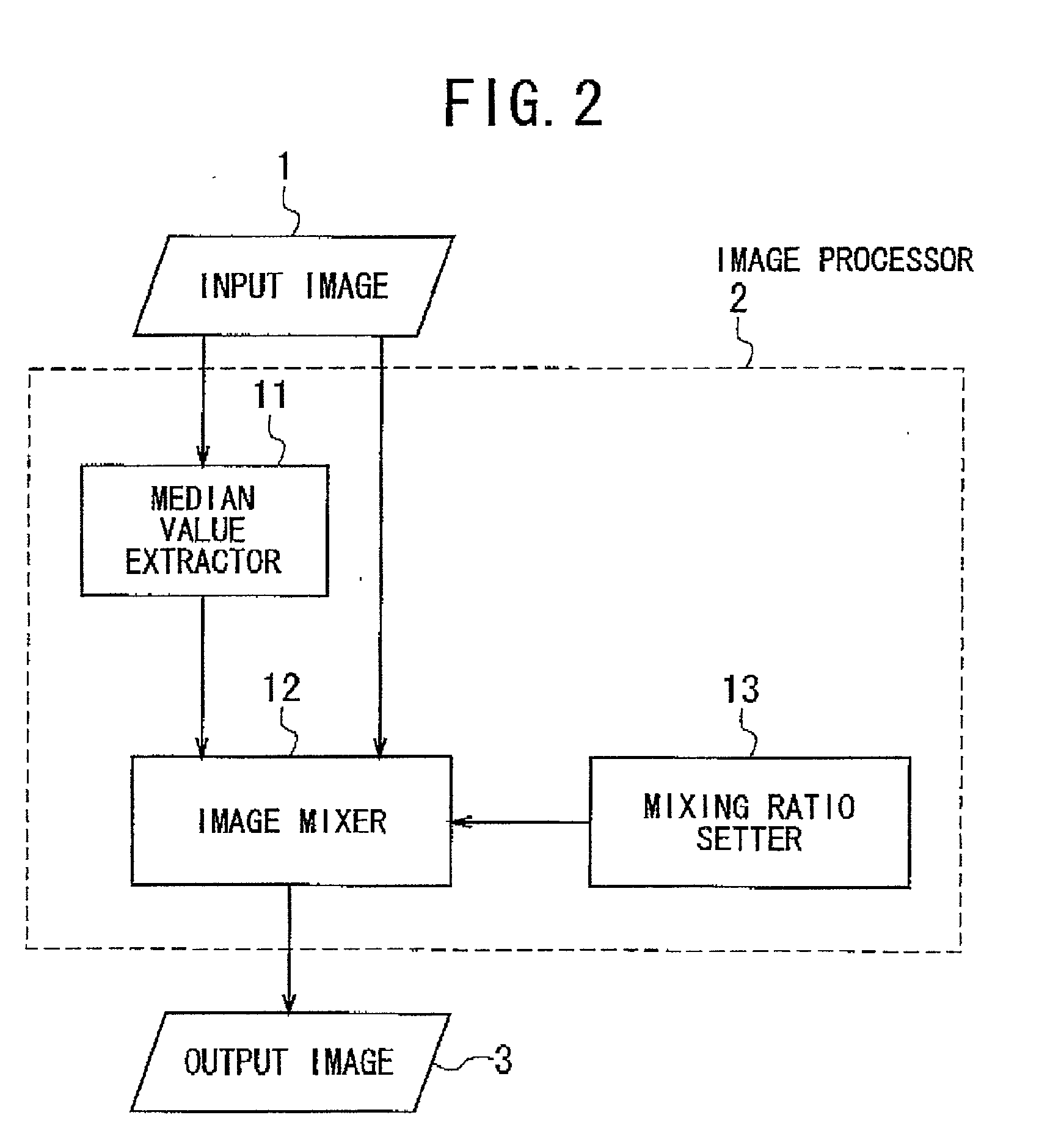

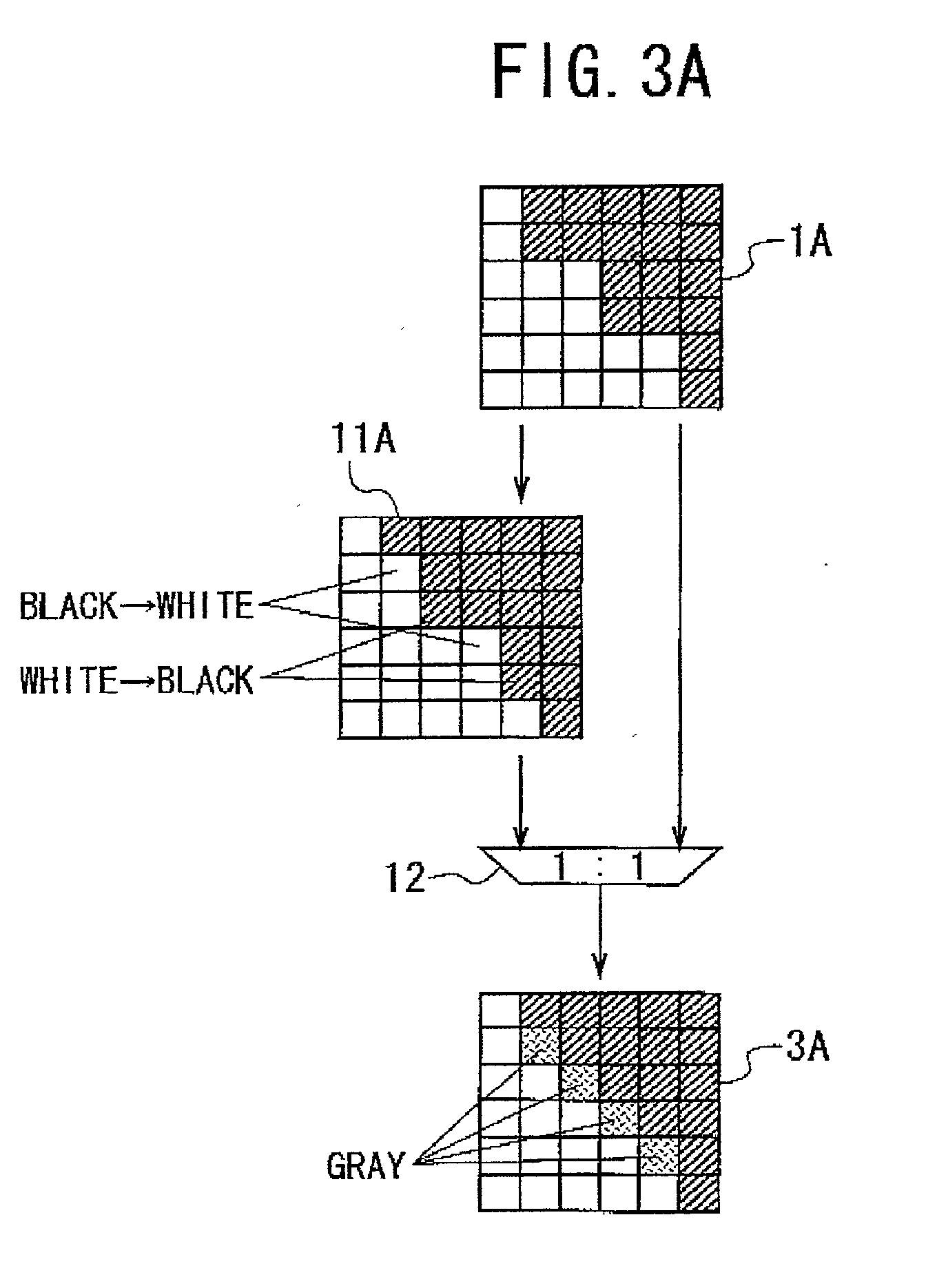

Image processing method and system for interpolation of resolution

An image processing method is provided, which makes it possible to enlarge an input or original image in such a way as to suppress or eliminate jaggies at the contours in the image, and which is applicable to a dot-matrix type display device with a fixed resolution. In the step (a) a local area is defined in an input image. The local area includes a target pixel and neighboring pixels surrounding the target pixel. In the step (b), a filtering operation is applied to the target pixel and the neighboring pixels in the local area while all the pixels in the local area are successively assigned to the target pixel, thereby outputting a filtered image. In the step (c), the filtered image and the input image are mixed together at a specific mixing ratio, thereby forming an output image. In the step (b), the median or average value is preferably used for forming the filtered image.

Owner:NEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com