Online detection device and method for abrasion of pantograph sliding plate based on images

A pantograph skateboard and detection device technology, which is applied in the field of traffic safety engineering, can solve the problems of large detection errors and low detection accuracy of skateboard wear, and achieve the effects of improving detection accuracy, ensuring operation safety, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

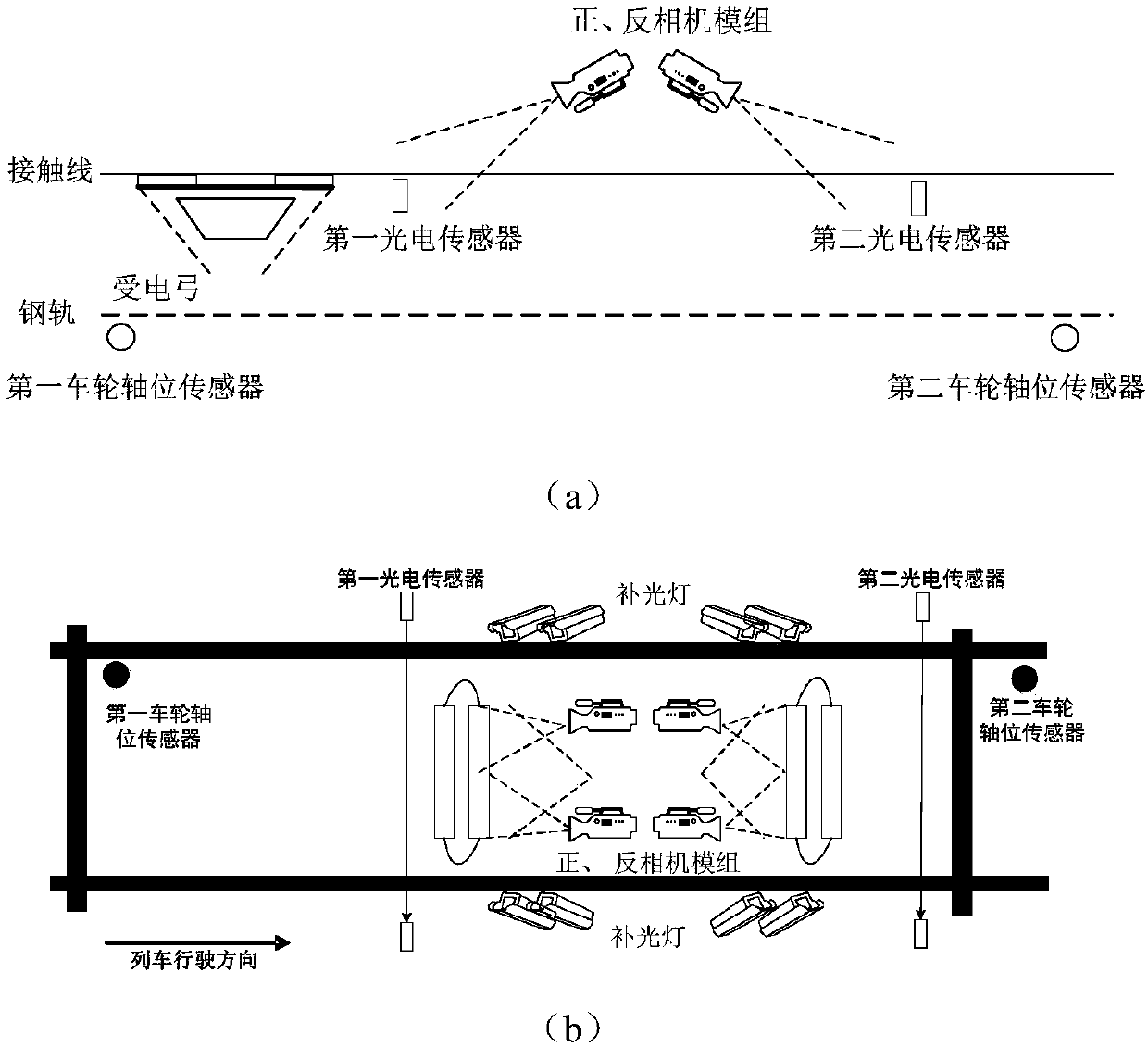

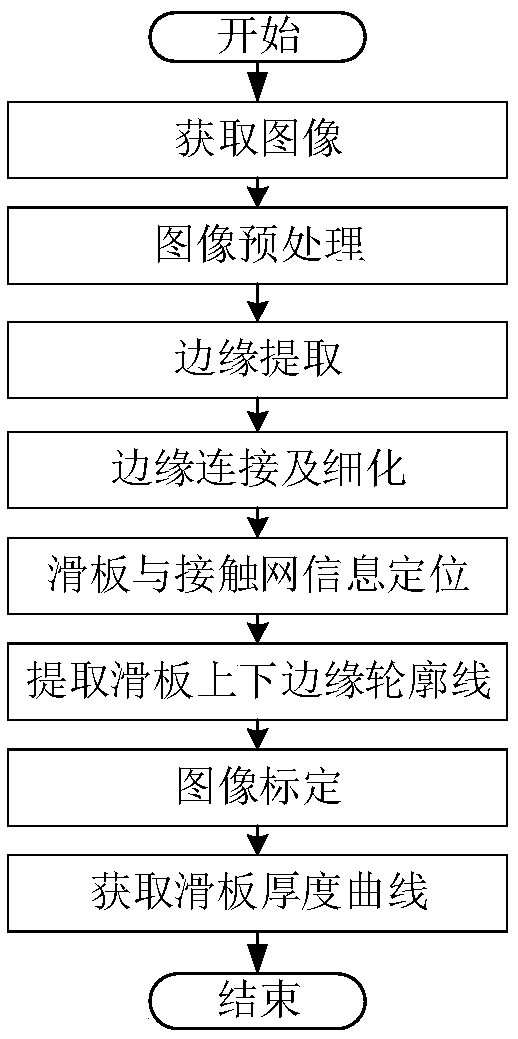

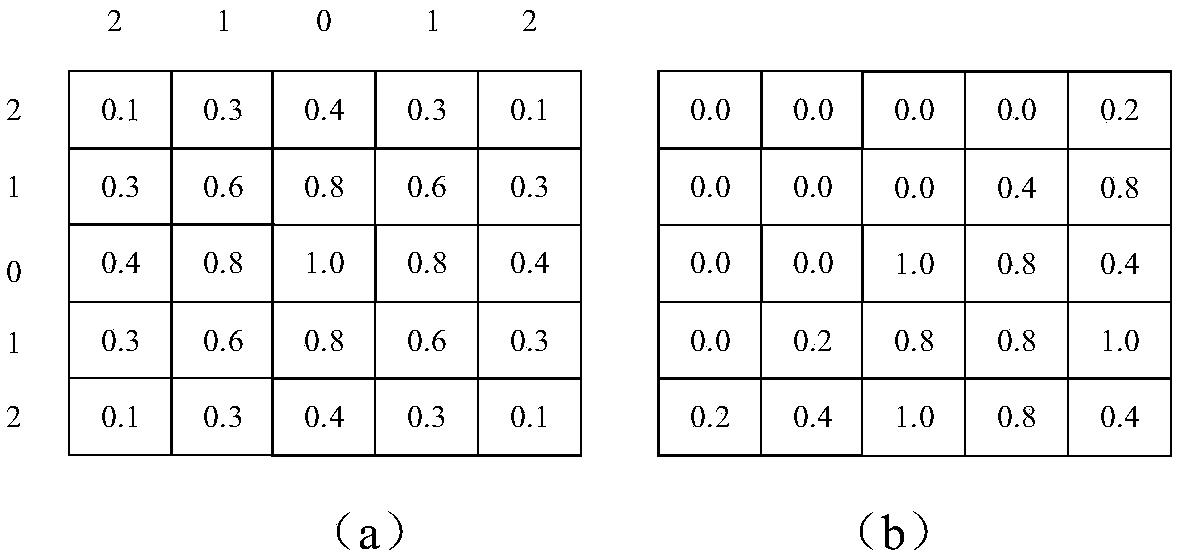

Method used

Image

Examples

Embodiment 1

[0119] For the captured image of the pantograph skateboard, the algorithm proposed by the invention is used to pre-filter and enhance the contrast of the above image, and then locate and extract the upper and lower edges of the skateboard to obtain the measurement result of the skateboard wear. Since the normal wear area of the skateboard is generally within the range of about 400mm from the centerline of the skateboard, the maximum, minimum and average values of the wear of the skateboard are calculated within this range. System skateboard wear test results Figure 11 .

[0120] From Figure 11 It can be seen that the maximum remaining thickness of the skateboard measured by the system is 14.9mm, the minimum remaining thickness is 13.2mm, the average wear of the skateboard is 6.1mm, and there is no crack on the surface of the skateboard.

[0121] The images collected in different environments, and the pantograph fault detection test were carried out, and the skateboard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com