Visual inspection method for chip electronic component position error based on edge fitting

An electronic component and edge fitting technology, applied in the field of image processing, can solve the problems of slow detection speed, poor accuracy, and reduced efficiency, and achieve the effect of fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

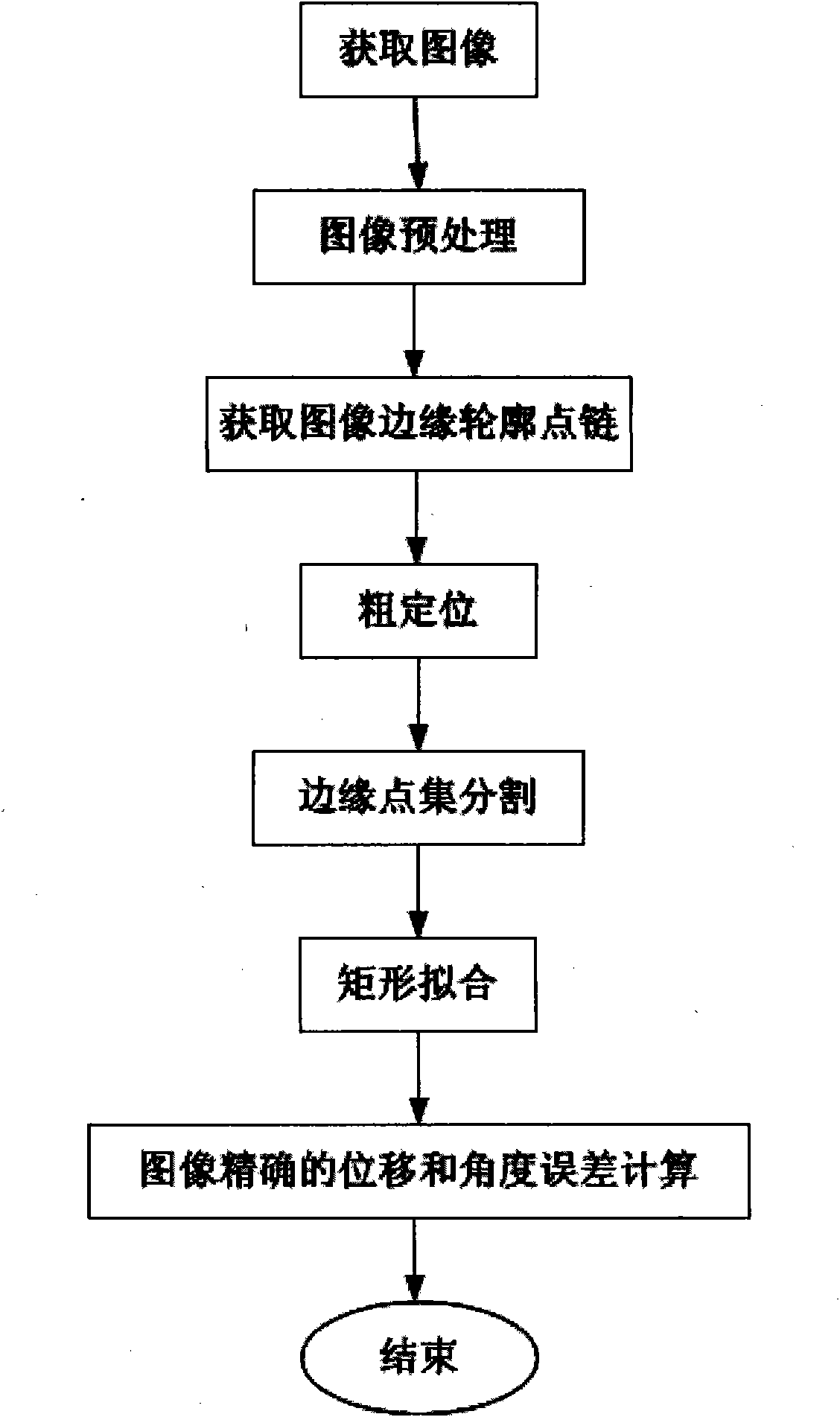

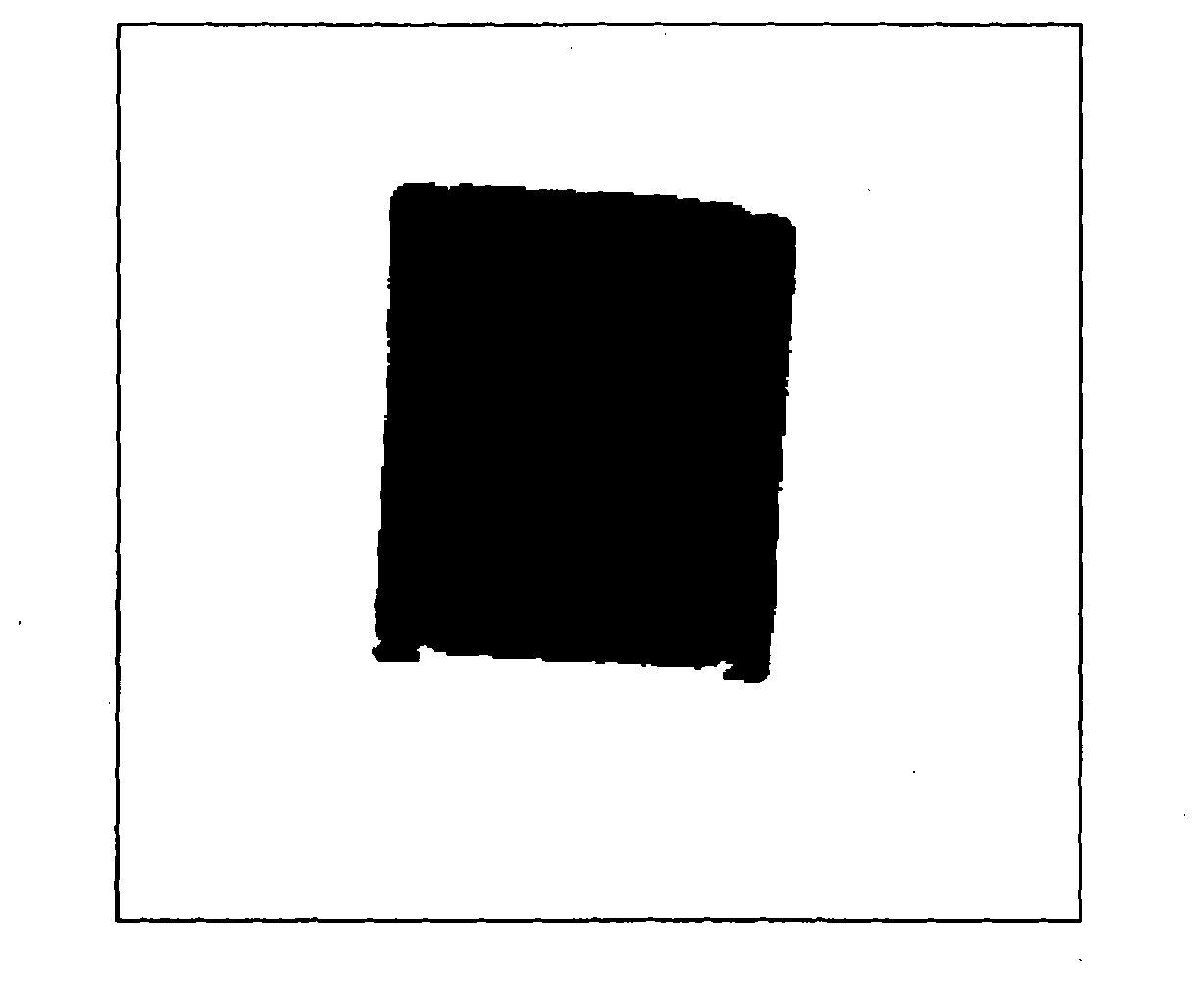

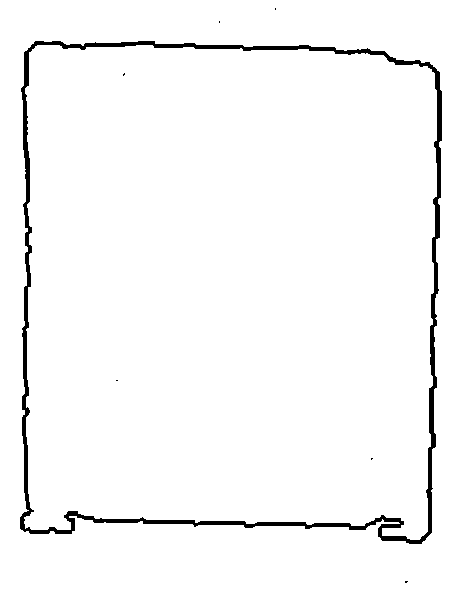

[0014] In the present invention, a general-purpose camera is first used to obtain a grayscale image of a chip electronic component, the image is preprocessed, and binarization is performed through threshold segmentation. After the binarization, the following is obtained: figure 2 image to isolate the target region. then to figure 2 The image after binary processing shown in the figure is subjected to edge detection and contour extraction at the same time. image 3 The edge contour of the image of the chip electronic component is shown, and then the boundary contour point set Ω of the entire image is obtained by boundary tracking, and the edge point chain structure of the image is generated.

[0015] Such as Figure 4 As shown, according to the obtained edge point chain structure, the center O(x c ,y c ) for preliminary calculation, the center coordinates of the contour (x c ,y c ) is calculated using the following contour center of gravity formula:

[0016] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com