Method for detecting potential defects of complicated-structure castings on basis of vertical cross line contour features

A technology of complex structures and contour features, applied in image data processing, instruments, calculations, etc., to achieve the effect of improving the final defect detection rate and reducing the impact of structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The method for detecting latent defects of castings with complex structures based on the profile features of vertical vertical and horizontal lines of the present invention will be further described below using the accompanying drawings and embodiments.

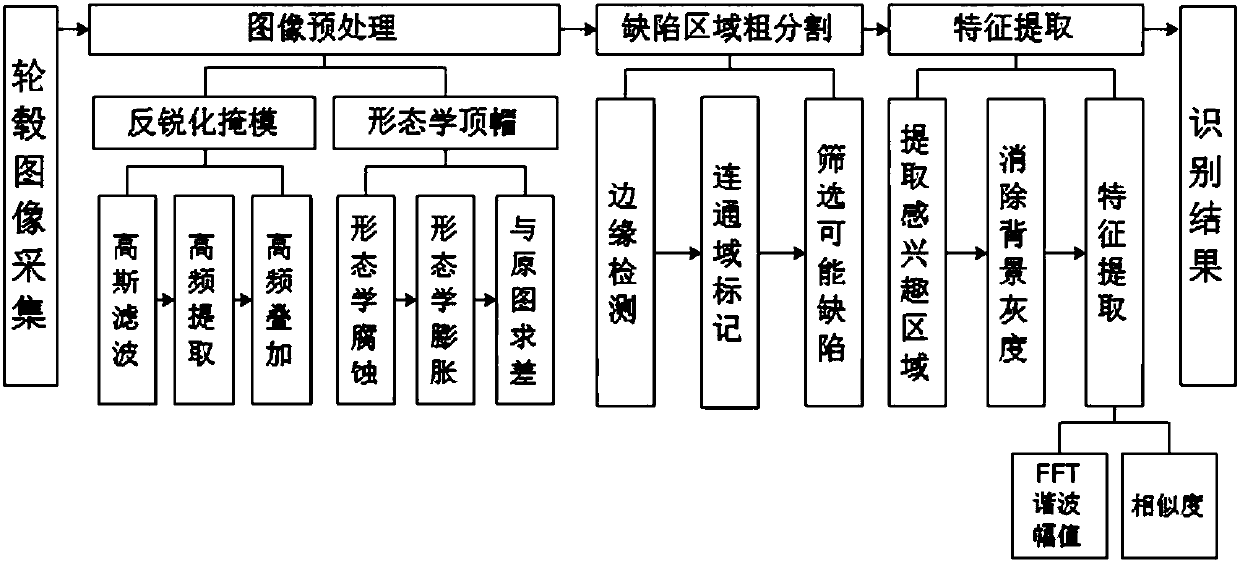

[0065] Such as figure 1 Shown, embodiment of the present invention is as follows:

[0066] Step 1: Use the unsharp mask algorithm to sharpen the original image, and use the gray-level morphological top-hat operation to highlight the local high-brightness areas to achieve image preprocessing. The process is as follows:

[0067] 1.1) First extract the high-frequency components of the image, and create a size of Gaussian operator, where A is the size of the preset potential defect, set the standard deviation to 4, perform Gaussian filtering on the original image, subtract the result of Gaussian filtering from the original image to obtain the high-frequency component of the image; then add the high-frequency image to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com