Patents

Literature

138results about How to "Improve defect detection rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

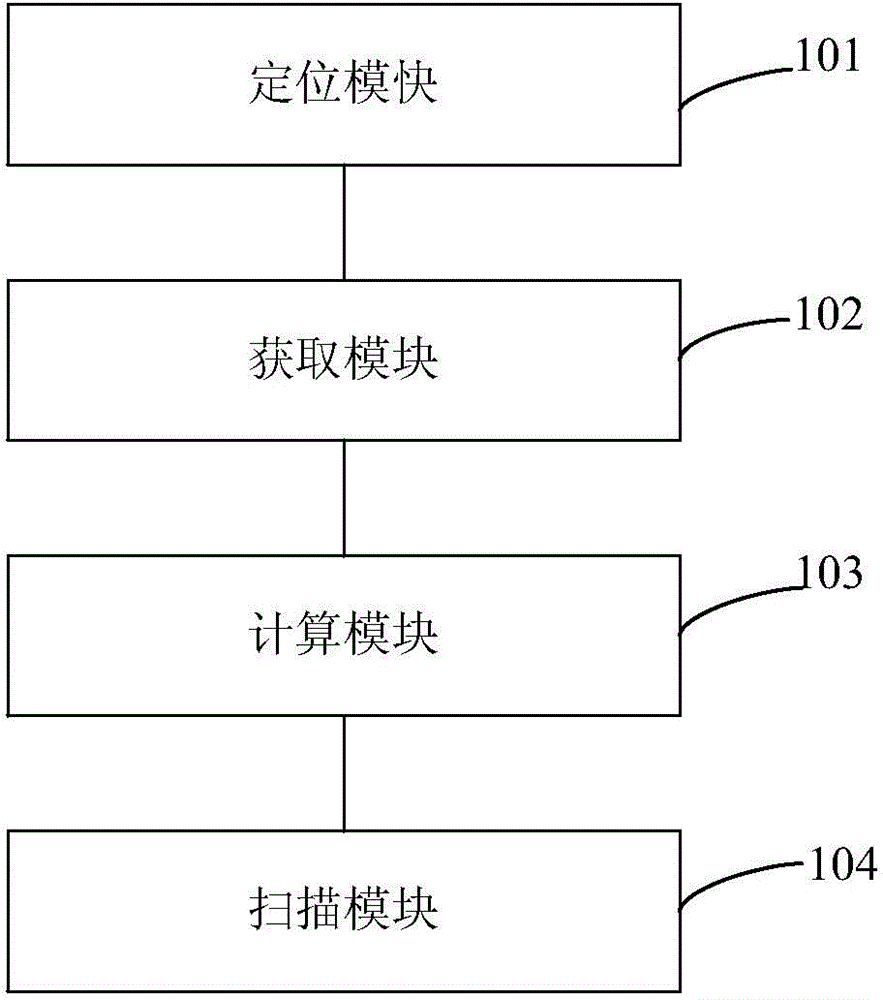

Microdefect detection method, device and equipment for CF substrate

InactiveCN107402218AImprove defect detection rateSolve defect omissionsOptically investigating flaws/contaminationNon-linear opticsComputer visionGray level

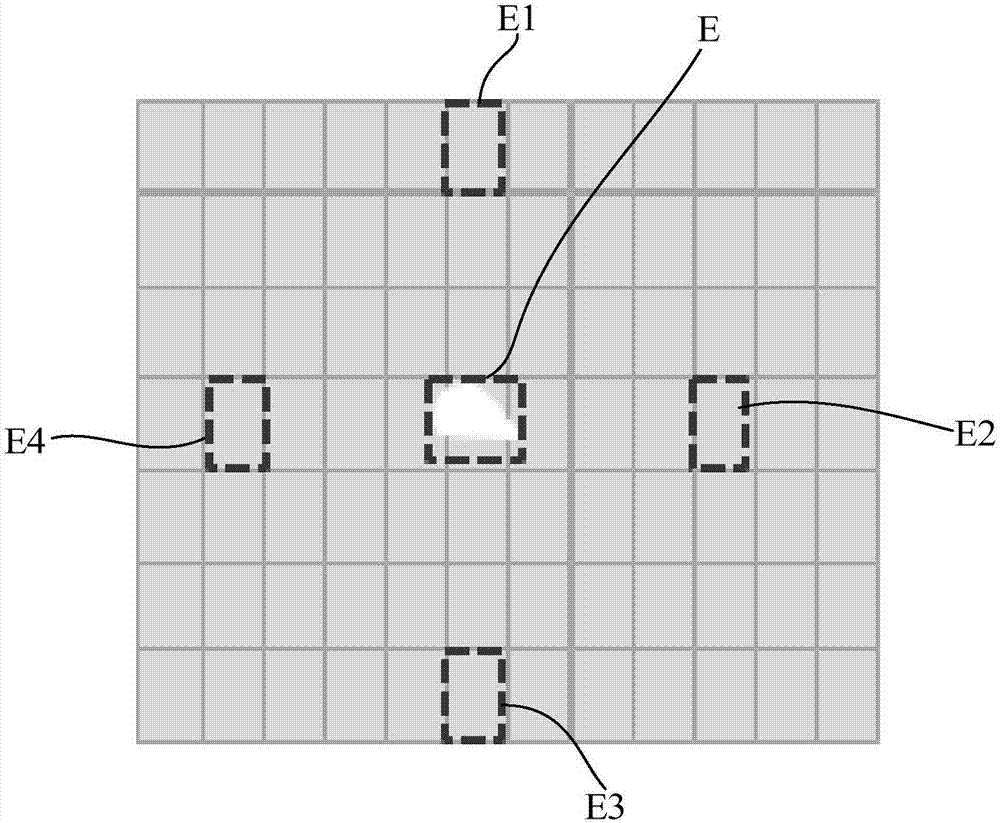

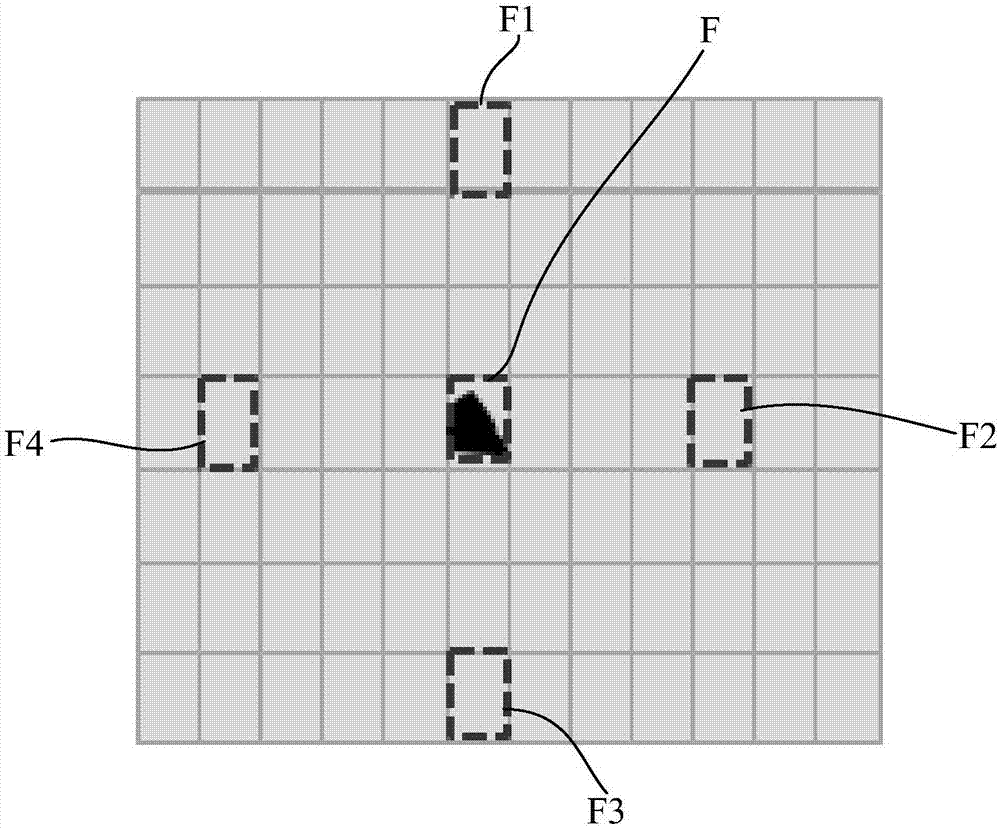

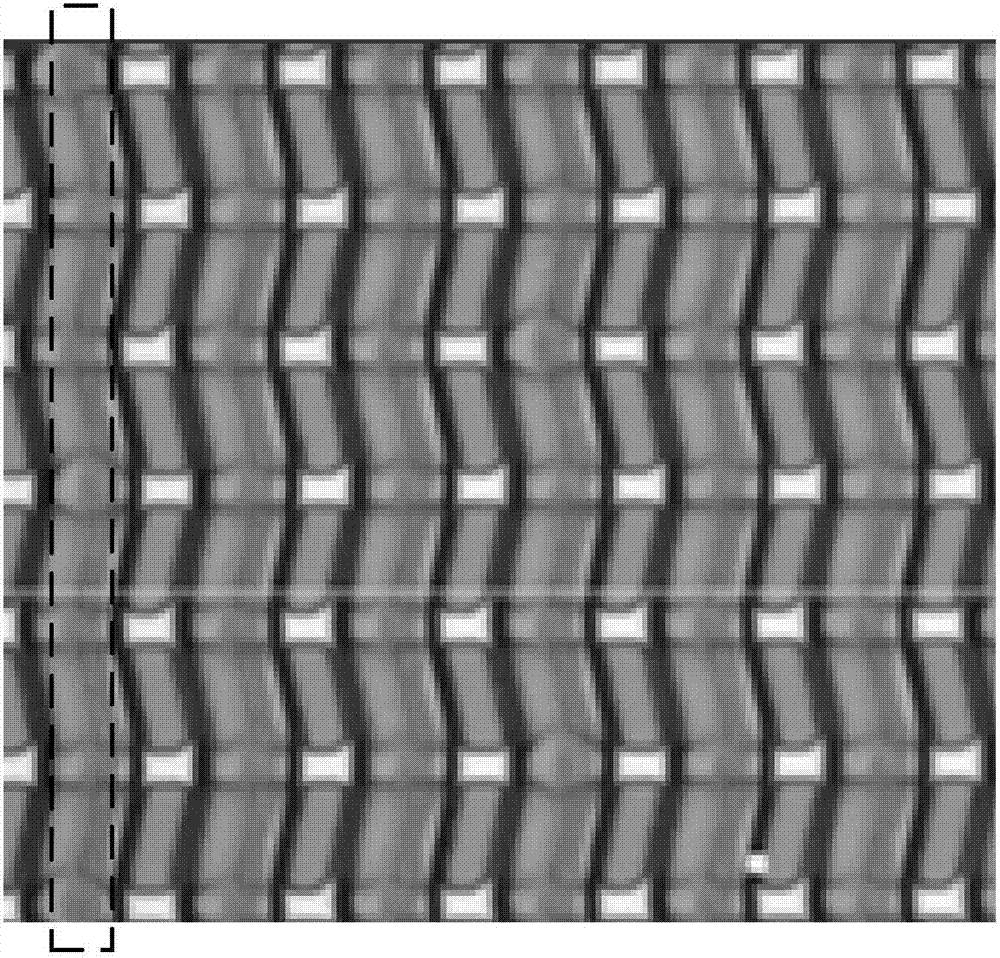

The invention provides a microdefect detection method, a device and equipment for a CF substrate. The detection method comprises the steps of: acquiring a gray-scale image of the CF substrate; detecting the gray-scale value of the gray-scale image's to-be-detected point; acquiring a corresponding normal gray-scale value range of the to-be-detected point in a color area; judging whether the gray-scale value of the to-be-detected point is in the corresponding normal gray-scale range; if the gray-scale value of the to-be-detected point is not in the corresponding normal gray-scale range, judging the to-be-detected point an abnormal point. The microdefect detection method, device and equipment for the CF substrate provided by the invention can conduct adaptive defect detection on different color areas of the CF substrate distinctively, thus improving the defect detection rate of the CF substrate, and effectively solving the problem of undetected defects.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

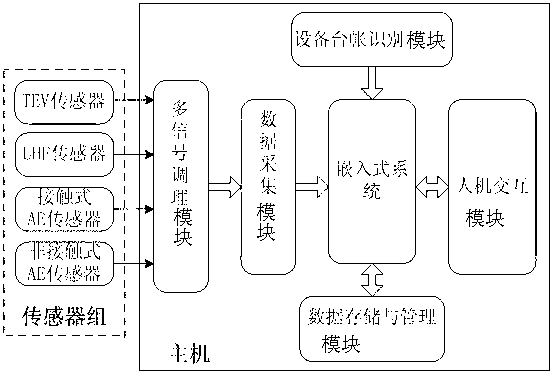

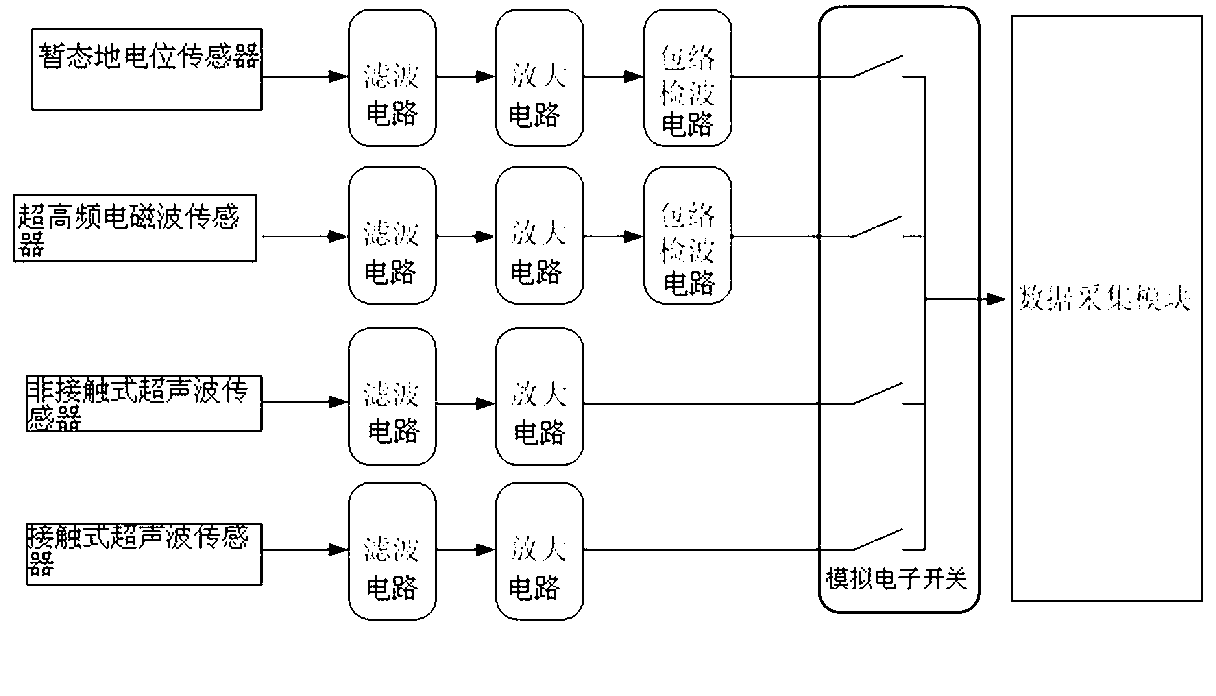

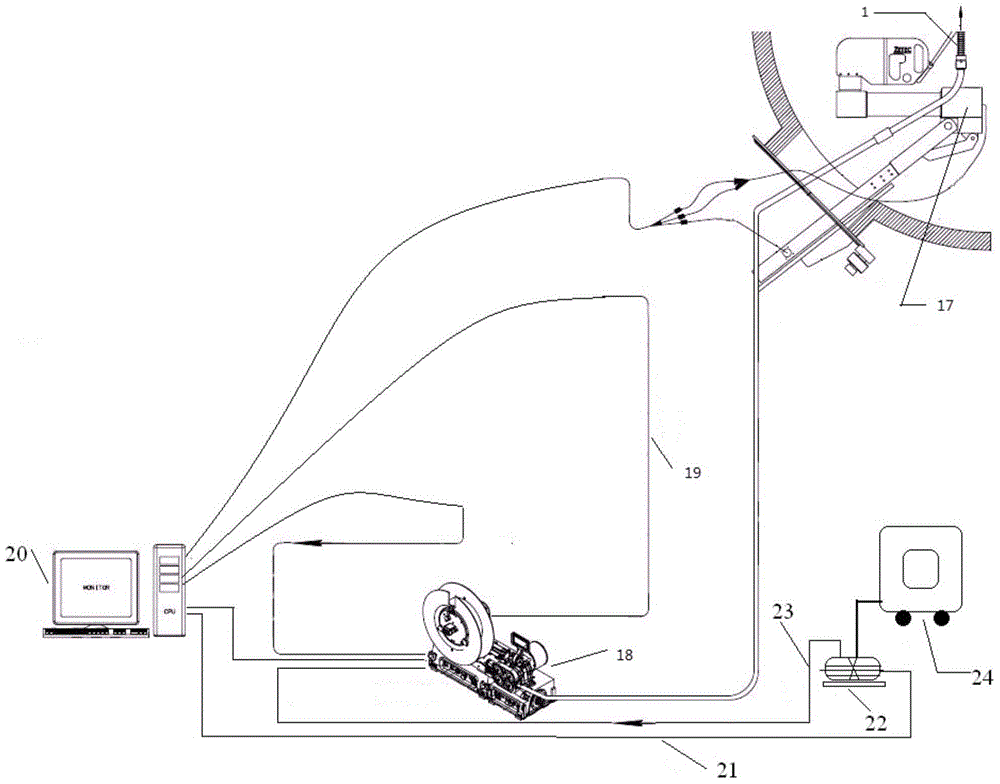

Partial discharge comprehensive itinerant detector for high voltage electric power equipment

ActiveCN103278751ARealize the comprehensive detection of partial dischargeImprove defect detection rateTesting dielectric strengthTransformerElectric power equipment

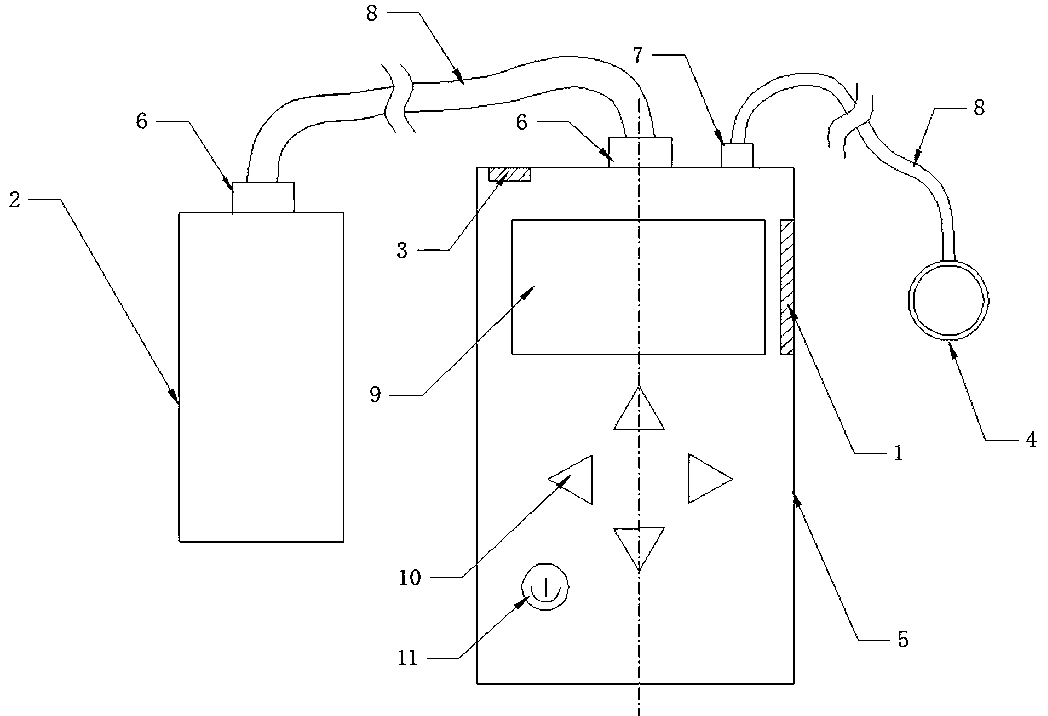

The invention discloses a partial discharge comprehensive itinerant detector for high voltage electric power equipment. The partial discharge comprehensive itinerant detector for the high voltage electric power equipment is characterized by comprising a host and a sensor group connected with the host, wherein the sensor group comprises a transient state ground potential sensor, an ultrahigh frequency electromagnetic wave sensor, a non-contacting ultrasonic sensor and a contacting ultrasonic sensor; the transient state ground potential sensor is used for detecting a current pulse signal on the shell of the electric power equipment; the ultrahigh frequency electromagnetic wave sensor is used for detecting an electromagnetic wave signal transmitted from the inside of the electric power equipment; the non-contacting ultrasonic sensor is used for detecting an ultrasonic wave signal transmitted from the inside of the electric power equipment; the contacting ultrasonic sensor is used for detecting shell vibration caused by the ultrasonic wave signal transmitted from the inside of the electric power equipment; and the transient state ground potential sensor, the ultrahigh frequency electromagnetic wave sensor, the non-contacting ultrasonic sensor and the contacting ultrasonic sensor are all connected with the host. According to the partial discharge comprehensive itinerant detector, a transformer, a composite apparatus (gas insulated switchgear) and a switch cabinet can be conveniently subjected to partial discharge electrification detection, and the partial discharge comprehensive itinerant detector for the high voltage electric power equipment has the outstanding advantages of convenience in carrying the instrument, as well as quickness and intellectualization in detection.

Owner:STATE GRID CORP OF CHINA +2

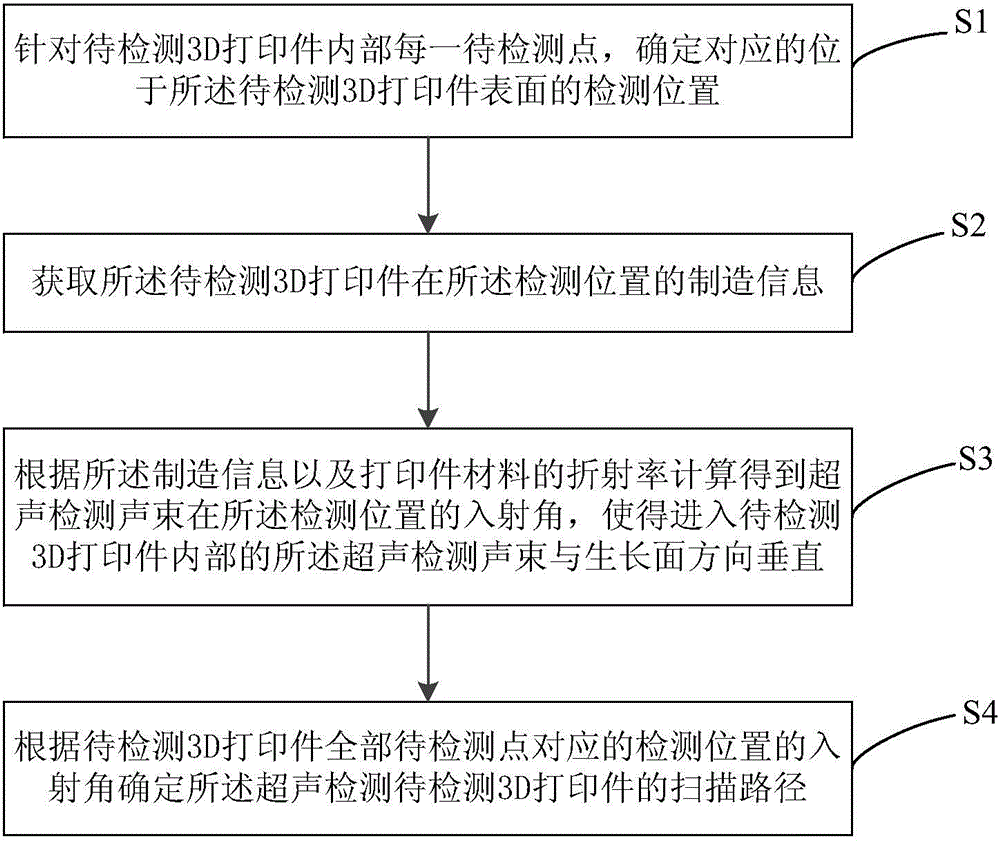

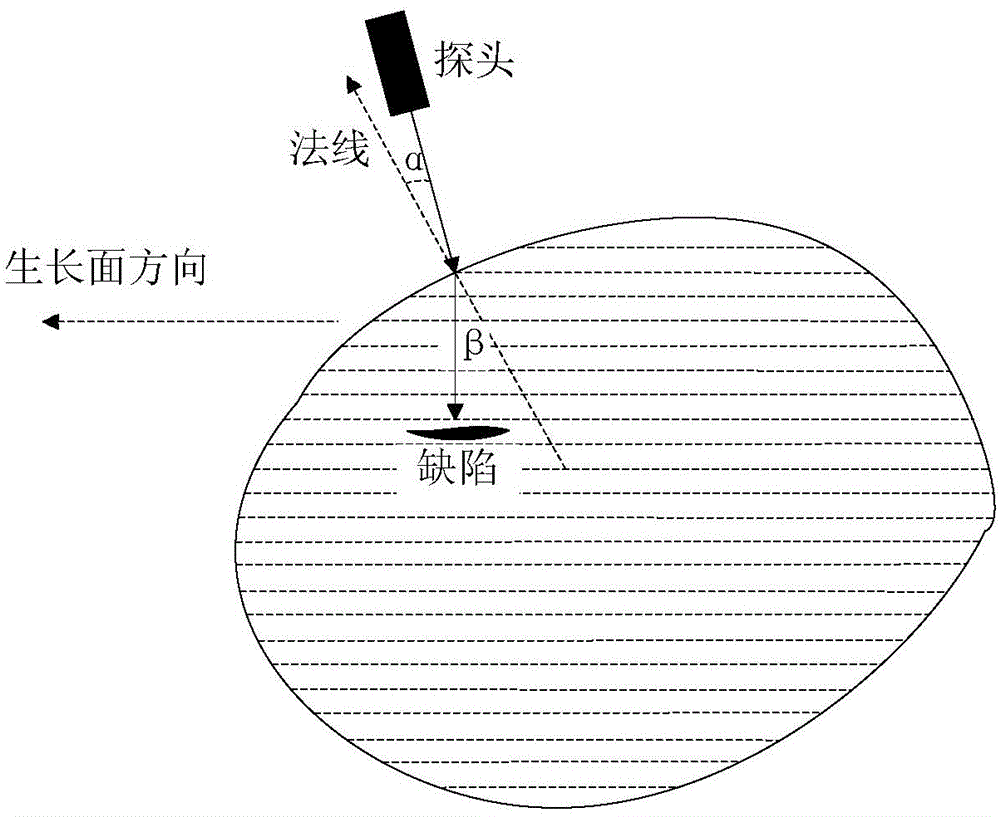

Ultrasonic detection control method and ultrasonic detection control device for 3D printed piece

ActiveCN104597125AImprove signal-to-noise ratioImprove defect detection rateAnalysing solids using sonic/ultrasonic/infrasonic wavesRefractive indexAcoustics

The invention relates to the technical field of ultrasonic nondestructive testing and in particular relates to an ultrasonic detection control method and an ultrasonic detection control device for a 3D printed piece. The method comprises the following steps: according to the normal direction of a detection point which corresponds to a to-be-detected point for a to-be-detected 3D printed piece and the workpiece growth surface direction, determining an incidence angle of ultrasonic detection sound beams entering the to-be-detected 3D printed piece from the detection position by combining the refractive index of the printed piece, and further controlling a probe of the ultrasonic detection equipment to scan according to the incidence angle of the detection position which corresponds to each to-be-detected point. Therefore, the signal to noise ratio and the defect detection rate of the 3D printed piece can be improved.

Owner:ALLRISING BEIJING TECH

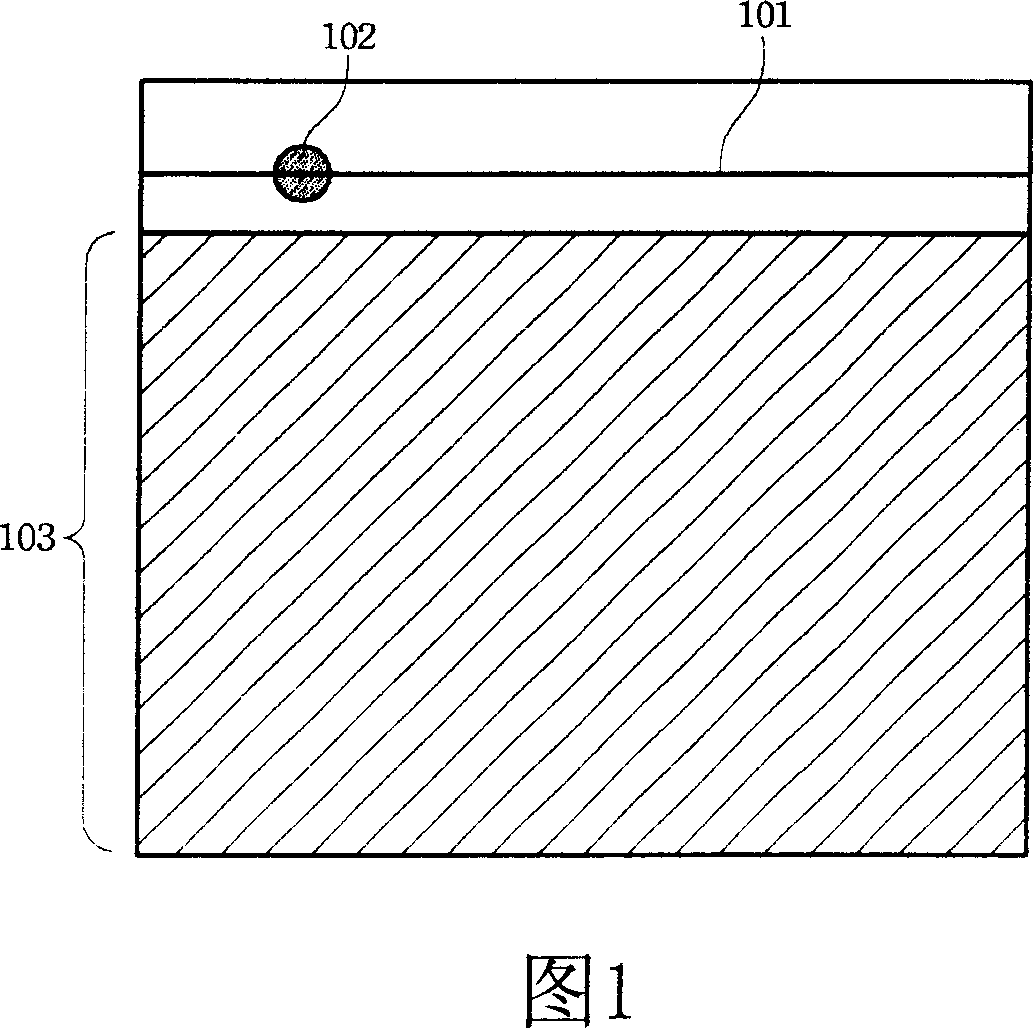

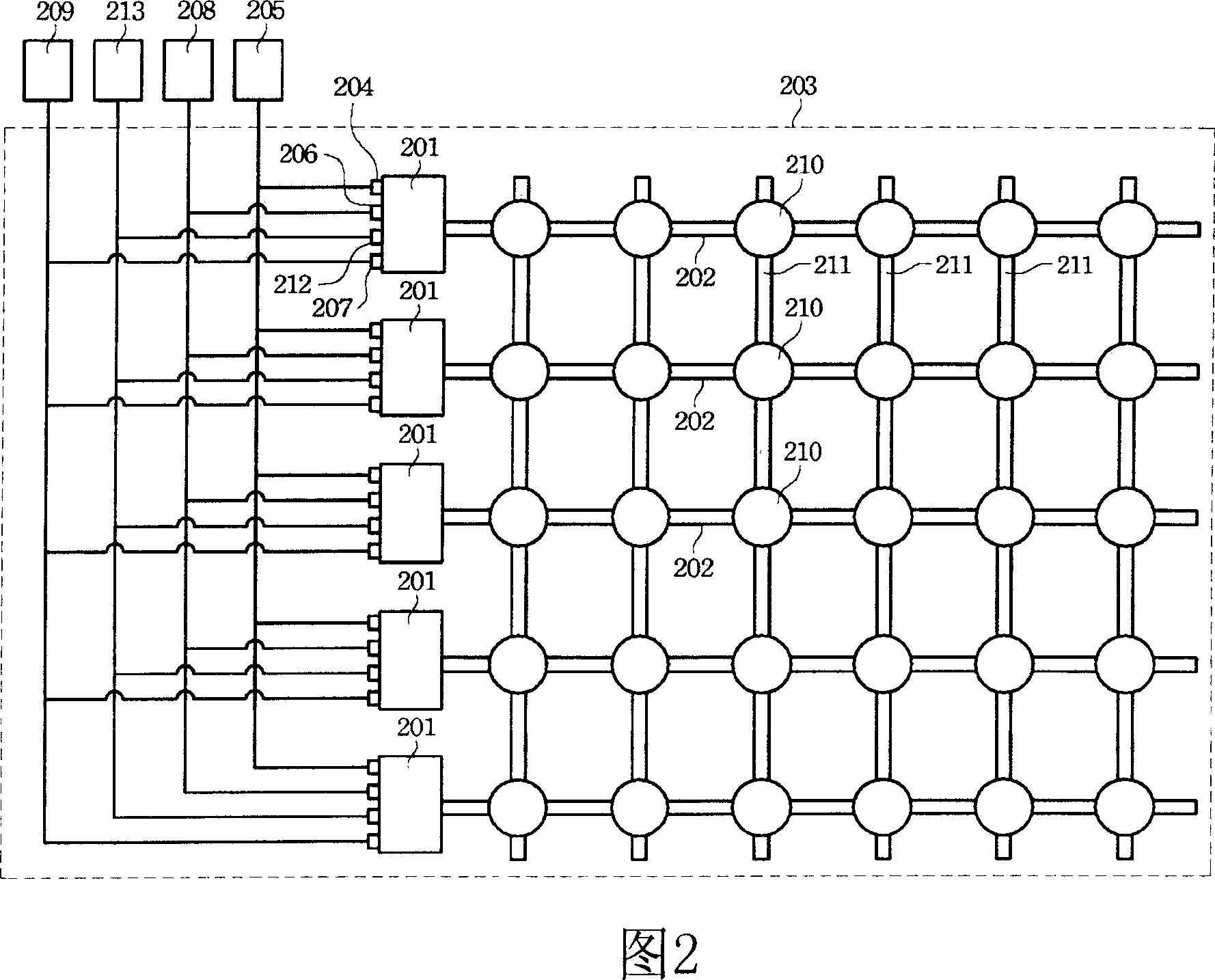

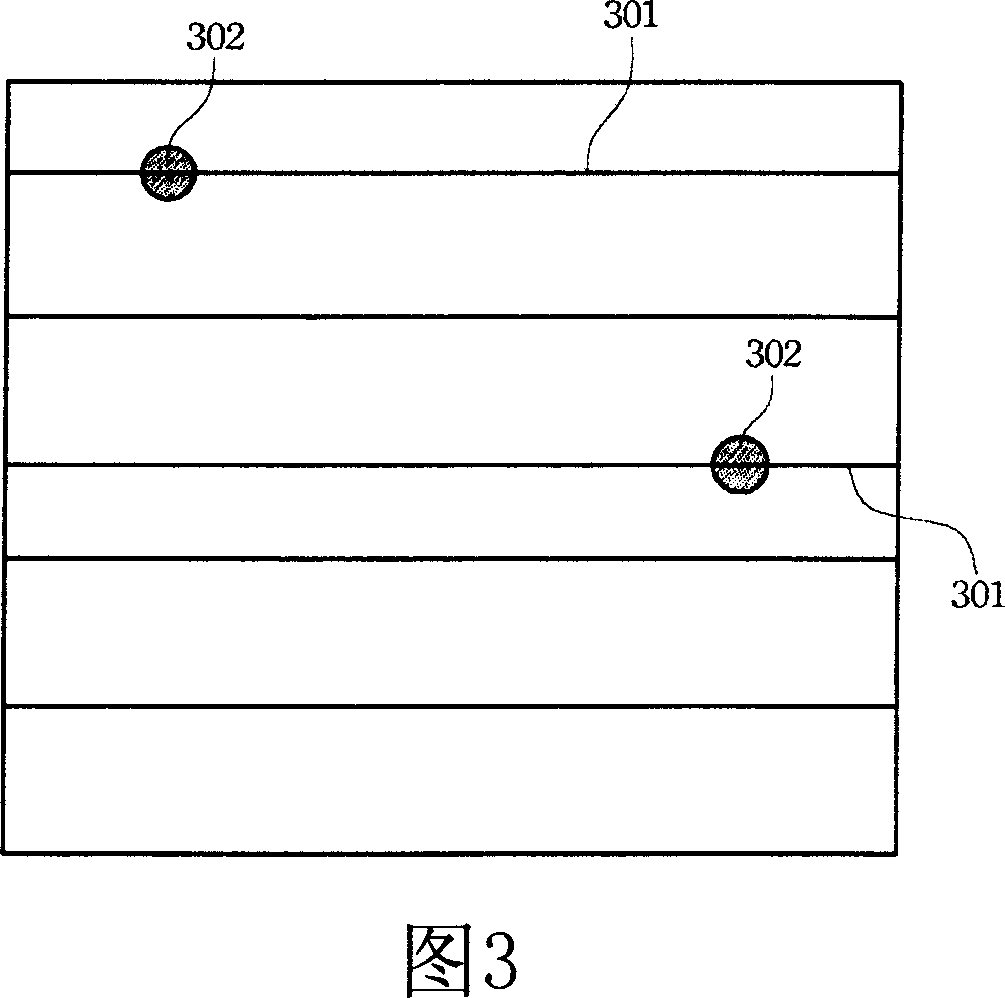

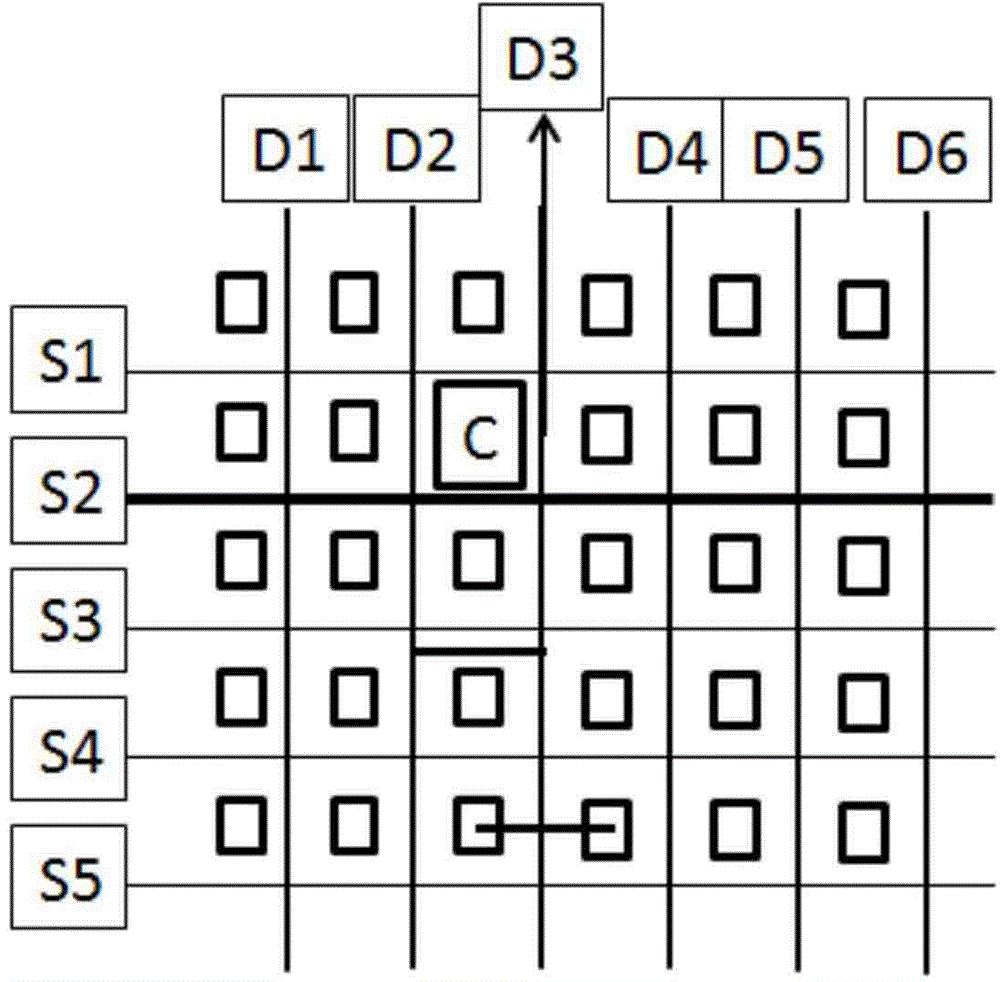

Test method for liquid crystal display panel

ActiveCN1996445AAvoid defect blind spotsImprove defect detection rateElectronic circuit testingStatic indicating devicesLiquid-crystal displayNegative phase

A way for testing LCD panel combines the LCD panel to grid through grid drive circuit, at least inputting positive and negative phase time sequence and lower pull signal to selected zone grid driver positive sequence input end, negative time sequence input end and lower pull signal input end. Inputting start signal at the same time to grid driver start signal input end to start selected area grid, and starting the selected thin film transistor at the same time. Send a testing signal by all data cables. It can also be used for local testing. It divides the panel into several zones with different testing areas.

Owner:AU OPTRONICS CORP

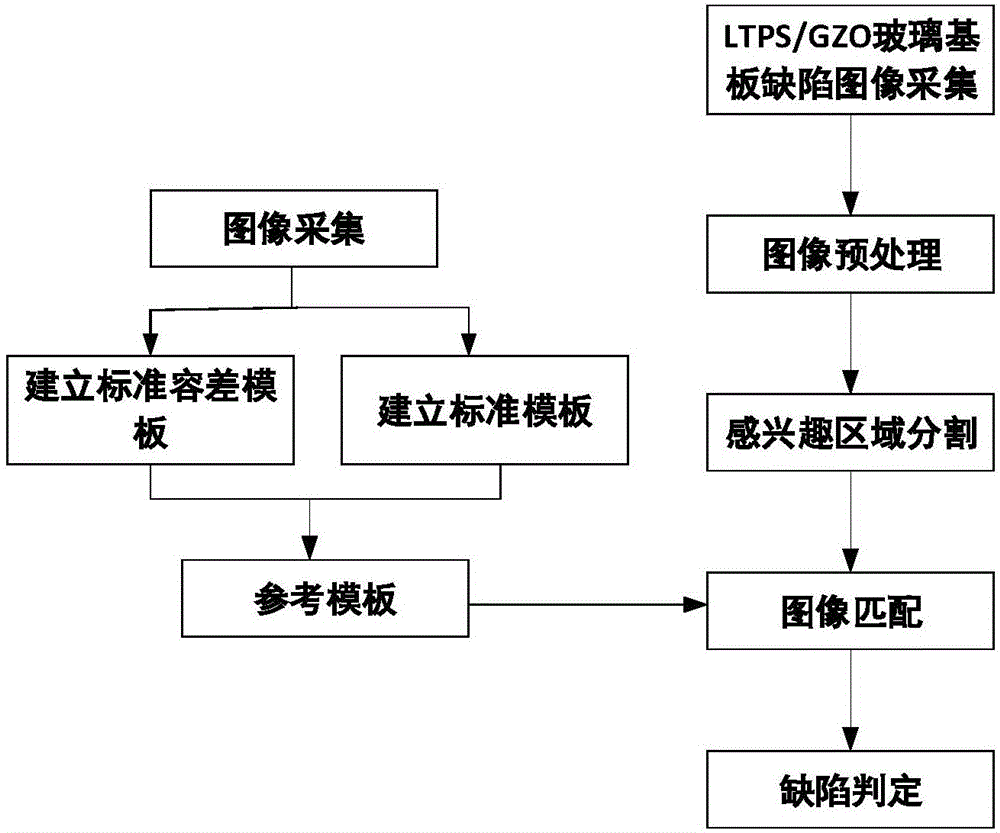

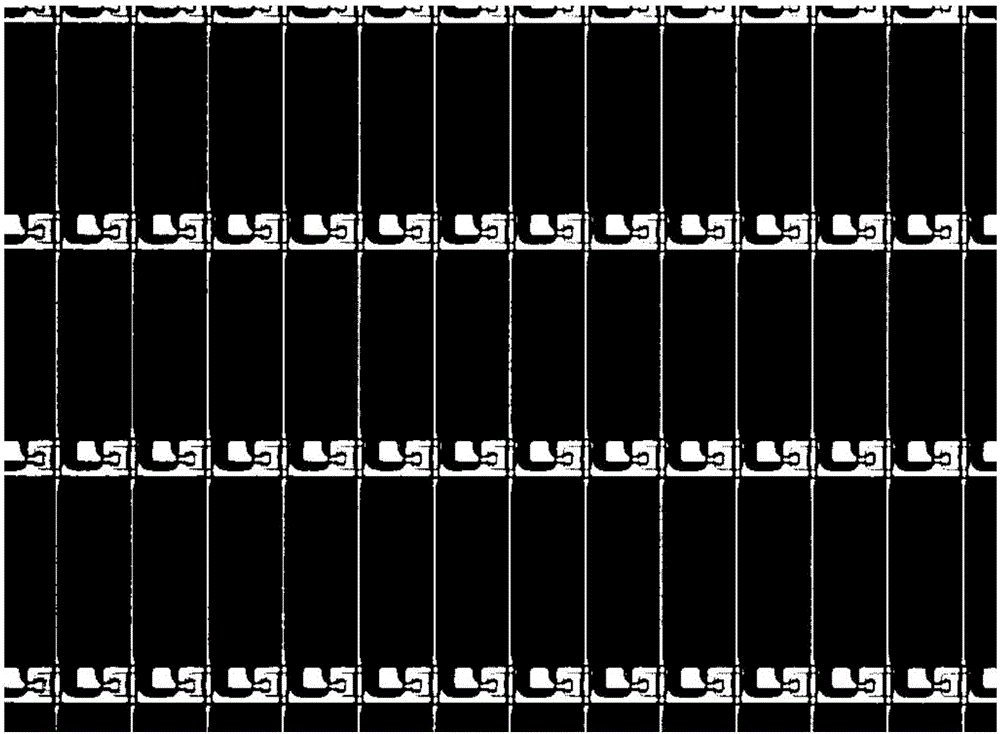

Quick detection method for LTPS-IGZO glass substrate broken hole

InactiveCN106198569AProcessing speedReliable processing speedMaterial analysis by optical meansOptical distortionDigital image

The invention relates to a quick detection method for an LTPS-IGZO glass substrate broken hole. The method is characterized by mainly comprising the following steps that an LTPS-IGZO glass substrate image is acquired through a high-capacity high-speed parallel digital image acquisition technology; image preprocessing is conducted, wherein optical distortion processing of the image, system vibration processing, dynamic aligning of the image and binarization processing are included; the area of interest of the acquired image is segmented; image matching is conducted, wherein the images subjected to segmenting processing are quickly matched by establishing a standard template, and then a difference value between the acquired image and a standard image can be judged; defect determining is conducted. According to the method, a broken hole defect of the high-capacity LTPS-IGZO glass substrate image with the size of 1 G can be quickly detected, the defect detection rate is high, time consumed by calculation is short, the high-capacity and high-resolution picture processing speed is high, and performance is reliable.

Owner:GUANGDONG UNIV OF TECH

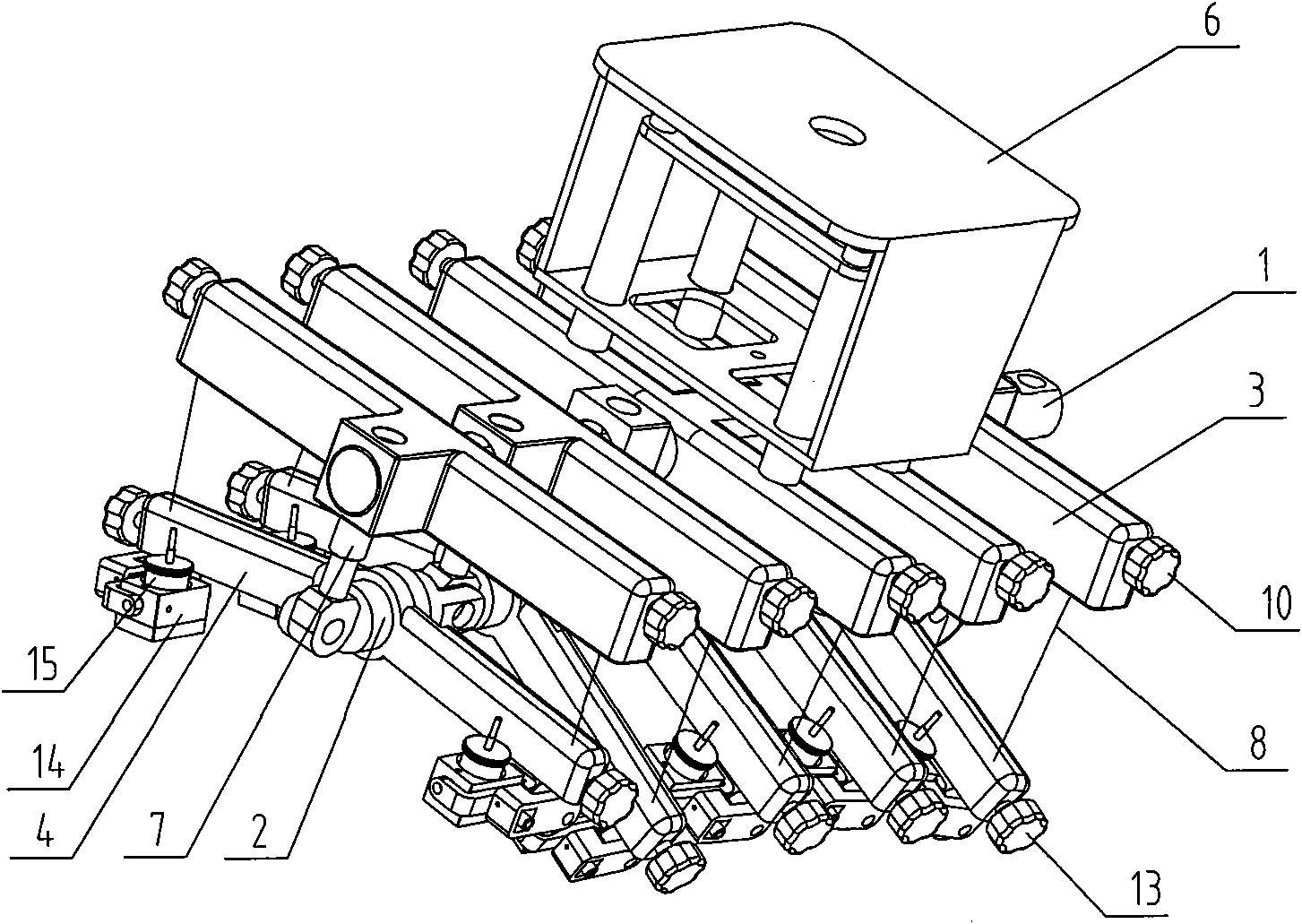

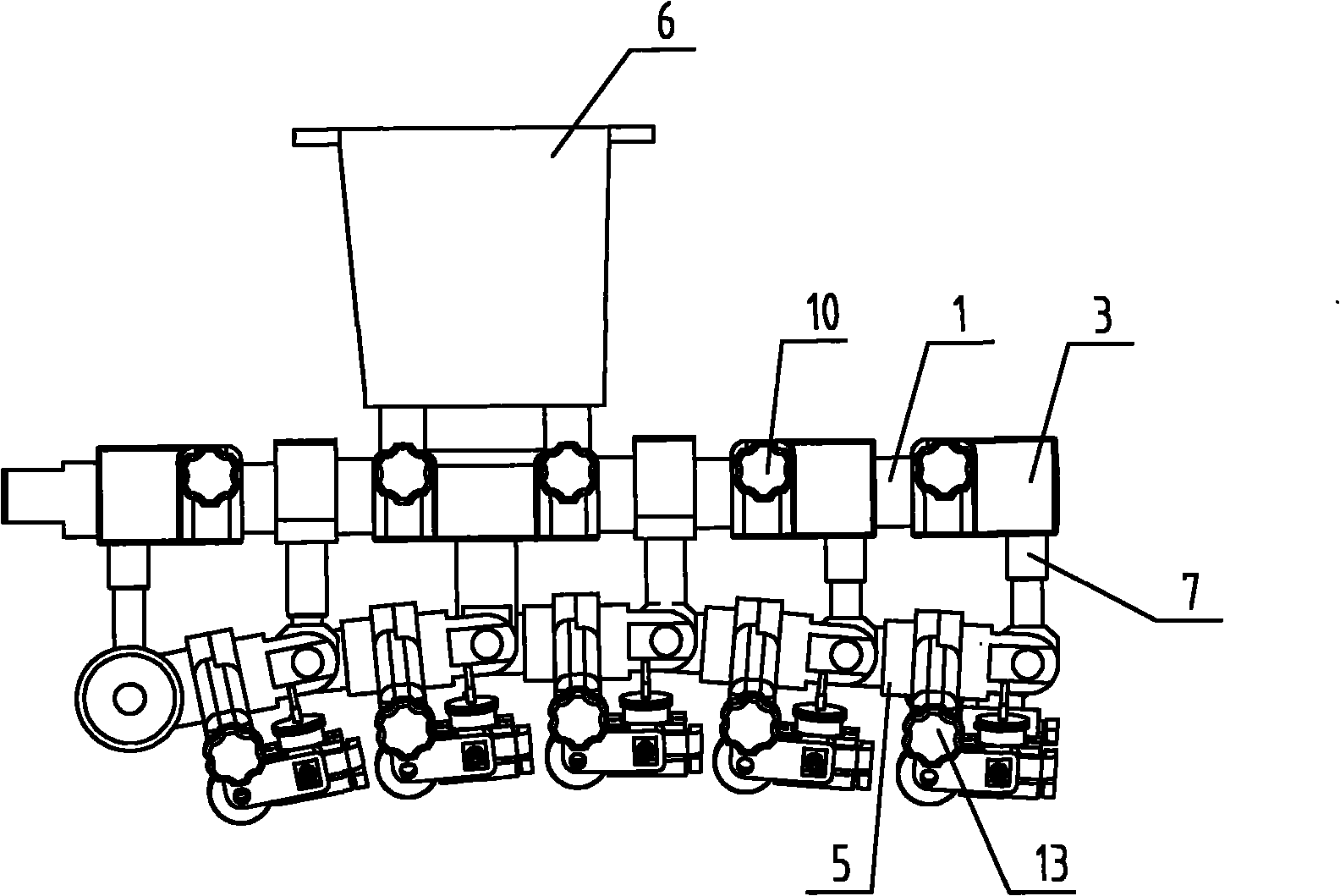

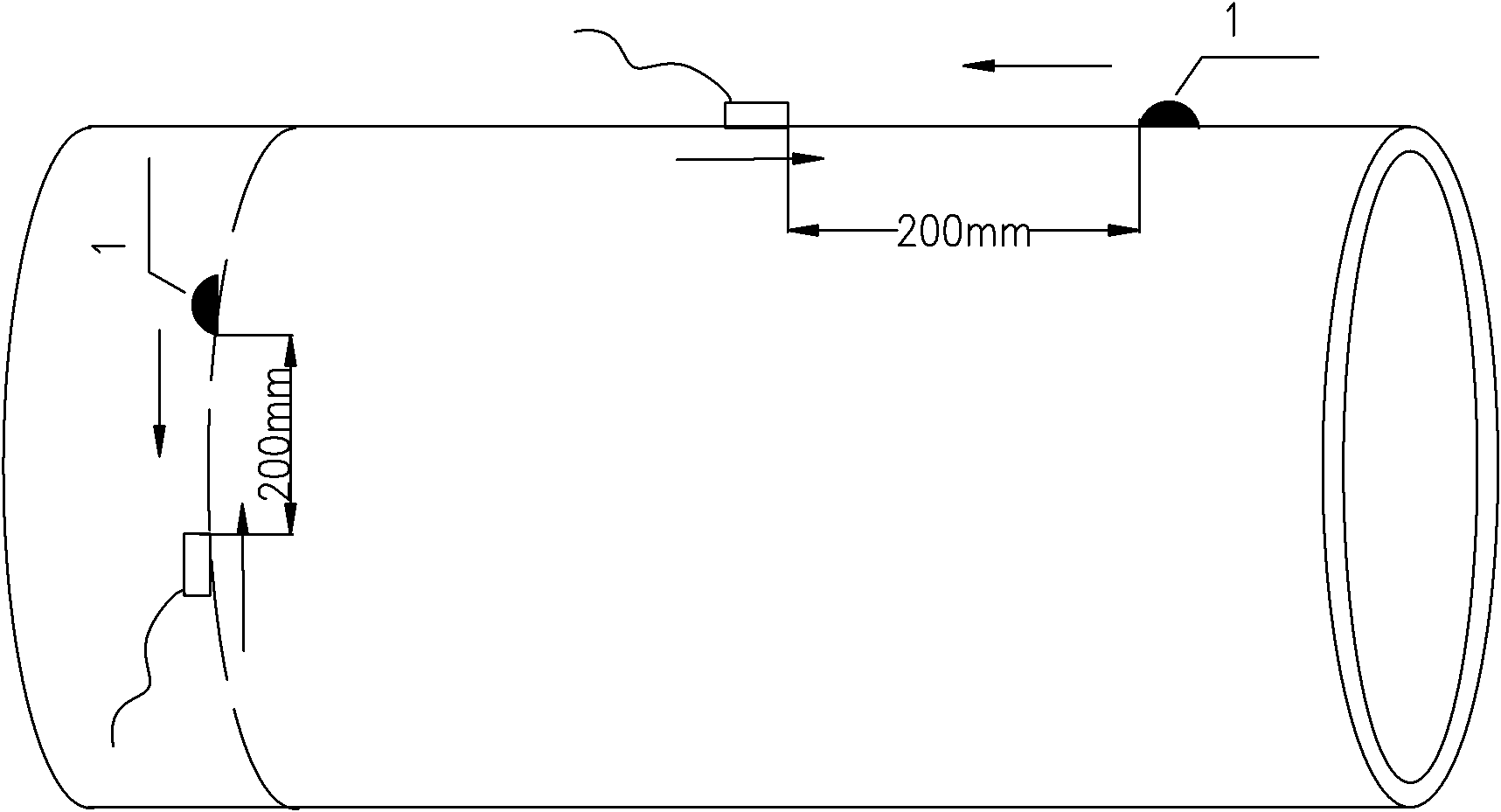

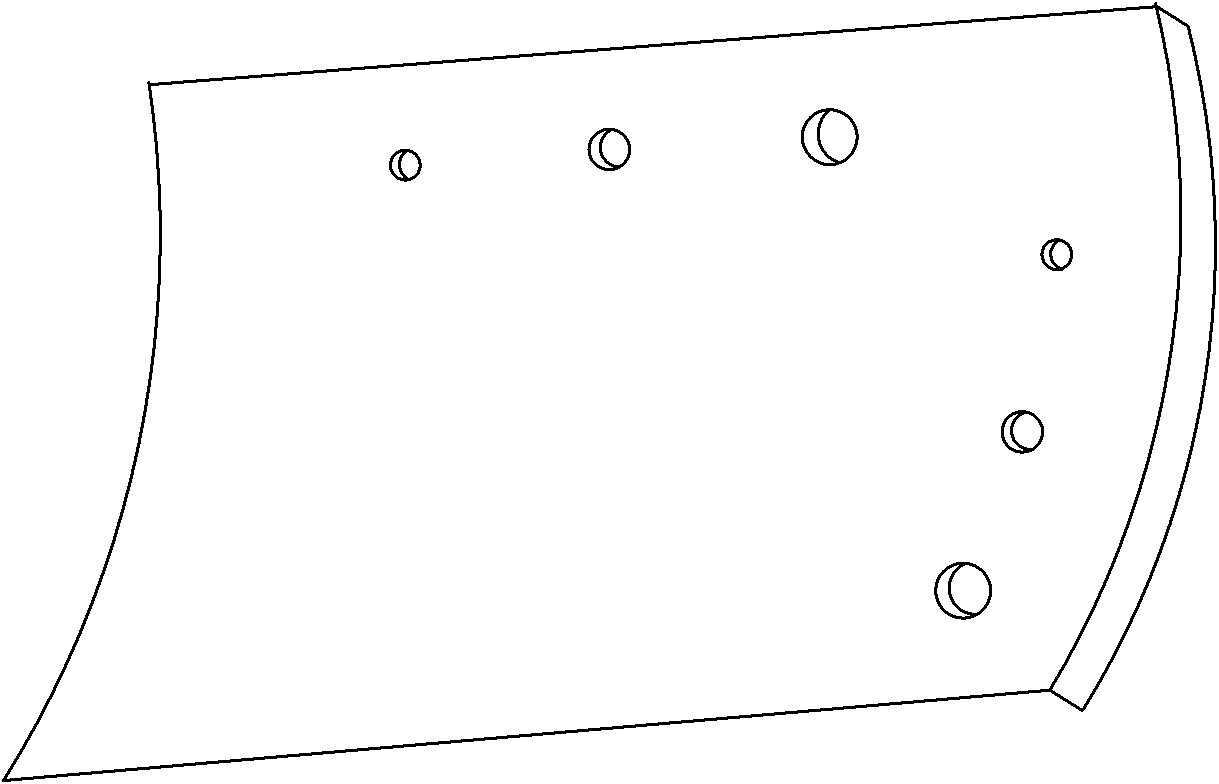

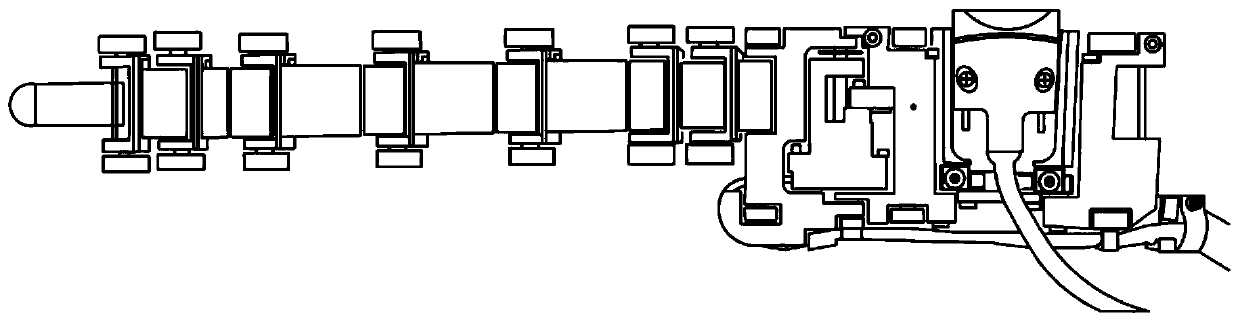

Spiral welded pipe weld seam probe frame

ActiveCN101788535AReduce flaw detection errorSimple structureAnalysing solids using sonic/ultrasonic/infrasonic wavesWeld seamSacroiliac joint

The invention relates to a spiral welded pipe weld seam probe frame which comprises a rigid spindle, a flexible spindle, fixed wing plates and swing wing plates; the rigid spindle and the flexible spindle are arranged up and down in parallel; the plurality of fixed wing plates are sequentially connected on the rigid spindle serially; the flexible spindle comprises a plurality of spindles which are connected end to end through joints; each spindle joint is provided with a pair of swing wing plates; the spindle joints and the fixed wing plates and the rigid spindles are connected by radian regulating screw rods; the swing wing plates are arranged below the swing wing plates; and both side ends of each swing wing plate are respectively connected with both side ends of each fixed wing plate through traction mechanisms. The spiral welded pipe weld seam probe frame has the benefits that: (1) the flexible spindle is adopted, so that a probe and a weld seam can be fully closed, so as to reduce error; (2) the rigid spindle and the flexible spindle are arranged up and down in parallel, and the adjusted shapes are stable; (3) the radian of the flexible spindle is manually regulated by the radian regulating screw rod, and the adjustment is flexible; and (4) is structure is applicable to a plurality of probe models, and the defect defection rate can be greatly improved.

Owner:鞍山长风无损检测设备有限公司

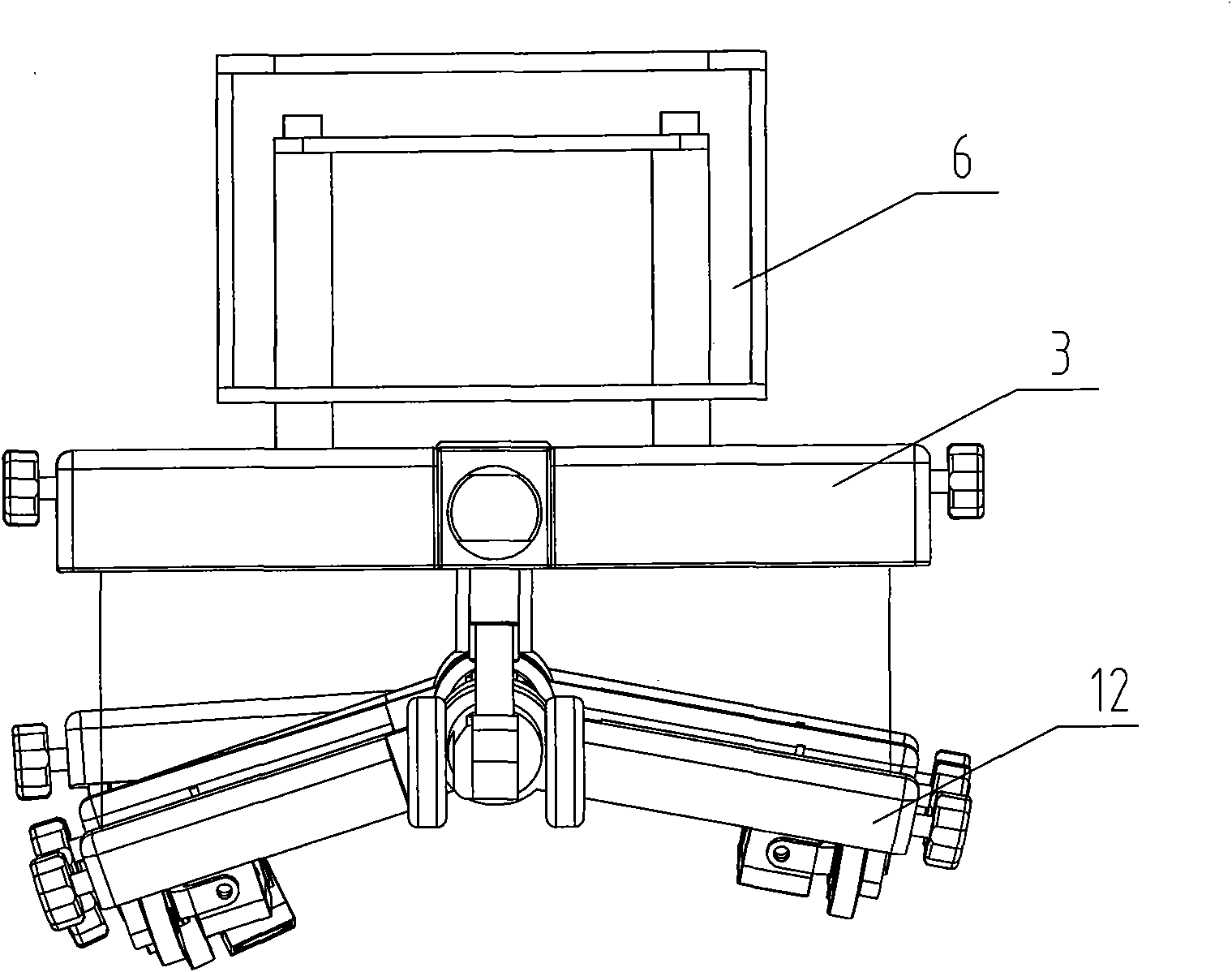

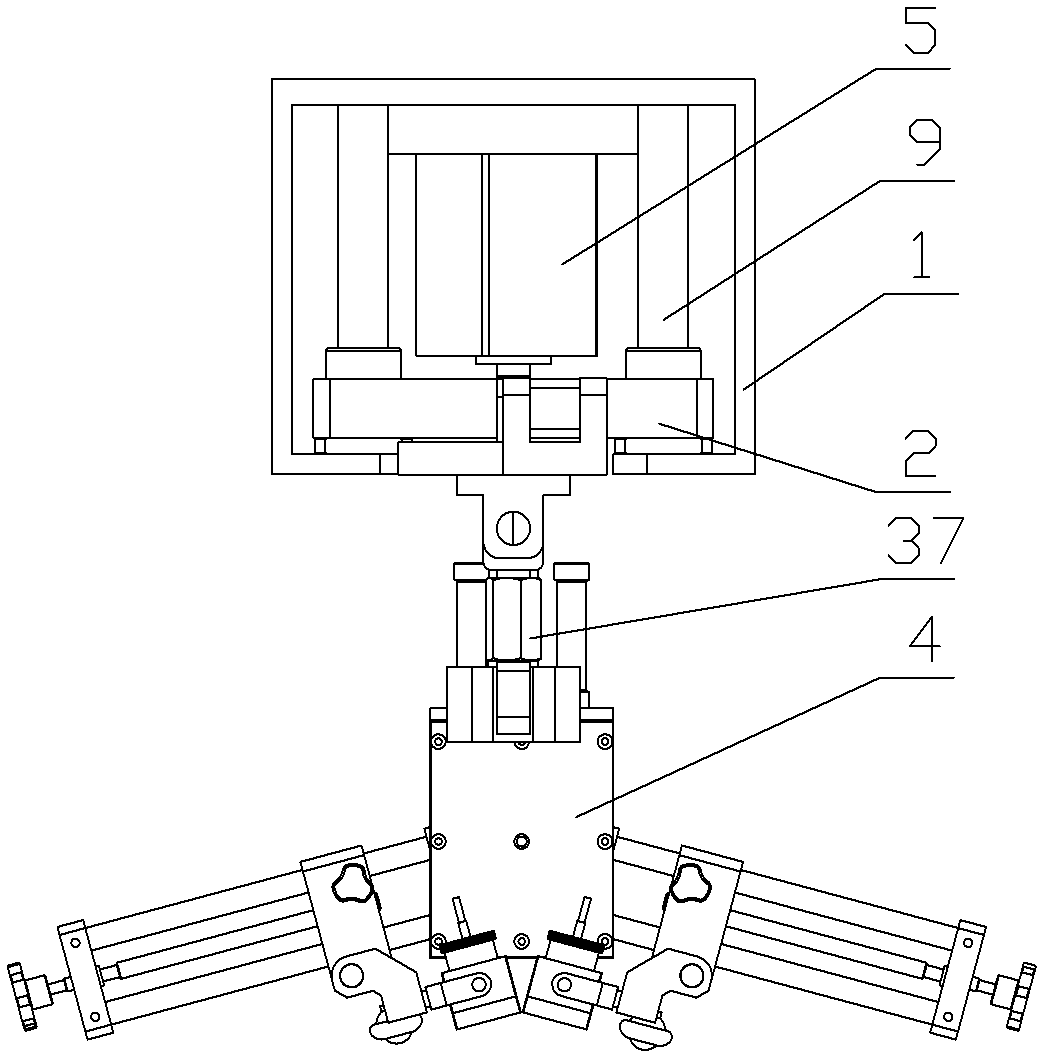

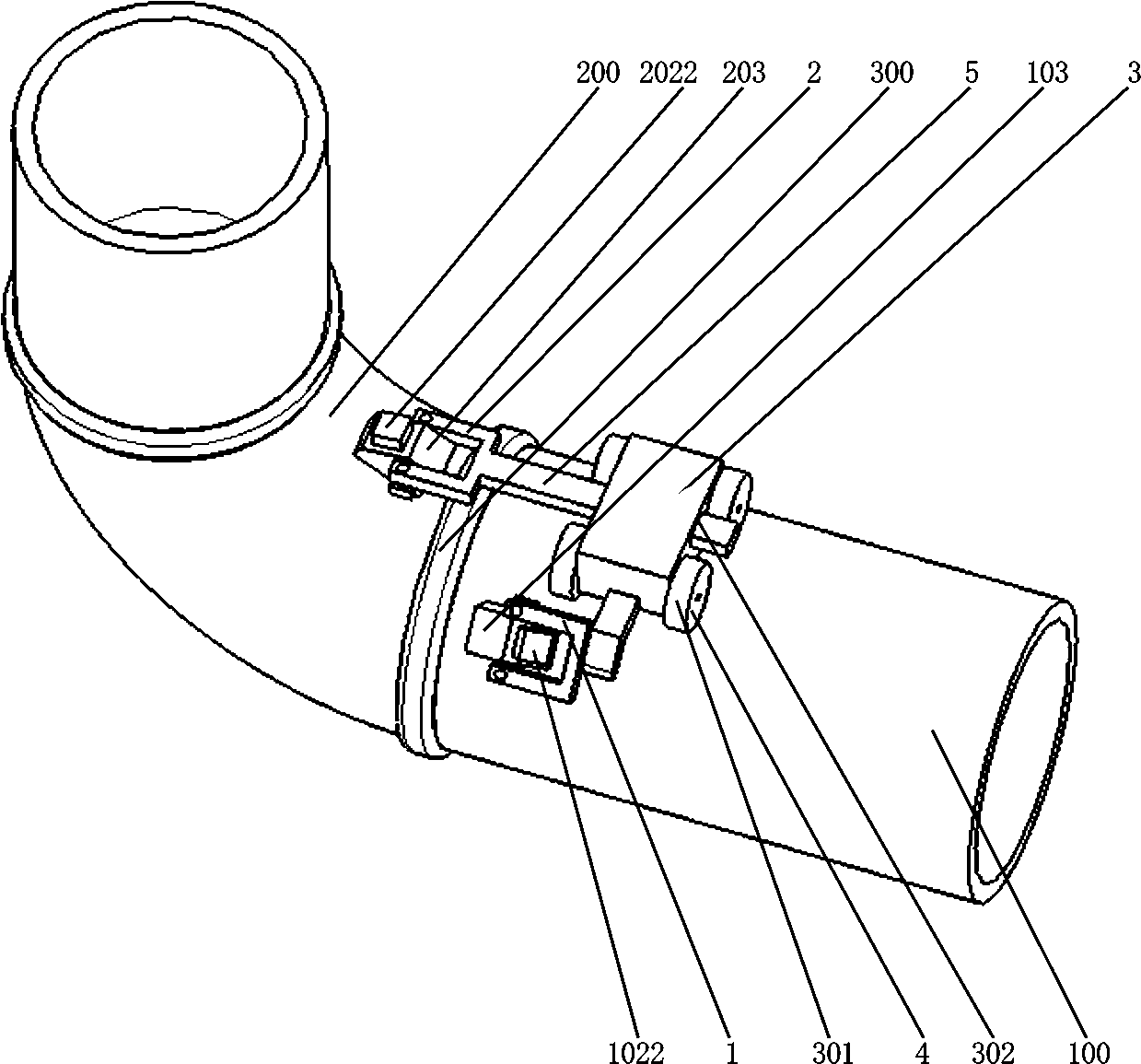

Multi-dimensional probe holder for ultrasonic flaw detection of weld joint on spiral welded pipe

ActiveCN102435677AGood degree of bridgingReduce flaw detection errorMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringMulti dimensional

The invention relates to the field of ultrasonic nondestructive test, particularly to a multi-dimensional probe holder for ultrasonic test of a weld joint on a spiral welded pipe. The invention is characterized in that: the multi-dimensional probe holder comprises a connecting seat, a horizontal beam, a flexible main shaft and probe clamping frames, wherein the connecting seat is arranged on the horizontal beam in a centering manner; a lifting cylinder is arranged in the groove-shaped connecting seat; the end part of the lifting cylinder is connected with the horizontal beam; the flexible main shaft is formed in a manner that more than three main shaft joints are hinged in sequence; the flexible main shaft is arranged below the horizontal beam and is connected with the horizontal beam by a central joint; adjusting screw rods are also arranged among the horizontal beam and other main shaft joints of the flexible main shaft; a probe clamping frame is arranged below each main shaft joint; and swing pins are arranged between the main shaft joints and the probe clamping frames. Compared with the prior art, the invention has the beneficial effects that: 1) the probe and the weld joint can be guaranteed to be fully bridged by the flexible main shaft, so that the test error is reduced; 2) the flexible main shaft takes a side swing joint as the first joint thereof, so that the probe and the weld joint can be bridged better; 3) the horizontal beam and the flexible main shaft are arranged in parallel up and down, so that stable shape and convenient regulation and control are realized.

Owner:鞍山长风无损检测设备有限公司

Ultrasonic detection method of ultrahigh-strength steel thin-wall spinning cylinder

InactiveCN101923074AImprove quality reliabilityImprove the safety of useAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringUltimate tensile strength

The invention discloses an ultrasonic detection method of an ultrahigh-strength steel thin-wall spinning cylinder, comprising the following steps of: processing through-hole artificial defect comparison samples, carrying out initial sensitivity calibration on the basis, adding plate wave detection on the basis of the original single-transverse wave detection, respectively detecting in an axial direction and an annular direction, and then positioning defects by adopting a liquid-drip interference method. Compared with the traditional detection method, the method has the advantages of high processing precision of the artificial defect comparison samples, small error of initial sensitivity calibration, simultaneous detection of plate waves on the surface quality, the near surface quality and the inner quality of the ultrahigh-strength steel thin-wall spinning cylinder high defect detectable rate, rapid and accurate positioning and the like, solves the problems of high quality control difficulty of the ultrahigh-strength steel thin-wall spinning cylinder and unstable quality condition of a solid engine steel shell, can effectively ensure the quality of the ultrahigh-strength steel thin-wall spinning cylinder and improve the using safety and reliability of the solid engine steel shell.

Owner:国营江北机械厂

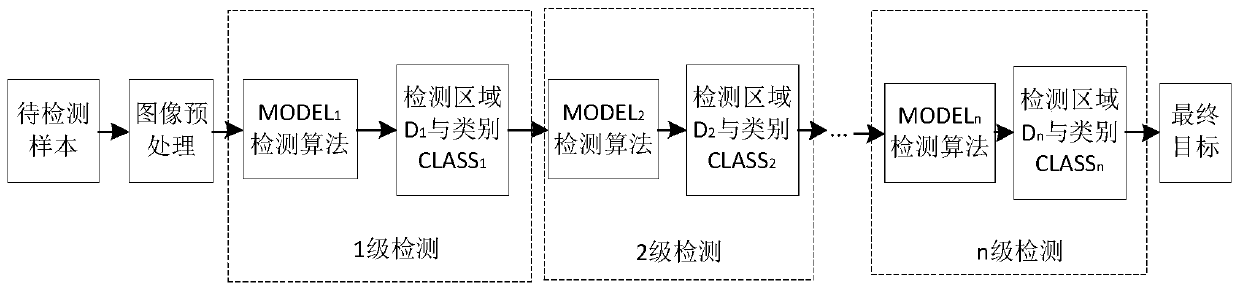

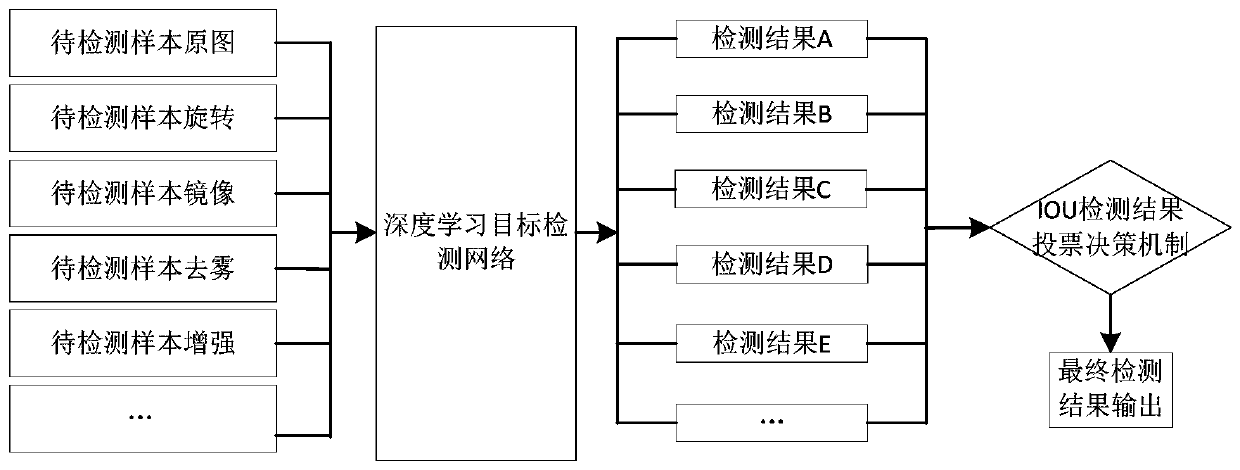

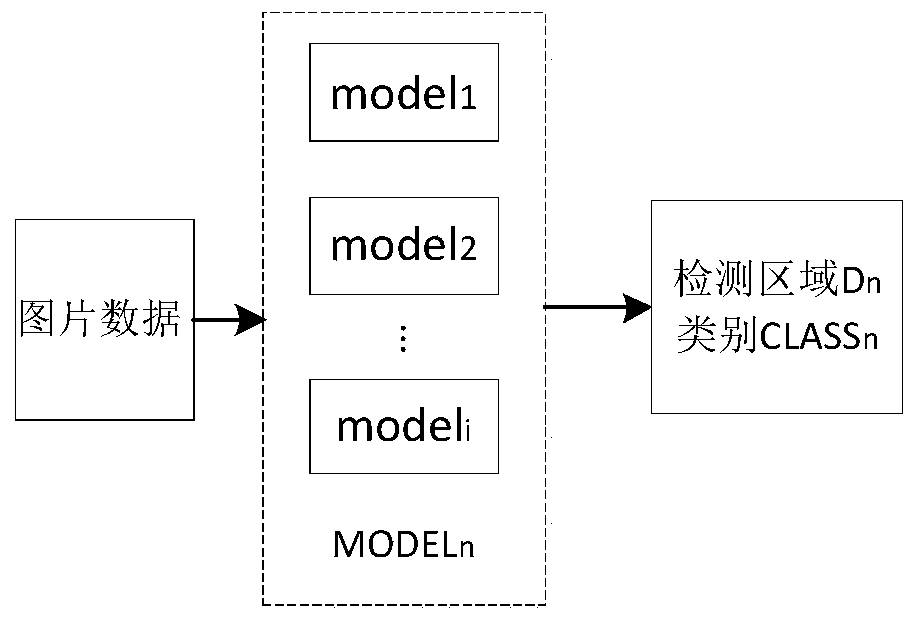

Cascade target recognition method and system based on deep learning

ActiveCN110688925AReduce distractionsSolve the problem of poor target detection effectCharacter and pattern recognitionNeural learning methodsPattern recognitionImaging quality

The invention provides a cascade target recognition method and system based on deep learning, and the method comprises the steps: obtaining a to-be-detected sample of an inspection image, marking a target detection sample, and expanding the number of samples; fusing multiple features of the image enhancement data to carry out a multi-stage deep learning detection algorithm, realizing significant equipment detection for a target with a large proportion, and eliminating noise interference of a complex background on the detection algorithm. Multi-stage deep learning algorithm detection is carriedout by fusing multiple features of image enhancement data, so that the detection accuracy of deep learning in small target detection is improved, and the influence of image quality on the detection algorithm is reduced.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

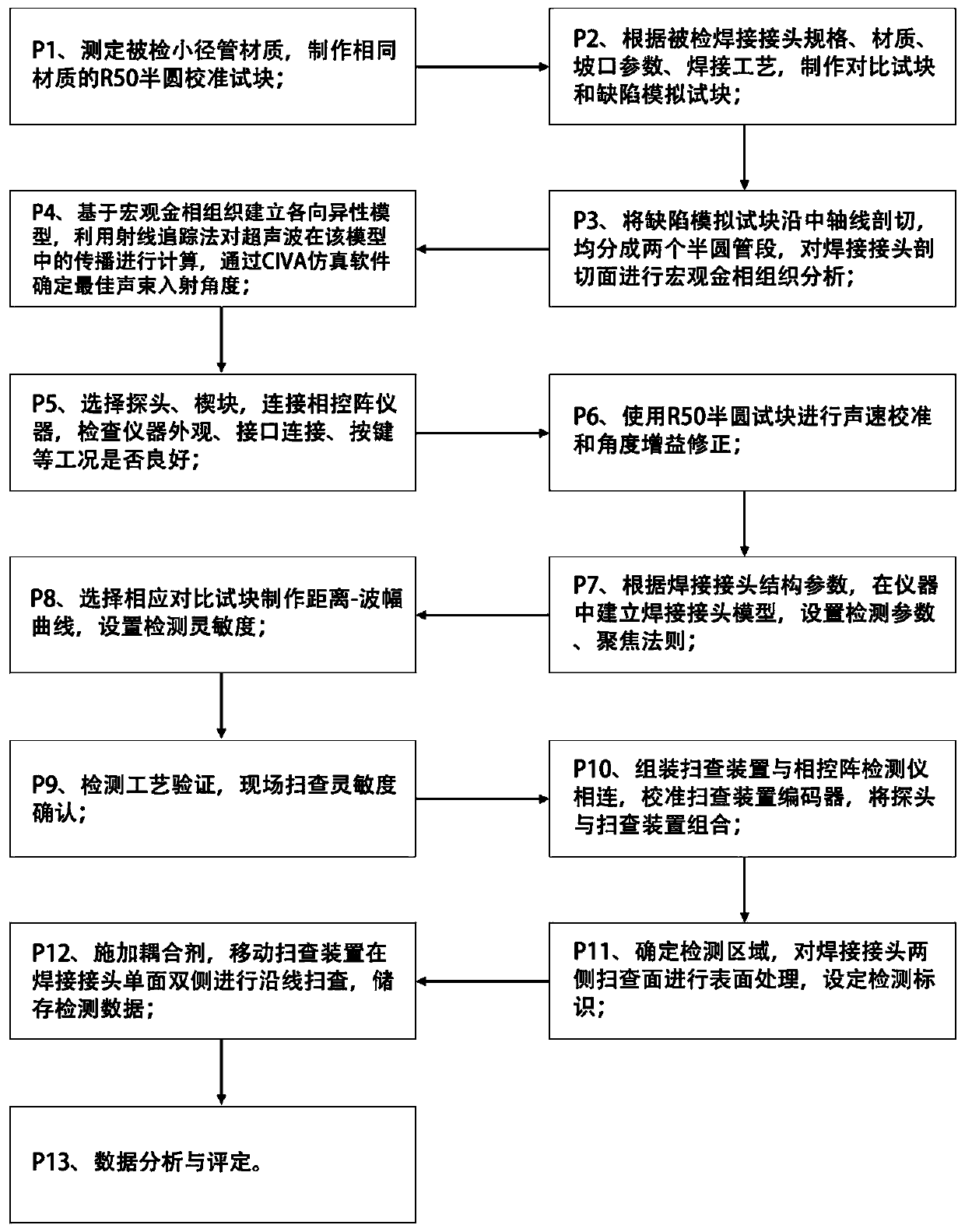

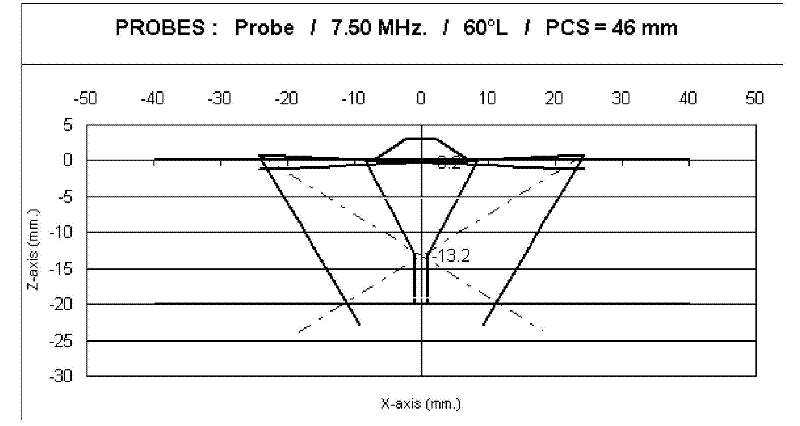

Phased array detection and evaluation method for austenitic stainless steel small-diameter pipe welding joint

PendingCN111537612AOptimizing Beam ParametersHigh detection sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalStructure analysisMetallurgy

The invention discloses a phased array detection and evaluation method for an austenitic stainless steel small-diameter pipe welding joint. The method comprises the steps of manufacturing a calibration test block; manufacturing a reference test block and a defect simulation test block; sectioning the defect simulation test block along the central axis, and carrying out metallographic structure analysis; establishing an anisotropic model, and determining an optimal acoustic beam incident angle; connecting a phased array instrument; carrying out sound velocity calibration and angle gain correction; establishing a welding joint model, and setting detection parameters; setting the detection sensitivity; verifying a detection process; assembling a scanning device; determining a detection area and carrying out surface treatment; applying a coupling agent, and scanning along the line; and conducting data analysis and evaluation. According to the method, the detection efficiency and precisionare improved, the detection quality of the austenitic stainless steel small-diameter pipe welding joint is guaranteed, and the radioactive source management risk and the detection cost are effectivelyreduced.

Owner:SHANDONG MECHANICAL ENG TESTING CO LTD

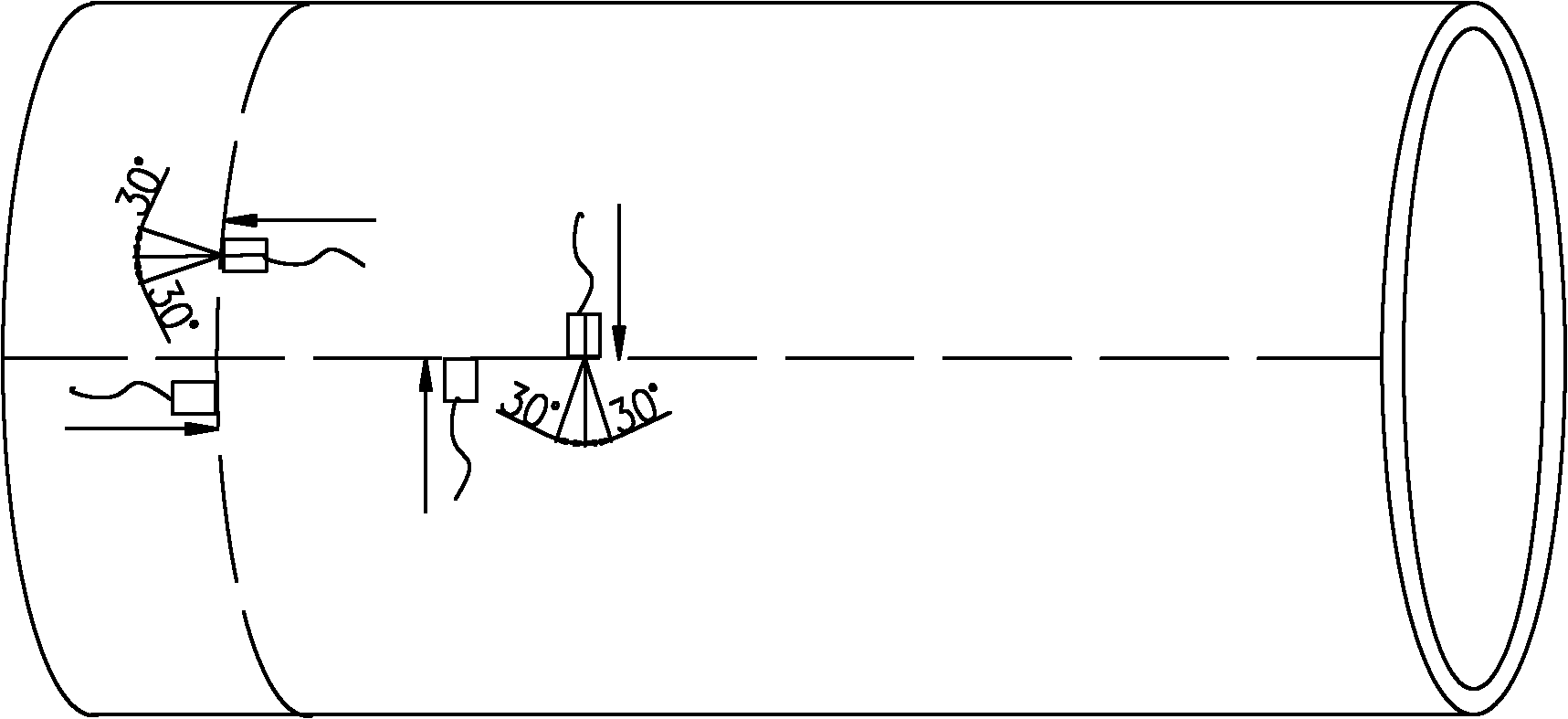

Single-sided bilateral multi-angle ultrasonic detection method for heterogeneous structure pattern pipe welds

ActiveCN108490078AImprove defect detection rateSimple resultAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringWelding defect

The invention provides a single-sided bilateral multi-angle ultrasonic detection method for heterogeneous structure pattern pipe welds. The single-sided bilateral multi-angle ultrasonic detection method comprises the following steps: establishing a 3D model with two multi-angle ultrasonic probes and a to-be-tested pipeline having flange or elbow welds, and allowing two simulated ultrasonic probesto simulate sector scanning at two sides of the simulated welds; recording the positions of two simulated ultrasonic probes on the simulated to-be-tested pipeline; assembling the two multi-angle ultrasonic probes onto a multi-angle bilateral ultrasonic scanning device; carrying out equidistant linear scanning along the circumference of the to-be-tested pipeline, and collecting detection data of the weld at the same time; and analyzing the weld condition of the to-be-tested pipeline having the flange or elbow welds. According to the invention, through simultaneous transmission of multi-angle ultrasonic waves to welds, only equidistant linear scanning is carried out, so dependence on heterogeneous structure pattern and size is reduced, and the positions and sizes of defects in the welds arequickly identified and calculated; thus, higher detection rate and more visual results of weld defects are achieved, the quality detection of the flange and elbow welds are guaranteed, and work efficiency and defect detection capability are greatly improved.

Owner:SHANTOU DONGFANG ULTRASONIC TECH

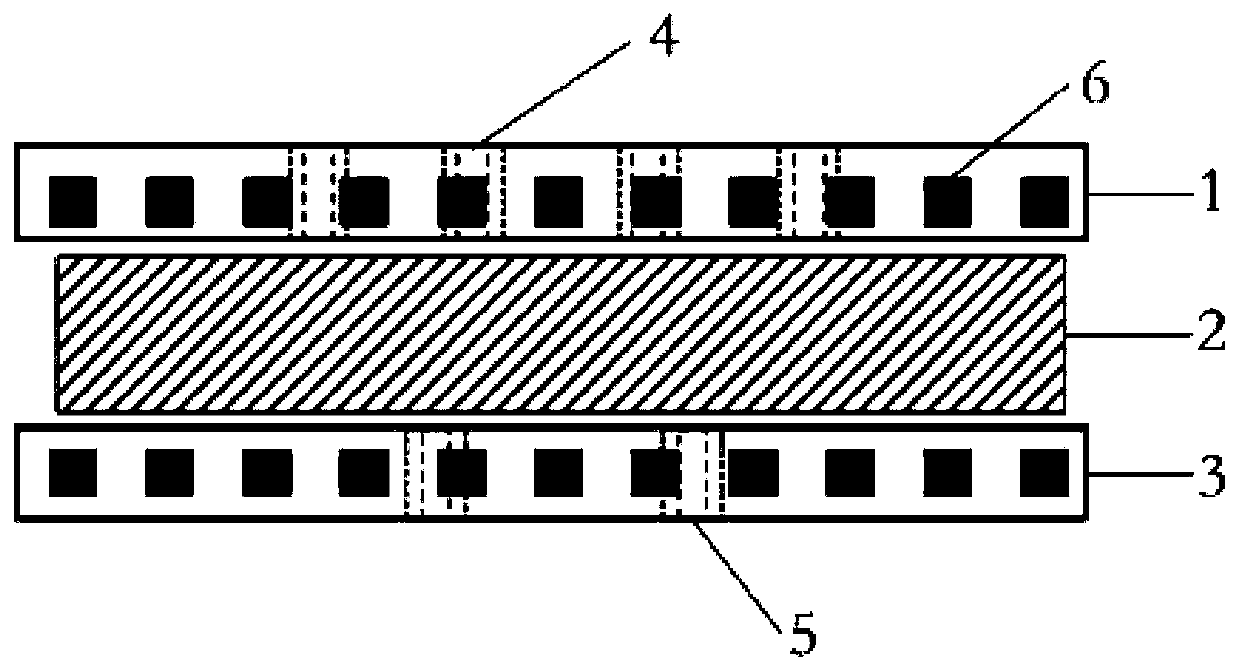

Double-layer symmetrical differential plane eddy current detection sensor

ActiveCN111398413AUniform vortexSensitive to surface defectsNuclear energy generationMaterial magnetic variablesSignal processing circuitsSoftware engineering

The invention discloses a double-layer symmetrical differential plane eddy current detection sensor. An excitation signal is generated by a signal generator and sent to a power amplifier; after beingamplified by the power amplifier, the signal is connected to a bonding pad of the exciting coil through a lead; the exciting coil generates a primary magnetic field under the driving of an exciting signal; when the tested piece is in the primary magnetic field, the primary magnetic field generates eddy current on the surface of the tested piece; the flow direction of the eddy current at the defectpart is changed; because the vortex changes, a secondary magnetic field generated by the eddy current is changed; the magnetic flux which passes a detecting coil changes; the amplitude and the phaseof the coil are further detected to be changed; therefore, the induced voltage generated by the primary magnetic field and the induced voltage generated by the secondary magnetic field are input intothe signal processing circuit through the bonding pad of the detection coil, then amplitude and phase extraction is carried out, the collected detection signals are processed through the upper computer after amplification and filtering processing, and then defect information is accurately detected.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

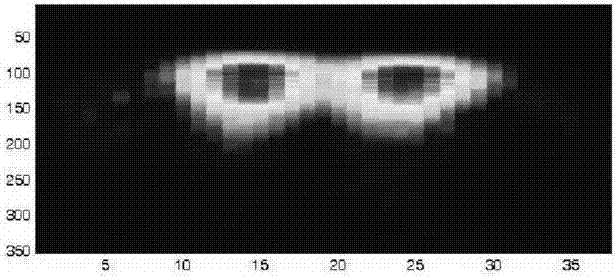

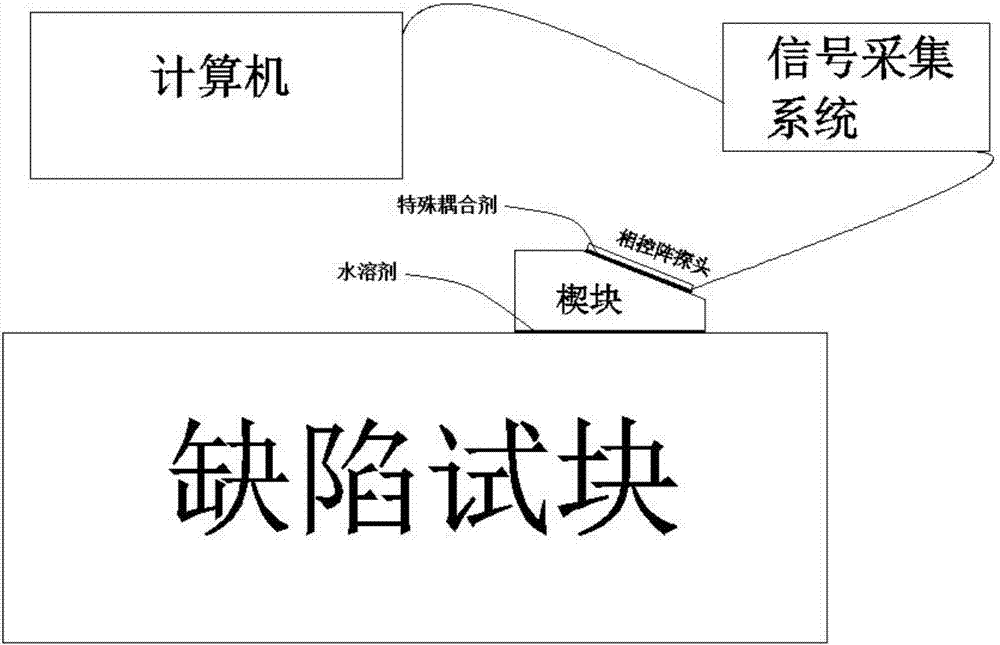

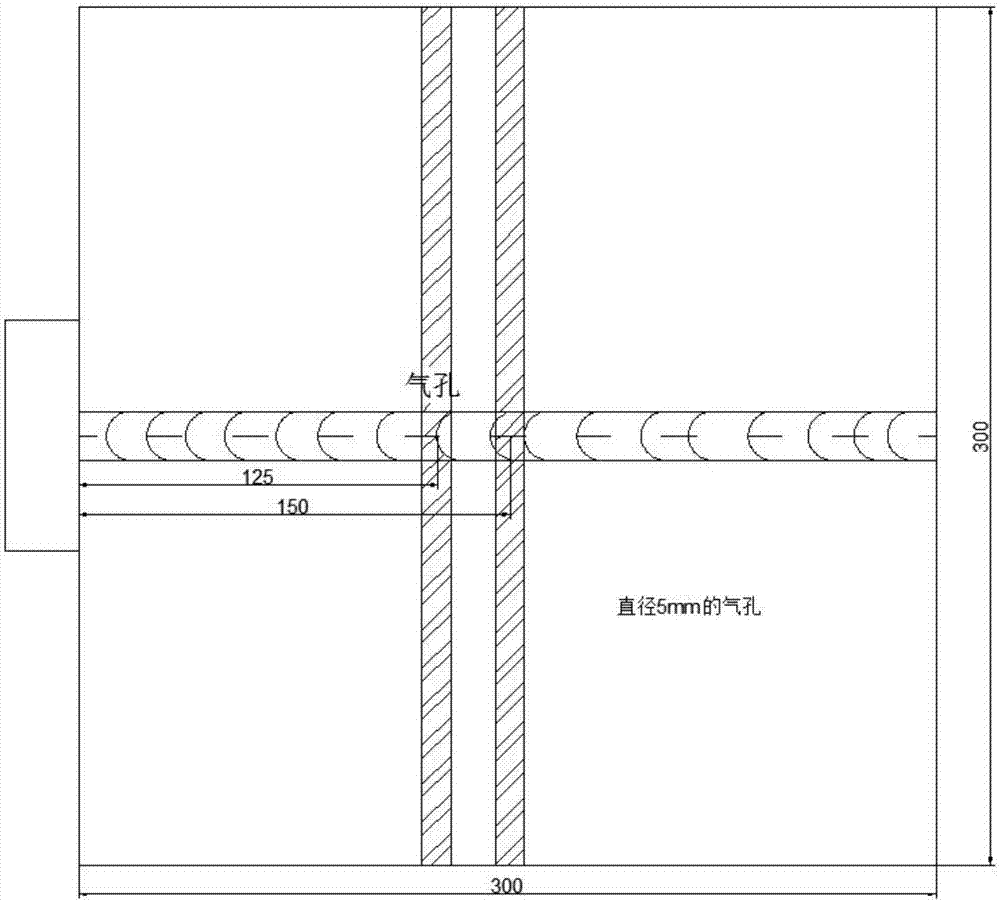

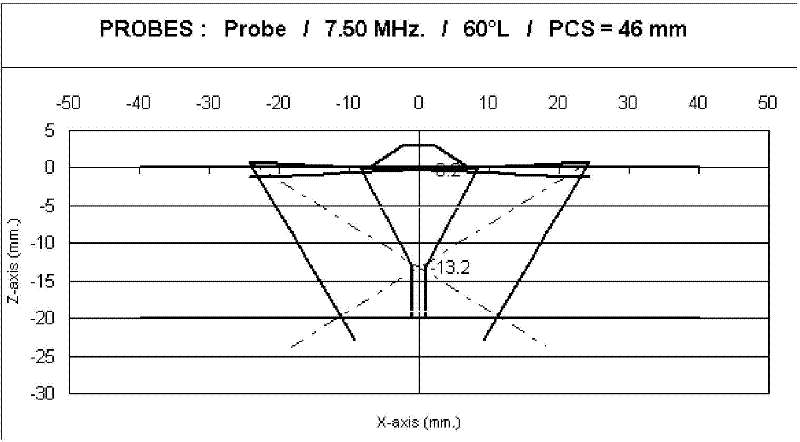

Ultrasonic phased array weld defect detection method based on oblique incidence

InactiveCN107356670AEasy to detectImprove beam coverageAnalysing solids using sonic/ultrasonic/infrasonic wavesImaging qualityImage resolution

The invention discloses an ultrasonic phased array weld defect detection method based on oblique incidence. An ultrasonic phased array detection system is included, and ultrasonic phased array detection steps are included, wherein the ultrasonic phased array detection system comprises a signal collecting system, a transducer probe, an organic glass wedge block, an aqueous solution connecting the organic glass wedge block with the test block surface, a coupling agent connecting the transducer probe with the organic glass wedge block and a computer used for calculating data of the signal collecting system. Accordingly, the defects can be well detected, a non-detection zone is reduced, the detection robustness and resolution are improved, the imaging quality of a far-field region can be obviously improved, and the imaging resolution and defect detection rate are increased.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

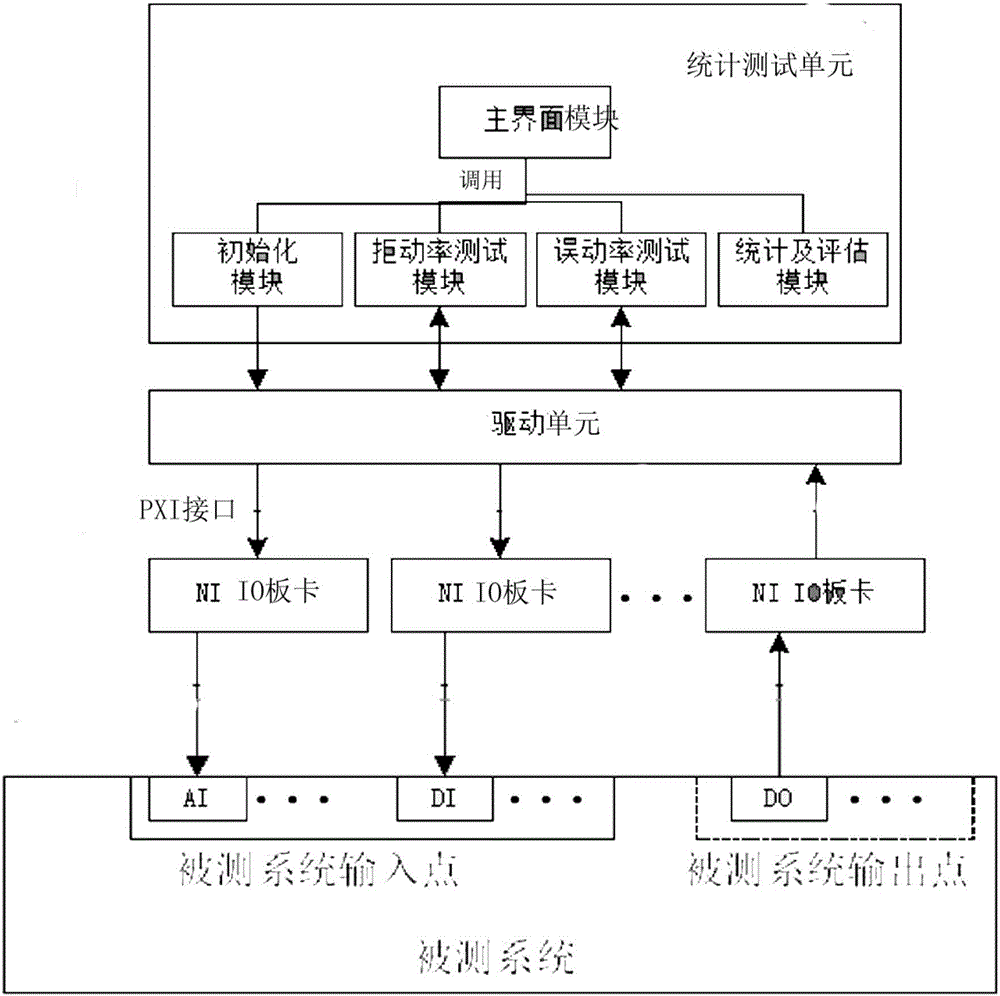

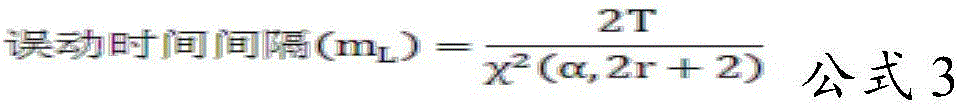

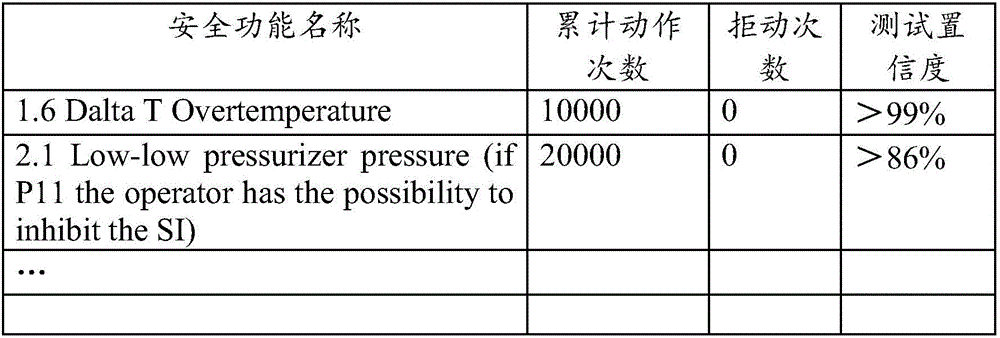

Statistical test device and method for verifying safety failure rate of nuclear safety class instrumentation and control platform

The invention discloses a statistical test device for verifying safety failure rate of a nuclear safety class instrumentation and control platform. The device comprises a statistical test unit, a driving unit, an information acquisition unit and a storage unit. The information acquisition unit is connected with the statistical test unit through the driving unit; and the statistical test unit realizes data interaction with the storage unit. According to a statistical test method based on the statistical test device, by carrying out system-level safety failure rate test in the platform development phase, possible defects of refusal of operation and misoperation in actual operation can be found in advance, thereby reducing maintenance cost and preventing safety risks; and meanwhile, actual measurement evidences are provided to check whether the platform meets nuclear power plant safety level instrumentation and control system safety failure rate indexes, and thus user confidence can be improved. Operation refusal rate is tested through a signal value random input method, thereby breaking a fixed input combination mode, and improving defect detection percentage to the maximum degree.

Owner:CHINA TECHENERGY +1

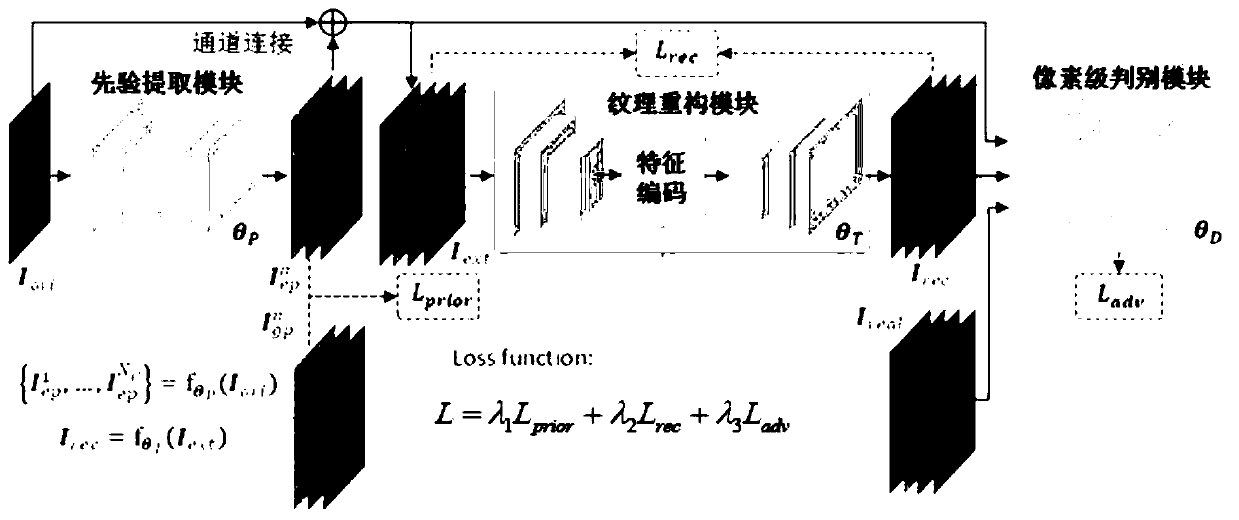

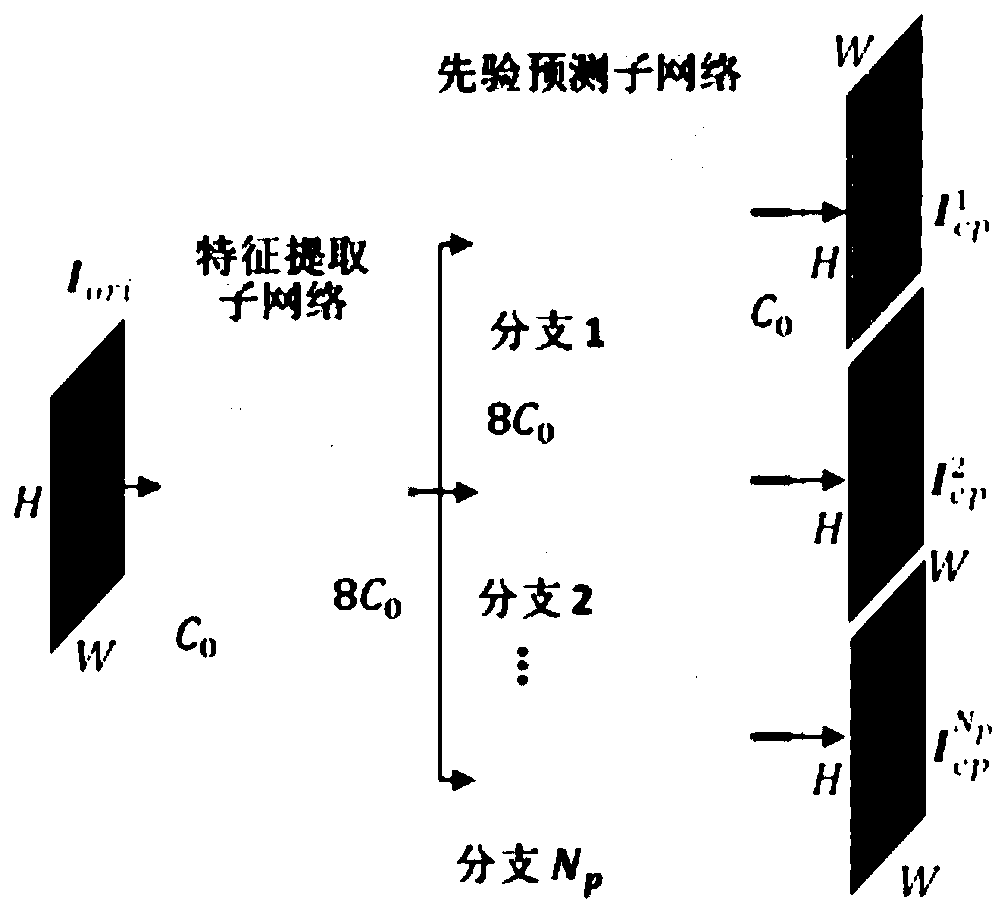

Texture surface defect detection method and system

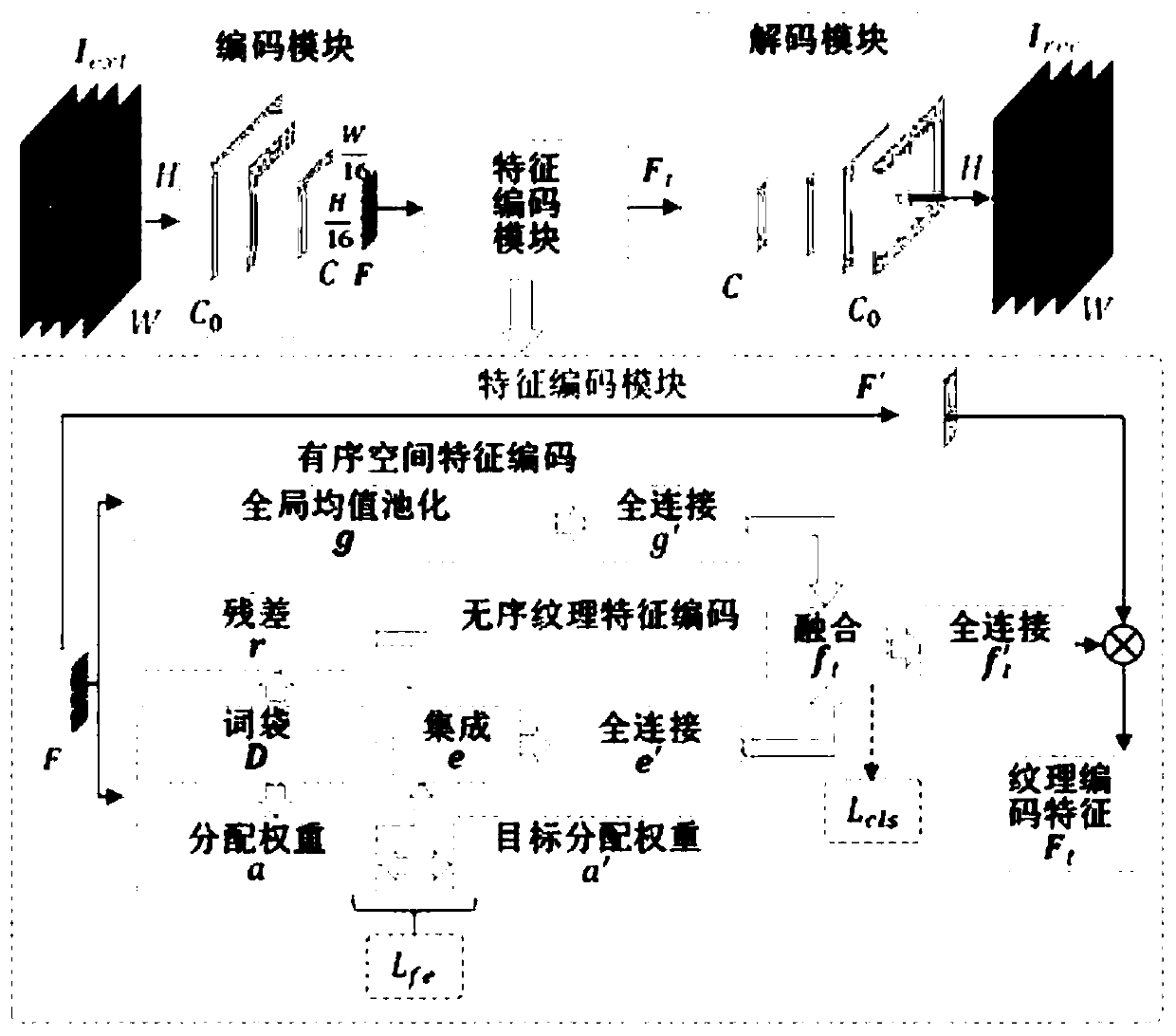

ActiveCN110969606AIncrease the amount of input informationImprove defectsImage analysisCharacter and pattern recognitionPattern recognitionImaging processing

The invention belongs to the field of image processing, and discloses a texture surface defect detection method and system. The method comprises an offline training stage and an online detection stageI; in the offline training stage, multi-channel texture priori of an input texture image is extracted through a priori extraction step; a texture background of the input image is accurately reconstructed through a texture reconstruction step under the guidance of the extracted priori, more accurate texture features are encoded in a hidden space of a texture reconstruction module, and defects are inhibited from being reconstructed in the texture background; and finally, through pixel-level adversarial learning, the texture reconstruction precision is further improved. During detection, the defects can be detected only by subtracting the reconstructed texture background image from the input image. The method has high detection precision for defects with different sizes and different contrastratios on different texture surfaces.

Owner:HUAZHONG UNIV OF SCI & TECH

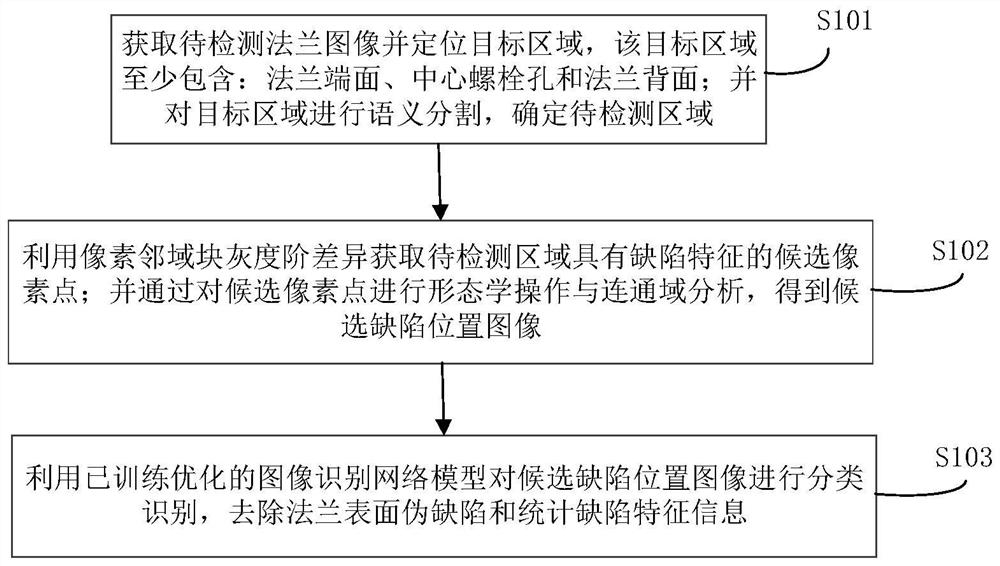

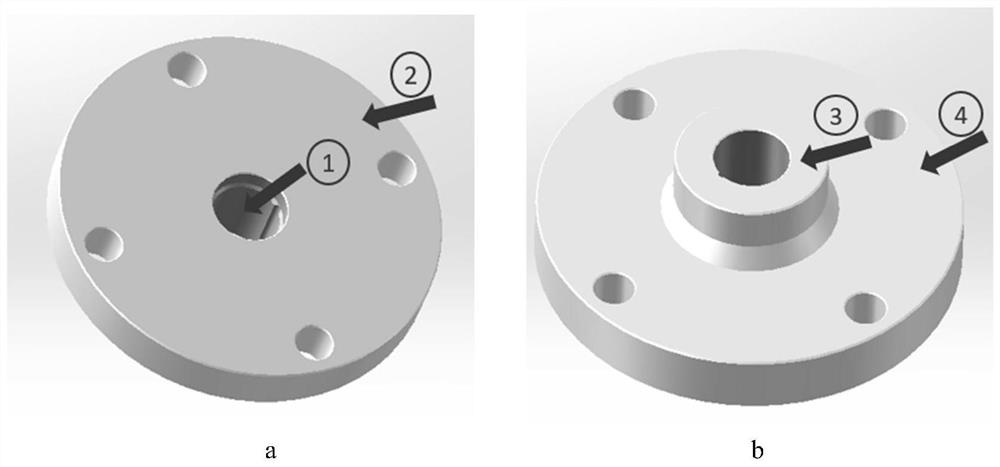

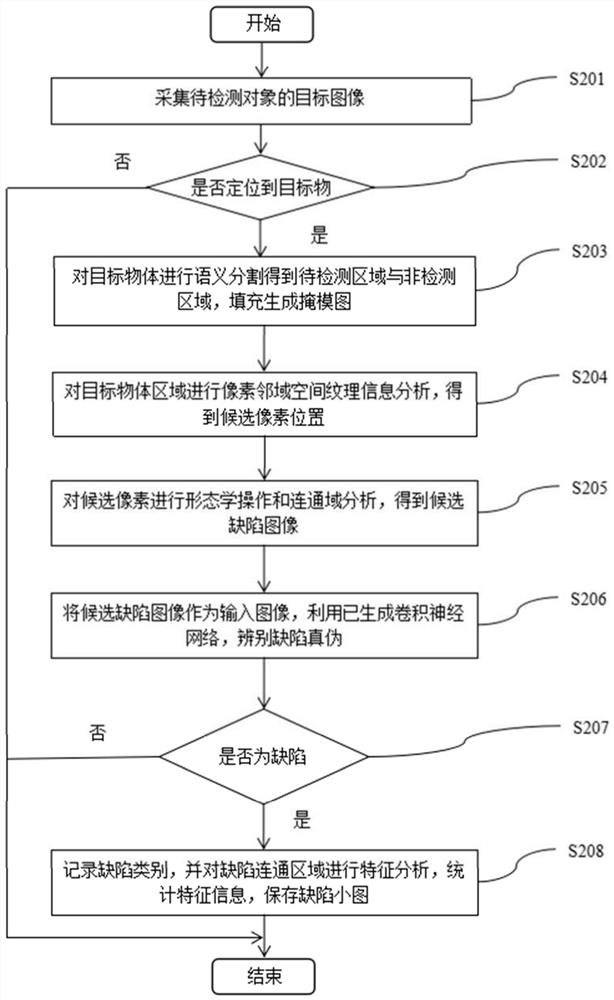

Flange surface defect detection method, system and equipment

ActiveCN112508939AImprove detection accuracyImprove detection efficiencyImage analysisNeural architecturesPattern recognitionGradation

The invention belongs to the technical field of industrial product appearance detection, and particularly relates to a flange surface defect detection method, system and equipment. The flange surfacedefect detection method comprises the steps: obtaining a to-be-detected flange image, and positioning a target region which at least comprises a flange end surface, a central bolt hole and a flange back surface; performing semantic segmentation on the target area to determine a to-be-detected area; obtaining candidate pixel points with defect characteristics in the to-be-detected area by utilizingthe gray scale difference of the pixel neighborhood blocks; performing morphological operation and connected domain analysis on the candidate pixel points to obtain a candidate defect position image;and carrying out classification and identification on the candidate defect position images by utilizing the trained and optimized image identification network model, removing flange surface pseudo defects and counting defect feature information. The method can effectively improve the automation degree of flange surface detection, improves the accuracy of flange product surface defect detection, reduces the labor intensity, and has a good application value.

Owner:ZHENGZHOU JINHUI COMP SYST ENG

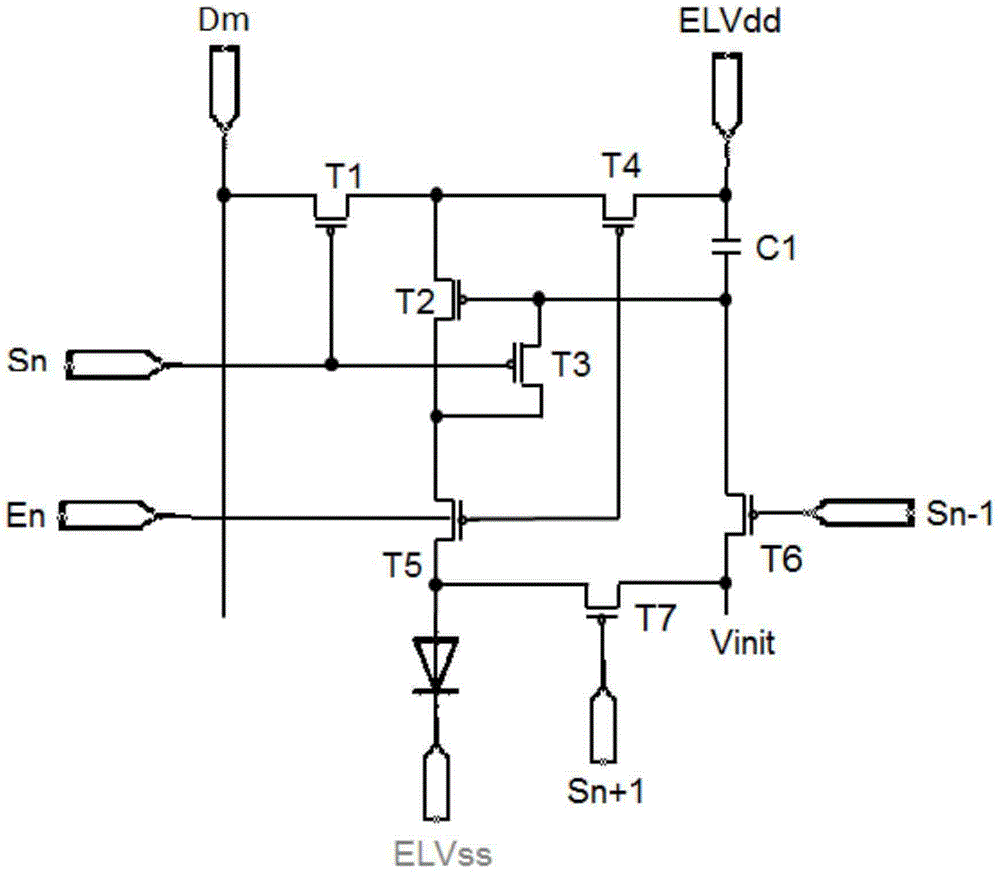

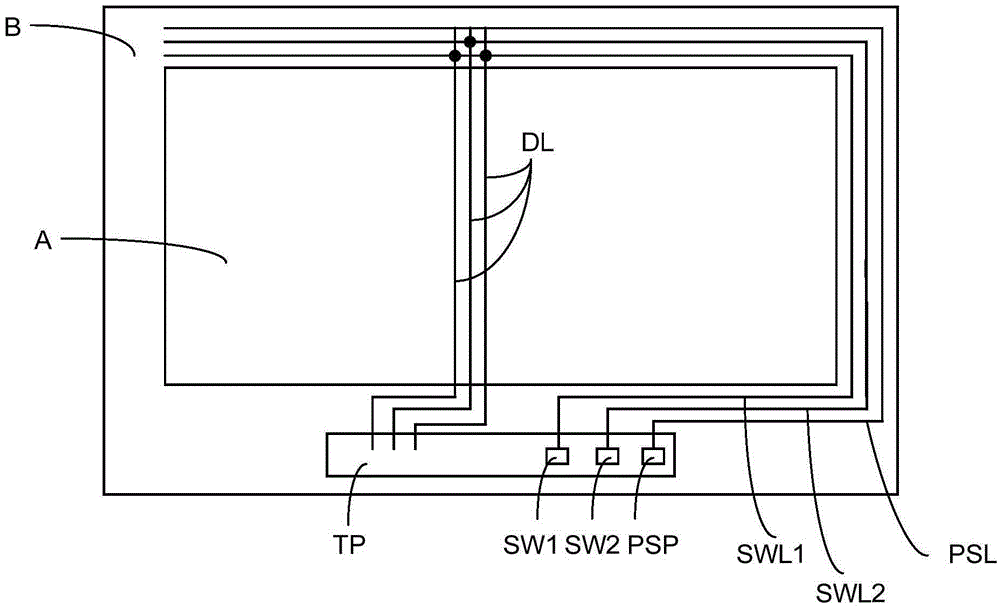

AMOLED (Active-Matrix Organic Light Emitting Diode) displayer, testing component thereof and defect testing method thereof

The invention discloses an AMOLED (Active-Matrix Organic Light Emitting Diode) displayer, a testing component of the displayer and a defect testing method of the displayer. The testing component comprises at least one odd switch, at least one even switch, a first switch circuit, a second switch circuit, and at least one signal source circuit, wherein the at least one odd switch is electrically connected with odd data lines of multiple data lines respectively, the at least one even switch is electrically connected with even data lines of multiple data lines respectively, the first switch circuit is electrically connected with the at least one odd switch and used for transmitting and controlling control signals for connecting and disconnecting the at least one odd switch, the second switch circuit is electrically connected with the at least one even switch and used for transmitting and controlling control signals for connecting and disconnecting the at least one even switch, and the at least one signal source circuit is used for receiving signals from a signal source respectively; each one of the at least one odd switch and the at least one even switch is electrically connected with one of the at lest one signal source circuit, so that signals are transmitted to the corresponding data line.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

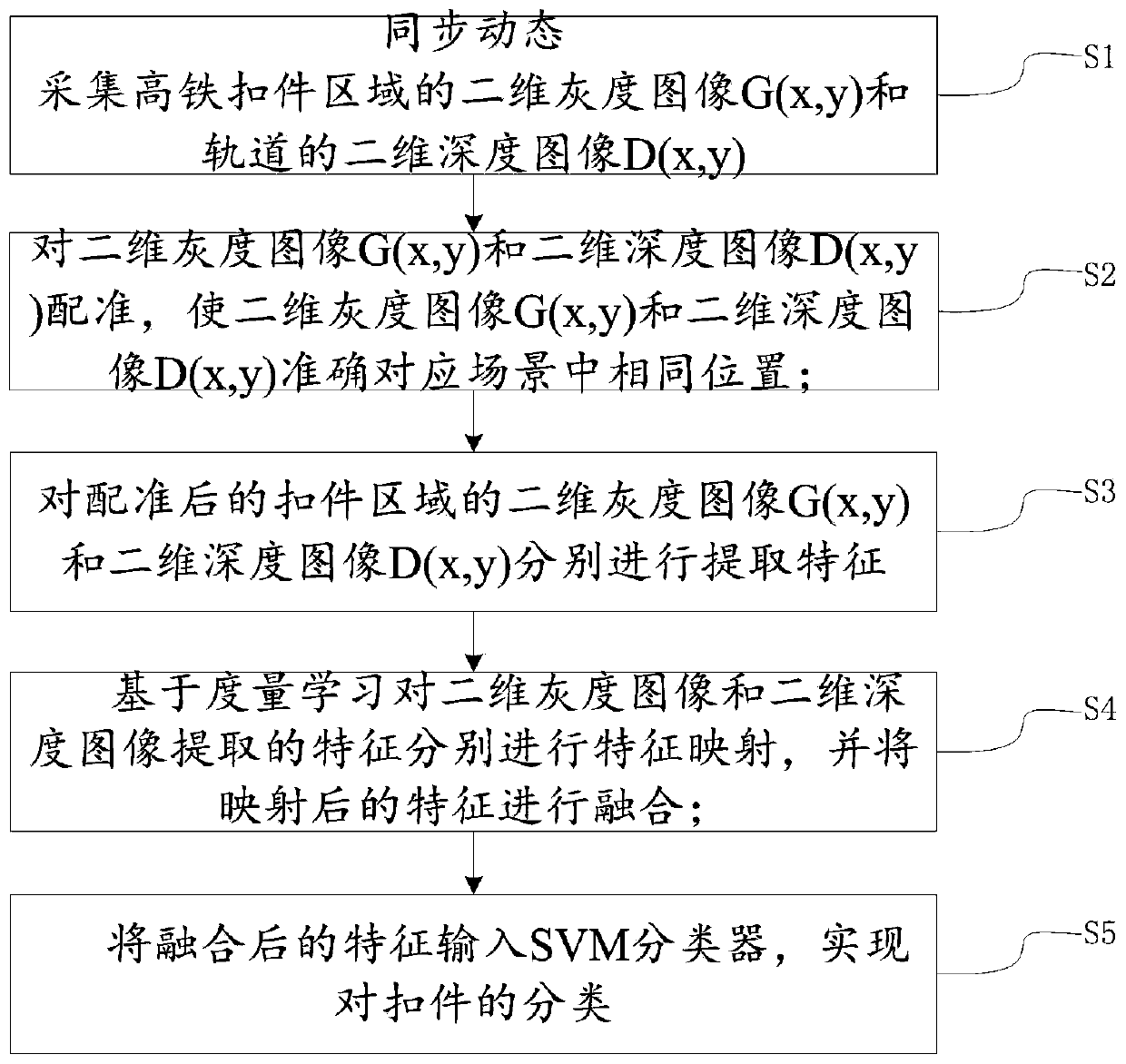

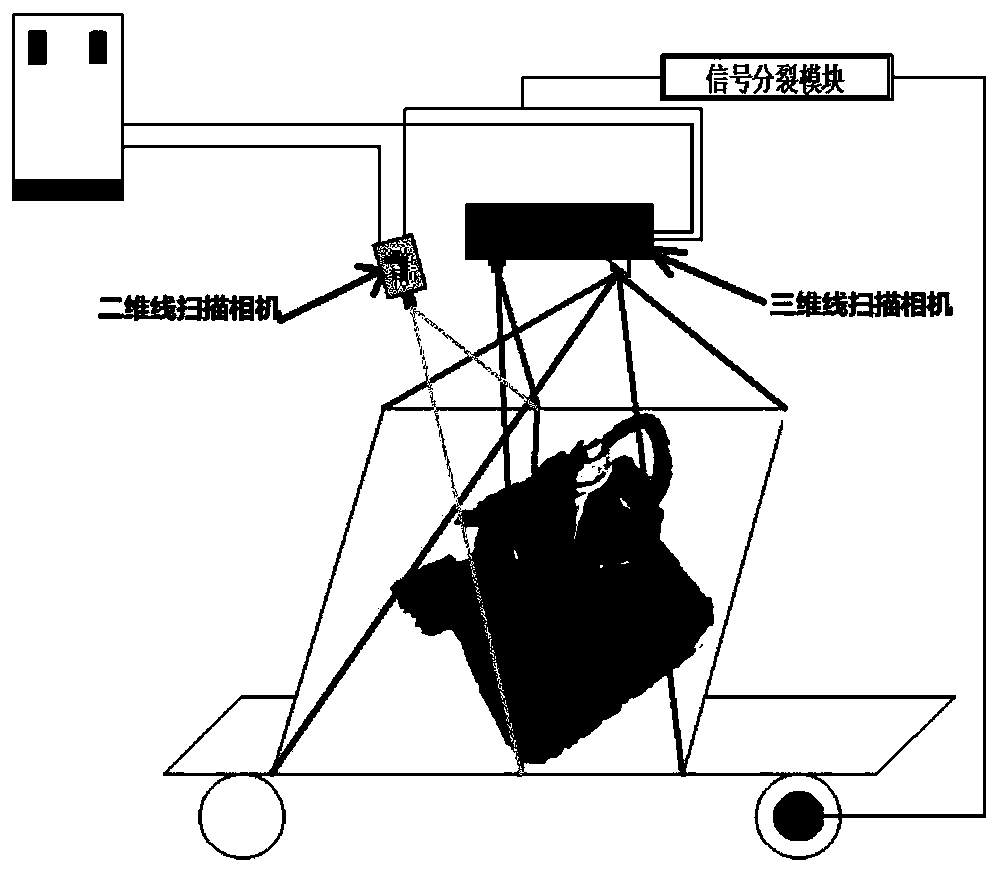

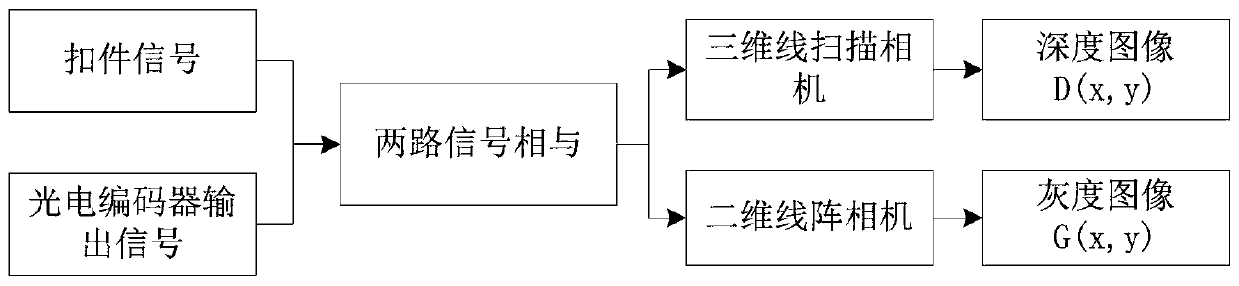

High-speed rail fastener defect identification method based on heterogeneous image fusion

ActiveCN111476767AImprove defect detection rateImplement defect detectionImage enhancementImage analysisImage extractionMachine vision

The invention relates to a high-speed rail fastener defect identification method based on heterogeneous image fusion, and belongs to the technical field of machine vision detection. The method comprises the following steps: S1, synchronously and dynamically acquiring a two-dimensional gray image G(x, y) of a high-speed rail fastener area and a two-dimensional depth image D(x, y) of a rail; S2, registering the two-dimensional grayscale image G(x, y) and the two-dimensional depth image D(x, y) to enable the two-dimensional grayscale image G(x, y) and the two-dimensional depth image D(x, y) to accurately correspond to the same position in the scene; S3, respectively carrying out feature extraction on the two-dimensional grayscale image G(x, y) and the two-dimensional depth image D(x, y) of the fastener area after registration; S4, performing feature mapping on features extracted from the two-dimensional grayscale image G(x, y) and the two-dimensional depth image based on metric learning,and fusing the mapped features; S5, inputting the fused features into an SVM classifier to realize classification of the fasteners. According to the invention, the defect detection rate of the fastener is improved, the omission ratio of the defective fastener is lower, the practicability is strong, and the method is worth popularizing.

Owner:NANCHANG INST OF TECH

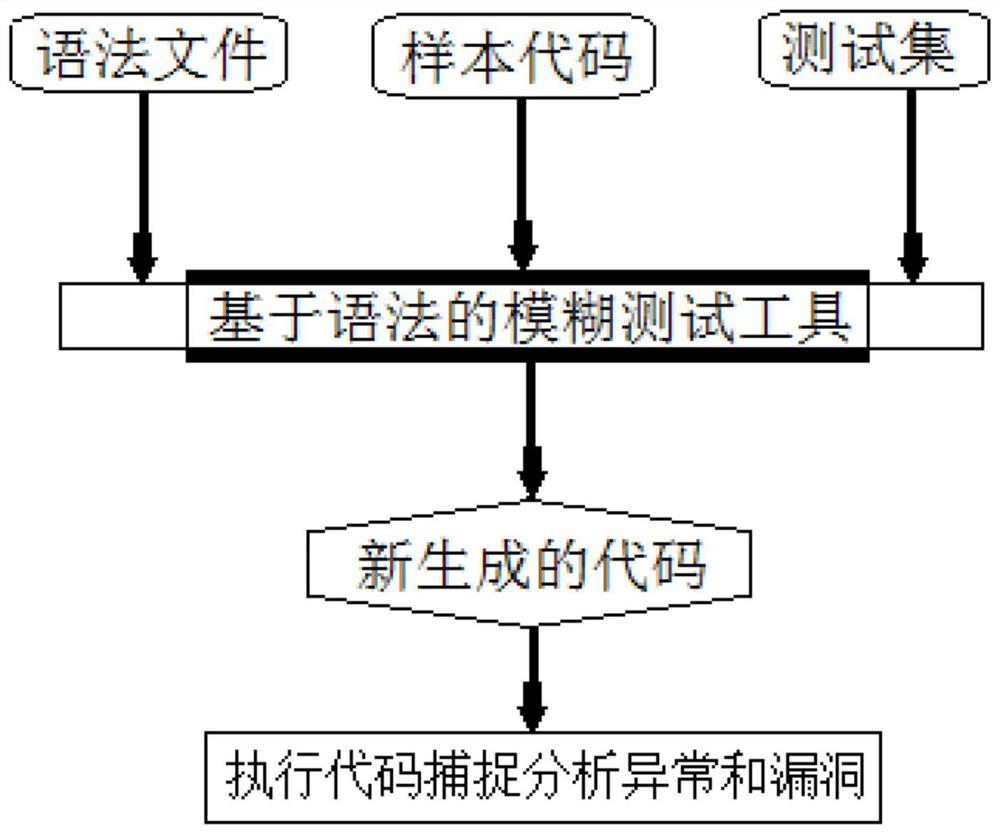

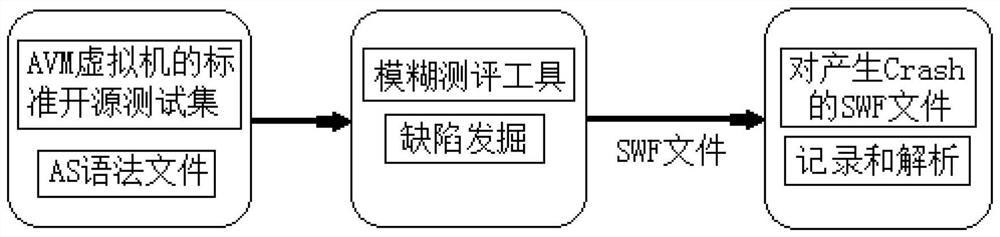

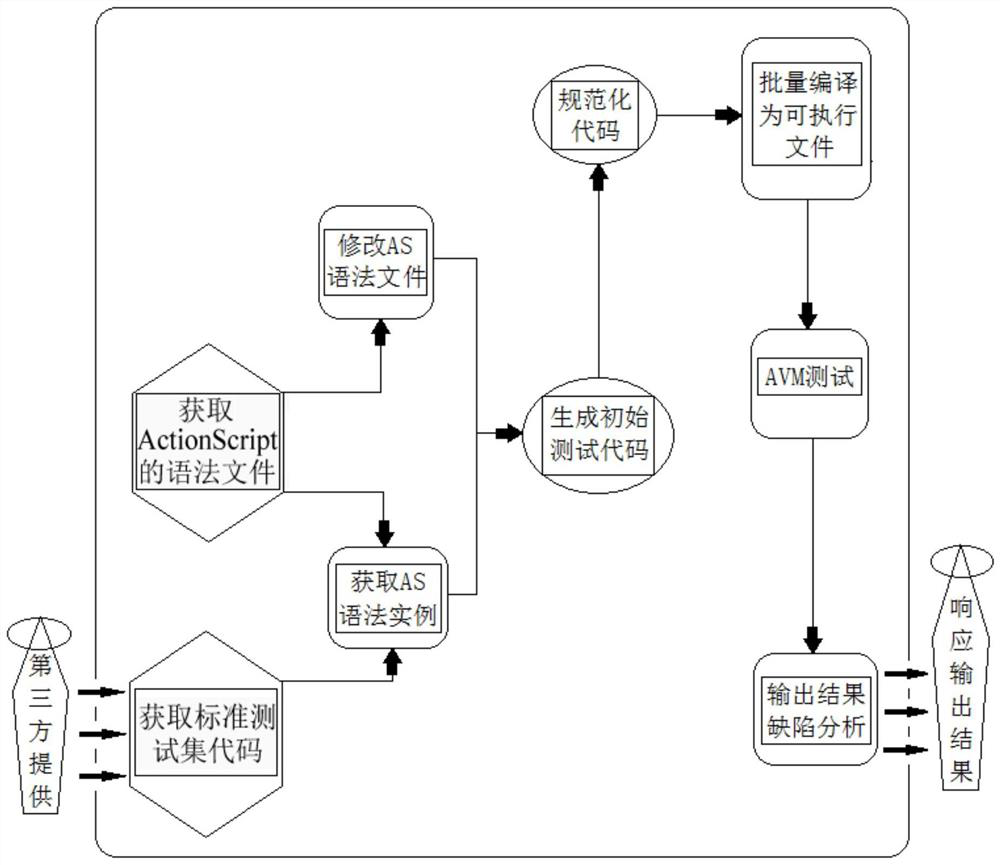

Flash defect fuzzy evaluation tool oriented to compiled language AS3

PendingCN111694746AImprove efficiencyIncrease coverageSoftware testing/debuggingSchema for Object-Oriented XMLVirtual machine

The invention provides a Flash defect fuzzy evaluation tool oriented to a compiled language AS3. Firstly, the adoption of a fuzzy test strategy is elaborated, and then a total architecture is described; the method mainly comprises the following steps: acquiring a grammar rule instance, modifying the grammar rule instance, generating an initial test code and a normalized code, compiling the test code to generate an executable file which can be identified by the AVM virtual machine, and modifying a selected algorithm strategy through different parameter configurations. The normalized code is used for enabling an initial test code which cannot be verified by a compiler to smoothly pass through the compiler to be verified and generate an executable file after being restrained and perfected. The Flash defect fuzzy evaluation tool provided by the invention has the advantages that the capability of finding the potential defects of the Flash software is strong, the effective rate of evaluationdata is high, the coverage rate of evaluation codes is high, and the mined Flash software errors can be captured in time.

Owner:荆门汇易佳信息科技有限公司

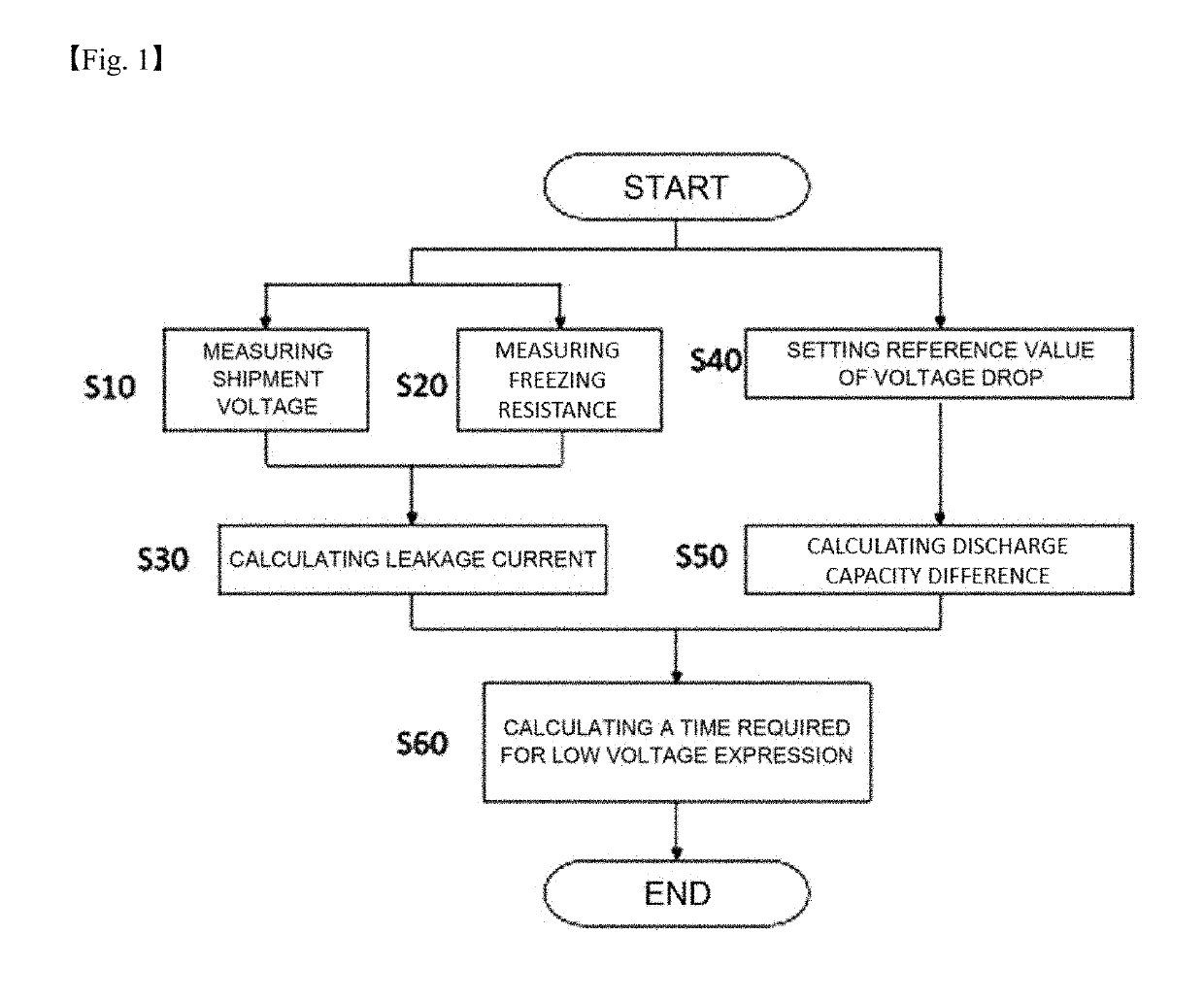

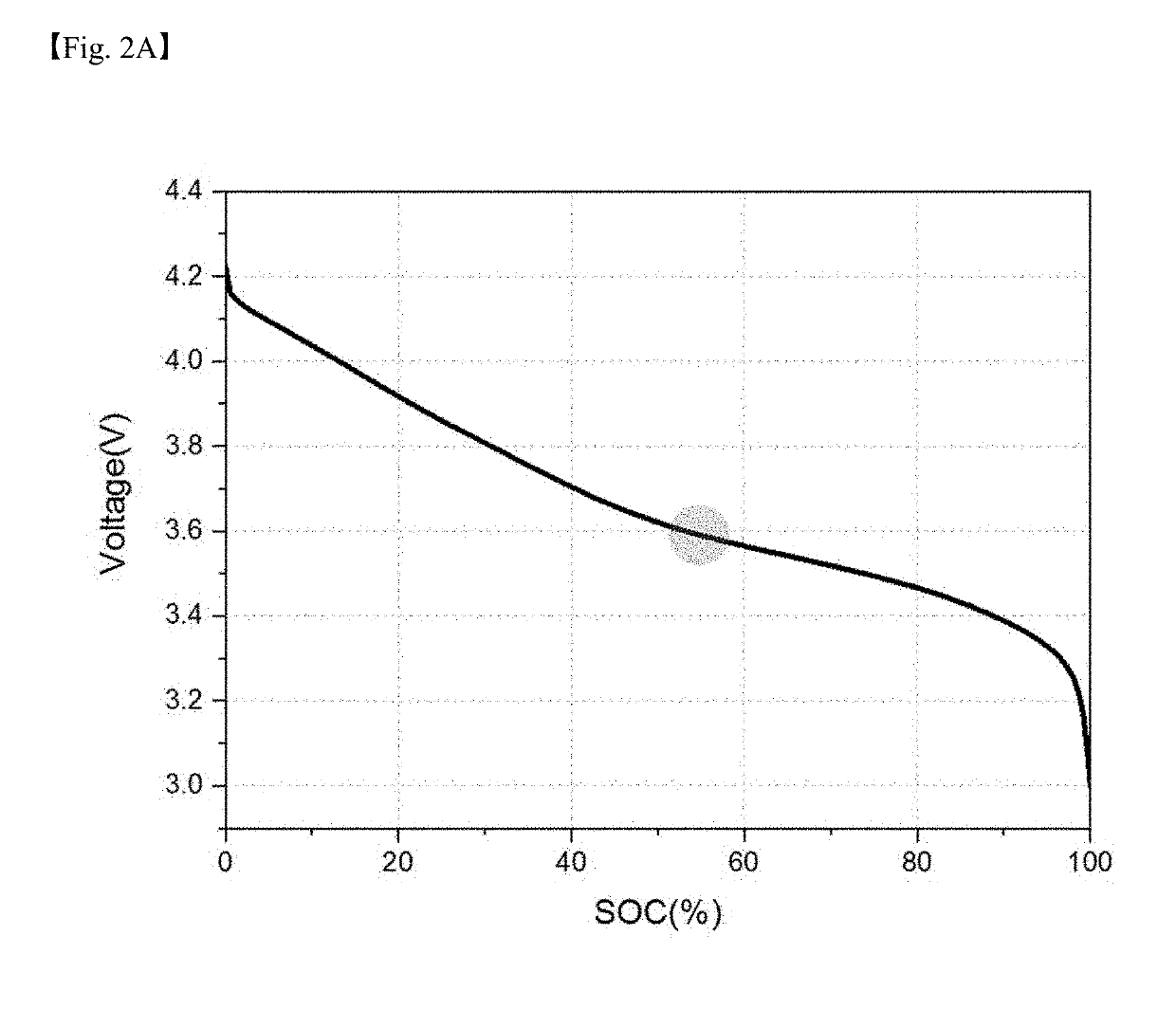

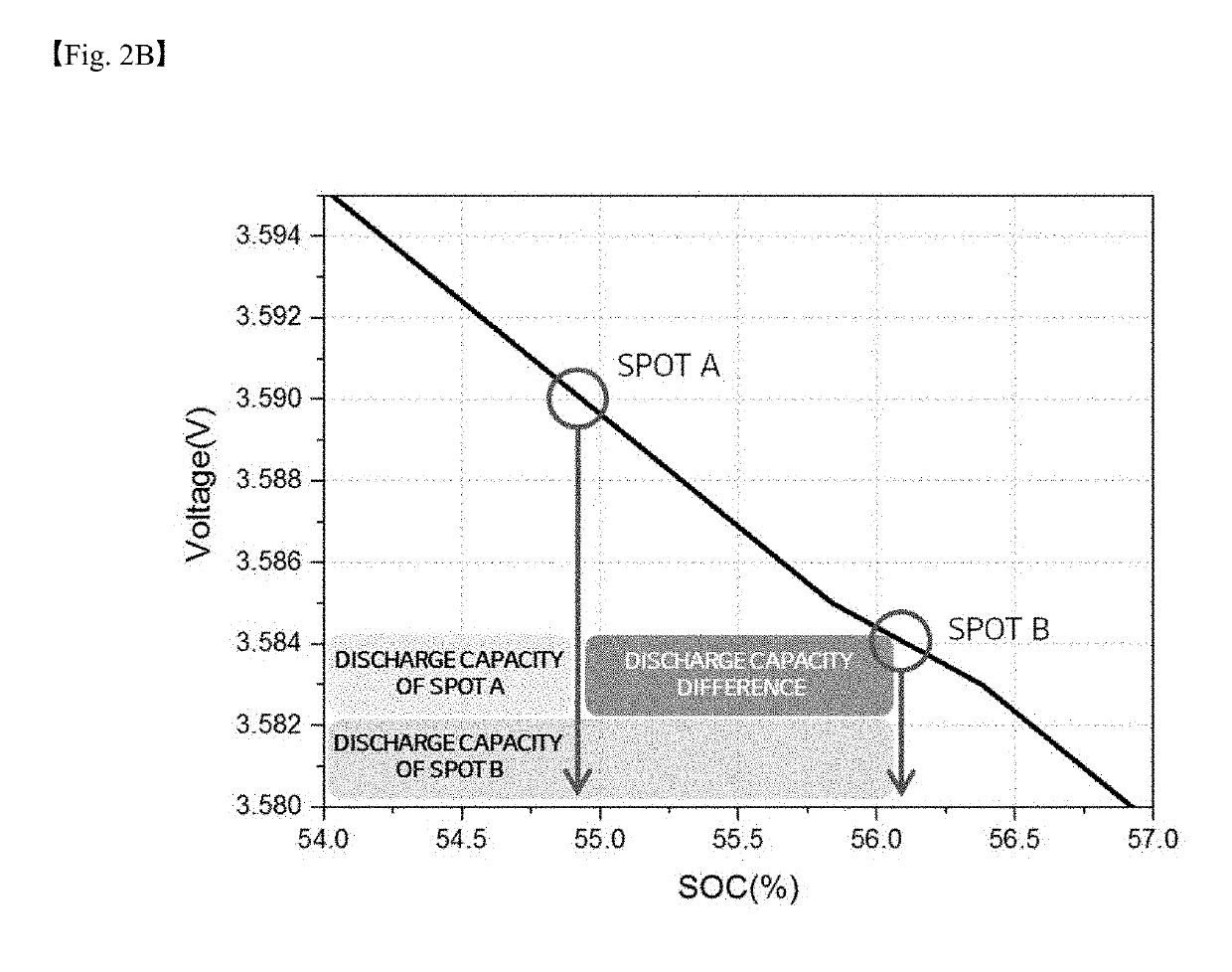

Method and system for predicting the time required for low voltage expression of a secondary battery, and aging method of the secondary battery using the same

ActiveUS20190271746A1Age process time of be shortenReduce processing timeCurrent/voltage measurementFinal product manufactureElectrical batteryCapacitance

A method and system for predicting the time required for low voltage expression of a secondary battery, including (a) obtaining a leakage current by inputting a voltage of a battery cell of the secondary battery, measuring a freezing resistance of a battery cell, and dividing an input voltage by a measured freezing resistance, (b) obtaining a discharge capacity difference by setting a reference value of a voltage drop for selecting a low voltage defect and obtaining a discharge capacity difference between the input voltage and a voltage dropped therefrom by the reference value, and (c) dividing the discharge capacity difference by the leakage current to thereby calculate a time required for low voltage expression.

Owner:LG ENERGY SOLUTION LTD

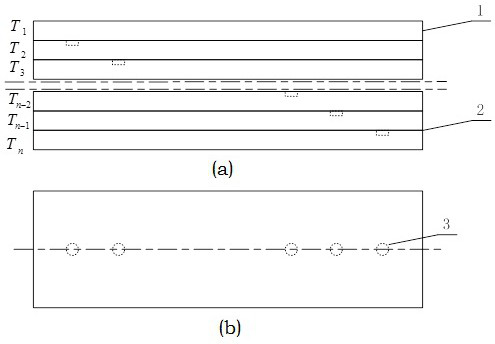

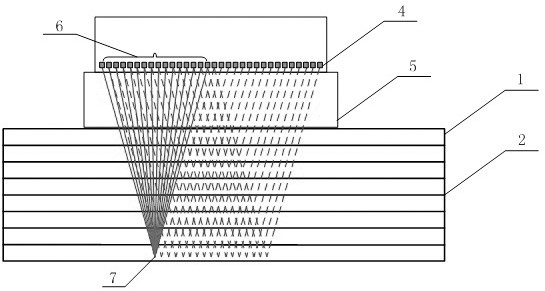

Multi-layer diffusion welding phased array ultrasonic detection method

PendingCN111812206ALarge adjustment rangeFlexible on-site testingAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationUltrasonic testingLinear Scan

The invention relates to a multi-layer diffusion welding phased array ultrasonic detection method. The method comprises the steps of reference block preparation, detection system basic configuration,excitation program setting, detection sensitivity setting, scanning detection, defect evaluation and the like. The detection sensitivity of different welding layers is calibrated by using a special reference block for multi-layer diffusion welding, a detection result is imaged and displayed by adopting a linear scanning scheme, the detection sensitivity is high, the defect detection rate is high,the detection result is reliable, the detection result is imaged in real time, repeated scanning at the defect position is facilitated, the defect recognition accuracy is improved, the key technical problem of phased array ultrasonic detection of a multi-layer diffusion welding structure is solved, limitation of a detection site is avoided, and rapid and reliable detection of products can be achieved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

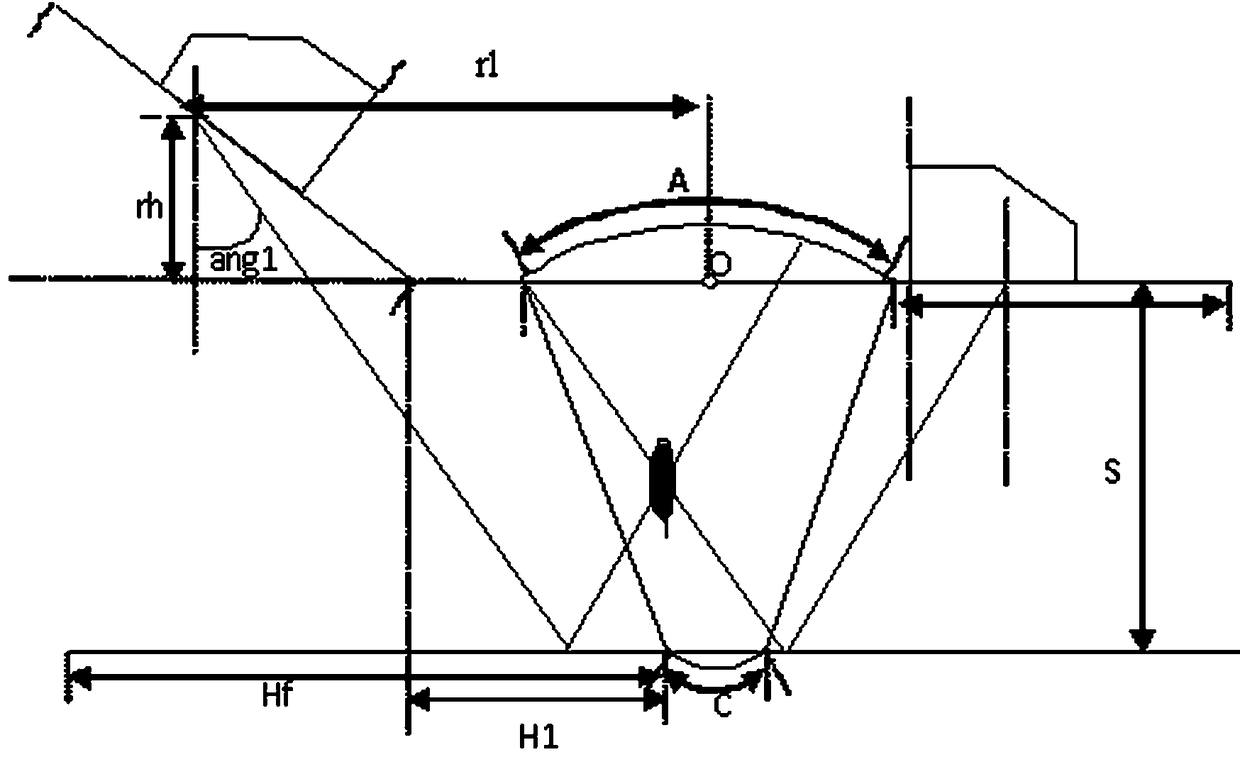

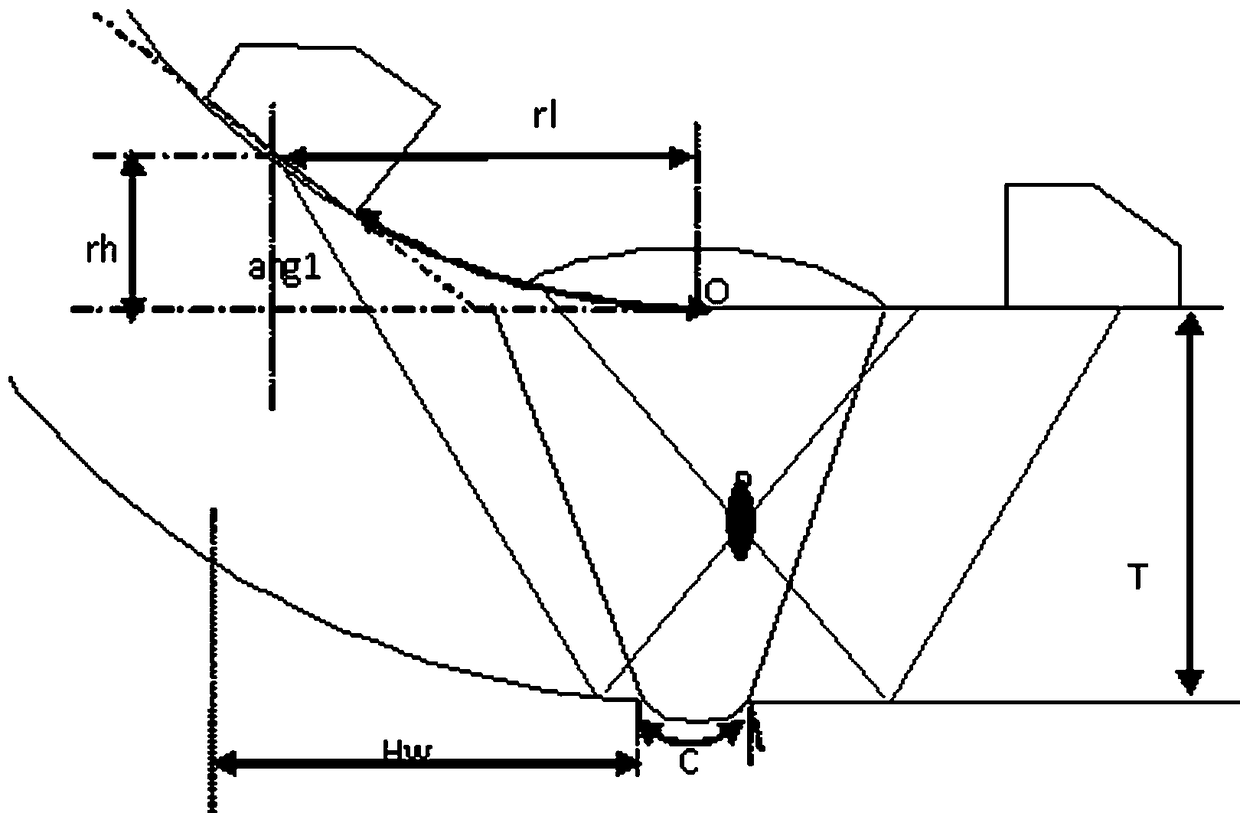

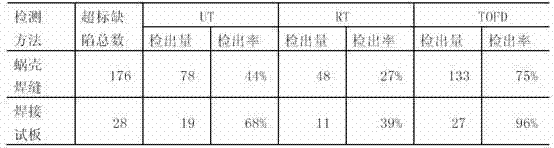

TOFD detection verification method of large-scale spiral case welding seam

InactiveCN102539533ANo radiation hazardImprove defect detection rateAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansPower stationValidation methods

The invention relates to a detection method of a spiral case welding seam. The TOFD detection verification method of a large-scale spiral case welding seam comprises the following steps: step one, preparing a sample, determining spiral case defect acceptance standards and TOFD detection technological parameters; step two, performing a spiral case welding seam contrast test in which TOFD, UT and RT are performed respectively, that is, firstly performing TOFD, then performing UT and RT respectively after detection, and finally dissecting unqualified defects determined respectively so as to verify respective detection accuracy; step three, performing a welding test plate contrast test, that is, preparing welding defects of cracks, incomplete fusion, lack of penetration, dense pores, slag inclusion, and the like on a test plate, and performing a contrast test with reference to step two; step four, performing contrast test analysis, and verifying TOFD reliability according to the defect detection rates of the three methods. The invention forms a TOFD, RT, and UT contrast test method of large-scale spiral case welding seams, and can be successfully applied to the detection of power station unit spiral case on-site installation welding seams.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

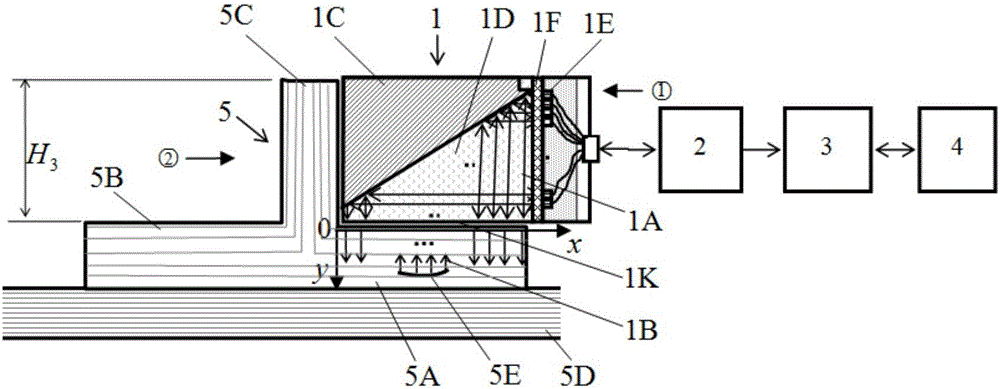

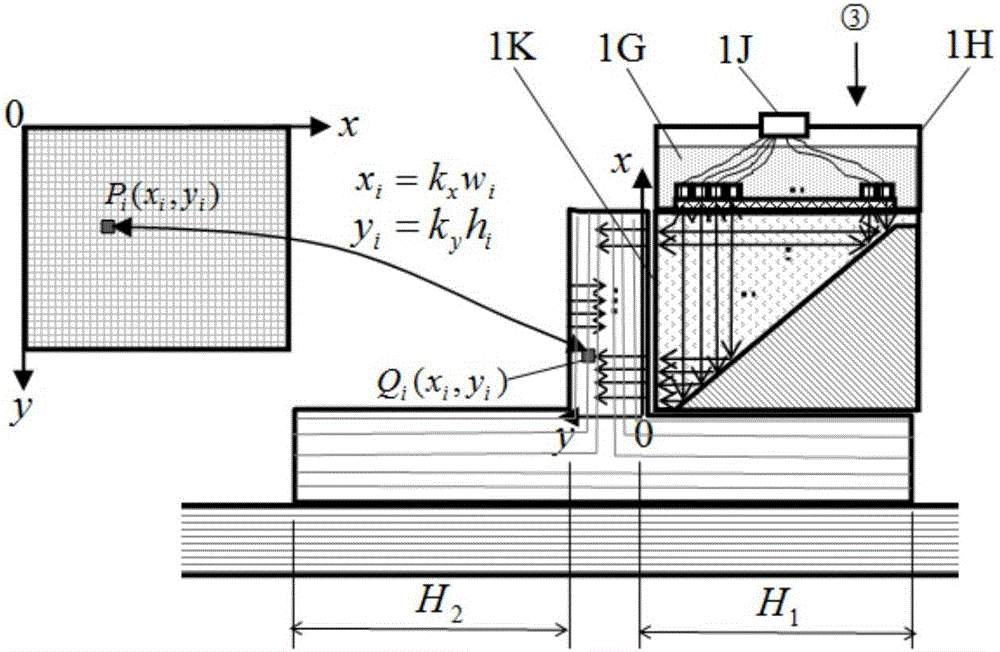

Ultrasonic visual imaging method for detecting composite structure stiffener zones

ActiveCN106770667AVisual imaging quality is clearEasy to detectAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationImaging quality

The invention belongs to the technical field of nondestructive detection and relates to an ultrasonic visual imaging method for detecting composite structure stiffener zones. On the basis of an ultrasonic reflection principle, a rapid ultrasonic scanning visual imaging method is established by selecting an ultrasonic reflector array linear scanning array transducer to realize rapid ultrasonic scanning visual imaging detections of different parts of the composite structure stiffener zone; through selecting different scanning modes and incident directions as well as the array transducer, ultrasonic visual imaging detections of different composite structure stiffener zones are realized. The actual detection effect shows that the visible degrees, defect detection rates and detection efficiencies of ultrasonic detections of the different parts of the composite structure stiffener zone are obviously enhanced; phi 3mm layering in the different parts of the composite structure stiffener zone can be detected; the visible imaging quality is very clear and a very good actual detection effect is achieved.

Owner:AVIC COMPOSITES

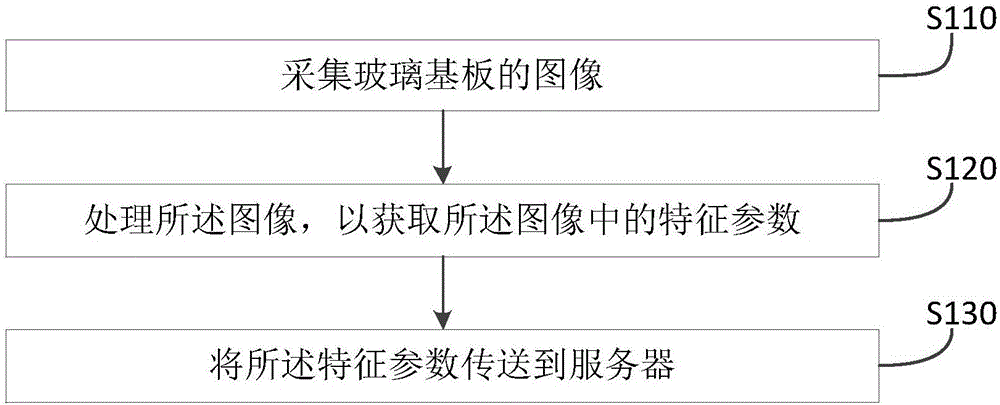

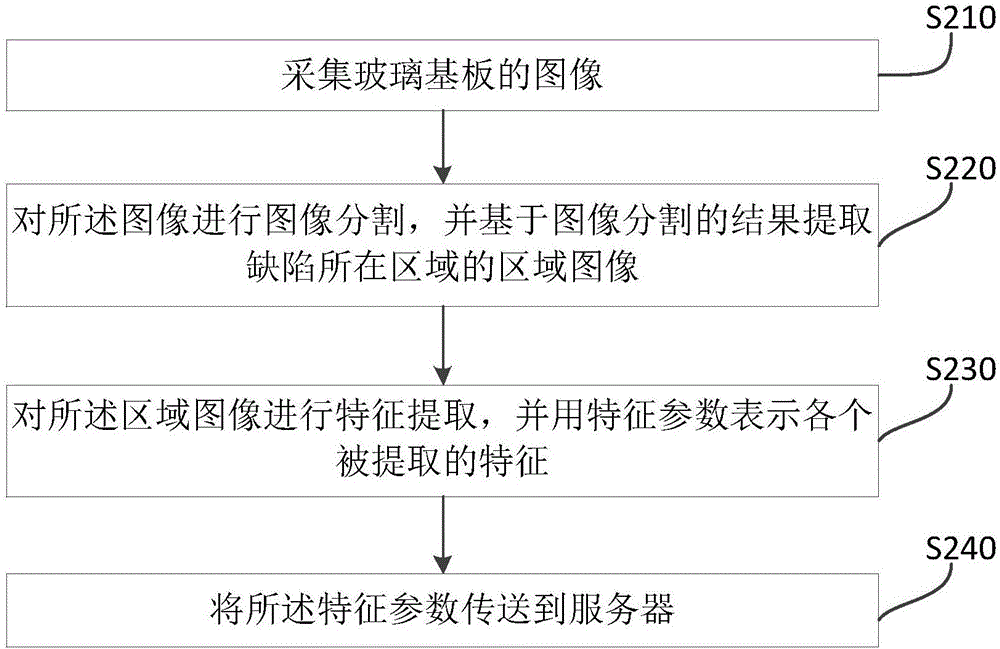

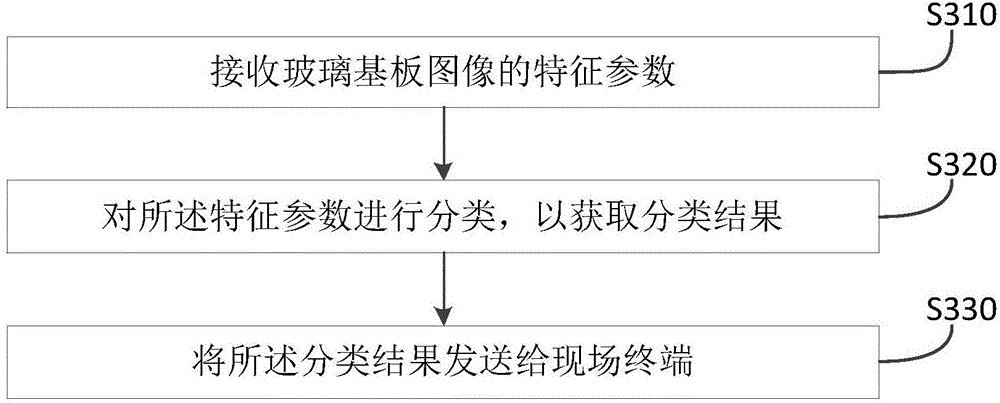

Method for checking defects of substrate glass, field terminal and server

InactiveCN106645180AShorten detection timeImprove accuracyOptically investigating flaws/contaminationDisplay deviceComputer terminal

The invention relates to the field of manufacturing of displays and discloses a method for checking the defects of substrate glass. The method comprises the following steps: acquiring an image of the substrate glass; processing the image to acquire characteristic parameters in the image; transmitting the characteristic parameters to a server. On the other hand, the invention also provides a method for checking the defects of the substrate glass. The method comprises the following steps: receiving the characteristic parameters of the substrate glass image; classifying the characteristic parameters to obtain classifying results; transmitting the classifying results to a field terminal. The invention also provides the field terminal and the server applying the method, as well as a system applying the field terminal and the server. By using the technical scheme provided by the invention, the classifying work of the defects can be concentrated in the server for executing, so that the classifying efficiency and accuracy can be improved.

Owner:TUNGHSU TECH GRP CO LTD +1

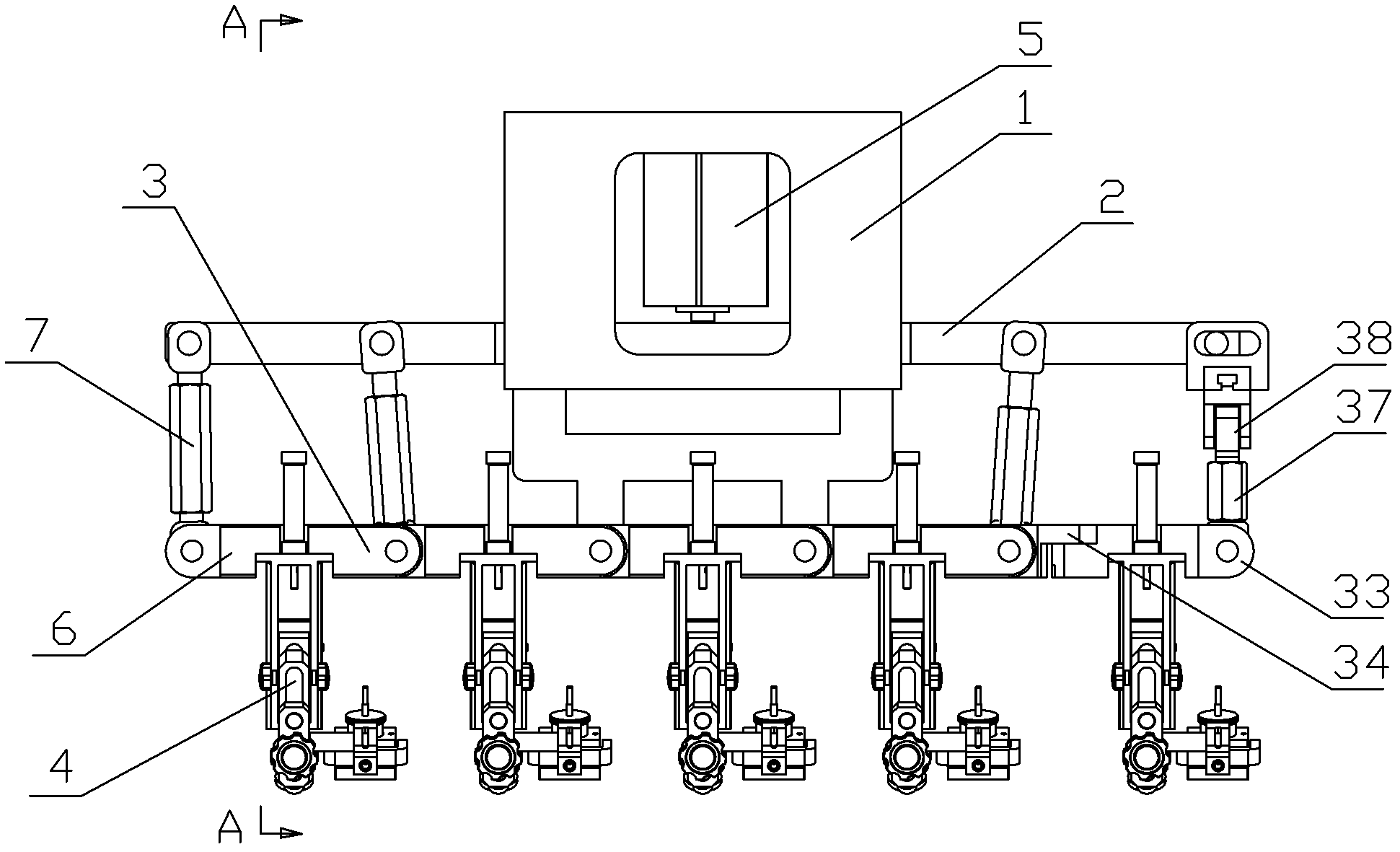

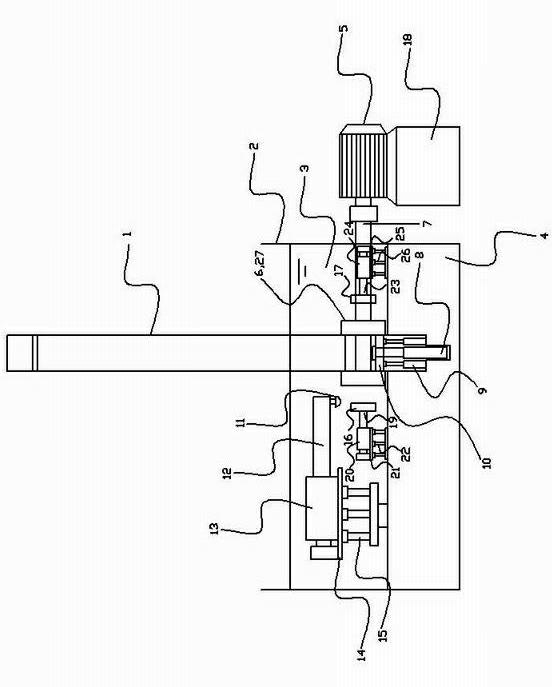

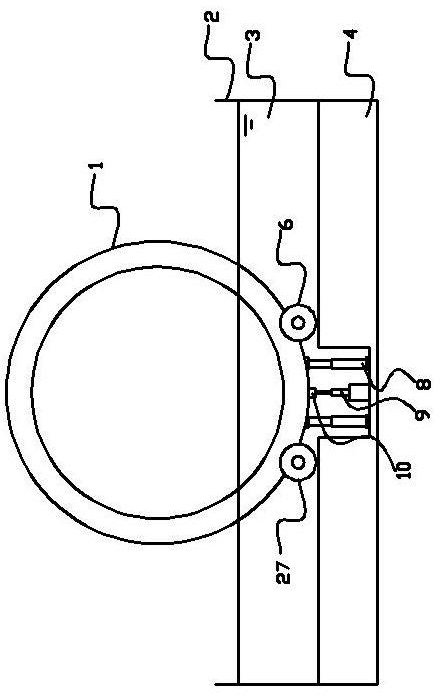

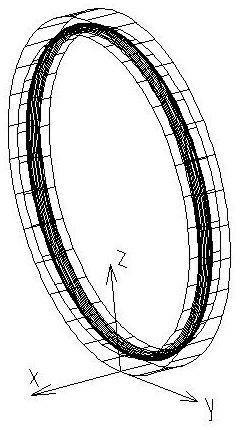

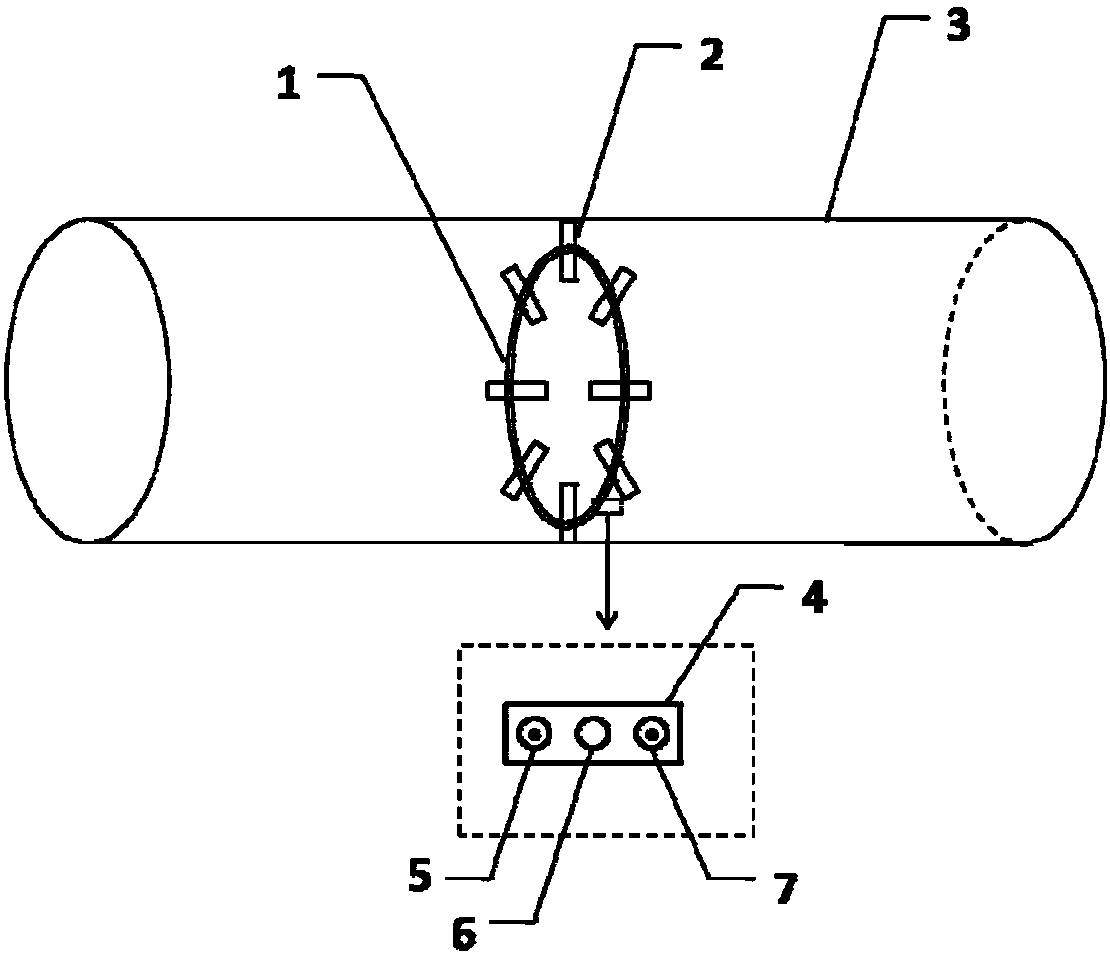

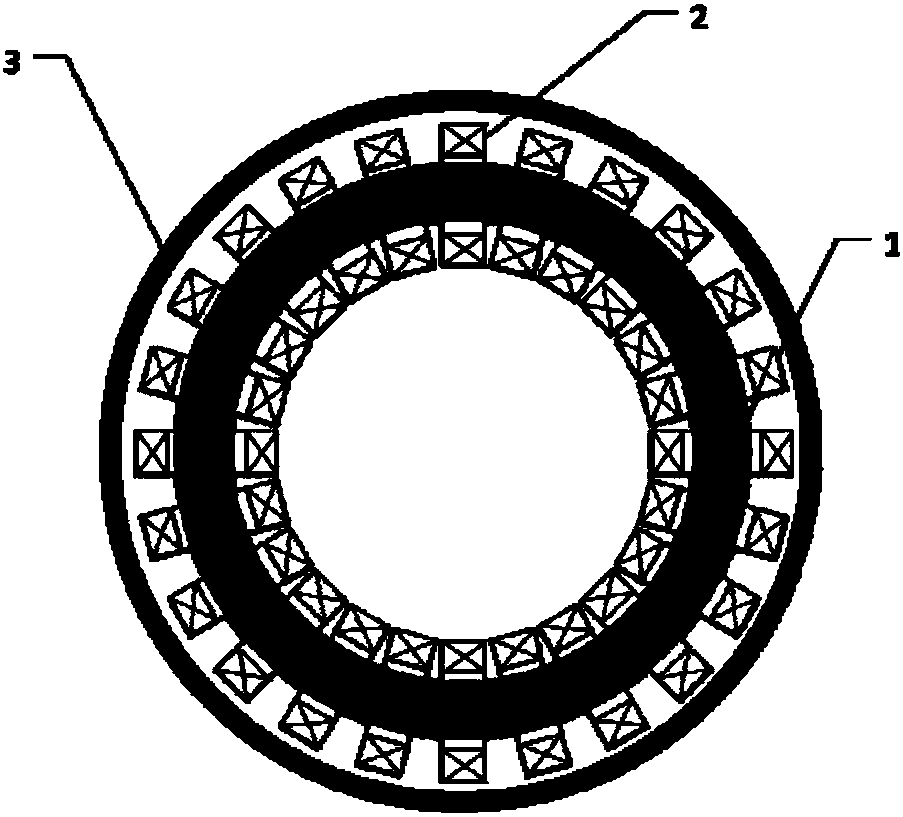

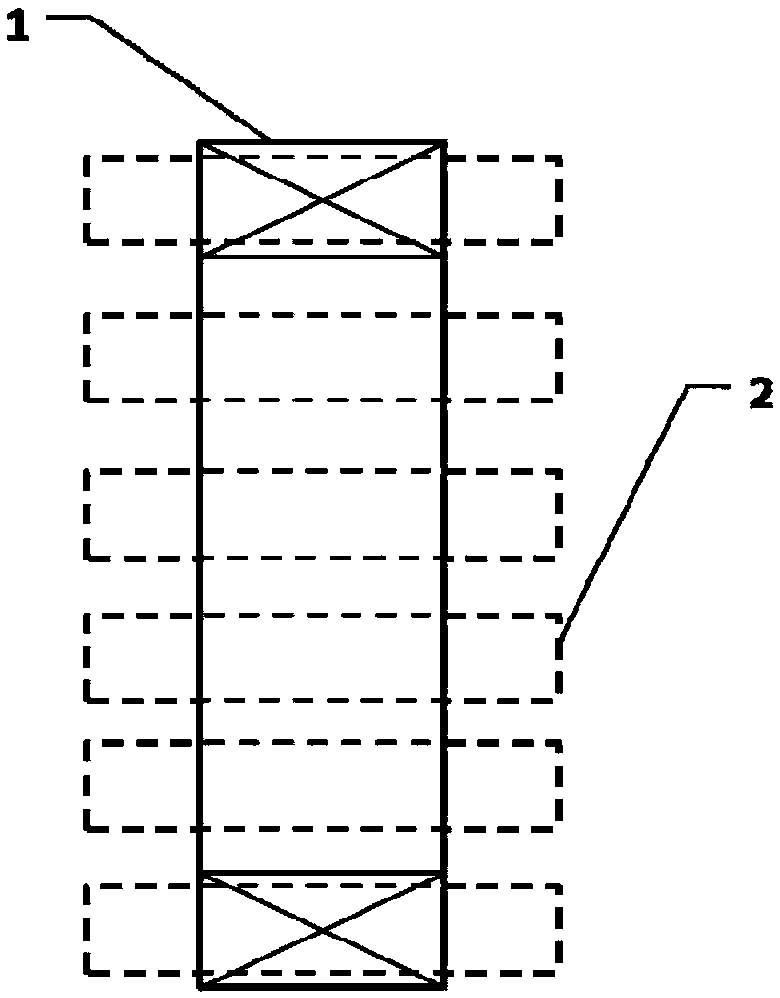

Ultrasonic flaw detection device for slewing ring bearings in wind power generation

ActiveCN102288677ADetection speedImprove efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesWind drivenSlewing bearing

The invention discloses an ultrasonic flaw detector for a wind-driven power-generating rotary support bearing, which comprises a power system, a roller part detection system, a tread detection system, a left side face detection system and a right side face detection system. The roller part detection system is used for detecting a roller part of an outer ring of a bearing needing surface detection, the tread detection system is used for detecting the outer surface of the bearing needing surface detection, the left side face detection system and the right side face detection system are used fordetecting the left side end face and the right side end face of the bearing needing surface detection, the tread detection system is arranged just below a workpiece, the left side face detection system and the right side face detection system are symmetrically arranged on the two sides of the workpiece, and the roller part detection system is arranged behind the left side face detection system. The device has high detection speed, high reliability and high degree of automation, and cracks and defects equivalent to flat-bottomed holes with the diameter phi greater than 1 on the roller surface,the tread and the two outer side faces of the wind-driven power-generating rotary support bearing can be effectively detected. Since the method of imaging detection is adopted, the quantification accuracy and the defect detection rate can be improved greatly.

Owner:NANCHANG HANGKONG UNIVERSITY

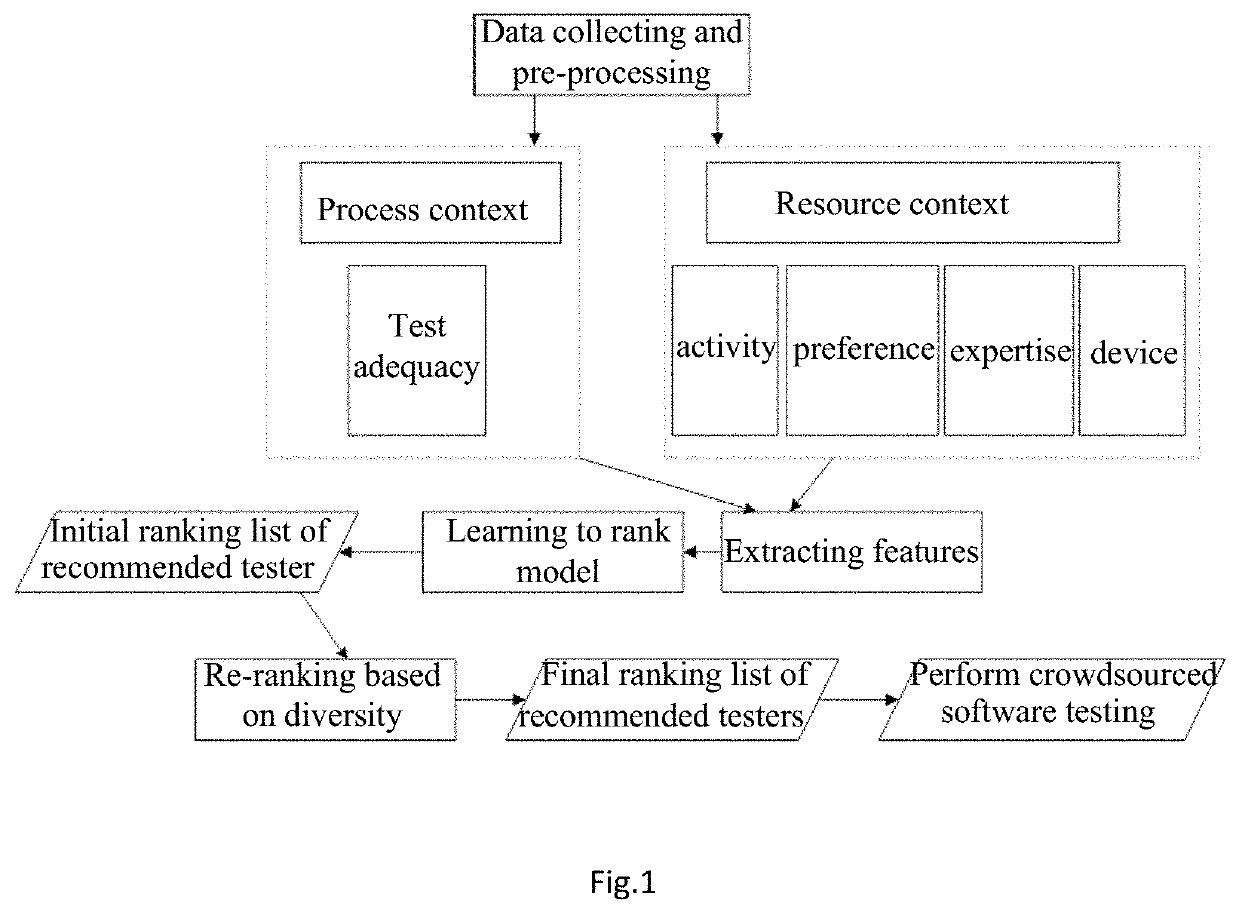

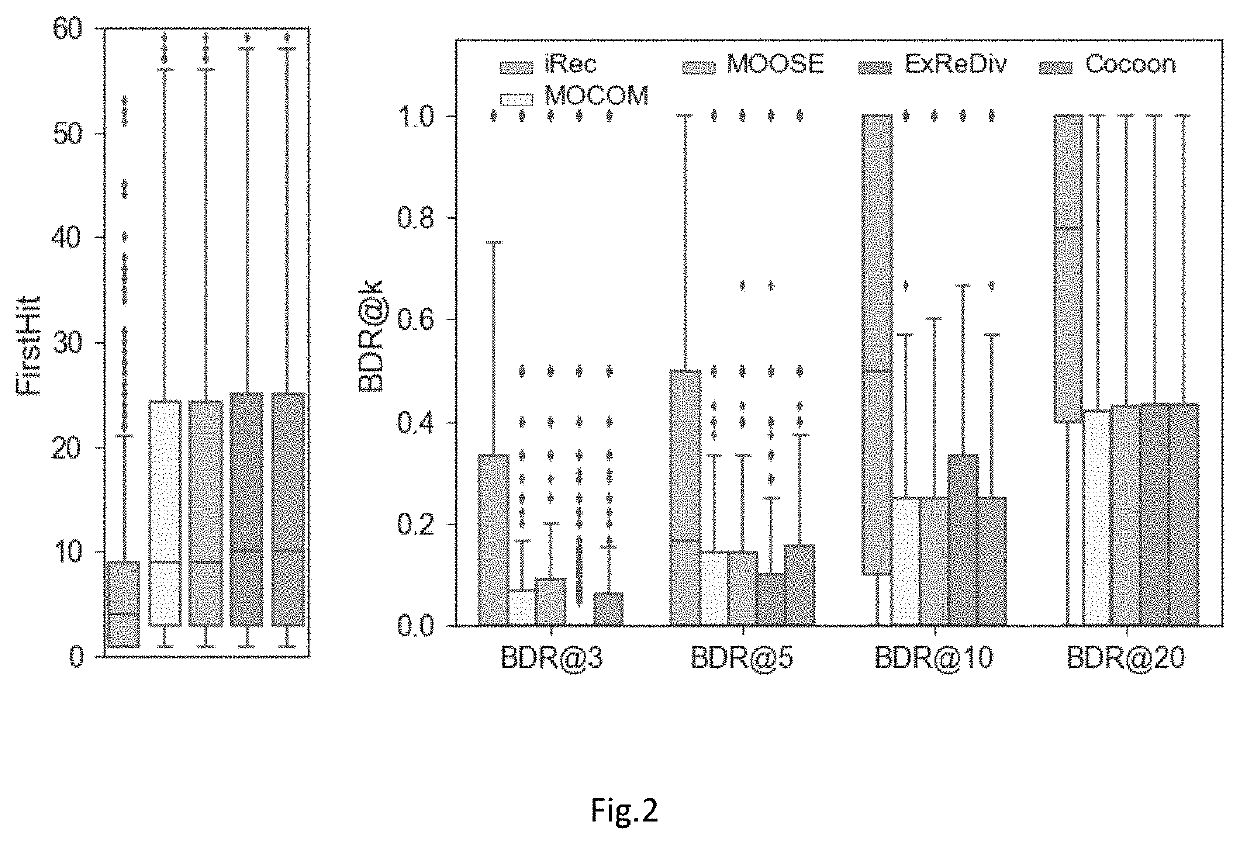

Method and electronic device for recommending crowdsourced tester and crowdsourced testing

PendingUS20210286708A1Accurate recommendationImprove defect detection rateDigital data information retrievalSoftware testing/debuggingCrowdsourced testingTester device

The disclosure provides a method and an electronic device for recommending crowdsourced tester and crowdsourced testing. The method comprises: collecting a requirement description of a crowd testing task at a time point in a process of crowd software testing and historical crowd testing reports of each tester to be recommended; obtaining a process context and a resource context of each tester to be recommended; inputting the extracted features into a learning to rank model to obtain an initial ranking list of the recommended testers, and re-ranking the initial ranking list based on diversity contributions of expertise and device to obtain a final ranking list. The disclosure can more accurately recommend testers to take accuracy and diversity of the recommended testers into consideration, so that the testers can be dynamically planned during the crowd testing to improve the bug detection rate, shorten the completion cycle of the crowd testing task.

Owner:INST OF SOFTWARE - CHINESE ACAD OF SCI

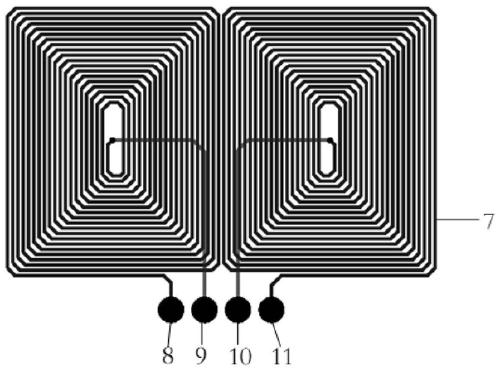

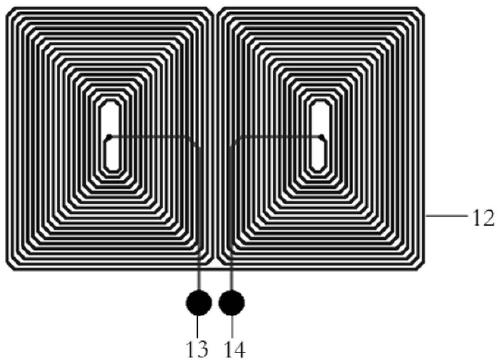

Aviation metal small diameter tube defect internal inspection probe and detection method

ActiveCN107941904AImprove detection efficiencyImprove defect detection rateMaterial magnetic variablesAviationEngineering

The invention discloses an aviation metal small diameter tube defect internal inspection probe and a method. The probe includes a disc coil and a circumferential rectangular coil group array that arefixed on a photosensitive resin coil skeleton together. The disc coil and the photosensitive resin coil skeleton are coaxial, rectangular coils in the circumferential rectangular coil group array areevenly arranged along the circumference, adjacent rectangular coils are in contact with each other, and the disc coil passes perpendicularly through the air field surrounded by each rectangular coil;the winding groups of the disc coil and the rectangular coils are respectively obtained by winding of three-core-wire groups, wherein each three-core-wire group comprises three side-by-side same-diameter copper core enameled wires; the winding group of each coil comprises three independent coils, a middle coil is an excitation coil, two side coils are detection coils, the two detection coils are connected in differential arrangement, and difference of induced voltage signals picked up by the two detection coils is taken as an output signal. The present invention also provides the detection method of the probe, and the detection method can detect aviation metal small diameter tube defects quickly and highly accurately, and has important engineering application value.

Owner:XI AN JIAOTONG UNIV

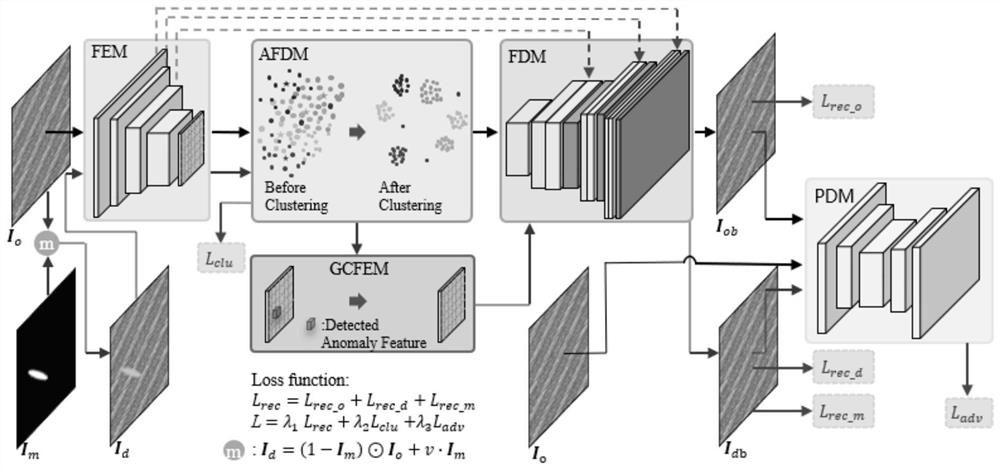

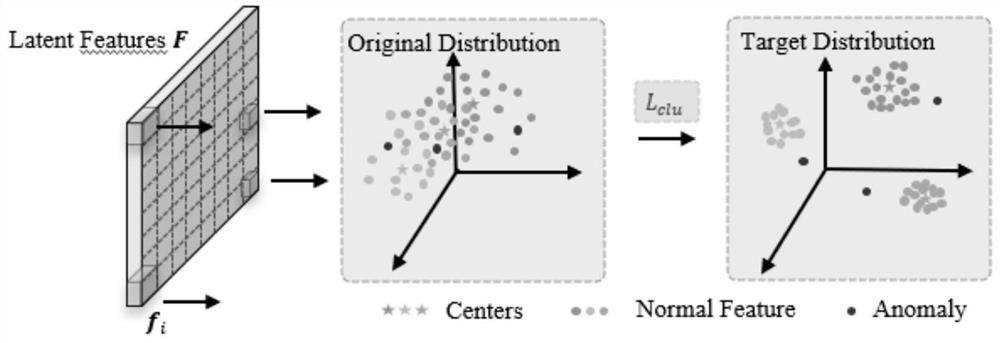

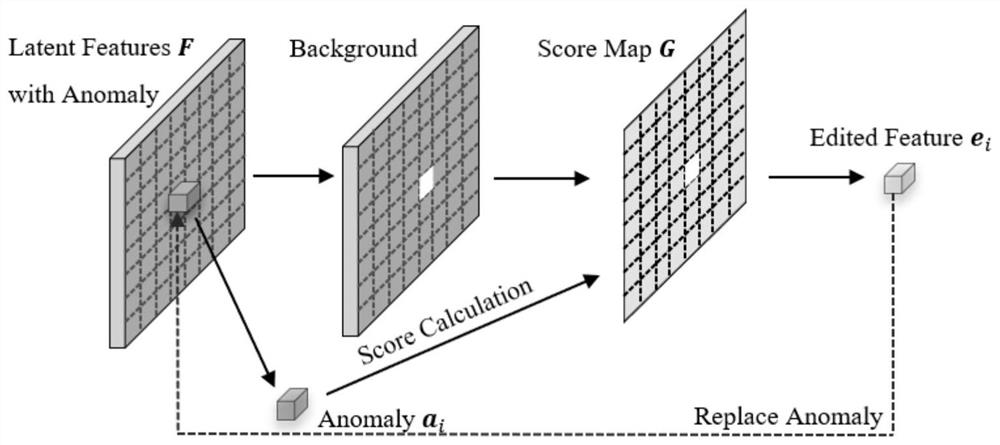

Adversarial network texture surface defect detection method based on abnormal feature editing

PendingCN112164033AReduce detection accuracyImprove detection accuracyImage enhancementImage analysisPattern recognitionData set

The invention belongs to the technical field of image processing, and particularly discloses an adversarial network texture surface defect detection method based on abnormal feature editing. The adversarial network texture surface defect detection method comprises the following steps of: acquiring defect-free good product images and corresponding defect images to form an image data set jointly; constructing an adversarial network which comprises a generator and a discriminator, wherein the generator is used for extracting image features, detecting abnormal features and then editing the abnormal features by using normal features to obtain a reconstructed image, and the discriminator is used for discriminating the good product images and the reconstructed image; training the adversarial network through using the image data set according to a pre-constructed optimization target, so as to obtain a reconstructed image generation model; and inputting an image to be detected into the reconstructed image generation model to obtain a reconstructed image corresponding to the image to be detected, and further acquiring the texture surface defects according to the image to be detected and thecorresponding reconstructed image. The adversarial network texture surface defect detection method has high detection precision for defects of different shapes, sizes and contrast ratios on differenttexture surfaces.

Owner:HUAZHONG UNIV OF SCI & TECH

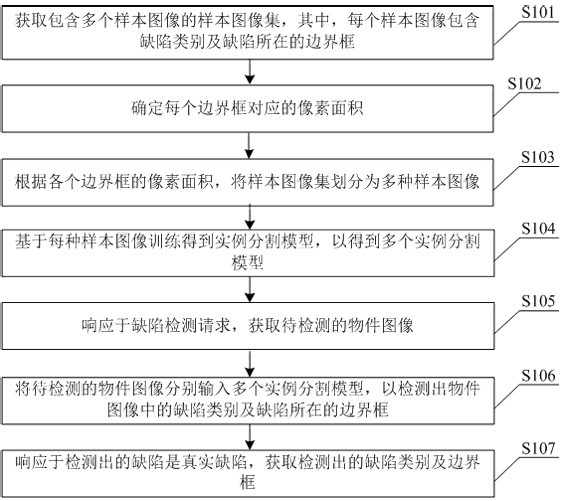

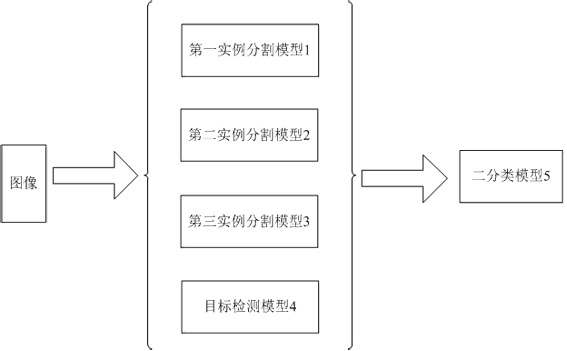

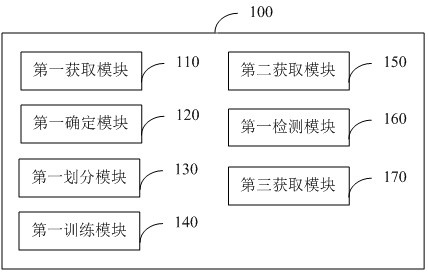

Object defect detection method and device

ActiveCN113096130AImprove defect detection rateImprove industrial applicabilityImage enhancementImage analysisEngineeringSample image

The invention provides an object defect detection method and device. The method comprises the following steps: acquiring a sample image set containing a plurality of sample images; determining a pixel area corresponding to each bounding box; dividing the sample image set into a plurality of sample images according to the pixel area of each bounding box; performing training based on each sample image to obtain an instance segmentation model; obtaining an object image to be detected; respectively inputting an object image to be detected into the plurality of instance segmentation models so as to detect a defect category in the object image and a bounding box where the defect is located; and in response to the fact that the detected defect is a real defect, obtaining a detected defect category and a bounding box. Therefore, after the sample images are classified, the multiple instance segmentation models are constructed, the object defects are detected through the multiple instance segmentation models, it can be guaranteed that the obtained defects are real defects, the defect detection rate is increased, the false detection rate is reduced, and the industrial practicability is high.

Owner:CHANGZHOU MICROINTELLIGENCE CO LTD

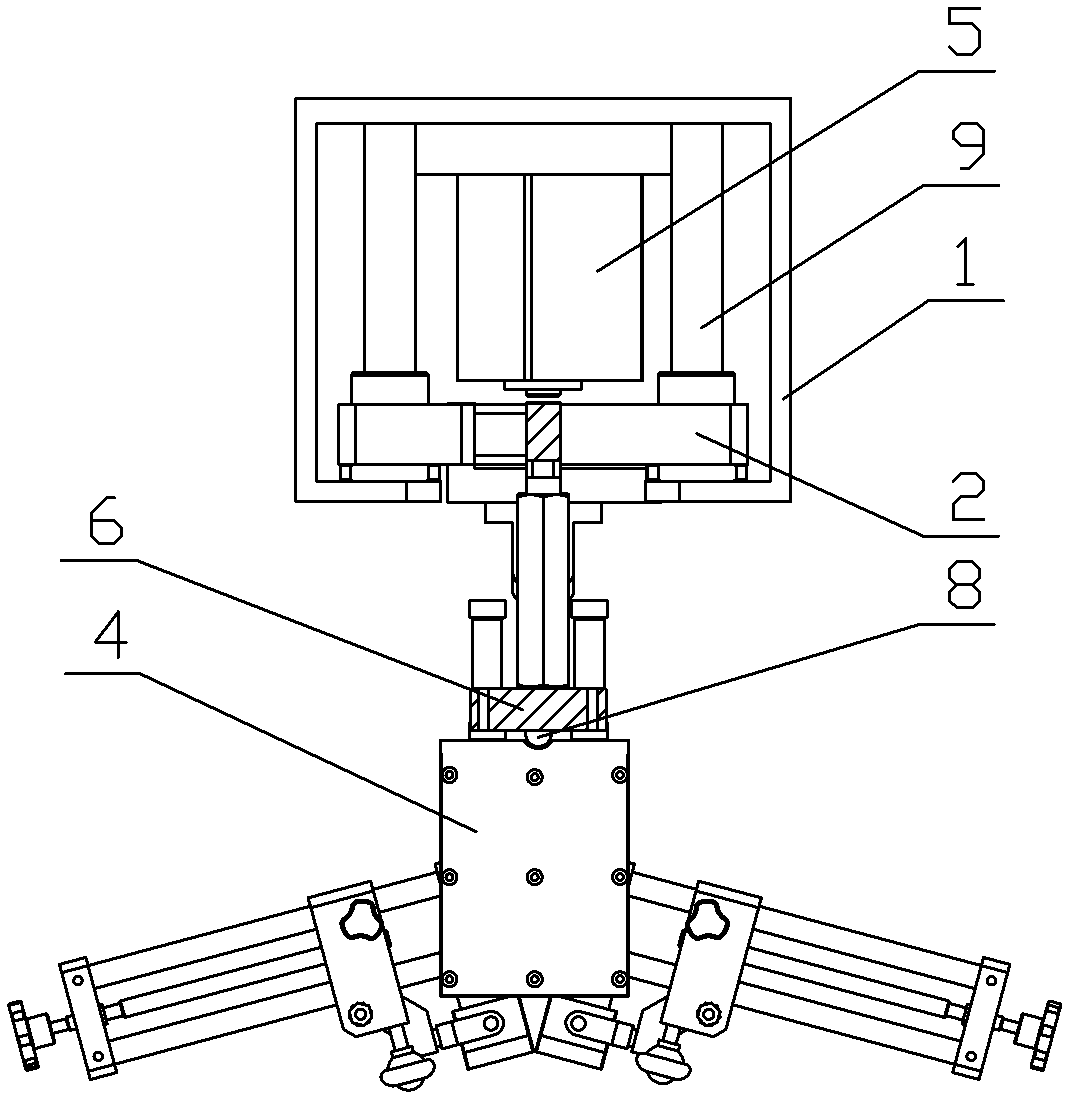

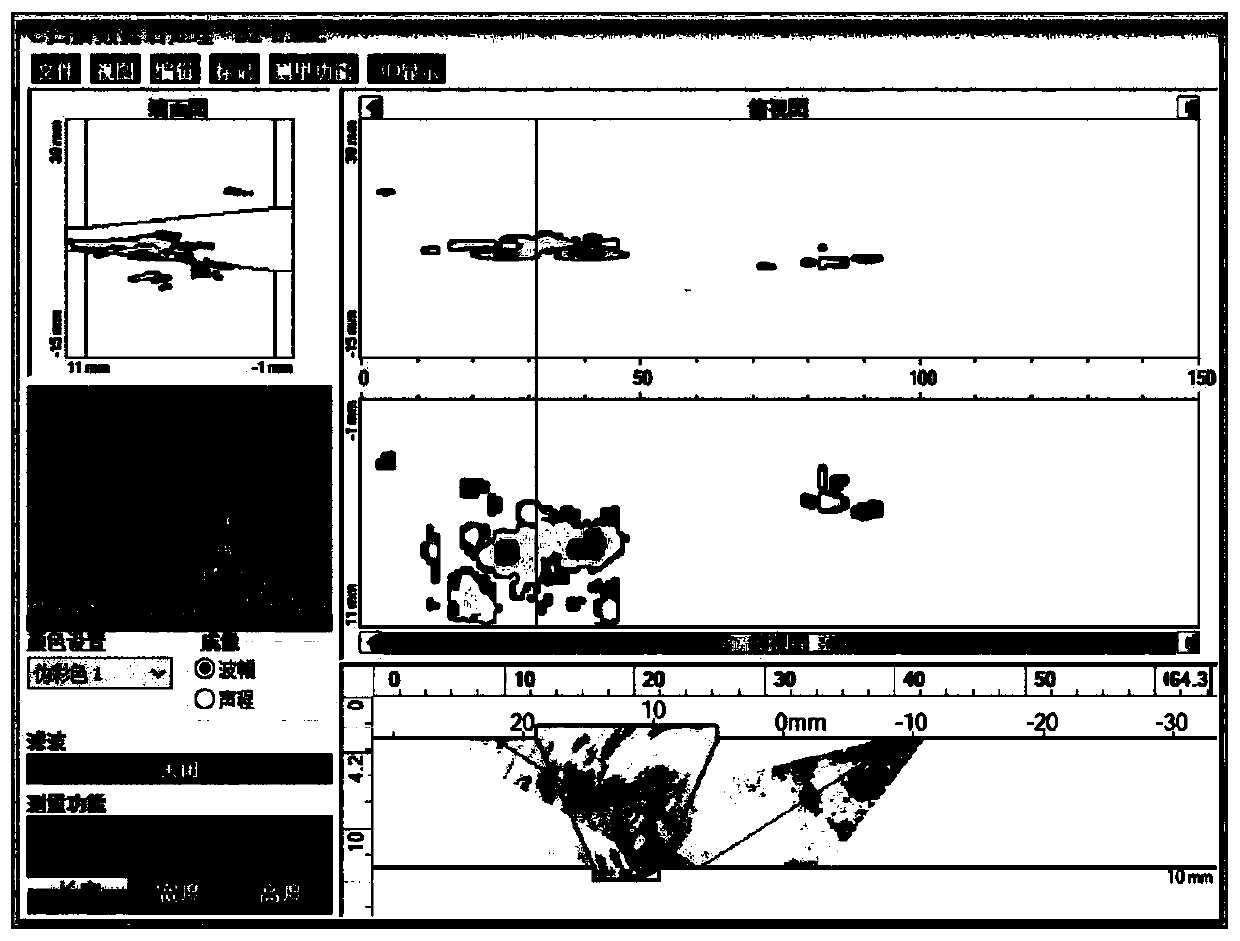

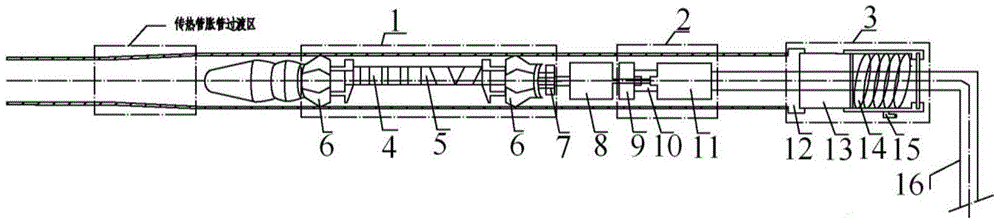

Steam generator heat-transfer pipe ultrasonic inspection system

ActiveCN105806937AImprove defect detection rateAccurate positioning and quantificationAnalysing solids using sonic/ultrasonic/infrasonic wavesWater immersionMetallic materials

The invention relates to a steam generator heat-transfer pipe ultrasonic inspection system. The system comprises a probe assembly, a probe rotation device, a probe gate device and a conduit. The probe assembly comprises a probe clamper, several probes on the probe clamper and an ultrasonic cable connected to the ultrasonic probes. The probe rotation device comprises a sliding brush and a motor. The sliding brush comprises a motion part and a fixed part. An ultrasonic cable is partly connected to the motion part of the sliding brush. A motor output shaft is partly connected to the motion part of the sliding brush and drives the probe assembly to integrally move. The probe gate device is provided with a water supply pipe connector communicated with the interior of the probe gate device. The conduit goes through the probe gate device and is connected to the probe rotation device. Several cables and a water supply pipe are arranged in the conduit. One end of the cable is respectively connected to the fixed part of the sliding brush and the motor. One end of the water supply pipe is connected to the water supply pipe connector. The system realizes regular examination of a steam generator heat-transfer pipe matrix metal material and especially is a water immersion ultrasonic inspection system for detecting a pipe expanding transition region of a heat-transfer pipe and a pipe plate.

Owner:CHINA NUCLEAR POWER OPERATION TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com