Multi-layer diffusion welding phased array ultrasonic detection method

A technology of diffusion welding and ultrasonic testing, which is used in the generation of ultrasonic/sonic/infrasonic waves, the analysis of solids using sonic/ultrasonic/infrasonic waves, and the analysis of materials using sonic/ultrasonic/infrasonic waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] 1. Preparation of multilayer diffusion welding comparison test block:

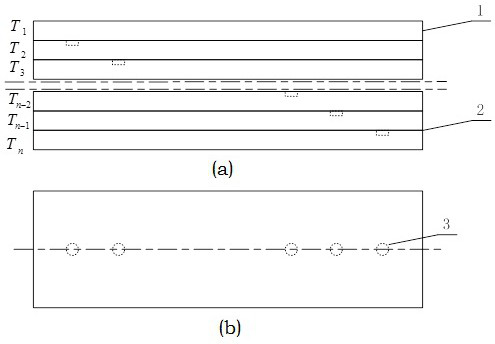

[0030] The structural form of the comparison test block should be the same as that of the workpiece to be inspected, that is, the welding material, number of welding layers, thickness of the welding layer and welding process must be consistent with the workpiece. The comparison test block is as follows: figure 1 shown, where figure 1 (b) for figure 1 In the top view of (a), a flat-bottomed hole 3 with the same diameter is provided on the diffusion-welded joint surface 2 of each plate layer 1. The diameter is selected according to the quality requirements, usually 0.8mm to 3.0mm, and the depth is 0.5mm. The flat-bottomed hole 3 Process the welding surface before welding, and directly form a reference reflector after welding. Except for the prefabricated reference reflector, there should be no other defects in the test block.

[0031] The flat-bottomed holes 3 are located on the centerline of the te...

Embodiment

[0045] The present invention will be described in more detail below in conjunction with specific examples. A multilayer diffusion welding phased array ultrasonic detection method of the present embodiment includes the following steps:

[0046] 1. Preparation of comparative test block:

[0047] The structure of the comparison test block produced in this example is the same as that of the inspected workpiece, the material is 316L, and there are 10 layers (9 diffusion welding interfaces) in total. Before welding, a plate with a diameter of 0.8 mm and a depth of 0.5 mm flat-bottomed holes, the horizontal distance between each flat-bottomed hole and the distance between the ends are 30mm, and the welding process is the same as that of the inspected workpiece.

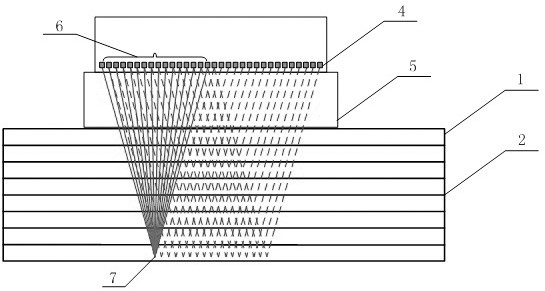

[0048] 2. Basic configuration of detection system

[0049] A 64-channel portable phased array ultrasonic detector is selected as the detection equipment, the maximum number of excitation apertures is 64, and the probe is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com