Method and apparatus of real-time automatic calibration and compensation for beam drift

An automatic calibration and beam technology, which is applied in the field of precision or ultra-precision optical measurement, can solve the problems of large crosstalk and adjust the beam collimation without involving energy drift, and achieve the effect of high adjustment accuracy and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be described in detail below in conjunction with embodiments and drawings, but the present invention is not limited to this.

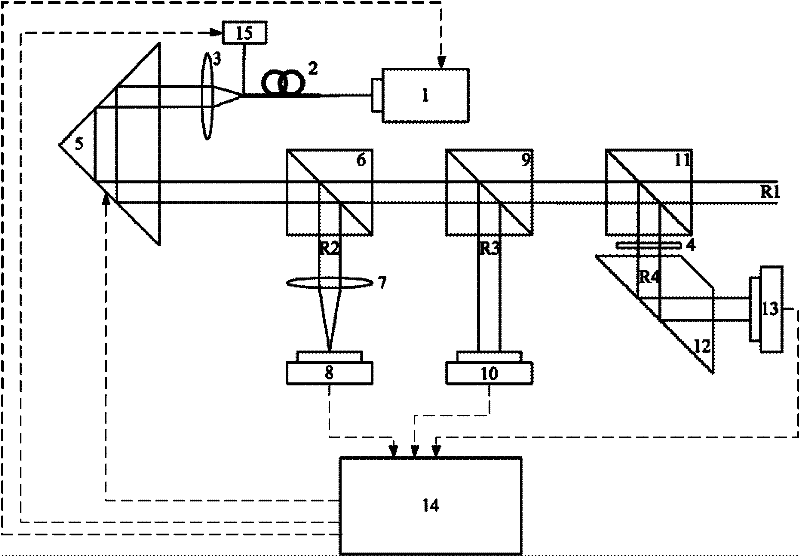

[0084] A real-time automatic correction and compensation device for beam drift, such as figure 1 Shown, including:

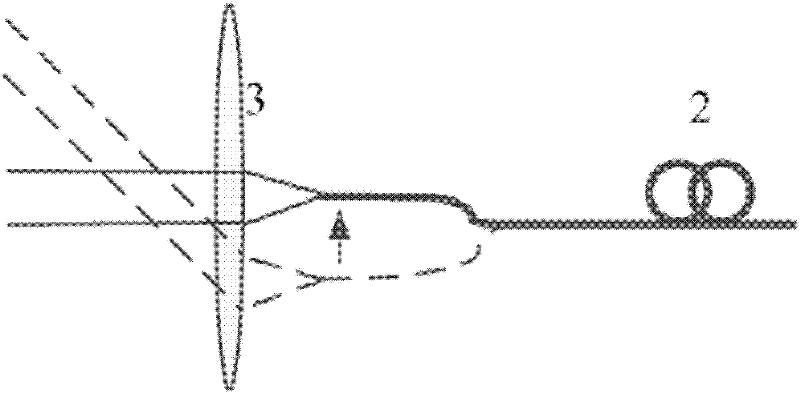

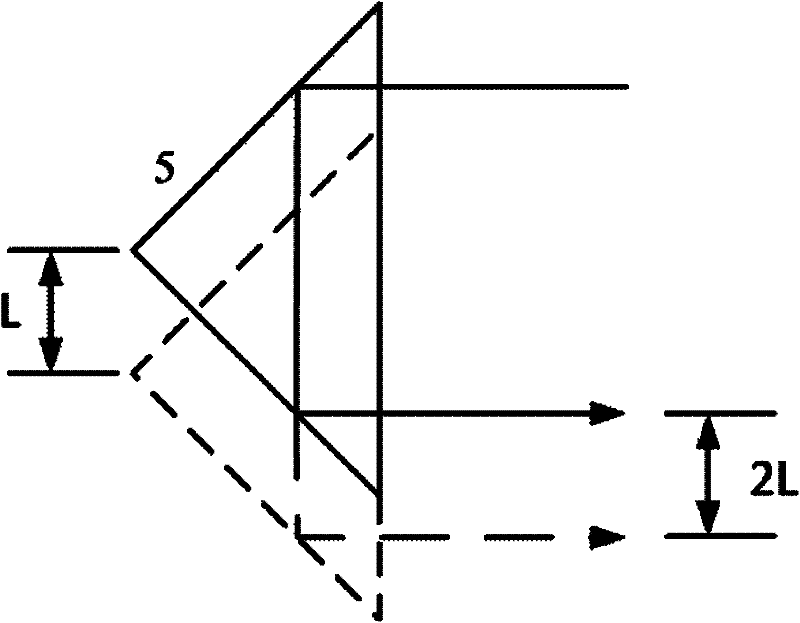

[0085] Laser 1, single-mode fiber 2, collimating lens 3, polarizer 4, corner cube 5, first beam splitter 6, plano-convex lens 7, first photoelectric sensor 8, second beam splitter 9, second photoelectric sensor The device 10, the third beam splitting prism 11, the rhombic prism 12, the third photoelectric sensing device 13, the computer 14 and the nano-translation stage 15, wherein the exit end face of the single-mode fiber 2 is located near the object focus of the collimating lens 3. The translation stage 15 is firmly connected to the exit end face of the single-mode optical fiber 2, and the relative positional relationship between the exit end face of the single-mode optical fiber 2 and the collimating lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com