Thermoplastic polyurethane elastomer foam bead and preparation method thereof

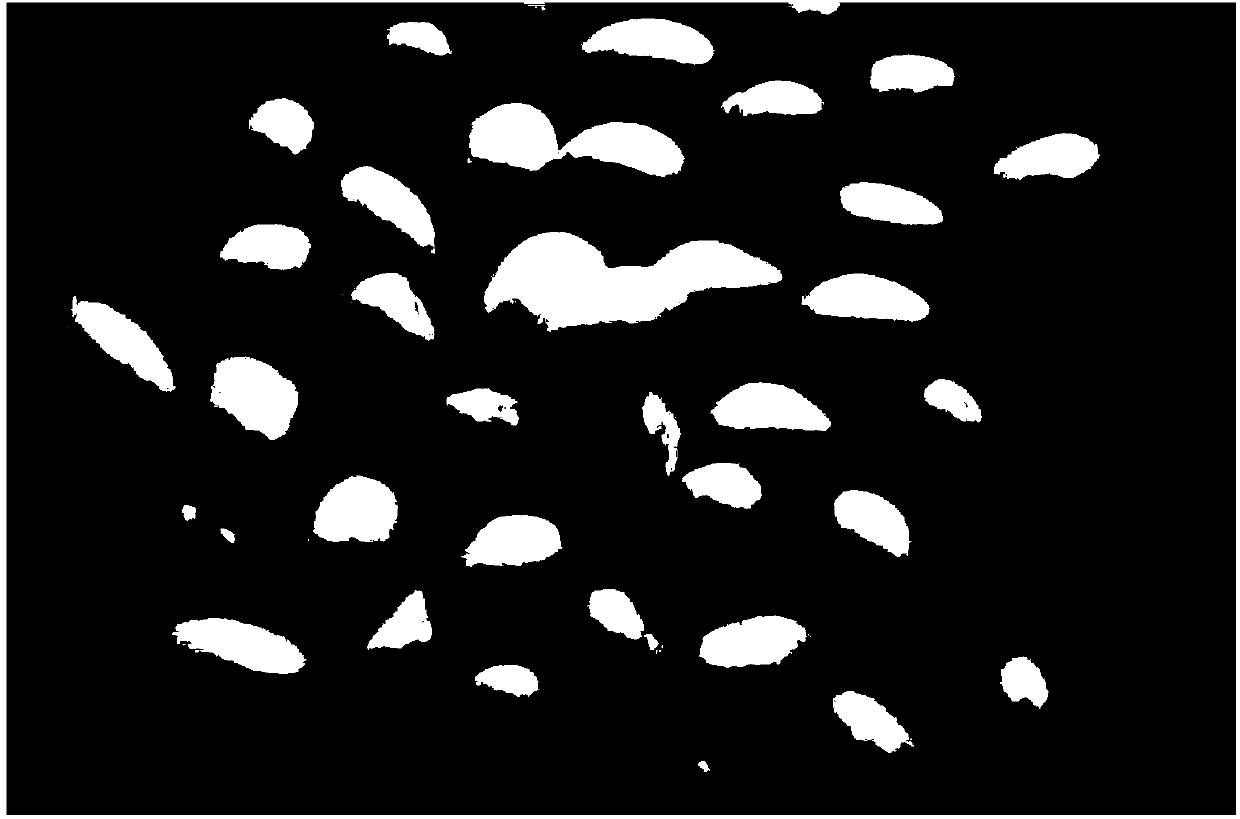

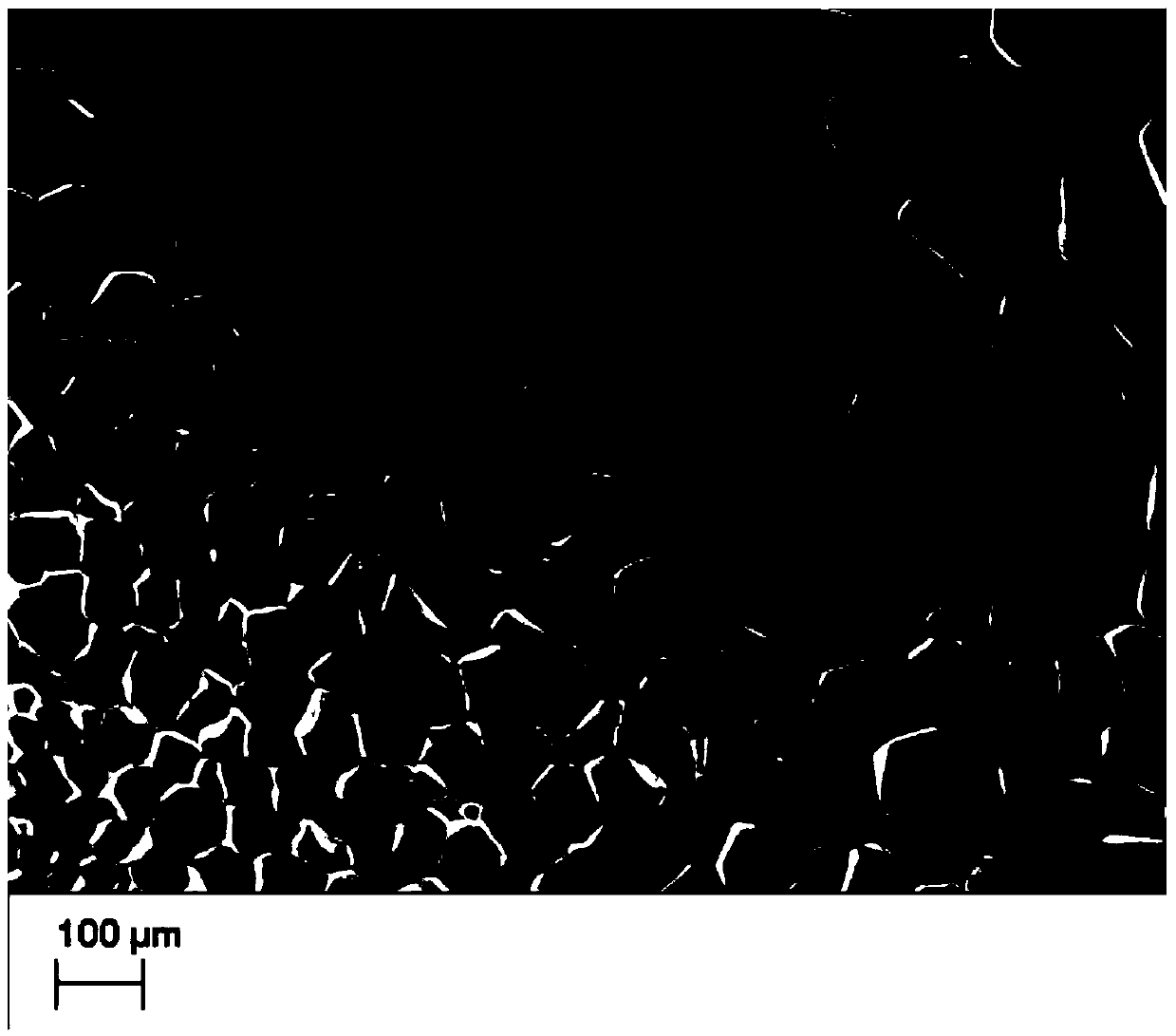

A technology of thermoplastic polyurethane and foamed beads, which is applied in the field of thermoplastic polyurethane elastomers, can solve the problems of insufficient density of foamed beads cells, high raw material cost and production cost, and insufficient strength, so as to avoid sags that cannot be recovered, The effect of high closed cell rate and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

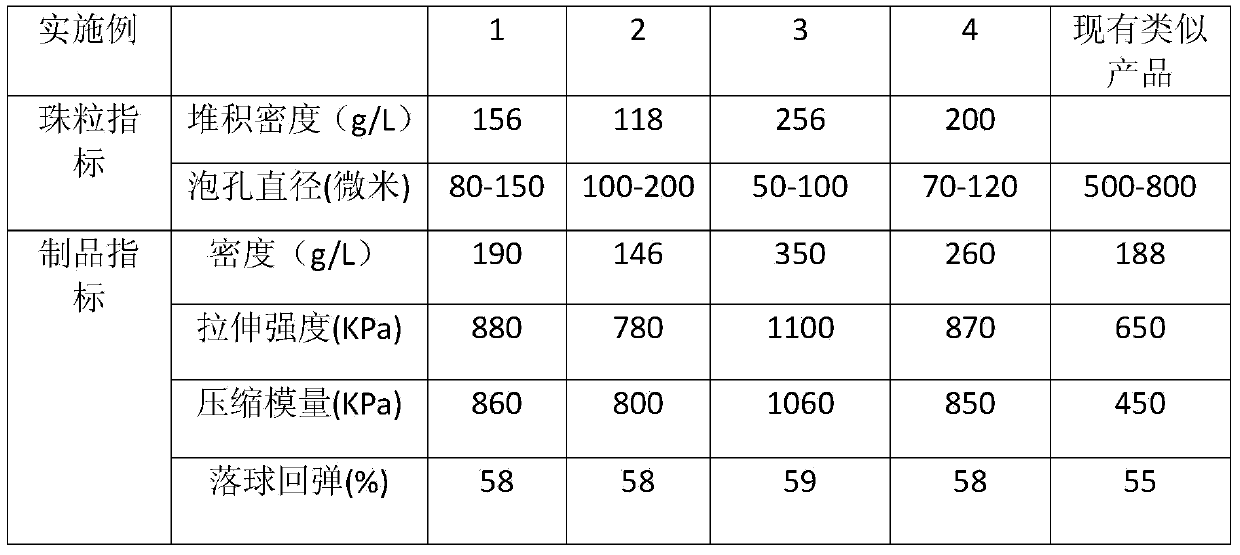

Examples

Embodiment 1

[0038] A preparation method of thermoplastic polyurethane elastomer foam beads, comprising the steps of:

[0039] 1) Shore hardness is 85A thermoplastic polyurethane elastomer ( TPU 1085A) 100Kg, water 100Kg into the reactor (FCH‐1500 / 20.0, magnetic drive reactor), start stirring;

[0040] 2) Add liquid carbon dioxide to the reactor, control the pressure in the reactor to 7.5 MPa, and the temperature to 50°C, so that the carbon dioxide in the foaming tank is in a supercritical state;

[0041] 3) Heating the reaction kettle, raising the temperature inside the kettle to 127℃ at a heating rate of 1.5℃ per minute, and keeping the temperature for 5 minutes;

[0042] 4) Through the valve connecting the reaction kettle and the pressure tank, the materials in the reaction kettle are put into the pressure tank under the action of pressure, kept at 0.5MPa, and naturally cooled to 60°C, and the thermoplastic polyurethane elastomer particles are foamed once, passed through The steam tr...

Embodiment 2

[0050] A preparation method of thermoplastic polyurethane elastomer foam beads, comprising the steps of:

[0051] 1) Shore hardness is 80A thermoplastic polyurethane elastomer ( Add 200 grams of TPU 1180A) and 400 grams of water into the reaction kettle (FCH-2 / 20.0 magnetic drive high-pressure test kettle), and start stirring;

[0052] 2) Add liquid carbon dioxide to the reactor, control the pressure in the reactor to 8.5 MPa, and the temperature to be as high as 65°C, so that the carbon dioxide in the foaming tank is in a supercritical state;

[0053] 3) Heating the reactor, raising the temperature inside the reactor to 139°C at a rate of 1°C per minute, and keeping the temperature for 6 minutes;

[0054] 4) Through the valve connecting the reaction kettle and the pressure tank, the materials in the reaction kettle are put into the pressure tank under pressure, kept at 0.5MPa, and cooled to 70°C, and the thermoplastic polyurethane elastomer particles are foamed once, and pa...

Embodiment 3

[0061] A preparation method of thermoplastic polyurethane elastomer foam beads, comprising the steps of:

[0062] 1) Shore hardness is 80A thermoplastic polyurethane elastomer ( TPU 85085A) 100g, water 400g into the reaction kettle (FCH‐2 / 20.0 magnetic drive high pressure test kettle);

[0063] 2) Add liquid carbon dioxide to the reactor, control the pressure in the reactor to 9.5 MPa, and the temperature to 83°C, so that the carbon dioxide in the foaming tank is in a supercritical state;

[0064] 3) Heating the reactor, raising the temperature inside the reactor to 95°C at a rate of 0.5°C per minute, and keeping it warm for 10 minutes;

[0065] 4) Through the valve connecting the reaction kettle and the pressure tank, the materials in the reaction kettle are put into the pressure tank under pressure, maintained at 0.3MPa, and cooled to 50°C to foam the thermoplastic polyurethane elastomer particles once, and pass The steam trap drains water; the total volume of the reactor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com