Patents

Literature

67results about How to "Dense cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

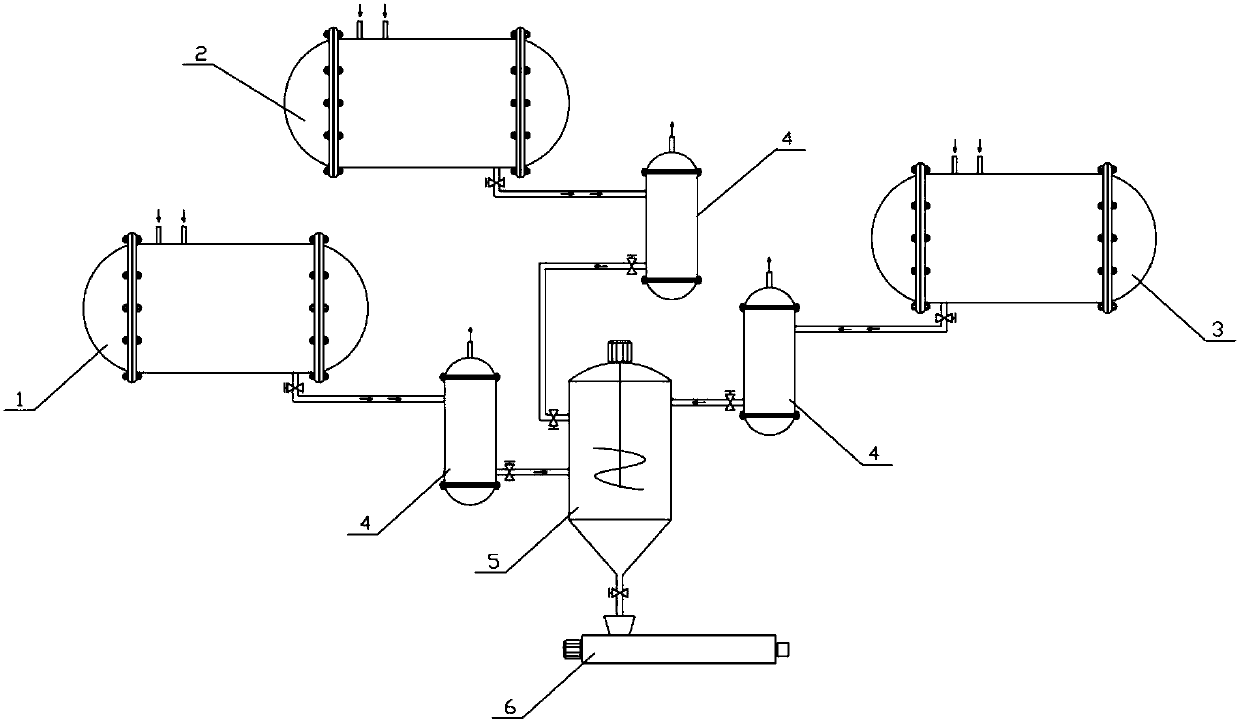

Thermoplastic polyurethane elastomer foam bead and preparation method thereof

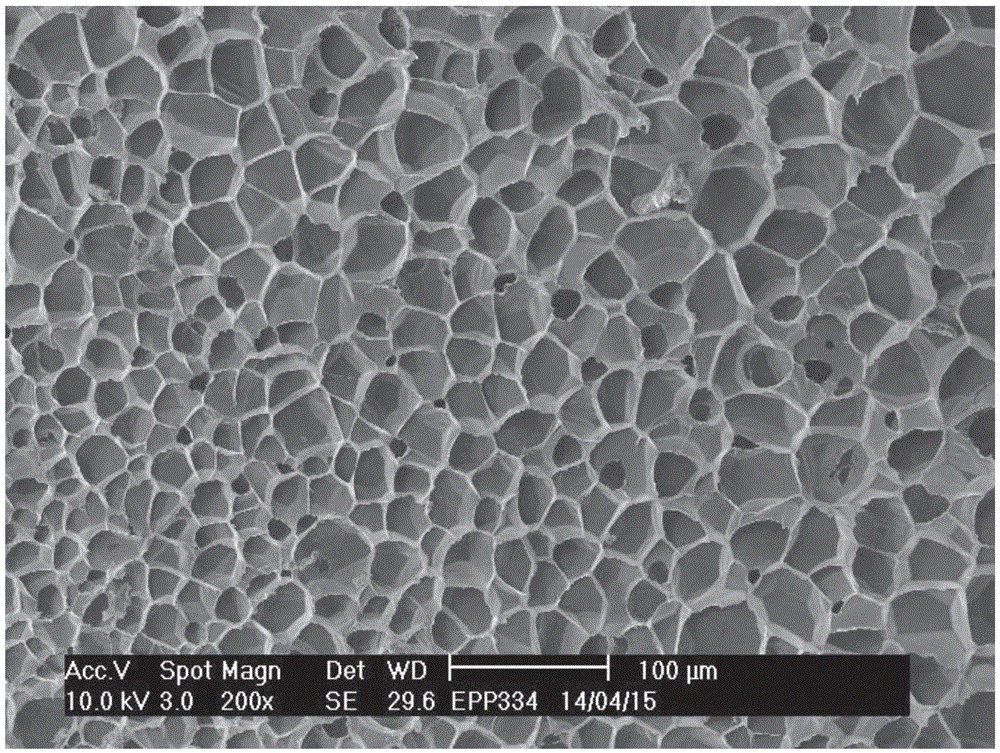

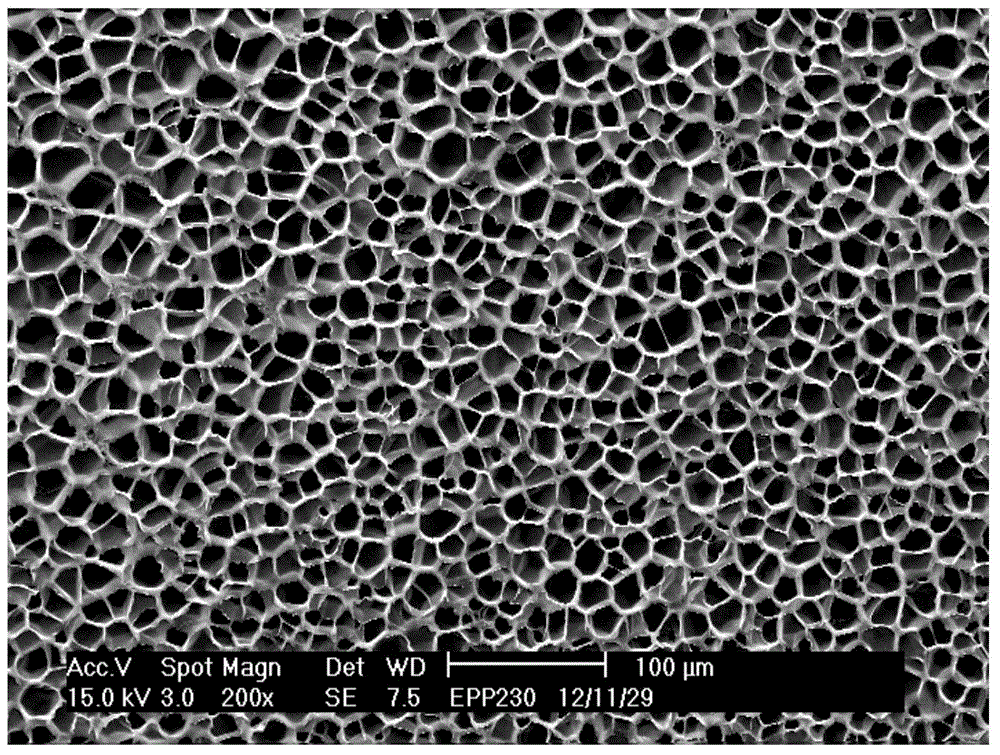

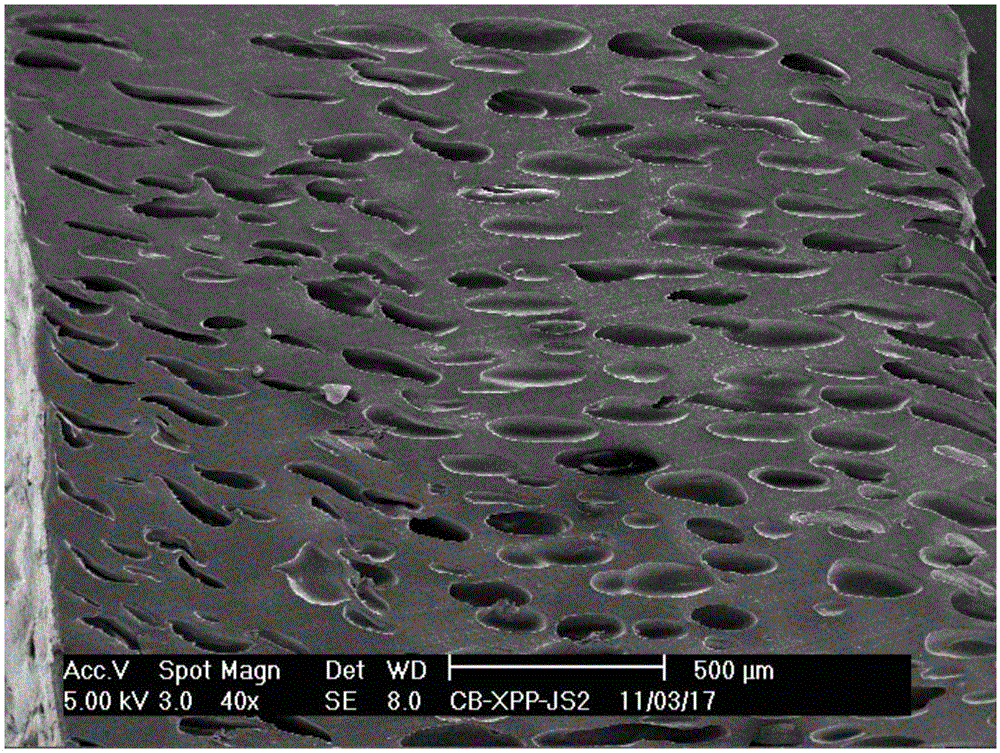

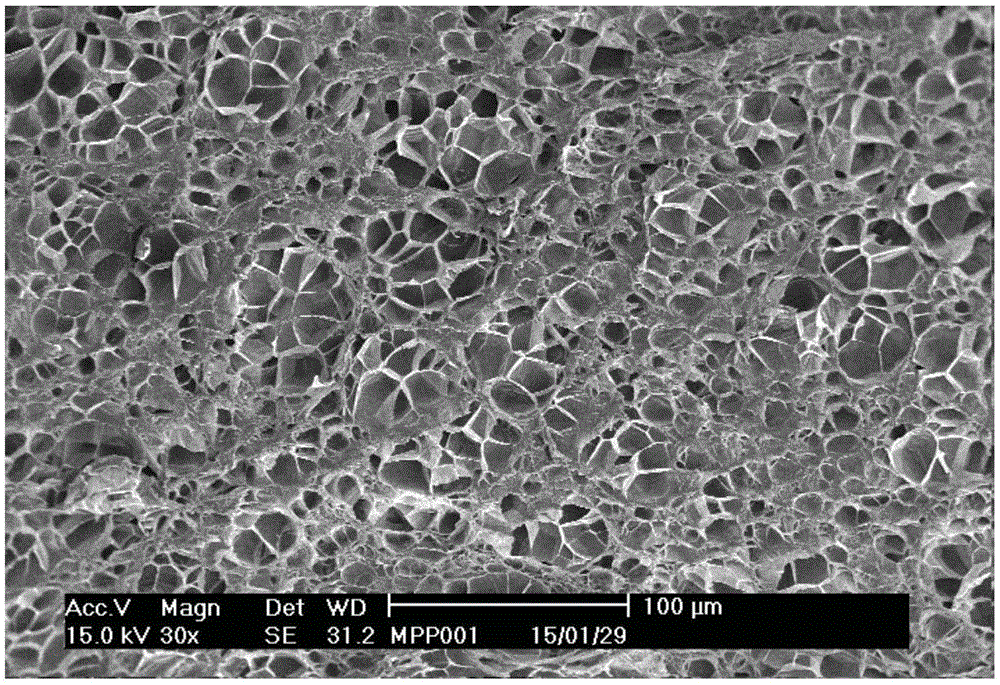

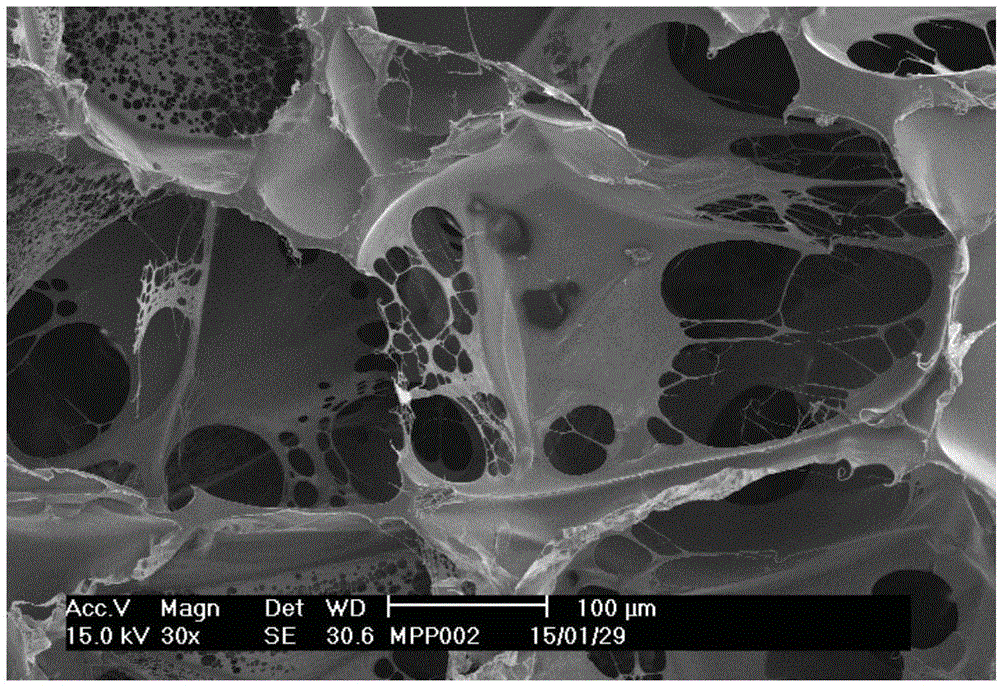

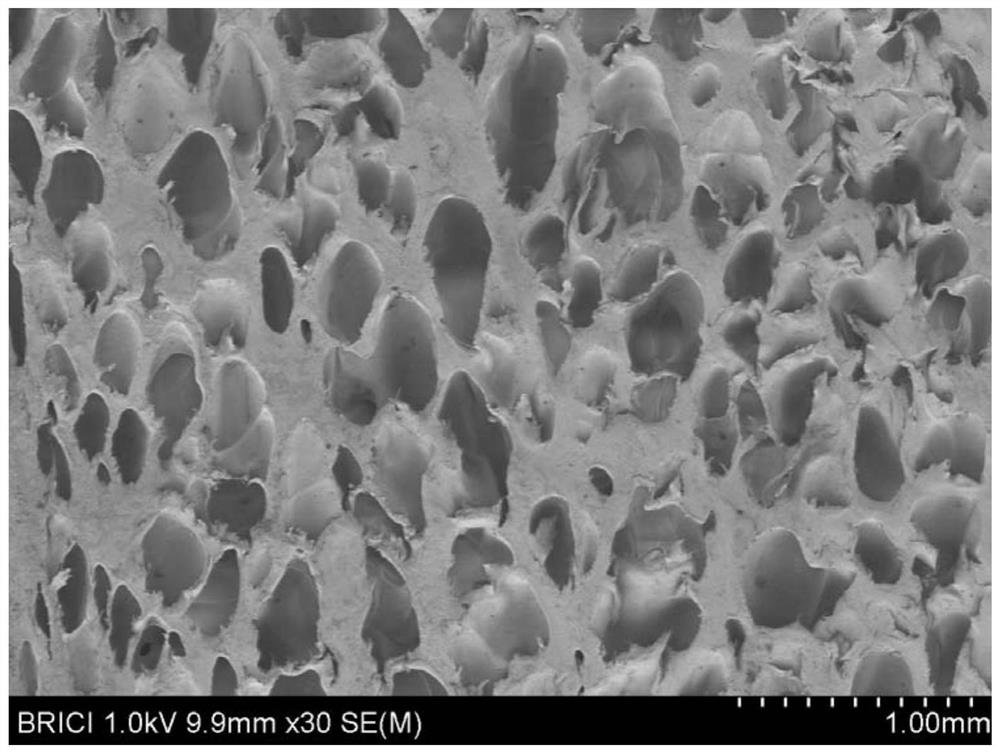

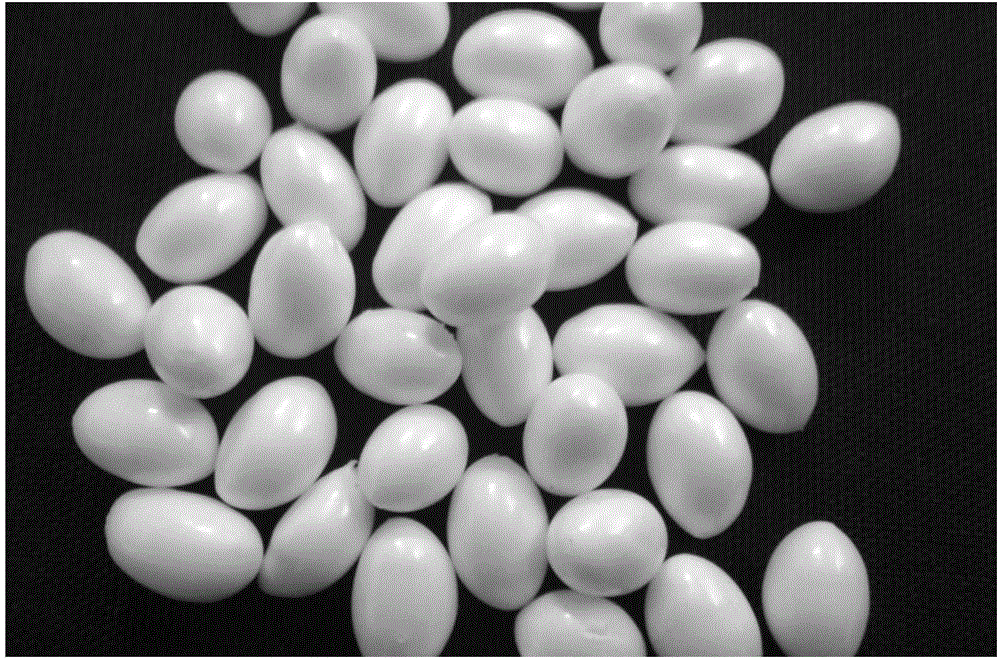

The invention discloses a thermoplastic polyurethane elastomer foam bead and a preparation method thereof. The method comprises the following steps: firstly, adding thermoplastic polyurethane particles and water to a reaction kettle according to the mass ratio of 1 to (0.8-4); adding liquid carbon dioxide to the reaction kettle, and controlling the intensity of pressure and the temperature in the reaction kettle, so that the carbon dioxide in the reaction kettle is in a super-critical state; raising the temperature inside the reaction kettle to 90-140 DEG C; carrying out heat preservation; putting the materials in the kettle into a pressure tank, maintaining pressure, and cooling to below 70 DEG C; foaming the thermoplastic polyurethane elastomer particles once, and controlling the volume ratio of the reaction pressure to the pressure tank to be 1 to (15-30); putting the disposable foam particles into a storage tank, and carrying out secondary normal pressure foaming to obtain thermoplastic polyurethane elastomer foam beads; and removing the surface moisture of the foam beads, and curing the foam beads at normal pressure and normal temperature for over 48 hours, so as to obtain the product. The product disclosed by the invention has the characteristics of even and compact cells, small size, high percentage of closed area, high molding product strength, good rebound resilience and the like.

Owner:新辉新材料(常州)有限公司

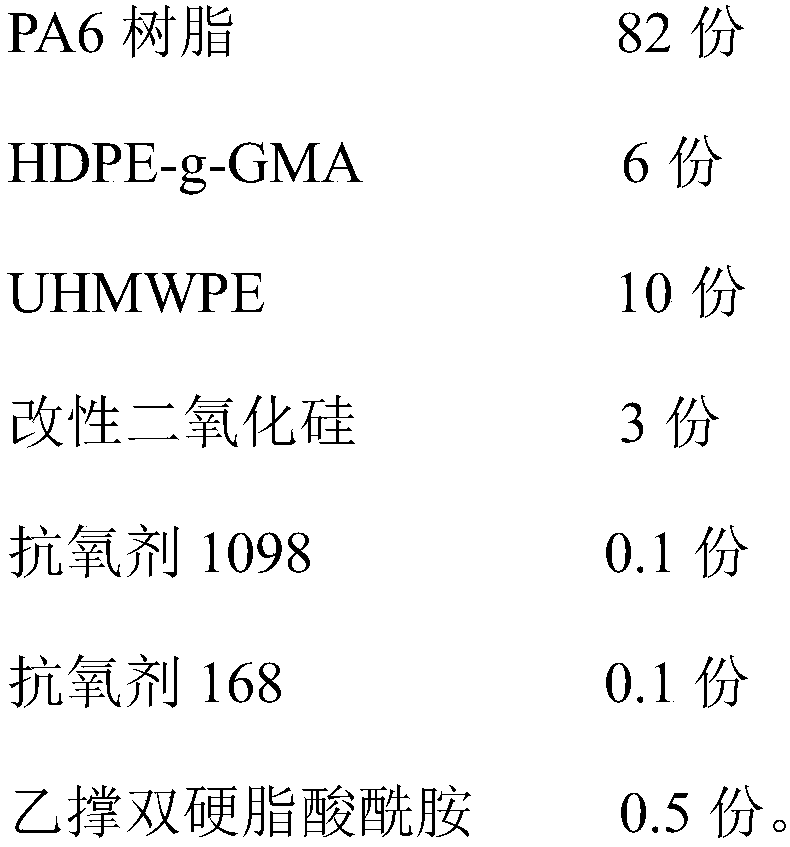

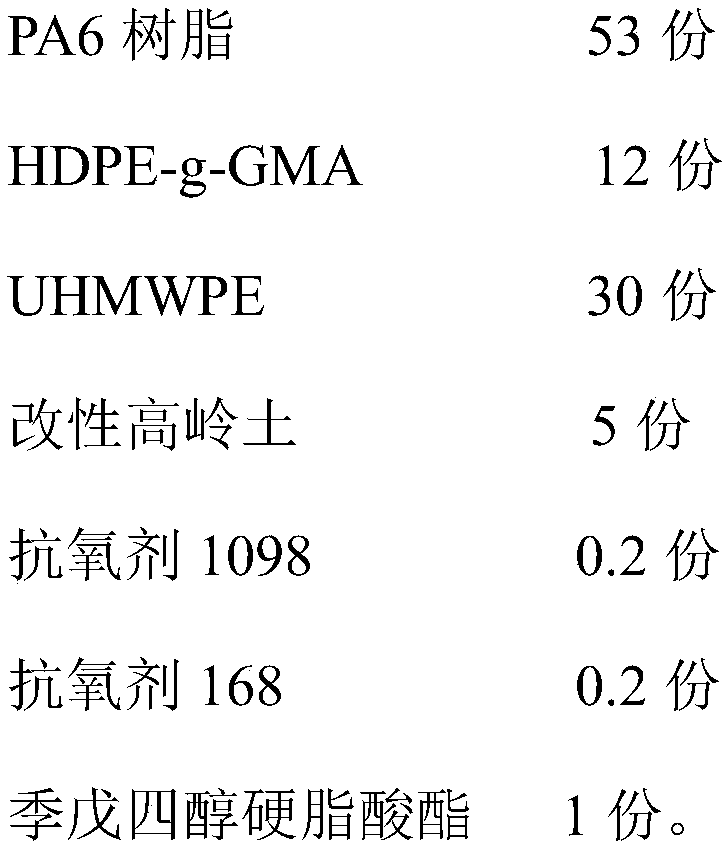

Light-weight, high-toughness and low-water-absorption-ratio ultra high molecular weight polyethylene/nylon 6 micro-foaming composite material and preparation method thereof

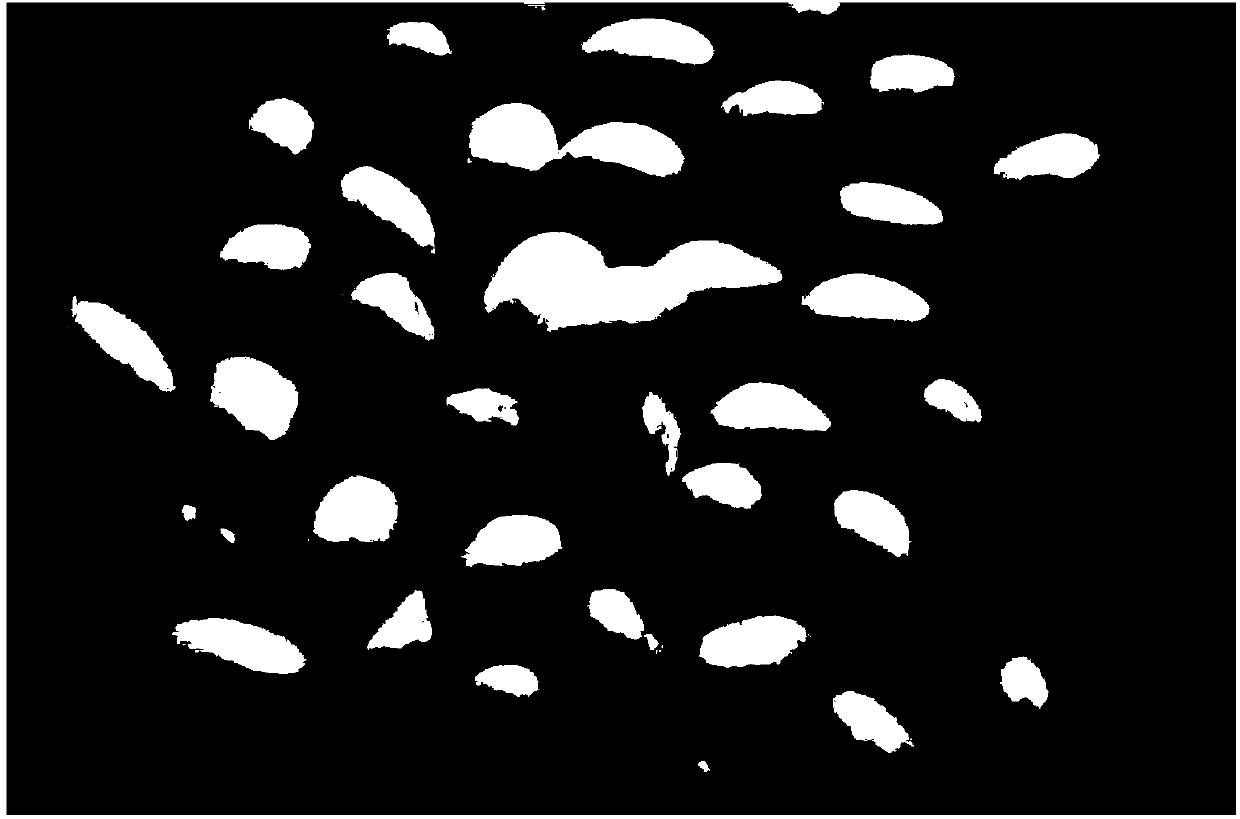

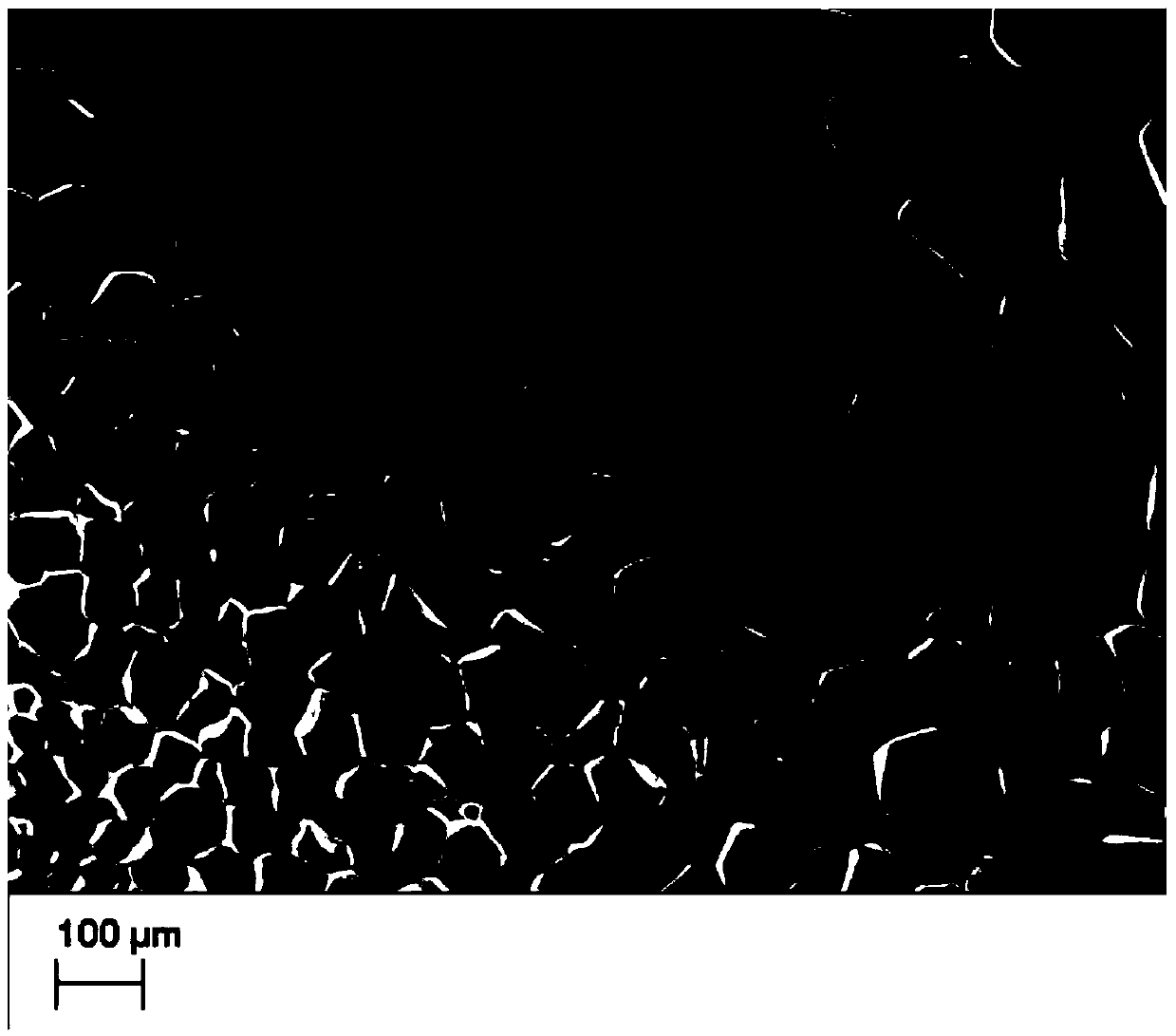

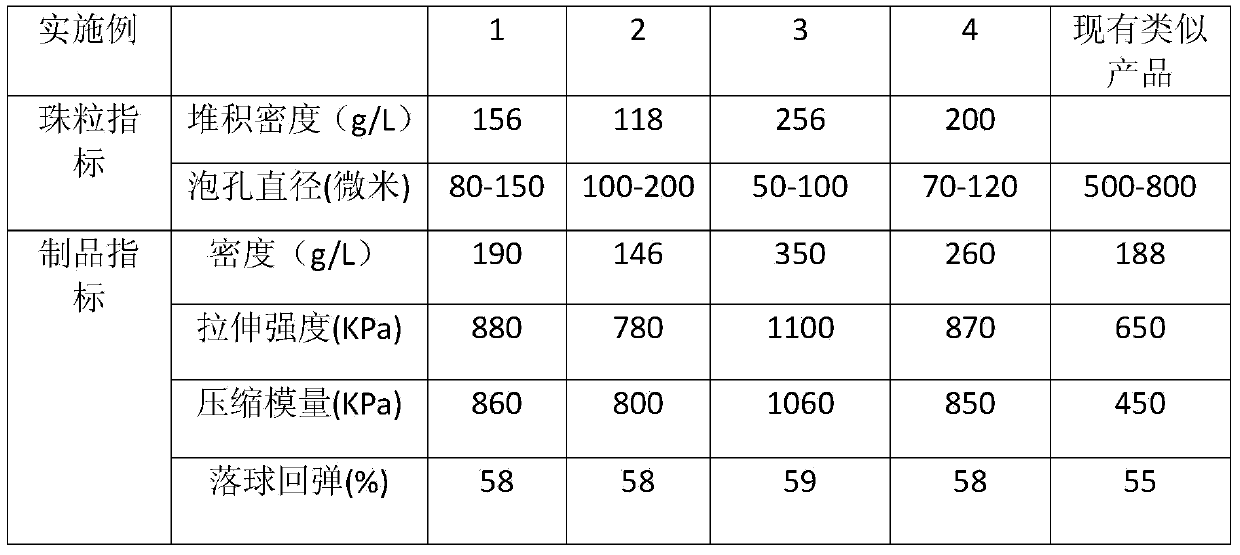

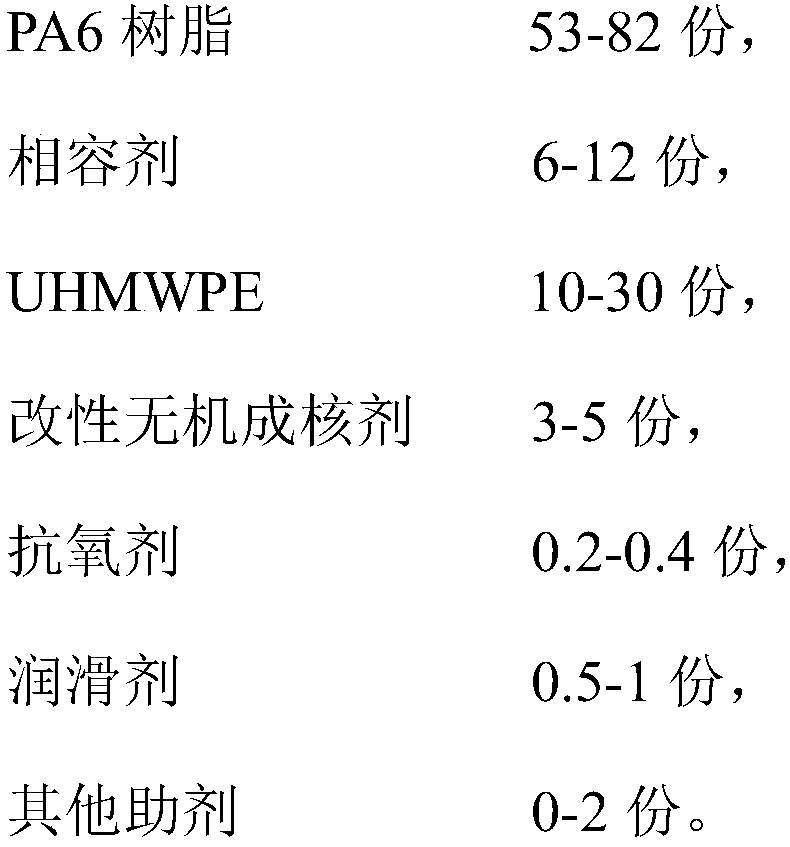

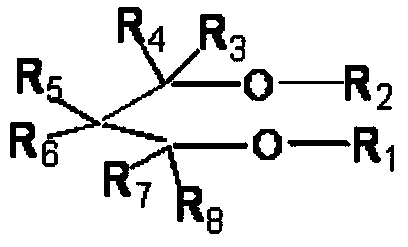

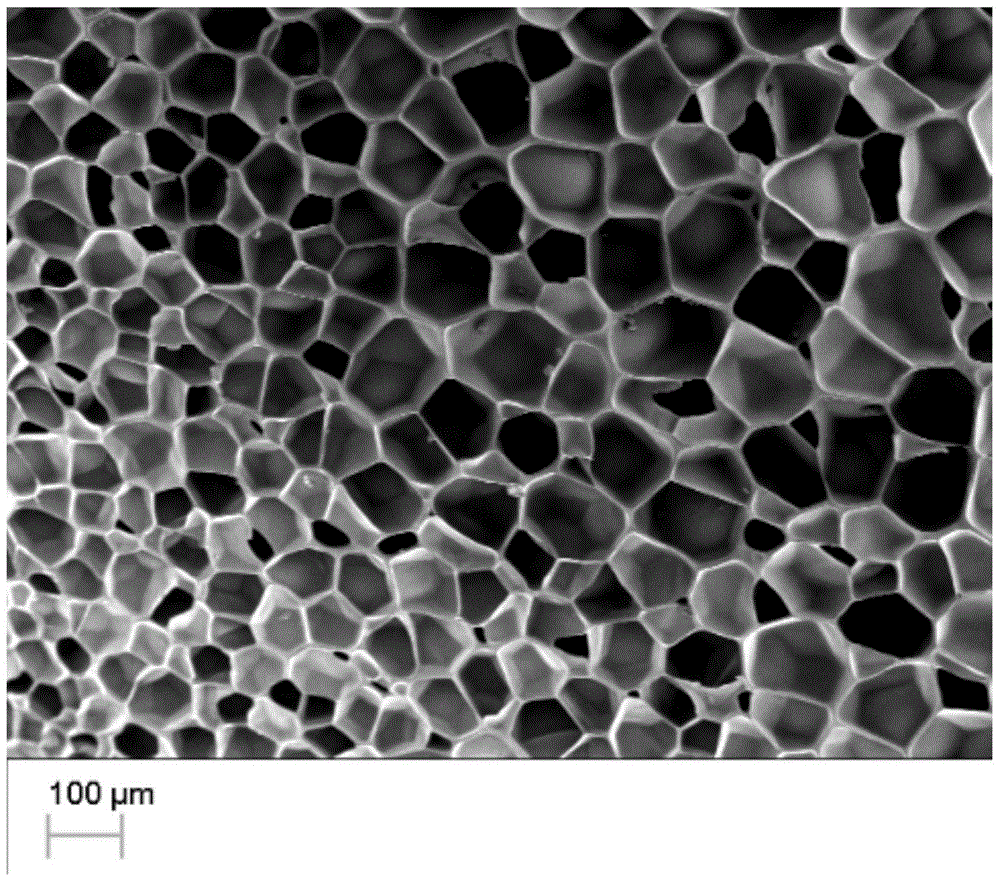

The invention discloses a light-weight, high-toughness and low-water-absorption-ratio ultra high molecular weight polyethylene (UHMWPE) / nylon 6 micro-foaming composite material and a preparation method thereof. The composite material is prepared from 97 to 99 weight percent of a polyamide composite material and 1 to 3 weight percent of a chemical foaming agent, wherein the polyamide composite material is prepared from the following components in parts by weight: 53 to 82 parts of PA6 (Polyamide 6), 6 to 12 parts of a compatilizer, 10 to 30 parts of UHMWPE, 3 to 5 parts of a modified inorganicnucleating agent, 0.2 to 0.4 part of an antioxidant, 0.5 to 1 part of a lubricant and 0 to 2 parts of other auxiliary agents. According to the light-weight, high-toughness and low-water-absorption-ratio ultra high molecular weight polyethylene / nylon 6 micro-foaming composite material, HDPE (High-density Polyethylene)-g-GMA (Glycidyl Methacrylate) is used as an interface bulking agent so that the interface binding force between the UHMWPE and the PA6 is enhanced, the impact strength of the PA6 is improved and the water absorption ratio of the PA6 is reduced; meanwhile, three-phase chain sections are mutually entwisted so that the melt strength of the PA6 is improved; the modified inorganic nucleating agent is subjected to chemical grafting modification through KH550 and GMA and the heterogeneous nucleation effect is remarkable; a dense bubble nucleation point is formed and the micro-foaming material with dense, fine and smooth bubble pores is obtained; the material has the characteristics of light weight, high impact strength, low water absorption ratio, high wear resistance and the like; foaming is realized through direct injection molding and a technology is simple; the material is widely applied to a lightweight technology of automobiles, household appliances, electronics and electrical appliances and the like.

Owner:ORINKO NEW MATERIAL CO LTD

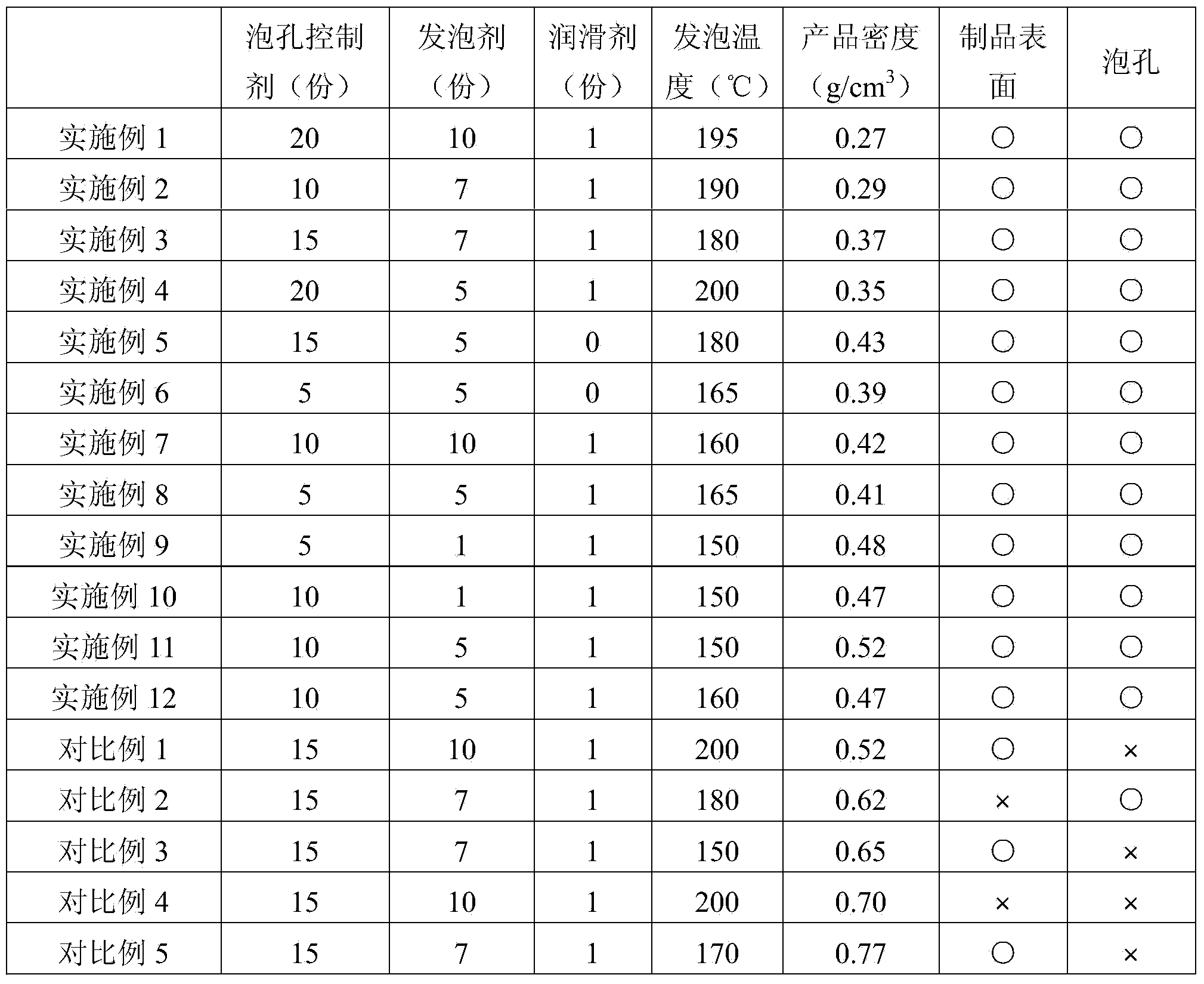

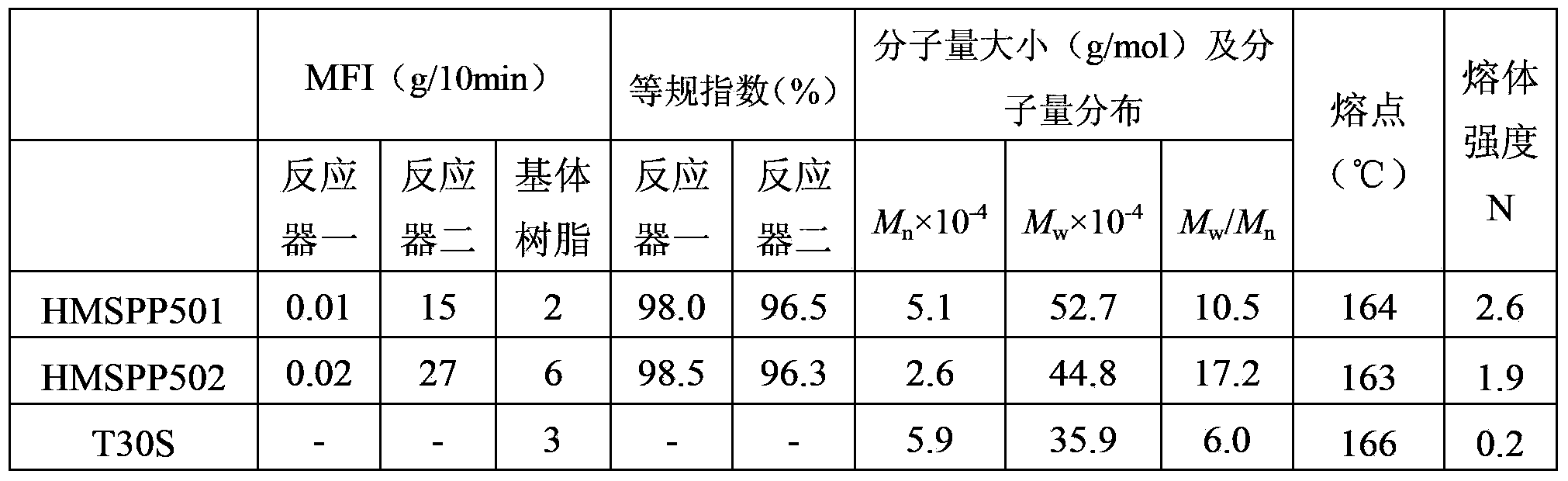

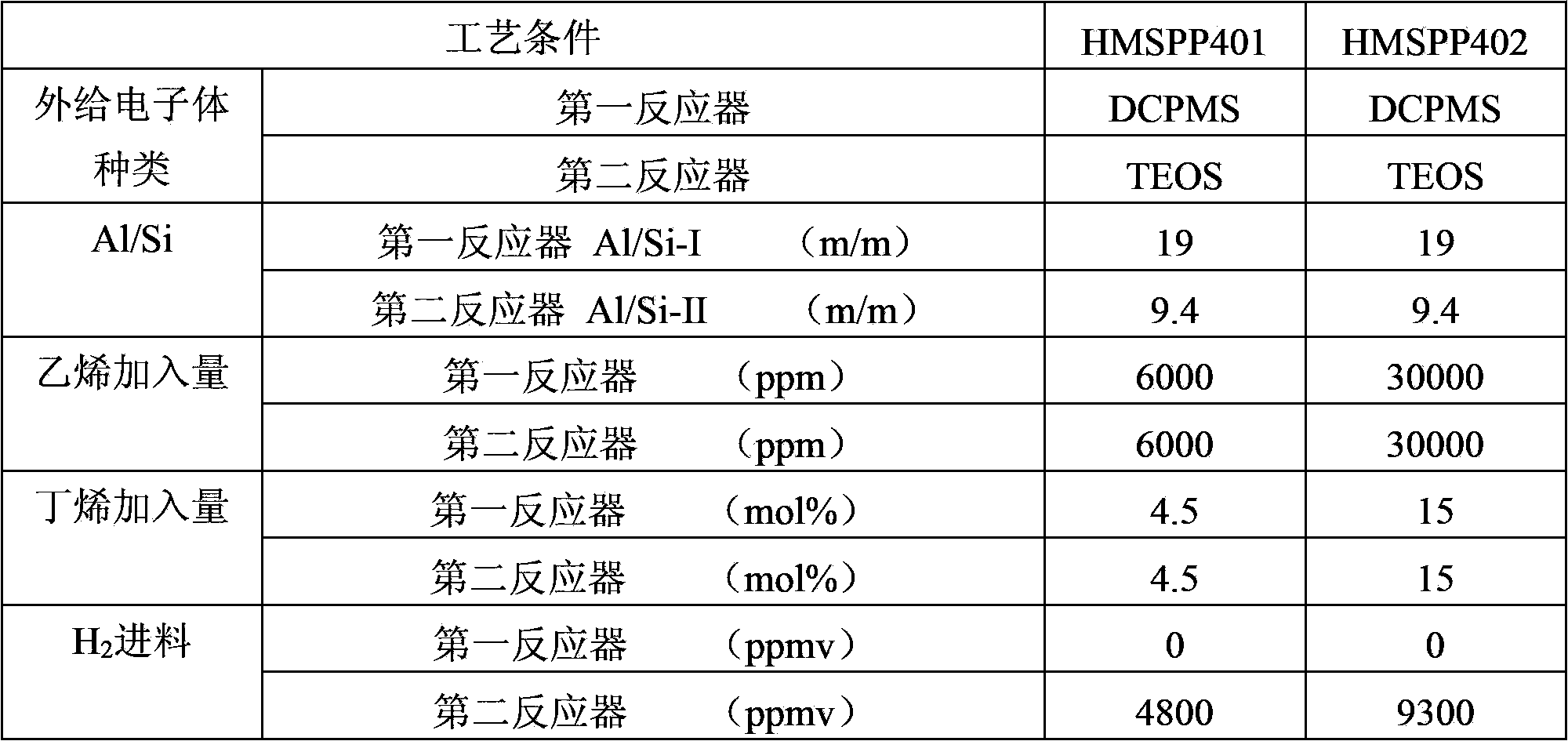

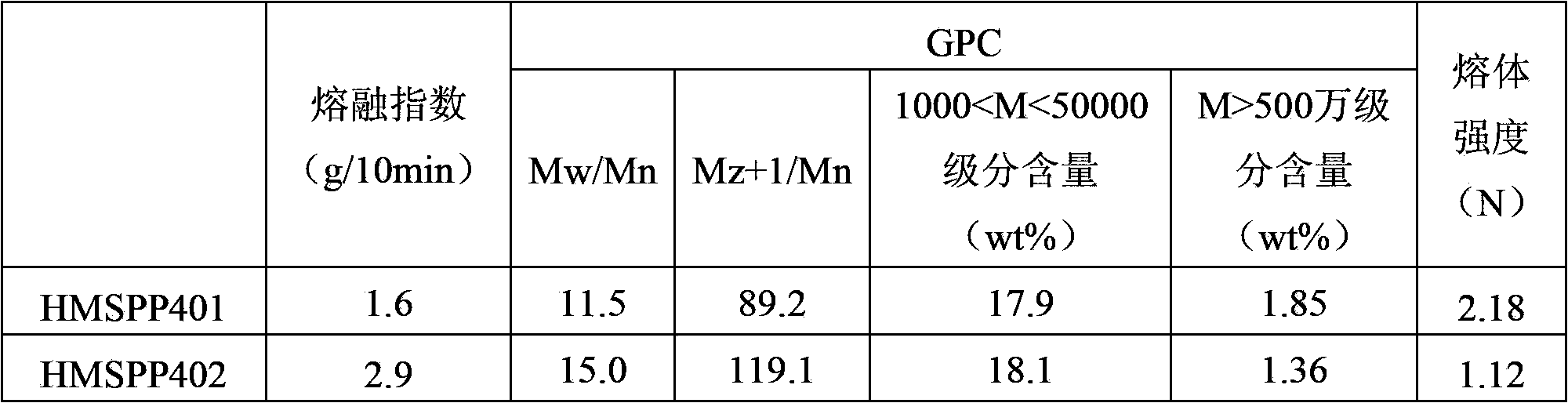

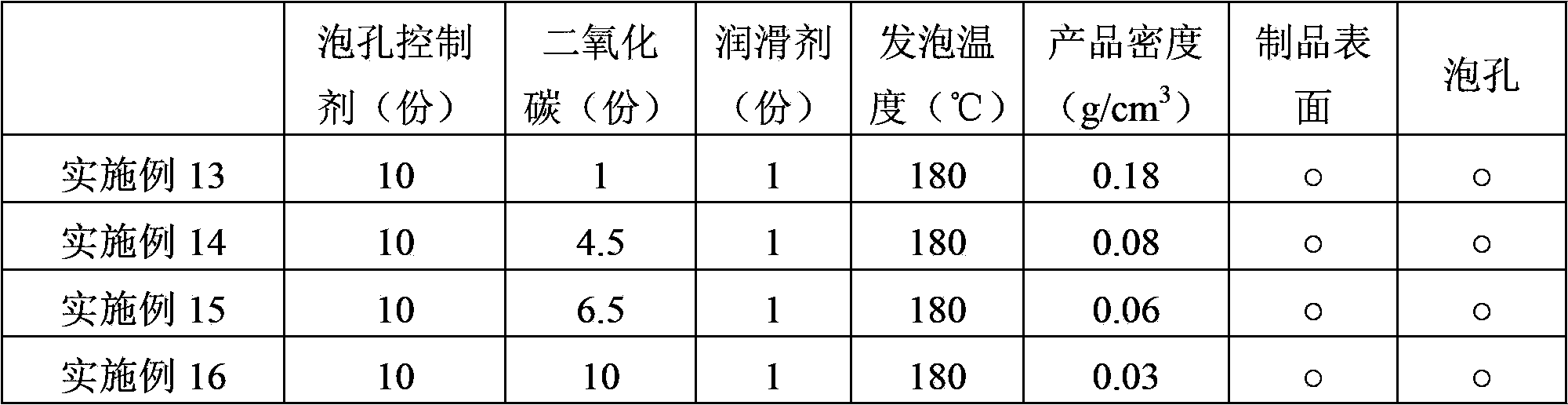

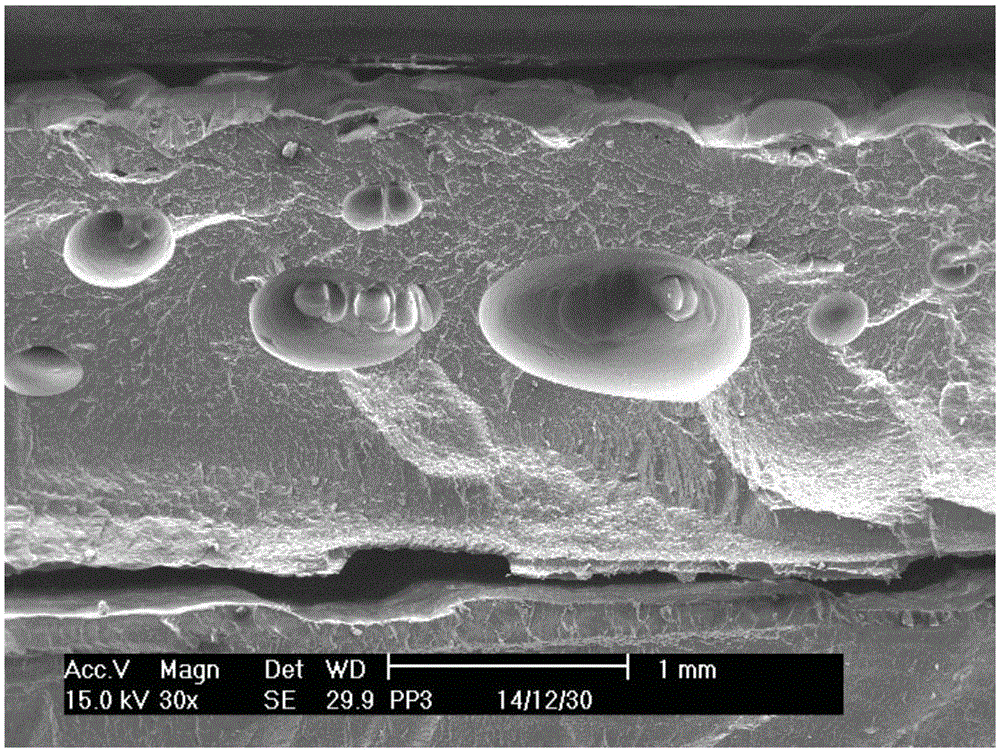

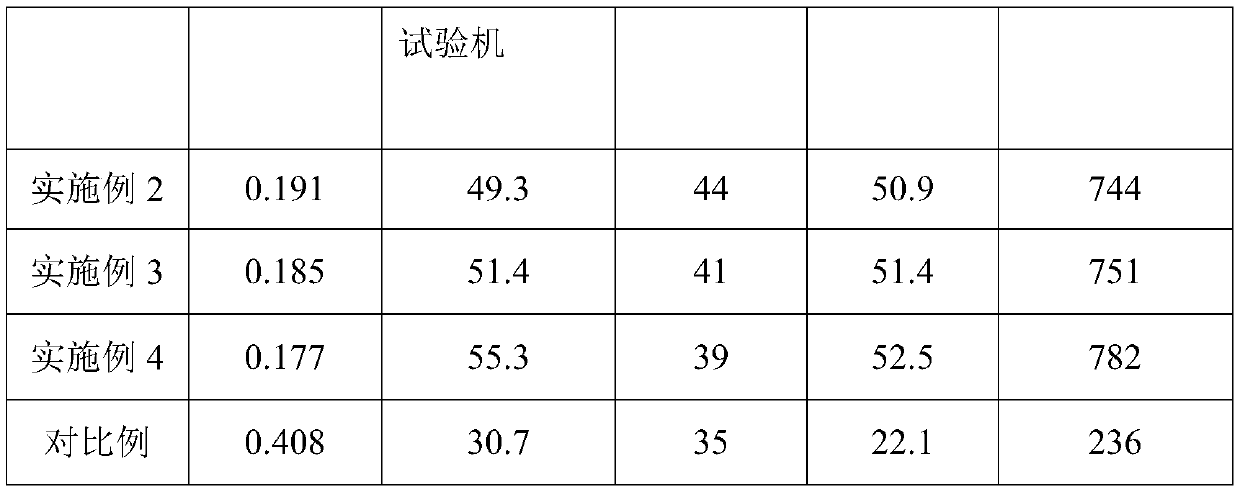

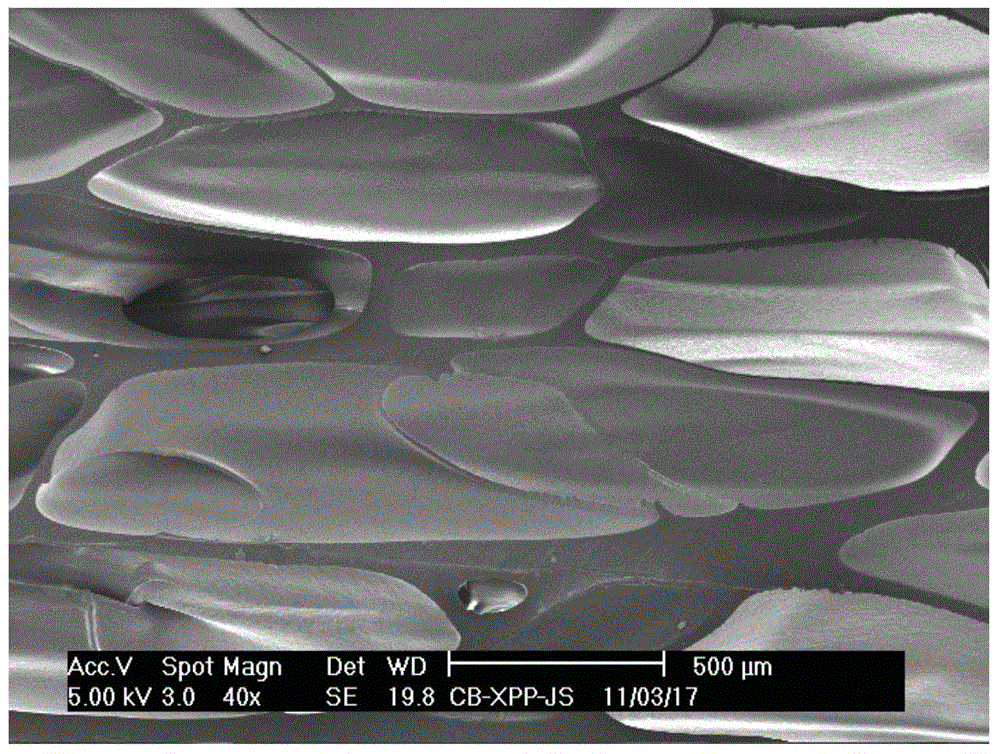

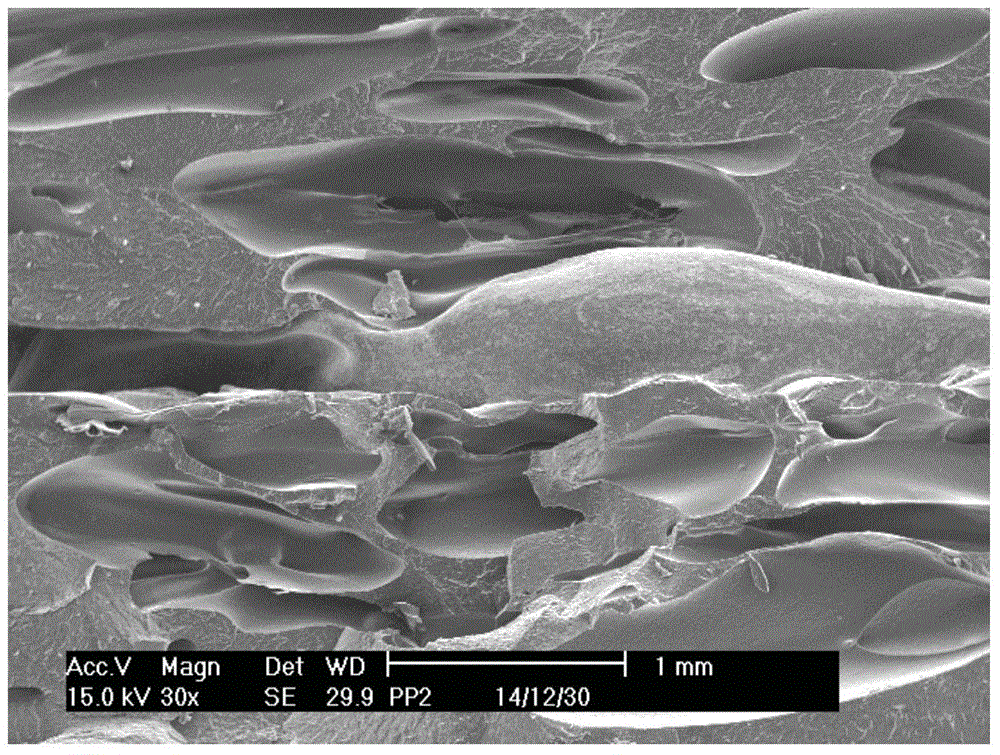

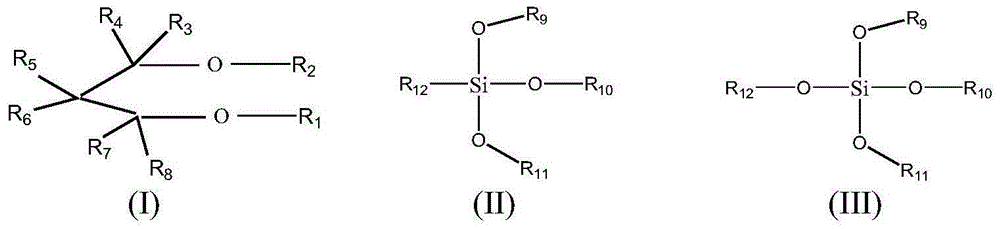

Preparation method of polypropylene foaming plate or sheet

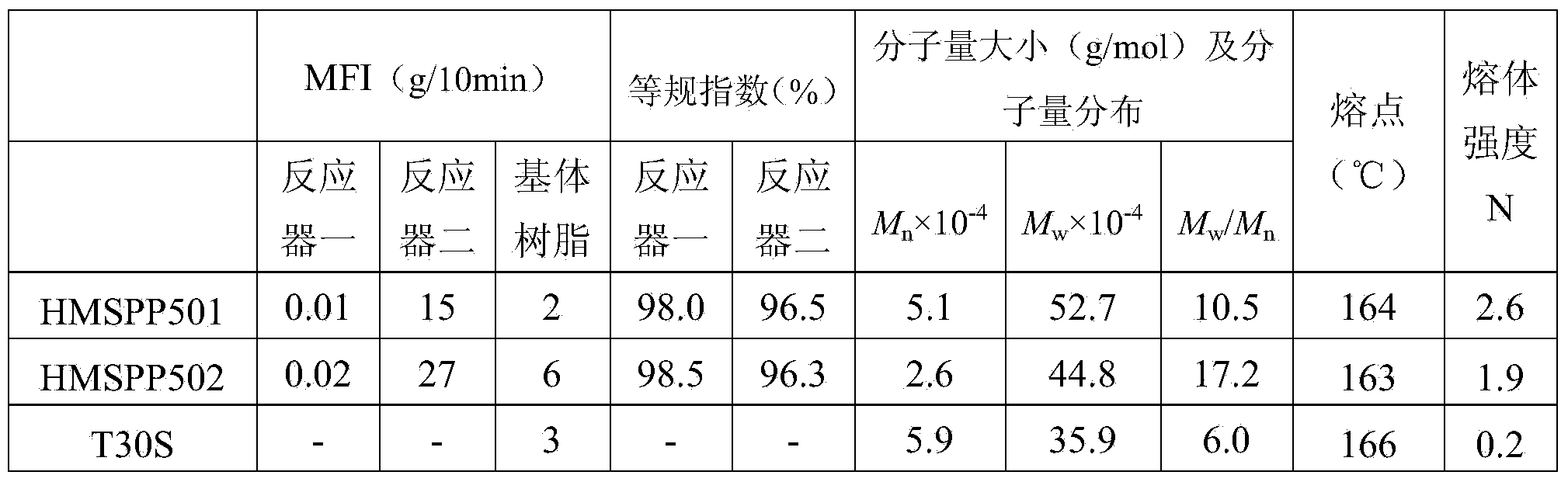

The present invention provides a preparation method of a polypropylene foaming plate or sheet. According to the preparation method, high melt strength homopolymerization polypropylene is adopted as a matrix resin and a foaming agent is adopted to foam to prepare the polypropylene foaming plate or sheet, wherein the homopolymerization polypropylene preparation method comprises: in two or more than two reactors having the series connection operation, carrying out a two-stage or multi-stage propylene homopolymerization reaction, wherein the external electron donors used in the two-stage reaction are respectively a silane compound and a diether compound. According to the present invention, the high melt strength polypropylene having the wide molecular weight distribution is adopted as the raw material to achieve the stabilization of the polypropylene raw material, such that the foaming window is effectively expanded, the process is easy to adjust, the polypropylene foaming plate or sheet having the smooth self-skinning, the uniform foam hole diameter, the closed hole rigid structure, the density of 0.2-0.9 g / cm<3> and the thickness of 0.1-400 mm can be prepared, and the polypropylene foaming plate or sheet can be widely used in the fields of heat-insulation tableware, automotive interiors, building templates, camping supplies, decoration material sandwiches, product vibration reduction packaging and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

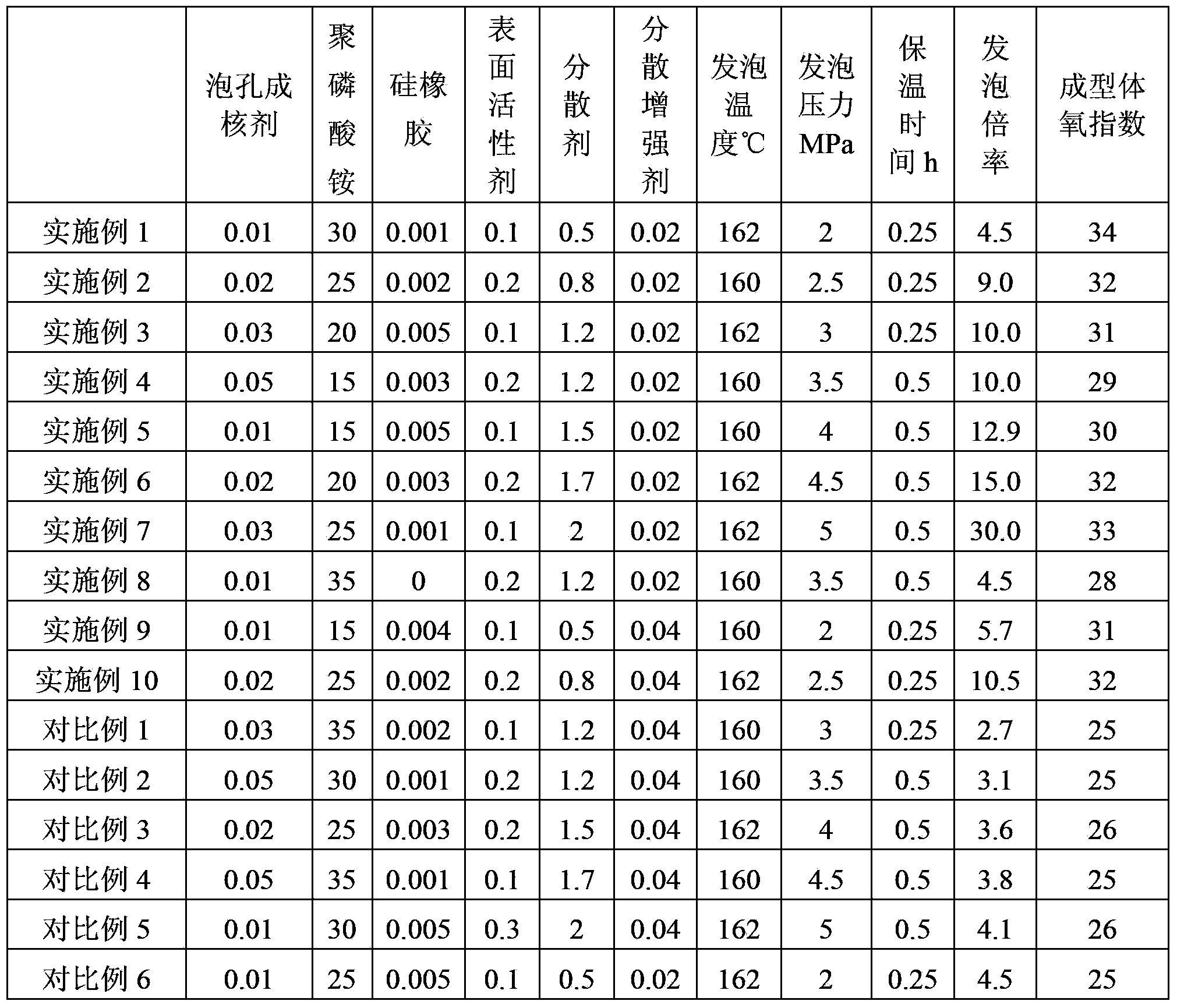

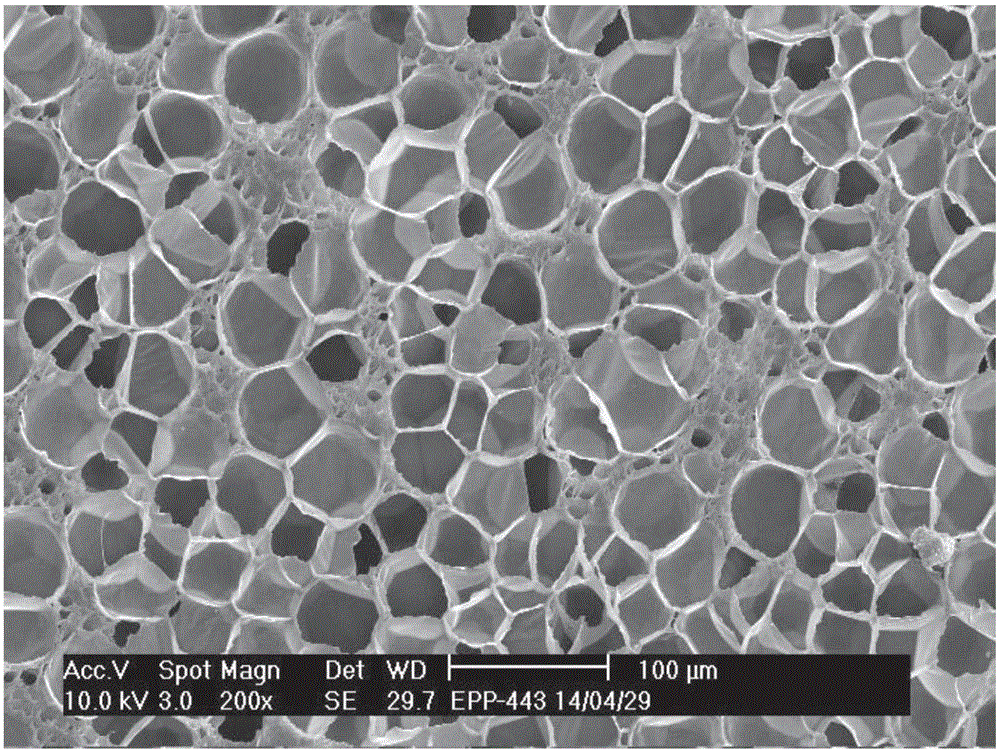

Preparation method of polypropylene foaming beads

The invention provides a preparation method of polypropylene foaming beads. Homo-polypropylene as base resin and ammonium polyphosphate as a fire retardant undergo foaming in the presence of a foaming agent so that the polypropylene foaming beads are prepared. The preparation method comprises that two or more stages of propylene homopolymerization reactions occur in two or more reactors connected in series, wherein external electron donors used in the two or more stages of reactions respectively comprise silane and diether compounds. The preparation method utilizes the wide-molecular weight distribution high-melt strength polypropylene as a raw material, realizes polypropylene raw material stabilization, effectively enlarges a foaming window, has easily adjustable processes and a low cost, can prepare the polypropylene foaming beads having uniform foam pore diameters, compact foam pores, uniform pore size distribution and a closed pore structure and can be widely used in occasions of automobile parts, electronic packaging and building decoration having high flame-retardation requirements on foamed plastic products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of epoxide resin based foam material

The invention discloses a method for preparing an epoxide resin foaming material. The method comprises the following steps that: 1. according to the mass ratio, epoxide resins, foaming agents, foam stabilizing agents and addition agents are respectively picked up and evenly mixed with high-speed stirring; 2. the mixture obtained is put in an oven with a temperature of between 40 and 80 DEG C and pre-heated for 0.5 to 1 hour, and the mixture is taken out and cooled down to a temperature of between 25 and 35 DEG C; 3. The mixture is added with curing agents and evenly mixed; 4. the mixture is put in a stainless steel mold and heated at the temperature of between 40 to 80 DEG C for 0.5 to 2 hours, and the mixture is cooled down to the room temperature and taken out, and finally the finished products are obtained. By controlling reaction conditions, the invention realizes the association control of the chemical foaming and the curing molding of epoxy, and the foaming multiplying factor is as high as 2.7, and products prepared by the method are good in water resistance, chemical corrosion resistance and strength. The method of the invention has the advantages of easy buying of materials, simple operation and easy industrialization, and provides a new path for preparing thermosetting foaming materials.

Owner:SHANGHAI INST OF TECH +1

Preparation method of polypropylene foaming sheet material

The invention provides a preparation method of a polypropylene foaming sheet material. Homo-polypropylene as base resin and ammonium polyphosphate as a fire retardant undergo foaming in the presence of a supercutical fluid foaming agent so that the polypropylene foaming sheet material is prepared. The preparation method comprises that two or more stages of propylene homopolymerization reactions occur in two or more reactors connected in series, wherein external electron donors used in the two or more stages of reactions respectively are silane and diether compounds. The halogen-free flame-retardation polypropylene foaming sheet material obtained by the preparation method has the advantages of low production cost, short production period, compact foam apertures, uniform aperture distribution and high burning oxygen index and can be used in occasions of automobile parts, steamships and aircraft weight reduction assemblies, and electronic packaging and building decoration having high flame-retardation requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-melt-strength anti-impact polypropylene foamed board and preparation and application thereof

The invention relates to a high-melt-strength anti-impact polypropylene foamed board. The foamed board is prepared through foaming with high-melt-strength anti-impact polypropylene as matrix resin. The high-melt-strength anti-impact polypropylene comprises a random copolymerization polypropylene continuous phase and a rubber dispersed phase of propylene-ethylene copolymer, wherein the content of room temperature dimethylbenzene soluble substances of the high-melt-strength anti-impact polypropylene is larger than 10 wt% and smaller than 35 wt%, and the ratio of Mw of room temperature trichlorobenzene soluble components to Mw of room temperature trichlorobenzene insoluble components is larger than 0.4 and smaller than 1. The invention further relates to a preparation method of the foamed material. The foamed material has higher melt strength, so foamed products with higher foaming ratio and better surface smoothness can be obtained, and the foamed material also has the characteristics of being high in rigidity, high in toughness and the like. Meanwhile, the foamed board has the advantages of being good in high-and-low-temperature anti-impact performance, high in physical heat resistance, high in percentage of close area, good in heat insulation and sound isolation performance, controllable in foaming ratio and foam pore structure and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

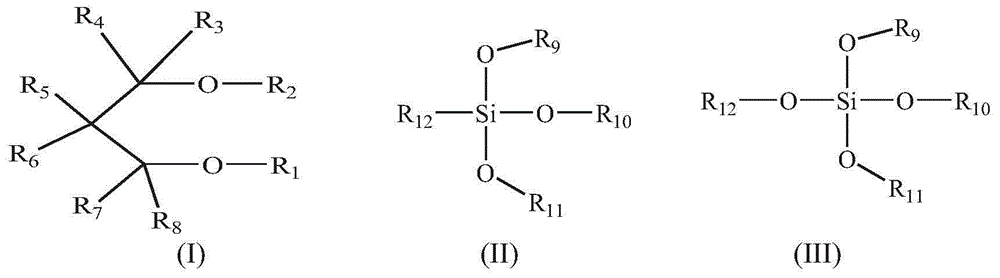

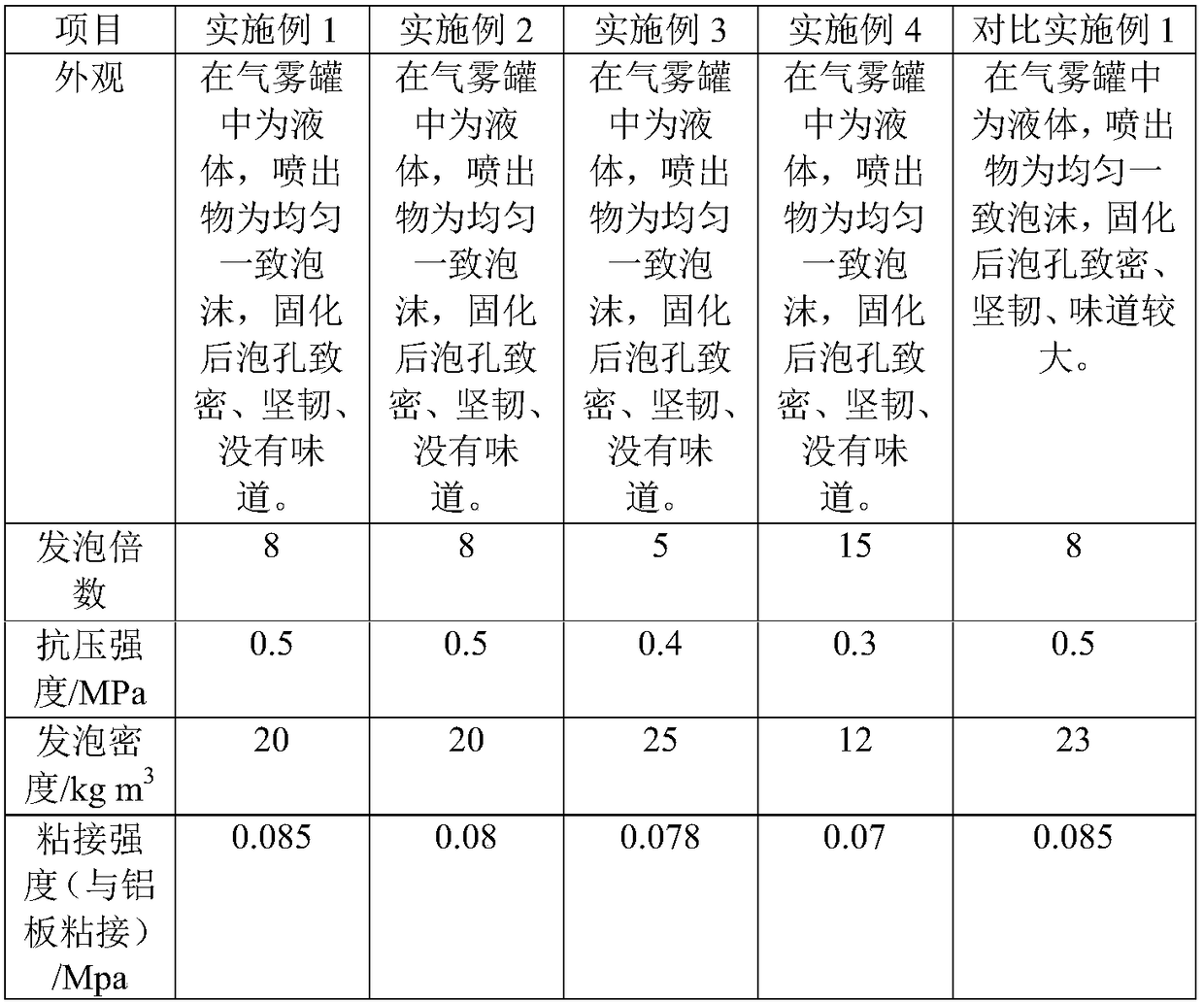

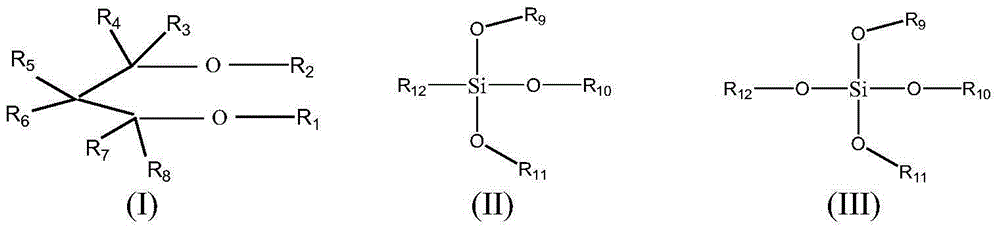

Single-component polyurethane foam rubber and preparation method thereof

InactiveCN108219097ADense cellsHigh foaming rateNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

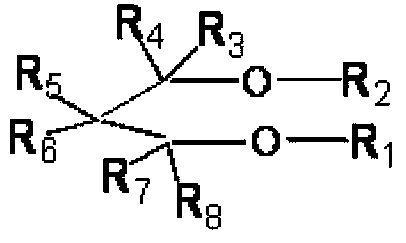

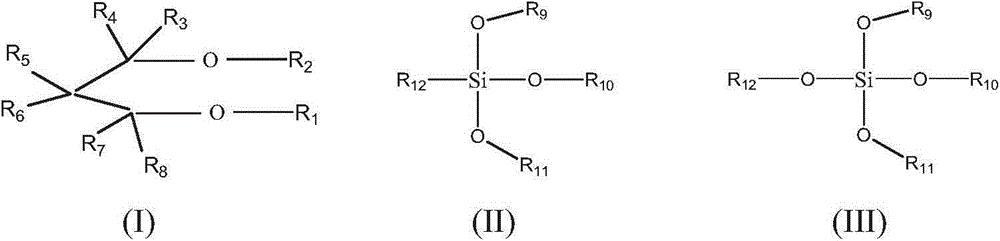

The invention discloses single-component polyurethane foam rubber and a preparation method thereof. The single-component polyurethane foam rubber is prepared from the following components in parts bymass: 30 to 100 parts of polyether polyol and / or polyester polyol, 0.5 to 5 parts of a crosslinking agent, 1 to 15 parts of an opening agent, 0.5 to 10 parts of gas-phase white carbon black, 1 to 3 parts of a foam stabilizer, 0.2 to 5 parts of a catalyst, 1 to 10 parts of supercritical fluid and 30 to 150 parts of polyisocyanate. According to the single-component polyurethane foam rubber and the preparation method thereof, a supercritical foaming technology and a single-component polyurethane foaming technology are integrated. The supercritical fluid of the single-component polyurethane foam rubber is used as a brand-new environmentally-friendly adhesive, so that the prepared single-component polyurethane foam rubber has dual advantages of foam hole compactness and high foaming rate, and is inevitably widely applied to occasions with requirements for high intensity.

Owner:SHANGHAI DONGDA CHEM

Preparation method of polypropylene foamed beads

ActiveCN104974369AImprove performanceMeet the requirements of weight reduction and light weightPolymer scienceElectron donor

The invention provides a preparation method of polypropylene foamed beads. The preparation method comprises the steps of preparing polypropylene according to a following method, adding organic peroxides into obtained polypropylene serving as matrix resin, and foaming by virtue of a physical foaming agent, so as to obtain the polypropylene foamed beads, wherein the method of polypropylene comprises the step of carrying out propylene polymerization reaction including two or more stages in two or more reactors which are connected in series for operation, wherein external electron donors used in the two stages are respectively alkane compounds and diether compounds. According to the preparation method, high-melt-strength polypropylene with wide molecular weight distribution is taken as a raw material, the organic peroxides are taken as a surface modifier of EPP beads, and the closed-hole-structured polypropylene foamed beads having the advantages that the diameters of foamed holes are uniform, the foamed holes are compact and the hole distribution is uniform can be prepared; the polypropylene foamed beads can be applied to the fields such as automobile manufacturing, packaging, building insulation, sport equipment, living goods, aerospace and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

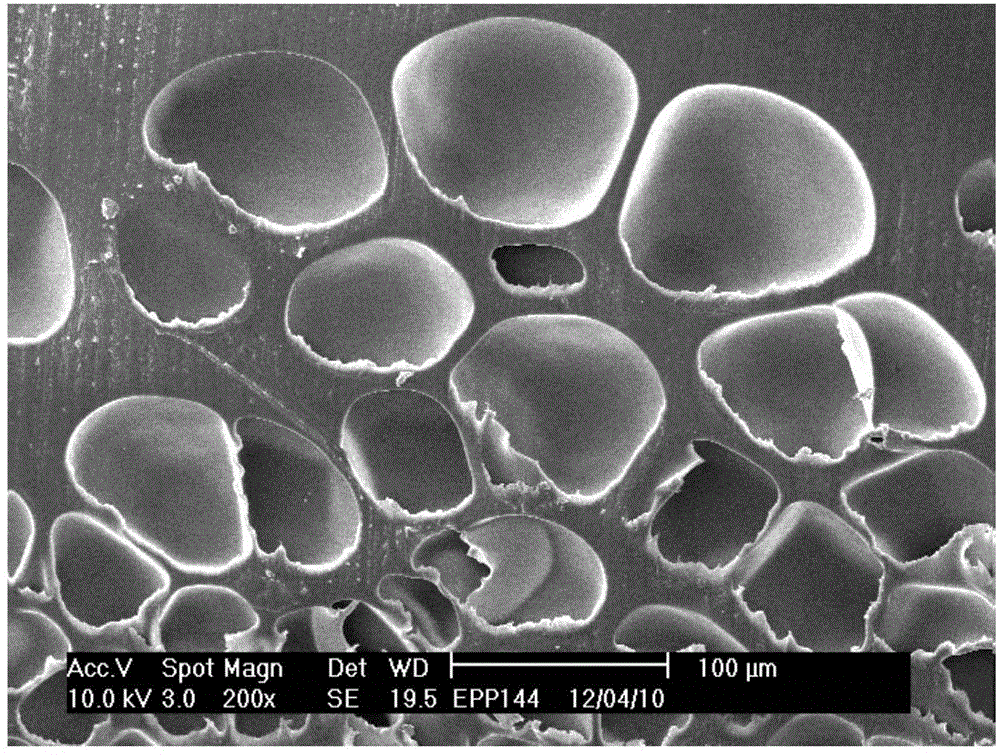

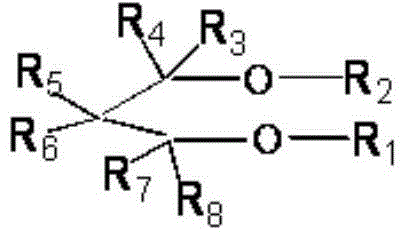

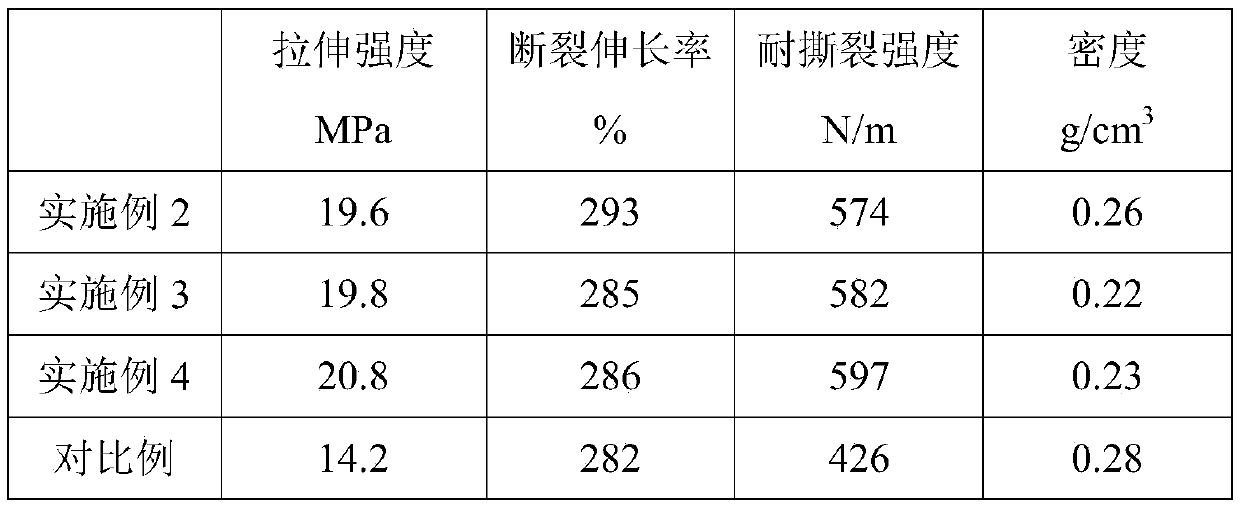

TPU/EVA supercritical foam composite material and preparation method thereof

InactiveCN110724375AGood foaming effectGood foaming efficiencyPolymer scienceThermoplastic polyurethane

The invention discloses a TPU / EVA supercritical foam composite material and a preparation method thereof. The TPU / EVA supercritical foam composite material is prepared from, by weight, 300-360 parts of a thermoplastic polyurethane elastomer, 66-73 parts of an ethylene-vinyl acetate copolymer, 25-33 parts of a maleic anhydride grafting modifier, 9-14 parts of peroxide and 1.2-1.6 parts of a nucleating agent. The TPU / EVA supercritical foam composite material has the advantages of good foaming effect, high foaming efficiency, uniform, small and dense cells, excellent mechanical properties and useproperties such as light weight and high strength, high tensile strength, large elongation at break, good mechanical properties, high tear strength, good tear resistance and low density.

Owner:福建安达福新材料科技有限公司

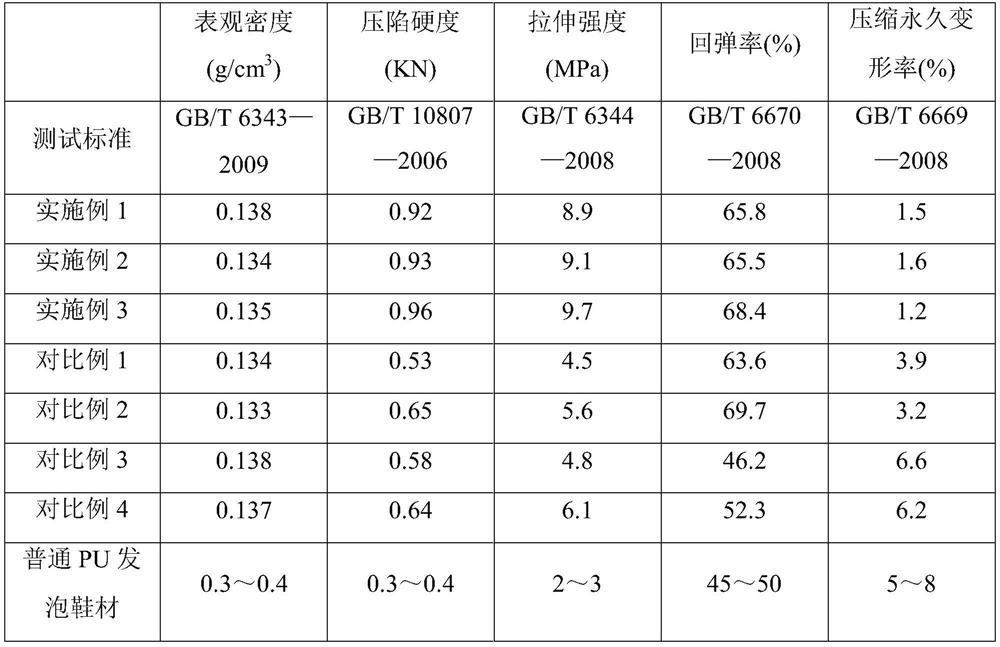

PU foaming shoe material capable of releasing negative ions and preparation method thereof

The invention discloses a PU foaming shoe material capable of releasing negative ions and a preparation method thereof. The PU foaming shoe material is prepared from the following raw materials in parts by weight: 70-80 parts of polyester polyurethane, 12-16 parts of ethylene-vinyl acetate copolymer, 5-7 parts of styrene-ethylene-butadiene-styrene block copolymer, 4-6 parts of a negative ion additive, 1.2-1.7 parts of 4-methylbenzenesulfonyl hydrazine, 0.45-0.55 parts of triethylene diamine, 0.08-0.12 parts of triallyl isocyanurate, 2-3 parts of talcum powder, 2-4 parts of titanium dioxide, 1-2 parts of zinc oxide, 2-4 parts of stearic acid and 1.5-2.7 parts of zinc stearate, wherein the negative ion additive is a mixture of opal powder and medical stone powder, and the mass ratio of opalpowder to medical stone powder is 1: (0.6-0.8). The PU foaming shoe material capable of releasing negative ions is small in density and light in weight; the indentation hardness is high, the tensile strength is high, and the mechanical property is good; the rebound rate is high, the compression set rate is low, the elasticity is good, and permanent deformation is not likely to happen in the usingprocess; and the overall performance is excellent.

Owner:ZHEJIANG SEMIR GARMENT CO LTD +1

Preparation of epoxide resin based foam material

The invention discloses a method for preparing an epoxide resin foaming material. The method comprises the following steps that: 1. according to the mass ratio, epoxide resins, foaming agents, foam stabilizing agents and addition agents are respectively picked up and evenly mixed with high-speed stirring; 2. the mixture obtained is put in an oven with a temperature of between 40 and 80 DEG C and pre-heated for 0.5 to 1 hour, and the mixture is taken out and cooled down to a temperature of between 25 and 35 DEG C; 3. The mixture is added with curing agents and evenly mixed; 4. the mixture is put in a stainless steel mold and heated at the temperature of between 40 to 80 DEG C for 0.5 to 2 hours, and the mixture is cooled down to the room temperature and taken out, and finally the finished products are obtained. By controlling reaction conditions, the invention realizes the association control of the chemical foaming and the curing molding of epoxy, and the foaming multiplying factor isas high as 2.7, and products prepared by the method are good in water resistance, chemical corrosion resistance and strength. The method of the invention has the advantages of easy buying of materials, simple operation and easy industrialization, and provides a new path for preparing thermosetting foaming materials.

Owner:SHANGHAI INST OF TECH +1

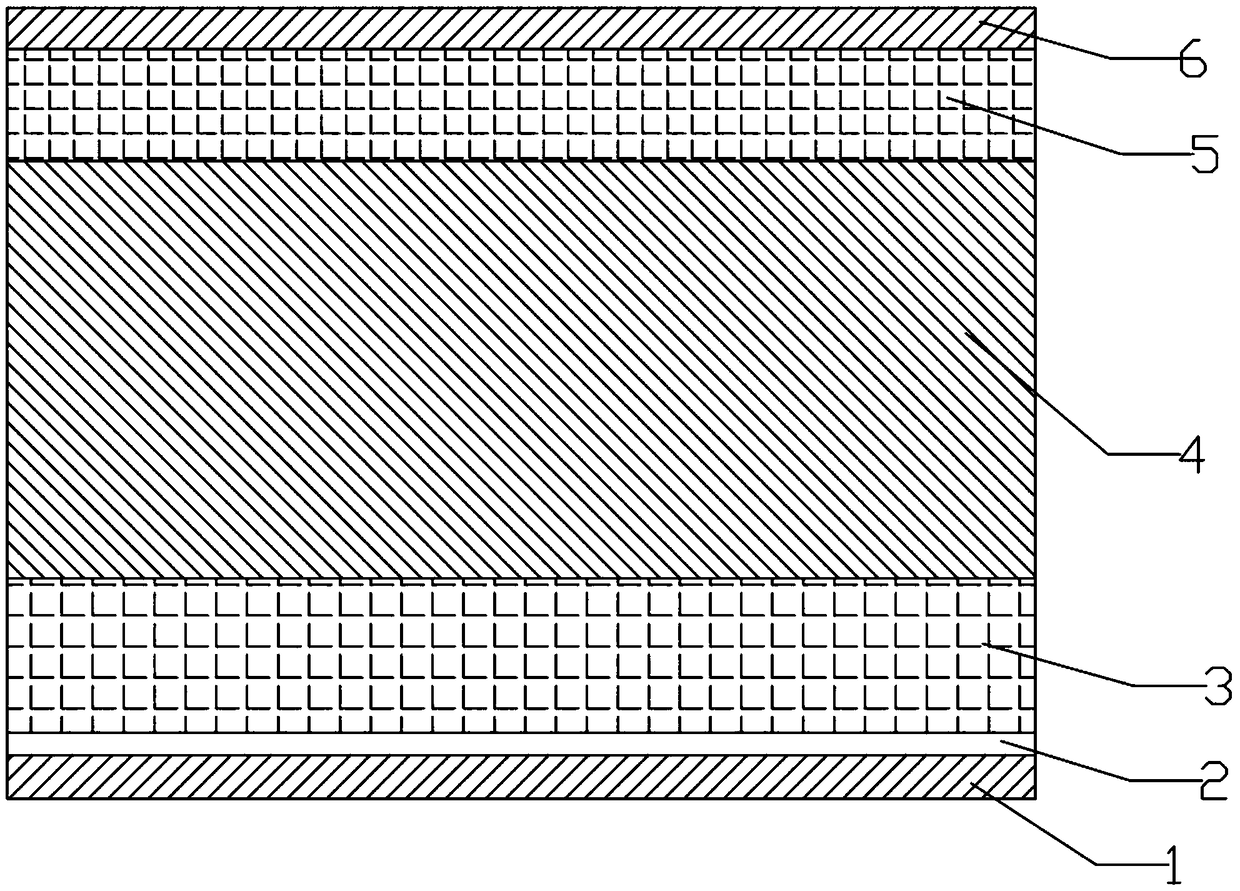

Phenolic foam heat insulation board of core-shell structure and preparing method thereof

The invention relates to a heat insulation board and a preparing method thereof, in particular to a phenolic foam heat insulation board of a core-shell structure and a preparing method thereof. Surface layers of the phenolic foam heat insulation board are made of phenolic foam, the core layer of the phenolic foam heat insulation board is made of polyurethane foam, a phenolic resin system accounts for 100 parts, and a polyurethane prepolymer system accounts for 20 parts by mass. The materials are foamed in a mold according to a preset synthetic process, solidified, cured and formed to obtain the phenolic aldehyde foam heat insulation board with good tenacity, and the defect that a phenolic foam board with certain tenacity is obtained through a traditional toughening method at the cost of fire resistance reduction is overcome. Phenolic resin is endowed with softness of the core layer polyurethane foam, the heat conductivity coefficient is further reduced, and the waterproof performance of the phenolic aldehyde foam board is improved. The phenolic aldehyde foam heat insulation board can be used as heat insulation and sound insulation materials.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Polyurethane foam gum with expandable graphite and diatomite to cooperatively enhance flame retarding

InactiveCN106065309AHigh oxygen indexImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDiethyl phosphateWear resistant

The invention discloses polyurethane foam gum with expandable graphite and diatomite to cooperatively enhance flame retarding, which is prepared from, by weight, 150-160 parts of diphenyl methane diisocyanate, 100-105 parts of trihydroxy polyoxypropylene ether, 100-110 parts of castor oil, 5-6 parts of glycerol, 40-43 parts of diethyl phosphate, a proper amount of a 1 mol / L sodium hydroxide solution, 13-15 parts of diatomite, 5-6 parts of distilled water, 2-3 parts of triethanol amine, 3-4 parts of dibutyltin dilaurate, 3-4 parts of lauryl sodium sulfate, 5-6 parts of silicon oil, 3-4 parts of the expandable graphite, a proper amount of anhydrous ethanol, 0.8-1 part of cetyl trimethyl ammonium bromide, and a proper amount of deionized water. The foam gum is used for sealing switch cabinets and machine cabinets, is high in strength and is wear-resistant, can achieve on-site foaming and reduce production cost, has high total sealing performance, has simple and easy-to-control production process, and is safe and environment-friendly.

Owner:HEFEI E CHON METAL PLATE TECH CO LTD

Planting method of selenium-rich oranges

InactiveCN107439120AQuality improvementImprove fertilityBio-organic fraction processingMagnesium fertilisersFruit juiceVitamin C

The invention provides a planting method of selenium-rich oranges. On the basis of a normal orange cultivation method, the planting method also comprises steps as follows: a selenium-rich nutritional agent is taken, strip-shaped fertilization ditches are formed in two opposite sides of the water drip edge of the crowns of orange trees in the flowering period during growth and cultivation of the oranges, and the selenium-rich nutritional agent and soil are blended uniformly and applied to the fertilization ditches; the selenium-rich nutritional agent and manure and urine of human beings or animals are taken and broadcast around the tree before raining or after raining in the rainy seasons of spring and summer; the selenium-rich nutritional agent, a plant surfactant and clear water are mixed and sprayed in the fruit bearing time during growth and cultivation of the oranges. After the selenium-rich nutritional agent is used, the edible rate of oranges of each mu can reach 85% or above, the juice rate reaches 50%-60%, the content of vitamin C of every 100 ml is 60-70 ml, and the content of selenium in each kilogram of orange fruits is larger than 23 mu g and is 10 times or higher that of ordinary oranges.

Owner:眉山市富农水稻种植专业合作社

Propylene-ethylene-butylene high-melt-strength polypropylene foamed board or sheet and preparation method thereof

The invention provides a polypropylene foamed board or sheet. The foamed board or sheet is prepared by foaming a base resin high-melt-strength polypropylene with a foaming agent, wherein the high-melt-strength polypropylene has the following characteristics: the melt index MFR is 0.2-10 g / 10 minutes, the molecular weight distribution Mw / Mn is 6-20, the content of substances with the molecular weight of greater than 5 million is greater than or equal to 0.8 wt%, the M[z+1] / Mn is greater than or equal to 70, the ethylene content is 0.1-15 wt%, and the butylene content is 0.1-15 wt%. The high-melt-strength polypropylene with wide molecular weight distribution is utilized as the raw material to implement stabilization of the polypropylene raw material, so that the foaming window is effectively enlarged, and the technique is easy to adjust; the method can be used for preparing the polypropylene foamed board or sheet with the density of 0.2-0.9 g / cm<3> and the thickness of 0.1-400mm, which has the advantages of smooth surface crust, uniform pore diameter and close cell hard structure; and the polypropylene foamed board or sheet can be widely used in the fields of thermal insulation tableware, automobile interior ornaments, architectural moldboards, camping supplies, decorating material interlayers, product damping packages and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Impact polypropylene foam plate with high melt strength and method for preparing impact polypropylene foam plate

The invention provides a polypropylene foam plate and a method for preparing the same. Impact polypropylene with high melt strength is used as basic resin for the polypropylene foam plate and is foamed and rolled to obtain the polypropylene foam plate. The impact polypropylene with the high melt strength comprises random copolymerization polypropylene continuous phases and propylene-ethylene copolymer rubber dispersion phases, the content of room-temperature dimethylbenzene soluble matters in the impact polypropylene is higher than or equal to 10% and is lower than or equal to 35% by weight, a proportion of the Mw (molecular weight) of room-temperature trichlorobenzene soluble matters in the impact polypropylene to the Mw of room-temperature trichlorobenzene insoluble matters in the impact polypropylene is higher than 0.4 and is lower than or equal to 1. The polypropylene foam plate and the method have the advantages that the polypropylene foam plate has smooth surfaces and bubbles, is uniform in pore diameter distribution, good in high-temperature and low-temperature impact resistance and high in melt strength and can be widely applied to the fields of automobile components, food and electronic packaging, building decoration and the like; the method is simple and is easy to implement and low in cost, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Double-waterproof polyurethane foam

InactiveCN106190000AHigh oxygen indexImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDiethyl phosphateWear resistant

The invention discloses double-waterproof polyurethane foam. The double-waterproof polyurethane foam is prepared from the following raw materials in parts by weight: 150 to 160 parts of diphenyl-methane-diisocyanate, 100 to 105 parts of propoxylated glycerin, 100 to 110 parts of castor oil, 5 to 6 parts of glycerol, 40 to 43 parts of diethyl phosphate, an appropriate amount of 1mol / L sodium hydroxide solution, 13 to 15 parts of diatomaceous earth, 5 to 6 parts of distilled water, 2 to 3 parts of triethanolamine, 3 to 4 parts of dibutyltin dilaurate, 3.5 to 4 parts of palmitic acid, 3 to 4 parts of N,N-dimethyldodecylamine-N-oxide, 2 to 3 parts of emulsified asphalt, 4 to 5 parts of sericite, 4 to 5 parts of polyuria, 0.6 to 0.8 part of silane coupling agent KH550 and a proper amount of absolute ethanol. The double-waterproof polyurethane foam is simple in process, can be foamed on the spot, can be applied to sealing of cabinets such as switch cabinets, is water-resistant and wear-resistant, is suitable for outdoor use, and has long service life.

Owner:HEFEI E CHON METAL PLATE TECH CO LTD

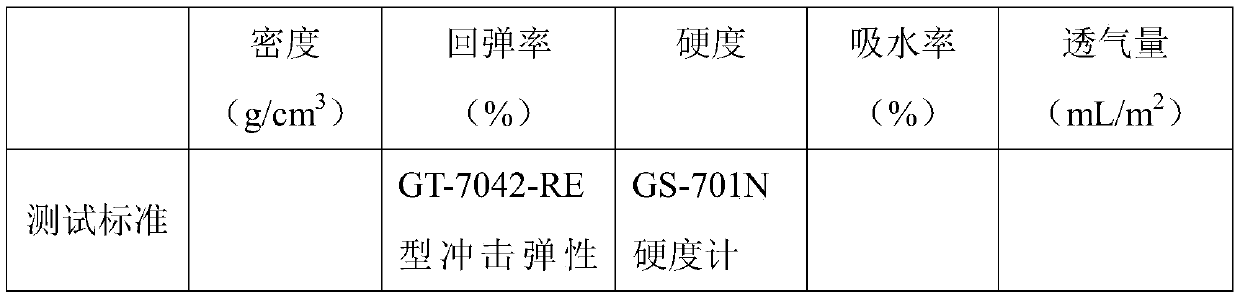

Ultra-light graphene rubber foamed insole and preparation method thereof

The invention discloses an ultra-light graphene rubber foamed insole and a preparation method thereof. The ultra-light graphene rubber foamed insole is prepared from the following raw materials in parts by weight: 65-72 parts of ethylene-vinyl acetate copolymer, 18-22 parts of liquid polyisoprene rubber, 5-7 parts of methyl vinyl phenyl silicone rubber, 6-9 parts of graphene, 12-19 parts of EVA color masterbatches, 4-7.2 parts of an aluminum silicate fiber pipe, 1.5-2.5 parts of a foaming agent, 0.9-1.2 parts of a micropore regulator, 3-6 parts of an antioxidant, 2-4.2 parts of a crosslinkingagent and 4-6 parts of zinc stearate. The ultra-light graphene rubber foamed insole is low in density, has ultra-light property, is high in resilience rate and durable, does not easily deform in a using process, is moderate, is comfortable, and has high quality, and the circumstance that the insole is damaged due to over large deformation; and the ultra-light graphene rubber foamed insole is highin water absorption rate and air permeability, good in moisture absorption, good in air permeability and comfortable to wear.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

Impact-resistant polypropylene foamed sheet with high melt strength and preparation method therefor

The invention provides a polypropylene foamed sheet and a preparation method therefor. The foamed sheet is prepared by taking impact-resistant polypropylene with high melt strength as base resin and carrying out foaming and rolling, wherein the impact-resistant polypropylene with high melt strength contains a propylene homopolymer ingredient and an ethylene-1-butylene copolymer ingredient, and the ratio of Mw of room-temperature trichlorobenzene soluble matters of the impact-resistant polypropylene with high melt strength to Mw of room-temperature trichlorobenzene insoluble matters of the impact-resistant polypropylene with high melt strength is greater than 0.5 and smaller than or equal to 1; and the content of room-temperature dimethylbenzene soluble matters in the impact-resistant polypropylene with high melt strength is higher than 10wt% and lower than 30wt%. The polypropylene foamed sheet provided by the invention has the advantages of smooth surface, uniform bubble and pore size distribution, good high- / low-temperature impact resistance, high melt strength and the like and can be extensively applied to the field of automotive parts, food and electronic packages, architectural decoration and the like; and the preparation method for the polypropylene foamed sheet is simple and is easy in operation and low in cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

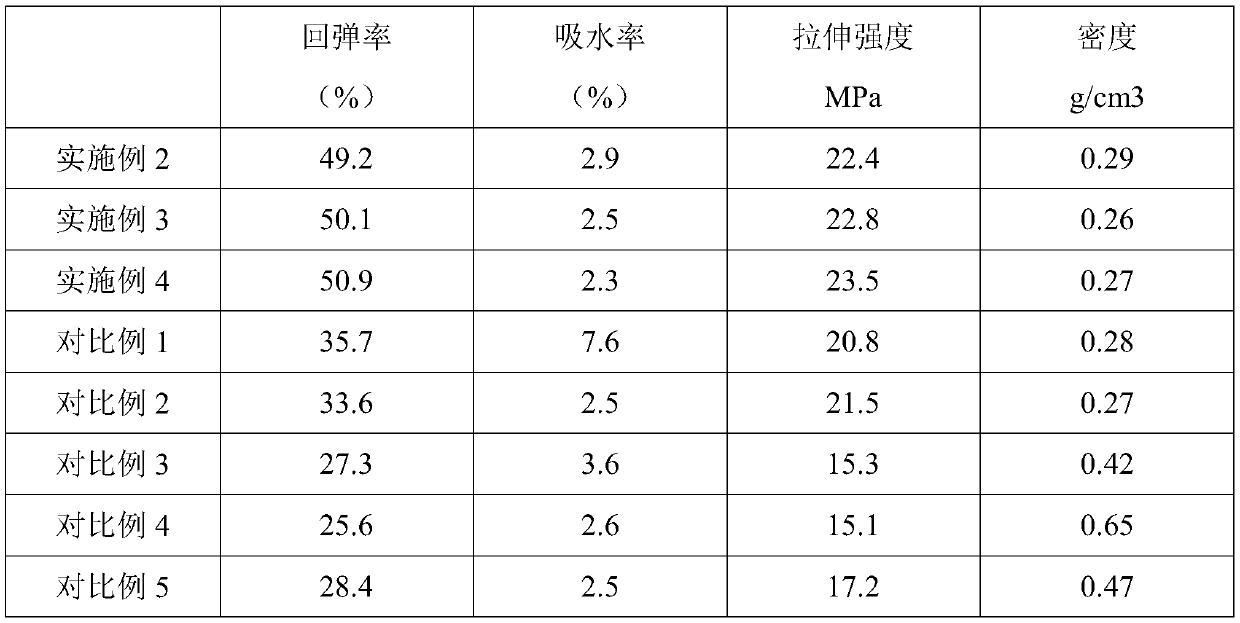

Nylon/polyurethane supercritical foamed composite material and preparation method thereof

The invention discloses a nylon / polyurethane supercritical foamed composite material and a preparation method thereof. The nylon / polyurethane supercritical foamed composite material is prepared from the following raw materials in parts by weight: 300-350 parts of polyamide, 60-72 parts of polyurethane, 40-48 parts of a polyamide-polysiloxane segmented copolymer, 6-8 parts of graphene fiber, 5-7 parts of a cross-linking agent and 3-4 parts of a nucleating agent. The nylon / polyurethane supercritical foamed composite material disclosed by the invention is good in foaming effect and high in foaming efficiency; the foam holes are uniform, small and compact; the advantages of high resilience rate, low water absorption rate, good dimensional stability, small irreversible deformation after being pressed, high tensile strength, good mechanical properties, light weight, high strength and the like excellent mechanical properties and use properties are achieved.

Owner:福建安达福新材料科技有限公司

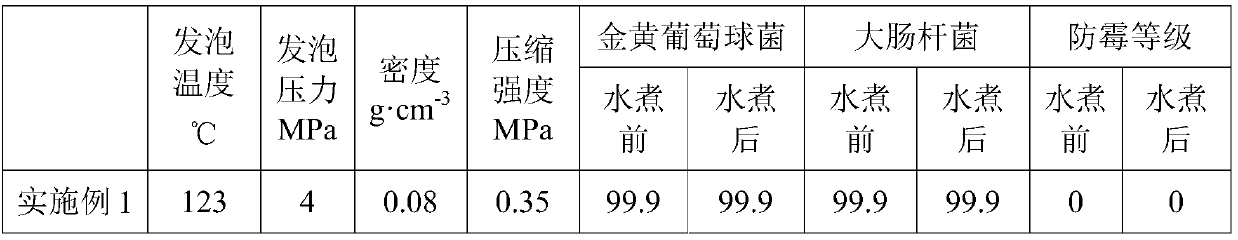

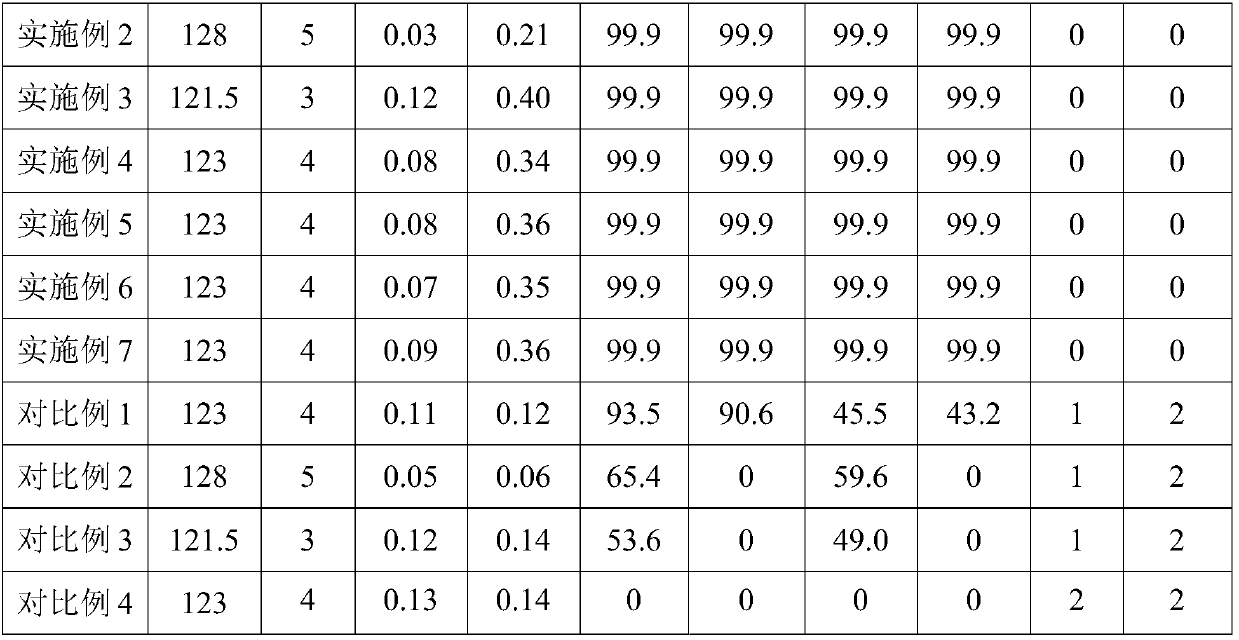

Antibacterial mildew-proof polyethylene composition and foamed beads, preparation method thereof, and molded body

The invention belongs to the field of antibacterial materials and products thereof, and relates to an antibacterial mildew-proof polyethylene composition and foamed beads, a preparation method thereof, and a molded body. The antibacterial and mildewproof polyethylene composition contains polyethylene base resin, a guanidine salt composite antibacterial agent, a mildewproof agent and an auxiliary agent, wherein the auxiliary agent contains a foam nucleating agent and an optional antioxidant; based on 100 parts by weight of the polyethylene base resin, the content of the guanidine salt compositeantibacterial agent is 0.05-2.0 parts by weight, the content of the mildew preventive is 0.01-5.0 parts by weight, the content of the foam nucleating agent is 0.01-10 parts by weight, and the contentof the antioxidant is 0-10 parts by weight. The antibacterial and mildewproof polyethylene composition is good in antibacterial and mildewproof effects, the water resistance is also improved, the foamed beads prepared from the antibacterial and mildewproof polyethylene composition have impact resistance and low molding temperature, and the obtained molded product is excellent in antibacterial andmildewproof performance and high in compression strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composition used for preparing polypropylene foaming material and prepared foaming formed body

The invention provides a composition used for preparing a polypropylene foaming material. The composition comprises high melt-strength anti-punching polypropylene as a base resin, the high melt-strength anti-punching polypropylene comprises a propylene homopolymer ingredient and a propylene-ethylene copolymer ingredient, and is characterized in that the molecular weight distribution Mw / Mn is less or equal to 10, and is greater or equal to 4; Mz+1 / Mw is greater than 10 and less than 20; the content of a room-temperature xylene soluble substance is greater than 10 wt% and less than 30 wt%; and the ratio of a room-temperature trichloro-benzenes soluble substance Mw to a room-temperature trichloro-benzenes insoluble substance is greater than 0.4 and less than 1. The invention also provides a polypropylene injection foaming formed body produced by the composition through injection foaming and a preparation method thereof, and the formed body is suitable for the fields with special requirements on the part shapes such as automobile, aircraft, and high-speed rail internal and external decoration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rigid PVC foam plastic manufactured by twin-screw extruder and preparation method thereof

The invention belongs to the technical field of PVC materials, in particular to a rigid PVC foam plastic manufactured by a twin-screw extruder and a preparation method thereof. The preparation methodcomprises the following steps: evenly mixing raw materials in a certain proportion by an extruder, performing extrusion molding by the twin-screw extruder to obtain a rigid plastic foam pre-foaming body, boiling the obtained pre-foaming body, and performing solidification shaping to obtain the final rigid plastic foam. The rigid PVC foam manufactured by the twin-screw extruder and the preparationmethod thereof can be continuously produced, so that the production time is greatly shortened, the production process is simplified, and the production efficiency is improved. The produced rigid cross-linked PVC foam plastic has compact bubble holes, and relatively good thermal insulation performance and flame resistance.

Owner:SICHUAN UNIV +1

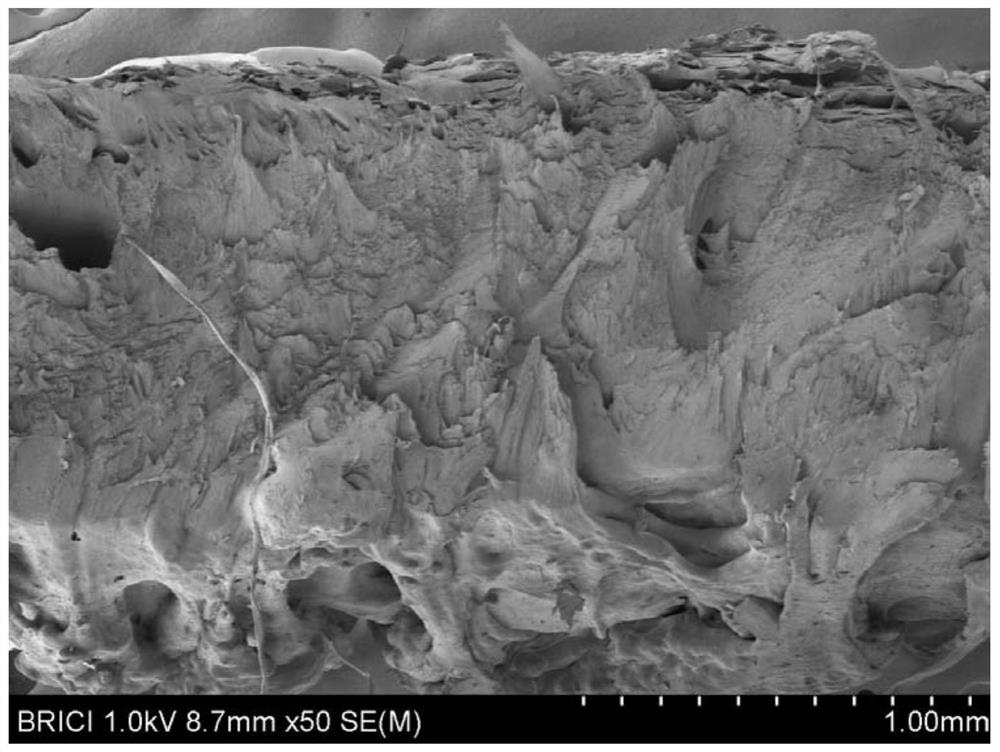

Preparation method of double-surface foamed high-wrinkle-resistance polyurethane leather

The invention discloses a preparation method of double-surface foamed high-wrinkle-resistance polyurethane leather. The preparation method comprises the following steps: (1) placing base cloth in polyurethane impregnation slurry, and extruding through extruding rolls to obtain a base cloth layer, wherein the distance between each two extruding rolls is 0.3-0.6 mm; and (2) coating the base cloth layer obtained in step (1) with first polyurethane foaming slurry in a scraping manner, then solidifying in a coagulating tank which contains a dimethylformamide-water system, washing via a plurality ofwashing tanks, and drying to obtain a wet-method semi-finished product of the base cloth layer and the first polyurethane foaming layer, wherein the temperature of a drying oven for drying is controlled to be 100-180 DEG C. According to the preparation method of the double-surface foamed high-wrinkle-resistance polyurethane leather, a two-surface foaming technology is adopted, and the obtained double-surface foamed high-wrinkle-resistance polyurethane leather is fine and smooth in folding mark and is stiff; the double-surface foamed high-wrinkle-resistance polyurethane leather has a six-layered structure; and the product is environmentally friendly, DMF residues are less, and wear resistance, scratching resistance and hydrolysis resistance are excellent.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

Polyurethane foaming glue with added large-molecular modified calcium carbonate

InactiveCN106190002AHigh oxygen indexImprove flame retardant performancePolyureas/polyurethane adhesivesDiethyl phosphateGlycerol

The invention discloses polyurethane foaming glue with added large-molecular modified calcium carbonate. The foaming glue is prepared from, by weight, 150-160 parts of diphenyl methane diisocyanate, 100-105 parts of propoxylated glycerin, 100-110 parts of castor oil, 5-6 parts of glycerol, 40-43 parts of diethyl phosphate, a proper amount of 1mol / L sodium hydroxide, 13-15 parts of diatomite, 5-6 parts of distilled water, 2-3 parts of triethanolamine, 3-4 parts of dibutyltin dilaurate, 3-4 parts of alpha-olefin sulfonate, 5-6 parts of simethicone, 9-10 parts of methyl methacrylate, 9-10 parts of butyl acrylate, 0.25-0.26 part of mercaptoethanol, a proper amount of methylbenzene, 0.015-0.02 part of azodiisobutyronitrile and 5-6 parts of nano calcium carbonate. The production process of the product is convenient to control, on-site foaming can be achieved, cost is low, and the prepared foaming glue is good in viscosity, excellent in sealing performance, suitable for sealing of switch cabinets and good in stability.

Owner:HEFEI E CHON METAL PLATE TECH CO LTD

High-compression-resilience polyurethane foam adhesive for sealing

InactiveCN106221656AHigh oxygen indexImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElastomerAdhesive

The invention discloses a high-compression-resilience polyurethane foam adhesive for sealing. The polyurethane foam adhesive is prepared from the following raw materials in parts by weight: 150-160 parts of diphenylmethane diisocyanate, 100-105 parts of trihydroxy polyoxypropylene ether, 100-110 parts of castor oil, 5-6 parts of glycerol, 40-43 parts of diethyl phosphoric acid, a right amount of 1 mol / L sodium hydroxide solution, 13-15 parts of diatomite, 5-6 parts of distilled water, 2-3 parts of triethanolamine, 3-4 parts of dibutyltin dilaurate, 3-4 parts of fatty acid polyoxyethylene ester, 3-4 parts of silicone oil, 3-4 parts of lignite, 3-4 parts of melamine formaldehyde resin, 2-3 parts of n-octadecane, 1-1.5 parts of gelatin and a right amount of deionized water. The foam adhesive can be used for sealing switch cabinets and other cabinets by foam in place, and has the advantages of no seam, uniform elastomer inside bubble structure, favorable compression resilience and favorable sealing effect.

Owner:HEFEI E CHON METAL PLATE TECH CO LTD

Foamed polypropylene composition, foamed polypropylene plate and preparation method thereof

The invention relates to the field of polypropylene foam materials, and discloses a foamed polypropylene composition, a foamed polypropylene plate and a preparation method thereof. The composition isprepared from the following components in parts by weight: 100 parts of high-melt-strength polypropylene, 0.05 to 2 parts of guanidine salt composite antibacterial agent, 0.05 to 5 parts of mildew preventive and 1 to 15 parts of foaming agent, wherein the high-melt-strength polypropylene is prepared from the following components in parts by weight: 100 parts of polypropylene, 0.1 to 0.3 part of antioxidant and 0.25 to 10 parts of mixed butene-maleic anhydride copolymer microspheres, wherein the particle size of the copolymer microspheres is 0.1-10 [mu] m. The foamed polypropylene which is compact in foam hole, uniform in pore size distribution, smooth in surface, high in thermo-oxidative aging resistance and capable of being recycled in a non-crosslinking mode can be prepared in an extrusion molding mode.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermoplastic polyurethane elastomer foam bead and preparation method thereof

The invention discloses a thermoplastic polyurethane elastomer foam bead and a preparation method thereof. The method comprises the following steps: firstly, adding thermoplastic polyurethane particles and water to a reaction kettle according to the mass ratio of 1 to (0.8-4); adding liquid carbon dioxide to the reaction kettle, and controlling the intensity of pressure and the temperature in the reaction kettle, so that the carbon dioxide in the reaction kettle is in a super-critical state; raising the temperature inside the reaction kettle to 90-140 DEG C; carrying out heat preservation; putting the materials in the kettle into a pressure tank, maintaining pressure, and cooling to below 70 DEG C; foaming the thermoplastic polyurethane elastomer particles once, and controlling the volume ratio of the reaction pressure to the pressure tank to be 1 to (15-30); putting the disposable foam particles into a storage tank, and carrying out secondary normal pressure foaming to obtain thermoplastic polyurethane elastomer foam beads; and removing the surface moisture of the foam beads, and curing the foam beads at normal pressure and normal temperature for over 48 hours, so as to obtain the product. The product disclosed by the invention has the characteristics of even and compact cells, small size, high percentage of closed area, high molding product strength, good rebound resilience and the like.

Owner:新辉新材料(常州)有限公司

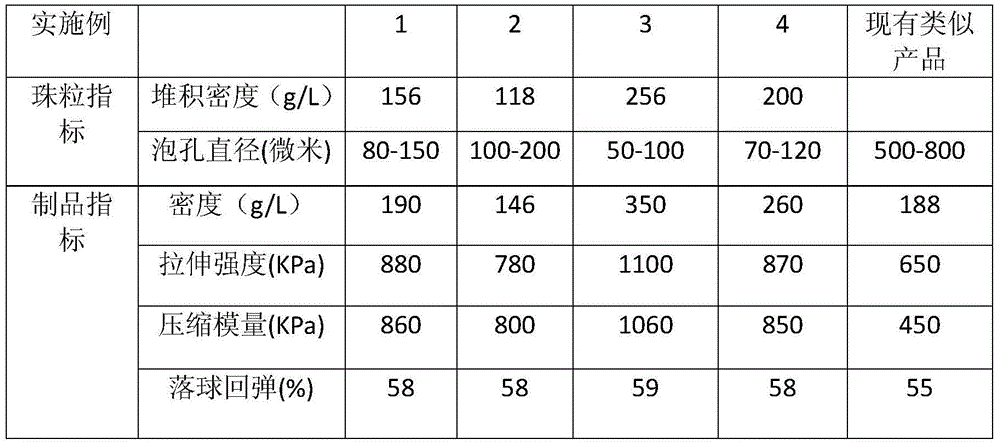

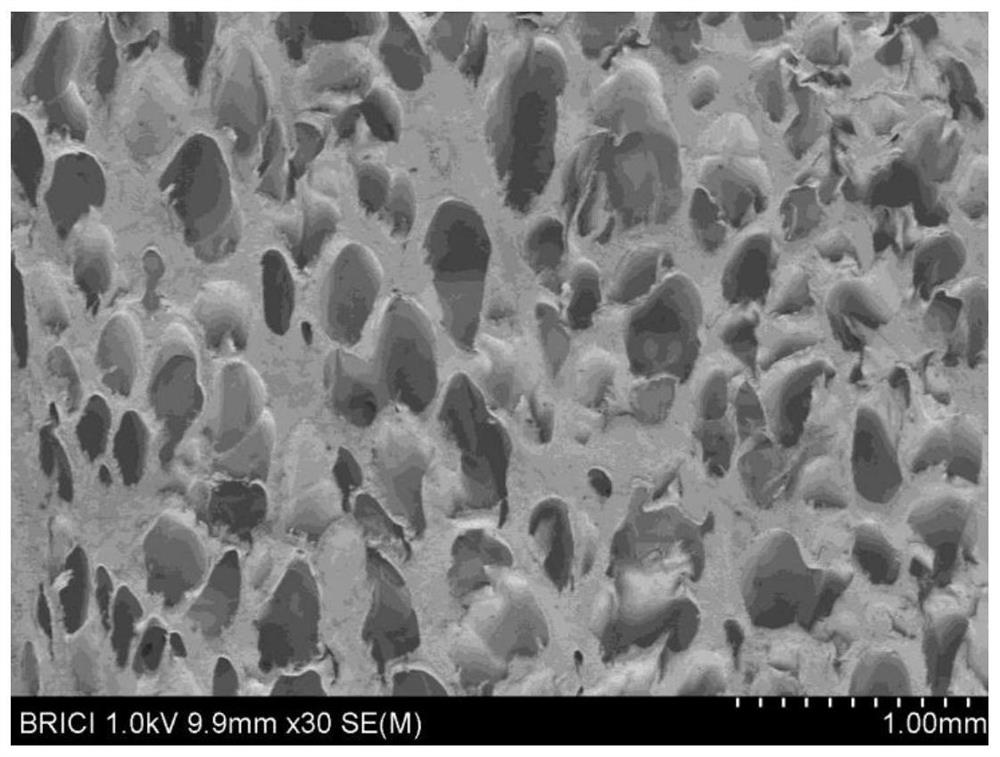

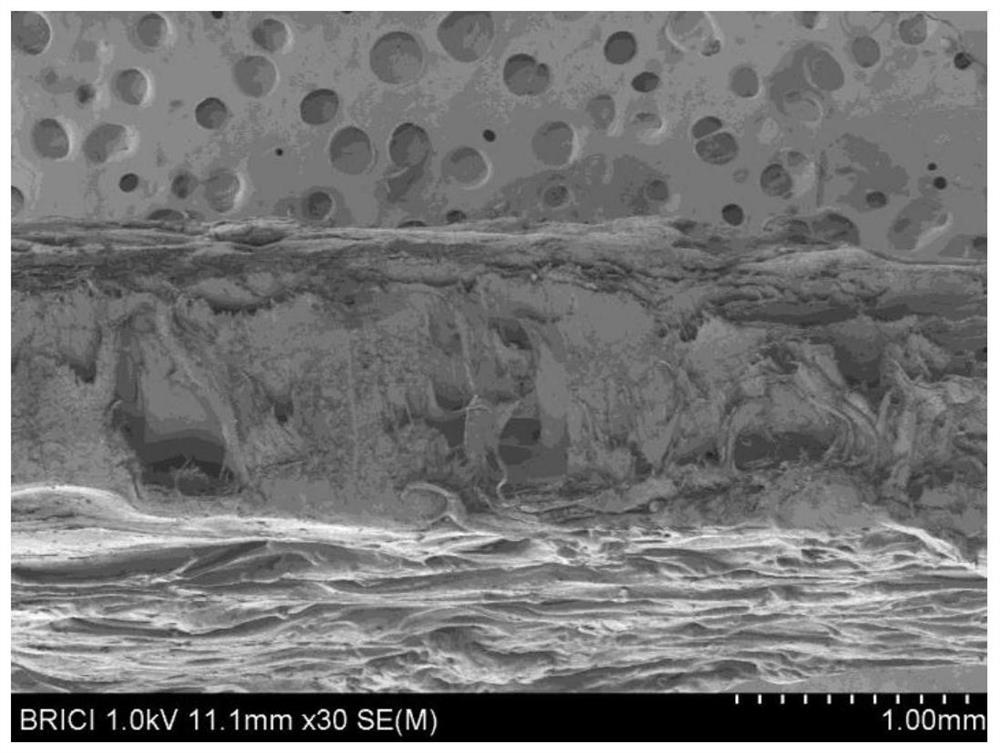

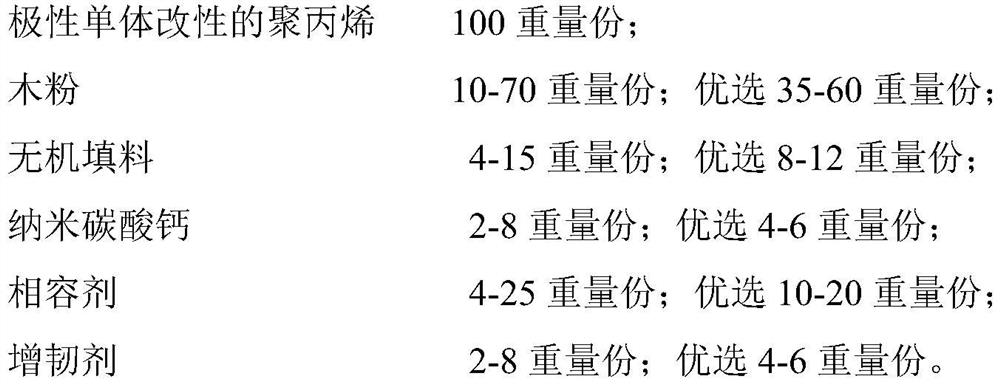

Composition for preparing polypropylene plastic-wood composite material, composite material prepared from composition and application of composite material

The invention provides a composition for preparing a polypropylene plastic-wood composite material. The composition comprises the following components in parts by weight: 100 parts of polar monomer modified polypropylene; 10-70 parts of wood flour, 4-15 parts by weight of an inorganic filler; 2-8 parts by weight of nano calcium carbonate; 4-25 parts by weight of a compatilizer; and 2-8 parts by weight of a flexibilizer. The foamed sheet prepared by foaming the plastic-wood composite material prepared from the composition has the characteristics of flat surface, compact cells, uniform cell diameter, low and controllable foaming ratio, closed-cell hard structure, good impact and bending properties and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com