TPU/EVA supercritical foam composite material and preparation method thereof

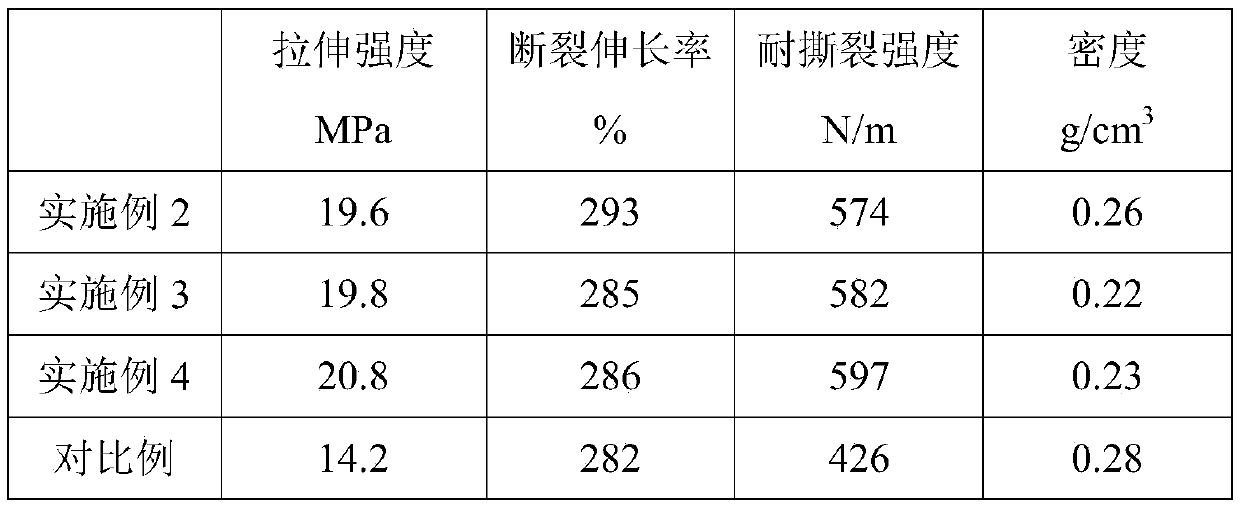

A composite material and supercritical technology, applied in the field of foaming materials, can solve the problems of poor tensile strength, tear strength mechanical properties and performance, rough particle surface, large cell structure size, etc., to achieve stable quality improvement High durability, light weight, and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of TPU / EVA supercritical foaming composite material, is made of the raw material that comprises following parts by weight:

[0045] 300-360 parts of thermoplastic polyurethane elastomer,

[0046] 66-73 parts of ethylene-vinyl acetate copolymer,

[0047] 25-33 parts of maleic anhydride graft modifier,

[0048] 9-14 parts of peroxide,

[0049] 1.2 to 1.6 parts of nucleating agent;

[0050] The thermoplastic polyurethane elastomer is a mixture of polyester polyurethane elastomer and polyether polyurethane elastomer;

[0051] The ethylene-vinyl acetate copolymer is a mixture of ethylene-vinyl acetate copolymer with a VA content of 25-30% and an ethylene-vinyl acetate copolymer with a VA content of 35-40% in a mass ratio of 1:1 ;

[0052] The maleic anhydride graft modifier is a polyethylene-grafted silicon-based modifier prepared by reacting epoxy-group-containing polysiloxane with a mass ratio of 1: (2-3) and maleic anhydride-grafted polyethylene. cluster copo...

Embodiment 2

[0067] A kind of TPU / EVA supercritical foaming composite material, is made of the raw material that comprises following parts by weight:

[0068] 300 parts of thermoplastic polyurethane elastomer,

[0069] 66 parts of ethylene-vinyl acetate copolymer,

[0070] 25 parts of maleic anhydride graft modifier,

[0071] 9 parts peroxide,

[0072] 1.2 parts of nucleating agent;

[0073] The thermoplastic polyurethane elastomer is a mixture of polyester polyurethane elastomer and polyether polyurethane elastomer;

[0074] The ethylene-vinyl acetate copolymer is a mixture of ethylene-vinyl acetate copolymer with a VA content of 25% and an ethylene-vinyl acetate copolymer with a VA content of 40% in a mass ratio of 1:1;

[0075] The maleic anhydride graft modifier is a polyethylene-grafted silicon-containing copolymer prepared by reacting epoxy-group-containing polysiloxane with maleic anhydride-grafted polyethylene at a mass ratio of 1:2.

[0076] In this embodiment, the mass ratio...

Embodiment 3

[0087] A kind of TPU / EVA supercritical foaming composite material, is made of the raw material that comprises following parts by weight:

[0088] Thermoplastic polyurethane elastomer 360 parts,

[0089] 73 parts of ethylene-vinyl acetate copolymer,

[0090] 33 parts of maleic anhydride graft modifier,

[0091] 14 parts peroxide,

[0092] 1.6 parts of nucleating agent;

[0093] The thermoplastic polyurethane elastomer is a mixture of polyester polyurethane elastomer and polyether polyurethane elastomer;

[0094] The ethylene-vinyl acetate copolymer is a mixture of ethylene-vinyl acetate copolymer with a VA content of 30% and an ethylene-vinyl acetate copolymer with a VA content of 35% in a mass ratio of 1:1;

[0095] The maleic anhydride graft modifier is a polyethylene-grafted silicon-group-containing copolymer prepared by reacting epoxy-group-containing polysiloxane with maleic anhydride-grafted polyethylene at a mass ratio of 1:3.

[0096] In this embodiment, the mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com