Patents

Literature

259results about How to "Improve foaming efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing thermoplastic polymer foamed beads

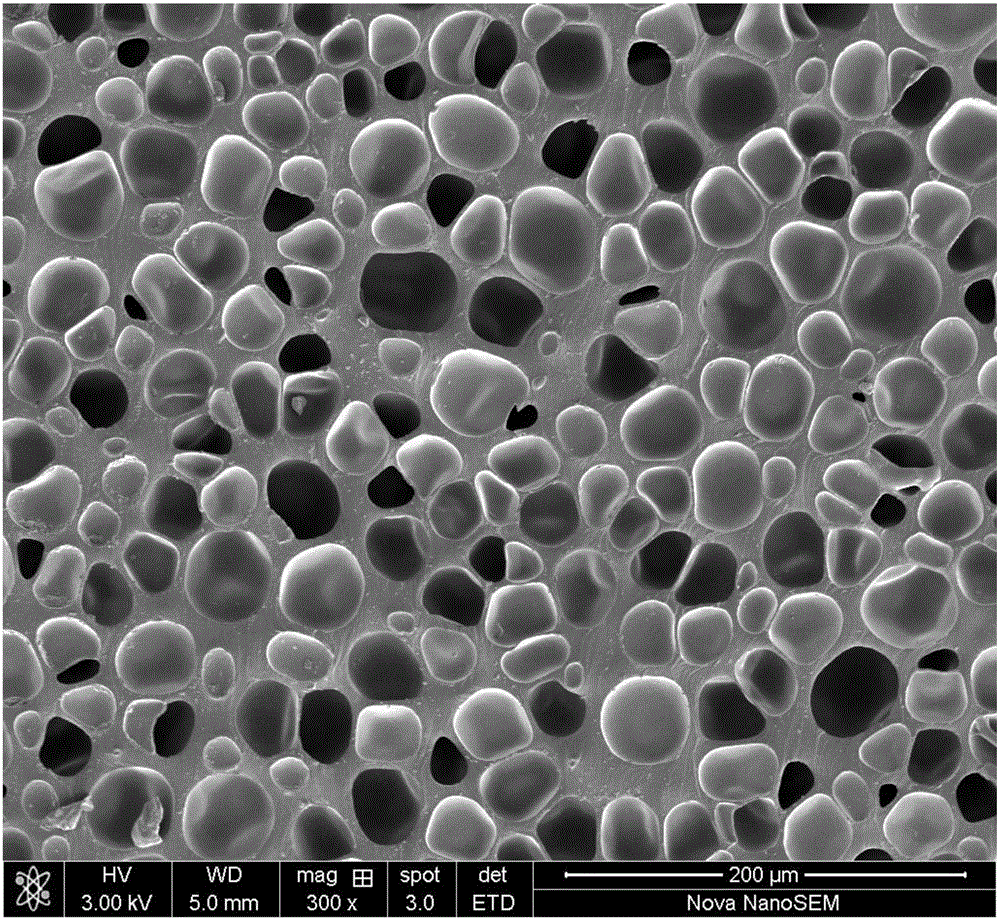

The invention discloses a method for preparing thermoplastic polymer foamed beads. The method comprises the following steps: 1) putting polymer particles into a sealed container heated to a foaming temperature, and putting the sealed container in a vacuum environment; 2) introducing supercritical fluid into the sealed container, and performing swelling diffusion; 3) after swelling diffusion of the supercritical fluid lasts for 5-60 minutes, releasing the pressure of the sealed container to discharge out the supercritical fluid, and controlling the pressure release velocity to induce nucleation and growth of foam pores so as to enable the polymer particles to swell and grow; 4) leading the polymer particles inside the sealed container into the vacuum environment to further swell and grow, thereby obtaining the polymer foamed beads with a high foaming ratio, wherein the foaming temperature in the step 1) is a temperature that the polymer particles can generate plastic deformation but cannot flow yet, the forming temperature is within Tg-Tg+40 DEG C for an amorphous polymer, and Tg is a glass-transition temperature of the amorphous polymer; for a crystallized polymer, the foaming temperature is within Tm-20 DEG C and Tm, and Tm is a melting point of the crystallized polymer.

Owner:HANGZHOU BOSTE NEW MATERIALS TECH CO LTD

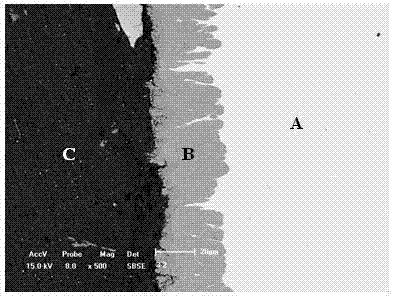

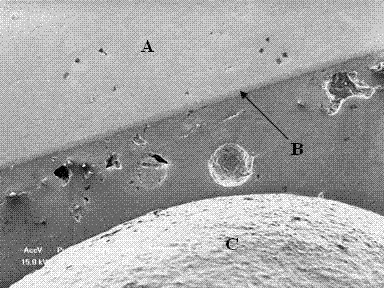

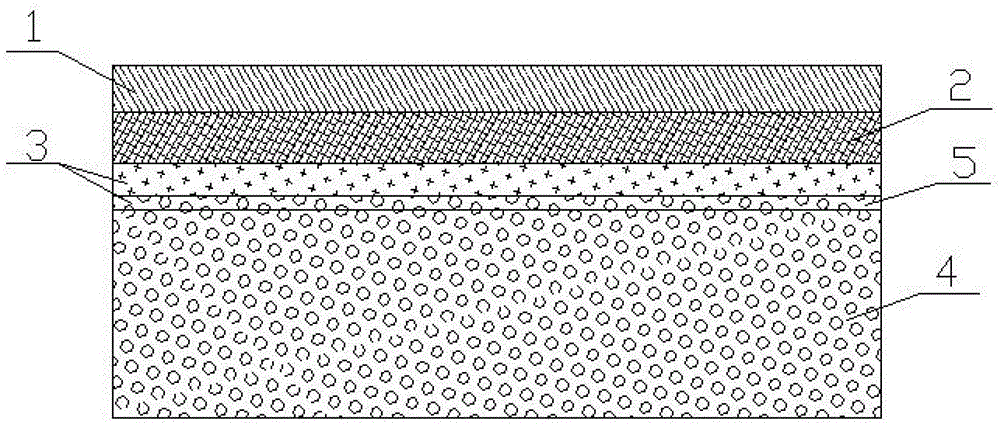

Preparation method of foamed aluminum sandwich plate

ActiveCN102390135AImprove mechanical propertiesAccurate thicknessLaminationLamination apparatusFoaming agentComposite plate

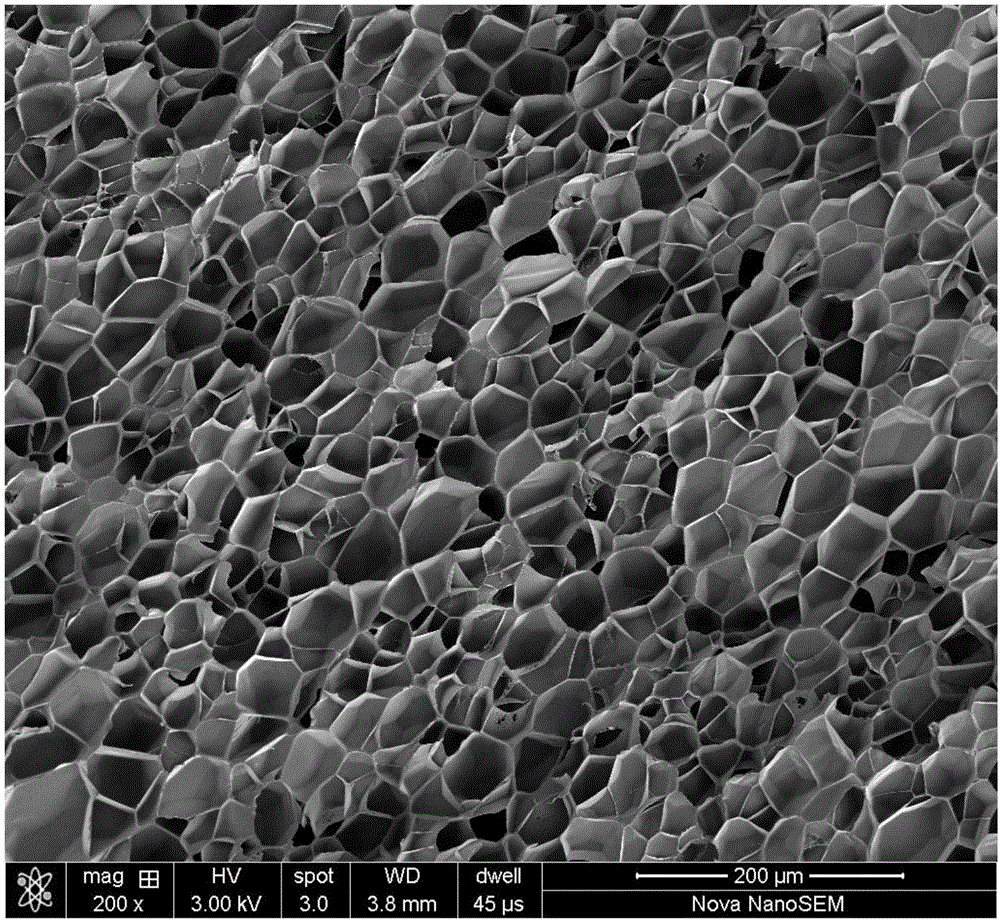

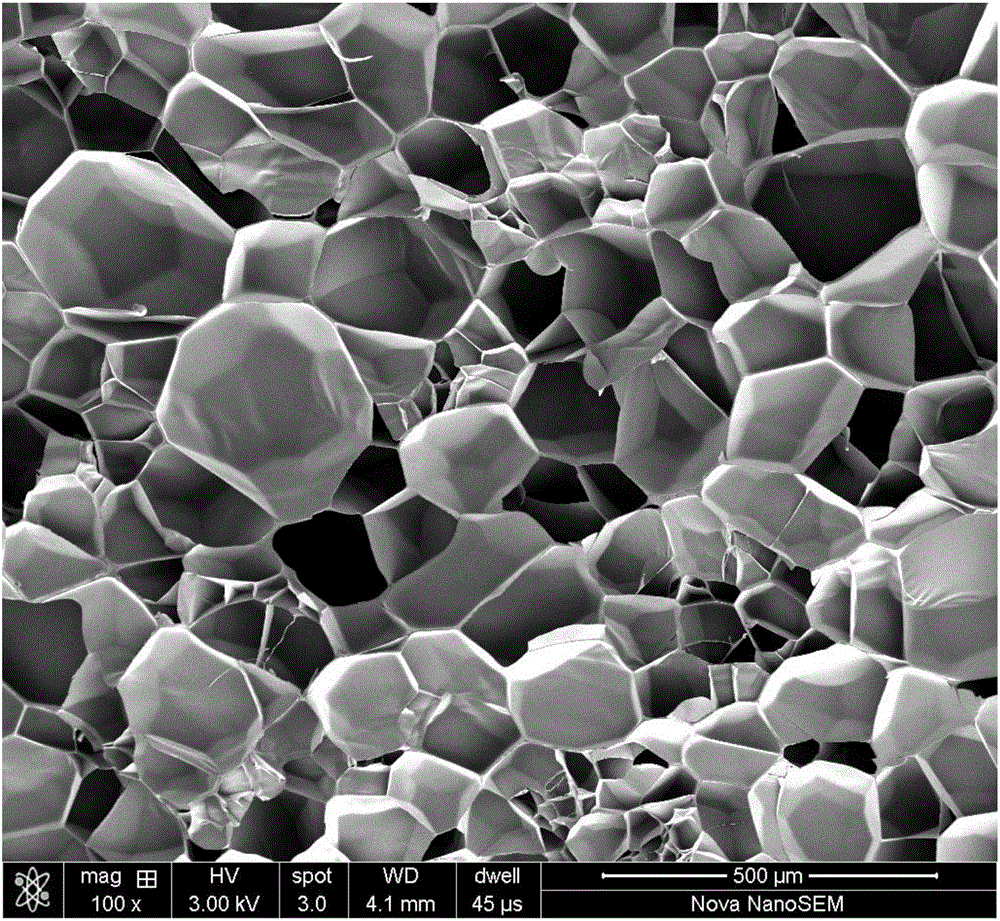

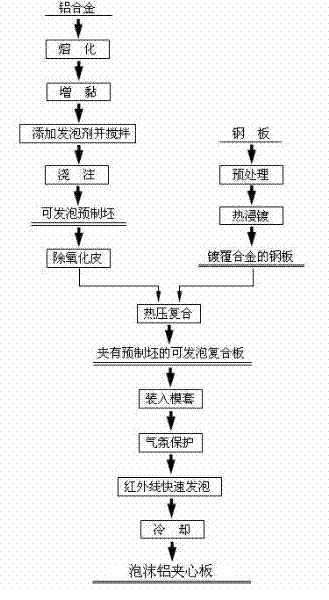

The invention relates to a preparation method of a layered composite material, in particular to a preparation method of a foamed aluminum sandwich plate. The method comprises the following steps of: firstly, uniformly mixing an aluminum alloy, a tackifier and a foaming agent to obtain a platy or blocky foamable precast blank material; then, performing hot-pressing compounding of the precast blankand a steel plate after the surface plating to obtain a foamable composite plate sandwiching the precast blank; placing the foamable composite plate sandwiching the precast blank in a mould sleeve closed around, and delivering into an infrared foaming furnace heating at the upper and lower parts at the same time so as to heat and foam the composite plate sandwiching the precast blank under infrared radiation; and finally, pulling the mould sleeve out of the foaming furnace, and cooling to obtain a foamed aluminum sandwich plate with a fixed thickness. The foamed aluminum sandwich plate prepared by the method provided by the invention has an accurate thickness, a uniform structure and a high yield; and moreover, the preparation processes in the invention can be automatically controlled, thereby being favorable for realizing semi-continuous preparation of the foamed aluminum sandwich plate.

Owner:NORTHEASTERN UNIV

Preparation method of self-adhesion silicon rubber foam material

The invention provides a preparation method of a self-adhesion silicon rubber foam material. The method comprises the following steps: mixing silicon rubber, a foaming agent, a vulcanizing agent, a reinforcing agent and micromolecular silicon oil as raw materials, milling and sheeting, and performing heat treatment foaming to obtain the self-adhesion silicon rubber foam material. Compared with an existing preparation method, the method has the characteristics that the used raw materials have few varieties and are simple and easy to prepare, low in cost and free of environmental pollution; moreover, by adopting the heat treatment foaming technology, the prepared silicon rubber material is a foam material for foaming, which is high in foaming efficiency, light in weight, excellent in heat insulation property, high and low-temperature resistance, chemical stability and physiological inertia and good in self-adhesion performance, and the force of adhesion between the foam material and an aluminum plate is 10-25N / mm.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

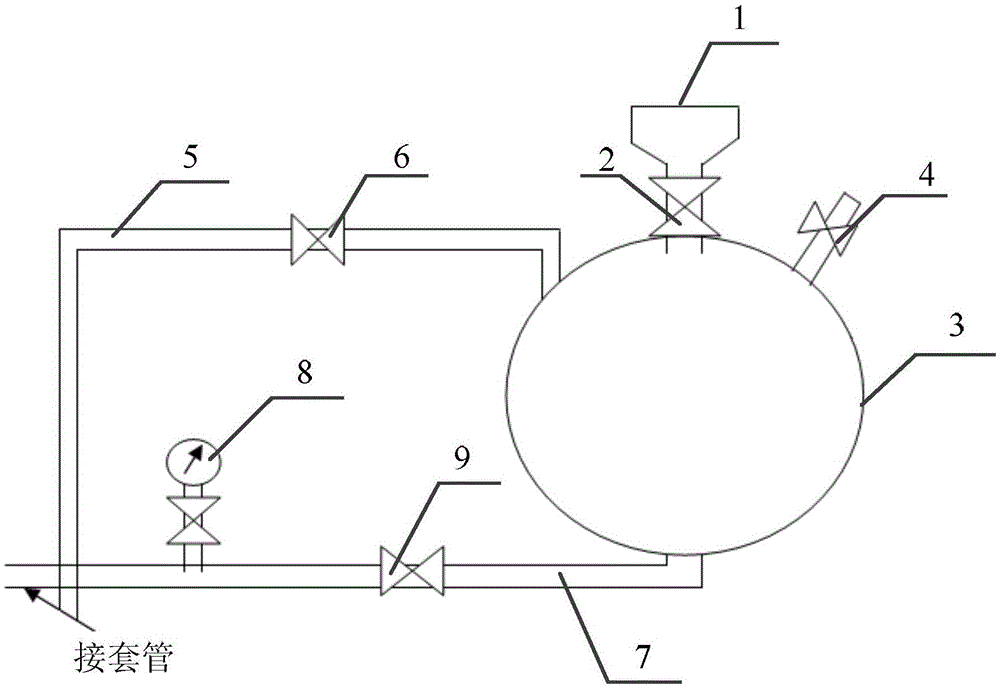

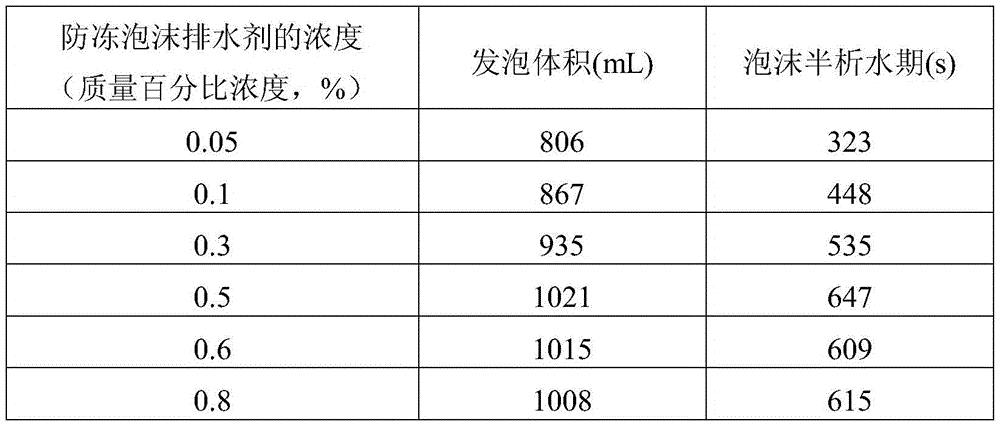

Antifreezing foaming drainage agent, and preparation method and application thereof

ActiveCN105670591AGood thermal stabilityImprove foaming efficiencyFluid removalDrilling compositionUreaChemistry

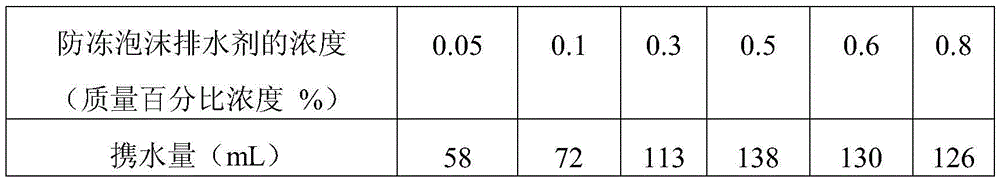

The invention provides an antifreezing foaming drainage agent, and a preparation method and application thereof. The antifreezing foaming drainage agent is prepared from the following raw materials in percentage by weight: 20-35% of fatty alcohol polyethenoxy ether phosphate sodium salt, 10-20% of sodium alpha-olefin sulfonate, 2-3% of polyanionic cellulose, 1-2% of coco fatty acid diethanol amide, 2-4% of alcohol, 1-1.5% of potassium carbonate, 1-1.5% of sodium chloride, 0.5-1% of urea, 0.5-1% of sodium acetate and the balance of water. The preparation method comprises the following step: sequentially adding the raw materials into a reaction vessel while stirring. The antifreezing foaming drainage agent provided by the invention has the advantages of excellent oil resistance, excellent salt tolerance, excellent foaming capacity, excellent water carrying capacity and low solidifying point (-30 DEG C), and is suitable for drainage and gas recovery operation of natural gas wells under severe cold conditions.

Owner:PETROCHINA CO LTD

Novel thermal insulation mortar foaming agent and preparation method thereof

The invention provides a novel thermal insulation mortar foaming agent and a preparation method thereof, belongs to the technical field of foaming agent and provides the novel thermal insulation mortar foaming agent, which is characterized by small generated foams, independent enclosing, high intensity, good stability and excellent uniformity and dispersity, and the preparation method thereof. The novel thermal insulation mortar foaming agent is prepared by the following components in part by weight: 4 to 20 parts of lauryl sodium sulfate, 5 to 15 parts of sodium dodecyl benzene sulfonate, 1 to 10 parts of alpha-olefin sulfonate, 0.01 to 3 parts of HPMC, 0.01 to 3 parts of gelatine powder, 1 to 10 parts of glue, 0.02 to 3 parts of polyether emulsion, 1 to 10 parts of animal protein, 50 to 70 parts of water, 5 to 10 parts of sodium alcohol ether sulphate, 10 to 15 parts of rosin, 0.01 to 2 parts of ninol, 1 to 10 parts of siliceous dust, 0.02 to 3 parts of silicon resin, 0.1 to 3 parts of water reducer, 1 to 5 parts of caustic soda and 0.1 to 2 parts of hydrochloric acid. The novel thermal insulation mortar foaming agent is applied to the technical field of foaming agent.

Owner:太原思科达科技发展有限公司

Polyurethane foam for all-plastic plastic runway and preparation method thereof

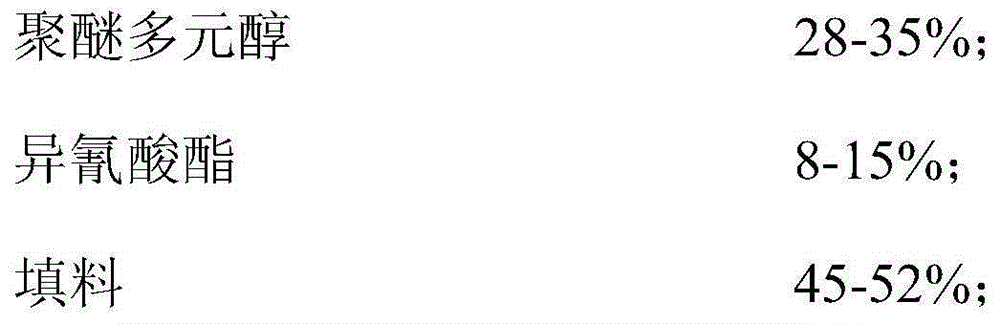

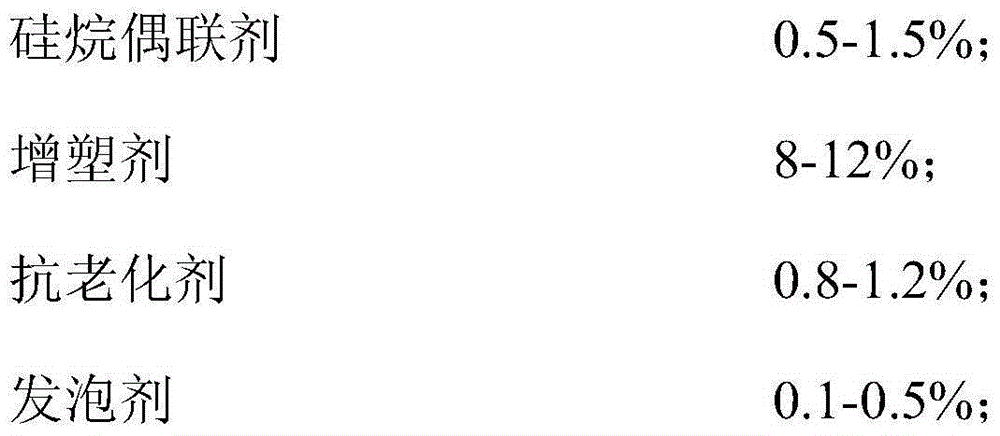

The invention provides polyurethane foam for an all-plastic plastic runway and a preparation method thereof. The preparation method comprises the steps that 28-35% of polyether polyol, 45-52% of stuffing, 8-12% of plasticizers and 8-15% of isocyanate are weighed by weight and react at 65-70 DEG C for 3-4 hours; the isocyanato quantity in the reaction system is detected; when the isocyanato quantity is 7.0-7.5, 0.5-1.5% of silane coupling agents are dropwise added in the reaction system until the isocyanato quantity in the system is 5.0-5.5; the temperature is lowered to 50-55 DEG C, then antiaging agents are added, the temperature is lowered, filtering and packaging are performed, and polyurethane is obtained; when construction is performed, foaming agents are added at room temperature for foaming to obtain the polyurethane foam. According to the polyurethane foam, the polyurethane is modified through the silane coupling agents, the foaming efficiency is improved, the better micro-air-bag structural material is obtained, and the requirements of an elastic layer of the plastic runway are met.

Owner:JIANGMEN CHANGHE CHEM IND GRP

Beef cattle breeding method

InactiveCN105638568AHigh nutritional valueEnhance physical fitnessAnimal husbandrySemenRectal examination

The invention provides a beef cattle breeding method. The beef cattle breeding method comprises the following steps that firstly, beef cattle of improved variety are selected; secondly, cows are raised; thirdly, a breeding method is conducted, wherein a, estrus induction is conducted on the cows close to the estrus, the cows are observed very carefully early in the morning and at nightfall, and observation is conducted every 4-5 hours in the daytime for estrus situation identification, and an outer observation method and a rectal palpation method for the follicular development degree are adopted as the estrus situation identification method, and b, artificial fertilization is conducted through a rectum grasping semen deposition method at estrus stage III; fourthly, the cows are kept under the precious care as long as pregnancy is confirmed according to the situation that the cows are not in estrus any longer within two to three months after semen deposition, or through rectum pregnancy check so that the cows can breed healthy calves, and if false pregnancy is found, re-copulation measures are taken in real time to reduce the breeding loss. By means of the method, the physique of the cows is improved, and the breeding rate of the beef cattle is further increased through estrus induction.

Owner:QUJING CHUANGYI FARMING CO LTD

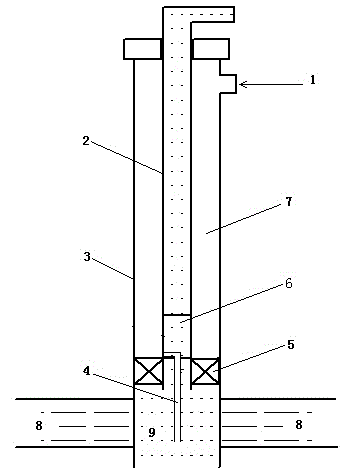

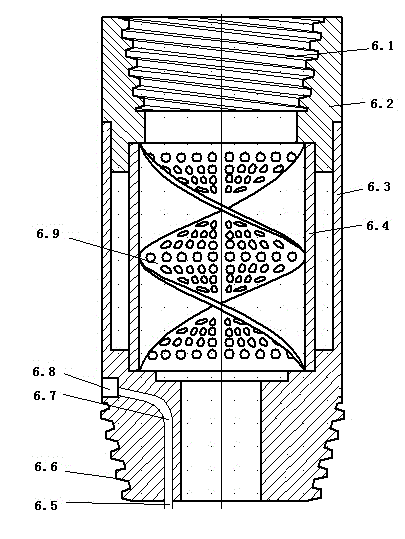

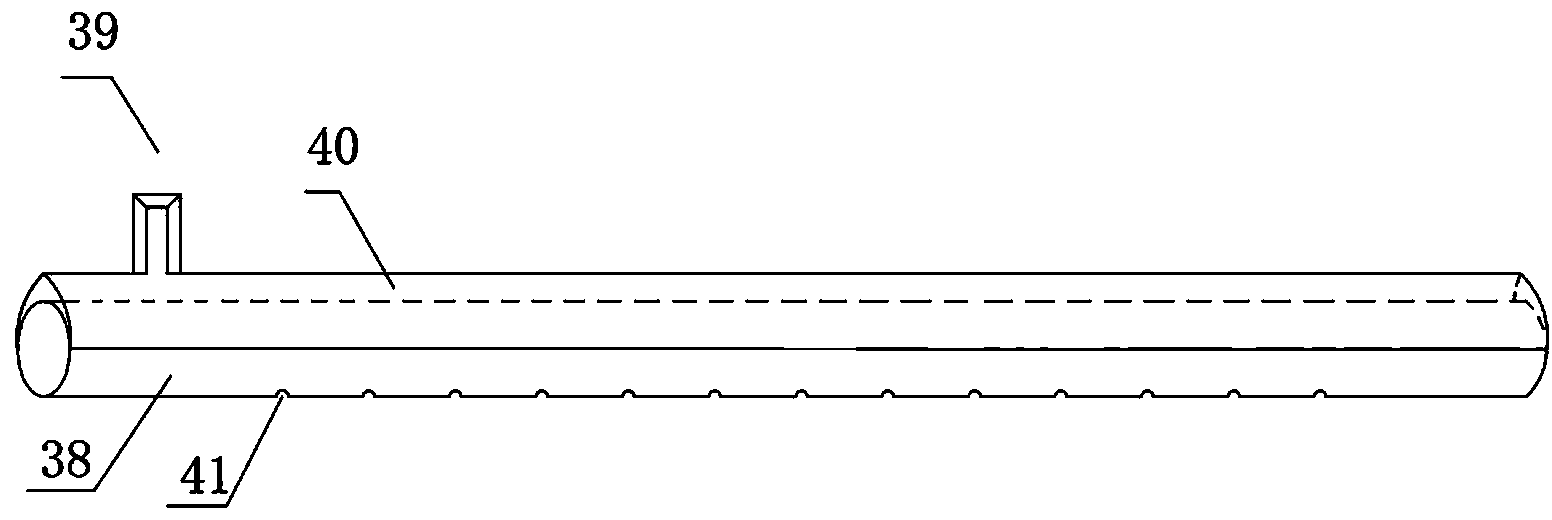

Liquid foaming agent injection method

The invention relates to a liquid foaming agent injection method, belonging to the field of natural gas exploitation. The method comprises the following steps: (1) mounting a packer at a pipe shoe of an oil pipe to separate the oil sleeve annulus and the well bottom; (2) mounting a short coupling on the upper part of the packer, wherein the side surface of the short coupling is provided with a foaming agent channel which communicates the oil sleeve annulus with the lower part of the short coupling, and the lower part of the short coupling is connected with capillaries and communicated to an accumulated liquid on the middle lower part of the well bottom all along; (3) injecting the foaming agent from a well mouth oil sleeve annulus gate to the oil sleeve annulus, wherein the foaming agent resides and gathers at the oil sleeve annulus on the upper part of the packer, and enters the accumulated liquid through the foaming agent channel of the short coupling and the capillaries on the lower part; and (4) mixing natural gas and the foaming agent solution, wherein the mixture passes through a torsional porous plate at the center of the short coupling, enters the oil pipe on the upper part, and is finally discharged. The invention enhances the utilization ratio of the foaming agent, the mixing degree of the foaming agent with the well bottom accumulated liquid, and the foaming efficiency, reduces the use amount of capillaries, and lowers the cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

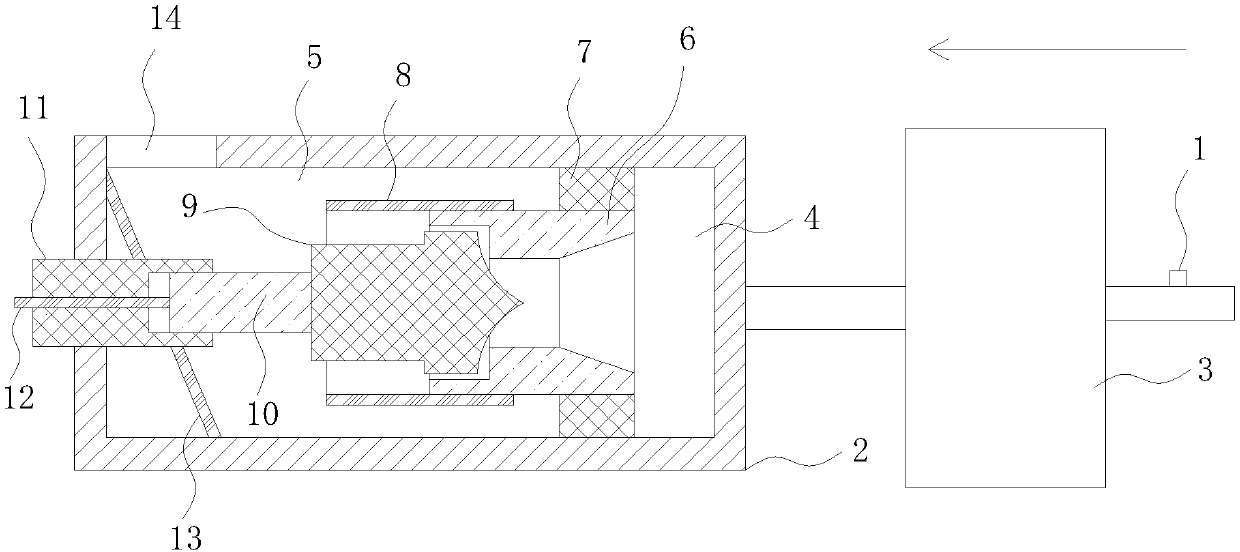

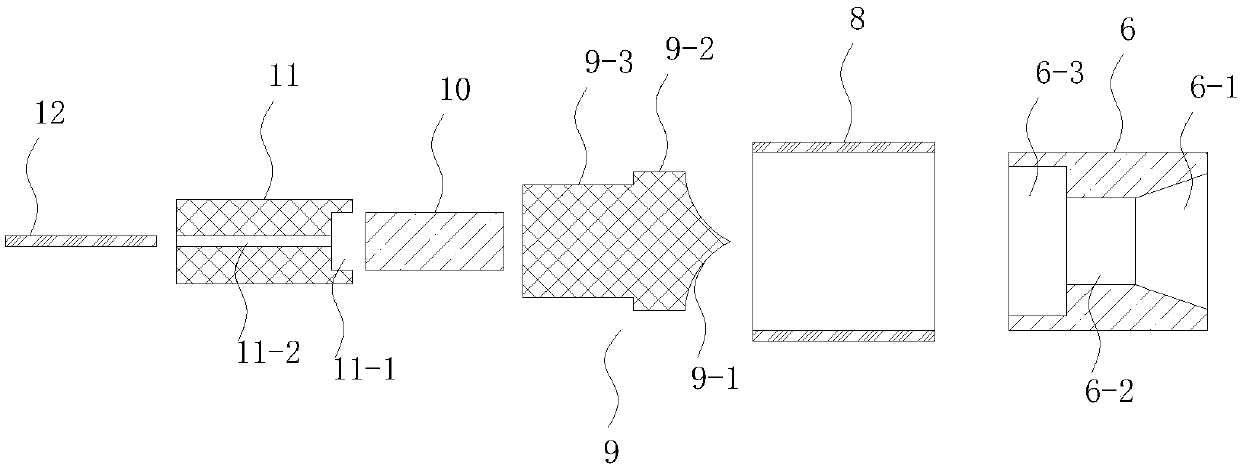

Micro-nano bubble generating device

ActiveCN107737537AEasy to operateLow costFlow mixersTransportation and packagingMicro nanoWater flow

The invention belongs to the technical field of micro-nano bubble equipment, and particularly relates to a micro-nano bubble generating device. The micro-nano bubble generating device comprises a multistage centrifugal pump and a pressure tank, wherein an air one-way valve air inlet is arranged on a water inlet pipe of the multistage centrifugal pump; a water outlet of the multistage centrifugal pump is communicated with a water inlet of the pressure tank through a pipeline; a flow guide pipe, a fixed plate and a sleeve are arranged in the pressure tank; the four side surfaces of the fixed plate are vertically and fixedly connected with the inner wall of the pressure tank; the inside of the pressure tank is divided into a water flow cavity and a bubble cavity; the flow guide pipe vertically sleeves the fixed plate and communicates with the water flow cavity; the sleeve sleeves the outer wall of the flow guide pipe and extends horizontally in a water flow direction; a movable piece is arranged in the flow guide pipe in clearance fit; one end of a movable piece is sleeved by the flow guide pipe, and the other end of the movable piece extends horizontally in the water flow direction;the other end surface of the movable piece is fixedly connected with one end of a connecting rod; and a moving device which can be used for adjusting the moving of the connecting rod in the axial direction of the connecting rod is arranged on the side surface of the pressure tank. The micro-nano bubble generating device provided by the invention has the advantages of simple operation, low cost, high foaming efficiency and low energy consumption.

Owner:金锐荣贸易有限公司

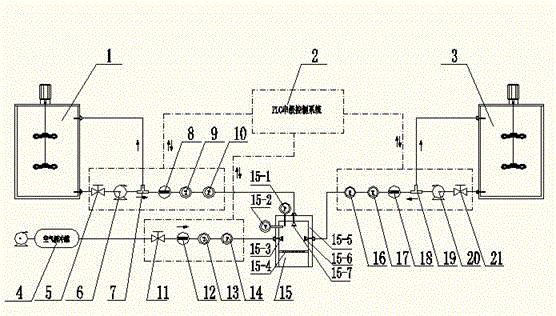

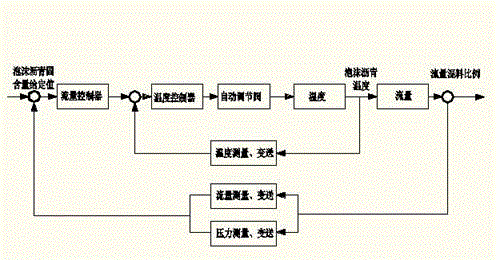

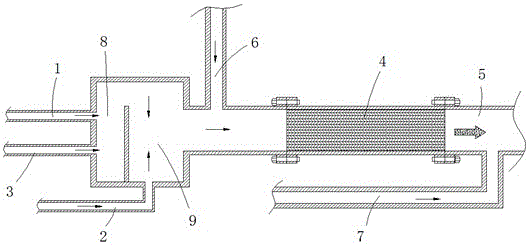

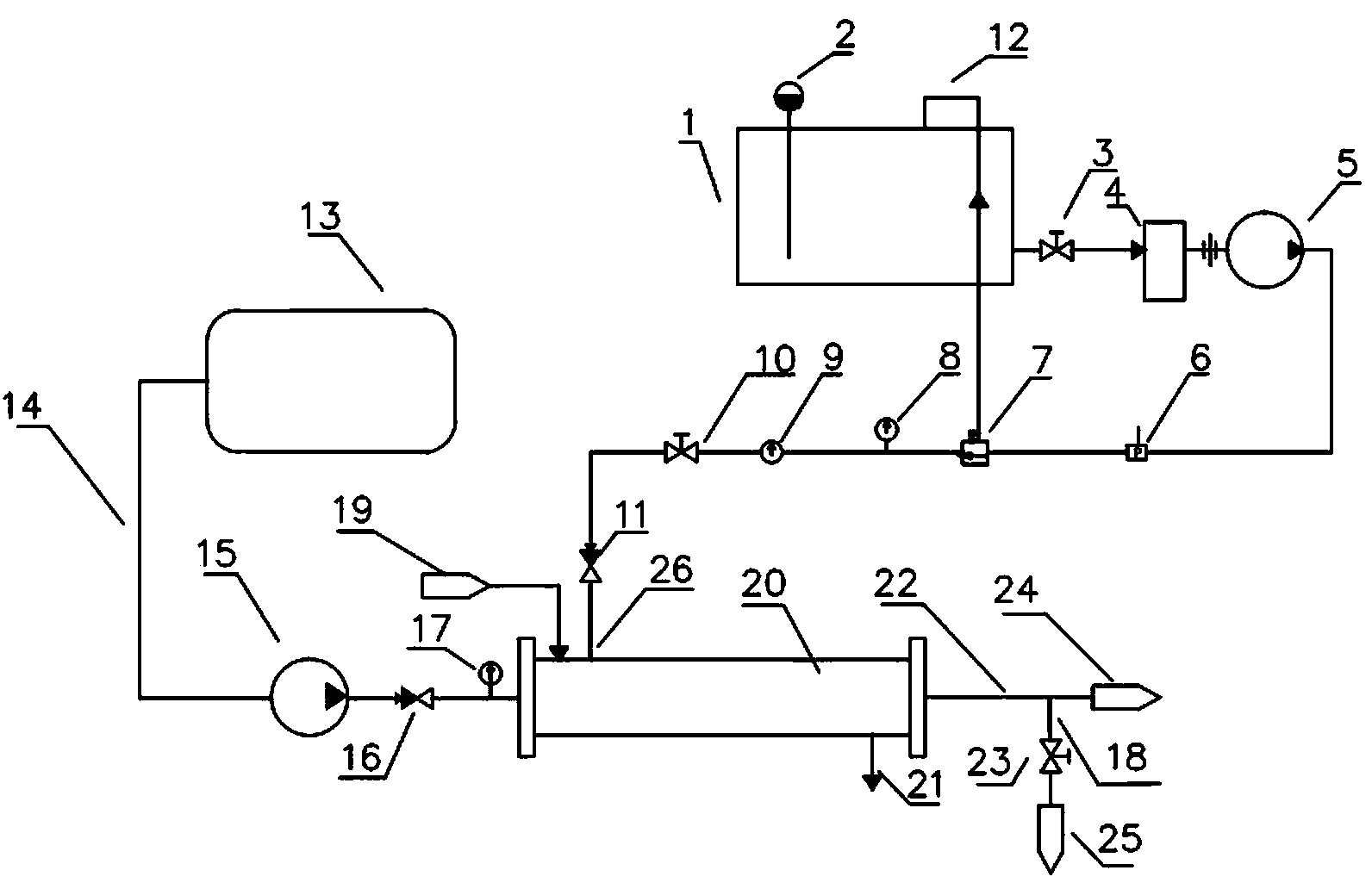

Foam asphalt production device and automatic production method

The invention discloses a foam asphalt production device and an automatic production method. The device comprises a hot asphalt tank, a water tank, an air compressor, a hot asphalt feeding device, a water feeding device, an air feeding device, a foam asphalt generator and a PLC control system. Hot asphalt, water, and air are mixed in the foam asphalt generator to generate foam asphalt, and the foamed asphalt is homogenized by the foam asphalt generator. The hot asphalt, water, and air feeding devices respectively transfer the hot asphalt, water, and air into the foam asphalt generator from the hot asphalt tank, the water tank, and the air compressor. The PLC control system sends the measured temperature, flow, and pressure signals of hot asphalt, water, and air to a PLC controller to perform control calculation, then carries out cascade-stage control adjustment on the flow, temperature, and pressure of hot asphalt, water and air according to the foaming degree of foam asphalt, and thus achieves the automatic production of foam asphalt.

Owner:UNIV OF JINAN

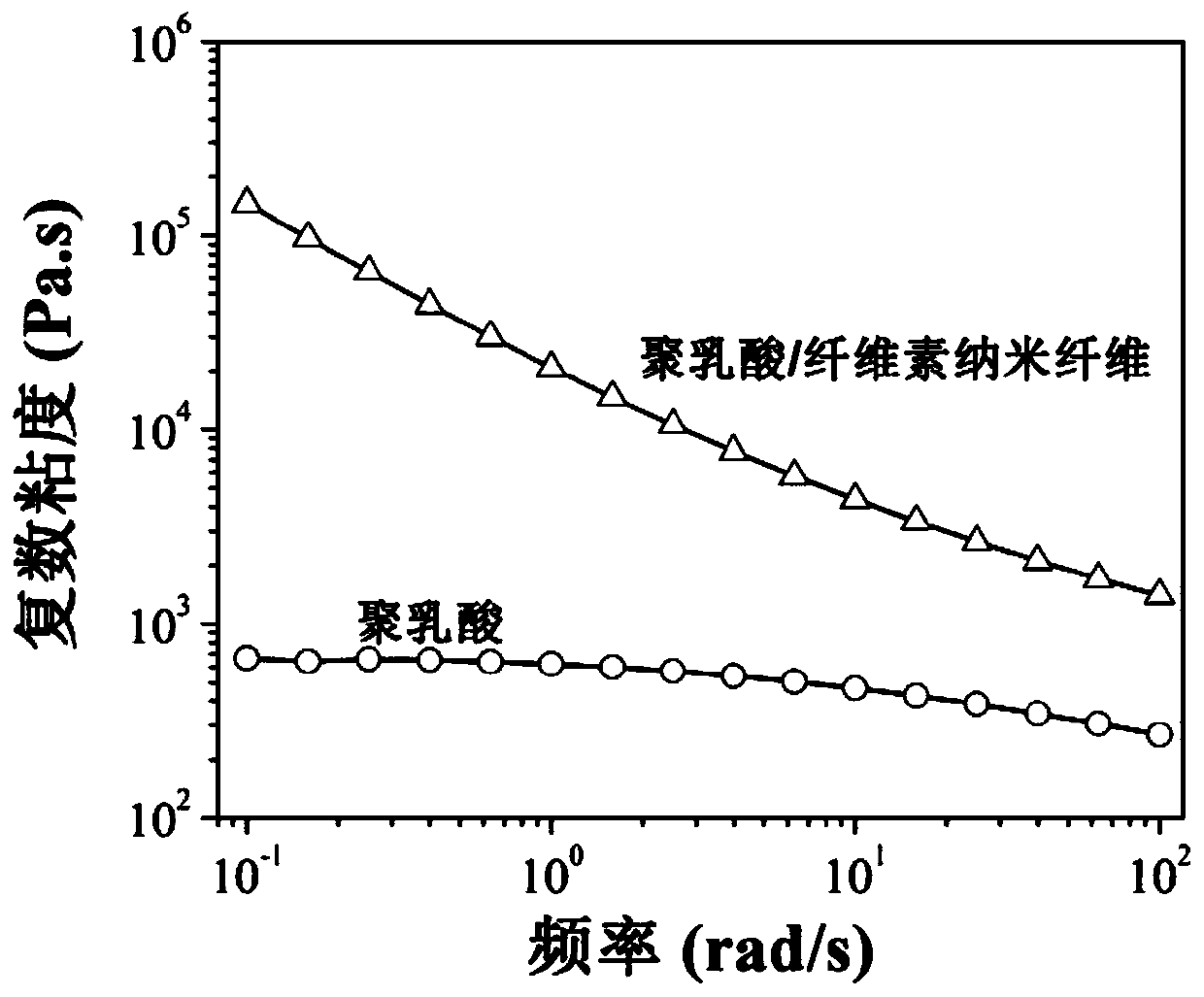

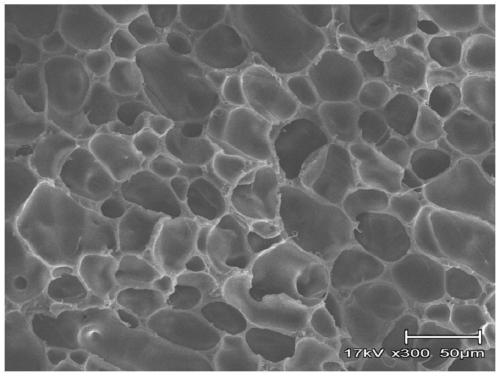

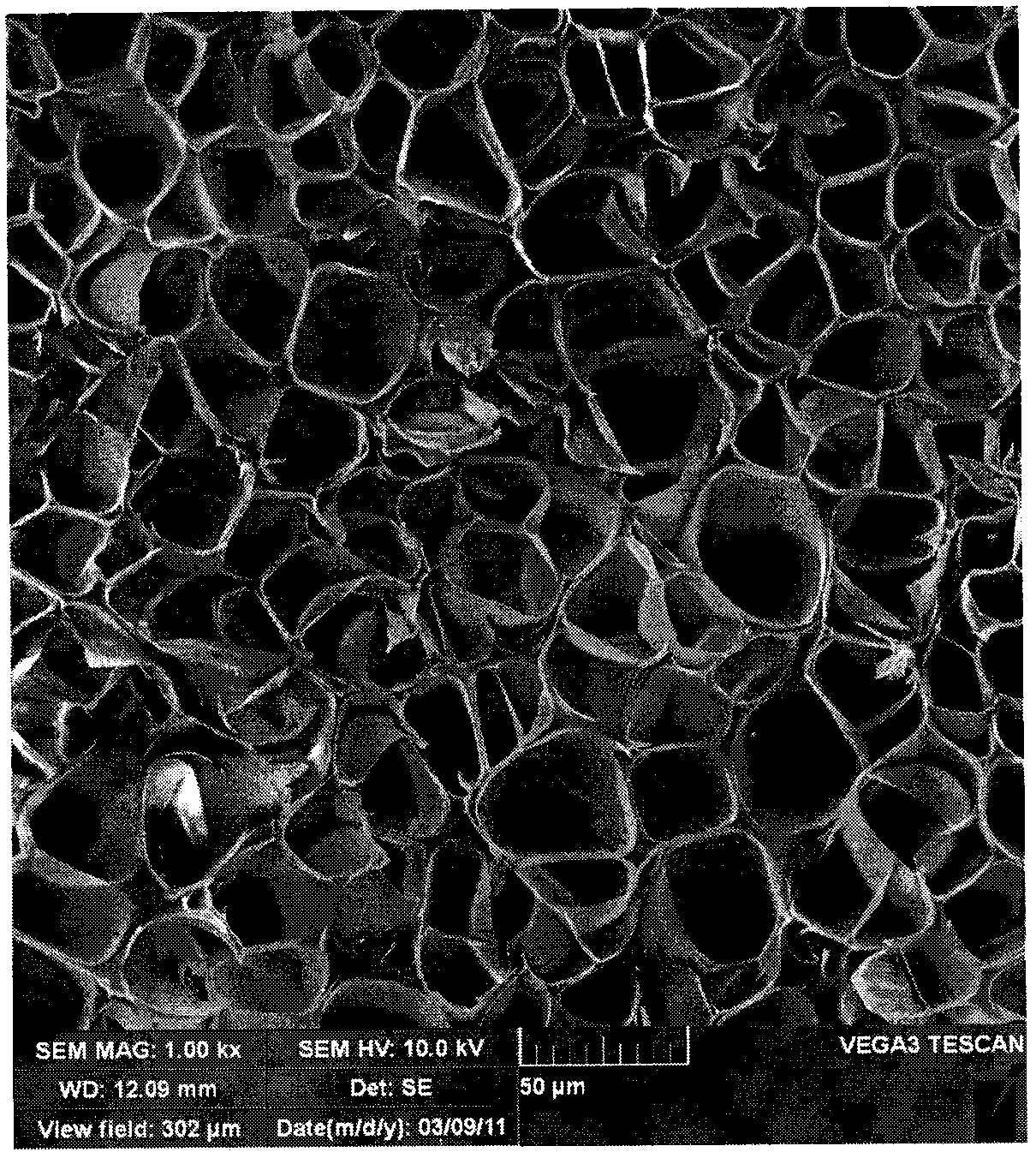

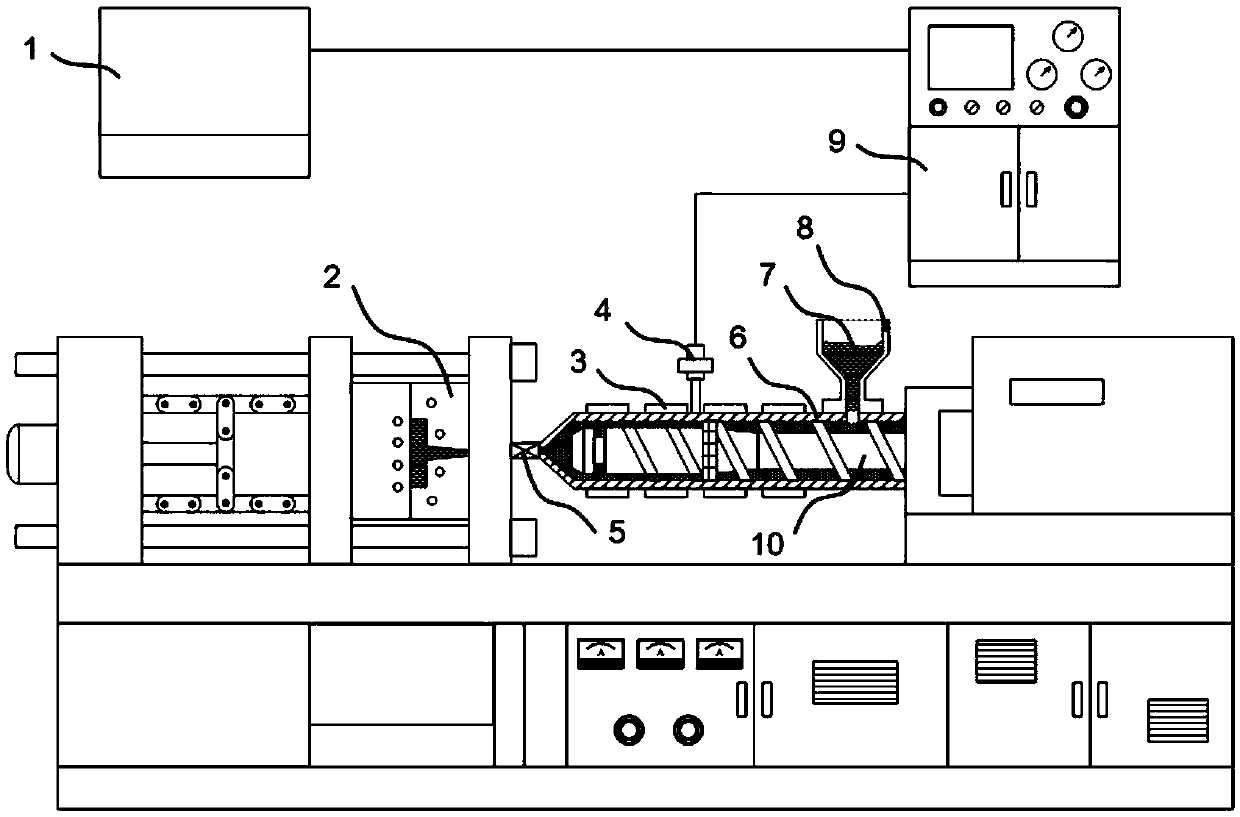

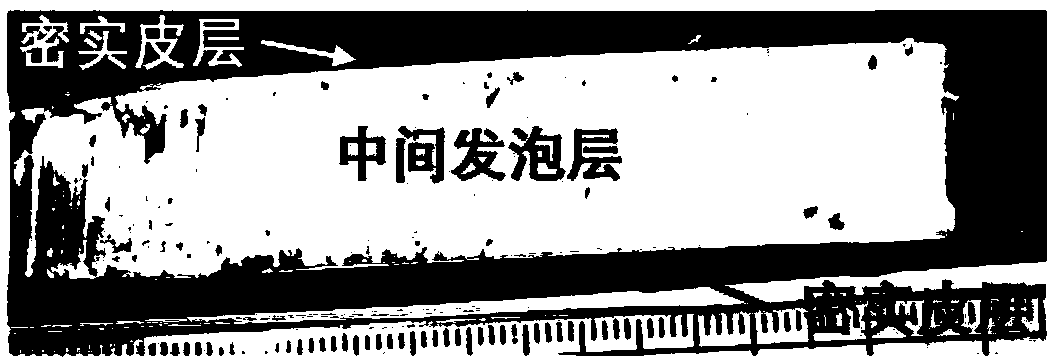

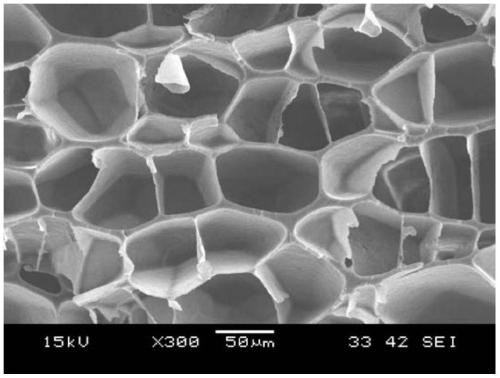

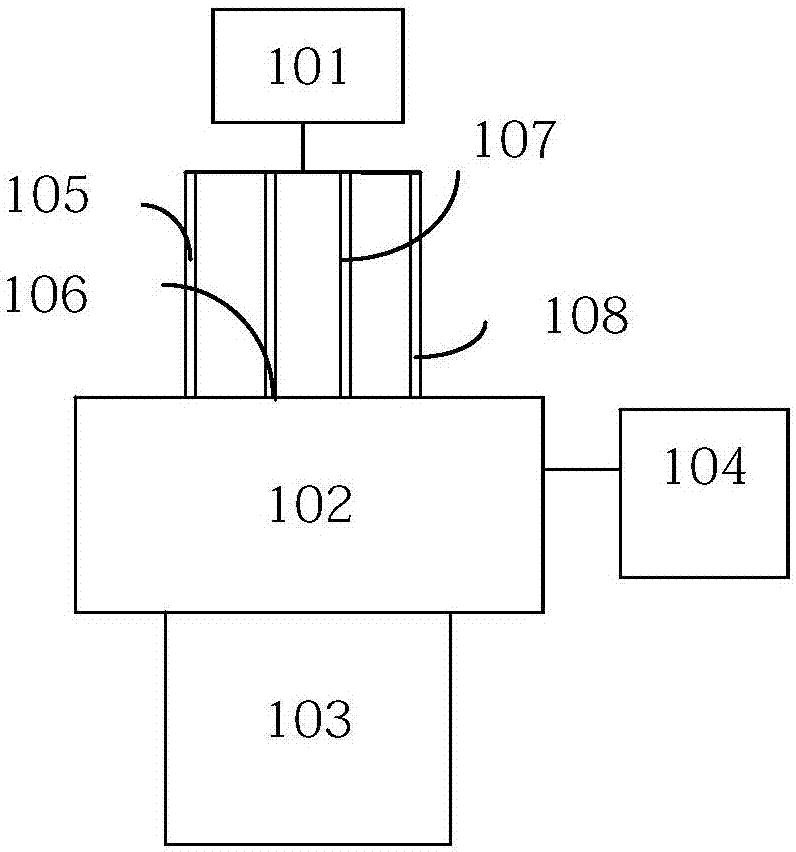

Supercritical fluid injection molding foaming polylactic acid foam material and preparation method thereof

ActiveCN111286070AIncrease cell densityHigh crystallinityLayered productsCellulose pulp after-treatment modificationCelluloseFoaming agent

The invention discloses a supercritical fluid injection molding foaming polylactic acid foam material and a preparation method thereof. The light high-strength polylactic acid foam material is prepared by modifying biological filler cellulose nanofibers, and the crystallization property and melt property of the polylactic acid material are improved by using the cellulose nanofibers as a nucleatingagent. The prepared cellulose nanofiber modified polylactic acid composite material is uniformly mixed with a supercritical fluid foaming agent in a microcellular foaming injection molding machine, and microcellular injection foaming molding is carried out through a mold opening and closing foaming device to obtain the full-bio-based polylactic acid foaming material. The microcellular foaming cellulose nanofiber / polylactic acid composite material which is uniform in cell size, high in cell density and good in performance is prepared, and the preparation method has the outstanding advantages of being high in production efficiency, high in operability, stable, reliable, easy for industrial production and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

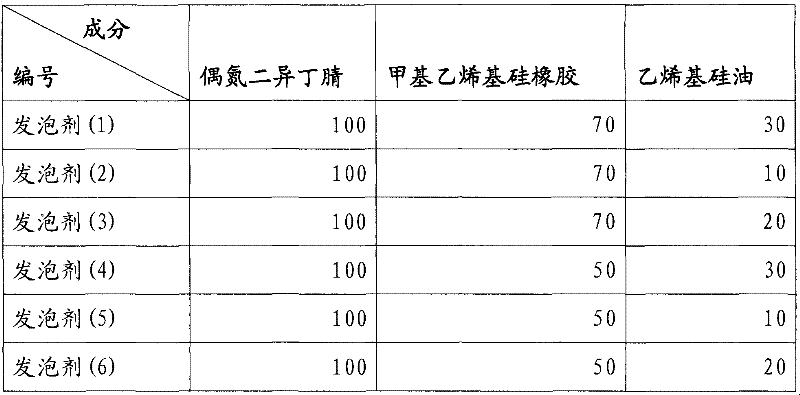

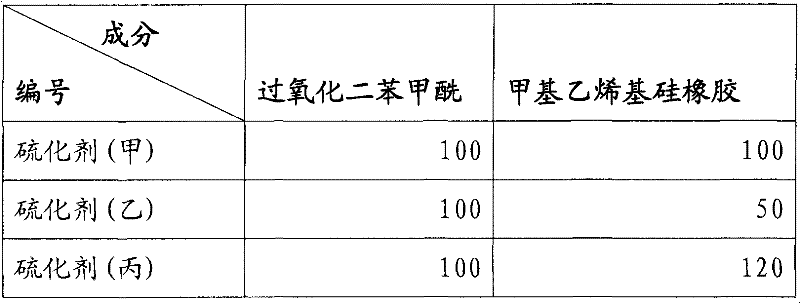

Composition for producing foaming silica gel plate and production method of foaming silica gel plate

InactiveCN102220003AImprove foaming efficiencyHigh foaming ratioFlat articlesContinuous productionDibenzoyl Peroxide

The invention discloses a composition for producing a foaming silica gel plate and a production method of the foaming silica gel plate. The composition for producing the foaming silica gel plate comprises the following ingredients by weight: 100 of silicon rubber, 3-4 of foaming agent, 1-2 of vulcanized agent and 1 of colorant, wherein the foaming agent comprises the following ingredients by weight, 100 of azodiisobutyronitrile, 50-80 of methyl vinyl silicone rubber, and 10-30 of vinyl silicon oil, and the vulcanized agent comprises 100 of dibenzoyl peroxide and 50-120 of methyl vinyl silicone rubber. The production method of the foaming silica gel plate comprises the following steps: mixing, calendaring, synchronization foaming under normal pressure and vulcanization, so as to prepare the continuous foaming silica gel plate. Compared with the prior art, the foaming silica gel plate has the advantages of high foaming multiplying power and low density; and the foaming silica gel plate can be continuously produced by adopting the production method of the foaming silica gel plate, and the production method has the advantages of high raw material utilization rate and low labor intensity.

Owner:罗华兴

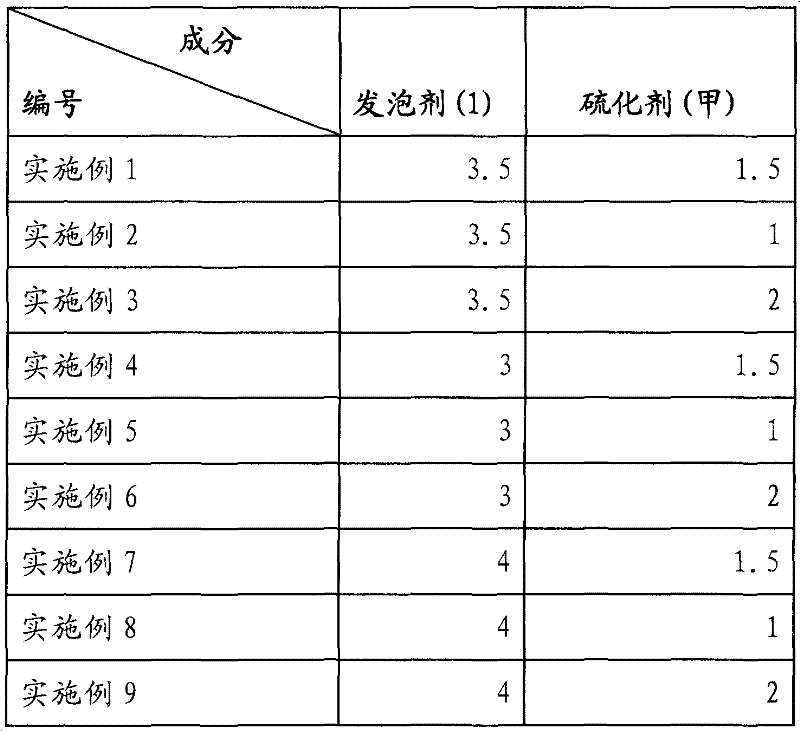

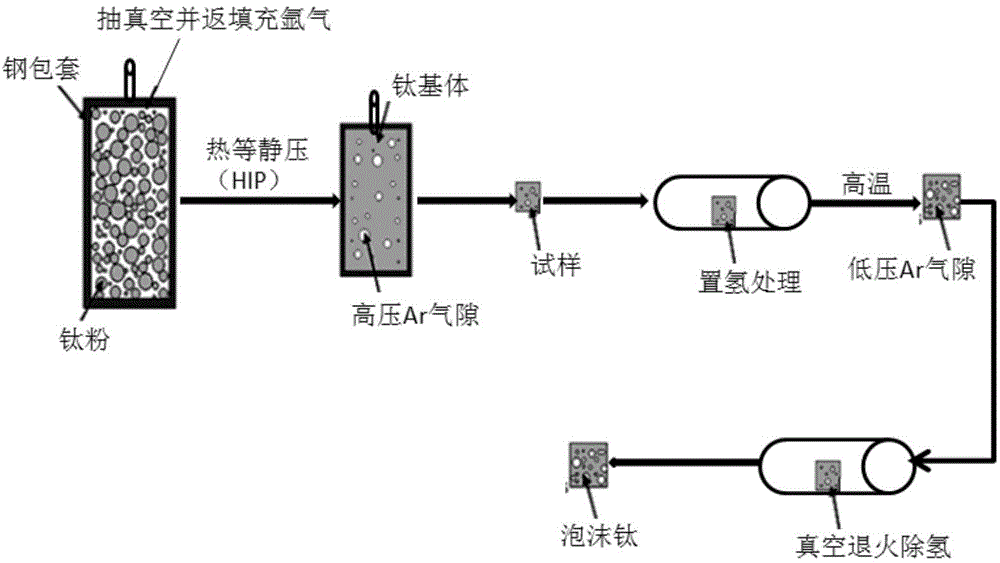

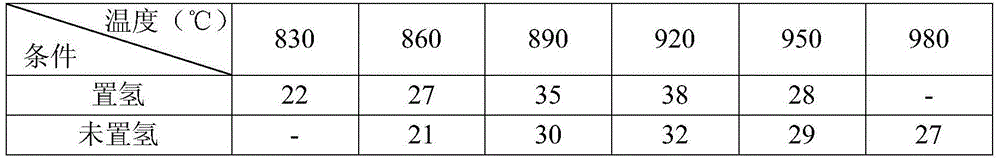

Preparation method of foam titanium under hydrogen-assisted action

The invention provides a preparation method of foam titanium under the hydrogen-assisted action. The preparation method comprises the following four steps: preparing a preformed blank test sample, hydrogenating, foaming at high temperature and removing hydrogen, and specifically comprises the following steps: filling titanium powder into a steel capsule, performing vacuum-pumping, re-filling a certain pressure of argon, carrying out hot isostatic pressure and processing a preformed blank formed by the hot isostatic pressure into a cuboid shape; then putting into a hydrogen treatment furnace and filling a certain content of hydrogen; carrying out high-temperature foaming in the vacuum environment; finally putting into the hydrogen treatment furnace to carry out vacuum annealing to obtain the foam titanium. The preparation method of the foam titanium under the hydrogen-assisted action has the benefits that the hydrogen is introduced in the process of preparing the foam titanium by adopting a gas capture method, hydrogen-induced high-temperature plasticity is utilized to improve the foaming performance of the foam titanium and improve the foaming efficiency and the porosity of the foam titanium, and finally, the hydrogen is removed to optimize the mechanical property of the foam titanium. The preparation method has the characteristics of high product porosity and low preparation cost, and the industrial production can be realized. The preparation method can be applied to the fields of aerospace and the like.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

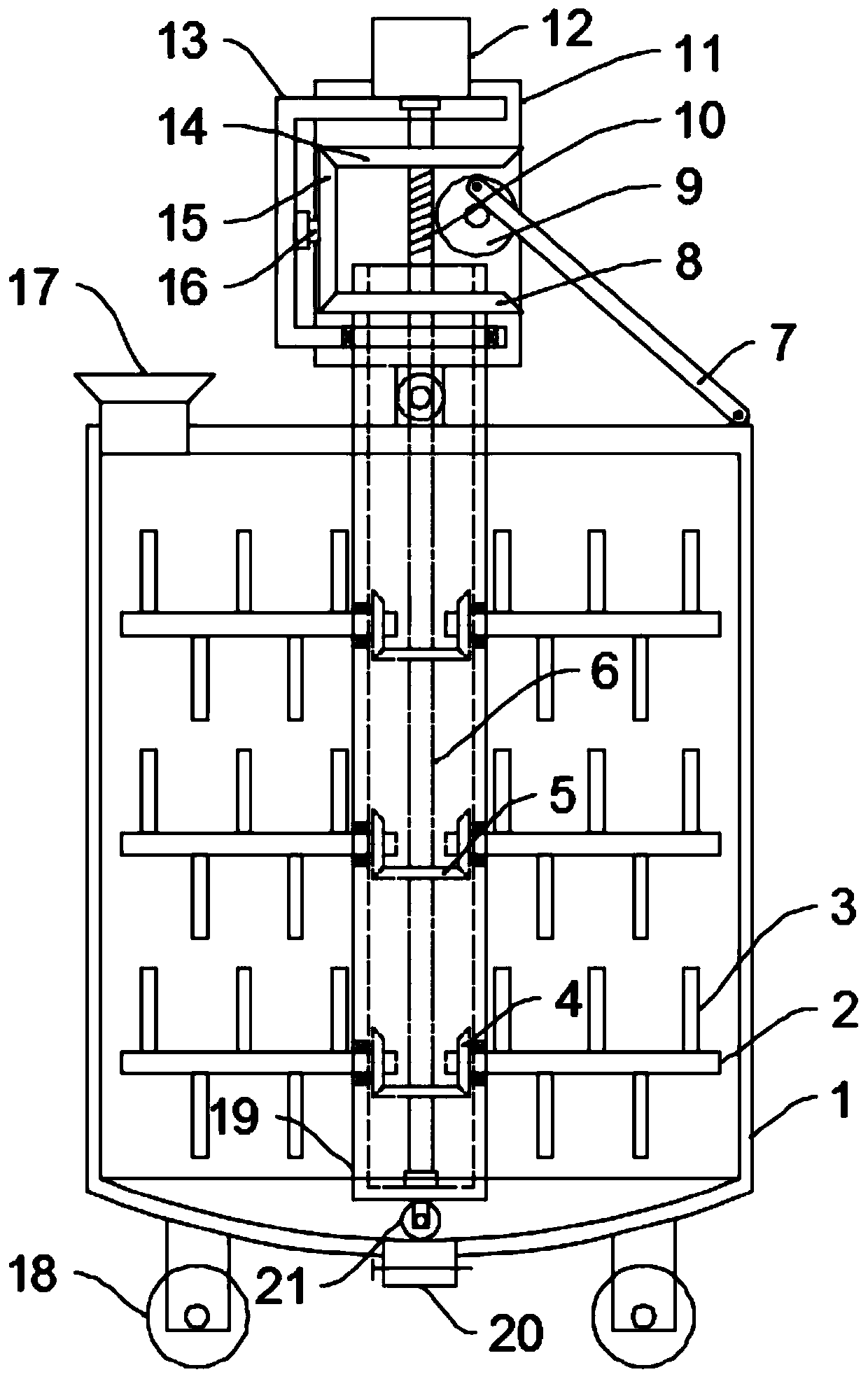

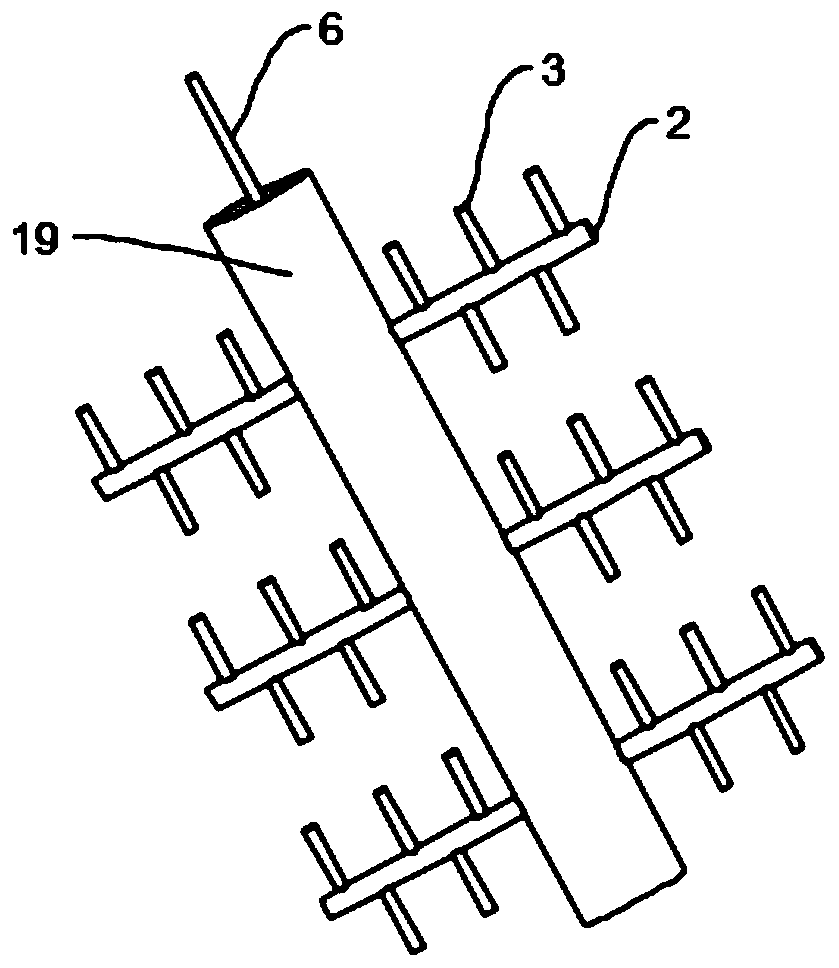

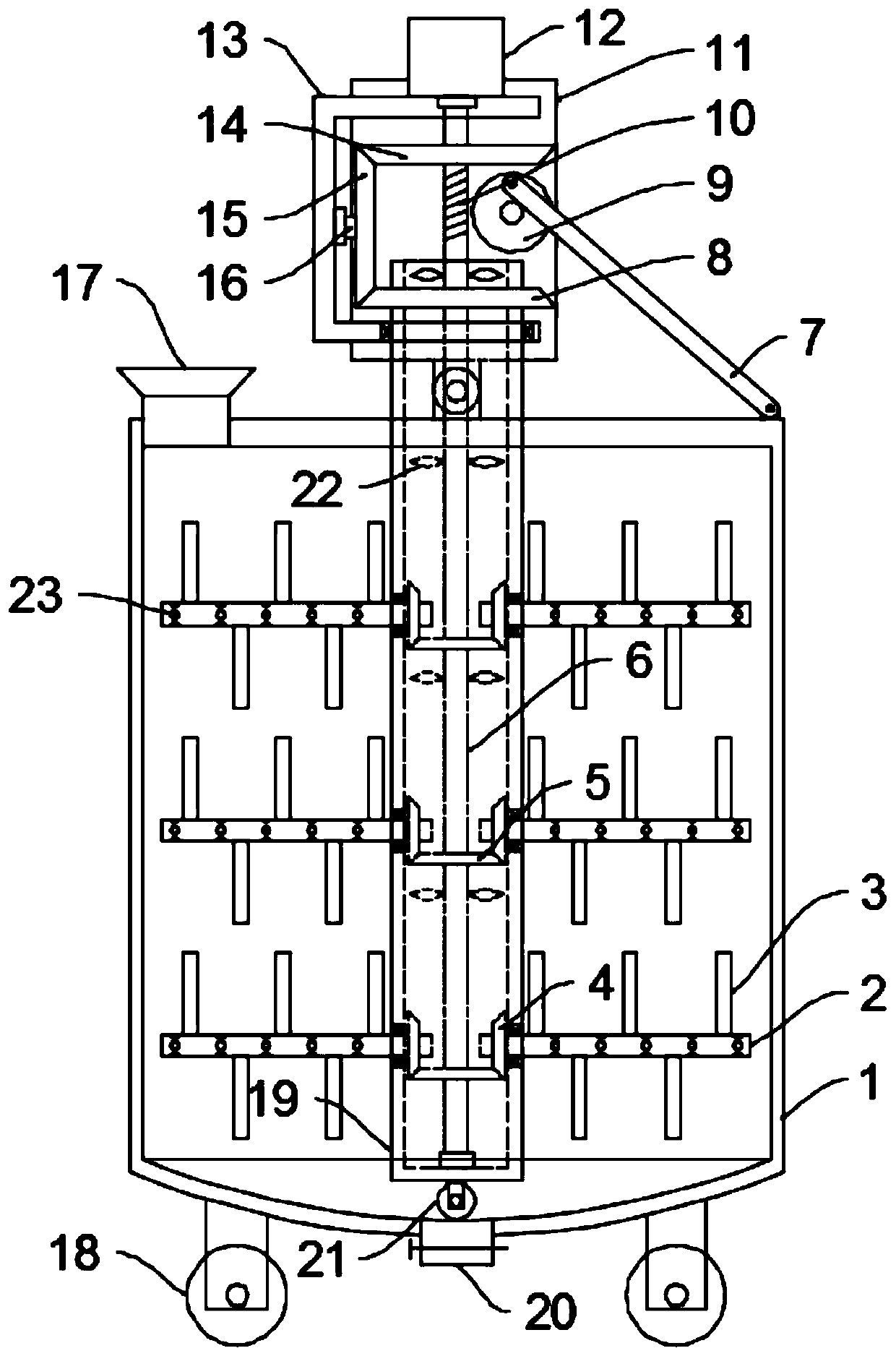

Machining equipment used for foamed concrete

InactiveCN111136792AStir wellImprove foaming efficiencyCement mixing apparatusElectric machineryEquipment use

The invention discloses machining equipment used for foamed concrete. The machining equipment comprises a barrel and a stirring assembly. The stirring assembly comprises a mounting column, a rotatingshaft, first bevel gears, second bevel gears, stirring rods, stirring branch rods, a mounting rack, a mounting plate, a motor, a driving bevel gear, a transmission bevel gear, a driven bevel gear, a worm segment, a worm gear and a connecting rod. An opening is formed in the top of the mounting column. Multiple air suction fan blades are mounted on the rotating shaft from top to bottom at intervals. Multiple aeration holes are evenly formed in the segment, located on the outer portion of the mounting column, of each stirring rod. The machining equipment is provided with the stirring assembly, the stirring rods drive the stirring branch rods to do autorotation while doing revolution, stirring is achieved sufficiently and evenly, and the concrete foaming efficiency is improved; by means of changes of the angles of the stirring rods and the stirring branch rods, the stirring range is widened; and the air suction fan blades and the aeration holes are arranged, when the rotating shaft rotates, wind is generated by the air suction fan blades, the wind enters the mounting column, then enters the stirring rods and is finally sprayed out from the aeration holes, more bubbles are generated, and the foaming efficiency is further improved.

Owner:JIANGSU PROVINCIAL CONSTR GRP CO LTD +2

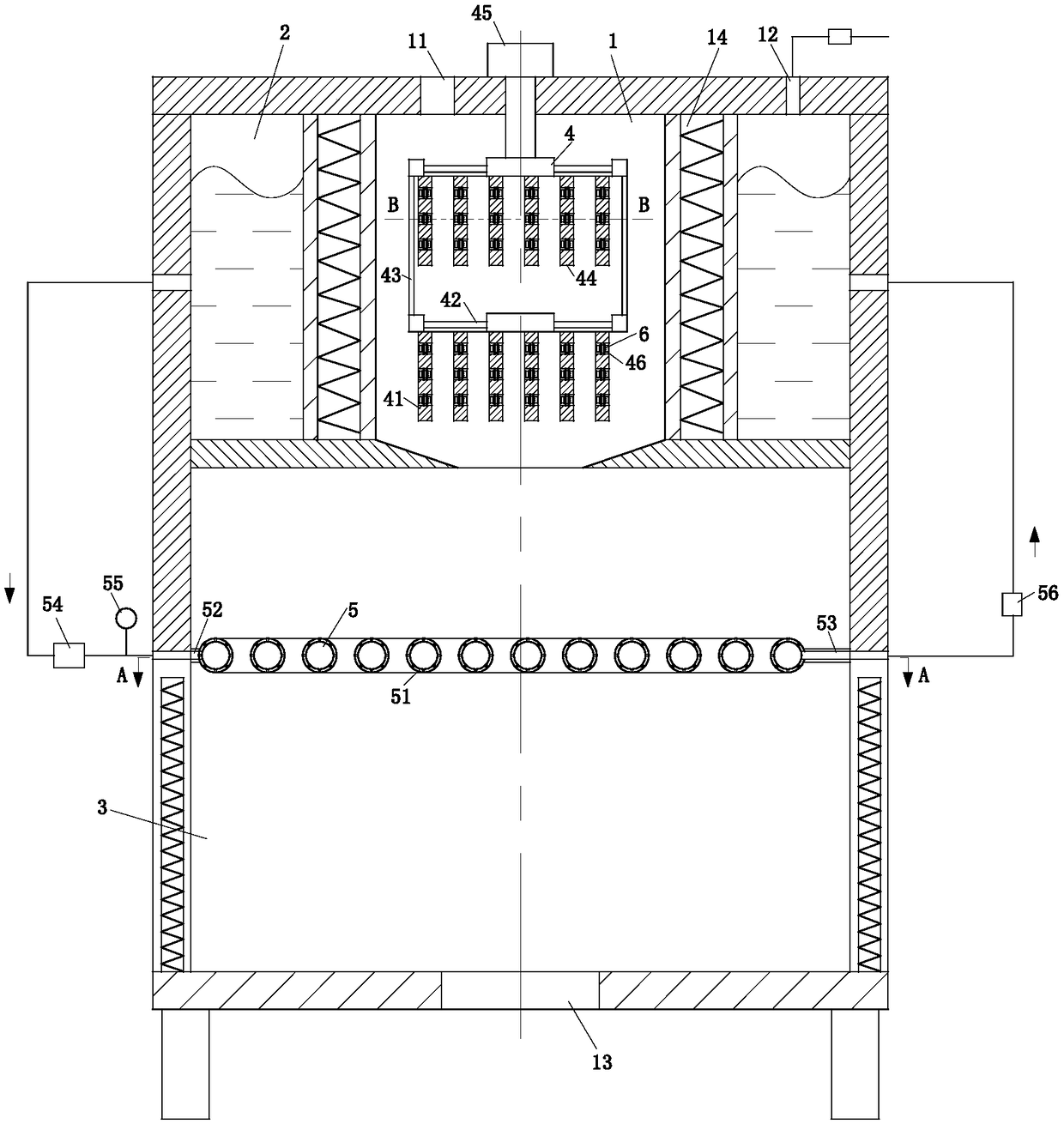

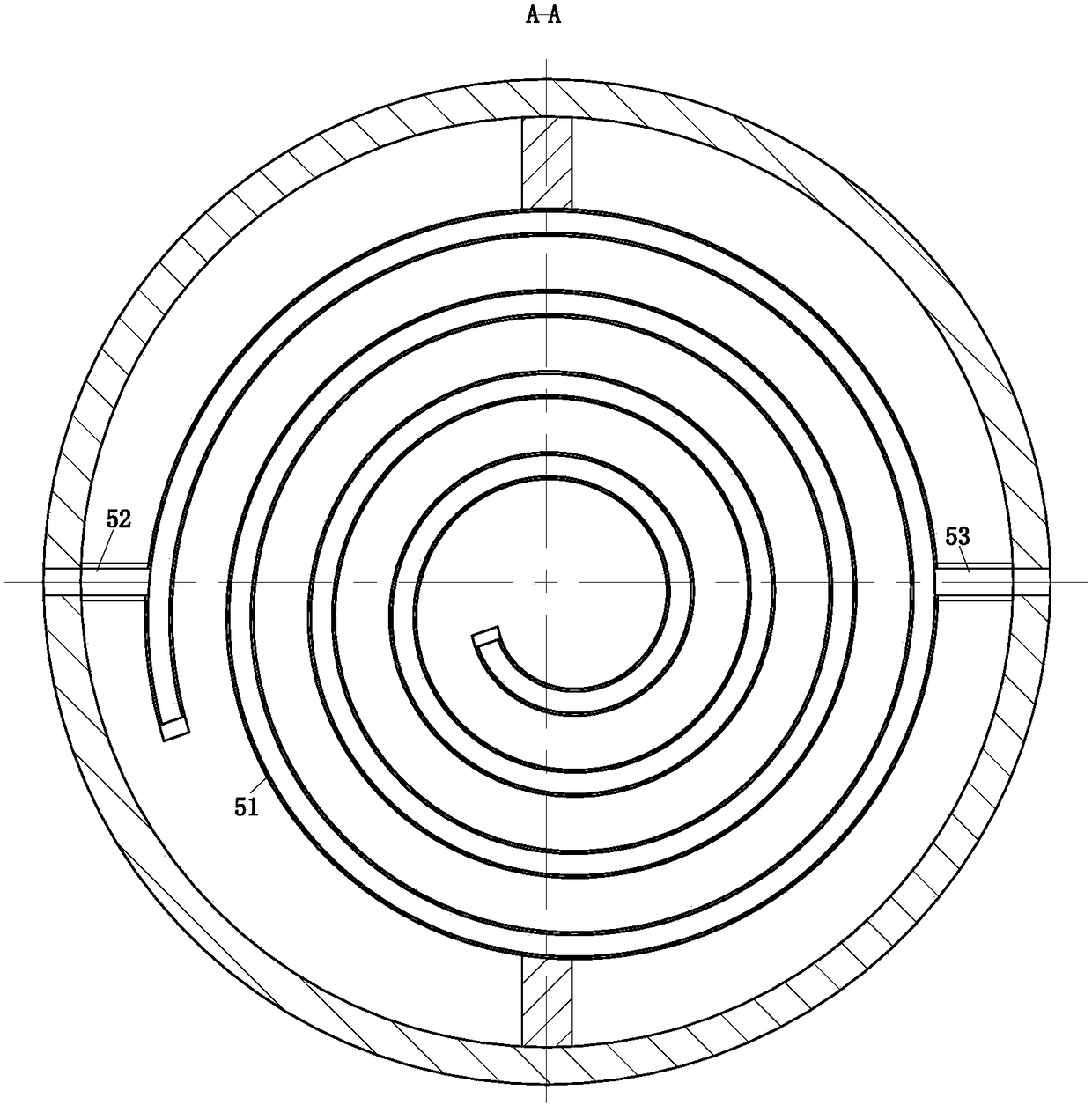

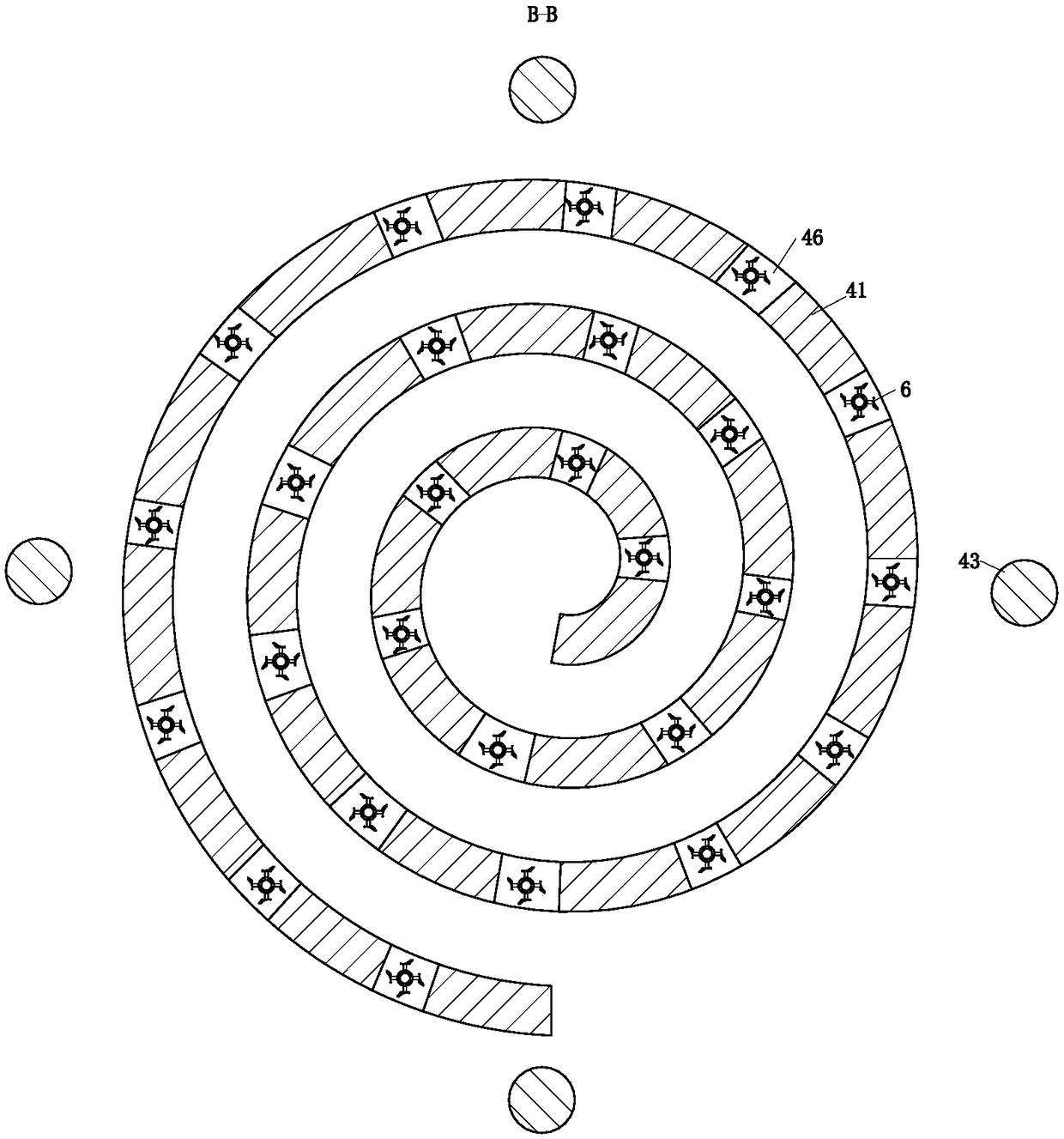

Polyurethane foaming system

The invention belongs to the technical field of polyurethane production equipment and particularly discloses a polyurethane foaming system. The polyurethane foaming system comprises a dual stirring unit and a water control unit, wherein a heating cylinder is fixedly mounted on the upper surface of an upper bottom plate II; a stirring bin is located in the heating cylinder; a water storage bin is located between the outer wall of the heating cylinder and a side plate I; a foaming bin is located between the upper bottom plate II and a lower bottom plate I; the dual stirring unit is located in the stirring bin; the water control unit is located in the foaming bin; a spiral plate I is fixedly mounted at the lower end of a connection rod I through a mounting rack I; the upper end of the connection rod I is fixedly connected with a mounting rack II; a spiral plate II is fixedly mounted on the lower surface of the mounting rack II. The invention discloses a processing method of dual stirringtype polyurethane heat insulation boards. The polyurethane foaming system is mainly used for producing the polyurethane heat insulation boards and is capable of rapidly and uniformly mixing the raw materials, accelerating the melting of the raw materials and improving the foaming quality of the raw materials.

Owner:于泽

Preparation method of polyvinyl alcohol microcellular foam material

InactiveCN107722332AShort saturation timeImprove foaming efficiencyMaterials preparationPVA - Polyvinyl alcohol

The invention relates to a method for preparing a polyvinyl alcohol microcellular foam material by utilizing the supercritical fluid technique. A polyvinyl alcohol composition is put in a device filled with a specific supercritical fluid at the specific soaking temperature at the soaking pressure, the heat and the pressure are preserved and maintained for a specific period of time, then the heat and the pressure are preserved and maintained for a specific period of time at the higher saturation temperature and higher saturation pressure of the supercritical fluid, the pressure is relieved at the specific decompression rate, and the polyvinyl alcohol microcellular foam material is obtained. The method is an efficient polyvinyl alcohol microcellular foam material preparation method suitablefor industrial production.

Owner:NINGBO UNIV

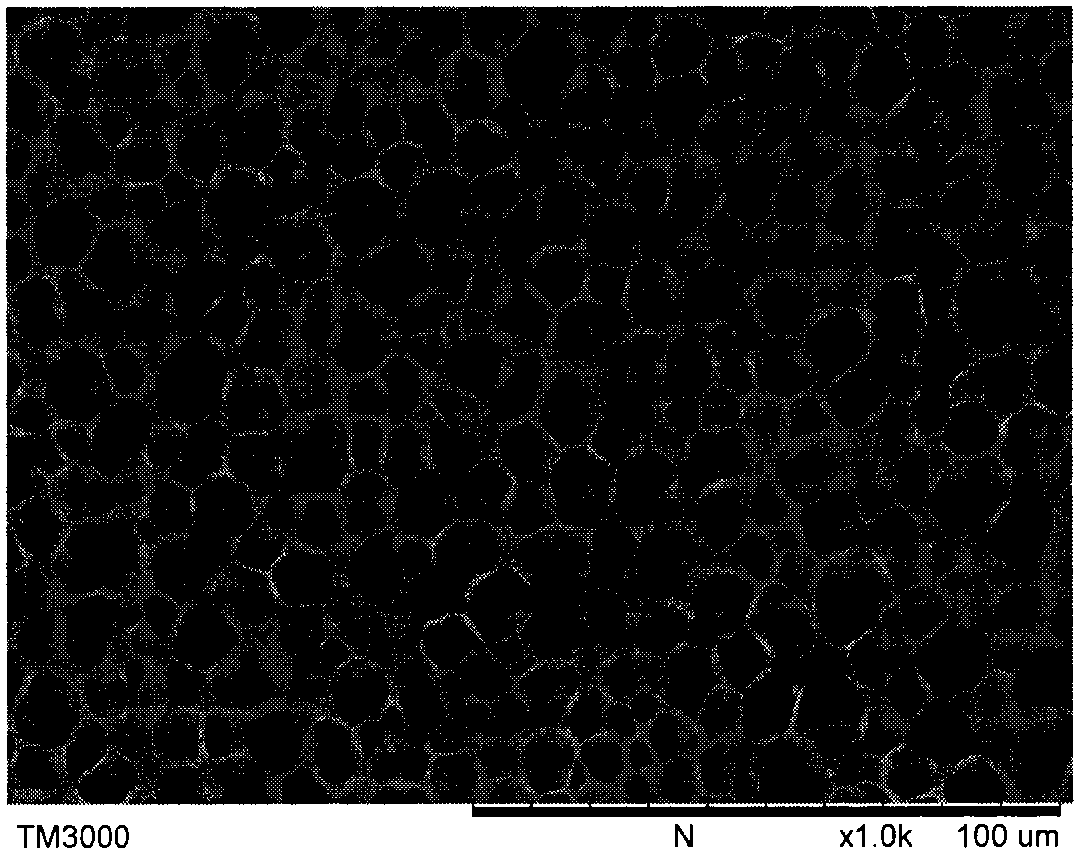

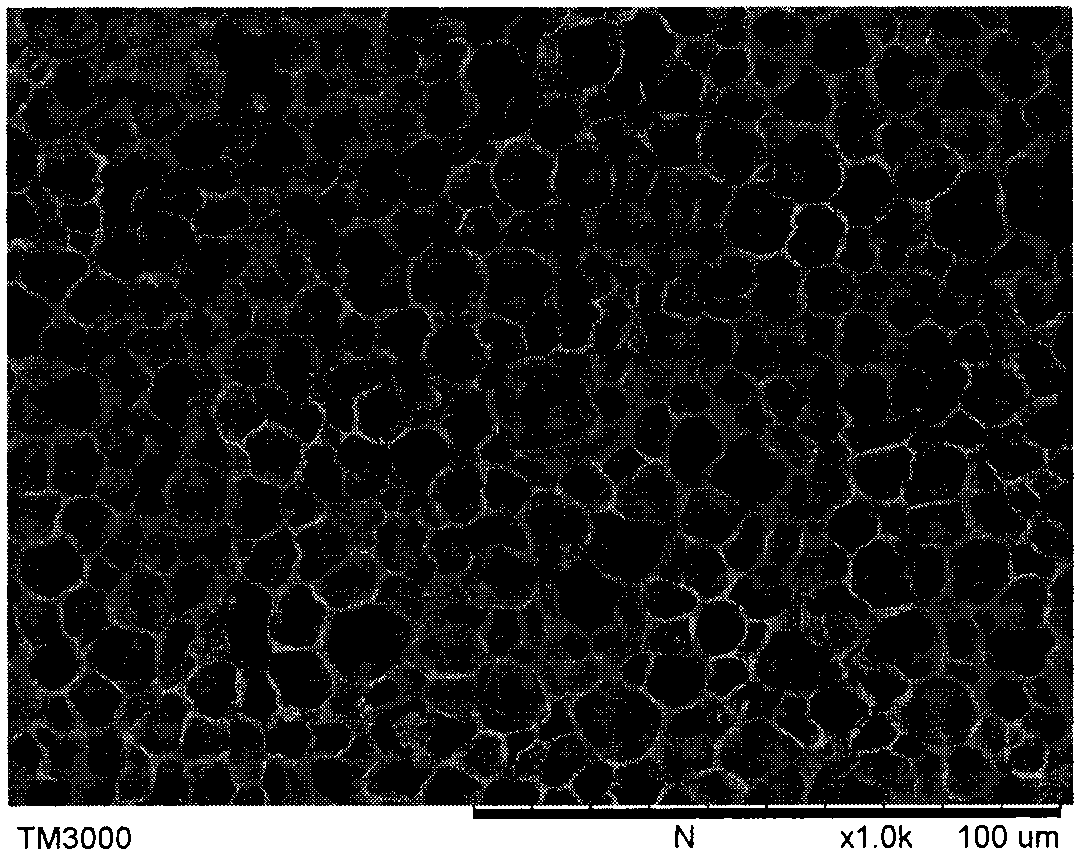

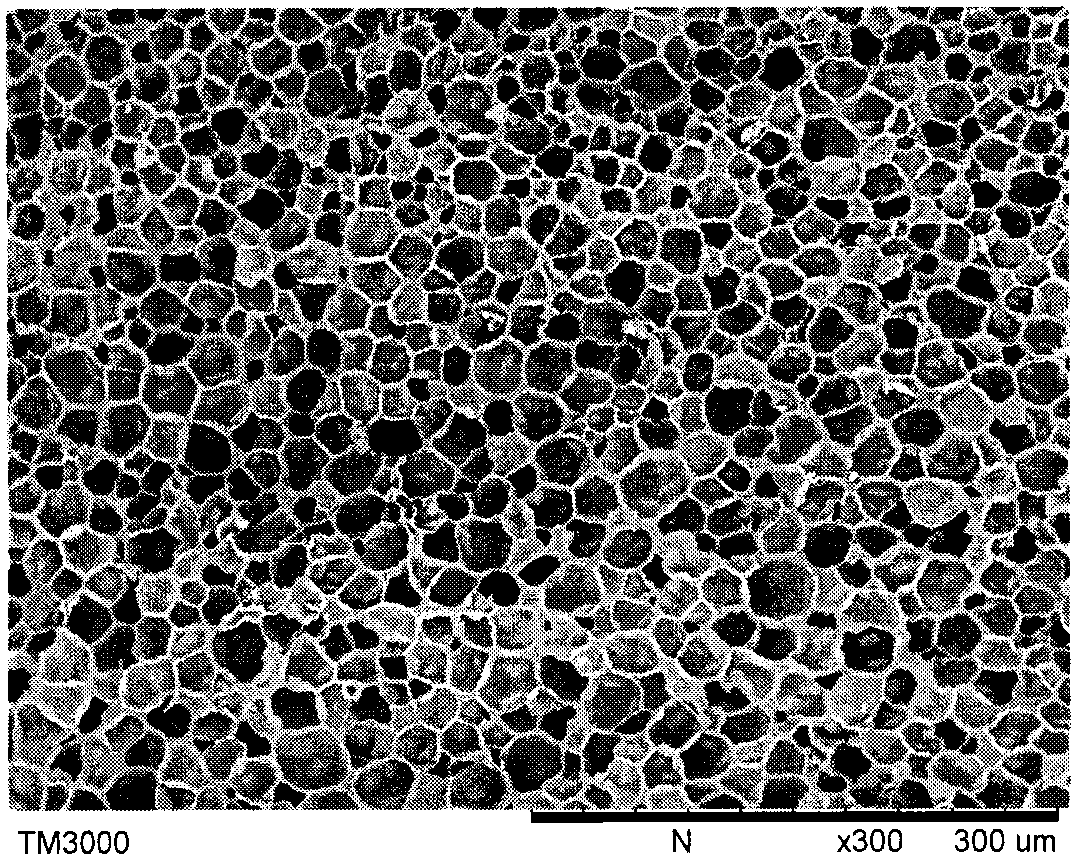

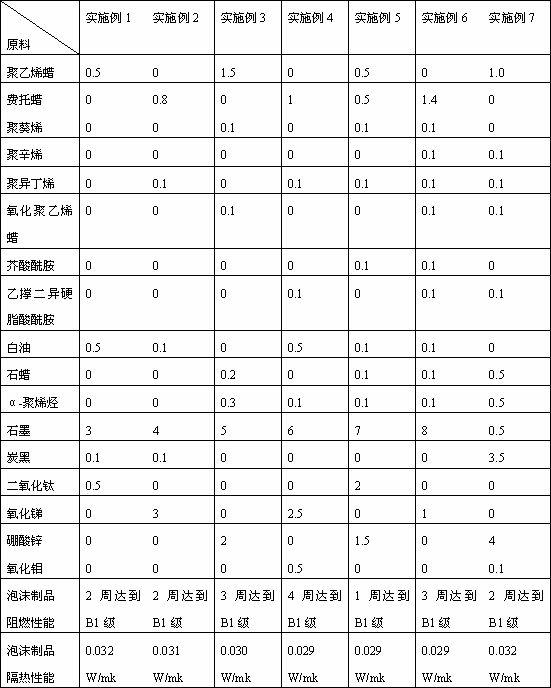

Additive composite used for preparing expandable polystyrene, and preparation method and application thereof

The invention discloses an additive composite used for preparing expandable polystyrene, and a preparation method and an application thereof. The additive comprises the following raw materials in parts by weight: 0.5-2 parts of pore regulator, 0.1-1 part of plasticizer, 2-8 parts of heat insulation agent, and 1-4 parts of synergistic flame retardant, wherein the pore regulator is polyolefin wax of which the dropping point is 95-135 DEG C, the needle penetration is less than 1mm at 25 DEG C, and the kinematic viscosity is less than 2000mm<2> / s at 149 DEG C; the plasticizer is olefin polymer without a polar functional group, and the kinematic viscosity of the olefin polymer is less than 20mm<2> / s at 100 DEG C; the heat insulation agent is graphite; and the synergistic flame retardant is antimony oxide or zinc borate. According to the preparation method of the additive provided by the invention, extruding granulation can be completed without the need for carriers and dispersing agents. The additive provided by the invention is convenient to convey, store and charge, and when the expandable polystyrene prepared by adding the additive is used for manufacturing a foaming product, the foaming efficiency is high, the cycle is short, environment is protected, and the characteristics of heat insulation and flame retardance are good.

Owner:上海容为实业有限公司

Thermal-insulation decorative plate and preparation method thereof

InactiveCN102720320AImprove bindingTightly boundCovering/liningsSynthetic resin layered productsThermal insulation

The invention relates to a thermal-insulation decorative plate, which comprises a foaming material layer and a cloth cover material layer arranged on the foaming material layer and capable of enabling the foaming material layer to permeate in. The cloth cover material layer is coated with a sand solidification material layer, and decorative sand for forming decorative patterns is solidified in the sand solidification material layer. The invention further relates to a preparation method of the thermal-insulation plate, during foaming, foaming materials in the foaming material layer enter the cloth cover material layer and bond with the cloth cover material layer to form the thermal-insulation decorative plate. By mean of the preparation method, bonding between a thermal-insulation layer and the sand solidification material layer of the thermal-insulation decorative plate is firm and not prone to layering.

Owner:辽宁兴胜防水材料科技发展有限公司

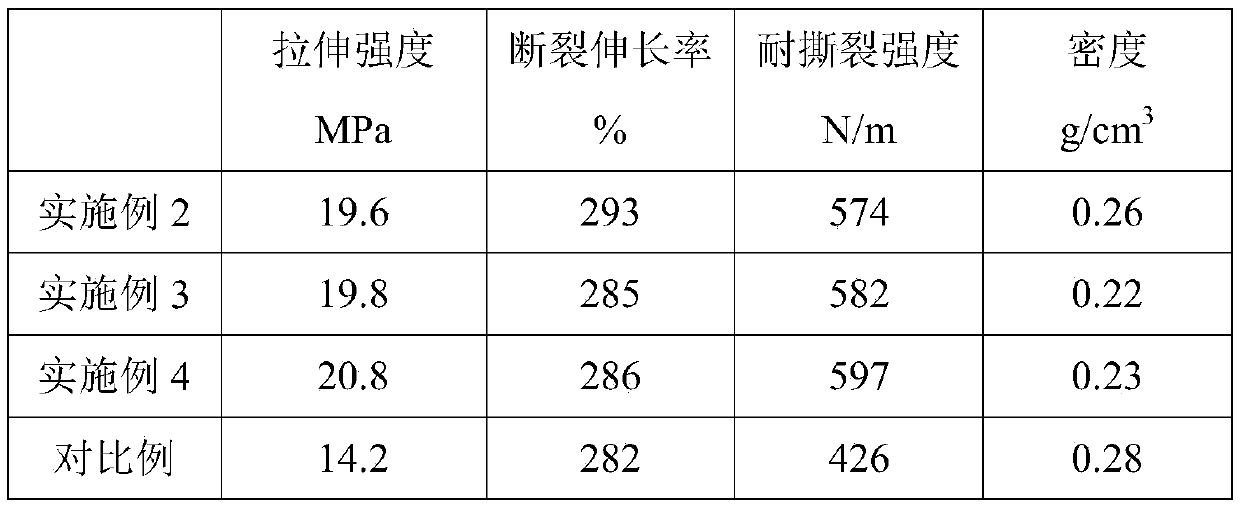

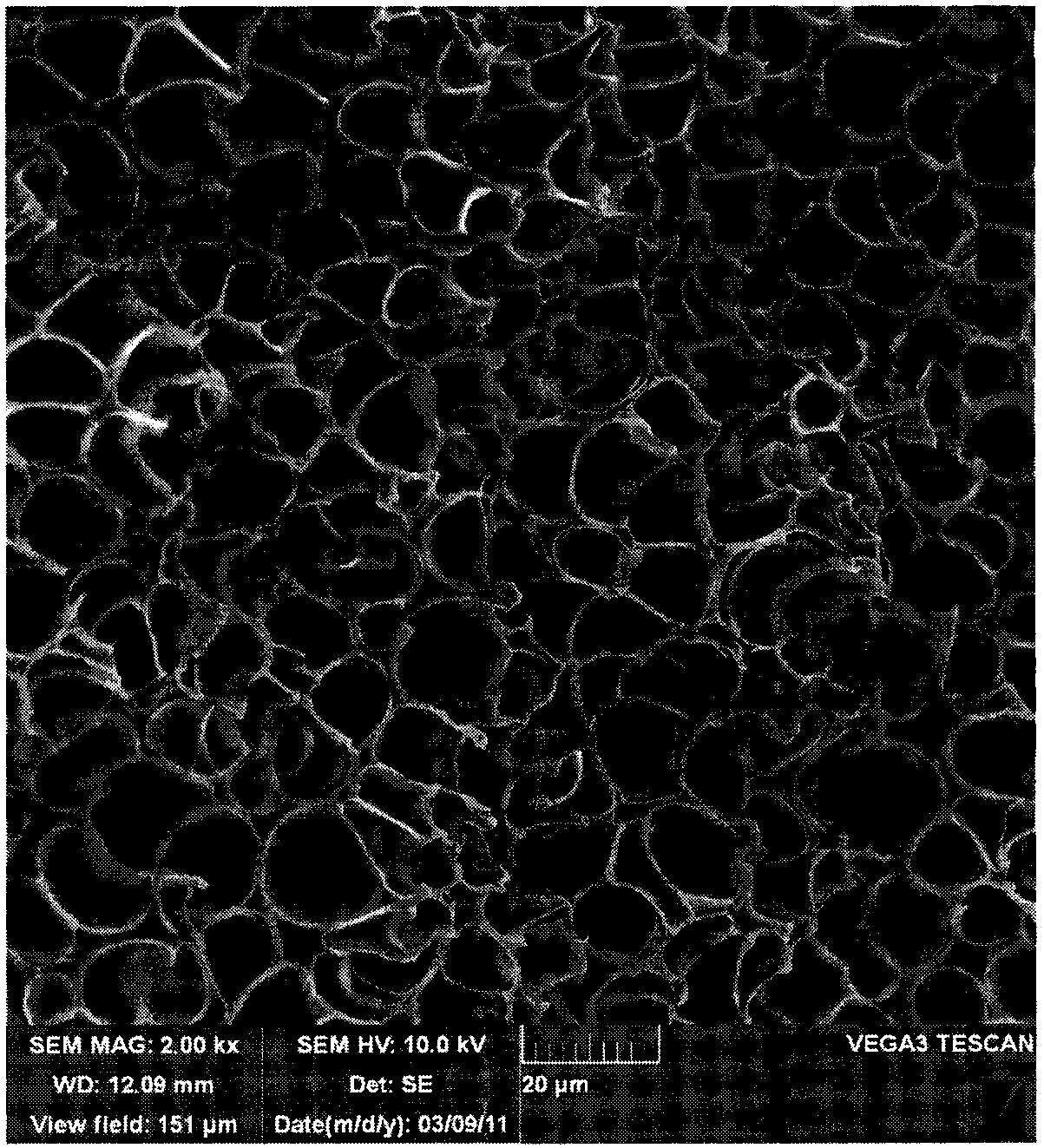

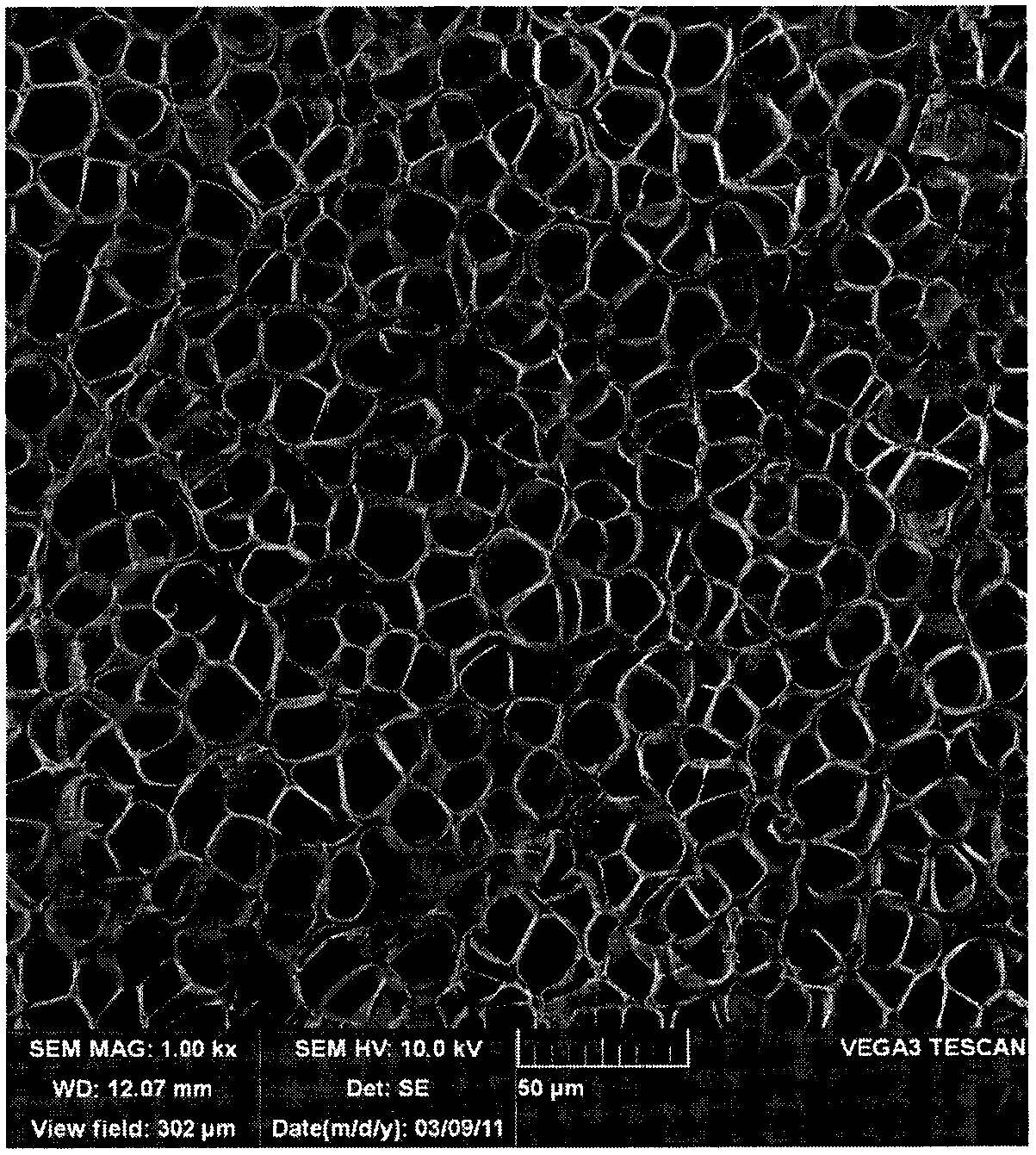

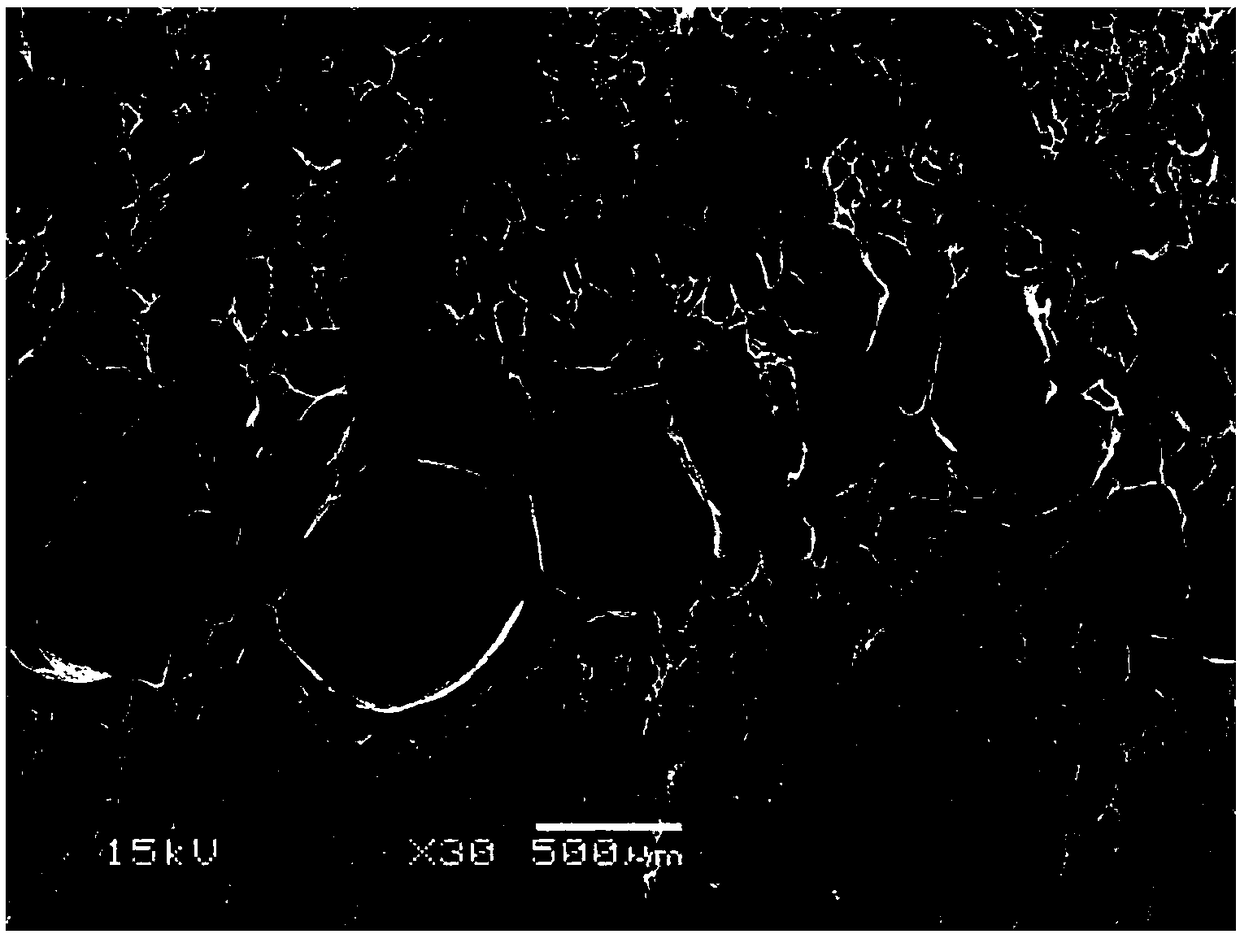

TPU/EVA supercritical foam composite material and preparation method thereof

InactiveCN110724375AGood foaming effectGood foaming efficiencyPolymer scienceThermoplastic polyurethane

The invention discloses a TPU / EVA supercritical foam composite material and a preparation method thereof. The TPU / EVA supercritical foam composite material is prepared from, by weight, 300-360 parts of a thermoplastic polyurethane elastomer, 66-73 parts of an ethylene-vinyl acetate copolymer, 25-33 parts of a maleic anhydride grafting modifier, 9-14 parts of peroxide and 1.2-1.6 parts of a nucleating agent. The TPU / EVA supercritical foam composite material has the advantages of good foaming effect, high foaming efficiency, uniform, small and dense cells, excellent mechanical properties and useproperties such as light weight and high strength, high tensile strength, large elongation at break, good mechanical properties, high tear strength, good tear resistance and low density.

Owner:福建安达福新材料科技有限公司

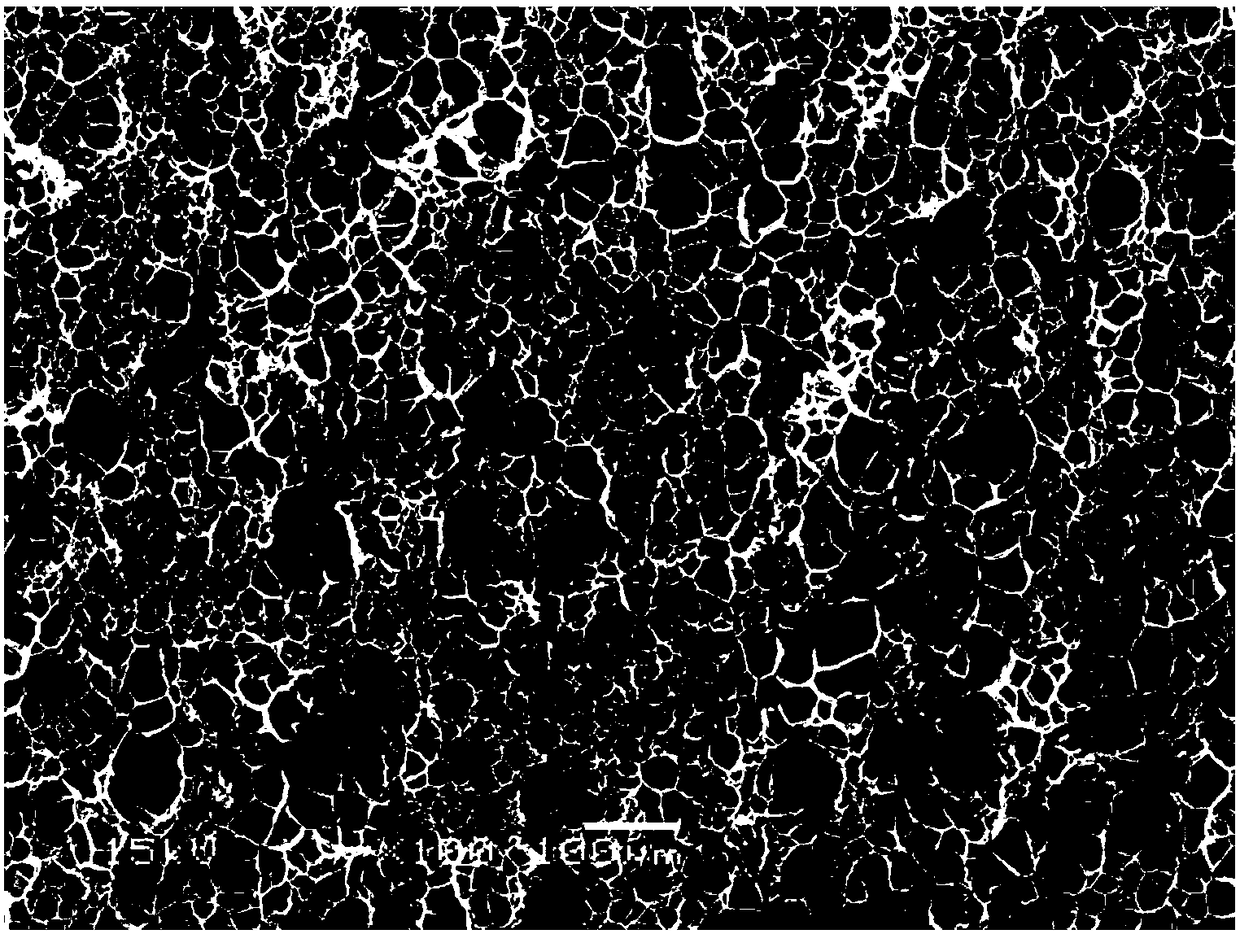

Preparation method for polycarbonate microcellular foaming material

The invention relates to a method for preparing a polycarbonate microcellular foaming material through a supercritical fluid technology. The method comprises the following steps: putting a polycarbonate material into a device with a specific wetting temperature and wetting pressure of a specific supercritical fluid, and preserving the heat and keeping the pressure for specific time; preserving theheat and keeping the pressure for specific time with a relatively high saturation temperature and relatively high critical fluid saturation pressure, and releasing pressure with a specific pressure releasing rate, thereby obtaining the polycarbonate microcellular foaming material. The method is a method which is suitable for industrially producing and efficiently preparing the polycarbonate microcellular foaming material.

Owner:宁波致微新材料科技有限公司

Light high-strength polylactic acid foam material and method for preparing same

InactiveCN109572130APrecise regulationReliable workmanshipSynthetic resin layered productsConstructions elementsPolymer sciencePolymer chemistry

The invention relates to a method for preparing a light high-strength polylactic acid foam material, and belongs to the field of polylactic acid foam materials. The light high-strength polylactic acidfoam material is prepared by the aid of the method on the basis of coupling modification between PTFE (polytetrafluoroethylene) and nucleating agents. PLA (polylactic acid) foam products with the light and high-strength characteristics can be directly formed and prepared by the aid of the method, and the density, the mechanical properties and the heat-insulation performance of the PLA foam products can be accurately regulated and controlled in wide ranges. The method has the outstanding advantages of stability, reliability, high production efficiency, low cost and the like.

Owner:SHANDONG UNIV +1

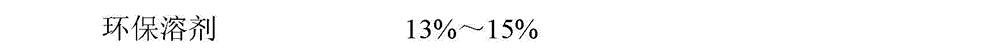

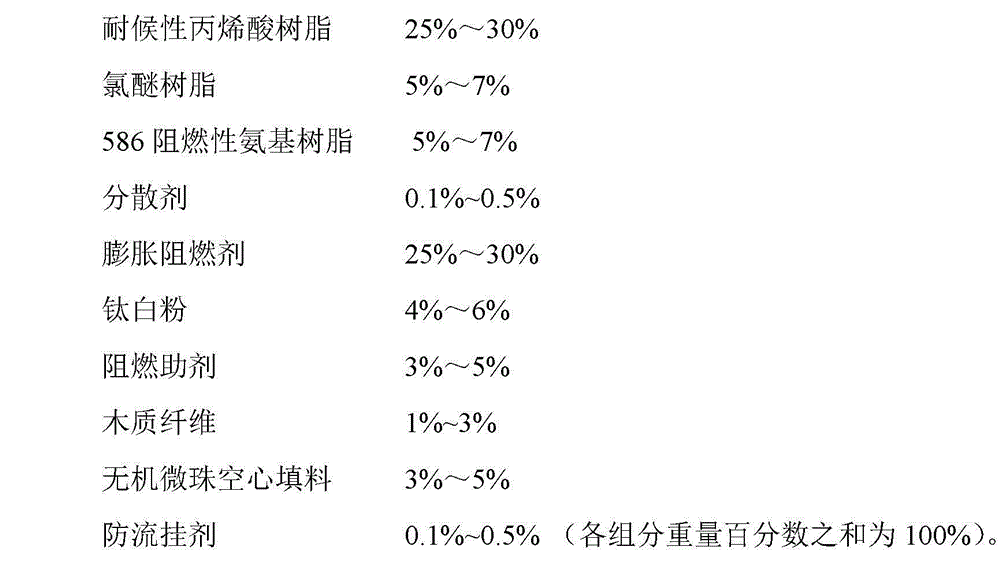

Fireproof coating and preparation method thereof

InactiveCN102977712AGood weather resistanceImprove acid resistanceFireproof paintsPolyether coatingsFiberAdhesion force

The invention discloses a fireproof coating and a preparation method thereof. The fireproof coating comprises the following components; environment-friendly solvents, weather resistant acrylic resins, chloric ether resins, 586 flame retardant amine resins, dispersing agents, an intumescent flame retardant, titanium white powder, flame retardant auxiliaries, wood fibers, inorganic microbead hollow fillers and anti-sag agents. The fireproof coating can be coated on various substrates, so that the fireproof coating is an ultra-thin effective fireproof coating which is specially applied to outdoors and can resist burning of hydrocarbon fire, has the chemical properties of high weather fastness, acid resistance and alkali resistance, is high in adhesion force, durable, fine and smooth in coating film, attractive in decoration effect, uniform in expansion, special in bubble body structure, high in fireproof effect, environment-friendly in products, free from environment pollution and convenient to construct, and can be used for coatings of various fireproof requirements, and production process is simplified.

Owner:WUXI HUHUANG PAINT

Novel preparation method of red mud light-weight wall material

InactiveCN102503507BHigh strengthLow thermal conductivitySolid waste disposalCeramicwareRed mudHeat conservation

The invention discloses a novel preparation method of red mud light-weight wall material, comprising the steps of mixing and grinding 1-10 wt% of waste glass powder, 1-10 wt% of rock wool waste, 1-10 wt% of fly ash, 1-20 wt% of gangue, 1-10 wt% of polished tile waste, 1-10 wt% of waste ceramic tile powder, 94-30 wt% of red mud and 5-10 wt% of additional pulverized coal, and then obtaining uniformmixed powder; baking the mixed powder for 1-4h at 600-1200 degrees centigrade; and cutting to obtain the red mud light-weight wall material. The aperture size of the prepared light-weight wall material is 0.1-3mm; the inner holes and outer holes are distributed uniformly and are closed holes; the heat preservation and shock resistance is far higher than those of aerated concrete block; used raw materials are all industrial wastes, so that the production cost is low and the environment pollution is reduced; and the prepared light-weight wall material has characteristics such as light weight, porous performance, heat insulation, no toxicity, no microbes, tasteless performance and so on, and is convenient to construct and is economic and environment-friendly. Most importantly, the effective solution to the world problem of pollution of industrial waste red mud is found.

Owner:SHANDONG UNIV OF TECH

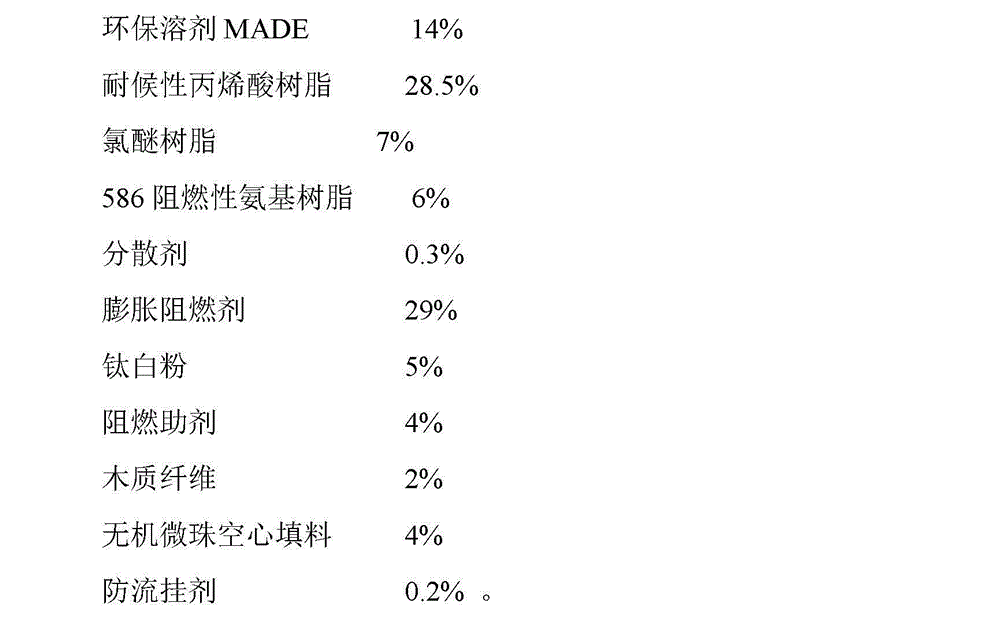

Liquid foaming backfilling material for toilet and preparation method thereof

The invention provides a liquid foaming backfilling material for a toilet and a preparation method thereof. The liquid foaming backfilling material is prepared from the following raw materials by weight: 280 to 400 parts of cement, 1 to 3 parts of a liquid foaming auxiliary agent, 2 to 5 parts of calcium formate, 1 to 5 parts of a water repellent, 1 to 2 parts of a water-retaining agent, 0.8 to 1.2 parts of crack-resistant fiber, 0.8 to 2 parts of a thickening agent and 200 to 240 parts of water, wherein the foaming auxiliary agent is at least one selected from the group consisting of an animal cement foaming agent and a plant cement foaming agent. The liquid foaming backfilling material provided by the invention solves the problem of complicated backfilling construction for the toilet dueto factors like a site. The liquid foaming backfilling material prepared by using the method provided by the invention has a bulk density of about 300 to 340 kg / m3, has good degree of flowing in backfilling construction, is tightly bonded with the wall body part of the to-be-backfilled area of the toilet, and has good overall flatness. The liquid foaming backfilling material has a hardening timeof 24 h in summer and about 48 h in winter, and has the advantages of no cracking, no shrinkage, good strength and leakage resistance after hardened. The liquid foaming backfilling material prepared by using the method provided by the invention has a hardening strength of more than 1 MPa and a water absorption rate of less than 30% after 7 days, meets the water absorption performance of 2 to 4 (v / v%), and has good waterproofness.

Owner:重庆老顽固实业有限公司

Foamed ceramic material and preparation method thereof

InactiveCN106631104ALower sintering temperatureImprove foaming efficiencyCeramicwareSodium BentoniteFoaming agent

The invention provides a foamed ceramic material and a preparation method thereof. The foamed ceramic material comprises, by weight, 40-60% of ceramic powder, 5-15% of silica sol, 6-18% of foaming agents, 2-6% of dispersing agents and the balance water. The ceramic powder comprises, by weight, 70-80% of silicon nitride, 10-20% of bentonite, 5-10% of coal ash, 1-5% of aluminum oxide and 1-5% of talcum powder. According to the preparation method, a ceramic sizing agent is prepared and is dried to obtain a blank, and the blank is sintered to obtain the foamed ceramic material. The foamed ceramic material has a uniform structure, and product performance stability can be improved while production cycle is shortened.

Owner:郑州峰泰纳米材料有限公司

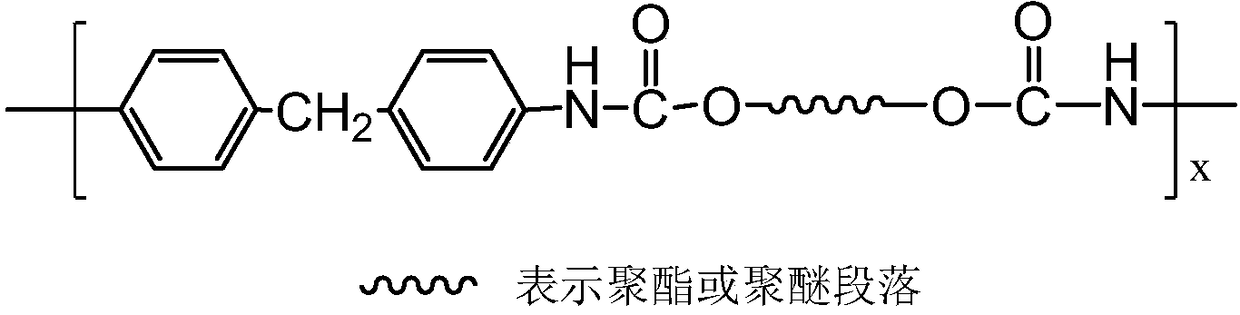

Thermoplastic polyurethane foaming bead particle and preparation method thereof

ActiveCN108503879AImprove foaming efficiencyHigh magnificationThermoplastic polyurethaneHigh pressure

The invention discloses a thermoplastic polyurethane foaming bead particle and a preparation method thereof. The preparation method comprises the following steps of (1) extruding a foaming-level thermoplastic polyurethane resin composition, and granulating, so as to form the to-be-foamed particles with uniform shape and weight; (2) uniformly heating the to-be-foamed particles by screw conveying heating equipment to approximate the foaming temperature, conveying into a constant-temperature high-pressure reaction kettle, filling supercritical fluid, permeating and swelling to reach dispersion balance, so as to form a polymer-supercritical fluid homogeneous system; (3) controlling the pressure release speed in the system, and foaming and swelling the to-be-foamed particles, so as to form thefoaming bead particle with special structure. The preparation method has the advantages that the production process is clean and environmentally friendly, the efficiency is higher, the prepared foaming bead particle has light specific weight and high mechanical property, and the thermoplastic polyurethane foaming bead particle can be applied to the fields of package, shoes, sports articles and thelike.

Owner:常州晟润新材料科技有限公司

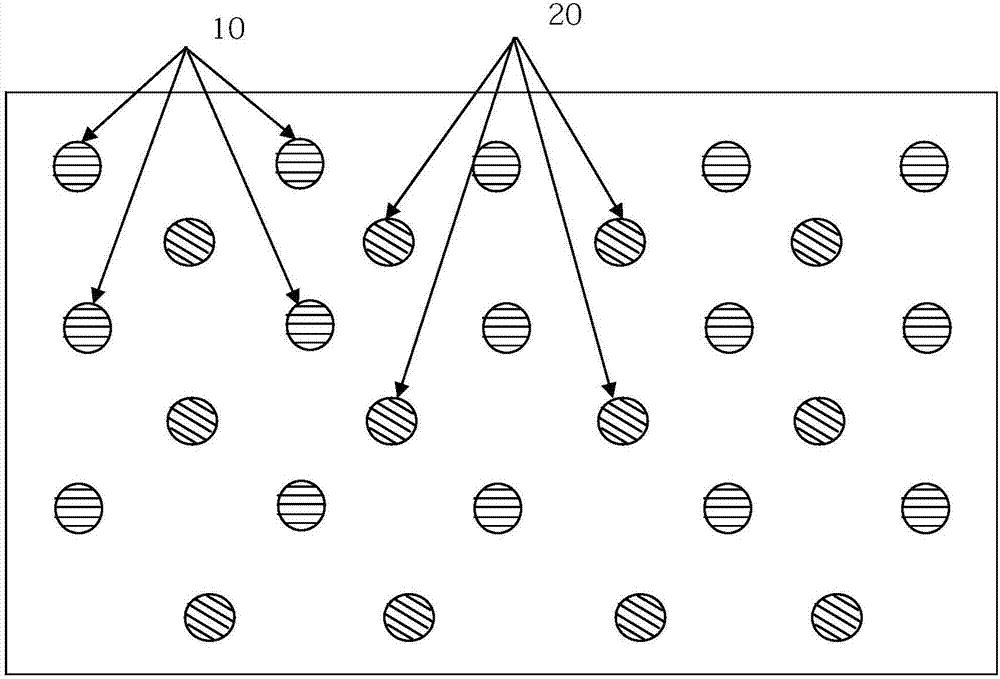

Gypsum board foaming mixing equipment and mixing method

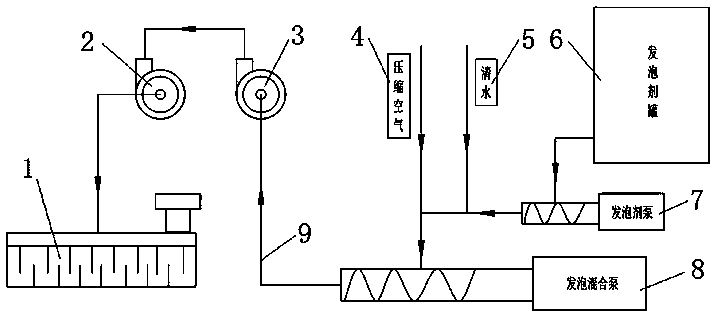

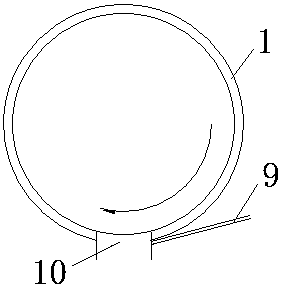

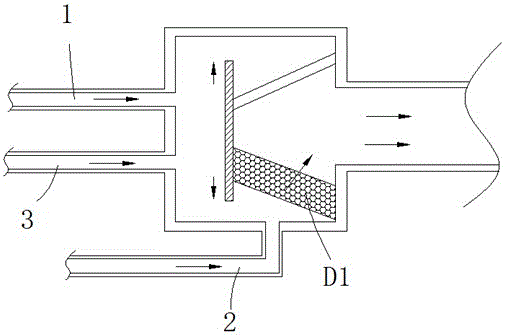

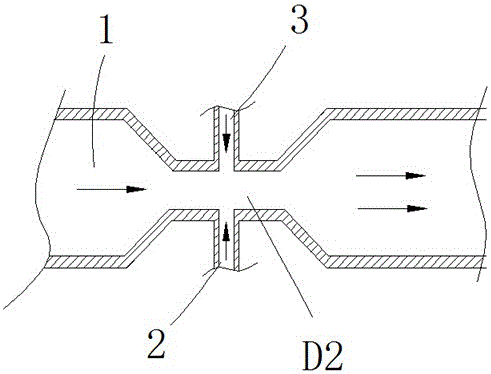

PendingCN108501216AGuaranteed mixing effectReduce lossesCement mixing apparatusFoaming agentHoneycomb

The invention relates to gypsum board foaming mixing equipment. The gypsum board foaming mixing equipment is characterized in that a foaming agent storage tank is connected to a mixer sequentially through a foaming agent pump, a foaming mixing pump and a pair of beating pumps via foaming agent conveying pipelines; a clean water inlet and a compressed air inlet are connected between the foaming agent pump and a foaming mixing pump; an outlet of the foaming agent mixing pipeline is arranged at the outer side of a material outlet of the mixer. The gypsum board foaming mixing equipment has the advantages that the adding position of a foaming agent is adjusted from the interior of the mixer to the outlet of the mixer, and the direction of the outlet is tangential to the rotation direction of the mixer, so as to ensure the mixing effect of the foaming agent and slurry, and reduce the foam loss of the foaming agent in the mixer; by adjusting and controlling the foaming system, the dense smallgas pore structure of a paper-surface gypsum board core is changed into a honeycomb-shaped large gas pore structure, so that at the premise of ensuring the strength and adhering property of the gypsum board, the weight is reduced, the toughness is improved, the defects of poor toughness, easiness in moisture absorbing and deformation and the like are overcome, the foaming effect is improved, andthe foaming efficiency is improved.

Owner:镇江北新建材有限公司

Foam generation device for toilet bowl

ActiveCN104988974ADecrease the velocity gradientMass gradient reductionLavatory sanitoryEngineeringMechanical engineering

The invention discloses a foam generation device for a toilet bowl. The foam generation device comprises a water inlet pipe, an air inlet pipe, a foaming agent pipe and a mixing device connected to the tail end of a pipe and used for fully mixing water, air and foaming agents and generating foam. The tail end of the mixing device is connected with a foam outlet pipe. The mixing device comprises at least one static mixing unit. A plurality of continuously twisting fins are arranged in each static mixing unit so that liquid entering the mixing device can change the flow direction continuously to achieve mixing of the air and the liquid, and fine foam is generated. The foam generation device has the advantages of being capable of generating high-quality foam continuously even at quite low pressure, not prone to blockage and excellent in foam pushing capacity.

Owner:江苏飞慕生物科技有限公司

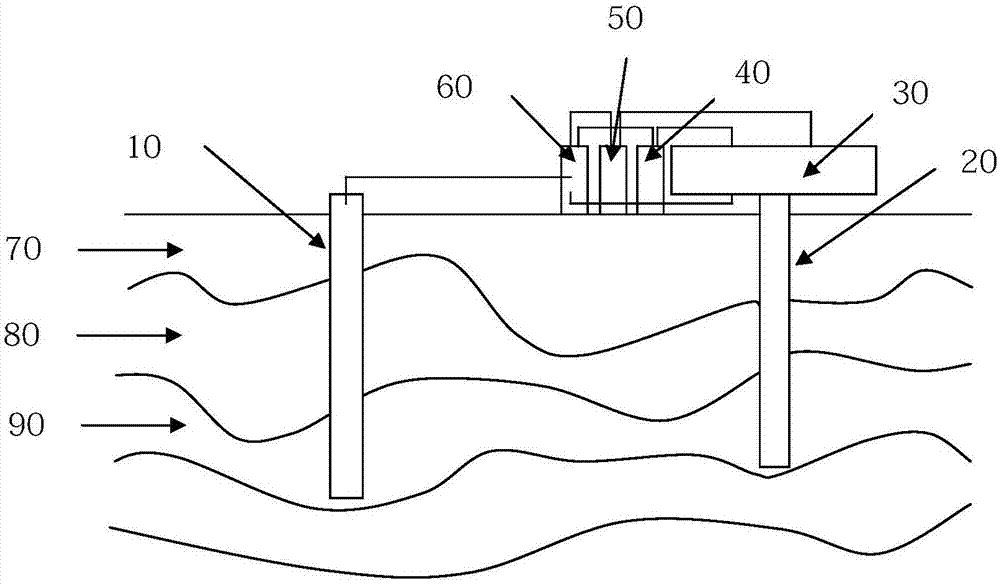

Chemical-enhancing type gas production technology

ActiveCN107130953AImprove foaming efficiencyGood foam stabilityFluid removalDrilling compositionChemistrySurface tension

The invention relates to a chemical-enhancing type gas production technology. The method is characterized in that at least a filling system, an output system and a gas-liquid separating device are used for performing chemical-enhancing gas production. The technology comprises the following steps: filling a foaming agent which comprises at least modified polyoxyethylene ether and Gemini sulfonate on the basis of the weight ratio of 15-20: 1 into a filling well at the specified rate through a filling system based on the analysis of an oil-gas well; the foaming agent disperses around the filling well after arriving at the stratum under the gravity and / or pressure effect in order to reduce the surface tension of stratum water and lift oil and / gas from the stratum to the gas-liquid separating device through the output system; the gas and liquid which are separated through the gas-liquid separating device can be correspondingly conveyed to a gas storing device or a liquid storing device to be stored; the separated filled water mixture is conveyed into a filled water mixture storing device to be stored; the filled water mixture and the foaming agent are filled into the water filling well through the filling system according to the analysis on the filled water mixture.

Owner:成都百联油田技术服务有限公司

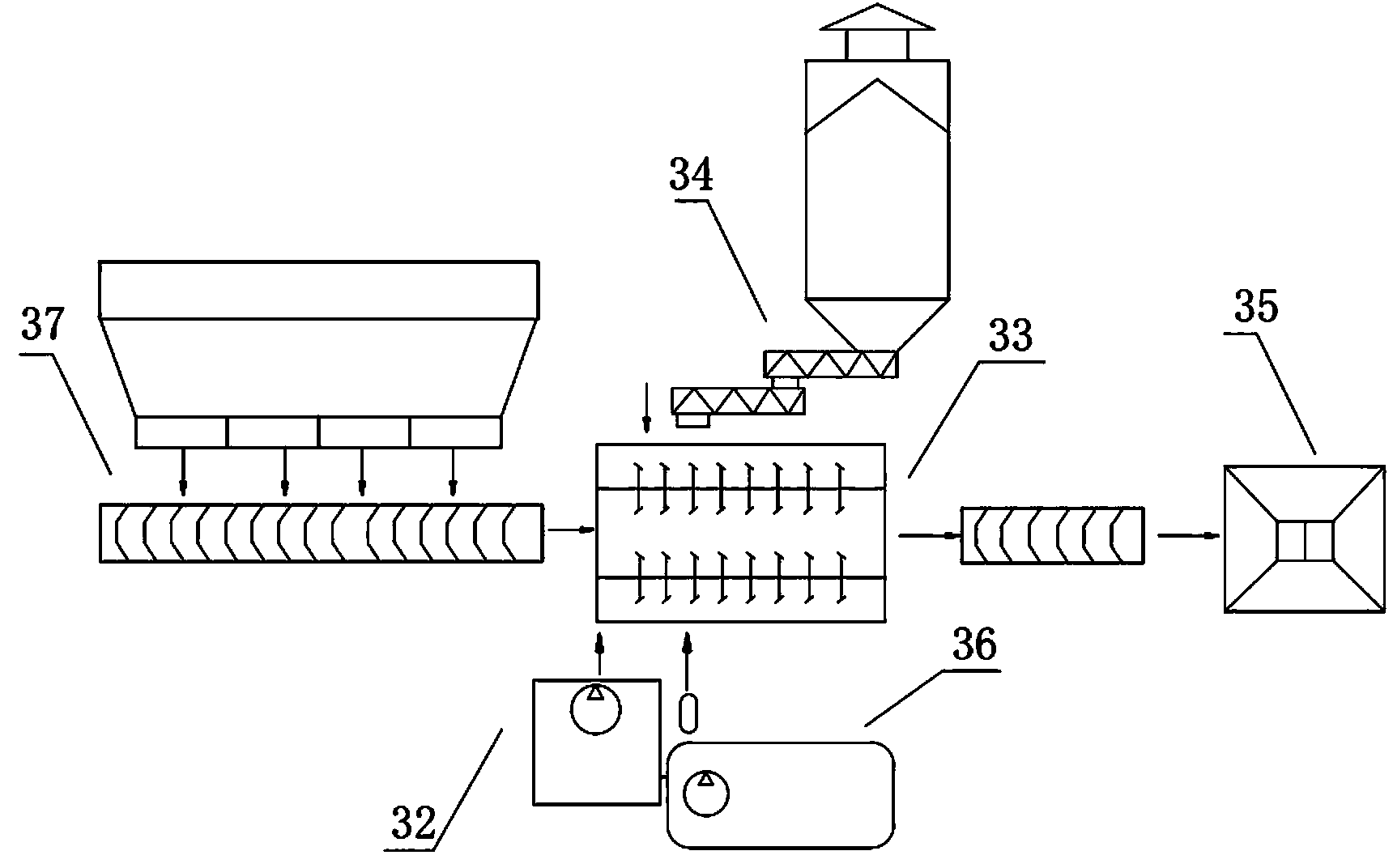

Plant-mixing cold-recycling foamed bituminous mixture production system

The invention discloses a plant-mixing cold-recycling foamed bituminous mixture production system, relating to the technical field of road paving devices. The plant-mixing cold-recycling foamed bituminous mixture production system comprises a stabilized soil mixing plant and a bitumen foaming device, wherein a bitumen jet pipe of the bitumen foaming device is communicated with a stirring device of the stabilized soil mixing plant, the bitumen foaming device comprises a new bitumen heating tank and a bitumen foaming pipe, the bitumen foaming pipe is of a double-layer sleeve pipe structure, and an inner-layer core pipe of the bitumen foaming pipe is sequentially provided with a self-spinning turbulator, a cross butt-jointing blade and a radial guide pipe from the inlet end to the outlet end. The plant-mixing cold-recycling foamed bituminous mixture production system is transformed by the existing stabilized soil mixing plant directly, the investment cost is low, and the stabilized soil mixing plant can achieve multiple purposes.

Owner:沧州市市政工程股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com