Chemical-enhancing type gas production technology

A chemical and gas extraction technology, applied in chemical instruments and methods, mining fluids, earth drilling and mining, etc., can solve the problems of poor foam stability, poor temperature and salt resistance, low foaming efficiency of foaming agents, etc., to achieve foam Good stability, good temperature and salt resistance, high foaming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

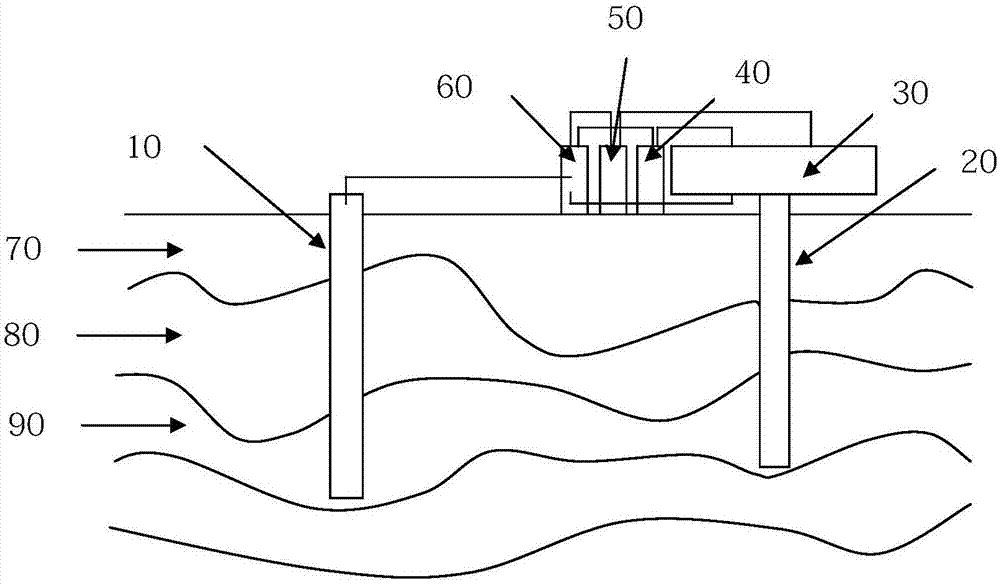

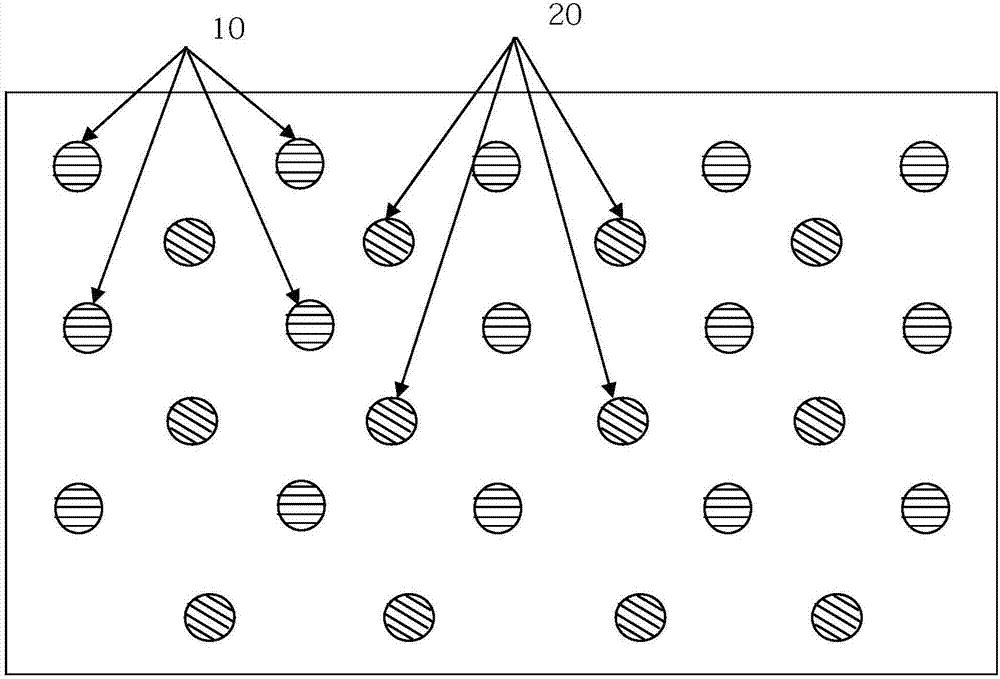

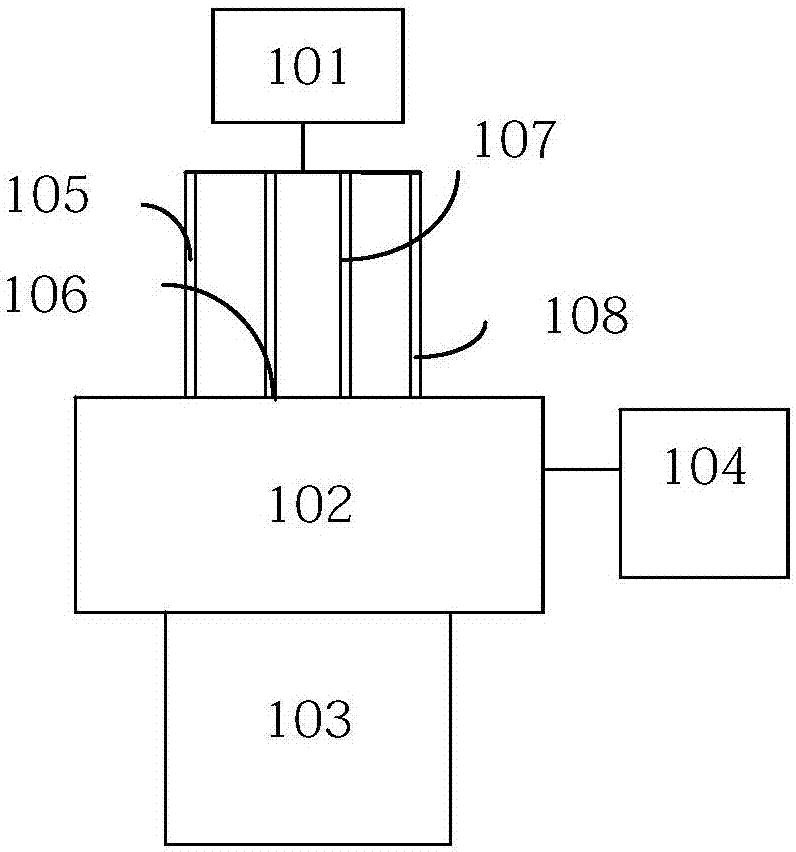

[0050] figure 1 A schematic diagram of the oil and / or gas production system of this embodiment is shown. like figure 1As shown, the system includes at least an injection system 10 , a production system 20 and a gas-liquid separation device 30 . The injection system 10 is used to inject a blowing agent into an oil and gas well. The production system 20 is used to lift oil and / or gas from the oil and gas well to a gas-liquid separation facility 30 . The gas-liquid separation device 30 separates the extracted substances. The gas separated by the gas-liquid separation device 30 is transported to the gas storage 40 for storage, the separated liquid is transported to the liquid storage 50 for storage, and the separated water injection mixture is transported to the water injection mixture storage 60 for storage. The water injection mixture contains the unreacted foaming agent, in order to improve the utilization rate of the foaming agent. The water injection mixture can be re-mi...

Embodiment 2

[0063] This embodiment is a further improvement on the basis of Embodiment 1, and only the improved part is described.

[0064] According to a preferred embodiment, the modified polyoxyethylene ether is obtained by sulfonation modification of fatty alcohol polyoxyethylene ether. Preferably, the modified polyoxyethylene ether is aliphatic alcohol polyoxyethylene ether sodium sulfate. The chemical formula of described fatty alcohol polyoxyethylene ether sodium sulfate is RO (CH 2 CHO) n SO 3 Na, where n is an integer between 2 and 10. Preferably, the fatty alcohol polyoxyethylene ether is prepared by using sodium hydroxide as a catalyst, and a long-chain fatty alcohol undergoes a ring-opening polymerization reaction with ethylene oxide in the absence of water and oxygen. The chemical reaction formula is:

[0065] ROH+n(C 2 H 4 O)→RO(CH 2 CHO) n H

[0066] Wherein, n is an integer between 2 and 10. The ether bond in the fatty alcohol polyoxyethylene ether molecule is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com