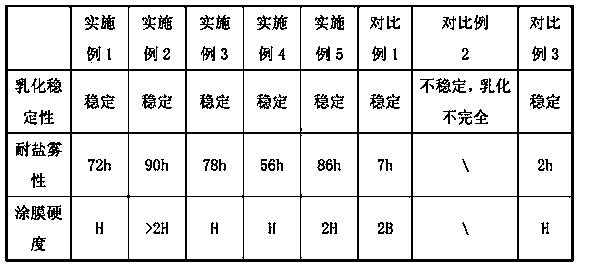

Patents

Literature

180results about How to "Good foam stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

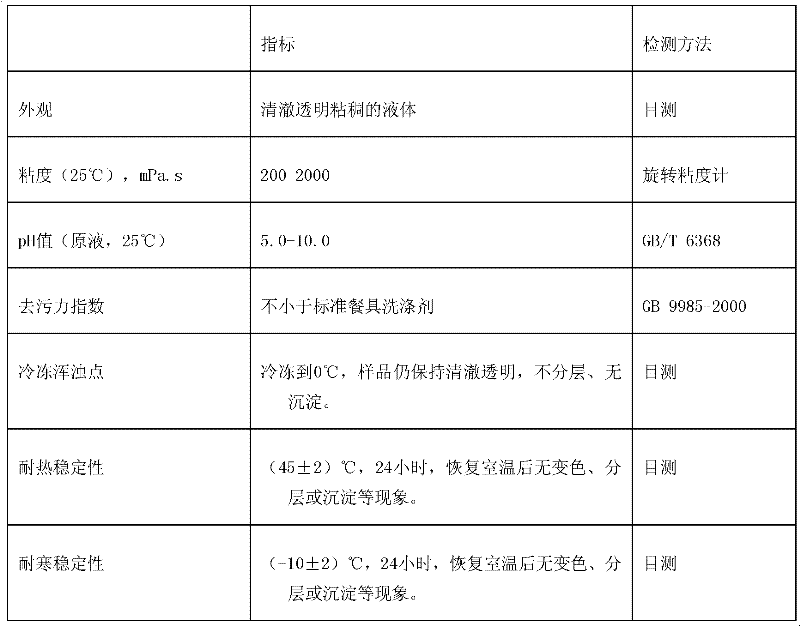

Compound type cleaning solution

InactiveCN102559406AExcellent decontamination synergisticGood thickeningAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsLiquid stateWater soluble

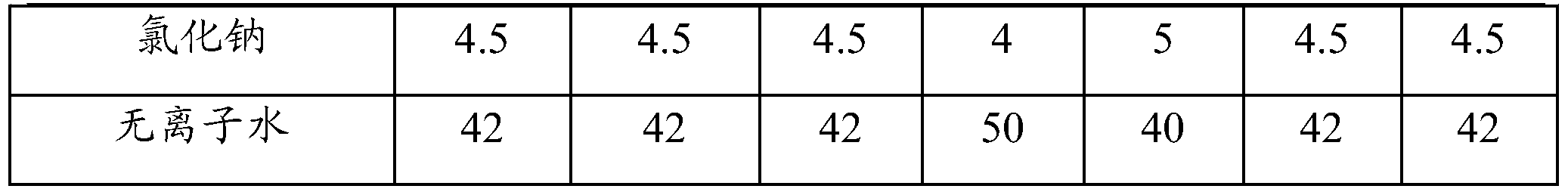

The invention relates to a compound type cleaning solution which comprises a component A, a component B and pure water, wherein the component A is composed of at least one amphoteric surfactant with 8 or more carbon atoms, and accounts for 0.1-15% of the cleaning solution by mass; the component B is at least one anionic surfactant, non-ionic surfactant or cationic surfactant with 8 or more carbon atoms, and accounts for 1-30% of the cleaning solution by mass; and the balance is pure water. In the invention, the amphoteric surfactant and other surfactants are compounded to prepare a dish hand-washing detergent which has excellent functions of cleaning, efficacy enhancing, thickening, foaming, foam stabilizing and the like and is very favorable for improving the performance of the product such as detergency, viscosity, storage stability and the like. Moreover, the amphoteric surfactant is generally in a water-soluble liquid state and can be easily mixed in a formula solution, thus the industrialization of the product provided by the invention can be easily realized.

Owner:WALCH GUANGZHOU COMMODITY

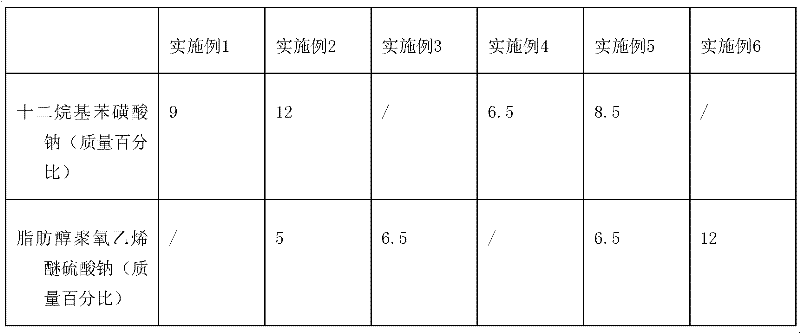

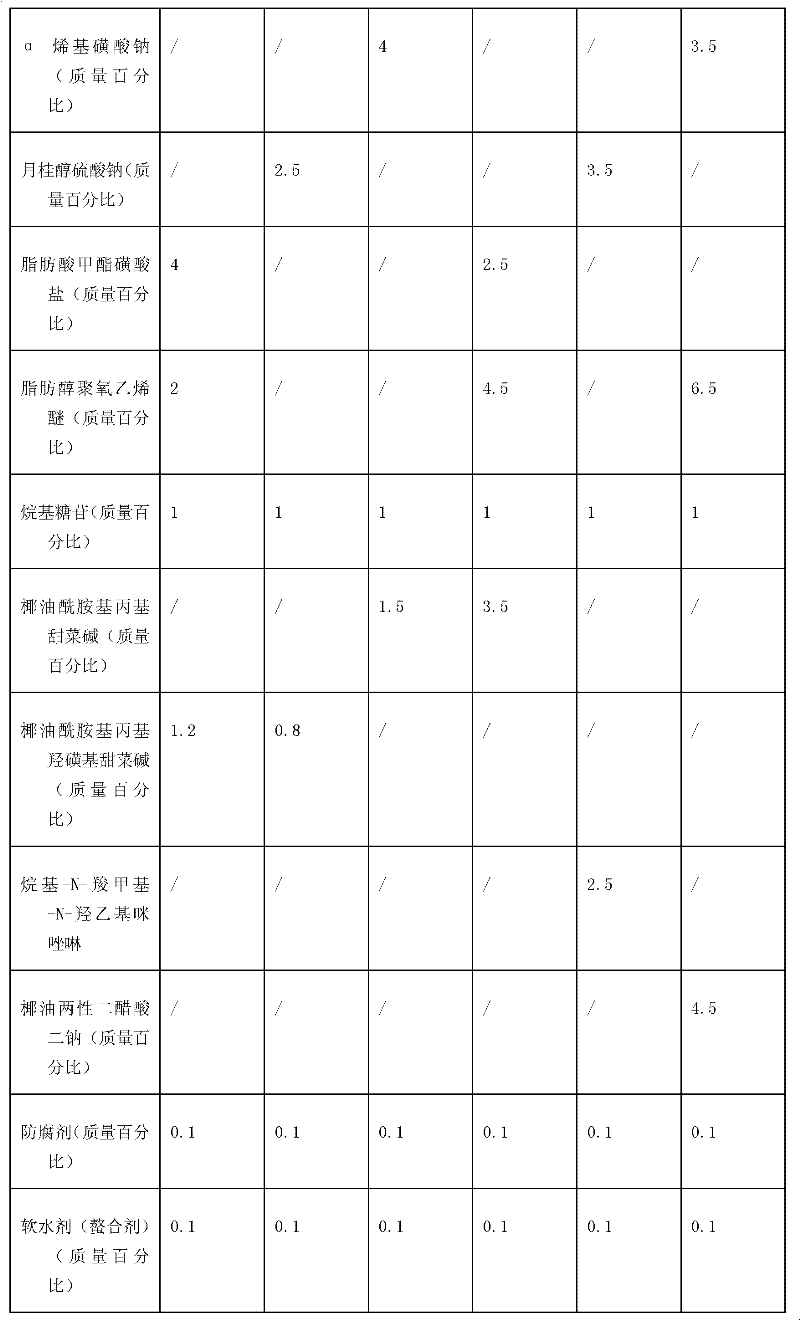

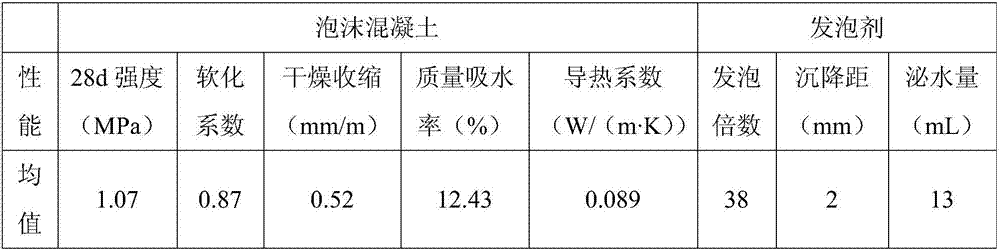

Foaming agent for hydrophobic foam concrete and preparation method of foaming agent

The invention belongs to the technical field of building materials and particularly relates to a foaming agent for hydrophobic foam concrete and a preparation method of the foaming agent. The foaming agent for the hydrophobic foam concrete is prepared from the following raw materials in parts by weight: 200-260 parts of a frother, 20-30 parts of a foam stabilizer, 1-2.5 parts of a thickener, 210-300 parts of an enhancer, 15-20 parts of a diluent, 1.5-2.5 parts of a preservative and 420-480 parts of water. The foaming agent for the hydrophobic foam concrete is good in stability of generated foams, good in foaming effect, high in closed pore ratio of generated foamed concrete, good in hydrophobicity and high in compressive strength.

Owner:河南华泰新材科技股份有限公司

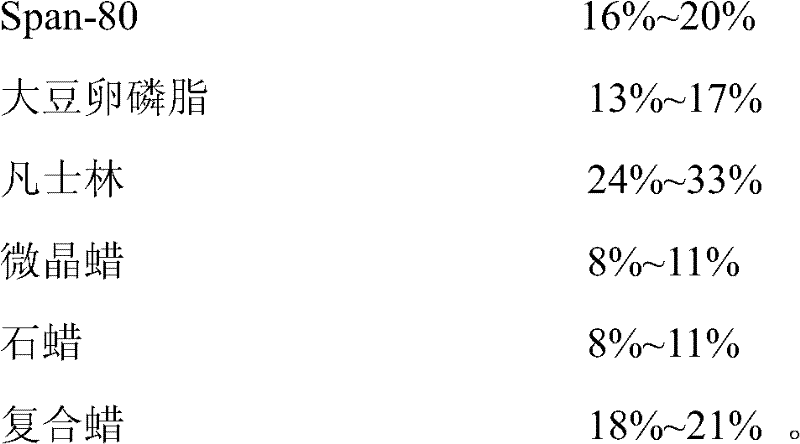

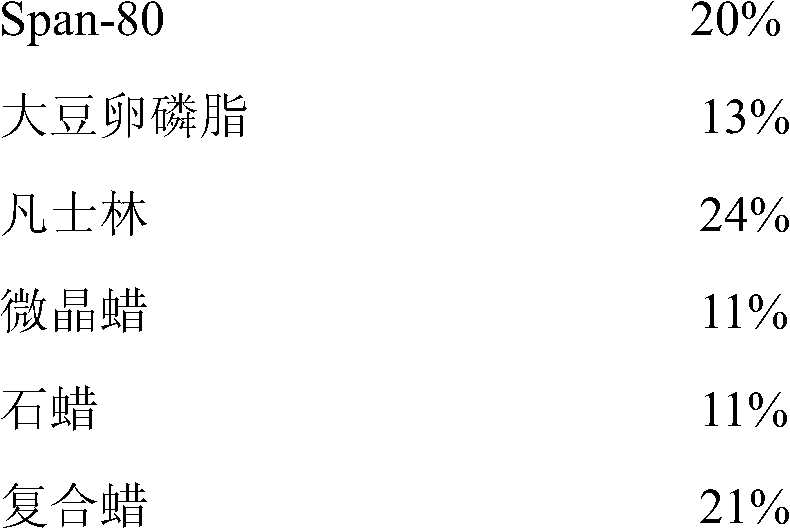

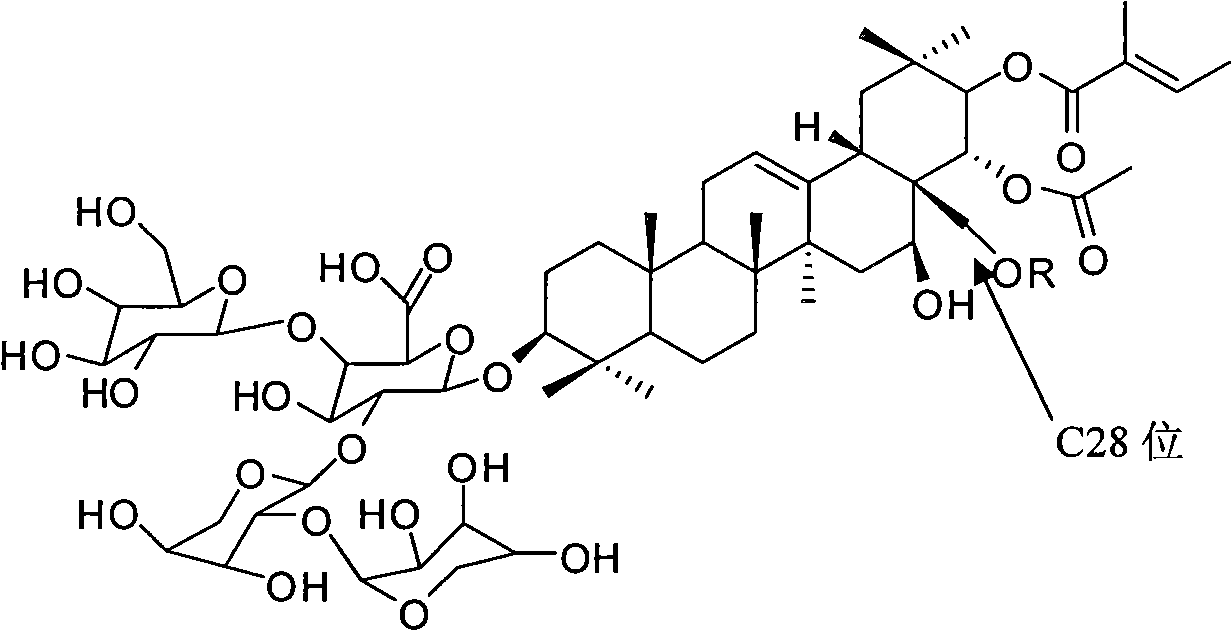

Special composite oil phase for emulsion explosive and preparation method thereof

ActiveCN102584501AExtensive sources of raw materialsLow costNon-explosive/non-thermic compositionsParaffin waxEmulsion explosive

The invention provides a special composite oil phase for an emulsion explosive and a preparation method thereof, which belong to the technical field of explosive composition. The composite oil phase comprises Span-80, soybean lecithin, vaseline, a microcrystalline wax, a paraffin wax and a composite wax, wherein during producing the emulsion explosive, an emulsion and a blending wax are melted after being mixed or mixed after being melted according to a mass ratio of 1:2 so as to obtain the special composite oil phase for the emulsion explosive. By using the composite oil phase provided by the invention, the problems of low performance, over-quickness for damping detonation capacity as well as short storage period of the traditional emulsion explosive are solved; and the special composite oil phase for the emulsion explosive, provided by the invention, can be used for producing the special composite oil phase materials for the emulsion explosive.

Owner:SHANDONG TIANBAO CHEM

Sterilization hand-guarding liquid detergent

ActiveCN1632093AIncrease mildnessGood skin compatibilityOrganic detergent compounding agentsNon-ionic surface-active compoundsPreservativeSurface-active agents

Disclosed is a hand protective cleaning, comprising the following components: negative ion surface active agent 16.00-22.00, nonion surface active agent 10.00-15.00, emollient0.50-1.50, antimicrobial0.05-0.20, essence0.05-020, citric acid0.030-0.50, chelating agent 0.05-0.10, preservative 0.01-0.05 and demonized water 61-74 . The invention dose not contain the raw materials such as alkali or phosphor, with the PH value of 7-705, stavle storage, outstanding effect of cleaning, it can also clear the germ and pesticide remained, has friendly quality as well as protects the hands.

Owner:克劳丽化妆品股份有限公司

Ammonium stearate emulsion and producing method thereof

The invention relates to ammonium stearate emulsion and a producing method thereof, belonging to the technical field of auxiliary chemicals. The ammonium stearate emulsion comprises the following components with the weight percentage: 15-35% of stearic acid, 6-14% of 20% ammonia water, 1-3% of lauryl sodium sulfate and the rest of water. The production technique is that a reaction vessel is sequentially added with the stearic acid, the lauryl sodium sulfate and the water according to the formulation amount, the temperature is regulated to be 10-25 DEG C; after being evenly stirred, the mixture in the reaction vessel is added with the ammonia water, and the mixing speed is adjusted; the prepared ammonium stearate liquid is absorbed into an emulsifying tank for emulsification, stands still for 1-2h, and then is filtered, so that the ammonium stearate emulsion is obtained. The invention is suitable for large scale continuous production, ensures the reaction to be very safe under normal temperature and pressure, and has the advantages of simple input equipment, saved cost, no pollution and emission in the whole production process, silvery white and lustrous finished products, excellent fluidness and stability, low product viscosity (being lower than or equal to 350cps), high purity, good dispersion effect and convenient use. The ammonium stearate emulsion can be fully dispersed in waterborne liquid, has about six-month shelf life and is hard to become thick after being placed for a long time.

Owner:海宁市树桥纺织科技有限公司

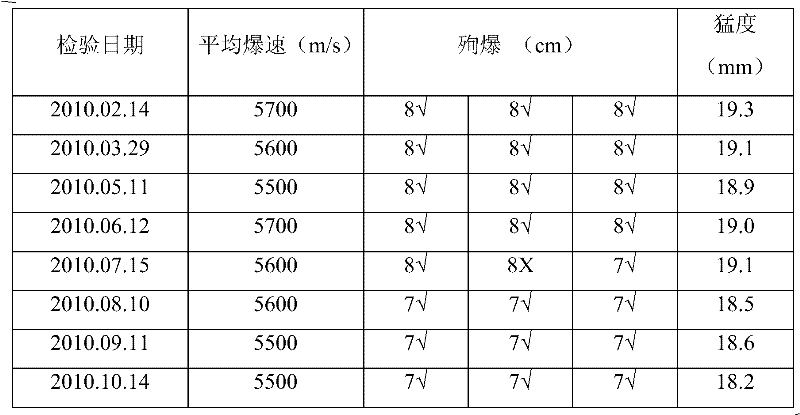

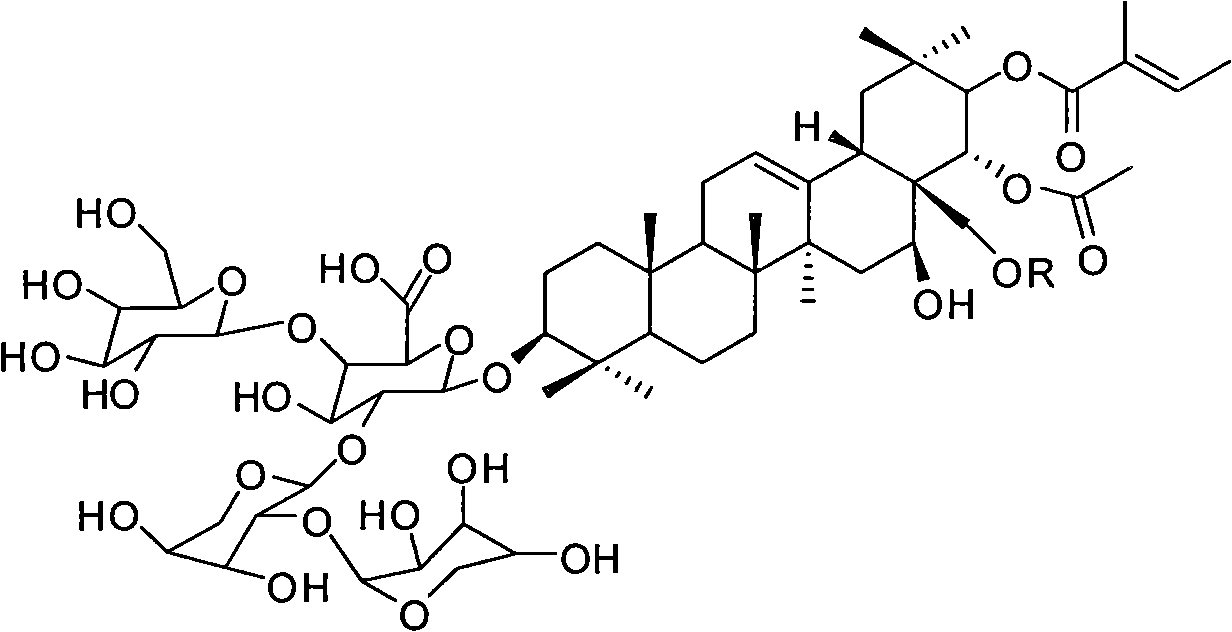

Theasaponin derivative as well as preparation method and application thereof

InactiveCN102030803AStrong foaming powerGood foam stabilityBiocideNon-ionic surface-active compoundsPhosphorus tribromideSugar

The invention relates to a theasaponin derivative as well as a preparation method and application thereof. The theasaponin derivative has a structure shown in the formula I and is prepared by the following steps of: (1) reacting triphenylchloromethane with theasaponin, and then adding bromobenzyl to react with the theasaponin; (2) reacting phosphorus tribromide with sugar, and then reacting with the bromobenzyl; (3) mixing the theasaponin obtained in the step (1) with the sugar obtained in the step (2), and then adding tritylation deprotective agents to react; and then adding phenmethyl deprotective agents in the presence of catalysts to obtain the theasaponin derivative shown in the formula I after the reaction. The preparation method has the advantages that the process is simple, the reaction conditions are easy to control, and the preparation method can be used for the commercial production. The prepared theasaponin derivative can be used as a surface active agent, the foaming power and the foam stabilization are stronger in high-salt and high-temperature environments, and the problem of poor foam stabilization in the high-salt and high-temperature environments of the traditional theasaponin is solved.

Owner:SOUTH CHINA UNIV OF TECH

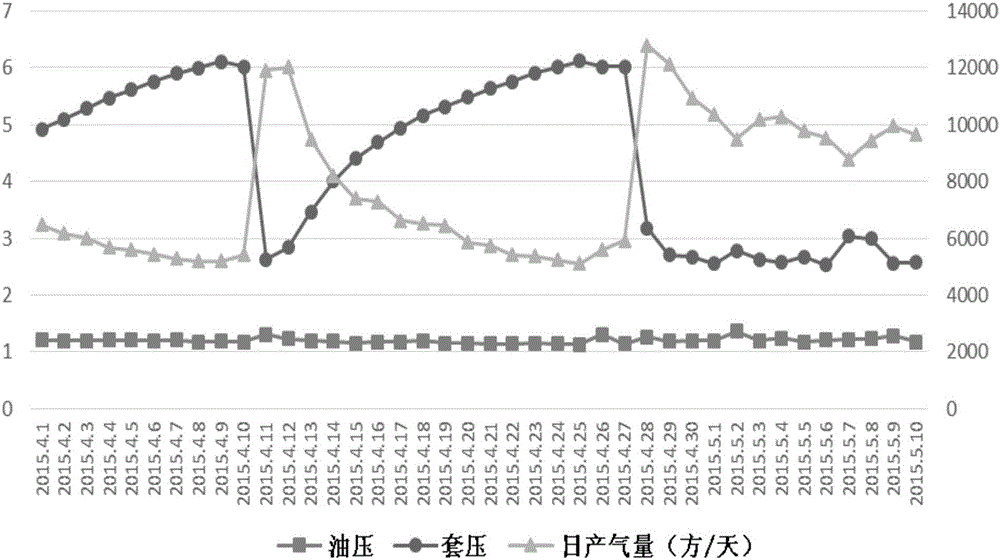

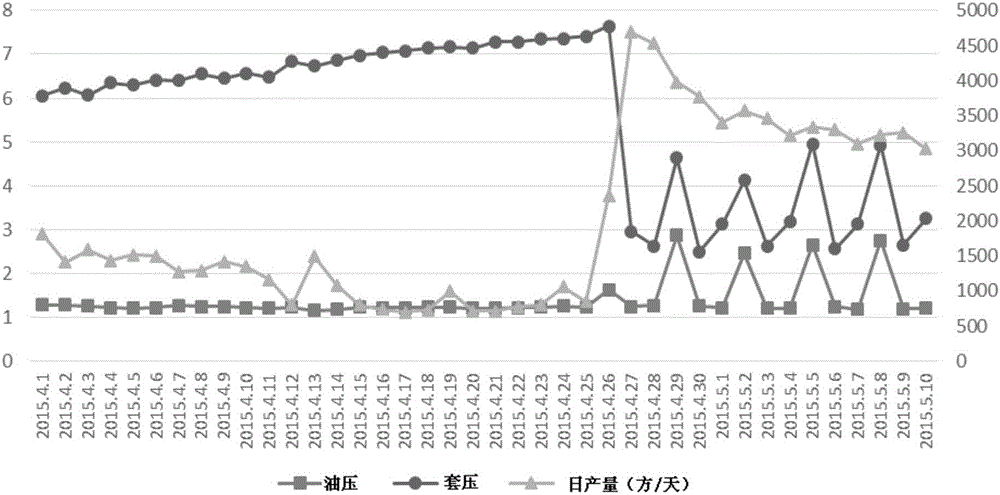

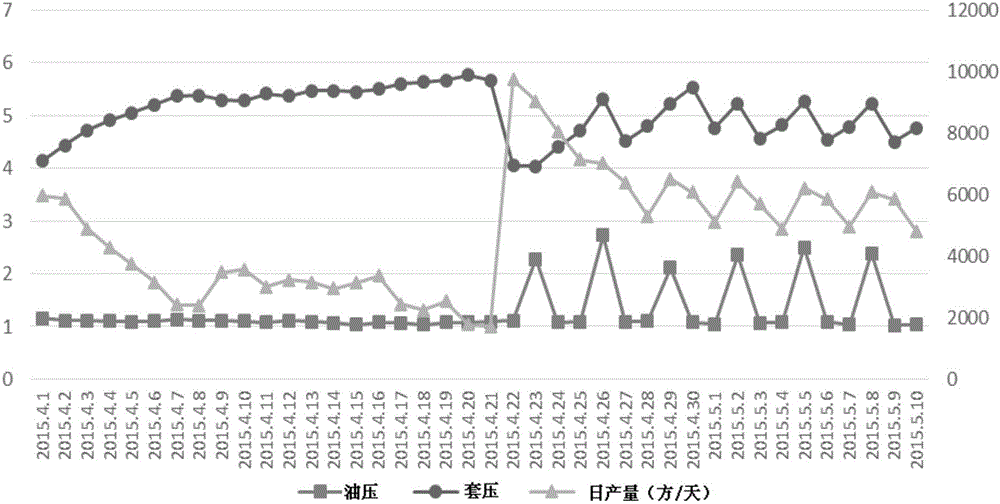

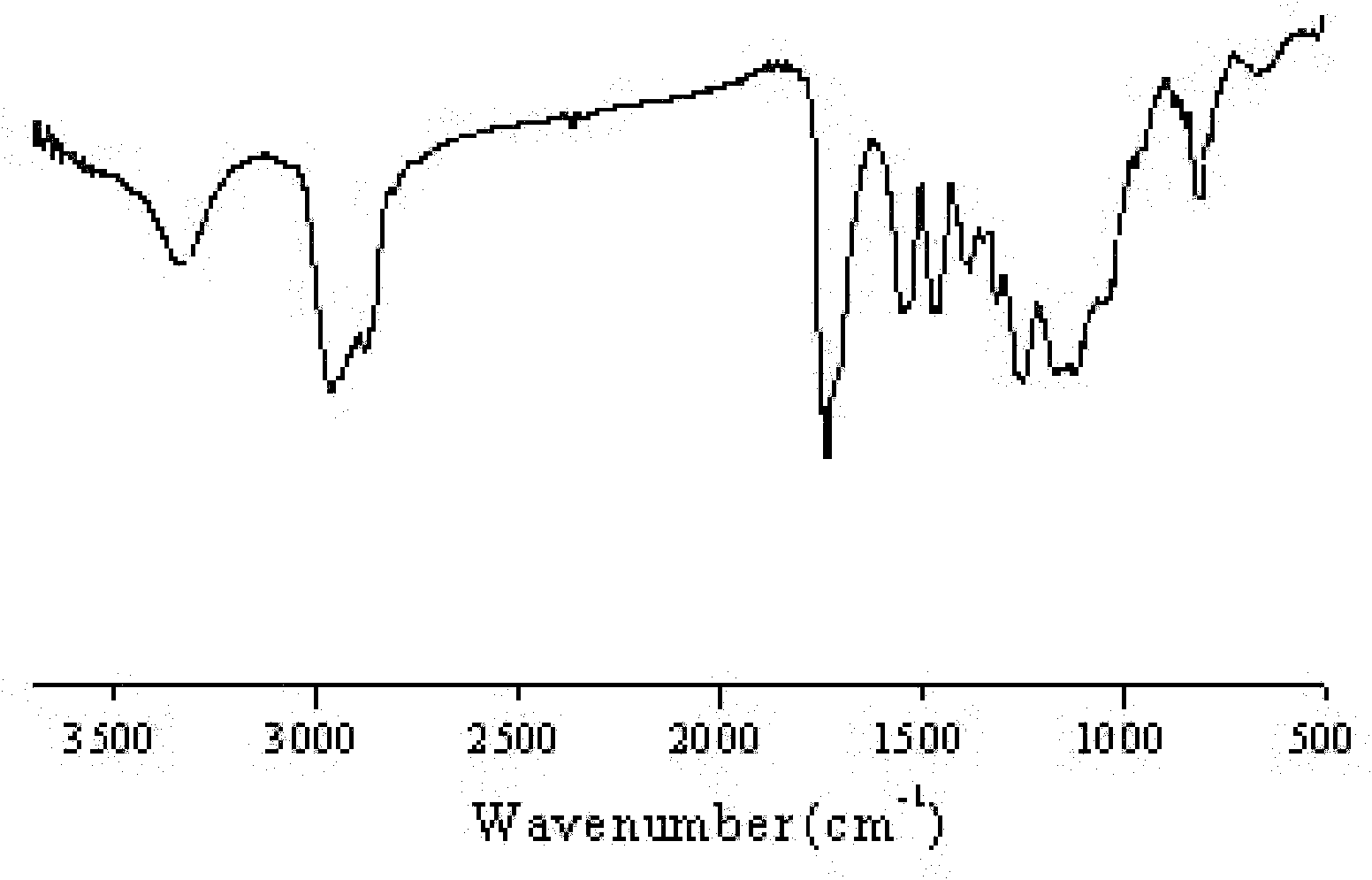

Environmental-friendly type foam water-draining agent and preparation method thereof

ActiveCN106244127AEasy to operateGood drainageDrilling compositionCocamidopropyl dimethylamineBetaine

The invention discloses an environmental-friendly type foam water-draining agent and a preparation method thereof. The environmental-friendly type foam water-draining agent adopts a biodegradable material; and the foam water drainage refers to discharging liquid accumulated at the bottom of a well out of the well by utilizing the water containing performance of foam and the own capability of the well bottom so as to realize the purpose of increasing the yield of the natural gas well. In a field experiment, the foam water-draining agent disclosed by the invention has the advantages that the foam water drainage gas producing process can be met by good foaming capability, foam stabilizing capability and liquid carrying capability, and the foam water-draining effect can be achieved. The environmental-friendly type foam water-draining agent is characterized by comprising the following components of: cocamidopropyl dimethylamine hydroxysultaine, dodecyl dimethyl betaine, alkyl glycoside, cocamidopropyl betaine, lauramidopropyl betaine, dodecyl dimethyl ammonium oxide, hexadecyl trimethyl ammonium chloride, fatty alcohol polyoxyethylene ether, urea and water.

Owner:北京众博达石油科技有限公司

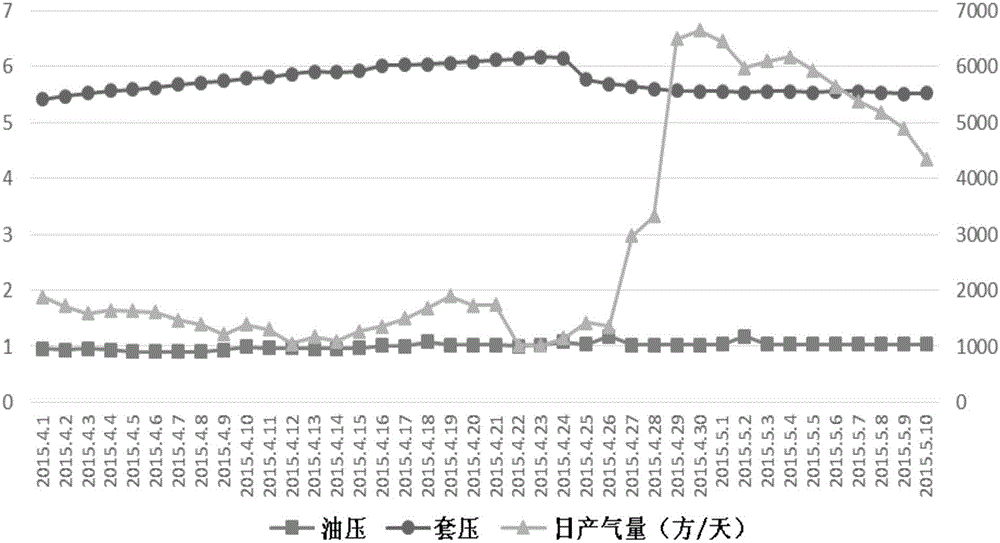

Environmental-friendly foam drainage bar, and preparation method thereof

ActiveCN106244128AEasy to carrySimple filling processDrilling compositionSodium bicarbonatePolyethyleneglycol stearate

The invention discloses an environmental-friendly foam drainage bar, and a preparation method thereof. The environmental protection performance of the environmental-friendly foam drainage bar is used for referring that the environmental-friendly foam drainage bar is prepared from biodegradable raw materials. Foam drainage is used for referring discharging of well bottom accumulated water or accumulated liquid out of wells via utilization of water-containing or fluid-carrying capability of foam, so that gas recovery factor of gas wells is increased fully. The environmental-friendly foam drainage bar is capable of satisfying requirements of foam draining gas recovery and achieving excellent foam draining effect in field tests because of the excellent foaming ability, foam stabilizing ability, and liquid carrying capacity of the environmental-friendly foam drainage bar. The environmental-friendly foam drainage bar comprises following raw materials: cocamidopropyl betaine, sodium lauryl oxyethyl sulfonate, sodium lauroyl glutamate, fatty alcohol polyoxyethylene ether, polyethylene glycol monostearate, urea, citric acid, sodium bicarbonate, and sodium carbonate.

Owner:北京众博达石油科技有限公司

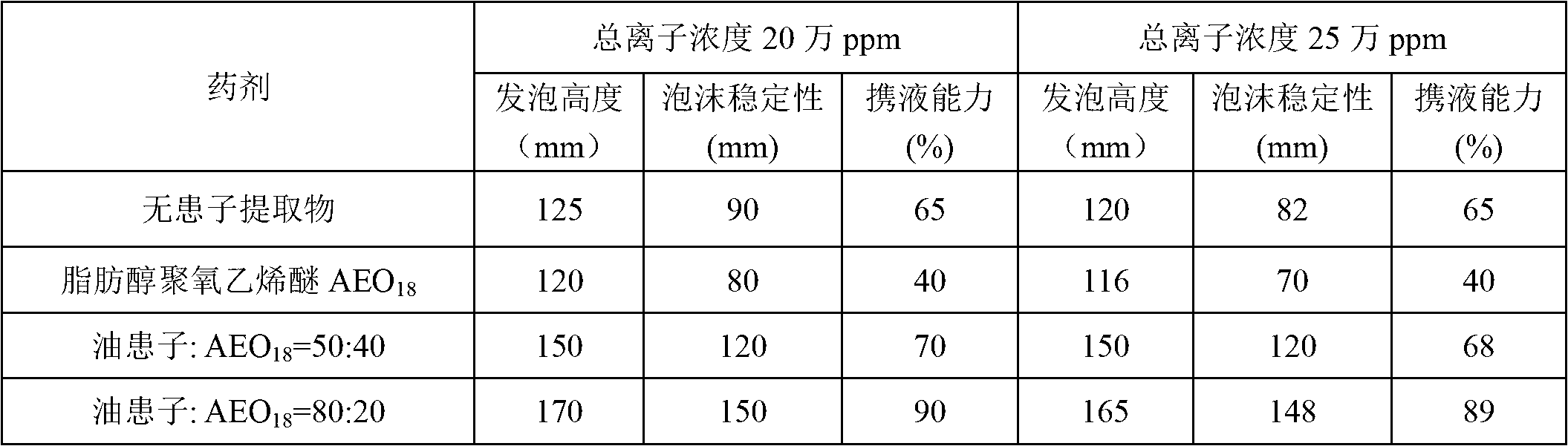

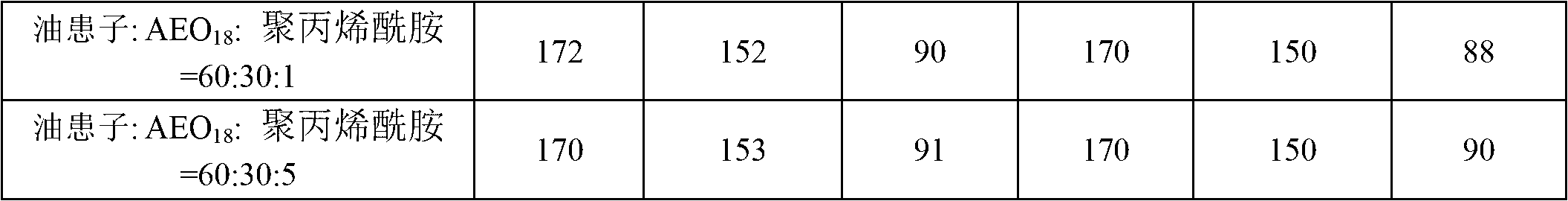

Foam water-drainage agent and its aqueous solution

ActiveCN103059826APromote degradationHigh resistance to mineralizationDrilling compositionChemical reactionTemperature resistance

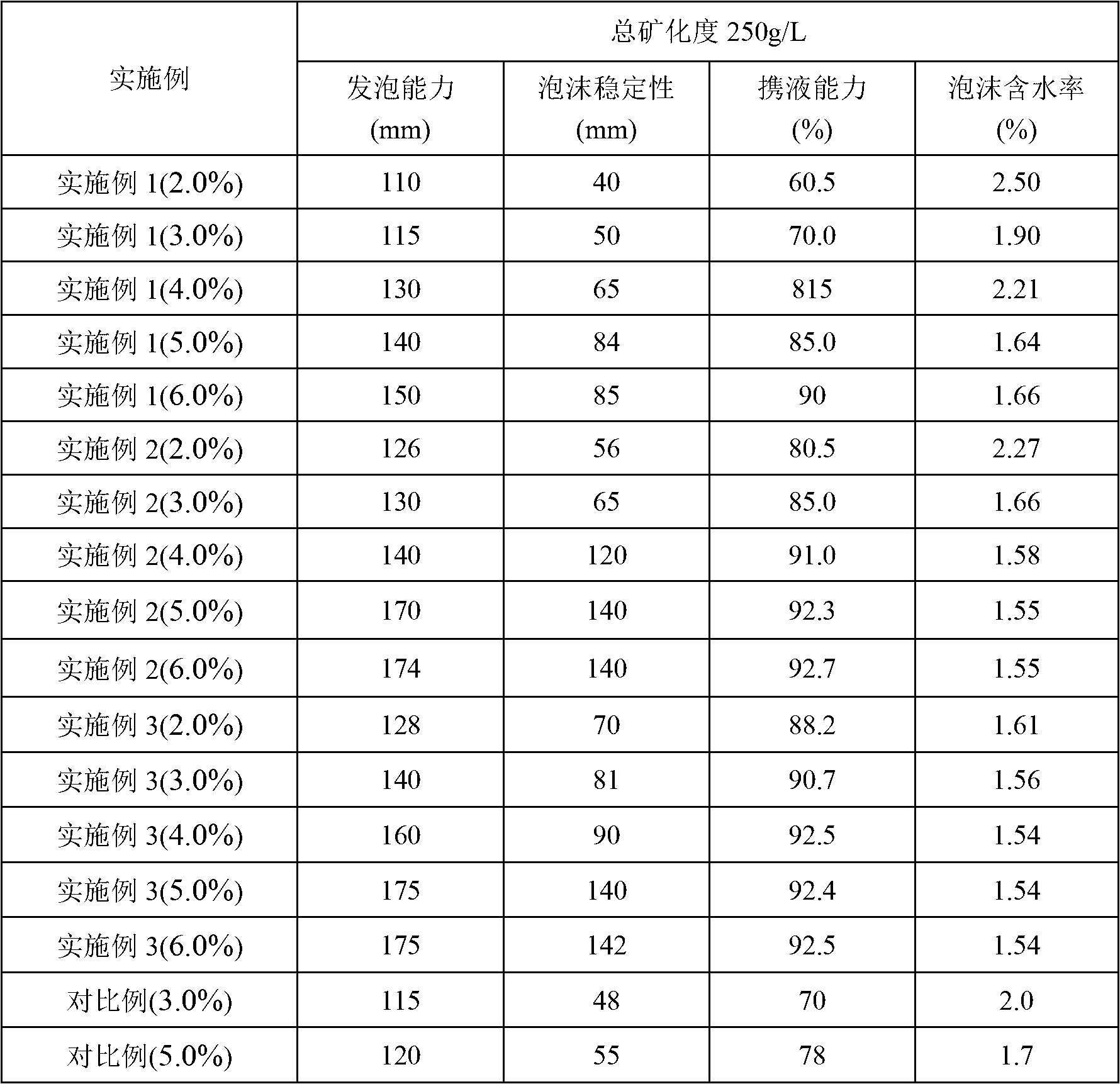

The invention discloses a foam water-drainage agent and its aqueous solution, and belongs to the technical field of the oilfield chemical engineering. The foam water-drainage agent is composed of 50-80 parts by weight of a Sapindus mukurossi Gaertn extract, 20-40 parts of fatty alcohol polyoxyethylene ether AEO18, 1-5 parts by weight of polyacrylamide and 5-10 parts by weight of triethanolamine. The foam water-drainage agent has the characteristics of strong foaming capability after meeting water, good foam stability, and high liquid carrying capability and high mineralization resistance of foams, and is suitable for the use in natural gas wells containing gas condensate and having a high mineralization and a large water output; the foam water-drainage agent has a foam stability of 170mm, has a foam water content of not more than 2.0%, has a mineralization resistance of 250g / L, has a gas condensate resistance of 30%, has a temperature resistance of 90DEG C, is non-toxic, is easy to degrade, and does not pollute the environment; and the foam water-drainage agent has the advantages of compatibility with chemicals comprising methanol, a corrosion inhibitor, a scale inhibitor and the like, no chemical reaction with gas or liquid components, no increase to the toxicities of gases or combustion products, and no corrosion to equipment or pipelines.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aqueous polyurethane-acrylate resin for use as foaming material for synthetic leather and preparation method thereof

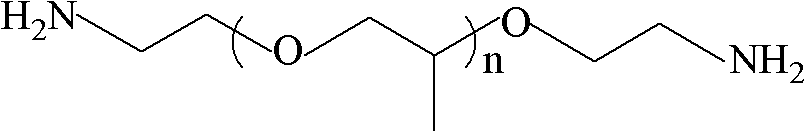

The invention discloses an aqueous polyurethane-acrylate resin for use as a foaming material for synthetic leather and a preparation method thereof. The aqueous polyurethane-acrylate resin has the structural characteristics that: the content of organosilicon element in the side chain of the molecule of the polyurethane is 3 to 7 percent; the content of a hydrophilic group in the side chain of the polyurethane is 1 to 3.5 percent; the content of a polyether and / or polyester and / or polybutadiene chain segment is 30 to 52 percent; and the content of a polyacrylate segment is 30 to 60 percent. The aqueous polyurethane-acrylate resin has the preparation characteristics that: a polymer material prepared by introducing siloxane into the side chain has high mechanical performance and high water resistance; and the use of alpha, omega-terminated amino polyoxypropylene as a chain extender improves the solid content of emulsion and the molecular weight of polyurethane- at the same time, and the introduced polyoxypropylene has high mechanical foaming performance. The aqueous polyurethane-acrylate resin prepared by the method disclosed by the invention is safe and environment-friendly, the emulsion is stable in performance and easy to foam, the foaming performance of the emulsion is high, and the aqueous polyurethane-acrylate resin is suitable for making the foamed layer of synthetic leather.

Owner:兰州科天水性科技有限公司

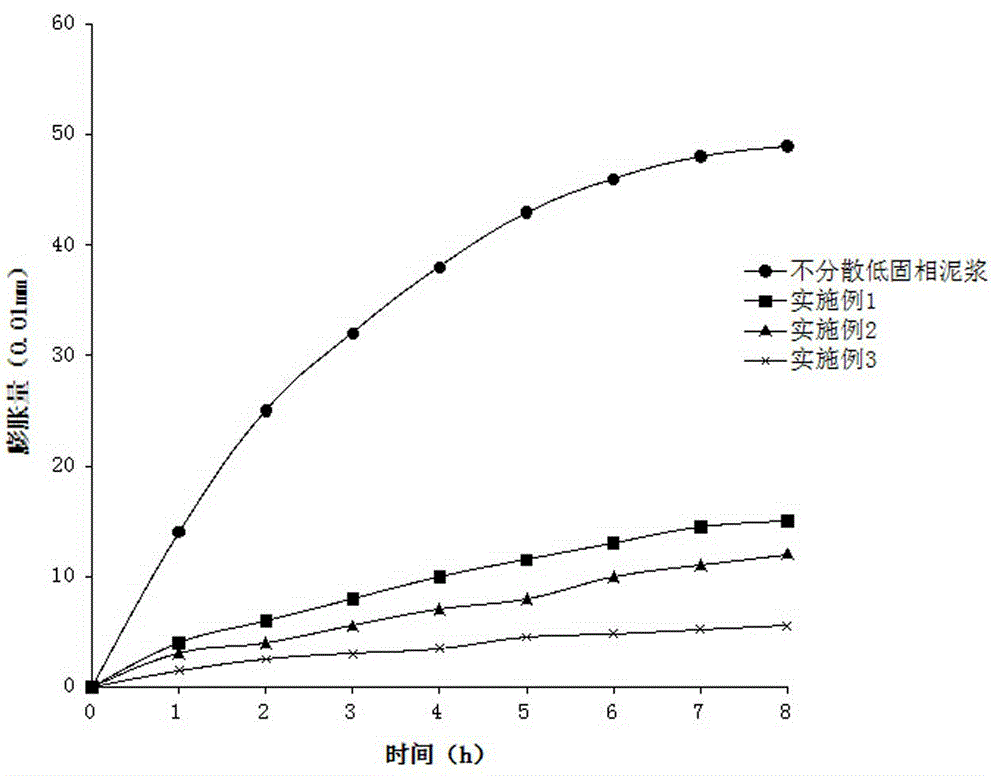

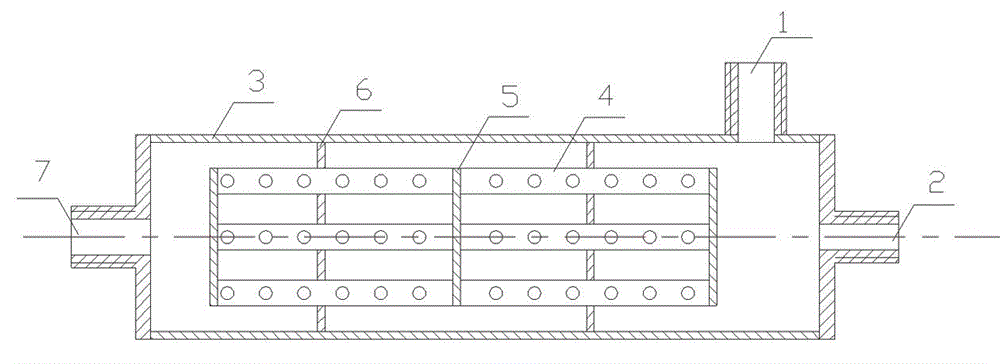

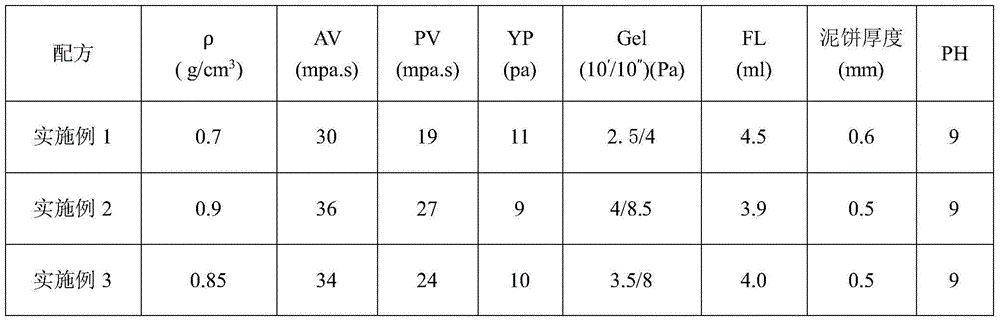

Fresh water-based micro bubble drilling fluid for drilling coal bed gas

The invention relates to a fresh water-based micro bubble drilling fluid for drilling coal bed gas. The fresh water-based micro bubble drilling fluid for drilling the coal bed gas is prepared from fresh water, sodium carbonate, sodium hydroxide, basic zinc carbonate, a flow pattern regulator, a foaming agent and a stabilizing agent. The main performance of the fresh water-based micro bubble drilling fluid for drilling the coal bed gas is not lower than that of a drilling fluid used in the conventional coal bed gas drilling process, and the drilling fluid has a good leakage controlling and leakage plugging effect, solves the problem that a low pressure easily-leaked coal bed is easily leaked in the drilling process, and can effectively improve the bearing capacity of a stratum; when the coal bed is not drilled and leaked, the drilling fluid has various engineering properties required by drilling; and when a leaked coal bed is met, the drilling fluid automatically plugs the stratum and drilling is continued; through the proportion of a treatment agent, the poor soil solid-phase contamination resistance and calcium resistance of the drilling fluid are improved; and the properties of the drilling fluid are easy to maintain.

Owner:CHINA UNITED COALBED METHANE +2

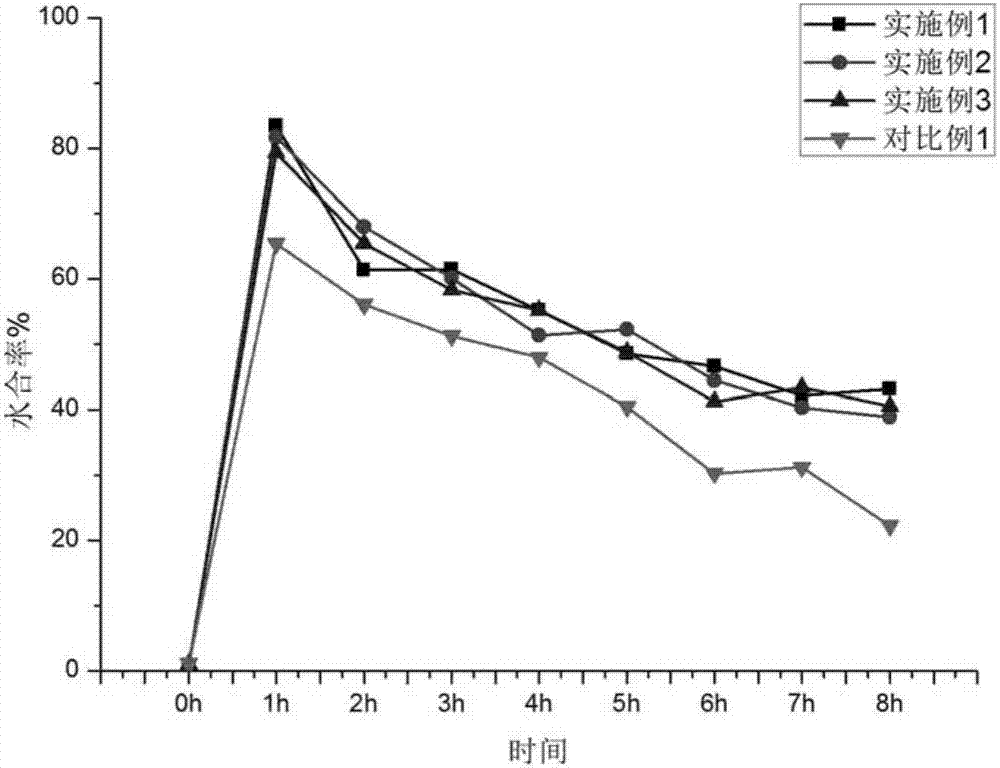

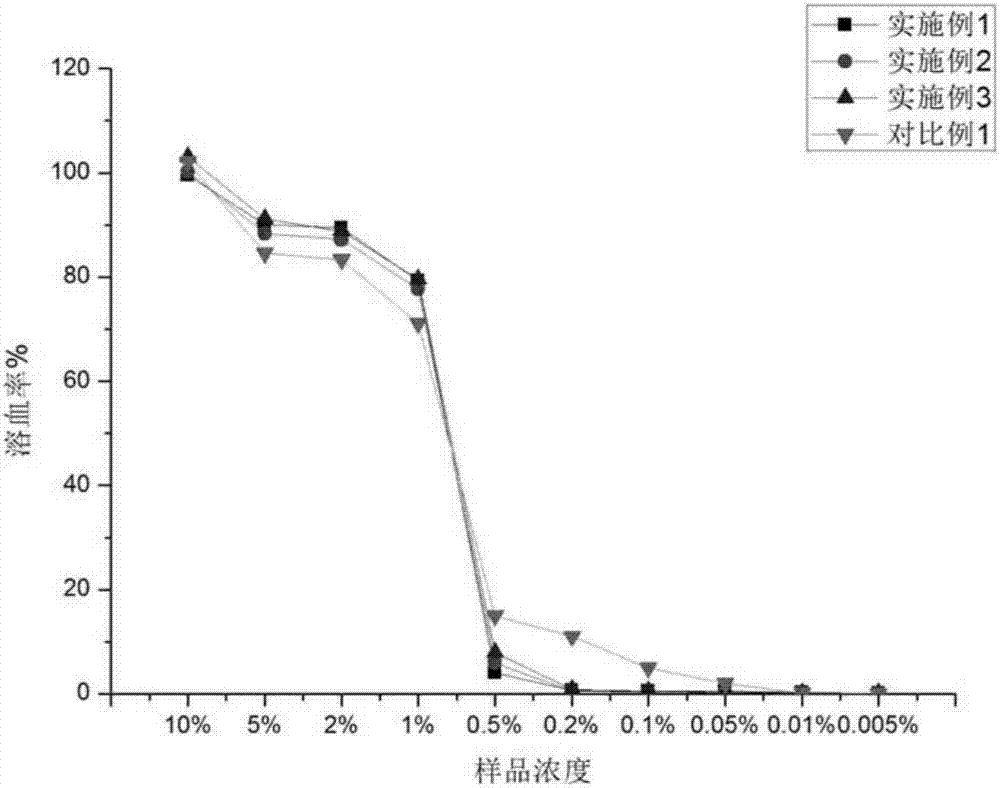

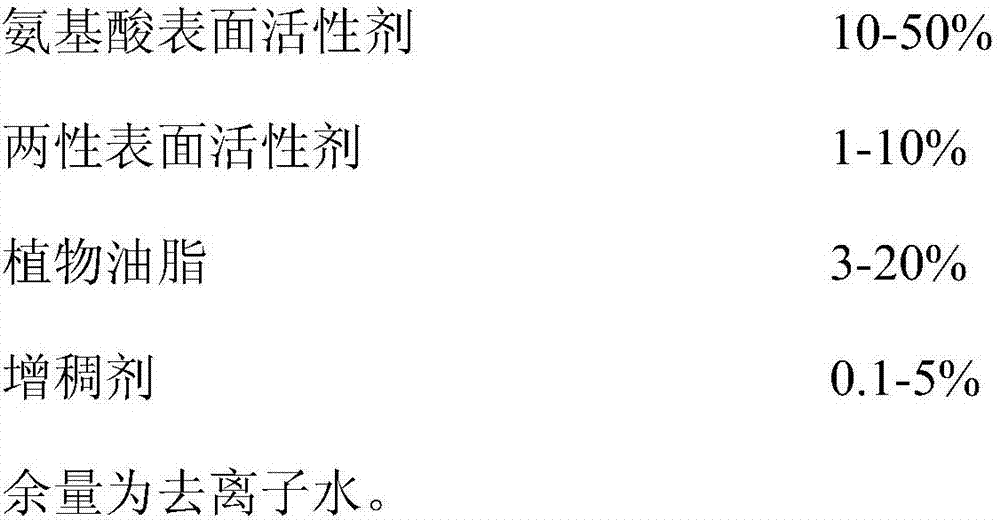

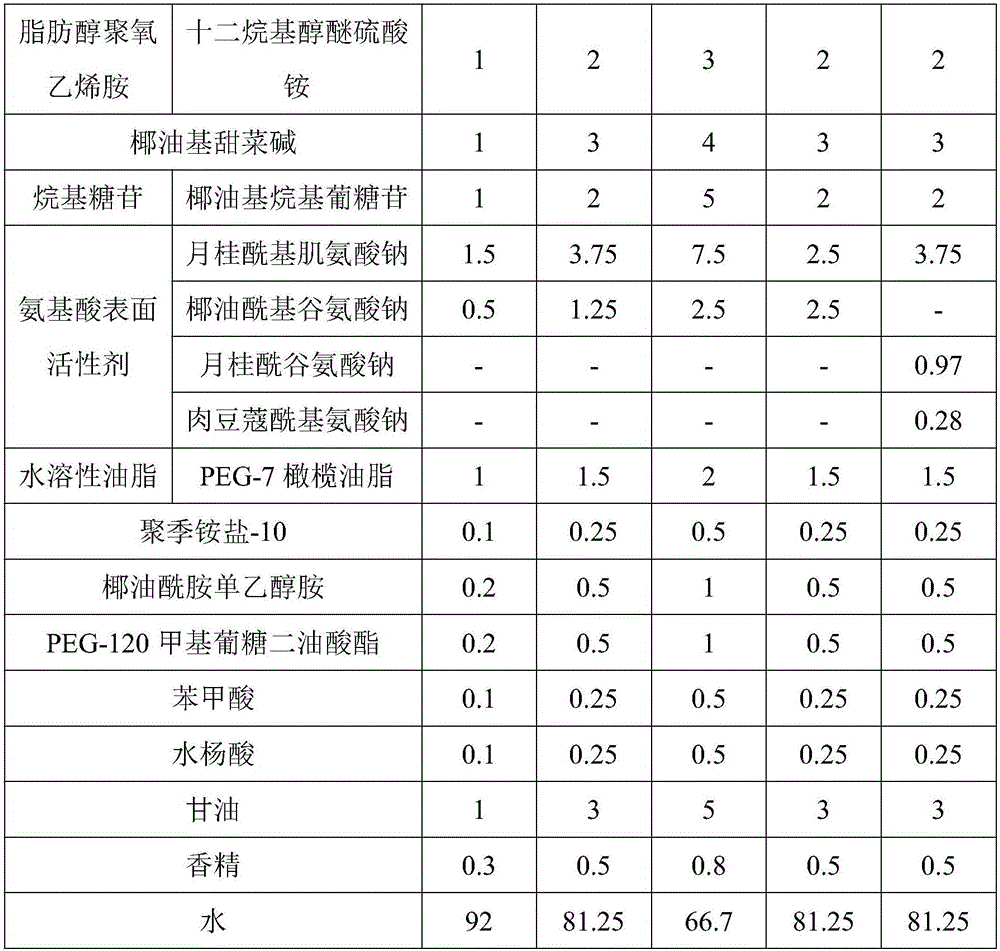

Amino acid face cleansing cream and preparation method thereof

InactiveCN107569410AMild in natureRich sparklingCosmetic preparationsToilet preparationsAdditive ingredientSURFACTANT BLEND

The invention provides amino acid face cleansing cream and a preparation method thereof. The amino acid face cleansing cream is prepared from the following ingredients in percentage by mass: 10 to 50percent of amino acid surfactants, 1 to 10 percent of amphoteric surfactants, 3 to 20 percent of plant grease, 0.1 to 5 percent of thickening agents and the balance of de-ionized water. The amino acidface cleansing cream provided by the invention has the advantages that the foam is rich; the grease is as high as 20 percent; the surfactants, the plant grease and the thickening agents achieve cooperated effects, so that the amino acid face cleansing cream has the advantages of relatively high cleaning and moisture preservation capability and nourishing and restoration efficacies.

Owner:GUANGZHOU HUANYA COSMETIC SCI & TECH CO LTD

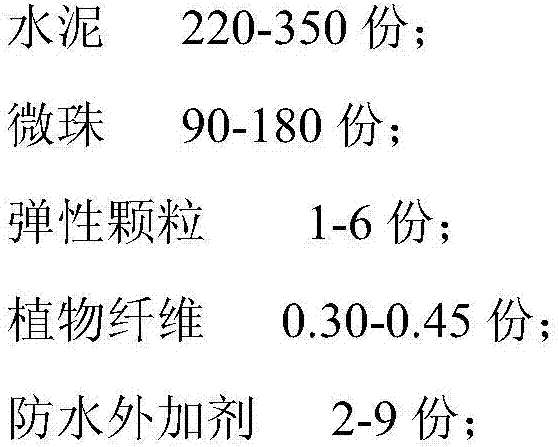

Waterproof crack-resistant foam concrete and manufacture method

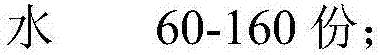

The invention discloses waterproof crack-resistant foam concrete and a manufacture method thereof. The waterproof crack-resistant foam concrete is formed by mixing and stirring of raw materials including, by weight, 220-350 parts of cement, 90-180 parts of microspheres, 1-6 parts of elastic particles, 0.30-0.45 parts of palm filaments, 60-160 parts of water, 2-9 parts of waterproof admixtures and foam. The waterproof crack-resistant foam concrete and the manufacture method thereof have the advantages that the raw materials such as industrial by-products, tailings powder or waste rubber powder and the palm filaments are adopted, and the multi-scale toughening principle on compounding of the elastic particles and fibers is followed, so that strength and crack resistance of the foam concrete are improved, and waste resource utilization is benefited; the adopted waterproof admixtures are highly compatible with other materials, and accordingly, water resistance and durability of the foam concrete are improved effectively; by the prepared foam which is fine, uniform and high in stability, anti-permeability and thermal performance of the foam concrete are improved; the foam concrete is applicable to heat insulation of building walls and roofs and roadbed refilling materials for highways in regions with soft soil and high water level.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

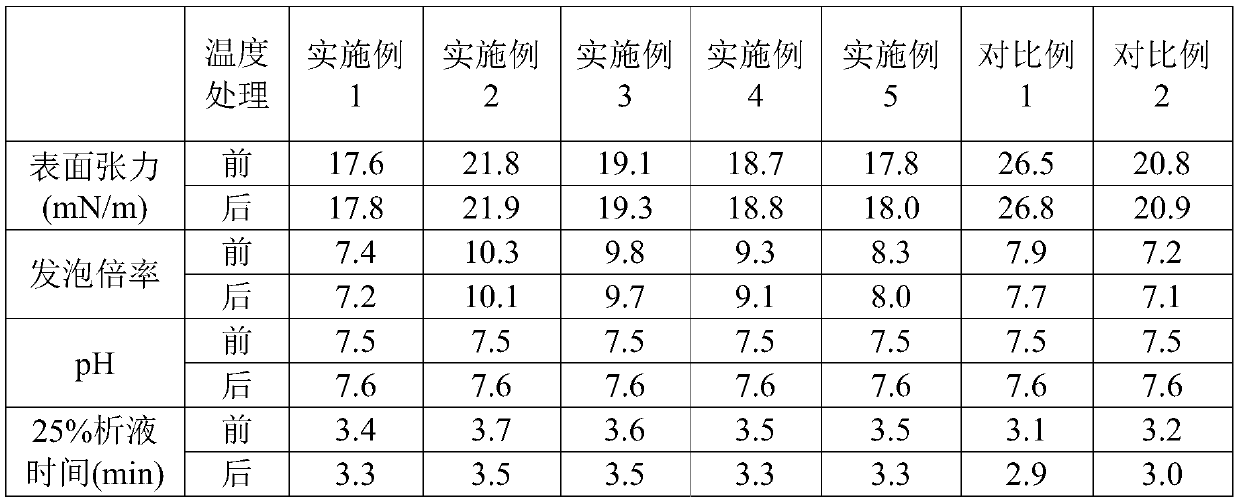

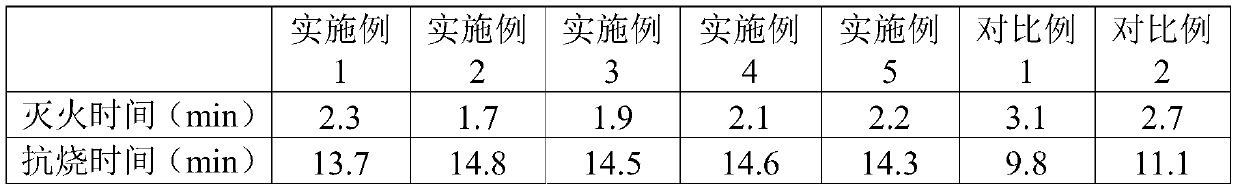

Fluoride-free environment-friendly efficient aqueous film-forming foam extinguishing agent and preparation method thereof

InactiveCN110639156AImprove performanceImprove fire extinguishing effectFire extinguisherActive agentProcess engineering

The invention relates to the technical field of fire extinguishing agents, in particular to a fire extinguishing agent composition, and a preparation method and application thereof. The fire extinguishing agent composition comprises an organic silicon surfactant, a hydrocarbon surfactant, an organic cosolvent, a foam additive and the like. The foam extinguishing agent has main advantages of not containing a fluorocarbon surfactant, and a polyether modified polysiloxane type organic silicon surfactant and / or a polyether trisiloxane organic silicon surfactant are / is used; on the basis of environmental protection, a compound of an anionic hydrocarbon surfactant, a nonionic hydrocarbon surfactant and an amphoteric hydrocarbon surfactant is adopted for compounding, so that better foam performance and fire extinguishing performance can be achieved; through joint adjustment and dosage matching of multiple components, low surface tension, good foaming performance and foam stabilizing performance and efficient fire extinguishing performance are achieved, and the defect that foaming performance and foam stabilizing performance of an organosilicon surfactant is relatively poor is overcome. .The fire extinguishing agent composition can achieve spreading boundary on an oil surface, can be degraded easily, is environmentally friendly, and is often applied to extinguishing oil fire.

Owner:北京南瑞怡和环保科技有限公司

Synthesizing process of fatty diglycollic amide

InactiveCN100999482ASimple processLess side effectsOrganic compound preparationCarboxylic acid amides preparationPotassium fluorideFiltration

This invention relates to a synthesis method of fatty acids diethanolamine. It takes fatty acid and diethanolamine as raw materials. The method includes follow steps: first fatty acids and a certain amount of diethanolamine for dehydration and condensation reaction, then adding the remaining diethanolamine and alkaline catalyst for aminolysis reaction, the final using activated clay for adsorption treatment, and through filtration to obtain fatty acid diethanolamine. The weight proportion between fatty acids and diethanolamine is 1:0.5 ~ 0.6; account for weight, 30 ~ 70% diethanolamine add in dehydration and condensation reaction, and the remaining add in aminolysis reaction; its alkaline catalyst is one of the alkali metal hydroxide, potassium fluoride and sodium borohydride, account for 0.3 to 2.0% of total weight of fatty and diethanolamine.

Owner:王伟松

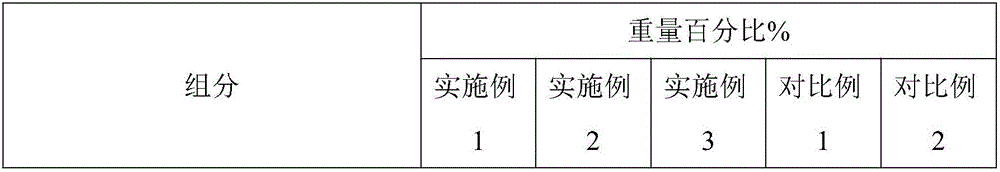

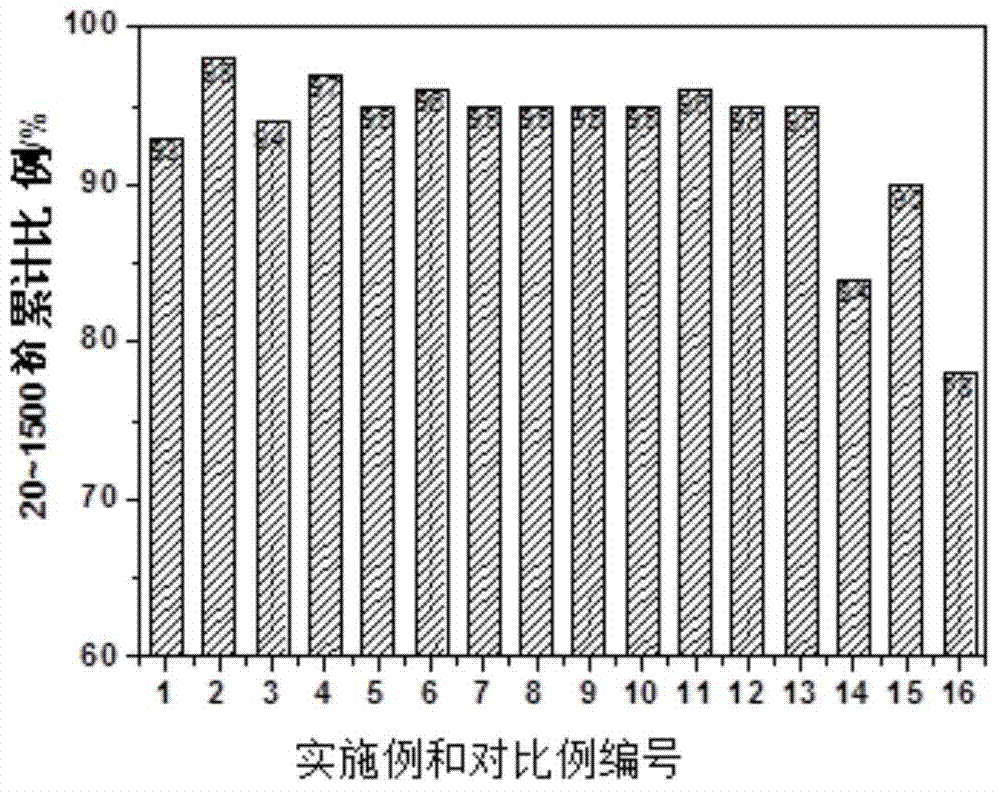

Moderate amino acid shampoo and preparation method thereof

The invention belongs to the field of daily chemical products, and particularly relates to moderate amino acid shampoo and a preparation method thereof. The amino acid shampoo comprises the following components: fatty alcohol polyoxyethylene amine, coco-betaine, alkyl polyglycoside, an amino acid surfactant, water-soluble grease, polyquaternium-10, cocamidopropyl monoethanolamine, PEG-120 methyl glucose dioleate, benzoic acid, salicylic acid, glycerin, essence and water. The amino acid shampoo has high foaming and foam stabilizing performance, moderate cleaning and washing capability and good moisturizing effects; washed hair is bright, smooth, elastic and high in combability; the amino acid shampoo is moderate, nontoxic and non-irritating to skin, comfortable, soft and moist.

Owner:壹田(广州)生活健康用品有限公司

Composite concrete air entraining agent, and preparation method and application thereof

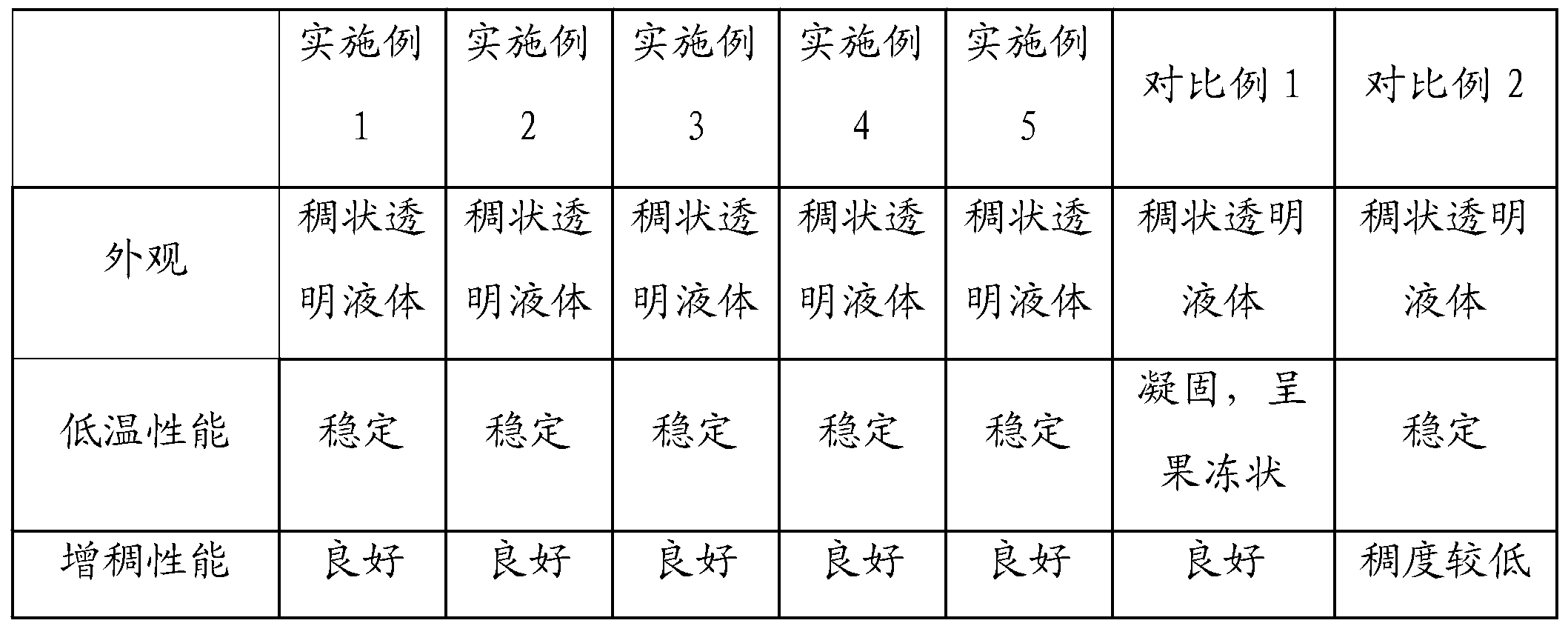

ActiveCN104496525ARemarkable foaming effectGood low temperature stabilityTransportation and packagingMixingNonionic surfactantAir content

The invention provides a composite concrete air entraining agent, and a preparation method and application thereof. The invention is characterized in that the composite concrete air entraining agent is composed of a sulfonate Gemini surfactant, a betaine amphoteric surfactant, an alkanolamide nonionic surfactant and water; and the solid content of the composite concrete air entraining agent is 20+ / -1%. The composite concrete air entraining agent has excellent air-entraining effect in concrete; and sufficient 20-150-mu m stable small bubbles can be introduced to improve the workability of the concrete (mortar), reduce the bleeding rate and sedimentation and avoid lowering the later strength of the concrete on the premise of enhancing the air content.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

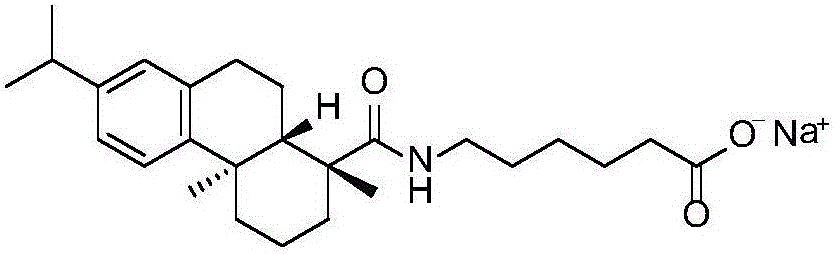

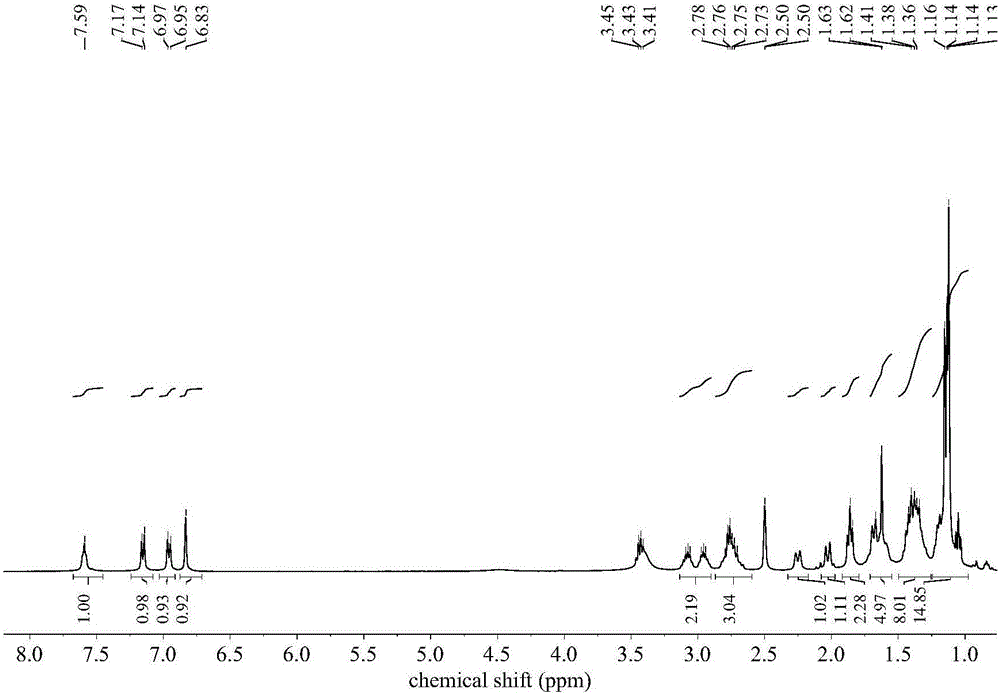

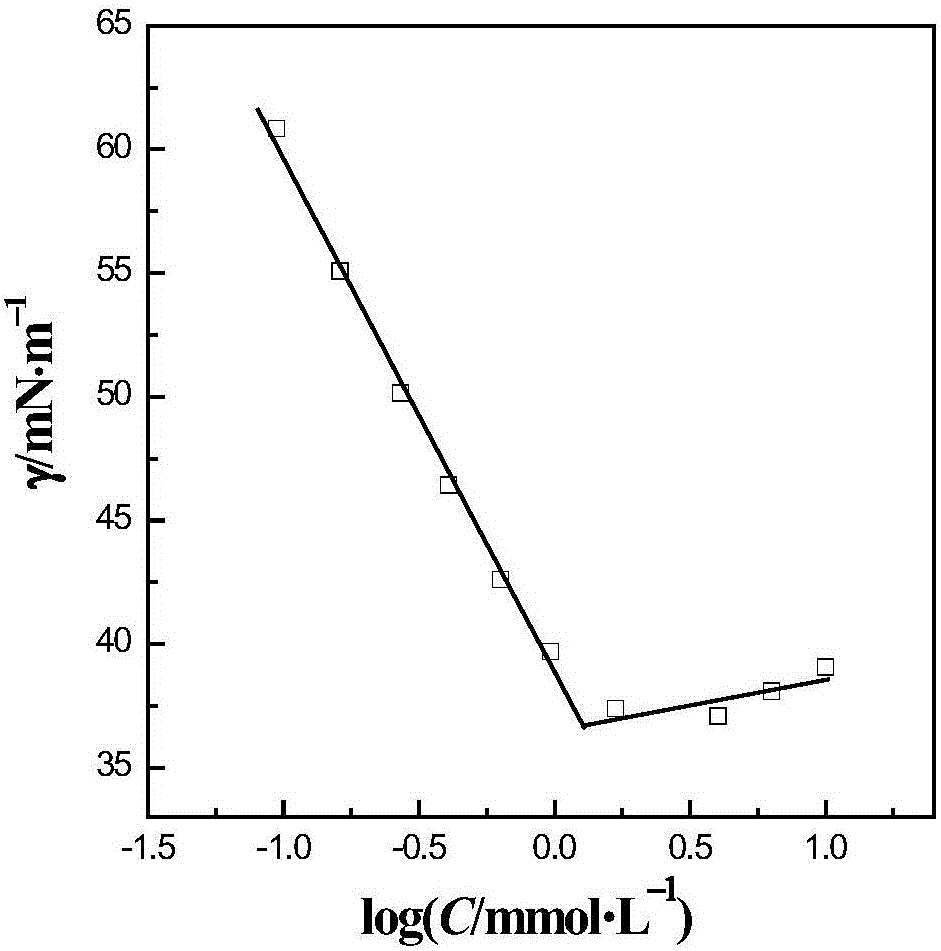

Dehydroabietic acid-based anionic surfactant and stable foam formed by same

InactiveCN106140006AGood foam stabilityReduce tensionOrganic compound preparationTransportation and packagingSolubilityCritical micelle concentration

The invention relates to a dehydroabietic acid-based anionic surfactant 6-dehydroabietic acylamino sodium caproate and stable foam formed by the same. The surfactant is prepared from the main synthetic raw materials of dehydroabietic acid and amino acid which are both from natural products and is a green surfactant. The solubility of 6-dehydroabietic acylamino sodium caproate at room temperature is larger than 0.8 mol / L, and 6-dehydroabietic acylamino sodium caproate has the capacity of being compounded with multiple components; the critical micelle concentration value of the surfactant is 1.26 mmol / L, and a high aggregation capacity is shown. In addition, 6-dehydroabietic acylamino sodium caproate has good foam stability. The surfactant can serve as an environment-friendly product with a good property and is applied in formulas of daily cleansers, detergents, dispersing agents, daily-use chemicals and foam stabilizers.

Owner:JIANGNAN UNIV

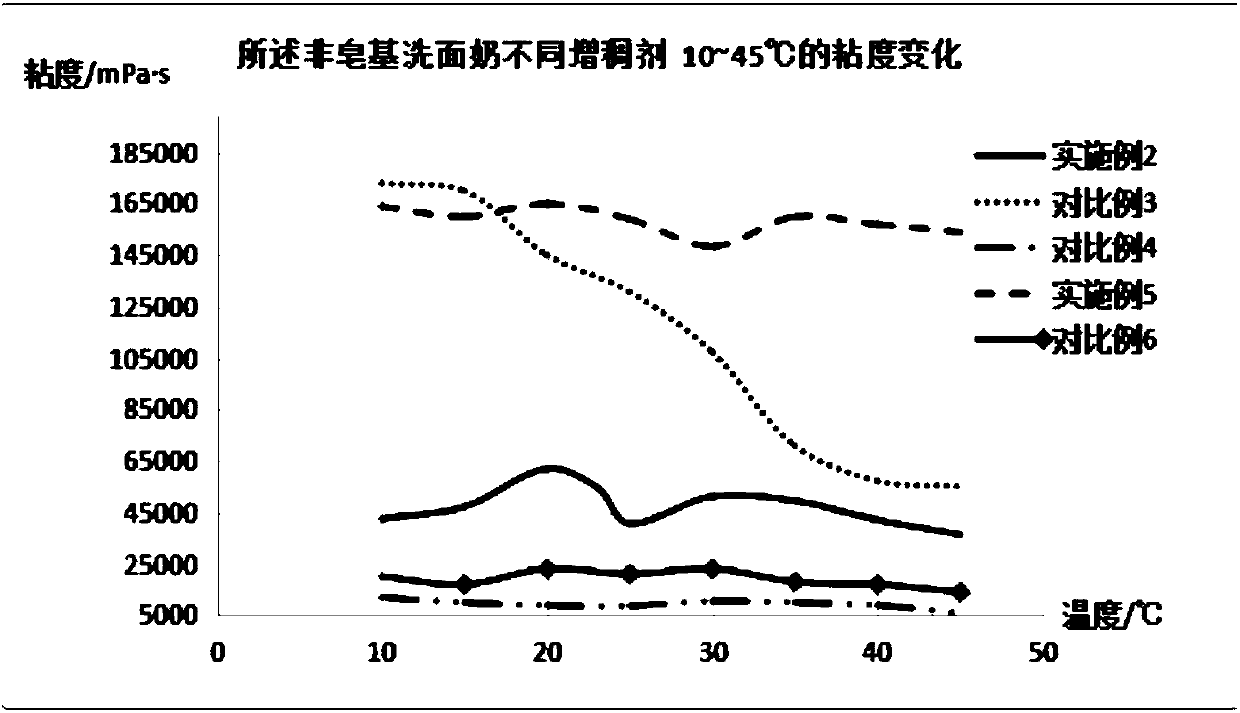

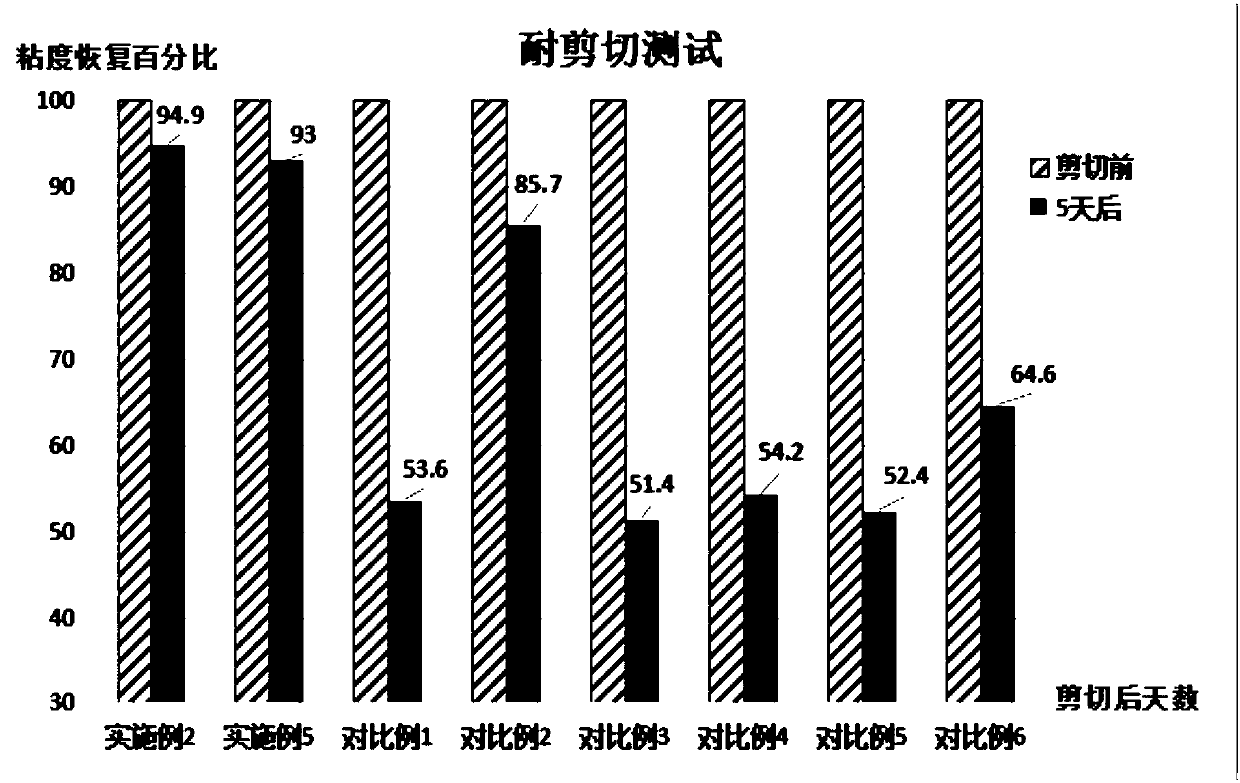

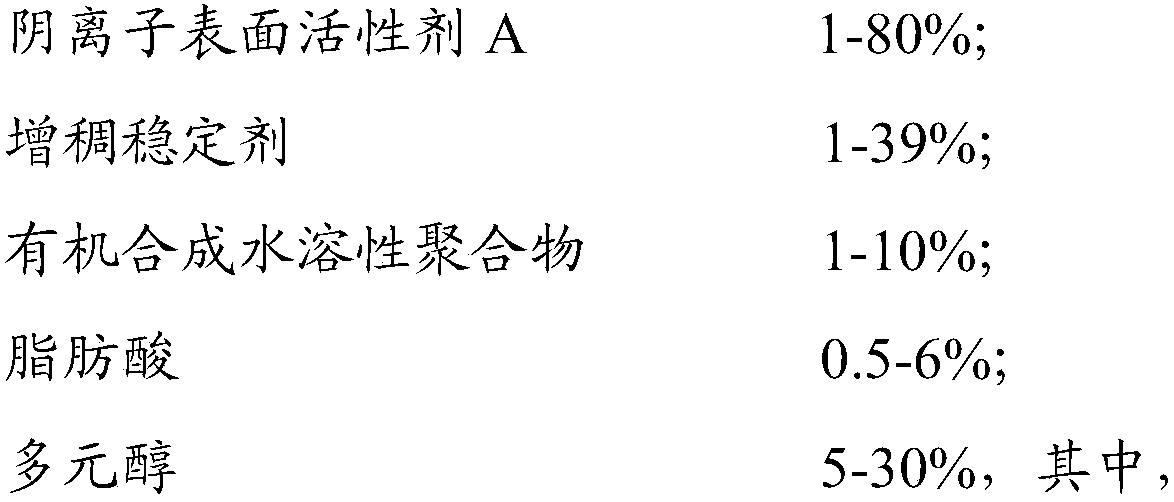

Non-soap-based facial cleanser and preparation method thereof

ActiveCN107582427AImprove shear resistanceGood viscosity stabilityCosmetic preparationsToilet preparationsPolymer scienceOrganic synthesis

The invention relates to a non-soap-based facial cleanser and a preparation method thereof. The non-soap-based facial cleanser is prepared from raw materials including at least one anionic surfactantof N-fatty acryl amino acid salt or alkyl phosphate, a thickening stabilizer, an organic synthesis water-soluble polymer, fatty acid and polyhydric alcohol, wherein the thickening stabilizer is obtained by compounding an organic natural water-soluble polymer and sulfosuccinate salt in a certain ratio and has a good thickening effect, and the thickened non-soap-based facial cleanser has high viscosity adjustable in a wide range; besides, the non-soap-based facial cleanser has excellent skin feeling, good viscosity stability and high / low-temperature stability during usage and also has good foaming capacity, foam stabilizing performance, high foaming speed, foam richness and washability.

Owner:GUANGZHOU HONDU FINE CHEM CO LTD

Method for preparing calcium stearate water-based dispersion liquid

ActiveCN103276625AGood foam stabilityAvoid problemsDefoamers additionPaper coatingWater basedSupersonic waves

The invention discloses a method for preparing a calcium stearate water-based dispersion liquid. The method comprises the following steps: adding water and an emulsifier, a dispersant and 20-40% of the total content of a defoaming agent in a reaction kettle in a certain proportion, stirring until the emulsifier is dispersed uniformly, then stopping stirring, adding calcium stearate into the reaction kettle, then rapidly stirring until calcium stearate is completely wetted, then reducing the stirring speed and continuing to stir for 30-45 min, then adding a preservative and 60-80% of the total content of the defoaming agent into the reaction kettle, after carrying out superfine grinding for 3-8 min, screening through a 1000-1500 mesh supersonic wave vibrating screen, and obtaining the calcium stearate water-based dispersion liquid with the particle size of 5-10 microns. The method has the advantages of being simple in formula, easy to operate, and short in time consumption; and the product is non-crusting, is good in homogeneity and stabilization, is environmentally friendly, has adjustable solid content of calcium stearate and adjustable viscosity of the final system in a certain scope, and has an ideal lubrication effect.

Owner:肇庆市至立自动化科技有限公司

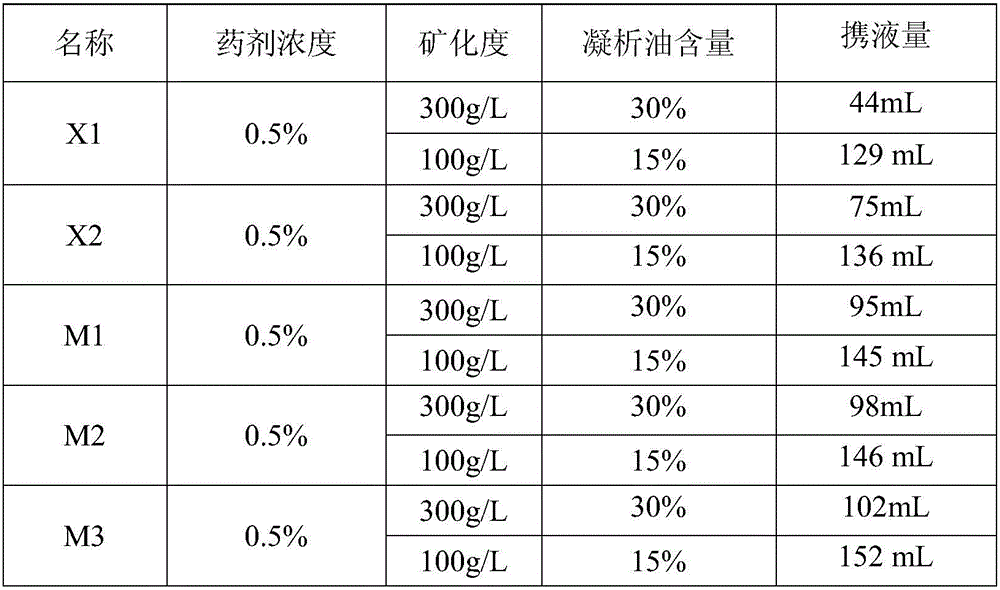

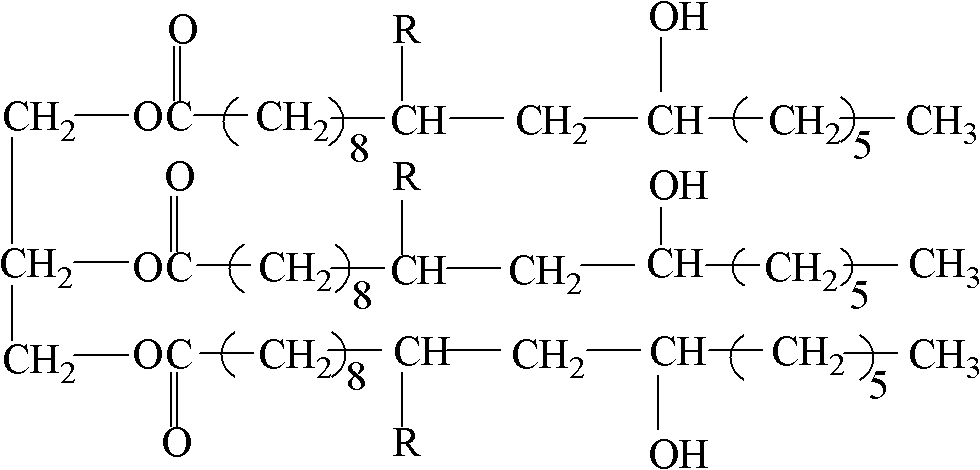

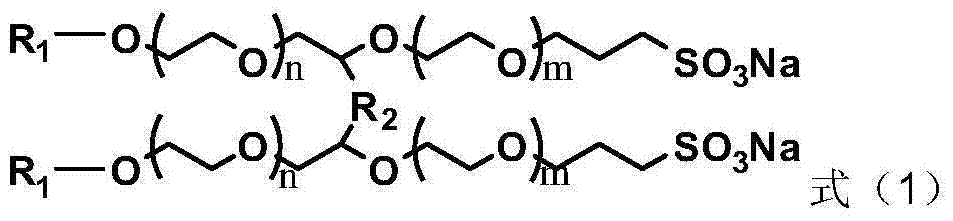

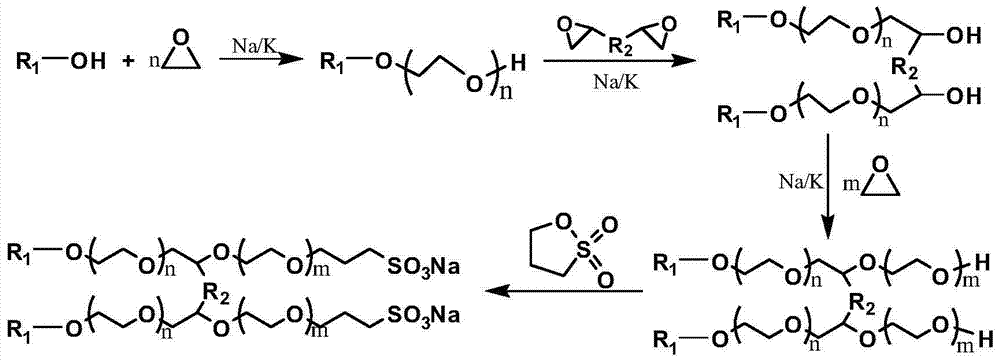

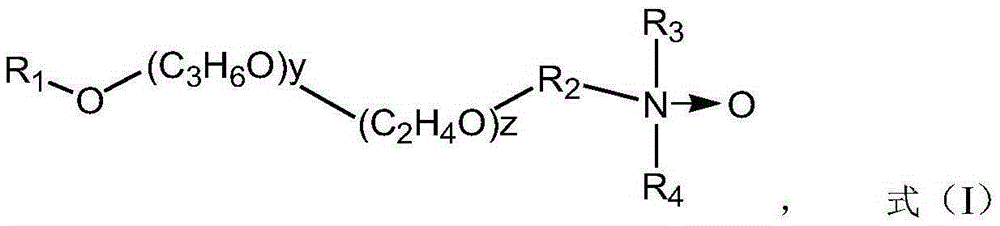

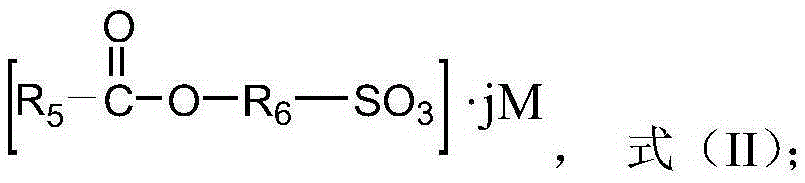

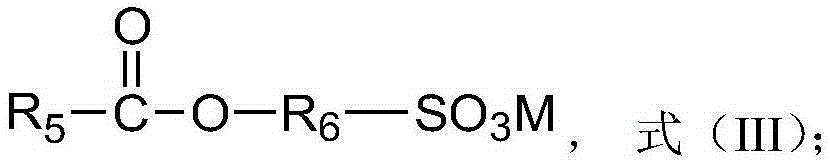

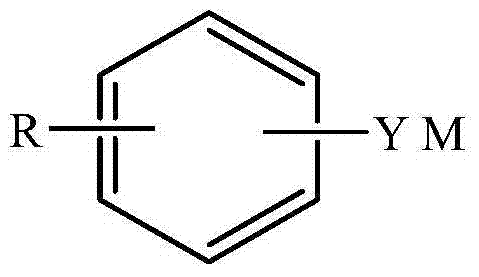

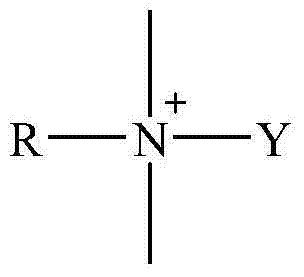

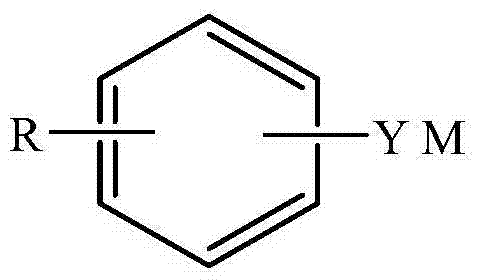

Hypersalinity resistant foam scrubbing agent composition used for drainage gas recovery and preparation method and application thereof

The invention relates to a hypersalinity resistant foam scrubbing agent composition used for drainage gas recovery and a preparation method and application thereof. The hypersalinity resistant foam scrubbing agent composition used for drainage gas recovery aims at solving the problems of reduction of output and even flowing stop of gas wells caused by excessive hydrops during developing of the current gas wells. According to the adopted technical scheme, the foam scrubbing agent is prepared from, by mole fraction, 1 part of long chain polyether nitrogen compound and 0.5-20 parts of sulfonated fatty acid alkyl ester, wherein the general molecular formula of the long chain polyether nitrogen compound is shown as a formula (I), and R1 is a fatty group of C8-C30; y is a PO chain segment adding number; z is a EO chain segment adding number; R2 is a alkylene of C1-C4; R3, R4 are any one of a alkyl group and a substituted alkyl group; the hypersalinity resistant foam scrubbing agent composition used for drainage gas recovery solves the problem well. The foaming height of the hypersalinity resistant foam scrubbing agent composition is larger than 200 mm, the liquid carrying capability of the hypersalinity resistant foam scrubbing agent composition is larger than 140 mL, and the hypersalinity resistant foam scrubbing agent composition can be used for the drainage gas recovery of hyperhaline gas wells. The formula is shown in the description.

Owner:CHINA PETROLEUM & CHEM CORP +1

Plastic product cleanser

InactiveCN104120045AClean up thoroughlyLess irritatingInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCleansers skinOctamethylcyclotetrasiloxane

The invention relates to plastic product cleanser. The cleanser comprises the following components in parts by weight: 80-100 parts of sodium perborate, 5-10 parts of citric acid, 5-15 parts of ampholytic surfactant, 1-5 parts of sodium chloride, 10-40 parts of sodium tripolyphosphate, 5-20 parts of sodium silicate, 10-30 parts of lauryl sodium sulfate, 2-10 parts of stabilizer, 2-10 parts of octamethylcyclotetrasiloxane and 1-5 parts of hydrogen peroxide. By adopting the plastic product cleanser disclosed by the invention, dirty stains, grease stains, oil stains and nicotine residual can be completely cleared; the plastic product cleanser disclosed by the invention is suitable for the cleaning of plastic products such as shutters, plastic furniture, office desktops, computers, audio equipment, television shells, boats, surfboards, window frames and the like.

Owner:陈启文

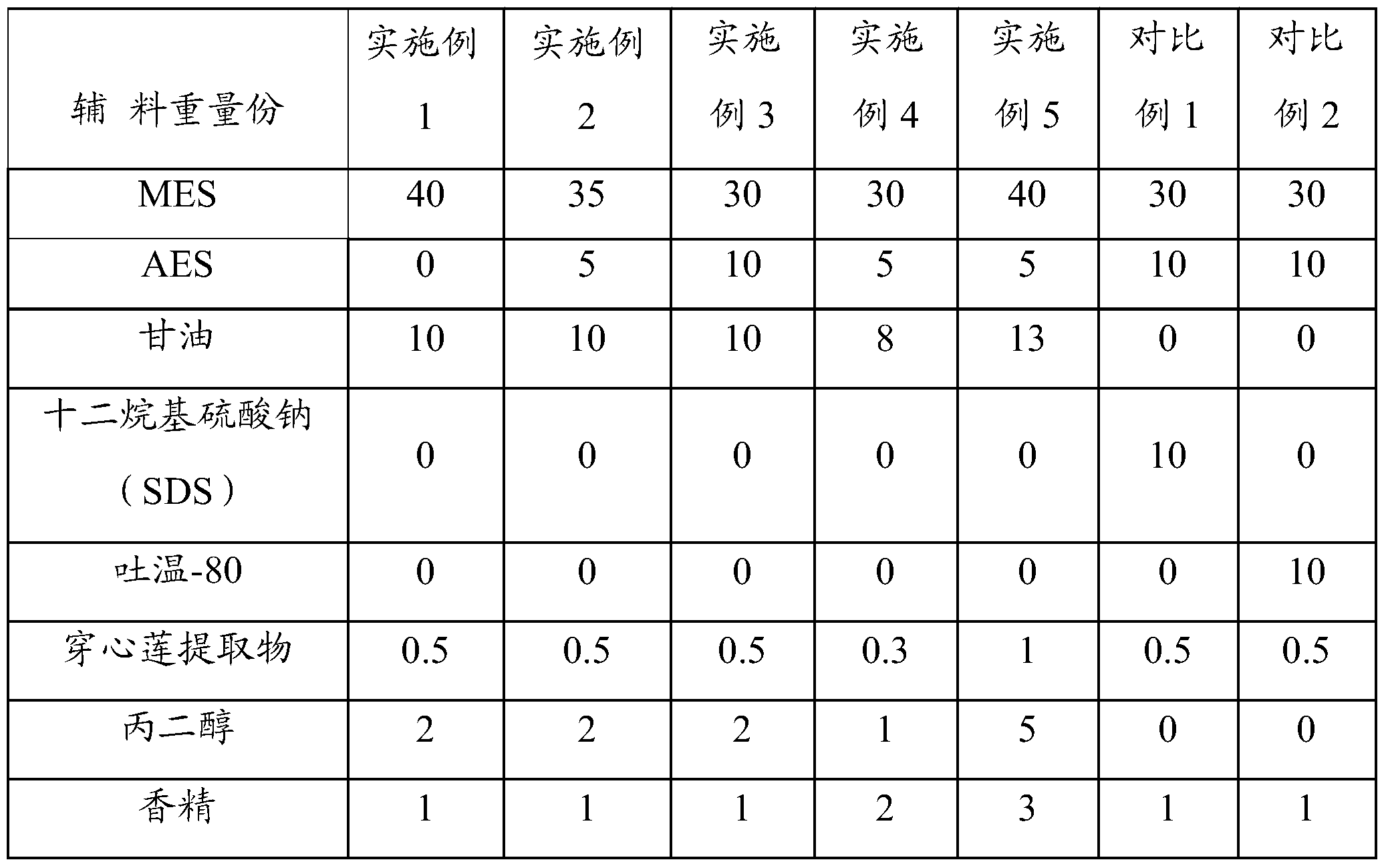

Andrographis paniculata hand sanitizer and preparation method thereof

InactiveCN103301049AImprove solubilityGuaranteed stabilityCosmetic preparationsToilet preparationsGlycerolHand sanitizer

The invention discloses an andrographis paniculata hand sanitizer and a preparation method thereof. The andrographis paniculata hand sanitizer has a formula comprising the following raw materials in parts by weight: 0.3 to 3 parts of andrographis paniculata extract, 20 to 50 parts of surface, 1 to 10 parts of propylene glycol, 8 to 15 parts of glycerinum, 1 to 5 parts of essence, 2 to 5 parts of sodium chloride, and 40 to 60 parts of water. According to the andrographis paniculata hand sanitizer, propylene glycol and glycerinum are used together in a certain proportion in the formula, so that the andrographis paniculata extract in the formula can be dissolved fully, and the stability of the hand sanitizer can be kept at a low temperature. The result of an in-vitro drug sensitive test shows that the andrographis paniculata hand sanitizer has a good antibacterial effect.

Owner:GUANGZHOU UNIVERSITY OF CHINESE MEDICINE

Anti-collapse and anti-leakage drilling washing fluid used during drilling and field production method thereof

ActiveCN104893696AImprove drilling efficiencyLower Drilling CostsDrilling compositionFoaming agentUltimate tensile strength

The invention discloses an anti-collapse and anti-leakage drilling washing fluid used during drilling and a field production method thereof, belongs to the technical field of geological core drilling technology, and aims to solve the problem that drilling washing fluid is poor in wall protecting effect under the stratum conditions of strong breaking and continuous leakage. The drilling washing fluid is characterized in that 30-50kg of bentonite, 2-4kg of soda ash, 2-5kg of tackifier, 20-50kg of fluid loss agent, 5-15kg of flow pattern regulator, 30-80kg of bridging agent, 20-50kg of blocking agent, 10-30kg of inhibitor and 1-3L of foaming agent are added to each cubic meter of water. The anti-collapse and anti-leakage drilling washing fluid has the advantages that the drilling washing fluid is good in collapse preventing effect, fast in leakage blocking, high in leakage blocking strength, wide in adaptive crack width range, and widely applicable to the drilling of water-sensitive and loose and broken stratums, low-pressure leakage layers and fracture hole developed stratums.

Owner:INST OF EXPLORATION TECH OF CHINESE ACAD OF GEOLOGICAL SCI

Organosilicon surfactant and application thereof in preparation of polyurethane flexible foam

The invention provides an organosilicon surfactant. The organosilicon surfactant has the following general formula: MDxD'yD ''zM, wherein M is selected from any one of (CH3) 3SiO1 / 2 and (CH3) 2RSiO1 / 2, D is (CH3) 2SiO2 / 2, D'is (CH3) 2 (R) SiO2 / 2, D ''is (CH3) 2 (R') SiO2 / 2, x + y + z is 70-100, x is 68-98, y is 1-16, and z is 1-16. The invention also provides an application of the organic siliconsurfactant in polyurethane flexible foam. Alkynediol polyether, high-molecular-weight hydrogen-containing silicone oil and at least one alkynediol polyether are introduced, and a high-molecular organosilicon copolymer surfactant is formed through hydrosilylation. The preparation method is used for preparing the polyurethane flexible foam, and the rebound resilience of the polyurethane flexible foam can be improved.

Owner:JIANGXI MENHOVER CHEM TECH CO LTD

Preparation method of acrylic acid modified waterborne polyurethane dispersion liquid used for metallic paint

The invention discloses a preparation method of an acrylic acid modified waterborne polyurethane dispersion liquid used for metallic paint. The preparation method of the acrylic acid modified waterborne polyurethane dispersion liquid used for the metallic paint comprises the following steps: uniformly mixing isophorone diisocyanate, polyether polylol and polyester polylol, performing reaction under the catalytic action of stannous octoate for 1-3 hours at the temperature of 80-95 DEG C, so as to obtain a prepolymer; adding a micromolecule chain extender and a hydrophilic monomer into the prepolymer, performing chain extension for 0.5-1 hour at the temperature of 80-85 DEG C, sealing residual end -NCO by utilizing hydroxyethyl acrylate, then adding a neutralizing agent for neutralization and salification, and adding water for emulsification, so that water-based dispersion liquid is obtained; adding an initiator, an emulsifier and other acrylic acid monomers into the water-based dispersion liquid, and performing free radical polymerization for 3-5 hours at the temperature of 85-100 DEG C, so that acrylic acid modified waterborne polyurethane dispersion liquid is obtained. According to the preparation method of the acrylic acid modified waterborne polyurethane dispersion liquid used for the metallic paint, ammonium persulphate is used as the initiating agent, polyether phosphate ester and alkylolamide surfactant are used as the emulsifier, completely successfully emulsified acrylic acid modified waterborne polyurethane dispersion liquid can be prepared, and the obtained acrylic acid modified waterborne polyurethane dispersion liquid has excellent acid resistance, alkali resistance and salt fog resistance and excellent hardness and mechanical property.

Owner:上海福岛新材料科技有限公司

High-temperature-resistant low-tension foam oil-displacing agent and application thereof

InactiveCN104745168AStrong high temperature resistanceGood foam stabilization performanceDrilling compositionTemperature resistanceMass concentration ratio

A high-temperature-resistant low-tension foam oil-displacing agent comprises an anionic surfactant and a zwitterionic surfactant, wherein the mass concentration ratio of the anionic surfactant to the zwitterionic surfactant is (1-50):1. The invention further discloses an application of the high-temperature-resistant low-tension foam oil-displacing agent to tertiary oil recovery to increase the recovery efficiency of crude oil in a high-temperature oil reservoir with the formation temperature of 80-200 DEG C. The high-temperature-resistant low-tension foam oil-displacing agent provided by the invention has the characteristics of ultralow interfacial tension, high foaming capacity, good foam stabilizing effect, good high-temperature resistance and the like, cannot be decomposed at the high temperature of 300DEG C. Ultralow interfacial tension less than 10<-2>mN / m can be achieved between an aqueous solution of the high-temperature-resistant low-tension foam oil-displacing agent and crude oil, wherein the concentration of the aqueous solution of the high-temperature-resistant low-tension foam oil-displacing agent is 0.1-0.5wt%.

Owner:丁国良

Asphalt emulsifier for anionic emulsified asphalt cement plaster

The invention discloses an asphalt emulsifier for anionic emulsified asphalt cement plaster. The asphalt emulsifier comprises the following components in percentage by mass: 10 to 50 percent of lignin perborate, 5 to 40 percent of nonionic surfactant and 10 to 85 percent of water, wherein the number-average molecular weight of the nonionic surfactant is between 600 and 5,800. The asphalt emulsifier for the CRTSII type anionic emulsified asphalt cement plaster has the advantages of moderate HLB value, low demulsification velocity, moderate foaming capability and high foam stability.

Owner:厦门华特公路沥青技术有限公司

Novel coal mine foam dedusting agent

PendingCN108285774AGood water solubilityImprove downhole operating environmentOther chemical processesCelluloseFoaming agent

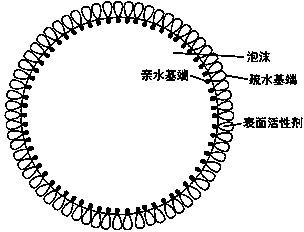

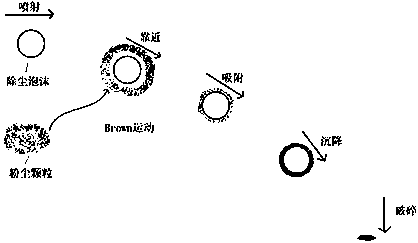

The invention discloses a novel coal mine foam dedusting agent. The agent is prepared from, by weight, 0.45-0.80% of foaming agent, 0.01-0.03% of foam stabilizer, 0.20-0.85% of wetting agent and 98.79-98.99% of water. Lauryl glucoside, polyanionic cellulose, alkylphenol polyoxyethylene ether and fatty alcohol-polyoxyethylene ether glucoside are fully mixed with water, then the liquid mixture is put into a foam dedusting foamer for mining to generate foam, the foam is conveyed to a dust source to cover the dust source, correspondingly dust generated by the dust source is caught and sedimented,and finally, a great operation environment under a coal mine well is ensured. Hydrophobic groups (also named as lipophilic groups), adsorbed to a water source layer, of wetting agent molecules are thefirst ones in contact with coal dust and are composed of long organic carbon chains; the molecular property of the hydrophobic groups is similar to that of the surface of the coal dust, and comparedwith water molecules, the hydrophobic groups can achieve adsorption more easily, so that the dust catching efficiency of the foam is improved, the dustfall rate is increased to 97% or above, and the dustfall efficiency is improved.

Owner:SHANDONG UNIV OF TECH

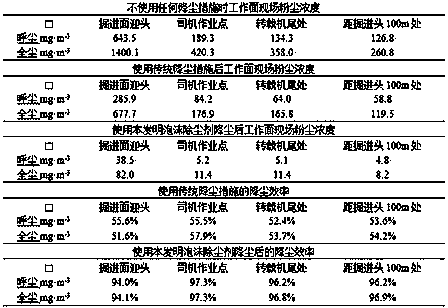

Composite cellulose ether high-temperature foam stabilizer for oil extraction

According to the technical scheme, the invention relates to a composite cellulose ether high-temperature foam stabilizer for oil extraction. The composite cellulose ether high-temperature foam stabilizer is suitable for anionic-nonionic surfactant foaming agents and comprises the following components in percentage by mass: 30-50% of high-viscosity carboxymethylcellulose (HV-CMC), 20-50% of hydroxyethyl cellulose ether (HEC), and 10-20% of hydrolyzed polyacryamide (HPAM). The composite cellulose ether high-temperature foam stabilizer for oil extraction disclosed by the invention has the beneficial effects that by compounding multiple foam stabilizers, the disadvantages of large usage amount, short half-life period and low cost when a single foam stabilizer is used under high-salinity and high-temperature conditions are made up; and during the use of the composite foam stabilizer in oil extraction of oil-water well, the composite foam stabilizer is used in combination with the anionic-nonionic surfactant foaming agents so as to achieve the advantages of good compatibility, water solubility and dispersion.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com