Dehydroabietic acid-based anionic surfactant and stable foam formed by same

A surfactant, dehydroabietic acid technology, applied in the field of dehydroabietic acid-based amino acid anionic surfactants, new dehydroabietic acid-based anionic surfactants, can solve the limitations of large volume and rosin-based surfactants , Aggregation ability is not strong and other problems, to achieve good foam stabilization performance, the effect of relieving the tension of oil and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the synthesis of dehydroabietoyl chloride. The dehydroabietic acid solid (10.6g, 0.05mol) is added in the there-necked flask equipped with tail gas absorbing device, reflux condenser, adds a small amount of 4-dimethylaminopyridine (DMAP) as catalyst, when temperature rises to 60 ℃, Slow dropwise addition of thionyl chloride (10 g, 0.08 mol) was started. During this process, a large amount of acid gas is generated, which is absorbed by the tail gas absorption device. After the dropwise addition, set the temperature to 72°C and continue the reaction for 3h. After the reaction was completed, excess thionyl chloride was removed by rotary evaporation under reduced pressure to obtain the crude product of dehydroabietoyl chloride.

Embodiment 2

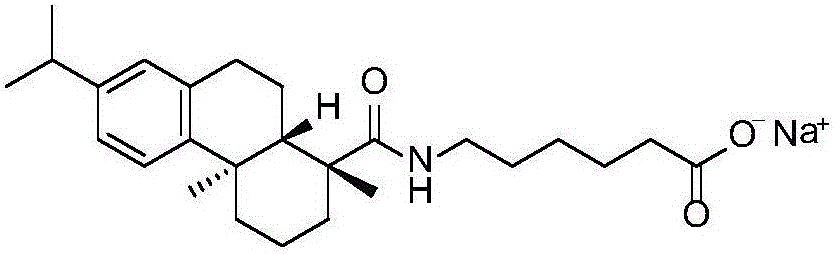

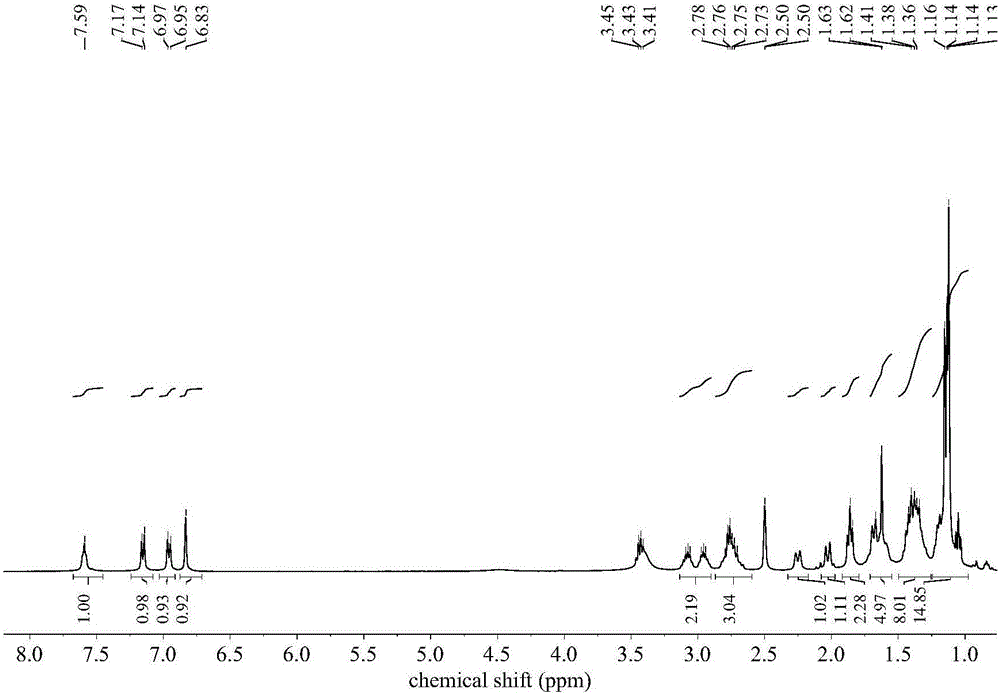

[0021] Embodiment 2: Synthesis of sodium 6-dehydroabietamido caproate. Add 6-aminocaproic acid (5.5 g, 0.04 mol) into the three-necked flask, and then add an appropriate amount of mixed solvent of acetone and water, the volume ratio of acetone and water is 1:1. Under full stirring, add dropwise an acetone solution containing 0.04 mol of dehydroabietoyl chloride and an aqueous solution containing 0.12 mol of sodium hydroxide respectively, control the reaction temperature at 10-20°C, and control the pH value of the reaction system at about 8-10. Reaction 2 -3h. After the reaction, the product was transferred to a 1000 mL beaker, and the pH value of the system was adjusted to 1-2 with 6 mol / L hydrochloric acid to produce a light yellow solid. Wash the product three times with water and petroleum ether respectively, add excess sodium hydroxide solid to make the product into sodium salt, and add 100 mL of ethanol after fully reacting. Add anhydrous sodium sulfate to the mixture t...

Embodiment 3

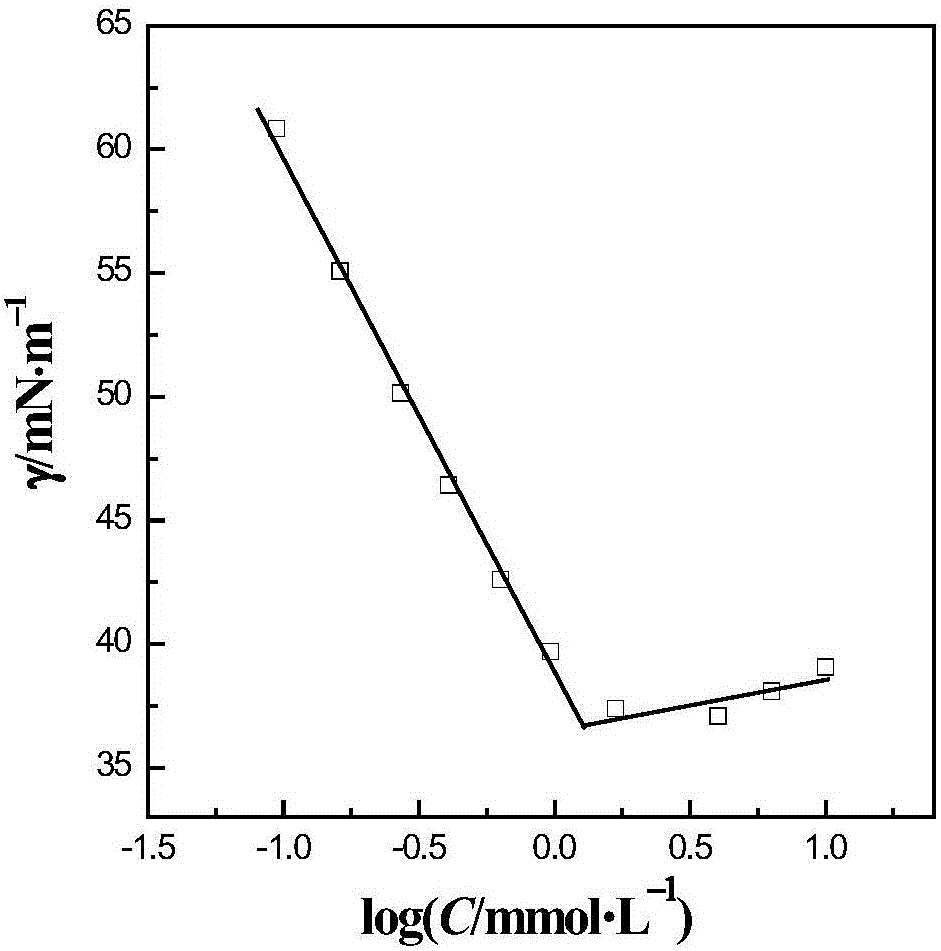

[0022] Embodiment 3: the mensuration of surface tension. A series of surfactant aqueous solutions with different concentrations were prepared, and the surface tension was measured by the suspension ring method at 25°C, and the relationship curve between the concentration of the sample aqueous solution and the value of the surface tension was drawn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com