Patents

Literature

427 results about "Abietic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

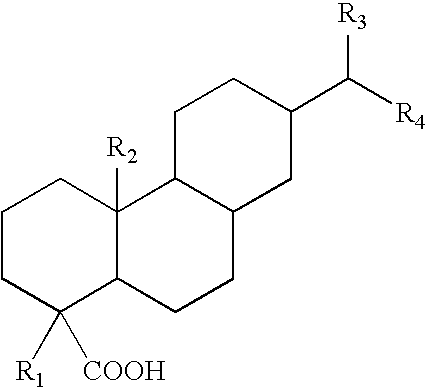

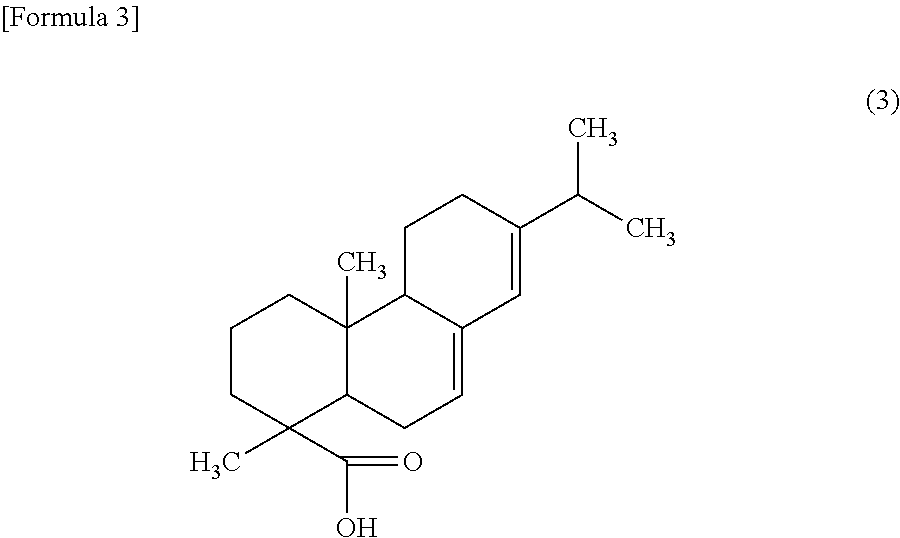

Abietic acid (also known as abietinic acid or sylvic acid) is an organic compound that occurs widely in trees. It is the primary component of resin acid, is the primary irritant in pine wood and resin, isolated from rosin (via isomerization) and is the most abundant of several closely related organic acids that constitute most of rosin, the solid portion of the oleoresin of coniferous trees. Its ester or salt is called an abietate.

Rejuvenation of reclaimed asphalt

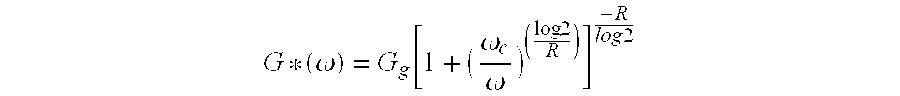

ActiveUS20140338565A1Low cloud and pour pointImprove thermal stabilityIn situ pavingsSolid waste managementCrack resistanceFatty acid

Asphalt compositions comprising reclaimed asphalt and a rejuvenating agent are disclosed. The reclaimed asphalt comprises aggregate and an aged binder. The rejuvenating agent, which has a cyclic content of at least 5 wt. %, comprises an ester or ester blend derived from an acid selected from aromatic acids, fatty acids, fatty acid monomers, fatty acid dimers, fatty acid trimers, rosin acids, rosin acid dimers, and mixtures thereof. The rejuvenating agent revitalizes the aged bitumen binder of reclaimed asphalt and restores its physical properties to those of the original performance-grade bitumen. Improvements include desirable softening, low-temperature cracking resistance, better fatigue cracking resistance, good elevated temperature performance, improved miscibility, and restored temperature sensitivity. The rejuvenating agents enable the use of higher levels of recovered asphalt, particularly RAP, in asphalt mixtures, reduce binder and aggregate costs, and help the road construction industry reduce its reliance on virgin, non-renewable materials.

Owner:KRATON CHEM LLC

Simulated mussel protein environment-friendly lithium ion battery adhesive

ActiveCN103342974AImprove adhesionEasy transferCell electrodesAcid polymer adhesivesAdhesiveLithium-ion battery

The invention relates to a preparation method and application of an environment-friendly lithium ion battery, and in particular relates to a simulated mussel protein environment-friendly lithium ion battery adhesive. By simulating the molecular structure and action mechanism of mussel protein, histidine and dopamine are connected to polyacrylic acid, polymaleic acid, sodium alginate, sodium carboxymethylcellulose, carboxymethyl chitin, carboxymethyl chitosan, abietic acid and other natural or synthesized polymer to prepare a series of aqueous adhesives. The adhesive has a good adhering effect for various cathode materials such as carbon black, graphite and silicon. By adopting the adhesive provided by the invention, various properties of a lithium ion battery can be obviously improved, and especially cycle property of a silicon cathode material in a battery can be obviously improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

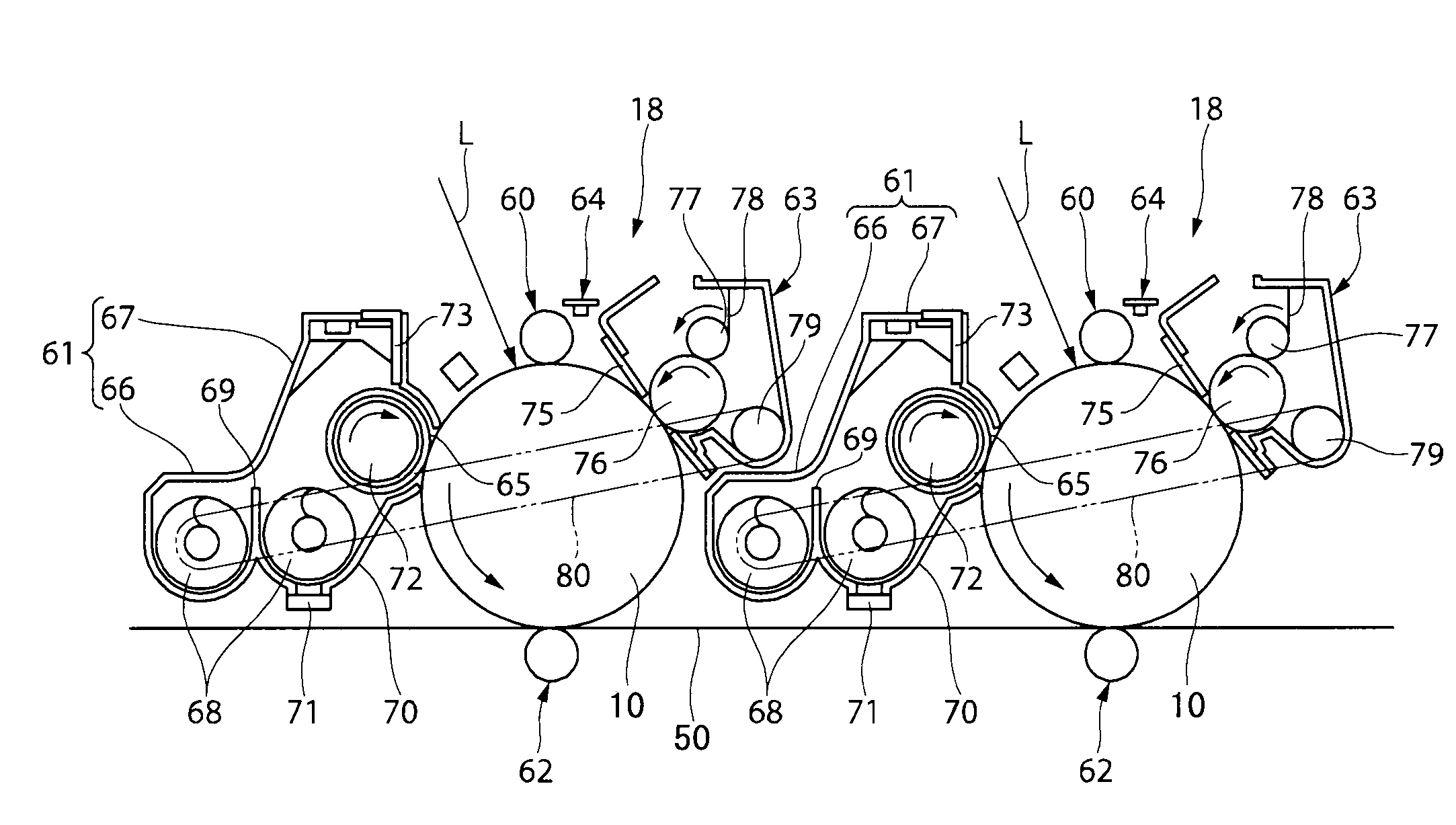

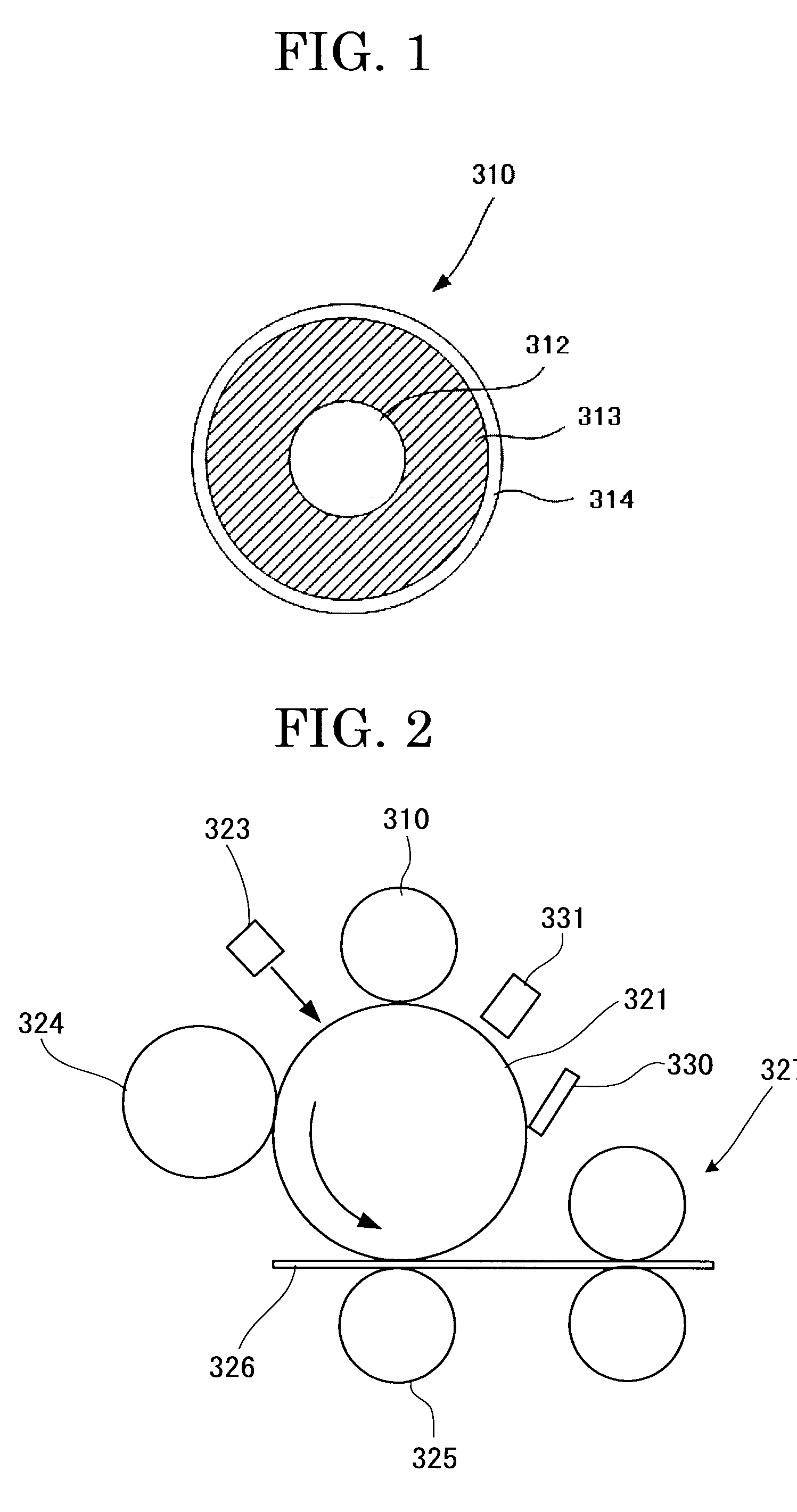

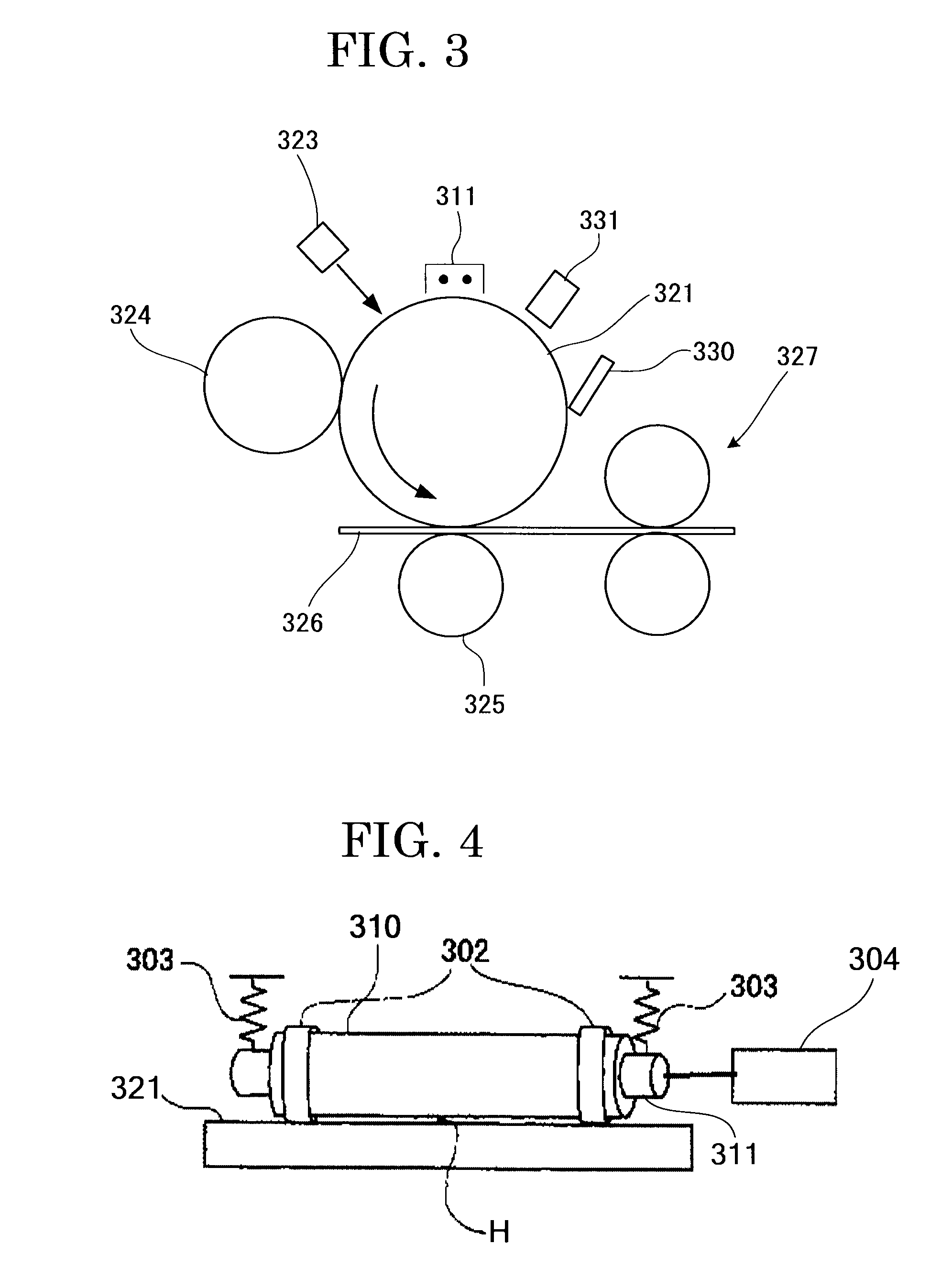

Toner, image forming apparatus, image forming method, and process cartridge

ActiveUS20090103950A1Quality improvementImprove chargeabilityElectrographic process apparatusDevelopersAlcoholImage formation

An image forming apparatus including: a latent electrostatic image bearing member, a charging unit, an exposing unit, a developing unit, a transfer unit, and a fixing unit, wherein the toner contains at least a binder resin and a colorant, the binder resin contains a polyester resin obtained by polycondensation of an alcohol component with a carboxylic acid component containing a rosin compound, the amount of the rosin compound contained in the carboxylic acid component is 5% by mass or more based on the total mass of the alcohol component and carboxylic acid component, and the amount of an abietic acid contained in the toner is 1% by mass or less.

Owner:RICOH KK

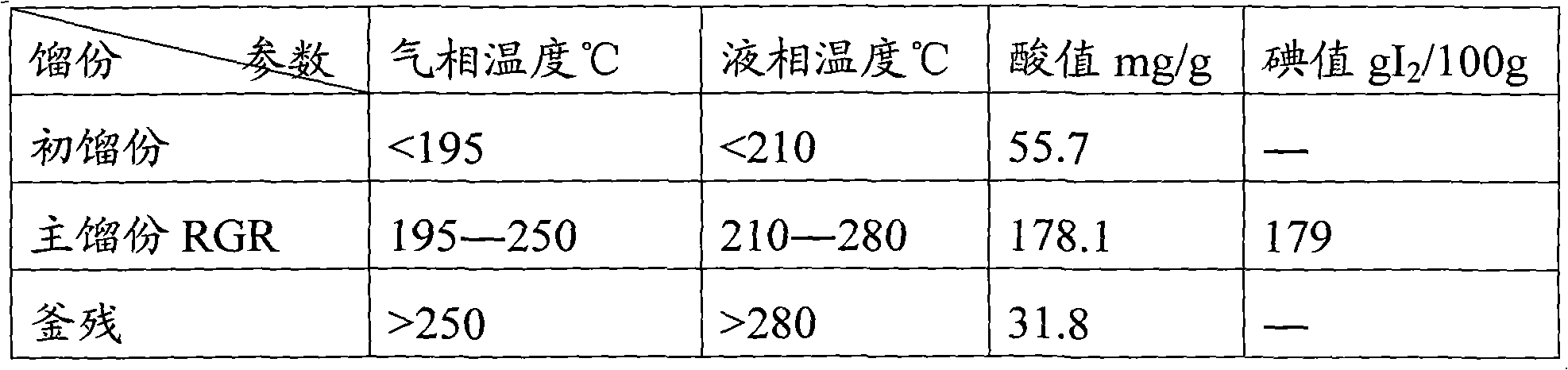

Method for producing pale disproportionated rosin with high content dehydroabietic acid and P-camphogen simultinuously

InactiveCN1616570APrevent browningPrevent oxidationNatural resin purificationNickel catalystDistillation

The process of producing pale disproportionated rosin with high dehydroabietic acid content and paracymene simultaneously includes the following steps: rinsing turpentine to eliminate impurity, dissolving turpentine in turpentine oil to form turpentine solution, catalytic disproportionating turpentine in solution in the presence of Pd / C catalyst, filtering and decompression distillation to obtain pale disproportionated rosin with high dehydroabietic acid content and disproportionated turpentine oil containing paracymene in 20-60 %, and distilling disproportionated turpentine oil to obtain paracymene and pinane. Or, the rinsed turpentine as material may be re-crystallized to purify and catalytically disproportionated to prepare pale disproportionated rosin containing high dehydroabietic acid in 72-82 %. The Pd / C catalyst may be replaced with skeletal nickel catalyst.

Owner:GUANGXI UNIV

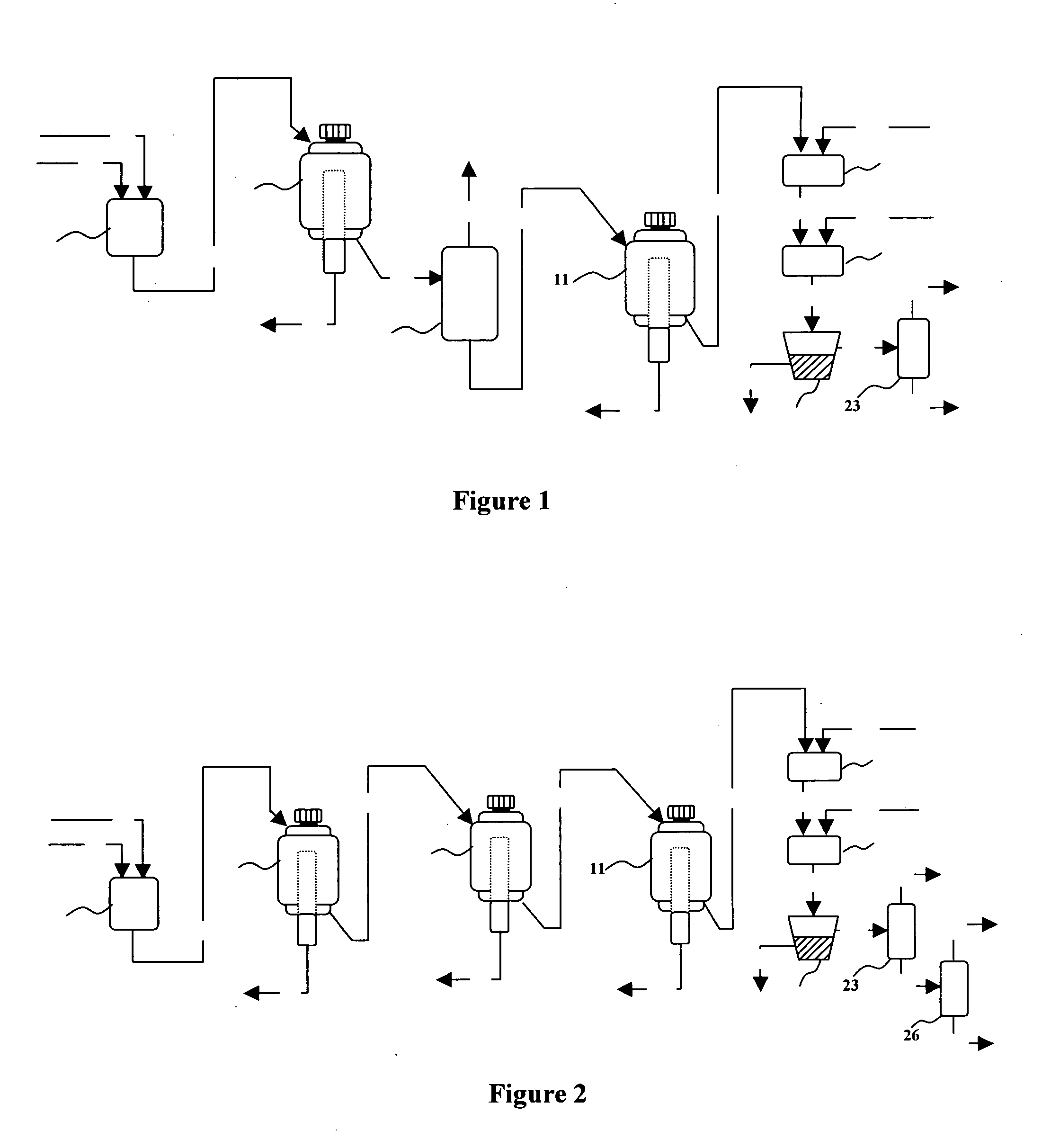

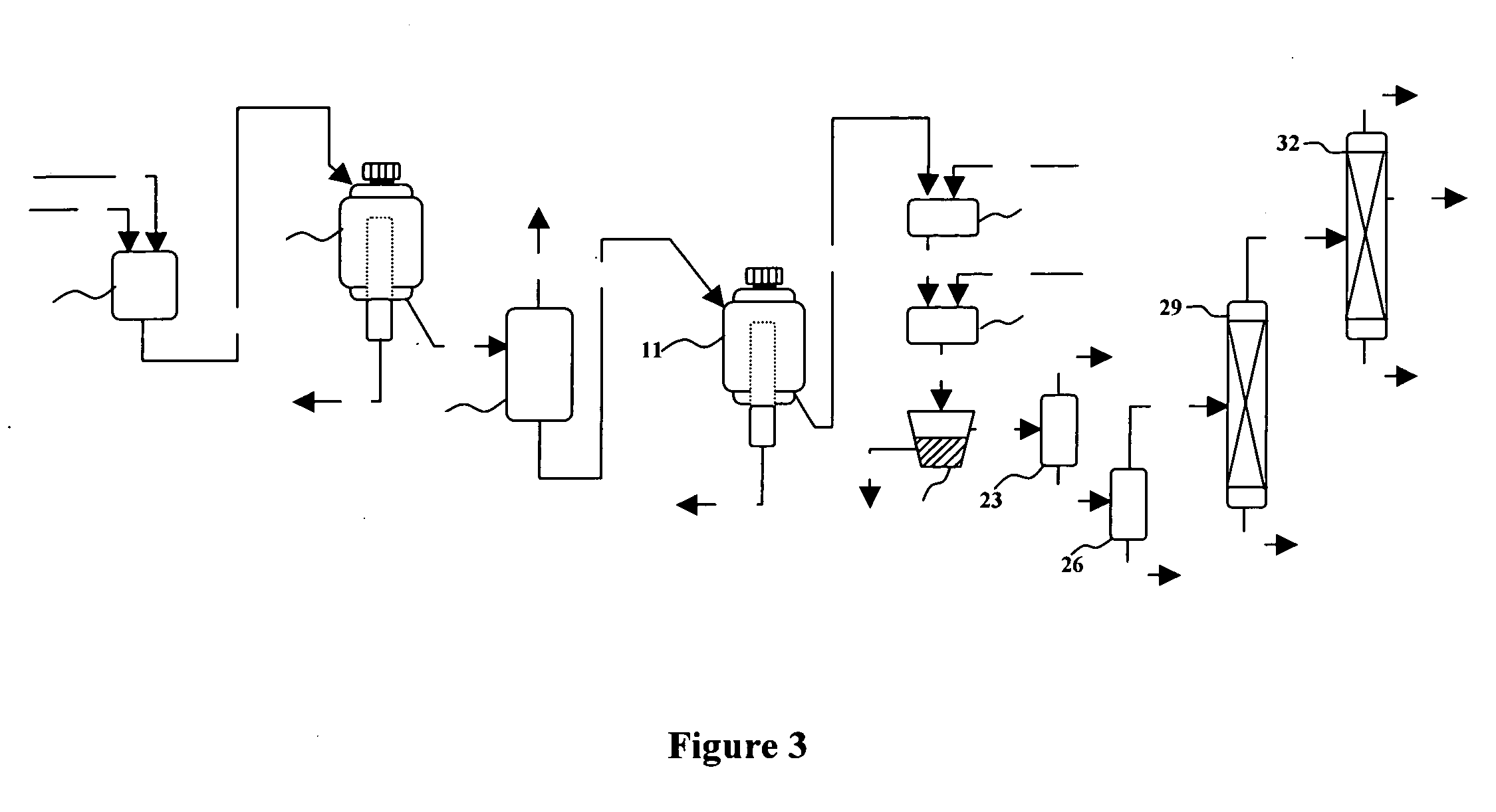

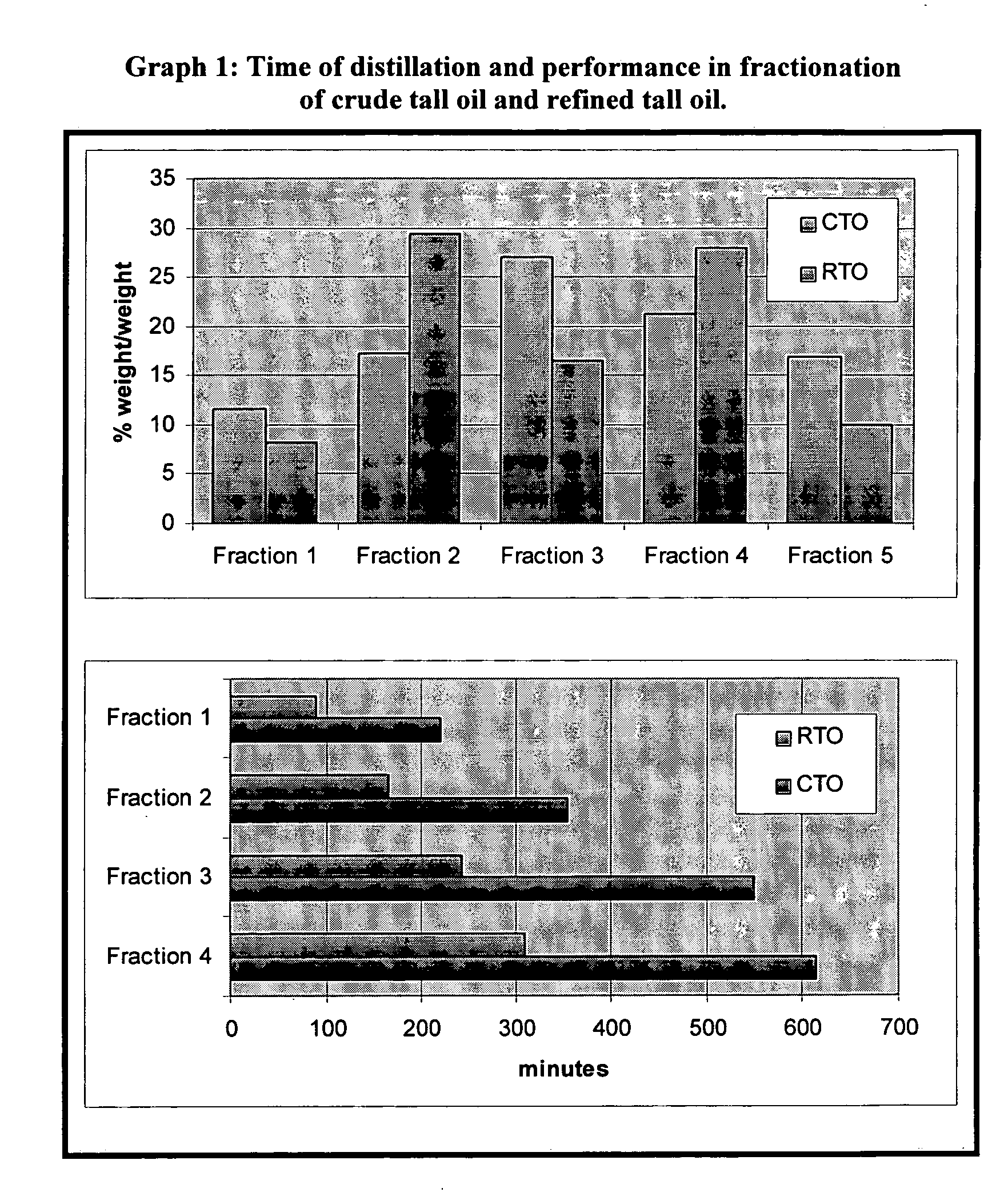

Process of refinement of crude tall oil using short path distillation

InactiveUS20050203279A1Avoid problemsEfficient ConcentrationFatty oils/acids recovery from wasteNatural resin processFractionationFatty acid

The present invention is related to a process for the production of high quality fatty acids and rosin acids and their mixtures from crude tall oil by means of short path distillation of saponified crude tall oil, acidulation and fractionation by distillation.

Owner:GLADE THOMAS FRANCIS HARTING

Rosin ester with low color and process for preparing same

A process for producing light color rosins ester resin, preferably based on tall rosin, is described. The process is conducted in the presence of less than 10 weight % of an acid functional organic compound and avoids the need for use of a stoichiometric excess of rosin acid, or a stoichiometric excess of polyol hydroxyl groups. The process allows for the use of lower colored or darker tall oil rosin in the production of low color rosin esters.

Owner:LAWTER

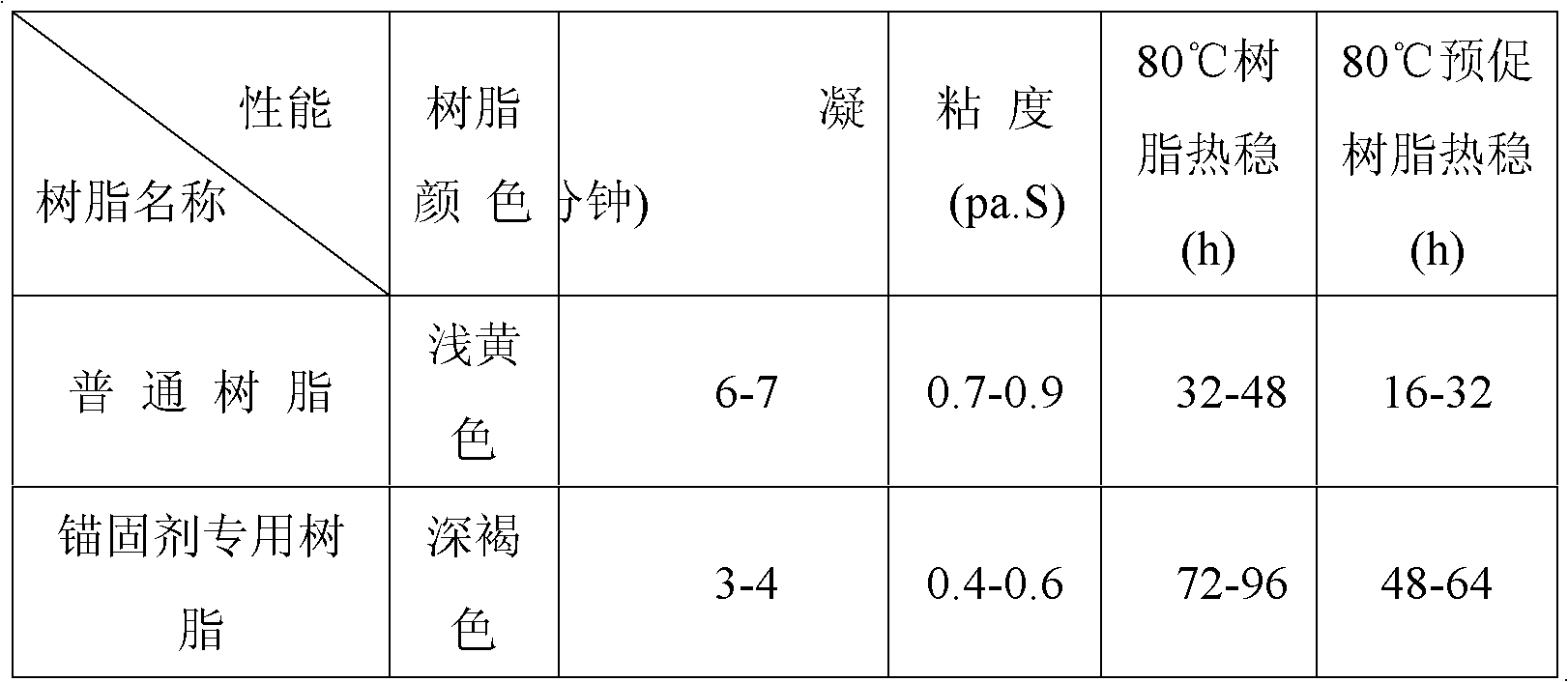

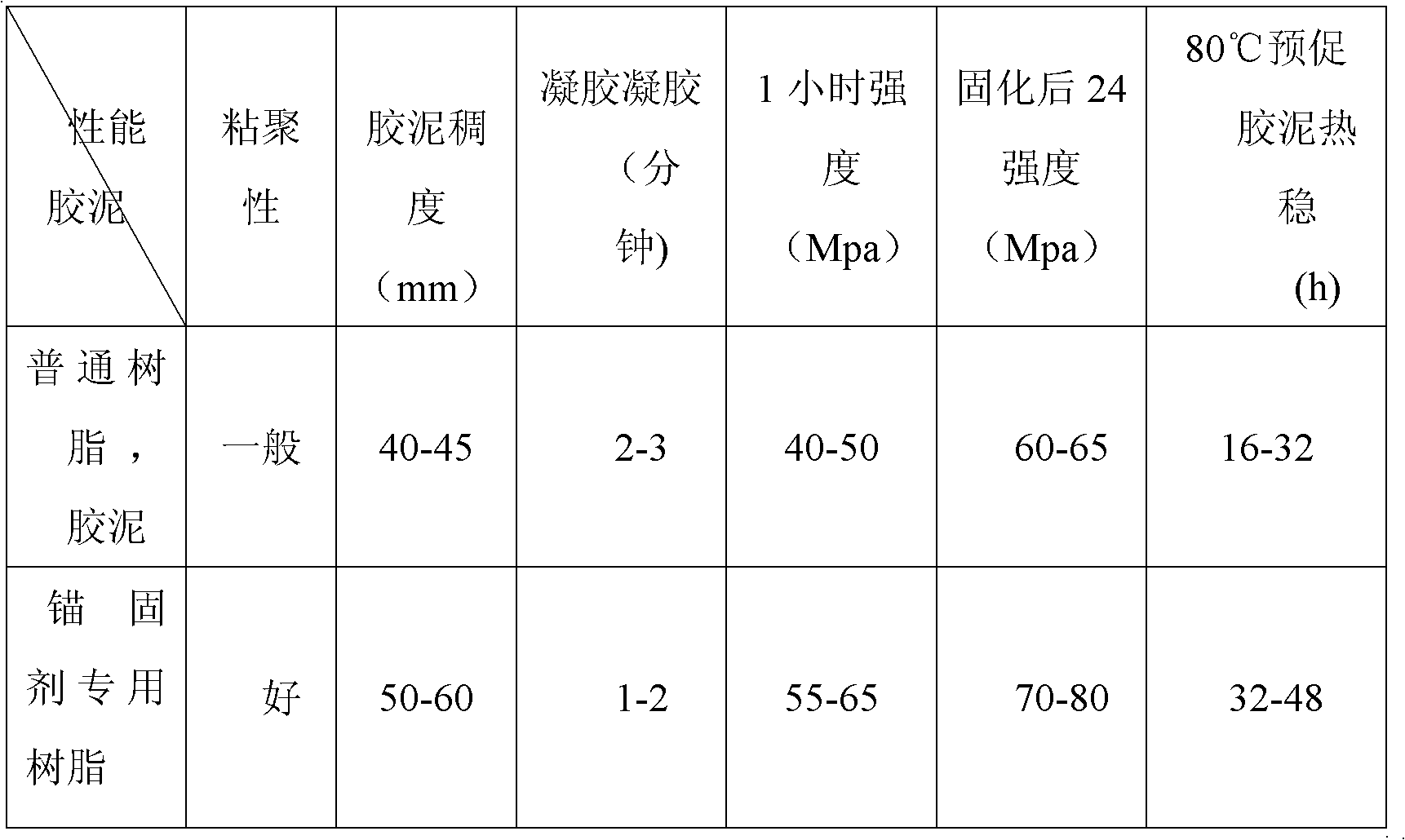

Resin special for anchoring agent and preparation method thereof

The invention discloses a resin special for an anchoring agent and a preparation method thereof. The resin is mainly prepared from terephthalic acid, fumaric acid, abietic acid, maleic anhydride, oxalic acid, glycerol, diglycol, a catalyst, a polymerization inhibitor, a stabilizing additive and styrene according to a certain proportion. A special resin which is most suitable to serve as an anchoring agent product is provided through means such as the adoption of a reasonable production process design formula, the adding of some chemical additives and the like. The gel time of the resin is short and is slightly affected by the temperature, the final curing strength is high, the early strength is quickly developed, the storage stability is high, the resin has high adhesion to mountain flourand has high adaptability to the mountain flour, and the doping amount of the mountain flour is large; and the cost is low, and each ton of the resin is 10 to 20 percent cheaper than each ton of an ordinary unsaturated resin.

Owner:淮南舜天合成材料有限责任公司

A kind of low-temperature sintering nano-silver paste and preparation method thereof

ActiveCN102290117ALower sintering temperatureHigh thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesPolyvinyl alcoholAlloy

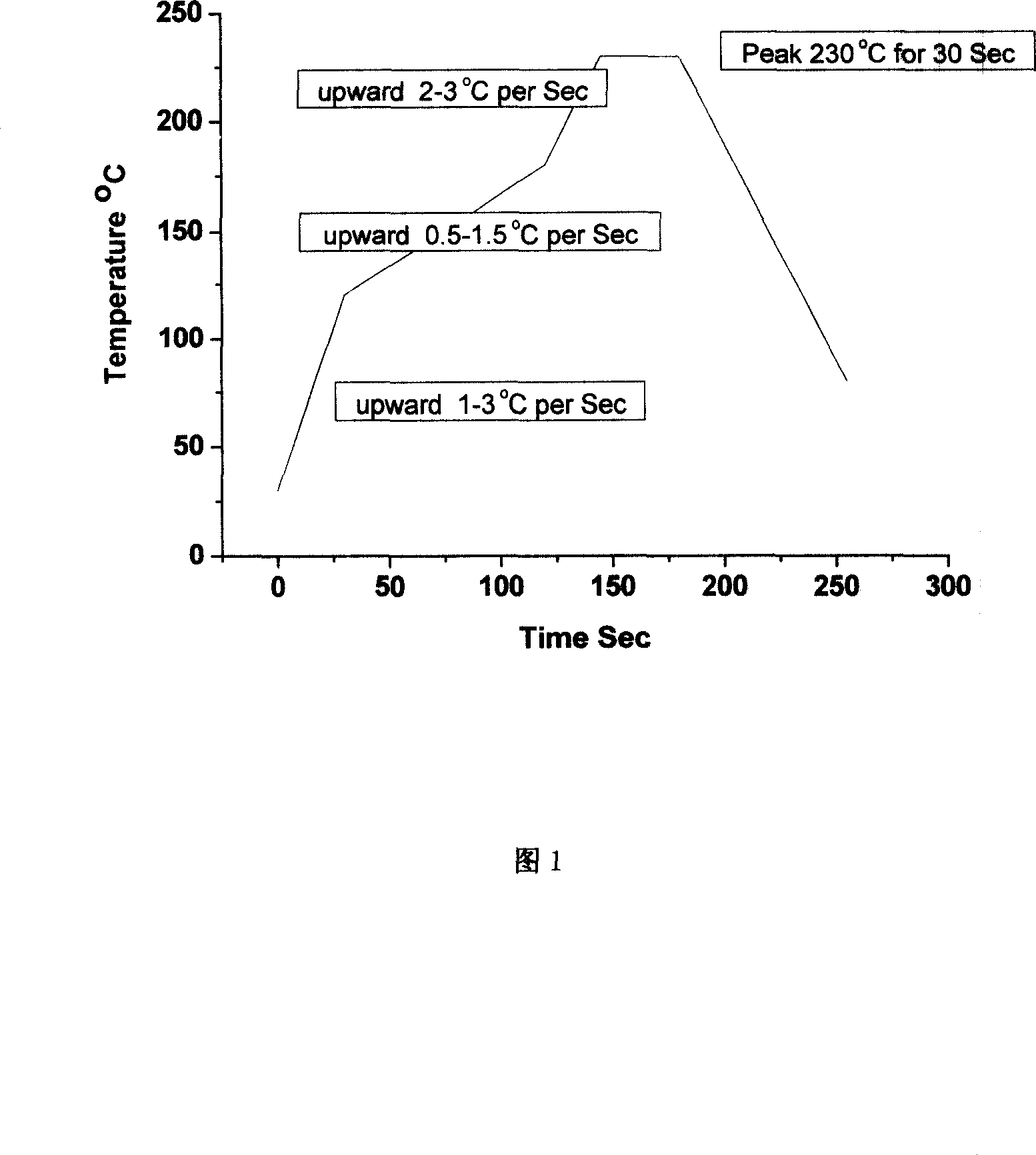

The invention discloses a low temperature-sintered nano silver paste and a preparation method thereof. The invention is characterized in that: by weight percent, the components of the nano silver paste are as follows: 78.5 to 89.5 percent of nano silver powder with the average grain size of 20nm to 50nm; 5.0 percent to 10.0 percent of polyvinyl alcohol as organic carrier; 5.0 percent to 10.0 percent of tributyl citrate as organic solvent; and 0.5 percent to 1.5 percent of abietic acid as surfactant. The nano silver paste preparation method sequentially includes the following steps: ethanol solution water heating, component adding and mixing, ultrasonic dispersion under zero DEG C, mechanical stirring and vacuum drying. The sintering temperature of the silver paste is notably decreased, and does not need to reach the softening temperature of glass, moreover, the silver content of the sintered material is at least 98 percent, the nano silver paste has high heat conductivity and high reliability, and the heat conductivity of the nano silver paste is three to four times higher than the heat conductivity of alloy solder, and thereby the heat-dissipating problem of packaging is effectively solved. The low temperature-sintered nano silver paste is particularly suitable for use as novel thermal interface material for the interconnection between power type chips in the field of electronic packaging.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

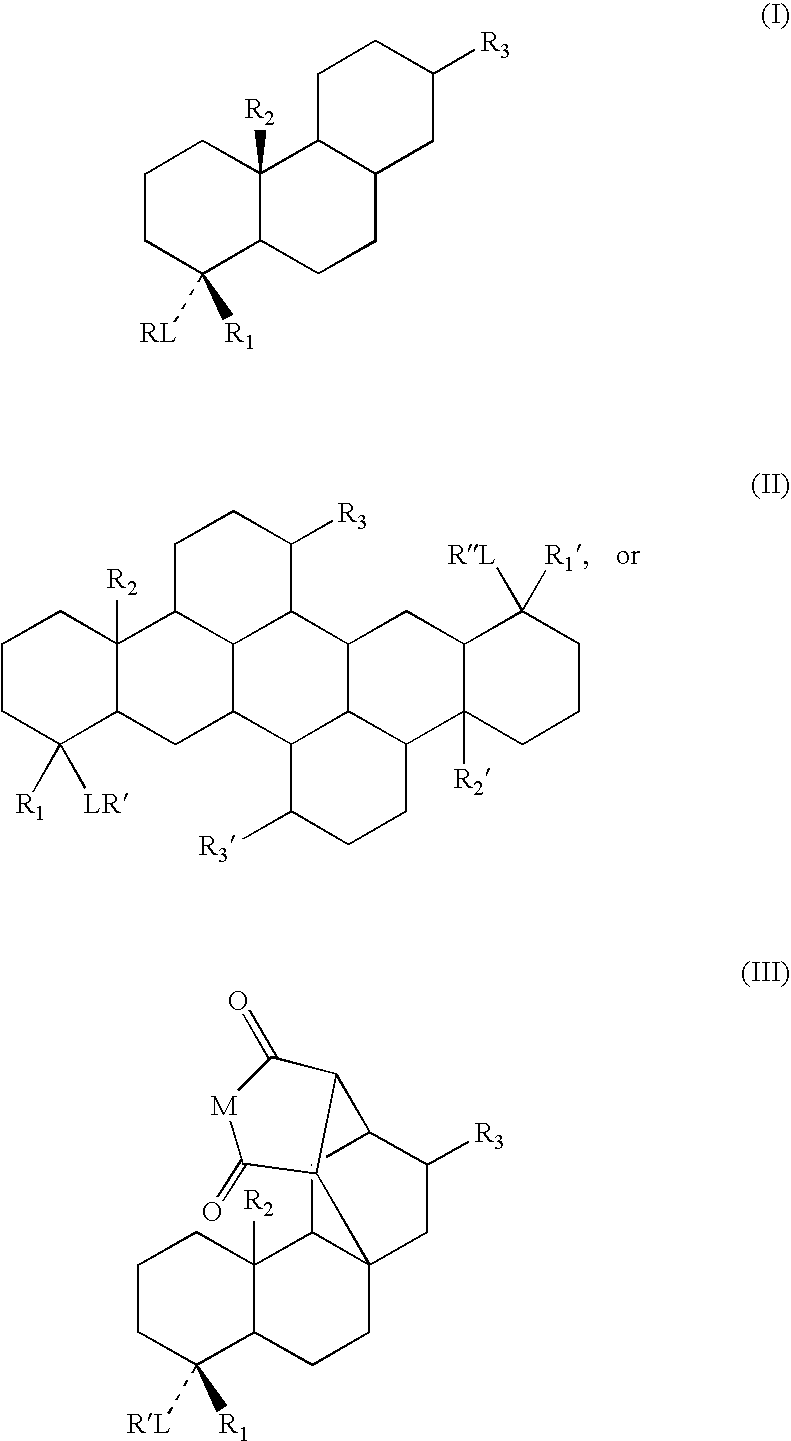

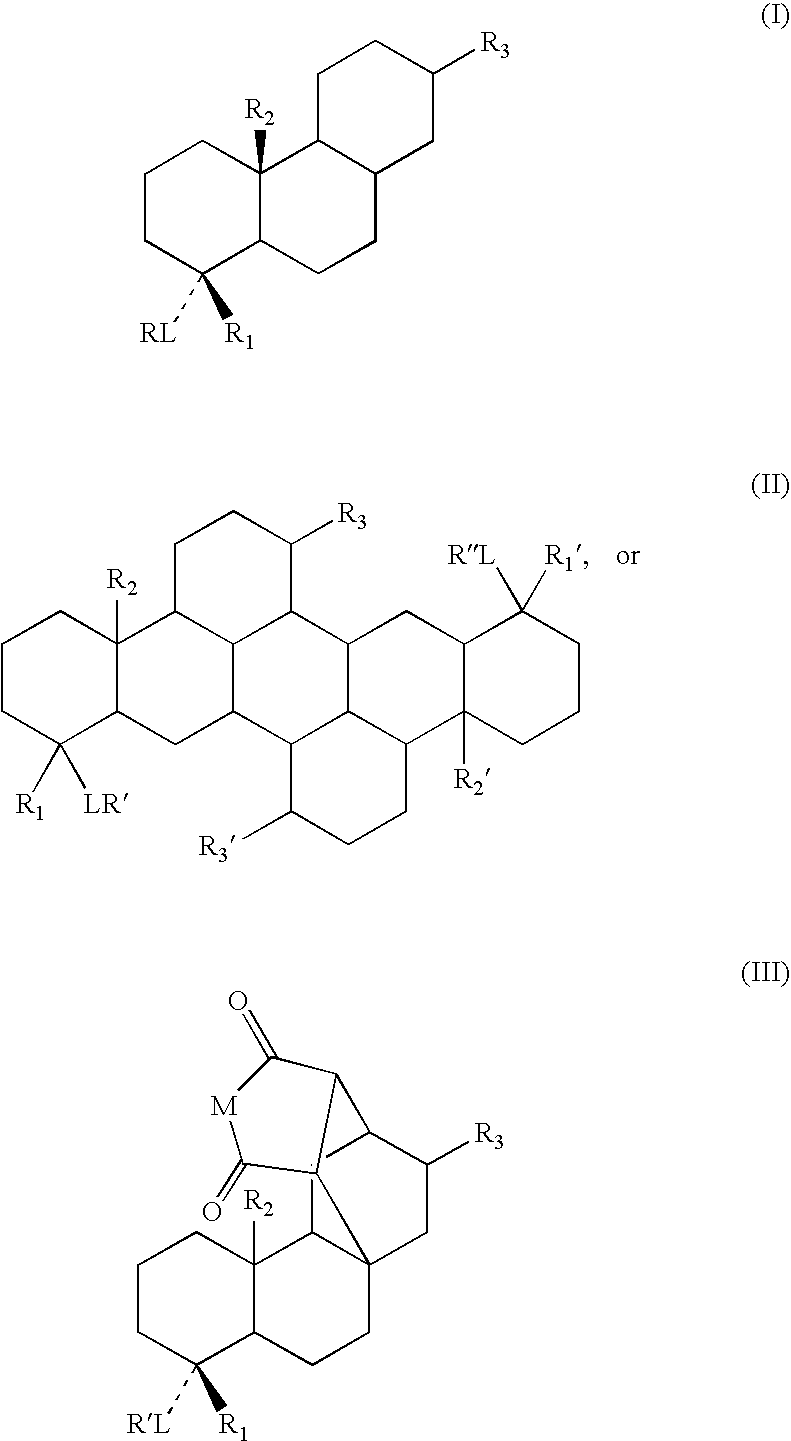

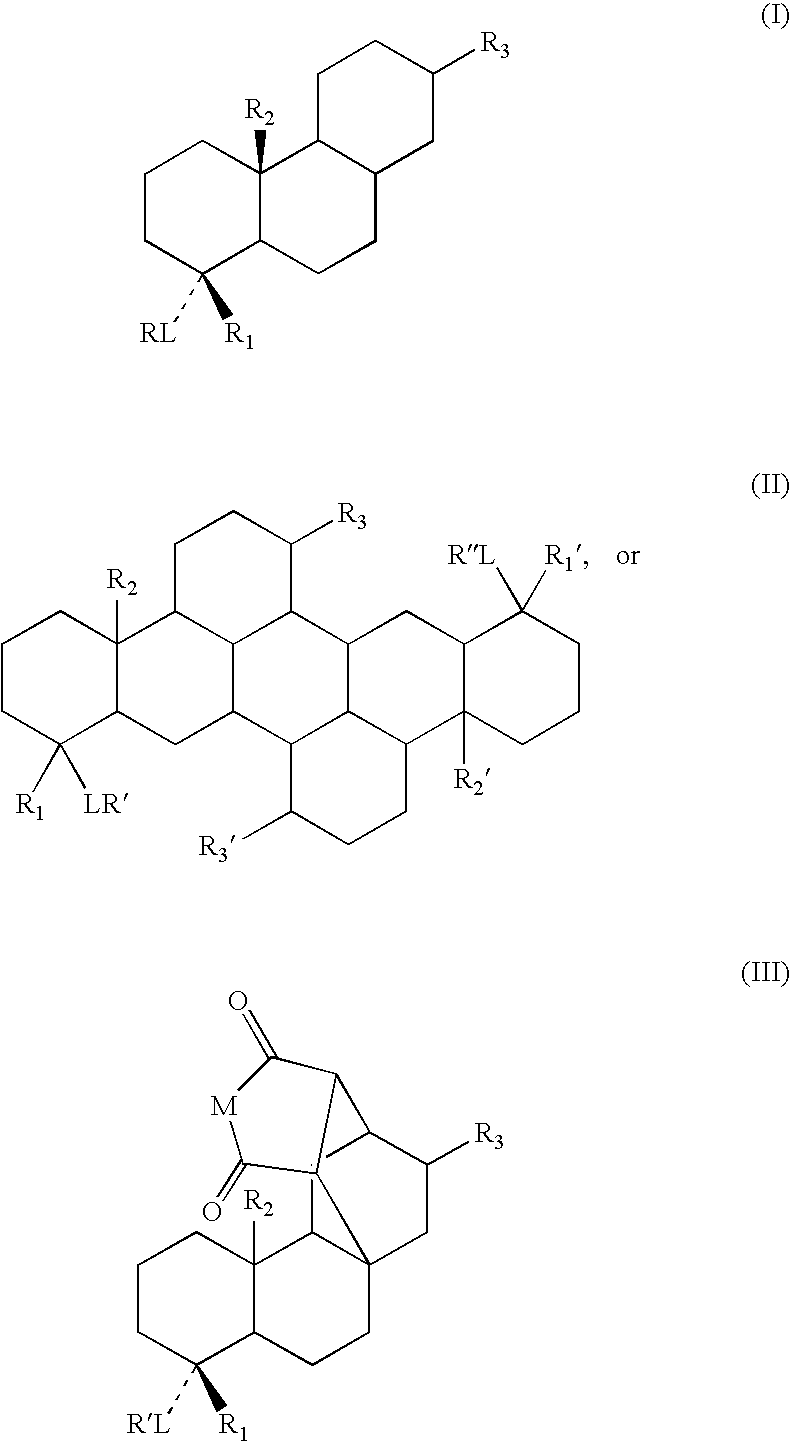

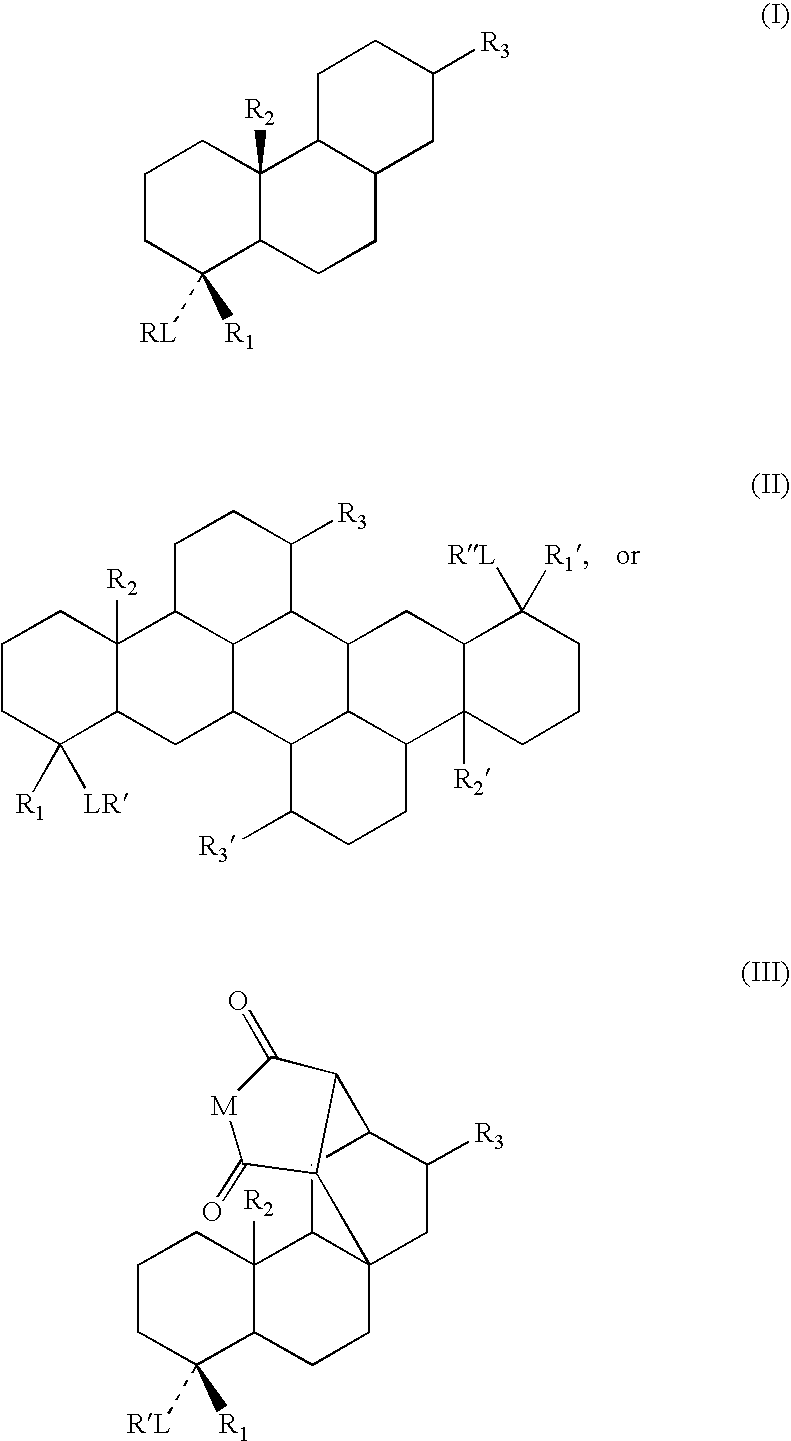

Temperature switchable adhesives comprising crystallizable abietic acid derivative-based tackifiers

Temperature switchable pressure sensitive adhesives comprising an elastomer and a crystallizable abietic acid derivative as tackifier are described. These pressure sensitive adhesives exhibit a sharp reduction in peel strength when the temperature is raised above the switching temperature. The adhesive properties of these adhesives may be readily tuned by adjusting the ratio of the elastomer and the crystallizable tackifier, and by altering the crystallizabe group on the tackifier. The temperature switchable pressure sensitive adhesives have use in medical, consumer, and industrial applications.

Owner:EI DU PONT DE NEMOURS & CO

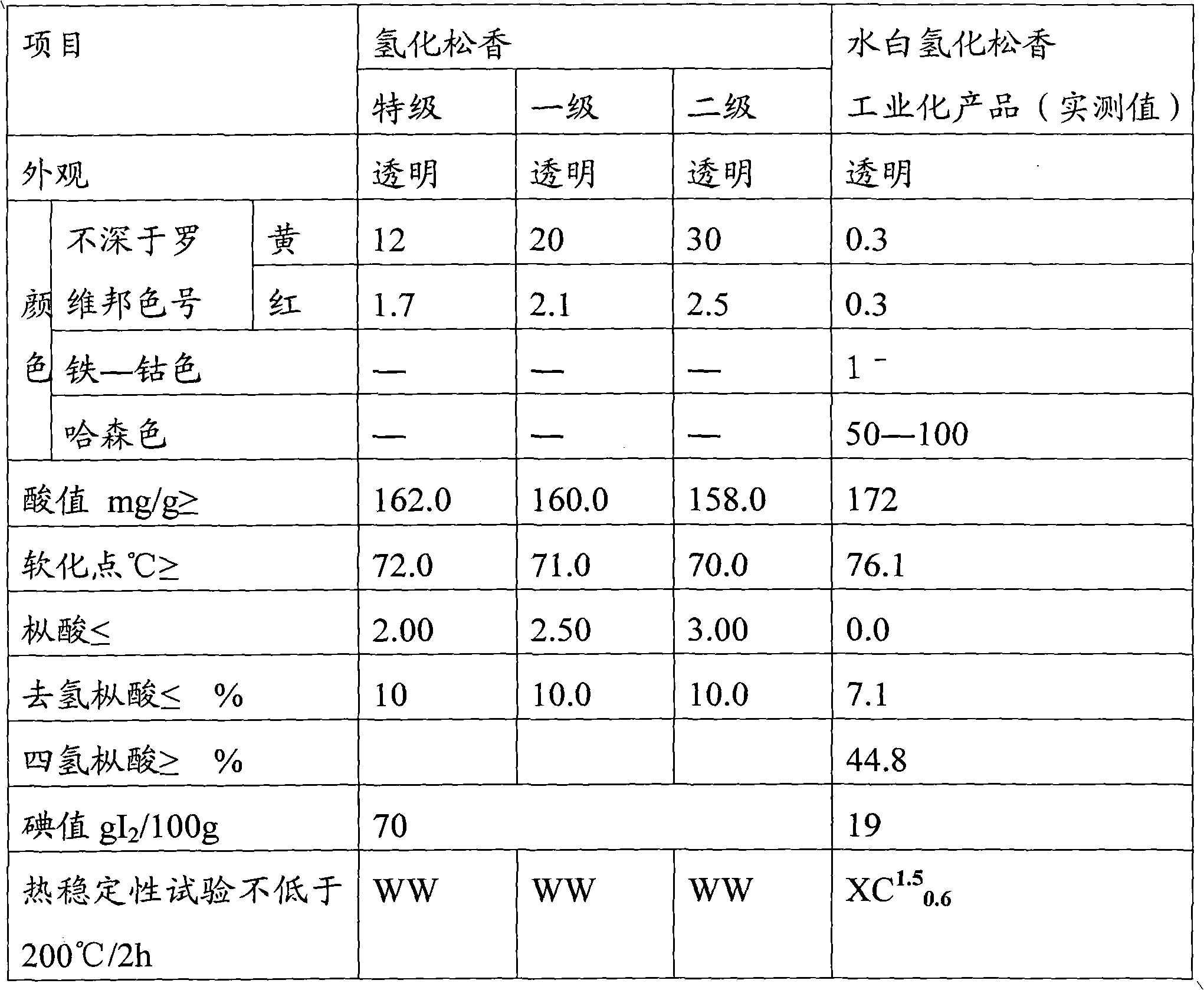

Method for producing water-white hydrogenated rosin

ActiveCN102070988ALow hydrogenation reaction temperatureRelieve pressureNatural resin chemical modificationDistillationSolvent

The invention relates to a method for producing water-white hydrogenated rosin, which comprises the following steps: using light color refined rosin obtained after purifying the rosin as hydrogenation raw materials, using a solvent for preparing solution, carrying out catalytic hydrogenation, then, separating out the solvent through distillation, and obtaining the water-white hydrogenated rosin. When the method provided by the invention is adopted, the water-white hydrogenated rosin with light color (the Lovibond color number of the yellow color is 0.3 to 1.0, and the Lovibond color number of the red color is 0.2 to 0.3), low iodine value and low abietic acid content can be obtained. Compared with the water-white hydrogenated rosin produced by a traditional method, the water-white hydrogenated rosin produced by the method provided by the invention has the advantages of lighter color, higher hydrogenation degree, better stability and lower cost, and the application value of products can be improved when the water-white hydrogenated rosin is applied to aspects such as electronics, paint, bonding agents, dyestuff and the like.

Owner:广西梧州日成林产化工股份有限公司

Temperature switchable adhesives comprising crystallizable abietic acid derivative-based tackifiers

Temperature switchable pressure sensitive adhesives comprising an elastomer and a crystallizable abietic acid derivative as tackifier are described. These pressure sensitive adhesives exhibit a sharp reduction in peel strength when the temperature is raised above the switching temperature. The adhesive properties of these adhesives may be readily tuned by adjusting the ratio of the elastomer and the crystallizable tackifier, and by altering the crystallizabe group on the tackifier. The temperature switchable pressure sensitive adhesives have use in medical, consumer, and industrial applications.

Owner:EI DU PONT DE NEMOURS & CO

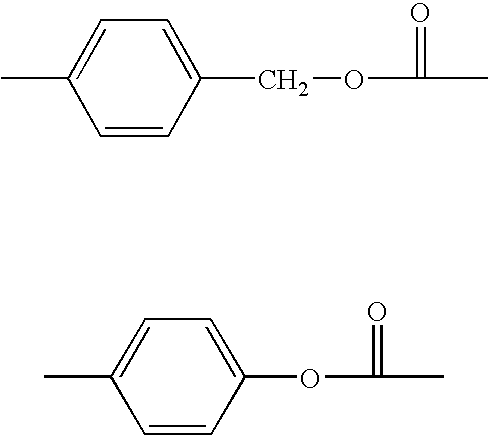

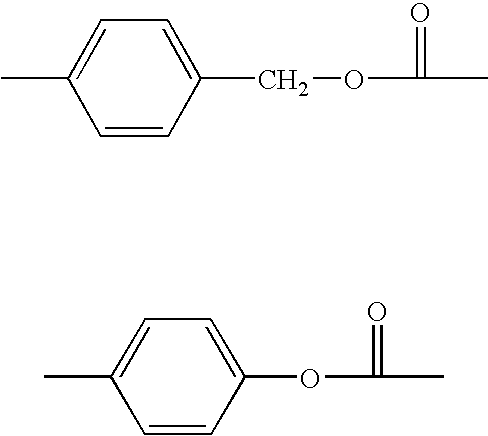

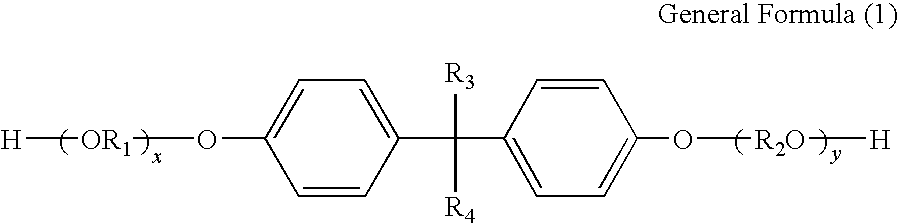

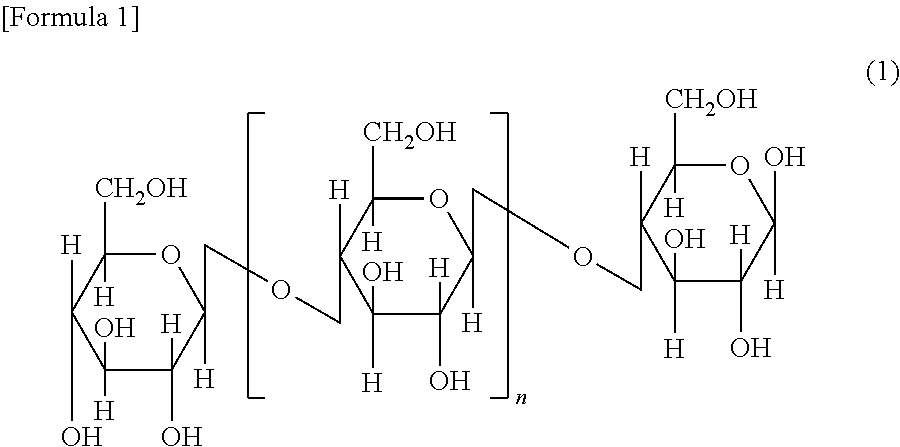

Toner and developer

ActiveUS20100136471A1Good Pigment DispersionLow-temperature fixabilityDevelopersAlcoholHydrogen atom

A toner, wherein a binder resin contains a polyester resin (A) produced by polycondensing an alcohol component with a carboxylic acid component which contains a rosin compound in an amount of 5% by mass or more of the total amount by mass of the alcohol component and the carboxylic acid component, and a polyester resin (B) produced by polycondensing an alcohol component containing an alkylene oxide adduct of bisphenol A represented by General Formula (1) given below with a carboxylic acid component, and wherein the toner contains abietic acid in an amount of 0.01% by mass to 1% by mass:where R1 and R2 each represent C2-C4 alkylene; R3 and R4 are each any one of a hydrogen atom, C1-C6 straight-chain alkyl, and C1-C6 branched-chain alkyl; and x and y each represent a positive integer and the sum of x and y is 1 to 16.

Owner:RICOH KK

Formula with whitening and anti-aging effects and application thereof

The invention provides a compound formula with whitening and anti-aging effects and application thereof. The formula is formed by compounding plant extract, vitamin and biochemical preparation. The plant extract consists of one or more of herbal plants of pine extract, vitamin A, vitamin E, rhodiola rosea extract, lily extract, dipotassium glycyrrhizate, hyaluronic acid, azelaic acid, propolis, grape seed, seaweed, phytic acid, green tea, sea-buckthorn, usnic acid, abietic acid, vitamin C, vitamin B, vitamin E, maltose, maltitol, glucose, glucitol, glucan, trehalose, glycyrrhizinic acid and the like; and proved by a large amount of clinical tests, the formula has good whitening and anti-aging effects on the skin. The formula can be prepared into cosmetics such as cleaning products, maintenance products, beautifying products and the like according to the conventional processes and accessories for preparing the cosmetics.

Owner:周杭静

Leadless alloy tin solder plaster and manufacturing method thereof

InactiveCN101011784AImprove wettabilityGood welding performanceWelding/cutting media/materialsSoldering mediaOrganic solventMonoglyceride

The invention discloses a tin solder plaster of leadless alloy and making method, which consists of soldering flux and leadless tin solder alloy powder, wherein the soldering flux is composed of organic solute and organic solvent; the organic solute contains macromolecular PVP, macromolecular PEG and or PVA, abietic acid or modified abietyl, aliphatic acid monoglyceride and aliphatic acid sorbate; the organic solvent is one or more composition of anhydrous alcohol, ethandiol, cycloethane, glycol ethylene and diglycol ethylene.

Owner:苏州盖依亚生物医药有限公司

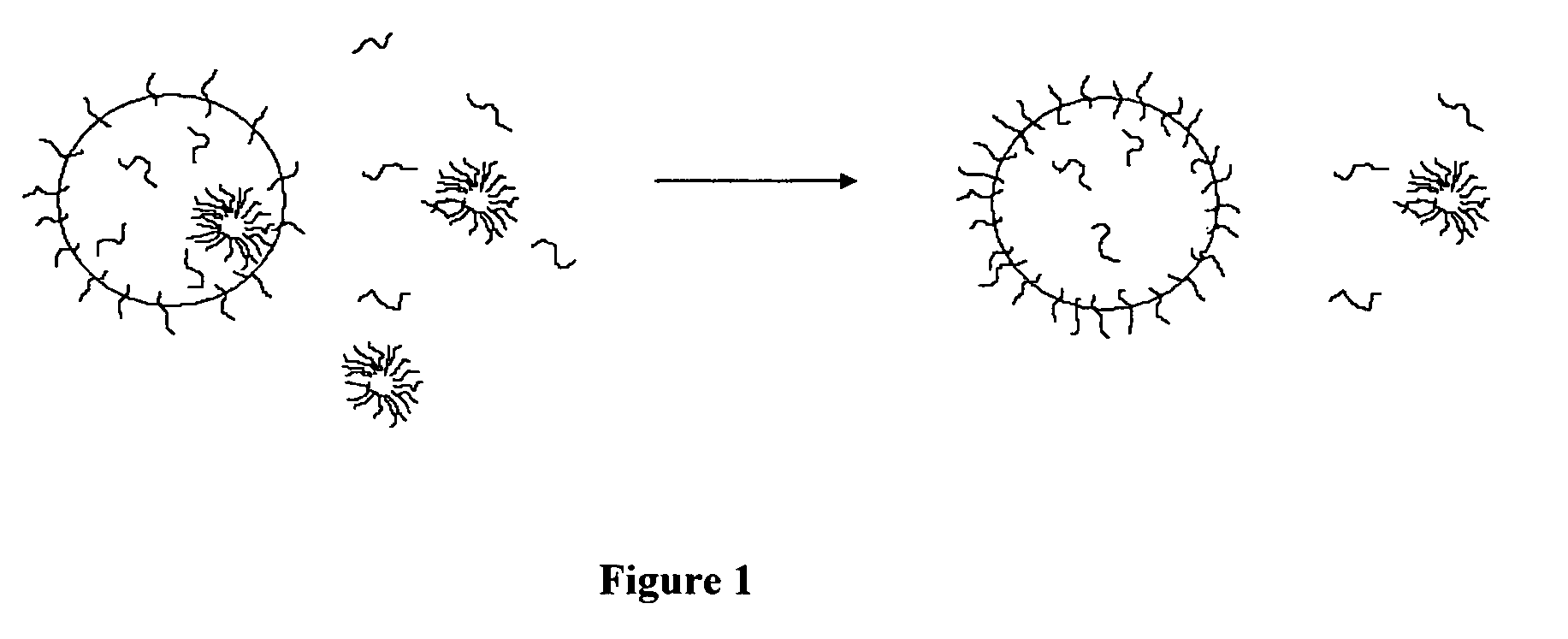

Emulsifiers for use in water-based tackifier dispersions

Anionic emulsifiers based on rosin acid or derivatives thereof, and to methods of preparing said emulsifiers. The emulsifiers are useful for preparing tackifier dispersions having improved properties with respect to foam stability. As such, said tackifier dispersions are advantageously used in water-based adhesives providing improved adhesive and cohesive properties. The adhesives may be used for labels on any kind of surface, packaging applications, flooring adhesives, road markings or for any type of water-based tapes, barrier coatings or sealants.

Owner:EASTMAN CHEM CO

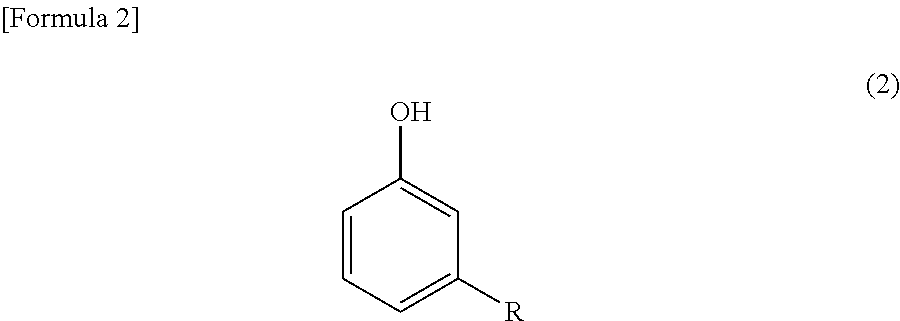

Infinite soluble pnenolic aldehyde modified rosin resin and production method thereof

The invention discloses a complete miscibility phenolic aldehyde modified abietic resin, which can be fully dissolved in petroleum cyclane solvent. The synthetic method comprises the following process steps: (1) adding the alkylphenol, aldehyde and solvent into a reactor, heating, blending and reacting for 4 to 12 hours under the alternating action of acid base catalyst at 65 to 110 degrees C and obtaining the long chain resol; (2) adding the rosin into the reactor, heating and dissolving, and then adding the long chain resol in, reacting with the abietic acid for 5 to 16 hours ar 150 to 270 degrees C and then obtaining the complete miscibility phenolic aldehyde modified abietic resin after adding the polylol in to esterify first and dehydrate then or esterify first and modify then. The complete miscibility phenolic aldehyde modified abietic resin is of much significance for producing the ink which is good for the high speed printing machine.

Owner:班小南

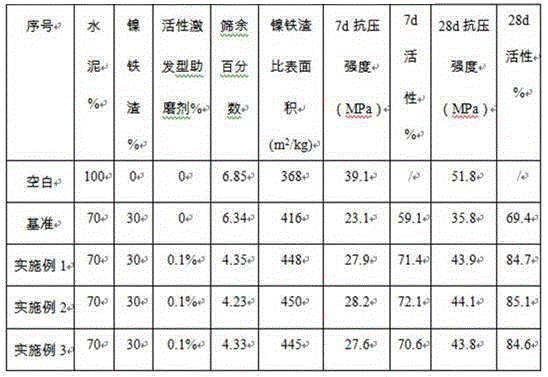

Active excitatory grinding aid for ferronickel slag and preparation method for active excitatory grinding aid

ActiveCN105084793ASolve the problem of poor wearabilityResolve low activitySolid waste managementPolyolMetallurgy

The invention discloses an active excitatory grinding aid for ferronickel slag and a preparation method for the active excitatory grinding aid. The grinding aid is composed of polymeric glycol, cocoanut fatty acid diethanolamide, sodium pyrophosphate, ethyl acetate, an excitant and water, wherein the excitant is composed of calcined alunite, water glass and sodium abietate. The additive amount of the grinding aid in the ferronickel slag is 0.02-0.10% by mass of the ferronickel slag. The active excitatory grinding aid disclosed by the invention is sufficient in raw materials, simple to process and prepare, low in doping amount, stable in performance and high in cost performance. As the ferronickel slag which is ground is added, the problem that the ferronickel slag is poor in grindability can be solved. Under the condition that the grinding time is equal, the specific surface area of the ferronickel slag micropowder can be improved by 4.5-9%, the mill output is increased by over 15%, the energy consumption is remarkably reduced, and moreover, the active index of the ferronickel slag can be further improved by 10-35%.

Owner:UNIV OF JINAN +1

Environmentally-friendly rubber anti-ageing agent and preparation method thereof

The invention discloses an environmentally-friendly rubber anti-ageing agent and a preparation method thereof, which are used for overcoming the defect that the using amount and use range of butadiene nitrile rubber are constrained greatly since a nonyl phenol anti-ageing agent which is not environmentally-friendly is taken as an anti-ageing agent of the conventional butadiene nitrile rubber. The environmentally-friendly rubber anti-ageing agent disclosed by the invention is prepared by compounding an antioxidant 2246, polybutyl bisphenol, tri(nonylphenyl)phosphite ester and disproportionate potassium rosinate in the weight ratio of 1:(1.5-3):(1.5-3):(2-3.5). The environmentally-friendly rubber anti-ageing agent has an excellent anti-ageing effect and very low environmental pollution.

Owner:NINGBO SHUNZE RUBBER

Biodegradable resin composition

ActiveUS20100063177A1Group 5/15 element organic compoundsConductive materialPhosphateCarboxylic acid

The invention relates to a biodegradable resin composition containing a biodegradable resin, a plasticizer and a crystal nucleus agent, the plasticizer being a compound containing two or more ester groups in the molecule thereof, wherein at least one alcohol component constituting the ester contains an alkylene oxide having 2 to 3 carbon atoms, added in the average amount of 0.5 to 5 moles per one hydroxyl group, and the crystal nucleus agent is a mixture of the following crystal nucleus agent (1) and crystal nucleus agent (2); the crystal nucleus agent (1) being the following crystal nucleus agent (1-1) or crystal nucleus agent (1-2): crystal nucleus agent (1-1): at least one selected from compounds having a hydroxyl group and an amide group in the molecule thereof; and crystal nucleus agent (1-2): at least one selected from hydroxy fatty acid esters; crystal nucleus agent (2): at least one selected from a metal salt of phenylphosphonic acid, a metal salt of a phosphate, a metal salt of an aromatic dialkyl sulfonate, a metal salt of rosinic acids, an aromatic carboxylic acid amide, rosinic acid amide, carbohydrazides, N-substituted ureas, salts of melamine compounds and uracils.

Owner:KAO CORP

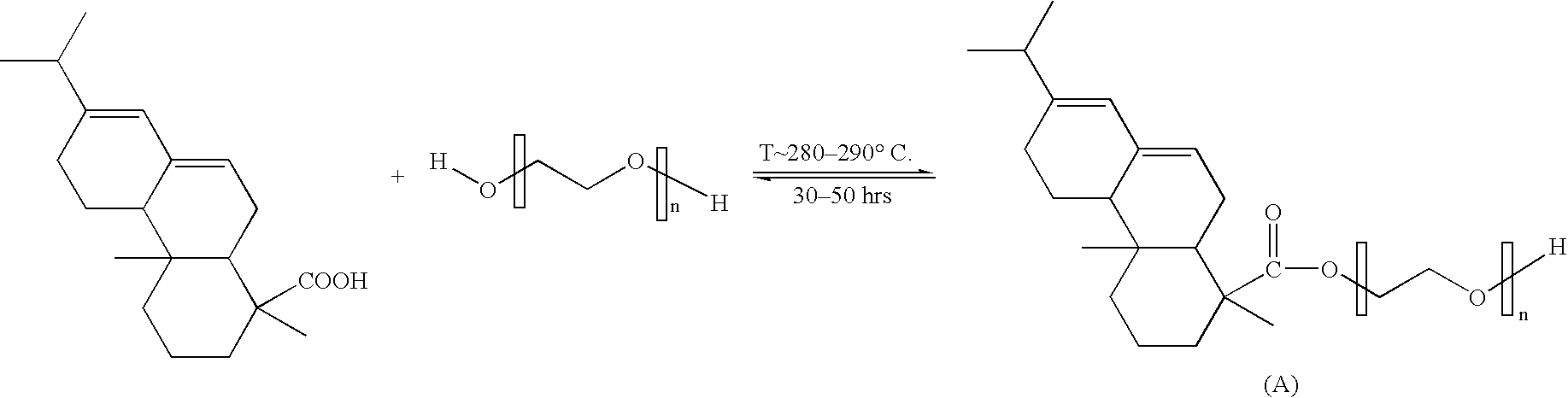

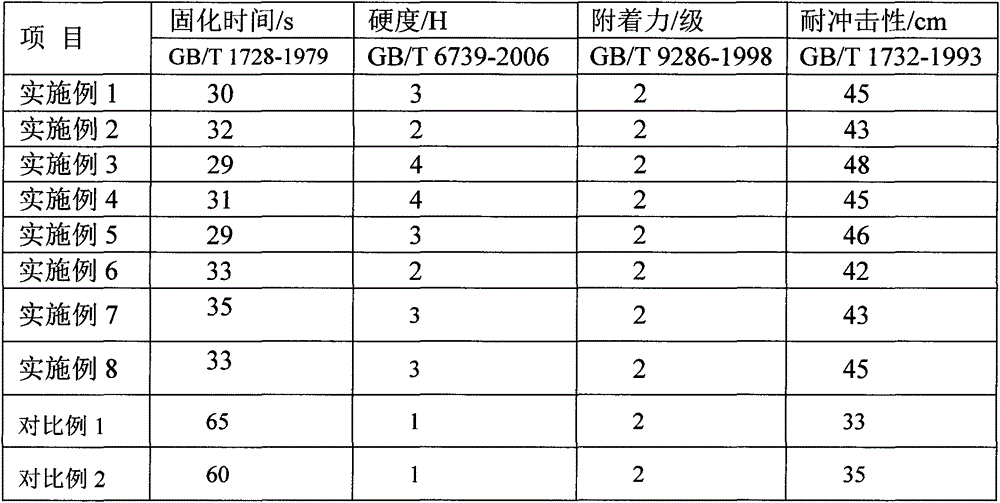

Ultraviolet light polymerized low polymer synthesized by utilizing rosin derivatives and preparation method of polymer

The invention provides a rosin derivative material suitable for photo-cured printing ink and paints and a preparation method of the rosin derivative material. The rosin derivative material contains an esterification chain segment which is prepared by performing esterification on abietic acid resins and polyol in a reactor and an olefine acid ester chain segment which is prepared by continuously performing reaction on a rosin composition having the esterification chain segment and an organic solvent solution of an acrylic acid compound in a reactor. According to the preparation method of the rosin derivative resin, the production cost is reduced, and the final cured film performance test shows that the pencil hardness, the adhesion, the shock resistance and the weather resistance of a coating meet the basic application requirement, so that the rosin derivative resin has wide market prospect in the fields of photo-cured printing ink and paints.

Owner:HUZHOU YIBANG CHEM PROD

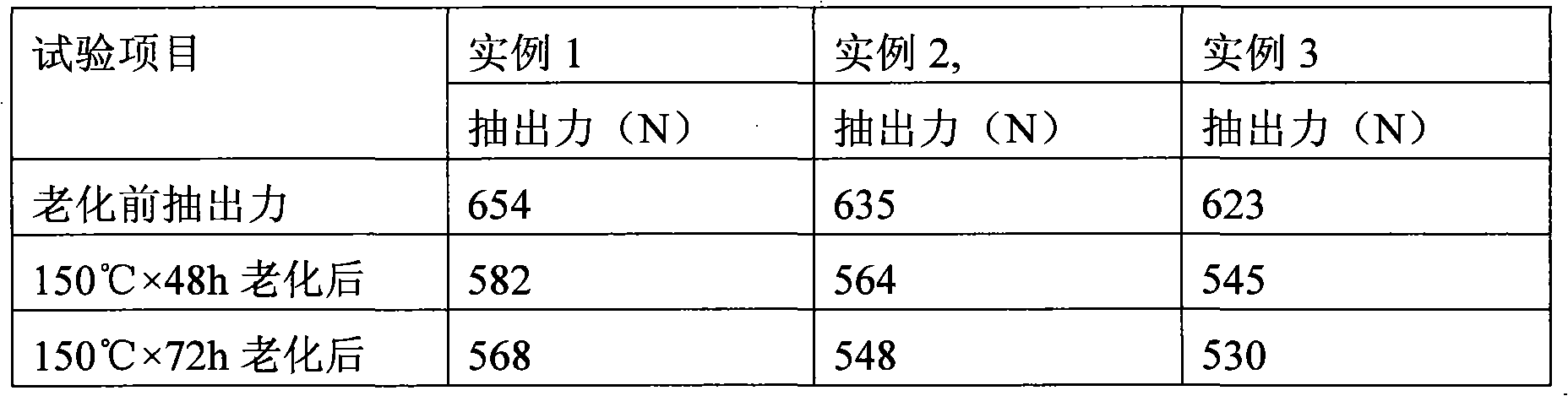

Preparation method of compound type cobalt stearate adhesion promoter

ActiveCN101864088ALower reaction conditionsReduce energy consumptionCarboxylic acid salt preparationReaction temperatureStearic acid

The invention discloses a preparation method of a compound type cobalt stearate adhesion promoter, comprising the following steps of: converting inorganic dissoluble cobalt salt into precipitant cobalt which is not easy to dissolve in water; reacting precipitant cobalt powder with composite organic weak acid in an organic solvent for 10-18 hours; raising the reaction temperature to stearic acid melting temperature from room temperature with the speed of 20-30 DEG C / h; raising the reaction temperature to 140 DEG C at the speed of 20 DEG C / h; then, remaining 2 hours at the temperature of 140 DEG C, wherein the composite organic acid is a mixture of stearic acid, isocaprylic acid and abietic acid;, steaming the residual organic solvent after the reaction is finished; and pelleting to obtain the compound type cobalt stearate adhesion promoter. In the compound type cobalt stearate adhesion promoter prepared by the preparation method, the cobalt content can completely satisfy standard requirements, and the reaction conditions are reduced, thereby the energy consumption is reduced. Meanwhile, because the organic acid with low molecular weight and branched chains is used, the service performance of the compound type cobalt stearate adhesion promoter is increased, and the binding performance and the ageing resistance of the compound type stearate adhesion promoter are particularly outstanding.

Owner:JIANGSU KAOU CHEM

Neutral rosin sizing agent and its prepn

The rosin sizing agent consists of main components including modified rosin, tall oil, stearic acid, pine gum and paraffin; and supplementary material including polyethenoxy ether sulfo succinate, abietate, polymer dispersant and disinfectant. It is prepared through low pressure process with relatively high controllability and production quality stability. The sizing agent has high compatibility with calcium carbonate stuffing, high sizing effect, low production cost and less mildew produced in storage. The sizing agent is suitable for use in producing high-grade paper and paper card.

Owner:上海埃格环保科技有限公司

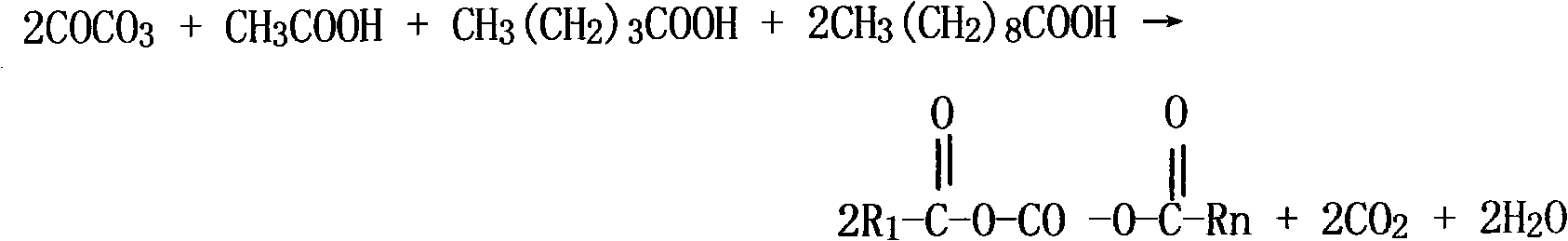

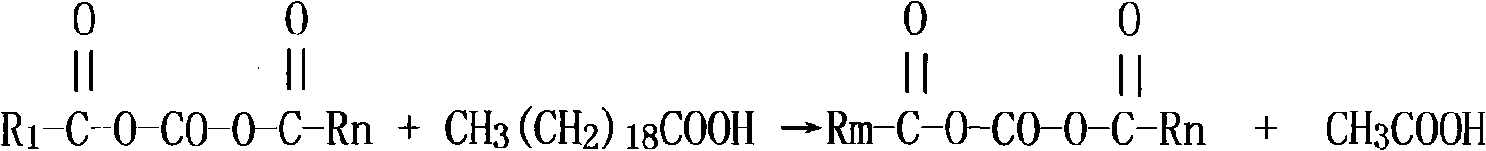

Preparation technique of cobalt decanoate by hybrid reaction of cobaltous carbonate and organic acid

InactiveCN101348426APrevent rustBalance pHCarboxylic acid salt preparationFiltrationOrganic synthesis

A preparation process for preparing organic cobalt salt compound mainly comprising cobalt neocaprate through the hybrid reaction between cobalt carbonate and organic acid belongs to the organic synthesis technical field. Taking cobalt carbonate as a raw material, the preparation process is characterized in that the process is carried out in turn according to the following steps that (1) taking cobalt carbonate, glacial acetic acid, neodecanoic acid and neopentanoic acid as raw materials, reaction is carried out inside a normal pressure sealed reactor for more than or equal to 3 hours with the temperature controlled between 90 and 100 DEG C; (2) abietic acid is added in the reaction system so as to carry out reaction at a temperature of between 160 and 168 DEG C for more than or equal to 1 hour, thereby displacing glacial acetic acid; then, cobalt neocaprate is generated through excluding displaced glacial acetic acid and water by means of vacuum reaction and filtration; and (3) activated calcium carbonate is added in the reaction system at a temperature of between 160 and 168 DEG C so as to prepare a finished product. Through replacing common cobalt hydroxide by cobalt carbonate to carry out reaction with organic acid, and adding abietic acid tackifier and activated calcium carbonate with amphoteric compound in neodecanoic acid, the preparation process effectively balances the pH degree in the system, thereby effectively preventing the product from metallic corrosion and increasing adhesion level.

Owner:逯大成

Method for preparing highly-doped fly ash lightweight heat-insulation bricks, and bricks prepared by same

The invention discloses a method for preparing highly-doped fly ash lightweight heat-insulation bricks. The preparation method comprises: preparing aluminum powder paste, sodium sulfate, sodium abietate, water, fly ash, carbide slag or lime powder and gypsum which are weighed in a ratio by weight into fly ash non-burnt ceramic particles; feeding fly ash, slag or coal gangue, carbide slag or lime powder, desulfurized gypsum or gypsum powder which are weighed in a ratio by weight into a wheel-grinding machine for wheel-grinding and obtaining a mixture; preparing rosin powder, sodium hydroxide, water together with gelatin and water together with triethanolamine which are weighed in a ratio by weight into admixture II; weighing the fly ash non-burnt ceramic particles, the mixture, cement and the admixture II in a ratio by weight and feeding the materials into a stirrer for stirring and adding water while stirring to adjust the water content of the materials to reach 17 to 21 percent; feeding the obtained product into a molding machine to prepare the obtained product into green brick bodies; and obtaining finished products through maintenance. The method has the advantages of low cost and no environmental pollution produced during production, and all standards of the lightweight heat-insulation bricks meet the requirements of national standards.

Owner:杜世永

Down feather detergent

InactiveCN104312762AGood conditionConvenient careSurface-active detergent compositionsFibre treatmentSodium bicarbonateMorpholine

The invention discloses a down feather detergent which comprises the following components in parts by weight: 100 parts of water, 3-4 parts of triethanolamine, 2-3 parts of octadecanol polyoxyethylene ether, 1-2 parts of abietic acid polyoxyethylene ester, 1-2 parts of polyglycerol monostearate, 1-2 parts of hydroxypropyl methyl cellulose, 3-4 parts of sodium laurate, 1-2 parts of dodecyl trimethyl ammonium sulfate, 1-2 parts of sodium persulfate, 1-2 parts of N-octyl isothiazolinone, 1-2 parts of phenyl silicon oil, 2-3 parts of aminomethyl propanol, 2-3 parts of morpholine, 1-2 parts of sodium bicarbonate, 1-2 parts of tea polyphenol, 2-3 parts of vinyl trimethoxy silane, 1-2 parts of polyisobutene, 3-4 parts of polyvinylpyrrolidone, 1-2 parts of dimer acid and 2-3 parts of maleic anhydride modified polyethylene. The down feather detergent disclosed by the invention can effectively remove stain on down feather and has a relatively good conditioning and caring function on down feather.

Owner:常熟市奥琪特服饰有限公司

Hot-melt adhesive composition

InactiveUS20150018470A1Remarkable effectImprove compatibilityFilm/foil adhesivesMacromolecular adhesive additivesAlpha-olefinHot-melt adhesive

The present invention provides a hot melt adhesive composition comprising (A) an ethylene copolymer obtained by copolymerizing ethylene and α-olefin using a single-site catalyst and (B) a rosin ester, in a hydrolyzate of which a dehydroabietic acid content is 30 wt % or less and an abietic acid content is 10 wt % or less, and in a methylated product of the hydrolyzate of which a content of components having a molecular weight of 320 is equal to or greater than 10 wt % of a total amount of components having a molecular weight of 314 to 320.

Owner:ARAKAWA CHEM IND LTD

High-efficiency low-temperature oil sludge de-emulsifier and preparation method thereof

ActiveCN104418474AImprove surface activityLess irritatingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesChemistryRosin

The invention discloses a high-efficiency low-temperature oil sludge de-emulsifier, the de-emulsifier comprises the following components by weight part: 4-21 parts of rosin-polythylene oxide ester, 3-18 parts of disodium cocoyl monoethanolamide sulfosuccina, 0.1-1 part of acid catalyst and 60-92 parts of water. A preparation method of the de-emulsifier comprises the following steps: uniformly mixing rosin-polythylene oxide ester, disodium cocoyl monoethanolamide sulfosuccina, an acid catalyst and water, and then obtaining the low-temperature oil sludge de-emulsifier. The oil sludge de-emulsifier has the advantages of good demulsification effect under low temperature, wide usage temperature scope and high oil recovery rate, and the method has the advantages of low production cost, environmental protection, simple process and wide application scope. The oil sludge de-emulsifier can be used for harmlessness treatment of oil sludge at bottom of pot, scummings and activated sludge, and also can be used for treating various kinds of oil-containing sludge generated by petroleum exploitation, storage and transportation enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cellulose resin and method for producing the same

InactiveUS20120196998A1Improved thermoplasticity and mechanical characteristic and water resistanceHigh vegetismCelluloseCardanol

A cellulose resin produced by binding cardanol or a derivative thereof and abietic acid or a derivative thereof to cellulose or a derivative thereof.

Owner:NEC CORP

Metal paste and film formation method using the same

InactiveUS20050127332A1Increasing the thicknessLower resistanceConductive materialNon-conductive material with dispersed conductive material2-Ethylhexanoic acidColloidal particle

Owner:TANAKA PRECIOUS METAL IND

Ferronickel slag geopolymer and preparation method thereof

The invention relates to a ferronickel slag geopolymer binding material and a preparation method thereof, and belongs to the technical field of recycling of inorganic nonmetallic materials and industrial solid waste. The ferronickel slag geopolymer binding material is prepared from 100 parts of ferronickel slag, 5-20 parts of alkali excitant and 20-40 parts of water. The alkali excitant is prepared from 100 parts of water glass, 0.1-1.0 part of hydrotalcite, 0.1-1.0 part of sodium abietate and 0.1-1.0 part of fatty alcohol-polyoxyethylene ether sodium sulfate. The invention further provides the preparation method of the ferronickel slag geopolymer binding material. Ferronickel slag geopolymers are high in curing speed, high in strength, good in durability and high in production efficiency. Meanwhile, the solid waste ferronickel slag is adopted as the main raw material, the preparation process is simple, cost is low, resources and energy can be saved, and environment friendliness can be achieved.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com